Page 1

Density

Illumination

Color

New Version

Spectrodensitometer

Spectrodensitometer

/

/

3-in-1 next-generation measurement tool

Color

Density

Illumination

Streamlines color adjustment in printing,

even on substrates with uorescent

whitening agents

Page 2

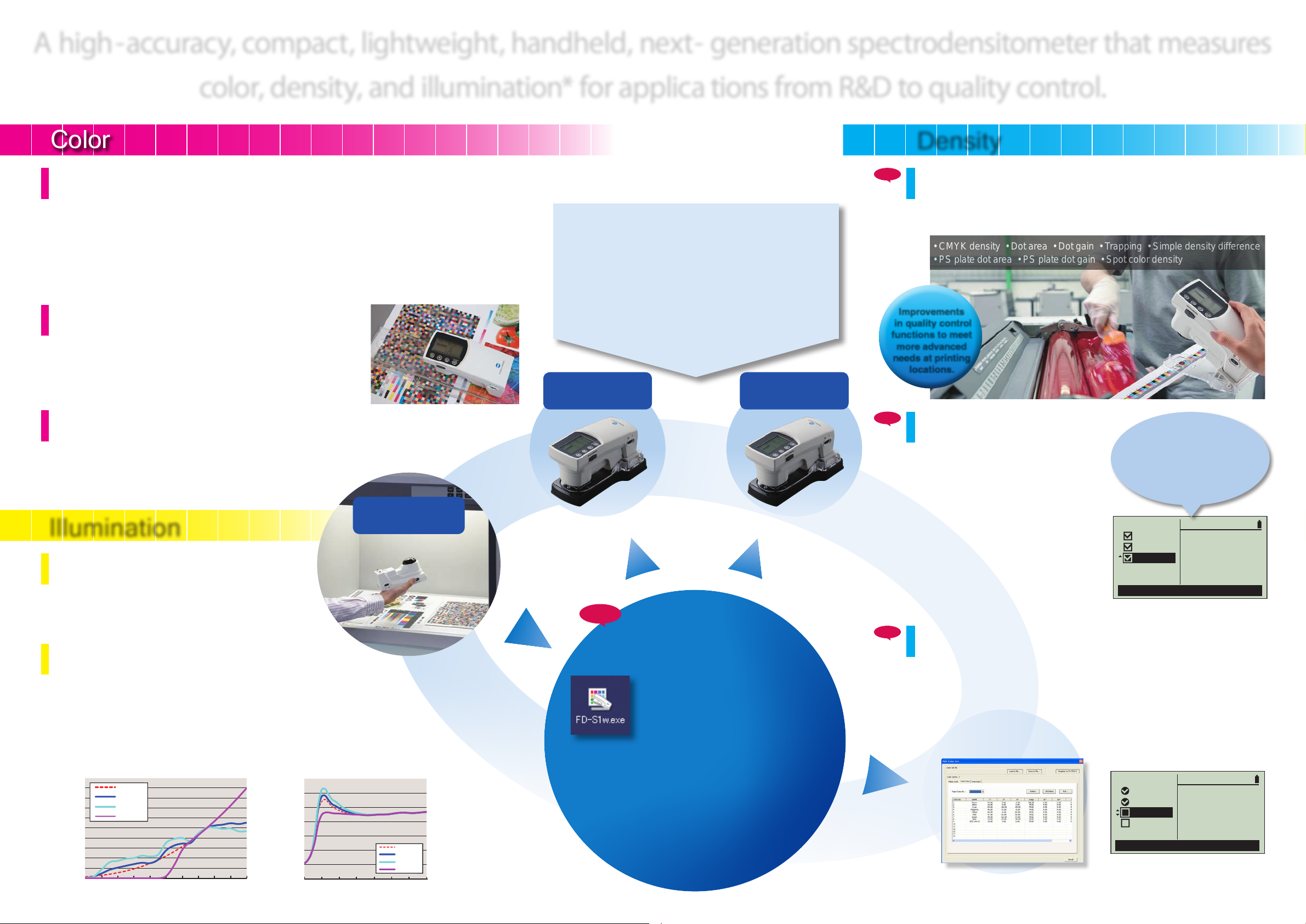

A high-accuracy, compact, lightweight, handheld, next- generation spectrodensitometer that measures

• CMYK density • Dot area • Dot gain • Trapping • Simple density difference

• PS plate dot area • PS plate dot gain • Spot color density

Relativeintensity(a.u.)

A

*FD-7 only

color, density, and illumination* for applica tions from R&D to quality control.

Color

The world’s first measuring instrument that corresponds

to Measurement Condition M1 of ISO 13655

• Konica Minolta’s original VFS (Virtual Fluorescence Standard) technology enables L*a*b* measurements

corresponding to ISO 13655 Measurement Condition M1.

• The FD-7 and FD-5 can take measurements corresponding to all four of the ISO 13655 Measurement

Conditions. Measurements corresponding to M1 are enabled by Konica Minolta’s original VFS (Virtual

Fluorescence Standard) technology, and measurements corresponding to M0 (CIE Illuminant A) and M2

(illumination with UV-cut filter) can also be taken. In addition, by attaching the included polarization filter,

measurements corresponding to M3 (M2+ polarization filter) can be taken.

Scan measurements can be performed.

• Manual scan measurements can be performed when the instrument is

connected to a PC.

• With optional software basICColor catch all, the colorimetric values,

density values, and spectral reflectance values of various test charts

(MediaWedge ECI2002, IT8.7/3, etc.) can be measured in a single

operation.

Spectral output

• When the FD-7 is connected to a computer, the spectral reflectance

data (380 to 730 nm) of samples under various illuminants and

the spectral irradiance data (360 to 730 nm) of the environmental

lighting can be measured and output to a computer. This makes

the FD-7 ideal for research and development applications.

(FD-7 only)

(FD-7 only)

Illumination

Illumination environment light

can be measured.

• The illuminance and color temperature in a color

viewing cabinet or the actual ambient light under which

printed materials will be evaluated can be measured.

Measured environmental light can be set as

illumination light source (user illuminant)

• In the past, when measuring printed materials containing fluorescent whitening agents

(FWA), large differences between measured values and visual evaluation sometimes

occurred. But with the FD-7, colorimetric values can be calculated under the measured

environmental light source, providing results which more closely correspond to on-site

visual evaluation. This ensures customers receive the colors they want and eliminates time

and labor lost resolving customer complaints due to the effects of FWA or metamerism.

Measuredlightsourceintensitydistribution

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

300 320 340 360 380 400 420 440 460 480 500

A

D50

D65

A(Uvcut)

Wavelength(nm)

(FD-7 only)

140

120

100

80

60

40

Spectralreflectance(%)

20

0

380 430 480 530 580 630 680 730

FD-7

(Master body)

D50

D65

A(UVcut)

Wavelength(nm)

By measuring the environmental light source with

an FD-7 master body and then transferring

the user illuminant data to multiple FD-5 or FD-7

working bodies, color control using the same

illumination light source at multiple locations can

be achieved. In addition, theautomatic wavelength

compensation function minimizes inter-instrument

errors when using multiple instruments.

FD-5

(Working body)

FD-5

(Working body)

NEW

Data Management

Software FD-S1w

(included as standard accessory)

Features:

• Transfer of measurement data to Excel® sheet.

• Reading/ registering of user illuminant data to/

from instrument and storage as PC file

• Color set management functions (for instrument

ISO 12647 Check and Target Match functions)*1*

System Requirements

OS Windows XP, Windows

Vista or Windows 7; 32bit or 64-bit versions

Excel Excel 2003 (Windows XP),

Excel 2007 (Widows Vista),

or Excel 2010 (32-bit version;

Windows 7)

The haedware or the computer

system to be used must meet or

exceed the recommended system

requirements for the compatible

OS and Excel version being used.

Compatible Instruments

Spectrodensitometer FD-7, FD-5

Display language

English, Japanese,

Chinese (Simplified)

(Select one during installation.)

Density

NEW

NEW

NEW

2

*1 Target colors (color sets) must be set using the included FD Data Management Software FD-S1w.

*2 Backing conversion function converts the target values to enable evaluation even when backing

conditions for samples do not match those of the targets.

Printing quality control functions

including trapping, dot gain, etc.

• A new industry-standard tool for commercial printing and packaging

printing to improve productivity and quality at low cost.

Improvements

in quality control

functions to meet

more advanced

needs at printing

locations.

Target Match function

• Displays the color difference of mixed

ink from the target color and the density

adjustment needed to bring the mixed

color closer to the target color.

By using the Target Match function,

*1*2

Measure color difference.

Result: Adjusting the

density of spot color with

400 nm peak from 0.86 to

1.16 is predicted to result in

a color difference of 0.48.

ink color adjustment can be performed

without a computer or special software.

· Ideal for spot colors or process colors.

· Displays color difference and density.

· Displays estimated density

TARGETMATCH

Paper

Target

Sample

adjustment needed to bring the

mixed color closer to the target

color and the predicted color

Measuresample

difference after adjustment.

Functions corresponding to

various printing standards

• Pass/fail judgment against ISO, JapanColor, GRACoL®/SWOP®,

PSO, or user-defined custom targets can be performed. The

FD-7 and FD-5 are ideal for on-site printing quality control.

· ISO 12647 check

Color difference, TVI, and mid-tone spread can be evaluated.

· Gray balance

Gray balance can be evaluated using the G7® evaluation method.

*1*2

ISOCHECK

Yellow40%

Red

Green

Blue

16/21

Red:Pass

M12°D50

⊿D(400)

⊿E*94

2.54 @

>>

0.48 @

M12°D50

+0.30D

L*

a*

b*

E*ab

CS01:PT1-AM-BB

0.86D

1.16D

-0.32

0.08

-0.22

0.40

Page 3

Industry's first automatic wavelength

Wavelength-direction shift

compensation function

• Wavelength compensation is performed during white calibration* without

requiring additional work.

• Until now, wavelength compensation could only be carried out as one part

Spectral reflectance

of manufacturer servicing. This task is now performed whenever white

calibration*3 is done, helping to maintain the high reliability of measurement

values until the next periodic servicing.

*3 Except when polarization filter is attached.

World's lightest

*4

• The main body weighs only about 350g, and even with the target

mask attached it's only about 430g, lighter than any previous

spectrodensitometer.

•

This reduces the load on the user's arm during work, improving

efficiency when taking measurements over a long time.

*4 Display-equipped spectrodensitometer. As of December 1, 2012

Worry-free after-sales service

• Worldwide service centers provide rapid support when needed.

• A comprehensive service network is in place to ensure that your instrument is always in top shape.

Wavelength

SYSTEM DIAGRAM

USB Cable (Shape may vary by region.)

IF-A17 (Europe)

IF-A23 (worldwide except Europe)

Spectrodensitometer

FD-7/FD-5

Protection Glass

FD-A04

White

Calibration Plate

FD-A06

Target Mask

FD-A01

Polarization Filter

FD-A08

PC

(commercially available)

Ruler

FD-A02

AC Adapter

(Shape may

vary by region.)

Illuminance Adapter

FD-A03

FD-5, FD-7

Standard accessories

Color Management

Software

basICColor catch all

Soft Case

FD-A05

Standard accessories

only of FD-7

CM-S100w

Spectra Magic® NX

ProfessionalEdition

Basic Edition

Data Management

Software

FD-S1w

XY Automatic ColorMeasurement Stage

ColorScoutA3+

Optional

accessories

DIMENSIONS

(Units: mm)

With removable target mask attached

171.5

165

25

φ6.2

90

70

84.2

Optional accessories

XY Automatic Color-Measurement

Stage ColorScoutA3+

The ColorScoutA3+ enables accurate, highefficiency measurements of color charts

with the Spectrodensitometer FD-7 and

FD-5. It enables automatic positioning and

measurement of the instrument, providing

higher repeatability and reducing labor

compared to manual measurements.

XY automatic color-measurement stage.

Table available with either white surface or black

surface.

Using the ColorScoutA3+ with the FD-7 or FD-5 makes it easier to measure

colorimetric data of color charts under ISO 13655 Measurement Condition M1 or a

user-defined illumination light source (user illuminant) to create user color profiles

that more closely match visual evaluation.

Maximum measurable chart size of 320 x 460 mm improves measurement efficiency

by allowing even large color charts to be measured in a single procedure without the

need to cut up or tile the charts.

Measurement of user-designed charts is also possible. The included ClrChrt software

makes it easy to create a definition file for measuring the user-designed chart.

ClrChrt software (Included)

Measurement data Chart design screen

ColorChart minimum computing requirements

OS; CPU Windows®XP(32-bit), Windows®Vista(32-bit); 300MHz or faster

Hard disk; Memory 30MB or more available disk space; 64MB or more

*1

Color Management Software

bas

olor catch all

ICC

Ideal software for quality control of process color printing targets for offset printing.

For major efficiency increases in daily color control work.

Enables color reproduction closer to visual evaluation with simple operation.

• With basICColor catch all, commonly used templates and jobs are already

included, so there is no need for measurement preparations such as setting

target values, tolerances, etc.

• When the software is started, just select the required measurement

conditions in the Job Management screen. You can then connect

immediately to the Spectrodensitometer FD-7 or FD-5, and PDF reports

can be created and output automatically.

• Data are stored in ISO format (ISO 12642-2), so they can be fed back to

profile creation software. Using Measurement Condition M1 or a userdefined illumination light source (user illuminant) enables color reproduction

closer to visual evaluation.

For ISO 12647-2 printing certification checks and print process quality

management.

•Enables measurement of Fogra® and

IDEAlliance® standards and certification

checking.

•In addition to CIELAB for color, evaluation

results for CMYK dot gain and mid-tone

spread as required for the above certification

checking can also be easily obtained. This

can help discover and resolve problems in

the printing process at an early stage.

Minimum computing requirements

OS Windows

CPU Intel® Pentium® 4 Processor

Memory 512MB

Hard disk At least 100MB of available disk space

®

Vista (32-bit); Windows® 7 (32-bit)

XP SP3 (32-bit); Windows®

*1

NEW

Color Data Software SpectraMagic®

Ideal for color-difference control of spot colors relative to target colors.

*1 Measurements with polarization filter attached cannot be performed.

Achieves overall ease of use with free selection

of evaluation equations and report formatting.

With the new E*94 and E00 color difference equations as

well as a user index that allows users to freely set their own

evaluation equations, SpectraMagic® NX can meet a wide

variety of user needs.

Measurement data can be displayed in list form or in objects

such as spectral graphs, color-difference graphs, etc. that the

user can freely lay out, and those objects can be copied and

pasted as is into other software such as Excel® for easy data

control. In addition, printing screens can also be designed

using the same objects to create user-defined formats for

easy-to-read reports.

List display

Color-difference graph object Pasted into Excel

Minimum Computing Requirements

OS

CPU

Memory

Hard disk

Windows® XP Professional 32-bit SP3, 64-bit SP2; Windows® Vista Business 32-bit, 64-bit;

Windows® 7 Professional 32-bit, 64-bit

(English, Japanese, German, French, Spanish, Italian, Traditional Chinese, Simplified Chinese,

Portuguese, and Hangul versions)

• The hardware of the computer system to be used must meet or exceed the greater of the

recommended system requirements for the compatible OS being used or the following specifications.

Pentium® lll 600 MHz or higher (recommended)

128 MB (256 MB recommended)

450 MB of available disk space (At least 400 MB of available space is required in the system drive.)

*1

NX

Printing screen

®

Page 4

Function

*★New

Density measurement functions

Density, density difference

Dot area

Dot gain

Trapping

PS plate dot area

PS plate dot gain

Spot color density

Gray balance

Midtone spread

ISO 12647 check

Tar g et mat ch

Colorimetric measurement functions

Lab

LCh

Hunter Lab

Yxy

XYZ

E*ab (CIE1976)

E*94 (CIE1994)

E00 (CIE2000)

E (Hunter)

CMC (l:c)

Illuminance measurement functions

Illuminance

Correlated color temperature

Paper index

WI/Tint (ASTME313-96)

ISO Brightness (ISO2470-1)

Brightness (ISO2470-2)

D

65

Fluorescence index

Spectral reflectance

Spectral data output

Memory

Target density 30 30

Tar g et col o r 3 0 30

Color sets of 15 colors each

Other functions

Manual scan

Automatic function

(density, dot area, color)

PASS/FAIL ju dgm en t

Software

basICColor catch all

FD-S1w

SpectraMagic NX

ClrChrt

(Included with ColorScoutA3+)

FD-7 FD-5

●●

●●

●●

★★

★★

★★

★★

★★

★★

★★

★★

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

●

●

●●

●●

●●

●●

●

3

50 50

2

●

●●

●●

●●

★★

★★

●●

Main specifications

1

Illumination/viewing

system

Spectral separation

device

45°a: 0°(annular illumination)

Conforms to CIE No. 15, ISO 7724/1, DIN5033 Teil 7, ASTM E 1164, and JIS Z

8722 Condition a for reflectance measurements.

Concave grating

Wavelength range Spectral reflectance: 380 to 730 nm; Spectral irradiance (FD-7 only): 360 to 730 nm

Wavelength pitch 10 nm

Half bandwidth Approx. 10 nm

Measurement area Ø3.5 mm

Light source LED

Measurement range Density: 0.0D to 2.5D; Reflectance: 0 to 150%

Density: ı0.01D

Without polarization filter: 0.0D ~ 2.5D, Yellow 0.0D ~ 2.0D

With polarization filter: 0.0D ~ 2.5D, Yellow 0.0D ~ 1.8D

Short-term repeatability

(When measurements taken 30 times at 10-second intervals after

white calibration has been performed)

Colorimetric: Within

(When white plate is measured 30 times at 10-second intervals

after white calibration has been performed)

E00 0.3 (Average of 12 BCRA Series II color tiles compared to values

Inter-instrument

agreement

Within

measured with a master body under Konica Minolta standard conditions; without

polarization filter )

Measurement time Approx. 1.4 s (single-point reflectance measurement without polarization filter)

Measurement

conditions

Illuminants

Corresponding to ISO 13655 Measurement Conditions M0 (CIE Illuminant A),

M1 (CIE Illuminant D50), M2 (illumination with UV-cut filter), and M3 (M2 +

polarization filter); User-defined illuminant

A, C, D50, D65, ID50, ID65, F2, F6, F7, F8, F9, F10, F11, F12, User-defined

illuminant

Observers 2° Standard Observer, 10° Standard Observer

Density ISO Status T, ISO Status E, ISO Status A, ISO Status I; DIN16536

Display language English, French, German, Spanish, Japanese, Chinese (Simplified)

Interface USB 2.0

Output data

Powe r

2

Displayed values; Spectral reflectance data (FD-7 only) ; Spectral irradiance data

(FD-7 only)

Rechargeable internal lithium-ion battery (Number of measurements per charge:

Approx. 2,000 when new without polarization filter); AC adapter; USB bus power

Dimensions (W × D × H) 70 × 165 × 83 mm (Body only); 90 × 172 × 84 mm (With target mask attached)

Weight Approx. 350 g (Body only); Approx. 430 g (With target mask attached)

Operating temperature/

humidity range

Storage temperature/

humidity range

10 to 35°C, 30 to 85% relative humidity with no condensation

0 to 45°C, 0 to 85% relative humidity with no condensation

White Calibration Plate, Target Mask, Protection Glass, AC Adapter, USB Cable,

Standard accessories

Soft Case, Polarization Filter, Data Management Soft ware FD-S1w, Illuminance

Adapter (FD-7 only), Ruler (FD-7 only)

Color Management Software basICColor catch all,

Optional accessories

XY Automatic Color Measurement Stage Color Scout A3+,

Color Management Software SpectraMagic NX

1 Illumination for wavelengths under 400nm is unidirectional.

2 Available when using PC software.

3 Used for ISO 12647 Check / Target match; Must be set using included FD-S1w software.

• Displays shown are for illustration purpose only.

• The specifications and drawings given here are su

• KONICA MINOLTA and the Konica Minolta logo and the symbol mark, and "Giving Shape to Ideas" and SpectraMagic™ are

registered trademarks or trademarks of KONICA MINOLTA, INC.

• The basICColor logo is a registered trademark of basICColor GmbH.

• Other company names and product names used herein are trademarks or registered trademarks of their respective companies.

bject to change without prior notice.

ı

E00 0.05 (Without polarization filter)

SAFETY PRECAUTIONS

For correct use and for your safety, be sure to read the instruction

manual before using the instrument.

Always connect the instrument to the specified power supply

s

voltage. Improper connection may cause a fire or electric shock.

Certificate No : LRQ 0960094/A

Registration Date : March 3, 1995

9242-4897-10 BDEGPK 7©2010 KONICA MINOLTA, INC.

Certificate No : JQA-E-80027

Registration Date : March 12, 1997

Loading...

Loading...