Standard EEPROM ICs

SLx 24C64

64 Kbit (8192 × 8bit)

Serial CMOS-EEPROM with

2

C Synchronous 2-Wire Bus

I

Data Sheet Preliminary 1998-07-27

SLx 24C64

Revision History: Current Version: Preliminary 1998-07-27

Previous Version: 05.98

Page

(in previous

Version)

Page

(in current

Version)

Subjects (major changes since last revision)

3 3 Text was changed to “Typical programming time 5 ms for up to

32 bytes”.

11, 12 11, 13 The erase/write cycle is finished latest after 10

21 21 The write or erase cycle is finished latest after 10

8ms.

4ms.

24 24 The line “erase/write cycle” was removed.

24 24 Chapter 8.4 “Erase and Write Characteristics” has been added.

I2CBus

2

Purchase of Siemens I

2

C system p rovided the system conforms to the I2C specifications defined by Philips.

the I

C components conveys the license under the Philips I2C patent to use the components in

Edition Preliminary 1998-07-27

Published by Siemens AG,

Bereich Halbleiter, MarketingKommunikation, Balanstraße 73,

81541 München

©

Siemens AG 1998.

All Rights Reserved.

Attention please!

As far as patents or other rights of third parties are concerned, liability is only assumed for components, not for applications, processes

and circuits implemented within components or assemblies.

The information describes the type of component and shall not be considered as assured characteristics.

Terms of delivery and rights to change design reserved.

For questions on technology, delivery and prices please contact the Semiconductor Group Offices in Germany or the Siemens Companies

and Representatives worldwide (see address list).

Due to technical requirements components may contain dangerous substances. For information on the types in question please contact

your nearest Siemens Office, Semiconductor Group.

Siemens AG is an approved CECC manufacturer.

Packing

Please use the recycling operators known to you. We can also help y ou – get in touch with your nearest sales office. B y agreement we

will take packing material back, if it is sorted. You must bear the costs of transport.

For pa cking material that is returned to us unsorted or which we are not obliged to accept, we shall have to invoice you for any costs incurred.

Components used in life-support devices or systems must be expressly authorized for such purpose!

Critical components

written appr oval of the Semiconductor Group of Siemens AG.

1 A critical component is a component used in a life-support device or system whose failure can reasonably be expected to cause the

failure of that life-support device or system, or to affect its safety or effectiveness of that device or system.

2 Life support devices or systems are intended (a) to be implanted in the human body, or (b) to support and/or maintain and sustain hu-

man life. If they fail, it is reasonable to assume that the health of the user may be endangered.

1

of the Semiconductor Group of Siemens AG, may only be used in life-support devices or systems2with the express

64 Kbit (8192 × 8bit)SerialCMOS

2

EEPROMs, I

Preliminary

Features

• Data EEPROM internally organized as

8192 bytes and 256 pages × 32 bytes

• Page Protection Mode for protecting the EEPROM

against unintended data changes

(SLx 24C64.../P types only)

• Low power CMOS

V

•

• Two wire serial interface bus, I

• Three chip select pins to address 8 devices

• Filtered inputs for noise suppression with

= 2.7 to 5.5 V operation

CC

Schmitt trigger

C Synchronous 2-Wire Bus

2

C-Bus compatible

SLx 24C64

P-DIP-8-4

• Clock frequency up to 400 kHz

• High programming flexibility

– Internal programming voltage

– Self timed programming cycle including erase

– Byte-write and page-write programming, between

1 and 32 bytes

– Typical programming time 5 ms for up to 32 bytes

• High reliability

6

– Endurance 10

cycles

– Data retention 40 years

1)

1)

– ESD protection 4000 V on all pins

• 8 pin DIP/DSO packages

• Available for extended temperature ranges

– Industrial: − 40 °C to + 85 °C

– Automotive: − 40 °C to + 125 °C

P-DSO-8-3

1)

Values are temperature dependent, for further information please refer to your Siemens sales office.

Semiconductor Group 3 Preliminary 1998-07-27

SLx 24C64

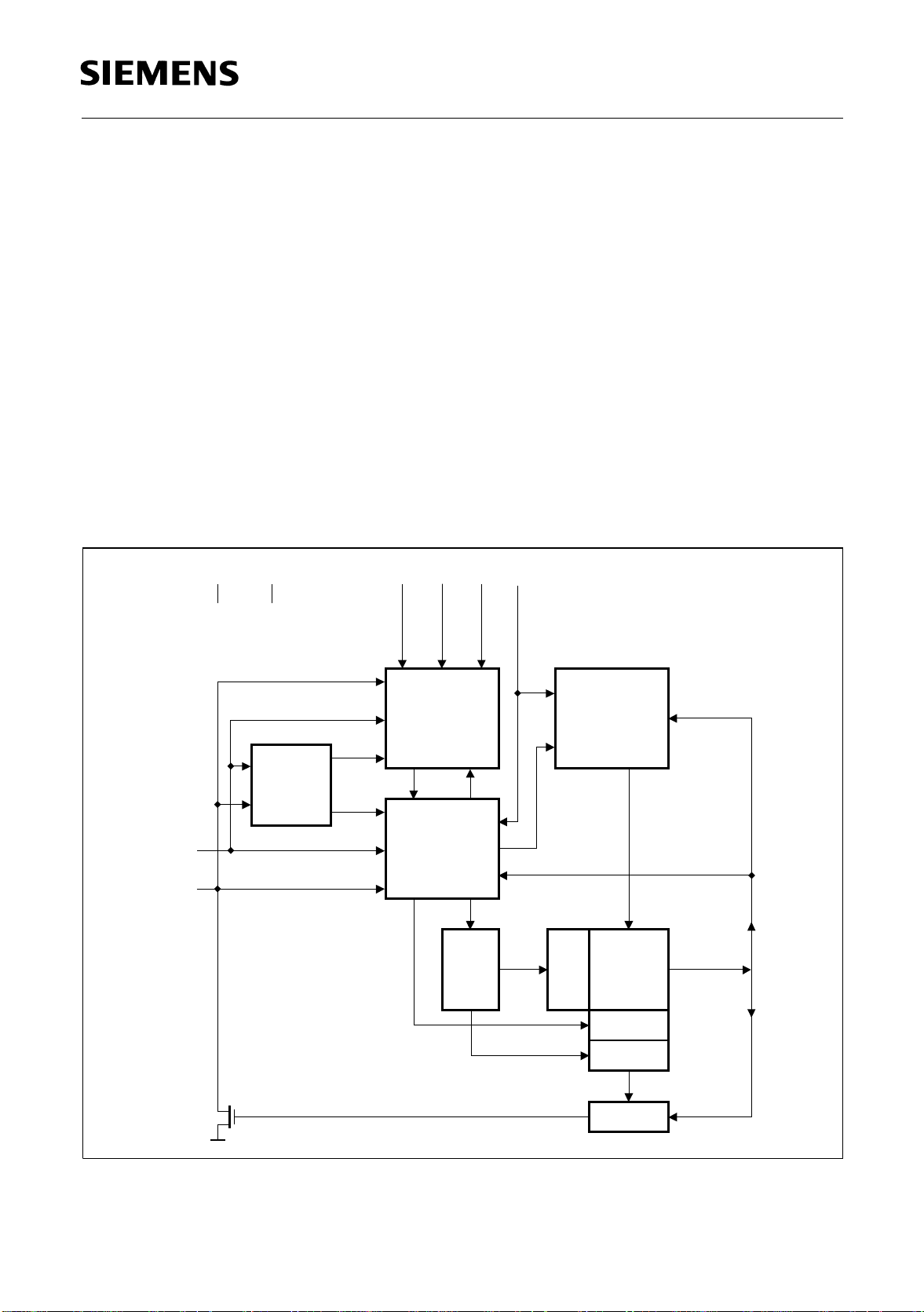

Ordering Information

Type Ordering Code Package Temperature Voltage

SLA 24C64-D

SLA 24C64-D/P

SLA 24C64-S

SLA 24C64-S/P

SLA 24C64-D-3

SLA 24C64-D-3/P

SLA 24C64-S-3

SLA 24C64-S-3/P

SLE 24C64-D

SLE 24C64-D/P

SLE 24C64-S

SLE 24C64-S/P

Q67100-H3768

Q67100-H3762

Q67100-H3767

Q67100-H3761

Q67100-H3766

Q67100-H3760

Q67100-H3765

Q67100-H3759

Q67100-H3238

Q67100-H3758

Q67100-H3239

Q67100-H3757

P-DIP-8-4 – 40 °C … + 85 °C 4.5 V...5.5 V

P-DSO-8-3 – 40 °C … + 85 °C 4.5 V...5.5 V

P-DIP-8-4 – 40 °C … + 85 °C 2.7 V...5.5 V

P-DSO-8-3 – 40 °C … + 85 °C 2.7 V...5.5 V

P-DIP-8-4 – 40°C … + 125 °C 4.5 V...5.5 V

P-DSO-8-3 – 40°C … + 125 °C 4.5 V...5.5 V

Other types are available on request:

– Temperature range (– 55 °C … + 150 °C)

– Package (die, wafer delivery)

– 3V types with automotive temperature range (– 40 °C … + 125 °C)

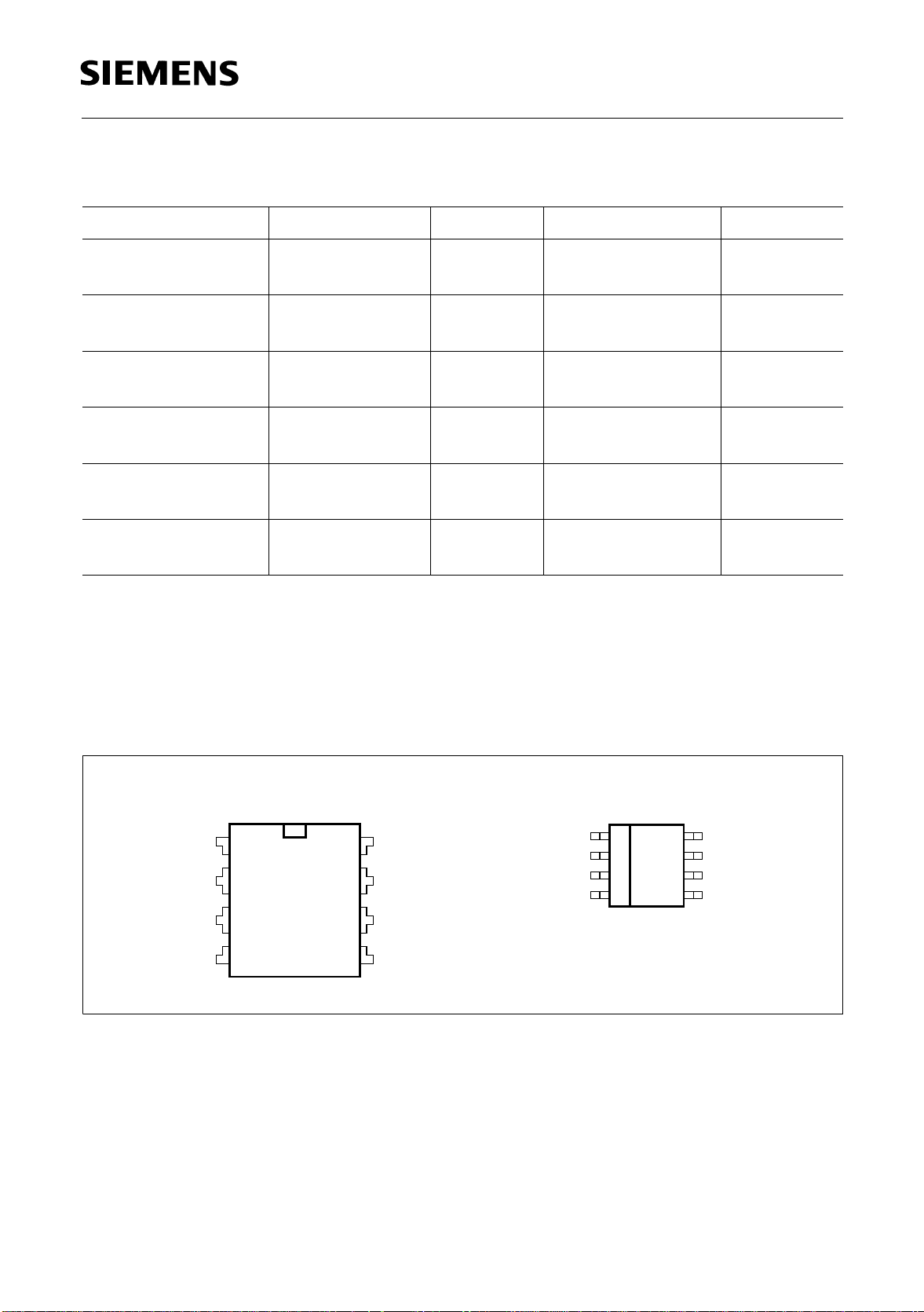

1 Pin Configuration

CS0

CS2

18

CS1

V

SS

IEP02125

Figure 1

Pin Configuration (top view)

P-DSO-8-3P-DIP-8-4

V

CC

72

WP

SCL63

SDA54

CS0

CS1

CS2

V

SS

1

2

3

4

IEP02124

V

8

CC

7

WP

6

SCL

SDA

5

Semiconductor Group 4 Preliminary 1998-07-27

Pin Definitions and Functions

Table 1

Pin No. Symbol Function

1, 2, 3 CS0, CS1, CS2 Chip select inputs

SLx 24C64

4

V

SS

Ground

5 SDA Serial bidirectional data bus

6 SCL Serial clock input

7 WP Write protection input

8

V

CC

Supply voltage

Pin Description

Serial Clock (SCL)

The SCL input is used to clock data into the device on the rising edge and to clock data

out of the device on the falling edge.

Serial Data (SDA)

SDA is a bidirectional pin used to transfer addresses, data or control information into the

device or to transfer data out of the device. The output is open drain, performing a wired

AND function with any number of other open drain or open collector devices. The SDA

V

bus requires a pull-up resistor to

CC

.

Chip Select (CS0, CS1, CS2)

The CS0, CS1 and CS2 pins are chip select inputs either hard wired or actively driven

V

to

or VSS. These inputs allow the selection of one of eight possible devices sharing

CC

acommonbus.

Write Protection (WP)

V

WP switched to

WP switched to

Semiconductor Group 5 Preliminary 1998-07-27

allows normal read/write operations.

SS

V

protects the EEPROM against changes (hardware write protection).

CC

SLx 24C64

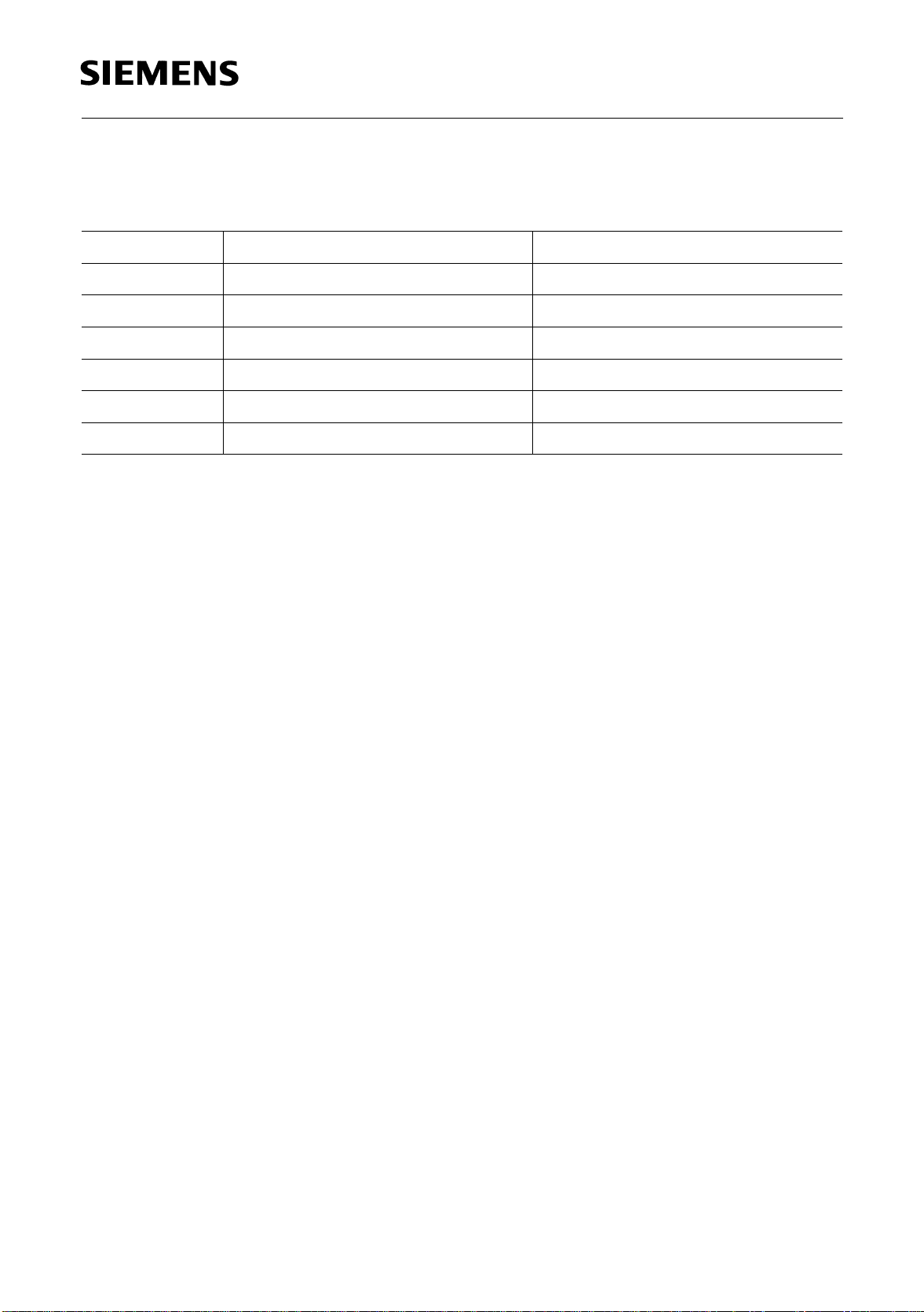

2 Description

The SLx 24C64 device is a serial electrically erasable and programmable read only

memory (EEPROM), organized as 8192 × 8 bit. The data memory is divided into

256 pages. The 32 bytes of a page can be programmed simultaneously.

2

The device conforms to the specification of the 2-wire serial I

2

pins allow the addressing of 8 devices on the I

C-Bus. Low voltage design permits

operation down to 2.7 V with low active and standby currents. All devices have a

6

minimum endurance of 10

erase/write cycles.

The device operates at 5.0 V ± 10% with a maximum clock frequency of 400 kHz and at

2.7 ... 5.5 V with a maximum clock frequency of 100 kHz. The device is available as 5 V

V

type (

applications and as 3 V type (

= 4.5 … 5.5 V) with two temperature ranges for industrial and automotive

CC

V

= 2.7 … 5.5 V) for industrial applications. The

CC

EEPROMs are mounted in eight-pin DIP and DSO packages or are also supplied as

chips.

C-Bus. Three chip select

SCL

SDA

V

SS

V

CC

Start/

Stop

Logic

CS0 CS1 CS2

Chip Address

Control

Logic

Serial

Control

Logic

Address

Logic

WP

Programming

Control

H.V. Pump

X

DEC

EEPROM

Page Logic

Y DEC

Dout/ACK

IEB02525

Figure 2

Block Diagram

Semiconductor Group 6 Preliminary 1998-07-27

SLx 24C64

3 I2C-Bus Characteristics

2

AccesstotheSLx24C64deviceisgivenviatheI

of two wires SCL and SDA for clock and data. The protocol is master/slave oriented,

where the serial EEPROM always takes the role of a slave.

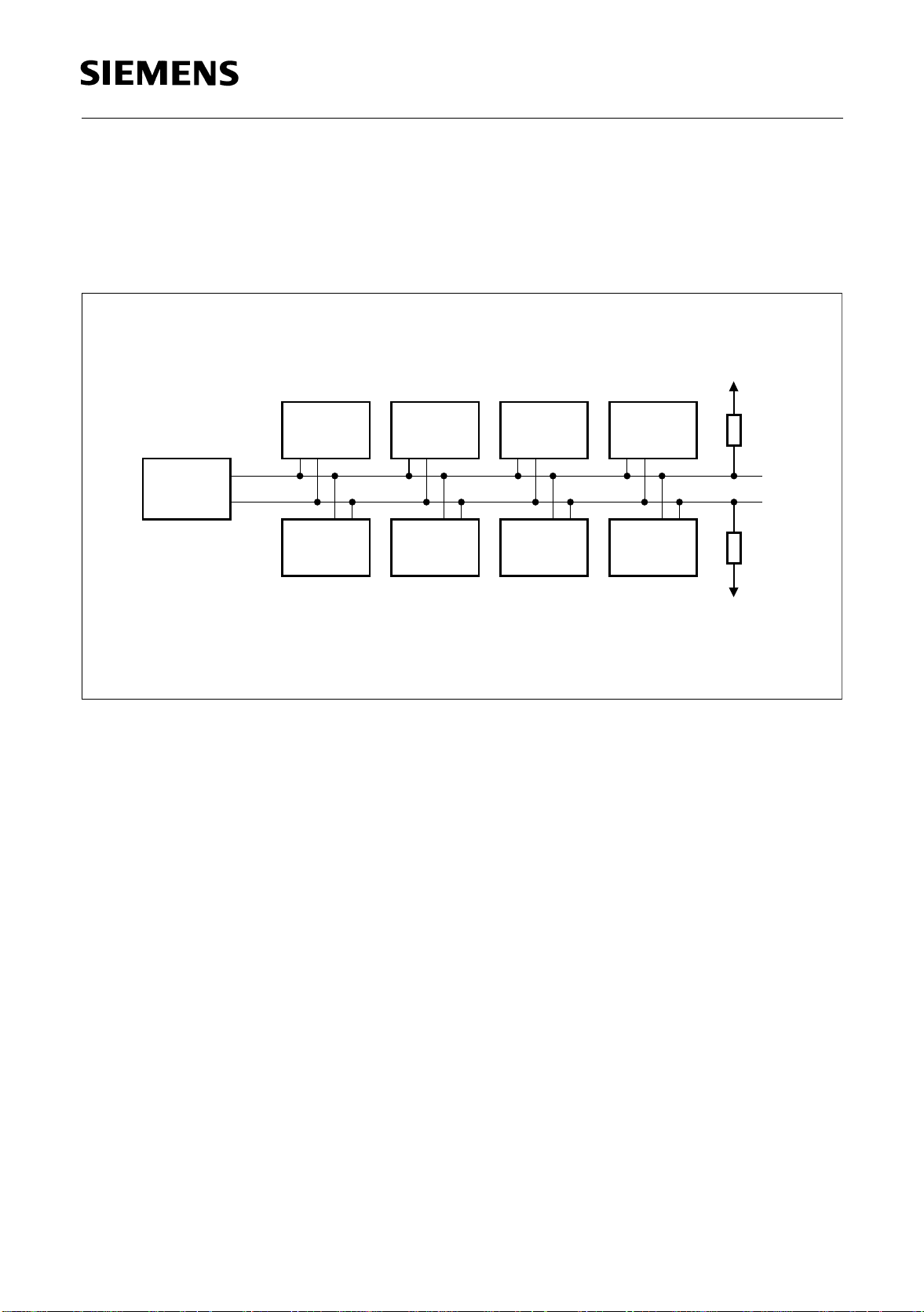

Slave 1 Slave 2 Slave 3 Slave 4

SCL

Master

SDA

C bus. This bidirectional bus consists

V

CC

Slave 8Slave 5 Slave 6 Slave 7

V

CC

IES02183

Figure 3

Bus Configuration

Master Device that initiates the transfer of data and provides the clock for transmit

and receive operations.

Slave Device addressed by the master, capable of receiving and transmitting

data.

Transmitter The device using the SDA as output is defined as the transmitter. Due to

the open drain characteristic of the SDA output the device applying a low

level wins.

Receiver The device using the SDA as input is defined as the receiver.

Semiconductor Group 7 Preliminary 1998-07-27

SLx 24C64

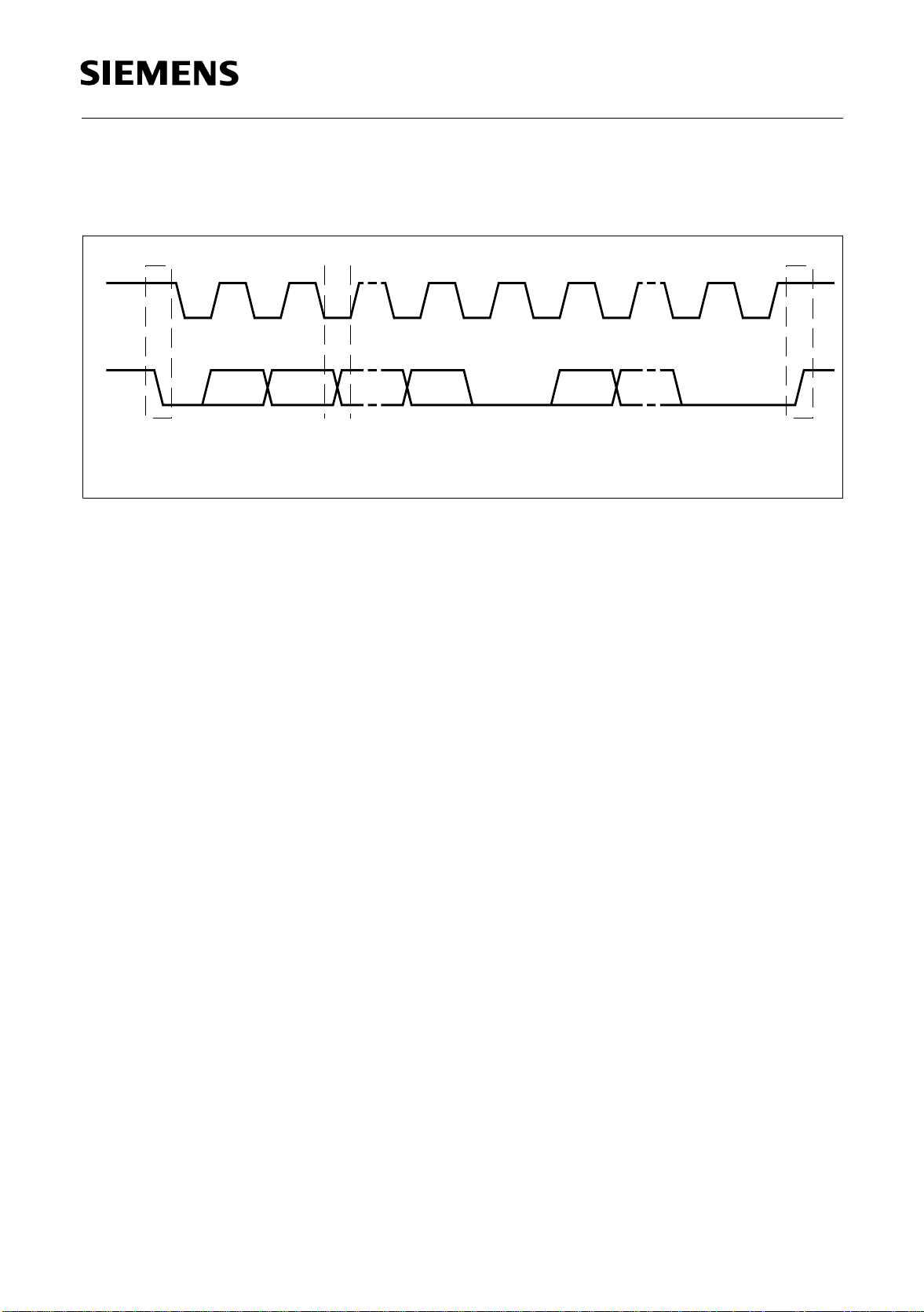

The conventions for the serial clock line and the bidirectional data line are shown in

figure 4.

SCL

SDA

START Condition Data allowed STOP Condition

12

to Change

8

Acknowledge

9

ACK ACK

1

9

IED02128

Figure 4

2

C-Bus Timing Conventions for START Condition, STOP Condition, Data

I

Validation and Transfer of Acknowledge ACK

Standby Mode in which the bus is not busy (no serial transmission, no

programming): both clock (SCL) and data line (SDA) are in high

state. The device enters the standby mode after a STOP condition

or after a programming cycle.

START Condition High to low transition of SDA when SCL is high, preceding all

commands.

STOP Condition Low to high transition of SDA when SCL is high, terminating all

communications. A STOP condition after writing data initiates an

EEPROM programming cycle. A STOP condition after reading

data from the EEPROM initiates the standby mode.

Acknowledge A successful reception of eight data bits is indicated by the

receiver by pulling down the SDA line during the following clock

cycle of SCL (ACK). The transmitter on the other hand has to

release the SDA line after the transmission of eight data bits.

The EEPROM as the receiving device responds with an

acknowledge, when addressed. The master, on the other side,

acknowledges each data byte transmitted by the EEPROM and

can at any time end a read operation by releasing the SDAline (no

ACK) followed by a STOP condition.

Data Transfer Data must change only during low SCL state, data remains valid

on the SDA bus during high SCL state. Nine clock pulses are

required to transfer one data byte, the most significant bit (MSB)

is transmitted first.

Semiconductor Group 8 Preliminary 1998-07-27

SLx 24C64

4 Device Addressing and EEPROM Addressing

After a START condition, the master always transmits a command byte CSW or CSR.

After the acknowledge of the EEPROM control bytes follow, their contents and the

transmitter depend on the previous command byte. The description of the command and

control bytes is shown in table 2.

Command Byte Selects one of the 8 addressable slave devices: The chip select

bits CS2, CS1 and CS0 (bit positions b3 to b1) are compared to their

corresponding hard wired input pins CS2, CS1 and CS0,

respectively.

Selects operation: the least significant bit b0 is low for a write

operation (Chip Select Write Command Byte, CSW) or set high for

a read operation (Chip Select Read Command Byte, CSR).

Control Bytes Following CSW (b0 = 0): The address bytes AHI/ALO containing

the address bits A0 to A12 are transmitted by the master.

Following CSR (b0 = 1): The EEPROM transmits the read out data.

EEPROM data are read as long as the master pulls down SDA after

each byte in order to acknowledge the transfer. The read operation

is stopped by the master by releasing SDA (no acknowledge is

applied) followed by a STOP condition.

Table 2

2

Command and Control Byte for I

C-Bus Addressing of Chip and EEPROM

Command Definition Function

b7 b6 b5 b4 b3 b2 b1 b0

CSW 1 0 1 0 CS2 CS1 CS0 0 chip select for write

CSR 1 0 1 0 CS2 CS1 CS0 1 chip select for read

AHI 0 0 0 A12 A11 A10 A9 A8 high address

ALO A7A6A5A4A3A2A1A0lowaddress

DATA D7 D6 D5 D4 D3 D2 D1 D0 data byte

The device has an internal address counter which points to the current EEPROM

address.

The address counter is incremented

– after a data byte to be written has been acknowledged, during entry of further data

byte

– during a byte read, thus the address counter points to the following address after

reading a data byte.

The timing conventions for read and write operations are described in figures 5 and 6.

Semiconductor Group 9 Preliminary 1998-07-27

Command Byte (CSW) Data Transfer to EEPROM

SLx 24C64

SCL

SDA

1234

0

1

1

5

CS2 CS1 CS0

0

6

START from Master Acknowledge from EEPROMAcknowledge from EEPROM

SCL

SDA

19

20

21 22

A6 A5

24

25 26

A1A2

A0

23

A3

A4A7

Acknowledge from EEPROM

Figure 5

Timing of the Command Byte CSW

8

7

10

9

11 12

0 000

27

ACK

13

A12

14

A11

15 16

A10 A9

17

A8

ACKACK

IED02526

18

Command Byte (CSR) Data Transfer from EEPROM

SCL

SDA

1234

0

1

1

5

CS2 CS1 CS0

0

6

START from Master Acknowledge from MasterAcknowledge from EEPROM

Figure 6

Timing of the Command Byte CSR

8

7

1

9

ACK

10

11 12

13

14

15 16

18

17

ACK

IED02517

Semiconductor Group 10 Preliminary 1998-07-27

SLx 24C64

5 Write Operations

Changing of the EEPROM data is initiated by the master with the command byte CSW.

Either one byte (Byte Write) or up to 32 byte (Page Write) are modified in one

programming procedure. Setting the Write Protection pin WP to V

hardware write protection and therefore any programming is suppressed. For normal

operation WP has to be set to V

.

SS

5.1 Byte Write Address Setting After a START condition the master transmits the Chip Select

Write byte CSW. The EEPROM acknowledges the CSW byte

during the ninth clock cycle. The following two bytes AHI/ALO

with the EEPROM address (A0 to A12) are loaded into the

address counter of the EEPROM and acknowledged by the

EEPROM.

activates the

CC

Transmission of Data Finally the master transmits the data byte which is also

acknowledged by the EEPROM into the internal buffer.

Programming Cycle Then the master applies a STOP condition which starts the

internal programming procedure. The data bytes are written in

the memory location addressed in the bytes AHI (A8 to A12)

and ALO (A0 to A7). The programming procedure consists of

an internally timed erase/write cycle. In the first step, the

selected byte is erased to “1”. With the next internal step, the

addressed byte is written according to the contents of the

buffer.

S

Master

SDA Line

Bus Activity

EEPROM

T

A

Command Byte

R

T

S

CSW

EEPROM Address

AHI

0

A

C

K

EEPROM Address

ALO

A

C

K

A

C

K

Data ByteBus Activity

S

T

O

P

P

A

C

K

IED02518

Figure 7

Byte Write Sequence

The erase/write cycle is finished latest after 8 ms. Acknowledge polling can be used for

speed enhancement in order to detect the end of the erase/write cycle. Please refer to

chapter 5.3, Acknowledge Polling for further information.

Semiconductor Group 11 Preliminary 1998-07-27

SLx 24C64

5.2 Page Write Address Setting Thepagewriteprocedureisthesameasthebytewrite

procedure up to the first data byte. In a page write instruction

however, entry of the EEPROM address bytes AHI/ALO are

followed by a sequence of one to a maximum of 32 data bytes

with the new data to be programmed. These bytes are

transferred to the internal page buffer of the EEPROM.

Transmission of Data The first entered data byte will be stored according to the

EEPROM address n given by AHI (A8 to A12) and ALO (A0 to

A7). The internal address counter is incremented

automatically after the entered data byte has been

acknowledged. The next data byte is then stored at the next

higher EEPROM address. EEPROM addresses within the

same page have common page address bits A5 through A12.

Only the respective five least significant address bits A0

through A4 are incremented, as all data bytes to be

programmed simultaneously have to be within the same page.

Writing over the page border will cause the address counter to

roll over to the first address of the page.

Programming Cycle The master stops data entry by applying a STOP condition,

which also starts the internally timed erase/write cycle. In the

first step, all selected bytes are erased to “1”. With the next

internal step, the addressed bytes are written according to the

contents of the page buffer.

Those bytes of the page that have not been addressed are not included in the

programming.

S

S

T

O

P

P

A

C

K

IED02519

Bus Activity

Master

SDA Line

Bus Activity

EEPROM

T

Command

A

Byte

R

CSW

T

S

EEPROM

Address

0

A

C

K

AHI

EEPROM

Address

ALO

A

C

K

A

C

K

Data

Byte n

Data

Byte n+1

A

C

K

Data

...

Byte n+31

A

C

K

Figure 8

Page Write Sequence

Semiconductor Group 12 Preliminary 1998-07-27

SLx 24C64

The erase/write cycle is finished latest after 8 ms. Acknowledge polling can be used for

speed enhancement in order to detect the end of the erase/write cycle. Please refer to

chapter 5.3, Acknowledge Polling for further information.

5.3 Acknowledge Polling

During the erase/write cycle the EEPROM will not respond to a new command byte until

the internal write procedure is completed. At the end of active programming the chip

returns to the standby mode and the last entered EEPROM byte remains addressed by

the address counter. To determine the end of the internal erase/write cycle acknowledge

polling can be initiated by the master by sending a START condition followed by a

command byte CSR or CSW (read with b0 = 1 or write with b0 = 0). If the internal erase/

write cycle is not completed, the device will not acknowledge the transmission. If the

internal erase/write cycle is completed, the device acknowledges the received command

byte and the protocol activities can continue.

Internal Programming

Procedure

Send Start

Send CS-Byte

Acknowledge

from EEPROM

received?

Yes

Next Operation

No

IED02131

Figure 9

Flow Chart “Acknowledge Polling”

Semiconductor Group 13 Preliminary 1998-07-27

STOP from Master initiates erase/write cycle

START from Master

CSR

CSR

SLx 24C64

CSR

SDA

SDA

P

S

STOP from Master initiates erase/write cycle

START from Master

CSW

P

S

1

S

CSW

0

S

Figure 10

Principle of Acknowledge Polling

1

S

Acknowledge of EEPROM

indicates complete erase/

write cycle

0

S S

S

Acknowledge of EEPROM

indicates complete erase/

write cycle

1

e.g. STOP condition

CSW

0

P

P

IED02166

Semiconductor Group 14 Preliminary 1998-07-27

SLx 24C64

6 Read Operations

Reading of the EEPROM data is initiated by the Master with the command byte CSR.

6.1 Random Read

Random read operations allow the master to access any memory location.

Address Setting The master generates a START condition followed by the

command byte CSW. The receipt of the CSW-byte is

acknowledged by the EEPROM with a low state on the SDA

line. Now the master transmits the EEPROM address (AHI/

ALO) to the EEPROM and the internal address counter is

loaded with the desired address.

Transmission of CSR After the acknowledge for the EEPROM address is received,

the master generates a START condition, which terminates

the initiated write operation. Then the master transmits the

command byte CSR for read, which is acknowledged by the

EEPROM.

Transmission of

EEPROM Data

STOP Condition from

Master

S

T

Bus Activity

Master

SDA Line

Bus Activity

EEPROM

A

Command Byte

R

T

S

CSW

Figure 11

Random Read

During the next eight clock pulses the EEPROM transmits the

data byte and increments the internal address counter by one

byte.

During the following clock cycle the masters releases the bus

and then transmits the STOP condition.

S

S

T

O

P

P

IED02520

EEPROM Address

AHI

0

A

C

K

EEPROM Address

ALO

A

C

K

T

A

Command Byte

R

T

S

A

C

K

CSR

1

A

C

K

Data Byte

Semiconductor Group 15 Preliminary 1998-07-27

SLx 24C64

6.2 Current Address Read

The EEPROM content is read without setting an EEPROM address, in this case the

current content of the address counter will be used (e.g. to continue a previous read

operation after the Master has served an interrupt).

Transmission of CSR For a current address read the master generates a START

condition, which is followed by the command byte CSR (Chip

Select Read). The receipt of the CSR-byte is acknowledged by

the EEPROM with a low on the SDA line.

Transmission of

EEPROM Data

STOP Condition from

Master

Bus Activity

Master

SDA Line

Bus Activity

EEPROM

Figure 12

Current Address Read

During the next eight clock pulses the EEPROM transmits the

data byte and increments the internal address counter by one

byte.

During the following clock cycle the masters releases the bus

and then transmits the STOP condition.

S

T

A

Command Byte

R

T

S

CSR

1

A

C

K

Data Byte

S

T

O

P

P

IED02132

Semiconductor Group 16 Preliminary 1998-07-27

SLx 24C64

6.3 Sequential Read

A sequential read is initiated in the same way as a current read or a random read except

that the master acknowledges the data byte transmitted by the EEPROM. The EEPROM

then continues the data transmission. The internal address counter is incremented by

one during each data byte transmission.

A sequential read allows the entire memory to be read during one read operation. After

the highest addressable memory location is reached, the internal address pointer “rolls

over” to the address 0 and the sequential read continues.

The transmission is terminated by the master by releasing the SDA line (no

acknowledge) and generating a STOP condition (see figure 13).

S

Bus Activity

Master

T

A

Command Byte

R

T

CSW

A

C

K

A

C

K

S

T

O

P

SDA Line

Bus Activity

EEPROM

Figure 13

Sequential Read

S

1

A

A

C

C

K

K

Data Byte n

Data Byte n+xData Byte n+1

P

IED02134

Semiconductor Group 17 Preliminary 1998-07-27

SLx 24C64

7 Page Protection Mode

TM

The page protection mode is supported by the SLx 24C64.../P types only. For example

SLA 24C64-D/P has the same functionality as SLA 24C64-D enhanced by page

protection mode.

Each page (32 bytes) in the data memory can be protected against unintended data

changes by an associated protection bit. The protection bit memory consists of an

additional EEPROM of 256 bit (figure 14).

Data in the data memory can be modified only if the assigned protection bit is erased

(logicalstate“1”).Afterwritingthedatabytestoapage,theprotectionisachievedby

writing the associated protection bit (logical state “0”). Further changes in the data in a

protected page is possible only after erasing the protection bit.

Data Memory Area

Page 0

Page 1

0

1

31. . .

2

3

.

.

..

Protection Bit Memory Area

n

IED02521

Page 2

Page 3

.

.

Page n

1023

.

.

.

Byte Bit

Figure 14

Data Page and Assigned Protection Memory

A special procedure to write or erase a protection bit guarantees proper activation or

deactivation of page protection. For protection bit write or erase all 32 data bytes of the

respective page have to be entered for verification. The data then are compared

internally with the data to be protected. In case of identity the protection bit is written or

erased respectively.

Semiconductor Group 18 Preliminary 1998-07-27

SLx 24C64

7.1 Protection Bit Handling

The bits of the protection memory can be addressed directly for reading or programming.

A protection bit address corresponds to the lowest address within the respective page

(A5 to A12, A0 to A4 = zero). The status of each protection bit is sensed internally. A

written state (“0”) prevents programming in the associated page. If an already protected

memory page is accidentally addressed for programming, the programming procedure

is suppressed.

2

The conventional I

Therefore an independent instruction sequence for addressing and manipulation of

protection bits is implemented. For protection bit instructions the command byte CSW

with its preceding START condition followed by the associated address bytes have to be

entered twice (figures 15 through 17). The first command byte CSW is followed by the

address bytes AHI/ALO with the bit/page address A0 through A4 always at zero. The

second CSW is required for entering a control byte CTx for protection bit manipulation.

The three control bytes for read, write or erase of a protection bit are listed below

(table 3):

C-Bus protocol allows data bytes to be read and programmed only.

Table 3

Control Byte for Protection Bit Manipulation

Address

Name

b7 b6 b5 b4 b3 b2 b1 b0

Definition Function

CTR xxxxxx00Protectionbitread

CTW xxxxxx01Protectionbitwrite

CTE xxxxxx11Protectionbiterase

Semiconductor Group 19 Preliminary 1998-07-27

SLx 24C64

7.2 Protection Bit Write and Erase

For writing or erasing a protection bit the data of the respective page have to be known

by the master. The master has to present the page data as a reference for comparison

by the EEPROM. A successful comparison is necessary in order to change the value of

the protection bit.

The data of the page are not affected by the write or erase procedure of the protection

2

bit. The I

protection bit erase.

C-Busprotocolisshowninfigure 15 for protection bit write and figure 16 for

S

T

Bus

Activity

Master

SDA Line

Bus Activity

EEPROM

A

R

T

Command

Byte

CSW

A

C

K

EEPROM

Address

AHI

EEPROM

Address

ALO

A

C

K

Figure 15

Sequence for Protection Bit Write

S

Bus

Activity

Master

SDA Line

Bus Activity

EEPROM

T

A

R

T

Byte

CSW

EEPROMCommand

Address

AHI

A

C

K

EEPROM

Address

ALO

A

C

K

S

T

Command

A

Byte

R

CSW

T

0

SS

A

C

K

S

T

Command DataDataControl Data

A

Byte

R

CSW

T

0

SS

AA

C

K

Control

Byte

CTW

0000000

1

A

C

K

Byte

CTE

000000

C

K

A

C

K

11

A

C

K

Data

Byte n

Data

Byte n+1

A

C

K

A

C

K

Data

...

Byte n+31

A

C

K

Byte n+31Byte n Byte n+1

A

C

K

S

T

O

P

P

A

C

K

IED02522

S

T

O

P

P

A

C

K

IED02523

Figure 16

Sequence for Protection Bit Erase

The first command byte CSW followed by the address bytes AHI/ALO determines the

page to be protected. The second command byte CSW (identical content of first CSW)

is followed by the control byte CTW = 01

for protection bit write or CTE = 03Hfor

H

protection bit erase. Depending on CTx, the addressed protection bit will be either

written or erased.

The control byte CTx is followed by 32 parameter bytes identical to the 32 data bytes of

the page to be protected or unprotected. The data of the first entered byte must be

identical to the data byte stored at the lowest address of the current page. The other

Semiconductor Group 20 Preliminary 1998-07-27

SLx 24C64

31 bytes have to be identical to the bytes stored in ascending address order within the

same page.

A successful verification of each byte is indicated by the EEPROM by pulling the SDA

line to low (acknowledge ACK).

The bit programming procedure is initiated by the STOP condition after verification of the

last byte. Programming is started only if all 256 bits of a page have been verified

successfully. If bit programming has taken place, the address counter points to the

uppermost address of the respective page. The write or erase cycle is finished latest

after 4 ms. Acknowledge polling can be used for speed enhancement in order to detect

the end of the write or erase cycle (refer to chapter 5.3, Acknowledge Polling).

7.3 Protection Bit Read The byte sequence for random bit read is shown in figure 17.

S

Bus

Activity

Master

SDA Line

Bus Activity

EEPROM

b = Protection Bit

T

A

Byte

R

CSW

T

SS

EEPROMCommand

Address

AHI

A

C

K

EEPROM

Address

ALO

A

C

K

S

T

Command

A

Byte

R

CSW

T

0

AA

C

K

Control

Byte

CTR

00 0000 0 0

C

K

bbb

A

Data

Byte n Byte n+1

C

K

A

C

K

Data

A

C

K

...

S

T

O

P

P

A

C

K

IED02524

Figure 17

Byte Sequence for Protection Bit Read

The first command byte CSW followed by the address bytes AHI/ALO determine the

protection bit to be read. The second command byte CSW is followed by the control byte

for protection bit read. The first bit (MSB) of the transferred byte is the protection bit

00

H

of the addressed page. The other 7 bits are not valid. The page protection status is

indicated as follows:

Protection Bit = 1: A normal write operation changes the data in the associated page

Protection Bit = 0: The data in the associated page are protected against changes.

If the master acknowledges a byte with a low state of the SDA line, the protection bit of

the next page can be read as the first bit of the following byte. If the master releases the

SDA line, a STOP condition has to complete the read procedure. Any number of bytes

with a page protection status at the first bit position can be requested by the master. After

the bit of the uppermost page has been addressed an overflow of the address counter

occurs and the protection bit of the first page will be read next.

Semiconductor Group 21 Preliminary 1998-07-27

SLx 24C64

8 Electrical Characteristics

The listed characteristics are ensured over the operating range of the integrated circuit.

Typical characteristics specify mean values expected over the production spread. If not

T

otherwise specified, typical characteristics apply at

voltage.

8.1 Absolute Maximum Ratings

Stresses above those listed here may cause permanent damage to the device. This is a

stress rating only and functional operation of the device at these or any other conditions

above those indicated in the operational section of this data sheet is not implied.

Exposure to absolute maximum ratings for extended periodsmay affect device reliability.

Parameter Limit Values Units

=25°C and the given supply

A

Operating temperature range 1 (industrial)

range 2 (automotive)

–40to+85

–40to+125

°C

°C

Storage temperature – 65 to + 150 °C

Supply voltage – 0.3 to + 7.0 V

V

All inputs and outputs with respect to ground – 0.3 to

+0.5 V

CC

ESD protection (human body model) 4000 V

8.2 DC Characteristics

Parameter Symbol Limit Values Units Test Condition

min. typ. max.

Supply voltage

Supply current

V

CC

V

CC

1)

I

CC

4.5 5.5 V 5 V type

2.7 5.5 V 3 V type

3mAVCC=5V;fc= 100 kHz

(write)

Standby

current

I

2)

SB

1 µA Inputs at VCCor V

SS

Input leakage

I

LI

0.1 1 µA VIN= VCCor V

SS

current

Output leakage

I

LO

0.1 1 µA V

= VCCor V

OUT

SS

current

Input low

V

IL

–0.3 0.3× V

CC

V

voltage

Semiconductor Group 22 Preliminary 1998-07-27

SLx 24C64

8.2 DC Characteristics (cont’d)

Parameter Symbol Limit Values Units Test Condition

min. typ. max.

Input high

V

IH

0.7 × V

voltage

Output low

V

OL

voltage

Input/output

C

I/O

capacitance

(SDA)

Input

C

IN

capacitance

(other pins)

1)

The values for ICCare maximum peak values

2)

Valid over the whole temperaturerange

3)

This parameter is characterized only

CC

V

+0.5 V

CC

0.4 V IOL=3mA;VCC=5V

I

=2.1mA;VCC=3V

OL

3)

8

3)

6

pF VIN=0V;VCC=5V

pF VIN=0V;VCC=5V

Semiconductor Group 23 Preliminary 1998-07-27

8.3 AC Characteristics

SLx 24C64

Parameter Symbol Limit Values

V

= 2.7-5.5 V

CC

min. max. min. max.

SCL clock frequency

Clock pulse width low

Clock pulse width high

SDA and SCL rise time

SDA and SCL fall time

Start set-up time

Start hold time

Data in set-up time

Data in hold time

SCL low to SDA data out valid

Data out hold time

Stop set-up time

f

SCL

t

low

t

high

t

R

t

F

t

SU.STA

t

HD.STA

t

SU.DAT

t

HD.DAT

t

AA

t

DH

t

SU.STO

4.7 1.2 µs

4.0 0.6 µs

4.7 0.6 µs

4.0 0.6 µs

200 100 ns

00µs

0.14.50.10.9µs

100 50 ns

4.0 0.6 µs

100 400 kHz

1000

300

Limit Values

V

= 4.5-5.5 V

CC

1)

1)

300 ns

300 ns

Units

Timethe bus must befree before

t

BUF

4.7 1.2 µs

a new transmission can start

SDA and SCL spike suppression

t

l

50 100 50 100 ns

time at constant inputs

1)

The minimum rise and fall times can be calculated as follows: (20 + (0.1/pF) × Cb)ns

C

Example:

= 100 pF → tR=(20+0.1× 100) ns = 30 ns

b

8.4 Erase and Write Characteristics Parameter Symbol Limit Values

V

= 2.7-5.5 V

CC

Limit Values

V

= 4.5-5.5 V

CC

Units

typ. max. typ. max.

Erase + write cycle (per page)

t

WR

5858 ms

Erasepageprotectionbit 2.5 4 2.5 4 ms

Write page protection bit 2.5 4 2.5 4 ms

Semiconductor Group 24 Preliminary 1998-07-27

SCL

SLx 24C64

t

R

t

F

t

LOW

t

HIGH

t

SU.STA

t

HD.STA

SDA In

Start Condition

SDA Out

Figure 18

Bus Timing Data

AA

t

HD.DAT

tt

DH

t

SU.DAT

t

SU.STO BUF

t

Stop Condition

IED02127

Semiconductor Group 25 Preliminary 1998-07-27

9 Package Outlines

P-DIP-8-4

(Plastic Dual In-line Package)

SLx 24C64

P-DSO-8-3

(PlasticDualSmall Outline Package)

GPD05583

Sorts of Packing

Package outlines for tubes, trays etc. are contained in our

Data Book “Package Information”.

SMD = Surface Mounted Device

Semiconductor Group 26 Preliminary 1998-07-27

Dimensions in mm

GPS09032

Loading...

Loading...