Siemens SIWAREX FTC Device Manual

SIWAREX® FTC

Device Manual

Module for Belt scale

Status 10.2010

Warning and Safety Terms

This manual contains notices that are for your personal safety and to prevent damage to

devices or surroundings. These notices are indicated by a warning triangle and are presented

as follows depending on the degree of danger:

!

!

!

Danger

means, that death, severe injury or considerable material damage may result, if

the respective safety measures are not taken.

Warning

Means that death, severe injury or serious material damage can result if the corresponding safety

precautions are not followed carefully.

Caution

Means that material damage or minor injuries can result if the corresponding safety precautions are

not followed carefully.

Caution

Means that material damage can result if the corresponding safety precautions

are not followed carefully.

Attention

Refers to important information on the product, handling of a product or a

corresponding segment of the documentation to which special attention should be

given.

Qualified Personnel

Commissioning and operation of a device may only be performed by qualified personnel. Qualified personnel as

indicated in the safety information in this manual are people that have the authorization to install, ground and label

devices, systems and power circuits.

Intended Utilization

Warning

!

Brand names / Trademarks

The device may only be utilized for the applications described in the catalog and the technical

description and only in conjunction with external devices and components that are approved or

recommended by Siemens.

Fault-free and safe operation of the product depend on proper transport, proper storage, assembly,

installation, operation and maintenance.

SIWAREX®, SIMATIC®, SIMATIC HMI® and SIMATIC NET® are trade marks of the

Siemens AG. The other designations in this info may be trade marks the use of which by third

persons for their own purposes might infringe proprietor rights.

Copyright

Circulation or duplication of this document, utilization and

disclosure of its contents are not permitted unless explicitly

approved. Offenders will be liable for damages. All rights

reserved, including rights created by granting of patents or

registration of a utility model or design.

Siemens AG

Automation & Drives Dept.

SIWAREX Weighing Systems

A&D SC PS1 WT

Östliche Rheinbrückenstr. 50

D-76187 Karlsruhe

©

Siemens AG 2006 All rights reserved

Disclaimer

We have tested the contents of this document for compatibility

with the hardware and software described. This does not

exclude the possibility of discrepancies, in which case we do

not guarantee the complete compatibility of this document.

The information in this document is assessed regularly and

any necessary corrections are included in the next revision.

We are grateful for any suggestions for improvement.

© Siemens AG 2007

Subject to change without notice.

iv SIWAREX FTC

SIWAREX FTC

SIWAREX FTC

Module for belt scale

Device Manual

Warning and Safety Terms

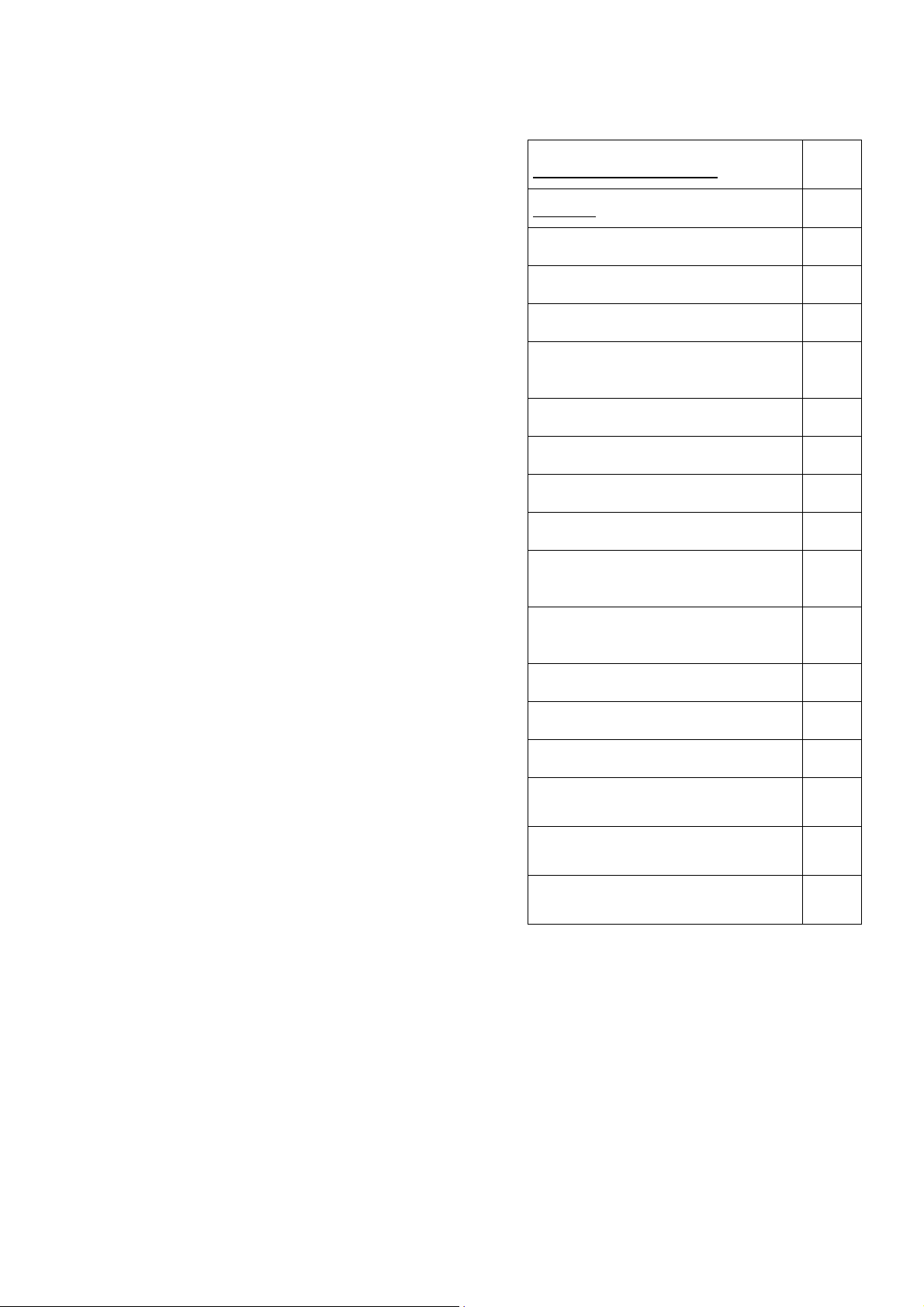

Contents

Preface

Scope of Delivery

Product Overview

Hardware Configuration and

Assembly

Weighing Functions and Parameters

Commands

Messages and Diagnosis

Programming in SIMATIC STEP 7

Commissioning with a PC –

SIWATOOL FTC_B

Firmware-Update with SIWATOOL

FTC_B

Empty

1

2

3

4

5

6

7

8

9

10

11

Revision 10/2010

Project planning in SIMATIC PCS 7

Accessories

Technical Data

Index

Abbreviations

12

13

14

15

16

SIWAREX FTC v

Contents

1 Preface....................................................................................................................................

1.1 ...............................................................................................1-1 PURPOSE OF MANUAL

1.2 ..................................................................................1-1 BASIC KNOWLEDGE REQUIRED

1.3 ...................................................................................................1-1 SCOPE OF MANUAL

1.4 ..................................................................................................1-3 FURTHER SUPPORT

2 Scope of Delivery .................................................................................................................. 2-4

2.1 .................................................................................................2-4 SCOPE OF DELIVERY

3 Product Overview..................................................................................................................3-5

3.1 ..................................................................................................................3-5 GENERAL

3.2 .....................................................................................3-5 ADVANTAGES AND BENEFITS

3.3 .................................................................................................3-6 APPLICATION RANGE

3.4 ..............................................................................................................3-6 STRUCTURE

3.5 .................................................................................................................3-6 FUNCTION

3.6 ............................................................................3-7 SYSTEM INTEGRATION IN SIMATIC

..........................................3-8 COMMISSIONING AND SERVICE WITH SIWATOOL FTC_B

3.7

.....................................................3-9 FIRMWARE DOWNLOAD WITH SIWATOOL FTC_B

3.8

............................3-9 READING THE STORED WEIGHING LOGS WITH SIWATOOL FTC_B

3.9

4 Hardware Configuration and Assembly........................................................................... 4-10

4.1 .............................................................4-11 CONFIGURING THE HARDWARE IN SIMATIC

...........................................................................4-11 STRUCTURE TO EMC GUIDELINES

4.2

4.2.1 .....................................................................................................4-11 Definition: EMC

...........................................................................................................4-11 Introduction

4.2.2

............................................................................4-12 Possible Effects of Interference

4.2.3

..........................................................................................4-12 Coupling Mechanisms

4.2.4

..............................................................4-12 Five Basic Rules for Guaranteeing EMC

4.2.5

.............................................................................4-13 ASSEMBLY ON THE PROFILE RAIL

4.3

4.4 .......................................................................................4-14 CONNECTION AND WIRING

4.4.1 ..................................................................4-14 Connection Areas for SIWAREX FTC

............................................................................................4-15 Shielding Connection

4.4.2

........................................................................4-16 Connection of 24 V Power Supply

4.4.3

.............................................................................4-16 Connections to Front Terminal

4.4.4

...........................................................................................4-16 Load Cell Connection

4.4.5

.........................................................................................................4-18 Digital Inputs

4.4.6

........................................................................................................4-20 Counter Input

4.4.7

......................................................................................................4-20 Digital Outputs

4.4.8

........................................................................................................4-22 Analog output

4.4.9

........................................4-22 Interface RS 485 for Mettler Toledo type WM or WMH

4.4.10

...................................................................................................4-24 RS 485 Interface

4.4.11

......................................................4-24 Connecting the Remote Display from Siebert

4.4.12

..............................................................4-25 Connecting the PC for SIWATOOL FTC

4.4.13

..........................................................................................4-26 LED Display Elements

4.4.14

..............................................................................4-26 Using the Micro Memory Card

4.4.15

...................................................................................4-27 PREPARING FOR OPERATION

4.5

4.6 ......................................................................................4-28 APPLICATION IN EX-ZONES

5 Weighing Functions and Parameters................................................................................5-30

5.1 ................................................................................................................5-30 GENERAL

5.2 .............................................................................5-32 DR3 ADJUSTMENT PARAMETERS

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.2.6

DR3 - Adjustment Digits 0, 1, 2, 3, 4, for the Zero Point and Adjustment

Weights 1, 2, 3, 4

..................................................................................................5-35

........................................................................5-39 DR3 - Characteristic Value Range

..........................................................5-39 DR3 – Filter Sequence for the Signal Filter

............................................................................5-39 DR3 - Type of Low-Pass Filters

..........................................................................................5-40 DR3 - Limit Frequency

..................................................................5-40 DR3 - Depth of Average Value Filters

1-1

vi SIWAREX FTC

SIWAREX FTC

5.2.7 ................................................................................................5-40 DR3 - Scale Name

.........................................................................5-40 DR3 - Number of Weight Ranges

5.2.8

.................................................................................................5-40 DR3 - Scale Type

5.2.9

..................................................5-40 DR3 - Activate Zero Setting upon Switching On

5.2.10

.............................5-41 DR3 - Activated Zero Setting upon Switch On, If Scale Tared

5.2.11

........................................................................5-41 DR3 - Automatic Zero Adjustment

5.2.12

.....................................................5-41 DR3 - Minimum Weight for Weighing Range 1

5.2.13

....................................................5-41 DR3 - Maximum Weight for Weighing Range 1

5.2.14

.....................................................5-42 DR3 - Minimum Weight for Weighing Range 1

5.2.15

....................................................5-42 DR 3 - Minimum Weight for Weighing Range 2

5.2.16

...................................................5-42 DR 3 - Maximum Weight for Weighing Range 2

5.2.17

....................................................5-42 DR 3 - Minimum Weight for Weighing Range 2

5.2.18

....................................................5-42 DR 3 - Minimum Weight for Weighing Range 3

5.2.19

...................................................5-42 DR 3 - Maximum Weight for Weighing Range 3

5.2.20

........................................................5-43 DR 3 - Numeral Step for Weighing Range 3

5.2.21

...........................................................................................5-43 DR 3 - Standstill Time

5.2.22

........................................................................................5-43 DR 3 - Standstill Range

5.2.23

.........................................................................5-43 DR 3 - Waiting Time for Standstill

5.2.24

...................5-44 DR 3 - Maximum Negative Weight for Zero Setting upon Switch On

5.2.25

....................5-44 DR 3 - Maximum Positive Weight for Zero Setting upon Switch On

5.2.26

.............................................5-44 DR 3 - Maximum Negative Weight for Zero Setting

5.2.27

...............................................5-44 DR 3 - Maximum Positive Weight for Zero Setting

5.2.28

..................................................................................5-44 DR 3 - Tare max. Weight T-

5.2.29

........................................................................................5-44 DR 3 – Operating Mode

5.2.30

.................................5-45 DR 3 - Weighing Operating Mode: NAWI Filling Procedure

5.2.31

...........................................5-45 DR 3 - Operating Mode: NAWI Emptying Procedure

5.2.32

......................................................5-45 DR 3 - Operating Mode: Force Measurement

5.2.33

......................................................................5-45 DR 3 - Operating Mode: Belt Scale

5.2.34

.....................................................5-45 DR 3 - Operating Mode: Loss-in-weight Scale

5.2.35

....................................5-45 DR 3 - Operating Mode: Bulk Flow Measurement Device

5.2.36

............................................................................................5-46 DR 3 - Load cell type

5.2.37

...................................................5-46 DR 3 – Monitoring time for the digital load cells

5.2.38

...............................................................................................5-47 DR 3 - Regulations

5.2.39

................................................................................................5-47 DR 3 - Weight Unit

5.2.40

.....................................................................................5-47 DR 3 – Large Weight Unit

5.2.41

......................................................................5-47 DR 3 - Length Unit (belt scale only)

5.2.42

.....................................................................................5-47 DR 3 - Conversion Factor

5.2.43

........................................................5-47 DR 3 – Determination Time (belt scale only)

5.2.44

..........5-48 THEORETICAL ADJUSTMENT – ADJUSTMENT WITHOUT ADJUSTMENT WEIGHTS

5.3

5.4 .........................................................................................5-48 DR 4 BASIS PARAMETER

5.4.1 .....................................................................5-49 DR 4 - Monitoring Time for Logging

.........................................................................5-49 DR 4 - Device for the Log Output

5.4.2

..................................................................5-49 DR 4 - Basis Weight for Limit Value 1

5.4.3

..................................................................5-49 DR 4 - Basis Weight for Limit Value 2

5.4.4

.........................................5-50 DR 4 - Basis Weight for Monitoring the Empty Range

5.4.5

.............................................................................................5-50 DR 4 - Empty Range

5.4.6

................................................................5-50 DR 4 - Switch-on Weight Limit Value 1

5.4.7

.....................................................................5-50 DR 4 - Cut-off Weight Limit Value 1

5.4.8

................................................................5-50 DR 4 - Switch-on Weight Limit Value 2

5.4.9

.....................................................................5-51 DR 4 - Cut-off Weight Limit Value 2

5.4.10

................................................................5-51 DR 4 - Switch-on Weight Limit Value 3

5.4.11

.....................................................................5-51 DR 4 - Cut-off Weight Limit Value 3

5.4.12

...............................................................................5-51 DR 5 BELT SCALE PARAMETER

5.5

5.5.1 ..........................................................................................5-52 DR 5 – Nominal speed

...................................................................5-52 DR 5 – Time basis for the belt speed

5.5.2

SIWAREX FTC vii

5.5.3 ..........................................................................................5-53 DR 5 – Pulse constant

..................................................................................5-53 DR 5 – Constant belt speed

5.5.4

.................................................................................5-53 DR 5 – Minimum belt speed

5.5.5

...............................................................................5-53 DR 5 – Maximum belt speed

5.5.6

..................................................5-53 DR 5 – Reaction time for belt monitoring at start

5.5.7

..........................................5-53 DR 5 – Reaction time for belt monitoring in operation

5.5.8

......................................................................................5-53 DR 5 – Nominal flow-rate

5.5.9

..................................................................................5-53 DR 5 – Effective belt length

5.5.10

..............................................................5-53 DR 5 – Correction factor for belt loading

5.5.11

....................................................................................5-54 DR 5 – Minimum flow-rate

5.5.12

...................................................................................5-54 DR 5 – Maximum flow-rate

5.5.13

................................................................................5-54 DR 5 – Minimum belt loading

5.5.14

...............................................................................5-54 DR 5 – Maximum belt loading

5.5.15

......................................................5-54 DR 5 – Maximum belt loading for zero setting

5.5.16

............................................................5-54 DR 5 - Minimum belt loading for totalizing

5.5.17

...............5-54 DR 5 – Delay time for the monitoring of the belt loading after the start

5.5.18

.........5-54 DR 5 – Delay time for monitoring the belt loading in continuous operation

5.5.19

.....................................................................5-55 DR 5 – Numeral step for totals 1...4

5.5.20

...............................................................5-55 DR 5 – Numeral step for the totals 4...5

5.5.21

....................................................................5-55 DR 5 – Material quantity per pulse 1

5.5.22

.......................................................5-55 DR 5 – Pulse duration 1 for the digital output

5.5.23

......................................5-55 DR 5 – Minimum pause duration 1 for the digital output

5.5.24

....................................................................5-55 DR 5 – Material quantity per pulse 2

5.5.25

.......................................................5-55 DR 5 – Pulse duration 2 for the digital output

5.5.26

......................................5-55 DR 5 – Minimum pause duration 2 for the digital output

5.5.27

.........................................................5-56 DR 5 – Over and under-load inhibition time

5.5.28

...................................................................................................5-56 DR 7 INTERFACES

5.6

5.6.1 ..............................................................5-61 DR 7 - Source for the Weight Simulation

...........5-61 DR 7 - Decade for Rounding the Decimal Places for the Process Values

5.6.2

........................................................................5-61 DR 7 - Force in Service Operation

5.6.3

.............................5-62 DR 7 - Process Value 1 for Fast Output to the SIMATIC CPU

5.6.4

.............................5-62 DR 7 - Process Value 2 for Fast Output to the SIMATIC CPU

5.6.5

................................5-62 DR 7 - Definition of the Process Alarms 0, 1, 2, 3, 4, 5, 6, 7

5.6.6

.................................................................5-63 DR 7 - S7-FB-Life Bit Monitoring Time

5.6.7

.....................................5-63 DR 7 – Input Value for the Adjustment Zero (0 or 4 mA)

5.6.8

.....................................................5-63 DR 7 - Input Value for the End Value (20 mA)

5.6.9

..................................5-63 DR 7 - Replacement Value for the Analog Output with OD

5.6.10

....................................................................5-63 DR 7 - Source for the Analog Output

5.6.11

.......................................................5-63 DR 7 - Current Range for the Analog Output

5.6.12

............................................................................5-64 DR 7 - RS232 Printer Baudrate

5.6.13

...................................................5-64 DR 7 - RS232 Transmission Control for Printer

5.6.14

..................................................................5-64 DR 7 – Protocol Selection for RS 485

5.6.15

......................................................5-64 DR 7 - Decimal Place for the Remote Display

5.6.16

......................................................................................5-64 DR 7 – RS 485 Baudrate

5.6.17

...........................................................................5-65 DR 7 - RS485 Character Frame

5.6.18

.................................5-65 DR 7 - Definition of the Digital Outputs 1, 2, 3, 4, 5, 6, 7, 8

5.6.19

..................................................5-65 DR 7 - Level Definition for Digital Outputs 1 to 8

5.6.20

..............5-66 DR 7 - Replacement Values for DO 1 to 8 with Fault or Output Disable

5.6.21

..................5-66 DR 7 - Replacement Values for Digital Outputs with Operating Error

5.6.22

..........................................5-67 DR 7 - Definition of Digital Inputs 0, 1, 2, 3, 4, 5, 6, 7

5.6.23

.....................................................5-67 DR 7 - Level Definition for Digital Inputs 1 to 7

5.6.24

5.6.25

5.6.26

5.6.27

DR 7 - MMC Log Overflow, MMC Trace Overflow, Target Memory for Trace

Function

................................................................................................................5-67

........................................................5-68 DR 7 - Memory Segment for Trace Function

..........................................................................5-68 DR 7 - Memory Segment for Log

viii SIWAREX FTC

SIWAREX FTC

5.6.28 ...............................................................5-68 DR 7 - Trace Function Recording Cycle

...................................................................................................5-68 DR 8 DATE / TIME

5.7

5.8 ...........................................................................................5-69 DR 9 INFO ON MODULE

5.8.1 ...........................................................................................5-70 DR 9 - Info on Module

..................................................................................................5-70 DR 14 TILT ANGLE

5.9

5.9.1 ...............................................................5-70 DR 14 – Tilt angle definition for the belt

................................................................................................5-70 DR 15 TARE ENTRY

5.10

5.10.1 ................................................................................................5-71 DR 15 - Tare Entry

..........................................................................5-71 DR 16 WEIGHT SIMULATION ENTRY

5.11

5.11.1 ...................................................................5-71 DR 16 - Weight Simulation Definition

..........................................................................5-71 DR 17 ANALOG OUTPUT CONTROL

5.12

5.12.1 .............................................................5-72 DR 17 - Ext. Definition for Analog Output

.................5-72 DR 18 CONTROL DISPLAY FOR NON-AUTOMATIC WEIGHING INSTRUMENT

5.13

5.14 .............................................................5-72 DR 21 PARAMETER FOR BATCH OPERATION

5.14.1 .....................................................................................5-73 DR 21 – Loading quantity

............................................................................5-73 DR 21 – Maximum loading time

5.14.2

........................................................................................5-73 DR 21 – Trailing weight

5.14.3

..........................................................................................5-73 DR 21 – Log Selection

5.14.4

.................5-73 DR 30 PROCESS STATUS 1 (NAWI, FORCE MEASUREMENT, BELT SCALE)

5.15

.....................................................................................5-74 DR 30 - NAWI Status Bits

5.15.1

...................................................................................5-75 DR 30 - Conti-Status Flags

5.15.2

...............................................................................5-76 DR 30 - Gross Process Value

5.15.3

...................................................................................5-76 DR 30 - Net Process Value

5.15.4

.................................................................................5-76 DR 30 - Tare Process Value

5.15.5

..............................................................................................5-76 DR 30 - G/N Weight

5.15.6

......................................................................................5-76 DR 30 - G/N Weight_x10

5.15.7

.........................................................................................................5-76 DR 30 - Tare

5.15.8

..............................................................................................5-76 DR 30 – Belt Speed

5.15.9

5.15.10

5.15.11

5.15.12

5.15.13

5.15.14

5.15.15

5.15.16

5.15.17

5.15.18

5.15.19

5.16

5.16.1

5.16.2

5.16.3

5.16.4

5.16.5

5.16.6

5.16.7

5.16.8

5.17

5.17.1 .............................................................................5-79 DR 33 – Distribution Memory 1

5.17.2

5.17.3

5.17.4

5.17.5

5.17.6

5.17.7

..................................................5-76 DR 30 – Belt Speed in % of the Nominal Speed

..................................................5-76 DR 30 – Belt Loading in % of the Nominal Load

..........................................................................................5-77 DR 30 - Nominal Load

.................................................................................................5-77 DR 30 - Belt Load

...............................................................................................5-77 DR 30 – Flowrate 1

...............................................................................................5-77 DR 30 – Flowrate 2

...............................................................................................5-77 DR 30 – Flowrate 3

...................................................5-77 DR 30 – Flowrate in % of the Nominal Flowrate

.......................................................................5-77 DR 30 – Operating Hours Counter

...............................................................................5-77 DR 30 – Pulse Counter Value

...............................................5-77 DR 31 PROCESS STATUS 2 (ALL OPERATING MODES)

...........................................................................5-78 DR 31 – Unfiltered Digital Value

...........................................................................5-78 DR 31 – Unfiltered Digital Value

.......................................................................................5-78 DR 31 – Operating Error

...............................................................................................5-78 DR 31 – Date Time

..................................................................................5-78 DR 31 – Max. Temperature

............................................................................5-78 DR 31 – Status of Digital Inputs

...................................................................5-78 DR 31 - Impedance Reference Value

........................................................................5-78 DR 31 – Impedance Actual Value

................................................................................5-78 DR 33 DISTRIBUTION MEMORY

.............................................................................5-79 DR 33 – Distribution Memory 2

.............................................................................5-79 DR 33 – Distribution Memory 3

.............................................................................5-79 DR 33 – Distribution Memory 4

.............................................................................5-79 DR 33 – Distribution Memory 5

.............................................................................5-79 DR 33 – Distribution Memory 6

.............................................................................5-80 DR 33 – Distribution Memory 7

SIWAREX FTC ix

5.17.8 .............................................................................5-80 DR 33 – Distribution Memory 8

.................................................................................5-80 DR 34 ASCII DISPLAY VALUE

5.18

5.19 ........................................5-80 DR 35 ENCODED INFORMATION FOR VERIFIABLE DISPLAY

5.20 ................................................................................5-80 DR 40 TO 43 LOG TEXT 1 TO 4

....................................................................................................5-83 DR 44 LAST LOG

5.21

5.21.1 ...................................................................................................5-83 DR 44 - MMC-ID

......................................................................................................5-83 DR 44 - Log ID

5.21.2

..........................................................................................5-83 DR 44 - Last Log Data

5.21.3

........................................................................................................5-83 DR 45 STRING

5.22

5.23 .....................................5-84 DR 46 PARAMETER FOR READING MMC LOGS IN SIMATIC

.........................................................................................5-85 DR 47 REQUESTED LOG

5.24

5.24.1 ...................................................................................................5-85 DR 47 - MMC-ID

......................................................................................................5-85 DR 47 - Log ID

5.24.2

..................................................................................................5-85 DR 47 - Log Data

5.24.3

......................................................................5-85 DR 120/121 TRACE - DATA LOGGING

5.25

5.26 ................................................................................5-86 DR 123 DATA CONTENT MMC

........................................................................................5-87 DR 122 LOG DATA MMC

5.27

6 Commands ...........................................................................................................................6-88

6.1 ................................................................................................6-88 COMMAND GROUPS

6.2 .......................................................................................................6-89 COMMAND LIST

7 Messages and Diagnosis....................................................................................................7-98

7.1 ....................................................................................................7-98 MESSAGE TYPES

7.2 ....................................................................................................7-98 MESSAGE PATHS

7.3 ............................................7-99 DETECTION OF MESSAGES USING SIWATOOL FTC_B

...................................................7-99 DETECTION OF MESSAGES USING FB SIWA_FTC

7.4

.7-99 DETECTION OF MESSAGES USING THE DIAGNOSTIC ALARMS IN THE SIMATIC-CPU.

7.5

......................................................7-100 MESSAGE LIST DATA AND OPERATING ERRORS

7.6

7.7 ...............................................................7-107 MESSAGE LIST TECHNOLOGY MESSAGES

7.8 ......................................................7-110 MESSAGE LIST OF THE OPERATING MESSAGES

8 Programming in SIMATIC STEP 7 ...................................................................................8-112

8.1 ..............................................................................................................8-112 GENERAL

8.2 ...........................................................................8-112 SIWAREX FTC IN HW CONFIG.

.............................................8-113 SIWAREX FTC IN THE CYCLIC STEP 7 – PROGRAM

8.3

8.4 ................................................................8-113 CALL PARAMETERS FOR FB SIWA_FTC

......................................................................................8-113 ADDR:= 256, Input, INT

8.4.1

...............................................................................8-114 DB_SCALE:= 18, Input, INT

8.4.2

............................................................................8-114 DB_VECTOR:= 17, Input, INT

8.4.3

..........................................8-114 CMD_IN:= "DB_SCALE".i_CMD_INPUT, Input, INT

8.4.4

.....................................8-114 SIM_VAL:= "DB_SCALE".r_SIM_VALUE, Input, REAL

8.4.5

.................8-114 ANA_OUT:= "DB_SCALE".r_ANALOG_OUT_VALUE, Input, REAL

8.4.6

..............8-114 DO_FORCE:= "DB_SCALE".b_DIG_OUTPUT_FORCE, Input, BYTE

8.4.7

...........8-114 CMD_INPR:= "DB_SCALE".bo_CMD_IN_PROGRESS, Output, BOOL

8.4.8

..............................8-114 CMD_INPR:= "DB_SCALE".bo_CMD_FOK, Output, BOOL

8.4.9

...............................8-115 CMD_ERR:= "DB_SCALE".bo_CMD_ERR, Output, BOOL

8.4.10

................8-115 CMD_ERR_C:= "DB_SCALE".b_CMD_ERR_CODE, Output, BYTE

8.4.11

....8-115 REF_COUNT:= "DB_SCALE".b_INFO_REFRESH_COUNT, Output, BYTE

8.4.12

...............8-115 PROC_VAL1:= "DB_SCALE".r_PROCESS_VALUE1, Output, REAL

8.4.13

.........8-115 PROC_VAL2:= "DB_SCALE".w_PROCESS_VALUE2, Output, DWORD

8.4.14

............8-115 SC_STATUS:= "DB_SCALE".dw_SCALE_STATUS, Output, DWORD

8.4.15

...............................8-115 ERR_MSG:= "DB_SCALE".bo_ERR_MSG, Output, BOOL

8.4.16

..........8-115 ERR_MSG_TYPE:= "DB_SCALE".b_ERR_MSG_TYPE, Output, BYTE

8.4.17

................8-116 ERR_MSG_C:= "DB_SCALE".b_ERR_MSG_CODE, Output, BYTE

8.4.18

......................................8-116 FB_ERR:= "DB_SCALE".bo_FB_ERR, Output, BOOL

8.4.19

................................................8-116 FB_ERR_C:= "DB_SCALE".b_FB_ERR_CODE

8.4.20

.........................8-117 START_UP:= "DB_SCALE".bo_START_UP_IN_PROGRESS

8.4.21

x SIWAREX FTC

SIWAREX FTC

8.4.22 ....................................................8-117 CMD_EN:= "DB_SCALE".bo_CMD_ENABLE

........................................8-117 ERR_MSG_Q:= "DB_SCALE".bo_ERR_MSG_QUIT

8.4.23

.............................................................................8-117 ALLOCATION OF THE SCALE DB

8.5

9 Commissioning with a PC – SIWATOOL FTC_B............................................................9-118

9.1 ..............................................................................................................9-118 GENERAL

9.2 ................................................9-118 WINDOWS AND FUNCTIONS IN SIWATOOL FTC_B

......................................................................................9-118 OFFLINE CONFIGURATION

9.3

9.4 ..............................................................................................9-118 ONLINE OPERATION

9.5 ....................................................................................................................9-119 HELP

10 Firmware-Update with SIWATOOL FTC_B..................................................................10-120

10.1 ............................................................10-120 ADVANTAGES OF THE FIRMWARE UPDATE

11 Empty.............................................................................................................................. 11-122

12 Project planning in SIMATIC PCS 7............................................................................. 12-123

13 Accessories ...................................................................................................................13-124

14 Technical Data ............................................................................................................... 14-126

14.1 ..........................................................................................14-126 24 V POWER SUPPLY

14.2 .........................................................14-126 POWER SUPPLY FROM S7 BACKPLANE BUS

14.3 ....................................................................................14-126 LOAD CELL CONNECTION

14.4 ................................................................................................14-127 ANALOG OUTPUT

14.5 ......................................................14-127 DIGITAL INPUTS (DI), DIGITAL OUTPUTS (DO)

.................................................................14-128 COUNTER INPUT CI (FOR BELT SCALE)

14.6

..........................................................................................14-128 RS 232C INTERFACE

14.7

14.8 .............................................................................................14-128 RS 485 INTERFACE

14.9 .....................................................................................14-129 DIMENSION AND WEIGHT

14.10 ..............................................................14-129 MECHANICAL REQUIREMENTS AND DATA

14.11 .............................................14-130 ELECTRICAL-, EMC- AND CLIMATIC REQUIREMENTS

14.11.1 ................................................14-130 Electrical Protection and Safety Requirements

14.11.2

14.12

14.13 ...........................................................................................................14-133 LICENSES

15 Index ............................................................................................................................... 15-134

16 Abbreviations ................................................................................................................16-137

..........................................................................14-130 Electromagnetic Compatibility

.............................................................................14-132 ENVIRONMENTAL CONDITIONS

Images

FIGURE 3-1

FIGURE 3-2

FIGURE 4-1

FIGURE 4-2

FIGURE 4-3

FIGURE 4-4

FIGURE 4-5

FIGURE 4-6

FIGURE 4-7

FIGURE 4-8

FIGURE 4-9

FIGURE 4-10

FIGURE 4-11

FIGURE 4-12

FIGURE 5-1

FIGURE 5-2

FIGURE 5-3

FIGURE 5-4

FIGURE 5-5

............. 3-8 CONFIGURATION OF SIMATIC S7/PCS7 WITH SIWAREX FTC

................................................................. 3-9 SIWATOOL FTC_B OVERVIEW

................................................................. 4-14 SIWAREX FTC FRONT VIEW

................................................................... 4-15 SHIELD CLAMP ASSEMBLY

.................................. 4-18 LOAD CELL CONNECTION IN 4-WIRE SYSTEM

.................................. 4-18 LOAD CELL CONNECTION IN 6-WIRE SYSTEM

..................................................................................... 4-19 DIGITAL INPUTS

.................................................................................... 4-20 COUNTER INPUT

................................................................................. 4-21 DIGITAL OUTPUTS

.................................................................................... 4-22 ANALOG OUTPUT

... 4-23 CONNECTING METTLER TOLEDO TYPE WM OR WMH TO RS 485

............................................................................. 4-24 RS 485 CONNECTION

........................................................ 4-25 CONNECTING THE S102 DISPLAY

............................................................................ 4-25 CONNECTING THE PC

....................................... 5-37 ADJUSTMENT DIGITS AND WEIGHT VALUE

.............. 5-38 LINEARIZATION OF THE SCALE CHARACTERISTIC CURVE

....................................................... 5-38 ADJUSTMENT DIGITS AND FORCE

................... 5-39 STEP RESPONSES OF THE DIGITAL LOW-PASS FILTER

.................................................................... 5-43 STANDSTILL MONITORING

SIWAREX FTC xi

FIGURE 5-6 ................................................... 5-50 DEFINING LIMIT VALUE PARAMETER

FIGURE 5-7

FIGURE 8-1

FIGURE 9-1

FIGURE 10-1

Tables

........................... 5-52 DEFINING BELT SCALE PARAMETER PARAMETER

............................................ 8-113 CALL PARAMETERS FOR FB SIWA_FTC

.............................................................. 9-119 SIWATOOL FTC_B WINDOWS

........... 10-121 DOWNLOADING THE FIRMWARE WITH SIWATOOL FTC_B

TABLE 1-1

TABLE 1-2

TABLE 4-1

TABLE 4-2

TABLE 4-3

TABLE 4-4

TABLE 4-5

TABLE 4-6

TABLE 4-7

TABLE 4-8

TABLE 4-9

TABLE 4-10

TABLE 4-11

TABLE 5-1

TABLE 5-2

TABLE 5-3

TABLE 5-4

TABLE 5-5

TABLE 5-6

TABLE 5-7

TABLE 5-8

TABLE 5-9

TABLE 5-10

TABLE 5-11

TABLE 5-12

TABLE 5-13

TABLE 5-14

TABLE 5-15

TABLE 5-16

TABLE 5-17

TABLE 5-18

TABLE 5-19

TABLE 5-20

TABLE 5-21

TABLE 5-22

TABLE 5-23

TABLE 5-24

TABLE 5-25

TABLE 5-26

TABLE 5-27 ..................................................................... 5-87 OVERVIEW OF MMC DATA

TABLE 5-28

TABLE 6-1

TABLE 6-2

TABLE 7-1

TABLE 7-2

TABLE 7-3

..................................................................... 1-1 VALIDITY OF THIS MANUAL

......................................................................... 1-2 OVERVIEW OF CHAPTER

............................. 4-11 REQUIREMENTS FOR N SIWAREX FTC MODULES

............................................................. 4-16 POWER SUPPLY CONNECTION

................................................................... 4-17 LOAD CELL CONNECTIONS

............................................................. 4-19 DIGITAL INPUT CONNECTIONS

.......................................................... 4-20 PULSE ENCODER CONNECTION

......................................................... 4-21 DIGITAL OUTPUT CONNECTIONS

.......................................................... 4-22 ANALOG OUTPUT CONNECTION

........................................................................... 4-23 RS 485 CONNECTIONS

............................................................................. 4-24 RS 485 CONNECTION

............................................................................ 4-25 CONNECTING THE PC

..................................................................... 4-26 DISPLAY ELEMENTS (LED)

.................................................................... 5-31 DATA RECORD OVERVIEW

.................................................................................... 5-35 DR3 ALLOCATION

............................................................................. 5-49 ALLOCATION OF DR 4

............................................................................. 5-61 ALLOCATION OF DR 7

............................................................................. 5-69 ALLOCATION OF DR 8

............................................................................. 5-70 ALLOCATION OF DR 9

........................................................................... 5-70 ALLOCATION OF DR 14

........................................................................... 5-71 ALLOCATION OF DR 15

........................................................................... 5-71 ALLOCATION OF DR 16

........................................................................... 5-72 ALLOCATION OF DR 17

........................................................................... 5-72 ALLOCATION OF DR 18

........................................................................... 5-73 ALLOCATION OF DR 21

........................................................................... 5-74 ALLOCATION OF DR 30

.................................................................... 5-75 DR 30 - NAWI STATUS BITS

.............................................................. 5-76 DR 30 - CONTI-STATUS FLAGS

........................................................................... 5-78 ALLOCATION OF DR 32

........................................................................... 5-79 ALLOCATION OF DR 33

........................................................................... 5-80 ALLOCATION OF DR 34

........................................................................... 5-80 ALLOCATION OF DR 35

........................................................................... 5-81 ALLOCATION OF DR 40

........................... 5-83 PROCESS VALUES FOR ALLOCATING LOG FIELDS

........................................................................... 5-83 ALLOCATION OF DR 44

........................................................................... 5-84 ALLOCATION OF DR 45

........................................................................... 5-84 ALLOCATION OF DR 46

........................................................................... 5-85 ALLOCATION OF DR 47

........................................ 5-86 COMBINATION OF RECORDING ELEMENTS

.................................................................................................. 5-87 MMC LOG

............................................................. 6-96 SIWAREX FTC COMMAND LIST

..................................................... 6-97 SIWAREX FTC COMMAND GROUPS

......................................... 7-106 LIST OF DATA AND OPERATING ERRORS

................................................... 7-109 LIST OF TECHNOLOGY MESSAGES

........................................ 7-110 LIST OF OPERATING MESSAGES –GOING

xii SIWAREX FTC

SIWAREX FTC

TABLE 7-4 ..................................... 7-111 LIST OF OPERATING MESSAGES – COMING

TABLE 14-1

TABLE 14-2

TABLE 14-3

TABLE 14-4

TABLE 14-5

TABLE 14-6

TABLE 14-7

TABLE 14-8

TABLE 14-9

TABLE 14-10

TABLE 14-11

TABLE 14-12

TABLE 14-13

.............................................................. 14-126 DATA: POWER SUPPLY 24 V

...................... 14-126 DATA: POWER SUPPLY FROM S7 BACKPLANE BUS

...................................................... 14-127 DATA: LOAD CELL CONNECTION

.................................................................... 14-127 DATA: ANALOG OUTPUT

.................................... 14-128 DATA: DIGITAL INPUTS, DIGITAL OUTPUTS

................................................................. 14-128 DATA: COUNTER INPUT CI

............................................................... 14-128 DATA: RS 232C INTERFACE

.................................................................. 14-128 DATA: RS 485 INTERFACE

.................................................... 14-129 DATA: DIMENSIONS AND WEIGHT

............................................. 14-129 DATA: MECHANICAL REQUIREMENTS

DATA: ELECTRICAL PROTECTION AND SAFETY

REQUIREMENTS

.................................................................................. 14-130

.................................. 14-131 DATA: ELECTROMAGNETIC COMPATIBILITY

.................................................... 14-132 DATA: CLIMATIC REQUIREMENTS

SIWAREX FTC xiii

1 Preface

1.1 Purpose of Manual

This manual contains all information required to set up and operate the

SIWAREX FTC.

1.2 Basic Knowledge Required

To understand this manual, a general knowledge of SIMATIC automation

technology is required. Weighing technology is also beneficial.

1.3 Scope of Manual

Preface

This manual applies to the SIWAREX FTC module:

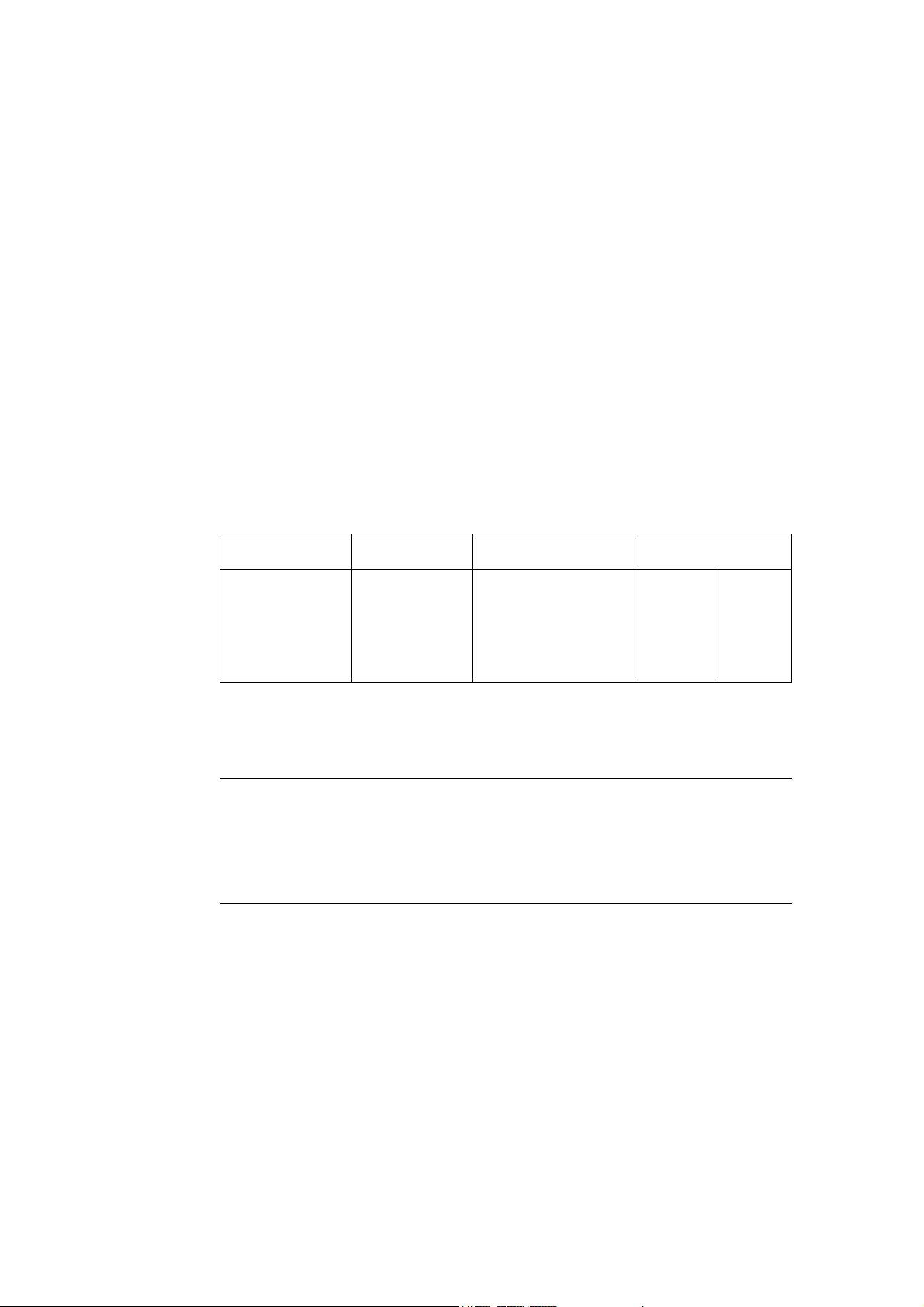

Type Name Order number From product

SIWAREX FTC SIWAREX

Flexible

Technology

Continuous

Weighing

Table 1-1 Validity of this manual

Note

This manual contains the description of all modules that are valid at the time of

publication.

We reserve the right to supply new modules or newer versions of modules with

product information containing current information about the module.

revision (Version)

7MH4900-3AA01 HW

V1.0.0

FW

V.2.1.4

SIWAREX FTC 1-1

PREFACE

The layout of this manual is based on activities that must be performed as part of

configuration, commissioning, operation and service / maintenance.

Chapter

1 Preface

2 Scope of Delivery

3 Preface

4 Hardware

5 Weighing Functions

6 Commands

7 Messages and

8 Programming in

9 Commissioning with a

10 Firmware-Update with

Description of Content

Notes on using this manual

Description of the scope of delivery for

SIWAREX FTC.

Overview of

-Structure

- Functionality

- System integration

of SIWAREX FTC.

Description

Configuration and

Assem

bly

and Parameters

Diagnosis

SIMATIC STEP 7

PC – SIWATOOL

FTC_B

- of individual hardware components

- of structure and installation

- of connections

- of preparations for operation.

Description of all weighing parameters and

corresponding functions. The operating modespecific parameters are indicated accordingly.

Description of commands that can be executed

by SIWAREX FTC.

Description of error messages with notes on

problem solutions

Description of data exchange with the

SIMATIC CPU. This chapter is only meant for

users who wish to write their own application

software.

Description

- Software installation

- Software functions

Description of software functions

SIWATOOL FTC_B

11 Empty

12 Project planning in

Empty

Description of planning for SIMATIC PCS 7

SIMATIC PCS 7

13 Accessories

14 Technical Data

15 Index

16 Abbreviations

Ordering information for optional components

such as:

- Digital remote displays

- Micro Memory Card

- Exi-Interface

Technical Data

Table 1-2 Overview of Chapter

1-2 SIWAREX FTC

PREFACE

1.4 Further Support

Do you still have questions concerning the use of the SIWAREX FTC?

Then please contact your Siemens representative in the office or business location

that is responsible for your area or technical support for SIWAREX

Tel.: +49 (0)721 595 2811.

Updated information on SIWAREX weighing technology can be found on the

Internet Site.

http://www.siemens.de/siwarex

SIWAREX FTC 1-3

2 Scope of Delivery

2.1 Scope of Delivery

A bus connector for the SIMATIC-bus, the conformity details from the manufacturer

and a sheet of additional, current product information belong to the SIWAREX FTC

scope of delivery.

Configuration packages are required for planning projects with the SIWAREX FTC

and these can be ordered separately:

- the SIWAREX FTC project configuration package for SIMATIC S7 for belt

scales

or

Scope of Delivery

- the SIWAREX FTC project configuration package for SIAMTIC PCS7 for belt

scales

The configuration package for SIMATIC S7 is made up of the following

components:

- Commissioning program SIWATOOL FTC_B for Windows

- Set-up for installation of the module in the SIMATIC Manager hardware

catalogue or update HSP (hardware software package)

- Device manuals in several languages

- SIWAREX FTC versions of "Getting started" for belt scale.

Introductory application software SIWAREX FTC „Getting started“ is very helpful

during the first steps in programming. The current version can be obtained free-ofcharge via the Internet (http://www.siemens.de/siwarex

The configuration package for SIMATIC PCS7 is made up of the following

components:

- Commissioning program SIWATOOL FTC_B for Windows

- Set-up for installation of the module in the SIMATIC Manager hardware

catalogue or update HSP (hardware support package)

- Device manuals in several languages

- Set-up for PCS7 Library (only configuration package for PCS7 for belt scale)

).

The required or optional accessories are compiled in chapter

SIWAREX FTC 2-4

13 Accessories.

PRODUCT OVERVIEW

3 Product Overview

3.1 General

SIWAREX FTC (Flexible Technology Continuous Weighing) is a versatile and

flexible weighing module.

The function module (FM) SIWAREX FTC is integrated in SIMATIC and uses all

features of the modern automation system such as integrated communication,

diagnostics system and project configuration tools to its advantage.

The scale functionality of the SIWAREX FTC utilizes the following modes of

operation:

NSW/Non automatic weighing instrument in accordance with OIML R-76

Force measurement

Belt scale

Bulk flow measurement device

Loss-in-weight scale.

The functionality of belt scale is described in chapter

available for other operating modes.

3.2 Advantages and Benefits

SIWAREX FTC is characterized by a few clear advantages:

o Uniform structure and universal communication through the integration in the

SIMATIC S7 and SIMATIC PCS7

o Standardized configuration with SIMATC

o Direct application in the SIMATIC automation system

o Application in the decentralized system concept through connection to

PROFIBUS-DP via ET 200M

o Weight measurement or force measurement to resolutions of 16 million parts

o Characteristic curve linearisation

o High accuracy 3 x 6000d, legal-for-trade OIML R76 (0,5 V pro e)

5. A separate manual is

o High sample rate of 10 ms

o PID controller with extensive setting options (Loss-in-weight scale)

o Integrated filter functions

o Parameterizable function for inputs and outputs

o Flexible adaptation to different requirements with SIMATIC

SIWAREX FTC

3-5

o Simple parameter definition with the SIWATOOL FTC_B program through the

RS 232 interface

o Exchange of module possible without readjusting the scales

o Scale progress logging – extensive optimization capabilities

o Intrinsically safe load cell supply for Ex-Zone 1 (optional)

o Application in Ex-Zone 2.

o Extensive monitoring and diagnostics functions

3.3 Application Range

SIWAREX FTC is the optimal solution wherever weighing technology requires high

speed and accuracy. Because of the high resolution (3 x 6000 d, legal-for-trade or

16 million parts internally), scales can be built to work accurately over broad areas.

SIWAREX FTC can be used for creating container scales, platform scales, force

measurement devices, belt scales, loss-in-weight scales and bulk flow

measurement devices.

3.4 Structure

SIWAREX FTC is a function module (FM) of the SIMATIC S7-300 and can be read

directly on the SIMATIC S7-300 or ET 200M bus. Installation / cabling efforts for

the 80 mm wide module is simplified with the profile rail assembly (snap-in

technology).

Connection with the load cells is done using 40-pin standard front terminal strips,

the power supply is through a 2-pin plug and the serial interface is through a 9-pin

D-type plug connector.

Operation of the SIWAREX FTC in SIMATIC guarantees complete integration of

weighing technology in the automation system.

3.5 Function

The primary task of the SIWAREX FTC is highly accurate measurement of the

current weight and exact determination of the material quantity.

There are different weighing or measurement procedures, for which the SIWAREX

FTC can be optimally configured by defining parameters.

The following operating modes can be defined:

- Non Automatic Weighing Instrument – in accordance with OIML R-76

Instrument

- Force measurement

- Belt scale

- Loss-in-weight scale

- Bulk flow measurement device

3-6 SIWAREX FTC

PRODUCT OVERVIEW

SIWAREX FTC monito

procedures. The optimized system internal data exchange enables a direct

evaluation of weighing signals and states in the PLC program.

The weighing procedure influence on the PLC enables a flexible adaptation to the

system characteristics.

SIWAREX FTC is already adjusted in-house. Therefore, the scale can be adjusted

to theoretical settings without using any adjustment weights and modules can be

exchanged without readjusting the scale.

The SIWAREX FTC has two serial interfaces. The RS 485 interface is used for

connecting digital remote displays (for operation as a non-automatic weighing

instrument) or force compensation load cells WM, WMH from the Mettler Toledo

company. A PC can be connected to the RS 232 interface for setting SIWAREX

FTC parameters.

The SIWAREX FTC weigh module can also be used in explosion hazard areas

(Zone 2). An optional Ex interface SIWAREX IS provides load cells with an

intrinsically safe power supply for applications in zone 1.

rs and controls a number of functions during the weighing

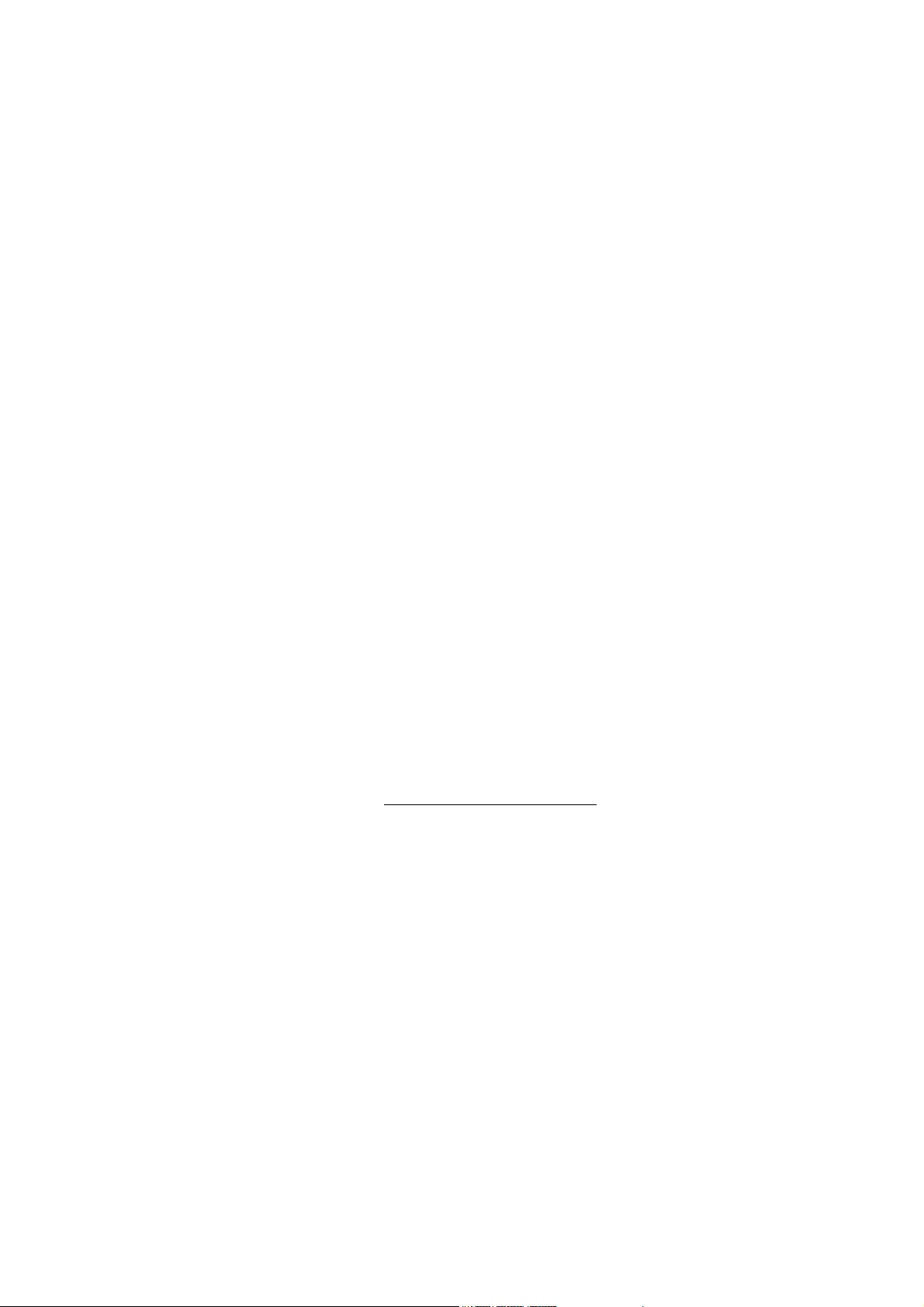

3.6 System Integration in SIMATIC

SIWAREX FTC is completely integrated in the SIMATIC S7 and SIMATIC PCS7.

The user is absolutely free to configure his automation solution including the

weighing application as desired. The optimum solution can be created for small,

medium and large systems by selectively combining the SIMATIC components.

The configuration package and the SIWAREX FTC "Getting started" example

applications can be used for developing customer-specific or industry-specific

solutions quickly and efficiently. The following figure shows a typical setup for a

medium sized system.

For project planning with SIMATIC PCS 7 (only for belt scales), the completed

function block FB SIWA for the automation system and the graphic blocks for the

operator station are used.

SIWAREX FTC

3-7

Figure 3-1 Configuration of SIMATIC S7/PCS7 with SIWAREX FTC

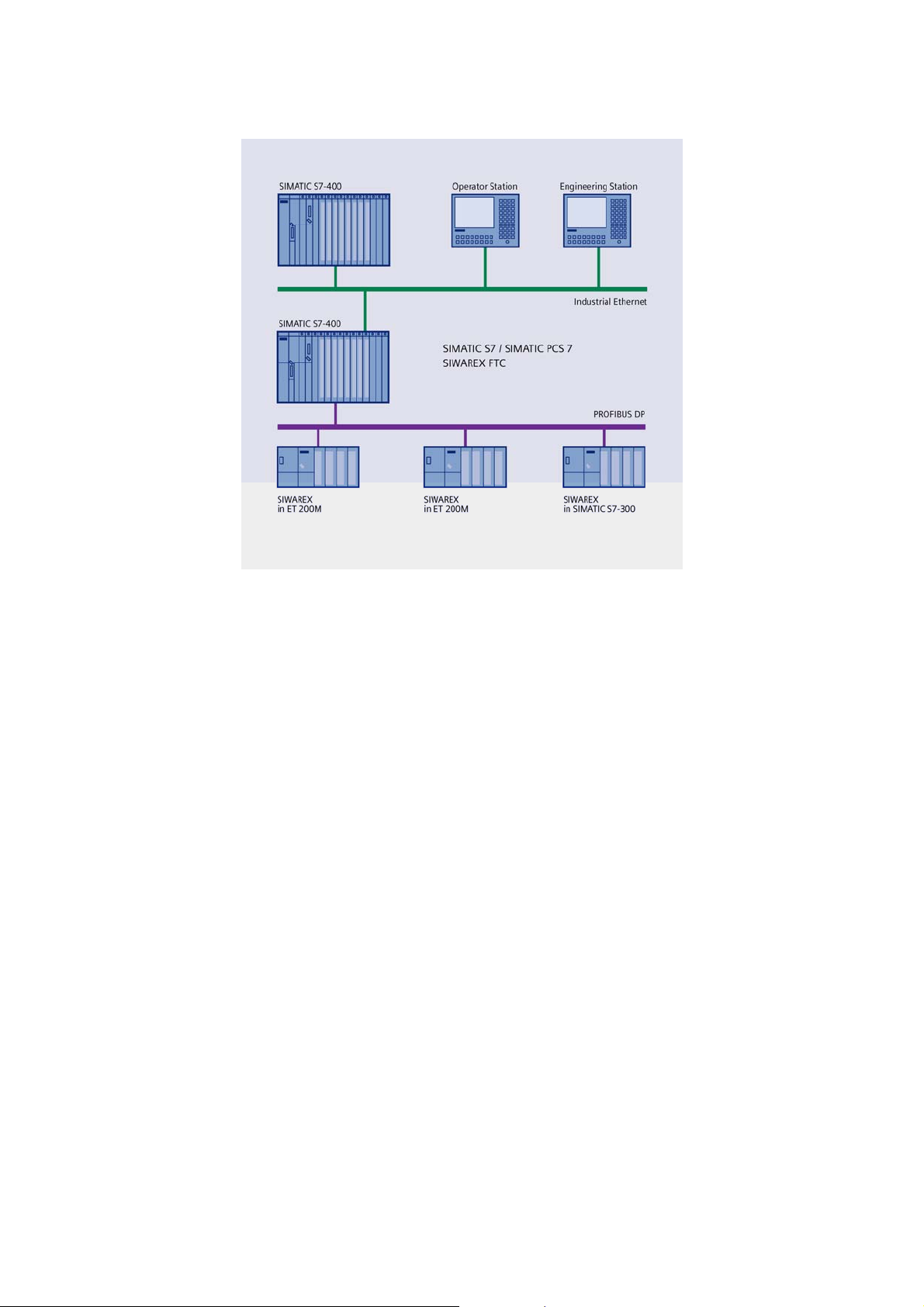

3.7 Commissioning and Service with SIWATOOL FTC_B

For commissioning and for service, there is a special program - SIWATOOL

FTC_B for belt scales and Windows operating systems.

The program enables commissioning of the scale without having to understand

automation technology. During a service procedures, you can analyze the

processes in the scale and test them with the help of a PC. Reading the

diagnostics buffer from the SIWAREX FTC is very helpful in analyzing events.

Besides complete access to all parameters, memory or print-outs of the weighing

file, the program can create weighing curves as well.

3-8 SIWAREX FTC

PRODUCT OVERVIEW

SIWATOOL

the calibratable scale memory.

The following figure shows the structure of the individual program windows.

FTC_B can also be used for reading the contents of the records from

Figure 3-2

SIWATOOL FTC_B Overview

SIWATOOL FTC_B does not only support the user in entering parameters. It is

very useful to analyze the diagnostic buffer, the contents of which can be saved

along with the parameters after reading from the module.

A trace mode exists in the SIWAREX FTC module for optimizing weighing

progress. The recorded data can be displayed in a curve diagram using MS Excel.

These records can then be used to e.g. analyze and optimize the material flow for

a shift.

3.8 Firmware Download with SIWATOOL FTC_B

Another feature of the SIWATOOL FTC_B program helps in loading a new version

of firmware onto the SIWAREX FTC, on-site. It allows upgrades or function

expansions for the firmware at any time and from anywhere.

3.9 Reading the Stored Weighing Logs with SIWATOOL FTC_B

The weighing logs are stored on an MMC (Micro Memory Card) that can be

inserted into the SIWAREX FTC. If a person disagrees with the results of a certain

weighing procedure, the weighing data for that weighing procedure can be

reconstructed from the MMC memory.

SIWAREX FTC

3-9

4 Hardware Configuration and Assembly

!

Warning Notes

This chapter contains information required for hardware planning, assembly and

preparations for operation.

The technical safety information is to be strictly adhered to.

!

Warning

Unqualified intervention in the device/system or not adhering to the warning notices

can result in serious injury or damage to equipment. Only qualified personnel are

permitted to access the operational components of this device / system.

!

Warning

The unit has been developed, manufactured, tested and documented in

accordance with the corresponding safety standards. The device itself will not

cause any danger to equipment or personal health under normal circumstances.

!

Danger

Commissioning is not permitted until it is guaranteed that the machine in which

these components are to be integrated meets with the guidelines in 89/392/EWG.

4-10 SIWAREX FTC

HARDWARE CONFIGURATION AND ASSEMBLY

4.1 Configuring the Hardware in SIMATIC

SIWAREX FTC is a function module (FM) in the SIMATIC S7 300 automation

system. It can be installed in any position designated for function modules.

Utilization with the SIMATIC S7 300 is possible in central operation, in an

expansion device or decentralized in the ET 200M system.

Operation with the SIMATIC S7 400 is only possible decentralized in the ET 200M

system. In this case, the active back-plane bus can be used.

In estimating the maximum number of SIWAREX FTC's that can be integrated

within one system, the following information may be helpful.

Total width Current requirements

(5V) from SIMATIC backplane bus

n x 80 mm n x 50 mA 4100 Bytes + n x 1200

Table 4-1 Requirements for n SIWAREX FTC modules

Max. amount in central operation – 8 SIWAREX FTC

Max. amount with multi-line expansion – 8 SIWAREX FTC per line

Max. amount in system ET 200M – 7 SIWAREX FTC per station

Selecting the suitable SIMATIC CPU, the SIMATIC HMI (Human Machine

Interface) and the communication modules does not only depend on

SIWAREX FTC requirements but also on the overall job that the automation

system has to perform.

4.2 Structure to EMC Guidelines

SIWAREX FTC is a highly accurate measuring device that has to dependably

measure the slightest signal. Proper assembly and wiring are therefore absolutely

essential for fault-free operation.

RAM requirements in

SIMATIC CPU

Bytes

4.2.1 Definition: EMC

EMC (Ele

function without faults in a defined electromagnetic environment without being

influenced by its surroundings and without negatively influencing the surroundings.

4.2.2 Introduction

Although SIWAREX FTC was devel

meets high EMC specifications, you should carry out EMC planning before

installing your controller to determine and take into account any possible

interference sources.

SIWAREX FTC

ctromagnetic Compatibility) describes the ability of an electrical device to

4-11

oped for use in industrial environments and

4.2.3 Possible Effects of Interference

Electromagnetic interference can influence the automation system and the

SIWAREX FTC in various ways:

- Electromagnetic fields that have a direct influence on the system

- Interference that infiltrates the environment through bus signals

(PROFIBUS DP etc.)

- Interference through process cabling (e.g. measurement lines)

- Interference infiltrating the system through the power supply and/or protective

ground

Interference can impair the fault-free functioning of the SIWAREX CF.

4.2.4 Coupling Mechanisms

Dep

ending on the means of distribution (conductive or non-conductive bound) and

the distance between the interference source and the device, interference can be

introduced into the automation system through four different coupling mechanisms.

Galvanic coupling

Capacitive coupling

Inductive coupling

Radiation coupling

4.2.5 Five Basic Rules for Guaranteeing EMC

If you follow these five basic rules, EMC can be guaranteed in most cases!

Rule 1: Large surface area grounding connection

Ensure that while installing the automation devices, a well-made large surface area

ground connection is made between the inactive metal components (see following

sections).

Connect all inactive metal components and low-impedance components with

ground (broad cross-section).

Use screwed connections on painted or anodized metal surfaces either with

special contact washers or remove the insulated protective surface at the contact

points.

Do not use aluminum components for ground connections if at all possible.

Aluminum oxidizes easily and is therefore less suitable for grounding connections.

Find a central location for connections between the grounding point and the ground

wiring system.

4-12 SIWAREX FTC

HARDWARE CONFIGURATION AND ASSEMBLY

Rule 2: Prop

Separate the cabling into groups (high-voltage lines, power supply lines, signal

lines, ground wiring, data lines etc.).

Run the high-voltage lines and ground wiring or data cables in separate channels

or bundles.

Run measurement lines as close to grounding surfaces as possible (e.g. support

beams, metal rails, cabinet panels).

Rule 3: Fixed cable shielding

Ensure that the cable shielding is connected properly.

Use shielded data lines only. The shielding must be fastened to ground using a

large surface area on both ends.

The shielding of measurement lines must be fastened to ground on both ends.

Run cable shielding directly under the SIWAREX FTC on the shielding channeling.

The shielding is to be run to the connection terminal.

The connection between the shielding rail / ground rail and the cabinet /housing

must be low impedance.

Use metallic or metal-plated connector housings for the shielded data lines.

er wiring

Rule 4: Special EMC measures

All inductivity that is to be controlled should be connected with suppressors.

Use interference suppressed fluorescent lighting or incandescent lamps for

illuminating cabinets or housings in the immediate vicinity of your controller.

Rule 5: Uniform reference potential

Create a uniform reference potential and ground all electrical operational elements.

If potential differences arise or can be expected between components of your

system, install adequately dimensioned potential equalizing lines. For applications

in areas with a risk of explosion, potential equalization is mandatory.

4.3 Assembly on the Profile Rail

When assembling the SIMATIC components and the SIWAREX FTC, the assembly

regulations must be completely fulfilled for the SIMATIC S7.

SIWAREX FTC is assembled in the following steps:

1. Check for whether the SIMATIC bus connector is connected to the left of the

SIWAREX FTC in the module group.

SIWAREX FTC

4-13

2. Connect the SIMATIC bus connector for the following module group in the

SIWAREX if necessary.

3. Install the shielding strip under SIWAREX.

4. Hang the SIWAREX FTC in its place.

5. Fasten the SIWAREX FTC with 2 screws in the lower area of the module.

6. Label the SIWAREX FTC corresponding with your identification system.

4.4 Connection and Wiring

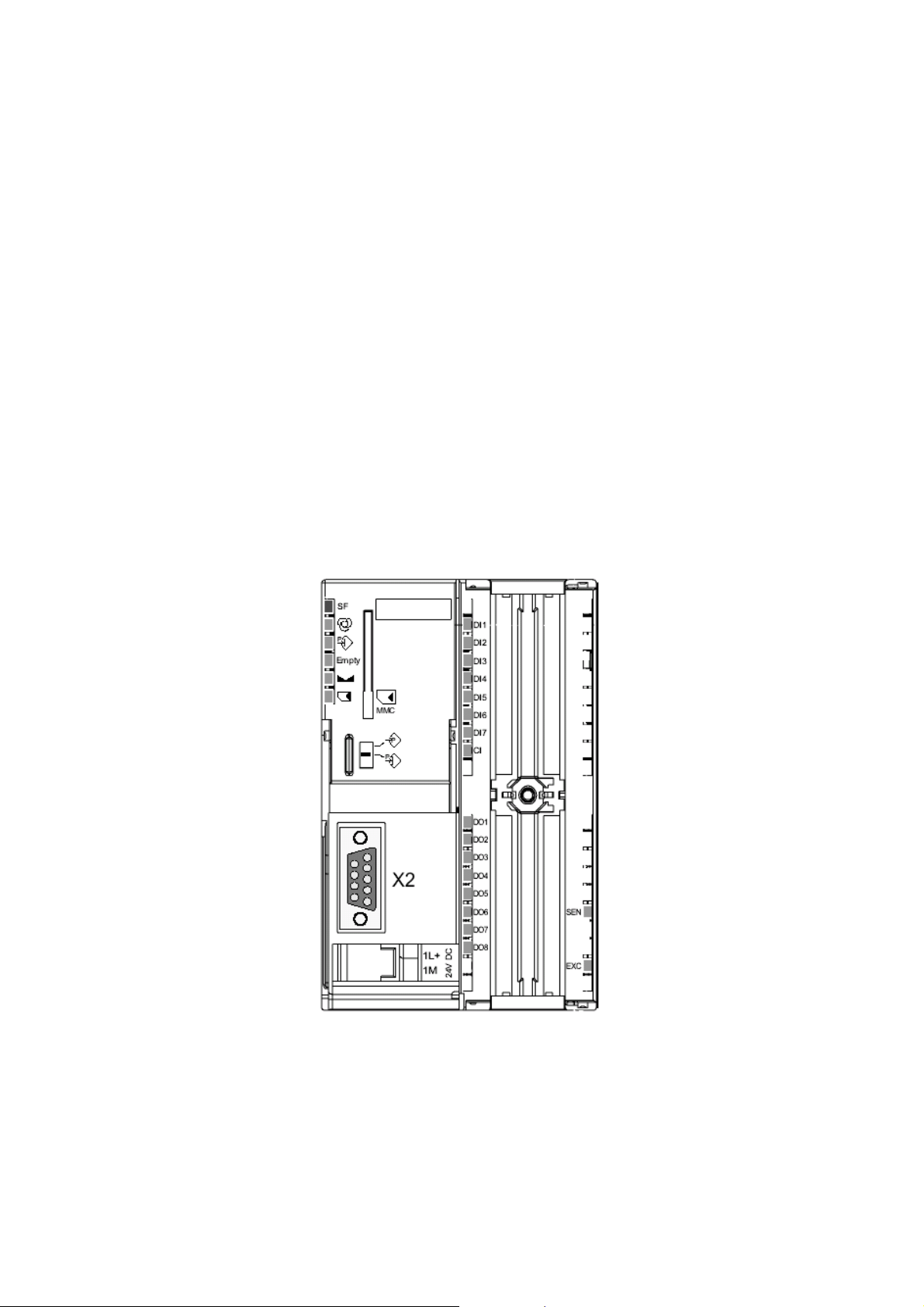

4.4.1 Connection Areas for SIWAREX FTC

The followi

- Screw-in connector for 24 V power supply

- 40 pin connector for load cell connection, digital input and output, RS 485,

- 9 pin D-sub socket for RS 232 to PC or printer connection

ng connection areas are found on the front:

analogue output, counter input

Figure 4-1

4-14 SIWAREX FTC

SIWAREX FTC front view

HARDWARE CONFIGURATION AND ASSEMBLY

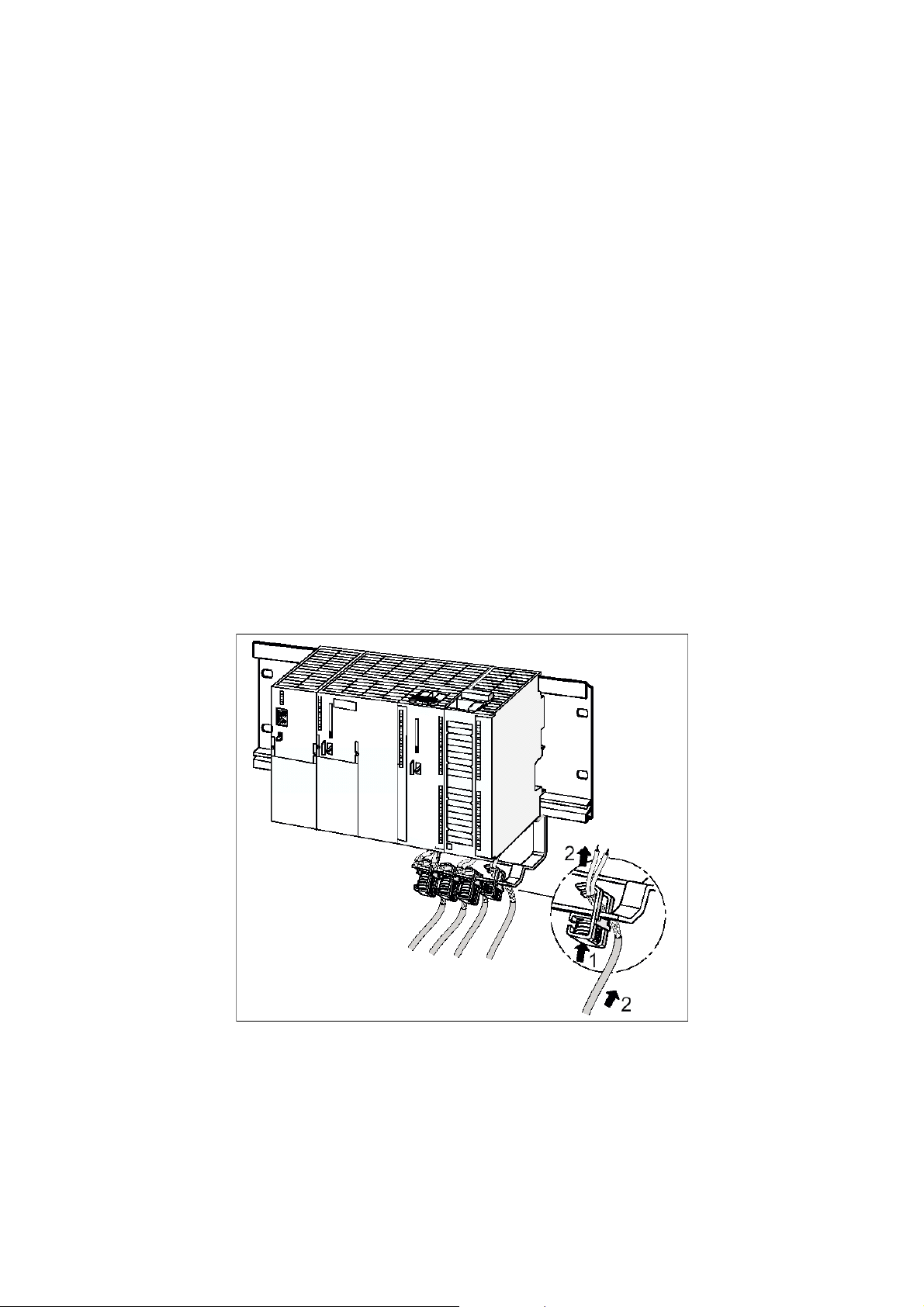

Shielding Connection

4.4.2

Special attent

The interference resistance of the system can only be guaranteed if the properly

constructed.

A cable is shielded to decrease the affects of magnetic, electrical and

electromagnetic interference on this line. Interference on cable shielding is routed

to ground through shielding rails that are conductively connected with the housing.

To ensure that this interference does not become a source of interference, a low

impedance connection to ground is especially important.

Use only lines with mesh-shielding. The shielding should provide at least 80%

coverage.

For fastening the meshed shielding, use only metal cable clamps. The clamps

must cover as much shielding as possible and ensure a good contact.

Shield clamps must be ordered separately from the grounding elements. The area

covered by the shielding clamp is to be chosen corresponding with the cable

diameter.

Approximately 1.5 cm of the cable insulation must be exposed in the area of the

cable to be fastened to the shielding clamp. The exposed shielding is then pressed

firmly against the grounding element with the shielding clamp.

The following figure shows the assembly of the shield clamps.

ion must be given to the shield strip for the shielded lines.

Figure 4-2 Shield clamp assembly

The shielding should be pressed against the shielding rail by the shielding clamp.

SIWAREX FTC

4-15

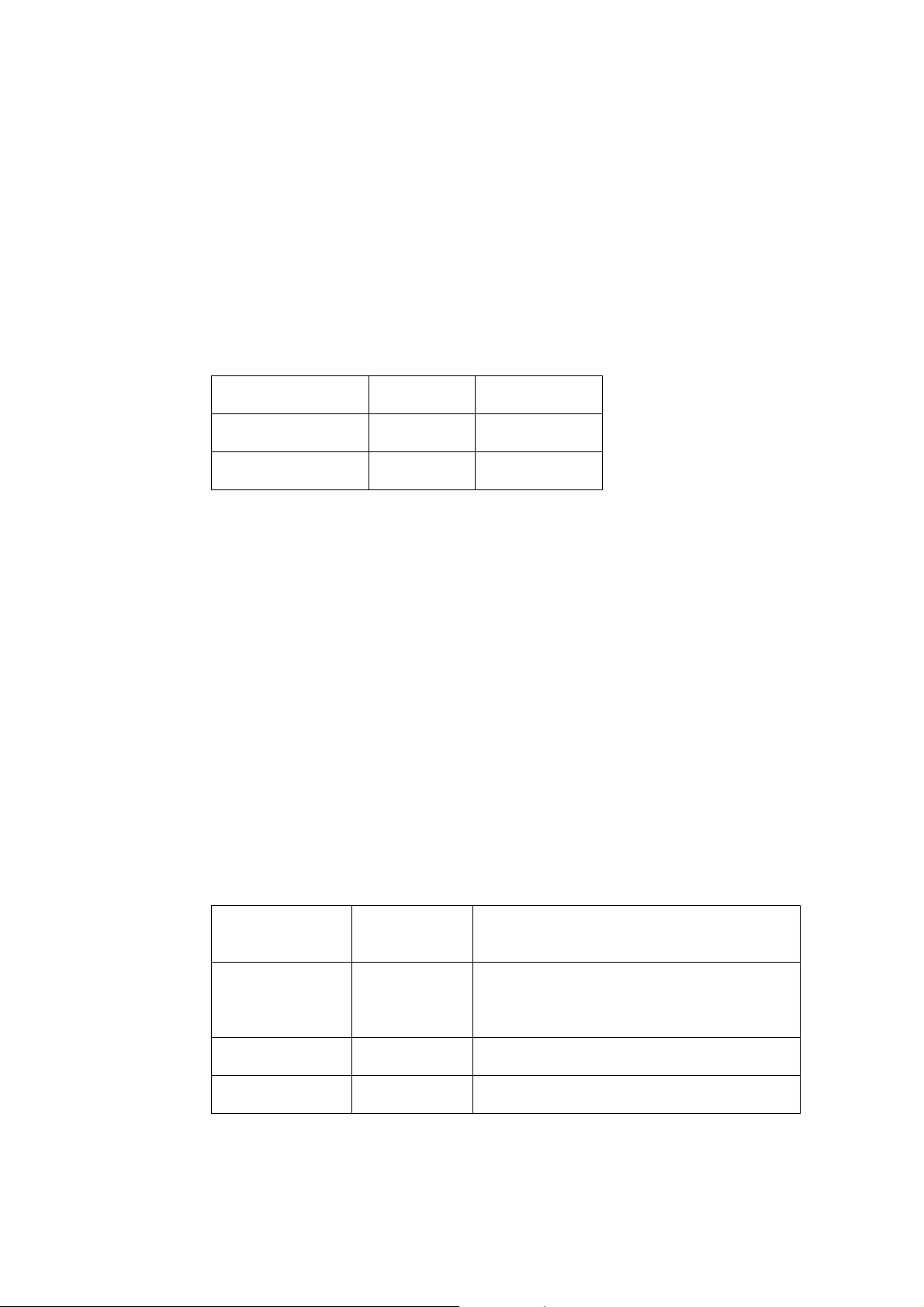

4.4.3 Connection of 24 V Power Supply

T

he 24 V supply voltage is connected with a screw connector. The connection is found

in the lower area of the module groups next to the D-sub connector for RS 232.

Note

In the S7 300 or ET200M system, the SIMATIC CPU or IM 153 and SIWAREX FTC

must be connected to the same 24 V supply.

Termination Clamp Signal Comment

1L+ 24 V DC 1L+ Power supply +

1M 24 V DC 1M Power supply M

Table 4-2 Power supply connection

4.4.4 Connections to Front Terminal

The SIMATIC con

struction guidelines apply for connecting the 40 pin connector.

Flexible cables with a cross-section of 0.25 to 1.5 mm

insulation from the cable for 6 mm and install wire end sleeves.

4.4.5 Load Cell Connection

rs equipped with strain gauges and that meet the following conditions can be

Senso

connected to the SIWAREX FTC:

- Characteristic value 1.... 4 mV/V

- Supply voltage of 10.2 V is permitted

The connection is made to the 40 pin front connector. The connection should be

made using the cable described in chapter

Termination

Clamp

Signal Comment

X1.34 AGND

2

can be used. Remove the

Accessories.

Analogue ground (is normally not connected,

on where required, e.g. with additional load

cell power requirement)

X1.35 SEN+ Sensor line +

X1.36 SEN- Sensor line -

4-16 SIWAREX FTC

HARDWARE CONFIGURATION AND ASSEMBLY

Termination

p

Clam

Signal Comment

X1.37 SIG+ Measurement line +

X1.38 SIG- Measurement line -

X1.39 EXC+ Load cell supply voltage +

X1.40 EXC- Load cell supply voltage -

Table 4-3 Load cell connections

The following rules are to be followed when connecting load cells (WZ).

Using a junction box is required if more than one LC is connected (the LC must be

connected parallel to one-another).

If the distance from the LC to the SIWAREX FTC is greater than the existing length

of the LC connection cable, then the extension box EB is to be used.

2. The cable shielding is normally run on the cable guide supports of the junction box.

In case of the danger of potential equalization currents on the cable shielding,

a potential equalization conductor is to be run parallel to the load cell cable or the

shield clamp is to be used in the junction box to the shield strip. Using the potential

equalization conductor is the preferred method of dealing with EMC

(Electromagnetic Compatibility).

3. Twisted pair cable is required for the indicated wiring:

- Sensor lines (+) and (-)

- Measurement voltage lines (+) and (-)

- Supply voltage lines (+) and (-)

4. The shielding is to be attached to the shielding strip on the SIWAREX FTC.

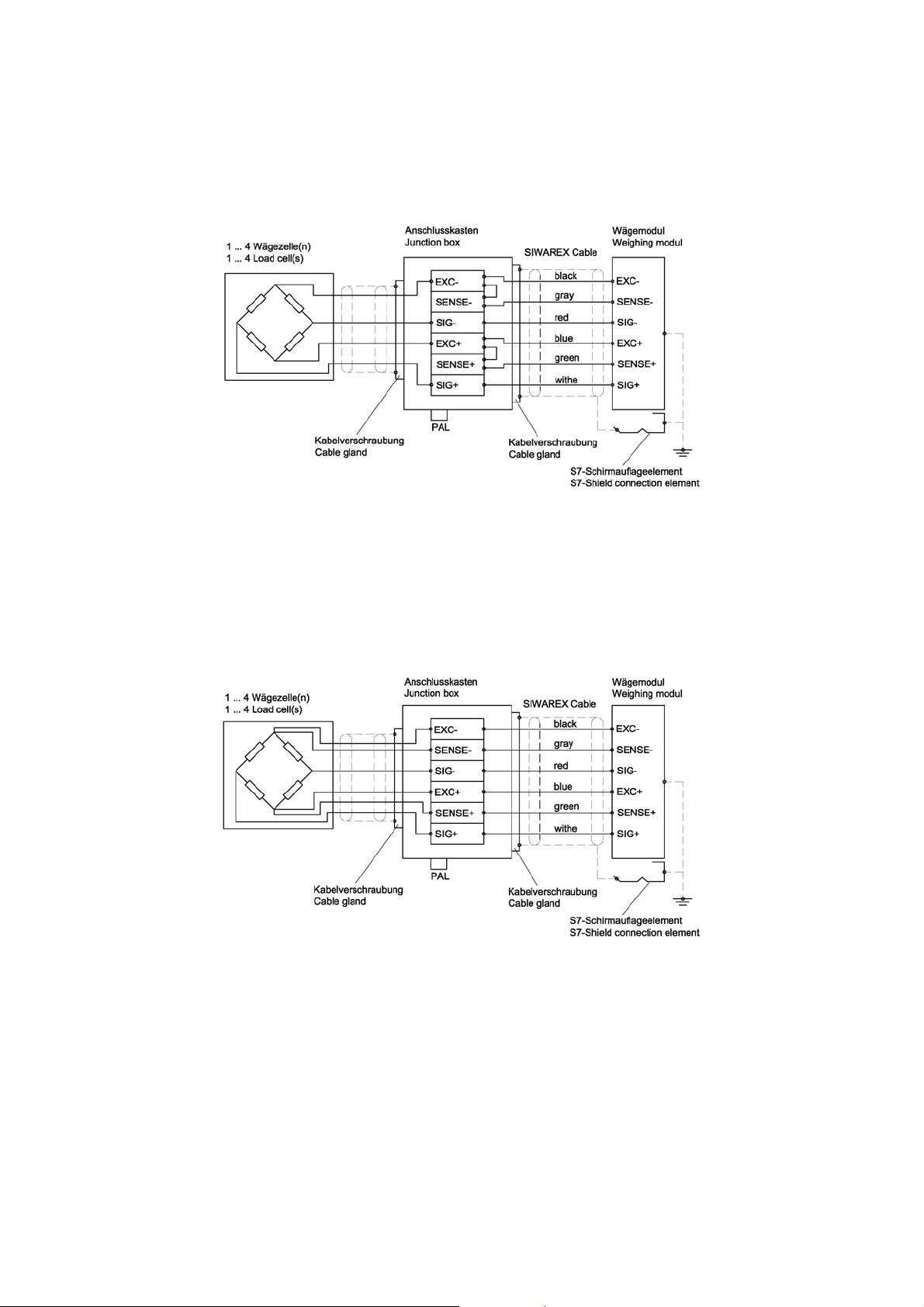

The two figures below show the load cell connection using 4-wire and 6-wire

systems.

SIWAREX FTC

4-17

Figure 4-3 Load cell connection in 4-wire system

Figure 4-4 Load cell connection in 6-wire system

4.4.6 Digital Inputs

SIWAREX FTC ha

module group. They have a common reference point (M).

4-18 SIWAREX FTC

s 7 digital inputs. These inputs are potentially isolated from the

Loading...

Loading...