Siemens SIWAREX FTA Device Manual

Device Manual

SIWAREX® FTA

Status 05/2017

Safety Guidelines

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

Qualified Personnel

qualified personnel

Prescribed Usage

WARNING

This device may only be used for the applications described in the catalog or the technical description and only

positioning and assembly as well as careful operation and maintenance.

Trademarks

Disclaimer of Liability

Siemens AG

Automation and Drives

Weighing Technology SIWAREX

Östliche Rheinbrückenstr. 50

Copyright © Siemens AG 2014

Technical data subject to change

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by

. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Note the following:

in connection with devices or components from other manufacturers which have been approved or

recommended by Siemens. Correct, reliable operation of the product requires proper transport, storage,

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

PD PA PI LW

ii SIWAREX FTA

SIWAREX FTA

1

2

3

4

5

6

7

8

9

12

13

14

15

16

Revision 05/2017

SIWAREX FTA

Weighing Electronics

Contents

Preface

Scope of Delivery

Product Overview

for Automatic Scale

Device Manual

Hardware Planning and Assembly

Weighing Functions

Warning and Safety Terms

Messages and Diagnostics

Programming in SIMATIC STEP 7

Project planning in SIMATIC PCS 7

Commissioning using a PC –

SIWATOOL FTA

Firmware-Update with SIWATOOL

FTA

10

11

Calibrating Applications

Accessories

Technical Data

Index

Abbreviations

SIWAREX FTA iii

Contents

1 Preface .................................................................................................................................... 1-1

1.1 PURPOSE OF THIS MANUAL .................................................................................................1-1

1.2 FUNDAMENTAL KNOWLEDGE REQUIREMENTS ....................................................................1-1

1.3 SCOPE OF THIS MANUAL .....................................................................................................1-1

1.4 FURTHER SUPPORT ..............................................................................................................1-3

2 Scope of Delivery .................................................................................................................. 2-4

2.1 SCOPE OF DELIVERY ...........................................................................................................2-4

3 Product Overview .................................................................................................................. 3-6

3.1 GENERAL INFORMATION .....................................................................................................3-6

3.2 BENEFITS ............................................................................................................................3-6

3.3 RANGE OF APPLICATION .....................................................................................................3-7

3.4 STRUCTURE .........................................................................................................................3-7

3.5 FUNCTION ...........................................................................................................................3-8

3.6 SYSTEM INTEGRATION IN SIMATIC ...................................................................................3-9

3.7 COMMISSIONING AND SERVICE WITH SIWATOOL FTA ..................................................3-10

3.8 FIRMWARE DOWNLOAD WITH SIWATOOL FTA .............................................................3-12

3.9 READING THE STORED WEIGHING LOGS WITH SIWATOOL FTA ......................................3-12

3.10 QUICK INSTALLATION WITH SIWATOOL FTA WIZZARD ................................................3-12

4 Hardware Planning and Assembly .................................................................................... 4-13

4.1 PLANNING THE HARDWAR E IN SIMATIC .........................................................................4-14

4.2 STAND-ALONE OPERATION ................................................................................................4-14

4.3 EMC-COMPATIBLE STRUCTURE .......................................................................................4-15

4.3.1 Definition: EMC ...............................................................................................................4-15

4.3.2 Introduction ......................................................................................................................4-15

4.3.3 Possible Effects of Interference ........................................................................................4-15

4.3.4 Coupling Mechanisms ......................................................................................................4-15

4.3.5 Five Basic Rules for Guaranteeing EMC .........................................................................4-16

4.4 ASSEMBLY ON THE PROFILE RAIL .....................................................................................4-17

4.5 CONNECTIONS AND CABLING ............................................................................................4-17

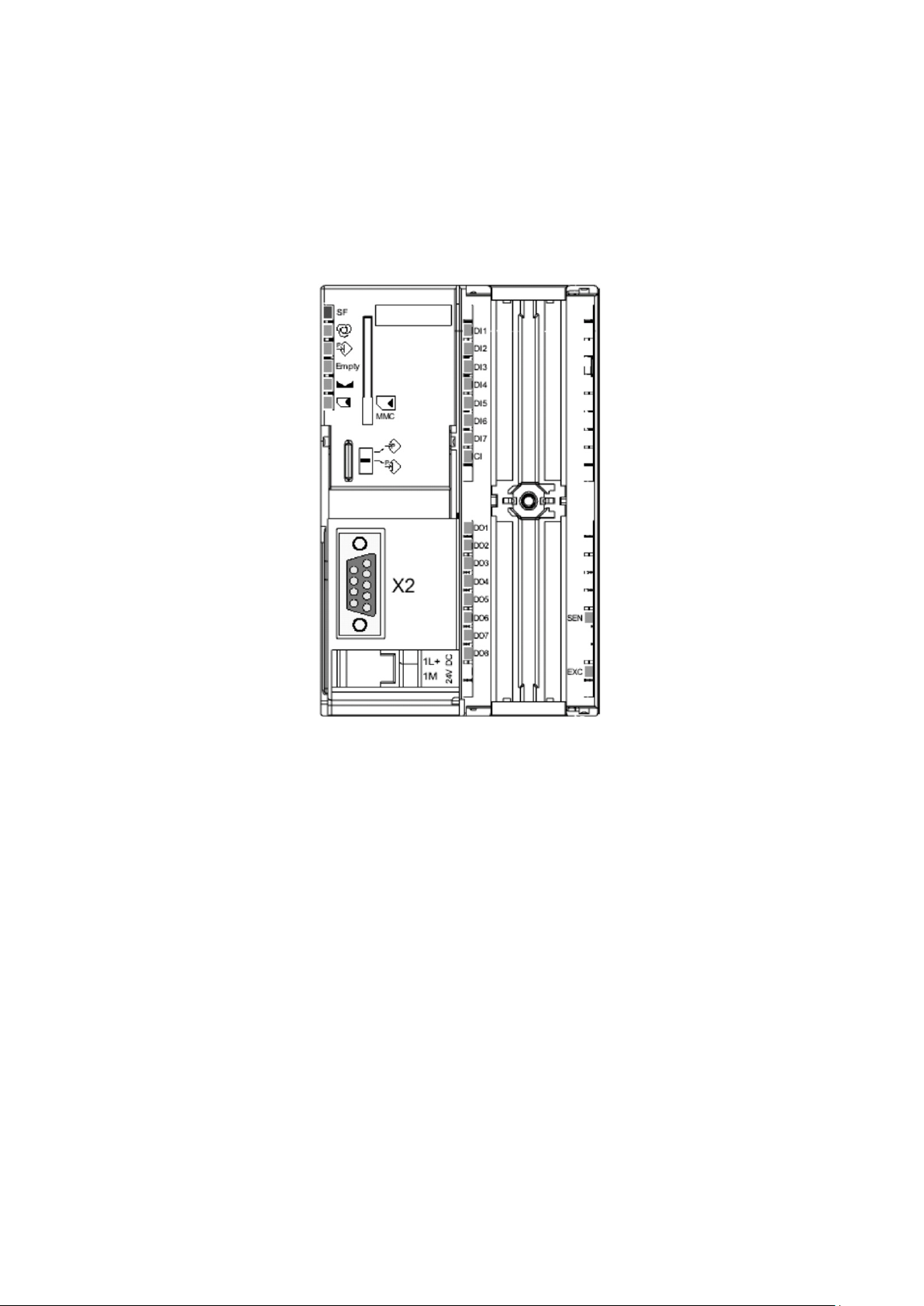

4.5.1 Connection areas for SIWAREX FTA ...............................................................................4-17

4.5.2 Shield connection .............................................................................................................4-19

4.5.3 Connecting the 24 V power supply ...................................................................................4-20

4.5.4 Connection to front connector ..........................................................................................4-21

4.5.5 Load cell connections .......................................................................................................4-21

4.5.6 Digital Inputs ....................................................................................................................4-25

4.5.7 Counter Input ...................................................................................................................4-26

4.5.8 Digital Outputs .................................................................................................................4-27

4.5.9 Analog Output ..................................................................................................................4-29

4.5.10 RS 485 interface for a METTLER TOLEDO ....................................................................4-29

4.5.11 RS 485 interface for load cells made by Wipotec/Kaiserslautern ....................................4-31

4.5.12 RS 485 interface for load cells made by PESA, Pfäffikon/Switzerland ............................4-32

4.5.13 Connecting the Remote Display by the Siebert company .................................................4-35

4.5.14 PC Connection for SIWATOOL FTA................................................................................4-36

4.5.15 LED Indicators .................................................................................................................4-37

4.5.16 Using the Micro Memory Card ........................................................................................4-37

4.6 OPERATIONAL PREPARATION ............................................................................................4-38

4.7 USE IN AREAS WITH RISK OF EXPLOSION ...........................................................................4-39

5 Weighing Functions ............................................................................................................ 5-41

5.1 GENERAL INFORMATION ...................................................................................................5-41

iv SIWAREX FTA

SIWAREX FTA

5.2 DR3 ADJUSTMENT PARAMETER (NAWI, AWI) ................................................................5-42

5.2.1 DR3 - Adjustment digits 0, 1, 2, 3, 4, for the zero point and Adjustment weights 1, 2, 3, 4 5-

45

5.2.2 DR3 - Characteristic value range ....................................................................................5-48

5.2.3 DR3 – Filter sequence of the signal filter .........................................................................5-48

5.2.4 DR3 - Type of low pass filters ..........................................................................................5-49

5.2.5 DR3 - Limit frequency ......................................................................................................5-49

5.2.6 DR3 - Type of average value filters ..................................................................................5-49

5.2.7 DR3 - Scale Name ............................................................................................................5-50

5.2.8 DR3 - Number of weight ranges .......................................................................................5-50

5.2.9 DR3 - Scale type ...............................................................................................................5-50

5.2.10 DR3 - Activate zero setting on start-up ............................................................................5-50

5.2.11 DR3 - Activated zero setting at start-up, if scale is tared .................................................5-50

5.2.12 DR3 - Automatic zero adjustment .....................................................................................5-52

5.2.13 DR3 - Tare selection (subtractive, additive).....................................................................5-52

5.2.14 DR3 - Minimum weight for weighing range 1 ..................................................................5-52

5.2.15 DR3 - Maximum weight for weighing range 1 .................................................................5-52

5.2.16 DR3 - Numeral Step for weighing range 1 .......................................................................5-53

5.2.17 DR3 - Minimum weight for weighing range 2 ..................................................................5-53

5.2.18 DR3 - Maximum weight for weighing range 2 .................................................................5-53

5.2.19 DR3 - Numeral step for weighing range 2 .......................................................................5-53

5.2.20 DR3 - Minimum weight for weighing range 3 ..................................................................5-53

5.2.21 DR3 - Maximum weight for weighing range 3 .................................................................5-54

5.2.22 DR3 - Numeral step for weighing range 3 .......................................................................5-54

5.2.23 DR3 - Stand-still time 1 ....................................................................................................5-54

5.2.24 DR3 - Stand-still range 1 ..................................................................................................5-54

5.2.25 DR3 - Waiting time for stand-still 1 .................................................................................5-55

5.2.26 DR3 - Maximum negative weight for zero setting at start-up ...........................................5-55

5.2.27 DR3 - Maximum positive weight for zero setting at start-up ............................................5-56

5.2.28 DR3 - Maximum negative weight for zero setting ............................................................5-56

5.2.29 DR3 - Maximum positive weight for zero setting .............................................................5-56

5.2.30 DR3 - Tare max. load T- ..................................................................................................5-56

5.2.31 DR3 - Load cell type .........................................................................................................5-56

5.2.32 DR3 – Monitoring time for the digital load cells .............................................................5-58

5.2.33 DR3 - Regulations ............................................................................................................5-58

5.2.34 DR3 - Unit of measurement ..............................................................................................5-58

5.2.35 DR3 - Stand-still range 2 ..................................................................................................5-58

5.2.36 DR3 - Stand-still time 2 ....................................................................................................5-59

5.2.37 DR3 - Maximum waiting time for stand-still 2 .................................................................5-59

5.2.38 DR 3 - Stand-still range 3 .................................................................................................5-59

5.2.39 DR3 - Stand-still time 3 ....................................................................................................5-59

5.2.40 DR3 - Minimum waiting time for stand-still 3 ..................................................................5-59

5.2.41 DR3 - Smallest set weight ∑min .......................................................................................5-60

5.2.42 DR3 - Totalising value dt .................................................................................................5-60

5.3 THEORETICAL ADJUSTMENT – ADJUSTMENT WITHOUT ADJUSTMENT WE IGHTS ..............5-60

5.4 DR 4 BASIS PARAMETER (NAWI, AWI) ...........................................................................5-61

5.4.1 DR 4 - Scale operating mode (Scale type) ........................................................................5-62

5.4.2 DR 4 - Type: weighing (additive) .....................................................................................5-62

5.4.3 DR 4 - Type: weighing (subtractive) ................................................................................5-62

5.4.4 DR 4 - Type: filling (additive) and emptying ....................................................................5-63

5.4.5 DR 4 - Type: filling (additive) without emptying ..............................................................5-64

5.4.6 DR 4 - Type: filling (subtractive) without emptying .........................................................5-65

5.4.7 DR 4 - Type: Check weight ...............................................................................................5-66

5.4.8 DR 4 - Type: Discontinuous totalizing .............................................................................5-67

5.4.9 DR 4 – Type: filling (additive)/(Big-bag) .........................................................................5-67

SIWAREX FTA v

5.4.10 DR 4 – Type: filling (subtractive)/(Big-bag) ....................................................................5-68

5.4.11 DR 4 – Type: filling (subtractive) and emptying ..............................................................5-68

5.5 WEIGHING STEPS – STANDARD WEIGHING PROCEDURE ....................................................5-68

5.5.1 Processing weighing step 0 - Wait ...................................................................................5-69

5.5.2 Description of Weighing step 1 – Taring/Zero setting .....................................................5-69

5.5.3 Description of Weighing step 2 – Coarse/Fine.................................................................5-69

5.5.4 Description of weighing step 3 - Post dosing ...................................................................5-69

5.5.5 Description of weighing step 4 - End/Intermediate check ................................................5-69

5.5.6 Description of weighing step 5 - Empty ............................................................................5-70

5.5.7 Description of weighing step 6 - End control AWI ...........................................................5-70

5.5.8 Description of Weighing Step 7 ........................................................................................5-70

5.5.9 DR 4 - Monitoring time for Logging ................................................................................5-70

5.5.10 DR 4 - Device for log output ............................................................................................5-70

5.5.11 DR 4 - Basis weight for the limit value 1 ..........................................................................5-70

5.5.12 DR 4 - Basis weight for the limit value 2 ..........................................................................5-70

5.5.13 DR 4 - Basis weight for monitoring the empty range .......................................................5-71

5.5.14 DR 4 - Empty range ..........................................................................................................5-71

5.5.15 DR 4 - Switch-on weight limit value 1 ..............................................................................5-71

5.5.16 DR 4 - Shut-off weight limit value 1 .................................................................................5-72

5.5.17 DR 4 - Switch-on weight limit value 2 ..............................................................................5-72

5.5.18 DR 4 - Shut-off weight limit value 2 .................................................................................5-72

5.5.19 DR 4 - Switch-on weight limit value 3 ..............................................................................5-72

5.5.20 DR 4 - Shut-off weight limit value 3 .................................................................................5-72

5.5.21 DR 4 - Minimum through-put limit value 1 ......................................................................5-72

5.5.22 DR 4 - Minimum through-put limit value 2 ......................................................................5-72

5.5.23 DR 4 - Filter depth of averaging filter for through-put calculation .................................5-72

5.6 DR 7 INTERFACES (NAWI, AWI) .....................................................................................5-72

5.6.1 DR 7 - Source for Weight Simulation ...............................................................................5-78

5.6.2 DR 7 - Decade used for rounding the decimal places of the process values ....................5-78

5.6.3 DR 7 - Force in Service Operation ...................................................................................5-78

5.6.4 DR 7 - Process value 1 for fast output to the SIMATIC CPU ..........................................5-79

5.6.5 DR 7 - Process value 2 for fast output to the SIMATIC CPU ..........................................5-80

5.6.6 DR 7 - Definition of the process alarms 0, 1, 2, 3, 4, 5, 6, 7 ............................................5-80

5.6.7 DR 7 - S7-FB-Life bit Monitoring Time ...........................................................................5-80

5.6.8 DR 7 - Weight for zero point (0 or 4 mA) .........................................................................5-81

5.6.9 DR 7 - Weight for end value (20 mA) ...............................................................................5-81

5.6.10 DR 7 - Replacement Value for the Analog Output with OD .............................................5-81

5.6.11 DR 7 - Source for the Analog Output ...............................................................................5-81

5.6.12 DR 7 - Current range for the Analog Output ...................................................................5-81

5.6.13 DR 7 - RS232 Printer baud rate .......................................................................................5-81

5.6.14 DR 7 - RS232- Printer transfer control ............................................................................5-82

5.6.15 DR 7 – Protocol selection for RS 485...............................................................................5-82

5.6.16 DR 7 - Decimal Place for Remote Display .......................................................................5-82

5.6.17 DR 7 – RS 485-Baudrate ..................................................................................................5-82

5.6.18 DR 7 - RS485-character frame .........................................................................................5-83

5.6.19 DR 7 - Definition of the Digital Outputs 1, 2, 3, 4, 5, 6, 7, 8 ............................................5-83

5.6.20 DR 7 - Level definitions for digital outputs 1 to 8 ............................................................5-83

5.6.21 DR 7 - Replacement value for DO 1 to DO 8 with Interference or Output Disable .........5-84

5.6.22 DR 7 - Replacement values for digital outputs with operational faults ............................5-84

5.6.23 DR 7 - Definition of the Digital Inputs 1, 2, 3, 4, 5, 6, 7 ..................................................5-85

5.6.24 DR 7 - Level definitions for digital inputs 1 to 7 ..............................................................5-85

5.6.25 DR 7 - Measurement time Pulse input ..............................................................................5-85

5.6.26 DR 7 - MMC Log Overflow, MMC Trace Overflow, Target storage for trace function ..5-85

5.6.27 DR 7 - Memory segment for trace function ......................................................................5-86

5.6.28 DR 7 - Memory segment for log .......................................................................................5-86

vi SIWAREX FTA

SIWAREX FTA

5.6.29 DR 7 - Trace function recording cycle .............................................................................5-86

5.7 DR 8 DATE / TIME (NAWI, AWI) .....................................................................................5-87

5.8 DR 9 INFO ON MODULE (NAWI, AWI) .............................................................................5-87

5.8.1 DR 9 - Info on Module ......................................................................................................5-88

5.9 DR 15 TARE ENTRY (NAWI, AWI) ...................................................................................5-89

5.9.1 DR 15 - Tare Entry ...........................................................................................................5-89

5.10 DR 16 WEIGHT SIMULATION ENTRY (NAWI, AWI) .........................................................5-89

5.10.1 DR 16 - Weight simulation entry ......................................................................................5-90

5.11 DR 17 ANALOG OUTPUT CONTROL (NAWI, AWI)...........................................................5-90

5.11.1 DR 17 - Ext. Definition for Analog Output .......................................................................5-90

5.12 DR 18 CONTROL DISPLAY (NAWI, AWI) ........................................................................5-90

5.12.1 External remote display definition ...................................................................................5-91

5.13 DR 20 SET WEIGHT (AWI) ...............................................................................................5-91

5.14 DR 21 LOAD SET VALUE (AWI) ........................................................................................5-91

5.15 DR 22 SCALE PARAMETER 1 (AWI) ..................................................................................5-92

5.15.1 DR 22 - Maximum Weighing Time ...................................................................................5-92

5.15.2 DR 22 - Trailing Weight ...................................................................................................5-93

5.15.3 DR 22 - Fine Weight .........................................................................................................5-93

5.15.4 DR 22 - Shut-off correction value ....................................................................................5-93

5.15.5 DR 22 - Timer pre-dosing ................................................................................................5-93

5.15.6 DR 22 –Tolerance TO1, Tolerance TU1, Tolerance TO2, Tolerance TU2 ......................5-93

5.16 DR 23 SCALE PARAMETER 2 (AWI) ..................................................................................5-95

5.16.1 DR 23 - Text Selection for automatic logging ................................................................ 5-100

5.16.2 DR 23 - Max. single set weight ....................................................................................... 5-100

5.16.3 DR 23 - Inhibition time - Coarse .................................................................................... 5-100

5.16.4 DR 23 - Fine Inhibition time .......................................................................................... 5-100

5.16.5 DR 23 - Inhibition time Set-Act comparison .................................................................. 5-100

5.16.6 DR 23 - Default value for analog output with course .................................................... 5-101

5.16.7 DR 23 - Default value for analog output with fine ......................................................... 5-101

5.16.8 DR 23 - Filter type for dosing ........................................................................................ 5-101

5.16.9 DR 23 - Depth of the mean value filter for dosing ......................................................... 5-101

5.16.10 DR 23 - Limit Frequency Filter for dosing ..................................................................... 5-101

5.16.11 DR 23 - Tare-/Zero setting mode .................................................................................... 5-101

5.16.12 DR 23 - Tare / Zero setting cycle ................................................................................... 5-102

5.16.13 DR 23 - Tare minimum weight ....................................................................................... 5-102

5.16.14 DR 23 - Tare max. weight .............................................................................................. 5-102

5.16.15 DR 23 - Time period for zero setting .............................................................................. 5-102

5.16.16 DR 23 - Step control through digital input 1, 2, 3, 4, 5, 6, 7 .......................................... 5-103

5.16.17 DR 23 - Monitor time step control.................................................................................. 5-103

5.16.18 DR 23 - Definition check stop points .............................................................................. 5-103

5.16.19 DR 23 - Automatic post dosing ....................................................................................... 5-103

5.16.20 DR 23 - Post dosing type ................................................................................................ 5-103

5.16.21 DR 23 - Stop on TO1 ...................................................................................................... 5-104

5.16.22 DR 23 - Stop on TO2 ...................................................................................................... 5-104

5.16.23 DR 23 - Stop with TU1 ................................................................................................... 5-104

5.16.24 DR 23 - Stop with TU2 ................................................................................................... 5-104

5.16.25 DR 23 – Continue upon stop because of TOL error ....................................................... 5-104

5.16.26 DR 23 - Control pauses .................................................................................................. 5-104

5.16.27 DR 23 - Pulse duration in pulse dosing .......................................................................... 5-105

5.16.28 DR 23 - Controller behaviour with dosage fault ............................................................ 5-105

5.16.29 DR 23 - Selection for type of controller ......................................................................... 5-106

5.16.30 DR 23 - Control factor Proportional controller ............................................................. 5-106

5.16.31 DR 23 - Maximum one-time correction with the proportional controller ...................... 5-106

5.16.32 DR 23 - Controller Optimum Plus .................................................................................. 5-107

5.16.33 DR 23 - Controller Optimum Minus ............................................................................... 5-107

SIWAREX FTA vii

5.16.34 DR 23 - Set value for fine time ....................................................................................... 5-107

5.16.35 DR 23 - Control factor fine time controller .................................................................... 5-108

5.16.36 DR 23 - Overlapping time .............................................................................................. 5-109

5.16.37 DR 23 - Emptying time ................................................................................................... 5-109

5.16.38 DR 23 - Maximum empty time ........................................................................................ 5-109

5.16.39 DR 23 - Filling with coarse ............................................................................................ 5-109

5.17 DR 26 INTERNAL PROCESS VALUE 1 (NAWI) ................................................................. 5-109

5.18 DR 27 INTERNAL PROCESS VALUE 2 (AWI) .................................................................... 5-110

5.19 DR 30 PROCESS VALUES 1 (NAWI, AWI) ...................................................................... 5-111

5.19.1 DR 30 - NAWI-Status bits ............................................................................................... 5-111

5.19.2 DR 30 - AWI status flags ................................................................................................ 5-112

5.19.3 DR 30 - Gross process value .......................................................................................... 5-113

5.19.4 DR 30 - Net process value .............................................................................................. 5-113

5.19.5 DR 30 - Tare process value ............................................................................................ 5-113

5.19.6 DR 30 - B/N weight ........................................................................................................ 5-113

5.19.7 DR 30 - B/N weight_x10 ................................................................................................. 5-113

5.19.8 DR 30 - Tare ................................................................................................................... 5-113

5.19.9 DR 30 - Net weight ......................................................................................................... 5-113

5.19.10 DR 30 - Pulse counter value ........................................................................................... 5-113

5.19.11 DR 30 - Totalising memory 1 (calibratable) .................................................................. 5-113

5.19.12 DR 30 - Totalising memory 2 ......................................................................................... 5-114

5.20 DR 31 PROCESS VALUES 2 (NAWI, AWI) ...................................................................... 5-114

5.20.1 DR 31 - Through-put per second .................................................................................... 5-115

5.20.2 DR 31 - Current trailing weight ..................................................................................... 5-115

5.20.3 DR 31 - Current fine weight ........................................................................................... 5-115

5.20.4 DR 31 - Unfiltered ADC value ....................................................................................... 5-115

5.20.5 DR 31 - Filtered ADC value after the signal filter ......................................................... 5-115

5.20.6 DR 31 - Filtered ADC value after the dosing filter ........................................................ 5-115

5.20.7 DR 31 - Current set value in load operation .................................................................. 5-115

5.21 DR 32 STATISTIC DATA (AWI) ....................................................................................... 5-115

5.21.1 DR 32 - Total number of weighing procedures .............................................................. 5-116

5.21.2 DR 32 - Number of control weighs ................................................................................. 5-116

5.21.3 DR 32 – Classification of tolerance evaluation .............................................................. 5-117

5.21.4 DR 32 - Set weight .......................................................................................................... 5-117

5.21.5 DR 32 - Average net weight value ................................................................................. 5-117

5.21.6 DR 32 - Standard deviation of net weight from 10 ......................................................... 5-117

5.21.7 DR 32 - Performance per hour ....................................................................................... 5-117

5.21.8 DR 32 - Weightings per hour.......................................................................................... 5-117

5.22 DR 34 ASCII WEIGHT VALUE (NAWI, AWI) ................................................................. 5-118

5.23 DR 35 CODED INFORMATION FOR CALIBRATABLE DISPLAY (NAWI, AWI) .................... 5-118

5.24 DR39 VERSION RECOGNITION SECUREOCX ................................................................... 5-119

5.25 DR 40 TO 43 LOG TEXT 1 TO 4 (NAWI, AWI) ................................................................ 5-119

5.26 DR 44 LAST LOG (NAWI, AWI) ..................................................................................... 5-120

5.26.1 DR 44 - MMC-ID ........................................................................................................... 5-121

5.26.2 DR 44 - Log ID ............................................................................................................... 5-121

5.26.3 DR 44 - Last log data ..................................................................................................... 5-121

5.27 DR 45 STRIN G (NAWI, AWI) ......................................................................................... 5-121

5.28 THE DR 46 PARAMETER FOR READING FROM MMC LOGS IN SIMATIC ......................... 5-122

5.29 DR 47 REQUESTED LOG (NAWI, AWI) ........................................................................... 5-122

5.29.1 DR 47 - MMC-ID ........................................................................................................... 5-123

5.29.2 DR 47 - Log ID ............................................................................................................... 5-123

5.29.3 DR 47 - Last log data ..................................................................................................... 5-123

5.30 DR 120/121 TRACE - DATA LOGGING ............................................................................. 5-123

5.31 DR 123 DATA CONTENT MMC ....................................................................................... 5-124

5.32 DR 122 LOG DATA MMC................................................................................................ 5-125

viii SIWAREX FTA

SIWAREX FTA

6 Commands ......................................................................................................................... 6-126

6.1 COMMAND GROUPS ......................................................................................................... 6-126

6.2 COMMAND LIST ............................................................................................................... 6-127

7 Messages and Diagnostics .............................................................................................. 7-137

7.1 MESSAGE TYPES .............................................................................................................. 7-137

7.2 MESSAGE PATHS ............................................................................................................. 7-137

7.3 RECOGNISING MESSAGES USING SIWATOOL FTA ........................................................ 7-138

7.4 RECOGNISING MESSAGES USING THE FB SIWA_FTA ..................................................... 7-138

7.5 RECOGNISING MESSAGES USING THE DIAGNOSTIC ALARMS IN THE SIMATIC-CPU ............. 7-138

7.6 MESSAGE LISTS DATA AND COMMAND ERRORS .............................................................. 7-139

7.7 MESSAGE LIST TECHNOLOGY MESSAGES ........................................................................ 7-151

7.8 MESSAGE LIST OF OPERATING MESSAGES ........................................................................ 7-156

8 Programming in SIMATIC STEP 7 ................................................................................... 8-159

8.1 GENERAL INFORMATION ................................................................................................. 8-159

8.2 SIWAREX FTA IN THE HW CONFIGURATION ............................................................... 8-159

8.3 SIWAREX FTA IN CYCLIC STEP 7 - PROGRAM ............................................................. 8-160

8.4 CALL PARAMETERS FOR FB SIWA_FTA ........................................................................ 8-161

8.4.1 ADDR:= 256, Input, INT ................................................................................................ 8-161

8.4.2 DB_SCALE:= 12, Input, INT ......................................................................................... 8-161

8.4.3 DB_VECTOR:= 11, Input, INT ...................................................................................... 8-162

8.4.4 CMD_IN:= “DB_SCALE”.i_CMD_INPUT, Input, INT ................................................ 8-162

8.4.5 SIM_VAL:= “DB_SCALE”.r_SIM_VALUE, Input, REAL ............................................ 8-162

8.4.6 ANA_OUT:= “DB_SCALE”.r_ANALOG_OUT_VALUE, Input, REAL ........................ 8-162

8.4.7 DO_FORCE:= “DB_SCALE”.b_DIG_OUTPUT_FORCE, Input, BYTE ..................... 8-162

8.4.8 TRANSITION:= “DB_SCALE”.b_TRANSITIONS, Input, BYTE ................................... 8-162

8.4.9 CMD_INPR:= “DB_SCALE”.bo_CMD_IN_PROGRESS, Output, BOOL ................... 8-162

8.4.10 CMD_INPR:= “DB_SCALE”.bo_CMD_FOK, Output, BOOL ..................................... 8-162

8.4.11 CMD_ERR:= “DB_SCALE”.bo_CMD_ERR, Output, BOOL ....................................... 8-163

8.4.12 CMD_ERR_C:= “DB_SCALE”.b_CMD_ERR_CODE, Output, BYTE ......................... 8-163

8.4.13 REF_COUNT:= “DB_SCALE”.b_INFO_REFRESH_COUNT, Output, BYTE ............ 8-163

8.4.14 PROC_VAL1:= “DB_SCALE”.r_PROCESS_VALUE1, Output, REAL ........................ 8-163

8.4.15 PROC_VAL2:= “DB_SCALE”.w_PROCESS_VALUE2, Output, DWORD .................. 8-163

8.4.16 SC_STATUS:= “DB_SCALE”.dw_SCALE_STATUS, Output, DWORD ....................... 8-163

8.4.17 ERR_MSG:= “DB_SCALE”.bo_ERR_MSG, Output, BOOL ........................................ 8-163

8.4.18 ERR_MSG_TYPE:= “DB_SCALE”.b_ERR_MSG_TYPE, Output, BYTE ..................... 8-164

8.4.19 ERR_MSG_C:= “DB_SCALE”.b_ERR_MSG_CODE, Output, BYTE .......................... 8-164

8.4.20 FB_ERR:= “DB_SCALE”.bo_FB_ERR, Output, BOOL ............................................... 8-164

8.4.21 FB_ERR_C:= “DB_SCALE”.b_FB_ERR_CODE ......................................................... 8-164

8.4.22 START_UP:= “DB_SCALE”.bo_START_UP_IN_PROGRESS .................................... 8-165

8.4.23 CMD_EN:= “DB_SCALE”.bo_CMD_ENABLE ........................................................... 8-165

8.4.24 ERR_MSG_Q:= “DB_SCALE”.bo_ERR_MSG_QUIT ................................................. 8-165

8.5 ALLOCATION IN THE SCALE DB ...................................................................................... 8-165

8.6 CALIBRATABLE WEIGHT DISPLAY FOR WINCC FLEXIB LE ................................................ 8-165

8.6.1 Functionality of the calibratable weight display ............................................................ 8-167

8.6.2 Installation and Project Planning for the Calibratable Weight Display ........................ 8-168

8.7 CALIBRATABLE WEIGHT DISPLAY WITH TIA-PORTAL ..................................................... 8-170

9 Project planning in SIMATIC PCS 7 ................................................................................. 9-172

10 Commissioning using a PC – SIWATOOL FTA .......................................................... 10-173

10.1 GENERAL ...................................................................................................................... 10-173

10.2 WINDOWS AND FUNCTIONS OF THE SIWATOOL FTA ................................................. 10-173

SIWAREX FTA ix

10.3 OFFLINE PROJECT PLANNING ........................................................................................ 10-173

10.4 ONLINE OPERATION ...................................................................................................... 10-173

10.5 RECORDER .................................................................................................................... 10-175

10.6 ASSISTANCE .................................................................................................................. 10-175

10.7 COMMISSIONING - WIZARD ........................................................................................... 10-175

11 Firmware-Update with SIWATOOL FTA ...................................................................... 11-176

11.1 ADVANTAGES OF THE FIRMWARE-UPDATE ................................................................... 11-176

12 Calibrating Applications ............................................................................................... 12-178

12.1 GENERAL NOTE ............................................................................................................ 12-178

12.2 CALIBRATABLE MAIN WEIGHT DISPLAY ........................................................................ 12-179

12.3 READING THE CALIBRATABLE LOGS WITH SIWATOOL FTA ....................................... 12-179

13 Accessories ................................................................................................................... 13-180

14 Technical Data ............................................................................................................... 14-183

14.1 24 V POWER SUPPLY ...................................................................................................... 14-183

14.2 POWER SUPPLY FROM S7 BACK-PLANE BUS ................................................................... 14-183

14.3 LOAD CELL CONNECTION .............................................................................................. 14-183

14.4 ANALOG OUTPUT .......................................................................................................... 14-184

14.5 DIGITAL INPUTS (DI), DIGITAL OUTPUTS (DO) ............................................................. 14-184

14.6 COUNTER INPUT CI ....................................................................................................... 14-185

14.7 RS 232C INTERFACE ..................................................................................................... 14-185

14.8 RS 485 INTERFACE ........................................................................................................ 14-185

14.9 DIMENSIONS AND WEIGHT ............................................................................................ 14-186

14.10 MECHANICAL REQUIREMENTS AND DATA ..................................................................... 14-186

14.11 ELECTRICAL, EMC AND CLIMATIC REQUIREMENTS ...................................................... 14-187

14.11.1 Electrical protection and safety requirements .............................................................. 14-187

14.11.2 Electromagnetic Compatibility ..................................................................................... 14-187

14.12 ENVIRONMENTAL CONDITIONS...................................................................................... 14-189

14.13 LICENSES ...................................................................................................................... 14-190

14.14 SCALE LICENSES ........................................................................................................... 14-190

15 Index ............................................................................................................................... 15-192

16 Abbreviations ................................................................................................................ 16-195

Images

MAGE 3-1 AREAS OF APPLICATION SIWAREX FTA IN THE PRODUCTION CHAIN ................................3-9

I

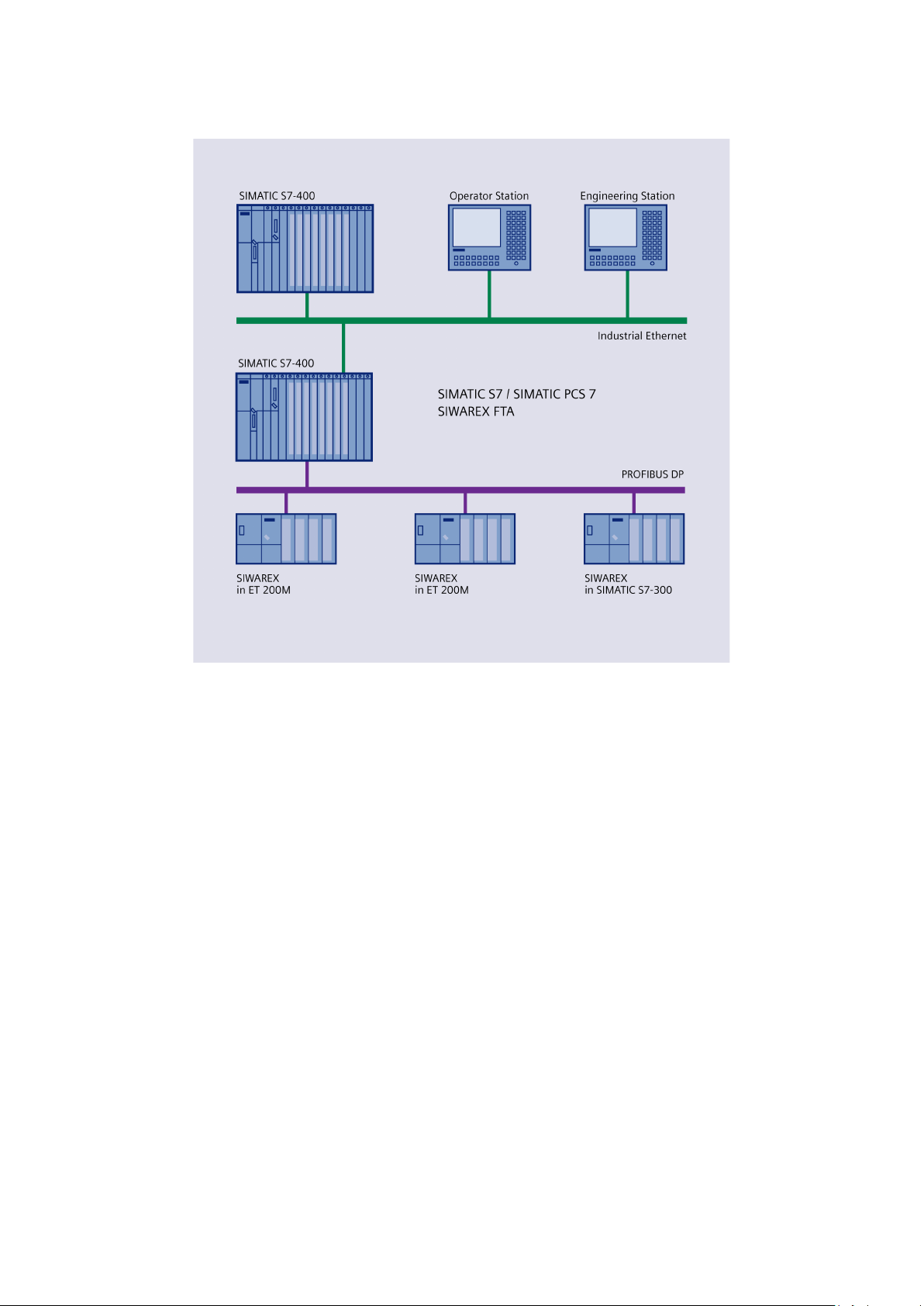

IMAGE 3-2 CONFIGURATION SIMATIC S7/PCS7 WITH SIWAREX FTA ...........................................3-10

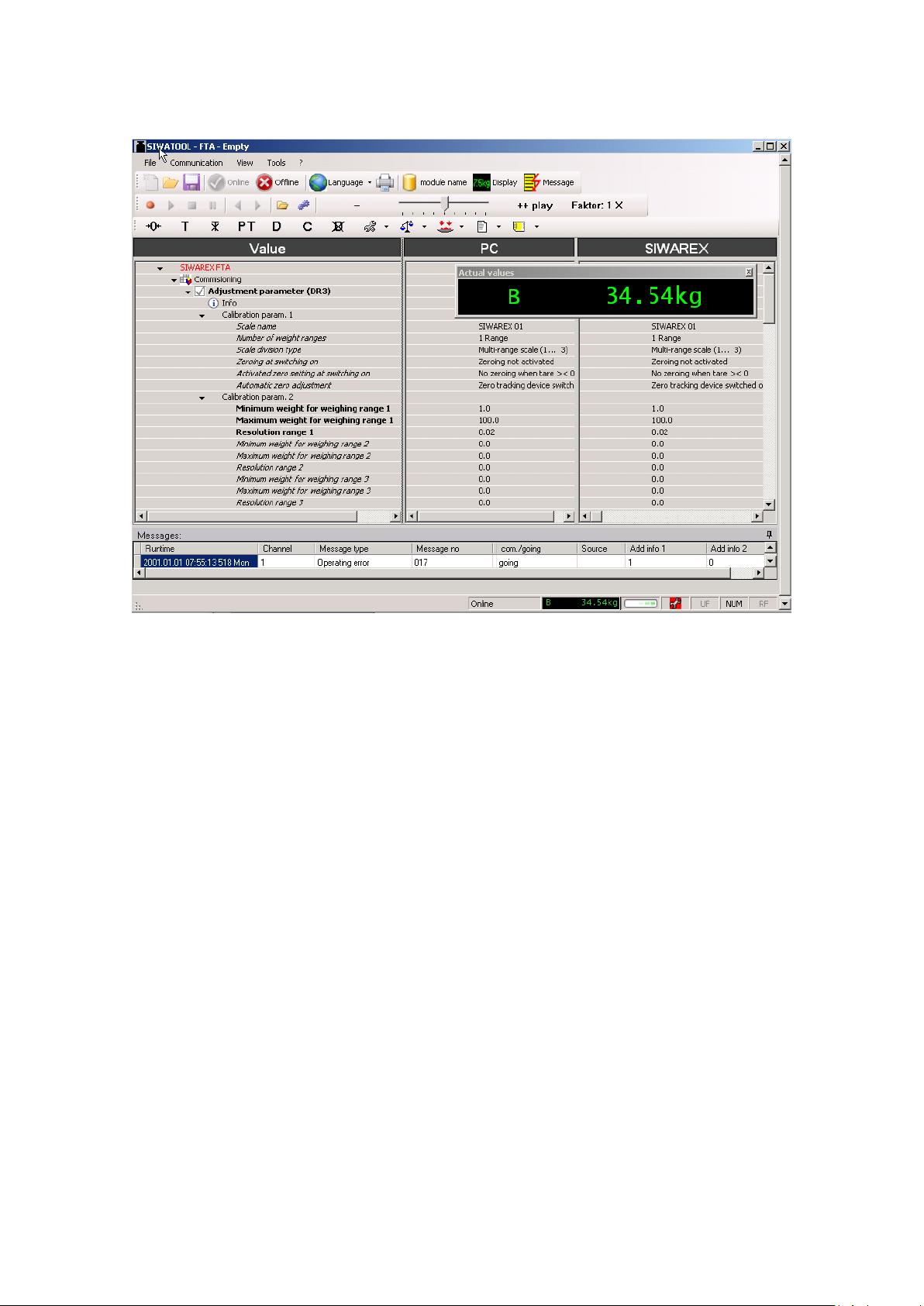

IMAGE 3-3 SIWATOOL FTA OVERVIEW ..........................................................................................3-11

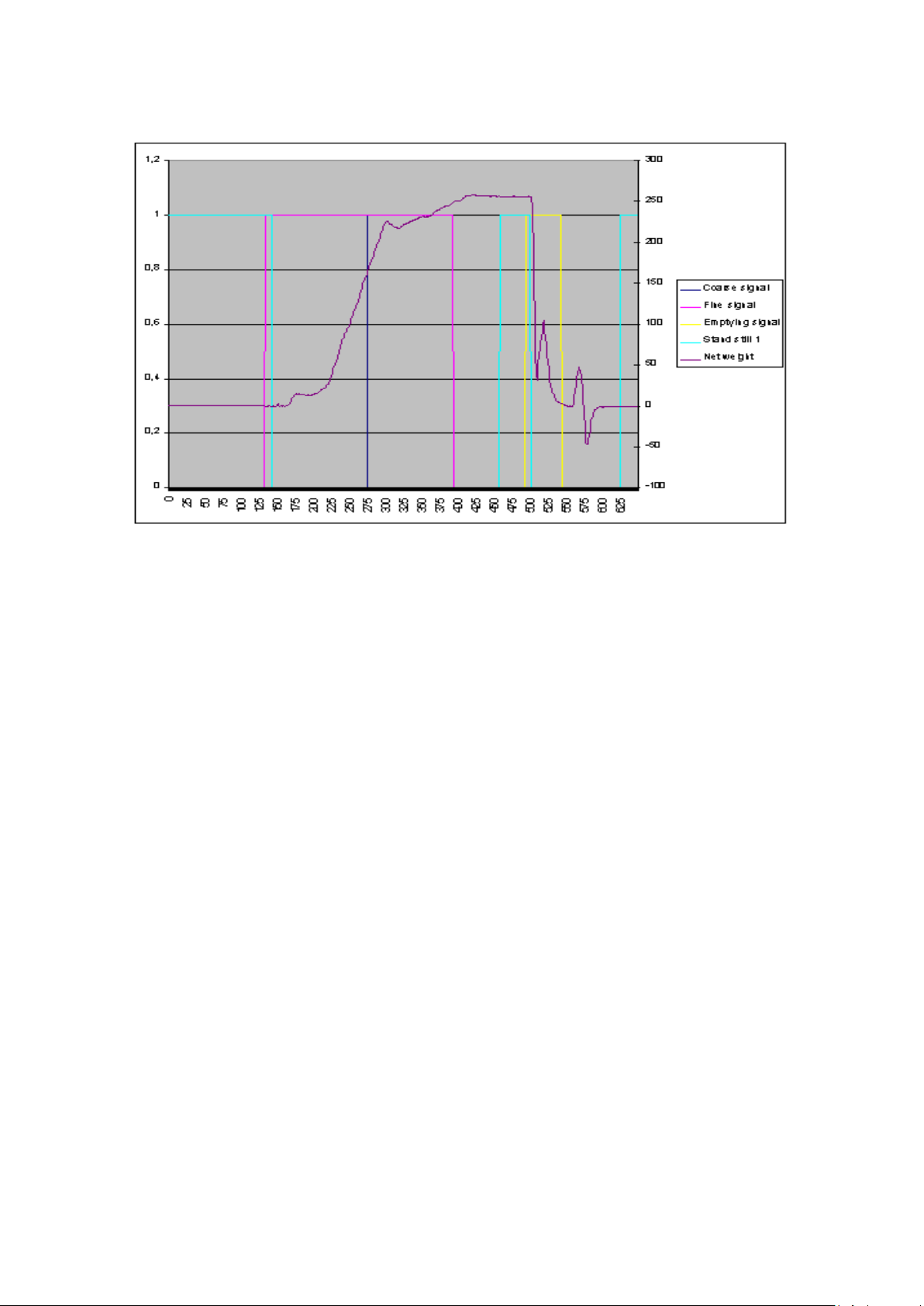

IMAGE 3-4 WEIGHING PROCEDURE PROGRESS DISPLAYED FROM THE TRACING IN SIWAREX FTA ...3-12

IMAGE 4-1 SIWAREX FTA FRONT VIEW ..........................................................................................4-18

IMAGE 4-2 SIWAREX FTA PIN ASSIGNMENTS .................................................................................4-19

IMAGE 4-3 SHIELD CLAMP ASSEMBLY.................................................................................................4-20

IMAGE 4-4 SHIELDING IN THE SCREW JOINT ........................................................................................4-22

IMAGE 4-5 PAIRS OF CONDUCTORS IN THE SHIELDED CABLE ..............................................................4-23

IMAGE 4-6 EXAMP LE – MOUNTING OF SHIELD CLAMPS ON MODULE ..................................................4-23

IMAGE 4-7 LOAD CELL CONNECTION IN 4-WIRE SYSTEM .....................................................................4-24

IMAGE 4-8 LOAD CELL CONNECTION IN 6-WIRE SYSTEM .....................................................................4-24

IMAGE 4-9 DIGITAL INPUTS ................................................................................................................4-26

IMAGE 4-10 COUNTER INPUT ...............................................................................................................4-27

IMAGE 4-11 DIGITAL OUTPUTS ............................................................................................................4-28

x SIWAREX FTA

SIWAREX FTA

IMAGE 4-12 ANALOG OUTPUT ..............................................................................................................4-29

IMAGE 4-13 CONNECTION OF LOAD CELL METTLER TOLEDO TYPE WM, WMH TO RS 485 ...........4-31

IMAGE 4-14 WIPOTEC LOAD CELL CONNECTION ..................................................................................4-32

IMAGE 4-15 PESA LOAD CELL CONNECTION .......................................................................................4-34

IMAGE 4-16 S102 DISPLAY CONNECTION ............................................................................................4-35

IMAGE 4-17 PC CONNECTION ..............................................................................................................4-36

IMAGE 5-1 ADJUSTMENT DIGITS AND WEIGHT VALUE .........................................................................5-46

IMAGE 5-2 LINEARISATION OF THE SCALE'S CHARACTERISTIC CURVE ...............................................5-48

IMAGE 5-3 DIGITAL LOW PASS FILTER STEP RESPONSE .......................................................................5-49

IMAGE 5-4 STAND-STILL MONITORING ...............................................................................................5-55

IMAGE 5-5 WEIGHING STEPS IN AUTOMATIC FILLING OPERATION AWI ..............................................5-63

IMAGE 5-6 WEIGHING STEPS FOR CATCH WEIGHING WITH FILLING AWI ............................................5-64

IMAGE 5-7 WEIGHING STEPS DURING AUTOMATIC CATCHW./GRAV IM. EMPTYING MODE ...................5-65

IMAGE 5-8 WEIGHING STEPS FOR A WEIGHT RECORDING (CHECK) AWI .............................................5-66

IMAGE 5-9 WEIGHING STEPS FOR AWI TOTALISING ...........................................................................5-67

IMAGE 5-10 DEFINING LIMIT VALUE PARAMETERS ..............................................................................5-71

IMAGE 5-11 TOLERANCE EVALUATION PROGRESS BY TIME WITH TU1 STATUS ....................................5-94

IMAGE 5-12 AUTOMATIC POST DOSING WITH TOLERANCE TU1 ......................................................... 5-105

IMAGE 8-1 FB SIWA_FTA CALL PARAMETERS. ............................................................................... 8-161

IMAGE 8-2 CALIBRATABLE DISPLAY IN TP/OP ................................................................................. 8-168

IMAGE 8-3 FUNCTION “SECUREOCX” IN WIN CC FLEXIBLE ............................................................ 8-170

IMAGE 10-1 SIWATOOL FTA WINDOW DISTRIBUTION ................................................................. 10-174

IMAGE 11-1 DOWNLOADING FIRMWARE WITH SIWATOOL FTA ................................................... 11-177

IMAGE 12-1 READ THE CALIBRATABLE MEMORY WITH SIWATOOL FTA ...................................... 12-179

Tables

T

ABLE 1-1 VALIDITY OF THIS MANUAL ...............................................................................................1-1

TABLE 1-2 CHAPTER OVERVIEW ..........................................................................................................1-2

TABLE 4-1 REQUIREMENTS FOR N SIWAREX FTA ...........................................................................4-14

TABLE 4-2 POWER SUPPLY CONNECTION ............................................................................................4-21

TABLE 4-3 LOAD CELL CONNECTION ..................................................................................................4-21

TABLE 4-4 DIGITAL INPUT CONNECTIONS ...........................................................................................4-25

TABLE 4-5 PULSE ENCODER CONNECTION ..........................................................................................4-26

TABLE 4-6 DIGITAL OUTPUT CONNECTIONS ........................................................................................4-28

TABLE 4-7 ANALOG OUTPUT CONNECTIONS .......................................................................................4-29

TABLE 4-8 RS 485 CONNECTIONS ......................................................................................................4-30

TABLE 4-9 RS 485 CONNECTIONS ......................................................................................................4-32

TABLE 4-10 RS 485 CONNECTIONS ......................................................................................................4-34

TABLE 4-11 ADDRESS OCCUPATION FOR THE S102 DISPLAY ................................................................4-35

TABLE 4-12 PC CONNECTION ..............................................................................................................4-36

TABLE 4-13 INDICATORS (LED) ..........................................................................................................4-37

TABLE 5-1 DR3 ALLOCATION ............................................................................................................5-45

TABLE 5-2 DR4 ALLOCATION ............................................................................................................5-62

TABLE 5-3 DR 7 ALLOCATION ............................................................................................................5-78

TABLE 5-4 SELECTION LIST FOR PROCESS VALUES ..............................................................................5-79

TABLE 5-5 TRACE ELEMENT DATA ......................................................................................................5-87

TABLE 5-6 DR 8 ALLOCATION ............................................................................................................5-87

TABLE 5-7 DR 9 ALLOCATION ............................................................................................................5-88

TABLE 5-8 DR 15 ALLOCATION ..........................................................................................................5-89

TABLE 5-9 DR 16 ALLOCATION ..........................................................................................................5-89

TABLE 5-10 DR 17 ALLOCATION .........................................................................................................5-90

TABLE 5-11 DR 18 ALLOCATION .........................................................................................................5-91

TABLE 5-12 DR 20 ALLOCATION .........................................................................................................5-91

SIWAREX FTA xi

TABLE 5-13 DR 21 ALLOCATION .........................................................................................................5-91

TABLE 5-14 DR 20 ALLOCATION .........................................................................................................5-92

TABLE 5-15 TOLERANCE INFORMATION EVALUATION .........................................................................5-95

TABLE 5-16 DR 23 ALLOCATION ....................................................................................................... 5-100

TABLE 5-17 DR 26 ALLOCATION ....................................................................................................... 5-110

TABLE 5-18 DR 30 ALLOCATION ....................................................................................................... 5-111

TABLE 5-19 DR 30 - NAWI STATUS BITS........................................................................................... 5-112

TABLE 5-20 DR 30 - AWI STATUS FLAGS .......................................................................................... 5-113

TABLE 5-21 DR 31 ALLOCATION ....................................................................................................... 5-115

TABLE 5-22 DR 32 ALLOCATION ....................................................................................................... 5-116

TABLE 5-23 DR 34 ALLOCATION ....................................................................................................... 5-118

TABLE 5-24 DISPLAY EXAMPLE FOR WEIGHT DISPLAY ....................................................................... 5-118

TABLE 5-25 DR 35 ALLOCATION ....................................................................................................... 5-118

TABLE 5-26 DR 39 ALLOCATION ....................................................................................................... 5-119

TABLE 5-27 DR 40 ALLOCATION ....................................................................................................... 5-119

TABLE 5-28 PROCESS VALUES FOR LOG FIELD ALLOCATION .............................................................. 5-120

TABLE 5-29 DR 44 ALLOCATION ....................................................................................................... 5-121

TABLE 5-30 DR 45 ALLOCATION ....................................................................................................... 5-121

TABLE 5-31 ALLOCATION OF DR 46 .................................................................................................. 5-122

TABLE 5-32 ALLOCATION OF DR 47 .................................................................................................. 5-123

TABLE 5-33 TRACE DATA RECORD ..................................................................................................... 5-123

TABLE 5-34 COMBINATION OF RECORDING ELEMENTS ...................................................................... 5-124

TABLE 5-35 OVERVIEW OF MMC DATA ............................................................................................ 5-125

TABLE 5-36 DR 122 MMC LOG ......................................................................................................... 5-125

TABLE 6-1 SIWAREX FTA COMMAND LIST .................................................................................... 6-135

TABLE 6-2 COMMAND GROUPS OF SIWAREX FTA ......................................................................... 6-136

TABLE 7-1 LIST OF DATA AND OPERATING ERRORS ......................................................................... 7-150

TABLE 7-2 LIST OF TECHNOLOGY MESSAGES ................................................................................... 7-155

TABLE 7-3 LIST OF OPERATING MESSAGES ...................................................................................... 7-158

TABLE 8-1 LIST OF HMI DEVICES FOR CALIBRATABLE DISPLAY ....................................................... 8-166

TABLE 14-1 DATA: 24 V POWER SUPPLY.......................................................................................... 14-183

TABLE 14-2 DATA: POWER SUPPLY FROM S7 BACK-PLANE BUS ....................................................... 14-183

TABLE 14-3 DATA: LOAD CELL CONNECTION .................................................................................. 14-184

TABLE 14-4 DATA: ANALOG OUTPUT .............................................................................................. 14-184

TABLE 14-5 DATA: DIGITAL INPUTS, DIGITAL OUTPUTS .................................................................. 14-185

TABLE 14-6 DATA: COUNTER INPUT CI ........................................................................................... 14-185

TABLE 14-7 DATA: RS 232C INTERFACE ......................................................................................... 14-185

TABLE 14-8 DATA: RS 485 INTERFACE ............................................................................................ 14-185

TABLE 14-9 DATA: DIMENSIONS AND WEIGHT ................................................................................ 14-186

TABLE 14-10 DATA: MECHANICAL REQUIREMENTS....................................................................... 14-186

TABLE 14-11 DATA: ELECTRICAL PROTECTION AND SAFETY REQUIREMENTS................................ 14-187

TABLE 14-12 DATA: ELECTROMAGNETIC COMPATIBILITY ............................................................ 14-188

TABLE 14-13 DATA: CLIMATIC REQUIREMENTS............................................................................. 14-189

xii SIWAREX FTA

1 Preface

Type

Name

Order number

from product status

(Version)

Instrument*

Note

This manual contains the description

publication.

We reserve the right to deliver production information along with new modules or

modules with a newer product status that contains the current information on the

module.

For the legal

description including additive SIWAREX FTA parameters and commands can be

found on the configuration package or in the

http://support.automation.siemens.com/WW/view/en/17831309/133300

1.1 Purpose of This Manual

All of the information required to construct and operation the SIWAREX FTA

is found in this manual.

1.2 Fundamental Knowledge Requirements

To understand this manual, a general knowledge of SIMATIC automation

technology is required. Weighing technology is also beneficial.

1.3 Scope of this Manual

This manual refers to the SIWAREX FTA module:

SIWAREX FTA SIWAREX

Flexible

Technology

Automatic

Weighing

Table 1-1 Validity of This Manual

*The name corresponds with the naming conventions of the OIML - Organisation Internationale

de Metrologie Legale and means “Automatic Weighing Instrument”.

-for-trade display SecureDisplay with TIA-Portal a comprehensive

7MH4900-2AA01 HW

V1.0.0

of all modules that are valid at the time of

internet under

FW

V.9.5.2

Preface

1-2

Chapter

Description of Content

1 Preface

Notes on using this manual

2 Scope of Delivery

Description of the SIWAREX FTA scope

of delivery

3 Product Overview

Overview of

of SIWAREX FTA

4 Hardware Planning and

Description

- of operating preparation.

5 Weighing Functions

6 Commands

Description of commands that can be executed

by SIWAREX FTA

7 Messages and

Diagnostics

Description of error messages with notes on

problem solutions

8 Programming in

Description of data exchange with the

software.

9 Project planning in

SIMATIC PCS 7

Description for the PCS 7 project planning

package

10 Commissioning using a

Description

- Software functions

11 Firmware-Update with

Description

- Software functions

12 Calibrating Applications

Description of conditions for calibration

13 Accessories

Ordering information for optional components

14 Technical Data

Technical Data

15 Index

16 Abbreviations

The layout of this manual is based on activities that must be performed in the

scope of project planning, commissioning, operation and service / maintenance.

-Structure

- Functionality

- System integration

Assembly

SIMATIC STEP 7

PC – SIWATOOL FTA

SIWATOOL FTA

- of individual hardware components

- of structure and installation

- of connections

SIMATIC CPU. This chapter is only meant for

users who wish to write their own application

- Software installation

- Software installation

such as:

- Digital remote display

- Micro Memory Card

- Exi-Interface

Table 1-2 Chapter Overview

SIWAREX FTA

1-3

1.4 Further Support

Do you have more questions about using the SIWAREX FTA? Then please contact

your Siemens representative in the office or business location that is responsible

for your area or technical support for SIWAREX - Tel.: +49 (0)721 595 2811.

Updated information on SIWAREX Weighing Technology can be found on the

respective Internet Site.

Preface

http://www.siemens.com/siwarex

SIWAREX FTA

Scope of Delivery

2-4

2 Scope of Delivery

2.1 Scope of Delivery

A bus connector for the SIMATIC bus, the conformity details from the manufacturer

and a sheet of additional product information belong to the SIWAREX FTA scope

of delivery.

For planning your work with the SIWAREX FTA, you will need:

- The SIWAREX FTA project planning package for SIMATIC S7

or

- The SIWAREX FTA project planning package for SIMATIC PCS7

These are not components included in the scope of delivery and must be ordered

separately.

The corresponding project planning package is combined of the following

components:

- SIWATOOL commissioning program for Windows

- HSP 2036 (Hardware Support Package) for installation of the module in the

SIMATIC Manager hardware catalogue (only S7 classic)

- Standard software for operating the SIWAREX FTA in SIMATIC S7 and TIA-

Portal

- Manual in several languages

- Description of the SecureDisplay with TIA-Portal

- Quick Guides for fast commissioning

- Set-up for PCS7 Library (Project planning package for PCS7 only)

- SIWAREX FTA Secure OCX – AddOn for WinCC flexible for configuration of

the legal for trade display, at the moment only for S7 Classic (Overview of the

suitable panels see chap. 8.6)

Application sample software can be very helpful for the first programming steps.

This software can be downloaded, free-of-charge over the Internet

(www.siemens.com/siwarex

).

With software packages:

- SIWAREX Multiscale for batch systems

- SIWAREX Multifill for filling/bagging operations

SIWAREX FTA

Scope of Delivery

2-5

there is a specially designed STEP 7 software available which enables a very

effective system software development.

The required optional accessories are provided in chapter 13 Accessories.

SIWAREX FTA

Product Overview

3-6

3 Product Overview

3.1 General Information

SIWAREX FTA (Flexible Technology, Automatic Weighing Instrument) is a

versatile and flexible weighing module which can be utilised wherever a scale

should fulfil its tasks automatically. Automatic scale operation is characterised by

an weighing procedure performed automatically according to a defined plan.

The function module (FM) SIWAREX FTA is integrated in SIMATIC and uses all

features of the modern automation system such as integrated communication,

diagnostics system and project planning tools to its advantage. The module can

also be used without SIMATIC, as a stand-alone module however.

The scale functionality of the SIWAREX FTA includes the non-automatic scale

(Non automatic weighing instrument conforming with OIML R-76), the automatic

scale for balancing (Automatic gravimetric filling Instrument conforming with OIML

R-61), the automatic scale for catch weighing (Automatic catch weighing

instrument conforming with OIML R-51) and the automatic scale for discontinuous

totalising (Discontinuous totalising automatic weighing instrument conforming with

OIML R-107)

3.2 Benefits

SIWAREX FTA is characterised by a few clear advantages:

o Uniform structure and universal communication through the integration in the

o Uniform project planning with SIMATIC

o Direct application in SIMATIC automation system

o Application in the decentralised system concept by connecting to PROFIBUS

o Weight measurement or force to resolutions of 16 million parts

o Precision of 3 x 6000d, calibratable (0.5 µV per e)

o Calibratable display with SIMATIC HMI standard operator panels

SIMATIC S7 and SIMATIC PCS7

DP/PROFINET through ET 200M

o Measurement rates of internal 2.5 msec, external 10 msec

o Exact dosage switching signals (< 1 msec)

o Several dosage speeds

o Smooth or step controlled dosage control

o Parameter definable inputs and outputs

SIWAREX FTA

3-7

o Automatic weighing operation parameter setting for different applications

o Flexible adjustment for various SIMATIC requirements

o Simple parameter definition with the SIWATOOL program through the RS 232

interface

o Theoretical adjustment without any adjustment weights possible

o Module exchanging without readjusting the scale is possible

o Scale status recording

o Intrinsically safe load cell supply for Ex-Zone 1 (optional)

o Application in Ex-Zone 2

o Extensive diagnostic functions

o Stand–alone operation possible

3.3 Range of Application

Product Overview

SIWAREX FTA is the optimal solution wherever weighing technology requires high

speed and precision. Because of the high resolution (3 x 6000 d, calibratable),

scales can be built to work precisely over broad areas. Calibratable weighing

systems, whether a filling system, unloading station, bagging operation,

rotopacker, mixer or control stations can be constructed with the SIWAREX FTA.

Typical fields of application are e.g.:

o Liquid filling

o Bagging in a packaging system

o Weighing catch levels as well as level decrease weighing and fill weighing

o Catch level testing

o Material loading with totalising

3.4 Structure

SIWAREX FTA is a function module (FM) of the SIMATIC S7-300 and can be read

directly on the SIMATIC S7-300- or ET 200M bus board. Installation / cabling

efforts for the 80 mm wide module are simplified with the profile rail assembly

(snap-in technology).

Connecting load cells, power supply and the serial interface is all done through the

40 pin standard front connector.

Operation of the SIWAREX FTA in SIMATIC guarantees complete integration of

weighing technology in the automation system.

In certain cases, the module can also be applied without the SIMATIC environment

in so-called stand-alone operation. The module then works as a compact module

that e.g. is connected to a PC.

SIWAREX FTA

Product Overview

3-8

3.5 Function

The primary task of the SIWAREX FTA consists of the precise measurement of the

current weight values in up to three measurement ranges and the exact control of

the weighing procedure. The control of the weighing procedure is completely run

from the weighing module as if in separately constructed weighing electronics. The

integration in SIMATIC enables the progress of the weighing procedure to be

influenced directly from the PLC program however. This enables reasonable task

distribution: The extremely fast weighing functions are performed in the SIWAREX

module, latching and signal linking is done in the PLC.

There are different automatic weighing procedures for which SIWAREX FTA can

be configured optimally by defining the corresponding parameters.

The following operating modes can be defined:

- Non Automatic Weighing Instrument – conforming with OIML R-76

- Automatic Gravimetric Filling Instrument – conforming with OIML R-61 (AWI)

- Automatic catch weighing instrument – conforming with OIML R51 (AW I)

- Automatic Totalising Filling Instrument- totalising – conforming with OIML R

107 (AWI)

During the weighing procedure, SIWAREX FTA monitors and controls a multitude

of signals. The optimised system internal data exchange enables a direct

evaluation of weighing signals and states in the PLC program.

The weighing procedure influence on the PLC enables a flexible adjustment to suit

the changes in the system technology.

SIWAREX FTA is already adjusted in-house. Therefore, the scale can be adjusted

to theoretical settings without using any adjustment weights and modules can be

exchanged without readjusting the scale. Exchanging modules during running

operation is also possible when working with “active bus modules”.

The SIWAREX FTA has two serial interfaces. An RS 485 interface is used for

connecting digital remote displays. A PC can be connected to the RS 232 interface

for setting SIWAREX FTA parameters.

The weighing module SIWAREX FTA can also be used in explosion hazard areas

(zones 21 and 22). Load cells are supplied with inherent safety with zone

1 applications using an optional Ex-interface SIWAREX IS.

If the regulation code OIML is set in the adjustment data, there will be a waiting

period of 60 seconds after rebooting the SIWAREX FTA before the weight value is

displayed. There is no waiting time when using digital load cells.

SIWAREX FTA

3-9

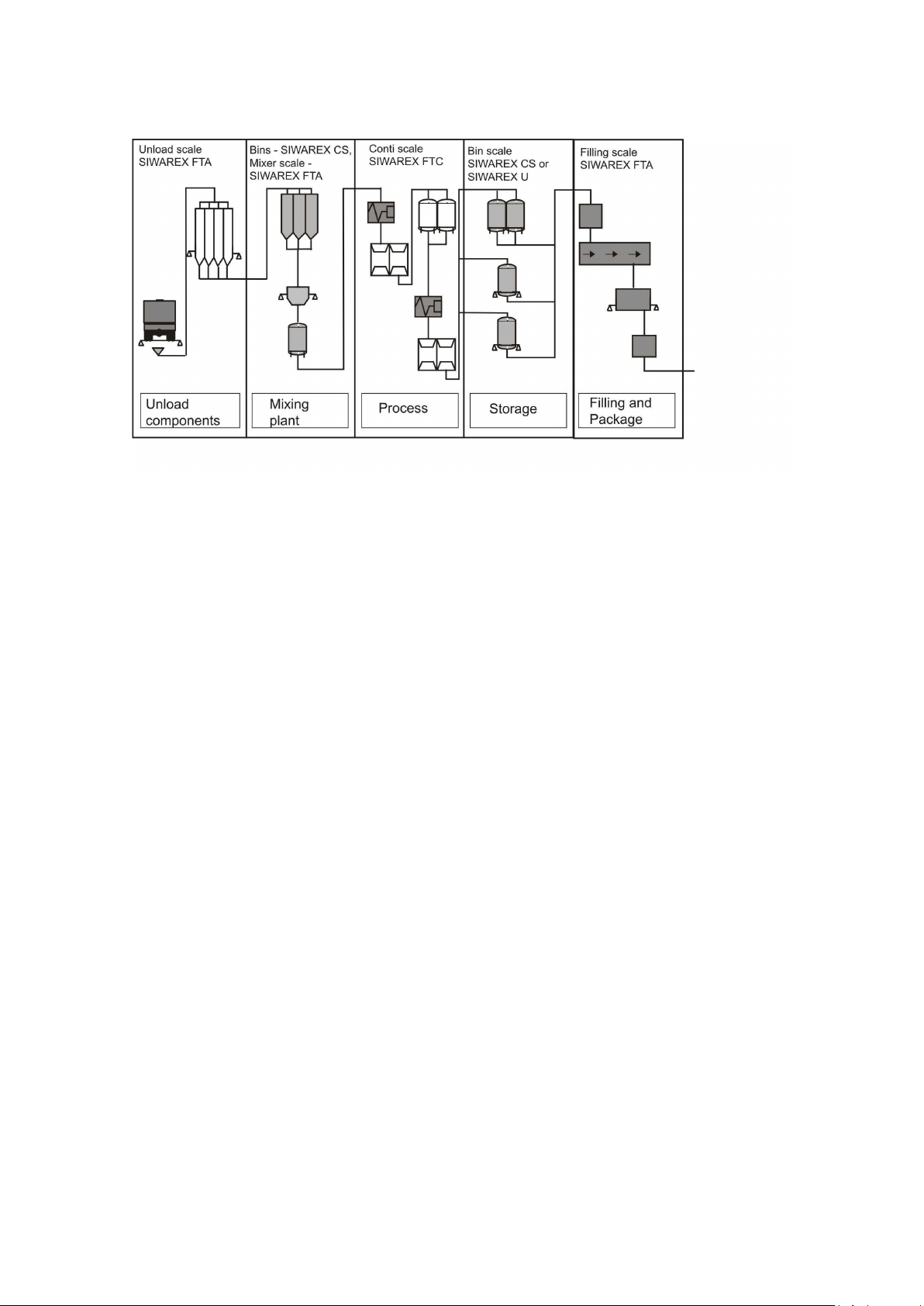

Image 3-1 Areas of application SIWAREX FTA in the production chain

Product Overview

3.6 System Integration in SIMATIC

SIWAREX FTA is completely integrated in the SIMATIC S7 and SIMATIC PCS7.

The user is absolutely free to configure his automation solution including the

weighing application as desired. The optimal solution can be created for small,

medium and large systems by selectively combining the SIMATIC components.

The project planning package and the example applications for SIMATIC can help

you to quickly and efficiently create customer specific or branch specific solutions.

The following image shows a typical assembly for a medium sized system.

For project planning with SIMATIC PCS 7, the completed function block FB SIWA

for the automation system and the graphic blocks for the operator station are used.

SIWAREX FTA

Product Overview

3-10

Image 3-2 Configuration SIMATIC S7/PCS7 with SIWAREX FTA

3.7 Commissioning and Service with SIWATOOL FTA

For commissioning, there is a special program SIWATOOL FTA for Windows

operating systems.

The program enables commissioning of the scale without having to understand

automation technology. During service procedures, you can analyse the processes

in the scale and test them with the help of a PC. Reading the diagnostics buffer

from the SIWAREX FTA is very helpful in analysing events.

Besides complete access to all parameters, memory or print-outs of the weighing

file, the program can create weighing curves as well.

SIWATOOL FTA can also be used for reading the contents of the calibratable

records from the calibratable scale memory.

The following image shows the structure of the individual program windows.

SIWAREX FTA

Product Overview

3-11

Image 3-3 SIWATOOL FTA Overview

Not only does the SIWATOOL FTA support the user for program entry. Analysing

the diagnostics buffer, the contents of which can be saved together with the

parameters after reading from the module is also very helpful.

A trace mode exists in the SIWAREX FTA module for optimising weighing

progress. The recorded data can be displayed in a curve diagram using the

MS Excel.

The following image shows the progress of a weighing procedure displayed with

the SIWATOOL FTA.

SIWAREX FTA

Product Overview

3-12

Image 3-4 Weighing procedure progress displayed from the tracing in SIWAREX FTA

3.8 Firmware Download with SIWATOOL FTA

Another feature of the SIWATOOL FTA program helps loading a new firmware

version for SIWAREX FTA on-site. It allows you to perform firmware upgrades at

any time and from anywhere.

3.9 Reading the stored weighing logs with SIWATOOL FTA

The weighing logs are stored on an MMC (Micro Memory Card) that is inserted into

the SIWAREX FTA for the period of time defined in the weights and measures act.

If a person disagrees with the results of a certain weighing procedure, the weighing