Siemens SINUMERIK MCU1720 Equipment Manual

SINUMERIK

SINUMERIK MC

MCU 1720

Valid for

Control system

SINUMERIK MC

Preface

1

Equipment Manual

System overview

Fundamental safety

instructions

Description

Application planning

Dimension drawings

Installation

Connecting

2

3

4

5

6

7

8

Service and maintenance

Technical specifications

Spare parts/accessories

Safety symbols

Appendix

9

10

11

12

A

09/2019

A5E47437728B AB

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Digital Industries

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E47437728B AB

Ⓟ 11/2019 Subject to change

Copyright © Siemens AG 2019.

All rights reserved

Table of contents

1 Preface .........................................................................................................................................................7

2 System overview ........................................................................................................................................11

2.1 Application..............................................................................................................................11

2.2 System configuration..............................................................................................................12

2.3 Ordering data .........................................................................................................................14

3 Fundamental safety instructions.................................................................................................................15

3.1 General safety instructions.....................................................................................................15

3.2 Equipment damage due to electric fields or electrostatic discharge ......................................18

3.3 Warranty and liability for application examples ......................................................................18

3.4 Industrial security ...................................................................................................................19

3.5 Residual risks of power drive systems ...................................................................................21

4 Description..................................................................................................................................................23

4.1 Characteristics .......................................................................................................................23

4.2 Operator control and display elements ..................................................................................26

4.2.1 Overview of operating and display elements .........................................................................26

4.2.2 LED displays ..........................................................................................................................27

4.2.3 Start-up and mode selector switch.........................................................................................30

4.3 Interfaces ...............................................................................................................................31

4.4 Type plates.............................................................................................................................32

5 Application planning ...................................................................................................................................35

5.1 Supplementary electrical conditions.......................................................................................35

5.1.1 Grounding concept.................................................................................................................35

5.1.2 RI suppression measures ......................................................................................................35

5.1.3 EMC limit values in South Korea............................................................................................36

5.2 Climatic and mechanical environmental conditions ...............................................................37

5.2.1 Shipping and storage conditions ............................................................................................37

5.2.2 Operating conditions ..............................................................................................................38

6 Dimension drawings ...................................................................................................................................41

6.1 Basic version..........................................................................................................................41

6.2 DIN rail mounting ...................................................................................................................42

6.3 Portrait mounting....................................................................................................................43

7 Installation ..................................................................................................................................................45

7.1 Safety instructions..................................................................................................................45

7.2 Preparing for installation ........................................................................................................47

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 3

Table of contents

7.2.1 Checking the delivery package ..............................................................................................47

7.2.2 Identification data of the device..............................................................................................48

7.2.3 Designs ..................................................................................................................................50

7.3 DIN rail mounting ...................................................................................................................51

7.3.1 Attaching the DIN rail bracket ................................................................................................51

7.3.2 Mounting on DIN rails.............................................................................................................52

7.4 Upright mounting....................................................................................................................53

7.5 Mounting strain reliefs ............................................................................................................54

8 Connecting .................................................................................................................................................57

8.1 Notes on connecting ..............................................................................................................57

8.2 Overview ................................................................................................................................58

8.3 Communication services and used port numbers ..................................................................60

8.4 Securing cables......................................................................................................................61

8.5 Connecting the protective conductor......................................................................................62

8.6 Connecting the terminal .........................................................................................................63

8.7 Connecting peripheral equipment ..........................................................................................64

8.8 Power supply X80 ..................................................................................................................65

8.8.1 Properties...............................................................................................................................65

8.8.2 Connecting the power supply.................................................................................................68

8.8.3 Requirements for the power supply .......................................................................................69

8.9 Use of Ethernet interfaces......................................................................................................71

8.10 PROFINET .............................................................................................................................72

8.11 Digital inputs/outputs..............................................................................................................74

8.11.1 DIO application.......................................................................................................................74

8.11.2 Block diagram ........................................................................................................................76

8.11.3 Connecting digital inputs/outputs ...........................................................................................76

8.11.4 Technical data........................................................................................................................78

8.12 CFast......................................................................................................................................79

8.13 DisplayPort.............................................................................................................................79

8.14 USB........................................................................................................................................80

8.15 SD card ..................................................................................................................................81

8.15.1 Properties of the SD card.......................................................................................................81

8.15.2 Inserting the SD card .............................................................................................................82

9 Service and maintenance ...........................................................................................................................83

9.1 Troubleshooting .....................................................................................................................84

10 Technical specifications..............................................................................................................................87

10.1 Technical Data .......................................................................................................................87

10.2 Standards and approvals .......................................................................................................89

10.3 Recycling and disposal ..........................................................................................................89

MCU 1720

4 Equipment Manual, 09/2019, A5E47437728B AB

Table of contents

11 Spare parts/accessories .............................................................................................................................91

11.1 Installing and removing the backup battery............................................................................91

11.2 Installing and removing CFast cards......................................................................................93

12 Safety symbols ...........................................................................................................................................95

A Appendix.....................................................................................................................................................97

A.1 Abbreviations .........................................................................................................................97

A.2 MC documentation overview................................................................................................100

Index.........................................................................................................................................................101

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 5

Table of contents

MCU 1720

6 Equipment Manual, 09/2019, A5E47437728B AB

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized into the following categories:

● General documentation/catalogs

● User documentation

● Manufacturer/service documentation

Additional information

1

You can find information on the following topics at the following address (

support.industry.siemens.com/cs/de/en/view/108464614):

● Ordering documentation/overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals/information)

If you have any questions regarding the technical documentation (e.g. suggestions,

corrections), please send an e-mail to the following address

(mailto:docu.motioncontrol@siemens.com).

mySupport/Documentation

At the following address (https://support.industry.siemens.com/My/ww/en/documentation),

you can find information on how to create your own individual documentation based on

Siemens' content, and adapt it for your own machine documentation.

Training

At the following address (http://www.siemens.com/sitrain), you can find information about

SITRAIN (Siemens training on products, systems and solutions for automation and drives).

FAQs

https://

You can find Frequently Asked Questions in the Service&Support pages under Product

Support (https://support.industry.siemens.com/cs/de/en/ps/faq).

SINUMERIK

You can find information about SINUMERIK at the following address (http://www.siemens.com/

sinumerik).

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 7

Preface

Target group

This documentation is intended for manufacturers of machine tools, particularly:

● Project engineers, electricians and installers

● Maintenance and service personnel

Benefits

The information in this manual facilitates installation and connection of the SINUMERIK MCU

1720 numerical control in the control cabinet.

Basic knowledge that is required

A sound understanding of personal computers and Microsoft operating systems is required.

General knowledge in the domain of automation technology is recommended.

Area of validity of this Equipment Manual

This equipment manual is applicable for all versions of the SINUMERIK MCU 1720.

Conventions

The terms "MCU" or "device" are sometimes used to refer to the SINUMERIK MCU 1720 in this

document.

Standard scope

This documentation only describes the functionality of the standard version. Extensions or

changes made by the machine tool manufacturer are documented by the machine tool

manufacturer.

Other functions not described in this documentation might be executable in the control. This

does not, however, represent an obligation to supply such functions with a new delivery or when

servicing.

Further, for the sake of simplicity, this documentation does not contain all detailed information

about all types of the product and cannot cover every conceivable case of installation, operation

or maintenance.

Note regarding the General Data Protection Regulation

Siemens observes standard data protection principles, in particular the principle of privacy by

design. That means that

this product does not process / store any personal data, only technical functional data (e.g. time

stamps). If a user links this data with other data (e.g. a shift schedule) or stores personal data

on the same storage medium (e.g. hard drive) and thus establishes a link to a person or

persons, then the user is responsible for ensuring compliance with the relevant data protection

regulations.

MCU 1720

8 Equipment Manual, 09/2019, A5E47437728B AB

Technical Support

Country-specific telephone numbers for technical support are provided on the Internet at the

following address (

area.

If you have any technical questions, use the online form in the "Support Request" area.

EC Declaration of Conformity

The EC Declaration of Conformity for the EMC Directive can be found on the Internet at the

following address (https://support.industry.siemens.com/cs/https://

support.industry.siemens.com/cs/ww/de/ps/14604/certww/en/ps/13231/cert).

Preface

https://support.industry.siemens.com/sc/ww/en/sc/2090) in the "Contact"

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 9

Preface

MCU 1720

10 Equipment Manual, 09/2019, A5E47437728B AB

System overview

2.1 Application

Overview

SINUMERIK MCU 1720 offers modularity, openness, flexibility and uniform structures for

operation, programming and visualization. It provides a system platform with trend-setting

functions for almost all technologies.

Together with SINAMICS S120 & SINAMICS S210 drive systems and SIMATIC S7-1500

automation system connected using PROFINET, SINUMERIK MCU 1720 forms a digital

system that is suitable for the medium and upper performance sectors.

SINUMERIK MCU 1720 sets itself apart as a result of:

● A high degree of flexibility

● Excellent dynamic response and precision

● Optimum integration into networks

● Compact design

● Maintenance-free operation

2

Benefits

● High degree of ruggedness

● Combines CNC, HMI, PLC, closed-loop control and communication tasks in one control

system, resulting in lower training costs, smaller spare parts inventories and fewer

interfaces.

● The SMC functionality of the S7-1500 is used, for example for positioning or speed axes, as

well as the CNC functionality of SINUMERIK for machining tasks.

● Customized user interfaces (WinCC, .Net) can be created based on the open windowsbased HMI configuration.

● Integrated safety functions for man and machine based on the fail-safe S7-1500 CPU

● Wide range of peripheral components and drives from a single source.

● Outstanding performance and flexibility for multi-axis systems of average to high complexity

based on scalable hardware and software.

● Universal openness of the user interface, the PLC and the NC kernel to allow integration of

your specialist know-how.

● Comprehensive range of products for integrating machine tools into communication,

engineering and production processes.

● Universal engineering in all configuring phases of a plant by integration in the Totally

Integrated Automation Portal (TIA Portal).

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 11

System overview

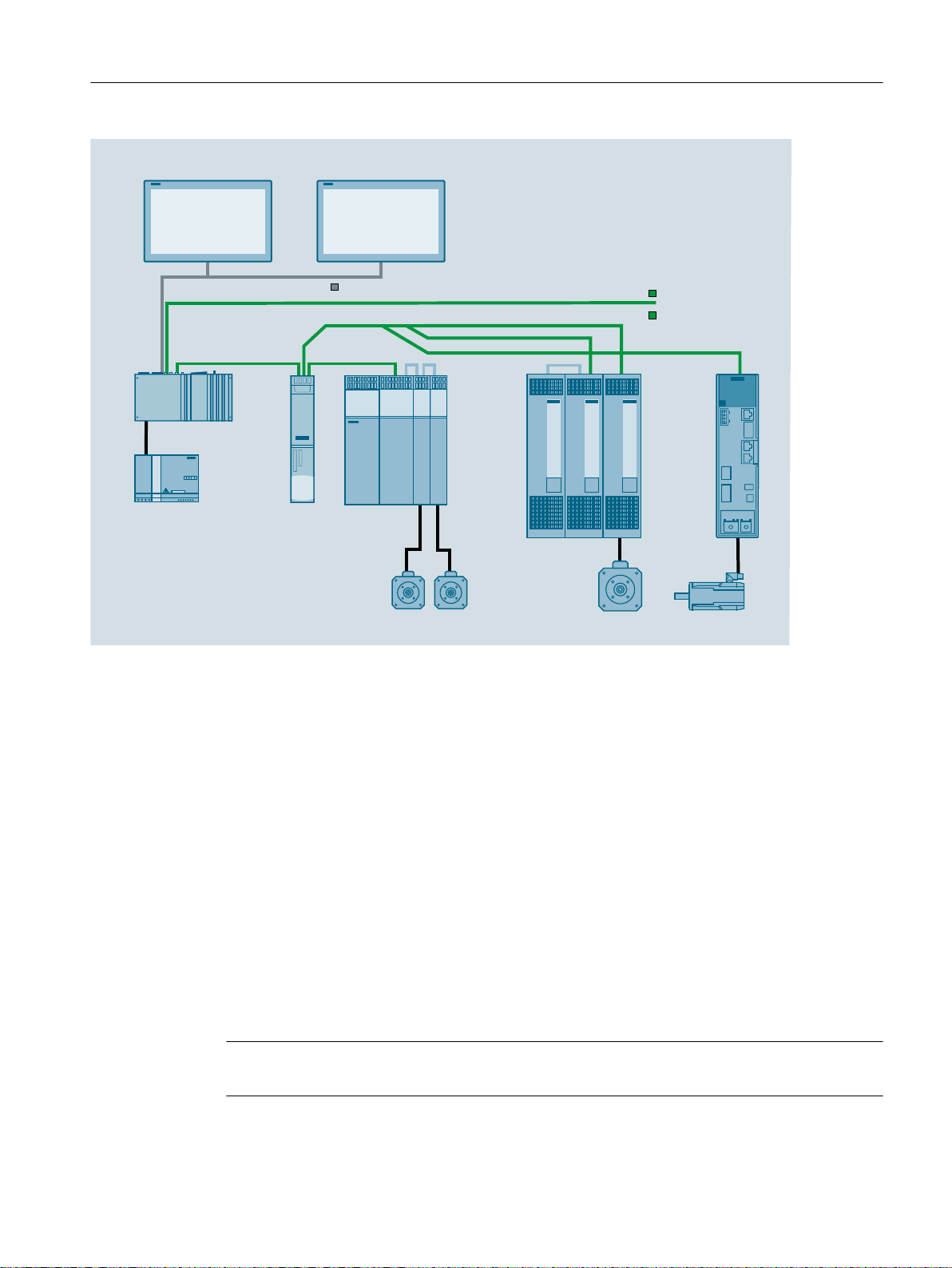

2.2 System configuration

Fields of application

SINUMERIK MC can be used worldwide for turning, drilling, milling, grinding, laser machining,

nibbling, punching, in tool and mold making, for high-speed cutting applications, for wood,

stone and glass processing, for handling operations, in transfer lines and rotary indexing

machines, for mass production and job shop production environments.

The system is available as an export version for use in countries where approval is required.

2.2 System configuration

SINUMERIK MC combines CNC, HMI, PLC, closed-loop control and communication tasks on

an MCU (motion control unit).

Components

Up to 2 OPs (Operator Panels) can be operated on one MCU.

The following components can be connected to the MCU:

● SINUMERIK operator panel front and machine control panel

● Distributed PLC I/O

– SIMATIC

e.g. ET200SP and ET200MP

– SINUMERIK via PROFINET IO:

SINUMERIK I/O modules PP 72/48D PN and PP 72/48D 2/2A PN

● SINAMICS S120 and SINAMICS S210 drive systems

● Feed motors, main spindle motors and direct-drive motors in synchronous and

asynchronous design:

– Feed motors: 1FT, 1FK

– Main spindle motors: 1PH, 1FE, 2SP1

– Direct-drive motors: 1FN3, 1FW6

Note

A specific software release is required. More detailed information can be found in the

corresponding SIOS article for the associated software release.

MCU 1720

12 Equipment Manual, 09/2019, A5E47437728B AB

Servomotor

SIMOTICS S-1FK2

0DLQVSLQGOHPRWRU

6HUYRPRWRUV

2SHUDWRUSDQHOIURQWV

3RZHUVXSSO\

352),1(7,2

6,1$0,&66FKDVVLV

6,1$0,&66

%RRNVL]H

&8

0&8

6,1$0,&66

'LVSOD\3RUW

,QGXVWULDO(WKHUQHW

System overview

2.2 System configuration

Figure 2-1 Topology example

PROFINET

The SINUMERIK MCU 1720 offers integrated PROFINET functionality:

● PROFINET I/O for PLC peripherals

● PROFINET I/O for NCK peripherals (isochronous)

● PLC isochronous drives:

– MC technology objects

● PLC non-isochronous drives:

– Basic positioner function module

– Closed loop position control function module

● NCK isochronous and non-isochronous drives (also with Safety Integrated)

● PROFIsafe V2

Note

Precondition: TIA Portal as of V15

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 13

System overview

2.3 Ordering data

As part of PROFINET, PROFINET IO is a communication concept that is used to implement

modular, distributed applications. PROFINET IO is based on Industrial Ethernet and allows

distributed field and I/O equipment to be connected to the central processing unit.

128 PROFINET IO devices can be operated on the MCU as an IO controller.

2.3 Ordering data

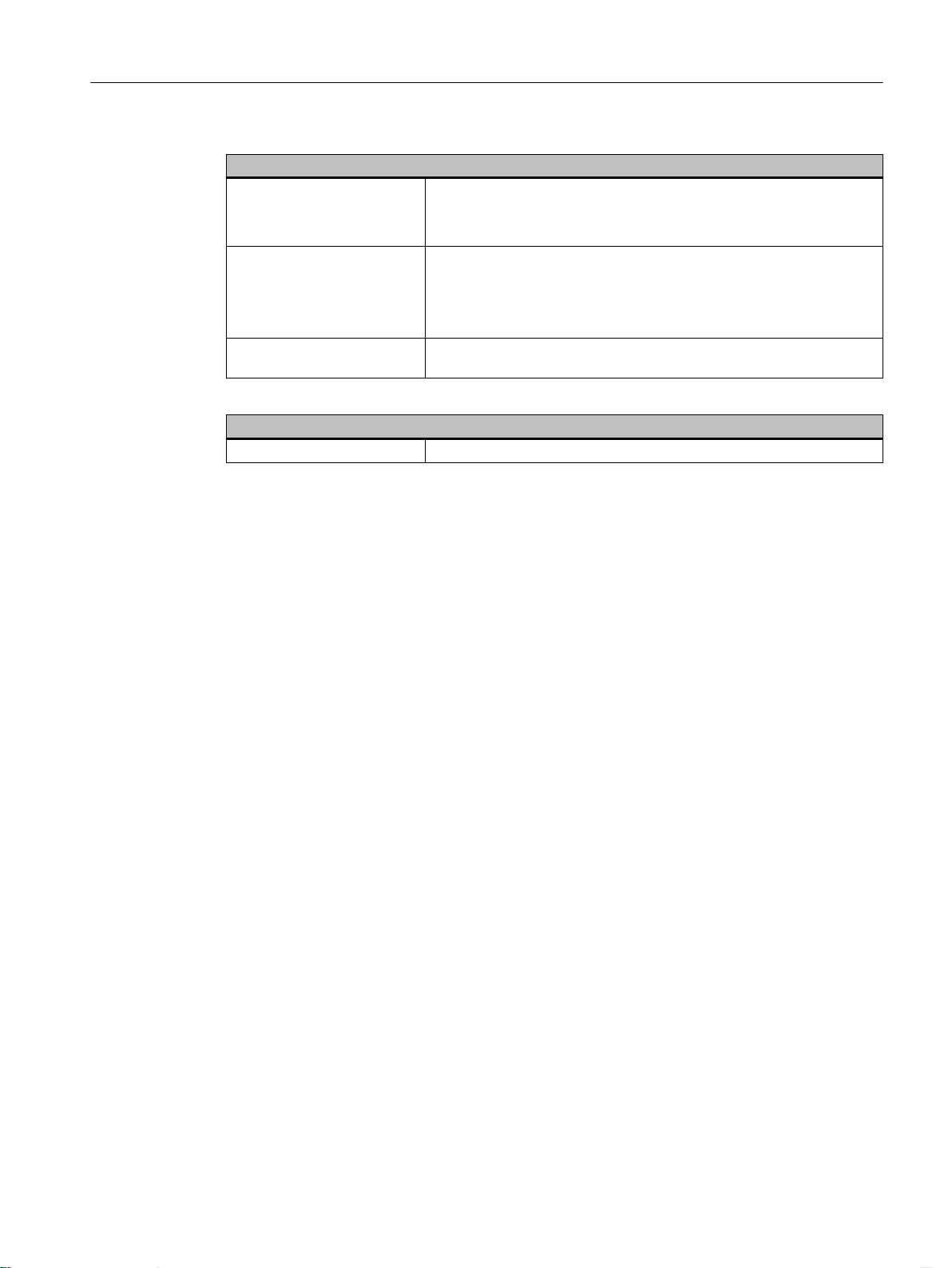

Table 2-1 Order data for system components

System component Article number

MCU 1720 with mounting rail 6FC5222-1AA00-0AA0

PP 72/48D PN I/O module 6FC5311-0AA00-0AA0

PP 72/48D 2/2A PN I/O module 6FC5311-0AA00-1AA0

USB FlashDrive 16 GB, USB 3.0 6ES7648-0DC60-0AA0

Ordering options

Table 2-2 Order data for mounting sets / spare parts / accessories

Mounting sets / spare parts / accessories Article number

Mounting rail brackets for rail mounting 6ES7648-1AA20-0YM1

Mounting bracket for portrait mounting 6ES7648-1AA20-0YP0

The described products can be found in the following catalogs:

● All the devices that belong to the SINUMERIK MC and SINAMICS S120 product families

can be found in Catalog NC 63. This catalog makes references to all other related catalogs.

You can also order the products online:

● Industry Mall: http://www.siemens.com/industrymall

● Spares On Web: http://workplace.automation.siemens.de/sparesonweb

MCU 1720

14 Equipment Manual, 09/2019, A5E47437728B AB

Fundamental safety instructions

3.1 General safety instructions

WARNING

Electric shock and danger to life due to other energy sources

Touching live components can result in death or severe injury.

● Only work on electrical devices when you are qualified for this job.

● Always observe the country-specific safety rules.

Generally, the following six steps apply when establishing safety:

1. Prepare for disconnection. Notify all those who will be affected by the procedure.

2. Isolate the drive system from the power supply and take measures to prevent it being

switched back on again.

3. Wait until the discharge time specified on the warning labels has elapsed.

4. Check that there is no voltage between any of the power connections, and between any of

the power connections and the protective conductor connection.

5. Check whether the existing auxiliary supply circuits are de-energized.

6. Ensure that the motors cannot move.

7. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water. Switch the energy sources to a safe state.

8. Check that the correct drive system is completely locked.

3

After you have completed the work, restore the operational readiness in the inverse sequence.

WARNING

Electric shock due to connection to an unsuitable power supply

When equipment is connected to an unsuitable power supply, exposed components may

carry a hazardous voltage. Contact with hazardous voltage can result in severe injury or death.

● Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 15

Fundamental safety instructions

3.1 General safety instructions

WARNING

Electric shock due to equipment damage

Improper handling may cause damage to equipment. For damaged devices, hazardous

voltages can be present at the enclosure or at exposed components; if touched, this can result

in death or severe injury.

● Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

● Do not use any damaged devices.

WARNING

Electric shock due to unconnected cable shields

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

● As a minimum, connect cable shields and the cores of cables that are not used at one end

at the grounded housing potential.

WARNING

Electric shock if there is no ground connection

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when touched,

can result in death or severe injury.

● Ground the device in compliance with the applicable regulations.

WARNING

Spread of fire from built-in devices

In the event of fire outbreak, the enclosures of built-in devices cannot prevent the escape of

fire and smoke. This can result in serious personal injury or property damage.

● Install built-in units in a suitable metal cabinet in such a way that personnel are protected

against fire and smoke, or take other appropriate measures to protect personnel.

● Ensure that smoke can only escape via controlled and monitored paths.

MCU 1720

16 Equipment Manual, 09/2019, A5E47437728B AB

Fundamental safety instructions

3.1 General safety instructions

WARNING

Unexpected movement of machines caused by radio devices or mobile phones

When radio devices or mobile phones with a transmission power > 1 W are used in the

immediate vicinity of components, they may cause the equipment to malfunction.

Malfunctions may impair the functional safety of machines and can therefore put people in

danger or lead to property damage.

● If you come closer than around 2 m to such components, switch off any radios or mobile

phones.

● Use the "SIEMENS Industry Online Support app" only on equipment that has already been

switched off.

WARNING

Fire due to inadequate ventilation clearances

Inadequate ventilation clearances can cause overheating of components with subsequent fire

and smoke. This can cause severe injury or even death. This can also result in increased

downtime and reduced service lives for devices/systems.

● Ensure compliance with the specified minimum clearance as ventilation clearance for the

respective component.

NOTICE

Overheating due to inadmissible mounting position

The device may overheat and therefore be damaged if mounted in an inadmissible position.

● Only operate the device in admissible mounting positions.

WARNING

Unexpected movement of machines caused by inactive safety functions

Inactive or non-adapted safety functions can trigger unexpected machine movements that

may result in serious injury or death.

● Observe the information in the appropriate product documentation before commissioning.

● Carry out a safety inspection for functions relevant to safety on the entire system, including

all safety-related components.

● Ensure that the safety functions used in your drives and automation tasks are adjusted and

activated through appropriate parameterizing.

● Perform a function test.

● Only put your plant into live operation once you have guaranteed that the functions relevant

to safety are running correctly.

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 17

Fundamental safety instructions

3.3 Warranty and liability for application examples

Note

Important safety notices for Safety Integrated functions

If you want to use Safety Integrated functions, you must observe the safety notices in the Safety

Integrated manuals.

3.2 Equipment damage due to electric fields or electrostatic discharge

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

NOTICE

Equipment damage due to electric fields or electrostatic discharge

Electric fields or electrostatic discharge can cause malfunctions through damaged individual

components, integrated circuits, modules or devices.

● Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of aluminum

foil.

● Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

● Only place electronic components, modules or devices on conductive surfaces (table with

ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

3.3 Warranty and liability for application examples

Application examples are not binding and do not claim to be complete regarding configuration,

equipment or any eventuality which may arise. Application examples do not represent specific

customer solutions, but are only intended to provide support for typical tasks.

As the user you yourself are responsible for ensuring that the products described are operated

correctly. Application examples do not relieve you of your responsibility for safe handling when

using, installing, operating and maintaining the equipment.

MCU 1720

18 Equipment Manual, 09/2019, A5E47437728B AB

3.4 Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Products and solutions from Siemens constitute one element of such a

concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be connected

to an enterprise network or the Internet if and to the extent such a connection is necessary and

only when appropriate security measures (e.g. using firewalls and/or network segmentation)

are in place.

For additional information on industrial security measures that can be implemented, please

visit:

Fundamental safety instructions

3.4 Industrial security

Industrial security (https://www.siemens.com/industrialsecurity)

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends that product updates are applied as soon as they become

available, and that only the latest product versions are used. Use of product versions that are

no longer supported, and failure to apply the latest updates may increase customer’s exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed at:

Industrial security (https://www.siemens.com/industrialsecurity)

Further information is provided on the Internet:

Industrial Security Configuration Manual (https://support.industry.siemens.com/cs/ww/en/

view/108862708)

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 19

Fundamental safety instructions

3.4 Industrial security

WARNING

Unsafe operating states resulting from software manipulation

Software manipulations, e.g. viruses, Trojans, or worms, can cause unsafe operating states

in your system that may lead to death, serious injury, and property damage.

● Keep the software up to date.

● Incorporate the automation and drive components into a holistic, state-of-the-art industrial

security concept for the installation or machine.

● Make sure that you include all installed products into the holistic industrial security concept.

● Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

● On completion of commissioning, check all security-related settings.

● Protect the drive against unauthorized changes by activating the "Know-how protection"

converter function.

MCU 1720

20 Equipment Manual, 09/2019, A5E47437728B AB

3.5 Residual risks of power drive systems

When assessing the machine- or system-related risk in accordance with the respective local

regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must

take into account the following residual risks emanating from the control and drive components

of a drive system:

1. Unintentional movements of driven machine or system components during commissioning,

operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables

and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of electronic

components

– External influences/damage

Fundamental safety instructions

3.5 Residual risks of power drive systems

– X-ray, ionizing radiation and cosmic radiation

2. Unusually high temperatures, including open flames, as well as emissions of light, noise,

particles, gases, etc., can occur inside and outside the components under fault conditions

caused by, for example:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specification

– External influences/damage

3. Hazardous shock voltages caused by, for example:

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a risk

to people with a pacemaker, implants or metal replacement joints, etc., if they are too close

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly

6. Influence of network-connected communication systems, e.g. ripple-control transmitters or

data communication via the network

For more information about the residual risks of the drive system components, see the relevant

sections in the technical user documentation.

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 21

Fundamental safety instructions

3.5 Residual risks of power drive systems

MCU 1720

22 Equipment Manual, 09/2019, A5E47437728B AB

Description

4.1 Characteristics

The software scalability – both from a CNC perspective and in terms of operation – means that

the SINUMERIK MCU1720 can be used in many domains. The possibilities range from simple

positioning tasks up to complex multi-axis systems.

4

The following elements characterize an MCU:

● Battery-backed real-time clock

● Slot for an SD Card

● Interfaces for operation:

– Ethernet interfaces

– PROFINET interfaces

– Digital inputs/outputs (6 of which can be parameterized as inputs for probes and BERO)

● Commissioning interfaces:

– Ethernet interface

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 23

Description

4.1 Characteristics

Application areas and performance

On the MCU, the number of axes and/or the performance of the drive control can be increased

to 8 axes by using the MC technology objects. This is achieved by using the CU320.

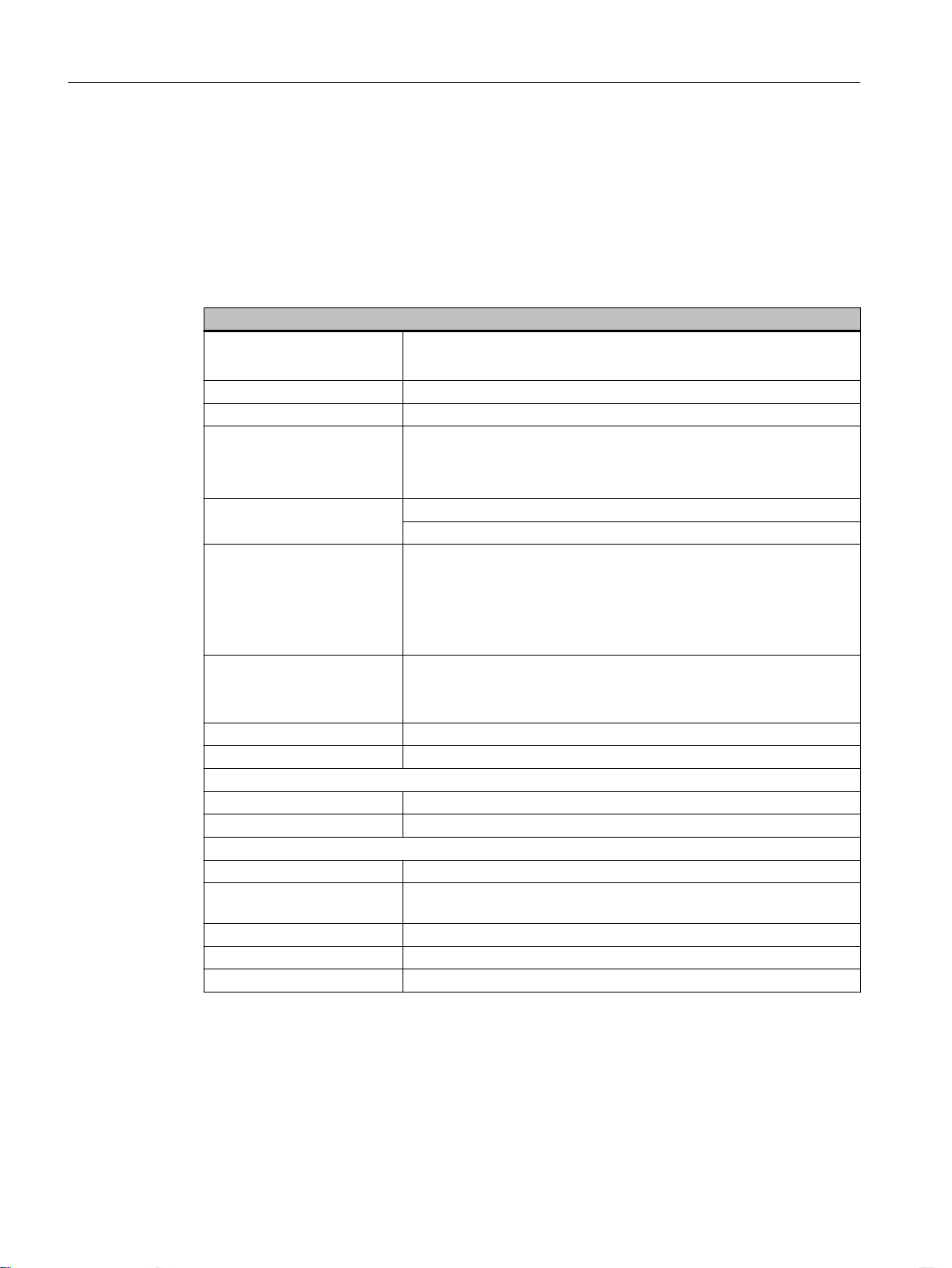

The following table lists the key characteristics and features of the MCU 1720:

Characteristics

Basic data

Mounting

Processor Intel® Core™ i5-6442EQ processor (6M cache, up to 2.7 GHz)

Main memory 8 GB DDR4-SDRAM SODIMM

Graphic

Power supply X80: 24 V DC (-15%/+20%) max. 5 A

Axes

Drives

Channels 4

Mode groups (BAG) 1

Drives and storage media

SSD (solid state disk) 2.5", ≥ 240 GB SATA

USB Stick Can be externally connected via USB interface

Interfaces

Graphic 2 x DisplayPorts DPP (DVI via DP++ to DVI adapter possible)

USB 6 × USB 3.0, max. 2 high current, can be operated simultaneously,

Ethernet 4 × RJ45 (10/100/1000 Mbit/s) teaming-capable

PROFINET 3 x RJ45 (10/100 Mbit/s) teaming-capable

Keyboard, mouse Can be connected via USB interface

● Attachment to DIN rail (horizontal mounting position)

● Portrait mounting (vertical mounting position)

● Intel® HD graphics 530

● 2 x DisplayPorts, maximum resolution 4096 x 2304 pixels

● Graphics memory is located in the main memory (dynamic UMA)

X142/X152: 24 V DC (-15%/+20%) max. 2 A

● Max. 8 CNC axes

● SIMATIC S7 Motion Control technology objects up to max. 2400

resources

● SINAMICS EPOS axes in regards to I/O addresses and

performance

● Max. 8 drives for CNC axes

● Max. 20 drives, controlled by SIMATIC S7 Motion Control

technology objects

downwardly compatible to USB 2.0/1.1

MCU 1720

24 Equipment Manual, 09/2019, A5E47437728B AB

Description

4.1 Characteristics

Extended device functions

Temperature monitoring

Watchdog

LED display 4 LEDs to display system states, of which 3 can be freely programmed

Software

Operating system Windows 10 IoT Enterprise LTSB 2016, 64 bit

● When the permissible temperature range is exceeded

● Alarm messages can be analyzed by the application program (local,

via LAN)

● Monitoring function for program execution

● Restart can be parameterized in the event of a fault

● Alarm messages can be analyzed by the application program (local,

via LAN)

by the user

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 25

Description

4.2 Operator control and display elements

4.2 Operator control and display elements

4.2.1 Overview of operating and display elements

① NCK commissioning switch: Rotary switch with 16 positions

② PLC mode selector: Toggle switch with the settings RUN/STOP/MRES

③ LED display of the NC (RDY, COM, DIAG)

④ LED display of the PLC (RUN, ERR, MT)

⑤ LED display of the HMIs (PC ON/WD, RUN/STOP, ERR, MT and user LEDs L1/L2/L3)

⑥ On/off switch: The on/off switch does not isolate the device from the power supply. Position "ON" when the "_" symbol

is pressed. When delivered, it is in the "OFF" position.

Figure 4-1 Position of operator control and display elements

MCU 1720

26 Equipment Manual, 09/2019, A5E47437728B AB

4.2.2 LED displays

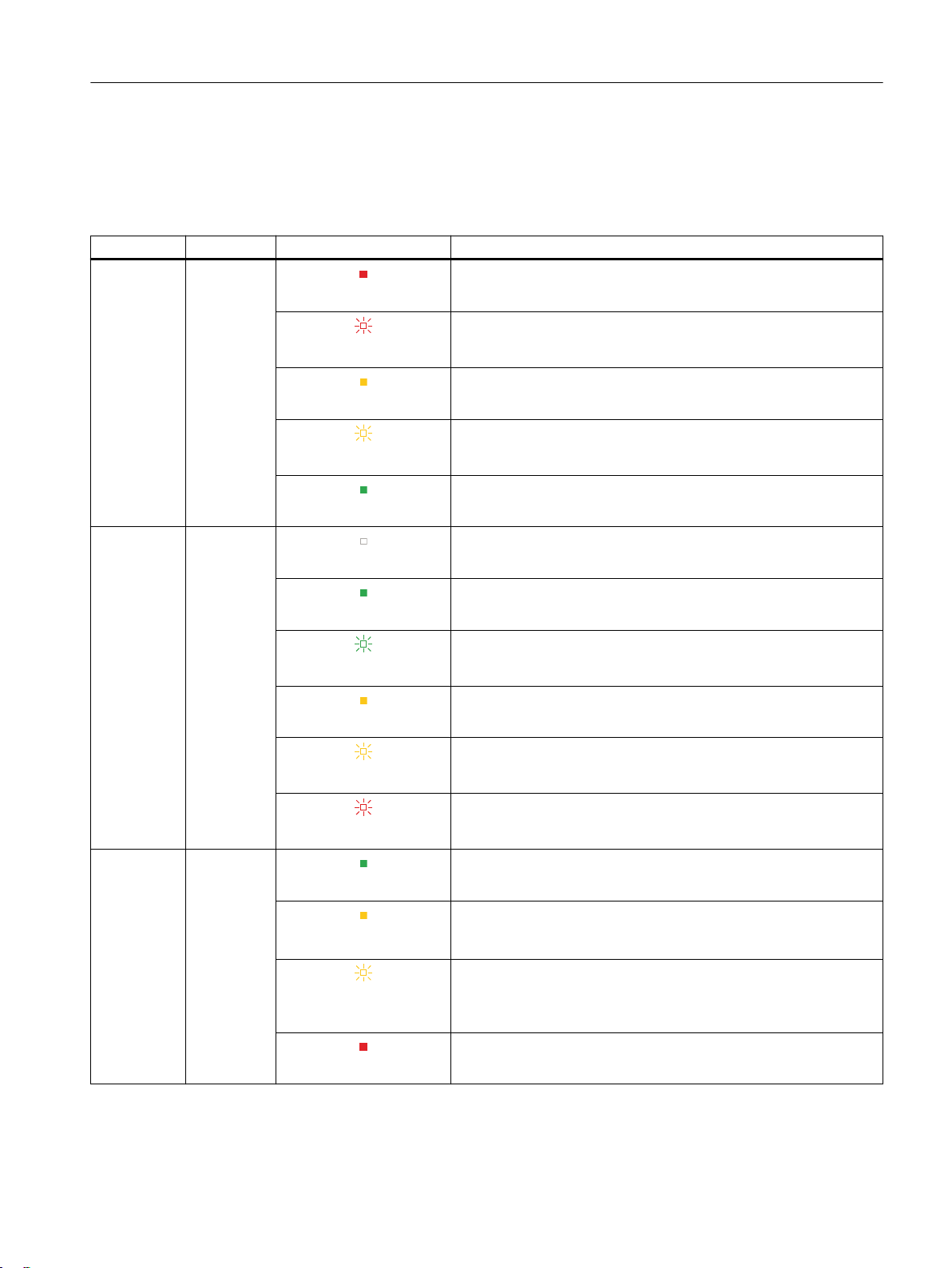

Meaning of the NC LEDs RDY, COM, DIAG and SD activity

Name Function Status Meaning

RDY Ready

COM Communi‐

cation

LED lights up red

LED flashes red (2 Hz)

LED lights up yellow

LED flashes yellow (2 Hz)

LED lights up green

LED off

At least one fault is active (e.g. RESET, watchdog monitoring etc.)

or the MCU is powering-up.

Not assigned (SINAMICS boot error).

The MCU powers up.

Firmware update is complete for components. Wait for POWER ON

for the components in question.

NC ramped up and everything in cyclic mode

CP not ramped up / started

Communication via CP possible (RUN operating state)

Description

4.2 Operator control and display elements

DIAG Diagnostics

LED lights up green

LED flashes green

LED lights up yellow

LED flashes yellow

LED flashes red

LED lights up green

LED lights up yellow

LED flashes yellow

(0.5 Hz)

LED lights up red

Communication possible (no configuration)

CP was stopped via PLC/TIA. No communication.

Configuration received and transition to the RUN operating state.

Error status (FATAL error)

Everything OK.

Software-related fault is pending, e.g. at PLC, HMI, Linux. Gener‐

ate the diagnostic data wit the Diag button and so contact the Hot‐

line.

The data backup operation initiated with the Diag button is running.

HW-related tests fail, e.g. memory test during switch on.

If no change occurs after multiple switch off/on, replace the device.

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 27

Description

4.2 Operator control and display elements

Name Function Status Meaning

SD Activity

LED

(directly on

the card slot)

LED off

LED flashes yellow

SD card not inserted or inactive.

Active access to SD card

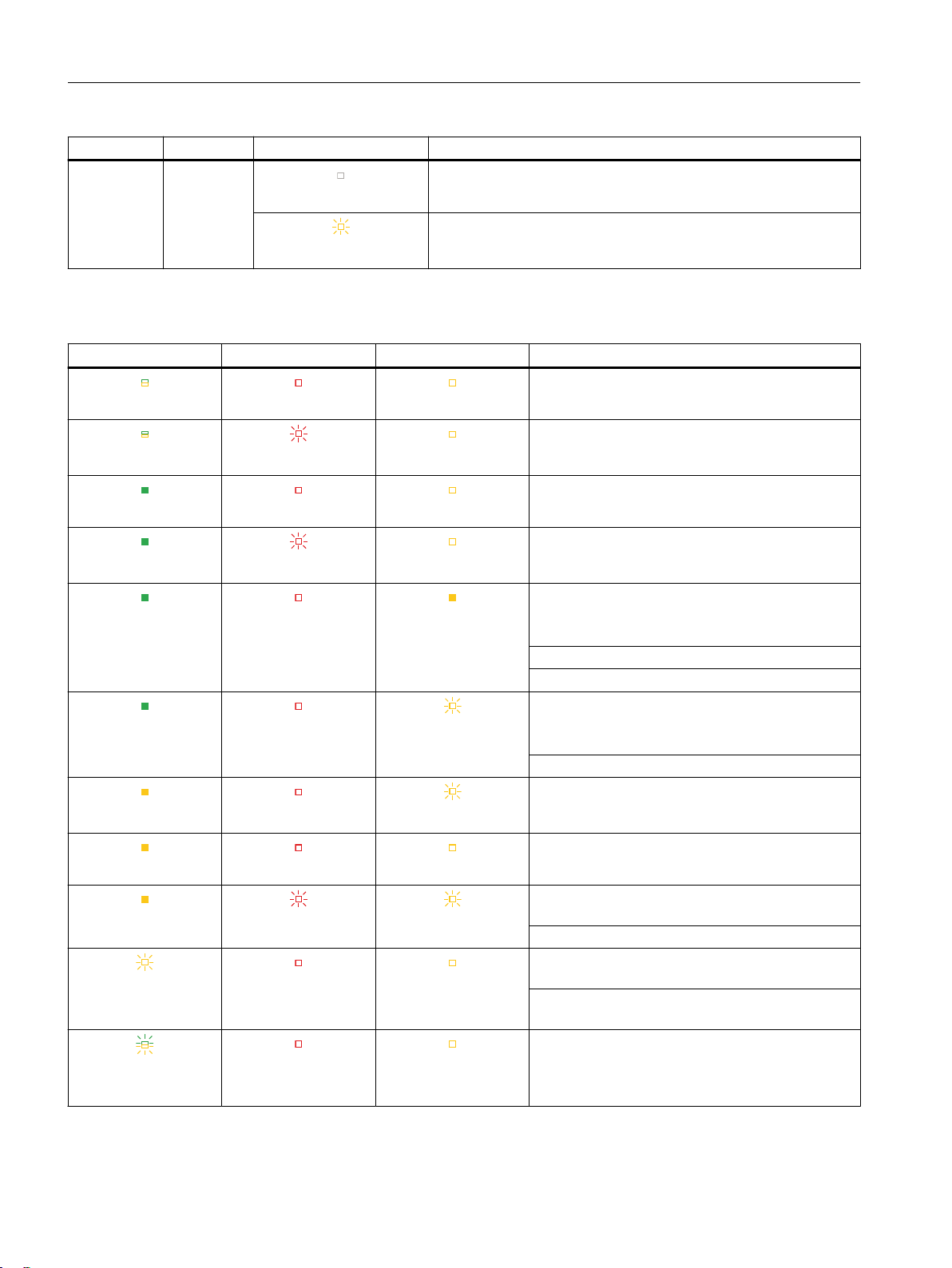

Meaning of the RUN/STOP, ERROR and MAINT PLC-LEDs

RUN/STOP LED ERROR LED MAINT LED Meaning

Supply voltage at the CPU not present or too low.

LED off LED off LED off

An error has occurred.

LED off

LED lights up green LED off LED off

LED lights up green

LED lights up green LED off LED lights up yellow

LED lights up green LED off

LED lights up yellow LED off

LED lights up yellow LED off LED off

LED lights up yellow

LED flashes yellow

LED flashes red

LED flashes red

LED flashes red LED flashes yellow

LED off LED off

LED off

LED off

LED flashes yellow

LED flashes yellow

The CPU is in the RUN operating state.

Diagnostic event pending.

A plant maintenance request is pending.

The affected hardware must be validated/replaced

within a short interval.

Active force job

PROFIenergy pause

A plant maintenance requirement is pending.

The affected hardware must be validated/replaced

within a foreseeable interval.

Configuration faulty

Firmware update completed successfully.

CPU is in STOP operating state.

The program on the SIMATIC Memory Card cau‐

ses a fault.

CPU defective

CPU performs internal activities during STOP, e.g.

ramp-up after STOP.

Downloading the user program from the SIMATIC

Memory Card

Startup (transition from RUN → STOP)

LED flashes

yellow/green

LED off LED off

MCU 1720

28 Equipment Manual, 09/2019, A5E47437728B AB

4.2 Operator control and display elements

RUN/STOP LED ERROR LED MAINT LED Meaning

Startup (booting the CPU)

LED flashes

yellow/green

LED flashes red LED flashes yellow

Test the LEDs during startup, insert a module.

LED flash test

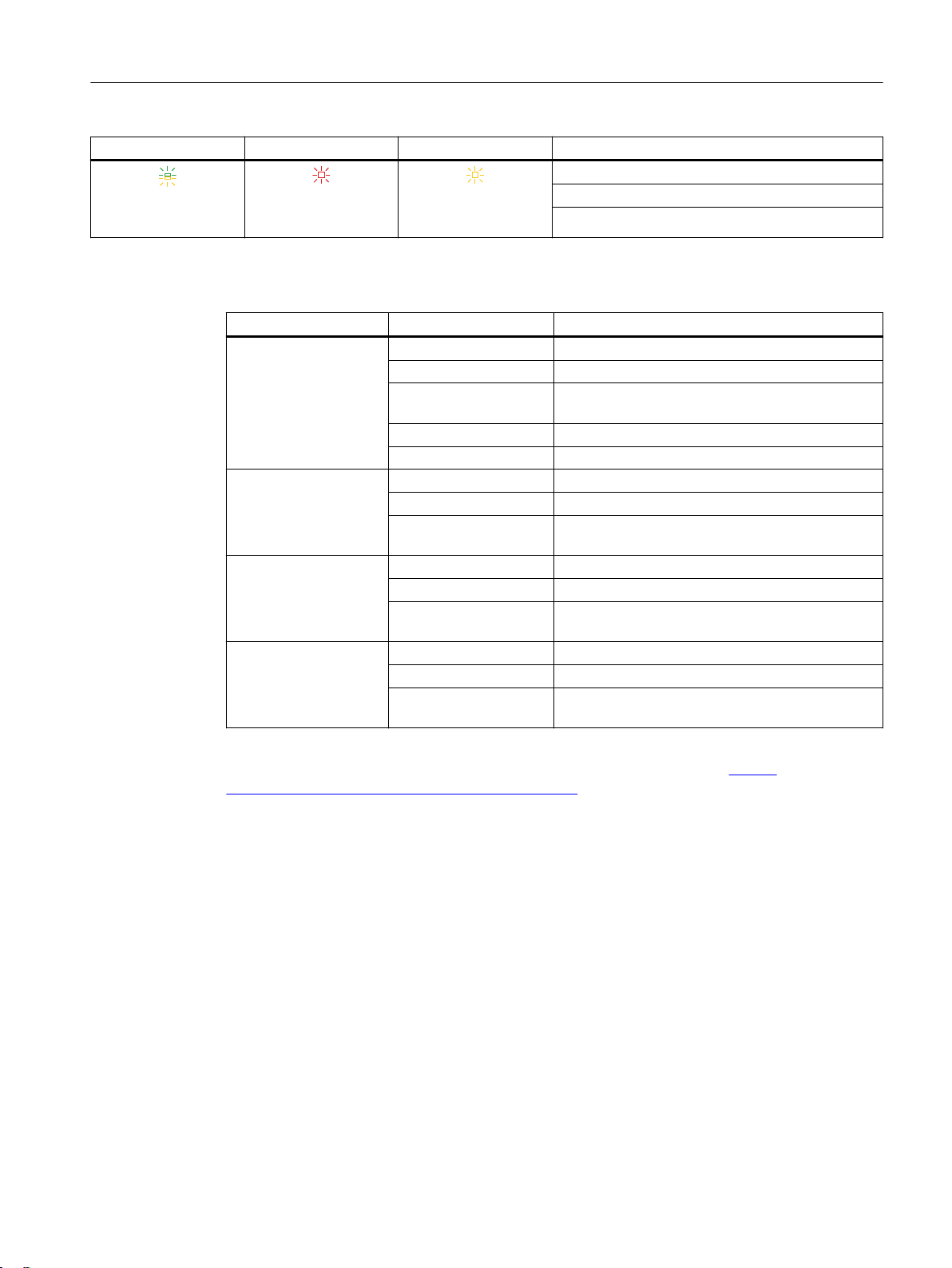

Meanings of the HMI LEDs

LED Status Description

PC ON/WD Off -

Green BIOS ready to boot; PC is running

Flashing green/yellow

(1 Hz)

Yellow Idle state

Flashing red (1 Hz) Watchdog status display: Active

RUN/STOP or L1 Off -

Green Can be controlled from the user program

Yellow Can be controlled from the control program

ERROR or L2 Off -

Red Flashing red Can be controlled from the user program or the

MAINT or L3 Off -

Yellow Red Can be controlled from the control program

BIOS in POST, power switch on

(e.g. WinAC)

control program (e.g. WinAC)

(e.g. WinAC)

Description

You can find program examples to control LEDs under the Windows operating systems at the

Customer Support page Industry Automation and Drive Technologies. (https://

support.industry.siemens.com/cs/start?lc=en-WW)

Important LED states

● If all the LEDs are flashing, the PLC must be reset (general reset) via the mode selector

switch (ramp-up with the switch in the "MRES" position).

● While the MCU is powering up, all LEDs briefly light up orange. You can carry out a detailed

diagnosis using a PG/PC and the operating software.

Further information

You can find more information about LED states during ramp-up here:

● Commissioning Manual, Basic Software and Operating Software

You can find more information about the drive faults and alarms here:

● List manual (LH1) SINAMICS S120/S150

MCU 1720

Equipment Manual, 09/2019, A5E47437728B AB 29

Description

4.2 Operator control and display elements

4.2.3 Start-up and mode selector switch

The MCU is equipped with an NCK rotary coding switch and a PLC mode selector switch as a

toggle switch with three switch positions:

● The NCK commissioning switch:

Setting during normal operation: "0"

Figure 4-2 NCK commissioning switch

● The PLC mode selector switch:

Setting during normal operation: "Run"

Further information

RUN Places the PLC in the RUN operating state.

STOP Places the PLC in the STOP operating state.

MRES Initiates the PLC reset.

Figure 4-3 PLC mode selector switch

You can find further information at:

● CNC Commissioning Manual Part 1 (NCK, PLC, drive)

MCU 1720

30 Equipment Manual, 09/2019, A5E47437728B AB

Loading...

Loading...