Siemens SINUMERIK FM-NC, SIMODRIVE 611 digital, SINUMERIK 840Di, SINUMERIK 810D, SINUMERIK 840D Installation And Startup Manual

SINUMERIK 840D/

SIMODRIVE 611 digital

Installation and Start-Up Guide 04.2000 Edition

Manufacturer/Service Documentation

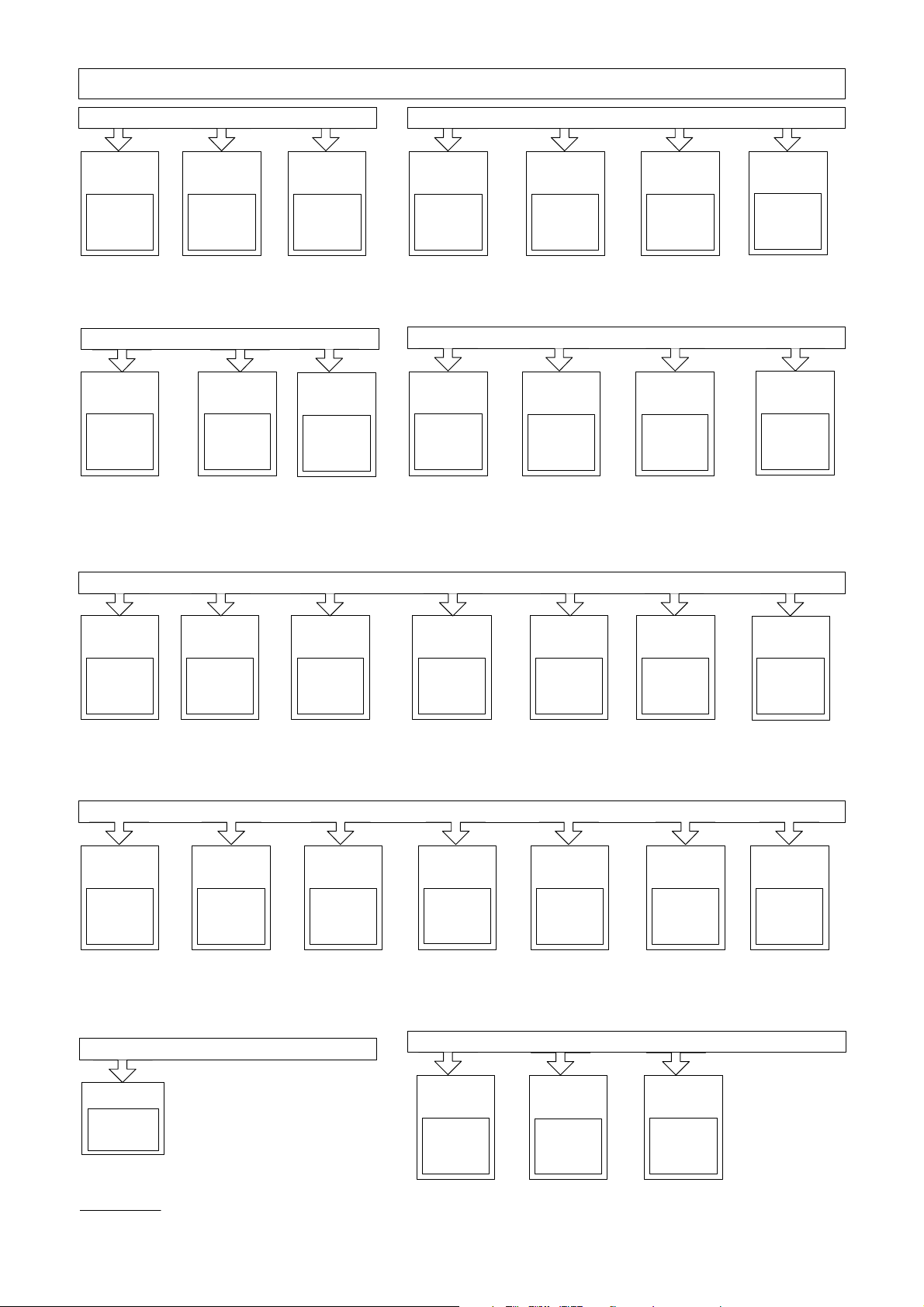

Overview of SINUMERIK 840D/840Di/810D/FM-NC Documentation (04.00)

General Documentation

SINUMERIK

840D/810D/

FM-NC

Brochure Catalog

SINUMERIK

840D/840Di/

810D/

FM-NC/611

Ordering Info

NC 60.1 *)

Technical Info.

NC 60.2

User Documentation

SINUMERIK

840D/840Di/

810D/

FM-NC

Program. Guide

– Short Guide

– Fundamentals *)

– Advanced *)

– Cycles

– Measuring Cycles

SINUMERIK

840D/810D

Operator’s Guide

– ManualTurn

– Short Guide ManualTurn

– ShopMill

– Short Guide ShopMill

SINUMERIK

SIROTEC

SIMODRIVE

Accessories

Catalog

Accessories NC-Z

SINUMERIK

840Di

System Overview

User Documentation

SINUMERIK

840D/810D/

FM-NC

AutoTurn

– Short Guide

– Programming (1)

– Setup (2)

SINUMERIK

840D/810D

Operator’s Guide

– Unit

Operator Panel

– HPU

– HT 6

SINUMERIK

840D/840Di/

810D/

FM-NC

Diagnostics

Guide *)

Manufacturer / Service Documentation

SINUMERIK

840D/810D

Description of

Functions

– ManualTurn

– ShopMill

SINUMERIK

840D/840Di/

810D

Description of

Functions

Synchronized

Actions

Wood, Glass,

Ceramics

SINUMERIK

840D/810D

Descr. of Functions

– Computer Link

– Tool Data

Information

System

SINUMERIK

840D/810D/

FM-NC

Operator’sGuide

– Short Guide

– Operator’s

Guide *)

SINUMERIK

Configuring

(HW) *)

– FM-NC

– 810D

– 840D

Manufacturer / Service Documentation

SINUMERIK

840D/840Di/

810D/

FM-NC

Operator

Components

(HW) *)

SINUMERIK

SIMODRIVE

611D

840D/810D

Description of

Functions

Drive Functions *)

SINUMERIK

840D/840Di/

810D/

FM-NC

Description of

Functions

– Basic Machine *)

– Extended Functions

– Special Functions

Manufacturer / Service Documentation

SINUMERIK

SIMODRIVE

Description of

Functions

SINUMERIK

Safety Integrated

SINUMERIK

840D

Description of

Functions

Digitizing

SINUMERIK

SIMODRIVE

Installation &

Start-up Guide *)

– FM-NC

– 810D

– 840D/611D

– MMC

Electronic Documentation

SINUMERIK

840D/810D/

FM-NC

Configuring Kit

MMC100/101

– Configuring

Syntax

– Development Kit

SINUMERIK

SIMODRIVE

840D/840Di/

810D

FM-NC

611D

Lists *)

SINUMERIK

840D/810D/

FM-NC

Screen Kit

MMC100/101

SW Update and

Configuration

SINUMERIK

SIMODRIVE

840D

611D

Description of

Functions

Linear Motor

SINUMERIK

840D/810D

Description of

Functions

Tool Management

SINUMERIK

SIMODRIVE

840D

611D

Description of

Functions

– Hydraulics

Module

– Analog Module

Manufacturer/Service Documentation

SINUMERIK

840D/810D/

FM-NC

Description of

Functions

Operator Interface

OP 030

SINUMERIK

SIMODRIVE

SIROTEC

EMC

Guidelines

SINUMERIK

SIMODRIVE

840D/810D/

FM-NC

611,

Motors

DOC ON CD *)

The SINUMERIK System

*) These documents are a minimum requirement for the control

SINUMERIK

840D/810D

Descr. of Functions

ISO Dialects for

SINUMERIK

SINUMERIK

Descr. of Functions

CAM Integration

DNC NT–2000

SINUMERIK

840Di

Manual

(HW + Installation

and Start-up)

General Preparations 1

Configuration 2

Settings, MPI/OPI 3

EMC/ESD Measures 4

SINUMERIK 840D

SIMODRIVE 611D

Installation and Start-Up Guide

Power On and Power Up 5

Parameterization of

Control

PLC Program 6

PLC Start-Up 7

Alarm and Message Texts 8

Axis/Spindle Dry Run 9

Drive Optimization 10

Data Backup 11

SW/HW Replacement 12

Valid for

Control Software Version

SINUMERIK 840D 5

SINUMERIK 840DE (export version) 5

Drive

SIMODRIVE 611D 4

04.00 Edition

MMC 13

Miscellaneous 14

Abbreviations A

References B

Index

y

3ls

SINUMERIK documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the “Remarks” column.

Status code in the “Remarks” column:

A New documentation.. . . . .

B Unrevised reprint with new Order No.. . . . .

C Revised edition with new status. . . . . .

If factual changes have been made on the page since the last edition,

this is indicated by a new edition coding in the header on that page.

Edition Order No. Remarks

06.94 6FC5 297–0AB10–0BP0 A

08.94 6FC5 297–0AB10–0BP1 C

02.95 6FC5 297–2AB10–0BP0 C

04.95 6FC5 297–2AB10–0BP1 C

09.95 6FC5 297–3AB10–0BP0 C

03.96 6FC5 297–3AB10–0BP1 C

08.97 6FC5 297–4AB10–0BP0 C

12.97 6FC5 297–4AB10–0BP1 C

12.98 6FC5 297–5AB10–0BP0 C

08.99 6FC5 297–5AB10–0BP1 C

04.00 6FC5 297–5AB10–0BP2 C

This manual is included in the documentation available on CD-ROM (DOCONCD)

Edition Order No. Remarks

04.00 6FC5 298–5CA00–0BG2 C

Trademarks

SIMATICr, SIMATIC HMIr, SIMATIC NETr, SIROTECr, SINUMERIKr and SIMODRIVEr are Siemens

trademarks. The other designations in this publication may also be trade marks, the use of which by third

parties may constitute copyright violation.

Further information is available on the Internet under:

http://www.ad.siemens.de/sinumerik

This publication was produced with Interleaf V 7.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority. Offenders

will be liable for damages. All rights, including rights created by patent

grant or registration of a utility model or design, are reserved.

Siemens AG 1994 – 2000. All rights reserved.

Printed in the Federal Republic of German

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

We have checked that the contents of this document correspond to

the hardware and software described. Nonetheless, differences might

exist. The information contained in this document is, however,

reviewed regularly and any necessary changes will be included in the

edition. We welcome suggestions for improvement.

Subject to technical changes without prior notice.

Siemens–AktiengesellschaftOrder No. 6FC5 297–5AB10–0BP2

03.96

PREFACE

SINUMERIK 840D Installation and Start-Up Guide

Preface

Structure of

documentation

Target group

Objective

Standard scope

The SINUMERIK documentation is divided into 3 different levels:

S General documentation

S User Documentation

S Manufacturer/Service Documentation

This document is intended for the manufacturers of machine tools incorporating

SINUMERIK 840D and SIMODRIVE 611D systems.

The Installation and Start-Up Guide provides all the relevant information

required for start-up, installation and servicing.

This document provides information about the control system design and the

interfaces of the individual components. It also describes the start-up and

installation procedure for SINUMERIK 840D with SIMODRIVE 611D including a

list of all data, signals and PLC blocks.

For detailed information about individual functions, function assignment and

performance data of individual components, please refer to the appropriate

document for the subject concerned (e.g. manuals, function descriptions etc.).

User-oriented activities such as the creation of part programs and control

operating procedures are described in detail in separate documents.

Separate descriptions are likewise provided of the tasks to be performed by the

tool manufacturer such as configuring, design and PLC programming.

Searching aids

In addition to the table of contents and indexes of figures and tables, we have

provided the following information in the appendix for your assistance:

1. Index of abbreviations

2. List of references

3. Index

For a complete list and description of SINUMERIK 840D alarms, please refer to

References: /DA/, Diagnostics Guide

For further useful information on start-up and troubleshooting, please refer to

References: /FB/, D1, “Diagnostics Tools”

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

v

SINUMERIK 840D Installation and Start-Up Guide

Preface

03.96

Symbols

The following symbols with special significance are used in the documentation:

Note

This symbol appears in this document to draw your attention to information

relevant to the subject in hand.

Important

!

This symbol appears in this document to draw your attention to an important

item of information.

Order data option

In this document, you will encounter the symbol shown on the left with a

reference to an ordering data option. Please note that the function described

can operate only if the specified option is installed in the control system.

Warnings

The following warnings with varying levels of severity are used in this document:

Danger

!

!

!

This symbol indicates that death, grievous injury or substantial property damage will occur if the appropriate precautions are not taken.

Caution

This symbol indicates minor injuries or property damage may occur if the appropriate precautions are not taken.

Warning

This symbol indicates that death, grievous injury or substantial property damage may occur if the appropriate precautions are not taken.

vi

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

03.96

Technical information

SINUMERIK 840D Installation and Start-Up Guide

Preface

Trademarks

Notation

Effectiveness of

changes

IBM is a registered trademark of the International Business Corporation.

MS–DOS

Corporation.

The following notation and abbreviations are used in this document:

and WINDOWST are registered trademarks of the Microsoft

S PLC interface signals –> IS “Signal name” (signal data)

Examples:

– IS “MMC–CPU1 ready” (DB10, DBX108.2), i.e. the signal is stored in

data block 10, data byte 108, bit 2.

– IS “Feedrate/spindle override” (DB31–48, DBB0), i.e. the signals are

stored for specific spindles/axes in data blocks 31 to 48, data block

byte 0.

S Machine data –> MD: MD_NAME (English designation)

S Setting data –> SD: SD_NAME (English designation)

S The character “” means “corresponds to”.

After data (e.g. machine data) have been changed, it must also be noted when

the change will become effective (e.g. after power ON or immediately). This information is therefore always provided.

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

vii

SINUMERIK 840D Installation and Start-Up Guide

Preface

Notes

04.00

03.96

viii

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

Contents

1 General Preparations 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Preconditions 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Standard/export version 1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Configuration 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Mechanical configuration 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Overview 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Mains infeed module 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 NCU 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 General configuration of SINUMERIK 840D system 2-23. . . . . . . . . . . . . .

2.2 Electrical configuration 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Component connections 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Connection of mains infeed module (U/E, I/RF) 2-25. . . . . . . . . . . . . . . . . .

2.2.3 Motor connection 2-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4 Encoder connection 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.5 Connection of MMC100 and MMC102/103 2-30. . . . . . . . . . . . . . . . . . . . . .

2.2.6 Configuration of components for digitizing 2-32. . . . . . . . . . . . . . . . . . . . . . .

3 Settings, MPI / OPI 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 MPI/OPI, network rules 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Standard configuration 3-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Standard configuration up to SW 3.1 3-38. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Standard configuration as from SW 3.2 3-40. . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Connection of a 2nd MCP/customer operator panel interface

and/or 1 HHU (up to SW 3.1) 3-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Connection to OPI bus 3-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Connection to MPI bus 3-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Example of a configuration of MCP and HHU via OPI 3-46. . . . . . . . . . . . .

3.3.4 Example of a configuration of HHU via MPI 3-47. . . . . . . . . . . . . . . . . . . . . .

3.4 Handheld unit 3-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Settings on the HHU up to software version 3.x 3-52. . . . . . . . . . . . . . . . . .

3.4.2 Settings on the HHU for software version 4.x and higher 3-53. . . . . . . . . .

3.4.3 Configuring the HHU, setting interface parameters 3-53. . . . . . . . . . . . . . .

3.4.4 Example: Connecting the HHU to the SINUMERIK 840D 3-55. . . . . . . . . .

3.5 Handheld programming unit 3-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Interface signals of the HPU 3-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Standard configuration of the HPU (without MCP) 3-58. . . . . . . . . . . . . . . .

3.5.3 Deviations from the standard HPU configuration

(up to SW 3.1) 3-59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Machine control panel (MCP) 3-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Customer operator panel interface 3-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

ix

SINUMERIK 840D Installation and Start-Up Guide

Contents

3.8 Second machine control panel 3-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 MMC 100/MMC 102/103 operator panel 3-69. . . . . . . . . . . . . . . . . . . . . . . .

3.9.1 Settings on the MMC 3-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.2 Language default 3-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 EMC / ESD Measures 4-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Measures to suppress interference 4-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Measures to protect ESD-sensitive components 4-74. . . . . . . . . . . . . . . . .

5 Power On and Power-Up 5-75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Startup sequence 5-76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Power on and power-up 5-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Power on 5-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Power-up 5-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 MMC100 – MMC102/103 power-up 5-80. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Error during control power-up (NC) 5-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Machine control panel (MCP) power-up 5-84. . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6 Drive system power-up 5-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.7 MMC102/103 BIOS setup 5-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

04.00

03.96

6 Assigning Parameters to the Control and the PLC Program 6-85. . . . . . . . . . . . .

6.1 Machine and setting data 6-87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Handling machine and setting data 6-89. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Protection level concept 6-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Machine data masking filter (SW 4.2 and higher) 6-92. . . . . . . . . . . . . . . . .

6.4.1 Function 6-92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Selecting and setting the machine data masking filters 6-92. . . . . . . . . . . .

6.4.3 Saving the filter settings 6-95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Example of start-up design concept 6-96. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 System data 6-99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 Basic settings 6-99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 Memory configuration 6-102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.1 Dynamic RAM memory 6-103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.2 Static RAM memory 6-104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8 Scaling machine data 6-106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 Axes and spindles 6-108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.1 Description of the axis configuration 6-108. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.2 Drive configuration (FDD, SLM, MSD) 6-111. . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.3 Setting the axis-specific setpoint/actual value parameters 6-114. . . . . . . . .

6.9.4 Drive parameterization (FDD, MSD) 6-116. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.5 Parameterization of incremental measuring systems 6-118. . . . . . . . . . . . . .

6.9.6 Parameterization of absolute measuring systems

(EnDat interface) 6-121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.7 Overview of optimization drive parameters 6-124. . . . . . . . . . . . . . . . . . . . . .

6.9.8 Axis data 6-127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.9 Velocity matching (axis) 6-129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.10 Position controller data (axis) 6-130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.11 Monitoring functions (axis) 6-133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

04.00

03.96

SINUMERIK 840D Installation and Start-Up Guide

6.9.12 Reference point approach (axis) 6-138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.13 Spindle data 6-140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.14 Spindle configuration 6-142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.15 Encoder matching (spindle) 6-142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.16 Speeds and setpoint adjustment for spindle 6-144. . . . . . . . . . . . . . . . . . . . .

6.9.17 Spindle positioning 6-145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.18 Spindle synchronization 6-146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.19 Spindle monitoring 6-148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.20 Example: Start-up of NCK I/O devices 6-150. . . . . . . . . . . . . . . . . . . . . . . . . .

6.10 Linear motors (1FN1 and 1FN3 motors) 6-152. . . . . . . . . . . . . . . . . . . . . . . . .

6.10.1 General information about starting up linear motors 6-152. . . . . . . . . . . . . . .

6.10.2 Start-up: Linear motor with one primary part 6-154. . . . . . . . . . . . . . . . . . . . .

6.10.3 Start-up: Linear motors with 2 identical primary parts 6-163. . . . . . . . . . . . .

6.10.4 Mounting dimensions 6-165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.5 Temperature sensors for 1FN1 and 1FN3 motors 6-166. . . . . . . . . . . . . . . .

6.10.6 Measuring system 6-169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.7 Parallel connection of linear motors 6-172. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.8 Test measurements on linear motor 6-174. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11 AM / U/F function 6-176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

6.12 System settings for power up, RESET and part program start 6-177. . . . . .

7 PLC Start-Up 7-181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 PLC start-up 7-181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Overview of organization blocks, function blocks and DBs 7-184. . . . . . . . .

8 Alarm and Message Texts 8-185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Alarm and message texts 8-186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Alarm text files for MMC 100 8-186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Alarm text files for MMC 102/103 8-188. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3 Alarm text files for HPU 8-190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.4 Syntax for alarm text files 8-192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.5 Properties of alarm list 8-195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Axis and Spindle Dry Run 9-197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Preconditions 9-197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Axis test run 9-198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Testing the spindle 9-200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Drive Optimization with Start-Up Tool 10-203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Instructions for use 10-204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.1 System requirements 10-205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.2 Installation 10-205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.3 Starting the program 10-206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.4 Terminating the program 10-206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Measuring functions 10-207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Interface signals Traverse request and Motion enable drive test 10-209. . . .

10.4 Aborting measuring functions 10-210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5 Frequency response measurement 10-211. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

xi

SINUMERIK 840D Installation and Start-Up Guide

Contents

10.5.1 Measurement of torque control loop 10-211. . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.2 Measurement of speed control loop 10-212. . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.3 Measurement of position control loop 10-216. . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6 Graphic display 10-219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7 Gantry axes (SW 5.1 and later) 10-221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.1 Description 10-221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.2 Conditions 10-221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8 Trace function (SW 4.2 and higher) 10-222. . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.1 Description 10-222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.2 Operation, basic display 10-223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.3 Parameterization 10-224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.4 Performing measurement 10-227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.5 Display function 10-228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.6 File function 10-230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.7 Print graph 10-231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.9 Analog output (DAC) 10-233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.10 Automatic controller adjustment

(only MMC 103, SW 4.3 and higher) 10-234. . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.10.1 Flow chart for self-optimization 10-236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.10.2 Input options for self-optimization 10-240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

04.00

03.96

11 Data Backup 11-245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 General information 11-245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Data backup via MMC 100 11-248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Data backup via MMC 102/103 11-254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.1 Data backup via V24 on the MMC 102/103 11-255. . . . . . . . . . . . . . . . . . . . . .

11.3.2 Output of drive data via V24 on MMC102/103 11-257. . . . . . . . . . . . . . . . . . .

11.3.3 Output of drive data via V24 on the MMC102/103 11-258. . . . . . . . . . . . . . . .

11.3.4 PLC data output via V24 on MMC102/103 11-262. . . . . . . . . . . . . . . . . . . . . . .

11.3.5 Output of MMC data via V24 on MMC102/103 11-262. . . . . . . . . . . . . . . . . . .

11.3.6 Output of the series start-up file via V24 on MMC102/103 11-263. . . . . . . . .

11.4 Back up hard disk via Norton GhostR (SW 4.4 and higher) 11-265. . . . . . . .

11.4.1 Back up hard disk / Import data backup 11-265. . . . . . . . . . . . . . . . . . . . . . . . .

11.4.2 Saving user data 11-268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.3 Back up hard disk 11-268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.4 Restore data to hard disk 11-270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5 Several SW versions on one MMC 103 (SW 5.2 and higher) 11-272. . . . . . .

11.6 Installing a replacement hard disk (SW 4.4 and higher) 11-274. . . . . . . . . . .

11.7 Data backup with VALITEK streamer on the MMC101/102/103

(SW 5.3 and lower) 11-276. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.8 Line checksums and MD numbers in MD files

(software Version 3.2 and higher) 11-281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.8.1 Line checksums (MD 11230 MD_FILE_STYLE) 11-281. . . . . . . . . . . . . . . . . .

11.8.2 Machine data numbers 11-282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.8.3 Aborting MD import 11-282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.9 Machine/setting data 11-284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xii

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

04.00

03.96

SINUMERIK 840D Installation and Start-Up Guide

11.10 Saving PLC data 11-284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Software and Hardware Replacement 12-285. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Software update 12-285. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 Upgrading the MMC 100/100.2/101 software 12-286. . . . . . . . . . . . . . . . . . . .

12.3 Upgrade of MMC 102/103 software Version 4.x or earlier 12-287. . . . . . . . . .

12.4 Upgrading the NC 12-288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.1 Standard upgrade 12-288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.2 Series start-up via NC card (SW 4.4 and higher) 12-289. . . . . . . . . . . . . . . . .

12.4.3 SINUCOPY–FFS (SW 4.4 and higher) 12-291. . . . . . . . . . . . . . . . . . . . . . . . . .

12.5 Hardware replacement 12-296. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.6 Battery/fan replacement 12-296. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 MMC 13-299. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 Miscellaneous 14-301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 Tool box software package 14-301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.1 Content of tool box 14-301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.2 Application of the tool box 14-301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

14.2 Machine data access via part program 14-302. . . . . . . . . . . . . . . . . . . . . . . . . .

A Abbreviations A-305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B References B-311. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Index Index-321. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

xiii

SINUMERIK 840D Installation and Start-Up Guide

Contents

Notes

04.00

03.96

xiv

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

1

General Preparations

1.1 Preconditions

Introduction

Software

requirements

This Installation and Start-Up Guide describes the procedure for starting up the

basic control functions including drive-related functions. More detailed information about special NCK, MMC, PLC or drive functions can be found in the Descriptions of Functions/Manuals (see “Documentation requirements”).

You will need the following software to start up the SINUMERIK 840D:

1. PCIN 4.4 for transmission of data to/from MMC

Order no.: 6FX2 060–4AA00–2XB0 (German, English, French), order from:

WK Fürth

2. Start-up tool for digital SIMODRIVE 611 (applies only to MMC100)

Order No. 6FC5 255–jAX00–0AB0, supplies on 3.5” floppies

3. SIMATIC Step7 HiGraph

4. Toolbox for SINUMERIK 840D

Order No. 6FC5 252–jAX21–0AB0

Supplied on 3.5” floppies:

– Basic PLC program

– Standard machine data blocks

– NC variable selector

5. Applies only to MMC100: Software for creating PLC alarm texts and for

transmission to MMC100 (integrated in MMC 100 system software)

1

Equipment and

accessory

requirements

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

You will need the following equipment and accessories to start up the

SINUMERIK 840D:

1. Programming device with MPI interface (PG740)

2. MPI cable for PG740

3. V.24 cable with 9-way connector (female)

1-15

1 General Preparations

1.2 Standard/export version

04.00

03.96

1

Documentation

requirements

You will need the following documentation to start up the SINUMERIK 840D:

1. Catalog NC 60.1, Ordering Information/BU/

Order no.: E86060–K4460–A101–A6

2. Manual /PHD/

Order no.: 6FC5 297–5AC10–0BP2

3. Operator Components Manual /BH/

Order no.: 6FC5 297–5AA50–0BP2

4. Description of Functions, Basic Machine (Part 1) /FB/

Order no.: 6FC5 297–5AC20–0BP2

5. Description of Functions, Drive Functions /FBA/

Order no.: 6SN1 197–0AA80–0BP5

6. Lists /LIS/

Order no.: 6FC5 297–5AB70–0BP2

7. Description PCIN 4.4 /PI/

Order no.: 6FX2 060–4AA00–4XB0

8. Diagnostics Guide /DA/

Order no.: 6FC5 297–5AA20–0BP2

1.2 Standard/export version

Export approval

On account of the approval required for certain control functions as stipulated in

the German Export List, two configuration variants are available for the

SINUMERIK 840D.

The standard version (840D) can contain the full scope of functions of the

control but this does mean that it requires export approval with regard to its

type.

In the export version (840DE) the following options are not available:

S Interpolation with more than 4 axes

S 5-axis milling package

S Helical interpolation 2D + n (n greater than 2)

S OEM package

The following restrictions apply to options that can be used:

S Sag compensation is restricted to the traversing of a path of up to 10 mm.

S Adaptive control

The corresponding option bits can be set but they have no effect (alarm when

programming the functions). The export version requires no export approval

with respect to its type.

Up-to-date information about types and scope of options can be found in

References: /BU/ Catalog NC 60.1.

(If a requirement exists for export approval with respect to the intended use this

is not affected and might even exist in addition.)

1-16

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

03.96

1 General Preparations

1.2 Standard/export version

The specific nature of the control is determined by the system software that is

available in two versions (standard and export). In other words, the

requirements for approval of the system software (refer also to the delivery

notes or invoice for information in this respect) is handed down to the control

system with the installation. This point must be observed in particular when

converting or upgrading the system software because the requirements for

export approval for the control can change accordingly.

1

Identification of

the

control

In addition to the information provided on the delivery note and invoice, the

hardware components supplied with the system software are also clearly

identified by adhesive labels as standard or export versions.

Note

The adhesive labels supplied additionally in the packaging are intended to

identify the control after installation and start-up and must be pasted into the

control logbook. In the case of license orders, a corresponding number of

labels is provided and the same applies to these.

When the control has been booted, the export versions can be identified by the

additional character ’E’ in the Service screen (NC information). The identification

of the control variants obtained by these measures is important for service

personnel and can also be helpful in providing evidence of conformance for

exports, in particular when making use of the negative certificates that are

provided for the export version.

J

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

1-17

1 General Preparations

1.2 Standard/export version

04.00

03.96

1

Notes

1-18

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

Configuration

2.1 Mechanical configuration 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Overview 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Mains infeed module 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 NCU 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 General configuration of SINUMERIK 840D system 2-23. . . . . . . . . . . . . .

2.2 Electrical configuration 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Component connections 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Mains infeed connection (OI, I/RF) 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Motor connection 2-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4 Encoder connection 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.5 Connection of MMC100 and MMC102/103 2-30. . . . . . . . . . . . . . . . . . . . . .

2.2.6 Configuration of components for digitizing 2-32. . . . . . . . . . . . . . . . . . . . . . .

2

2

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

2-19

2

2 Configuration

2.1 Mechanical configuration

2.1 Mechanical configuration

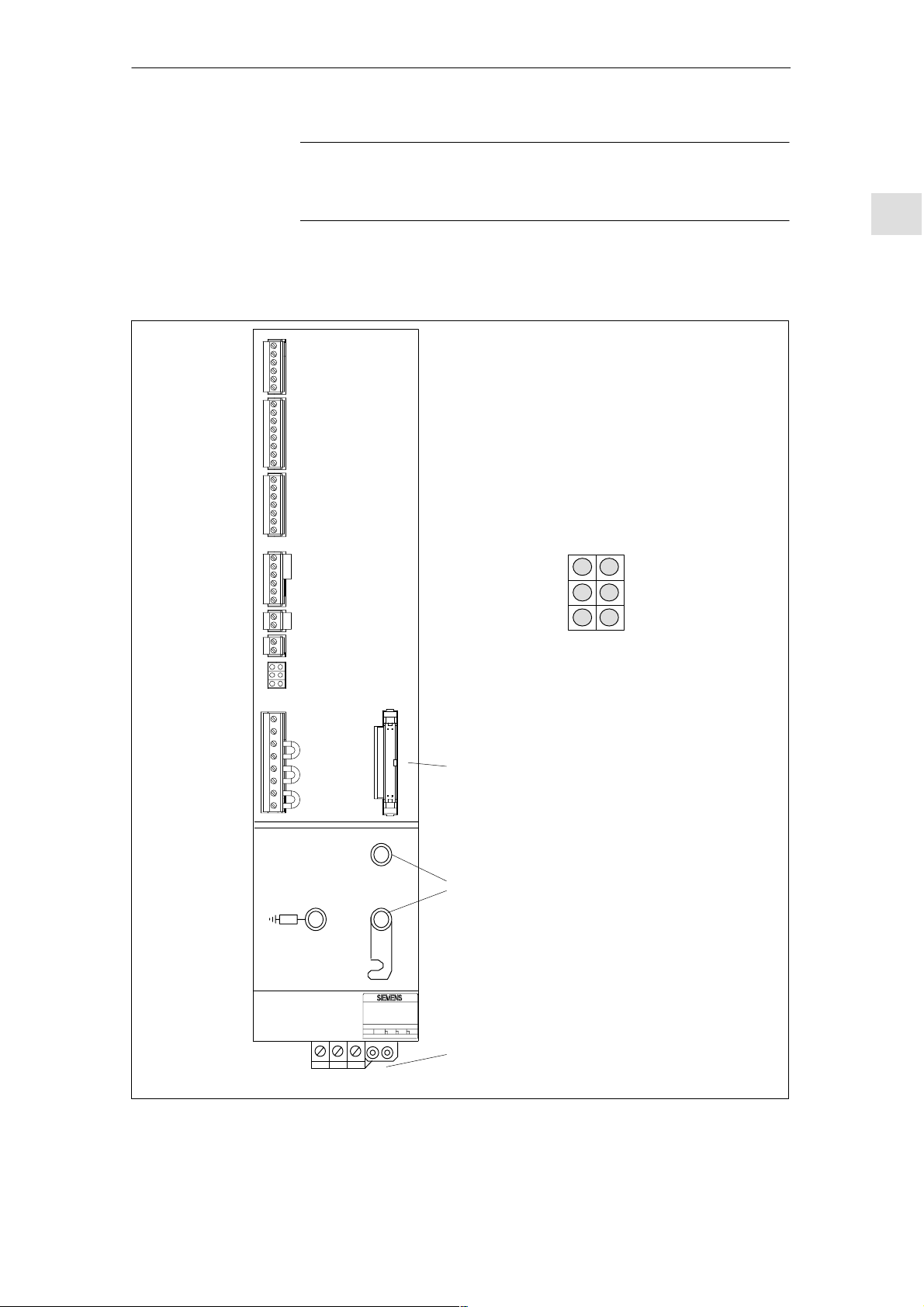

2.1.1 Overview

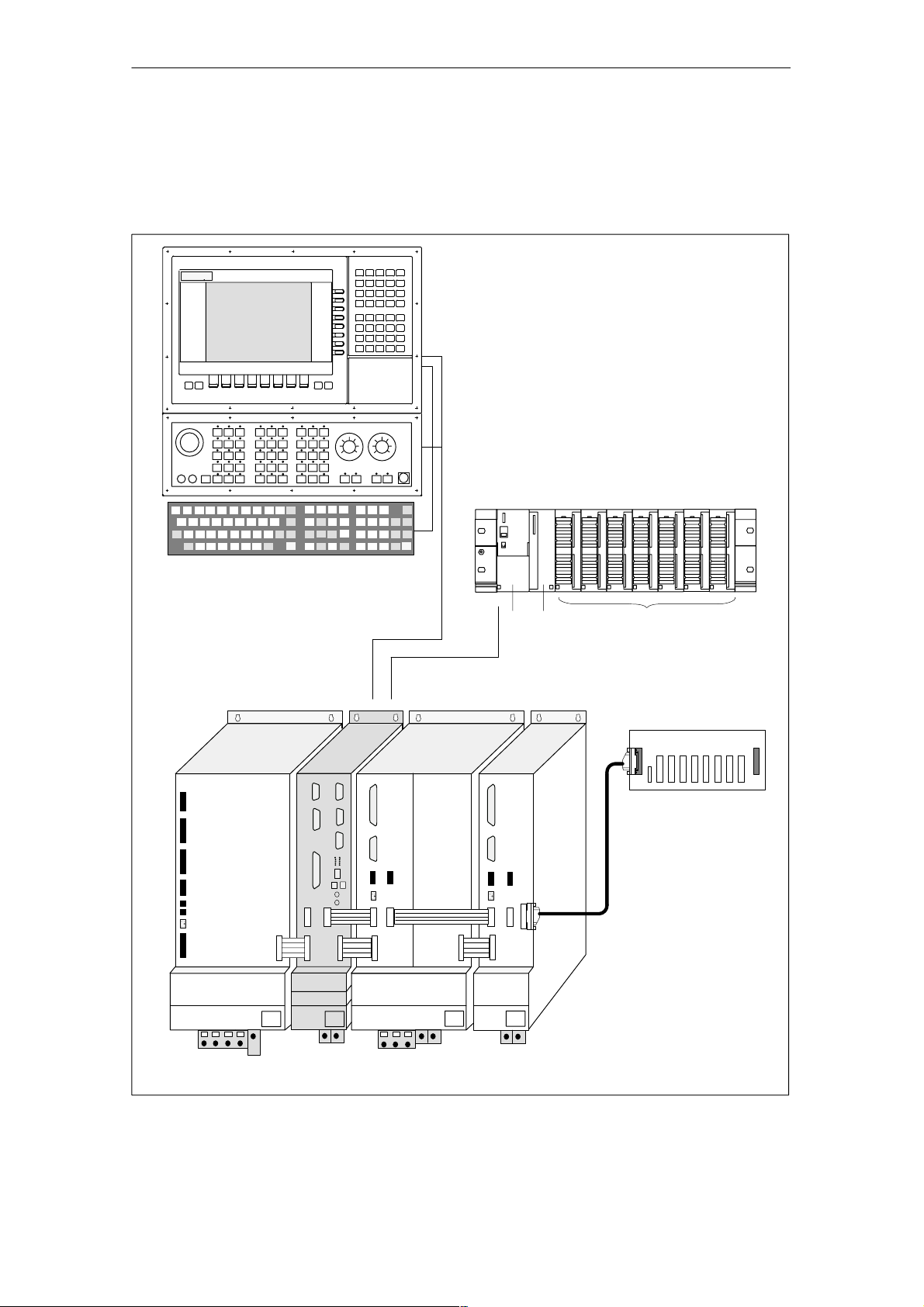

SIEMENS

03.96

Operator panel

Machine control panel

QWERTY keyboard

SIEMENS

SIMODRIVE

PS IM

SMs

SIMATIC STEP7–300 I/O devices

NCU terminal block

SIMODRIVE 611D

SINUMERIK 840D

MS (I/RF, OI)

Fig. 2-1 System overview of SINUMERIK 840 with SIMODRIVE 611 (diagrammatic)

2-20

NCU MSD

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

FDD

Siemens AG 2000 All Rights Reserved

03.96

2.1.2 Mains infeed module

2 Configuration

2.1 Mechanical configuration

Mains infeed

module

Open-loopcontrolled infeed

OI

Infeed/regenerative

feedback module

I/RF

Arrangement of

mains infeed

module

The mains infeed module performs the following tasks:

S Supplies power for the SINUMERIK 840D and axis modules

S Generates the DC link voltage for the motors

S Regenerative feedback (I/RF) or braking resistor (OI) for generator-mode

operation

If the internal braking resistance is not sufficient, pulsed resistor modules can be

installed.

The I/RF module feeds back into excess DC link energy generated during braking the supply system.

The I/RF or OI module is installed as the first module on the left.

References: PJ1/ Planning Guide for SIMODRIVE 611D

2

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

2-21

2

2 Configuration

2.1 Mechanical configuration

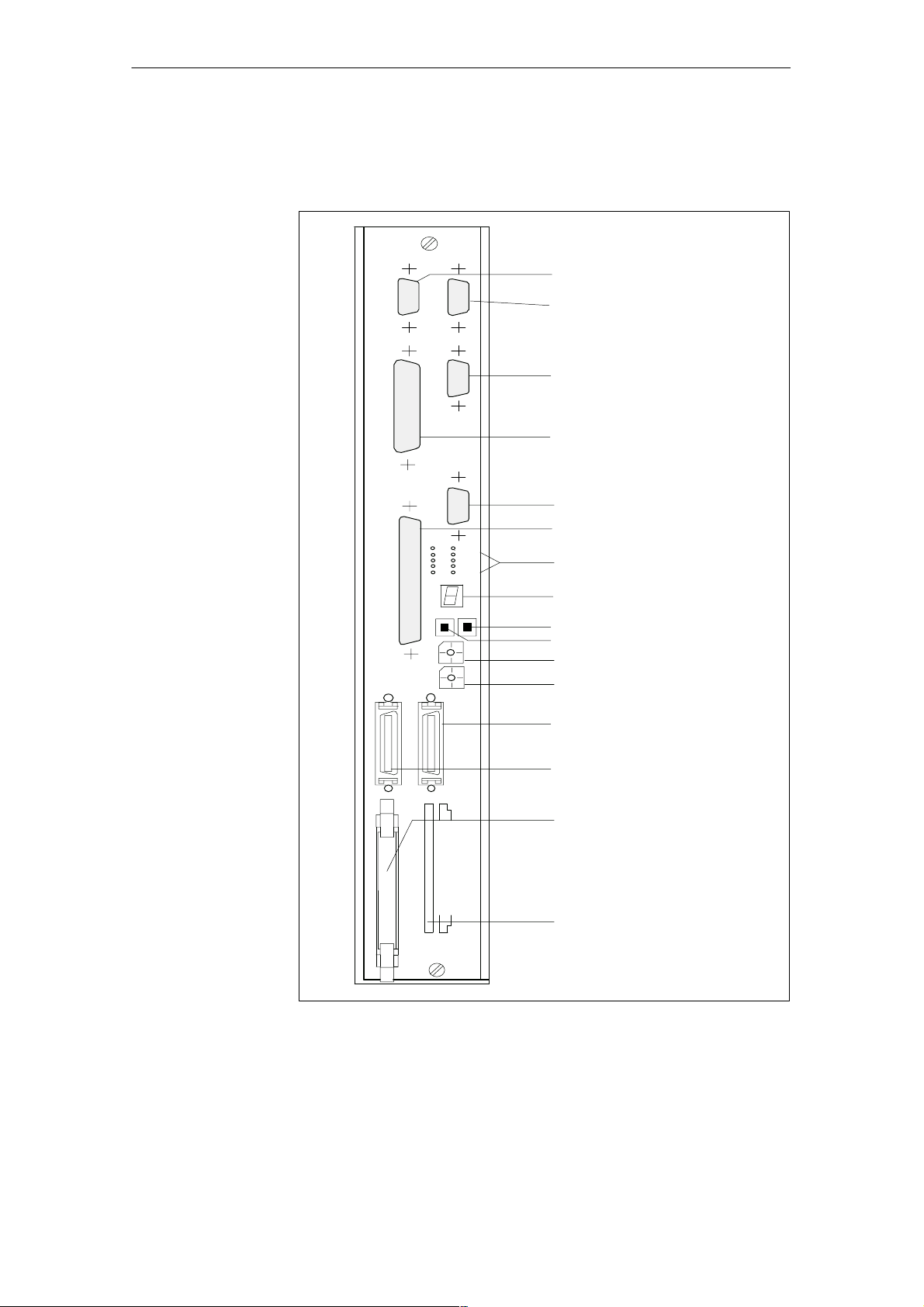

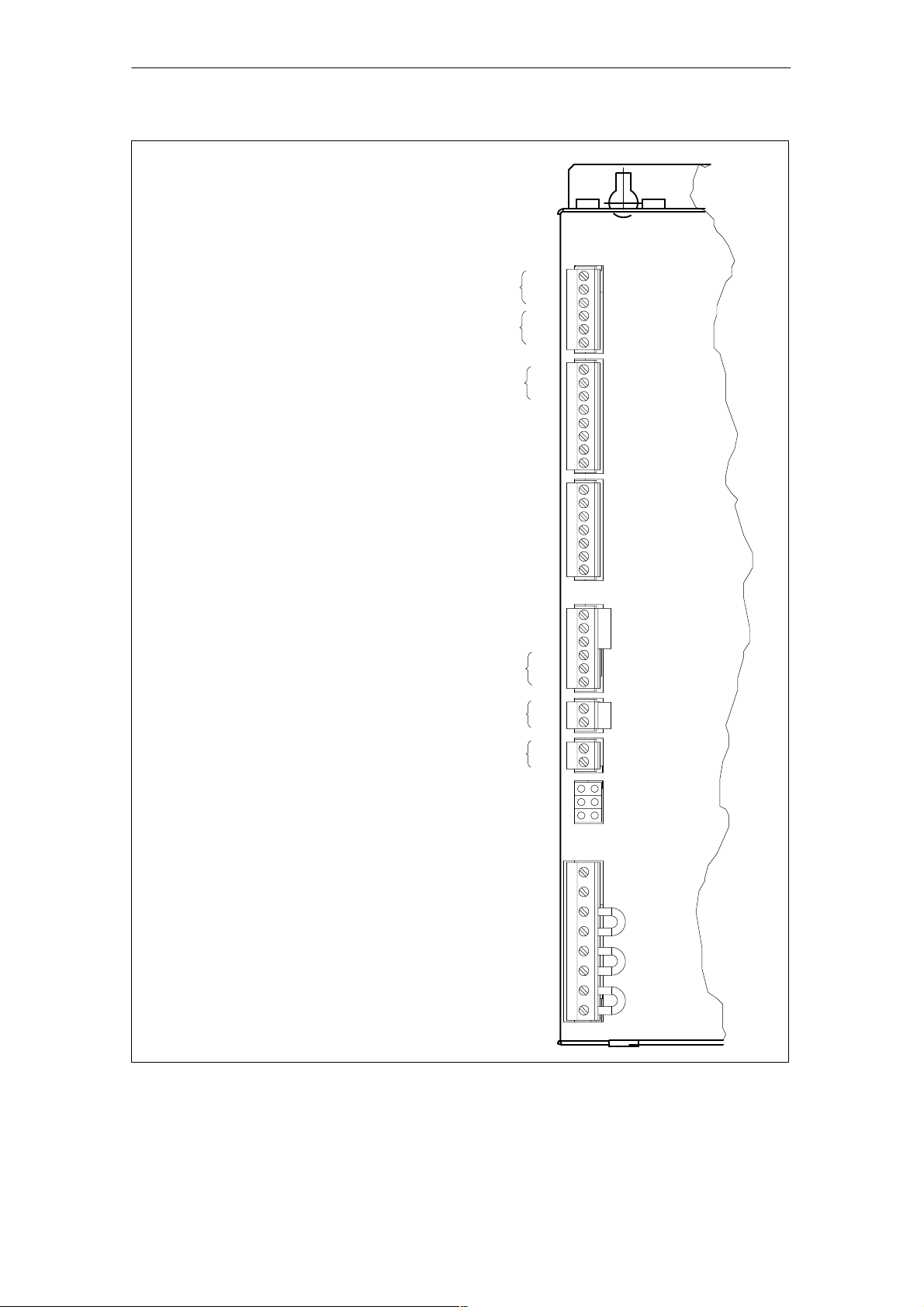

2.1.3 NCU

X101

03.96

X102/

103

Operator panel interface

L2DP

Reserved

X112

X122

P–BUS/K–BUS interface

(PLC I/O devices)

PG–MPI interface

I/O device interface

+5 V

PR

PS

NF

PF

CF

PF0

CB

–

X121 X111

CP

RESETNMI

(cable distribution cabinet)

Various error and status LEDs

(H1/H2)

7-segment display (H3)

NMI button (S2)

S3

S4

RESET button (S1)

NCK start-up switch

PLC start-up switch

SIMODRIVE 611D interface

X130B

X130A

Digitizing module connection

Device bus interface

2-22

X172

MEMORY–CARD

PCMCIA slot

(X173)

Fig. 2-2 Interfaces, control and display elements of NCU module

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

03.96

2.2 Electrical configuration

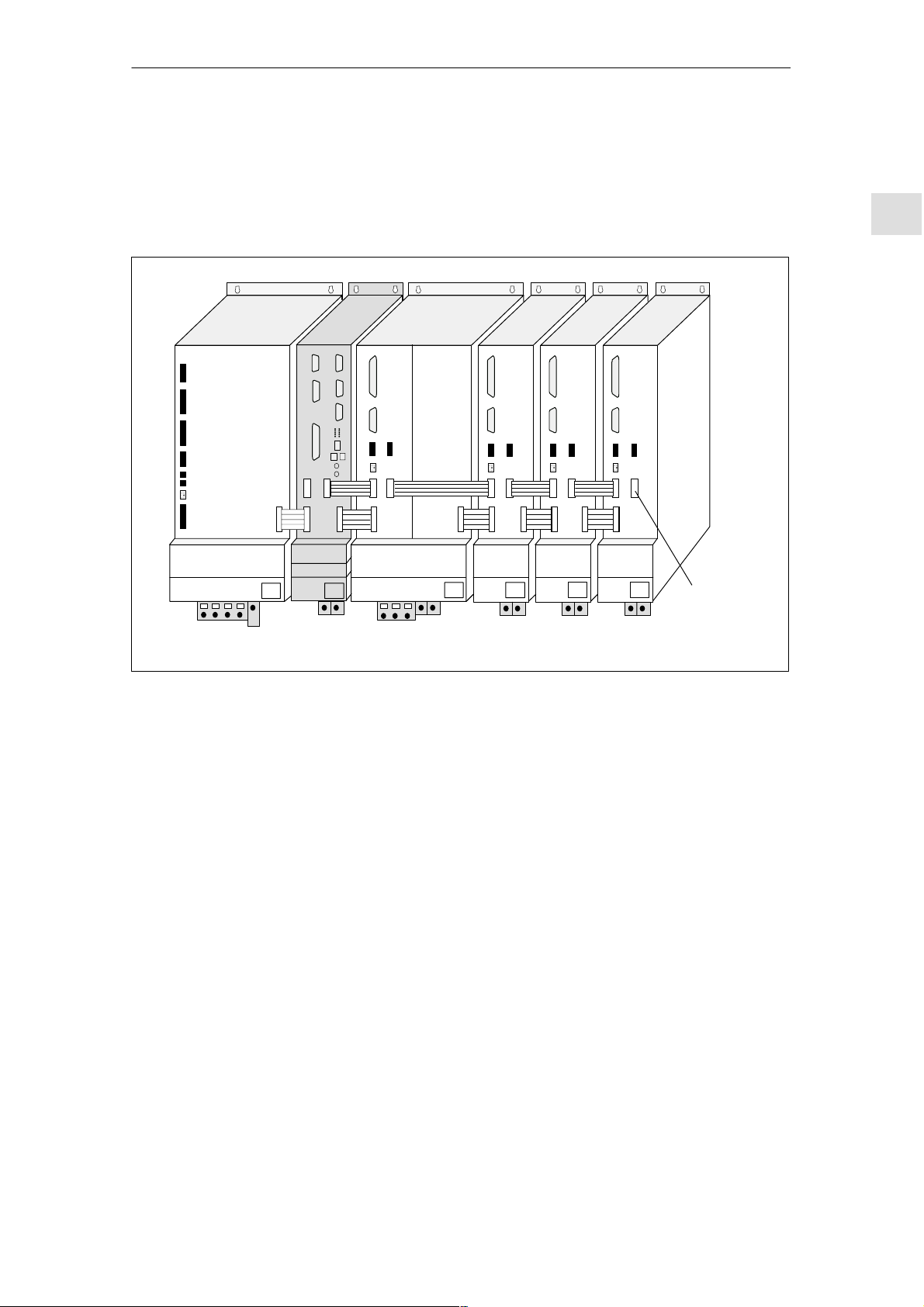

2.1.4 General configuration of SINUMERIK 840D system

2 Configuration

2

SIEMENS

SIMODRIVE

NE (I/RF, UE)

Fig. 2-3 General configuration of SINUMERIK 840D

NCU MSD

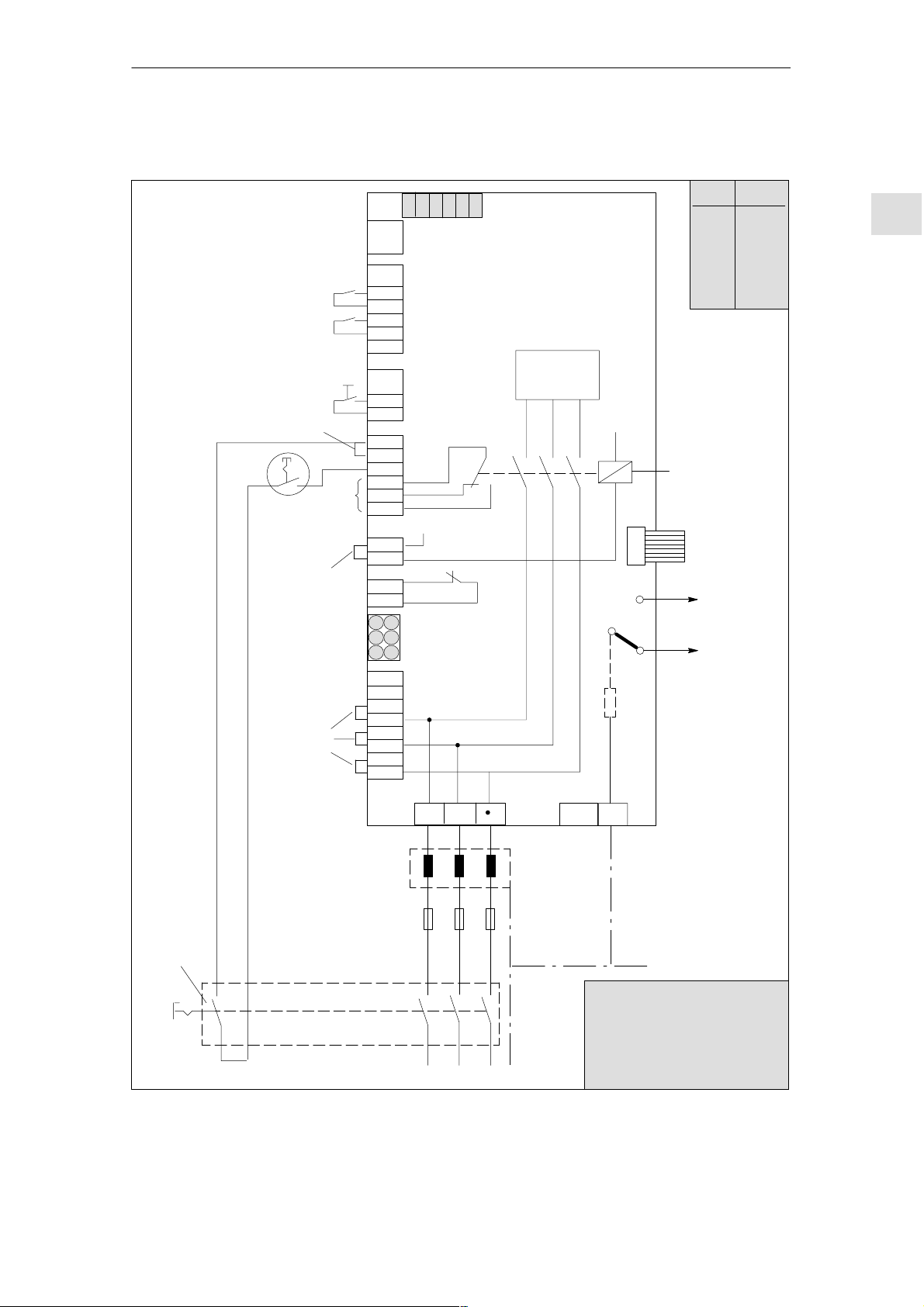

2.2 Electrical configuration

2.2.1 Component connections

FDD

Bus terminating

connector

FDD FDD

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

2-23

2 Configuration

2.2 Electrical configuration

03.96

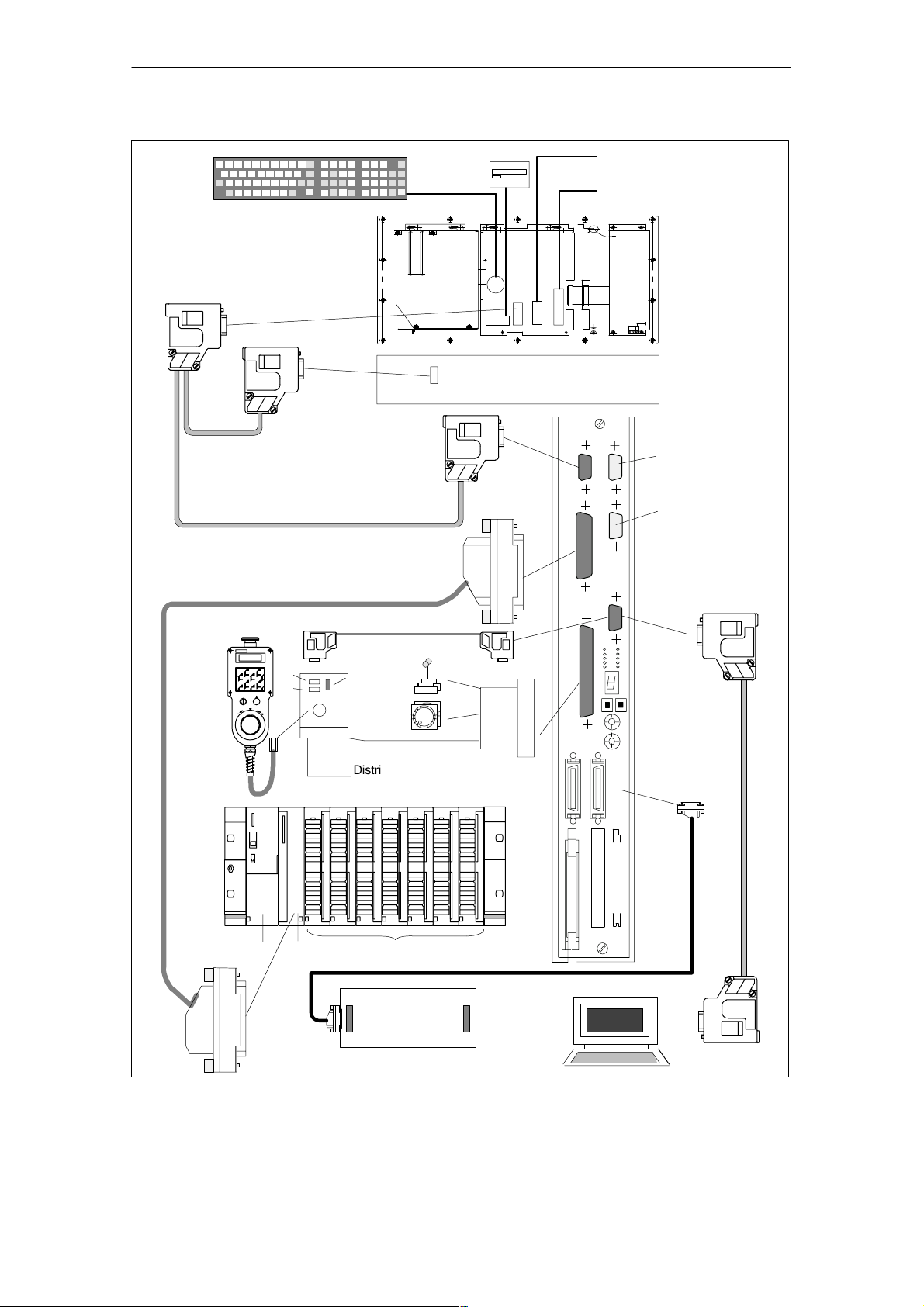

2

QWERTY

1) X8/X9 on MMC 101/102 only

MPI bus cable

SIMATIC S7–300 IM connecting cable

ISA adapter

X20

Floppy

X9

MMC

X10

X4

1)

Cable for data

input/output V24

Parallel interface

1)

e.g. printer/streamer

Operator panel

X8

X6

(rear view)

Power supply

MCP

(rear view)

–X101

–X102

NCU

L2DP

Reserved

for servicing

–X111

–X112

–X122

HHU

MPI cable

X1

X2

X5

X4

X3

HHU handwheel

Distributor box

SIMATIC S7–300 I/O devices

X2

IM

PS SMs

IN OUT

X20 X21

NCU terminal block

Cable distribution

cabinet

to drive bus

–X121

X130B

–X172

MPI cable

or

MPI–PG cable

X130A

MEMORY–CARD

PG

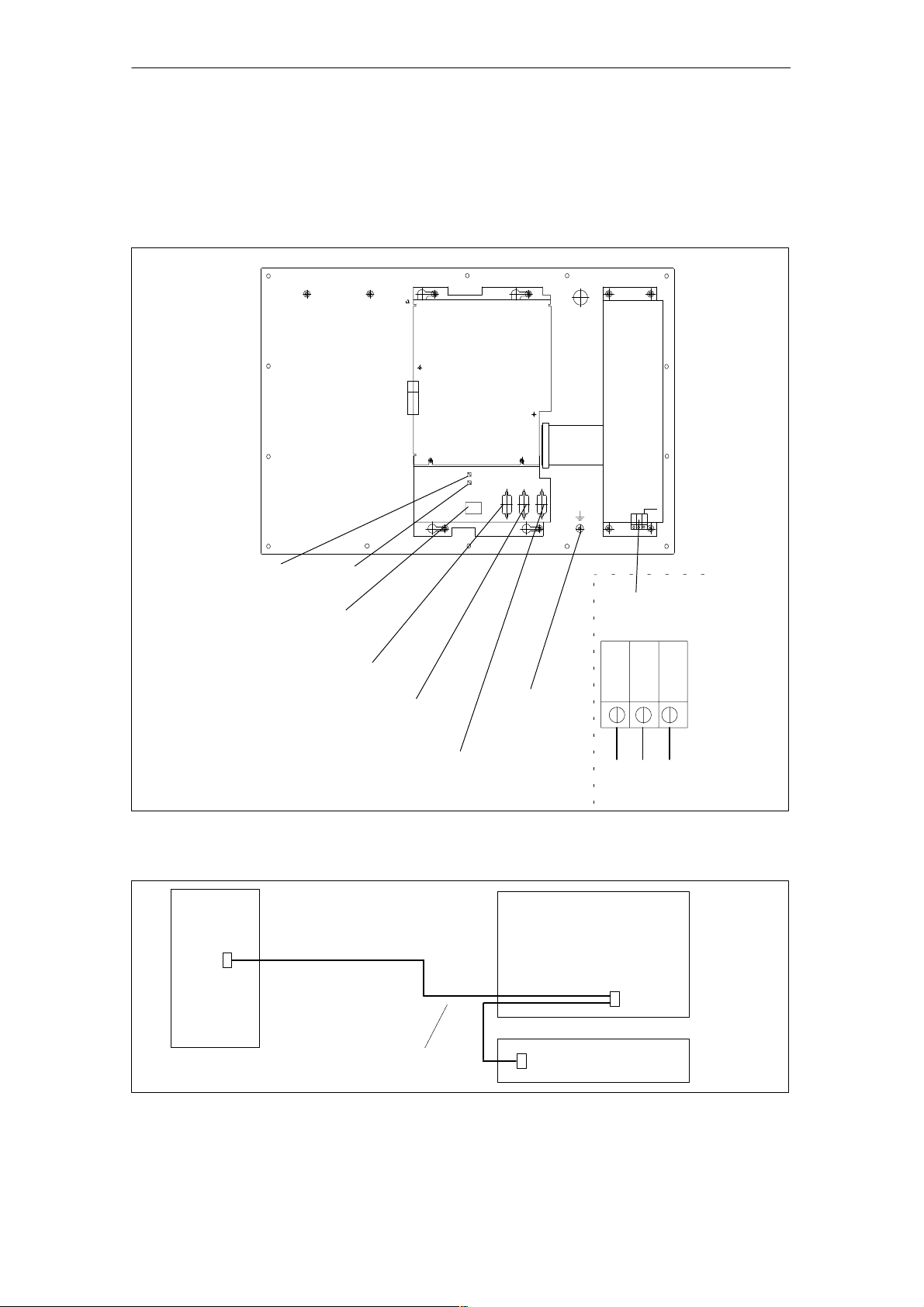

Fig. 2-4 Connection configuration

2-24

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

03.96

2.2 Electrical configuration

Note

For cables and connectors, see

References: /PHD/, Configuring Manual 840D

2.2.2 Connection of mains infeed module (OI, I/RF)

X111

X121

X141

2 Configuration

2

X161

X171

X172

LED

displays

X181

P600

M600

X351

Electronics power

supply faulty

Device is not ready,

no enable signal

(term. 63, 64 or 48)

Mains fault

Device bus

DC link connection

LED displays

Red

Green

Red

Red

Yellow

Red

5V voltage

level faulty

Device ready

(DC link

precharged)

DC link overvoltage

Power supply

U1 V1 W1 PE1

Fig. 2-5 Interfaces for OI and I/RF module 10–55KW

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

2-25

2

2 Configuration

2.2 Electrical configuration

03.96

Relay contact

for

Ready message

Relay contact for group message I

and motor overtemperature

Pulse enable

Enable voltage

Enable voltage

Reference potential for enable voltage

Enabling signal for internal mains

contactor

Signaling contact for starting lockout

(NC contact)

Drive enable signal

P24

P15

N15

N24

M

M

RESET (R+term.15)

Enable voltage

Setting-up mode

Contactor energization,

start

Signaling contact

from mains contactor

NC contact

NO contact

2

74

73.1

73.2

–X111

72

5.3

t

5.2

–X121

5.1

63

9

9

64

19

7

–X141

45

44

10

15

15

R

9

–X161

112

48

111

213

113

NS1

NS2

AS1

AS2

–X171

–X172

DC link power supply for mains buffering

M500

P500

External infeed for electronics power supply

2U1

1U1

External infeed for electronics power supply

2V1

1V1

External infeed for electronics power supply

2W1

1W1

Fig. 2-6 Connection terminals on SIMODRIVE 611 mains supply module 10–55 KW

2-26

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

LED displays

–X181

03.96

2 Configuration

2.2 Electrical configuration

Typical circuit

I/RF module

Pushbutton contact

1)

1)

1)

63

9

9

64

19

15

R

9

112

48

111

213

113

NS1

NS2

AS1

AS2

M500

P500

2U1

1U1

2V1

1V1

2W1

1W1

S1.6

S1.5

X111

X121

X141

X161

L+

X171

X172

LEDs

X181

S1.4

S1.3

S1.2

S1–DIP switch

S1.1

Mains supply module

Power section

L–

P600

M600

100 k

X351

S1 Default

S1.1

S1.2

S1.3

S1.4

S1.5

S1.6

*Do not alter

Internal mains

contactor

Device bus

P600

to the

axis modules

M600

off

off

off

off*

off

off*

2

W1V1U1

1U2 1V2 1W2

Commutating

reactor, on I/RF

module only

Mains fuses for

Leading

contact

Fig. 2-7 Example of three-conductor connection (standard circuit)

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

I/RF or OI

module

Master switch

Supply

1U1 1W11V1

L1 L2 L3

PE

X131

PE

1) Jumpers inserted in

delivery state

Important!

Terminal 48 must be de-energized 10 ms before the mains

contacts of the master switch

open (e.g. by means of leading

contact)

2-27

ÊÊ

ÊÊ

ÊÊ

2 Configuration

2.2 Electrical configuration

2.2.3 Motor connection

03.96

2

X411

Motor

encoder

Axis 1

X421

Direct position

Axis 1

X431

Relay terminals

Pulse enable

X141

Drive bus

X151

Device bus

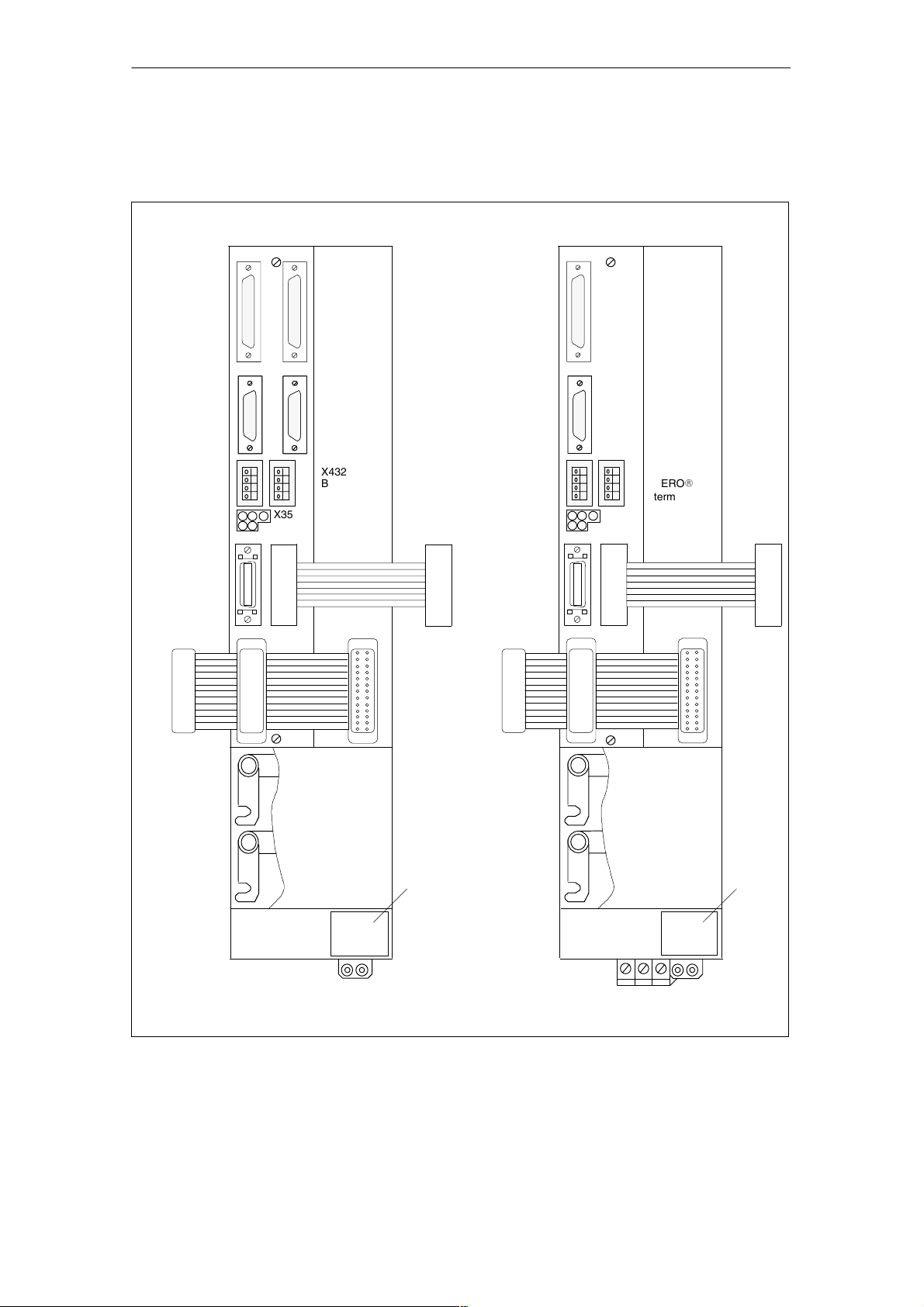

2-axis FDD module 1-axis FDD/MSD module

X35

X34

X412

Motor encoder

Axis 2

X422

Direct position

Axis 2

X432

BEROR

terminals

X341

X351

X411

Motor

encoder

X421

Direct position

X431

Relay terminals

Pulse enable

X141

Drive bus

X151

Device bus

X35

X34

X432

BEROR

terminals

X341

X351

P600

DC link

busbar

M600

PE terminals PE1 PE2

Fig. 2-8 Design of FDD/MSD modules

Rating plate

Motor

connecting

terminals

A1 and A2

DC link

busbar

Motor

connecting

terminals

P600

M600

Rating plate

X131

U2 V2 W2 PE1 PE2

2-28

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

03.96

2.2.4 Encoder connection

2 Configuration

2.2 Electrical configuration

Motor measuring

system and motor

connection

The motor measuring system of the connected motor must always be connected to connector X411 of the same module.

SIEMENS

SIMODRIVE

MS (I/RF, OI)

NCU MSD

Scheme for

shielding bus

FDD

2

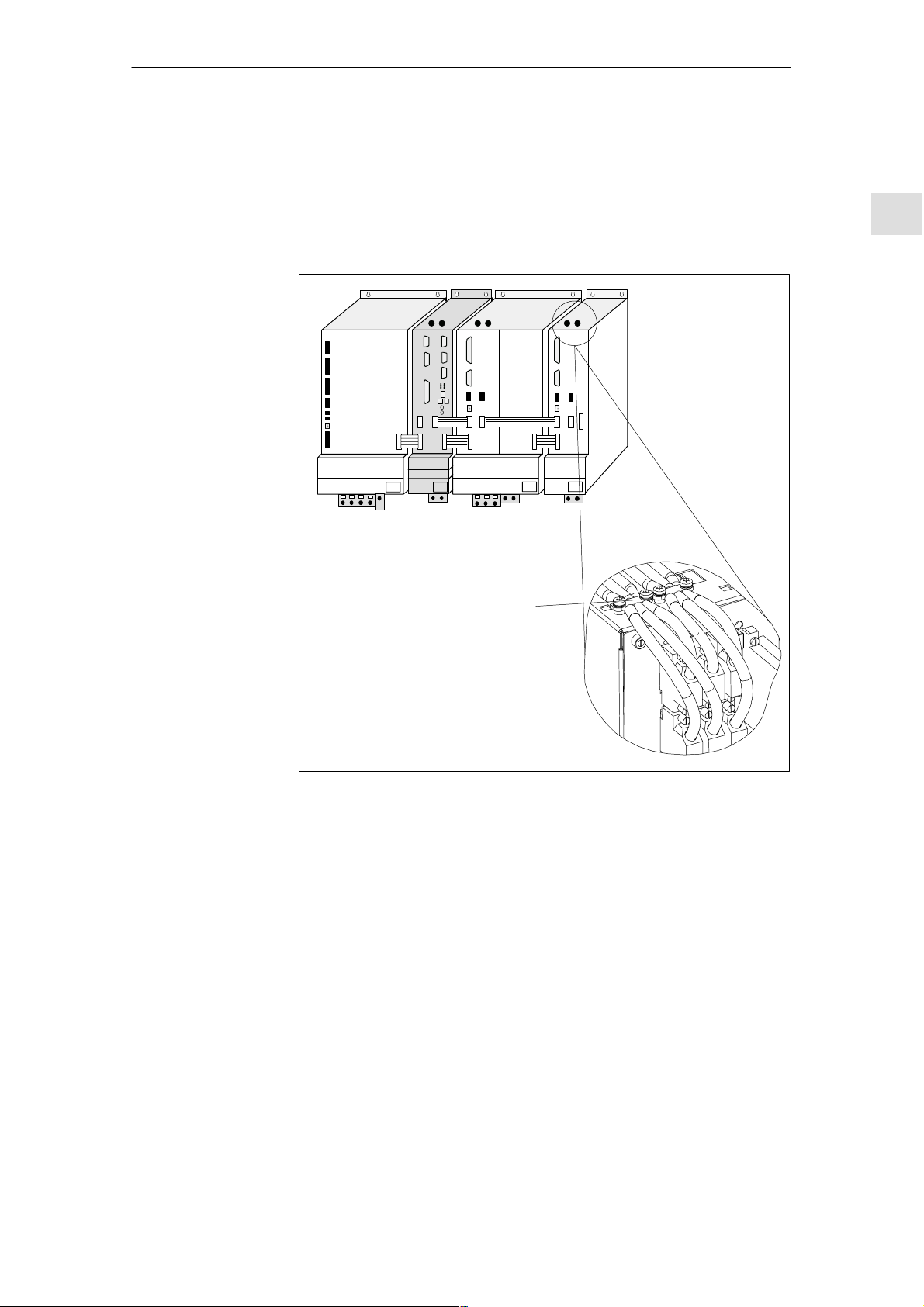

Fig. 2-9 Connection of encoder cables

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

2-29

2 Configuration

2.2 Electrical configuration

2.2.5 Connection of MMC100 and MMC102/103

03.96

2

MMC100

RESET

button

External keyboard interface

(the keyboard must be set

to the XT setting)

NMI

button

MMC 100

S1

S2

X10

Power supply

X3

X5 X4

X6

Chassis

Voltage

supply

RS 232 serial interface

VGA

interface

MPI interface for

connection of operator panel

Fig. 2-10 Rear of operator panel with MMC 100

X101

840D

6FX2 002–4EA04–1xx0 or

6FX2 002–4EA02–1xx0

Fig. 2-11 Connection of MMC100/102/103 to SINUMERIK 840D system

PE conductor

terminal

X20

24 V 0 V PE

MMC 100/102/103

X4

MCP

2-30

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Siemens AG 2000 All Rights Reserved

Loading...

Loading...