Siemens SINUMERIK 840D sl TCU 30.3 User Manual

SINUMERIK

SINUMERIK 840D sl

TCU 30.3

Valid for: 6FC5312-0DA00-1AA1

Replaces the following products:

TCU.1: 6FC5312-0DA00-0AA0 and

6FC5312-0DA00-0AA1

TCU20.2: 6FC5312-0DA00-0AA2

TCU30.2: 6FC5312-0DA00-1AA0

Fundamental safety

instructions

1

Manual

Description

Mounting

Connection

Networking

Service and maintenance

Technical data

Spare parts / accessories

2

3

4

5

6

7

8

Safety symbols

9

09/2017

A5E40874197

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E40874197

Ⓟ 08/2017 Subject to change

Copyright © Siemens AG 2007 - 2017.

All rights reserved

Table of contents

1 Fundamental safety instructions...................................................................................................................5

1.1 General safety instructions.......................................................................................................5

1.2 Equipment damage due to electric fields or electrostatic discharge........................................8

1.3 Warranty and liability for application examples........................................................................8

1.4 Industrial security.....................................................................................................................9

1.5 Residual risks of power drive systems...................................................................................10

2 Description..................................................................................................................................................11

2.1 Overview................................................................................................................................11

2.2 Configurations........................................................................................................................12

2.3 Interfaces...............................................................................................................................13

2.4 Rating plate............................................................................................................................17

3 Mounting.....................................................................................................................................................19

3.1 Introduction............................................................................................................................19

3.2 Mounting the TCU on the operator panel front with mounting bracket...................................19

3.3 Mounting the TCU on the operator panel front without mounting bracket..............................23

4 Connection.................................................................................................................................................25

4.1 Pin assignment of the interfaces............................................................................................25

4.1.1 Power supply..........................................................................................................................25

4.1.2 USB interfaces.......................................................................................................................25

4.1.3 Ethernet RJ45 interface.........................................................................................................27

4.1.4 LVDS display interface...........................................................................................................28

4.1.5 Direct key interface................................................................................................................29

5 Networking..................................................................................................................................................33

5.1 System settings......................................................................................................................33

5.1.1 Thin Client Unit (TCU)............................................................................................................33

5.1.2 Settings for SINUMERIK solution line....................................................................................34

5.1.3 System boot with system network..........................................................................................36

5.1.4 Factory default settings..........................................................................................................37

5.2 Commissioning TCU..............................................................................................................39

5.2.1 Key assignment......................................................................................................................39

5.2.2 Settings in the "TCU.ini" file...................................................................................................40

5.2.3 Displacement mechanism for TCUs.......................................................................................41

5.2.4 Disable switchover between TCU via PLC.............................................................................42

5.2.5 Example: How to select the behavior of the TCUs during boot up.........................................44

5.3 Network configuration............................................................................................................45

5.3.1 Permissible network topologies..............................................................................................45

TCU 30.3

Manual, 09/2017, A5E40874197 3

Table of contents

5.3.2 Networks without connection to the company network..........................................................46

5.3.2.1 Configuration 1: NCU and TCU..............................................................................................46

5.3.3 Networks with NCU connection to the company network......................................................47

5.3.3.1 Configuration 2: NCU and TCU..............................................................................................47

5.3.3.2 Configuration 3: PCU with TCU on NCU................................................................................48

5.3.3.3 Connecting the programming device (PG) to the NCU..........................................................49

5.3.4 Example: Configuring a VNC connection to a PC..................................................................49

5.4 Service and diagnostics.........................................................................................................51

5.4.1 Using the TCU's main menu..................................................................................................51

5.4.2 Operating the TCU menu "Service sessions"........................................................................53

5.4.3 Operating the TCU menu "Service menu".............................................................................56

5.4.4 Operating the TCU menu "Modify settings"...........................................................................59

5.4.5 Operating the menu for a new TCU or spare part TCU.........................................................60

5.4.6 How to register a TCU on the system network.......................................................................65

5.4.7 This is how you register a spare part TCU.............................................................................68

5.4.8 Booting of the TCU ...............................................................................................................69

5.4.8.1 Messages during booting.......................................................................................................69

5.4.8.2 Diagnostics options during booting .......................................................................................70

6 Service and maintenance...........................................................................................................................73

7 Technical data............................................................................................................................................75

7.1 Technical data........................................................................................................................75

7.2 Supplementary electrical conditions.......................................................................................76

7.2.1 Power supply..........................................................................................................................76

7.2.2 Grounding concept.................................................................................................................77

7.2.3 RI suppression measures......................................................................................................77

7.2.4 SINUMERIK_SouthKorea_Note.............................................................................................78

7.3 Climatic and mechanical environmental conditions...............................................................79

7.3.1 Transport and storage conditions...........................................................................................79

7.3.2 Operating conditions..............................................................................................................80

7.4 Standards and approvals.......................................................................................................82

7.5 Recycling and disposal..........................................................................................................82

8 Spare parts / accessories...........................................................................................................................83

8.1 Accessories............................................................................................................................83

8.2 Handling membrane connectors............................................................................................83

9 Safety symbols...........................................................................................................................................85

Index...........................................................................................................................................................87

TCU 30.3

4 Manual, 09/2017, A5E40874197

Fundamental safety instructions

1.1 General safety instructions

WARNING

Electric shock and danger to life due to other energy sources

Touching live components can result in death or severe injury.

● Only work on electrical devices when you are qualified for this job.

● Always observe the country-specific safety rules.

Generally, the following six steps apply when establishing safety:

1. Prepare for disconnection. Notify all those who will be affected by the procedure.

2. Isolate the drive system from the power supply and take measures to prevent it being

switched back on again.

3. Wait until the discharge time specified on the warning labels has elapsed.

4. Check that there is no voltage between any of the power connections, and between any

of the power connections and the protective conductor connection.

5. Check whether the existing auxiliary supply circuits are de-energized.

6. Ensure that the motors cannot move.

7. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water. Switch the energy sources to a safe state.

8. Check that the correct drive system is completely locked.

1

After you have completed the work, restore the operational readiness in the inverse sequence.

WARNING

Electric shock due to connection to an unsuitable power supply

When equipment is connected to an unsuitable power supply, exposed components may

carry a hazardous voltage that might result in serious injury or death.

● Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

TCU 30.3

Manual, 09/2017, A5E40874197 5

Fundamental safety instructions

1.1 General safety instructions

WARNING

Electric shock due to equipment damage

Improper handling may cause damage to equipment. For damaged devices, hazardous

voltages can be present at the enclosure or at exposed components; if touched, this can

result in death or severe injury.

● Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

● Do not use any damaged devices.

WARNING

Electric shock due to unconnected cable shields

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

● As a minimum, connect cable shields and the cores of cables that are not used at one end

at the grounded housing potential.

WARNING

Electric shock if there is no ground connection

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when touched,

can result in death or severe injury.

● Ground the device in compliance with the applicable regulations.

WARNING

Spread of fire from built-in devices

In the event of fire outbreak, the enclosures of built-in devices cannot prevent the escape of

fire and smoke. This can result in serious personal injury or property damage.

● Install built-in units in a suitable metal cabinet in such a way that personnel are protected

against fire and smoke, or take other appropriate measures to protect personnel.

● Ensure that smoke can only escape via controlled and monitored paths.

TCU 30.3

6 Manual, 09/2017, A5E40874197

Fundamental safety instructions

1.1 General safety instructions

WARNING

Unexpected movement of machines caused by radio devices or mobile phones

When radio devices or mobile phones with a transmission power > 1 W are used in the

immediate vicinity of components, they may cause the equipment to malfunction.

Malfunctions may impair the functional safety of machines and can therefore put people in

danger or lead to property damage.

● If you come closer than around 2 m to such components, switch off any radios or mobile

phones.

● Use the "SIEMENS Industry Online Support App" only on equipment that has already been

switched off.

WARNING

Fire due to inadequate ventilation clearances

Inadequate ventilation clearances can cause overheating of components with subsequent

fire and smoke. This can cause severe injury or even death. This can also result in increased

downtime and reduced service lives for devices/systems.

● Ensure compliance with the specified minimum clearance as ventilation clearance for the

respective component.

WARNING

Unexpected movement of machines caused by inactive safety functions

Inactive or non-adapted safety functions can trigger unexpected machine movements that

may result in serious injury or death.

● Observe the information in the appropriate product documentation before commissioning.

● Carry out a safety inspection for functions relevant to safety on the entire system, including

all safety-related components.

● Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing.

● Perform a function test.

● Only put your plant into live operation once you have guaranteed that the functions relevant

to safety are running correctly.

Note

Important safety notices for Safety Integrated functions

If you want to use Safety Integrated functions, you must observe the safety notices in the Safety

Integrated manuals.

TCU 30.3

Manual, 09/2017, A5E40874197 7

Fundamental safety instructions

1.2 Equipment damage due to electric fields or electrostatic discharge

1.2 Equipment damage due to electric fields or electrostatic discharge

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

NOTICE

Equipment damage due to electric fields or electrostatic discharge

Electric fields or electrostatic discharge can cause malfunctions through damaged individual

components, integrated circuits, modules or devices.

● Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of aluminum

foil.

● Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

● Only place electronic components, modules or devices on conductive surfaces (table with

ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

1.3 Warranty and liability for application examples

The application examples are not binding and do not claim to be complete regarding

configuration, equipment or any eventuality which may arise. The application examples do not

represent specific customer solutions, but are only intended to provide support for typical tasks.

You are responsible for the proper operation of the described products. These application

examples do not relieve you of your responsibility for safe handling when using, installing,

operating and maintaining the equipment.

TCU 30.3

8 Manual, 09/2017, A5E40874197

1.4 Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens products and solutions only represent one component of such a

concept.

The customer is responsible for preventing unauthorized access to its plants, systems,

machines and networks. Systems, machines and components should only be connected to

the enterprise network or the internet if and to the extent necessary and with appropriate

security measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit:

Industrial security (http://www.siemens.com/industrialsecurity).

Fundamental safety instructions

1.4 Industrial security

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends to apply product updates as soon as available and to always

use the latest product versions. Use of product versions that are no longer supported, and

failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed at:

Industrial security (http://www.siemens.com/industrialsecurity).

WARNING

Unsafe operating states resulting from software manipulation

Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe operating

states in your system that may lead to death, serious injury, and property damage.

● Keep the software up to date.

● Incorporate the automation and drive components into a holistic, state-of-the-art industrial

security concept for the installation or machine.

● Make sure that you include all installed products into the holistic industrial security concept.

● Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

TCU 30.3

Manual, 09/2017, A5E40874197 9

Fundamental safety instructions

1.5 Residual risks of power drive systems

1.5 Residual risks of power drive systems

When assessing the machine- or system-related risk in accordance with the respective local

regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must

take into account the following residual risks emanating from the control and drive components

of a drive system:

1. Unintentional movements of driven machine or system components during commissioning,

operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables

and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of electronic

components

– External influences/damage

– X-ray, ionizing radiation and cosmic radiation

2. Unusually high temperatures, including open flames, as well as emissions of light, noise,

particles, gases, etc., can occur inside and outside the components under fault conditions

caused by, for example:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specification

– External influences/damage

3. Hazardous shock voltages caused by, for example:

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a risk

to people with a pacemaker, implants or metal replacement joints, etc., if they are too close

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly

6. Influence of network-connected communication systems, e.g. ripple-control transmitters or

data communication via the network

For more information about the residual risks of the drive system components, see the relevant

sections in the technical user documentation.

TCU 30.3

10 Manual, 09/2017, A5E40874197

Description

2.1 Overview

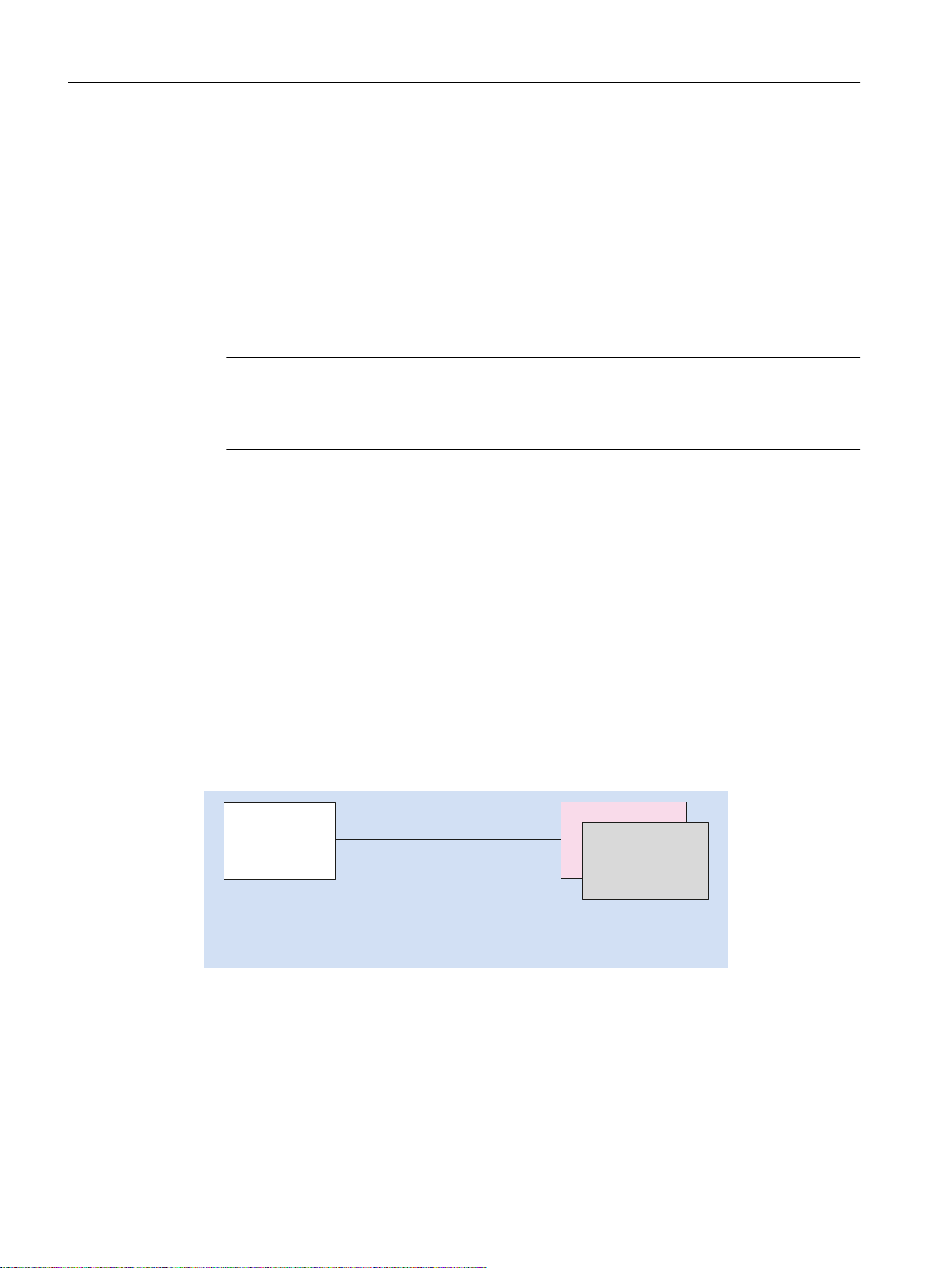

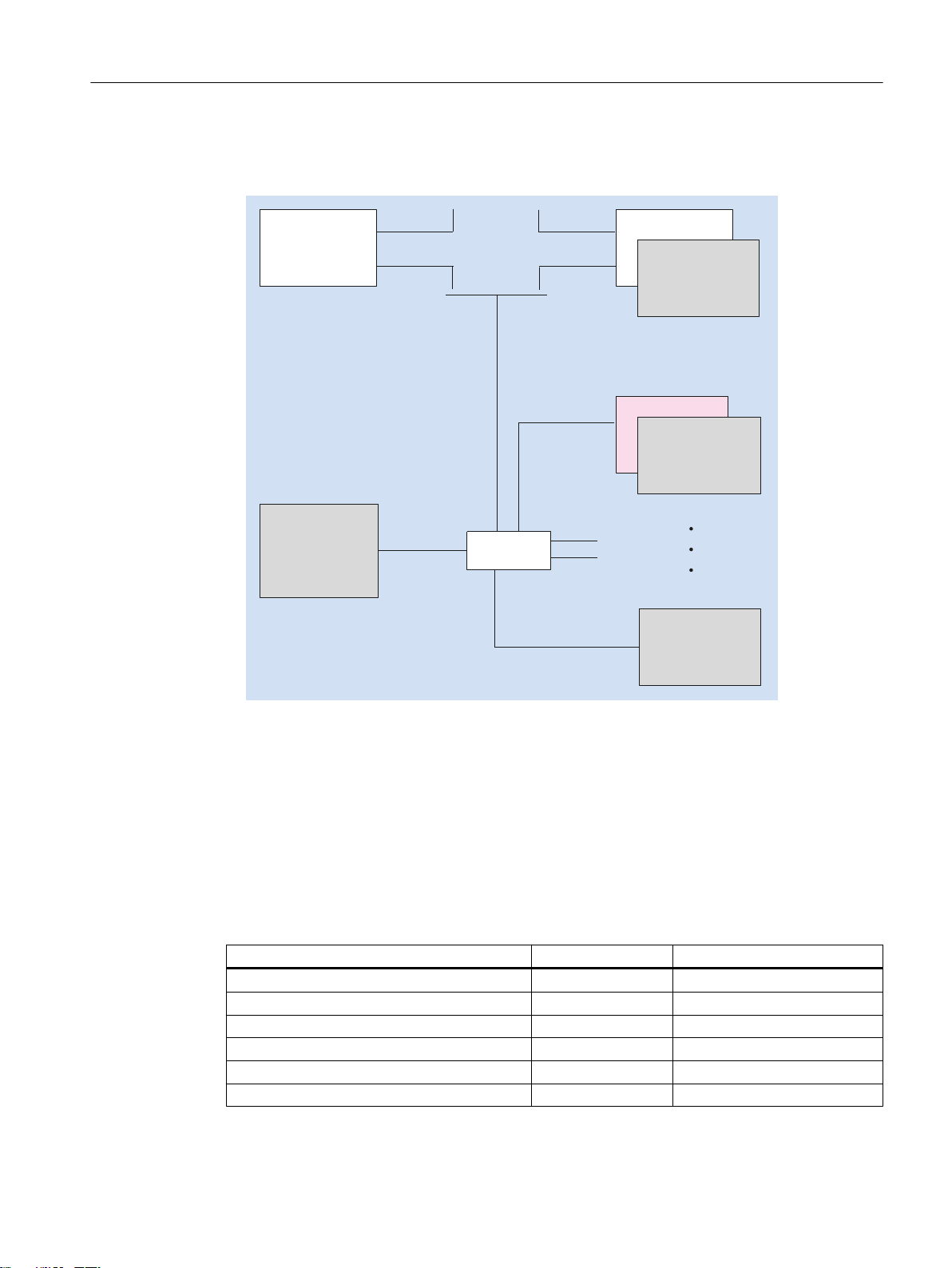

A Thin Client Unit (TCU) allows the spatial separation between an operator panel (OP) / touch

panel (TP) and the Panel Control Unit (PCU) / Numerical Control Unit (NCU). For this reason,

the user interface is copied to one/several operator panel fronts, each with a TCU.

Validity

The description applies to the following TCU:

Designation Article number

Thin Client Unit 30.3 6FC5312-0DA00-1AA1

Features

● Implementation of flat operator panels through the shallow installation depth and low power

loss.

● Color depth: 32 bits

2

Preconditions

● 640 x 480 to 1280 x 1024 pixels

● Vibration-free mounting of the PCU in the control cabinet.

● Effective operation of larger machines.

● Signal transmission between PCU/NCU and operator panel via Industrial Ethernet

The distance of the components is determined by the maximum distance between two

network nodes / access points (100 m).

● The same operating screen is shown synchronously on all operator panel fronts and can

be operated from all operator panel fronts.

● The operation on an operator panel front connected via TCU has the same access rights

as the operation on an operator panel front connected directly to the PCU.

● The mixed operation of operator panel fronts connected via TCU and an operator panel

front connected directly to the PCU is possible.

● With restrictions to the interfaces (see Section "Operating the menu for a new TCU or

replacement TCU (Page 60)"), the TCU 30.3 is compatible to the previous models and

therefore mixed operation is possible.

● NCU 7x0

● Operator panel fronts:

– OP 010, OP 010C, OP 010S, OP 012, OP015, OP 015A, TP 015A, OP 019

TCU 30.3

Manual, 09/2017, A5E40874197 11

5HTXLUHGPRXQWLQJEUDFNHWV

)RU7&8)&$)$$QRWUHTXLUHGIRU236

$GGLWLRQDO7&8QRWUHTXLUHGIRURSHUDWRUSDQHOIURQWVZLWKLQWHJUDWHG7&8

2SHUDWRUSDQHOIURQW

7&8

,QGXVWULDO(WKHUQHW

1&8

Description

2.2 Configurations

Design

The TCUs are coupled via Ethernet as Thin Clients in a dedicated subnetwork (via DHCP

server on the PCU/NCU) to the PCU/NCU.

Interfaces:

● 4 x USB 2.0 Hi-Speed to connect the mouse, keyboard and USB flash drive

● Ethernet 10/100/1000 Mbit/s

The transmission rate in Ethernet system networks automatically sets itself to the maximum

possible value. 1000 Mbit/s can only be achieved with NCU 7x0.3B PN and PCU 50.5 (if a

PCU is required).

Note

The Ethernet interface has so-called Auto MDI-X functionality. If required, the send and

receive lines of the Ethernet cable are crossed in the PHY. If, however, the partner does

not have "Autocrossover", a crossover cable is required.

Information about third-party software used

This product contains open source software. License information can be obtained via the

shortcut "License files" on your SINUMERIK PCU desktop, or navigate to the SINUMERIK

Operate Readme OSS path "Setup/system data: System CF card/siemens/oss-license" on

your SINUMERIK NCU and read the appropriate OSS file for this device.

2.2 Configurations

Configurations

The following distributed configurations are possible with a TCU 30.3:

Figure 2-1 Minimum configuration with an operator panel front

12 Manual, 09/2017, A5E40874197

TCU 30.3

2SHUDWRUSDQHO

IURQW

2SHUDWRUSDQHO

IURQW

2SHUDWRUSDQHOIURQW

ZLWKLQWHJUDWHG

7&8

)RUPRXQWLQJRQRSHUDWRUSDQHOIURQW

7&83&8

)&$)$$

QRWUHTXLUHGIRU236

0RXQWLQJEUDFNHWVUHTXLUHG

)RUPRXQWLQJLQFRQWUROFRQWUROFDELQHW

3&8

)&$)$$RU

)&$)$$

,QGXVWULDO

(WKHUQHW

,QGXVWULDO

(WKHUQHW

,QGXVWULDO

(WKHUQHW

,QGXVWULDO(WKHUQHW

3&8

7&8

7&8

3&8

6ZLWFK

1&8[31

Description

2.3 Interfaces

Figure 2-2 Maximum configuration, several TCUs connected to an NCU 7x0

2.3 Interfaces

Overview

For information about TCU commissioning, see the section titled "Networking".

Function Designation Description

Double USB interface 1

Double USB interface 2

Interface for direct keys X205 2 x 10-pin plug connector

24 VDC power supply X206 3-pin terminal block

TCU 30.3

Manual, 09/2017, A5E40874197 13

I/O USB interface K1

LVDS display interface K2

1)

1)

2) 3)

2) 3)

X203 / X204 2 x USB 2.0 Hi-Speed type A

X212 / X213 2 x USB 2.0 Hi-Speed type A

X207 2 x 13-pin plug connector

X208 2 x 10-pin plug connector

Description

2.3 Interfaces

Function Designation Description

LVDS display interface K3

Ethernet interface X202 8-pin RJ45 socket

1)

One of the interfaces can be loaded with 500 mA, the other with 100 mA.

2)

To connect to a 10" to 15" operator panel front

3)

To connect to an OP 019 operator panel front

3)

X209 2 x 10-pin plug connector

The following special requirements apply to the connecting cables:

● The 24 VDC cable must be approved for temperatures up to 70° C.

● Select the permitted conductor cross-section in accordance with the national regulations

(NEC, VDE,...) and the "Power supply connectors for TCU30.3" table below. The line

protection in accordance with the national regulations (NEC, VDE,...) must be guarantied

as appropriate for the selected conductor cross-section.

● Strip the cables (7 mm) for connection to the 24 VDC connector plug.

● Flame resistance of the 24 VDC cable according to UL 2556 VW-1/ tested according to IEC

60332-1-2.

● Observe the permissible bending radii of the cables.

● Rotate the panel only in a way that does not cause pinching of the cables.

● Route all of the cables so that they do not come into contact with chafing edges.

WARNING

Warning for areas subject to NEC or CEC:

Safety notice for connectors with Ethernet marking:

A Ethernet or Ethernet segment, with all its associated interconnected equipment, shall be

entirely contained within a single low-voltage power distribution and within a single building.

The Ethernet is considered to be in an "environment A" according IEEE802.3 or "environment

0" according IEC TR 62102, respectively.

Never make direct electrical connection to TNV-circuits (Telephone Network) or WAN (Wide

Area Network).

TCU 30.3

14 Manual, 09/2017, A5E40874197

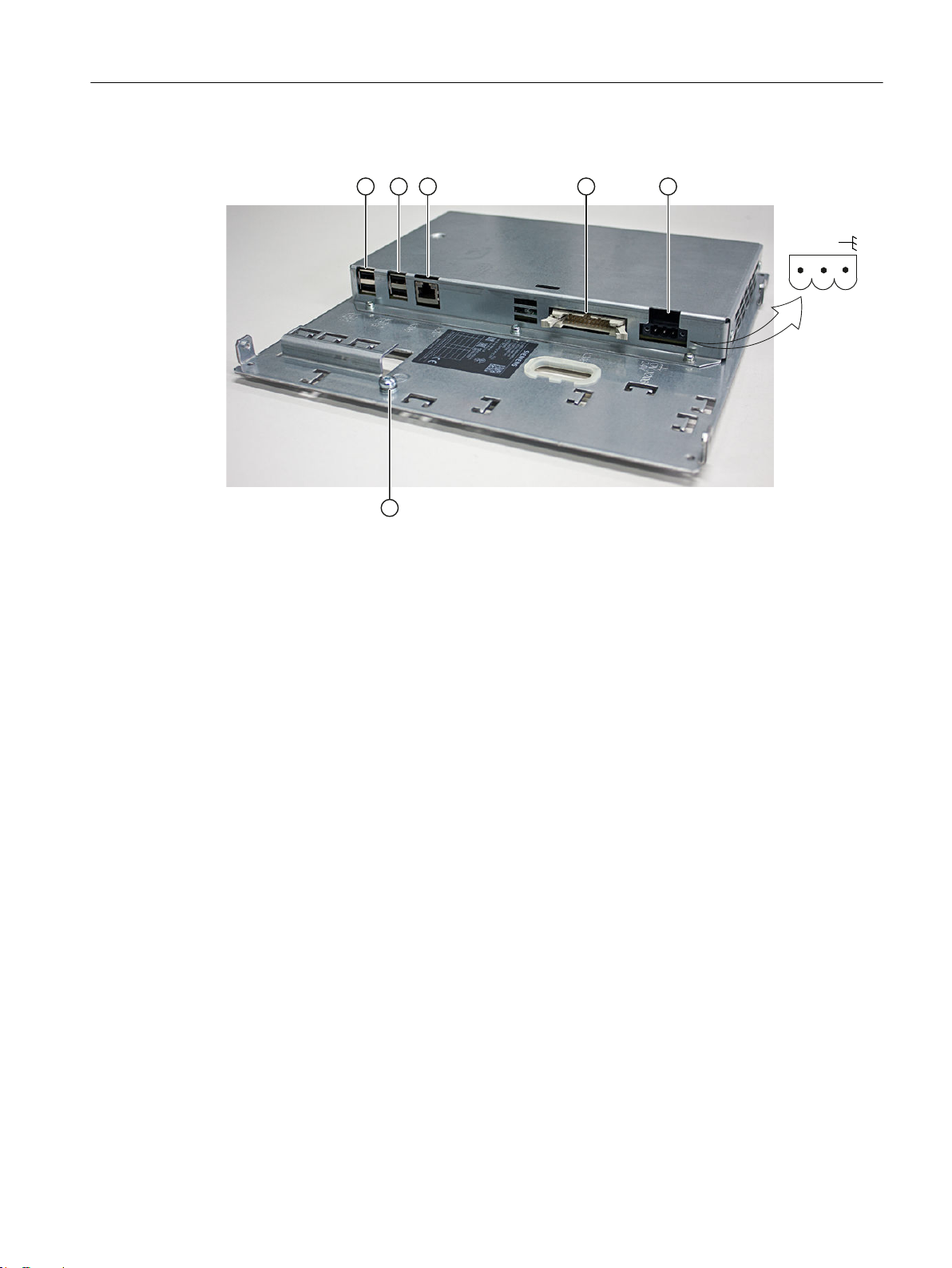

View

9

9

Description

2.3 Interfaces

① X203/X204 Double USB interface 1

② X212/X213 Double USB interface 2

③ X202 Ethernet interface

④ X205 Interface for direct keys

⑤ X206 24 VDC power supply

⑥ - Protective conductor connection

Figure 2-3 Front view of the TCU 30.3 with interfaces

TCU 30.3

Manual, 09/2017, A5E40874197 15

Description

2.3 Interfaces

⑦ X207 I/O USB interface K1

⑧ X208 LVDS display interface K2

⑨ X209 LVDS display interface K3 (not for TCU 20.2)

Figure 2-4 Rear view of the TCU 30.3 with interfaces

The K1, K2, K3 interfaces are suitable only for connecting operator panel fronts OP 010, OP

010S, OP 010C, OP 012, OP 015, OP 015A, TP 015A and OP 019.

Power supply connector for the TCU30.3

Connection type Strain-relief clamp connection

Connection screw M2.5 screw with cross-slot

Operating tool Screwdriver blade 0.6x3.5, PH0, PZ0 (DIN

Prescribed tightening torque Nm 0.4 ... 0.5

Conductor cross-section min./max.

Solid mm² 1.3 … 3.3

Finely stranded mm² 1.3 … 3.3

With end sleeve with sleeve DIN46228/4 mm² 1.3 … 2.5

With end sleeve DIN46228/1 mm² 1.3 … 3.3

AWG cables, solid or stranded AWG 12 … 16

Pin assignment

5264, ISO 8764/2-PH, ISO 8764/2-PZ)

The pin assignments of the interfaces are described in Section "Connect" > "Pin assignment

of the interfaces" (Page 25).

16 Manual, 09/2017, A5E40874197

TCU 30.3

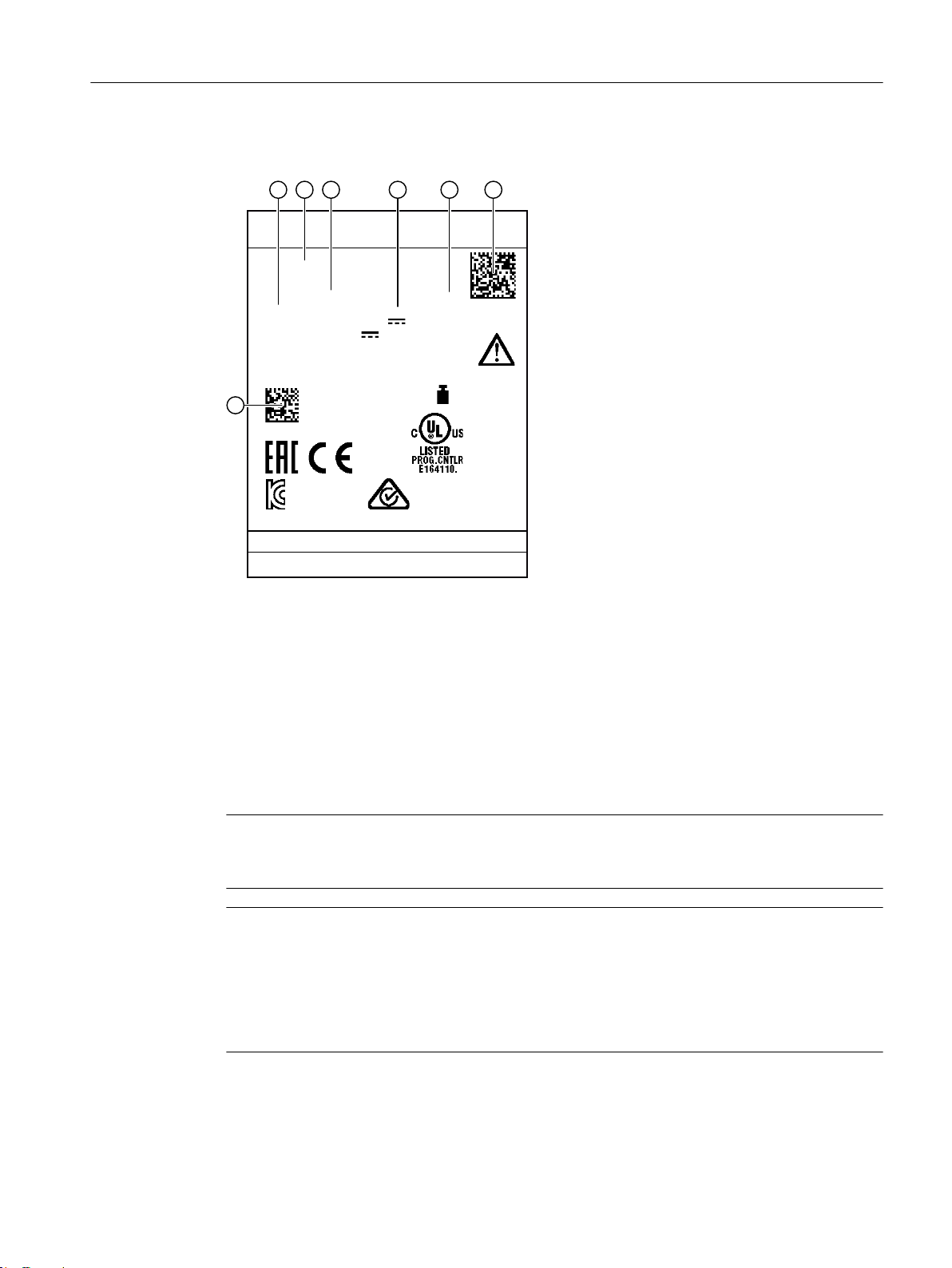

2.4 Rating plate

s

SINUMERIK Bedientafelfront

A5E35520880

Made in Germany

Siemens AG, Frauenauracher Str. 80, DE-91056 Erlangen

TCU 30.3 (thin client unit)

S

2,9ATa 0...55°C SUPPLY 24V

6FC5312-0DA00-1AA11P

T-HD6000297

FS: A

KCC-REM-S49-

2,0 kg

SINUMERIK

00-1F-F8-29-ED-0C

Protection:

http://support.automation.siemens.com

refer to user manual

0,5ADigital Output 24V

Description

2.4 Rating plate

① Material number

② Component name

③ Article number

④ Serial number

⑤ Hardware revision level

⑥ Product code

⑦ MAC address

Figure 2-5 Example graphic of a TCU30.3 rating plate

Note

The contents of the individual rating plate fields on the front of the TCU may differ from those

described in this manual (e.g. new product version, approvals and markings not yet issued).

Note

Product code scanning

The product code contains the article number of the device. Scan the product code with the

aid of the Siemens Industry Online Support App to be taken directly to the Internet Webpage

for the product, including all of the technical information and graphical data.

The app is available for iPhone, iPad, Android and Windows Phone.

TCU 30.3

Manual, 09/2017, A5E40874197 17

Description

2.4 Rating plate

TCU 30.3

18 Manual, 09/2017, A5E40874197

Mounting

3.1 Introduction

Before assembling the two components, the interface cables of the operator panel front (IO/

USB cable K1, K2 display cable and, if necessary, K3) must be inserted into the corresponding

socket of the TCU (visible behind the housing cut-out).

Note

Since some of the interfaces do not have a cable strain relief for the cables to be connected,

it is recommended to secure the cables to the u-shaped lugs on the supporting plate using

cable ties.

WARNING

Electric shock in the event of an individual error when grounding is insufficient

If the panel is installed in an environment with hazardous voltages with insufficient grounding,

this may cause an electric shock in the event of an individual error, which can lead to death,

serious injury and property damage.

To prevent electric shocks, sufficiently ground the conductive parts of the panel according to

the nationally applicable regulations. To do this, use the relevant fuse ratings of the circuits

with hazardous voltages for the possible individual error scenarios as the basis for

dimensioning the protective conductor connection.

3

WARNING

Parasitic voltage

If the device is installed in an environment with higher / more hazardous voltages with

insufficient insulation, parasitic voltages can lead to death, serious injury and property

damage.

To prevent parasitic voltages, insulate the cables corresponding to the highest voltage that

will be dealt with.

The safety of a system with an integrated TCU with operator panel front is the responsibility

of the system installer.

Observe all relevant information from this manual regarding the mounting of the chosen

operator panel front.

The mounting at the installation site is performed in accordance with the instructions of the

chosen operator panel front.

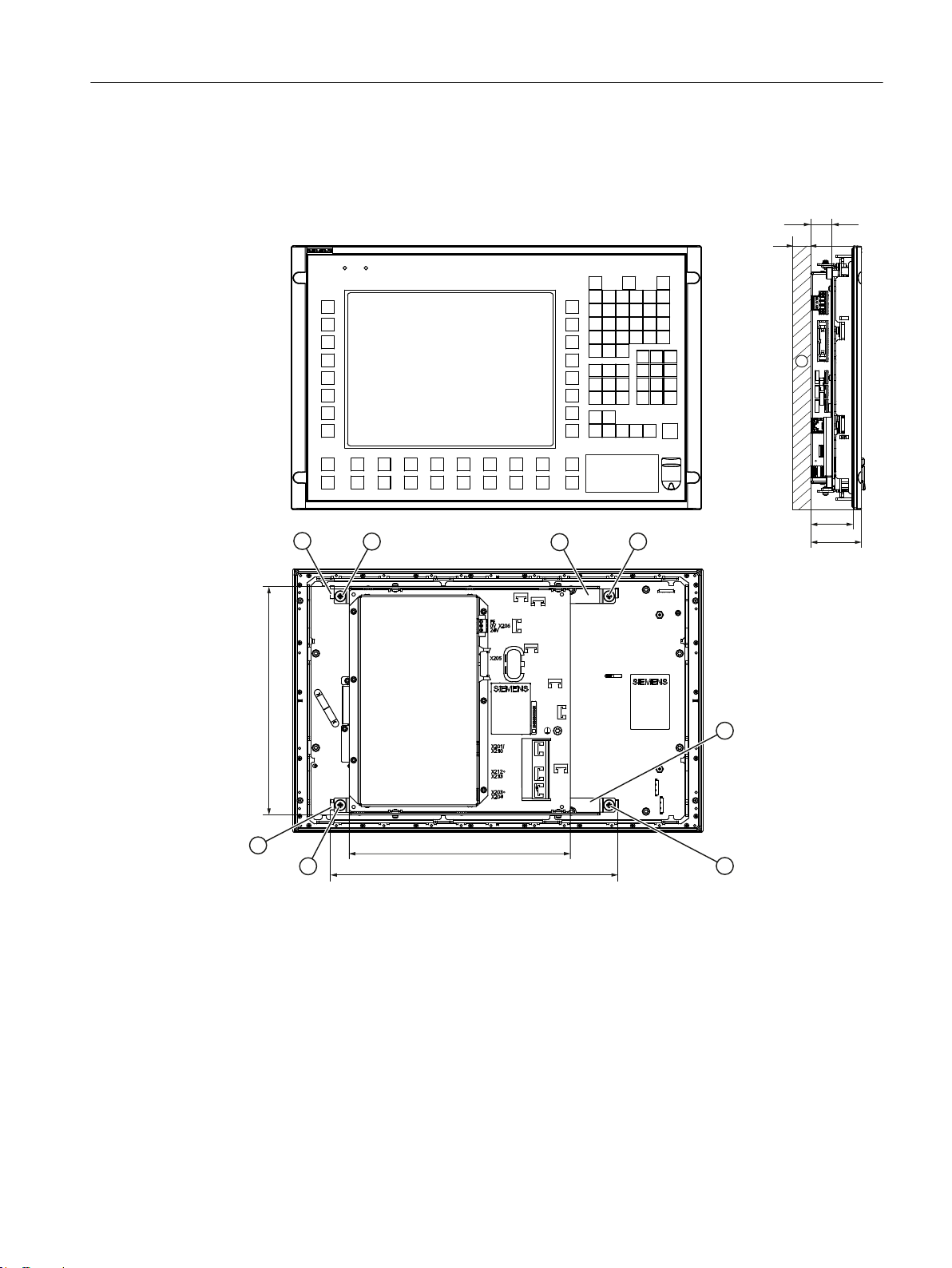

3.2 Mounting the TCU on the operator panel front with mounting bracket

This description applies to mounting a TCU on the following operator panel fronts:

TCU 30.3

Manual, 09/2017, A5E40874197 19

Mounting

3.2 Mounting the TCU on the operator panel front with mounting bracket

OP 010, OP 010S, OP 010C, OP 012, OP 015, OP 015A, TP 015A and OP 019

Two mounting brackets (must be ordered separately) are required for mounting these operator

panel fronts (see Section "Accessories (Page 83)").

1. Screw the mounting bracket ③ onto the TCU.

2. Use the two hinge catches ① to suspend the TCU mounting bracket unit (like a PCU) in

the operator panel front.

TCU 30.3

20 Manual, 09/2017, A5E40874197

Mounting

3.2 Mounting the TCU on the operator panel front with mounting bracket

3. Insert cables K1, K2 and K3 (only for OP 019).

4. Close the cabled TCU mounting bracket unit and attach it using the four knurled screws

②.

① 2 x hinge catches

② 4 x knurled screws for attaching the mounting brackets to the operator panel front

③ 2 x mounting brackets

④ 10 mm clearance

Figure 3-1 Mounted TCU (example with OP 012) in front, side and rear view

TCU 30.3

Manual, 09/2017, A5E40874197 21

Mounting

3.2 Mounting the TCU on the operator panel front with mounting bracket

NOTICE

Impermissible mounting positions can cause malfunctions

Observe the permissible mounting position: Deviating by up to 5º from the vertical.

Only the shown mounting position is permitted.

TCU 30.3

22 Manual, 09/2017, A5E40874197

7&8

236

Mounting

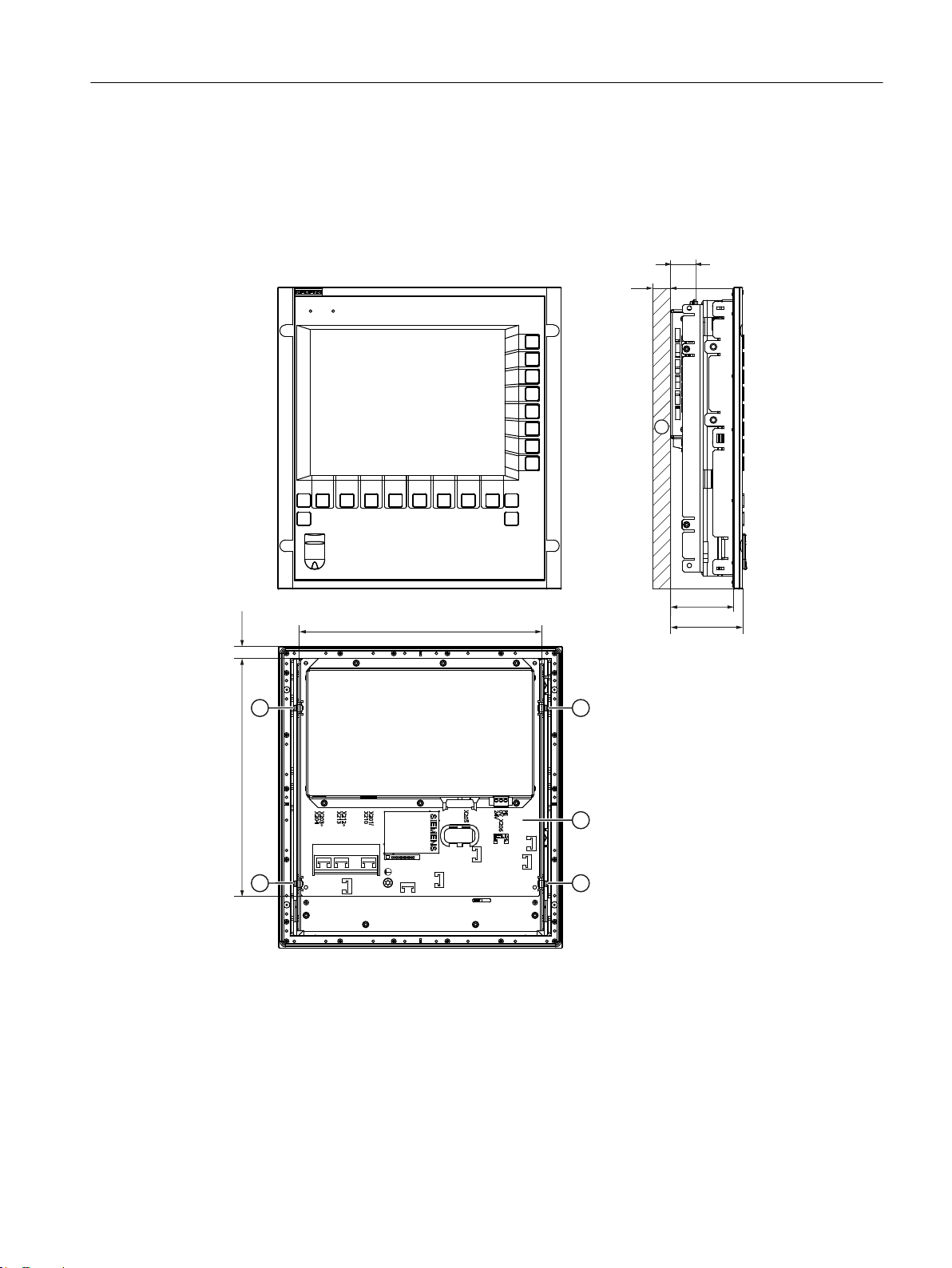

3.3 Mounting the TCU on the operator panel front without mounting bracket

3.3 Mounting the TCU on the operator panel front without mounting

bracket

The OP 010S operator panel front and the TCU can be screwed together without any additional

mounting brackets.

① 4 x M3 screws to fasten the TCU support plate to the OP 010S

② TCU support plate

③ 10 mm clearance

Figure 3-2 Mounted TCU with OP 010S, front, side and rear view

TCU 30.3

Manual, 09/2017, A5E40874197 23

Mounting

3.3 Mounting the TCU on the operator panel front without mounting bracket

NOTICE

Impermissible mounting positions can cause malfunctions

Observe the permissible mounting position: Deviating by up to 5º from the vertical.

TCU 30.3

24 Manual, 09/2017, A5E40874197

Connection

4.1 Pin assignment of the interfaces

The pins of the component interfaces are assigned as specified in the tables below. Any

deviations are indicated at the relevant point.

Signal type

I Input

O Output

B Bidirectional (inputs/outputs)

V Power supply

- Ground (reference potential) or N.C. (not connected)

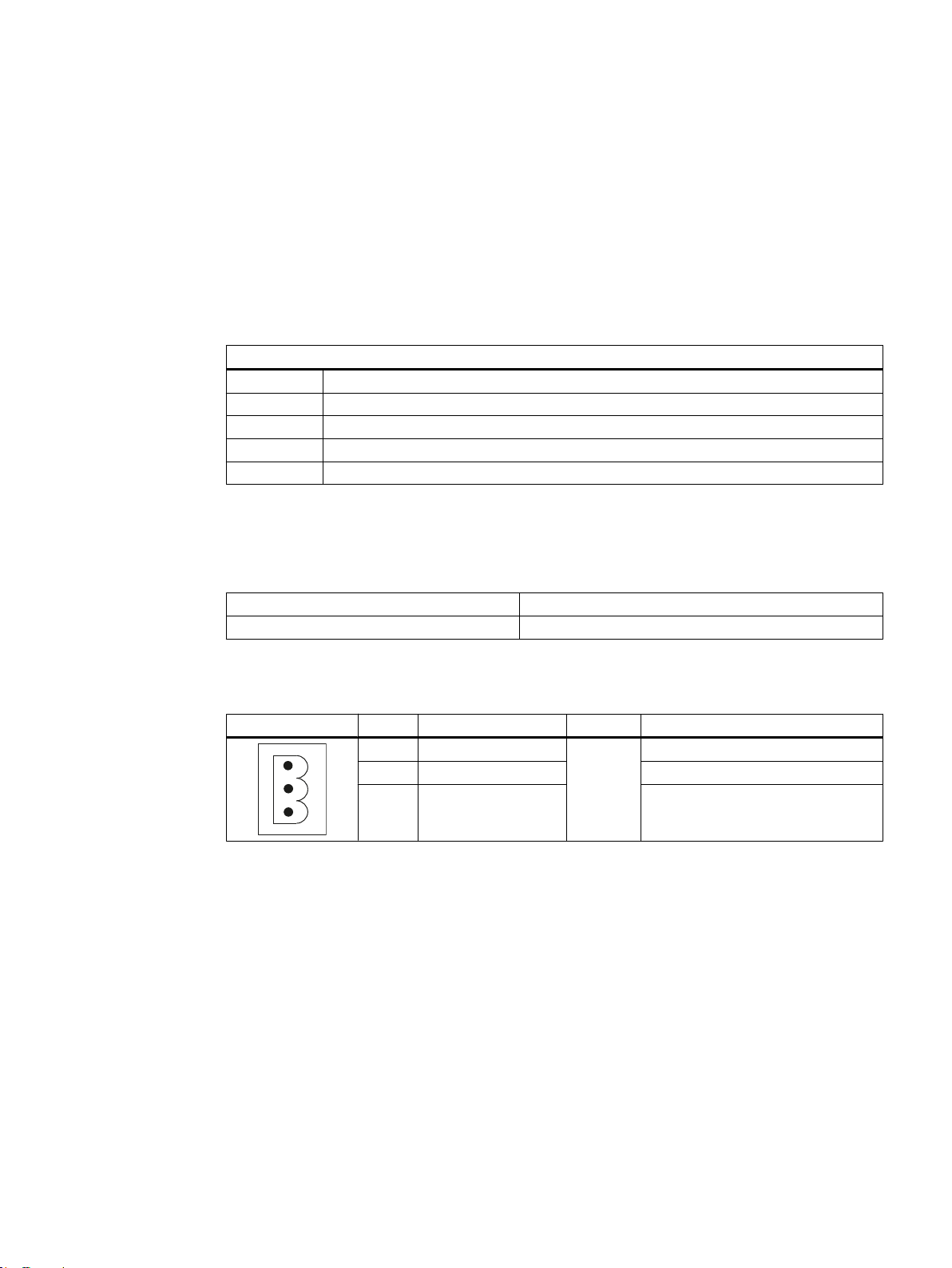

4.1.1 Power supply

Connector type: Terminal block, 3-pin contact strip, screw type

Max. cable length: 10 m

4

Table 4-1 Assignment of the power supply interface

Pin Name Type Meaning

4.1.2 USB interfaces

The USB interfaces are implemented as sockets and comply with the generally valid standard.

The version information (1.1, 2.0 etc.), the maximum velocity (low speed, full speed, etc.) and

the socket type (A or B) are documented in the individual sections for the associated devices.

1 P24 (+)

2 M24 (-) 0 V

3 Functional earth Connection for grounding the hous‐

V/V/-

24 VDC potential (20.4 to 28.8 VDC)

ing

TCU 30.3

Manual, 09/2017, A5E40874197 25

Connection

4.1 Pin assignment of the interfaces

In principle, USB interfaces have the following characteristics:

● Integrated power supply up to 500 mA for each socket.

● Maximum cable length 3 m (Length including the supply cable to the hub and the connected

terminal device; only 1 hub is permitted. It should be noted that some keyboards already

have a hub.)

Note

Cables that are too long can result in malfunctions or faults on the screen

Observe the following restrictions for the USB front interface for connecting operator panels

to the keyboard, mouse or USB FlashDrive:

● Maximum cable length: 1.8 m

● Extension cables are not permissible

● Hot-plugging-capable devices are connected during operation and are identified

automatically.

Note

Correct identification is only guaranteed for USB I/Os that comply to 100% with the USB

specification.

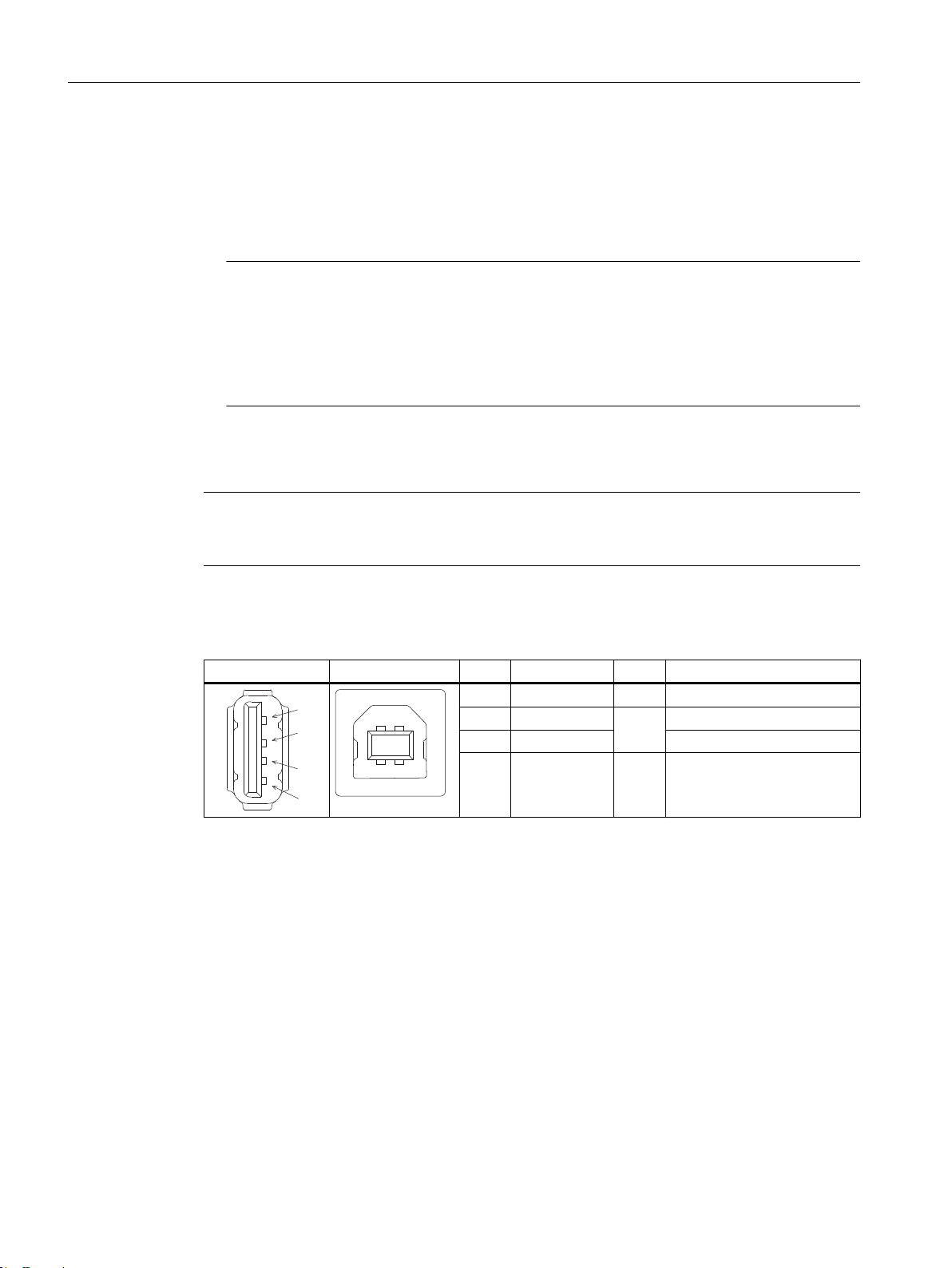

Table 4-2 Assignment of the USB interface

Type A socket Type B socket Pin Name Type Remark

1 P5V_fused V + 5 V (fused)

2 Data3 Data+ Data +

4 GND V Ground (reference potential)

Data -

B

USB sticks

If you want to connect a USB stick to the USB interface, preferably use the tested SIMATIC

USB stick 16 GB for this purpose (Article No.: 6ES7648-0DC60-0AA0). Alternatively, you can

use a USB stick with any memory size. It must, however, meet the following minimum

requirements:

● File system: FAT16 or FAT32

● Partitioning: only in PC partition format (MBR)

USB sticks that deviate from these requirements have not been tested and may not be

recognized by the NCU.

26 Manual, 09/2017, A5E40874197

TCU 30.3

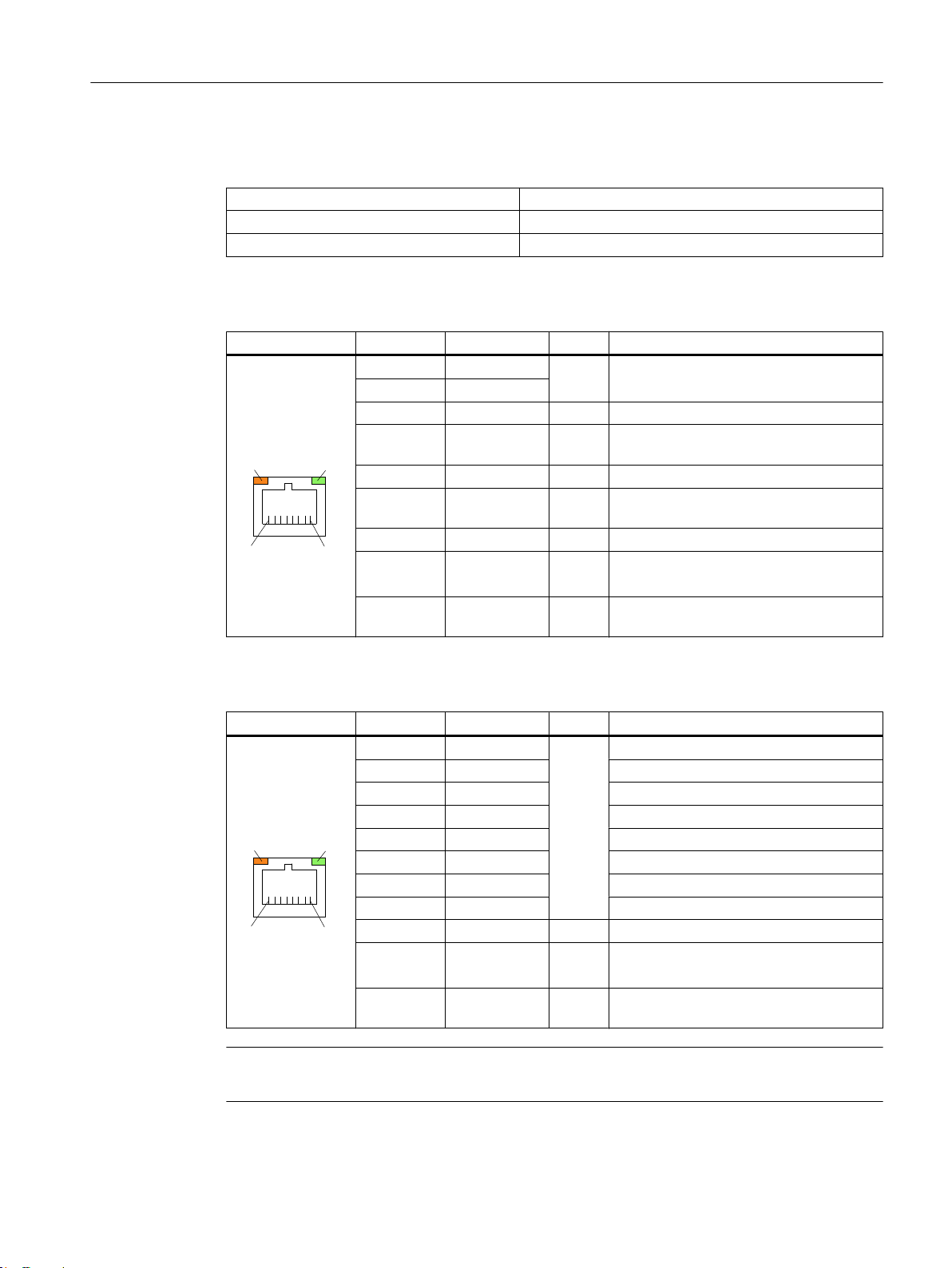

4.1.3 Ethernet RJ45 interface

/('/('

/('/('

Connector type: Standard RJ45 socket

Max. data transmission rate: 10/100/1000 Mbit/s

Max. cable length: 100 m

Table 4-3 Assignment of the Ethernet RJ45 interface 10/100 Mbit/s

Connector Pin Name Type Remark

4/5 GND - (terminated internally with 75 Ω; not re‐

7/8 GND - (terminated internally with 75 Ω; not re‐

Shield - - On connector housing

4.1 Pin assignment of the interfaces

1 TxD+

2 TxD3 RxD+ I Receive data

6 RD- I Receive data

- Green LED

(right)

- Orange LED

(left)

O Transmit data

quired for data transmission)

quired for data transmission)

- Illuminated: 10 or 100 Mbit/s

Off: No or faulty connection

- Illuminated: Data exchange

Off: No data exchange

Connection

Table 4-4 Assignment of the Ethernet RJ45 interface 1000 Mbit/s

Connector Pin Name Type Remark

1 DA+ B Bidirectional pair A+

2 DA- Bidirectional pair A3 DB+ Bidirectional pair B+

4 DC+ Bidirectional pair C+

5 DC- Bidirectional pair C6 DB- Bidirectional pair B7 DD+ Bidirectional pair D+

8 DD- Bidirectional pair D-

Shield - - On connector housing

- Green LED

(right)

- Orange LED

(left)

- Illuminated orange: 1000 Mbit/s

Off: No or faulty connection

- Illuminated: Data exchange

Off: No data exchange

Note

Connection only on LAN, not on telecommunication networks!

TCU 30.3

Manual, 09/2017, A5E40874197 27

Loading...

Loading...