Page 1

Preface

SINUMERIK

SINUMERIK 840D sl/828D

Job planning

Programming Manual

Flexible NC programming

File and Program Management

Protection zones

Special Motion Commands

Coordinate transformation

(FRAMES)

Transformations

Tool offsets

Path traversing behavior

Axis couplings

Motion synchronous actions

1

2

3

4

5

6

7

8

9

10

Validfor

Controlsystem

SINUMERIK840Dsl/840DEsl

SINUMERIK828D

SoftwareVersion

CNC-Software2.7CNCsoftwareversion2.7

Oscillation

Punching and nibbling

Grinding

Additional functions

User stock removal programs

Programming cycles externally

Tables

Appendix

11

12

13

14

15

16

17

A

02/2011

6FC5398-2BP40-1BA0

Page 2

Legal information- Warning notice system

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation for the specific task, in particular its warning notices and safety

instructions. Qualified personnel are those who, based on their training and experience, are capable of identifying

risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the SiemensAG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

order number:6FC5398-2BP40-1BA0

Ⓟ 12.2010

Copyright © SiemensAG2011.

Technical data subject to change

Page 3

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized in the following categories:

• General documentation

• User documentation

• Manufacturer/service documentation

Additional information

You can find information on the following topics at www.siemens.com/motioncontrol/docu:

• Ordering documentation/overview of documentation

• Additional links to download documents

• Using documentation online (find and search in manuals/information)

Please send any questions about the technical documentation (e.g. suggestions for

improvement, corrections) to the following address:

docu.motioncontrol@siemens.com

My Documentation Manager (MDM)

Under the following link you will find information to individually compile OEM-specific machine

documentation based on the Siemens content:

www.siemens.com/mdm

Training

For information about the range of training courses, refer under:

• www.siemens.com/sitrain

SITRAIN - Siemens training for products, systems and solutions in automation technology

• www.siemens.com/sinutrain

SinuTrain - training software for SINUMERIK

FAQs

You can find Frequently Asked Questions in the Service&Support pages under Product

Support. http://support.automation.siemens.com

Job planning

Programming Manual 02/2011, 6FC5398-2BP40-1BA0

3

Page 4

Preface

SINUMERIK

You can find information on SINUMERIK under the following link:

www.siemens.com/sinumerik

Target group

This publication is intended for:

• Programmers

• Project engineers

Benefits

With the programming manual, the target group can develop, write, test, and debug programs

and software user interfaces.

Standard scope

Technical Support

This Programming Guide describes the functionality afforded by standard functions.

Extensions or changes made by the machine tool manufacturer are documented by the

machine tool manufacturer.

Other functions not described in this documentation might be executable in the control. This

does not, however, represent an obligation to supply such functions with a new control or

when servicing.

Further, for the sake of simplicity, this documentation does not contain all detailed information

about all types of the product and cannot cover every conceivable case of installation,

operation or maintenance.

You will find telephone numbers for other countries for technical support in the Internet under

http://www.siemens.com/automation/service&support

Job planning

4 Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

Page 5

Information on structure and contents

"Fundamentals" and "Advanced" Programming Manual

The description of the NC programming is divided into two manuals:

1. Fundamentals

This "Fundamentals" Programming Manual is intended for use by skilled machine

operators with the appropriate expertise in drilling, milling and turning operations. Simple

programming examples are used to explain the commands and statements which are also

defined according to DIN 66025.

2. Job planning

The Programming Manual "Advanced" is intended for use by technicians with in-depth,

comprehensive programming knowledge. By virtue of a special programming language,

the SINUMERIK control enables the user to program complex workpiece programs (e.g.

for free-form surfaces, channel coordination, ...) and makes programming of complicated

operations easy for technologists.

Preface

Availability of the described NC language elements

All NC language elements described in the manual are available for the SINUMERIK 840Dsl.

The availability regarding SINUMERIK828D can be found in table"Operations: Availability for

SINUMERIK 828D [Page 877]" of the "".

Job planning

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

5

Page 6

Preface

Job planning

6 Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

Page 7

Table of contents

Preface.........................................................................................................................................................3

1 Flexible NC programming .........................................................................................................................17

1.1 Variables.................................................................................................................................... 17

1.1.1 General information about variables .......................................................................................... 17

1.1.2 System variables ....................................................................................................................... 18

1.1.3 Predefined user variables: Arithmetic parameters (R) ............................................................... 21

1.1.4 Predefined user variables: Link variables .................................................................................. 23

1.1.5 Definition of user variables (DEF) .............................................................................................. 25

1.1.6 Redefinition of system variables, user variables, and NC language commands (REDEF) ....... 31

1.1.7 Attribute: Initialization value ....................................................................................................... 34

1.1.8 Attribute: Limit values (LLI, ULI) ................................................................................................ 37

1.1.9 Attribute: Physical unit (PHU) .................................................................................................... 39

1.1.10 Attribute: Access rights (APR, APW, APRP, APWP, APRB, APWB) ........................................ 41

1.1.11 Overview of definable and redefinable attributes ...................................................................... 46

1.1.12 Definition and initialization of array variables (DEF, SET, REP) ............................................... 47

1.1.13 Definition and initialization of array variables (DEF, SET, REP): Further Information .............. 52

1.1.14 Data types ................................................................................................................................. 55

1.2 Indirect programming................................................................................................................. 56

1.2.1 Indirectly programming addresses ............................................................................................ 56

1.2.2 Indirectly programming G codes ................................................................................................ 59

1.2.3 Indirectly programming position attributes (BP) ......................................................................... 60

1.2.4 Indirectly programming part program lines (EXECSTRING) ..................................................... 63

1.3 Arithmetic functions ................................................................................................................... 64

1.4 Comparison and logic operations .............................................................................................. 67

1.5 Precision correction on comparison errors (TRUNC) ................................................................ 69

1.6 Variable minimum, maximum and range (MINVAL, MAXVAL and BOUND)............................. 71

1.7 Priority of the operations............................................................................................................ 73

1.8 Possible type conversions ......................................................................................................... 74

1.9 String operations ....................................................................................................................... 75

1.9.1 Type conversion to STRING (AXSTRING) ................................................................................ 76

1.9.2 Type conversion from STRING (NUMBER, ISNUMBER, AXNAME) ...

1.9.3

1.9.4 Conversion to lower/upper case letters (TOLOWER, TOUPPER) ............................................ 79

1.9.5 Determine length of string (STRLEN) ........................................................................................ 80

1.9.6 Search for character/string in the string (INDEX, RINDEX, MINDEX, MATCH) ........................ 81

1.9.7 Selection of a substring (SUBSTR) ........................................................................................... 82

1.9.8 Selection of a single character (STRINGVAR, STRINGFELD) ................................................. 83

1.9.9 Formatting a string (SPRINT) .................................................................................................... 84

1.10 Program jumps and branches ................................................................................................... 93

1.10.1 Return jump to the start of the program (GOTOS) .................................................................... 93

1.10.2 Program jumps to jump markers (GOTOB, GOTOF, GOTO, GOTOC) .................................... 94

1.10.3 Program branch (CASE ... OF ... DEFAULT ...) ........................................................................ 97

Concatenation of strings (<<) .................................................................................................... 78

..................................... 77

Job planning

Programming Manual 02/2011, 6FC5398-2BP40-1BA0

7

Page 8

Table of contents

1.11 Repeat program section (REPEAT, REPEATB, ENDLABEL, P)............................................... 99

1.12 Check structures...................................................................................................................... 106

1.12.1 Program loop with alternative (IF, ELSE, ENDIF) .................................................................... 107

1.12.2 Continuous program loop (LOOP, ENDLOOP) ....................................................................... 109

1.12.3 Count loop (FOR ... TO ..., ENDFOR) .....................................................................................110

1.12.4 Program loop with condition at start of loop (WHILE, ENDWHILE) ......................................... 112

1.12.5 Program loop with condition at the end of the loop (REPEAT, UNTIL) ................................... 113

1.12.6 Program example with nested check structures ...................................................................... 114

1.13 Program coordination (INIT, START, WAITM, WAITMC, WAITE, SETM, CLEARM) ............. 115

1.14 Interrupt routine (ASUB) .......................................................................................................... 120

1.14.1 Function of an interrupt routine ................................................................................................ 120

1.14.2 Creating an interrupt routine .................................................................................................... 121

1.14.3 Assign and start interrupt routine (SETINT, PRIO, BLSYNC) ................................................. 122

1.14.4 Deactivating/reactivating the assignment of an interrupt routine (DISABLE, ENABLE) .......... 124

1.14.5 Delete assignment of interrupt routine (CLRINT) .................................................................... 125

1.14.6 Fast retraction from the contour (SETINT LIFTFAST, ALF) .................................................... 126

1.14.7 Traversing direction for fast retraction from the contour .......................................................... 128

1.14.8 Motion sequence for interrupt routines .................................................................................... 131

1.15 Axis replacement, spindle replacement (RELEASE, GET, GETD).......................................... 132

1.16 Transfer axis to another channel (AXTOCHAN)...................................................................... 137

1.17 Activate machine data (NEWCONF) ....................................................................................... 139

1.18 Write file (WRITE).................................................................................................................... 140

1.19 Delete file (DELETE) ............................................................................................................... 146

1.20 Read lines in the file (READ) ................................................................................................... 148

1.21 Check for presence of file (ISFILE).......................................................................................... 152

1.22 Read out file information (FILEDATE, FILETIME, FILESIZE, FILESTAT, FILEINFO) ............ 154

1.23 Checksum calculation using an array (CHECKSUM) .............................................................. 158

1.24 Roundup (ROUNDUP)............................................................................................................. 160

1.25 Subprogram technique ............................................................................................................ 161

1.25.1 General information ................................................................................................................. 161

1.25.1.1 Subprogram ............................................................................................................................. 161

1.25.1.2 Subprogram names ................................................................................................................. 162

1.25.1.3 Nesting of subprograms ................................

.................................................................

.......... 163

1.25.1.4 Search path ............................................................................................................................. 164

1.25.1.5 Formal and actual parameters ................................................................................................. 165

1.25.1.6 Parameter transfer ................................................................................................................... 166

1.25.2 Definition of a subprogram ....................................................................................................... 168

1.25.2.1 Subprogram without parameter transfer .................................................................................. 168

1.25.2.2 Subprogram with call-by-value parameter transfer (PROC) .................................................... 169

1.25.2.3 Subprogram with call-by-reference parameter transfer (PROC, VAR) .................................... 170

1.25.2.4 Save modal G functions (SAVE) .............................................................................................. 172

1.25.2.5 Suppress single block execution (SBLOF, SBLON) ................................................................ 173

1.25.2.6 Suppress current block display (DISPLOF, DISPLON, ACTBLOCNO) ................................... 179

1.25.2.7 Identifying subprograms with preparation (PREPRO) ............................................................. 183

1.25.2.8 Subprogram return M17 ........................................................................................................... 184

Job planning

8

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

Page 9

Table of contents

1.25.2.9 RET subprogram return ........................................................................................................... 185

1.25.2.10Parameterizable subprogram return jump (RET ...) ................................................................ 186

1.25.3 Subprogram call ...................................................................................................................... 193

1.25.3.1 Subprogram call without parameter transfer ........................................................................... 193

1.25.3.2 Subprogram call with parameter transfer (EXTERN) .............................................................. 195

1.25.3.3 Number of program repetitions (P) .......................................................................................... 197

1.25.3.4 Modal subprogram call (MCALL) ............................................................................................. 199

1.25.3.5 Indirect subprogram call (CALL) .............................................................................................. 201

1.25.3.6 Indirect subprogram call with specification of the calling program part

(CALL BLOCK ... TO ...) .......................................................................................................... 202

1.25.3.7 Indirect call of a program programmed in ISO language (ISOCALL) ...................................... 203

1.25.3.8 Calling subroutine with path specification and parameters (PCALL) ....................................... 205

1.25.3.9 Extend search path for subprogram calls (CALLPATH) .......................................................... 206

1.25.3.10Execute external subroutine (EXTCALL) ................................................................................. 208

1.25.4 Cycles ...................................................................................................................................... 212

1.25.4.1 Parameterizing user cycles ..................................................................................................... 212

1.26 Macro technique (DEFINE ... AS)............................................................................................ 216

2 File and Program Management ...............................................................................................................219

2.1 Program memory..................................................................................................................... 219

2.2 Working memory (CHANDATA, COMPLETE, INITIAL) .......................................................... 224

2.3 Structuring instruction in step editor (SEFORM) ..................................................................... 227

3 Protection zones .....................................................................................................................................229

3.1 Definition of the protection zones (CPROTDEF, NPROTDEF) ............................................... 229

3.2 Activating/deactivating protection zones (CPROT, NPROT)................................................... 233

3.3 Checking for protection zone violation, working area limitation and software limits

(CALCPOSI) ............................................................................................................................ 237

4 Special Motion Commands .....................................................................................................................245

4.1 Approaching coded positions (CAC, CIC, CDC, CACP, CACN) ............................................. 245

4.2 Spline interpolation (ASPLINE, BSPLINE, CSPLINE, BAUTO, BNAT, BTAN, EAUTO, ENAT,

ETAN, PW, SD, PL)................................................................................................................. 246

4.3 Spline grouping (SPLINEPATH).............................................................................................. 257

4.4 NC block compression (COMPON, COMPCURV, COMPCAD, COMPOF) .....

....................... 259

4.5 Polynomial interpolation (POLY, POLYPATH, PO, PL)........................................................... 262

4.6 Settable path reference (SPATH, UPATH).............................................................................. 268

4.7 Measurements with touch trigger probe (MEAS, MEAW) ....................................................... 271

4.8 Extended measuring function (MEASA, MEAWA, MEAC) (option)......................................... 274

4.9 Special functions for OEM users (OMA1 ... OMA5, OEMIPO1, OEMIPO2, G810 ... G829) ... 283

4.10 Feed reduction with corner deceleration (FENDNORM, G62, G621)...................................... 284

4.11 Programmed end-of-motion criterion (FINEA, COARSEA, IPOENDA, IPOBRKA,

ADISPOSA) ............................................................................................................................. 285

4.12 Programmable servo parameter set (SCPARA)...................................................................... 288

Job planning

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

9

Page 10

Table of contents

5 Coordinate transformation (FRAMES) ....................................................................................................289

5.1 Coordinate transformation via frame variables ........................................................................ 289

5.1.1 Predefined frame variable ($P_BFRAME, $P_IFRAME, $P_PFRAME, $P_ACTFRAME) ...... 291

5.2 Frame variables / assigning values to frames ......................................................................... 297

5.2.1 Assigning direct values (axis value, angle, scale) ................................................................... 297

5.2.2 Reading and changing frame components (TR, FI, RT, SC, MI) ............................................. 300

5.2.3 Linking complete frames .......................................................................................................... 301

5.2.4 Defining new frames (DEF FRAME) ........................................................................................ 303

5.3 Coarse and fine offsets (CFINE, CTRANS)............................................................................. 304

5.4 External zero offset.................................................................................................................. 306

5.5 Preset offset (PRESETON) ..................................................................................................... 307

5.6 Frame calculation from three measuring points in space (MEAFRAME) ................................ 309

5.7 NCU global frames ................................................................................................................. 313

5.7.1 Channel-specific frames ($P_CHBFR, $P_UBFR) .................................................................. 314

5.7.2 Frames active in the channel ................................................................................................... 315

6 Transformations ......................................................................................................................................321

6.1 General programming of transformation types ........................................................................ 321

6.1.1 Orientation movements for transformations ............................................................................. 324

6.1.2 Overview of orientation transformation TRAORI ..................................................................... 327

6.2 Three, four and five axis transformation (TRAORI) ................................................................. 329

6.2.1 General relationships of universal tool head ............................................................................ 329

6.2.2 Three, four and five axis transformation (TRAORI) ................................................................. 332

6.2.3 Variants of orientation programming and initial setting (ORIRESET) ...................................... 334

6.2.4 Programming of the tool orientation (A..., B..., C..., LEAD, TILT) ............................................ 335

6.2.5 Face milling (3D-milling A4, B4, C4, A5, B5, C5) .................................................................... 342

6.2.6 Orientation axis reference (ORIWKS, ORIMKS) ..................................................................... 344

6.2.7 Programming orientation axes (ORIAXES, ORIVECT, ORIEULER, ORIRPY, ORIRPY2,

ORIVIRT1, ORIVIRT2) ............................................................................................................ 346

6.2.8 Orientation programming along the peripheral surface of a taper (ORIPLANE, ORICONCW,

ORICONCCW, ORICONTO, ORICONIO) ............................................................................... 348

6.2.9 Specification of orientation for two contact points (ORICURVE, PO[XH]=, PO[YH]=,

PO[ZH]=) ................................................................................................................................. 352

6.3 Orientation polynomials (PO[angle], PO[coordinate]).........

6.4

Rotations of the tool orientation (ORIROTA, ORIROTR, ORIROTT, ORIROTC, THETA) ...... 356

..................................................... 354

6.5 Orientations relative to the path............................................................................................... 359

6.5.1 Orientation types relative to the path ....................................................................................... 359

6.5.2 Rotation of the tool orientation relative to the path (ORIPATH, ORIPATHS,

angle of rotation) ...................................................................................................................... 361

6.5.3 Interpolation of the tool rotation relative to the path (ORIROTC, THETA) ............................... 362

6.5.4 Smoothing of orientation characteristic (ORIPATHS A8=, B8=, C8=) ..................................... 364

6.6 Compression of the orientation (COMPON, COMPCURV, COMPCAD)................................. 366

6.7 Smoothing the orientation characteristic (ORISON, ORISOF) ................................................ 369

6.8 Kinematic transformation ......................................................................................................... 371

6.8.1 Milling on turned parts (TRANSMIT) ........................................................................................ 371

10

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

Job planning

Page 11

Table of contents

6.8.2 Cylinder surface transformation (TRACYL) ............................................................................. 375

6.8.3 Inclined axis (TRAANG) .......................................................................................................... 383

6.8.4 Inclined axis programming (G05, G07) .................................................................................... 386

6.9 Cartesian PTP travel ............................................................................................................... 388

6.9.1 PTP for TRANSMIT ................................................................................................................. 393

6.10 Constraints when selecting a transformation........................................................................... 397

6.11 Deselect transformation (TRAFOOF) ...................................................................................... 398

6.12 Chained transformations (TRACON, TRAFOOF).................................................................... 399

7 Tool offsets .............................................................................................................................................401

7.1 Offset memory ......................................................................................................................... 401

7.2 Additive offsets ........................................................................................................................ 404

7.2.1 Selecting additive offsets (DL) ................................................................................................. 404

7.2.2 Specify wear and setup values ($TC_SCPxy[t,d], $TC_ECPxy[t,d]) ....................................... 406

7.2.3 Delete additive offsets (DELDL) .............................................................................................. 407

7.3 Special handling of tool offsets................................................................................................ 408

7.3.1 Mirroring of tool lengths ........................................................................................................... 410

7.3.2 Wear sign evaluation ............................................................................................................... 411

7.3.3 Coordinate system of the active machining operation (TOWSTD, TOWMCS, TOWWCS,

TOWBCS, TOWTCS, TOWKCS) ............................................................................................ 412

7.3.4 Tool length and plane change ................................................................................................. 415

7.4 Online tool offset (PUTFTOCF, FCTDEF, PUTFTOC, FTOCON, FTOCOF) .......................... 416

7.5 Activate 3D tool offsets (CUT3DC..., CUT3DF...).................................................................... 421

7.5.1 Activating 3D tool offsets (CUT3DC, CUT3DF, CUT3DFS, CUT3DFF, ISD) .......................... 421

7.5.2 3D tool offset peripheral milling, face milling ........................................................................... 423

7.5.3 3D tool offset Tool shapes and tool data for face milling ......................................................... 425

7.5.4 3D tool offset Compensation on the path, path curvature, insertion depth (CUT3DC, ISD) .... 426

7.5.5 3D tool offset Inside/outside corners and intersection procedure (G450/G451) ...................... 429

7.5.6 3D tool offset 3D circumferential milling with limitation surfaces ............................................. 430

7.5.7 3D tool offset Taking into consideration a limitation surface (CUT3DCC, CUT3DCCD) ......... 431

7.6 Tool orientation (ORIC, ORID, OSOF, OSC, OSS, OSSE, ORIS, OSD, OST)....................... 435

7.7 Free assignment of D numbers, cutting edge numbers........................................................... 441

7.7.1 Free assignment of D numbers, cutting edge numbers (CE address) .................................... 441

7.7.2 Free assignment of D numbers: Checking D numbers (CHKDNO)

7.7.3

Free assignment of D numbers: Rename D numbers (GETDNO, SETDNO) ......................... 442

......................................... 441

7.7.4 Free assignment of D numbers: Determine T number to the specified D number

(GETACTTD) ........................................................................................................................... 443

7.7.5 Free assignment of D numbers: Invalidate D numbers (DZERO) ........................................... 444

7.8 Tool holder kinematics............................................................................................................. 445

7.9 Tool length compensation for orientable toolholders (TCARR, TCOABS, TCOFR, TCOFRX,

TCOFRY, TCOFRZ) ................................................................................................................ 451

7.10 Online tool length compensation (TOFFON, TOFFOF)........................................................... 454

7.11 Cutting data modification for tools that can be rotated (CUTMOD) ......................................... 457

Job planning

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

11

Page 12

Table of contents

8 Path traversing behavior .........................................................................................................................463

8.1 Tangential control (TANG, TANGON, TANGOF, TLIFT, TANGDEL)...................................... 463

8.2 Feedrate response (FNORM, FLIN, FCUB, FPO) ................................................................... 470

8.3 Program sequence with preprocessing memory (STOPFIFO, STARTFIFO, FIFOCTRL,

STOPRE)................................................................................................................................. 475

8.4 Conditionally interruptible program sections (DELAYFSTON, DELAYFSTOF)....................... 478

8.5 Preventing program position for SERUPRO (IPTRLOCK, IPTRUNLOCK) ............................. 483

8.6 Repositioning to a contour (REPOSA, REPOSL, REPOSQ, REPOSQA, REPOSH,

REPOSHA, DISR, DISPR, RMI, RMB, RME, RMN)................................................................ 486

8.7 Influencing the motion control.................................................................................................. 495

8.7.1 Percentage jerk correction (JERKLIM) .................................................................................... 495

8.7.2 Percentage velocity correction (VELOLIM) .............................................................................. 496

8.7.3 Program example for JERKLIM and VELOLIM ....................................................................... 499

8.8 Programmable contour/orientation tolerance (CTOL, OTOL, ATOL) ...................................... 500

8.9 Tolerance for G0 motion (STOLF) ........................................................................................... 504

9 Axis couplings .........................................................................................................................................507

9.1 Coupled motion (TRAILON, TRAILOF) ................................................................................... 507

9.2 Curve tables (CTAB)................................................................................................................ 511

9.2.1 Define curve tables (CTABDEF, CATBEND) ........................................................................... 512

9.2.2 Check for presence of curve table (CTABEXISTS) ................................................................. 518

9.2.3 Delete curve tables (CTABDEL) .............................................................................................. 519

9.2.4 Locking curve tables to prevent deletion and overwriting (CTABLOCK, CTABUNLOCK) ....... 520

9.2.5 Curve tables: Determine table properties (CTABID, CTABISLOCK, CTABMEMTYP,

CTABPERIOD) ........................................................................................................................ 521

9.2.6 Read curve table values (CTABTSV, CTABTEV, CTABTSP, CTABTEP, CTABSSV, CTABSEV,

CTAB, CTABINV, CTABTMIN, CTABTMAX) .......................................................................... 523

9.2.7 Curve tables: Check use of resources (CTABNO, CTABNOMEM, CTABFNO, CTABSEGID,

CTABSEG, CTABFSEG, CTABMSEG, CTABPOLID, CTABPOL, CTABFPOL, CTABMPOL) 528

9.3 Axial leading value coupling (LEADON, LEADOF).................................................................. 530

9.4 Electronic gear (EG) ................................................................................................................ 536

9.4.1 Defining an electronic gear (EGDEF) ......................................................................................536

9.4.2 Switch-in the electronic gearbox (EGON, EGONSYN, EGONSYNE)

3 Switching-in the electronic gearbox (EGOFS, EGOFC) .......................................................... 541

9.4.

..................................... 538

9.4.4 Deleting the definition of an electronic gear (EGDEL) ............................................................. 542

9.4.5 Rotational feedrate (G95) / electronic gear (FPR) ................................................................... 542

9.5 Synchronous spindle ............................................................................................................... 543

9.5.1 Synchronous spindle: Programming (COUPDEF, COUPDEL, COUPON, COUPONC,

COUPOF, COUPOFS, COUPRES, WAITC) ........................................................................... 544

9.6 Master/slave group (MASLDEF, MASLDEL, MASLON, MASLOF, MASLOFS)...................... 555

10 Motion synchronous actions ....................................................................................................................559

10.1 Basics ...................................................................................................................................... 559

10.1.1 Area of validity and machining sequence (ID, IDS) ................................................................. 561

10.1.2 Cyclically checking the condition (WHEN, WHENEVER, FROM, EVERY) ............................. 563

Job planning

12

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

Page 13

Table of contents

10.1.3 Actions (DO) ............................................................................................................................ 565

10.2 Operators for conditions and actions ....................................................................................... 566

10.3 Main run variables for synchronized actions ........................................................................... 568

10.3.1 System variables ..................................................................................................................... 568

10.3.2 Implicit type conversion ........................................................................................................... 570

10.3.3 GUD variables ......................................................................................................................... 571

10.3.4 Default axis identifier (NO_AXIS) ............................................................................................ 573

10.3.5 Synchronized action marker ($AC_MARKER[n]) .................................................................... 574

10.3.6 Synchronized action parameters ($AC_PARAM[n]) ................................................................ 575

10.3.7 Arithmetic parameter ($R[n]) ................................................................................................... 575

10.3.8 Read and write NC machine and NC setting data ................................................................... 576

10.3.9 Timer variable ($AC_Timer[n]) ................................................................................................ 578

10.3.10 FIFO variables ($AC_FIFO1[n] ... $AC_FIFO10[n]) ................................................................. 579

10.3.11 Information about block types in the interpolator ($AC_BLOCKTYPE,

$AC_BLOCKTYPEINFO, $AC_SPLITBLOCK) ....................................................................... 581

10.4 Actions in synchronized actions .............................................................................................. 584

10.4.1 Overview of possible actions in synchronized actions ............................................................. 584

10.4.2 Output of auxiliary functions .................................................................................................... 586

10.4.3 Set read-in disable (RDISABLE) ............................................................................................. 587

10.4.4 Cancel preprocessing stop (STOPREOF) ............................................................................... 588

10.4.5 Delete distance-to-go (DELDTG) ............................................................................................ 589

10.4.6 Polynomial definition (FCTDEF) .............................................................................................. 591

10.4.7 Synchronized function (SYNFCT) ........................................................................................... 594

10.4.8 Closed-loop clearance control with limited correction ($AA_OFF_MODE) .............................. 597

10.4.9 Online tool offset (FTOC) ........................................................................................................ 600

10.4.10 Online tool length compensation ($AA_TOFF) ........................................................................ 603

10.4.11 Positioning movements ........................................................................................................... 605

10.4.12 Position axis (POS) ................................................................................................................. 606

10.4.13 Position in specified reference range (POSRANGE) ............................................................... 608

10.4.14 Start/stop axis (MOV) .............................................................................................................. 609

10.4.15 Axis replacement (RELEASE, GET) ........................................................................................610

10.4.16 Axial feed (FA) ........................................

..................................................................

............... 614

10.4.17 Software limit switch ................................................................................................................ 614

10.4.18 Axis coordination ..................................................................................................................... 615

10.4.19 Set actual values (PRESETON) .............................................................................................. 616

10.4.20 Withdrawing the enable for the axis container rotation (AXCTSWEC) .................................... 617

10.4.21 Spindle motions ....................................................................................................................... 620

10.4.22 Coupled motion (TRAILON, TRAILOF) ................................................................................... 621

10.4.23 Leading value coupling (LEADON, LEADOF) ......................................................................... 623

10.4.24 Measuring (MEAWA, MEAC) .................................................................................................. 626

10.4.25 Initialization of array variables (SET, REP) ............................................................................. 627

10.4.26 Set/delete wait markers (SETM, CLEARM) ............................................................................. 628

10.4.27 Fault responses (SETAL) ........................................................................................................ 629

10.4.28 Travel to fixed stop (FXS, FXST, FXSW, FOCON, FOCOF) ................................................... 630

10.4.29 Determining the path tangent in synchronized actions ............................................................ 632

10.4.30 Determining the current override ............................................................................................. 633

10.4.31 Time use evaluation of synchronized actions .......................................................................... 634

10.5 Technology cycles ................................................................................................................... 636

10.5.1 Context variable ($P_TECCYCLE) ..........................................................................................639

10.5.2 Call-by-value parameters ........................................................................................................ 640

Job planning

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

13

Page 14

Table of contents

10.5.3 Default parameter initialization ................................................................................................ 640

10.5.4 Control processing of technology cycles (ICYCOF, ICYCON) ................................................ 641

10.5.5 Cascading technology cycles .................................................................................................. 642

10.5.6 Technology cycles in non-modal synchronized actions ........................................................... 642

10.5.7 Check structures (IF) ............................................................................................................... 643

10.5.8 Jump instructions (GOTO, GOTOF, GOTOB) ......................................................................... 643

10.5.9 Lock, unlock, reset (LOCK, UNLOCK, RESET) ....................................................................... 644

10.6 Delete synchronized action (CANCEL).................................................................................... 646

10.7 Control behavior in specific operating states ........................................................................... 647

11 Oscillation ................................................................................................................................................651

11.1 Asynchronous oscillation (OS, OSP1, OSP2, OST1, OST2, OSCTRL, OSNSC, OSE, OSB) 651

11.2 Oscillation controlled by synchronized actions (OSCILL) ........................................................ 657

12 Punching and nibbling .............................................................................................................................665

12.1 Activation, deactivation ............................................................................................................ 665

12.1.1 Punching and nibbling on or off (SPOF, SON, PON, SONS, PONS, PDELAYON,

PDELAYOF, PUNCHACC) ...................................................................................................... 665

12.2 Automatic path segmentation .................................................................................................. 670

12.2.1 Path segmentation for path axes ............................................................................................. 673

12.2.2 Path segmentation for single axes ........................................................................................... 675

13 Grinding ...................................................................................................................................................677

13.1 Grinding-specific tool monitoring in the part program (TMON, TMOF).................................... 677

14 Additional functions .................................................................................................................................679

14.1 Axis functions (AXNAME, AX, SPI, AXTOSPI, ISAXIS, AXSTRING, MODAXVAL)................ 679

14.2 Replaceable geometry axes (GEOAX) .................................................................................... 682

14.3 Axis container (AXCTSWE, AXCTSWED, AXCTSWEC) ........................................................ 687

14.4 Wait for valid axis position (WAITENC) ................................................................................... 693

14.5 Check scope of NC language present (STRINGIS)................................................................. 695

14.6 Function call ISVAR and read machine data array index ........................................................ 699

14.7 Learn compensation characteristics (QECLRNON, QECLRNOF) .......................................... 701

14.8 Interactively call the window from the part program (MMC) .................................................... 703

14.9 Program runtime/part counter..................................

................................................................ 704

14.9.1 Program runtime/part counter (overview) ................................................................................ 704

14.9.2 Program runtime ...................................................................................................................... 705

14.9.3 Workpiece counter ................................................................................................................... 709

14.10 Output to an external device/file (EXTOPEN, WRITE, EXTCLOSE)....................................... 710

14.11 Alarms (SETAL)....................................................................................................................... 719

14.12 Drive-integrated extended stop and retract (ESR)................................................................... 721

14.12.1 Configuring drive-integrated stopping (ESRS) ......................................................................... 721

14.12.2 Configuring drive-integrated retraction (ESRS) ....................................................................... 722

14

Job planning

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

Page 15

Table of contents

15 User stock removal programs .................................................................................................................725

15.1 Supporting functions for stock removal ................................................................................... 725

15.2 Generate contour table (CONTPRON).................................................................................... 726

15.3 Generate coded contour table (CONTDCON)......................................................................... 732

15.4 Determine point of intersection between two contour elements (INTERSEC) ........................ 736

15.5 Execute the contour elements of a table block-by-block (EXECTAB) ..................................... 738

15.6 Calculate circle data (CALCDAT) ............................................................................................ 739

15.7 Deactivate contour preparation (EXECUTE) ........................................................................... 741

16 Programming cycles externally ...............................................................................................................743

16.1 Technology cycles ................................................................................................................... 743

16.1.1 Introduction .............................................................................................................................. 743

16.1.2 Drilling, centering - CYCLE81 .................................................................................................. 745

16.1.3 Drilling, counterboring - CYCLE82 .......................................................................................... 746

16.1.4 Reaming - CYCLE85 ............................................................................................................... 747

16.1.5 Deep-hole drilling - CYCLE83 ................................................................................................. 748

16.1.6 Boring - CYCLE86 ................................................................................................................... 750

16.1.7 Tapping without compensating chuck - CYCLE84 .................................................................. 751

16.1.8 Tapping with compensating chuck - CYCLE840 ..................................................................... 754

16.1.9 Thread milling - CYCLE78 ....................................................................................................... 756

16.1.10 Freely programmable positions - CYCLE802 .......................................................................... 758

16.1.11 Row of holes - HOLES1 .......................................................................................................... 760

16.1.12 Grid or frame - CYCLE801 ...................................................................................................... 761

16.1.13 Circle of holes - HOLES2 ........................................................................................................ 762

16.1.14 Face milling - CYCLE61 .......................................................................................................... 763

16.1.15 Milling a rectangular pocket - POCKET3 .................................................................................765

16.1.16 Milling a circular pocket - POCKET4 ....................................................................................... 768

16.1.17 Rectangular spigot milling - CYCLE76 .................................................................................... 770

16.1.18 Circular spigot milling - CYCLE77 ........................................................................................... 772

16.1.19 Multiple-edge - CYCLE79 ........................................................................................................ 774

16.1.20 Longitudinal slot - SLOT1 ........................................................................................................ 776

16.1.21 Circumferential slot - SLOT2 ................................................................................................... 779

16.1.22 Mill open slot - CYCLE899 ...................................................................................................... 781

16.1.23 Elongated hole - LONGHOLE ................................................................................................. 783

16.1.24 Thread milling - CYCLE70 ....................................................................................................... 785

16.1.25 Engraving cycle - CYCLE60 ..............................

.................................................................

..... 787

16.1.26 Contour call - CYCLE62 .......................................................................................................... 790

16.1.27 Path milling - CYCLE72 ........................................................................................................... 791

16.1.28 Predrilling a contour pocket - CYCLE64 .................................................................................. 794

16.1.29 Milling a contour pocket - CYCLE63 ........................................................................................ 796

16.1.30 Stock removal - CYCLE951 ..................................................................................................... 798

16.1.31 Groove - CYCLE930 ................................................................................................................ 801

16.1.32 Undercut forms - CYCLE940 ................................................................................................... 804

16.1.33 Thread turning - CYCLE99 ...................................................................................................... 807

16.1.34 Thread chain - CYCLE98 ........................................................................................................ 810

16.1.35 Cut-off - CYCLE92 ................................................................................................................... 813

16.1.36 Contour grooving - CYCLE952 ................................................................................................ 815

16.1.37 Swiveling - CYCLE800 ............................................................................................................ 819

16.1.38 High Speed Settings - CYCLE832 ........................................................................................... 822

Job planning

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

15

Page 16

16.1.39 High speed cutting (HSC) - CYCLE_HSC ............................................................................... 823

17 Tables .....................................................................................................................................................825

17.1 Operations ............................................................................................................................... 825

17.2 Operations: Availability for SINUMERIK 828D ........................................................................ 877

17.3 Currently set language in the HMI ........................................................................................... 899

A Appendix .................................................................................................................................................901

A.1 List of abbreviations................................................................................................................. 901

A.2 Overview.................................................................................................................................. 906

Glossary...................................................................................................................................................909

16

Job planning

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

Page 17

Flexible NC programming

1.1 Variables

1.1.1 General information about variables

The use of variables, especially in conjunction with arithmetic functions and check structures,

enables part programs and cycles to be set up with extremely high levels of flexibility. For this

purpose the system makes three different types of variable available.

• System variables

System variables are variables with a fixed predefined meaning; they are defined in the

system and made available to the user. They are also read and written by the system

software. Example: Machine data

The meaning of a system variable is, to a large extent, predefined by the system and its

properties are fixed. However, minor modifications can be made to the properties by the

user in the form of redefinition. See "Redefinition of system variables, user variables, and

NC language commands (REDEF) [Page 31]".

• User variables

1

User variables are variables whose meaning is not known to the system; they are not

evaluated by the system. The meaning is defined exclusively by the user.

User variables are subdivided into:

- Predefined user variables

Predefined user variables are variables which have already been defined in the system

and whose number simply has to be parameterized by the user via specific machine

data. The user can make significant changes to the properties of these variables. See

"Redefinition of system variables, user variables, and NC language commands

(REDEF) [Page 31]".

- User-defined variables

User-defined variables are variables which are defined exclusively by the user and are

not created by the system until runtime. Their number, data type, visibility, and all other

properties are defined exclusively by the user.

See "Definition of user variables (DEF) [Page 25]".

Job planning

Programming Manual 02/2011, 6FC5398-2BP40-1BA0

17

Page 18

Flexible NC programming

1.1 Variables

See also

System variables System variables [Page 18]

Predefined user variables: Arithmetic parameters (R) Predefined user variables: Arithmetic

parameters (R) [Page 21]

Predefined user variables: Link variables Predefined user variables: Link variables [Page 23]

Attribute: Initialization value Attribute: Initialization value [Page 34]

Attribute: Limit values (LLI, ULI) Attribute: Limit values (LLI, ULI) [Page 37]

Attribute: Physical unit (PHU) Attribute: Physical unit (PHU) [Page 39]

Attribute: Access rights (APR, APW, APRP, APWP, APRB, APWB) Attribute: Access rights

(APR, APW, APRP, APWP, APRB, APWB) [Page 41]

Overview of definable and redefinable attributes Overview of definable and redefinable

attributes [Page 46]

Definition and initialization of array variables (DEF, SET, REP) Definition and initialization of

array variables (DEF, SET, REP) [Page 47]

Data types Data types [Page 55]

1.1.2 System variables

System variables are variables which are predefined in the system and provide access to the

actual parameter settings associated with the control, as well as machine, control, and

process statuses, in part programs and cycles.

Preprocessing variables

Preprocessing variables are system variables that are read and written in the context of

preprocessing; in other words, at the point in time at which the part program block in which

the system variable is programmed is interpreted. Preprocessing variables do not trigger

preprocessing stops.

Main run variables

Main run variables are system variables which are read and written in the context of the main

run; in other words at the point in time at which the part program block in which the system

variable is programmed is executed. The following are main run variables:

• System variables which can be programmed in synchronized actions (read/write)

• System variables which can be programmed in the part program and trigger preprocessing

stops (read/write)

• System variables which can be programmed in the part program and whose value is

calculated during preprocessing but not written until the main run (main run synchronized:

write only)

Job planning

18 Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

Page 19

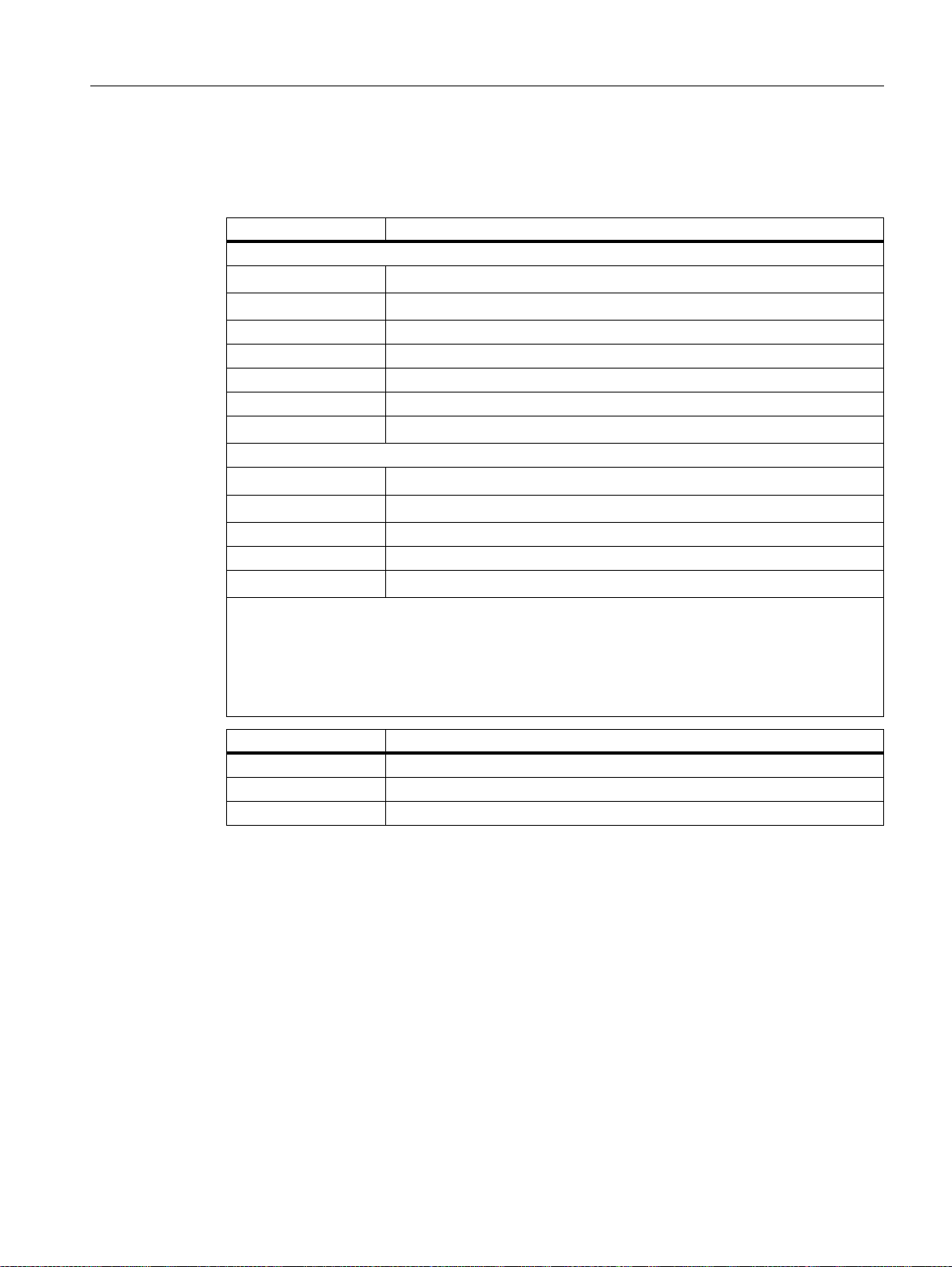

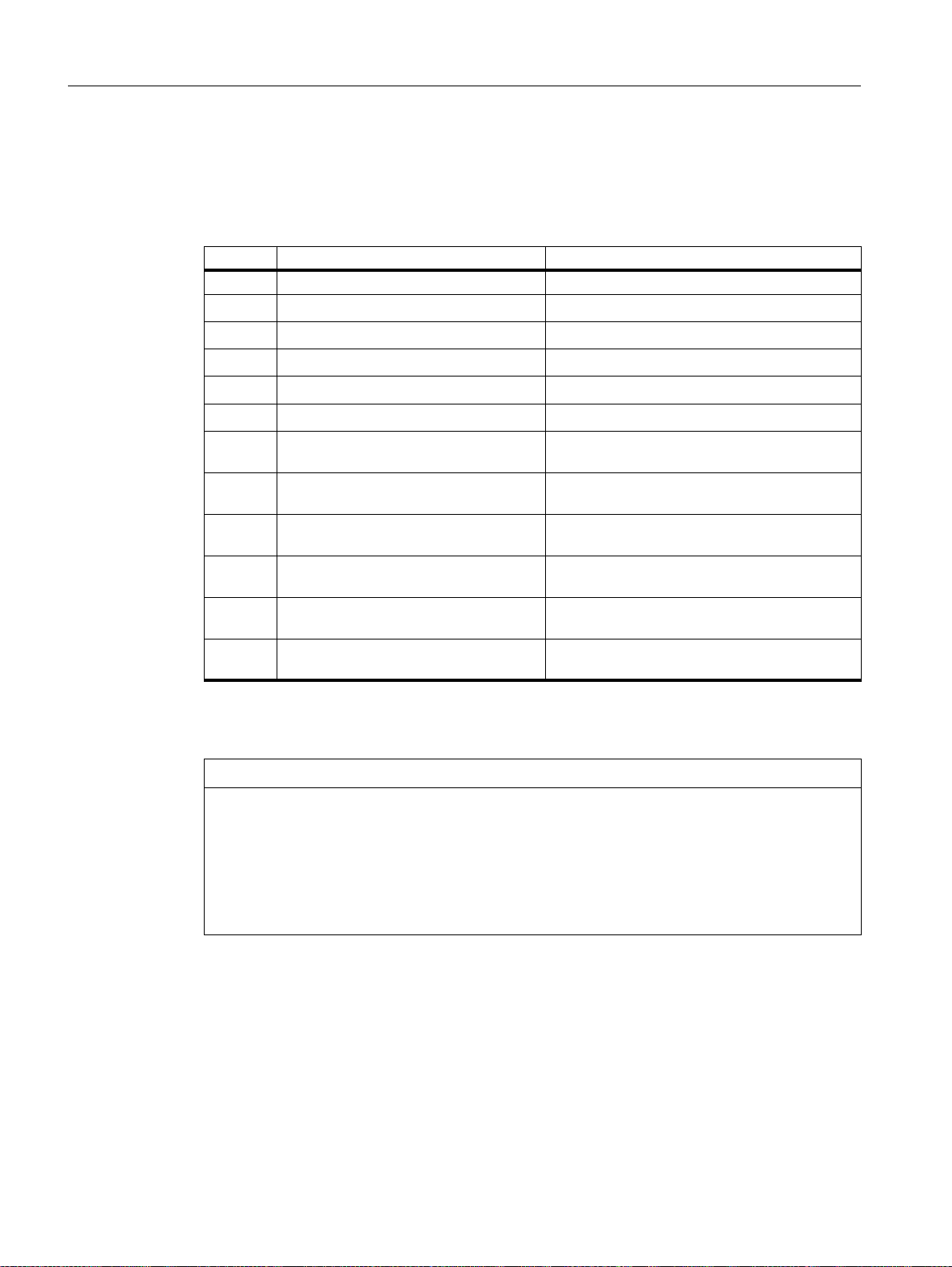

Prefix system

Flexible NC programming

1.1 Variables

In order that they can be specifically identified, the names of system variables are usually

preceded by a prefix comprising the $ sign followed by one or two letters and an underscore.

$ + 1. Letter Significance: Data type

System variables which are read/written during preprocessing

$M

$S

Machine data

Setting data, protection zones

$T Tool management data

$P Programmed values

$C Cycle variables of ISO envelope cycles

$O Option data

R

R-parameters (arithmetic parameters)

System variables which are read/written during the main run

$$M

$$S

Machine data

Setting data

$A Up-to-date main run data

$V Servo data

$R

1)

When machine and setting data are used in the part program/cycle as preprocessing variables, the

R-parameters (arithmetic parameters)

prefix is written with one $ sign. When they are used in synchronized actions as main run variables,

the prefix is written with two $ signs.

2)

When an R-parameter is used in the part program/cycle as a preprocessing variable, the prefix is

omitted, e.g. R10. When it is used in a synchronized action as a main run variable, a $ sign is written

as a prefix, e.g. $R10.

1)

1)

2)

1)

1)

2)

2. Letter Significance: Visibility

N NCK-global variable (NCK)

C Channel-specific variable (Channel)

A Axis-specific variable (Axis)

General conditions

Exceptions in the prefix system

The following system of variables deviate from the prefix system specified above:

• $TC_...: Here, the 2nd letter C does not refer to channel-specific system variables but to

toolholder-specific system variables (TC= tool carrier).

• $P_ ...: Channel-specific system variables

Job planning

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

19

Page 20

Flexible NC programming

1.1 Variables

Use of machine and setting data in synchronized actions

When machine and setting data are used in synchronized actions, the prefix can be used to

define whether the machine or setting data will be read/written synchronous to the

preprocessing run or the main run.

If the data remains unchanged during machining, it can be read synchronous to the

preprocessing run. For this purpose, the machine or setting data prefix is written with a $ sign:

Program code

ID=1 WHENEVER G710 $AA_IM[z] < $SA_OSCILL_REVERSE_POS2[Z]–6 DO $AA_OVR[X]=0

If the data changes during machining, it must be read/written synchronous to the main run.

For this purpose, the machine or setting data prefix is written with two $ signs:

Program code

ID=1 WHENEVER $AA_IM[z] < $$SA_OSCILL_REVERSE_POS2[Z]–6 DO $AA_OVR[X]=0

Note

Writing machine data

When writing an item of machine or setting data, it is important to ensure that the access

level which is active when the part program/cycle is executed permits write access and that

the data is set to take "IMMEDIATE" effect.

References

See also

A list of the properties of all system variables appears in:

List Manual, system variable

General information about variables General information about variables [Page 17]

Job planning

20 Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

Page 21

1.1.3 Predefined user variables: Arithmetic parameters (R)

Function

Arithmetic parameters or R-parameters are predefined user variables with the designation R,

defined as an array of the REAL data type. For historical reasons, notation both with array

index, e.g. R[10], and without array index, e.g. R10, is permitted for R-parameters.

When using synchronized actions, the $ sign must be included as a prefix, e.g. $R10.

Syntax

When used as a preprocessing variable:

R<n>

R[<expression>]

When used as a main run variable:

$R<n>

$R[<expression>]

Flexible NC programming

1.1 Variables

Significance

R: Identifier when used as a preprocessing variable, e.g. in the part program

$R: Identifier when used as a main run variable, e.g. in synchronized actions

Type: REAL

Range of

values:

For a non-exponential notation:

± (0.000 0001 to 9999 9999)

Note:

A maximum of 8 decimal places are permitted.

For an exponential notation:

± (1*10

-300

to 1*10

+300

)

Note:

• Notation: <Mantisse>EX<exponent> e.g. 8.2EX-3

• A maximum of 10 characters are permitted including

sign and decimal point.

Job planning

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

21

Page 22

Flexible NC programming

1.1 Variables

<n>: Number of the R-parameter

Type: INT

Range of

values:

0 - MAX_INDEX

Note

MAX_INDEX is calculated from the parameterized

number of R-parameters:

MAX_INDEX = (MD28050 $MN_MM_NUM_R_PARAM)

- 1

<expression>

:

Array index

Any expression can be used as an array index, as long as the result of

the expression can be converted into the INT data type (INT, REAL,

BOOL, CHAR).

Example

Assignments to R-parameters and use of R-parameters in mathematical functions:

Program code Comment

R0=3.5678 ; Assignment in preprocessing

R[1]=-37.3 ; Assignment in preprocessing

R3=-7 ; Assignment in preprocessing

$R4=-0.1EX-5 ; Assignment in main run: R4 = -0.1 * 10^-5

$R[6]=1.874EX8 ; Assignment in main run: R6 = 1.874 * 10^8

R7=SIN(25.3) ; Assignment in preprocessing

See also

R[R2]=R10 ; Indirect addressing using R-parameter

R[(R1+R2)*R3]=5 ; Indirect addressing using math. expression

X=(R1+R2) ; Traverse axis X to the position resulting from the

sum of R1 and R2

Z=SQRT(R1*R1+R2*R2) ; Traverse axis Z to the square root position (R1^2 +

R2^2)

General information about variables General information about variables [Page 17]

Job planning

22 Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

Page 23

1.1.4 Predefined user variables: Link variables

Function

Link variables can be used in the context of the "NCU-Link" function for cyclic data exchange

between NCUs which are linked on a network. They facilitate data-format-specific access to

the link variables memory. The link variables memory is defined both in terms of size and data

structure on a system-specific basis by the user/machine manufacturer.

Link variables are system-global user variables which can be read and written in part

programs and cycles by all NCUs involved in a link if link communication has been

configured. Unlike global user variables (GUD), link variables can also be used in

synchronized actions.

On systems without an active NCU link, link variables can be used locally on the control as

additional global user variables alongside global user variables (GUD).

Syntax

$A_DLB[<index>]

$A_DLW[<index>]

$A_DLD[<index>]

$A_DLR[<index>]

Flexible NC programming

1.1 Variables

Significance

$A_DLB: Link variable for BYTE data format (1 byte)

Data type: UINT

Range of values: 0 to 255

$A_DLW: Link variable for WORD data format (2 bytes)

Data type: INT

Range of values: -32768 to 32767

$A_DLD: Link variable for DWORD data format (4 bytes)

Data type: INT

Range of values: -2147483648 to 2147483647

$A_DLR: Link variable for REAL data format (8 bytes)

Data type: REAL

Range of values:

±(2,2*10

-308

… 1,8*10

+308

)

Job planning

Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

23

Page 24

Flexible NC programming

1.1 Variables

<index>: Address index in bytes, counted from the start of the link variable memory

Data type: INT

Range of values: 0 - MAX_INDEX

Note

• MAX_INDEX is calculated from the

parameterized size of the link variables

memory: MAX_INDEX = (MD18700

$MN_MM_SIZEOF_LINKVAR_DATA) - 1

• Only indices may be programmed, so that the

bytes addressed in the link variables memory

are located on a data format limit ⇒

Index = n * bytes, where n = 0, 1, 2, etc.

– $A_DLB[i]: i = 0, 1, 2, etc.

– $A_DLW[i]: i = 0, 2, 4, etc.

– $A_DLD[i]: i = 0, 4, 8, etc.

– $A_DLR[i]: i = 0, 8, 16, etc.

Example

An automation system contains 2 NCUs (NCU1 and NCU2). Machine axis AX2 is connected

to NCU1. It is traversed as a link axis of NCU2.

NCU1 writes the actual current value ($VA_CURR) of axis AX2 cyclically to the link variables

memory. NCU2 reads the actual current value transmitted via link communication cyclically

and displays alarm 61000 if the limit value is exceeded.

The data structure in the link variables memory is illustrated in the following figure. The actual

current value is transmitted in the REAL value.

/LQNYDULDEOHVPHPRU\

0'01B00B6,=(2)B/,1.9$5B'$7$

,QGH[

%<7( %<7( :25' ':25'

':25' ':25'

5($/

NCU1

NCU1 uses link variable $A_DLR[ 16 ] to write the actual current value of axis AX2 to the link

variables memory cyclically in the interpolation cycle in a static synchronized action.

Program code

N111 IDS=1 WHENEVER TRUE DO $A_DLR[16]=$VA_CURR[AX2]

Job planning

24 Programming Manual, 02/2011, 6FC5398-2BP40-1BA0

Page 25

NCU2

NCU2 uses link variable $A_DLR[ 16 ] to read the actual current value of axis AX2 from the

link variables memory cyclically in the interpolation cycle in a static synchronized action. If the

actual current value is greater than 23.0 A, alarm 61000 is displayed.

Program code

N222 IDS=1 WHEN $A_DLR[16] > 23.0 DO SETAL(61000)

See also

General information about variables General information about variables [Page 17]

1.1.5 Definition of user variables (DEF)

Function

Flexible NC programming

1.1 Variables

The DEF command is used to define user-specific variables and assign values to them. To set

them apart from system variables, these are called user-defined variables or user variables

(user data).

According to range of validity (in other words, the range in which the variable is visible) there

are the following categories of user variable:

• Local user variables (LUD)

Local user variables (LUD) are variables defined in a part program which is not the main

program at the time of execution. They are created when the part program is called and

deleted at the end of the part program or when the NC is reset. Local user variables can

only be accessed within the part program in which they are defined.

• Program-global user variables (PUD)

Program-global user variables (PUD) are user variables defined in a part program used as

the main program. They are created when the part program starts up and deleted at the

end of the part program or when the NC is reset. It is possible to access PUD in the main

program and in all subprograms of the main program.

• Global user variables (GUD)

Global user variables (GUD) are NC- or channel-global variables which are defined in a