Page 1

SINUMERIK

SINUMERIK 840D sl / 828D / 808D

SINUMERIK Integrate Access

MyMachine /P2P (PC)

Valid for: AMM Software Version V4.7 SP1

CNC Software Version 4.7 SP4

Preface

1

Operating Manual

Introduction

Safety notes

Description

Connection to the control

Operator control (software)

Reference

Troubleshooting/FAQs

2

3

4

5

6

7

8

11/2016

A5E39356962B AA

Page 2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E39356962B AA

Ⓟ 11/2016 Subject to change

Copyright © Siemens AG 2016.

All rights reserved

Page 3

Table of contents

1 Preface.........................................................................................................................................................7

1.1 SINUMERIK documentation.....................................................................................................7

1.2 Target group.............................................................................................................................9

1.3 Hotline and Internet address..................................................................................................10

2 Introduction.................................................................................................................................................11

2.1 Scope of functions and supported SINUMERIK control systems...........................................11

3 Safety notes................................................................................................................................................15

3.1 Fundamental safety instructions for the software documentation (for all product families)......15

3.1.1 Fundamental safety instructions............................................................................................15

3.1.1.1 General safety instructions.....................................................................................................15

3.1.1.2 Industrial security...................................................................................................................16

3.2 Security information on the product.......................................................................................17

4 Description..................................................................................................................................................19

4.1 Structure of the user interface................................................................................................19

4.2 First start................................................................................................................................20

5 Connection to the control............................................................................................................................21

5.1 Establishing a connection to the control system: An overview...............................................21

5.2 Assigning the connection parameters ...................................................................................22

5.2.1 Enable control ports...............................................................................................................22

5.2.1.1 Overview................................................................................................................................22

5.2.1.2 Enabling ports from the HMI..................................................................................................22

5.2.1.3 Otherwise: Enable ports via basesys.ini................................................................................24

5.2.1.4 Otherwise: Enabling ports via the service shell......................................................................25

5.2.2 Assigning parameters for direct connection (peer-to-peer Ethernet).....................................25

5.2.3 Assigning parameters for network connection.......................................................................27

5.2.4 Converting an SSH key file....................................................................................................29

5.3 Establishing the connection...................................................................................................31

5.3.1 Establishing a direct connection (peer-to-peer Ethernet).......................................................31

5.3.2 Establishing a network connection.........................................................................................32

5.4 Disconnect connection ..........................................................................................................35

5.5 Establishing a modem connection.........................................................................................36

5.5.1 General information................................................................................................................36

5.5.2 Setting up the PG/PC interface..............................................................................................37

5.5.3 Parameterize the TeleService adapter IE with the "TeleService" software............................38

5.5.3.1 Overview of TeleService Adapter parameter assignment......................................................38

5.5.3.2 Inserting the system...............................................................................................................39

5.5.3.3 Assigning parameters for the TS Adapter..............................................................................43

5.5.3.4 Administrating the TS Adapter...............................................................................................45

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 3

Page 4

Table of contents

5.5.3.5 Assigning parameters for the internal modem.......................................................................52

5.5.3.6 Testing the connection...........................................................................................................54

5.5.4 Parameterize the TeleService adapter IE without the "TeleService" software.......................59

5.5.5 Establishing a connection/Cabling.........................................................................................60

5.5.6 Create modem connection under Windows 7........................................................................62

5.5.7 Establish modem connection under Windows 7....................................................................67

5.5.8 Create a modem connection under Windows 10...................................................................69

5.5.9 Establish a modem connection under Windows 10...............................................................74

5.5.10 Connecting AMM to the control system via the modem connection......................................75

5.5.11 Further information.................................................................................................................76

6 Operator control (software).........................................................................................................................77

6.1 Remote control of the control system.....................................................................................77

6.1.1 Overview of remote control....................................................................................................77

6.1.2 Approving remote control of the control system on the HMI..................................................78

6.1.2.1 Approving remote control on the HMI....................................................................................78

6.1.2.2 Approving remote control via the control system...................................................................81

6.1.2.3 Further documentation...........................................................................................................82

6.1.3 Functional scope of the remote control..................................................................................82

6.1.3.1 Starting/ending remote control...............................................................................................82

6.1.3.2 Operation...............................................................................................................................85

6.1.3.3 Using remote control to generate the screen of the control system's HMI user interface......87

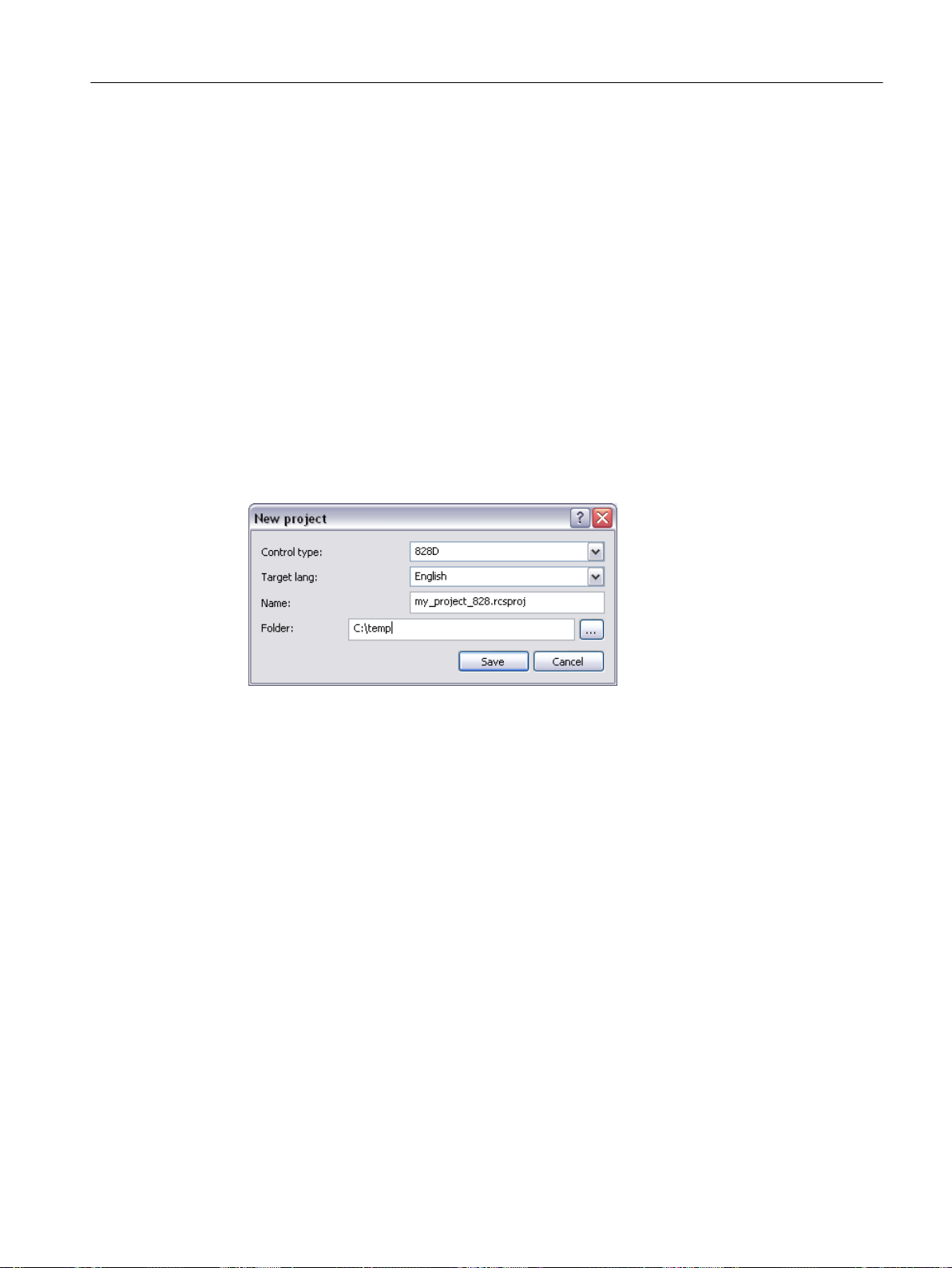

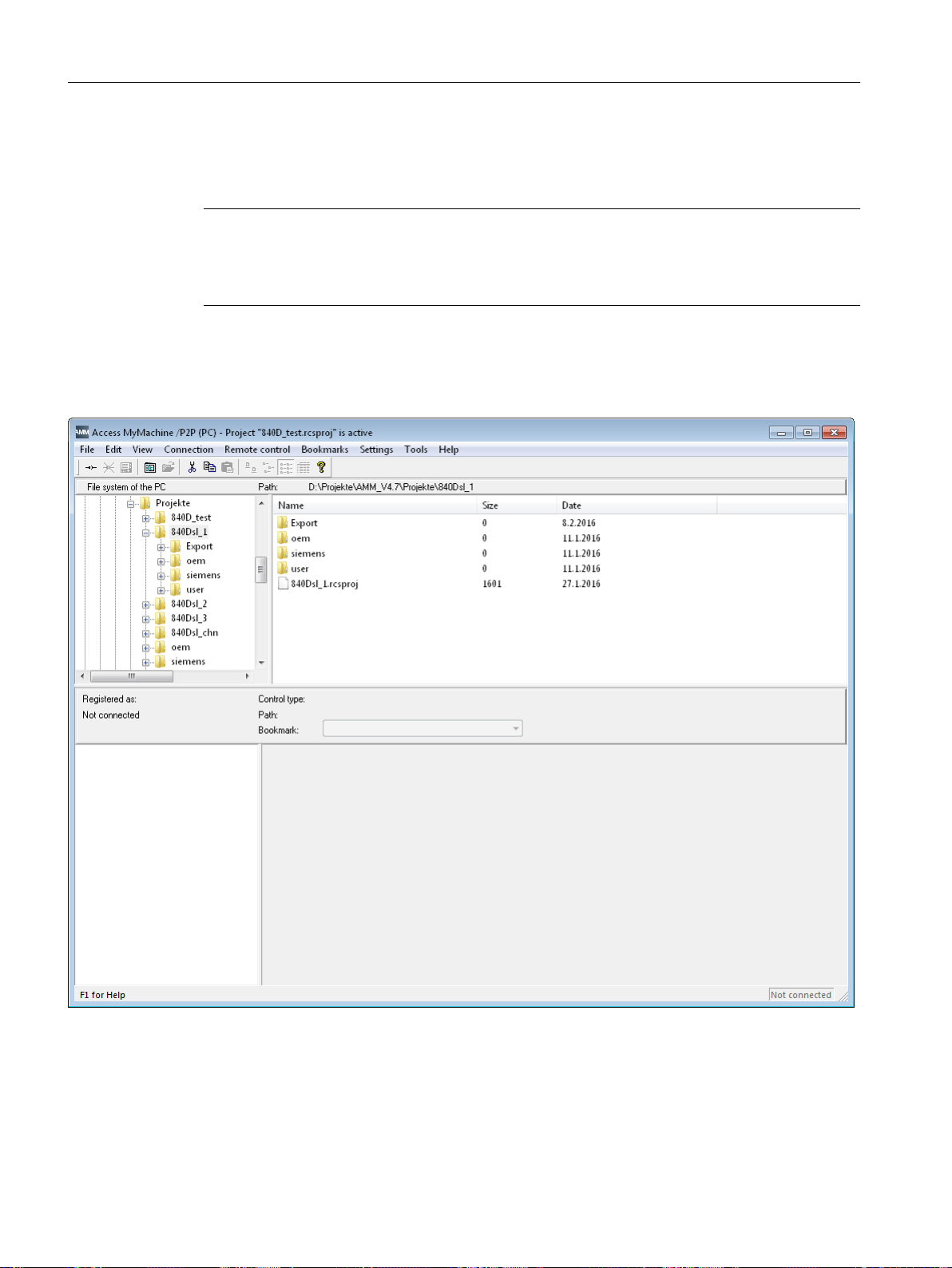

6.2 Project....................................................................................................................................89

6.2.1 Project overview.....................................................................................................................89

6.2.2 Creating a project (OFFLINE)................................................................................................91

6.2.3 Create a project and read the files from the control system (ONLINE)..................................92

6.2.4 Opening an existing project....................................................................................................95

6.2.5 Closing the project.................................................................................................................99

6.2.6 Deleting a project.................................................................................................................100

6.2.7 Creating a new language.....................................................................................................101

6.2.8 Adding a file.........................................................................................................................103

6.2.9 Deleting a file.......................................................................................................................105

6.2.10 Exporting a file.....................................................................................................................106

6.2.11 Import file.............................................................................................................................109

6.2.12 Edit file.................................................................................................................................111

6.2.13 Compare archives................................................................................................................113

6.2.14 Transferring individual files from the project to the control system......................................115

6.2.15 Transferring individual files from the control to the project...................................................119

6.2.16 Deleting files on the control using the project dialog............................................................121

6.2.17 Recommended procedure when translating files.................................................................124

6.2.18 Activating the alarm text files on the control using an HMI restart.......................................126

6.3 Access to NC file system.....................................................................................................130

6.3.1 NC file system of the 840D sl and 828D controls.................................................................130

6.3.2 NC file system of the 808D control.......................................................................................131

6.4 Backing up/restoring a CompactFlash Card........................................................................133

6.4.1 Overview of backing up/restoring a CompactFlash Card.....................................................133

6.4.2 Generating an image from the CompactFlash Card/USB-FlashDrive..................................133

6.4.3 Writing an image to the CompactFlash Card/USB-FlashDrive............................................135

6.4.4 Writing a SINUMERIK 828D boot system............................................................................136

6.5 CNC Lock function...............................................................................................................139

SINUMERIK Integrate Access MyMachine /P2P (PC)

4 Operating Manual, 11/2016, A5E39356962B AA

Page 5

Table of contents

6.5.1 CNC lock function overview.................................................................................................139

6.5.2 Activating the CNC lock function..........................................................................................139

6.5.3 Extending the CNC lock function.........................................................................................141

6.5.4 Deactivating the CNC lock function......................................................................................144

6.5.5 Reading in Lockset file.........................................................................................................146

6.5.6 Further information...............................................................................................................147

7 Reference.................................................................................................................................................149

7.1 Supported files.....................................................................................................................149

7.2 Languages supported by SINUMERIK Operate...................................................................151

7.3 Toolbar.................................................................................................................................152

7.4 View overview......................................................................................................................153

7.5 Data structure on the CompactFlash Card system..............................................................155

7.5.1 Data structure on the CompactFlash card (SINUMERIK 840D sl / 828D)...........................155

7.5.2 Data structure on the system CompactFlash card (SINUMERIK 808D)..............................158

7.5.3 Editing a file externally.........................................................................................................159

7.6 Open source software / licenses..........................................................................................161

8 Troubleshooting/FAQs..............................................................................................................................163

8.1 Password forgotten..............................................................................................................163

8.2 Trace files for error correction..............................................................................................164

8.3 Problems connecting to the control......................................................................................165

8.4 Setting up series machines..................................................................................................166

8.5 840D sl: Activate remote control for the VNC Viewer. ........................................................167

8.6 CNC Lock function...............................................................................................................170

8.7 Activating the alarm text files on the control using an HMI restart.......................................171

8.8 Recommended procedure when translating files.................................................................174

8.9 Backing up commissioning data on the control....................................................................177

Index.........................................................................................................................................................179

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 5

Page 6

Table of contents

SINUMERIK Integrate Access MyMachine /P2P (PC)

6 Operating Manual, 11/2016, A5E39356962B AA

Page 7

Preface

1.1 SINUMERIK documentation

SINUMERIK documentation

The SINUMERIK documentation is organized in the following categories:

● General documentation

● User documentation

● Manufacturer/service documentation

Additional information

1

You can find information on the following topics at the link (

motioncontrol/docu):

● Ordering documentation / overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals/information)

Please send an e-mail (mailto:docu.motioncontrol@siemens.com) if you have any questions

about the technical documentation (e.g. suggestions for improvement, corrections) to:

My Documentation Manager (MDM)

Under the following link (http://www.siemens.com/mdm) you will find information to individually

compile OEM-specific machine documentation based on the Siemens content:

Training

For information about the range of training courses, refer to:

● SITRAIN (www.siemens.com/sitrain) - training courses from Siemens for automation

products, systems and solutions

● SinuTrain (www.siemens.com/sinutrain) - training software for SINUMERIK

http://www.siemens.com/

FAQs

You can find Frequently Asked Questions in the Service & Support pages (www.siemens.com/

automation/service&support) at Product Support.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 7

Page 8

Preface

1.1 SINUMERIK documentation

SINUMERIK

You can find information on SINUMERIK at the following link. (

sinumerik)

http://www.siemens.com/

SINUMERIK Integrate Access MyMachine /P2P (PC)

8 Operating Manual, 11/2016, A5E39356962B AA

Page 9

1.2 Target group

Target group

This documentation is intended for operators of the "SINUMERIK Integrate Access

MyMachine /P2P (PC)" software and teaches them how to utilize all the software functions

correctly and completely.

Benefits

The operating manual familiarizes the target group with the control elements and commands.

Based on the manual, the target group is capable of responding to problems and to take

corrective action.

Standard scope

This documentation only describes the functionality of the standard scope. Additions or

revisions made by the machine manufacturer are documented by the machine manufacturer.

Preface

1.2 Target group

Other functions not described in this documentation might be executable in the control. This

does not, however, represent an obligation to supply such functions with a new control or when

servicing.

For the sake of simplicity, this documentation does not contain all detailed information about

all types of the product and cannot cover every conceivable case of installation, operation, or

maintenance.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 9

Page 10

Preface

1.3 Hotline and Internet address

1.3 Hotline and Internet address

Technical Support

You can find country-specific telephone numbers for technical support on the Internet at the

following address: Product support (

www.siemens.com/automation/service&support).

SINUMERIK Integrate Access MyMachine /P2P (PC)

10 Operating Manual, 11/2016, A5E39356962B AA

Page 11

Introduction

2.1 Scope of functions and supported SINUMERIK control systems

The "SINUMERIK Integrate Access MyMachine /P2P (PC)" tool (previously "RCS

Commander") supports the commissioning and maintenance of machines with SINUMERIK

Operate as of software version 2.6 using a standard Windows PC.

From here on, the following terms/abbreviations are used synonymously in this document:

"Access MyMachine" and "AMM".

Functionality

AMM allows simple file management on your PC and on the SINUMERIK controls.

AMM provides the following functions:

● Exchanging data between the SINUMERIK control and your PC.

● Generating and restoring an image from the CompactFlash card of your control to backup

data.

● Writing images to a CompactFlash card.

● Loading of all files relevant for the commissioning directly to the CompactFlash card of your

SINUMERIK control, and loading these files from the control to your PC.

2

● Managing the NC data of the SINUMERIK control (part programs: *.mpf, *.spf).

You can copy files directly from the PC to the NC and from the NC to the PC.

● Process monitoring and remote control of the SINUMERIK via a remote control function

using VNC.

● Saving the screenshot of the HMI on the PC.

This function is used to represent your control and improves support in the event of an error.

● User-friendly editing of the following OEM files on the PC (Page 149):

– PLC alarm texts

– Color attribute files

– Configuration files

– Cycle alarm texts

– Part program messages

– EasyScreen files

– Tool management texts

– EasyExtend files

– Maintenance scheduler files

– Archives

● Creating and loading an archive from the control.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 11

Page 12

Introduction

2.1 Scope of functions and supported SINUMERIK control systems

● Comparing and loading archives with the aid of the SINUMERIK Integrate "Create MyConfig

- Diff" software.

● Managing the OEM files mentioned above with the following options (Page 89):

– Creating a project OFFLINE.

– Creating a project for which the OEM files mentioned above are automatically copied

from the control.

– Copying individual files using the project dialog to the control or copying from the control

to the project.

– Deleting the OEM files using the project dialog on the control.

● Converting alarm texts from powerline format to solution line format.

● CNC lock function

Using the CNC lock function, you can activate, extend or deactivate a date in the control

as of which the NC Start is locked.

Supported SINUMERIK controls

The following SINUMERIK controls are supported:

Foreign languages

● SINUMERIK 840D sl (NCUs)

● SINUMERIK 828D (PPUs)

● SINUMERIK 808D (as of AMM version 4.6, PPU141.2 and PPU161.2)

● The AMM itself can be switched into various interface languages. The following languages

are available:

– German

– English

– Chinese (Simpl.)

– Chinese (Trad.)

– Spanish

– Italian

– French

– Portuguese (Braz.)

– Japanese

– Korean

– Russian

● The HMI of the control can also handle several language packages and the associated

language selection. The creation and installation of such language packages and/or

individual language files is supported by the AMM in the project.

SINUMERIK Integrate Access MyMachine /P2P (PC)

12 Operating Manual, 11/2016, A5E39356962B AA

Page 13

Connections

Introduction

2.1 Scope of functions and supported SINUMERIK control systems

In Windows, activate the support for Asian languages at "Region and Language" so that Asian

characters are displayed correctly.

The following connections to a SINUMERIK solution line control are available:

● Modem (56k)

via TeleService Adapter IE on X127

● Peer-to-peer Ethernet

● Ethernet network

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 13

Page 14

Introduction

2.1 Scope of functions and supported SINUMERIK control systems

SINUMERIK Integrate Access MyMachine /P2P (PC)

14 Operating Manual, 11/2016, A5E39356962B AA

Page 15

Safety notes

3

3.1 Fundamental safety instructions for the software documentation (for all product families)

3.1.1 Fundamental safety instructions

3.1.1.1 General safety instructions

WARNING

Danger to life if the safety instructions and residual risks are not observed

If the safety instructions and residual risks in the associated hardware documentation are not

observed, accidents involving severe injuries or death can occur.

● Observe the safety instructions given in the hardware documentation.

● Consider the residual risks for the risk evaluation.

WARNING

Danger to life or malfunctions of the machine as a result of incorrect or changed

parameterization

As a result of incorrect or changed parameterization, machines can malfunction, which in turn

can lead to injuries or death.

● Protect the parameterization (parameter assignments) against unauthorized access.

● Respond to possible malfunctions by applying suitable measures (e.g. EMERGENCY

STOP or EMERGENCY OFF).

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 15

Page 16

Safety notes

3.1 Fundamental safety instructions for the software documentation (for all product families)

3.1.1.2 Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens products and solutions only represent one component of such a

concept.

The customer is responsible for preventing unauthorized access to its plants, systems,

machines and networks. Systems, machines and components should only be connected to

the enterprise network or the internet if and to the extent necessary and with appropriate

security measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit:

Industrial security (http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends to apply product updates as soon as available and to always

use the latest product versions. Use of product versions that are no longer supported, and

failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed at:

Industrial security (http://www.siemens.com/industrialsecurity).

WARNING

Danger to life as a result of unsafe operating states resulting from software manipulation

Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe operating

states in your system that may lead to death, serious injury, and property damage.

● Keep the software up to date.

● Incorporate the automation and drive components into a holistic, state-of-the-art industrial

security concept for the installation or machine.

● Make sure that you include all installed products into the holistic industrial security concept.

● Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

SINUMERIK Integrate Access MyMachine /P2P (PC)

16 Operating Manual, 11/2016, A5E39356962B AA

Page 17

3.2 Security information on the product

NOTICE

No confidential data on the control and in the AMM project

Confidential data must not be loaded to the control and not downloaded to the AMM project

from there. The data is not adequately protected there.

This applies particularly to confidential data that is not part of SINUMERIK.

NOTICE

Misuse of data

Note that it is essential to use secure data storage when saving your AMM-relevant data particularly your confidential data. It is best to store this data encrypted locally or encrypted

on the network. Make sure that this data cannot be accessed by unauthorized personnel.

This applies to the following data:

● SSH key files

● Archive files

● Image files

● Project files

● Trace files

● Safety-relevant files

Safety notes

3.2 Security information on the product

Further information on secure data storage can be found in the Auto-Hotspot.

NOTICE

Danger due to insecure Internet connection

Make sure that before establishing a network connection, your PC is connected to the Internet

via a secure connection (VPN connection). This also applies to connections via VNC Viewer.

This VPN connection can be made, for example, with a SCALANCE S Security Module. Note

the security-relevant information when using the SCALANCE S Module. Further information

on the use of SCALANCE S can be found in the Auto-Hotspot.

NOTICE

Security risk through administrator rights

If you operate AMM on a PC with permanent administrator rights, there is an increased

security risk. Therefore, ensure that there is a secure operating environment for AMM, and

only assign administrator rights temporarily and selectively.

Further information on the secure administration of user accounts and the assignment of

rights can be found in the Auto-Hotspot.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 17

Page 18

Safety notes

3.2 Security information on the product

See also

Industrial Security Configuration Manual (

108862708)

https://support.industry.siemens.com/cs/us/en/view/

SINUMERIK Integrate Access MyMachine /P2P (PC)

18 Operating Manual, 11/2016, A5E39356962B AA

Page 19

Description

4.1 Structure of the user interface

AMM user interface

The following shows an overview of the AMM user interface with the most important windows,

status indicators and operator controls.

4

① Main menu

② View of the computer file system (local file system)

③ View of the file system of the connected control (remote file system)

④ Status bar

⑤ Status window for messages concerning the connection and actions in the control.

⑥ Toolbar

Figure 4-1 User interface

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 19

Page 20

Description

4.2 First start

4.2 First start

Operating sequence

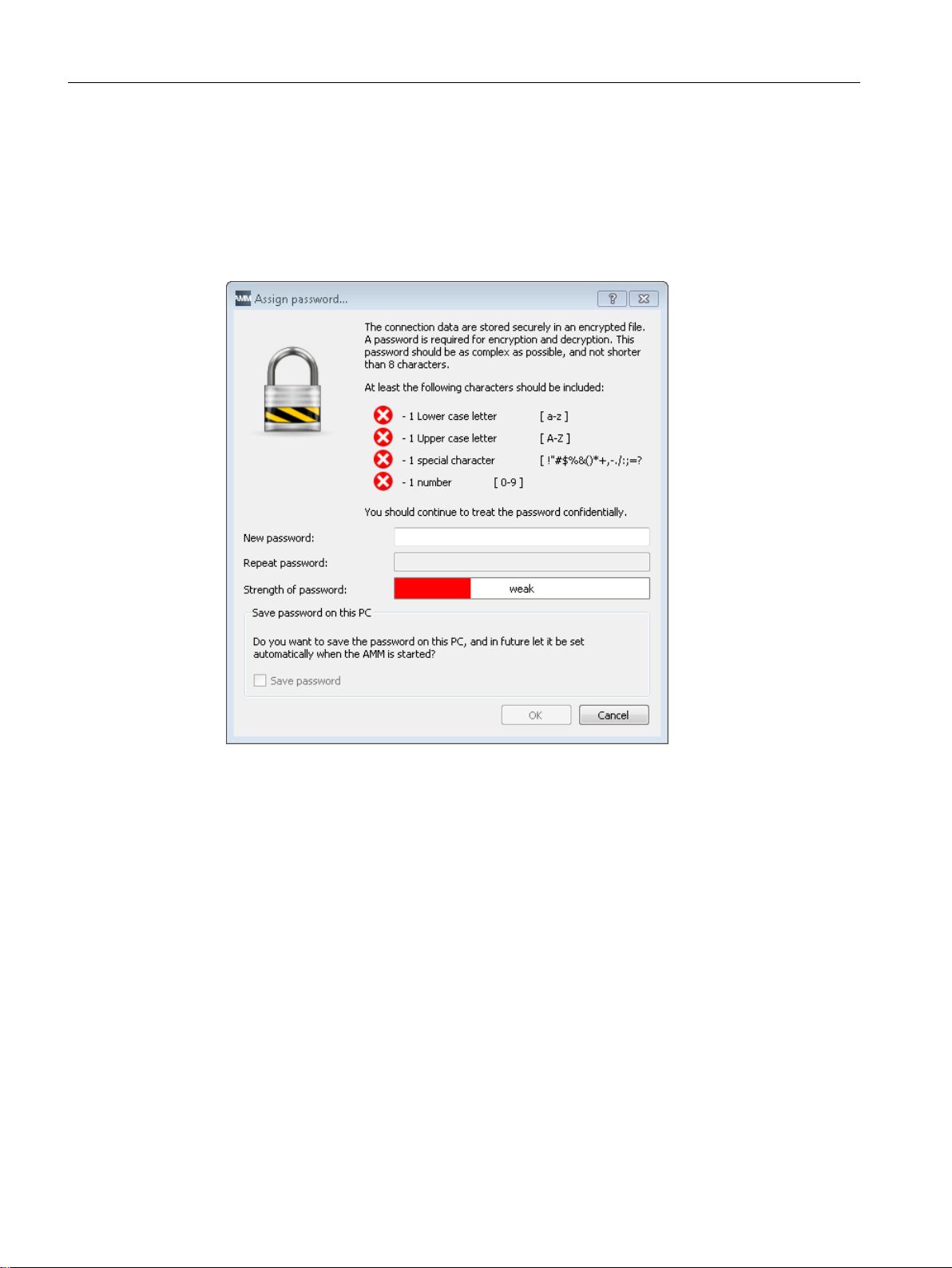

The following prompts appear when AMM is started for the first time:

1. Enter a password. AMM always requires a password when started for the first time.

Figure 4-2 Enter password

– With the password, the file with the connection data of AMM is encrypted.

– The password can be subsequently changed at any time.

– In order to change the password, the previously entered password must be entered to

ensure that only authorized users change the password.

2. Press "OK".

AMM starts up with the language set in Windows.

If the relevant language is not available in AMM, English is automatically set.

The set language can be changed at any time via AMM.

3. If earlier versions of AMM are installed on your PG/PC, you are given the option of accepting

the connection data of the earlier versions. Confirm the acceptance of the data with "Yes"

or reject with "No".

You have successfully completed the first start of AMM. You can now use all the functions of

AMM.

SINUMERIK Integrate Access MyMachine /P2P (PC)

20 Operating Manual, 11/2016, A5E39356962B AA

Page 21

Connection to the control

5.1 Establishing a connection to the control system: An overview

AMM offers two options for establishing a connection to a control system:

1. Direct connection (peer-to-peer Ethernet)

Direct connection involves connecting the PG/PC to the control system's X127 interface

directly.

You can establish this type of connection if you are where the control system is located.

Note

The SINUMERIK 808 control uses the X130 interface instead of the X127 interface for a

direct connection. Follow the corresponding control manuals when assigning parameters.

2. Network connection

A network connection is a connection between the PG/PC and the control system via a

local area network (LAN).

This type of connection is also possible if the control system is at another location.

Note

Connection via modem is a special feature.

5

See also

You will find a manual explaining how a modem connection is set up (e.g. via TS adapter

IE (analog)) at Establishing a modem connection (Page 36).

Assigning parameters for direct connection (peer-to-peer Ethernet) (Page 25)

Assigning parameters for network connection (Page 27)

Establishing a direct connection (peer-to-peer Ethernet) (Page 31)

Establishing a network connection (Page 32)

Establishing a modem connection (Page 36)

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 21

Page 22

Connection to the control

5.2 Assigning the connection parameters

5.2 Assigning the connection parameters

5.2.1 Enable control ports

5.2.1.1 Overview

You must access port 22 to establish a connection from AMM to the control. You must access

port 5900 to establish a connection from AMM via remote control.

Three ways of enabling a port are described below for each port access required.

● Enabling ports from the HMI (Page 22)

● Otherwise: Enable ports via basesys.ini (Page 24)

● Otherwise: Enabling ports via the service shell (Page 25)

Note

Ports on the SINUMERIK 808D and 828D controls can only be enabled from the user interface.

5.2.1.2 Enabling ports from the HMI

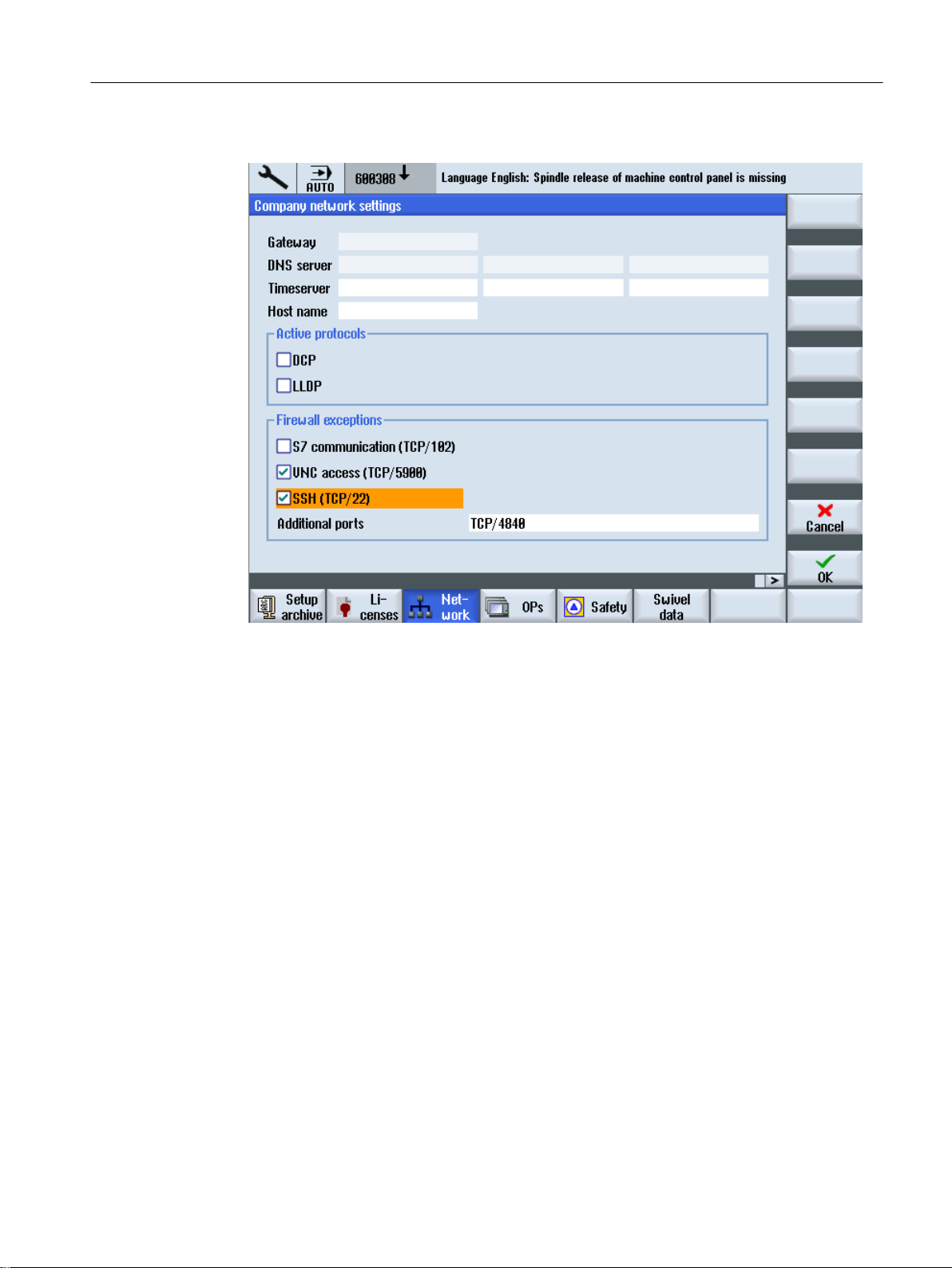

Operating sequence for 840D sl/828D controls

1. Open the "Commissioning > Network" menu on your control.

2. Open extended horizontal softkeys with the right arrow key.

3. Open the "Workplace network" menu on your control.

4. The "Workplace network settings" window opens.

SINUMERIK Integrate Access MyMachine /P2P (PC)

22 Operating Manual, 11/2016, A5E39356962B AA

Page 23

5. Press the "Change" softkey.

Connection to the control

5.2 Assigning the connection parameters

Figure 5-1 Settings of the 840 sl workplace network

6. Set a check mark in the "Firewall exceptions" area for the following options:

– VNC access (TCP/5900)

– SSH (TCP/22)

Use the arrow keys of your control to select the particular port. Use the SELECT button to

enable/disable the particular port.

7. Select "OK" to save the changes.

8. Restart the control to make the changes effective.

Operating sequence for an 808D control

1. Change to the <SYSTEM> operating area with the shortcut <Shift> + <SYSTEM ALARM>.

2. Open extended horizontal softkeys with the right arrow key.

3. Press the "Serv. display" and "Service control" softkeys.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 23

Page 24

Connection to the control

5.2 Assigning the connection parameters

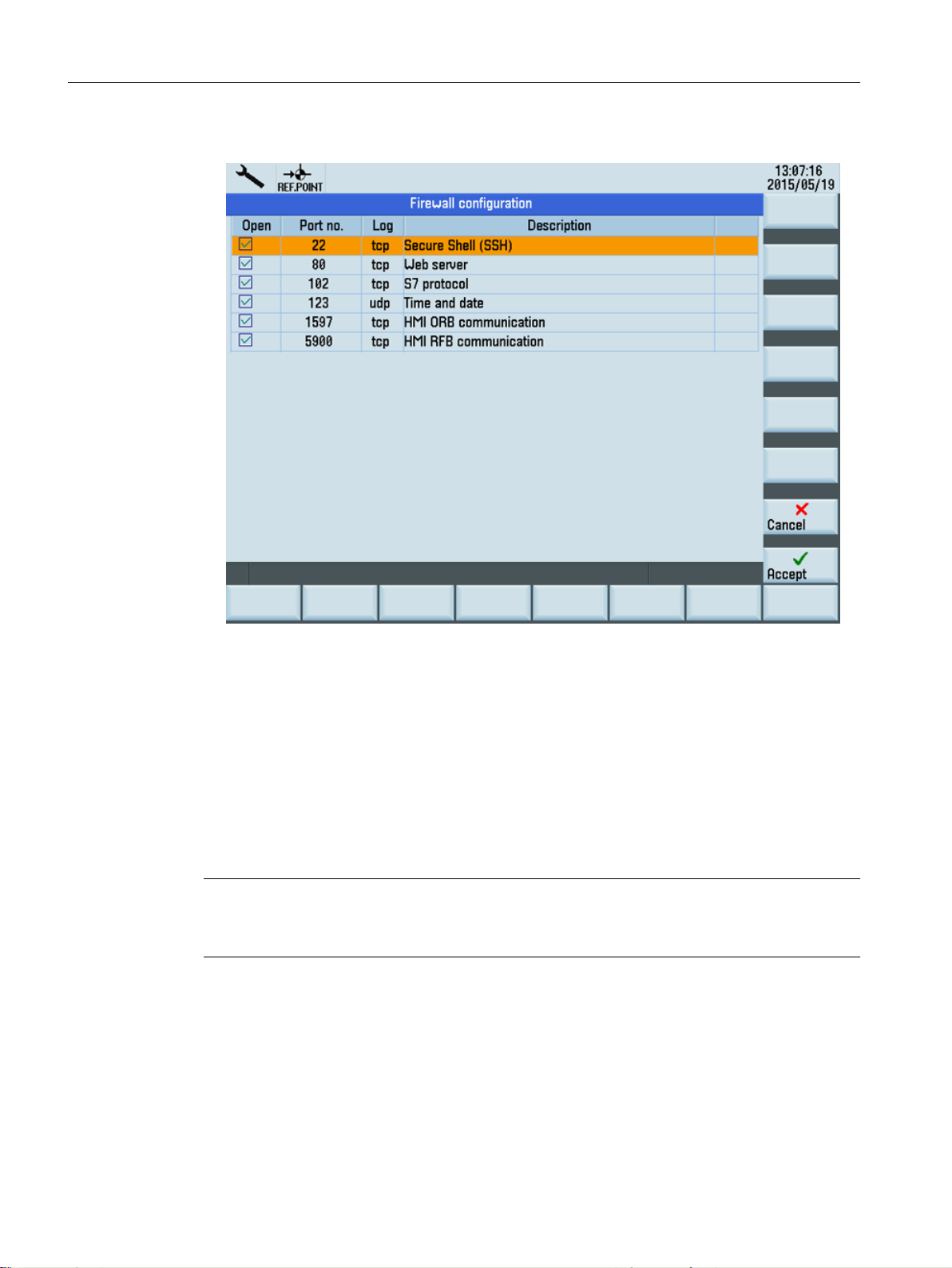

4. Open "Firewall configuration" via "Service network".

Figure 5-2 Firewall settings for the 808D

5. Select the desired port with the cursor.

6. Press the "INPUT" key to disable the selected port.

7. Select the "Accept" softkey to save the changes.

8. Restart the control to make the changes effective.

5.2.1.3 Otherwise: Enable ports via basesys.ini

Note

The port enable procedure applies only to the following SINUMERIK control:

● SINUMERIK 840D sl

Operating sequence

1. Open the "/user/system/etc/basesys.ini" file on your control.

2. Under the variable "FirewallOpenPorts" enter the port "TCP/22" or if needed the port "TCP/

5900".

3. Restart the control to make the changes effective.

SINUMERIK Integrate Access MyMachine /P2P (PC)

24 Operating Manual, 11/2016, A5E39356962B AA

Page 25

5.2.1.4 Otherwise: Enabling ports via the service shell

Note

The port enable procedure applies only to the following SINUMERIK control:

● SINUMERIK 840D sl

Operating sequence

1. Open a service shell on the TCU.

2. Enter the command "sc openport tcp/22 <IP Address>".

3. This command opens port 22 in the firewall on the workplace network (X130) for a default

time of 15 minutes. The default time can be adjusted via the option -MINUTES. The

maximum possible time is 60 minutes.

If necessary you can repeat the command for port 5900.

Connection to the control

5.2 Assigning the connection parameters

5.2.2 Assigning parameters for direct connection (peer-to-peer Ethernet)

Requirement

● You are connected to the X127 interface of the control by an Ethernet cable.

Note

The SINUMERIK 808 control uses the X130 interface instead of the X127 interface for a

direct connection. Follow the corresponding control manuals when assigning parameters.

● The SSH port 22 in the firewall to the company network is enabled (Page 22).

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 25

Page 26

Connection to the control

5.2 Assigning the connection parameters

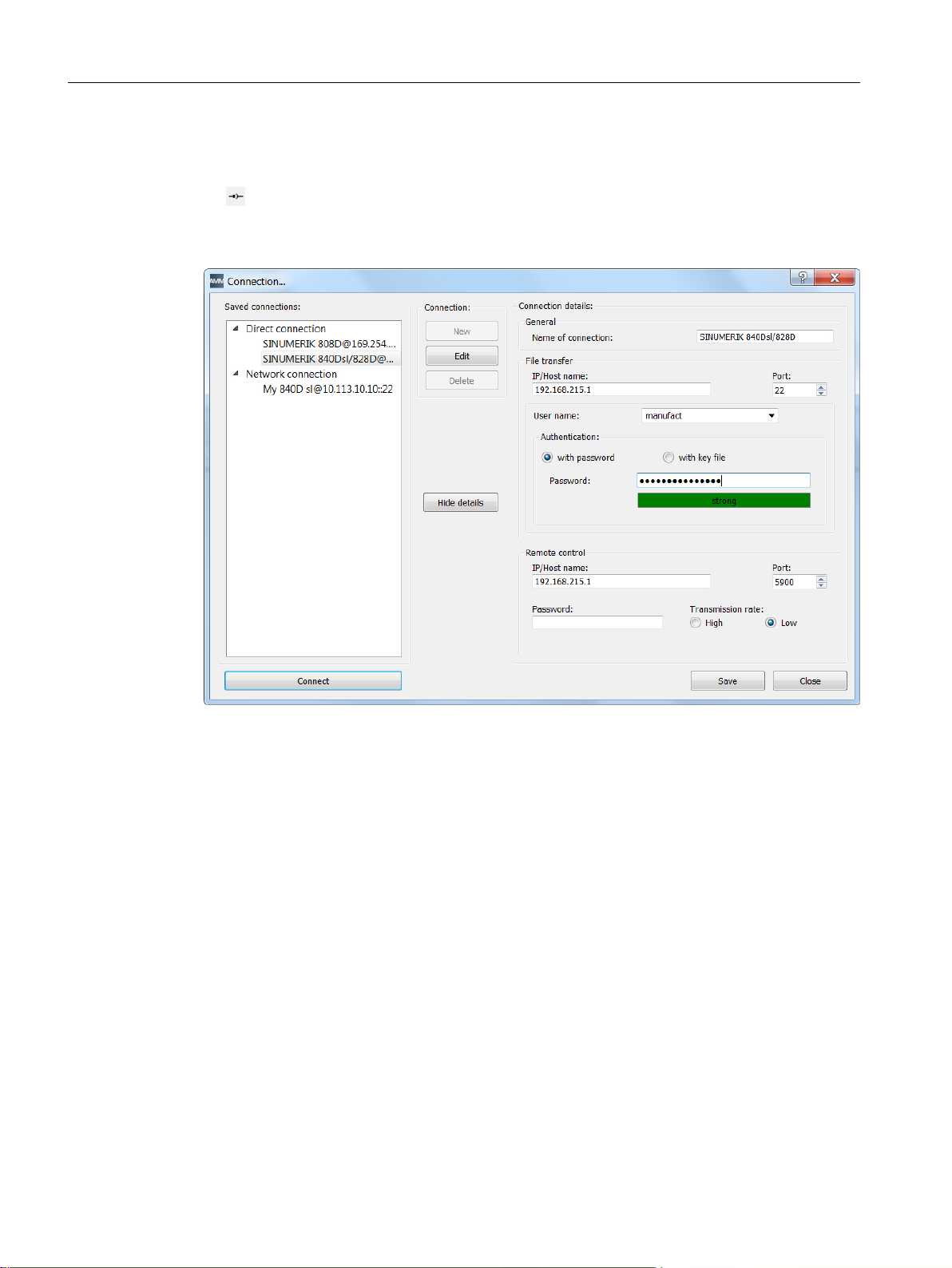

Operating sequence

1. Press the "Connection" icon.

- OR Select "Connection" > "Connect..." in the main window menu.

The following dialog appears:

Figure 5-3 Settings for direct connection

2. Select a direct connection, and click the "Edit" button.

SINUMERIK Integrate Access MyMachine /P2P (PC)

26 Operating Manual, 11/2016, A5E39356962B AA

Page 27

Connection to the control

5.2 Assigning the connection parameters

3. A direct connection is always established through the IP address 192.168.215.1 or IP

169.254.11.22 and via port 22.

Enter the following authentication data:

– Select a user name and enter the appropriate password.

OR

– Select a user name and an SSH key file (Page 29).

NOTICE

The SSH key file must be available in OpenSSH format and must also be password

protected.

Note

If the authentication fields are not filled in, the authentication prompt appears on its own

when establishing the connection.

Note

Note that the same access levels should be activated in the HMI and in AMM in order

to avoid error sources.

4. Press "Save".

See also

Establishing a connection to the control system: An overview (Page 21)

5.2.3 Assigning parameters for network connection

Requirement

● You are connected to the X130 interface of the control by an Ethernet cable.

● The ports required in the firewall to the company network are enabled (Page 22).

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 27

Page 28

Connection to the control

5.2 Assigning the connection parameters

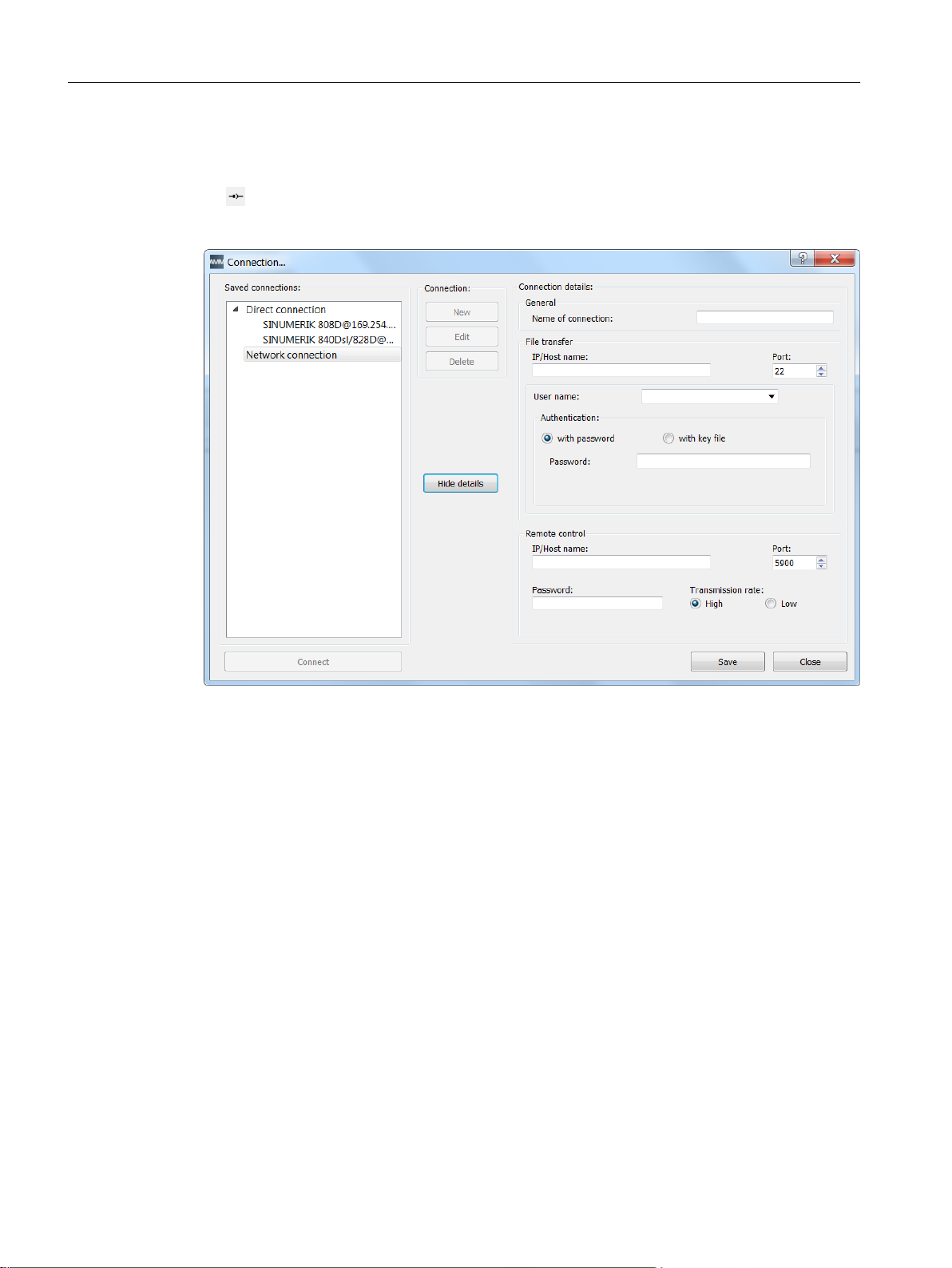

Operating sequence

1. Press the "Connection" icon.

- OR Select "Connection > Connect..." in the main window menu. The following dialog appears:

Figure 5-4 Network connection

2. Press "New" to create a new connection.

3. Select a suitable connection name.

4. When establishing a network connection to the control, select the IP address and the port

22 of the control.

SINUMERIK Integrate Access MyMachine /P2P (PC)

28 Operating Manual, 11/2016, A5E39356962B AA

Page 29

Connection to the control

5.2 Assigning the connection parameters

5. Enter the following authentication data:

– Select a user name and enter the appropriate password.

OR

– Select a user name and an SSH key file (Page 29).

NOTICE

The SSH key file must be available in OpenSSH format and must also be password

protected.

Note

If the authentication fields are not filled in, the authentication prompt appears on its own

when establishing the connection.

Note

Note that the same access levels should be activated in the HMI and in AMM in order

to avoid error sources.

6. If the control is remote controlled, enter the IP address of the control and port 5900.

7. Set the desired transmission rate.

Note

The transmission rate "low" should be selected for a connection via a modem.

Also select the transmission rate "low" if the network connection is poor. This will ensure

that you can also operate the control remotely if the network connection is poor.

"High" can be selected if the network connection is good. This setting displays the control's

screen with a higher color resolution.

This setting has no effect on file operations such as "Copy".

8. Press "Save".

The new network connection will be saved and added.

See also

Establishing a connection to the control system: An overview (Page 21)

5.2.4 Converting an SSH key file

As of software version V4.7, the key file must have a specific format for authentication via SSH

on a control. You can convert this format, for example with the aid of PuTTYgen software. The

PuTTYgen program is a freely available open source program for Windows.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 29

Page 30

Connection to the control

5.2 Assigning the connection parameters

Requirement

This description is applicable to the PuTTYgen version 0.64:

Note

Note the central security information in Section Auto-Hotspot.

Operating sequence

Result

1. Download the PuTTYgen program from the Internet (

~sgtatham/putty/download.html).

2. Start the program.

3. Load the key file via "Load".

Note

If the key file is not shown, change the file extension to "*.*".

4. Select "Conversions > Export OpenSSH key" in the menu.

5. Select a password via the "Key passphrase" input field and confirm the assigned password

in the "Confirm passphrase" input field.

NOTICE

The SSH key file must be password protected.

6. Assign a file name and click "Save".

Note

The file name does not need an extension. The string length is not specifically limited.

http://www.chiark.greenend.org.uk/

You can now use the key file for authentication in AMM.

SINUMERIK Integrate Access MyMachine /P2P (PC)

30 Operating Manual, 11/2016, A5E39356962B AA

Page 31

5.3 Establishing the connection

5.3 Establishing the connection

5.3.1 Establishing a direct connection (peer-to-peer Ethernet)

Operating sequence

1. There are two ways of establishing a "direct connection":

– Select "Connection" > "Connect..." in the main window menu.

Connection to the control

– Press the "Connect" button

Select the direct connection from a selection dialog.

in the toolbar to set up a connection.

Figure 5-5 Direct connections

2. Press the "Connect" button.

3. If the authentication data for the direct connection has already been saved, a connection

to the control is set up immediately.

If not, a dialog for entering the authentication data opens.

See also

Establishing a connection to the control system: An overview (Page 21)

Industrial Security Configuration Manual (https://support.industry.siemens.com/cs/us/en/view/

108862708)

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 31

Page 32

Connection to the control

5.3 Establishing the connection

5.3.2 Establishing a network connection

Requirement

Note

Note the central security information in Section Auto-Hotspot.

SINUMERIK Integrate Access MyMachine /P2P (PC)

32 Operating Manual, 11/2016, A5E39356962B AA

Page 33

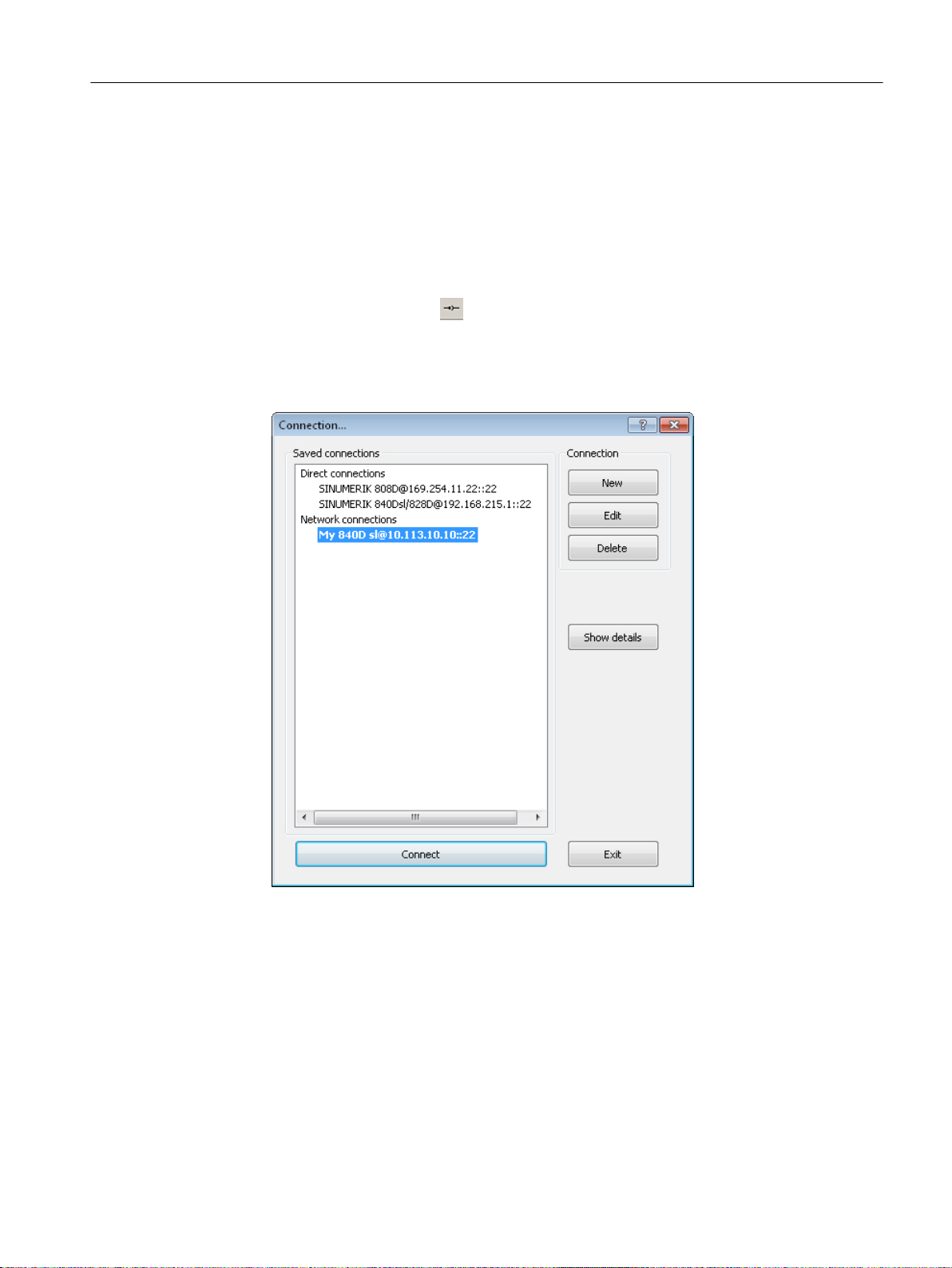

Operating sequence

1. The following ways of establishing a "network connection" are available:

Connection to the control

5.3 Establishing the connection

– Select "Connection" in the main window menu.

The last five network connections are offered for selection.

Select one of the menu entries.

The connection to the selected control is established.

- OR -

– Press the "Connection"

button in the toolbar.

- OR -

– Select "Connection" > "Connect..." in the main window menu.

A selection dialog opens, in which you still have to select the corresponding connection.

All the saved connections are available for selection here.

Figure 5-6 Select connection...

2. Press the "Connect" button in the selection dialog.

3. If a selection dialog containing only the direct connection opens when you press the

"Connect" button in the toolbar, this means you have not yet parameterized any network

connections. Parameters have to be assigned to them in advance. Proceed as described

in Section Assigning parameters for network connection (Page 27).

4. If you have not entered any authentication data, a dialog for entering the authentication

data opens.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 33

Page 34

Connection to the control

5.3 Establishing the connection

See also

Establishing a connection to the control system: An overview (Page 21)

SINUMERIK Integrate Access MyMachine /P2P (PC)

34 Operating Manual, 11/2016, A5E39356962B AA

Page 35

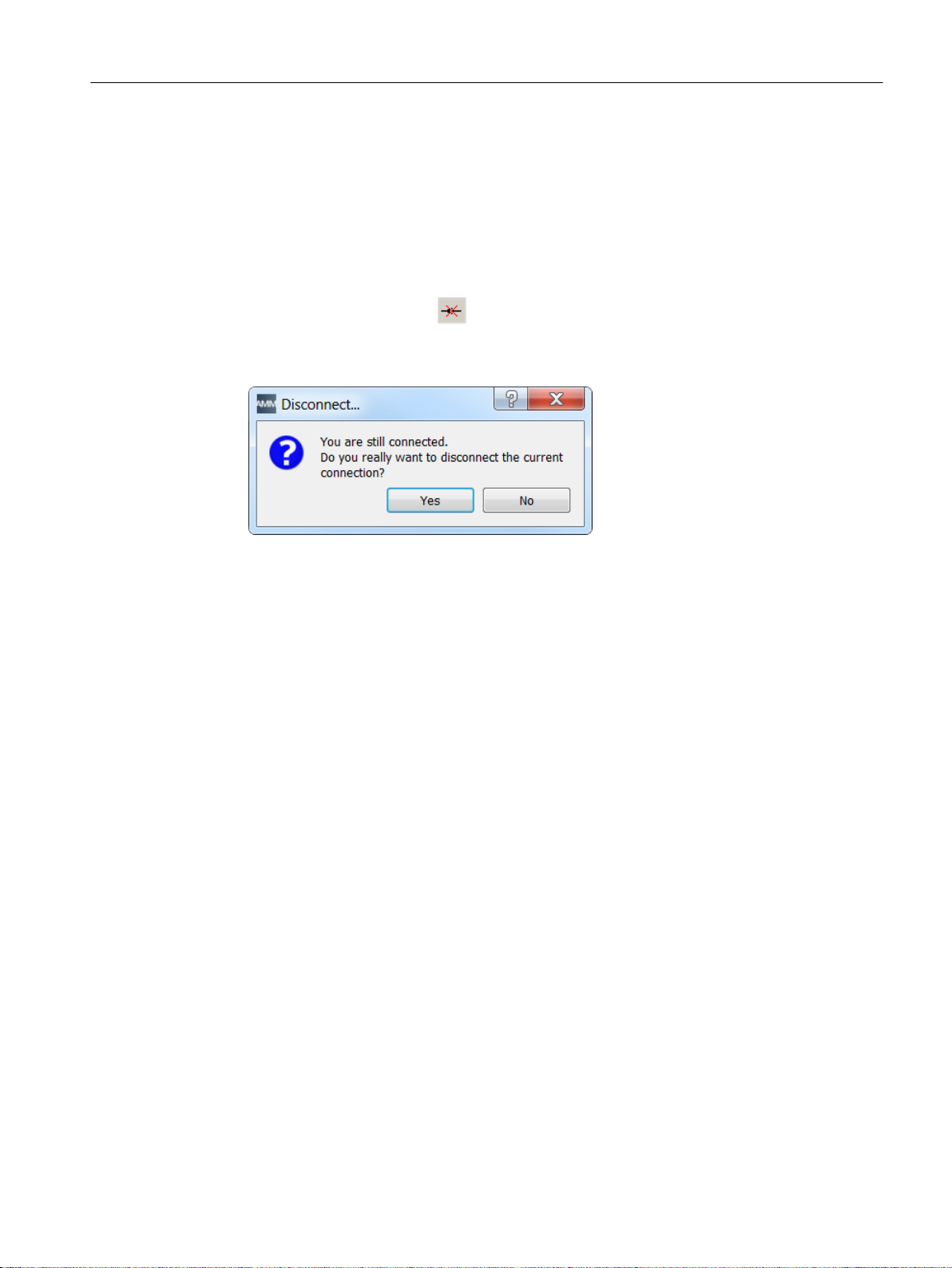

5.4 Disconnect connection

You can disconnect a current connection to the control. Note that disconnecting the connection

to the control also ends the remote control of your control.

Operating sequence

1. There are two ways of disconnecting an active connection:

– Press the "Disconnect" button in the toolbar.

– Select "Connection > Disconnect" in the main window menu.

2. Confirm the prompt dialog with "Yes".

Connection to the control

5.4 Disconnect connection

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 35

Page 36

'VO

7&8

1&8

7HOH6HUYLFH$GDSWHU,(

,QWHUDFWLRQ

(WKHUQHWFRQQHFWLRQ

*HQHUDOWHOHSKRQH

QHWZRUN

;

WHUPLQDO

;

WHUPLQDO

;

WHUPLQDO

/RFDO3&

NPRGHPFRQQHFWLRQ

NPR

GHP

FR

QQHFW

LRQ

Connection to the control

5.5 Establishing a modem connection

5.5 Establishing a modem connection

5.5.1 General information

There are various ways to set up a modem connection from the PC to the control.

This brief guide describes a modem connection to the 840D sl control using the

TeleService Adapter IE (TS Adapter).

This brief guide describes the following two options for the parameterization:

● TeleService Adapter with the "TeleService" software

● TeleService Adapter without the "TeleService" software

The "TeleService" software is included with the TeleService Adapter. More information about

the software can be found in the Help for the TeleService adapter.

Figure 5-7 Modem connection from the PC to the control via the network and the TeleService Adapter IE

Note

You can only establish (Page 60) the connection/cabling as shown in the figure after you have

assigned parameters (Page 38) for the TeleService Adapter IE with the PC.

36 Operating Manual, 11/2016, A5E39356962B AA

SINUMERIK Integrate Access MyMachine /P2P (PC)

Page 37

See also

Setting up the PG/PC interface (Page 37)

Establishing a connection/Cabling (Page 60)

Parameterize the TeleService adapter IE with the "TeleService" software (Page 38)

Parameterize the TeleService adapter IE without the "TeleService" software (Page 59)

5.5.2 Setting up the PG/PC interface

Operating sequence

During the installation of the "TeleService" software you are prompted to set up the PG/PC

interface

.

1. Check the dialog box "Set up PG/PC interface".

Connection to the control

5.5 Establishing a modem connection

– If the "TS Adapter IE" interface is included in the selection list, go to

step 5.

– If the "TS Adapter IE" interface is missing from the list, continue with

step 2.

2. To add or remove interfaces, click

"Select...".

The "Install/Remove Interface" dialog box opens.

3. Select the "TS Adapter IE" module from the selection list and

install the adapter.

4. Click "Close" to close the dialog box.

5. In the "Set up PG/PC interface" dialog box select the TS adapter IE.

6. Click "Properties".

The "Properties - TS Adapter IE" dialog box opens.

7. Open the "Local Modem" tab.

8. Under "Modem:" select the modem with which you want to connect to the TS adapter IE.

Under ISDN select the protocol "B-Kanal-Protokoll X.75",

e.g. "AVM ISDN SoftCompensation X.75-V.42bis"

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 37

Page 38

7HOH6HUYLFH$GDSWHU,(

,QWHUDFWLRQ

(WKHUQHWFRQQHFWLRQ

*HQHUDOWHOHSKRQH

QHWZRUN

/RFDO3&

NPRGHPFRQQHFWLRQ

Connection to the control

5.5 Establishing a modem connection

9. Under "Location > Name:" select the location of your PG/PC.

Click "Edit" if needed to open up the "Phone and

Modem Options" dialog box to set up a new location.

For more information on the location, refer to the help function for the "Edit location" dialog

box.

10.Click

"OK" to exit the "Properties - TS Adapter IE" dialog box.

If you have changed an access path in these settings, a

warning message then appears.

To accept the changes, click

"OK".

See also

Parameterize the TeleService adapter IE with the "TeleService" software (Page 38)

Assigning parameters for the TS Adapter (Page 43)

Parameterize the TeleService adapter IE without the "TeleService" software (Page 59)

5.5.3 Parameterize the TeleService adapter IE with the "TeleService" software

5.5.3.1 Overview of TeleService Adapter parameter assignment

Introduction

Parameters are assigned for the TeleService Adapter IE from the PC via the network.

Requirements

You must have connected the PC and the TeleService Adapter IE with an Ethernet cable via

the network (see figure below).

Network connection of the PC to the TeleService Adapter IE

38 Operating Manual, 11/2016, A5E39356962B AA

SINUMERIK Integrate Access MyMachine /P2P (PC)

Page 39

You must have installed the "TeleService" software and the license on the PC.

Note

The "SINUMERIK Integrate Access MyMachine /P2P (PC)" (6FC5800-0AP30-0YB0) option

is required for remote access via TeleService Adapter.

Note

The software is usually installed at C:\Program Files\Siemens\TeleService

The license is on the supplied USB flash drive.

In the first step, insert the plant (e.g. "840D sl") into the "TeleService" software.

Principle operating sequence

Parameter assignment involves the following steps:

1. Insert the plant.

Connection to the control

5.5 Establishing a modem connection

2. Assign parameters for the TS Adapter.

3. Administrate the TS Adapter.

4. Assign parameters for the internal modem of the TS Adapter.

5. Test the connection.

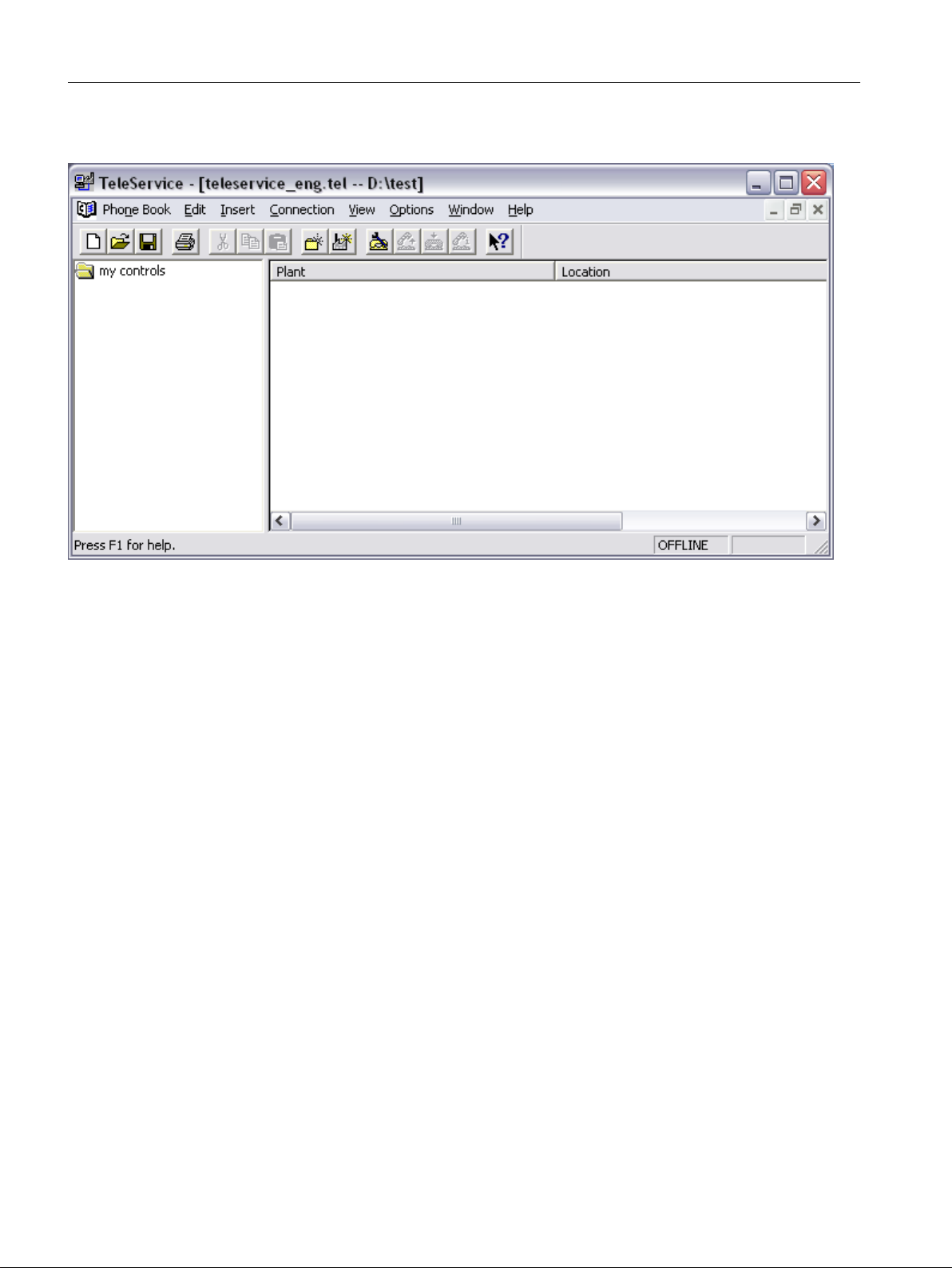

5.5.3.2 Inserting the system

Operating sequence

1. Start the "TeleService" Software.

2. Close all internal windows and select "Phone book" > "New".

3. Call it "newphonebook.tel".

4. Press <F3>.

A new folder is created.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 39

Page 40

Connection to the control

5.5 Establishing a modem connection

5. Call it "my control systems".

Figure 5-8 TeleService

SINUMERIK Integrate Access MyMachine /P2P (PC)

40 Operating Manual, 11/2016, A5E39356962B AA

Page 41

6. Press <F4>.

A new system is inserted.

Connection to the control

5.5 Establishing a modem connection

Figure 5-9 Inserting a new system

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 41

Page 42

Connection to the control

5.5 Establishing a modem connection

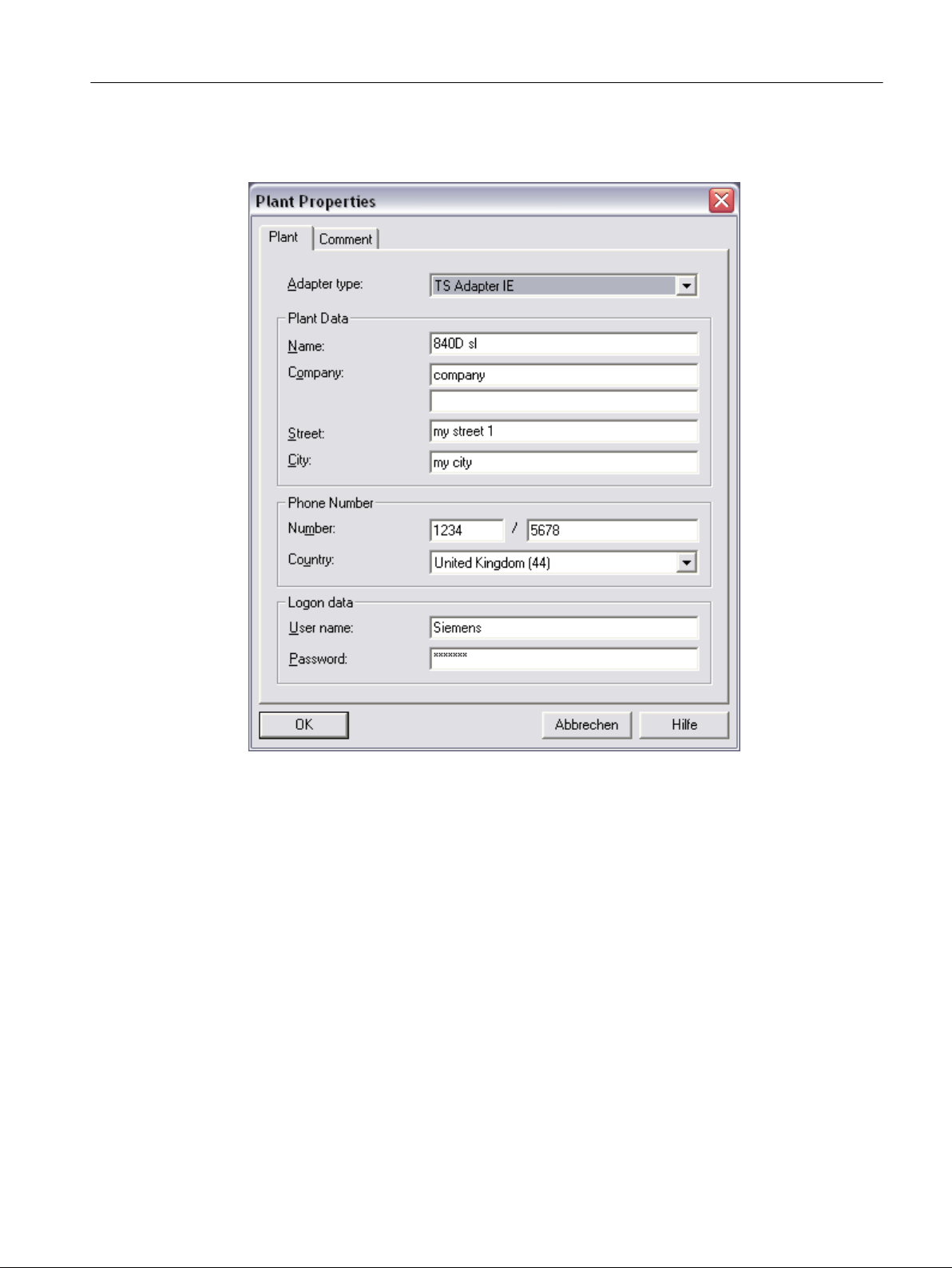

7. Enter the data for the system (see figure for an example).

– Enter "840D sl" as the name and select "TS Adapter IE" as the adapter type.

– Enter the telephone number for contacting the TS Adapter as the number.

– The log-on data must specify a user created in the TS Adapter.

You can leave these fields empty at this point or enter "Administrator" + "admin" as the

default user.

8. Select "OK".

The application should now resemble the figure below.

Figure 5-10 System after insertion

You will now assign parameters for the TS Adapter.

See also

Assigning parameters for the TS Adapter (Page 43)

SINUMERIK Integrate Access MyMachine /P2P (PC)

42 Operating Manual, 11/2016, A5E39356962B AA

Page 43

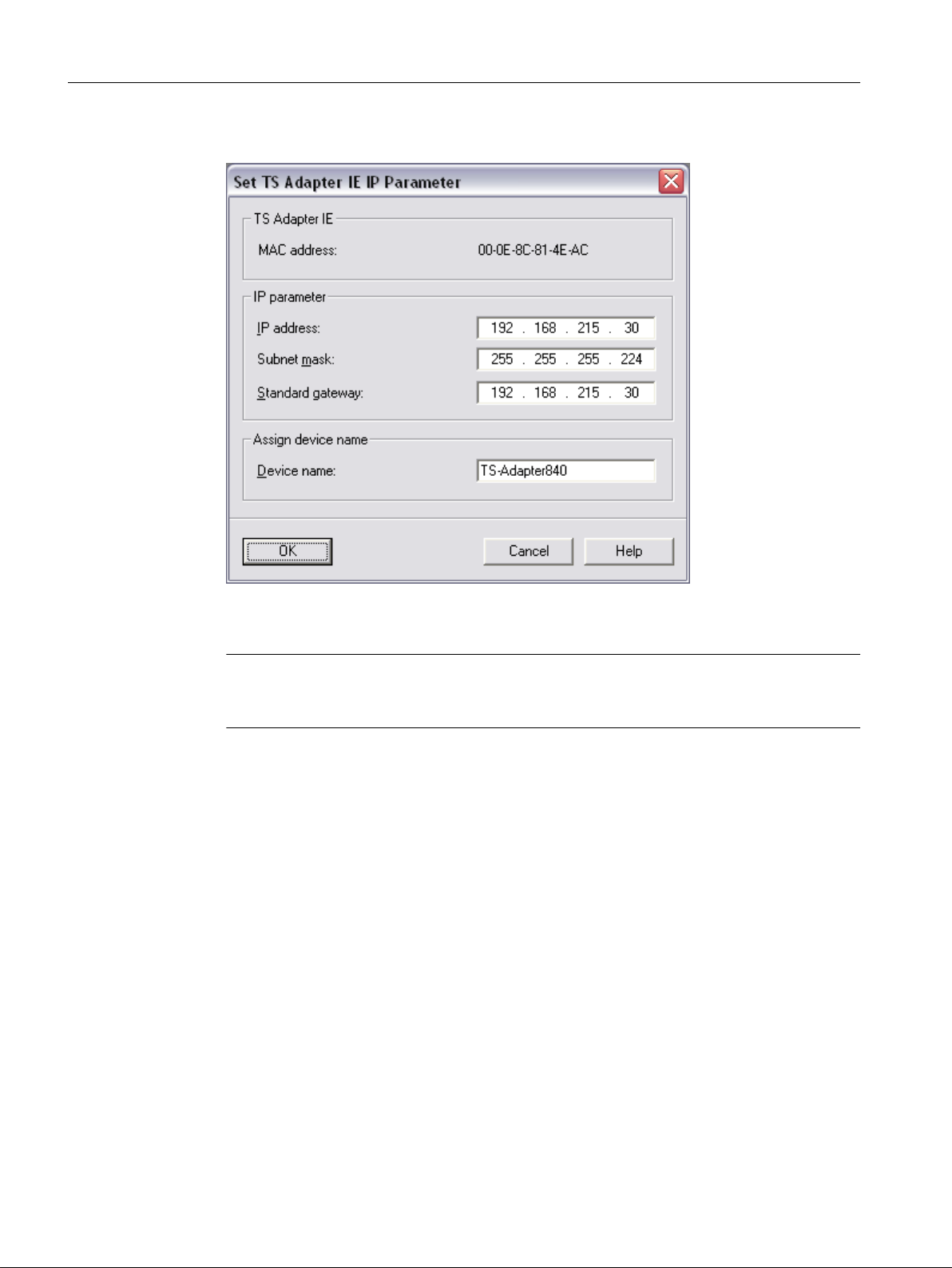

5.5.3.3 Assigning parameters for the TS Adapter

Operating sequence

1. In the PG/PC interface, set the access point you wish to use when connecting to the

TS Adapter. In this instance, we are using a network connection to the PC via USB.

2. Select "Options" > "Settings".

The following dialog appears.

Connection to the control

5.5 Establishing a modem connection

Figure 5-11 Settings

3. Set the network connection to connect you with the TS Adapter directly.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 43

Page 44

Connection to the control

5.5 Establishing a modem connection

4. Select "Options" > "Set TS Adapter IE IP Parameter...".

See also

Figure 5-12 Setting parameters

5. Compare the MAC address with the MAC address printed on the TS Adapter.

Note

If the MAC addresses are different, select "Options" > "Settings". Now select the appropriate

TS Adapter in the "Settings" dialog.

6. Make the settings shown in the "Setting parameters" figure.

Make sure the TS Adapter and the control system are in the same subnet.

7. Select "OK".

You will now administrate the TS Adapter IE.

Administrating the TS Adapter (Page 45)

SINUMERIK Integrate Access MyMachine /P2P (PC)

44 Operating Manual, 11/2016, A5E39356962B AA

Page 45

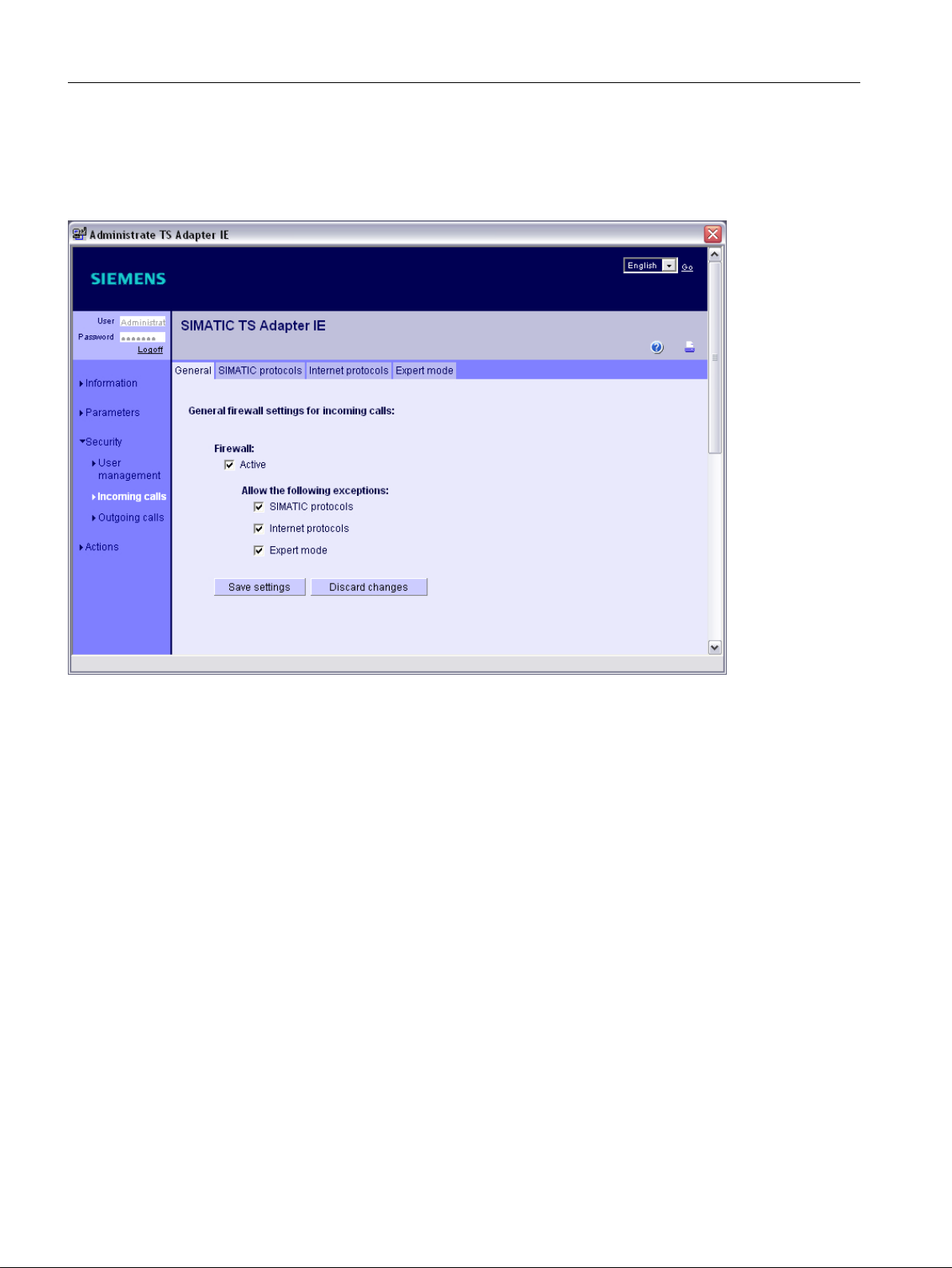

5.5.3.4 Administrating the TS Adapter

Operating sequence

1. Select "Options" > "Administrate TS Adapter IE" in the "TeleService" software menu.

The following window appears.

Connection to the control

5.5 Establishing a modem connection

Figure 5-13 Administrate TS Adapter IE

2. Log on by entering "Administrator" and "admin" in the top-left section of the window.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 45

Page 46

Connection to the control

5.5 Establishing a modem connection

3. Generate at least one additional user in the "Security" > "User administration" window (see

figure below) and assign admin rights to this user.

Example: "Siemens" + "siemens"

This user will be required again later and used to establish the connection to the TS Adapter.

Note

Delete the default user for security purposes.

Figure 5-14 User administration

SINUMERIK Integrate Access MyMachine /P2P (PC)

46 Operating Manual, 11/2016, A5E39356962B AA

Page 47

Connection to the control

5.5 Establishing a modem connection

4. Activate the following (see figure below) for the TS Adapter on the "General" tab in the

"Security" > "Incoming calls" window:

– "Firewall"

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 47

Page 48

Connection to the control

5.5 Establishing a modem connection

– "Allow the following exceptions"

"Expert mode"

The "expert mode" function is used subsequently to enable the port for the VNC

connection.

Figure 5-15 "Security" > "Incoming calls" > "General" tab

SINUMERIK Integrate Access MyMachine /P2P (PC)

48 Operating Manual, 11/2016, A5E39356962B AA

Page 49

Connection to the control

5.5 Establishing a modem connection

Figure 5-16 "Security" > "Incoming calls" > "SIMATIC protocols" tab

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 49

Page 50

Connection to the control

5.5 Establishing a modem connection

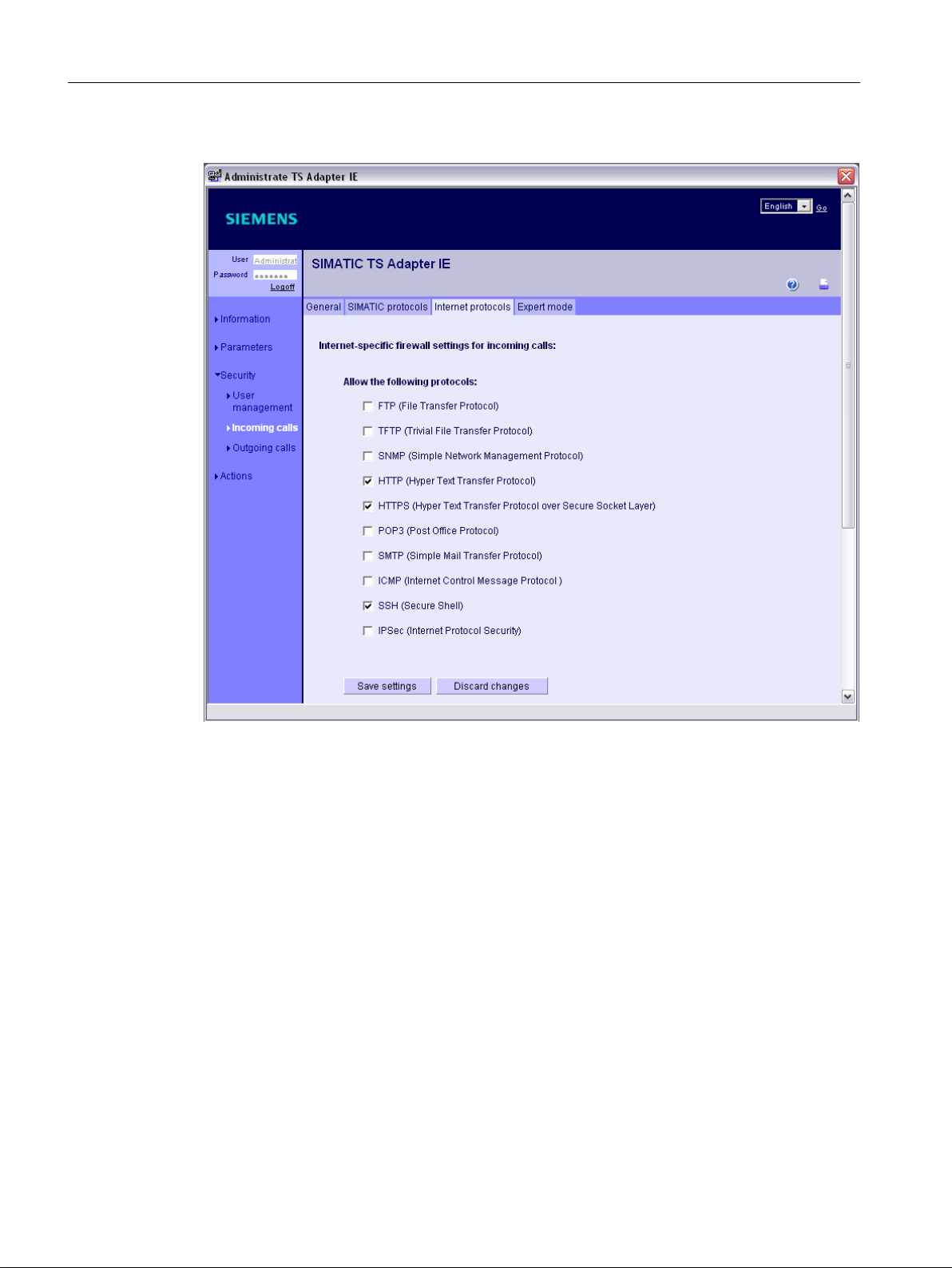

5. It is important that SSH is approved (see figure below).

Figure 5-17 "Security" > "Incoming calls" > "Internet protocols" tab

6. As already mentioned, VNC still requires approval. This is done in expert mode.

Port 5900 for VNC must be opened (see figure below).

SINUMERIK Integrate Access MyMachine /P2P (PC)

50 Operating Manual, 11/2016, A5E39356962B AA

Page 51

Connection to the control

5.5 Establishing a modem connection

See also

Figure 5-18 "Security" > "Incoming calls" > "Expert mode" tab

Note

Make the same settings for "outgoing calls".

You will now assign parameters for the internal modem of the TS Adapter IE.

Assigning parameters for the internal modem (Page 52)

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 51

Page 52

Connection to the control

5.5 Establishing a modem connection

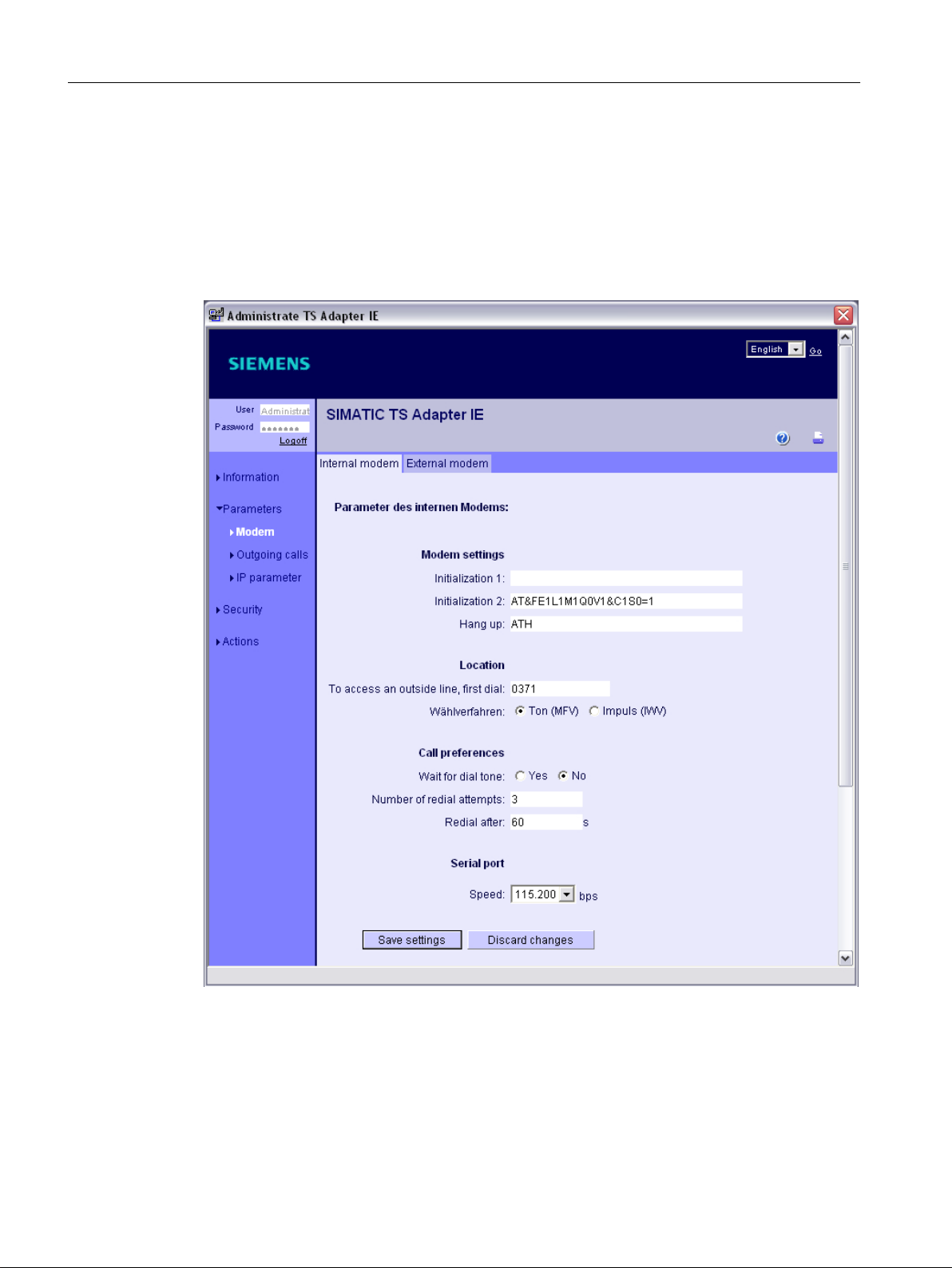

5.5.3.5 Assigning parameters for the internal modem

Operating sequence

1. Select "Options" > "Administrate TS Adapter IE" in the "TeleService" software menu.

2. Assign the parameters for the internal modem as shown.

If you are using an external modem, you will have to make the appropriate settings there.

Figure 5-19 "Parameters" > "Modem" > "Internal modem" tab

3. Enter the external access code which applies to you.

SINUMERIK Integrate Access MyMachine /P2P (PC)

52 Operating Manual, 11/2016, A5E39356962B AA

Page 53

Connection to the control

5.5 Establishing a modem connection

4. Check the IP parameters you set earlier with the TeleService software.

Figure 5-20 "Parameters" > "IP parameters"

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 53

Page 54

Connection to the control

5.5 Establishing a modem connection

5. To finish, reenter the contact telephone number for your modem on the PC.

Figure 5-21 "Parameters" > "Outgoing calls"

6. Close the window.

You will now test the connection which has been set.

See also

Testing the connection (Page 54)

5.5.3.6 Testing the connection

Operating sequence

1. Right-click to access "Object properties..." via the shortcut menu.

2. Select the object properties of the "840D sl" system created previously (see figure below).

SINUMERIK Integrate Access MyMachine /P2P (PC)

54 Operating Manual, 11/2016, A5E39356962B AA

Page 55

Connection to the control

5.5 Establishing a modem connection

3. Enter the data for the user you have just created as the log-on data (e.g. "Siemens" +

"siemens").

Figure 5-22 "Insert new system" > "Log-on data"

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 55

Page 56

Connection to the control

5.5 Establishing a modem connection

4. You can now test the connection you have set. To do this, select the system and choose

"Establish" in the "Connection" menu (<F7> button).

Figure 5-23 "Establish connection"

SINUMERIK Integrate Access MyMachine /P2P (PC)

56 Operating Manual, 11/2016, A5E39356962B AA

Page 57

Connection to the control

5.5 Establishing a modem connection

5. Choose the modem and location and click "Select".

If connection is successful, the "ONLINE" field in the status bar will become green.

Figure 5-24 "ONLINE" system connection

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 57

Page 58

Connection to the control

5.5 Establishing a modem connection

6. Select "Connection" > "Current connection" to observe the status of the connection currently

established (see figure).

Figure 5-25 Current connection

7. Parameter assignment for your TS Adapter is now complete.

Make the following changes to the cabling (Page 60).

Connect the control system for X127 with the TS Adapter.

The PC should be already connected with the modem cable and the TS Adapter with the

other modem cable.

SINUMERIK Integrate Access MyMachine /P2P (PC)

58 Operating Manual, 11/2016, A5E39356962B AA

Page 59

'VO

7&8

1&8

7HOH6HUYLFH$GDSWHU,(

,QWHUDFWLRQ

(WKHUQHWFRQQHFWLRQ

*HQHUDOWHOHSKRQH

QHWZRUN

;

WHUPLQDO

;

WHUPLQDO

;

WHUPLQDO

/RFDO3&

NPRGHPFRQQHFWLRQ

NPR

GHP

FR

QQHFW

LRQ

Connection to the control

5.5 Establishing a modem connection

Figure 5-26 Modem connection from the PC to the control system via the network and the TeleService Adapter IE

See also

Establishing a connection/Cabling (Page 60)

5.5.4 Parameterize the TeleService adapter IE without the "TeleService" software

Operating sequence

1. Item 7.16 (Reset parametrization with the P RES button) (see Help for TS adapters).

2. Modem selection (long-distance data transmission network), (see Create modem

connection under Windows 7 (Page 62) and Establish modem connection under Windows

7 (Page 67)).

IP address 192.168.0.2 or 192.168.0.3 is assigned.

3. Start Internet browser and link up with http://192.168.0.1.

4. Log in with user Administrator and Password admin.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 59

Page 60

Connection to the control

5.5 Establishing a modem connection

5. Enter IP parameter as described as from Assigning parameters for the TS Adapter

(Page 43) Step 4.

6. Continue through the following steps:

– see Administrating the TS Adapter (Page 45)

– see Assigning parameters for the internal modem (Page 52)

– see Establishing a connection/Cabling (Page 60)right through to Connecting AMM to

the control system via the modem connection (Page 75)

See also

Create modem connection under Windows 7 (Page 62)

Establish modem connection under Windows 7 (Page 67)

Assigning parameters for the TS Adapter (Page 43)

Administrating the TS Adapter (Page 45)

Assigning parameters for the internal modem (Page 52)

Establishing a connection/Cabling (Page 60)

Connecting AMM to the control system via the modem connection (Page 75)

5.5.5 Establishing a connection/Cabling

Components

You will need the following components:

● Two modem terminals in the general telephone network for the following components:

– PC

– TeleService adapter IE

● PC with 56k modem

● TeleService adapter IE

● Ethernet cable

● Control system (840D sl with NCU 720.1 in this example)

Requirement

You need to have assigned parameters (Page 38) for the TeleService adapter IE.

SINUMERIK Integrate Access MyMachine /P2P (PC)

60 Operating Manual, 11/2016, A5E39356962B AA

Page 61

Establishing a modem connection via the general telephone network

'VO

7&8

1&8

7HOH6HUYLFH$GDSWHU,(

,QWHUDFWLRQ

(WKHUQHWFRQQHFWLRQ

*HQHUDOWHOHSKRQH

QHWZRUN

;

WHUPLQDO

;

WHUPLQDO

;

WHUPLQDO

/RFDO3&

NPRGHPFRQQHFWLRQ

NPR

GHP

FR

QQHFW

LRQ

Set up the network via the modem terminals as follows (please also refer to the figure below):

1. Connect the PC with the general telephone network via the modem terminal.

2. Connect the TS adapter with the general telephone network via the modem terminal.

3. Connect the TS adapter with the control system's X127 interface via the Ethernet interface.

Use an Ethernet cable for this purpose.

There is no need to integrate the TS adapter into the system network/workplace network,

as the control system operates its own DHCP server on the X127 interface.

The TS adapter is automatically assigned an IP address from this X127 interface.

Note

The control system is still accessible via the X130 interface, for example.

Connection to the control

5.5 Establishing a modem connection

Figure 5-27 Modem connection from the PC to the control system via the network and the TeleService adapter IE

See also

Parameterize the TeleService adapter IE with the "TeleService" software (Page 38)

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 61

Page 62

Connection to the control

5.5 Establishing a modem connection

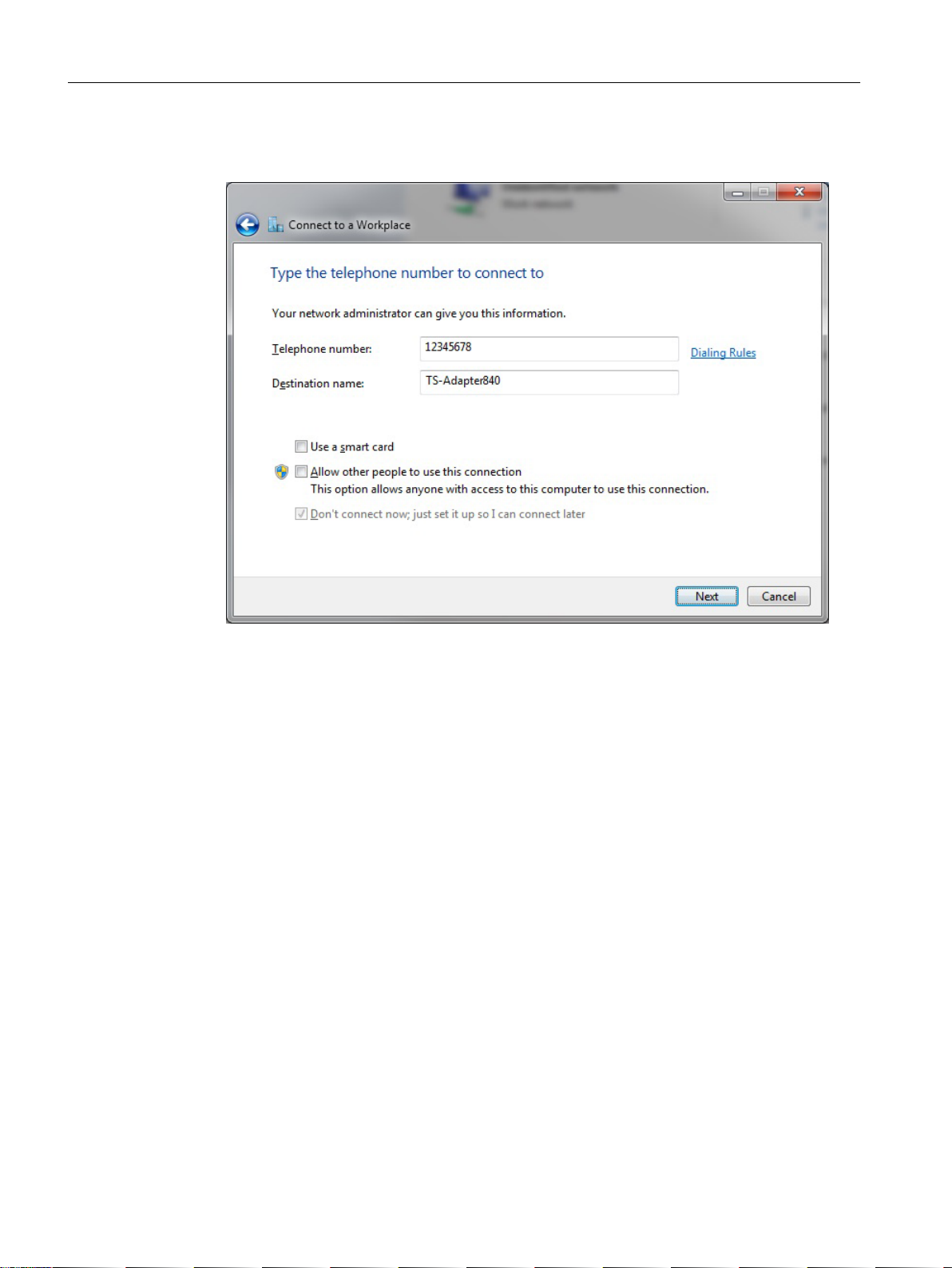

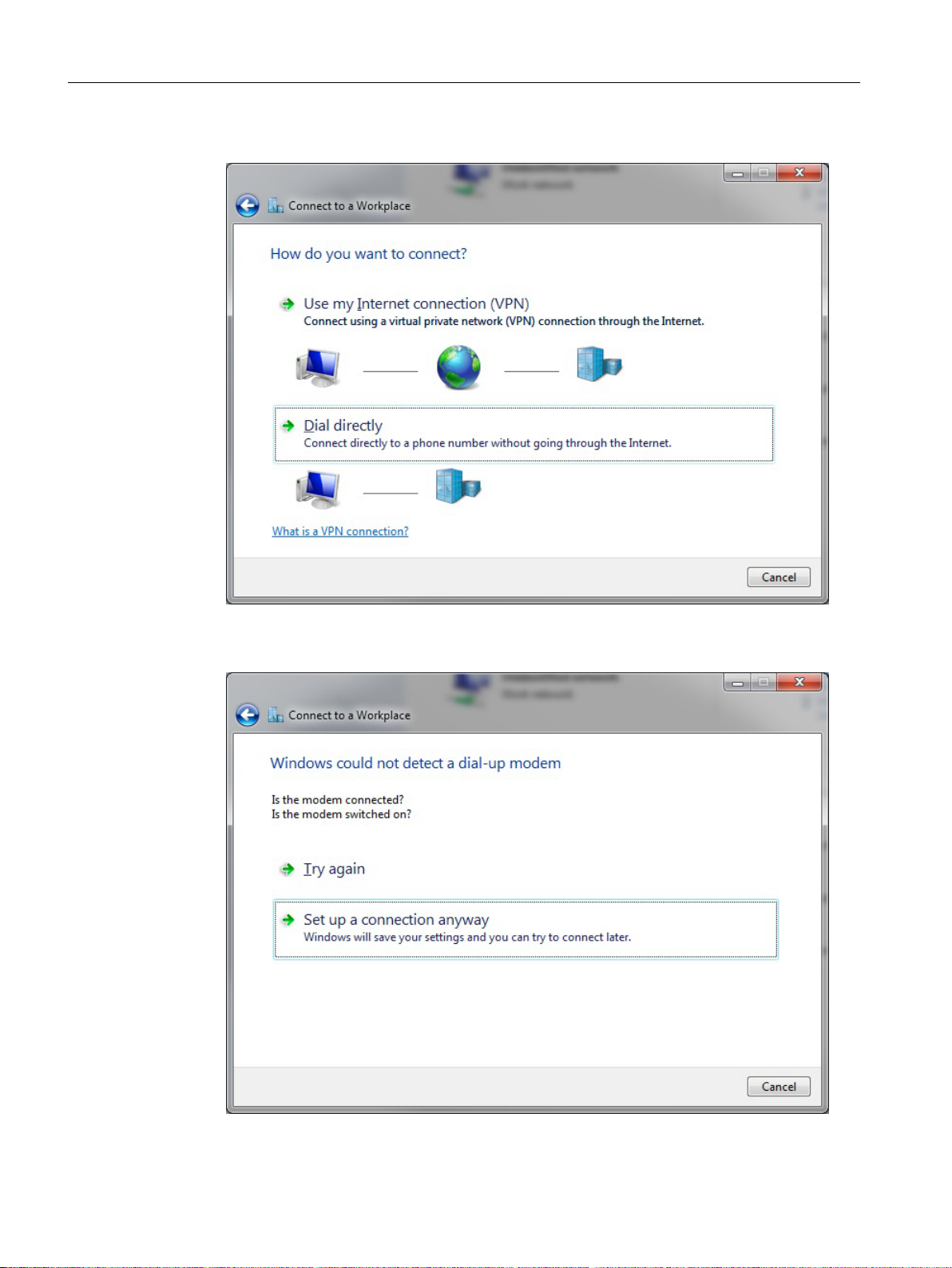

5.5.6 Create modem connection under Windows 7

Operating sequence

1. Select "Start > Control Panel > Network and Sharing Center > Set up a new connection or

network".

2. Select the connection option "Connect to a workplace".

Figure 5-28 Connect to a workplace

3. Press "Next".

SINUMERIK Integrate Access MyMachine /P2P (PC)

62 Operating Manual, 11/2016, A5E39356962B AA

Page 63

4. Select "Dial directly".

Connection to the control

5.5 Establishing a modem connection

Figure 5-29 Dial directly

5. Press "Set up a connection anyway". Connect a modem later if no modem is connected.

Figure 5-30 Set up a connection anyway

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 63

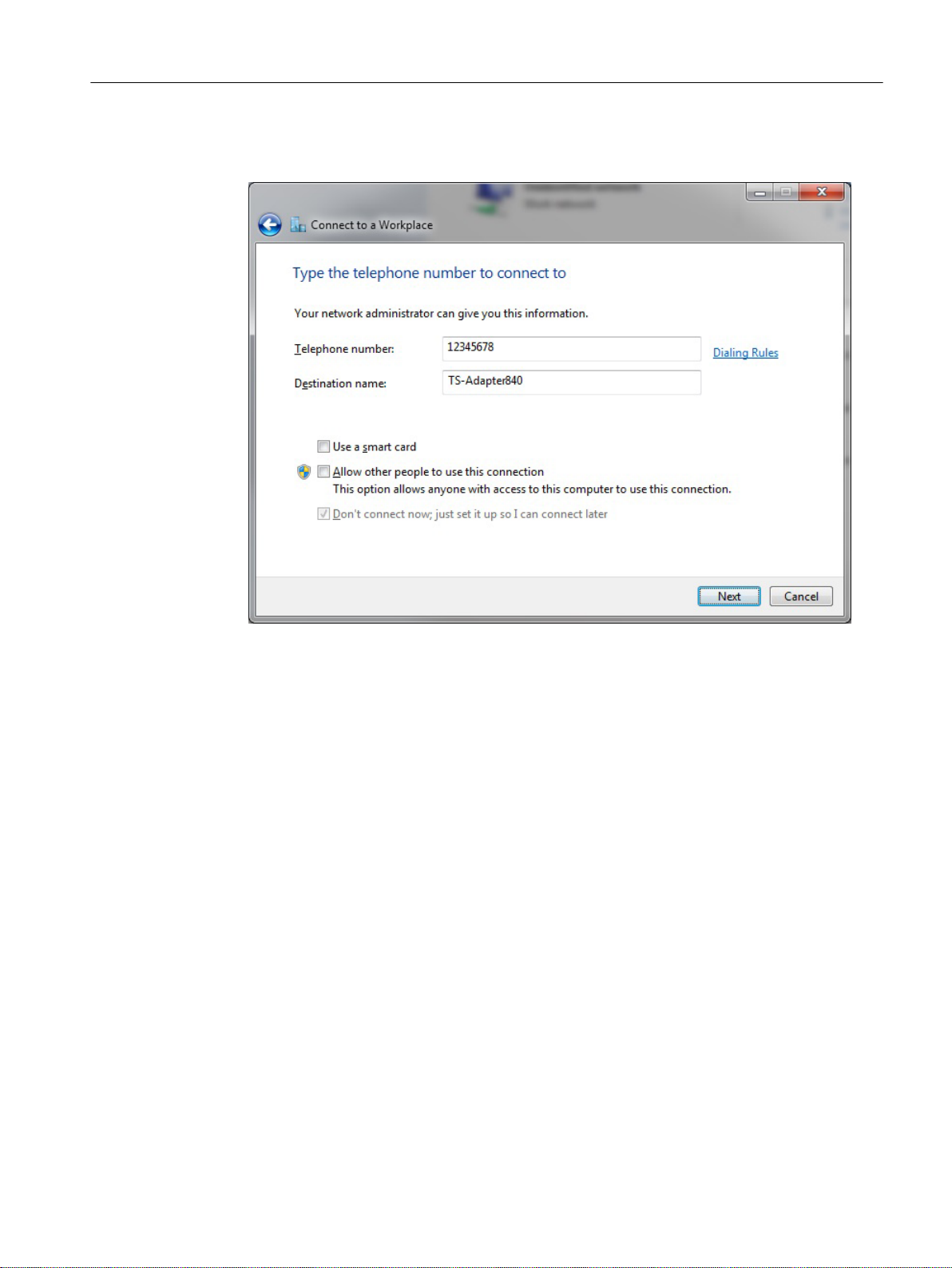

Page 64

Connection to the control

5.5 Establishing a modem connection

6. Enter the telephone number for contacting your TS adapter and assign a name to the

connection.

Figure 5-31 Enter telephone number

7. Press "Next".

SINUMERIK Integrate Access MyMachine /P2P (PC)

64 Operating Manual, 11/2016, A5E39356962B AA

Page 65

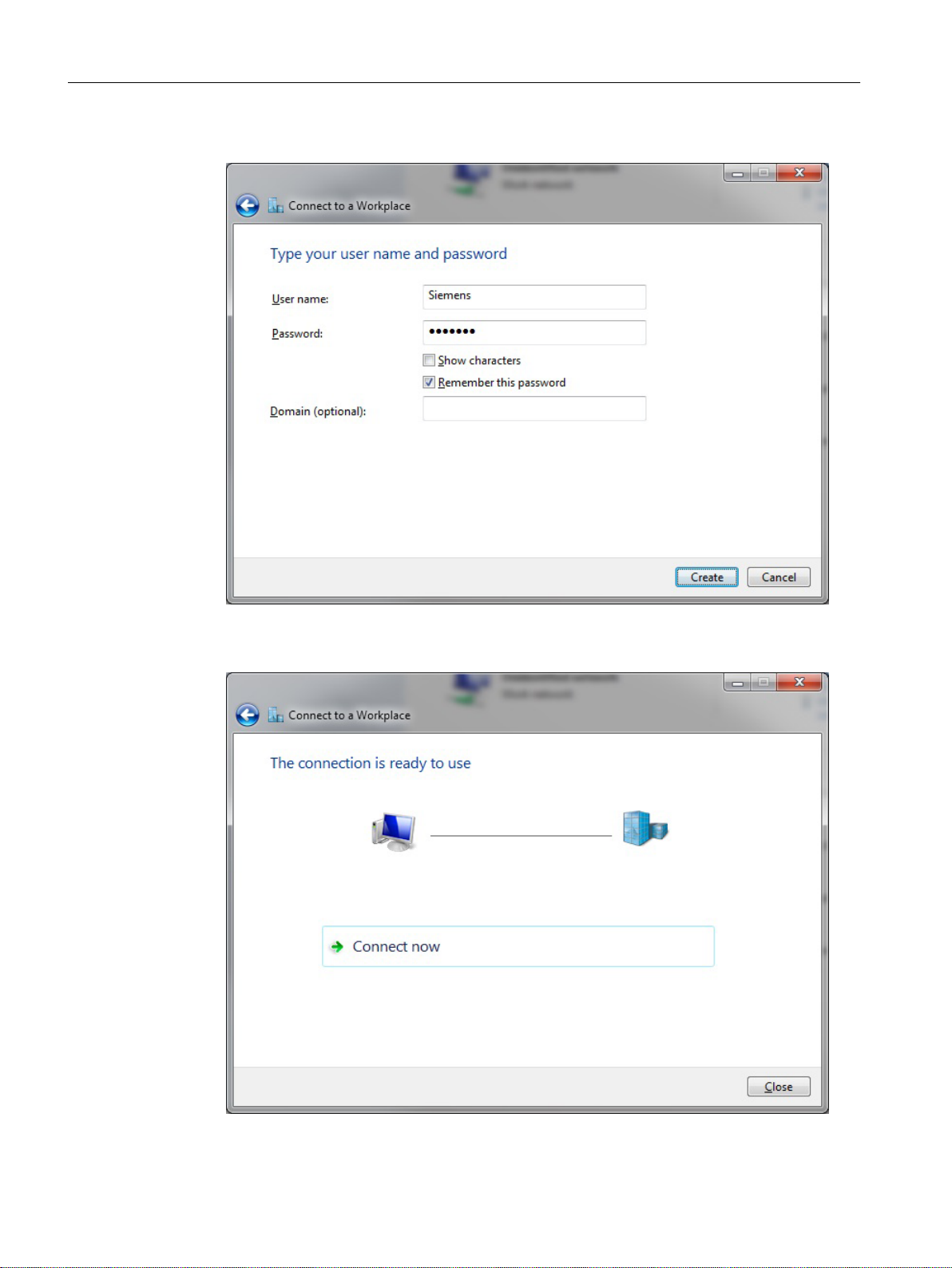

8. Enter the user name and password of the TS adapter.

Connection to the control

5.5 Establishing a modem connection

Figure 5-32 Enter user name and password:

9. Press "Create".

Figure 5-33 Establish connection

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 65

Page 66

Connection to the control

5.5 Establishing a modem connection

Connection successfully established You can close the dialog or establish a connection.

SINUMERIK Integrate Access MyMachine /P2P (PC)

66 Operating Manual, 11/2016, A5E39356962B AA

Page 67

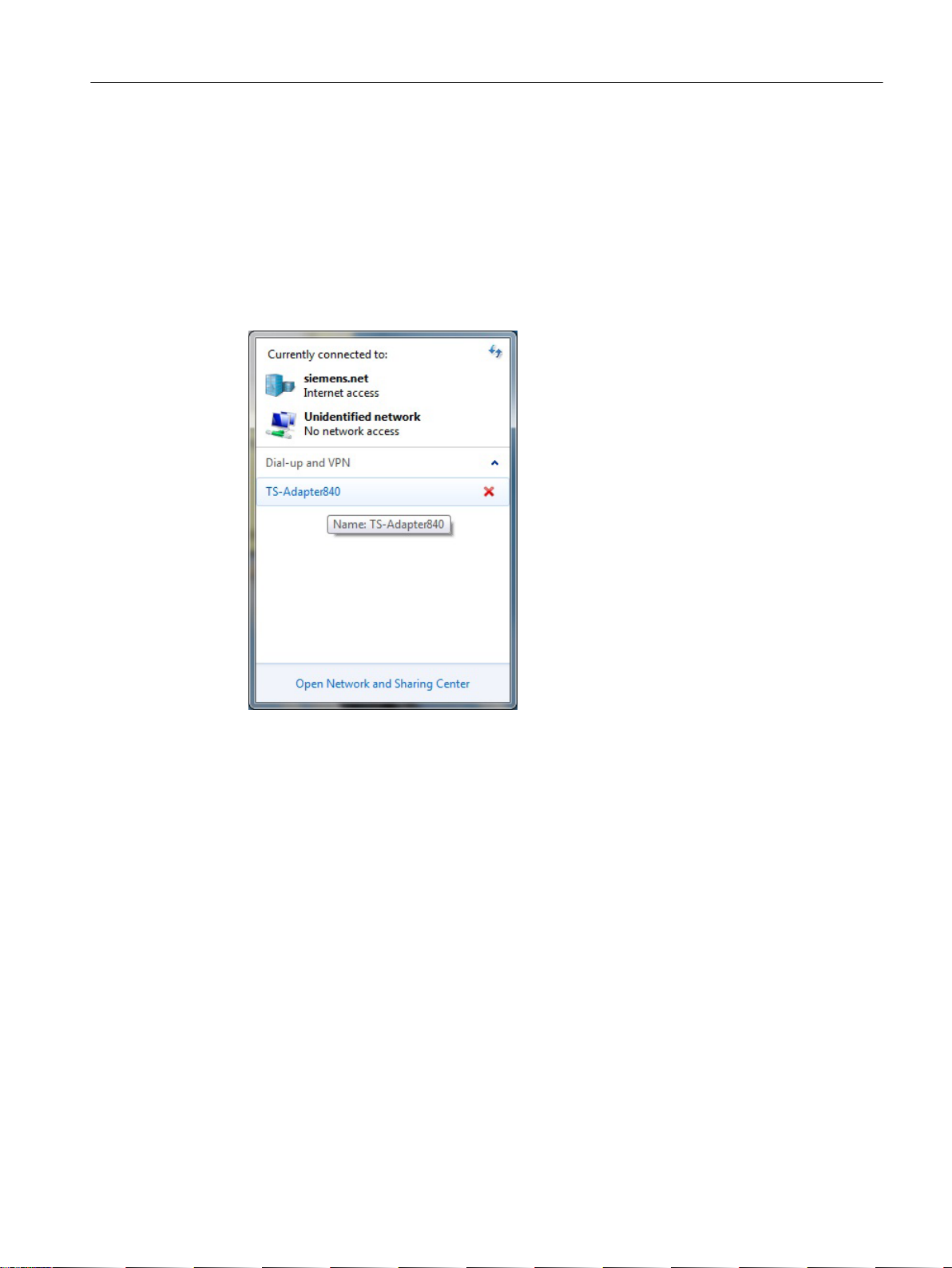

5.5.7 Establish modem connection under Windows 7

Operating sequence

Establish a connection to your TS adapter as follows.

1. In Windows, select "Start > Control panel > Network and sharing center > Connect to a

network".

2. Click the dial-up connection with the name you have assigned.

Connection to the control

5.5 Establishing a modem connection

Figure 5-34 Select modem connection

3. Press "Connect".

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 67

Page 68

Connection to the control

5.5 Establishing a modem connection

Figure 5-35 Connecting

A connection is established to the TS adapter.

SINUMERIK Integrate Access MyMachine /P2P (PC)

68 Operating Manual, 11/2016, A5E39356962B AA

Page 69

5.5.8 Create a modem connection under Windows 10

Operating sequence

1. Select Start > Settings > Network and Internet > Dial-up > Set up a new connection".

2. Select the connection option "Connect to a workplace".

Connection to the control

5.5 Establishing a modem connection

Figure 5-36 Connect to a workplace

3. Press "Next".

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 69

Page 70

Connection to the control

5.5 Establishing a modem connection

4. Select "Dial directly".

Figure 5-37 Dial directly

5. Press "Set up a connection anyway". Connect a modem later if no modem is connected.

Figure 5-38 Set up a connection anyway

SINUMERIK Integrate Access MyMachine /P2P (PC)

70 Operating Manual, 11/2016, A5E39356962B AA

Page 71

Connection to the control

5.5 Establishing a modem connection

6. Enter the telephone number for contacting your TS adapter and assign a name to the

connection.

Figure 5-39 Enter telephone number

7. Press "Next".

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 71

Page 72

Connection to the control

5.5 Establishing a modem connection

8. Enter the user name and password of the TS adapter.

Figure 5-40 Enter user name and password:

9. Press "Create".

Figure 5-41 Establish connection

SINUMERIK Integrate Access MyMachine /P2P (PC)

72 Operating Manual, 11/2016, A5E39356962B AA

Page 73

Connection to the control

5.5 Establishing a modem connection

Connection successfully established You can close the dialog or establish a connection.

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 73

Page 74

Connection to the control

5.5 Establishing a modem connection

5.5.9 Establish a modem connection under Windows 10

Operating sequence

Establish a connection to your TS adapter as follows.

1. In Windows, select "Start > Settings > Network and Internet > Dial-up".

2. Click the dial-up connection with the name you have assigned.

Figure 5-42 Dial up - select modem connection

3. Press "Connect".

SINUMERIK Integrate Access MyMachine /P2P (PC)

74 Operating Manual, 11/2016, A5E39356962B AA

Page 75

Connection to the control

5.5 Establishing a modem connection

Figure 5-43 Dial up - establish connection

A connection is established to the TS adapter.

5.5.10 Connecting AMM to the control system via the modem connection

Operating sequence

1. Establish a modem connection (Page 67) to your TS adapter.

2. Next, start AMM and select the direct connection (see Establishing the connection

(Page 31)). Enter the authentication data you wish to use when logging onto the control

system. This is not the same data you entered for the TS adapter.

3. Once you have established the connection, you can copy files in either direction and operate

the control system remotely.

Note

When making the settings for the connection used (direct connection or network

connection) in AMM, you should set the "Transmission type" to transmission rate "Low". If

you do not do this, you may not be able to operate the control remotely, and the connection

may suffer from frequent interruptions.

This setting only applies to remote control: it does not apply to file transfers.

See also

Establishing the connection (Page 31)

Establish modem connection under Windows 7 (Page 67)

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 75

Page 76

Connection to the control

5.5 Establishing a modem connection

5.5.11 Further information

For more detailed information on parameter assignment for the TS Adapter, please refer to

the supplementary material provided ("TS Adapter IE – Handbuch.pdf") or the following online

sources:

Product Support (http://support.automation.siemens.com/WW/view/de/10805406/130000)

TeleService Adapter Manual (http://support.automation.siemens.com/WW/view/de/

24623021)

SINUMERIK Integrate Access MyMachine /P2P (PC)

76 Operating Manual, 11/2016, A5E39356962B AA

Page 77

Operator control (software)

6.1 Remote control of the control system

6.1.1 Overview of remote control

With the "remote control" function you can:

● Monitor and operate the control from the PG/PC (remotely).

● Generate screenshots of the control's HMI, and save them to the PG/PC. This enables you

to inform support personnel of errors in the control's HMI via screenshots.

Software option

The "SINUMERIK Integrate Access MyMachine /P2P (PC) (6FC5800-0AP30-0YB0)" option is required for

remote access via TeleService Adapter.

See also

Starting/ending remote control (Page 82)

6

Using remote control to generate the screen of the control system's HMI user interface

(Page 87)

SINUMERIK Integrate Access MyMachine /P2P (PC)

Operating Manual, 11/2016, A5E39356962B AA 77

Page 78

Operator control (software)

6.1 Remote control of the control system

6.1.2 Approving remote control of the control system on the HMI

6.1.2.1 Approving remote control on the HMI

Operating sequence for 840D sl/828D controls

1. Press the "Remote diagnostics" softkey in the "Diagnosis" operating area.

Figure 6-1 "Remote diagnostics" on the HMI

2. The following settings can be made:

– Remote access rights

SINUMERIK Integrate Access MyMachine /P2P (PC)