Siemens SINUMERIK 840D sl, SINUMERIK 840D sl OP 010, HT 8, SINUMERIK 840DE sl User Manual

SINUMERIK

SINUMERIK 840D sl

Operator panel front: OP 012

Valid for:

Control system

SINUMERIK 840D sl/840DE sl

General information and

networking

1

Manual

Description

Operator control and display

elements

Interfaces

Installation

Technical data

Spare parts

2

3

4

5

6

7

09/2016

A5E36371591B

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E36371591B

Ⓟ 09/2016 Subject to change

Copyright © Siemens AG 2007 - 2016.

All rights reserved

Table of contents

1 General information and networking.............................................................................................................5

1.1 Fundamental safety instructions..............................................................................................5

1.1.1 General safety instructions.......................................................................................................5

1.1.2 Handling electrostatic sensitive devices (ESD)........................................................................8

1.1.3 Industrial security.....................................................................................................................8

1.1.4 Residual risks of power drive systems...................................................................................10

1.2 Application planning...............................................................................................................11

1.2.1 Secondary electrical conditions..............................................................................................11

1.2.1.1 Power supply..........................................................................................................................11

1.2.1.2 Grounding concept.................................................................................................................12

1.2.1.3 EMC compatibility..................................................................................................................12

1.2.2 Ambient climatic and mechanical conditions..........................................................................14

1.2.2.1 Transport and storage conditions...........................................................................................14

1.2.2.2 Operating conditions..............................................................................................................16

1.2.2.3 Cooling...................................................................................................................................17

1.2.3 Standards and approvals.......................................................................................................20

1.2.4 Recycling and disposal..........................................................................................................21

1.3 Connecting.............................................................................................................................22

1.3.1 Pin assignment of the interfaces............................................................................................22

1.3.2 Handling membrane connectors............................................................................................36

1.4 Networking.............................................................................................................................36

1.4.1 System settings......................................................................................................................36

1.4.1.1 Settings for SINUMERIK solution line....................................................................................36

1.4.1.2 System boot with system network..........................................................................................38

1.4.1.3 Thin Client Unit (TCU)............................................................................................................39

1.4.1.4 Factory default settings..........................................................................................................40

1.4.2 Commissioning TCU..............................................................................................................42

1.4.2.1 Using the TCU's main menu..................................................................................................42

1.4.2.2 Using additional TCU menus.................................................................................................45

1.4.2.3 How to register a TCU on the system network.......................................................................55

1.4.2.4 How to calibrate a touch panel...............................................................................................59

1.4.2.5 Connecting-up the SIMATIC Thin Client Touch Panel...........................................................61

1.4.2.6 This is how you configure the SIMATIC Thin Client Touch Panel..........................................62

1.4.2.7 Settings in the "config.ini" file.................................................................................................64

1.4.2.8 Settings in the "TCU.ini" file...................................................................................................66

1.4.2.9 Displacement mechanism for TCUs.......................................................................................72

1.4.2.10 Disable switchover between TCU via PLC.............................................................................74

1.4.2.11 Example: How to select the behavior of the TCUs during boot up.........................................76

1.4.3 Network configuration............................................................................................................77

1.4.3.1 Permissible network topologies..............................................................................................77

1.4.3.2 Networks without connection to the company network..........................................................78

1.4.3.3 Networks with NCU connection to the company network......................................................80

1.4.3.4 Example: Configuring a VNC connection to a PC..................................................................83

1.4.3.5 Application example...............................................................................................................85

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 3

Table of contents

1.4.4 Service and diagnostics.........................................................................................................87

1.4.4.1 Booting of the TCU ...............................................................................................................87

2 Description..................................................................................................................................................89

3 Operator control and display elements.......................................................................................................91

3.1 View.......................................................................................................................................91

3.2 Keyboard................................................................................................................................92

3.3 Screen saver..........................................................................................................................93

3.4 Touchpad mouse...................................................................................................................94

4 Interfaces....................................................................................................................................................95

5 Installation..................................................................................................................................................97

5.1 Preparation for mounting........................................................................................................97

5.2 Assembling an OP 012 and a PCU........................................................................................98

5.3 Mounting on the mounting wall............................................................................................101

5.4 Softkey labeling....................................................................................................................102

6 Technical data..........................................................................................................................................103

7 Spare parts...............................................................................................................................................105

7.1 Overview..............................................................................................................................105

7.2 Replacement........................................................................................................................106

Index.........................................................................................................................................................109

Operator panel front: OP 012

4 Manual, 09/2016, A5E36371591B

General information and networking

1.1 Fundamental safety instructions

1.1.1 General safety instructions

DANGER

Danger to life due to live parts and other energy sources

Death or serious injury can result when live parts are touched.

● Only work on electrical devices when you are qualified for this job.

● Always observe the country-specific safety rules.

Generally, six steps apply when establishing safety:

1. Prepare for shutdown and notify all those who will be affected by the procedure.

2. Disconnect the machine from the supply.

– Switch off the machine.

– Wait until the discharge time specified on the warning labels has elapsed.

– Check that it really is in a no-voltage condition, from phase conductor to phase

conductor and phase conductor to protective conductor.

– Check whether the existing auxiliary supply circuits are de-energized.

– Ensure that the motors cannot move.

3. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water.

4. Isolate or neutralize all hazardous energy sources by closing switches, grounding or shortcircuiting or closing valves, for example.

5. Secure the energy sources against switching on again.

6. Ensure that the correct machine is completely interlocked.

1

After you have completed the work, restore the operational readiness in the inverse sequence.

WARNING

Danger to life through a hazardous voltage when connecting an unsuitable power supply

Touching live components can result in death or severe injury.

● Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 5

General information and networking

1.1 Fundamental safety instructions

WARNING

Danger to life when live parts are touched on damaged devices

Improper handling of devices can cause damage.

For damaged devices, hazardous voltages can be present at the enclosure or at exposed

components; if touched, this can result in death or severe injury.

● Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

● Do not use any damaged devices.

WARNING

Danger to life through electric shock due to unconnected cable shields

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

● As a minimum, connect cable shields and the cores of cables that are not used at one end

at the grounded housing potential.

WARNING

Danger to life due to electric shock when not grounded

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when touched,

can result in death or severe injury.

● Ground the device in compliance with the applicable regulations.

WARNING

Danger to life due to fire spreading if housing is inadequate

Fire and smoke development can cause severe personal injury or material damage.

● Install devices without a protective housing in a metal control cabinet (or protect the device

by another equivalent measure) in such a way that contact with fire is prevented.

● Ensure that smoke can only escape via controlled and monitored paths.

Operator panel front: OP 012

6 Manual, 09/2016, A5E36371591B

General information and networking

1.1 Fundamental safety instructions

WARNING

Danger to life through unexpected movement of machines when using mobile wireless

devices or mobile phones

Using mobile wireless devices or mobile phones with a transmit power > 1 W closer than

approx. 2 m to the components may cause the devices to malfunction, influence the functional

safety of machines therefore putting people at risk or causing material damage.

● Switch the wireless devices or mobile phones off in the immediate vicinity of the

components.

WARNING

Danger to life due to fire if overheating occurs because of insufficient ventilation clearances

Inadequate ventilation clearances can cause overheating of components with subsequent

fire and smoke. This can cause severe injury or even death. This can also result in increased

downtime and reduced service lives for devices/systems.

● Ensure compliance with the specified minimum clearance as ventilation clearance for the

respective component.

WARNING

Danger to life when safety functions are inactive

Safety functions that are inactive or that have not been adjusted accordingly can cause

operational faults on machines that could lead to serious injury or death.

● Observe the information in the appropriate product documentation before commissioning.

● Carry out a safety inspection for functions relevant to safety on the entire system, including

all safety-related components.

● Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing.

● Perform a function test.

● Only put your plant into live operation once you have guaranteed that the functions relevant

to safety are running correctly.

Note

Important safety notices for Safety Integrated functions

If you want to use Safety Integrated functions, you must observe the safety notices in the Safety

Integrated manuals.

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 7

General information and networking

1.1 Fundamental safety instructions

1.1.2 Handling electrostatic sensitive devices (ESD)

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

NOTICE

Damage through electric fields or electrostatic discharge

Electric fields or electrostatic discharge can cause malfunctions through damaged individual

components, integrated circuits, modules or devices.

● Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of aluminum

foil.

● Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

● Only place electronic components, modules or devices on conductive surfaces (table with

ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

1.1.3 Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this in mind, Siemens’

products and solutions undergo continuous development. Siemens recommends strongly that

you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state-of-the-art industrial security concept. Third-party products that may be in use should also

be considered. For more information about industrial security, visit this address (http://

www.siemens.com/industrialsecurity).

To stay informed about product updates as they occur, sign up for a product-specific

newsletter. For more information, visit this address (http://support.automation.siemens.com).

Operator panel front: OP 012

8 Manual, 09/2016, A5E36371591B

General information and networking

1.1 Fundamental safety instructions

WARNING

Danger as a result of unsafe operating states resulting from software manipulation

Software manipulation (e.g. by viruses, Trojan horses, malware, worms) can cause unsafe

operating states to develop in your installation which can result in death, severe injuries and/

or material damage.

● Keep the software up to date.

You will find relevant information and newsletters at this address (http://

support.automation.siemens.com).

● Incorporate the automation and drive components into a holistic, state-of-the-art industrial

security concept for the installation or machine.

You will find further information at this address (http://www.siemens.com/

industrialsecurity).

● Make sure that you include all installed products into the holistic industrial security concept.

WARNING

Danger to life due to software manipulation when using exchangeable storage media

Storing files onto exchangeable storage media amounts to an increased risk of infection, e.g.

with viruses and malware. As a result of incorrect parameterization, machines can

malfunction, which in turn can lead to injuries or death.

● Protect files stored on exchangeable storage media from malicious software by taking

suitable protection measures, e.g. virus scanners.

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 9

General information and networking

1.1 Fundamental safety instructions

1.1.4 Residual risks of power drive systems

When assessing the machine- or system-related risk in accordance with the respective local

regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must

take into account the following residual risks emanating from the control and drive components

of a drive system:

1. Unintentional movements of driven machine or system components during commissioning,

operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables

and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of electronic

components

– External influences/damage

– X-ray, ionizing radiation and cosmic radiation

2. Unusually high temperatures, including open flames, as well as emissions of light, noise,

particles, gases, etc., can occur inside and outside the components under fault conditions

caused by, for example:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specification

– External influences/damage

3. Hazardous shock voltages caused by, for example:

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a risk

to people with a pacemaker, implants or metal replacement joints, etc., if they are too close

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly

For more information about the residual risks of the drive system components, see the relevant

sections in the technical user documentation.

Operator panel front: OP 012

10 Manual, 09/2016, A5E36371591B

1.2 Application planning

1.2.1 Secondary electrical conditions

1.2.1.1 Power supply

Requirements for DC power supplies

DANGER

Danger of death caused by unsafe power supply

The DC power supply must be implemented as a circuit of Category PELV/DVC A according

to EN 61800-5-1.

WARNING

General information and networking

1.2 Application planning

Inadequately fused supply cables can be life-threatening

In the case of supply lines > 10 m, protectors must be installed at the device input in order to

protect against lightning (surge).

The DC power supply must be connected to the ground/shield of the NC for EMC and/or

functional reasons. For EMC reasons, this connection should only be made at one point. As

a rule, the connection is provided as standard in the S7-300 I/Os. In exceptional

circumstances when this is not the case, the ground connection should be made on the

grounding rail of the NC cabinet (also refer to /EMC/EMC Installation Guide.)

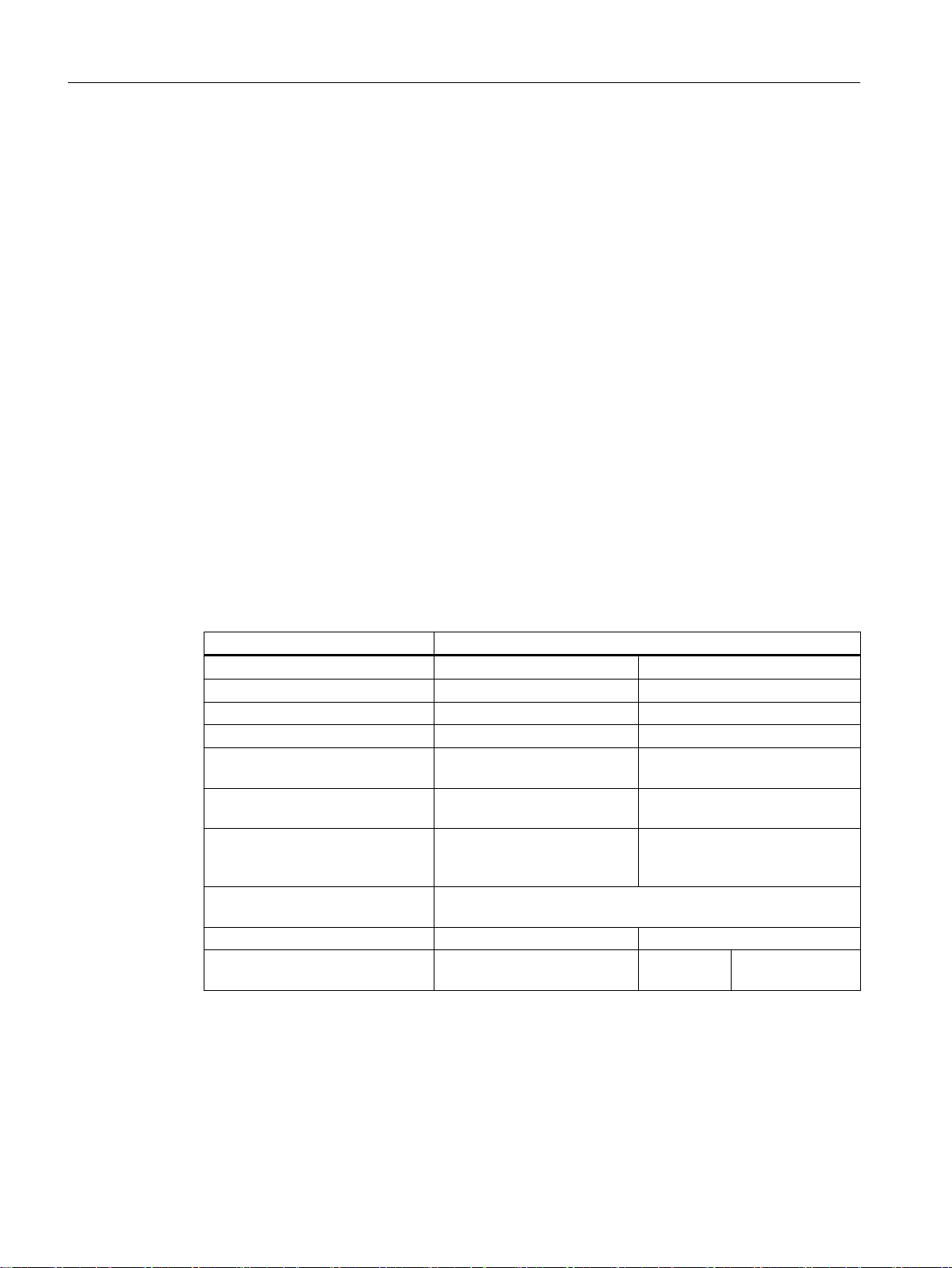

Table 1-1 Requirements of the DC power supply

Rated voltage According to EN 61131-2

Voltage range (mean value)

Voltage ripple, peak/peak

Powering up time when switched

on

Non-periodic overvoltages

Period of overvoltage

Recover time

Events per hour

Transient voltage interruptions Downtime

Recovery time

Events per hour

24 VDC

20.4 VDC to 28.8 VDC

5% (unsmoothed 6-pulse recti‐

fication)

any

≤ 35 V

≤ 500 ms

≥ 50 s

≤ 10

≤ 3 ms

≥ 10 s

≤ 10

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 11

General information and networking

1.2 Application planning

1.2.1.2 Grounding concept

Components

The SINUMERIK 840D sl system consists of a number of individual components which have

been designed so that the system complies with the appropriate EMC and safety standards.

The individual system components are:

● Numerical Control Unit (NCU)

● Machine Control Panel (MCP), Machine Pushbutton Panel (MPP)

● Keyboard

● Operator panels (operator panel front + TCU/PCU)

● Distributor box and handheld unit

● S7-300 I/O with IM 153 interface module

Grounding measures

The individual modules are attached to a metal cabinet panel. Insulating paints on the mounting

points (e.g. tension jacks) must be removed.

It is permissible to cluster the operator control components regarding connection/potential

bonding.

Example: The control panel on the swivel arm.

It is sufficient in this instance to connect the ground connections of, for example, the PCU,

TCU, and operator panel front using a cable and to route a shared grounding conductor to the

central ground connection in the control cabinet.

Additional references

EMC Design Guidelines

1.2.1.3 EMC compatibility

In addition to the protective grounding of system components, special precautions must be

taken to guarantee safe, trouble-free operation of the system. These measures include

shielded signal lines, special equipotential bonding connections, and isolation and shielding

measures.

Shielded signal cables

● For safe and fault-free operation of the system, the specified cables must be used.

● For digital signal transmission, the shield must have a conductive connection at both sides

of the housing.

Operator panel front: OP 012

12 Manual, 09/2016, A5E36371591B

Cable definition

Definition:

● Signal cables (example)

– Data cables (Ethernet, PROFIBUS, sensor cables, etc.)

– Digital I/Os

– Cables for safety functions (emergency stop, enabling)

● Power cables (example)

– Low-voltage supply lines (230 VAC, +24 VDC, etc.)

– Motor cables

Rules for routing cables

In order to achieve the greatest possible EMC compatibility for the complete system (control,

power unit, machine), the following EMC measures must be carefully observed:

● If necessary, signal and power cables may cross one another (if possible at an angle of

90°), but must never be laid close or parallel to one another.

General information and networking

1.2 Application planning

● Only use cables approved by SIEMENS for the signal lines from and to the Control Unit.

● Signal cables must not be routed close to strong external magnetic fields (e.g. motors and

transformers).

● If signal lines cannot be routed a sufficient distance away from other cables, they must be

installed in grounded cable ducts (metal).

● The operator panel fronts, MCPs, MPPs, and full keyboards must be installed in metallically

enclosed EMC-compatible housings.

Note

For further information on interference suppression measures and the connection of

shielded cables, please refer to the EMC Installation Guide.

EMC limit values in South Korea

The EMC limit values to be complied with for South Korea correspond to the limit values of the

EMC product standard for variable-speed electric drives EN 61800-3, Category C2, or limit

value class A, Group 1 according to EN 55011. By applying suitable supplementary measures,

the limit values according to Category C2 or according to limit value class A, Group 1, are

maintained. Further, additional measures may be required, for instance, using an additional

radio interference suppression filter (EMC filter).

The measures for EMC-compliant design of the system are described in detail in this manual

respectively in the Installation Guideline EMC.

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 13

General information and networking

1.2 Application planning

Please note that the final statement on compliance with the standard is given by the respective

label attached to the individual unit.

1.2.2 Ambient climatic and mechanical conditions

1.2.2.1 Transport and storage conditions

The components of the SINUMERIK 840D sl system exceed the requirements according to

EN 61800‑2 with regard to shipping and storage conditions.

The following data applies under the following conditions:

● Long-term storage in the transport and product packaging:

At weather-protected locations that have continuous contact with outside air through

openings.

● Transport in the transport packaging:

– In unventilated containers under conditions not protected from weather effects.

– In the “cold" in accordance with outside air.

– Air transport in the air-conditioned cargo hold.

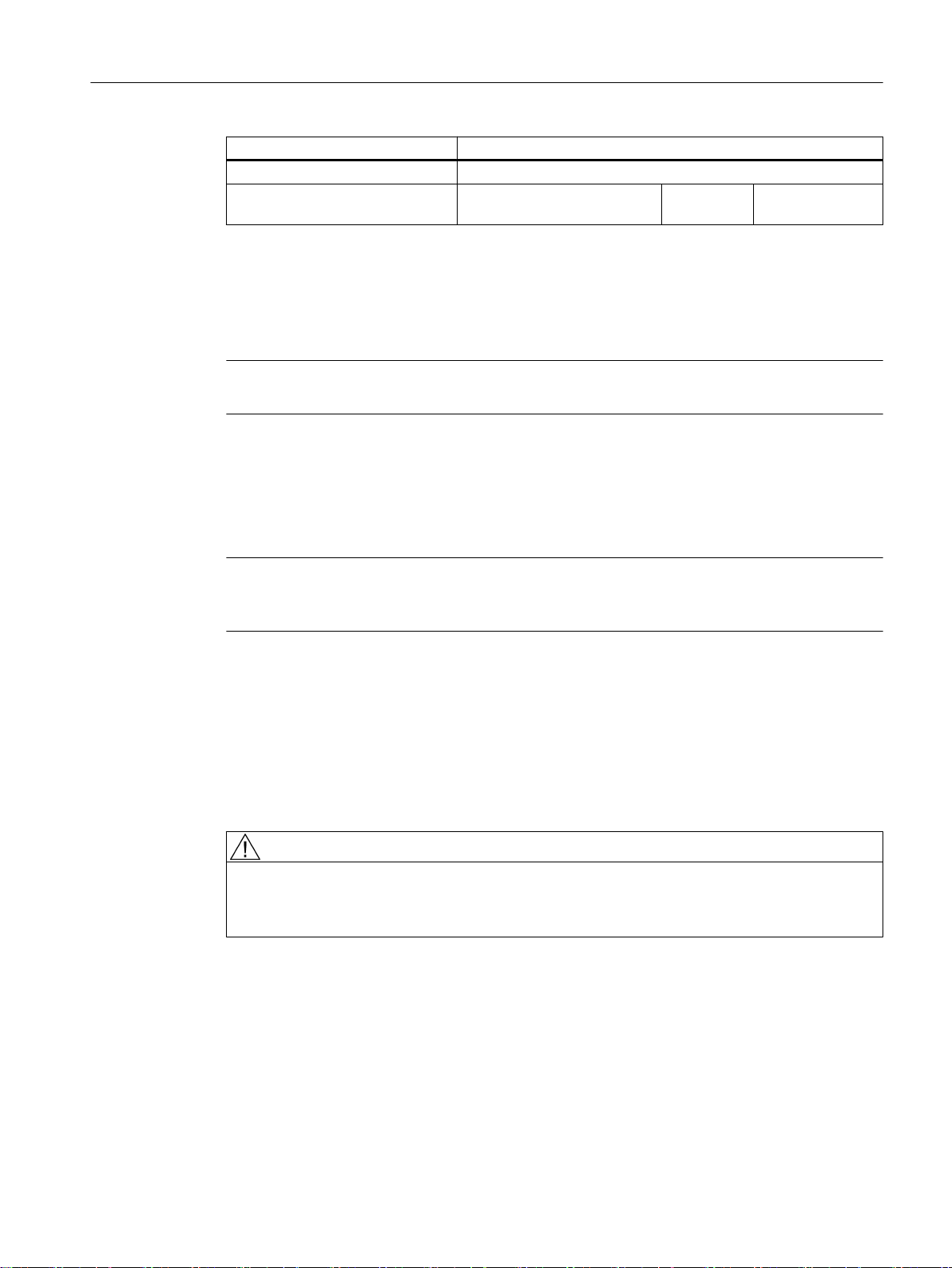

Table 1-2 Ambient conditions during storage and transport

Type of condition Permissible range/class

Transport Storage

Classification EN 60721-3-2 EN 60721-3-1

Climate class 2K4 1K4

Ambient temperature

Biological environmental condi‐

tions

Chemically active environmental

conditions

Maximum permissible tempera‐

ture change

Relative humidity (without conden‐

sation)

Precipitation, rain 6 mm/min

Water other than rain 1 m/s and wet loading surfa‐

1)

-40° C ... +70° C -25° C ... +55° C

2)

2B1

3)

2C2

Direct interaction in air/air:

1B1

1C2

30 k/h

2)

3)

-40°/+30° C at 95% relative

humidity

5 to 95%

ces

2)

Not permis‐

4)

Not permissible

5)

sible

1 m/s and wet

loading surfaces

4)

Operator panel front: OP 012

14 Manual, 09/2016, A5E36371591B

Type of condition Permissible range/class

Height Max. 4,000 m above sea level

Condensation, splash water,

icing, salt spray

1)

Transport and storage of operator panel fronts and diskette drives: -20° C to +55° C.

2)

Mold growth, slime, rodents, termites and other animal vermin are not permissible.

3)

In marine- and weather-resistant transport packaging (container).

4)

For storage in the transport packaging.

5)

For storage in the product packaging.

Note

Remove the transport protective foil and packaging material before installing the components.

Shipping backup batteries

Backup batteries must only be shipped in the original packaging. No special authorization is

required to ship backup batteries. The lithium content is approximately 300 mg.

General information and networking

1.2 Application planning

Permissible Not permis‐

sible

5)

Permissible

4)

Note

The backup battery is classified as a hazardous substance, Class 9 in accordance with the

relevant air-freight transportation regulations.

Storage of backup batteries

Always store backup batteries in a cool and dry place. The batteries have a maximum shelf

life of 10 years.

Rules for handling backup batteries

WARNING

Incorrect handling of backup batteries can lead to a risk of ignition, explosion and combustion

The stipulations of DIN EN 60086-4, in particular regarding avoidance of mechanical or

electrical tampering of any kind, must be complied with.

● Do not open a battery. Replace a faulty battery only with the same type.

● Obtain replacement batteries only from Siemens.

● Always try to return low batteries to the manufacturer or deliver these to a registered

recycling company.

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 15

General information and networking

1.2 Application planning

1.2.2.2 Operating conditions

The components of the SINUMERIK 840D sl system are intended for a weatherproof, fixed

location. The documented

environmental conditions apply to the climate in the immediate vicinity of the units and to the

entry of the cooling air. They exceed the requirements according to EN 60204-1, EN 61800-2,

EN 61131-2 and IEC 62477-1.

NOTICE

Damage to components by coolants and lubricants

The SINUMERIK operator components have been designed for industrial use, particularly on

machine tools and production machines. This also takes into account the use of commercially

available coolants and lubricants. The use of aggressive compounds and additives can

damage components and result in their failure.

Contact between the operator components and coolants and lubricants should be avoided

as far as possible, as resistance to all coolants and lubricants cannot be guaranteed.

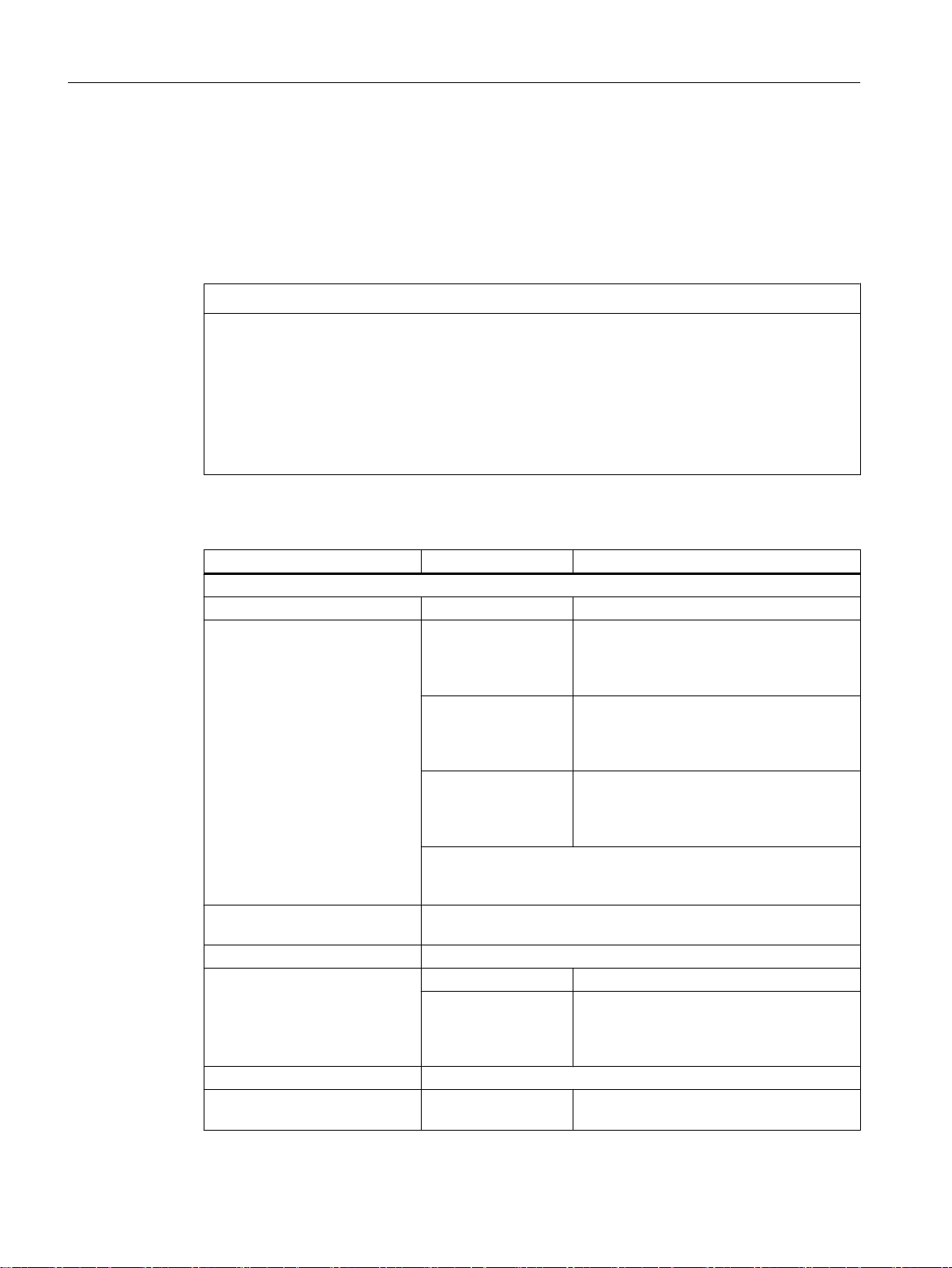

Table 1-3 Ambient conditions for operation

Environmental conditions Application areas Remarks

Climatic environmental conditions

Climate class Better than class 3K3 According to EN 60721‑3-3

Permissible ambient tempera‐

ture when installed vertically

Relative humidity (without con‐

densation)

Condensation, formation of ice Not permissible

Dripping water, spray, splash

water, jet-water according to de‐

gree of protection

Max. installation altitude Up to 4000 m (13123 ft) above sea level

Air pressure 620 hPa ... 1060 hPa According to altitude range 0 m to 4000 m

0 ... 45 °C (32 ... 113

°F), up to 2000 m

(6562 ft) above sea

level

0 ... 55 °C (32 ... 131

°F), up to 2000 m

(6562 ft) above sea

level

5 ... 55 °C (41 ... 131

°F), up to 2000 m

(6562 ft) above sea

level

Above an altitude of 2000 m (6562 ft), the max. ambient temperature

decreases by 7 °C (44.6 °F) for every 1000 m (3281 ft) increase in

altitude

5% to 95% (60% when corrosive gases and/or dusts are present)

Not permissible All components, except ...

Permissible For handheld units, front side of operator

Except PCU50.5;

front-side for OP, MCP/MPP and CNC

standard keyboards KB.

All, rear-side for OP, MCP/MPP and CNC

standard keyboards KB.

For PCU50.5

and machine control panels (MCP and

MPP), front side of the keyboards KB 310

and KB 483C

(0 ft to 13123 ft) above sea level

Operator panel front: OP 012

16 Manual, 09/2016, A5E36371591B

General information and networking

1.2 Application planning

Environmental conditions Application areas Remarks

Biological, chemical and mechanical influences, pollutants

Biological environmental conditions Class 3B1 according to EN 60 721-3-3:

Mold, mold growth, slime, rodents, termite

and other animal vermin are not permissible.

Chemically active environmental conditions Class 3C1 according to EN 60721‑3‑3

Mechanically active environmental conditions Class 3S1 according to EN 60721‑3‑3:

Conductive dust not permissible.

Classification of the mechanical

environment

Degree of contamination 2

EMC conducted / radiation Class C3 according to EN 61800-3

3M3 for components on the machine

3M1/3M2 for components in the control cab‐

inet

Note

The user must consider radio interference for the complete system. Particular attention should

be paid to cabling. Please contact your sales representative for assistance and support.

If compliance with limit value class C2 is required, please contact your local sales

representative.

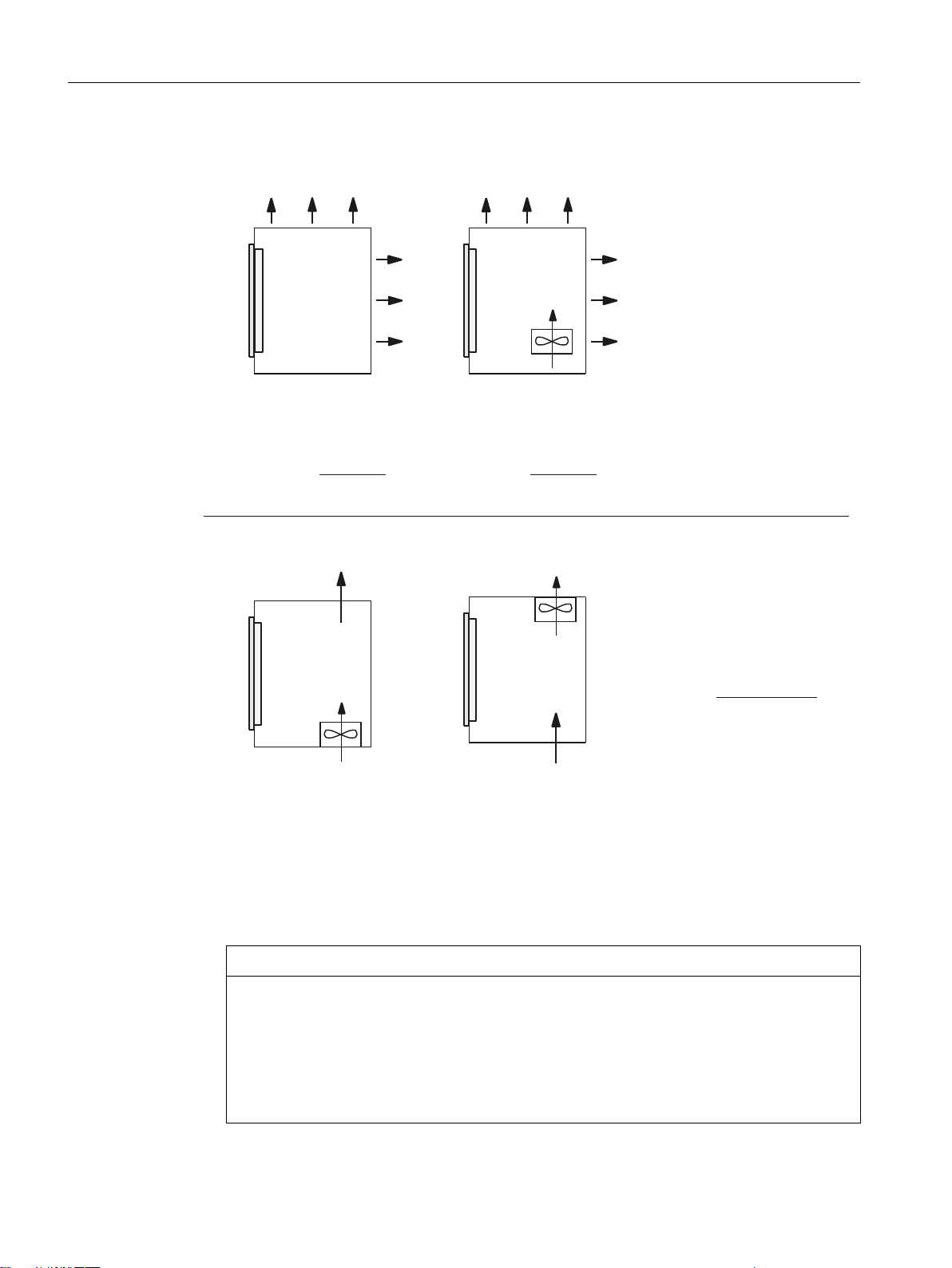

1.2.2.3 Cooling

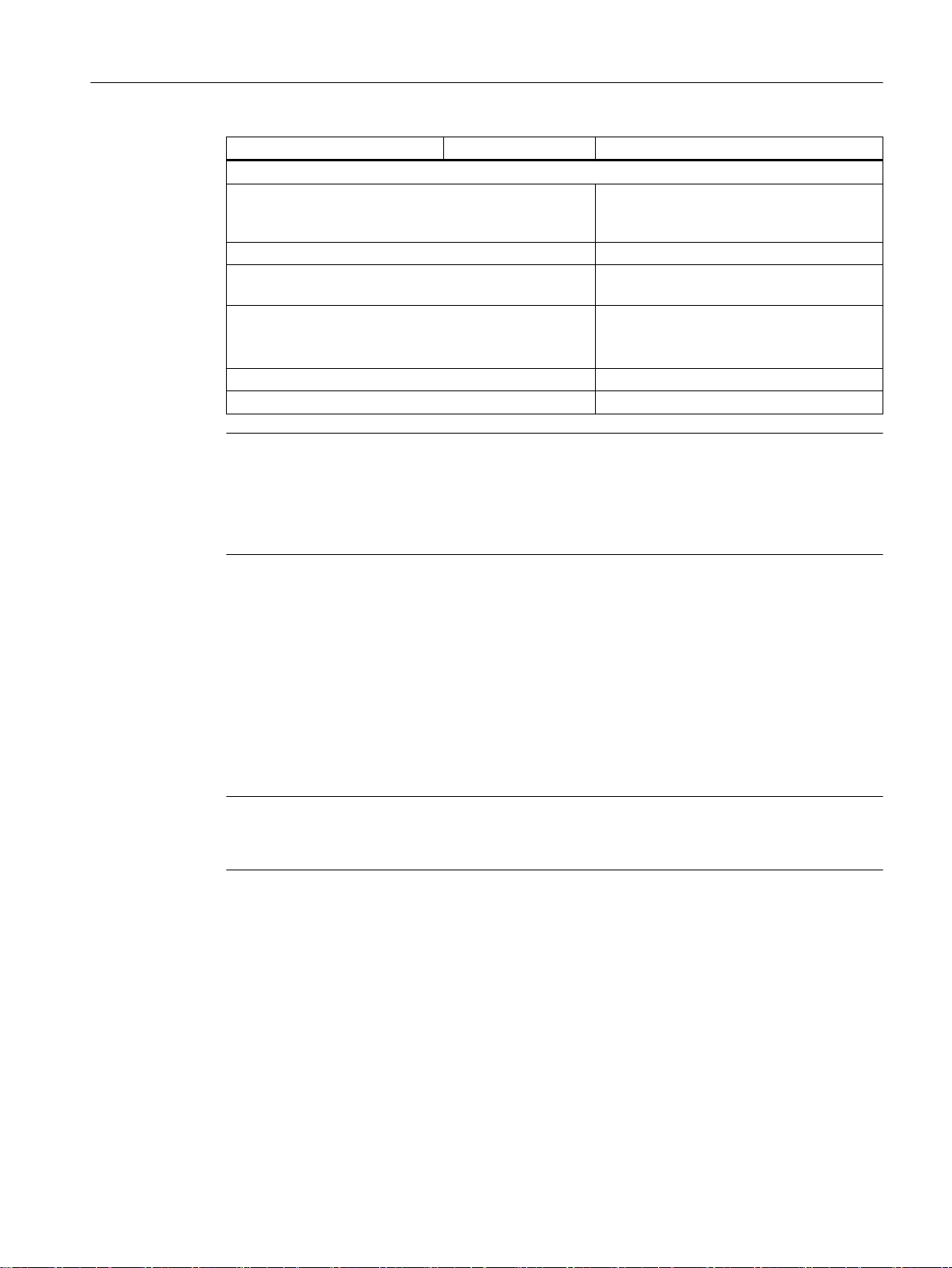

To calculate the heat dissipation, the total power loss P

in a housing must be taken into account.

Total power loss P

Convection surface area A [m2]:

The surface areas of the front and bottom sides are not included in the convection surface

area calculation.

Note

A recommended value for the power loss of the operator control components is contained in

the "Technical data" section of the associated component (see "Power consumption").

Means of heat dissipation

Heat dissipation can take place as follows:

● Heat dissipation by natural convection

● Heat dissipation by natural convection and internal air turbulence

● Heat dissipation by open-circuit cooling

● Heat dissipation by open-circuit ventilation

= PV1 + PV2 + PV3 +... [W]

Vtotal

of all heat-generating components

Vtotal

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 17

+HDWGLVVLSDWLRQ

XVLQJRSHQFLUFXLWYHQWLODWLRQ

2SHUDWRU

SDQHOIURQW

+HDWGLVVLSDWLRQ

XVLQJRSHQFLUFXLWYHQWLODWLRQ

7KHUHTXLUHGYROXPHWULF

IORZIRUGLVVLSDWLQJWKHKHDW

ORVVLVFDOFXODWHGXVLQJ

DSSUR[LPDWLRQVIURP

2SHUDWRU

SDQHOIURQW

+HDWGLVVLSDWLRQ

XVLQJQDWXUDOFRQYHQWLRQDQG

LQWHUQDOWXUEXOHQFH

+HDWGLVVLSDWLRQ

XVLQJQDWXUDOFRQYHFWLRQ

7KHUHTXLUHGIUHHFRQYHFWLRQVXUIDFH$>P@RIWKH

URRPWREHFRQYHUWHGVWHHORUDOXPLQXPVKHHWLQJPPWKLFNQHVVLVFDOFXODWHGEDVHGRQ

DWHPSHUDWXUHGLIIHUHQFH77 ෙ7ุ.DSSUR[LPDWHGIURP

YROXPHWULFIORZRIWKHIDQ

PK

2SHUDWRU

SDQHOIURQW

2SHUDWRU

SDQHOIURQW

39

JHV

>:@

39

JHV

>:@39

JHV

>:@

7

7

˂7>.@

9>PK@

7

7

˂7>.@

$>P@

7

7

˂7>.@

$>P@

7

7

General information and networking

1.2 Application planning

Figure 1-1 Means of heat dissipation

Fan design

● The fan must be positioned to produce an optimum heat dissipation. A clearance of 10 mm

must be maintained in front of the fan.

● The inlet and outlet slots must remain free for the open-circuit ventilation.

● Air filters must be provided to maintain the permitted environmental conditions.

NOTICE

Damage to the operating components caused by temperatures that are too high or too low

Contaminated air filters impair the desired heat dissipation. For handling the air filters, pay

attention to:

● Proper handling

● Regular replacement

● Correct disposal

18 Manual, 09/2016, A5E36371591B

Operator panel front: OP 012

Guidelines

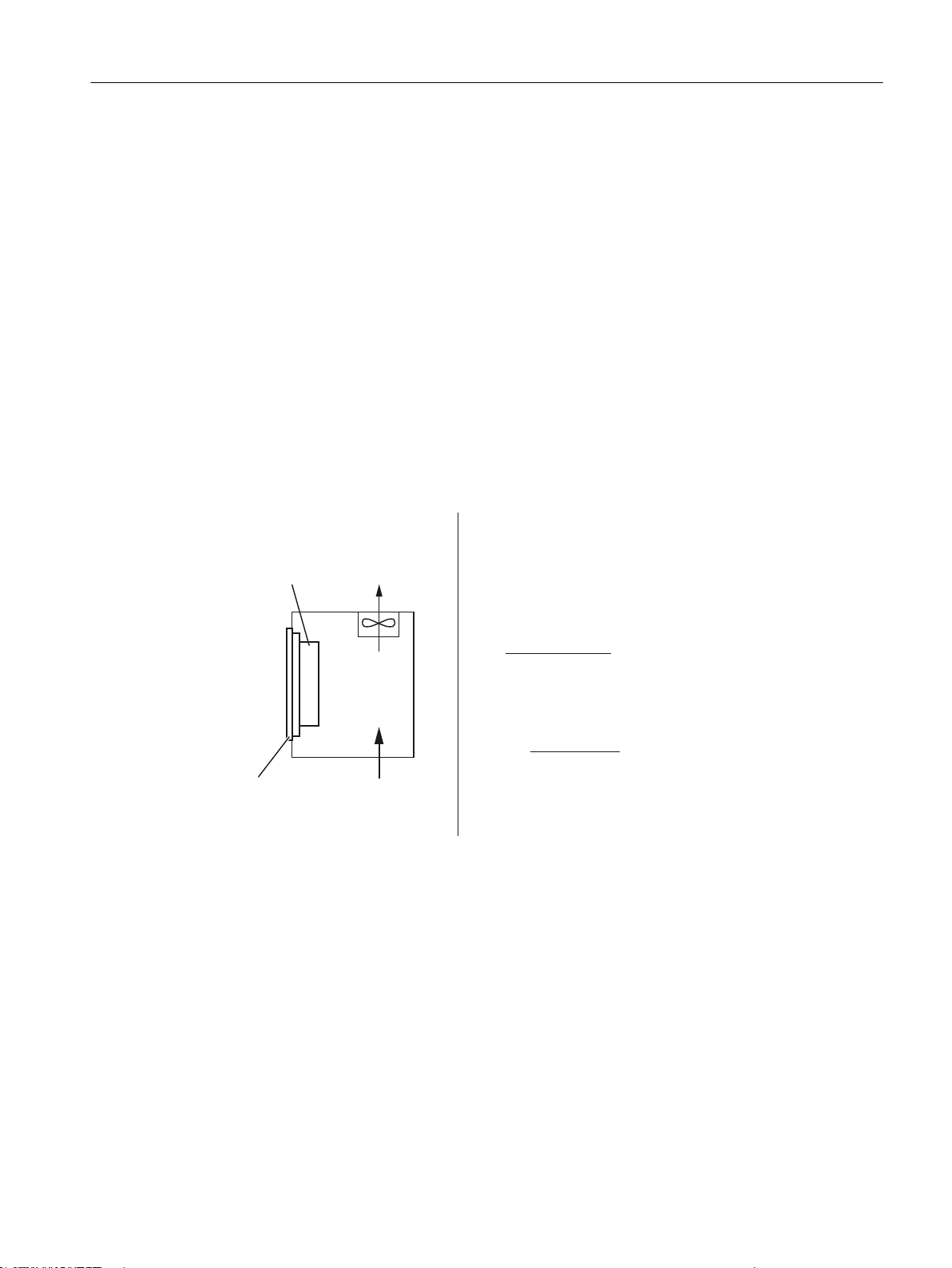

&DOFXODWLRQRIWKHSRZHUORVV

LQFOXGLQJLQWHUQDOSRZHUVXSSO\XQLW

([DPSOHIRUKHDWGLVVLSDWLRQZLWKRSHQFLUFXLWYHQWLODWLRQ

3&8ZLWK23

PD[:

,QWHUQDOWHPSHUDWXUH 7 r&

([WHUQDOWHPSHUDWXUH 7 r&

9 >PK@

39

JHV

>:@

39

JHV

:

˂7>.@

3&8:

23:

7

7

ය˂7 .

3&8

23

General information and networking

1.2 Application planning

If the convection area A [m2] does not suffice for the "heat dissipation using natural convection",

then use:

● "Heat dissipation using natural convection and internal turbulence" for hot spots and heat

concentrations in housings subject to space constraints. The total power loss P

Ltot

for

thermally critical applications can be determined as follows:

– Current measurement for a 24 V supply voltage

– Power loss P

● Heat dissipation using open-circuit ventilation

Calculation of the volumetric flow

The power loss (thermal) dissipated by the components in an operator unit is to be dissipated

using open-circuit ventilation. The volumetric flow V required for this should be calculated at

a difference in temperature of T2 - T1 = ΔT ≥ 10K.

[W] = U (24 V) * |measured value in ampères|

Ltot

Figure 1-2 Calculating heat dissipation for PCU 50.5 with OP 019

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 19

General information and networking

1.2 Application planning

1.2.3 Standards and approvals

Approvals

CE approval

Figure 1-3 CE marking

The operator panels and the safety-relevant accessories satisfy the requirements and

protection objectives of the following EC directives. The operator panels and the safetyrelevant accessories comply with the harmonized European standards (EN), promulgated in

the Official Journals of the European Community:

● 2004/108/EC "Electromagnetic Compatibility" (EMC directive)

● Directive 2006/42/EC of the European Parliament and Council of May 17, 2006, on

machinery, and Directive 95/16/EC (amendment)

SIBE Switzerland Certification Service

For the HT 2 and HT 8 units.

Figure 1-4 Symbol of the certifying body

HT 2

The HT 2 operator panel and the safety-relevant accessories (is identified in the "Accessories"

section for the respective devices) satisfy Category 3, PL d according to EN ISO 13849-1:2008.

The safety function Enabling device for special mode control and the emergency stop button

satisfy the following requirements:

● Category 3, PL d according to EN ISO 13849-1:2008

● Requirements of EN 60204-1:2006, when complying with the safety instructions in the

relevant chapters of this documentation

HT 8

The HT 8 operator panel and the safety-relevant accessories (is identified in the "Accessories"

section for the respective devices) satisfy Category 3, PL d according to EN ISO 13849-1:2008.

The emergency stop button meets the following requirements:

● Category 3, PL d according to EN ISO 13849-1:2008

● Requirements of EN 60204-1:2006, when complying with the safety instructions in the

relevant chapters of this documentation

Operator panel front: OP 012

20 Manual, 09/2016, A5E36371591B

Risk assessment

General information and networking

1.2 Application planning

The safety function Enabling device for special mode control satisfies the following

requirements:

● Category 4, PL e according to EN ISO 13849-1:2008

● Requirements of EN 60204-1:2006, when complying with the safety instructions in the

relevant chapters of this documentation

Address:

NSBIV AG, SIBE Switzerland, Brünigstrasse 18, CH-6005 Lucerne

Accreditation SCESp 0046 / Notified Body 1247

Number of the prototype test certificate: No. 1416

The following standards must be used to perform the risk assessment:

● EN ISO 12100-1:2003 and EN ISO 12100-2:2003, General Design Guidelines for Machines

● EN ISO 14121-1:2007, Risk Assessment for Machinery

● EN ISO 13849-1:2008, Safety-related Parts of Machines

These considerations result in a category (B, 1, 2, 3, 4) and a performance level (PL a to e) in

accordance with EN ISO 13849-1:2008 that ultimately dictate how the safety-related parts of

the system to be monitored must be constructed.

The connection examples with different monitoring units in "Handheld units", Section: "HT 2",

Section: "Connections" → "Connection examples for acknowledgment button and Emergency

Stop button" can also be used for other operator panels and demonstrate how Category 3, PL

d according to EN ISO 13849-1:2008 can be attained with the safety-related parts of the

operator panels. Note that the overall concept of the installation must be designed with this in

mind.

1.2.4 Recycling and disposal

Products should be disposed of corresponding to the relevant national regulations.

The products described in this manual can be mostly recycled due to the fact that they contain

very few damaging substances. To recycle and dispose of your old device in an

environmentally friendly way, please contact an appropriate disposal company.

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 21

General information and networking

1.3 Connecting

1.3 Connecting

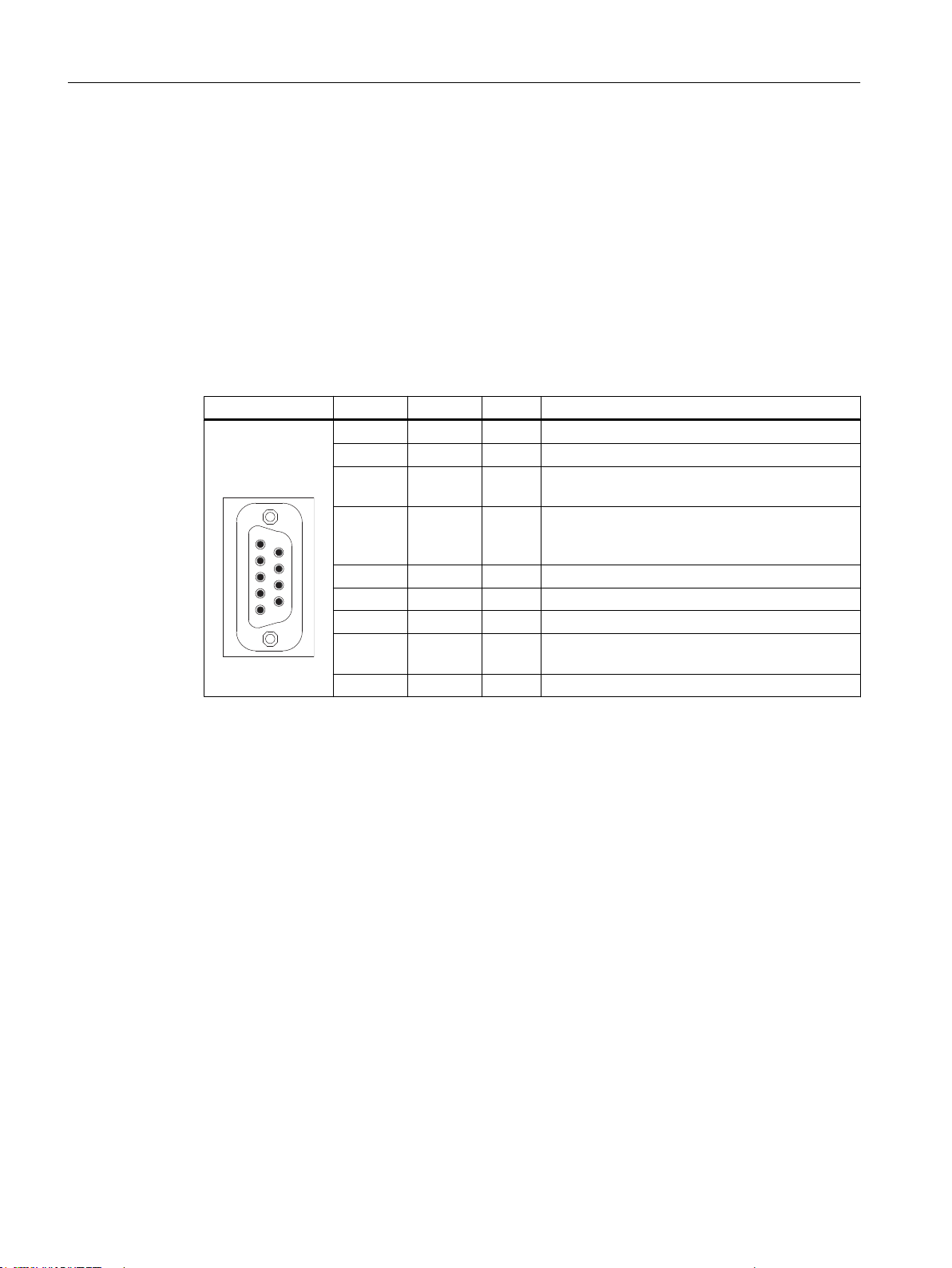

1.3.1 Pin assignment of the interfaces

The pins of the component interfaces are assigned as specified in the tables below. Any

deviations are indicated at the relevant point.

Signal type:

I Input

O Output

B Bidirectional (inputs/outputs)

V Power supply

- Ground (reference potential) or N.C. (not connected)

Power supply interface

Serial interface COM1

Connector type: Terminal block, 3-pin plug connector

Max. cable length: 10 m

Table 1-4 Assignment of the power supply interface

Pin Name Type Meaning

1 P24 (+) - 24 VDC potential (20.4 to 28.8 VDC)

2 M24 (-)

3 SHIELD (PE) Shield potential

VI

Ground 24 V

9-pin sub-D connector

Table 1-5 Assignment of the serial interface COM1 (V.24/RS232)

Connector Pin Name Type Remark

1 DCD (M5)

2 RxD (D2) Serial receive data

3 TxD (D1)

4 DTR (S1) Data terminal ready

5 GND (E2) - Ground (reference potential)

6 DSR (M1) I Data Set Ready

7 RTS (S2) O Request To Send

8 CTS (M2)

9 RI (M3) Incoming call

Receive signal level (carrier)

I

Serial transmit data

O

Clear To Send

I

22 Manual, 09/2016, A5E36371591B

Operator panel front: OP 012

USB interfaces

General information and networking

1.3 Connecting

The USB interfaces are implemented as sockets and comply with the generally valid standard.

The version information (1.1, 2.0 etc.), the maximum velocity (low speed, full speed, etc.) and

the socket type (A or B) are documented in the individual sections for the associated devices.

In principle, USB interfaces have the following characteristics:

● Integrated power supply up to 500 mA for each socket.

● Maximum cable length 3 m (Length including the supply cable to the hub and the connected

terminal device; only 1 hub at maximum is permitted. It should be noted that some

keyboards already have a hub.)

NOTICE

Cables that are too long can cause the screen to freeze

Observe the following restrictions for the USB front interface for connecting operator

panels to the keyboard, mouse or USB FlashDrive:

● Maximum cable length: 1.8 m

● Extension cables are not permissible

● Hot-plugging-capable devices are connected during operation and are identified

automatically.

Note

Correct identification is only guaranteed for USB I/Os that comply to 100% with the USB

specification.

Table 1-6 Assignment of the USB interface

Type A socket Type B socket Pin Name Type Remark

1 P5V_fused V + 5 V (fused)

2 Data3 Data+ Data +

4 GND V Ground (reference potential)

Data -

B

USB sticks

If you want to connect a USB stick to the USB interface, preferably use the tested SIMATIC

USB stick 16 GB for this purpose (Article No.: 6ES7648-0DC60-0AA0). Alternatively, you can

use a USB stick with any memory size. It must, however, meet the following minimum

requirements:

● File system: FAT16 or FAT32

● Partitioning: only in PC partition format (MBR)

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 23

General information and networking

1.3 Connecting

USB sticks that deviate from these requirements have not been tested can may not be

recognized by the NCU.

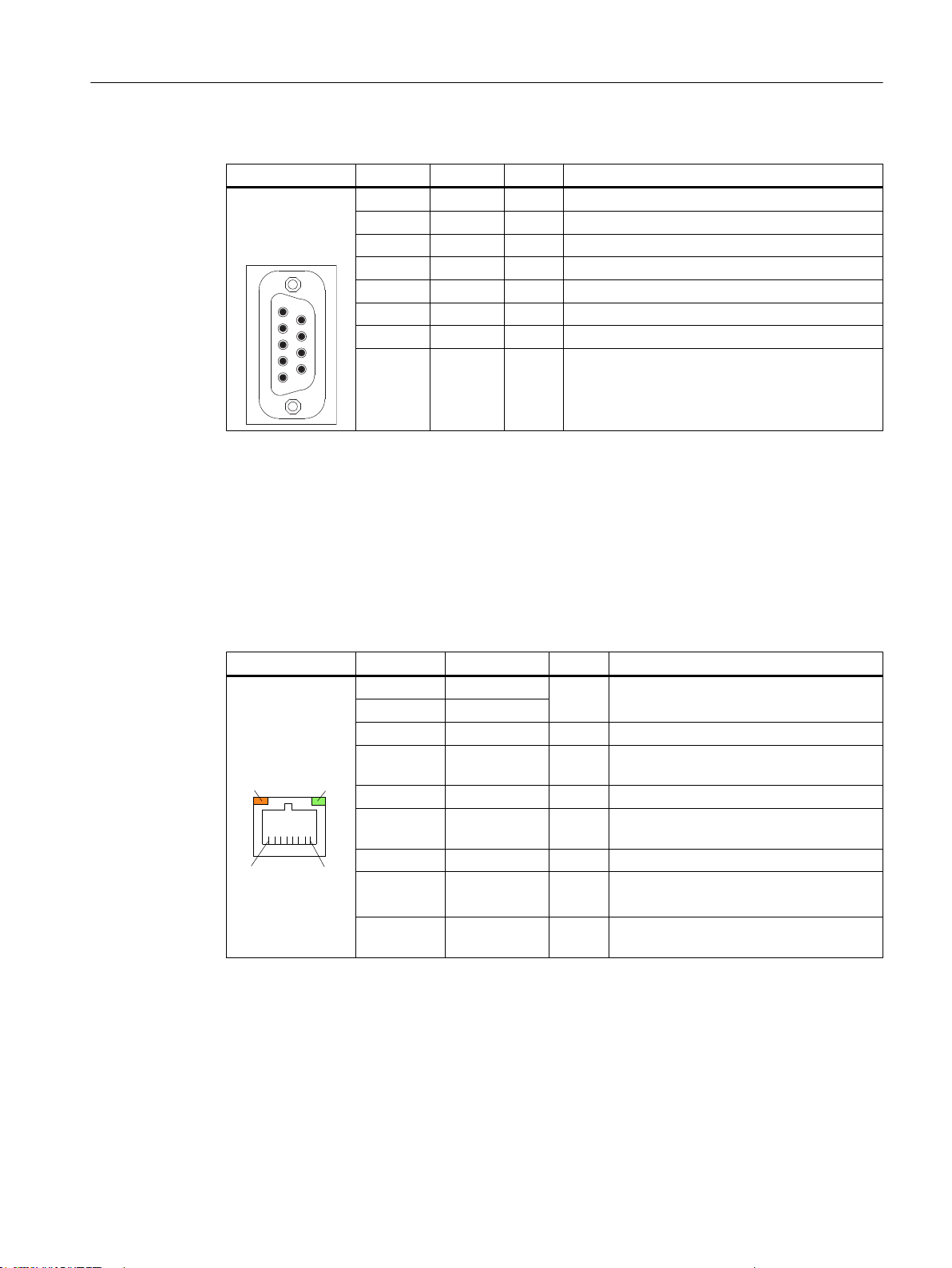

PROFIBUS DP / MPI interface

Connector type: 9-pin sub-D socket

Max. data transmission rate: 12 Mbit/s

Max. cable length: 100 m

Table 1-7 Assignment of the PROFIBUS DP / MPI interface

Connector Pin Name Type Remark

1,2 N.C. - Not connected

3 LTG_B B Signal line B of MPI module

4 RTS_AS I Control signal for receive data current. Signal 1

active if directly connected control is sending.

5 M5EXT V Return line (GND) of 5 V supply. Current load

from a load of 90 mA max. connected between

P5EXT and M5EXT.

6 P5EXT V 5 V supply (current load see M5EXT)

7 N.C. - Not connected

8 LTG_A B Signal line A of MPI module

9 RTS_PG O RTS signal of MPI module; signal is "1", when

PG is sending

Shield - On connector housing

PROFIBUS DP interface

Connector type: 9-pin sub-D socket

Max. data transmission rate: 12 Mbit/s

Max. cable length: 100 m

Operator panel front: OP 012

24 Manual, 09/2016, A5E36371591B

Table 1-8 Assignment of the PROFIBUS DP interface

/('/('

Connector Pin Name Type Remark

Ethernet RJ45 interface

Connector type: Standard RJ45 socket

Max. data transmission rate: 10/100/1000 Mbit/s

Max. cable length: 100 m

General information and networking

1.3 Connecting

1,2 N.C. - Not connected

3 RS_DP B RS-485 differential signal

4 RTS_DP O Request To Send

5 M5EXT V 5 V external ground

6 P5EXT V 5 V external potential

7 N.C. - Not connected

8 XRS_DP B RS-485 differential signal

9 N.C. - Not connected

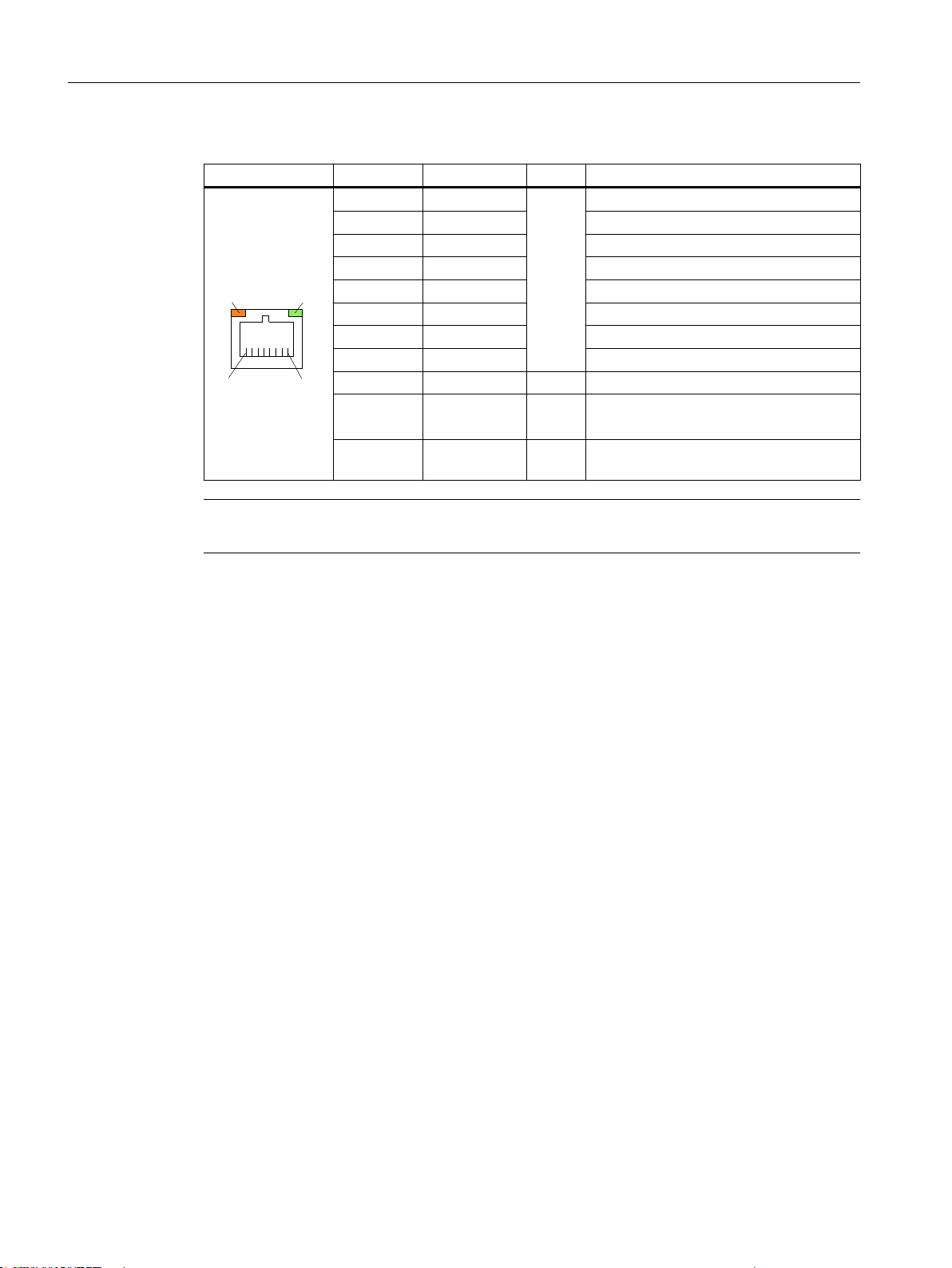

Table 1-9 Assignment of the Ethernet RJ45 interface 10/100 Mbit/s

Connector Pin Name Type Remark

1 TxD+

2 TxD3 RxD+ I Receive data

4/5 GND - (terminated internally with 75 Ω; not re‐

6 RD- I Receive data

7/8 GND - (terminated internally with 75 Ω; not re‐

Shield - - On connector housing

- Green LED

(right)

- Orange LED

(left)

O Transmit data

quired for data transmission)

quired for data transmission)

- Lights up: 10 or 100 Mbit/s

Off: No or faulty connection

- Illuminated: Data exchange

Off: No data exchange

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 25

/('/('

General information and networking

1.3 Connecting

Table 1-10 Assignment of the Ethernet RJ45 interface 1000 Mbit/s

Connector Pin Name Type Remark

Note

1 DA+ B Bidirectional pair A+

2 DA- Bidirectional pair A3 DB+ Bidirectional pair B+

4 DC+ Bidirectional pair C+

5 DC- Bidirectional pair C6 DB- Bidirectional pair B7 DD+ Bidirectional pair D+

8 DD- Bidirectional pair D-

Shield - - On connector housing

- Green LED

(right)

- Orange LED

(left)

- Illuminated orange: 1000 Mbit/s

Off: No or faulty connection

- Illuminated: Data exchange

Off: No data exchange

Connection only on LAN, not on telecommunication networks!

26 Manual, 09/2016, A5E36371591B

Operator panel front: OP 012

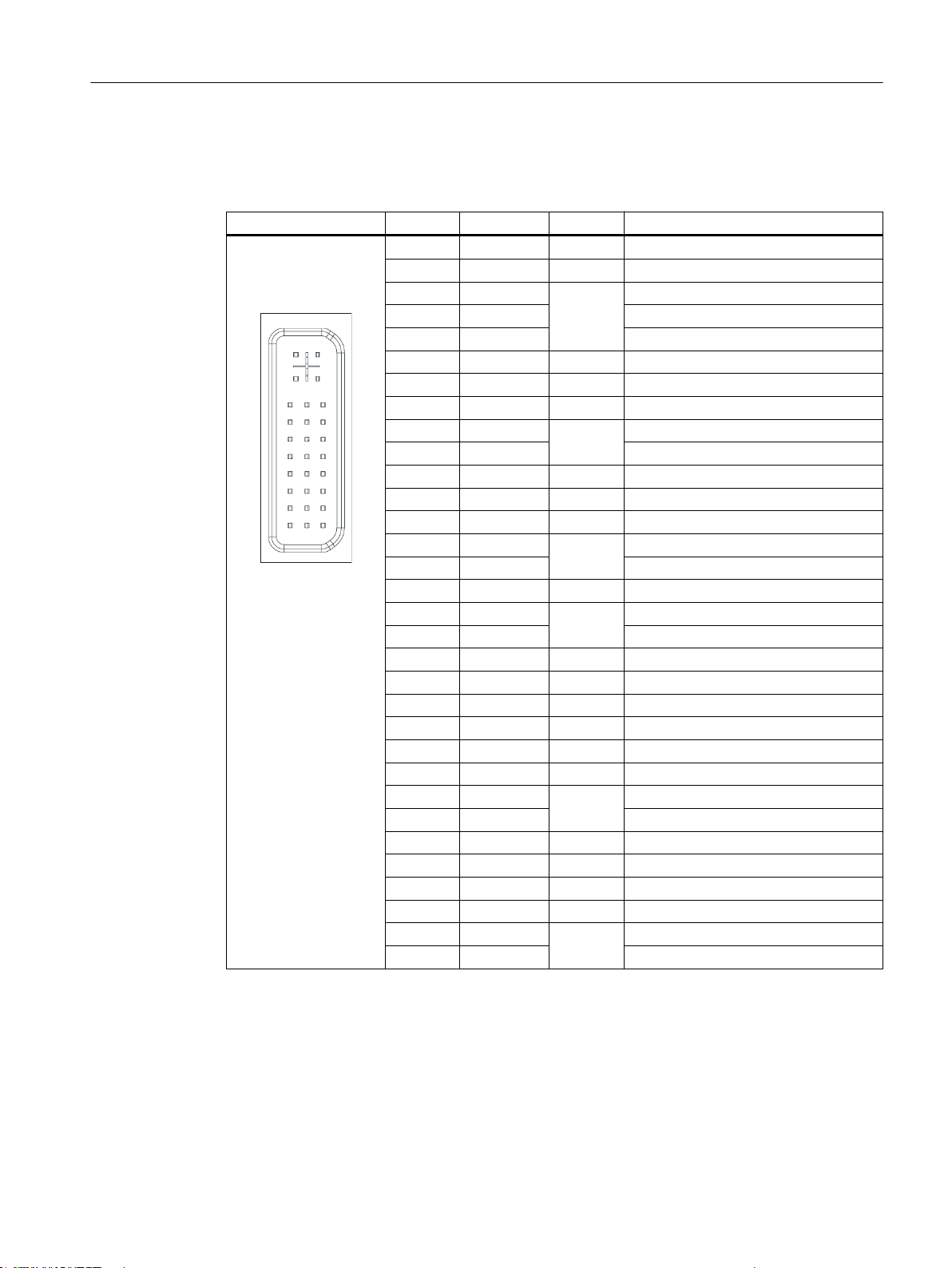

DVI-I interface

&

&

&

&&

Table 1-11 Assignment of DVI-I interface

Connector Pin Name Type Remark

S GND - Ground

S1 GND - Ground

C1 R

C2 G Green

C3 B Blue

C4 HSYNC O Horizontal synchronizing pulse

C5 GND - Ground

CSA GND - Ground

1 TX2N

2 TX2P TDMS data 2+

3 GND - Ground

4 N.C. - Not connected

5 N.C. - Not connected

6 DDC CLK

7 DDC CLK DDC data

8 VSYNC O Vertical synchronizing pulse

9 TX1N

10 TX1P TDMS data 1+

11 GND - Ground

12 N.C. - Not connected

13 N.C. - Not connected

14 + 5 V VO + 5 V

15 GND VO Ground

16 MONDET I Hot plug detect

17 TX0N

18 TXoP TDMS data 0+

19 GND - Ground

20 N.C. - Not connected

21 N.C. - Not connected

22 GND - Ground

23 TXCP

24 TXCN TDMS clock -

General information and networking

1.3 Connecting

Red

O

TDMS data 2-

O

DDC clock

B

TDMS data 1-

O

TDMS data 0-

O

TDMS clock +

O

I/O USB interface

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 27

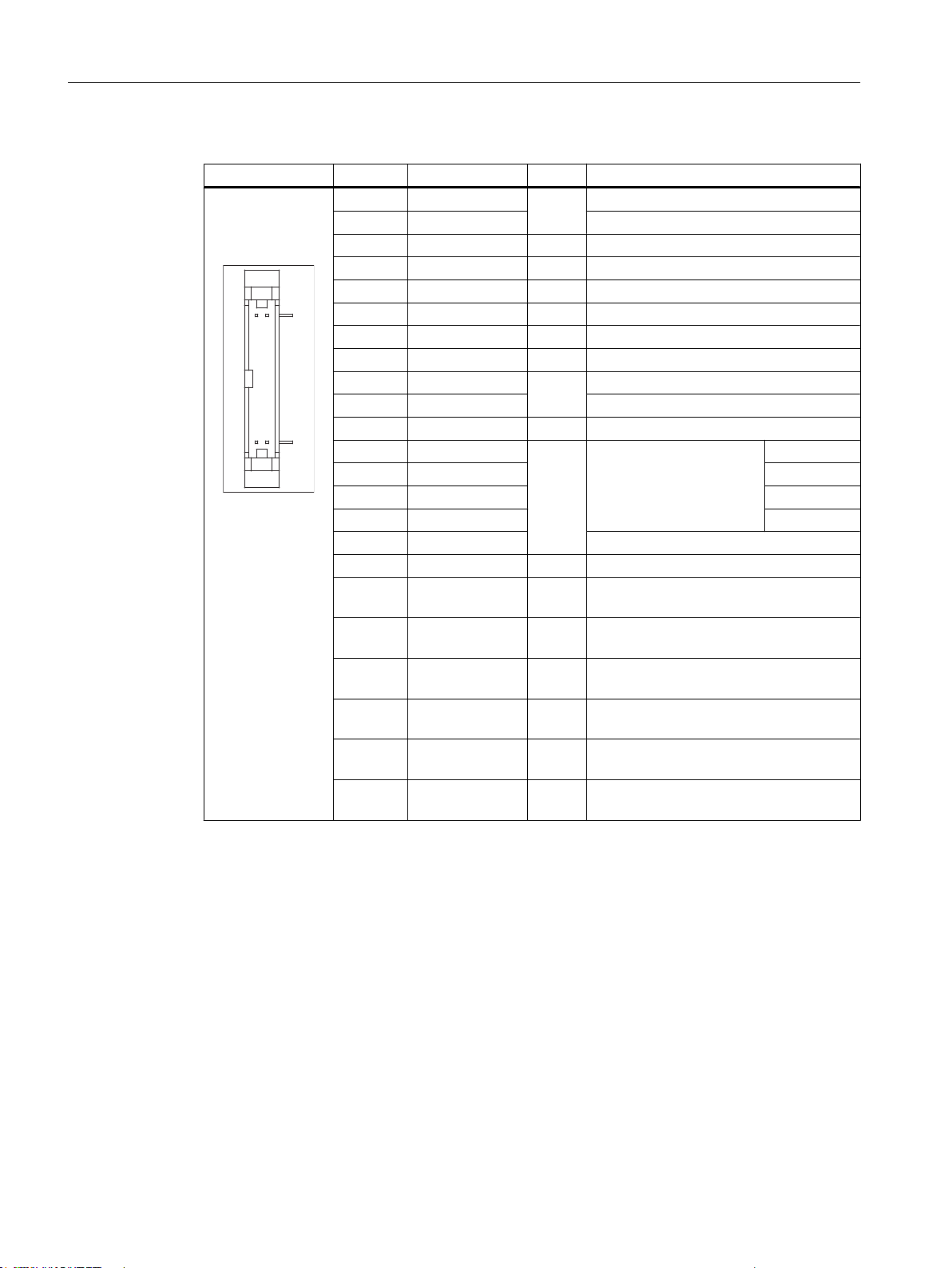

All signals required for connecting operator panel fronts, with the exception of the display

interface, are assigned to this interface.

Associated interface cable: K1

Connector type: 2 x 13-pin socket connector

General information and networking

1.3 Connecting

Table 1-12 Allocation of the I/O USB interface

Connector Pin Name Type Meaning

1 GND

2 P12C +power supply for backlight inverter

3 BL_ON O Backlight On

4 P5V_fused VO +5 V VCC (fused in PCU/TCU)

5 GND VO Ground

6 P3V3_fused VO +3.3 V VCC (fused in PCU/TCU)

7 - 10 N.C. - Not connected

11 P5V_fused VO +5 V VCC (fused in PCU/TCU)

12 USB_D1M

13 USB_D1P USB data+ Channel 1

14 GND VO Ground

15 LCD_SEL0

16 LCD_SEL1 2

17 LCD_SEL2 3

18 LCD_SEL3 4

19 RESET_N Reset signal (low active)

20 reserved - Reserved

21 HD_LED O HD LED, anode with 1 kΩ in series on the

22 DP_LED O MPI/DP LED, anode with 1 KΩ in series

23 Ethernet_LED O Ethernet LED, anode with 1 kΩ in series

24 TEMP_ERR O LED temperature sensor; anode with 1

25 RUN_R *) O Watchdog error LED, anode with 1 kΩ in

26 RUN_G O Watchdog OK LED, anode with 1 kΩ in

Ground

VO

USB data- Channel 1

B

Display type select signal

I

motherboard

on the motherboard

on the motherboard

kΩ in series on the board

series on the motherboard

series on the motherboard

1

LVDS display interface channel 1

28 Manual, 09/2016, A5E36371591B

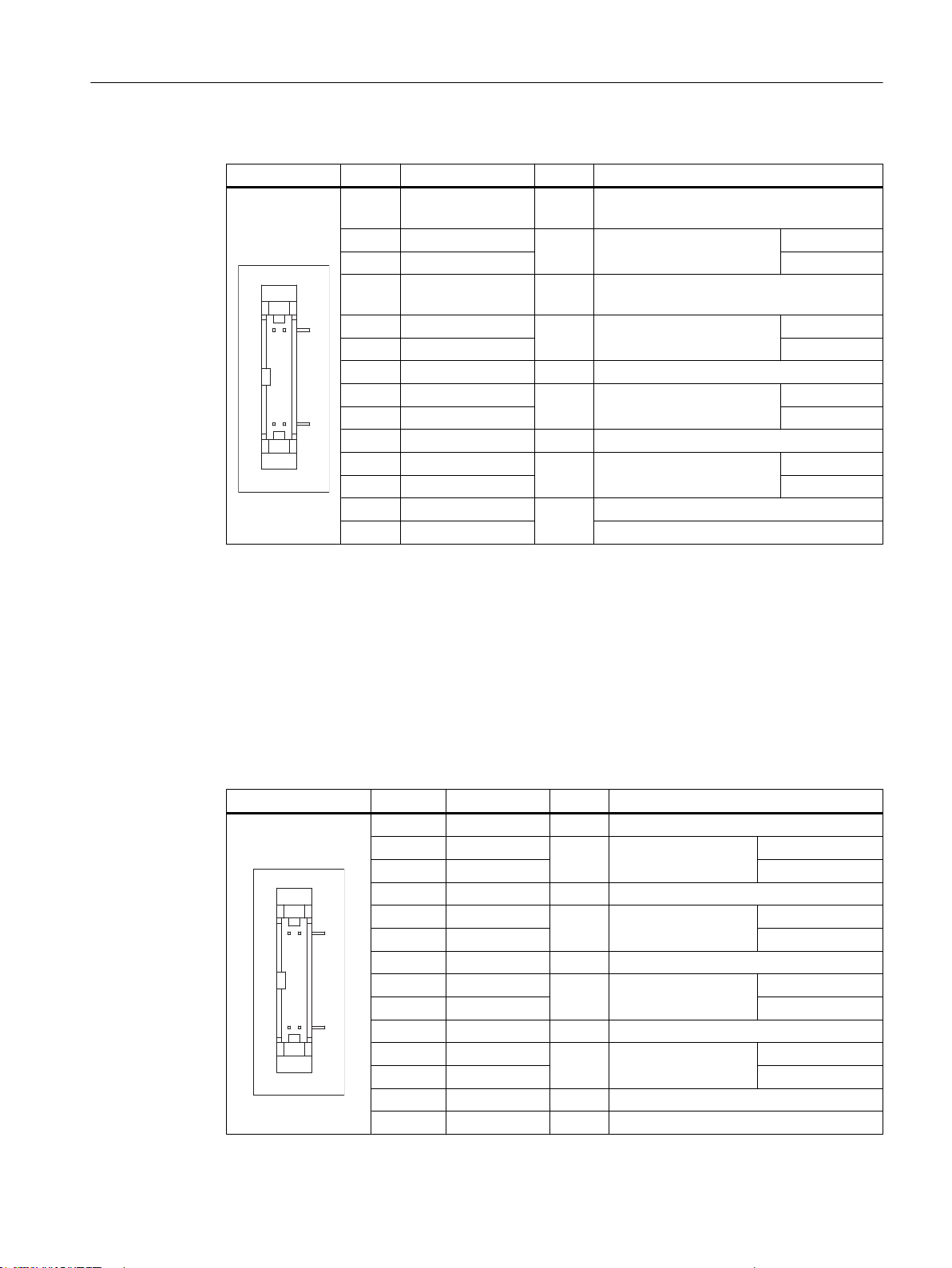

Used to connect operator panel fronts with TFT displays with 640 x 480 pixels (VGA), 800 x

600 pixels (SVGA) or 1024 x 768 pixels (XGA).

Associated interface cable: K2, max. length: 0.5 m

Connector type: 2 x 10-pin socket connector

Operator panel front: OP 012

Table 1-13 Allocation of the LVDS display interface

Connector Pin Name Type Meaning

1/2 P5V_D_fused VO +5 V display supply voltage (fused in PCU/

3 RXIN04 RXIN0+ Bit 0 (+)

5/6 P3V3_D_fused VO +3.3 V display supply voltage (fused in PCU/

7 RXIN18 RXIN1+ Bit 1 (+)

9/10 GND - System ground (reference potential)

11 RXIN212 RXIN2+ Bit 2 (+)

13/14 GND - System ground (reference potential)

15 RXCLKIN-

16 RXCLKIN+ (+)

17/18 GND

19/20 N.C. Not connected

I LVDS input signal

I LVDS input signal

I LVDS input signal

O LVDS cycle clock signal

-

General information and networking

1.3 Connecting

TCU)

Bit 0 (-)

TCU)

Bit 1 (-)

Bit 2 (-)

(-)

System ground (reference potential)

LVDS display interface channel 2

Used for expanding the LVDS display interface channel 1 to control TFT displays with 1280 x

1024 pixels (SXGA).

Associated interface cable: K3

Connector type: 2 x 10-pin socket connector

Table 1-14 Allocation of the LVDS display interface

Connector Pin Name Type Meaning

1/2 GND - System ground (reference potential)

3 RXIN104 RXIN10+ Bit 0 (+)

5/6 GND - System ground (reference potential)

7 RXIN18 RXIN1+ Bit 1 (+)

9/10 GND - System ground (reference potential)

11 RXIN212 RXIN2+ Bit 2 (+)

13/14 GND V Ground

15 RXCLKIN16 RXCLKIN+ (+)

17 GND V Ground

18-20 P12VF VO +12 V fused

LVDS input signal Bit 0 (-)

I

LVDS input signal Bit 1 (-)

I

LVDS input signal Bit 2 (-)

I

LVDS cycle clock sig‐

O

nal

(-)

Operator panel front: OP 012

Manual, 09/2016, A5E36371591B 29

General information and networking

1.3 Connecting

Rotary switch: Feed override X30

Connector designation: X30

Connector type: 2 x 5-pin plug connector, according to EN 60603-13 with coding

Max. cable length: 0.6 m

Table 1-15 Assignment of X30 connector (on delivery)

Pin Name Type Meaning

1 N.C. - Not connected

2 N.C. - Not connected

3 M V Ground

4 N.C. - Not connected

5 P5 V 5 V supply

6 OV_VS16

7 OV_VS8 Override rotary switch value 8

8 OV_VS4 Override rotary switch value 4

9 OV_VS2 Override rotary switch value 2

10 OV_VS1 Override rotary switch value 1

Override rotary switch value 16

I

Rotary switch: Spindle override X31

Connector designation: X31

Connector type: 2 x 5-pin plug connector, according to EN 60603-13 with coding

Max. cable length: 0.6 m

Table 1-16 Assignment of X31 connector (on delivery)

Pin Name Type Meaning

1 N.C. - Not connected

2 N.C. - Not connected

3 M V Ground

4 N.C. - Not connected

5 P5 V 5 V supply

6 OV_SP16

7 OV_SP8 Override rotary switch value 8

8 OV_SP4 Override rotary switch value 4

9 OV_SP2 Override rotary switch value 2

10 OV_SP1 Override rotary switch value 1

Override rotary switch value 16

I

Operator panel front: OP 012

30 Manual, 09/2016, A5E36371591B

Loading...

Loading...