Siemens Sinumerik 840D Series, Simodrive 611 digital, SINUMERIK 840DiE, SINUMERIK 840D, SINUMERIK 840DE Function Manual

...Page 1

Description of Functions 10/2003 Edition

sinumerik

& simodrive

HLA Module

SINUMERIK 840D

SIMODRIVE 611 digital

Page 2

Page 3

General 1

Configuration 2

Installation and Start-Up 3

Firmware Drive Functions 4

SINUMERIK 840D

SIMODRIVE 611 digital

HLA module

Description of Functions

Hardware Drive Functions 5

Hydraulics Diagnostics 6

Peripherals/Accessories 7

Service 8

Valid for

Control Software Version

SINUMERIK 840D 5, 6

SINUMERIK 840DE (export version) 5, 6

SINUMERIK 840Di 2

SINUMERIK 840DiE (export version) 2

10.03 Edition

Hydraulics A

Abbreviations B

Definition of Terms C

References D

EC Declaration of

Conformity E

Index F

Page 4

O

Printed in Germany

3ls

SINUMERIK Documentation

Revision history

Brief details of this edition and previous editions are listed below.

The status of each edition is indicated by the code in the “Remarks” column.

Status code in the “Remarks” column:

A New documentation. . . . . .

B Unmodified reprint with new order number . . . . .

C Revised version with new edition status. . . . . .

If the technical subject matter shown on the page has changed compared to the

previous edition status, this is indicated by the changed edition status in the header

of the respective page.

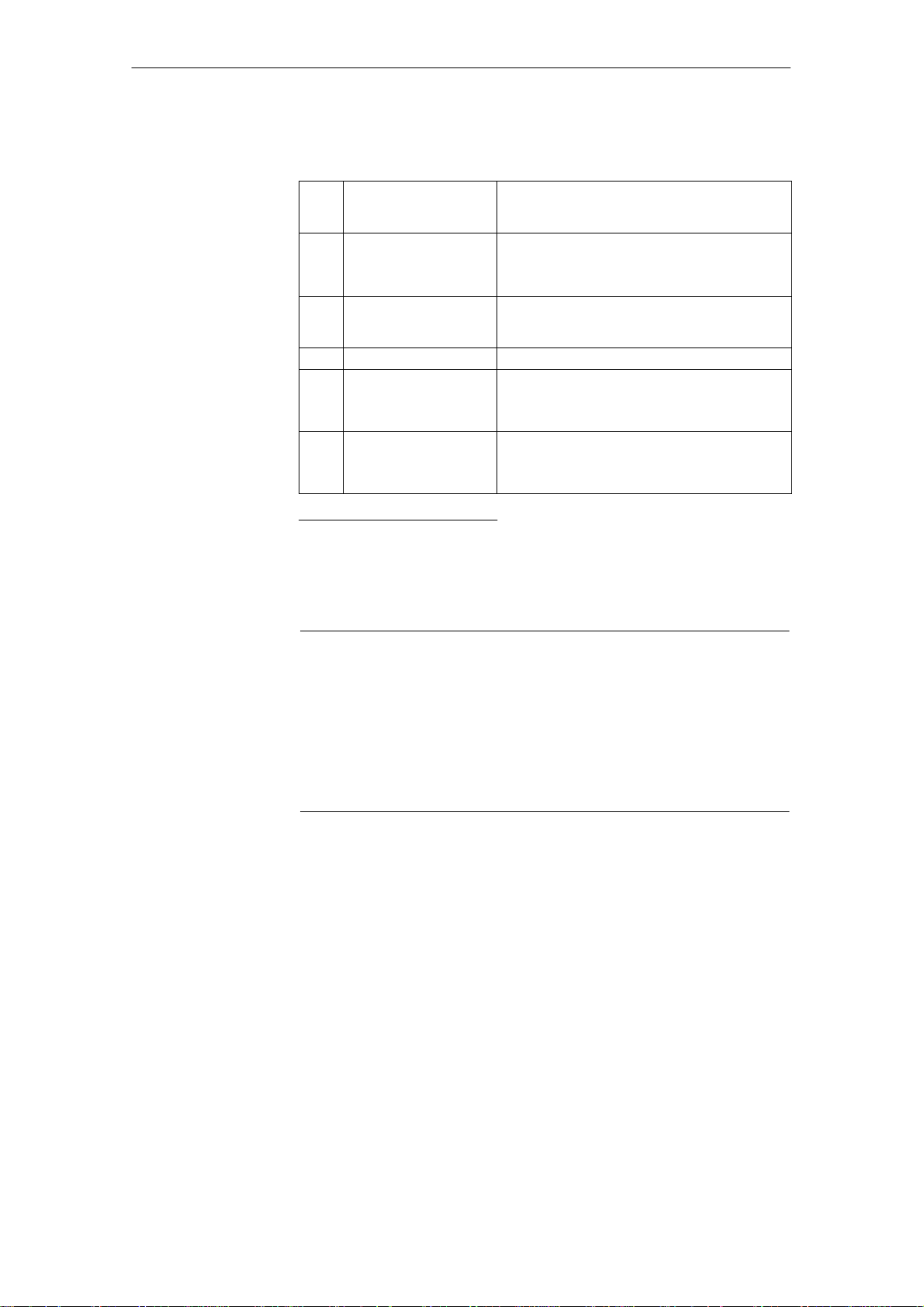

Edition Order no. Remarks

02/99 6SN1197-0AB60-0BP0 A

08/99 6SN1197-0AB60-0BP1 C

04/00 6SN1197-0AB60-0BP2 C

10/03 6SN1197-0AB60-0BP3 C

This manual is supplied as part of the CD-ROM documentation (DOCONCD)

Edition Order no. Remarks

03/04 6FC5 298-7CA00-0BG3 C

Trademarks

SIMATICr, SIMATIC HMIr, SIMATIC NETr, SIROTECr, SINUMERIKr, SIMODRIVEr and

MOTION-CONNECTr are registered trademarks of Siemens AG. Other names in this publication might be

trademarks whose use by a third party for his own purposes may violate the rights of the registered holder.

More information is available on the Internet at:

http://www.siemens.com/motioncontrol

This document was created with Interleaf V 7

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority. Offenders

will be liable for damages. All rights, including rights created by patent

grant or registration or a utility model or design, are reserved.

Siemens AG, 1999-2004. All rights reserved

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

We have checked that the contents of this document correspond to

the hardware and software described. Nevertheless, differences

might exist and therefore we cannot guarantee that they are

completely identical. The information given in this publication is

reviewed at regular intervals and any corrections that might be

necessary are made in subsequent editions. We welcome all

recommendations and suggestions.

Subject to change without prior notice

rder no. 6SN1197-0AB60-0BP3

Siemens Aktiengesellschaft.

Page 5

Preface

Notes for the Reader

Structure of the

documentation

Target group

The documentation for SIMODRIVE 611/SINUMERIK 840D is organized on the

following levels:

S General Documentation

S Manufacturer/Service Documentation

S Electronic Documentation

The description of functions of the HLA module is part of the

SIMODRIVE/SINUMERIK documentation.

For further information about the publications listed in the documentation overview and other available SIMODRIVE/SINUMERIK publications, please contact

your local Siemens sales office.

This Description of Functions does not purport to cover all details or variations

in equipment, nor to provide for every possible contingency to be met in connection with installation, operation or maintenance.

The contents of this document shall neither become part of nor modify any prior

or existing agreement, commitment or relationship. The Sales Contract contains

the entire obligations of Siemens. The warranty contained in the contract between the parties is the sole warranty of Siemens. Any statements contained

herein do not create new warranties or modify the existing warranty.

This documentation is intended for use by machine manufacturers and

servicing personnel who use the “HLA modules”.

Objective

This Description of Functions provides the information required to configure and

start up the hydraulic drive module.

S Chapter 2 describes the procedures for configuring the electric and hydraulic

components.

S Chapter 3 shows how the hydraulic drive is started up with the support of a

menu-driven user interface.

S The firmware and the HLA module hardware functionality are explained in

Chapters 4 and 5.

S Chapter 6 explains how to check and interpret status displays and alarms

(hydraulic diagnostics).

S Chapter 7 describes the accessories required, e.g. measuring systems and

cables.

S Appendix A contains general information and an explanation of the hydraulic

system functionality.

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

v

Page 6

Note

Preface

Hydraulics In this document, information about specific hydraulic functions

refers to functions provided by Bosch Rexroth AG.

10.03

How to use this

manual

Definition of

qualified persons

The following guide information is provided to help you reference information in

this Description of Functions:

S General table of contents

S Header (as orientation aid):

- The top line of the header is the main section number

- The second line of the header is the subsection number

S Appendix with

- abbreviations, terms and references

- Glossary (index)

For the purpose of this manual and product labels, a “qualified person” is one

who is familiar with the installation, mounting, start-up and operation of the

equipment and the hazards involved.

S Training or instruction/permit for connecting electric circuits and devices in

accordance with safety technology standards.

S Training and instruction in maintenance and use of adequate safety equip-

ment according to safety regulations.

S Trained in rendering first aid.

Software version

The SW versions specified in this documentation refer to the SINUMERIK 840D

control system and the HLA module.

The Description of Functions applies only to the software versions specified.

When a new software version is released, the Description of Functions for that

version must be ordered.

vi

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 7

10.03

Preface

Explanation of

symbols

The following danger and warning concept is used in this document:

Danger

!

!

!

This symbol appears whenever death, severe physical injury or substantial material damage

will occur if appropriate precautions are not taken.

Warning

This symbol appears whenever death, severe physical injury or substantial material damage

may occur if appropriate precautions are not taken.

Caution

This symbol appears whenever minor physical injury or material damage may occur if

appropriate precautions are not taken.

Caution

This warning (without warning triangle) indicates that material damage may occur if

appropriate precautions are not taken.

Notice

This warning indicates that an undesirable result or an undesirable state may occur if the

information is ignored.

Note

In the context of this document, it is advisable to take note of the warning information.

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

vii

Page 8

Hotline

Preface

10.03

The hotline phone numbers appear in Chapter 8.

Should you have any questions about the documentation (suggestions, correc-

tions), please fax them to:

Fax: +49 (9131) 98-2176

Fax form: See the reply form at the end of the brochure

viii

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 9

10.03

Preface

Danger and warning notices

Danger

!

Commissioning should not start until you have ensured that the machine

in which the components described here are to be installed complies with

Directive 98/37/EC.

Only appropriately qualified personnel may commission/start-up this

equipment.

The personnel must take into account the information provided in the technical

customer documentation for the product, and be familiar with and observe the

specified danger and warning notices.

When electrical devices are operated, the electrical circuits automatically

conduct a dangerous voltage.

Dangerous mechanical movements may occur in the system during operation.

All work on the electrical system must be carried out when the system has

been disconnected from the power supply.

Warning

!

!

Proper transportation, expert storage, installation and mounting, as well as

careful operation and maintenance are essential for this device to operate

correctly and reliably.

In addition to the danger and warning information provided in the technical

customer documentation, applicable national, local, and system-specific

regulations must be taken into account.

The information given in catalogs and quotations applies additionally to special

versions of machines and equipment.

Caution

When attaching the connecting cables, you must ensure that:

S They must not be damaged

S They must not be stressed

S They cannot come into contact with rotating parts

Caution

As part of routine tests, the devices undergo a voltage test in accordance with

EN 50178. During voltage testing of electrical equipment on industrial

machines in accordance with EN 60204-1, Section 19.4, all SIMODRIVE

device connections must be disconnected/removed. This is necessary in order

to avoid damaging the SIMODRIVE devices.

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

ix

Page 10

10.03

Preface

ESD notices

Electrostatic Sensitive Devices

Components which can be destroyed by electrostatic discharge are individual

components, integrated circuits or boards which, when handled, tested or

transported, could be destroyed by electrostatic fields or electrostatic

discharge. These components are designated as ESDS (ElectroStatic

Discharge Sensitive Devices).

Handling of modules containing devices sensitive to electrostatic discharge:

S When handling components which can be destroyed by electrostatic

discharge, it must be ensured that personnel, the workstation and

packaging are well grounded,.

S As a general principle, electronic modules should only be touched if this is

absolutely unavoidable (owing to repair work, etc.).

S Touch components only if

- you are constantly grounded by an antistatic armband,

- you are wearing ESD boots or ESD boots with grounding strips in

conjunction with ESD flooring.

S Modules may be placed only on electrically conductive surfaces (table with

ESD top, conductive ESD foam plastic, ESD packing bags, ESD transport

containers).

S Keep modules away from visual display units, monitors or TV sets

(minimum distance from screen > 10 cm).

S Do not bring ESD-sensitive modules into contact with chargeable and

highly-insulating materials, such as plastic, insulating table tops or clothing

made of synthetic materials.

S Measurements on modules are allowed only if

- the measuring instrument is properly grounded (e.g. equipment

grounding conductor), or

- before measuring, with an isolated measuring instrument, the

measuring head is briefly discharged (e.g. touching a bare metal control

housing).

S Closed-loop control modules, option modules and memory submodules

may only be held by the front plate or on the board edges.

J

x

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 11

Table of Contents

1 General 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Typical applications 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Comparison of electric and hydraulic drive systems 1-16. . . . . . . . . . . . .

1.3 Structure of an electro-hydraulically-controlled drive axis 1-18. . . . . . . .

1.3.1 Machine guideway 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Cylinder 1-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Servo solenoid valve 1-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.4 Valve amplifier 1-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.5 Shutoff valve 1-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.6 Position measuring system 1-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.7 SINUMERIK 840D/SIMODRIVE 611 digital 1-20. . . . . . . . . . . . . . . . . . . .

1.3.8 Hydraulic power unit 1-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Configuration 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Configuring steps 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Procedure for configuring electrical components 2-21. . . . . . . . . . . . . . .

2.1.2 Procedure for configuring hydraulic components 2-22. . . . . . . . . . . . . . .

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital 2-24. . . . . . . .

2.2.1 System overview 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Required FW packages 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Hardware requirements 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Configuring the hydraulic drive 2-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Cylinder selection 2-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Selection of servo solenoid valves 2-32. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3 Selection of shutoff valves 2-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.4 Natural frequency of the hydraulic drive 2-42. . . . . . . . . . . . . . . . . . . . . . .

2.3.5 Hydraulic power unit 2-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Connection 2-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Internal power supply 2-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 External power supply 2-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.3 Grounding concept/Electromagnetic compatibility (EMC) 2-48. . . . . . . .

3 Installation and Start-Up 3-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Overview of start-up process 3-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Drive configuration 3-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Modify drive machine data 3-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Valve selection 3-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Cylinder selection 3-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Mounting/supply data 3-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Measuring system data 3-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 Modifying data 3-59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 Fine adjustment and optimization 3-62. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

xi

Page 12

3.9.1 Control direction, travel direction 3-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

3.9.2 Offset adjustment 3-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.3 Velocity adjustment 3-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.4 Referencing data for HLA 3-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.5 Controller optimization 3-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.6 Controller adaptation 3-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.7 Hydraulic/electrical interpolation 3-74. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10 File functions 3-75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.11 Start-up functions 3-76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.11.1 Measurement function 3-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.11.2 Function generator 3-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.11.3 Circularity test 3-88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.11.4 Servo trace 3-88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.11.5 DAC parameter settings 3-89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12 User views 3-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.13 Display options 3-91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.14 Configuring an OEM valve list 3-92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.03

3.15 System variables 3-94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Firmware Drive Functions 4-95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Block diagram of closed-loop control 4-95. . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Functions 4-97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Overview of functions 4-97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Parameter set changeover 4-98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Closed-loop velocity control 4-99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Velocity adaptation/feedforward control 4-99. . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Velocity controller 4-106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 Dynamic stiffness control (DSC) 4-114. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Closed-loop force control 4-115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Force limitation 4-117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Static friction injection 4-118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Force controller 4-119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Manipulated voltage output 4-124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 Characteristic compensation 4-124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 Control output filter 4-130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.3 Manipulated voltage limitation 4-132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Supply unit data 4-133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Valve 4-134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Cylinder drive 4-136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Drive data 4-137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 Position measuring system 4-140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11 Pressure sensing system 4-145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 Terminals 4-146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13 Monitoring functions 4-152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xii

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 13

10.03

Contents

4.13.1 Alarms 4-152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13.2 Variable signaling functions 4-154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14 Service functions 4-159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14.1 Min/max display 4-159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14.2 Monitor 4-160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14.3 Diagnostic machine data 4-161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15 Parameters table 4-165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Hardware Drive Functions 5-175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Interface overview 5-175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Measuring system 5-178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Pressure sensor system 5-179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Servo solenoid valve 5-180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 Terminals 5-181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.5 Test sockets (diagnostics) 5-182. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.6 Bus interfaces 5-183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 System environment 5-184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Notes 5-185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Climatic and mechanical environmental conditions in operation 5-185. . .

5.3.2 Transport and storage conditions 5-186. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Stress caused by contaminants 5-187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Hydraulics Diagnostics 6-189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Peripherals/Accessories 7-219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Measuring systems 7-219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Encoders, linear scales 7-219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Connection diagrams 7-222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 BERO (X432) 7-226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Pressure sensor 7-227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Sensor equipment 7-227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Connection diagrams 7-231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Connection diagrams for servo solenoid valves 7-232. . . . . . . . . . . . . . . .

8 Service 8-237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Areas of responsibility at Siemens/Bosch Rexroth 8-237. . . . . . . . . . . . . .

8.2 Hotline and contacts 8-238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Hydraulics A-239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Servo solenoid valves A-239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1.1 General A-239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1.2 Directly-controlled servo solenoid valves, sizes 6 and 10 A-247. . . . . . . .

A.1.3 Pilot-controlled servo solenoid valves, sizes 10 and 16 A-249. . . . . . . . . .

A.1.4 HR servo solenoid valves A-252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Cylinder A-254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

xiii

Page 14

B Abbreviations B-257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

C Definition of Terms C-259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D References D-261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.1 Electrical applications D-261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2 Hydraulic applications D-274. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E EC Declaration of Conformity E-275. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Index Index-279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.03

xiv

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 15

General

1.1 Typical applications

1

Applications

Objective

Interfaces

The NCU 573.2 of the SINUMERIK 840D is capable of handling axis configurations of a maximum of 31 axes on up to 10 different channels. This functional

sophistication makes the SINUMERIK 840D an increasingly popular system for

the automation of rotary indexing machines. These machines are often highly

compact in design and frequently equipped with hydraulic axes (cylinders and

servo solenoid valves). The hydraulics (HLA) module provides a means of controlling hydraulic axes directly from the SINUMERIK 840D system via the digital

drive bus.

The HLA module is a closed-loop control plug-in unit of the modular

SIMODRIVE 611 converter system mounted in a 50 mm carrier module

(universal empty housing).

The gating and closed-loop control electronics for operating controlled hydraulic

drives are integrated on the HLA module.

From the point of view of the manufacturer of modern servo solenoid valves, an

innovative step in the field of hydraulic drive systems has been taken by treating

electric and hydraulic drives as equal partners and integrating them into a standard NC.

To place equal emphasis on the functional importance of both hydraulic and

electric drives and make them available as a combined system within an interpolating axis grouping.

S Firmware

The communications interface is compatible with the SIMODRIVE 611D

SRM(FDD)/ARM(MSD) for supported services. Code and data management

is analogous to the SIMODRIVE 611D SRM(FDD)/ARM(MSD). The hydraulics software is stored as a separate program code in the control system.

S Hardware

The mode of integration into the SIMODRIVE 611 system is compatible with

the SIMODRIVE 611 digital SRM(FDD)/ARM(MSD). This basically involves

the following interfaces:

- Drive bus

- Device bus

- Power supply system

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

1-15

Page 16

1.2 Comparison of electric and hydraulic drive systems

1 General

1.2 Comparison of electric and hydraulic drive systems

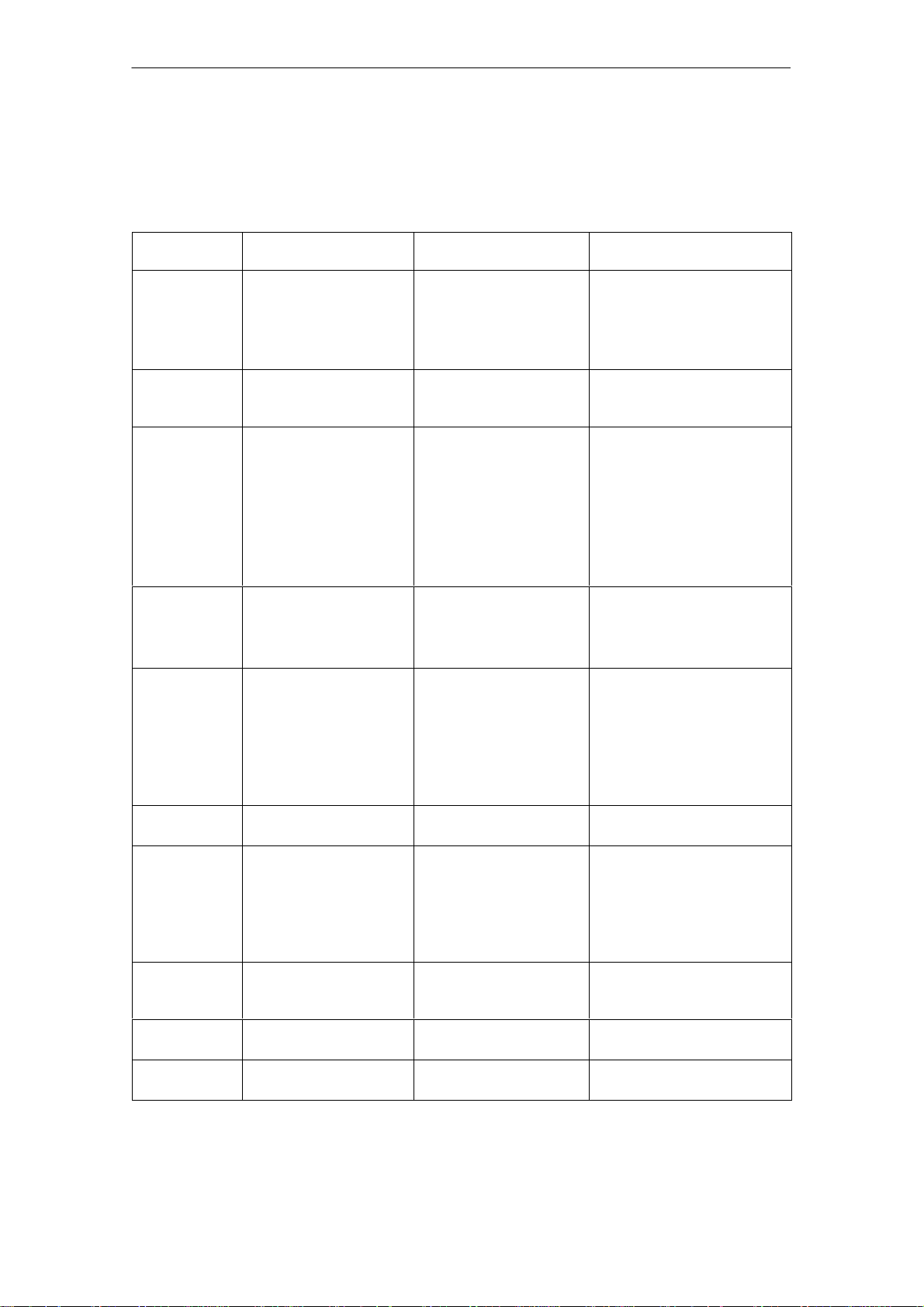

Table 1- 1 Comparison of electric and hydraulic drive systems

10.03

Criterion Electric direct drive Electric drive with

Power density /

mounting

space requirements

Mass inertia of

moving parts

Operational

reliability,

service life

S Low weight and

S reduced spatial re-

quirements of the

electric part on the

machine table.

Electric part on machine

table has low mass.

Service life depends in

principle only on linear

guides.

S Servomotor and leads-

S Problematic with lim-

Servomotor and leadscrew have high mass moment of inertia.

S Shock-sensitive.

S Service life limited by

leadscrew

crew large and heavy.

ited mounting space.

leadscrew.

S Sudden failure

possible.

Servicing Simple replacement Expensive replacement

and repair of leadscrew by

specialists.

Energy storage Peak requirement must

be installed as no storage

is possible.

Maximum

forces

Load stiffness Very good;

maximum velocity

Maximum

travel path

Collision

protection

Peak thrust per unit area

approx. 40 to 80 kN/m

Servo gain can be set to

betw. 10-100 times

higher than on the other

two drives.

Up to 500 m/min v

Unlimited

Mechanically difficult Mechanically possible Mechanically possible

Peak requirement must be

installed as no storage is

possible.

Restriction with larger

2

forces.

S Elasticity under large

forces.

S Elasticity of leadscrew

is largely compensated as a control

function.

@ ω

max=hs

h

=thread lead

s

ω

=max. motor speed

max

v 6 m v 3 m

max

/2π

Hydraulic drive

S Cylinder and servo sole-

noid valve are light-weight

and compact.

S Transfer of E motor to

hydraulic power unit.

Piston and piston rod have

very low mass

S Protected against overload

by pressure limitation.

S Sturdy, insensitive to

shocks.

S Cylinder seals and valve

control edges have long

service life.

S Warning of wear.

S Simple error diagnosis

S Simple replacement and

repair of valves and cylinders.

S Compensation of energy

requirement peaks by hydraulic accumulator.

S Rapid traverse in differen-

tial circuit.

S Reduction of installed ca-

pacity.

Practically unlimited

(cylinderφ, p

=700 bar)

max

S Oil compressibility is com-

pensated as a control

function (I component).

S Good zero overlap quality

of valve ensures very high

rigidity under load.

30...300 m/min

(depending on which cylinder

seal kit is used)

1-16

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 17

1 General

02.99

10.03

1.2 Comparison of electric and hydraulic drive systems

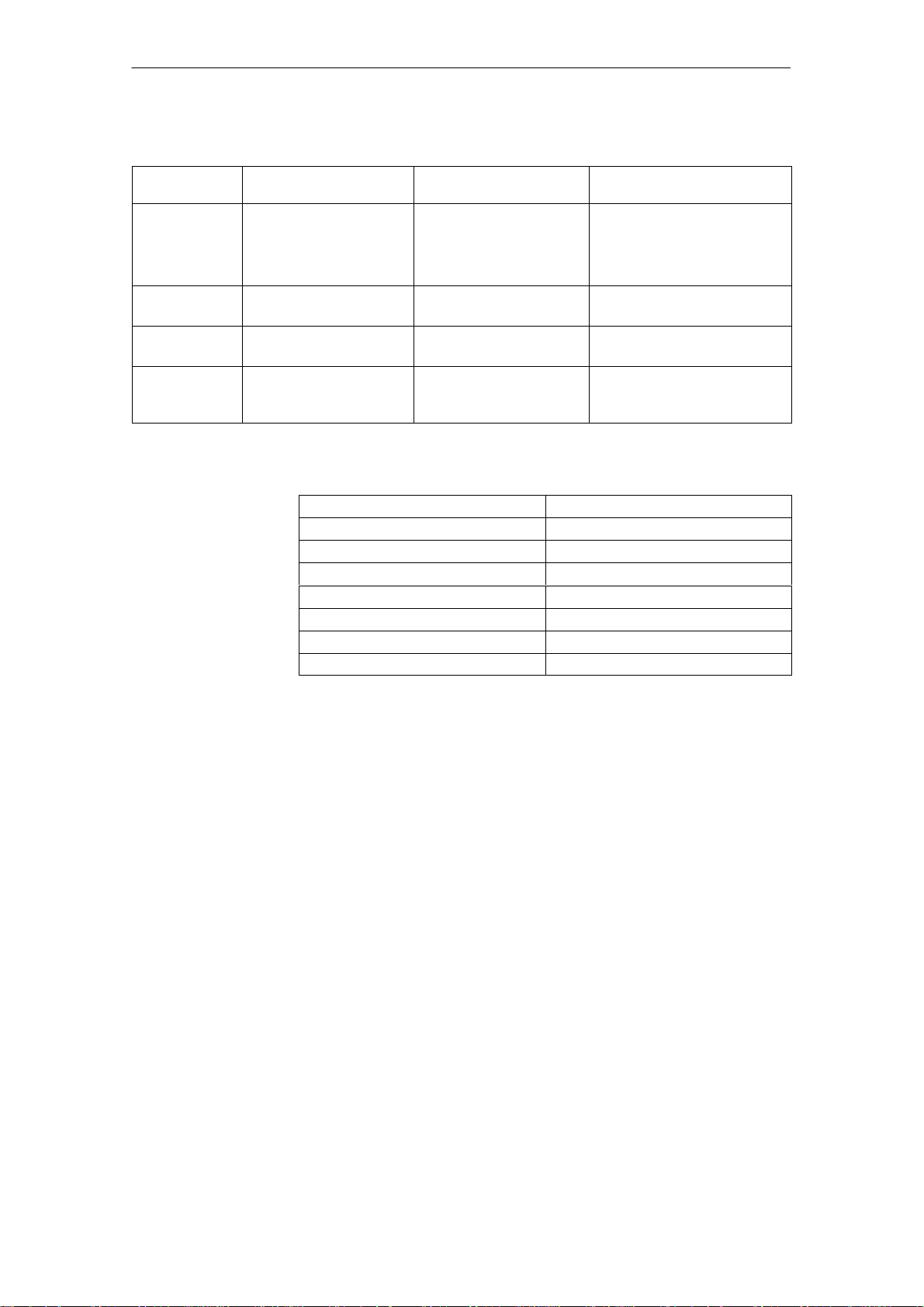

Table 1-1 Comparison of electric and hydraulic drive systems

Criterion Hydraulic driveElectric drive with

Noise Noise produced by

Acceleration

Electric direct drive

leadscrew

Noise produced by servo-

linear guides

motor and leadscrew

max. 45 g max. 1 g max. 2 g

characteristics

Drive cooling Absolutely essential Required only at high

speeds

Sensitivity to

High Low Low

ferromagnetic

swarf

Table 1-2 Analogy of characteristic data

Electric Hydraulic

Spindle speed Velocity Velocity

Current flowrate

DC link voltage System pressure

Power Flow rate @ Valve pressure differential

Transistor/power section Valve

Motor Drive cylinder

S Flow through valve may

produce noise.

S Pump noise on

hydraulic power unit.

Required in some cases, in

power unit only

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

1-17

Page 18

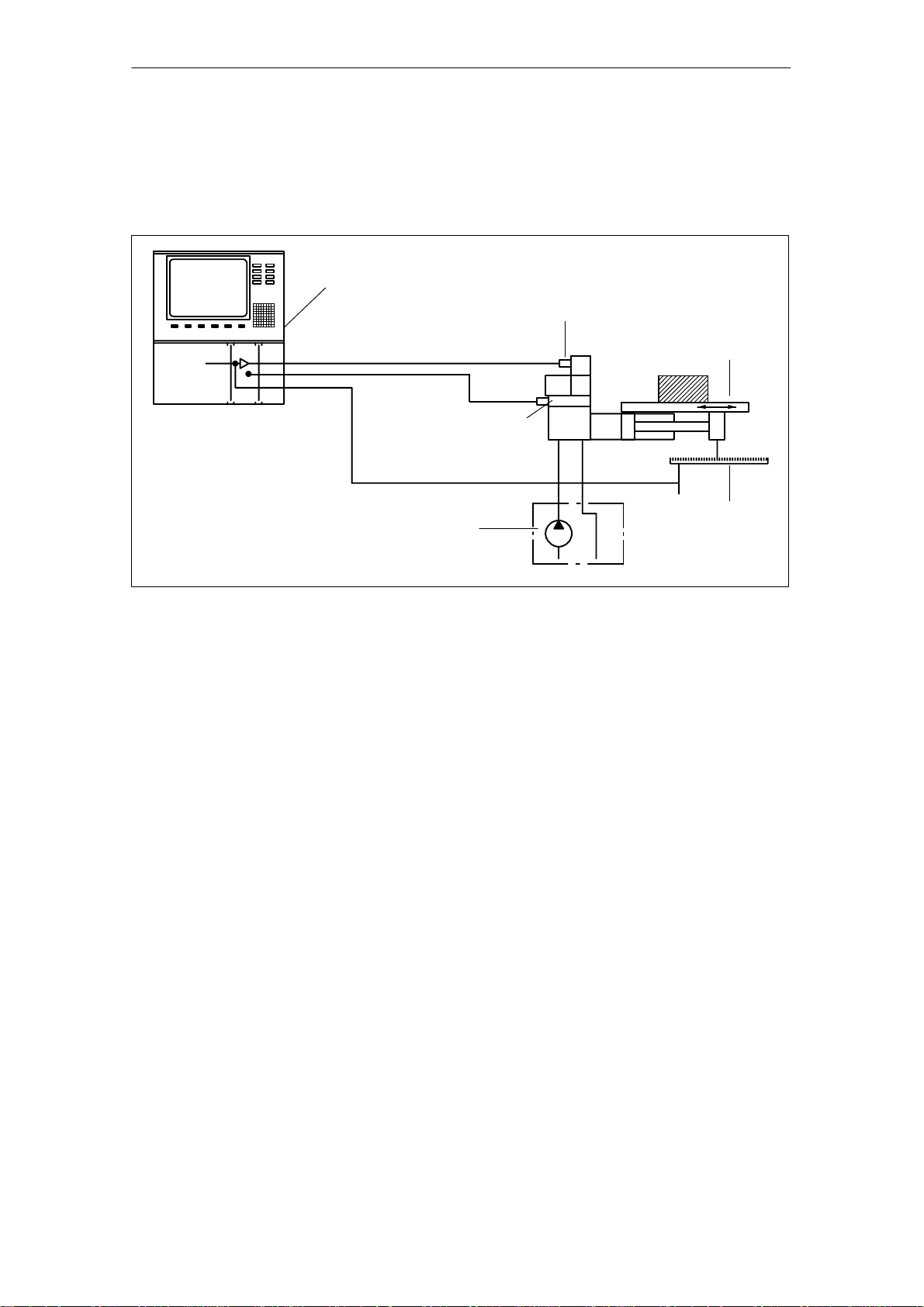

1.3 Structure of an electro-hydraulically-controlled drive axis

1 General

1.3 Structure of an electro-hydraulically-controlled drive

axis

SINUMERIK 840D,

SIMODRIVE 611 digital

with HLA module

Shutoff valve

Servo solenoid value with

valve amplifier (OBE)

Machine guideway

02.99

10.03

Hydraulic power unit

Fig. 1-1 Construction of an electro-hydraulically controlled drive axis

1.3.1 Machine guideway

Guide mechanism

Friction

Hydrodynamic and hydrostatic slideways or roller slideways allow machine

slides and tables to move in straight lines with minimum friction and maximum

precision.

A degree of friction can be very useful for damping oscillations.

However, excessive friction, especially pronounced transitions from static to

sliding friction, have a negative effect on the control result and impair the control

loop stability.

Position

measuring

system

1-18

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 19

1 General

02.99

10.03

1.3.2 Cylinder

1.3 Structure of an electro-hydraulically-controlled drive axis

Construction

Quality criteria

The cylinder represents the simplest form of linear motor and can be integrated

easily into the machine guide. The cylinder normally has a piston rod at one

end.

The following are critical quality criteria:

S The surface quality of barrel and piston rod and

S The seals and guides (low-friction, servo quality...).

1.3.3 Servo solenoid valve

Task

Function

This is the final control element in the closed control loop and forms the electrohydraulic converter.

The valve steplessly converts electrical signals into a hydraulic flow.

Its quality is defined by static and dynamic parameters, such as

S Zero overlap

S Hysteresis

S Limit frequency, etc.

1.3.4 Valve amplifier

This circuit contains the power electronics for the solenoid in the servo solenoid

valve which adjusts the valve spool position.

The position controller in the valve amplifier (on-board electronics - OBE) controls the position of the valve spool proportionally to the output value

(U=0..."10 V).

1.3.5 Shutoff valve

Shut-off valves are used to add safety functions to a valve control with servo

solenoid valve. Shut-off valves can prevent uncontrolled motion of the cylinder.

1.3.6 Position measuring system

Task

The position measuring system supplies the actual value for the position of the

moving machine element.

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

1-19

Page 20

1.3 Structure of an electro-hydraulically-controlled drive axis

1 General

02.99

10.03

Function

The speed is acquired by continuous differentiation of the distance over time.

Various systems are available depending on the level of accuracy required.

The highest accuracy requirements are fulfilled by digital systems (glass scale

with photoelectric evaluation circuit) mounted directly on the machine.

The most widely used digital incremental systems require a reference point approach at the beginning of a machining operation.

1.3.7 SINUMERIK 840D/SIMODRIVE 611 digital

SINUMERIK controls and SIMODRIVE drive systems are specially designed for

machine tools, manipulators and special-purpose machines.

The numerical control processes the machine program and converts it into control commands. It also monitors command execution continuously.

The control structures for the electrohydraulic control loop and the interfaces to

S the shutoff valve,

S the servo solenoid valve,

S the position measuring system and

S the central arithmetic logic unit

are all provided by the HLA module.

The HLA module is an integral component of the SINUMERIK 840D and

SIMODRIVE 611 digital systems.

A range of different NCU modules with graded scope of functions is provided to

allow the SINUMERIK 840D system to be tailored to the varying functional requirements of machines. The control can therefore be optimally adapted to individual machines and machining applications and is suitable for equipping standardized machine series.

1.3.8 Hydraulic power unit

This unit supplies hydraulic energy.

It is installed at a distance from the drive axis. Accumulators are employed to

compensate for strongly fluctuating hydraulic energy requirements and to minimize the installed power.

J

1-20

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 21

Configuration

2.1 Configuring steps

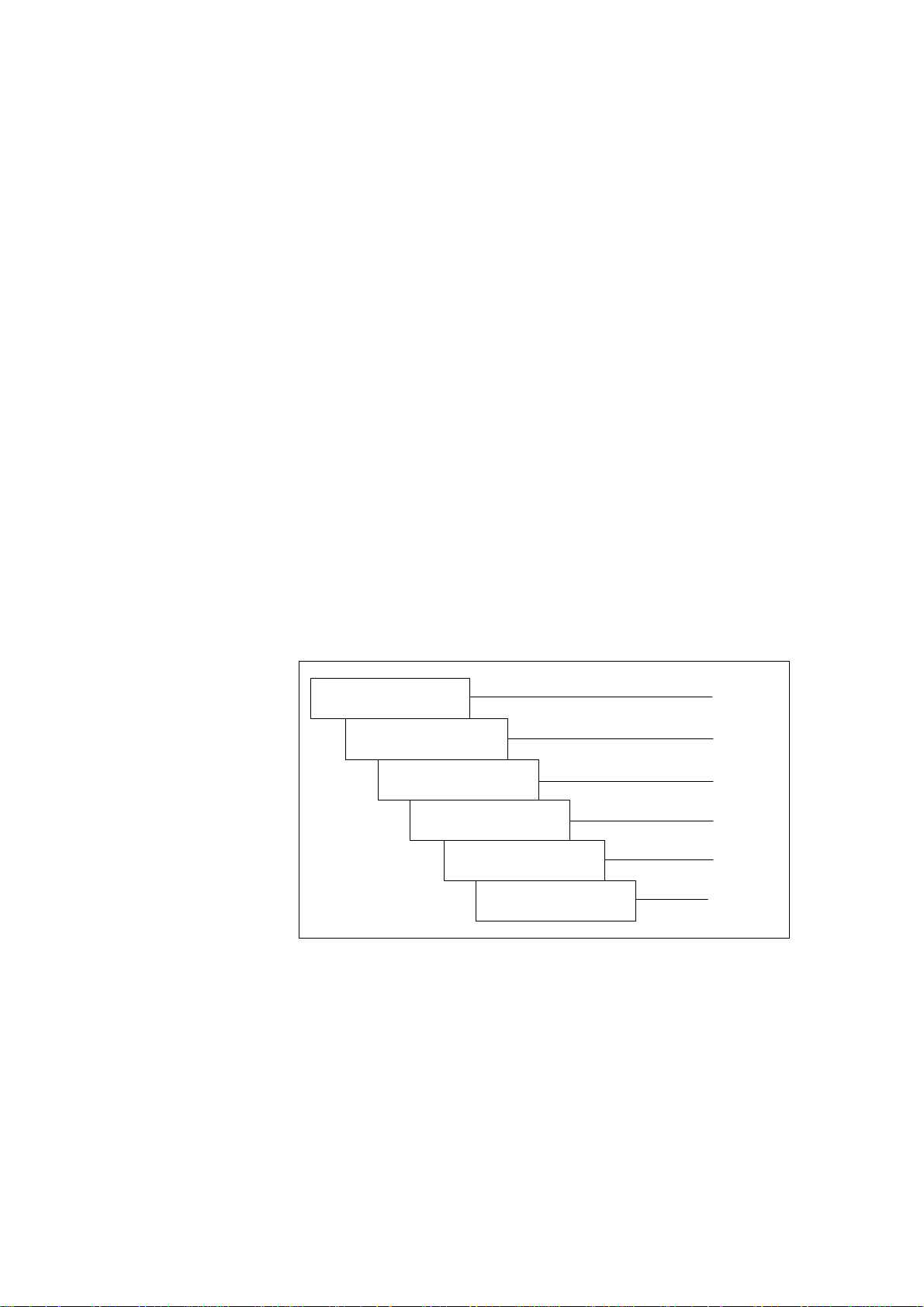

2.1.1 Procedure for configuring electrical components

The procedure for configuring an HLA module is divided into steps in such a

way that the user is guided through the full range of relevant settings, from the

required force, to the hydraulics components, and finally the HLA and its encoder evaluation circuitry. This initial configuring phase may be followed by a

second in some cases, in which the corresponding circuit recommendations

and EMC measures are taken into account.

The functions of SIMODRIVE components are described with keywords in this

Planning Guide. Limit values for functions may be specified in some cases.

For further details (e.g. characteristics), please refer to the Installation and

Start-Up Guides for SIMODRIVE 611 digital and SINUMERIK 840 digital.

Further configuring instructions and detailed ordering information can be found

in Catalogs NC 60 and NC Z.

Phase 1

Selection of hydraulic

components

Dimensioning of incoming

mains supply

Dimensioning of

power modules

Dimensioning of external

power supply

Dimensioning of closedloop control components

and publication from Bosch Rexroth AG

and publication 6SN1197-0AA00

and publication 6SN1197-0AA00

2

Section 2.3

Section 2.2

Section 2.2

Section 2.4

Chapter 4

Dimensioning of position

sensor (measuring system)

Fig. 2-1 Configuring steps in start-up sequence

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Section 7.1

2-21

Page 22

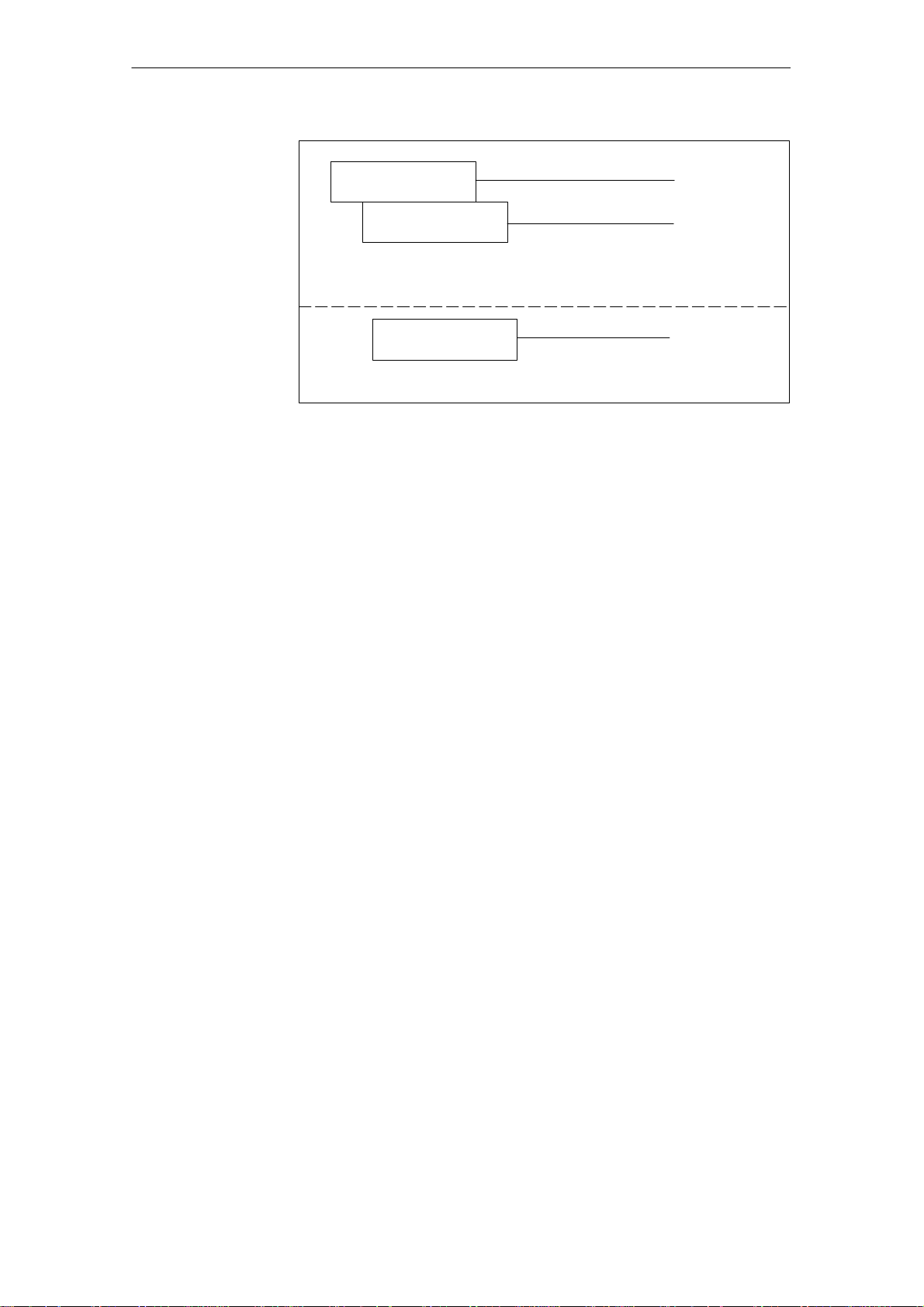

2.1 Configuring steps

2 Configuration

Phase 2

Recommended circuits

EMC measures

10.03

Section 2.4

Block diagrams/

connection diagrams

Abbreviations,

terms and index

Fig. 2-2 2. configuring phase

2.1.2 Procedure for configuring hydraulic components

Hydraulically controlled drives are normally configured by the technical sales

and marketing personnel of the hydraulics supplier (e.g. Bosch

Rexroth, see Chapter 8) in close co-operation with the machine manufacturer.

This configuring phase is divided into the following steps:

S Selection of the cylinder on the basis of forces and velocities required and

the cylinder mounting conditions in the machine

(see Subsection 2.3.1).

Section 2.2

Appendix

S Selection of the servo solenoid valves on the basis of the cylinder data,

forces, velocities and dynamic requirements (see Subsection 2.3.2, 2.3.3).

S Selection of the position measuring system and optionally the pressure sen-

sors with regard to the measuring range, accuracy and linearity (see Section

7.1, 7.3).

S Dimensioning of the hydraulic power unit, taking all loads into account (see

Subsection 2.3.5).

S Calculation of the natural frequency of the drive for an initial assessment of

whether the expected control result can be achieved (see Subsection 2.3.4).

S In difficult cases, it may be worthwhile carrying out a dynamic simulation of

the drive as an aid to configuration.

The basic data required to design a system are obtained from a question-

naire.

2-22

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 23

2 Configuration

02.99

10.03

2.1 Configuring steps

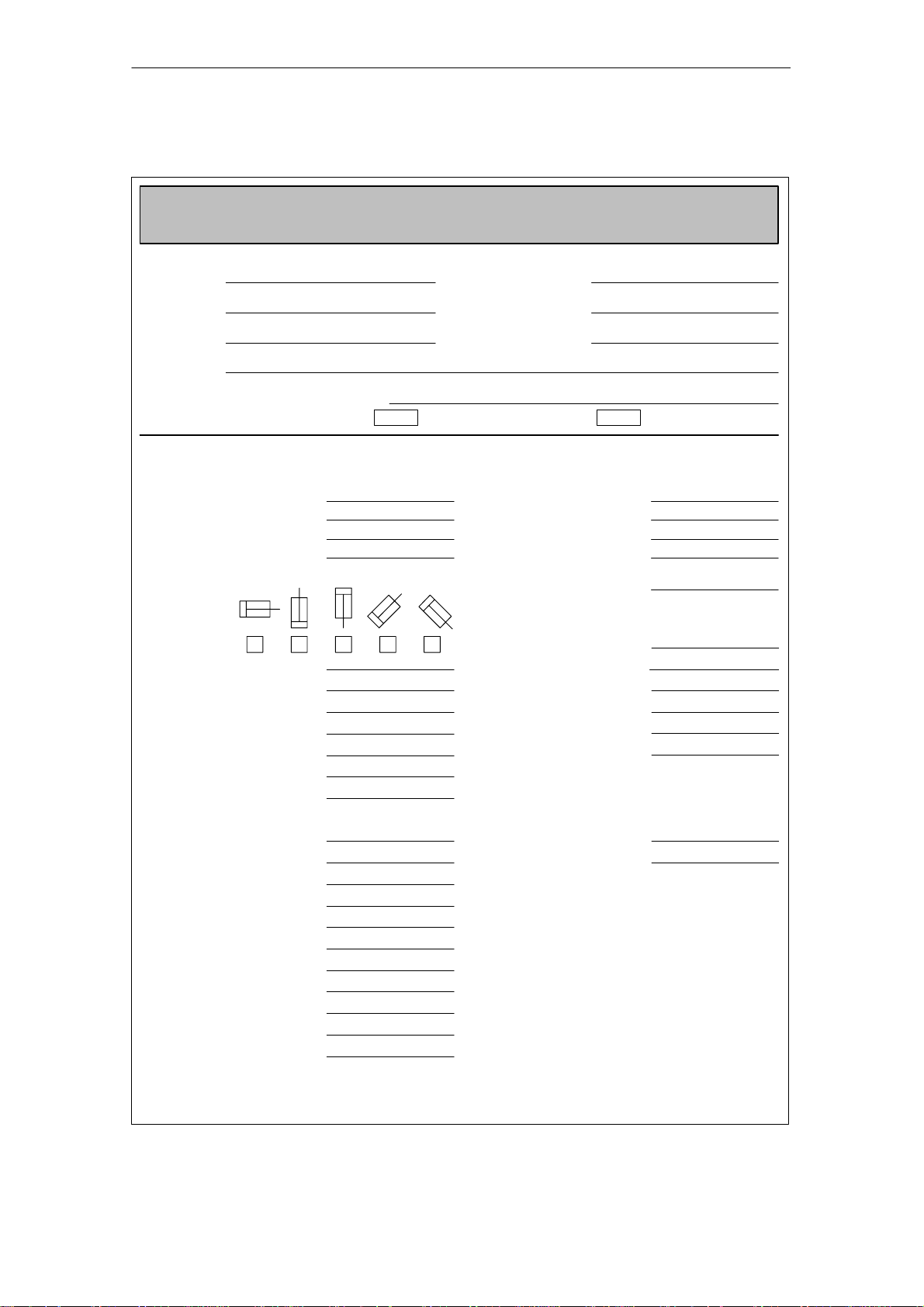

Questionnaire

Company:

Address:

Machine:

Axis: Function/designation:

Straight-cut control: Continuous-path control:

Drive specification

Cylinder dimensions [mm]

Piston diameter:

1st rod diameter:

2nd rod diameter:

Stroke:

Cylinder mounting position: Velocity tolerance

051-001/

Design of hydraulic NC axes

Hydraulic NC axes

Dimensioning of systems with linear motions

Contact person:

Department:

Phone:

Accuracy requirements

Positioning precision [µm]

from rapid traverse:

from feedrate:

Path accuracy:

[mm/min]:

Connection: Position measuring

Valve - cylinder

Pipe/hose length [mm]:

Pipe/hose diameter [mm]:

Moved mass [kg]:

Machining forces [N]

Piston advance:

Piston retraction:

Slide guide friction

µ:

FR [N]:

Pump pressure [bar]:

Velocities [m/min]

Rapid traverse advance:

Rapid traverse retract:

Machining feed advance:

Machining feed retract:

Acceleration rates [m/s2]

Max. acceleration:

Max. delay:

system

Make:

Type:

Other:

Resolution [µm]:

Numerical control

Make:

Type:

incremental,

output signal ...

SIEMENS

840D

Processed by: Dept.: No. of pages: Date:

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

2-23

Page 24

2 Configuration

02.99

10.03

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital

2.2.1 System overview

Components

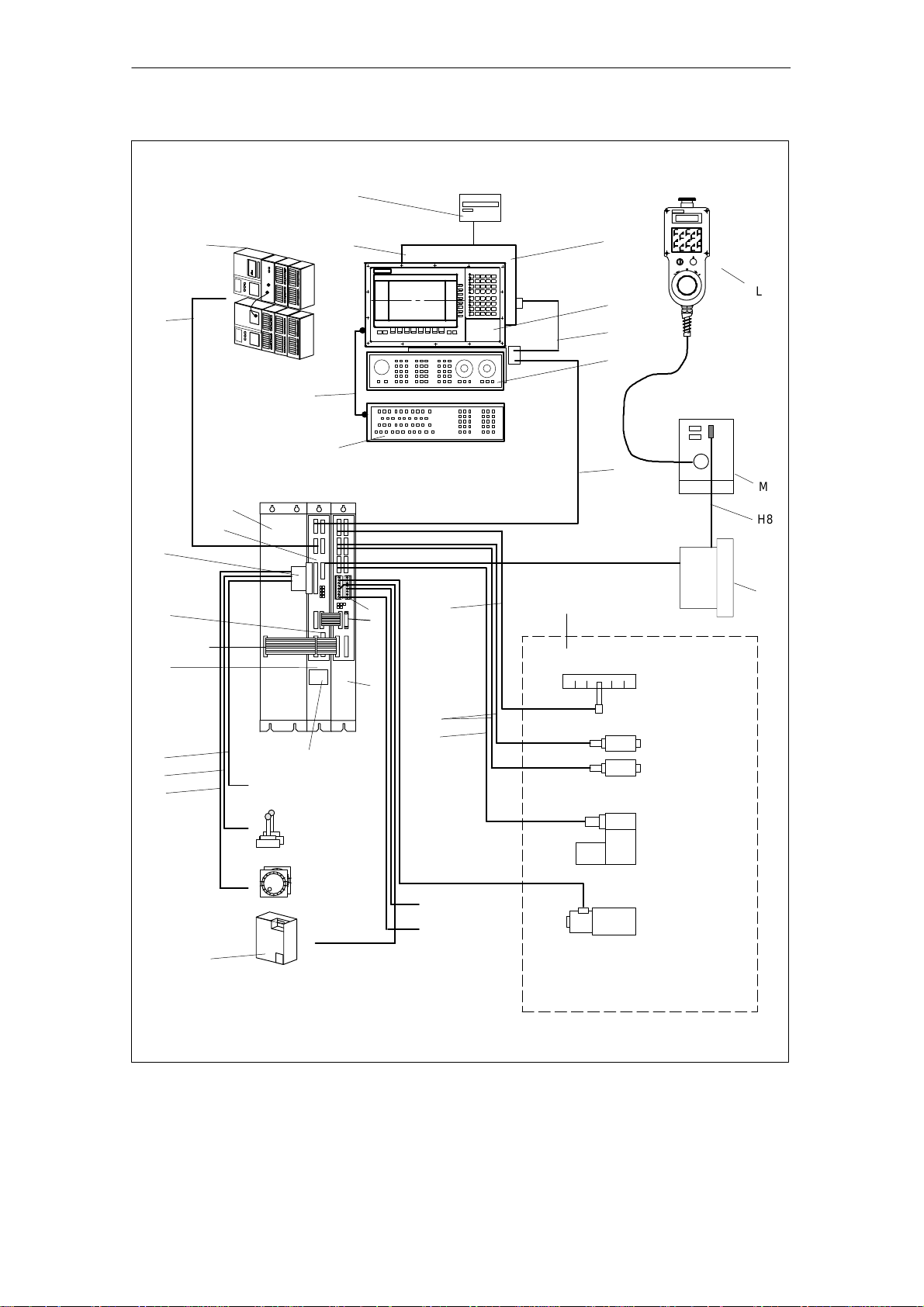

A complete SINUMERIK 840 digital control system with HLA module consists of

various individual components. These are listed below.

Table 2- 1 Components of SINUMERIK 840 digital control with HLA module (number,

No.in

Fig.

2-3

O NCU box

B NC CPU

component, description)

Component Description

S Enclosure for NC CPU

S Central processing unit of 840D

S Execution of NC program,

S Contains modules with e.g. PLC, communications

functions

S NCU 573.2 includes a fan module

B1 Cable distributor

1)

C

Operator panel

1)

D

MMC module

S For insertion in NCU

S Display, keyboard, power supply unit and

operator controls for NC

S Operator panel calculator (integrated in panel),

S MMC 103 with hard disk

I Mains supply module

(MS)

1)

F

Machine control panel

G11)ISA adapter

G21)Full CNC keyboard

References: /PJ1/ SIMODRIVE 611

S Machine operation

S Allows AT modules to be used in conjunction with

the MMC module MMC103 (mounted in operator

panel)

S Full keyboard for connection to MMC module

G3 Memory card (PCMCIA)

S Contains the system program,

S can be slotted into the NCU 561.2, 571.2, 572.2,

573.2

G4 Diskette unit (accessory)

H1 to

Cable References: /Z/, Catalog of Accessories NC Z

H 9

H10

Cable See Chapter 7, Peripherals/Accessories

to

H12

I SIMODRIVE hydraulics

module (HLA module)

50 mm carrier module

(universal empty housing)

I1 Phoenix cable connection

S Built-in unit for connection to MMC module

S Closed-loop control of hydraulic drive

S Actuation of servo solenoid valve

Holder for HLA closed-loop control plug-in module

(see Fig. 2-6)

S Shutoff valve

S External 24 V supply

S BERO input

S “Power enable”

J SIMATIC components References: /S7H/, Manual

K Terminator Terminator for drive bus (inserted in last module in

drive grouping)

2-24

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 25

10.03

2 Configuration

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital

Table 2-1 Components of SINUMERIK 840 digital control with HLA module (number,

No.in

Fig.

2-3

1)

L

component, description)

Handheld unit

DescriptionComponent

S Connect HHU to K bus via MPI

S Handwheel, EMERGENCY STOP button, key-ac-

tuated switch, override, agreement buttons, dis-

1)

M

Distribution box

play, unassigned keys

S For linking the hand-held unit to the MPI bus

S Connection for EMERGENCY STOP circuit, en-

able keys, handwheel, 24 V DC

N Cable distributor

O Hydraulic Drive References:

P External 24 V supply

1) A description of these components can be found in:

References: /BH/, Operator Components Manual

S 24V supply for connection to MPI connector

/BR1/, “Servo solenoid valves” catalog

/BR2/, “Sensors and electronics” catalog

/BR3/, “Adapter plate valves” catalog

S SITOP stabilized power supply modules

References: SITOP catalog

Order No. E860060-K2410-A101-A4

Note

An HLA module must never be operated directly on a SIMODRIVE monitoring

module, i.e. it must always be connected via a mains infeed module.

For information about connecting further additional SIMODRIVE monitoring

modules in configurations with several HLA modules, please refer to the

Planning Guide for SIMODRIVE 611 Converters /PJU/.

In a multi-tier configuration, all the infeed supply units must be connected

simultaneously.

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

2-25

Page 26

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital

2 Configuration

02.99

10.03

Floppy

G4

J

G1

MMC CPU

D

S7-300

C

L

H1

H5

MCP

F

H4

G2

H6

M

E

B

(GND)

H8

B1

G3

Device bus

A

H2

H3

H9

SITOP power

(external PS)

P

MS

module

HLA

NCU

Battery and plug-in fan

unit

Digital I/O

(high-speed NC I/O)

Measurement (2x)

Handwheel

(2x) (1x of M)

External 26.5 V

supply

I1

H10

O

N

K

I

Position sensing

H11

H12

Pressure sensor A

Pressure sensor B

Servo solenoid

valve

BERO

inputs

Enable

Shutoff valve

Note:

Display of hydraulics for one axis

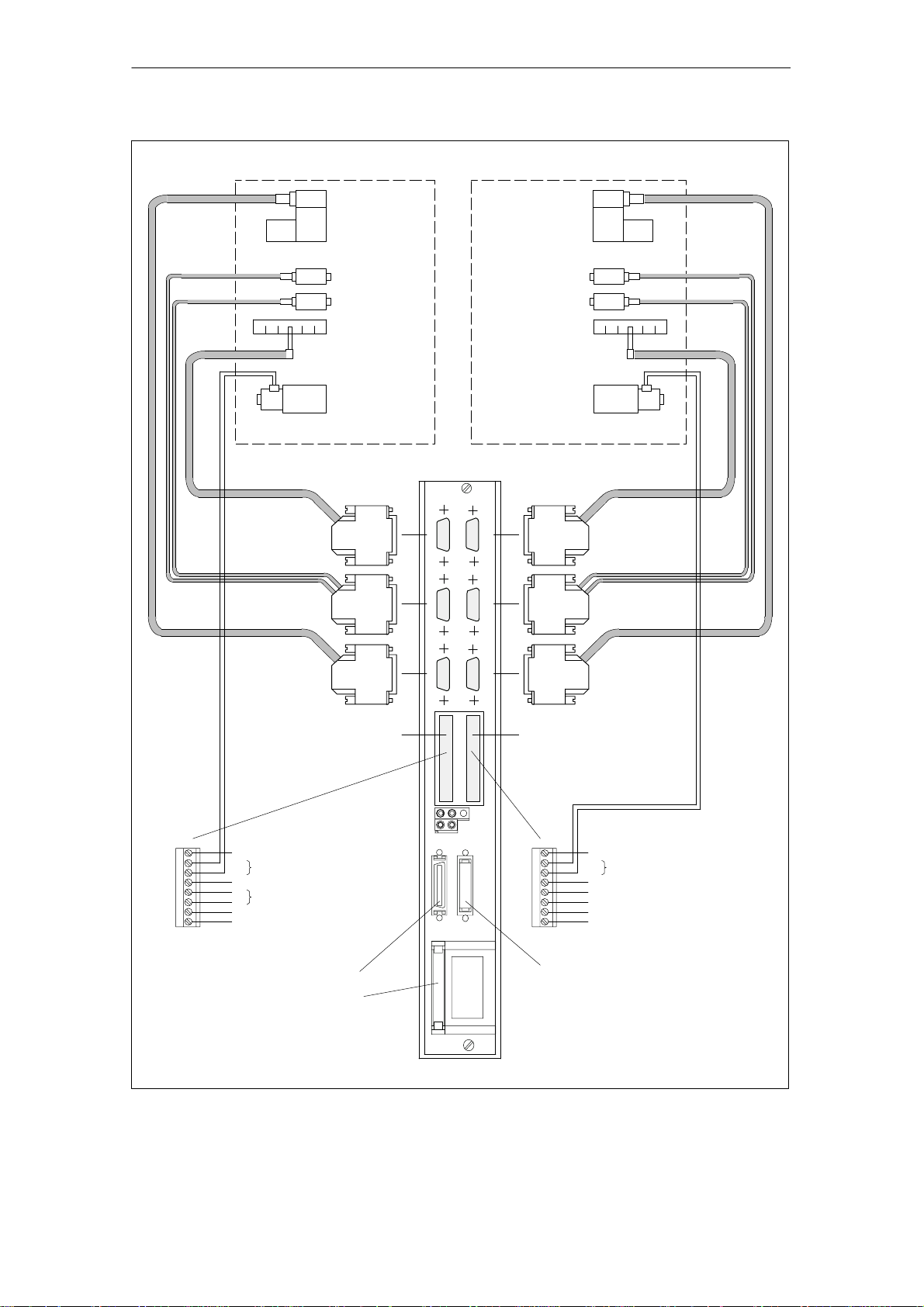

Fig. 2-3 System components

2-26

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 27

2 Configuration

02.99

10.03

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital

O

B

Hydraulic drive, axis 1

Position

measuring

system

Pressure sensor

Servo solenoid

valve

Pressure

sensor A

Pressure

sensor B

Position sensing

Shutoff valve

Servo solenoid valve

Pressure sensor A

Pressure sensor B

Position sensing

Shutoff valve

O

B

Hydraulic drive, axis 2

Axis 1

HLA

-X101

BOBB

-X102

Axis 2

Position

measuring

system

O

-X111

-X112

Pressure sensor

Servo solenoid

-X121

X431 X432

-X34

M

PV1

MV1

C1

P24

M24

663

9

Functional ground

+

Shutoff valve, axis 1

-

Reserved, do not use!

+

External 26.5 V supply

-

Power enable at term. 663

Internal +24 V enabling voltage

X1141

Drive bus

Device bus interface (X151)

1) Only required if external 26.5 V is not electrically separated safely!

Fig. 2-4 Connection configuration for HLA module

-X35

-X122

X1341

Servo solenoid

valvevalve

M

PV2

MV2

C2

B1

19

B2

9

Functional ground

+

Shutoff valve, axis 2

-

Reserved, do not use!

BERO input, axis 1

Internal 0 V enabling voltage

BERO input, axis 2

Internal +24 V enabling voltage

Drive bus/drive bus terminator on last

module

1)

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

2-27

Page 28

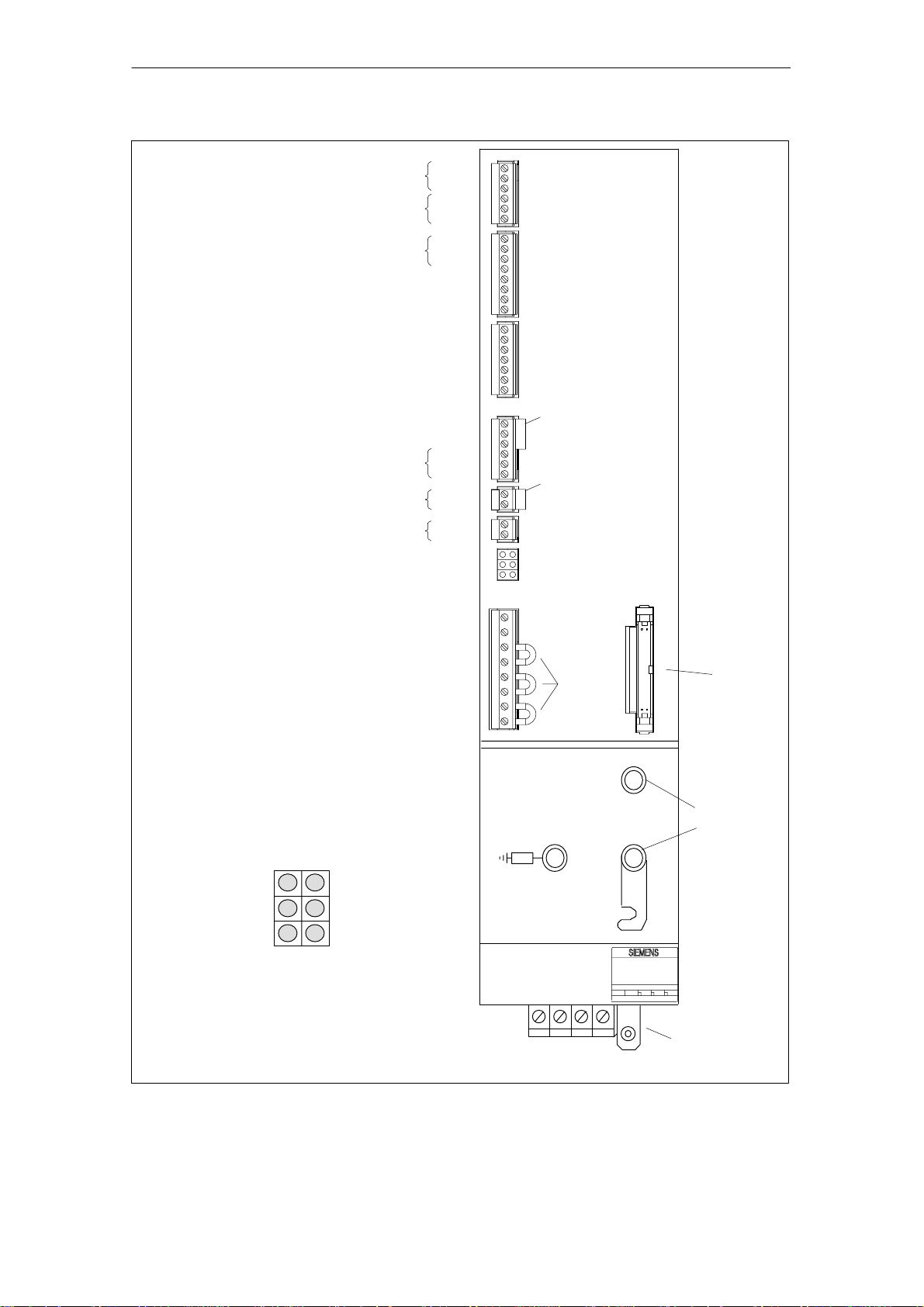

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital

2 Configuration

02.99

10.03

Relay contact,

Ready to operate

message

Relay contact for group message

2

t and motor overtemperature

I

Reference potential for enable voltage

Enabling signal for internal line contactor

Signaling contact for starting lockout (NC contact)

DC link power supply for bridging line failures

Electronics power supply from external source

Electronics power supply from external source

Electronics power supply from external source

Power disable

Enabling voltage

Enabling voltage

Drive enable

P24

P15

N15

N24

M

M

RESET (R+term.15)

Enabling voltage

Setup mode

Contactor energization, start

Signaling contact,

line contactor

NC

contact

NO

contact

74

73.1

73.2

72

5.3

5.2

5.1

63

9

9

64

19

7

45

44

10

15

15

R

9

112

48

111

213

113

NS1

NS2

AS1

AS2

M500

P500

2U1

1U1

2V1

1V1

2W1

1W1

X111

X121

X141

1)

X161

1)

X171

X172

LED displays

X181

1)

X351

Device bus

LED displays

Electronics power

supply faulty

Device is not ready,

no enable signal

(term. 63, 64 or 48)

Line fault

Red

Green

Red

Red

Yellow

Red

5 V voltage level

fault

Device ready

(DC link

precharged)

DC link

overvoltage

1) Jumpers inserted in delivery state

Fig. 2-5 Interfaces on mains supply module (OI and I/RF module)

P600

DC link

connection

M600

Power supply

U1 V1 W1 X131 PE

2-28

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 29

10.03

2 Configuration

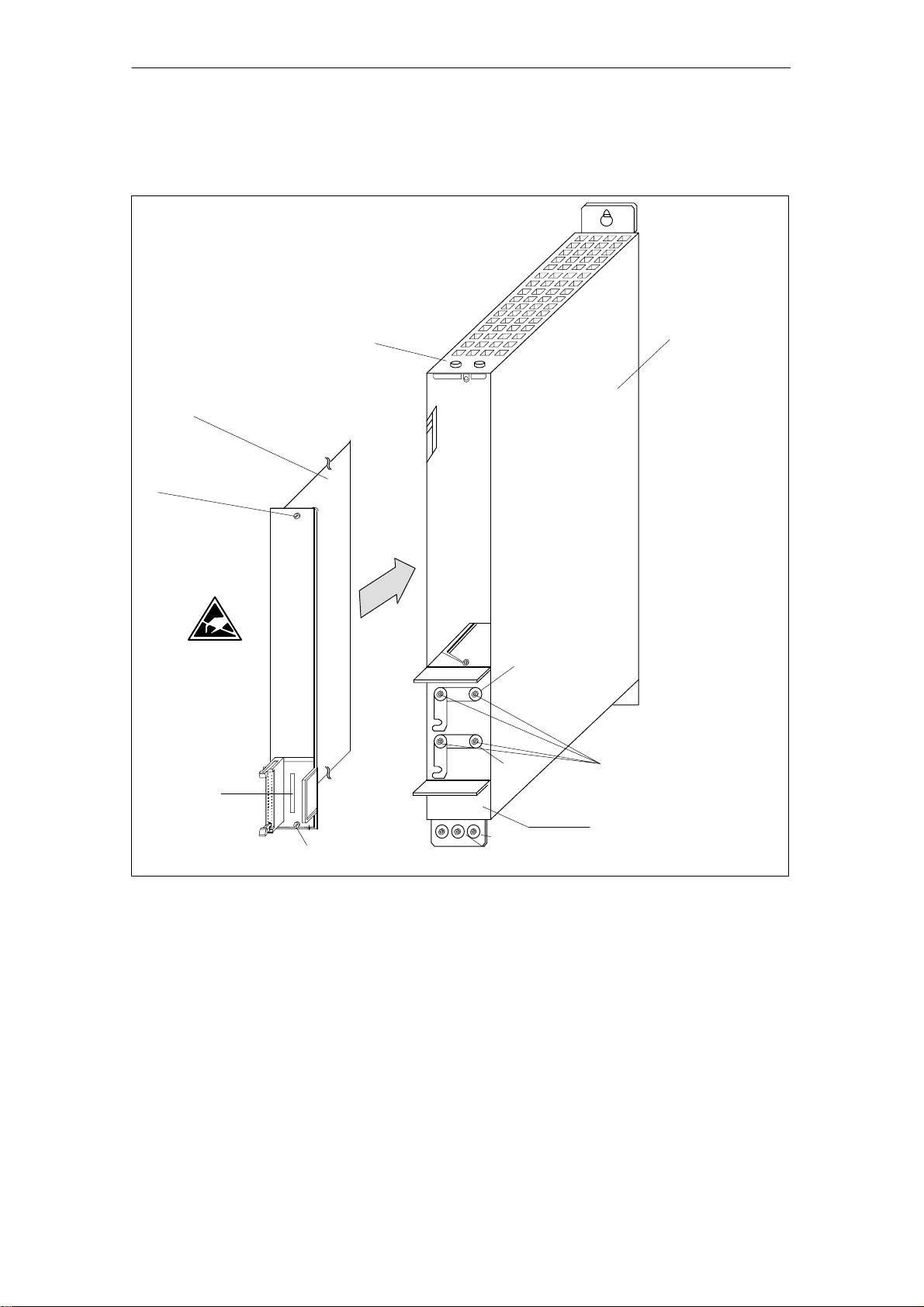

Mounting the HLA

closed-loop control

plug-in module

HLA closed-loop control plug-in

module (6SN1115-0BA11-0AA1)

Slotted screw

M3 / 0.8 Nm

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital

Shield connection

50 mm carrier module

(universal empty housing)

(6SN1162-1AA00-0AA0)

P600

M600

Order No.

Slotted screw

M3 / 0.8 Nm

Fig. 2-6 Mounting the HLA closed-loop control plug-in module in 50 mm carrier module (universal empty housing)

PE

M5 / 3.0 Nm

M4 / 1.8 Nm

Rating plate/Order No.

2.2.2 Required FW packages

S SINUMERIK 840D NCK SW w5.1

including SIMODRIVE 611 digital HLA module w1.0

S SINUMERIK 840D MMC SW u5.1

or

SINUMERIK 840D HMI SW w6

2.2.3 Hardware requirements

S NCU 561.2, 571.2, 572.2, 573.2

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

2-29

Page 30

2.3 Configuring the hydraulic drive

2 Configuration

2.3 Configuring the hydraulic drive

10.03

General

Hydraulic drives are generally configured by technical sales personnel from the

hydraulics supplier, Rexroth.

The configuration is based on the data from the questionnaire in

Subsection 2.1.2 .

Please refer to Appendix A for a description of hydraulic components.

The hydraulic drive is configured in the sequence of steps described below.

2.3.1 Cylinder selection

Piston and rod

diameter

The piston and rod diameters are calculated according to Pascal’s theorem on

the basis of the necessary compressive and tensile forces F and a standard

pressure value of P=40...100 bar for machine tools (a maximum pressure setting of 350 bar is permitted).

The force value calculation must include friction and acceleration forces

as well as the actual feed force. Pistons and rods with the following standard

diameter dimensions are available:

Table 2-2 Typical cylinder data

Description Diameter

Piston ∅ 25 32 40 50 63 80 100 125

Rod ∅ Standard 12 14 18 22 28 36 45 56

Rod ∅ Optional 18 22 28 36 45 56 70 90

p =

F

O

Stroke length

2-30

The stroke is identical to the working stroke of the drive except that

it includes a few additional safety reserves.

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 31

10.03

2 Configuration

2.3 Configuring the hydraulic drive

Mounting

Mounting position

In order to ensure good control quality, backlash-free mountings, e.g. base or

flange mountings, must be used.

Flange mounting

Flange at front Flange at rear

Base mounting

Fig. 2-7 Cylinder mounting methods

This is will depend on the machine’s situation and affects the choice of shutoff

valves (see Subsection 2.3.3). Vertical loads must be protected via poppet

valves. Forces due to weight must be taken into account in the final calculation

of the operating pressure (MD 5151: CYLINDER_A_ORIENTATION).

See Fig. 4-17 in Section 4.9 for the possible cylinder mounting positions.

Seal, friction

Cylinder pipes

Position

measuring system

Suitable seals must be used to minimize friction. Transitions from static to sliding friction have a particularly adverse affect on the control result.

The slide guide friction must be added to the cylinder friction. A friction compensation setting has been provided in the HLA module (MD 5460:

FRICTION_COMP_GRADIENT) for the purpose of counteracting initial friction.

The distance between the cylinder and servo solenoid valve must be kept as

short as possible for the sake of the drive’s natural frequency (compressibility of

the oil volume). In ideal cases, the servo solenoid valve is flange-mounted

directly on the cylinder.

The incremental and absolute position measuring systems supported by the

HLA module are mounted on the machine slide. It is also possible to use position measuring systems (SSI encoders) integrated in the cylinder.

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

2-31

Page 32

2.3 Configuring the hydraulic drive

2 Configuration

2.3.2 Selection of servo solenoid valves

References: /BR1/, “Servo solenoid valves” catalog

Valve types

(overview)

Table 2-3 Overview of servo solenoid and HR servo solenoid valves from Bosch Rexroth AG

The HLA module supports servo solenoid valves with on-board electronics

(OBE) supplied by Bosch Rexroth AG. The technical data for these valves and

valves supplied by other manufacturers is stored in the HLA module software.

The drive is parameterized automatically when the order number is entered.

The following table lists the various types of servo solenoid valve and HR (=

High Response) servo solenoid valves available from Bosch Rexroth AG.

For a complete list, please see Tables 2-4 to 2-10.

10.03

Title Nomi-

4WRPEH

(directly-controlled

servo solenoid valve)

4WRPE

(pilot-controlled

servo solenoid valve)

4WRPEH

(directly-controlled

HR servo solenoid valve)

nal

size

6 up to 40 / 35 bar linear and

10 up to 100 / 35 bar linear and

10 up to 70 / 5 bar with knee 40

16 up to 150 / 5 bar with knee 40

6 up to 40 / 35 bar linear and

Nominal flowrate (l/min)

for nominal pressure drop

per control edge (bar)

curve Limit fre-

110

with knee

with knee

210

with knee

quency

1)

85

(Hz)

4WRVE

(pilot-controlled

HR servo solenoid valve)

1) The characteristic values specified for the valve limit frequencies relate to an amplitude of "5% and a

phase offset in the Bode diagram of -90°, see also data in catalog supplied by Bosch Rexroth AG.

2-32

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

10 up to 70 / 35 bar with knee 80

16 up to 150 / 5 bar with knee 80

Siemens AG, 2003. All rights reserved

Page 33

10.03

2 Configuration

2.3 Configuring the hydraulic drive

The choice of valve for a particular application is made with reference to the

following criteria.

Servo solenoid or

HR servo solenoid

valves

Valve size

HR (High Response) valves are characterized by their improved dynamic quality, i.e. by a higher limit frequency compared to servo solenoid valves. They

react with greater sensitivity to setpoint changes especially in the small-signal

range. The use of HR servo solenoid valves is recommended in the following

cases:

1. When extremely high contour precision is required in high-speed continuous-path control machining operations.

2. When very high response sensitivity is required to achieve the best possible

positioning accuracy.

Note that HR servo solenoid valves do not generally have a fail-safe position.

The connector is also 12-pin, rather than 7-pin as with servo solenoid valves.

The valve size is determined by the maximum flowrate Q

. This maximum flow-

X

rate is calculated according to the law of flow:

=v @ A

Q

X

v: Maximum drive speed for extension and retraction

A: associated cylinder surface area

The calculated maximum flow rate must not exceed the limit for use of the

valve. This limit is generally specified in the catalog by the valve manufacturer

(e.g. Rexroth: /BR1/, “Servo solenoid valves” catalog).

Within the limits for use, the flow rate that can be achieved with the valve is calculated by

Q=Q

nom

@

p

p

nom

Linear/knee-shape

d flowrate

characteristic

In practice, the cylinder speeds that can actually be achieved depend on the

operating pressure, the load pressure and flow-specific characteristics of the

drive. The dimensioning is left to the hydraulic configuration engineer, who has

access to a number of design calculation and simulation programs.

V alues with either a linear or knee-shaped characteristic can be selected.

The latter are suitable for obtaining a higher resolution in the low signal range

(machining) and sufficient flow in the high signal range (rapid traverse).

The definition of the knee-point position as 40% or 60% means that only 10% of

the nominal opening cross-section (nominal flowrate) is released at 40% or 60%

of the nominal control signal (i.e. at U=4 V or 6 V).

The knee-shaped characteristic of the valve must be linearized in the HLA module to adapt it to the closed-loop control of the entire drive (cylinder).

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

2-33

Page 34

2.3 Configuring the hydraulic drive

2 Configuration

10.03

Q/Q

nom

Rapid traverse

10%

40%

Fig. 2-8 Diagram of a knee-shaped servo solenoid valve characteristic and its correction in the HLA module

U/U

nom

Machining velocity

10%

Q/Q

nom

40%

Valve characteristic

Linearized

characteristic

U/U

nom

compensation

Note

Recommended selection:

Servo solenoid valves are generally recommended for applications where there

is a clear separation between machining operation and rapid traverse.

Asymmetrical

flowrate

characteristics

It is a good idea to use valves with asymmetrical restriction cross-sections for

differential cylinders or for cylinders that are not arranged horizontally and move

large loads. This improves the hydraulic clamping of the cylinder and adjusts

the controlled system gain of the hydraulic servo-drive for both directions of

travel.

Q

A

P

A

P

B

Q

OB

PT

Fig. 2-9 Asymmetrical characteristics

B

Q

v

U

G

2-34

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 35

10.03

2 Configuration

2.3 Configuring the hydraulic drive

Fail-safe position

Pin assignments

Directly-controlled servo solenoid valves have a fail-safe position, i.e. the control

spool moves to a safe position when the valve is disconnected from the power

supply. The fail-safe position is either “closed” (A, B, P, T disabled) or “open” (A,

B and T connected and P disabled). It should be noted that the “crossed”

switching position is necessarily passed when the valve is switched on and off,

and there can be temporary responses from the cylinder at these moments.

Separate shut-off valves are therefore required in order to implement safety

functions, such as a totally safe cylinder stop.

Pilot-controlled servo solenoid valves, pilot-controlled HR servo solenoid valves

and directly-controlled HR servo solenoid valves do not have a fail-safe position

and thus do not have a safe basic position when switched off. Any safety functions nmust therefore be implemented via separate shut-off valves.

Fail-safe closed Fail-safe open

OB

PT

Fig. 2-10 Fail-safe position in the valve graphical symbol

OB

PT

A distinction must be made between servo solenoid valves and HR servo solenoid valves.

S Servo solenoid valves (directly and pilot-actuated): 7-pin round connector

2.5 AF

+24 V=O

B

C

100k

100k

10k

Fig. 2-11 Connector pin assignment on servo solenoid valves

D

I

F

0 V

0 V

Sign.

Supply

Reference point for actual

valve spool value

Setpoint 0..."10 V

Actual value spool value

Protective

conductor

Shield

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

2-35

Page 36

2.3 Configuring the hydraulic drive

OB

PT

PT

PT

PT

2 Configuration

S HR servo solenoid valves (directly and pilot-controlled); 12-pin round

connector

+U

B

100k

100k

10k

10

11

10.03

2.5 AF

+24 V=

0 V

1

2

3

4

5

6

7

8

9

24 V

Sign.

0 V

24 V

+24 V =/v0.5 A

0 V

24 V

Output stage supply

enabling of

Setpoint 0..."10 V

Actual value spool value

Enable acknowledgement

Electronics supply

Error message

Protective

conductor

Shield

Fig. 2-12 Connector assignment for HR servo solenoid valves

Preferred range

of servo solenoid

valves

Table 2-4 NG6 directly-controlled servo solenoid valves; model code 4WRPEH 6

HLA

code

no.

10 0 811 404 601 12 Linear.

11 0 811 404 602 24 Linear.

12 0 811 404 603 40 Linear.

13 0 811 404 610 4 Linear. OB

14 0 811 404 611 12 Linear.

15 0 811 404 612 24 Linear.

16 0 811 404 613 40 Linear.

17 0 811 404 642 15 60

18 0 811 404 747 25 60

19 0 811 404 644 40 40

20 0 811 404 645 15 60 OB

21 0 811 404 646 25 60

22 0 811 404 647 40 40

Rexroth

order number

9 0 811 404 600 4 Linear. 7-pin

The following tables list all the servo solenoid valves and HR servo solenoid

valves supplied by Bosch Rexroth AG for which technical data is stored in the

HLA module.

Q

nom

(l/min) for

np / edge

= 35 bar

Character-

istic kneep-

oint (%)

No. of

connector pins

Graphic symbol Rexroth

OB

OB

PT

PT

catalog

/BR1/

2-36

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 37

10.03

2 Configuration

2.3 Configuring the hydraulic drive

Table 2-4 NG6 directly-controlled servo solenoid valves; model code 4WRPEH 6

HLA

code

no.

Rexroth

order number

Q

nom

(l/min) for

np / edge

Character-

istic kneep-

oint (%)

connector pins

Graphic symbolNo. of

= 35 bar

23 0 811 404 648 A:40; B:20

1)

40 7-pin

OB

PT

24 0 811 404 649 A:40; B:20

1)

40 OB

PT

Table 2-5 NG10 directly-controlled servo solenoid valves; model code 4WRPEH 10

HLA

code

no.

Rexroth

order number

Q

nom

(l/min) for

np / edge =

Character-

istic kneep-

oint (%)

No. of

connector pins

Graphic symbol Rexroth

35 bar

41 0 811 404 800 50 Linear. 7-pin

OB

42 0 811 404 801 100 Linear.

PT

43 0 811 404 802 50 Linear. OB

Rexroth

catalog

/BR1/

catalog

/BR1/

44 0 811 404 803 100 Linear.

45 0 811 404 822 50 40

46 0 811 404 823 100 40

47 0 811 404 824 50 40 OB

48 0 811 404 825 100 40

B:50

B:50

1)

1)

1)

1)

40 OB

40

40 OB

40

49 0 811 404 826 A:50; B:25

50 0 811 404 827 A:100;

51 0 811 404 828 A:50; B:25

52 0 811 404 829 A:100;

1) Asymmetrical characteristic

PT

OB

PT

PT

PT

PT

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

2-37

Page 38

2.3 Configuring the hydraulic drive

s

u

s

u

PTX Y

s

u

s

u

PTX Y

OB

PT

PT

OB

PTX Y

PTX Y

2 Configuration

Table 2-6 NG10 pilot-controlled servo solenoid valves; model code 4WRLE 10

10.03

HLA

code

no.

Rexroth

order number

Q

nom

(l/min) for

np / edge =

Character-

istic kneep-

oint (%)

No. of

connector pins

Graphic symbol Rexroth

5 bar

25 0 811 404 686 40 40 7-pin

OB

26 0 811 404 687 70 40

27 0 811 404 688 A:40; B:20

28 0 811 404 689 A:70; B:40

1)

1)

40

40

X Y

PT

Table 2-7 NG16 pilot-controlled servo solenoid valves; model code 4WRLE 16

HLA

code

no.

Rexroth

order number

Q

nom

(l/min) for

np / edge =

Character-

istic kneep-

oint (%)

No. of

connector pins

Graphic symbol Rexroth

5 bar

1 0 811 404 263 90 40 7-pin

OB

2 0 811 404 264 150 40

B:90

1)

1)

40

40

X Y

PT

3 0 811 404 265 A:90; B:50

4 0 811 404 266 A:150;

Table 2-8 NG6 directly-controlled HR servo solenoid valves; model code 4WRREH 6

catalog

/BR1/

catalog

/BR1/

HLA

code

no.

Rexroth

order number

Q

nom

(l/min) for

np / edge =

Character-

istic kneep-

oint (%)

No. of

connector pins

Graphic symbol Rexroth

35 bar

33 0 811 404 720 40 Linear. 12-pin

OB

34 0 811 404 721 24 Linear.

35 0 811 404 722 12 Linear.

36 0 811 404 723 8 Linear.

37 0 811 404 725 15 60

38 0 811 404 726 25 60

39 0 811 404 727 40 40

40 0 811 404 728 A:40; B:20

1)

40

Table 2-9 NG10 pilot-controlled HR servo solenoid valves; model code 4WRVE 10

HLA

code

no.

Rexroth

order number

Q

nom

(l/min) for

np / edge =

Character-

istic kneep-

oint (%)

No. of

connector pins

Graphic symbol Rexroth

5 bar

29 0 811 404 693 40 40 12-pin

OB

30 0 811 404 694 70 40

31 0 811 404 695 A:40; B:20

32 0 811 404 696 A:70; B:40

1)

1)

40

40

catalog

/BR1/

HRV - Size 6

catalog

/BR1/

1) Asymmetrical characteristic

2-38

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 39

10.03

OB

PTX Y

PTX Y

2 Configuration

2.3 Configuring the hydraulic drive

Table 2-10 NG16 pilot-controlled HR servo solenoid valves; model code 4WRVE 16

HLA

code

no.

1) Asymmetrical characteristic

Rexroth

order number

5 0 811 404 296 90 40 12-pin

6 0 811 404 297 150 40

7 0 811 404 298 A:90; B:50

8 0 811 404 299 A:150;

Q

nom

(l/min) for

np / edge =

5 bar

1)

B:90

Character-

istic kneep-

1)

oint (%)

40

40

2.3.3 Selection of shutoff valves

References:/BR3/, “Adapter plate valves” catalog

General

!

The shutoff valves are automatically enabled and disabled in the correct switching sequence by the HLA module.

Start condition: The hydraulic pressure must be available before

the system is switched on.

Warning

In the event of sudden failure (e.g. open circuit) of the external 24 V supply, an

axial storage capacitor on the HLA module provides energy to supply the servo

solenoid valve until such time as the pressure supply for a configured shutoff

valve is disabled.

The machine manufacturer must verify the interaction between valves, making

allowance for all tolerances in the controlled system.

The energy content of the storage capacitors is dependent upon

No. of

connector pins

Graphic symbol Rexroth

OB

catalog

/BR1/

S the tolerances of the capacitors,

S the voltage level of the external supply and

S the charging time of the integrated capacitors (instant of voltage failure).

The available response time is mainly defined by

S the power required for the current machining step,

S the response time of the shutoff valves and

S the trip threshold of the servo solenoid valves.

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

2-39

Page 40

2.3 Configuring the hydraulic drive

2 Configuration

10.03

Examples

Figure 2-13 shows an electrically-switched sandwich-type shut-off valve used to

shut off the system pressure at the servo solenoid valve.

Interruption of the hydraulic power circuit upstream of the servo solenoid valve

is sufficient to meet simple safety requirements. When a servo solenoid valve in

the closed fail-safe position is switched off, then approximate shut-off of the consumer connections with respect to the cylinder is guaranteed.

There are some safety limitations, however, since the servo solenoid valve’s

fail-safe position is not totally free of leakage oil, and thus does not work without

some cylinder drift. In addition, when the servo solenoid valve is switched on

and off, the “crossed” position is necessarily passed, which can result in cylinder movement.

OB

b

S

PT

a

T BOP

U

Servo

solenoid

valve

Shut-off valve

(electrically

switched)

Fig. 2-13 A typical example for an electrically-controlled shut-off valve

The circuit in Figure 2-14 achieves a high level of safety. In this case, an additional barrier block closes the consumer connections to the cylinder safely and

with no leakage of oil. This means that even heavy loads on non-horizontal axis

can be quickly stopped and held safely, regardless of the state of the servo solenoid valve. Totally safe scenarios for switching the drive on and off can thus

be implemented.

OB

b

S

PT

a

T BOP

U

Servo

solenoid

valve

Shutoff valve

(barrier block)

Shutoff valve

(electrically

switched)

2-40

Fig. 2-14 Typical example for the combination of an electrically-switched shut-off valve

with an additional barrier block

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

Siemens AG, 2003. All rights reserved

Page 41

10.03

2 Configuration

2.3 Configuring the hydraulic drive

Preferred range

of shut-off valves

Table 2-11 Shutoff valves

Rexroth

order number

0 811 024 120 6

0 811 020 040 10

0 811 024 125 6

0 811 024 123 6

Nominal

size

Bosch Rexroth shut-off valves from the following table should ideally be used