Page 1

Preface

SINUMERIK 840Di sl/840D sl

SINUMERIK 840Di/840D

ePS Network Services

Function Manual

Introduction

Machine information

Setting up functions

Organizational tasks

Statistics/export

Management

1

2

3

4

5

6

Applies to:

Software Version

ePS Network Services 4.6

Establishing a

connection and

diagnostics

Appendix

7

A

Release 08/2008

Page 2

SINUMERIK® Documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the "Remarks" column.

Status codes in the "Remarks" columns:

A .... New documentation.

B .... Unrevised reprint with new Order No.

C .... Revised edition with new status.

Release Order no. Remark

08/2008 -- C

11/2007 -- C

04/2007 -- C

11/2006 -- C

08/2006 -- C

04/2006 -- C

11/2005 -- C

Registered Trademarks

All designations with the trademark symbol ® are registered trademarks of Siemens AG. Other

designations in this documentation may be trademarks whose use by third parties for their own

purposes can violate the rights of the owner.

Exclusion of Liability

We have checked that the contents of this document correspond to the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency.

However, the information in this publication is reviewed regularly and any necessary corrections are

included in subsequent editions.

Siemens AG

Industry Sector

P.O. Box 3180

91050 Erlangen

GERMANY

Copyright © Siemens AG 2008

Subject to change without prior notice.

Page 3

08/2008 Preface

Preface

SINUMERIK documentation

The SINUMERIK documentation is available in three versions:

• General documentation

• User documentation

• Manufacturer/service documentation

A monthly overview of publications with the available languages is available on

the Internet at:

http://www.siemens.com/motioncontrol

Follow menu items "Support" "Technical Documentation" "Ordering

Documentation" "Printed Documentation".

The Internet version of the DOConCD (DOConWEB) is available at:

http://www.automation.siemens.com/doconweb

Information about training courses and FAQs (frequently asked questions) are

available on the Internet under:

http://www.siemens.com/motioncontrol

Target group

This publication is intended for project engineers, programmers, technologists (of

machine manufacturers), and system startup engineers (of systems/machines).

Use

The Function Manual describes the functions so that the target group is familiar

with and can select them. It provides the target group with the information required to implement the functions.

Utilization phase: Planning and configuration phase, implementation phase, setup

and commissioning phase

, under the menu item "Support".

Standard scope

This documentation only describes the functionality of the standard version. Additions or revisions made by the machine tool manufacturer are documented by the

machine tool manufacturer.

Other functions not described in this documentation might be executable in the

control. This does not, however, represent an obligation to supply such functions

with a new control or when servicing.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

iii

Page 4

Preface 08/2008

Further, for the sake of simplicity, this documentation does not contain all detailed

information about all types of the product and cannot cover every conceivable

case of installation, operation, or maintenance.

Questions about this document

If you have any queries (suggestions, corrections) in relation to this documentation, please fax or e-mail us:

Fax +49 9131 98 2176

E-mail docu.motioncontrol@siemens.com

A fax form is available at the end of this document.

SINUMERIK Internet address

http://www.siemens.com/sinumerik

Technical Support

If you have any technical questions, please contact our hotline:

Europe/Africa

Phone

Fax

Internet

America

Phone

Fax

E-mail

Asia/Pacific

Phone

Fax

E-mail

Note

Country-specific telephone numbers for technical support are provided under the

following Internet address: http://www.siemens.com/automation/service&support

+49 180 5050 222

+49 180 5050 223

http://www.siemens.com/automation/support-request

+1 423 262 2522

+1 423 262 2200

techsupport.sea@siemens.com

+86 1064 719 990

+86 1064 747 474

techsupport.asia@siemens.com

Calls are subject to charge, e.g. 0.14 €/min. on the German landline network.

Tariffs of other phone providers may differ.

© Siemens AG 2008 All Rights Reserved

iv ePS Network Services, Function Manual (FH) - Release 08/2008

Page 5

08/2008 Preface

EC declaration of conformity

The EC Declaration of Conformity for the EMC Directive can be found on the

Internet at: http://support.automation.siemens.com

or under the Order No. 15257461 or at the relevant branch office of the A&D MC

Division of Siemens AG.

Safety information

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. Notices referring to your

personal safety are highlighted in the manual by a safety alert symbol; notices referring to property damage only have no safety alert symbol. Depending on the

hazard level, warnings are indicated in a descending order as follows:

!

!

!

Danger

Indicates that death or serious injury will result if proper precautions are not

taken.

Warning

Indicates that death or serious injury may result if proper precautions are not

taken.

Caution

(With warning triangle) indicates that slight personal injury may result if proper

precautions are not taken.

Caution

(Without warning triangle) indicates that property damage may result if proper

precautions are not taken.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

Notice

Indicates that an unwanted result or situation may result if the appropriate advice

is not taken into account.

In the event of a number of levels of danger prevailing simultaneously, the warning corresponding to the highest level of danger is always used. A notice warning

of injury to persons with a warning symbol may also include a warning relating to

property damage.

v

Page 6

Preface 08/2008

Qualified persons

The associated device/system must only be set up and operated using this documentation. Commissioning and operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes in this

documentation qualified persons are defined as persons who are authorized to

commission, ground and label devices, systems and circuits in accordance with

established safety practices and standards.

Intended purpose

Please observe the following:

!

Warning

Siemens products must only be used for the applications specified in the catalog

and in the technical documentation. If third-party products and components are

used, they must be recommended or approved by Siemens.

To ensure trouble-free and safe operation of the products, they must be appropriately transported, stored, assembled, installed, commissioned, operated and

maintained. The permissible ambient conditions must be adhered to. The notes in

the associated documentation must be complied with.

© Siemens AG 2008 All Rights Reserved

vi ePS Network Services, Function Manual (FH) - Release 08/2008

Page 7

08/2008 Contents

Contents

1 Introduction .................................................................................... 1-11

1.1 Overview of functions ................................................................... 1-11

1.2 Operating concept ........................................................................ 1-13

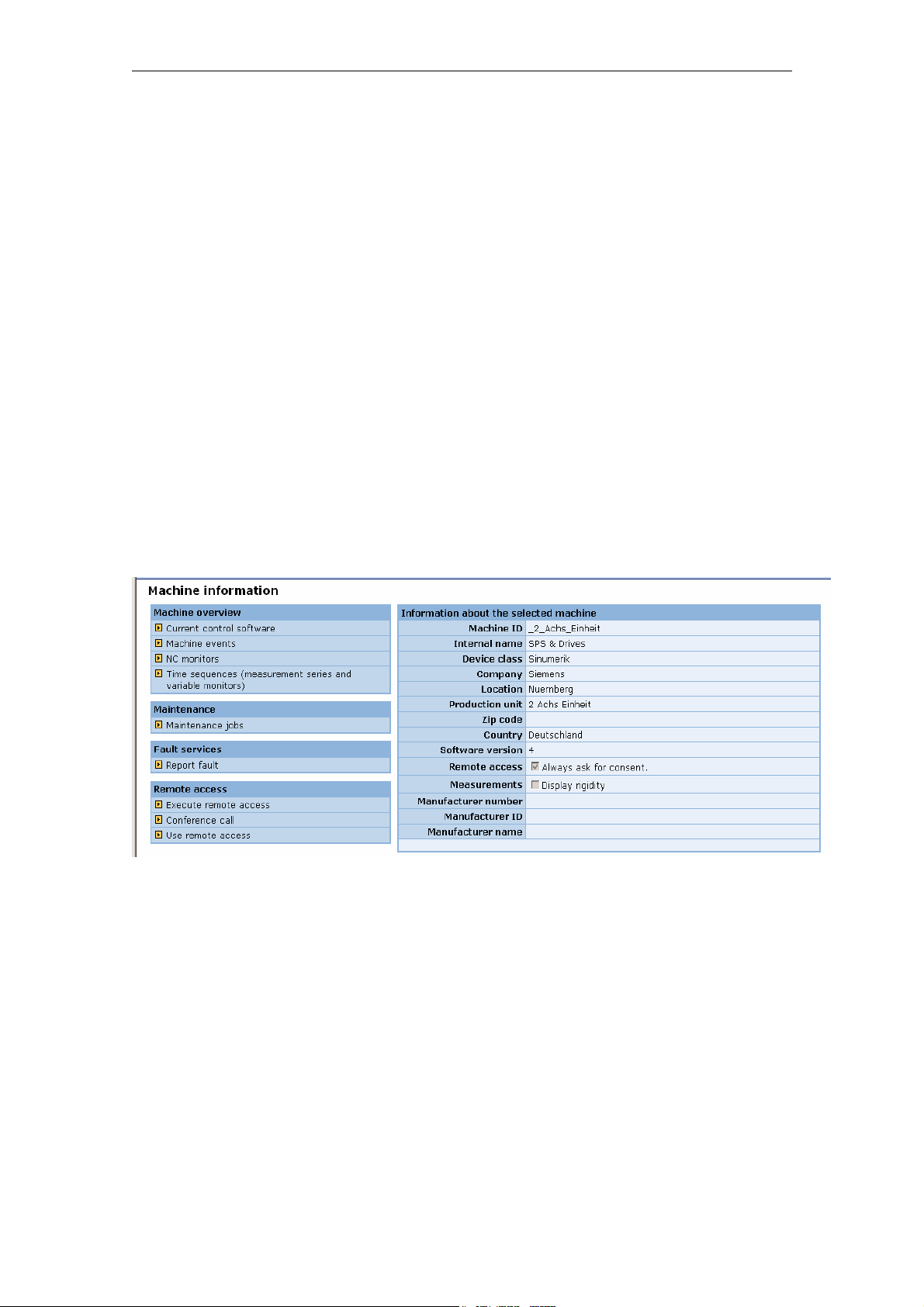

2 Machine information...................................................................... 2-15

2.1 Machine overview ......................................................................... 2-15

2.1.1 Current control software ............................................................ 2-16

2.1.2 Machine events - List view......................................................... 2-16

2.1.3 Machine events - Detailed view................................................. 2-19

2.1.4 Evaluation of workflow actions................................................... 2-20

2.1.5 Evaluation of diagnostics data................................................... 2-21

2.1.6 NC monitors............................................................................... 2-30

2.2 Measurements and measurement series ..................................... 2-32

2.2.1 Analyzing on the PC .................................................................. 2-32

2.2.2 Operating diagrams ................................................................... 2-35

2.2.3 Control elements of the diagrams for individual measurements 2-39

2.2.4 Circularity test ............................................................................ 2-42

2.2.5 Synchronous operation axis test................................................ 2-43

2.2.6 Universal axis test...................................................................... 2-45

2.2.7 Variable monitors....................................................................... 2-46

2.3 Test series on the machine........................................................... 2-49

2.3.1 Performing measurement series................................................ 2-49

2.3.2 Requirements for performing the test........................................ 2-50

2.3.3 Prolog and epilog program for a measurement......................... 2-52

2.3.4 Program example ...................................................................... 2-55

2.3.5 Commissioning measurements ................................................. 2-59

2.3.6 Release protocol between PLC and ePS system...................... 2-59

2.3.7 Contour test ............................................................................... 2-60

2.4 Maintenance ................................................................................. 2-61

2.5 Remote access ............................................................................. 2-63

2.5.1 Remote access functions........................................................... 2-63

2.5.2 Functions of a service session................................................... 2-64

2.5.3 Starting a service session.......................................................... 2-65

2.5.4 Example of a session via remote access .................................. 2-68

2.5.5 Granting permission to execute functions ................................. 2-69

2.5.6 Setting up a service conference call.......................................... 2-73

2.5.7 Remote control via the keyboard............................................... 2-76

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

vii

Page 8

Contents 08/2008

3 Setting up functions ...................................................................... 3-77

3.1 Maintenance ................................................................................. 3-79

3.1.1 Creating maintenance schedules .............................................. 3-79

3.1.2 Configuring variable monitors.................................................... 3-81

3.1.3 Configuring NC monitors ........................................................... 3-87

3.2 Configuring measurements and measurement series.................. 3-88

3.2.1 Circularity test ............................................................................ 3-88

3.2.2 Synchronous operation axis test................................................ 3-90

3.2.3 Universal axis test...................................................................... 3-91

3.2.4 Performing test series................................................................ 3-93

3.3 Fault services................................................................................ 3-95

3.3.1 Control monitors - List view ....................................................... 3-95

3.3.2 Control monitors - Detailed view................................................ 3-99

3.3.3 Machine triggers and server triggers ......................................... 3-101

3.3.4 Machine trigger on "alarm group" .............................................. 3-103

3.3.5 Machine trigger on "PLC variable"............................................. 3-104

3.3.6 Machine trigger for "PLC timeout trigger" .................................. 3-108

3.3.7 Combined machine trigger on "alarm group"

AND "PLC variable"................................................................... 3-110

3.3.8 Machine trigger for "Time-based trigger"................................... 3-112

3.3.9 Trigger on "Fault message at HMI/PC"...................................... 3-116

3.3.10 Server trigger on "Measurement series reaches limit value"... 3-116

3.3.11 Server trigger on "Maintenance jobs due" ............................... 3-117

3.3.12 Server trigger on "Variable monitor reaches limit value" ......... 3-119

3.3.13 Cyclic server trigger for NC monitors and variable monitors... 3-121

3.3.14 Workflow actions...................................................................... 3-126

3.3.15 Diagnostic actions.................................................................... 3-129

3.4 Global settings .............................................................................. 3-138

3.4.1 Setting the notification limit........................................................ 3-138

3.4.2 PLC and NC settings ................................................................. 3-138

3.5 Copying......................................................................................... 3-141

3.5.1 Functions from other machines ................................................. 3-141

3.6 Client/server communication ........................................................ 3-146

3.6.1 Synchronization times................................................................ 3-146

3.6.2 Offline synchronization .............................................................. 3-147

3.6.3 Monitoring ePS services ............................................................ 3-150

4 Organizational tasks...................................................................... 4-151

4.1 Maintenance ................................................................................. 4-151

4.1.1 Selecting a maintenance job for a machine............................... 4-154

4.1.2 Opening a maintenance job (PC) .............................................. 4-156

4.1.3 Executing a maintenance job (HMI) .......................................... 4-159

4.2 Service cases................................................................................ 4-163

4.2.1 Service cases - List view ........................................................... 4-164

4.2.2 Service cases - Detailed view.................................................... 4-166

4.2.3 Requesting fault processing at the HMI..................................... 4-169

© Siemens AG 2008 All Rights Reserved

viii ePS Network Services, Function Manual (FH) - Release 08/2008

Page 9

08/2008 Contents

5 Statistics/export............................................................................. 5-171

5.1 Multi-machine views ..................................................................... 5-172

5.1.1 Multi-machine events................................................................. 5-172

5.1.2 Measurement series .................................................................. 5-174

5.1.3 Reports ...................................................................................... 5-180

5.2 Import............................................................................................ 5-187

5.2.1 Active import processes............................................................. 5-188

5.2.2 Importing a file ........................................................................... 5-189

5.2.3 Importing a directory (requires ActiveX) .................................... 5-189

5.3 Export............................................................................................ 5-190

5.4 Overviews ..................................................................................... 5-191

5.4.1 Synchronization overview.......................................................... 5-191

5.4.2 Monitoring ePS services ............................................................ 5-191

6 Management ................................................................................... 6-195

6.1 Organization management ........................................................... 6-195

6.1.1 Addresses.................................................................................. 6-196

6.1.2 User ........................................................................................... 6-197

6.1.3 Machines.................................................................................... 6-198

6.1.4 Creating a machine in the form of a copy.................................. 6-203

6.1.5 Organizational data.................................................................... 6-209

6.1.6 Download areas......................................................................... 6-211

6.2 Personal settings .......................................................................... 6-213

7 Establishing a connection and diagnostics................................ 7-215

7.1 Connecting a machine to the HMI ................................................ 7-215

7.1.1 Uploading an alarm model......................................................... 7-219

7.1.2 Synchronizing the machine........................................................ 7-220

7.1.3 Disconnecting the machine (at HMI and PC) ............................ 7-221

7.1.4 Repetition strategy..................................................................... 7-224

7.1.5 Editing the prolog and epilog program....................................... 7-225

7.2 Cooperation areas ........................................................................ 7-226

7.2.1 Releasing a machine to an organization ................................... 7-227

7.2.2 Machines in a cooperation area................................................. 7-229

7.3 Client diagnostics.......................................................................... 7-231

7.3.1 Components of client diagnostics.............................................. 7-232

7.3.2 Performing a diagnostics session.............................................. 7-234

7.3.3 Other functions .......................................................................... 7-235

7.4 1:N connections ............................................................................ 7-236

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

ix

Page 10

Contents 08/2008

A Appendix ........................................................................................ A-239

A.1 Useful functions of the various device classes............................. A-239

A.2 Functions of the various roles (privilege matrix)........................... A-242

A.3 References ................................................................................... A-244

I Index.................................................................................................. I-245

© Siemens AG 2008 All Rights Reserved

x ePS Network Services, Function Manual (FH) - Release 08/2008

Page 11

08/2008 1 Introduction

1.1 Overview of functions

1

1 Introduction

1.1 Overview of functions

What are ePS Network Services?

The ePS Network Services support machine tool manufacturers and manufacturing

companies with maintenance and services. This is carried out using software services that are available on a CNC control, S7 control, IPC or standard PC.

This requires both a control on the machine that complies with the specifications,

and Internet access.

The ePS Network Services include:

Remote access

Remote access to the control via a secure Internet infrastructure.

This service permits remote access to the control.

• Desktop control

• File transfer

• Chat

• Video ...

Control monitor services

Recording of events in a history and documentation of the current status of the

control at this point. This allows the status of the device to be analyzed and compared with earlier states should a fault occur.

The current status of the machine is documented using the following events and

data:

• Alarms, PLC events, time intervals, combinations of machine signals

• Limit value violation and time delay violation from condition monitoring

• Series of measurements/tests and operating performance monitors

• Manual help request by the machine operator in the event of faults

• HMI action log, machine data, NC status data

• PLC trace, PLC data blocks

• Certain files (e.g. log files) of the control

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

1-11

Page 12

1 Introduction 08/2008

1.1 Overview of functions

Condition monitoring services

Measurement and documentation of the current machine status on the basis of

predefined, standardized tests and continuous recording of status characteristics

(traverse path, traverse time and traverse operations for one axis). The test parameters can be defined centrally and configured with appropriate warning limits.

Using series of measurements, it is also possible to identify trends and apply them

as a basis for optimizing maintenance and service activities.

The machine operator can then carry out these predefined tests quickly and easily

and without additional test equipment.

The following tests and monitors are available:

• Circularity test

• Synchronous operation axis test

• Universal axis test

• NC monitor

• Variable monitor

Data services

Save the current control archives (NCK and PLC archives) on the ePS Server. In

the event of faults, they can be reimported into the controller in a controlled manner

and used as reference for comparisons of control monitors.

Workflow services

Triggering of service and maintenance processes by notification via media that are

internal and external to the system (SMS, e-mail, service cases). Planning,

monitoring, and documentation of maintenance activities on the machine.

Maintenance schedules support you in the following tasks:

• "Look Ahead" maintenance relating to load and usage (see: Control monitors

with machine and service triggers)

• Automated triggering of operating sequences when faults are detected (see:

Maintenance schedules, maintenance jobs, fault help requests, and service

cases).

• Planning condition monitors in terms of dates and content, and monitoring

their processing (see: Maintenance schedules, maintenance jobs and control

monitors)

The Workflow Services can respond to all event sources of the Control Monitor

Services and Condition Monitor Services.

© Siemens AG 2008 All Rights Reserved

1-12 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 13

08/2008 1 Introduction

1.2 Operating concept

Administration services

Functions for the administration of the system:

• Creation and administration of machines

• Creation and administration of users

• Assignment of access rights for external organizations

• Access to use data/invoices

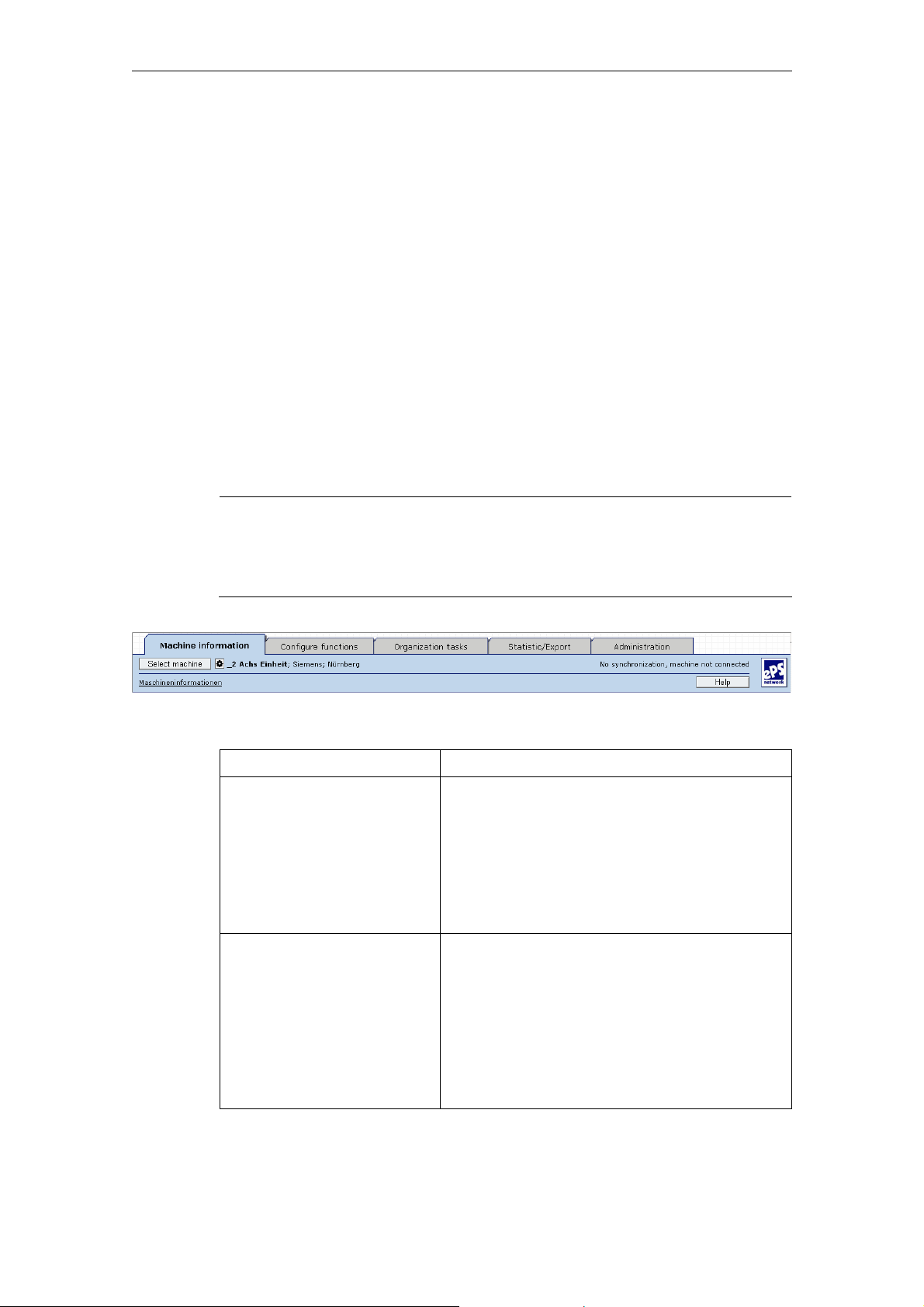

1.2 Operating concept

Overview

The functions of the ePS Network Services are divided into five main categories

which can be reached via tabs. The "Machine information" and "Set up functions"

tabs always apply to the selected machine.

Fig. 1-1: Basic principle of operation

Note

The availability of each function to the machine operator in each of the various

roles is described in the Appendix.

Please see the descriptions in each section for details of the functions.

Tab/Section Description

Machine information The "Machine information" tab contains impor-

Setting up functions The "Set up functions" tab allows you to make

tant information on a particular selected ma-

chine.

It is divided into the following areas:

• Machine overview

• Maintenance

• Fault services

• Remote access

all the settings that apply to a particular selected machine.

It is divided into the following areas:

• Maintenance

• Fault services

• Global settings

• Copying function settings

• Client/server communication

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

1-13

Page 14

1 Introduction 08/2008

1.2 Operating concept

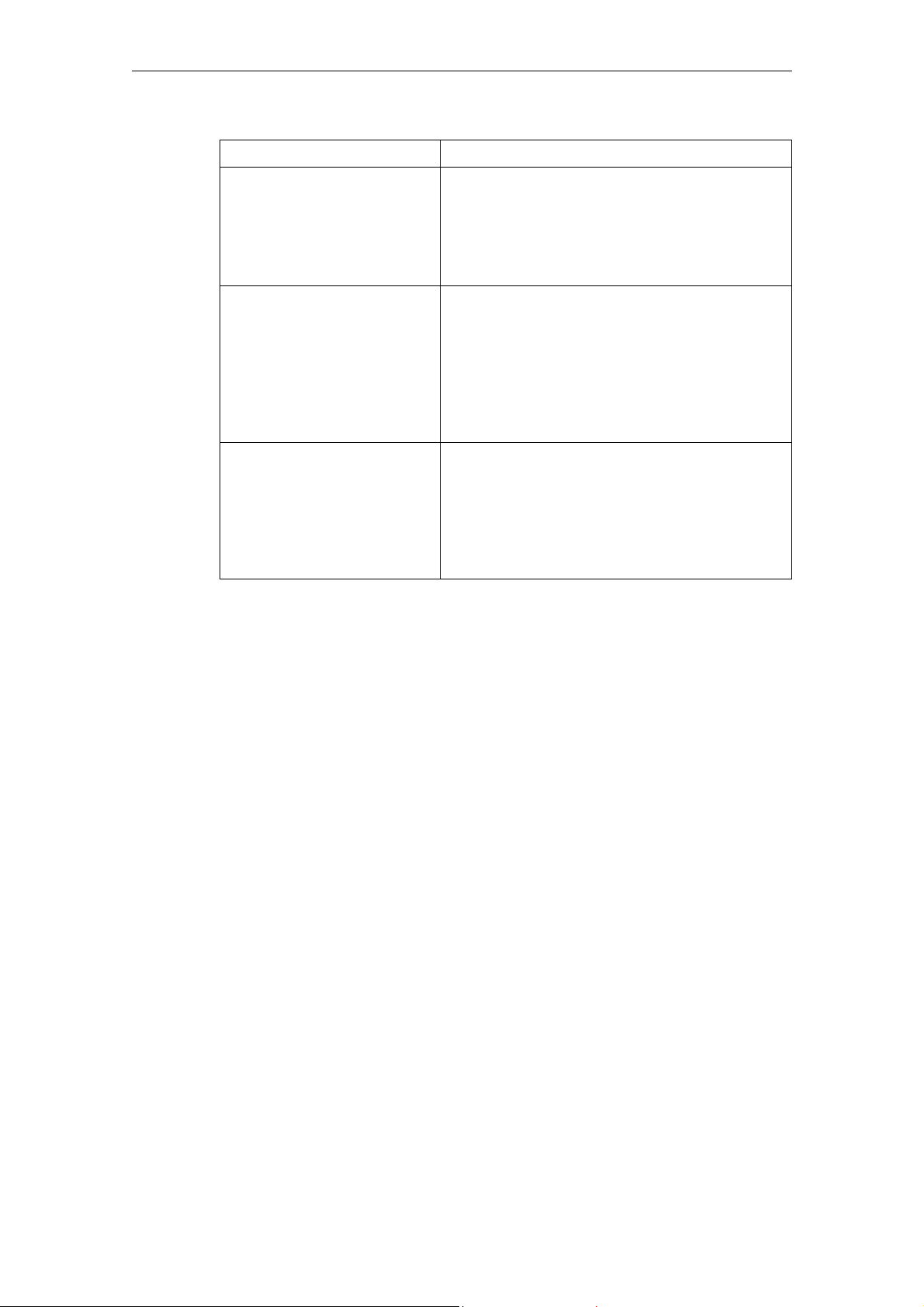

Tab/Section Description

Organizational tasks The "Organizational tasks" tab contains func-

tions and services that apply to all machines of

an organization.

It is divided into the following areas:

• Maintenance jobs

• Service cases

Statistics/export The "Import/Export" tab contains functions and

services that apply to all machines of an organization.

It is divided into the following areas:

• Multi-machine views

• Import

• Export

• Overviews

Management The "Administration" tab contains functions and

services that apply to the settings of an organi-

zation.

It is divided into the following areas:

• Organization management

• Personal settings

© Siemens AG 2008 All Rights Reserved

1-14 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 15

08/2008 2 Machine information

2.1 Machine overview

2

2 Machine information

2.1 Machine overview

Overview

Machine events in the machine information:

The machine events of an individual machine can be viewed in the same way as

the multi-machine events (see Section 5.1.1 "Multi-machine views") and always refer to the selected machine only.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-15

Page 16

2 Machine information 08/2008

2.1 Machine overview

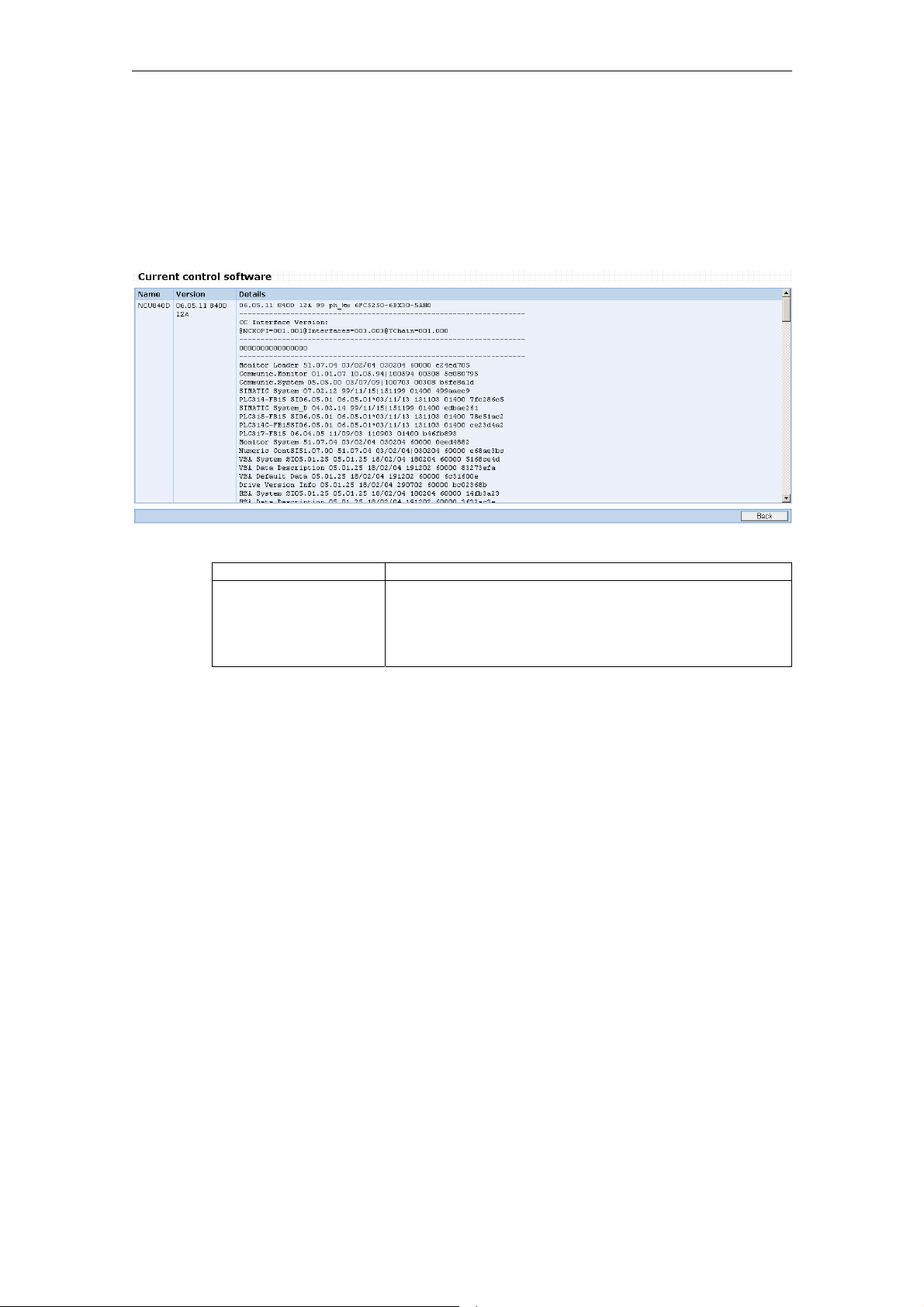

2.1.1 Current control software

Description of functions

In the Machine information area under Current Control Software, you can view all

versions of the software packages currently installed on the control

Fig. 2-1: Control software

Function Description

Current control

software

Displays the installed software version:

The display depends on the device class.

For device class SINUMERIK these are the NCU and

HMI version.

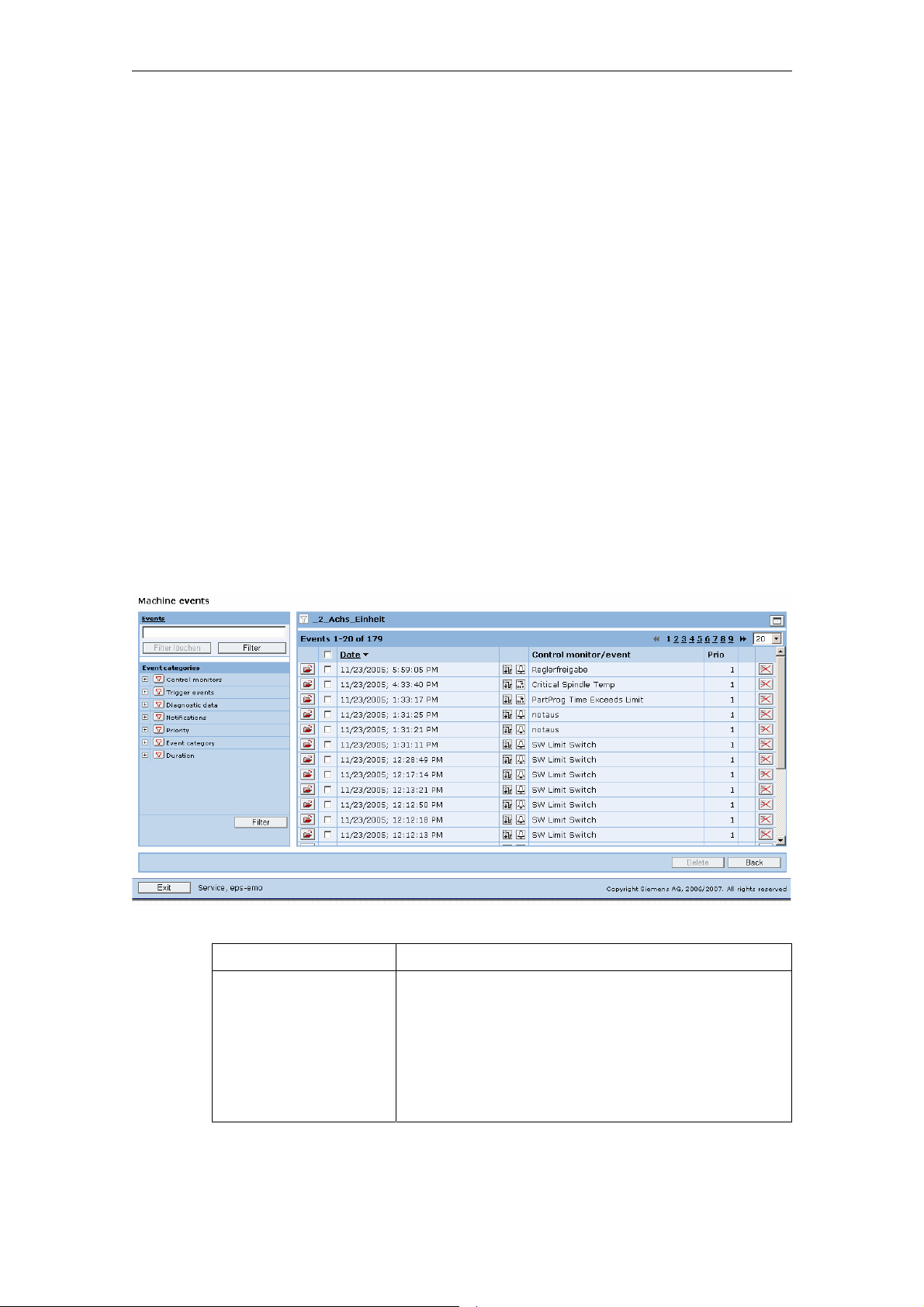

2.1.2 Machine events - List view

Description of functions

Under Machine events in the machine information area you can view the following events for the selected machine as a list:

• Events from Control Monitor Services

- Alarm or PLC events

- Fault processing request

- Cyclic events (time trigger)

Events that have been configured by control monitors with the identification

"Without entry in the machine events" do not generate an entry, and their details cannot be viewed either.

• Events from condition monitor services

- Exceeded interval limits of variable monitors or NC operating performance

monitors

- Limit value violation for measurement series/test series

© Siemens AG 2008 All Rights Reserved

2-16 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 17

08/2008 2 Machine information

2.1 Machine overview

• System events

- NC/PLC archives created

- Service sessions performed

For each event, you can view additional diagnostic information or triggered workflow services and evaluate them (in some cases graphically):

• Workflow services elements

- Transmitted notifications (SMS/e-mail)

- Generated maintenance jobs

- Service cases

• Diagnostics data

- Files

- HMI action log

- Machine data or NC status data

- PLC traces or PLC data blocks

- Variable monitors

To ascertain differences between machine data, NC status data, and data of the

HMI action log, you can compare this data with data of the same type for several

events on the same machine.

Fig. 2-2: Machine events - List view

Function Description

Filter events You can filter events according to their properties.

Various filter criteria are available:

• Filter according to type of event (alarm, PLC, time

trigger, trigger from performance monitors, etc.)

• Filter according to type of diagnostics data (e.g.

files, PLC Traces)

• Filter according to type of triggered Workflow Services Elements (e.g. maintenance jobs)

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-17

Page 18

2 Machine information 08/2008

2.1 Machine overview

Function Description

• Filter according to event priority

• Filter according to time periods (e.g. today, this

week, from/to)

Note:

The filter can be hidden to make it easier to evaluate

the event history at lower screen resolutions. However,

the filter settings still remain active.

Find events You can browse events using a free text search. The

search is applied to the "Designation" and "Details"

fields.

Note:

Localized alarm texts of the machine loaded into the

ePS server are also found, even if another language is

currently set on your workstation (browser).

Open event You can open the detail view of events, for example, to

view and compare diagnostics data.

Sort events You can sort events according to time stamp (date),

designation or priority.

Delete event

Delete several events

Note:

If the list of events has already been reduced by filtering and/or a search, the reduced list is sorted.

You can delete individual events.

You can delete several events simultaneously:

• Click the check box in the "Select all" header,

followed by the "Delete" button.

• Select individual entries using the check boxes in

the line and then click the "Delete" button.

Note:

You can select events in the control monitor services

to be "not deletable" (e.g. for verification purpose). You

cannot remove these from the list!

Notice:

Diagnostics data generated with an event are also

deleted; however, triggered Workflow Services Elements (e.g. maintenance jobs) are not deleted!

© Siemens AG 2008 All Rights Reserved

2-18 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 19

08/2008 2 Machine information

2.1 Machine overview

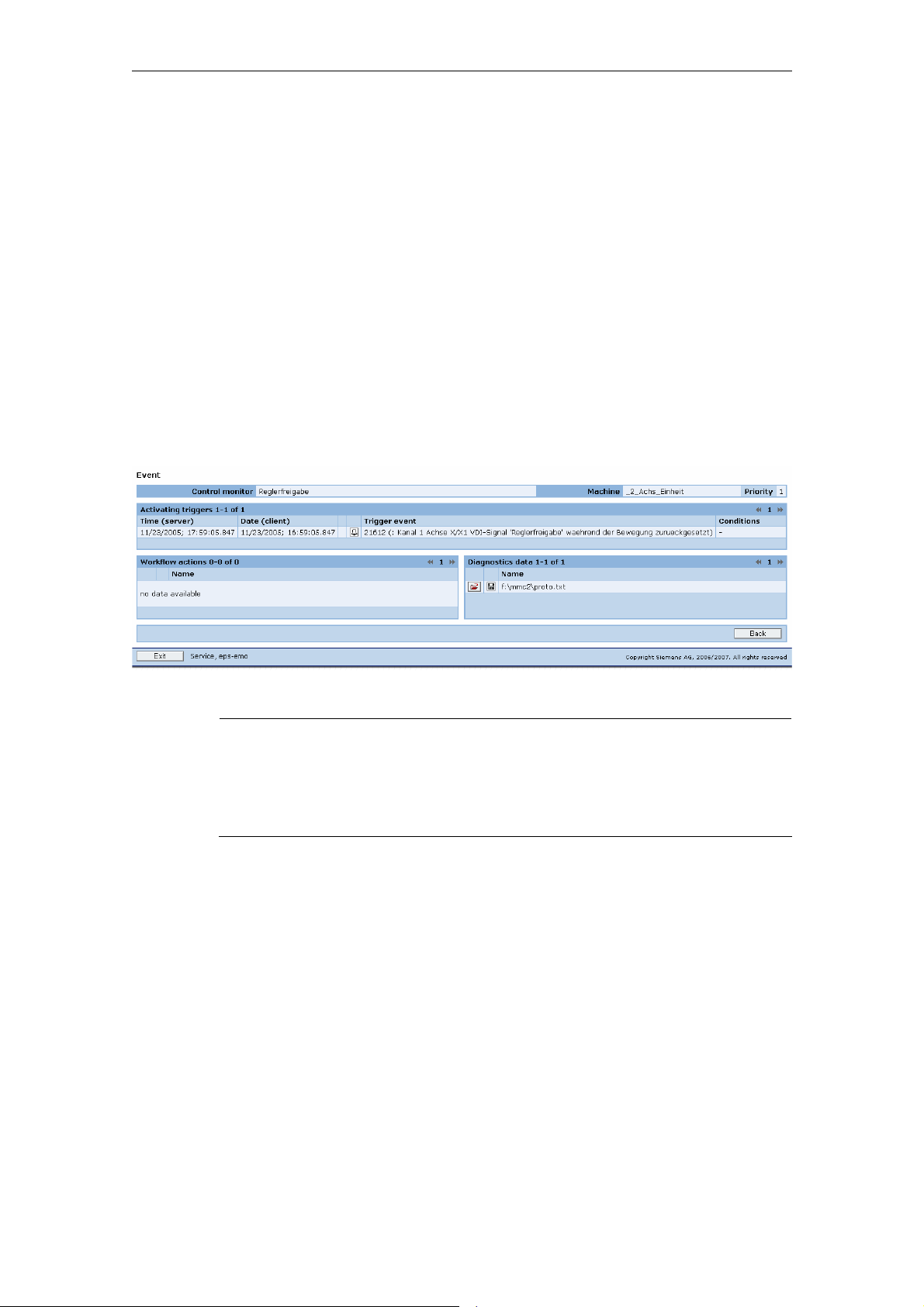

2.1.3 Machine events - Detailed view

Description of functions

In the detailed view of an event you can view detailed information about a trigger

event and the diagnostics data and triggered workflow service elements it generates.

The detailed view of an event is divided into three areas:

• Trigger

• Workflow actions: Opening displayed actions

(maintenance job, notification)

• Diagnostics data: Opening displayed actions

The visualization is performed analogous to the configuration of a control monitor

except for the restricted editing functions.

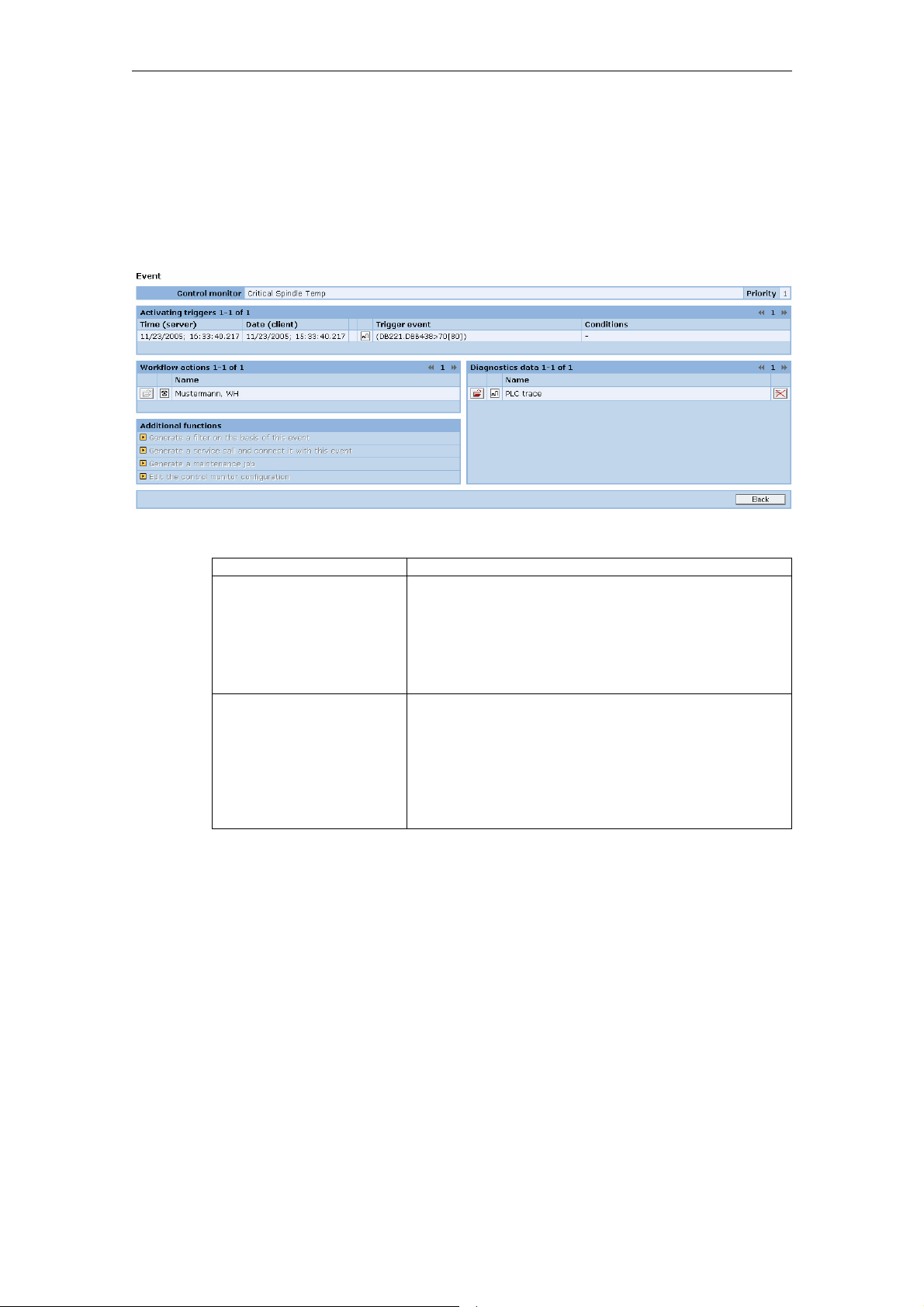

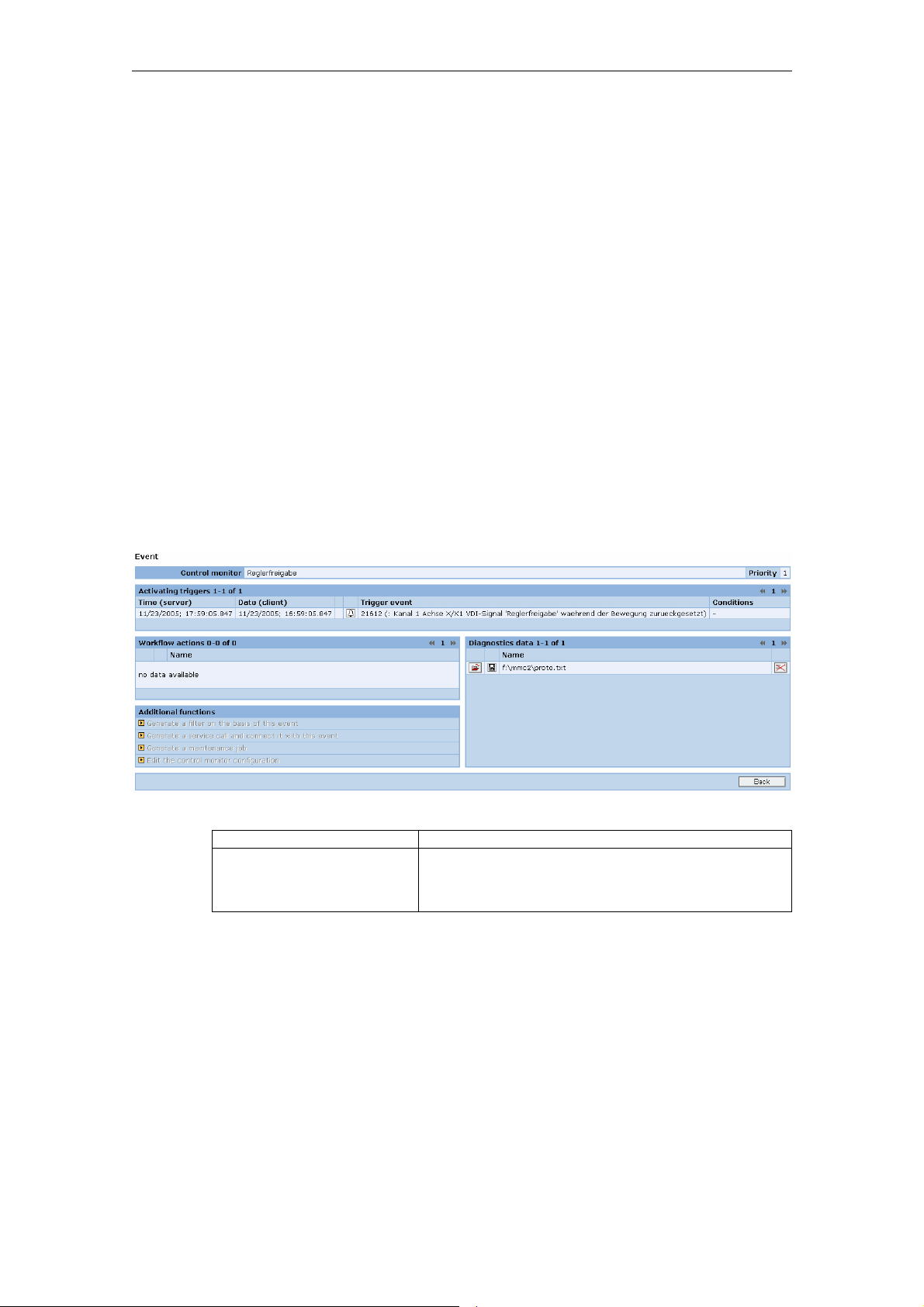

Fig. 2-3: Machine events - Detailed view

Note

The detailed information displayed for a particular event depends on the event

type. The timestamp is displayed for all event types.

The time stamp is based on the time set on the machine, in order to achieve a

true-to-life time-based payment for the event.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-19

Page 20

2 Machine information 08/2008

2.1 Machine overview

2.1.4 Evaluation of workflow actions

Description of functions

To view notifications, you can jump directly from the evaluation of one diagnostics

data item to another, if it belongs to the same event.

Fig. 2-4: Display of completed workflow actions

Function Description

View workflow element You can view workflow elements in detail. The work-

flow element will open, but it will not be possible to

edit it (e.g. maintenance job).

Note:

Notifications and maintenance jobs cannot be edited.

Delete workflow element You cannot delete workflow elements retroactively

from events that have already occurred, since these

show the documentation history.

Note:

Notifications, maintenance jobs and service cases

cannot be deleted.

© Siemens AG 2008 All Rights Reserved

2-20 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 21

08/2008 2 Machine information

2.1 Machine overview

2.1.5 Evaluation of diagnostics data

Description of functions

ePS Network Services offers evaluation tools for data acquired from the actions.

These are either a text viewer (e.g. for machine data) or contain graphic views (e.g.

PLC trace). A comparison tool is available for the machine data, NC status data,

and HMI action log data types of diagnostics data. You can switch directly between

different diagnostics data records of an event.

The following evaluation tools are available for the various diagnostics data:

• Viewing file lists

• Viewing HMI action log

• Viewing machine data

• Viewing NC status data

• Viewing PLC trace (the view can be configured and offers evaluation -

functions.)

• Viewing PLC data block/list

• Visualize variable monitors

Fig. 2-5: Display of recorded diagnostics data

Function Description

Diagnostics data You can switch directly from viewing data for one

action to viewing data for another, provided that it

belongs to the same machine event.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-21

Page 22

2 Machine information 08/2008

2.1 Machine overview

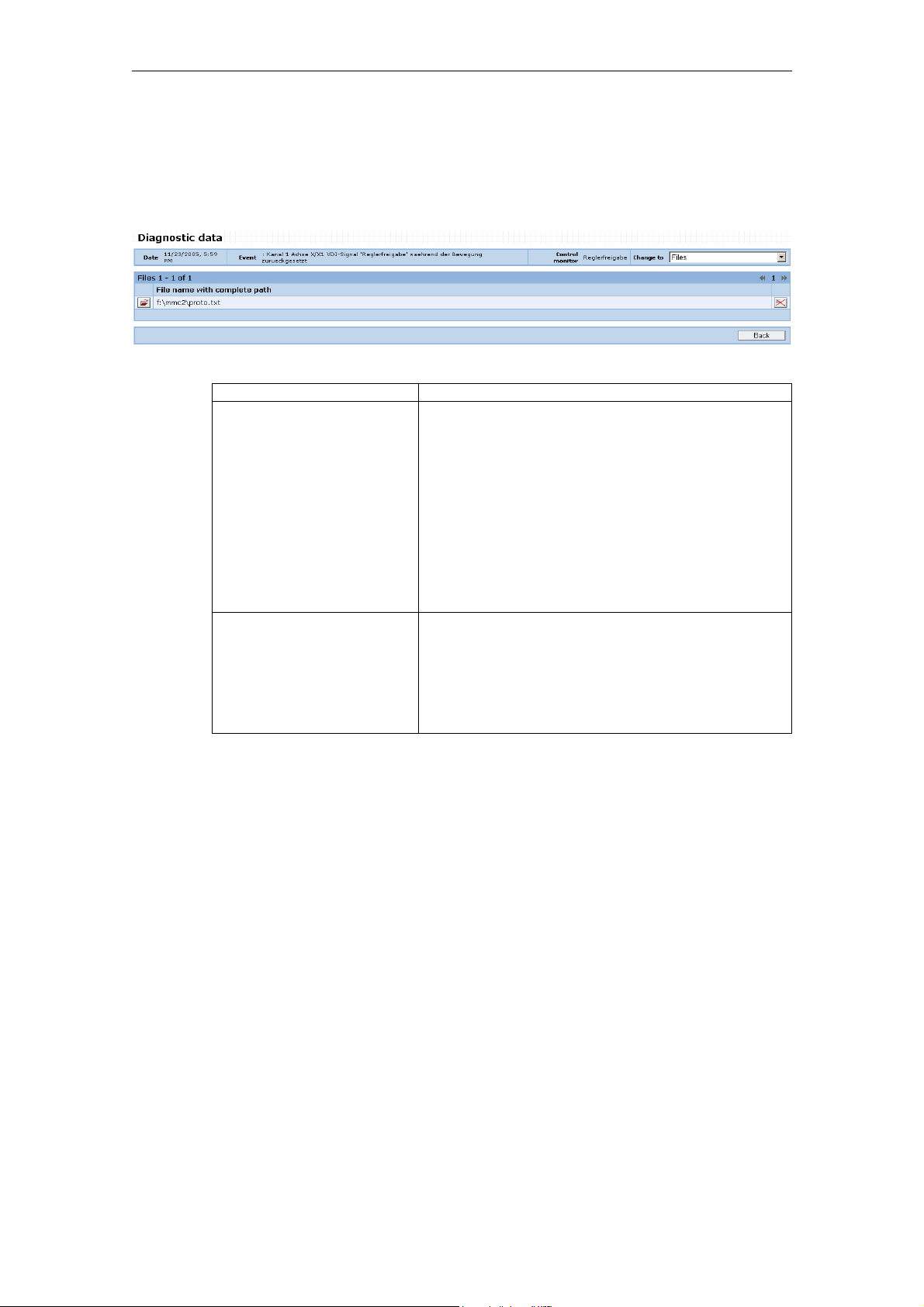

File list

The files uploaded from the control with a particular event can be displayed in the

Browser or in another application, or stored on a data carrier.

Fig. 2-6: List of uploaded files

Function Description

Display/save file You can open a file in either a separate browser

window or another application. Alternatively, you

can save the file to a data carrier.

Note:

The type of display depends on the data type and

the applications installed on your system. Pure text

or HTML documents are displayed in a separate

browser window. Applications registered in the

operating system are usually opened directly. You

must save any files with unregistered data types

and open them manually with your application.

Delete file You cannot delete individual files from machine

events; it is only possible to delete the entire event

entry.

Note:

Deleting individual details from an event constitutes

illegal manipulation of the archived document.

© Siemens AG 2008 All Rights Reserved

2-22 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 23

08/2008 2 Machine information

2.1 Machine overview

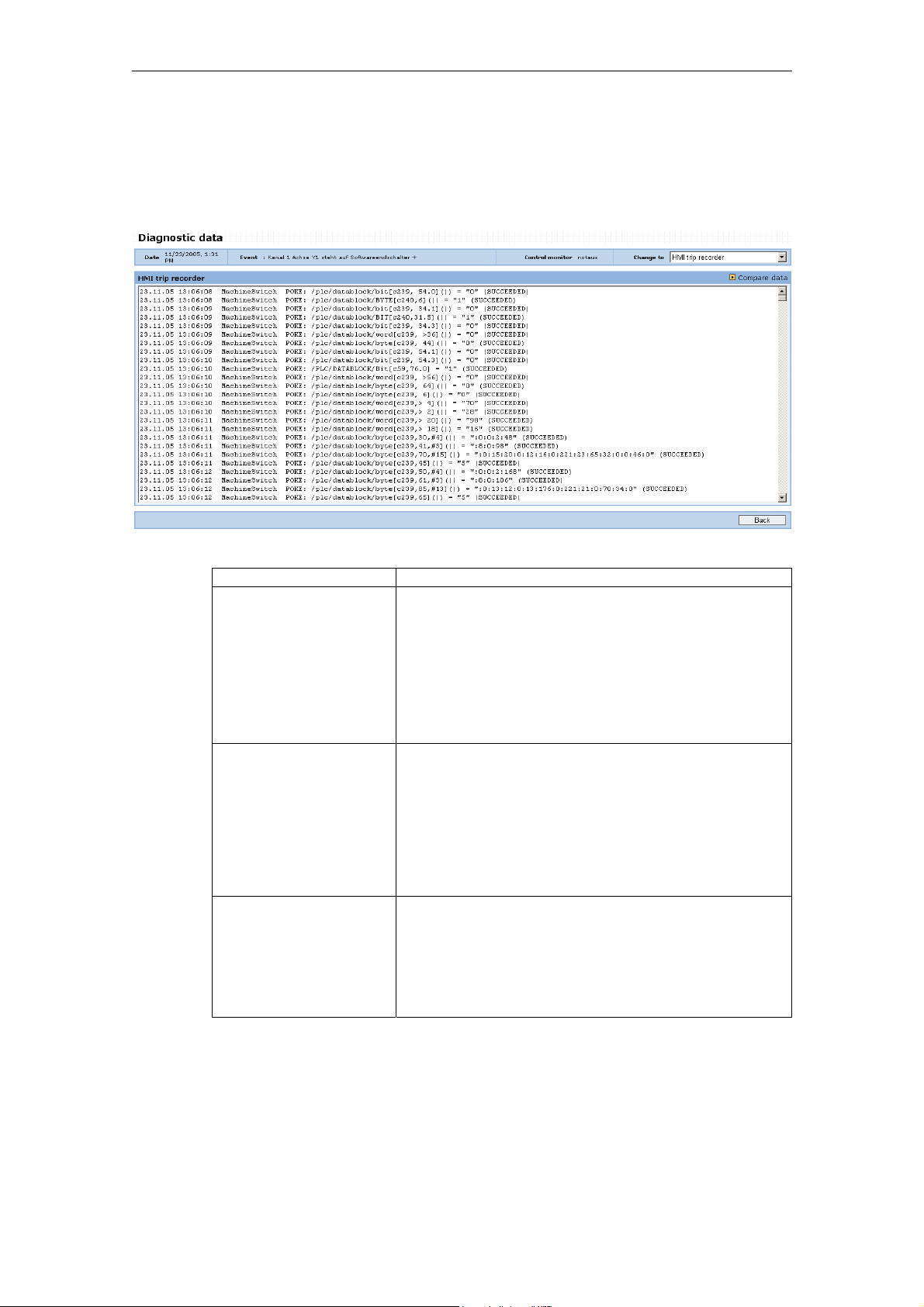

HMI action log

An HMI action log uploaded with an event can be displayed in the browser and

compared with other HMI action logs.

Fig. 2-7: HMI action log display

Function Description

Display the HMI action

log

Compare HMI action

logs

Delete HMI action log You cannot delete individual HMI action log files from

You can display and evaluate the content of an HMI

action log in a text window.

Note:

The content of the HMI action log is defined via local

settings on the control (see Section 3.4 "Global settings"). The time stamp of the recorded information is

generated from the PLC clock at the time of its occurrence.

You can compare the HMI action log currently selected

with another. For this purpose, the system provides a

list of all the HMI action logs available for the currently

selected machine.

The HMI action logs are displayed in two horizontally

adjacent windows and can be compared with each

other. The event is displayed for each HMI action log,

together with the event details and time stamp.

machine events; it is only possible to delete the entire

event entry.

Note:

Deleting individual details from an event constitutes

illegal manipulation of the archived document.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-23

Page 24

2 Machine information 08/2008

2.1 Machine overview

Machine data

Machine data uploaded with an event can be displayed in the browser and compared with other machine data.

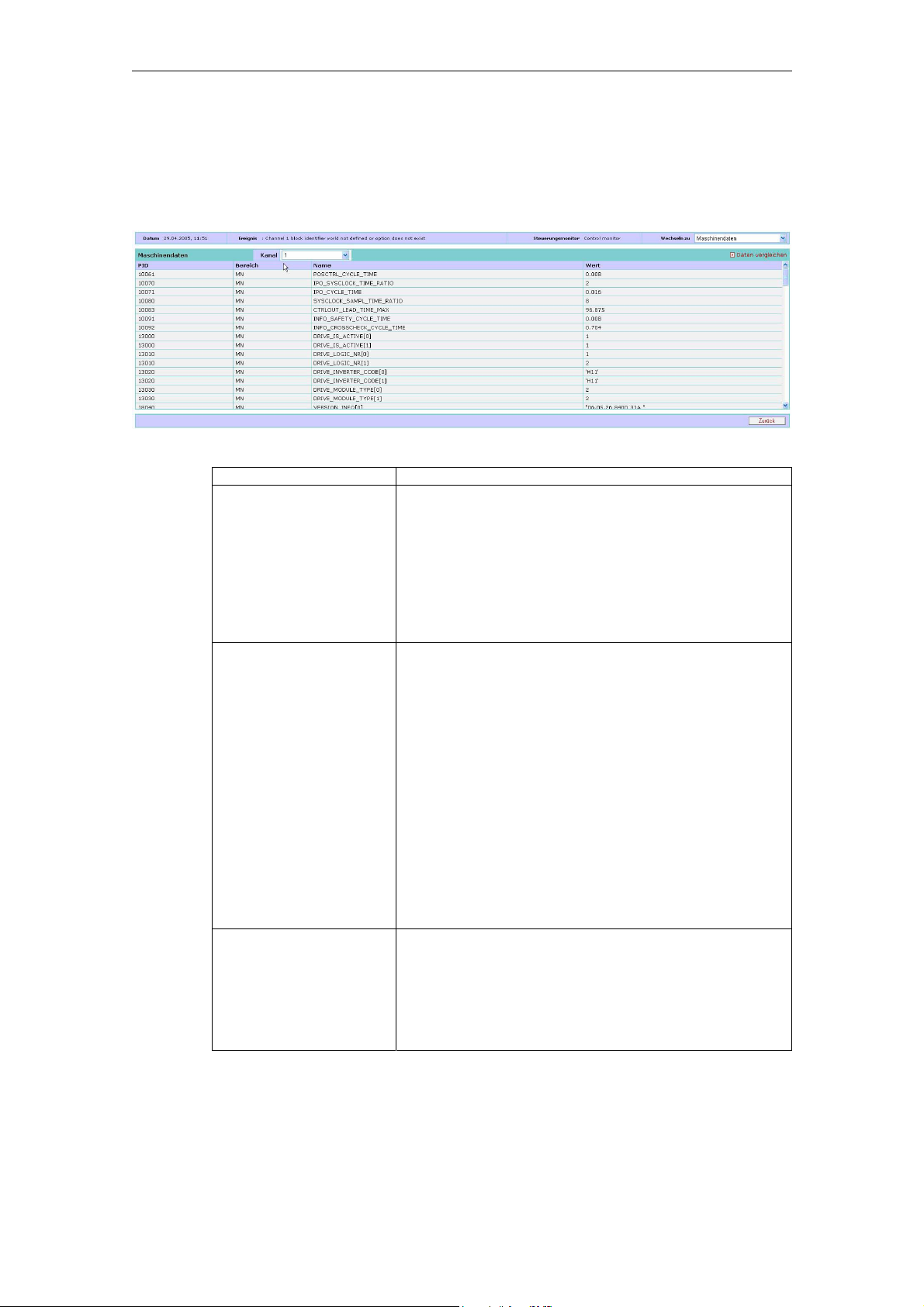

Fig. 2-8: Machine data display

Function Description

Display machine data You can display and evaluate the content of the ma-

chine data in a table. You can select which channel

you want to view machine data for.

Note:

Machine data without a channel reference is displayed

in the first channel. The machine data generated with

control monitor services does not include any drive

machine data.

Compare machine data You can compare the machine data record currently

selected with another. The system offers you a list of

all available machine data records of the currently

selected machine. The machine data values are displayed side by side for each machine data item. Any

machine data items with different values in the original

data record and the data record you are comparing

with is highlighted. The event is displayed for each

machine data record, together with the event details

and time stamp.

It is only possible to display differences. The system

then hides all machine data with identical values in the

original data record and data record being compared.

Note:

Drive machine data is not compared.

Delete machine data You cannot delete individual machine data record files

from machine events; it is only possible to delete the

entire event entry.

Note:

Deleting individual details from an event constitutes

illegal manipulation of the archived document.

© Siemens AG 2008 All Rights Reserved

2-24 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 25

08/2008 2 Machine information

2.1 Machine overview

NC status data

NC status data uploaded with an event can be displayed in the browser and compared with other NC status data.

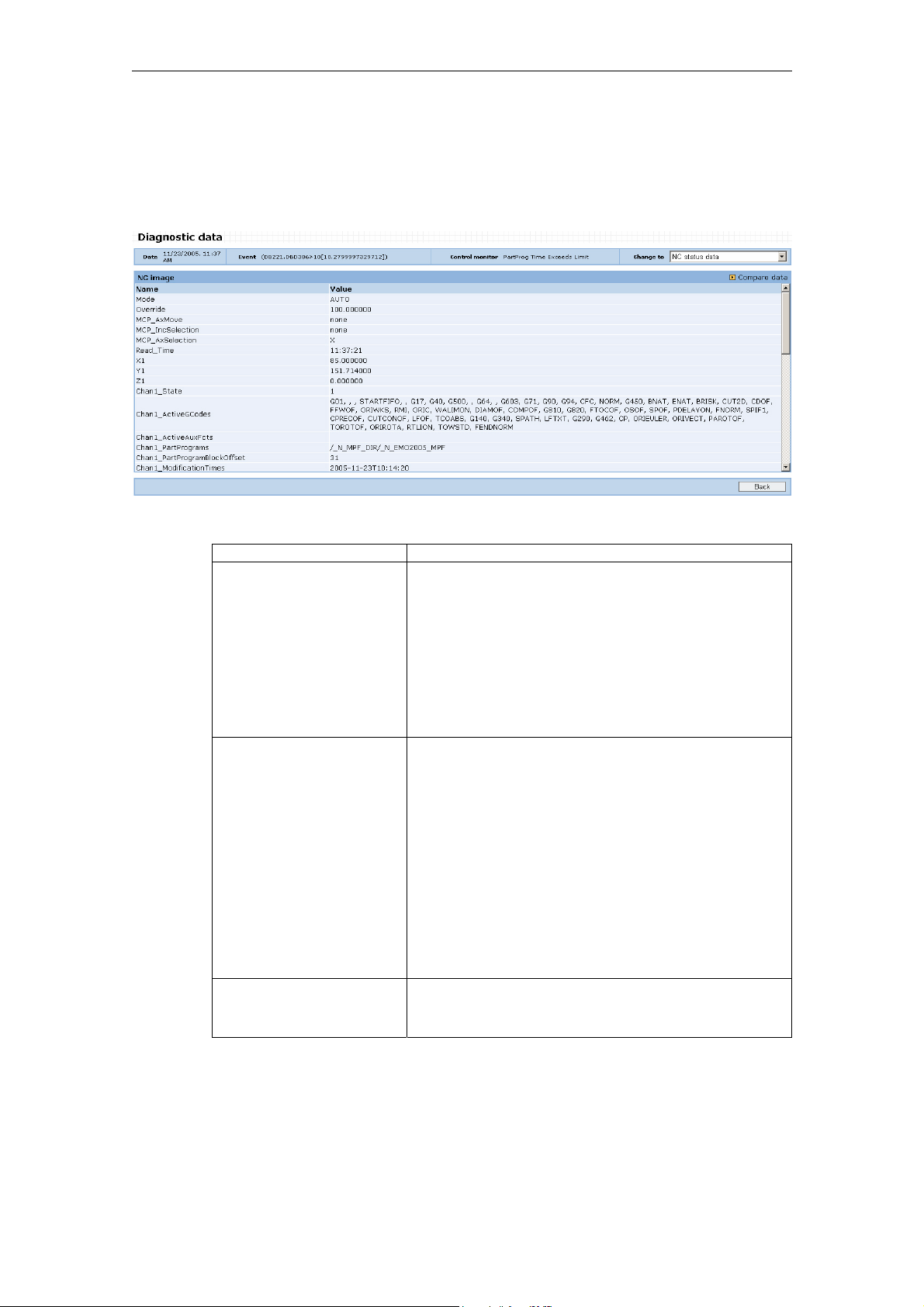

Fig. 2-9: NC status data display

Function Description

Display NC status data You can display and evaluate the content of the NC

status data in a table and evaluate it.

Notice:

The NC status data reproduces the status of the

relevant NC variables after an event occurs. For

some events (e.g. RESET alarms) there is a danger

of misinterpretation as the event itself influences the

variable value (example: pointer to current block is

reset by alarm).

Compare NC status data You can compare the NC status data record currently

selected with another data record. The system offers

you a list of all available NC status data records of

the currently selected machine. The values of the NC

status data records are listed next to each other by

variable for comparison purposes. Any variable with

different values in the original data record and the

data record you are comparing is highlighted. The

event is displayed for each NC status data record,

together with the event details and time stamp.

It is only possible to display differences. The system

then hides all variables with identical values in the

original data record and data record being compared.

Delete NC status data You cannot delete individual NC status data items

from machine events; it is only possible to delete the

entire event entry.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-25

Page 26

2 Machine information 08/2008

2.1 Machine overview

Function Description

Note:

Deleting individual details from an event constitutes

illegal manipulation of the archived document.

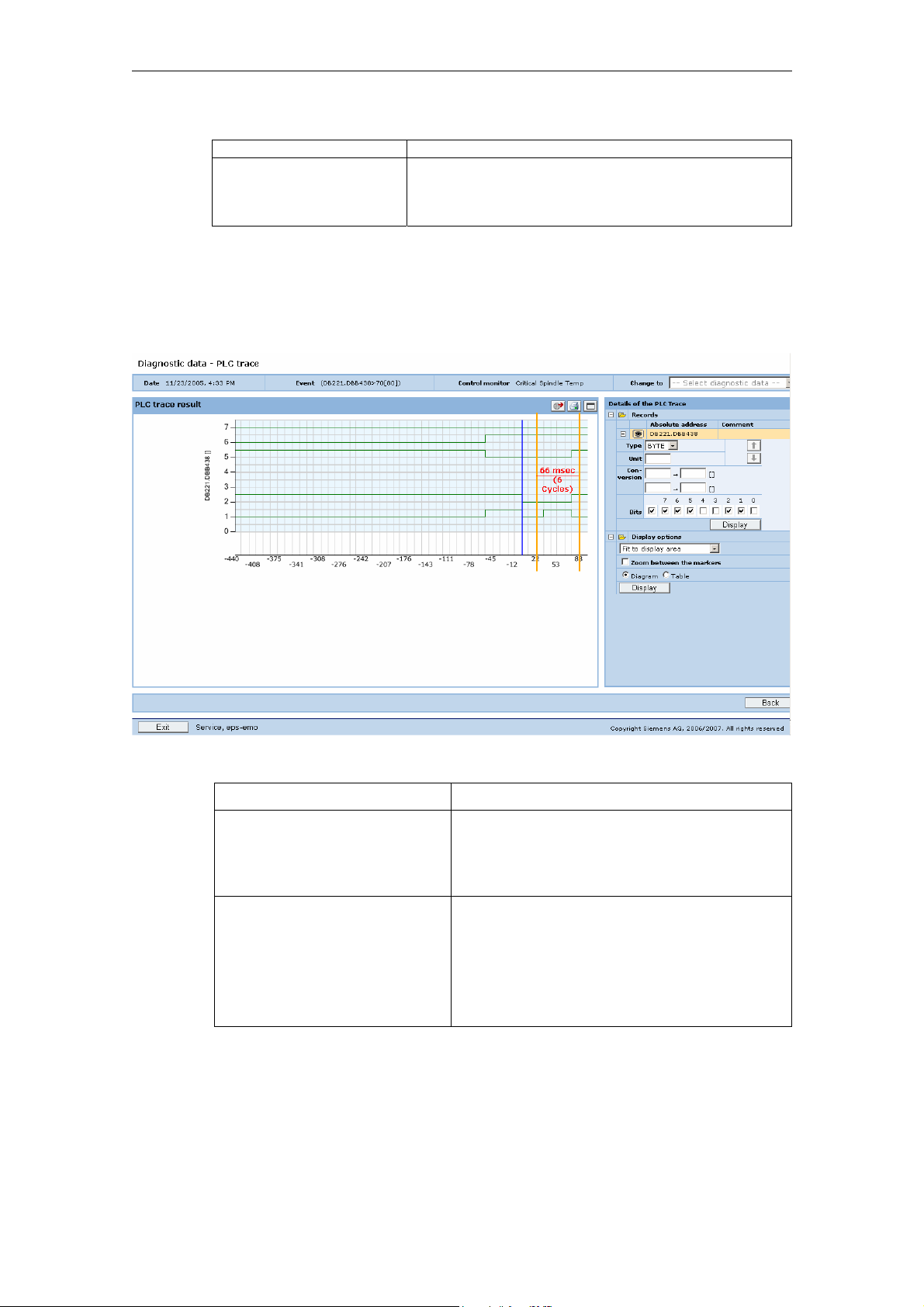

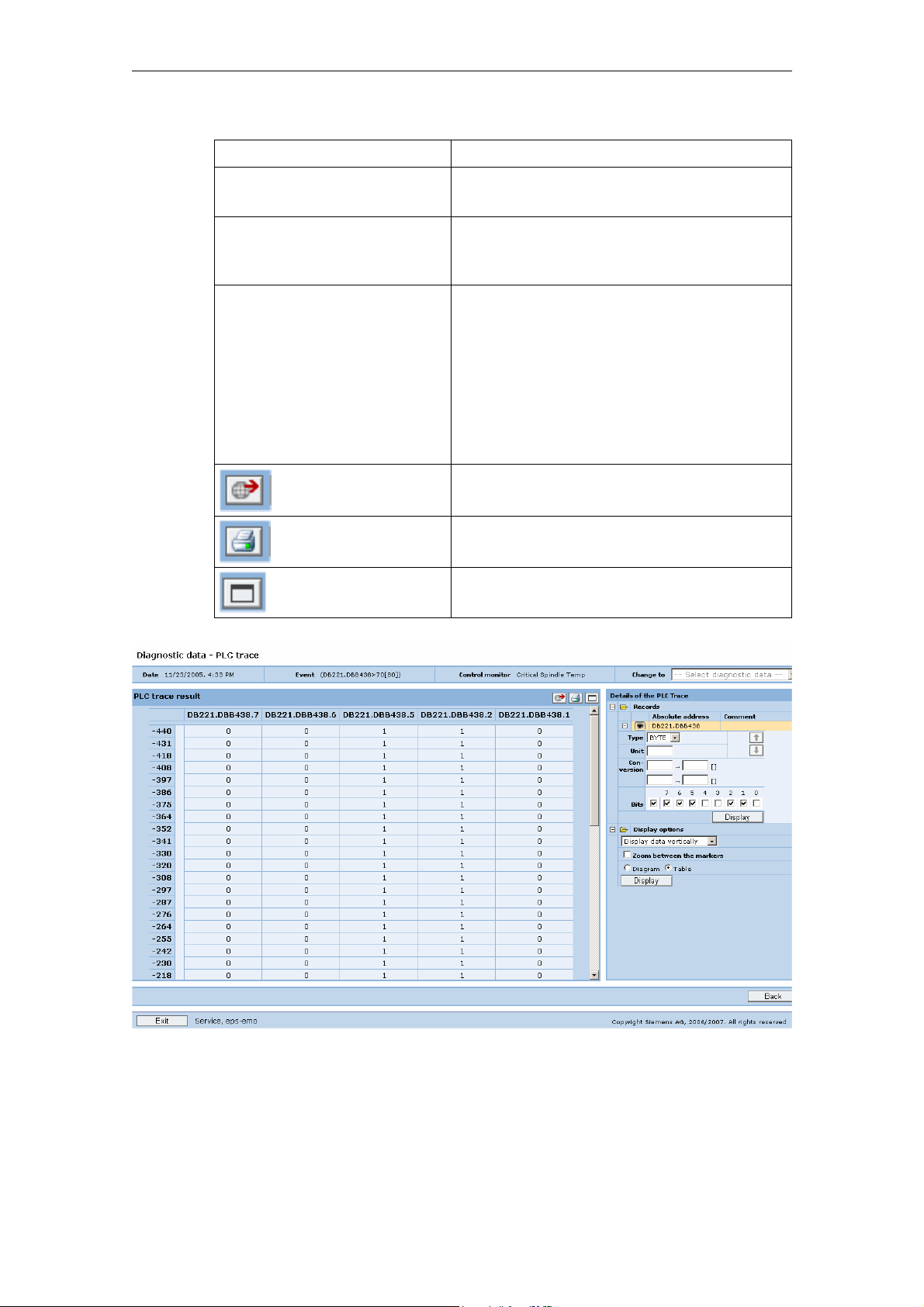

PLC trace

PLC trace data created with an event can be displayed in the browser and evaluated with graphical tools. Signal curves can be checked by displaying variable values in the graphical display, setting markers, and zooming.

Fig. 2-10: PLC trace display as diagram

Function Description

Change to As this menu is a detail of the machine events,

Display The PLC trace is displayed for all configured

and several details may exist for the event, you

can quickly change to other existing diagnostics

data of the event via a menu.

variables in the specified format.

The signal triggering the recording is displayed

and selected as 0 cycle/0 time.

Display updates the display with the predefined

details for the PLC trace.

© Siemens AG 2008 All Rights Reserved

2-26 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 27

08/2008 2 Machine information

2.1 Machine overview

Function Description

+ /− Opening and closing of the details for:

• Recordings

• Display options

• Variables

PLC trace:

Showing/hiding

variables

Showing/hiding the graph of the variable in the

display: For a clearer view, variables can be

hidden in the display in order that individual

variable configurations can be viewed.

Type Format of the variables.

Unit Dimension of evaluated variable values

(e.g. ° C).

Conversion

of display scaling

Evaluation of variable values for the dimension

adjustment, linearly through two defined value

assignments.

The variables can be scaled linearly via two

defined points for the display (e.g. byte value 16

corresponds to 20° C, byte value 128 corresponds to 90° C).

Bits Display of a variable in byte format; not as a

value, but individually as a binary signal for

each selected bit. Variables configured as byte

can also be displayed as individual bits (BOOL).

If not all of the individual bits are required in the

view, they can be specifically selected for the

display.

Variable display:

Changing the

sequence

The sequence of the variables can be changed

so that they can be compared directly next to

each other.

PLC trace: Time/cycles display The horizontal axis is always displayed with a

millisecond specification for each cycle. This

can be changed to the cycle number, each

calculated with the starting point 0 from the

trigger.

Display options PLC trace diagrams can be displayed in a de-

fault setting that can be evaluated on every

monitor.

A complete recording can be displayed in a

compressed format, by means of a zoom setting in a single view. However, this may result in

a loss of information. Every detail is displayed

in an optimized compressed display, but in the

smallest possible view. The minimum level of

precision that can be set for the graph view is

the pixel level, but marking should allow a cycle

level of precision to be set dynamically.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-27

Page 28

2 Machine information 08/2008

2.1 Machine overview

Function Description

Diagram/table A graphical or tabular display of the variable

values can be selected.

PLC trace: Data display

Horizontal/vertical

The display of the data table can be changed

from a horizontal (time/cycle axis) to a vertical

(variable axis) view.

PLC trace: Markings Markings can be set in the PLC trace display

that are used for the difference calculation and

display of the current values.

The markings are retained when using the

zoom function. Depending on the resolution,

they can be positioned on a cycle-specific basis; the minimum level of precision that can be

set is the pixel level, where all cycles appear

between the markings.

PLC trace:

Data export

PLC trace:

Printing data

PLC trace:

representation

The PLC trace data can be exported as a file

for further processing.

The PLC trace data can be printed on an installed printer.

The window for the PLC trace display can be

maximized/minimized.

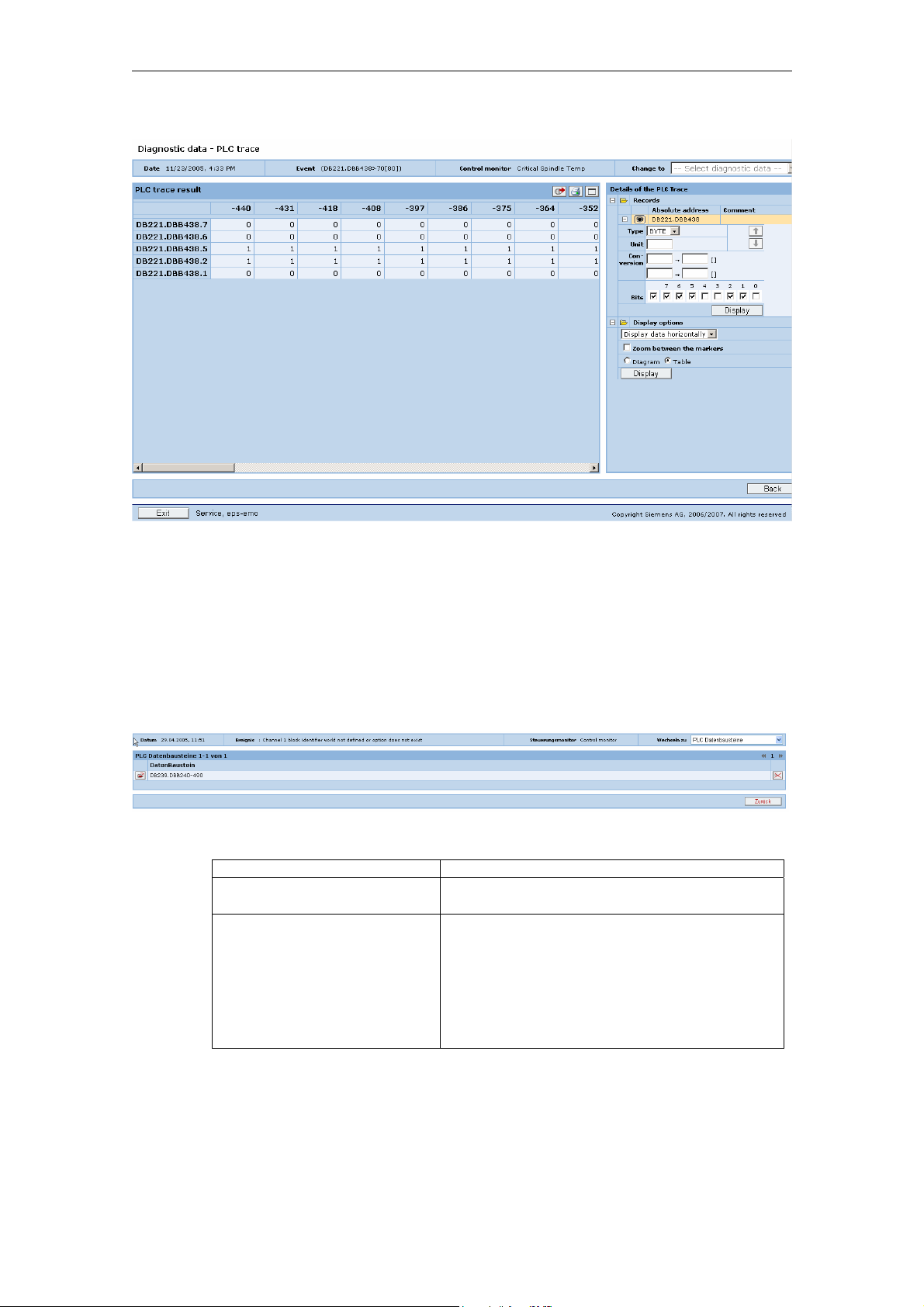

Fig. 2-11: PLC trace values displayed vertically

© Siemens AG 2008 All Rights Reserved

2-28 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 29

08/2008 2 Machine information

2.1 Machine overview

Fig. 2-12: PLC trace values displayed horizontally

PLC traces uploaded with an event can be displayed in the browser and evaluated

with graphical tools. Incorrect signal curves can easily be found by displaying variable values in the graphical display, setting markers, and zooming.

PLC data blocks/list

PLC data blocks uploaded from the control on an event can be saved to a data carrier.

Fig. 2-13: PLC data block display

Function Description

Save PLC data block You can save a PLC data block to an external

Delete PLC data block You cannot delete individual PLC data blocks

data carrier.

from machine events; it is only possible to

delete the entire event entry.

Note:

Deleting individual details from an event constitutes illegal manipulation of the archived

document.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-29

Page 30

2 Machine information 08/2008

2.1 Machine overview

Variable monitors

The data of a variable monitor saved with a machine event can be displayed.

Fig. 2-14: Variable monitor data

Function Description

Open variable monitor You can open the variable monitor and display

the variations with time of all the recorded

monitor data.

Delete variable monitor data

from the event

You cannot delete individual variable monitor

data from machine events; it is only possible to

delete the entire event entry.

2.1.6 NC monitors

Function description

The life-cycle loads of machine axes (linear, rotary, and main spindle) can be collected and analyzed using the monitors. NC variables (counters) related to maintenance, such as the traverse path, traverse time, or number of traverses are summated over the life cycle or time intervals and can be viewed by the machine operator in the form of time charts.

Maintenance can be performed based on this load data, in connection with warning

limits and critical limits.

Note:

Deleting individual details from an event

constitutes illegal manipulation of the archived

document.

© Siemens AG 2008 All Rights Reserved

2-30 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 31

08/2008 2 Machine information

2.1 Machine overview

Fig. 2-15: Time chart NC monitor

This information provides support with specifying new machine designs because

the real load data is available for machine dimensioning.

Availability and privileges

The time charts of the NC monitors can only be displayed on the PC. The current

counter states of an NC monitor can also be viewed on the operator panel. The authorization required to use the NC monitors is described in detail in Appendix A.2.

Fig. 2-16: Counter states of an NC monitor on the operator panel

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-31

Page 32

2 Machine information 08/2008

2.2 Measurements and measurement series

2.2 Measurements and measurement series

2.2.1 Analyzing on the PC

Description of functions

The performance and status of a machine and its modules can be analyzed with

measurements and measurement series that have been performed on the machine. This includes measurement curves generated from the measurements and

characteristics, as well as additional information about the measurement result.

Trend curves can be generated from characteristics in measurement series. The

machine operator can use the measurement results to make an analysis at a later

point, while away from the machine. Status changes can be derived from the trend

curves. Limit values will show whether any maintenance work is necessary at an

early stage.

Selection and filter area

Fig. 2-17: Overview of the time series for the machine selected

Function Description

Select the time series The measurement series can be selected from

the machine axes in the selection tree. It is

possible to select several measurement series.

Select individual measurements This function displays a table for the axis

concerned containing all the measurements

that do not belong to a measurement series.

Several measurements for the display can be

selected in the table.

Advertisements The "Display" function shows the selected

measurement series in diagrams.

© Siemens AG 2008 All Rights Reserved

2-32 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 33

08/2008 2 Machine information

2.2 Measurements and measurement series

Function Description

Filter time series

Test types:

Synchronous operation

axis test

This function opens the menu for the purpose

of filtering the measurement series displayed

in the selection. Measurement series can be

filtered according to the type of measurement

series.

Circularity test

Universal axis test

Filtering The "Filtering" function causes the selected

filter setting to take effect.

Show/hide filter areas This function shows or hides the entire filter

area.

Displaying diagrams of the selected time series

If the user clicks the "Display" text button under the time series selection tree, the

graphs for the selected time series are displayed.

Displaying the measurement results

You can view measurement results both on the machine operator panel and on the

PC. Trend curves produced by measurement series can only be viewed on the PC.

The warning and critical limits of the characteristics can give the machine operator

evaluation information about how far the qualitative state of the machine is from the

limit criterion.

Fig. 2-18: Examples of time series

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-33

Page 34

2 Machine information 08/2008

2.2 Measurements and measurement series

The trend curve can be generated from the measuring type-specific characteristics

(characteristic over time) by cyclic repetition of individual measurements. This is

used in particular as a basis for condition-oriented maintenance. For this, measurement series can be generated based on existing individual measurements.

This ensures that the measurement series is based on the same measurement.

Measurement series are used as the basis for condition-oriented maintenance because the trend curve and the limit values provide a basis for planning maintenance activities.

How each test is conducted is described in Section 2.3 Test series on the

machine.

The machine operator can view the measurement results on the operator panel of

the machine and on the PC. Trend curves derived from measurement series can

only be viewed by the operator on the PC.

Individual measurements for an axis

Measurements that are not generated by the measurement series are displayed in

a table. The measurements to be displayed can be selected in this table. Several

measurements can be selected.

Fig. 2-19: Table of individual measurements

Displaying individual measurements

The "Display table of individual measurements" function opens each of the individual measurements selected in a separate diagram.

© Siemens AG 2008 All Rights Reserved

2-34 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 35

08/2008 2 Machine information

2.2 Measurements and measurement series

2.2.2 Operating diagrams

General control elements

Function Description

Minimize diagram Reduces the diagram so that only the header line

is visible.

Restore diagram Restores the minimized diagram to its standard

size.

Maximize diagram Magnifies the diagram so that it fills the entire

diagram space.

Close diagram Closes the diagram

Setting and displaying

markings

Display in new diagram If the user clicks the "Display in new diagram"

The regenerated diagram assumes all of the dis-

Export diagram The data points represented in the diagram are

A pair of markings can be set in the diagram. Left-

click to set the first marking. Move the cursor

without pressing any buttons to position the sec-

ond marking, and then left-click. The markings

can be reset if you wish.

The markings are deleted by means of the "Delete

markings" function in the "Display" menu.

button on the right-hand side next to the drop-

down list box, a new diagram of the same type will

be displayed below the diagram that is already

shown.

play properties of the original diagram (character-

istic selected, markings, display, selection and

sequence of time series, etc.), with the exception

of its scale. In a new diagram, the scale is always

set to Auto/Auto.

saved in a CSV file.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-35

Page 36

2 Machine information 08/2008

2.2 Measurements and measurement series

Changing the characteristic

Fig. 2-20: Drop-down list box for circularity test characteristics

The drop-down list box contains the list of characteristics for each test type. If the

user selects a characteristic, the diagram that has been displayed up to this point

will be replaced by the time series diagram for the characteristic selected.

"Actions" menu

Entries menu

Warm boot Regenerates the diagram.

All parameters A table containing the parameters for all of the

Fig. 2-21: Parameters for all measurement series

measurement series shown in the diagram is displayed.

© Siemens AG 2008 All Rights Reserved

2-36 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 37

08/2008 2 Machine information

2.2 Measurements and measurement series

"Display" menu

The display settings of the diagram may be controlled using this menu.

Entries menu

Display all data Displays the complete progression over time of

the time series

Between the markings Displays the time domain between the two mark-

ings

Last month

|

|

|

Last year

Back to previous zoom Generates the diagram with the previous zoom

Time-based distribution The horizontal axis represents the time. The

Equal distribution The measured values are distributed equally

Delete markings Removes the markings from the diagram.

These options are used to select the zoom fac-

tor. When the zoom level is changed, the dia-

gram is regenerated to reflect this; however, all

of the other settings (in particular, the markings)

remain the same.

setting

measuring points are plotted along this accord-

ing to their date.

across the X axis; it is not possible to draw any

further conclusions about the time of the meas-

urement from the points on the X axis.

List of machines and time series with control elements

Fig. 2-22: Displaying/hiding individual measurement series

Function Description

Hide measurement series This function removes the measurement series

graph from the diagram. The diagram is redrawn,

which involves recalculating the scale.

Display limit values This function plots the limit values of the selected

measurement series in a line in the diagram. If the

limit values are outside the range of values displayed, an icon indicating this will appear.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-37

Page 38

2 Machine information 08/2008

2.2 Measurements and measurement series

Context menu of the time series diagram

If the user points the cursor to an individual measuring point within the time series

in the diagram and right-clicks, a context menu containing actions relating to that

measuring point appears. The functions executed via the context menu relate to either the entire measurement range to which the measuring point belongs (i.e. the

measurement range and the measurement), or simply the measurement represented by the data point.

Entries menu

Measurement series comment Displays the measurement series comment. This

can be changed and saved.

Save graphic

Measurement/measurement

series parameters

Supplementary conditions for

measurement

© Siemens AG 2008 All Rights Reserved

2-38 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 39

08/2008 2 Machine information

2.2 Measurements and measurement series

Entries menu

Characteristic/limit values

measurement

Measurement comment

Display measurement Displays a diagram with the individual meas-

urement selected below the time series diagram

shown.

2.2.3 Control elements of the diagrams for individual measurements

Fig. 2-23: Header line for individual measurement diagram

Changing the diagram type

The drop-down list box contains the list of diagram types that are available for each

type of test. If the user clicks a name of a type of diagram, it replaces the type that

has been displayed up until this point.

New type of diagram in a separate diagram

If the user clicks the "Display in new diagram" button on the right-hand side next to

the drop-down list box of diagram types, a new diagram of the same type will be

displayed below the diagram that is already shown.

The new diagram adopts all of the display characteristics of the original diagram

(markings, zoom, etc.), with the exception of the scale. The scale of a cloned diagram is always Auto/Auto.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-39

Page 40

2 Machine information 08/2008

2.2 Measurements and measurement series

Where individual measurement diagrams are concerned, the "Actions" menu and

context menu have the same options:

Entries menu

Parameters Shows the pop-up window with the list of measurement

parameters. The same pop-up window can be opened

from the context of the time series.

Limit conditions Shows the pop-up window with the list of measurement

parameters.

Comment Pop-up with measurement comment

Scaling Setting for the diagram scale (for the synchronous op-

eration axis test only). In the case of the diagrams for

the circularity test and universal axis test, the "Actions"

menu does not contain "Scaling".

Scaling for the synchronous operation axis test

Fig. 2-24: Scaling for the synchronous operation axis test

"Display" menu

This menu is only available for the individual measurement diagram of the synchronous operation axis test.

Entries menu

All without ramps Displays the entire measuring range, but without

All with ramps Displays the entire measuring range, including

Between the markings Adjusts the zoom factor of the diagram at the

the acceleration ramps

the acceleration ramps

area between the markings. This function assumes that both of the markings have been set.

© Siemens AG 2008 All Rights Reserved

2-40 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 41

08/2008 2 Machine information

2.2 Measurements and measurement series

Navigating to previous/next measurement

The two buttons for this function can be used to navigate to the previous or next

measurement of the measurement series in question.

Displaying the characteristics and limit values

Fig. 2-25: Table of characteristics and limit values

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-41

Page 42

2 Machine information 08/2008

2.2 Measurements and measurement series

2.2.4 Circularity test

Description of functions

The circularity test produces a polar plot of the circular path and circularity-specific

characteristics:

Characteristic Meaning

Circular deviation The circular deviation is measured on the basis of

ISO 230-4 as difference between the maximum and

minimum radius at movement of a circle in one direction. A value is calculated for each direction of

movement.

Circular hysteresis As defined in ISO 230-4 the circular hysteresis is de-

termined by establishing the maximum difference of

measured radii on an angular position between the

two directions of movement.

The measurement type-relevant parameters are also specified. The goal is to test

the drive dynamics and accuracy of the two axes involved.

Fig. 2-26: Measuring result of a circularity test

© Siemens AG 2008 All Rights Reserved

2-42 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 43

08/2008 2 Machine information

2.2 Measurements and measurement series

2.2.5 Synchronous operation axis test

Description of functions

The synchronous operation axis test result returns the torque/force measurement

curve over the axis position and various torque characteristics. The characteristics

are determined for each direction of movement separately. If nothing else is described for the characteristics, the characteristics refer to the position range without

the acceleration and braking ramps.

Characteristic Meaning

Maximum torque The maximum returns the maximum torque in the

measured position range. With torque characteristics

with linear trend, the proportion the trend is computed

for determining the maximum torque.

Minimum torque The minimum returns the minimum torque in the

measured position range. With torque characteristics

with linear trend, the proportion of the trend is computed for determining the minimum torque.

Average torque The characteristic returns the mean torque in the

measured position range with the configured speed.

Independently of the direction, a larger value always

corresponds to a larger torque in the direction of

movement.

Standard deviation The characteristic represents the standard deviation of

the torque characteristic in the measured position

range at the configured speed. With torque characteristics with a linear trend, the proportion of the trend is

eliminated from the standard deviation.

Increase in the linear

trend of torque characteristic

Maximum torque of the

acceleration ramp

For axes that also have a direct measuring system the overall rigidity curve over

the axis position is also displayed. The rigidity is determined independently of the

direction. The following rigidity characteristics are calculated:

The characteristic indicates the increase in the change

to the torque at position changes.

The characteristic indicates the maximum torque which

is run in the acceleration ramp.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-43

Page 44

2 Machine information 08/2008

2.2 Measurements and measurement series

Characteristic Meaning

Maximum rigidity The characteristic returns the maximum rigidity

value via the rigidity characteristic in the measured

position range at the configured speed.

Minimum rigidity The characteristic returns the minimum rigidity value

via the rigidity characteristic in the measured position range at the configured speed.

Average rigidity For calculating the characteristic, the mean rigidity

value is determined in the measured position range

at the configured speed.

Standard deviation of the

rigidity

For calculating the characteristic, the standard deviation of the rigidity is determined in the measured

position range at the configured speed.

The synchronous operation axis test notifies the machine operator of faults and interference resistances from feed axis elements. The curve of the recorded values

indicates at which axis position the disturbance is located. A trend analysis of the

characteristics will indicate any change in the status of the drive train.

Fig. 2-27: Measurement results of a synchronous operation axis test

© Siemens AG 2008 All Rights Reserved

2-44 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 45

08/2008 2 Machine information

2.2 Measurements and measurement series

2.2.6 Universal axis test

Description of functions

With the universal axis test different characteristics are calculated which describe

the mechanical properties of an axis.

Characteristic Meaning

Residual torque (Res) This characteristic is not supported.

Coulomb friction (Coul) The Coulomb friction describes the proportion of the

friction which is independent of the speed.

Mixed friction (Mix) This characteristic is not supported.

Viscous friction (Visc) This characteristic describes the proportion of the

friction which increases linear to the speed

Moment of inertia (Inr) The characteristic describes the entire moment of

inertia that needs to be moved by the electrical

drive. This includes the moment of inertia of the

motor.

Torque offset (Const) With axes which are pretensioned in one direction

(e.g. vertical axes) the characteristic indicates the

torque required for compensating for this pretension.

Coherence (K) The coherence indicates how much a model param-

eterized with the calculated characteristics can

simulate the measured torque characteristics.

Circular deviation (G) The characteristic describes the maximum position

deviation with axis movement on the basis of a ve-

locity profile. The calculation of the characteristic is

based on ISO 230-4 as is the case with the circular-

ity test.

The measurement type-relevant parameters are also specified.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-45

Page 46

2 Machine information 08/2008

2.2 Measurements and measurement series

Fig. 2-28: Time series for a universal axis test

2.2.7 Variable monitors

Description of functions

Variable monitors enable the recording in the control of changes over time of any

status data. The variable monitors are essentially for long-term recording in slow

data recording cycles (as opposed to the PLC trace).

Up to 32 variables can be recorded in a common cycle in a variable monitor. The

PLC variables recorded can be from the PLC environment: inputs, outputs, counters, flags, and any data addresses in PLC blocks. From the NC environment, they

can be machine data, setting data, system variables and others.

The variables recorded can be scaled and assigned freely definable units. Individual variables of a variable monitor can be identified as counting variables (e.g.

workpiece counters). These variables can be used in the configuration of interval

triggers to trigger recurring actions after a certain number of counting units have

elapsed. Counting variables are counted up monotonically. Resetting of the variables in the control is compensated for by the system because the count is resumed on the basis of the last value before reset.

Limit values can be configured for each variable for automatic monitoring of the

state. Actions can be triggered when limit values are violated. This is the same as

described for the control monitors.

© Siemens AG 2008 All Rights Reserved

2-46 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 47

08/2008 2 Machine information

2.2 Measurements and measurement series

Selection and filter area

Fig. 2-29: Select variable monitors

Displaying diagrams of the selected variables

To display variables in a diagram, select them in the selection area. Activate the

"Display" field to display all selected variables in one common diagram in graphs.

Any variables from different variable monitors can be displayed together in one

diagram. If you select additional variables and activate the "Display" button, a new

diagramm is created which displays the newly selected variables. Any number of

diagrams can be generated.

Operating diagrams

The diagrams for displaying variable monitors are operated in the same way as the

diagrams for displaying measurement series. Some of the available functions may

differ slightly due to the differences between measurement series and variable

monitors. These differences are described in more detail in the following sections.

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-47

Page 48

2 Machine information 08/2008

2.2 Measurements and measurement series

List of displayed variable monitors and variables with control elements

Fig. 2-30: List of displayed variables

Function Description

Hide variable monitor This function removes all variable monitor graphs

from the diagram. The diagram is redrawn, which

involves recalculating the scale.

Hide variable This function removes the variable graph from the

diagram. The diagram is redrawn, which involves

recalculating the scale.

Display limit values This function plots the limit values of the selected

variable in a line in the diagram. If the limit values

are outside the range of values displayed, an icon

indicating this will appear.

"Actions" menu

Entries menu

Warm boot Regenerates the diagram.

Variable details A table is displayed showing detail information

about the displayed variables.

© Siemens AG 2008 All Rights Reserved

2-48 ePS Network Services, Function Manual (FH) - Release 08/2008

Page 49

08/2008 2 Machine information

2.3 Test series on the machine

2.3 Test series on the machine

2.3.1 Performing measurement series

Perform measurement

The following alternatives are available for performing measurements on the machine:

• Performing a single measurement with manual entry of parameters before per-

forming the actual test

• Performance of a single measurement as the repetition of an existing meas-

urement without changing the parameters

• Performance of a further measurement as part of a series of measurements,

based on the parameters predefined in the measurement series

• Performance of a measurement of a measurement series prescribed by a

maintenance job

• Performance of measurements configured in a test series

• Performance of measurements in a test series by means of a maintenance job

• Performance of measurements in a test series without a machine operator, by

means of a maintenance job under the control of the PLC.

Availability and privileges

Measurements, measurement series, and test series can only be performed on the

operator panel. The authorization required to perform measurements, measurement series, and test series is described in detail in the Appendix.

Measurement sequence

The sequence is performed as follows independently of the different types of execution and type of test:

• Machine operator selects measurement, measurement series, or test series

• Confirmation of the parameters of the measurement and display of the meas-

urement series contained in the test series

• A contour test to check collision can be performed before the actual measure-

ment

• Check release by the PLC

• Machine operator sets AUTO mode and feedrate override to 100% on the con-

trol

• Machine operator presses NC START on the control

• Perform machine-specific prolog of the measurement movement

• Perform the measurement movement with data recording

• Perform machine-specific epilog of the measurement movement

© Siemens AG 2008 All Rights Reserved

ePS Network Services, Function Manual (FH) - Release 08/2008

2-49

Page 50

2 Machine information 08/2008

2.3 Test series on the machine

• Result display

• Save the result

Notice

Please observe the information on the operator panel!

2.3.2 Requirements for performing the test

Requirements on the control

When making measurements, the machine axes must be moved with precisely the

motion profile that is defined in the NC program. In addition, it must also be guaranteed that the motion is also executed in the machine coordinates.

The following functions in the NCK could be problematical when carrying out

measurements (sample selection):

• Asynchronous subprograms

• Static synchronized actions

• Coupled axes

• Kinematic transformations

• Superimposed (overlaid) motion, such as DRF, external work offset

• Tool length compensation

• Functions, that influence the velocity, such as G95

• Functions that change the position, such as DIAMON

• Axis replacement/geometry axis replacement

• Axis is passed over to the PLC (PLC axis)

The NC program for performing the measurement does not affect the functions

listed above. Only the zero offsets are disabled and the offset produced by DRF

and external zero point offset is compensated statically, i.e. the value is corrected

by the value that applies at the beginning of the measurement.

Orientation transformations are a special case. It is possible to execute measurements with the geometry axes when transformation is active. However, the offset of

the geometry axis coordinates produced by the orientation axes is not compensated for. It is therefore advisable to deactivate transformation.

Couplings between axes should be separated before the measurement movement

(e.g. in the prolog program). The NC program of the ePS system does not separate