Siemens SINUMERIK 840C, SIMODRIVE 611-D Installation Manual

SINUMERIK 840C

SIMODRIVE 611-D

Installation Guide 09.2001 Edition

Installation Lists

Service Documentation

SINUMERIK 840C

SIMODRIVE 611-D

Installation Lists

Installation Guide

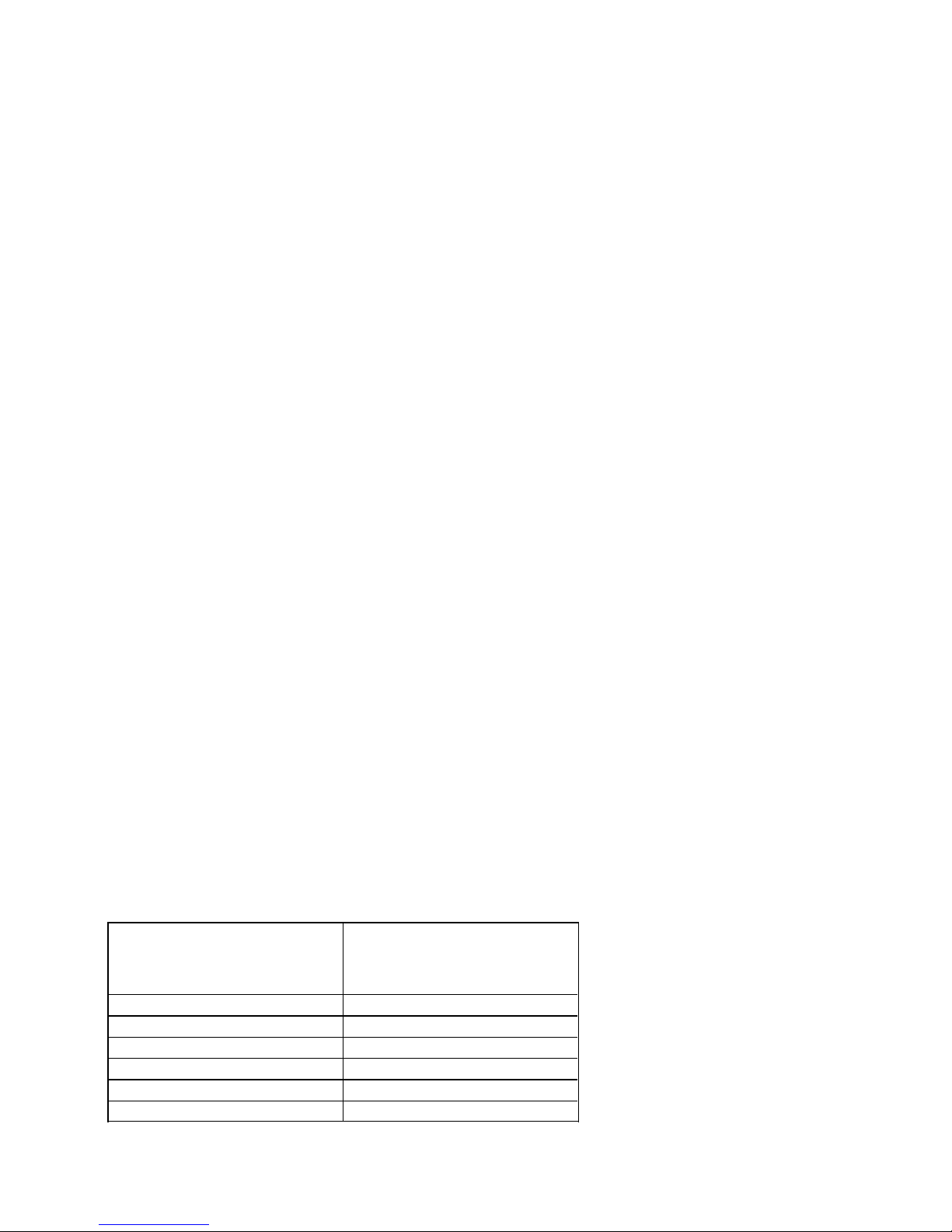

Valid for:

Control SINUMERIK 840C/CE

Standard/Export Version

Software Version Software Version

1.x

2.x

3.x 1.x

4.x 2.x

5.x 3.x

6.x 4.x

09.2001 Edition

Drive SIMODRIVE 611-D

SINUMERIK® documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the ”Remarks” column.

Status code in ”Remarks” column:

A . . . New documentation.

B . . . Unrevised reprint with new Order No.

C . . . Revised edition with new status.

If factual changes have been made on the page since the last edition, this is

indicated by a new edition coding in the header on that page.

Edition Order No. Remarks

11.92 6FC5197-0AA60-1BP0 A

06.93 6FC5197-2AA60-0BP0 C

12.93 6FC5197-3AA60-0BP0 C

10.94 6FC5197-4AA60-0BP0 C

03.95 6FC5197-4AA60-0BP1 C

09.95 6FC5197-5AA60-0BP0 C

04.96 6FC5197-5AA60-0BP1 C

08.96 6FC5197-5AA60-0BP2 C

07.97 6FC5197-6AA60-0BP0 C

01.99 6FC5197-6AA60-0BP1 C

09.01 6FC5197-6AA60-0BP2 C

This manual is included in the documentation on CD-ROM (DOCONCD)

Edition Order No. Remarks

10.01 6FC5198-6CA00-0BG2 C

Trademarks

SIMATIC®, SIMATIC HMI®, SIMATIC NET®, SIROTEC®, SINUMERIK® and SIMODRIVE® are trademarks of Siemens AG. All other product and system names are registered trademarks of their

respective companies and must be treated accordingly.

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

For more information, refer to the Internet:

http://www.ad.siemens.de/sinumerik

The publication was produced on the Siemens 5800 Office System.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including created by

patent grant or registration of a utility model or design, are reserved,

© Siemens AG 1992-2001

All Rights Reserved

obligation to supply such functions with a new control or when

servicing.

We have checked that the contents of this publication agree with

the hardware and software described herein. The information given

in this publication is reviewed at regular intervals and any

corrections that might be necessary are made in the subsequent

printings. Suggestions for improvement are welcome at all times.

Subject to change without prior notice.

Order No. 6FC5197-6AA60-0BP2

Printed in the Federal Republic of Germany

Siemens-Aktiengesellschaft

Preliminary Remarks

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Notes for the reader

a

a

a

a

a

a

a

a

This manual is intended for manufacturers of machine tools who use SINUMERIK 840C.

The "Installation Instructions" discuss the installation and start-up procedures, from installation

of the system through the testing of the most important functions.

The SINUMERIK 840C Installation Guide is divided into two separate manuals:

• 840C Installation Instructions

• 840C Installation Lists

The supplementary manual, which is entitled "SINUMERIK 840, Installation Lists", provides

additional aids in the form of lists and detailed information on NC and PLC machine data and

setting data, as well as lists of control and programmer alarms.

The manufacturer documentation for the SINUMERIK 840C control is divided into the

following parts:

• Interface

Part 1: Signals

Part 2: Connection Conditions

• Planning Guide PLC 135 WB/WB2/WD

• Function Macros

• Function Blocks

Package 0: Basic Functions

Package 1: Tool Management

Package 4/5:Computer Link

Package 7: Code Carrier

Package 8: PLC-controlled Data Input/Output

Additional SINUMERIK publications which are valid for all SINUMERIK controls may also be

consulted (e.g. Universal Interface, Measuring Cycles, CL800 Cycle Language).

Please contact your local SIEMENS office for further details.

Technical notes

A new Installation Guide is required for each new software version. Old Installation Guides can

be used only in part for new software versions.

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

As from software version 4, please refer to the Installation Lists manual

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

As from software version 3, the data relevant to SIMODRIVE 611-D

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

for a description of the alarms (Monitoring section).

This manual is valid for software versions 1, 2, 3, 4, 5 and 6.

is also provided.

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

CAUTION

This warning notice (without warning triangle) means that a material

damage can result if the appropriate precautions are not taken.

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

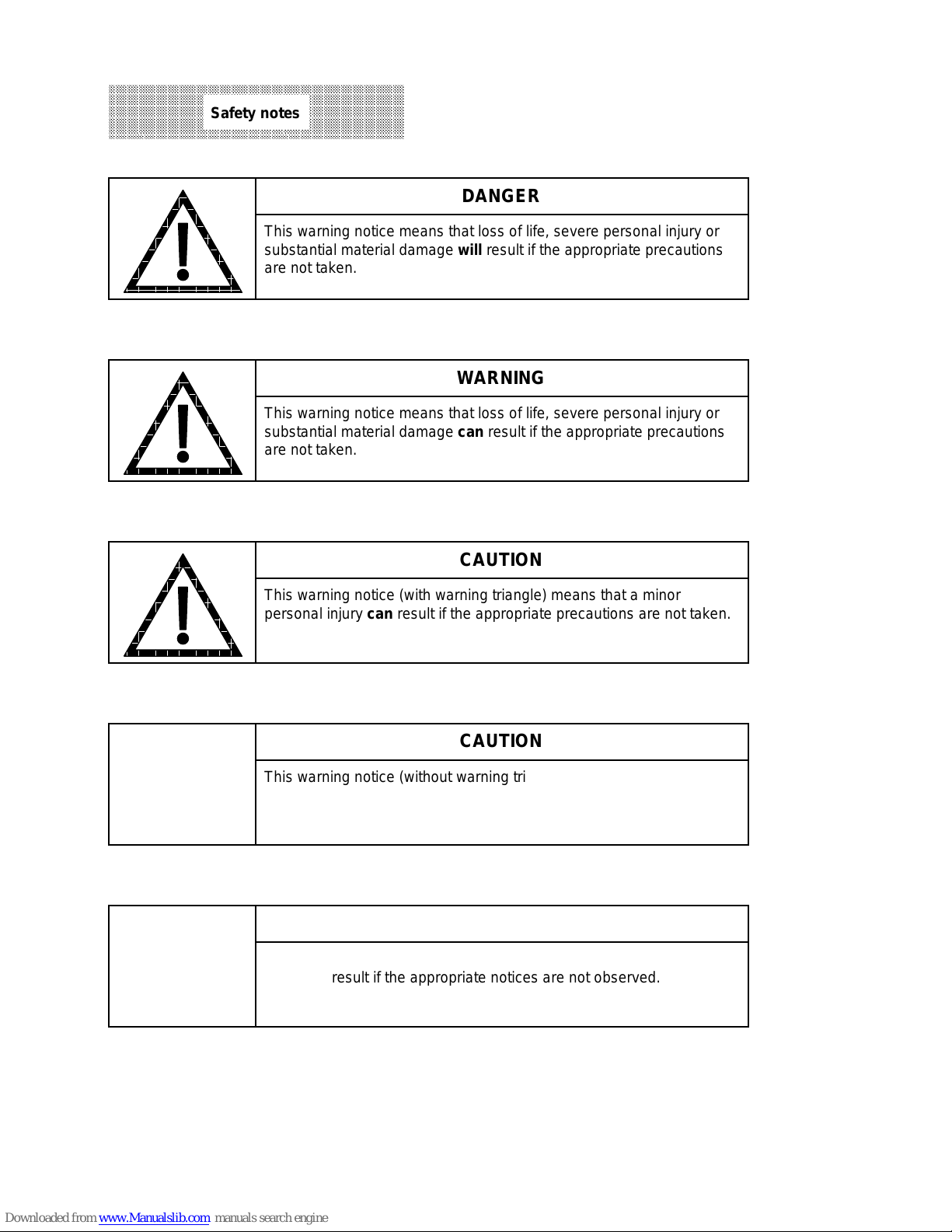

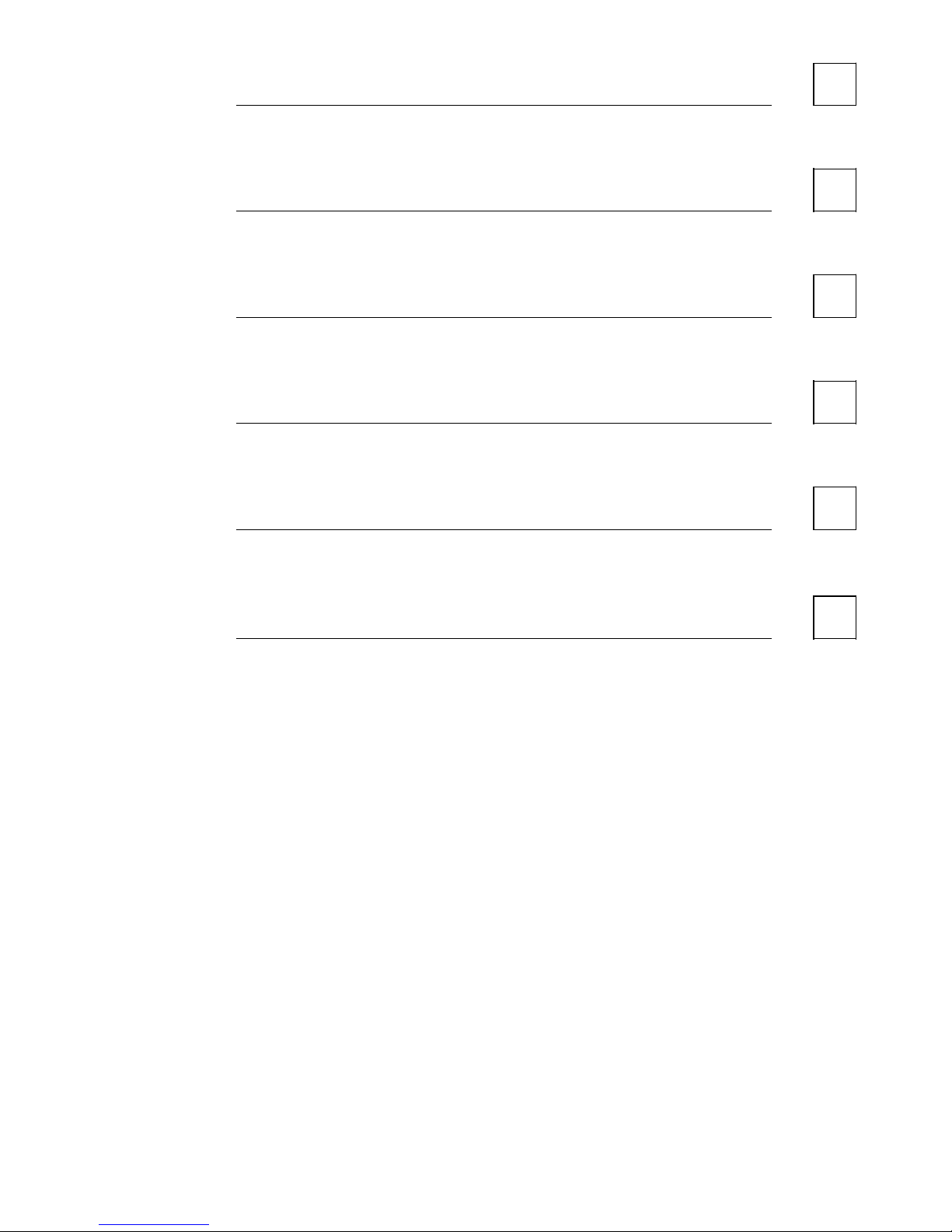

Safety notes

This warning notice means that loss of life, severe personal injury or

substantial material damage will result if the appropriate precautions

are not taken.

This warning notice means that loss of life, severe personal injury or

substantial material damage can result if the appropriate precautions

are not taken.

a

a

a

a

a

a

a

a

DANGER

WARNING

CAUTION

This warning notice (with warning triangle) means that a minor

personal injury can result if the appropriate precautions are not taken.

NOTICE

This warning notice means that an undesired event or an undesired

state can result if the appropriate notices are not observed.

NC/Drive Machine Data 1

PLC Machine Data 2

Cycles Machine Data 3

NC Setting Data 4

PLC Interface 5

Startup, Flowcharts 6

Contents

Page

1 NC/Drive Machine Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1.1 General values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1.2 Channel-specific values (max. 4 channels)

(as from SW 4: 6 channels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

1.3 Axis-specific values (max. 30 axes, 15 real and 15 fictitious) . . . . . . . 1–10

1.4 Spindle-specific values (max. 6 spindles) . . . . . . . . . . . . . . . . . . . . 1–13

1.5 General bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–18

1.5.1 General bits, standard assignments . . . . . . . . . . . . . . . . . . . . . . . . 1–24

1.6 Spindle-specific bits (max. 6 spindles) . . . . . . . . . . . . . . . . . . . . . . 1–27

1.6.1 Spindle-specific bits, standard assignments . . . . . . . . . . . . . . . . . . . 1–28

1.7 Channel-specific bits (max. 4 channels)

(as from SW 4: 6 channels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–29

1.7.1 Channel-specific bits 1, standard assignments . . . . . . . . . . . . . . . . . 1–30

1.8 Axis-specific MD bits 1 (max. 30 axes) . . . . . . . . . . . . . . . . . . . . . . 1–31

1.8.1 Axis-specific MD bits 1, standard assignments . . . . . . . . . . . . . . . . 1–32

1.9 Compensation points for leadscrew error compensation . . . . . . . . . . 1–34

1.9.1 Channel-specific bits 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–35

1.9.2 Axis-specific MD 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–36

1.9.3 Axis-specific MD bits 2 (max. 30 axes) . . . . . . . . . . . . . . . . . . . . . . 1–42

1.10 MD for display screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–43

1.10.1 Spindle-specific MD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–44

1.10.2 Axis-specific MD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–47

1.10.3 MD bits for collision detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–49

1.10.4 MDs for flexible memory configuration . . . . . . . . . . . . . . . . . . . . . . 1–50

1.11 611A drive machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–52

1.11.1 611A drive machine data MSD (SW 3) . . . . . . . . . . . . . . . . . . . . . . 1–52

1.11.2 611D drive machine data FDD (SW3) . . . . . . . . . . . . . . . . . . . . . . . 1–62

1.11.3 611D drive machine data FDD/MSD (as from SW 4) . . . . . . . . . . . . 1–66

1.11.4 FDD/MSD specific diagnostics/service MD (as from SW 4) . . . . . . . . 1–77

1.11.5 Servo service data (SSD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–78

1.12 Safety Integrated (SI) machine data . . . . . . . . . . . . . . . . . . . . . . . . 1–79

1.12.1 SI NC machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–79

1.12.2 SI drive machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–85

1.12.3 SI service data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–87

1.13 Coding of resolutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–88

1.14 Code table for axis name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–89

2 PLC Machine Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2.1 PLC machine data for operating system (DB 60) . . . . . . . . . . . . . . . 2–1

2.2 General PLC machine data for function blocks (DB 61) . . . . . . . . . . 2–5

2.3 User PLC machine data (DB 62) . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2.4 General bits (DB 63) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

2.4.1 PLC MD bits standard assignment . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

2.5 General PLC machine data bits for function blocks (DB 64) . . . . . . . 2–13

2.5.1 PLC machine data bits for user (DB 65) . . . . . . . . . . . . . . . . . . . . . 2–14

2.6 DBs set up for user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–14

2.6.1 Data words for user (DB 68) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–14

2.6.2 Data bits for user (DB 71) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–14

3 Cycles Machine Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

4 NC Setting Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.1 NC values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.2 NC setting data bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

5 PLC Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.1 Overview PLC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.1.1 Inputs, outputs, flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.1.2 Data blocks (DB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

5.1.3 Function blocks (FB, FX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

5.2 Basic signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–13

5.2.1 Assignment of DB 1 (diagnostics) . . . . . . . . . . . . . . . . . . . . . . . . . 5–15

5.2.2 Fast data channels (SW 4 and higher) . . . . . . . . . . . . . . . . . . . . . . 5–19

5.2.2.1 DB 2 configuring DB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–19

5.2.3 DB 3 data transfer areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–20

5.3 NCK/PLC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–21

5.3.1 Channel-specific signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–21

5.3.1.1 Signals to NCK channel (DB 10 - DB 13) . . . . . . . . . . . . . . . . . . . . 5–21

5.3.1.2 Signals from NCK channel (DB 10 to DB 13) . . . . . . . . . . . . . . . . . 5–23

5.3.1.3 Auxiliary functions from NCK channel (DB 10 to DB 13) . . . . . . . . . 5–24

5.3.2 Axis-specific signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–32

5.3.2.1 Axis-specific signals Safety Integrated (DB28) (SW 5 and higher) . . . 5–32

5.3.2.2 Axis-specific GI signals (DB 29) . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–34

5.3.2.3 Axis-specific 611-D signals (DB 29) . . . . . . . . . . . . . . . . . . . . . . . . 5–35

5.3.3 M signals decoded according to list (DB 30) . . . . . . . . . . . . . . . . . . 5–36

5.3.4 Spindle-specific signals (DB31) . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–37

5.3.4.1 Signals from spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–37

5.3.4.2 Spindle-specific GI signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–37

5.3.4.3 Signals to spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–38

5.3.4.4 Spindle-specific GI signals to spindle . . . . . . . . . . . . . . . . . . . . . . . 5–38

5.3.4.5 Spindle-specific 611 D signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–39

5.3.5 Axis-specific signals (DB 32) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–40

5.3.6 Data transfer PLC/NC (DB 36) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–42

5.3.7 Data transfer initiated using DB 37 . . . . . . . . . . . . . . . . . . . . . . . . . 5–43

5.3.8 Operator panel signals / PLC (DB 40) . . . . . . . . . . . . . . . . . . . . . . . 5–44

5.3.8.1 Key signals from operator panel (DB 40) . . . . . . . . . . . . . . . . . . . . . 5–44

5.3.8.2 Display dialog line (DB 40) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–46

5.3.8.3 Menu selection (DB 40)* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–47

5.3.8.4 Cursor data (DB 40) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–48

5.3.8.5 User key signals (DB 40) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–49

5.3.9 Interface command channel (DB 41) . . . . . . . . . . . . . . . . . . . . . . . 5–51

5.3.10 General interface NC/PLC (DB 48) . . . . . . . . . . . . . . . . . . . . . . . . . 5–53

5.3.11 PLC messages (DB 58) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–55

5.3.11.1 Softkey function calls DB 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–60

5.3.12 DBs for PLC machine data (DB 60-65) . . . . . . . . . . . . . . . . . . . . . . 5–61

5.3.13 DBs set-up for user (DB 66, 67, 68, 71) . . . . . . . . . . . . . . . . . . . . . 5–61

5.3.14 Decoding lists for M signals (DB 80...DB 83) . . . . . . . . . . . . . . . . . . 5–62

6 Startup, Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

6.1 Restart after failure or replacement of the central service board . . . . 6–1

6.2 Saving the PLC program on the hard disk of the MMC . . . . . . . . . . . 6–3

6.3 Saving on/or loading from the hard disk (MMC) . . . . . . . . . . . . . . . . 6–4

6.4 Data transfer NC PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–5

6.5 Loading the archive file from an external PC to the NC . . . . . . . . . . 6–7

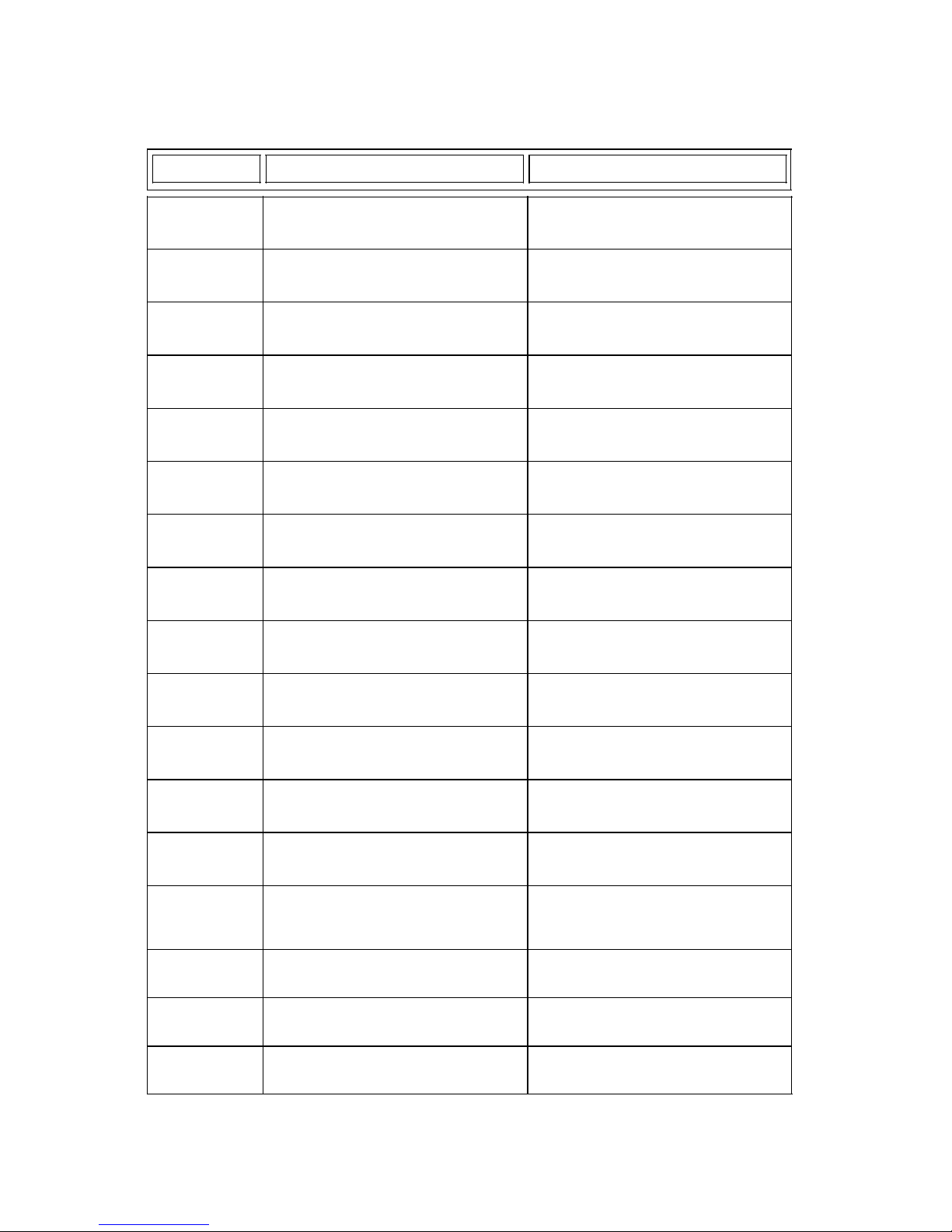

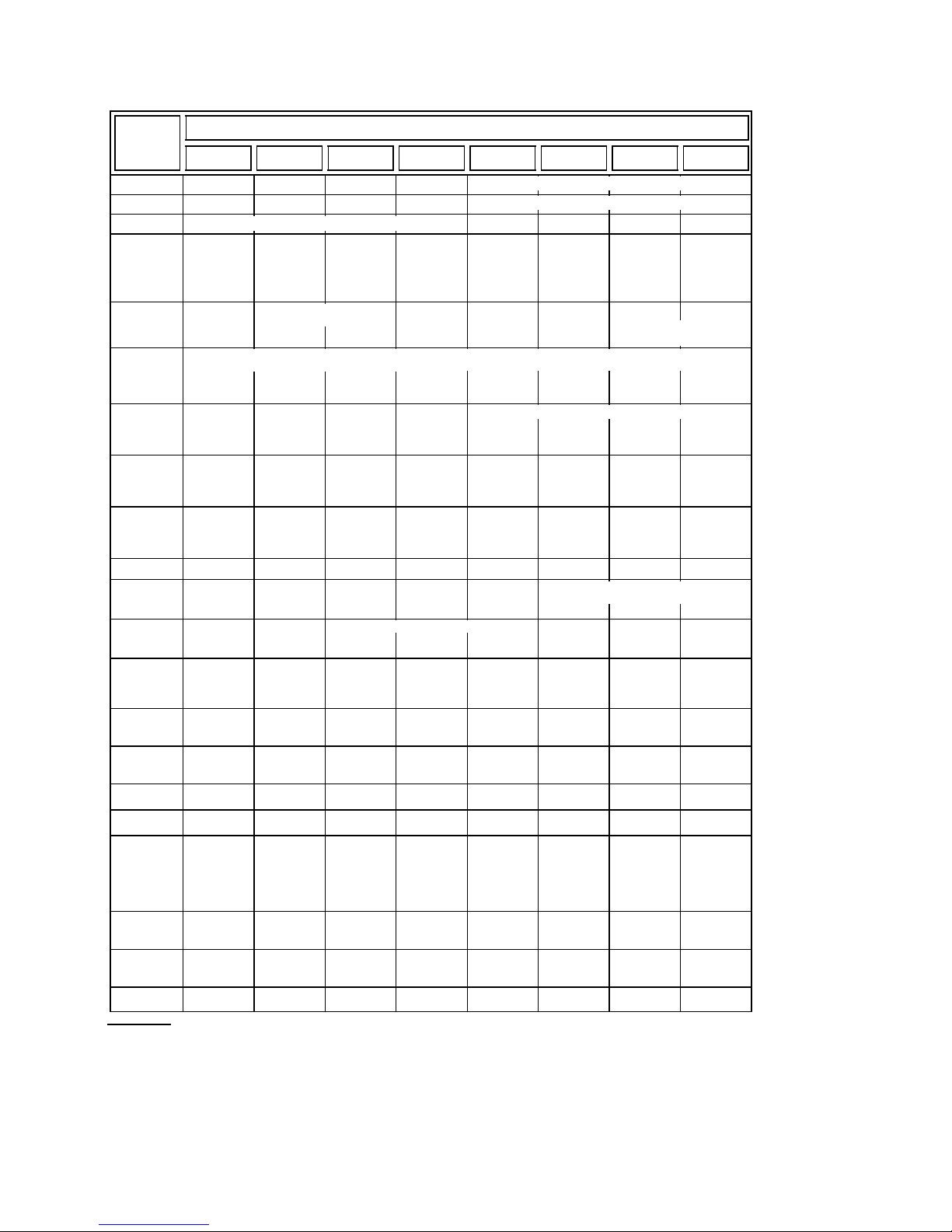

07.97 1 NC/Drive Machine Data

1 NC/Drive Machine Data

NC MD/Drive MD allocation

MD

1000

1599

2000

3999

4000

4999

5000

5199

5200

5399

5400

5599

5600

5999

6000

6999

9000

9299

11000

17969

18000

18599

20400

20449

2400*

3944*

6000*

62029

18000

4000*

4740*

to

999

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

Meaning

0

General MDs General data

Channel-specific MDs Channel data

Axis-specific MD 1 Axial data 1

Spindle-specific MD Spindle data

General MD bits General bits

Spindle-specific MD bits Bit displays

Channel-specific MD bits 1 Channel bits 1

Axis-specific MD bits 1 Axial bits 1

Leadscrew error,

compensation bits

Channel-specific MD bits 2 Channel bits 2

Axis-specific MD 2 Axial data 2

Axis-specific MD bits 2 Axial bits 2

MDs for multi-channel display Channel memory

set changeover, dynam. software

1

MDs for parameter

limit switch

Collision detection

MDs for flexible

memory configuration

Simodrive drive MD

(SW 3 and higher)

Safety Integrated MD

(SW 5.4 and higher)

(see Description of Functions

Softkey

Compensation flags

––––––

Various

axial data

––––––

Safety functions

Safety Integrated)

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

1–1

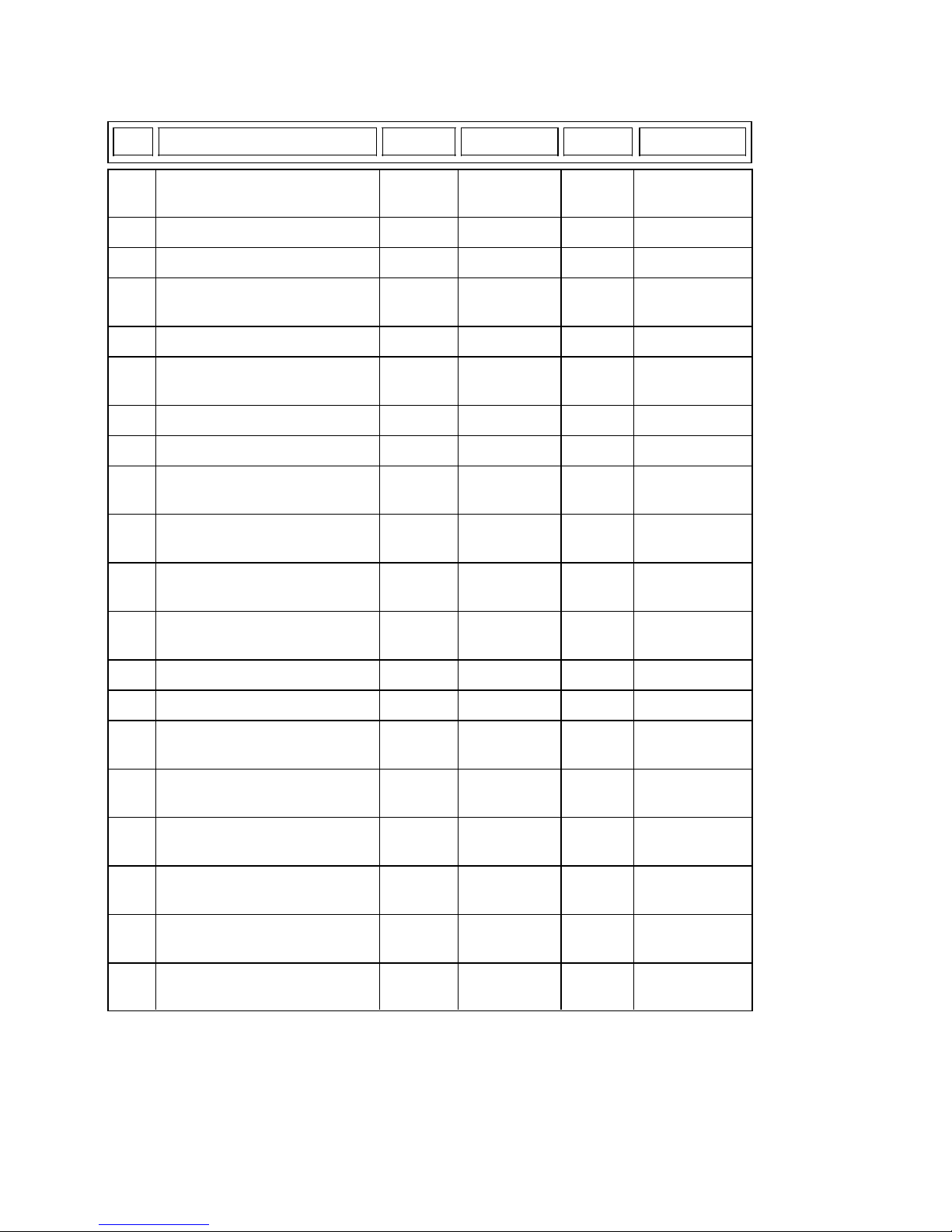

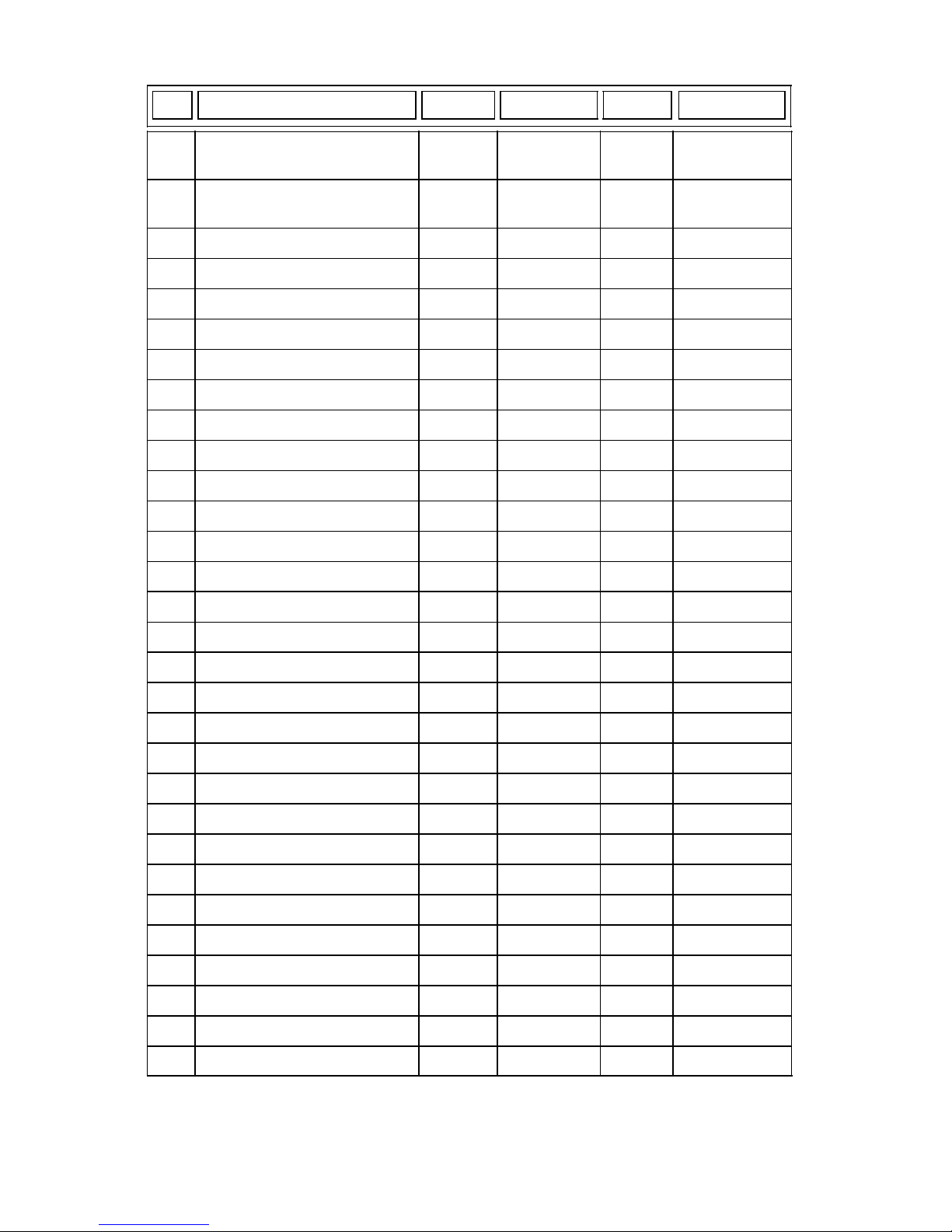

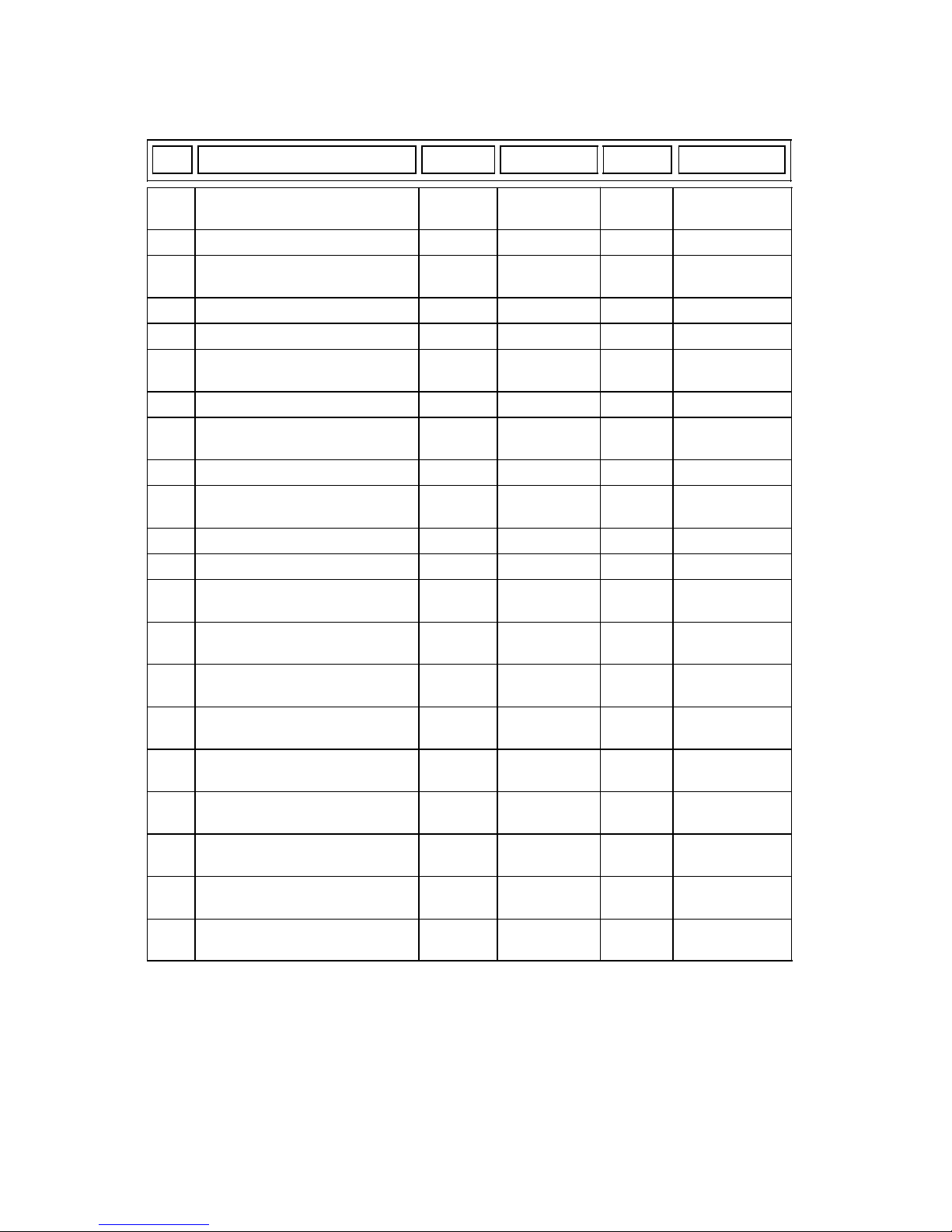

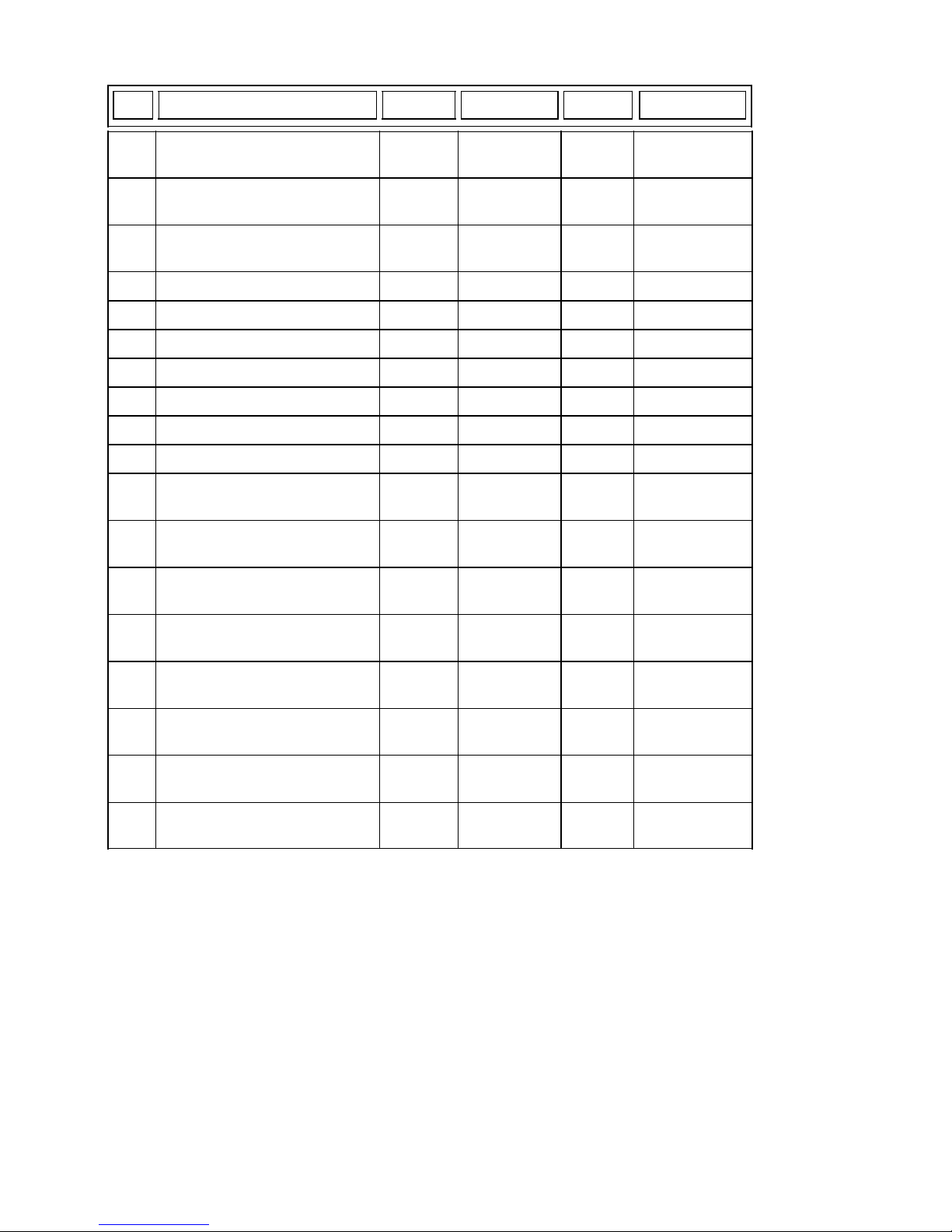

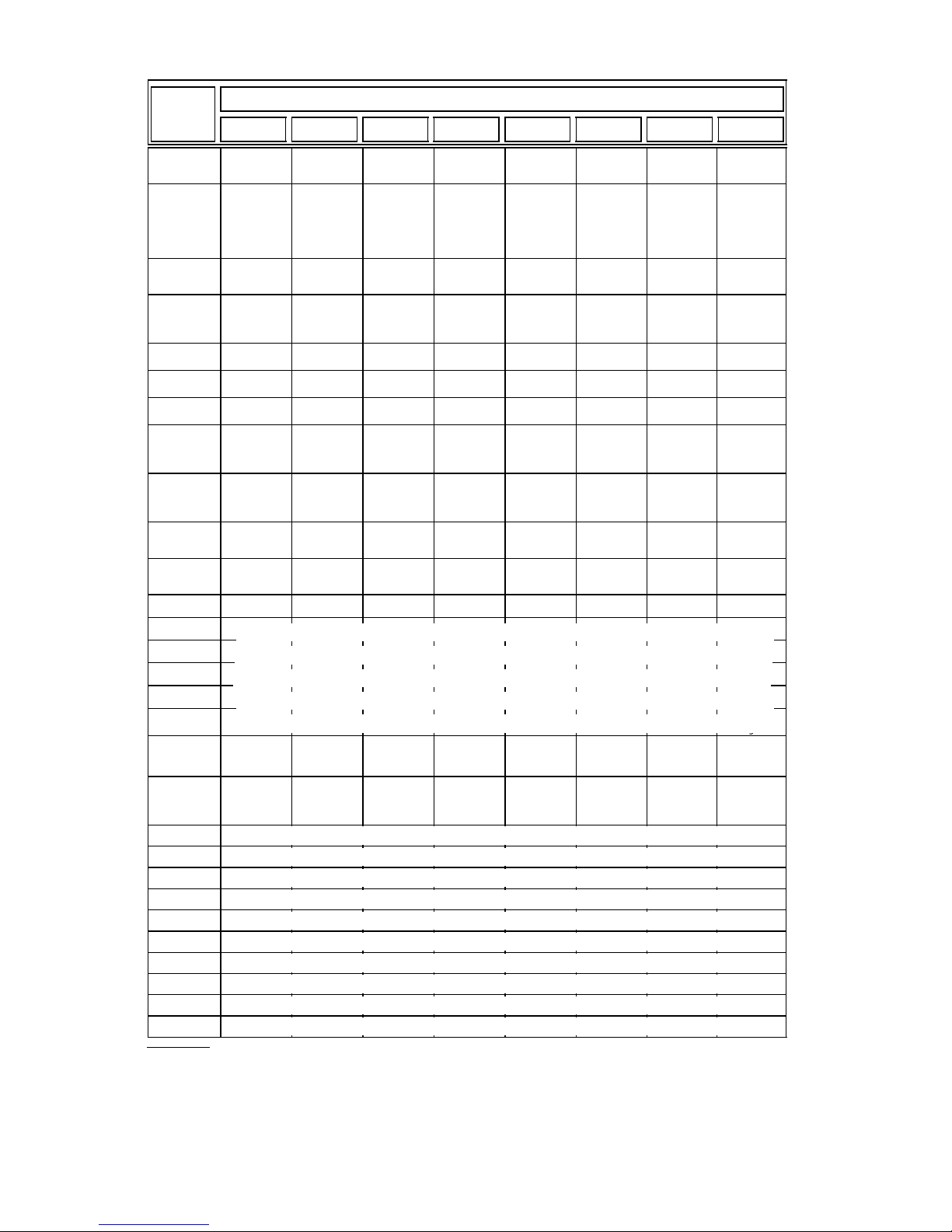

1 NC/Drive Machine Data 09.95

1.1 General values

1.1 General values

MD

No.

D e s i g n a t i o n

Standard

value

Maximum

input value

Reference

system

Input

unit

1 Speed after prelimit switch 500 100000 IS 1000 units/min

2

3 Corner deceleration rate 500 100000 IS 1000 units/min

6 Threshold for point of intersect.

switch

1000 16000

2000

IS units

*)

7 Circle end point monitoring 5 32000 IS units

9 Error window on reapproach to

200 32000 IS units

circle contour

10 Feed after block search 1000 100000 IS 1000 units/min

13 Number of TO parameters 10 32 --

14 First password protected R

parameter

15 Last password protected R

parameter

16 First keyswitch protected R

parameter

0 999

1299

0 999

1299

0 999

1299

*)

*)

*)

--

--

--

17 Last keyswitch protected R

parameter

0 999

1299

*)

--

18 Zero offset group (L960) 1 10 --

20 Basic angle for nutating head 0 180000 IS 10

23 Number of buffer pairs

16 16 --

CP 231

24 Number of buffer pairs

16 16 -- --

CP 315 - 1

25 Number of buffer pairs

16 16 --

CP 315 - 2

26 User program useful data

234 254

*)

-- characters

length CP 231

27 User program useful data

234 254

*)

--

length CP 315 - 11 - 16

28 User program useful data

234 254

*)

--

length CP 315 - 2

_______

*) SW 4 and higher

-3

degrees

--

--

characters

characters

1–2

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

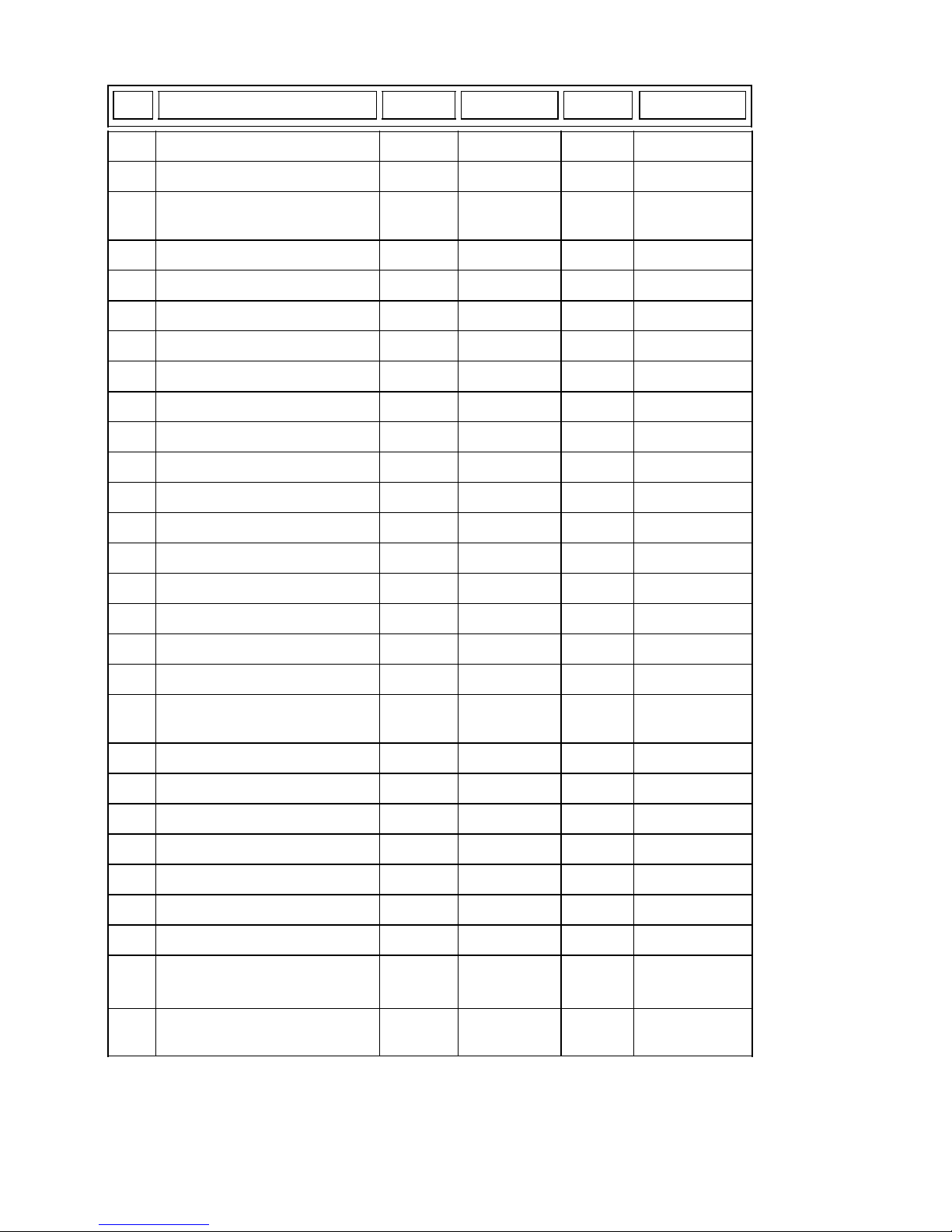

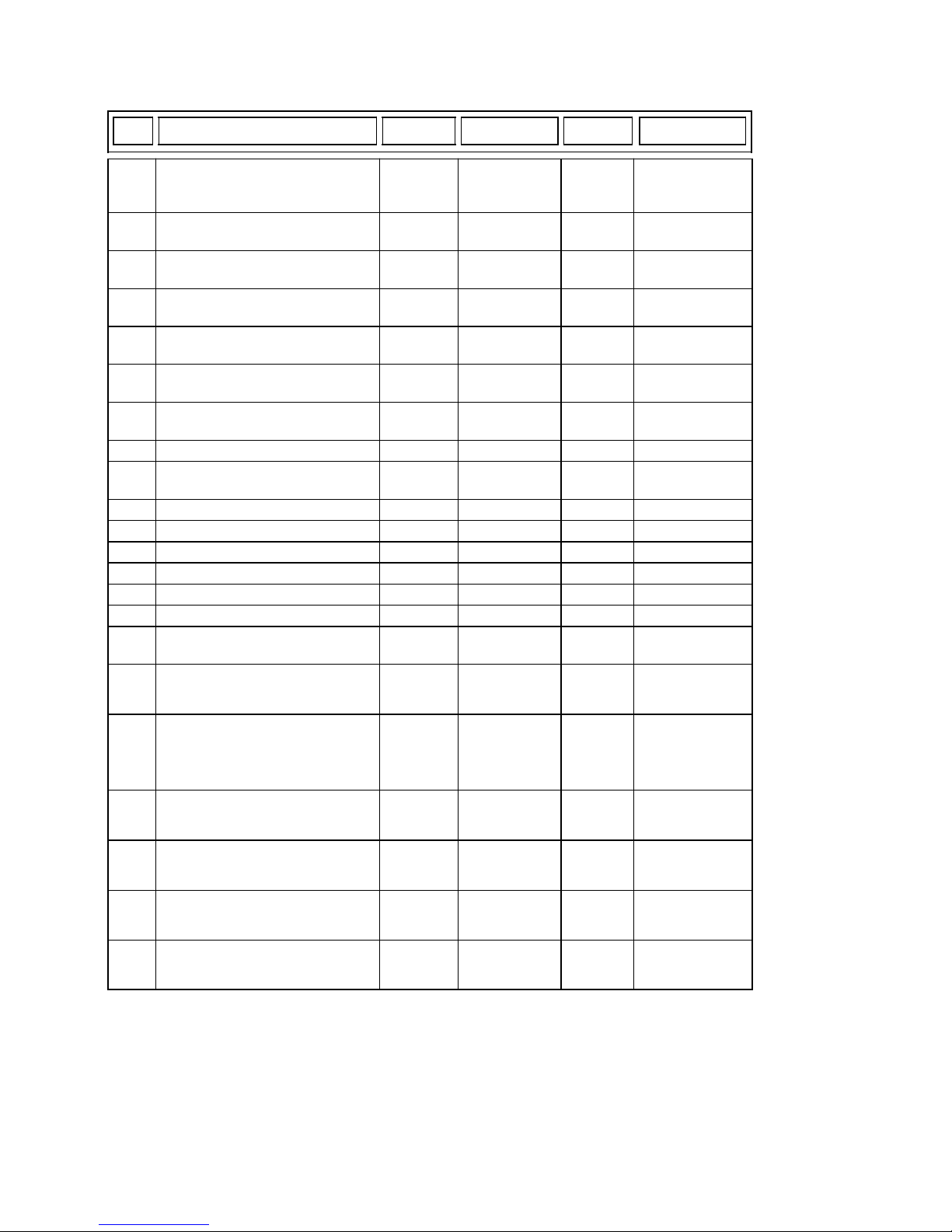

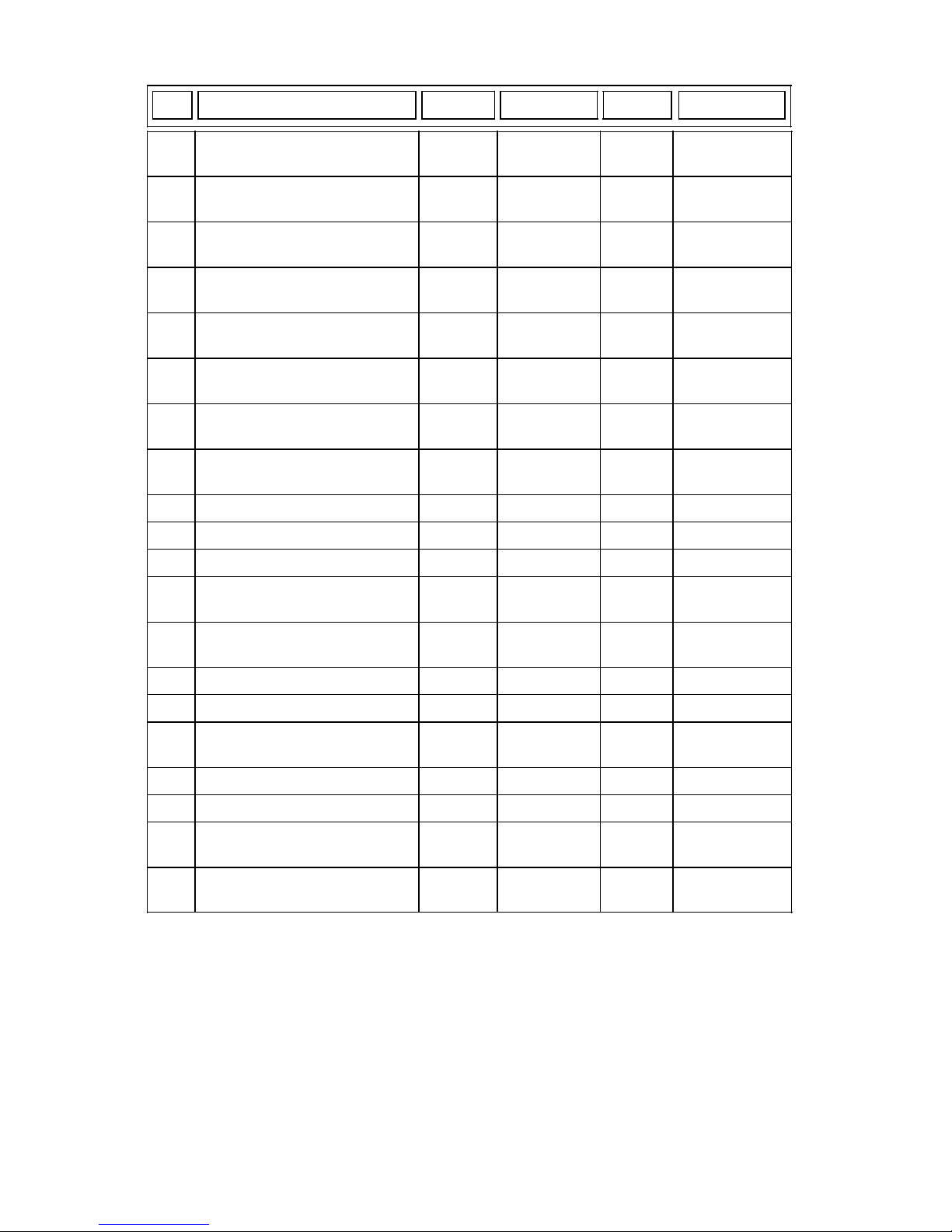

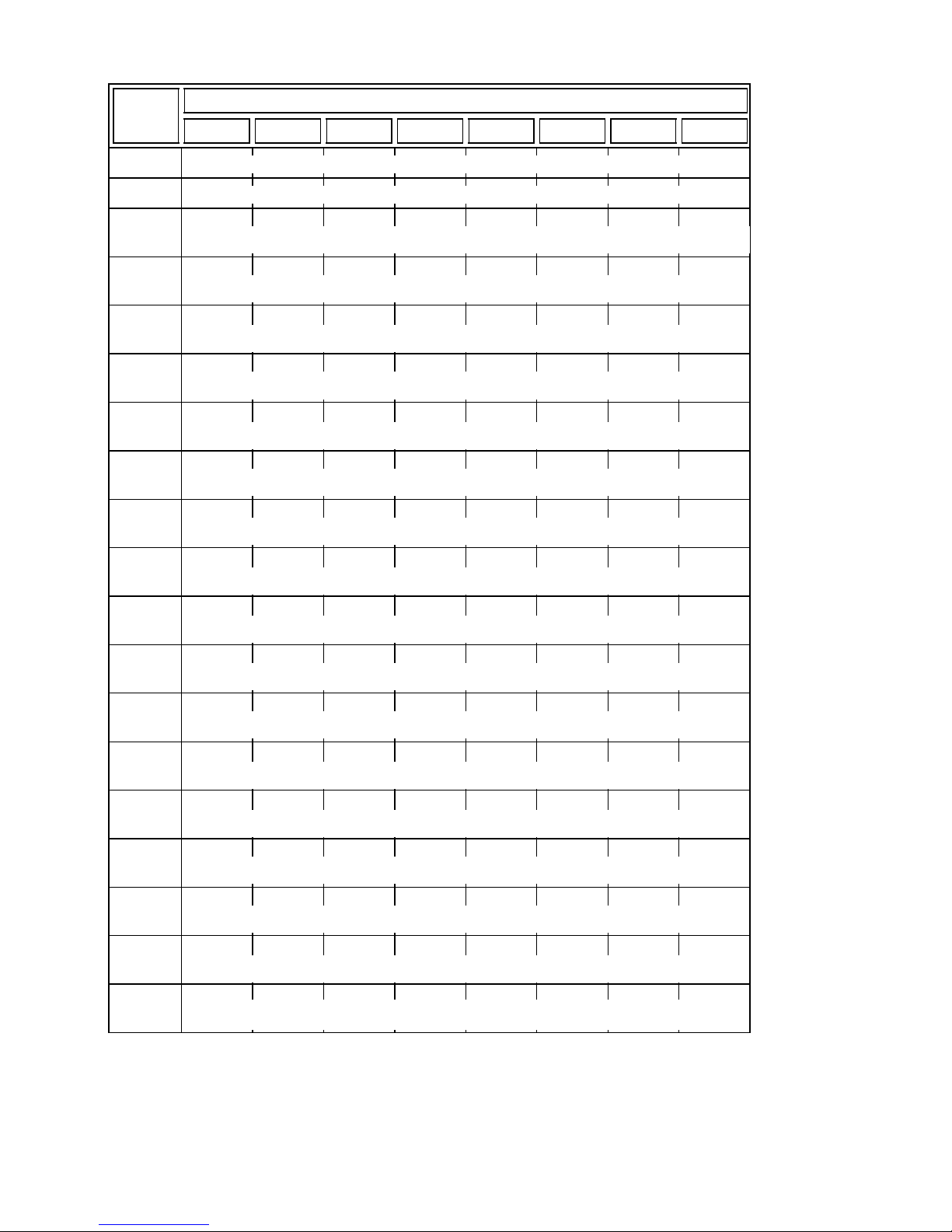

09.95 1 NC/Drive Machine Data

1.1 General values

MD

No.

D e s i g n a t i o n

30 Number of sectors in pro-

Standard

value

Maximum

input value

Reference

system

10 1000 -- Sector

Input

cessing memory

100 Feedrate override

1 150 -- %

switch position 2

101 - // - 3 2 150 -- %

102 - // - 4 4 150 -- %

103 - // - 5 6 150 -- %

104 - // - 6 8 150 -- %

105 - // - 7 10 150 -- %

106 - // - 8 20 150 -- %

107 - // - 9 30 150 -- %

108 - // - 10 40 150 -- %

109 - // - 11 50 150 -- %

110 - // - 12 60 150 -- %

111 - // - 13 70 150 -- %

unit

112 - // - 14 75 150 -- %

113 - // - 15 80 150 -- %

114 - // - 16 85 150 -- %

115 - // - 17 90 150 -- %

116 - // - 18 95 150 -- %

117 - // - 19 100 150 -- %

118 - // - 20 105 150 -- %

119 - // - 21 110 150 -- %

120 - // - 22 115 150 -- %

121 - // - 23 120 150 -- %

122 - // - 24 0 150 -- %

123 - // - 25 0 150 -- %

124 - // - 26 0 150 -- %

125 - // - 27 0 150 -- %

126 - // - 28 0 150 -- %

127 - // - 29 0 150 -- %

128 - // - 30 0 150 -- %

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

1–3

1 NC/Drive Machine Data 09.95

1.1 General values

MD

No.

D e s i g n a t i o n

Standard

value

Maximum

input value

Reference

system

Input

129 - // - 31 0 150 -- %

130 - // - 32 0 150 -- %

131 Spindle override

50 150 -- %

switch position 1

132 - // - 2 55 150 -- %

133 - // - 3 60 150 -- %

134 - // - 4 65 150 -- %

135 - // - 5 70 150 -- %

136 - // - 6 75 150 -- %

137 - // - 7 80 150 -- %

138 - // - 8 85 150 -- %

139 - // - 9 90 150 -- %

140 - // - 10 95 150 -- %

141 - // - 11 100 150 -- %

unit

142 - // - 12 105 150 -- %

143 - // - 13 110 150 -- %

144 - // - 14 115 150 -- %

145 - // - 15 120 150 -- %

146 - // - 16 120 150 -- %

147 Rapid override

1 100 -- %

switch position 1

148 - // - 2 10 100 -- %

149 - // - 3 50 100 -- %

150 - // - 4 100 100 -- %

151 - // - 5 0 100 -- %

152 - // - 6 0 100 -- %

153 - // - 7 0 100 -- %

154 - // - 8 0 100 -- %

155 Position controller basic cycle 4 40 --

Multiple of the

drive’s basic

cycle

156 Switch-off delay

Controller enable

1–4

200 1000 -- ms

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

09.01 1 NC/Drive Machine Data

1.1 General values

MD

No.

D e s i g n a t i o n

157 Control type for

standard cycles

Standard

value

T 61..

M 62..

Maximum

input value

--

--

Reference

system

-- --

Input

160 Interpolation cycle 4 32 -- --

161 Number of IKA configurations via

032----

PLC/DB 48

164 Deadtime for calculation for

extended thread

28

36

4)

48 --

1

/8 of IPO clock

frequency

168 Basic cycle time for drive 16 32 -- 62.5 µs

200 Reserved

208 Maximum tool wear P5, P6 999 999 999 999

99 999 999

209 Maximum tool wear P7 999 999 999 999

99 999 999

3)

3)

-- 0.01 units

0.00001

-- 0.01 units

0.00001

210 Number of TO areas 1 4 -- --

211 Start D No. for TO area 1 1 809 -- --

212 ” ” 2 0 809 -- --

213 ” ” 3 0 809 -- --

214 ” ” 4 0 809 -- --

228 User menu for MDA 0 1000 -- --

229 User menu for JOG 0 1000 -- --

230 User menu for TEACH IN 0 1000 -- --

231 User menu for AUTOMATIC 0 1000 -- --

232 User menu for JOG/REFPOINT 0 1000 -- --

250 Change of language

260 M function ”C axis ON”

261 M function ”C axis OFF”

300 Tool allowance for protection

1)

0 1 -- --

-

1 9999 -- --

-

1 9999 -- -0 9999 9999 IS --

zone adjustment

310

Output byte to user interface 0 94

2)

Output byte to mixed I/O 0 22

311

2)

312 Assignment of outputs

module

2)

for emergency

022

999

999

3)

3)

2)

2

-- --

-- --

-- --

retraction 1st mode grp

313:Assignment of outputs

module

2)

for emergency

022----

retraction 2nd mode grp

317 Assignment of outputs

module

2)

for emergency

022

2)

2

-- --

retraction 6th mode grp

MDs 314 to 317 (as from SW 4)

_______

1)

Up to SW 1

2)

SW 3 and higher

3)

SW 4 and higher

4)

SW 5 and higher

unit

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

1–5

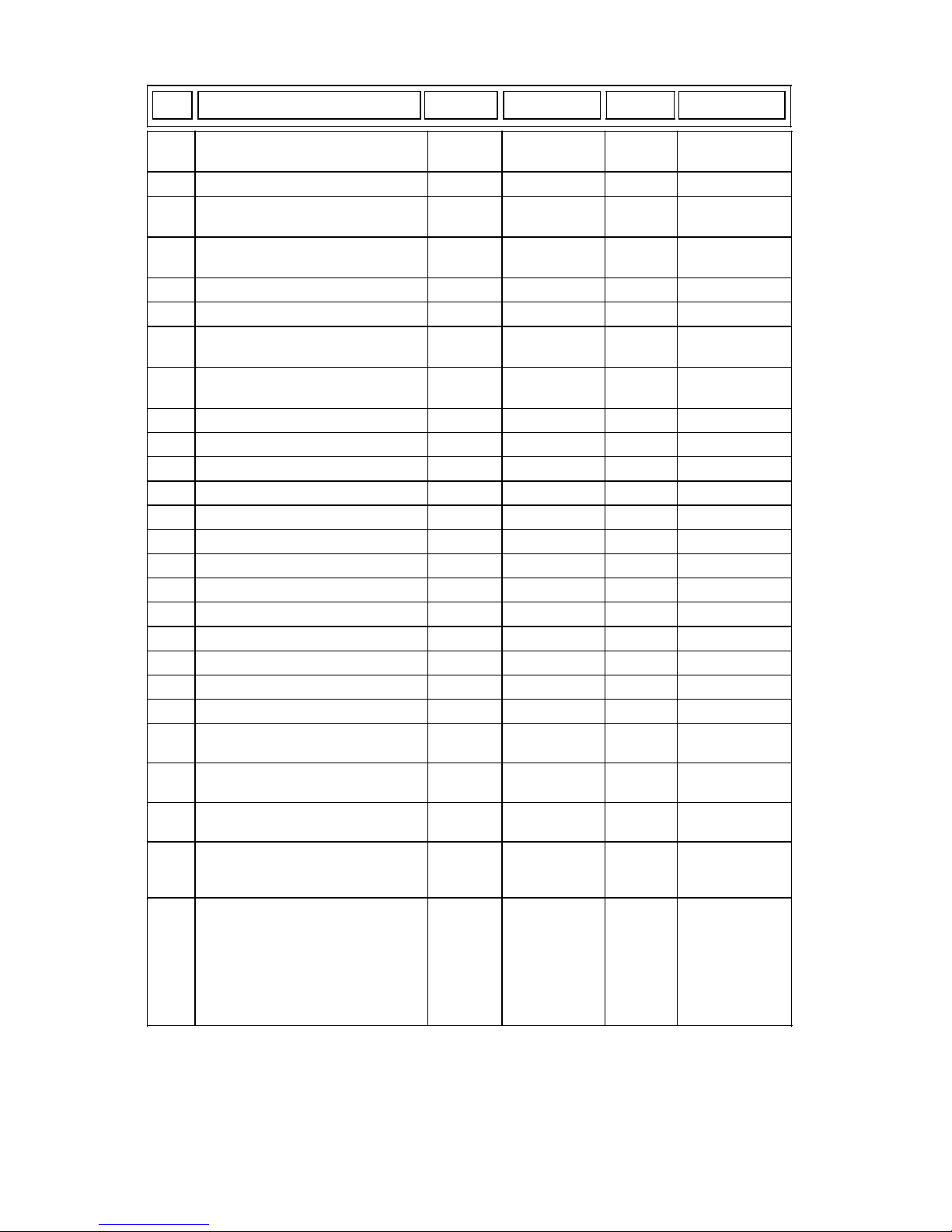

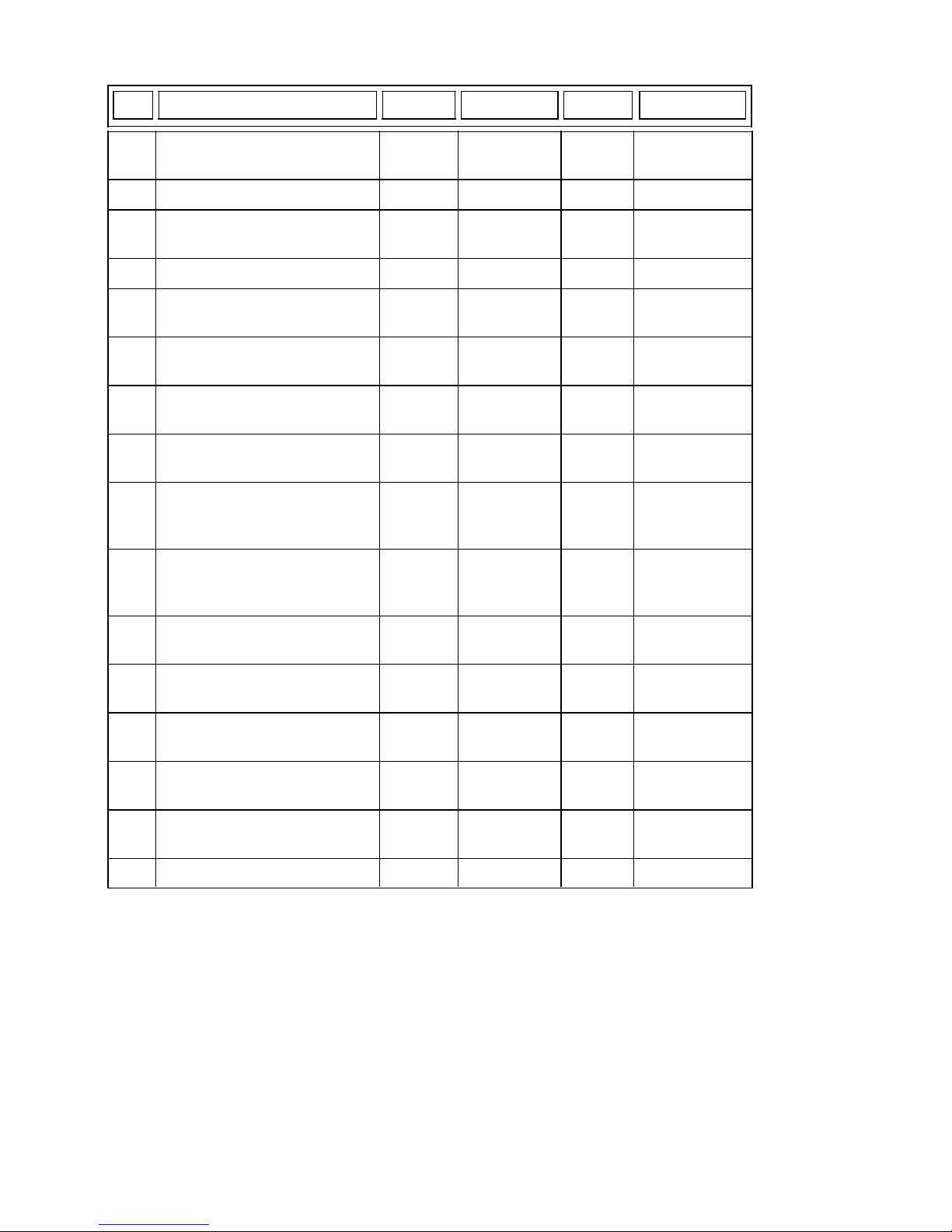

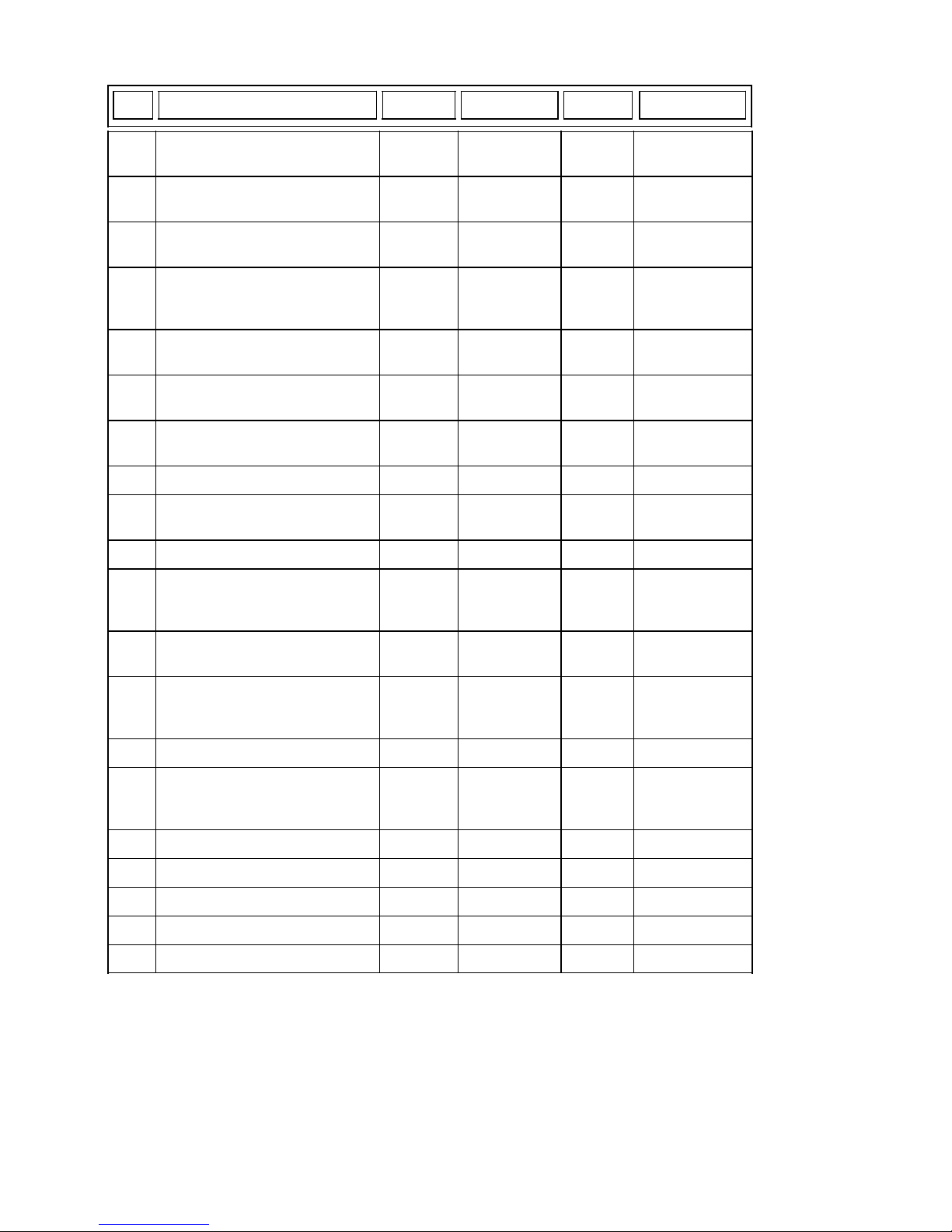

1 NC/Drive Machine Data 01.99

1.1 General values

MD

No.

318

323

D e s i g n a t i o n

Assignment of inputs of Mixed

I/O module for retraction of one

:

mode group 1st mode group

6th mode group

324 Time for interpolator-controlled

continuation

325 Maximum time for interpolator-

controlled deceleration

330 Deadtime compensation for

dwell axis actual value

331 Sine of angular range for

tangential transitions TRC

332 Deadtime compensation dwell

axis setpoint

333 Deadtime compensation dwell

spindle actual value

334 Deadtime compensation dwell

spindle setpoint

335 Min. reduction factor

(velocity limitation FA warning

threshold)

336 Velocity increase factor

(velocity linitation FA warning

threshold)

337 2nd MCS displacement in X

coordinates

338 2nd MCS displacement in Y

coordinates

339 2nd MCS displacement in Z

coordinates

340 3rd MCS displacement in X

coordinates

341 3rd MCS displacement in Y

coordinates

342 3rd MCS displacement in Z

coordinates

343 4th MCS displacement in X

coordinates

344 4th MCS displacement in Y

coordinates

345 4th MCS displacement in Z

coordinates

_______

1) As fromSW 4

2) As from SW 5

3) As from SW 6

:

1)

1)

1)

2)

2)

2)

3)

3)

3)

3)

3)

3)

3)

3)

3)

3)

3)

1)

ˆ=approx.

0.0005 deg.

Standard

value

081

0 1 000

0 1 000

Maximum

input value

1)

8

16 000

16 000

1)

1)

Reference

system

-- --

-- ms

-- ms

550 16 000 -- % of IPO

2

16 000

ˆ=approx.

4.5 degrees

-- 0.5 * 10

450 16 000 -- % of IPO

550 16 000 -- % of IPO

450 16 000 -- % of IPO

100 100 -- %

0 1000 -- 0.01 %

0 9999 9999 IS units

550 16 000 IS units

550 16 000 IS units

550 16 000 IS units

550 16 000 IS units

550 16 000 IS units

550 16 000 IS units

550 16 000 IS units

550 16 000 IS units

Input

unit

cycle

cycle

cycle

cycle

-5

1–6

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

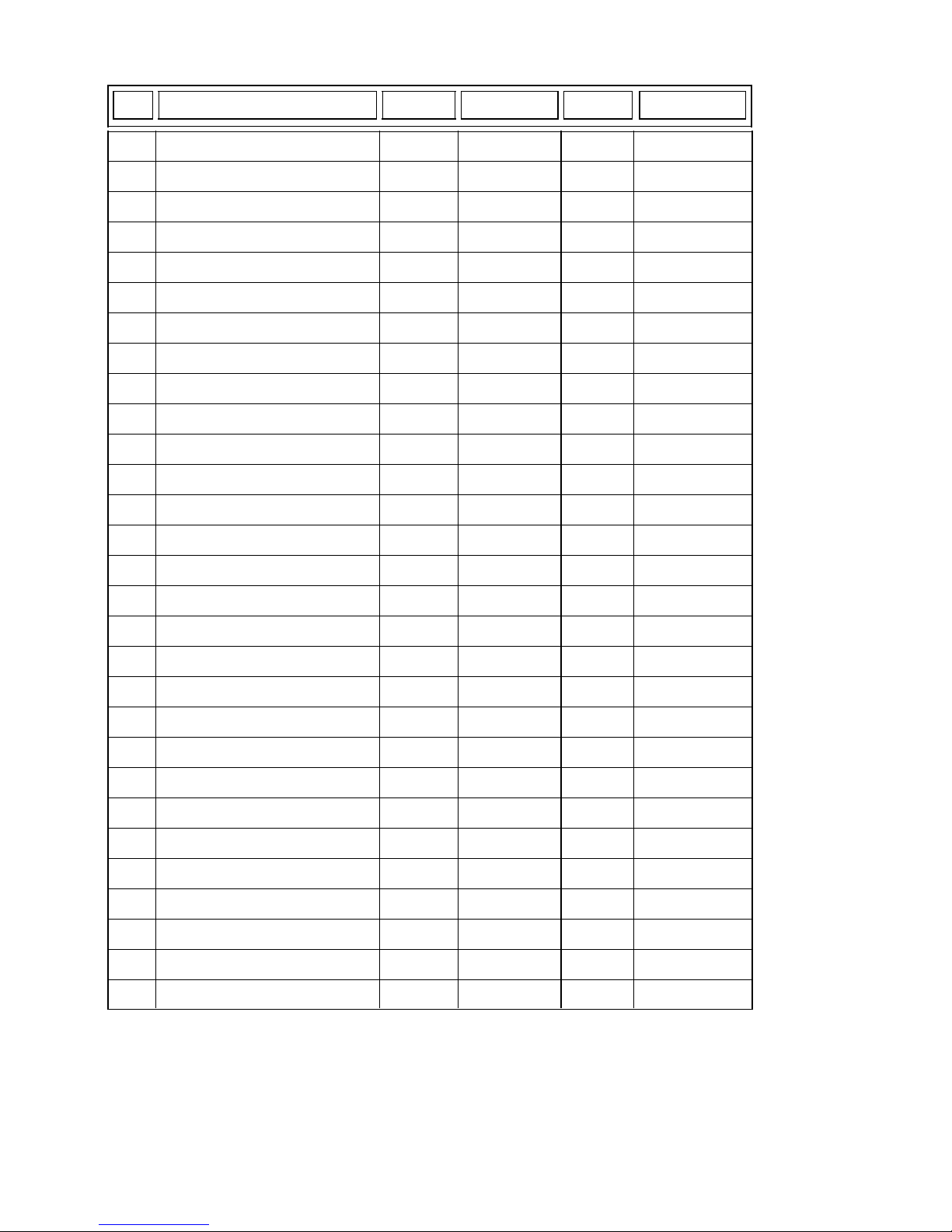

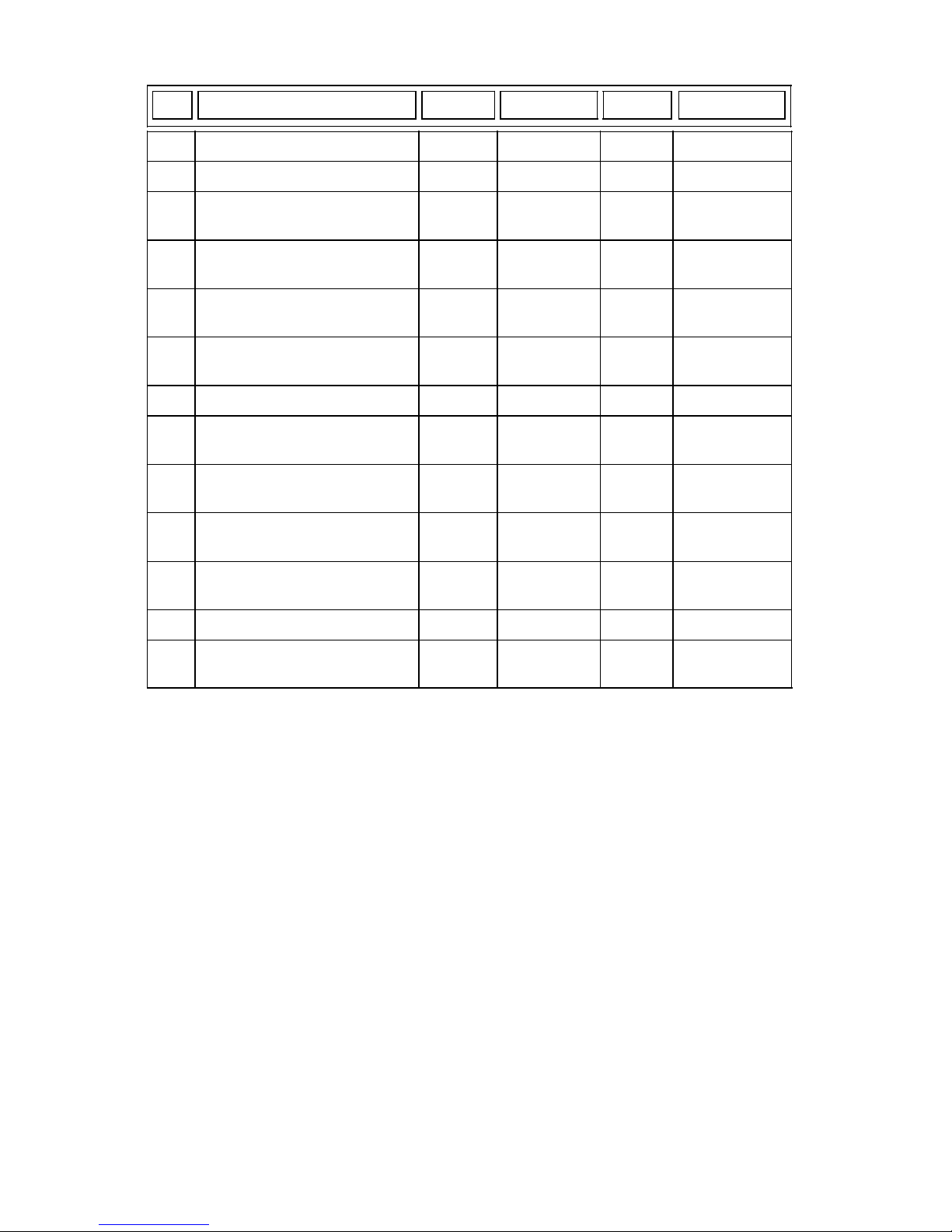

01.99 1 NC/Drive Machine Data

1.1 General values

MD

No.

D e s i g n a t i o n

Standard

value

Maximum

input value

Reference

system

Input

unit

730 Delta X offset 0 ±99999999 IS units

731 Delta Y offset 0 ±99999999 IS units

732 Delta Z offset 0 ±99999999 IS units

733 Angle of rotation X 0 ±99999999 IS 10

734 Angle of rotation Y 0 ±99999999 IS 10

735 Angle of rotation Z 0 ±99999999 IS 10

-5

-5

-5

736 Parameter 7 0 ±99999999 IS units

737 Parameter 8 0 ±99999999 IS units

738 Minimum speed for TRANSMIT 10 ±99999999 IS units/IPO cycle

739 Axis with constant cutting

speed

0 30 Number of the

axis for G96

740 2nd transformation, param. 1 0 ±99999999 IS units

. - // -- // -- // -- // -- // -

750 3rd transformation, param. 1 0 ±99999999 IS units

. - // -- // -- // -- // -- // -

760 4th transformation, param. 1 0 ±99999999 IS units

. - // -- // -- // -- // -- // -

770 5th transformation, param. 1 0 ±99999999 IS units

. - // -- // -- // -- // -- // -

780 6th transformation, param. 1 0 ±99999999 IS units

. - // -- // -- // -- // -- // -

790 7th transformation, param. 1 0 ±99999999 IS units

. - // -- // -- // -- // -- // -

800 8th transformation, param. 1 0 ±99999999 IS units

. - // -- // -- // -- // -- // -

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

1–7

1 NC/Drive Machine Data 09.95

1.1 General values

MD

No.

876 Leading axis No. 1 0 9 ---

877 Following axis No. 1 0 9 ---

878 Leading axis No. 2 0 9 ---

879 Following axis No. 2 0 9 ---

880 Leading axis No. 3 0 9

881 Following axis No. 3 0 9

882 Leading axis No. 4 0 9

883 Following axis No. 4 0 9

884 Leading axis No. 5 0 9

885 Following axis No. 5 0 9

886 Leading axis No. 6 0 9

887 Following axis No. 6 0 9

888 Leading axis No. 7 0 9

889 Following axis No. 7 0 9

D e s i g n a t i o n

Standard

value

Maximum

input value

Reference

system

--- ---

--- ---

--- ---

--- ---

--- ---

--- ---

--- ---

--- ---

--- ---

--- ---

Input

unit

---

---

---

---

890 Leading axis No. 8 0 9

891 Following axis No. 8 0 9

892 Leading axis No. 9 0 9

893 Following axis No. 9 0 9

894 Leading axis No. 10 0 9

895 Following axis No. 10 0 9

896 Leading axis No. 11 0 9

897 Following axis No. 11 0 9

898 Leading axis No. 12 0 9

899 Following axis No. 12 0 9

900

901

902

903

904

--- ---

--- ---

--- ---

--- ---

--- ---

--- ---

--- ---

--- ---

--- ---

--- ---

1–8

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

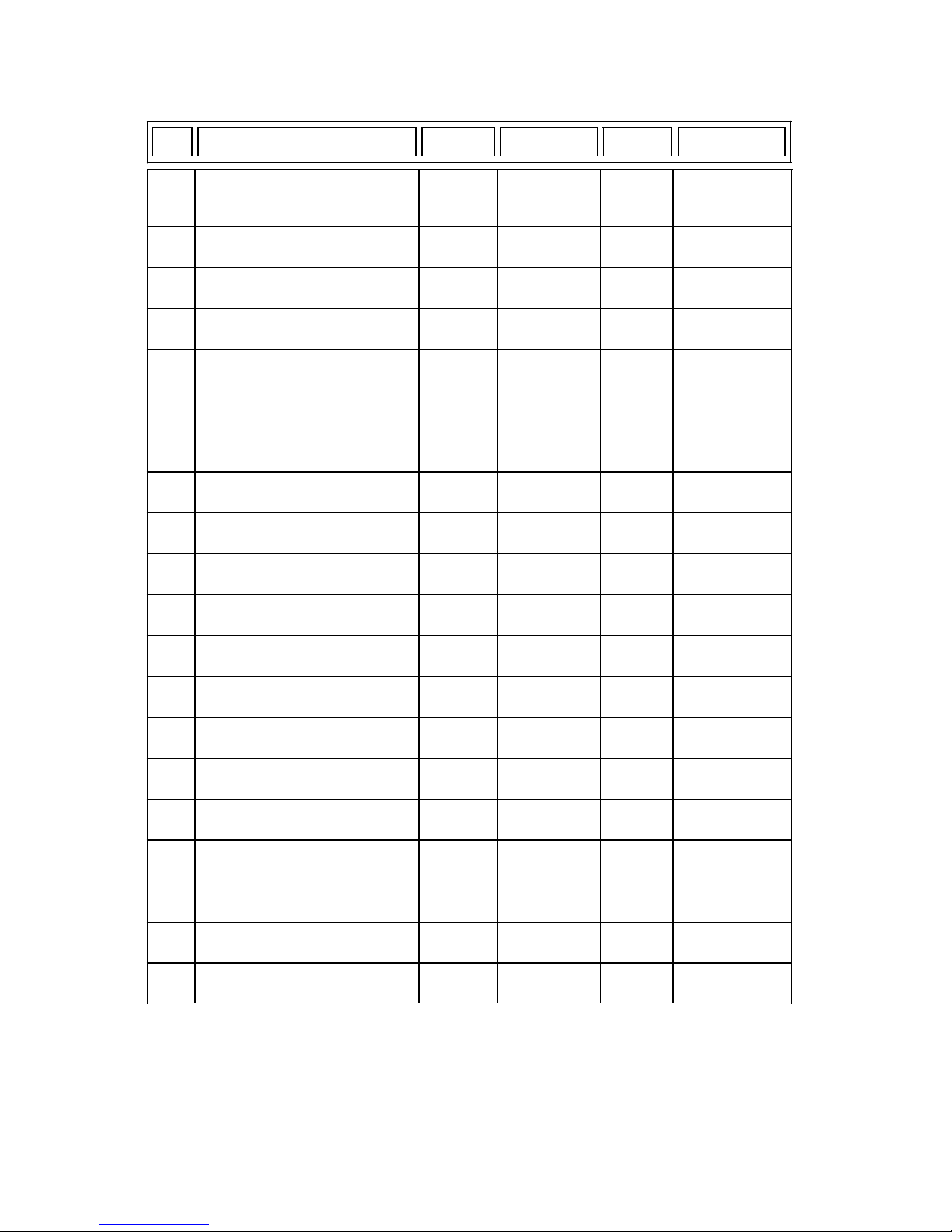

01.99 1 NC/Drive Machine Data

1.2 Channel-specific values (max. 4 channels) (as from SW 4: 6 channels)

1.2 Channel-specific values (max. 4 channels)

(as from SW 4: 6 channels)

MD

No.

D e s i g n a t i o n

100* Mode group 1 2

Standard

value

Maximum

input value

6

4)

Reference

system

-- --

102* Reserved

104* TO area for channel 1 4

6

106* No. of enabled program 0

4)

1)

-- --

-- --

108* Initial setting 1st G group 1 35 --

110* Initial setting 3rd G group M:17

19 -- --

T:18

112* Initial setting 6th G group 54 57 -- --

114* Initial setting 8th G group M:60

64 -- --

T:64

116* Initial setting 9th G group

118* Initial setting 12th G group M:94

0 0 -- --

97 -- --

T:95

120* Initial setting 15th G group 150 159 -- --

122* Initial setting 25th G group

3)

130* Device type for execution from

450 451 -- --

0 0. 5 -- --

external

132* Device number for execution

0 0 -- --

from external

134* Cycle number on

program start

136* Cycle number on

program end

140* Initial setting of

6th G group

142* Initial setting of tool offset

block

146* Corner deceleration speed

G620/G00

148* Corner deceleration

G62 w/o G36

150* Corner deceleration G62 with

G36

_______

1) % +9999

L - 9999

all %, L = 0

2) SW 3 and higher

3) SW 2 and higher

4) SW 4 and higher

4)

4)

2)

2)

4)

4)

4)

0 9 999 -- --

0 9 999 -- --

54 57 -- --

0 819 -- --

0 100 000 IS 1000 units/min

0 100 000 IS 1000 units/min

0 100 000 IS 1000 units/min

Input

unit

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60 1–9

SINUMERIK 840C (IA)

1 NC/Drive Machine Data 01.99

1.3 Axis-specific values (max. 30 axes, 15 real and 15 fictitious)

1.3 Axis-specific values (max. 30 axes, 15 real and 15 fictitious)*

MD

No.

D e s i g n a t i o n

200* 1st measuring system

connection

2000

Setpoint on digital drive 0 --

2)

1)

6)

Standard

value

0

0

0

Maximum

input value

05 03 00 00

15 02 10 15

30 02 10 30

Reference

system

Analog

Digital

Digital

2-3

2000

SPC/HMS setpoint output 0

4-5

2000

Drive/servo loop module No. 0

6-7

204* Exact stop limit coarse 40

208* Exact stop limit fine 10

212* Zero speed control 100

16000

99 999 999

16000

99 999 999

16000

99 999 999

5)

5)

5)

MS units

MS units

MS units

216* Reserved

220* Backlash compensation

0 +/- 16000 MS units

1st measuring system

224* 1st software limit switch plus 99 999999 +/- 99999999 MS units

228* 1st software limit switch minus - 99999999 +/- 99999999 MS units

232* 2nd software limit switch plus +99999999 +/- 99999999 MS units

236* 2nd software limit switch minus - 99999999 +/- 99999999 MS units

240* Reference point value 0 +/- 99999999 MS units

244* Reference point offset 0 +/- 99999999 MS units

252* Servo gain factor 1666 10000

6)

80 000

256* Scaling max. velocity 10000 99999999 --

0.01 s

mm/min,

inch/min,

deg/min

260* Scaling max. setpoint speed

8000 99999999 mV

2)

5)

264* Threshold for drive error

Max. set speed

268*

(IPO-STOP)

272* Drift compensation

1)

2)

1)

2)

5)

1)

2)

276* Acceleration 50

_______

1) Up to SW 2

2) SW 3 and higher

4) SW 4 and higher

5) SW 4.4 and higher

6) SW 5 and higher

*) SW 5: 30 real axes

10000

9000

9600

12000

20000

20000

15000

20000

8192

20000

20000

0

+/- 500 --

0

2)

16000

9999 9999

9900 0000

4)

5)

0.01 % of max.

setpoint

--

VELO

0.01 % of max.

motor speed

--

VELO

0.01 % of max.

motor speed

VELO

0.01 % of max.

motor speed

IS 10000 units/s

Input

unit

--

-1

2

1–10 © Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

09.95 1 NC/Drive Machine Data

1.3 Axis-specific values (max. 30 axes, 15 real and 15 fictitious)

MD

No.

D e s i g n a t i o n

Standard

value

Maximum

input value

Reference

system

Input

unit

280* Max. speed at G00 10000 99999999 IS 1000 units/min

284* Ref. point creep velocity 300 99999999 IS 1000 units/min

288* Jog velocity 2000 99999999 IS 1000 units/min

292* Jog rapid 5000 99999999 IS 1000 units/min

296* Ref. point approach velocity 10000 99999999 IS 1000 units/min

300* Incremental velocity 500 99999999 IS 1000 units/min

304* Interpolation parameter name

T:

M:

1, 2, 3

3040 = 1

3041 = 3

3042 = 0

3640 = 1

3041 = 2

3042 = 3

3

308* Cut-off frequency C encoder 200 16000 kHz

312* Feedforward factor 0 1000 0.1%

316* Reference pointer

0 249 -- MD offset

compensation plus

320* Reference pointer

compensation minus

324* Distance between 2 leadscrew

error compensation values

328* Compensation value with

leadscrew error compensation

0 249 -- MD offset

0 32000 MS units

0 100 MS units

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60 1–11

SINUMERIK 840C (IA)

1 NC/Drive Machine Data 01.99

1.3 Axis-specific values (max. 30 axes, 15 real and 15 fictitious)

MD

No.

D e s i g n a t i o n

332* Tolerance band contour

Standard

value

1000 99999999 MS units

Maximum

input value

Reference

system

Input

unit

monitoring

336* Threshold velocity contour 5 1000000 IS 1000 units/min

344* Module value rotary axis for

360000 + 92160000 MS units

leadscrew error compensation

356* IKA warning unit

1)

±99999999 MS units

360* Mode group 1 2

3)

6

364* u: Pulses var. increment

weighting

368* v: Traversing path var.

increment weighting

1 16000

99999999

2 16000

99999999

2)

-- --

MS --

2)

372* Delay zero speed control 200 1000 ms

376* Acceleration with controlled

0 99 999 999 IS 10 000 units/s

emergency retraction

(G425) (SW 6 and higher)

2

384* Setpoint output

3840

Setpoint on digital drive

2-3

3840

SPC/HMS setpoint output

1)

4)

3)

3)

0

0

0

0 12

05120000

15001000

30001000

ANALOG

DIGITAL

DIGITAL

4-5

3840

Drive/servo loop

6-7

module No.

388* Weighting factor for path

3)

0 30

0 99999999 -- --

conversion

392* Time constant symmetrizing

0 1000 0.1 ms

filter

396* Absolute offset 0 99999999 MS units

_______

1) SW 3 and higher

2) SW 2 and higher

3) SW 4 and higher

4) SW 5 and higher

--

1–12 © Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

08.96 1 NC/Drive Machine Data

1.4 Spindle-specific values (max. 6 spindles)

1.4 Spindle-specific values (max. 6 spindles)

MD

No.

D e s i g n a t i o n

400* Assignment spindle 0

4000

Setpoint on digital drive 0

Standard

value

05 03 00 00

0

15 02 10 15

0

30 02 10 30

Maximum

input value

2)

3)

4)

Reference

system

ANALOG

DIGITAL

DIGITAL

Input

2-3

4000

SPC/HMS setpoint output 0 12

4-5

4000

Drive/servo loop module No. 0 30

6-7

401* Drift compensation 0 +/- 500 -- VELO

0.01 % of max.

motor speed

402* -403* Max. speed for gear stage

500 99999 -- rev/min

--

-- --

1

404* - // - gear stage

1000 99999 -- rev/min

2

405* - // - gear stage

4000 99999 -- rev/min

3

406* - // - gear stage

4000 99999 -- rev/min

4

407* - // - gear stage

4000 99999 -- rev/min

5

408* - // - gear stage

4000 99999 -- rev/min

6

409* - // - gear stage

4000 99999 -- rev/min

7

410* - // - gear stage

4000 99999 -- rev/min

8

411* Min. speed for gear stage

50 99999 -- rev/min

1

412* - // - gear stage

500 99999 -- rev/min

2

413* - // - gear stage

1000 99999 -- rev/min

3

414* - // - gear stage

2000 99999 -- rev/min

4

415* - // - gear stage

2000 99999 -- rev/min

5

416* - // - gear stage

2000 99999 -- rev/min

6

_______

1) If MD 520* bit 3 = 1, input resolution 0.1 rev/min

2) Up to SW 2

3) SW 3 and higher

4) SW 5 and higher

unit

--

2)

3)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60 1–13

SINUMERIK 840C (IA)

1 NC/Drive Machine Data 08.96

1.4 Spindle-specific values (max. 6 spindles)

MD

No.

D e s i g n a t i o n

417* - // - gear stage

Standard

value

2000 99999 -- rev/min

Maximum

input value

Reference

system

Input

unit

7

418* - // - gear stage

2000 99999 -- rev/min

8

419* Acceleration time constant

800 50000 -- 1 ms

for gear stage 1

420* - // - gear stage 2 800 50000 -- 1 ms

421* - // - gear stage 3 800 50000 -- 1 ms

422* - // - gear stage 4 800 50000

--

1 ms

423* - // - gear stage 5 800 50000 -- 1 ms

424* - // - gear stage 6 800 50000 -- 1 ms

425* - // - gear stage 7 800 50000 -- 1 ms

426* - // - gear stage 8 800 50000 -- 1 ms

427* Creep speed M19,

gear stage 1

428* - // - gear stage 2 100 1500

429* - // - gear stage 3 100 1500

430* - // - gear stage 4 100 1500

431* - // - gear stage 5 100 1500

432* - // - gear stage 6 100 1500

433* - // - gear stage 7 100 1500

434* - // - gear stage 8 100 1500

100 1500

16 000

16 000

16 000

16 000

16 000

16 000

16 000

16 000

4)

-- rev/min

-- rev/min

4)

-- rev/min

4)

rev/min

4)

-- rev/min

4)

-- rev/min

4)

-- rev/min

4)

-- rev/min

4)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

_____

1) If MD 520* bit 3=1, input resolution is 0.1 rev/min

2) Up to SW 2

3) SW 3 and higher

4) SW 4 and higher

1–14 © Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

09.95 1 NC/Drive Machine Data

1.4 Spindle-specific values (max. 6 spindles)

MD

No.

D e s i g n a t i o n

435* Gain factor for M19

gear stage 1

436* - // - gear stage 2 1666 10000

437* - // - gear stage 3 1666 10000

438* - // - gear stage 4 1666 10000

439* - // - gear stage 5 1666 10000

440* - // - gear stage 6 1666 10000

441* - // - gear stage 7 1666 10000

442* - // - gear stage 8 1666 10000

Standard

value

Maximum

input value

1666 10000

80 000

80 000

80 000

80 000

80 000

80 000

80 000

80 000

5)

5)

5)

5)

5)

5)

5)

5)

Reference

system

-- 0.01 s

-- 0.01 s

-- 0.01 s

-- 0.01 s

-- 0.01 s

-- 0.01 s

-- 0.01 s

-- 0.01 s

Input

unit

443* Position limit for M19 2000 720000 MS units

444* Tolerance of spindle speed 10 100 -- %

-1

-1

-1

-1

-1

-1

-1

-1

445* Tolerance max. spindle speed 10 100 -- %

446* Tolerance zero speed 100 10 000

4)

-- 0.01 %

16000

447* Switch-off delay controller

1000 16000 -- ms

enable

448* Lowest set spindle speed 3 16000 -- rev/min

449* Desired speed 50 99999 -- rev/min

450* Set oscillation speed 2)

3)

50

50

1000

10000

-- 0.01 % of max.

motor speed

451* Max. spindle speed 4000 99999 -- rev/min

452* Spindle position with ext. M19 0 35999 -- 0.01 degree

453* Mode group 1 2

455* u: Pulses variable increment

weighting

_____

1) If MD 520* bit 3=1, input resolution is 0.1 rev/min

2) Up to SW 2

3) SW 3 and higher

4) SW 4 and higher

5) SW 5 and higher

32 65000

99999999

6

4)

3)

--

-- --

1)

1)

1)

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60 1–15

SINUMERIK 840C (IA)

1 NC/Drive Machine Data 08.96

1.4 Spindle-specific values (max. 6 spindles)

MD

No.

D e s i g n a t i o n

456* v: Traversing path variable

increment weighting

458* f: Pulse multiplication

EXE/611D/HMS

459* Zero mark offset 0 ±99999999

460* Setpoint output

4600

Setpoint on digital drive

2-3

4600

SPC/HMS setpoint output

4-5

4600

Drive/servo loop

6-7

module No.

2)

3)

4)

3)

3)

3)

Standard

value

5625 65000

Maximum

input value

99999999

0 128

3)

Reference

system

-- --

-- units (MS)

512

-- 0.01 degrees

4)

ANALOG

DIGITAL

DIGITAL

0

05 12 00 00

0

15 00 10 00

0

30 00 10 10

18 000

0 -- --

0 12 -- --

0 30

4)

-- --

Input

461* Assigned C axis 0 30 -- --

462* Cut-off frequency of spindle

200 16000 -- kHz

encoder

unit

--

--

465* Feedforward factor 0 1000 -- 0.1 %

466* Position controller clock

spindle

467* Time constant for feedforward

control

468* Normalization max. set

rev/min 3)

2)

1 64 --

0 9999

1000

10000

10000

4)

9000

32000

4)

32000

20000

Multiple of position

controller's basic

clock frequency

-- 0.1 ms

--

--

4)

mV, 0.01 % of

max. motor

speed

469* Factor for gain changeover 100 16000 -- %

478* Acceleration time constant with

2000 50000 -- 1 ms

position controller

Gear stage 1

479* - // - Gear stage 2 2000 50000 -- 1 ms

480* - // - Gear stage 3 2000 50000 -- 1 ms

481* - // - Gear stage 4 2000 50000 -- 1 ms

482* - // - Gear stage 5 2000 50000 -- 1 ms

483* - // - Gear stage 6 2000 50000 -- 1 ms

_______

1) If MD 520* bit 3=1, input resolution is 0.1 rev/min

2) Up to SW 2

3) SW 3 and higher

4) SW 5 and higher

1–16 © Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

04.96 1 NC/Drive Machine Data

1.4 Spindle-specific values (max. 6 spindles)

MD

No.

D e s i g n a t i o n

Standard

value

Maximum

input value

Reference

system

Input

unit

484* - // - Gear stage 7 2000 50000 -- 1 ms

485* - // - Gear stage 8 2000 50000 -- 1 ms

486* Time constant position setpoint

487* P component compensatory

488* I component compensatory

489* D component compensatory

490* Time constant parallel model

491* Tolerance band for synchonism

492* Tolerance band for synchonism

493* Emergency retraction

)

1

filter

controller

controller

controller

)

3

fine

)

coarse

3

threshold

)

3

)

3

)

3

3

)

3

)

55 16000 -- 0.1 ms

0 16000 -- 1

0 16000 -- 1

0 16000 -- 1

6000 16000 -- 0.01 ms

40 16000

99999999

100 16000

99999999

MS 1 units

5)

MS 1 units

5)

400 16000 MS 1 units

494* Warning threshold n

a

max

)

3

max

495* Delay-controlled follow-up

496* Default of link type

_______

1) SW 2 and higher

2) Up to SW 2

3) SW 3 and higher

4) SW 4 and higher

5) SW 5 and higher

and

90 100 -- %

)

3

3

16000 16000 -- 1

)

0 3

4

4)

--

--

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60 1–17

SINUMERIK 840C (IA)

1 NC/Drive Machine Data 09.01

1.5 General bits

1.5 General bits

Bit No.

MD No.

7 6 5 4 3 2 1 0

5000

5001

5002

5003

5004

No delay at

limit switch

Var. increm.

with DRF

(SW 6) Type B Type A

5005

5006

5007

5008

TO in

diameter

Path dimen.

from PLC

without

NC Stop

5009

5010

5011

5D tool length

compensation

@read /

load

5012

5013

5014

Circle

program-

ming

Tool radius

compensa-

tion (TRC)

5015

5016

5017

5018 2nd CP

Slave axis

sorting

Transform-

ation

machine data

change

without warm

restart

(SW 6.2, 5.8)

module

5019

5020

Input resolution

Working area

limitat.

effective with

JOG.

Mode group-specific

Keyswitch group

configurable

Axis/spindle

converter

(as from

SW2)

Do not

include

TO wear

REPOS in

jog mode

Tool offset

for gear cut.

tools

Act. value

display

Polar

coordinates

programming

Blueprint

program-

ming

5)

Transform.

mach. data

change with

active

transform.

permiss.

(SW 6.2, 5.8)

1st CP

module

Soft

approach

and retract

Interpolation

parameters

dependent on

single block

Mixed prog-

G90/G91 in

INC and

REF in jog

G91 pro-

gramming

(Reference

conditioning)

Path dim.

from PLC

G90/G91

ramming

block

mode

Diameter function for

Cycles

Scale

factor

Polar coordi-

nate angle

dependent on

G90/G91

Own rapid

override

ZO fine

ELG pro-

gramming

via input

display

TO type 0

like type 20

G90 progr.

+ TO wear

Feed not

related to

contour

Division

from PLC

Name of radius and chamfer

Name of angle

Internal WAIT

PRESEToffset

not deleted at

Power On

NC-Start

without ref.

point for

all axes

K e y s w i t c h e f f e c t i v e i n

ZO coarse R

parameters

Angle of rot.

K e y s w i t c h e f f e c t i v e w i t h

Part prog.

manual

input

TO basic

dimension

active

Command

chan. on mode

group disable

(from SW 5)

Auxil. function

output before

traversing

p o s i t i o n 1 - 2 - 3

TO wear

Dry run

feedrate

No output

of M17

mark synchro-

nization with

block search

(SW 5.6 and

higher)

handwheel available

geometry

DRF Overstore

G53 like

@706

Type 5D tool length compensation

TO geometry

(Type 1-9)

Do not delete

workpc. name

on PLC progr.

2)

selection

Extended

contour

definition prog.

Coupled

motion of

axes

Incr. dim.

(hand-

wheel), DRF

Writing of

machine data

disabled

by @

M and S add.

extens. for

spindle at PLC

File

tranfer

High

resolution

rotary axis

Emergency

retraction off

Zero offset TO wear

Sign change

handwheel 2

(from

SW 6.3)

Tapping

without

encoder

External

data input

Mem. expans.

to 819 tools

No NC Stop in

dwell block

G045/G14/G24

(SW 5.4 and

higher)

2nd 1st

TO

Tool length

comp. also in

non-program.

axes

CANCEL key

acts channel-

specific (as

from SW2)

Sign change

handwheel 1

(from

SW 6.3)

G63 without

delay

Thread and

revol. feedrate

G33/G95

3D inter-

polation

Mem. expans.

3)

to 409 tools

6)

3)

2) SW 3 and higher

3) Up to SW 2

4) SW 4 and higher

5) SW 4.4 and higher

6) SW 6 and higher

1–18

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

01.99 1 NC/Drive Machine Data

1.5 General bits

Bit No.

MD No.

5021

1)

5022

1)

5024

5025

5026

5027

5028

5029

5030

from

SW 6.3

5038

5039

5040

5041

5042

5043

5044

5051

5052

5053

5060

5061

5062

5063

5064

5065

5066

5067

5068

5069

7 6 5 4 3 2 1 0

NC-Ready

signal delay by

1 Ipo cycle

with PLC

failure or 5 V

undervoltage

(from SW 6.3)

Reload

workpiece at

POWER ON

(SW2+)

CSB input 7

signal from

UPS: power

failure

F62 pro-

gramming

(from SW 6.3)

Consid. SW

limit switch

Emergency

retract. (from

SW 6)

Endlessly

turning

rotary axis

CSB input 6

signal from

UPS: power

failure

Progr. predec.

with G171/172

(from SW 5)

Neutral pos.

of outputs f.

mode gr. 6

5 V under-

voltage

(from

SW 6.3)

"Alarm" axis

not in C axis

mode (from

SW 5)

CSB input 5

signal from

UPS: power

failure

Neutral pos.

of outputs f.

mode gr. 5

Retract when

PLC failure

(from

SW 6.3)

CSB input 4

signal from

UPS: power

failure

Neutral pos.

of outputs f.

mode gr. 4

Travel thru

transform.

centre

CSB input 3

signal from

UPS: power

failure

Bits for menu selection

Bits for menu selection

Bits for menu selection

Bits for menu selection

Bits for menu selection

2)

1)

1)

1)

1)

1)

Neutral pos.

of outputs f.

mode gr. 3

Extended

threading

package

2nd MCS

mirroring Z

3rd MCS

mirroring Z

4th MCS

mirroring Z

CSB input 2

signal from

UPS: power

failure

Neutral pos.

of outputs f.

mode gr. 2

Autom. bl. end

value synchr.

Axis-specific

G function to

3)

mirroring Y

3)

mirroring Y

3)

mirroring Y

CSB input 1

signal from

UPS: power

interpol. with

4 axes (SW 6)

axes for all

mode groups

(from SW 6)

Extended

stopping

G105/G119

PLC 1)

2nd MCS

3rd MCS

4th MCS

failure

Cylinder

Display of

Channel number of the transformation (1st transformation block)

G function for transformation selection (1st transformation block)

1st fictitious axis (1st transformation block)

2nd fictitious axis (1st transformation block)

3rd fictitious axis (1st transformation block)

1st real axis (1st transformation block)

2nd real axis (1st transformation block)

3rd real axis (1st transformation block)

4th real axis (1st transformation block)

5th real axis (1st transformation block)

Neutral pos.

of outputs f.

Emerg. OFF

contour vio-

3)

mirroring X

3)

mirroring X

3)

mirroring X

Dynamic SW

CSB input 0

UPS: power

Display PLC

setting data

No automat.

Channel-spec.

axis a. spindle

mode gr. 1

Stopping

also on

Abort on

lation CRC

2nd MCS

3rd MCS

4th MCS

limit switch

Following

3)

axes

signal from

failure

Declaration

of PLC (up

to SW 3)

config. (up

to SW 3)

Cycle

gen. of

2)

G68

2)

display

3)

3)

3)

1) SW 4 and higher

2) SW 5 and higher

3) SW 6 and higher

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

1–19

1 NC/Drive Machine Data 04.96

1.5 General bits

Bit No.

MD No.

5070

5071

5072

5073

5074

5075

5076

5077

5078

5079

7 6 5 4 3 2 1 0

Channel number of transformation (2nd transformation block)

G function for transformation selection (2nd transformation block)

1st fictitious axis (2nd transformation block)

2nd fictitious axis (2nd transformation block)

3rd fictitious axis (2nd transformation block)

1st real axis (2nd transformation block)

2nd real axis (2nd transformation block)

3rd real axis (2nd transformation block)

4th real axis (2nd transformation block)

5th real axis (2nd transformation block)

5080

5081

5082

5083

5084

5085

5086

5087

5088

Channel number of transformation (3rd transformation block)

G function for transformation selection (3rd transformation block)

1st fictitious axis (3rd transformation block

2nd fictitious axis (3rd transformation block)

3rd fictitious axis (3rd transformation block)

1st real axis (3rd transformation block)

2nd real axis (3rd transformation block)

3rd real axis (3rd transformation block)

4th real axis (3rd transformation block)

1–20

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

Loading...

Loading...