Siemens SINAMICS S120 Series Function Manual

___________________

___________________

___________________

___________________

SINAMICS

S120

Communication

Function Manual

Valid as of:

Firmware version 5.2

12/2018

6SL3097

Preface

Fundamental safety

instructions

1

General information

2

Communication according to

PROFIdrive

3

Communication via

PROFIBUS DP

4

Communication via

PROFINET IO

5

Communication via Modbus

TCP

6

Communication via

Ethernet/IP (EIP)

7

Communication via

SINAMICS Link

8

Appendix

A

-5BD00-0BP0

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: 6SL3097-5BD00-0BP0

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

11/2018 Subject to change

Preface

SINAMICS documentation

The SINAMICS documentation is organized in the following categories:

● General documentation/catalogs

● User documentation

● Manufacturer/service documentation

Additional information

You can find information on the topics below at the following address

(https://support.industry.siemens.com/cs/de/en/view/108993276):

● Ordering documentation/overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals/information)

Please send any questions about the technical documentation (e.g. suggestions for

improvement, corrections) to the following email address

(mailto:docu.motioncontrol@siemens.com).

Siemens MySupport/Documentation

At the following address (https://support.industry.siemens.com/My/ww/en/documentation),

you can find information on how to create your own individual documentation based on

Siemens' content, and adapt it for your own machine documentation.

Training

At the following address (http://www.siemens.com/sitrain), you can find information about

SITRAIN (Siemens training on products, systems and solutions for automation and drives).

FAQs

You can find Frequently Asked Questions in the Service&Support pages at Product Support

(https://support.industry.siemens.com/cs/de/en/ps/faq).

SINAMICS

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

You can find information about SINAMICS at the following address

(http://www.siemens.com/sinamics).

3

Preface

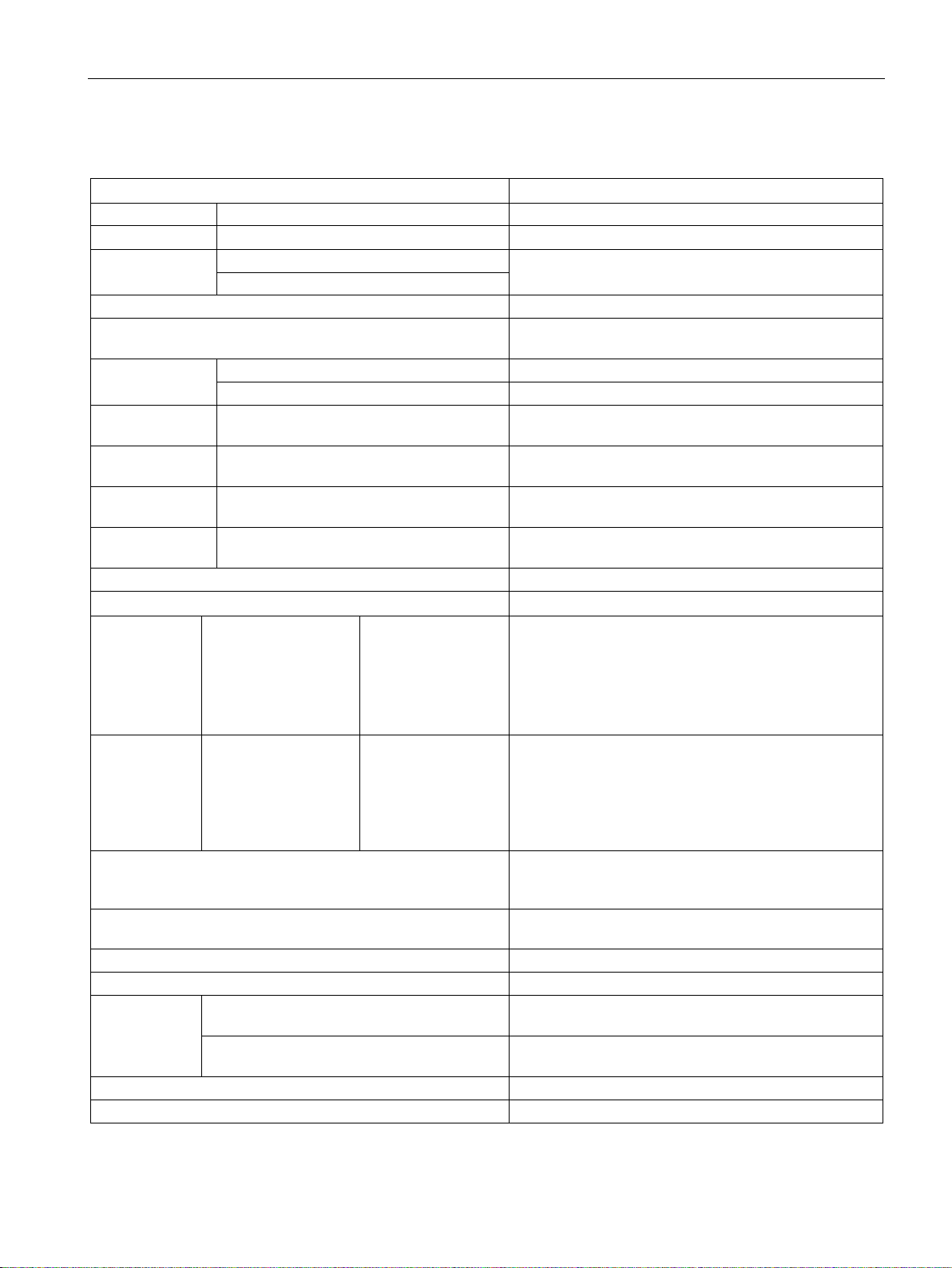

Usage phase

Document/tool

Orientation

SINAMICS S Sales Documentation

Usage phases and their documents/tools (as an example)

Planning/configuration

Deciding/ordering SINAMICS S120 catalogs

Installation/assembly

Commissioning

Usage/operation

Maintenance/servicing

References

• SIZER Engineering Tool

• Configuration Manuals, Motors

• SINAMICS S120 and SIMOTICS (Catalog D 21.4)

• SINAMICS Converters for Single-Axis Drives and SIMOTICS Motors (Cata-

log D 31)

• SINAMICS Converters for Single-Axis Drives – Built-In Units (D 31.1)

• SINAMICS Converters for Single-Axis Drives – Distributed Converters (D 31.2)

• SINUMERIK 840 Equipment for Machine Tools (Catalog NC 62)

• SINAMICS S120 Equipment Manual for Control Units and Additional System

Components

• SINAMICS S120 Equipment Manual for Booksize Power Units

• SINAMICS S120 Equipment Manual for Booksize Power Units C/D Type

• SINAMICS S120 Equipment Manual for Chassis Power Units

• SINAMICS S120 Equipment Manual for Chassis Power Units, Liquid-cooled

• SINAMICS S120 Equipment Manual water-cooled chassis power units for com-

mon cooling circuits

• SINAMICS S120 Equipment Manual for Chassis Power Units, Air-cooled

• SINAMICS S120 Equipment Manual for AC Drives

• SINAMICS S120 Equipment Manual Combi

• SINAMICS S120M Equipment Manual Distributed Drive Technology

• SINAMICS HLA System Manual Hydraulic Drives

• Startdrive Commissioning Tool

• SINAMICS S120 Getting Started

• SINAMICS S120 Commissioning Manual

• SINAMICS S120 Function Manual Drive Functions

• SINAMICS S120 Safety Integrated Function Manual

• SINAMICS S120 Function Manual Communication

• SINAMICS S120/S150 List Manual

• SINAMICS HLA System Manual Hydraulic Drives

• SINAMICS S120 Commissioning Manual

• SINAMICS S120/S150 List Manual

• SINAMICS HLA System Manual Hydraulic Drives

• SINAMICS S120 Commissioning Manual

• SINAMICS S120/S150 List Manual

• SINAMICS S120/S150 List Manual

Communication

4 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

Preface

Software

Manual

Alarms

Described in order of ascending numbers

SINAMICS S120/S150 List Manual

Sorted according to topic

Described in order of ascending numbers

Drive functions

SINAMICS S120 Function Manual Drive Functions

firmware V5.2)

Basic and Extended Functions

SINAMICS S120 Safety Integrated Function Manual

Basic Functions

SINAMICS S120 Function Manual Drive Functions

STARTER

SINAMICS S120 Commissioning Manual (up to firmware

V5.1 SP1)

Startdrive

V5.2)

Web server

SINAMICS S120 Function Manual Drive Functions

Hardware

Manual

Units, Air-cooled or Liquid-cooled

AC drive components

SINAMICS S120 Equipment Manual for AC Drives

S120 Combi components

SINAMICS S120 Equipment Manual Combi

V5.1 SP1)

V5.2)

Meaning of the LEDs

Equipment Manuals

High Frequency Drive components

SINAMICS S120 System Manual High Frequency Drives

Where can the various topics be found?

Parameters Described in order of ascending numbers SINAMICS S120/S150 List Manual

Function block

diagrams

Communication topics SINAMICS S120 Function Manual Communication (from

Safety Integrated

SINAMICS S120/S150 List Manual

Commissioning Of a simple SINAMICS S120 drive with

Commissioning With STARTER

Commissioning Of a simple SINAMICS S120 drive with

Commissioning With Startdrive SINAMICS S120 Commissioning Manual (from firmware

Control Units And expansion com-

ponents:

• Control Units

• Option Boards

• Terminal Modules

Power units

booksize

Power units, booksize C/D type format SINAMICS S120 Equipment Manual for Booksize Power

Chassis power units SINAMICS S120 Equipment Manual for Chassis Power

• Line connection

• Line Modules

• Motor Modules

• HUB Modules

• VSM10

• Encoder system

connection

• DC link compo-

nents

• Braking resistors

• Control cabinet

design

Getting Started (up to Firmware V5.1 SP1)

Getting Started (from Firmware V5.2)

SINAMICS S120 Equipment Manual for Control Units

and Additional System Components

SINAMICS S120 Equipment Manual for Booksize

Power Units

Units

C/D Type

Diagnostics via

LEDs

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

STARTER SINAMICS S120 Commissioning Manual (up to firmware

Startdrive SINAMICS S120 Commissioning Manual (from firmware

5

Preface

Target group

This documentation is intended for machine manufacturers, commissioning engineers, and

service personnel who use the SINAMICS drive system.

Benefits

This manual provides all of the information, procedures and operator actions required for the

particular usage phase.

Standard scope

The scope of the functionality described in this document can differ from that of the drive

system that is actually supplied.

● Other functions not described in this documentation might be able to be executed in the

drive system. However, no claim can be made regarding the availability of these functions

when the equipment is first supplied or in the event of service.

● The documentation can also contain descriptions of functions that are not available in a

particular product version of the drive system. Please refer to the ordering documentation

only for the functionality of the supplied drive system.

● Extensions or changes made by the machine manufacturer must be documented by the

machine manufacturer.

For reasons of clarity, this documentation does not contain all of the detailed information on

all of the product types, and cannot take into consideration every conceivable type of

installation, operation and service/maintenance.

Technical Support

Country-specific telephone numbers for technical support are provided in the Internet at the

following address (https://support.industry.siemens.com/sc/ww/en/sc/2090) in the "Contact"

area.

Information about CANopen

Information about communication via CANopen is provided in the following Manual:

● SINAMICS S120 Commissioning Manual CANopen Interface

Compliance with the General Data Protection Regulation

Siemens respects the principles of data protection, in particular the data minimization rules

(privacy by design).

For this product, this means:

The product does not process neither store any person-related data, only technical function

data (e.g. time stamps). If the user links these data with other data (e.g. shift plans) or if he

stores person-related data on the same data medium (e.g. hard disk), thus personalizing

these data, he has to ensure compliance with the applicable data protection stipulations.

Communication

6 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

Preface

•

Fault 12345

•

Alarm 67890

•

Safety message

•

Adjustable parameter 918

•

Display parameter 1024

•

Adjustable parameter 1

•

Adjustable parameter 2098, index 1 bit 3

•

Adjustable parameter 99, indices 0 to 3

•

Display parameter 945, index 2 of drive object 3

•

Adjustable parameter 795, bit 4

Notation

The following notation and abbreviations are used in this documentation:

Notation for faults and alarms (examples):

F12345

A67890

C23456

Notation for parameters (examples):

p0918

r1024

p1070[1]

p2098[1].3

p0099[0...3]

r0945[2](3)

p0795.4

070, index 1

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

7

Preface

Communication

8 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

Table of contents

Preface ................................................................................................................................................... 3

1 Fundamental safety instructions ............................................................................................................ 13

1.1 General safety instructions ..................................................................................................... 13

1.2 Warranty and liability for application examples ...................................................................... 13

1.3 Industrial security .................................................................................................................... 14

2 General information .............................................................................................................................. 17

2.1 Field of application .................................................................................................................. 17

2.2 Platform Concept and Totally Integrated Automation ............................................................. 18

2.3 System overview ..................................................................................................................... 20

2.4 X127 LAN (Ethernet)............................................................................................................... 22

2.5 Communication services and used port numbers .................................................................. 23

2.6 Time synchronization between the control and converter ...................................................... 26

2.6.1 Setting SINAMICS time synchronization ................................................................................ 28

2.6.2 Set NTP time synchronization ................................................................................................ 29

2.6.3 Messages and parameters ..................................................................................................... 30

3 Communication according to PROFIdrive .............................................................................................. 31

3.1 PROFIdrive application classes .............................................................................................. 34

3.2 Cyclic communication ............................................................................................................. 37

3.2.1 Telegrams and process data .................................................................................................. 37

3.2.2 Information about control words and status words ................................................................. 41

3.2.3 Examples ................................................................................................................................ 42

3.2.4 Motion control with PROFIdrive .............................................................................................. 45

3.3 Parallel operation of communication interfaces ...................................................................... 48

3.4 Acyclic communication............................................................................................................ 51

3.4.1 General information about acyclic communication ................................................................. 51

3.4.2 Structure of requests and responses ...................................................................................... 53

3.4.3 Determining the drive object numbers .................................................................................... 59

3.4.4 Example 1: read parameters .................................................................................................. 60

3.4.5 Example 2: Writing parameters (multi-parameter request)..................................................... 62

3.5 Diagnostics channels .............................................................................................................. 66

3.5.1 PROFINET-based diagnostics ................................................................................................ 67

3.5.2 PROFIBUS-based diagnostics ............................................................................................... 70

3.5.2.1 Standard diagnostics .............................................................................................................. 71

3.5.2.2 Identifier-related diagnostics ................................................................................................... 71

3.5.2.3 Status messages/module status ............................................................................................. 72

3.5.2.4 Channel-related diagnostics ................................................................................................... 73

3.5.2.5 Data sets DS0/DS1 and diagnostics alarm............................................................................. 74

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

9

Table of contents

3.6 Configuring telegrams in Startdrive........................................................................................ 75

3.6.1 Displaying telegram configuration .......................................................................................... 75

3.6.2 Settings for SINAMICS S120, S150, G150, G130, MV ......................................................... 76

4 Communication via PROFIBUS DP ....................................................................................................... 79

4.1 General information about PROFIBUS .................................................................................. 79

4.1.1 General information about PROFIBUS for SINAMICS .......................................................... 79

4.1.2 Example: telegram structure for cyclic data transmission ..................................................... 82

4.2 Commissioning PROFIBUS ................................................................................................... 85

4.2.1 Setting the PROFIBUS interface ............................................................................................ 85

4.2.2 PROFIBUS interface in operation .......................................................................................... 88

4.2.3 Commissioning PROFIBUS ................................................................................................... 89

4.2.4 Diagnostics options ................................................................................................................ 90

4.2.5 SIMATIC HMI addressing ...................................................................................................... 90

4.2.6 Monitoring telegram failure .................................................................................................... 92

4.3 Motion Control with PROFIBUS ............................................................................................. 94

4.4 Slave-to-slave communication ............................................................................................... 98

4.4.1 Setpoint assignment in the subscriber ................................................................................. 100

4.4.2 Activating/parameterizing slave-to-slave communication .................................................... 100

4.4.3 Commissioning PROFIBUS slave-to-slave communication ................................................ 102

4.4.4 Diagnosing PROFIBUS slave-to-slave communication ....................................................... 108

4.5 Messages via diagnostics channels..................................................................................... 108

5 Communication via PROFINET IO ....................................................................................................... 111

5.1 General information about PROFINET IO ........................................................................... 111

5.1.1 Real-time (RT) and isochronous real-time (IRT) communication ........................................ 113

5.1.2 Addresses ............................................................................................................................ 114

5.1.3 Dynamic IP address assignment ......................................................................................... 116

5.1.4 DCP flashing ........................................................................................................................ 118

5.1.5 Data transfer ........................................................................................................................ 118

5.1.6 Communication channels for PROFINET ............................................................................ 120

5.1.7 References ........................................................................................................................... 121

5.1.8 Overview of important parameters ....................................................................................... 122

5.2 RT classes for PROFINET IO .............................................................................................. 124

5.3 PROFINET GSDML ............................................................................................................. 129

5.4 Motion Control with PROFINET ........................................................................................... 131

5.5 Communication with CBE20 ................................................................................................ 135

5.6 Communication via PROFINET Gate .................................................................................. 136

5.6.1 Functions supported by PN Gate ......................................................................................... 137

5.6.2 Preconditions for PN Gate ................................................................................................... 138

5.7 PROFINET with 2 controllers ............................................................................................... 139

5.7.1 Control Unit settings ............................................................................................................. 139

5.7.2 Configuring Shared Device .................................................................................................. 141

5.7.3 Overview of important parameters ....................................................................................... 150

5.8 PROFINET media redundancy ............................................................................................ 151

5.9 PROFINET system redundancy ........................................................................................... 152

Communication

10 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

Table of contents

5.9.1 Overview ............................................................................................................................... 152

5.9.2 Design, configuring and diagnostics ..................................................................................... 153

5.9.3 Messages and parameters ................................................................................................... 154

5.10 PROFIenergy ........................................................................................................................ 155

5.10.1 Tasks of PROFIenergy ......................................................................................................... 157

5.10.2 PROFIenergy commands ..................................................................................................... 158

5.10.3 PROFIenergy measured values ........................................................................................... 159

5.10.4 PROFIenergy energy-saving mode ...................................................................................... 160

5.10.5 PROFIenergy inhibit and pause time .................................................................................... 160

5.10.6 Function diagrams and parameters ...................................................................................... 161

5.11 Messages via diagnostics channels ..................................................................................... 161

5.12 Support of I&M data sets 1...4 .............................................................................................. 163

6 Communication via Modbus TCP ........................................................................................................ 165

6.1 Overview ............................................................................................................................... 165

6.2 Configuring Modbus TCP via interface X150 ....................................................................... 167

6.3 Configuring Modbus TCP via interface X1400 ..................................................................... 168

6.4 Mapping tables ...................................................................................................................... 169

6.5 Write and read access using function codes ........................................................................ 172

6.6 Communication via data set 47 ............................................................................................ 175

6.6.1 Communication details.......................................................................................................... 176

6.6.2 Examples: Read parameter .................................................................................................. 176

6.6.3 Examples: Write parameter .................................................................................................. 178

6.7 Communication procedure .................................................................................................... 180

6.8 Messages and parameters ................................................................................................... 181

7 Communication via Ethernet/IP (EIP) .................................................................................................. 183

7.1 Overview ............................................................................................................................... 183

7.2 Connecting the drive device to EIP ....................................................................................... 184

7.3 Requirements for communication ......................................................................................... 185

7.4 Configuring EIP via the onboard PROFINET X150 interface ............................................... 186

7.5 Configuring EIP via the X1400 interface at the CBE20 ........................................................ 187

7.6 Supported objects ................................................................................................................. 188

7.7 Integrating the drive device into the EIP network via DHCP ................................................ 200

7.8 Messages and parameters ................................................................................................... 201

8 Communication via SINAMICS Link .................................................................................................... 203

8.1 Basic principles of SINAMICS Link ....................................................................................... 203

8.2 Topology ............................................................................................................................... 205

8.3 Configuring and commissioning ............................................................................................ 207

8.4 Example ................................................................................................................................ 211

8.5 Communication failure when booting or in cyclic operation.................................................. 214

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

11

Table of contents

8.6 Examples: Transmission times for SINAMICS Link ............................................................. 214

8.7 Function diagrams and parameters ..................................................................................... 215

A Appendix ............................................................................................................................................. 217

A.1 List of abbreviations ............................................................................................................. 217

A.2 Documentation overview ...................................................................................................... 227

Index ................................................................................................................................................... 229

Communication

12 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

1

WARNING

Danger to life if the safety instructions and residual risks are not observed

WARNING

Malfunctions of the machine as a result of incorrect or changed parameter settings

1.1 General safety instructions

If the safety instructions and residual risks in the associated hardware documentation are

not observed, accidents involving severe injuries or death can occur.

• Observe the safety instructions given in the hardware documentation.

• Consider the residual risks for the risk evaluation.

As a result of incorrect or changed parameterization, machines can malfunction, which in

turn can lead to injuries or death.

• Protect the parameterization (parameter assignments) against unauthorized access.

• Handle possible malfunctions by taking suitable measures, e.g. emergency stop or

emergency off.

1.2 Warranty and liability for application examples

Application examples are not binding and do not claim to be complete regarding

configuration, equipment or any eventuality which may arise. Application examples do not

represent specific customer solutions, but are only intended to provide support for typical

tasks.

As the user you yourself are responsible for ensuring that the products described are

operated correctly. Application examples do not relieve you of your responsibility for safe

handling when using, installing, operating and maintaining the equipment.

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

13

Fundamental safety instructions

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and net

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement

security concept. Siemens’ products and solutions constitute one ele

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the Internet if and to the exte

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit:

Industrial security

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customer’s exposure

to cyber threats.

To stay informed about product upd

Feed at:

Industrial security (

1.3 Industrial security

1.3 Industrial security

works.

– and continuously maintain – a holistic, state-of-the-art industrial

ment of such a concept.

nt such a connection is

(http://www.siemens.com/industrialsecurity)

ates, subscribe to the Siemens Industrial Security RSS

http://www.siemens.com/industrialsecurity)

Further information is provided on the Internet:

Industrial Security Configuration Manual

(https://support.industry.siemens.com/cs/ww/en/view/108862708)

Communication

14 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

Fundamental safety instructions

WARNING

Unsafe operating states resulting from software manipulation

1.3 Industrial security

Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe

operating states in your system that may lead to death, serious injury, and property

damage.

• Keep the software up to date.

• Incorporate the automation and drive components into a holistic, state-of-the-art

industrial security concept for the installation or machine.

• Make sure that you include all installed products into the holistic industrial security

concept.

• Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

• Protect the drive against unauthorized changes by activating the "know-how protection"

drive function.

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

15

Fundamental safety instructions

1.3 Industrial security

Communication

16 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

2

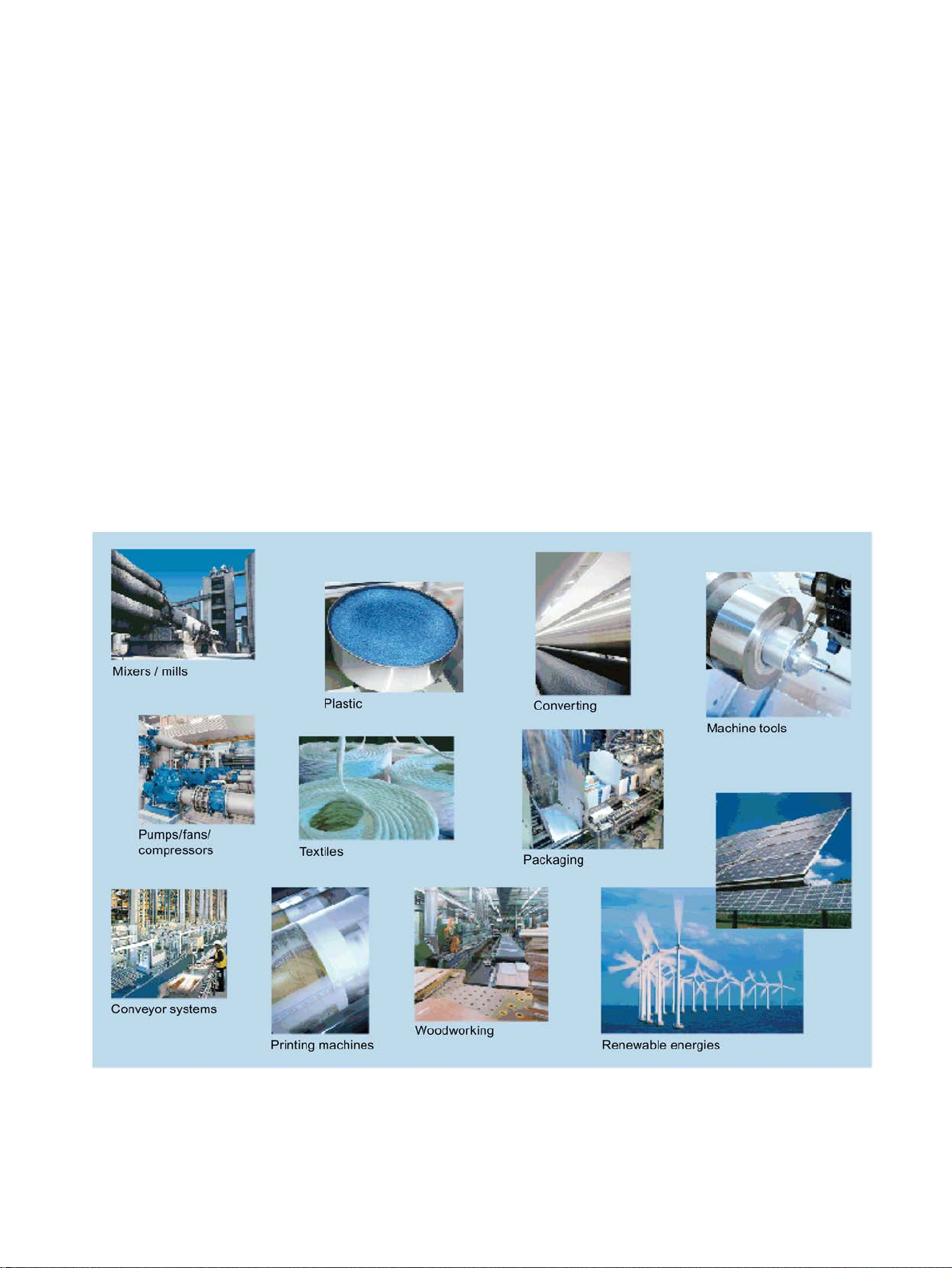

2.1 Field of application

SINAMICS is the family of drives from Siemens designed for machine and plant engineering

applications. SINAMICS offers solutions for all drive tasks:

● Simple pump and fan applications in the process industry

● Complex single drives in centrifuges, presses, extruders, elevators, as well as conveyor

and transport systems

● Drive line-ups in textile, plastic film, and paper machines as well as in rolling mill plants

● High-precision servo drives in the manufacture of wind turbines

● Highly dynamic servo drives for machine tools, as well as packaging and printing

machines

Figure 2-1 SINAMICS applications

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

17

General information

2.2 Platform Concept and Totally Integrated Automation

Depending on the application, the SINAMICS range offers the ideal variant for any drive

task.

● SINAMICS S handles complex drive tasks with synchronous motors and induction motors

and fulfills stringent requirements regarding:

– the dynamic performance and accuracy

– the integration of extensive technological functions in the drive control system

● SINAMICS G is designed for standard applications with induction motors. These

applications have less stringent requirements regarding the dynamic performance of the

motor speed.

● SINAMICS V is designed to address applications where basic drive functions are

available quickly and at a favorable cost - and which are easy to handle.

2.2 Platform Concept and Totally Integrated Automation

All SINAMICS versions are based on a platform concept. Joint hardware and software

components, as well as standardized tools for design, configuration, and commissioning

tasks ensure high-level integration across all components. SINAMICS handles a wide variety

of drive tasks with no system gaps. The different SINAMICS versions can be easily

combined with each other.

Totally Integrated Automation (TIA) with SINAMICS S120

Apart from SIMATIC, SIMOTION and SINUMERIK, SINAMICS is one of the core

components of TIA. It is thus possible to parameterize, program and commission all

components in the automation system via the Startdrive commissioning tool using a

standardized engineering platform and without any system transitions (seamless

engineering). The system-wide data management functions ensure consistent data and

simplify archiving of the entire plant project.

From V14, the Startdrive commissioning tool is an integral element of the TIA platform.

SINAMICS S120 supports communication via PROFINET and PROFIBUS DP.

Communication via PROFINET

This Ethernet-based bus enables control data to be exchanged at high speed via

PROFINET IO with IRT or RT and makes SINAMICS S120 a suitable choice for integration

in high-performance multi-axis applications. At the same time, PROFINET also uses

standard IT mechanisms (TCP/IP) to transport information, e.g. operating and diagnostic

data, to higher-level systems. This makes it easy to integrate into an IT corporate network.

Communication via PROFIBUS DP

This bus provides a high-performance, system-wide and integrated communication network

which links all automation components of the automation solution:

● HMI (operator control and monitoring)

● Control

● Drives and I/O

Communication

18 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

General information

2.2 Platform Concept and Totally Integrated Automation

Figure 2-2 SINAMICS as part of the Siemens modular automation system

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

19

General information

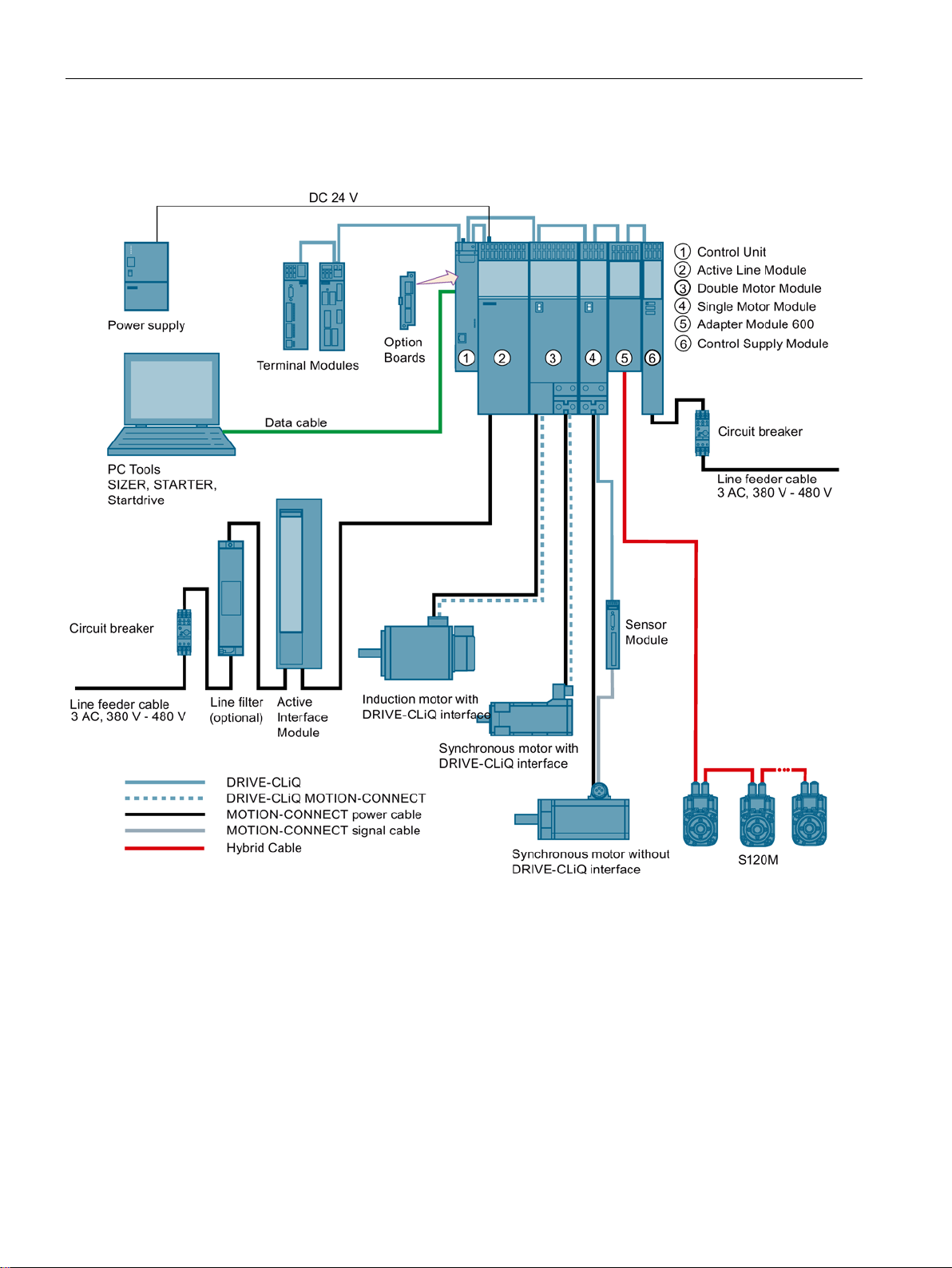

2.3 System overview

2.3 System overview

Figure 2-3 System overview, SINAMICS S120 with distributed servo drive technology S120M

Modular system for sophisticated drive tasks

SINAMICS S120 solves complex drive tasks for a wide range of industrial applications and

is, therefore, designed as a modular system. You can choose from many different

harmonized components and functions to create a solution that best meets your

requirements. SIZER, a high-performance engineering tool, makes it easier to select and

determine the optimum drive configuration.

Communication

20 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

General information

2.3 System overview

SINAMICS S120 is supplemented by a wide range of motors. SINAMICS S120 optimally

supports:

● SINAMICS S120M

● Synchronous and induction motors

● Linear and torque motors

System architecture with a central Control Unit

On the SINAMICS S120, the drive intelligence is combined with closed-loop control functions

into Control Units. These units are capable of controlling drives in the vector, servo and V/f

control modes. They also perform the speed and torque control functions plus other

intelligent drive functions for all axes on the drive. Cross-axis couplings can be established

within a component and easily configured in the Startdrive commissioning tool using a

mouse.

Functions for higher efficiency

● Basic functions: Speed control, torque control, positioning functions

● Intelligent starting functions for independent restart after power supply interruption

● BICO technology with interconnection of drive-related I/Os for easy adaptation of the

drive system to its operating environment

● Integrated safety functions for rational implementation of safety concepts

● Regulated infeed/regenerative feedback functions for preventing undesirable reactions on

the supply, allowing recovery of braking energy and ensuring greater stability against line

fluctuations.

DRIVE-CLiQ – the digital interface between SINAMICS components

Most of the SINAMICS S120 components, including the motors and encoders, are

connected to each other via the common DRIVE-CLiQ serial interface. The standardized

cables and connectors reduce the variety of different parts and cut storage costs. Encoder

evaluations for converting standard encoder signals to DRIVE-CLiQ are available for thirdparty motors or retrofit applications.

Electronic rating plates in all components

An important digital linkage element of the SINAMICS S120 drive system are the electronic

type plates integrated in every component. They allow all drive components to be detected

automatically via a DRIVE-CLiQ link. As a result, data does not have to be entered manually

during commissioning or component replacement – helping to ensure that drives are

commissioned more reliably.

The rating plate contains all the relevant technical data about that particular component. For

motors, these are the parameters of the electrical equivalent circuit diagram and key values

of the integrated motor encoder, for example.

In addition to the technical data, the type plate includes logistical data (manufacturer ID,

article number and ID). Since this data can be called up electronically on site or remotely, all

the components used in a machine can always be individually identified, which helps simplify

servicing.

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

21

General information

Note

Use

Ethernet interface X127 is intended for commissioning and diagnostics, which means that it

must always be accessible (e.g. for service).

Further, the following restrictions apply to

•

•

2.4 X127 LAN (Ethernet)

2.4 X127 LAN (Ethernet)

X127:

Only local access is possible

No networking - or only local networking in a closed and locked electrical cabinet

permissible

If it is necessary to remotely access the electrical cabinet, then additional security measures

must be applied so that misuse through sabotage, unqualified data manipulation and

intercepting confidential data is completely ruled out (also see "Industrial security

(Page 14)").

Communication

22 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

General information

Protocol

Port number

(2) Link layer

(4) Transport layer

Function

Description

PROFINET protocols

Unique Identifier

01-80-C2-00-00-0E

Identifier

2.5 Communication services and used port numbers

2.5 Communication services and used port numbers

SINAMICS converters support the communication protocols listed in the following table. The

address parameters, the relevant communication layer, as well as the communication role

and the communication direction are decisive for each protocol. You require this information

to match the security measures for the protection of the automation system to the used

protocols (e.g. firewall). The security measures are restricted to Ethernet and PROFINET

networks.

The following table shows the various layers and protocols that are used.

Layers and protocols

DCP

Discovery and Con-

figuration Protocol

LLDP

Link Layer Discovery

Protocol

MRP

Media Redundancy

Protocol

Not relevant (2) Ethernet II and

IEEE 802.1Q and

Ethertype 0x8892

(PROFINET)

Not relevant (2) Ethernet II and

IEEE 802.1Q and

Ethertype 0x88CC

(PROFINET)

Not relevant (2) Ethernet II and

IEEE 802.1Q and

Ethertype 0x88E3

(PROFINET)

Accessible nodes,

PROFINET Dis-

covery and configuration

PROFINET Link

Layer Discovery

protocol

PROFINET medium redundancy

DCP is used by PROFINET to

determine PROFINET devices

and to make basic settings.

DCP uses the special multicast MAC address:

xx-xx-xx-01-0E-CF,

xx-xx-xx = Organizationally

LLDP is used by PROFINET

to determine and manage

neighborhood relationships

between PROFINET devices.

LLDP uses the special multicast MAC address:

MRP enables the control of

redundant routes through a

ring topology.

MRP uses the special multicast MAC address:

xx-xx-xx-01-15-4E,

xx-xx-xx = Organizationally

Unique

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

23

General information

Protocol

Port number

(2) Link layer

(4) Transport layer

Function

Description

Unique Identifier

IO devices via Ethernet.

Connection-oriented communication protocols

ter p8908.

DHCP mode.

and can be deactivated.

and is always required.

2.5 Communication services and used port numbers

PTCP

Precision Transpar-

ent Clock Protocol

PROFINET IO data Not relevant (2) Ethernet II and

PROFINET Context

Manager

FTP

File Transfer Protocol

Not relevant (2) Ethernet II and

IEEE 802.1Q and

Ethertype 0x8892

(PROFINET)

IEEE 802.1Q and

Ethertype 0x8892

(PROFINET)

34964 (4) UDP PROFINET con-

21 (4) TCP Server/

PROFINET

send clock and

time synchronisation, based on

IEEE 1588

PROFINET Cyclic

IO data transfer

nection less RPC

incoming

PTC enables a time delay

measurement

between RJ45 ports and

therefore the send cycle synchronization and time synchronization.

PTCP uses the special multicast MAC address:

xx-xx-xx-01-0E-CF,

xx-xx-xx = Organizationally

The PROFINET IO telegrams

are used to cyclically transfer

IO data between the

PROFINET IO controller and

The PROFINET context manager provides an endpoint

mapper in order to establish

an application relationship

(PROFINET AR).

FTP can be used for the first

commissioning.

FTP can be activated/deactivated using parame-

DHCP

Dynamic Host Con-

figuration Protocol

http

Hypertext Transfer

Protocol

ISO on TCP

(according to

RFC 1006)

Communication

68 (4) UDP Dynamic Host

80 (4) TCP Hypertext transfer

102 (4) TCP ISO-on-TCP proto-

24 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

Configuration Protocol

protocol

col

Is used to query an IP address.

Is closed when delivered, and

is opened when selecting the

http is used for the communication with the CU-internal

web server.

Is open in the delivery state

ISO on TCP (according to

RFC 1006) is used for the

message-oriented data exchange to a remote CPU,

WinAC, or devices of other

suppliers.

Communication with ES, HMI,

etc.

Is open in the delivery state

General information

Protocol

Port number

(2) Link layer

(4) Transport layer

Function

Description

SNMP enables the reading out

and is always required.

and can be deactivated.

project data.

not specify the local port.

EtherNet/IP protocols

EtherNet/IP.

EtherNet/IP.

Modbus TCP protocols (server)

Modbus TCP.

2.5 Communication services and used port numbers

SNMP

Simple Network

Management Protocol

https

Secure Hypertext

Transfer Protocol

Internal

protocol

Reserved 49152...65535 (4) TCP

Explicit messaging 44818 (4) TCP

161 (4) UDP Simple network

443 (4) TCP Secure Hypertext

5188 (4) TCP Server/

(4) UDP

(4) UDP

management protocol

transfer protocol

incoming

- Dynamic port area that is used

- Is used for parameter access,

and setting of network management data (SNMP managed Objects) by the SNMP

manager.

Is open in the delivery state

https is used for the communication with the CU-internal

web server via Transport Layer Security(TLS).

Is open in the delivery state

Communication with commissioning tools for downloading

for the active connection endpoint if the application does

etc.

Is closed when delivered, and

is opened when selecting

Implicit messaging 2222 (4) UDP - Is used for exchanging I/O

Request & Response 502 (4) TCP - Is used for exchanging data

data.

Is closed when delivered, and

is opened when selecting

packages.

Is closed when delivered, and

is opened when selecting

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

25

General information

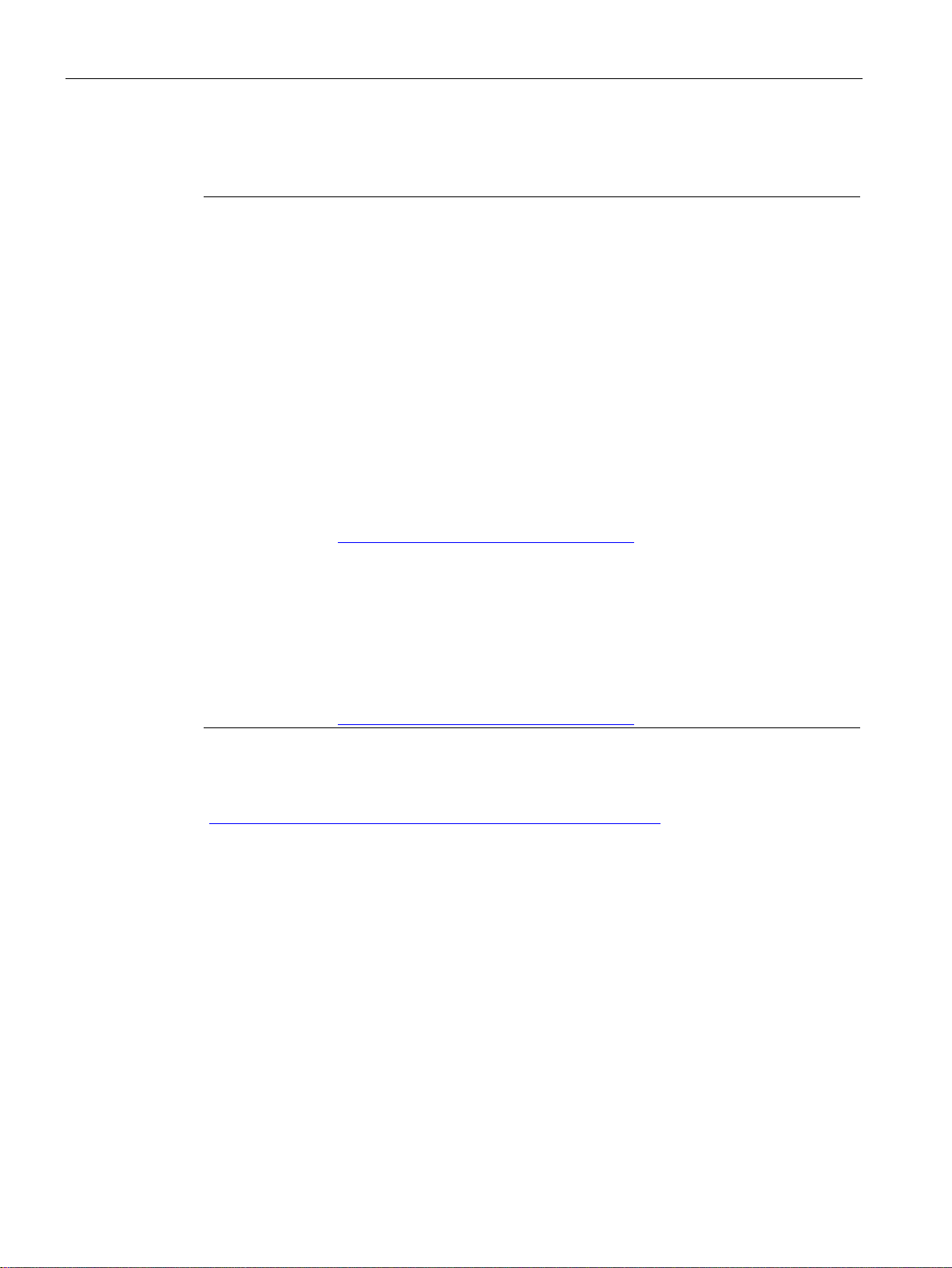

Synchronization type

Accuracy

Basic synchronization

approx. 100ms

Synchronization using ping compensation for isochronous communication

approx. 1 ms

Synchronization with the Network Time Protocol via a PROFINET connection

approx. 10 ms

2.6 Time synchronization between the control and converter

2.6 Time synchronization between the control and converter

In the factory setting, SINAMICS S120 drives use an operating hours counter. Based on the

operating hours, SINAMICS S120 saves alarms and warnings that occur. Using this method,

it is not possible to have a comparable timestamp between various converters.

In order to obtain a comparable timestamp between several converters, you must change

over the operating hours counting to time in the UTC format and synchronize with the time

master (control system).

This means that the events of all bus nodes, which are synchronized with the control system

time, can be referenced with one another.

Benefits: Improved diagnostic options by having a comparable time stamp of the bus nodes

involved.

Converters provide the following options to synchronize the time:

Synchronization using ping compensation for non-isochronous communication approx. 10 ms

Principle of operation of time synchronization

Basic synchronization

The control system transfers the time to the converter at time intervals that you specify in the

control system. Transfer is realized acyclically in the UTC format. The converter accepts this

time as soon as transfer has been completed without correcting the transfer duration. The

converter logs alarms and warnings based on this time.

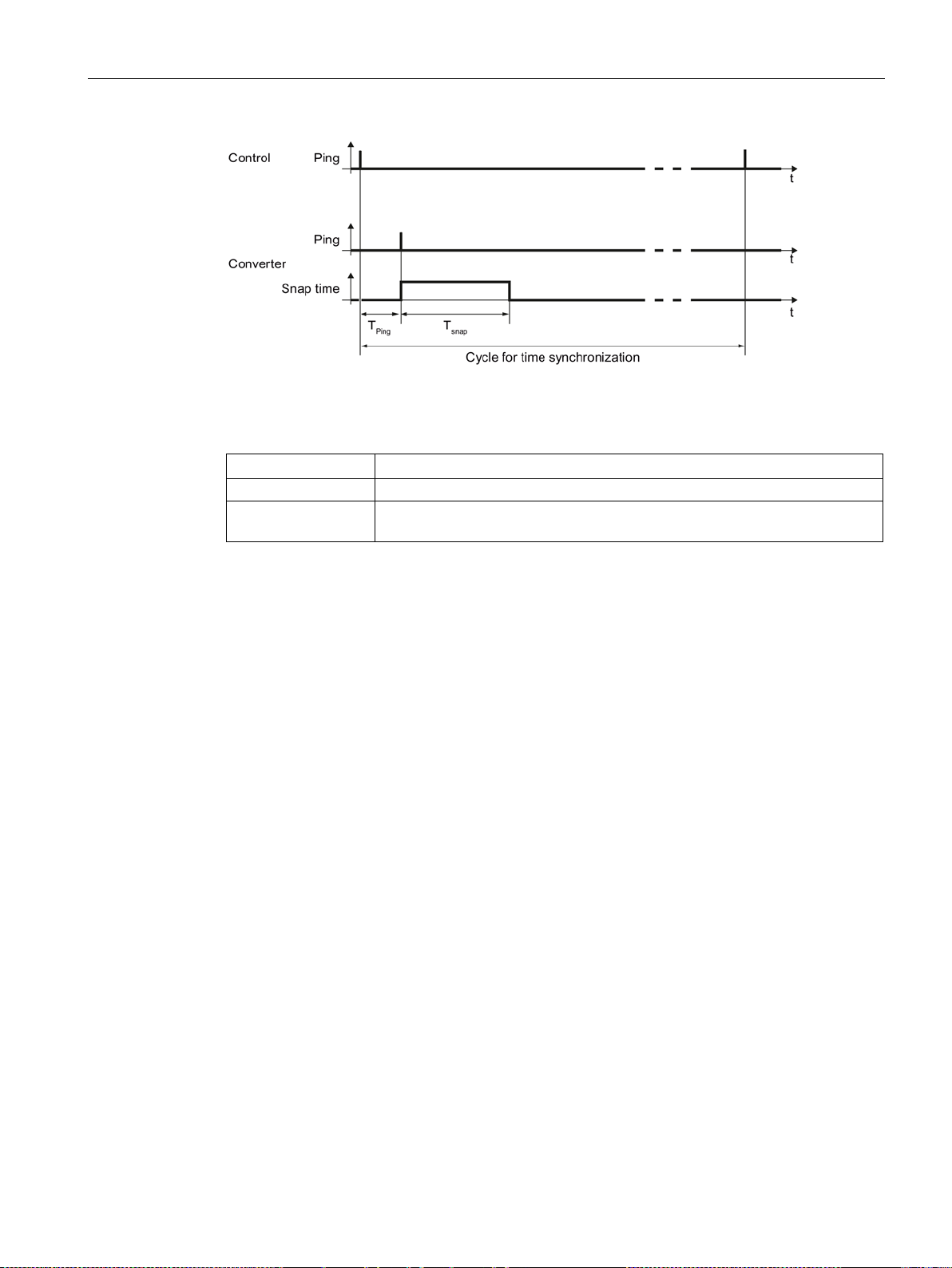

Time synchronization with ping compensation

At intervals that you specify in the control system, the control system sends a ping (a positive

signal edge) cyclically to the converter. Simultaneously, in acyclic operation, the device

sends the time in the UTC format in what is known as "snap".

As soon as the ping has been received in the drive, a timer starts which measures the time

until the snap has been completely transferred. The drive accepts the time that the snap

transfers. It then corrects it by the time that has expired between receiving the ping and the

complete transfer of the snap.

If the snap has not been transferred within 5 s after receiving the ping, then this

synchronization cycle is not used.

Communication

26 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

General information

Communication

Description

sampling time (p2048).

2.6 Time synchronization between the control and converter

Figure 2-4 Ping snap

Differences for isochronous and non-isochronous communication:

Isochronous The ping compensation value is determined in the converter.

not isochronous You can influence the accuracy of the ping compensation using the PZD

Time synchronization via Network Time Protocol (NTP)

Through NTP, all computers worldwide can synchronize their time. An inverter configured as

an NTP client synchronizes the time via a PROFINET connection to an NTP server (a time

source).

As NTP server, the following constellations are possible:

● Local NTP server that receives the time via GPS or DCF77 (e.g. SICLOCK).

● Control as NTP server if the plant network is divided into a control level and a field level.

Communication

Function Manual, 12/2018, 6SL3097-5BD00-0BP0

27

General information

2.6 Time synchronization between the control and converter

2.6.1 Setting SINAMICS time synchronization

Setting time synchronization

1. Using p3100, changeover the time format from operating hours into the UTC format (see

"Changing the time format").

2. Set the synchronization technique:

– Basic synchronization (p3103 = 2)

– Time synchronization with ping compensation (p3103 = 0)

3. Using p3104, set the ping source:

– If you are working with one of the telegrams 390, 391 or 392, then the source of the

ping (p3104) is internally connected with bit 1 of the CU control word

(DO1:CU_STW.1). In this case, parameter p3104 is blocked.

– If you are using a free telegram (999), interconnect the ping source (p3104) via BICO

in the control word.

– If you are working with CANopen, interconnect a free bit in the CANopen control word

with p3104 via a BICO connection.

Result:

After time synchronization, the current time is obtained from the time transferred by the time

master plus the necessary delay time associated with the transfer (ping-snap time).

The actual UTC time is displayed in the drive system using r3102.

At certain intervals, synchronization (according to the same technique) is repeated

(depending on the setting in the time master).

If a previously defined tolerance window is exceeded, then alarm A01099 is output. Define

the tolerance window for time synchronization using p3109. If alarm A01099 occurs, then

generally the synchronization interval is too long.

In this case, reduce the synchronization interval in your control system.

Changing the time format

The time format is entered via parameter p3100. This parameter cannot be changed online

To change the value, proceed as follows:

1. Connect Startdrive ONLINE with the converter.

2. Carry out an upload using the "Load from device" function.

3. In Startdrive, exit the ONLINE mode.

4. Offline, make the setting p3100 = 1.

5. Reactivate the ONLINE mode.

6. Carry out a parameter download ("Load to device").

7. Save the settings in a non-volatile fashion on the memory card of the drive.

You have now changed over the converter time format to the UTC format.

Application example

You can find an application example for SINAMICS time synchronization in the SIEMENS

"Industry Online Support":

Example: Specific SINAMICS time synchronization

(https://support.industry.siemens.com/cs/de/en/view/88231134)

Communication

28 Function Manual, 12/2018, 6SL3097-5BD00-0BP0

Loading...

Loading...