Page 1

Preface

Open Source Software

Table of Contents

SICAM

Feeder Condition Monitor

V03.30

Manual

Delivery

Introduction

Hardware Components and Drawings

Device Functions

Technical Data

Type Testing

Connection Diagrams

Parameterization

Modbus Registers

1

2

3

4

5

6

7

A

B

E50417-H8940-C580-A4

Glossary

Index

Page 2

i

i

NOTE

For your own safety, observe the warnings and safety instructions contained in this document, if available.

Disclaimer of Liability

This document has been subjected to rigorous technical

review before being published. It is revised at regular intervals, and any modifications and amendments are included

in the subsequent issues. The content of this document has

been compiled for information purposes only. Although

Siemens AG has made best efforts to keep the document as

precise and up-to-date as possible, Siemens AG shall not

assume any liability for defects and damage which result

through use of the information contained herein.

This content does not form part of a contract or of business

relations; nor does it change these. All obligations of

Siemens AG are stated in the relevant contractual agreements.

Siemens AG reserves the right to revise this document from

time to time.

Document version: E50417-H8940-C580-A4.01

Edition: 03.2019

Version of the product described: V03.30

Copyright

Copyright © Siemens AG 2019. All rights reserved.

The disclosure, duplication, distribution and editing of this

document, or utilization and communication of the content

are not permitted, unless authorized in writing. All rights,

including rights created by patent grant or registration of a

utility model or a design, are reserved.

Trademarks

SIPROTEC™, DIGSI™, SIGRA™, SIGUARD™, SAFIR™, and

SICAM™ are trademarks of Siemens AG. Any unauthorized

use is illegal. All other designations in this document can

be trademarks whose use by third parties for their own

purposes can infringe the rights of the owner.

Page 3

Preface

Purpose of the Manual

This manual describes the application, functions, installation, and operation of the SICAM Feeder Condition

Monitor (FCM) 6MD232xx.

Target Audience

Protection system engineers, commissioning engineers, persons entrusted with the setting, testing and maintenance of automation, selective protection and control equipment, and operational crew in electrical installations and power plants.

Scope

This manual applies to SICAM Feeder Condition Monitor (FCM) 6MD232xx; firmware version V03.30.

Indication of Conformity

This product complies with the directive of the Council of the European Communities

on the harmonization of the laws of the Member States relating to electromagnetic

compatibility (EMC Directive 2014/30/EU) and concerning electrical equipment for use

within specified voltage limits (Low Voltage Directive 2014/35/EU) as well as restriction

on usage of hazardous substances in electrical and electronic equipment (RoHS Directive 2011/65/EU).

This conformity has been proved by tests performed according to the Council Directive

and in accordance with the generic standard IEC/EN 61326-1 (for EMC directive) and

with the standards IEC/EN 61010-1 and IEC/EN 61010-2-30 (for Low Voltage Directive)

by Siemens AG.

The device is designed and manufactured for application in an industrial environment.

RoHS directive 2011/65/EU is met using the standard EN 50581.

The product conforms with the international standards of IEC 61326-1.

Standards

IEEE Std C 37.90 and EN 55011

IEC/EN 62271-1: 2007-10

IEC/EN 61243-5: 1997-06

Support

Our Customer Support Center provides a 24-hour service.

Siemens AG

Customer Support Center

Humboldtstraße 59

90459 Nürnberg

Germany

SICAM, Feeder Condition Monitor, Manual 3

E50417-H8940-C580-A4, Edition 03.2019

Page 4

!

!

!

Preface

Phone: +49 (180) 524-7000

Fax: +49 (180) 524-2471

E-mail: support.energy@siemens.com

Additional Support

For questions about the system, please contact your Siemens sales partner.

Training Courses

Inquiries regarding individual training courses should be addressed to our Training Center:

Siemens AG

Siemens Power Academy TD

Humboldtstraße 59

90459 Nürnberg

Germany

Phone: +49 (911) 433-7415

Fax: +49 (911) 433-7929

E-mail: poweracademy@siemens.com

Internet: www.siemens.com/poweracademy

Notes on Safety

This document is not a complete index of all safety measures required for operation of the equipment (module

or device). However, it comprises important information that must be followed for personal safety, as well as

to avoid material damage. Information is highlighted and illustrated as follows according to the degree of

danger:

DANGER

DANGER means that death or severe injury will result if the measures specified are not taken.

²

WARNING

WARNING means that death or severe injury may result if the measures specified are not taken.

²

CAUTION

Comply with all instructions, in order to avoid death or severe injuries.

Comply with all instructions, in order to avoid death or severe injuries.

CAUTION means that medium-severe or slight injuries can occur if the specified measures are not taken.

Comply with all instructions, in order to avoid moderate or minor injuries.

²

4 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 5

NOTICE

i

i

NOTICE means that property damage can result if the measures specified are not taken.

Comply with all instructions, in order to avoid property damage.

²

NOTE

Important information about the product, product handling or a certain section of the documentation

which must be given particular attention.

Qualified Electrical Engineering Personnel

Only qualified electrical engineering personnel may commission and operate the equipment (module, device)

described in this document. Qualified electrical engineering personnel in the sense of this manual are people

who can demonstrate technical qualifications as electrical technicians. These persons may commission,

isolate, ground and label devices, systems and circuits according to the standards of safety engineering.

Proper Use

The equipment (device, module) may be used only for such applications as set out in the catalogs and the

technical description, and only in combination with third-party equipment recommended and approved by

Siemens.

Problem-free and safe operation of the product depends on the following:

Preface

Proper transport

•

Proper storage, setup and installation

•

Proper operation and maintenance

•

When electrical equipment is operated, hazardous voltages are inevitably present in certain parts. If proper

action is not taken, death, severe injury or property damage can result:

The equipment must be grounded at the grounding terminal before any connections are made.

•

All circuit components connected to the power supply may be subject to dangerous voltage.

•

Hazardous voltages may be present in equipment even after the supply voltage has been disconnected

•

(capacitors can still be charged).

Operation of equipment with exposed current-transformer circuits is prohibited. Before disconnecting the

•

equipment, ensure that the current-transformer circuits are short-circuited.

The limiting values stated in the document must not be exceeded. This must also be considered during

•

testing and commissioning.

Used Symbols on Device

Symbol Description

No.

1 Direct current, IEC 60417-5031

2 Alternating current, IEC 60417-5032

3 Direct and alternating current, IEC 60417-5033

4 Earth (ground) terminal, IEC 60417-5017

5 Protective conductor terminal, IEC 60417-5019

SICAM, Feeder Condition Monitor, Manual 5

E50417-H8940-C580-A4, Edition 03.2019

Page 6

Preface

No. Symbol Description

6 Caution, risk of electric shock

7 Caution, risk of danger, ISO 7000-0434

8 Protective Insulation, IEC 60417-5172, Safety Class II devices

9 Guideline 2002/96/EC for electrical and electronic devices

10 Guideline for the Eurasian Market

6 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 7

Open Source Software

The product contains, among other things, Open Source Software developed by third parties. The Open

Source Software used in the product and the license agreements concerning this software can be found in the

Readme_OSS. These Open Source Software files are protected by copyright. Your compliance with those

license conditions will entitle you to use the Open Source Software as foreseen in the relevant license. In the

event of conflicts between Siemens license conditions and the Open Source Software license conditions, the

Open Source Software conditions shall prevail with respect to the Open Source Software portions of the software. The Open Source Software is licensed royalty-free. Insofar as the applicable Open Source Software

License Conditions provide for it you can order the source code of the Open Source Software from your

Siemens sales contact - against payment of the shipping and handling charges - for a period of at least 3 years

since purchase of the Product. We are liable for the Product including the Open Source Software contained in

it pursuant to the license conditions applicable to the Product. Any liability for the Open Source Software

beyond the program flow intended for the Product is explicitly excluded. Furthermore any liability for defects

resulting from modifications to the Open Source Software by you or third parties is excluded. We do not

provide any technical support for the Product if it has been modified.

SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

7

Page 8

8 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 9

Table of Contents

Preface..........................................................................................................................................................3

Open Source Software..................................................................................................................................7

1 Delivery.......................................................................................................................................................11

1.1 Delivery............................................................................................................................ 12

2 Introduction................................................................................................................................................13

2.1 Overview ......................................................................................................................... 14

2.2 Environmental Protection Hints......................................................................................... 20

3 Hardware Components and Drawings........................................................................................................21

3.1 Hardware Components..................................................................................................... 22

3.2 Terminal Diagram............................................................................................................. 23

3.3 Dimensional Drawings ......................................................................................................25

4 Device Functions........................................................................................................................................ 29

4.1 Description....................................................................................................................... 30

4.1.1 Measurements and Derived Values.............................................................................. 30

4.1.2 Fault Detection............................................................................................................30

4.1.3 Fault-Reset Mechanism................................................................................................32

4.1.4 Enhanced Fault Validation and Fault-Reset Function.....................................................33

4.1.5 Trip Time DMT and IDMT .............................................................................................36

4.1.6 Ground-Fault Parameter Active Group Setting.............................................................. 37

4.1.7 Fault Indication........................................................................................................... 37

4.1.8 DO Configuration........................................................................................................ 38

4.1.9 Operating Modes.........................................................................................................38

4.1.10 Correction Factors for LoPo VT and LoPo CT (IEC 61869-10, IEC 61869-11)................... 38

4.1.11 Power-Flow Direction Reversal .................................................................................... 39

4.1.12 P,Q Sign...................................................................................................................... 39

4.1.13 3-Phase Angle Calculations.......................................................................................... 40

4.1.14 Phase-Sequence Monitoring........................................................................................ 40

4.1.15 Determination of Fault Direction..................................................................................41

4.1.16 Direction Determination of Phase Elements..................................................................42

4.1.17 Directional Ground Fault (Compensated/Resonant-Grounded) ..................................... 43

4.1.18 Directional Ground Fault (in Isolated Electrical Power Systems).................................... 43

4.1.19 Ground-Fault Direction for Solidly Grounded System.................................................... 44

4.1.20 Ground-Fault Detection with Cos φ/Sin φ Measurement............................................... 45

4.1.21 Determination of a Ground Fault with the Pulse-Location Detection Mechanism........... 46

4.1.22 Determination of the Ground-Fault Phase.................................................................... 49

4.1.23 Determination of Repeated Phase Faults with Automatic Reclosing ..............................49

SICAM, Feeder Condition Monitor, Manual 9

E50417-H8940-C580-A4, Edition 03.2019

Page 10

Table of Contents

4.1.24 Intermittent Ground Fault............................................................................................49

4.1.25 Inrush-Current Detection/Blocking ...............................................................................50

4.1.26 Primary Current Settings..............................................................................................51

4.1.27 Ground-Current Calculation......................................................................................... 51

4.1.28 Network Voltage Ratio................................................................................................. 52

4.1.29 Voltage Measurements with Sensors as per IEC 60044-7, IEC 61869-11 and with

Conventional Voltage Sensors......................................................................................52

4.1.30 Low-Voltage Measurement.......................................................................................... 53

4.1.31 Determination of Medium Voltage via Low-Voltage Measurements.............................. 53

4.1.32 Voltage Measurement via Integrated Voltage-Detecting Systems..................................54

4.1.33 Energy Measurement...................................................................................................55

4.1.34 RTC Synchronization....................................................................................................55

4.1.35 Remote Firmware Updates...........................................................................................56

4.1.36 Password Menu Access................................................................................................ 56

4.1.37 Device Alerts............................................................................................................... 57

4.1.38 Archive Logging.......................................................................................................... 58

4.1.39 Battery Freshness Mode...............................................................................................59

5 Technical Data............................................................................................................................................ 61

5.1 Device Technical Data....................................................................................................... 62

6 Type Testing............................................................................................................................................... 65

6.1 Type Testing..................................................................................................................... 66

7 Connection Diagrams................................................................................................................................. 69

7.1 Connection Diagrams........................................................................................................70

7.2 Installing the Device..........................................................................................................73

7.3 Sensor Connections.......................................................................................................... 74

7.4 Modbus Connection of SICAM FCM with RTU..................................................................... 78

A Parameterization........................................................................................................................................ 81

A.1 Parameterization...............................................................................................................82

A.2 Parameterizing the User Interface......................................................................................83

A.3 Editing the Device Settings................................................................................................91

B Modbus Registers....................................................................................................................................... 93

B.1 Modbus Registers..............................................................................................................94

B.2 Implementation of the Modbus Protocol ...........................................................................95

B.3 Bit-Type Data.................................................................................................................. 107

B.4 Register-Type Data – Holding Registers............................................................................110

B.5 Register-Type Data – Input Registers................................................................................131

B.6 Register-Type Data – Analog Input Registers.................................................................... 144

B.7 Register-Type Data - Events............................................................................................. 150

B.8 Register-Type Data – Trailing Pointers..............................................................................153

B.9 Self-Test Mode................................................................................................................ 156

Glossary.................................................................................................................................................... 171

Index.........................................................................................................................................................173

10 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 11

1

Delivery

1.1 Delivery 12

SICAM, Feeder Condition Monitor, Manual 11

E50417-H8940-C580-A4, Edition 03.2019

Page 12

!

i

i

i

i

Delivery

1.1 Delivery

1.1

Delivery Note

Contents of Delivery

Delivery

The SICAM FCM device is delivered in a cardboard box containing the Siemens logo.

1 SICAM FCM device

•

1 document with safety instructions

•

1 ground wire

•

WARNING

Danger of explosion of the battery.

Noncompliance with the safety instructions means that death, severe injuries, or considerable material damages can occur.

Do not throw the SICAM FCM device containing a battery into a fire.

²

NOTE

SICAM FCM with 1 contained lithium metal cell (0.6 g lithium content) meets the preconditions of Special

Provision 188 of the UN Recommendations on the Transport of Dangerous Goods, 17th revised edition and

is classified according to:

ADR/RID/ADN/IMDG-Code: UN 3091 lithium metal batteries contained in equipment, 9, preconditions

•

of SP 188

ICAO-TI/IATA-DGR: UN 3091 lithium metal batteries contained in equipment, 9, preconditions of

•

Section II PI 970

NOTE

Do not transport the SICAM FCM in battery-activated mode. Before transportation, ensure that the SICAM

FCM is in Battery Freshness Mode (BFM).

12 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 13

2

Introduction

2.1 Overview 14

2.2 Environmental Protection Hints 20

SICAM, Feeder Condition Monitor, Manual 13

E50417-H8940-C580-A4, Edition 03.2019

Page 14

Introduction

2.1 Overview

2.1

Overview

SICAM Feeder Condition Monitor (FCM) is an Intelligent Electronic Device (IED) used for detecting and indicating short circuits or ground faults with and without directional information. SICAM FCM accurately monitors, measures, and displays operational measured values and performs the condition monitoring task in a

medium-voltage distribution system. SICAM FCM is typically used in the medium-voltage and low-voltage

secondary substation that ranges from 0.4 kV to 36 kV.

SICAM FCM measures the RMS value for alternating voltage, alternating current, and power frequency.

SICAM FCM calculates the active power (P), reactive power (Q), apparent power (S), power factor (cos φ),

phase angle, energy, and other relevant values.

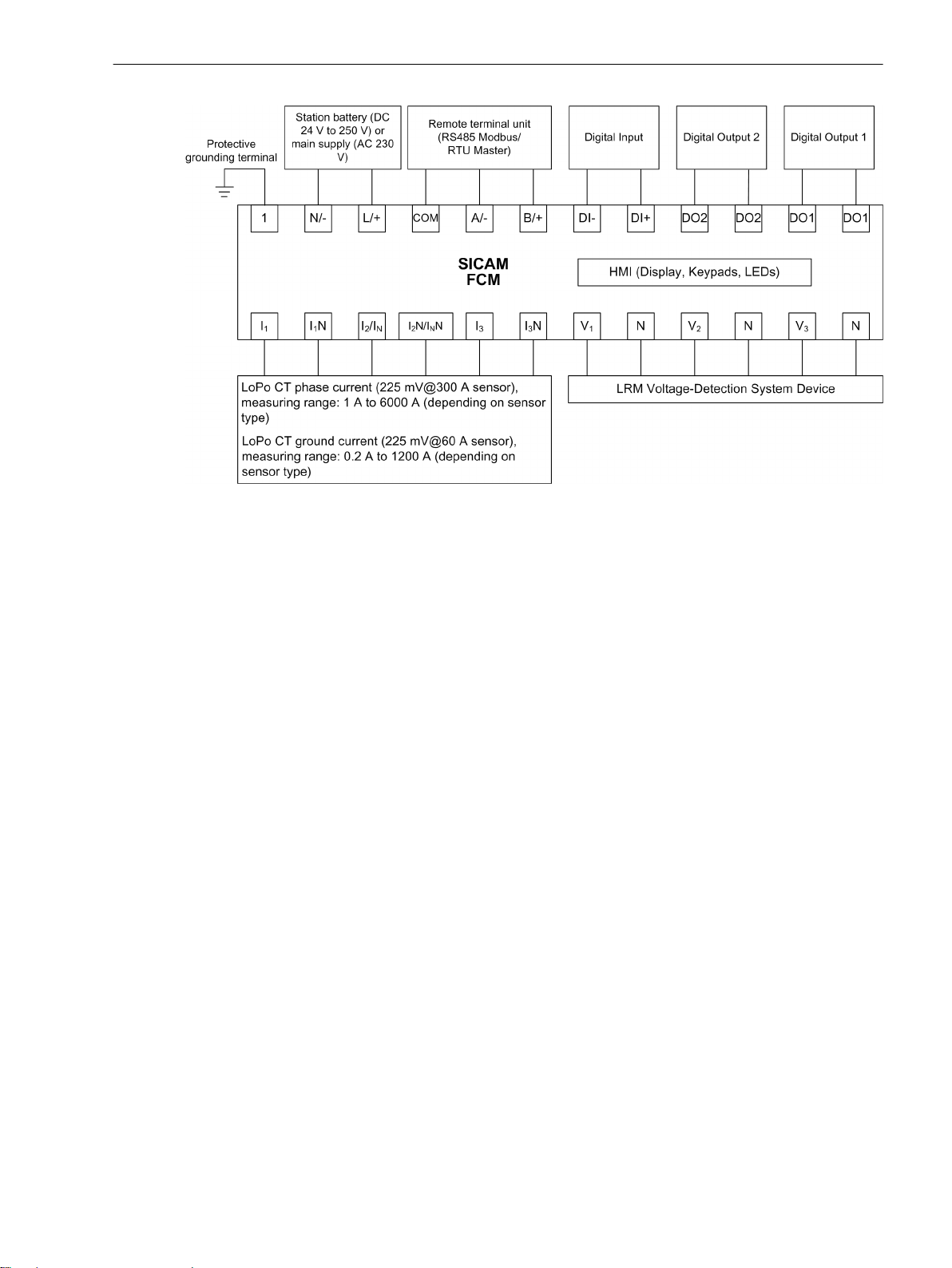

SICAM FCM consists of the following hardware interfaces:

3 current inputs

•

3 voltage inputs

•

1 digital input

•

2 digital outputs

•

1 RS 485 interface (Modbus RTU)

•

1 auxiliary power supply

•

[dw_fcm_block_diagram2321, 3, en_US]

Figure 2-1 SICAM FCM Block Diagram for MLFB 6MD2321-1AA00-1AA0

14 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 15

[dw_fcm_block_diagram2322, 2, en_US]

Figure 2-2 SICAM FCM Block Diagram for MLFB 6MD2322-1AA00-1AA0

Introduction

2.1 Overview

Applications

SICAM FCM is used:

As a directional and non-directional short circuit and ground-fault detector suitable for solid, isolated, and

•

compensated networks in medium-voltage and low-voltage distribution systems

As a simple power quality meter and energy measurements in various applications

•

Flush Mounting

SICAM FCM can be flush-mounted in the panel and operated inside an enclosed dry room. To mount

SICAM FCM in the panel, proceed as follows:

Cut a rectangle in the Ring-Main Unit (RMU) panel measuring 92.0 mm + 0.8 mm × 45.0 + 0.8 mm (W ×

•

H).

Carry out all the required internal wiring connections.

•

For more information about terminal diagrams, refer to 3.2 Terminal Diagram.

Flush SICAM FCM into the panel and lock it with the clamps.

•

For more information about installation, refer to 7.2 Installing the Device.

•

Device Ordering Information

Use the following ordering information to order SICAM FCM and other related accessories.

SICAM, Feeder Condition Monitor, Manual 15

E50417-H8940-C580-A4, Edition 03.2019

Page 16

Introduction

2.1 Overview

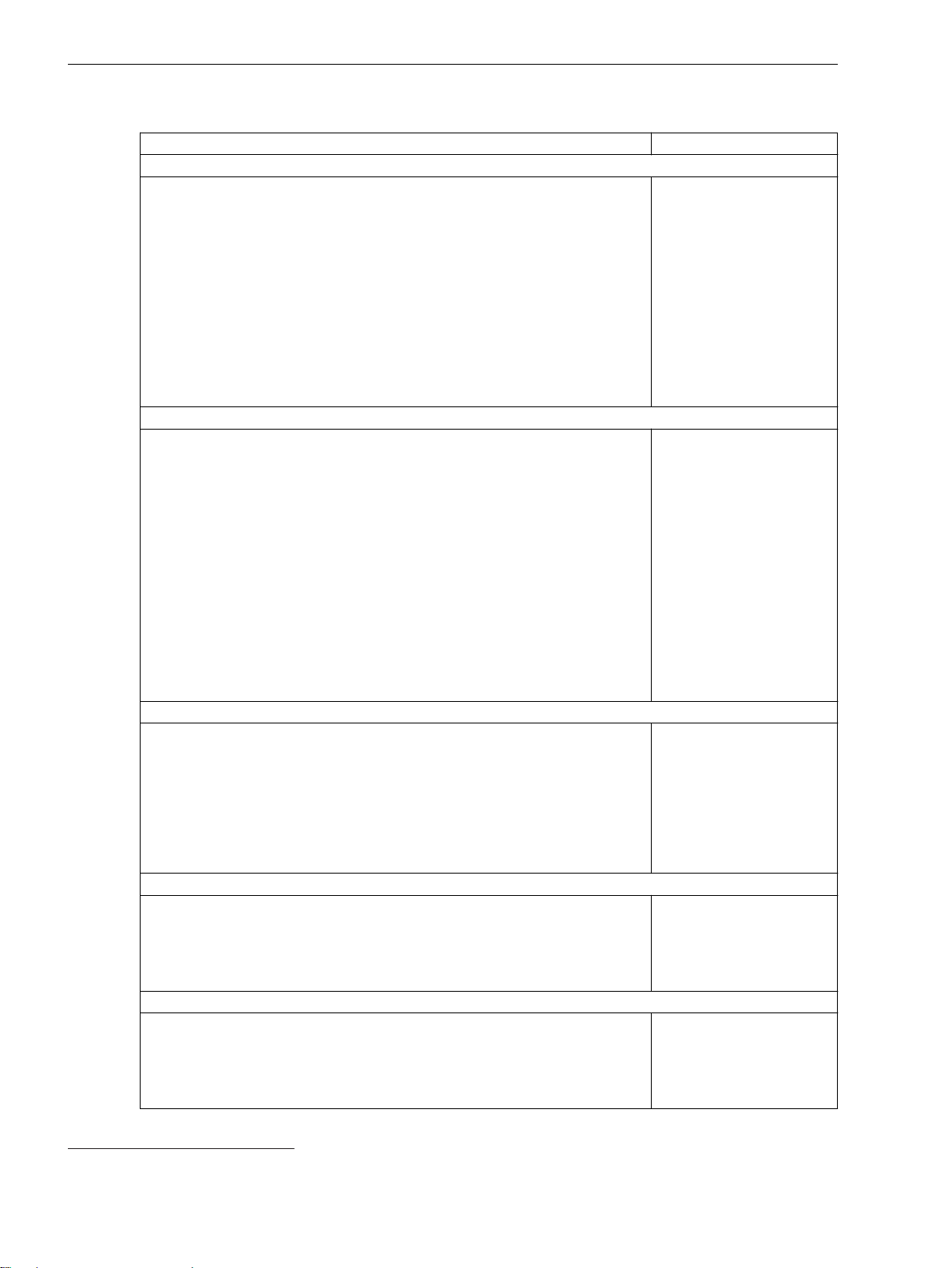

Table 2-1 SICAM FCM and Accessories Ordering Information

Description Order Number

SICAM FCM

Voltage measurements: LoPo VTs according to IEC 60044-7, IEC 61869-11,

•

conventional VT and 230 V

Current measurements: LoPo CTs according to IEC 60044-8, IEC 61869-10

•

Fault indicator with directional information and measurements of V, I, f, P,

•

Q, S, cos φ, and power-flow direction

Panel mounted

•

Dimensions in mm: 96 × 48 × 109.5

•

1 digital input

•

2 digital outputs

•

Modbus RTU

•

SICAM FCM

For voltage measurement with LRM voltage-detecting systems according

•

to IEC 61243-5

Current measurements: LoPo CTs according to IEC 60044-8, IEC 61869-10

•

Fault indicator with directional information and measurements of V, I, f, P,

•

Q, S, cos φ, and power-flow direction

Panel mounted unit with display

•

Dimensions in mm: 96 × 48 × 109.5

•

1 digital input

•

2 digital outputs

•

Modbus RTU

•

The mandatory interface cable (6MD2322-0AA80-0AB3) for linkage to the

•

Voltage-Detection System (VDS) has to be ordered separately.

Voltage-Detection System (VDS) Interface Cable

4-wire connection lead with integrated protection circuit to connect

•

SICAM FCM 6MD2322-1AA00-1AA0/CC with the LRM voltage detection

system

1 ground input

•

Length: 0.3 m

•

Mandatory accessory for each SICAM FCM 6MD2322-1AA00-1AA0 with

•

hardware revision number “CC” or higher

Adapter 1 A to low power IEC 60044-8

3 inputs, transformer ratio 225 mV@1 A

•

Accuracy class: 1

•

Thermal overload: 100 A for 1 s

•

Coil diameter: 5.8 mm

•

Adapter 5 A to low power IEC 60044-8

3 inputs, transformer ratio 225 mV@5 A

•

Accuracy class: 3

•

Thermal overload: 100 A for 1 s

•

Coil diameter: 5.8 mm

•

6MD2321-1AA00-1AA0/XX

6MD2322-1AA00-1AA0/XX

6MD2322-0AA80-0AB3

6MD2320-0AA10-1AA0

6MD2320-0AA20-1AA0

1

1

1

XX represents the hardware revision number

16 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 17

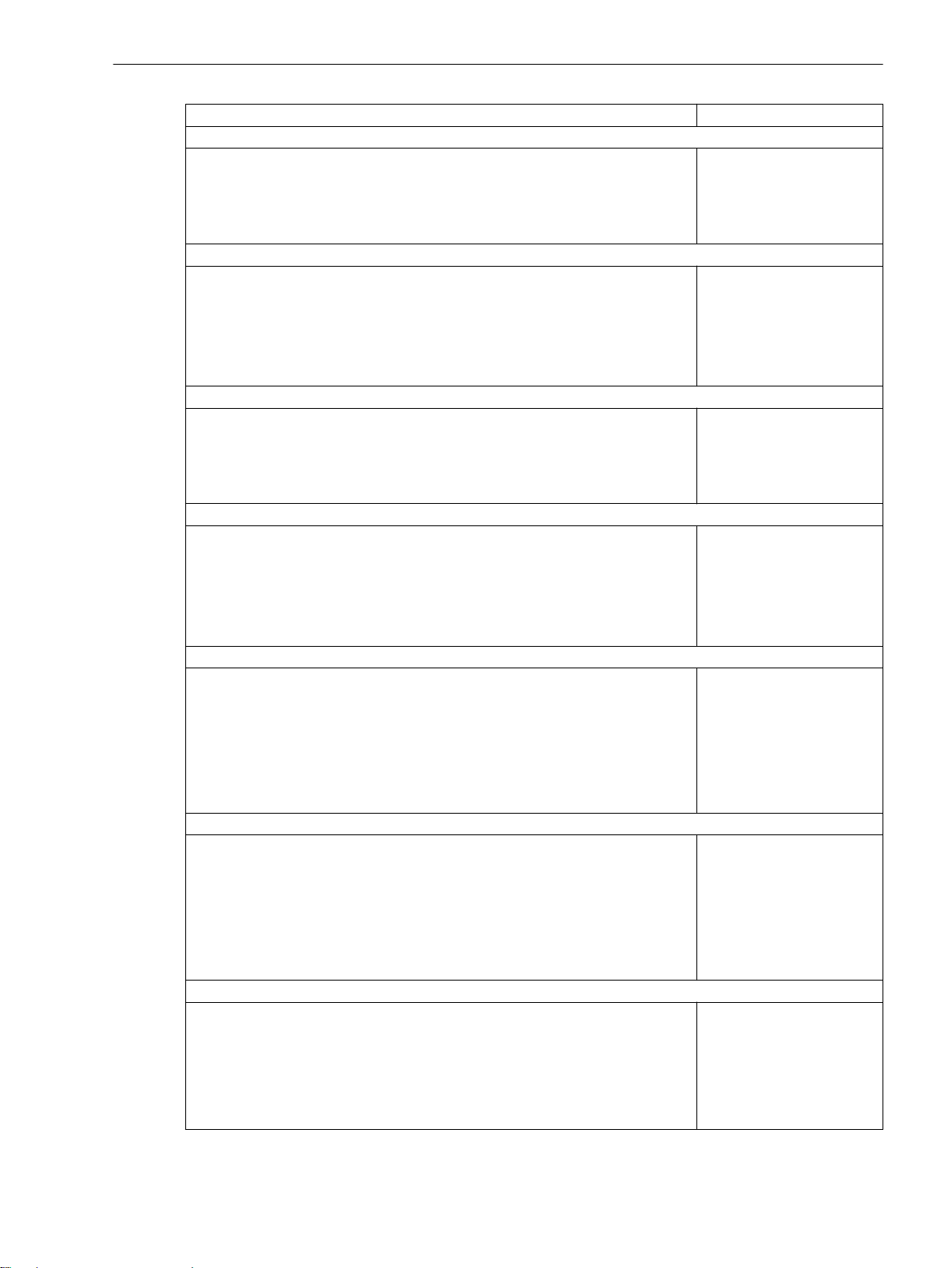

Description Order Number

Phase current sensor – split core

Ratio: 225 mV@300 A, IEC 61869-10

•

Accuracy class: 0.5/1 extension 200 %, 5P10

•

Connection cable: 2.0 m, open end

•

Internal diameter: 65 mm

•

Phase current sensor – closed ring core

Ratio: 225 mV@700 A, IEC 60044-8

•

Accuracy class: 0.5, 5P10

•

Connection cable: 3.5 m, open end

•

Internal diameter: 82 mm

•

GOST certificate

•

Core balance current sensor – split core

Ratio: 225 mV@60 A, IEC 61869-10

•

Accuracy class: 1/3

•

Connection cable: 2.0 m

•

Window diameter: 160 mm

•

Core balance current sensor – split core

Ratio: 225 mV@60 A, IEC 60044-8

•

Accuracy class: 1

•

Connection cable: 3.5 m

•

Window diameter: 120 mm

•

GOST certificate

•

Voltage Sensor 10 kV

10 kV/√3 : 3.25/√3

•

Accuracy class: 1

•

IEC 60044-7 for symmetrical T connectors with C cone for cables: Nexans

•

(K) 440TB/ Cellpack CTS-S/Südkabel SEHDT13 and SEHDT23

Voltage factor: 1.2 V

•

Voltage factor: 1.9 VN for maximum of 8 hours

•

Voltage Sensor 10 kV

10 kV/√3 : 3.25/√3

•

Accuracy class: 1

•

IEC 60044-7 for asymmetric T connectors of nkt cables type CB-24, CC-24

•

and Raychem RSTI-58xx/RSTI-CC-58xx

Voltage factor: 1.2 V

•

Voltage factor: 1.9 VN for maximum of 8 hours

•

Voltage Sensor 10 kV

10 kV/√3 : 3.25/√3

•

Accuracy class: 0.5

•

IEC 60044-7 for asymmetric T connectors of nkt cables type CB-24

•

Voltage factor: 1.2 V

•

Voltage factor: 1.9 VN for maximum of 8 hours, GOST certificate

•

N

N

N

Introduction

2.1 Overview

6MD2320-0GA00-1AA0

6MD2320-0JA00-0BA1

6MD2320-0AF00-1AA0

6MD2320-0AF00-1AA1

6MD2320-0AA04-1AA0

6MD2320-0AA04-1AB0

6MD2320-0AA04-0AB1

SICAM, Feeder Condition Monitor, Manual 17

E50417-H8940-C580-A4, Edition 03.2019

Page 18

Introduction

2.1 Overview

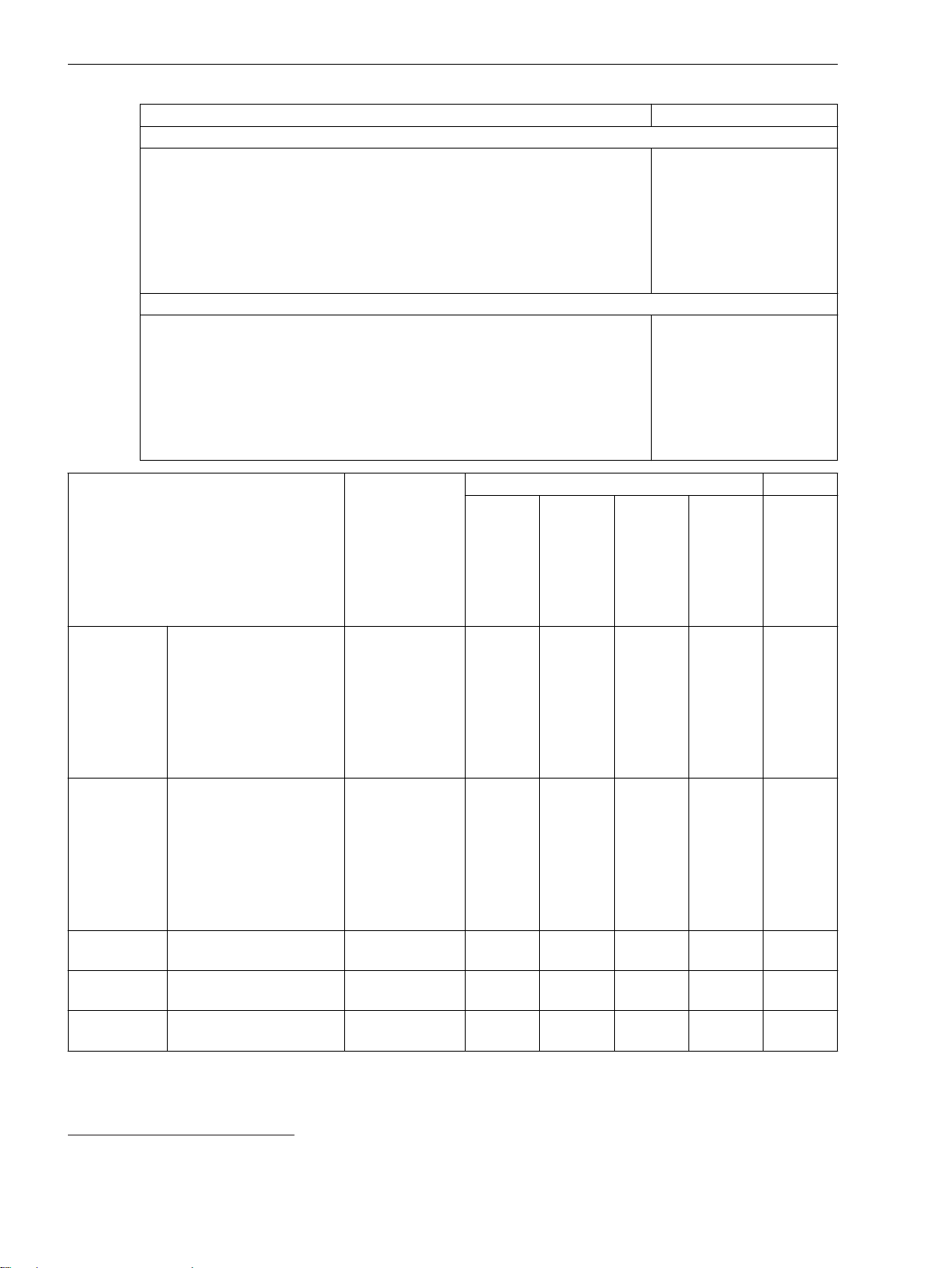

Description Order Number

Voltage Sensor 20 kV

20 kV/√3 : 3.25/√3

•

Accuracy class: 0.5/1

•

IEC 61869-11 for symmetric T connectors with C cone for cables: Nexans

•

(K) 440TB/ Cellpack CTS-S/Südkabel SEHDT13 and SEHDT23

Voltage factor: 1.2 V

•

Voltage factor: 1.9 VN for maximum of 8 hours

•

Voltage Sensor 20 kV

20 kV/√3 : 3.25/√3

•

Accuracy class: 1

•

IEC 61869-11 for asymmetric T connectors of nkt cables type CB-24, CC-24

•

and Raychem RSTI-58xx/RSTI-CC-58xx

Voltage factor: 1.2 V

•

Voltage factor: 1.9 VN for maximum of 8 hours

•

Typical Ordering Combinations MLFB Number Use Case

SICAM FCM For resistive voltage

dividers, conventional VTs,

and 230 V.

Fault indicator with directional information and

measurements of V, I, f, P,

Q, S, cos φ, power-flow

direction, 2 digital outputs

SICAM FCM For voltage detecting

systems

Fault indicator with direc-

tional information and

measurements of V, I, f, P,

Q, S, cos φ, and powerflow direction, 2 digital

outputs

1 A adaptor 3 inputs @225mV low-

power signal

5 A adaptor 3 inputs @225mV low-

power signal

Phase-current

sensor

Depending on requirements

N

N

LoPo

sensors

available

6MD2321-1AA00

-1AA0/XX

6MD2322-1AA00

-1AA0/XX

6MD2320-0AA10

-1AA0

6MD2320-0AA20

-1AA0

Refer to Table 2-1 – 3 x 2 x – –

1

1

1 x 1 x 1 x 1 x –

1 x 1 x 1 x 1 x

– – – 1 x –

– – – 1 x –

Neutralpoint

treatment:

Solid/lowresistant

6MD2320-0AA07-1AA0

6MD2320-0AA07-1AB0

Neutralpoint

treatment:

Isolated/

compensated

Conventional

1 A/ 5 A

CTs available

Connecting cable

2

1 x

2

In order to set up SICAM FCM (MLFB: 6MD2322-1AA00-1AA0/CC and above) with voltage-detection system, an appropriate

connecting cable (MLFB: 6MD2322-0AA80-0AB3) must be used.

18 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 19

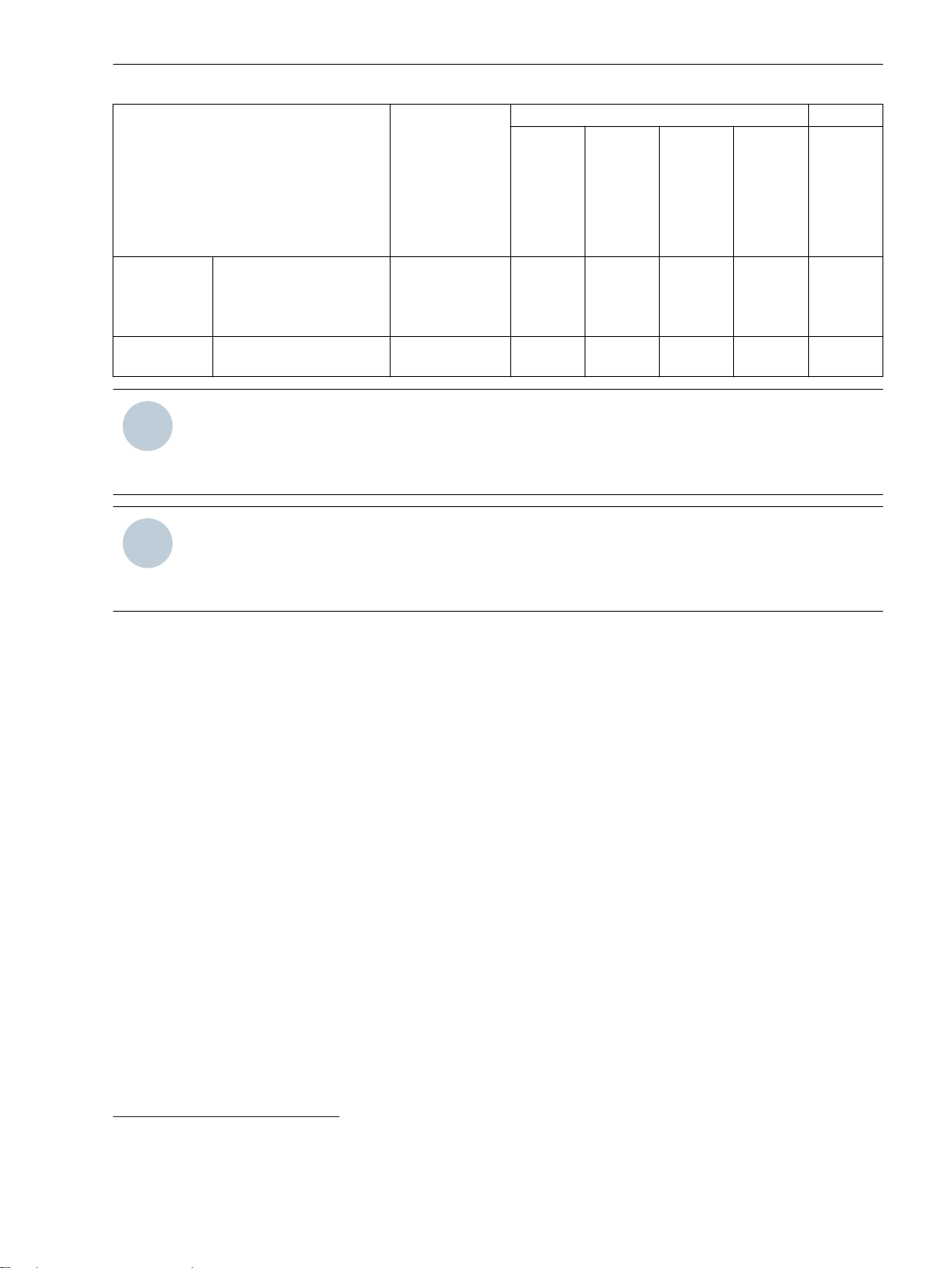

Typical Ordering Combinations MLFB Number Use Case

i

i

i

i

LoPo

sensors

available

Core balance

current sensor

Voltage

sensor

Depending on requirements

For example, GOST certificate

Depending on voltage

level and form factor

NOTE

The device with MLFB number 6MD2321-1AA00-1AA0/DD and above must be loaded with firmware

V03.XX only.

The device with MLFB number 6MD2321-1AA00-1AA0/CC must be loaded with firmware V02.XX only.

Refer to Table 2-1 – –

Refer to Table 2-1 –

Neutralpoint

treatment:

Solid/lowresistant

4

(3 x)

Neutralpoint

treatment:

Isolated/

compensated

3

1 x

4

(3 x)

2.1 Overview

Conventional

1 A/ 5 A

CTs available

– –

– –

Introduction

Connecting cable

Accessories

NOTE

The device with MLFB number 6MD2322-1AA00-1AA0/CC and above must be loaded with firmware V03.XX

only.

The device with MLFB number 6MD2322-1AA00-1AA0/BB must be loaded with firmware V02.XX only.

You can download the current version of the SICAM FCM manual from Siemens Powerquality.

3

The ground current can also be calculated in isolated/compensated electrical power systems. Consider information regarding accuracy.

4

Optional for measuring purpose or for directional information

SICAM, Feeder Condition Monitor, Manual 19

E50417-H8940-C580-A4, Edition 03.2019

Page 20

i

i

i

i

Introduction

2.2 Environmental Protection Hints

2.2

Disposal of Old Equipment and Batteries (Applicable only for European Union and Countries with a Recycling

System)

Disposal of Mobile Storage Devices (e.g. USB Sticks and Memory Cards)

Environmental Protection Hints

The disposal of our products and possible recycling of their components after decommissioning has to be

carried out by an accredited recycling company, or the products/components must be taken to applicable

collection points. Such disposal activities must comply with all local laws, guidelines and environmental specifications of the country in which the disposal is done. For the European Union the sustainable disposal of electronic scrap is defined in the respective regulation for "waste electrical and electronic equipment" (WEEE).

The crossed-out wheelie bin on the products, packaging and/or accompanying documents means

that used electrical and electronic products and batteries must not be mixed with normal household waste.

According to national legislation, penalties may be charged for incorrect disposal of such

waste.

By disposing of these products correctly you will help to save valuable resources and prevent any potential

negative effects on human health and the environment.

NOTE

Our products and batteries must not be disposed of as household waste. For disposing batteries it is necessary to observe the local national/international directives.

When disposing of/transferring mobile storage devices, using the format or delete functions only changes the

file management information and does not completely delete the data from your mobile storage device. When

disposing of or transferring a mobile storage device, Siemens strongly recommends physically destroying it or

completely deleting data from the mobile storage device by using a commercially available computer data

erasing software.

REACH/RoHS Declaration

You can find our current REACH/RoHS declarations at:

https://www.siemens.com/global/en/home/products/energy/ecotransparency/ecotransparency-downloads.html

NOTE

You can find more information about activities and programs to protect the climate at the EcoTransparency

website:

https://www.siemens.com/global/en/home/products/energy/ecotransparency.html

20 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 21

3

Hardware Components and Drawings

3.1 Hardware Components 22

3.2 Terminal Diagram 23

3.3 Dimensional Drawings 25

SICAM, Feeder Condition Monitor, Manual 21

E50417-H8940-C580-A4, Edition 03.2019

Page 22

Hardware Components and Drawings

3.1 Hardware Components

3.1

Hardware Components

In this manual, SICAM FCM is also referred as device.

Microcontroller

•

The device uses a low-power ARM MCU which includes high-precision 16-bit ADCs.

Battery

•

The device contains a battery with 3.6 V and a capacity of 1.2 Ah.

LCD

•

LCD is used to view real-time values, events, archives, and device parameters.

Keypads

•

The 4 navigation keys are used to navigate through the device menu and to select the desired parameters. The functions of the navigation keys are specific to different menu sections.

LEDs

•

The device consists of 3 LEDs which indicate the status of the process.

– FAULT (Red)

Indicates when any distribution-system fault is detected

– COM (Yellow)

Indicates that the communication is active between Modbus master and the SICAM FCM

– RUN (Green)

Indicates the healthy condition of the device and operating on the auxiliary voltage

Digital Input

•

The device consists of 1 digital input for resetting the fault indication.

Digital Output

•

The device consists of 2 digital outputs for indicating fault conditions.

[dw_sfcmhwbd, 1, en_US]

Figure 3-1 SICAM FCM Hardware Block Diagram

22 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 23

Hardware Components and Drawings

3.2 Terminal Diagram

3.2

Terminal Diagram

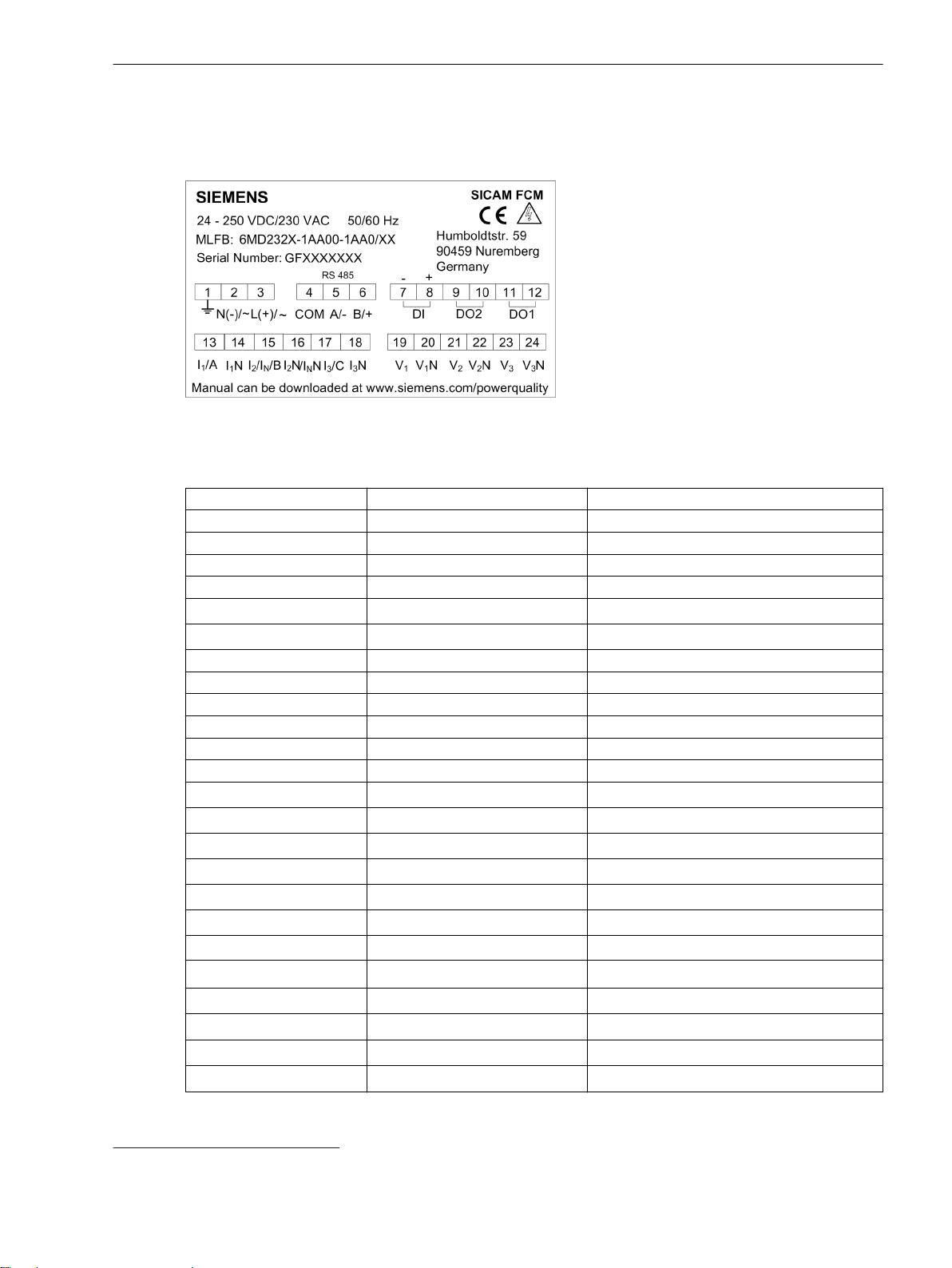

The terminal diagram is located on top of the housing and displays the terminal numbers and terminals.

[dw_sfcmtrml, 2, en_US]

Figure 3-2 Terminal Diagram

Table 3-1 Terminal Specifications

Terminal Number Terminal Name Description

(1) 1 Functional ground

(2) N(-)/~ Auxiliary voltage

(3) L(+)/~ Auxiliary voltage

(4) COM Modbus - Common

(5) A/- Modbus - T

(6) B/+ Modbus - R

(7) DI1(-) Digital input (-)

(8) DI1(+) Digital input (+)

(9) DO2 Digital output 2

(10) DO2 Digital output 2

(11) DO1 Digital output 1

(12) DO1 Digital output 1

(13) I1/A Phase current I

(14) I1N Neutral

(15) I2/IN/B Phase current I2 or ground current I

(16) I2/INN Neutral

(17) I3/C Phase current I

(18) I3N Neutral

(19) V

(20)

(21) V

(22)

(23) V

(24)

1

V1N

2

V2N

3

V3N

5

5

5

Voltage input V

Neutral

Voltage input V

Neutral

Voltage input V

Neutral

x

x

1

N

3

1

2

3

5

V1N, V2N, V3N are internally shorted

SICAM, Feeder Condition Monitor, Manual 23

E50417-H8940-C580-A4, Edition 03.2019

Page 24

Hardware Components and Drawings

3.2 Terminal Diagram

Terminal Connections

You can connect the device terminals with a wire of cross-section ranging from 0.75 mm2 to 2.5 mm2. Use the

following options to connect the terminals:

Spring-cage connection

•

Spring-cage connection is used to connect the upper row of terminals. From terminal 1 to terminal 12.

Screw connection

•

Screw connection is used to connect the bottom row of terminals. From terminal 13 to terminal 24.

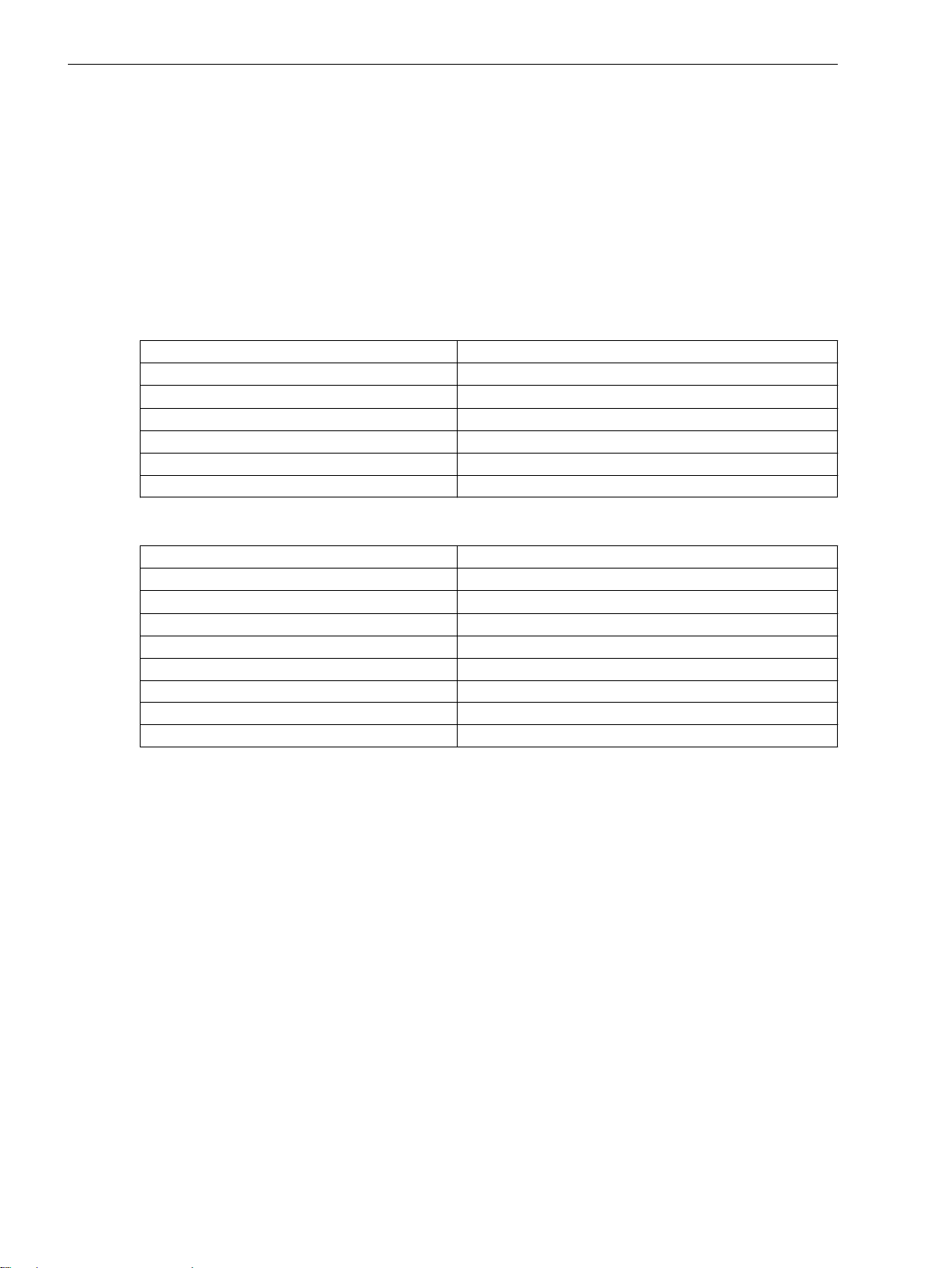

The following tables show the technical details of the different connection methods.

Table 3-2 Spring-Cage Connection

Connection Elements Specifications

Connection method Spring cage

Conductor size (solid)

Conductor size (stranded)

Stripping length 8.0 mm

AWG (max.) 12.0

AWG (min.) 24.0

4.0 mm

2.5 mm

2

2

Table 3-3 Screw Connection

Connection Elements Specifications

Connection method Screw connection

Conductor size (solid)

Conductor size (stranded)

1.0 mm

1.0 mm

2

2

Stripping length 8.0 mm

AWG (max.) 16.0

AWG (min.) 26.0

Torque 0.5 Nm

Screwdriver size 3/32 inch or 2.5 mm

24 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 25

Hardware Components and Drawings

3.3 Dimensional Drawings

3.3

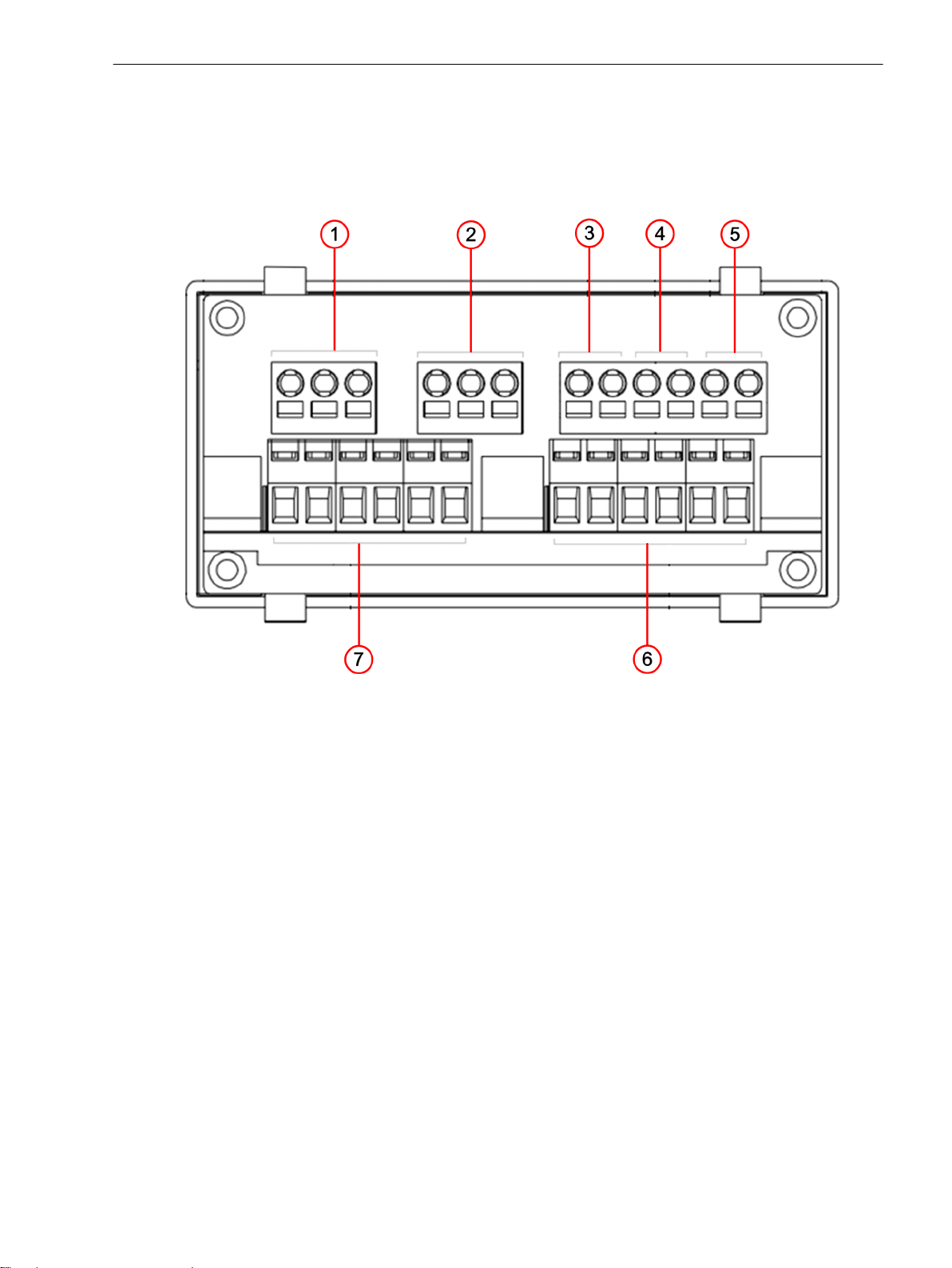

Rear View

Dimensional Drawings

This chapter shows the dimensional drawings and different views of the device.

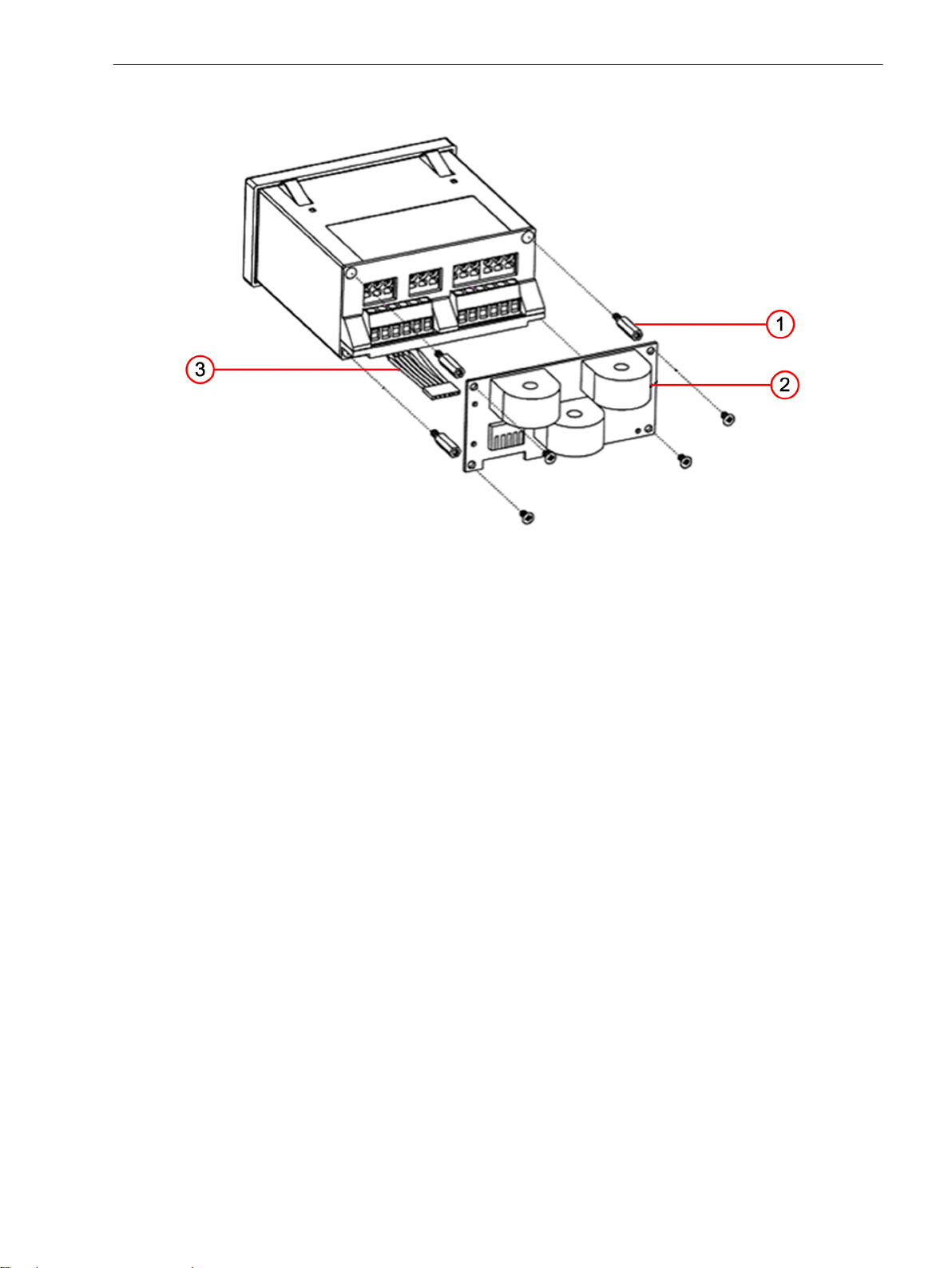

[le_sfcmrearview, 1, --_--]

Figure 3-3

(1) Power supply

(2) Modbus

(3) Digital input

(4) Digital output 2

(5) Digital output 1

(6) Voltage input

(7) Current input

Rear View with Terminals

SICAM, Feeder Condition Monitor, Manual 25

E50417-H8940-C580-A4, Edition 03.2019

Page 26

Hardware Components and Drawings

3.3 Dimensional Drawings

Front View

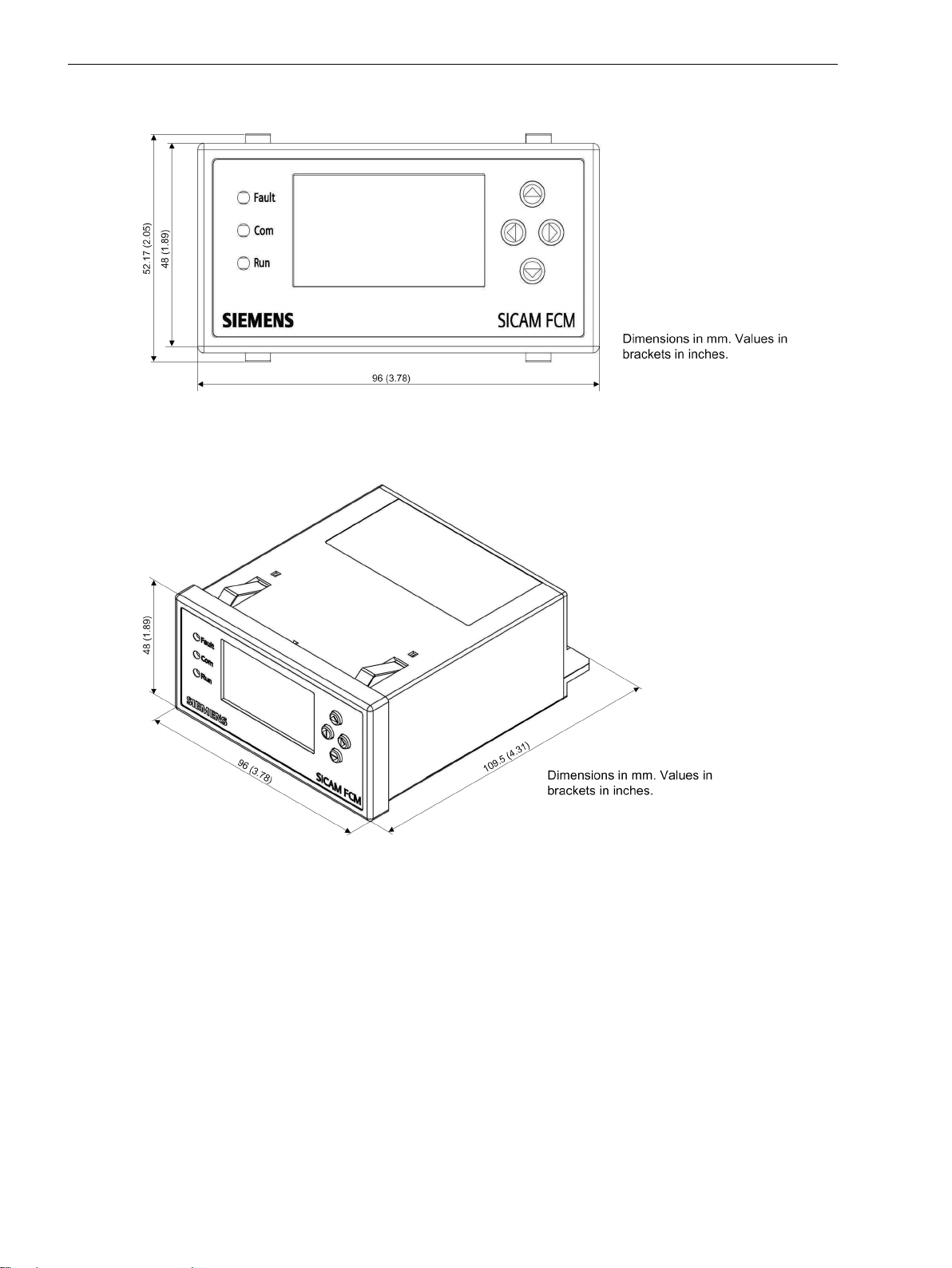

[dw_fcm_front, 1, en_US]

Figure 3-4 Front View

Isometric View

[dw_fcm_iso_view, 1, en_US]

Figure 3-5 Isometric View

26 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 27

1 A/5 A Adaptor Drawing

Hardware Components and Drawings

3.3 Dimensional Drawings

[le_sfcm1aadap-231015, 1, --_--]

Figure 3-6 1 A/5 A Adaptor

(1) Threaded stud

(2) CT adaptor PCB

(3) Cable assembly

SICAM, Feeder Condition Monitor, Manual 27

E50417-H8940-C580-A4, Edition 03.2019

Page 28

Hardware Components and Drawings

3.3 Dimensional Drawings

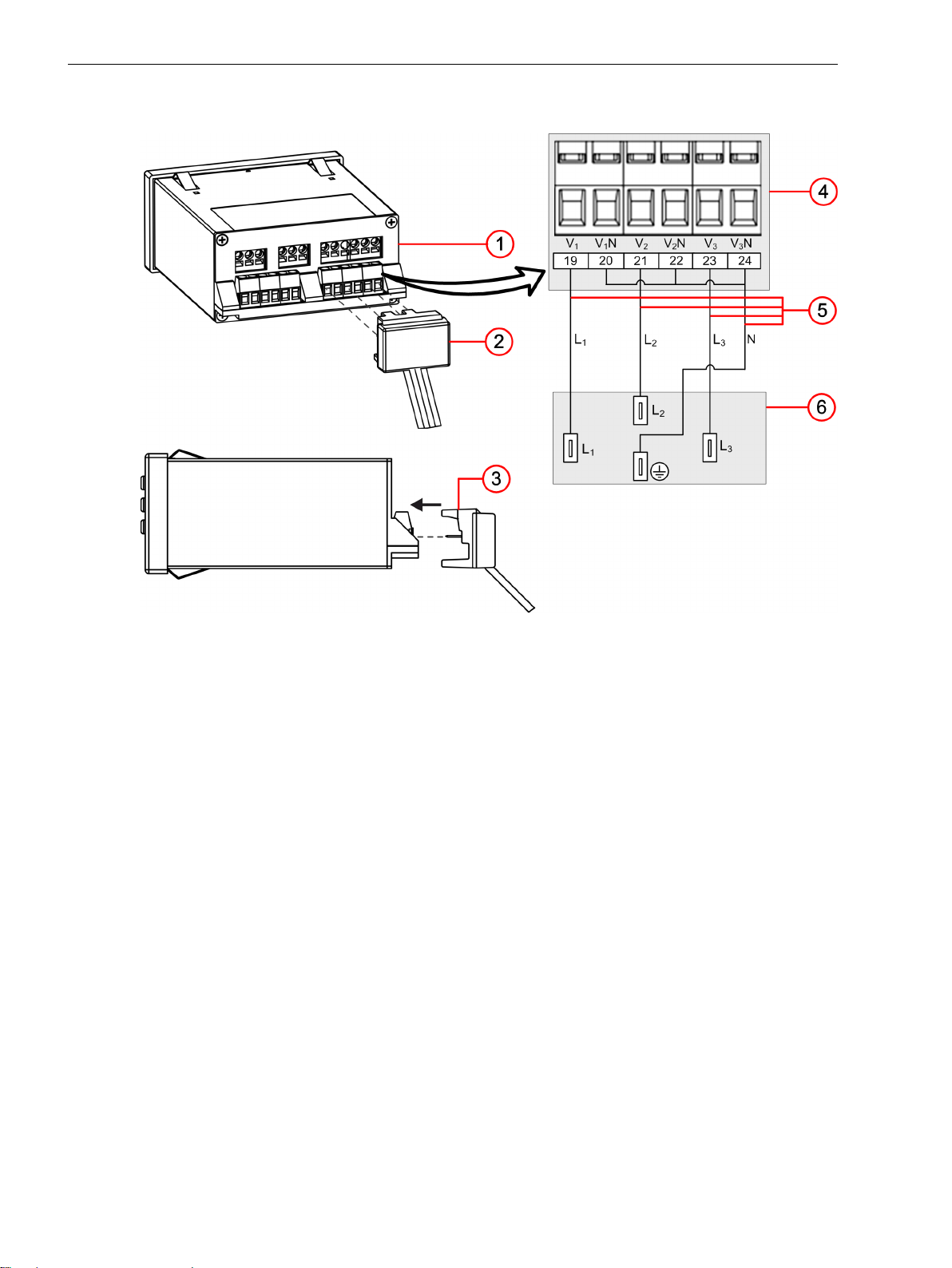

SICAM FCM with Connecting Cable (only for 6MD2322-1AA00-1AA0)

[le_sfcm-capconncbl, 2, --_--]

Figure 3-7

Connecting Cable of SICAM FCM

(1) SICAM FCM

(2) Connecting cable (6MD2322-0AA80-0AB3); necessary for 6MD2322-1AA00-1AA0

(3) Orientation of connecting cable to SICAM FCM voltage-input terminals

(4) SICAM FCM voltage-input terminals

(5) Connecting cable (L1, L2, L3, ground)

(6) Voltage-detection system

28 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 29

4

Device Functions

4.1 Description 30

SICAM, Feeder Condition Monitor, Manual 29

E50417-H8940-C580-A4, Edition 03.2019

Page 30

i

i

Device Functions

4.1 Description

4.1

4.1.1

4.1.2

Description

Measurements and Derived Values

The device measures and calculates the values which are displayed on the HMI/Modbus. The following table

shows the measured values and derived values of the device when it is connected to the medium-voltage

system and low-voltage system.

Table 4-1 Measurements and Derived Values

Measurements Derived Values

Phase I1, phase I2, phase I

Phase I1, ground IN, phase I

Phase V1, V2, V

Frequency 50 Hz/60 Hz –

– Active power, reactive power, and apparent power

– cos φ (power factor)

– Phase angle

– Active import energy, active export energy, reactive import energy, and

3

3

3

Fault Detection

IN and 2nd harmonic of the phase current

I2 and 2nd harmonic of the phase current

Phase-to-phase voltages (V12, V23, V31)

reactive export energy

The device determines the fault based on the following criteria:

Overcurrent detection for phase currents (I>, I>>) and ground current (IN>)

•

Ground-current and neutral-point displacement voltage (IN> and VNG>) for resonant-grounded/isolated

•

system

where VNG is an internally calculated value.

You can configure the individual time-delay setting for phase current and ground currents.

Table 4-2

tI> Timer for the low-set current threshold I>

tI>> Timer for the high-set current threshold I>>

tIN> Timer for the ground-current threshold IN>

tVNG> Timer for neutral-point displacement voltage VNG>

NOTE

For fault detection, the highest values of one of the timers are considered.

The device uses the Definite Minimum Time (DMT) or Inverse Definite Minimum Time (IDMT) characteristics

for detecting the fault. It identifies the type of the fault and also determines the direction.

The following logic diagram shows the fault indication.

Timer Configuration

30 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 31

i

i

i

i

Device Functions

4.1 Description

[lo_sfcm_phase_fault_indication, 2, en_US]

Figure 4-1

[lo_ground_fault_reset, 3, en_US]

Figure 4-2 Logic Diagram for Ground-Fault Detection

For isolated ground:

IN (Watt-metric) = IN ⋅ sin φ

For resonant ground:

IN (Watt-metric) = IN ⋅ cos φ

For more information about ground-fault detection by watt-metric method, refer to chapter 4.1.20 Ground-

Fault Detection with Cos φ/Sin φ Measurement

NOTE

For solid ground or if I

Logic Diagram for Phase-Fault Indication

is set to 0, I

dir

is disabled and only IN is used for detecting the ground fault.

dir

NOTE

For solid ground or if VNG is set to 0, VNG is disabled and only IN/IN (Watt-metric) is used for detecting the

ground fault.

SICAM, Feeder Condition Monitor, Manual 31

E50417-H8940-C580-A4, Edition 03.2019

Page 32

i

i

Device Functions

4.1 Description

NOTE

For isolated/compensated systems in case of 2-phase-to-ground and 3-phase-to-ground faults, whenever a

ground fault and phase fault occur at a same time, SICAM FCM indicates phase fault as a priority event on

HMI/Modbus.

For more information about direction determination, refer to 4.1.15 Determination of Fault Direction,

4.1.16 Direction Determination of Phase Elements, 4.1.17 Directional Ground Fault (Compensated/Resonant-

Grounded) , and 4.1.18 Directional Ground Fault (in Isolated Electrical Power Systems).

For more information about fault-detection parameters, see Table A-2 for the Fault Parameters > Phase-Fault

Detection menu and Table A-3 for the Fault Parameters > Ground-Fault Detection menu.

4.1.3

Fault-Reset Mechanism

The fault status of the device can be reset through anyone of the following mechanisms:

Auto reset as per user-defined time setting

•

Digital input (DC 24 V to DC 60 V)

•

User interface through keypad (Reset)

•

RS485/Modbus interface

•

The following logic diagram shows the fault-reset mechanism.

[lo_sfcm_faultresetmech, 2, en_US]

Figure 4-3

(1) Binary contact 1, indication on HMI and Modbus, event logs

(2) Binary contact 2, indication on HMI and Modbus, event logs

(3) Binary contact 1 and Binary contact 2, indication on HMI and Modbus, event logs

32 SICAM, Feeder Condition Monitor, Manual

Logic Diagram for Fault Indication and Fault Reset Mechanism

E50417-H8940-C580-A4, Edition 03.2019

Page 33

Device Functions

4.1 Description

4.1.4

Enhanced Fault Validation and Fault-Reset Function

The enhanced fault validation provides an additional functionality by detecting the absence of voltage or

current and enables a delay of the fault indication and fault reset.

The fault can be detected and reset by additionally configuring the following timers:

Timer Description

T1 Monitoring period for fault validation

T2 Absence of voltage and current monitoring time

T3 Auto reset time after resumption of voltage or current

When the system phase current exceeds the set current thresholds (I>, low-set or I>>, high-set) and persists

for the defined time (tI>), the device starts monitoring the pickup time (T1). When the fault is isolated, the

system voltage/current drops. When this condition is reached, the device monitors the absence of voltage for a

time T2 for the drop in voltage or current as long as it reaches values below 6 kV (phase-to-ground) or 5 A

respectively. The fault is indicated if the absence of voltage or current persists until the timer T2 elapses

(T2<T1).

For the ground fault, configure the threshold for the neutral-point displacement voltage (VNG>) and the

ground current (IN>). If the threshold exceeds the setting and the fault persists for the times tIN> and tVNG>,

the device indicates the ground fault based on the timers T1 and T2.

If the timer T3 is configured, then the auto reset of the fault indication occurs after the resumption of voltage

or currents. The device monitors if the voltages or currents of the system increase for this time period T3

above 6 kV or 5 A respectively. After elapse of the set time, the device resets the fault indication.

The following logic diagrams illustrates the fault-detection initiation and fault reset.

[lo_sfcmfaultdetect-reset, 2, en_US]

Figure 4-4

SICAM, Feeder Condition Monitor, Manual 33

E50417-H8940-C580-A4, Edition 03.2019

Logic Diagram for Fault-Detection Initiation and Fault Reset

Page 34

i

i

i

i

Device Functions

4.1 Description

[lo_fault_det_ini_and_reset, 3, en_US]

Figure 4-5

For isolated ground:

IN (Watt-metric) = IN ⋅ sin φ

For resonant ground:

IN (Watt-metric) = IN ⋅ cos φ

For more information about ground-fault detection by watt-metric method, refer to chapter 4.1.20 Ground-

Fault Detection with Cos φ/Sin φ Measurement

NOTE

For solid ground or if I

NOTE

For solid ground or if VN> is set to 0, VNG is disabled and only IN/IN (Watt-metric) is used for detecting the

ground fault.

The following logic diagram illustrates the fault indication and fault reset.

Logic Diagram for Fault-Detection Initiation and Fault Reset

is set to 0, I

dir

is disabled and only IN is used for detecting the ground fault.

dir

34 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 35

Device Functions

4.1 Description

[lo_sfcm_fltindrst, 2, en_US]

Figure 4-6

Logic Diagram for Fault Indication and Fault Reset

The following figure describes the timer-based fault-indication operation.

[lo_medvolsup, 2, en_US]

Figure 4-7 Timer-Based Fault Indication

SICAM, Feeder Condition Monitor, Manual 35

E50417-H8940-C580-A4, Edition 03.2019

Page 36

i

i

Device Functions

4.1 Description

NOTE

If any of the timers T1, T2, and T3 is set to 0, the other 2 timers are disabled. For example, if T1=0, T2 and

T3 are disabled.

4.1.5

Definite Minimum Time (DMT)

Trip Time DMT and IDMT

SICAM FCM supports both the DMT and IDMT function.

DMT is applicable for both the phase fault and the ground fault.

The 3 DMT settings are I>, I>>, IN>. Each setting consists of the independent trip-time delays tI>, tI>>, and tIN>.

The user-defined DMT setting is used to configure various current thresholds for the entire dynamic primary

current range.

If the current in the system exceeds the set threshold and persists for the set time specified, the device indi-

cates a fault. The device provides an option to set for 2 current thresholds and 2 time delay thresholds.

The following table illustrates the parameter settings and the values.

Table 4-3 Reference

Parameter Attribute Value

I> Setting 50 A to 2500 A

tI> Delay setting 40 ms to 60 s

I>> Setting 50 A to 2500 A

tI>> Delay setting 40 ms to 60 s

IN> Setting 0.4 A to 2000 A

tIN> Delay setting 40 ms to 60 s

Table 4-4 Operate Level

Parameter Attribute Value

I> Operate level 110 % of I> ±5 %

I>> Operate level 110 % of I>> ±5 %

Table 4-5 Operate Time

Parameter Attribute Value

tI> Operate time 40 ms ±25 ms

tI>> Operate time 40 ms ±25 ms

Inverse Definite Minimum Time (IDMT)

IDMT characteristics are defined as Inverse because the trip time is inversely proportional to the fault current

being measured.

In SICAM FCM, the IDMT function supports the Normal Inverse (NI) characteristics. The ANSI codes supported

by the IDMT function are non-directional (51) and directional (67) for overcurrent indication.

IDMT function is applicable only for the phase currents I1, I2, and I3.

The following table illustrates the parameter settings and the values.

Table 4-6

Parameter Attribute Value

I> Setting 50 A to 2500 A

Reference

36 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 37

i

i

i

i

Device Functions

4.1 Description

Table 4-7 Operate Level

Parameter Attribute Value

I> Operate level 110 % of I> ±5 %

Table 4-8 Operate Time

Parameter Attribute Value

Operate time char = IEC-NI ±5 % absolute or ±40 ms

Time multiplier setting (k) 0.09 –

NOTE

The IDMT function is not applicable for the ground fault IN.

If tI> is set to zero, the NI trip time curve according to the IEC characteristics is calculated based on the

following formula.

I

is the fault current. I

fault

The fixed value of k is 0.09.

is the setting value of the pickup current.

set

4.1.6

4.1.7

NOTE

For setting the IDMT characteristics curves, set tI> = 0.

Ground-Fault Parameter Active Group Setting

The device provides 2 groups of settings (Group 1 and Group 2) for the Neutral-point treatment parameter (solid, resonant, isolated) and Ground-fault parameters (IN>, tIN>, VNG>, tVNG>, and I

You can select the active group and its group parameter from HMI and Modbus, by holding register (address

42) or by turning ON the coil 12. When the device is indicating a fault, you cannot change the active group

and its parameters.

At any time, only one selected group of settings is active. These parameters are used for detecting the ground

fault.

For more information about the active-group switching coil, refer to Table B-10.

For more information about the active group, refer to Active Group, Page 121.

).

dir

Fault Indication

When the device detects a fault, the following components are activated:

LED

•

The red LED is turned on and indicates a fault.

LCD

•

The LCD displays fault current values with the fault type.

Modbus

•

The device sends the fault current, fault type, and additional fault information to the RTU.

If a fault is detected, the red LED flashes every 1 s if the device is not powered through an auxiliary supply.

SICAM, Feeder Condition Monitor, Manual 37

E50417-H8940-C580-A4, Edition 03.2019

Page 38

i

i

Device Functions

4.1 Description

NOTE

For the temperatures below -20 °C, the LCD display can take up to 2 min to start or display the data.

4.1.8

4.1.9

DO Configuration

The digital output (DO) is configured to indicate either the fault direction or the device-health

status by using the DO configuration parameter.

If the DOs are configured to indicate the fault direction:

DO1 operates to indicate a forward fault direction and DO2 operates to indicate a reverse fault direction.

•

Operation of both DOs indicates that the fault direction could not be determined.

•

If the DOs are configured to indicate the device-health status:

DO1 operates to indicate an unhealthy device (DO2 is deactivated).

•

If both DOs do not operate, this is an indication that the device is healthy.

•

The DO configuration can only be switched if SICAM FCM does not indicate any faults.

For more information about the DO configuration parameter, refer to DO Configuration, Page 123.

Operating Modes

The device goes to the sleep mode when disconnected from an auxiliary supply. In this mode, the communication with the RTU is not available. In the sleep mode, you can press any of the keys to view the events.

The device enters the deep sleep mode after 8 hours in the sleep mode and requires an auxiliary supply to

recover from this mode.

4.1.10

Correction Factors for LoPo VT and LoPo CT (IEC 61869-10, IEC 61869-11)

IEC 61869-10 and IEC 61869-11 allow to adjust the magnitudes and phases of current and voltage sensors. If

any inaccuracies are stable within the measuring range, then the overall accuracy of sensors is improved to

higher level.

Sensors which specify individual correction factors on their labels and in routine tests can be configured

•

in SICAM FCM to improve system accuracy.

Sensors which are used in combination with SICAM FCM and do not have correction factors, disable the

•

respective correction factors. In this way, the device works with secondary values as measured without

any influence on magnitudes and phase angles.

The correction factors are expressed in terms of magnitude and angle offset per phase of voltage/current. By

enabling the Correction Factor parameter via HMI or Modbus, then the device applies these correction

factors to improve the measuring accuracy of the sensor.

The correction factor works as per the following logic:

The measured phase-to-ground voltages and measured phase currents/ground currents are multiplied by

•

the respective voltage and current magnitude factor.

The measured phase-to-ground voltage and phase currents/ground current angles are added for positive

•

angle offset or subtracted for negative angle offset.

The correction factor is applied on all measured values and reflects on all derived values.

•

If Correction Factor parameter (holding register address 79) is set to 0 (disabled), then the correction

factors with the holding addresses 80 to 91 are set to 0 and not applied in voltage/current measurements.

38 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 39

i

i

Device Functions

4.1 Description

If Correction Factor parameter (holding register address 79) is set to 1 (enabled), then the correction

factors with the holding addresses 80 to 91 are set to the default values. For more information about holding

registers, refer to Table B-5.

NOTE

The voltage magnitude and voltage angle offset are applicable only for the 3.25/√3 LoPo VT.

The current magnitude and current angle offset are applicable only for the LoPo current sensor.

4.1.11

Power-Flow Direction Reversal for Solidly-Grounded System

Power-Flow Direction Reversal

The following power-flow direction parameters define the polarity of the CT/LoPo sensor for I1, I2, and I3 measurements:

I1 power-flow direction

•

I2/IN power-flow direction

•

I3 power-flow direction

•

If the CT/LoPo sensor is connected in the opposite direction, the current measured using the CT/LoPo sensor

has an additional phase shift of 180°. The power-flow direction parameters are used to compensate the additional phase shift.

If the power-flow direction parameters are set to reversed, the power-flow direction is reversed by adding

180° to the respective measured phase-current angle.

If the power-flow direction parameters are set to not reversed, it restores the power-flow direction to the

original direction.

For more information about power-flow direction parameters, refer to I1 Power-Flow Direction, Page 124.

The following power-flow direction reversal parameters affect the respective power-flow direction, fault direction, and power:

I

•

1

I

•

2

I

•

3

They also affect the IN angle, IN power-flow direction, and IN> fault direction. The corrected angles for I1, I2,

and I3 are displayed in the Modbus input register.

If the power-flow direction parameters are set to reversed, the fault direction is shifted by 180°.

Power-Flow Direction Reversal for Resonant/Isolated Grounded System

The power-flow direction reversal for IN affects the IN power-flow direction, IN fault direction, and watt-metric

ground current. The original IN angle before correction is displayed in the Modbus input register and is used

for deriving the I2 angle.

The power-flow direction reversal for I1 and I3 affects the respective power-flow direction, fault direction, and

power. The corrected angles for I1 and I3 are displayed in the Modbus input register.

If the power-flow direction parameters are set to not reversed, the fault direction is shifted by 180°.

4.1.12

SICAM, Feeder Condition Monitor, Manual 39

E50417-H8940-C580-A4, Edition 03.2019

P,Q Sign

The P,Q sign parameter is used to reverse the sign of active power (P) and reactive power (Q) for all phases.

The P,Q sign parameter cannot be configured for individual phases.

Page 40

Device Functions

4.1 Description

If the P,Q sign parameter value is set to not reversed, the sign of active power (P) and reactive power

(Q) for all phases indicates the original active power (P) and reactive power (Q). If the P,Q sign parameter

value is set to reversed, the signs of active power (P) and reactive power (Q) for all phases get reversed. The

P,Q sign parameter is independent of the power-flow direction parameter. The P,Q sign parameter

affects the total active power (P) and reactive power (Q). The P,Q sign parameter does not affect the

power-flow direction, fault direction, current angle, and power factor for all phases. It also does not affect the

watt-metric ground current.

For more information about the P,Q sign parameter, refer to P,Q Sign, Page 125.

4.1.13

3-Phase Angle Calculations

A phase sequence defines the sequential timing in which each phase-to-ground voltage phasor lags each

phase-to-ground voltage phasor in the counter-clockwise direction.

Figure 4-8 shows the 3-phase sequence. The sequence shown below implies that V12 leads V23 by 120° and

V23 leads V31 by 120°. In addition, V1N leads V2N by 120° and V2N leads V3N by 120°. It is mandatory to

establish the balanced phase sequence before any calculations. In the device, V1N is considered as a reference

phasor at 0°. This phase sequence is needed to relate the calculated phasor angles with reference to the

phasor V1N.

[dw_sfcm3phangcalc, 1, en_US]

Figure 4-8 3-Phase Angle Calculations

In a standard balanced system, all phase-to-phase voltages are phase-to-neutral voltages multiplied by √3 and

lead the phase-to-neutral voltage phasors by 30°. For example, in a standard 4-wire, 3-phase wye system with

phase-to-neutral voltages of 120 V and V1N selected as the reference phasor, then phase-to-phase voltages

are as follows: V12 = 208∠ 30°; V23 = 208∠ 270°; V31 = 208∠ 150°.

4.1.14

40 SICAM, Feeder Condition Monitor, Manual

Phase-Sequence Monitoring

The phase sequence of the measured phase-to-ground voltages is checked by monitoring the angle difference

between phase-to-ground and phase-to-phase voltages.

SICAM FCM monitors the phase sequence of voltage signals from voltage sensors and displays it on the HMI/

Modbus. The phase-sequence monitoring algorithm uses measured phase-to-ground voltage and phase-tophase voltage angles in balanced condition. For monitoring the phase sequence, the threshold voltage is at

least 50 % of primary voltage.

E50417-H8940-C580-A4, Edition 03.2019

Page 41

i

i

Device Functions

4.1 Description

If the phase sequence is clockwise, then it is denoted as ABC. Similarly if the phase sequence is counter-clockwise, then it is denoted as ACB. The monitored phase sequence is also displayed as 2 discrete inputs in the

Modbus register.

The following phasor diagram shows the clockwise and counter-clockwise phase sequences:

[dw_sfcm-phasesequence, 1, en_US]

Figure 4-9 Clockwise and Counter-Clockwise Phase Sequences

4.1.15

In the HMI, the status of the phase sequence is shown as PH SEQ: ABC or PH SEQ: ACB or ---, if the phase

sequence cannot be determined.

If the phase sequence is ABC, then the discrete input (33) of the Modbus register is set to 1.

If the phase sequence is ACB, then the discrete input (34) of the Modbus register is set to 1.

If the phase sequence is not detected, then the discrete inputs (33, 34) of the Modbus registers are set to 0.

If the phase-to-ground voltage is below the threshold voltage, then the phase sequence is displayed as --- on

the HMI and the Modbus register is set to 0.

If there are any device alerts and a fault is detected in the system, then the phase sequence is displayed as ---

on the HMI and the Modbus register is set to 0.

NOTE

Protection functions implemented in SICAM FCM are designed for clockwise phase sequence only.

Determination of Fault Direction

The fault direction for the phase faults is determined by calculating the phase angles between the fault

current and the corresponding phase-to-phase voltages.

Pickup

1 I

2 – – I

3 – – – – I

N – – – – – – –

1, N I

2, N – – I

3, N – – – – I

Measuring Element

1 2 3 N

1

1

V2 - V

V2 - V

– – – – – –

3

2

– – – – I

3

2

V3 - V

V3 - V

1

1

– – – –

3

V1 - V

2

– – I

3

V1 - V

2

– –

N

N

I

N

6

V

NG

6

V

NG

6

V

NG

6

V

NG

6

VNG = V1 + V2 + V3 (derived value)

SICAM, Feeder Condition Monitor, Manual 41

E50417-H8940-C580-A4, Edition 03.2019

Page 42

i

i

Device Functions

4.1 Description

Pickup Measuring Element

1, 2 I

2, 3 – – I

1, 3 I

1, 2, N I

2, 3, N – – I

1, 3, N I

1, 2, 3 I

1, 2, 3, N I

1 2 3 N

1

1

1

1

1

1

V2 - V

V2 - V

V2 - V

V2 - V

V2 - V

V2 - V

I

3

2

2

– – I

3

I

3

2

2

– – I

3

I

3

2

I

3

2

V3 - V

V3 - V

V3 - V

V3 - V

V3 - V

V3 - V

1

1

1

1

1

1

– – – –

I

3

3

V1 - V

V1 - V

2

2

– – I

I

3

3

I

3

I

3

V1 - V

V1 - V

V1 - V

V1 - V

2

2

2

2

– –

– –

N

I

N

I

N

– –

I

N

6

V

NG

6

V

NG

6

V

NG

6

V

NG

4.1.16

Direction Determination of Phase Elements

In the device, the directional overcurrent element operates for any faults either in forward direction or in

reverse direction.

The directional determination of phase elements works in the quadrature connection to prevent the loss of

polarizing quantity for close-in phase faults. Each current element has a direction by a voltage derived from

the other 2 phases. This connection introduces a 90° phase jump (current leading voltage) between reference

voltages and operating quantities (currents). A fault is determined to be in the selected direction if its phase

relationship lies within a quadrant of ± 85° on either side of the characteristic angle. It is hard-coded as +45°.

[dw_sfcm-dirdetphaelm, 1, en_US]

Figure 4-10 Direction Determination of Phase Elements

NOTE

The undetermined area for the device MLFB 6MD2321-1AA00-1AA0 is 10° and the respective angles

change accordingly.

The undetermined area for the device MLFB 6MD2322-1AA00-1AA0 is 20° and the respective angles

change accordingly.

42 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 43

i

i

Device Functions

4.1 Description

4.1.17

Directional Ground Fault (Compensated/Resonant-Grounded)

In the compensated/resonant-grounded system, the Petersen coil is configured to match the capacitive

charging currents, such that when a ground fault occurs, a negligible fault current flows. The characteristic

angle is set to 0°. A boundary of +90° is used to detect the direction of the resistive component within residual

currents.

With the cos φ method, the watt-metric residual current is calculated in case of a fault. This method of determining the ground-fault detection is implemented in the watt-metric method. For more information about the

watt-metric method, refer to 4.1.20 Ground-Fault Detection with Cos φ/Sin φ Measurement.

In the vector method, the ground-fault detection occurs if the total current IN> is exceeded.

The device calculates the active power of the zero sequence (P0) and if the value is falling in the 1st and the

4th quadrant, then the direction is forward. If the active power of the zero sequence (P0) is falling in the 2nd

and 3rd quadrant, then the direction is shown as reverse.

For more information about directional ground-fault parameters (compensated/resonant-grounded), see

Table A-3 and refer to the Fault Parameter > Ground-Fault Detection > Neutral-point Treatment menu.

4.1.18

[dw_sfcm-grndflt-comp-res, 1, en_US]

Figure 4-11 Directional Ground Fault (Compensated/Resonant-Grounded) for Vector Method

NOTE

The undetermined area for the device MLFB 6MD2321-1AA00-1AA0 is 10° and the respective angles

change accordingly.

The undetermined area for the device MLFB 6MD2322-1AA00-1AA0 is 20° and the respective angles

change accordingly.

Directional Ground Fault (in Isolated Electrical Power Systems)

During ground fault on the isolated distribution system, no fault path is detected and subsequently no fault

current flows. The phase-to-neutral capacitive charging current of the healthy phases for the entire system is

supplied through the fault path. This produces a current that is used to detect the presence of the ground

fault. It appears as a residual current which lags the residual voltage by 90°. The characteristic angle is -90°.

The device calculates the reactive power of the zero sequence (Q0). If the value is falling in the 1st and the

2nd quadrant, then the direction is reverse. If the reactive power of the zero sequence (Q0) is falling in the 3rd

and 4th quadrant, then the direction is shown as forward.

For more information about directional ground-fault parameters (isolated grounded), see Table A-3 and refer

to the Fault Parameter > Ground-Fault Detection > Neutral-point Treatment menu.

SICAM, Feeder Condition Monitor, Manual 43

E50417-H8940-C580-A4, Edition 03.2019

Page 44

i

i

Device Functions

4.1 Description

[dw_sfcm-grndflt-iso, 1, en_US]

Figure 4-12 Directional Ground Fault (Isolated Grounded) for Vector Method

NOTE

The undetermined area for the device MLFB 6MD2321-1AA00-1AA0 is 10° and the respective angles

change accordingly.

The undetermined area for the device MLFB 6MD2322-1AA00-1AA0 is 20° and the respective angles

change accordingly.

4.1.19

Ground-Fault Direction for Solidly Grounded System

The solidly grounded system is a common system arrangement in which the neutral is solidly connected to the

ground. For the solid-grounded connection, the neutral-point displacement voltage is sufficient to measure

and determine the directional information. This results in determining the ground-fault direction based on the

rotation angle of the reference vector.

[dw_sfcm-grndflt-sol, 1, en_US]

Figure 4-13 Ground-Fault Direction for Solidly Grounded System

44 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 45

i

i

Device Functions

4.1 Description

NOTE

The undetermined area for the device MLFB 6MD2321-1AA00-1AA0 is 10° and the respective angles

change accordingly.

The undetermined area for the device MLFB 6MD2322-1AA00-1AA0 is 20° and the respective angles

change accordingly.

For more information about ground-fault direction of solidly grounded system, see Table A-3 and refer to the

Fault Parameter > Ground-Fault Detection > Neutral-point Treatment menu.

4.1.20

Ground-Fault Detection with Cos φ/Sin φ Measurement

The ground-fault detection with cos φ/sin φ measurement method is used to detect the ground fault based on

the active part of the current (resonant system) or reactive part of the current (isolated system). The groundfault detection with cos φ/sin φ measurement method is enabled when the I

the resistive part of the ground current) parameter is configured to the values as in Table 4-9. If I

the device detects the ground fault based on the vector method.

The ground-fault detection with cos φ/sin φ measurement method is only applicable for resonant-grounded

systems and isolated-grounded systems.

If the ground current ((IN>) and the resistive current exceed the set threshold (IN> and I

the time delay tIN> is greater than the set threshold, the device indicates a fault.

If I

is set to 0 (vector method), irrespective of the selected ground-type connection, the total ground current

dir

is compared with the set current IN> for fault detection.

For resonant-ground connections, if I

method), the active part of the ground current is compared with I

IN> for ground-fault detection.

For isolated-ground connections, if I

method), the reactive part of the ground current is compared with I

and IN> for ground-fault detection.

For more information about I

Detection menu.

The following logic diagram illustrates the ground-fault detection with cos φ/sin φ measurement method.

parameters, see Table A-3 and refer to the Fault Parameters > Ground-Fault

dir

is not 0 (ground-fault detection with cos φ/sin φ measurement

dir

in addition to the total ground current and

dir

is not 0 (ground-fault detection with cos φ/sin φ measurement

dir

in addition to the total ground current

dir

(user-settable parameter for

dir

is set to 0,

dir

respectively) and if

dir

[lo_sfcm-grndfltdet-cossine, 2, en_US]

Figure 4-14 Logic Diagram for Ground-Fault Detection with Cos φ/Sin φ Measurement Method

The following table displays the I

method status:

SICAM, Feeder Condition Monitor, Manual 45

E50417-H8940-C580-A4, Edition 03.2019

range and the ground-fault detection with cos φ/sin φ measurement

dir

Page 46

i

i

Device Functions

4.1 Description

Table 4-9 Ground-Fault Detection with Cos φ/Sin φ Measurement Method Range

I

dir

0 Vector method is enabled

0.2 A to 30 A Ground-fault detection with cos φ/sin φ measurement method is enabled

NOTE

Range Status

4.1.21

In the solidly grounded system, set the I

parameter to 0.

dir

Determination of a Ground Fault with the Pulse-Location Detection Mechanism

The Pulse-location detection mechanism detects a faulty feeder during a permanent ground fault in

overcompensated systems. The Pulse-location detection mechanism is applicable for resonanlt-grounded

systems only and not applicable to the undercompensated systems.

Figure 4-15 shows a simplified network with the pulse-location detection mechanism. The pulse pattern in the

ground current IN is generated by switching on and off a capacitor in parallel to the arc-suppression coil:

When the capacitor is switched on, an additional capacitive ground current is generated and the ground-

•

current compensation changes.

When the capacitor is switched off, the additional capacitive ground current no longer exists and the

•

ground-current compensation returns to the normal state.

46 SICAM, Feeder Condition Monitor, Manual

E50417-H8940-C580-A4, Edition 03.2019

Page 47

Device Functions

4.1 Description

[lo_sfcm_pulse_pattern_mech, 1, en_US]

Figure 4-15

C

S

Network in Pulse-Location Detection