Page 1

SIBAG HSD 3.0

High Speed Diverter

Service Manual

Document No.: 747-01695, Rev. 03

Page 2

SIBAG HSD 3.0 Service Manual

ii

Document No.: 747-01695, Rev. 03

2021-March-03

02

2020-September-10

Updated control panels

Information in this document is subject to change without notice. No part of this

document may be reproduced or transmitted in any form or by any means,

electronic or mechanical, for any purpose, without the express written permission

of Siemens Logistics LLC.

2021 Siemens Logistics LLC. All rights reserved.

This document contains confidential information, trade secrets and/or know-how

which is the property of Siemens Logistics LLC, and may not be disclosed to any

third party without the written permission of Siemens Logistics LLC.

Product and company names herein may be the trademarks of their respective

owners.

Siemens Logistics LLC

2700 Esters Blvd.

Suite 200B

DFW Airport, TX 75261

www.siemens-logistics.com

972-947-7100

1-800-938-7378 (Parts and Service)

Important: Prior to operating any of the equipment or performing any of the

maintenance procedures described within this manual, it is strongly

recommended that the operator and maintenance technician read the

information provided within the applicable sections of this manual. All personnel

shall pay particular attention to the notes, cautions, warnings, and dangers

presented in this manual and posted on or in the area of the equipment. This

equipment has been designed for use by trained and qualified operators. Every

possible effort to prevent injury to the operator or maintenance personnel has

been taken in the preparation of this manual. Damage to the equipment is

possible when the procedures contained within this manual are not followed.

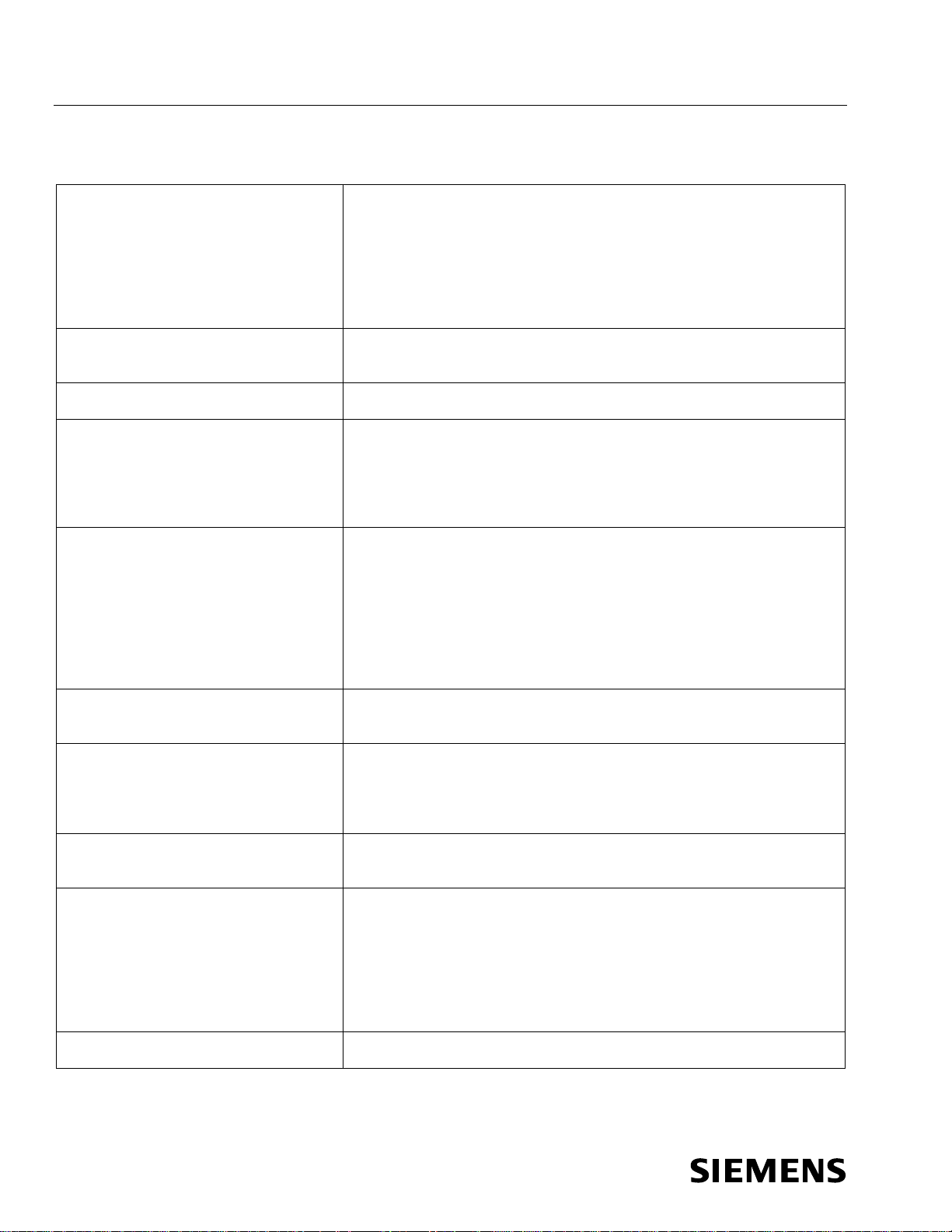

Revision History

Revision Date Description

01 2020-March-05

Updated telegram structure, added Ethernet/IP conf iguration, updated spare

parts list updated HMI screens, added TIA Profinet configuration

03 2021-March-03 Updated control panels

Page 3

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

i

Warranty

Goods and Services

Siemens Logistics LLC warrants that the Goods and/or services as set forth in the Sales

Agreement and Proposal and sold by Siemens Logistics LLC to Purchaser will be free from defects

in material and workmanship for a per iod of: one (1) year from the date of (i) c om pl etion of

installation, (ii) Purchaser acceptance, or (iii) beneficial use; or two thousand hours of operation;

whichever occurs first (“Warranty Period”), subject to the following ter m s and conditions. Where

someone other than Siemens Logis tics LLC installs the Goods, the Warranty Period will

commence with shipment of the Goods. S iemens Logistics LLC’s obligation under the warranty is

limited to repairing or replacing, at Siemens Logistics LLC’s option, F.O.B. manufacturing plant,

any part of the Goods found to be defective within the Warranty Period.

The warranty obligation is conditioned upon receipt by Siemens Logistic s LLC of prompt written

notice of the claimed defect, including a description of the defect and its discovery, and the

opportunity for Siemens Logis tics LLC to inspect the Goods in Purchaser's facility.

The warranty obligation does not include costs of labor or other charges inc ur red in removing or

reinstalling parts; and does not apply to Goods damaged by misuse, abuse, neglect or accident or

to Goods which have been improperly applied, installed, adjusted, operated, maintained, repaired

or altered by persons other than Siemens Logistics LLC.

If Siemens Logistics LLC fails to repair or replace any defective Goods unde r warranty within a

reasonable time, then Siemens Logis tics LLC shall be liable to Purchas er for the lesser of (1) the

reasonable costs of repair or replacement by a third party or (2) that part of t he purchase price of

the defective item that shall have been paid by Purchaser, but Purchaser shall not obtain repair or

replacement by a third party without giv i ng Siemens Logistics LLC at leas t twenty (20) days prior

written notice, during which tim e Siemens Logistics LLC may repair or replace the defective i tem.

Siemens Logistics LLC makes no warranties or representations, nor assumes any obligations with

regard to Purchaser’s existing equipm ent or for any equipment supplied by Purchaser or a third

party contracted by Purchaser and used in the Siemens Logistics LLC system and Purchaser

assumes full responsibility for the use and operation of such equipment, including compliance with

any federal, state and local law, code or regulations

Computer Software and Hardware

For computer software manufactured by Siemens Logistics LLC under the Agreement, Siemens

Logistics LLC provides emergency t elephone support (1-800-938-7378), which is available 24

hours per day, 7 days per week, at no charge for defective computer software dur ing the Warranty

Period. Purchaser’s call will be ref erred to and promptly handled by a Siem ens Logistics LLC

technician who will attempt to quickly res olve the problem through telephone discussion. Should

troubleshooting efforts by the Siem ens Logistics LLC technician det ermine that assistance by

Siemens Logistics LLC Engineering is required, Siemens Logistics LLC will respond in a timely

(best effort) manner. Should on-site service be required to resolve a software defect, Siemens

Logistics LLC Software Emergency On-Site Service is available, on best effort response, and on a

time and expense basis.

For computer hardware supplied b y Siemens Logistics LLC under the Agreement, the computer

hardware warranty includes next-business day response for defective computer hardware by the

computer equipment manufacturer or qualified distributor, from 8 a.m. to 5 p.m. site time, Monday

Page 4

SIBAG HSD 3.0 Service Manual

ii

Document No.: 747-01695, Rev. 03

2021-March-03

through Friday, during the Warranty Period. If defective computer hardware covered under

warranty is detected, replacement par ts will be ordered promptly by the equipment manufacturer or

qualified distributor and installed upon their arrival. Some parts are warranted by Siemens

Logistics LLC and require return to Siemens Logistics LLC for Repair/Replacement. It is the

responsibility of Purchaser to reinstall these parts in the computer system as directed by Siemens

Logistics LLC.

The warranty does not include updates/upgrades for new versions of computer software and

hardware.

The warranty for computer software and hardware will be void and inapplicable to computer

software or hardware damaged by misuse, abuse, neglect or accident or to com puter hardware or

software which has been improperly applied, installed, adjusted, operated, maintained, repaired,

modified, changed or altered by pers ons other than Siemens Logistics LLC or its subcontractors;

or to computer software or hardware that is installed or modified by someone other than Siemens

Logistics LLC or its subcontract or s without the written direction or authority of Siemens Logistics

LLC. The computer hardware supplied by Siemens Logistics LLC is suited for an environmentally

controlled office environment (e.g., air conditioned, heated and clean office environment) and

unless the computer hardware is us ed i n that environment, the computer har dware warranty is null

and void for failures.

If the Goods include computer hardware or software acquired from original manufacturers,

Siemens Logistics LLC’s obligation will be limited to conveying and transferring to Purchaser any

license, interest, rights and/or warr anties which Siemens Logistics LLC may obtain from the

original manufacturer.

Disclaimer

Siemens Logistics LLC does not warrant and is not responsible for warranties or licenses for any,

computer hardware or computer software supplied by Purchaser or acquired from a third party by

Purchaser and used in the Siemens Logistics LLC system. Purchaser will be responsible for all

such licenses and warranties under t hose circumstances, including any problems detected while

the equipment, computer hardware or software is being used for developm ent at Siemens

Logistics LLC.

Siemens Logistics LLC, herein after known as the Company, makes no other warranty of any kind

whatsoever expressed or implied and t he Company hereby disclaims all warranties of

merchantability and fitness for particular purpose. The Company shall in no case be subject to any

other obligations or liabilities whatsoever with respect to product s or services manufactured or

furnished by it or any acts or omissions relating thereto. The remedy provided u nder this warranty

should be the sole, exclusive and onl y rem edy available to Purchaser. Under no circumstances

shall the Company be liable for any special, indirect, incidental or cons equential damages,

expenses, losses or delays howsoever caused.

No statement, representation, agr eement or understanding, oral or written, made by any agent,

distributor representative or e m pl oyee of the Company which is not contained in this Warranty will

be binding upon the Company unless made in writing and executed by an offi c er of the Company.

Any adjustment made pursuant to t hi s warranty shall not be construed as an admission by the

Company that any product was not so warranted.

Page 5

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

iii

Contents

1 Safety ............................................................................................... 1

1.1 Philosophy of Safety ......................................................................... 1

1.2 Training ............................................................................................. 2

1.3 Maintenance Safety Procedures ....................................................... 2

1.3.1 Safety Tips Prior to Servicing ............................................................ 2

1.3.2 Safety Tips during Servicing ............................................................. 3

1.3.3 Safety Tips after Servicing ................................................................ 4

1.4 Control of Hazardous Energy (Lockout/Tagout) ............................... 4

1.5 Basic Safety Rules ............................................................................ 7

1.5.1 Basic Maintenance Safety Rules ...................................................... 8

1.6 Safety Design Features .................................................................... 8

1.6.1 Emergency Stop Devices .................................................................. 8

1.6.2 Emergency Stop Procedure .............................................................. 8

1.6.3 Spill Guards ...................................................................................... 9

1.6.4 Headroom and Aisles ........................................................................ 9

1.6.5 General Guarding ............................................................................. 9

1.6.6 Safety and Warning Labels ............................................................... 9

1.6.7 Additional Safety References .......................................................... 12

1.7 ASME B20.1-2012 Operational & Maintenance Safety .................. 13

2 Model Description ......................................................................... 14

2.1 Description of Operation ................................................................. 16

2.1.1 Hardware Overview ........................................................................ 16

2.1.2 Diverter Control Panel (DCP) Status Light ...................................... 17

2.1.3 Basic Operation .............................................................................. 17

2.1.4 Human Machine Interface (HMI) ..................................................... 18

2.1.5 Automatic Mode Operation .............................................................

19

2.1.6 Manual Mode Operation ................................................................. 20

2.1.7 Settings Mode Operation ................................................................ 22

3 Installation ..................................................................................... 23

3.1 Installation Sequence and Startup Checklist .................................. 23

3.2 Mechanical Installation .................................................................... 23

3.2.1 Unloading and Handling .................................................................. 23

3.2.2 Unit Identification ............................................................................ 24

3.2.3 Installation ....................................................................................... 24

3.3 Electrical Instructions ...................................................................... 25

3.3.1 Specifications .................................................................................. 26

3.3.2 Installation ....................................................................................... 26

3.3.3 Setup Using HMI ............................................................................. 27

3.4 Initial Startup and Operation ........................................................... 39

3.5 Installation Inspection Report .......................................................... 40

Page 6

SIBAG HSD 3.0 Service Manual

iv

Document No.: 747-01695, Rev. 03

2021-March-03

4 Preventive Maintenance ............................................................... 41

4.1 General ........................................................................................... 41

4.2 Preventive Maintenance Schedule ................................................. 42

4.3 Inspection ....................................................................................... 43

4.3.1 Daily Inspections during Normal Operation .................................... 43

4.3.2 Monthly Inspections during Non-Operational Hours ....................... 43

5 Corrective Maintenance ............................................................... 45

5.1 General ........................................................................................... 45

5.2 Lubrication ...................................................................................... 45

5.2.1 Roller Bearings ............................................................................... 45

5.2.2 Pivot Bearings ................................................................................ 45

5.2.3 Tie Rod End Bearings .................................................................... 46

5.2.4 Servo Gearmotor ............................................................................ 46

5.2.5 Drive Pulley .................................................................................... 47

5.3 Cleaning ......................................................................................... 49

5.3.1 Control Panel .................................................................................. 49

5.4 Adjustment ...................................................................................... 49

5.4.1 Paddle Belt Tracking and Tension .................................................. 49

5.4.2 Paddle Position ............................................................................... 50

5.4.3 Setting Power Supply Output ......................................................... 51

5.4.4 Tightening Servo Gearmotor Mount Hardware ............................... 52

6 Troubleshooting ........................................................................... 53

6.1 Mechanical Troubleshooting ........................................................... 53

6.1.1 Paddle Positioning .......................................................................... 53

6.1.2 Servo Gearmotor (Motor) ............................................................... 54

6.1.3 Pillow Block Bearings .....................................................................

54

6.1.4 Paddle Nose Rollers and Drive Pulley ............................................ 55

6.1.5 Paddle Belting ................................................................................ 58

6.2 Electrical/Controls Troubleshooting ................................................ 59

6.2.1 Diverter Faults ................................................................................ 59

6.2.2 System Faults (Optional) ................................................................ 63

6.2.3 Servo Faults ................................................................................... 63

7 Repair ............................................................................................ 66

7.1 Torque Values for Hardware .......................................................... 67

7.2 Testing HSD Operation .................................................................. 67

7.3 High Speed Diverter Top Level Assembly ...................................... 68

7.3.1 Long Tie Rod .................................................................................. 68

7.4 Conveyor Assembly ........................................................................ 71

7.4.1 Return Roller .................................................................................. 71

7.5 Drive Subassembly ......................................................................... 72

7.5.1 Paddle Assembly (Drive Side) ........................................................ 73

7.5.2 Servo Gearmotor ............................................................................ 74

7.5.3 Pivot Bearings ................................................................................ 75

7.5.4 Short Dampened Tie Rod Assembly .............................................. 76

7.5.5 Bumpers ......................................................................................... 78

7.6 Paddle Assembly ............................................................................ 79

Page 7

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

v

7.6.1 Paddle Belt...................................................................................... 80

7.6.2 Paddle Nose Roller ......................................................................... 80

7.6.3 Paddle Drive Pulley ......................................................................... 81

7.7 Transition Subassembly .................................................................. 83

7.7.1 Paddle Assembly (Non-Drive Side) ................................................ 83

7.7.2 Pivot Bearings ................................................................................. 84

7.7.3 Transition Rollers ............................................................................ 85

7.8 Control Panel .................................................................................. 86

7.8.1 Motor Power Cable ......................................................................... 86

7.8.2 Motor Control Cable ........................................................................ 87

7.8.3 Servo Control Unit and Memory Card Module ................................ 87

7.8.4 Reprogram Servo Control Unit ........................................................ 88

8 Parts ............................................................................................... 92

8.1 Locating Replacement Parts ........................................................... 92

8.2 Spare Parts ..................................................................................... 92

8.3 Ordering Parts ................................................................................. 93

8.3.1 Business Hours ............................................................................... 93

8.3.2 Phone Numbers .............................................................................. 93

8.3.3 Web Site ......................................................................................... 93

8.3.4 Order Processing and Shipping ...................................................... 93

8.3.5 Repairs............................................................................................ 93

8.3.6 Returns ........................................................................................... 93

8.3.7 Parts Warranty ................................................................................ 94

8.4 Illustrations and Parts Lists ............................................................. 94

8.4.1 HSD 3.0 Top Level Assembly 68.0021.100-XX .............................. 96

8.4.2 Tie Rod Assemblies, Long 68.0020.000-38 and 68.0020.001-12 ...

98

8.4.3 Conveyor Assembly 68.0021.114-XX ........................................... 100

8.4.4 Drive Subassembly 68.0021.125-XX ............................................ 102

8.4.5 Tie Rod Assembly, Dampened 68.0021.000-14 ........................... 103

8.4.6 Transition Subassembly 68.0021.121-XX ..................................... 105

8.4.7 Paddle Assembly 68.0021.110-XX ............................................... 107

8.4.8 HSD 3.0 Control Panel 68.0021.201 (120VAC US), 68.0021.202

(24VDC US), 68.0021.203 (24VDC INTL), 68.0021.206 (120VAC

US), 68.0021.207 (24VDC US), Front Door .................................. 109

8.4.9 HSD 3.0 Control Panel 68.0021.201 (120VAC US), 68.0021.202

(24VDC US), 68.0021.203 (24VDC INTL), 68.0021.206 (120VAC

US), 68.0021.207 (24VDC US), Inside ......................................... 111

8.5 Recommended Spare Parts .......................................................... 115

8.5.1 Mechanical Spares ....................................................................... 115

8.5.2 Electrical Spares ........................................................................... 116

9 Manufacturers’ Literature ........................................................... 117

10 Electrical Drawings ..................................................................... 118

Page 8

SIBAG HSD 3.0 Service Manual

vi

Document No.: 747-01695, Rev. 03

2021-March-03

Safety

Figures

Figure 1 Lockout/Tagout Equipment Examples ............................................... 6

Figure 2 Safety and Warning Label Locations ............................................... 11

Figure 3 SIBAG HSD 3.0 ................................................................................ 14

Figure 4 HMI Touch Button Symbols ............................................................. 19

Figure 5 HMI Automatic Mode ........................................................................ 19

Figure 6 HMI Manual Mode ............................................................................ 21

Figure 7 HMI Settings Screen ........................................................................ 22

Figure 8 Crated HSD ...................................................................................... 24

Figure 9 Area Guards ..................................................................................... 25

Figure 10 HMI Setup Screen ............................................................................ 28

Figure 11 HMI Setup Options and Setup Speed Screens ................................ 28

Figure 12 HMI Setup Screen Administrator Button .......................................... 29

Figure 13 HMI Admin Screen ........................................................................... 29

Figure 14 Hardware Configuration Screen (SIMATIC Manager) ...................... 31

Figure 15 Config Screens (TIA portal) .............................................................. 32

Figure 16 EtherNet/IP Configuration (Studio 5000) .......................................... 33

Figure 17 Tag List (Studio 5000) ...................................................................... 34

Figure 18 Drive Pulley Oil Level ....................................................................... 47

Figure 19 HMI Teach Screens ......................................................................... 51

Figure 20 Torquing the Servo Gearmotor Mount Hardware ............................. 52

Figure 21 Servo Control Unit 320-2 LEDs During Booting ............................... 60

Figure 22 Servo Control Unit LEDs during Operation ...................................... 61

Figure 23 HSD Top Level Assembly ................................................................ 68

Figure 24 Tie Rod Assembly, Long .................................................................. 70

Figure 25 Conveyor Assembly ......................................................................... 71

Figure 26 Drive Subassembly ..........................................................................

Figure 27 Tie Rod Assembly, Short Dampened ............................................... 78

Figure 28 Paddle Assembly ............................................................................. 79

Figure 29 Transition Subassembly ................................................................... 83

Figure 30 Control Panel, Inside ........................................................................ 86

Figure 31 Sinamics Servo Control Unit and Modules ....................................... 89

Figure 32 CF Memory Module Card Files ........................................................ 90

Figure 33 HSD 3.0 Top Level Assembly 68.0021.100-XX ............................... 95

Figure 34 Tie Rod Assemblies, Long 68.0020.000-38 and 68.0020.001-12 .... 98

Figure 35 Conveyor Assembly 68.0021.114-XX .............................................. 99

Figure 36 Drive Subassembly 68.0021.125-XX ............................................. 101

Figure 37 Tie Rod Assembly, Dampened 68.0021.000-14 ............................ 103

Figure 38 Transition Subassembly 68.0020.103-XX68.0021.121-XX ............ 104

Figure 39 Paddle Assembly 68.0021.110-XX ................................................ 106

Figure 40 HSD 3.0 Control Panel 68.0021.201 (120VAC US), 68.0021.202

(24VDC US), 68.0021.203 (24VDC INTL), 68.0021.206 (120VAC

US), 68.0021.207 (24VDC US), Front Door ................................... 108

Figure 41 HSD 3.0 Control Panel 68.0021.201 (120VAC US), 68.0021.202

(24VDC US), 68.0021.203 (24VDC INTL), 68.0021.206 (120VAC

US), 68.0021.207 (24VDC US), Inside .......................................... 110

72

Page 9

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

1

Safety

1 Safety

This manual contains basic guidelines for baggage handling safety,

lockout/tagout procedures, safety design features, product features, and general

operational and maintenance safety. Its purpose is to improve safety and safety

education in the workplace. The safety section is not intended to cover all

situations or circumstances, and is not a regulatory publication. Much of the

information in this manual comes from the “ASME B20.1 - Safety Standards for

Conveyors and Related Equipment” accredited by American National Standards

and sponsored by the American Society of Mechanical Engineers (ASME). To

request copies of the publication contact: American National Standards Institute,

3 Park Avenue, New York, NY 10016-5990, Phone: 212-591-8500, Fax: 212591-8501.

1.1 Philosophy of Safety

The philosophy of safety is best described in the following manner:

● Design engineering controls to remove or separate the hazard from people.

● Use administrative controls to separate the hazard from personnel by time

or distance.

● Utilize PPE as a final protective measure.

● Warn against the hazard.

The most preferred method of negating a hazard is to design it out of the

equipment or installation. Engineering controls, such as guarding, is one of many

possible controls against hazards.

● Guards: these are physical barriers that prevent contact. They can be fixed,

interlocked, adjustable, or self-adjusting.

● Devices: these limit or prevent access to the hazardous area. These can be

presence-sensing devices such as light curtains, pullback or restraint straps,

safety trip controls, two-hand controls, or gates.

● Administrative Controls: machine location or distance. This method

separates the hazard from the operator’s work area.

● Personal Protective Equipment (PPE): if engineering and administrative

controls fail to fully remove the hazard, the final protective measure is PPE.

● Posted warning signs and labels shall be used to remind personnel of the

potential hazards. Warnings should also be used to protect against

dangerous practices.

Page 10

SIBAG HSD 3.0 Service Manual

2

Document No.: 747-01695, Rev. 03

2021-March-03

Safety

Belts and chains moving over pulleys, sprockets, and sheaves create pinch and

nip points which must be guarded. These points present a risk of injury if not

guarded properly.

● Ensure that all barriers and warning signs are in place to warn personnel

about equipment that cannot be guarded.

● Do NOT operate equipment with guards or safety units removed.

● Operate the equipment with TRAINED personnel ONLY.

● Do NOT perform service or maintenance until all power is disconnected and

locked out.

1.2 Training

In addition to the initial training of personnel (when equipment is first placed into

operation), continuous training is required on a scheduled and periodic basis.

The purpose of continuous training is to reinforce the importance of safe work

practices by ALL employees, including all new hires and transfers working with

or around the equipment.

The employer is responsible for providing trained employees knowledgeable in

the safe maintenance practices of the baggage handling equipment. Siemens

recommends the video presentation “Safety is in Your Hands” as part of each

training program. This video addresses the key points relating to safe work

practices around baggage handling equipment. To order a copy of this video

presentation, contact the Customer Service Department.

1.3 Maintenance Safety Procedures

This section describes safety precautions that should be followed before, during

and after maintenance and troubleshooting tasks. Since voltages encountered in

this equipment can cause lethal shock if mishandled, these safety instructions

should be strictly adhered to.

1.3.1 Safety Tips Prior to Servicing

● Follow OSHA Control of Hazardous Energy (Lockout/Tagout) procedure

before servicing any equipment.

● Utilize OSHA compliant lockout/tagout devices at all pertinent disconnect

switches.

● Inform personnel in the area that maintenance tasks are being performed.

● ALWAYS stop the equipment before attempting to clear jams.

● Whenever possible, service electrical equipment with the power "OFF."

● Hot work on electrical equipment is highly hazardous and should only be

performed by properly trained personnel familiar with hot electrical work and

arc flash protection processes.

Page 11

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

3

Yellow wires in a control cabinet remain hot even when the disconnect

Safety

● Secure proper tools and wiring diagrams. Be sure that an adequate test

instrument is available.

● READ any instructions or test procedures BEFORE attempting them.

● Before beginning work, ensure that power is actually removed by checking

various points to ground with test meter. Even though power to the device

being serviced is removed, some points of the device may be energized due

to interconnections with other equipment. Such areas are appropriately

marked.

switch is turned OFF. Use extreme caution when servicing a control

cabinet with an outside power source.

● NEVER “ride” or walk on energized conveyors.

1.3.2 Safety Tips during Servicing

While working never forget that other pieces of equipment can be involved when

a particular START or STOP pushbutton is pressed. For example, a conveyor in

a remote area may be energized by a particular operation. Before energizing

ANY element of the system it is essential that you be sure to:

● Inform all affected personnel in that area.

● Confirm that all other systems are STILL disabled.

● Stay clear of all chain drives, motor couplings, and belts during equipment

operation, especially if guards have been removed.

● Wear personal protective equipment appropriate for the task at all times

when performing maintenance duties.

● NEVER wire or tape down limit switches.

● ALWAYS observe the signals of the warning lights.

● Be alert to any deficiency of the equipment.

● NEVER "ride" on a conveyor.

● Do not leave tools or parts where they may be a safety hazard or

obstruction.

● Be absolutely certain that all personnel are clear of any moving parts before

starting the conveyor system.

● Report all accidents resulting in personal injury or damage to the equipment

to the Supervisor.

In the unlikely event of electrocution, do not touch the victim until the

high voltage circuit is broken.

Page 12

SIBAG HSD 3.0 Service Manual

4

Document No.: 747-01695, Rev. 03

2021-March-03

Safety

1.3.3 Safety Tips after Servicing

● Follow OSHA Control of Hazardous Energy (Lockout/Tagout) procedures for

the removal of lock out tag out devices.

● When servicing is complete, replace all guards and safety devices; remove

test equipment and tools. Remove and properly dispose of any damaged

components and close all panels.

● Do not leave tools or parts where they may be a safety hazard or

obstruction.

● Finally, remove all lockout/tagout equipment and inform all affected

personnel in the area that servicing is completed before restarting

equipment.

1.4 Control of Hazardous Energy (Lockout/Tagout)

The primary purpose for a lockout/tagout procedure is to protect workers from

injury caused by the unexpected energization or start-up of equipment.

Occupational Safety and Health Administration (OSHA) standard 29CFR

1910.147, Appendix A, outlines the minimum requirements for the control of

hazardous energy in general industry. It is the opinion of Siemens that this

standard applies to all workplaces utilizing powered conveyors. The OSHA

standard centers on the control of potentially hazardous energy and how to

secure it to prevent harm to employees. The rule requires that energy sources

for equipment be turned off or disconnected, and that the switches be locked or

labeled with a warning tag. This ensures that the equipment has been shut down

for servicing or maintenance and will not reactivate while employees are working

on it. The regulation defines servicing and maintenance as covering “lubrication,

cleaning or unjamming of machines or equipment... where the employee may be

exposed to the unexpected energization or startup of the equipment...” among

other things.

We are bringing this to your attention in the event you are not aware of the

standard. We urge you to review the applicability and requirements of the

standard with respect to your facilities. The lockout/tagout procedure is

considered to be just one element of the control procedures for hazardous

energy. The employer is responsible for providing procedures that include deenergization of equipment, isolation of energy sources, verification that

equipment has been de-energized, and complete diffusion of stored energy.

The standard requires the employer to create an ongoing program of control

procedures, equipment specific Lockout/Tagout procedures for each piece of

equipment, and employee training by the employer (regardless of training

provided by the equipment vendor at the time of sale) to ensure that the purpose

and functions of energy controls are understood and applied.

Page 13

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

5

Safety

For information regarding the Control of Hazardous Energy (Lockout/Tagout)

requirements in the General Industry, refer to 29 CFR 1910 section 147.

● Lockout/tagout should take place before any service or maintenance work

begins. Alert affected personnel of power disconnection. Isolate the power

source.

● Attach lockout tags to each lock indicating name of service person, date,

contact phone number, and purpose of the lockout.

● Use padlocks with only one key for all lockout purposes. If duplicate keys

exist, keep them under strict management supervision.

● Check for stored energy. Test the equipment to be sure that it will not

operate. Before beginning work, ensure that power is actually removed by

checking various points to ground with test meter. Even though power to the

device being serviced is removed, some points of the device may be

energized due to interconnections with other equipment. Such areas are

appropriately marked.

● The service person who locks and tags a machine must be the one who

unlocks it.

● Never remove a lock or tag that is not yours.

● Never lockout or tag equipment for another person.

● If a lock or tag needs to be left on during a shift change, the individual who

initiated the lockout shall transfer the lockout/tagout responsibility to an

authorized employee of the oncoming shift. If a lockout is left in place by a

previous shift and no transfer of responsibility has taken place, assume the

equipment is locked or tagged for a good reason; do not remove the

lockout. Contact your supervisor or manager who will make the decision on

how to proceed.

● Before removing a lockout and energizing the equipment, communicate to

all affected personnel in the area that the system is about to be reactivated.

Page 14

SIBAG HSD 3.0 Service Manual

6

Document No.: 747-01695, Rev. 03

2021-March-03

Safety

Figure 1 Lockout/Tagout Equipment Examples

Page 15

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

7

Safety

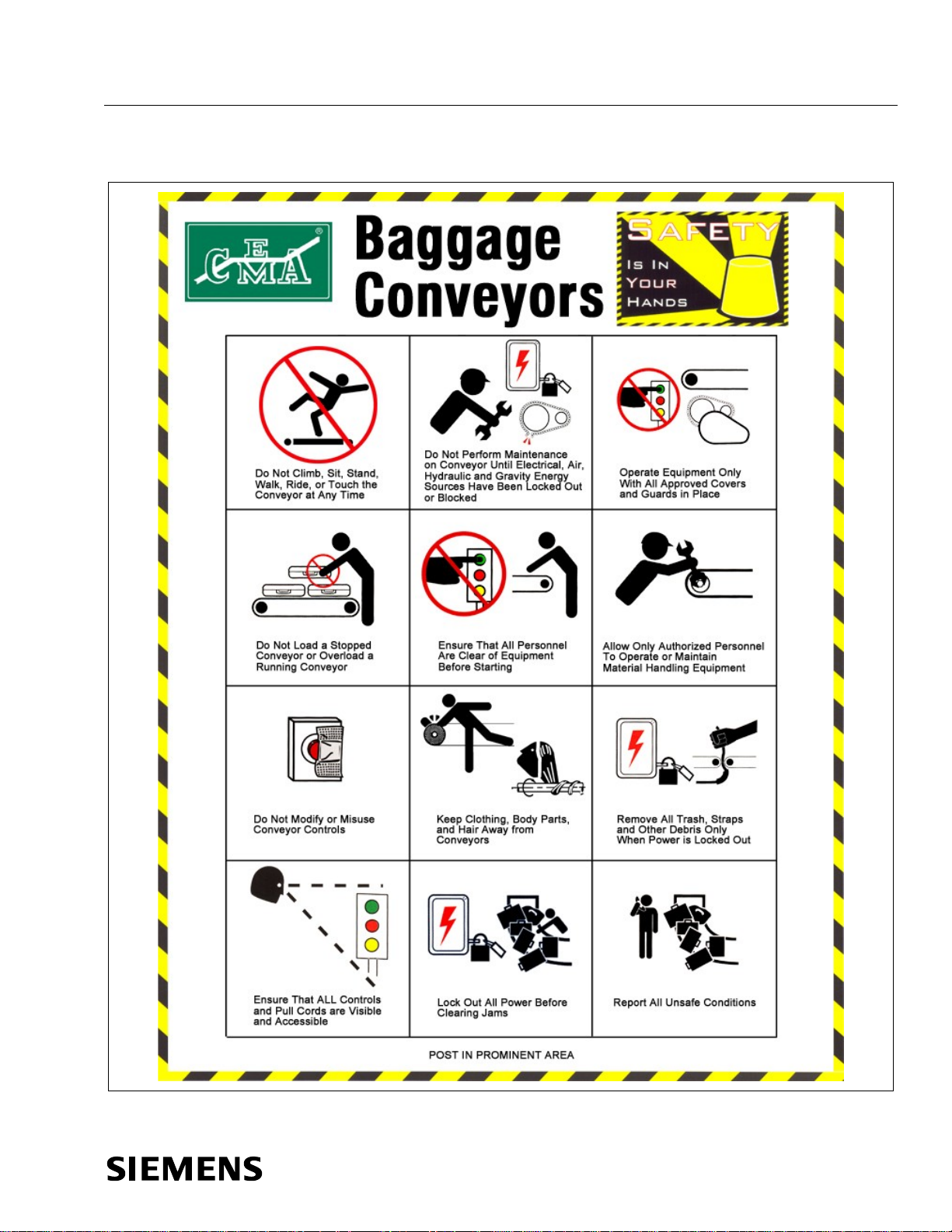

1.5 Basic Safety Rules

Page 16

SIBAG HSD 3.0 Service Manual

8

Document No.: 747-01695, Rev. 03

2021-March-03

E-stop devices are not intended to disable equipment to provide

Safety

1.5.1 Basic Maintenance Safety Rules

The maintenance staff also plays a key role in the overall safety of the material

handling equipment. Creating and practicing a preventive approach to safety

helps establish an effective safety program.

● Lockout/tagout must take place before any service or maintenance work

begins per section 1.4 Control of Hazardous Energy (Lockout/Tagout.

● All maintenance or service is to be performed by qualified, trained personnel

only.

● Always report unsafe conditions or anything out of the ordinary to the

supervisor.

1.6 Safety Design Features

Baggage handling equipment has safety design features for worker protection.

Basic baggage handling safety design features are outlined on the pages that

follow.

1.6.1 Emergency Stop Devices

Illuminated red emergency stop (E-STOP) push-pull buttons, limit switches,

emergency pull cords, and other similar emergency stop devices are located

throughout the system for operator protection during emergency situations and

are for reaction to an incident or hazardous situation where imminent danger to

personnel exists.

These emergency stop devices are normally used at or near each potential work

station. E-stop devices are also provided at reasonable intervals throughout

material handling systems in areas routinely occupied by operations personnel.

protection for personnel in non-emergency circumstances. For example,

maintenance, jam clearing, and/or other similar activities require

adherence to established lockout/tagout procedures.

E-stops ideally control all movement visible from and related to the equipment or

location of the control device.

1.6.2 Emergency Stop Procedure

Emergency Stop and restart the entire system as follows:

1. Activate any E-STOP pushbutton (this will stop the associated conveyors).

2. Fix the reason for pushing the E-STOP pushbutton.

3. Reset the activated E-STOP pushbutton.

4. Pull the activated E-STOP pushbutton and restart the system as normal.

Page 17

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

9

DANGER: Indicates an imminently hazardous situation that, if not avoided, will

WARNING: Indicates a potentially hazardous situation that, if not avoided,

Safety

1.6.3 Spill Guards

Many portions of material handling equipment run overhead and around areas

accessible to personnel. It is important that these areas be protected with spill

guards or other guarding design features.

1.6.4 Headroom and Aisles

When conveyors run above aisles, passageways or exits designated as fire exit

pathways, warnings will be provided if head clearance is less than 6 feet 8

inches (2 meters). The clearance of 6 feet 8 inches (2 meters) is measured from

the floor to the lowest part of the conveyor or guards. Other aisles or

passageways with less than 6 feet 8 inches (2 meters) clearance will be

protected by safety tape and warning signs.

In designated aisleways, all moving equipment parts to an elevation of 8 feet (2.4

meters) will be guarded.

1.6.5 General Guarding

When necessary for the proper protection of workers, it is required that areas be

properly guarded where equipment meets or exposed moving parts present a

potential hazard. It is recommended that warning and caution signs be

positioned in the employees’ line of sight.

Guarding shall never be removed or disabled for normal operations. Removal of

guarding shall only be done in accordance with established maintenance and

lockout/tagout procedures.

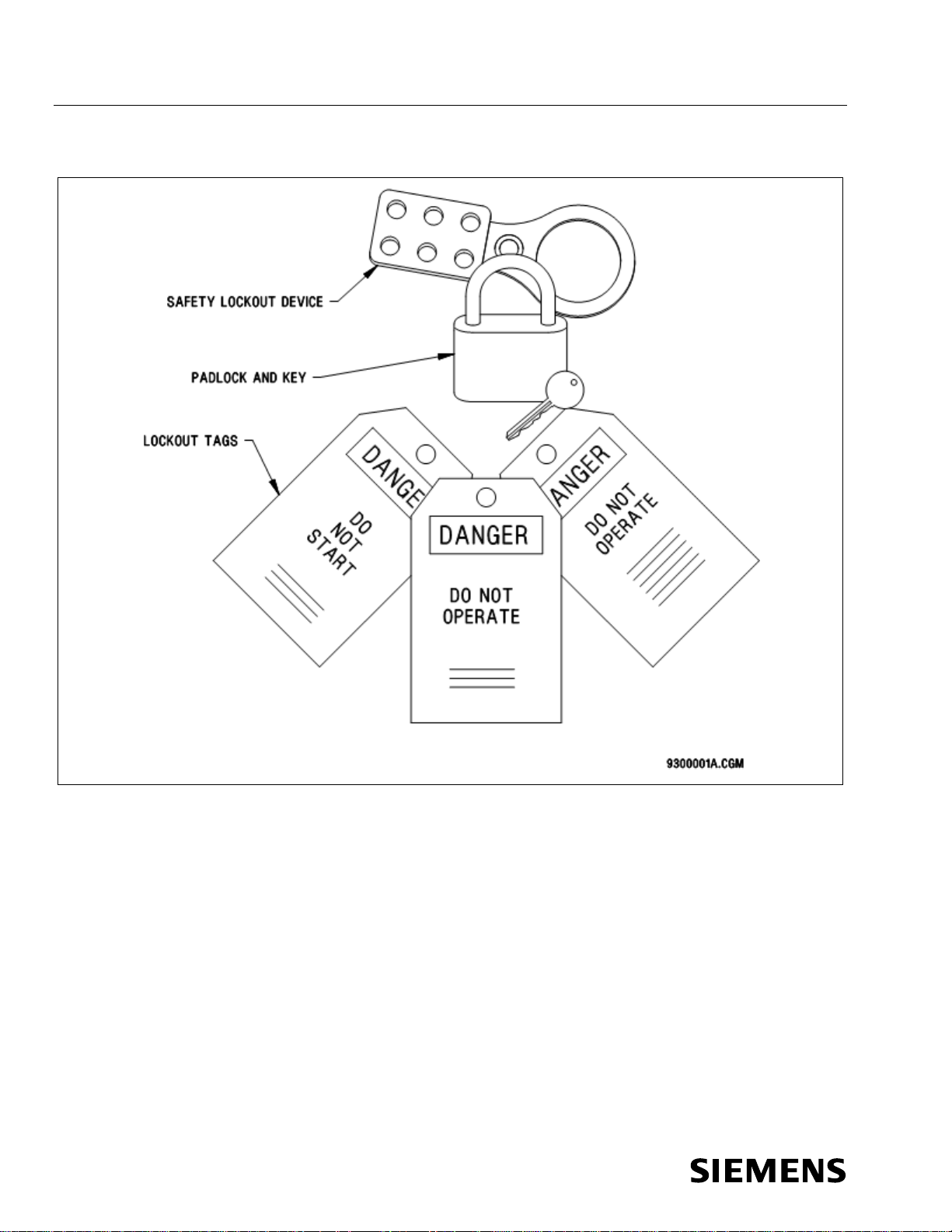

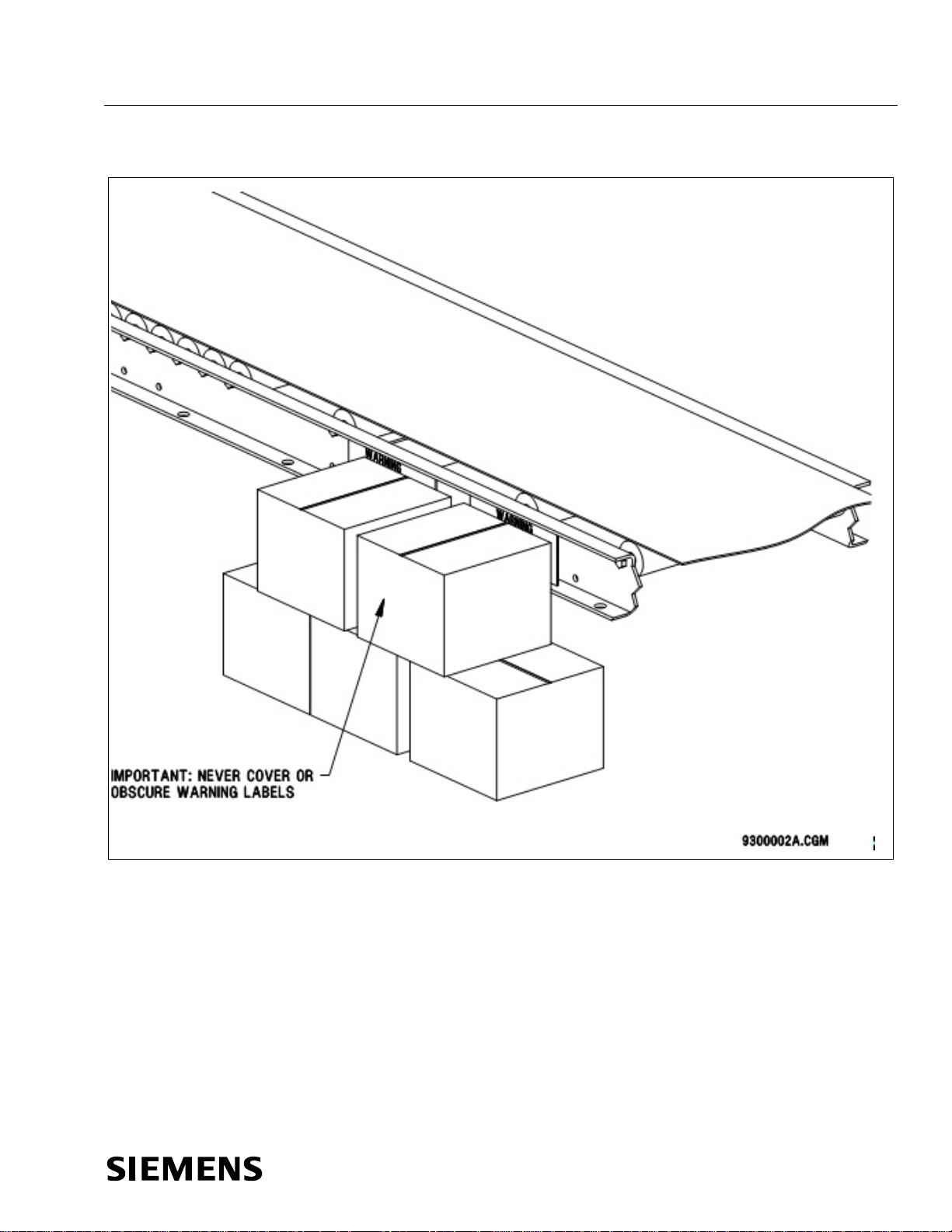

1.6.6 Safety and Warning Labels

Warning and safety labels are factory installed by the manufacturer or applied

after installation. Siemens equipment has safety labels attached with messages

warning of potential risks. These labels are located to be useful in any

application. Individual installations may have a unique need for additional labels

in other mounting locations. Therefore, more of the standard labels are readily

available.

These labels and signs may need to be supplemented by other warnings of

individual design that may be obtained from local sources or nationally

distributed catalogs.

result in death or severe injury. The use of danger labels is limited to the most

extreme situations

could result in death or severe injury

Page 18

SIBAG HSD 3.0 Service Manual

10

Document No.: 747-01695, Rev. 03

2021-March-03

CAUTION: Indicates a potentially hazardous situation that, if not avoided, will

Safety

result in minor or moderate injury. It may also be used to alert against unsafe

practices.

DANGER or WARNING should not be considered for property damage accidents

unless personal injury risk appropriate to these levels is also involved. CAUTION

is permitted for property-damage-only accidents. Sign placement shall be in the

immediate vicinity of the hazard, readily visible so the viewer can recognize the

hazard and take appropriate action.

Safety Signs and Labels Verification: On a quarterly basis, walk through the

entire material handling system and make sure that all safety signs and labels

are clearly legible and in good condition. Particularly if the system has been

reconfigured, verify that the signs and labels are still in the proper locations. If

there is a problem with any sign or label, reorder and replace it according to the

following identification and ordering pages.

Page 19

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

11

Safety

Figure 2 Safety and Warning Label Locations

Page 20

SIBAG HSD 3.0 Service Manual

12

Document No.: 747-01695, Rev. 03

2021-March-03

ANSI – American National

B 11.19 Performance Requirements for Risk Reduction Measures:

Z 535.5 Safety Tags and Barricade Tapes (NEMA)

CEMA – Conveyor Equipment

102 Term s and Defini tions

402 Bel t Conveyors

OSHA – Occupational Safety and

Health Administration

Subpart C (1917) Cargo Handling

1917.43 Powered Industrial Trucks

1917.49 Spouts, Chutes, Hoppers, Etc.

Subpart D (1910) Walking/Working

1910.21 Scope and Definitions

1910.30 Training requirements

Subpart J (l910) General

1910.144 Safety Color Codes for Marking Physical Haz ards

1910.147 The Control of Hazardous Energy (Lockout/Tagout)

Subpart N (1926) Cranes, Derricks,

1926.551 Cranes and Derricks

1926.555 Conveyors

Subpart O (1910) Machinery and

1910.211 Definitions

1910.219 Mechanical Power-Transmission Apparatus

Subpart S (1910) Electrical

1910.301 Introduction

1910.308 Special Systems

NFPA – National Fire Protection

Association

70E - Standard for Electrical Safety in the Work place

79 - Electrical Standard for Industrial Machinery

Safety

1.6.7 Additional Safety References

Standards Institute

Manufacturer's Association

Gear and Equipment

Surfaces

Safeguarding and other Means of Reducing Risk (AMT)

B 20.1 Safety Standard for Conveyors (ASME)

Z 535.1 Safety Colors (NEMA)

Z 535.2 Environ. and Facility Safety Signs (NEM A )

Z 535.3 Criteria for Safety Symbols (NEMA)

Z 535.4 Product Safety Signs and Labels (NEMA)

201 Safety Label Brochure

1917.44 General Rules Vehicles

1917.45 Cranes and Derricks

1917.46 Crane Load and Limit Devices

1917.48 Conveyors

1910.22 General Requirements

1910.23 Ladders

1910.25 Stairways

1910.28 Duty to have fall protection and falling object

protection

1910.29 Fall protection systems and falling object protection—

criteria and practices

Environmental Controls

Hoists, Elevators, and Conveyors

1910.145 Specifications for Accident Prevention Signs a nd T ags

1926.552 Material Hoists

1926.553 Base Mounted Drum Hoists

1926.554 Overhead Hoists

Machine Guarding

1910.212 General Requirements for All Machines

1910.302 Electric Utilization Systems

1910.303 General

1910.304 Wiring Design and Protection

1910.305 Wiring Methods, Components, and

Equipment-General Use

1910.307 Hazardous Locations

Page 21

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

13

Introduction

Likewise, the

Those portions of this standard relating to maintenance and

Maintenance and service shall be performed by

condition, the user shall establish a maintenance

program to ensure that conveyor components are

, or

protect all persons or groups involved with the

Lockout/Tagout of Energy

5.4 Adjustment or Maintenance

. Wherever conditions

standards but such guarding would render the

serviceable and operational condition. Warning

kept clear of obstructions that could endanger

Routine inspections and corrective maintenance

operation unless proper maintenance or service

Safety

1.7 ASME B20.1-2012 Operational & Maintenance Safety

Portions of the ANSI “Safety Standards of Conveyors and Related Equipment”

(ASME B20.1-2012) relate to operational and maintenance personnel.

Accidents resulting from the manual handling of materials have been

reduced by the use of conveying and other forms of mechanical

handling equipment. A further reduction in the accident rate can be

gained by following safe practices in the design, construction,

installation, operation, and maintenance of such equipment.

The design and installation of conveyors and conveyor systems

should be supervised by qualified engineers.

maintenance of conveyors and systems should be supervised by

trained personnel.

The purpose of this standard is to present certain guides for the

design, construction, installation, operation, and maintenance of

conveyors and related equipment.

operation procedures are fully as important as those relating to

design and installation. The best design features may be negated by

faulty maintenance and operating practices. It is important that

operating and maintenance personnel be instructed in recognizing

hazards and pertinent safety precautions.

5.2 Maintenance (Repair)

a.

qualified and trained personnel.

b. Where lack of maintenance would cause a hazardous

maintained in a condition that does not constitute a

hazard to personnel.

c. No maintenance shall be performed when a conveyor

is in operation except as outlined in 5.3 and 5.4.

d. When a conveyor is stopped for maintenance or repair

purposes, the starting devices, prime movers

powered accessories shall be locked out or tagged out

in accordance with a formalized procedure designed to

conveyor against unexpected restart. Personnel should

be alerted to the hazard of stored energy, which may

exist after the power source is locked out. Refer to

ANSI Z244.1-1982, American National Standard for

Personnel Protection –

Sources – Minimum Safety Requirements and OSHA

29 CFR 1910.147 The Control of Hazardous Energy

(Lockout/Tagout).

e. All safety devices and guards shall be replaced before

starting equipment for normal operations.

5.3 Lubrication

a. Conveyors shall not be lubricated while in operation

unless it is impractical to shut down for lubrication. Only

trained and qu alified personnel who are aware of the

hazard of a conveyor in motion shall be allowed to

lubricate a conveyor that is operating.

b. Where the drip of lubricants or process liquids on the

floor constitutes a hazard, drip pans or other means of

eliminating the hazard shall be provided.

When adjustment or maintenance is required while equipment

is in operation, only trained and qualified personnel who are

aware of the hazard of the conveyor in motion shall be

allowed to make the adjustment or perform the maintenance

or service.

5.9.1 General Requirements of Guarding

5.9.1.3 Guarding Exceptions

prevail that would require guarding under these

conveyor unusable, prominent warnings shall be

provided in the area or on the equipment in lieu of

guarding.

5.9.1.4 Maintenance of Guards and Safety Devices.

Guards and safety devices shall be maintained in a

signs provided in accordance with 5.9.1.3 shall be

maintained in a legible, operational condition.

5.12 Operation

a. Only a trained person shall be permitted to operate a

conveyor. Training shall include instruction in operation

under normal conditions and emergency situations.

b. Where safety is dependent upon stopping devices or

starting devices or both, they shall be kept free from

obstructions to permit ready access.

c. The area around loading and unloading points shall be

personnel.

d. No person shall ride on a conveyor, unless it is a

conveyor engineered for that purpose.

e. Personnel working on or near a conveyor shall be

instructed as to the location and operation of pertinent

stopping devices.

f. A conveyor shall be used to t ransport only loads it is

designed to handle safely.

g. Under no circumstances shall the safety character istics

of the conveyor be altered without proper authorization

from the manufacturer.

h.

measures shall be conducted to ensure that all guards

and safety features are retained and function properly.

i. Personnel should be alerted to the potential hazard of

entanglement in conveyors caused by such items such

as long hair, loose clothing, and jewelry.

j. Conveyors shall not be maintained or serviced while in

requires the conveyor to be in motion. In which case,

personnel shall be made aware of the hazards and ho w

the task may be safely accomplished.

NOTE: Contact the American Society of Mechanical Engineers at

the address shown above for the complete ASME B20.1-2012.

NOTE: These excerpts are printed with the permission of ASME.

Page 22

SIBAG HSD 3.0 Service Manual

14

Document No.: 747-01695, Rev. 03

2021-March-03

Model Description

2 Model Description

The SIBAG High Speed Diverter 3.0 (HSD 3.0) is a device with two paddles

mounted on a horizontal belt conveyor used to divert the flow of one of several

bags by moving the paddles into the baggage stream. For better baggage flow,

the paddles are equipped with actively driven belts. The HSD 3.0 is designed to

be an integral part of a mainline belt conveyor sort system. The activated

paddles of the diverter form a 45 degree vertical powered belt wall for the

transfer of luggage from a main sort line to a pier chute or take-away conveyor.

The baggage contacts the diverter in a smooth, non-destructive manner, which

minimizes the impact forces applied during the sort process.

The HSD 3.0 is designed to handle virtually all types of normal baggage, but it is

not intended to process hazardous or volatile materials and liquids.

Figure 3 SIBAG HSD 3.0

Page 23

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

15

Model Description

A single servo gearmotor efficiently powers the diverting action of the HSD 3.0,

rotating the paddles 45 degrees across the conveyor belt between their diverting

and non-diverting positions. It delivers motion to the pivot shaft of both the drive

side and non-drive side paddles simultaneously via a tie rod assembly. A drive

pulley powers the belt on each paddle.

When system control determines a need, the HSD 3.0 is energized, and the

paddle belts begin running. Diverter position is determined by the diverter control

panel by evaluating the output of the servo gearmotor encoder.

The HSD 3.0 is available in the configurations listed in Table 1. This manual

provides service and parts information for all versions.

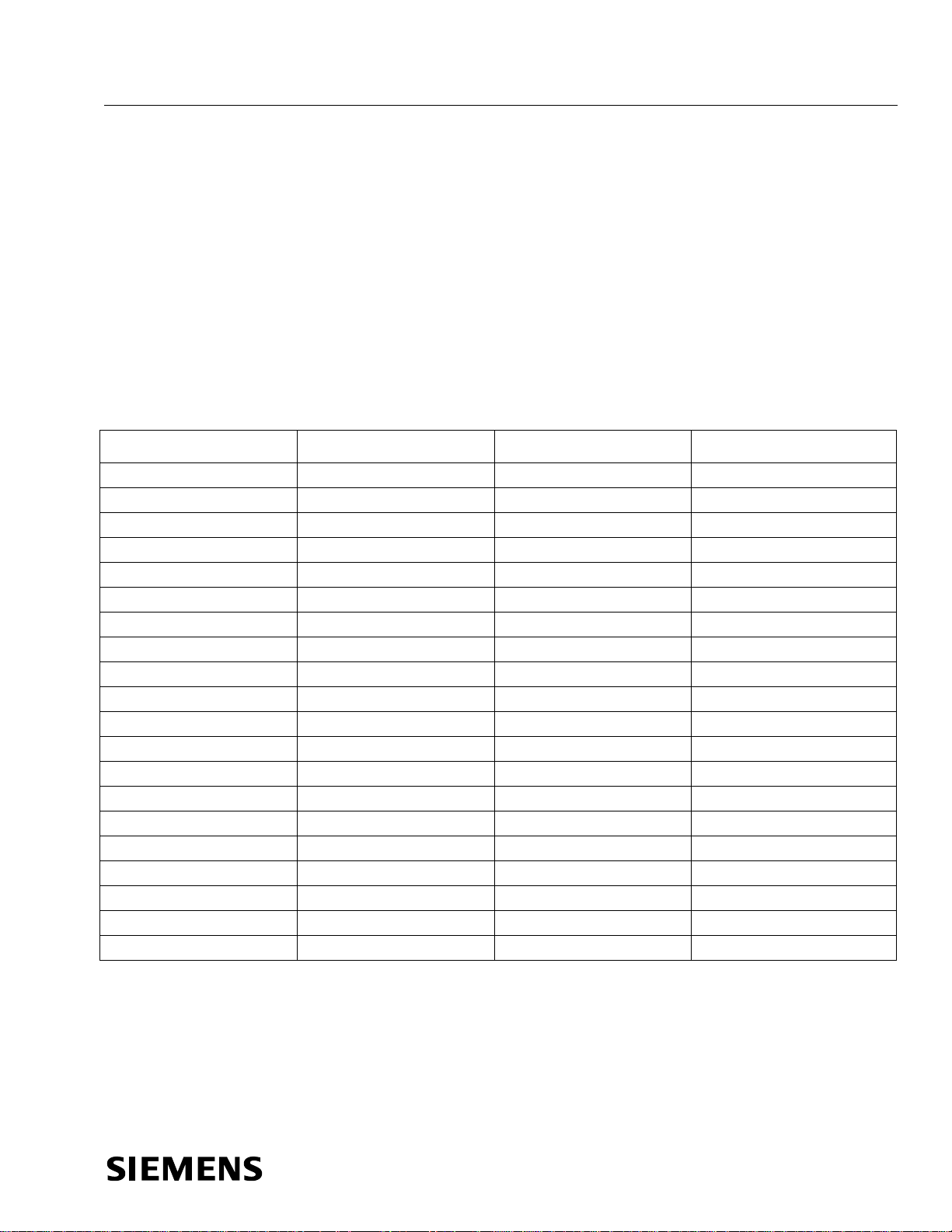

Table 1 Available HSD 3.0 Versions

Part Number Conveyor Width Transition Width Hand

68.0021.100-01 39 in. 7 in. Left

68.0021.100-02 39 in. 7 in. Right

68.0021.100-03 39 in. 10 in. Left

68.0021.100-04 39 in. 10 in. Right

68.0021.100-05 1000mm 180mm Left

68.0021.100-06 1000mm 180mm Right

68.0021.100-07 1000mm 250mm Left

68.0021.100-08 1000mm 250mm Right

68.0021.100-09 1050mm 180mm Left

68.0021.100-10 1050mm 180mm Right

68.0021.100-11 1050mm 250mm Left

68.0021.100-12 1050mm 250mm Right

68.0021.100-13 45 in. 7 in. Left

68.0021.100-14 45 in. 7 in. Right

68.0021.100-15 45 in. 10 in. Left

68.0021.100-16 45 in. 10 in. Right

68.0021.100-17 1200mm 180mm Left

68.0021.100-18 1200mm 180mm Right

68.0021.100-19 1200mm 250mm Left

68.0021.100-20 1200mm 250mm Right

Page 24

SIBAG HSD 3.0 Service Manual

16

Document No.: 747-01695, Rev. 03

2021-March-03

Model Description

2.1 Description of Operation

The HSD 3.0 uses a Sinamics drive configuration with a Siemens programmable

servo control unit CU320-2 and two separate output channels (axles), one for

servo-positioning of the paddles (SERVO) and one for asynchronous movement

of the paddle-belts (VECTOR).

The main supply voltage is separate from the control voltage. Disconnect

and lock out/tag out both the main supply voltage and control voltage

before performing maintenance.

There is a Human Machine Interface (HMI) on the control panel door to select

manual or auto modes or to change settings.

A high level PLC with user-defined parameters is used which selects between

common signal exchanges wired to communicate via Digital I/O, PROFIBUS,

PROFINET, or Ethernet/IP interface (depending on how the HSD 3.0 was

ordered).

NOTE: The HSD 3.0 cannot hold the paddles in position when the power is off.

For that reason, the unit should always be powered unless maintenance is being

performed. If the unit needs to be removed from service, it should be disabled at

the PLC level (control room).

2.1.1 Hardware Overview

The HSD 3.0 is controlled by a Sinamics Drive System with programmable servo

control module. The control module is comprised of the following:

● Servo Control Unit Sinamics S120 CU320-2

● Smart Line Servo Power Module

● Double Servo Motor Module

● Servo gearmotor with absolute encoder for positioning

● Asynchronous motors without encoder for paddle belts

● Basic Operator Panel BOP20

Page 25

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

17

Model Description

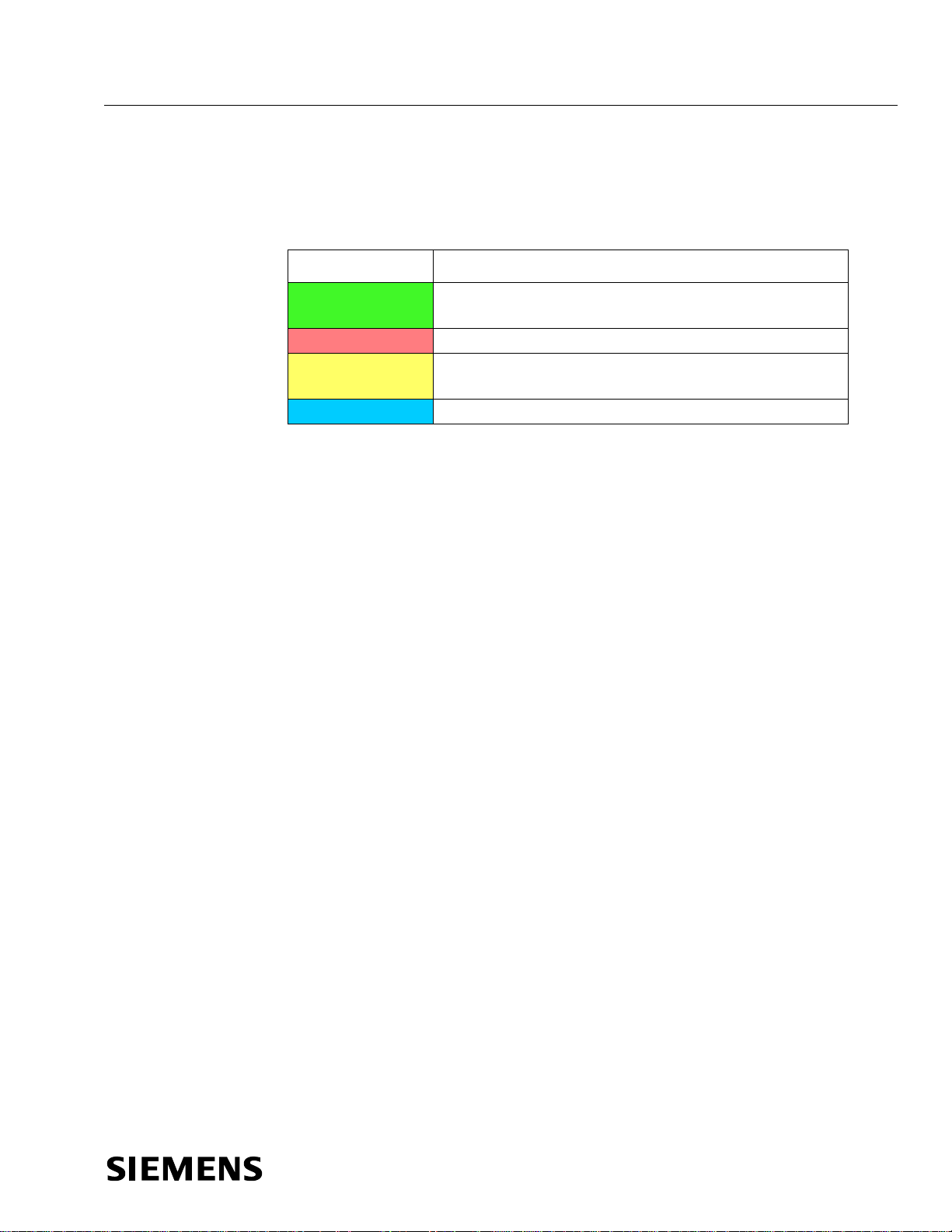

2.1.2 Diverter Control Panel (DCP) Status Light

A color indicator light shows the HSD status according to the following table.

Table 2 DCP Status Light Colors

Color Definition

Green Steady – Ready for automatic operation

Flashing – Ready for manual operation

Red Steady – Stopped or E-stopped

Yellow Steady – Fault

Flashing – Saving adjusted settings

Blue Steady – Motor overload

2.1.3 Basic Operation

In the BHS PLC operation, a bag arriving at the tracking photocell (provided by

BHS integrator), located at least 12 inches (305mm) upstream of the HSD 3.0 on

the conveyor bed, is checked to see if it requires diverting from the main

conveyor line. Once a determination is made, the diverter responds as outlined

below.

If the bag is to be diverted, one of the following occurs:

● If the diverter is in the RETRACTED position, the paddle belt drive pulleys

are started via a maintained PADDLE BELT RUN signal when the tracking

photocell is blocked, and when the bag is tracked nearly to the pivot point of

the first paddle, the servo gearmotor is energized via a leading edge trigger

of the EXTEND PADDLES signal so that the diverter is moved to the

EXTENDED position which will allow the bag to divert.

● If the diverter is already in the EXTENDED position, the paddle belt drive

pulleys are started when the tracking photocell is blocked, and the paddles

remain stationary, allowing the bag to divert.

After either case, the paddle belt motors shall continue to run for at least 20

seconds to allow for following sort operations without restarting the motors. This

20 second period is reset as each new bag passes the 12 inches (305mm)

upstream tracking photocell. If no sort action is required during those 20

seconds, the HSD 3.0 paddle belt drive pulleys are deactivated by the PLC

removing the PADDLE BELT RUN signals until the next time they are needed.

Page 26

SIBAG HSD 3.0 Service Manual

18

Document No.: 747-01695, Rev. 03

2021-March-03

Model Description

If the bag does not require diverting, the following occurs:

● If the diverter is in the EXTENDED position when the bag is tracked to

nearly the pivot point of the first paddle, the servo gearmotor is energized

via a leading edge trigger of the RETRACT PADDLES signal so that the

diverter will return to the RETRACTED position which allows the bag to

pass through. The paddle belt drive pulleys do not need to be activated for

this action.

● If the diverter is already in the RETRACTED position, the motors remain off

and the paddles remain stationary, allowing the bag to pass through.

Ideally, the HSD 3.0 motors are energized only when a sort action is required.

Additionally, the paddles are actuated to a different position only when required

to do so. If bag spacing is not adequate no sort action shall be attempted. The

HSD 3.0 will complete a position change actuation in approximately 310 ms (or

400 ms for widths over 1050 mm)

NOTE: Reliable operation of the diverter at chutes or parallel takeaways requires

a minimum “gap” between bags of at least 24 inches (610 mm). The average

length of each piece of baggage plus the 24 inch (610 mm) gap defines the bag

window size.

The PLC should also monitor for fault conditions in the HSD 3.0. If the HSD 3.0

does not complete an intended position change, the Servo Control Unit will

indicate a fault condition.

The HMI and the BOP20 will display the code for any alarms or faults. The list of

alarms and faults can be found in the Siemens Sinamics S List Manual.

The HSD 3.0 can be operated in three different modes, selected on the HMI

located on the HSD 3.0 Diverter Control Panel (DCP):

● Automatic

● Manual

● Settings

2.1.4 Human Machine Interface (HMI)

There is a Human Machine Interface (HMI) on the control panel door to select

manual or auto modes or to change settings. Both manual and settings modes

are available without the high level PLC running.

All screens have the following touch buttons at the bottom of the screen for

operation and navigation:

Page 27

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

19

Model Description

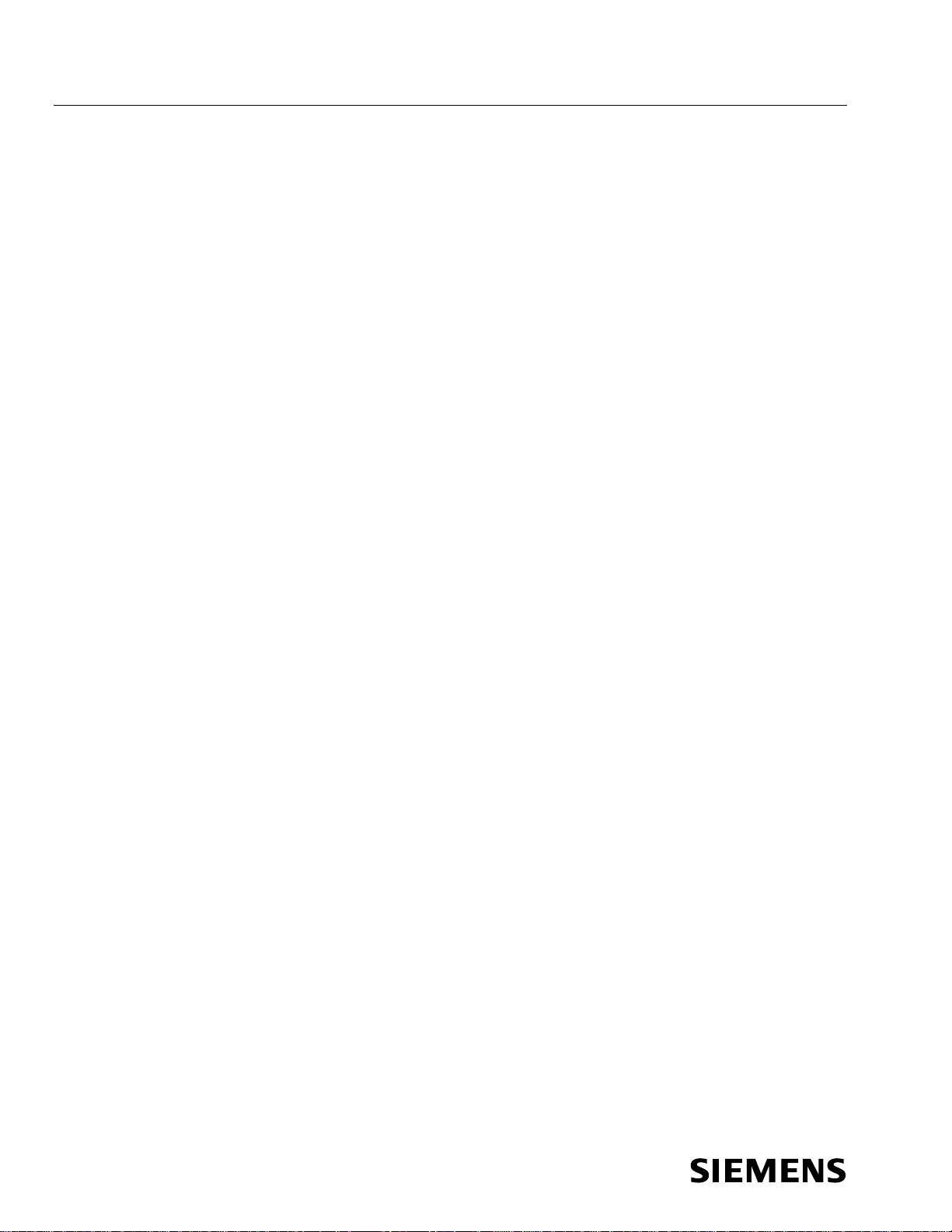

Figure 4 HMI Touch Button Symbols

AUTO MANUAL SETTINGS DIAGNOSTICS RESET BACK

Some screens can only be accessed with administrator-provided login privileges.

See section 3.3.3 Setup Using HMI.

2.1.5 Automatic Mode Operation

Touch the Auto button on the HMI on the door of the DCP for automatic

operation. The HMI displays the HSD paddles in their current positions. Servo

Status and Emergency Stop buttons indicate the status of the servo and e-stop.

Figure 5 HMI Automatic Mode

RH, Extended RH, Retracted

Table 3 Servo Status and Emergency Stop Button Status Colors

Button and Color Description

Servo Status Green Running; no servo fault

Servo Status Grey E-stop activated; no servo fault

Servo Status Yellow Servo fault present

Emergency Stop Green Running; no estop activated

Emergency Stop Red E-Stop activated

NOTE: Divert All Operation: If there is a need to divert all bags off of the

mainline, the Baggage Handling System (BHS) logic controller will need to

provide the signal to maintain the paddles in the extended position while the

diverter remains in the Automatic mode.

Page 28

SIBAG HSD 3.0 Service Manual

20

Document No.: 747-01695, Rev. 03

2021-March-03

Model Description

In Automatic mode, touch the Reset button to reset a fault after it has been

cleared.

There are two methods of controlling the HSD 3.0 in Automatic mode:

● Common input/output exchange through the use of 120 VAC or 24 VDC

control relays. These relays are located in the HSD 3.0 control panel and

are wired to the CU320-2 servo control unit.

● Network communications over PROFIBUS, PROFINET, or EtherNet/IP

There is a parameter in the HSD 3.0 drives that will select the method of control

in Automatic mode. This can be adjusted by using the HMI Settings screens,

Siemens Starter program, or by using the Basic Operator Panel on the HSD 3.0

drive. If this parameter is set to 0, the control relays will operate the HSD 3.0. A

setting of 1 will enable the PROFIBUS communications, etc.

NOTE:

When one of the network communication types is selected, it is still

necessary to make a direct electrical connection to the e-stop safety relay for a

safety stop to occur.

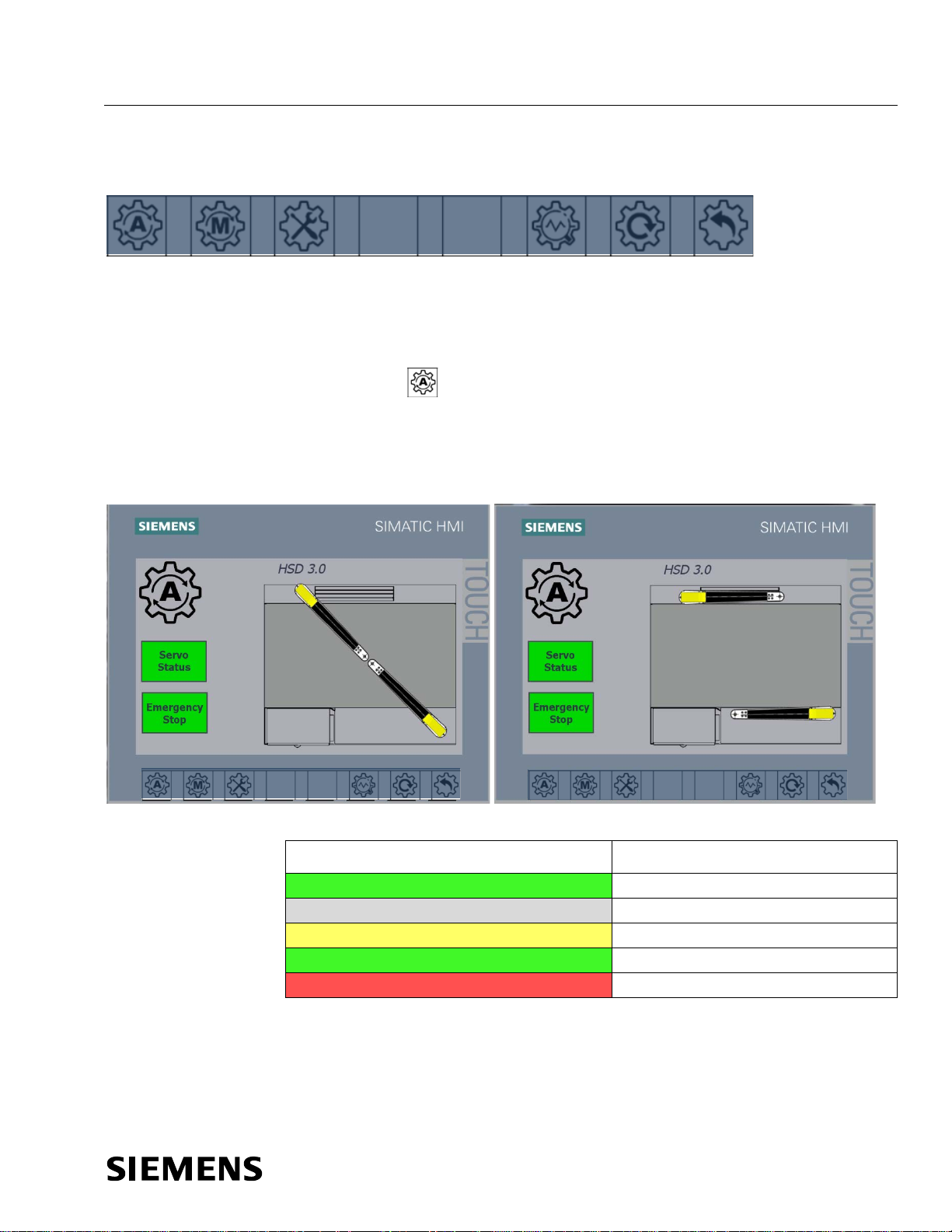

2.1.6 Manual Mode Operation

Touch the Manual button on the HMI on the door of the DCP for manual

operation. The HMI displays the HSD paddles in their current position. When the

HSD paddles are not in a known position (in between extend or retract), they are

not shown.

NOTE: When the HSD paddles are not shown, press the Retract button to

retract the paddles to the retract position, as shown in Figure 6 (LH, In Between).

This displays the paddles on the HMI screen and allows the BHS controller to

know the paddle positions when the HSD is returned to the Automatic mode.

In this mode, touching the Extend/Retract and Paddle Belt

buttons manually operate the HSD. Touching the Extend/Retract buttons will

return the paddles to the extend/retract positions saved in the memory. Touching

the Paddle Belt button will run the paddle belt. In this mode, the diverter will not

respond to BHS signals EXTEND PADDLES, RETRACT PADDLES, or PADDLE

BELT RUN.

NOTE: Divert All Operation: If there is a need to divert all bags off of the

mainline, the Baggage Handling System (BHS) logic controller will need to

provide the signal to maintain the paddles in the extended position while the

diverter remains in Automatic mode. Because Manual mode replaces the

automatic function signals from the BHS controller, the HSD 3.0 would no longer

have the ability to turn off the motors in the event of a cascade or normal timeout

situation. For this reason, it is not acceptable to use Manual mode for the

purpose of sustained Divert All operation.

Page 29

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

21

Model Description

Figure 6 HMI Manual Mode

LH, Retracted LH, Extended

LH, In Between

Page 30

SIBAG HSD 3.0 Service Manual

22

Document No.: 747-01695, Rev. 03

2021-March-03

Model Description

2.1.7 Settings Mode Operation

Touch the Settings button on the HMI on the door of the DCP for settings

mode. In this mode the Teach, I/O Status, and Setup buttons on the HMI are

enabled:

● Teach is used to define new end positions for the servo cycle commands.

The paddle extend and retract positions are factory configured, but

reconfiguring them might be necessary if the mechanism has been adjusted

or repaired. See section 5.4.2 Paddle Position.

● I/O Status is used to view the status of the outputs from the servo control

unit (first 6) and inputs to the servo control unit (last 4) for diagnostics and

troubleshooting. This screen is accessible without entering a password.

● Setup is used to set up the HSD by Siemens during manufacturing to

configure the communication type, conveyor width, and diverter hand. It is

used during installation commissioning by the system integrator to set the

speed. See section 3.3.3.2 Set Mainline Conveyor Belt Speed and Other

Options.

In this mode, the diverter will not respond to BHS signals EXTEND PADDLES,

RETRACT PADDLES, or PADDLE BELT RUN.

Figure 7 HMI Settings Screen

Page 31

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

23

Fasten HSD conveyor bed to adjacent conveyor beds using Grade 5 (or Class 8.8) hardware.

Level the HSD bed.

Connect incoming power to diverter control panel.

Adjust the encoder and setpoint configurations using the Teach functions, if necessary.

Test to verify correct paddle belt speed.

Test the HSD operation.

Test the e-stop operation.

Installation

3 Installation

3.1 Installation Sequence and Startup Checklist

Lock Out and Tag Out procedures should be followed with respect to

both the mainline conveyor and the HSD 3.0 before performing this

checklist.

Table 4 Installation Sequence and Startup Checklist

Procedure Completed

Review service manual installation procedures.

Review installation layout and detail dr awings.

Remove the back covers and visually inspect all f actory wiring and inside devices for any damage

that may have occurred during shipment.

Install upstream, downstream, and takeaway conveyor beds (including belts and sideguards).

Manually move the paddles by hand. Operation should be smo oth with no binding or catch points.

Test to verify correct belt direction for paddle belts.

3.2 Mechanical Installation

3.2.1 Unloading and Handling

Each HSD is separately crated for easy fork-lift handling at the job site (see

Figure 8). When out of the crate, the HSD should only be handled from the

bottom with all of the packing removed. The HSD should only be handled with

the long length dimension perpendicular to the lifting forks.

Store each HSD separately, and do NOT stack any other materials on top

of the HSD.

Page 32

SIBAG HSD 3.0 Service Manual

24

Document No.: 747-01695, Rev. 03

2021-March-03

Installation

The weight of the HSD is 1530 lbs. (694kg) (approximately 1800 lbs. (816kg)

crated). While 74 percent of the weight is on the drive side of the unit, the weight

of the HSD is approximately equal from one end to the other.

Prior to installation, remove the back covers and visually inspect all factory wiring

and inside devices for any damage that may have occurred during shipment.

Notify Siemens immediately if any damage is visible.

If lifting with a crane, use straps under the unit with spreader bars to properly

distribute the load while preventing damage to the electrical control panel and

safety guarding.

Figure 8 Crated HSD

3.2.2 Unit Identification

Each HSD has an engraved serial number name plate mounted on the diverter

control panel. Each HSD may also have a conveyor identification number on the

rear cover. Refer to the separate installation layout drawings to determine where

each HSD will be installed.

3.2.3 Installation

NOTE: Adjacent conveyor beds must be installed and leveled prior to attaching

the HSD bed.

1. Lift HSD into position using forklift forks perpendicular to HSD bed.

2. Fasten four HSD conveyor assembly bed conveyor interface brackets to

upstream and downstream conveyor bed frames using 3/8 in Grade 5 (or 10

mm Class 8.8) hardware.

Page 33

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

25

Installation

3. Level HSD bed.

4. Remove back covers and visually inspect all factory wiring and inside

devices for any damage that may have occurred during shipment.

5. Install conveyor bed belt and tension.

6. Install adjacent conveyor bed sideguards.

7. Match drill and install HSD area guards.

Figure 9 Area Guards

Additional area guards are required BY THE INTEGRATOR where a pinch

point exists at the tail of the divert side paddle against the sideguard.

3.3 Electrical Instructions

The HSD is delivered with a preconfigured memory module card in the Sinamics

servo control unit, which already contains a HSD standard project with

application program, as well as all typical motor and machine specific data

including the speed of the vertical paddle belts.

The encoder and setpoint configurations have also been factory adjusted, but

fine tuning may be required (see section 3.3.3.1 Teach Paddle Position). The

speed of the mainline conveyor belt running under the paddle arms shall be set

during installation commissioning by the system integrator (see section 3.3.3.1

Set Mainline Conveyor Belt Speed and Other Options). The HMI then calculates

and adjusts the paddle belt speeds to be compatible with the speed of the

mainline conveyor belt.

Page 34

SIBAG HSD 3.0 Service Manual

26

Document No.: 747-01695, Rev. 03

2021-March-03

Installation

The HSD comes with all the electrical devices wired to the terminal strip located

in the Diverter Control Panel (DCP) located on the frame of the HSD.

The HSD does not include a PLC or any other means of automated control, but

the motor controller provides the protection circuitry for each of the motors. The

automation controls are normally included in the sort line motor control panel that

is connected to the HSD on the terminal strip located in the DCP.

NOTE: The HSD cannot hold the paddles in position when the power is off. For

that reason, the unit should always be powered unless maintenance is being

performed. If the unit needs to be removed from service, it should be disabled at

the PLC level (control room).

NOTE: It is recommended to send a paddle positioning command (either extend

or retract) to the HSD during a system reset or system restart in order to return

the paddles to a known position.

3.3.1 Specifications

Although there are different versions of the HSD depending on where the HSD

will be installed, the specifications are almost identical, as shown in the following

table:

Table 5 Controls Specifications

Specification 120VAC Control 24VDC Control

Primary Power 380-500VAC, 50/60Hz, 10.7A 380-500VAC, 50/60Hz, 10.7A

Control Voltage 120 VAC, 1 phase, 60Hz 24 VDC

Controls Interface

3.3.2 Installation

1. Connect incoming and outgoing control signal wires to diverter control

2. Connect incoming power to diverter control panel.

NOTE: Paddle positions (encoder and setpoint configurations) are set before

shipment and should not need to be changed.

NOTE: In order to initiate safe torque off stop to machine, e-stop circuit should

de-energize CR265.

panel.

Digital I/O, PROFIBUS,

PROFINET, or Ethernet/IP

Digital I/O, PROFIBUS,

PROFINET, or Ethernet/IP

3. Connect e-stop relay to e-stop circuit for HSD operational area. Refer to

appropriate control panel drawing.

● Control Panel 68.0021.201 (PROFINET, Digital I/O, or EtherNet/IP Interface

with 120VAC control, US) requires 120VAC connection to CR265

Page 35

Service Manual SIBAG HSD 3.0

Document No.: 747-01695, Rev. 03

2021-March-03

27

Installation

● Control Panel 68.0021.202 (PROFINET, Digital I/O, or EtherNet/IP Interface

with 24VDC control, US) requires 24VDC connection to CR265

● Control Panel 68.0021.203 (PROFINET, Digital I/O, or EtherNet/IP Interface

with 24VDC Control, International) requires 24VDC connection to CR265

● Control Panel 68.0021.206 (Digital I/O only Interface with 120VAC control,

US) requires 120VAC connection to CR265

● Control Panel 68.0021.207 (Digital I/O only Interface with 24VDC control,

US) requires 24VDC connection to CR265

3.3.3 Setup Using HMI

3.3.3.1 Teach Paddle Position

The encoder and setpoint configurations have also been factory adjusted, but

fine tuning may be required. The HMI contains special “Teach Functions”. The

testing technician has to teach the actual extend/retract position values to the

setpoint parameters. (see section 5.4.2 Paddle Position).

3.3.3.2 Set Mainline Conveyor Belt Speed and Other Options

1. On Settings screen on HMI Teach, I/O Status, and Setup buttons on

HMI are enabled.

2. Touch Setup button. Setup screen displays (see Figure 10) and the

following two selections are enabled:

● Speed is used to configure HSD for mainline conveyor belt speed.

Touch Units button to select meters per second (MPS) or feet per minute