Page 1

TM

ISGS

Intelligent SwitchGear System

Operators Manualfirmware version V3

Manual No. SG8158-00

Page 2

IMPORTANT

The information contained herein is general in nature and not intended for

specific application purposes. It does not relieve the user of responsibility to

use sound practices in application, installation, operation, and maintenance

of the equipment purchased. Siemens reserves the right to make changes

at any time without notice or obligations. Should a conflict arise between the

general information contained in this publication and the contents of drawings or supplementary material, or both, the latter shall take precedence.

QUALIFIED PERSON

For the purposes of this manual, a qualified person is one who is familiar

with the installation, construction, or operation of the equipment and the

hazards involved. In addition, this person has the following qualifications:

(a) is trained and authorized to de-energize, clear, ground, and tag cir-

cuits and equipment in accordance with established safety practices.

(b) is trained in the proper care and use of protective equipment such as

rubber gloves, hard hat, safety glasses or face shields, flash

clothing, etc. in accordance with established safety procedures.

(c) is trained in rendering first aid.

NOTE

These instructions do not purport to cover all details or variations in equipment, nor to provide for every possible

contingency to be met in connection with installation, operation, or maintenance. Should further information be

desired or should particular problems arise which are not covered sufficiently for the purchasers purposes, the

matter should be referred to the local sales office.

The contents of the instruction manual shall not become part of or modify any prior or existing agreement, commitment or relationship. The sales contract contains the entire obligation of Siemens Energy & Automation, Inc.

The warranty contained in the contract between parties is the sole warranty of Siemens Energy & Automation, Inc.

Any statements contained herein do not create new warranties or modify the existing warranty.

Page 3

Introduction

1

Table

of

Contents

Installation

User Interface

Hardware Configuration

Protective Function Configuration

Control & Communications

Data Acquisition

ISGS Wisdom Software

2

3

4

5

6

7

8

Trip Curves & Equations

Metering

Menu Structure

Acceptance Test Procedures

Schematics

Settings Worksheet

Glossary

A

B

C

D

E

S

G

Index

Siemens Energy & Automation, Inc.

I

Page 4

Page 5

Table of Contents

1 Introduction ...............................................1

1.1 About this Manual............................................. 1

1.2 Safety................................................................ 1

1.3 Product Description .......................................... 2

1.3.1 Standard Configuration......................... 2

1.3.2 Optional Configurations ........................ 3

1.4 Wisdom Software.............................................. 3

1.5 Technical Specifications ................................... 4

2 Installation .................................................5

2.1 Unpacking......................................................... 5

2.2 Storing............................................................... 5

2.3 Mounting ........................................................... 5

2.4 Wiring................................................................ 6

2.5 Communications............................................... 8

2.5.1 PC Communications (RS-232) ..............8

2.5.2 Network Communications (RS-485) ..... 8

2.6 Cradle Assembly............................................... 8

2.6.1 Removing .............................................. 8

2.6.2 Inserting ................................................ 8

3 User Interface............................................9

3.1 Keypad.............................................................. 9

3.2 Indicators .......................................................... 9

3.2.1 LEDs...................................................... 9

3.2.2 LCD ..................................................... 10

3.3 Password Protection....................................... 10

3.4 Menu ............................................................... 11

3.5 Standard Operating Procedures..................... 11

4 Hardware Configuration.........................15

4.1 Startup ............................................................15

4.1.1 Power On Display................................ 15

4.1.2 Power On Meter Display ..................... 15

4.2 Device Configuration ...................................... 16

4.3 Setting Binary Input Voltages.......................... 16

4.4 CT Configuration............................................. 18

4.5 VT Configuration ............................................. 18

5 Protective Function Configuration ........21

5.1 Overview ......................................................... 21

5.2 Instantaneous Phase Overcurrent (50)............ 21

5.3 High-Set Instantaneous Phase

Overcurrent (50HS) ......................................... 22

5.4 Instantaneous Neutral or Ground

Overcurrent (50N)............................................ 22

5.5 High-Set Instantaneous Neutral or

Ground Overcurrent (50HSN).......................... 22

5 Protective Function Configuration (cont.)

5.6 Phase Time Overcurrent (51)...........................23

5.7 Neutral Time Overcurrent (51N) ......................23

5.8 Blocking Capability for Breaker or

Interrupter Saving............................................ 24

5.9 Directional Phase Time Overcurrent (67).........24

5.10 Directional Neutral or Ground Time

Overcurrent (67N)............................................25

5.11 Overvoltage (59) ..............................................26

5.12 Undervoltage (27)............................................26

5.13 Phase Sequence Voltage (47) .........................27

5.14 Negative Sequence Voltage (47N) ..................27

5.15 Overfrequency (81O) ....................................... 28

5.16 Underfrequency (81U) ..................................... 28

5.17 Breaker Failure (50BF)..................................... 28

5.18 Demand Setpoints ..........................................29

5.19 Power Setpoints.............................................. 30

6 Control & Communications ................... 31

6.1 Matrixing Events to Outputs ...........................31

6.2 Binary Inputs ...................................................33

6.3 Binary Outputs ................................................33

6.4 Trip Contacts ...................................................34

6.5 Comm Events.................................................. 34

6.6 Breaker Monitoring..........................................34

6.7 Logs and Breaker Monitor Reset ....................35

6.8 Breaker Operations Count ..............................36

6.9 Hardware Status (Relay Data) ......................... 36

6.10 Self-Monitoring (Value Supervision) ................ 37

6.11 Parameter Sets ...............................................39

6.11.1 Active Set ............................................40

6.11.2 Default Set........................................... 40

6.11.3 Switching Sets ....................................40

6.11.4 Copying Sets.......................................40

6.12 Communications Port .....................................41

6.13 Passwords.......................................................41

6.14 Date and Time Setting ....................................41

7 Data Acquisition ..................................... 43

7.1 Event Log ........................................................43

7.2 Trip Logs ......................................................... 43

7.3 Min/Max Logs .................................................44

7.3.1 Current Minimum/Maximum Log ........44

7.3.2 Voltage Minimum/Maximum Log ........45

7.3.3 Power Minimum/Maximum Log ..........45

7.3.4 Frequency Minimum/Maximum Log ...45

Siemens Energy & Automation, Inc. i

Page 6

Table of Contents

7 Data Acquisition (cont.)

7.4 Metered Data ..................................................46

7.4.1 Current Values .....................................46

7.4.2 Voltage Values .....................................46

7.4.3 Power Values....................................... 46

7.4.4 Frequency Values................................46

7.5 Meter Display ..................................................47

7.6 Waveform Capture .......................................... 47

8 ISGS Wisdom Software ..........................49

8.1 Overview .........................................................49

8.2 Setup...............................................................49

8.3 Menus .............................................................49

8.4 Demo Mode ....................................................51

A Trip Curves & Equations.........................53

A.1 Instantaneous Curve ........................................ 53

A.2 Standard Time Overcurrent Equation ..............53

A.3 Definite Inverse Equation .................................55

A.4 I-Squared-T Curve ...........................................56

A.5 Custom Protective Curve................................. 56

A.6 Over/Undervoltage Curves ..............................56

B Metering.................................................. 58

B.1 Accuracy ..........................................................58

B.2 Power Conventions..........................................59

C Menu Structure....................................... 60

D Acceptance Test Procedures ................ 63

E Schematics ............................................. 79

E.1 DC Trip System ................................................79

E.2 AC (Capacitor) Trip Systems............................80

Settings Worksheet

Glossary

Index

Service Request Form

ACCESS, CBPM, ISGS, SEAbus, WinPM, and Wisdom are trademarks of Siemens Energy & Automation, Inc. SIEMENS is a registered trademark of Siemens AG. All other brands and product names are trademarks of their respective companies.

ii Siemens Energy & Automation, Inc.

Page 7

Introduction

1

1

1 Introduction

The Intelligent SwitchGear System (ISGS) from Siemens is

a high-speed, numerical, microprocessor-based protective

relay designed to be easily incorporated into a computermonitored medium voltage power system. The relay is

designed and manufactured in accordance with the latest

provisions of the applicable IEEE, ANSI, and NEMA standards. You must thoroughly read and understand this operators manual before you begin any work with the ISGS relay.

Successful application and operation of this equipment

depends as much upon proper installation and maintenance

by the user as it does upon the careful design and fabrication

by Siemens.

1.1 About this Manual

The purpose of this manual is to assist the operator in developing safe and efficient procedures for the installation, maintenance, and use of the equipment.

This manual provides the necessary information to safely

install, operate, configure, maintain, and troubleshoot the

ISGS relay. In addition, the manual offers worksheets for

parameter settings, acceptance test procedures, and troubleshooting. For quick reference, a complete menu structure,

metering accuracies, trip curves, equations, and schematics

are included in the appendix.

Contact the nearest Siemens representative if any additional

information is desired.

1.2 Safety

Qualified Person

For the purpose of this manual and product labels, a Qualified Person is one who is familiar with the installation, con-

struction, and operation of this equipment, and the hazards

involved. In addition, this person has the following qualifications.

Training and authorization to energize, de-energize,

clear, ground, and tag circuits and equipment in accordance with established safety practices

Training in the proper care and use of protective equip-

ment such as rubber gloves, hard hat, safety glasses or

face shields, flash clothing, etc., in accordance with

established safety procedures

Training in rendering first aid

Siemens Energy & Automation, Inc. 1

Page 8

1

Introduction

Signal Words

The signal words Danger, Warning, and Caution used in

this manual indicate the degree of hazard that the user or

operator can encounter. These words are defined as follows:

Danger - indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury

Warning - indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury

Caution - indicates a potentially hazardous situation

which, if not avoided, could result in moderate or minor

injury

Required Procedures

In addition to normal safety practices, user personnel must

adhere to the following procedures:

1. Always work on de-energized equipment. Always deenergize a breaker or contactor, and remove it from the

equipment before performing any tests, maintenance, or

repair.

2. Always perform maintenance on equipment employing

springs after the spring-charged mechanisms are discharged.

3. Always let an interlock device or safety mechanism perform its function without forcing or defeating the device.

Field Service Operation

Siemens can provide competent, well-trained Field Service

Representatives to provide technical guidance and advisory

assistance for the installation, overhaul, repair, and maintenance of Siemens equipment, processes, and systems.

Contact regional service centers, sales offices, or the factory

for details.

1.3 Product Description

The ISGS relay is a general purpose, multifunction, microprocessor-based protective relay. It performs protection, metering, and monitoring for three phase current transformer (CT)

inputs and one ground CT input.

The ISGS relay provides two breaker tripping contacts and

one relay disabled (alarm) contact. The relay disabled contact

is a normally closed contact which opens when the relay is

functioning properly.

1.3.1 Standard Configuration

The ISGS relay base unit includes the following standard protection, metering, and monitoring features:

Instantaneous Phase Overcurrent (50) protection

Instantaneous Neutral or Ground Overcurrent (50N)

protection

Phase Time Overcurrent (51) protection

Neutral or Ground Time Overcurrent (51N) protection

ISGS

System

Pickup

Trip

Direct

Target

Reset

Pass

Addr

word

Trip

Target

Log

Reset

F

ISGS

Cat# C552-100V-5D0-000

VPSn120VAC/250VDC

IPH 5A IC 5A

Ser# Beta05HW15W2.XX

LR

7

4

1

Pass

word

Yes No

8

5

2

0

∞

Data Port

9

6

3

-/+

Enter

Figure 1.1 Intelligent SwitchGear System (ISGS) Relay

Nine selectable time overcurrent curves and one custom

curve

Breaker Failure (50BF) protection

Phase and neutral current as well as average current

metering

Minimum/maximum logs for storing metering data

Waveform capture

Trip log for recording information on last eight trip events

Event log for monitoring and recording relay functions

for status changes

2-line by 16-character liquid crystal display (LCD) for

viewing measured data

26-key membrane keypad for local access and selected

manual data entry.

LED indicators for general relay status information

Standard RS-232 communications port for local access

to all parameter settings using a personal computer (PC)

and Wisdom software

Password security

The ISGS relay is supplied in an M1-size drawout case with

dust tight front cover. The case is compatible with XLA connecting plugs that are commonly used to test relays.

2 Siemens Energy & Automation, Inc.

Page 9

Introduction

1

1.3.2 Optional Configurations

The ISGS relay is a dynamic, feature-rich device that can be

used in numerous industrial and utility applications. It allows

the addition of options or configuration changes at any time

without discarding the basic hardware.

There are four optional configurations that can be added to

the ISGS relay base unit.

Metering

Adding metering to the ISGS relay provides the relay with

three inputs for the connection of VTs. Each input can be set

from 100 V to 120 V. These inputs extend metering capabilities as follows:

Rms and average rms voltages

Active and apparent power

Kilowatt demand and kilowatt demand hours

Power factor

Frequency

The installation of the voltage input card now also allows the

setting of these protective functions:

High-Set Instantaneous Phase Overcurrent (50HS)

High-Set Instantaneous Neutral or Ground Overcurrent

(50HSN)

The metering option is also a prerequisite for the next two

options: additional protective functions and remote communications.

Additional Protective Functions

For an ISGS relay with the metering option installed, the following additional protective functions offer a powerful extension of its protection capabilities:

Under/Overvoltage (27/59)

Phase Sequence Voltage (47)

Negative Sequence Voltage (47N)

Directional Time Overcurrent (67/67N)

Over/Underfrequency (81U/O)

Communications

Adding communications to the ISGS relay provides the relay

with an RS-485 port. Using the SEAbus communications

protocol, this port allows remote communications and control via the ACCESS electrical distribution and communication system (ACCESS system).

Communications allows configuration, measurement, and

protection functions to be performed or reviewed easily from

a remote location using Wisdom software.

1.4 Wisdom Software

While it is possible to completely set up and configure the

ISGS relay using the front panel keyboard and display, the

free Wisdom software package provided with the relay

reduces the complexity of configuring the relay, reading

metered values, and retrieving stored data. For more information on Wisdom software, refer to Chapter 8.

Siemens Energy & Automation, Inc. 3

Page 10

1

Introduction

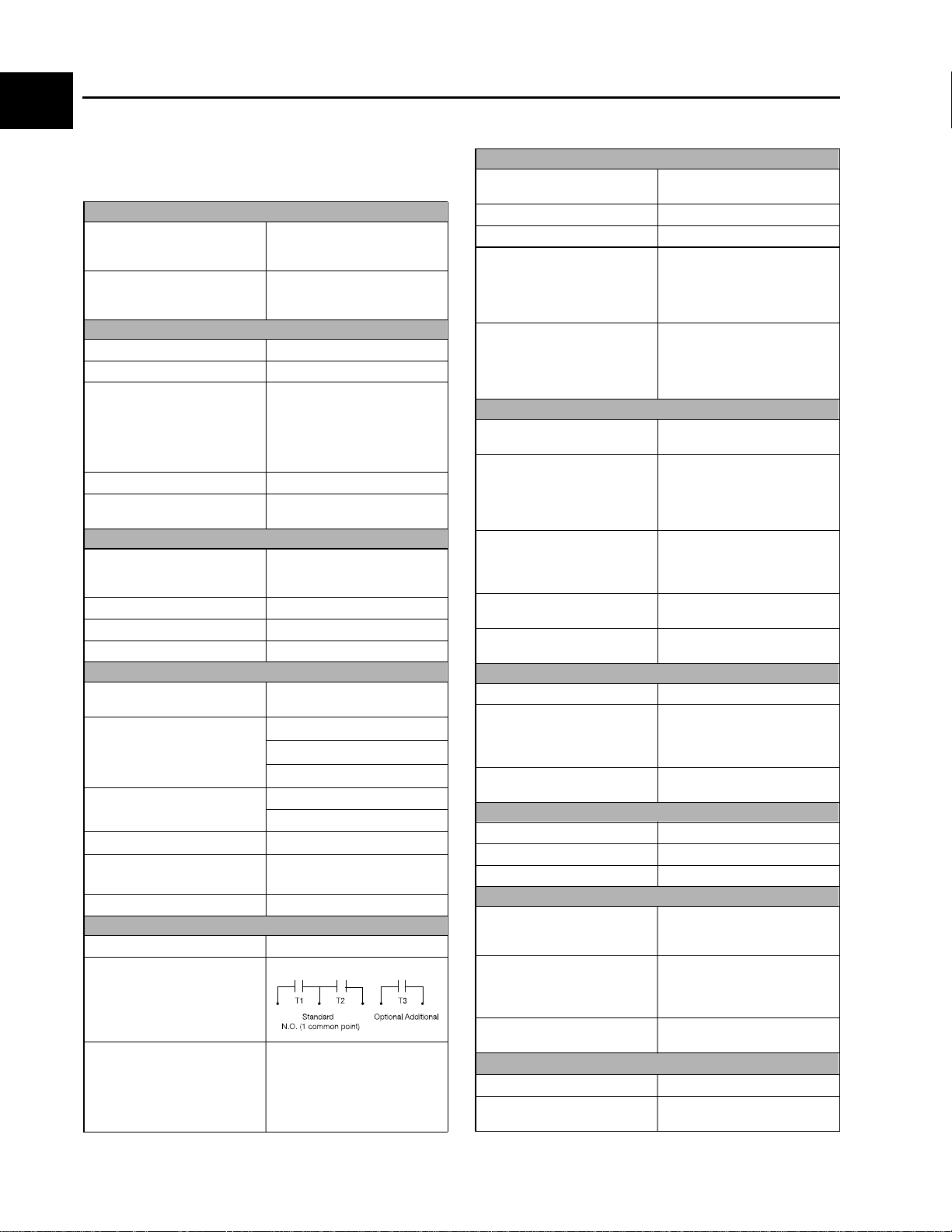

1.5 Technical Specifications

Applicable Standards

ANSI / IEEE C37.90-1989 IEEE Standard Relays and Relay

IEC 255-4 Single Input Energizing Quantity

General Technical Data

Operating ambient temperature -20°C to +55°C (-4°F to +131°F)

Storage temperature -40°Cto +75°C (-40°F to +167°F)

Relative humidity The average relative humidity

Altitude < 1500 meters

Frequency 50 Hz or 60 Hz, software select-

Power Supply AC/DC

DC Rated voltages 48 V (19-56 V),

Permissible ripple <10%

AC Rated voltage 120 V rms (102-132 V, 50-60 Hz)

Power consumption <15W

Input Circuit Ratings

Rated current (In) 1 or 5 A, independently for

Maximum input current 4 x In continuous

CT burden <0.1 VA for 1A CT

Rated voltage (Vn) 115 or 120 volts

Maximum input voltage for measurement: 1.25 x Vn

VT burden 150k

Tripping relays 2 or 3

Contact configuration

(Trip 1, Trip 2, Trip 3)

Contact rating IEEE/ANSI C37.90-1989, Sec-

Systems Associated With Electric Power Apparatus

Measuring Relays With Dependent or Independent Time

may be up to 55% outside of

enclosure for temperatures up to

40°C, with excursions up to

95% for a maximum of 96

hours, without condensation.

able

125 V (46-144 V),

250 V (92-288 V)

phase and ground inputs

10 x In for 10 s

100 x In for 1 s

<0.5 VA for 5A CT

MOV protected at: 2.5 x Vn

Ω

Trip Circuit

tion 6.7 (Make and carry 30 A for

at least 2000 duty cycles, resistive load, interrupted by independent means. Duty cycle:

200 ms on, 15 s off, 250 V)

Trip Circuit (continued)

Binary output contacts

(BO1 and BO2)

Maximum switching voltage 300 VDC, 250 VAC

Maximum switching current 8 A

Maximum switching capacity (for currents not interrupted by independent

means)

Trip source monitor 215 mA for 48 VDC supply

Applicable standards ANSI/IEEE C37.90-1989,

Between all circuits (except

communications interfaces, analog inputs and outputs) and

ground, and between these circuits.

Between communications interfaces, analog inputs and outputs

and ground, and between these

circuits

Across open contacts rated for

tripping

Across open contacts not rated

for tripping

Applicable standards IEC 255-4, IEC 255-5

For all circuits (except communications interfaces, analog

inputs and outputs), transverse

and common mode

RS-485 and local communications interfaces, analog I/Os

Electrostatic Discharge

Applicable standards IEC 801-2 (test without cover)

Contact discharge class 3, 6 kV

Air discharge class 3, 8 kV

Surge Withstand Capability

Applicable standards ANSI/IEEE C37.90-1989,

For all circuits except communications interfaces, analog

inputs and outputs

For RS-485 interface, analog

inputs and outputs

Electromagnetic Field

Applicable standards ANSI/IEEE C37.90.2

All six faces 10 V/m (+100%, -0%),

2 x N.O. (independent,

not rated for tripping)

DC: voltage dependent;

50 W at V

100 W at 48 VDC

270 W at 35 VDC

AC: 2000 VA

63 mA for 125 VDC supply

36 mA for 250 VDC supply

Source quality checked approximately every 4 minutes

Isolation

IEC 255-4, IEC 255-5

2 kV rms, 50/60 Hz, 1 minute

500 VDC, 1 minute

1500 V rms, 50/60 Hz, 1 minute

1000 V rms, 50/60 Hz, 1 minute

Impulse

class 3, 5 kV, 1.2/50

class 1, 0 kV

IEC 255-4, IEC 255-22-1,

IEC 41B (CO) 53

ANSI: Oscillatory and Fast Transient, transverse and common

mode

IEC: Class 3, 2.5 kV

IEC: Class 1, 0.5 kV

2-1000 MHz

≥70 VDC

µs, 0.5 J

4 Siemens Energy & Automation, Inc.

Page 11

Installation

2 Installation

This chapter explains the installation of the ISGS relay and

includes procedures for unpacking, storing, mounting, and

wiring the relay. Prior to installation, ensure that the system

power is off and that you have all required tools and test

equipment available.

2.1 Unpacking

Upon receipt of the relay, inspect the carton for signs of damage. If the carton has been opened or damaged, carefully

inspect and verify the contents against the packing list. If

pieces are missing or damaged, contact the shipping agent

or your Siemens representative. Refer to Figure 2.1 to iden-

tify the different parts of the relay.

Note: To avoid damage to the relay, transport or

store the relay in the original packing material. Always transport the cradle assembly

inside the case.

.

2.3 Mounting

The ISGS relay is typically installed in a switchgear unit or

relay panel. The required panel opening and a side view of

the relay are shown in Figure 2.2.

5.69

14.63

(371.5)

7.31

(185.7)

(144.5)

2.84

(72.1)

7.13

(181.0)

4X .25 (6.4) DIA

14.25

(362.0)

2

Figure 2.1 Case, Cradle, Paddles, and Cover of ISGS Relay

2.2 Storing

Extended storage of the relay should adhere to the following

guidelines:

Store the relay in a clean, dry location in the original

packing material

Storage temperature range is -40°F to +167°F

(-40°C

to +75°C)

Note: This device contains electrolytic capacitors,

which can degrade over time when stored

at temperatures over 86°F (30°C). Take care

not to store the relay at high temperatures

for extended periods.

After extended storage, connect the relay to its auxiliary voltage source for one or two days prior to taking it into actual

service. This serves to regenerate the electrolytic capacitors

of the auxiliary supply.

(77.0)

6.06

(154.0)

6.19

(157.2)

(7.9)

7.06

(179.4)

7.06

(179.4)

(7.9)

MOUNTING PANEL

Figure 2.2 Mounting Dimensions

3.03

.31

.31

.63

(16.0)

.63

(16.0)

10-32

SCREWS

10-32

SCREWS

Siemens Energy & Automation, Inc. 5

Page 12

Installation

2

Mount the relay using the following steps.

1. Install the relay M1-type case in the panel opening on

the switchgear equipment.

2. Connect the case ground to the terminal lug on the

back of the M1-type case as shown in Figure 2.3.

3. Wire as described in Section 2.4.

Use toothed washers to

ensure solid metal contact

through paint of cover and

panel

Case ground, #12

or braided cable to

good cubicle ground,

as short as possible

IMPORTANT:

Any unused terminals must remain disconnected. They are for factory use only.

Relay Disabled 2

Relay Disabled 1

Impedance Sense

Impedance Source

Ground Monitor

BI Trip

BI B Switch

Power Input +

Power Input -

Top

BI1A 21

BI1B 22

BI2A 23

BI2B 24

BI3A 25

BI3B 26

BI4A 27

BI4B 28

Trip 3A 29

Trip 3B 30

19

20

17 15 13 11

18 16 14 12

41 VT1+

42 VT143 VT2+

44 VT245 VT3+

46 VT347 NC (unused)

48 SEAbus Signal +

49 SEAbus Signal 50 SEAbus Ref

Trip 2

Figure 2.3 Case Grounding

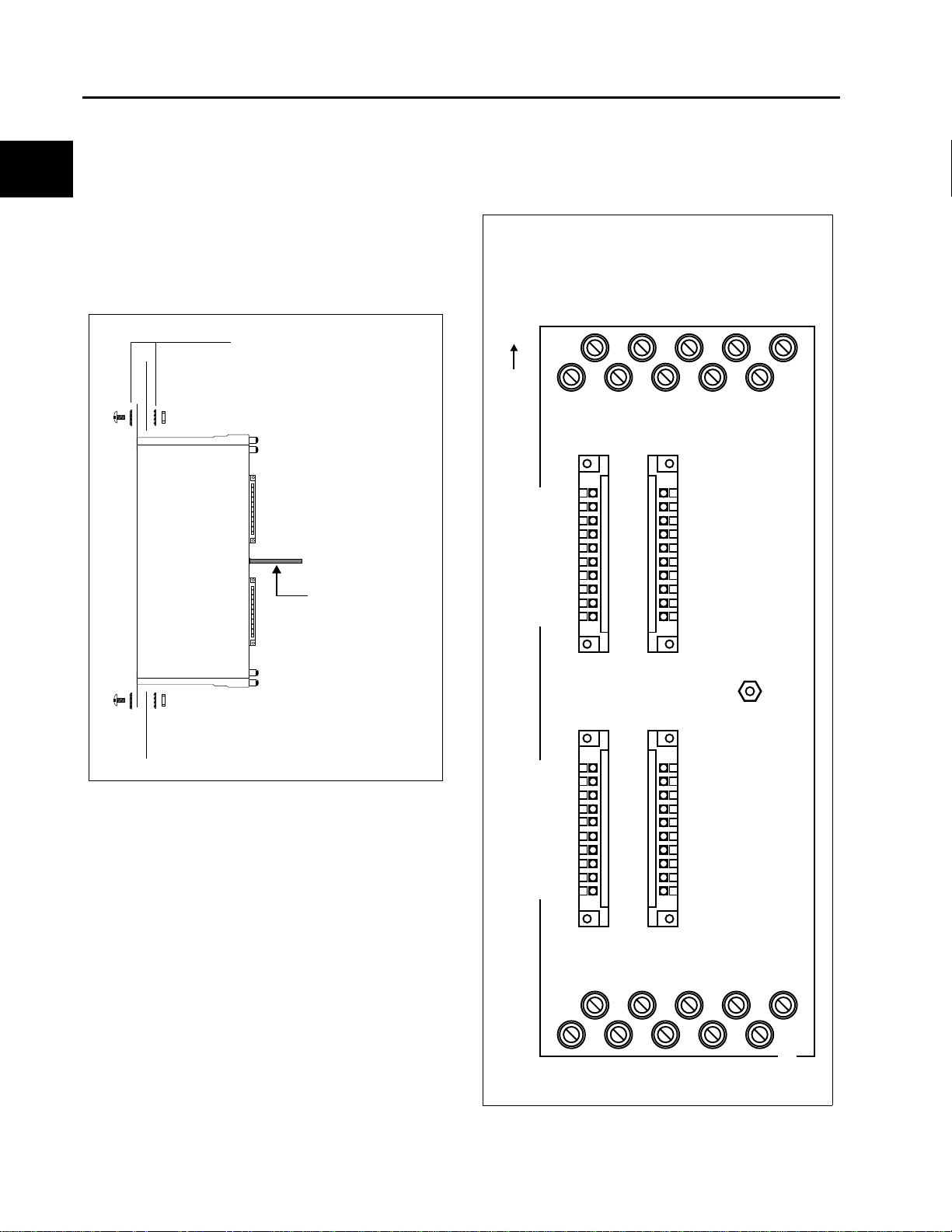

2.4 Wiring

Wire the ISGS relay after the case is installed. Connect the

wiring to the applicable terminals to support the desired features. Refer to Figure 2.4 for terminal locations. Figure 2.5

shows the internal connections of the ISGS relay. To avoid

injury to personnel or the equipment, perform power connections after all other wiring has been completed.

Assure that all power is off before performing any wiring. Terminals 1 through 20 accept ring-tongue or forked spade terminals and are suitable for 14 AWG to 10 AWG wire.

Terminals 21 through 60 are for directly inserting the appropriate wire and are suitable for 22 AWG to 14 AWG wire.

Communications connections made to terminals 48 to 50

require shielded twisted pair wire.

CT connections should be made with the polarity end of the

CT connected to current terminal marked with an asterisk (*).

BO1A 31

BO1B 32

BO2A 33

BO2B 34

AI1+ 35

AI1- 36

AI2+ 37

AI2- 38

AO1+ 39

AO1- 40

9

10

CTN-2

7531

8642

CTN-1*

CT3-2

CT3-1*

Figure 2.4 Terminal Locations

Case Ground

CT2-2

CT2-1*

CT1-2

CT1-1*

Trip 1

Trip Common

6 Siemens Energy & Automation, Inc.

Page 13

Current

Input

Voltage

Input

BI B Switch

CT 1-1

CT 1-2

CT 2-1

CT 2-2

CT 3-1

CT 3-2

CT N-1

CT N-2

VT 1+

VT 1VT 2+

VT 2-

VT 3+

VT 3-

Installation

2

ISGS

3

4

5

6

7

8

9

10

41

42

43

44

45

46

14

2 Trip 1

Trip Common

1

11

Trip 2

29

Trip 3

30

Relay Disabled 1

19

20

Relay Disabled 2

31

BO 1

32

33

BO 2

34

Binary

Outputs

Trip

Relays

Relay Disabled

Alarm Contact

Breaker and

Trip Source

Monitor

BI Trip

Impedance Source

Impedance Sense

Ground Monitor

1

Binary

Input

Power

Supply

2

3

4

V

H

Communications

In

Data +

RxD

15

17

18

16

+

21

-

22

+

23

-

24

+

25

-

26

+

27

-

28

13

12

48

(3)

DC

DC

RS-485 SEAbus

RS-232

Front Panel

Communications

Out

49

Data -

50

Reference

(2)

TxD

(7)

Reference

Ground

+

-

Figure 2.5 Internal Connections

Note: The relay disabled contact should be wired to plant-wide distributed control system or external alarm.

Siemens Energy & Automation, Inc. 7

Page 14

Installation

2

2.5 Communications

The ISGS relay must be connected to a host computer in

order for it to communicate with other devices. The relay

supports both RS-232 and RS-485 (optional) data interfaces. The use of either of these data interfaces will allow the

same level of access to the system as the front panel keypad, but configuration through communications does not

require a password.

The next section describes the connection to the interfaces.

For more information about operating the ISGS relay via the

data interfaces, refer to the documentation for the communications software, such as WinPM or Wisdom. Keypad

operations are described in Chapter 3.

2.5.1 PC Communications (RS-232)

The RS-232 interface (front port) is intended only for shortterm connections to a portable computer. Use this interface

to perform initial setup or to read the ISGS relay data logs or

waveform buffers using an appropriate software program. To

connect your PC to the front port, follow these instructions:

1. Remove the relay case front cover.

2. Locate the RS-232 connector on the front panel of the

cradle assembly.

3. Connect the PC to the front panel RS-232 port using a

standard DB-9 serial port connection cable (DB-9 male

to DB-9 female or DB-25 female depending on the type

of port on the computer). This connection does not

require the use of special adapters or a null-modem

cable.

2.5.2 Network Communications (RS-485)

The optional RS-485 interface (rear port) allows remote communication over a shielded twisted pair wire at distances of

up to 4000 feet. Use this interface together with an appropriate software program for remote monitoring and control of

the ISGS relay.

To connect the ISGS relay to your communications system,

follow these instructions:

1. Locate the RS-485 connector on the rear of the M1

case.

2.6 Cradle Assembly

Some of the setup and maintenance procedures in this manual require removal of the relay cradle assembly from the

drawout case. Use the following instructions for the proper

removal and insertion of the cradle assembly.

IMPORTANT:

The relay module contains CMOS circuits. Electrostatic discharges into or around the relay cradle or

any of its components must be avoided. Use

grounding straps or touch a grounded metal surface before handling the relay cradle.

2.6.1 Removing

Use the following procedure to remove the cradle assembly

from the case:

1. Remove the relay case front cover.

2. Remove the top and bottom connecting plugs

(paddles).

3. Loosen the cradle assembly by pulling the top release

lever to the left and the bottom release lever to the right

until the assembly ejects from the case.

4. Grasp the cradle assembly by the edges of the front

panel and pull it out of the drawout case.

5. Place the cradle assembly on an anti-electrostatic surface and perform the desired work.

2.6.2 Inserting

Use the following procedure to insert the cradle assembly

into the drawout case:

1. Insert the cradle assembly until the release levers come

in contact with the protrusions on the case.

2. Position the top and bottom release levers until the slots

on the levers align with the protrusions on the case.

3. Use the release levers to finish inserting the cradle

assembly into the case. Apply pressure to the cradle

assembly front panel until the assembly fully seats in the

case.

2. Use shielded twisted pair wire to connect pins 48, 49,

and 50 to your electrical distribution system.

To connect the ISGS relay to your PC via the rear port

directly, use an RS-232 to RS-485 converter.

via modem, use an RS-232 to RS-485 converter and a

null modem.

8 Siemens Energy & Automation, Inc.

4. Insert the top and bottom paddles.

5. Check for proper insertion of the cradle assembly by

seeing if the expected measured values are observed on

the relay display.

6. Install the front cover.

Page 15

User Interface

3 User Interface

Operation, parameter selection, and control of the ISGS relay

are performed using the front panel controls and indicators.

They consist of a 26-key membrane keypad, a 2-line by

16-character liquid crystal display (LCD), three light-emitting

diodes (LEDs), and the front port.

3.1 Keypad

The relay can be controlled via the keypad, the front port, or

the optional rear port. This manual covers only keypad operations. For information about communicating with the ISGS

relay via the data ports, refer to the documentation supplied

with the communications software (WinPM or Wisdom).

The ISGS relay keypad allows access to any relay information or function for display or parameter changes where

applicable. The keypad consists of 26 keys. Table 3.1 pro-

vides a detailed description of each key type.

To access relay information or functions for display or modification, use the Arrow keys to scroll through relay addresses

or use the Direct Addr key and the specific address number

to go directly to the information or function.

Use the Double Arrow keys to scroll through the address

blocks and use the Single Arrow keys to scroll within an

address block.

3.2 Indicators

The indicators on the front panel display consist of three

LEDs and a two-line LCD.

.

Key Name Function

Password Accesses the password function,

Direct Addr

l

Trip Log Displays the trip log.

Target Reset Resets the Trip LED.

Double Arrow Scrolls through the address

Single Arrow Scrolls through the addresses

F Saves new settings when followed

Numeric Used to enter an address number

which is required for programming

relay settings.

Allows direct entry of addresses.

blocks.

within an address block.

by Enter, enters or exits subaddress level, or switches to alternate parameter set when followed

by 1 or 2 and Enter.

after pressing Direct Addr, or to

enter a numeric setting.

3

3.2.1 LEDs

The LED indicators are used to provide general status information, which alerts the operator to an event or problem and

prompts the operator to use the LCD to review the logs for

more detailed information. The three LEDs and their functions are listed below.

LED Color Function

System Green Denotes the relay is operating properly

(always on when relay is in service).

Pickup Red Denotes a protective function is in

pickup.

Trip Red Denotes a protective function or

remote command has initiated a trip.

Both the Pickup and the System LED operate automatically

and do not require a reset.

The System LED remains on as long as power is applied

and the relay is functioning properly.

The Pickup LED is illuminated as long as a protective

function is in pickup.

Decimal Point Indicates a decimal point or the

separation between month, day,

and year, or between hours, minutes, and seconds.

Plus/Minus Toggles between positive and

negative values.

Backspace Deletes one character to the left or

selects backwards.

Infinity Programs the setting to the high-

est possible value.

Enter Chooses the setting option, enters

a setting value, or confirms the

address entered after pressing

Direct Addr.

Yes Accepts the displayed setting, or

replies yes to the displayed

prompt.

No Rejects the displayed setting,

allows entry of a numeric setting,

replies No to the displayed

prompt, or selects forward.

Table 3.1 Front Panel Keys

Siemens Energy & Automation, Inc. 9

Page 16

User Interface

3

The Trip LED is illuminated until the Target Reset key is

depressed. Reset the Trip LED by momentarily depressing

the Target Reset key.

Note: If the Trip LED is on and power is removed, it

will still be set to on when power is restored.

3.2.2 LCD

The two-line by sixteen-character LCD allows the viewing of

parameters, measured data, and keypad entries. The LCD

also displays messages returned by events such as a relay

going into pickup.

Whenever a relay goes into pickup, in addition to lighting the

pickup LED, the LCD shows a message that indicates which

protection element is in pickup. A pickup message is displayed as follows:

PICKUP FFF Pxxxx

MM/DD hh:mm:ss

In this message

FFF is the two or three character ANSI pro-

tection code number, for example, 50,

or 50N.

xxxx is a sequence of the characters 1, 2, 3,

and/or N, indicating which phase or

combination of phases and neutral

have picked up.

MM/DD hh:mm:ss is the date and time of the event.

Level 3 includes additional access to all matrixing, the

changing of which can cause a device reset.

Password configuration is described in Section 9.4.

To access any password protected information or function,

either first enter the password (up to five digits) and then go

to the desired address, or first access the address block and

then enter the password as described in the following steps:

1. Press the Password key. The password dialog box

appears.

Password:

2. Enter a password (00000 to 99999) using the number

keys from the keypad. The LCD displays each digit

entered as an @ symbol.

Password:

@@@@@

3. Press the Enter key after completing the entry.

4. If a correct password has been entered, the dialog box

displays a confirmation message that depends on the

level password that was entered.

Password:

User PW Three OK

These messages are displayed until superseded by another

pickup, a trip message, a target reset, or a request by the

operator to display other information.

3.3 Password Protection

A password should be used to prevent any accidental or

unauthorized parameter changes. While relay information

can be accessed for display without a password, all changes

to parameter settings require a user password.

Note: The ISGS relay is not password protected

when making parameter changes through

Wisdom software.

The ISGS relay offers three password protected access levels:

Level 1 consists of simple settings such as all protective

and setpoint settings that do not cause a reset.

These simple settings include communications

and time and date settings.

Level 2 consists of protective function settings such as

CT and VT ratios, the changing of which can

cause a device reset.

For a level 1 or level 2 password, the word Three in the

illustration above would be replaced by One and

Two, respectively.

If the wrong password has been entered, the dialog box

displays the following message:

Password:

Rejected

5. When the confirmation message appears, press the

Enter key. This action returns the display that was in

use before entering the password.

For example, if the address block of the parameter to be

changed was displayed prior to entering the password,

the display returns to this address block and the device

is ready to accept changes.

10 Siemens Energy & Automation, Inc.

Page 17

User Interface

3.4 Menu

The ISGS relay menu (or memory map) is organized in a hierarchical structure that is made up of address blocks and

addresses. The first level consists of address blocks. Each

address block represents one complete function or two

related functions and is identified by a unique four-digit number ending in two zeros (for example, 1500). Refer to

Figure 3.1.

The second level consists of individual addresses confined to

an address block. Each address represents a part of a functionthe changeable parameteror the measured value of

a displayed parameter. The parameter is identified by a

unique four-digit number that consists of the first two digits

of the address block and two digits indicating the parameters number within the address block (for example, 1502).

Refer to Figure 3.1.

Block Function Address Parameter

A1500 Instantaneous

Phase Overcurrent

(50)

High-Set Instantaneous Phase Overcurrent (50HS)

A1900 Directional Phase

Time Overcurrent

(67)

A2200 Overvoltage (59) --- ---

Figure 3.1 Example of Menu Structure Displaying Address

Blocks with Two Related Functions, an Individual Function,

and an Unavailable Function.

A complete ISGS relay menu with parameter listing is provided in Appendix C. The various parameter settings are

shown in the respective section describing the complete

function.

1501

Function 50

1502

Pickup 50

1504

Delay 50

1510

Freeze Wfm 1 50

1511

Freeze Wfm 2 50

1512

Block 50

1551

Function 50HS

1552

Pickup 50HS

1560

Freeze Wfm 1 HS

1561

Freeze Wfm 2 HS

1901

Function

1902

Curve

1903

Pickup

1905

Time Dial

1906

Filter

1907

Impedance

1908

Direction

1910

Freeze Wfm 1

1911

Freeze Wfm 2

The LCD identifies functions that include parameters configurable for A and B settings by preceding the functions

address block number with the letter A or the letter B,

depending on which parameter set is currently displayed.

Refer to Figure 3.2.

3

A1500 Instantaneous

Phase Overcurrent 50

Figure 3.2 LCD Display of a Function that Includes

Parameters Configurable for A and B Settings.

In addition, when scrolling through the individual parameters

of an ISGS relay, the LCD identifies each parameter that is

configurable for A and B settings by preceding the parameters address number with the letter A or the letter B,

depending on which parameter set is currently displayed.

Refer to Figure 3.3

A1502 Pickup 50

110A

Figure 3.3 LCD Display of a Parameter that is Configurable

for A and B Settings

When accessing the ISGS relay menu through the keypad,

the Arrow keys allow scrolling through all available functions

and parameters. If an option is not installed, the LCD only

displays the address block that is reserved for this option. In

this case, second level addresses are not available.

3.5 Standard Operating Procedures

Before attempting to display or configure any of the relay

data, ensure that the relay has control power which is indicated by the system LED (green) being lit.

The steps for displaying data, configuring parameters, saving

data, and switching to the alternate parameter set for either

display or configuration are described in detail in Table 3.1,

Standard Operating Procedures.

Only certain protective function parameters have two settings. All A settings are grouped under parameter set A, and

all B settings are grouped under parameter set B. Each

parameter set automatically includes all the regular parameters that can be programmed to only one setting at a time

and, therefore, apply to both sets. Examples are protective

function enable settings and matrixed output contacts such

as waveform buffers and blocking. For more information on

parameter sets, refer to Section 6.11.

Siemens Energy & Automation, Inc. 11

Page 18

3

User Interface

Displaying function names (address blocks), parameter

names and their settings or values (addresses), and subparameter settings (subaddress, where applicable), does not

require a password (except for viewing the password itself).

Data can be displayed by following steps 1 to 3 of the standard operating procedures described in Table 3.1. Viewing

passwords requires the entry of an appropriate level user

password (refer to Section 3.3 for more information on

passwords).

Configuring parameters requires a password. Use steps 1

and 2 or steps 1 to 3 to display the desired parameter or its

subparameters. Continue with step 4 to make changes to

this parameter or subparameter.

When leaving a function or before scrolling to the waveform

parameters of the same function, the relay prompts to indicate the end of the password operation and whether the

changes made so far shall be saved. When the message

End of Password Operation ? appears, press the Ye s key

to continue to the next function. Press the No key to scroll

back through the parameters of this one function. Pressing

the Ye s key returns the message SAVE NEW SETTINGS ?.

Press the Yes key again to save the settings, or press the No

key to abort any changes made after the last saving procedure.

12 Siemens Energy & Automation, Inc.

Page 19

Table 3.1 Standard Operating Procedures

Step Task Description

Display Data

1 Display data at

Address Block

(xx00)

Use Double Arrow keys to scroll forward or backward between address blocks.

OR

Press Direct Addr key; enter address of desired address block using the numeric keypad; press Enter key.

To view passwords, carry out step 4 before continuing with the next step.

User Interface

3

2 Display data at

Address

(xxxx)

3 Display data at

Subaddress

(0xx)

4 Enter Password Press Password key; enter the password; press Enter key twice to return to screen displayed last before

5 Configure at

Address

(xxxx)

6 Configure at

Subaddress

(0xx)

Use Single Arrow keys to scroll forward or backward between parameter addresses.

Skip step 3 if function has no subaddresses.

OR

Press Direct Addr key; enter address of desired parameter using the numeric keypad; press Enter key.

Skip step 3 if function has no subaddresses.

Press F key once to enter subaddress level; use Single Arrow keys to scroll forward or backward between

subaddresses.

Press F key again to return to address level.

Configure Parameters

password entry.

Leaving an address block, leaving a function within an address block, or before scrolling to the waveform

parameters within a function prompts for renewed password entry.

For password levels, proper password entry, and display messages, refer to Section 3.3.

Display cursor is blinking (otherwise repeat step 4).

Change displayed value by entering a new value using the keypad. Press Enter key.

Change displayed selection by pressing the No key to scroll forward through options until desired option

appears. Press Enter key.

Skip step 6 if function has no subaddresses.

Press F key once to enter subaddress level; use Single Arrow keys to scroll forward or backward between

subaddresses.

Change displayed selection by pressing No key to scroll forward through options until desired option appears.

Press Enter key.

Press F key again to return to address level.

Save Changes

7 Enter Save

Procedure

Undo Changes To abort any changes made, press No key. After message SAVING PROCEDURE ABORTED appears,

Save Changes To save settings and reset relay to new parameters, press Yes key followed by Enter key. After message

8 Switch

Parameter Set

9 Display/Config-

ure Alternate

Parameter Set

Press F key. At the blinking cursor position, the letter F is displayed. Press Enter key. Message SAVE NEW

SETTINGS? appears.

press Enter key to return to screen displayed last before aborting settings.

Settings can be undone any time while still in the same function by simply returning to the parameter and

assigning a new value.

NEW SETTINGS SAVED appears, press Enter key to return to screen displayed last before saving settings.

Leaving an address block, leaving a function within an address block, or before scrolling to the waveform

parameters within a function prompts for the saving of the function settings.

Switch Parameter Set

Press F key followed by either 1 (for normal settings) or 2 (for alternate settings) on the numeric keypad.

The message PARAMETER SET COPIED TO EDIT appears. Press Enter key.

Display shows address block (xx00) with either A or B prefix in address (Axx00 or Bxx00).

A indicates parameter set 1; B indicates parameter set 2.

Repeat steps 1 to 3 or steps 1 to 7 to display or configure the alternate parameter set.

Siemens Energy & Automation, Inc. 13

Page 20

3

Notes:

14 Siemens Energy & Automation, Inc.

Page 21

Hardware Configuration

4 Hardware Configuration

This chapter explains the device startup and how to configure the basic ISGS relay parameters. The relay must be configured with certain system parameters, such as phase

sequence and frequency. In addition, information regarding

the manner in which the ISGS relay is connected in the

installation must be configured.

All parameter changes require a password. Refer to

Section 3.3 for instructions on how to enter your password.

Viewing parameter settings does not require a password.

Note: The ISGS relay is not password protected

when making parameter changes through

Wisdom software.

Perform parameter changes using steps 1 through 9 of the

standard operating procedure described in Section 3.5.

4.1 Startup

Block Function Address Parameter

0000 Power On/

Configuration

Display

This section describes the content of address block 0000

represented by the initial Power On display and the initial

Power On Meter display.

When the relay is powered on, following a brief hardware initialization check, the green System LED illuminates and the

LCD shows the contents of address 0000. First, the Power

On display indicates your relay configuration. After approximately five seconds, the Power On display is replaced by the

Power On Meter display showing two values. Prior to placing

the relay in service, verify that the correct relay configuration

was preloaded at the factory. To return to the Power On display, press the Direct Addr key and key in 0000 followed by

the Enter key.

4.1.1 Power On Display

The two lines of the Power On display indicate your relay

configuration. Line 1 contains the function address 0000 and

the relays firmware version. Line 2 identifies the relays catalog number which depends on the options you ordered with

your relay (see Figure 4.2 for catalog numbers).

Reading from left to right in Figure 4.1, line 1 shows the

address block 0000 and the ISGS firmware version

ISGS-3V3.00. Line 2 displays the catalog number

D553100VSDF00000. The first character of this number, D,

indicates a 120 VAC power supply, the fourth character, 3,

voltage inputs for energy metering, and the eighth through

eleventh characters, VSDF, indicate Under/Overvoltage pro-

tection, Negative Sequence Voltage protection, Directional

Overcurrent protection, and Under/Overfrequency protection, respectively.

--- ---

0000 ISGS-3V3.00

D553100VSDF00000

Figure 4.1 Power On Display

123 4567 891011 121314

-

ISGS

Nominal Supply Voltage

48 VDC

125 VDC

120VAC

250VDC

Phase CT Secondary

Rating

1A

5A

Neutral or Ground CT Rating

1A

5A

Voltage Inputs, Power Metering,

RS-485 Communications

Without

With

Additional I/O

Without

With

*

Under/Overvoltage Protection (27/59),

Negative Sequence Voltage Protection (47/47N),

Directional Overcurrent Protection (67/67N),

Under/Overfrequency Protection (81 U/O)

Without

With

*

* Voltage Inputs required.

A

B

D

E

1

5

1

5

00

31

0

I

0000

VSDF

---

0 0 00

Figure 4.2 Relay Configuration (Catalog Number)

4.1.2 Power On Meter Display

The Power On Meter display consists of two measured values. The default setting for Line 1 displays average current,

and Line 2 shows average current demand. The type of

default values displayed can be changed in address block

7000, Operating Parameters, described in Chapter 7.

Iavg = xx A

Idmdavg = xx A

Figure 4.3 Power On Meter Display

The Power On Meter display is replaced with other information anytime an event message is displayed or the LCD is

used to set parameters or check logs. To return the LCD to

the Power On Meter Display, press the Trip Log key followed

by the Target Reset key.

4

Siemens Energy & Automation, Inc. 15

Page 22

Hardware Configuration

4

4.2 Device Configuration

The Device Configuration function allows you to set up the

ISGS relay to match line frequency, phase sequence, and

breaker connection settings of your system.

4.3 Setting Binary Input Voltages

Binary inputs are jumpered to correspond to the auxiliary

supply voltage of the relay in which they are installed. The

inputs will correctly respond to DC or AC depending on the

jumpering. The jumpers can be placed to allow the inputs to

work with any of the available voltages, independent of the

auxiliary supply voltage. Refer to Figure 4.5 and Table 4.1.

13

ISGS

Relay

125 VDC Bus

21

BI 1

22

12

Figure 4.4 Binary Inputs Independent of Supply Voltage

Table 4.1 lists the possible jumper positions for setting

binary input voltages. The numbers in this table each refer to

a pin from and to which a jumper can be moved.

Table 4.1 Jumper Positions

120 VAC

Aux Relay

120 VAC Source

to be Monitored

1000 Device Configuration

Address Parameter Options

1002 Frequency 50Hz or 60Hz

1003 Phase Sequence 123 (ABC) or 132 (ACB)

1004 Breaker

Connection

1005 Trip Time 0.01-32.00 s (0.01 s steps)

Trip 1, Trip 2, Trip 3, Trip 1 & 2,

Trip 1 & 3, Trip 2 & 3, or

Trip 1 & 2 & 3

The frequency parameter (1002) must be set to the nominal

frequency of your system. Phase sequence (1003) selects

the phase sequence of your system as it enters the ISGS

relay. The breaker connection parameter (1004) selects the

trip contact that your breaker is connected to. Many functions use this parameter to determine if the device is

attempting to open the breaker. Breaker failure can be initiated by either one of the three trips (if the Breaker Failure

function is enabled). The default is set to Trip 1.

Voltage

Supply

48 V X111-X112 X23-X22 X34-X35 X46-X47

125 V

(Default)

120 VAC X110-X111 X24-X23 X35-X36 X47-X48

250 VDC X111-X112 X23-X22 X34-X35 X46-X47

h

BI 1

Te rm in a ls

21/22

X13-X14 X25-X26 X37-X38 X49-X50

X16-X17 X28-X29 X40-X41 X52-X53

X19-X20 X31-X32 X43-X44 X55-X56

X111-X112 X23-X22 X34-X35 X46-X47

X13-X14 X25-X26 X37-X38 X49-X50

X17-X18 X29-X30 X41-X42 X53-X54

X19-X20 X31-X32 X43-X44 X55-X56

X14-X15 X26-X27 X38-X39 X50-X51

X17-X18 X29-X30 X41-X42 X53-X54

X20-X21 X32-X33 X44-X45 X56-X57

X14-X15 X26-X27 X38-X39 X50-X51

X17-X18 X29-X30 X41-X42 X53-X54

X19-X20 X31-X32 X43-X44 X55-X56

BI 2

Terminals

23/22

BI 3

Terminals

25/26

BI 4

Te rm in a ls

27/28

16 Siemens Energy & Automation, Inc.

Page 23

Hardware Configuration

Figure 4.5 shows option board 2 and its jumpers. The drawing indicates the jumpers associated with each binary input.

The enlarged set of pins shows an example of pin labeling

and a jumper at location X17-X18.

350

350

350

350

Changing Jumper Positions

IMPORTANT:

The relay module contains CAMS circuits. Electrostatic discharges into or around the relay cradle or

any of its components must be avoided. Use

grounding straps or touch a grounded metal surface before handling the relay cradle.

1. Remove the cradle assembly from the case as

described in Section 2.6.1.

2. Set the relay on its back.

3. With a small screwdriver, remove the four screws (on the

sides of the relay) that hold the front panel to the relay

cradle.

4. Lift the front panel and hang it in the slots provided on

the left side of the casing. Take care not to damage the

ribbon cables that connect the electronics in the cradle

to the front panel electronics.

5. Disconnect the two ribbon cables from the main board

and the option board 2. The main board is the center

board which is screwed to the option board 2 on its

right.

6. Withdraw these two attached boards and set them on

the workplace with the jumper side up (see Figure 4.5).

7. Each jumper is pushed over two out of three pins. Each

pin is labeled with numbers identical to those in

Tab l e 4 . 1. The numbers of two side-by-side pins represent a possible jumper position.

4

.22 163 .22 163 .22 163 .22 163

Figure 4.5 Option Board 2 with Binary Inputs

8. With a small needle nose pliers, lift the desired jumper

off of its pins and push it down over another two pins of

the same set.

Example: In Figure 4.5, the jumper is over pins X17

and X18, a default setting for a 125 V power supply. For

a 48 V power supply, set this jumper to X16-X17.

Repeat this step until all desired jumpers are repositioned.

9. Insert the attached boards back into the cradle. The

connectors of each board must snap into the terminals

of the casing.

10. Reattach the two ribbon cables to the main board and

the option board 2.

11. Unhook the front panel and carefully place it over the

cradle. Lift the front panel slightly to make sure that the

ribbon cables connected to the front panel are positioned in their assigned space to prevent damage.

12. Insert and tighten the four front panel screws.

13. Insert the cradle into the casing as described in

Section 2.6.2.

Siemens Energy & Automation, Inc. 17

Page 24

4

Hardware Configuration

4.4 CT Configuration

The CT Configuration function allows you to set up the ISGS

relay to match the phase CT primary rating, the neutral or

ground CT primary rating, and the CT inputs normal power

flow setting of your system. For CT connections refer to

Figure 4.8.

Main Bus

ISGS

ISGS

Power

Normal Power Flow

(Into CT Polarity Mark)

Figure 4.6 Normal/Reverse Power Flow

(Out of CT Polarity Mark)

Power

Reverse Power Flow

4.5 VT Configuration

Use this address block to configure the ISGS relay to match

the VT primary rating and the VT connection setting for your

system. These settings are available only if the voltage input

option is installed on the relay.

1100 CT Configuration

Address Parameter Options

1101 Phase CT Primary

Rating

1102 Neutral or Ground

CT Primary Rating

1104 Power Flow Normal or Reverse

The phase (1101) and neutral/ground (1102) CT primary ratings are independently configurable. However, when a residual sensing method is used for ground fault protection, the

primary current ratings for the neutral CT and the phase CT

must be equal. The CT secondary ratings (1A or 5A) are set

at the factory and are not changeable from the front panel.

Power flow is also referred to as top feed or bottom feed. If

the power enters the polarity mark on the CTs, set the Power

Flow parameter (1104) to Normal. If power leaves the polarity

mark, enter Reverse. Figure 4.6 illustrates examples of nor-

mal and reverse power flow.

18 Siemens Energy & Automation, Inc.

5-8000 A (1 A steps)

5-8000 A (1 A steps)

Page 25

Hardware Configuration

1200 VT Configuration

Address Parameter Options

1201 Primary Rating 120-138,000 V (1 V steps)

1202 VT Connect Line-to-Line or Line-to-Neutral

1203 Sec. VT Rating 100-120 V (1 V steps)

Voltage transformers may be connected in either of two

ways:

Two VTs connected open delta-open delta

Three VTs connected wye-wye

For brevity, the open delta connection is referred to as L-L

(line-to-line), while the wye connection is referred to as L-N

(line-to-neutral). Wye-delta or delta-wye connection of VTs is

not allowed. Figure 4.7 shows the correct VT connections

and polarities.

Voltage transformers are specified with an input to output

voltage ratio (for example, 12000:120). The secondary voltage rating of the VTs can be set by the Secondary Voltage

Rating parameter (1203).

Before leaving the hardware configuration blocks, (only when

changing parameters, not when viewing) the ISGS relay displays the message END OF PASSWORD OPERATION?.

Press the No button to return to one of the configuration

blocks. The message PRESS ANY KEY TO CONTINUE

appears. Press any key to return to the screen displayed last

before the message prompt appeared. Press the Ye s button

if you are finished with the configuration changes. The device

prompts you to save the settings.

Press the Yes button to save the settings. The relay

resets and displays the Power On and Power Meter On

displays.

123

123

Wye-Wye VT Connection

41

42

43

44

45

46

41

42

ISGS

V1

4

V2

V3

ISGS

V12

Press the No button if you do not want to save the

changes The message SAVING PROCEDURE

ABORTED appears. Press Enter to return to the last

address block.

Note: For CT configuration, CTs on the neutral

must be the same rating as other CTs for

residual ground sensing, directional neutral

sensing, or direct ground sensing.

For VT connections, VTs must be either wye-wye

or delta-delta. Wye-delta or delta-wye connections are not permissible.

Open Delta-Open Delta VT Connection

Figure 4.7 Voltage Transformer Connections

Siemens Energy & Automation, Inc. 19

43

44

45

46

V23

V31

Page 26

Hardware Configuration

4

1

2

3

ISGS

1

3

4

2

56

3

7

8

N

910

52 52

Three Phase Current with Residual Ground Sensing

1

2

3

ISGS

1

3

4

2

56

3

7

8

1

2

3

3

ISGS

1

4

N

2

56

3

7

8

N

910

Three Phase Current with Direct Neutral Sensing

1

2

3

3

ISGS

1

4

G

2

56

3

78

52

N

910

52

N

910

Three Phase Current with Zero Sequence CT Three Phase Current with Direct Ground Sensing

52 = Power Circuit Breaker

= ISGS Internal CT

Figure 4.8 Current Transformer Configuration

20 Siemens Energy & Automation, Inc.

Page 27

Protective Function Configuration

5 Protective Function Configuration

5.1 Overview

This chapter explains how to set the parameters for the

protective functions of the ISGS relay.

Password

All parameter changes require a password. Refer to

Section 3.3 on how to enter your password. Viewing

parameter settings does not require a password.

Note: The ISGS relay is not password protected

when making parameter changes through

Wisdom software.

Configuration Steps

Perform parameter changes using steps 1 through 9 of the

standard operating procedures described in Section 3.5.

Parameter Sets

Many protective functions can be set to two different parameter setsset A and set B. These functions are indicated by

the letter A or B preceding the address block number. Alternate sets are useful for seasonal settings or for special operating periods. Either set can be selected (in address block

7100) to be the active set that controls the relay operation.

The parameters for both sets are entered in the relevant

address blocks. Waveform capture buffer settings apply to

both parameter sets. Unless you do not desire an alternate

set, configure both sets when configuring the relay.

Note: The settings for parameter sets A and B are

entered in the address block. However, the

parameter set which the ISGS relay is

actively using is selected at address block

7100. Refer to Section 6.11 for discussion

of parameter sets.

Actions on Pickup or Trip

Protective functions can be set to have actions occur on

pickup or on trip. Binary outputs can be set to be actuated

on pickup of a protective function. A protective function is set

to trip a breaker by assigning the trip contact that is connected to the breaker (default is Trip 1). Binary outputs can

also be assigned to trip a breaker. It is possible, however to

have a protective function enabled and not assigned to any

output. Events and their sequences are entered in the trip log

as usual, but the breaker will not be affected. This setting is

useful for monitoring and alarming without tripping, and for

waveform capture. For more information on the control of

inputs and outputs, refer to Chapter 6.

Pickup

When testing induction disk relays, an established practice is

to set the pickup value to 1.0 A of secondary CT output. The

time overcurrent curves will show a pickup, but the relay will

not trip in a predefined repeatable manner until it reaches 1.3

to 1.5 A. With numerical relays like the ISGS, however, a sustained pickup indication means definite operation. To

account for measurement inaccuracies, and to guarantee

that the relay will never trip at 100% of pickup or below, the

pickup point is set at 106% of the pickup setting to avoid any

unintended nuisance trips.

Neutral or Ground

The availability of protective functions for neutral or ground

depends on how the external CTs are connected. If a ground

or zero-sequence CT is used and connected to the fourth

internal CT, the ground or neutral protective function is a

ground function. If the fourth CT is connected in the common

return of the other three internal CTs (residual), the function is

indicated as being neutral. There does not need to be an

explicit selection of neutral or ground.

Custom Curve

The custom curve is one user-defined curve that can be

used by one or more protective functions that have the custom curve option in the curve list.

Wisdom Software

While the ISGS relay protective functions can be completely

configured manually using the LCD and the keypad, Wisdom

software allows faster and easier configuration when it is

used on a PC connected to either data port. For data port

connections refer to Section 2.5.

5.2 Instantaneous Phase Overcurrent (50)

The Instantaneous Phase Overcurrent function consists of a

phase instantaneous overcurrent function and an adjustable

delay. This function begins timing when any individual phase

current exceeds the pickup at 100% of set pickup point and

drops out at 95% of the pickup point.

A1500 Instantaneous Phase Overcurrent (50)

Address Parameter Option

1501 Function Enabled or Disabled

1502 Pickup 5 A CTs: 1-120 A

1 A CTs: 0.2-24 A

(0.1 A steps)

1504 Time Delay 0-60 s (0.01 s steps)

1510 Freeze Wfm1 on Pickup, on Trip, or None

1511 Freeze Wfm2 on Pickup, on Trip, or None

1512 Blocked by None, 50HS & 50HSN, 50 HSN,

or 50HS

The function can be enabled or disabled (1501).

The range of the pickup value (1502) depends on the secondary phase CT rating (1 A or 5 A), and the value is in secondary amperes.

The time delay (1504) represents the time between pickup

and trip and can be adjusted from 0 to 60 seconds in steps

of 0.1 second. If the function remains in pickup for longer

than the time delay, the function causes a trip. The delay can

also be set to infinity so that the function never times out.

Each of the two waveform capture buffers (1510 and 1511)

can be independently programmed to freeze snapshots on

pickup or trip.

The function is able to actuate any binary output contact on

pickup, and any trip or binary output contact on trip.

5

Siemens Energy & Automation, Inc. 21

Page 28

Protective Function Configuration

5

5.3 High-Set Instantaneous Phase

Overcurrent (50HS)

The High-Set Instantaneous Phase Overcurrent function

causes an undelayed trip when any individual measured

phase current exceeds the preprogrammed threshold

(pickup value). The relay will trip at 100% of the set pickup

point.

A1500 High-SetInstantaneous Phase Overcurrent (50HS)

Address Parameter Option

1551 Function Enabled or Disabled

1552 Pickup 5A CTs: 5-120 A or

1A CTs: 0.2-24 A

(0.1 A steps)

1560 Freeze Wfm1 on Trip, or None

1561 Freeze Wfm2 on Trip, or None

The function can be enabled or disabled (1551). The range of

the pickup value (1552) depends on the secondary phase CT

rating (1 A or 5 A) and the value is in secondary amperes.

Each of the two waveform capture buffers (1560 and 1561)

can be independently programmed to freeze snapshots on

trip.

The function is able to actuate any binary output contact on

pickup, and any trip or binary output contact on trip.

The Instantaneous Neutral or Ground Overcurrent function

can be enabled or disabled (1601). The form of protection

provided depends on the manner in which the external CTs

are connected to the ISGS relay. Figure 4.5 in Chapter 4

shows correct CT connections and polarities.

The range of the pickup value (1602) depends on the secondary neutral CT rating (1 A or 5 A) and the value is in secondary amperes.

The time delay (1604) represents the time between pickup

and trip and can be adjusted from 0 to 60 seconds in steps

of 0.1 second. If the function remains in pickup for longer

than the time delay, this parameter causes a trip. The delay

can also be set to infinity so that the function never times out.

Each of the two waveform capture buffers (1610 and 1611)

can be independently programmed to freeze snapshots on

pickup or trip.

The function is able to actuate any binary output contact on

pickup, and any trip or binary output contact on trip.

5.5 High-Set Instantaneous Neutral or

Ground Overcurrent (50HSN)

The High-Set Instantaneous Neutral or Ground Overcurrent

function causes an undelayed trip when any individual measured phase current exceeds the preprogrammed threshold

(pickup value). The relay will trip at 100% of the set pickup

point.

5.4 Instantaneous Neutral or Ground

Overcurrent (50N)

The Instantaneous Neutral or Ground Overcurrent function

has an adjustable delay whose input is the current measured

by the neutral CT. It begins timing when the neutral or ground

current exceeds the pickup value. The ISGS relay will pickup

at 100% of set pickup point and drop out at 95% of the

pickup point.

A1600 Instantaneous Neutral or Ground Overcurrent

(50N)

Address Parameter Option

1601 Function Enabled or Disabled

1602 Pickup 5 A CTs: 1-120 A or

1 A CTs: 0.2-24 A

(0.1 A steps)

1604 Time Delay 0-60 s (0.01 s steps)

1610 Freeze Wfm1 on Pickup, on Trip, or None

1611 Freeze Wfm2 on Pickup, on Trip, or None

1612 Blocked by None, 50HS & 50HSN, 50HSN,

or 50HS

A1600 High-Set Instantaneous Neutral or Ground

Overcurrent (50HSN)

Address Parameter Option

1651 Function Enabled or Disabled

1652 Pickup 5 A CTs: 5-120 A or

1 A CTs: 0.2-24 A

(0.1 A steps)

1660 Freeze Wfm1 on Trip, or None

1661 Freeze Wfm2 on Trip, or None

The High-Set Instantaneous Neutral or Ground Overcurrent

function can be enabled or disabled (1651).

The range of the pickup value (1652) depends on the secondary phase CT rating (1 A or 5 A) and the value is in secondary amperes.

Each of the two waveform capture buffers (1660 and 1661)

can be independently programmed to freeze snapshots on

trip.

The function is able to actuate any binary output contact on

pickup, and any trip or binary output contact on trip.

22 Siemens Energy & Automation, Inc.

Page 29

Protective Function Configuration

5.6 Phase Time Overcurrent (51)

The Phase Time Overcurrent function uses a selected time

overcurrent characteristic curve to determine the trip time for

the applied phase currents. The defined characteristic curves

are valid over a range of multiple of pickup values. The function also includes the ability to select a customer defined

curve. This function is always enabled. Refer to Appendix A

for detailed trip curve information.

A1700 Phase Time Overvurrent (51)

Address Parameter Option

1702 Curve Inverse

1703 Pickup 5 A CTs: 0.5-20 A or

1705 Time Dial 0.1-9.9 (0.1 steps)

1706 Filter rms or fundamental

1709 Reset Instantaneous or Disk Emulation

1710 Freeze Wfm1 on Pickup, on Trip, or None

1711 Freeze Wfm2 on Pickup, on Trip, or None

1712 Blocked by None, 50HS, 50HSN, or

The Curve parameter (1702) allows the selection of the preprogrammed characteristic curve used by this function. The

ISGS relay comes with nine standard and one custom overcurrent characteristic curves that can be adjusted with the

Time Dial parameter. The custom curve is a user-definable

protective curve that integrates with instantaneous reset. The

lower limit of the custom curve is 1.10. The maximum time to

trip is the time at 1.10.

The range of the pickup value (1703) depends on the secondary phase CT rating (1 A or 5 A) and the value is in secondary amperes. The function begins timing when any

individual phase current exceeds the pickup current setting.

Note: The pickup point is 1.06 of the pickup set-