Page 1

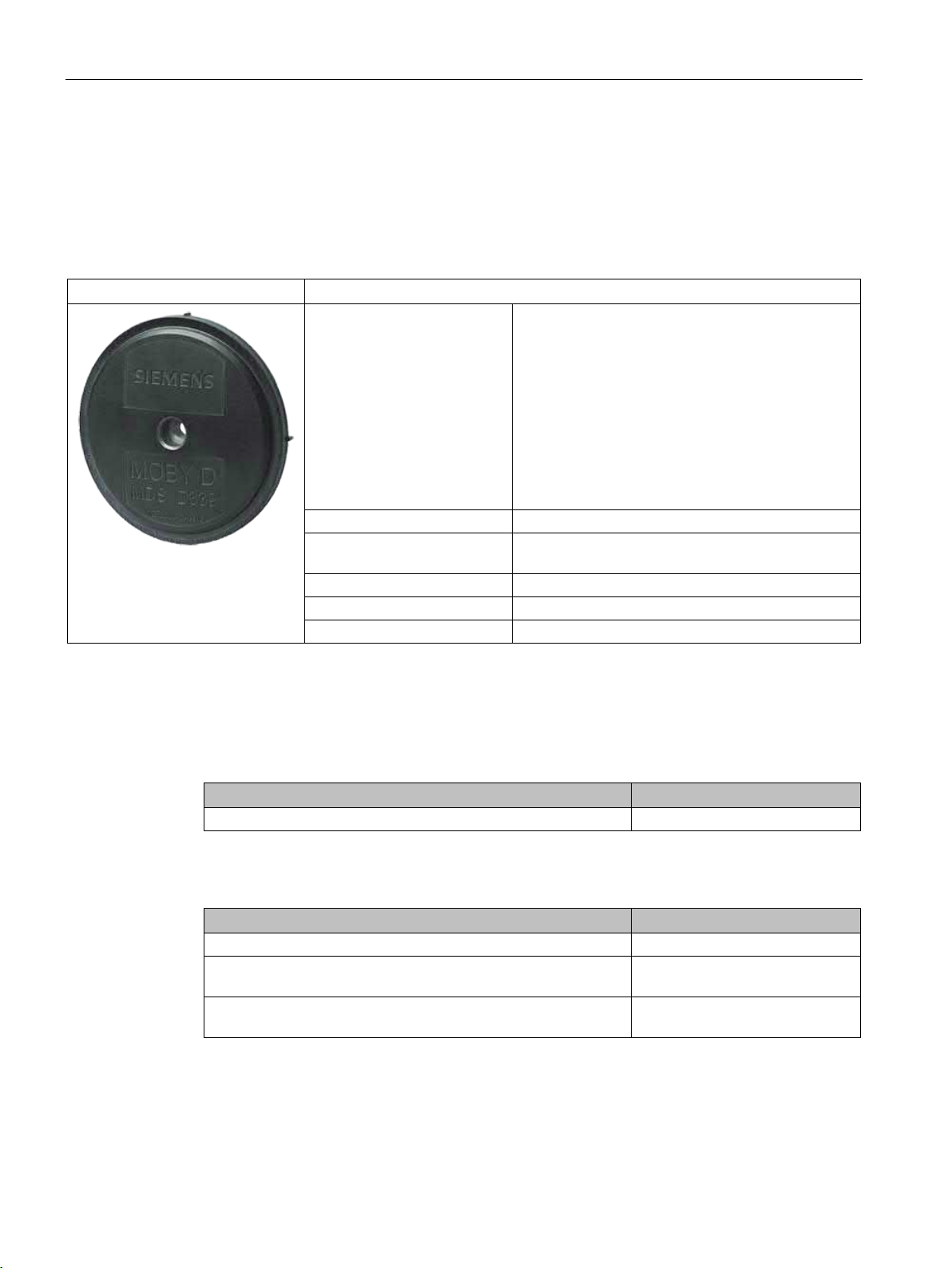

ISO transponder

8.7.2

Ordering data

Article number

MDS D139

6GT2600-0AA10

Article number

Spacer

6GT2690-0AA00

(Ø x H): 22 x 60 mm

(Ø x H): 22 x 47 mm

8.7.3

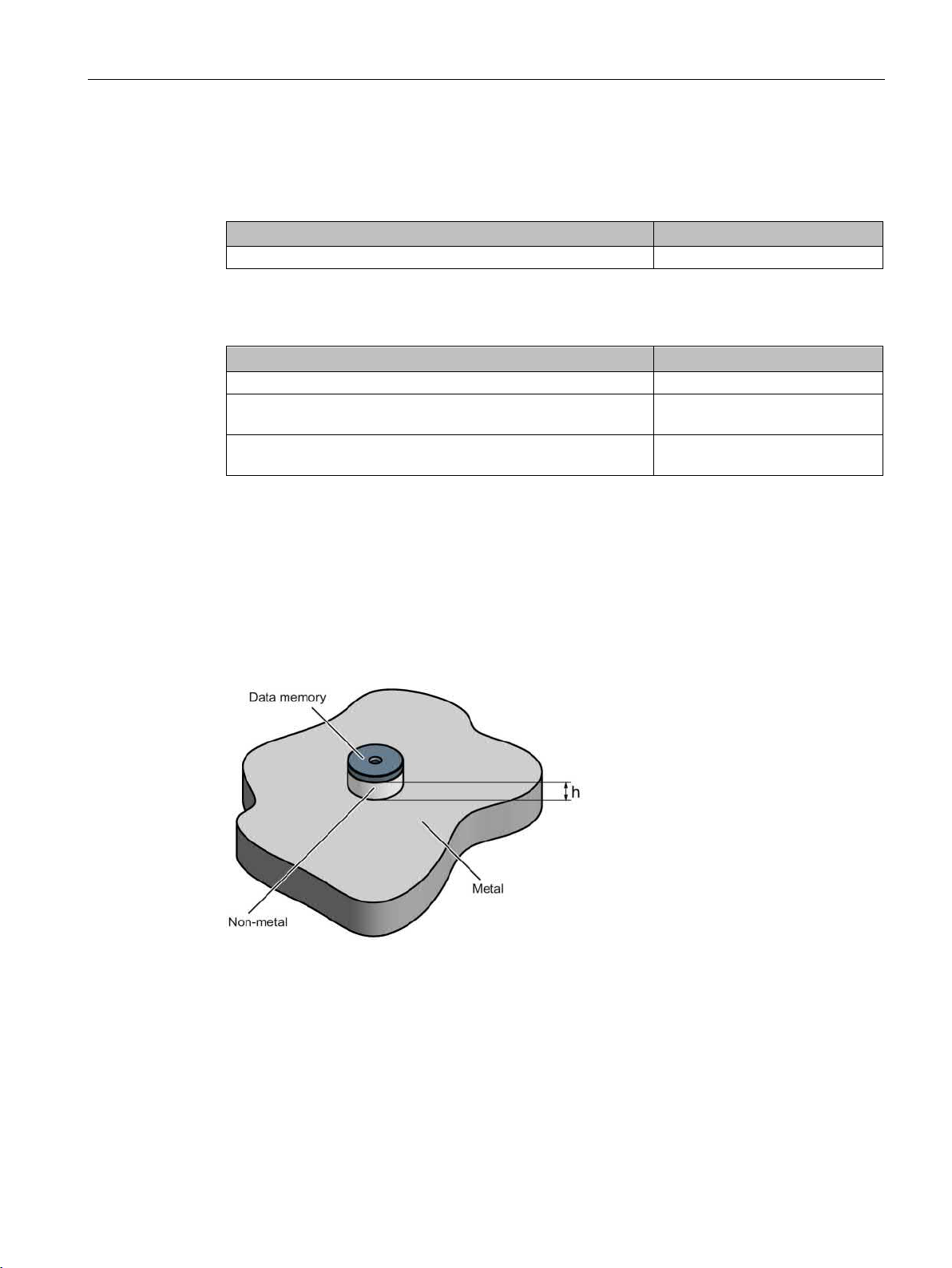

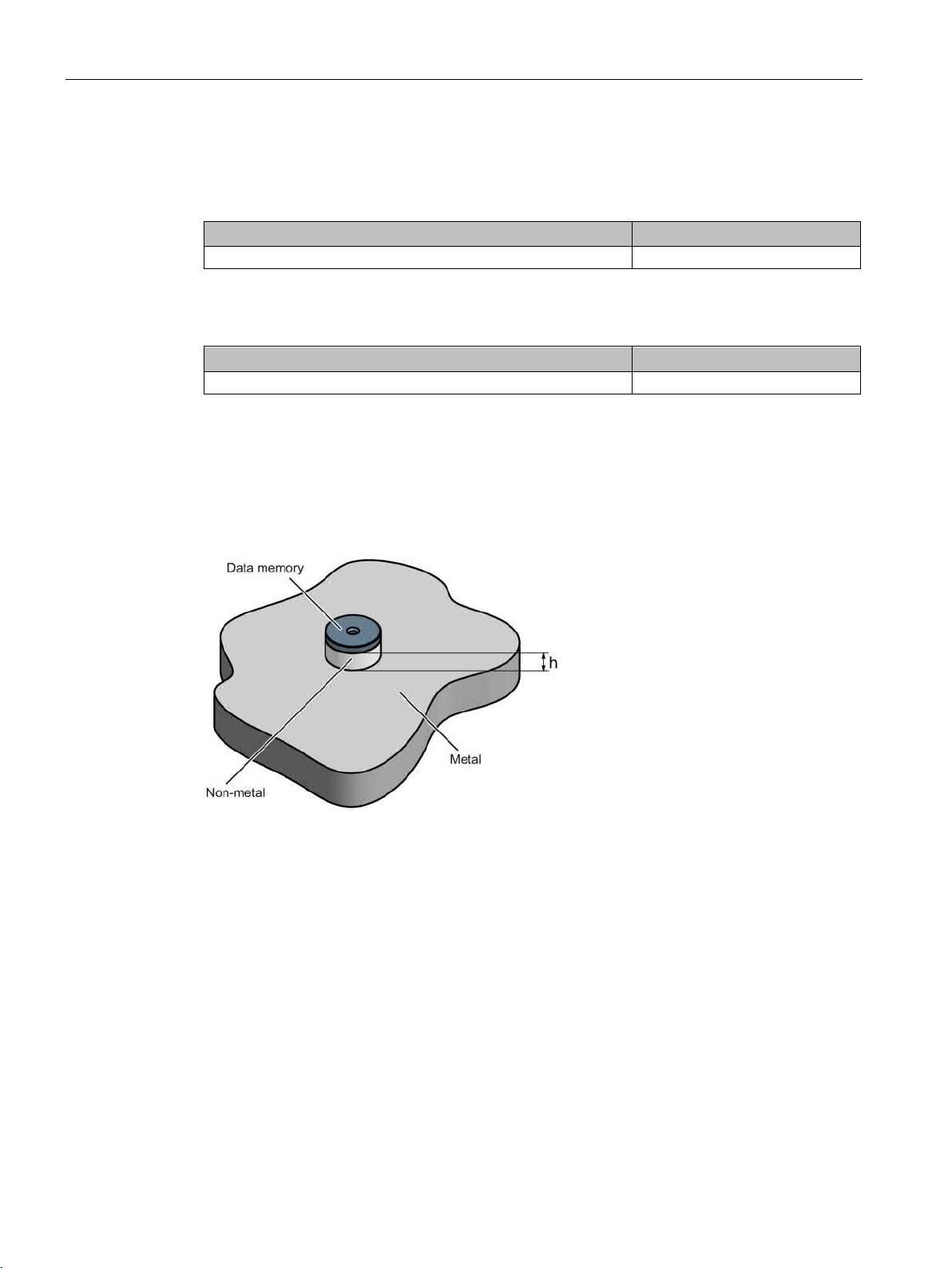

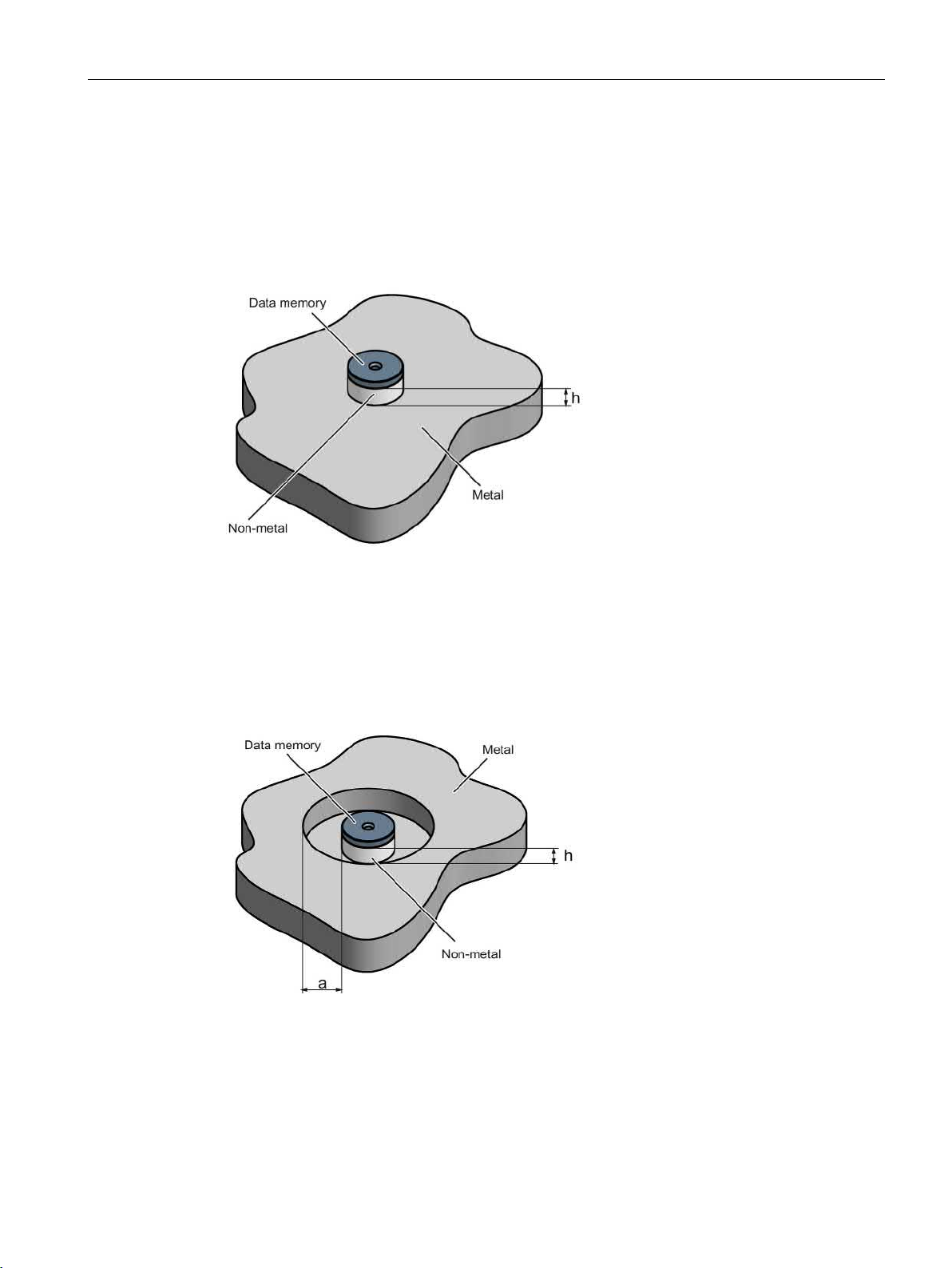

Mounting on metal

Mounting on metal

h

≥ 30 mm

8.7 MDS D139

Table 8- 15 Ordering data for MDS D139

Table 8- 16 Ordering data for MDS D139 accessory

Direct mounting of the MDS D139/D339 on metal is not allowed. A distance of ≥ 30 mm is

recommended. This can be achieved using spacers (see "Ordering data (Page 441)").

Quick change holder

Quick change holder

6GT2690-0AH00

6GT2690-0AH10

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

Figure 8-14 Mounting the MDS D139/D339 on metal with spacer

301

Page 2

ISO transponder

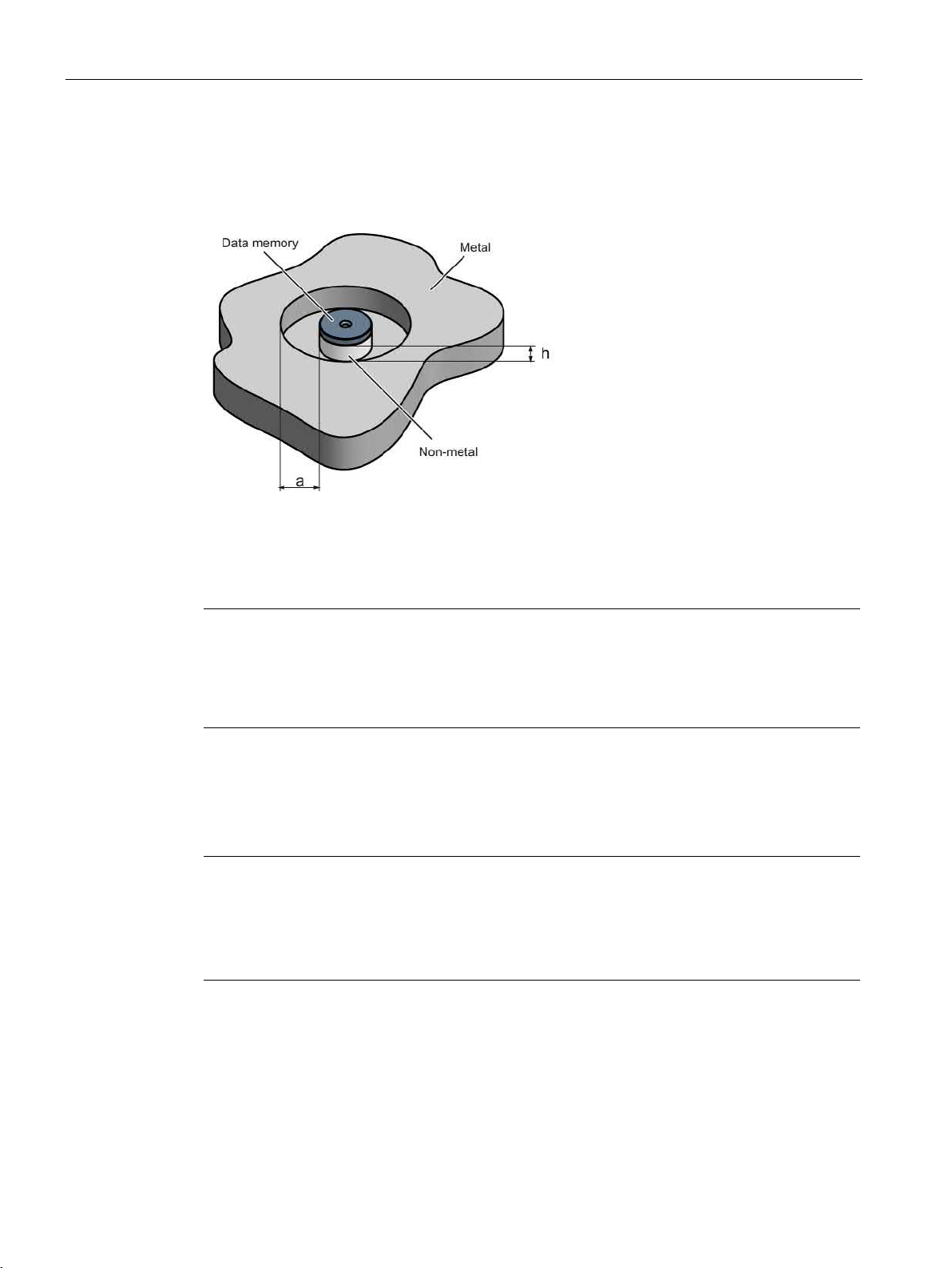

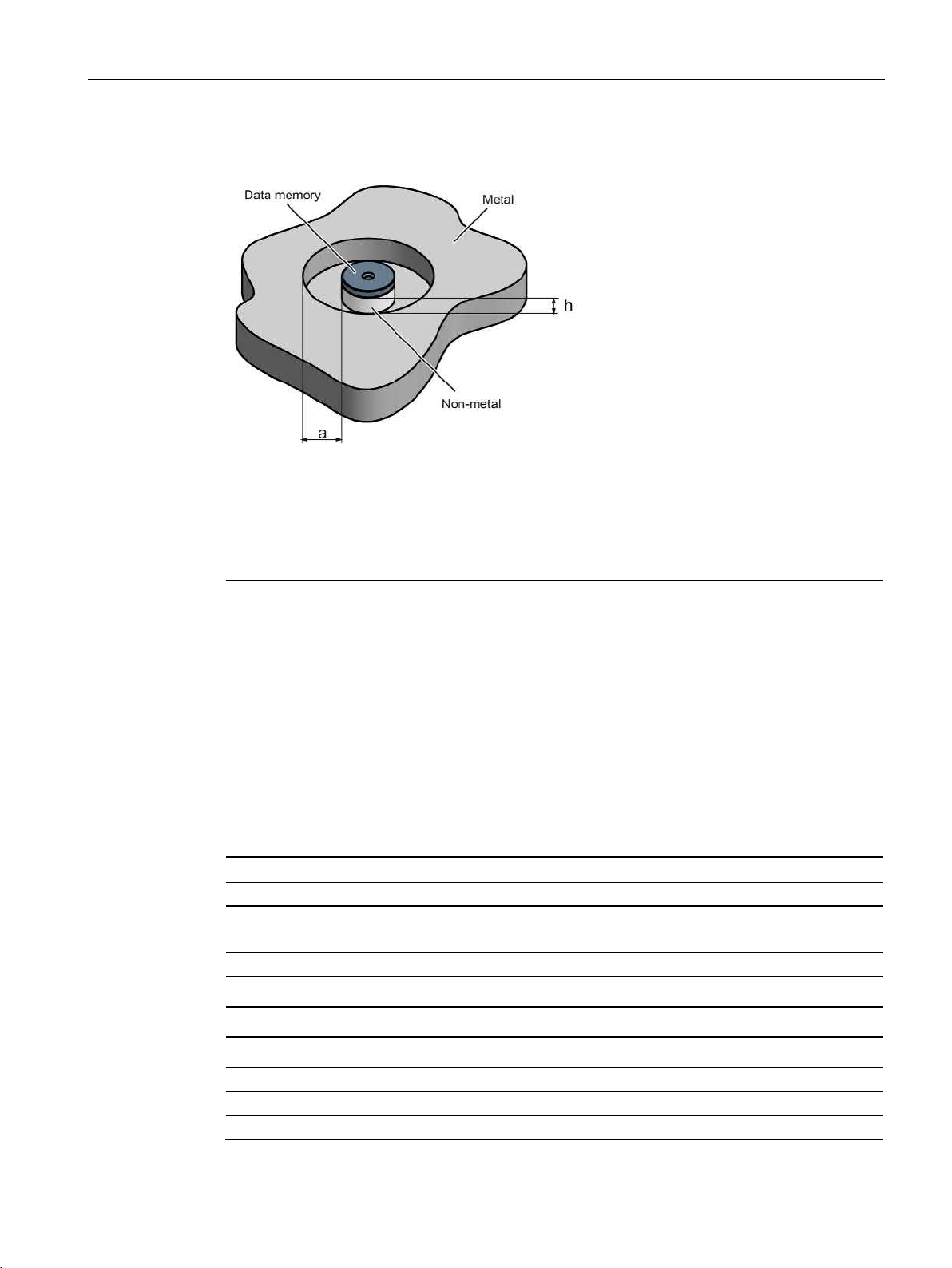

Flush-mounting

h

≥ 30 mm

a

≥ 100 mm

Note

Going below the distances

If the distances (a and h) are not observed, a reduction of the field data results. It is possible

to mount the MDS with

recommended that a test is performed in critical applications.

8.7.4

Cleaning the mobile data memory

Note

Do not clean the transponder with mechanical tools, sand

cleaning methods result in damage to the transponder.

Clean the transponder only with the chemical cleansing agents listed in Chapter

resistance of the readers and transponders

8.7 MDS D139

It is possible to mount the MDS D139/D339 in metal. With large antennas, for example ANT

D5, this leads to a reduction of ranges.

Figure 8-15 Flush-mounting of the MDS D139/D339 in metal with spacer

metal screws (M5). This has no tangible impact on the range. It is

-blasting or pressure hose. These

Chemical

(Page 97).

SIMATIC RF300

302 System Manual, 07/2017, C79000-G8976-C345-07

Page 3

ISO transponder

8.7.5

Technical specifications

6GT2600-0AA10

Product type designation

SIMATIC MDS D139

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 106

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 30 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

8.7 MDS D139

Table 8- 17 Technical specifications for MDS D139

• UID • 8 bytes

• User memory • 112 bytes EEPROM

• OTP memory • 16 bytes (EEPROM)

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • PPS

• Color • Black

• during write/read access • -25 … +140 °C

• from +125 ℃: 20% reduction in the limit dis-

tance

• outside the read/write field • -40 to +220 ℃

• at +200 ℃: Tested up to 5000 hours or

6000 cycles

• at +220 ℃: Tested up to 2000 hours or

2000 cycles

• during storage • -40 to +100 ℃

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

303

Page 4

ISO transponder

6GT2600-0AA10

Shock according to EN 60721-3-7 Class 7M31)

500 m/s2

Vibration according to EN 60721-3-7 Class 7M31)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

85 x 15 mm

Weight

50 g

1.5 Nm

1

2)

ing the MDS in high temperatures (expansion coefficient).

8.7.6

Use of the MDS D139 in hazardous areas

8.7 MDS D139

Degree of protection to EN 60529

Type of mounting 1 x M5 screw 2)

The values for shock and vibration are maximum values and must not be applied continuously.

For mounting with the spacer (6GT2690-0AA00), use a stainless steel M5 screw to avoid damag-

• IP68

• IPx9K

2 hours, 2 bar, +20 °C

steam jet: 150 mm; 10 to 15 l/min; 100 bar; 75

°C

The MDS D139 mobile data memory is classed as a piece of simple, electrical equipment

and can be operated in Protection Zone 2, Device Group II, Category 3G.

The following requirements of the 94/9/EC directive are met:

● EN 60079-0:2006

● EN 60079-15:2005

● EN 61241-0:2006

● EN 61241-1:2004

SIMATIC RF300

304 System Manual, 07/2017, C79000-G8976-C345-07

Page 5

ISO transponder

Identification

WARNING

Gefahr durch elektrostatische Entladungen

Potential electrostatic charging hazard

Danger potentiel de charges électrostatiques

Note

Installations- und Betriebsbedingungen für den Ex-Schutzbereich:

a

untersagt.

b) Das Gerät ist mechanisch geschützt zu montieren.

c) Die Montage muss auf einem geerdeten, leitenden Untergrund erfolgen.

d) Die Reinigung darf nur mit feuchtem T

Installation and operating conditions for hazardous areas:

a) Use of the equipment in the vicinity of processes generating high charges is not allowed.

b) The equipment must be mechanically protected when installed.

c) Installation must be p

d) Cleaning only with a wet cloth

Conditions d'installation et de mise en oeuvre pour la zone de protection Ex :

a) L'utilisation de l'appareil près de processus générant de fortes charges est interd

b) L'appareil doit être monté de manière à être protégé mécaniquement.

c) Le montage doit être effectué sur un socle conducteur mis à la terre.

d) Nettoyage uniquement avec un chiffon humide

8.7 MDS D139

II 3 G Ex nA II T2

II 3 D Ex tD A22 IP68 T 220°C

KEMA 09 ATEX 0133 X

Ta: -25 ... +220°C

) Der Einsatz des Gerätes in der Nähe von stark ladungserzeugenden Prozessen ist

uch erfolgen.

erformed on a grounded and conductive mounting surface.

ite.

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

305

Page 6

ISO transponder

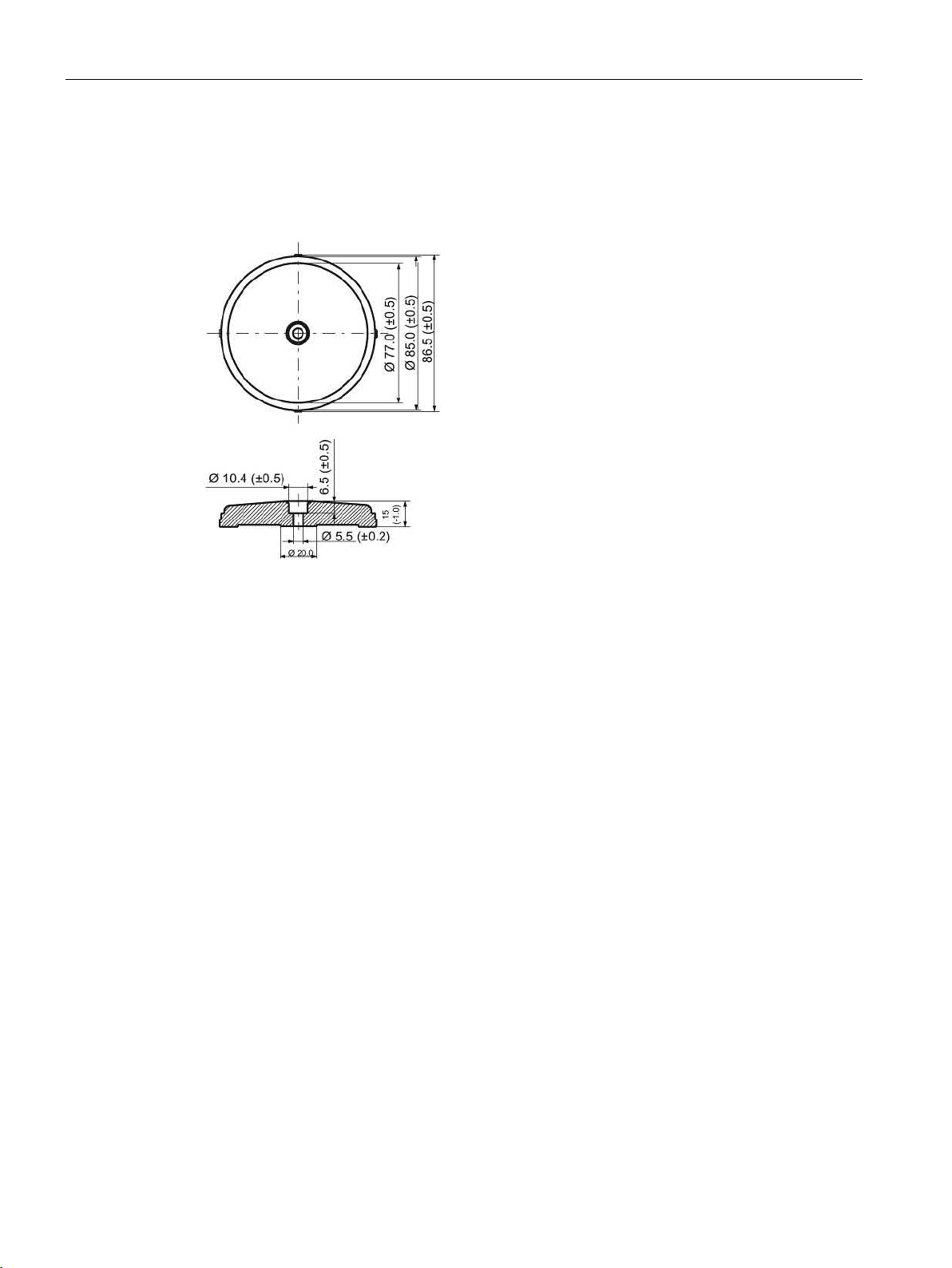

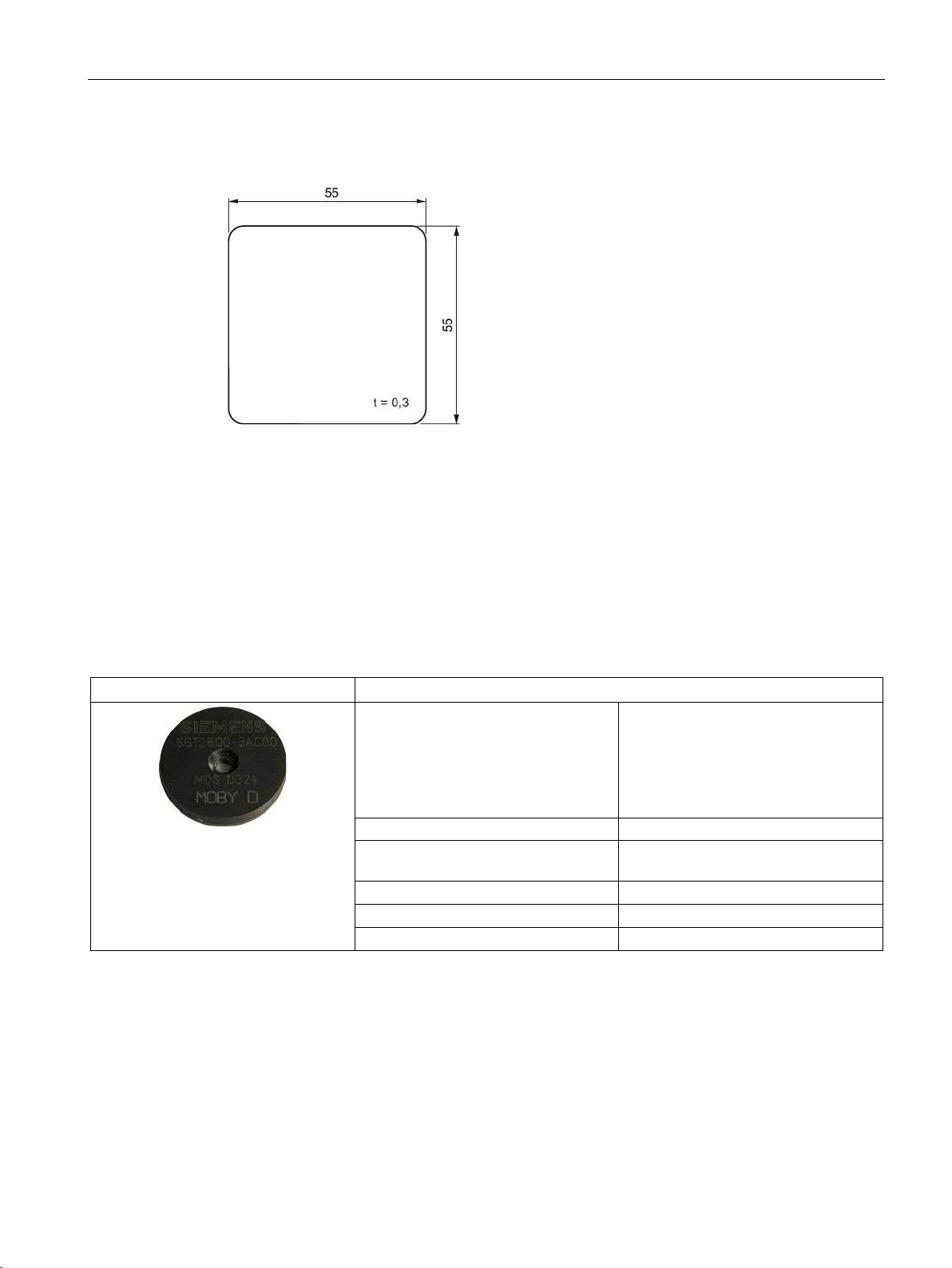

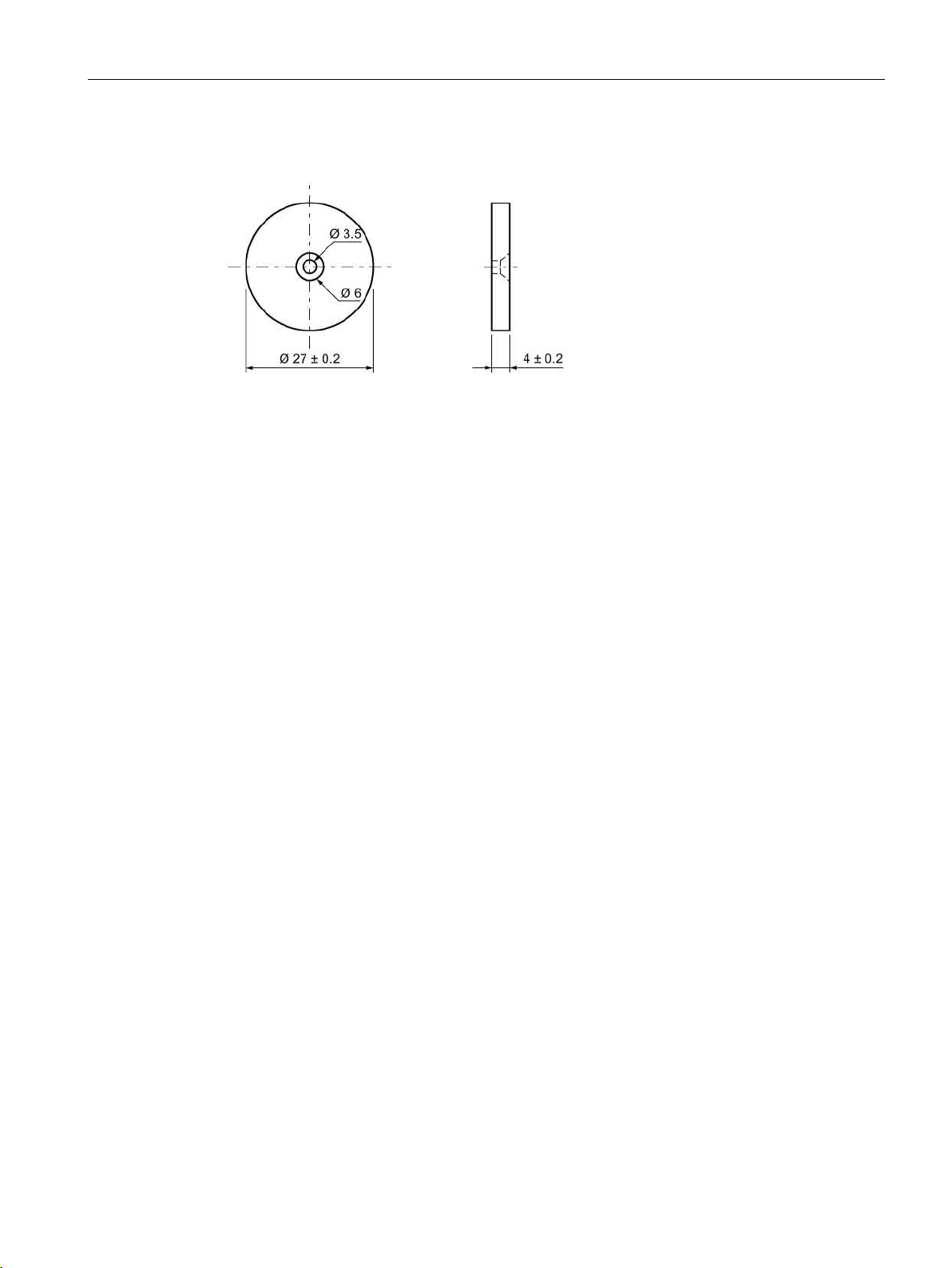

8.7.7

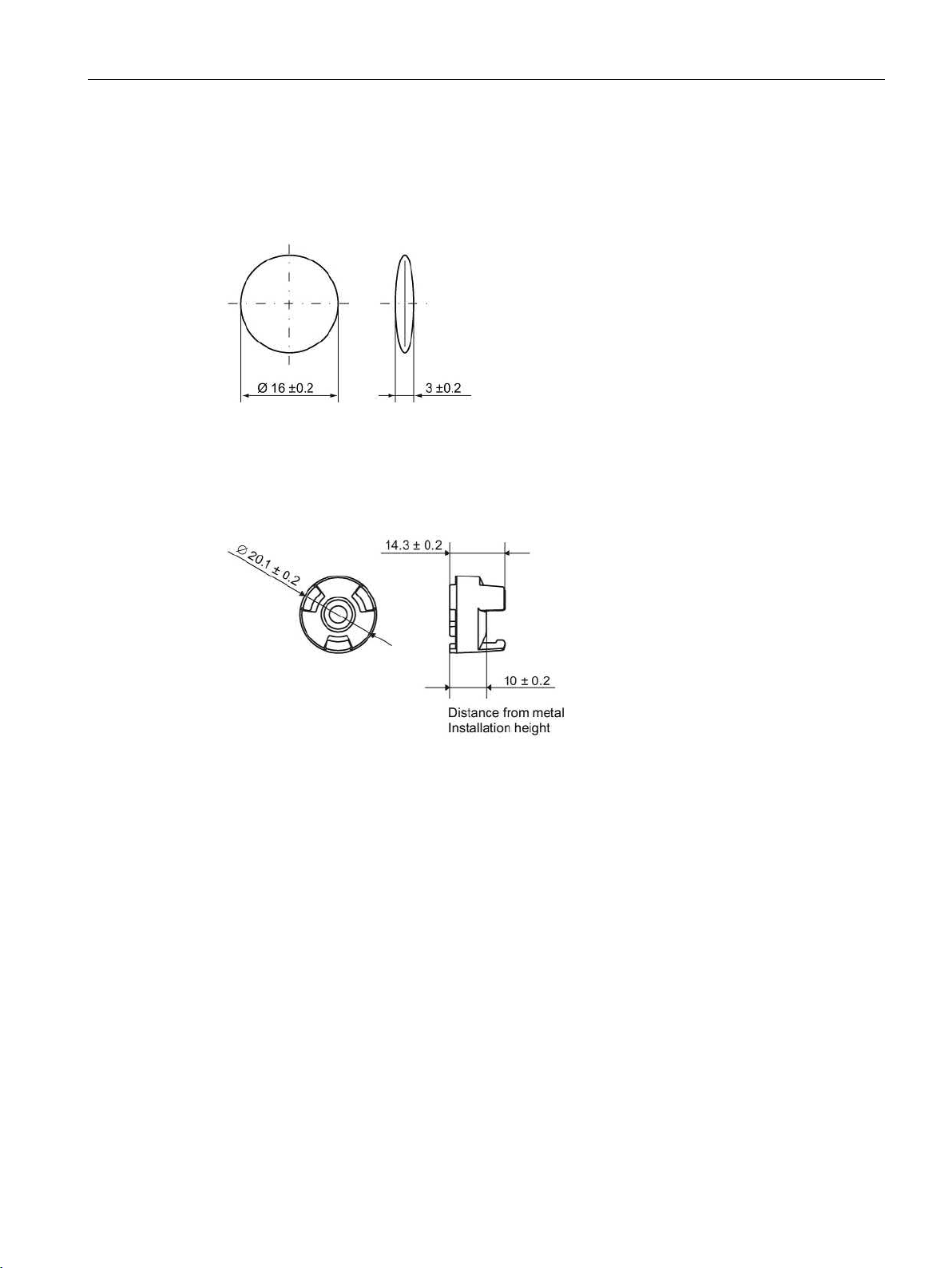

Dimension drawings

Dimensional drawing of MDS D139

8.7 MDS D139

Figure 8-16 Dimensional drawing of MDS D139

Dimensions in mm

SIMATIC RF300

306 System Manual, 07/2017, C79000-G8976-C345-07

Page 7

ISO transponder

8.8

MDS D160

8.8.1

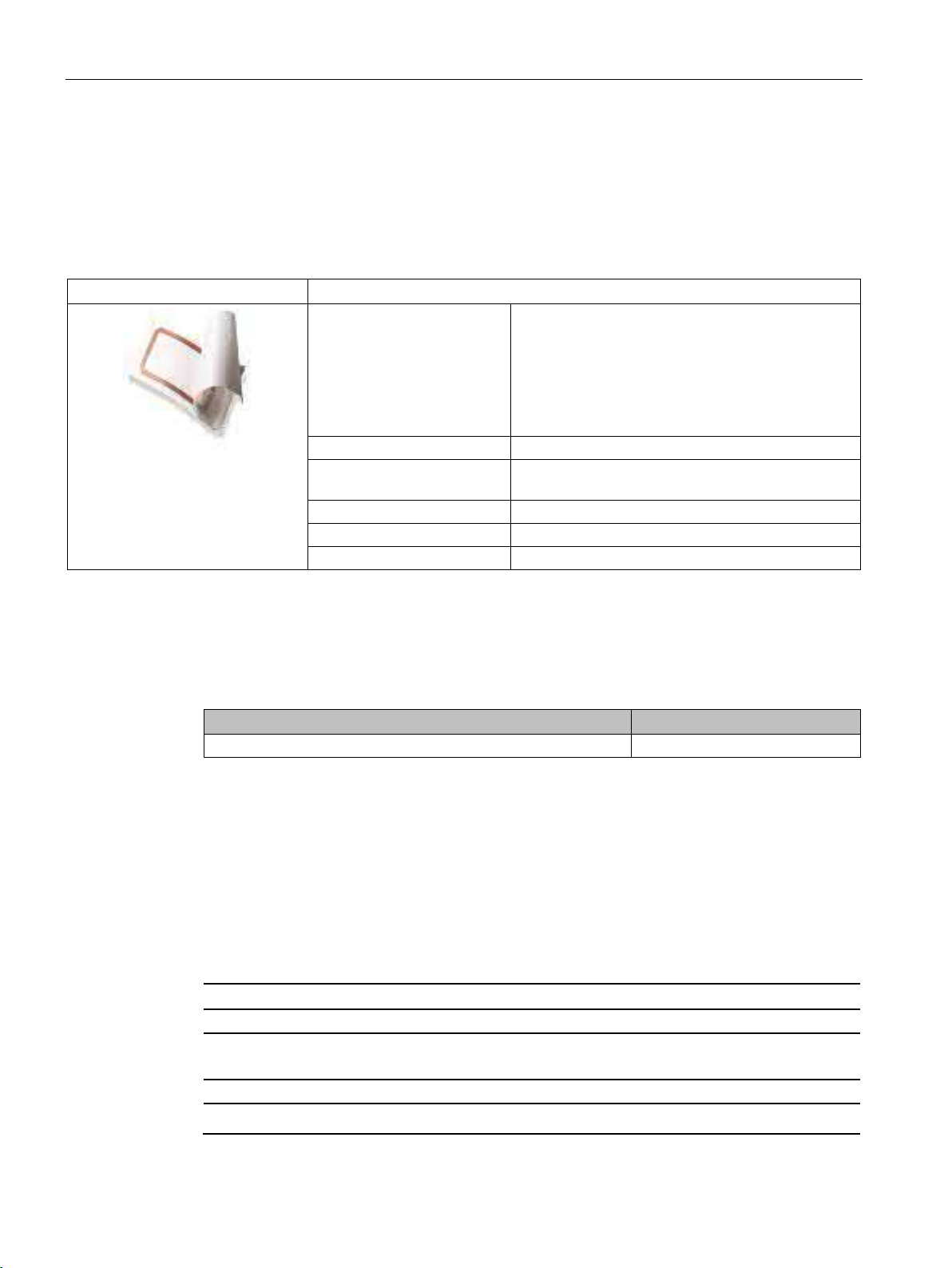

Characteristics

MDS D160

Characteristics

Write/read range

See section Field data of ISO transponders (MDS D) (Page 56).

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP68/IPx9K

8.8.2

Information for RF300 compatibility

Note

Compatibility with SIMATIC RF300 depending on MLFB number

Only the MDS D160 with MLFB

8.8 MDS D160

Area of application Thanks to its rugged packaging, the MDS D160 is a transponder that

can be used under extreme environmental conditions. It is washable,

heat-resistant and resistant to all chemicals generally used in the

Memory size 112 bytes of EEPROM user memory

laundry process.

Typical applications are, for example:

• Rented work clothing

• Hotel laundry

• Surgical textiles

• Hospital clothing

• Dirt collection mats

• Clothing for nursing homes/hostels

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

6GT2600-0AB10 is compatible with SIMATIC RF300.

307

Page 8

ISO transponder

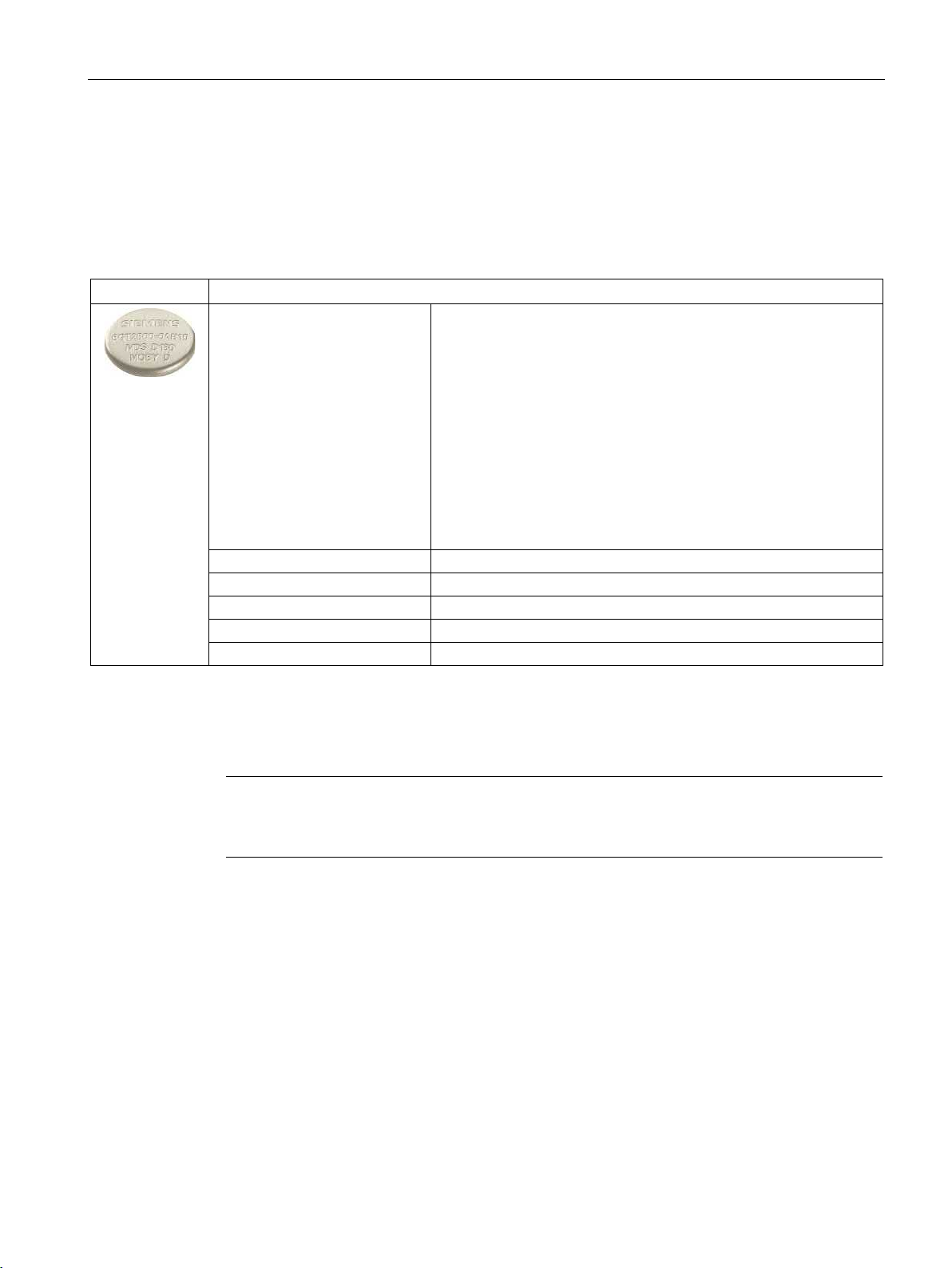

8.8.3

Ordering data

Article number

MDS D160

6GT2600-0AB10

Article number

Spacer

6GT2690-0AG00

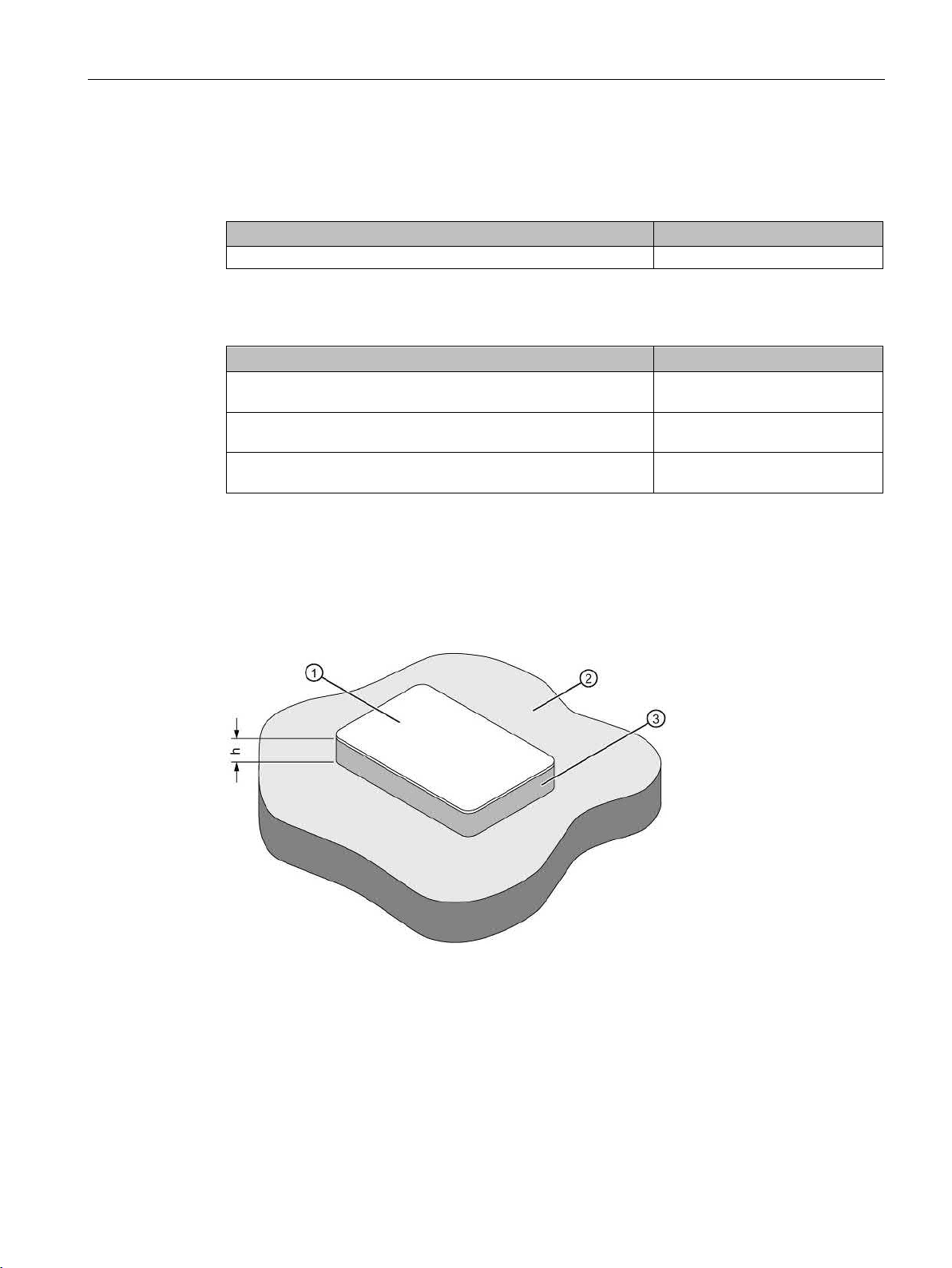

8.8.4

Mounting on metal

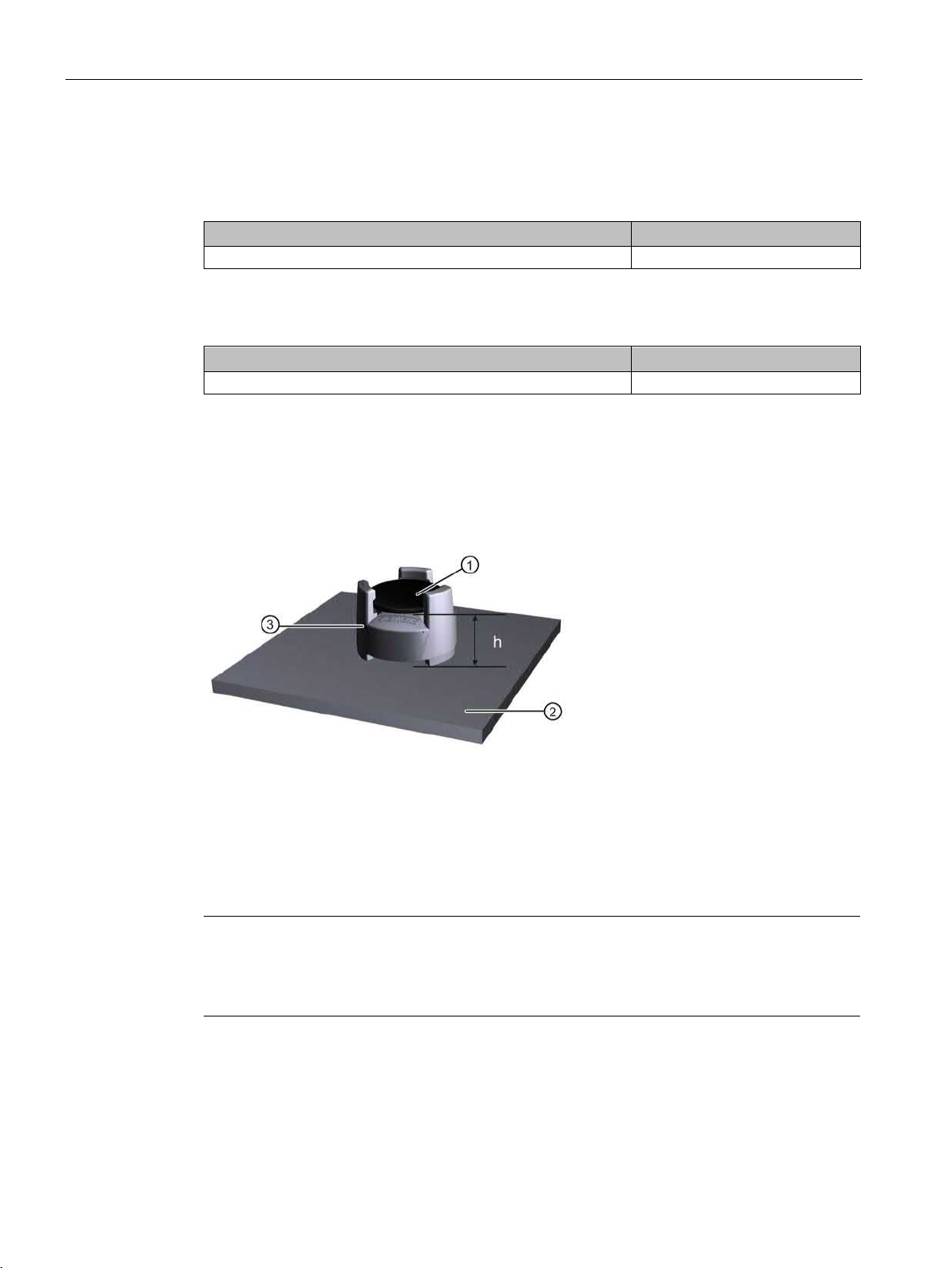

Mounting on metal

①

Transponder

②

Metal carrier

③

Spacer

h

≥ 10 mm

Note

Going below the minimum distance (h)

If the minimum distance (h) is not observed, a reduction of the fie

In critical applications, it is recommended that a test is performed.

Flush-mounting

8.8 MDS D160

Table 8- 18 Ordering data for MDS D160

Table 8- 19 Ordering data for MDS D160 accessories

Figure 8-17 Mounting the MDS D160 on metal with spacer

Flush-mounting of the MDS D160 in metal is not permitted!

SIMATIC RF300

308 System Manual, 07/2017, C79000-G8976-C345-07

ld data results.

Page 9

ISO transponder

8.8.5

Technical specifications

6GT2600-0AB10

Product type designation

SIMATIC MDS D160

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 106

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Recommended distance to metal

≥ 10 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Mechanical strength

8.8 MDS D160

Table 8- 20 Technical specifications for the MDS D160

• UID • 8 bytes

• User memory • 112 bytes EEPROM

• OTP memory • 16 bytes (EEPROM)

Write/read distance (Sg) Dependent on the reader used, see section "Field

Housing

• Material

• Color

• during write/read access

• outside the read/write field • -40 … +175 °C

• during storage • -25 to +100 ℃

• PPS

• beige

• -25 … +85 °C

• from +125 ℃: for 1000 hours, 20% reduction

of the limit distance

• at +175 ℃: 100 washing cycles tested

• at +220 ℃: Tested once for up to 30 seconds

• Isostatic pressure • 300 bar for 5 min

• Axial pressure • 1000 N for 10 s

• Radial pressure • 1000 N for 10 s

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

309

Page 10

ISO transponder

6GT2600-0AB10

cess

MDS lifespan

At least 100 wash cycles

18 ms; 6 axes; 2000 repetitions/h

10 ... 2000 Hz; 3 axes; 2.5 h

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

16 x 3 mm

Weight

1.2 g

1)

2)

The processing instructions of the adhesive manufacturer must be observed.

Note

Regeneration time between washing cycles

The regeneration time for the MDS D160 between washing cycles must be at lea

8.8 MDS D160

Resistance to chemicals All chemicals normally used in the washing pro-

Degree of protection

• IP68

24 hours, 2 bar, +20 °C

• IPx9K

Shock according to IEC 68-2-271) 400 m/s2

Vibration according to IEC 68-2-61) 100 m/s2

Type of mounting

• Patched

• Sewn in

2)

• Glued

The values for shock and vibration are maximum values and must not be applied continuously.

SIMATIC RF300

310 System Manual, 07/2017, C79000-G8976-C345-07

st 24 hours.

Page 11

ISO transponder

8.8.6

Dimension drawings

Dimensional drawing of MDS D160

Dimensions in mm

Dimensional drawing of spacer

Dimensions in mm

8.8 MDS D160

Figure 8-18 Dimensional drawing of MDS D160

Figure 8-19 Dimensional drawing of spacer

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

311

Page 12

ISO transponder

8.9

MDS D165

8.9.1

Features

MDS D165 (special version)

Characteristics

cation.

Memory size

112 bytes of EEPROM user memory

(Page 56).

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP65

8.9.2

Ordering data

Article number

MDS D165 (special version ISO-CARD)

6GT2600-1AB00-0AX0

Type of delivery

8.9.3

Technical data

6GT2600-1AB00-0AX0

Product type designation

SIMATIC MDS D165

Memory

Memory configuration

8.9 MDS D165

Area of application The design of the transponder (self-adhesive label)

permits a variety of designs, guaranteeing optimum

dimensioning for the widest variety of applications.

From simple identification such as electronic barcode

replacement/supplementation, through warehouse

and distribution logistics, right up to product identifi-

Write/read range See section Field data of ISO transponders (MDS D)

Table 8- 21 Ordering data for MDS D165

Minimum order quantity: 1250 units (5 rolls with 250 units each)

Table 8- 22 Technical specifications for MDS D165

• UID • 8 bytes

SIMATIC RF300

312 System Manual, 07/2017, C79000-G8976-C345-07

Page 13

ISO transponder

6GT2600-1AB00-0AX0

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 106

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 25 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

durability of the adhesive.

Degree of protection

IP65

Design, dimensions and weight

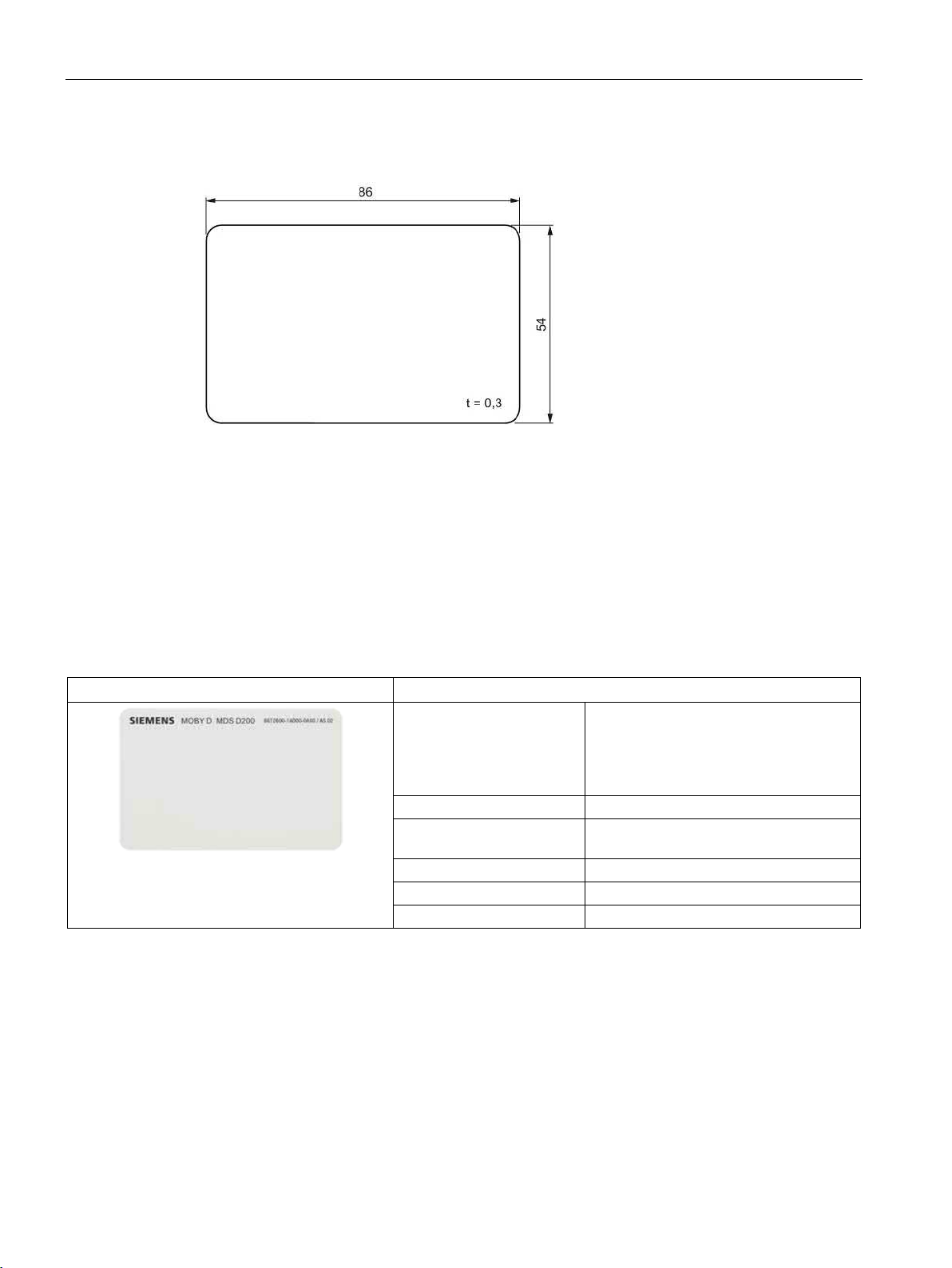

Dimensions (L x W x H)

86 x 54 x 0.3 mm

1)

The processing instructions of the adhesive manufacturer must be observed.

8.9 MDS D165

• User memory • 112 bytes EEPROM

• OTP memory • 16 bytes (EEPROM)

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Top • PET plastic (label

material)

• Inlay • PET plastic (carrier

material)

• Antenna • Aluminum

• Bottom • Double-sided trans-

• Color • White

• during write/read access • -25 ... +80 °C

• outside the read/write field • -25 to +80 ℃

• during storage • +20 to +30 ℃

Can be stored for 2 years, determined by the

fer adhesive on silicon paper

Weight 1 g

Type of mounting Glued with self-adhesive label 1)

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

313

Page 14

ISO transponder

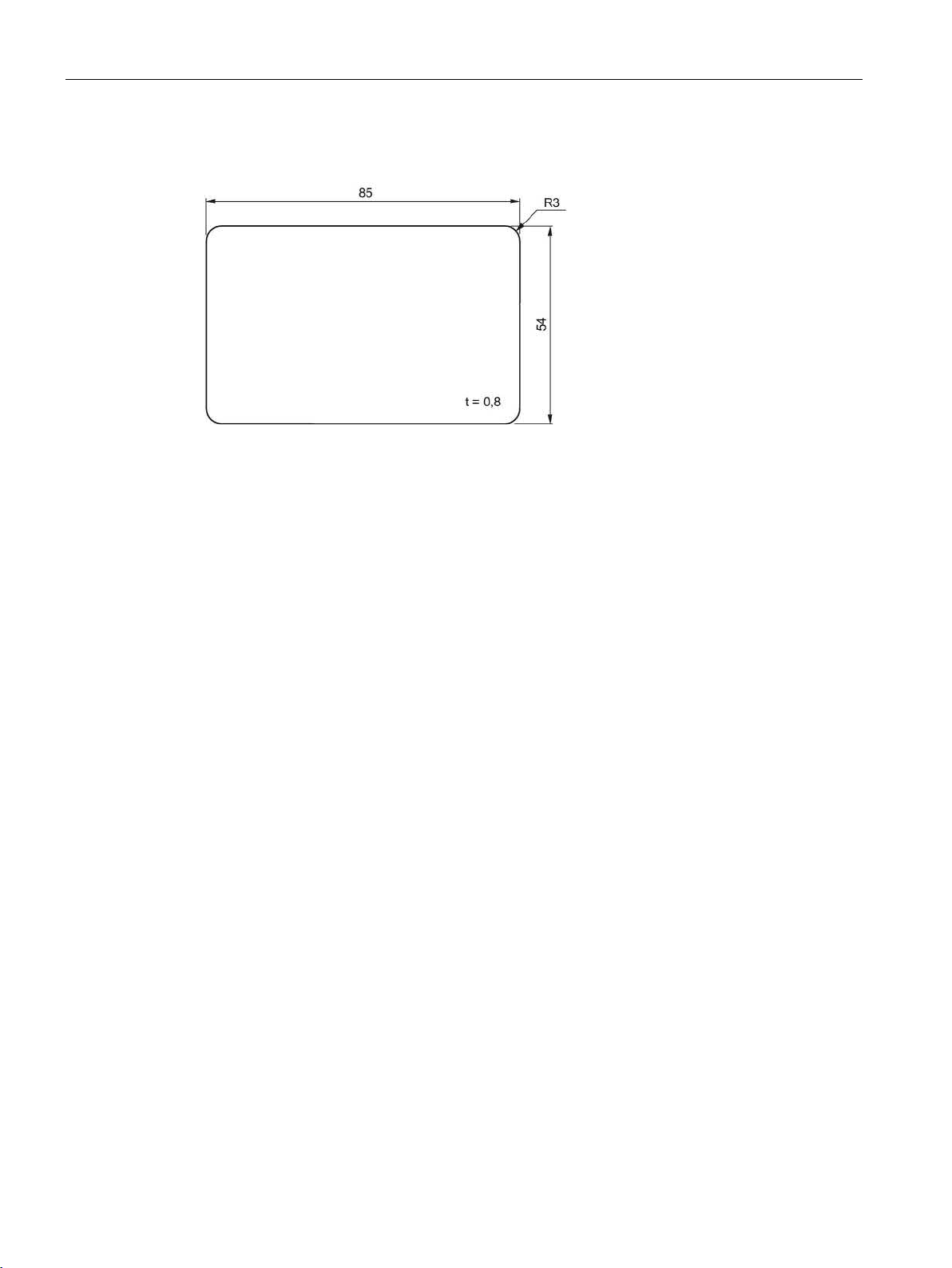

8.9.4

Dimension drawing

Dimensions in mm

8.10

MDS D200

8.10.1

Features

MDS D200

Characteristics

up to product identification.

Memory size

256 bytes of EEPROM user memory

Mounting on metal

Yes, with spacer

ISO standard

15693 with Tag-it HFI technology

Degree of protection

IP67

8.10 MDS D200

Figure 8-20 Dimension drawing of MDS D165

Area of application From simple identification such as elec-

tronic barcode replacement/supplementation, through

warehouse and distribution logistics, right

Write/read range See section Field data of ISO transpond-

ers (MDS D) (Page 56).

SIMATIC RF300

314 System Manual, 07/2017, C79000-G8976-C345-07

Page 15

ISO transponder

8.10.2

Ordering data

Article number

MDS D200 (special version ISO-CARD)

6GT2600-1AD00-0AX0

Article number

(in conjunction with spacer 6GT2190-0AA00)

(not suitable for fixing directly onto metal)

8.10.3

Mounting on metal

Mounting on metal

h

≥ 20 mm

①

Transponder

②

Metal

③

Non-metal

8.10 MDS D200

Table 8- 23 Ordering data for MDS D200

Table 8- 24 Ordering data for MDS D200 accessories

Spacer

(in conjunction with fixing pocket 6GT2190-0AB00)

Fixing pocket

Fixing pocket

6GT2190-0AA00

6GT2190-0AB00

6GT2390-0AA00

Figure 8-21 Mounting of the MDS D200 on metal with spacer

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

315

Page 16

ISO transponder

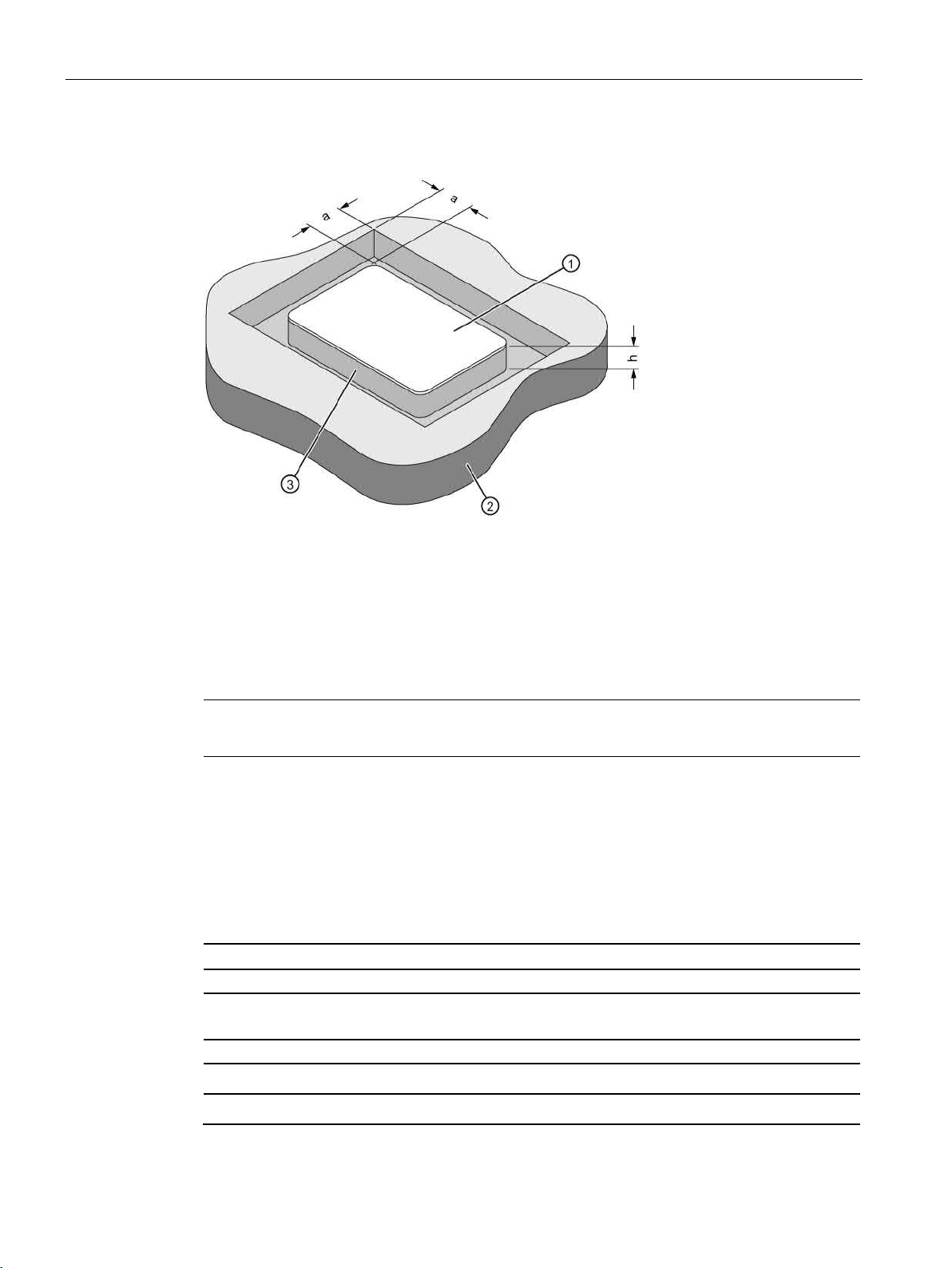

Flush-mounting

a

≥ 20 mm

h

≥ 20 mm

①

Transponder

②

Metal

③

Non-metal

Note

If the minimum guide values (h) are not observed, a reductio

8.10.4

Technical data

6GT2600-1AD00-0AX0

Product type designation

SIMATIC MDS D200

Memory

Memory configuration

8.10 MDS D200

Figure 8-22 Flush-mounting of MDS D200 in metal with spacer

n of the field data results.

Table 8- 25 Technical specifications for MDS D200

• UID • 8 bytes

• User memory • 256 bytes EEPROM

SIMATIC RF300

316 System Manual, 07/2017, C79000-G8976-C345-07

Page 17

ISO transponder

6GT2600-1AD00-0AX0

Read cycles (at < 25 ℃)

> 1014

Write cycles (at < 25 ℃)

> 106

Data retention time (at < 25 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 20 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Degree of protection to EN 60529

IP67

Shock-resistant to EN 60721-3-7 class 7M3

ISO 10373 / ISO 7810 1)

Vibration-resistant to EN 60721-3-7, class 7M3

ISO 10373 / ISO 7810 1)

Torsion and bending load

ISO 10373/ISO 7816-1

Design, dimensions and weight

Dimensions (L x W x H)

85 x 54 x 0.8 mm

Weight

5 g

1

2)

The processing instructions of the adhesive manufacturer must be observed.

8.10 MDS D200

• OTP memory • 16 bytes (EEPROM)

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • PET

• Color • White

• during write/read access • -20 to +60 ℃

• outside the read/write field • -20 to +60 ℃

• during storage • -20 to +60 ℃

Type of mounting

)

The values for shock and vibration are maximum values and must not be applied continuously.

• Fixing pocket

2)

• Glued

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

317

Page 18

ISO transponder

8.10.5

Dimension drawing

Dimensions in mm

8.11 MDS D261

Figure 8-23 Dimension drawing of MDS D200

SIMATIC RF300

318 System Manual, 07/2017, C79000-G8976-C345-07

Page 19

ISO transponder

8.11

MDS D261

8.11.1

Features

MDS D261

Characteristics

cation.

Memory size

256 bytes of EEPROM user memory

(Page 56).

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP65

8.11.2

Ordering data

Article number

MDS D261

6GT2600-1AA00-0AX0

Type of delivery

8.11.3

Technical data

6GT2600-1AA01-0AX0

Product type designation

SIMATIC MDS D261

Memory

Memory configuration

8.11 MDS D261

Area of application The design of the transponder (self-adhesive label)

permits a variety of designs, guaranteeing optimum

dimensioning for the widest variety of applications.

From simple identification such as electronic barcode

replacement/supplementation, through warehouse

and distribution logistics, right up to product identifi-

Write/read range See section Field data of ISO transponders (MDS D)

Table 8- 26 Ordering data for MDS D261

Minimum order quantity: 1250 units (5 rolls with 250 units each)

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

Table 8- 27 Technical specifications of MDS D261

• UID • 8 bytes

319

Page 20

ISO transponder

6GT2600-1AA01-0AX0

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 106

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 25 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

durability of the adhesive

Degree of protection

IP65

Design, dimensions and weight

Dimensions (L x W x H)

55 x 55 x 0.3 mm

1)

The processing instructions of the adhesive manufacturer must be observed.

8.11 MDS D261

• User memory • 256 bytes EEPROM

• OTP memory • 16 bytes (EEPROM)

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Top • PET plastic (label

material)

• Inlay • PET plastic (carrier

material)

• Antenna • Aluminum

• Bottom • Double-sided trans-

• Color • White

• during write/read access • -20 ... +60 °C

• outside the read/write field • -20 … +85 °C

• During transportation and storage • +20 to +30 ℃

Can be stored for 2 years, determined by the

fer adhesive on silicon paper

Weight 1 g

Type of mounting Glued with self-adhesive label 1)

SIMATIC RF300

320 System Manual, 07/2017, C79000-G8976-C345-07

Page 21

ISO transponder

8.11.4

Dimension drawing

Dimensions in mm

8.12

MDS D324

8.12.1

Characteristics

MDS D324

Characteristics

Memory size

992 bytes of EEPROM user memory

sponders (MDS D) (Page 56)."

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP67; IPx9K

8.12 MDS D324

Figure 8-24 Dimension drawing of MDS D261

Area of application Production and distribution logistics

and product identification

Can also be used in harsh environ-

ments under extreme environmental

conditions (e.g. with higher temperature

load).

Write/read range See section "Field data of ISO tran-

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

321

Page 22

ISO transponder

8.12.2

Ordering data

Article number

MDS D324

6GT2600-3AC00

Article number

Spacer

6GT2690-0AK00

8.12.3

Mounting on metal

Mounting on metal

h

≥ 15 mm

8.12 MDS D324

Table 8- 28 Ordering data MDS D324

Table 8- 29 Ordering data MDS D324 accessories

SIMATIC RF300

322 System Manual, 07/2017, C79000-G8976-C345-07

Figure 8-25 Mounting the MDS D124/D324/D424/D524/E624 and RF320T on metal with spacer

Page 23

ISO transponder

Flush-mounting

h

≥ 15 mm

a

≥ 25 mm

Note

Going below the distances

If the distances (a and h) are not observed, a reduction of the field data results. It is possible

to mount the MDS with metal screws (M3 counters

impact on the range.

8.12.4

Technical specifications

6GT2600-3AC00

Product type designation

SIMATIC MDS D324

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 106

Data retention time (at < 40 ℃)

> 10 years

8.12 MDS D324

Figure 8-26 Flush-mounting of the MDS D124/D324/D424/D524/E624 and RF320T in metal with

spacer

unk head screws). This has no tangible

Table 8- 30 Technical specifications of MDS D324

• UID • 8 bytes

• User memory • 992 bytes EEPROM

• OTP memory • 16 bytes (EEPROM)

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

323

Page 24

ISO transponder

6GT2600-3AC00

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 15 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock according to EN 60721-3-7 Class 7M31)

1000 m/s2

Vibration according to EN 60721-3-7 Class 7M31)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

27 x 4 mm

Weight

5 g

1)

2

3)

The processing instructions of the adhesive manufacturer must be observed.

8.12 MDS D324

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Epoxy resin

• Color • Black

• during write/read access • -25 to +125 ℃

• outside the read/write field • -40 to +140 ℃

• during storage • -40 to +140 ℃

Degree of protection to EN 60529

• IP67

• IPx9K

Type of mounting

• 1 x M3 screw

2)

≤ 1 Nm

• Glued 3)

The values for shock and vibration are maximum values and must not be applied continuously.

) To prevent it loosening during operation, secure the screw with screw locking varnish.

SIMATIC RF300

324 System Manual, 07/2017, C79000-G8976-C345-07

Page 25

ISO transponder

8.12.5

Dimension drawing

8.12 MDS D324

Figure 8-27 Dimension drawing of MDS D324

All dimensions in mm

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

325

Page 26

ISO transponder

8.13

MDS D339

8.13.1

Characteristics

MDS D339

Characteristics

(Page 56).

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP68/IPx9K

8.13.2

Ordering data

Article number

MDS D339

6GT2600-3AA10

Article number

Spacer

6GT2690-0AA00

(Ø x H): 22 x 60 mm

(Ø x H): 22 x 47 mm

8.13 MDS D339

Area of application Applications in production automation with high

temperature demands (up to +220 °C)

Typical application areas:

• Paintshops and their preparatory treatments

• Primer coat, electrolytic dip area, cataphoresis

with the associated drying furnaces

• Top coat area with drying furnaces

• Washing areas at temperatures > 85 °C

• Other applications with higher temperatures

Memory size 992 bytes of EEPROM user memory

Write/read range See section Field data of ISO transponders (MDS D)

Table 8- 31 Ordering data for MDS D339

Table 8- 32 Ordering data for MDS D339 accessories

Quick change holder

Quick change holder

6GT2690-0AH00

6GT2690-0AH10

SIMATIC RF300

326 System Manual, 07/2017, C79000-G8976-C345-07

Page 27

ISO transponder

8.13.3

Mounting on metal

Mounting on metal

h

≥ 30 mm

Flush-mounting

h

≥ 30 mm

a

≥ 100 mm

8.13 MDS D339

Direct mounting of the MDS D139/D339 on metal is not allowed. A distance of ≥ 30 mm is

recommended. This can be achieved using spacers (see "Ordering data (Page 326)").

Figure 8-28 Mounting the MDS D139/D339 on metal with spacer

It is possible to mount the MDS D139/D339 in metal. With large antennas, for example ANT

D5, this leads to a reduction of ranges.

Figure 8-29 Flush-mounting of the MDS D139/D339 in metal with spacer

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

327

Page 28

ISO transponder

Note

Going below the distances

If the distances (a and h) are not observed, a reduction of the field data results. It is possible

to mount the MDS with

recommended that a test is performed in critical applications.

8.13.4

Cleaning the mobile data memory

Note

Do not clean the transponder with mechanical tools, sand

cleaning methods result in damage to the transponder.

Clean the transponder only with the cleaning agents listed in the section "Chemical

resistance of the MDS".

8.13.5

Technical specifications

6GT2600-3AA10

Product type designation

SIMATIC MDS D339

Memory

Memory configuration

Data retention time (at < 40 ℃)

> 10 years

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

8.13 MDS D339

metal screws (M5). This has no tangible impact on the range. It is

-blasting or pressure hose. These

Table 8- 33 Technical specifications of MDS D339

• UID • 8 bytes

• User memory • 992 bytes EEPROM

• OTP memory • 16 bytes (EEPROM)

Read cycles (at < 40 ℃) > 1014

Write cycles (at < 40 ℃) > 106

Write/read distance (Sg) Dependent on the reader used, see section "Field

data of ISO transponders (MDS D) (Page 56)"

• Material • PPS

SIMATIC RF300

328 System Manual, 07/2017, C79000-G8976-C345-07

Page 29

ISO transponder

6GT2600-3AA10

Recommended distance to metal

≥ 30 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock according to EN 60721-3-7 Class 7M31)

500 m/s2

Vibration according to EN 60721-3-7 Class 7M31)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

85 x 15 mm

Weight

50 g

1.5 Nm

1

2)

ing the MDS in high temperatures (expansion coefficient).

8.13 MDS D339

• Color • Black

• during write/read access • -25 to +100 ℃

• outside the read/write field • -40 to +220 ℃

• from +125 ℃: 20% reduction in the limit dis-

tance

• at +200 ℃: Tested up to 5000 hours or

6000 cycles

• at +220 ℃: Tested up to 2000 hours or

2000 cycles

• during storage • -40 to +100 ℃

Degree of protection to EN 60529

• IP68

2 hours, 2 bar, +20 °C

• IPx9K

steam jet: 150 mm; 10 to 15 l/min; 100 bar; 75

°C

Type of mounting 1 x M5 screw 2)

The values for shock and vibration are maximum values and must not be applied continuously.

For mounting with the spacer (6GT2690-0AA00), use a stainless steel M5 screw to avoid damag-

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

329

Page 30

ISO transponder

8.13.6

Use of the MDS D339 in hazardous areas

Identification

WARNING

Gefahr durch elektrostatische Entladungen

Potential electrostatic charging hazard

Danger potentiel de charges électrostatiques

8.13 MDS D339

The MDS D339 mobile data memory is classed as a piece of simple, electrical equipment

and can be operated in Protection Zone 2, Device Group II, Category 3G.

The following requirements of the 94/9/EC directive are met:

● EN 60079-0:2006

● EN 60079-15:2005

● EN 61241-0:2006

● EN 61241-1:2004

II 3 G Ex nA II T6

Ii 3 D Ex tD A22 IP68 T 210°C

KEMA 09 ATEX 0133 X

SIMATIC RF300

330 System Manual, 07/2017, C79000-G8976-C345-07

Page 31

ISO transponder

Note

Installations- und Betriebsbedingungen für den Ex-Schutzbereich:

a) Der Einsatz des Gerätes in der Nähe von stark ladungserzeugenden Prozessen ist

untersagt.

b) Das Gerät ist mechanisch geschützt zu montieren.

c) Die Montage muss auf eine

d) Die Reinigung darf nur mit feuchtem Tuch erfolgen.

Installation and operating conditions for hazardous areas:

a) Use of the equipment in the vicinity of processes generating high charges is not allowed.

b) Th

c) Installation must be performed on a grounded and conductive mounting surface.

d) Cleaning only with a wet cloth

Conditions d'installation et de mise en oeuvre pour la zone de protection Ex :

a)

b) L'appareil doit être monté de manière à être protégé mécaniquement.

c) Le montage doit être effectué sur un socle conducteur mis à la terre.

d) Nettoyage uniquement

8.13 MDS D339

m geerdeten, leitenden Untergrund erfolgen.

e equipment must be mechanically protected when installed.

L'utilisation de l'appareil près de processus générant de fortes charges est interdite.

avec un chiffon humide

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

331

Page 32

ISO transponder

8.13.7

Dimensional drawing

MDS D339

8.13 MDS D339

Figure 8-30 Dimension drawing of the MDS D339

Dimensions in mm

SIMATIC RF300

332 System Manual, 07/2017, C79000-G8976-C345-07

Page 33

ISO transponder

8.14

MDS D400

8.14.1

Features

MDS D400

Characteristics

tion logistics right through to product identification.

(Page 56)"

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP67

8.14.2

Ordering data

Article number

MDS D400

6GT2600-4AD00

Article number

(in conjunction with fixing pocket 6GT2190-0AB00)

(in conjunction with spacer 6GT2190-0AA00)

(not suitable for fixing directly onto metal)

8.14 MDS D400

Area of application

Memory size 2000 bytes of FRAM user memory

Write/read range See section "Field data of ISO transponders (MDS D)

Table 8- 34 Ordering data of MDS D400

Simple identification such as electronic barcode replacement/supplements, from warehouse and distribu-

Table 8- 35 Ordering data of MDS D400 accessories

Spacer

Fixing pocket

Fixing pocket

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

6GT2190-0AA00

6GT2190-0AB00

6GT2390-0AA00

333

Page 34

ISO transponder

8.14.3

Mounting on metal

Mounting on metal

h

≥ 20 mm

①

Transponder

②

Metal

③

Non-metal

8.14 MDS D400

It is possible to mount the MDS D400 on metal.

Figure 8-31 Mounting of the MDS D400 on metal with spacer

SIMATIC RF300

334 System Manual, 07/2017, C79000-G8976-C345-07

Page 35

ISO transponder

Flush-mounted in metal

a

≥ 20 mm

h

≥ 20 mm

①

Transponder

②

Metal

③

Non-metal

Note

If the minimum guide values (h) are not observed, th

data.

8.14.4

Technical specifications

6GT2600-4AD00

Product type designation

SIMATIC MDS D400

Memory

Memory configuration

8.14 MDS D400

Figure 8-32 Flush-mounting of MDS D400 in metal with spacer

is will result in a reduction of the field

Table 8- 36 Technical specifications for MDS D400

• UID • 8 bytes

• User memory • 2000 bytes FRAM

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

335

Page 36

ISO transponder

6GT2600-4AD00

Read cycles (at < 25 ℃)

> 1012

Write cycles (at < 25 ℃)

> 1012

Data retention time (at < 25 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 20 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Degree of protection to EN 60529

IP67

Vibration-resistant to EN 60721-3-7, class 7M3

ISO 10373 / ISO 7810 1)

Torsion and bending load

ISO 10373/ISO 7816-1

Design, dimensions and weight

Dimensions (L x W x H)

85 x 54 x 0.8 mm

Weight

5 g

1)

2)

The processing instructions of the adhesive manufacturer must be observed.

8.14 MDS D400

• OTP memory • 16 bytes FRAM

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • PVC

• Color • White

• during write/read access • -20 to +60 ℃

• outside the read/write field • -20 to +60 ℃

• during storage • -20 to +60 ℃

Type of mounting

• Fixing lug

2)

• Glued

The values for vibration are maximum values and must not be applied continuously.

SIMATIC RF300

336 System Manual, 07/2017, C79000-G8976-C345-07

Page 37

ISO transponder

8.14.5

Dimension drawing

8.14 MDS D400

Figure 8-33 Dimensional drawing MDS D400 (dimensions in mm)

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

337

Page 38

ISO transponder

8.15

MDS D421

8.15.1

Characteristics

MDS D421

Characteristics

lems.

Memory size

2000 bytes of FRAM user memory

(Page 56)"

Mounting on metal

Yes, flush-mounted in metal

ISO standard

ISO 15693

Degree of protection

IP67/IPx9K

8.15.2

Ordering data

Article number

MDS D421

6GT2600-4AE00

8.15 MDS D421

Area of application The MDS D421 is designed for tool coding in accordance

with DIN 69873.

Write/read range See section "Field data of ISO transponders (MDS D)

It can be used wherever small data carriers and exact positioning are required, e.g. tool identification, workpiece holders.

The rugged housing of the MDS D421 means that it can

also be used in a harsh industrial environment without prob-

Table 8- 37 Ordering data of MDS D421

SIMATIC RF300

338 System Manual, 07/2017, C79000-G8976-C345-07

Page 39

ISO transponder

8.15.3

Mounting on metal

Mounting on metal

Flush-mounting

8.15 MDS D421

Figure 8-34 Mounting of MDS D421/D521/E623 on metal

Figure 8-35 Mounting of MDS D421/D521/E623 in metal

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

339

Page 40

ISO transponder

Flush-mounting of the MDS in metal with tools

b1

0.5 x 45°

b2

0.3 x 45° or R0.3

d1

10 (-0.04... -0.13)

d2

10 (+0.09... 0)

t1

4.5 (-0 ... -0.1)

t2

4.6 (+0.2 ... 0)

All dimensions in mm

Note

Installation instruction

The MDS s

contour.

The mounting instructions of the MDS and the conditions associated with the application

(e.g. peripheral speed, temperature, and use of coolant) must be observed during

installation.

Mounting information for adhesion

8.15 MDS D421

Figure 8-36 Flush-mounting of MDS D421/D521/E623 in metal with tools

hould not protrude out of the locating hole; it must be flush with the outside

● Drill installation hole

● The adhesive surfaces must be dry, free from dust, oil, stripping agents and other

impurities

● Apply adhesive according to the manufacturer's processing instructions

● Press in transponder using your fingers; with antenna side to the outside (see figure

above)

● Remove residues of adhesive

the

● Allow to cure according to the manufacturer's instructions

● Flush-mounting of the transponder in metal with tools

SIMATIC RF300

340 System Manual, 07/2017, C79000-G8976-C345-07

Page 41

ISO transponder

Installation examples

8.15.4

Technical specifications

6GT2600-4AE00

Product type designation

SIMATIC MDS D421

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1012

Write cycles (at < 40 ℃)

> 1012

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

8.15 MDS D421

Figure 8-37 Installation example of MDS D421/D521/E623 in a steep cone

Figure 8-38 Installation example of MDS D421/D521/E623 in a stud bolt

Table 8- 38 Technical specifications for the MDS D421

• UID • 8 bytes

• User memory • 2000 bytes FRAM

• OTP memory • 16 bytes FRAM

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Epoxy resin

• Color • Black

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

341

Page 42

ISO transponder

6GT2600-4AE00

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock according to EN 60721-3-7 Class 7M31)

1000 m/s2

Vibration according to EN 60721-3-7 Class 7M31)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

10 x 4.5 mm

Weight

Approx. 1 g

Type of mounting

Glued 2)

1)

2)

The processing instructions of the adhesive manufacturer must be observed.

8.15.5

Dimension drawing

8.15 MDS D421

• during write/read access • -25 to +85 ℃

• outside the read/write field • -40 to +100 ℃

• during storage • -40 to +100 ℃

Degree of protection to EN 60529

The values for shock and vibration are maximum values and must not be applied continuously.

• IP67

• IPx9K

steam jet: 150 mm; 10 to 15 l/min; 100 bar; 75

°C

Figure 8-39 Dimension drawing of MDS D421

All dimensions in mm

SIMATIC RF300

342 System Manual, 07/2017, C79000-G8976-C345-07

Page 43

ISO transponder

8.16

MDS D422

8.16.1

Characteristics

MDS D422

Characteristics

containers

Memory size

2000 bytes of FRAM user memory

(Page 56).

Mounting on metal

Yes

ISO standard

ISO 15693

Degree of protection

IP68

8.16.2

Ordering data

Article number

unit

8.16 MDS D422

Area of application

Write/read range See section "Field data of ISO transponders (MDS D)

Identification of metallic workpiece holders, workpieces or

Table 8- 39 Ordering data of MDS D422

MDS D422

A screw-in aid is included in the scope of supply per packaging

6GT2600-4AF00

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

343

Page 44

ISO transponder

8.16.3

Mounting in metal

Flush-mounting

Mounting information for screws

Mounting information for adhesion

8.16.4

Technical specifications

6GT2600-4AF00

Product type designation

SIMATIC MDS D422

Memory

Memory configuration

8.16 MDS D422

Figure 8-40 Mounting of MDS D422 in metal

You can screw the transponder into a pre-drilled threaded hole using the screw-in aid.

● Drill installation hole

● The adhesive surfaces must be dry, free from dust, oil, stripping agents and other

impurities

● Apply adhesive according to the manufacturer's processing instructions

● Press in MDS D422 using your fingers; with antenna to the outside

● Remove residues of adhesive

● Allow to cure according to the manufacturer's instructions

● Flush-mounting of MDS D422 in metal with tools

Table 8- 40 Technical specifications for the MDS D422

SIMATIC RF300

344 System Manual, 07/2017, C79000-G8976-C345-07

Page 45

ISO transponder

6GT2600-4AF00

Read cycles (at < 40 ℃)

> 1012

Write cycles (at < 40 ℃)

> 1012

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

285 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

2 hours, 2 bar, +20 °C

Shock according to EN 60721-3-7 Class 7M31)

500 m/s2

Vibration according to EN 60721-3-7 Class 7M31)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

20 x 6 mm

Weight

13 g

1)

2)

The processing instructions of the adhesive manufacturer must be observed.

8.16 MDS D422

• UID • 8 bytes

• User memory • 2000 bytes FRAM

• OTP memory • 16 bytes FRAM

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Plastic PA 6.6 GF; brass nickel plated

• Color • Black/silver

• during write/read access • -25 to +85 ℃

• outside the read/write field • -40 to +100 ℃

• during storage • -40 to +100 ℃

Degree of protection to EN 60529 IP68

Type of mounting

• Glued

2)

• 1 x transponder thread M20

≤ 1 Nm

The values for shock and vibration are maximum values and must not be applied continuously.

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

345

Page 46

ISO transponder

8.16.5

Dimension drawing

Dimensions in mm

8.17

MDS D423

8.17.1

Characteristics

MDS D423

Characteristics

pieces or containers, production automation

D) (Page 56)"

ISO standard

ISO 15693

8.17.2

Ordering data

Article number

MDS D423

6GT2600-4AA00

Article number

Fixing hood RF330T / MDS D423

6GT2690-0AE00

8.17 MDS D423

Figure 8-41 Dimensional drawing of MDS D422

Area of application

Identification of metallic workpiece holders, work-

Memory size 2000 bytes of FRAM user memory

Write/read range See section "Field data of ISO transponders (MDS

Mounting on metal Yes, flush-mounted in metal

Degree of protection IP68/IPx9K

Table 8- 41 Ordering data of MDS D423

Table 8- 42 Ordering data of MDS D423 accessories

SIMATIC RF300

346 System Manual, 07/2017, C79000-G8976-C345-07

Page 47

ISO transponder

8.17.3

Mounting on metal

Mounting on metal

Flush-mounted in metal

a

≥ 10 mm

8.17 MDS D423

Direct mounting of the MDS D423 on metal is possible.

Figure 8-42 Mounting the MDS D423 on metal

It is possible to mount the MDS D423 in metal.

Figure 8-43 Flush-mounting of the MDS D423 in metal with 10 mm clearance

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

347

Page 48

ISO transponder

Note

Reduction of the write/read range

Note that when the device is flush

mm, the write/read range is significantly reduced.

8.17.4

Technical specifications

6GT2600-4AA00

Product type designation

SIMATIC MDS D423

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1012

Write cycles (at < 40 ℃)

> 1012

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

8.17 MDS D423

Figure 8-44 Flush-mounting of the MDS D423 in metal without clearance

-mounted in metal without a surrounding clearance ≥ 10

Table 8- 43 Technical specifications of MDS D423

• UID • 8 bytes

• User memory • 2000 bytes FRAM

• OTP memory • 16 bytes FRAM

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Plastic PPS

SIMATIC RF300

348 System Manual, 07/2017, C79000-G8976-C345-07

Page 49

ISO transponder

6GT2600-4AA00

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock according to EN 60721-3-7 Class 7M31)

500 m/s2

Vibration according to EN 60721-3-7 Class 7M31)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

30 x 8 mm

Weight

15 g

≤ 1 Nm

1)

2

) To prevent it loosening during operation, secure the screw with screw locking varnish.

8.17 MDS D423

• Color • Black

• during write/read access • -25 to +85 ℃

• outside the read/write field • -40 to +100 ℃

• during storage • -40 to +100 ℃

Degree of protection to EN 60529

• IP68

2 hours, 2 bar, +20 °C

• IPx9K

steam jet: 150 mm; 10 to 15 l/min; 100 bar; 75

°C

Pressure resistance

• Low pressure resistant

vacuum dryer: up to 20 mbar

• High pressure resistant

(see degree of protection IPx9K)

Type of mounting 1 x M4 screw 2)

The values for shock and vibration are maximum values and must not be applied continuously.

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

349

Page 50

ISO transponder

8.17.5

Dimensional drawing

Dimensions in mm

8.18

MDS D424

8.18.1

Characteristics

MDS D424

Characteristics

without problem

Memory size

2000 bytes of FRAM user memory

D) (Page 56)."

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP67; IPx9K

8.18 MDS D424

Figure 8-45 Dimension drawing for MDS D423

Area of application Production and distribution logistics as well as in

Write/read range See section "Field data of ISO transponders (MDS

assembly and production lines,

can also be used in a harsh industrial environment

SIMATIC RF300

350 System Manual, 07/2017, C79000-G8976-C345-07

Page 51

ISO transponder

8.18.2

Ordering data

Article number

MDS D424

6GT2600-4AC00

Article number

Spacer

6GT2690-0AK00

8.18.3

Mounting on metal

Mounting on metal

h

≥ 15 mm

8.18 MDS D424

Table 8- 44 Ordering data of MDS D424

Table 8- 45 Ordering data of MDS D424 accessories

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

Figure 8-46 Mounting the MDS D124/D324/D424/D524/E624 and RF320T on metal with spacer

351

Page 52

ISO transponder

Flush-mounting

h

≥ 15 mm

a

≥ 25 mm

Note

Going below the distances

If the distances (a and h) are not observed,

to mount the MDS with metal screws (M3 countersunk head screws). This has no tangible

impact on the range.

8.18.4

Technical specifications

6GT2600-4AC00

Product type designation

SIMATIC MDS D424

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1012

Write cycles (at < 40 ℃)

> 1012

Data retention time (at < 40 ℃)

> 10 years

8.18 MDS D424

Figure 8-47 Flush-mounting of the MDS D124/D324/D424/D524/E624 and RF320T in metal with

spacer

a reduction of the field data results. It is possible

Table 8- 46 Technical specifications for the MDS D424

• UID • 8 bytes

• User memory • 2000 bytes FRAM

• OTP memory • 16 bytes FRAM

SIMATIC RF300

352 System Manual, 07/2017, C79000-G8976-C345-07

Page 53

ISO transponder

6GT2600-4AC00

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 15 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock according to EN 60721-3-7 Class 7M31)

1000 m/s2

Vibration according to EN 60721-3-7 Class 7M31)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

27 x 4 mm

Weight

5 g

1)

2)

3

) To prevent it loosening during operation, secure the screw with screw-locking varnish.

8.18 MDS D424

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Epoxy resin

• Color • Black

• during write/read access • -25 to +85 ℃

• outside the read/write field • -40 to +100 ℃

• during storage • -40 to +100 ℃

Degree of protection to EN 60529

• IP67

• IPx9K

Type of mounting

• Glued

• 1x screw M3

2)

3)

≤ 1 Nm

The values for shock and vibration are maximum values and must not be applied continuously.

The processing instructions of the adhesive manufacturer must be observed.

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

353

Page 54

ISO transponder

8.18.5

Dimension drawing

8.19

MDS D425

8.19.1

Characteristics

MDS D425

Characteristics

lem

Memory size

2000 bytes of FRAM user memory

(Page 56)".

Mounting on metal

Yes

Degree of protection

IP68/IPx9K

8.19 MDS D425

Figure 8-48 Dimension drawing of MDS D424

All dimensions in mm

Area of application Compact and rugged ISO transponder; suitable for screw

mounting

Use in assembly and production lines in the powertrain

Write/read range See section "Field data of ISO transponders (MDS D)

ISO standard ISO 15693

sector; ideal for mounting on motors, gearboxes, and workpiece holders

Rugged packaging of the MDS D425; can therefore also be

used under extreme environmental conditions without prob-

SIMATIC RF300

354 System Manual, 07/2017, C79000-G8976-C345-07

Page 55

ISO transponder

8.19.2

Ordering data

Article number

MDS D425

6GT2600-4AG00

8.19.3

Application example

8.19.4

Technical specifications

6GT2600-4AG00

Product type designation

SIMATIC MDS D425

Memory

Memory configuration

8.19 MDS D425

Table 8- 47 Ordering data of MDS D425

Figure 8-49 Application example

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

Table 8- 48 Technical specifications for the MDS D425

• UID • 8 bytes

• User memory • 2000 bytes FRAM

• OTP memory • 16 bytes FRAM

355

Page 56

ISO transponder

6GT2600-4AG00

Read cycles (at < 40 ℃)

> 1012

Write cycles (at < 40 ℃)

> 1012

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock according to IEC 68-2-271)

500 m/s2

Vibration according to IEC 68-2-61)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

24 x 10 mm (without set screw)

Weight

35 g

1)

The values for shock and vibration are maximum values and must not be applied continuously.

8.19 MDS D425

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Plastic PA 6.6 GF

• Color • Black

• during write/read access • -25 to +85 ℃

• outside the read/write field • -40 to +125 ℃

• during storage • -40 to +125 ℃

Degree of protection to EN 60529

• IP68

2 hours, 2 bar, +20 °C

• IPx9K

steam jet: 150 mm; 10 to 15 l/min; 100 bar; 75

°C

Type of mounting 1x transponder set screw M6

SW 22; ≤ 6 Nm

SIMATIC RF300

356 System Manual, 07/2017, C79000-G8976-C345-07

Page 57

ISO transponder

8.19.5

Dimension drawing

Dimensions in mm

8.20

MDS D426

8.20.1

Characteristics

MDS D426

Characteristics

harsh conditions

Memory size

2000 bytes of FRAM user memory

Write/read range

See section Field data of ISO transponders (MDS D) (Page 56)

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP68

8.20 MDS D426

Figure 8-50 Dimension drawing of MDS D425

Area of application

Compact and rugged ISO transponder; suitable for identification of

transport units in production-related logistics; can also be deployed in

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

357

Page 58

ISO transponder

8.20.2

Ordering data

Article number

MDS D426

6GT2600-4AH00

Article number

Spacer

6GT2690-0AL00

8.20.3

Mounting on metal

Mounting on metal

h

≥ 25 mm

8.20 MDS D426

Table 8- 49 Ordering data of MDS D426

Table 8- 50 Ordering data of MDS D426 accessories

SIMATIC RF300

358 System Manual, 07/2017, C79000-G8976-C345-07

Figure 8-51 Mounting the MDS D126 / D426 / D526 on metal with spacer

Page 59

ISO transponder

Flush-mounted in metal

h

≥ 25 mm

a

≥ 50 mm

8.20.4

Technical specifications

6GT2600-4AH00

Product type designation

SIMATIC MDS D426

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1012

Write cycles (at < 40 ℃)

> 1012

data of ISO transponders (MDS D) (Page 56)"

Mechanical specifications

Housing

Recommended distance to metal

≥ 25 mm

8.20 MDS D426

Figure 8-52 Flush installation of the MDS D126 / D426 / D526 in metal with spacer

Table 8- 51 Technical specifications for the MDS D426

• UID • 8 bytes

• User memory • 2000 bytes FRAM

• OTP memory • 16 bytes FRAM

Data retention time (at < 40 ℃) > 10 years

Write/read distance (Sg) Dependent on the reader used, see section "Field

MTBF (Mean Time Between Failures) 228 years

• Material • Plastic PA 6.6 GF

• Color • Black

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

359

Page 60

ISO transponder

6GT2600-4AH00

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

2 hours, 2 bar, +20 °C

Shock according to IEC 68-2-271)

50 m/s2

Vibration according to IEC 68-2-61)

20 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

50 x 3.6 mm

Weight

13 g

≤ 1 Nm

1)

2

) To prevent it loosening during operation, secure the screw with screw locking varnish.

8.20.5

Dimension drawing

Dimensions in mm

8.20 MDS D426

• during write/read access • -25 to +85 ℃

• outside the read/write field • -40 to +100 ℃

• during storage • -40 to +100 ℃

Degree of protection to EN 60529 IP68

Type of mounting 1 x M4 screw 2)

The values for shock and vibration are maximum values and must not be applied continuously.

Figure 8-53 Dimension drawing of MDS D426

SIMATIC RF300

360 System Manual, 07/2017, C79000-G8976-C345-07

Page 61

ISO transponder

8.21

MDS D428

8.21.1

Characteristics

MDS D428

Characteristics

problems.

Memory size

2000 bytes of FRAM user memory

(Page 56)"

Mounting on metal

Yes

ISO standard

ISO 15693

Degree of protection

IP68/IPx9K

8.21.2

Ordering data

Article number

MDS D428

6GT2600-4AK00-0AX0

8.21 MDS D428

Area of application Compact and rugged ISO transponder; suitable for screw

mounting.

Use in assembly and production lines in the powertrain

sector.

The rugged housing of the MDS D428 means that it can

also be used in extreme environmental conditions without

Write/read range See section "Field data of ISO transponders (MDS D)

Table 8- 52 Ordering data of MDS D428

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

361

Page 62

ISO transponder

8.21.3

Application example

8.21.4

Technical specifications

6GT2600-4AK00

Memory

Write cycles (at < 40 ℃)

> 1012

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

8.21 MDS D428

Figure 8-54 Application example

Table 8- 53 Technical specifications for the MDS D428

Product type designation SIMATIC MDS D428

Memory configuration

• UID • 8 bytes

• User memory • 2000 bytes FRAM

• OTP memory • 16 bytes FRAM

Read cycles (at < 40 ℃) > 1012

Write/read distance (Sg) Dependent on the reader used, see section "Field

SIMATIC RF300

362 System Manual, 07/2017, C79000-G8976-C345-07

Page 63

ISO transponder

6GT2600-4AK00

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock according to IEC 68-2-271)

500 m/s2

Vibration according to IEC 68-2-61)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

24 x 20 mm (without set screw)

Weight

35 g

SW 22; ≤ 8 Nm

1)

The values for shock and vibration are maximum values and must not be applied continuously.

8.21 MDS D428

• Material • Plastic PA 6.6 GF

• Color • Black

• during write/read access • -25 to +85 ℃

• outside the read/write field • -40 to +125 ℃

• during storage • -40 to +125 ℃

Degree of protection to EN 60529

• IP68

2 hours, 2 bar, +20 °C

• IPx9K

steam jet: 150 mm; 10 to 15 l/min; 100 bar; 75

°C

Type of mounting 1x transponder set screw M8

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

363

Page 64

ISO transponder

8.21.5

Dimension drawing

Dimensions in mm

8.22

MDS D460

8.22.1

Characteristics

MDS D460

Characteristics

Memory size

2000 bytes of FRAM user memory

Write/read range

See section "Field data of ISO transponders (MDS D) (Page 56).

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP67/IPx9K

8.22 MDS D460

Figure 8-55 Dimension drawing of MDS D428

Area of application Identification in small assembly lines; can also be used in a harsh in-

dustrial environment

SIMATIC RF300

364 System Manual, 07/2017, C79000-G8976-C345-07

Page 65

ISO transponder

8.22.2

Ordering data

Article number

MDS D460

6GT2600-4AB00

Article number

Spacer

6GT2690-0AG00

8.22.3

Mounting on metal

Mounting option on metal with spacer

①

Transponder

②

Metal

③

Spacer

h

≥ 10 mm

Note

If the minimum guide values (h) are not observed, a reduction of the field data results.

In critical applications, it is recommended that a test is performed.

Flush-mounting

8.22 MDS D460

Table 8- 54 Ordering data of MDS D460

Table 8- 55 Ordering data of MDS D460 accessories

Figure 8-56 Mounting the MDS D460 on metal with spacer

Flush-mounting of the MDS D460 in metal is not permitted!

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

365

Page 66

ISO transponder

8.22.4

Technical specifications

6GT2600-4AB00

Product type designation

SIMATIC MDS D460

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1012

Write cycles (at < 40 ℃)

> 1012

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 10 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock according to IEC 68-2-271)

500 m/s2

Vibration according to IEC 68-2-61)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

16 x 3 mm

8.22 MDS D460

Table 8- 56 Technical specifications for MDS D460

• UID • 8 bytes

• User memory • 2000 bytes FRAM

• OTP memory • 16 bytes FRAM

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Epoxy resin

• Color • Black

• during write/read access • -25 to +85 ℃

• outside the read/write field • -40 to +100 ℃

• during storage • -40 to +100 ℃

Degree of protection to EN 60529

• IP67

• IPx9K

steam jet: 150 mm; 10 to 15 l/min; 100 bar; 75

°C

SIMATIC RF300

366 System Manual, 07/2017, C79000-G8976-C345-07

Page 67

ISO transponder

6GT2600-4AB00

Weight

3 g

1)

2)

The processing instructions of the adhesive manufacturer must be observed.

8.22.5

Dimension drawings

Dimensional drawing of MDS D460

Dimensions in mm

Dimensional drawing of spacer

Dimensions in mm

8.22 MDS D460

Type of mounting

The values for shock and vibration are maximum values and must not be applied continuously.

Figure 8-57 Dimensional drawing of MDS D460

2)

• Glued

• With spacer

Figure 8-58 Dimensional drawing of spacer

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

367

Page 68

ISO transponder

8.23

MDS D521

8.23.1

Characteristics

MDS D521

Characteristics

used in a harsh industrial environment without problems.

Memory size

8192 bytes of FRAM user memory

Write/read range

See section "Field data of ISO transponders (MDS D) (Page 56)"

Mounting on metal

Yes, flush-mounted in metal

ISO standard

ISO 15693

Degree of protection

IP67/IPx9K

8.23.2

Ordering data

Article number

MDS D521

6GT2600-5AE00

8.23.3

Mounting on metal

Mounting on metal

8.23 MDS D521

Area of application The MDS D521 is designed for tool coding according to DIN

69873.

It can be used wherever small data carriers and exact positioning

are required, e.g. tool identification, workpiece holders.

The rugged housing of the MDS D521 means that it can also be

Table 8- 57 Ordering data for MDS D521

Figure 8-59 Mounting of MDS D421/D521/E623 on metal

SIMATIC RF300

368 System Manual, 07/2017, C79000-G8976-C345-07

Page 69

ISO transponder

Flush-mounting

Flush-mounting of the MDS in metal with tools

b1

0.5 x 45°

b2

0.3 x 45° or R0.3

d1

10 (-0.04... -0.13)

d2

10 (+0.09... 0)

t1

4.5 (-0 ... -0.1)

t2

4.6 (+0.2 ... 0)

All dimensions in mm

Note

Installation instruction

The MDS should not protrude out of the locating hole; it must be flush with the outside

contour.

The mounting

(e.g. peripheral speed, temperature, and use of coolant) must be observed during the

installation.

8.23 MDS D521

Figure 8-60 Mounting of MDS D421/D521/E623 in metal

Figure 8-61 Flush-mounting of MDS D421/D521/E623 in metal with tools

instructions of the MDS and the conditions associated with the application

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

369

Page 70

ISO transponder

Mounting information for adhesion

Installation examples

8.23.4

Technical specifications

6GT2600-5AE00

Product type designation

SIMATIC MDS D521

Memory

Memory configuration

8.23 MDS D521

● Drill installation hole

● The adhesive surfaces must be dry, free from dust, oil, stripping agents and other

impurities

● Apply adhesive according to the manufacturer's processing instructions

● Press in transponder using your fingers; with antenna side to the outside (see figure

above)

● Remove residues of adhesive

● Allow to cure according to the manufacturer's instructions

● Flush-mounting of the transponder in metal with tools

Figure 8-62 Installation example of MDS D421/D521/E623 in a steep cone

Figure 8-63 Installation example of MDS D421/D521/E623 in a stud bolt

Table 8- 58 Technical specifications for MDS D521

SIMATIC RF300

370 System Manual, 07/2017, C79000-G8976-C345-07

• UID • 8 bytes

• User memory • 8192 bytes FRAM

Page 71

ISO transponder

6GT2600-5AE00

Read cycles (at < 40 ℃)

> 1012

Write cycles (at < 40 ℃)

> 1012

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock according to EN 60721-3-7 Class 7M31)

1000 m/s2

Vibration according to EN 60721-3-7 Class 7M31)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

10 x 4.5 mm

Weight

1 g

Type of mounting

Glued 2)

1)

2)

The processing instructions of the adhesive manufacturer must be observed.

8.23 MDS D521

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Epoxy resin

• Color • Black

• during write/read access • -25 to +85 ℃

• outside the read/write field • -40 to +100 ℃

• during storage • -40 to +100 ℃

Degree of protection to EN 60529

• IP67

• IPx9K

steam jet: 150 mm; 10 to 15 l/min; 100 bar; 75

°C

The values for shock and vibration are maximum values and must not be applied continuously.

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

371

Page 72

ISO transponder

8.23.5

Dimension drawing

8.24

MDS D522

8.24.1

Characteristics

MDS D522

Characteristics

pieces or containers

(Page 56)."

Mounting in metal

Yes

ISO standard

ISO 15693

Degree of protection

IP68

8.24.2

Ordering data

Article number

unit.

8.24 MDS D522

Figure 8-64 Dimension drawing of MDS D521

All dimensions in mm

Area of application Identification of metallic workpiece holders, work-

Memory size 8192 bytes of FRAM user memory

Write/read range See "Field data of ISO transponders (MDS D)

Table 8- 59 Ordering data for MDS D522

MDS D522

Units in a package: 10 units

A mounting aid is included in the scope of supply per packaging

6GT2600-5AF00

SIMATIC RF300

372 System Manual, 07/2017, C79000-G8976-C345-07

Page 73

ISO transponder

8.24.3

Mounting in metal

Flush-mounting

Mounting information for screws

Mounting information for adhesion

8.24.4

Technical specifications

6GT2600-5AF00

Product type designation

SIMATIC MDS D522

Memory

Memory configuration

8.24 MDS D522

Figure 8-65 Mounting of MDS D522 in metal

You can screw the transponder into a pre-drilled threaded hole using the screw-in aid.

● Drill installation hole

● The adhesive surfaces must be dry, free from dust, oil, stripping agents and other

impurities

● Apply adhesive according to the manufacturer's processing instructions

● Press in MDS D522 using your fingers; with antenna to the outside

● Remove residues of adhesive

● Allow to cure according to the manufacturer's instructions

● Flush-mounting of MDS D522 in metal with tools

Table 8- 60 Technical specifications for MDS D522

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

373

Page 74

ISO transponder

6GT2600-5AF00

Read cycles (at < 40 ℃)

> 1012

Write cycles (at < 40 ℃)

> 1012

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

285 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

2 hours, 2 bar, +20 °C

Shock according to EN 60721-3-7 Class 7M31)

500 m/s2

Vibration according to EN 60721-3-7 Class 7M31)

200 m/s2

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

20 x 6 mm

1)

2)

The processing instructions of the adhesive manufacturer must be observed.

8.24 MDS D522

• UID • 8 bytes

• User memory • 8192 bytes FRAM

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Plastic PA 6.6 GF; brass nickel plated

• Color • Black/silver

• during write/read access • -25 to +85 ℃

• outside the read/write field • -40 to +100 ℃

• during storage • -40 to +100 ℃

Degree of protection to EN 60529 IP68

Weight 13 g

Type of mounting

• Glued

2)

• 1 x transponder thread M20

≤ 1 Nm

The values for shock and vibration are maximum values and must not be applied continuously.

SIMATIC RF300

374 System Manual, 07/2017, C79000-G8976-C345-07

Page 75

ISO transponder

8.24.5

Dimension drawing

8.25

MDS D522 special variant

8.25.1

Characteristics

MDS D522 special version

Characteristics

pieces

Memory size

8192 bytes of FRAM user memory

(Page 56)."

Mounting in metal

Yes

ISO standard

ISO 15693

8.25.2

Ordering data

Article number

8.25 MDS D522 special variant

Figure 8-66 Dimensional drawing of MDS D522

All dimensions in mm

Area of application

Identification of metallic workpiece holders or work-

Write/read range See "Field data of ISO transponders (MDS D)

Degree of protection IP68

Table 8- 61 MDS D522 special version

MDS D522 special version

Units in a package: 10 units

A mounting aid is included in the scope of supply per packaging

unit.

6GT2600-5AF00-0AX0

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

375

Page 76

ISO transponder

8.25.3

Mounting in metal

Flush-mounting

8.25.4

Installation instructions

8.25 MDS D522 special variant

Figure 8-67 Flush installation of the MDS D522 special version in metal without clearance

The transponder MDS D522 special version is designed to be mounted once.

Note the following instructions when mounting the MDS D522 in a workpiece to avoid

damaging the transponder:

● Prepare the workpiece according to the following drawing.

● Using the accompanying mounting aid, press the transponder with uniform and evenly

distributed pressure into the drilled hole until the transponder locks in place. Make sure

that the transponder does not become tilted.

SIMATIC RF300

376 System Manual, 07/2017, C79000-G8976-C345-07

Page 77

ISO transponder

8.25 MDS D522 special variant

Figure 8-68 Dimension drawing: Workpiece drill hole for mounting the MDS D522 special version

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

377

Page 78

ISO transponder

8.25.5

Technical specifications

6GT2600-5AF00-0AX0

Product type designation

SIMATIC MDS D522 special version

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1012

Write cycles (at < 40 ℃)

> 1012

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 56)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

2 hours, 2 bar, +20 °C

Shock according to EN 60721-3-7 Class 7M31)

500 m/s2

Vibration according to EN 60721-3-7 Class 7M31)

200 m/s2

Design, dimensions and weight

Weight

Approx. 1.2 g

Type of mounting