Page 1

SIMATIC Industrial PC SIMATIC Rack PC IL 43

DOCUMENTATION

Operating Instructions Edition 09/2005

Industrial PC

Rack PC IL 43

simatic

DOCUMENTATION

Page 2

Page 3

SIMATIC

Industrial PC

Rack PC IL 43

Operating Instructions

Introduction

Safety information

Description

Deployment planning

Installation

Connecting

Commissioning

1

2

3

4

5

6

7

Integration

Functions

Expansions and

configuration

Maintenance and service

Troubleshooting

Technical data

Dimensional drawings

8

9

10

11

12

13

14

Edition 09/2005

A5E00432875-01

Detailed descriptions

Appendix

ESD Guidelines

Abbreviations

15

A

B

C

Page 4

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended

by Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

GERMANY

Order No.: A5E00432875-01

Edition 09/2005

Copyright © Siemens AG 2005.

Technical data subject to change

Page 5

Table of contents

1 Introduction............................................................................................................................................. 1-1

1.1 Preface....................................................................................................................................... 1-1

1.2 Guide for the operating instructions........................................................................................... 1-2

2 Safety information................................................................................................................................... 2-1

2.1 General safety instructions ........................................................................................................ 2-1

3 Description.............................................................................................................................................. 3-1

3.1 Overview .................................................................................................................................... 3-1

3.2 Areas of application ................................................................................................................... 3-2

3.3 Highlights ................................................................................................................................... 3-2

3.4 Function ..................................................................................................................................... 3-3

3.5 Features..................................................................................................................................... 3-3

3.6 Design........................................................................................................................................ 3-6

3.6.1 External structure....................................................................................................................... 3-6

3.6.2 Operator controls ....................................................................................................................... 3-7

3.6.3 Connecting elements ................................................................................................................. 3-8

3.6.4 Status displays........................................................................................................................... 3-9

4 Deployment planning.............................................................................................................................. 4-1

4.1 Transport.................................................................................................................................... 4-1

4.2 Unpacking and checking the delivery unit ................................................................................. 4-1

4.3 Ambient and environmental conditions...................................................................................... 4-3

5 Installation .............................................................................................................................................. 5-1

5.1 Installing the device ................................................................................................................... 5-1

6 Connecting ............................................................................................................................................. 6-1

6.1 Connecting peripherals .............................................................................................................. 6-1

6.2 Connecting the device to power................................................................................................. 6-2

7 Commissioning ....................................................................................................................................... 7-1

7.1 Prerequisites for commissioning................................................................................................ 7-1

7.2 Basic commissioning - initial power-up...................................................................................... 7-1

7.3 Notes on operation..................................................................................................................... 7-2

7.3.1 DVD ROM/CD RW..................................................................................................................... 7-2

7.3.2 DVD burner ................................................................................................................................ 7-3

7.3.3 Removable hard disks ............................................................................................................... 7-4

7.3.4 RAID system .............................................................................................................................. 7-5

8 Integration............................................................................................................................................... 8-1

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

iii

Page 6

Table of contents

9 Functions................................................................................................................................................ 9-1

9.1 Overview of the ......................................................................................................................... 9-1

9.2 Temperature monitoring/display ................................................................................................ 9-1

9.3 Watchdog (WD).......................................................................................................................... 9-2

9.4 Fan monitoring ........................................................................................................................... 9-2

10 Expansions and configuration............................................................................................................... 10-1

10.1 Open the device ....................................................................................................................... 10-1

10.2 Memory expansion ................................................................................................................... 10-4

10.3 Installing expansion cards........................................................................................................ 10-4

10.3.1 Notes on the modules .............................................................................................................. 10-4

10.3.2 Installing an expansion module................................................................................................ 10-5

10.4 Installing disk drives ................................................................................................................. 10-6

10.4.1 Options of installing disk drives................................................................................................ 10-6

10.4.2 Installing and removing a disk drive or removable rack........................................................... 10-6

10.4.3 Installing and removing a hard disk ......................................................................................... 10-8

11 Maintenance and service...................................................................................................................... 11-1

11.1 Removing and installing hardware components ...................................................................... 11-1

11.1.1 Repairs..................................................................................................................................... 11-1

11.1.2 Replacing the backup battery .................................................................................................. 11-2

11.1.3 Removing the power supply module........................................................................................ 11-3

11.1.4 Removing the motherboard...................................................................................................... 11-4

11.1.5 Remove filter and device fan.................................................................................................... 11-5

11.1.6 Processor replacement ............................................................................................................ 11-6

11.2 Reinstalling the software .......................................................................................................... 11-8

11.2.1 General installation procedure ................................................................................................. 11-8

11.2.2 Restoring the Factory State of the Software Using the Restore DVD ..................................... 11-8

11.2.3 Installing Windows ................................................................................................................... 11-9

11.2.3.1 Setting up the partitions for Windows operating systems...................................................... 11-10

11.2.3.2 Installing Microsoft Windows operating systems ................................................................... 11-11

11.2.4 Setting up the language selection for Windows 2000 MUI .................................................... 11-12

11.2.5 Language selection on Windows XP Professional and Windows Server 2003..................... 11-13

11.2.6 Installing drivers and software ............................................................................................... 11-13

11.2.7 Installing the RAID Controller software .................................................................................. 11-14

11.2.8 Installing burner or DVD software .......................................................................................... 11-14

12 Troubleshooting.................................................................................................................................... 12-1

12.1 General problems..................................................................................................................... 12-1

12.2 Problems when using modules of third-party manufacturers................................................... 12-2

13 Technical data ...................................................................................................................................... 13-1

13.1 General specifications.............................................................................................................. 13-1

13.2 Power requirements of components (maximum values).......................................................... 13-5

13.3 AC voltage supply .................................................................................................................... 13-5

13.4 Technical data of the telescopic rails ....................................................................................... 13-6

SIMATIC Rack PC IL 43

iv Operating Instructions, Edition 09/2005, A5E00432875-01

Page 7

Table of contents

14 Dimensional drawings........................................................................................................................... 14-1

14.1 Dimensional drawing of the device .......................................................................................... 14-1

14.2 Dimensional drawing for the use of telescopic rails................................................................. 14-2

14.3 Dimensional drawings for the installation of expansion modules ............................................ 14-2

15 Detailed descriptions ............................................................................................................................ 15-1

15.1 Motherboard............................................................................................................................. 15-1

15.2 System resources .................................................................................................................... 15-1

15.3 BIOS Setup .............................................................................................................................. 15-2

A Appendix.................................................................................................................................................A-1

A.1 Guidelines and declarations....................................................................................................... A-1

A.2 Certificates and approvals .........................................................................................................A-2

A.3 Service and support ................................................................................................................... A-4

A.4 Retrofitting instructions ..............................................................................................................A-6

B ESD Guidelines ......................................................................................................................................B-1

B.1 ESD Guidelines..........................................................................................................................B-1

C Abbreviations..........................................................................................................................................C-1

C.1 Abbreviations .............................................................................................................................C-1

Glossary ..................................................................................................................................... Glossary-1

Index................................................................................................................................................ Index-1

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

v

Page 8

Table of contents

SIMATIC Rack PC IL 43

vi Operating Instructions, Edition 09/2005, A5E00432875-01

Page 9

Introduction

1.1 1.1 Preface

Purpose of this document

These operating instructions contain all the information you need for commissioning and

using the SIMATIC Rack PC IL 43.

It is intended both for programming and testing/debugging personnel who commission the

device itself and connect it with other units (automation systems, further programming

devices), as well as for service and maintenance personnel who install expansions or carry

out fault/error analyses.

Where this documentation is valid

This documentation is valid for all supplied variations of the SIMATIC Rack PC IL 43 and

describes the state of delivery as of September 2005.

Position in the information scheme

The operating instructions are available on the supplied "Documentation and Drivers" CD.

1

For supplementary instructions on how to handle the software, please refer to the

corresponding manuals.

Conventions

The abbreviation Rack PC or device is also used within this documentation for the product

name SIMATIC Rack PC IL 43.

History

Currently released versions of this operating manual:

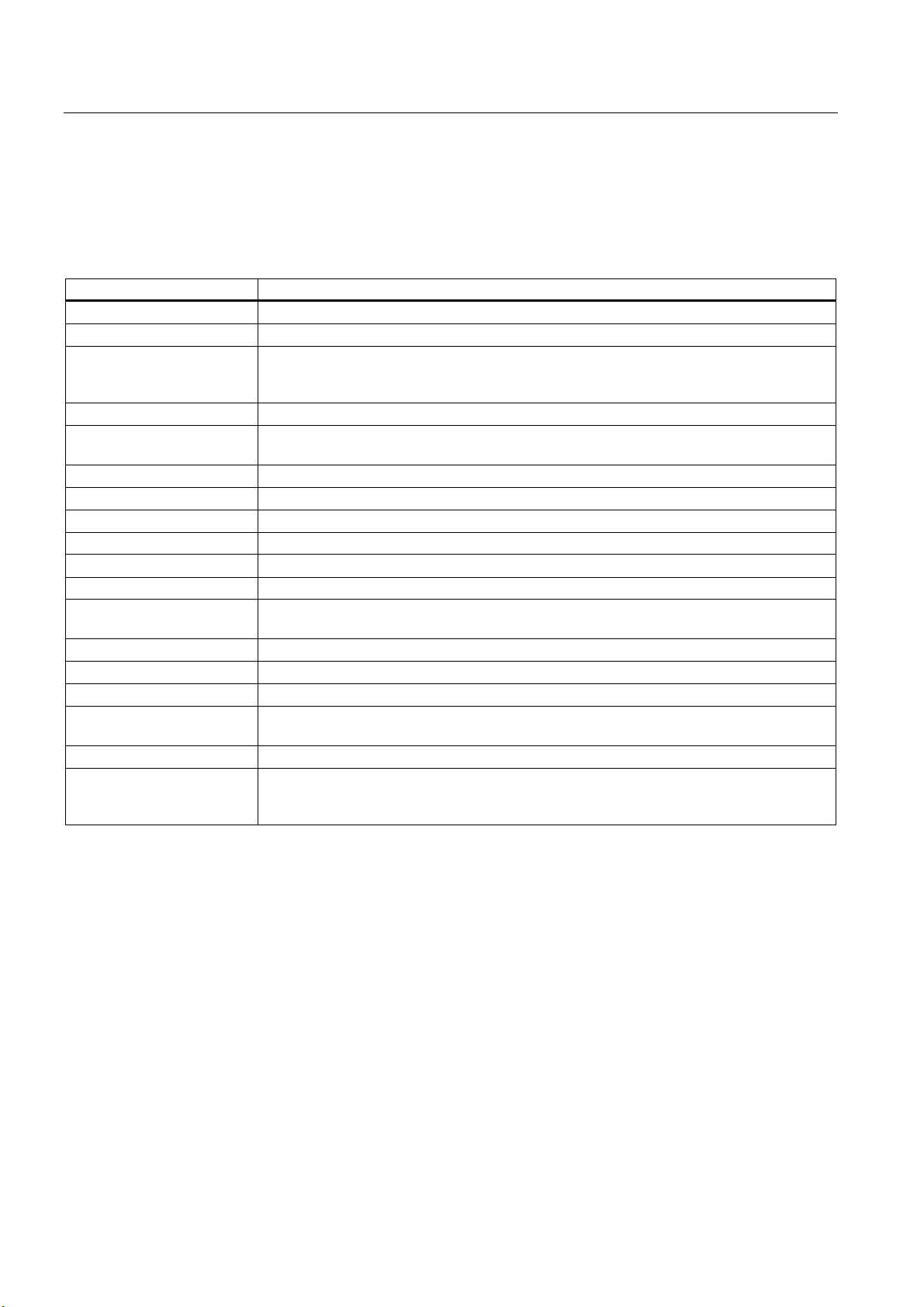

Edition Remarks

09/05 First edition

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

1-1

Page 10

Introduction

1.2 Guide for the operating instructions

1.2 1.2 Guide for the operating instructions

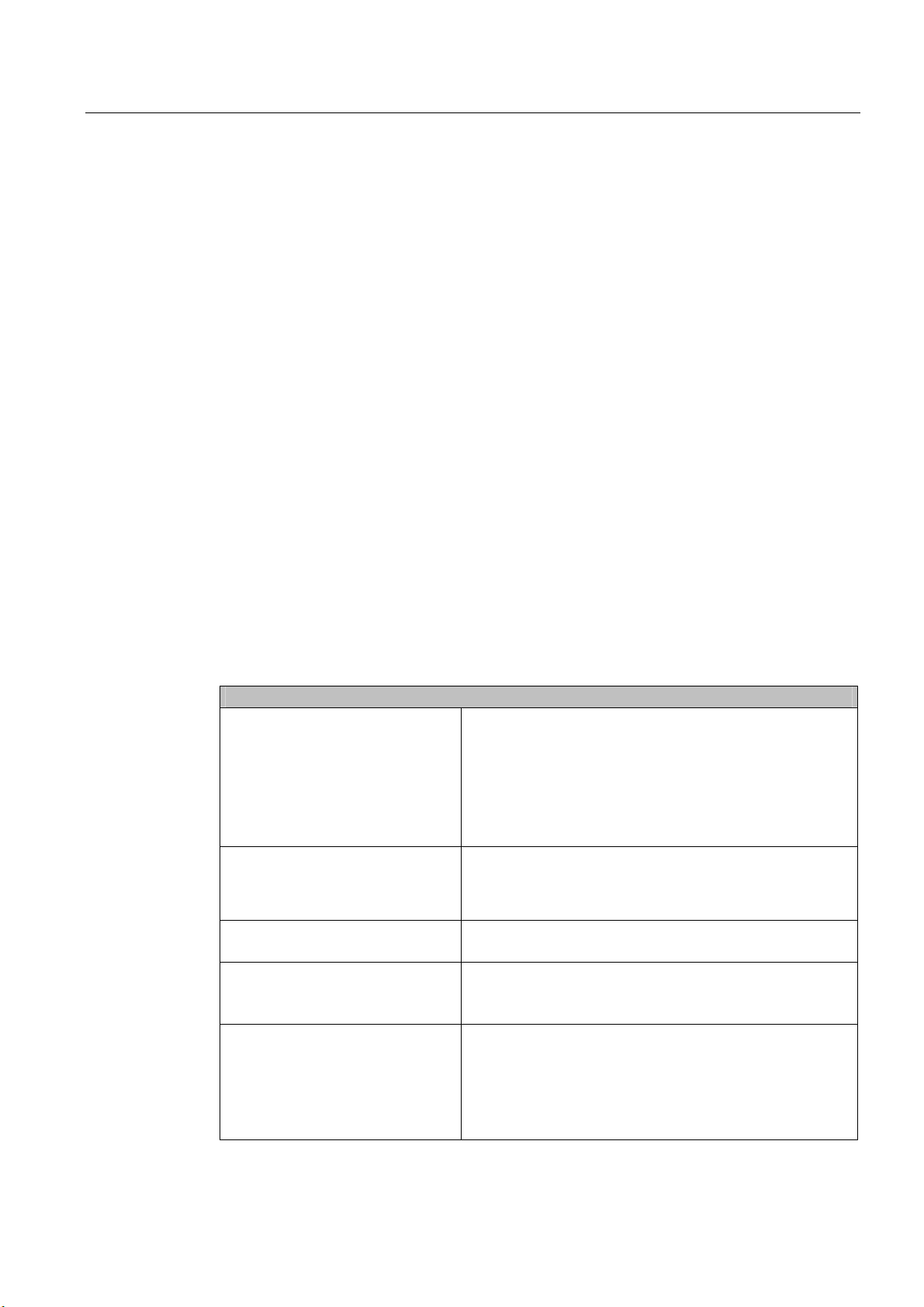

Contents format Table of Contents

Table of Contents Organization of the documentation, including the index of pages and chapters

Introduction Purpose, layout and description of the important topics

Safety Information Refers to all the valid safety-technological aspects which are derived from statutory

regulations and should be adhered to when installing, commissioning and operating the

product/system

Description Fields of application, the features and the structure of the product/system

Deployment planning Aspects of storage, transport, environmental and EMC conditions to be considered in the

preparatory stage

Installation Product installation options and installation instructions

Connecting Options of connecting the product and connection instructions

Commissioning Commissioning the product/system.

Integration Options of integrating the product into existing or planned system environments/networks

Functions Monitoring and display functions.

Expansions / Configuration Procedure for expansion devices (memory, modules, drives)

Maintenance and Service Replacement of hardware components, restoring and setup of the operating system,

installation of drivers and software

Troubleshooting Problems, cause, remedy

Technical specifications General specifications in compliance with relevant standards and current/voltage values

Dimensional drawings Dimensions of the device and of modules

Detailed descriptions Structure, function and features of the vital components, allocation of system resources and

use of the BIOS Setup

Appendix Guidelines and certifications, service and support, notes on retrofitting

Guidelines for Handling

Electrostatic Sensitive

Devices (ESD)

General ESD guidelines.

SIMATIC Rack PC IL 43

1-2 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 11

Safety information

2.1 2.1 General safety instructions

Caution

Please observe the safety instructions on the back cover of this documentation. You should

not expand your device unless you have read the relevant safety instructions.

This device is compliant with the relevant safety measures to IEC, EN, VDE, UL, and CSA. If

you have questions about the validity of the installation in the planned environment, please

contact your service representative.

Repairs

Only authorized personnel are permitted to repair the device.

2

Warning

Unauthorized opening of and improper repairs to the device may result in substantial

damage to equipment or endanger the user.

System expansions

Only install system expansion devices designed for this device. If you install other expansion

devices, you may damage the system or violate the safety requirements and regulations on

RF suppression. Contact your technical support team or where you purchased your PC to

find out which system expansion devices may safely be installed.

Caution

If you install or exchange system expansions and damage your device, the warranty

becomes void.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

2-1

Page 12

Safety information

2.1 General safety instructions

Battery

This device is equipped with a Lithium battery. Batteries may only be replaced by qualified

personnel.

Caution

There is the risk of an explosion if the battery is not replaced as directed. Replace only with

the same type or with an equivalent type recommended by the manufacturer. Dispose of

used batteries in accordance with local regulations.

Warning

Risk of explosion and release of harmful substances!

Therefore, do not throw Lithium batteries into an open fire, do not solder or open the cell

body, do not short-circuit or reverse polarity, do not heat up above 100° C, dispose as

regulated and protected against direct exposure to sunlight, humidity and dewing.

ESD guidelines

Modules containing electrostatically sensitive devices (ESDs) can be identified by the

following label:

Strictly follow the guidelines mentioned below when handling modules which are sensitive to

ESD:

• Always discharge your body´s static electricity before handling modules which are

sensitive to ESD (for example, by touching a grounded object).

• All devices and tools must be free of static charge.

• Always pull the power plug and disconnect the battery before you install or remove

modules which are sensitive to ESD.

• Handle modules fitted with ESDs by their edges only.

• Do not touch any wiring posts or conductors on modules containing ESDs.

SIMATIC Rack PC IL 43

2-2 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 13

Description

3.1 3.1 Overview

The SIMATIC Rack PC IL 43 is a powerful industrial PC in 19" rack format design (4HE). It is

perfectly suited for high-performance industrial PC applications.

• High-level performance

• Attractive price

3

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

3-1

Page 14

Description

3.2 Areas of application

3.2 3.2 Areas of application

The SIMATIC Rack PC IL 43 offers system integrators, cabinet designers, system engineers

and machine designers a 19" rack PC platform for high-performance IT applications on the

control and cell levels. It can be used for:

• Process and visualization applications

• Industrial image processing

• Quality assurance / surveillance tasks

• Measurement, control and rule-based tasks

• Data acquisition and management

The SIMATIC Rack PC IL 43 has CE certification for use in the industrial sector as well as in

residential and commercial areas, and small businesses. In addition to the industrial

applications, it can also be used in building services automation or in facilities open to the

public.

3.3 3.3 Highlights

Highlights

Latest PC technology:

• State-of-the-art Intel technology

• High performance and scalability

• PCI-, PCIe x1-, PCIe x16 slots

Industrial suitability:

• Dust protection

• Service-friendly

• CE certification for industrial and office use

• Transport safety for expansion cards

• Monitoring functions

Investment security:

• Guaranteed spare parts availability for at least 3 years

High system availability:

• Preventative data back-up with the SIMATIC PC/PG Image Creator

• RAID1 – redundant data storage on two hard drives, also "hot swap" in connection with

SATA mounting frames.

SIMATIC Rack PC IL 43

3-2 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 15

Description

3.4 Function

3.4 3.4 Function

• Integrated, assigned monitoring functions

– Fan speed (CPU, power supply and front fan)

– Temperature (case, processor)

– Program execution (watchdog)

• RAID1 for automatic data mirroring of two serial ATA hard drives

• Intel Hyper Treading (HT) processor technology

Thanks to efficient resource utilization, the Intel Pentium 4 with hyper threading (HT)

technology can process two tasks (threads) simultaneously, as in this case it behaves like

two virtual processors. The following requirements must be met by the system:

• Processor with HT technology

• Activated HT technology support in system BIOS

• An HT technology capable, optimized operating system

• Customer applications optimized for HT technology

3.5 3.5 Features

General features

Installation design

Enclosure

Drive bays

Slots for expansion cards

Graphics

• 19” rack, 4 HE

• Robust full metal rack design case, lacquered outside and

coated inside

• Prepared for mounting telescopic rails

• Horizontal and vertical installation is possible

• Tower installation by means of tower kit

• Lockable front cover as access protection

• Dust protection by means of overpressure ventilation using

bearing seated front fan through filter

• Card retainer for reliable operation of PC modules under

vibration and shock conditions

• Front: 3 x 5.25" and 2 x 3.5"

• Internal: 2x 3.5"

• 4 x PCI long

• 2 x PCIe x1 long

• 1 x PCIe x16 long

• Onboard Intel® GMA950 graphics controller

Chipset integrated 2-D and 3-D engine,

up to 2048 x 1536 at 75 Hz

Dynamic Video Memory Technology

up to 800 x 600 at 120 Hz / 32 bit color

up to 1280x1024 at 100 Hz / 32 bit color

up to 2048 x1536 at 75 Hz / 16 bit colors

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

3-3

Page 16

Description

3.5 Features

General features

• in PCIe x16 slot (optional)

PCIe x16 graphic card (dual head: 2x VGA),

64 MB RAM

Up to 2048 x 1536 at 75 Hz / 32-bit color depth

Interfaces

Ethernet 10/100/1000 Mbps (RJ45)

USB 4 x front, 2 x back; high-current

Serial COM1 (V.24), COM2 (V.24) optional

Parallel LPT1

VGA 1 x

Keyboard PS/2

Mouse PS/2

Power supply 100 - 230 V AC, wide range; with short-term buffering against

power failure: max. 16 ms at 0.85 rated voltage

Monitoring functions

Temperature

Fan

Watchdog

Voltage monitoring

Status LEDs

• Overshoot/undershoot of permissible operating

temperature

• RPM monitoring, wear monitoring

• Monitoring of program execution

• Monitoring time can be parameterized in software

• Restart can be parameterized in the event of a fault

• Monitoring of +5 V, +12 V and battery voltage

• POWER (internal power supply unit, PC switched On)

• HARDDISK (access to hard disk)

• STATUS (temperature status)

Standard versions

Processor Intel Pentium 4 CPU no. 551 (3.4 GHz, 800 FSB, with Hyper

Threading, EM64T)

RAM expansion 256 MB SDRAM DDR2 533 (PC2 4200)

Single Channel

4 slots for maximum 4 GB

Disk drives

Floppy disk 1.44 MB

Hard disk drives 120 GB SATA, 3.5", internal installation

Operating system without

Optional accessories

Processor Intel Celeron D CPU no. 331 (2.66 GHz, 533 MHz FSB,

EM64T)

RAM expansion Up to 3 GB, dual-channel

SIMATIC Rack PC IL 43

3-4 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 17

Description

3.5 Features

Optional accessories

Disk drives

DVD ROM Read:

DVD ROM: Single layer 16x, Dual Layer 8x

DVD+R/RW, DVD-R/RW 8x, DVD-RAM 2x

CD-ROM, CD-R 32x, CD-RW 20x

DVD ROM/CD RW Read:

DVD ROM: Single Layer 16x, Dual Layer 8x

DVD-R/-RW/+R/+RW 8x

CD-ROM 52x, CD-R/RW 32x

Writing:

CD-R 52x, CD-RW 32x

DVD burner Read:

DVD ROM: Single Layer 16x, Dual Layer 12x

DVD-R/+R: Single Layer 16x, Dual Layer 7x

DVD-RW/+RW 13x

CD-ROM/CD-R 48x, CD-RW 40x

Writing:

DVD+R 16x, DVD+RW 8x, DVD-R 16x, DVD-RW 6x,

DVD+R9 (DL) 8x, DVD-R DL 6x

CD-R 48x, CD-RW 32x

Hard disk drives

Operating system Preinstalled / supplied on Restore CD

• 2x 120 GB SATA; 3.5"

• 1x or 2x 120 GB SATA; 3.5“, in removable racks

• RAID1; 3.5" (mirrored drives) internal

• RAID1; 3.5" (mirrored drives) in removable racks "Hot

swap"

• Windows 2000 Professional MUI*

• Windows XP Professional MUI*

• Windows Server 2003 including 5Client MUI*

*MUI: Multi language User Interface; 5 languages (German,

English, French, Spanish, Italian)

Optional expansions

SIMATIC PC Image Creator SW Software tool for saving data locally

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

3-5

Page 18

Description

3.6 Design

3.6 3.6 Design

3.6.1 External structure

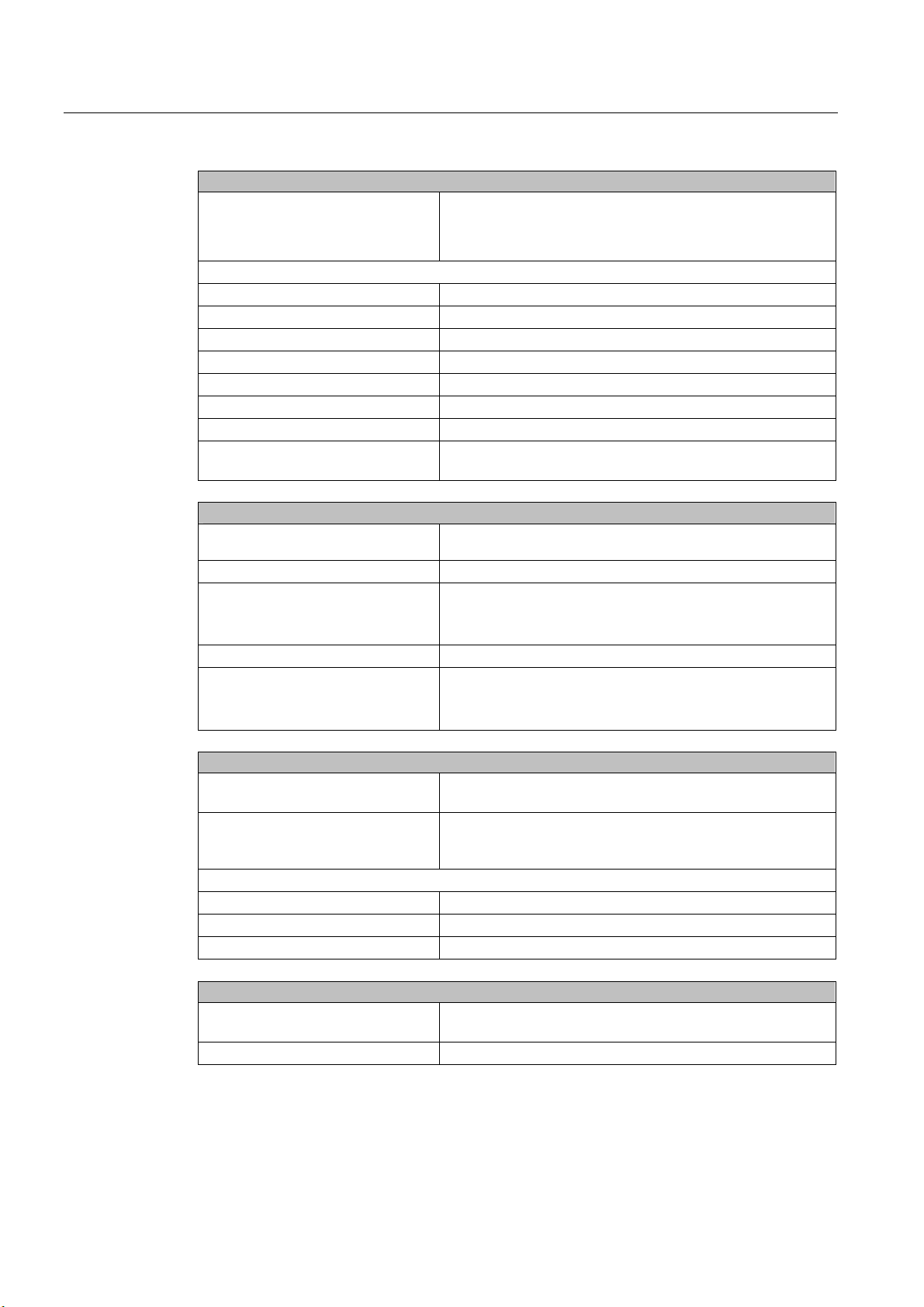

Front view of the device Pos Description

(1) Front panel with aperture for ventilation of the

device (filter mat and fan are located behind this

front panel)

(2) Option for installing DVD-ROM,

DVD-ROM/CD-RW drives, DVD burner and

removable racks for hard disks

(3) Option for installing DVD-ROM,

DVD-ROM/CD-RW drive, DVD burner

(4) On/off button

(5) Front door with lock,

provides protection against dirt and

unauthorized access. Keep the door closed

during normal operation.

(6) Floppy disk

(7) USB ports

(8) Status displays

Rear view of the device Pos Description

(1) Power unit fan

(2) Option for installing a cover for external ports

(3) Expansion slots

4 x PCI, 2x PCIe x1, 1x PCIe x16

(4) Connecting elements

(5) Rating plate (may also be mounted on the

inside of the front panel door)

(6) Fan aperture

Installation option for 60 mm fan

(7) Power supply connection

SIMATIC Rack PC IL 43

3-6 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 19

Description

3.6 Design

3.6.2 Operator controls

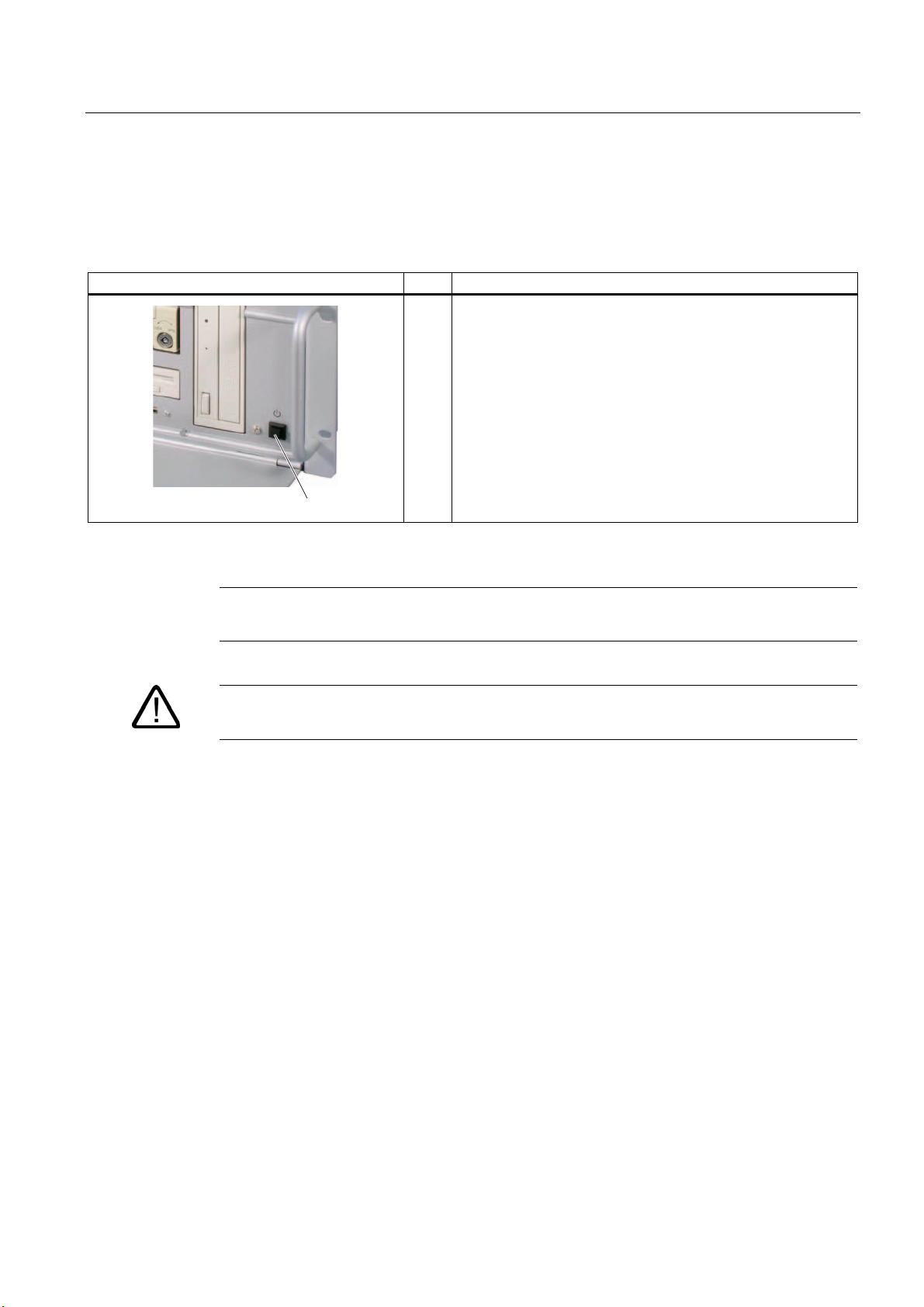

Operator control on/off button Pos Description

(1) The on/off/reset buttons have three functions:

- Switch on the PC (press briefly 1x)

- Shut down the operating system and PC

(press briefly 1x)

- Switch off the PC without shutting down the operating system

(press and hold more than 4 seconds) = hardware reset

Caution

Data may be lost when the PC performs a hardware reset.

Warning

The on/off button signal does not switch off power to the PC!

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

3-7

Page 20

Description

3.6 Design

3.6.3 Connecting elements

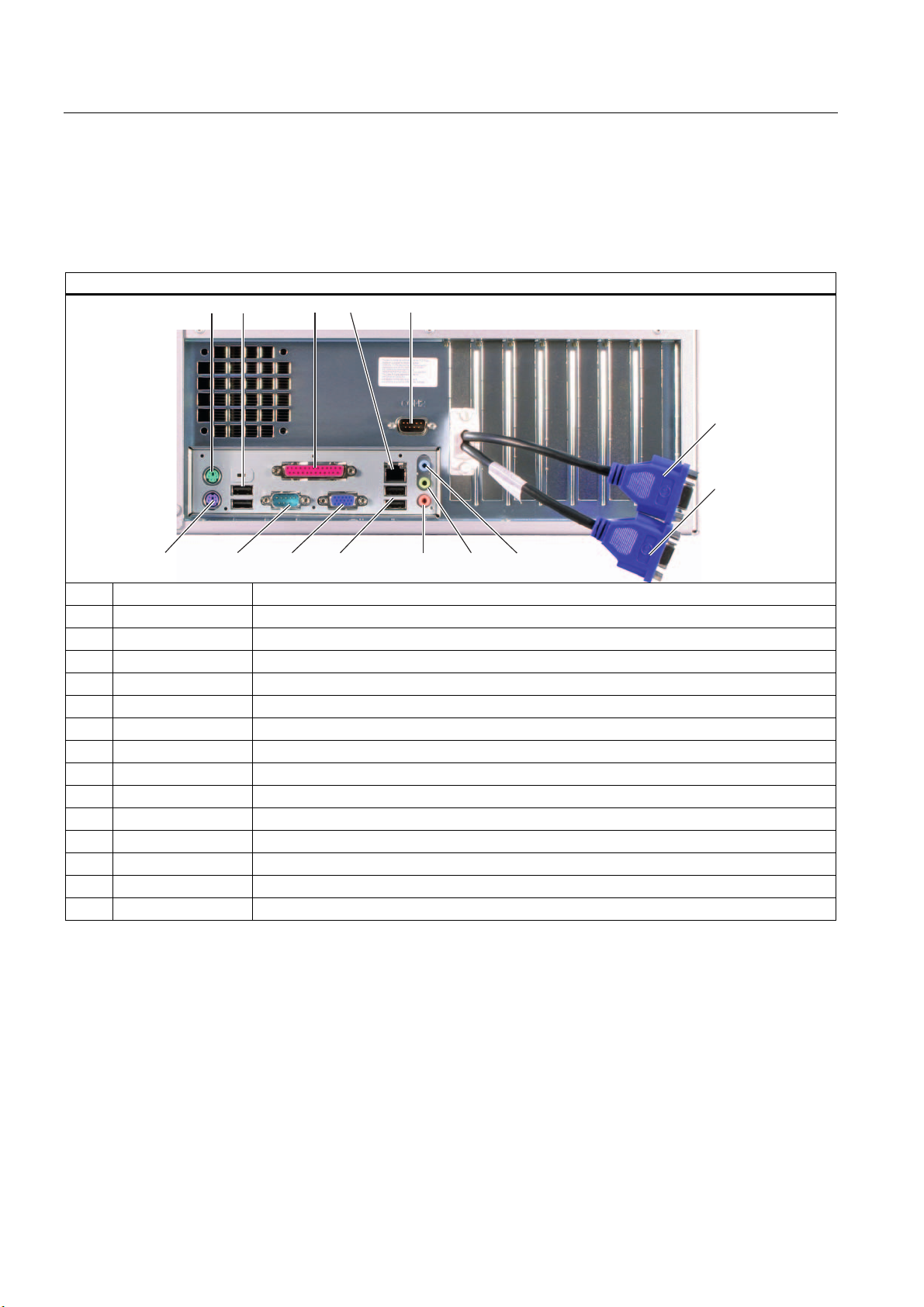

Interfaces

Layout of the interfaces on the rear of the device

Pos Name Description

(1) MOUSE Connection for a PS/2 mouse

(2) USB C and D USB connector

(3) LPT Parallel interface, 25-pin

(4) LAN RJ 45 Ethernet connection 10/100/1000 Mbps

(5) COM 2 Serial port 1 (V.24), 9-pin Cannon connector (optional)

(6) VGA 1 Dual Head VGA adapter (optional)

(7) VGA 2 Dual Head VGA adapter (optional)

(8) Micro (input) Microphone connection

(9) Audio (output) Headphone connection

(10) Audio (input) Connection for linear audio source

(11) USB A and B USB connector

(12) VGA Connection for VGA monitor

(13) COM 1 Serial port 1 (V.24), 9-pin Cannon connector

(14) KEYBOARD Connection for a PS/2 keyboard

SIMATIC Rack PC IL 43

3-8 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 21

Description

3.6 Design

Power supply

Position of the IEC power plug Description

IEC power connector for the AC power supply to the device. The

maximum permitted power range is 120 V AC to 240 V AC

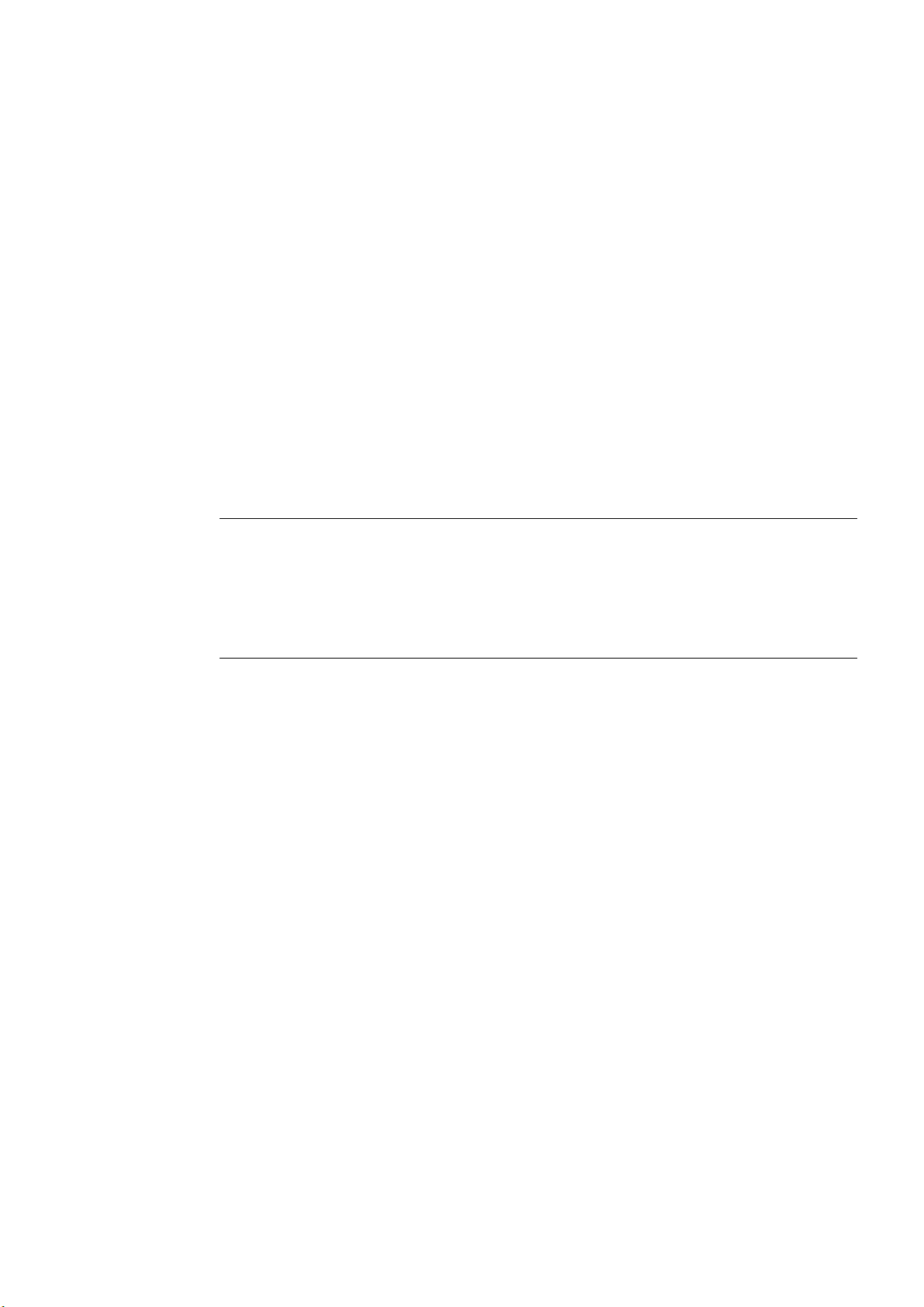

3.6.4 Status displays

Status displays

Display Meaning LED Description

(1) POWER PC status display OFF

(2) HARDDISK Display for hard disk

access

(3) STATUS Fan status FLASH

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

YELLOW

GREEN

OFF

GREEN

RED

• Hibernate, switched off or power off

• Windows standby

• PC in operation

• no access

• Access

• CPU temperature critical

• CPU heatsink fan fault

• Enclosure fan fault

• Power supply fan fault

3-9

Page 22

Description

3.6 Design

SIMATIC Rack PC IL 43

3-10 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 23

Deployment planning

4.1 4.1 Transport

Although the Rack PC has a rugged design, its internal components are sensitive to severe

vibrations or shock. You must therefore protect the PC from severe mechanical stress when

transporting it.

You should always use the original packaging for shipment of the device.

Caution

Risk of damage to the device!

When transporting the PC in cold weather it may be submitted to extreme variations in

temperature. In this situation, make sure that condensation does not develop on or inside

the device.

If condensation develops, wait at least 12 hours before switching on the device.

4

4.2 4.2 Unpacking and checking the delivery unit

Unpacking the device

Note the following points when you unpack the unit

• It is advisable not to dispose of the original packing material. Keep it in case you have to

transport the unit again.

• Please keep the documentation in a safe place. It is required for initial commissioning and

is part of the device.

• Check the delivery unit for any visible transport damage.

• Verify that the shipment contains the complete unit and your separately ordered

accessories.

• Please inform your local dealer of any disagreements or transport damages.

• Please inform Siemens AG by means of the enclosed SIMATIC IPC/PG quality control

report form.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

4-1

Page 24

Deployment planning

4.2 Unpacking and checking the delivery unit

Noting the device identification data

The device can identified uniquely with the help of these numbers in case of repairs or theft.

Enter the following data in the table below:

• Serial number: The serial number (S VP) is located on the type plate either on the rear

panel of the device or on the inside of the front door.

Figure 4-1 Rating plate

• Order number of the device

• Ethernet address: You find the Ethernet address of the device in your BIOS Setup

(F2 function key) , under Info > (F1 function key) > LAN Address.

Device equipment

• Microsoft Windows "Product Key" from the "Certificate of Authenticity" (COA). The COA

label is found on the inside of the front door.

You may need the Product Key in case you reinstall the operating system.

Figure 4-2 COA label

Serial number S VP ...

Order No. 6AG ...

Microsoft Windows Product Key

Ethernet address

You will find a list of device equipment on a sign behind the front door.

SIMATIC Rack PC IL 43

4-2 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 25

Deployment planning

4.3 Ambient and environmental conditions

4.3 4.3 Ambient and environmental conditions

When you plan your project, you should make allowances for:

• Note the climatic and mechanical environmental conditions specified in the technical data

in your operating manual.

• Avoid extreme ambient conditions as much as possible. Protect your PC from dust,

moisture, and heat.

• The device has been designed for usage in a normal industrial environment according to

IEC 60721-3-3 (pollutant class 3C2 for chemical influence, 3S2 for sand and dust.)

SIMATIC Rack PCs may not be used in severe operating environments, for example

locations with acidic vapors or gasses, without additional protective measures (such as

the provision of clean air.)

• Keep the PC out of direct sunlight.

• Mount the PC as safely as possible to prevent danger (for example, of falling over).

• The device satisfies protection class IP 30 on the front panel.

• The clearance in the area of the ventilation slots must be at least 50 mm, so that the PC

is sufficiently ventilated.

• Do not cover the vent slots of the device.

• The device enclosure satisfies fire protection requirements to EN 60950. It may therefore

be installed without additional fire-proofing measures.

Warning

If these conditions are not upheld while mounting the system, the approvals according to

UL 60950, EN 60950 are forfeited and there is a danger of overheating and personal

injury.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

4-3

Page 26

Deployment planning

4.3 Ambient and environmental conditions

SIMATIC Rack PC IL 43

4-4 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 27

Installation

5.1 5.1 Installing the device

Possible areas of installation

The device may be installed in control desks, switching cabinets and 19`` rack systems, both

horizontally and vertically.

Possible mounting methods

Options of mounting the device

• Mounting on angle brackets

• Installation on device bases

• Tower installation: a separate tower kit can be ordered for tower installation.

• Installing with telescopic rails

When telescopic rails are used, the devices can be completely removed from the cabinet

or rack.

Refer to the sections "Technical data of the telescopic rails" and "Dimensional drawing for

the use of telescopic rails" for more detailed information.

5

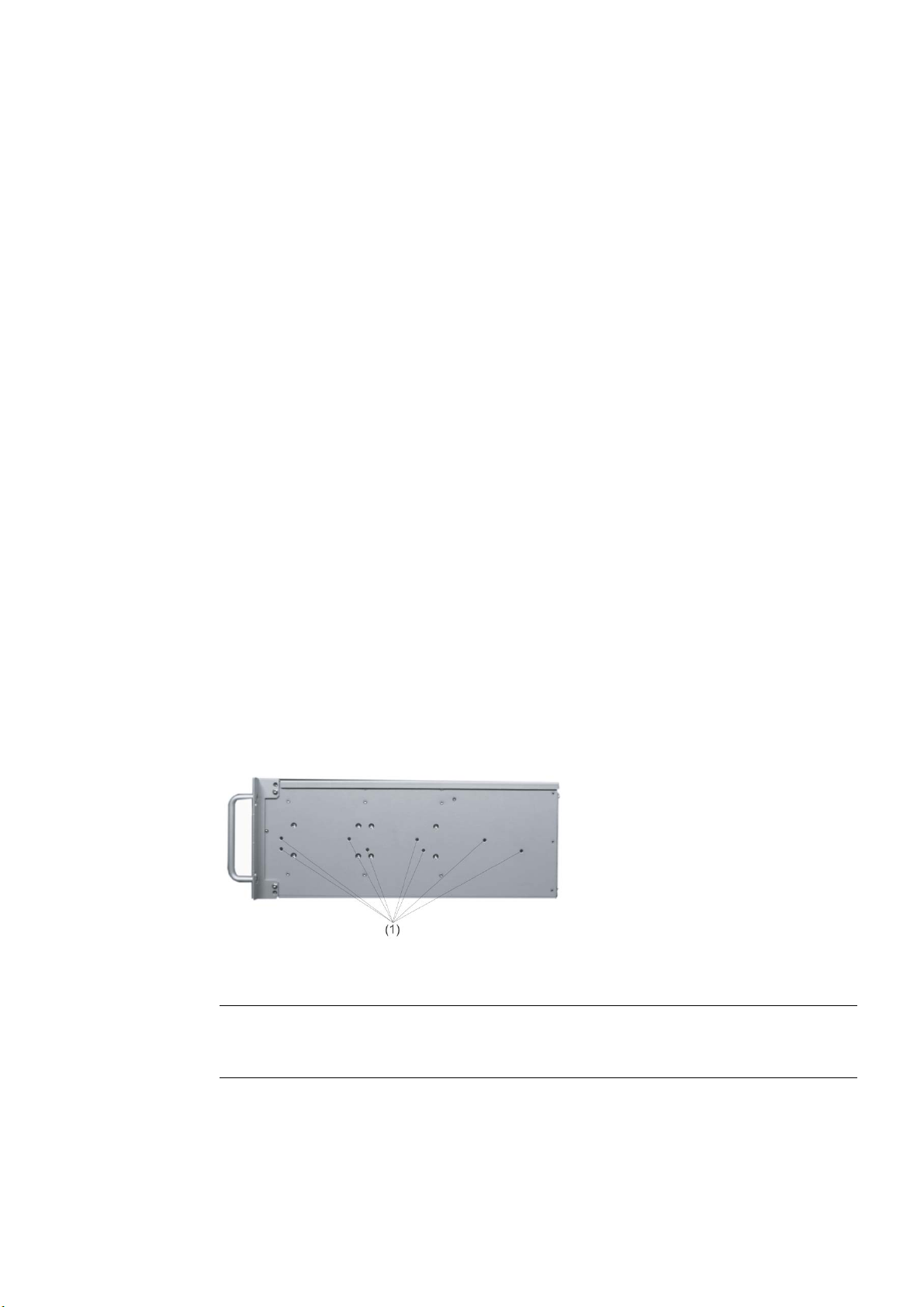

Position of the mounting holes (1) for angle brackets or telescopic rails

Caution

The mounting screws of the telescopic rails may not protrude into the enclosure by more

than 5 mm.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

5-1

Page 28

Installation

5.1 Installing the device

Note

For vertical operation, install the device on a horizontal metal base and secure it against

tipping. The following decide bases are available from Rittal for this purpose:

Rittal Type TE 7000.620, Rittal Type VR 3861.580, Rittal Type DK 7063.710.

Please refer to the case manufacturer's instructions regarding device bases.

Caution

Danger of bodily harm!

It is not permitted to install the device only on the 19" brackets of the front panel.

SIMATIC Rack PC IL 43

5-2 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 29

Connecting

6.1 6.1 Connecting peripherals

Note before connecting

Notice

Connect only I/O modules approved for industrial applications to EN 61000-6-2:2001.

Note

Hot-plug I/O modules (USB) may be connected while the PC is in operation.

Caution

I/O devices not capable of hot-plugging may only be connected after the device has been

disconnected from the power supply.

6

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

Caution

Strictly adhere to the specifications for I/O modules.

6-1

Page 30

Connecting

6.2 Connecting the device to power

6.2 6.2 Connecting the device to power

To be noted before you connect the device

Note

The long-range power supply module is designed for operation on 100-240 networks. It is

not necessary to adjust the voltage range.

Warning

Do not connect or disconnect power and data cables during thunderstorms.

Warning

The device is designed for operation on grounded power supply networks (TN systems to

VDE 0100, part 300, or IEC 60364-3).

Operation on ungrounded or impedance-grounded power networks (IT networks) is

prohibited.

Warning

The permitted rated voltage of the device must conform with local mains voltage.

Caution

The mains connector must be disconnected to fully isolate the device from mains. Ensure

easy access to this area.

A master mains disconnect switch must be installed if the device is mounted in a switch

cabinet. Always ensure free and easy access to the power inlet on the device, or that the

safety power outlet of the building installation is freely accessible and located close to the

device.

SIMATIC Rack PC IL 43

6-2 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 31

Connecting

6.2 Connecting the device to power

Localized information

Outside of the USA and Canada, operation on a 230 V power supply:

This device is equipped with a safety-tested power cord which may only be connected to

grounded shockproof power outlet. If you choose not to use this cable, you must use a

flexible cable of the following type: min. 18 AWG conductor cross-section and 15-A / 250-V

shockproof connector. The cable set must be compliant with the safety regulations and

stipulated IDs of the country where the system is to be installed.

For the USA and Canada:

For the United States and Canada, a CSA or UL-listed power cord must be used.

The connector must be compliant with NEMA 5-15.

120 V AC power supply

To be used is a flexible power cord approved to UL and with CSA label, and which has the

following features: Type SJT with three leads, min. 18 AWG conductor cross-section, max.

4.5 m long and tandem ground contact connector 15 A, min. 125 V.

240 V supply voltage

Use a flexible power cord with UL approval and with CSA label, and with the following

features: Type SJT with three leads, min. 18 AWG conductor cross-section, max. 4.5 m long

and tandem ground contact connector 15 A, min. 250 V.

Connecting

Steps for connecting the device to mains

1 Connect the IEC connector.

2 Connect the power cord to the mains outlet,

then switch on the mains isolation switch (if

this exists).

The yellow power LED (standby) on the front

panel of the PC lights up.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

6-3

Page 32

Connecting

6.2 Connecting the device to power

Secure the power plug

You can secure the power plug in order to avoid unintentional disconnection of the power

cord.

Steps in securing the power plug

1 Remove the fastening screw (1) on the

power supply module.

2 Power plug clamp (2) screw it to the power

supply module

Warning

If the power plug is secured with a clamp, the power outlet must be freely accessible to allow

the device to be easily removed from the mains.

SIMATIC Rack PC IL 43

6-4 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 33

Commissioning

7.1 7.1 Prerequisites for commissioning

• Before you switch on the device, you should verify that the peripherals are connected, i.e.

the keyboard, mouse, monitor and the power supply.

• The operating system of your device is preinstalled on the hard disk.

7.2 7.2 Basic commissioning - initial power-up

Caution

Risk of damage to the device!

Make sufficient allowances for the device to acquire room temperature before you put it

into use. If condensation develops, wait at least 12 hours before switching on the device.

The Rack PC operating system is automatically set up the first time you switch on the

device. Procedure:

7

1. Press the on/off button. The green power LED lights up. The PC performs a POST. During

this self-test, this message appears:

Press <F2> to enter SETUP

2. Wait until this message is cleared, then follow the instructions on the screen.

3. Type in the Product Key as required. You can find this key on the "Certificate of

Authentication", in the "Product Key" line.

Notice

The PC may not be switched off when you run setup.

Do not change the default BIOS settings as this will disrupt the operating system installation.

4. Automatic restart

After you have entered all necessary information and after the operating system

setup is completed, the PC is automatically restarted and displays the user interface of the

relevant operating system.

From now on, after you switch on the PC, the user interface of the operating system is

automatically opened when the startup routine is completed.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

7-1

Page 34

Commissioning

7.3 Notes on operation

Switch off the device

Note

On a Windows platform, always shut down the PC by clicking Start > Close.

Press the on/off button behind the front panel door. The green power LED is switched off.

Disconnect the mains connector to isolate the device from mains.

7.3 7.3 Notes on operation

7.3.1 DVD ROM/CD RW

The DVD-ROM/CD-RW drive is an optional feature. Recording methods supported by the

disk drive: Disc at once, Track at once, Session at once, Packet writing, whereby Disc at

once und Track at once are recommended due to their compatibility to other CD drives.

DVD-ROM, CD-ROM, CD-R and Video CDs can be read.

Burner/DVD player software

To utilize the full functionality of our DVD-ROM/CD-RW drive, you need to install additional

software (burning or DVD player software). This software is included on the CD supplied with

the device. Insert the CD in the drive, run setup and follow the instructions on the screen.

Notice

When first starting the burner software, no data carriers should be inserted in the drive. This

is because data carriers with errors can interrupt the automatic hard drive recognition. The

correct display of the possible burning function will therefore not be given.

Notes on burning optical data carriers

Caution

Danger of data errors when burning optical data carriers

Burning operation is permissible only in an undisturbed environment, i.e. shock and vibration

stress must be avoided. Because of heavy fluctuation in the quality of CD-Rs, data may be

corrupted in a burning session, even if no error message is initially displayed. The written

data can only be verified by comparing these with the source. To be on the safe side, data

should be verified after every burning session.

SIMATIC Rack PC IL 43

7-2 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 35

Commissioning

7.3 Notes on operation

7.3.2 DVD burner

The DVD burner drive is an optional feature. Recording methods supported by the disk drive:

Disc-at-once, Track-at-once, Session-at-once, Packet writing. CD-R, CD-RW, DVD+R,

DVD-R, DVD-RW and DVD+RW and dual layer media can be used.

Burner software

To utilize the full functionality of the DVD burner, you need to install additional software

(burner software). This software is included on the CD supplied with the device. Insert the

CD in the drive, run setup and follow the instructions on the screen.

Notice

When first starting the burner software, no data carriers should be inserted in the drive. This

is because data carriers with errors can interrupt the automatic hard drive recognition. This

makes it impossible to correctly display the possible burner functions.

Notes on burning optical data carriers

Caution

Danger of data errors when burning data carriers!

Burning is permissible only in an undisturbed environment, i.e. shock and vibration stress

must be avoided. Because of heavy fluctuation in the quality of CD-Rs, data may be

corrupted in a burning session, even if no error message is initially displayed. The written

data can only be verified by comparing these with the source. To be on the safe side, data

should be verified after every burning session.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

7-3

Page 36

Commissioning

7.3 Notes on operation

7.3.3 Removable hard disks

The removable disk racks can also be hot swapped in connection to RAID1.

Replacing a hard disk

Caution

Hard drives may only be swapped out of the removable frames when the disks are inactive

and the device status displays are off.

How to remove the hard disk drive:

1. Establish which hard disk drive of the RAID controller was reported as faulty (hard disk

drive to channel 1 or 2).

(1) Power LED

voltage supply available

(2) HDD activity display

This display is always off. Please

note the activity display HARDDISK

(3) on the front of the device.

The following table details the layout of the removable frames in the device according to the

RAID system reports:

You will find information regarding the reconfiguration of the RAID association in the next

section.

1. Set the key switch to the "OPEN" position.

2. Push up the bezel of the hard disk cartridge.

3. Remove the hard disk cartridge.

Notes on operation

Notice

To ensure reliable operation of the devices in a removable disk rack, you need to interlock

the hard disk cartridge with the disk rack.

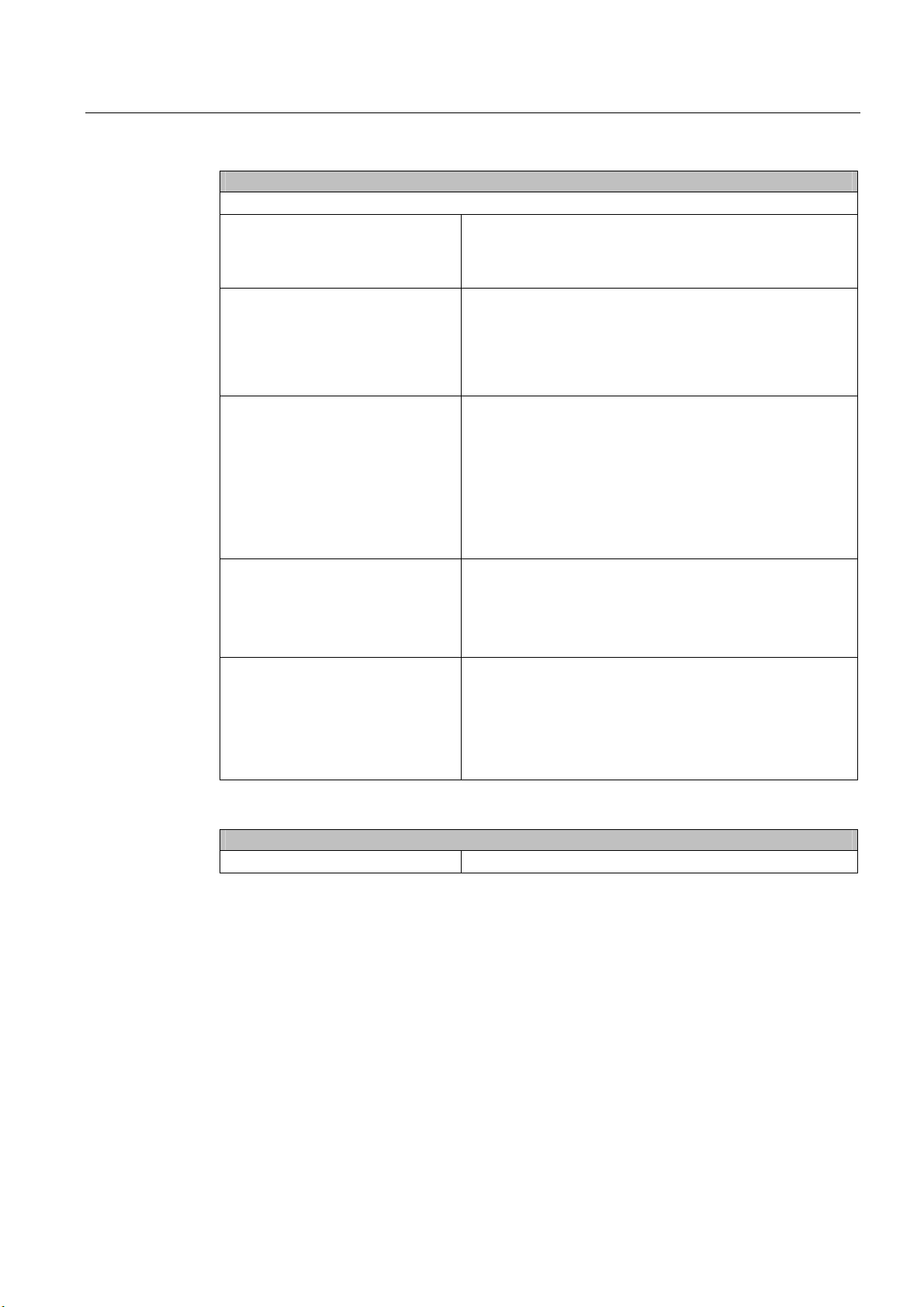

RAID BIOS RAID Software SATA interface Installation location

Port 0 Device Port 0 SATA1 (4) Removable frame 1

Port 2 Device Port 2 SATA3 (5) Removable frame 2

SIMATIC Rack PC IL 43

7-4 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 37

Commissioning

7.3 Notes on operation

7.3.4 RAID system

This is a RAID1 system configuration (mirroring with two hard disks). This enables the

system to continue to operate when there is a problem with a faulty hard drive or cable in a

channel and therefore increases the availability of the system.

Note

You can find information regarding Intel RAID controllers in the RAID documentation on the

supplied "Documentation and Drivers" CD in the Drivers\RAID\Intel directory.

Intel(R) Matrix Storage Manager option ROM v5.0.3.1001 ICH7R wRAID5

Copyright(C) 2003-05 Intel Corporation. All Rights Reserved.

RAID Volumes:

ID Strip Size BootableLevel Status

Name

0 N/A 111.8GB YesRAID1(Mirror) NormalVolume0

Physical Disks:

Port Size Serial # Type/Status(Vol ID)Drive Model

0 111.8GB4MS08NS5 Member Disk(0)ST3120026AS

2 111.8GB4MS08NVV Member Disk(0)ST3120026AS

Press

<CTRL-I>

to enter Configuration Utility...

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

7-5

Page 38

Commissioning

7.3 Notes on operation

Functions for RAID system management

The preinstalled software of the RAID system offers enhanced functions for using and

managing the RAID system. It can be started via "Start > Programs > Intel Matrix storage

manager.

The command "View -> Advanced Mode" displays the details of the RAID association.

The command "View -> System Report" produces a report with details of the RAID

association.

Notice

The details of the RAID status are produced by default as a Windows event display and

written to the program's log file.

In case of malfunction, a drive can be synchronized at the operating system level. It may

take up to several hours to synchronize a new disk in the background, depending on the size

of the hard disk and on system load.

The redundant system state RAID 1 is reached again only after synchronization is

completed.

SIMATIC Rack PC IL 43

7-6 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 39

Commissioning

7.3 Notes on operation

Comments about faults

Notice

Input delay

Depending on the load on the processor and the hard disk activity at the time, the system

may become briefly overloaded when a disk fails due to the synchronization process.

In extreme cases, input from the keyboard and touchscreen may be delayed for a brief

period.

Replace faulty drive in RAID system

In order to return to the safe RAID1 state after a malfunction, the faulty drive must be

replaced with a new drive. The RAID software reports which drive is faulty and gives details

of the functioning drive.

The functioning drive is displayed by BIOS together with its port number and by the RAID

software with its RAID device port number.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

7-7

Page 40

Commissioning

7.3 Notes on operation

The functioning drive can be localized by means of the following table.

RAID BIOS RAID Software SATA interface Installation location

Port 0 Device Port 0 SATA1 (1) Removable frame 1

Port 2 Device Port 2 SATA3 (2) Removable frame 2

Port 0 Device Port 0 SATA1 (3) Side panel 1

Port 2 Device Port 2 SATA3 (4) Side panel 2

SIMATIC Rack PC IL 43

7-8 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 41

Commissioning

7.3 Notes on operation

Please replace the faulty drive with a new one of the same type and capacity.

Notice

You can exchange the drive without switching the device off (hot swap) on devices with

removable frames.

For devices without removable frames, drives may only be exchanged in switched off state.

The new drive can be configured into the RAID association at operating system level by

means of the RAID software. This is not possible as BIOS level.

Associate new hard drive

The command "Rescan for Plug and Play Devices" searches for and displays new drives.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

7-9

Page 42

Commissioning

7.3 Notes on operation

The command "Rebuild to this Hard drive" starts the synchronization of the RAID1

association.

SIMATIC Rack PC IL 43

7-10 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 43

Integration

The following options are available for the integration of the device in existing or planned

system environments/networks:

Ethernet

The integrated Ethernet port (10/100/1000 Mbps) can be used for communication and for

data exchange with automation devices such as SIMATIC S7.

For this purpose you require the software package “SOFTNET S7”.

Further information

For further information, refer to the catalog and to the online ordering system of Siemens

A&D.

Internet address: https://mall.ad.siemens.com

8

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

8-1

Page 44

Integration

SIMATIC Rack PC IL 43

8-2 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 45

Functions

9.1 9.1 Overview of the following monitoring functions

The individual functions are implemented:

• Temperature monitoring and over/under temperature indication

• Watchdog

• Fan monitoring

9.2 9.2 Temperature monitoring/display

Notice

The "SystemGuard" and "DeskView" software cannot be installed simultaneously.

Simultaneous installation and operation can result in errors because both programs

access the same interfaces.

A description of the drivers and SystemGuard is available on the enclosed "Documentation

and Drivers" CD in the utilities directory.

9

Temperature monitoring

Temperature errors do not occur under normal operation. If a temperature does occur, check

for the following possible causes:

• Are the fan apertures covered?

• Is the filter dirty?

• Is the fan functioning correctly?

• Is the ambient temperature within the specified range?

• Is the total output of the power supply within the specified limit?

The temperature error is retained until the temperatures have fallen below the thresholds

and are reset by one of the following measures:

• The error alarm is acknowledged by pressing the Info button on the SystemGuard user

interface.

• Restart of the device.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

9-1

Page 46

Functions

9.3 Watchdog (WD)

9.3 9.3 Watchdog (WD)

function

The watchdog monitors the program execution and reports a program crash to the user by

means of various reactions.

You can find additional information on the supplied "Documentation and Drivers" CD in the

utilities\sysguard directory.

9.4 9.4 Fan monitoring

The operation of the front fan, processor fan and power unit are monitored. If a fan fails, the

status LED on the front panel is activated.

You can find additional information on the supplied "Documentation and Drivers" CD in the

utilities\sysguard directory.

SIMATIC Rack PC IL 43

9-2 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 47

Expansions and configuration

10.1 10.1 Open the device

Tools

Caution

Work on the open device may only be carried out by authorized and qualified personnel. The

device must always be kept closed, otherwise device safety cannot be ensured.

Caution

The device contains electronic components which may be destroyed by electrostatic charge.

You therefore need to take precautionary measures before you open the device. Refer to the

(ESD) directives for handling components which are sensitive to electrostatic charge.

All mechanical installation tasks on the device can be carried out with Torx T10 and TORX

T15 screwdrivers (only for hard drive securing screws.)

10

Preparation

Isolate the device from mains.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

10-1

Page 48

Expansions and configuration

10.1 Open the device

Open the device

Steps for opening the enclosure cover

1 Remove the mounting screws (1).

2 Lift up the lid from the back and

remove it.

SIMATIC Rack PC IL 43

10-2 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 49

Expansions and configuration

10.1 Open the device

Steps for opening the device front

1 Tilt the front door (1) forward.

2 Remove the fan cover (2).

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

10-3

Page 50

Expansions and configuration

10.2 Memory expansion

10.2 10.2 Memory expansion

Memory expansion options

The motherboard is equipped with four slots for memory modules. This allows you to expand

the memory capacity of your Rack PC to a maximum of 4 GB.

You will find a detailed description of possible memory expansion options in the motherboard

technical manual D2156-S on the supplied "Documentation and Drivers" CD.

10.3 10.3 Installing expansion cards

10.3.1 Notes on the modules

Notes on module specifications

The device is designed for use with modules conforming to ATX-/PCI-/PCIe specifications.

The dimensions of the cards may not exceed the specified dimensions. If the height is

exceeded, you may experience contact problems, malfunctions and difficulties with the

assembly. The permitted dimensions of the modules are found in the dimensional drawings

section.

Notice

The performance is limited for PCI modules with 5V supply voltage. The output of the

modules may not exceed 25W in total.

Note about long PCI, PCIe modules

Before long modules can be inserted into the guide rails, they must be fitted with an extender

(this should form part of the scope of supply of long modules).

Notes on the allocation of resources

Due to the number of functions on the motherboard, there are no reserved interrupts for PCI

modules. If the new expansion module requires exclusive resources, you have to disable the

functions on the motherboard. You will find notes on the allocated resources in the

motherboard technical manual D2156-S on the supplied "Documentation and Drivers" CD.

SIMATIC Rack PC IL 43

10-4 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 51

Expansions and configuration

10.3 Installing expansion cards

10.3.2 Installing an expansion module

Preparation

Isolate the device from mains

Installing expansion modules

Steps for installing an expansion module:

1 Open the device.

2 Remove the fastening screws (1) and

lift out the module bracket (2)

3 Remove the relevant steel slot cover

(3).

4 Insert the expansion module (4) into

the relevant slot.

5 Screw down the steel slot cover (3)

for the expansion module.

6 Insert the module bracket again.

7 Loosen free module bracket (5),

mount and screw down on the

expansion module

8 Close the device.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

10-5

Page 52

Expansions and configuration

10.4 Installing disk drives

10.4 10.4 Installing disk drives

10.4.1 Options of installing disk drives

The driver carrier module consists of a horizontal and vertical driver carrier. A DVD-ROM,

DVD-ROM/CD-RW, DVD burner, floppy drive or removable rack can be installed in the driver

carrier module.

Driver carrier module Pos Description

(1) Horizontal drive carrier

(2) Vertical driver carrier

(3) Floppy Disk 3.5" (FD)

(4) 5.25`` mounting bays for DVD/CD or

hard drives in removable frames

10.4.2 Installing and removing a disk drive or removable rack

Preparation

1. Unplug the device from mains and disconnect all cables.

2. Open the device.

SIMATIC Rack PC IL 43

10-6 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 53

Expansions and configuration

10.4 Installing disk drives

Removing the drive carrier module

The driver carrier module consists of a horizontal and vertical driver carrier.

Steps for removing the drive carrier module

1 Loosen the mounting screws of the drive

carrier module.

2 Disconnect the power cable and the

data cable from the installed disk drives.

3 Lift the drive carrier module (1) out of the

device until you can access the cables

of the floppy disk drive. Disconnect

these cables.

4 Remove the drive carrier completely

from the device.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

10-7

Page 54

Expansions and configuration

10.4 Installing disk drives

Disk drive or removable disk rack installation

Steps for installing a disk drive in a horizontal drive carrier

1 Slide the disk drive into the carrier from

the front.

2 Remove any vertical drive carrier The

only way to get at the mounting screws

on the right side of the drive is through

the openings of the vertical carrier.

3 Mount the disk drive into the drive

carrier using four screws.

4 Insert the drive carrier module again.

5 Connect the power and data cables to

the disk drive.

10.4.3 Installing and removing a hard disk

Preparation

1. Unplug the device from mains and disconnect all cables.

2. Open the device.

Installing a disk drive

Steps for installing a disk drive

1 Connect the power and data cables

2 Hold the drive on the drive carrier

to the disk drive.

plate and secure it with 4 screws

(1).

SIMATIC Rack PC IL 43

10-8 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 55

Maintenance and service

11.1 11.1 Removing and installing hardware components

11.1.1 Repairs

Carrying out repairs

Only authorized personnel are permitted to repair the device.

Warning

Unauthorized opening and improper repairs on the device may result in substantial damage

to equipment or endanger the user.

• Before you open the device, first switch it off and then disconnect the power plug.

• Install only system expansion devices designed for this computer. If you install other

expansion devices, you may damage the system or violate the safety requirements and

regulations on RF suppression. Contact your technical support team or where you

purchased your PC to find out which system expansion devices may safely be installed.

11

If you install or exchange system expansions and damage your device, the warranty

becomes void.

Limitation of Liability

Tools

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

Notice

Note the EGB instructions.

All technical specifications and licenses apply only to expansions approved by SIEMENS.

No liability can be accepted for impairment of functions caused by the use of devices and

components of other manufacturers.

All mechanical installation tasks on the device can be carried out with TORX T8, Torx T10

and TORX T15 screwdrivers as well as a side-cutter.

11-1

Page 56

Maintenance and service

11.1 Removing and installing hardware components

11.1.2 Replacing the backup battery

To be noted before you replace the battery

Disposal

Preparation

Caution

Risk of damage!

The lithium battery may only be replaced with an identical battery or with a type

recommended by the manufacturer.

Caution

Depleted batteries must be disposed of in accordance with with local regulations.

Note

The configuration data of the device are deleted when the battery is replaced. Note the

current BIOS Setup settings. You can conveniently back up the BIOS settings by means of

the SIMATIC PC BIOS manager.

Replacing the battery

The location of the backup battery on the motherboard and the procedure for replacing it is

described in technical manual, D2156-S.pdf, on the supplied "Documentation and Drivers"

CD.

Reconfiguring the BIOS Setup

When a battery is exchanged, the configuration data of the device is lost and must be

reentered in the BIOS setup.

SIMATIC Rack PC IL 43

11-2 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 57

Maintenance and service

11.1 Removing and installing hardware components

11.1.3 Removing the power supply module

Warning

Only qualified personnel is authorized to exchange the power supply module.

Preparation

1. Unplug the device from mains and disconnect all cables.

2. Open the device.

Removing the power supply module

How to remove the power supply module

1. Disconnect the power cables from

the disk drives and motherboard.

2. Remove the tie-wraps holding the

power cables in the housing.

3. Remove the mounting screws

(TORX T10) (1).

4. Lift the power supply module out of

the enclosure until you can access

the power cable of the floppy disk

drive.

5. Disconnect this power cable from

the floppy disk drive.

6. Remove the screws (2) on the

steel bracket.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

11-3

Page 58

Maintenance and service

11.1 Removing and installing hardware components

11.1.4 Removing the motherboard

Preparation

1. Unplug the device from mains and disconnect all cables.

2. Open the device.

Removing the motherboard

How to remove the motherboard

1. Remove all modules from their slots.

2. Strip all cables off the motherboard, noting down their assignment while doing so.

3. Remove ten screws from the motherboard.

A replacement motherboard is supplied without processor and memory modules.

SIMATIC Rack PC IL 43

11-4 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 59

Maintenance and service

11.1 Removing and installing hardware components

11.1.5 Remove filter and device fan

Preparing for equipment fan exchange

Unplug the device from mains.

Remove filter and fan

Filter meshes are available under the following order numbers: A5E00246975

Steps

1. Tilt the front door (1) downwards.

2. Remove filter cover (2) and remove

filter. Please carry out the

additional steps to remove the fan.

3. Open the device cover.

4. Unplug the fan connector from the motherboard.

5. Remove all fan screws.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

11-5

Page 60

Maintenance and service

11.1 Removing and installing hardware components

Installing the fan

Notice

Always install a fan of the same type!

Caution

Ensure that the arrow on the fan points away from the fan bracket.

11.1.6 Processor replacement

Preparation

Caution

The processor replacement may only be carried out by authorized qualified personnel.

1. Unplug the device from mains.

2. Open the device.

Removing the processor

How to remove the processor

1. Unhook the fan holder on the heat sink

and pull off towards the front.

2. Disconnecting the processor fan

connector

3. Loosen the four screws and remove the

heat sink.

SIMATIC Rack PC IL 43

11-6 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 61

Maintenance and service

11.1 Removing and installing hardware components

How to remove the processor

4. Unlock the CPU socket and lift off socket

cover.

5. Remove processor.

Additional instructions can be found in the supplied Documentation & Drivers CD in the

D2156-S manual.

Caution

Operating a processor at a frequency higher than it specified speed can result in damage to

the device and the loss of data.

Only certified and approved processors can be used with the supplied motherboard. For

more information contact your local Siemens representative.

http://www.siemens.com/automation/partner

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01

11-7

Page 62

Maintenance and service

11.2 Reinstalling the software

11.2 11.2 Reinstalling the software

11.2.1 General installation procedure

In case of software errors, you can reinstall your software using the Recovery CD, the

Documentation and Drivers CD or the Restore DVD.

Recovery CD:

The new recovery procedure is based on Windows PE (Preinstall Environment). The CD

contains the Windows PE user interface with tools for configuring the hard drives and the

operating system.

Documentation and Drivers CD:

Contains the documentation and the hardware drivers.

Restore DVD:

Contains a hard disk image file with the original software (operating system with installed

hardware drivers).

11.2.2 Restoring the Factory State of the Software Using the Restore DVD

You can restore the software to the original factory state using the Restore CD (not included

in all package variants). The DVD contains the necessary images and tools for transferring

the factory software to the hard disk of your PC. You can restore the entire hard disk with

drive C: (system) and drive D: or only drive C:. at the command line input. This allows you to

retain any user data on drive D:.

Retrieving an authorization or license key from the hard disk

• Check if you can retrieve your authorization or license key from the hard disk and perform

the procedure described below if this is possible.

• If it is not possible to backup your authorization, please contact the Customer Support

Hotline. There you can obtain information necessary for your software authorization.

SIMATIC Rack PC IL 43

11-8 Operating Instructions, Edition 09/2005, A5E00432875-01

Page 63

Maintenance and service

11.2 Reinstalling the software

Caution

With the option "Restore system partition only", all data on drive C: (System) will be

deleted. All data, user settings and all authorizations or license keys on drive C: will be

lost in the process! All data on drive C: of your hard disk will be deleted. Setup formats

the hard disk partition and reinstalls the original factory software.

When you select the "Restore entire hard disk" option, ALL the data, user settings and

authorizations or license keys will be lost on the hard disk.

Restoring the factory state

To restore the factory state, proceed as follows:

• Place the Restore DVD into the drive and restart the device using the on/off switch.

• During the self-test phase, press the F12 key. After initialization, a "Boot Menu" is

displayed.

• Select the optical drive with the cursor keys.

• Now follow the instructions on the screen.

Caution

All existing data, programs, user settings and authorizations or license keys will bedeleted

from the hard disk and are therefore lost.

For information on the functions, refer to the README.TXT file on the Restore DVD.

11.2.3 Installing Windows

Use the Recovery CD to install Windows to meet your special requirements. The operating

system used is Windows Preinstall Environment (WinPE). You will also need the supplied

Documentation and Drivers CD.

Booting with the CD Recovery

1. To boot from the Recovery CD, press the F12 key during the BIOS self-test. After

initialization, a boot menu is displayed, indicating all bootable devices.

2. Select the CD/DVD drive.

Follow the instructions on the screen until the "Siemens SIMATIC Recovery“ window is

displayed.

SIMATIC Rack PC IL 43

Operating Instructions, Edition 09/2005, A5E00432875-01