Siemens IM 155-6 PN ST User Manual

Manual

IM 155-6 PN ST interface module

(6ES7155-6AU01-0BN0)

Edition

SIMATIC

ET 200SP

04/2017

support.industry.siemens.com

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

ET 200SP

IM 155-6 PN ST interface module

(6ES7155-6AU01-0BN0)

Manual

04/2017

A5E03576904

-AE

Preface

Guide

1

Product overview

2

Wiring

3

Parameters/address space

4

Interrupts, diagnostics, error,

and system messages

5

Compatibility

6

Technical specifications

7

Dimension drawing

A

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E03576904-AE

Ⓟ

04/2017 Subject to change

Copyright © Siemens AG 2012 - 2017.

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

4 Manual, 04/2017, A5E03576904-AE

Preface

Purpose of the documentation

This manual supplements the ET 200SP distributed I/O system

(http://support.automation.siemens.com/WW/view/en/58649293) system manual.

Functions that generally relate to the system are described in this manual.

The information provided in this manual and in the system/function manuals supports you in

commissioning the ET 200SP distributed I/O system.

Conventions

Please also observe notes marked as follows:

Note

A note contains important information on the product described in the documentation, on the

handling of the product or on the section of the documentation to which particular attention

should be paid.

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

(http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity).

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

Manual, 04/2017, A5E03576904-AE

5

Table of contents

Preface ................................................................................................................................................... 4

1 Guide ...................................................................................................................................................... 6

2 Product overview .................................................................................................................................. 10

2.1 Properties ................................................................................................................................ 10

2.2 Functions ................................................................................................................................ 13

2.2.1 PROFIenergy .......................................................................................................................... 19

2.2.2 Use of fail-safe modules ......................................................................................................... 20

2.2.3 Use of technology modules .................................................................................................... 20

2.2.4 Configuration control (option handling) ................................................................................... 20

3 Wiring ................................................................................................................................................... 21

3.1 Pin assignment ....................................................................................................................... 21

3.2 Schematic circuit diagram ....................................................................................................... 24

4 Parameters/address space ................................................................................................................... 25

4.1 Parameters ............................................................................................................................. 25

4.2 Explanation of parameters ...................................................................................................... 25

4.2.1 Configuration control ............................................................................................................... 25

4.3 Substitute value behavior ....................................................................................................... 26

4.4 Status of the supply voltage L+ of the I/O modules ................................................................ 27

5 Interrupts, diagnostics, error, and system messages ............................................................................. 28

5.1 Status and error displays ........................................................................................................ 28

5.2 Interrupts ................................................................................................................................. 33

5.2.1 Triggering of a diagnostics interrupt ....................................................................................... 33

5.2.2 Triggering a hardware interrupt .............................................................................................. 34

5.2.3 Triggering a swapping interrupt .............................................................................................. 34

5.3 Alarms ..................................................................................................................................... 35

5.3.1 Diagnostics alarms .................................................................................................................. 35

5.3.2 Maintenance events ................................................................................................................ 36

5.3.3 Channel diagnostics................................................................................................................ 37

5.3.4 Invalid configuration states of the ET 200SP on PROFINET IO ............................................ 41

5.3.5 Failure of supply voltage L+ at BaseUnit BU...D .................................................................... 41

5.3.6 STOP of the IO controller and recovery of the IO device ....................................................... 42

6 Compatibility ......................................................................................................................................... 43

7 Technical specifications ........................................................................................................................ 45

A Dimension drawing ............................................................................................................................... 50

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

6 Manual, 04/2017, A5E03576904-AE

1

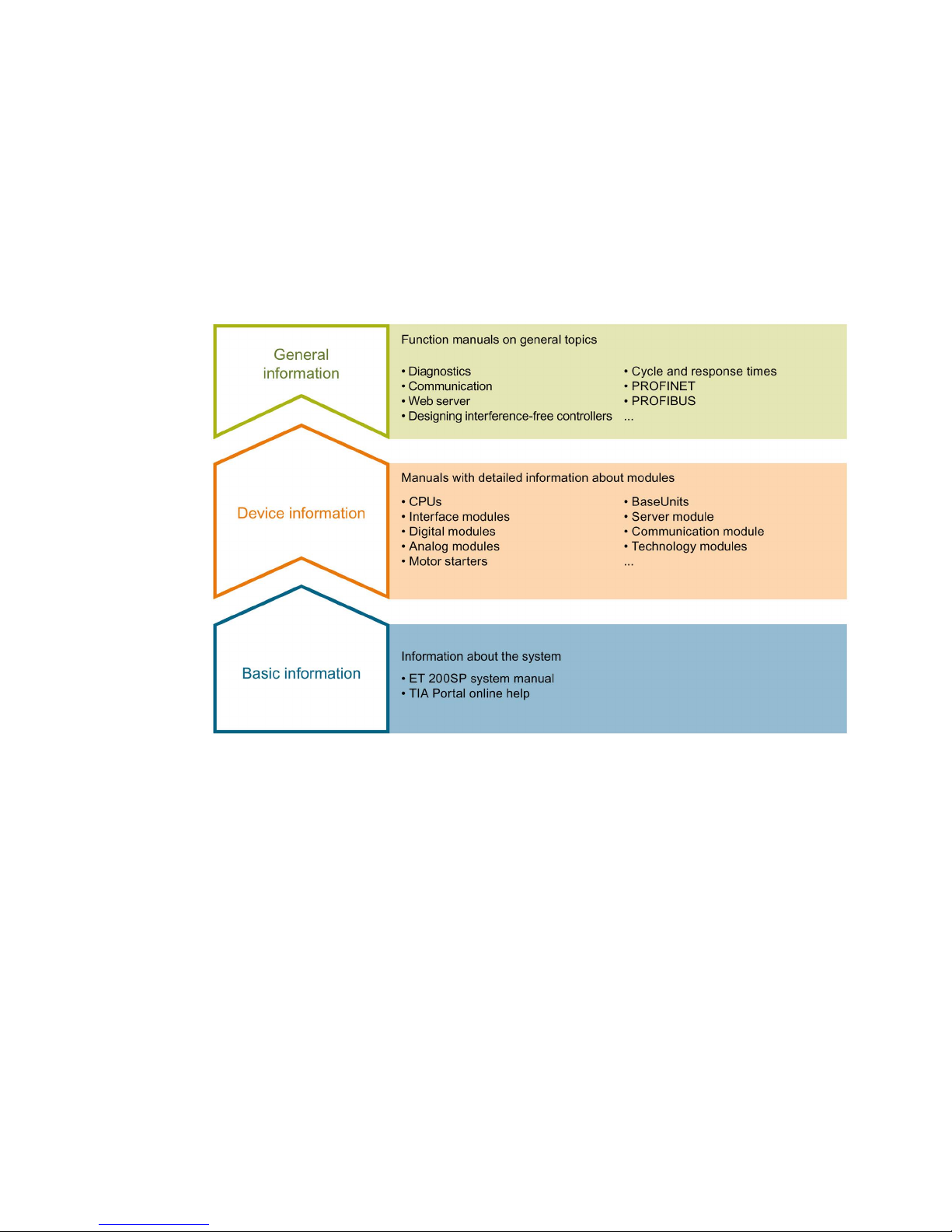

The documentation for the SIMATIC ET 200SP distributed I/O system is arranged into three

areas.

This arrangement enables you to access the specific content you require.

Basic information

The system manual describes in detail the configuration, installation, wiring and

commissioning of the SIMATIC ET 200SP. distributed I/O system. The STEP 7 online help

supports you in the configuration and programming.

Device information

Product manuals contain a compact description of the module-specific information, such as

properties, wiring diagrams, characteristics and technical specifications.

Guide

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

Manual, 04/2017, A5E03576904-AE

7

General information

The function manuals contain detailed descriptions on general topics regarding the SIMATIC

ET 200SP distributed I/O system, e.g. diagnostics, communication, Web server, motion

control and OPC UA.

You can download the documentation free of charge from the Internet

(http://w3.siemens.com/mcms/industrial-automation-systems-simatic/en/manual-

overview/tech-doc-et200/Pages/Default.aspx).

Changes and supplements to the manuals are documented in a Product Information.

You can download the product information free of charge from the Internet

(https://support.industry.siemens.com/cs/us/en/view/73021864).

Manual Collection ET 200SP

The Manual Collection contains the complete documentation on the SIMATIC ET 200SP

distributed I/O system gathered together in one file.

You can find the Manual Collection on the Internet

(http://support.automation.siemens.com/WW/view/en/84133942).

"mySupport"

With "mySupport", your personal workspace, you make the most of your Industry Online

Support.

In "mySupport" you can store filters, favorites and tags, request CAx data and put together

your personal library in the Documentation area. Furthermore, your data is automatically

filled into support requests and you always have an overview of your current requests.

You need to register once to use the full functionality of "mySupport".

You can find "mySupport" in the Internet (https://support.industry.siemens.com/My/ww/en).

"mySupport" - Documentation

In the Documentation area of "mySupport", you have the possibility to combine complete

manuals or parts of them to make your own manual.

You can export the manual in PDF format or in an editable format.

You can find "mySupport" - Documentation in the Internet

(http://support.industry.siemens.com/My/ww/en/documentation).

Guide

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

8 Manual, 04/2017, A5E03576904-AE

"mySupport" - CAx Data

In the CAx Data area of "mySupport", you can have access the latest product data for your

CAx or CAe system.

You configure your own download package with a few clicks.

In doing so you can select:

● Product images, 2D dimension drawings, 3D models, internal circuit diagrams, EPLAN

macro files

● Manuals, characteristics, operating manuals, certificates

● Product master data

You can find "mySupport" - CAx Data in the Internet

(http://support.industry.siemens.com/my/ww/en/CAxOnline).

Application examples

The application examples support you with various tools and examples for solving your

automation tasks. Solutions are shown in interplay with multiple components in the system separated from the focus in individual products.

You can find the application examples on the Internet

(https://support.industry.siemens.com/sc/ww/en/sc/2054).

TIA Selection Tool

With the TIA Selection Tool, you can select, configure and order devices for Totally

Integrated Automation (TIA).

This tool is the successor of the SIMATIC Selection Tool and combines the known

configurators for automation technology into one tool.

With the TIA Selection Tool, you can generate a complete order list from your product

selection or product configuration.

You can find the TIA Selection Tool on the Internet

(http://w3.siemens.com/mcms/topics/en/simatic/tia-selection-tool).

Guide

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

Manual, 04/2017, A5E03576904-AE

9

SIMATIC Automation Tool

You can use the SIMATIC Automation Tool to run commissioning and maintenance activities

simultaneously on various SIMATIC S7 stations as a bulk operation independently of the TIA

Portal.

The SIMATIC Automation Tool provides a multitude of functions:

● Scanning of a PROFINET/Ethernet network and identification of all connected CPUs

● Address assignment (IP, subnet, gateway) and station name (PROFINET device) to a

CPU

● Transfer of the data and the programming device/PC time converted to UTC time to the

module

● Program download to CPU

● Operating mode switchover RUN/STOP

● Localization of the CPU by means of LED flashing

● Reading out CPU error information

● Reading the CPU diagnostic buffer

● Reset to factory settings

● Updating the firmware of the CPU and connected modules

You can find the SIMATIC Automation Tool on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/98161300).

PRONETA

With SIEMENS PRONETA (PROFINET network analysis), you analyze the plant network

during commissioning. PRONETA features two core functions:

● The topology overview independently scans PROFINET and all connected components.

● The IO check is a fast test of the wiring and the module configuration of a system.

You can find SIEMENS PRONETA on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/67460624).

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

10 Manual, 04/2017, A5E03576904-AE

Product overview

2

2.1 Properties

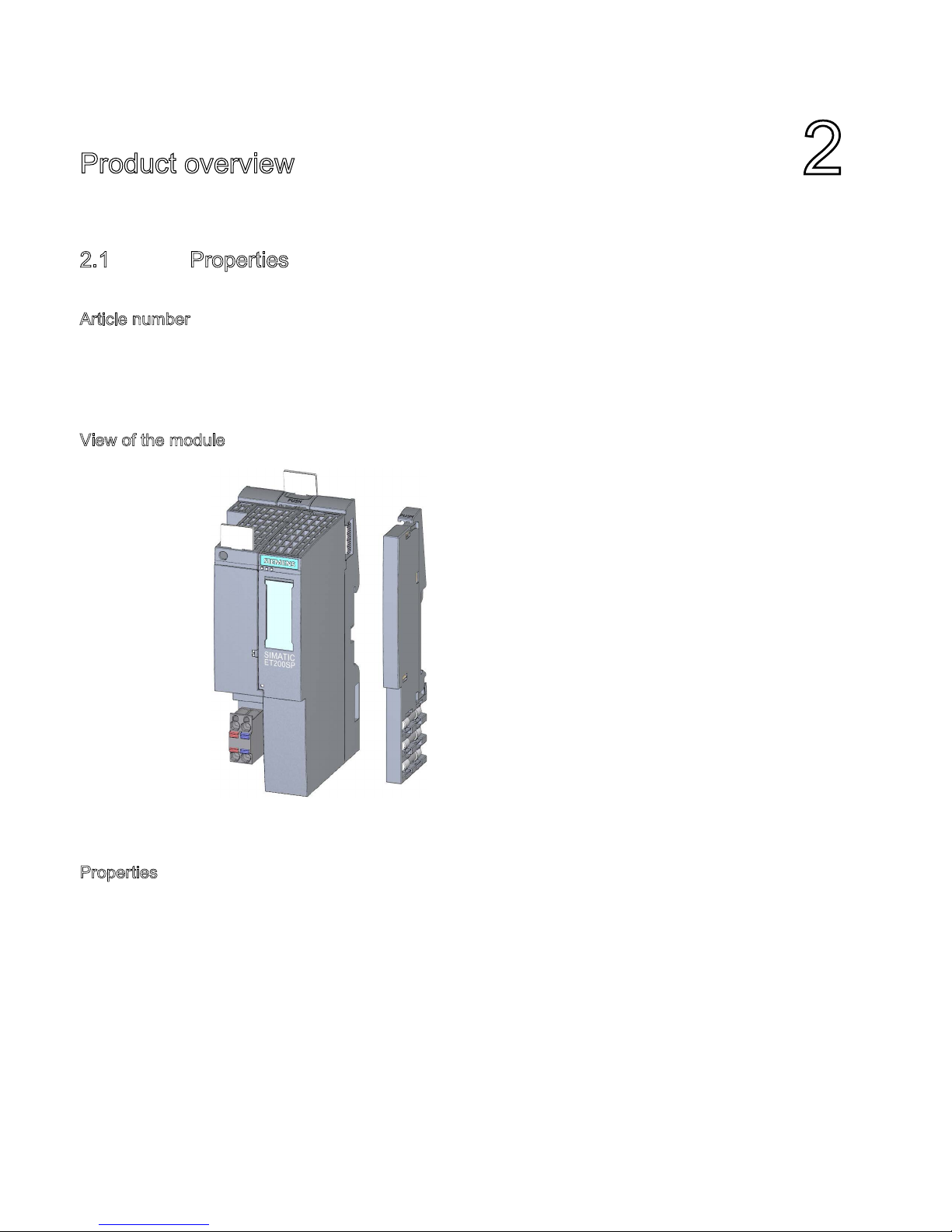

Article number

6ES7155-6AU01-0BN0 (IM 155-6 PN ST interface module and server module)

6ES7155-6AA01-0BN0 (IM 155-6 PN ST interface module with BusAdapter BA 2×RJ45 and

server module)

View of the module

Figure 2-1 View of the IM 155-6 PN ST interface module and the server module

Properties

The module has the following technical properties:

● Connects the ET 200SP distributed I/O system with PROFINET IO

● Supply voltage 1L+ 24 V DC (SELV/PELV). The connection plug is included in the scope

of delivery of the interface module.

● PROFINET IO connection via selectable BusAdapter for RJ45 bus connector

(BA 2×RJ45) or for direct connection of the bus cable (BA 2×FC)

● Use of fail-safe modules

● As of firmware version V 3.0, you can plug a light-colored or a dark-colored BaseUnit into

slot 1.

The module supports the following functions (Page 13)

Product overview

2.1 Properties

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

Manual, 04/2017, A5E03576904-AE

11

Maximum configuration

● 32 I/O modules

● 512 bytes I/O data

● 1 m backplane bus (without interface module)

Accessories

The following accessories can be ordered separately:

● BA 2xRJ45 BusAdapter

● BA 2xFC BusAdapter

● 24 V DC connector

● Labeling strips

● Reference identification label

Note

The interface module is also available as a bundle with the BusAdapter BA 2xRJ45 (and the

server module). The article number is 6ES7155

-6AA01-0BN0.

A detailed list of the available accessories can be found in the system manual ET 200SP

distributed I/O system (http://support.automation.siemens.com/WW/view/en/58649293).

Server module

The server module is included in the scope of delivery of the interface module and available

separately as an accessory.

The server module has the following properties:

● Terminates the backplane bus of the ET 200SP distributed I/O system

● Features a holder for 3 spare fuses (5 × 20 mm)

● Identification data I&M 0 to 3

Note

You need to configure and assign parameters to the server module in the configuration

software.

To do this, place the server module in the last configuration slot and enable the parameter

Group diagnostics: Missing supply voltage L+. When there are 32 I/O

modules, the server

module is inserted in slot 33.

You can find more information in the Server module

(http://support.automation.siemens.com/WW/view/en/63257531) manual.

Product overview

2.1 Properties

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

12 Manual, 04/2017, A5E03576904-AE

First BaseUnit of an ET 200SP in the configuration (as of V3.0)

Note

First BaseUnit of an ET 200SP in the configuration

The first BaseUnit of an ET 200SP station may be a dark

-colored one if an AC I/O module or

AI

Energy Meter ST is plugged. Please note the information on limiting the overvoltage and

power rating in the AC I/O module manuals.

A light

-colored BaseUnit must be plugged into the slot of the first 24 V DC I/O module in

order to route the 24

V DC supply voltage via a fuse.

Pay attention to the type of the BaseUnits during the configuration.

As of firmware V3.x, the interface modules support plugging dark-colored BaseUnits in slot

1. This means that modules without a connection to the integrated voltage buses P1 and P2

can now also be configured starting with slot 1. Currently, this applies to the following

modules:

● AI EnergyMeter

● DI 4x120..230VAC ST (6ES7131-6FD00-0BB1)

● DQ 4x24..230VAC/2A ST (6ES7132-6FD00-0BB1)

Requirement for configuration of these modules in slot 1:

● Configuration via GSD or GSDML

● Configuration as of STEP 7 V5.5 SP4 with

– HSP0241 V2.0 for IM155-6 PN ST

– HSP0242 V2.0 for IM155-6 DP HF

– HSP0255 V3.0 for IM155-6 PN HF

● Configuration as of STEP 7 V13 SP1

Product overview

2.2 Functions

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

Manual, 04/2017, A5E03576904-AE

13

2.2

Functions

Introduction

The interface module supports the following PROFINET IO functions:

● Integrated switch with 2 ports

● Supported Ethernet services: ping, arp, network diagnostics (SNMP)/MIB-2, LLDP-MIB

and MRP-MIB

● Port diagnostics

● Disabling ports

● Isochronous real-time communication

● Minimum update time 1 ms

● Prioritized startup

● Media redundancy (MRP)

● Shared device

● Support of submodules on suitable I/O modules

● Module-internal Shared Input/Shared Output (MSI/MSO)

● Device replacement without PG and without topological configuration

● Reset to factory settings via PROFINET IO

● Firmware update via PROFINET IO

● Station extension via ET-Connection

● The BusAdapter provides the connection system for PROFINET IO. The following

versions are available for the IM 155-6 PN ST interface module:

– For standard RJ45 connector: BA 2×RJ45

– For direct connection of the bus cable: BA 2×FC

The interface module supports additional functions:

● Identification data I&M 0 to 3

● PROFIenergy

● Use of fail-safe modules

● Configuration control (option handling)

● Value status (quality information, QI) of I/O modules

Product overview

2.2 Functions

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

14 Manual, 04/2017, A5E03576904-AE

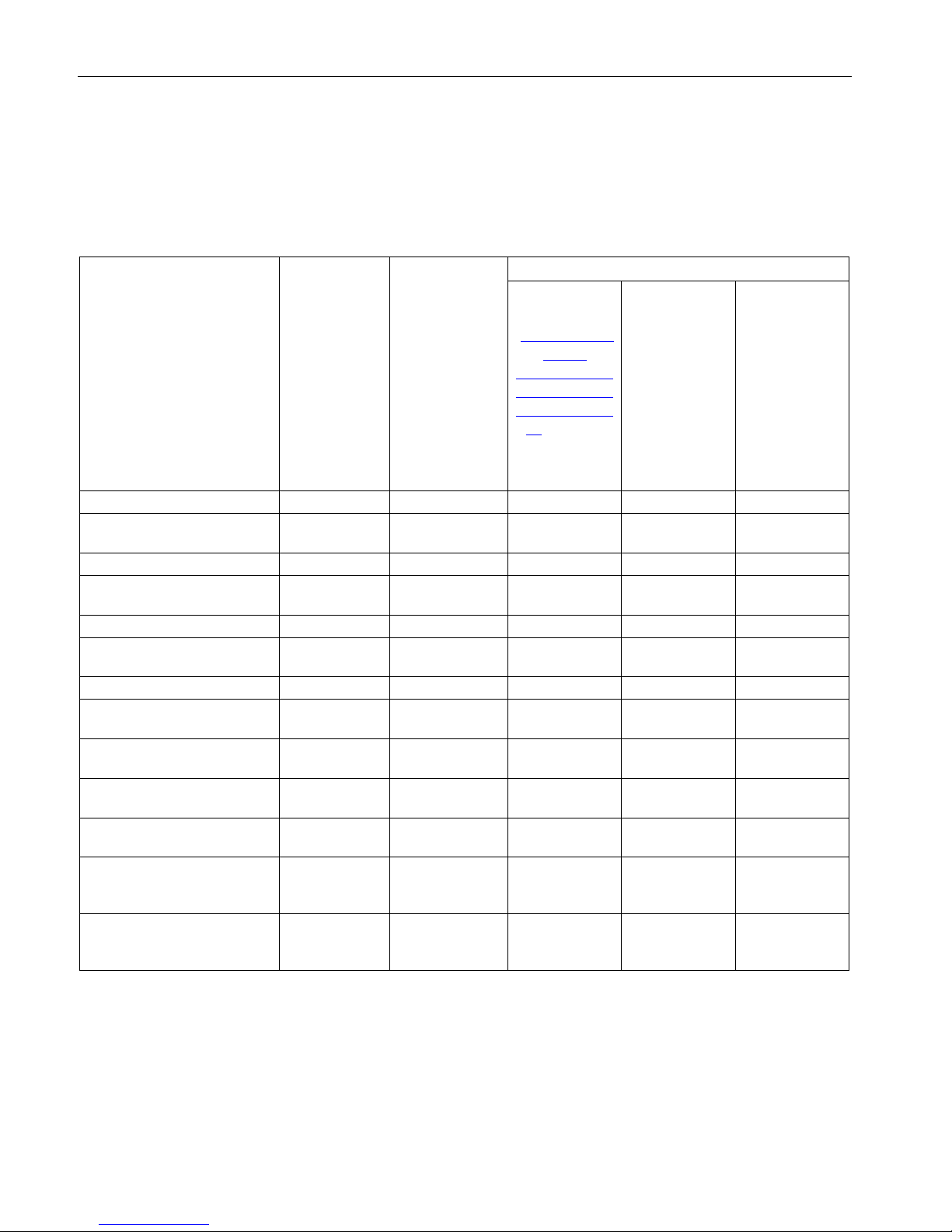

Requirements

The table below shows the software requirements for a configuration with the

IM 155-6 PN ST interface module:

Table 2- 1 Version dependencies of other module functions

Function

Product version

of the module

as of

Firmware version

of the module as

of

Configuration software

Configuration

with GSD file

(http://support.a

utomation.siemens.co

m/WW/view/en/

19698639/1300

00)/software

from a third-

party manufac-

turer 1

STEP 7 as of

V5.5 SP3 with

HSP241

STEP 7

(TIA Portal), as

of V11 SP2

Real-time communication

1

V1.0.0 X X

X

Isochronous real-time com-

munication

1 V1.0.0 X X X

Prioritized startup

1

V1.0.0 X X

X

Device replacement without

programming device

1 V1.0.0 X X X

Media redundancy (MRP)

1

V1.0.0 X X

X

Shared device 1 V1.0.0 X X X (as of V13

SP1)

PROFIenergy

1

V1.0.0

--- X X

Use of fail-safe modules 1 V1.0.1 X X X (as of V13

SP1)

Module-internal Shared In-

put/Shared Output (MSI/MSO)

1 V3.1.0 X X X (as of V13

SP1)

Station extension via ET-

Connection

5 V3.1.0 X X X (as of V13

SP1)

User data 512 bytes 1 V3.1.0 X X X (as of V13

SP1)

Distribution of module channels to multiple submodules

1 V3.3.0 X X (as of V5.5

SP4, HSP0241

V3)

X (as of V13

SP1, Update 6)

Interface module;

article number: 6ES7155-

6AU01-0BN0

1 V4.1 X X (as of V5.5

SP4, HSP241

V4)

X (as of V14

HSP205)

1

Systems of third-party manufacturers: Depending on the range of functions of the third-party system

Product overview

2.2 Functions

IM 155-6 PN ST interface module (6ES7155-6AU01-0BN0)

Manual, 04/2017, A5E03576904-AE

15

Cabling with fixed connection setting

If you set a fixed connection setting of the port in STEP 7, you should also disable

"Autonegotiation/Autocrossover".

You can find more information on this topic in the STEP 7 online help and:

● As of STEP 7 V12, in the PROFINET with STEP 7 V13

(http://support.automation.siemens.com/WW/view/en/49948856) function manual

● As of STEP 7 V5.5, in the system manual PROFINET System Description

(http://support.automation.siemens.com/WW/view/en/19292127)

Isochronous real-time communication

Synchronized transmission method for cyclic exchange of IRT data between PROFINET

devices. A reserved bandwidth within the send clock is available for IRT data. The reserved

bandwidth ensures that the IRT data can also be transferred without being affected by

another high network load (e.g. TCP/IP communication or additional real time

communication) at reserved, chronologically synchronized intervals.

A topological configuration is required for IRT.

Note

IO controller as sync master with IRT communication

We recommend also operating the IO controller as a sync master when configuring the IRT

communication.

Otherwise, IO devices with IRT and RT configuration could fail as a result of sync master

failure.

You can find more information on the configuration of synchronized PROFINET devices in

sync domains in the STEP 7 online help and:

● As of STEP 7 V12, in the PROFINET with STEP 7 V13

(http://support.automation.siemens.com/WW/view/en/49948856) function manual

● As of STEP 7 V5.5, in the system manual PROFINET System Description

(http://support.automation.siemens.com/WW/view/en/19292127)

Loading...

Loading...