Siemens IL222AT, IL221AT, IL223AT Datasheet

IL221AT/IL222AT/IL223AT

PHOTODARLINGTON

SMALL OUTLINE

SURFACE MOUNT OPTOCOUPLER

NEW

FEATURES

• High Current Transfer Ratio, I

IL221AT, 100% Minimum

IL222AT, 200% Minimum

IL223AT, 500% Minimum

• Withstand Test Voltage, 2500 VAC

=1 mA,

F

RMS

• Electrical Specifications Similar to

Standard 6 Pin Coupler

• Industry Standard SOIC-8 Surface

Mountable Package

• Standard Lead Spacing, .05"

• Available in Tape and Reel (suffix T)

(Conforms to EIA Standard RS481A)

• Compatible with Dual Wave, Vapor Phase

and IR Reflow Soldering

• Underwriters Lab File #E52744

(Code Letter P)

DESCRIPTION

The IL221AT/IL222AT/IL223AT is a high current

transfer ratio (CTR) optocoupler with a Gallium

Arsenide infrared LED emitter and a silicon NPN

photodarlington transistor detector.

This device has a CTR tested at an 1 mA LED

current. This low drive current permits easy interfacing from CMOS to LSTTL or TTL.

This optocoupler is constructed in a standard SOIC8 foot print which makes it ideally suited for high

density applications. In addition to eliminating

through-holes requirements, this package conforms

to standards for surface mounted devices.

Maximum Ratings

Emitter

Peak Reverse Voltage............................................ 6.0 V

Continuous Forward Current ...............................60 mA

Power Dissipation at 25°C .................................. 90 mW

Derate Linearly from 25°C ............................ 1.2 mW/°C

Detector

Collector-Emitter Breakdown Voltage ..................... 30 V

Emitter-Collector Breakdown Voltage ....................... 5 V

Collector-Base Breakdown Voltage ........................ 70 V

Power Dissipation ............................................. 150 mW

Derate Linearly from 25°C ........................... 2.0 mW/°C

Package

Total Package Dissipation at 25°C Ambient

(LED + Detector) ........................................... 240 mW

Derate Linearly from 25°C ........................... 3.3 mW/°C

Storage Temperature ......................... – 55°C to +150°C

Operating Temperature ..................... – 55°C to +100°C

Soldering Time at 260°C .................................... 10 sec.

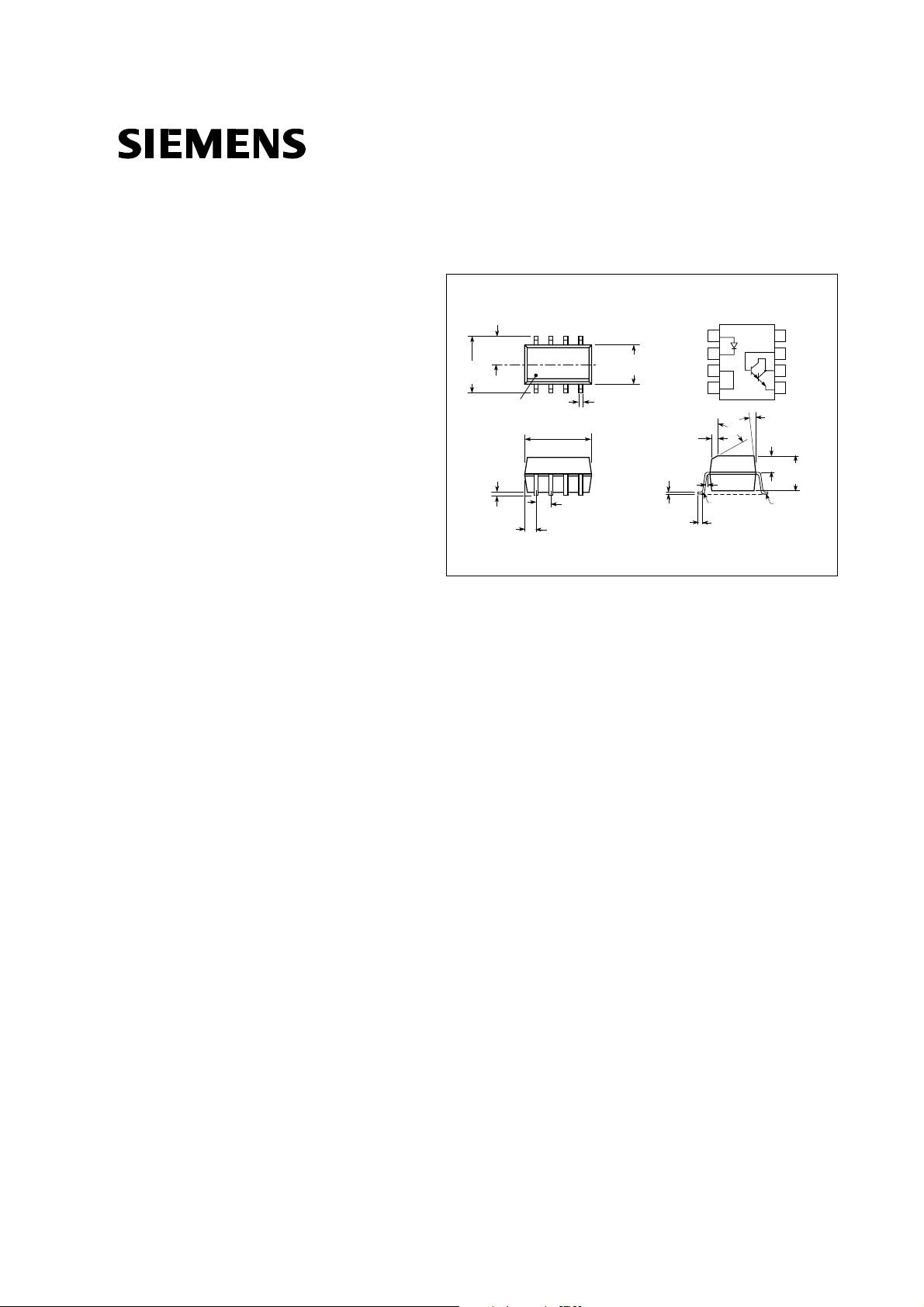

Package Dimensions in Inches (mm)

Anode

.120±.005

(3.05±.13)

.240

(6.10)

.004 (.10)

.008 (.20)

Pin One ID

.192±.005

(4.88±.13)

C

L

.016 (.41)

.050 (1.27)

typ.

.040 (1.02)

.154±.005

(3.91±.13)

.015±.002

(.38±.05)

.008 (.20)

.020±.004

(.15±.10)

2 plcs.

TOLERANCE: ±.005 (unless otherwise noted)

Cathode

NC

NC

1

2

3

4

40°

5° max.

R.010

(.25) max.

7°

.058±.005

(1.49±.13)

Characteristics (TA=25°C)

Emitter

Forward Voltage V

Reverse Current I

Capacitance C

Detector

Breakdown Voltage

Collector-Emitter BV

Emitter-Collector BV

Collector-Base Voltage BV

Collector-Emitter

Capacitance C

Package

DC Current Transfer I

Ratio CTR

IL221AT 100

IL222AT 200

IL223AT 500

Collector-Emitter I

Saturation Voltage V

Isolation Test

Voltage V

Capacitance,

Input to Output C

Resistance,

Input to Output R

Specifications subject to change.

Symbol Min. Typ. Max. Unit Condition

F

R

O

CEO

ECO

CBO

CE

DC

CE sat

IO

IO

IO

1.0 1.5 V IF=1mA

0.1 100 µAV

25 pF VF=0 V,

30 V I

5VI

70 I

3.4 pF VCE=10 V

1VIF=1 mA

2500 VAC

0.5 pF

100 GΩ

RMS

8

NC

7

Base

6

Collector

5

Emitter

.125±.005

(3.18±.13)

Lead

Coplanarity

±.0015 (.04)

max.

=6.0 V

R

F=1 MHz

=100 µA

C

=100 µA

E

=10 µA

C

=1 mA,

F

VCE=5 V

=0.5 mA,

CE

t=1 sec.

Semiconductor Group 4–10

10.95

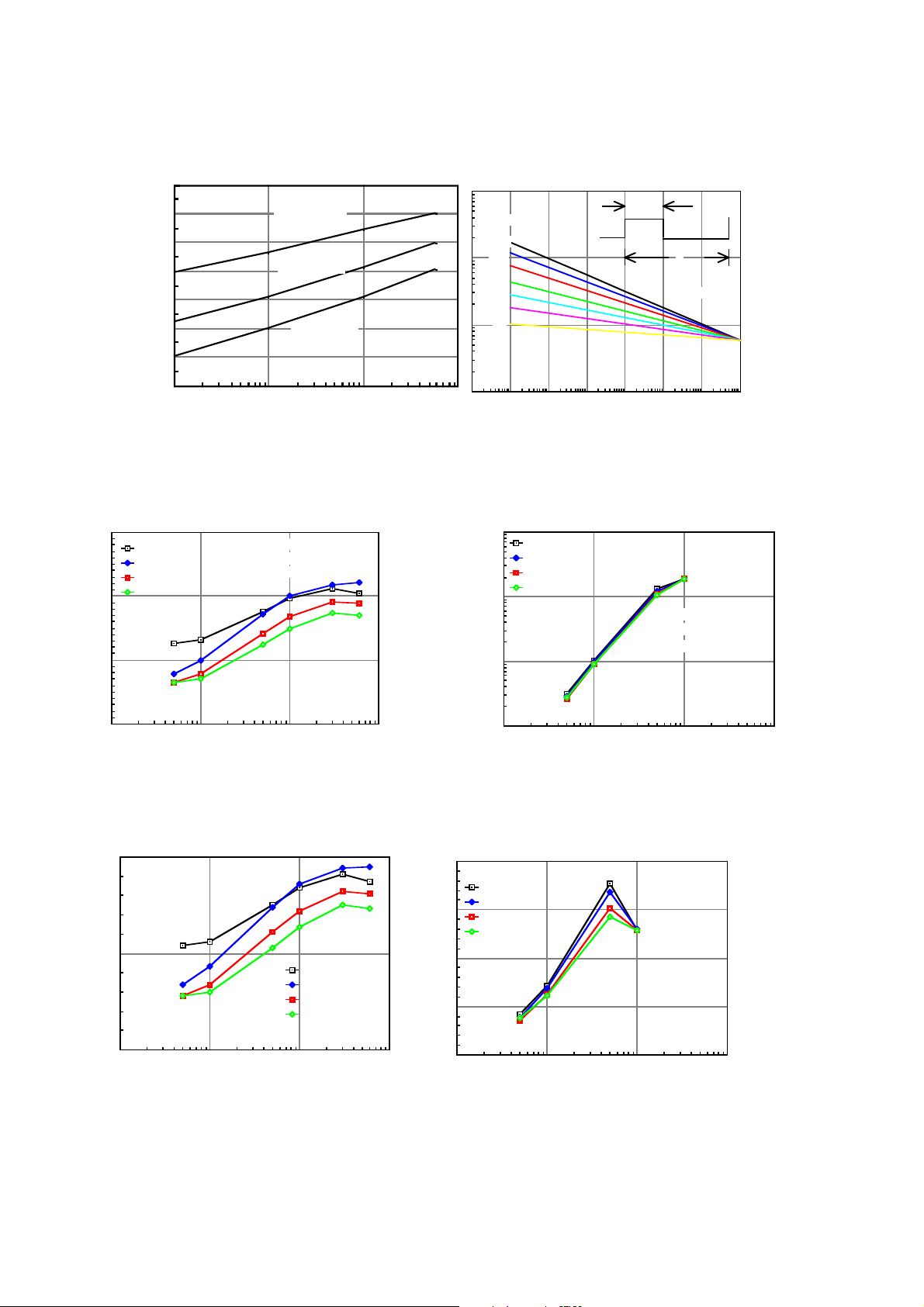

Figure 1. Forward voltage versus forward current Figure 2. Peak LED current versus duty factor, Tau

1.4

1.3

1.2

1.1

1.0

0.9

0.8

VF - Forward Voltage - V

0.7

Figure 3. Normalized CTR

3

Ta = -20°C

Ta = 25°C

Ta = 50°C

Ta =70°C

2

1

Normalized CTRcb

Ta = -55°C

Ta = 25°C

Ta = 85°C

IF - Forward Current - mA

versus I

CB

Normalized to:

If = 1mA, Ta = 25°C

Vcb = 10V

F

10000

Duty Factor

.005

1000

If(pk) - Peak LED Current - mA

100101.1

.01

.02

.05

.1

.2

.5

100

10

10-610-510-410-310-210-110010

t - LED Pulse Duration - s

τ

Figure 4. Normalized CTRCE versus LED current

100

10

Normalized CTRce

Ta = -20°C

Ta = 25°C

Ta = 50°C

Ta = 70°C

1

t

τ

DF = /t

1

Normalized to:

If = 1mA, Vce = 5V

Ta = 25°C

= τ/t

0

.1 1 10 100

If - LED Current - mA

Figure 5. CTR

0.10

versus LED current Figure 6. CTR versus LED current

CB

VCB =10 V

0.05

Ta = -20°C

If/Icb - CTRcb - %

0.00

.1 1 10 100

If - LED Current - mA

Ta = 25°C

Ta = 50°C

Ta = 70°C

.1

.1 1 10 100

If - LED Current - mA

2000

Ta = -20°C

1500

1000

500

CTRce - Current Transfer Ratio -%

Ta = 25°C

Ta = 50°C

Ta = 70°C

0

.1 1 10 100

If - LED Current - mA

Vce = 10V

Semiconductor Group 4–11

Loading...

Loading...