Page 1

Service Manual

Level 1-2

for

EF71

Release Date Department Notes to change

R 1.0 12.09.2006 BenQ Mobile CC S CES New document

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 1 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 2

Table of Content

1 Key Feature................................................................................................................................3

2 Spare Part Overview of EF71....................................................................................................4

3 Disassembly of EF71 ................................................................................................................6

4 Assembly of EF71 ...................................................................................................................18

5 BenQ Service Equipment User Manual.................................................................................29

6 Setup of the Software..............................................................................................................30

7 Software basic settings ..........................................................................................................31

8 Software Download procedure...............................................................................................32

9 Download PPF (Handset configuration)................................................................................34

10 Backup and Restore of Wap and Network Setting...............................................................35

11 Backup and Restore of Media Center content......................................................................36

12 Unlock Tool..............................................................................................................................37

13 JPICS (Java based Product Information Controlling System)............................................39

14 International Mobile Equipment Identity, IMEI......................................................................45

15 General Testing Information...................................................................................................46

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 2 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 3

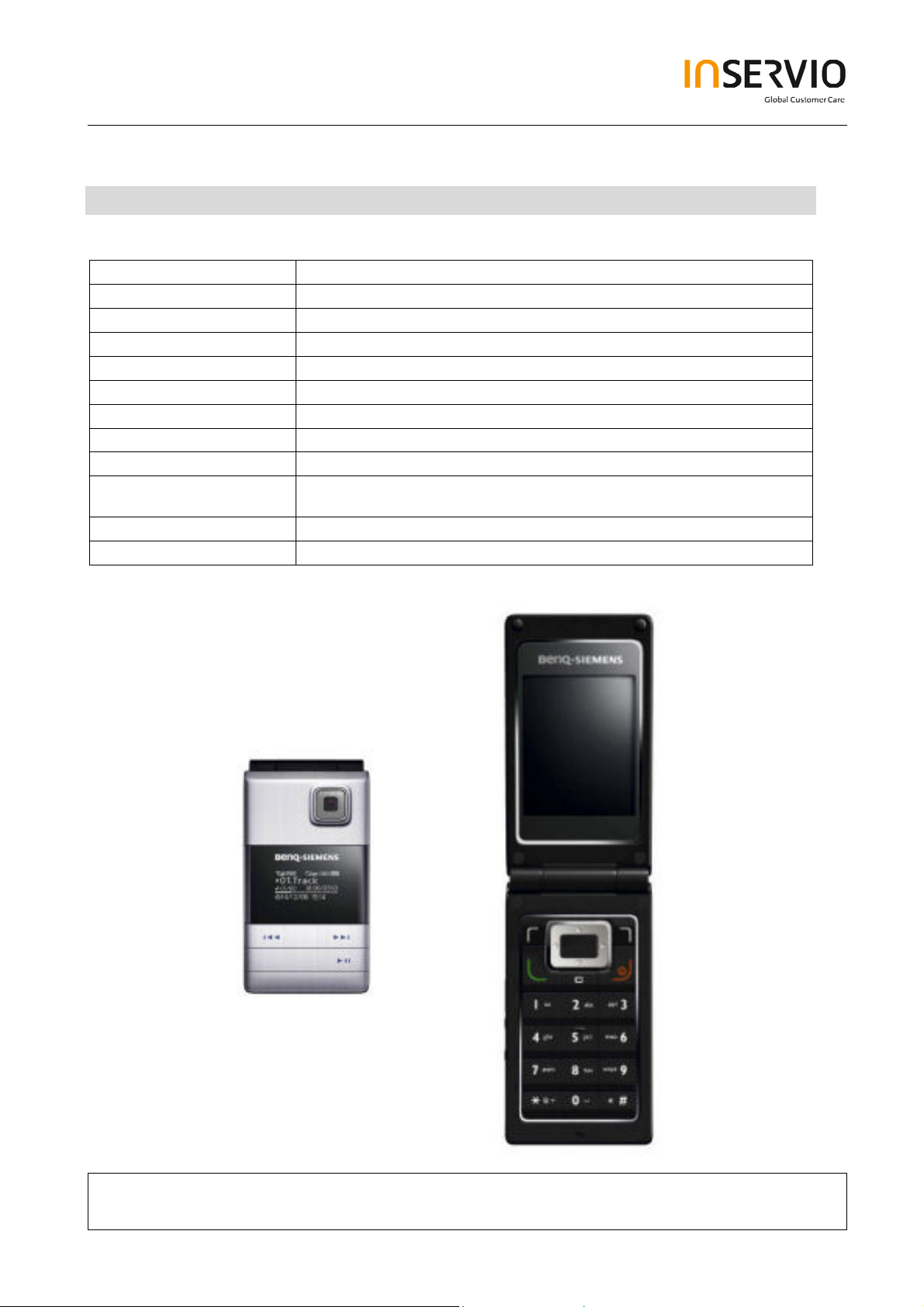

1 Key Feature

System

Battery

Stand – by Time

Talking Time

Antenna

Main Display

Sub - Display

Storage

Camera

Connectivity

Memory Slot

Processor

• Tri-Band GSM 900/1800/1900

• Li-Ion 750 mAh

• Up to 225h

• Up to 3 h

• Integrated

• 262, 144 TFT, 176x220 pixels, 2.2 inches

• White OLED, 128 x 64 pixels

• 24 MB

• 2.0 megapixel, 3 x linear digital zoom

• USB 1.1, Bluetooth: Object Push Profile, Object

Exchange, Handsfree Profile, Headset Profile

• MicroSD

• TI

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 3 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 4

7

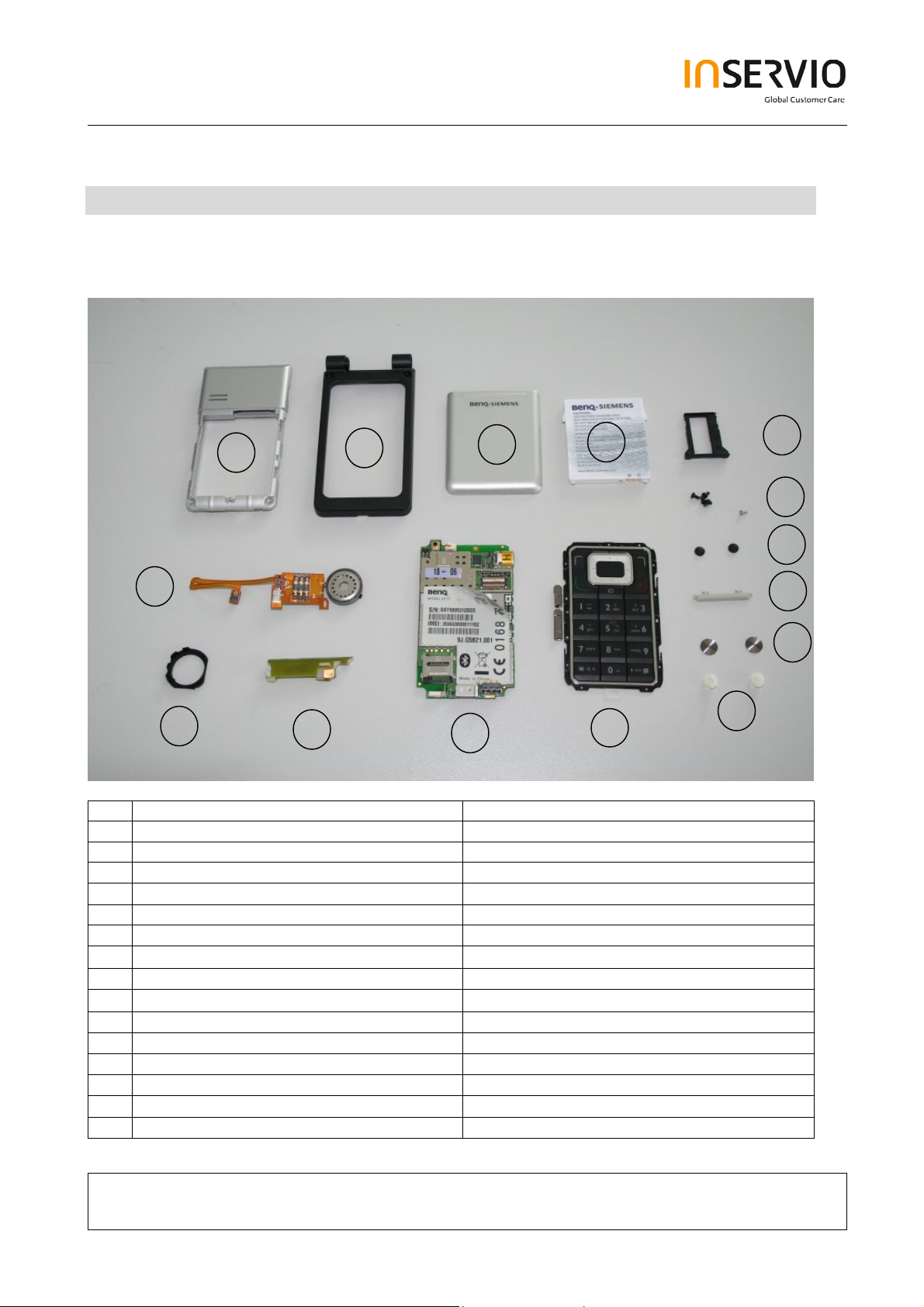

2 Spare Part Overview of EF71

Overview Upper Parts

2

3

5

6

15

14

13

12

11

10

No. Description CM Order Number

1. Lower Base Case Shell Tbd.

2. Upper Base Case Shell Tbd.

3. Battery Cover Tbd.

4. Battery Tbd.

5. Transflash card holder Tbd.

6. Base Screws Tbd.

7.

Screw Cover

Tbd.

8. Side Key Left Tbd.

9.

Screw Cover

Tbd.

10. Screw caps Tbd.

11. Keypad Tbd.

12. RF Control Board Tbd.

13. Side Key PCB Tbd.

14. Rubber gasket Tbd.

15. Vibra Alert Tbd.

8

Technical Documentation

08/2006

TD_Repair_L1-L3_CF61_R1.0.pdf Page 4 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

Page 5

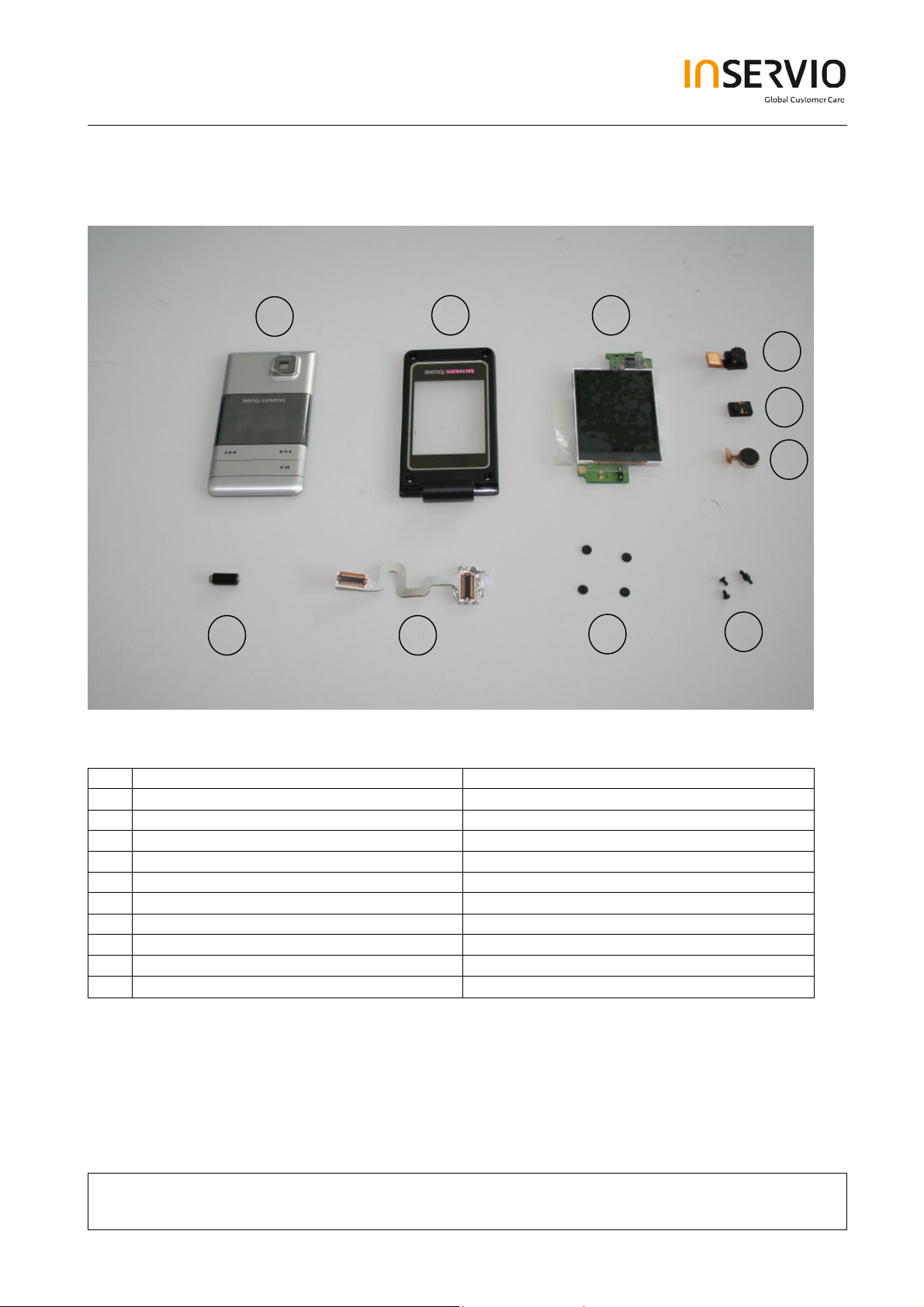

Overview Lower Parts

16

17

18

19

20

21

25

24

23

22

No. Description CM Order Number

16. Lift Case Cap Tbd.

17. Upper Lift Case Shell Tbd.

18. Display Module Tbd.

19. Camera Module Tbd.

20. Earpiece Tbd.

21. ??? Tbd.

22. Lift Screws Tbd.

23. Screw Cover Tbd.

24. Flex Cable Tbd.

Hinge Tbd.

25.

Technical Documentation

08/2006

TD_Repair_L1-L3_CF61_R1.0.pdf Page 5 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

Page 6

3 Disassembly of EF71

All repairs as well as disassembling and assembling have to be carried out in an ESD

protected environment and with ESD protected equipment/tools. For all activities the

international ESD regulations have to be considered.

For more details please check information in c – market

https://market.benqmobile.com/SO/welcome.lookup.asp

There you can find the document “ESD Guideline”.

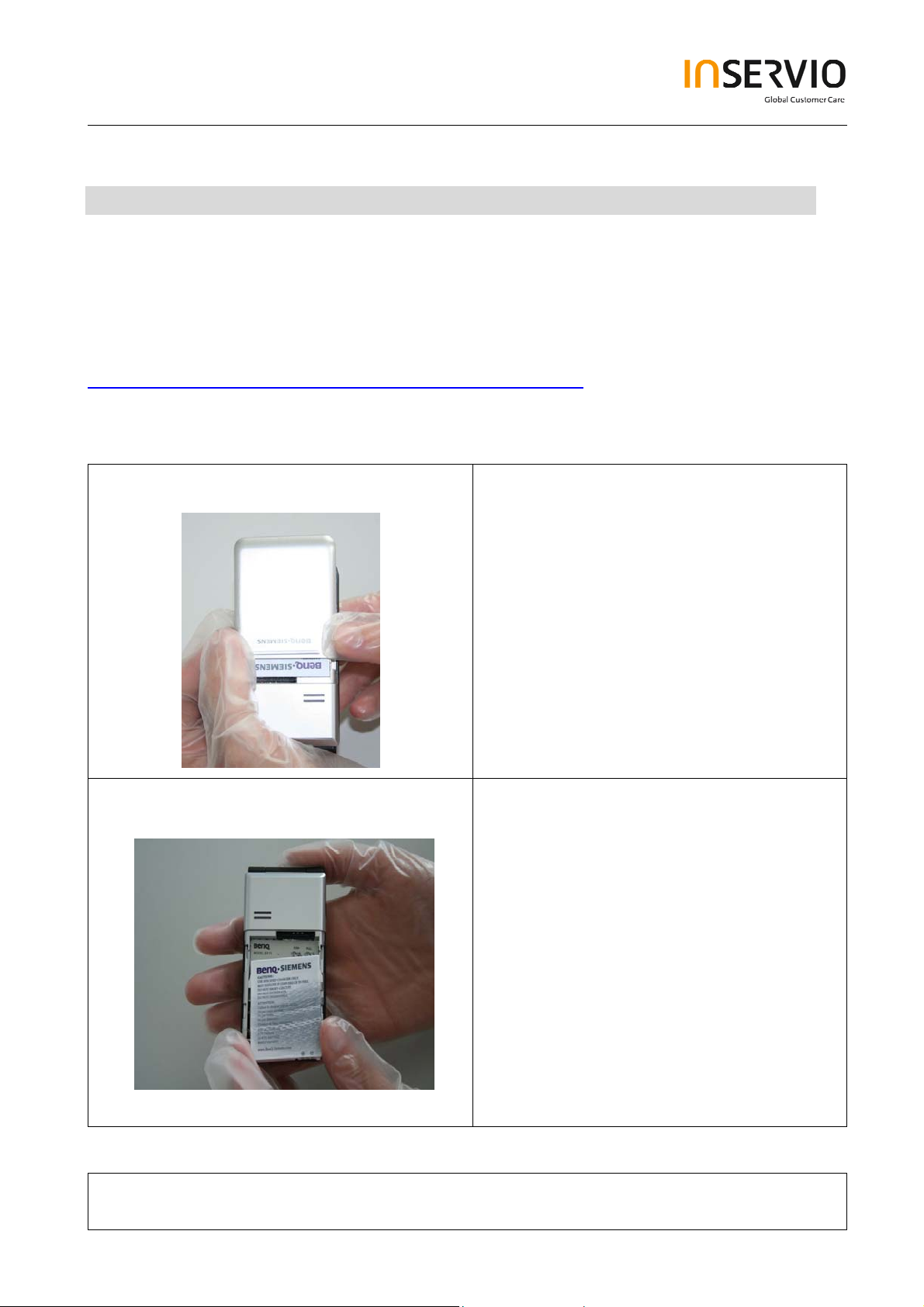

Step 1

Step 2

Remove Battery Cover.

Remove Battery.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 6 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 7

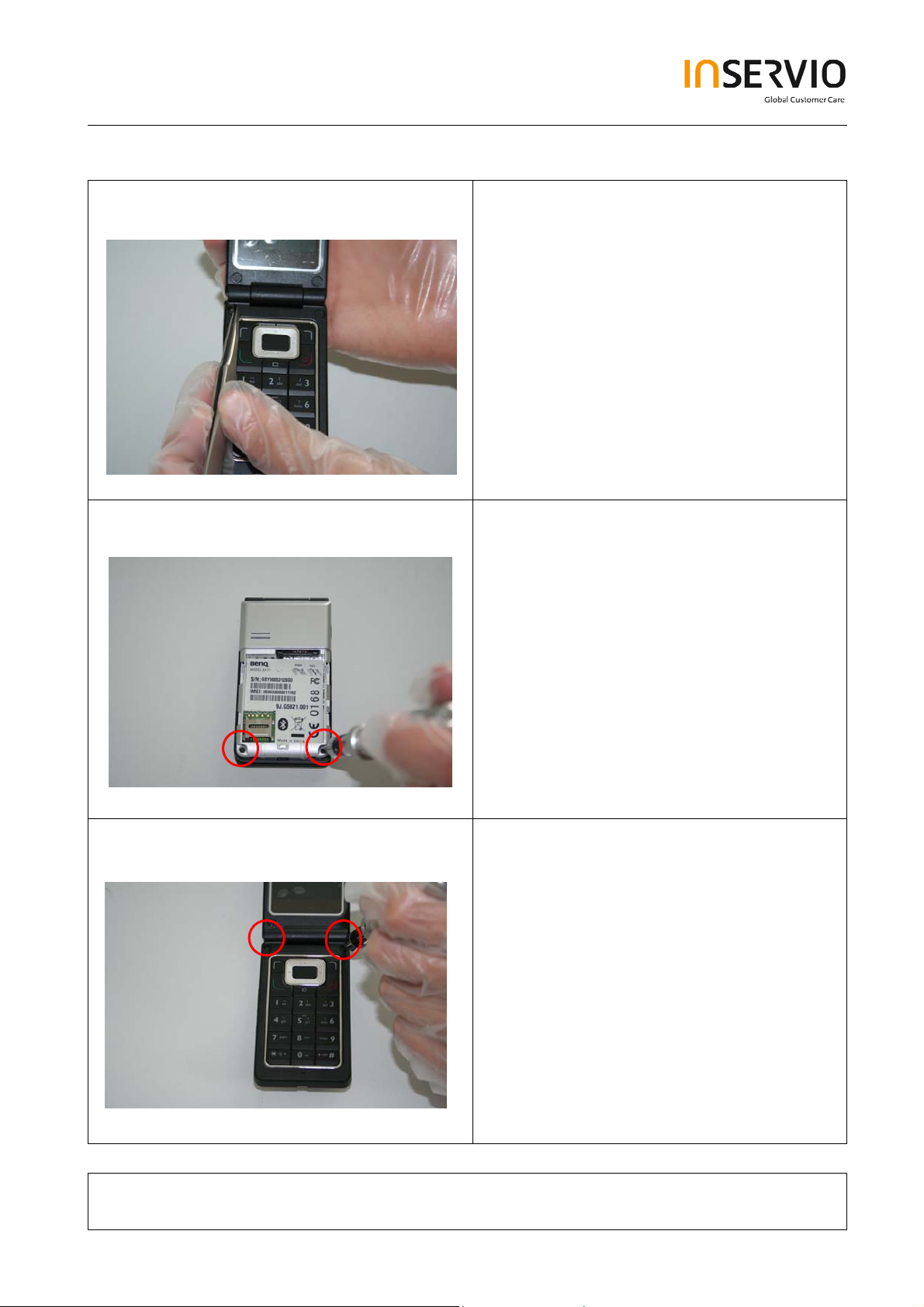

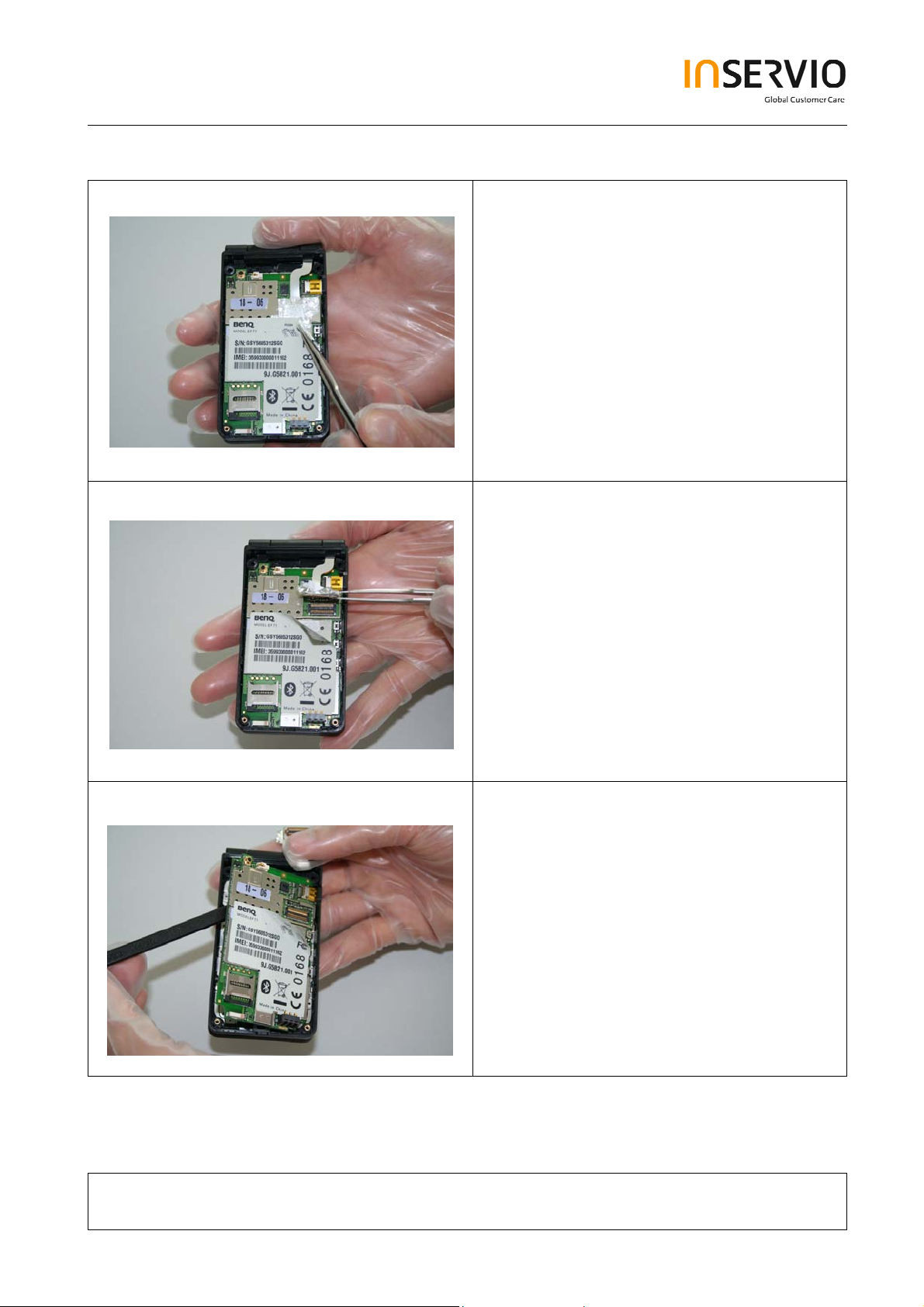

Step 3

Step 4

Remove Screw Cover by

using Tweezers.

Remove screws with the Torque –

Screwdriver T5+

Step 5

Remove screws with the Torque –

Screwdriver T5+

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 7 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 8

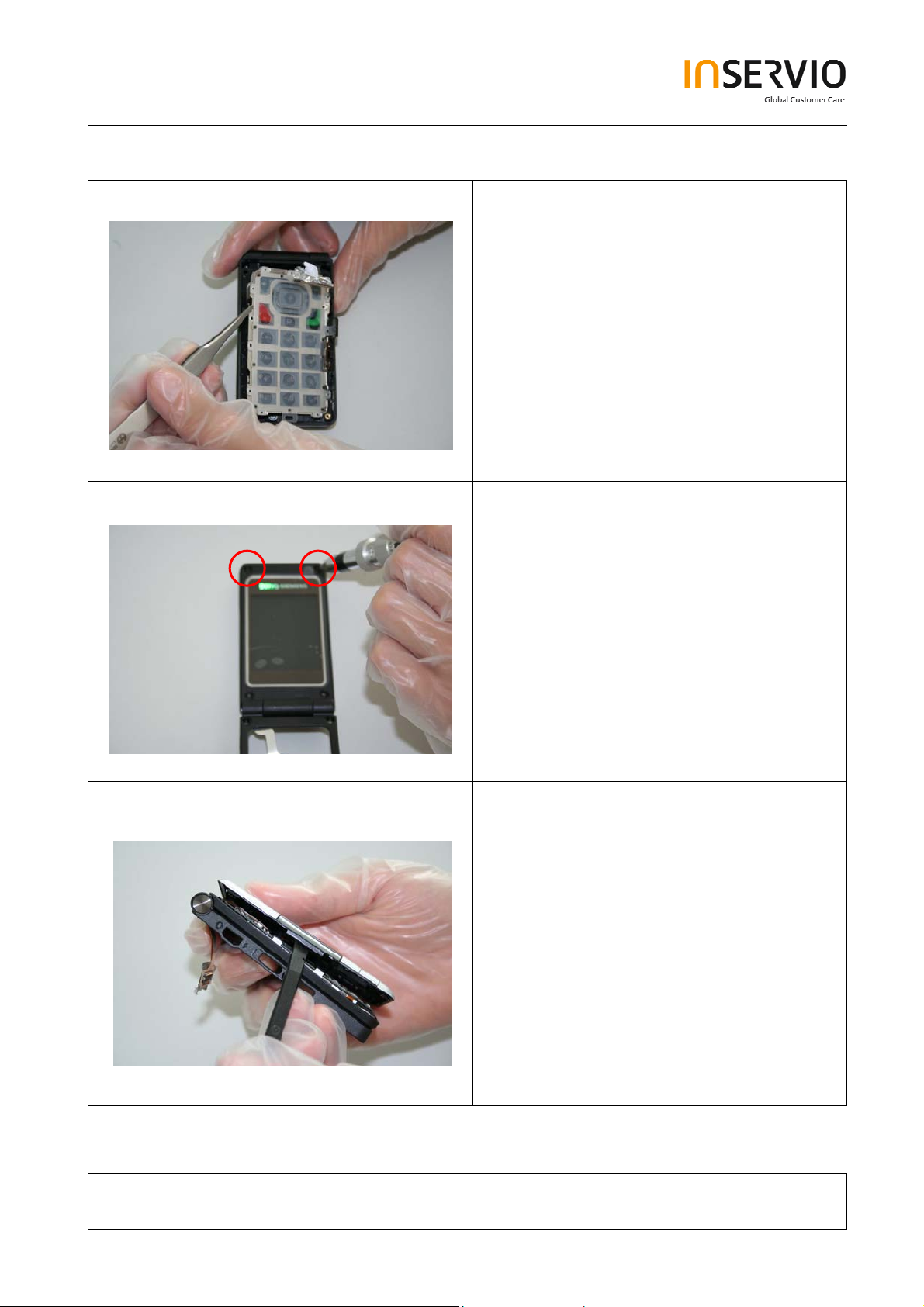

Step 6

Step 7

Remove Lower Base Case Shell with the

Alternative Opening Tool carefully.

Use Tweezers to disconnect the Flex

Cable from the RF Control Board socket.

Step 8

Remove rubber gasket from ringer.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 8 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 9

Step 9

Step 10

Remove Screws with the Torque –

Screwdriver

Remove Vibra Alert

with the Alternative Opening Tool carefully

Step 11

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 9 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 10

Step 12

Step 13

Remove the antenna PCB.

Remove the Side Key .

Step 14

Remove Transflash card holder

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 10 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 11

Step 15

Step 16

.

Step 17

Remove the Keypad PCB.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 11 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 12

Step 18

Step 19

Remove the Keypad by using Tweezers.

Remove screws with the Torque –

Screwdriver T5+.

.

Step 20

Remove Lower Lift Case Cap by using the

Alternative Opening Tool carefully.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 12 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 13

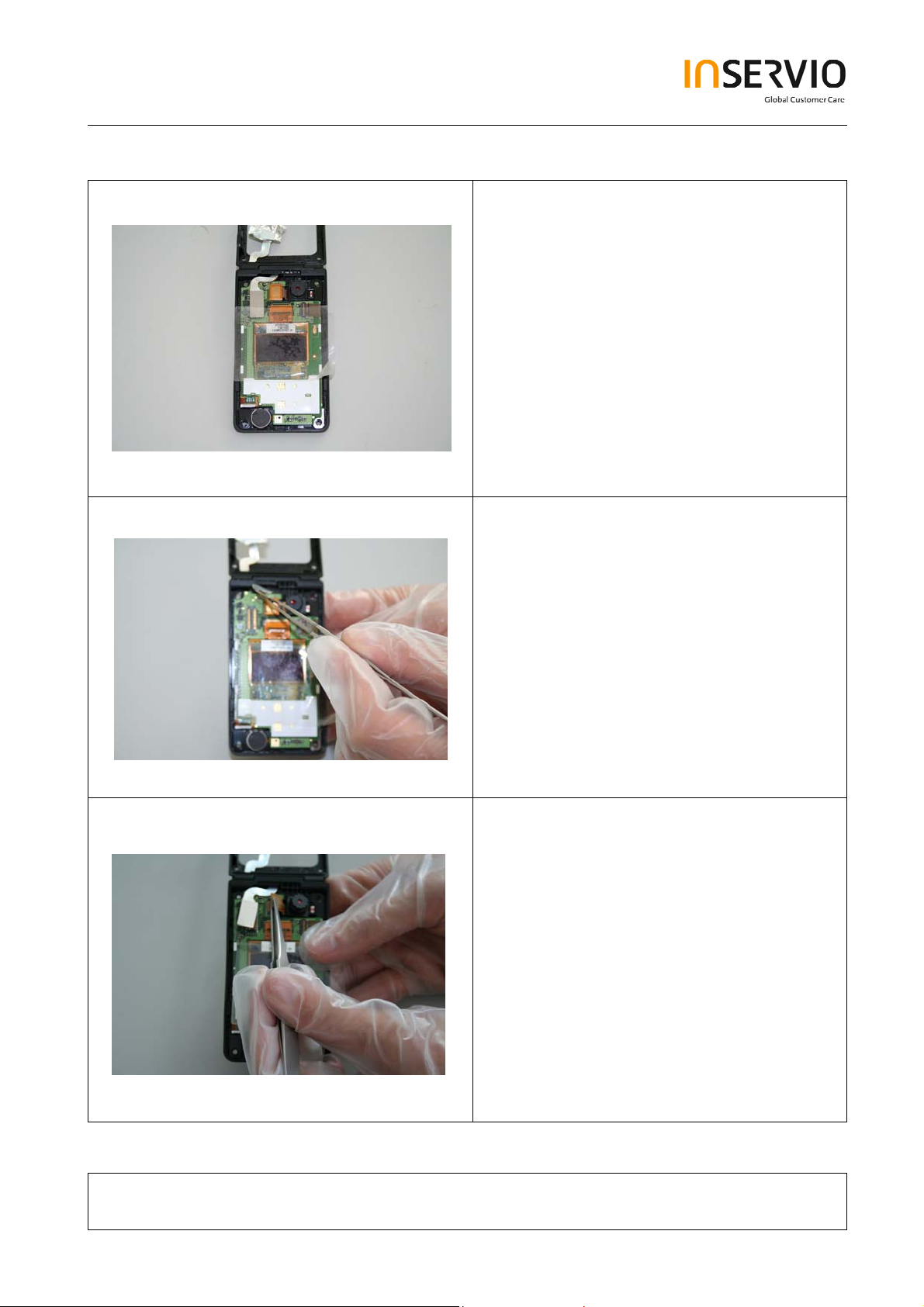

Step 21

Step 22

It is mandatory to place a Protection Foil

onto the Display.

Disconnect the Flex Cable.

Step 23

Remove the Camera Module by

disconnecting it from the socket.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 13 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 14

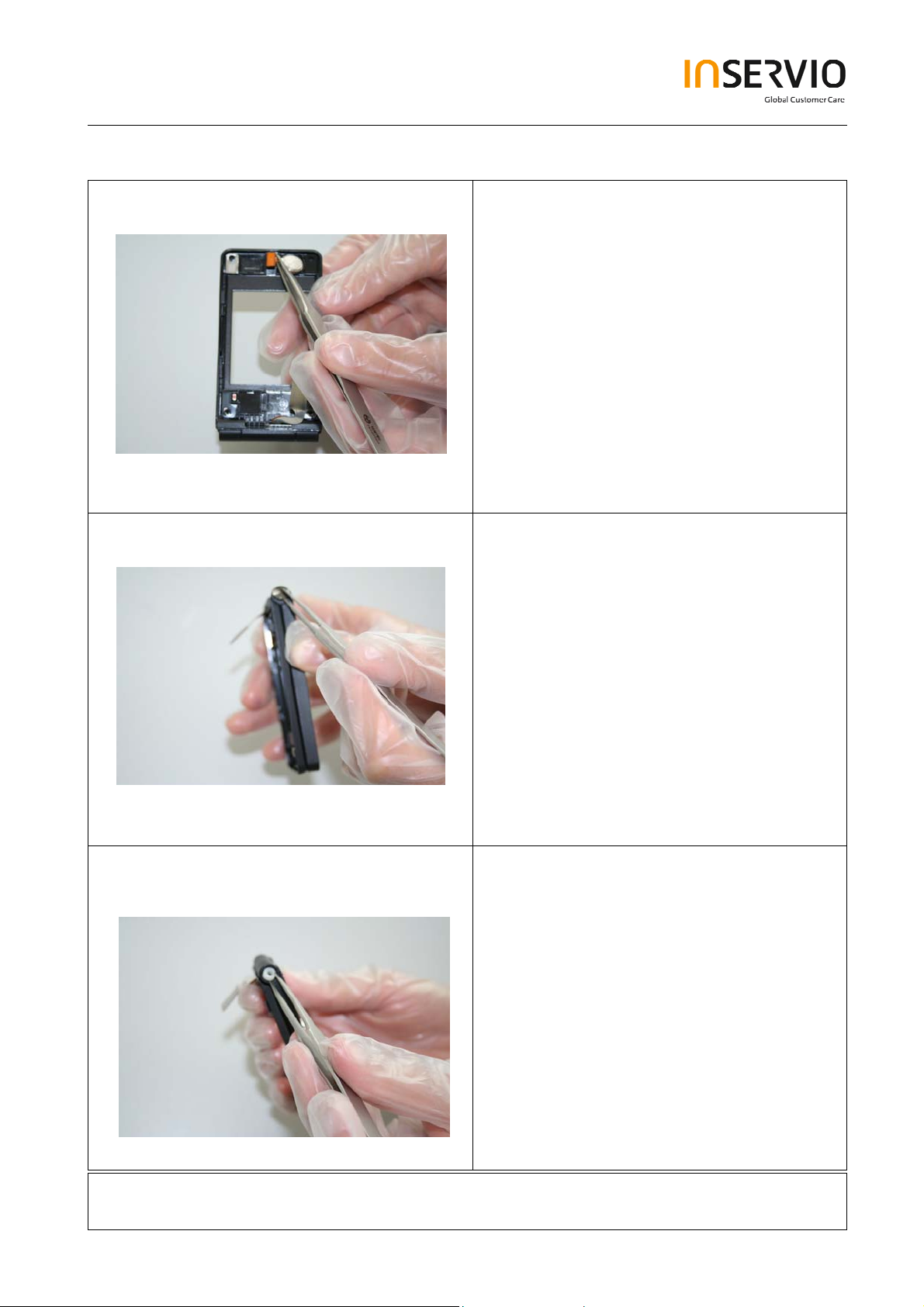

Step 24

Step 25

It is mandatory to place a Protection Foil

onto the Display to avoid scratches.

Step 26

Remove Vibra carefully by using tweezers

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 14 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 15

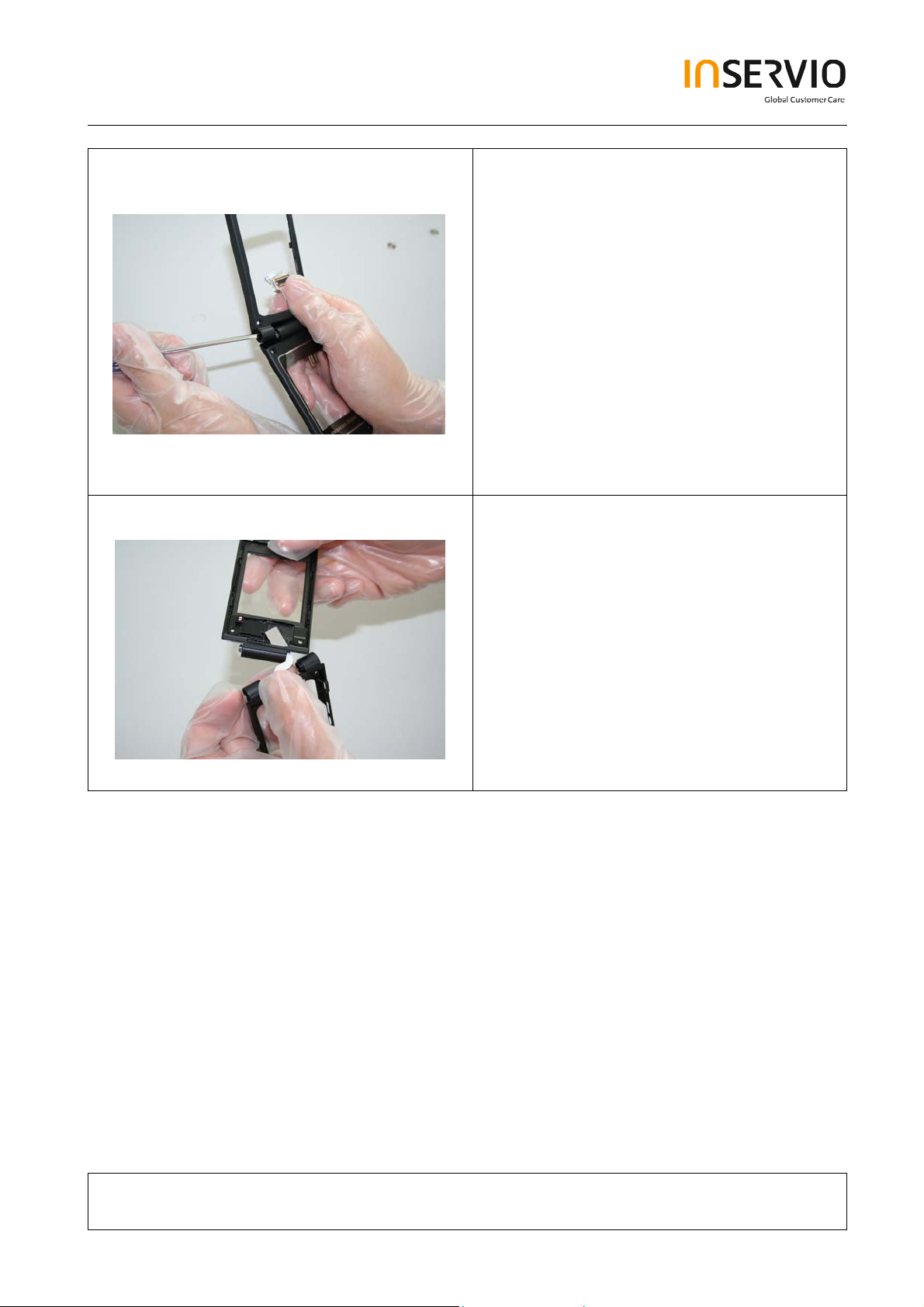

Step 27

Step 28

Remove hinge cap

Step 29

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 15 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 16

Step 30

Step 31

Use the Hinge Tool very carefully to

remove the Upper Base Case Shell from

the Lower Lift Case Shell.

Take care of the Flex Cable, it easily rips.

.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 16 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 17

Step 32

Step 33

.

Remove the Ringer by using Tweezers

carefully.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 17 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 18

4 Assembly of EF71

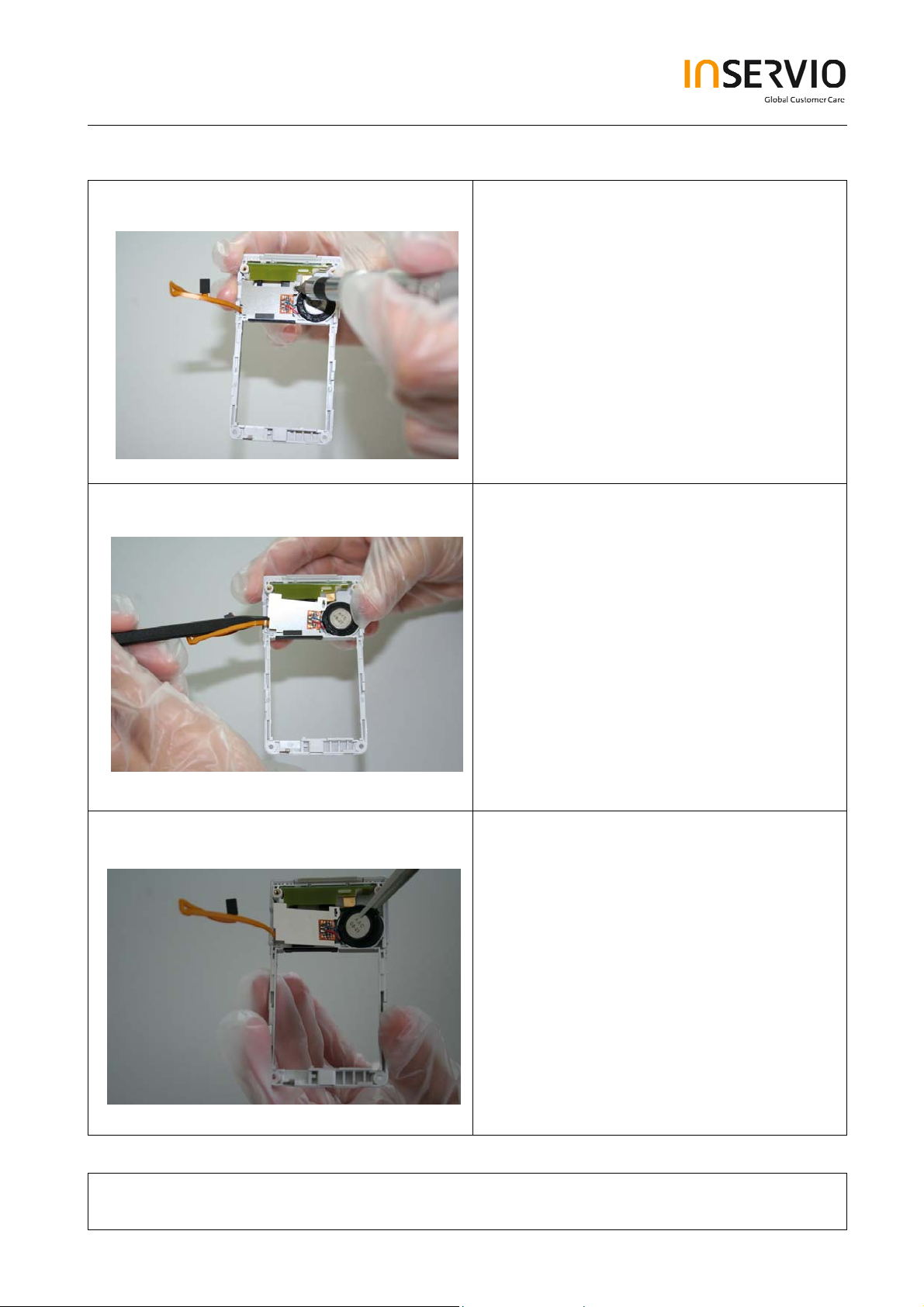

Step 1

Step 2

Assemble the Hinge.

Assemble the Flex Cable. Take care of it!

Step 3

Insert the Flex Cable into the Lower Lift

Case Shell.

.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 18 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 19

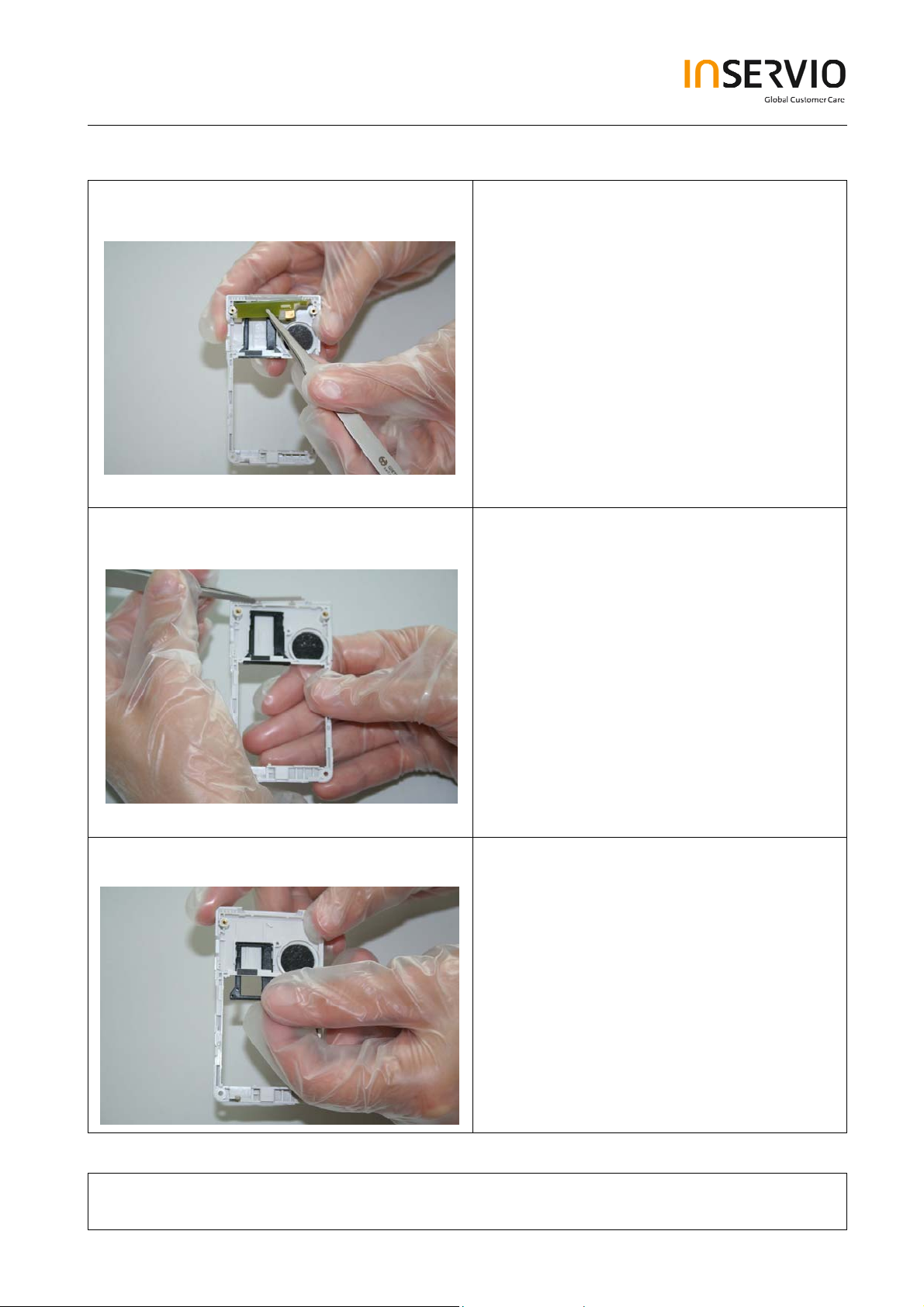

Step 4

Step 5

Assemble the Lower Lift Case Shell and

the Upper Base Case Shell by using the

Hinge Tool.

Step 6

Assemble the Lower Lift Case Shell and

the Upper Base Case Shell by using the

Hinge Tool.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 19 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 20

Step 7

Step 8

Assemble Screw Cover by

using Tweezers.

Step 9

Assemble the vibra.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 20 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 21

Step 10

Step 11

Remove Display Foil.

Assemble the Display Module.

.

Step 12

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 21 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 22

Step 13

Step 14

Step 15

Assemble the Camera Module by

connecting it to the socket.

Remove Display Foil.

Assemble Upper Lift Case and Lower Lift

Case.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 22 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 23

Step 16

Step 17

Step 18

Place screws by using the Torque –

Screwdriver T5+.

Assemble Keypad.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 23 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 24

Step 19

Step 20

Assemble the Side Key PCB by using

Tweezers.

Assemble Keypad PCB.

Step 21

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 24 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 25

Step 22

Step 23

Assemble transflash card holder.

Assemble the Side Key by using

Tweezers.

Step 24

Assemble the antenna PCB by using

Tweezers.

.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 25 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 26

Step 25

Step 26

Assemble the Ringer-Alert by using

Tweezers.

Place screws by using the Torque –

Screwdriver T5+.

Step 27

Assemble rubber gasket.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 26 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 27

Step 28

Step 29

Connect flex cable connector.

Assemble the Lower Base Case Shell.

Step 30

Place screws with Torque – Screwdriver

T5+.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 27 of 51

Created by in GmbH bile GmbH & Co. OHG - Company Confidential2006©inservio servio for BenQ mo

08/2006

Page 28

Step 31

Step 32

Place screws with Torque – Screwdriver

T5+.

.

Assemble Battery.

Step 33

Assemble Battery Cover.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 28 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 29

5 BenQ Service Equipment User Manual

Introduction

Every LSO repairing BenQ handset must ensure that the quality standards are

observed. BenQ has developed an automatic testing system that will perform all

necessary measurements. This testing system is known as:

BenQ Mobile Service Equipment

• For disassembling / assembling

Torque – Screwdriver

Part Number: F 30032 – P 228 – A1

• For SW UPDATE

Opening tool

(Case opening without destroying)

Part Number: F 30032 – P 38 – A1

Alternative Opening tool

Part Number: F30032 – P583 – A1

Tweezers

Torque – Screwdriver

Part Number: F 30032 – P 228 – A1

• For testing

All mobile phones have to be tested with the GRT – Software. The service partner

is responsible to ensure that all required hardware is available.

For additional Software and Hardware options as well as the supported GRT

equipment, please check the GRT User manual.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 29 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 30

6 Setup of the Software

Download of the required software:

Download the driver, the XCSD software mobile software (core-software and language files)

from the Technical Support Page:

https://market.benqmobile.com/so/welcome.lookup.asp

Installation of USB – Serial converter boot cable:

Start the “DataCableDrvInstaller.exe” file and follow the instructions of the installer.

Plug in the Data cable and follow the installation instructions to complete the process.

Check the Comport number of the data cable in the device manager.

(XCSD tool supports only Comport 1 to 10)

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 30 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 31

Installation of XCSD tool:

Start “setup.exe” file and follow the instructions.

The installer creates a shortcut in the start menu bar. Start – Programs – XCSDTool_L1 BenQS

7 Software basic settings

Start the software (BenQS.exe). The XCSD tool will be shown on the screen

Select Model (for example see the screenshot below):

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 31 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 32

Select Com port (Setting – Com port):

8 Software Download procedure

Select Download Option (View – Download):

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 32 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 33

Select Program Code (example: E22 1 11710.mot) and

Language Pack (example E22 L 11711.mot)

Status bar colour scheme:

yellow waiting for update

blue update in progress

red error occurred

black Comport not

available

green Update successful

Connect mobile phone with data cable. Phone must be switched off. Click on “Start”

button and press the power on button on the handset to start the download. During

download process status bar shows the state of the process of P = Program code, L =

Language file and S = Set default (if activated). After successful SW download, the

status bar of the used Com port is changed to green.

Erase of customer data:

Select the “Power-off set default” option to erase all customer data of the phone during the

download process.

Click the “Set E2p” to erase the customer data without software update.

SW files naming rules:

Program Code E22111710

Language Pack E22L11711

E22 Project name

117 Program Code

L Language Pack

117 Version 1.17

10/11 Program Code ID

Technical Documentation

08/2006

TD_Repair_L1-L3_CF61_R1.0.pdf Page 33 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

Page 34

9 Download PPF (Handset configuration)

Select write PPF option (View – Write PPF):

Select Database File (example: E22111710.bin) and

PPF File (example benq_m315_twn.ppf)

Connect mobile phone with data cable. Phone must be switched on. Click to “Write PPF”

button to start the process.

Confirmation about successful write of PPF appears after process is completed.

Don’t activate

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 34 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 35

10 Backup and Restore of Wap and Network Setting

Select Back and Restore of Wap and Network Settings option

(View – Wap/Network Bkp/Restore):

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 35 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 36

Select Database File (example: E22111710.bin) and

Setting File (create new txt file and rename it to ntk file for settings

backup)

Connect mobile phone with data cable. Phone must be switched off.

Click to “Backup” button to start the transfer the settings into the selected file.

Click to “Restore” button to start the transfer from selected file into handset.

11 Backup and Restore of Media Center content

Select Back and Restore of Media center (View – Media center Bkp/Restore):

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 36 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 37

Select Media File (create new txt file and rename it to mmd file)

Connect mobile phone with data cable. Phone must be switched on.

Click to “Backup” button to start the transfer the settings into the selected file.

Click to “Restore” button to start the transfer from selected file into handset.

12 Unlock Tool

Select Unlock tool function (View – Unlock Tool):

Technical Documentation

08/2006

TD_Repair_L1-L3_CF61_R1.0.pdf Page 37 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

Page 38

Select Database File (example: E22111710.bin)

Click to “Show PW” button to get the codes.

Unlock the codes in the mobile phone menu.

Click to “Hide PW” button to hide the codes.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 38 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 39

13 JPICS (Java based Product Information Controlling System)

Overview

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 39 of 51

The following functions are available for the LSO:

• General mobile information

• Generate PINCODE

• Generate SIMLOCK – UNLOCK – Code

• Print IMEI labels

08/2006

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

Page 40

The access to the JPICS server which is located in Kamp – Lintfort is protected by chip

card and in addition using secure socket layer (SSL) connection.

The JPICS server is only available for authorized users with a specially coded smart

card. These smart cards and the administration of the JPICS web server and the PICS

database – server can only be provided by the JPICS – TRUST – Center of the

responsible department

in Kamp – Lintfort.

In case of any questions or requests concerning smart cards or administration of the

databases please ask your responsible BenQ Customer Care Manager.

Technical Documentation

08/2006

TD_Repair_L1-L3_CF61_R1.0.pdf Page 40 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

Page 41

Installation overview

The following installation description assumes that a web browser is already installed.

JPICS is tested with the following browsers:

Internet Explorer Version 5.5 and higher

1.

Netscape Version 6 and higher

2.

For further information regarding supported browsers, browser version and supported

operating systems, see the

Sun FAQ’s.

Here is a step by step instruction to install all the required components:

It is necessary to follow this order!

Smart Card Reader (Omnikey: Cardman 2020 USB or Cardman 3121 USB)

1.

CardOS interface (Siemens Version 3.0 B)

2.

Java Runtime Environment (Sun)

3.

Java additional components

4.

Every user is responsible for a proper installation matching the license

agreements.

For installation and further access you need the following:

1. The JPICS Installation – CD

2. The Smart Card JPICS.

Remark: We recommend using Cardman 2020 USB or Cardman 3121 USB. Serial card

readers are not supported!!!

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 41 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 42

Generate Codes

In the JPICS application you can choose to generate:

• Masterphone codes

• Simlock – Unlock – Codes

Masterphone codes

The Masterphone code is used to unlock blocked mobiles.

Masterphone codes can only be supplied for mobiles which have been delivered in a

regular manner.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 42 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 43

Simlock – Unlock – Code

The Simlock – Unlock – Codes can only be generated if the following conditions are

given:

• Mobile must have an active Simlock inside.

• The user must be given the authorization to obtain Simlock – Unlock – Codes

for the variant of the operator to which the mobile was delivered last time.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 43 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 44

Printing IMEI label

The module “printing IMEI label” offers the possibility to re-print IMEI labels for

mobiles again.

You are able to print 1 label in just one step.

To prevent that misaligned labels are being printed, the setting “Print test labels =

” is

activated by default. After having printed a well aligned test label you can uncheck the

setting and print the correct label.

Hint:

For correct printing of IMEI labels you must have a Zebra – label printer with special

material that fits for label printing. This printer has to be connected to local LPT1 printer

port

(also see Installation of IMPRINT) and MUST feature a printing resolution of 300dpi.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 44 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 45

14 International Mobile Equipment Identity, IMEI

The mobile equipment is uniquely identified by the International Mobile Equipment

Identity, IMEI, which consists of 15 digits. Type approval granted to a type of mobile is

allocated 6 digits. The final assembly code is used to identify the final assembly plant

and is assigned with 2 digits. 6 digits have been allocated for the equipment serial

number for manufacturer and the last digit is spare.

CF61 series IMEI label is accessible by removing the battery.

Re – use of IMEI label is possible by using a hair – dryer to remove the IMEI label.

Date code is shown on IMEI label: Detailed description on how to read date code is

given in Annex 2.

To display the IMEI number, exit code and SW/HW version, key: * # 300 #

Code *#301# activates self diagnosis.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 45 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 46

15 General Testing Information

General Information

The technical instruction for testing GSM mobile phones is to ensure the best repair

quality.

Validity

This procedure is to apply for all from Siemens AG authorized level 2 up to 2.5e

workshops.

Procedure

All following checks and measurements have to be carried out in an ESD protected

environment and with ESD protected equipment/tools. For all activities the international

ESD regulations have to be considered.

Get delivery:

Ensure that every required information like fault description, customer data a.s.o.

is available.

Ensure that the packing of the defective items is according to packing

requirements.

Ensure that there is a description available, how to unpack the defective items

and what to do with them.

Enter data into your database:

(Depends on your application system)

Ensure that every data, which is required for the IRIS-Reporting is available in

your database.

Ensure that there is a description available for the employees how to enter the

data.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 46 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 47

Incoming check and check after assembling:

!! Verify the customers fault description!!

After a successful verification pass the defective item to the responsible

troubleshooting group.

If the fault description can not be verified, perform additional tests to save time

and to improve repair quality.

- Switch on the device and enter PIN code if necessary unblock phone.

- Check the

- Check the display for error in

function of all keys including side keys.

line and row, and for illumination.

- Check the ringer/loudspeaker acoustics by individual validation.

- Perform a GSM Test as described on page 36.

Check the storage capability:

Check internal resistance and capacity of the battery.

Check battery charging capability of the mobile phone.

Check charging capability of the power supply.

Check current consumption of the mobile phone in different mode.

Visual inspection:

Check the entire board for liquid damages.

Check the entire board for electrical damages.

Check the housing of the mobile phone for damages.

SW update:

Carry out a software update and data reset according to the master tables and

operator/customer requirements.

Repairs:

The disassembling as well as the assembling of a mobile phone has to be

carried out by considering the rules mentioned in the dedicated manuals. If

special equipment is required the service partner has to use it and to ensure

the correct function of the tools.

If components and especially soldered components have to be replaced all

rules mentioned in dedicated manuals or additional information e.g. service

information have to be considered

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 47 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 48

GSM Test:

With the availability of the GRT Test /Alignment software, this tool has to be used to

perform the outgoing test!

>Connect the mobile/board via internal antenna (antenna coupler) and external antenna

(car cradle/universal antenna clip) to a GSM tester

>Use a Test SIM

For Triple Band phones use a separate test case, if the test software allows only one

handover.

Skip the GSM Band test cases if not performed by the mobile phone

Example: 1. Test file Band 1 = GSM900 / Band 2 = GSM1800

2. Test file Band 1 = GSM1900

Internal Antenna

Test case Parameter Measurements Limits

1 Location Update • GSM Band 1

• BS Power = -55 dBm

• middle BCCH

2 Call from BS • low TCH

• highest PCL

• BS Power = -75 dBm

• middle BCCH

3 TX GSM Band 1 • low TCH

• highest PCL

• BS Power = -75 dBm

• middle BCCH

4 Handover to GSM Band 2

Including Handover

Check

5 TX GSM Band 2 • low TCH

6 Call release from BS

• highest PCL0

• BS Power = -75 dBm

• middle BCCH

• Display check • individual

check

• Ringer/Loudspeaker

check

• Frequency Error

• Phase Error RMS

• Phase Error Peak

• Average Power

• Power Time Template

• Frequency Error

• Phase Error RMS

• Phase Error Peak

• Average Power

• Power Time Template

• individual

check

• GSM Spec.

• GSM Spec.

Technical Documentation

08/2006

TD_Repair_L1-L3_CF61_R1.0.pdf Page 48 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

Page 49

External Antenna

7 Call from MS • GSM900

• high TCH

• second highest PCL

• BS Power = -75 dBm

• middle BCCH

8 TX GSM Band 1 • high TCH

• second highest PCL

• BS Power = -75 dBm

• middle BCCH

9 RX GSM Band 1 • high TCH

• BS Power = -102 dBm

• 50 Frames

• middle BCCH

10 Handover to GSM Band 2

Including Handover

Check

11 TX GSM Band 2 • high TCH

12 RX GSM Band2 • high TCH

13 Call release from MS

• second highest PCL

• BS Power = -75 dBm

• middle BCCH

• BS Power = -102 dBm

• 50 Frames

• middle BCCH

• Keyboard check • individual

check

• Frequency Error

• Phase Error RMS

• Phase Error Peak

• Average Power

• Power Time Template

• RX Level

• RX Qual

• BER Class Ib

• BER Class II

• BER Erased Frames

• Frequency Error

• Phase Error RMS

• Phase Error Peak

• Average Power

• Power Time Template

• RX Level

• RX Qual

• BER Class Ib

• BER Class II

• BER Erased Frames

• GSM Spec.

• GSM Spec.

• GSM Spec.

• GSM Spec.

Final Inspection:

The final inspection contains:

1) A 100% network test (location update, and set up call).

2) Refer to point 3.3.

3) A random sample checks of:

- Data reset (if required)

- Optical appearance

- complete function

4) Check if PIN-Code is activated (delete the PIN-Code if necessary).

Basis is the international standard of DIN ISO 2859.

Use Normal Sample Plan Level II and the Quality Border 0,4 for LSO.

Remark: All sample checks must be documented.

Technical Documentation

08/2006

TD_Repair_L1-L3_CF61_R1.0.pdf Page 49 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

Page 50

Annex 1

Test SIM Card

There are two different “Test SIM Cards” in use:

1) Test SIM Card from the company “ORGA”

Pin 1 number: 0000

PUK 1 : 12345678

Pin 2 number: 0000

PUK 2 : 23456789

2) Test SIM Card from the company “T-D1”

Pin 1 number: 1234

PUK : 76543210

Pin 2 number: 5678

PUK 2 : 98765432

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 50 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Page 51

Annex 2

Device Date Code overview

GSN rule:

(ex: GS11500001TG0)

GS 1 9 5 00001 TG0

Big class Date Month Year S/N Factory

Based on the definition above, GSC55... below means 2005/05/12.

Technical Documentation

TD_Repair_L1-L3_CF61_R1.0.pdf Page 51 of 51

Created by inservio GmbH for BenQ mobile GmbH & Co. OHG - Company Confidential2006©inservio

08/2006

Loading...

Loading...