Page 1

Preface, Contents

Advanced PC Configuration -

Introduction

Getting Started

1

SIMATIC NET

Commissioning PC Stations

- Manual and Quick Start

Manual

Configured Mode

PG Operation

Additional Functions

Configuring the OPC Server

Using the CP 1616 as a

PROFINET IO Controller/Device

Examples

Industrial Ethernet

PROFIBUS-DP

Unspecified S7 Connection

SNMP

PROFINET

Tools

2

3

4

5

6

7

8

9

10

11

Release 5/2005

C79000-G8976-C156-07

Station Configuration Editor

NCM PC

PC Station Wizard

Symbol File Configurator

Configuration Console

OPC Scout

DCOM Settings

Appendix

12

13

14

15

16

17

18

Page 2

Classification of the Safety-Related Notices

follows according to the level of danger:

This manual contains notices which you should observe to ensure your own

personal safety, as well as to protect the product and connected equipment. These

notices are highlighted in the manual by a warning triangle and are marked as

Danger

!

!

!

indicates that death or severe personal injury will result if proper precautions are

not taken.

Warning

indicates that death or severe personal injury can result if proper precautions are

not taken.

Caution

with warning triangle indicates that minor personal injury can result if proper

precautions are not taken.

Caution

without warning triangle indicates that damage to property can result if proper

precautions are not taken.

Notice

indicates that an undesirable result or status can occur if the relevant notice is

ignored.

Note

highlights important information on the product, using the product, or part of the

documentation that is of particular importance and that will be of benefit to the

user.

2

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 3

Trademarks

SIMATICR, SIMATIC HMIR and SIMATIC NETR are registered trademarks of

SIEMENS AG.

Third parties using for their own purposes any other names in this document which

refer to trademarks might infringe upon the rights of the trademark owners.

Safety Instructions Regarding your Product:

Before you use the product described here, read the safety instructions below

thoroughly.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment.

Qualified persons are defined as persons who are authorized to commission, to

ground, and to tag circuits, equipment, and systems in accordance with established safety practices and standards.

Correct Usage of Hardware Products

Note the following

Warning

!

This device and its components may only be used for the applications described in

the catalog or the technical description, and only in connection with devices or

components from other manufacturers which have been approved or

recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set

up, and installed correctly, and operated and maintained as recommended.

Before you use the supplied sample programs or programs you have written

yourself, make certain that no injury to persons nor damage to equipment can

result in your plant or process.

EU Directive: Do not start up until you have established that the machine on which

you intend to run this component complies with the directive 89/392/EEC.

Correct Usage of Software Products

Note the following

Warning

!

This software may only be used for the applications described in the catalog or the

technical description, and only in connection with software products, devices, or

components from other manufacturers which have been approved or

recommended by Siemens.

Before you use the supplied sample programs or programs you have written

yourself, make certain that no injury to persons nor damage to equipment can

result in your plant or process.

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

3

Page 4

Prior to Startup

Before putting the product into operation, note the following:

Caution

Before installing and starting the module, read the instructions in the

corresponding documentation. For ordering data of the documentation, please

refer to catalogs or contact your local Siemens representative.

DisclaimerCopyright E Siemens AG 2001-2005 All rights reserved

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of

a utility model or design, are reserved.

Siemens AG

Automation and Drives

Industrial Communication

Postfach 4848, D-90327 Nürnberg

4

Siemens Aktiengesellschaft G79000-G8976-C156-07

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be precluded

entirely, we cannot guarantee full agreement. However, the data in this

manual are reviewed regularly and any necessary corrections included in

subsequent editions. Suggestions for improvement are welcomed.

Commissioning PC Stations - Manual and Quick Start

Subject to technical change.

Release 5/2005

C79000-G8976-C156-07

Page 5

This manual...

... supports you when commissioning your SIMATIC NET PC modules in a PC

station and helps you to use them successfully.

... introduces all the tools made available by the SIMATIC NET software for solving

your communication tasks.

... along with the OPC documentation on the SIMATIC NET PC / Windows CD

answers your questions on all aspects of communication:

Manual

Commissioning PC

stations

S Commissioning:

how to go about it

S General

information on PC

tools

S Functions of NCM

PC

S Configuring the

OPC Server

S OPC application

with

communication

over Ethernet.

S OPC application

with access to a

DP master system

S PROFInet

applications

S SNMP

Project engineering /

commissioning

OPC from A to Z

Examples

OPC Documentation

“Industrial

Communication with PG/PC”

Y ou will find tools for

every situation here:

S Detailed OPC

description

S Extensive sample

programs

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

5

Page 6

This manual...

Among other things, this release includes the following new functions:

S Using the CP 1616 as a PROFINET IO Controller/Device

The manual now includes a detailed description of how the CP 1616 can be

configured as a PROFINET IO controller and device.

The Documentation in the “S7-CPs / NCM S7” Documentation Package and on

the Internet

You can order this manual along with other documents in a manual package.

You will find the current version of the manual on the Internet at:

http://www4.ad.siemens.de/view/cs/de/13542666

Additional Information on SIMATIC S7 and STEP 7

The documentation on SIMATIC S7 and STEP 7 contains additional information on

the STEP 7 basic software of the SIMATIC automation system. You can obtain

these from your local Siemens office.

Validity of this Manual

The information in this manual applies to

S Version 5.3 SP1 and higher of the project engineering software SIMATIC NCM

PC / STEP 7 with the NCM S7 option;

S CD 11/2003 and higher from SIMATIC NET

6

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 7

Symbols used in this manual

This symbol appears in the margin to draw your attention to useful tips.

This symbol highlights particularly relevant literature.

Passages marked with this symbol indicate that there is useful information you

should refer to in the basic help of STEP 7.

This symbol indicates that detailed help is available in the context-sensitive help.

F1

You can display this with the F1 key or by clicking on the “Help” button in the

relevant dialog.

Conventions

This manual...

References to other manuals and documentation are indicated by numbers in

slashes /.../. These numbers refer to the titles of manuals listed in the References

section of the Appendix.

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

7

Page 8

Contents

Contents

This manual... 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Welcome to Advanced PC Configuration 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 A New Concept for Your Benefit 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 PC Stations in SIMATIC 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 A Brief Introduction to Tools and Utilities 18. . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Guide to Installation and Commissioning 19. . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 PG Operation or Configured Mode - Considerations 19. . . . . . . . . . . . . .

1.4.2 Commissioning for PG Operation - Overview 21. . . . . . . . . . . . . . . . . . . .

1.4.3 Commissioning for Configured Mode - Overview 22. . . . . . . . . . . . . . . . .

Getting Started

2 Getting Started “Configured Mode” 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Steps in Creating Project Engineering Data 27. . . . . . . . . . . . . . . . . . . . . .

2.2 Steps for Initial Configuration 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Case a) Initial configuration using remote configuration with STEP 7 /

NCM PC 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Case b) Initial configuration with XDB file 37. . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Initial configuration without XDB file 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Getting Started “PG Operation” 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Configuration for PG Operation - Programming Device (PG/PC) 42. . . .

3.2 Configuration for PG Operation - HMI Stations 44. . . . . . . . . . . . . . . . . . .

4 Using Additional Functions - Special Features to Note 49. . . . . . . . . . . . . . . . . . .

4.1 Checking the Configuration and Diagnostics 49. . . . . . . . . . . . . . . . . . . . .

4.2 Testing with the OPC Scout 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Detecting Errors in Communication with the OPC Scout 50. . . . . . . . . . .

4.3 Further Functions / Special Features 52. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Adopting the Project Engineering and Symbols from PROFINET iMap and

SIMOTION Scout 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Configuring Access Points for STEP 7 and STEP 5 53. . . . . . . . . . . . . . .

4.3.3 Points to Note with SOFTNET Industrial Ethernet Modules 55. . . . . . . . .

5 Project Engineering for the OPC Server 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Significance of Project Engineering 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Specifying the Properties of the OPC Server in Project Engineering 58.

5.3 Specifying Connection Properties for the OPC Server in

Project Engineering 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Using Symbols for S7 Connections 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Configuring OPC Properties for SNMP in Project Engineering 65. . . . . .

Commissioning PC Stations - Manual and Quick Start

8

Release 5/2005

C79000-G8976-C156-07

Page 9

5.5.1 Significance in SIMATIC NET 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 SNMP Traps 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Using the CP 1616 as a PROFINET IO Controller/Device 68. . . . . . . . . . . . . . . . . . .

6.1 Initialize CP 1616 (IP address and device name) 71. . . . . . . . . . . . . . . . .

6.2 Configuring the CP 1616 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Example: Installing Linux Drivers (Suse Linux 9.2) 77. . . . . . . . . . . . . . . .

6.4 installing the PROFINET IO Sample Program (Suse Linux 9.2) 78. . . . .

Examples

7 Example — OPC Application for Industrial Ethernet 79. . . . . . . . . . . . . . . . . . . . . .

7.1 Overview 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Hardware and Software Installation 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Creating the STEP 7 Project 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 STEP 7 Project Engineering on a Central Engineering Station 82. . . . . .

7.3.2 Using Symbol Files 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

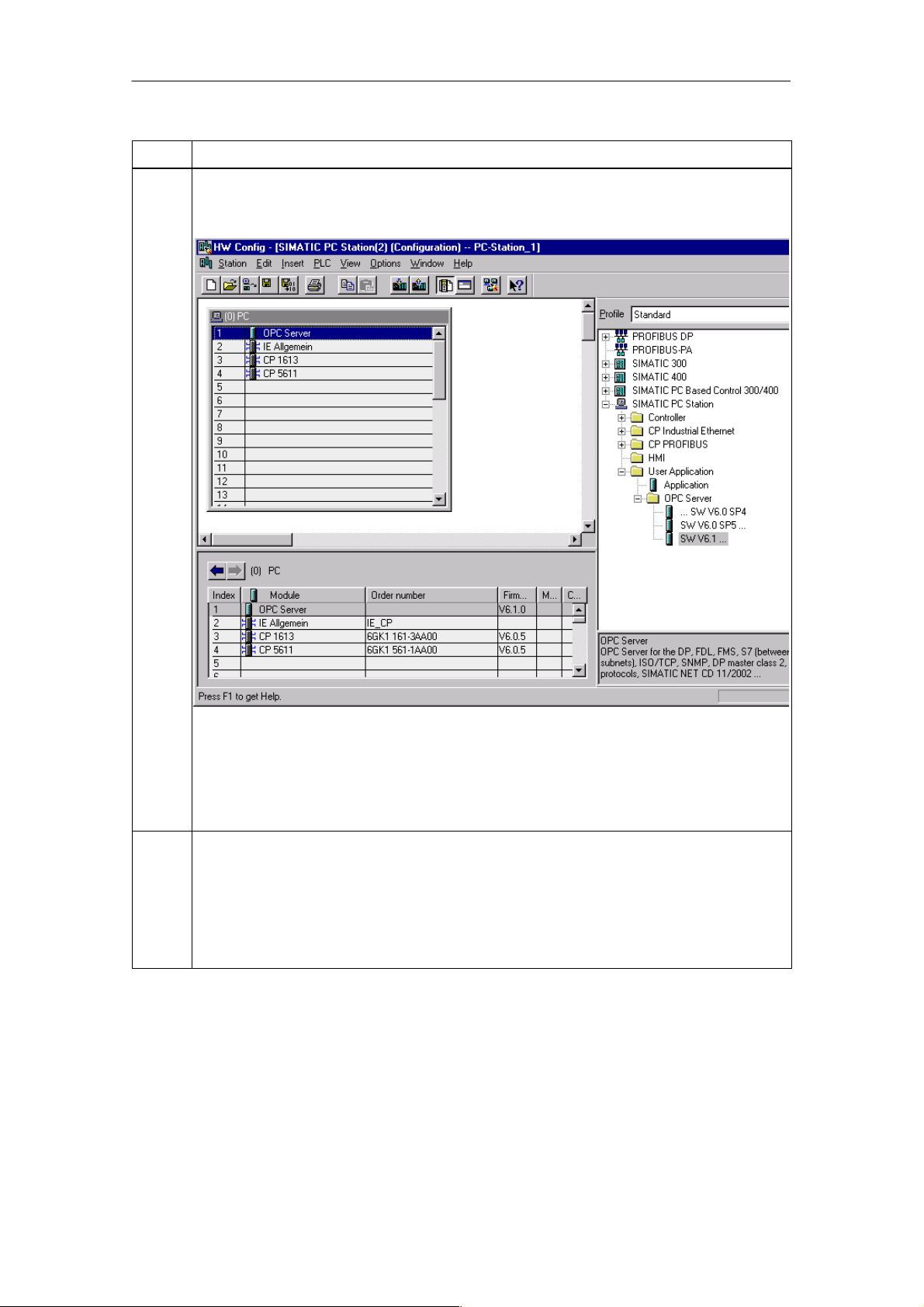

7.4 Configuring the PC Station 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Using the OPC Scout 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.1 Establishing a Connection to the Server 90. . . . . . . . . . . . . . . . . . . . . . . . .

7.5.2 Inserting a Group and Variables 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.3 Displaying and Modifying Values of Variables 93. . . . . . . . . . . . . . . . . . . . .

8 Example — OPC Application for PROFIBUS-DP 94. . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Overview 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Hardware and Software Installation 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Configuring the PC Station 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Changing the configuration on the PC station 100. . . . . . . . . . . . . . . . . . . .

8.4.1 Changing the Hardware Configuration - Preparations 100. . . . . . . . . . . . .

8.4.2 Inserting a DP Master System 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.3 Inserting a DP Slave 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Using the OPC Scout 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 Establishing a Connection to the Server 105. . . . . . . . . . . . . . . . . . . . . . . . .

8.5.2 Inserting Groups and Variables 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.3 Displaying and Modifying Values of Variables 107. . . . . . . . . . . . . . . . . . . . .

9 Example — Unspecified Connection from a PC Application 109. . . . . . . . . . . . . . .

9.1 Overview 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Installing the Software 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Configuring the PC Station 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Creating, Editing and Downloading a STEP 7 Project 116. . . . . . . . . . . . . .

9.4.1 Creating a New Project 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.2 Edit the Network and Connection Project Engineering Data 118. . . . . . . .

9.4.3 Downloading the Project Engineering Configuration 124. . . . . . . . . . . . . . .

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

9

Page 10

Contents

9.5 Configuration Console 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Example — SNMP Communication with OPC 128. . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Hardware and Software Installation 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Configuration of the SNMP OPC Server 130. . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 Editing the Plant Configuration 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Configuring the PC Station 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Using the OPC Scout 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.1 Establishing a Connection to the Server 138. . . . . . . . . . . . . . . . . . . . . . . . .

10.4.2 Inserting a Group 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.3 Setting the Trap Recipient based on the Example of an OSM/ESM 141. .

10.5 Creating a Device Profile with the MIB Compiler 143. . . . . . . . . . . . . . . . . .

11 Example — PROFINET Communication with OPC 147. . . . . . . . . . . . . . . . . . . . . . .

11.1 Hardware and Software Installation 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Configuring the PC Station 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Using Symbol Files 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools and Utilities

12 Station Configuration Editor Tool 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Characteristics, Functions and Activation 153. . . . . . . . . . . . . . . . . . . . . . . .

12.2 Managing Components: “Components” Tab 154. . . . . . . . . . . . . . . . . . . . . .

12.3 Evaluating Messages: “Diagnostics” Tab 158. . . . . . . . . . . . . . . . . . . . . . . . .

12.4 Setting the Station Configuration Editor: “Properties” Dialog 158. . . . . . . .

13 SIMATIC NCM PC Project Engineering Tool 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Characteristics, Functions and Activation 160. . . . . . . . . . . . . . . . . . . . . . . .

13.2 Relationship Between SIMATIC NCM PC and STEP 7 163. . . . . . . . . . . .

13.3 Creating a PC Station 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4 Configuring a PC Station with SIMATIC NCM PC Config 168. . . . . . . . . . .

13.5 Creating the DP Master System 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6 Creating a PROFINET IO System 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7 Configuring Connections 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.8 Project Engineering for a PC Station as DP Slave 177. . . . . . . . . . . . . . . .

13.8.1 DP Master is Known in NCM / STEP 7 177. . . . . . . . . . . . . . . . . . . . . . . . . .

13.8.2 Configuration with a “Third-party” DP Master 182. . . . . . . . . . . . . . . . . . . .

13.9 Downloading Project Engineering Data to the PC Station (after Initial

Configuration) 184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.9.1 Online Mode 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.9.2 Offline Mode (Engineering Station and Runtime PC Separate) - XDB Import 187

Commissioning PC Stations - Manual and Quick Start

10

C79000-G8976-C156-07

Release 5/2005

Page 11

13.10 Adapting Mismatched Configurations 189. . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 PC Station Wizard 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 Symbol File Configurator Too 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 Characteristics, Functions and Activation 192. . . . . . . . . . . . . . . . . . . . . . . .

15.2 The Meaning of Symbols 195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3 Menus of the Symbol File Configurator in Detail 197. . . . . . . . . . . . . . . . . .

15.4 Managing Symbols 199. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4.1 How to Insert a New Symbol 199. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4.2 How to Insert a New Folder 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4.3 How to Add a Name Space Prefix 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4.4 How to Delete Folders or Symbols 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4.5 How to Import a Symbol File 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4.6 How to Export a Symbol File 202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 Configuration Console Tool 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.1 Characteristics, Function and Activation 203. . . . . . . . . . . . . . . . . . . . . . . . .

16.2 Support During Commissioning and Operation 205. . . . . . . . . . . . . . . . . . .

16.2.1 Triggering a Restart on the Module 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2.2 Forcing the OPC Server to Close Down 207. . . . . . . . . . . . . . . . . . . . . . . . .

16.2.3 Activating Configured Protocols Step by Step 209. . . . . . . . . . . . . . . . . . . .

16.2.4 Setting a Symbol File for OPC 211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2.5 Setting Traces 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2.6 Language Setting 217. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2.7 Automatic Startup of Applications and Services; 218. . . . . . . . . . . . . . . . . .

16.2.8 Security Setting (Windows XP + SP2 only) 221. . . . . . . . . . . . . . . . . . . . . . .

16.2.9 Configuration Examples 223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

16.3 Editing the Configuration 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.1 Changing the Mode of a Module 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.2 Displaying and Setting the Industrial Ethernet Network Parameters for a CP

1613 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.3 Setting the Industrial Ethernet Station Addresses 228. . . . . . . . . . . . . . . . .

16.3.4 Assigning Access Points to the Individual Modules 229. . . . . . . . . . . . . . . .

16.3.5 Setting the PROFIBUS DP Slave 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.4 Diagnostics with “Configuration Console” 233. . . . . . . . . . . . . . . . . . . . . . . .

16.4.1 Displaying the Operability of a PROFIBUS Module 233. . . . . . . . . . . . . . . .

16.4.2 Displaying the Industrial Ethernet Network Parameters for a CP 1613 235

16.4.3 Displaying PROFIBUS Network Nodes 236. . . . . . . . . . . . . . . . . . . . . . . . . .

16.4.4 Displaying PROFIBUS Network Parameters 238. . . . . . . . . . . . . . . . . . . . .

16.4.5 Displaying Version Information of Hardware and Firmware 239. . . . . . . . .

17 OPC Scout 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1 Characteristics, Functions and Activation 240. . . . . . . . . . . . . . . . . . . . . . . .

17.2 Connecting the OPC Scout to a Local Server 242. . . . . . . . . . . . . . . . . . . .

17.3 Connecting the OPC Scout to a Remote Server 242. . . . . . . . . . . . . . . . . .

17.4 Create a Group 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.5 Browsing the Process Space - OPC Navigator 243. . . . . . . . . . . . . . . . . . .

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

11

Page 12

Contents

17.6 Create New Variables 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.7 Adding and Monitoring Variables 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.8 Customizing the Display 246. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.9 Display Attributes 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.10 Change Values 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.11 Menus of the OPC Scout in Detail 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.11.1 File Menu 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.11.2 View Menu 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.11.3 Server Menu 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.11.4 Group Menu 250. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.11.5 Item Menu 250. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.11.6 ? Menu 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 DCOM Settings with the dcomcnfg System Program 252. . . . . . . . . . . . . . . . . . . . .

18.1 Characteristics, Functions and Activation 252. . . . . . . . . . . . . . . . . . . . . . . .

18.2 ”Default Properties” Tab 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.3 ”Default Security” / ”Default COM Security” / ”COM Security” Tab 257. . .

18.4 DCOM Configuration / “Applications” Tab 260. . . . . . . . . . . . . . . . . . . . . . . .

18.5 “Default Protocols” Tab 261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.6 Configuration of the Server Computer 262. . . . . . . . . . . . . . . . . . . . . . . . . . .

18.6.1 “General” Tab: Registering the OPC Server 263. . . . . . . . . . . . . . . . . . . . . .

18.6.2 “Location” Tab 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.6.3 “Identity” Tab 265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.6.4 “Security” Tab 267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.7 Configuration of the Client Computer 273. . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Notes for Users of Older Versions 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 LDB and XDB Databases - Overview 266. . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Project Engineering up to SIMATIC NET CD 05/2000 267. . . . . . . . . . . . .

A.3 Continued Use of Previous Project Engineering 269. . . . . . . . . . . . . . . . . .

A.4 Industrial Ethernet - Effects on Older Product Versions

(SIMATIC NET CD 05/2000 and earlier) 270. . . . . . . . . . . . . . . . . . . . . . . . .

A.5 PROFIBUS - Effects on Older Product Versions

(SIMATIC NET CD 05/2000 and earlier) 272. . . . . . . . . . . . . . . . . . . . . . . . .

B Description of the PROFINET Configuration File 276. . . . . . . . . . . . . . . . . . . . . . . . .

C References and Literature 281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Glossary 284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 13

1 Welcome to Advanced PC Configuration

1 Welcome to Advanced PC Configuration

1.1 A New Concept for Your Benefit

Advanced PC Configuration is the new tool with which you can commission a PC

station as part of an industrial communication network.

SIMATIC NET supports the option of using Advanced PC Configuration on a

central engineering station (ES) to configure not only PC stations but also, for

example, operator stations (OS). The engineering station is a networked PC with

the SIMATIC NCM PC program or STEP 7 installed.

Characteristics - Comparison with Previous Products

The new features of the SIMATIC NET software involve several changes to the

previous configuration and project engineering procedures and these are

summarized below:

S You can make all settings with one tool during project engineering and

download them completely to the PC station.

The tool is SIMATIC NCM PC or STEP 7. Depending on your system

configuration, you also use the Station Configuration Editor during the initial

configuration.

The functions of these two tools are now so clearly delineated that you no

longer need the aid of a further tool the Commissioning Wizard.

S Properties that you previously configured using the “Set PG/PC Interface”

program are now part of the project engineering and are downloaded to the PC

station. These include, for example, the station address and the bus

parameters. It is no longer necessary to create several databases.

S Properties that were previously specified in various project engineering

programs are now configured in the project engineering in SIMATIC NCM PC /

STEP 7. Examples of such project engineering tools include COML S7, COM

PROFIBUS.

S Configuration parameters for the OPC Server that were previously stored in

TXT files are now configured in the project engineering in SIMATIC NCM PC /

STEP 7 and downloaded to the PC station.

S The OPC server can also handle communication on unconfigured S7

connections in PG operation. This function is, for example, required for use in

HMI stations.

Supported Modules

You will find a list of modules supported and not supported by Advanced PC

Configuration in the “hinw_e.rtf” file on the SIMATIC NET product CD (<CD drive>

/ sw / cdintern / hinw_e.rtf).

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

13

Page 14

1 Welcome to Advanced PC Configuration

LDB Databases no Longer Required

By configuring on a central station and with the option of downloading, LDB

databases are no longer required for the DP, FMS, and S7 protocols. Configuration

and project engineering data can be exported to XDB files in STEP 7; they must

be imported into the central data management on the PC station using the Station

Configuration Editor.

Note

For more detailed information on the differences compared with the previous

procedure and handling the software and modules, refer to Appendix A.

14

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 15

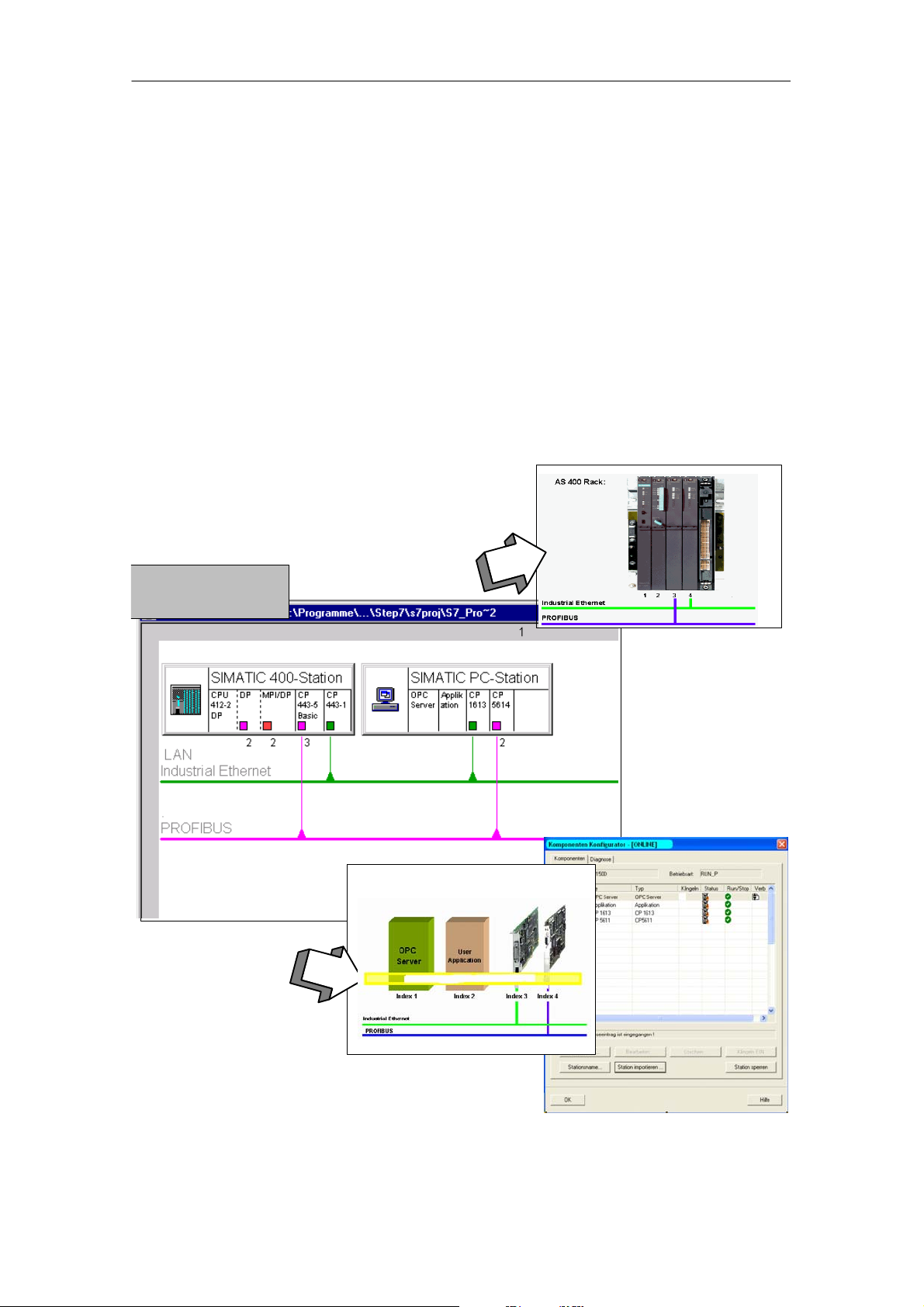

1.2 PC Stations in SIMATIC

Use of PCs in Automation

A “PC station” is a PC with communication modules and software components

within an automation solution with SIMATIC.

The hardware configuration of a PC station can be compared with the configuration

of an S7 controller In SIMATIC:

In an SIMATIC S7-400,

modules are inserted in the

slots in the rack.

1 Welcome to Advanced PC Configuration

In the same way, components of

a PC station, for example

modules, are assigned to a

virtual slot per software.

The virtual rack is implemented

on the PC station by software.

Virtual rack in the PC stationVirtual rack in the PC station

PC Station

Software - The OPC Server as Central Component

A PC station contains SIMATIC NET communication modules and software

applications. One typical software application with which user programs can

communicate is the SIMATIC NET OPC server.

Slot

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

15

Page 16

1 Welcome to Advanced PC Configuration

Uniform Engineering Environment

The PC station is handled just like a SIMATIC S7 controller during project

engineering with STEP 7 / NCM PC: You connect the S7 stations and PC stations

to the network in the network view and specify communication connections.

The project engineering data is downloaded to the stations at the touch of a button.

With PC stations, you have two options:

S Remote Configuration and Download:

Direct initial configuration or modification of a configuration and transfer of

project engineering data to an (online) PC station over an Ethernet adapter.

S Load a PC Station (XDB import)

In this situation, project engineering data is saved to a file and can be imported

into the PC station using any method of data transfer (applies to PROFIBUS

and Ethernet).

Project engineering

tool STEP 7 /

NCM PC

S Remote

Configuration /

Download

S Load a PC

Station

(XDB import)

S Download

Virtual rack in the PC station

16

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 17

Index for Every Component

To allow communication between the components in the PC station and to receive

project engineering data, each component is assigned a unique identification

number. The identification number for modules, applications, and other

components in a PC station is the index. Analogous to the slot of a module in an

S7-400 controller, the index corresponds to a virtual slot in a PC station.

Note

Be careful not to confuse this “index” with a hardware slot, for example on the PCI

bus of the computer. The slot on the PCI bus is not relevant for commissioning

and is not used at any point.

1 Welcome to Advanced PC Configuration

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

17

Page 18

1 Welcome to Advanced PC Configuration

1.3 A Brief Introduction to Tools and Utilities

Once you have installed the SIMATIC NET software, you have the following tools

available:

Basic tools:

Station Configuration Editor

With this tool, you insert the modules and components into the “virtual”

slots of the PC station and assign them addresses and parameters.

Project engineering tool SIMATIC NCM PC

SIMATIC NCM PC is a version of STEP 7 specially for project engineering

of PC stations. It provides the full range of features of STEP 7 for PC

stations.

Additional tools / utilities:

PC Station Wizard

The PC Station Wizard supports you when creating projects in SIMATIC

NCM PC or STEP 7. It allows the automatic adoption of configuration on

the local PC station. This helps you to make sure that your configuration

data is consistent.

Symbol File Configurator

With the Symbol File Configurator, you can create symbol files that allow

you the option of access to symbolic variables over the SIMATIC NET

OPC server.

Configuration Console

The Configuration Console provides a variety of options for configuration

and diagnostics of PC hardware components and PC user programs as

well as the OPC server.

SIMATIC NET Information Service

The information service displays information on events that occurred due

to activated trace requests. Trace requests can be made in the

Configuration Console.

OPC Scout

With the OPC Scout, you can test an OPC application or commission the

OPC server.

18

DCOM Settings (Windows system program)

To allow a client to use a COM object on another computer, the properties

of the COM object must be configured on the client and on the remote

computer.

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 19

1 Welcome to Advanced PC Configuration

mode

1.4 Guide to Installation and Commissioning

Before you start commissioning, you should clarify the area of operation of your

PC station and select the required mode for your communication module. The

steps involved in commissioning differ depending on the mode you select for your

communication module.

Below, you can see an overview of the steps involved in commissioning. The

sections following then describe the individual steps and tools in greater detail.

1.4.1 PG Operation or Configured Mode - Considerations

When commissioning and operating a SIMATIC PC station, distinctions must be

made between the following areas of application: Depending on the area of

application, select the mode of the communication module.

S PG Operation

This is the default mode for a programming device (PG/PC) and HMI station.

S Configured Mode

This mode should be selected for productive communication between

applications in the PC station and the programmable controllers, for example

SIMATIC S7-400.

The primary use of your PC station

is:

S For diagnostics and maintenance

and for programming and project

engineering (STEP 7).

S For process control tasks (operator

control and monitoring).

It should be possible to use the

station independent of a STEP 7

project.

S For project engineering (STEP 7) in

an automated plant operated with

S7 stations

S For tasks in process control and

visualization.

S As an automation system

networked with programmable

controllers.

resulting area of

application:

Programming

device (PG/PC)

HMI station

Engineering

station (ES)

Runtime PC

Selectable mode:

PG operation

(default)

Configured

mode

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

19

Page 20

1 Welcome to Advanced PC Configuration

Mixed operation is possible.

Since you can set the mode for individual communication modules, you can also

use the PC station in mixed operation.

Mixed operation, in this sense, means the use of several communications modules

some in the configured and some in the PG mode.

Depending on the selected mode, the information below applies to the individual

modules of the PC station.

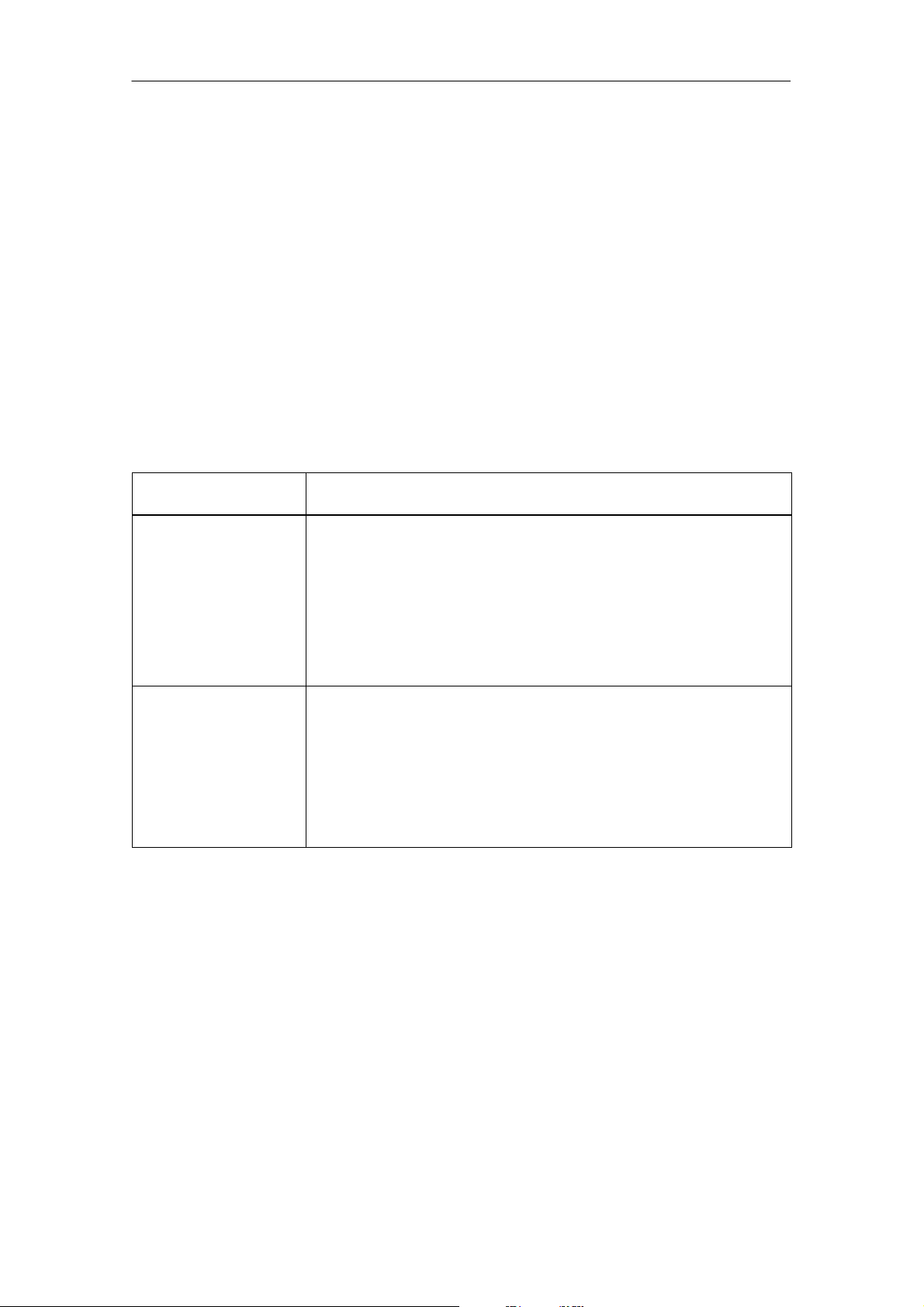

Characteristics of the Selectable Modes

The table below shows the differences between the two selectable modes and how

this affects handling of the PC station during commissioning and operation.

Table 1-1

Mode

PG operation (default

mode)

Configured mode The PC station along with the modules planned in the project engineering is

Characteristics/Advantages when Commissioning and During

Operation

The module used in a PC station in this mode is not included in the STEP 7

project (it is, however, possible to take this module into account in the bus

parameter calculation using the PG/PC station object).

If your module in the PG or engineering station is configured for this mode,

you must specify the interface on the PG or the engineering station explicitly

with the “Set PG/PC Interface” or Configuration Console tool.

With HMI stations, connections to communication partners are set up for

process control over unconfigured S7 connections.

included in a STEP 7 project so that the communication relations with the

stations can be planned in the project.

This has the following advantages:

S Very simple commissioning (initial configuration) by using this

configuration.

S Networking parameters stored in the project are adopted (PROFIBUS).

20

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 21

1 Welcome to Advanced PC Configuration

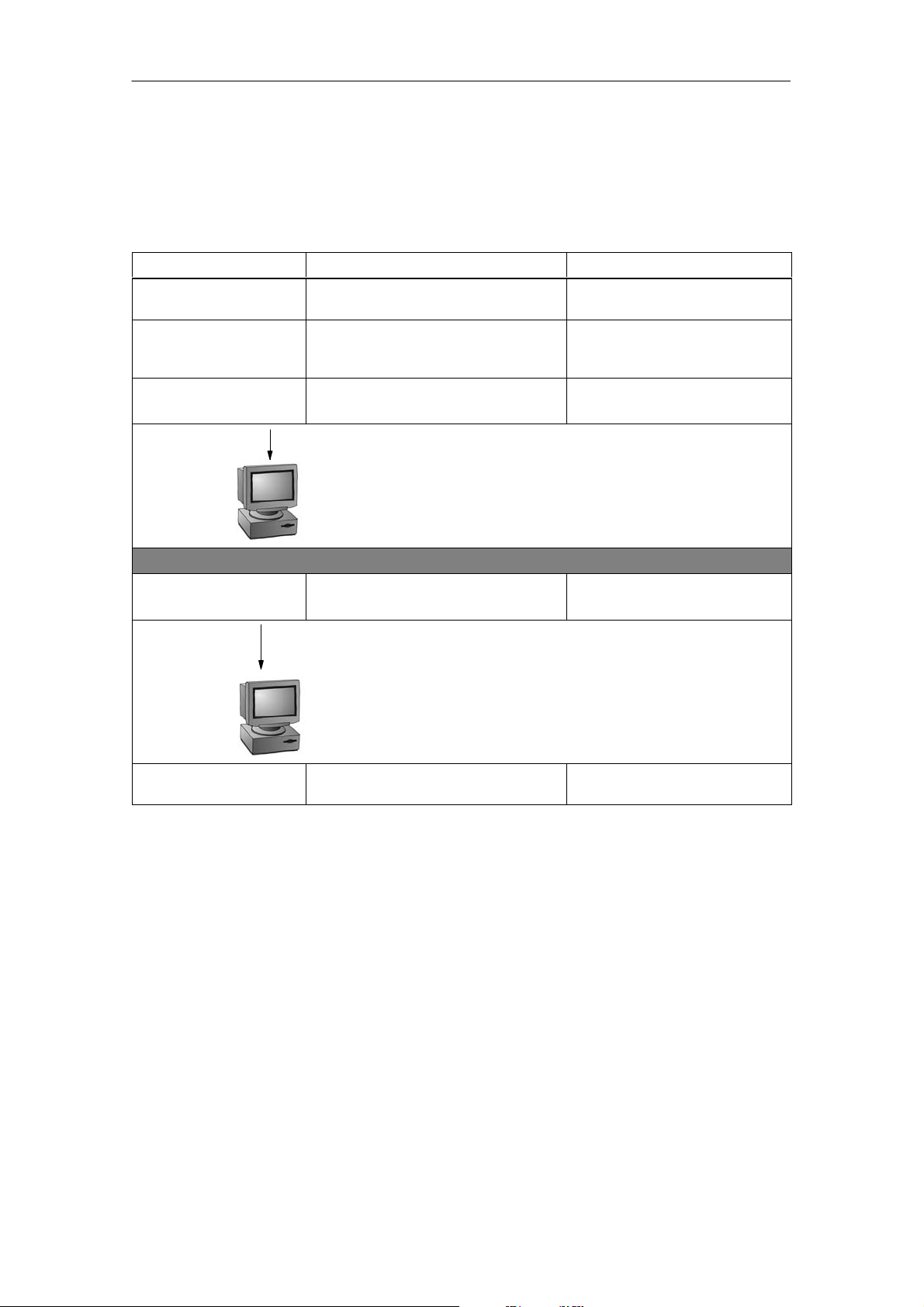

1.4.2 Commissioning for PG Operation - Overview

PG operation is the default mode for programming devices (PG/PC) and HMI

stations.

Step How does it work? Tool

1. Installing SIMATIC

NET software

2. Installing the

hardware (PC

modules)

3. Configuration for PG

operation

Install the SIMATIC NET software

based on the installation instructions

Install the communication module in the

PC station

Assign addresses and interface

parameters to the modules

Result:

PC station ready for PG/PC operation

SIMATIC NET CD / Windows

Configuration Console

Set PG/PC Interface

Next step for HMI stations only:

4. Configuration for HMI

stations

5. Testing the

configuration

Specify the access points for the

applications

Configuration Console Configuration Console

Configuration Console

Set PG/PC Interface

Result:

HMI station and applications ready for operation

Communication over unconfigured S7 connections is possible.

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

21

Page 22

1 Welcome to Advanced PC Configuration

1.4.3 Commissioning for Configured Mode - Overview

When commissioning in the configured mode, three situations can be

distinguished. The situation depends on whether or not project engineering data is

already available in the form of an XDB file or whether commissioning is

independent of project engineering (no XDB file).

Initial configuration means the step in commissioning at which the module is

switched to “configured mode” and obtains addresses and network parameters .

S Case aInitial Configuration by Remote Configuration with STEP 7 / NCM

PC

With this method, it is assumed that the PC station and its components and

applications is first created in project engineering in STEP 7 / NCM PC. The

target PC station that can be reached over an Ethernet adapter (online) is then

configured remotely over STEP 7 / NCM PC (applies to Ethernet and

PROFIBUS).

The advantage of this is that the project engineering data and the PC

configuration are consistent and the total effort is minimal.

Step How does it work? Tool

1. Installing SIMATIC

NET Software on the

Engineering PC/PG

and on the PC Station

2. Installing the

hardware (PC

modules)

3. Project Engineering

on the PC Station

Install the SIMATIC NET software

based on the installation instructions

Install the communication module in the

PC station

Steps in project engineering of the PC

station:

S Create the PC station in NCM PC

S Enter modules and applications S HW Config

S Create connections in NetPro

S Use symbols (in the project

engineering of the OPC server)

4. Initial configuration Remote configuration with the menu

command “PLC

5. Downloading the

Project Engineering

Data to the PC Station

Download the project engineering data

with the menu command ”PLC

Download”

Result:

PC station is ready for productive communication

"

Configure”

"

SIMATIC NET CD / Windows

Refer to the documentation on the

CP

NCM PC / STEP 7

S SIMATIC Manager

S NetPro

S HW Config

NCM PC / STEP7

NCM PC / STEP7

6. Testing the

configuration

22

Configuration Console Configuration Console

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 23

S Case b) Initial configuration with existing project engineering (XDB file)

With this method, it is assumed that the PC station and its components and

applications is first created in project engineering in STEP 7 / NCM PC. This

produces a database (XDB file) that is then available for the commissioning

engineer for the initial configuration.

The advantage of this is that the project engineering data and the PC

configuration are consistent and the total effort is minimal.

Step How does it work? Tool

Project engineering

(as prerequirement for

initial configuration)

1 Welcome to Advanced PC Configuration

Steps in project engineering of the PC

station:

S Create the PC station in NCM PC

NCM PC / STEP 7

S SIMATIC Manager

S Enter modules and applications S HW Config

S Create connections in NetPro

S Use symbols (in the project

engineering of the OPC server)

S NetPro

S HW Config

S Project engineering data of the PC

station is saved in an XDB file .

1. Installing SIMATIC

NET software

2. Installing the

hardware (PC

modules)

3. Initial configuration Import XDB

4. Testing the

configuration

Install the SIMATIC NET software

based on the installation instructions

Install the communication module in the

PC station

Project engineering data is transferred

to the PC station.

Result:

PC station is ready for productive communication

Configuration Console Configuration Console

S SIMATIC Manager

SIMATIC NET CD / Windows

Refer to the documentation on the

CP

Station Configuration Editor

(later download of project

engineering data also possible

with NCM PC / STEP 7)

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

23

Page 24

1 Welcome to Advanced PC Configuration

S Case c) Initial configuration without existing project engineering (XDB

file)

This is, for example, the situation when the commissioning personnel do not

have an XDB file but the devices need to be installed in a plant and their

functionality checked.

Regardless of the initial configuration, the stations and their connections can be

(PC and PLC) can be set up in the project engineering. The project engineering

data is then transferred to the previously configured PC stations in the system.

Depending on the availability of the station, this is achieved by download or

loading the station (XDB import).

To ensure that the configuration on the PC station and the project engineering

are consistent, it is advisable to import the configuration data from the PC

station.

Step How does it work? Tool

1. Installing SIMATIC

NET software

2. Installing the

hardware (PC

modules)

3. Initial configuration Module configuration Station Configuration Editor

Install the SIMATIC NET software

based on the installation instructions

Install the communication module in the

PC station

SIMATIC NET CD / Windows

Refer to the documentation on the

CP

4. Testing the

configuration

5. optional:

Data export

6. Project engineering

(this is not dependent on

the previous steps that is

necessary for step 7.)

Result:

The PC station with its modules and

applications is configured and ready to

receive project engineering data

Configuration Console Configuration Console

Enter the configuration in a new

(temporary) STEP 7 project “PC

station”.

Steps in project engineering of the PC

station:

S Create the PC station in NCM PC

PC Station Wizard / NCM PC

NCM PC / STEP 7

S PC Station Wizard (local only)

/ SIMATIC Manager

S optional (see Step 5): Adopting the

configuration from the project

created in Step 5.

S Enter modules in applications

(identical to changes in the Station

Configuration Editor)

S Create connections in NetPro

S HW Config

S NetPro

S Use symbols (in the project

engineering of the OPC server)

24

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 25

Step ToolHow does it work?

7. Downloading the

Project Engineering

Data to the PC Station

1 Welcome to Advanced PC Configuration

S for “offline mode”: Save project

engineering data of the PC station in

XDB.

Depending on how the PC station can

be reached:

S online: (local or remote) load project

engineering data on station

S HW Config / NetPro

S SIMATIC Manager

S Import XDB S Station Configuration Editor

Result:

PC station is ready for productive

communication

8. Testing the

configuration

Configuration Console Configuration Console

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

25

Page 26

2 Getting Started “Configured Mode”

2 Getting Started “Configured Mode”

The “configured mode” should be selected for productive communication between

applications in the PC station and the programmable controllers, for example

SIMATIC S7-400.

This chapter explains how to commission your PC station with communication

modules for this mode for the first time (initial configuration).

In conjunction with the project engineering, we will explain how to handle the data

exchange between the PC station and the project engineering tool.

Requirement: SIMATIC NET PC software and hardware are installed

Before you work through the steps described here, you must first install the

SIMATIC NET software and the hardware on your PC station.

S Installing SIMATIC NET PC Software

Follow the procedure described in the Installation Instructions that accompany

every SIMATIC NET PC module to install the products of the SIMATIC NET PC

Software CD.

The installed products are described in detail in the “Tools” section.

S Installing hardware (PC modules)

Install the hardware in your computer as described in the Installation

Instructions that accompany every module.

26

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 27

2 Getting Started “Configured Mode”

2.1 Steps in Creating Project Engineering Data

To create the project engineering data, you use the SIMATIC NCM PC or SIMATIC

STEP 7 tool.

Why do we need project engineering data?

To allow the device networked in a plant to communicate, the devices must be

supplied with data on the components and the communication connections. Before

devices can go over to productive operation, the project engineering data must first

be created and loaded on the devices.

This project engineering includes not only the PLC such as SIMATIC S7 stations

but also the PC stations so that the communication relations between all devices of

the plant can be specified. This makes a consistency check and synchronization of

the elements of the system possible.

Apart from specifying the PLC and PC stations and their properties on the LAN,

project engineering also includes defining communication connections and

symbols for process variables on the OPC server.

Result

Once the project engineering data have been downloaded to or imported into the

PC station, the applications can communicate over the established communication

networks with the stations accessible over the network.

Initial Situation

S Case a) Initial configuration using remote configuration with STEP7 / NCM PC

To be able to make the initial configuration on the PC station (available online)

in the next step, you must first create the project engineering data for the PC

station with NCM PC / STEP 7.

S Case b) An XDB file for initial configuration is available

To be able to make the initial configuration in the next step, you must first

create the project engineering data for the PC station with NCM PC / STEP 7

and then make this data available in an XDB file.

S Case c) The initial configuration has already been made on the PC station

Project engineering data is downloaded or imported as an XDB file following

initial configuration.

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

27

Page 28

2 Getting Started “Configured Mode”

Follow the steps below:

Steps in Project Engineering

1. Start the SIMATIC NCM PC from the Start menu.

"

(Start

As an alternative if “online local” : Use the PC Station Wizard

If you want to create the project engineering database on the PC station you are configuring

(online local) and the initial configuration has been made, you can start the PC Station Wizard

as an alternative.

This gives you the option of adopting the configuration data created previously in the Station

Configuration Editor in a new or existing STEP 7 project.

Since we are assuming that we are commissioning the station for the first time, you can select

the following options provided by the PC Station Wizard:

SIMATIC "SIMATIC NCM PC).

S Editing a saved configuration

Open an existing project and compare the local configuration with the information in the

project. “

This adds the current PC station to a project in which, for example, project engineering data

for S7 stations already exists.

S Creating a new configuration

Create a new project and transfer the local configuration to the project.

Tip:

You can also select this option when you want to backup the project engineering data in an

archive. This archive file can be used on an engineering system in STEP 7.

2. Create a PC station in an existing or new project.

Note:

This is omitted when the data is entered by the PC Station Wizard or when an archived

configuration is used (see above).

28

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 29

2 Getting Started “Configured Mode”

Steps in Project Engineering

3. Change to NCM PC Config / HW Config and enter the intended modules and applications (take

them from the catalog).

(omitted if data entered by the PC Station Wizard)

The software applications that use communication services directly must also be specified in

project engineering. One direct use is calling the protocol-specific function libraries. The OPC

server uses communication services directly and must be included in project engineering. OPC

clients only require indirect access via the OPC server and do not need to be configured in

project engineering.

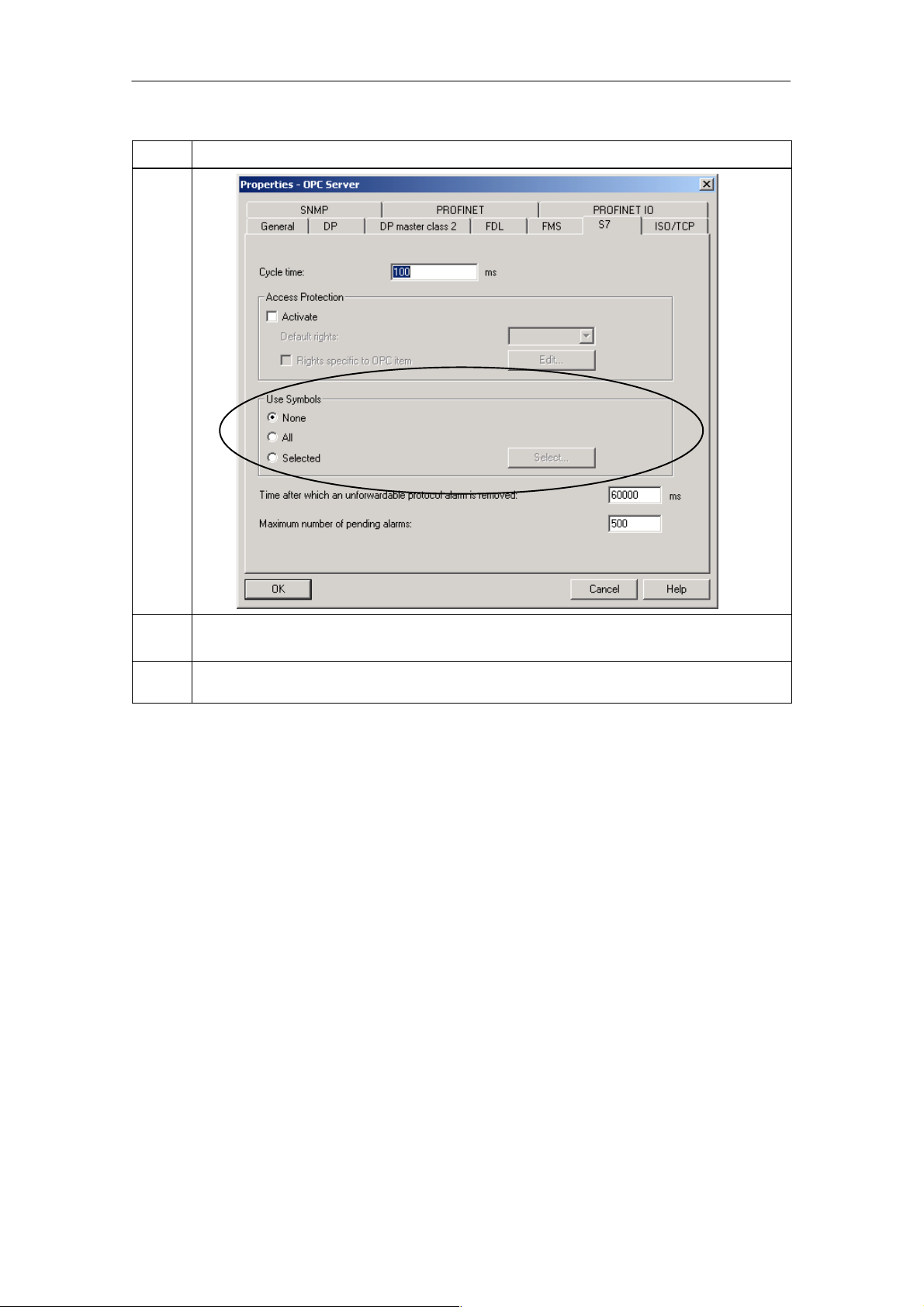

4. Optional:

If symbol tables were created for S7 stations in your project, you can make them accessible to

the OPC server.

When you later import the XDB file or download the project engineering data to the PC station,

these symbol tables are included.

Open the properties dialog of the OPC server to make your selection:

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

29

Page 30

2 Getting Started “Configured Mode”

Steps in Project Engineering

5. Save the configuration.

(omitted if data entered by the PC Station Wizard)

6. Change to NetPro to network the station and to create the connections in the project

engineering.

30

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 31

2 Getting Started “Configured Mode”

Steps in Project Engineering

Note:

You can create the S7 station shown in the screenshot only with STEP 7/HW Config.

In SIMATIC NCM PC, you can open and edit a project containing S7 stations. You can,

however, only create and download project engineering data for PC stations.

7. XDB export for offline mode:

When you save and compile the project, the project engineering data of the PC station is saved

in an XDB file.

Y ou will find information on the storage location of the XDB file in the “Configuration” tab in the

Properties PC Station dialog.

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

31

Page 32

2 Getting Started “Configured Mode”

Steps in Project Engineering

8. If the PC station is available online (local or remote), the next step is the initial configuration of

the station.

Note: To load the project engineering data locally, you must set the access point S7ONLINE for

the PC station to PC-internal (local).

Summary

In the “project engineering” step described here, the following activities were

explained:

1. Creating a STEP 7 project or using an existing STEP 7 project.

2. Creating a PC station in the STEP 7 project (NetPro / HW Config).

3. Inserting and networking PC modules in the PC station (HW Config/NetPro).

4. Creating applications (here the OPC server).

5. Creating the engineering data for connections between the applications.

6. Storing the project engineering data in an XDB database.

For offline mode, the XDB database is then available and can be used to import

the engineering data on the PC station.

32

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 33

Where to go from here - optional activities

Once the project engineering configuration has been accepted, the PC station is

operational. The following steps allowing the use of symbols, diagnostics, and

calling the OPC Scout are optional. You should, however, check that the modules

in your PC station are operational using the diagnostic functions.

2 Getting Started “Configured Mode”

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

33

Page 34

2 Getting Started “Configured Mode”

2.2 Steps for Initial Configuration

For the initial configuration, use one of the following tools depending on the

procedure:

S Station Configuration Editor

S STEP 7 / NCM PC

Why do we need an initial configuration?

When a module is started up for the first time, it must be configured. This initial

configuration is necessary for all newly installed modules.

After the initial configuration of the modules, the PC station is prepared to receive

project engineering data. This step is comparable with inserting components in the

rack of an S7-400 station.

Result

When you start the PC station, the PC module of the PC station is initially in the

PG operation mode.

By adding the communication module in the Station Configuration Editor, the

module is automatically switched to the “configured mode” and the index (the

“virtual slot number”) of the module is set.

Interaction between Initial Configuration and Project Engineering

Depending on the area of application, two situations must be distinguished:

S Case a) Initial configuration using remote configuration with STEP7 / NCM PC

S Case b) Initial configuration with existing project engineering data (XDB file)

S Case c) Initial configuration without existing project engineering data (XDB file)

34

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 35

2 Getting Started “Configured Mode”

2.2.1 Case a) Initial configuration using remote configuration with STEP 7 / NCM PC

The target PC station that is available online is configured directly with STEP7 /

NCM PC remote.

The advantage of this is that the project engineering data and the PC configuration

are consistent and the total effort is minimal. Address parameters are adopted

from the project engineering.

You can also transfer project engineering data to the PC station later by

downloading or loading the station (importing an XDB file).

Follow the steps below:

How to Make the ”Initial Configuration with an XDB File”

1. Select the PC station engineered in your STEP7 project.

2. Select the menu command “PLC " Configure” to open the “Configure: Zielrechner”

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

35

Page 36

2 Getting Started “Configured Mode”

How to Make the ”Initial Configuration with an XDB File”

3. Follow the instructions in the online help of the dialog to create and complete the remote

configuration.

Result:

The PC station with its modules and applications is configured and

ready to receive project engineering data

36

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 37

2 Getting Started “Configured Mode”

2.2.2 Case b) Initial configuration with XDB file

In this case, you can import the XDB file with the project engineering data for the

PC station directly.

The advantage of this is that the project engineering data and the PC configuration

are consistent and the total effort is minimal. Address parameters are adopted

from the project engineering.

Follow the steps below:

How to Make the ”Initial Configuration with an XDB File”

1 Start the Station Configuration Editor from the Start menu.

"

(Start

SYSTRAY.

Y ou first see an empty configuration list.

2 Import the XDB file using the “Import Station...” button.

All the modules and applications specified in the project engineering are entered and displayed

in a window.

During import, all the project engineering data; in other words, station name, modules,

applications, communication connections, and symbols are entered in the PC station.

Importing is possible only when the imported configuration matches the existing local

configuration.

Station Configuration Editor) or by double-clicking on the icon in the Windows

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

37

Page 38

2 Getting Started “Configured Mode”

How to Make the ”Initial Configuration with an XDB File”

3 If you want to prevent project engineering data from being transferred online at a later point in

time, select the “Work offline...” option...”. The default is that project engineering data can be

transferred online.

Result:

PC station is ready for productive communication

S Module addresses are set;

S Communication connections configured in the project engineering

are established;

S Variables can be accessed using symbols configured in the project

engineering.

Tip:

You can also follow this procedure in the example “OPC Configuration for Industrial

Ethernet” in this manual; see Section 7.

Where to we go from here?

you can now use the other tools from SIMATIC NET for diagnostics,

commissioning, and testing.

See also Section 1.3.

38

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 39

2 Getting Started “Configured Mode”

2.2.3 Initial configuration without XDB file

In this case, you specify the modules during initial configuration in the Station

Configuration Editor.

You can transfer project engineering data to the PC station later by downloading or

importing an XDB file.

You can also create project engineering data locally on the PC station and then

import it later into the engineering system (NCM PC). This makes it extremely

simple to create a configuration in the project engineering system that matches the

configuration on the real PC station.

Follow the steps below:

How to Make the Initial Configuration without an XDB File

1 Start the Station Configuration Editor from the Start menu.

"

(Start

SYSTRAY.

Y ou first see an empty configuration list.

2 Assign the station name using the “Station Name...” button.

3 In the next step, you enter the components.

Using the “Add...” button, select the module that will be put into “configured mode”. All the

modules installed in the local station are not yet configured are displayed for selection.

Caution:

If there are several Softnet PROFIBUS modules, only one can be configured in project

engineering.

Station Configuration Editor) or by double-clicking on the icon in the Windows

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

39

Page 40

2 Getting Started “Configured Mode”

How to Make the Initial Configuration without an XDB File

4 In the properties dialog that opens, give the module an address.

In some cases, you can also set further module parameters, for example bus parameters,

(mandatory with PROFIBUS).

5 Repeat the steps for all other modules that exist in the local station and that you want to

operate in configured mode.

6 Using the “Add” button, add the applications to be operated on the station.

7 Repeat the steps for all other applications you want to use for the configured mode.

Result:

PC station is configured with modules and applications and ready

to receive project engineering data (select online mode)

Tip:

You will also find this procedure in our example “OPC Configuration for

PROFIBUS”; see Section 8.

Where to we go from here?

In the next step, you supply the PC station with project engineering data.

40

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 41

3 Getting Started “PG Operation”

3 Getting Started “PG Operation”

This chapter shows you how you can configure your PC module in PG operation.

In this situation, we distinguish two modes:

S Programming device (PG/PC)

S HMI stations

The default setting for the PC modules is PG operation.

Requirement: SIMATIC NET PC software and hardware are installed

Before you work through the steps described here, you must first install the

SIMATIC NET software and the hardware on your PC station.

S Installing SIMATIC NET PC software

Follow the procedure described in the Installation Instructions that accompany

every SIMATIC NET PC module to install the products of the SIMATIC NET PC

Software CD.

S Installing hardware (PC modules)

Install the hardware in your computer as described in the Installation

Instructions that accompany every module.

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

41

Page 42

3 Getting Started “PG Operation”

3.1 Configuration for PG Operation - Programming Device (PG/PC)

You configure a module using the “Set PG/PC Interface“ tool.

Follow the steps below:

How to Configure for PG Operation

1. You can start the configuration program from the Windows taskbar:

" SIMATIC " SIMATIC NET " Set PG/PC Interface.

Start

As an alternative you can also start it from the Control Panel:

"

Start

Settings " Control Panel " Set PG/PC Interface.

2. Assign the access point for your application to the module.

2.1 To make your module usable for STEP 7, follow the steps outlined below in the “Set PG/PC

Interface” configuration program:

Select the access point “S7ONLINE” in the “Access Point of the Application” list box. The

current assignment then appears at the bottom in the list box “Interface Parameter Assignment

Used”.

2.2 Select the required entry in the “Interface Parameter Assignment Used” list box. Some modules

offer alternatives, for example the CP 1613 as follows:

S If you use the TCP protocol - “CP1613(RFC1006)”,

S if you use the ISO protocol - ”CP1613(ISO)”

or CP 5613/CP 5614 as follows:

S Normal situation - “CP5613_5614(PROFIBUS)”,

S on an MPI chain - “CP5613_5614(MPI)”.

For further details on setting access points, refer to the section ”Tools”.

42

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 43

3 Getting Started “PG Operation”

How to Configure for PG Operation

3. Set the required communication parameters.

With your module selected, you can click on “Properties” and then set the communication

parameters. In normal situations, the parameter settings do not need to be modified (for more

detailed information on the parameters, refer to the online help that you can display by clicking

the “Help” button in the Settings dialog).

For more information on certain module types, see below.

4. When you close the Properties window, you return to the start dialog of the “Set PG/PC

Interface” communication program.

5. Close the configuration program with the “OK” button.

The module is now set up for PG operation.

Note

Remember that by clicking on a module to make settings, it is possible to change

the assignment. If you have accidentally changed an assignment, make sure you

correct it again.

Setting Communication Parameters - Extra Information

Prior to operation, the following communications parameters must be set:

S For PROFIBUS modules (for example CP 5613, CP 5511, CP 5611, CP 5512):

- Programming device / PC is the only master on the bus

- Address

- Transmission rate

- Profile (depending on the application: DP for the DP protocol, otherwise the

fast setting “Standard” or the safe setting “Universal“)

S For CP 1613 TCP:

The IP address, subnet mask, and gateway address in the “Ethernet (MAC)

and IP Addresses” tab

S For SOFTNET TCP (for example CP 1512, CP 1612):

The IP address, subnet mask and gateway address must be set. You can do

this directly in the Windows Control Panel in “Network” or here using the

“Network Properties” button in the “TCP/IP Network” tab.

For CP1613 ISO and SoftNet ISO, it is not normally necessary to make any

communication parameter settings.

Please note that you can also use diagnostic functions by clicking the “Diagnostics”

button in the start dialog of “Set PG/PC Interface“.

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

43

Page 44

3 Getting Started “PG Operation”

3.2 Configuration for PG Operation - HMI Stations

You configure a module using the “Set PG/PC Interface” tool.

Initially the procedure is identical to configuration for PG operation - programming

device (PG/PC) as described in Section 3.1.

The communication module remains in “PG operation”; it is then configured so that

applications can communicate over communication interfaces without further

connection configuration in the project engineering.

The applications access the communication module using access points. If new

access points need to be entered, this can also be done with the “Set PG/PC

Interface“ or “Configuration Console” tools.

Finally, you use the OPC Scout to assign the required items and connection

parameters to the user program.

Setting Access Points - Follow the steps below:

How to Configure for HMI Operation

1. You start in the same way as described for commissioning for PG operation in the previous

section:

You can start the configuration program from the Windows taskbar:

" SIMATIC " SIMATIC NET " Set PG/PC Interface.

Start

As an alternative you can also start it from the Control Panel:

"

Start

Settings " Control Panel " Set PG/PC Interface.

2. Assign the access point for your application to the module.

Note: You can generally also select the “S7ONLINE” access point here.

44

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 45

3 Getting Started “PG Operation”

How to Configure for HMI Operation

2.1 Select the access point in the “Access Point of the Application” list box. The current assignment

then appears at the bottom in the list box “Interface Parameter Assignment Used”.

2.2 If the suitable access point for your application is not present, click the “Select” button in the

“Add/Remove” field.

This opens the dialog in which you can add new access points. Example:

Commissioning PC Stations - Manual and Quick Start

Release 5/2005

C79000-G8976-C156-07

45

Page 46

3 Getting Started “PG Operation”

2.3 Confirm your entries.

How to Configure for HMI Operation

As an alternative, you can also specify new access points in the “Configuration Console” tool.

-> see “Tools”

2.4 In the “Interface Parameter Assignment Used“ list box (or “Assigned Interface Parameter

Assignment”), select the entry you require. Some modules offer alternatives, for example the

CP 1613 as follows:

S If you use the TCP protocol - “CP1613(RFC1006)”,

S If you use the ISO protocol - “CP1613(ISO)”,

or CP 5613/CP 5614 as follows:

S Normal situation - “CP5613_5614(PROFIBUS)”,

S on an MPI chain - “CP5613_5614(MPI)”.

For further details on setting access points, refer to the section ”Tools”.

3. Set the required communication parameters.

For more detailed information on the module-dependent settings, refer to the previous section

“Step: Configuration for PG operation - programming device (PG/PC)”.

4. When you close the Properties window, you return to the start dialog of the “Set PG/PC

Interface” communication program.

5. Close the configuration program with the “OK” button.

Note

Remember that by clicking on a module to make settings, it is possible to change

the assignment. If you have accidentally changed an assignment, make sure you

correct it again.

46

Commissioning PC Stations - Manual and Quick Start

C79000-G8976-C156-07

Release 5/2005

Page 47

3 Getting Started “PG Operation”

Entries in the Client Program

For communication without project engineering data as described here, all the data

of the partner device relevant for communication must be known. Apart from the

access point described above, this includes the connection name and the station

address. The necessary parameters are described in detail in the manual on OPC

/1/.

Below, we want to show you how to add the ITEM and its parameters to the user

program.

Adding items - Follow the steps below:

How to Configure for HMI Operation

1. Open the client program and create an item. In the OPC Scout program, open the input boxes

for inserting items by selecting “Add Item” in the context menu on the right-hand side of the

program window. Browsing for the unconfigured connection is not yet possible at this time.

2. Add item

Enter the item with the previously described parameters in the “Add Item” dialog and click on

the “Add Item” button. If the syntax is correct, the item appears in the name space under the

“S7” branch.

3.

Commissioning PC Stations - Manual and Quick Start