Page 1

Installation Instructions

Document No. 550-139

October 26, 2016

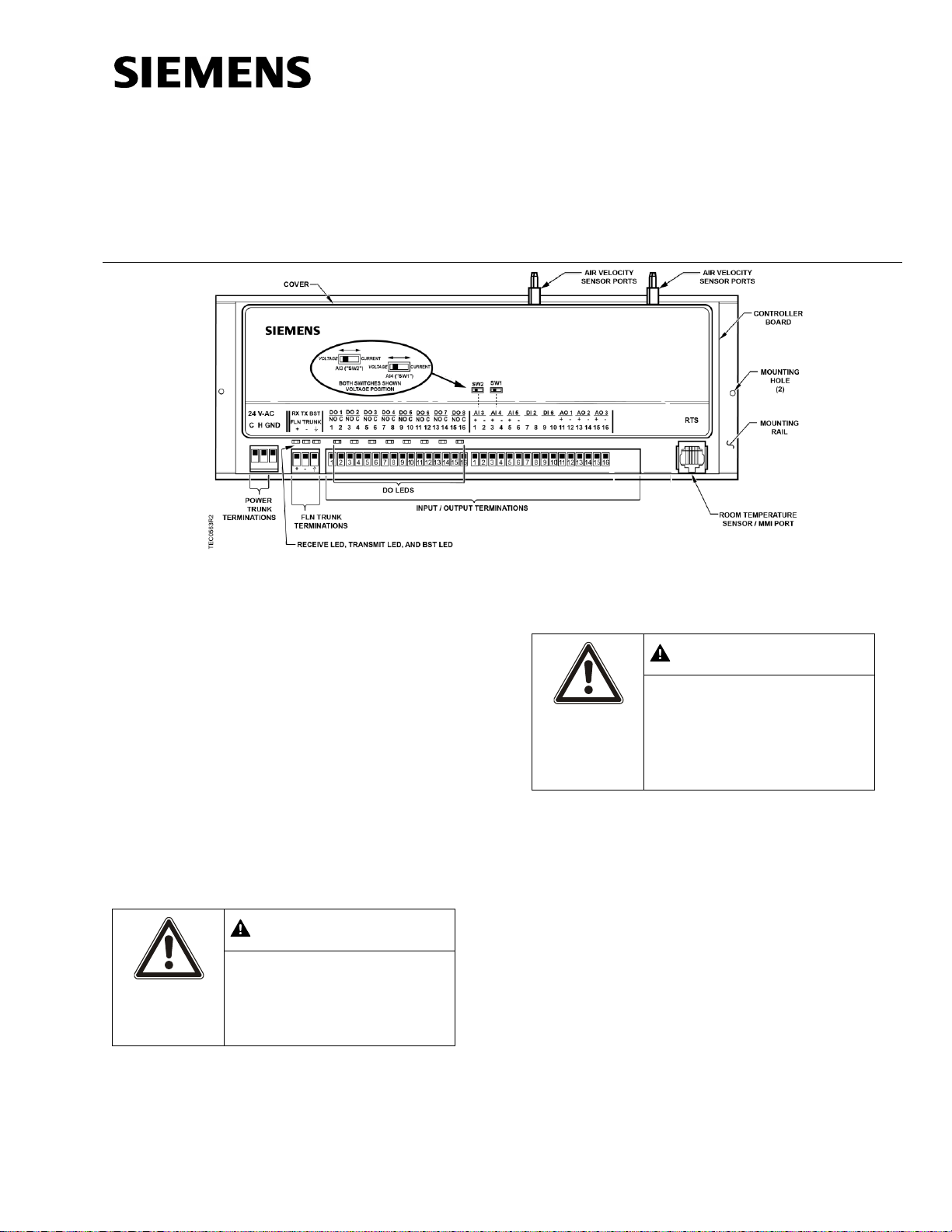

BACnet PTEC Dual Duct 2 AVS

Controller

Generic Controller I/O Layout. See Wiring Diagram for application specific details.

WARNING

Personal injury/loss of life may

occur if you do not follow the

procedures as specified.

CAUTION

Equipment damage or loss of

data may occur if you do not

follow the procedures as

specified.

Siemens BACnet PTEC Dual Duct

2 AVS Controller

550-497PA

Control Applications

6665 through 6669

Product Description

These instructions explain how to field install or

replace a Siemens BACnet PTEC Dual Duct 2 AVS

Controller.

Warning/Caution Notation

Product Numbers

Shipping carton includes a controller assembly, a

mounting rail, and two self-tapping/drilling screws.

Item No. 550-139. Rev. CA Page 1 of 6

Page 2

Document No. 550-139

CAUTION

Keep the unit in its static-proof

bag until installation.

Otherwise, you run the risk of

damage to the printed circuit

board from electrostatic

discharge.

Low cost temporary

temperature sensor, 10K

thermistor with RJ11 (1”

long), that enables space

control if the permanent room

or duct sensor is not installed

(pack of 25).

540-658P25

Duct Temperature Sensor,

NTC 10K Ω Type 2, 3" Probe

for Commissioning only

QAM1030.008P50

New controller installation

10 Minutes

Replacement (old controller has

removable terminal blocks)

6 Minutes

Replacement (old controller does

not have removable terminal

blocks)

16 Minutes

NOTE:

You may require additional time for

database work at the field panel.

NOTE:

If the controller is being installed on a

box with 1 or more stages of electric

heat, the 550-809 MOV with preterminated spade connectors must be

installed across the manufacturersupplied airflow switch. MOVs can be

installed at the time the controller is

factory mounted; coordinate with the

box manufacturer prior to order

placement. For field installation, see

Metal Oxide Varistor Kit Installation

Instructions

(540-986).

NOTE:

A low-cost temporary RTS (540658P25) is available that plugs into the

RTS port on the controller, providing

temperature input and actual space

control until a permanent RTS is

installed.

NOTE:

All wiring must conform to national and

local codes and regulations (NEC, CE,

etc.).

Installation Instructions

October 26, 2016

Accessories

Room temperature sensor installed (optional).

24 Vac Class II power available.

Supply power to the unit is OFF.

Any application specific hardware or devices

installed.

Air velocity sensors installed in ducts.

Expected Installation Time

Required Tools and Equipment

Small flat-blade screwdriver (1/8-inch blade

width)

Cabling and connectors

Cordless drill/driver set

ESD wrist strap

Prerequisites

Wiring conforms to NEC and local codes and

regulations. For further information see the

Wiring Guidelines Manual

(125-3002).

Page 2 of 6 Siemens Industry, Inc.

Installation Instructions

1. Secure the mounting rail in the controller’s

desired location.

2. Place the ESD wrist strap on your wrist and

attach it to a good earth ground.

3. Remove the controller from the static proof bag

and snap it into place on the mounting rail.

Page 3

4. Connect the FLN.

CAUTION

It is very important that the

neutral that supplies the TEC

be earth grounded at the source

of the 24 Vac power.

Possible erratic equipment

operation or damage if neutral

is left floating.

CAUTION

The controller’s DOs control 24

Vac loads only. The maximum

rating is 12 VA for each DO. An

external interposing relay is

required for any of the following:

• VA requirements higher than

the maximum

• 110 or 220 Vac requirements

• DC power requirements

• Separate transformers used to

power the load

(for example part number 540147, Terminal Equipment

Controller Relay Module)

5. Connect the point wiring (see

Wiring Diagram

s).

6. Plug the room temperature sensor cable into the

RTS port.

7. Connect the power trunk. DO NOT apply power

to the controller without first consulting the

specialist. This TEC is designed to work with 2-

Document No. 550-139

Installation Instructions

October 26, 2016

Wiring Diagrams

wire AC power (Neutral and Phase (hot) at 24

Vac +/-20%. Use of the earth terminal is optional

and if used it should be connected to the nearest

earth ground (building steel, conduit or duct work

(if earthed)).)

The installation is complete.

Siemens Industry, Inc. Page 3 of 6

Page 4

Document No. 550-139

NOTE:

If the voltage/current switch is set to

current and a 4 to 20 mA sensor is

connected to an AI, then special

wiring requirements must be followed.

NOTE:

When wiring any actuator that uses a 0 to

10V control signal and ties AC neutral to DC

common, an additional wire must connect

the actuator AC neutral to the DC common

of the PTEC/TEC AO being used to control

the actuator.

Actuator

Symbol

TEC

Connection

Function

Terminal

Connection

Standard

Color

1 H Supply (SP)

G

Red

2 C Neutral (SN)

G0

Black

8

AO3 – 15

(+)

0 to 10V

input signal

Y

Gray

--

C to AO3

16 (-)

Common

jumper

--

--

Installation Instructions

October 26, 2016

Wiring for AI with a 4 to 20 mA Sensor.

24 Vac Modulating Control.

Page 4 of 6 Siemens Industry, Inc.

Page 5

Document No. 550-139

Installation Instructions

October 26, 2016

Applications 6665, 6666, 6667, and 6668 with Hot

Water Reheat.

Applications 6665, 6666, 6667, and 6668 with Electric

Auxiliary Reheat.

Siemens Industry, Inc. Page 5 of 6

Page 6

Document No. 550-139

Information in this document is based on specifications believed correct at the time of publication. The right is reserved to make changes as

design improvements are introduced. Product or company names mentioned herein may be the trademarks of their respective owners. ©

2016 Siemens Industry, Inc.

Siemens Industry, Inc.

Building Technologies Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

USA

Tel. 1 + 847-215-1000

Your feedback is important to us. If you have

comments about this document, please send them

to SBT_technical.editor.us.sbt@siemens.com.

Document No.550-139

Printed in the USA

Page 6 of 6

Installation Instructions

October 26, 2016

Cyber security disclaimer

Products, solutions and services from Siemens

include security functions to ensure the secure

operation of building automation and control, fire

safety, security management, and physical security

systems. The security functions on these products,

solutions and services are important components of

a comprehensive security concept.

Drafting, implementing and managing a

comprehensive and up-to-date security concept,

customized to individual needs, is nevertheless

necessary, and may result in additional plant- or

site-specific preventive measures to ensure secure

operation of your site regarding building automation

and control, fire safety, security management, and

physical security. These measures may include, for

example, separating networks, physically protecting

system components, user training, multi-level

defensive measures, etc. For additional information

on security as part of building technology and our

product, solution and service offerings, please

contact your Siemens sales representative or project

department. We strongly recommend to always

comply with our security advisories on the latest

security threats, patches and other related

measures. http://www.siemens.com/cert/en/cert-

security-advisories.htm

Application 6669 – Variable Air Volume with

Changeover with Hot Water Reheat.

Loading...

Loading...