Page 1

SIMOGEAR gearbox

BA 2030

Operating Instructions · 06/2012

SIMOGEAR

Answers for industry.

Page 2

Page 3

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

BA 2030

SIMOGEAR

Gearbox

BA 2030

Operating Instructions

General information and

_________________

safety notes

_________________

Technical description

Incoming goods, transport,

_________________

and storage

_________________

Installation

_________________

Commissioning

_________________

Operation

_________________

Faults, causes and remedies

_________________

Service and maintenance

_________________

Disposal

_________________

Technical data

_________________

Spare parts

_________________

Declaration of Incorporation

1

2

3

4

5

6

7

8

9

10

11

12

Original Operating Instructions

06/12

70000004040207

Page 4

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

70000004040207

Ⓟ 07/2012 Technical data subject to change

Copyright © Siemens AG 2012.

All rights reserved

Page 5

Table of contents

1 General information and safety notes ........................................................................................................ 7

1.1

1.2

1.3

1.4

1.5

2

Technical description............................................................................................................................... 13

2.1

2.2

2.3

2.4

2.5

2.5.1

2.5.2

2.5.3

Incoming goods, transport, and storage................................................................................................... 19

3

3.1

3.2

3.2.1

3.2.2

General information .......................................................................................................................7

Copyright........................................................................................................................................8

Intended use ..................................................................................................................................9

Obligations of the user ...................................................................................................................9

Particular types of hazards ..........................................................................................................11

General technical description.......................................................................................................13

Shaft seals ...................................................................................................................................14

Cooling.........................................................................................................................................14

Rating plate..................................................................................................................................15

Surface treatment ........................................................................................................................15

General information on surface treatment ...................................................................................15

Painted version ............................................................................................................................16

Primed version .............................................................................................................................18

Incoming goods............................................................................................................................19

Transport......................................................................................................................................20

General information on transport .................................................................................................20

Fastening for suspended transport ..............................................................................................21

3.3

3.3.1

3.3.2

3.3.3

3.3.3.1

3.3.3.2

3.3.3.3

Installation ............................................................................................................................................... 25

4

4.1

4.2

4.3

4.4

4.5

4.6

4.7

BA 2030

Operating Instructions, 06/12, 70000004040207

Storage.........................................................................................................................................22

General information for storage ...................................................................................................22

Storage up to 6 months................................................................................................................22

Storage up to 36 months with long-term preservation (optional).................................................23

Notes for storage up to 36 months ..............................................................................................23

Gearbox filled with operating oil and anti-corrosive agent...........................................................23

Gearbox completely filled with oil.................................................................................................23

Unpacking ....................................................................................................................................25

General information on installation ..............................................................................................25

Thread sizes and tightening torques for fastening bolts ..............................................................27

Fastening in the case of high shock loads...................................................................................28

Gearbox with foot mounting.........................................................................................................28

Gearboxes in foot or flange version.............................................................................................29

Mounting an input or output element on the gearbox shaft .........................................................29

3

Page 6

Table of contents

4.8 Removing and installing the protection cover ............................................................................. 32

4.9 Installing and removing the shaft-mounted gearbox................................................................... 33

4.9.1

4.9.2

4.9.2.1

4.9.2.2

4.9.3

4.9.3.1

4.9.3.2

4.9.3.3

4.9.3.4

4.9.4

4.9.5

4.9.5.1

4.9.5.2

4.9.5.3

Commissioning ........................................................................................................................................ 47

5

General information on installing the shaft-mounted gearbox .................................................... 33

Mounting and removing the hollow shaft with feather key.......................................................... 34

Mounting the hollow shaft with parallel key................................................................................. 34

Removing the hollow shaft with parallel key ............................................................................... 35

Mounting the hollow shaft with shrink disk.................................................................................. 37

Mounting the hollow shaft with shrink disk.................................................................................. 37

Mounting the shrink disk ............................................................................................................. 38

Pulling off the shrink disk ............................................................................................................ 41

Cleaning and lubricating shrink disks.......................................................................................... 41

Mounting the hollow shaft with splines........................................................................................ 42

Torque arms with shaft-mounted gearboxes .............................................................................. 43

General information regarding torque arms................................................................................ 43

Mounting torque arms on parallel shaft gearboxes..................................................................... 44

Mounting torque arms on bevel gearboxes................................................................................. 45

5.1

5.2

5.3

6

Operation................................................................................................................................................. 49

7

Faults, causes and remedies................................................................................................................... 51

8

Service and maintenance ........................................................................................................................ 55

8.1

8.2

8.2.1

8.2.2

8.2.3

8.2.4

8.2.5

8.2.5.1

8.2.5.2

8.2.5.3

8.2.5.4

8.2.6

8.2.7

8.2.8

8.2.9

General information for commissioning ...................................................................................... 47

Checking the oil level prior to commissioning............................................................................. 47

Mounting the oil expansion unit .................................................................................................. 48

General notes about maintenance work ..................................................................................... 55

Checking and changing lubricants .............................................................................................. 57

General safety notes for checking and changing lubricants ....................................................... 57

Checking the oil level .................................................................................................................. 58

Checking the oil level using the oil sight glass (optional)............................................................ 59

Checking the oil quality ............................................................................................................... 59

Changing the oil .......................................................................................................................... 60

General safety notes for changing the oil ................................................................................... 60

Draining the oil ............................................................................................................................ 61

Flushing the gearbox when changing between incompatible oils............................................... 62

Filling in oil................................................................................................................................... 63

Topping up with oil ...................................................................................................................... 64

Changing the roller bearing grease............................................................................................. 64

Service life of the lubricants ........................................................................................................ 65

Recommended lubricants ........................................................................................................... 67

8.3

8.4

8.5

8.6

8.7

8.8

BA 2030

Checking the gearbox for leaks .................................................................................................. 69

Replacing the vent valve............................................................................................................. 69

Checking the oil level sensor (optional) ...................................................................................... 70

Cleaning the gearbox.................................................................................................................. 70

Checking tightness of fastening bolts ......................................................................................... 71

Inspecting the gearbox or geared motor..................................................................................... 71

4 Operating Instructions, 06/12, 70000004040207

Page 7

Table of contents

9 Disposal................................................................................................................................................... 73

10 Technical data ......................................................................................................................................... 75

10.1

10.2

10.3

10.4

10.5

10.5.1

10.5.2

10.5.3

10.5.4

10.6

10.6.1

10.6.2

10.6.3

Spare parts............................................................................................................................................ 107

11

11.1

11.2

11.3

11.4

11.5

Type designation..........................................................................................................................75

General technical data .................................................................................................................76

Weight..........................................................................................................................................78

Sound energy level ......................................................................................................................78

Mounting positions .......................................................................................................................79

General notes on mounting positions ..........................................................................................79

Two- and three-stage helical gearboxes......................................................................................80

Parallel shaft gearbox ..................................................................................................................87

Bevel gearboxes ..........................................................................................................................93

Oil quantities ..............................................................................................................................102

Helical gearbox ..........................................................................................................................102

Parallel shaft gearbox ................................................................................................................104

Bevel gearboxes ........................................................................................................................105

Stocking of spare parts ..............................................................................................................107

Helical gearboxes D / Z, sizes 19 - 89 .......................................................................................108

Parallel shaft gearboxes F sizes 29 - 89....................................................................................110

Bevel gearbox B sizes 29 - 49 ...................................................................................................113

Bevel gearbox K sizes 39 - 89 ...................................................................................................116

12

Declaration of Incorporation................................................................................................................... 119

BA 2030

Operating Instructions, 06/12, 70000004040207

5

Page 8

Table of contents

BA 2030

6 Operating Instructions, 06/12, 70000004040207

Page 9

General information and safety notes

1.1 General information

NOTICE

Siemens does not accept liability for any damage or outages resulting from non-compliance

with these operating instructions.

These operating instructions are an integral part of the gearbox supplied and must be kept in

its vicinity for reference at all times.

These operating instructions apply to the standard version of SIMOGEAR gearboxes:

● Helical gearboxes Z and D, sizes 19 to 89

● Parallel shaft gearboxes FZ and FD, sizes 29 to 89

● Bevel gearboxes B, K, sizes 29 to 89

The precise type designation is described in Section Type designation (Page 75).

1

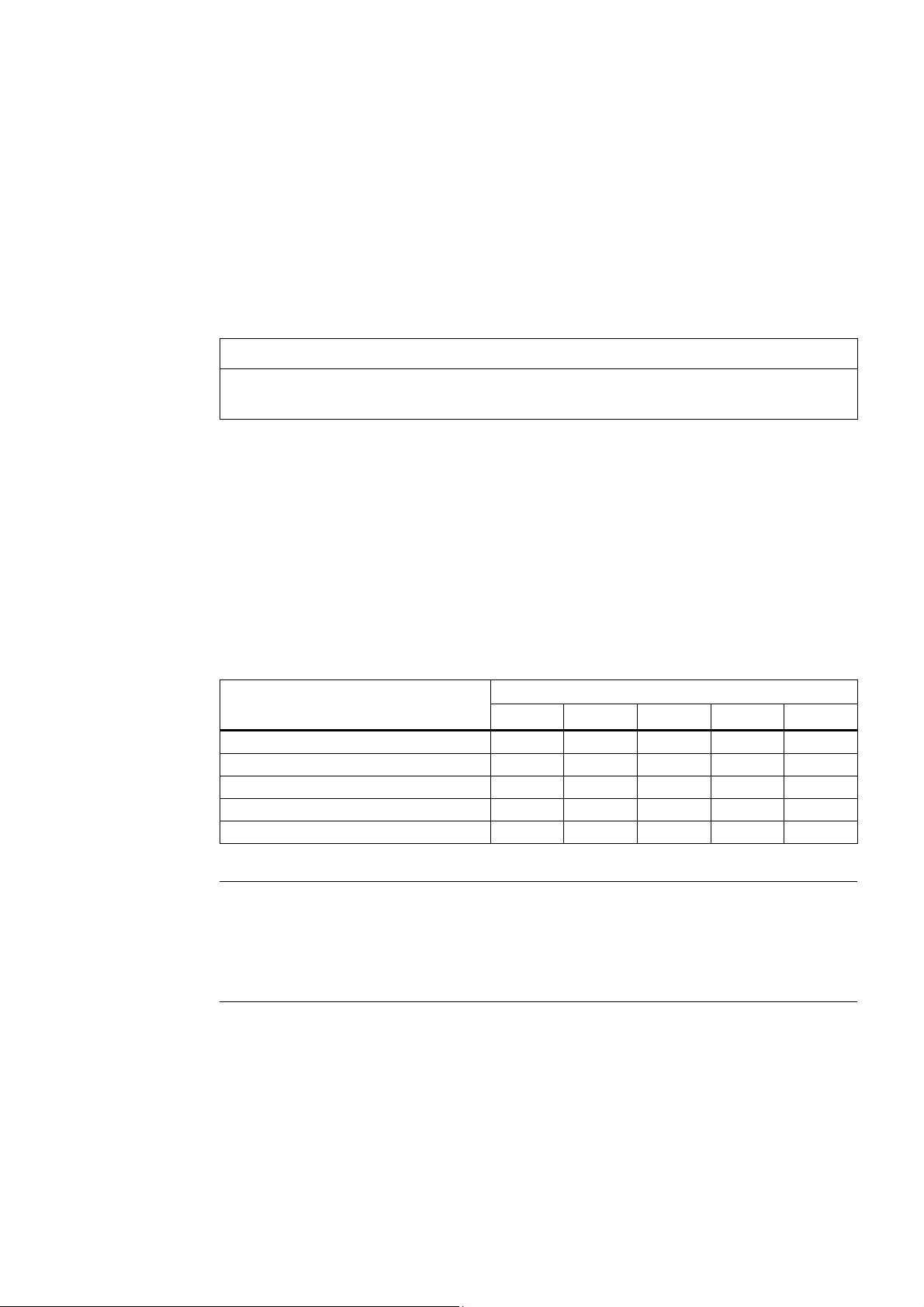

Table 1- 1 Order number code

SIMOGEAR gearbox

Helical gearbox Z 2 K J 3 1

Helical gearbox D 2 K J 3 2

Parallel shaft gearbox FZ 2 K J 3 3

Parallel shaft gearbox FD 2 K J 3 4

Bevel gearbox B, K 2 K J 3 5

Note

In addition to these operating instructions, special contractual agreements and technical

documentation apply to special gearbox designs and the associated supplementary

equipment.

Please refer to the other operating instructions supplied with the product.

Structure of the order number - Position

1 2 3 4 5

BA 2030

Operating Instructions, 06/12, 70000004040207

7

Page 10

General information and safety notes

1.2 Copyright

The gearboxes described here correspond to the state of the art at the time these operating

instructions were printed.

In the interest of technical progress we reserve the right to make changes to the individual

assemblies and accessories which we regard as necessary to preserve their essential

characteristics and improve their efficiency and safety.

If you have any technical questions, please contact Technical Support.

Europe - Germany

Phone: +49 (0) 911 895 7222

Fax: +49 (0) 911 895 7223

America - USA

Phone: +1 42 32 62 25 22

Asia - China

Phone: +86 10 64 75 75 75

Email: support.automation@siemens.com

Internet German: http://www.siemens.de/automation/support-request

Internet English: http://www.siemens.com/automation/support-request

Applicable operating instructions

BA 2030 operating instructions for SIMOGEAR gearboxes.

BA 2330 operating instructions for LA / LE motors for mounting on SIMOGEAR gearboxes.

1.2 Copyright

The copyright to these operating instructions is held by Siemens AG.

These operating instructions must not be wholly or partly reproduced for competitive

purposes, used in any unauthorized way or made available to third parties without our

agreement.

BA 2030

8 Operating Instructions, 06/12, 70000004040207

Page 11

General information and safety notes

1.3 Intended use

1.3 Intended use

The SIMOGEAR gearboxes described in these operating instructions have been designed

for stationary use in general engineering applications.

Unless otherwise agreed, the gearboxes have been designed for use in plants and

equipment in industrial environments.

The gearboxes have been built using state-of-the-art technology and are shipped in an

operationally reliable condition. Changes made by users could affect this operational

reliability and are forbidden.

Note

The performance data assumes an ambient temperature of -20 °C to +40 °C and an

installation altitude of up to 2 000 m above sea level.

In the case of other ambient temperatures and installation altitudes, please contact Technical

Support.

The gearboxes have been designed solely for the application described in Technical data

(Page 75). Do not operate the gearboxes outsi

de the specified power limits. Other operating

conditions must be contractually agreed.

Do not stand or walk on the gearbox or place objects on the gearbox.

1.4 Obligations of the user

The operator must ensure that all persons assigned to work on the gearbox have read and

understood these operating instructions and that they follow them in all points in order to:

● Eliminate the risk to life and limb of users and others

● Ensure the safety and reliability of the gearbox

● Avoid disruptions and environmental damage through incorrect use.

BA 2030

Operating Instructions, 06/12, 70000004040207

9

Page 12

General information and safety notes

1.4 Obligations of the user

Note the following safety information:

Shut down the geared motors and disconnect the power before you carry out any work on

them.

Make sure that the drive unit cannot be turned on accidentally, e.g. lock the key-operated

switch. Place a warning notice at the drive connection point which clearly indicates that work

is in progress on the geared motor.

Carry out all work with great care and with due regard to safety.

Ensure compliance with the relevant safety and environmental regulations during transport,

mounting and dismantling, operation, and care and maintenance of the unit.

Read the instructions on the rating plates attached to the geared motor. The rating plates

must be kept free from paint and dirt at all times. Replace any missing rating plates.

In the event of changes during operation, immediately switch off the drive unit.

Take appropriate protective measures to prevent accidental contact with rotating drive parts,

such as couplings, gear wheels or belt drives.

Take appropriate measures to prevent accidental contact with parts and equipment that heat

up to over +70 °C during operation.

When removing protective equipment, keep fasteners in a safe place. Re-attach removed

protective equipment before commissioning.

Collect and dispose of used oil in accordance with regulations. Remove oil spillages

immediately with an oil-binding agent in compliance with environmental requirements.

Do not carry out any welding work on the gearbox. Do not use the gearbox as a grounding

point for welding operations.

Carry out equipotential bonding in accordance with applicable regulations and directives.

Such work must be carried out by qualified electrical personnel only.

Do not use high-pressure cleaning equipment or sharp-edged tools to clean the gearbox.

Observe the permissible tightening torque of the fastening bolts.

Replace damaged bolts with new bolts of the same type and strength class.

We will only accept liability for original spare parts supplied by Siemens AG.

If the geared motor is being installed in a plant or equipment, the manufacturers of such

plant or equipment must ensure that the contents of these operating instructions are

incorporated into their own instructions, information, and descriptions.

BA 2030

10 Operating Instructions, 06/12, 70000004040207

Page 13

General information and safety notes

1.5 Particular types of hazards

1.5 Particular types of hazards

WARNING

Depending on operating conditions, the gearbox may exhibit extreme surface

temperatures.

Hot surfaces over +55 °C pose a burn risk.

Cold surfaces below 0 °C pose a risk of damage due to freezing.

Do not touch the gearbox without protection.

WARNING

Danger of scalding caused by hot oil emerging from the unit.

Before starting any work wait until the oil has cooled down to below +30 °C.

WARNING

Avoid breathing in vapors when working with solvents.

Ensure adequate ventilation.

WARNING

Risk of explosion when working with solvents.

Ensure adequate ventilation. Do not smoke!

WARNING

Risk of eye injury.

Rotating parts can throw off small foreign particles such as sand or dust. Wear protective

eyewear!

In addition to the required personal protective equipment, wear suitable protective gloves

and eyewear when working with the gearbox or the geared motor.

BA 2030

Operating Instructions, 06/12, 70000004040207

11

Page 14

General information and safety notes

1.5 Particular types of hazards

BA 2030

12 Operating Instructions, 06/12, 70000004040207

Page 15

Technical description

2.1 General technical description

The gearbox is supplied with two or three transmission stages.

The gearbox is suitable for various mounting positions. Observe the correct oil level.

Housing

The housings for sizes 19 and 29 are made of die-cast aluminum.

Depending on the gearbox type, the housings of sizes 39 and 49 are made of die-cast

aluminum or cast iron.

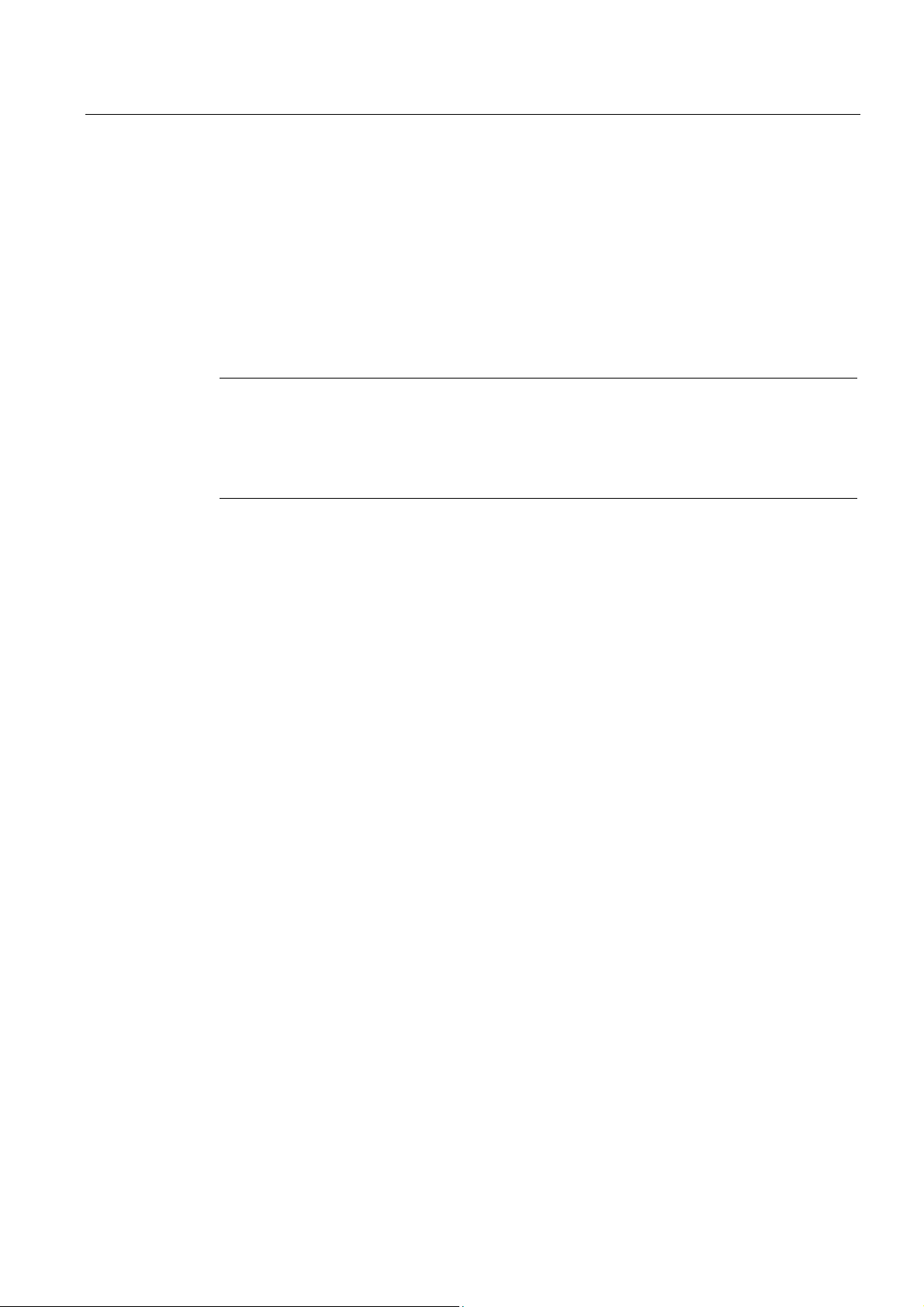

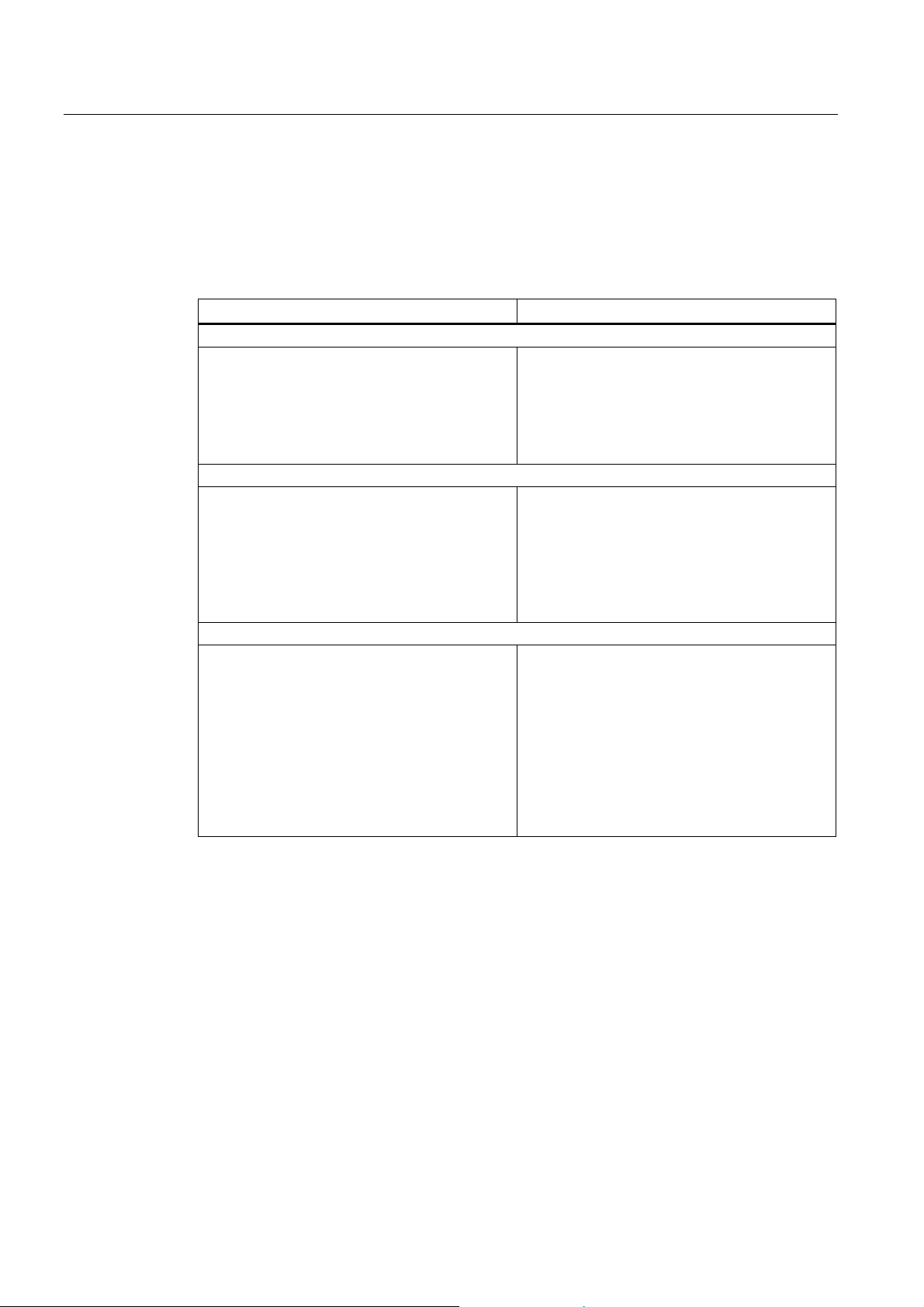

Table 2- 1 Housing material

Gearbox type

Helical gearbox Aluminum Cast iron

Parallel shaft gearbox Cast iron Cast iron

Bevel gearbox B Aluminum Aluminum

Bevel gearbox K Cast iron Cast iron

Size

39 49

2

From size 59, the gearbox housings are made of cast iron.

Geared components

The geared components are hardened and ground.

The bevel gear stage is lapped in pairs.

Lubrication

The geared components are supplied with adequate lubricant by means of dip lubrication.

Shaft bearings

All shafts are mounted in roller bearings. The roller bearings are lubricated by means of dip

lubrication or oil spray lubrication. Bearings that are not supplied with lubricant are closed

and grease-lubricated.

BA 2030

Operating Instructions, 06/12, 70000004040207

13

Page 16

Technical description

2.2 Shaft seals

2.2 Shaft seals

The shaft seals on the output side prevent lubricant from escaping from the housing at the

shaft outlet and prevent pollution from entering the housing.

The optimum use of the seals depends on the ambient conditions and the lubricant being

used.

Radial shaft sealing ring

A high-quality radial shaft sealing ring is used as standard seal. It is provided with an

additional dust lip to protect against contaminants from outside.

Seal for a longer service life (optional)

The radial shaft sealing ring with dust lip has an additional buffer axial seal towards the

inside of the gearbox. This has a sinusoidally shaped sealing lip to protect against the

ingress of pollution in the oil in the sealing ring.

Seal to handle increased environmental stress (optional)

This seal is equipped with an additional fiber washer. In addition to a longer service life, it

also provides higher protection against increased environmental stress as a result of

humidity and dust.

2.3 Cooling

NOTICE

Dust deposits prevent heat radiation and cause high housing temperatures.

Keep the gearbox free from dirt, dust, etc.

The gearbox does not normally require additional cooling. The generously dimensioned

housing surface is sufficient for dissipating heat losses where there is free convection. If the

housing temperature exceeds a value of +80 °C, please contact Technical Support.

BA 2030

14 Operating Instructions, 06/12, 70000004040207

Page 17

Technical description

2.4 Rating plate

2.4 Rating plate

The rating plate on the gearbox or geared motor is of coated aluminum foil. It is covered with

a special masking film which ensures permanent resistance to UV radiation and media of all

kinds, such as oils, greases, salt water and cleaning agents.

The adhesive and the material ensure firm adhesion and long-term legibility within the

operating temperature range from -40 °C to +155 °C.

The edges of the rating plate are paint-finished to match the color of the gearbox or motor to

which it is affixed.

2.5 Surface treatment

2.5.1 General information on surface treatment

All paint finishes are sprayed on.

NOTICE

Any damage to the paint finish will destroy the exterior protection and cause corrosion.

Do not damage the paint finish.

Note

Information about repaintability is not a guarantee of the quality of the paint product

purchased from your supplier.

Only the paint manufacturer is liable for the quality and compatibility.

BA 2030

Operating Instructions, 06/12, 70000004040207

15

Page 18

Technical description

2.5 Surface treatment

2.5.2 Painted version

The corrosion protection system is classified according to the corrosiveness categories in

DIN EN ISO 12944-2.

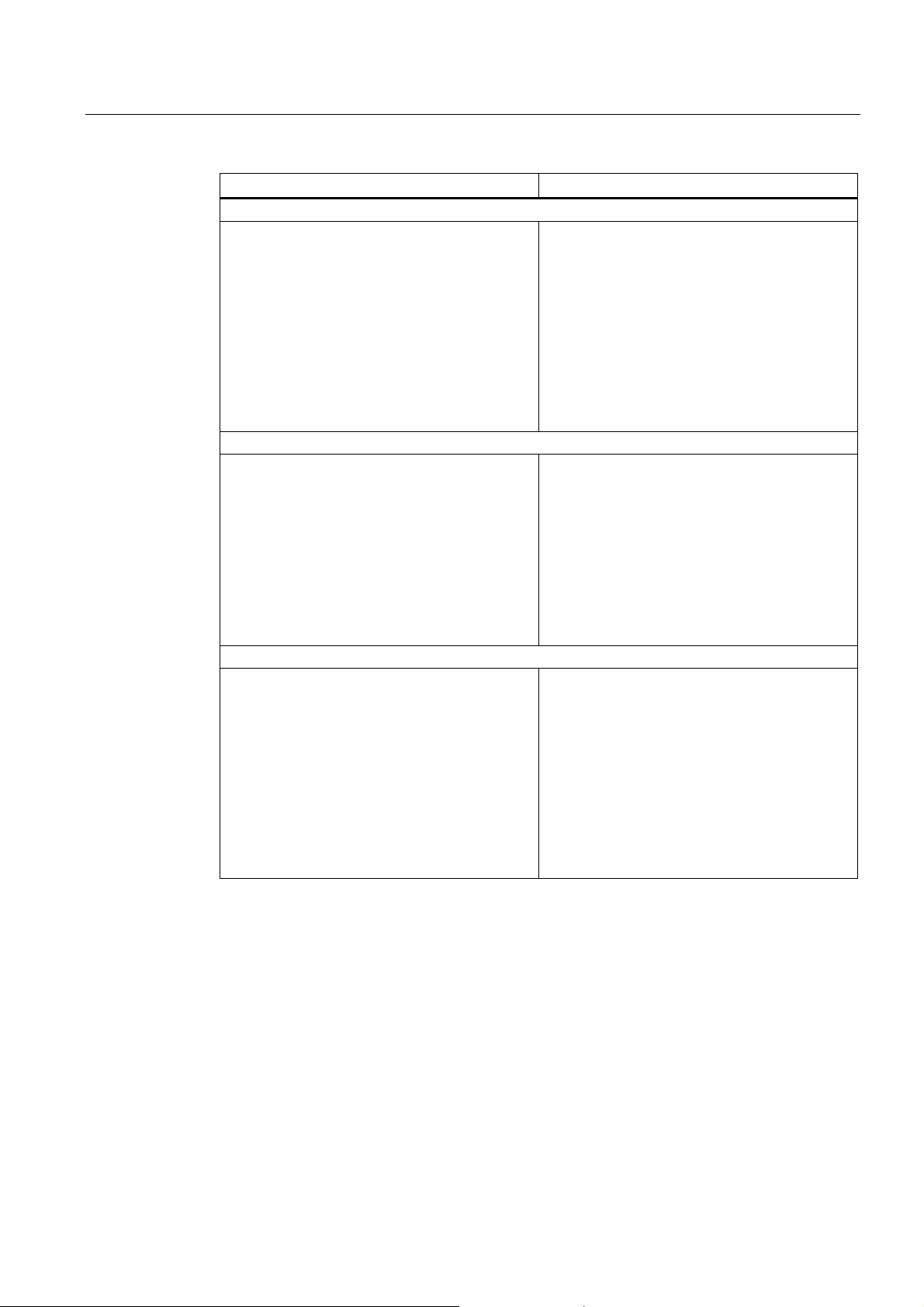

Table 2- 2 Paint according to corrosiveness categories

Paint system Description

Corrosiveness category C1, unpainted for gearbox housings made of aluminum

Corrosiveness category C1 for normal environmental stress

1-component hydro paint, top coat

Corrosiveness category C2 for low environmental stress

2-component polyurethane base coat

2-component, polyurethane top coat

Indoor installation

Heated buildings with neutral atmospheres

Resistance to greases and some resistance

to mineral oils, aliphatic solvents

Standard

Indoor installation

Heated buildings with neutral atmospheres

Resistance to greases and some resistance

to mineral oils, aliphatic solvents

Standard paint for gearbox casings made of

cast iron

Indoor and outdoor installation

Unheated buildings with condensation,

production areas with low humidity,

e.g. warehouses and sports facilities

Atmospheres with little contamination, mostly

rural areas

Resistance to greases, mineral oils and

sulfuric acid (10 %), caustic soda (10 %) and

some resistance to aliphatic solvents

BA 2030

16 Operating Instructions, 06/12, 70000004040207

Page 19

Technical description

2.5 Surface treatment

Paint system Description

Corrosiveness category C3 for medium environmental stress

2-component polyurethane base coat

2-component, polyurethane top coat

Corrosiveness category C4 for high environmental stress

2-component epoxy

zinc phosphate base coat

2-component polyurethane top coat

Corrosiveness category C5 for very high environmental stress

2-component epoxy

zinc phosphate base coat

2-component epoxy iron mica intermediate coat

2-component polyurethane top coat

Indoor and outdoor installation

Production areas with high humidity and some

air contamination, e.g. food production areas,

dairies, breweries and laundries

Urban and industrial atmospheres, moderate

contamination from sulfur dioxide, coastal

areas with low salt levels

Resistance to greases, mineral oils, aliphatic

solvents, sulfuric acid (10 %), caustic

soda (10 %)

Indoor and outdoor installation

Chemical plants, swimming pools, wastewater

treatment plants, electroplating shops, and

boathouses above seawater

Industrial areas and coastal areas with

moderate salt levels

Resistance to greases, mineral oils, aliphatic

solvents, sulfuric acid (10 %), caustic

soda (10 %)

Indoor and outdoor installation

Buildings and areas with almost constant

condensation and high contamination,

e.g. malt factories and aseptic areas

Industrial areas with high humidity and

aggressive atmosphere, coastal areas and

offshore environments with high salt levels

Resistance to greases, mineral oils, aliphatic

solvents, sulfuric acid (10 %), caustic

soda (20 %)

In case of corrosiveness category C1, can be overpainted with 1-component hydrosystem

after prior rubbing down.

In case of corrosiveness categories C2 to C5, can be overpainted with 2-component

polyurethane paint, 2-component epoxide paint and 2-component acrylic paint after prior

rubbing down.

BA 2030

Operating Instructions, 06/12, 70000004040207

17

Page 20

Technical description

2.5 Surface treatment

2.5.3 Primed version

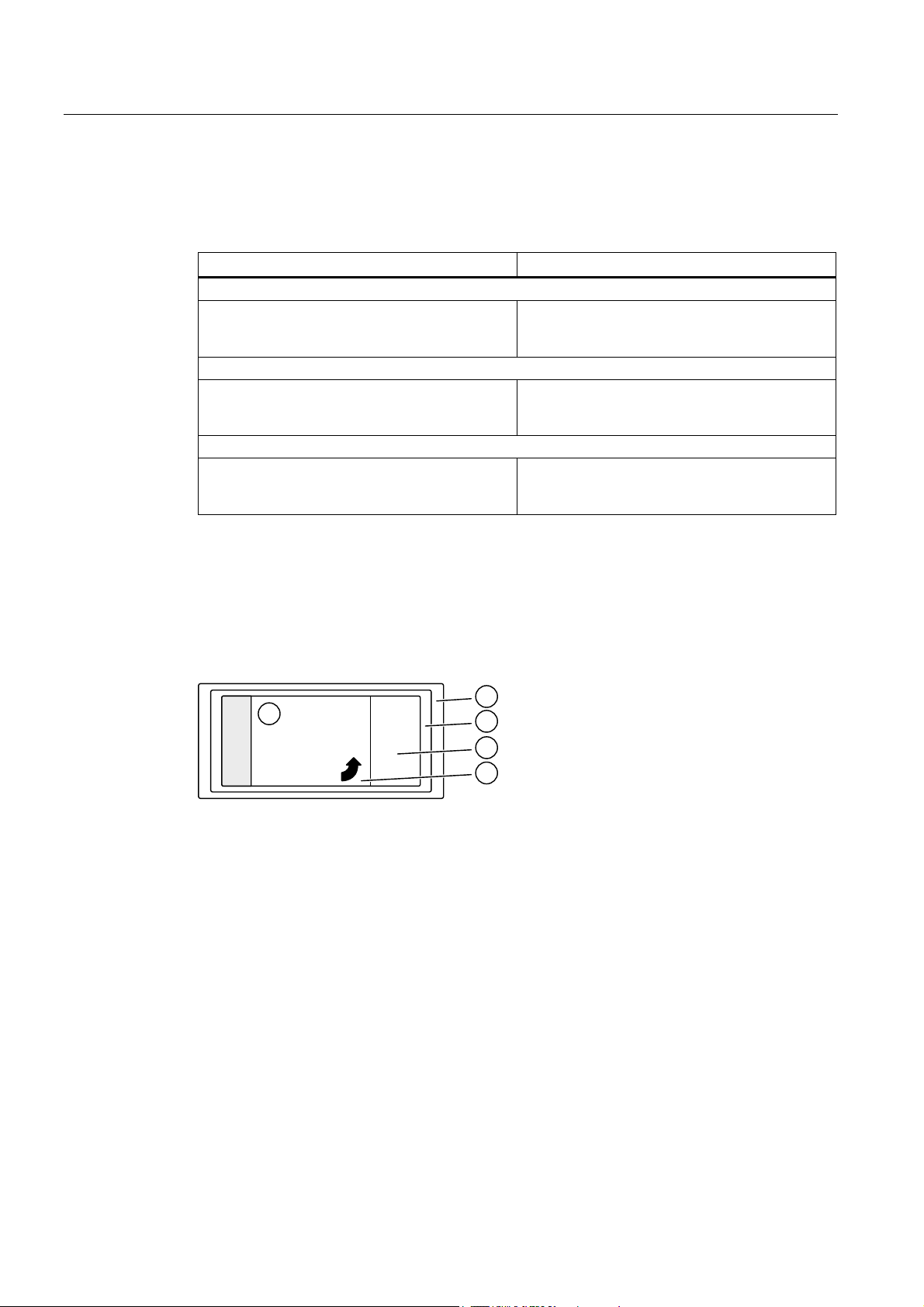

Table 2- 3 Primer according to corrosiveness category

Paint system Can be overpainted with

Unpainted corrosiveness category C1

Cast iron parts immersion primed, steel parts

primed or zinc-plated, aluminum and plastic parts

untreated

Primed according to corrosiveness category C2 G

2-component metal primer, desired coat

thickness 60 μm

Primed according to corrosiveness category C4 G

2-component epoxy zinc phosphate, desired coat

thickness 120 μm

On gearbox or geared motor versions which are primed or unpainted the rating plate and the

masking film are covered with a paint-protective film. These facilitate repainting without

further preparation, e.g., masking with adhesive tape.

Plastic paint, synthetic resin paint, oil paint,

2-component polyurethane paint,

2-component epoxide paint

2-component polyurethane paint,

2-component epoxide paint and

acid-hardening paint, 2-component acrylic paint

2-component polyurethane paint,

2-component epoxide paint and

acid-hardening paint, 2-component acrylic paint

Peeling off the paint-protective film

The paint coat must have fully hardened before the paint-protective film is peeled off (be at

least "touch-proof").

① Company logo

② Masking film

③ Rating plate

④ Paint-protective film

⑤ Peeling tab

Figure 2-1 Rating plate with paint-protective film

Procedure

1. Pull the peeling tab

2. Carefully peel the paint-protective film

the plate).

⑤ up.

④ off diagonally from one corner (not parallel to

3. Blow any paint fragments away or wipe them off with a clean cloth.

You have now removed the paint-protective film.

BA 2030

18 Operating Instructions, 06/12, 70000004040207

Page 21

Incoming goods, transport, and storage

3.1 Incoming goods

NOTICE

Make sure that damaged gearboxes or geared motors are not put into operation.

Note

Do not open or damage parts of the packaging that preserve the product.

Note

Check that the technical specifications are in accordance with the purchase order.

Inspect the delivery immediately on arrival for completeness and any transport damage.

Notify the freight company of any damage caused during transport immediately (this is the

only way to have damage rectified free of charge). Siemens AG will not accept any claims

relating to items missing from the delivery and which are submitted at a later date.

3

The gearbox or geared motor is delivered in a fully assembled condition. Additional items

may be delivered packaged separately.

The products supplied are listed in the dispatch papers.

BA 2030

Operating Instructions, 06/12, 70000004040207

19

Page 22

Incoming goods, transport, and storage

3.2 Transport

3.2 Transport

3.2.1 General information on transport

NOTICE

The use of force will damage the gearbox or geared motor.

Transport the gearbox or geared motor carefully. Avoid knocks.

Before putting the drive into operation, remove any transport fixtures and keep them safe or

render them ineffective. You can then use them again for transporting further items or you

can apply them again.

Different forms of packaging may be used, depending on the size of the gearbox or geared

motor and the method of transport. Notwithstanding contractual agreements to the contrary,

the seaworthy packaging complies with HPE Packaging Guidelines (Bundesverband

Holzpackmittel Paletten Exportverpackungen e.V., the German Federal Association for

wooden packaging, pallets, and export packaging).

Note the symbols which appear on the packaging. These have the following meanings:

This way up

Center of gravity

Fragile

Do not use hand hook

Keep dry

Attach here

Keep cool

BA 2030

20 Operating Instructions, 06/12, 70000004040207

Page 23

Incoming goods, transport, and storage

3.2 Transport

3.2.2 Fastening for suspended transport

WARNING

Gearboxes or geared motors may come loose and fall down during transport if not secured

sufficiently.

Use only the transport eye or eyebolt of the gearbox to transport the gearbox or geared

motor. This is only designed for the weight of the gearbox or geared motor, and it is not

permissible to add additional loads.

Do not use the integrally cast lifting eyes on the motor for transport because of the risk of

breaking.

If necessary, use additional, suitable lifting accessories for transport or during installation.

When attaching by a number of chains and ropes just two strands must be sufficient to bear

the entire load. Secure lifting accessories against slipping.

CAUTION

Do not rig eyebolts to the front threads at the shaft ends for transportation purposes.

Table 3- 1 Maximum load of the eyebolt on the gearbox

m d

[kg] [mm]

M8 140 36 M20 1 200 72

M10 230 45 M24 1 800 90

M12 340 54 M30 3 200 108

M16 700 63

m d

3

Thread size

[kg] [mm]

Thread size

3

The eyebolt corresponds to DIN 580.

BA 2030

Operating Instructions, 06/12, 70000004040207

21

Page 24

Incoming goods, transport, and storage

3.3 Storage

3.3 Storage

3.3.1 General information for storage

WARNING

Do not stack gearboxes or geared motors one on top of another.

NOTICE

Mechanical damage (scratches), chemical damage (acids, alkalis) and thermal damage

(sparks, welding beads, heat) cause corrosion which may render the external protective

coating ineffective.

Do not damage the paint finish.

Note

Notwithstanding contractual agreements to the contrary, the guarantee period for the

standard preservative lasts 6 months from the date of delivery.

In the case of storage in transit over 6 months, special arrangements must be made for

preservation. Please contact Technical Support.

Store the gearbox or geared motor in dry, dust-free rooms that are maintained at a constant

temperature.

The storage location must be vibration- and shock-free.

The free shaft ends, sealing elements and flange surfaces must have a protective coating.

3.3.2 Storage up to 6 months

The gearbox or geared motor must be covered and stored in its position of use on a

horizontal wooden support in a dry place not subject to significant temperature fluctuations.

BA 2030

22 Operating Instructions, 06/12, 70000004040207

Page 25

Incoming goods, transport, and storage

3.3 Storage

3.3.3 Storage up to 36 months with long-term preservation (optional)

3.3.3.1 Notes for storage up to 36 months

Store the gearbox or geared motor in dry, dust-free rooms that are maintained at a constant

temperature. Special packing is then not necessary.

Otherwise, the gearbox or geared motor must be packed in plastic film or packed in airtight

sealed film and water absorbing agents. Cover them to provide protection against heat,

direct sunlight and rain.

The permissible ambient temperature range is -25 °C to +50 °C.

The life of the corrosion protection is 36 months from delivery.

3.3.3.2 Gearbox filled with operating oil and anti-corrosive agent

NOTICE

Check the oil level before commissioning.

Observe the information and procedures in Section Checking the oil level (Page 58).

The gearbox is filled with oil corresponding to the mounting position so that it is ready for

operation, and is sealed airtight using a screw plug or with a pressure breather valve with

transport fixture.

For storage up to 36 months, a VCI anti-corrosion agent (Volatile Corrosion Inhibitor) is

added.

3.3.3.3 Gearbox completely filled with oil

NOTICE

The gearbox is completely filled with operating oil.

Check the oil level before commissioning.

Observe the information and procedures in Section Checking the oil level (Page 58).

When using biologically degradable oils or oils for the foodstuff area, the gearboxes are

completely filled with operating oil and sealed airtight using a screw plug or with a pressure

breather valve with transport fixture.

Do not lower the oil level during short-time commissioning for 10 minutes in no-load

operation.

BA 2030

Operating Instructions, 06/12, 70000004040207

23

Page 26

Incoming goods, transport, and storage

3.3 Storage

BA 2030

24 Operating Instructions, 06/12, 70000004040207

Page 27

Installation

4.1 Unpacking

4.2 General information on installation

NOTICE

Make sure that damaged gearboxes or geared motors are not put into operation.

Check the gearbox or geared motor for completeness and for damage. Report any missing

parts or damage immediately.

Remove packaging and transport fixtures and dispose of them properly.

WARNING

The entire system must be load-free so that there is no danger during this work.

NOTICE

Irreparable damage to toothed components and bearings due to welding.

4

Do not carry out any welding work on the gearbox. The gearbox must not be used as a

grounding point for welding operations.

BA 2030

Operating Instructions, 06/12, 70000004040207

NOTICE

Overheating of the gearbox due to exposure to direct sunlight.

Provide suitable protective equipment such as covers or roofs. Prevent heat accumulation.

25

Page 28

Installation

4.2 General information on installation

NOTICE

Malfunction resulting from foreign objects.

The operator must ensure that no foreign objects impair the function of the gearbox.

NOTICE

Exceeding the permissible oil sump temperature due to incorrect settings of temperature

monitoring equipment.

A warning must be given when the maximum permissible oil sump temperature is reached.

The geared motor must be switched off when the maximum permissible oil sump

temperature is exceeded. This switching off can cause plant shutdown.

Note

Use headless screws of strength class 8.8 or higher to fasten the gearbox.

Exercise particular care during mounting and installation. The manufacturer cannot be held

liable for damage caused by incorrect mounting and installation.

Make sure that there is sufficient space around the gearbox or geared motor for mounting,

maintenance and repair.

On geared motors with a fan, leave sufficient free space for the entry of air. Observe the

installation conditions for the geared motor.

Provide sufficient lifting gear at the start of mounting and fitting work.

Observe the mounting position specified on the rating plate. This ensures that the correct

quantity of lubricant is provided.

Use all the fastening means that have been assigned to the particular mounting position and

mounting type.

Cap screws cannot be used in some cases due to a lack of space. In such cases, please

contact Technical Support quoting the type of gearbox.

BA 2030

26 Operating Instructions, 06/12, 70000004040207

Page 29

Installation

4.3 Thread sizes and tightening torques for fastening bolts

4.3 Thread sizes and tightening torques for fastening bolts

The general tolerance for the tightening torque in Nm is 10 %. The friction coefficient is

0.14 μ.

Table 4- 1 Tightening torques for fastening bolts

Thread size

M4 3 4 5

M5 6 9 10

M6 10 15 18

M8 25 35 41

M10 50 70 85

M12 90 120 145

M16 210 295 355

M20 450 580 690

M24 750 1 000 1 200

M30 1 500 2 000 2 400

M36 2 500 3 600 4 200

Table 4- 2 Thread size of fastening bolts for gearboxes in a foot-mounted design

Thread size

M8 29, 39 29, 39 B29, B39

M10 49 B49, K39, K49

M12 49, 59, 69 69, 79 K69, K79

M16 79, 89 89 K89

Tightening torque at strength class

8.8 10.9 12.9

[Nm] [Nm] [Nm]

Helical gearbox Parallel shaft gearbox Bevel gearbox

Size Size Size

Table 4- 3 Thread size of fastening bolts for gearboxes in a flange-mounted design

Thread

size

M6 A120 19, 29, 39 29 B29

M8 A140, A160 19, 29, 39, 49, 59 29, 39 B29, B39, K39

M10 A200 39, 49, 59, 69 49 B39, B49, K49

M12 A250, A300 59, 69, 79, 89 69, 79, 89 K69, K79, K89

M16 A350 89

BA 2030

Operating Instructions, 06/12, 70000004040207

Flange

Helical gearbox Parallel shaft gearbox Bevel gearbox

Size Size Size

27

Page 30

Installation

4.4 Fastening in the case of high shock loads

4.4 Fastening in the case of high shock loads

In the case of high shock loads provide additional suitable positive fastenings such as

cylindrical taper pins or spring pins.

NOTICE

Do not use spring washers, serrated lock washers, spring or toothed lock washers, cup

washers or conical spring washers as a substitute for the above positive fastenings.

Do not subject the housing to excessive stress when tightening the fastening bolts.

4.5 Gearbox with foot mounting

NOTICE

Do not subject the gearbox to excessive stress when tightening the fastening bolts.

The foundation must be level and free from dirt.

The levelness deviation of the gearbox support must not exceed the following values:

For gearboxes up to size 89: 0.1 mm

The foundation should be designed in such a way that no resonance vibrations are created

and no vibrations are transmitted from adjacent foundations.

The foundation structure on which the gearbox is to be mounted must be torsionally rigid. It

must be dimensioned according to the weight and torque, taking into account the forces

acting on the gearbox. If the substructure is too weak, it will cause radial or axial

displacement, which cannot be measured at a standstill.

When using foundation blocks to fasten the gearbox to a concrete foundation, suitable

recesses should be made in the foundation.

Align and grout the slide rails into the foundation.

Align the gearbox carefully with the units on the input and output side. Take into account the

elastic deformation due to operating forces.

Prevent displacement from external forces due to lateral impacts.

Use stud bolts or headless screws of strength class 8.8 or higher for the mounting foot.

Observe the tightening torque.

BA 2030

28 Operating Instructions, 06/12, 70000004040207

Page 31

Installation

4.6 Gearboxes in foot or flange version

4.6 Gearboxes in foot or flange version

NOTICE

Do not subject the gearbox housing to excessive stress by adding add-on elements to the

foot or flange.

Add-on elements must not transmit forces, torques, and vibrations to the gearbox.

The gearbox must only be mounted at either the flange or the foot to transmit force and

torque in order to prevent excessive stress to the gearbox housing, see Gearbox with foot

mounting

The se

(Page 28).

cond mounting option (foot or flange) is intended for add-on elements, e.g. protection

covers with an intrinsic weight of up to max. 30 % of the weight of the gearbox.

4.7 Mounting an input or output element on the gearbox shaft

WARNING

Risk of burns due to hot parts.

Do not touch the gearbox without protection.

NOTICE

Damage to shaft sealing rings caused by solvent or benzine.

Avoid contact at all times.

NOTICE

Damage to shaft sealing rings caused by heating over 100 °C.

Protect shaft sealing rings from heating up due to radiant heat using thermal shields.

BA 2030

Operating Instructions, 06/12, 70000004040207

29

Page 32

Installation

4.7 Mounting an input or output element on the gearbox shaft

NOTICE

Alignment errors caused by excessive angle or axial displacement of the shaft ends to be

joined lead to premature wear or material damage.

Ensure precise alignment of the individual components.

NOTICE

Damage to bearings, housing, shaft, and locking rings due to improper handling.

Do not use impacts or knocks to force the input and output elements to be mounted onto

the shaft.

Note

Deburr the parts of elements to be fitted in the area of the hole or keyways.

Recommendation: 0.2 x 45°

Where couplings are to be fitted in a heated condition, observe the specific operating

instructions for the coupling. Unless otherwise specified, the heat can be applied inductively,

using a torch or in a furnace.

Use the center holes in the shaft end faces.

Use a fitting device to fit the input or output elements.

Figure 4-1 Example of a fitting device

BA 2030

30 Operating Instructions, 06/12, 70000004040207

Page 33

Installation

4.7 Mounting an input or output element on the gearbox shaft

Observe the correct mounting arrangement to minimize stress on shafts and bearings due to

lateral forces.

Correct Incorrect

))

Procedure

D

D

a Hub

F Force

Figure 4-2 Mounting arrangement for the lowest possible stress on shafts and bearings

1. Using either benzine or solvent, remove the anti-corrosion protection from the shaft ends

and flanges and remove the protective skin provided.

2. Fit the input and output elements onto the shafts and secure them if necessary.

You have now fitted the input or output element.

BA 2030

Operating Instructions, 06/12, 70000004040207

31

Page 34

Installation

4.8 Removing and installing the protection cover

4.8 Removing and installing the protection cover

The protection cover is delivered ready-fitted to the gearbox flange. The protection cover

must be removed in order to fit the output shaft.

① Bolt

② Protection cover

③ Gearbox housing

④ Flat seal

Figure 4-3 Protection cover for hollow shaft and hollow shaft with shrink disk

Procedure

1. Release the screws ① and remove the protection cover ② and the flat seal ④.

2. Fit the output shaft.

3. Using a suitable cleaning agent, clean the contact surface of the protection cover

the gearbox.

4. Ensure that the flat seal

5. Screw on the protection cover

6. Protect all remaining bare areas with a suitable permanent anti-corrosive agent.

You have now installed the protection cover for operation.

BA 2030

32 Operating Instructions, 06/12, 70000004040207

④ is correctly seated.

②.

② on

Page 35

Installation

4.9 Installing and removing the shaft-mounted gearbox

4.9 Installing and removing the shaft-mounted gearbox

4.9.1 General information on installing the shaft-mounted gearbox

NOTICE

Damage to shaft sealing rings caused by solvent or benzine.

Avoid contact at all times.

NOTICE

Misalignment of and stress on the hollow shaft can lead to excessive load and cause the

bearings to fail.

The hollow shaft must be flush with the machine shaft to avoid misalignment.

Do not subject the hollow shaft to axial and radial stress.

NOTICE

For shrink disks:

Lubricants in the area between the hollow shaft and machine shaft impair torque

transmission.

Keep the bore in the hollow shaft and the machine shaft completely grease-free.

Do not use impure solvents and soiled cleaning cloths.

Note

Coat the contact surfaces with the mounting paste supplied with the product or any suitable

lubricant to prevent frictional corrosion.

Note

Observe the permissible concentricity tolerance of the cylindrical shaft extension of the

machine shaft to the housing axle according to DIN 42955.

BA 2030

Operating Instructions, 06/12, 70000004040207

33

Page 36

Installation

4.9 Installing and removing the shaft-mounted gearbox

4.9.2 Mounting and removing the hollow shaft with feather key

4.9.2.1 Mounting the hollow shaft with parallel key

* Not included in scope of supply

① Machine shaft

② Hollow shaft

③ Hexagon nut

④ Threaded spindle

⑤ Disk

⑥ Locking ring

⑦ Parallel key

⑧ Mounting paste

Procedure

Figure 4-4 Mounting the hollow shaft with parallel key

Instead of the nut and threaded spindle shown in the diagram, other types of equipment such

as hydraulic lifting equipment may be used.

1. Using benzine or a solvent, remove the anti-corrosion protection from the shaft ends and

flanges.

2. Check the seats or edges of the hollow and machine shafts for damage. Please contact

Technical Support if you notice any damage.

3. Evenly apply the mounting paste

4. Fit the gearbox using the disk

the hollow shaft

5. Replace the nut

specified torque.

You have now mounted the hollow shaft.

Table 4- 4 Tightening torque for setscrews

Thread size M5 M6 M8 M10 M12 M16 M20 M24 M30

Tightening torque [Nm] 5 8 8 14 24 60 120 200 400

②.

③ and threaded spindle ④ with a setscrew and tighten them to the

⑧ to the machine shaft ①.

⑤, threaded spindle ④ and nut ③. Support is provided by

BA 2030

34 Operating Instructions, 06/12, 70000004040207

Page 37

Installation

4.9 Installing and removing the shaft-mounted gearbox

4.9.2.2 Removing the hollow shaft with parallel key

NOTICE

Before driving out the machine shaft, fasten a suitably dimensioned means of absorbing the

load at the gearbox.

Slightly pretension the pulling equipment so that the gearbox does not drop onto it when the

insert shaft is released.

NOTICE

It is essential to prevent misalignment when removing the unit.

Note

If frictional corrosion has occurred on the seat surfaces, use rust solvent to facilitate the

removal of the gearbox. Allow an adequately long time for the rust solvent to take effect.

① Disk

② Threaded block

③ Parallel key

④ Hexagon nut

⑤ Threaded spindle

Figure 4-5 Removing the hollow shaft with parallel key

Items ① to ⑤ are not included in the scope of delivery.

Procedure

1. Remove the axial locking element from the hollow shaft.

2. Drive out the machine shaft using the disk

threaded spindle

You have now removed the hollow shaft with parallel key.

BA 2030

Operating Instructions, 06/12, 70000004040207

①, threaded block ②, parallel key ③,

⑤, and hexagon nuts ④.

35

Page 38

Installation

4.9 Installing and removing the shaft-mounted gearbox

Design suggestion for threaded block and disk

X

W

G

V

E

G

E

E

G

b10 b11 b12 d10 d11 t

s11

[mm] [mm] [mm] [mm] [mm]

u Size

max

[mm] [mm]

19.9 10 M6 22.5 6 29 3 15 10

24.9 14 M8 28 8

39

- - 14 M8 28

6

15 10

29.9 18 M10

33

38 10

34.9 24 10 49 6 15 5

M12 43

39.9 28

39.9 28 12 69 6 20 9

M16 48.5

44.9 33

79 6 20 9 39.9 28 M16 48.5 12

49.9 36 14 89 7 20 10

M16 64

59.9 45

8

12

14

18

BA 2030

36 Operating Instructions, 06/12, 70000004040207

Page 39

Installation

4.9 Installing and removing the shaft-mounted gearbox

4.9.3 Mounting the hollow shaft with shrink disk

4.9.3.1 Mounting the hollow shaft with shrink disk

D

E

a Greased

b Absolutely grease-free

* Not included in scope of supply

① Machine shaft

② Hollow shaft

③ Hexagon nut

④ Threaded spindle

⑤ Disk

⑧ Bronze bushing

Figure 4-6 Mounting the hollow shaft with shrink disk

E

Instead of the nut and threaded spindle shown in the diagram, other types of equipment such

as hydraulic lifting equipment may be used.

Procedure

1. Using benzine or a solvent, remove the anti-corrosion protection from the shaft ends and

flanges.

2. Check the seats or edges of the hollow and machine shafts for damage. Please contact

Technical Support if you notice any damage.

3. Fit the gearbox using the disk

the hollow shaft

4. Remove the disk

You have now mounted the hollow shaft.

BA 2030

Operating Instructions, 06/12, 70000004040207

⑤, threaded spindle ④ and nut ③. Support is provided by

②.

⑤, threaded spindle ④ and nut ③.

37

Page 40

Installation

4.9 Installing and removing the shaft-mounted gearbox

4.9.3.2 Mounting the shrink disk

WARNING

Risk of injury due to freely rotating parts.

Fit a cover cap or protection cover.

NOTICE

The shrink disk is delivered ready for installation.

Do not dismantle it before the initial fitting.

NOTICE

Lubricants in the area of the shrink disk seat impair torque transmission.

Keep the bore in the hollow shaft and the machine shaft completely grease-free.

Do not use impure solvents and soiled cleaning cloths.

NOTICE

Plastic deformation of the hollow shaft when tightening the tightening bolts before fitting the

machine shaft.

First fit machine shaft. Then tighten the tightening bolts.

NOTICE

Avoid overloading the individual bolts.

Do not exceed the maximum tightening torque for tightening bolt.

Sizes 29 - 69:

Tighten the tightening bolts

③.

Sizes 79 - 89:

What is of prime importance is that the end faces of the outer ring

① and inner ring ② are

flush with one another. If they are not flush with one another when tensioning, the tolerance

of the insert shaft must be checked.

BA 2030

38 Operating Instructions, 06/12, 70000004040207

Page 41

Installation

4.9 Installing and removing the shaft-mounted gearbox

Note

The machine shaft material must comply with the following criteria in order to safely and

reliably transfer the forces and torques.

Yield point, Re >= 360 Nm / mm

Modulus of elasticity: approx. 206 kN / mm

Note

2

-2

The hollow shaft is axially secured on the machine shaft by means of a shrink disk

connection.

Note

Apply a thin layer of grease to the shrink disk seat on the hollow shaft.

Note

Coat with a suitable lubricant to prevent frictional corrosion of the contact surface on the

customer's machine shaft in the vicinity of the bush.

Sizes 29 - 69 Sizes 79 - 89

DD DDD

E

a Greased

b Absolutely grease-free

E

BA 2030

Operating Instructions, 06/12, 70000004040207

39

Page 42

Installation

4.9 Installing and removing the shaft-mounted gearbox

① Outer ring

② Inner ring

③ Tightening bolt

④ Hollow shaft

⑤ Machine shaft

Figure 4-7 Mounting the shrink disk

Procedure

1. Locate the shrink disk on the hollow shaft:

3-section (sizes 29-69) up to the endstop.

2-section (sizes 79-89) flush with the shaft end.

2. To start, tighten the tightening bolts

clamping flanges are coplanar with one another.

3. To do this, turn each of the tightening bolts

opposite) using a torque wrench, repeating this procedure several times, until the screw

tightening torque is reached.

4. Attach the rubber cover or protection cover included in the scope of delivery,

see Removing and installing the prote

You have now installed the shrink disk.

Table 4- 5 Tightening torque for tightening bolt

Gearbox size Thread size Strength class

29 M5 8.8 5

39 - 69 M6 8.8 12

79 - 89 M10 12.9 35

③ by hand, and then align the shrink disk so that the

③ equally by 1/6 revolution (not diagonally

ction cover (Page 32).

Tightening torque

[Nm]

BA 2030

40 Operating Instructions, 06/12, 70000004040207

Page 43

Installation

4.9 Installing and removing the shaft-mounted gearbox

4.9.3.3 Pulling off the shrink disk

Procedure

1. Going around several times, release the tightening bolts ③ one after the other by a

¼ turn each time using a wrench. Do not completely remove the screws.

2. Pull the shrink disk off the hollow shaft.

Sizes 79 - 89:

If the outer ring does not come away from the inner ring, remove some of the tightening bolts

and insert them into neighboring forcing threads.

You will then be able to release the rings without difficulty.

4.9.3.4 Cleaning and lubricating shrink disks

Soiled shrink disks must be cleaned and regreased prior to fitting.

Shrink disks that have been released need not be disassembled and regreased before being

retensioned.

Procedure

1. Only grease the inner friction surfaces of the shrink disks. To do this, use a solid lubricant

with a friction coefficient of μ = 0.04.

2. Use a paste containing MoS

to grease the bolts, applying the paste to the thread and

2

underneath the head.

The shrink disk is now ready for fitting.

Table 4- 6 Lubricants for shrink disks

Lubricant Sold as Manufacturer

Molykote 321 R (lubricant paint)

Molykote spray (powder spray)

Molykote G Rapid Spray or paste

Molykombin UMFT 1 Spray

Unimily P5 Powder

Aemasol MO 19 P Spray or paste A. C. Matthes

Spray

DOW Corning

Klüber Lubrication

BA 2030

Operating Instructions, 06/12, 70000004040207

41

Page 44

Installation

4.9 Installing and removing the shaft-mounted gearbox

4.9.4 Mounting the hollow shaft with splines

* Not included in scope of supply

① Machine shaft

② Hollow shaft

③ Hexagon nut

④ Threaded spindle

⑤ Disk

⑥ Locking ring

⑦ Mounting paste

Procedure

Figure 4-8 Mounting the hollow shaft with splines

Instead of the nut and threaded spindle shown in the diagram, other types of equipment such

as hydraulic lifting equipment may be used.

1. Using benzine or a solvent, remove the anti-corrosion protection from the shaft ends and

flanges.

2. Check the seats or edges of the hollow and machine shafts for damage. Please contact

Technical Support if you notice any damage.

3. Evenly apply the assembly paste

4. Fit the gearbox using the disk

the hollow shaft

5. Replace the nut

specified torque.

You have now mounted the hollow shaft.

Table 4- 7 Tightening torque for setscrews

Thread size M5 M6 M8 M10 M12 M16 M20 M24 M30

Tightening torque [Nm] 5 8 8 14 24 60 120 200 400

②.

③ and threaded spindle ④ with a setscrew and tighten them to the

⑦ to the machine shaft ①.

⑤, threaded spindle ④ and nut ③. Support is provided by

BA 2030

42 Operating Instructions, 06/12, 70000004040207

Page 45

Installation

4.9 Installing and removing the shaft-mounted gearbox

4.9.5 Torque arms with shaft-mounted gearboxes

4.9.5.1 General information regarding torque arms

Torque arms can absorb the reaction torque and the weight force of the gearbox.

NOTICE

Dangerously high transient torques due to excess backlash.

Ensure that the torque arm does not result in excessive constraining forces (e.g. due to the

driven shaft running out-of-true).

NOTICE

Do not tension torque arms when mounting.

NOTICE

Worn or irreparably damaged rubber elements will not function properly.

Solvents, oils, greases, and fuels damage rubber elements. Keep them away from the

rubber elements.

BA 2030

Operating Instructions, 06/12, 70000004040207

43

Page 46

Installation

4.9 Installing and removing the shaft-mounted gearbox

4.9.5.2 Mounting torque arms on parallel shaft gearboxes

We recommend using pretensioned, damping rubber elements.

Fixing accessories such as brackets, bolts, nuts, etc., are not included in the scope of

delivery.

O[

O

G

FPLQ

\

\

Procedure

G

G

G

5=

\

5=

Figure 4-9 Mounting suggestion for torque arms on F.29 - F.89

Size

Rubber buffer

Washer

untensioned tensioned

l1 l1x d6 d1 d5 c6

[mm] [mm] [mm] [mm] [mm] [mm]

29 15 14.0 30 10.5 40 4

39 15 13.5 30 10.5 40 4

49 20 18.5 40 12.5 50 6

69 20 18.5 40 12.5 50 6

79 20 17.5 40 12.5 50 6

89 30 28 60 21 75 8

1. Use the washers according to the table above.

min

2. Use 2 nuts to secure the screw connection (lock nuts).

3. Tighten the screws until the rubber buffers are pretensioned to the dimension l1x.

You have now mounted the torque arm.

BA 2030

44 Operating Instructions, 06/12, 70000004040207

Page 47

Installation

4.9 Installing and removing the shaft-mounted gearbox

4.9.5.3 Mounting torque arms on bevel gearboxes

NOTICE

The torque arm bush must be supported by bearings on both sides.

Figure 4-10 Mounting suggestion for torque arms on bevel gearbox K

Procedure

Figure 4-11 Mounting suggestion for torque arms on bevel gearbox B

The torque arm can be mounted in various positions, depending on the hole circle pitch.

1. Clean the contact surfaces between the housing and the torque arm.

2. Tighten the screws to the specified torque.

You have now mounted the torque arm.

Table 4- 8 Tightening torque for screws of strength class 8.8 when mounting the torque arm

Thread size M8 M10 M12 M16 M20 M24 M30

Tightening torque [Nm] 25 50 90 210 450 750 1 500

BA 2030

Operating Instructions, 06/12, 70000004040207

45

Page 48

Installation

4.9 Installing and removing the shaft-mounted gearbox

BA 2030

46 Operating Instructions, 06/12, 70000004040207

Page 49

Commissioning

5.1 General information for commissioning

WARNING

Secure the drive unit to prevent it from being started up unintentionally.

Attach a warning notice to the start switch.

WARNING

Remove any oil spillage immediately with an oil-binding agent in compliance with

environmental requirements.

Checking the pressure breather valve

Check that the pressure breather valve is activated.

If the pressure breather valve has a transport fixture, then this must be removed before

commissioning.

5

Figure 5-1 Pressure breather valve with securing clip

Remove the transport fixture by pulling the securing clip ① in the direction of the arrow.

5.2 Checking the oil level prior to commissioning

Check the oil level before commissioning and top up if necessary, see Checking and

changing lubricants (Page 57).

arboxes with long-term preservation that are shipped completely filled with oil, we

For ge

recommend that for storage times exceeding 24 months, the oil is completely

replaced Checking and changing lubricants (Page 57).

BA 2030

Operating Instructions, 06/12, 70000004040207

47

Page 50

Commissioning

5.3 Mounting the oil expansion unit

5.3 Mounting the oil expansion unit

An oil expansion unit can be used depending on the power, drive speed, type of construction

and transmission ratio. This is used to equalize changes in the oil volume caused by

temperature fluctuations in operation.

The oil expansion unit is supplied as mounting set, and can either be mounted vertically on

the geared motor or at an angle.

The oil expansion unit for sizes 39 to 89 is mounted using a screw connection at the highest

hole on the gearbox housing or motor bearing shield.

Before commissioning the gearbox, replace the pressure breather valve that is already

installed by the oil expansion unit provided.

Figure 5-2 Example of an oil expansion unit

Procedure:

1. Completely unscrew the pressure breather valve with transport fixture.

2. Screw in the completely preassembled oil equalization unit.

3. Align the oil equalization unit so that it is in a vertical position.

The vent valve must be replaced every year to ensure perfect functioning. When replacing,

prevent dirt and damaging atmospheres from entering the gearbox.

BA 2030

48 Operating Instructions, 06/12, 70000004040207

Page 51

Operation

6

CAUTION

In the event of changes during operation, the drive unit must be switched off immediately.

Determine the cause of the fault using the fault table in Section Faults, causes and

reme

dies (Page 51).

dy faults or have faults remedied.

Reme

Check the gearbox during operation for:

● Excessive operating temperature

● Changes in gear noise

● Possible oil leakage at the housing and shaft seals.

BA 2030

Operating Instructions, 06/12, 70000004040207

49

Page 52

Operation

BA 2030

50 Operating Instructions, 06/12, 70000004040207

Page 53

Faults, causes and remedies

Note

Faults and malfunctions occurring during the warranty period and requiring repair work on

the gearbox must be remedied only by Technical Support. In the case of faults and

malfunctions occurring after the warranty period, the cause of which cannot be precisely

identified, we advise our customers to contact our Technical Support.

If you need the help of Technical Support, please provide the following information:

Data on the rating plate

Nature and extent of the fault

Suspected cause.

Table 7- 1 Faults, causes and remedies

Faults Causes Remedy

Unusual noises on the gearbox

Oil level too low Check the oil level, see

Foreign bodies in oil (irregular

noise)

Excessive bearing play and / or

bearing defective

Defective gearing Check the gearing and replace

Fastening bolts loose Tighten bolts / nuts; see

Excessive external load on drive

input and output

Damage in transit Check the gearbox for damage

Damage due to blockage during

commissioning

7

Checking and changing

lubricants (Page 57)

Check the oil quality, see

Checking the oil quality

(Page 59). Clean the gearbox.

Change the oil, see Checking

and changing lubricants

(Page 57)

Check bearing and replace

if necessary

if necessary

Checking tightness of fastening

bolts (Page 71)

Check load against rated data

(you might need to correct the

belt tension, for example)

in transit

Call Technical Support

BA 2030

Operating Instructions, 06/12, 70000004040207

51

Page 54

Faults, causes and remedies

Faults Causes Remedy

Unusual motor noises

Oil leak

Oil leak at the gearbox vent

Excessive bearing play and / or

bearing defective

Motor brake rubbing Check air gap and adjust

Inverter parameterization Correct parameterization

Incorrect oil level for the

mounting position being used

Overpressure due to lack of

venting

Overpressure due to soiled

venting

Shaft sealing rings defective Replace the shaft sealing rings

Cover / flange bolts loose Tighten bolts / nuts, see

Surface sealing defective

(e.g. on cover, flange)

Damage in transit (e.g. hairline

cracks)

Incorrect oil level for the

mounting position used and / or

incorrect venting position

Frequent cold starts, during

which the oil foams up

Check bearing and replace

if necessary

if necessary

Check the mounting position,

see Mounting positions

(Page 79). Check the oil level,

see Checking and changing

lubricants (Page 57)

Mount the venting as

appropriate for the mounting

position, see Mounting positions

(Page 79).

Clean the venting, see

Replacing the vent valve

(Page 69).

Checking tightness of fastening

bolts (Page 71). Continue to

monitor the gearbox

Reseal

Check the gearbox for damage

in transit

Check the venting and mounting

position, see Mounting positions

(Page 79). Check the oil level,

see Checking and changing

ants (Page 57)

lubric

Call Technical Support

BA 2030

52 Operating Instructions, 06/12, 70000004040207

Page 55

Faults, causes and remedies

Faults Causes Remedy

Gearbox overheating

Output shaft does not turn when

motor is running

Geared motor only starts with

difficulty or not at all

Motor fan cover and / or

gearbox very dirty

Incorrect oil level for the

mounting position being used

Incorrect oil being used

(e.g. incorrect viscosity)

Oil is out of date Check date of last oil change

Excessive bearing play and / or

bearing defective

Force flow interrupted by

breakage in gearbox