Siemens 6EP1351-1SH03, 6EP1311-1SH03, 6EP1311-1SH13, 6EP1322-1SH03, 6EP1321-1SH03 Operating Instructions Manual

...Page 1

LOGO!Power

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

__________________

_

_________________

_

_

_________________

_

Power supply

LOGO!Power

Operating Instructions

6EP1311-1SH03 5 V/3 A

6EP1311-1SH13 5 V/6.3 A

6EP1321-1SH03 12 V/1.9 A

6EP1322-1SH03 12 V/4.5 A

6EP1351-1SH03 15 V/1.9 A

6EP1352-1SH03 15 V/4 A

6EP1331-1SH03 24 V/1.3 A

6EP1332-1SH43 24 V/2.5 A

6EP1332-1SH52 24 V/4 A

02.2011

C98130-A7560-A999-1-7619

Overview

Description, device design,

dimension drawing

1

Mounting/Disassembly

2

Mounting position,

installation clearances

3

Installation

4

Applications

5

Technical data

6

EMC

7

Ambient conditions

8

Safety

9

Certifications

10

MTBF

11

Environment

12

Accessories

13

Service & Support

14

Page 2

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation for the specific task, in particular its warning notices and

safety instructions. Qualified personnel are those who, based on their training and experience, are capable of

identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

C98130-A7560-A999-1-7619

Ⓟ 02/2011

Copyright © Siemens AG 2011.

Technical data subject to change

Page 3

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

3

Overview

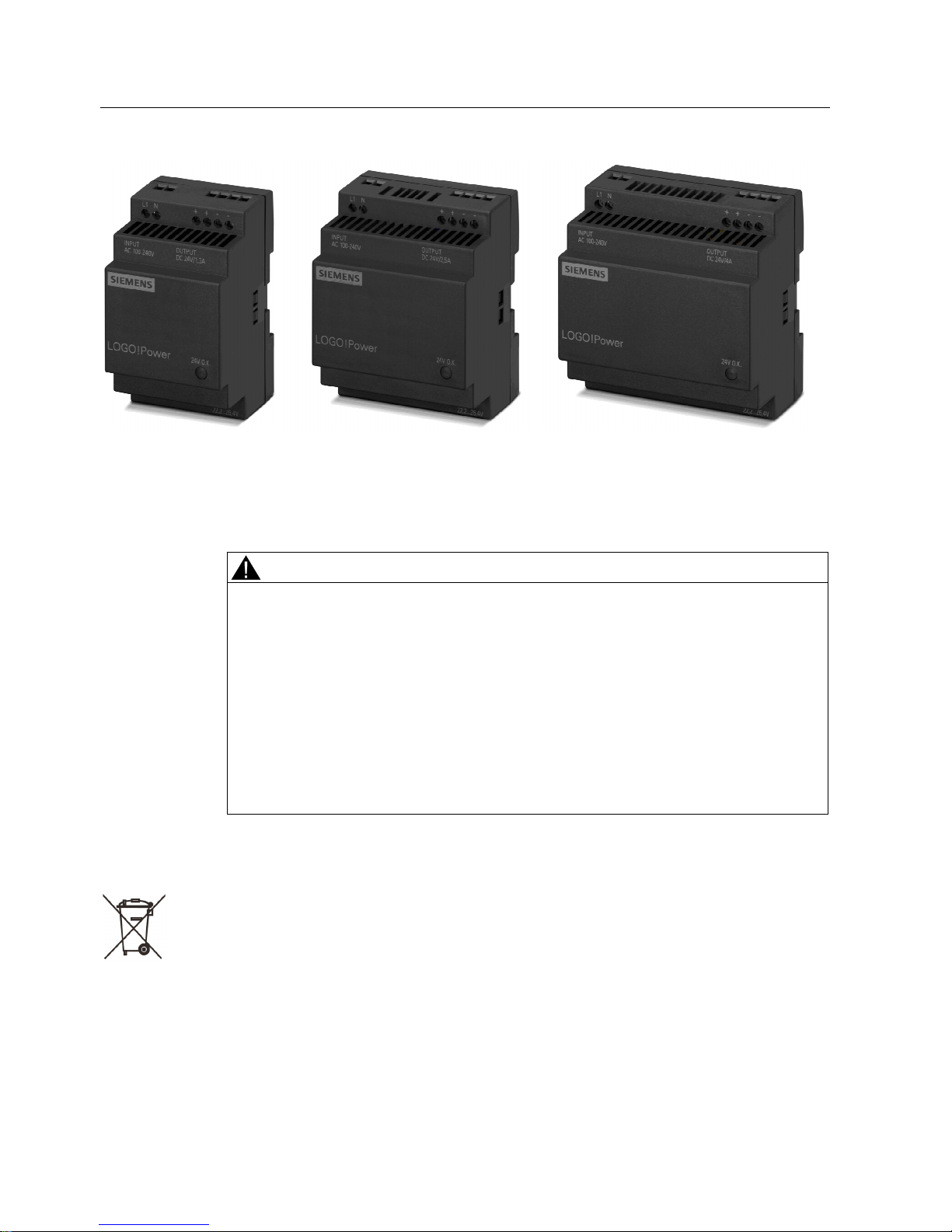

Description

LOGO!Power are powerful power supplies, which - thanks to their flat stepped profile - are

extremely flexible for use in a host of applications (for example, in installation distribution

boards). The 12 V and 24 V versions are ideal as power supplies for the LOGO! logic

modules.

The key benefits of the product include:

● Flat LOGO! mechanical design

● Wide-range input for voltages from 85 to 264 V AC and operation with DC voltage

● Adjustable output voltage

● Green LED for "Output voltage OK"

● Ambient temperature -20 °C to +70 °C (derating from +55 °C)

● Constant current under overload conditions for reliable connection of difficult loads

● When you turn on the power supply, a power reserve of 1.5 times rated current is

available for typ. 200 ms

● Export benefits thanks to global certifications

The following device options are available:

Input Output Width

100 - 240 V 1-phase AC 5 V DC / 3 A 54 mm

100 - 240 V 1-phase AC 5 V DC / 6.3 A 72 mm

100 - 240 V 1-phase AC 12 V DC / 1.9 A 54 mm

100 - 240 V 1-phase AC 12 V DC / 4.5 A 72 mm

100 - 240 V 1-phase AC 15 V DC / 1.9 A 54 mm

100 - 240 V 1-phase AC 15 V DC / 4 A 72 mm

100 - 240 V 1-phase AC 24 V DC / 1.3 A 54 mm

100 - 240 V 1-phase AC 24 V DC / 2.5 A 72 mm

100 - 240 V 1-phase AC 24 V DC / 4 A 90 mm

Page 4

Overview

LOGO!Power

4 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Safety and warning information

WARNING

When operating electrical devices, it is inevitable that certain components will carry

dangerous voltages.

Therefore, failure to handle the units properly can result in death or serious physical injury

as well as extensive property damage.

Only appropriately qualified personnel may work on or in the vicinity of this equipment.

Perfect, safe, and reliable operation of this equipment is dependent on proper

transportation, storage, installation and mounting.

Before installation or maintenance work can begin, the system's main switch must be

switched off and measures taken to prevent it being switched on again.

If this instruction is not observed, touching live parts can result in death or serious injury.

Disposal guidelines

Packaging and packaging aids can and should always be recycled.

The product itself may not be disposed of as domestic refuse.

Page 5

Overview

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

5

Ordering data

LOGO!Power

regulated power supply

6EP1311-1SH03 5 V / 3 A

6EP1311-1SH13 5 V / 6.3 A

6EP1321-1SH03 12 V / 1.9 A

6EP1322-1SH03 12 V / 4.5 A

6EP1351-1SH03 15 V / 1.9 A

6EP1352-1SH03 15 V / 4 A

6EP1331-1SH03 24 V / 1.3 A

6EP1332-1SH43 24 V / 2.5 A

6EP1332-1SH52 24 V / 4 A

Page 6

Overview

LOGO!Power

6 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Page 7

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

7

Table of contents

Overview.................................................................................................................................................... 3

1 Description, device design, dimension drawing ......................................................................................... 9

1.1 Device description..........................................................................................................................9

1.2 Connections and terminal designation.........................................................................................10

1.3 Potentiometer...............................................................................................................................10

1.4 Status displays and signaling.......................................................................................................11

1.5 Block diagram ..............................................................................................................................11

1.6 Dimensions and weight ................................................................................................................12

2 Mounting/Disassembly............................................................................................................................. 13

3 Mounting position, installation clearances................................................................................................ 15

3.1 Standard mounting position .........................................................................................................15

3.2 Other mounting positions .............................................................................................................15

4 Installation ............................................................................................................................................... 17

4.1 Line-side connection ....................................................................................................................17

4.2 Output-side connection ................................................................................................................18

5 Applications ............................................................................................................................................. 19

5.1 Parallel connection to increase power rating ...............................................................................19

5.2 Parallel connection for redundancy .............................................................................................20

5.3 Series connection for increased voltage......................................................................................21

5.4 Protection against short-time voltage dips ...................................................................................21

6 Technical data ......................................................................................................................................... 23

6.1 Input .............................................................................................................................................23

6.2 Output ..........................................................................................................................................25

6.3 Closed-loop control ......................................................................................................................27

6.4 Efficiency and power loss ............................................................................................................27

6.5 Protection and monitoring ............................................................................................................28

7 EMC ........................................................................................................................................................ 29

8 Ambient conditions ...........................................

....................................................................................... 31

9 Safety ...................................................................................................................................................... 33

10 Certifications............................................................................................................................................ 35

11 MTBF....................................................................................................................................................... 37

Page 8

Table of contents

LOGO!Power

8 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

12 Environment ............................................................................................................................................ 39

13 Accessories ............................................................................................................................................. 41

14 Service & Support.................................................................................................................................... 43

Page 9

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

9

Description, device design, dimension drawing

1

1.1 Device description

LOGO!Power are primary switched-mode power supplies for connection to a 1-phase AC

system or to DC systems. An electronically regulated DC voltage that can be set via a

potentiometer is available at the output of the device. The output of the device is isolated,

no-load proof and short-circuit proof. The LED display indicates the operating status.

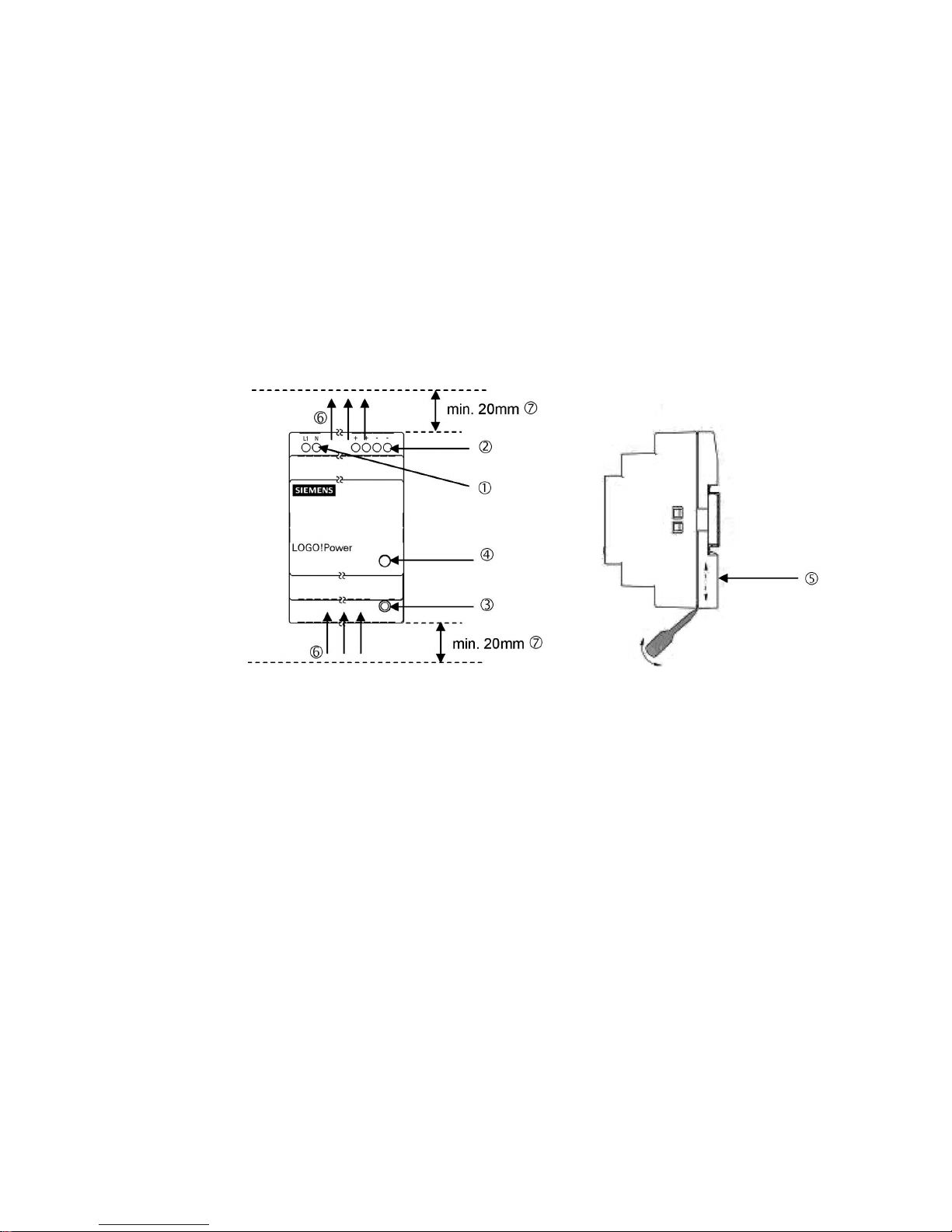

① Line input

② DC output

③ Potentiometer

④ Indicator light (output voltage OK)

⑤ DIN rail slider

⑥ Natural convection

⑦ Clearance above/below

Figure 1-1 Structure

Page 10

Description, device design, dimension drawing

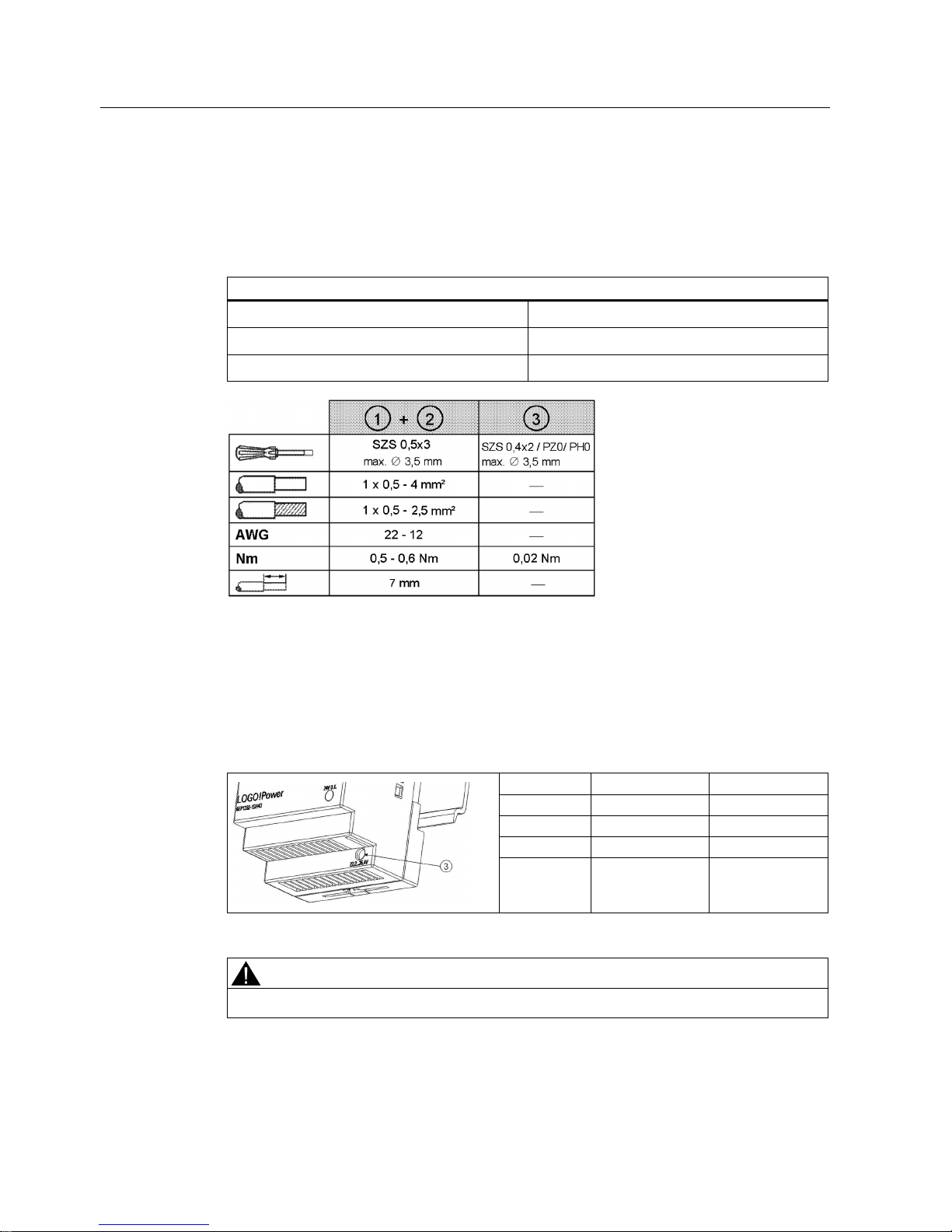

1.2 Connections and terminal designation

LOGO!Power

10 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

1.2 Connections and terminal designation

The line input terminals ① can be used to establish the connection to supply voltage. The

output terminals

② to be supplied are used to connect the loads (see also Section

Installation (Page 17)).

Connections and terminal designations

① Supply input L1, N

One screw terminal each for 0.5 to 2.5 mm²

② Output +

2 screw terminals for 0.5 mm to 2.5 mm²

② Output –

2 screw terminals for 0.5 mm to 2.5 mm²

Figure 1-2 Terminal data

1.3 Potentiometer

The potentiometer ③ on the front of the device is used to set the output voltage. The output

voltage is set to the rated value at the factory and can be set within certain limits; for

example, to compensate voltage drops across long supply lines to the connected load.

Type Factory setting Setting range

5 V 5 V 4.6 to 5.4 V

12 V 12 V 10.5 to 12.9 V

15 V 15 V 13.9 to 16.1 V

24 V 24 V 22.2 to 26.4 V

WARNING

Actuation of the potentiometer is allowed only be means of an insulated screwdriver.

Notes on potentiometer operation (such as a screwdriver, torque) refer to Chapter

Connections and terminal designation (Page 10), Fig. Terminal data.

Page 11

Description, device design, dimension drawing

1.4 Status displays and signaling

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

11

1.4 Status displays and signaling

Status display Green LED for output voltage OK

Signaling

LED ④ lights up green

Normal operation, output

voltage in setpoint range

LED ④ off

Supply voltage missing or

output voltage is not in

setpoint range due to

overload

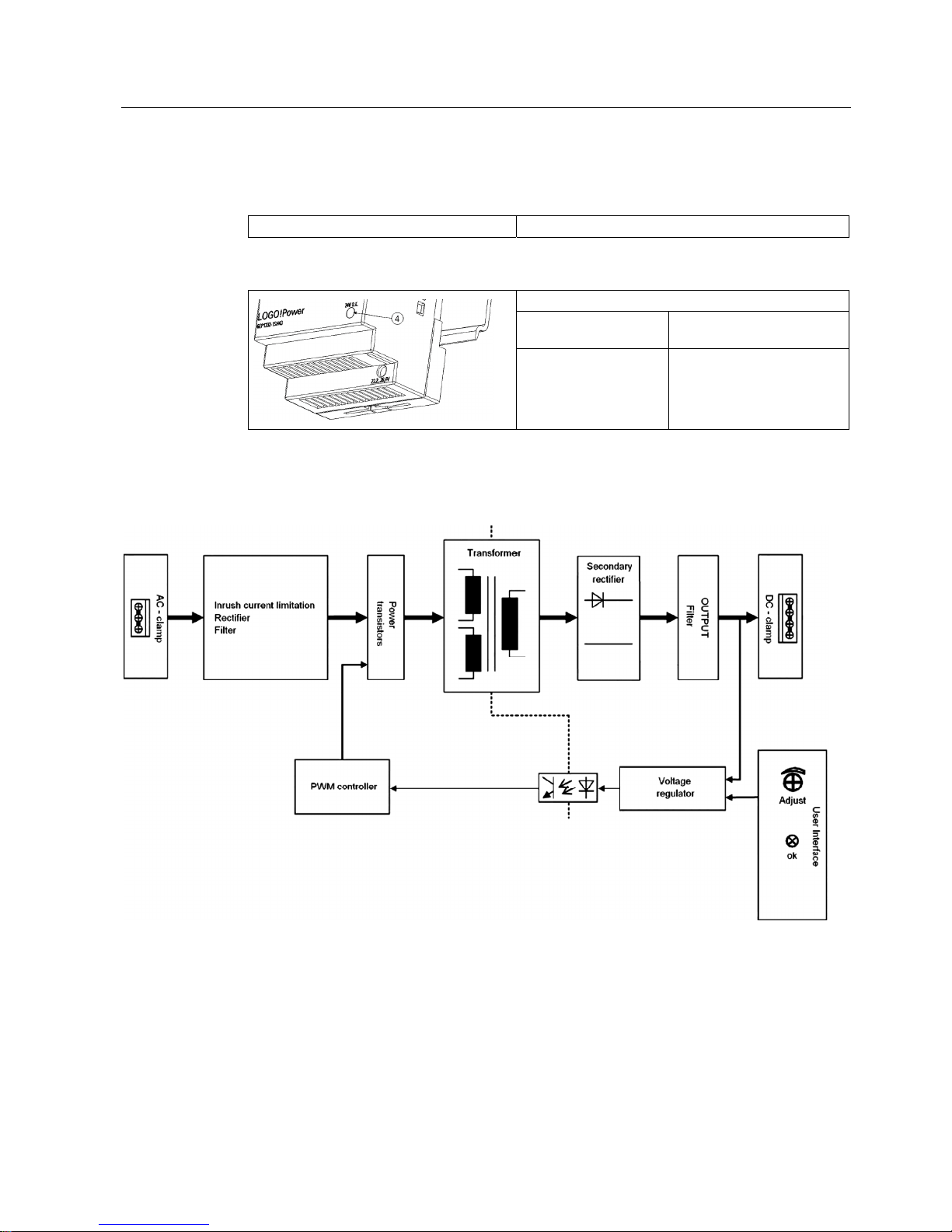

1.5 Block diagram

Figure 1-3 Block diagram

Page 12

Description, device design, dimension drawing

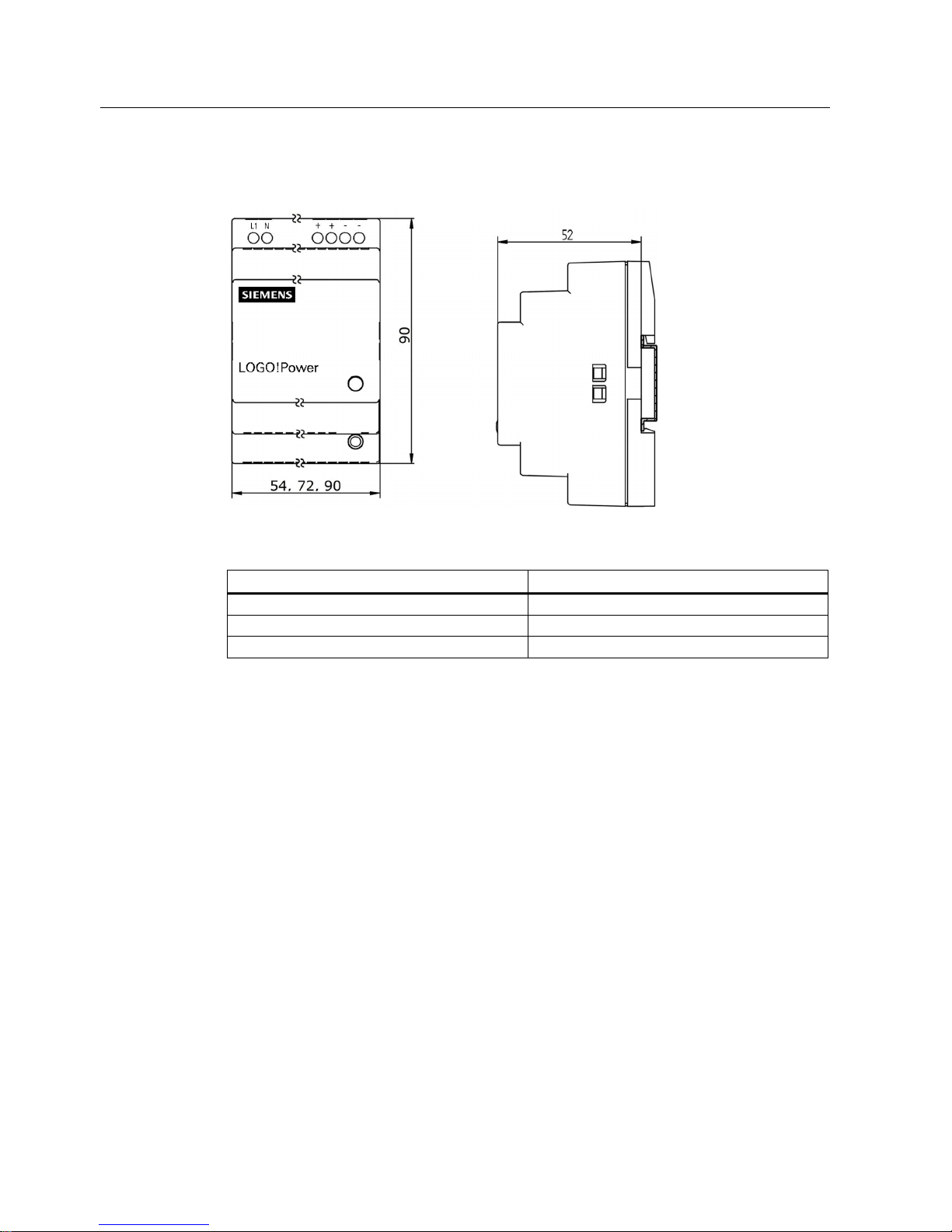

1.6 Dimensions and weight

LOGO!Power

12 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

1.6 Dimensions and weight

Figure 1-4 Dimension drawing

Dimensions (W × H × D) Weight

54 × 90 × 55 mm Approx. 160 g

72 × 90 × 55 mm Approx. 250 g

90 × 90 × 55 mm Approx. 320 g

Page 13

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

13

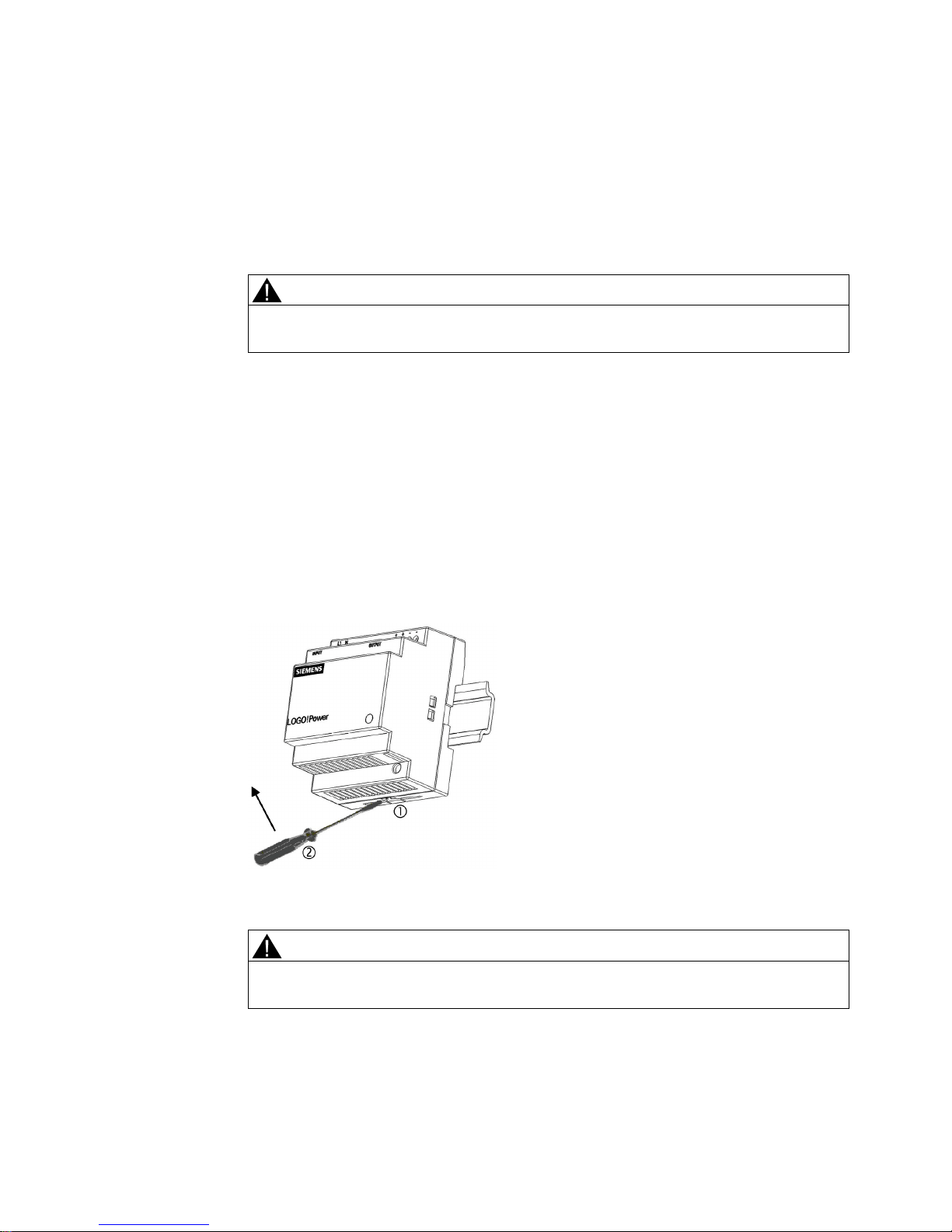

Mounting/Disassembly

2

WARNING

The LOGO!Power power supplies are built-in units. They must be installed in a casing or

control cabinet to which only qualified personnel have access.

The devices can be snapped onto standard mounting rail EN 60715 35x7.5/15 for installation

in a control cabinet.

Installation

To mount the device, position it with the mounting rail guideway at the upper edge of the DIN

rail and press down to lock it into place. If this is too difficult, press slider

① at the same

time, as described for "Disassembly".

Deinstalling

To remove, pull up the slider

① using a screwdriver ② and disengage the device at the

bottom edge of the DIN rail. Then you can remove the device from the upper edge of the DIN

rail.

Figure 2-1 Deinstalling

WARNING

If the device is to be used in a hazardous area (Ex II 3G Ex nA IIC T3) it must be installed

in a distributor box with degree of protection IP54 or higher.

Page 14

Mounting/Disassembly

LOGO!Power

14 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Page 15

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

15

Mounting position, installation clearances

3

3.1 Standard mounting position

The device is designed for installation on a standard mounting rail EN 60715 35x7.5/15. The

device must be mounted vertically to ensure proper cooling, and with the input terminals and

output terminals at the top.

A clearance of at least 20 mm should be maintained above and below the device. No space

is required at the side.

3.2 Other mounting positions

For mounting positions that deviate from the standard mounting position, derating factors

(reduction of the output power or the permissible ambient temperature) must be observed in

accordance with the following diagrams.

Figure 3-1 Mounting position (1)

Figure 3-2 Mounting position (2)

Page 16

Mounting position, installation clearances

3.2 Other mounting positions

LOGO!Power

16 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Figure 3-3 Mounting position (3)

Figure 3-4 Mounting position (4)

NOTICE

In the case of mounting postilions that deviate from the standard mounting position,

reduced mechanical resistance of the devices against vibration and shock must be

expected. Particularly when installing on a vertically fastened standard mounting rail,

additional measures may be required, e.g. to prevent the device from slipping on the

standard mounting rail.

Page 17

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

17

Installation

4

WARNING

Before installation or maintenance work can begin, the system's main switch must be

switched off and measures taken to prevent it being switched on again. If this instruction is

not observed, touching live parts can result in death or serious injury.

4.1 Line-side connection

The LOGO!Power power supplies are power packs acc. to safety class II (without protective

conductor or equivalent without PE). LOGO!Power are designed for connection to a 1-phase

AC supply network (TN or TT system in accordance with VDE 0100 T 300 / IEC 364-3) with

rated voltage 1-phase 100-240 V AC, 50/60 Hz or to a power supply with 110-300 V DC .

Figure 4-1 Line connection

The connection of power supply network is made via the terminals L1 and N (see Fig. 4-1)

and must be established in accordance with IEC 60364 and EN 50178. A protective device

(miniature circuit breaker or circuit breaker) and a disconnection unit for the power supply

must be provided. A residual current circuit-breaker must not be used as the only protective

measure against indirect contact; this applies to the entire supply system that is protected by

the residual current operated circuit breaker.

Line-side protection (IEC 898) to be implemented upstream:

● Circuit breaker characteristic C, from 10 A or

● circuit breaker characteristic B, from 16 A

Other country-specific regulations may have to be observed when installing the device.

Page 18

Installation

4.2 Output-side connection

LOGO!Power

18 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

4.2 Output-side connection

The LOGO!Power power supplies provide an isolated (= non-grounded) SELV (Safety Extra

Low Voltage) output voltage at the output. The output of the power supplies is no-load,

overload, and short-circuit proof. If overload occurs, the electronic current limitation limits the

output current to a maximum value (refer to chapter Technical data, Output (Page 25)).

Figure 4-2 Connection of the output voltage

The output voltage is connected via the + and - terminals at the output of the power supply

(see Fig. 4-2). Make sure that the output cables are dimensioned correctly for the maximum

output current rms value and fused accordingly.

Note

When using LOGO!Power in conjunction with devices of the protection class I (with

protective conductor), a connection must be established between "-" and "PE" with at least

1.5 mm².

Page 19

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

19

Applications

5

5.1 Parallel connection to increase power rating

To enhance performance, two LOGO!Power power supplies of the same type can be

galvanically connected in parallel.

The following must be observed:

● The cables connected to each power supply at terminals "+" and "-" must have identical

lengths and the same cable cross-sections (or the same impedance) up to a common

external network junction (terminal strip) if possible.

● The parallel-switched power supplies must be switched on simultaneously with a

common switch in the mains supply line (e.g. with the main switch available in control

cabinets).

● The output voltages measured in no-load operation for the power supplies that are not yet

connected in parallel should not deviate more than a maximum of 0.2 %. This usually

corresponds to the factory setting. If the output voltage is changed, you should connect

the "-" terminals and then, in no-load operation, measure the voltage difference between

the "+" terminals that have not yet been connected. The voltage difference should not

exceed 0.2%.

Figure 5-1 Parallel connection to increase power rating

CAUTION

For connection of more than two power supplies in parallel, additional measures must be

taken to prevent high backward feeding currents in the event of a secondary device fault.

For this purpose, a suitable protective circuit (e.g. decoupling diode) must be installed

between each "+" terminal of the power supply and the common connection point.

Page 20

Applications

5.2 Parallel connection for redundancy

LOGO!Power

20 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

5.2 Parallel connection for redundancy

The parallel switching of several LOGO!Power power supplies for redundancy is required

when the demands for reliability of the supply are particularly high.

If a component in the redundant supply fails, the power supply for the loads must be fully

accommodated by the remaining component. It is therefore important when dimensioning the

system to make sure that n+1 redundant switched power supplies can handle the total power

requirement of the remaining n power supplies.

To prevent loading of the remaining power supplies in the event of a secondary-side error

when one power supply fails, the respective "+" terminals of the power supplies must be

decoupled via diodes.

NOTICE

For a high reliability of the supply, it is recommended that the redundant switched power

supplies are fused separately on the line-side and, if possible, be connected to different

power supply networks.

Figure 5-2 Parallel connection for redundancy

Page 21

Applications

5.3 Series connection for increased voltage

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

21

5.3 Series connection for increased voltage

To achieve a higher output voltage, two LOGO!Power power supplies of the same type can

be connected in series. In this case, connect the "-" terminal of the first power supply to the

"+" terminal of the second power supply. The "+" terminal of the first power supply and the "-"

terminal of the second power supply are routed to the load.

Depending on grounding point of the secondary output voltage, voltages of +2×U

A

, ±UA or -

2×U

A

can be implemented.

In the case of asymmetric load distribution, it is not possible to ensure correct functionality.

WARNING

When two power supplies are connected in series, it is not possible to ensure the

permanently permissible SELV voltage of maximum of 60 V DC acc. to EN 60950 in the

event of a fault.

Figure 5-3 Series connection

5.4 Protection against short-time voltage dips

During a drop in the primary-side supply voltage, the LOGO!Power power supplies still

maintain the output voltage over a short millisecond period (see section Technical data, Input

(Page 23)).

Page 22

Applications

5.4 Protection against short-time voltage dips

LOGO!Power

22 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Page 23

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

23

Technical data

6

6.1 Input

Rated voltage

V

e rated 1-phase 100 - 240 V AC wide-range input

AC voltage range 85 … 264 V AC

Voltage* range DC 110 to 300 V DC

Connect/shutdown threshold Typ. 80 V/70 V

Overvoltage resistance 2,3 × Ve rated, 1.3 ms

Rated line frequency; rated line frequency range 50/60 Hz; 47 to 63 Hz

6EP1311-1SH03 0.20 A

6EP1311-1SH13 0.43 A

6EP1321-1SH03 0.29 A

6EP1322-1SH03 0.67 A

6EP1351-1SH03 0.35 A

6EP1352-1SH03 0.70 A

6EP1331-1SH03 0.36 A

6EP1332-1SH43 0.69 A

Rated current

I

e rated at Ve = 230 V

6EP1332-1SH52 0.99 A

6EP1311-1SH03 < 30 A

6EP1311-1SH13 < 55 A

6EP1321-1SH03 < 30 A

6EP1322-1SH03 < 55 A

6EP1351-1SH03 < 30 A

6EP1352-1SH03 < 55 A

6EP1331-1SH03 < 30 A

6EP1332-1SH43 < 50 A

Switch-on current limitation

(+25 °C)

6EP1332-1SH52 < 30 A

6EP1311-1SH03 0.4 A2s

6EP1311-1SH13 1.2 A2s

6EP1321-1SH03 0.4 A2s

6EP1322-1SH03 1.2 A2s

6EP1351-1SH03 0.4 A2s

6EP1352-1SH03 1.2 A2s

6EP1331-1SH03 0.4 A2s

6EP1332-1SH43 1.2 A2s

I2t value

6EP1332-1SH52 1.3 A

2

s

Built-in line-side fuse Fuse

Required protection in the mains supply

conductor

Miniature circuit breakers (IEC 898

)characteristic C 10 A

or characteristic B 16 A

Mains buffering at Ia rated >40 ms (for 187 V)

Page 24

Technical data

6.1 Input

LOGO!Power

24 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Figure 6-1 Mains buffering

Page 25

Technical data

6.2 Output

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

25

6.2 Output

Rated voltage

V

a rated Controlled, isolated DC voltage

5 V DC, 12 V, 15 V or 24 V

Total tolerance

Static line smoothing

Static load smoothing

±3 %

Approx. ±0.5 %

Approx. ±1 %

12 V, 15 V, 24 V < 200 mVpp Residual ripple

5 V < 100 mVpp

12 V, 15 V, 24 V < 300 mVpp Spikes (bandwidth: 20 MHz)

5 V < 100 mVpp

5 V 4.6 to 5.4 V

12 V 10.5 to 12.9 V

15 V 13.9 to 16.1 V

Setting range

24 V 22.2 to 26.4 V

Response on activation/deactivation No overshoot of Va (soft start)

Startup delay/voltage rise < 1.5 s/< 500 ms (typ. 70 ms/typ. 10

ms) (see the figure below)

6EP1311-1SH03 3 A

6EP1311-1SH13 6.3 A

6EP1321-1SH03 1.9 A

6EP1322-1SH03 4.5 A

6EP1351-1SH03 1.9 A

6EP1352-1SH03 4 A

6EP1331-1SH03 1.3 A

6EP1332-1SH43 2.5 A

Rated current Ia rated

6EP1332-1SH52 4 A

Current range

• Up to +55 °C

• Derating

0 ... 100% Ia rated

0 ... 70% Ia rated (at +70 °C)

Power reserve When you turn on the power supply 1.5 x Ia rated

for typ. 200 ms

Parallel switching for enhanced performance Yes, 2 units

Output characteristic (see illustration below)

Page 26

Technical data

6.2 Output

LOGO!Power

26 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Figure 6-2 Startup delay/voltage rise

Figure 6-3 Output characteristic (typical behavior)

The device supplies a constant output voltage until the current limit is reached. In the event

of an overload, the output current and the output voltage are reduced. The device does not

switch off.

Page 27

Technical data

6.3 Closed-loop control

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

27

6.3 Closed-loop control

Dyn. mains compensation (Ve rated ±15 %) <3% Va

Dyn. load compensation (Ia: 10/90/10 %) Typ. ±2% Va

Load-step settling time

• 10 to 90 %

• 90 to 10 %

< 20 ms (typ. 0.2 ms)

< 20 ms (typ. 0.2 ms)

6.4 Efficiency and power loss

6EP1311-1SH03 Approx. 77 %

6EP1311-1SH13 Approx. 80 %

6EP1321-1SH03 Approx. 78 %

6EP1322-1SH03 Approx. 84 %

6EP1351-1SH03 Approx. 80 %

6EP1352-1SH03 Approx. 85 %

6EP1331-1SH03 Approx. 83 %

6EP1332-1SH43 Approx. 87 %

Efficiency at

Va rated, Ia rated

(at Ve 230 V)

6EP1332-1SH52 Approx. 87 %

6EP1311-1SH03 Approx. 4.6 W

6EP1311-1SH13 Approx. 8.1 W

6EP1321-1SH03 Approx. 6.4 W

6EP1322-1SH03 Approx. 10.2 W

6EP1351-1SH03 Approx. 7.1 W

6EP1352-1SH03 Approx. 10.8 W

6EP1331-1SH03 Approx. 6.3 W

6EP1332-1SH43 Approx. 8.7 W

Efficiency at Va rated, Ia

rated

(at Ve 230 V)

6EP1332-1SH52 Approx. 13.8 W

6EP1311-1SH03 Approx. 1.5 W

6EP1311-1SH13 Approx. 1.5 W

6EP1321-1SH03 Approx. 1.8 W

6EP1322-1SH03 Approx. 1.9 W

6EP1351-1SH03 Approx. 2.1 W

6EP1352-1SH03 Approx. 2.3 W

6EP1331-1SH03 Approx. 2.0 W

6EP1332-1SH43 Approx. 1.8 W

No-load power loss

(at Ve 230 V)

6EP1332-1SH52 Approx. 2.0 W

Page 28

Technical data

6.5 Protection and monitoring

LOGO!Power

28 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

6.5 Protection and monitoring

Output overvoltage protection Yes, acc. to EN 60950

Current limitation Typ. 110 % … 130 % of Ia rated when you turn

on the power supply overload capability with 150

% of Ia rated for typ. 200 ms

Short-circuit protection Characteristic curve up to 0 V

6EP1311-1SH03 Approx. 3.9 A

6EP1311-1SH13 Approx. 8.0 A

6EP1321-1SH03 Approx. 2.3 A

6EP1322-1SH03 Approx. 4.4 A

6EP1351-1SH03 Approx. 2.3 A

6EP1352-1SH03 Approx. 4.4 A

6EP1331-1SH03 Approx. 1.6 A

6EP1332-1SH43 Approx. 3.5 A

Sustained short-circuit current

rms value

6EP1332-1SH52 Approx. 7.2 A

Overload/short-circuit indicator -

Page 29

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

29

EMC

7

EN 61000-6-2 Immunity for industrial environments

Generic standards

EN 61000-6-3 Emission for residential areas

Electrostatic discharges EN 61000-4-2 6 kV contact, 8 kV air

Electromagnetic fields EN 61000-4-3 80 to 1000 MHz 10 V/m

1000 to 2000 MHz 3 V/m

2000 to 2700 MHz 1 V/m

High-speed transient disturbance

variables (burst)

EN 61000-4-4 4 kV on mains connections

2 kV at DC output

Power surges EN 61000-4-5 2 kV symmetrically on mains connections

4 kV symmetrically on mains connections

500 V symmetrical/asymmetrical on DC

output lines

High-frequency fields EN 61000-4-6 10 V; 0.15 to 80 MHz

Voltage dips EN 61000-4-11 100 % for 20 ms

60 % for 200 ms

30 % for 500 ms

Voltage interruptions EN 61000-4-11 100 % for 5000 ms

Emitted interference EN 55022 Class B

Harmonic currents EN 61000-3-2 Class A

Page 30

EMC

LOGO!Power

30 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Page 31

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

31

Ambient conditions

8

Humidity class Climate class 3K3 to EN 60721, no condensation

Ambient temperature -20 ... +70 °C with natural convection

Derating:

• from +55 °C 2 %/K

Tested to:

• EN 60068-2-1 coldness

• EN 60068-2-2 dry heat

• EN 60068-2-78 damp heat, constant

• EN 60068-2-14 change of temperature

Transport/storage temperature -40 ... +85 °C

Tests (packed for shipping) according to:

• EN 60068-2-1 coldness

• EN 60068-2-2 dry heat

• EN 60068-2-30 damp heat, cyclic

Mechanical stressing in operation Tested to:

• EN 60068-2-6 vibration, test Fc

– 7 mm deflection in the range 5 - 9 Hz

– 2 G acceleration in the range 9 - 150 Hz

• EN 60068-2-27 shock, test Ea

– Acceleration 150 m/s2, test duration 11 ms

Damaging gases Tested to:

• EN 60068-2-42 sulfur dioxide: 10 cm

3/m3

, 4 days

• EN 60068-2-43 sulfur dioxide: 1 cm

3/m3

, 4 days

Atmospheric pressure Tested to:

• EN 60068-2-13

Operation:

• 1080 ... 795 hPa (-1000 to +2000 m)

• >2000 m: Derating factor of 5 % / 1000 m

Storage:

• 1080 ... 660 hPa (-1000 to +3500 m)

Page 32

Ambient conditions

LOGO!Power

32 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Page 33

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

33

Safety

9

Primary/secondary isolation Yes, SELV output voltage Ua according to EN

60950 and EN 50178

Test voltage Primary/secondary 3 kVAC or corresponding DC

value

Protection class Class II (without protective conductor)

Leakage current < 250 µA

Degree of protection (EN 60529) IP20

Page 34

Safety

LOGO!Power

34 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Page 35

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

35

Certifications

10

Certifications

CE marking Yes (2004/108/EC and 2006/95/EC)

UL/cUL approval cULus-listed (UL 508, CSA C22.2 No.107.1), File

E197259

cURus (UL60950, CSA C22.2 No. 60950) File

E151273

NEC Class2 for types:

6EP1311-1SH03 5 V/3 A

6EP1321-1SH03 12 V/1,9 A

6EP1351-1SH03 15 V/1,9 A

6EP1331-1SH03 24 V/1,3 A

6EP1332-1SH43 24 V/2,5 A

CSA approval CLASS 5318 01 - Power Supplies - for

Hazardous Locations

CLASS 5318 81 - Power Supplies - for

Hazardous Locations - Certified to U.S. Standard

Class I, Division 2, Groups A,B,C and D, T4

Class I, Zone 2, Ex nA II T4 IP20, AEx nA II T4

IP20

FM Class I, Div. 2, Groups A, B, C, and D; T4

CB scheme IEC 60950-1

Explosion protection ATEX II 3G Ex nA IIC T3 X

EN 60079-0:2006 and EN 60079-15:2005

SEMI F47 compliance 208 V-240 V IEC 61000-4-11

Marine approval Germanischer Lloyd (GL)

6EP1352-1SH52: Cert. No.:24184-04HH

All other types: Cert. No.:47994-03HH

ABS, DNV, BV, LRS in preparation for selected

types

Page 36

Certifications

LOGO!Power

36 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Page 37

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

37

MTBF

11

Mean Time Between Failures In accordance with SN29500: >3500000 h at

40 °C, rated load, 24-h operation

Page 38

MTBF

LOGO!Power

38 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Page 39

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

39

Environment

12

The device is RoHS-compatible.

As a rule, only non-silicon precipitating materials are used.

Page 40

Environment

LOGO!Power

40 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Page 41

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

41

Accessories

13

No accessories.

Page 42

Accessories

LOGO!Power

42 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Page 43

LOGO!Power

Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

43

Service & Support

14

Further information via the home page

http://www.siemens.de/sitop/manuals

or

http://support.automation.siemens.com

Phone: +49 (0) 911 895 7222

Page 44

Service & Support

LOGO!Power

44 Operating Instructions, 02.2011, C98130-A7560-A999-1-7619

Loading...

Loading...