Siemens 6DR50 Series, 6DR53 Series, 6DR51 Series, 6DR52 Series, SIPART PS2 Operating Instructions Manual

Page 1

SIPART

Electropneumatic positioners

SIPART PS2 with and without HART

Operating Instructions

Edition 09/2014

Answers for industry.

Page 2

Page 3

SIPART PS2 with and without HART

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________

___________________

___________________

SIPART

Electropneumatic positioners

SIPART PS2 with and without

HART

Operating Instructions

6DR50.. - Positioner without HART

6DR51..

6DR52..

6DR53..

proof

09/2014

A5E00074631

Introduction

1

Safety information

2

Description

3

Installing/mounting

4

Connection

5

Operating

6

Commissioning

7

Functional safety

8

Parameterizing/addressing

9

Alarm, error, and system

messages

10

Service and maintenance

11

Technical data

12

Dimension drawings

13

Spare

parts/accessories/scope of

delivery

14

Appendix

A

Abbreviations

B

- Positioner with HART, not explosion-proof

- Positioner with HART, explosion-proof

- Positioner without HART, not explosion-

-12

Page 4

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: A5E00074631

Ⓟ

Copyright © Siemens AG 2014.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

10/2014 Subject to change

Page 5

Table of contents

1 Introduction ........................................................................................................................................... 11

2 Safety information ................................................................................................................................. 15

3 Description ............................................................................................................................................ 19

4 Installing/mounting ................................................................................................................................ 31

1.1 Purpose of this documentation ............................................................................................... 11

1.2 History ..................................................................................................................................... 11

1.3 Purpose ................................................................................................................................... 12

1.4 Checking the consignment ..................................................................................................... 12

1.5 Transportation and storage ..................................................................................................... 13

1.6 Product information ................................................................................................................. 13

1.7 Notes on warranty ................................................................................................................... 13

2.1 Requirements for safe use ...................................................................................................... 15

2.1.1 Warning symbols on the device .............................................................................................. 15

2.1.2 Laws and directives ................................................................................................................ 16

2.1.3 Conformity with European directives ...................................................................................... 16

2.2 Improper device modifications ................................................................................................ 16

2.3 Requirements for special applications .................................................................................... 17

2.4 Use in hazardous areas .......................................................................................................... 17

3.1 Function .................................................................................................................................. 19

3.2 Structure ................................................................................................................................. 19

3.2.1 Overview of structure .............................................................................................................. 19

3.2.2 Nameplate layout .................................................................................................................... 22

3.3 Device components ................................................................................................................ 24

3.3.1 Overview of device components ............................................................................................. 24

3.3.2 Basic electronics ..................................................................................................................... 25

3.4 Mode of operation ................................................................................................................... 26

3.4.1 Control algorithm ..................................................................................................................... 27

3.4.2 Block circuit diagram for single-acting or double-acting actuators ......................................... 28

3.4.3 Mode of operation of the HART function ................................................................................ 29

3.4.4 HART system configuration .................................................................................................... 29

3.4.5 SIMATIC PDM ........................................................................................................................ 30

4.1 Basic safety instructions ......................................................................................................... 31

4.1.1 Proper mounting ..................................................................................................................... 34

4.2 Mounting the linear actuator ................................................................................................... 34

4.3 Mounting the part-turn actuator .............................................................................................. 40

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

3

Page 6

Table of contents

5 Connection ........................................................................................................................................... 69

6 Operating ............................................................................................................................................. 103

4.4 Using the positioner in a humid environment ......................................................................... 44

4.5 Positioners subjected to fast acceleration or strong vibration ............................................... 45

4.6 External position detection ..................................................................................................... 48

4.7 Installing option modules ....................................................................................................... 48

4.7.1 General information on installing option modules .................................................................. 48

4.7.1.1 Installing optional modules in the standard and intrinsically safe version ............................. 49

4.7.1.2 Installing the optional modules in the "flameproof enclosure" version ................................... 52

4.7.2 Position feedback module ...................................................................................................... 56

4.7.3 Alarm module ......................................................................................................................... 57

4.7.4 Slot initiator alarm module ..................................................................................................... 59

4.7.4.1 Setting the limits of the slotted initiator alarm module ........................................................... 61

4.7.5 Mechanical limit switch module .............................................................................................. 62

4.7.5.1 Setting the limits of the mechanical limit switch module ........................................................ 64

4.7.5.2 Label set for limit contact module .......................................................................................... 65

4.7.6 EMC filter module................................................................................................................... 66

4.7.7 Accessories ............................................................................................................................ 68

5.1 Basic safety instructions ........................................................................................................ 69

5.2 Electric ................................................................................................................................... 73

5.2.1 Device 6DR5..0/1/2/3-0N or 6DR5..5-0E ............................................................................... 73

5.2.1.1 Basic electronics with 6DR5..0/1/2/3-0N or 6DR5..5-0E ....................................................... 73

5.2.1.2 Option modules with 6DR5..0/1/2/3-0N or 6DR5..5-0E ......................................................... 77

5.2.2 Device 6DR5..0/1/2/3-0E/D/F/G/K ......................................................................................... 81

5.2.2.1 Breakdown of the article numbers 6DR5..0/1/2/3-0E/D/F/G/K .............................................. 81

5.2.2.2 Basic electronics with 6DR5..0/1/2/3-0E/D/F/G/K .................................................................. 82

5.2.2.3 Option modules with 6DR5..0/1/2/3-0E/D/F/G/K ................................................................... 86

5.2.3 Connecting NCS to EMC filter module .................................................................................. 91

5.2.4 Connecting the external position detection system to the EMC filter module ....................... 93

5.3 Pneumatic .............................................................................................................................. 95

5.3.1 Pneumatic connections .......................................................................................................... 95

5.3.1.1 Pneumatic connection for 6DR5..0/1/2/3 ............................................................................... 95

5.3.1.2 Integrated pneumatic connection ........................................................................................... 95

5.3.1.3 Pneumatic connection for 6DR5..5-0E... ............................................................................... 96

5.3.1.4 Reaction to failure of auxiliary powers ................................................................................... 97

5.3.2 Pneumatic connection .......................................................................................................... 100

5.4 Restrictors ............................................................................................................................ 101

6.1 Operating elements .............................................................................................................. 103

6.1.1 Display ................................................................................................................................. 103

6.1.2 Buttons ................................................................................................................................. 105

6.1.3 Firmware version.................................................................................................................. 106

6.2 Operating modes.................................................................................................................. 106

6.2.1 Overview of operating modes .............................................................................................. 106

6.2.2 Changing the operating mode .............................................................................................. 107

6.2.3 Overview of configuration .................................................................................................... 108

6.2.4 Description of operating modes ........................................................................................... 108

6.2.5 Optimization of controller data ............................................................................................. 111

SIPART PS2 with and without HART

4 Operating Instructions, 09/2014, A5E00074631-12

Page 7

Table of contents

7 Commissioning ................................................................................................................................... 113

8 Functional safety ................................................................................................................................. 139

9 Parameterizing/addressing .................................................................................................................. 145

7.1 Basic safety instructions ....................................................................................................... 113

7.2 Commissioning overview ...................................................................................................... 115

7.3 Sequence of automatic initialization ..................................................................................... 117

7.4 Purge air switching ................................................................................................................ 122

7.5 Commissioning linear actuators ............................................................................................ 123

7.5.1 Preparing linear actuators for commissioning ...................................................................... 123

7.5.2 Automatic initialization of linear actuators............................................................................. 125

7.5.3 Manual initialization of linear actuators ................................................................................. 127

7.6 Commissioning part-turn actuators ....................................................................................... 131

7.6.1 Preparing part-turn actuators for commissioning .................................................................. 131

7.6.2 Automatic initialization of part-turn actuators ........................................................................ 132

7.6.3 Manual initialization of part-turn actuators ............................................................................ 134

7.7 Device replacement .............................................................................................................. 137

8.1 Range of applications for functional safety ........................................................................... 139

8.2 Safety function ...................................................................................................................... 139

8.3 Safety Integrity Level (SIL) ................................................................................................... 141

8.4 Settings ................................................................................................................................. 142

8.5 Safety characteristics ............................................................................................................ 143

8.6 Maintenance/check ............................................................................................................... 144

9.1 Parameter chapter ................................................................................................................ 145

9.2 Configuration schematic for parameter operating principle .................................................. 146

9.3 Parameter overview .............................................................................................................. 147

9.3.1 Overview of initialization parameters 1 to 5 .......................................................................... 147

9.3.2 Overview of application parameters 6 to 52 ......................................................................... 148

9.3.3 Overview of advanced diagnostics parameters A to P ......................................................... 152

9.4 Description of parameters ..................................................................................................... 156

9.4.1 Description of initialization parameters 1 to 5 ....................................................................... 156

9.4.1.1 '1.YFCT' Type of actuator ..................................................................................................... 156

9.4.1.2 '2.YAGL' Rated angle of rotation of feedback ....................................................................... 157

9.4.1.3 '3.YWAY' Range of stroke..................................................................................................... 158

9.4.1.4 '4.INITA' Initialization (automatically) .................................................................................... 158

9.4.1.5 '5.INITM' Initialization (manual) ............................................................................................. 159

9.4.2 Description of application parameters 6 to 52 ...................................................................... 159

9.4.2.1 '6.SCUR' Current range of setpoint ...................................................................................... 159

9.4.2.2 '7.SDIR' Setpoint direction .................................................................................................... 160

9.4.2.3 '8.SPRA' Setpoint split range start / '9.SPRE' Setpoint split range end ............................... 160

9.4.2.4 '10.TSUP' Setpoint ramp UP / '11.TSDO' Setpoint ramp DOWN ......................................... 161

9.4.2.5 '12.SFCT' Setpoint function .................................................................................................. 162

9.4.2.6 '13.SL0' ... '33.SL20' Setpoint turning point .......................................................................... 162

9.4.2.7 '34.DEBA' Deadband of closed-loop controller ..................................................................... 163

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

5

Page 8

Table of contents

10 Alarm, error, and system messages ..................................................................................................... 199

9.4.2.8 '35.YA' Start of manipulated variable limit / '36.YE' End of manipulated variable limit ........ 164

9.4.2.9 '37.YNRM' Standardization of manipulated variable............................................................ 164

9.4.2.10 '38.YDIR' Direction of manipulated variable for display and position feedback ................... 166

9.4.2.11 '39.YCLS' Tight closing with manipulated variable .............................................................. 166

9.4.2.12 '40.YCDO' Lower value for tight closing / '41.YCUP' Upper value for tight closing ............. 166

9.4.2.13 '42.BIN1' / '43.BIN2' Function binary inputs ......................................................................... 167

9.4.2.14 '44.AFCT' Alarm function ..................................................................................................... 169

9.4.2.15 '45.A1' / '46.A2' Response threshold of alarms ................................................................... 170

9.4.2.16 '47._FCT' Function fault message output ............................................................................ 171

9.4.2.17 '48._TIM' Monitoring time for setting of fault message "Control deviation" .......................... 172

9.4.2.18 '49._LIM' Response threshold for fault message "Control deviation" .................................. 172

9.4.2.19 '50.PRST' Preset .................................................................................................................. 173

9.4.2.20 '51.PNEUM' Fail in place ..................................................................................................... 174

9.4.2.21 '52.XDIAG' Activating for extended diagnostics ................................................................... 174

9.4.3 Description of advanced diagnostics parameters A to P ..................................................... 175

9.4.3.1 Partial stroke test "A._PST" ................................................................................................. 175

9.4.3.2 Monitoring of dynamic control valve behavior "b._DEVI" ..................................................... 181

9.4.3.3 Monitoring pneumatic leakage "C._LEAK" ........................................................................... 183

9.4.3.4 Monitoring the stiction (slipstick) "d._STIC" ......................................................................... 185

9.4.3.5 Monitoring the deadband "E._DEBA"................................................................................... 187

9.4.3.6 Monitoring the lower endstop "F._ZERO" ............................................................................ 188

9.4.3.7 Monitoring the upper endstop "G._OPEN" ........................................................................... 190

9.4.3.8 Monitoring the lower limit temperature "H._TMIN" ............................................................... 192

9.4.3.9 Monitoring the upper limit temperature "J._TMAX" .............................................................. 193

9.4.3.10 Monitoring the number of total strokes "L._STRK" .............................................................. 194

9.4.3.11 Monitoring the number of changes in direction "O._DCHG" ................................................ 195

9.4.3.12 Monitoring the position average value "P._PAVG" .............................................................. 197

10.1 Output of system messages in the display .......................................................................... 199

10.1.1 System messages before initialization ................................................................................. 199

10.1.2 System messages during initialization ................................................................................. 200

10.1.3 System messages when exiting the Configuration mode .................................................... 203

10.1.4 System messages during operation..................................................................................... 204

10.2 Diagnostics ........................................................................................................................... 205

10.2.1 Display of diagnostics values ............................................................................................... 205

10.2.2 Overview of diagnostics values ............................................................................................ 206

10.2.3 Meaning of the diagnostics parameters ............................................................................... 209

10.2.3.1 Diagnostics parameter '1.STRKS' Number of total strokes ................................................. 209

10.2.3.2 Diagnostics parameter '2.CHDIR' Number of changes in direction ..................................... 209

10.2.3.3 Diagnostics parameter '3._CNT' Number of fault messages ............................................... 209

10.2.3.4 Diagnostics parameters '4.A1CNT' Number of alarms 1 / '5.A2CNT' Number of alarms

2 ........................................................................................................................................... 209

10.2.3.5 Diagnostics parameter '6.HOURS' Number of operating hours .......................................... 210

10.2.3.6 Diagnostics parameter '7.HOURR' Resettable operating hours counter ............................. 210

10.2.3.7 Diagnostics parameter '8.WAY' - Determined travel ............................................................ 210

10.2.3.8 Diagnostics parameters '9.TUP' Travel time UP / '10.TDOWN' Travel time DOWN ........... 210

10.2.3.9 Diagnostics parameter '11.LEAK' Leakage test ................................................................... 211

10.2.3.10 Diagnostics parameter '12.PST' Monitoring of partial stroke test ........................................ 212

10.2.3.11 Diagnostics parameter '13.PRPST' Time since last partial stroke test ................................ 212

10.2.3.12 Diagnostics parameter '14.NXPST' Time until next partial stroke test ................................ 213

10.2.3.13 Diagnostics parameter '15.DEVI' General control valve fault .............................................. 213

SIPART PS2 with and without HART

6 Operating Instructions, 09/2014, A5E00074631-12

Page 9

Table of contents

10.2.3.14 Diagnostics parameter '16.ONLK' Pneumatic leakage ......................................................... 213

10.2.3.15 Diagnostics parameter '17.STIC' Stiction (slipstick) ............................................................. 214

10.2.3.16 Diagnostics parameter '18.ZERO' Lower endstop ................................................................ 214

10.2.3.17 Diagnostics parameter '19.OPEN' Displacement of upper end stop .................................... 214

10.2.3.18 Diagnostics parameter '20.PAVG' Position average ............................................................ 215

10.2.3.19 Diagnostics parameters '21.P0' Potentiometer value of bottom end stop / '22.P100'

Potentiometer value of top end stop ..................................................................................... 216

10.2.3.20 Diagnostics parameters '23.IMPUP' Impulse length UP / '24.IMPDN' Impulse length

DOWN ................................................................................................................................... 218

10.2.3.21 Diagnostics parameter '25.PAUTP' Interpulse period .......................................................... 218

10.2.3.22 Diagnostics parameters '26.DBUP' Deadband UP / '27.DBDN' Deadband DOWN ............. 218

10.2.3.23 Diagnostics parameters '28.SSUP' Slow step zone UP / '29.SSDN' Slow step zone

DOWN ................................................................................................................................... 219

10.2.3.24 Diagnostics parameter '30.TEMP' Current temperature ....................................................... 219

10.2.3.25 Diagnostics parameters '31.TMIN' Minimum temperature / '32.TMAX' Maximum

temperature ........................................................................................................................... 219

10.2.3.26 Diagnostics parameters '33.T1' ... '41.T9' Number of operating hours in the

temperature range 1 to 9 ...................................................................................................... 220

10.2.3.27 Diagnostics parameters '42.VENT1' / '43.VENT2' ................................................................ 220

10.2.3.28 Diagnostics parameters '44.VEN1R' / '45.VEN2R' ............................................................... 221

10.2.3.29 Diagnostics parameter '46.STORE' Save maintenance data ............................................... 221

10.2.3.30 Diagnostics parameters '47.PRUP' Prediction UP / '48.PRDN' Prediction DOWN .............. 222

10.2.3.31 Diagnostics parameters '49.WT00' ... '56.WT95' Number of operating hours in the

travel range WT00 to WT95 .................................................................................................. 222

10.2.3.32 Diagnostics parameter '57.mA' Setpoint current .................................................................. 222

10.3 Online diagnostics ................................................................................................................. 223

10.3.1 Overview of online diagnostics ............................................................................................. 223

10.3.2 Overview of error codes ........................................................................................................ 224

10.3.3 XDIAG parameter ................................................................................................................. 226

10.3.4 Meaning of error codes ......................................................................................................... 226

10.3.4.1 1 Remaining control deviation .............................................................................................. 226

10.3.4.2 2 Device not in "Automatic" mode ........................................................................................ 226

10.3.4.3 3 Binary input BIN1 or BIN2 active ....................................................................................... 226

10.3.4.4 4 Monitoring the number of total strokes .............................................................................. 227

10.3.4.5 5 Monitoring the number of changes in direction .................................................................. 227

10.3.4.6 6 Monitoring the lower endstop / 7 Monitoring the upper endstop ....................................... 227

10.3.4.7 8 Monitoring deadband ......................................................................................................... 228

10.3.4.8 9 Partial stroke test ............................................................................................................... 228

10.3.4.9 10 Monitoring of dynamic control valve behavior ................................................................. 228

10.3.4.10 11 Monitoring the pneumatic leakage ................................................................................... 228

10.3.4.11 12 Monitoring of stiction (slipstick) ........................................................................................

228

10.3.4.12 13 Monitoring the lower limit temperature............................................................................. 228

10.3.4.13 14 Monitoring the upper limit temperature ............................................................................ 228

10.3.4.14 15 Monitoring the position average value ............................................................................. 229

10.3.4.15 16 Monitoring the plausibility of values for the partial stroke test ......................................... 229

10.4 Fault correction ..................................................................................................................... 229

10.4.1 Fault identification ................................................................................................................. 229

10.4.2 Remedial measures table 1 .................................................................................................. 230

10.4.3 Remedial measures table 2 .................................................................................................. 231

10.4.4 Remedial measures table 3 .................................................................................................. 232

10.4.5 Corrective measures Table 4 ................................................................................................ 233

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

7

Page 10

Table of contents

11 Service and maintenance ..................................................................................................................... 235

12 Technical data ..................................................................................................................................... 241

13 Dimension drawings ............................................................................................................................. 259

14 Spare parts/accessories/scope of delivery ............................................................................................ 265

10.4.6 Remedial measures table 5 ................................................................................................. 234

11.1 Basic safety instructions ...................................................................................................... 235

11.2 Cleaning of the screens ....................................................................................................... 236

11.2.1 Positioners with Makrolon enclosure 6DR5..0, aluminum enclosure 6DR5..3, and

flameproof aluminum enclosure 6DR5..5 ............................................................................ 236

11.2.2 Positioners with stainless steel enclosure 6DR5..2 and narrow aluminum enclosure

6DR5..1 ................................................................................................................................ 237

11.3 Fail in Place: replacing the basic electronics ....................................................................... 238

11.4 Repair/Upgrading ................................................................................................................. 238

11.5 Return procedure ................................................................................................................. 239

11.6 Disposal ............................................................................................................................... 239

12.1 Rated conditions .................................................................................................................. 241

12.2 Pneumatic data .................................................................................................................... 242

12.3 Construction ......................................................................................................................... 243

12.4 Controller .............................................................................................................................. 245

12.5 Certificates, approvals, explosion protection ....................................................................... 246

12.6 Electrical data ....................................................................................................................... 247

12.7 Technical data for natural gas as actuator medium ............................................................. 249

12.8 Option modules .................................................................................................................... 250

12.8.1 Alarm module ....................................................................................................................... 250

12.8.2 Position feedback module .................................................................................................... 251

12.8.3 SIA module ........................................................................................................................... 252

12.8.4 Mechanical limit switch module ............................................................................................ 253

12.8.5 EMC filter module................................................................................................................. 254

12.8.6 Non-contacting position sensor ............................................................................................ 255

12.8.7 External position detection system ...................................................................................... 256

13.1 Positioner with Makrolon enclosure 6DR5..0 and stainless steel enclosure 6DR5..2 ......... 259

13.2 Positioner with narrow aluminum enclosure 6DR5..1 .......................................................... 260

13.3 Positioner with aluminum enclosure 6DR5..3 ...................................................................... 261

13.4 Terminal strip for positioners with Macrolon enclosure 6DR5..0 and aluminum

enclosure 6DR5..3 ............................................................................................................... 262

13.5 Positioner with flameproof aluminum enclosure 6DR5..5 .................................................... 263

14.1 Overview .............................................................................................................................. 265

14.2 Spare parts ........................................................................................................................... 267

14.3 Scope of delivery of small part sets ..................................................................................... 268

SIPART PS2 with and without HART

8 Operating Instructions, 09/2014, A5E00074631-12

Page 11

Table of contents

A Appendix............................................................................................................................................. 273

B Abbreviations ...................................................................................................................................... 277

Glossary ............................................................................................................................................. 281

Index................................................................................................................................................... 291

14.4 Scope of delivery of external position detection system ....................................................... 270

14.5 Scope of delivery of mechanical limit switch module ............................................................ 270

14.6 Scope of delivery EMC filter module ..................................................................................... 271

14.7 Accessories ........................................................................................................................... 272

A.1 Operation with boosters ........................................................................................................ 273

A.2 Certificates ............................................................................................................................ 274

A.3 Literature and catalogs ......................................................................................................... 274

A.4 Technical support .................................................................................................................. 274

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

9

Page 12

Table of contents

SIPART PS2 with and without HART

10 Operating Instructions, 09/2014, A5E00074631-12

Page 13

1

1.1

Purpose of this documentation

1.2

History

Edition

Firmware identifier nameplate

09/2014

As of FW 5.00.00

Edition

Note

These instructions contain all information required to commission and use the device. Read

the instructions carefully prior to installation and commissioning. In order to use the device

correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

This history establishes the correlation between the current documentation and the valid

firmware of the device.

The documentation for this revision is applicable for the following firmware:

The most important changes in the documentation compared with the previous edition are

shown in the following table.

09/2014

1. Chapter "Parameter overview (Page 147)"

New parameters and values:

– 1.YFCT - Actuator > Initialization of actuators with inverted direction of action

is now possible.

– 50.PRST - Preset > Resetting of individual parameter groups is now possi-

ble.

– 51.PNEUM > Fail in place function can now be activated with appropriate

pneumatic system.

2. Chapter "Parameter overview (Page 147)"

New functions for the advanced diagnostics parameters:

– A5.RPMD and A6.RPRT > Partial stroke test is now possible in ramp mode.

– A7.FLBH > Response following failed PST can now be defined.

3. Chapter "Diagnostics (Page 205)"

Functions for the diagnostics values:

– 7.HOURR - Resettable operating hours counter added

– 11 LEAK > Offline leakage test added.

– 21 P0 and 22 P100 > Modification of upper and lower end stops now possi-

ble without initialization.

– 25 PAUTP > Adjustable no-pulse period added.

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

11

Page 14

Introduction

See also

1.3

Purpose

1.4

Checking the consignment

WARNING

Using a damaged or incomplete device

1.3 Purpose

Structure (Page 19)

Construction (Page 243)

Positioner with flameproof aluminum enclosure 6DR5..5 (Page 263)

The electropneumatic positioner is used for the continuous control of process valves with

pneumatic actuators in the following industries.

● Chemicals

● Oil and gas

● Energy production

● Food and beverages

● Pulp and paper

● Water/waste water

● Pharmaceutical industry

● Offshore plants

Operate the device according to the specifications in Chapter "Technical data (Page 241)".

For additional information, refer to the operating instructions for the device.

1. Check the packaging and the delivered items for visible damage.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

Danger of explosion in hazardous areas.

• Do not use damaged or incomplete devices.

SIPART PS2 with and without HART

12 Operating Instructions, 09/2014, A5E00074631-12

Page 15

Introduction

1.5

Transportation and storage

CAUTION

Insufficient protection during storage

1.6

Product information

See also

1.7

Notes on warranty

1.5 Transportation and storage

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly

packaged to provide sufficient protection during transport. Siemens cannot assume

liability for any costs associated with transportation damages.

The packaging only provides limited protection against moisture and infiltration.

• Provide additional packaging as necessary.

Special conditions for storage and transportation of the device are listed in "Technical data"

(Page 241).

The programming manual is an integral part of the CD, which is either supplied or can be

ordered. The programming manual is also available on the Siemens homepage.

On the CD, you will also find the catalog extract with the ordering data, the Software Device

Install for SIMATIC PDM for additional installation, and the required software.

SIPART PS2 product information (http://www.siemens.com/sipartps2)

Contacts (http://www.siemens.com/processinstrumentation/contacts)

Process instrumentation catalog (http://www.siemens.com/processinstrumentation/catalogs)

The contents of this manual shall not become part of or modify any prior or existing

agreement, commitment or legal relationship. The sales contract contains all obligations on

the part of Siemens as well as the complete and solely applicable warranty conditions. Any

statements regarding device versions described in the manual do not create new warranties

or modify the existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

13

Page 16

Introduction

1.7 Notes on warranty

SIPART PS2 with and without HART

14 Operating Instructions, 09/2014, A5E00074631-12

Page 17

2

2.1

Requirements for safe use

2.1.1

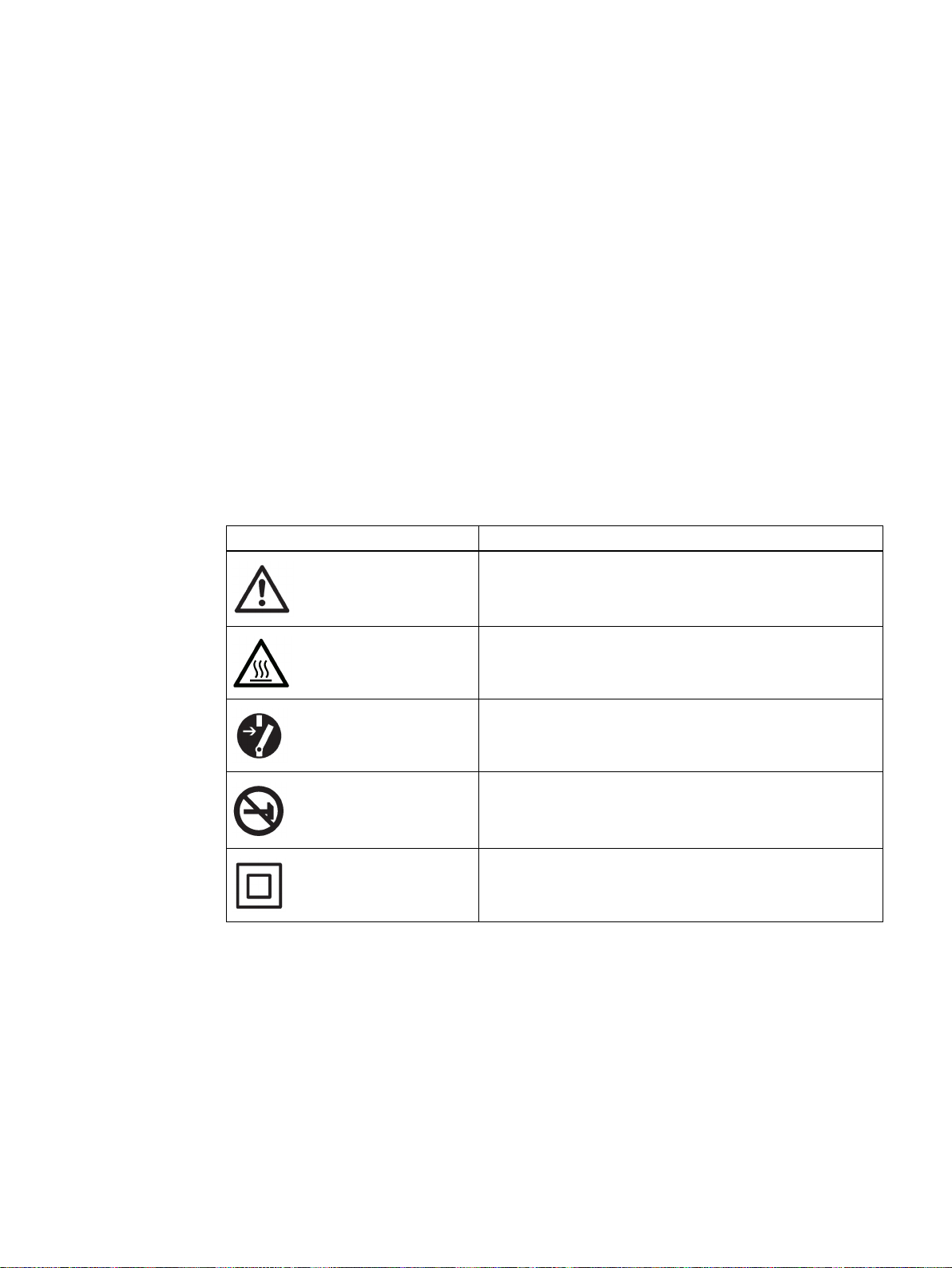

Warning symbols on the device

Symbol

Meaning

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or

symbols from the device. Always keep the information and symbols in a completely legible

state.

Consult operating instructions

Hot surface

Isolate the device from power using a circuit-breaker

Protect the device from shocks (otherwise the specified degree of protection is not guaranteed)

Protective insulation; device in protection class II

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

15

Page 18

Safety information

2.1.2

Laws and directives

See also

2.1.3

Conformity with European directives

Electromagnetic Compat

ity EMC

2004/108/EC

Directive of the European Parliament and of the Council on the

approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EEC.

Atmosphère explosible

ATEX

94/9/EC

Directive of the European Parliament and the Council on the

approximation of the laws of the Member States concerning

equipment and protective systems intended for

ly explosive atmospheres.

LVD 2006/95/EC

Directive of the European Parliament and of the Council of the

harmonisation of the laws of Member States relating to electr

cal equipment designed for use within certain voltage limits.

2.2

Improper device modifications

WARNING

Improper device modifications

2.2 Improper device modifications

Observe the test certification, provisions and laws applicable in your country during

connection, assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EC)

Certificates (http://www.siemens.com/processinstrumentation/certificates)

The CE marking on the device shows conformity with the regulations of the following

European guidelines:

ibil-

The applied standards can be found in the EC conformity declaration of the device.

use in potential-

i-

Danger to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

• Only carry out modifications that are described in the instructions for the device. Failure

to observe this requirement cancels the manufacturer's warranty and the product

approvals.

SIPART PS2 with and without HART

16 Operating Instructions, 09/2014, A5E00074631-12

Page 19

Safety information

2.3

Requirements for special applications

Note

Operation under special ambient conditions

We highly recommend that you contact your Siemens representative or our application

department b

encountered in nuclear power plants or when the device is used for research and

development purposes.

2.4

Use in hazardous areas

Qualified personnel for hazardous area applications

WARNING

Unsuitable device for the hazardous area

2.3 Requirements for special applications

Due to the large number of possible applications, each detail of the described device

versions for each possible scenario during commissioning, operation, maintenance or

operation in systems cannot be considered in the instructions. If you need additional

information not covered by these instructions, contact your local Siemens office or company

representative.

efore you operate the device under special ambient conditions as can be

Persons who install, connect, commission, operate, and service the device in a hazardous

area must have the following specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and

systems according to the safety regulations for electrical circuits, high pressures,

aggressive, and hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for

hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment

according to the pertinent safety regulations.

Danger of explosion.

• Only use equipment that is approved for use in the intended hazardous area and

labelled accordingly.

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

17

Page 20

Safety information

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

2.4 Use in hazardous areas

If the device has already been operated in non-intrinsically safe circuits or the electrical

specifications have not been observed, the safety of the device is no longer ensured for use

in hazardous areas. There is a danger of explosion.

• Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe

circuit.

• Observe the specifications for the electrical data on the certificate and/or in Chapter

"Technical data (Page 241)".

SIPART PS2 with and without HART

18 Operating Instructions, 09/2014, A5E00074631-12

Page 21

3

3.1

Function

3.2

Structure

3.2.1

Overview of structure

● The electropneumatic positioner, in combination with the actuator, forms a control

system. The current position of the actuator is detected using a potentiometer and

returned as the actual value x. The setpoint and actual value are output simultaneously

on the display.

● The setpoint w forms a current applied to the positioner, which in two-wire mode is also

used to power the positioner. In 3- and 4-wire mode, power is supplied through a 24-V

power input.

● The positioner works as a predictive five-point controller, through whose output value ±Δy

the integrated valves can be controlled by pulse length modulation.

● These positioning signals cause pressure changes in the actuator chamber(s) and thus

repositioning of the actuator until the control deviation returns to zero.

● Using three buttons and the display with the enclosure cover removed, operation (manual

mode) and configuration (structuring, initialization, and parameter assignment) can be

performed.

● By default, the basic electronics has a binary input (BIN1). This binary input can be

individually configured and used e.g. to block the control levels.

● To be able to use the positioner in a variety of mechanically different rotational and linear

actuators, it has a friction clutch and a switchable gear.

● In the case of positioners with the "Fail in Place" function, the current position of the

actuator is held if the electric and/or pneumatic auxiliary power fails. Does not function in

conjunction with SIL.

The following sections describe the mechanical and electrical structure, components, and

principle functionality of the positioner.

The positioner is used to move and control pneumatic actuators. The positioner works

electropneumatically, using compressed air as auxiliary power. The positioner is used to

control valves, for example, with:

● Linear actuator

● Part-turn actuator VDI/VDE 3845

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

19

Page 22

Description

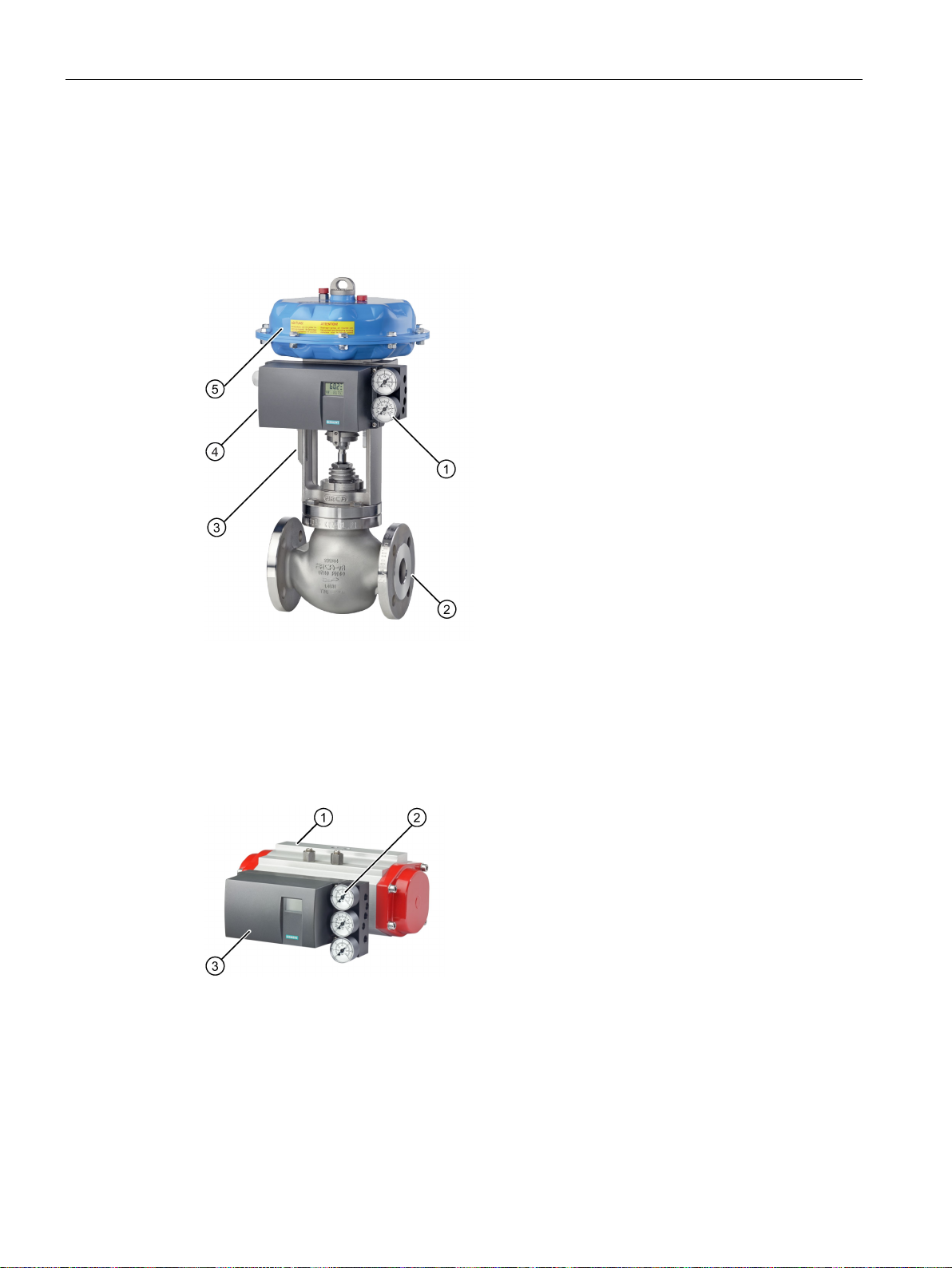

①

Pressure gauge block, single-acting

②

Valve

③

Yoke / actuator yoke

④

Single-acting positioner in non-flameproof aluminum enclosure

⑤

Actuator

①

Part-turn actuator

②

Pressure gauge block, double-acting

③

Double-acting positioner in Makrolon enclosure

3.2 Structure

Various add-on extensions are available for linear actuators:

● IEC 60534-6-1 (NAMUR)

● Integrated addition to ARCA

● Integrated addition to SAMSON in non-flameproof aluminum enclosure

Figure 3-1 Positioner attached to a single-acting linear actuator

Figure 3-2 Positioner attached to double-acting part-turn actuator

SIPART PS2 with and without HART

20 Operating Instructions, 09/2014, A5E00074631-12

Page 23

Description

①

Single-acting positioner in flameproof aluminum enclosure

②

Pressure gauge block, single-acting

③

Yoke / actuator yoke

④

Actuator

①

Part-turn actuator

②

Double-acting positioner in flameproof aluminum enclosure

③

Pressure gauge block, double-acting

3.2 Structure

Figure 3-3 Positioner in flameproof aluminum enclosure attached to linear actuator

Figure 3-4 Positioner in flameproof aluminum enclosure attached to part-turn actuator

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

21

Page 24

Description

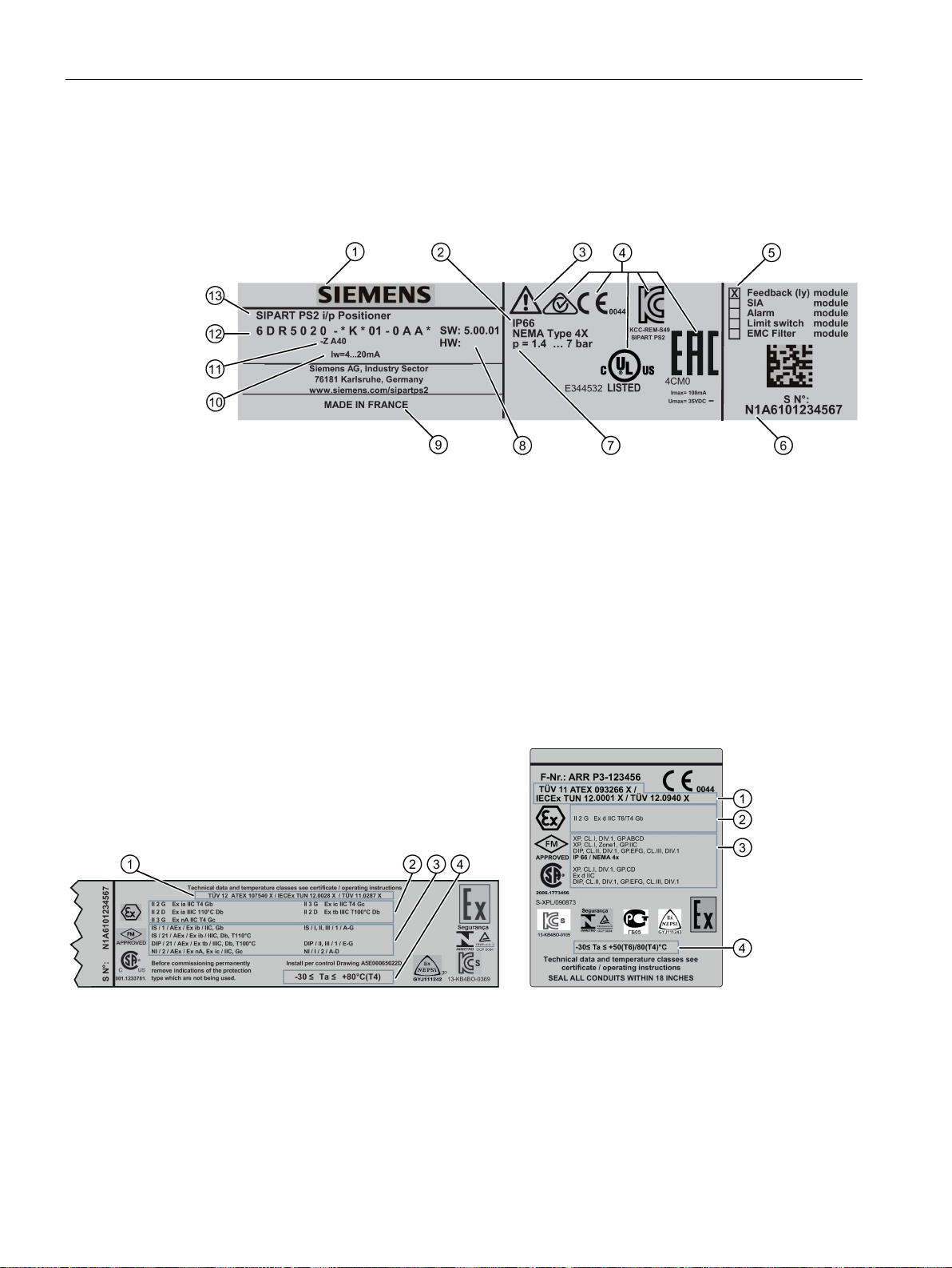

3.2.2

Nameplate layout

Layout of the nameplate

①

Manufacturer

⑧

Software/hardware version

②

Safety class

⑨

Place of manufacture

③

Consult operating instructions

⑩

Auxiliary power

④

Conformity with country-specific directives

⑪

Ordering supplement (Order code)

⑤

⑫

⑥

Serial number

⑬

Product name

⑦

Auxiliary power (supply air PZ)

Layout of Ex nameplate

①

Approvals

③

FM/CSA marking for hazardous area

②

④

area of the corresponding temperature class

3.2 Structure

Built-in option module

Figure 3-5 Nameplate layout, example

Article number

ATEX/IECEx marking for hazardous area

Figure 3-6 Ex nameplate layout, example

SIPART PS2 with and without HART

22 Operating Instructions, 09/2014, A5E00074631-12

Permitted ambient temperature for the hazardous

Page 25

Description

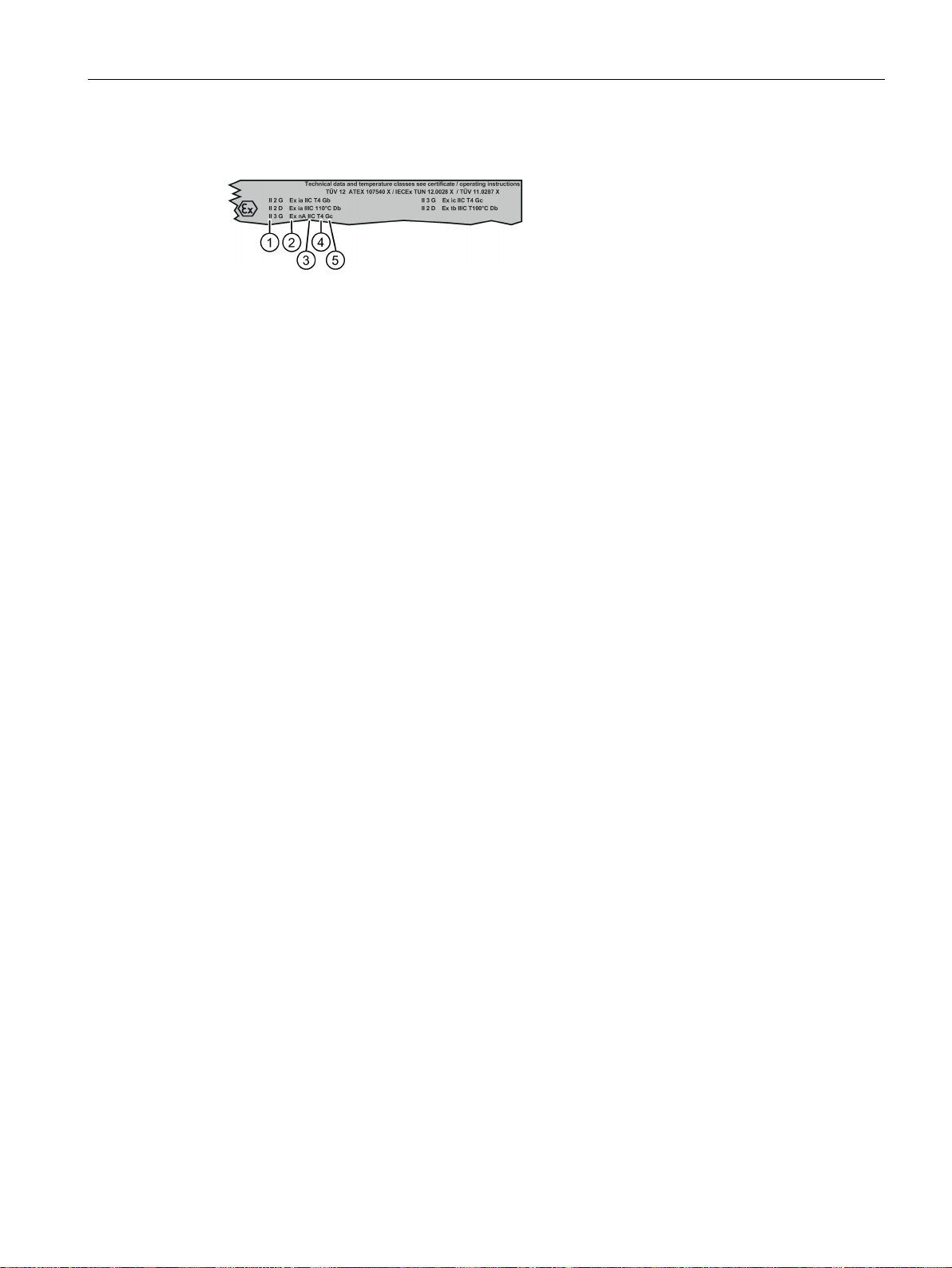

Explanation of Ex information

①

④

ture class)

②

Type of protection

⑤

Device protection level

③

Group (gas, dust)

3.2 Structure

Category for operating range

Figure 3-7 Explanation of Ex information

Maximum surface temperature (tempera-

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

23

Page 26

Description

3.3

Device components

3.3.1

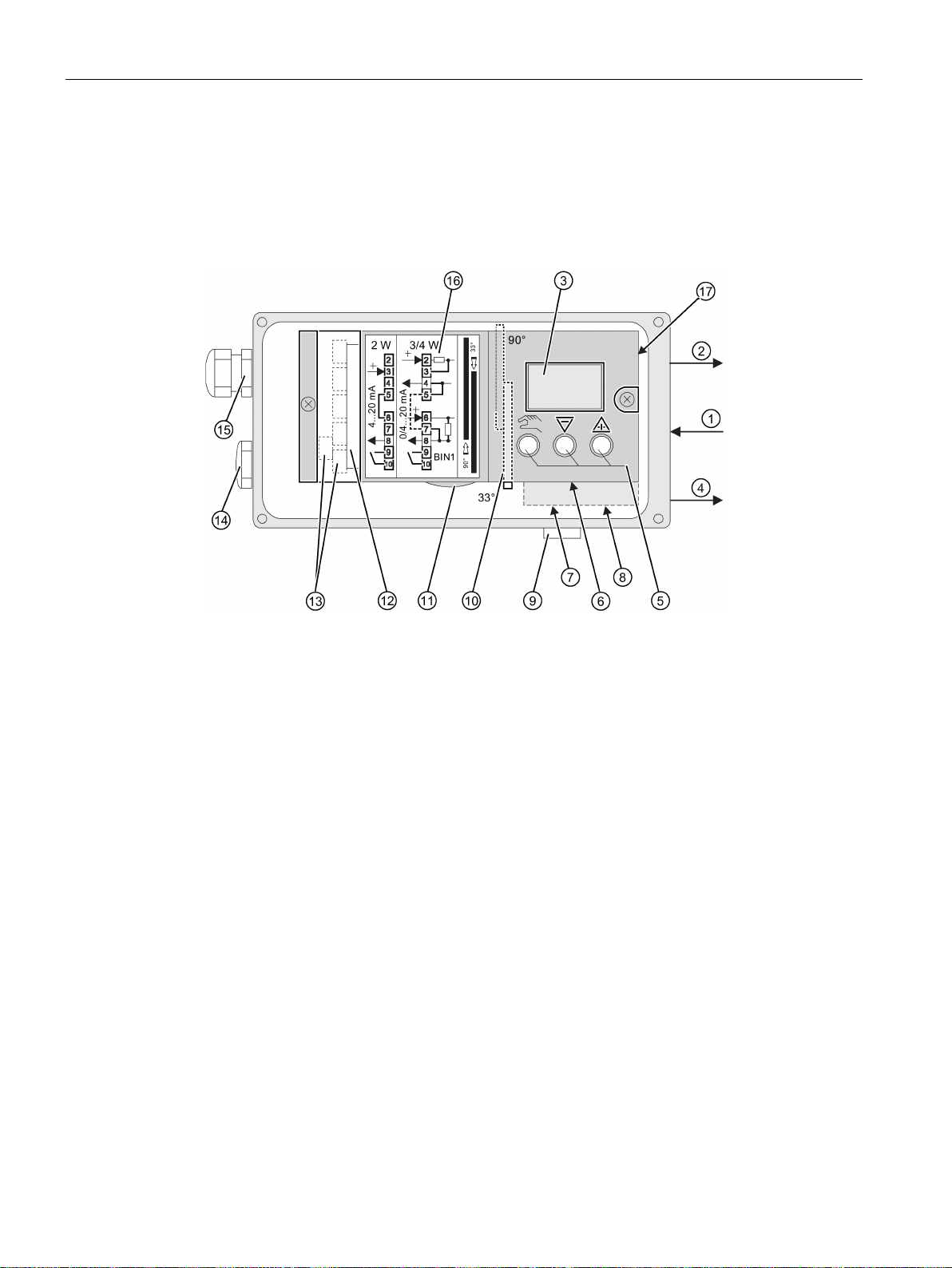

Overview of device components

①

Input: Supply air PZ

⑩

Transmission ratio selector 2)

②

Output: Actuating pressure Y1

⑪

Friction clutch adjustment wheel

③

Display

⑫

Basic electronics

④

Output: Actuating pressure Y2 1)

⑬

Connecting terminals of option modules

⑤

Buttons

⑭

Dummy plug

⑥

Restrictor Y1 for single-acting actuators

⑮

Cable gland

⑦

Restrictor Y1 for double-acting actuators

⑯

Wiring diagram on module cover

⑧

Restrictor Y2 for double-acting actuators

⑰

Purging air selector

⑨

Exhaust air outlet with a sound absorber

for double-acting actuators

only possible when positioner is open

3.3 Device components

1)

2)

Figure 3-8 View of positioner with cover open

SIPART PS2 with and without HART

24 Operating Instructions, 09/2014, A5E00074631-12

Page 27

Description

①

Input: Supply air PZ

⑧

Restrictor Y2 1)

②

Output: Actuating pressure Y1

⑨

Friction clutch adjustment wheel

③

Display

⑩

Connecting terminals of option modules

④

Output: Actuating pressure Y2 1)

⑪

Connecting terminals of basic electronics

⑤

Buttons

⑫

Safety catch

⑥

Transmission ratio selector 2)

⑬

Ground terminal

⑦

Restrictor Y1

1) for double-acting actuators

only possible when positioner is open

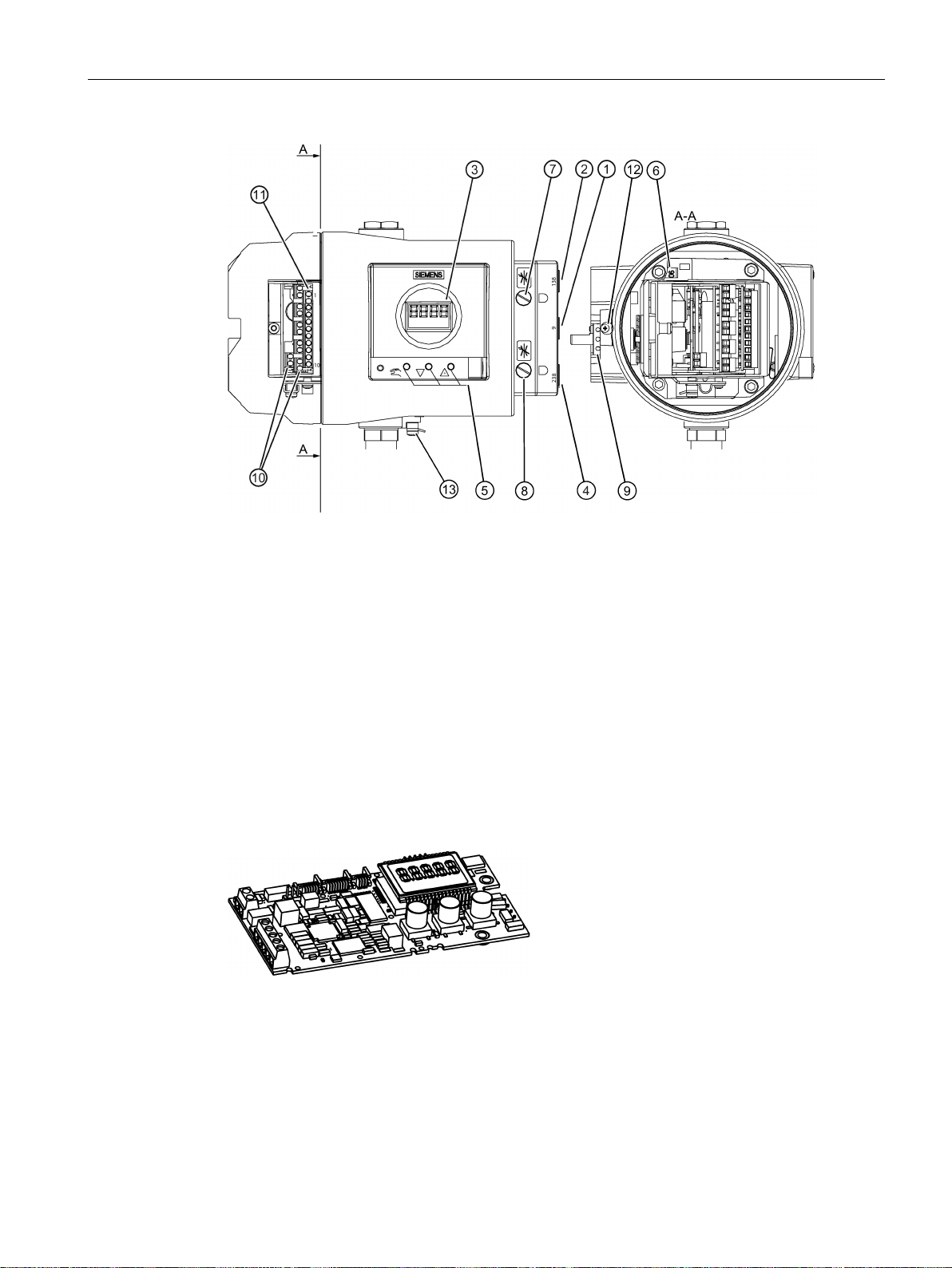

3.3.2

Basic electronics

3.3 Device components

2)

Figure 3-9 View of positioner in flameproof enclosure, cover opened

Figure 3-10 Basic electronics, schematic representation

The basic electronics contains:

● CPU

● Memory

● Analog-to-digital converter

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

25

Page 28

Description

3.4

Mode of operation

Control loop

N

See also

3.4 Mode of operation

● Display

● Buttons

● Terminal strips to connect the option module to the basic electronics

The electropneumatic positioner forms a control loop with the pneumatic actuator:

● The actual value x represents the position of the actuator spindle for linear actuators or

the position of the actuator shaft for part-turn actuators.

● The control value w represents the positioning current of a closed-loop controller or a

manual control station from 0/4 to 20 mA.

The stroke or rotary movement of the actuator is transferred to a potentiometer using

suitable attachments, positioner shaft and a backlash-free, switchable gear drive, and then to

the analog input of the microcontroller.

The current position can also be forwarded to the positioner using an external sensor. A

on-Contacting Position Sensor (NCS) is used to record the stroke or rotary angle directly

on the actuator.

The microcontroller:

● Corrects the angle error of the shaft pick-up if necessary.

● Compares the potentiometer voltage as actual value x with the setpoint w. The setpoint w

is connected to terminals 6 and 7 by means of PROFIBUS communication.

● Calculates the manipulated variable increments ±∆y.

The piezo-controlled inlet or exhaust air valve is opened depending on the magnitude and

direction of the control deviation (x-w). The actuator volume integrates the controller

increment for the actuating pressure y which is proportional to the drive rod or the drive

shaft. This controller increment change the actuating pressure until the control deviation

becomes zero.

Pneumatic actuators are available in single and double-acting versions. In a single-acting

version, only one pressure chamber is ventilated and depressurized. The pressure

developed works against a spring. In a double-acting version, two pressure chambers work

against each other. Ventilating the volume of one chamber simultaneously depressurizes the

volume of the other.

Block circuit diagram for single-acting or double-acting actuators (Page 28)

SIPART PS2 with and without HART

26 Operating Instructions, 09/2014, A5E00074631-12

Page 29

Description

3.4.1

Control algorithm

3.4 Mode of operation

The control algorithm is an adaptive, predictive five-point controller.

In case of large control deviations, the valves are controlled using permanent contact. This

takes place in the so-called fast step zone.

In case of medium control deviations, valves are controlled using pulse-length modulated

pulses. This takes place in the so-called slow step zone.

Figure 3-11 Functional principle of five-point controller

Small control deviations do not send control pulses in the zone. This takes place in the socalled adaptive deadband. The deadband adaptation and the continuous adaptation of

minimum pulse lengths in "Automatic" mode ensure the best possible control accuracy with

the smallest number of operating cycles. The start parameters are determined during the

initialization phase and stored in the non-volatile memory. The most important start

parameters are:

● The real actuator travel with end positions

● Travel times

● The deadband size

The number of fault messages, changes in direction, and the number of strokes are

continuously determined during operation and saved every 15 minutes. You can read and

document these parameters using communication programs such as PDM and AMS. By

comparing the old values with the current ones, you can draw conclusions about the wear

and tear of the valve. You can use the diagnostics function for this.

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

27

Page 30

Description

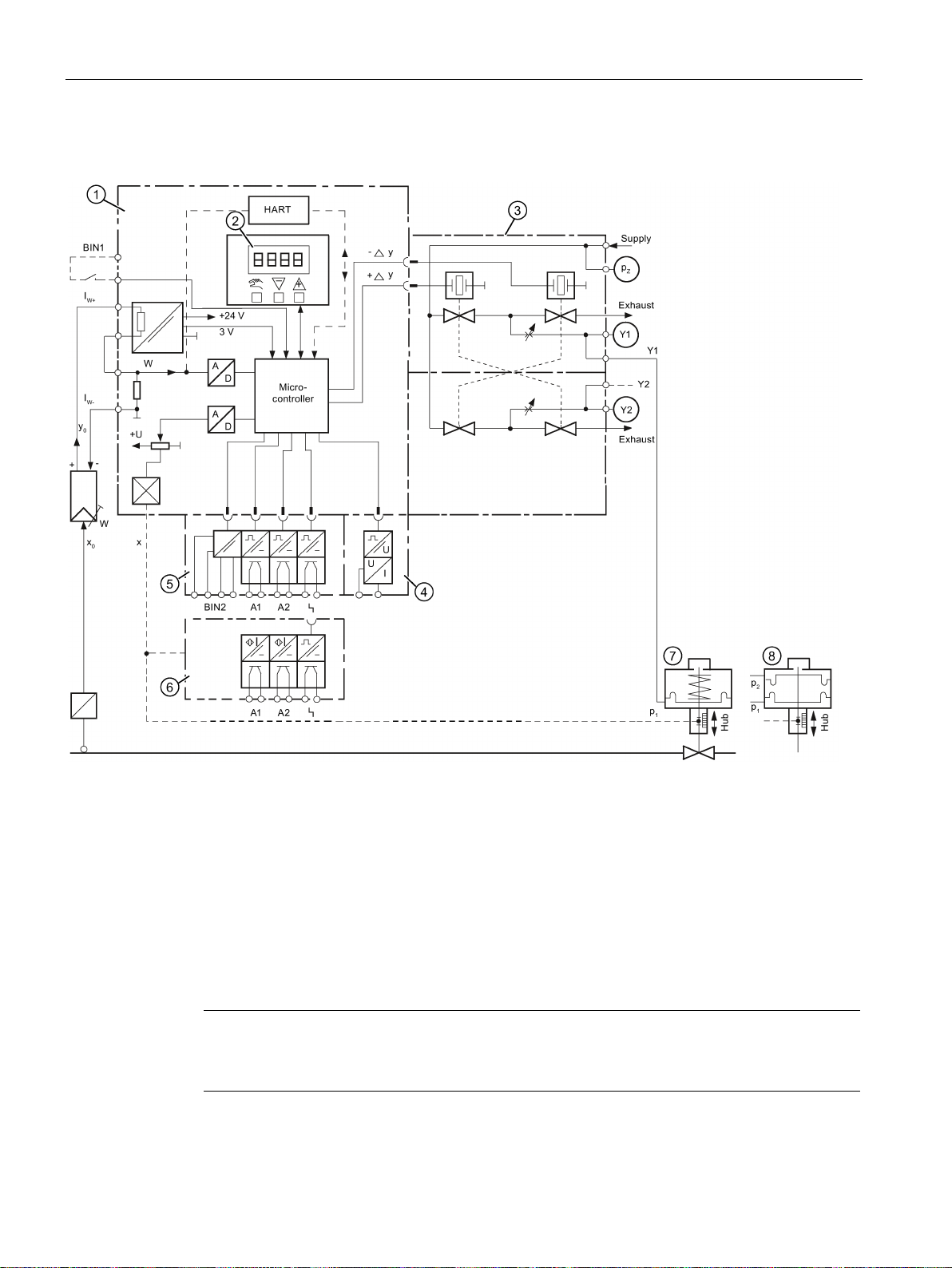

3.4.2

Block circuit diagram for single-acting or double-acting actuators

①

Basic electronics with microcontroller and input circuit

②

Control pad with display and buttons

③

Single-acting or double-acting pneumatic block

④

Position feedback module for positioner

⑤

Alarm module for three alarm outputs and one binary input

⑥

SIA module (slot initiator alarm module)

⑦

Spring-loaded pneumatic actuator (single-acting)

⑧

Pneumatic actuator (double-acting)

Note

Alarm module and SIA module

Alarm module

3.4 Mode of operation

Figure 3-12 Block circuit diagram for the electropneumatic positioner, functional diagram

SIPART PS2 with and without HART

28 Operating Instructions, 09/2014, A5E00074631-12

⑤ and SIA module ⑥ can only be alternatively used.

Page 31

Description

3.4.3

Mode of operation of the HART function

Note

Priority of operation / failure of power supply

•

•

Function

3.4.4

HART system configuration

Overview

3.4 Mode of operation

Operation at the positioner has priority over specifications from the HART communicator.

Failure of the auxiliary power to the positioner also interrupts communications.

The positioner is also available with built-in HART functionality. The HART protocol allows

you to communicate with your device using a HART communicator, PC, or programming

unit. You can do the following with your device:

● Convenient configuration

● Store configurations

● Call up diagnostic data

● Show online measured values

Communication takes place as frequency modulation on the existing signal lines for the

control values of 4 to 20 mA.

The positioner is integrated into the following parameter assignment tools:

● HART communicator

● PDM (Process Device Manager)

● AMS (Asset Management System)

The positioner can be used in a number of system configurations:

● Stand-alone, supplied with the required auxiliary power supply; communication with

supplementary units (handheld), for example

● As part of a complex system environment, e.g. SIMATIC S7

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

29

Page 32

Description

System communication

3.4.5

SIMATIC PDM

3.4 Mode of operation

Communication is via the HART protocol, using:

● HART Communicator (load 230 ... 1100 Ω)

● PC with HART modem, on which appropriate software is installed, e.g. SIMATIC PDM

(load 230 ... 500 Ω)

● Control system which can communicate via the HART protocol, e.g. SIMATIC PCS7

Figure 3-13 Typical system configurations

SIMATIC PDM is a software package for configuring, parameter assignment, commissioning,

diagnostics and maintenance of this device and other process devices.

SIMATIC PDM offers simple monitoring of process values, alarms, and device status

information.

SIMATIC PDM allows the process device data to be:

● displayed

● set

● modified

● saved

● diagnosed

● checked for plausibility

● managed

● simulated

SIPART PS2 with and without HART

30 Operating Instructions, 09/2014, A5E00074631-12

Page 33

4

4.1

Basic safety instructions

WARNING

Unsuitable device for the hazardous area

WARNING

High operating force with pneumatic actuators

WARNING

Lever for position detection

WARNING

Impermissible accessories and spare parts

Danger of explosion.

• Only use equipment that is approved for use in the intended hazardous area and

labelled accordingly.

Risk of injury when working on control valves due to the high operating force of the

pneumatic actuator.

• Please observe the corresponding safety instructions for the pneumatic actuator in use.

Danger of crushing and shearing with mounting kits which use a lever for position detection.

During commissioning and ongoing operation, severing or squeezing of limbs could occur

as a result of the lever. Risk of injury when working on control valves due to the high

operating force of the pneumatic actuator.

• Do not reach into the range of motion of the lever following mounting of the positioner

and mounting kit.

Danger of explosion in areas subject to explosion hazard.

• Only use original accessories or original spare parts.

• Observe all relevant installation and safety instructions described in the instructions for

the device or enclosed with the accessory or spare part.

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

31

Page 34

Installing/mounting

WARNING

It is possible to damage the cover gasket

WARNING

Open cable inlet or incorrect cable gland

See also

WARNING

Exceeded maximum ambient or process media temperature

CAUTION

Unsuitable compressed air

4.1 Basic safety instructions

If the cover gasket is not positioned correctly in the groove of the base plate, it could be

damaged when the cover is mounted and screwed tight.

• Therefore make sure that the gasket is seated correctly.

Danger of explosion in hazardous areas.

• Close the cable inlets for the electrical connections. Only use cable glands or plugs

which are approved for the relevant type of protection.

Construction (Page 243)

Danger of explosion in hazardous areas.

Device damage.

• Make sure that the maximum permissible ambient and process media temperatures of

the device are not exceeded. Refer to the information in Chapter "Technical data

(Page 241)".

Device damage. As a general rule, the positioner must only be operated with dry and clean

compressed air.

• Use the customary water separators and filters. An additional dryer is required in

extreme cases.

• Use dryers, especially if you operate the positioner at low ambient temperatures.

SIPART PS2 with and without HART

32 Operating Instructions, 09/2014, A5E00074631-12

Page 35

Installing/mounting

CAUTION

Please note the following before working on the control valve and when attaching the

positioner

– Commission the positioner.

WARNING

Mechanical impact energy

NOTICE

Torque with NPT screwed gland

4.1 Basic safety instructions

Danger of injury.

• Prior to working on the control valve, you must move the control valve into a completely

pressureless state. Proceed as follows:

– Depressurize the actuator chambers.

– Switch off the supply air PZ.

– Lock the valve in its position.

• Make sure that the valve has reached the pressureless state.

• If you interrupt the pneumatic auxiliary power to the positioner, the pressureless position

may only be reached after a certain waiting time.

• When mounting, observe the following sequence imperatively to avoid injuries or

mechanical damage to the positioner/mounting kit:

– Mount the positioner mechanically.

– Connect the electrical auxiliary power supply.

– Connect the pneumatic auxiliary power supply.

In order to ensure the degree of protection of the housing (IP66), protect the housing

versions of the positioners listed here from mechanical impact energy:

• 6DR5..3; not greater than 2 Joule

• 6DR5..0; not greater than 1 Joule

• 6DR5..1 with inspection window; not greater than 1 Joule

Device damage. The maximum torque of the cable gland must not be exceeded.

• To avoid damage to the device, you must hold the NPT adapter in place while screwing

the NPT gland into the NPT adapter. Refer to the section "Technical specifications >

Construction (Page 243)" for the torque value.

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

33

Page 36

Installing/mounting

4.1.1

Proper mounting

NOTICE

Incorrect mounting

CAUTION

Loss of degree of protection

4.2

Mounting the linear actuator

Requirements

4.2 Mounting the linear actuator

The device can be damaged, destroyed, or its functionality impaired through improper

mounting.

• Before installing ensure there is no visible damage to the device.

• Make sure that process connectors are clean, and suitable gaskets and glands are

used.

• Mount the device using suitable tools. Refer to the information in Technical data

(Page 241) for installation torque requirements.

Damage to device if the enclosure is open or not properly closed. The degree of protection

specified on the nameplate or in Chapter "Technical data (Page 241)" is no longer

guaranteed.

• Make sure that the device is securely closed.

There are linear actuators for standard mounting in accordance with IEC 60534 and for

integrated pneumatic mounting. Use the reduced mounting kit 6DR4004-8VK for actuators

with integrated mounting.

SIPART PS2 with and without HART

34 Operating Instructions, 09/2014, A5E00074631-12

Page 37

Installing/mounting

Actuator type

Required installation components

⑧

⑧

⑦

4.2 Mounting the linear actuator

This section describes how to connect the positioner to the actuator using the mounting kit

6DR4004-8V. You require different installation parts of this mounting kit depending on the

selected actuator type. All installation parts listed in the following table are included in the

product package of the mounting kit 6DR4004-8V. The mounting kit is suitable for a stroke of

3 to 35 mm. In the event of a larger range of stroke, you require the accessory "Lever for

strokes greater than 35 to 130 mm", article number 6DR4004-8L, in addition to the mounting

set 6DR4004-8V. Keep the suitable installation parts ready:

Yoke with fin

Yoke with

plane surface

• Hexagon bolt

• Washer

• Spring lock washer

• Four hexagon bolts

• Washer

• Spring lock washer

⑪

⑪

⑩

⑩

SIPART PS2 with and without HART

Operating Instructions, 09/2014, A5E00074631-12

Yoke with

columns

• Two U–bolts

• Four hexagon nuts

• Washer

• Spring lock washer

⑪

⑳

⑩

35

Page 38

Installing/mounting

Procedure

"Linear actuator IEC 60534 (3 to 35 mm)" mounting kit 6DR4004-8V and 6DR4004-8L

Sr. No. *)

Quantity

Name

Note

①

IEC 60534

surface

②

③

④

⑤

⑥

8L is additionally required for ranges of stroke

> 35 mm to 130 mm (not included in the scope of delivery).

⑧

tions > Construction (Page 243)"

⑩

⑫

⑬

⑭

⑮

⑯

⑰

⑱

⑳

4.2 Mounting the linear actuator

⑦

⑨

⑪

⑲

1 NAMUR mounting bracket

1 Pick-up bracket Guides the pulley with the carrier pin and rotates the lever arm.

2 Clamping piece Installs the pick-up bracket on the actuator spindle

1 Carrier pin

1 Pulley

1 Lever For the range of stroke from 3 mm to 35 mm

2 U–bolts Only for actuators with columns

4 Hexagon bolt M8x20 DIN 933–A2

2 Hexagon bolt M8x16 DIN 933–A2, torque see the section "Technical specifica-

6 Spring lock washer A8 - DIN 127–A2

6 Washer B8.4 - DIN 125–A2

2 Washer B6.4 - DIN 125–A2

1 Spring VD-115E 0.70 x 11.3 x 32.7 x 3.5

1 Spring lock washer A6 - DIN 137A–A2

1 Lock washer 3.2 - DIN 6799–A2

3 Spring lock washer A6 - DIN 127–A2

3 Socket cap screw M6x25 DIN 7984–A2

1 Hexagon nut M6 - DIN 934–A4

1 Square nut M6 - DIN 557–A4