Page 1

Manual Edition12/2006

Controller

SIPART DR22

6DR2210

sipart

Page 2

Page 3

SIPART DR22

6DR2210

Edition 12/2006

Manual

SIPART DR22 6DR2210

C79000-G7476-C154-03

1

Page 4

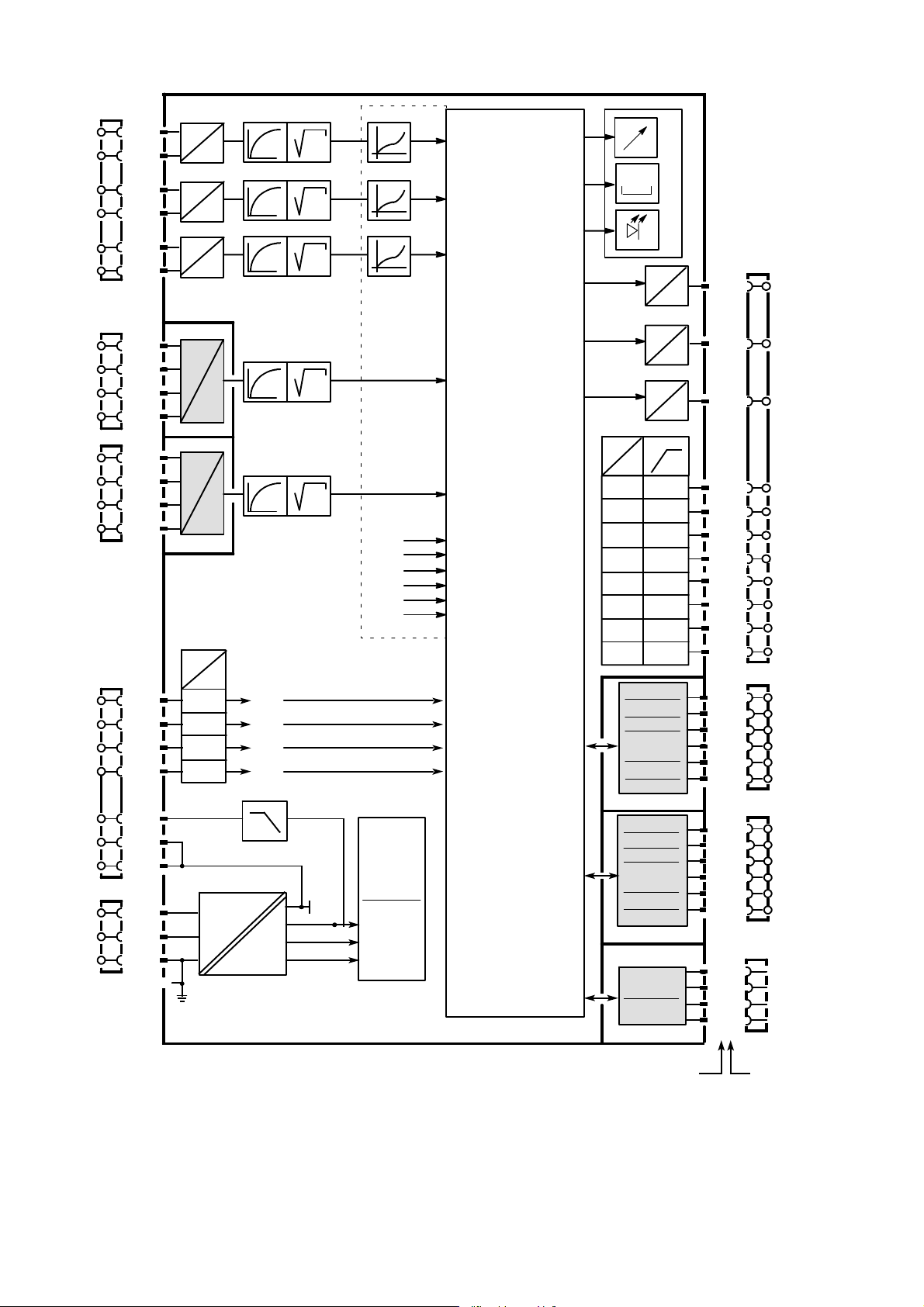

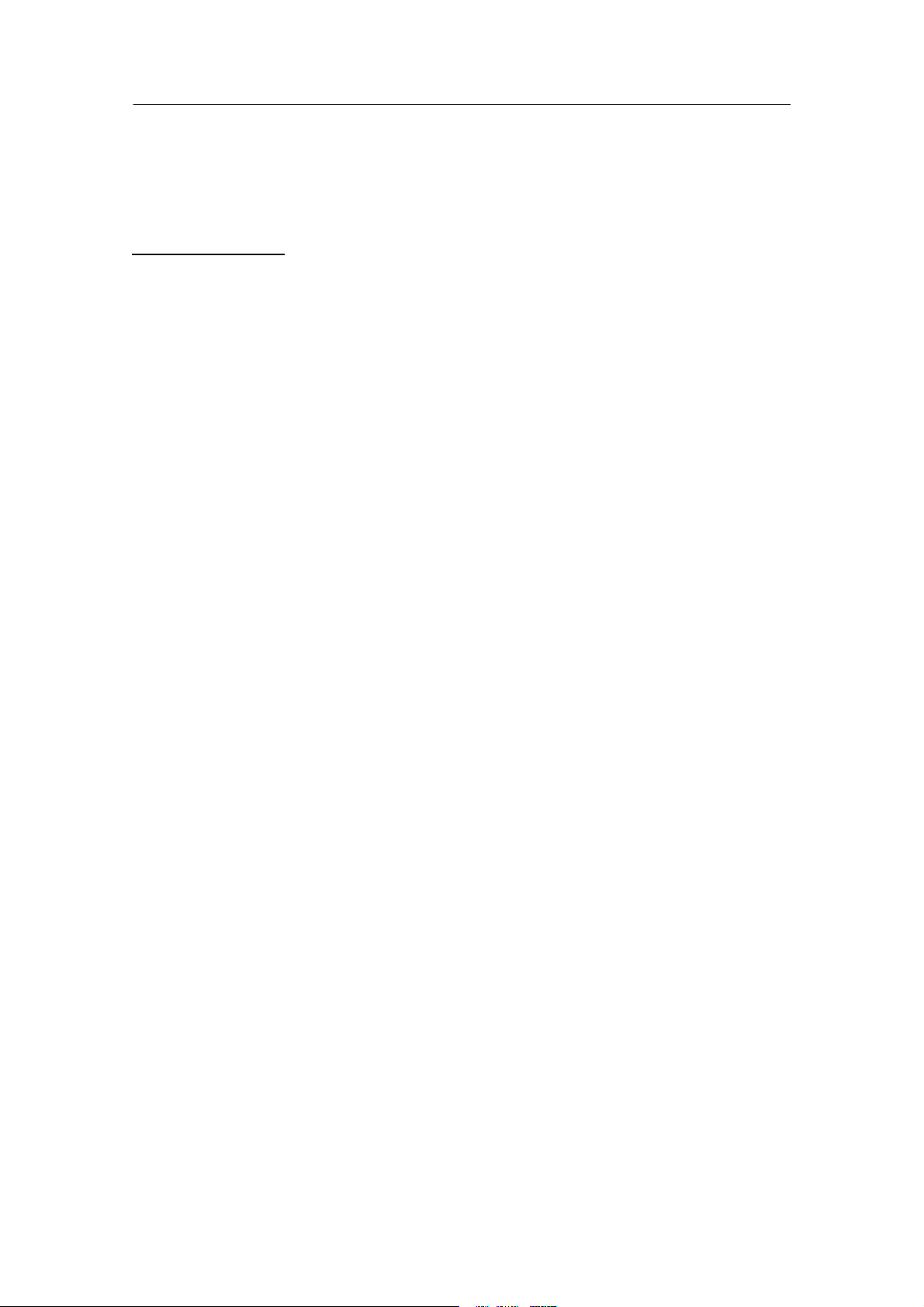

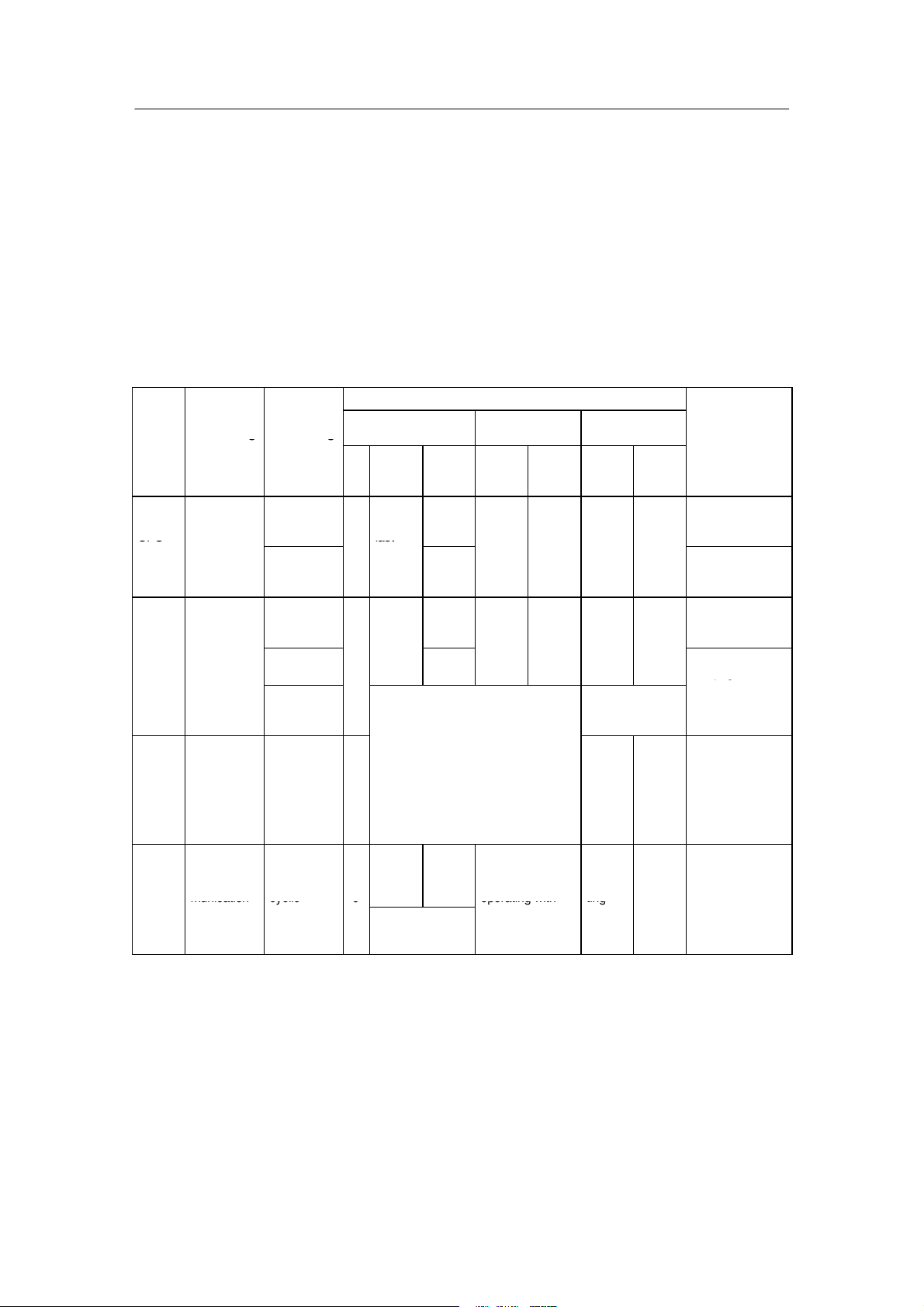

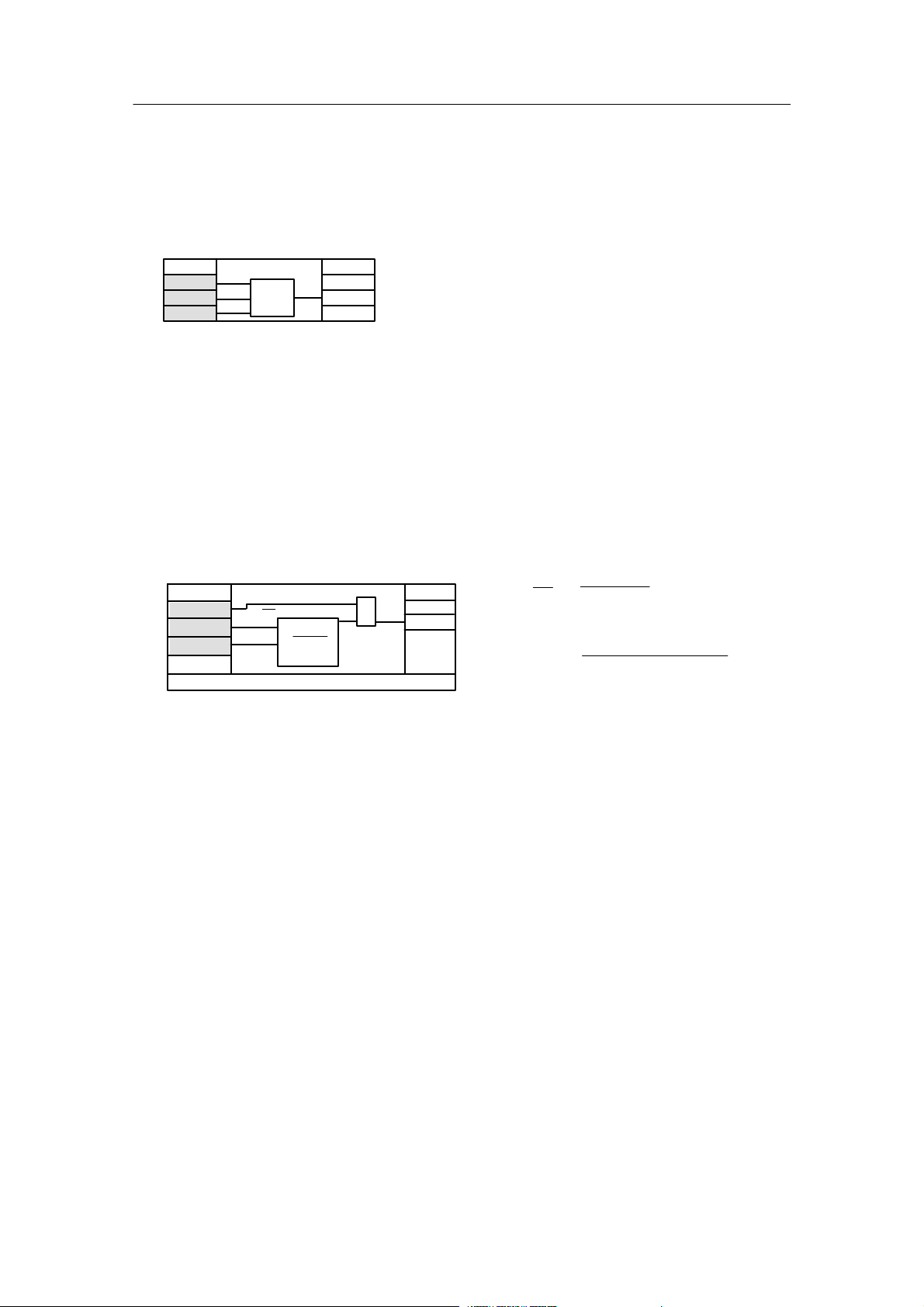

Block diagram

AE1

AE2

AE3

AE4

AE5

BE1

2

3

BE4

L+

+

-

+

-

+

-

Options

M

M

S5

1/20

1/19

1/22

1/21

1/24

1/23

2/4

2/3

2/2

2/1

3/4

3/3

3/2

3/1

1/15

1/16

1/17

1/18

1/3

1/2

1/1

N

PE

I,U

U

S6

I,U

U

S7

I,U

U

S8

I,U,R

UNI,

P,

T,

V

U

Slot 2

S9

I,U,R

UNI,

P,

T,

V

U

Slot 3

24 V

5V

S3

L

«

6DR2210-4 24 V UC

6DR2210-5 115/230 V AC switchable

bE01

bE02

bE03

bE04

I

–

S10

AE1A

t

S11

AE2A

t

S12

AE3A

t

S13

AE4A

t

S14

AE5A

t

M

+24V

+5V

U

REF

S20

S20

S20

drawn:

S4 = 0

at S4 = 1 freely

connectable

S212 to S217

FE7

FE8

FE9

FE10

FE11

FE12

User

program

memory for:

onPA on

AdAP line

oFPA

FdEF

FCon off

FPoS line

APSt

FPST

S15

Standard

FE1

settings

S16

Analog inputs

FE2

Assembly

S17

Slot 5 and 6

FE3

Digital inputs

Setpoint command

S18

Control algorithm

FE4

Y switching

Y display

S98

Analog outputs

FE5/6

Digital outputs

Limit value alarms

Restart

conditions

Serial interface

S0 to S4

S5 to S21,

S200 to S217

S22, S23

S24toS48,

S218 to S228

S49toS53

S54toS60

S61toS66

S67toS68

S69toS75,

S247 to S257

S76toS93,

S258 to S266

S94toS98,

S267 to S268

S99, S100

S101 to S107

F

r

o

n

t

0000

m

o

d

u

l

e

U

U

U

I

5V

24 V I

3AE

1AA y

hold

5BE

4BA24V

+2BE

2BA Rel.

3AO/3BE

Slot 6

3AE

1AA y

hold

5BE

4BA 24V

+2BE

2BA Rel.

3AO/3BE

Slot 5

RS 232

RS 485

PROFIBUS

Slot 4

Slot Terminal

1/12

1/13

1/14

1/4

1/5

1/6

1/7

1/8

1/9

1/10

1/11

6/6

6/5

6/4

6/3

6/2

6/1

Options

5/6

5/5

5/4

5/3

5/2

5/1

4/2

4/7

4/8

4/3

AA1

AA2

AA3

BA1

2

3

4

5

6

7

BA8

Options

2

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 5

Manual

Classification of safety--related notices

This manual contains notices which you shouldobserve toensure your own personalsafety, as well

as to protect the product and connected equipment. These notices are highlighted in the manual

by a warning triangle and are marked as follows according to the level of danger:

DANGER

!

!

!

indicates an immenently hazardous situation which, if not avoided, will result in

death or serious inury.

WARNING

indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

used with the safety alert symbol indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION

used without the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

NOTICE

indicates a potential situation which, if not avoided, may result in an undesirable

result or state.

.

Copyright e Siemens AG 2006 All rights reserved

The reproduction, transmission or use of this docu-

ment or its contents is not permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of a utility model or design,

are reserved.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

DEUTSCHLAND

NOTE

highlights important information on the product, using the product, or part of the

documentation that is of particular importance and that will be of benefit to the

user.

Disclaimer of Liability

We have checked the contents of this manual for

agreement with the hardware and software described. Since deviations cannot be precluded entirely,

we cannot guarantee full agreement. However, the

data in this manual are reviewed regularly and any

necessary corrections included in subsequent editions. Suggestions for improvement are welcomed.

e Siemens AG 2006

Technical data subject to change.

SIPART DR22 6DR2210

C79000-G7476-C154--03

3

Page 6

Trademarks

SIMATICR,SIPARTR,SIRECR, SITRANSR registered trademarks of Siemens AG.

Third parties using for their own purposes any other names in this document which refer to trade-

marks might infringe upon the rights of the trademark owners.

4

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 7

Manual Contents

Conents

Page

1 Technical Description 7...................................................

1.1 Safety notes and scope of delivery 7..................................................

1.2 Range of Application 8..............................................................

1.3 Design (Hardware) 9...............................................................

1.4 Function principle 12................................................................

1.4.1 Standard controller 12.................................................................

1.4.2 Description of the option modules 13....................................................

1.4.3 CPU self-diagnostics 20...............................................................

1.4.4 Data storage, User program memory 21.................................................

1.5 Functional description of the structure switches 22.......................................

1.5.1 Analog input signal processing permanently connected 22..................................

1.5.2 Analog input signal processing freely connected (S4 = 1) 25.................................

1.5.2.1 Arithmetic Ar1 to Ar6 27...............................................................

1.5.2.2 Function transmitter Fu1 and Fu2 27....................................................

1.5.2.3 Maximum value selection MA1 to MA3 27................................................

1.5.2.4 Minimum value selection Mi1 to Mi3 28...................................................

1.5.2.5 Correction computer for ideal gases rE1 28...............................................

1.5.2.6 Switch for analog variables AS1 to AS5 33...............................................

1.5.2.7 Comparator with adjustable hysteresis Co1, Co2 33........................................

1.5.2.8 AND NOT function (NAND) nA1, nA2 33.................................................

1.5.2.9 OR NOT function (NOR) no1, no2 33....................................................

1.5.3 Digital input signal processing 34.......................................................

1.5.3.1 Digital inputs BE1 to BE14 34..........................................................

1.5.3.2 Assignment and direction of effect of the digital inputs 35....................................

1.5.3.3 Linking the digital inputs BE1 bis BE14 to the control signals via the SES 35...................

1.5.3.4 Functional explanation of the digital control signals 39......................................

1.5.4 Controller types (S1, S49 to S53) 40.....................................................

1.5.4.1 General, recurrent functions 40.........................................................

1.5.4.2 S1 = 0: Fixed setpoint controller with 2 independent setpoints 48...........................

1.5.4.3 S1= 1: Fixed setpoint controller with 2 dependent setpoints 51.............................

1.5.4.4 S1 = 2: DDC fixed setpoint controller 52................................................

1.5.4.5 S1 = 3: Follow-up controller, synchronized controller, SPC-controller 58.....................

1.5.4.6 S1 = 4: commanded ratio controller 64.................................................

1.5.4.7 S1 = 5: Cascade control 69..........................................................

1.5.4.8 S1 = 6: Ratio-cascade control 74......................................................

1.5.4.9 S1 = 7/8: Override control 77...........................................................

1.5.4.10 S1 = 9: Process display 83...........................................................

1.5.4.11 S1 = 10: Fixed setpoint controller with 1 setpoint (control system coupling) 84.................

1.5.4.12 S1 = 11: Follow-up controller without Int/Ext switching (control system coupling) 85.............

1.5.4.13 S1=12: Double fixed setpoint/follow-up controller 86......................................

1.5.5 Control algorithm, parameter control, adaptation 89........................................

1.5.5.1 Control algorithm 89..................................................................

1.5.6 Controller output structures (S2, S61 to S68) 99...........................................

1.5.6.1 S2 = 0: Continuous (K) controller 99...................................................

1.5.6.2 S2 = 1: Three-position step (S) -controller with internal feedback 104.........................

1.5.6.3 S2 = 2: Three-position step (S) -- controller with external feedback 107.......................

1.5.7 Analog output signal processing (S69 to S75, S247 to S257) 120..............................

1.5.8 Digital output signal processing (S76 to S93 and S258 to S266) 121...........................

1.5.9 Limit value alarms (S94 to S100, S267 to S268) 124........................................

1.5.10 Restart conditions (S99, S100) 126.......................................................

1.5.11 Serial interface and PROFIBUS-DP (S101 to S107) 126.....................................

1.6 Technical Data 127...................................................................

1.6.1 General data 127......................................................................

1.6.2 Standard Controller 129................................................................

1.6.3 Technical data of the options modules 133.................................................

SIPART DR22 6DR2210

C79000-G7476-C154-03

5

Page 8

2 Installation 143.............................................................

2.1 Mechanical Installation 143............................................................

2.2 Electrical Connection 143.............................................................

2.2.1 Connection standard controller 147.......................................................

2.2.2 Wiring of option modules 150............................................................

2.2.3 Alternative connection for I- and U-input 158...............................................

2.2.4 Connection of the interface 163..........................................................

3 Operation 167..............................................................

3.1 Process operation 167................................................................

3.2 Selection level 169...................................................................

3.3 Configuring level (parameterization and structuring mode) 172..............................

3.3.1 Paramterization 172...................................................................

3.3.2 Parameterization mode onPA (online parameters) 173.......................................

3.3.3 Parameterization mode AdAP (Adaptation) 175.............................................

3.3.4 Structuring mode oFPA (offline Parameters) 182............................................

3.3.5 Structuring mode PASt (parameter control) 184.............................................

3.3.6 Structuring mode StrS (structure switches) 186.............................................

3.3.7 Structuring mode FdEF (define functions) 201..............................................

3.3.8 Structuring mode FCon (connect functions, connection) 202..................................

3.3.9 Structuring mode FPoS (position functions) 205............................................

3.3.10 Structuring mode FPSt (Functions Preset, factory setting) 209................................

3.3.11 Structuring mode APSt (All Preset, factory setting) 210......................................

3.3.12 Set structuring mode CAE4/CAE5 -- UNI module(s) 211.....................................

3.3.12.1 Measuring range for mV (SEnS=Mv.) 212.................................................

3.3.12.2 Measuring range for U, I (SEnS=Mv.) 212.................................................

3.3.12.3 Measuring range for thermocouple with internal reference point (SEnS=tc.in) 213................

3.3.12.4 Measuring range for thermocouple with external reference point (SEnS=tc.EH) 213..............

3.3.12.5 Measuring range for PT100-4-wire and PT100-3-wire connection (SEnS=Pt.3L/PT.4L) 213........

3.3.12.6 Measuring range for PT100-2-wire connection (SEnS=Pt.2L) 214.............................

3.3.12.7 Measuring range for resistance potentiometer

(SEnS=r._ for R < 600 W, SEnS=r. for R< 2.8 kW) 214......................................

ManualContents

4 Commissioning 215........................................................

4.1 Adapting the controller direction of effect to the controlled system 215........................

4.2 Setting the split range outputs and the actuating time in K-controllers (S2 = 0) 217.............

4.3 Adaptation of the S-controller to the actuating drive 218....................................

4.4 Setting the filter and the response threshold 219..........................................

4.5 Automatic setting of control parameters 220..............................................

4.6 Manual setting of the control parameters 224.............................................

4.7 Manual setting of the control parameters 225.............................................

5 Maintenance 227...........................................................

5.1 General information and handling 227...................................................

5.2 Spare parts list 231...................................................................

6 Ordering data 233..........................................................

7 Application examples for configuring the controller 235.......................

8 Configuring tool 241........................................................

9 Explanation of abbreviations 253............................................

Index 259........................................................................

6

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 9

Manual 1 Technical Description

1.1 Safety notes and scope of delivery

1 Technical Description

1.1 Safety notes and sco p e of delivery

!

D Scope of delivery

When the controller is delivered the box contains:

1 Controller as ordered

1 three-pin plug at 115/230 V AC or special plug at 24 V UC

2 Clamps, pluggable

1 Assembly and installation instructions

Order number C79000-M7474-C38

WARNING

This device is electrically operated. When operating electrical

equipment, certain parts of this equipment automatically carry

dangerous voltages. Failure to observe these instructions could

therefore lead to serious injury or material damage. Only properly

trained and qualified personnel are allowed to work on this

equipment. This personnel must be fully conservant with all the

warnings and commissioning measures as described in this user’s

guide.

The perfect and safe operation of this equipment is conditional upon

proper transport, proper storage, installation and assembly as well as

on careful operation and commissioning.

D Basic equipment

The following variants of the SIPART DR22 are available:

Order number Power Supply

6DR2210-4

6DR2210-5

D Option modules

Signal convertors have separate ordering and delivery items. For handling reasons basic

equipment and signal convertors which were ordered at the same time may be delivered by

separate mail.

D Documentation

This user’s guide is available in the following languages:

English C79000-G7476-C154

German C79000-G7400-C154

SIPART DR22 6DR2210

C79000-G7476-C154-03

24 V UC

115/230 V AC, switchable

7

Page 10

1.2 Range of Application

Manual1 Technical Description

D Subject to change

The user’s guide has been compiled with great care. However, it may be necessary within

the scope of product care to make changes to the product and its operation without prior

notice which are not contained in this user’s guide. We are not liable for any costs ensuing

for this reason.

1.2 Range of Application

The SIPART DR22 is a digitally operating device in the top class range. Its program memory

contains a large number of prepared function blocks for calculating, controlling, regulating in

technical processes which the user can implement without programming knowledge and

additional tools.

In addition a robust adaptation procedure is available in this device which makes it much easier

to commission even critical controlled systems. The controller determines the optimized control

parameters independently on request without the user being expected to have any prior

knowledge of how the control loop may respond. The applied procedure is suitable for systems

with compensation and aperiodic transient behavior; even greater dead times are taken into

account.

For more complicated applications the fixed connection of the individual functions can be

canceled in the input range and replaced by a free structuring. The user can easily add extra

analog function blocks and connect them to each other and to the interfaces of the input range

with the software. This achieves optimum adaptation even to complex problems.

The named programming possibilities guarantee a great flexibility in the use of the controller

and allow fast, easy adapting of the device to the problem so that the SIPART DR22 can be

used universally for control jobs in processing engineering, e.g. as

-- fixed setpoint controller for one, two or three-component control, optionally with two

setpoints

-- DDC fixed setpoint controller for one-, two- or three-component control

-- follow-up controller (synchronized controller, SPC controller) with internal/external switching

-- fixed or commanded ratio controller with Internal/External switching

-- cascade controller (double controller)

-- ratio-cascade controller (double controller)

-- override controller with Min or Max selection of the manipulated variable (double controller)

-- double controller with two independent control channels

The extensive hardware equipment of the instrument by which numerous interfaces are

available for connecting the field cables is of advantage for the universal utilization. The

instrument can also be connected to master systems via a plug-in serial interface or operated

and monitored centrally by a Personal Computer.

The SIPART DR22 can be used alternatively as a continuous controller with a current output

signal or as a three-position step controller for controlling electric motor drives without changing

the hardware equipment.

8

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 11

Manual 1 Technical Description

1.3 Design (Hardware)

1.3 Design (Hardware)

The process controller SIPART DR22 has a modular structure and is therefore maintenance

friendly and easy to convert and retrofit. Other signal convertors can be installed in the generously equipped, fully functional standard controller to expand the range of application. These

modules are inserted in backplane slots of the enclosed instrument (Fig. 1-2, page 11).

The standard controller consists of

-- the front module with the control and display elements

-- the main board with CPU and terminal strips

-- the plastic casing with an interface board

-- the power supply unit.

The electrical connections between the modules are made by an interface board screwed into

the casing. The main board is pushed into rear slot 1 and locked. It holds a 10-pin and a 14-pin

terminal strip to which all inputs and outputs of the standard controller are connected. Five other

slots can be equipped with option modules if the number of terminals to the process available in

the standard controller are not sufficient for the planned task.

The standard controller always has three permanently installed analog inputs (AE) with electronic potential isolation which can be wired alternatively with standardized voltage signals

(0/0.2 to 1 V or 0/2 to 10 V) or current signals (0/4 to 20 mA). There are also four digital inputs

(BE, 0/24 V) and eight digital outputs (BA, 0/24 V, 50 mA) which can be used for different functions depending on the configuration.

The SIPART DR22 also has three analog outputs (AA) which can all supply a current signal

from 0 to 20 mA or 4 to 20 mA and be assigned to different variables.

A short-circuit-proof L+--output (DC 24 V, 100 mA) is available for supplying transmitters.

The power supply unit is located in a fully enclosed metal casing and is screwed tightly to the

plastic casing of the controller. This power supply is available in two different versions so that

two types of SIPART DR22 are available:

6DR2210-4 for power supply connection UC 24 V

6DR2210-5 for power supply connection AC 230 V, switchable to AC 115 V

Many applications can be implemented with the three permanently available analog inputs of

the standard controller alone. Two additional input modules can be inserted in slots 2 and 3 for

complex jobs or for the connection of other input signals. These input modules are available in

addition to for processing normalized current and voltage signals for the direct connection of

resistance thermometers Pt100 and all common thermocouples and resistance sensors or

potentiometers. In addition a module with 3 analog inputs (equipment as in the standard

controller) can be inserted in slots 5 and 6. This increases the number of inputs to a total of 11.

Slot 4 serves to accommodate an interface module (SES) with V.28-point-pointoutput or

SIPART bus interface for serial communication with a master system. A PROFIBUS interface

module can be equipped optionally here.

SIPART DR22 6DR2210

C79000-G7476-C154-03

9

Page 12

1.3 Design (Hardware)

The slots 5 and 6 can accommodate signal convertors of different functions and can be

equipped optionally with modules for expanding digital inputs or digital outputs.

The following assemblies are possible:

2 relays

4 digital outputs/2 digital inputs

5 digital inputs

3 analog outputs/3 digital inputs

1 analog output with digital fault output (y

function) with remote supply

hold

3 analog inputs

1

Manual1 Technical Description

3

Figure 1-1 Front view of the SIPART DR22

2

1 Power supply unit

2Casing

3 Front module

10

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 13

Manual 1 Technical Description

1

12

11

Legend:

10

2

9

8

3

1 PE conductor -- contact spring

2Slot6

3Slot5

4 Slot 1 (basic board)

5Slot2

6Slot3

7 Slot 4 (SES: RS 232/

RS 485, Profibus DP)

8 Grounding screw

9 DIN rail (delivered with the

interface relay)

10 Selector switch Mains voltage

11 Mains plug

12 Power supply unit

1.3 Design (Hardware)

7 6 5 4

Figure 1-2 Rear view of the SIPART DR22

SIPART DR22 6DR2210

C79000-G7476-C154-03

11

Page 14

1.4 Function principle

1.4.1 Standard controller

Manual1 Technical Description

1.4 Function principle

1.4.1 Standard controller

The standard controller consists of three function blocks:

-- Power supply unit

-- Front module

-- Main board

Power supply unit

Primary clocked power supply plug with high efficiency for AC 115/230 V (switchable) or for UC

24 V. It generates the secondary internal supply voltages +24 V and +5 V from the power

supply. The metal body is mounted on PE conductors (protection class I). The power supply

and internal supply voltages are isolated from each other by safe separation by a protective

shield. The internal supply voltages are functional extra-low voltages due to overvoltage cutoff

in the event of an error. Since no other voltages are generated in the instrument, these

statements apply for all field signal cables (used standards, see chapter 1.6, page 127). A total of

450 mA are available for the outputs L+, AA and BA due to the design for a high power output.

Front module

The front module contains the control and display elements and the appropriate trigger components for the displays.

All display elements are designed in LED technology which provides a longer service life and

higher light density as well as a good viewing angle. The control elements are short-stroke

switches with a tangible ”pressure point” and high return force.

Main board

The main board contains the field signal conditioning of the standard controller, the CPU

(Central Processing Unit) and the connections (through the interface board) to the module slots.

The field signals are fed through protective circuits for external static or dynamic overvoltages

and then adapted to the signal levels of the CPU by the appropriate circuits. This adaptation is

performed for the analog inputs, the analog outputs and the digital outputs by modern thick-film

circuits.

The microcontroller used has integrated AD- and DA converters and operates with 32k batterybacked RAM. The user-specific configuration is stored in an user program memory with a serial

4k EEPROM. When replacing the main board the user memory can be plugged from the old

onto the new module. The whole CPU is designed in C-MOS technology.

A process image is generated at the start of every routine. The analog and digital inputs and

actuation of the front buttons is included and the process variables received from the serial

interface are accepted. All calculations are made with these input signals according to the

configured functions. Then the data are output to the display elements, the analog outputs and

the digital outputs as well as storage of the calculated variables on standby for the serial

interface transmitter. The interface traffic runs in interrupt mode.

12

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 15

Manual 1 Technical Description

1.4.2 Description of the option modules

1.4 Function principle

A large number of prepared functions for controlling processing plants as well as machines and

apparatus is stored in the set value memory of the SIPART DR22. The user programs the

instrument himself by selecting the desired functions by setting structure switches. The total

functioning of the instrument is given by the combination of the individual structure switches.

Programming knowledge is not necessary for the settings. All settings are made without an

additional programming unit exclusively through the front panel of the SIPART DR22 or through

the serial interface. The job-specific program written in this way is saved in the non-volatile user

program memory.

1.4.2 Description of the option modules

The following option modules are described in this chapter

6DR2800-8A Module with 3 AE, U- or I-input

6DR2800-8J I/U module

6DR2800-8R R module

6DR2800-8V UNI module

6DR2805-8A Reference junction terminal

6DR2805-8J Measuring range for TC, internal connector

6DR2801-8D Module with 2 BA (relays)

6DR2801-8E Module with 2 BE and 4 BA

6DR2801-8C Module with 5 BE

6DR2802-8A Analog output module with y-hold function

6DR2802-8B Module with 3AA and 3BE

6DR2803-8P Serial interface PROFIBUS-DP

6DR2803-8C Serial interface RS 232 / RS 485

6DR2804-8A Module with 4 BA relays

6DR2804-8B Module with 2 BA relays

6DR2800-8A Module with 3 AE, U- or I-input

D Inputs for current and voltage

To expand the analog inputs.

For a description of the module and technical data, see chapter 1.6.2, page 129 (Inputs standard

controller).

SIPART DR22 6DR2210

C79000-G7476-C154-03

13

Page 16

1.4 Function principle

1.4.2 Description of the option modules

Manual1 Technical Description

6DR2800-8J I/U module

D Input variables current 0/4 to 20 mA or voltage 0/0.2 to 1 V or 0/2 to 10 V

The input amplifier of the module is designed as a differentiating amplifier with jumperable gain

for 0 to 1 V or 0 to 10 V input signal. For current input signals the 49.9 Ω 0.1 % impedance is

switched on by plug-in bridges on the module. The start value 0 mA or 4 mA or 0 V or 0.2 V

(2 V) is defined by configuration in the standard controller. The differentiating amplifier is

designed for common mode voltages up to 10 V and has a high common mode suppression.

As a result it is possible to connect the current inputs in series as for electrical isolation when

they have common ground. At voltage inputs this circuit technique makes it possible to

suppress the voltage dips on the ground rail by two--pole wiring on non floating voltage supplies.

We refer to an electronic potential isolation.

6DR2800-8R R module

D Input for resistance or current potentiometer

Potentiometers with rated values of 80 Ω to 1200 Ω can be connected as resistance

potentiometers. A constant current of Is = 5 mA is fed to the potentiometer wiper. The wiper

resistance is therefore not included in the measurement. Resistances are switched parallel to

the potentiometer by a slide switch on the module and a rough range selection made. Range

start and end are set with the two adjusting pots on the back of the module.

This fine adjustment can be made by the displays on the front module (with the appropriate

structuring). For adjustment with a remote measuring instrument, the analog output can be assigned to the appropriate input.

The external wiring must be changed for resistance potentiometers which cannot withstand the

5 mA wiper current or which have a rated resistance

> 1kΩ. The constant current is then not

fed through the wiper but through the whole resistance network of the potentiometer. A voltage

divider measurement is now made through the wiper. Coarse adjustment is made by a remote

parallel resistor to the resistance potentiometer.

This module can also be used as a current input with adjustable range start and full scale. The

load is 49.9 Ω and is referenced to ground.

6DR2800-8V UNI module

D Direct connection of thermocouple or Pt100 sensors, resistance of mV transmitters

Measured value sensors such as thermocouples (TC), resistance thermometers Pt100 (RTD),

resistance potentiometers (R) or voltage transmitters in the mV range can be connected directly. The measuring variable is selected by configuring the controller in the HdeF level

(AE4/AE5); the range and the other parameters are set in the CAE4/CAE5 menu. The sensorspecific characteristics (linearization) for thermocouples and Pt100 resistance thermometers are

stored in the contoller’s program memory and are automatically taken into account. No settings

need to be made on the module itself.

14

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 17

Manual 1 Technical Description

1.4.2 Description of the option modules

1.4 Function principle

The signal lines are connected by a plug terminal block with screw terminals. When using thermocouples with internal reference junction terminal, this terminal block must be replaced by the

terminal 6DR2805-8A. With the measuring for TC, internal connector 6DR2805-8J in place of

the terminal block, the measuring range of the direct input (0/20 to 100 mV) can be extended to

0/2upto10Vor0/4upto20mA.

The UNI module operates with an AD converter with 18 bit resolution. The measuring inputs

and ground of the standard controller are electrically isolated with a permissible common mode

voltage of 50 V UC.

6DR2805-8A reference junction terminal

D Terminal with internal reference junction terminal for thermocouples

This terminal is used in connection with the UNI module for temperature measuring with thermocouples at an internal reference junction terminal. It consists of a temperature sensor which

is preassembled on a terminal block and plated to avoid mechanical damage.

6DR2805-8J measuring for TC, internal connector

D measuring for TC, internal connector for current 0/4 to 20 mA or voltage 0/2 to 10 V

The measuring for TC, internal connector is used in connection with the UNI module to

measure current orvoltage. The input variable is reduced to 0/20 to 100 mV by a voltage divider

or shunt resistors in the measuring for TC, internal connector.

Wiper resistors with 250 Ω or 50 Ω are available optionally at 2 different terminals for 0/4 to

20 mA signals.

The electrical isolation of the UNI module is retained even when the measuring for TC, internal

connector is used.

6DR2801-8D Module with 2 BA relays

D Digital output module with 2 relay contacts

To convert 2 digital outputs to relay contacts up to 35 V UC.

This module is equipped with 2 relays whose switching contacts have potential free outputs.

The RC combinations of the spark quenching elements are respectively parallel to the rest and

working contacts.

In AC consumers with low power the current flowing through the capacitor of the spark

quenching element when the contact is open may interfere (e.g. the hold current of some

switching elements is not exceeded). In this case the capacitors (1 μF) must be removed and

replaced with low capacitance capacitors.

The 68 V suppressor diodes parallel to the capacitors act additionally to reduce the induced

voltage.

SIPART DR22 6DR2210

C79000-G7476-C154-03

15

Page 18

1.4 Function principle

1.4.2 Description of the option modules

Manual1 Technical Description

!

WARNING

The relays used on the digital output module are designed for a

maximum rating up to UC 35 V. The same applies for the air and creep

lines on the circuit board. Higher voltages may therefore only be

switched through appropriately approved series connected circuit

elements under observance of the technical data and the pertinent

safety regulations.

6DR2801-8E Module with 2 BE and 4 BA

D Digital signal module with 2 digital inputs and 4 digital outputs

The module serves to extend the digital inputs and digital outputs already existing in the standard controller.

The inputs are designed for the 24 V logic and are non-floating. The functions are assigned to

the inputs and outputs by the configuration of the controller.

The digital outputs are short-circuit-proof and can drive commercially available relays or the

interface relays 6DR2804--8A/8B directly.

6DR2801-8C Module with 5 BE

D Digital input module with 5 digital inputs

The module serves to extend the digital inputs already existing in the standard controller.

The inputs are designed for the 24 V logic and are non-floating. The function is assigned to the

input by the configuration of the controller.

6DR2802-8A Analog output module with y-hold function

For auxiliary control device function when servicing and for extending the analog outputs AA1 to

AA3 existing in the standard controller.

Can be inserted in slot 5/6, S22/S23=4 to be set in the structure mode StrS,

Start value of the outputs S72/S249 can be set in StrS.

The y

module contains a microprocessor which maintains serial data communication with the

hold

processor on the main board through the Rxd/Txd lines. The processor feeds the U/I converter

and the CPU fault message output St

through its analog output. The module can be externally

supplied through an auxiliary voltage input which is OR--linked with the controller power supply.

The analog output of the module is freely available.

-- y

-function

hold

If data communication to the y

processor is interrupted, the analog output receives its last

hold

value. The processor reads the current variable first when data traffic is recovered. The output current is maintained if:

16

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 19

Manual 1 Technical Description

1.4.2 Description of the option modules

1.4 Function principle

-- the self diagnostics of the CPU (see chapter 1.4.3, page 20) responds.

-- the supply voltage of the SIPART DR22 fails and the y

-- all modules except the power supply unit are removed (if the y

-module is powered externally.

hold

module is powered

hold

externally).

-- the y

module is removed (Attention: electrostatically sensitive module! Observe the

hold

safety precautions!), if it is powered externally (error message on the front module

oP. *.6 Err/oP.*.5, see chapter 5, page 227). *.6 Err/oP.*.5, see chapter 5).

In this way it is possible to perform all maintenance work right up to replacing the instrument

whilst maintaining the controller controlled variable.

Handling during module replacement, see chapter 5 ”Maintenance”.

Fault message output

-- S t

This digital output is always high when there is no error and becomes low in the event of an

error. It responds when:

-- the self diagnostics of the CPU (see chapter 1.4.3, page 20) responds.

-- the controller power supply fails,

-- the Y

module is removed,

hold

-- the main board is removed.

6DR2802-8B Module with 3AA and 3BE

To extend the analog outputs (0/4 to 20 mA) and digital inputs

can be inserted in slot 5: AA7, AA8, AA9 BE5, BE6, BE7

and in slot 6: AA4, AA5, AA6 BE10, BE11, BE12

6DR2803-8P Serial interface PROFIBUS-DP

The module 6DR2803-8P is a PROFIBUS-DP interface module with RS 485 driver and electrical isolation to the controller. It operates as an intelligent converter module and adapts the private SIPART to the open PROFIBUS-DP protocol.

This optional card can be inserted in all SIPART-DR controllers in slot 4. The following settings

must be made with the appropriate configurations for the serial interface:

-- Interface on

-- Even parity

-- LRC without

-- Baud rate 9600

-- Parameters/process values writable (as desired)

-- Station number according to selection 0 to 125

Make sure that the station number is not assigned double on the bus. The PROFIBUS module

serves to connect the SIPART controllers to a master system for control and monitoring.

In addition the parameters and configuring switches of the controller can be read and written.

Up to 32 process variables can be selected and read out cyclically by configuration of the

PROFIBUS module.

SIPART DR22 6DR2210

C79000-G7476-C154-03

17

Page 20

1.4 Function principle

1.4.2 Description of the option modules

Manual1 Technical Description

The process data are read out of the controller in a polling procedure with an update time <

300 ms. If the master writes process data to the slave, these become active after a maximum 1

controller cycle.

The description and the controller base file (*.GSD) can be downloaded from Internet under

www.fielddevices.com

.

A technical description including the controller base file (*.GSD) is available for creating a master-slave linking software for interpreting the identifications and useful data from and to the SIPART controller.

The programs SIPART S5 DP and S7 DP are offered for certain hardware configurations.

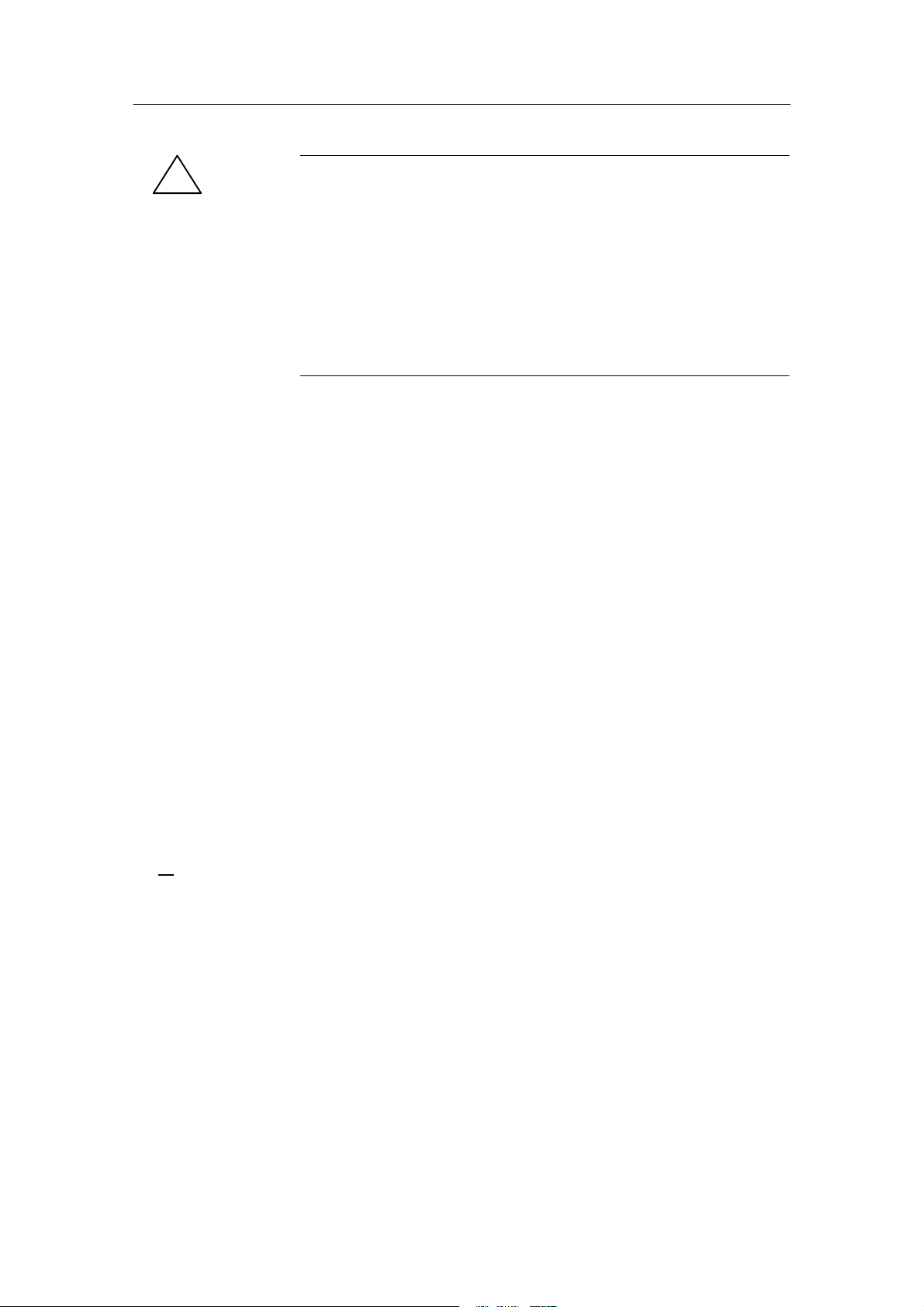

6DR2803-8C Serial interface RS 232 / RS 485

D Serial interface for RS 232 or RS 485 with electrical isolation

Canbeinsertedinslot4.

For connecting the controller SIPART DR22 to a master system for control and monitoring. All

process variables can be sent, the external setpoint, tracking variable, operating modes, parameters and configurations sent and received.

The interface traffic can take place as follows:

RS 232 as point-to-point connection

SIPART Bus

The SIPART bus is no longer available. Therefore please implement multipoint

connections via RS 485 or PROFIBUS DP.

RS 485 As a serial data bus with up to 32 users.

The interface module 6DR2803-8C offers electrical isolation between Rxd/Txd and the controller. Switching can be performed between RS 232, SIPART bus and RS 485 with a plug-in

bridge.

A detailed technical description of the telegram traffic is available for creating an interface software.

18

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 21

Manual 1 Technical Description

1.4.2 Description of the option modules

Txd

24 V

0V

+7.5 V

-7.5 V

+7.5V

+1

-7.5 V

RS 232

SIPART

bus

24 V

0V

Txd

2

Txd

7

Rxd

+7.5 V

1.4 Function principle

RS 485 + 150R

+7.5 V

+7.5 V

RS 485

8

3

Rxd/

Txd A

Rxd/

Txd B

Rxd

-1

Figure 1-3 Block diagram serial interface

for RS 232 / SIPART BUS

-7.5 V

Other connections: NC

3

Rxd

8

Rxd/

Txd

NC2, 7

Other connections: NC

Figure 1-4 Block diagram serial interface for

RS 485

6DR2804-8A Module with 4 BA relays

6DR2804-8B Module with 2 BA relays

D Interface relay module with 2 or 4 relays

To convert 2 or 4 binary outputs to relay contacts up to 230 V UC.

The module can be snapped onto a mounting rail on the back of the controller. The mounting

rail is delivered with the interface relay module.

One or two relay modules with 2 relays each are installed depending on the version. Every relay

has a switching contact with spark quenching in both switching branches. In AC consumers with

a very low power, the current flowing (e.g. hold current in contactors) through the spark quenching capacitor (33nF) when the contact is open interferes. In this case they should be replaced

by capacitors of the same construction type, voltage strength and lower value.

The switching contact is fed to the plug terminals with 3 poles so that rest and working circuits

can be switched. The relays can be controlled directly from the controller’s digital outputs by

external wiring.

SIPART DR22 6DR2210

C79000-G7476-C154-03

19

Page 22

1.4 Function principle

1.4.3 CPU self-diagnostics

Manual1 Technical Description

!

WARNING

The relays used on the interface relay module are designed for a

maximum rating of AC 250 V in overvoltage class III and

contamination factor 2 according to DIN EN 61010 Part 1.

The same applies for the air and creep lines on the circuit board.

Resonance increases up to twice the rated operating voltage may

occur when phase shift motors are controlled. These voltages are

available at the open relay contact. Therefore such motors may only

be controlled under observance of the technical data and the

pertinent safety conditions via approved switching elements.

1.4.3 CPU self-diagnostics

The CPU runs safety diagnostics routines which either can only after a reset or cyclically. The

CPU is familiar with two different types of reset.

-- Power on reset

Power-On-Reset always takes place when the 5-V supply drops below 4.45 V, i.e. the power

supply is interrupted for longer than specified in the technical data.

All parameters and configurations are reloaded from the user program memory into the

RAM.

At S100 = 1 the digital x-display flashes as indication after a Power-On-Reset, it is

acknowledged by the Shift key (12).

Flashing is suppressed by S100 = 0.

-- Watch dog reset

When a watch-dog-reset occurs the parameters and configurations from the user program

memory are reloaded into the RAM. The current process variables and the status signals are

read out of the RAM for further processing.

There are no flashing signals on the front module.

CPU-tESt appears in the digital displays dd1 and dd2 for a maximum 5 s after every reset.

Every error detected by the self-diagnostics leads to a flashing error message on the digital displays dd1 and dd2 with defined states of the analog and digital outputs. The fault message output St

of the y

module becomes low. The reactions listed in the table are only possible of

hold

course (since this is a self-test) if the errors occur in such a way that the appropriate outputs or

the front module can still be controlled properly or the outputs themselves are still functioning.

There are other error messages for the input range which indicate defective structurings within

this range (see chapter 1.5.6 ”Error messages”, page 99).

In addition error messages are output in the adaptation (see chapter 3.3.2

”Parameterization mode AdAP”, page 173).

The digital displays flash in the case of error messages.

20

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 23

Manual 1 Technical Description

g

/

sages

gofg

Errorcause/

CPU

RAM

0last

0mA00

0

A

y

0mA00

0

memor

y

p

g

)

1

)

municatio

n

cyclic0

operatingwith

tin

g

matchtheplugged

1.4 Function principle

1.4.4 Data storage, User program memory

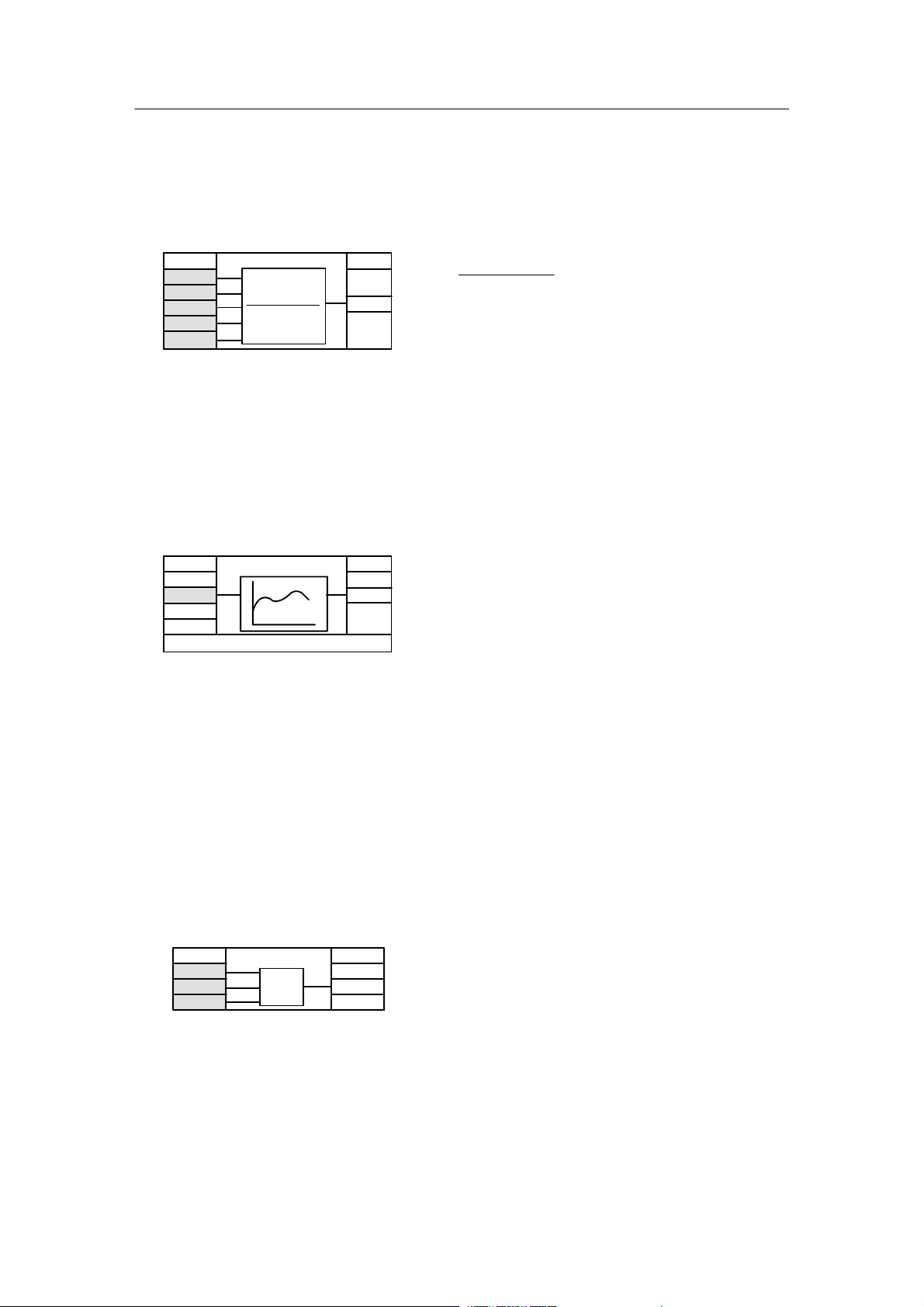

1.4.4 Data storage, User program memory

All data are written in the RAM first and then transfered to the user program memory

(EEPROM) when returning to the process operation mode (manually or via the SES).

Writing time

The writing time after leaving the parameterization and configuring modes is up to 30 s. Then

the data are stored in a non-volatile memory.

Error messages of the CPU

Reactions

Error

y

mes-

sa

dd1

dd2

CPU

Err

MEM

Err

es

Monitoring

EEPROM,

EPROM

User

program

memor

Monitoring

time

Power

On-Reset

Watch

Dog-Reset

Power

On-Reset

Watch

Dog-Reset

St

0

hold

AA4/7

with

U

last

value

last

value

-module

H

AA4/7

without

U

H

0mA

last

value

0mA

last

value

when

storing

continues operating with current

oP.5.*.

1)

oP.*.6.

1

Data communication

μP-slot 5

Data communication

μP-slot 6

cyclic 0

cyclic 0

pulled

last

value

defective,

pulled

0mA

undefined

1)

Also double error display oP.5.6 possible,

* means digit dark.

2)

At BE5 to 9 and BE10 to 14 the effect of the digital inputs (after inversion) are set to 0 in the event of an error.

Standard

controller

AA1

to 3

0m

data

continues

operating with

current data

Options

BA1

to 8

BA9

to 12

0 0 0

continues

operating with

current data

last

state

or undefined

continues

operating

with

current

data

2)

BA13

to 16

continues

operating

with

current

data

last

state

or undefined

Primary

Error cause

Remedy

Monitored components of the CPU

defective/change

main board

User program

memory not plugged

or defective/plug or

change

Monitored components of the CPU

defective/change

main board

User program

memory not plugged

or defective/plug or

change

Option not plugged,

defective or setting in

hdEF oP5 does not

match the plugged

option.

Plug option or replace

or correct oP5

Option not plugged,

defective or setting in

hdEF oP5 does not

match the plugged

option.

Plug option or replace

or correct oP6

3)

3)

Table 1-1 Error message of the CPU

SIPART DR22 6DR2210

C79000-G7476-C154-03

21

Page 24

1.5 Functional description of the structure switches

1.5.1 Analog input signal processing permanently connected

Manual1 Technical Description

1.5 Functional description of the structure switches

(S0 to S107, S200 to S268)

In the factory setting (setting when the device is delivered) most of the structure switches are

set to 0. This corresponds to the most usual setting of the individual functions so that only few

structure switches need to be set selectively during commissioning. However, it is recommendable to compare the individual structure switch settings with the task.

With structure switch S0 the user program can be identified by a number from 1 to 254 in the

structuring mode Strs. The setting 0 corresponds to the factory setting and is regenerated automatically in the APSt function (All Preset). All changes in parameters or structures in relation to

the factory setting automatically set S0 from 0 to 1.

The structure switches S1 and S2 are fundamentally significant. With S1 the controller type is

set and thus the processing of command variable, main controlled variable and auxiliary controlled variables up to control difference generation determined. With S2 the controller output

structure is set and thus the processing of the automatic-, manual-, safety- and follow--up variables as well as the manipulated variable output determined as a K- or S-output.

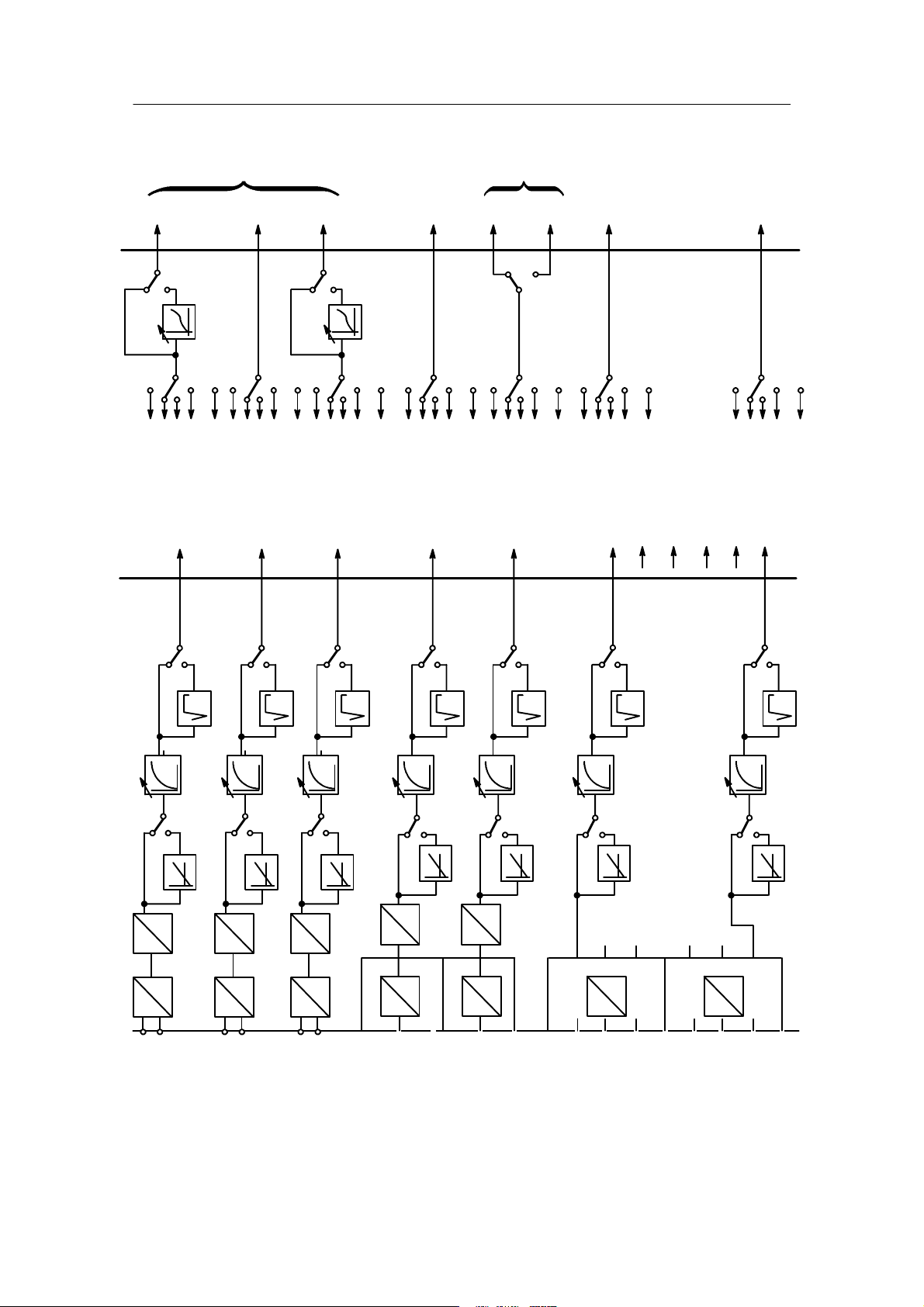

1.5.1 Analog input signal processing permanently connected

(S3 to S21, S200 to 205)

In the structure switch setting S4=0 the analog input range is permanently connected

(see figure 1-5, page 24). With S4=1 the permanent connection is canceled and converted into

a freely connectable input range (see chapter 1.5.2, page 25).

Every one of the maximum 11 analog inputs is fed through an AD converter which performs the

50 or 60 Hz interference suppression by averaging over 20 or 16 2/3 ms. After this the signal

range 0 to 20 mA or 4 to 20 mA is normalized to 0 to 100% calculated value per channel with

S5 to S9 or S200 to S205.

At the same time it is decided with S5 to S9 or S200 to S205 whether operation is to take place

with or without range monitoring (transmitter fault). The monitor signals per channel on dropping

below --2.5 % or exceeding +106.25 % with a hysteresis of 0.25 % to the digital x and w display.

By an OR link of all single messages the group transmitter fault MUF is formed which can be

assigned to the digital outputs and negated optionally (see chapter 1.5.8, page 121). Only the

analog inputs selected with the transmitter fault monitor are monitored, displayed on the front

panel (the appropriate position stays dark in the case of analog inputs not selected with transmitter fault) and signaled with the OR link. The error message is acknowledged with the Shift

key (12). The fault message signal via the OR link is available until the appropriate analog inputs are back in the working range.

After the range monitoring the 11 analog inputs are fed through a 1st order filter which can be

set by the parameters tF1 to tFb in the range of oFF, 0.1 to 1000 s in the parameterization

mode onPA. The factory setting is 1 s.

With S10 to S14 or S206 to S211 every channel can now be root extracted optionally. After root

extraction, the 11 analog inputs are available for further processing as AEA1 to AEbA.

22

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 25

Manual 1 Technical Description

1.5.1 Analog input signal processing permanently connected

1.5 Functional description of the structure switches

The function inputs FE1 and FE3 are preceded by a linearizer which enables non-linear process

variables to be displayed physically correctly (for operating method see chapter 1.5.2, page 25)

function block Fu, setting of the 13 vertex values, see chapter 1.5.4, figure 1-19, page 45 to

figure 1-23, page 46).

The outputs of the analog inputs AE1A to AEbA are now assigned to the function inputs FE1 to

FE12 by the structure switches S15 to S19 or S212 to S217. The outputs AE1A to AEbA and

the function inputs FE1 to FE12 are available for the assignment to analog outputs, the limit

value alarm and the parameter control and can be read through the SES. With this input

structure most control tasks can be solved in connection with the different controller types and

controller output structures.

SIPART DR22 6DR2210

C79000-G7476-C154-03

23

Page 26

1.5 Functional description of the structure switches

1.5.1 Analog input signal processing permanently connected

Manual1 Technical Description

see fig. 1-24 (pg. 48) to

fig. 1-44 (pg. 83)

FE1

FE2

see fig. 1-50

(pg. 90)

FE3

see fig. 1-58 (pg. 102) to

fig. 1-62 (pg. 109)

FE4

FE5Zy

N

FE6

R

y

FE7

FE12

function inputs

S20

1

0

--1 .1

to 11.1

S15

0

o%

1

2

AE1A

AE2A

0

3

11

1

2

...

o%

AE3A

AEbA

AE1A

AE2A

S21

1

0

--1 .3

to 11.3

S16

3

11

...

AE3A

AEbA

0

o%

S17

3

1

11

2

...

AE1A

AE2A

AE3A

AEbA

0

o%

S18

0

3

1

11

2

AE1A

AE2A

o%

AE3A

AEbA

1, 2

0

S2

...

S19

3

1

11

2

...

AE1A

AE2A

AE3A

AEbA

0

o%

S212

3

1

11

2

...

AE1A

AE2A

AE3A

AEbA

0

o%

S217

3

1

11

2

...

AE1A

AE2A

AE3A

AEbA

connectable

AE7A

AE8A

AE1A

S4 = 1 drawn

at S4 = 1 freely

AE2A

AE3A

AE4A

AE5A

AE6A

AE9A

AEAA (AE10A)

AEbA (AE11A)

Outputs of the

tF1

A

+

1/20

analog outputs

AE1

S5

0, 1

AE1A

S10

0

1

AE2A

S11

0

1

AE3A

S12

0

1

AE4A

S13

0

1

AE5A

S14

0

1

AE6A

S206

0

1

AEbA

(AE11A)

S211

0

1

...

tF2

S6

2, 3

0, 1

4bis20mA

D

D

A

U

--

1/19

I, U

+

1/22

AE1

U

--

1/21

I, U

tF3

S7

2, 3

0, 1

4to20mA

D

A

U

+

--

1/23

1/24

AE1

I, U

tF4

S8

2, 3

0, 1

4to20mA

D

A

U

Slot 2

AE4

I, U, R,

P, T

tF5

S9

2, 3

0, 1

4to20mA

D

A

U

Slot 3

AE5

I, U, R,

P, T

tF6

...

S200

2, 3

4to20mA

2, 3

0, 1

...

4bis20mA

D

Slot 6

AE6

I, U

AE7

I, UAAE8

Slot 5

I, U

AE9

tFb

S205

2, 3

0, 1

4to20mA

D

AE10

I, UAAE11

I, U

I, U

Figure 1-5 Analog input signal processing permanently connected (S4 = 0)

24

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 27

Manual 1 Technical Description

1.5.2 Analog input signal processing freely connected (S4 = 1)

1.5 Functional description of the structure switches

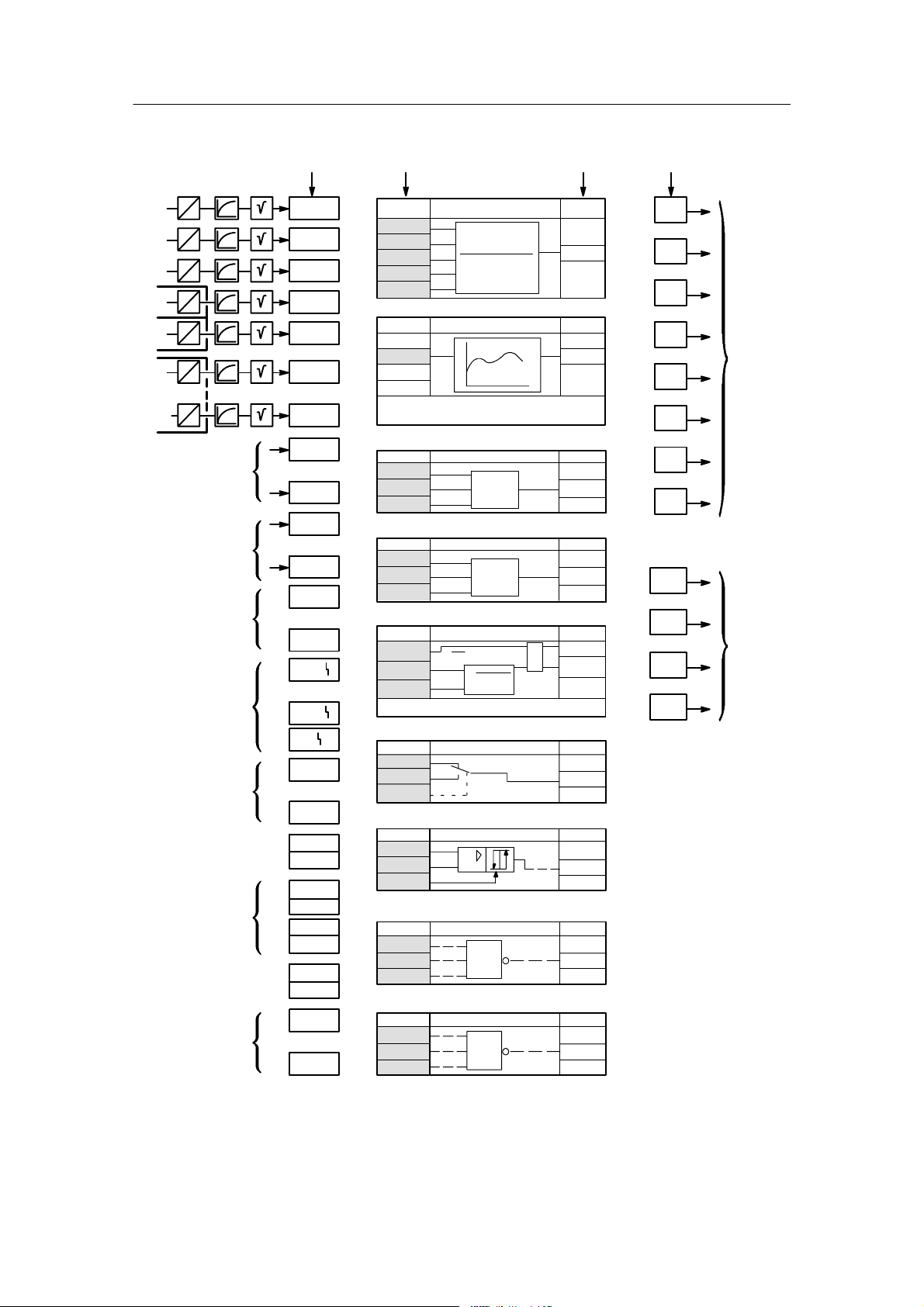

1.5.2 Analog input signal processing freely connected (S4 = 1)

The structure switch setting S4=1 cancels the permanent connection at S4=0 in the analog input range and replaces it with a freely connectable input range. The freely connectable input

range basically represents a multifunctional unit, configuring takes place according to the same

rules.

Up to the outputs AE1A to AEbA (AE11A), the signal processing is identical to that described in

chapter 1.5.1, page 22. The function inputs FE1 to FE12 also operate in the same way with the

difference that FE5 (follow-up input) and FE6 (position feedback input) can be used in parallel

and with the difference that FE5 (follow--up input) and FE6 (position feedback input) can be

used in parallel and connected with different signals.

Nine different function blocks which occur with different frequency can now be connected

absolutely freely between the outputs AE1A to AEbA and the function inputs FE1 to FE12. The

outputs AE1A to AEbA represent data sources whilst the function inputs FE1 to FE12 are data

sources. Parallel to the outputs, 15 connectable linear parameters are arranged with a setting

range of -1.999 to 19.999 (corresponding to -199.9 % to 1999.9 %), a number of normal

constants as well as other variables gained from the controller as data source.

The function blocks have a different number of inputs (data sinks) and 1 output each (data

source) depending on the function depth.

The function blocks ”function transmitter” and ”correction computer” have assigned parameters

which can be set in the structuring mode oFPA. The connectable parameters P1 to P15 are set

in the parameterization mode onPA.

By structuring on the front module the necessary functions are selected or defined (structuring

mode FdEF), connected (structuring mode FCon) and correctly positioned in time in the cycle

(structuring mode FPoS), see chapter 3.3.7, page 201 to 3.3.9, page 205. Connection is absolutely free, i.e. any data source can be connected with any data sink. The operating effort is

minimized by fading the data sources and sinks from undefined function blocks. In addition the

data sinks which are not obliagatory for a function are pre--occupied by constants which can be

overwritten. The inputs pre--occupied with ncon (not connected) are absolutely essential for the

function and must be connected. This very variable connection facility in the analog input range

also enables complex control tasks to be solved.

No distinction is made between analog and digital signals. Digital inputs have a threshold value

of 0.5. Digital outputs supply a value of 0 % (0) or 100 % (1).

SIPART DR22 6DR2210

C79000-G7476-C154-03

25

Page 28

1.5 Functional description of the structure switches

1.5.2 Analog input signal processing freely connected (S4 = 1)

Data sources Data sinks Data sources Data sinks

Manual1 Technical Description

AE1

AE2

AE3

AE4

AE5

AE6

AE11

Connectable

parameters

Constants

Digital inputs

Fault message

AE1.A

AE2.A

AE3.A

AE4.A

AE5.A

AE6.A

AEb.A

P01

.

.

.

P15

--1,0

.

.

.

1.05

BE01

.

.

.

BE09

AE1

.

.

.

AE5

Ar .F

Ar .1

Ar .2

Ar .3

Ar .4

Ar .5

Fu .F

Fu .1

Parameter:

Vertex value at -10, 0, 10 to 90, 100, 110

MA .F

MA .1

MA .2

MA .3

Mi .F

Mi .1

Mi .2

Mi .3

rE1 .F

rE1 .1

rE1 .2

rE1 .3

Parameter. tA, tE, PA, PE

Ar1 to Ar6

E1

E2

E1 · E2+E3-E4

E3

E4

E5

Fu1, Fu2

E

A

MA1 to MA3

E1

E2

E3

Mi1 to Mi3

E1

E2

E3

rE1

ΔP

E2

f(E2·E3)

E3

E5

Max

Min.

A

A

E

A

A

x

A

nr

Ar .6

nr

Fu .2

nr

MA .4

nr

Mi .4

nr

rE .4

FE1

FE2

FE3

FE4

FE5

FE6

FE7

FE8

FE9

FE10

FE11

FE12

Analog

signals

Analog

or

digital

signals

Alarms A1 to A4

AE

A1

.

.

.

AS .F

AS .1

AS .2

AS .3

AS1 to AS5

E1

E2

E3

A

A4

Status message

Setpoints w1/w2

Manipulated

variable y *)

Serial analog value

Int1

Int2

SPI1

SPI2

SP1

SP2

yI

yII

SAA1

.

.

.

SAA4

Co .F

Co .1

Co .2

Co .3

nA .F

nA .1

nA .2

nA .3

no .F

no .1

no .2

no .3

Co1, Co2

E1

+

E2

-

E3

nA1, nA2

E1

E2

E3

no1, no2

E1

E2

E3

&

≥1

A

H

A

A

Figure 1-6 Analog input signal processing freely connectable (S4=1)

26

nr

AS .4

nr

Co .4

nr

nA .4

nr

no .4

SPI 1/2: internal setpoint

SP 1/2: active setpoint

*) y1: Manipulated value

*) y2: Manipulated value

controller 1/2

controller1/2

y controller 1

y controller 2

(for S1 = 12)

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 29

Manual 1 Technical Description

1.5.2 Analog input signal processing freely connected (S4 = 1)

1.5 Functional description of the structure switches

The individual function blocks are described below.

1.5.2.1 Arithmetic Ar1 to Ar6

Ar1toAr6

ncon

ncon

0.000

0.000

1.000

Ar .F

Ar .1

Ar .2

Ar .3

Ar .4

Ar .5

E1

E2

E1 · E2+E3-E4

E3

E4

E5

E5

Figure 1-7 Function block Arithmetic Ar1 to Ar6

-- With this function block the four basic arithmetic functions are implemented with appropriate

assignment of inputs 0 and 1 respectively. The preset E3=E4=0, E5=1 gives A = E1×E2.

-- Typical process-technical applications are dosing or evaluation (E1×E2), range fade-outs

(E1×E2+E3) or differentiations (E3 - E4).

nr

A

Ar .6

E1 · E2 + E3 - E4

A=

E5

E5 is limited to values ≥0.5 %.

1.5.2.2 Function transmitter Fu1 and Fu2

Fu1, Fu2

Fu .F

ncon

Fu .1

-10, 0, 10 bis 90, 100, 110oFPA

E

nr

AA

Fu .2

E

A=f(E)

Figure 1-8 Function block function transmitter

The function transmitter assigns every value of the input variable E in the range from -10 % to

+110 % an output variable A in the range from -199,9 % to +199,9 % with the function entered

by the user: A = f(E). The function is entered by the parameters ”vertex value 1 to 13” for -10 %

to +110 % of E in intervals of 10 %. Parabolae are set by the computing program between

these vertex values which interlink tangentially the vertex values so that a constant function is

produced. The vertex values at -10 % and +110 % of E are required for the overflow. The last

rise remains constant in the case of further overmodulation of E. When used as a linearizer for

the displays, the linearization function is entered by the 13 vertex values so that the series

circuiting of the sensor function gives a linear equation with the linearization function

(see chapter 1.5.4, figure 1-20 to figure 1-23, page 46).

1.5.2.3 Maximum value selection MA1 to MA3

MA1.F to MA3.F

ncon

ncon

0.050

MA .F

MA .1

MA .2

MA .3

E1

E2

E3

Max

nr

A

MA .4

A = max (E1,E2, E3)

The greatest of the three input values is

connected through to the output.

Figure 1-9 Function block maximum value selection

With the preset the greater value of E1 or E2 is connected through to A and at the same time

limited to the value of E3 (-5 %). Typical applications are maximum value selection circuits and

minimum value limitings.

SIPART DR22 6DR2210

C79000-G7476-C154-03

27

Page 30

1.5 Functional description of the structure switches

1.5.2 Analog input signal processing freely connected (S4 = 1)

Manual1 Technical Description

If only 2 inputs are required, the 3rd input must be set outside the working range of the two

inputs to a minimum value otherwise minimum value limiting takes place.

1.5.2.4 Minimum value selection Mi1 to Mi3

Mi1.F to Mi3.F

ncon

ncon

1.050

Mi .F

Mi .1

Mi .2

Mi .3

E1

E2

E3

Min.

Figure 1-10 Function block minimum value selection

With the preset the smaller value of E1 or E2 is connected through to A and at the same time

limited to the value of E3 (105%). Typical applications are minimum value selection circuits. If

only 2 inputs are required, the 3rd input must be set outside the working range to a maximum

value, otherwise a maximum value limiting takes place.

nr

A

Mi ..4

A = min (E1, E2, E3)

The smallest of the three input values is

connected through to the output.

1.5.2.5 Correction computer for ideal gases rE1

rE1

rE1 .F

1.000

ncon

ncon

rE1 .1

rE1 .2

rE1 .3

E2

E

3

ΔP

f(E2·E3)

x

Figure 1-11 Function block correction computer rE1 for ideal gases

The rooted signal of the active pressure must be applied at input c**.1. The measuring ranges

are normalized to the calculation state with the parameters PA, PE, tA, tE (correction quotients

start/end for pressure and temperature).

Range of Application

The correction computer is used to calculate the flow of gases from the active pressure Δp

depending on pressure and temperature. The medium must be in pure phase, i.e. so that no

liquid separations may take place. This should be noted particularly for gases close to the

saturation point.

nr

A

rE .4

A = Δp·f(E2,E3)

f(E2, E3) =

(oFPA)tA, tE, PA, PE

(PE – PA) E2 + PA

(tE – tA) E3 + tA

Errors due to fluctuating status variables of the medium (pressure, temperature) are corrected

by the flow correction computer here.

28

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 31

Manual 1 Technical Description

1.5.2 Analog input signal processing freely connected (S4 = 1)

1.5 Functional description of the structure switches

q

Pressure p Temperature t

2

Kp/cm

t

e

Figure 1-12 Active pressure measuring method, Principle

Active pressure Δp

Measured value

transmission

Δp

Calculation

Function block rE

q

Physical notes

The active pressure measuring method is based on the law of continuity and Bernoulli’s energy

equation.

According to the law of continuity the flow of a flowing liquid in a pipe is the same at all places.

If the cross-section is reduced at one point, the flow speed at this point should increase. According to Bernoulli’s energy equation the energy content of a flowing material is made up of the

sum of the kinetic energy (due to the speed) and the potential energy (of the pressure).

An increase in speed therefore causes a reduction in pressure.

This drop in pressure, the so-called ”active pressure” Δp is a measure of the flow q.

The following applies:

q = c· Δp

with c as a factor which depends on the dimensions of the pipe, the shape of the constriction,

the density of the flowing medium and some other influences.

The equation states that the active pressure generated by the constriction is in the same ratio

as the square of the flow.

SIPART DR22 6DR2210

C79000-G7476-C154-03

29

Page 32

1.5 Functional description of the structure switches

1.5.2 Analog input signal processing freely connected (S4 = 1)

Δp

1.00

0.81

0.49

0.25

0.09

Manual1 Technical Description

0

Figure 1-13 Relationship between flow q and active pressure Δp

0.3 0.70.5 0.9 1.0 q

To measure the flow, a choke is installed at the measuring point which constricts the pipe and

has two connections for tapping the active pressure.

If the properties of the choke and the measuring material are known to the extent that the

equation specified above can be calculated, the active pressure is a measure of the flow.

If you have chosen a certain choke, the flow can be described in the calculation state or

operation state.

= K· ρ

q

B

· Δpor q = K· ρ· Δp

B

Since the density is included in the measuring result according to the above equation,

measuring errors occur when the density in the operating state differs from the value based on

the calculation of the choke. Therefore a correction factor F is introduced for the density in

operating condition.

F=

V

=

B

B

V

with V=

1

as specific volume.

as specific volume.

In order to be able to perform the correction with the factor F, the current specific volume must

be determined first.

For the dry gases the densities change according to the laws for ideal gases:

T

T

1

=

ρ

p

The correction factor is then given as:V = R

F =

·p

B

p

·T

B

with p as absolute pressure and T as absolute temperature.

30

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 33

Manual 1 Technical Description

1.5.2 Analog input signal processing freely connected (S4 = 1)

1.5 Functional description of the structure switches

m3/kg

V

B

P

to P

abs.A

to Â

Â

A

Figure 1-14 Display of the correction range

abs.E

E

Correction range

Â

A

Â

B

Range of pressure of the transmitter

Range of temperature of the transmitter

Â

E _C

P

abs.A

P

abs.B

P

abs.E

P

abs.

bar

qFlow

ρ Density

Δp Active pressure

p Pressure

Temperature (_C)

T Temperature (K)

V Specific volume

R Gas constant

F Correction factor f (p, T)

Indices:

Â

AStart

EEnd

B Calculation state

abs Absolute variable

m Ground

v Volume

This gives for the corrected flow

T

·p

q = F·K· ρ

· Δp= K· ρ

B

The factor contained in the formula

· Δp·

B

K· ρ

B

P

·T

B

is already taken into account in the measurement of

B

the active pressure and can therefore be ignored by the computer.

Related to the correction factor it follows:

A = Δp

·f(E2,E3)with F = f(E2, E3)=

(PE − PA) E2 + PA

(tE − tA) E3 + tA

The measuring ranges are normalized to the calculation state with the parameters PA, PE, tA,

tE (correction quotients start/end for pressure and temperature).

Mass flow computer, m

2

A=qm,E2=p,E3=Â

PA =

tA =

P

absA

,PE=

P

B

T

A

,tE=

T

B

P

T

T

absE

P

B

E

with T

B

,

[K]

A∕E∕B

SIPART DR22 6DR2210

C79000-G7476-C154-03

31

Page 34

1.5 Functional description of the structure switches

1.5.2 Analog input signal processing freely connected (S4 = 1)

Manual1 Technical Description

Volume flow computer related to the operating status q

V

Since the volume is reciprocally proportional to the density, a volume flow computer can be

made out of this mass flow computer by changing the inputs E2 and E3.

A=q

PA =

tA =

Volume flow computer related to the standard status q

,E2=Â,E3=p

v

T

A

,PE=

T

B

P

absA

,tE=

P

B

T

E

T

B

P

absE

P

B

with T

A∕E∕B

[K],

VN

Since the output signal is now related to the volume flow in the standard status, TN= 273. 15 K,

= 1.01325 bar

P

N

A=q

VN

T

tA =

PA =

A

T

B

P

,E2=p,E3=Â

,tE=

absA

,PE=

P

B

and no longer to the operating state, it must be corrected accordingly.

abs

T

E

T

P

with T

B

absE

P

B

A∕E∕B

[K],

The following applies for all computers:

p

T

absA

to T

A

to p

E

absE

Transmitter range absolute pressure (bar)

Transmitter range absolute temperature (K)

is formed from the transmitter range Â

to ÂEby conversion:

A

T(K) = 273, 15 + Â (_C)

p

B,TB

Pressure and temperature range of the calculation state of the measuring

panel (absolute values)

p

and TBmust be within the range of the transmitter; and may not be more than the factor 100

B

away from the range limits.

PA, tA = 0.01 to 1

PE, tE = 1 to 99.99

The input rE1.1 Δp is limited to values ≥0.

If the adjustable ranges for PA, PE, tA, tE are not sufficient a linear equation can be switched in

front of the appropriate input for adaptation (function block Ar).

32

SIPART DR22 6DR2210

C79000-G7476-C154-03

Page 35

Manual 1 Technical Description

1.5 Functional description of the structure switches

1.5.2 Analog input signal processing freely connected (S4 = 1)

1.5.2.6 Switch for analog variables AS1 to AS5

E3 A

0(<0,5)

≥0,5)

1(

E1

E2

ncon

ncon

0.0

1.5.2.7 Comparator with adjustable hysteresis Co1, Co2

(two-position switch, e.g. limit value sensor)

Inputs Output A