Page 1

Industrial Controls

Monitoring and Control Devices

3UG4 / 3RR2 Monitoring Relays

GerätehandbuchManual

Edition

05/2016

siemens.com

Page 2

Page 3

3UG4 / 3RR2 monitoring relays

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Industrial Controls

Monitoring and control devices

3UG4 / 3RR2 monitoring relays

Manual

05/2016

NEB927043002000/RS

Introduction

1

Safety information

2

System overview

3

3RR2 current monitoring

relays

4

3UG4501 filling level

monitoring relay

5

3UG4.1 line monitoring relay

6

3UG4621/3UG4622 current

monitoring relays

7

3UG4625 residual current

monitoring relay with 3UL23

transformer

8

3UG458. insulation

monitoring relay.

9

3UG463. voltage monitoring

relay

10

3UG4641 cos phi and active

current monitoring relay

11

3UG4651 speed monitoring

relay

12

Accessories

13

References

A

Parameters

B

Dimension Drawings

C

Menu-based operation

D

-AC/004

Page 4

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

3ZX1012-0UG40-0AC0

Ⓟ

Copyright © Siemens AG 2011.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

05/2016 Subject to change

Page 5

Table of contents

1 Introduction................................................................................................................................. 11

2 Safety information ....................................................................................................................... 17

3 System overview ......................................................................................................................... 19

4 3RR2 current monitoring relays ..................................................................................................... 45

1.1 Service&Support ............................................................................................................... 11

1.2 Technical data in Siemens Industry Online Support ........................................................... 14

1.3 DataMatrix code ................................................................................................................ 15

2.1 Standards.......................................................................................................................... 17

2.2 Product-specific safety information .................................................................................... 18

2.3 Approvals, test certificates, characteristics ......................................................................... 18

3.1 Product description ............................................................................................................ 19

3.2 Application planning .......................................................................................................... 20

3.3 Connection methods.......................................................................................................... 21

3.3.1 Screw-type connection ...................................................................................................... 21

3.3.2 Spring-loaded connection .................................................................................................. 23

3.3.3 Device replacement by means of removable terminals ....................................................... 28

3.4 Mounting / removal ............................................................................................................ 29

3.4.1 Mounting 3RR2 current monitoring relay ............................................................................ 29

3.4.2 Mounting the 3UG4 monitoring relay .................................................................................. 34

3.4.3 Installing the 3UG458. monitoring relay. ............................................................................ 35

3.5 Overview of the functions .................................................................................................. 36

3.5.1 3RR2 current monitoring relays ......................................................................................... 36

3.5.2 3UG45 / 3UG46 monitoring relays ..................................................................................... 37

3.6 Menu-based operation ....................................................................................................... 39

4.1 Product description ............................................................................................................ 45

4.2 Application areas ............................................................................................................... 47

4.3 Performance features of current monitoring relays ............................................................. 48

4.3.1 General data ..................................................................................................................... 49

4.3.2 Properties.......................................................................................................................... 50

4.3.3 Configuration of load feeders ............................................................................................. 51

4.3.4 Combinations with 3RT20 contactor .................................................................................. 52

4.4 3RR21 current monitoring relays ....................................................................................... 53

4.4.1 Operator controls and connection terminals ....................................................................... 53

4.4.2 Function ............................................................................................................................ 54

4.4.3 Operation .......................................................................................................................... 56

4.4.4 Diagnostics ....................................................................................................................... 58

4.4.5 Circuit diagrams ................................................................................................................ 59

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

5

Page 6

Table of contents

5 3UG4501 filling level monitoring relay ............................................................................................ 89

6 3UG4.1 line monitoring relay ....................................................................................................... 101

4.4.6 Technical data ....................................................................................................................60

4.5 3RR22 current monitoring relays ........................................................................................70

4.5.1 Operator controls and connection terminals ........................................................................70

4.5.2 Function .............................................................................................................................71

4.5.3 Operation ...........................................................................................................................75

4.5.4 Diagnostics ........................................................................................................................77

4.5.5 Circuit diagrams .................................................................................................................78

4.5.6 Technical data ....................................................................................................................79

5.1 Application areas ................................................................................................................89

5.2 Operator controls and connection terminals ........................................................................90

5.3 Functions ...........................................................................................................................91

5.4 Operation ...........................................................................................................................94

5.5 Diagnostics ........................................................................................................................94

5.5.1 Diagnostics with LED .........................................................................................................94

5.6 Circuit diagrams .................................................................................................................95

5.7 Technical data ....................................................................................................................96

6.1 Application areas ..............................................................................................................102

6.2 3UG4511 line monitoring relay .........................................................................................103

6.2.1 Operator controls and connection terminals ......................................................................103

6.2.2 Function ...........................................................................................................................104

6.2.3 Diagnostics ......................................................................................................................105

6.2.3.1 Diagnostics with LED .......................................................................................................105

6.2.4 Circuit diagrams ...............................................................................................................106

6.2.5 Technical data ..................................................................................................................107

6.3 3UG4512 line monitoring relay .........................................................................................111

6.3.1 Operator controls and connection terminals ......................................................................111

6.3.2 Function ...........................................................................................................................112

6.3.3 Diagnostics ......................................................................................................................114

6.3.3.1 Diagnostics with LED .......................................................................................................114

6.3.4 Circuit diagrams ...............................................................................................................115

6.3.5 Technical data ..................................................................................................................116

6.4 3UG4513 line monitoring relay .........................................................................................121

6.4.1 Operator controls and connection terminals ......................................................................121

6.4.2 Function ...........................................................................................................................122

6.4.3 Operation .........................................................................................................................124

6.4.4 Diagnostics ......................................................................................................................125

6.4.4.1 Diagnostics with LED .......................................................................................................125

6.4.5 Circuit diagrams ...............................................................................................................126

6.4.6 Technical data ..................................................................................................................127

6.5 3UG4614 line monitoring relay .........................................................................................131

6.5.1 Operator controls and connection terminals ......................................................................131

6.5.2 Functions .........................................................................................................................132

6.5.3 Operation .........................................................................................................................135

3UG4 / 3RR2 monitoring relays

6 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 7

Table of contents

7 3UG4621/3UG4622 current monitoring relays ............................................................................... 173

8 3UG4625 residual current monitoring relay with 3UL23 transformer ................................................. 191

6.5.4 Diagnostics ..................................................................................................................... 136

6.5.4.1 Indications on the display ................................................................................................ 136

6.5.4.2 Reset .............................................................................................................................. 137

6.5.5 Circuit diagrams .............................................................................................................. 137

6.5.6 Technical data ................................................................................................................. 138

6.6 3UG4615 / 3UG4616 line monitoring relays ..................................................................... 142

6.6.1 Operator controls and connection terminals ..................................................................... 142

6.6.2 Functions ........................................................................................................................ 143

6.6.3 Operation ........................................................................................................................ 146

6.6.4 Diagnostics ..................................................................................................................... 147

6.6.4.1 Indications on the display ................................................................................................ 147

6.6.4.2 Reset .............................................................................................................................. 149

6.6.5 Circuit diagrams .............................................................................................................. 150

6.6.6 Technical data ................................................................................................................. 151

6.7 3UG4617 / 3UG4618 line monitoring relays ..................................................................... 156

6.7.1 Operator controls and connection terminals ..................................................................... 156

6.7.2 Functions ........................................................................................................................ 157

6.7.3 Operation ........................................................................................................................ 161

6.7.4 Diagnostics ..................................................................................................................... 162

6.7.4.1 Indications on the display ................................................................................................ 162

6.7.4.2 Reset .............................................................................................................................. 164

6.7.5 Circuit diagrams .............................................................................................................. 165

6.7.5.1 Internal circuit diagrams................................................................................................... 165

6.7.5.2 Wiring examples .............................................................................................................. 166

6.7.6 Technical data ................................................................................................................. 167

7.1 Application areas ............................................................................................................. 173

7.2 Operator controls and connection terminals ..................................................................... 174

7.3 Functions ........................................................................................................................ 175

7.4 Operation ........................................................................................................................ 179

7.5 Diagnostics ..................................................................................................................... 180

7.5.1 Indications on the display ................................................................................................ 180

7.5.2 Reset .............................................................................................................................. 181

7.6 Circuit diagrams .............................................................................................................. 182

7.6.1 Internal circuit diagrams................................................................................................... 182

7.6.2 Wiring examples (3UG46..-.AW30) .................................................................................. 182

7.6.3 Wiring examples (3UG462.-.AA30) .................................................................................. 183

7.7 Technical data ................................................................................................................. 184

8.1 Application areas ............................................................................................................. 191

8.2 Operator controls and connection terminals ..................................................................... 192

8.3 Functions ........................................................................................................................ 193

8.4 Operation ........................................................................................................................ 202

8.5 Diagnostics ..................................................................................................................... 203

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

7

Page 8

Table of contents

9 3UG458. insulation monitoring relay ............................................................................................. 213

10 3UG463. voltage monitoring relay ................................................................................................ 271

8.5.1 Indications on the display .................................................................................................203

8.5.2 Reset ...............................................................................................................................205

8.6 Circuit diagrams ...............................................................................................................206

8.6.1 Internal circuit diagrams ...................................................................................................206

8.6.2 Wiring examples ...............................................................................................................207

8.7 Technical data ..................................................................................................................208

9.1 Application areas ..............................................................................................................215

9.2 Performance features of the insulation monitoring relays ..................................................216

9.3 3UG4581 insulation monitoring relay ................................................................................218

9.3.1 Operator controls and connection terminals ......................................................................218

9.3.2 Functions .........................................................................................................................219

9.3.3 Operator control ...............................................................................................................224

9.3.4 Diagnostics ......................................................................................................................226

9.3.4.1 Diagnostics with LEDs ......................................................................................................226

9.3.5 Circuit diagrams ...............................................................................................................227

9.3.5.1 Internal circuit diagrams ...................................................................................................227

9.3.6 Characteristics .................................................................................................................231

9.3.7 Technical data ..................................................................................................................233

9.4 3UG4582/3UG4583 insulation monitoring relays...............................................................235

9.4.1 Operator controls and connection terminals ......................................................................235

9.4.2 Functions .........................................................................................................................238

9.4.2.1 Function diagrams ............................................................................................................243

9.4.3 Operator control ...............................................................................................................249

9.4.4 Diagnostics ......................................................................................................................253

9.4.4.1 Diagnostics with LEDs ......................................................................................................253

9.4.5 Circuit diagrams ...............................................................................................................255

9.4.5.1 Internal circuit diagrams ...................................................................................................255

9.4.5.2 Wiring examples ...............................................................................................................256

9.4.6 Characteristics .................................................................................................................261

9.4.7 Technical data ..................................................................................................................265

9.4.7.1 3UG4582 .........................................................................................................................265

9.4.7.2 3UG4583 .........................................................................................................................269

10.1 Application areas ..............................................................................................................271

10.2 3UG4631 / 3UG4632 voltage monitoring relay ..................................................................272

10.2.1 Operator controls and connection terminals ......................................................................272

10.2.2 Functions .........................................................................................................................273

10.3 3UG4633 voltage monitoring relay ....................................................................................275

10.3.1 Operator controls and connection terminals ......................................................................275

10.3.2 Functions .........................................................................................................................276

10.4 Operation .........................................................................................................................278

10.5 Diagnostics ......................................................................................................................279

10.5.1 Indications on the display .................................................................................................279

10.5.2 Reset ...............................................................................................................................280

3UG4 / 3RR2 monitoring relays

8 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 9

Table of contents

11 3UG4641 cos phi and active current monitoring relay .................................................................... 289

12 3UG4651 speed monitoring relay ................................................................................................ 307

13 Accessories .............................................................................................................................. 323

10.6 Circuit diagrams .............................................................................................................. 281

10.6.1 Internal circuit diagrams................................................................................................... 281

10.6.2 Wiring examples .............................................................................................................. 282

10.7 Technical data ................................................................................................................. 283

11.1 Application areas ............................................................................................................. 289

11.2 Operator controls and connection terminals ..................................................................... 290

11.3 Functions ........................................................................................................................ 291

11.4 Operation ........................................................................................................................ 296

11.5 Diagnostics ..................................................................................................................... 297

11.5.1 Indications on the display ................................................................................................ 297

11.5.2 Reset .............................................................................................................................. 298

11.6 Circuit diagrams .............................................................................................................. 299

11.6.1 Internal circuit diagrams................................................................................................... 299

11.6.2 Wiring examples .............................................................................................................. 300

11.7 Technical data ................................................................................................................. 302

12.1 Application areas ............................................................................................................. 307

12.2 Operator controls and connection terminals ..................................................................... 308

12.3 Functions ........................................................................................................................ 309

12.4 Operation ........................................................................................................................ 312

12.5 Diagnostics ..................................................................................................................... 313

12.5.1 Indications on the display ................................................................................................ 313

12.5.2 Reset .............................................................................................................................. 314

12.6 Circuit diagrams .............................................................................................................. 315

12.6.1 Internal circuit diagrams................................................................................................... 315

12.6.2 Wiring examples .............................................................................................................. 316

12.7 Technical data ................................................................................................................. 317

13.1 Accessories for 3RR2 current monitoring relays ............................................................... 323

13.1.1 Sealable cover ................................................................................................................ 323

13.1.2 Terminal support for stand-alone assembly...................................................................... 324

13.2 Accessories for 3UG4 monitoring relays .......................................................................... 327

13.2.1 Sealable cover ................................................................................................................ 327

13.2.2 Push-in lugs .................................................................................................................... 328

13.2.3 Probes for the 3UG4501 monitoring relay ........................................................................ 329

13.2.4 Summation current transformer for the 3UG4624 monitoring relay ................................... 332

13.2.5 3UL23 residual current transformers for 3UG4625 monitoring relays................................ 333

13.2.5.1 General information ......................................................................................................... 333

13.2.5.2 Installation specifications ................................................................................................. 335

13.2.5.3 Potential for optimization ................................................................................................. 339

13.2.5.4 Installation faults.............................................................................................................. 341

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

9

Page 10

Table of contents

A References ............................................................................................................................... 361

B Parameters ............................................................................................................................... 363

C Dimension Drawings .................................................................................................................. 375

D Menu-based operation ................................................................................................................ 389

Index ........................................................................................................................................ 407

13.2.5.5 Internal circuit diagram .....................................................................................................343

13.2.5.6 Installing ...........................................................................................................................344

13.2.5.7 Technical data ..................................................................................................................346

13.2.5.8 Dimension drawings .........................................................................................................348

13.3 Accessories for 3UG458. insulation monitoring relays. ......................................................352

13.3.1 Sealable cover .................................................................................................................352

13.3.2 3UG4983 upstream module for the 3UG4583 monitoring relay .........................................353

13.3.2.1 Internal circuit diagrams ...................................................................................................355

13.3.2.2 Technical data ..................................................................................................................358

C.1 Dimension drawings 3RR2 monitoring relay......................................................................375

C.2 Dimension drawings 3UG4 monitoring relays ....................................................................383

C.2.1 Dimension drawings 3UG4 monitoring relays. (2 connecting terminals) .............................383

C.2.2 Dimension drawings 3UG4 monitoring relays. (3 connecting terminals) .............................384

C.2.3 Dimension drawings 3UG4 monitoring relays. (4 connecting terminals) .............................385

C.2.4 Dimension drawings 3UG458 insulation monitoring relay. (3UG4983 upstream

module) ............................................................................................................................387

3UG4 / 3RR2 monitoring relays

10 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 11

1

Purpose of the manual

Required basic knowledge

Scope of the manual

1.1

Service&Support

Online Support

Links:

This manual describes the 3UG4 monitoring relays for stand-alone assembly and the 3RR2

current monitoring relays for mounting on 3RT2 contactors

The manual provides overview information for integrating the monitoring relays into the

system environment, and it describes the hardware and software components of the devices.

The information in this manual enables you to commission the monitoring relays.

To understand these operating instructions you should have a general knowledge of

automation engineering and low-voltage switchgear.

The manual is valid for these monitoring relays. It contains a description of the devices that

is valid at the time of publication.

The Online Support in the Service&Support portal is an extensive information system for all

questions relating to Siemens products and solutions. This service enables direct and central

access to in-depth information concerning the products, systems and applications for

industry and to a large number of programming, configuration and application examples. Its

content is available via a mobile app.

The Technical Forum of the Online Support provides the opportunity for users to swap

information. Support Request allows contact to be established with Siemens experts in

Technical Support.

Siemens Industry Online Support ensures that users in industry are always kept up-to-date

with news, software updates and announcements by means of newsletters and Twitter.

(http://support.automation.siemens.com/WW/view/en/16605022)

Service&Support Portal (http://support.automation.siemens.com), Online Support

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

11

Page 12

Introduction

Product Support

Link:

CAx data

Link:

1.1 Service&Support

Are you looking for product information such as technical data, updates or FAQs? Here, the

"Product Support" section of the Service & Support Portal offers an extensive collection of all

information about the Siemens Industry Automation and Drive Technologies products and

solutions:

● Answers to frequently asked questions (FAQs)

● Updates/upgrades, service packs and support tools for downloading

● Manuals and operating instructions

● Technical data/CAx data

● Approvals and certificates

● Test certificates and characteristic curves

All Product Support information is at your disposal free of charge and around the clock, and

you always get the current version.

Product Support (http://support.automation.siemens.com/WW/view/en/4000024)

The CAx Download Manager provides you with a simple means of gaining access to up-todate product data for your CAx or CAe system.

You configure your own download package with just a few clicks. You can choose from the

following information for products

● Product images

● 2D dimensional drawings

● 3D models

● Internal circuit diagrams

● EPLAN macro files

● Manuals

● Characteristics

● Operating instructions

● Certificates

● Product master data

CAx Download Manager

(http://support.automation.siemens.com/WW/view/en/42455541)

3UG4 / 3RR2 monitoring relays

12 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 13

Introduction

Applications & Tools

Link:

My Documentation Manager

Link:

Reference

1.1 Service&Support

Applications & Tools supports you with various tools and examples when it comes to solving

your automation tasks. Solutions are presented in interaction with several components in the

system, without focusing on individual products.

● Application examples

● Function blocks & tools

● Background and system descriptions

● Performance statements

● Demonstration systems/videos

Applications & Tools (http://support.automation.siemens.com/WW/view/en/20208582)

My Documentation Manager enables you to compile your own documentation from our

standard documents (manuals), which are located in the Product Support section. Under

mySupport, you have the opportunity to create and manage you own compilations in a

structure of their own.

MyDocumentationManager (http://support.automation.siemens.com/WW/view/en/38715968)

You can find further information on structure and navigation in Online Support here

(http://support.automation.siemens.com/WW/view/en/11774658).

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

13

Page 14

Introduction

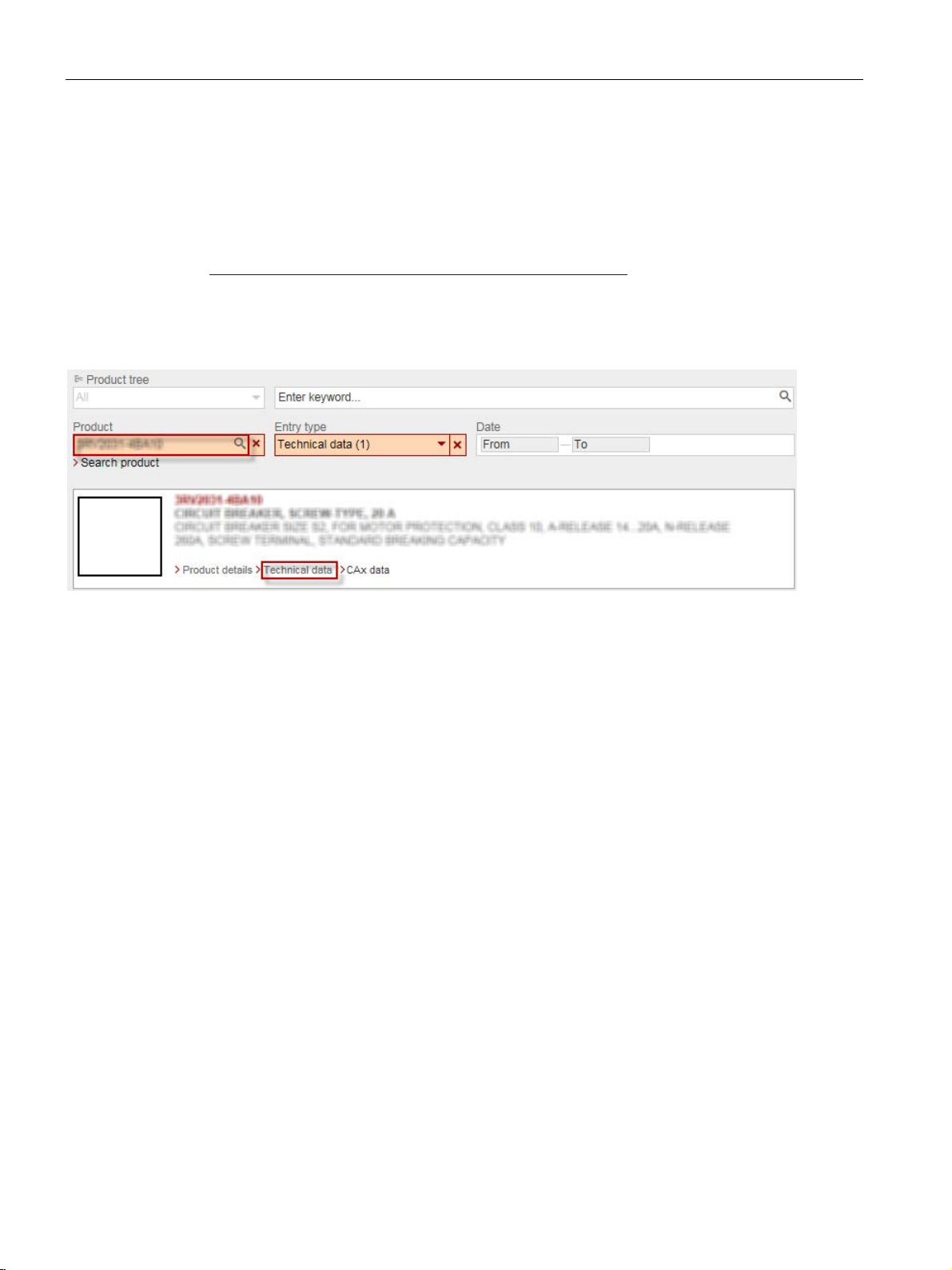

1.2

Technical data in Siemens Industry Online Support

Technical data sheet

Compare products

Further documentation

1.2 Technical data in Siemens Industry Online Support

You can find all the technical data of the product in the Siemens Industry Online Support

(https://support.industry.siemens.com/cs/ww/en/ps/16364/td).

1. Enter the full article number of the desired device in the "Product" field, and confirm with

the Enter key.

2. Click the "Technical data link.

You can compare the technical data of the products in Siemens Industry Online Support.

1. Select the products you want to compare.

2. Click the "Compare technical data" button.

To install and connect the monitoring relays, you require the operating instructions of the

monitoring relays used.

The Appendix "References (Page 361)" has a list of the operating instructions.

3UG4 / 3RR2 monitoring relays

14 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 15

Introduction

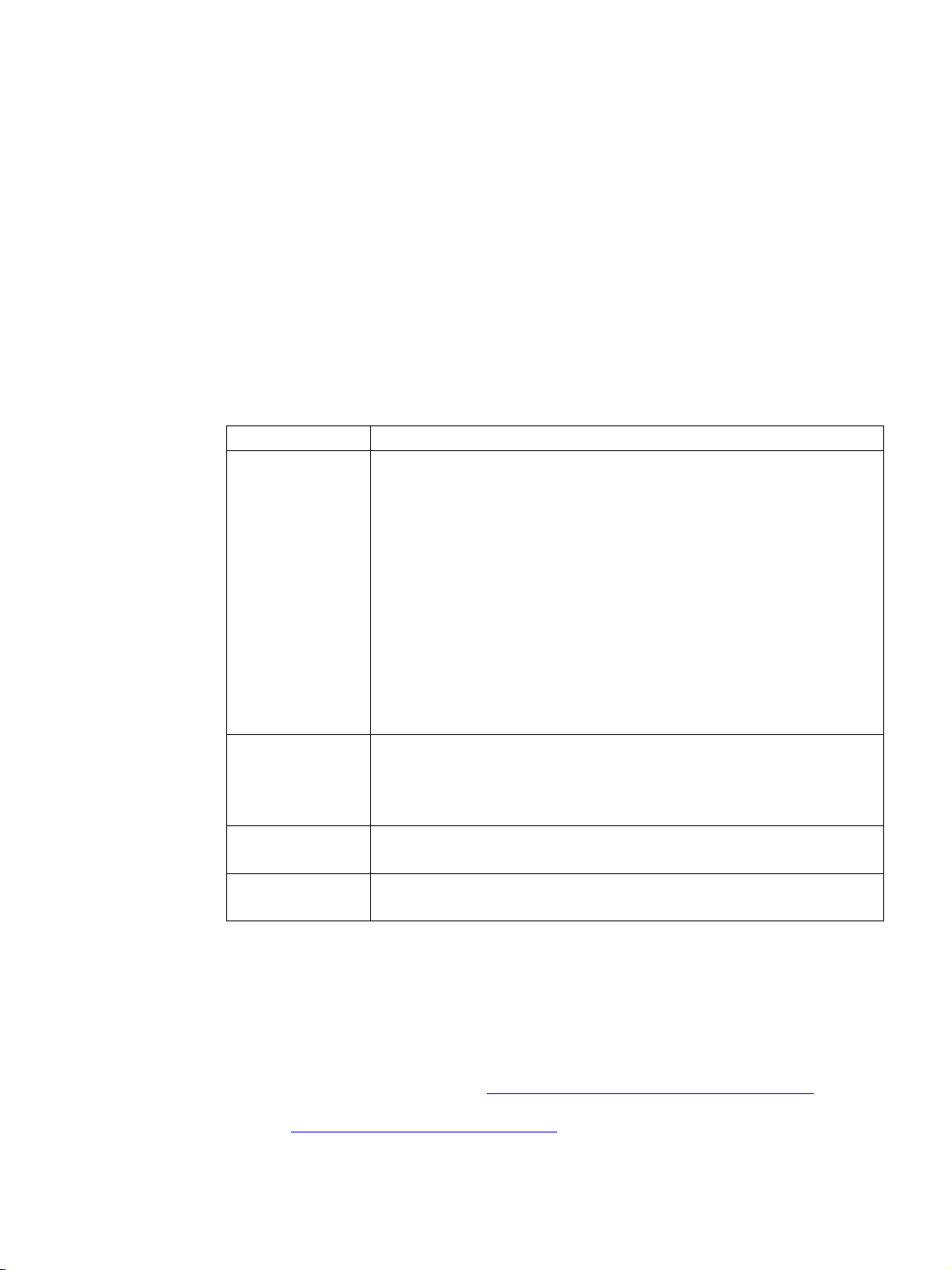

1.3

DataMatrix code

1P Article

number

+ S Location

Date

Serial number

Data

identifier

User

content

Separator

User content

Separator

User content

User content

Note

The information content is displayed without spaces.

1.3 DataMatrix code

A DataMatrix code is lasered onto all 3UG4/3RR2 monitoring relay devices underneath the

label.

The DataMatrix codes are standardized in ISO/IEC 16022. The DataMatrix codes on

Siemens devices use ECC200 coding for powerful error correction.

The following device information is encoded in the DataMatrix codes as a bit stream:

● Article number

● Serial number

● If applicable, MAC address

This information is stored in the following format in the DataMatrix code:

/

This machine-readable information simplifies and accelerates handling of the respective

devices.

As well as fast access to the serial numbers of the respective devices for unique

identification, the DataMatrix codes simplify communication with Siemens Technical Support.

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

15

Page 16

Introduction

SIEMENS Industry Support App

Link for Android

Link for iOS

Recycling and disposal

Up-to-the-minute information

Technical Assistance:

or on the Internet at:

1.3 DataMatrix code

DataMatrix codes primarily enable extremely fast and convenient access to all devicespecific information relating to an article number in the SIEMENS Service&Support Portal,

such as operating instructions, manuals, data sheets, FAQs, etc.

We provide the SIEMENS Industry Support app free for this purpose and it can be used on

most commercially available smartphones and tablets.

The SIEMENS Industry Support app is available for iOS and Android-based devices and can

be accessed via the following links:

These devices can be recycled thanks to their low pollutant content. For environmentallyfriendly recycling and disposal of your electronic waste, please contact a company certified

for the disposal of electronic waste.

You can obtain further assistance by calling the following numbers:

Telephone: +49 (911) 895-5900 (8 a.m. to 5 p.m. CET)

Fax: +49 (911) 895-5907

E-mail: (mailto:technical-assistance@siemens.com)

Internet: (www.siemens.com/industrial-controls/technical-assistance)

3UG4 / 3RR2 monitoring relays

16 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 17

2

2.1

Standards

Applicable standards

Part 2: Additional requirements

Monitoring relays are safe to touch in accordance with IEC / EN 60529.

1)

interference. Users may have to take suitable measures.

Reference

The monitoring relays comply with the following standards:

Table 2- 1 Standards - monitoring relays

Device standards

EMC standard1)

Resistance to

extreme climates

Touch protection

• IEC / EN 60947-1 "Low-voltage switchgear and controlgear: General rules"

• IEC / EN 60947-4-1 "Contactors and motor-starters: Electromechanical

contactors and motor-starters"

• IEC / EN 60947-5-1 "Control circuit devices and switching elements:

Electromechanical control circuit devices";

VDE 0660 "Low-voltage switchgear"

• IEC / EN 61557-8 "Equipment for testing, measuring or monitoring of

protective measures - Electrical safety in low voltage distribution systems

up to 1000 V AC and 1500 V DC, Part 8: Insulation monitoring devices for

IT systems".

• DIN EN 50042 "Terminal marking"

• DIN EN 61869-2 "Instrument transformers -

for current transformers"

• IEC / EN 61000-6-2 "Generic standards - Immunity for industrial

environments"

• IEC / EN 61000-6-4 "Generic standards - Emission standard for industrial

environments"

• IEC 60721-3-3 "Classification of environmental conditions"

The monitoring relays are climate-proof according to IEC 60721-3.

• IEC / EN 60529 "Degrees of protection provided by enclosures"

This is a device of Class A. When used in domestic areas, the device can cause radio

SIRIUS components have been approved by a whole range of bodies for various sectors

(shipbuilding, etc.). An up-to-date list of approvals appears in Chapter 10 of the Catalog

IC 10 - SIRIUS "Industrial Controls" (www.siemens.com/industrial-controls/catalogs), and

more information, as well as an option to download certificates, can be obtained on the

Internet (www.siemens.com/automation/csi_en).

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

17

Page 18

Safety information

2.2

Product-specific safety information

Intended use

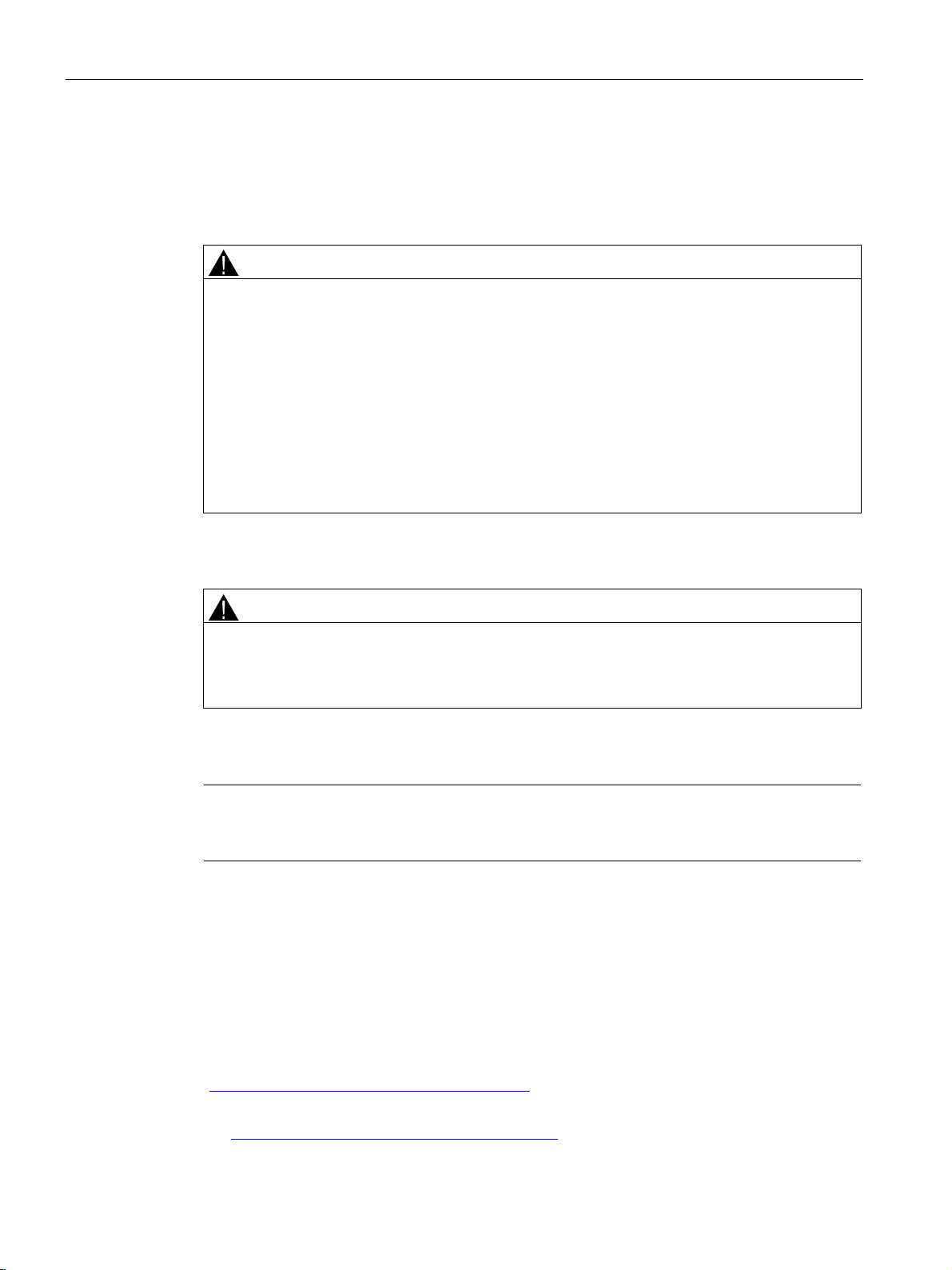

WARNING

Intended use

Can Cause Death, Serious Injury, or Property Damage.

Hazardous Voltage

WARNING

Hazardous Voltage.

Radio interference

Note

The devices have been built as Class

Use of these devices in domestic areas can result in radio interference!

2.3

Approvals, test certificates, characteristics

Approvals, test certificates, characteristics

2.2 Product-specific safety information

The devices may only be used for the applications described in the catalog and the

technical description, and only in conjunction with equipment or components from other

manufacturers which have been approved or recommended by Siemens.

This product can function correctly and reliably only if it is transported, stored, assembled,

and installed correctly, and operated and maintained as recommended.

Before you run any sample programs or programs that you have written yourself, make

sure that running the plant cannot cause injury to anyone else or damage to the machine

itself.

Will cause death or serious injury.

Turn off and lock out all power supplying this device before working on this device.

A devices.

3UG4 / 3RR2 monitoring relays

18 Manual, 05/2016, NEB927043002000/RS-AC/004

You can find an overview of the certifications available for low-voltage controls and

distribution products and other technical documentation, updated daily, on the Internet

(www.siemens.com/industrial-controls/support).

You will find further information in the Catalog IC 10 - SIRIUS "Industrial Controls," Chapter

10 (www.siemens.com/industrial-controls/catalogs).

Page 19

3

3.1

Product description

Product description

The tried and tested SIRIUS monitoring relays for electrical and mechanical quantities

enable constant monitoring of all important characteristic quantities that provide information

about the reliability performance of the plant. Sudden disturbances and gradual changes,

which may reveal a maintenance requirement, for example, are both indicated. By means of

relay outputs, the monitoring relays enable direct shutdown of the affected sections of the

plant as well as issuing an alarm (e.g. by switching on a warning lamp). To respond flexibly

to short-term disturbances such as voltage dips or load variation, the monitoring relays have

settable delay times. This avoids unnecessary alarming and shutdowns while enhancing

plant availability.

The individual 3UG4 monitoring relays offer the following functions in various combinations:

● Undershoot and/or overshoot of liquid levels

● Phase sequence

● Phase failure, neutral failure

● Phase asymmetry

● Undershoot and/or overshoot of voltage thresholds

● Undershoot and/or overshoot of current thresholds

● Undershoot and/or overshoot of power factor thresholds

● Monitoring of the active current or apparent current

● Monitoring of the fault current

● Monitoring the insulation resistance

● Undershoot and/or overshoot of speed thresholds

The 3RT2 contactors for mounting on 3RR2 current monitoring relays offer:

● Phase sequence

● Phase failure

● Undershoot and/or overshoot of current thresholds

● Monitoring of the active current or apparent current

● Monitoring of the fault current

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

19

Page 20

System overview

3.2

Application planning

Installation altitude

Operating conditions and resistance to extreme climates

Special application environments

3.2 Application planning

The following information must be taken into account when planning applications involving

the SIRIUS monitoring relays.

The monitoring relays are approved for installation altitudes up to 2,000 m. The reduced air

density at altitudes higher than 2,000 meters affects the electrical characteristics of the

monitoring relays. The reduction factors which have to be taken into account when using

monitoring relays at altitudes higher than 2,000 m can be obtained on request on the Internet

(www.siemens.com/automation/csi_en).

The monitoring relays are climate-proof. They are intended for use in enclosed spaces in

which no severe operating conditions prevail (e.g. dust, caustic vapors, hazardous gases).

Appropriate measures must be taken when installing in areas subject to dust and humidity.

Condensation on the devices is not permissible.

The SIRIUS devices have been approved by a whole range of bodies for various sectors

(shipbuilding, etc.). An up-to-date list of approvals is provided in Chapter 10 of the Catalog

IC 10 - SIRIUS "Industrial Controls." You will find more information and an option to

download certificates on the Internet (www.siemens.com/automation/csi_en).

3UG4 / 3RR2 monitoring relays

20 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 21

System overview

3.3

Connection methods

3.3.1

Screw-type connection

Screw-type connection

Connection cross-sections of the removable terminal blocks with screw-type connections

Removable terminal

1 x (0.5 to 4) mm²

AWG

2 x (20 to 14)

3.3 Connection methods

Use the following tool to establish the connection: All SIRIUS monitoring relays feature

size PZ 2 screws for Pozidriv screwdrivers.

The devices have screw terminals with captive screws and washers. The screw terminals

also allow for the connection of 2 conductors with different cross-sections.

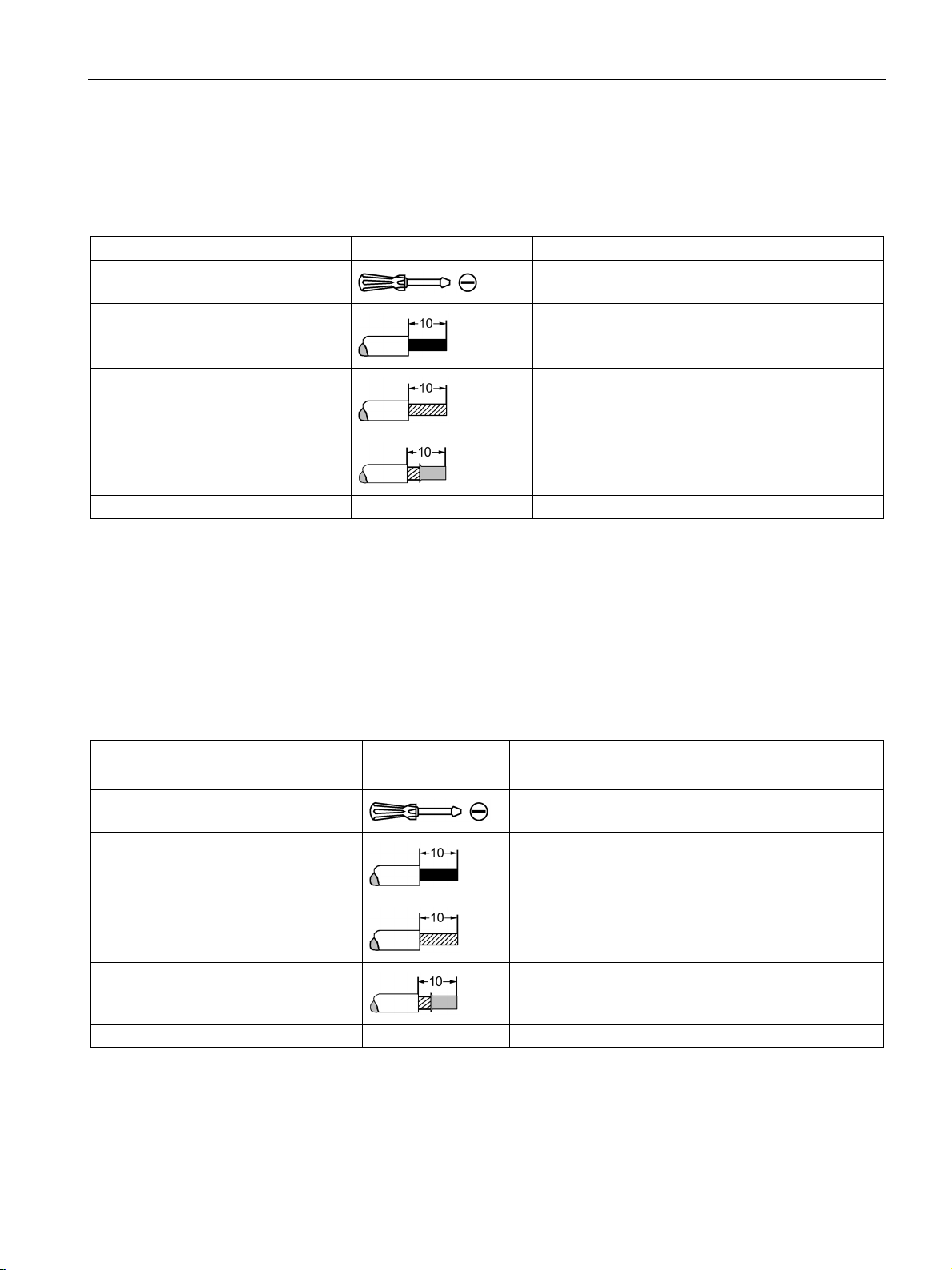

Table 3- 1 Removable terminal block with screw-type connections - monitoring relays

Tool

Tightening torque 0.8 to 1.2 Nm

Solid and stranded

Finely stranded without end sleeve

Finely stranded with end sleeve

Pozidriv size PZ 2, Ø 5 to 6 mm

2 x (0.5 to 2.5) mm²

---

1 x (0.5 to 2.5) mm²

2 x (0.5 to 1.5) mm²

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

21

Page 22

System overview

Connection cross-sections of the permanently connected terminal blocks with screw-type connections

Permanently connected terminal

Size S00

Size S0

Size S2

Tightening torque

0.8 to 1.2 Nm

2 - 2.5 Nm

3 to 4.5 Nm (27 to 40 lb.in)

2 x (0.5 to 1.5) mm²

2 x (1 to 2.5) mm²

2 x (1.0 to 35 mm²)

2 x (0.75 to 2.5) mm²

2 x (0.5 to 1.5) mm²

2 x (1 to 2.5) mm²

2 x (1.0 to 25 mm²)

2 x (2.5 to 6) mm²

max. 1 x 10 mm²

2 x (20 to 14)

2 x (16 to 12)

2 x (18 to 2)

3.3 Connection methods

The following table lists the permissible conductor cross-sections for the main conductor

connections of 3RR2 current monitoring relays with analog and digital setting (size S00, S0

and S2) with screw-type connections.

Table 3- 2 Permanently connected terminal block with screw-type connection - Main conductor terminals of the 3RR2

current monitoring relays

Tool

Solid and stranded

Finely stranded

without end sleeve

Finely stranded

with end sleeve

AWG

Pozidriv size PZ 2,

Ø 5 to 6 mm

max. 2 x (1 ... 4) mm²

--- --- ---

2 x (0.75 to 2.5) mm²

1 x 12 2 x (14 to 8) 1 x (18 to 1)

Pozidriv size PZ 2,

Ø 5 to 6 mm

2 x (2.5 to 10) mm² 1 x (1.0 to 50 mm²)

Pozidriv size PZ 2

Ø 5 to 6 mm

1 x (1.0 to 35 mm²)

3UG4 / 3RR2 monitoring relays

22 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 23

System overview

3.3.2

Spring-loaded connection

Spring-loaded connection

①

Solid

②

Finely stranded

③

Stranded

④

Finely stranded with end sleeve

a

Spring-loaded terminal

b

Busbar

3.3 Connection methods

All SIRIUS monitoring relays have spring-loaded connections. They make wiring quick and

maintenance-free, while also meeting high demands in terms of vibration and shock

resistance. If the cross-section of a connectable wire is greater than 6 mm², the forces

required for operation of the tension spring are so high that the spring-loaded connection can

no longer be used in a problem-free manner. For this reason, size S2 current monitoring

relays are only offered with screw-type or spring-loaded terminals in the control circuit. The

terminals of the main current paths are always screw-type terminals.

Image 3-1 Spring-loaded terminal

The conductors can be clamped directly or you can pre-treat them to add a form of splice

protection. This could involve attaching end sleeves or pin cable lugs to the ends of the

conductors; the tidiest solution is to use conductors whose ends have been sealed by means

of ultrasound.

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

23

Page 24

System overview

3.3 Connection methods

The devices are equipped with a two-wire terminal, i.e. two independent connections for

each current path (exception: in the case of 3RR2, terminals of the main current paths have

one clamping point). Just one conductor is connected to each clamping point. The springloaded terminal presses the conductor against the busbar, which curves around inside the

terminal. The high contact pressure per unit area achieved in this way is gas-tight. The

spring-loaded terminal presses flat against the conductor, but does not damage it. The

spring force of the spring-loaded terminal has been dimensioned such that the clamping

force adjusts to the conductor diameter automatically. This ensures that any conductor

deformation caused by settling, creepage, or yielding is compensated for. The clamping

point cannot become loose of its own accord. This connection is vibration- and shock-proof.

Vibrations or shocks will not damage the conductor, nor will they cause contact separation.

These terminals are particularly well suited for use with machines and systems which are

subject to stresses such as these, e.g. vibrators, rail vehicles, and elevators.

The contact pressure between the conductor and the busbar is set to an optimum level, so

this clamp connection is appropriate for high-voltage applications, as well as for transferring

voltages and currents in the mV or mA range within instrumentation and electronic

components.

A standardized screwdriver (3 mm slot; 3RA2908-1A) is offered in the Catalog IC10

"Industrial Controls" (www.siemens.com/industrial-controls/catalogs) as an actuation tool for

opening the spring-loaded terminals.

3UG4 / 3RR2 monitoring relays

24 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 25

System overview

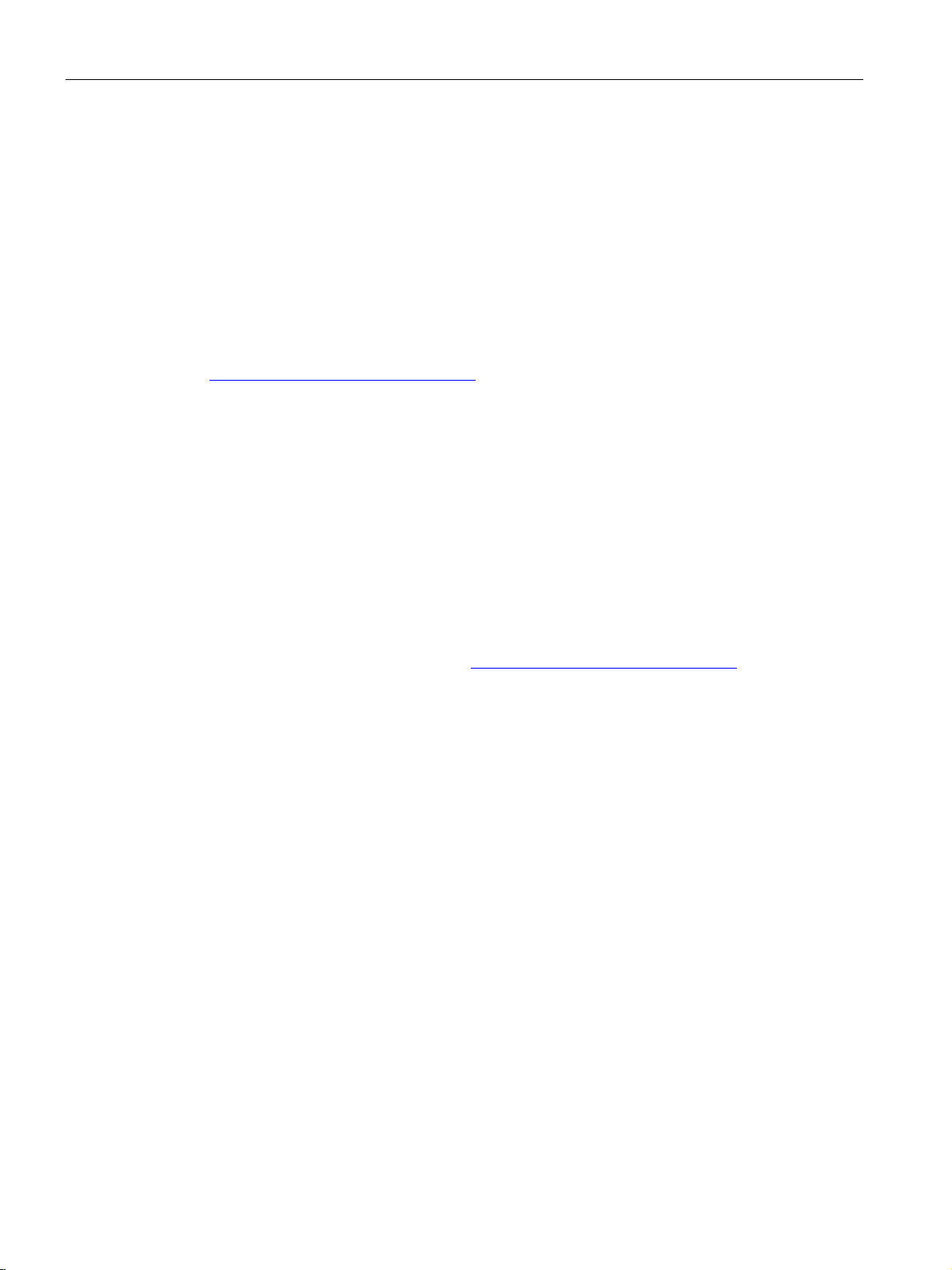

Spring-loaded connection for mountable 3RR2 current monitoring relays

DANGER

Hazardous Voltage.

Step

Instructions

Figure

automatically.

connection slot.

is now securely clamped.

Note

Damage to spring-loaded terminal on the 3RR2 current monitoring relay!

If you insert the screwdriver into the central opening (main circuit S00 and S0 only) on the

spring

Do not insert the screwdriver into the central opening on the spring-loaded terminal.

3.3 Connection methods

The table below describes the procedure for creating a spring-loaded connection:

Will cause death or serious injury.

Turn off and lock out all power supplying this device before working on this device.

Table 3- 3 Connecting the 3RR2 current monitoring relay spring-loaded terminal

1 Insert the screwdriver into the

respective operating slot.

2 Press the screwdriver down, then

push it into the operating slot as far

as it will go.

The screwdriver blade keeps the

spring-loaded terminal open

3 Insert the conductor into the oval

4 Remove the screwdriver. The

terminal closes and the conductor

-loaded terminal, this could damage the terminal.

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

25

Page 26

System overview

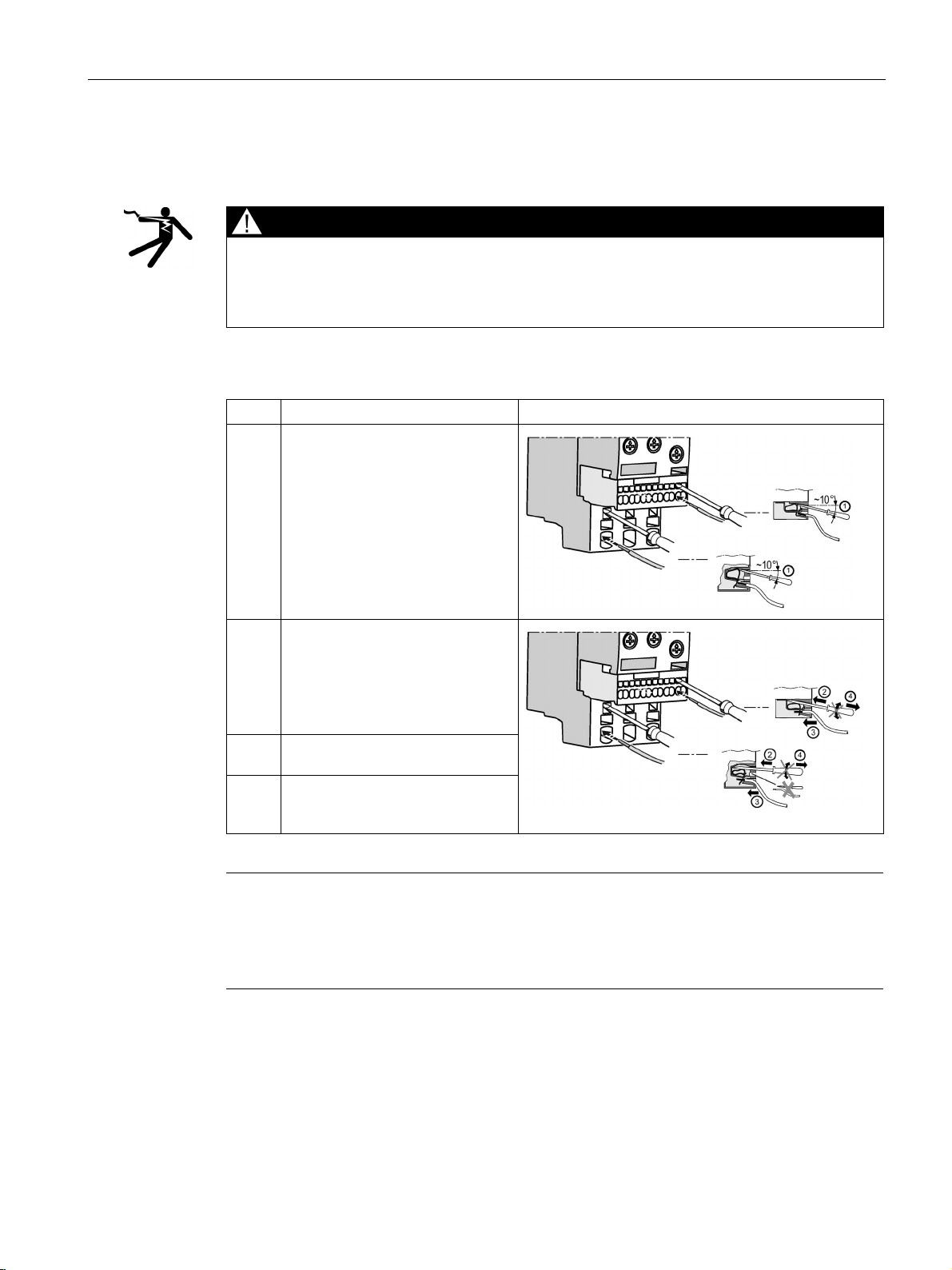

Spring-loaded terminal for 3UG4 monitoring relay

Step

Operating instruction

Figure

side.

connection slot.

3.3 Connection methods

Table 3- 4 Connecting the monitoring relay spring-loaded terminal

1 Insert the screwdriver into the

topmost (A) or bottommost (B)

operating slot on the right-hand

2 Press the screwdriver up (A) or

down (B), then push it into the

operating slot as far as it will go.

The screwdriver blade keeps the

spring-loaded terminal open

automatically.

3 Insert the conductor into the oval

4 Remove the screwdriver. The

terminal closes and the

conductor is now securely

clamped.

3UG4 / 3RR2 monitoring relays

26 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 27

System overview

Connection cross-sections of the removable terminal blocks with a spring-loaded connection (3RR

and 3UG)

Removable terminal

AWG

2 x (24 to 16)

Connection cross-sections of the permanently connected terminal blocks with a spring-loaded

connection

Permanently connected terminal

Size S00

Size S0

3.3 Connection methods

Table 3- 5 Removable terminal block with spring-loaded connections - monitoring relays

Tool

Solid and stranded

Finely stranded without end sleeve

Finely stranded with end sleeve

Ø 3.0 x 0.5 (3RA2908-1A)

2 x (0.25 to 1.5) mm²

2 x (0.25 to 1.5) mm²

2 x (0.25 to 1.5) mm²

The following table lists the permissible conductor cross-sections for the main conductor

terminals of the 3RR2 current monitoring relays for analog and digital setting (size S00 and

S0) with a spring-loaded connection.

Table 3- 6 Permanently connected terminal block with spring-loaded connection - main conductor terminals of

3RR2 current monitoring relays

Tool

Solid

Finely stranded without end sleeve

Finely stranded with end sleeve

AWG 1 x (20 to 12) 1 x (18 to 8)

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

Ø3.0 x 0.5 (3RA2908-1A) Ø3.0 x 0.5 (3RA2908-1A)

1 x (0.5 to 4) mm² 1 x (1 to 10) mm²

1 x (0.5 to 2.5) mm² 1 x (1 to 6) mm²

1 x (0.5 to 2.5) mm² 1 x (1 to 6) mm²

27

Page 28

System overview

3.3.3

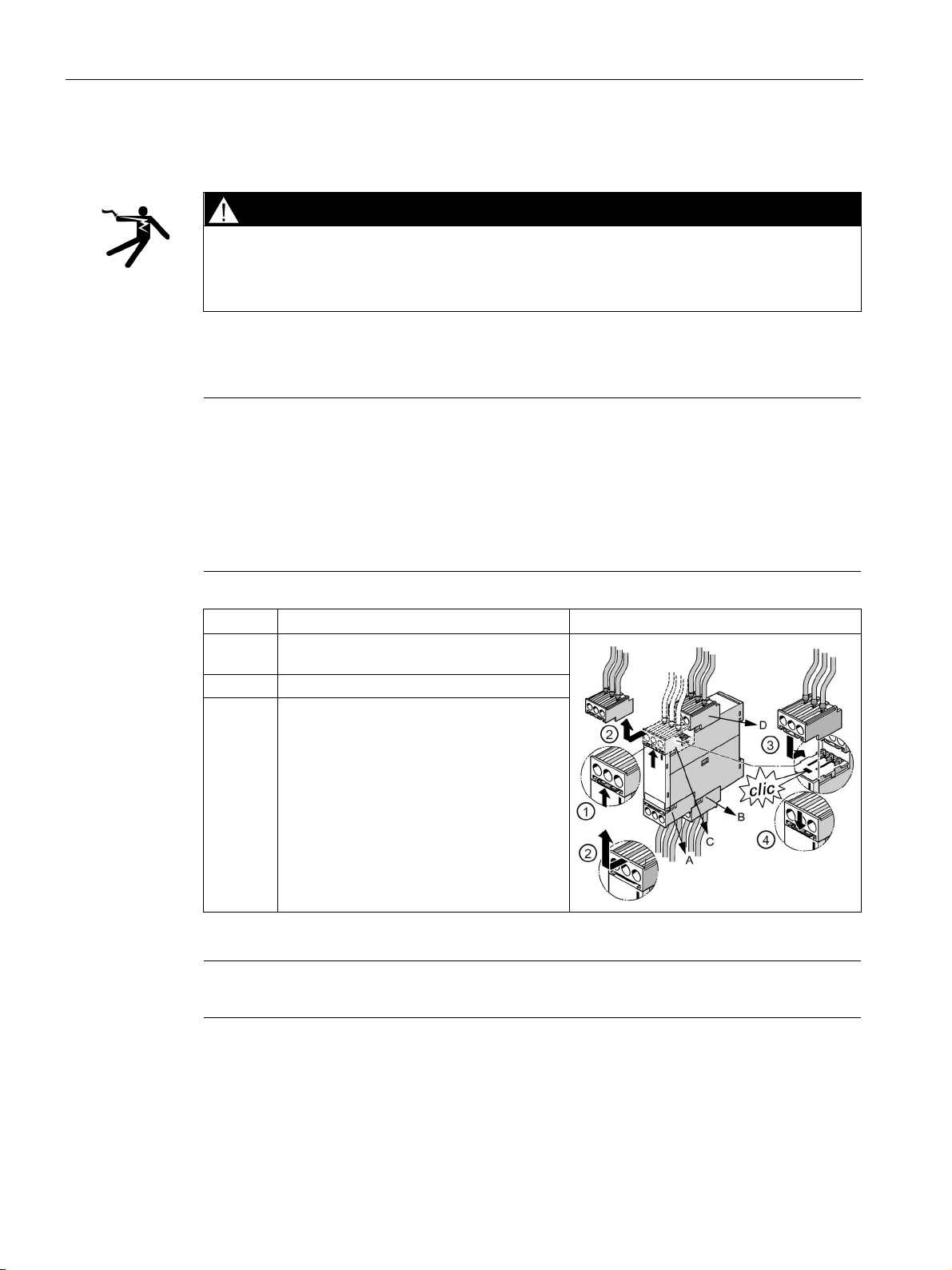

Device replacement by means of removable terminals

DANGER

Hazardous Voltage

Note

The terminals can only be dismantled in the

monitoring relay:

1.

2.

3.

4.

Step

Instructions

Figure

2

Remove the terminal to the front.

Note

The procedure is similar on devices with fewer connection terminals.

3.3 Connection methods

Will cause death or serious injury.

Turn off and lock out power before working on this equipment.

The removable terminals of 3UG4 monitoring relays facilitate device replacement when

necessary. The mechanical coding on the terminals prevents mix-ups.

following order due to their arrangement on the

Lower, front terminal (A)

Lower, rear terminal (B)

Upper, front terminal (C)

Upper, rear terminal (D)

1 Press the interlock in the direction of the

removable terminal.

3 / 4 Attach the new terminal and press the

terminal into the device until the interlock

audibly engages.

3UG4 / 3RR2 monitoring relays

28 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 29

System overview

3.4

Mounting / removal

3.4.1

Mounting 3RR2 current monitoring relay

Mounting options

Minimum clearance

Mounting position

3.4 Mounting / removal

3RR2 current monitoring relays are matched to 3RT2 contactors and 3RF34 (size S0) solidstate contactors in terms of their electrical and mechanical features. As a result, direct

mounting can be achieved easily.

Alternatively, the devices can also be installed individually in the case of stand-alone

assembly or if a 3RU2 / 3RB3 overload relay is being used at the same time. The

accessories required for separate mounting are described in Chapter "Terminal support for

stand-alone assembly (Page 324)."

The following minimum clearances from grounded and live parts must be complied with

when installing the 3RR2 monitoring relay:

● At the side: 6 mm

● Forward (on front): 6 mm

It can be mounted in any position.

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

29

Page 30

System overview

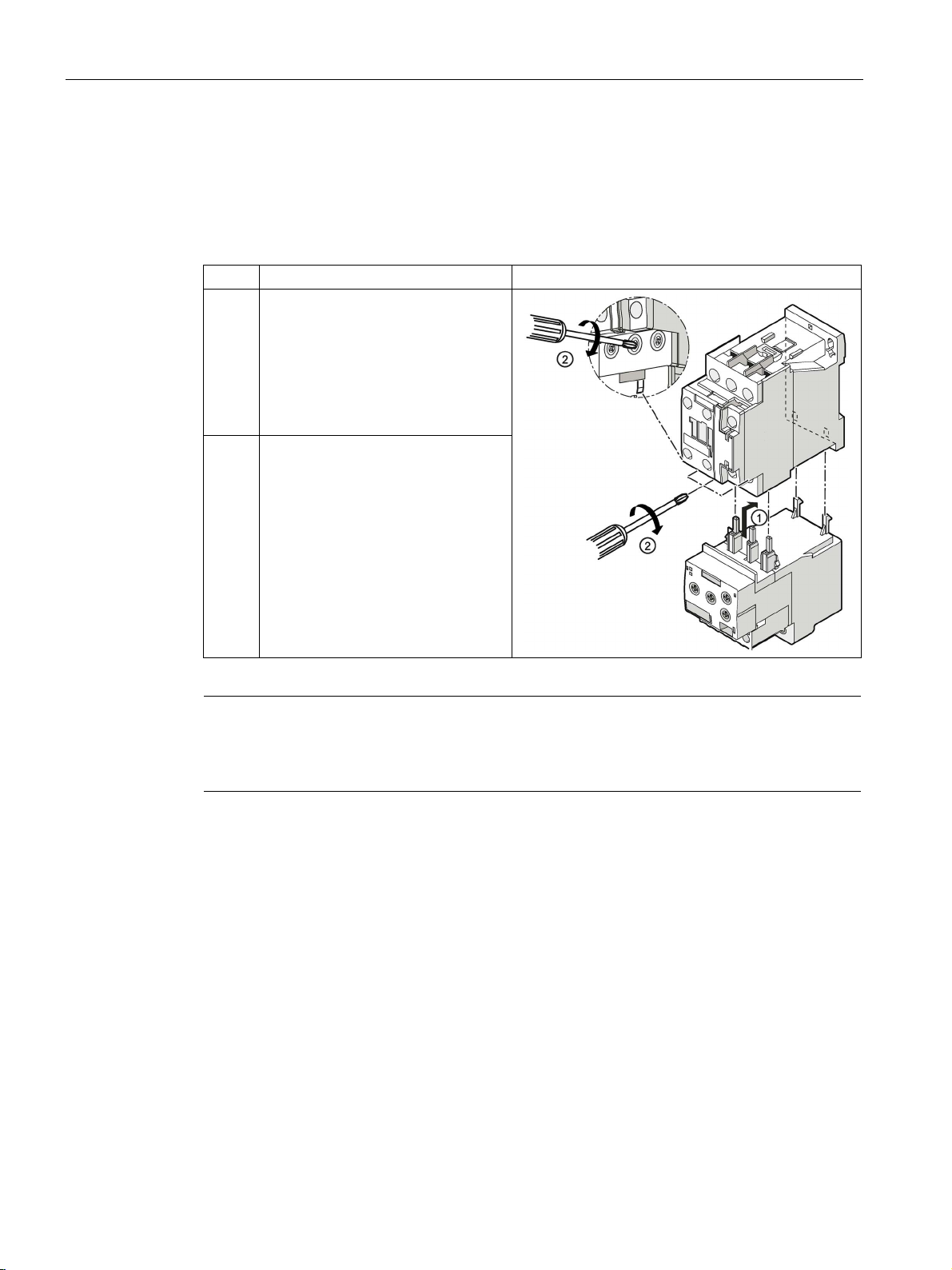

Direct mounting on 3RT2 contactor / 3RF34 (size S0) solid-state contactor

Step

Instructions

Figure

contactor.

Note

The connection cross

with screw

(Page

3.4 Mounting / removal

The diagram below shows an example mounting scenario based on mounting the

3RR21 analog setting current monitoring relay, size S0, on the 3RT2 contactor.

Table 3- 7 Mounting of 3RR2 current monitoring relay, screw-type connection system (size S0)

1 Push the current monitoring relay into

the contactor from below. Attach the

two hooks on the current monitoring

relay to the two openings on the rear

of the contactor. This pushes the

main current contacts into the

corresponding terminals on the

2 Tighten the screws on the contactor

with a Pozidriv size 2 (S00) or

Pozidriv size 3 (S0) screwdriver

(tightening torque 0.8 ... 1.2 Nm).

Check that the cable is clamped tight.

-sections of the removable and permanently connected terminal blocks

-type connections are described in the Chapter "Screw-type connection

21)".

3UG4 / 3RR2 monitoring relays

30 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 31

System overview

Step

Instructions

Figure

tabs (zoom view) are inserted into the

Main conductor terminal on the contactor (a)

(S00):

Main conductor terminal on the contactor (a)

(S0):

Note

Adapter for direct mounting on 3RF34 solid-state contactor

For direct mounting on a 3RF34 solid

0QA88 adapter

is required, which is attached to the solid

"SIRIUS solid state contact

(

3.4 Mounting / removal

Table 3- 8 Mounting of 3RR2 current monitoring relay, spring-loaded connection system (size S0)

1 Insert the contacts (a) into the central

opening of the spring-loaded

terminals on the contactor (see

below, a), with the contacts flush to

the right. Make sure that the guide

designated slots on the contactor.

The current monitoring relay will sit

correctly flush with the contactor on

the left- and right-hand sides.

The figures below show the openings of the main conductor terminals on the contactor (S00

and S0) into which the contacts on the current monitoring relay have to be inserted.

http://support.automation.siemens.com/WW/view/en/44362244) operating instructions.

-state contactor, an additional 3RF3900-

-state contactor. Information is provided in the

ors / solid state reversing contactors"

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

31

Page 32

System overview

Disassembly

Step

Instructions

Figure

conductor terminals.

Step

Instructions

Figure

contactor.

3.4 Mounting / removal

To disassemble the S00/S0/S2 assemblies from the DIN rail, press the contactor down and

pull it toward you.

Table 3- 9 Removing the 3RR2 current monitoring relay, screw-type connection system (size S0)

1 Undo the screws on the main

2 Pull the current monitoring relay

down and away from the contactor.

Table 3- 10 Removing the 3RR2 current monitoring relay, spring-loaded connection system (size

S00)

1 Position the screwdriver on the

current monitoring relay as shown

in the figure. Carefully dislodge the

current monitoring relay from the

2 Pull the current monitoring relay

toward you and away from the

contactor.

3UG4 / 3RR2 monitoring relays

32 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 33

System overview

Step

Instructions

Figure

terminals.

3

screwdriver

5

Swing the contactor

Separately mounted

Note

The accessories required for separate mounting are described in

support for stand

3.4 Mounting / removal

Table 3- 11 Removing the 3RR2 current monitoring relay (size S2)

1 Undo the screws on

the main conductor

2 Pull the current

monitoring relay down

and away from the

contactor

Push the release slide

4

down with a

upwards to remove it

-alone assembly (Page 324)".

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

the Chapter "Terminal

33

Page 34

System overview

3.4.2

Mounting the 3UG4 monitoring relay

Mounting position

Screw mounting

Step

Operating instruction

Image

secure the device by screwing suitable screws through the

Standard-rail mounting

Step

Operating instruction

Image

3.4 Mounting / removal

It can be mounted in any position.

The illustration below shows how to screw-mount the 3UG4 monitoring relay.

Table 3- 12 Mounting the monitoring relay (screw mounting)

1 Slide the push-in lugs into the openings on the monitoring

relay at the top and bottom, and use the screwdriver to

holes in the push-in lugs.

The illustration below shows how to mount the 3UG4 monitoring relay onto a standard rail.

Table 3- 13 Mounting the monitoring relay (mounting on and removing from standard rail)

1 Position the device on the top edge of the mounting rail

and press it down until it snaps onto the bottom edge of

the rail.

To remove the device, press it down, pushing against the

mounting springs, and swivel the device to remove it.

3UG4 / 3RR2 monitoring relays

34 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 35

System overview

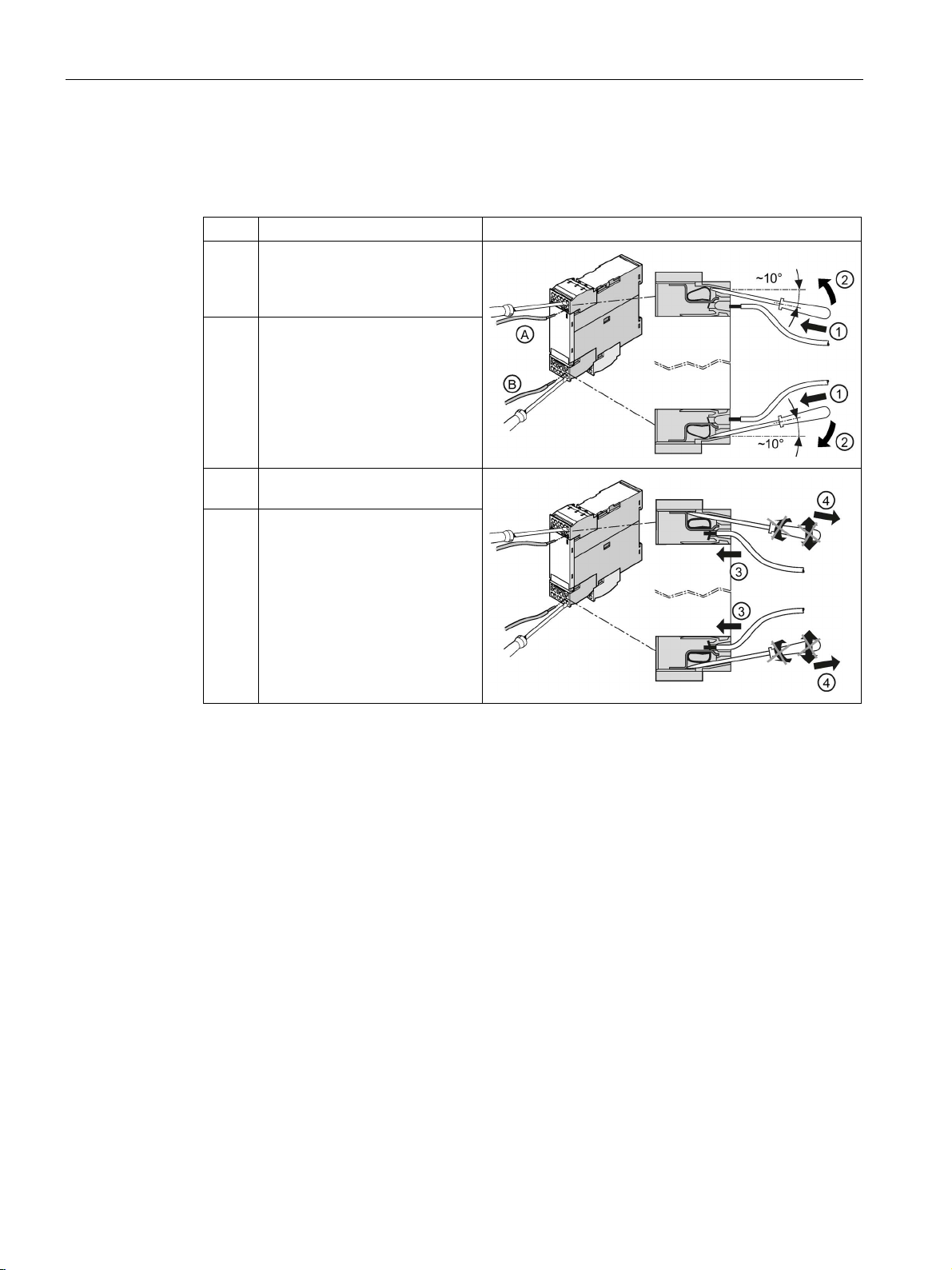

3.4.3

Installing the 3UG458. monitoring relay.

Rail mounting

Step

Instructions

Figure

DIN rail and press down until it snaps onto

Step

Instructions

Figure

spring.

3.4 Mounting / removal

The figure below shows how to install the 3UG458. insulation monitoring relay on a standard

rail.

Table 3- 14 Installing the 3UG458. insulation monitoring relay (mounting onto standard rail)

1 / 2 Position the device on the top edge of the

the bottom edge of the DIN rail.

Table 3- 15 Removing the 3UG458. insulation monitoring relay. (Removing from standard rail)

1 / 2 To remove, apply the screwdriver to the

device and push it up with a twisting

motion against the tension of the fixing

3 Swing the device upwards to remove it.

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

35

Page 36

System overview

3.5

Overview of the functions

3.5.1

3RR2 current monitoring relays

Function

Current monitoring relay

3RR21

3RR22

Current monitoring

Monitoring for undercurrent

2p

3p

Monitoring for overcurrent

2p

3p

Apparent current monitoring

✓

✓

Range monitoring

2p

3p

Monitoring for phase sequence

— ✓ Internal ground-fault detection (fault current monitoring)

—

✓

Blocking current monitoring

—

✓

Supply voltage

Self-powered, without auxiliary voltage

—

—

Externally powered, with auxiliary voltage

✓

✓

✓

2p: Monitoring is 2

3p: Monitoring is 3

— : Function not available

3.5 Overview of the functions

Table 3- 16 Functions of the 3RR21 / 3RR22 current monitoring relays for analog and digital setting

Active current monitoring — ✓

Monitoring for phase failure, wire break 2p 3p

: Function available

-phase

-phase

3UG4 / 3RR2 monitoring relays

36 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 37

System overview

3.5.2

3UG45 / 3UG46 monitoring relays

Function

Monitoring relays

3UG45

3UG46

01

11

12

13 8 14

15

16

17

18

31

32

33

21

22

41

25

51

Line monitoring and voltage monitoring

Monitoring for phase

sequence

— ✓ ✓ ✓ — ✓ ✓ ✓ ✓ ✓ — — — — — — —

—

failure

asymmetry

undervoltage

overvoltage

failure

sequence

Power factor monitoring and current monitoring

undercurrent

monitoring

monitoring

Power factor monitoring

— — — — — — — — — — — — — — — ✓ —

—

Fault current monitoring/insulation monitoring

current/ground fault

Insulation monitoring

— — — — ✓ — — — — — — — — — — — —

—

Filling level monitoring

overshoot

undershoot

3.5 Overview of the functions

Table 3- 17 Functions of the 3UG45/3UG46 monitoring relays for analog and digital setting

Monitoring for phase

Monitoring for

Monitoring for

Monitoring for

Monitoring for N

conductor

Automatic direction of

rotation correction in the

case of incorrect phase

Monitoring for

Monitoring for

overcurrent

Active current

Apparent current

— ○1) ✓ ✓ — ✓ ✓ ✓ ✓ ✓ — — — — — — — —

— — 10 % 20 % — ✓ ○2) ○2) ✓ ✓ — — — — — — — —

— — — 3p — 3p 3p 3p 3p 3p 1p 1p 1p — — — — —

— — — — — — 3p 3p 3p 3p 1p 1p 1p — — — — —

— — — — — — — ✓ — ✓ — — — — — — — —

— — — — — — — — ✓ ✓ — — — — — — — —

— — — — — — — — — — — — — 1p 1p 1p — —

— — — — — — — — — — — — — 1p 1p 1p — —

— — — — — — — — — — — — — — — ✓ — —

— — — — — — — — — — — — — ✓ ✓ — — —

Monitoring for fault

Monitoring for filling level

overshoot / resistance

Monitoring for filling level

undershoot / resistance

3UG4 / 3RR2 monitoring relays

Manual, 05/2016, NEB927043002000/RS-AC/004

— — — — — — — — — — — — — — — — ✓ —

✓ — — — — — — — — — — — — — — — — —

✓ — — — — — — — — — — — — — — — — —

37

Page 38

System overview

Function

Monitoring relays

3UG45

3UG46

01

11

12

13 8 14

15

16

17

18

31

32

33

21

22

41

25

51

Speed monitoring

undershoot

Rated control supply voltage

auxiliary voltage

auxiliary voltage

✓

1p: Monitoring is 1

3p: Monitoring is 3

—

○: Function available with limitations

1)

2)

By monitoring the voltage thresholds.

True root mean square measurement (tRMS) / use with frequency converters:

3.5 Overview of the functions

Monitoring for speed

overshoot

Monitoring for speed

Self-powered, without

Externally powered, with

: Function available

-phase

-phase

: Function not available

Detection causes problems with regenerative power recovery.

— — — — — — — — — — — — — — — — — ✓

— — — — — — — — — — — — — — — — — ✓

— ✓ ✓ ✓ — ✓ ✓ ✓ ✓ ✓ — — ✓ — — ✓ — —

✓ — — — ✓ — — — — — ✓ ✓ — ✓ ✓ — ✓ ✓

The monitoring relays work with an electronic measuring method which calculates the actual

(effective) value of a measured value (tRMS), regardless of whether the measured variable's

waveform is purely sinusoidal or distorted.

The measured signal must only meet the following requirements:

● Periodic waveform (sinusoidal) within the specified frequency range

● Continuous zero crossings

As long as the line on the primary or the secondary side in the environment of a frequency

converter fulfills these requirements, the monitoring relays can also be operated upstream or

downstream of frequency converters. The required line quality can be ensured by using line

filters/sine-wave filters where applicable. Of course, the suitability of the relevant monitoring

relay for the monitored line frequencies must also be considered.

3UG4 / 3RR2 monitoring relays

38 Manual, 05/2016, NEB927043002000/RS-AC/004

Page 39

System overview

3.6

Menu-based operation

Operator controls

3.6 Menu-based operation

The digitally adjustable monitoring relays have three keys for navigating on the menu levels:

● SET key

● 2 arrow keys

Navigation through the menu system of the monitoring relays is explained below in a

schematic diagram.

Depending on the device version and as long as no faults have occurred, one or

different measuring values

of a fault, the display indicates the type of fault

repeatedly pressing the SET key briefly, it is possible to set the desired type of monitoring

(overshoot, undershoot, or range monitoring) and parameterize the lower and/or upper

threshold

key for at least 2.5 s, in a further step, the basic device parameters