Page 1

_

_

_

_

_

_

_

_

_

_

SIMATIC HMI Fail-safe operation of the Mobile Panel 277F IWLAN

SIMATIC HMI

Fail-safe operation of the

Mobile Panel 277F IWLAN

Function Manual

No. Designation Drawing number Edition

1 Product Information A5E01005059-01 09/2008

2 Product Information A5E01004934-02 10/2008

The following supplement is part of this documentation:

Preface

Overview and definition of

terms

_____________

Safety instructions,

standards and notes

_____________

Application Planning

_____________

Configuration

_____________

System commissioning

_____________

Operation

_____________

Diagnostics

_____________

Maintenance

_____________

Technical data

_____________

Application example: Safety

Functions

_____________

1

2

3

4

5

6

7

8

9

A

Version 1.04

Order No. 6AV6691-1FQ01-2AB0

08/2008

A5E01003779-01

Page 2

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

WARNING

This device may only be used for the applications described in the catalog or the technical description and only

in connection with devices or components from other manufacturers which have been approved or

recommended by Siemens. Correct, reliable operation of the product requires proper transport, storage,

positioning and assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order-No.: 6AV6691-1FQ01-2AB0

Ⓟ 08/2008

Copyright © Siemens AG 2008.

Technical data subject to change

Page 3

Preface

Purpose of the function manual

This function manual provides all information required for operation of the Mobile

Panel 277F IWLAN in fail-safe systems.

Readership of this function manual:

● Plant designers

● Project engineers

● Commissioning engineers

● Users

● Service technicians

● Maintenance technicians

Please pay particular attention to the "Safety instructions, standards and notes" chapter.

Basic knowledge required

General knowledge in the field of automation technology, safety technology, and process

communication is a prerequisite for comprehension of this function manual.

It is also assumed that those using the manual have experience in using personal computers

and knowledge of Microsoft operating systems.

Valid scope of the function manual

The function manual covers the Mobile Panel 277F IWLAN HMI device in combination with

the software packages STEP 7 V5.4 SP2 or higher, S7 Distributed Safety V5.4 SP3 and

WinCC flexible 2007 with HSP Mobile Panel 277 Wireless.

Position in the information landscape

This function manual is part of the SIMATIC HMI documentation. The section below provides

an overview of the documentation which is relevant to applications with Mobile

Panel 277F IWLAN.

Additional documentation for Mobile Panel 277F IWLAN

● Operating instructions for Mobile Panel 277F IWLAN

● Mobile Panel IWLAN Getting Started

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

3

Page 4

Preface

Documentation for fail-safe systems

● System description "Safety technology in SIMATIC S7"

– Provides general information on the use, structure, and mode of operation of the fail-

safe automation systems S7 Distributed Safety and S7 F/FH Systems

– Contains detailed technical information which can be represented for the fail-safe

technology both in S7-300 and S7-400.

– Contains information about the calculation of monitoring and reaction times of the fail-

safe systems S7 Distributed Safety and of S7 F/FH Systems.

● "S7 Distributed Safety, Configuring and Programming" Manual / Online Help

Describes the configuration of the F-CPU and of the fail-safe I/O and the programming of

the F-CPU in F-FBD or F-LAD

● "Automation System S7-400, CPU Data" Reference Manual

Describes the standard functions of CPU 416F-3 PN/DP, CPU 414-3 PN/DP and

CPU 416-3 PN/DP

● "Automation System S7-300, CPU Data" Reference Manual

Describes the standard functions of CPU 315F-2 PN/DP, CPU 317F-2 PN/DP,

CPU 315-2 PN/DP and CPU 317-2 PN/DP

User manuals

Getting started

● WinCC flexible Compact/ Standard/ Advanced

Describes basic principles of configuration using the WinCC flexible Compact

Engineering System/WinCC flexible Standard/WinCC flexible Advanced.

● WinCC flexible Runtime

Describes how to commission and operate your runtime project on a PC.

● Communication

– Communication Part 1 describes the connection of the HMI device to SIMATIC PLCs.

– Communication Part 2 describes the connection of the HMI device to third-party PLCs.

● WinCC flexible for first time users

Based on an example project, this is a step-by-step introduction to the basics of

configuring screens, alarms, recipes and screen navigation.

● WinCC flexible for power users

Based on an example project, this is a step-by-step introduction to the basics of

configuring logs, project reports, scripts, user management, multilingual projects and

integration in STEP 7.

● WinCC flexible options

Based on an example project, this is a step-by-step introduction to the basics of

configuring the WinCC flexible Sm@rtServices, Sm@rtAccess and OPC server options.

Fail-safe operation of the Mobile Panel 277F IWLAN

4 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 5

Preface

Online availability

The link below guides you to the multilingual technical documentation offered for the

SIMATIC products and systems.

http://www.automation.siemens.com/simatic/portal/html_76/techdoku.htm"

"

Screens

The HMI device is sometimes represented in the form of photographs in this function

manual. The photographs of the HMI device may differ slightly from the factory state of the

HMI device.

Conventions

Configuration and runtime software differ with regard to their names as follows:

● "WinCC flexible 2007" for example, refers to the configuration software.

The term "WinCC flexible" is used in a general context. The full name, for example

"WinCC flexible 2007", is always used when it is necessary to differentiate between

different versions of the configuration software.

● "WinCC flexible Runtime" refers to the runtime software that can run on HMI devices.

Trademarks

The following text notation facilitates the reading of this function manual:

Notation Scope

"Add screen"

"File > Edit" Operational sequences, for example menu commands, shortcut

<F1>, <Alt+P> Keyboard operation

• Terminology that appears in the user interface, for example

dialog names, tabs, buttons, menu commands

• Inputs required, for example limit values, tag values

• Path information

menu commands.

Please observe notes labeled as follows:

Note

Notes contain important information concerning the product, its use or a specific section of

the documentation to which you should pay particular attention.

Names labeled with a ® symbol are registered trademarks of the Siemens AG. Other names

used in this documentation may be trademarks, the use of which by third parties for their

own purposes could violate the rights of the owner.

®

● HMI

● SIMATIC

● SIMATIC HMI

● SIMATIC ProTool

● SIMATIC WinCC

®

®

®

®

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

5

Page 6

Preface

Representatives and offices

If you have any further questions relating to the products described in this manual, please

contact your local representative at the Siemens branch nearest you.

Your Siemens representative can be found at "http://www.automation.siemens.com/partner

Training center

Siemens AG offers a variety of training courses to familiarize you with automation systems.

Please contact your regional training center, or our central training center in 90327

Nuremberg, Germany, for details.

Internet: "http://www.sitrain.com

Technical support

You can contact Technical Support as follows:

Using the support request form on the web at:

"http://www.siemens.com/automation/support-request

Further information about our technical support is available on the Internet at

"http://www.siemens.com/automation/service

Service & Support on the Internet

Service & Support provides additional comprehensive information on SIMATIC products

through online services at "http://www.siemens.com/automation/support

● The newsletter offers you the latest information about your products

".

"

"

".

":

● A large document base is available using our Service & Support search engine

● A forum for global exchange of information by users and experts

● Current product information, FAQs and downloads

● Your local Automation & Drives representative

● Information about on-site services, repairs, spare parts, and more

Fail-safe operation of the Mobile Panel 277F IWLAN

6 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 7

Table of contents

Preface ......................................................................................................................................................

1 Overview and definition of terms..............................................................................................................

1.1 Using the Mobile Panel 277F IWLAN ..........................................................................................

1.2 Areas in the plant .........................................................................................................................

1.3 Switch-off behavior ......................................................................................................................

1.4 Integration and segregation .........................................................................................................

1.5 Log on and log off at the effective range .....................................................................................

1.6 Safety-oriented operator controls.................................................................................................

1.6.1 Emergency stop button................................................................................................................

1.6.2 Enabling button ............................................................................................................................

1.7 "Override" mode...........................................................................................................................

2 Safety instructions, standards and notes .................................................................................................

2.1 Safety instructions........................................................................................................................

2.2 Guidelines, standards, certificates and approvals .......................................................................

2.3 Operating safety...........................................................................................................................

2.4 Power supply................................................................................................................................

2.5 Notes about usage.......................................................................................................................

2.6 Risk analysis ................................................................................................................................

3

11

11

12

16

18

19

20

20

22

24

27

27

30

33

34

36

37

2.7 Safety functions of the emergency stop button............................................................................

2.8 Safety functions of the enabling button........................................................................................

3 Application Planning ................................................................................................................................

3.1 Check list: Planning the application .............................................................................................

3.2 Application and ambient conditions .............................................................................................

3.3 Check list: Planning the system ...................................................................................................

3.4 Planning effective ranges.............................................................................................................

3.5 For the "Override" mode: Planning the protective devices ..........................................................

3.6 Check list: Data security ..............................................................................................................

4 Configuration ...........................................................................................................................................

4.1 Check list: Configuration ..............................................................................................................

4.2 Procedure for configuration..........................................................................................................

4.3 STEP 7: HW Config .....................................................................................................................

4.3.1 Integrating the GSD file in STEP 7 ..............................................................................................

4.3.2 Assigning parameters for communication between the HMI device and the controller...............

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

37

39

41

41

42

45

46

49

50

53

53

53

55

55

55

7

Page 8

Table of contents

4.4 S7 Distributed Safety .................................................................................................................. 58

4.4.1 Checklist: Creation of the safety program...................................................................................

4.4.2 Using F-FBs ................................................................................................................................

4.4.3 FB161: Mobile Panel Status (F_FB_MP) ....................................................................................

59

60

63

4.4.4 FB162: Effective range for 4 Mobile Panel (F_FB_RNG_4) / FB 163 Effective range for 16

Mobile Panel (F_FB_RNG_16)....................................................................................................

67

4.5 WinCC flexible.............................................................................................................................

4.5.1 Configuration overview................................................................................................................

4.5.2 Effective ranges editor ................................................................................................................

4.5.3 Objects for the Mobile Panel 277F IWLAN .................................................................................

5 System commissioning............................................................................................................................

5.1 Acceptance of the system...........................................................................................................

5.2 Accepting effective ranges and transponders.............................................................................

6 Operation.................................................................................................................................................

6.1 Organizational measures ............................................................................................................

6.2 Typical applications.....................................................................................................................

6.2.1 Overview .....................................................................................................................................

6.2.2 Switch on the HMI device............................................................................................................

6.2.3 Integrating and segregating the HMI device ...............................................................................

6.2.3.1 Integrating the HMI device (start project)....................................................................................

6.2.3.2 Communication error for the integrated HMI device ...................................................................

6.2.3.3 Discrepancy error during enabling ..............................................................................................

6.2.3.4 Segregate....................................................................................................................................

6.2.4 Log on and log off at the effective range.....................................................................................

6.2.4.1 Detecting the effective range ......................................................................................................

6.2.4.2 Log on at the effective range ......................................................................................................

6.2.4.3 Log off at the effective range ......................................................................................................

6.2.5 Behavior in the effective rage .....................................................................................................

6.2.5.1 Exiting the effective range without log off ...................................................................................

6.2.6 "Override" mode..........................................................................................................................

6.2.6.1 Activating "override" mode..........................................................................................................

6.2.6.2 Terminating "override" mode.......................................................................................................

6.2.7 Special operating conditions .......................................................................................................

6.2.7.1 Internal error................................................................................................................................

6.2.7.2 Communication error with the HMI device logged on in the effective range ..............................

72

72

73

73

77

77

79

83

83

84

84

85

86

86

87

88

90

91

91

92

93

94

94

95

95

96

97

97

98

7 Diagnostics..............................................................................................................................................

7.1 Alarm messages .........................................................................................................................

7.2 Diagnostics................................................................................................................................

8 Maintenance..........................................................................................................................................

8.1 Function tests............................................................................................................................

8.2 Maintenance cycles...................................................................................................................

8.3 Cleaning, repairs and spare parts.............................................................................................

9 Technical data .......................................................................................................................................

9.1 Technical data for fail-safe operation........................................................................................

9.2 HMI device ................................................................................................................................

9.3 Charging station ........................................................................................................................

Fail-safe operation of the Mobile Panel 277F IWLAN

99

99

101

105

105

105

106

109

109

111

112

8 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 9

Table of contents

A Application example: Safety Functions.................................................................................................. 113

A.1 Configuration and operation.......................................................................................................

A.2 Components and settings used .................................................................................................

A.3 Safety program S7 Distributed Safety .......................................................................................

Index......................................................................................................................................................

113

116

121

127

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

9

Page 10

Table of contents

Fail-safe operation of the Mobile Panel 277F IWLAN

10 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 11

Overview and definition of terms

1.1 Using the Mobile Panel 277F IWLAN

Use

The Mobile Panel 277F IWLAN offers the possibility of having the mobile safety functions of

emergency stop and enable available at any point of a machine or plant. An effective range

limit has been implemented for the Mobile Panel 277F IWLAN. Depending on his location,

the operator obtains a safe, electronically monitored operator control enable.

The HMI device communicates with an access point via WLAN. Thus the operator can

operate the various machines or process cells without bothersome cable. The HMI device is

connected via the access point with a PROFINET network in which it communicates with an

F-CPU via the PROFIsafe protocol.

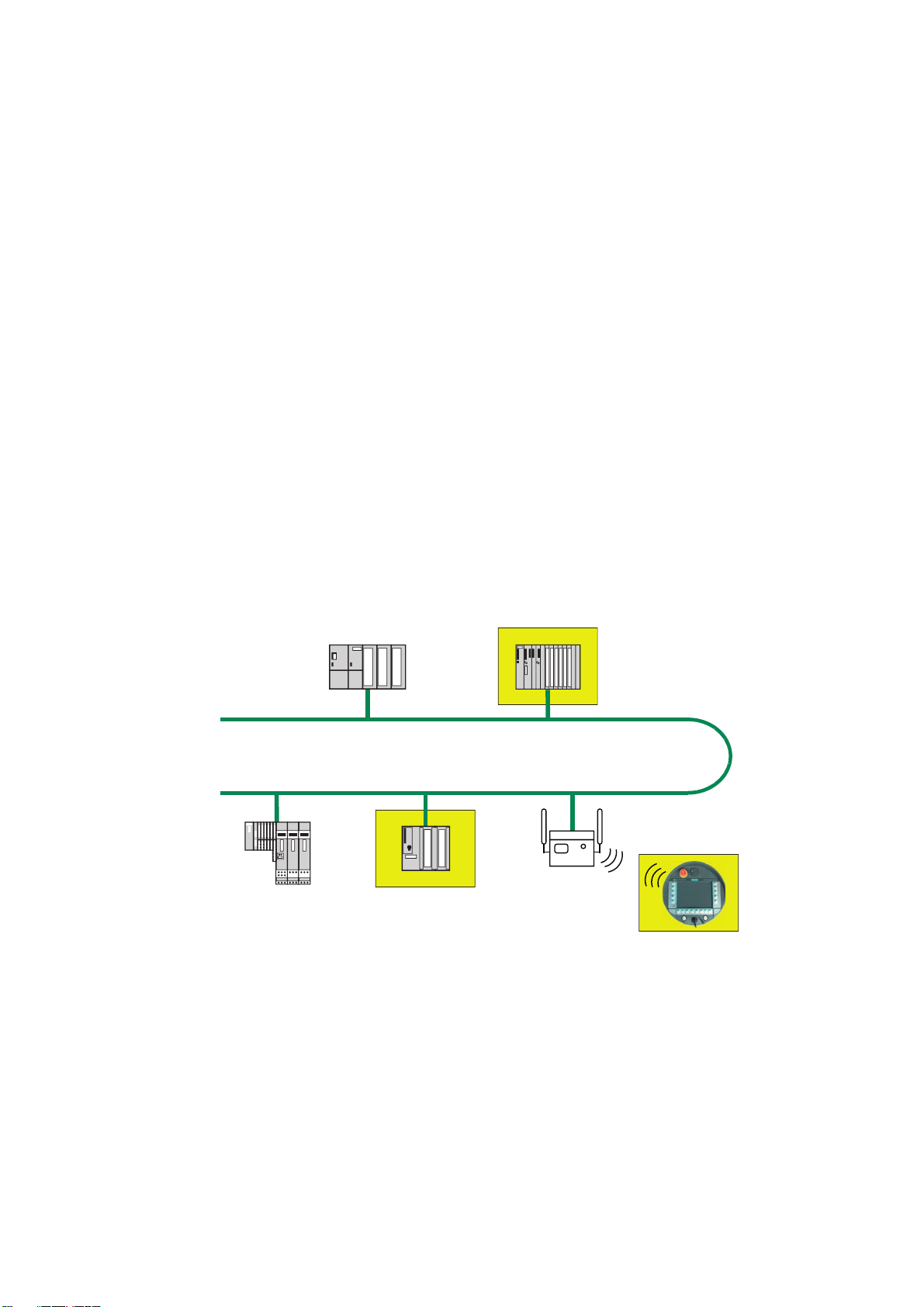

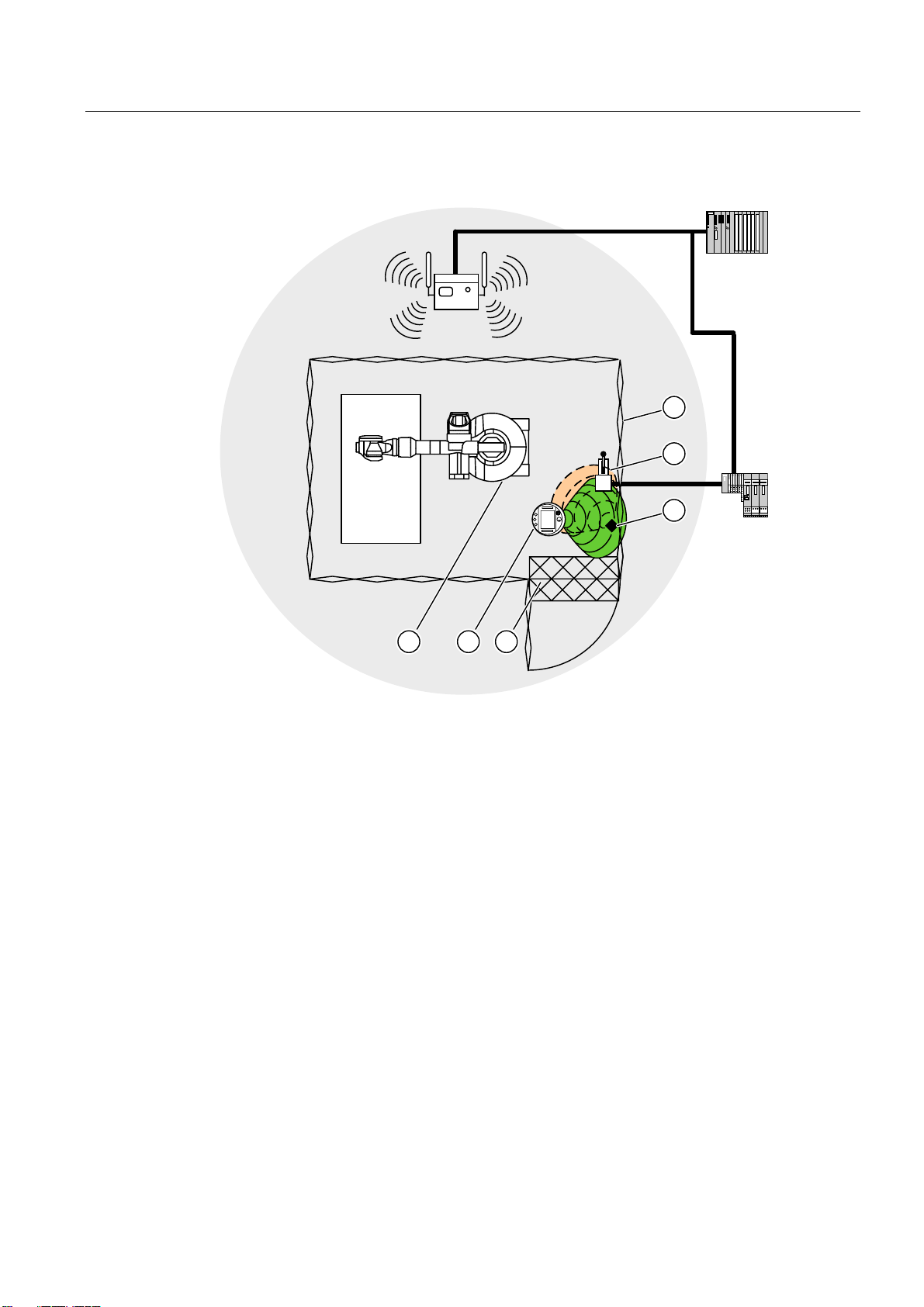

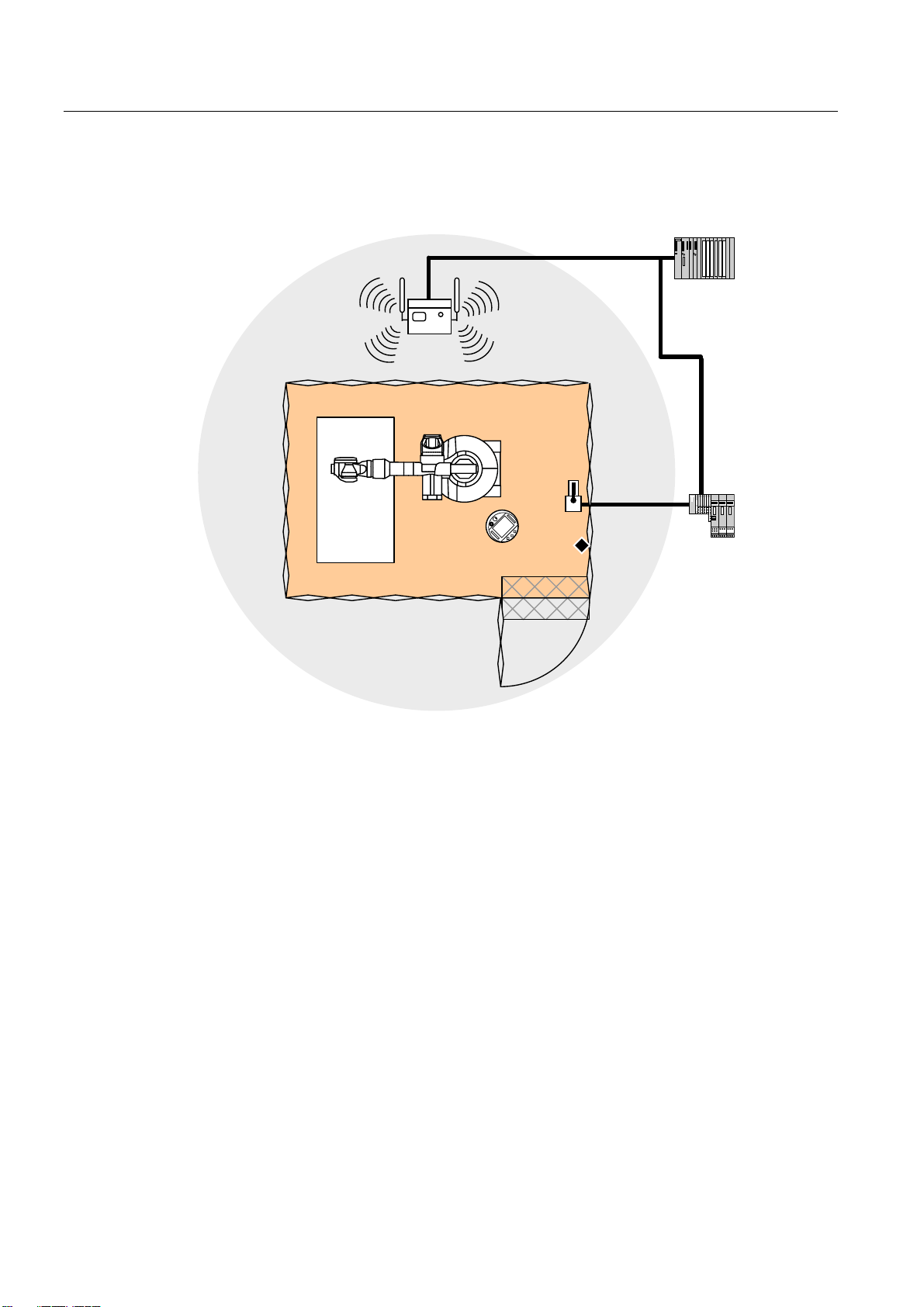

Sample installation - F-system with Mobile Panel 277F IWLAN

6,0$7,&6)31'3DV

352),1(7,2FRQWUROOHU

6

1

Basic terms

352),1(7

6&$/$1&(

(76

In the depicted configuration, each PROFINET IO device communicates with a single

PROFINET IO controller. In this example the Mobile Panel 277F IWLAN communicates

exclusively with the F-CPU as F-PROFINET IO controller.

In the following chapters several basic terms are explained that you must learn before you

use the HMI device.

)DLOVDIH,2DV

352),1(7,2GHYLFH

$FFHVV3RLQW

0RELOH3DQHO),:/$1

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

11

Page 12

Overview and definition of terms

1.2 Areas in the plant

1.2 Areas in the plant

WLAN area

The WLAN area is the area in the plant where the HMI device communicates with other

communication nodes over a wireless local area network.

352),VDIH

① Access point is the network transition from WLAN to LAN

② WLAN area in which communication with the access point is possible

③ Mobile panel in the WLAN area; the emergency stop button is active, the enabling buttons are

without function.

When the PROFIsafe communication between the controller and operator panel is

established in the WLAN area, the emergency stop button on the HMI device becomes

active.

Safe operation of the plant with the enabling buttons only becomes possible when the HMI

device is logged on in an effective range within the WLAN area.

Fail-safe operation of the Mobile Panel 277F IWLAN

12 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 13

Overview and definition of terms

1.2 Areas in the plant

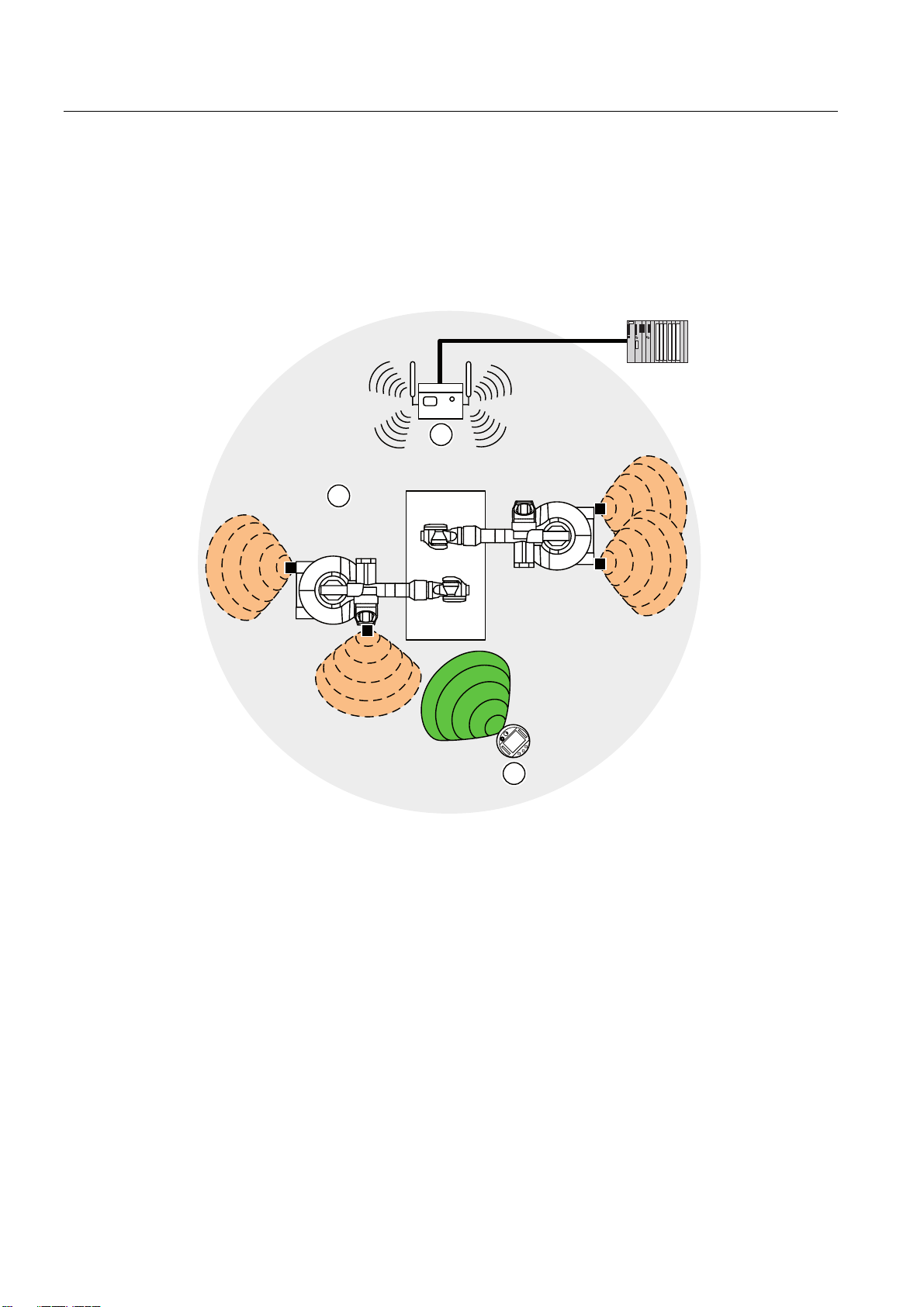

Effective range

An effective range is the range in which sections of the plant, e.g. a machine can be

operated with the enabling buttons of the HMI device. An effective range is formed physically

with transponders that are mounted in the vicinity of the machine. Each transponder has a

unique ID. The transponder emits this ID in a lobe-shaped area. The ID is received by the

HMI device, which enables the HMI device to determine its distance from the transponder.

Additional information about the transponders is provided in the chapter

ranges (Page

46) and in the operating instructions for the HMI device.

352),VDIH

Planning effective

① Effective range 1, formed by a transponder

② Effective range 2, formed by two transponders

③ The mobile panel is located in effective range 3. The emergency stop button is active The

enabling buttons are active after logon in the effective range.

When the HMI device detects that it is within an effective range the operator can log the HMI

device on at the effective range. Safe operation of the plant unit delimited by the effective

range is only possible after successful connection.

Effective ranges should not overlap.

All effective ranges available in the plant are stored in the project. The effective ranges are

verified in the acceptance procedure for the plant.

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

13

Page 14

Overview and definition of terms

1.2 Areas in the plant

Note

In addition to the effective ranges you can define zones in your project. The zones are not

relevant for fail-safe operation. They are used merely to control the project depending on the

location of the operator. For example a picture change can be configured for zone entry or

zone exit.

Zones and effective range are independent of each other.

Additional information on zones is provided in the Operating instructions for the HMI device.

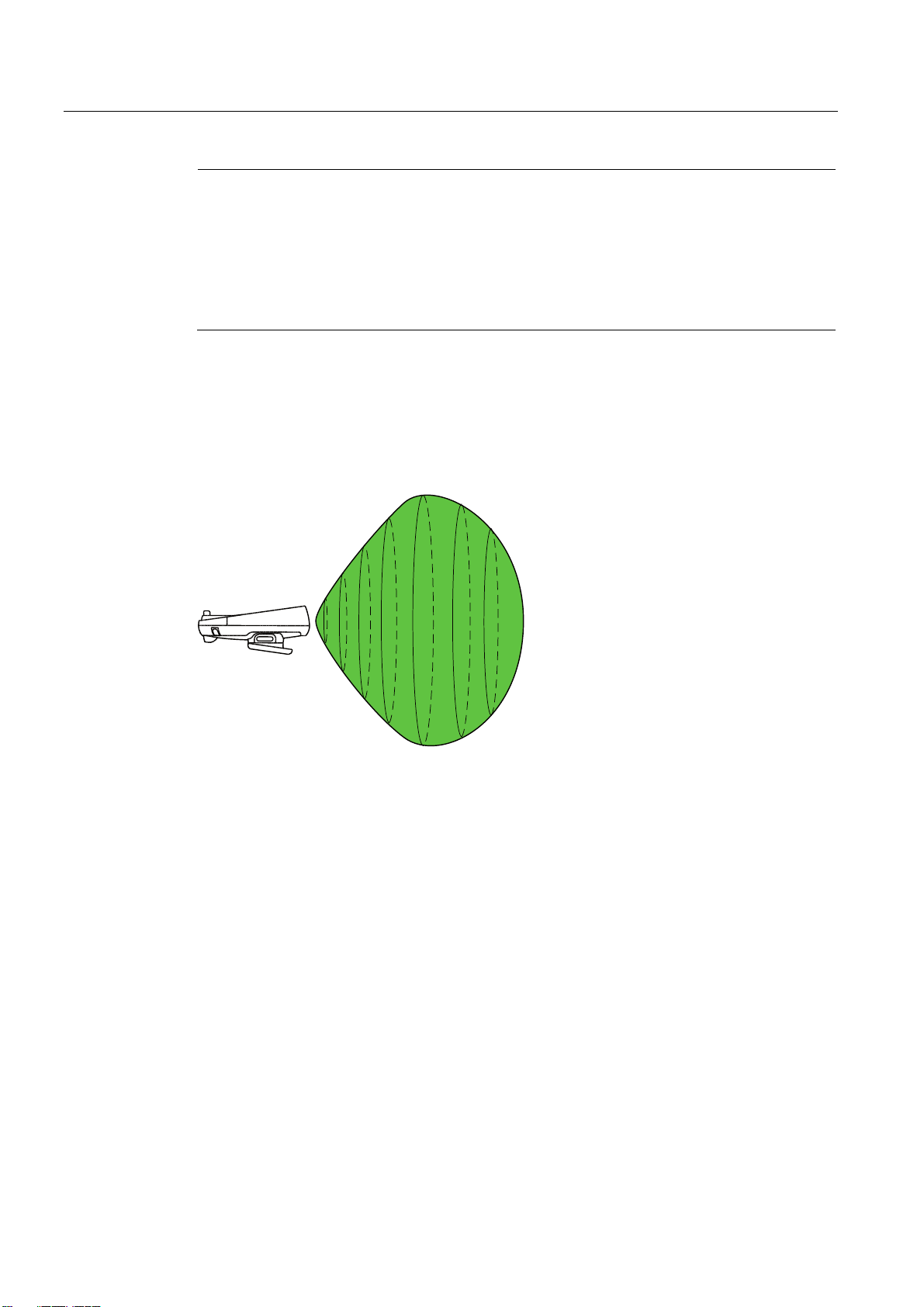

Distance measurement between HMI device and transponder

The transmitting range of the transponder and the receiving range of the HMI device have

the approximate shape of a lobe with a range of approximately 8 m.

The detailed representation of the radiation characteristics of HMI device and transponder is

provided in the appendix of the Operating instructions.

A distance measurement between HMI device and transponder is only possible if both

devices are in range of each other. The following table shows when a distance measurement

is successful.

Fail-safe operation of the Mobile Panel 277F IWLAN

14 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 15

Overview and definition of terms

1.2 Areas in the plant

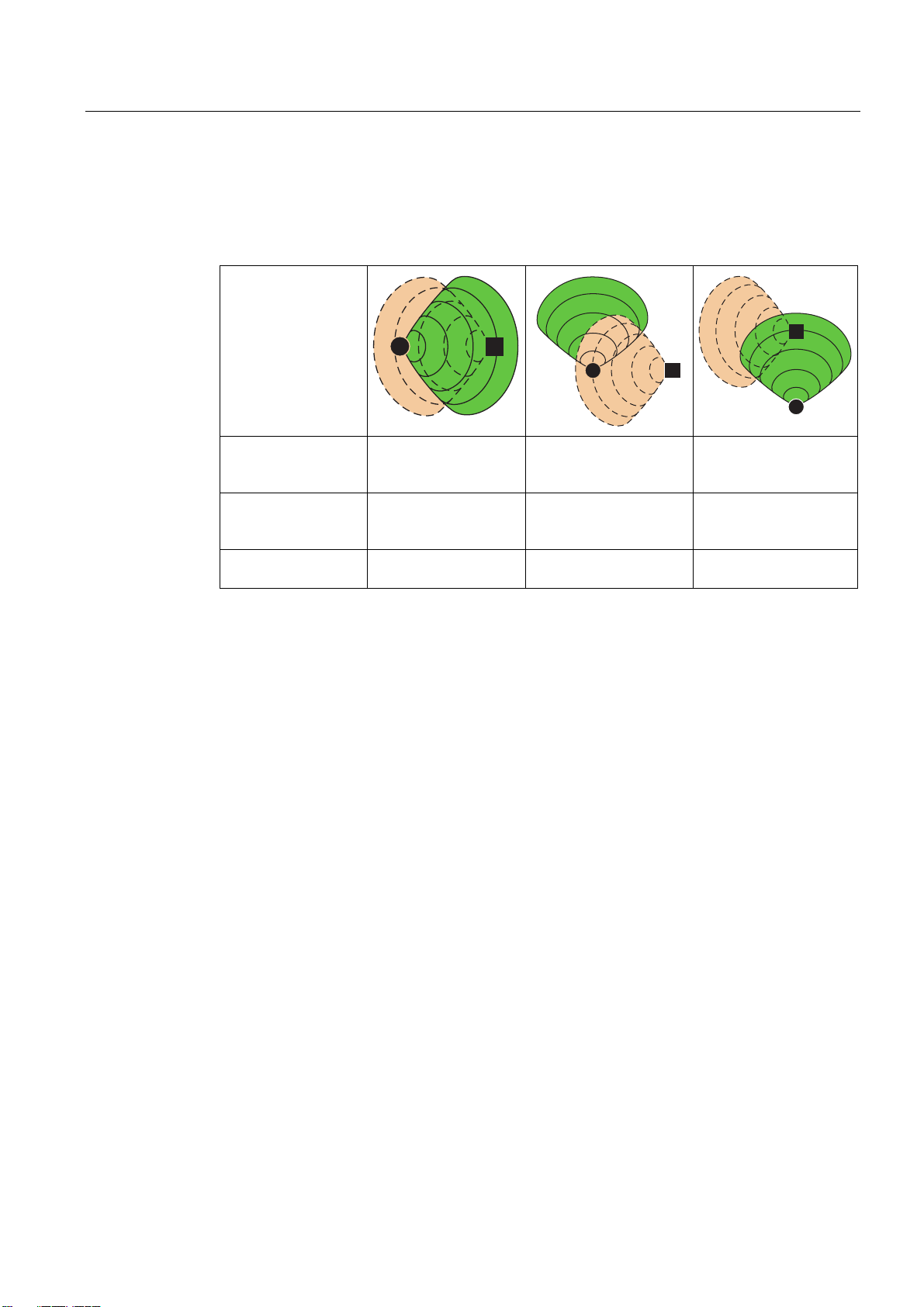

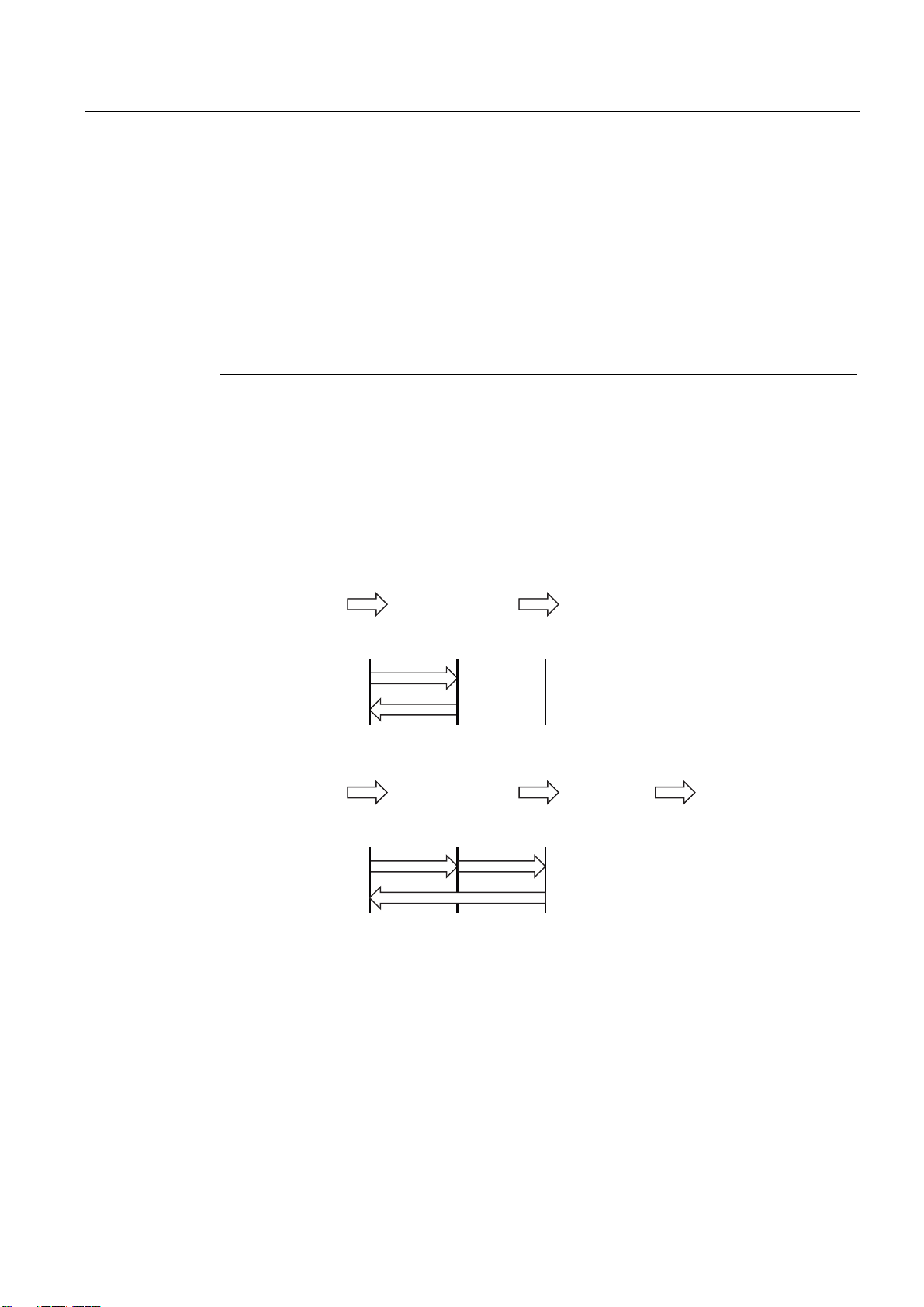

In the figures the HMI device and transponder are represented as follows:

● The HMI device as circle

● The transponder as square

See also

HMI device in the

transmitting range of

the transponder

Transponder in the

receiving range of the

HMI device

Result Successful distance

Yes Yes No

Yes No Yes

measurement

Distance measurement

not possible

Distance measurement

not possible

The distance measurement is executed in the following manner:

● The HMI device emits signals in the current project.

● The transponder reacts to the signal from the HMI device and transmits its ID to the HMI

device.

● The HMI device evaluates the ID and only measures the distance to the configured

transponders.

Integration and segregation (Page 18)

Planning effective ranges (Page 46)

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

15

Page 16

Overview and definition of terms

1.3 Switch-off behavior

1.3 Switch-off behavior

Introduction

Different switch-off behavior is possible depending on the situation in the plant:

● Emergency stop

● Shutdown

● Local rampdown.

● Global rampdown

Emergency stop

Shutdown

Plant switch-off differs in its triggers and effects.

DANGER

No switch off triggering

In the plant the described switch-off behavior is only triggered if the F-CPU has been

programmed accordingly.

The operator triggers the emergency stop by pressing the emergency stop button.

Emergency stop is a procedure in response to an emergency that is intended to stop a

process or movement that could result in danger (from EN 60204-1 Appendix D).

The emergency stop immediately stops all machines that are assigned to the F-CPU via the

safety program.

The emergency stop depends on the effective ranges.

The emergency stop button is always active if there is PROFIsafe communication between

HMI device and F-CPU, i.e. if the HMI device is integrated in the PROFIsafe communication.

Shutdown is triggered if the F-CPU detects a communication error on an HMI device which is

logged on in the effective range.

Shutdown is the immediate stopping of the machines which belong to the effective range.

The shutdown is always specific to the effective range.

Local rampdown.

Local rampdown is triggered if the HMI device is logged on at the effective range and if it is

removed from the effective range for longer than 30 seconds.

Local rampdown is the defined shutdown of the machines belonging to the effective range

within a defined time period.

Local rampdown is always specific to the effective range.

Fail-safe operation of the Mobile Panel 277F IWLAN

16 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 17

Overview and definition of terms

1.3 Switch-off behavior

Global rampdown

Global rampdown is triggered if the F-CPU detects a communication error on an HMI device

which is integrated in the PROFIsafe communication.

Global rampdown is the defined shutdown of the machines assigned in the safety program

within a defined time period.

Global rampdown is independent of the effective ranges.

In the safety program of the F-CPU, ensure that global rampdown is available in the event

that a communication error occurs on an HMI device which is integrated in the PROFIsafe

communication.

Trigger

The switch off can have the following triggers:

● The operator presses the emergency stop button.

● A communication error occurs.

● Timeout: The HMI device is logged on at the effective range and the operator leaves the

effective range with his HMI device for longer than 30 seconds.

Triggering the switch off

The following table shows the effect of the different triggers depending on the operating

situation:

Trigger Operating situation

Emergency stop

pressed

HMI not integrated --- --- --HMI

integrated

HMI device logged on

at the effective range

HMI device is logged off from the effective range Emergency stop Global

HMI device is in the

effective range

HMI device is outside of the

effective range for less than

30 seconds

HMI device is outside of the

effective range for longer

than 30 seconds

Emergency stop Shutdown ---

Emergency stop Shutdown ---

Emergency stop Shutdown Local

Communication

error

rampdown

Timeout

rampdown.

---

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

17

Page 18

Overview and definition of terms

1.4 Integration and segregation

1.4 Integration and segregation

Introduction

In fail-safe operation a safety program runs in the F-CPU. This safety program

communicates with the HMI device. The F-CPU monitors this communication for errors and

analyzes the signals. The terms "integrate" and "segregate" refer to the integration and

segregation of the HMI device in/from the safety program of the F-CPU.

Integrate

If the HMI device is configured for the safety program then when the HMI device starts it is

automatically integrated in the safety program. The integration process is concluded as soon

as the LED"SAFE" is illuminated.

The emergency stop button is active as soon as the HMI device is integrated.

Segregation

Segregation means the desired segregation of the HMI device from the safety program.

See also

The operator has the following alternatives for segregating the HMI device:

● The operator terminates the project.

● The operator presses the ON/OFF button for longer than 4 seconds. After the

segregation process the HMI device switches off.

When the operator segregates the HMI device there are no side effects, e.g. a global

rampdown. When the segregation process is terminated the LED "SAFE" and the

emergency stop button are no longer active.

Safety functions of the emergency stop button (Page 37)

Fail-safe operation of the Mobile Panel 277F IWLAN

18 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 19

Overview and definition of terms

1.5 Log on and log off at the effective range

1.5 Log on and log off at the effective range

Introduction

An effective range is the range within which plant units, e.g. a machine, can be operated with

the enabling buttons of the HMI device. The prerequisite for this is that the operator must log

the HMI device on at the effective range.

Logging on at the effective range

If the operator enters an effective range with the HMI device the system shows that he can

log the HMI device on at the effective range via the "Effective range name" object.

To log on he touches the "Effective range name" object. Then he reads the effective range

ID in the plant and enters this ID in the ""Effective range logon" dialog box.

If the entered effective range ID agrees with the configured ID then the HMI device is logged

on.

When the HMI device is logged on the enabling buttons are active.

The system alerts the operator that the HMI device is logged on at the effective range in the

following manner:

● The LED "RNG" is illuminated.

● The "Effective range name" object is displayed in green.

● In the process cell the indicator for the effective range is active, e.g. a lamp.

When the HMI device is logged on at the effective range the following rules apply:

● The operator should not leave the effective range without logging off. Local rampdown

occurs if the operator leaves the effective range for longer than 30 seconds without

logging off.

● No other HMI device can log on at this effective range.

Log off at the effective range

Before the operator exits the effective range at which the HMI device is logged on, he must

log off from the effective range. To log off he touches the "Effective range name" object and

edits the dialog box ""Effective range logoff".

When the HMI device is logged off the enabling buttons are no longer active. The

LED "RNG" is not illuminated.

See also

Log on and log off at the effective range (Page 91)

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

19

Page 20

Overview and definition of terms

1.6 Safety-oriented operator controls

1.6 Safety-oriented operator controls

Introduction

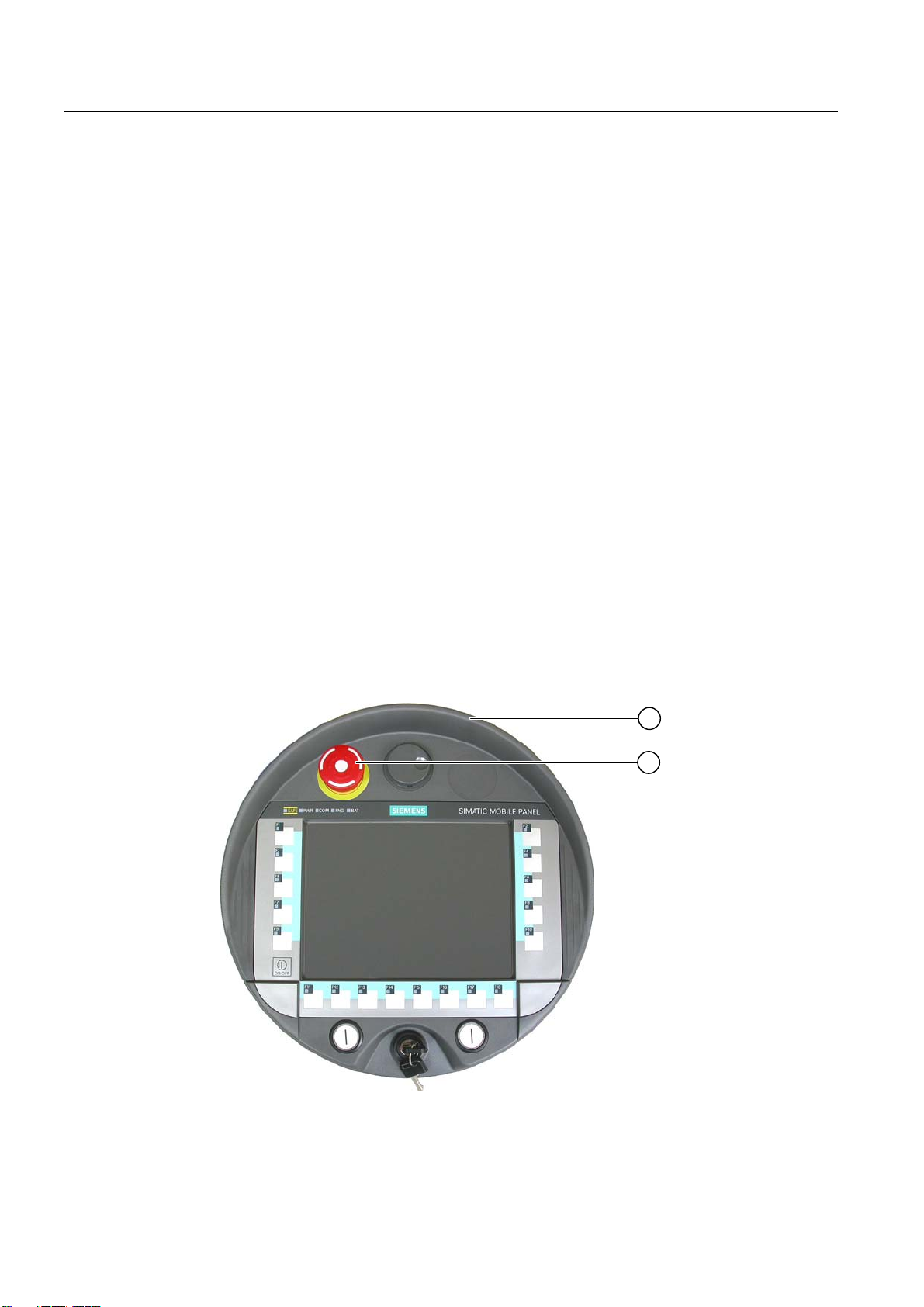

The Mobile Panel 277F IWLAN has the following elements for safe operation of a process

cell:

● Emergency stop button

● Enabling button

1.6.1 Emergency stop button

Introduction

The emergency stop button is designed with 2-channels and enables an emergency stop of

the configured system.

The emergency stop button satisfies the requirements specified in DIN IEC 60947-5-5;1997

Annex K.

For additional safety instructions please refer to the chapter, Safety instructions, standards

and notes.

When using the emergency stop button the following F-FBs must be linked in the safety

program of the F-CPU:

● F_FB_MP

● F_FB_RNG_n

① Fall protection

② Emergency stop button

Fail-safe operation of the Mobile Panel 277F IWLAN

20 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 21

Overview and definition of terms

1.6 Safety-oriented operator controls

Due to its position, the emergency stop button is equally accessible for both left-handed and

right-handed individuals.

Due to its profiled design, the emergency stop button is easily accessible. A collared

enclosure is used to protect the operator controls against damage. This applies in particular

to the emergency stop button The emergency stop button may still trigger if the HMI device

falls and hits the floor.

Operation

The operator triggers the emergency stop by pressing the emergency stop button. The

emergency stop button engages in the emergency stop position.

Releasing the emergency stop button

See also

WARNING

If you have activated the emergency stop button and thereby brought the configured

system to a standstill, the emergency stop button should only be released under the

following conditions:

• The reasons for the emergency stop have been eliminated.

• A safe restart is possible.

• The restart should not be executed by releasing the emergency stop button.

The operator must strictly ensure that he executes a separate operator action to

commence the restart. The safety program must ensure that release of the emergency

stop button alone does not trigger an automatic restart of the system.

In order to release the emergency stop button, turn it in a clockwise direction. The

emergency stop button then returns on its own to the initial position.

Safety functions of the emergency stop button (Page 37)

S7 Distributed Safety (Page 58)

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

21

Page 22

Overview and definition of terms

1.6 Safety-oriented operator controls

1.6.2 Enabling button

Introduction

The enabling device consists of the two enabling buttons mounted on both sides of the

Mobile Panel 277F IWLAN. The switch setting of the two enabling buttons is determined by

electrical momentary contact switches.

Operation

Note

The HMI device analyzes the switch settings of the two enabling buttons in the form of an

OR gate.

① Enabling button

WARNING

Unintentional enabling

Press the enabling button only until the operation you wish to enable is completed.

Enabling is a conscious operator action. It is not permissible to continuously press the

enabling button or to fix it in any way.

The following happens if you leave the effective range for a period of up to 30 seconds with

the enabling button pressed: Enabling is revoked 5 seconds after leaving the effective

range.

If you reenter the effective range within 30 seconds, you must release the enabling button

and press it again for enabling to take effect again.

The enabling button has three switch settings:

● Neutral position: The enabling button is not pressed.

● Enable: The enabling button is pressed to a mid position. This switch setting is used to

allow another command, for example an input with the membrane keyboard.

Fail-safe operation of the Mobile Panel 277F IWLAN

22 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 23

Overview and definition of terms

1.6 Safety-oriented operator controls

● Panic: The "Panic" switch setting is reached as soon as one of the two enabling buttons

is fully pressed. The switch setting of the other enabling button is unimportant in this

case. The "Panic" switch setting has the same effect as releasing the enabling button,

namely, it revokes the enable.

You only have to activate one enabling button. The PLC gets the same signal regardless as

to whether one or two enabling buttons of the Mobile Panel 277F IWLAN have been

pressed.

Switch settings

Note

The enabling button and the membrane keyboard can be operated at the same time.

When using the enabling button the following F FBs must be linked in the safety program of

the F CPU:

● F_FB_MP

● F_FB_RNG_n

The following figure shows the switching sequence for enable.

1HXWUDOSRVLWLRQ

6ZLWFKVHWWLQJ

(%OHIW(%ULJKW

(%OHIW(%ULJKW

[ \

[

(QDEOH

\

1HXWUDOSRVLWLRQ

(%(QDEOLQJEXWWRQ

The following figure shows the switching sequence during panic usage.

1HXWUDOSRVLWLRQ

6ZLWFKVHWWLQJ

(%OHIW(%ULJKW

(%OHIW(%ULJKW

[ X

If the operator has pressed the enabling button through to the "Panic" setting, the "Enable"

setting will not be evaluated when leaving the panic setting. A new enable can only be

triggered by releasing the enabling button.

See also

Safety functions of the enabling button (Page 39)

S7 Distributed Safety (Page 58)

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

(QDEOH

[

X

\

3DQLF 1HXWUDOSRVLWLRQ

(%(QDEOLQJEXWWRQ

\

23

Page 24

Overview and definition of terms

1.7 "Override" mode

1.7 "Override" mode

Introduction

The effective range functionality of the HMI device can be extended through the "override"

mode.

Applications

"Override" mode can be used in the following cases:

● Use of existing protective measures instead of the effective range functionality

If protective measures, such as protective fences are already available in your plant, then

you can integrate them in your safety concept with the "override" mode. Thus you achieve

a consistent concept for safe plant operation.

● If plant units, which do not allow themselves transponder coverage, (such as inside a

robot cell), will be operated with the enabling buttons.

In this case you must secure the plant area with additional protective measures, such as

a protective fence.

Requirements

Only use "override" mode in delimited plant units that are secured by additional protective

measures.

Entering and leaving the protected area must be monitored by the F-CPU.

The operator must be able to fully see the area for which "override" mode applies. The

danger location must be visible from every point of the override area.

When using the "override" mode you must install a switch within an effective range that is

independent of the HMI device. The operator activates "override" mode with this switch.

WARNING

Inadmissible activation of the "override" mode

The operator has to activate "override" mode through a conscious operator action, e.g. by

activating a switch. The "override" mode should not be automatically activated, e.g. when

the safety area is entered.

The application program in conjunction with F-FB must ensure that the "override" mode is

revoked when the area is left.

Fail-safe operation of the Mobile Panel 277F IWLAN

24 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 25

Overview and definition of terms

1.7 "Override" mode

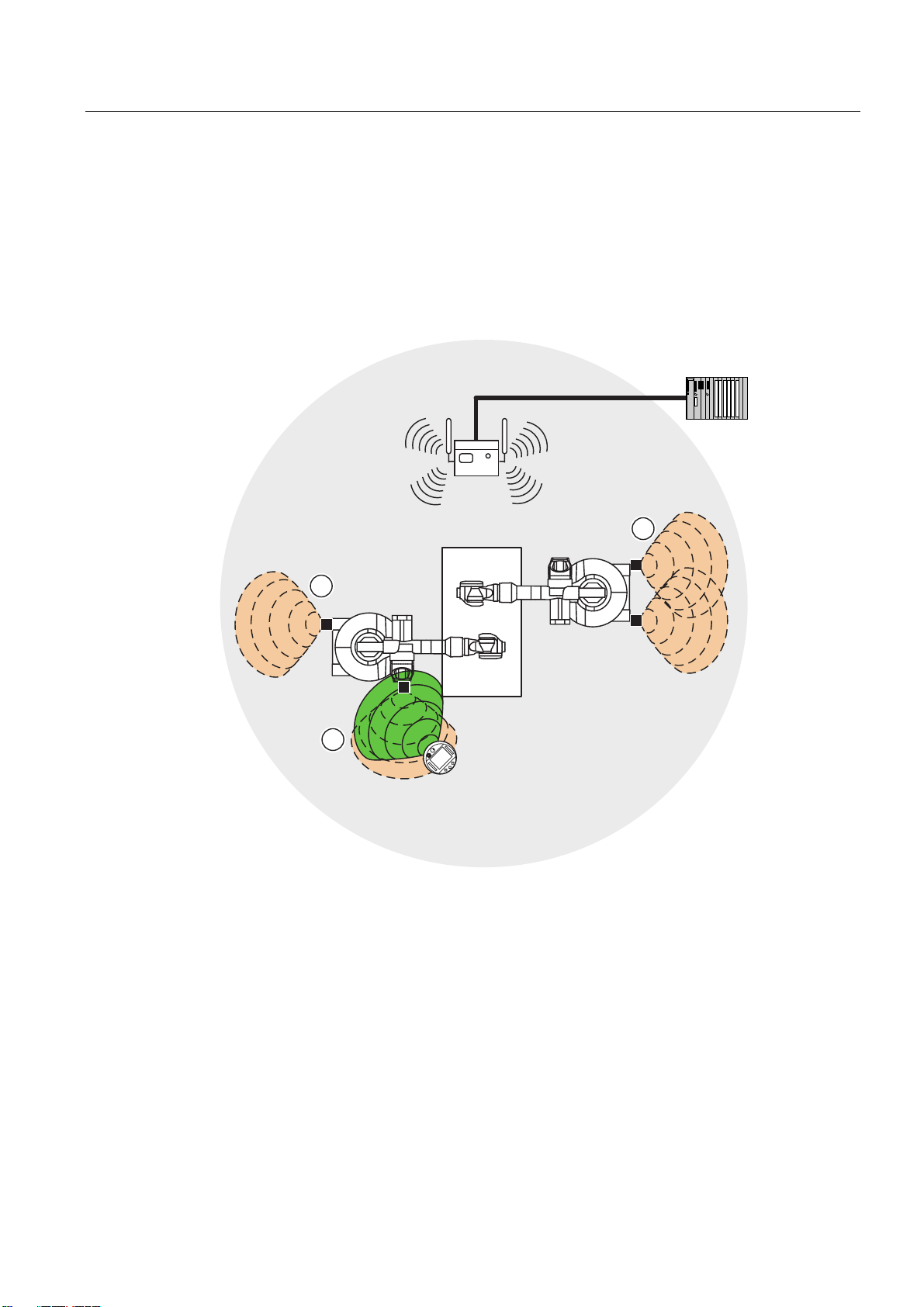

Sample configuration

352),VDIH

① Protective fence

② Switch for activating "override" mode

③ Transponder for logging on at the effective range

④ Foot grating for access monitoring

⑤ HMI device

⑥ Machine that will be operated

Activation of the "override" mode

The operator activates "Override" mode in the following manner:

1. The operator enters the protected area through a light barrier or across a foot grating.

The protective device is activated.

2. The operator logs on at the effective range in which the override switch is located.

3. The operator activates the override switch.

"Override" mode is now active until either the operator deactivates "Override" mode with the

override switch or until he leaves the protected area.

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

25

Page 26

Overview and definition of terms

1.7 "Override" mode

Operating principle

In the following figure you see the plant area for which "override" mode is active.

352),VDIH

If "override" mode is activated the operator can safely operate the associated plant area with

the enabling buttons. The HMI device is considered to be permanently logged on in the

effective range, without analyzing the transponder signals.

Deactivation of "override" mode

The operator deactivates "override" mode in the following manner:

1. The operator activates the override switch.

"Override" mode is deactivated by the safety program.

2. The operator logs off from the effective range.

Subsequent logon at this effective range is only possible if the operator has terminated

"override" mode with the override switch.

3. The operator leaves the protected area.

If the operator leaves the protected area without deactivating "override" mode, "override"

mode is deactivated by the safety program.

See also

For the "Override" mode: Planning the protective devices (Page 49)

Configuration and operation (Page 113)

Fail-safe operation of the Mobile Panel 277F IWLAN

26 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 27

Safety instructions, standards and notes

2.1 Safety instructions

Safety regulations

Configuration requirements

WARNING

Injury or material damage

Strictly observe all instructions in this document at all times. Otherwise, hazardous

situations can arise or the safety functions integrated in the HMI device can be rendered

ineffective.

Observe the safety and accident prevention instructions applicable to your application in

addition to the safety instructions given in this manual.

2

Injury or material damage

The configuration engineer for a machine or system PLC must take precautions to ensure

that an interrupted program can be restarted normally after communication errors, voltage

dips, or power failures.

Dangerous operating modes must not occur, not even temporarily, from the entire

sequence of the user program up to troubleshooting.

Proper use

Commissioning of the HMI device is forbidden until it has been absolutely ensured that the

machine which is to be operated with the HMI device complies with Directive 98/37/EC.

Fault-free operation

Interference with other systems

When using the HMI device in accordance with DIN EN 13557 you must ensure that the

HMI device does not interfere with other systems at the site, or that other systems do not

interface with the HMI device.

WARNING

WARNING

WARNING

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

27

Page 28

Safety instructions, standards and notes

2.1 Safety instructions

Safety measures during operation

WARNING

Non-functional emergency stop button

The emergency stop button must be checked annually for proper function.

WARNING

HMI device failure

After a hard impact to the HMI device, check the safety-relevant features for functional

capability, for example in the event that the HMI device is dropped.

WARNING

Danger of injury

Manual movements controlled with the HMI should only be executed in conjunction with the

enabling buttons and at reduced velocity.

WARNING

Exclusive operating right

When operating the plant with the HMI device it is not permitted to operate the plant

concurrently from a different HMI device.

Prevent concurrent operation through appropriate configuration.

High frequency radiation

WARNING

Unintentional operating situations

High-frequency radiation, for example from cellular phones, can lead to undesirable

operating situations.

Fail-safe operation of the Mobile Panel 277F IWLAN

28 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 29

Safety instructions, standards and notes

2.1 Safety instructions

Information for handling the battery:

CAUTION

Charging and discharging the battery

In the following cases, there is a risk of fire and, in extreme cases, explosion!

• Incorrect charging and discharging of the battery

• Reverse polarity

• Short-circuit

Only charge the bridging battery in the HMI device.

Only charge the main battery in the HMI device or in the charging compartment of the

charging station.

CAUTION

The battery is a lithium ion battery. The following safety notes apply to these rechargeable

batteries:

• Do not crush

• Do not expose to heat and do not burn

• Do not short-circuit

• Do not take apart

• Do not immerse in liquid – the battery might crack or burst

• Store unused batteries away from the following items, which can cause the contacts to

be bridged

– Paper clips

– Coins

– Keys

– Nails

– Screws or other small metal objects

CAUTION

Danger of injury

If used incorrectly, fluid can leak from the battery. Avoid contact with the battery fluid. If fluid

comes into contact with the skin, rinse with water.

If fluid comes into contact with the eyes, rinse with water and seek medical advice.

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

29

Page 30

Safety instructions, standards and notes

2.2 Guidelines, standards, certificates and approvals

Instructions for battery replacement in Mobile Panel 277F IWLAN

CAUTION

Local rampdown of logged on HMI device

If the HMI device which is logged on at the effective range no longer recognizes the

transponder and, therefore, the effective range, it triggers a local rampdown.

To change the battery, rest the HMI device on its front. Align the HMI device so that it is still

possible to measure the distance between the HMI device and the transponder.

If possible, log the HMI device off from the effective range.

NOTICE

Pay attention to cleanliness. Foreign bodies or liquids must not come into contact with the

printed circuit board or penetrate the inside of the HMI device.

Place the HMI device with the front side facing down on a flat, clean surface to protect

against damage.

CAUTION

Malfunctions

If the HMI device is resting on its front, the following can be activated:

• The emergency stop button

This can bring the system to a standstill unintentionally.

• The key-operated switch or an illuminated pushbutton

This can result in malfunctions.

Components and modules endangered by electrostatic discharge (ESD)

When working in the open housing, ensure that current-carrying conductors do not come

into contact with electrical circuits.

Note the ESD instructions.

2.2 Guidelines, standards, certificates and approvals

Certifications

Fail-safe operation of the Mobile Panel 277F IWLAN

30 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

CAUTION

The following overview shows possible approvals.

The only valid approvals for the HMI device, the charging station, the power supply module,

and the transponder are those shown on the label on the rear panel.

Page 31

Safety instructions, standards and notes

2.2 Guidelines, standards, certificates and approvals

CE approval

The HMI device, charging station, power supply unit, and transponder satisfy the

requirements and protection objectives of the EC Directives below. The HMI device,

charging station, power supply unit, and transponder comply with the harmonized European

standards (EN) published in the Official Journals of the European Union for programmable

controllers:

● 2004/108/EC Electromagnetic Compatibility Directive (EMC Directive)

● 98/37/EG Directive of the European Parliament and Council of 22 June 1998 on the

approximation of the laws and administrative regulations of the Member States

concerning machinery

● Specific absorption rate in accordance with EN 50392

EC Declaration of Conformity

The EC Declarations of Conformity are available to the relevant authorities at the following

address:

Siemens AG

Industry Sector

I IA AS RD ST PLC

PO Box 1963

D-92209 Amberg

UL approval

Underwriters Laboratories Inc., to

● UL 508 (Industrial Control Equipment)

● CSA C22.2 No. 142 (Process Control Equipment)

The approval is only valid in the case of battery operation or when stationary in the charging

station.

Marking for Australia

The HMI device, charging station, power supply unit, and transponder satisfy the

requirements of Standard AS/NZS 2064 (Class A).

N117

Wireless approval

The HMI device wireless approvals for the various countries are located as follows:

● On the rear of the HMI device

● In the product information supplied together with the HMI device

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

31

Page 32

Safety instructions, standards and notes

2.2 Guidelines, standards, certificates and approvals

TÜV

The TÜV confirms that the HMI device satisfies the requirements of the standards below with

regard to its safety functions.

● SIL3 to IEC 61508-1 to 4

● Category 4 in accordance with EN 954-1.

● Pl e and Cat. 4 in accordance with EN ISO 13849-1

● EN 60204-1

● ISO 13850

● IEC 62061

Requesting certificates

Copies of the certificates and associated reports can be requested from the following

address:

Siemens AG

Industry Sector

I IA AS RD ST

PO Box 1963

D-92209 Amberg

Fail-safe operation of the Mobile Panel 277F IWLAN

32 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 33

Safety instructions, standards and notes

2.3 Operating safety

2.3 Operating safety

Standards

The HMI device complies with the following standards:

● EN 954-1

Safety of machinery

● EN 60204-1

Safety of machinery – Electrical equipment of machines

● EN 62061

Safety of machinery – Functional safety of safety-related electrical, electronic and

programmable electronic control systems

● EN ISO 13849-1

Development, testing and certification of safety-related machine controls

● ISO 13850

Safety of machinery – Emergency stop – Principles for design

● IEC 61508

Functional safety of electrical/electronic/programmable electronic-related systems

● EN 61131-1 and EN 61131-2

Programmable Controllers

● The HMI device was tested for EMC in accordance with the following standards:

– EN 61000-6-4, Generic standard – emitted interference

– EN 61000-6-2, Generic standard, Immunity, industrial environments

– EN 61131-2, Programmable Controllers

● EN 300 328 V1.6.1, EN 300 440-1 V1.3.1, EN 301 893, EN 301 489-1, EN 301 489-17,

FCC Part 15.245, 15.247, 15.407

Wireless approval

● EN 50 360, IEEE 1528-X, EN 50371, EN 50 392

Radiation protection requirements (SAR/EMF)

If the HMI device is used in a system, the following standards are fulfilled:

● prEN 1921, Industrial automation systems – safety of integrated manufacturing systems

● EN 12417:2001, Machine tools – safety – machining centers

● UL 508, Industrial Control Equipment

● CSA C22.2 No.14, Industrial Control Equipment

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

33

Page 34

Safety instructions, standards and notes

2.4 Power supply

2.4 Power supply

Safety specifications

CAUTION

Damage to the HMI device

Only operate the HMI device with approved components:

• Batteries

• Charging station

• For office environments only: Tabletop power supply unit

Order information of the components is available on the Internet at

http://mall.automation.siemens.com".

"

WARNING

Injury or material damage

You may operate the HMI device in the plant only with the battery or in the charging station.

Operation with the desktop power supply module is not permitted.

WARNING

Effectiveness of the emergency stop button

The emergency stop button only has an effect if the HMI device is integrated into the safety

program.

Charging station

WARNING

Injury or material damage

The charging station complies with the following standards:

• EN 50335-2-29

• DIN EN 60204-1

• Protection class III in accordance with EN 61131-2 or EN 50178.

The 24 VDC power supply must be ensured by safely isolating the low voltage from

hazardous voltages, e.g. by using a safety transformer or equivalent equipment.

Allowance should be made for the loss of voltage on the connection cable during

dimensional analysis of the supply!

Fail-safe operation of the Mobile Panel 277F IWLAN

34 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 35

Safety instructions, standards and notes

2.4 Power supply

WARNING

Injury or material damage

Configure the 24 VDC supply for the charging station correctly, otherwise components of

your automation system can be damaged and persons may be injured.

Use only voltage generated as protective extra-low voltage (PELV) for the 24 VDC supply

of the charging station.

CAUTION

Safe electrical separation

Use only power supply units with safety isolation complying with IEC 60364-4-41 or

HD 384.04.41 (VDE 0100, Part 410), for example according to the PELV standard, for the

charging station's 24 VDC supply.

The supply voltage must be within the specified voltage range. Malfunctions in the charging

station may otherwise result.

Applies to non-isolated system design:

Connect the connection for GND 24 V from the 24 V power supply output to equipotential

bonding for uniform reference potential.

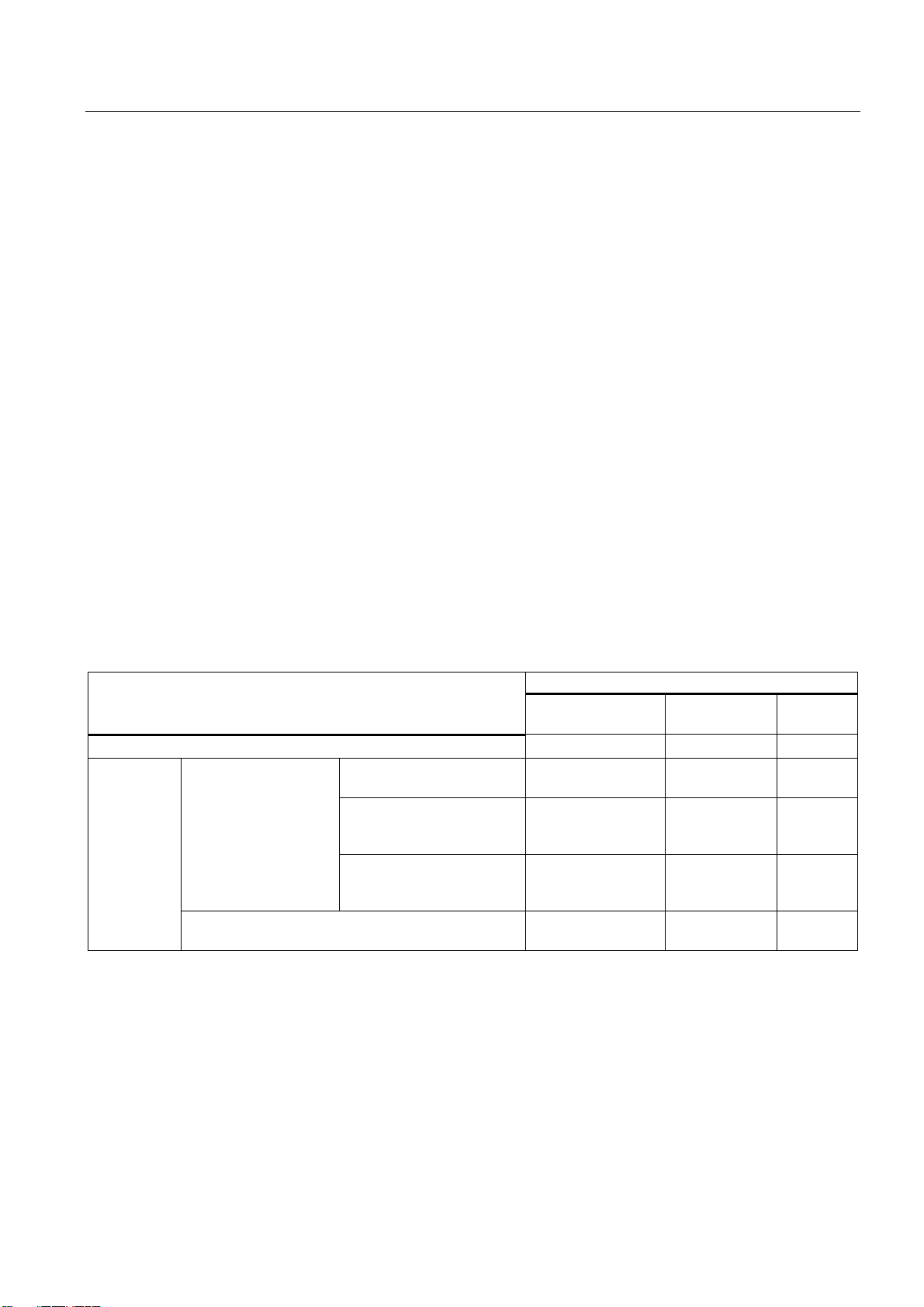

The following table shows the technical data of the supply voltage for the charging station:

Nominal voltage

Range, permissible

Transients, maximum permissible 35 V (500 ms)

Time between two transients, minimum 50 sec

Current consumption with Mobile Panel

• Typical

• Constant current, maximum

2

• Power on current surge I

t

+24 VDC

19.2 V to 28.8 V (–20 %, +20 %)

• Approximately 1.5 A

• Approx. 1.8 A

• Approx. 1.7 A2s

Current consumption with Mobile Panel and batteries in

charging compartment

• Typical

• Constant current, maximum

• Power on current surge I

Fuse, internal Electronic

Connection to the supply voltage

Wire the supply voltage to the cable terminal box included with the charging station using a

3-wire flexible cable (0.75 mm²). For additional information, refer to the operating instructions

of the HMI device.

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

• Approximately 2.8 A

2

t

• Approximately 3.4 A

• Approximately 1.7 A

2

s

35

Page 36

Safety instructions, standards and notes

2.5 Notes about usage

Tabletop power supply unit

CAUTION

Please note that the mains connector must be removed for a complete disconnection from

the mains.

Do not operate the HMI device in the plant with the table power supply unit.

The tabletop power supply unit is only suitable for an office environment.

The device is designed for operation on grounded power supply networks (TN systems to

VDE 0100, Part 300, or IEC 364-3).

Operation is not authorized on ungrounded or impedance-grounded power networks

(IT networks).

2.5 Notes about usage

Using the HMI device

A list indicating the country or geographical region of a country in which the HMI device is

certified is included in the product information supplied with the HMI device.

Use in industry

The HMI device is designed for industrial use. For this reason, the following standards are

met:

● Interference emission requirements, paragraph 7.3, DIN EN 60947-1, Environment A

● Interference immunity requirements DIN EN 61326

Residential use

Note

The HMI device is not suitable for use in residential areas: If you use the HMI device in

residential areas, the radio/TV reception may be impeded.

If the HMI device is used in a residential area, you must take measures to achieve Limit

Class B conforming to EN 55011 for RF interference.

A suitable measure for achieving the required RF interference level for Limit Class B

includes for example:

● Use of filters in electrical supply lines

Individual acceptance is required.

Fail-safe operation of the Mobile Panel 277F IWLAN

36 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 37

Safety instructions, standards and notes

2.6 Risk analysis

Use of cable-free control equipment

WARNING

When using cable-free control equipment you must ensure that it does not interfere with

other systems at the site, or that other systems do not interfere with it.

2.6 Risk analysis

Carrying out a risk analysis

The following standards must be used to perform the risk analysis:

● EN ISO 12100-1 and EN ISO 12100-2, General design guidelines for machines

● EN 1050 Risk Assessment for Machinery

● EN 954-1 Safety of Machinery

These considerations result in a safety category (B, 1, 2, 3, 4) in accordance with EN 954-1

that ultimately dictates how the safety-related aspects of the system that will be configured

must be furnished.

With the safety-related parts of the Mobile Panel 277F IWLAN the following requirements are

satisfied:

● Category 4 in accordance with EN 954-1.

● SIL 3 in accordance with IEC 61508

● Pl e and Cat. 4 in accordance with EN ISO 13849-1

The risk assessment must take into account that the overall concept of the plant must be

configured accordingly. More detailed instructions on risk assessment and risk reduction are

provided in the system manual "Safety Integrated".

2.7 Safety functions of the emergency stop button

Safety instructions

There is an emergency stop button on the Mobile Panel 277F IWLAN.

The emergency stop button on the Mobile Panel 277F IWLAN brings about a safety-related

stop of the configured machine in accordance with EN 60204-1:1997, Section 9.2.5.3. You

have the option of implementing a Category 0, 1, or 2 Stop function in accordance with

EN 60204-1: 1997, Section 9.2.2. The stop function category must be selected on the basis

of a risk assessment.

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

37

Page 38

Safety instructions, standards and notes

2.7 Safety functions of the emergency stop button

WARNING

Emergency stop button not available

The emergency stop button on the HMI device must not used as a replacement for a

permanently-wired emergency stop/emergency off on the machine.

Install stationary emergency stop buttons that are available at all times on the configured

system.

WARNING

Effectivity of the emergency stop button

The following requirements must be met in order to render the emergency stop button

effective:

• The HMI device must be operated in the charging station or operated with the battery.

• The project must be running on the Mobile Panel 277F IWLAN.

• The HMI device must be integrated in the safety program of the F-CPU.

If these prerequisites are satisfied the following applies:

• The SAFE LED on the HMI device is illuminated.

• The emergency stop button of the Mobile Panel 277F IWLAN is effective.

Category 0 or 1 Stop

If a Category 0 or 1 Stop circuit is implemented, the stop function must be in effect

regardless of the operating mode. A Category 0 Stop must have precedence. Release of

the emergency stop button should not cause a hazardous situation (see also EN

60204:1997 chapter 9.2.5.3).

The stop function is not to be used as a replacement for safety equipment.

NOTICE

The emergency stop button can be triggered unintentionally

The emergency stop button is evaluated under the following conditions:

• The Mobile Panel 277F IWLAN is integrated in the safety program of the F CPU.

In the following cases, the emergency stop button can be triggered unintentionally, bringing

the configured system to a standstill:

• If the HMI device falls down

• When opening one of the coverings on the rear of the HMI device

WARNING

Emergency stop button disabled

If a global rampdown has been triggered by a communication error, the emergency stop will

no longer be available on the Mobile Panel in question.

You have the option of configuring the "Global rampdown" signal to trigger an emergency

stop.

Fail-safe operation of the Mobile Panel 277F IWLAN

38 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 39

Safety instructions, standards and notes

2.8 Safety functions of the enabling button

Storing the HMI device

WARNING

Non-functional emergency stop button

If the HMI device is not integrated, the emergency stop button does not function.

To avoid confusion between effective and non-effective emergency stop buttons, only one

integrated HMI device should be freely accessible.

If the HMI device is not in use, it must be stored in an secure place.

See also

Emergency stop button (Page 20)

2.8 Safety functions of the enabling button

Introduction

The enabling mechanism is comprised of two enabling buttons mounted on both sides of the

HMI device.

Numerically controlled machines and systems are equipped with the operating modes

"Automatic mode" and "Special mode".

Special mode

Safety instructions

Safety is ensured in automatic mode by means of closed, isolating protective devices and/or

with functional non-isolating protective devices that block access.

In special mode, safety has to be ensured in a different manner than in automatic mode. In

special mode, the danger zones of the machine or system are entered, where controlled

movements have to be possible.

A reduced speed on the machine or in the system has to be specified for special mode

based on the risk assessment. Movement of the machine should only be possible when the

enabling device is activated. The operator must have the necessary qualifications and be

acquainted with the details of the intended application.

The safety-related aspects of the velocity reduction control and those for the enabling device

are designed in such a way that they satisfy the EN 954-1 safety category determined by the

risk analysis.

The operating principles of enabling devices are described in EN 60204. Through the

findings from accident investigations and the existence of technical solutions, the 3-stage

enabling button became state of the art. Positions 1 and 3 of the enabling button are Off

functions. Only the middle position allows the enabling function. EN 60204-1:1997 is

identical to IEC 60204-1, whereby the 3-stage enabling button is gaining international

importance.

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

39

Page 40

Safety instructions, standards and notes

2.8 Safety functions of the enabling button

The Stop category of the enabling device must be selected on the basis of a risk assessment

and correspond to a Category 0 or 1 Stop.

WARNING

Injury or material damage

Enabling buttons should only be used when the following applies for the person activating

the enabling button:

• The person can see the danger zone.

• The person is capable of recognizing personal injury hazards in good time.

• The person is capable of taking immediate measures to avoid danger.

The only person allowed to remain in the danger zone is the person who is activating the

enabling button.

Commands for unsafe conditions are not permitted to be issued with one enabling button

alone. For this purpose, a secondary, intentional start command by means of a button on

the Mobile Panel 277F IWLAN is required.

The following happens if you leave the effective range for a period of up to 30 seconds with

the enabling button pressed: Enabling is revoked 5 seconds after leaving the effective

range.

If you reenter the effective range within 30 seconds, you must release the enabling button

and press it again for enabling to take effect again.

NOTICE

Enabling button not effective

The enabling button is only effective if the HMI device is logged on in the effective range

and the "RNG" LED on the HMI device lights up.

If the operator leaves the effective range, the enabling button is deactivated after 5

seconds. The "Exit effective range without logoff" dialog opens after 30 seconds. The

"RNG" LED only goes off when the operator confirms this dialog.

Risk from improper use

To avoid the danger of unauthorized use of the enabling button due to impermissible holddown, on each project start the enabling button must be pressed all the way down, and then

released.

See also

Enabling button (Page 22)

Fail-safe operation of the Mobile Panel 277F IWLAN

40 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 41

Application Planning

3.1 Check list: Planning the application

Application planning

For application planning of the HMI device go through the following steps.

Check list for application planning

Step Information Check

Check the application conditions and

environmental conditions

Plant planning for application of the HMI device Check list: Planning the system

Planning the effective ranges Planning effective ranges (Page 46)

Only for the "override" mode: Planning the

protective devices

Planning measures to increase data safety Check list: Data security (Page 50)

Application and ambient conditions

(Page 42)

(Page 45)

For the "Override" mode: Planning the

protective devices (Page 49)

3

Fail-safe operation of the Mobile Panel 277F IWLAN

Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

41

Page 42

Application Planning

3.2 Application and ambient conditions

3.2 Application and ambient conditions

Mechanical and climatic conditions of use

The HMI device is designed for use in a location protected from the effects of the weather.

The conditions of use are compliant with requirements to DIN IEC 60721-3-3:

● Class 3M3 (mechanical requirements)

The table applies to the HMI device, charging station, and transponder.

Tested for Test standard Comments

Sinusoidal vibration, stationary DIN IEC 60721-3-3 Frequency range:

2 ≤ f ≤ 200 Hz

Deflection:

1.5 mm/5 m/s2

Shocks, non-stationary,

Total shock response spectrum

● Class 3K3 (climatic requirements)

DIN IEC 60721-3-3 Shock amplitude: 70 m/s2

Shock duration: 22 ms

The table applies to the HMI device, charging station, and transponder.

Ambient conditions Permitted range Comments

Air temperature 5 to 40 °C

Relative humidity 5 to 85 %,

Absolute humidity 1 to 25 g/m3

Atmospheric pressure 70 to 106 kPa Corresponds to an elevation of up to

Use with additional measures

In the following cases the use of the HMI device requires additional measures:

● In locations with a high degree of ionizing radiation

● In locations with difficult operating conditions, for example due to:

– Corrosive vapors, gases, oils or chemicals

– Electrical or magnetic fields of high intensity

● In systems that require special monitoring, for example:

– Elevators

no condensation

Corresponds to relative humidity, load

degree 2 in accordance with

IEC 61131, part 2

3,000 m

– Systems in especially hazardous rooms

Fail-safe operation of the Mobile Panel 277F IWLAN

42 Function Manual, 08/2008, 6AV6691-1FQ01-2AB0

Page 43

Application Planning

3.2 Application and ambient conditions

Testing for mechanical environmental conditions

The following table provides information on the type and scope of tests to determine