Page 1

Configuring the operating system

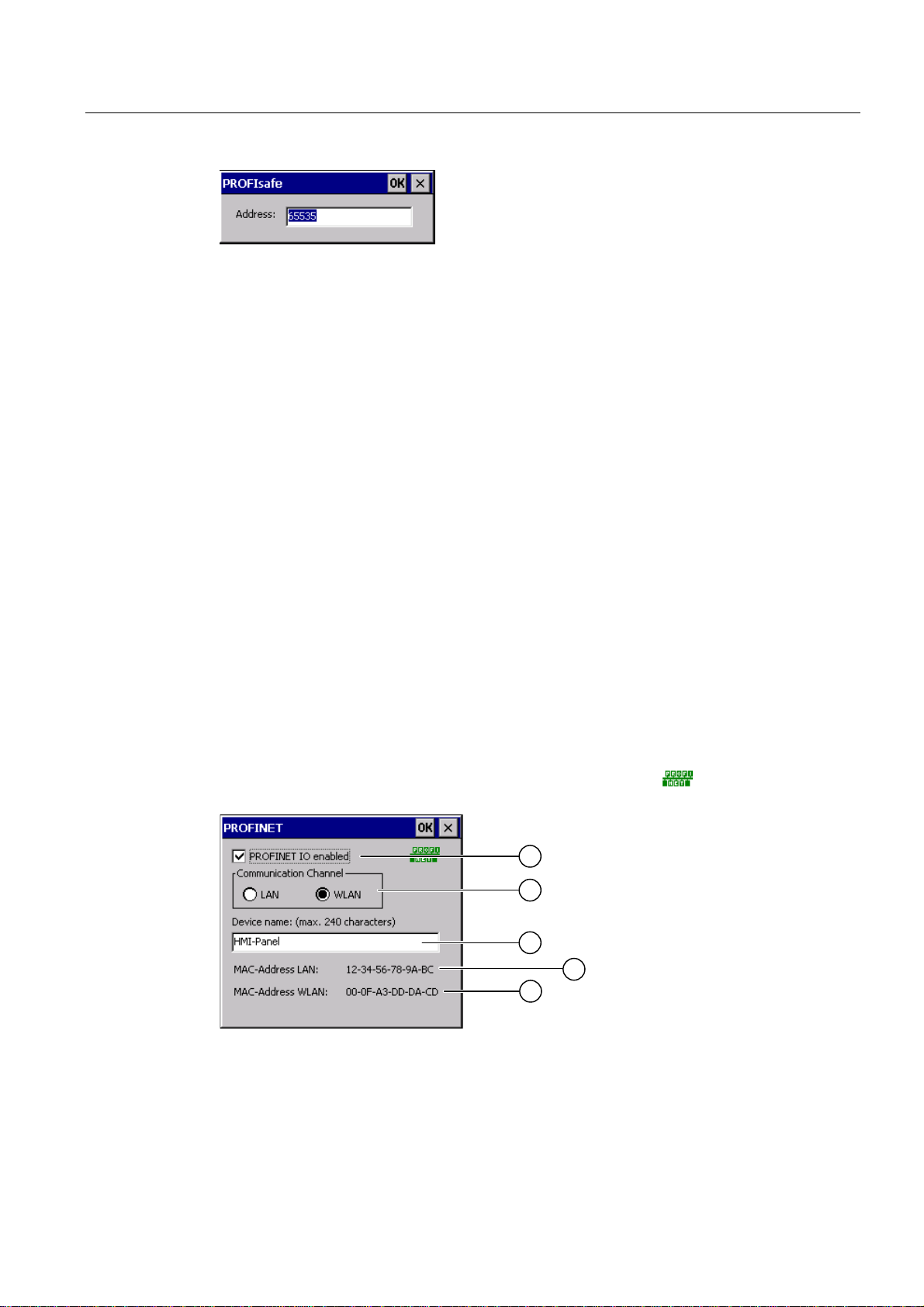

6.10 Enabling PROFINET IO

Procedure

Proceed as follows:

1. If you wish the HMI device to load the PROFIsafe address set in the Control Panel, enter

a value between 1 and 65,534 in the "Address:" text box.

2. If you wish the HMI device to load the PROFIsafe address set in the project, enter a value

between the invalid PROFIsafe address 65,535 in the "Address:" text box.

Result

The PROFIsafe address is set.

6.10 Enabling PROFINET IO

PROFINET IO

Function keys or buttons can be configured as PROFINET IO direct keys. If PROFINET IO

direct keys are used in the project, they must be enabled.

Requirements

You have opened the "PROFINET" dialog with the "PROFINET" icon.

① Check box to enable or block PROFINET IO direct keys

② Group for communications link

③ Text box for the device name

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

165

Page 2

Configuring the operating system

6.10 Enabling PROFINET IO

④ MAC address of the LAN interface

⑤ MAC address of the WLAN interface

Procedure

1. To enable PROFINET IO direct keys, select the "PROFINET IO enabled" check box.

2. Select the communications link.

Note

Select "LAN" for service purposes only. If you select "LAN", the HMI device is connected

directly to the network via the RJ45 interface.

If you connect the configuring PC directly to the HMI device through the RJ45 interface,

you must open the connection compartment. If the connection bay is open, degree of

protection IP 65 is not fulfilled.

1. Enter the device name of the HMI device.

The device name can have a maximum of 240 characters.

NOTICE

Addressing error of PROFINET IO device

The device name does not correspond to the computer name in Windows CE.

The device name must match the device name entered in the HW Config of STEP 7.

1. Confirm your entries.

The dialog closes.

2. Reboot the HMI device after saving the settings.

Result

The PROFINET IO direct keys are enabled.

See also

Restarting the HMI device (Page 156)

Direct keys (Page 234)

Required properties of the WLAN connection (Page 57)

Mobile Panel 277F IWLAN

166 Operating Instructions, 12/2007, A5E01003940-01

Page 3

Configuring the operating system

6.11 Configuring network operation

6.11 Configuring network operation

6.11.1 Overview of network operation

Introduction

You connect the HMI device to a PROFINET network.

The connection to a network offers, for example, the following options:

● Printing via a network printer

● Saving, exporting and importing of recipe data records on or from a server

● Setting up of message and data archives

● Transferring a project

Addressing

● Saving data

NOTICE

The HMI device can only be used in PROFINET networks.

The HMI device only has client functionality in the PC network. This means that users

can access files of a node with TCP/IP server functionality from the HMI device via the

network. However, you cannot, for example, access data on the HMI device from a PC

via the network.

Note

Information on communication using SIMATIC S7 via PROFINET is provided in the

"WinCC flexible communication" user manual.

Within a PROFINET network, computers are usually addressed using device names. These

device names are translated from a DNS or WINS server to TCP/IP addresses.

The corresponding servers are generally available in PROFINET networks.

Note

The use of TCP/IP addresses to address PCs is not supported by the HMI device's operating

system.

So to address the HMI device using device names in a PROFINET network, you need a

DNS or WINS server.

Consult your network administrator if you have questions in this regard

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

167

Page 4

Configuring the operating system

6.11 Configuring network operation

Printing via a network printer

The HMI device's operating system does not support line by line alarm logging via a network

printer. All other printing functions, for example hardcopy or logs are available without

restriction via the network.

Preparation

Before beginning the configuration, request the following network parameters from your

network administrator.

● Does the network use DHCP for dynamic assignment of network addresses?

If not, get a new TCP/IP network address for the HMI device.

● Which TCP/IP address does the default gateway have?

● If a DNS network is used, what are the addresses of the name server?

● If a WINS network is used, what are the addresses of the name server?

General procedure for configuring the network

The HMI device must be configured prior to network operation. The configuration is basically

divided into the following steps:

Proceed as follows:

1. Enter the device name of the HMI device.

2. Configure the network address.

3. Set the logon information.

4. Save the settings.

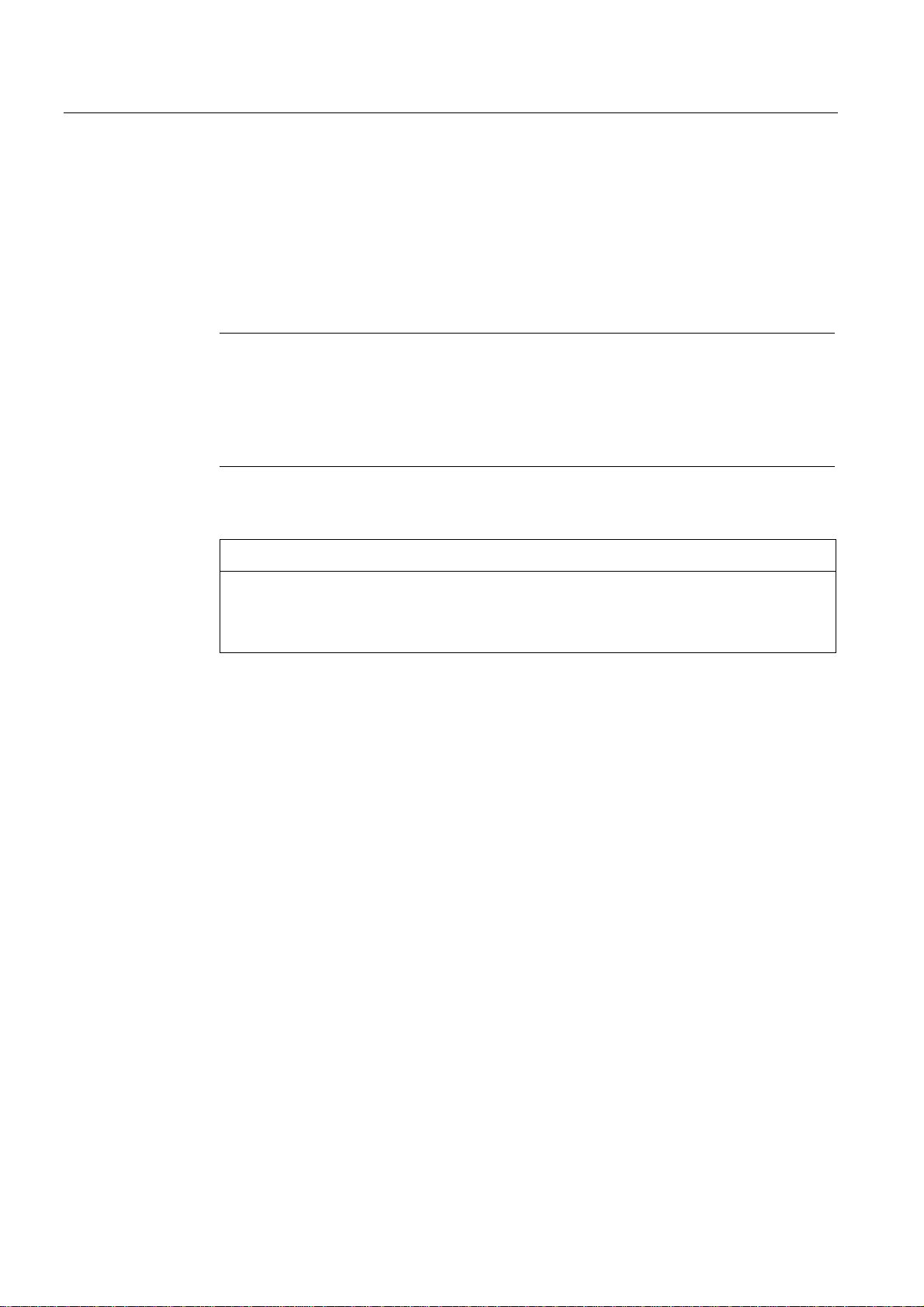

6.11.2 Setting the device name of the HMI device

Introduction

The HMI device uses the device name to identify itself in the network.

Requirements

You have opened the "System Properties" dialog with the "System" icon.

Mobile Panel 277F IWLAN

168 Operating Instructions, 12/2007, A5E01003940-01

Page 5

Configuring the operating system

6.11 Configuring network operation

① Device name of the HMI device

② Description for the HMI device (optional)

Procedure

Result

See also

Note

To activate the network functions, enter a unique device name in the Device name text box.

Proceed as follows:

1. Enter the device name for the HMI device in the "Device name:" text box.

2. If necessary, enter a description for the HMI device in the "Device description:" text box.

3. Confirm your entries.

The dialog closes.

The device name for the HMI device is now set.

Overview of network operation (Page 167)

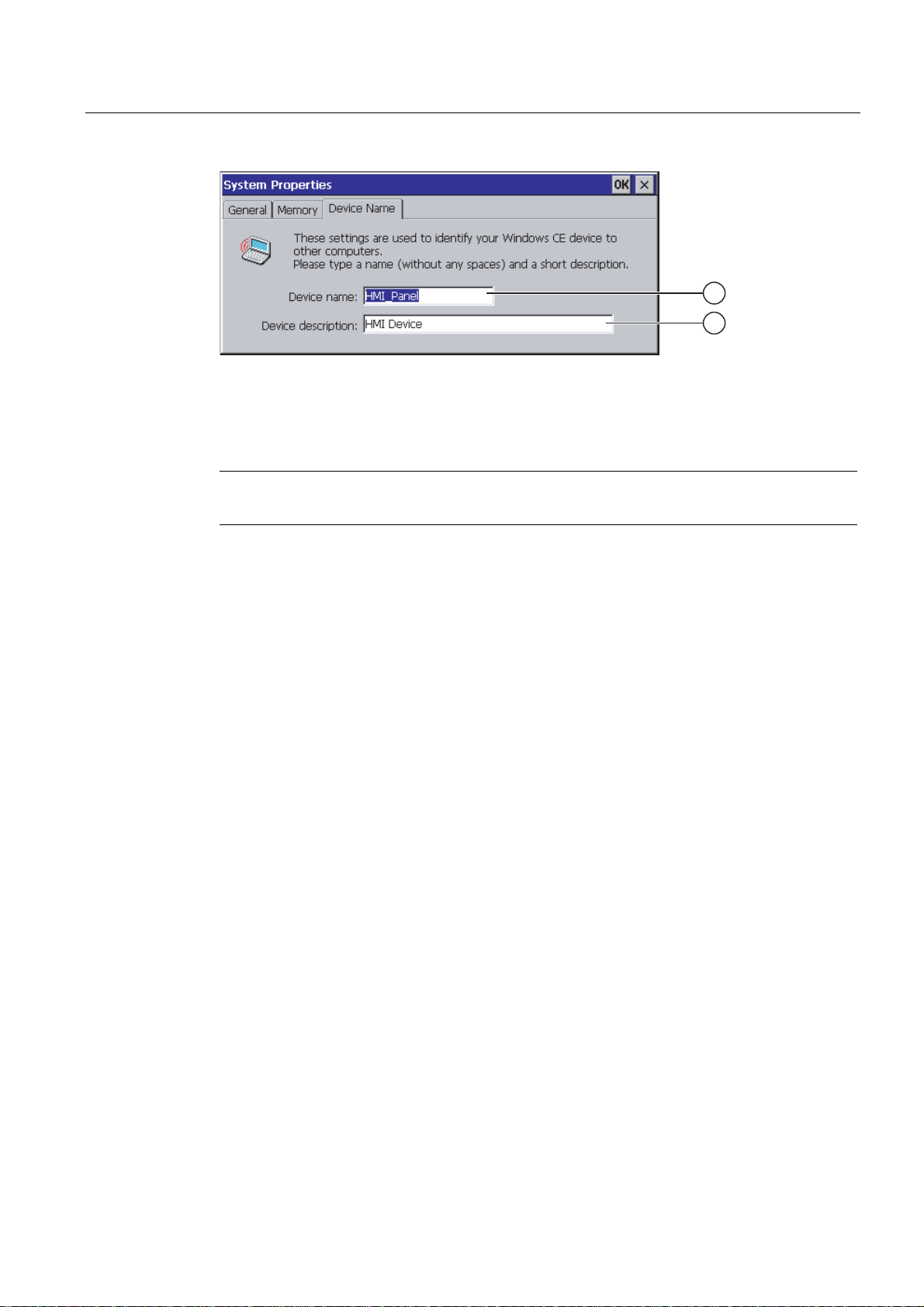

6.11.3 Changing the network configuration

Introduction

You can change the network settings for the WLAN and LAN connection under "Network and

Dial-Up Connections".

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

169

Page 6

Configuring the operating system

6.11 Configuring network operation

Requirements for changing WLAN or LAN connection settings

You have opened the following display by touching the "Network and Dial-Up Connections"

icon.

You can enter the connection parameters for the WLAN and LAN connection. The

parameterization is identical.

Procedure for setting the connection parameters

The following procedure shows how to set the connection parameters using the WLAN

connection.

Proceed as follows:

1. Open the "WLAN" entry.

– The "''WLAN' Settings" dialog box opens.

1. Select either automatic address assignment via DHCP or manual address assignment.

2. If you assign the address manually, enter the corresponding addresses in the text boxes

for "IP Address", "Subnet Mask" and, if used, "Default Gateway".

3. If a name server is used in the network, change to the "Name Servers" tab.

Mobile Panel 277F IWLAN

170 Operating Instructions, 12/2007, A5E01003940-01

Page 7

Configuring the operating system

6.11 Configuring network operation

1. Enter the appropriate addresses.

2. Confirm your entries.

The dialog closes.

3. Close the "Network and Dial-Up Connections" display.

The Control Panel is displayed again.

Result

The WLAN / LAN connection parameters for the HMI device have been set.

See also

Overview of network operation (Page 167)

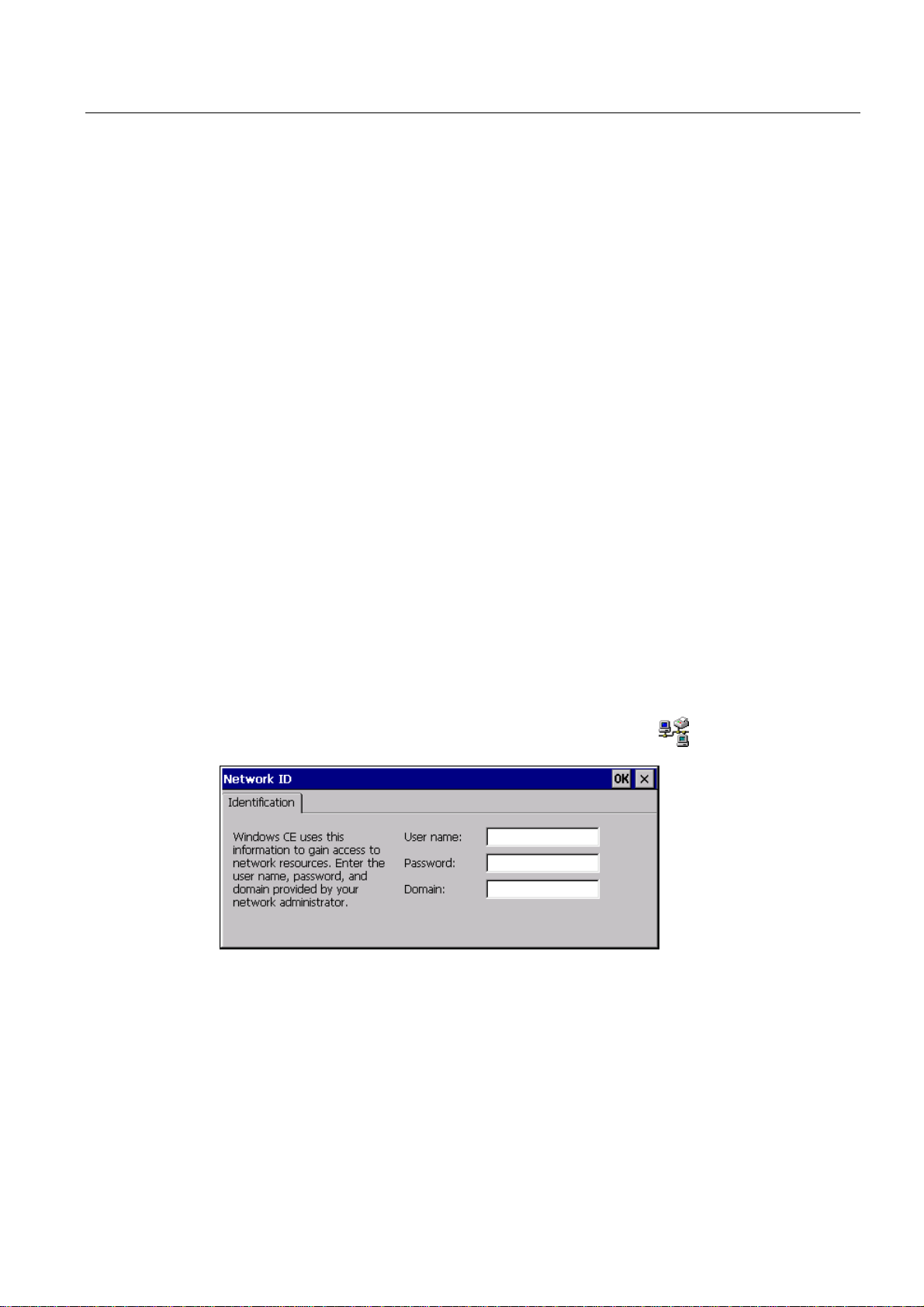

6.11.4 Changing the logon data

Introduction

Requirements

Procedure

In order to access certain network resources you need to log on to the network as a user.

Your administrator will issue you with a user name and password and the name of the

domain.

You have opened the "Network ID" dialog with the "Network ID" icon.

Proceed as follows:

1. Enter the user name in the "User name" text box.

2. Enter your password in the "Password" text box.

3. Enter the domain name in the "Domain" text box.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

171

Page 8

Configuring the operating system

6.11 Configuring network operation

4. Confirm your entries.

The dialog closes.

Result

The logon data has now been set.

See also

Overview of network operation (Page 167)

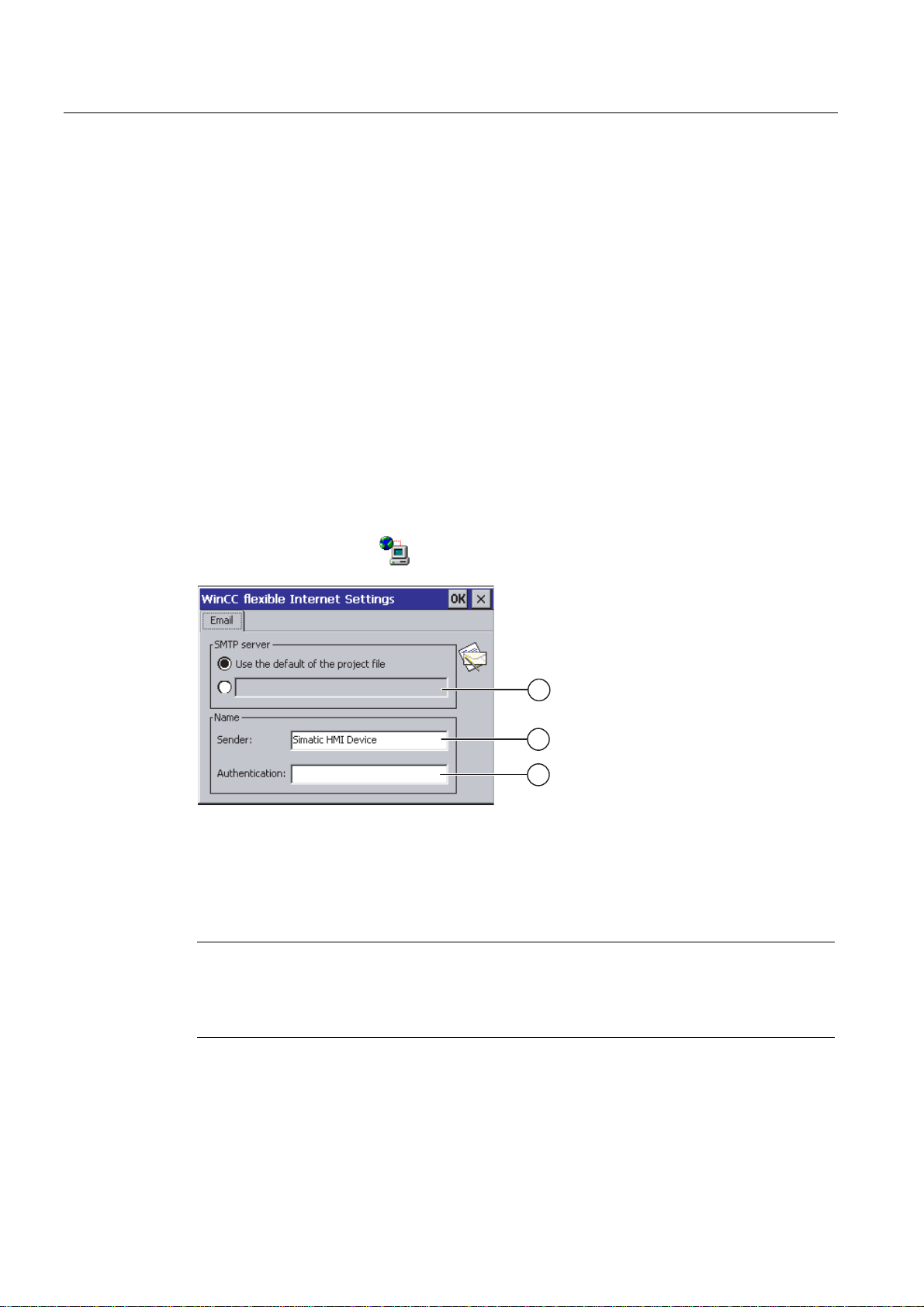

6.11.5 Changing e-mail settings

Requirements

You have opened the "WinCC flexible Internet Settings" dialog with the

"WinCC Internet Settings"

icon.

① Setting the SMTP server

② Name for the sender

③ E-mail account

Note

Options

Additional tabs may appear in the "WinCC flexible Internet Settings" dialog. This depends on

the options that have been enabled for network operation in the project.

Procedure for changing e-mail settings

Proceed as follows:

Mobile Panel 277F IWLAN

172 Operating Instructions, 12/2007, A5E01003940-01

Page 9

Configuring the operating system

6.12 Changing internet settings

1. Specify the SMTP server.

– Select the "Use the default of the project file" option button if you want to use the

SMTP server configured in the project.

– Clear the "Use the default of the project file" option button if you do not want to use the

SMTP server configured in the project. Specify the required SMTP server.

2. Enter the name for the sender in the "Sender" text box.

3. Enter the e-mail account for your e-mail in the "Authentication:" text box.

Some e-mail providers only allow you to send mail if you specify the e-mail account. The

"Authentication:" text box can remain empty if your e-mail provider allows you to send

mail without checking the account.

4. Confirm your entries.

The dialog closes.

Result

The e-mail settings have been changed.

See also

Overview of network operation (Page 167)

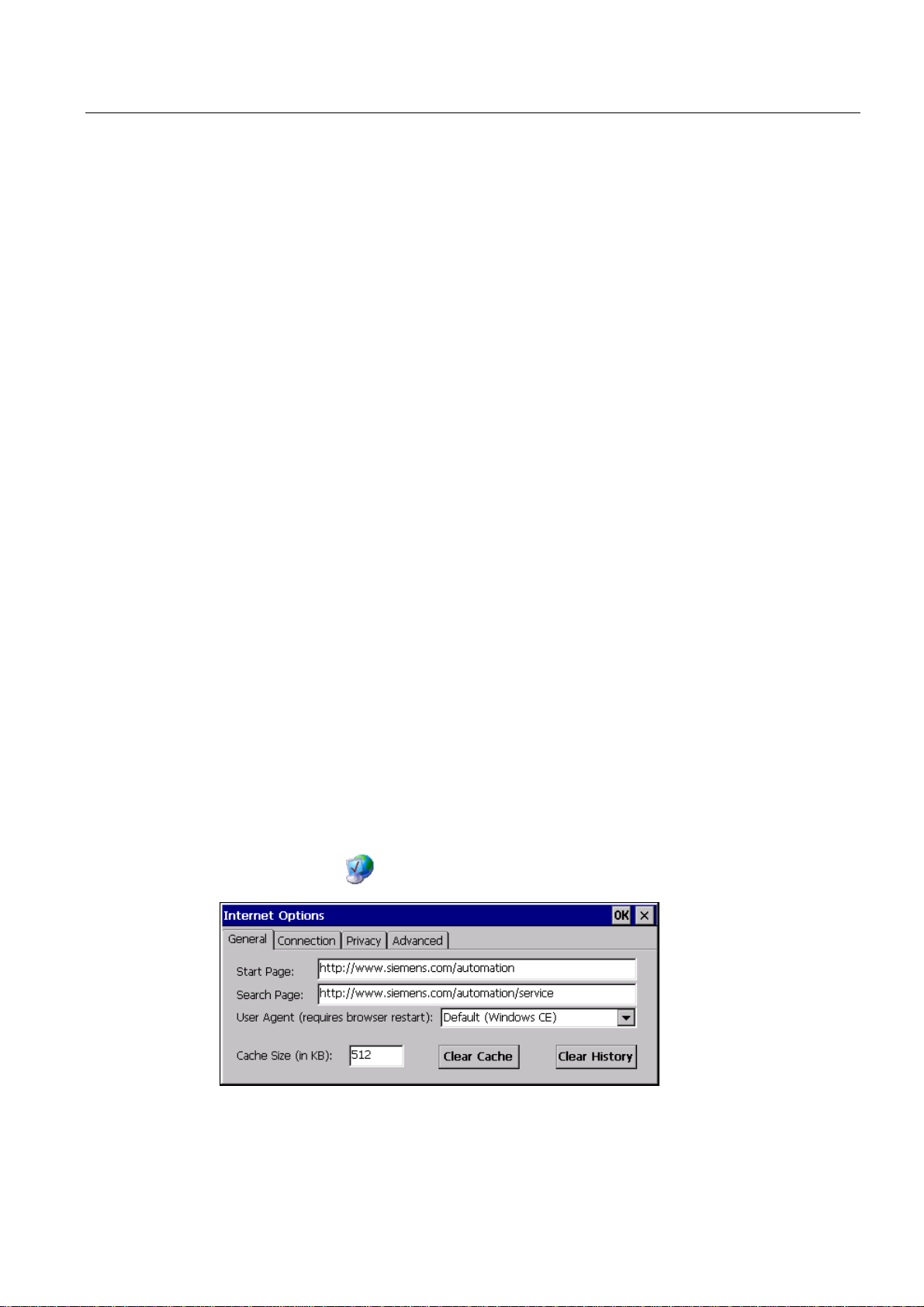

6.12 Changing internet settings

6.12.1 Changing internet settings

Requirements

You have opened the "Internet Options" dialog box, "General" tab, by touching the

"Internet Options"

icon.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

173

Page 10

Configuring the operating system

6.12 Changing internet settings

Procedure

Result

Note

Do not change the settings in the "User Agent" box.

Proceed as follows:

1. Enter the homepage for the Internet browser in the "Start Page" text box.

2. Enter the address of the required search engine in the "Search Page" text box.

3. Enter the required cache memory size in the "Cache" text box.

4. If you want to delete the cache memory, press the "Clear Cache" button.

5. If you want to delete the history, press the "Clear History" button.

6. Confirm your entries.

The dialog closes.

The general parameters for the Internet browser have been set.

6.12.2 Setting the proxy server

Requirements

You have opened the "Internet Options" dialog box, "Connection" tab, by touching the

"Internet Options"

Procedure

Proceed as follows:

1. Select the "Use LAN (no autodial)" check box.

icon.

Mobile Panel 277F IWLAN

174 Operating Instructions, 12/2007, A5E01003940-01

Page 11

Configuring the operating system

6.12 Changing internet settings

2. If you are using a proxy server, in the "Network" group, select the

"Access the Internet using a proxy server" check box.

Specify the address of the proxy server and the interface.

3. If you want to bypass the proxy server for local addresses, select the

"Bypass proxy server for local addresses" check box.

4. Confirm your entries.

The dialog closes.

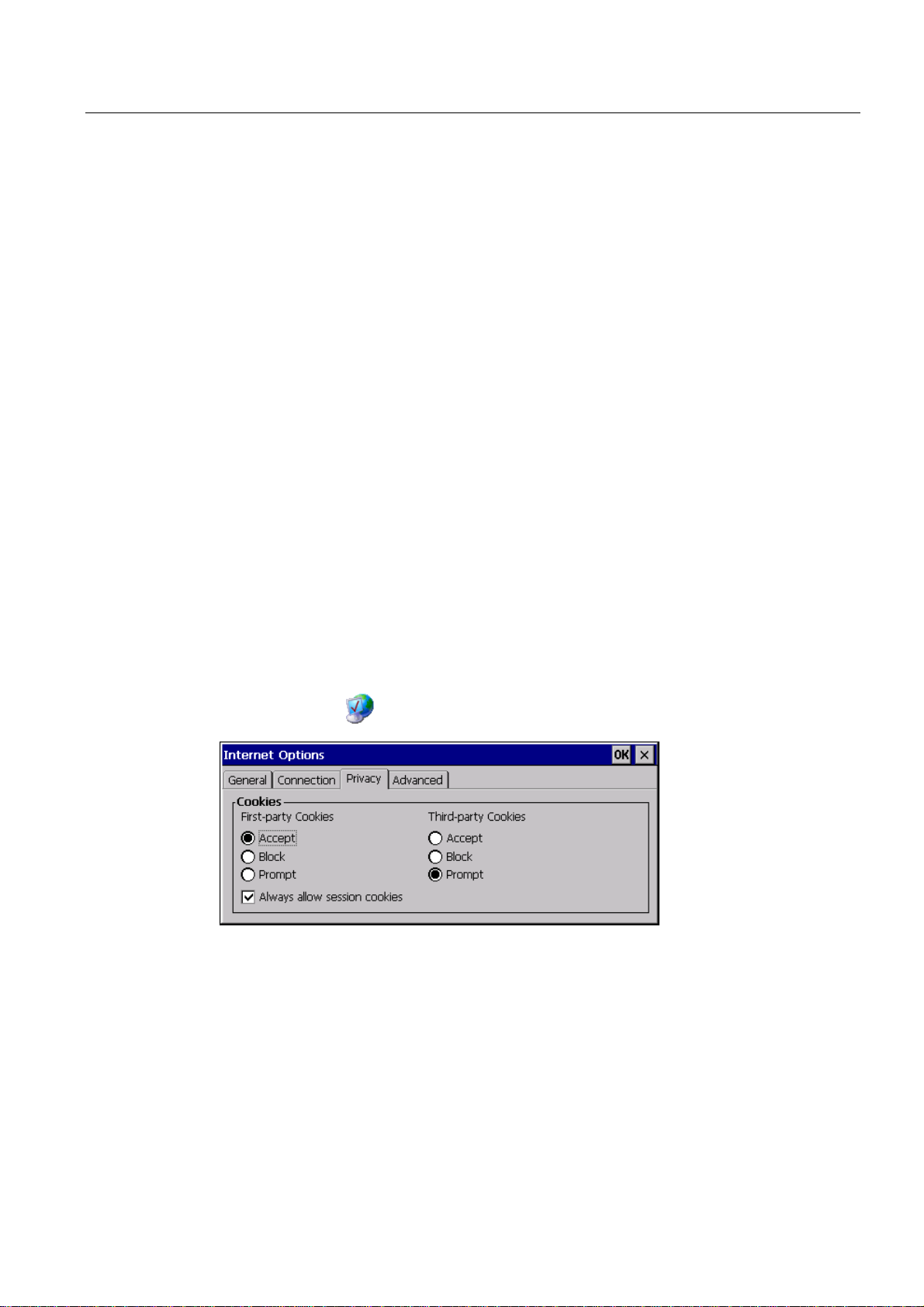

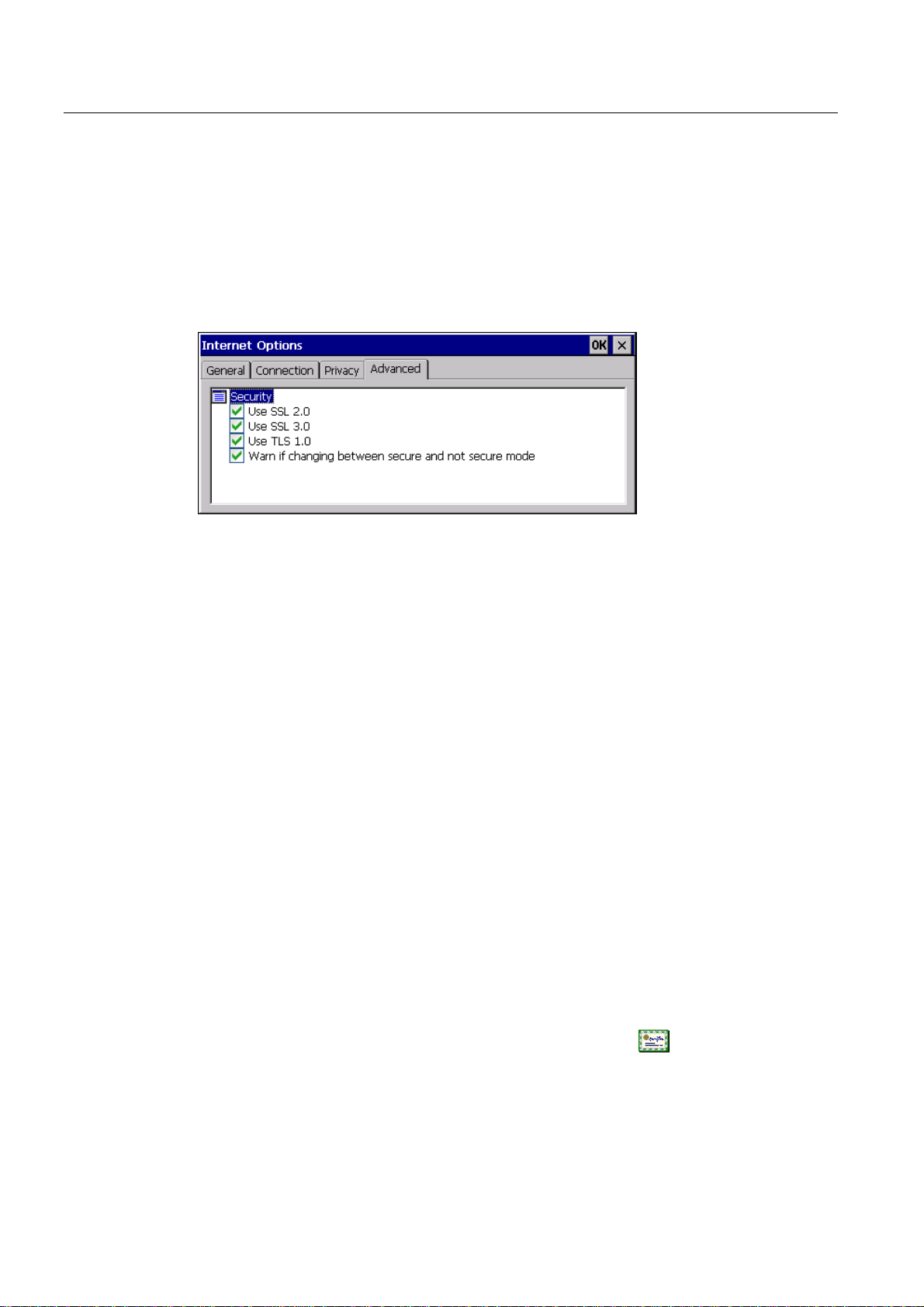

6.12.3 Changing data protection settings

Cookies and encryption

Cookies are pieces of information sent by a web server to a browser. In the event of

subsequent access to the web server, the cookies are sent back. This enables information to

be stored between the accesses.

In order to ensure a high level of privacy, data are sent via the Internet in encrypted form.

Common encryption protocols include SSL and TLS. You can activate or deactivate the

usage of encryption protocols.

Requirements

Procedure

The required settings can be obtained from your network administrator.

You have opened the "Internet Options" dialog box, "Privacy" tab, by touching the

"Internet Options"

Proceed as follows:

1. Select the required cookie behavior by means of the radio buttons.

icon.

– "Accept"

Cookies are stored without request.

– "Block"

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

175

Page 12

Configuring the operating system

6.12 Changing internet settings

Cookies will not be stored.

– "Prompt"

Cookies will be stored on request.

2. If you want allow cookies which are restricted to a single session, select the

"Always allow session cookies" check box.

3. Change to the "Advanced" tab.

1. Activate the required encryption protocol.

2. Confirm your entries.

The dialog closes.

Result

The safety settings have now been set.

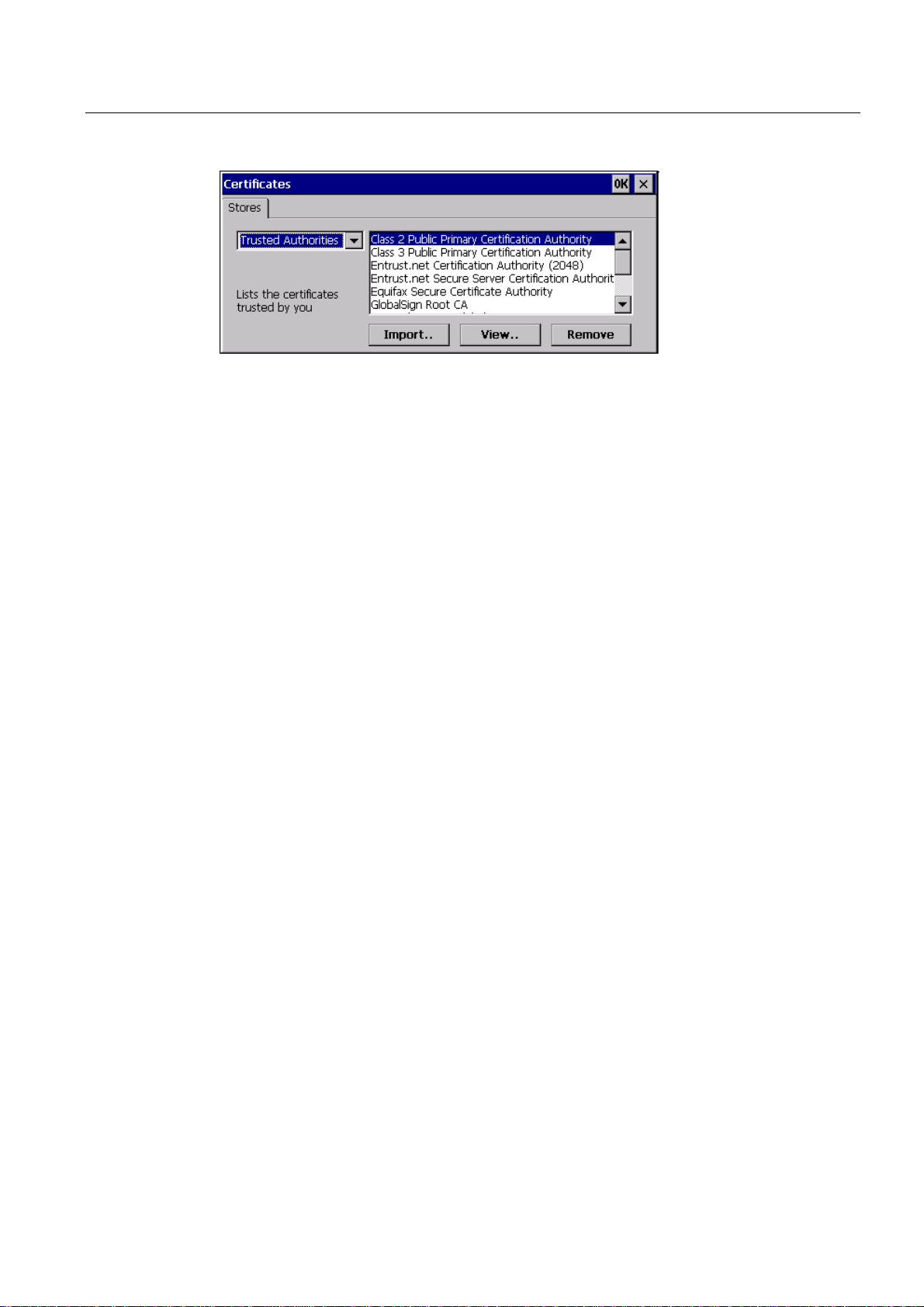

6.12.4 Importing and deleting certificates

Overview

You can import, view and delete certificates. The certificates differ in the following ways:

● Certificates that you trust

● Own certificates

● Other certificates

The required settings can be obtained from your network administrator.

Requirements

You have opened the "Certificates" dialog with the "Certificates" icon.

Mobile Panel 277F IWLAN

176 Operating Instructions, 12/2007, A5E01003940-01

Page 13

Configuring the operating system

6.13 Backing up and restoring with an external memory medium

Procedure

Proceed as follows:

1. Select the type of certificate from the selection box:

– "Trusted Authorities"

– "My Certificates"

– "Other Certificates"

2. If required, start the importing process with the "Import.." button.

A dialog with source details will open.

3. If required, delete the certificate.

– Mark the desired certificate.

– Delete the selected certificate using the "Remove" button.

4. The "View.." button enables you to list the properties of the selected certificate.

5. Close the dialog.

Result

The changes to the certificates have been carried out.

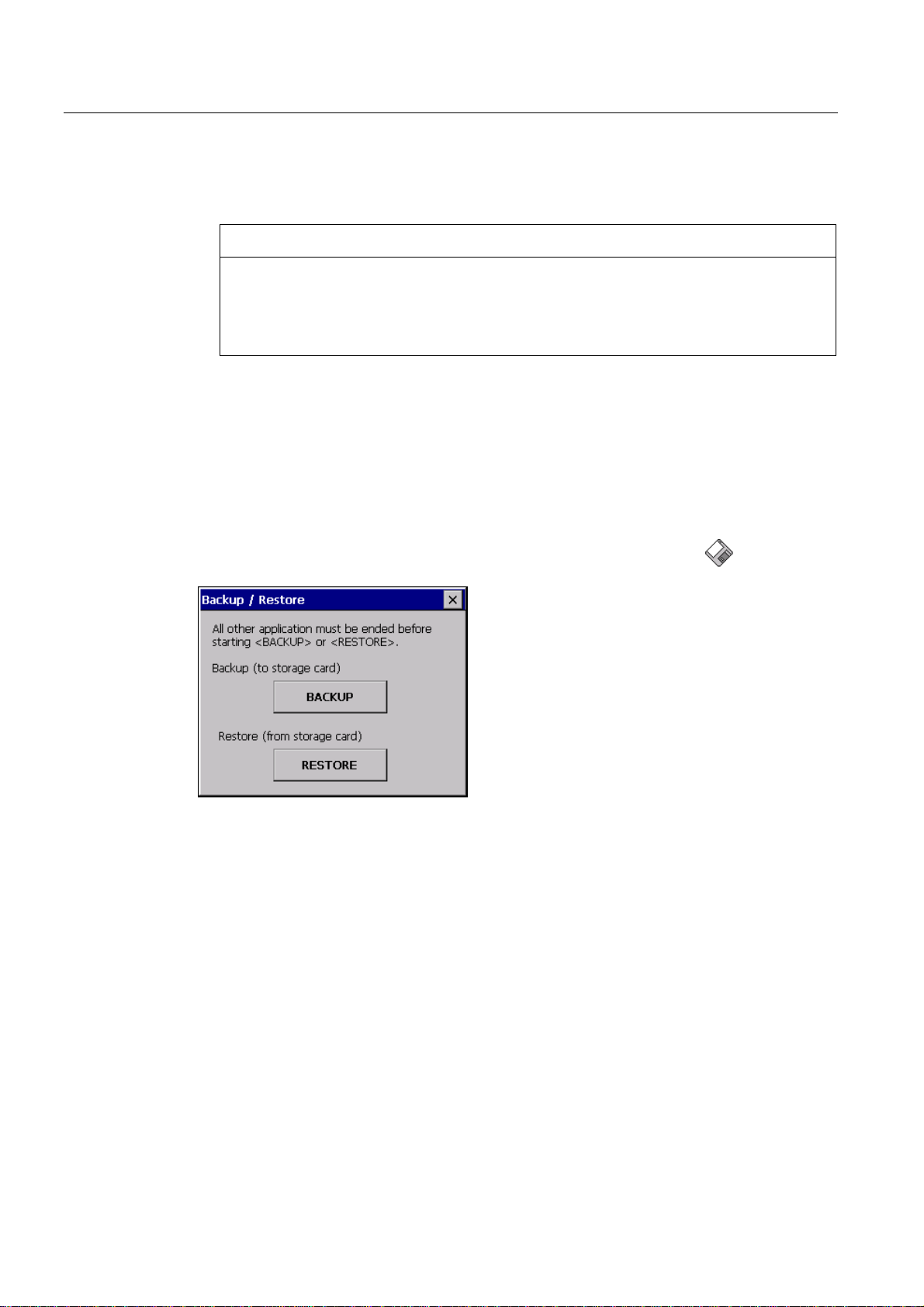

6.13 Backing up and restoring with an external memory medium

Backup

During a backup, the following data is copied from the HMI device's internal flash memory to

an external memory medium.

● Operating system

● Applications

● Data

The following external storage devices are possible:

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

177

Page 14

Configuring the operating system

6.13 Backing up and restoring with an external memory medium

● Memory card

● USB memory stick

CAUTION

IP65 degree of protection not fulfilled

To insert or remove the memory card, you must open the HMI device's connection

compartment. If the connection bay is open, degree of protection IP 65 is not fulfilled.

It is preferable to back up onto a USB memory stick.

Requirements for backup

● The current project and all other applications are closed, except Control Panel.

● The HMI device features an external storage device with sufficient free space.

The size of the internal flash memory is displayed with information about the HMI device.

If the available space on the external memory medium is insufficient, a warning is

displayed and backup is aborted.

You have opened the "Backup/Restore" dialog with the "Backup/Restore"

icon.

Procedure for backup

Proceed as follows:

1. Select "BACKUP" to start Backup.

The HMI device checks the external memory.

The HMI device issues messages in the following situations:

– More than one external memory is available:

Select the desired memory.

– The external memory is not available or is defective:

Acknowledge the displayed messages.

The Control Panel is displayed again.

Replace the external memory. Start the backup process again.

Mobile Panel 277F IWLAN

178 Operating Instructions, 12/2007, A5E01003940-01

Page 15

Configuring the operating system

6.13 Backing up and restoring with an external memory medium

– Data is already stored on the external memory.

2. Follow the instructions of the HMI device.

The following messages are displayed in sequence during backup:

– "Checking Registry"

– "Backup Progress"

– "Saving CE-Image"

A progress bar shows the status of the backup process.

If backup was successful, the following message is displayed:

"Backup successfully completed. Press OK and remove your storage card."

3. Click "OK" button to acknowledge the message.

Remove the external memory medium.

Result

The HMI device data is now saved on the external memory.

Requirements for restoring

The HMI device features an external memory medium that stores the backup.

Procedure for restoring

NOTICE

Deleting the flash memory

A restore operation deletes the old data from flash memory of the HMI device on

confirmation. The data stored on the external memory is then copied to the internal flash

memory. Existing license keys are deleted following your confirmation.

The restore process involves the following steps:

● The Windows CE image is restored.

● The HMI device starts.

● All other data is restored.

NOTICE

Cancel restore

If the external memory is removed during the restore process, the process is canceled.

Ensure that the external memory is not removed at any point during the restore process.

Proceed as follows:

1. Select "RESTORE" to start Restore.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

179

Page 16

Configuring the operating system

6.13 Backing up and restoring with an external memory medium

The HMI device checks the external memory.

The HMI device issues messages in the following situations:

– The external memory is not available or is defective:

Acknowledge the displayed messages.

The Control Panel is displayed again.

Replace the external memory.

– More than one external memory with valid backup is available:

Remove all external memories with backups that are not needed.

If necessary, you can check the available external memories using the "REFRESH"

button.

2. If necessary, start the restore process with the "RESTORE" button.

The data to be restored is checked.

When the check is complete, one of the following prompts is displayed:

– "You are starting RESTORE now. All files (except files on storage cards) and the

registry will be erased. Are you sure?"

Result

At this point you can cancel the restore using the "No" button to prevent the data on

the HMI device from being deleted.

– You are now starting RESTORE. All files on the panel and the licenses listed below as

well as the registry will be erased. Are you sure?

This query is displayed when license keys are available both on the HMI device and in

the backup data. If necessary, cancel the restore process with the "No" button and first

back up the HMI device's license keys. Then restart the restore process.

3. Start to restore the data by selecting "Yes".

A progress bar shows the status of the restoration of the Windows CE image.

When restore is completed, the following message is displayed:

"Restore succesfully finished. Press ok, remove your storage card and reboot your

device."

4. Remove the external memory.

5. Acknowledge this message.

The HMI device starts.

The backed-up data has been restored to the HMI device.

Note

Calibrating the touch screen

After the restore, you may have to re-calibrate the touch screen.

Mobile Panel 277F IWLAN

180 Operating Instructions, 12/2007, A5E01003940-01

Page 17

Configuring the operating system

6.14 Displaying battery status

See also

Displaying information about the HMI device (Page 157)

Using a memory card with the HMI device (Page 113)

6.14 Displaying battery status

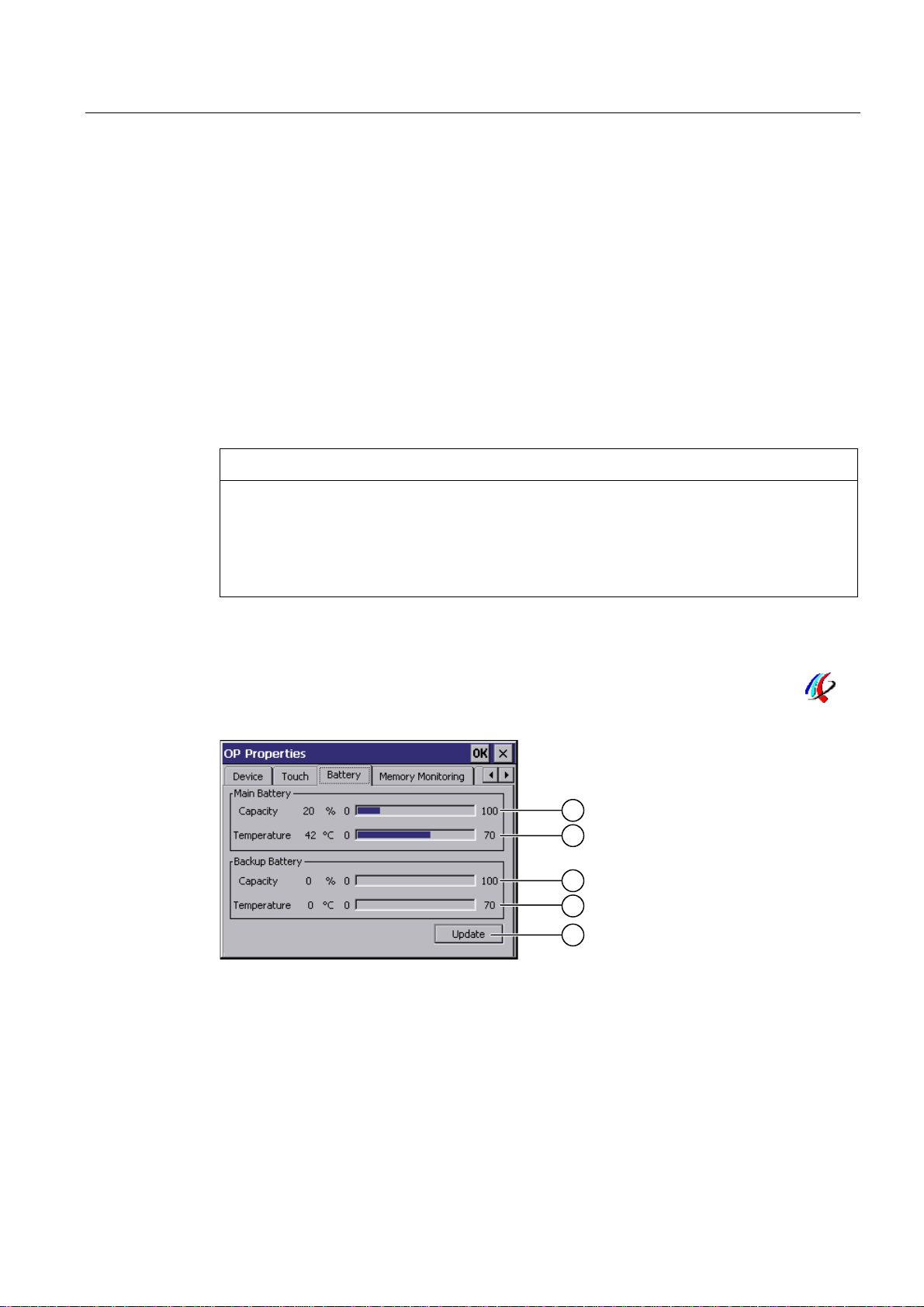

Introduction

You can check the charging status and the temperature of the main battery and the bridging

battery.

Requirements

NOTICE

Battery cannot be charged

To charge the batteries, the ambient temperature / battery temperature must not exceed

40 °C The higher the temperature, the longer it will take for the battery to charge.

Find a place with a cool ambient temperature for the charging station. If necessary, allow

the battery to cool first.

You have opened the "OP Properties" dialog box, "Battery" tab, by touching the "OP"

icon.

① Charging status of main battery

② Temperature of main battery

③ Charging status of bridging battery

④ Temperature of bridging battery

⑤ Button to update the display

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

181

Page 18

Configuring the operating system

6.15 Activate memory management

Procedure

Proceed as follows:

1. Update the display if required by pressing the "Update" button.

2. Close the dialog.

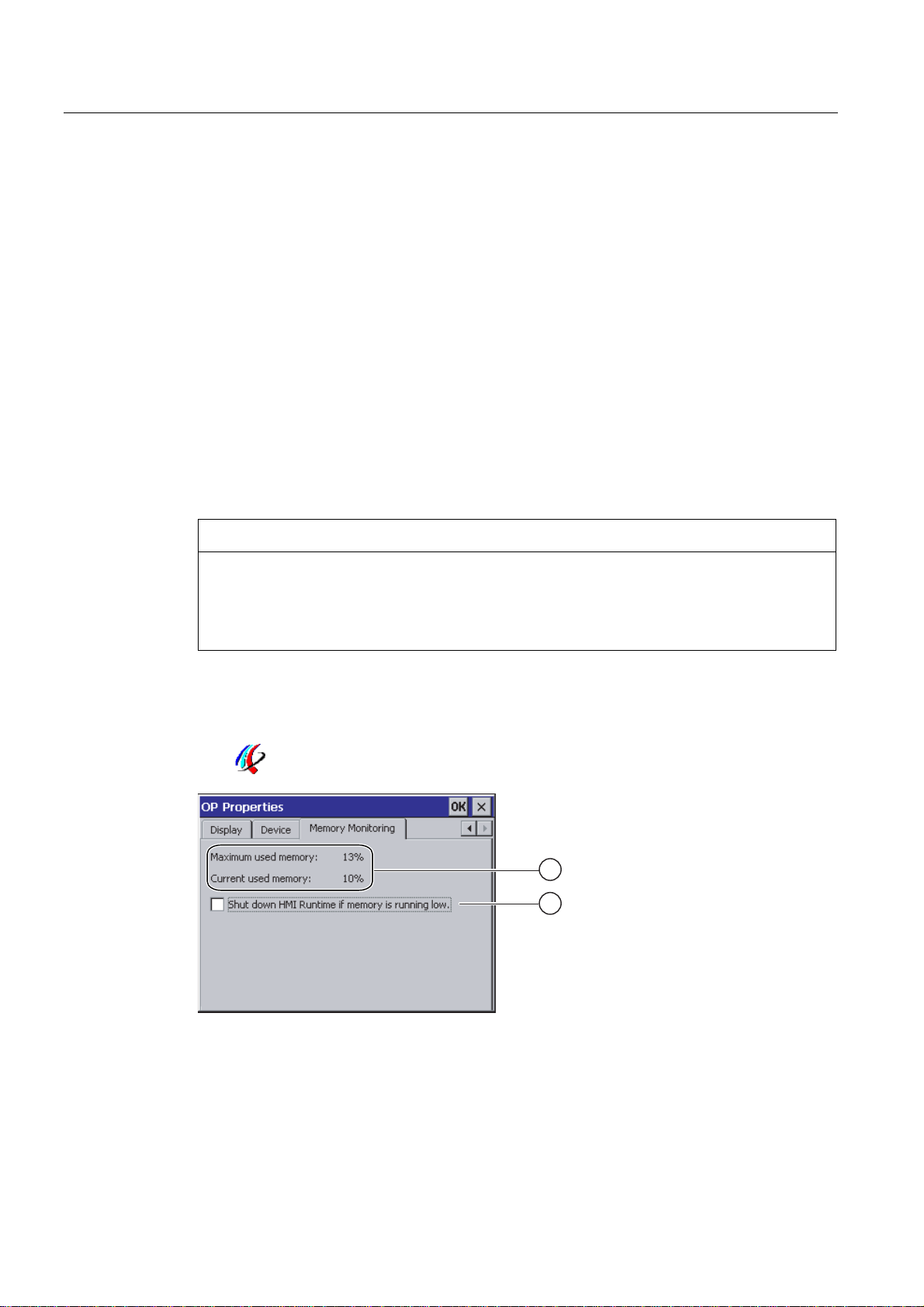

6.15 Activate memory management

Memory management

Provided the memory management is activated, the HMI device will automatically close the

project if the memory needs reorganizing during an active project.

The project is shut down and the HMI device will display a message. You have to restart the

project.

Requirements

NOTICE

Memory management

If you do not activate memory management, undefined states can occur during the runtime

of the project.

Select memory management in the "OP Properties" dialog box.

You have opened the "OP Properties" dialog box, "Memory Monitoring" tab, by touching the

"OP"

icon.

① The maximum used memory since last power on of the HMI device and the current used

memory in percent.

② Check box for selecting memory management

Mobile Panel 277F IWLAN

182 Operating Instructions, 12/2007, A5E01003940-01

Page 19

Configuring the operating system

6.15 Activate memory management

Procedure

Proceed as follows:

1. In order to start memory management, select the check box.

2. Confirm your entries.

The dialog closes.

Result

Memory management is activated.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

183

Page 20

Page 21

Commissioning the HMI device

7.1 Overview

Operating the HMI device

The HMI device is operated in the system as follows:

● As mobile device, with a battery

● As stationary device, in the charging station

For transfer and testing purposes, you can operate the HMI device in an office environment

as follows:

● As mobile device, with a battery

● As stationary device, with a tabletop power supply unit

● As stationary device, in the charging station

HMI device commissioning requirements

You must take the following steps before commissioning a project on the HMI device:

7

1. Install and connect up charging station

Alternatively, connect the HMI device to the tabletop power supply unit.

2. Charging the battery and inserting it in the HMI device

To charge the battery, you have the following possibilities:

– In the charging compartment of the charging station

– In the HMI device, in the charging station

– In the HMI device when connected to the tabletop power supply unit

3. Switch on the HMI device with the ON/OFF button

4. Commission and test WLAN

5. Define the settings for the transfer in the Control Panel.

6. Transfer project to the HMI device

Commissioning

Start the project once you have transferred it to the HMI device.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

185

Page 22

Commissioning the HMI device

7.2 Operating modes

Note

If the project contains effective ranges, you must perform an acceptance test for the effective

ranges and transponders.

You can only start the project on the HMI device once the acceptance test is complete.

● If necessary: Testing zones

See also

Mounting the charging station (Page 66)

Connection of the charging station to the power supply (Page 70)

Programming the data channel (Page 160)

Acceptance of the system (Page 196)

7.2 Operating modes

Operating modes

The HMI device may be in the following operating modes:

● Offline

● Online

● Transfer

"Offline mode" and "Online mode" can be set on both the configuring PC and the HMI

device. To set these modes on the HMI device, use a corresponding operating element of

the project.

Changing the operating mode

The configuration engineer must have configured an appropriate operating element to allow

a change of the operating mode on the HMI device during ongoing operation.

Please refer to your system documentation to check whether additional information on this

subject is available there.

"Offline" operating mode

In this operating mode, the HMI device and the PLC do not communicate via the connections

configured in the WinCC flexible project. You can operate the current project on the HMI

device, but the project data will not be transferred.

Mobile Panel 277F IWLAN

186 Operating Instructions, 12/2007, A5E01003940-01

Page 23

Commissioning the HMI device

7.3 Using existing projects

Note

Emergency stop button active

In "Offline" mode, the emergency stop button is active when the following requirements are

met:

• The HMI device is in an area with sufficient WLAN coverage.

• The HMI device is integrated in the safety program of the CPU.

"Online" operating mode

In this mode, the HMI device and PLC communicate. You can operate the plant on the HMI

device according to your system configuration.

"Transfer" mode

In this mode, you can transfer a project from the configuring PC to the HMI device or backup

and restore HMI device data, for example.

The following options are available for setting "Transfer" mode on the HMI device:

● When the HMI device starts up

Start "Transfer" mode manually in the HMI device Loader.

● During ongoing operation

Start the "Transfer" mode manually within the project using an operating element. With

automatic transfer, following a prompt the HMI device toggles to "Transfer" mode when a

transfer is initiated on the configuring PC.

7.3 Using existing projects

Note

Safety-related operator controls

The behavior and possible fields of application of the enabling button and emergency stop

button on the Mobile Panel 277F IWLAN are different from those of its predecessors, which

do not have Safety Integrated functions.

In this respect, you cannot reuse existing control programs.

For additional information on the safety-related operator controls, refer to the section titled

"Particular features of fail-safe operation" and the Function manual "Fail-safe operation of

the Mobile Panel 277F IWLAN".

You can reuse WinCC flexible projects for the following HMI devices:

● Mobile Panel 177 PN

● Mobile Panel 177 DP

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

187

Page 24

Commissioning the HMI device

7.4 Data transmission options

● Mobile Panel 277

Carry out an HMI device switch in WinCC flexible.

Adaptations

You must adapt the following aspects of the WinCC flexible project:

● Communication via WLAN

● Zone recognition and point recognition

– If you have used point detection with box ID in an existing project, you have the

following option:

Instead of using the connection box, use a zone consisting of at least one transponder

and set the previous box ID as the ID in this zone.

– If you are using zone recognition, you will need one or more transponders for one

zone.

In WinCC flexible, you can parameterize zones in "Device settings".

You can use zones to configure an easy way of selecting a zone-specific screen.

In this case you may also need to modify the control program from previous devices.

Additional information on this subject can be found in the WinCC flexible online help or in the

"WinCC flexible migration" user manual.

7.4 Data transmission options

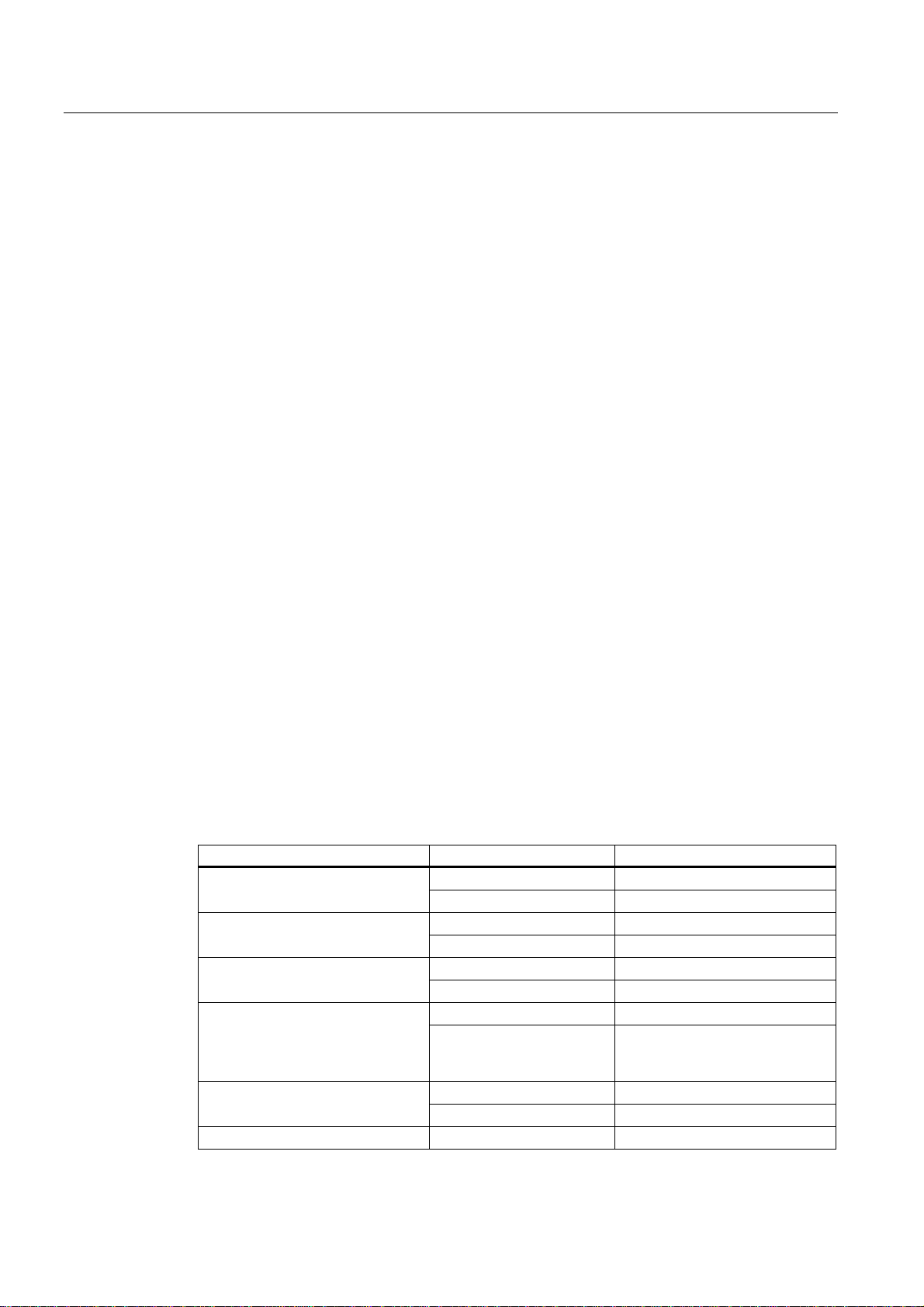

Overview

The following table shows the options for data transfer between Mobile Panel 277 Wireless

and a configuring PC.

The Ethernet data channel is used for communication via WLAN and LAN (RJ45).

Type Data channel Mobile Panel 277 Wireless

reset to factory settings

Installing or removing an option USB Yes

USB Yes Backup

Ethernet Yes

USB Yes Restoring

Ethernet Yes

USB Yes Updating the operating system

Ethernet Yes

USB No Updating the operating system with

Ethernet via the RJ 45

interface

USB Yes Transferring a project

Ethernet Yes

Yes

Mobile Panel 277F IWLAN

188 Operating Instructions, 12/2007, A5E01003940-01

Page 25

Commissioning the HMI device

7.5 Preparing and backing up a project

Type Data channel Mobile Panel 277 Wireless

Ethernet Yes

USB Yes License key transferring or

transferring back

Ethernet Yes

7.5 Preparing and backing up a project

7.5.1 Overview

Introduction

In order to operate the system with the HMI device, you must transfer the WinCC flexible

project to the HMI device.

Transferring the project to the HMI device

You can transfer a project to an HMI device as follows:

● Transfer from the configuring PC

● Restore from a PC using ProSave

In this case, an archived project is transferred from a PC to the HMI device.

WinCC flexible need not be installed on this PC.

Commissioning and recommissioning

● When the HMI device is commissioned there is no project at first.

The HMI device is also in this state after the operating system has been updated.

● When recommissioning, any project already on the HMI device is replaced.

See also

Operating modes (Page 186)

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

189

Page 26

Commissioning the HMI device

7.5 Preparing and backing up a project

7.5.2 Transfer

7.5.2.1 Overview

Transfer

At the end of the configuration phase, transfer the executable project from the configuring

PC to the HMI device.

You can start the "Transfer" mode manually or automatically on the HMI device.

Transferred data is written directly to the internal flash memory on the HMI device. For the

transfer, you use a data channel which you have to configure before starting a transfer.

Backtransfer

You have the option to transfer the compressed project file together with the runtime project

to the HMI device. If necessary, the compressed project file can be transferred back to the

configuring PC and edited.

The HMI device must be equipped with an external memory to which the compressed project

file can be saved.

NOTICE

No checking of the project files

WinCC flexible does not check whether the compressed project file stored on the HMI

device corresponds to the existing runtime project.

7.5.2.2 Starting manual transfer

Introduction

You can manually switch the HMI device to "Transfer" mode as follows:

● With a configured operating element during ongoing operation

● In the Loader of the HMI device

Requirements

● The project "*.hmi" that you want to transfer is open in WinCC flexible on the configuring

PC

● The HMI device is connected to this configuring PC

● The data channel is programmed on the HMI device

● The HMI device is in "Transfer" mode

Mobile Panel 277F IWLAN

190 Operating Instructions, 12/2007, A5E01003940-01

Page 27

Commissioning the HMI device

7.5 Preparing and backing up a project

Procedure

Proceed as follows:

1. On the configuring PC, select the "Transfer settings" command in the menu "Project >

Transfer" in WinCC flexible.

The "Select devices for transfer" dialog opens.

2. Select the HMI device in the left area of the dialog.

3. Select the type of connection between the HMI device and the configuring PC.

4. Set the connection parameters.

5. Set the transfer parameters in the right area of the dialog.

6. If you wish to transfer the compressed project file together with the executable project to

the HMI device:

Select the "Enable backtransfer" check box.

7. Start transfer in WinCC flexible with "Transfer".

The configuring PC checks the connection to the HMI device. The project is transferred to

the HMI device. If the connection is not available or is defective, an error message is

displayed on the configuring PC.

Result

When the transfer is completed successfully, the project can be found on the HMI device.

The transferred project is then started automatically.

See also

Operating modes (Page 186)

Data transmission options (Page 188)

Programming the data channel (Page 160)

7.5.2.3 Starting automatic transfer

Introduction

If automatic transfer is selected, the HMI device automatically switches to "Transfer" mode

during operation as soon as a transfer is initiated on the connected configuring PC.

Note

The HMI device only switches to "Transfer" mode in the current project.

Automatic transfer is particularly suited for the test phase of a new project since transfer is

completed without interfering with the HMI device.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

191

Page 28

Commissioning the HMI device

7.5 Preparing and backing up a project

Requirements

NOTICE

Undesired system responses

If automatic transfer has been selected on the HMI device and a transfer is then initiated on

the configuring PC, the current project is automatically terminated following a prompt.

The HMI device then automatically switches to "Transfer" mode. The transfer mode can

trigger undesired responses in the system.

After the commissioning phase, deactivate the automatic transfer so that the HMI device

cannot be inadvertently switched to transfer mode.

You can issue a password in the Control Panel to restrict access to the transfer settings

and thus avoid unauthorized modifications.

● The project "*.hmi" that you want to transfer is open in WinCC flexible on the configuring

PC

● The HMI device is connected to this configuring PC

● The data channel is programmed on the HMI device

● The automatic transfer is activated in the data channel for the transfer

● The project is started on the HMI device

Procedure

Proceed as follows:

1. On the configuring PC, select the "Transfer settings" command in the menu "Project >

Transfer" in WinCC flexible.

The "Select devices for transfer" dialog opens.

2. Select the HMI device in the left area of the dialog.

3. Select the type of connection between the HMI device and the configuring PC.

4. Set the connection parameters.

5. Set the transfer parameters in the right area of the dialog.

6. If you wish to transfer the compressed project file together with the executable project to

the HMI device:

Select the "Enable backtransfer" check box.

7. Start transfer in WinCC flexible with "Transfer".

The configuring PC checks the connection to the HMI device.

If the HMI device is integrated, it displays the "Start removal" dialog box.

8. Press one of the enabling buttons to confirm the dialog box.

The HMI device is removed. The current project is terminated. The HMI device then

automatically switches to transfer mode. The project is transferred to the HMI device. If

Mobile Panel 277F IWLAN

192 Operating Instructions, 12/2007, A5E01003940-01

Page 29

Commissioning the HMI device

7.5 Preparing and backing up a project

the connection is not available or is defective, an error message is displayed on the

configuring PC.

Result

When the transfer is completed successfully, the project can be found on the HMI device.

The transferred project is then started automatically.

See also

Operating modes (Page 186)

Data transmission options (Page 188)

Programming the data channel (Page 160)

7.5.2.4 Starting backtransfer

Requirements

● No project is open on the configuring PC in WinCC flexible

Procedure

● The HMI device is connected to this configuring PC

● The data channel is programmed on the HMI device

● The HMI device is in "Transfer" mode

● The memory card containing the compressed project file is inserted into the HMI device

Proceed as follows:

1. On the configuring PC, select the "Communication settings" command in the menu

"Project > Transfer" in WinCC flexible.

The "Communication settings" dialog box opens.

2. Select the type of HMI device.

3. Select the type of connection between the HMI device and the configuring PC.

4. Set the connection parameters.

5. Close the dialog with "OK".

6. Select the "Transfer" > "Backtransfer" command in the "Project" menu.

The "Backtransfer" dialog opens.

7. Click "OK" to start the backtransfer process.

The configuring PC checks the connection to the HMI device. The compressed project file

is transferred back from the HMI device to the configuring PC. If the connection is not

available or is defective, an error message is displayed on the configuring PC.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

193

Page 30

Commissioning the HMI device

7.5 Preparing and backing up a project

Result

After successful backtransfer, the project is opened on the configuring PC in WinCC flexible.

See also

Operating modes (Page 186)

Data transmission options (Page 188)

Programming the data channel (Page 160)

7.5.3 Testing a project

Introduction

There are two options to test a project:

● Test the project on the configuring PC

You can test a project at a configuring PC, using a simulator. For detailed information,

refer to the "WinCC flexible" user manual and to the WinCC flexible online help.

● Offline testing of the project on the HMI device

Offline testing means that communication between the HMI device and PLC connections,

which have been configured in WinCC flexible, is down while the test is being carried out.

The PROFIsafe connection between the HMI device and PLC is also available in "Offline"

mode.

● Online testing of the project on the HMI device

Online testing means that the HMI device and PLC communicate with each other during

testing.

Perform the tests, starting with the "Offline test", followed by the "Online test".

Note

You should always test the project on the HMI device on which the project will be used.

Check the following:

1. WLAN coverage

2. Zone recognition, if zones have been configured

3. Check the correct layout of the screens

4. Check the screen navigation

5. Check the input objects

6. Enter the tag values

The test increases the certainty that the project will run error-free on the HMI device.

Mobile Panel 277F IWLAN

194 Operating Instructions, 12/2007, A5E01003940-01

Page 31

Commissioning the HMI device

7.5 Preparing and backing up a project

Note

Test without effective ranges

Perform the test without effective ranges.

A system acceptance test must be performed as soon as you have configured effective

ranges in your project. The effective ranges and assigned transponders will be tested as part

of the acceptance test.

Test the effective ranges separately.

Requirements for offline testing

● The project has been transferred to the HMI device

● The HMI device is in "Offline" mode.

Procedure

In "Offline" mode, you can test individual project functions on the HMI device without them

being affected by the PLC. PLC tags, therefore, are not updated.

Test the operating elements and visualization of the project as far as possible without

connecting to the PLC.

Requirements for online testing

● The project has been transferred to the HMI device

● The HMI device is in "Online" mode

Procedure

In "Online" mode, you can test individual project functions on the HMI device without them

being affected by the PLC. PLC tags are updated in this case.

You have the option to test all communication-dependent functions, for example alarms, etc.

Test the operating elements and views of the project.

See also

Acceptance of the system (Page 196)

Testing zones (Page 200)

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

195

Page 32

Commissioning the HMI device

7.5 Preparing and backing up a project

7.5.4 Acceptance of the system

7.5.4.1 Overview

Introduction

The acceptance of the system includes the following areas:

● Configuring the F CPU and fail-safe I/O

● Safety program

● Effective ranges and transponders

Acceptance steps that you must execute in order to operate the Mobile Panel 277F IWLAN

HMI device in a system with effective ranges are described in detail in these operating

instructions.

The following manuals contain more detailed notes on acceptance of the system:

● Function manual "Fail-safe operation of the Mobile Panel 277F IWLAN"

● Manual "S7 distributed safety, configuring and programming", Chapter "System

acceptance test".

Acceptance of the effective ranges and transponders

For acceptance of the effective ranges and transponders you must determine a CRC

checksum in the plant and enter it in the project. After subsequent project transfer to the HMI

device you can operate the plant with the HMI device.

Note

If you change transponders in the plant you must execute another acceptance of the plant.

When executing an acceptance test of the system, all of the relevant application-specific

standards must be observed.

7.5.4.2 Accepting effective ranges and transponders

Introduction

For safe operation, the project of the HMI device must precisely match the plant.

For this reason when first starting a project in the plant, you must verify all effective ranges

with all transponders. The result of the verification is a CRC checksum that you must enter in

the project. Then you must transfer the project to the HMI device again.

Note

Transponders that are exclusively assigned to one zone are not considered in this

verification.

Mobile Panel 277F IWLAN

196 Operating Instructions, 12/2007, A5E01003940-01

Page 33

Commissioning the HMI device

7.5 Preparing and backing up a project

Acceptance if there are changes

If you change the configuration of transponders and effective ranges in the system, then you

must adjust the configuration. Then you must accept the effective ranges and transponders

again.

Requirements

● In the project:

– Effective ranges and transponders must be configured in the project.

– The project has been transferred to the HMI device.

● In the plant:

– The transponders must be mounted in the plant in such a manner that the effective

ranges stored in the project are formed.

– Batteries must be inserted in the transponders. The ID must be set on the

transponders that is stored in the project for these transponders.

– The IDs of the effective ranges must be marked in the plant.

– The quality of the WLAN range must be sufficient.

Procedure

Proceed as follows:

1. Switch on the HMI device.

The Windows CE desktop with Loader is displayed.

2. If the project does not start automatically, start the project.

The "Transponder test" dialog box opens.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

197

Page 34

Commissioning the HMI device

7.5 Preparing and backing up a project

To the left you will see the list with the names of all configured effective ranges.

3. In the "Effective ranges" list highlight the first effective range that you want to verify.

In the "Transponder" list on the right, the names of the transponders are displayed that

are assigned to the effective range in the project.

4. Go to the first transponder that you want to verify in the "Transponder" list.

5. In the system, read the ID of the highlighted effective range and enter this ID in the

"Effective range" box.

6. Enter the ID of the transponder where you are located in the "Transponder" box.

7. Verify the entered ID with the "Test" button.

When the HMI device receives the signal of the transponder specified, that transponder is

considered to be checked. The transponder will be marked with a check mark in the list.

8. Repeat steps 4 to 7 for all transponders of this effective range.

If you have successfully checked all transponders of an effective range, that effective

range will be indicated with a check mark in the list.

9. Select the next effective range in the list.

10. Repeat steps 4 to 7 for all transponders assigned to this effective range.

11. Verify all additional effective ranges in the list to the left.

12. When you have successfully verified all effective ranges, touch the "Calculate" button.

The HMI device calculates the CRC checksum. The CRC checksum is displayed in the

"CRC" box.

Mobile Panel 277F IWLAN

198 Operating Instructions, 12/2007, A5E01003940-01

Page 35

Commissioning the HMI device

7.5 Preparing and backing up a project

13. Open the project in WinCC flexible ES.

14. Enter the checksum in the "Effective ranges" editor.

15. Transfer the project to the HMI device again.

Result

The HMI device can now be used for operating and monitoring the system.

7.5.4.3 Testing effective ranges

After successful verification of the transponders and effective ranges you must test in the

plant whether the expansion of the configured effective ranges corresponds to the planning.

If the operating elements "Effective range name" and "Effective range quality" are available

in the project, you can check the effective ranges on the HMI device.

In particular, check the following cases:

● Do the limits of the effective range run as planned?

Note particularly that machine operations from excessive distances are not permitted.

● Does the indicator that belongs to the effective range show whether an HMI device is

logged on at the effective range?

● Are moving machine parts influencing the reception of the transponders? Check also the

extreme positions of moving machine parts.

● Is WLAN coverage ensured everywhere in the effective range?

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

199

Page 36

Commissioning the HMI device

7.5 Preparing and backing up a project

7.5.5 Testing zones

If zones are present in the system, you need to test whether the HMI device is detecting

them.

Note

The following requirements must be fulfilled in order to test zones:

• The project has been transferred to the HMI device and started

• The HMI device is in online mode

• The transponders have been fitted and the transponder IDs are set

If the operating elements "Zone label" and "Zone quality" are present in the project, you can

check the zones on the HMI device.

In particular, check the following cases:

● Are the zone limits operating as planned?

Are moving machine parts influencing the reception of the transponders? Check also the

extreme positions of moving machine parts.

● Is WLAN coverage ensured in all parts of the zone?

7.5.6 Backup and restore

7.5.6.1 Overview

Backup and restore

You can back up and restore the following data found in the internal flash memory of the HMI

device with a PC:

● Project and HMI device image

● Password list

● Recipe data

● License keys

Use one of the following tools for backup and restore:

● WinCC flexible

Mobile Panel 277F IWLAN

200 Operating Instructions, 12/2007, A5E01003940-01

● ProSave

Note

Alternatively, use the Control Panel to back up to an external memory device.

Page 37

Commissioning the HMI device

7.5 Preparing and backing up a project

General information

NOTICE

Resetting to factory defaults required

If a complete restore operation is interrupted due to power failure on the HMI device, the

operating system of the HMI device may be deleted! In this case, you have to reset the HMI

device to its factory settings.

Compatibility conflict

If a message is output on the HMI device warning of a compatibility conflict during the

restore operation, the operating system must be updated.

7.5.6.2 Backup and restore using WinCC flexible

Requirements

● No project is open on the configuring PC in WinCC flexible

● The HMI device is connected to this configuring PC

● The data channel is programmed on the HMI device

Procedure for backup

Proceed as follows:

1. On the configuring PC, select the "Communication settings" command in the menu

"Project > Transfer" in WinCC flexible.

The "Communication settings" dialog box opens.

2. Select the type of HMI device.

3. Select the type of connection between the HMI device and the configuring PC.

4. Set the connection parameters.

5. Close the dialog with "OK".

6. Select the "Backup" command in the menu "Project > Transfer" in WinCC flexible.

The "Backup settings" dialog opens.

7. Select the data to be backed up.

8. Select a destination folder and a file name for the "*.psb" backup file.

9. Set "Transfer" mode on the HMI device.

10. Start the backup operation in WinCC flexible with "OK" on the configuring PC.

If automatic transfer has been selected on the HMI device, following a prompt the HMI

device automatically switches to "Transfer" mode when a backup is initiated.

11. Follow the instructions in WinCC flexible.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

201

Page 38

Commissioning the HMI device

7.5 Preparing and backing up a project

A status view opens to indicate the progress of the operation.

Result

The system outputs a message when the backup is completed.

The relevant data is now backed up on the configuring PC.

Procedure for restoring

Proceed as follows:

1. On the configuring PC, select the "Communication settings" command in the menu

"Project > Transfer" in WinCC flexible.

The "Communication settings" dialog box opens.

2. Select the type of HMI device.

3. Select the type of connection between the HMI device and the configuring PC.

Set the connection parameters.

4. Close the dialog with "OK".

Result

5. Select the "Restore" command in the menu "Project > Transfer" in WinCC flexible.

The "Restore settings" dialog opens.

6. Select the "*.psb" backup file to be restored from the "Open" field.

You can see the HMI device for which the backup file was created and the type of backup

data the file contains.

7. Set "Transfer" mode on the HMI device.

If automatic transfer has been selected on the HMI device, following a prompt the HMI

device automatically switches to "Transfer" mode when a restore operation is initiated.

8. Start the restore operation in WinCC flexible with "OK" on the configuring PC.

If there are license keys both on the HMI device and in the backup, a dialog box will

appear. Use this dialog to establish whether you want to overwrite the license keys or

abort the restore process.

– If necessary, abort the backup and first back up the HMI device's license keys.

– Then restart the restore process.

Follow the instructions in WinCC flexible.

A status view opens to indicate the progress of the operation.

When the restore is successfully completed, the data backed up on the configuring PC is

now on the HMI device.

See also

Operating modes (Page 186)

Mobile Panel 277F IWLAN

202 Operating Instructions, 12/2007, A5E01003940-01

Page 39

Commissioning the HMI device

7.5 Preparing and backing up a project

Data transmission options (Page 188)

Programming the data channel (Page 160)

Overview (Page 200)

7.5.6.3 Backup and restore using ProSave

Requirements

● The HMI device is connected to a PC on which ProSave is installed

● The data channel is programmed on the HMI device

Procedure for backup

Proceed as follows:

1. From the Windows Start menu, start ProSave on the PC.

2. Select the HMI device type in the "General" tab.

3. Select the type of connection between the HMI device and the PC.

4. Set the connection parameters.

5. Select the data to be backed up in the "Backup" tab.

6. Select a destination folder and a file name for the "*.psb" backup file.

7. Set "Transfer" mode on the HMI device.

If automatic transfer has been selected on the HMI device, following a prompt the HMI

device automatically switches to "Transfer" mode when a backup is initiated.

8. Start the backup operation in ProSave with "Start Backup".

9. Follow the instructions in ProSave.

A status view opens to indicate the progress of the operation.

Result

The system outputs a message when the backup is completed.

The relevant data is now backed up on the PC.

Procedure for restoring

Proceed as follows:

1. From the Windows Start menu, start ProSave on the PC.

2. Select the HMI device type in the "General" tab.

3. Select the type of connection between the HMI device and the PC.

4. Set the connection parameters.

5. Select the "*.psb" backup file to be restored from the "Restore" tab.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

203

Page 40

Commissioning the HMI device

7.5 Preparing and backing up a project

You can see the HMI device for which the backup file was created and the type of backup

data the file contains.

6. Set "Transfer" mode on the HMI device.

If automatic transfer has been selected on the HMI device, following a prompt the HMI

device automatically switches to "Transfer" mode when a restore operation is initiated.

7. Start the restore operation in ProSave on the PC with "Start Restore".

If there are license keys both on the HMI device and in the backup, a dialog box will

appear. Use this dialog to establish whether you want to overwrite the license keys or

abort the restore process.

– If necessary, abort the restore and first back up the HMI device's license keys.

– Then restart the restore process.

8. Follow the instructions in ProSave.

A status view opens to indicate the progress of the operation.

Result

When the restore is successfully completed, the data backed up on the PC is now on the

HMI device.

See also

Operating modes (Page 186)

Data transmission options (Page 188)

Programming the data channel (Page 160)

Overview (Page 200)

7.5.7 Updating the operating system

7.5.7.1 Overview

Updating the operating system

A compatibility conflict may occur when transferring a project to the HMI device. This is

caused by different versions of the configuration software used and the HMI device image

available on the HMI device. If there are different versions, the transfer is aborted. A

message indicating a compatibility conflict is displayed on the configuring PC.

There are two ways to match the versions:

● Update the HMI device image if the project was created with the most recent version of

the configuration software

● Transfer a matching version of the HMI device image if you do not want to adapt the

project for the HMI device to the most recent version of the configuration software for the

project

Mobile Panel 277F IWLAN

204 Operating Instructions, 12/2007, A5E01003940-01

Page 41

Commissioning the HMI device

7.5 Preparing and backing up a project

General information

NOTICE

Resetting to factory defaults required

If the update of the HMI device image is interrupted due to a power failure on the HMI

device, the operating system of the HMI device may be deleted. In this case, you have to

reset the HMI device to its factory settings.

NOTICE

Data loss

All data on the HMI device, such as the project and passwords, will be deleted when you

update the operating system.

Note

Calibrating the touch screen

After updating the operating system, you may have to recalibrate the touch screen.

Resetting to factory settings

In ProSave or WinCC flexible, you can update the operating system with or without resetting

to factory settings.

CAUTION

IP65 degree of protection not fulfilled

To update the operating system and reset to factory settings, you need an Ethernet

connection over the RJ45 interface.

If you connect the configuring PC directly to the HMI device through the RJ45 interface, you

must open the connection compartment. If the connection bay is open, degree of protection

IP 65 is not fulfilled.

● Updating the operating system without resetting to factory settings

First, switch into "Transfer" mode on the HMI device or use the automatic transfer

function if the project is active. Then start the operating system update in ProSave or

WinCC flexible.

● Updating the operating system with reset to factory setting

NOTICE

Loss of license keys

The license keys on the HMI device will be deleted when resetting to factory settings.

The license keys on the HMI device will be retained when updating the operating system

without resetting to factory settings.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

205

Page 42

Commissioning the HMI device

7.5 Preparing and backing up a project

NOTICE

Data channels

When resetting to factory settings, all data channel parameters are reset. The transfer

can only be started following reconfiguration of the data channels.

Note

You have to perform an operating system update with reset to factory settings if the HMI

device does not yet have an operating system or if the operating system of the HMI

device is corrupt.

First, start the operating system update in ProSave or WinCC flexible and switch the

power on the HMI device off and on again when prompted.

7.5.7.2 Updating the operating system using WinCC flexible

Requirements

● No project is open on the configuring PC in WinCC flexible

Procedure

● The HMI device is connected to this configuring PC

● The data channel is programmed on the HMI device

Proceed as follows:

1. On the configuring PC, select the "Communication settings" command in the menu

"Project > Transfer" in WinCC flexible.

The "Communication settings" dialog box opens.

2. Select the type of HMI device.

3. Select the type of connection between the HMI device and the configuring PC.

4. Set the connection parameters.

5. Close the dialog with "OK".

6. In WinCC flexible, select the command "Update OS" in the "Project > Transfer" menu.

7. In "Image path", select the HMI device image file "*.img".

The HMI device image files are available under "WinCC flexible Images" in the

WinCC flexible installation folder or on the WinCC flexible installation CD.

In the output area, you are provided information on the version of the HMI device image

file after it is opened.

8. Set "Transfer" mode on the HMI device.

If automatic transfer has been activated on the HMI device, following a prompt the HMI

device automatically switches to "Transfer" mode when an update is initiated.

9. In WinCC flexible, select "Update OS" on the configuring PC to run the operating system

update.

Mobile Panel 277F IWLAN

206 Operating Instructions, 12/2007, A5E01003940-01

Page 43

Commissioning the HMI device

7.5 Preparing and backing up a project

10. Follow the instructions in WinCC flexible.

During the operating system update a status view opens to indicate progress.

Result

A message is displayed when the operating system update is successfully completed.

This operation has deleted the project data from the HMI device.

See also

Operating modes (Page 186)

Data transmission options (Page 188)

Programming the data channel (Page 160)

Overview (Page 204)

7.5.7.3 Updating the operating system using ProSave

Requirements

Procedure

● The HMI device is connected to a PC on which ProSave is installed

● The data channel is programmed on the HMI device

Proceed as follows:

1. From the Windows Start menu, start ProSave on the PC.

2. Select the HMI device type in the "General" tab.

3. Select the type of connection between the HMI device and the PC.

4. Set the connection parameters.

5. Select the "OS Update" tab.

6. In "Image path", select the HMI device image file "*.img".

The HMI device image files are available under "WinCC flexible Images" in the

WinCC flexible installation folder or on the WinCC flexible installation CD.

In the output area, you are provided information on the version of the HMI device image

file after it is opened.

7. Set "Transfer" mode on the HMI device.

If automatic transfer has been activated on the HMI device, following a prompt the HMI

device automatically switches to "Transfer" mode when an update is initiated.

8. Select "Update OS" on the PC to run the operating system update.

9. Follow the instructions in ProSave.

During the operating system update a status view opens to indicate progress.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

207

Page 44

Commissioning the HMI device

7.5 Preparing and backing up a project

Result

A message is displayed when the operating system update is successfully completed.

This operation has deleted the project data from the HMI device.

See also

Operating modes (Page 186)

Data transmission options (Page 188)

Programming the data channel (Page 160)

Overview (Page 204)

7.5.7.4 Resetting to factory settings with WinCC flexible

Requirements

● No project is open on the configuring PC in WinCC flexible

● The HMI device is connected to this configuring PC over the Ethernet

● Have the MAC address of your HMI device's Ethernet interface to hand.

– The MAC address is displayed briefly when the HMI device is turned on.

– The MAC address is displayed in the "PROFINET" dialog in the Control Panel.

Procedure for setting the PC interface

1. Select "Start > Control Panel > Set PG/PC interface".

2. Select "S7ONLINE (STEP7) -> TCP/IP" from the "Application access point" area.

3. Select the interface which is connected to the HMI device from the "Interface

parameterization used" area.

4. Confirm your entries.

Procedure for resetting to factory settings

Proceed as follows:

1. Turn off the power supply to the HMI device.

2. On the configuring PC, select the "Communication settings" command in the menu

"Project > Transfer" in WinCC flexible.

The "Communication settings" dialog box opens.

3. Select the HMI device type from the "General" tab, and select "Ethernet" from the

"Connection" area.

4. Enter an IP address.

Mobile Panel 277F IWLAN

208 Operating Instructions, 12/2007, A5E01003940-01

Page 45

Commissioning the HMI device

7.5 Preparing and backing up a project

Note

Possible address conflicts with incorrect IP address

Do not use a dynamic IP configuration for "Reset factory settings".

Define an IP address which the HMI device is going to receive from the configuration

station during the update process.

If the HMI device has already been used with WinCC flexible or ProSave you can use the

existing IP address for "Reset factory settings".

Result

1. Confirm your entries.

2. In WinCC flexible, select the command "Update OS" in the "Project > Transfer" menu.

3. Select the "Reset factory settings" check box.

A text box opens where you can enter the MAC address.

4. Enter the HMI device's MAC address in the text box.

5. In "Image path", select the HMI device image file "*.img".

The HMI device image files are available under "WinCC flexible Images" in the

WinCC flexible installation folder or on the WinCC flexible installation CD.

In the output area, you are provided information on the version of the HMI device image

file after it is opened.

6. In WinCC flexible, select "Update OS" on the configuring PC to run the operating system

update.

7. Follow the instructions in WinCC flexible.

During the operating system update a status view opens to indicate progress.

A message is displayed when the operating system update is successfully completed.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

209

Page 46

Commissioning the HMI device

7.5 Preparing and backing up a project

This operation has deleted the project data from the HMI device. The factory settings are

reset.

Note

Calibrating the touch screen

After the restore, you may have to re-calibrate the touch screen.

See also

Operating modes (Page 186)

Data transmission options (Page 188)

Programming the data channel (Page 160)

Overview (Page 204)

7.5.7.5 Resetting to factory settings with ProSave

Requirements

● The HMI device is connected over the Ethernet to a PC on which ProSave is installed

● When updating the operating system with reset to factory setting only:

Have the MAC address of your HMI device's Ethernet interface to hand.

– The MAC address is displayed briefly when the HMI device is turned on.

– The MAC address is displayed in the "PROFINET" dialog in the Control Panel.

Procedure for setting the PC interface

1. Select "Start > Control Panel > Set PG/PC interface".

2. Select "S7ONLINE (STEP7) -> TCP/IP" from the "Application access point" area.

3. Select the interface which is connected to the HMI device from the "Interface

parameterization used" area.

4. Confirm your entries.

Procedure for resetting factory settings

Proceed as follows:

1. Turn off the power supply to the HMI device.

2. From the Windows Start menu, start ProSave on the PC.

3. Select the HMI device type from the "General" tab, and select "Ethernet" from the

"Connection" area.

4. Enter an IP address.

Mobile Panel 277F IWLAN

210 Operating Instructions, 12/2007, A5E01003940-01

Page 47

Commissioning the HMI device

7.5 Preparing and backing up a project

Note

Possible address conflicts with incorrect IP address

Do not use a dynamic IP configuration for "Reset factory settings".

Define an IP address which the HMI device is going to receive from the configuration

station during the update process.

If the HMI device has already been used with WinCC flexible or ProSave you can use the

existing IP address for "Reset factory settings".

1. Change to the "OS Update" tab.

2. Select the "Reset factory settings" check box.

A text box opens where you can enter the MAC address.

3. Enter the MAC address of the HMI device

4. In "Image path", select the HMI device image file "*.img".

The HMI device image files are available under "WinCC flexible Images" in the

WinCC flexible installation folder or on the WinCC flexible installation CD.

In the output area, you are provided information on the version of the HMI device image

file after it is opened.

5. Select "Update OS" on the PC to run the operating system update.

6. Follow the instructions in ProSave.

During the operating system update a status view opens to indicate progress.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

211

Page 48

Commissioning the HMI device

7.5 Preparing and backing up a project

Result

A message is displayed when the operating system update is successfully completed.

This operation has deleted the project data from the HMI device. The factory settings are

reset.

Note

Calibrating the touch screen

After the restore, you may have to re-calibrate the touch screen.

See also

Operating modes (Page 186)

Data transmission options (Page 188)

Programming the data channel (Page 160)

Overview (Page 204)

7.5.8 Installing and removing options

7.5.8.1 Overview

Installing and removing options

You can install options on the HMI device, for example, additional programs developed

especially for the HMI device.

You can also remove the option from the HMI device again.

Note

License key

A license key may be needed to run an option. The license key unlocks the option for use.

7.5.8.2 Installing and removing options using WinCC flexible

Requirements

● No project is open on the configuring PC in WinCC flexible

● The HMI device is connected to this configuring PC

● The data channel is programmed on the HMI device

Mobile Panel 277F IWLAN

212 Operating Instructions, 12/2007, A5E01003940-01

Page 49

Commissioning the HMI device

7.5 Preparing and backing up a project

Procedure for installing an option

Proceed as follows:

1. On the configuring PC, select the "Communication settings" command in the menu

"Project > Transfer" in WinCC flexible.

The "Communication settings" dialog box opens.

2. Select the type of HMI device.

3. Select the type of connection between the HMI device and the configuring PC.

4. Set the connection parameters.

5. Close the dialog with "OK".

6. Select the "Options" command in the menu "Project > Transfer" in WinCC flexible.

7. Select the desired option under "Available options".

8. Set "Transfer" mode on the HMI device.

If automatic transfer is activated on the HMI device, following a prompt the HMI device

automatically switches to "Transfer" mode when the installation of an option is initiated.

9. Start the installation of the option in WinCC flexible on the configuring PC with the ">>"

button.

10. Follow the instructions in WinCC flexible.

A status display appears indicating the progress of the installation.

Result

The option has now been installed on the HMI device.

Procedure for removing an option

Proceed as follows:

1. On the configuring PC, select the "Communication settings" command in the menu

"Project > Transfer" in WinCC flexible.

The "Communication settings" dialog box opens.

2. Select the type of HMI device.

3. Select the type of connection between the HMI device and the configuring PC.

4. Set the connection parameters.

5. Close the dialog with "OK".

6. Select the "Options" command in the menu "Project > Transfer" in WinCC flexible.

7. Press the "Device status" button to update the display.

8. Select the desired option under "Installed options".

9. Set "Transfer" mode on the HMI device.

If automatic transfer is activated on the HMI device, following a prompt the HMI device

automatically switches to "Transfer" mode when the removal of an option is initiated.

Mobile Panel 277F IWLAN

Operating Instructions, 12/2007, A5E01003940-01

213

Page 50

Commissioning the HMI device

7.5 Preparing and backing up a project

10. Start the removal of the option in WinCC flexible on the configuring PC with the "<<"

button.

11. Follow the instructions in WinCC flexible.

A status display appears indicating the progress of the removal.

Result

The option has now been removed on the HMI device.

See also

Operating modes (Page 186)

Data transmission options (Page 188)

Programming the data channel (Page 160)

Overview (Page 212)

7.5.8.3 Installing and removing options using ProSave

Requirements

● The HMI device is connected to a PC on which ProSave is installed

● The data channel is programmed on the HMI device

Procedure for installing an option

Proceed as follows:

1. From the Windows Start menu, start ProSave on the PC.

2. Select the HMI device type in the "General" tab.

3. Select the type of connection between the HMI device and the PC.

4. Set the connection parameters.

5. Select the "Options" tab.

6. Select the desired option under "Available options".

7. Set "Transfer" mode on the HMI device.

If automatic transfer is activated on the HMI device, following a prompt the HMI device

automatically switches to "Transfer" mode when the installation of an option is initiated.

8. Start the installation of the option in ProSave with the ">>" button.

9. Follow the instructions in ProSave.

A status display appears indicating the progress of the installation.

Mobile Panel 277F IWLAN

214 Operating Instructions, 12/2007, A5E01003940-01

Page 51

Commissioning the HMI device

7.5 Preparing and backing up a project

Result

The option has now been installed on the HMI device.

Procedure for removing an option

Proceed as follows:

1. From the Windows Start menu, start ProSave on the PC.

2. Select the HMI device type in the "General" tab.

3. Select the type of connection between the HMI device and the PC.

4. Set the connection parameters.

5. Select the "Options" tab.

6. Press the "Device status" button to update the display.

7. Select the desired option under "Installed options".

8. Set "Transfer" mode on the HMI device.

If automatic transfer is activated on the HMI device, following a prompt the HMI device

automatically switches to "Transfer" mode when the removal of an option is initiated.

9. Start the removal of the option in ProSave with the "<<" button.

10. Follow the instructions in ProSave.

A status display appears indicating the progress of the removal.

Result

The option has now been removed on the HMI device.

See also

Operating modes (Page 186)

Data transmission options (Page 188)

Programming the data channel (Page 160)

Overview (Page 212)