Siemens 270 series,SIMATIC TP 270,SIMATIC OP 270 Specification

Siemens ST 80 · 2006

2/110

Operator Control and Monitoring Devices

SIMATIC TP 270

Panels — 270 series

2

■

Overview

• Touch panel with extensive functional scope for demanding

machine visualization applications

• Pixel graphics 5.7" or 10.4” STN Touch Screen (analog/resistive),

color (256 colors)

• All interfaces on board, e.g. MPI, PROFIBUS DP, USB;

Ethernet optional

• The SIMATIC TP 270 Touch Panels are innovative successors

to the SIMATIC TP27 Touch Panels

■

Benefits

• Integral component of Totally Integrated Automation (TIA):

Increases productivity, minimizes the engineering outlay,

reduces the lifecycle costs

• Modular expansion possible with options such as:

- WinCC flexible /Sm@rtAccess for communication between

various SIMATIC HMI systems

- WinCC flexible /Sm@rtService for remote maintenance and

servicing of machines/plants via the Internet/intranet

• Reduces the service and start-up costs due to:

- Backup/restore via USB, MPI, PROFIBUS DP, RS 232 (serial)

and optionally via Ethernet (TCP/IP) or compact flash card

(CF card)

- Remote downloading/uploading of the configuration and

firmware

- Specific drivers can be downloaded

- Long service life of the backlighting

• Graphics library is available complete with ready-to-use

display objects

• Can be used worldwide:

- 32 languages can be configured (including Asiatic and

Cyrillic character sets)

- Up to 5 languages are selectable online

• Standard hardware and software interfaces to increase

flexibility:

- CF card, used for recipe data sets and for backing up the

configuration and system data

- Integrated USB interface for "Hot plug-in/out“ of I/O devices

(printer, keyboard, mouse, barcode reader)

- Standard Windows storage format (CSV) for archives

and recipes for further processing using standard tools

(e.g. MS Excel)

- Optional Ethernet (TCP/IP) for centralized data management

and project management;

connection of PLC to SIMATIC S7 when configuring with

WinCC flexible

■

Application

The SIMATIC TP 270 Touch Panels can be used in all applications in which operator control and monitoring of machines and

installations is required on site – whether in production automation, process automation or building service automation. They

are in use in an extensive range of sectors and applications.

Their operation without a hard disk or fan, real-time capability as

well as short start-up times make demanding machine visualization tasks possible even under harsh industrial conditions.

■

Design

• 5.7” (TP 270 6“) or 10.4“ (TP 270 10“) STN color display,

256 colors

• Resistive analog Touch

• Compact design with small installation depth

• Rugged plastic (TP 270 6") or aluminum die-cast housing

(TP 270 10") with IP65/NEMA 4/NEMA 12 (front) or IP20

(rear of unit) degree of protection

• The front is resistant to various oils, greases and standard

detergents

• High electromagnetic compatibility (EMC) and extreme vibration resistance

• Plug-type terminals for connection of a 24 V DC power supply

• Interfaces:

- Serial RS 232 interface and RS 485/422 for process con-

nections and for downloading the configuration (MPI and

PROFIBUS DP up to 12 Mbit/s)

- Serial RS 232 interface (printer, download/upload)

- USB for mouse, keyboard, printer and downloading/

uploading configurations

- Optional Ethernet (TCP/IP) using network card for exchang-

ing data with a higher-level PC, connecting a network printer

and downloading/uploading configurations;

connection of PLC to SIMATIC S7 when configuring with

WinCC flexible

• Slot for compact flash card

© Siemens AG 2007

Siemens ST 80 · 2006

2/111

Operator Control and Monitoring Devices

Panels — 270 series

SIMATIC TP 270

2

■

Function

• Displaying and modifying process parameters

• Process display:

- TP 270 6“:

QVGA resolution (320 x 240 pixels),

TP 270 10“:

VGA resolution (640 x 480 pixels)

with 256 colors for display elements

- Vector graphics (various line-drawn and solid objects)

- Dynamic positioning and dynamic showing/hiding of objects

- Pixel graphics displays, curves and bar displays

- Presentation of up to 8 curves in a curve field;

curve graphics with scroll and zoom functions for accessing

historical values and for flexible selection of the displayed

time frame;

cross-hair for reading off current values and display in a table

- Comprehensive image libraries (SIMATIC HMI

Symbol Library)

- Graphics objects: Slider, gauge, clock

- Cyclic function processing using timers

• Multiplex function for variables

• Message system

- administration of status, fault and system messages

- Status and fault messages with message history

- Preconfigured message display, message window and message line

• Archiving of messages and process values (on CF Card,

optionally over Ethernet)

- Different archive types: short-term archive and sequence

archive

- Storage of archive data in standard Windows format (CSV)

- Online evaluation of process value archives through curves

- External evaluation using standard tools (MS Excel and

MS Access) is possible

• Message log and shift log

• Print functions (see "recommended printers")

• Language selection

5 online languages, 32 configuration languages incl. Asiatic

and Cyrillic character sets

• Password protection with 10 levels

• Recipe management

- With additional data storage (on CF Card)

- Online/offline processing at the panel

- Storage of recipe data in standard Windows format (CSV)

- External processing using standard tools MS Excel and

MS Access is possible

• PG functions STATUS/CONTROL VAR in combination with

SIMATIC S5 and SIMATIC S7

• Display selection from the PLC

supports operator prompting from the PLC

• Visual Basic Script, flexibility through the implementation of

new functions including linking to ProTool variables (comparison operations, loops, etc.)

• Help texts

for process diagrams, messages and variables

• Mathematical functions

• Limit value monitoring

for reliable process control of inputs and outputs

• Permanent window;

permanent display area for the output of information that is not

specific to the particular display (e.g. important process variables, date and time)

• Simple maintenance and configuration through

- Backup and restoring the configuration, operating system,

data records and firmware on the optional CF Card (Compact

Flash Card) or optionally over Ethernet

- Backup and restoring the configuration, operating system,

data records and firmware on a PC using ProSave

- Configuration download/upload over

USB/MPI/PROFIBUS DP/RS 232/Ethernet (optional)/modem

and CF Card (optional)

- Automatic transfer identification

- Individual contrast settings

- Configuration simulation directly on the configuration computer

• Import/export of all texts including messages in CSV format for

translation using standard word processing programs

Additional functions when configuring with WinCC flexible

• Project-specific picture blocks that can be modified centrally

• Message system

- Bit messages and analog messages (limit value messages)

as well as the Alarm S message frame procedure for SIMATIC

S7 and SIMOTION

- Freely-definable message classes (e.g. status/fault mes-

sages) for definition of acknowledgment response and display of message events

• Language selection:

- Language-dependent texts and graphics

• Permanent window expanded by template concept;

- generation of screen templates

• User administration (security)

- User-oriented access protection according to requirements

of specific sectors

- Authentication by means of user ID and password

- Privileges specific to user groups

• Visual Basic Runtime object model

• Service functions

(optionally with "WinCC flexible/Sm@rtService")

- E-mail generation

- Remote operation of the SIMATIC HMI system based on

Internet explorer

- Web server with status HTML pages and control functions

• Client/server functions

(optionally with "WinCC flexible /Sm@rtAccess")

- Remote operation and monitoring of other SIMATIC HMI

systems

- Plant-wide scanning of information and archiving of process

data

© Siemens AG 2007

Siemens ST 80 · 2006

2/112

Operator Control and Monitoring Devices

SIMATIC TP 270

Panels — 270 series

2

■

Function (continued)

Configuration

Configuring is performed using the configuring software

SIMATIC ProTool or SIMATIC ProTool/Pro Configuration (see HMI

software/configuring software or visualization software) or using

the engineering software SIMATIC WinCC flexible Standard or

Advanced (see HMI software/SIMATIC WinCC flexible engineering software).

Projects generated using ProTool can be imported into WinCC

flexible.

Applications/options

When configuring with ProTool

• SIMATIC ProAgent/MP;

fast, localized fault diagnosis in plants and machines for

SIMATIC S7 and SIMATIC HMI (see HMI software/process

diagnostics software SIMATIC ProAgent)

When configuring with WinCC flexible

• WinCC flexible /ProAgent;

fast, localized fault diagnosis in plants and machines for

SIMATIC S7 and SIMATIC HMI (see HMI software/process

diagnostics software SIMATIC ProAgent)

• WinCC flexible /Sm@rtAccess;

Remote control and monitoring as well as communication

between different SIMATIC HMI systems (see WinCC flexible

RT options)

• WinCC flexible /Sm@rtService;

Remote monitoring and servicing of machines/plants over the

Internet/intranet (see WinCC flexible RT options)

■

Integration

The TP 270 can be connected to:

• SIMATIC S7-200/-300/-400

• SIMATIC WinAC Software/Slot PLC

• SIMATIC S5

• SIMATIC 505

•SINUMERIK

•SIMOTION

• Non-Siemens controllers

- Allen Bradley

- Mitsubishi

- Telemecanique

1)

- LG GLOFA GM

- Modicon

- GE-Fanuc

-Omron

• Over Ethernet (TCP/IP) to higher-level PC and network printer

(optionally over NE2000-compatible network card)

Additionally when configuring with WinCC flexible

• Ethernet communication with SIMATIC S7 (optionally over

NE2000-compatible network card)

• Multi-protocol capability

• HTTP communication to other SIMATIC HMI systems (optionally with the "WinCC flexible /Sm@rtAccess" option)

•SINUMERIK

(optionally with "SINUMERIK HMI copy license

WinCC flexible CE"; the "SINUMERIK HMI engineering package WinCC flexible" is additionally necessary for configuration;

for further information, see Catalog NC 60)

1) Cannot be connected in conjunction with WinCC flexible

Note:

For further information, see "System interfaces".

© Siemens AG 2007

Siemens ST 80 · 2006

2/113

Operator Control and Monitoring Devices

Panels — 270 series

SIMATIC TP 270

2

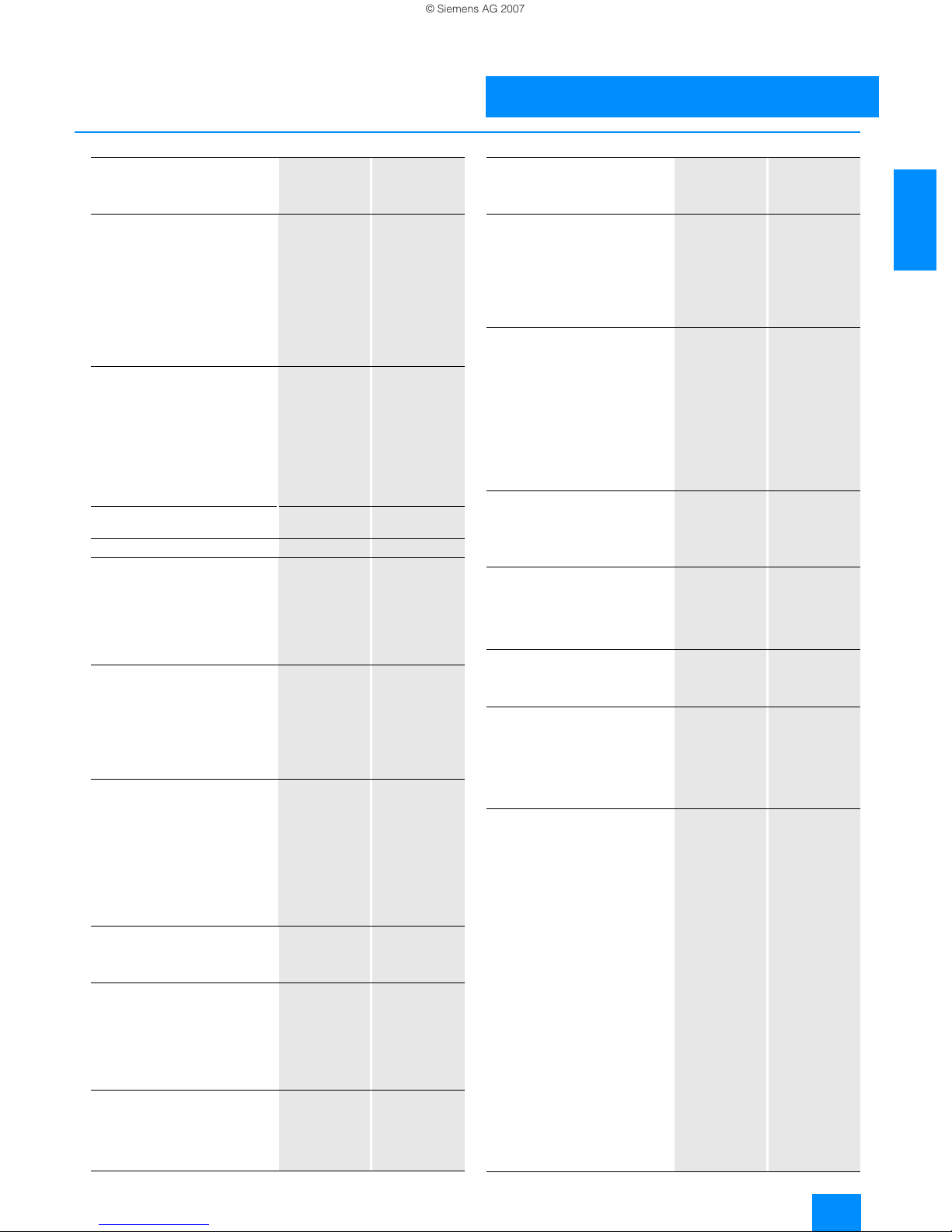

■

Technical specifications

SIMA TIC

TP 270

5,7“ Color

STN Display

SIMA TIC

TP 270

10,4“ Color

STN Display

Display

• Display type STN liquid

crystal display

(LCD)

STN liquid

crystal display

(LCD)

•Size

5.7" 10.4"

• Resolution (W x H in pixels)

320 x 240 640 x 480

• Colors

256 colors 256 colors

• MTBF of background lighting

(at 25 °C)

approx.

40,000 hours

approx.

60,000 hours

Operating mode

• Control elements Touch screen Touch screen

• Operating options

Touch Touch

• Touch screen

Analog,

resistive

Analog,

resistive

• Numeric/alphanumeric input

Yes/Yes Yes/Yes

• External mouse/keyboard/

barcode reader

USB/USB/USB USB/USB/USB

Processor/HW

RISC 32 bits,

180 MHz

RISC 32 bits,

180 MHz

Operating systems

Windows CE Windows CE

Memory

• Type Flash/RAM Flash/RAM

• Usable memory for project data

2028 KB user

memory/without additional

memory for

options

2028 KB user

memory/without additional

memory for

options

Interfaces (some only as options)

• Interfaces 2 x RS232,

1 x RS422,

1 x RS485

max. 12 Mbit/s

2 x RS232,

1 x RS422,

1 x RS485

max. 12 Mbit/s

• CF card slot

1 x CF card slot 1 x CF card slot

• USB (universal serial bus)

1 x USB 1 x USB

Supply voltage

• Supply voltage 24 V DC 24 V DC

• Permissible range

+18 to

+30 V DC

+18 to

+30 V DC

• Rated current

0.6 A 0.6 A

•Output

15 W 15 W

• UPS can be connected (serial)

Yes Yes

• Backup battery

Optional 3.6 V Optional 3.6 V

Clock

Hardware

clock, batterybacked and

synchronized

Hardware

clock, batterybacked and

synchronized

Degree of protection

• Front IP65, NEMA 4,

NEMA 4x,

NEMA 12;

(when

mounted)

IP65, NEMA 4,

NEMA 4x,

NEMA 12;

(when

mounted)

• Rear

IP20 IP20

Certification

(some only as options)

CE, GL, ABS,

DNV, LRS, FM

Class I Div. 2,

UL, cULus,

EX zone 2/22,

C-TICK

CE, GL, ABS,

DNV, LRS, FM

Class I Div. 2,

UL, cULus,

EX zone 2/22,

C-TICK

SIMATIC

TP 270

5,7“ Color

STN Display

SIMA TIC

TP 270

10,4“ Color

STN Display

Mechanical components/

dimensions

• Front panel W x H (mm) 212 x 156 335 x 275

• Mounting cutout/depth W x H x D

(mm)

198 x 142/

59 mm depth

of unit

310 x 248/

59 mm depth

of unit

•Weight

1 kg 4.5 kg

Ambient conditions

• Max. relative humidity (in %) 85% 85%

• Mounting position

Vertical Vertical

- Max. permissible angle of

inclination without external fan

+/- 35° +/- 35°

•Temperature

- Operation (vertical installation)

0 to +50 °C 0 to +50 °C

- Operation

(max. angle of inclination)

0 to +35 °C 0 to +40 °C

- Transportation and storage

-20 to +60 °C -20 to +60 °C

Expansions for operator-process

communication

(may only be an option)

• DP direct keys (buttons as input

peripherals)

4 bytes or

coded

5 bytes or

coded

Peripherals/applications/options

•I/O Printer, bar-

code reader

Printer, barcode reader

• Applications/options

(with ProTool)

ProAgent ProAgent

Configuring

• Configuration tool ProTool ProTool

• Configuration tool

WinCC flexible WinCC flexible

Functionality

(with WinCC flexible)

• Scheduler Yes Yes

• Help system

Yes Yes

• Status/Control

with SIMATIC

S5/S7

with SIMATIC

S5/S7

Protocols

• Interface to control

(may only be an option)

S5, S7-200,

S7-300/400,

505Win AC,

PC (TCP/IP),

SINUMERIK,

SIMOTION,

Allen Bradley

(DF1),

Allen Bradley

(DF485),

Mitsubishi (FX),

Telemecanique

(ADJUST),

OMRON

(LINK/Multilink), Modicon

(Modbus)

and other

non-Siemens

drivers

S5, S7-200,

S7-300/400,

505Win AC,

PC (TCP/IP),

SINUMERIK,

SIMOTION,

Allen Bradley

(DF1),

Allen Bradley

(DF485),

Mitsubishi (FX),

Telemecanique

(ADJUST),

OMRON

(LINK/Multilink), Modicon

(Modbus)

and other

non-Siemens

drivers

© Siemens AG 2007

Siemens ST 80 · 2006

2/114

Operator Control and Monitoring Devices

SIMATIC TP 270

Panels — 270 series

2

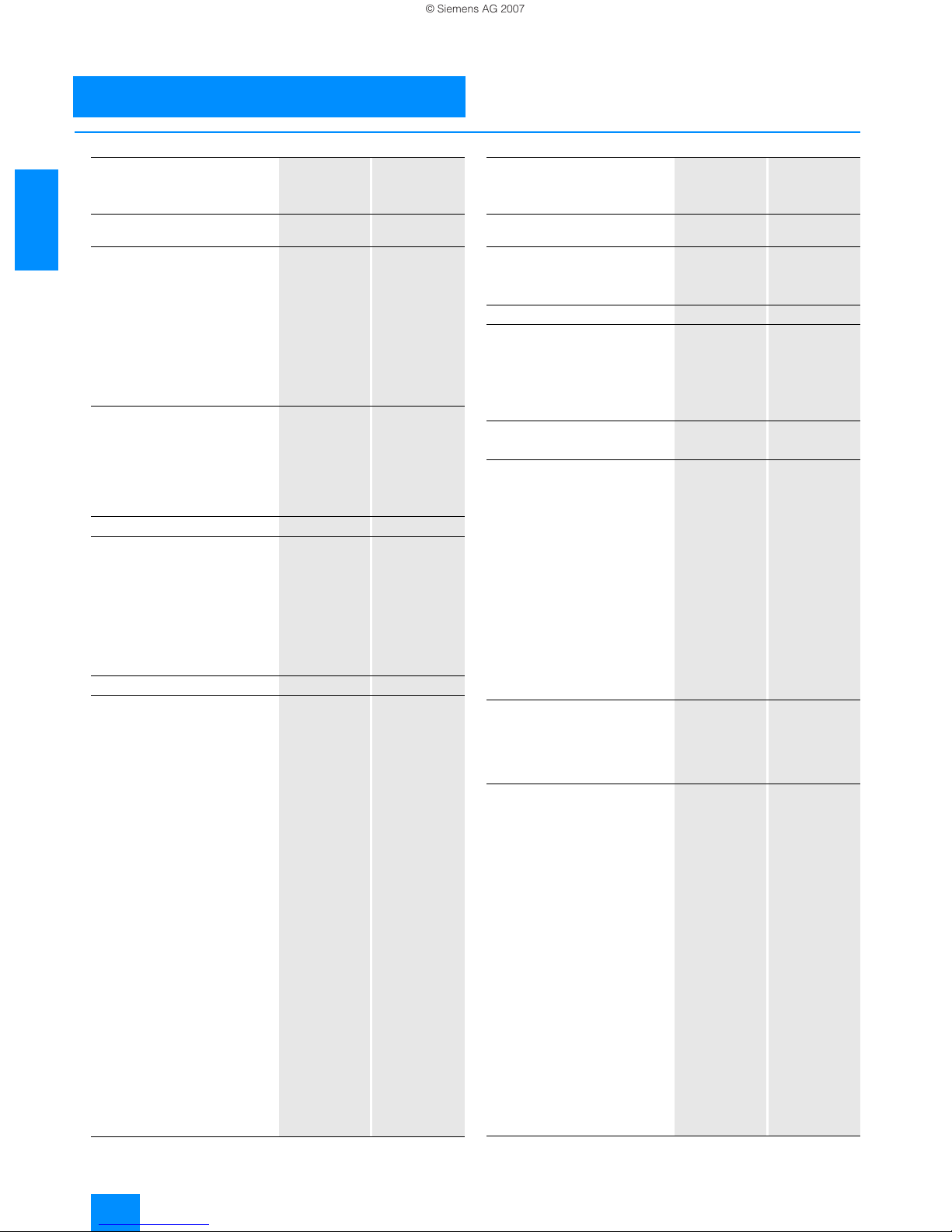

■

Technical specifications (continued)

SIMA TIC

TP 270

5,7“ Color

STN Display

SIMA TIC

TP 270

10,4“ Color

STN Display

Functionality

(with WinCC flexible) (continued)

Signaling system

• Number of messages 4000 4000

• Discrete alarms

Yes Yes

• Analog messages

Yes Yes

• Message length (in characters)

70 70

• Number of process values per

message

8 8

• Acknowledgement groups

99 99

• Message buffer

Ring buffer, 512

entries each

Ring buffer, 512

entries each

Recipes

• Recipes 300 300

• Data records per recipe

500 500

• Entries/data record

1000 1000

• Recipe memory

64 KB integrated Flash,

expandable

64 KB integrated Flash,

expandable

Process images

300 300

Picture elements

• Text objects 10,000 text ele-

ments

10,000 text elements

• Fields per screen

200 200

• Variables/screen

200 200

• Graphics objects

Bitmaps, icons,

vector graphics

Bitmaps, icons,

vector graphics

• Dynamic objects

Diagrams, hidden buttons

Diagrams, hidden buttons

Variables

2048 2048

Archiving

• Number of archives per project 20 20

• Number of process tags

per archive

0 0

• Number of entries per archive

10,000 10,000

• Archive types

Sequence

archive, shortterm archive,

alarm log,

process value

archive

Sequence

archive, shortterm archive,

alarm log,

process value

archive

• Memory location

CF card,

Ethernet

CF card,

Ethernet

• Data storage format

CSV file, can be

read, e.g., in

MS Excel, MS

Access

CSV file, can be

read, e.g., in

MS Excel, MS

Access

• External evaluation

Can be read,

e.g., in MS

Excel, MS

Access, etc.

Can be read,

e.g., in MS

Excel, MS

Access, etc.

• Size of archive

Dependent on

the memory

space available on the

external

card/stick or

spare hard disk

memory via the

network drive

Dependent on

the memory

space available on the

external

card/stick or

spare hard disk

memory via the

network drive

• Online evaluation

Using trend

curves

Using trend

curves

SIMATIC

TP 270

5,7“ Color

STN Display

SIMA TIC

TP 270

10,4“ Color

STN Display

Functionality

(with WinCC flexible) (continued)

Security

• Number of user groups 10 10

• Exportable passwords

Yes Yes

Visual Basic Script

not possible not possible

Logging/printer driver

• Printing/logging Messages,

report/log,

color print

Messages,

report/log,

color print

• Printer driver

ESC/P2,

PCL3/PCL6

ESC/P2,

PCL3/PCL6

Fonts

• Keyboard fonts US English US English

Languages

• Online languages 5 5

• Project languages:

D, GB, F, I, E,

CHN "traditional", CHN

"simplified", DK,

FIN, GR, J,

KP/ROK, NL, N,

PL, P, RUS, S,

CZ/SK, TR, H

D, GB, F, I, E,

CHN "traditional", CHN

"simplified", DK,

FIN, GR, J,

KP/ROK, NL, N,

PL, P, RUS, S,

CZ/SK, TR, H

• Character sets

Tahoma,

ideographic

languages,

2 further character sets can

be loaded, all

freely scalable

Tahoma,

ideographic

languages,

2 further character sets can

be loaded, all

freely scalable

Data carrier support

(may only be an option)

• CF card Ye s Yes

• Applications/options

(with WinCC flexible)

ProAgent ProAgent

Transfer under ProTool

(upload/download)

• Transfer of the configuration MPI/PROFIBUS

DP, serial, USB,

Ethernet (automatic transfer

recognition)

MPI/PROFIBUS

DP, serial, USB,

Ethernet (automatic transfer

recognition)

© Siemens AG 2007

Loading...

Loading...