Page 1

Sieme n s Gas Valve Actuator Replacement Kit # 27086-TAB Instructions

TECHNICAL INSTRUCTIONS

Siemens Actuator

Siemens

P/N 27086-TAB

Technical Instruction Document TID-0092_0E

Gas Valve Actuator

Replacement Kit

Description of Document:

This TID provides the procedures to

replace and set up the Siemens Gas

Valve Actuator in all AERCO boilers

featuring double-block and double-

block-and-bleed gas trains.

Actuator Replacement Kit for AERCO Boilers, P/N 27086-1

Boilers ITEM PART NO. QTY DESCRIPTION

All AERCO

Boilers

(except

BMK6000)

1 12951-4 1 Control Box Bushing

2 69038 1

3 TID-0092 1 Instruction Document

Actuator, Siemens SKP15.013U1

(without POC switch)

Boilers ITEM PART NO. QTY DESCRIPTION

BMK6000

Last Revised: 01/28/2015

VD2: 01/28/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 1 of 9

Actuator Replacement Kit for BMK6000 Boilers, P/N 27086-2

1 12951-4 2 Control Box Bushing

(Only)

2 124138 1

3 TID-0092 1 Instruction Document

Actuator, Siemens SKP15.012U1

(with POC switch)

Page 2

Sieme n s Gas Valve Actuator Replacement Kit # 27086-TAB Instructions

Technical Support:

1-800-526-0288

www.aerco.com

Technical Instruction Document TID-0092_0E

TABLE OF CONTENTS

1. INTRODUCTION ................................................................................ 3

2. SPECIFICATIONS .............................................................................. 3

3. DIMENSIONS..................................................................................... 4

4. REQUIRED TOOLS ............................................................................ 4

5. REPLACEMENT KIT CONTENTS ...................................................... 4

6. PREPARATONS ................................................................................. 5

7. REPLACEMENT PROCEDURE ........................................................... 6

(Mon–Fri, 8am-5pm EST)

Disclaimer

The information contained in this manual is subject to change without notice from

AERCO International, Inc. AERCO makes no warranty of any kind with respect to this

material, including, but not limited to, implied warranties of merchantability and fitness for

a particular application. AERCO International is not liable for errors appearing in this

manual. Nor for incidental or consequential damages occurring in connection with the

furnishing, performance, or use of this material.

VD2: 01/28/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 2 of 9

Page 3

Sieme n s Gas Valve Actuator Replacement Kit # 27086-TAB Instructions

Dimensions

See Figure 1

Technical Instruction Document TID-0092_0E

1. INTRODUCTION

The Siemens electro-hydraulic gas valve actuators are used in combination with VG series gas

valves to provide safety shut-off control for industrial and commercial burner applications. It is

featured in all double-block and double-block-and-bleed gas trains used in AERCO boilers.

The electro-hydraulic actuator consists of a cylinder filled with oil, a piston containing an electric

oscillating pump, and a relief system. When power is supplied to the actuator, the relief system

closes, and the pump moves oil from the reservoir into the pressure chamber. This action

causes the piston to move downward in the cylinder, opening the gas valve. When power to the

actuator is interrupted, the relief system opens and the gas valve closes in less than 0.8

seconds. A position indicator, visible through the transparent portion of the terminal cover,

shows the entire stroke range of the actuator. A light, which is visible through the lower left

transparent portion of the terminal cover, indicates when the actuator receives power. An

optional, non-adjustable SPDT proof of closure over travel switch signals the closed position

after the gas valve has closed. An optional SPDT auxiliary switch is adjustable between 40%

and 100% of the stroke. The adjustment screw and scale are located on the right side in the

terminal box, and are visible through the transparent portion of the terminal cover.

2. SPECIFICATIONS

Agency approvals

Power Supply

Operating

Environment

Physical

Characteristics

Connections

As Safety Shut-Off Valve

Operating Voltage 110 to 120 VAC + 10% to -15%

Operating Frequency 50 to 60 Hz + 6%

Power Consumption 3.5 VA

Duty Cycle Continuous

Ambient Operating Temperature 5°F to 140°F (–15°C to 60°C)

Mounting Position Any position except upside down

Weight 2.4 lb (1.1 kg)

Enclosure

Conduit Connection

Electrical Connection

UL/429, FM/7400, ANSI

Z21.21/CGA6.5 C/I

NEMA 1, 2, 5, and 12 for indoor

use

Two 1/2-inch NPSM threaded

knock-outs

Spring loaded terminals for 14

AWG wires

Output Force 100 lbs. (450 N)

Operating

Characteristics

VD2: 01/28/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 3 of 9

Maximum Stroke 1 inch (26 mm)

Opening Time For Maximum

Stroke

Closing Time <0.8 seconds

Varies with valve size, 14 seconds

for maximum stroke.

Page 4

Sieme n s Gas Valve Actuator Replacement Kit # 27086-TAB Instructions

Boilers

ITEM

PART NO.

QTY

DESCRIPTION

Boilers

ITEM

PART NO.

QTY

DESCRIPTION

1

12951-4

2

Control Box Bushing

(with POC switch)

3

TID-0092

1

Instruction Document

Technical Instruction Document TID-0092_0E

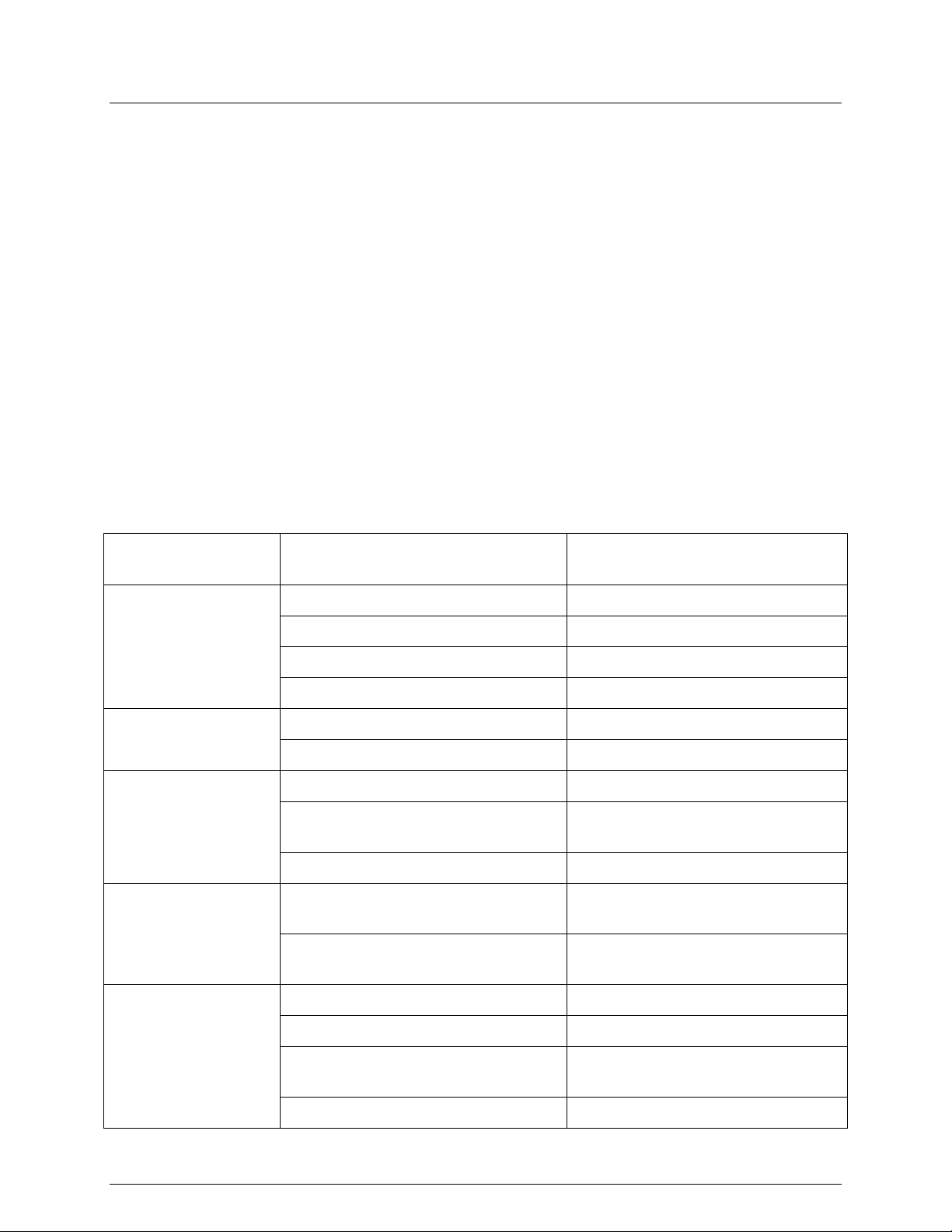

3. DIMENSIONS

Figure 1: Actuator Dimensions

4. REQUIRED TOOLS

The following tools are required to perform the instructions in this bulletin.

Standard set of screwdrivers

4mm Allen key driver

5. REPLACEMENT KIT CONTENTS

The contents of replacement kits are shown in Tables 1 and 2, below:

Table 1: Actuator Replacement Kit, P/N 27086-1 (All BMK, Except BMK 6000)

All AE R C O

Boilers

(except

BMK6000)

Table 2: Actuator Replacement Kit, P/N 27086-2 (BMK 6000 Only)

1 12951-4 1 Control Box Bushing

2 69038 1

3 TID-0092 1 Instruction Document

Actuator, Siemens SKP15.013U1

(without

POC Switch)

BMK6000

(Only)

VD2: 01/28/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 4 of 9

2 124138 1

Actuator, Siemens SKP15.012U1

Page 5

Sieme n s Gas Valve Actuator Replacement Kit # 27086-TAB Instructions

Technical Instruction Document TID-0092_0E

6. PREPARATONS

To prepare the boiler for the retrofit, perform the following:

• Remove power from the unit by shutting off electrical power upstream from the boiler.

• Turn off the supply gas upstream from the boiler.

WARNING

HIGH VOLTAGES OF 120 VAC, 220 VAC OR 460 VAC

ARE USED IN AERCO BOILERS. IT IS REQUIRED TH AT

ALL POWER APPLIED TO THESE BOILERS IS

REMOVED FIRST BEFORE PERFO RMING ANY OF THE

PROCEDURES DESCRIBED IN THIS DOCUMENT. USE

EXTREME CARE WHEN ACCESSING CIRCUITS AND

ELECTRICAL CONNECTIONS WI THIN THE EQUIPMENT.

SERIOUS PERSONAL INJURY OR DE ATH MAY OCCUR

IF THIS WARNING IS NOT OBSERVED.

IMPORTANT!

Observe local requirements and lockout procedures when working

on the boiler.

Personal injury or loss of life may occur if procedures are not

followed as specified. All installations must be performed by

qualified personnel only.

Do NOT pull the actuator shaft of the actuator.

WARNING

WARNING

VD2: 01/28/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 5 of 9

Page 6

Sieme n s Gas Valve Actuator Replacement Kit # 27086-TAB Instructions

VG Series

Valve Body

4mm Allen

(x4)

Semi-Transparent

Cover

Technical Instruction Document TID-0092_0E

7. REPLACEMENT PROCEDURE

Replacement instructions for the actuator are as follows:

1. After ensuring that all electrical power is removed from the boiler, remove boiler side panels

as necessary to access the actuator. Depending upon the boiler model, the actuator may be

installed at any angle except upside down. The example shown in Figure 2 is a double-block

gas train.

2. Use a standard Phillips head screwdriver to remove the screw holding the semi-transparent

wiring compartment cover of the old actuator and make a note of all wire connections.

3. After making a note of the wire connections, release the wires from the connections by

pushing down on the spring loaded lever under each wire terminal and remove wires.

4. Pull all loose wires from out of the wire conduit in the side. A spare bushing for the wiring

conduit hole is included in the kit in case it is needed.

5. Remove the four 4mm Allen bolts that hold the actuator to the valve body (Figure 2) and

then remove the actuator.

6. Install new actuator from replacement kit and affix to valve body with 4mm Allen bolts

captured in the body of the new actuator.

7. On all BMK 1.5 – 3000 models, and on BMK 6000 units with the newer actuator shown in

Figure 4, remove the new actuator cover, punch out the holes in the plastic to accommodate

the wiring, then insert the wires through wire conduit and wire it identically to the old

actuator. Skip this step on older BMK 6000 units with the original actuator (which included

an Auxiliary Switch Adjustment Screw) as shown in Figure 5, and complete Step 8, below.

Siemens Actuator

(P/N 69038 or

124138)

Wire Compartment

Keyed Bolts

VD2: 01/28/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 6 of 9

Figure 2: Actuator Installati on on Valve Body

Page 7

Sieme n s Gas Valve Actuator Replacement Kit # 27086-TAB Instructions

Wire Conduit

Opening

Cover

Wire

Conduits

Wire Conduit

Opening

Actuator, P/N 69038 Actuator, P/N 124138 (BMK 6000 Only)

Technical Instruction Document TID-0092_0E

Semi-

Transparent

Figure 3: Actuator External Features

Electrical

Ground

Screw

Wire

Terminals

Cover Screw

Transparent

Window showing

Valve Position

Valve

Position

Indicator

Figure 4: Actuator Wiring Compartment

VD2: 01/28/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 7 of 9

Page 8

Sieme n s Gas Valve Actuator Replacement Kit # 27086-TAB Instructions

WIRE 153 – TO C-MORE

Auxiliary Switch

LOW GAS

LOW GAS

Technical Instruction Document TID-0092_0E

8. Complete this step ONLY on BMK 6000 units with the original actuator, as shown in

Figure 5. Remove the new actuator cover, punch out the holes in the plastic to

accommodate the wiring, then insert the wires through wire conduit and wire it as follows:

• Wire Terminals 4, 5, N, N, L and L identically to the old actuator

• Remove & dispose of the two wires attached to Terminals 1 and 2 and wire nut, and the

wire connecting Terminal 3 to the Low Gas Pressure Switch (dashed lines)

PRESSURE

SWITCH

(DUNGS)

Adjustment Screw

Older Actuator Before Replacement, P/N 124138 (BMK 6000 Only)

Figure 5: Wiring Compartment

9. Disconnect Wire 153 (dotted line) from Terminal 3 and connect it to the Low Gas Pressure

Switch.

PRESSURE

SWITCH

(DUNGS)

WIRE 153 – FROM C-MORE

VD2: 01/28/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 8 of 9

Figure 6: Wiring Diagram After Replacing Actuator

--- END ---

Page 9

Sieme n s Gas Valve Actuator Replacement Kit # 27086-TAB Instructions

Technical Instruction Document TID-0092_0E

Change Log

Date Description Changed By

11/24/2014

1/28/2015

Rev D:

PIR 839-2: Replace 69171 with 124138 in kit # 27086-2

Rev E:

PIR 934-155: Added Figures 5 & 6 and steps 8 & 9 to

explain how to wire older BMK 6000 Actuators

Chris Blair

Chris Blair

International Inc.

© AERCO International, Inc., 2015

VD2: 01/28/2014 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 Page 9 of 9

Loading...

Loading...