Page 1

s

Installation . Operation .

Maintenance Instructions

!

WARNING

Supply Voltage is hazardous and can

cause Electric Shock and burns.

Disconnect Power before proceeding with

any work on this equipment.

Operating Instruction and

Maintenance Manual

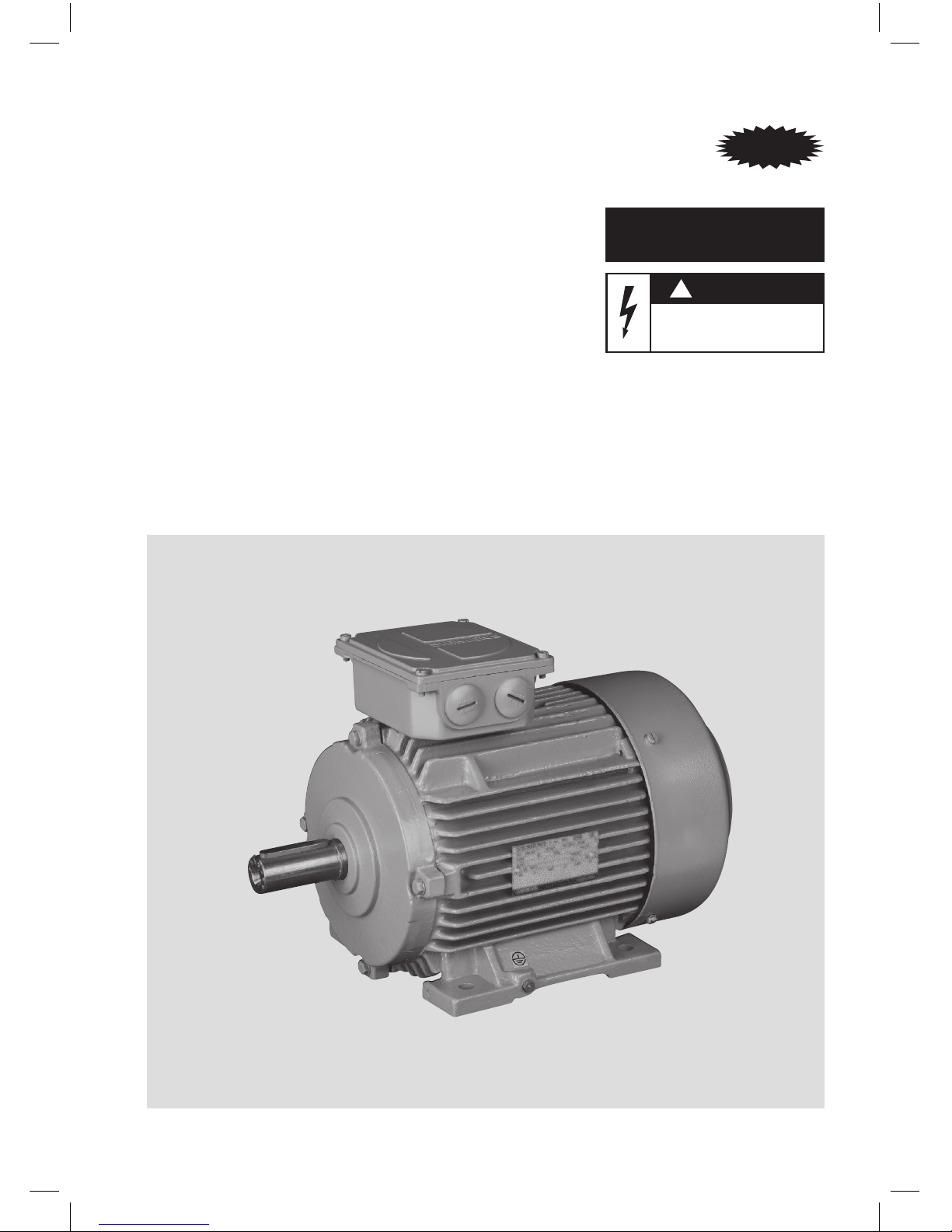

Three-phase induction motor Type 1SE0/1LA2

63-132 frame sizes

IE Motors

Page 2

2

Table of Content

Pg. No.

1. Safety information ............................................................................................ 3

1.1 Denitions, warning information ...............................................................3

1.2 Safety and application information ............................................................ 5

2. Description .......................................................................................................5

2.1 General ..................................................................................................... 5

2.2 Terminal Box ............................................................................................. 5

3. Operation ....................................................................................................... 6

3.1 Inspection, storage and transport .............................................................. 6

3.2 Mounting .................................................................................................. 7

3.3 Installation ................................................................................................ 7

3.4 Electrical connection ................................................................................. 8

3.4.1 Earthing ..........................................................................................9

3.5 Checking the insulation resistance ............................................................. 9

3.6 Bearing and lubrication............................................................................ 10

3.7 Balancing, Transmission elements ............................................................ 10

3.8 Commissioning ....................................................................................... 10

4 Electromagnetic Compatibility ........................................................................ 12

5 Maintenance ................................................................................................... 12

5.1 General ................................................................................................... 13

5.2 Dismantling............................................................................................. 13

5.2.1 Pressing on and pulling off drive elements ..................................... 13

5.2.2 Fans .............................................................................................. 13

5.2.3 Removal of bearing ........................................................................ 14

5.3 Reassembly ............................................................................................. 14

6 Spare Parts ..................................................................................................... 15

Applicable Standards ......................................................................................... 15

7 Motor Troubleshooting Chart .......................................................................... 16

Fig.1 Exploded view for Frame Size upto 132 .................................................... 18

Fig.2 Pressing on and pulling off drive elements, changing bearings ................ 19

Fig.3 Terminal Box for 63, 71, 80, 90S and 90L frames .................................... 20

Fig.4 Terminal Box for 100L, 112M, 132S and 132M frames ............................. 21

Page 3

3

1 Safety information

1.1 Denitions, warning information

General Note

Warning

The data and recommendations

specied in all the instructions supplied,

and in all other related instructions,

must always be observed in order to

avoid hazardous situations and the

risk of possible injury or damage.

Furthermore, the pertinent national,

local and plant-specic regulations

and requirements should be kept in

mind!

Special designs and other versions

may vary in technical details! If

in doubt, be sure to contact the

manufacturer, quoting the type

designation and serial number, or

have maintenance work done by one of

SIEMENS Service Centers.

Warning

The disposal of waste generated during

operation & maintenance of the motor

should be done as per the applicable

local environmental legislations.

• Waste grease & greased cloth to be

collected as hazardous waste and

sent to hazardous waste disposal

facility for incineration.

• Waste copper windings to be

collected as hazardous waste and

sent to registered recyclers approved

by the respective State Pollution

Control Board.

Qualied persons

Only qualied persons who have carefully

read and understood the content of this

documentation should be entrusted with

the commissioning and operation of

machines, equipment or systems. Qualied

persons as far as the safety instructions

given in this documentation are concerned

are those who have the necessary

authorization to commission, earth and

identify equipment, systems and circuits

in accordance with the relevant safety

standards.

Safety guidelines

This documentation contains instructions,

which must be followed closely in order to

ensure personal safety and avoid damage

to the equipment and machines.

Personal safety instructions are highlighted

in the manual by a warning triangle,

while damage avoidance instructions are

marked as follows depending on the level

of danger:

Danger

Danger means that death or grievous

injury will occur if the appropriate

precautions are not taken.

Warning

Warning means that death or grievous

injury may occur if the appropriate

precautions are not taken.

Page 4

4

Caution

Caution with a warning triangle means

that minor personal injury may occur

if the appropriate precautions are not

taken.

Caution

Caution without a warning triangle means

that damage to property may occur if the

appropriate precautions are not taken.

Notice

Notice means that an undesirable result

or state might occur if the relevant

instructions are not followed.

Note

Note draws particular attention to an

important item of information about the

product, its use or the corresponding

section of the documentation, which could

be useful to the user or operator.

Proper usage

Please pay close attention to the following:

Warning

The electrical equipment contains

components that are at a dangerous

voltage. Before any work is carried out,

it must be ensured that the equipment

is isolated from the supply.

Only qualied persons may work with

this equipment.

These persons must be familiar with all

instructions and precautions to be taken

/ specied in this documentation that

are relevant for safety.

Safe and satisfactory operation of

this motor presumes satisfactory

transport, proper storage, installation

and assembly and careful subsequent

operation and maintenance.

This motor may only be used for the

applications specied in the catalog

and the technical description or for

which it is seleteced, and only in

conjunction with third-party devices

and components recommended and/or

approved by SIEMENS.

Failing to adhere to these instructions

may result in severe injury and/or

damage to property.

National safety regulations must be

closely observed.

Page 5

5

1.2 Safety and application information

The safe use of electrical machines

Danger

These electrical machines are designed

for use in industrial power systems.

Rotating or live and uninsulated parts

pose a danger.

There is consequently a risk of

fatal or severe personal injury or

substantial damage to property if the

necessary covers are removed without

authorization or if the equipment

is handled improperly, operated

incorrectly or maintained inadequately.

If the motors are used outside industrial

areas, the installation site must be

safeguarded against unauthorized

access by means of suitable protection

facilities (e.g. fencing) and appropriate

warning signs.

The persons responsible for the safety

of the system are under an obligation to

ensure that:

• The basic planning work for the system

and all work relating to transportation,

assembly, installation, commissioning,

maintenance and repairs are carried out

by qualied persons and checked by

responsible, suitably skilled persons.

• These instructions and the motor

documentation are made available at all

times while work is in progress.

• The technical data and specications

relating to the permissible installation,

connection, ambient and operating

conditions are taken into account at all

times.

• The system-specic erection and safety

regulations are observed and personal

protective gear is used.

• Work on these machines, or in

the vicinity of these machines, by

unqualied persons is prohibited.

These instructions therefore only contain

the information, which is necessary for the

motors to be used by qualied persons in

accordance with their intended purpose.

Note

We recommend engaging the support

and services of your local SIEMENS service

center for all planning, installation,

commissioning and maintenance work.

2 Description

2.1 General

The Champion series motors are three

phase cage induction motors, totally

enclosed fan cooled (TEFC) type for low

voltage supply. General-purpose motors

type 1SE0/1LA2 conform to IS:12615. The

motors comply with the type of protection

IP55 in accordance with IS 4691/IS/IEC 60034-5. The degree of protection of the

motor is specied on the rating plate.

IMB3 is the standard mode of construction.

Other constructions are given on customer

request.

Unless otherwise specied, the rated

outputs apply to continuous duty (S1) at a

frequency of 50 Hz, an ambient temperature

between 0°C and 50°C and site altitude not

exceeding 1000m above mean sea level.

2.2 Terminal box

The terminal box conforms to type of

protection IP55 in accordance with IS:4691/

IS/IEC - 60034-5.

For foot-mounted motors, the terminal box

is provided on the top with cable entry from

RHS (as seen from drive end) as a standard

feature. If specically ordered, terminal box

Page 6

6

position on the right or the left-hand side

(when viewed from the drive end) can be

supplied for frame size 90 and above.

In order to provide for different directions

for cable entry, the orientation of the

terminal box can be altered in steps of 90°.

In case of motor provided with Brake, the

possibility of terminal box rotation in steps

of 90° to be checked physically.

3 Operation

Warning

Before starting any work on the

machine, be sure to isolate it from

the power supply.

Warning

All covers which are designed to

prevent active or rotating parts from

being touched, or which are necessary

to ensure correct air guidance and thus

effective cooling, must not be opened

during operation.

All deviations from normal operation

(higher power consumption,

temperature or vibration level,

unusual noises or odours, tripped

monitoring devices, etc.) are

indications that the motor is no longer

functioning correctly. In such cases,

the maintenance technician must be

immediately notied in order to prevent

disturbances that could either directly

or indirectly lead to severe personal

injury or substantial material damage.

If in doubt, power-down the motor

immediately in conformance with the

system-specic safety requirements!

Caution

The surfaces of the machines can reach

high temperatures, which can lead to

burns in case of contact. Appropriate

measures to avoid accidental contact

must be taken.

3.1 Inspection, Storage & Transport

Warning

The motors may only be transported

and hoisted in a position corresponding

to their type of construction (i.e.

horizontal construction types in

horizontal position and vertical

construction types in vertical position).

The motors may only be hoisted using

the lifting eyebolt(s) provided on the

stator housing. Use appropriate rope

guidance or spreading equipment (for

weight see rating plate or technical

data).

Warning

For lifting assembled machine

sets (such as built-on gearboxes,

fan units), always use the lifting

eyebolt(s) or lifting pegs provided on

both the units! Machine sets should

not be lifted by suspending the

individual machines! Check the lifting

capacity of the hoist!

Page 7

7

Warning

Only the intended openings, eyebolts

and lifting pin on the base plates may

be used for transporting motor sets.

Always pay attention to the carrying

capacity of the lifting device. Motor sets

must not be lifted by attachment to the

individual motors.

NOTE: The motors should not be lifted

using the centre holes on the shaft DE and

NDE, because the weight of the motor

shall harm the bearing and reduce its

performance and operational life.

Check the packing of the motor on arrival

and in case any damage is observed, please

report to the nearest Siemens ofce.

Make sure that the right type of motor as

ordered has arrived. The motor nameplate

provides relevant information.

If the motor is not installed immediately, it

should be stored in a dry and vibration free

room.

Caution

(Environmental Protection)

Disposal of packing material: On

unpacking the motors, the packing

material shall be disposed as per the

Local / Statutory requirements.

Special attention should be given to

Polythene bags, thermocole packing

and nylon straps etc., which are not

biodegradable.

3.2 Mounting

All standard motors are suitable for

horizontal as well as vertical mounting. i.e.

Standard foot mounted motors can be used

in IM-B3, B6, B7, B8, V5, V6 constructions

or ange-mounted motor can be used

in IM-B5, V1, and V3 constructions. Face

mounted motors can be used in IMB14,

IMV18 and IMV19 constructions. For

installation of foot mounted motors on a

wall, adequate support should be provided

to the mounting feet. The motor must be

securely installed to a rigid foundation or

mounting surface to minimize vibration

and maintain alignment between the

motor and shaft load. Failure to provide

a proper mounting surface may cause

vibration, misalignment and bearing

damage.

After installation is complete and

accurate alignment of the motor and

load is accomplished, the base should be

grouted to the foundation to maintain

this alignment. All motors which have

a shaft extension pointing upwards (V6

construction) must have a means (provided

by the user) of preventing the ingress of

dust and of liquids along the shaft.

3.3 Installation

After installation, screwed-in lifting

eyebolt(s) should either be removed or

tightened down.

Check the free running of the rotor by

rotating the shaft by hand.

The shaft extension, face and spigot of

the ange of the motor are coated with

an anticorrosion agent. To remove this

coating use kerosene / thinner. Do not use

sandpaper or scraper.

Before mounting the motor, see that the

motor feet are properly cleaned.

The transmission elements to be tted to

the motor should be dynamically balanced.

Please note that the rotors of the motors

are dynamically balanced with half key

inserted in the shaft extension of the

Page 8

8

motor. Preferably tolerance of the bore

of pulley/coupling/pinion should be H7.

Transmission elements must be tted and

removed only by means of suitable tool.

Refer g.2. Transmission elements should

never be hammered as this will damage

the bearings.

Caution

The keys are only secured against

falling-out during transport. If the motor

has two shaft ends, and a power takeoff element is only tted to one end,

steps must be taken to prevent the key

at the other end from being slung out.

Install the motor in such a manner that the

cooling air has free access and can escape

unobstructed. Discharged air or hot air

from neighboring equipment, must not be

sucked in again. Clean the entire path of air

over the motor (between ribs and air inlet

in fan cowl) at regular intervals to remove

any foreign deposits, preferably by means

of compressed air.

For foot mounted motors to be xed on the

wall a support should be provided for the

mounting feet from below.

In the case of motors with shaft end

facing upwards or downwards, measures

must be taken (by the user) to ensure that

no water or dust can penetrate into the

upper bearing.

Motors that are directly coupled should

be carefully & correctly aligned. The axes

of the driven machine shaft and motor

shaft should be in a straight line and

there should be no angular displacement

between these two. Shafts can be aligned

perfectly by keeping metal shims under the

foot of the motor. The center-lines of the

shafts should be parallel and the parallel

displacement between the two centerlines should not be more than 0.03mm.

The clearance between the couplings

halves measured at four peripheral points

must also be within 0.03mm.

If belt drive is used, install the machine in

such a manner that it can be shifted on its

base (e.g. on slide rails) to obtain correct

belt tension. Excessive belt tension may

result in damage to the bearing and /or

shaft. For permissible radial loads on shaft

extension and recommended pulley sizes

refer the Siemens catalog or contact our

ofce.

Caution

Excessive belt tension may result in

damage to the shaft / bearings; for

permissible values, see catalog or

enquire.

Due attention should be given to the

measures necessary to prevent accidental

touching of rotating parts (couplings,

pulleys, etc.)

Quiet running

Stable foundations or mounting conditions,

exact alignment of the motors and a

well-balanced transmission element are

essential for quiet vibration-free running. If

necessary, shims should be inserted under

the motor feet to prevent strain.

3.4 Electrical connection

Examine the rating plate data and ensure

that it matches with the power circuit to

which the motor is to be connected. Check

to see that system voltage and frequency

agree with the data given on the rating

plate. Motors up to 1.5kW are connected in

star & above 1.5kW are connected in delta.

Page 9

9

In both the cases 6 terminals are brought

out & connection is made externally by

terminal links. Select the size of supply

cables as required for the particular current

rating. Connect the supply cables in

accordance with the connection diagram

shown inside the terminal box cover.

Danger

All work on the motor must only be

performed by qualied personnel, with

the motor in a stationary state. The supply should be secured so that it cannot

be switched back on again. Check that

no voltage is present before commencing work.

Connection and arrangement of the

terminal links must agree with the diagram

provided in the terminal box.

Refer g. 3 and g. 4 for various Terminal

box arrangements.

Please refer to the table below for

tightening torques for terminal bolts and

nuts (except for terminal strips).

Thread-ø Nm M4 M5 M6 M8 M10 M12

Tightening

Torque(Nm)

Min 0.08 0.18 0.28 0.56 0.92 1.43

Max 0.12 0.25 0.41 0.82 1.33 2.04

Ensure that the direction of rotation of

the motor is as required. For induction

motors, the direction of rotation can be

reversed by interchanging two supply

phase connections in the terminal box. All

motors of type 1SE0 / 1LA2 are suitable for

bi-directional rotation.

Before closing the terminal box ensure

that:

– Interior of the terminal box is clean and

free of cable residue.

– All terminal screws and bolts are rmly

tightened.

– Minimum air-clearance (>10mm

upto 500V. >14mm upto 1000V) is

maintained.

– Unused cable entries are sealed off with

the plugging elements rmly screwed in.

– All sealing surfaces have adequate

contact.

In humid environments, motors which

are not in used should be connected to

Anti-Condensation Heaters to prevent

condensation of moisture. In case there

are no anti-condensation heater, a suitable

voltage (1ph) approximately 4 to 10 % of

the rated motor voltage should be applied

to stator terminals U1 and V1; 20 to 30

% of rated motor current is generally

sufcient to heat the motor enough to

prevent condensation. For safety reasons,

rotor should be locked to prevent rotation.

When the motors are provided with anticondensation heaters, ensure that the

supply to heaters is switched off before

switching on the motor.

Before starting and during operation,

make sure that all the relevant safety and

statutory regulations pertaining to the area

of operation is complied with.

3.4.1 Earthing

Connect the earthing conductor to the

terminal with the earth marking in the

Terminal box as well as on the Stator

housing.

Clean the area underneath the earthing

terminal and smear it with petroleum jelly

before making earthing connections.

3.5 Checking the insulation resistance

The insulation resistance of the windings

must be measured prior to initial startup

of the machine, and after long periods

of storage or standstill (approximately 6

months).

Page 10

10

Warning

While the measurement is being

taken and immediately afterwards,

some of the terminals carry

dangerous voltages and must not be

touched.

Measurement

The insulation resistance of the windings

to ground is measured with 500V DC. The

winding temperature should be 30ºC±15ºC.

Checking

Minimum insulation resistance value (at

40°C) as specied in IS: 4722 is Rm = kV

+ 1, where kV is the rated voltage of the

machine. Thus, for 415V rated voltage the

insulation resistance of the winding should

not be less than 1.42 MOhm.

If less the winding must be suitably dried as

per IS: 900

3.6 Bearing and lubrication

All motors, as a standard feature, are

provided with oating bearing at drive end

and xed bearing at non-drive end.

62 series deep groove ball bearings

shielded on both the sides (ZZ) are

provided in motors upto 132 frame. Motors

up to and including frame 112 will have

bearing with “Normal” clearance whereas

bearings for 132 will have C3 clearance.

The grease used is lithium complex soap

based Exxon Mobil, UNIREX N3, NLGI

Class 3 or equivalent.

The double sealed (ZZ) bearings are prelubricated for life. Under normal operating

condition, these offer a service life of

20,000 continuous working hours and

must be replaced after such period or 3

years whichever is earlier.

3.7 Balancing, transmission elements

A suitable device should always be used

for tting and removing the transmission

elements (coupling halves, pulleys,

pinions).

As standard, the rotors are dynamically

balanced with the half key inserted.

When tting the transmission element,

keep the type of balance in mind!

Balance with half key.

Warning

The usual measures should be taken

to guard transmission elements

from touch. If a motor is started

up without transmission element

attached, the key should be secured

to prevent it being thrown out.

3.8 Commissioning

NOTE: Where the torque is very uneven

(the drive of a reciprocating type

compressor, for example), the inevitable

result is a non-sinusoidal motor current,

whose harmonics can lead to excessive

system perturbation or excessive

electromagnetic interference.

In case of converter-fed motors, high-

frequency current or voltage harmonics

in the motor cables can give rise to

electromagnetic interference. This is why

the use of shielded cables is recommended.

Page 11

11

Warning

Only expert persons should be

entrusted with work on power

installations. All covers which are

designed to prevent active or rotating

parts from being touched, or which are

necessary to ensure correct air guidance

and thus effective cooling, must be

installed prior to commissioning.

Before commissioning, check that:

- The minimum insulation resistances are

adhered to.

- The rotor turns freely without rubbing.

- The motor is properly assembled and

aligned.

- The transmission elements are correctly

adjusted (e.g. belt tension) and the

transmission element is suitable for the

given operating conditions.

- All electrical connections, mounting

screws and connecting elements are

properly tted and tightened.

- All protective conductors are properly

installed.

- Any auxiliaries that may be tted

(brakes, speedometer, separate fan) are

in working order.

- Touch protection guards are installed

around moving and live parts.

- The maximum speed n

max

is not

exceeded, especially for motors with

variable speed drive.

NOTE: The maximum speed n

max

is the

highest operating speed permitted for

short periods. It should be kept in mind

that motor noise and vibration are worse at

this speed, and bearing life is reduced.

(For details refer catalogue or contact

nearest Siemens ofce).

Caution

After motor installation, the brake, if

tted, should be checked for proper

functioning.

It is not possible to formulate a

complete checklist for all operations

and applications. Other checks may

also be necessary!

For motors tted with brakes, also

refer to manual of brake enclosed

with the motor.

For motors tted with encoder, also

refer to manual of encoder enclosed

with the motor.

Page 12

12

4. Electromagnetic

Compatibility

When used for their intended purpose

and operated on electrical supply systems

with features specied (in EN 50160),

the machines satisfy the requirements

of the EU Directive on Electromagnetic

Compatibility 89/336/EU, and IEC 60034-1

Clause 13.

Electromagnetic interference emission:

Note: Very uneven torque (such as

with reciprocating compressor drives)

forces a non sinusoidal motor current,

the harmonics of which can cause both

impermissible reaction on the system and

impermissibly strong electromagnetic

interference emission.

Note: In the case of converter fed

machines, high frequency harmonic

currents in the motor supply leads can

give rise to electromagnetic interference

emission, the magnitude of which

depends upon the converter design (type,

interference suppression measures, and

manufacturer). That is why the use of

shielded supply cables is recommended. In

order to avoid exceeding the limit values

specied in EN 50081 with a converter /

motor drive system, the EMC data provided

by the converter manufacturer should

always be followed. If they recommend

the use of shielded supply cables, the

shielding is most effective if it is connected

over a large area right up to the motor

terminal box (with a metal cable gland). In

the case of motors with built in detectors

(e.g. PTC thermisters), interference

voltages can occur in the detector cables

due to converter related reasons.

Electromagnetic interference immunity:

The requirements of immunity to

interference to EN 50082 are in principle,

satised by the motors. In the case of

motors with built in detectors (e.g. PTC

thermisters), the operator himself must

provide immunity to interference by

selecting a suitable detector signaling

cables with shielding (similar to the main

motor leads).

Noise while operations with VFD supply:

Motors when used in VFD supply may

exhibit higher noise level due to harmonics

in the supply. Suitable measures should be

employed to reduce this – if required.

5. Maintenance

Caution

(Environmental Protection)

The disposal of waste generated during

operation & maintenance of the motor

should be done as per the applicable local

environmental legislations.

Caution

(Environmental Protection)

Waste Copper windings during repair

and maintenance - to be collected as

segregated waste and sent to registered

recyclers approved by the respective

State Pollution Control Board.

Page 13

13

Safety Precautions

Warning

Before starting any work on

the motor or other equipment,

particularly before opening covers

over live or moving parts, the motor

must be properly isolated from the

power supply. Besides the main

circuits, any additional or auxiliary

circuits that may be present must

also be isolated.

The “5 Safety rules” to be followed

are:

• Isolate the equipment

• Take effective measures to prevent

reconnection

• Verify equipment is dead

• Ensure proper earthing

connections

• Cover or fence off adjacent live

parts

The precautions listed above should

remain in force until all maintenance

work is nished and the motor has

been fully assembled.

Certain parts of the motor may reach

temperatures above 50°C.

When cleaning the motor with

compressed air, ensure that suitable

exhaustion measures are used and

you use personal protective gear

(goggles, face mask/lter or similar)!

If chemical cleaning agents are used,

observe the instructions and any

warnings.

Chemical agents must be compatible

with the motor’s components/parts,

especially when it involves plastics.

5.1 General

Periodic overhauling of the motor is

recommended to ensure long trouble free

service.

Before starting the maintenance work,

make sure that the supply is disconnected.

These motors are provided closely pitched

ribs for effective cooling of the motor.

These ribs should be cleaned at regular

intervals either by oil free compressed air,

or by scraping, depending on the level of

contamination.

The inside of the motor should be cleaned

using dry compressed air during normal

overhauling of the motor. Special care

should be taken while cleaning the

windings to remove loose dust, moisture

etc.

5.2 Dismantling

5.2.1 Pressing on and pulling off drive

elements

Use the tapped hole provided in the end

of the shaft for tting drive components

such as couplings, gearwheels, belt pulleys

etc. and, if possible, heat the components

as necessary. Use a suitable puller tool for

removing the components. Do not strike

the components, e.g. with a hammer or

similar tool, when tting or removing them

and do not exert more than the maximum

value of radial or axial force – according

to the catalog – transmitted to the motor

bearings through the shaft extension.

5.2.2 Fans

Plastic fan

Thermo plastic fans have two cast-on tabs

that snap into the ring groove on the shaft

to prevent axial movement. Before the fan

is pulled off the shaft, the two tabs must be

disengaged (lifted up) and held temporarily

in that position, e.g. by inserting packing.

Page 14

14

Thermoplastic fans have two openings

for the insertion of the puller arms so that

the pulling force can directly act on the

fan hub. On delivery, a lm of plastic may

cover these openings and later on they

should be punched.

A suitable device (puller) should be used

for pulling the fan off and pressing it back

on. Hammer blows must be avoided to

protect the fan and bearings.

Cast Iron fan

Cast iron fans are axial locked with separate

circlip. Cast iron fans are best removed by

engaging the puller arms on the outer rim

of the fan. In case of larger fans, the puller

holes provided on the hub can be used.

5.2.3 Removal of Bearings

For removing bearings use proper pullers.

Re-usable bearings, which are nonseparable (e.g. Deep groove ball bearing),

should be withdrawn by attaching puller

arms to the inner ring of the bearing. If it

is a must to apply puller arms on the outer

ring of the bearing, the bearing should be

rotated during withdrawal to avoid damage

to the bearing.

Caution

(Environmental Protection)

Waste grease & greased cloth - to be

collected as hazardous waste and sent

to hazardous waste disposal facility for

incineration.

Removal of bearings or inner rings which

are not to be used is fascilitated by heating

them with gas or welding torch.

5.3 Re-assembly

The motor must be assembled in a dust

free, dry and clean location.

As the motor conforms to the type of

protection IP55, all machined mating

surfaces are provided with a thin even coat

of bearing grease. Provide a fresh coat of

this grease at the time of re-assembly.

Unmatched surfaces are provided with

rubber gaskets. At the time of re-assembly,

ensure that the gaskets are in good

condition. Place the gaskets carefully to

achieve the correct sealing. Replace the

gaskets with the new ones if the same are

damaged.

All fasteners that are used on the exterior

of the motor are provided with a coat of

bearing grease to prevent ingress of water

and dust through tapped holes. Ensure

that the same is provided at the time of

re-assembly.

Do not interchange location (DE & NDE) of

bearing covers, as the spigot dimensions

may be different.

A bearing must be replaced if it is

damaged. Damage to bearing is often

difcult to recognize; in doubtful cases,

replace the bearing. Bearings, which

have been removed, should be reused

only if they show no trace of damage and

provided they are thoroughly cleaned

beforehand.

Clean bearings using proper cleaning agent

like White spirit. It is advisable to wear

gloves.

Caution

The cleaned bearing must be free of

foreign bodies (bres from cleaning

rags, hair from brushes, etc.)

Page 15

15

Caution

(Environmental Protection)

The bearing to be discarded must be

thoroughly cleaned from grease and

should be intentionally damaged (using

weld marks or cutters etc) to avoid

reuse.

The removed grease is a hazardous

waste and is harmful to environment

causing soil pollution and water

pollution. It should only be incinerated

at an authorized agency and not

disposed by any other means.

It is recommended that the new rolling

contact bearings be installed as follows:

Heat the deep groove ball bearing in oil

or air to a temperature of approximately

80°C and slip them over the shaft. Heavy

blows may damage the bearing and must

be avoided.

When replacing the bearings, it is also

advisable to replace any sealing elements

that are subject to wear (e.g. oil seal, felt

etc.).

Caution

(Environmental Protection)

Waste insulation material is a hazardous

waste and it should only be incinerated

at an authorized agency and not

disposed by any other means.

Replace any other damaged parts. For

Spare parts contact the nearest SIEMENS

sales ofce.

5.5 Joint sealing

When reassembling machines with degree

of protection IP56 (see rating plate), the

joint between the motor frame and the

endshields are sealed with rubber ‘O’ rings.

It should be ensured that these are not

damaged.

6. Spare Parts

When ordering spare parts, please indicate

the correct Motor Type, Serial Number (as

shown on the rating plate) and also the

correct part description. This will ensure

speedy and correct delivery of spare parts.

Please refer to the exploded view of the

motor (Fig.1).

Caution

(Environmental Protection)

Disposal of the product at the end

of its life: When it is decided that

the product cannot be repaired and

is to be disposed off, care should be

taken to adhere to Local / Statutory

environmental requirements. It should

be noted that the product contains

grease, copper windings, insulation

materials that are not biodegradable

and are hazardous to the environment.

NOTE:

In addition to the above information, it is

recommended that the user refer to IS: 900

– “Code of practice for installation and

maintenance of Induction Motors”.

Applicable Standards

The motors comply with the following

standards:

IS: 12615: Specication for three phase

induction motors

IS: 900: Code of practice for installation

and maintenance of induction motors.

IS: 4691: Degree of protection provided by

enclosure for rotating electrical machinery

Page 16

16

7. Motor Troubleshooting Chart

Sr.

No.

Trouble Cause Remedy

1 Hot bearings Excessive belt pull Decrease belt tension.

Pulley too far away Move pulley closer to bearing.

Pulley dia. too small Use larger pulley.

Misalignment Correct by realignment of drive.

Broken ball or rough races Replace bearings.

Excess lubricant Reduce quantity of grease

(Bearing should be lled only half).

Overloaded bearings Check alignment, side thrust & end thrust.

Bearing running dry Regrease the bearing.

2 Motor connected but

does not start

No supply voltage/ One

phase open/ Voltage too low

Check voltage on each phase.

Motor may be overloaded Reduce load or start at no load.

Control gear defective Examine each step of the control gear for

bad contacts or open circuit.

Starting torque too high If with autotransformer starting, change to

higher tap.

Rotor defective Look for broken rings.

Short circuit to earth Check with Megger.

Fault in starter or star/delta

switch

Check contacts & connections.

3 Motor runs & then stops

down

Power failure Check for loose connections to line, fuses &

control gear.

Over load Examine overload trips & see that they are

set at approx. 150% of full load current.

IS: 7816: Guide for testing insulation

resistance of rotating machines.

IS: 9628: Specication for Three phase

induction motors with type of protection

‘n’.

IS: 6381: Specication for construction and

testing of apparatus with type of protection

‘e’.

IS: 12065: Permissible limits of noise level

for rotating electrical machines.

IS: 12075: Mechanical vibration of rotating

electrical machines with shaft heights

56mm and higher – Measurement,

Evaluation and Limits of Vibration severity.

IS/IEC: 60034-1: Rotating electrical

machines – Part 1: Rating and

Performance.

IS/IEC: 60034-5: Degree of protection for

rotating electrical machines.

EN: 60204: Safety of machinery –Electrical

equipment of machines.

Page 17

17

Sr.

No.

Trouble Cause Remedy

4 Motor starts sluggishly,

speed falls when load

is put on

Rating not proper Get correct type of motor.

Voltage too low at motor

terminals because of line

drop

- do -

Starting load torque too

high

Check load characteristics with motor

speed torque.

Broken rotor bars Look for cracks near the ring & if required

get new rotor.

5 Motor starts with

difculty on star

connection or not at all

Load too high Reduce load or use larger motor.

Supply voltage low Check supply lines to motor.

Contacts burnt in star/delta

starter

Overhaul or replace starter.

6 Stator heats up quickly

& takes large no load

current

Stator wrongly connected Check connection.

Phase short Rewind

Multiple earth Rewind

7 Motor overheats while

running on load

Overload Reduce load.

One phase open Check connections.

Shorted stator coil Repair & check wattmeter reading.

Faulty connection Correct the connections.

Motor operated on load

cycle not in accordance with

the name plate

Run the motor on duty for which it is

specied.

High or low voltage Check voltmeter reading.

Foreign material in air gap Dismantle & remove obstruction.

Rotor rubs stator bore Recondition the rotor. Replace worn out

bearings.

8 Motor vibrates after

connections are made

Motor misaligned Realign.

Weak foundation Provide strong base.

Coupling out of balance Balance coupling.

Driven equipment un-

balanced.

Re-balance.

Balancing weights shifted. Re-balance the rotor.

Defective bearings Replace bearings.

Bearings not in line Line up properly.

Excessive end play Adjust bearings or add washers. Use

shims for alignment. Use vibration pads to

dampen external vibrations.

9 Scraping noise Fan touching fan cover Remove interference.

Loose on bed plates Tighten mounting bolts.

10 Magnetic noise Airgap not uniform Check & correct bearings.

Loose bearings Correct or replace bearings.

11 Shaft end breaks or

stator rotor rubbing

Excessive radial loads due to

pulley drives

Check for suitability.

12 Heavy vibrations Load unbalance Re-balance.

13 Current unbalance Unbalanced supply voltage Check voltage.

Page 18

18

Note: The graphic displayed here is solely for the purpose of

explaination. The actual product may be different in appearance.

Exploded view for Frame Size upto 132

Fig. 1

8.20

8.10

5.10

5.00

4.00

20.00

10.50

10.00

10.15

3.00

6.00

11.00

12.01

12.70

3.00 Rolling contact bearing assembly

(xed bearing)

4.00 Rolling contact bearing assembly

(oating bearing)

5.00 Endshield drive end

5.10 Flange endshield

6.00 Endshield, non-drive end

8.10 Shaft

8.20 Cage rotor

10.00 Stator housing with integral feet and wound core packet

10.15 Earthing clamp

10.50 Lifting eyebolt

11.00 External fan

12.01 Fan Cowl

20.00 Terminal box

12.70 Canopy

Page 19

19

Fig. 2

Pressing on and pulling off drive elements

Changing bearings

Page 20

20

Fig. 3

Terminal box for frame sizes 63, 71, 80, 90S and 90L

Type: 1 x B0 096

Section A-B

Page 21

21

Fig. 4

Terminal box for frame sizes 100L, 112M, 132S and 132M

Type: 1 x B0 132

Section A-B

View without terminal box cover

All dimensions in mm.

Page 22

22

Motor Service Network in India

Customer Care Desk

Toll Free Number: 1800 20 90987

Toll Free From BSNL/MTNL: 1800 22 0987

Phone : 022 2760 0150

Fax : 022 2762 3722

Email : ics.india@siemens.com

East - +91 - 9830256240

West - +91 - 9820507909

North - +91 - 9810205655

Page 23

23

Siemens Expert House

Region Ofce Name Mobile no.

East Kolkotta Kishor Yadao 9830912630

WR-1 Mumbai Mr Kunwar Pratap Singh 9833041401

WR-1 Ahemdabad Mr Haresh Shah 9825300909

WR-2 Pune Mr Sandeep Pataskar 9822976541

WR-2 Nagpur Mr Sandeep Pataskar 9822976541

North Delhi Abhishek Pandey 9910991211

North Lucknow Abhishek Pandey 9910991211

North Chandigarh Abhishek Pandey 9910991211

North Jaipur Abhishek Pandey 9910991211

South-1 Chennai Praveen Pai 9840323334

South-1 Coimbatore Praveen Pai 9840323334

South-2 Bangalore Prakash Hegde 9632506222

South-2 Hyderabad Prakash Hegde 9632506222

For Service Support:

Siemens Customer Care Desk

Toll Free From BSNL/MTNL: 1800 22 0987

Phone: 022 2760 0150

Fax: 022 2762 3722

Email: ics.india@siemens.com

For Spares contact nearest stockist or send

enquiries to:

“Pragati” Quotation Center

Email: quoteccr.india@siemens.com

Page 24

Siemens Ltd.

MOT-02-120-050

Customer care Toll free no. 1800 220 987.

Email: ics.india@siemens.com

Order No.: 104808383

Product development is a continuous process. Consequently the data

indicated in this booklet is subject to change without prior notice.

Siemens Ltd.

Industry Sector

I DT LD P LV Motors

R&D Technology Centre

6th Floor, Kalwa Works

Thane Belapur Road, Thane - 400 601

Fax: +91 22 33265504

E-mail: motors.in@siemens.com

Disposal

Siemens Products are environment friendly,

which predominantly consist of recyclable

materials.

For disposal we recommend disassembling and

separation into following materials:

METALS: Segregate into Ferrous & Non Ferrous

types for recycling through authorised dealer.

PLASTICS: Segregate as per material type for

recycling through authorised dealer.

Because of the long lifetime of Siemens products

the disposal guidelines may be replaced by other

national regulations when taking the product out

of service.

The local customer care service is available at any

time to answer disposal-related questions

Loading...

Loading...