Shop fox W1774 User Manual

MODEL W1774

18-GAUGE BRAD NAILER

OWNER'S MANUAL

(FOR MODELS MANUFACTURED SINCE 01/14)

Phone: (360) 734-3482 • Online Technical Support: tech-support@shopfox.biz

COPYRIGHT © JUNE, 2007 BY WOODSTOCK INTERNATIONAL, INC., REVISED NOVEMBER, 2017 (MN)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

#9551TS Printed in China

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property

damage from negligence, improper training, machine modifications or

misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Model W1774 18-Gauge Brad Nailer

SAFETY

For Your Own Safety Read Instruction Manual

Before Operating This Equipment

The purpose of safety symbols is to attract your attention to possible hazardous

conditions. This manual uses a series of symbols and signal words which are intended

to convey the level of importance of the safety messages. The progression of

symbols is described below. Remember that safety messages by themselves do not

eliminate danger and are not a substitute for proper accident prevention measures.

Indicates an imminently hazardous situation which, if

not avoided, WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, MAY result in minor or moderate injury.

It may also be used to alert against unsafe practices.

NOTICE

This symbol is used to alert the user to useful

information about proper operation of the

equipment.

Safety Instructions for Pneumatic Tools

KEEP ALL SAFETY DEVICES IN PLACE

and in working order.

REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are

removed from tool before operation.

KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

DO NOT USE IN DANGEROUS

ENVIRONMENT. Do not use pneumatic

tools in damp or wet locations, or where

any flammable or noxious fumes may

exist. Keep work area well lighted.

KEEP CHI LDR EN AND VISITORS AWAY. All

children and visitors should be kept at a

safe distance from work area.

MAKE WORKSHOP CHILD PROOF by lock-

ing the shop and shutting off air valves.

DO NOT FORCE TOOL. It will do the job

better and safer at the rate for which it

was designed.

USE THE RIGHT TOOL. Do not force tool

or attachment to do a job for which it

was not designed.

DO NOT USE UNDER INFLUENCE OF

DRUGS OR ALCOHOL.

-1-

Model W1774 18-Gauge Brad Nailer

Safety Instructions for Pneumatic Tools

USE PROPER AIR HOSE for the tool. Make

sure your air hose is in good condition and

is long enough to reach your work area

without stretching.

WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Non-slip footwear

is recommended. Wear a protective hair

covering to contain long hair.

ALWAYS USE SAFETY GLASSES. Also use

a face or dust mask if operation is dusty.

Everyday eyeglasses only have impact

resistant lenses, they are NOT safety

glasses.

WEAR APPROVED HEARING

PROTECTION. Air escaping from pneu-

matic tools can exceed safe exposure

limits and may cause hearing damage

with prolonged exposure.

AWKWARD POSITIONS. Keep proper foot-

ing and balance at all times when operating tool. Do not overreach! Avoid awkward hand positions that make workpiece

control difficult or increase the risk of

accidental injury.

REDUCE THE RISK OF UNINTENTIONAL

FIRING. Do not carry tool with hand on

trigger and always disconnect from air

when not in use.

CHECK FOR DAMAGED PARTS. Regularly

inspect tool for any condition that may

affect safe operation. Immediately repair

or replace damaged or mis-adjusted parts

before operating tool.

DISCONNECT TOOLS before servicing,

changing accessories, or moving to another location.

USE RECOMMENDED ACCESSORIES.

Consult this owner’s manual or the manufacturer for recommended accessories.

Using improper accessories will increase

the risk of serious injury.

NEVER LEAVE UNATTENDED TOOL

CONNECTED TO AIR. Disconnect the

air hose and do not leave tool until it is

relieved of any built up pressure.

NEVER ALLOW UNTR AINED USERS TO

USE THIS TOOL WHILE UNSUPERVISED.

IF YOU ARE UNSURE OF THE INTENDED

OPERATION, STOP USING TOOL. Seek

formal training or research books or magazines that specialize in pneumatic tools.

BE AWARE OF HOSE LOCATION WHEN

USING PNEUMATIC TOOLS. Hoses can

easily become a tripping hazard when

laid across the floor or spread out in a

disorganized fashion.

SECURE WORK. When required, use

clamps or vises to secure workpiece. A

secured workpiece protects hands and

frees both of them to operate the tool.

MAINTAIN TOOLS WITH CARE. Keep

tools lubricated and clean for best and

safest performance. Follow instructions

for lubricating and changing accessories.

-2-

Model W1774 18-Gauge Brad Nailer

Additional Safety Instructions for Nailers/

Staplers

HAND INJURIES: Do not place your hands

near the nail/staple point of entry. A

nail/staple can deflect and tear through

the surface of the workpiece, puncturing

your hand or fingers.

COMBUSTIBLE GASES: Never connect the

nailer/stapler to pressurized oxygen or

other combustible gases as an air source.

Only use filtered, lubricated, and regulated compressed air.

HOSE USAGE: Make sure your air hose is

designed for the tool in use, is in good

condition, and is long enough to reach

your work without stretching. However,

an overly long air hose in the work area

may be a tripping hazard.

OPERATING QUESTIONS: If you are not

sure about the intended operation, stop

using the nailer/stapler. Seek formal

training.

SAFE HANDLING: Never point the nailer/

stapler at others! Do not keep the trigger

pulled when loading fasteners, carrying,

or holding tool. Carry the tool only by the

handle, never by any other part. Do not

carry the tool by the air hose. Disconnect

the nailer/stapler from the air hose when

going up and down ladders.

MODIFICATIONS: DO NOT modify this

tool or bypass the safety nose mechanism.

COMPRESSED AIR RATING: Do not connect the nailer/stapler to compressed air

that exceeds 120 PSI.

Never point this nailer at yourself

or another person! Always pay

attention to the direction this nailer

is pointed. Use this tool with respect

and caution to lessen the possibility

of operator or bystander injury.

Ignoring this warning may result in

serious personal injury.

CLEANING: Never use gasoline or other

flammable liquids to clean the nailer;

vapors in the nailer/stapler will ignite by

a spark and cause it to explode.

MAINTENANCE: Always disconnect air

from the nailer/stapler when servicing

or installing nails. During maintenance,

a nailer/stapler connected to air may

fire accidentally, causing serious personal injury.

CHECK VALVE: Do not use a check valve

or any other fitting that allows air to

remain in the tool after it is disconnected from the air source.

Nailer/stapler accidents routinely

happen while moving the gun to

another location, such as up ladders,

to another room, or even another

job site. Always disconnect the gun

immediately after use and never

transport the gun while connected to

the air—even if the air compressor is

disconnected from its power source!

-3-

Model W1774 18-Gauge Brad Nailer

INTRODUCTION

Woodstock Technical

Support

This Model W1774 18 Gauge Brad Nailer

has been specially designed to provide

many years of trouble-free service. Close

attention to detail, ruggedly built parts

and a rigid quality control program assure

safe and reliable operation.

Woodstock International, Inc. is committed to customer satisfaction. Our intent

with this manual is to include the basic

information for safety, setup, operation,

maintenance, and service of this product.

We stand behind our tools! In the

event that questions arise about

your tool, please contact Woodstock

International Technical Support at

(360) 734-3482 or send e-mail to:

tech-support@shopfox.biz. Our knowledgeable staff will help you troubleshoot

problems and process warranty claims.

If you need the latest edition of this

manual, you can download it from

http://ww w.shop fox.biz .

Machine Data

Nail Size ............................. 18 Gauge

Nail Length ..............................5⁄8"–2"

Magazine Capacity ................. 100 Nails

Air Inlet ................................1⁄4" NPT

Weight .................................3 1⁄2 lbs.

Operating Pressure ...............60–100 PSI

Read the manual before operation.

Become familiar with this nailer, its

safety instructions, and its operation

before beginning any work. Serious

personal injury may result if safety

or operational information is not

understood or followed.

If you have comments about this

manual, please contact us at:

Woodstock International, Inc.

Attn: Technical Documentation

Manager

P.O. Box 2309

Bellingham, WA 98227

Email: manuals@woodstockint.com

No list of safety guidelines can be

complete. Every shop environment

is different. Always consider safety

first, as it applies to your individual

working conditions. Use this and

other tools with caution and respect.

Failure to do so could result in serious

personal injury, damage to equipment

or poor work results.

-4-

Model W1774 18-Gauge Brad Nailer

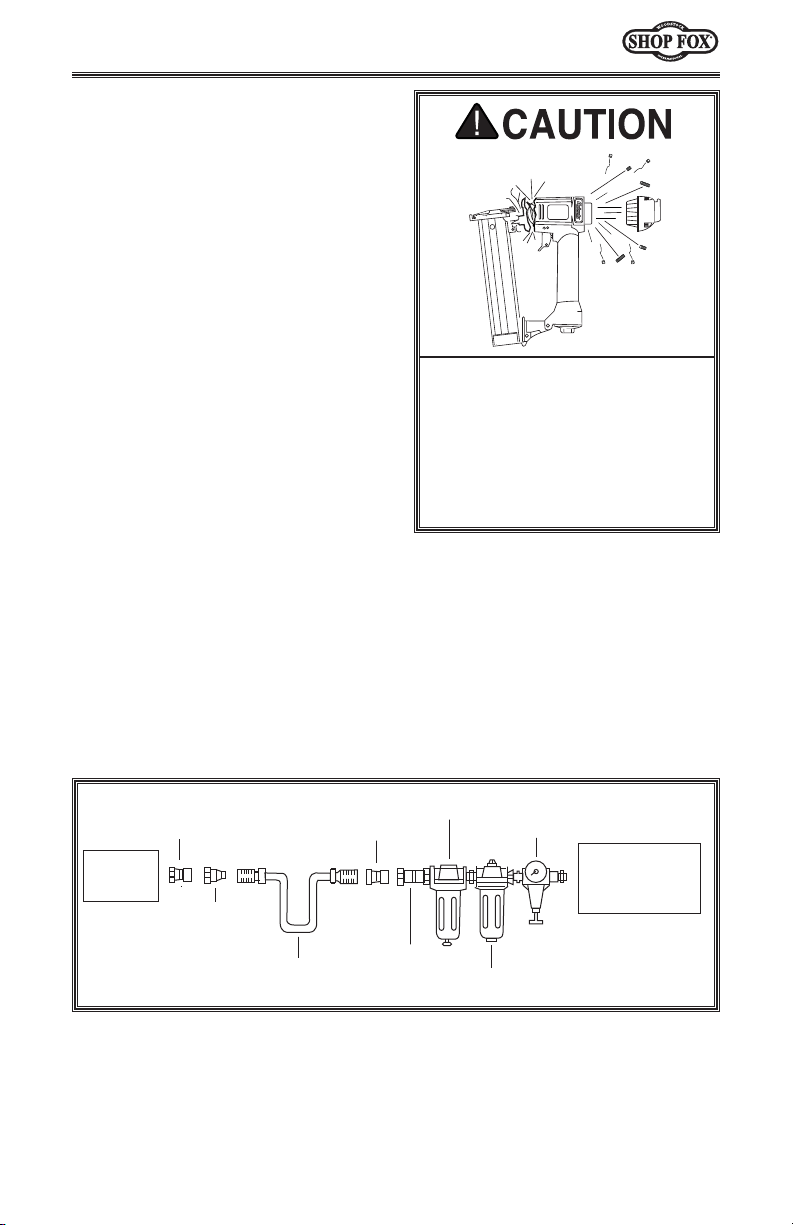

Compressed Air System

The Model W1774 is designed to be

operated at 60-100 PSI using clean,

dry, regulated, compressed air. Do not

exceed the 120 PSI maximum operating

pressure for your model.

Before using your nailer, regulate the

air pressure to find the optimum setting

within the specified operating range.

Start by testing the nailer at a low

setting, then increase the air pressure as

needed for satisfactory results.

An in-line filter/lubricator/regulator unit,

can be installed as depicted in Figure 1.

This filter/lubricator/regulator unit

will protect your tool from damaging

water build-up, allow you to adjust and

maintain regulated air pressure to your

tool, and save you the inconvenience of

having to manually lubricate your tool

every time you use it.

Exceeding the maximum permissible

operating pressure may damage the

nailer and cause it to malfunction.

To protect yourself from personal

injury, DO NOT allow the air pressure

to exceed the recommended

pressure for this nailer!

If you plan on installing a filter/

lubricator/regulator unit in your

compressed air system, always follow the

connection instructions that come with

the unit.

Quick

Connector

Quick

Connector

Your

Tool

Quick

Coupler

Air Hose

Figure 1. Typical filter/lubricator/regulator installation order.

Lubricator

Quick

Coupler

-5-

Regulator

Air

Compressor

Filter

Loading...

Loading...