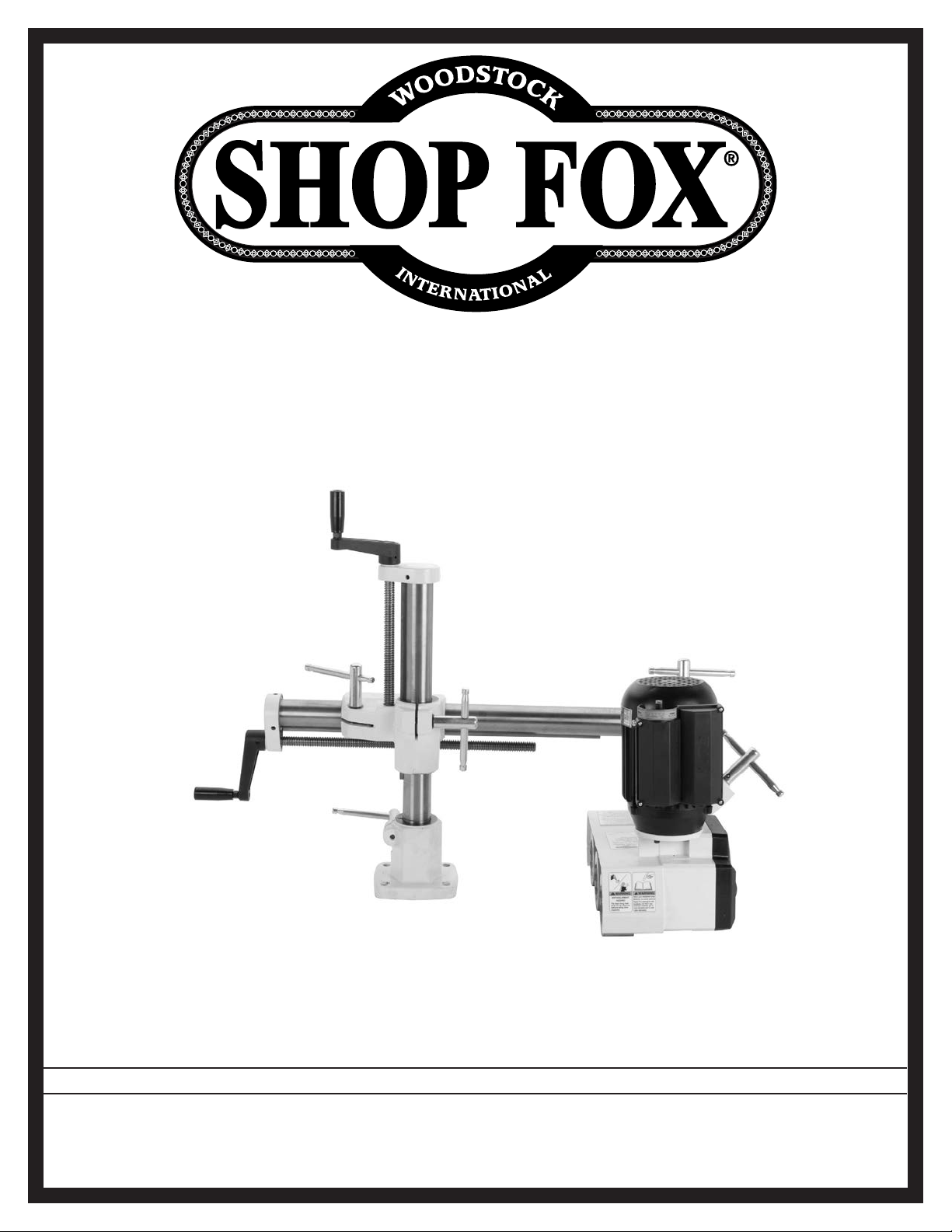

Shop fox W1766 User Manual

MODEL W1766

1/2 HP POWER FEEDER

OWNER'S MANUAL

Phone: (360) 734-3482 • Online Technical Support: tech-support@shopfox.biz

COPYRIGHT © SEPTEMBER, 2007 BY WOODSTOCK INTERNATIONAL, INC., REVISED JULY, 2014 (MN)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

#9772CR

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in Taiwan

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property

damage from negligence, improper training, machine modifications or

misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Contents

INTRODUCTION ...................................... 2

Woodstock Technical Support .................. 2

Data Sheet ........................................ 3

SAFETY ................................................ 6

Standard Safety Instructions ................... 6

Additional Safety for Power Feeders ..........8

ELECTRICAL ..........................................9

220V Operation ................................... 9

Extension Cords .................................. 9

Electrical Specifications ........................ 9

SETUP ............................................... 10

Unpacking ....................................... 10

Inventory ........................................ 10

Machine Placement ............................ 11

Cleaning Machine ............................... 11

Assembly ......................................... 12

Base Mounting .................................. 13

Test Run .......................................... 15

OPERATIONS ........................................ 16

General .......................................... 16

Changing Feed Speed .......................... 17

ACCESSORIES ....................................... 18

Power Feeder Accessories .................... 18

MAINTENANCE ..................................... 19

General .......................................... 19

Cleaning ......................................... 19

Lubrication ...................................... 19

SERVICE ............................................. 20

General .......................................... 20

Wheel Replacement............................ 20

Troubleshooting ................................. 21

Electrical ........................................ 22

PARTS ............................................... 23

Stand ............................................. 25

Label Placement ............................... 26

SAFETYINTRODUCTION

SET UPELECTRICAL MAINTENANCE

OPERATIONS

SERVICE PARTS

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

W1766 1⁄2 HP Power Feeder

INTRODUCTION

INTRODUCTION

Woodstock Technical Support

This machine has been specially designed to provide many years of trouble-free service. Close attention

to detail, ruggedly built parts and a rigid quality control program assure safe and reliable operation.

Woodstock International, Inc. is committed to customer satisfaction. Our intent with this manual is to

include the basic information for safety, setup, operation, maintenance, and service of this product.

We stand behind our machines! In the event that questions arise about your machine, please contact

Woodstock International Technical Support at (360) 734-3482 or send e-mail to: tech-support@shopfox.

biz. Our knowledgeable staff will help you troubleshoot problems and process warranty claims.

If you need the latest edition of this manual, you can download it from http://www.shopfox.biz.

If you have comments about this manual, please contact us at:

Woodstock International, Inc.

Attn: Technical Documentation Manager

P.O. Box 2309

Bellingham, WA 98227

Email: manuals@woodstockint.com

-2-

W1766 1⁄2 HP Power Feeder

MACHINE

MACHINE

SPECIFICATIONS

SPECIFICATIONS

Phone #: (360) 734–3482 • Online Tech Support: tech–support@shopfox.biz • Web: www.shopfox.biz

INTRODUCTION

Data Sheet

MODEL W1766

1/2 HP POWER FEEDER

Motor

Type ......................................................................................... TEFC Capacitor Start Induction

Horsepower .............................................................................................................. 1/2 HP

Voltage ......................................................................................................................220V

Prewired .................................................................................................................... 220V

Phase ...................................................................................................................... Single

Amps ......................................................................................................................... 5.5A

Speed .................................................................................................................. 1725 RPM

Cycle ........................................................................................................................ 60 Hz

Number of Speeds ............................................................................................................. 1

Power Transfer ...................................................................................................... Gear Box

Bearings ................................................................................................... Lubricated for Life

Main Specifications

Operation Info

Minimum Workpiece Length ....................................................................................... 6 in.

Number of Feed Speeds ............................................................................................... 4

Feed Speeds ....................................................................................... 9.5, 15, 25, 38 FPM

Swing ............................................................................................................ 360 deg.

Vertical Movement ........................................................................................... 10-1/4 in.

Horizontal Movement ........................................................................................ 16-3/8 in.

Rotation .............................................................................................. Forward, Reverse

Roller Info

Number of Rollers ....................................................................................................... 3

Roller Width .......................................................................................................... 2 in.

Roller Diameter ..................................................................................................... 4 in.

Roller Suspension Travel ..................................................................................... 15/16 in.

Maximum Height of Rollers .................................................................................. 7-7/8 in.

Distance Between Rollers .................................................................................... 4–3/4 in.

Overall Dimensions

Weight ........................................................................................................... 104 lbs.

Length/Width/Height ........................................................................... 45 x 18 x 28–1/2 in.

Column Diameter ............................................................................................... 1–1/2 in.

Construction Materials

Roller Construction .................................................................................. Synthetic Rubber

Housing Construction .................................................................................. Cast Aluminum

Supports Construction ......................................................................................... Cast Iron

Column Construction .............................................................................................. Steel

Paint ................................................................................................................. Epoxy

-3-

INTRODUCTION

W1766 1⁄2 HP Power Feeder

Shipping Dimensions

Carton #1

Type ............................................................................................................ Cardboard

Content ...........................................................................................................Machine

Weight ..............................................................................................................70 lbs.

Length/Width/Height ................................................................................. 20 x 11 x 19 in.

Carton #2

Type ............................................................................................................ Cardboard

Content ..............................................................................................................Stand

Weight ..............................................................................................................48 lbs.

Length/Width/Height ................................................................................... 30 x 11 x 9 in.

Electrical

Switch ............................................................................................... Forward/Reverse Barrel

Switch Voltage ............................................................................................................. 220V

Cord Length ................................................................................................................. 9 ft.

Cord Gauge ............................................................................................................ 18 gauge

Recommended Breaker Size ..........................................................................................10 amp

Included Plug ..................................................................................................................No

Other

ISO Factory ............................................................................................................ ISO 9001

Country of Origin ...................................................................................................... Taiwan

Warranty ................................................................................................................ 2 Years

Assembly Time .................................................................................................... 45 minutes

Optional Accessories

Extra Roller ....................................................................................................... Model D3872

Features

Spring Tensioned Rollers

Heavy–Duty Gear Reduction Gearbox with Hardened Gears

Universal Positioning with Handle Locks

-4-

W1766 1⁄2 HP Power Feeder

Controls and Features

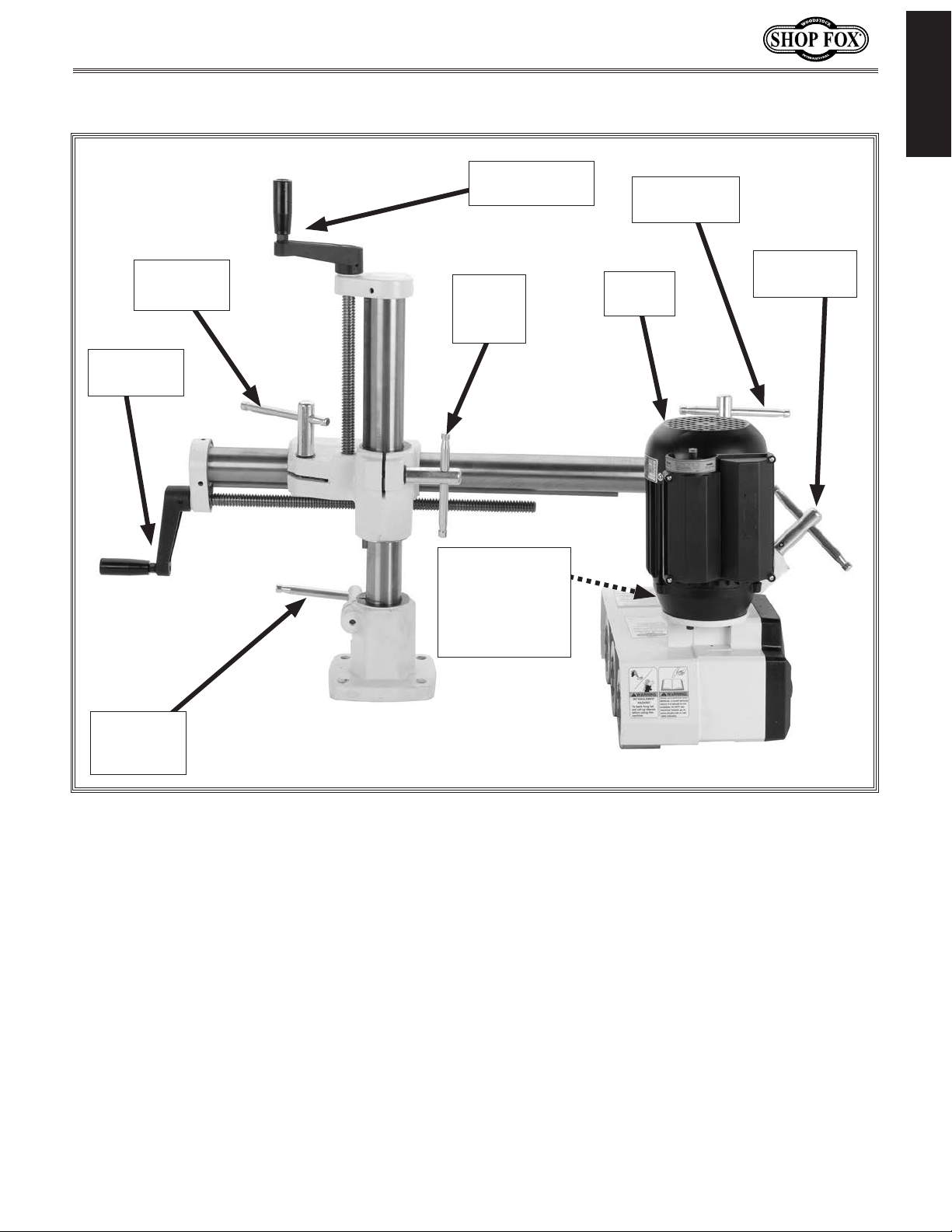

Vertical Travel

Handcrank

Upper Elbow

Joint Lock

INTRODUCTION

Horizontal

Travel Lock

Horizontal

Handcrank

Vertical

Travel

Lock

Gearbox Oil

Plug Labeled

"OIL" Located

on Top of Case

Behind Motor

1

⁄2 HP

Motor

Lower Elbow

Joint Lock

Rotary

Movement

Lock

Figure 1. Controls and Features.

-5-

W1766 1⁄2 HP Power Feeder

SAFETY

READ MANUAL BEFORE OPERATING MACHINE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

SAFETY

NOTICE

RESULT IN PERSONAL INJURY.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury.

This symbol is used to alert the user to useful information about proper

operation of the equipment, and/or a situation that may cause damage

to the machinery.

Standard Safety Instructions

1. READ THROUGH THE ENTIRE MANUAL BEFORE STARTING MACHINERY. Machinery presents serious

injury hazards to untrained users.

2. ALWAYS USE ANSI APPROVED SAFETY GLASSES WHEN OPERATING MACHINERY. Everyday

eyeglasses only have impact resistant lenses—they are NOT safety glasses.

3. ALWAYS WEAR AN NIOSH APPROVED RESPIRATOR WHEN OPERATING MACHINERY THAT

PRODUCES DUST. Wood dust is a carcinogen and can cause cancer and severe respiratory

illnesses.

4. ALWAYS USE HEARING PROTECTION WHEN OPERATING MACHINERY. Machinery noise can cause

permanent hearing damage.

5. WEAR PROPER APPAREL. DO NOT wear loose clothing, gloves, neckties, rings, or jewelry which

may get caught in moving parts. Wear protective hair covering to contain long hair and wear nonslip footwear.

6. NEVER OPERATE MACHINERY WHEN TIRED, OR UNDER THE INFLUENCE OF DRUGS OR ALCOHOL.

Be mentally alert at all times when running machinery.

7. ONLY ALLOW TRAINED AND PROPERLY SUPERVISED PERSONNEL TO OPERATE MACHINERY. Make

sure operation instructions are safe and clearly understood.

8. KEEP CHILDREN AND VISITORS AWAY. Keep all children and visitors a safe distance from the

work area.

9. MAKE WORKSHOP CHILD PROOF. Use padlocks, master switches, and remove start switch keys.

-6-

W1766 1⁄2 HP Power Feeder

10. NEVER LEAVE WHEN MACHINE IS RUNNING. Turn power off and allow all moving parts to come to

a complete stop before leaving machine unattended.

11. DO NOT USE IN DANGEROUS ENVIRONMENTS. DO NOT use machinery in damp, wet locations, or

where any flammable or noxious fumes may exist.

12. KEEP WORK AREA CLEAN AND WELL LIT. Clutter and dark shadows may cause accidents.

13. USE A GROUNDED EXTENSION CORD RATED FOR THE MACHINE AMPERAGE. Undersized cords

overheat and lose power. Replace extension cords if they become damaged. DO NOT use

extension cords for 220V machinery.

14. ALWAYS DISCONNECT FROM POWER SOURCE BEFORE SERVICING MACHINERY. Make sure switch

is in OFF position before reconnecting.

15. MAINTAIN MACHINERY WITH CARE. Keep blades sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

16. MAKE SURE GUARDS ARE IN PLACE AND WORK CORRECTLY BEFORE USING MACHINERY.

17. REMOVE ADJUSTING KEYS AND WRENCHES. Make a habit of checking for keys and adjusting

wrenches before turning machinery ON.

18. CHECK FOR DAMAGED PARTS BEFORE USING MACHINERY. Check for binding and alignment of

parts, broken parts, part mounting, loose bolts, and any other conditions that may affect machine

operation. Repair or replace damaged parts.

SAFETY

19. USE RECOMMENDED ACCESSORIES. Refer to the instruction manual for recommended accessories.

The use of improper accessories may cause risk of injury.

20. DO NOT FORCE MACHINERY. Work at the speed for which the machine or accessory was designed.

21. SECURE WORKPIECE. Use clamps or a vise to hold the workpiece when practical. A secured

workpiece protects your hands and frees both hands to operate the machine.

22. DO NOT OVERREACH. Keep proper footing and balance at all times.

23. MANY MACHINES WILL EJECT THE WORKPIECE TOWARD THE OPERATOR. Know and avoid

conditions that cause the workpiece to "kickback."

24. ALWAYS LOCK MOBILE BASES (IF USED) BEFORE OPERATING MACHINERY.

25. BE AWARE THAT CERTAIN DUST MAY BE HAZARDOUS to the respiratory systems of people and

animals, especially fine dust. Make sure you know the hazards associated with the type of dust

you will be exposed to and always wear a respirator approved for that type of dust.

-7-

W1766 1⁄2 HP Power Feeder

Additional Safety for Power Feeders

READ and understand this

entire instruction manual

before using this machine.

SAFETY

1. SAFETY ACCESSORIES. Always use appropriate machine guards.

2. TOOL SPEED. Make sure all cutting tools are rotating at the operating speed before feeding the

workpiece.

3. FEEDING SPEED. DO NOT overload the cutting tool by feeding too quickly. The cutting tool will

perform better and be safer working at the rate for which it was designed.

4. HAND SAFETY. Keep hands away from rotating parts on the feeder and the cutting tool. Do not

allow hands or clothing to be pinched between the rollers and workpiece.

5. WORKPIECE SUPPORT. DO NOT feed long workpieces without providing adequate support at the

outfeed end of the table.

Serious personal injury

may occur if safety and

operational information is

not understood and followed. DO NOT risk your

safety by not reading!

USE this and other machinery with caution

and respect. Always consider safety first,

as it applies to your individual working

conditions. No list of safety guidelines can

be complete—every shop environment is

different. Failure to follow guidelines could

result in serious personal injury, damage

to equipment or poor work results.

6. STOPPING FEEDER. Always stop the feeder before stopping the cutting tool.

7. ADJUSTMENTS. Disconnect the feeder from its power source before cleaning, repairing, or making

adjustments.

8. EXPERIENCING DIFFICULTIES. If at any time you are experiencing difficulties performing the

intended operation, stop using the machine! Contact Tech Support at (360) 734-3482.

9. MACHINE MANUAL. This manual only covers the power feeder. It is not a replacement for the

manual that came with the machine on which the power feeder is mounted. Make sure to read that

manual also for correct operation instructions and safety precautions.

-8-

Loading...

Loading...