Page 1

MODEL W1704

BENCH TOP LATHE

INSTRUCTION MANUAL

Phone: 1-360-734-3482 • On-Line Technical Support: tech-support@shopfox.biz

COPYRIGHT © DECEMBER, 2003 BY WOODSTOCK INTERNATIONAL, INC. REVISED APRIL, 2013 (TR)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in China#5378TR

Page 2

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property

damage from negligence, improper training, machine modifications or

misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Page 3

CONTENTS

INTRODUCTION ............................................................................................ 2

About Your New Lathe ......................................................................................... 2

Woodstock Technical Support .................................................................................2

Warranty and Returns .......................................................................................... 3

Specifications .................................................................................................. 3

SAFETY ...................................................................................................... 4

Standard Safety Instructions .................................................................................. 4

Know Your Machine ............................................................................................. 6

Important Lathe Terms & Definitions ........................................................................ 7

Safety Instructions for Your Lathe ........................................................................... 8

Avoiding Potential Injuries .................................................................................... 9

110V Operation ............................................................................................... 10

Extension Cords ............................................................................................... 10

Grounding ...................................................................................................... 10

INTRODUCTION

SAFETY

ASSEMBLY

ASSEMBLY ..................................................................................................11

Unpacking ...................................................................................................... 11

Inventory ....................................................................................................... 11

Shop Preparation ............................................................................................. 12

Initial Cleaning ................................................................................................ 12

Installing Centers ............................................................................................. 13

Removing Centers ............................................................................................ 13

Face Plate ..................................................................................................... 14

Tool Rest ....................................................................................................... 14

ADJUSTMENTS ............................................................................................15

Lock Handles .................................................................................................. 15

Tailstock Barrel ............................................................................................... 15

OPERATIONS...............................................................................................16

Test Run ........................................................................................................ 16

Operation Tips ................................................................................................ 17

Selecting Turning Tools ...................................................................................... 18

Spindle Turning ................................................................................................ 19

Face Plate Turning ............................................................................................ 20

Sanding/Finishing ............................................................................................. 21

MAINTENANCE ............................................................................................22

General ......................................................................................................... 22

Lubrication .................................................................................................... 22

ADJUSTMENTS

OPERATIONS

MAINTENANCE

WIRING DIAGRAM .........................................................................................23

PARTS ...................................................................................................... 24

TROUBLESHOOTING ......................................................................................26

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

PARTS

Page 4

INTRODUCTION

This machine has been specially designed to provide many years of trouble-free service. Close attention

to detail, ruggedly built parts and a rigid quality control program assure safe and reliable operation.

Woodstock International, Inc. is committed to customer satisfaction. Our intent with this manual is to

include the basic information for safety, setup, operation, maintenance, and service of this product.

We stand behind our machines! In the event that questions arise about your machine, please contact

Woodstock International Technical Support at (360) 734-3482 or send e-mail to: tech-support@shopfox.

biz. Our knowledgeable staff will help you troubleshoot problems and process warranty claims.

If you need the latest edition of this manual, you can download it from http://www.shopfox.biz.

If you have comments about this manual, please contact us at:

INTRODUCTION

Woodstock Technical Support

Woodstock International, Inc.

Attn: Technical Documentation Manager

P.O. Box 2309

Bellingham, WA 98227

Email: manuals@woodstockint.com

-2-

Page 5

WARRANTY

WARRANTY

Woodstock International, Inc. warrants all Shop Fox machinery to be free of defects from workmanship

and materials for a period of two years from the date of original purchase by the original owner.

This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or

accidents, lack of maintenance, or reimbursement of third party expenses incurred.

Woodstock International, Inc. will repair or replace, at its expense and at its option, the Shop Fox

machine or machine part, which in normal use has proven to be defective, provided that the original

owner returns the product prepaid to a Shop Fox factory service center with proof of their purchase

of the product within two years, and provides Woodstock International, Inc. reasonable opportunity to

verify the alleged defect through inspection. If it is determined there is no defect, or that the defect

resulted from causes not within the scope of Woodstock International Inc.'s warranty, then the original

owner must bear the cost of storing and returning the product.

This is Woodstock International, Inc.'s sole written warranty and any and all warranties that may

be implied by law, including any merchantability or fitness, for any particular purpose, are hereby

limited to the duration of this written warranty. We do not warrant that Shop Fox machinery complies

with the provisions of any law or acts. In no event shall Woodstock International, Inc.'s liability under

this warranty exceed the purchase price paid for the product, and any legal actions brought against

Woodstock International, Inc. shall be tried in the State of Washington, County of Whatcom. We shall

in no event be liable for death, injuries to persons or property or for incidental, contingent, special or

consequential damages arising from the use of our products.

INTRODUCTION

INTRODUCTION

Every effort has been made to ensure that all Shop Fox machinery meets high quality and durability

standards. We reserve the right to change specifications at any time because of our commitment to

continuously improve the quality of our products.

Specifications

Motor Size ..........................................................1⁄3 HP, 110V, Universal-Type Motor

Motor Speed ................................................................................ 700-3200 RPM

Amp Draw ................................................................................................ 4 A

Distance Between Centers ............................................................................ 13"

Turning Diameter .........................................................................................8"

Spindle Taper ......................................................................................... MT #1

Tailstock Taper ....................................................................................... MT #1

3

Spindle Size .............................................................................

Machine Weight ......................................................................................45 lbs

Footprint .........................................................................................23

⁄4" x 16 TPI (RH)

1

⁄2" X 5"

-3-

Page 6

SAFETY

SAFETY

READ MANUAL BEFORE OPERATING MACHINE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

SAFETY

1. READ THROUGH THE ENTIRE MANUAL BEFORE STARTING MACHINERY. Machinery presents serious

2. ALWAYS USE ANSI APPROVED SAFETY GLASSES WHEN OPERATING MACHINERY. Everyday eye-

3. ALWAYS WEAR A NIOSH APPROVED RESPIRATOR WHEN OPERATING MACHINERY THAT PRODUCES

RESULT IN PERSONAL INJURY.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury.

This symbol is used to alert the user to useful information about proper

NOTICE

operation of the equipment, and/or a situation that may cause damage

to the machinery.

Standard Safety Instructions

Standard Machinery Safety

injury hazards to untrained users.

glasses only have impact resistant lenses—they are NOT safety glasses.

DUST. Wood dust is a carcinogen and can cause cancer and severe respiratory illnesses.

4. ALWAYS USE HEARING PROTECTION WHEN OPERATING MACHINERY. Machinery noise can cause

permanent hearing damage.

5. WEAR PROPER APPAREL. DO NOT wear loose clothing, gloves, neckties, rings, or jewelry which may

get caught in moving parts. Wear protective hair covering to contain long hair and wear non-slip

footwear.

6. NEVER OPERATE MACHINERY WHEN TIRED, OR UNDER THE INFLUENCE OF DRUGS OR ALCOHOL.

Be mentally alert at all times when running machinery.

7. ONLY ALLOW TRAINED AND PROPERLY SUPERVISED PERSONNEL TO OPERATE MACHINERY. Make

sure operation instructions are safe and clearly understood.

8. KEEP CHILDREN AND VISITORS AWAY. Keep all children and visitors a safe distance from the work

area.

9. MAKE WORKSHOP CHILD PROOF. Use padlocks, master switches, and remove start switch keys.

-4-

Page 7

10. NEVER LEAVE WHEN MACHINE IS RUNNING. Turn power OFF and allow all moving parts to come to

a complete stop before leaving machine unattended.

11. DO NOT USE IN DANGEROUS ENVIRONMENTS. DO NOT use machinery in damp, wet locations, or

where any flammable or noxious fumes may exist.

12. KEEP WORK AREA CLEAN AND WELL LIT. Clutter and dark shadows may cause accidents.

13. USE A GROUNDED EXTENSION CORD RATED FOR THE MACHINE AMPERAGE. Undersized cords over-

heat and lose power. Replace extension cords if they become damaged. DO NOT use extension cords

for 220V machinery.

14. ALWAYS DISCONNECT FROM POWER SOURCE BEFORE SERVICING MACHINERY. Make sure switch is

in OFF position before reconnecting.

15. MAINTAIN MACHINERY WITH CARE. Keep blades sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

16. MAKE SURE GUARDS ARE IN PLACE AND WORK CORRECTLY BEFORE USING MACHINERY.

17. REMOVE ADJUSTING KEYS AND WRENCHES. Make a habit of checking for keys and adjusting

wrenches before turning machinery ON.

SAFETY

18. CHECK FOR DAMAGED PARTS BEFORE USING MACHINERY. Check for binding and alignment of

parts, broken parts, part mounting, loose bolts, and any other conditions that may affect machine

operation. Repair or replace damaged parts.

19. USE RECOMMENDED ACCESSORIES. Refer to the instruction manual for recommended accessories.

The use of improper accessories may cause risk of injury.

20. DO NOT FORCE MACHINERY. Work at the speed for which the machine or accessory was designed.

21. SECURE WORKPIECE. Use clamps or a vise to hold the workpiece when practical. A secured

workpiece protects your hands and frees both hands to operate the machine.

22. DO NOT OVERREACH. Keep proper footing and balance at all times.

23. MANY MACHINES WILL EJECT THE WORKPIECE TOWARD THE OPERATOR. Know and avoid condi-

tions that cause the workpiece to "kickback."

24. ALWAYS LOCK MOBILE BASES (IF USED) BEFORE OPERATING MACHINERY.

25. BE AWARE THAT CERTAIN DUST MAY BE HAZARDOUS to the respiratory systems of people and

animals, especially fine dust. Make sure you know the hazards associated with the type of dust you

will be exposed to and always wear a respirator approved for that type of dust.

-5-

Page 8

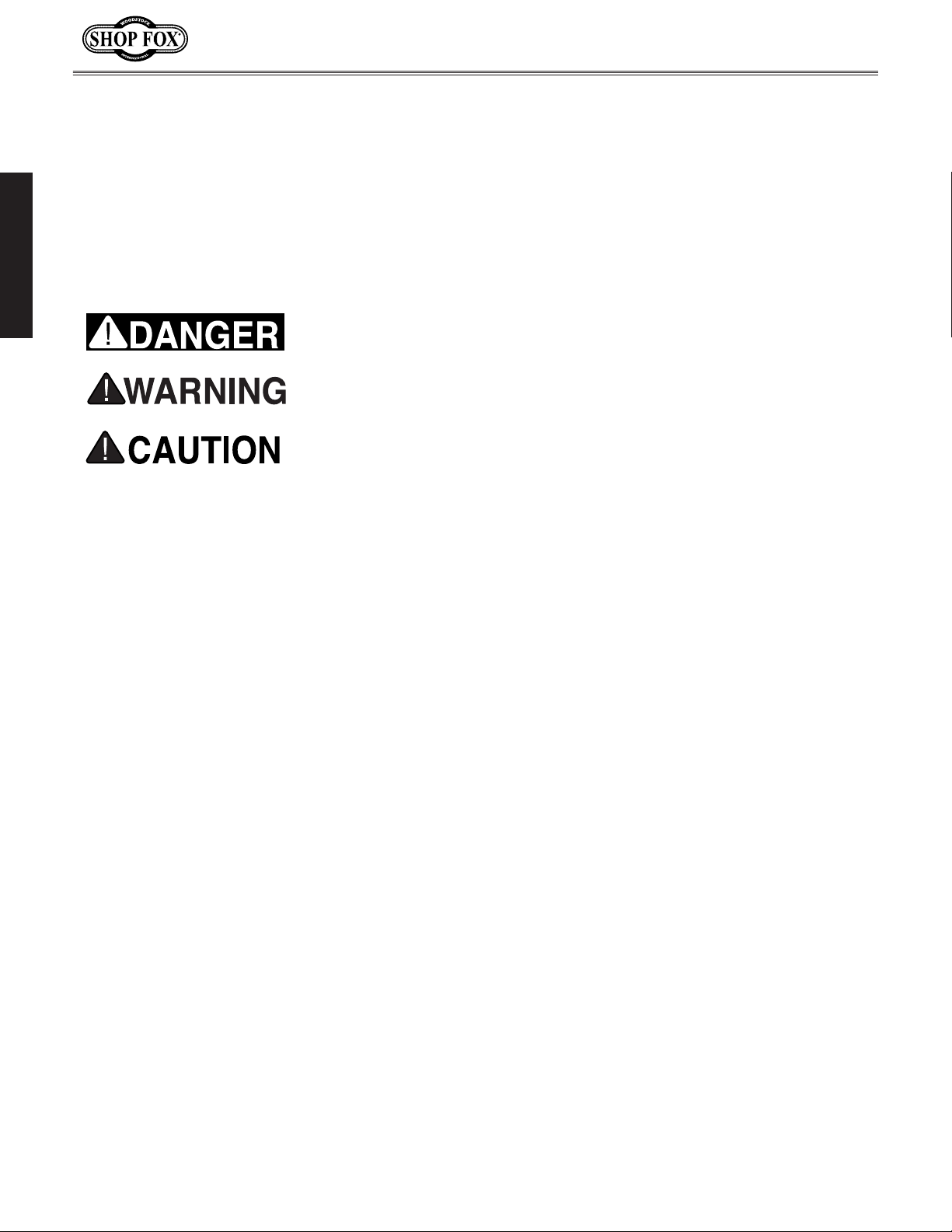

Know Your Machine

An important part of safety is knowing your machine and its components. Please take the time to learn

the items shown in the pictures below. The letters in the picture correspond to the following descriptions in the text.

SAFETY

B

A

N

C

M

D

E

L

F

K

J

G

H

I

P

O

-6-

Page 9

A. Variable Speed Control Dial—Controls the

speed of the lathe spindle. Always turn this

dial to the lowest setting before starting the

lathe.

B. Headstock—The housing that holds the spin-

dle on the lathe.

C. Headstock Spindle—Tapered at the inside

end to accept the shank of a Morse Taper

#1 (MT#1) spur center and threaded on the

outside end to accept the threads of a face

plate. The headstock spindle is also hollow

for easy removal of the spur center with a

knock-out tool.

D. Spur Center—Attaches the workpiece to the

spindle for turning operations.

E. Tool Rest—Supports tools used during turn-

ing operations.

M. Lathe Bed—Provides a sliding surface for

the tool rest holder and tailstock adjustments.

N. Lock-Out Paddle Switch—Turns lathe ON/

OFF only when the safety key is installed.

O. Knock-Out Tool—Used to remove the spur

and live centers from their tapered spindles.

P. Face Plate—Threads onto the headstock

spindle for non-spindle turning (usually used

for making bowls or other items that cannot

be supported from the tailstock).

Important Lathe

Terms & Definitions

SAFETY

F. Live Center—Mounts in the tailstock barrel

taper and supports the workpiece from the

opposite side of the spur center by engaging

in the workpiece and spinning freely.

G. Tailstock Barrel Lock—Locks the tailstock

barrel in place after being driven into the

workpiece and before starting the lathe.

H. Tailstock Adjustment Knob—Moves the

tailstock barrel in/out to firmly embed the

live center into the workpiece.

I. Tailstock Lock—Locks the tailstock into

position along the bed.

J. Tool Rest Holder—Mounts the tool rest to

the bed and adjusts perpendicular to the

bed to bring the tool rest closer/farther

from the workpiece.

K. Tool Rest Lock—Secures the tool rest into

position at the proper height needed for the

workpiece.

In order for the safety warnings and operation

instructions to be fully understood, please take

time to learn these important lathe terms and

definitions.

Spindle Turning—When a workpiece is mounted between both spur (headstock) and live

(tailstock) centers.

Face Plate Turning—When a workpiece is

mounted to the face plate, which is mounted to

the headstock spindle. The face plate has holes

for attaching the workpiece or a backing block

with screws.

Backing Block—A waste board that is screwed

or bolted to the face plate, then centered and

glued to the workpiece, so that the workpiece

can be attached to the face plate without drilling or screwing marks.

Center Line—The imaginary line running from

the center of the headstock spindle to the center of the tailstock barrel.

L. Tool Rest Holder Lock—Secures the tool

rest holder when the tool rest is the proper

distance from the workpiece.

Rough Cutting—The initial stage of all turning

operations when the workpiece still has corners

and has not been rounded. Rough cutting strains

the lathe and operator more than regular turning; therefore, special precautions will apply.

-7-

Page 10

1. KEEPING GUARDS IN PLACE. Make sure all guards are in place and that the lathe sits on a flat, stable

2. EYE/FACE PROTECTION. Always wear eye protection or a face shield when operating the lathe.

3. RESPIRATORY PROTECTION. Always wear a respirator when using this machine. Wood dust may

SAFETY

SAFETY

4. MOUNTING WORKPIECE. Before starting, be certain the workpiece has been properly imbedded on

5. WORKPIECE CONDITION. Always inspect the condition of your workpiece. DO NOT turn pieces with

6. ADJUSTING TOOL REST. Adjust tool rest to provide proper support for the turning tool you will be

7. TURNING SPEED. Select the correct turning speed for your work, and allow the lathe to gain full

Additional Safety for Wood Lathes

surface.

cause allergies or long-term respiratory health problems.

the headstock and tailstock centers and that there is adequate clearance for the full rotation.

knots, splits, and other potentially dangerous conditions. Make sure joints of glued-up pieces have

high quality bonds and won't fly apart during operation.

using. Test tool rest clearance by rotating workpiece by hand before turning lathe ON.

speed before using.

8. USING SHARP CHISELS. Keep lathe chisels properly sharpened and held firmly in position when turning.

9. OPERATING DAMAGED LATHE. Never operate the lathe with damaged or worn parts.

10. ADJUSTMENTS/MAINTENANCE. Make sure your wood lathe is turned OFF, disconnected from its

power source, and all moving parts have come to a complete stop before starting any inspection,

adjustment, or maintenance procedure.

11. STOPPING LATHE. DO NOT stop the lathe by using your hand against the workpiece. Allow the lathe

to stop on its own.

12. AVOIDING ENTANGLEMENT. Keep long hair and loose clothing articles such as sleeves, belts, and

jewelry items away from the lathe spindle.

13. FACEPLATE TURNING. When face plate turning, use lathe chisels on the downward spinning side of

the workpiece only.

14. SANDING/POLISHING. Remove the tool rest when performing sanding or polishing operations on the

rotating spindle.

15. MATERIAL REMOVAL RATE. Removing too much material at once may cause workpiece to fly out of

the lathe.

16. REDUCING WORKPIECE VIBRATION. If the workpiece vibrates, immediately turn the lathe OFF.

Check to make sure the workpiece is centered and balanced. Trim excess waste off corners with a

bandsaw or table saw to reduce vibration. Make sure workpiece is securely attached in setup.

-8-

-8-

Page 11

Avoiding Potential Injuries

SAFETY

Figure 1. Center fully embedded in workpiece.

Figure 3. Sleeves rolled up and out of the way

of the moving machinery.

Figure 2. DO NOT operate without centers

firmly embedded in workpiece.

Figure 4. DO NOT operate with long sleeves

rolled down near moving machinery.

Figure 5. Always use the tool rest.

Figure 6. DO NOT cut without using tool rest.

-9-

Page 12

ELECTRICAL

The Model W1704 is wired for 110V operation. Always connect this machine to a dedicated circuit (wire, breaker,

plug, receptacle) with a verified ground, using the recommended circuit size and plugs/receptacles listed at the

SAFETY

SAFETY

bottom of this page.

We recommend connecting this machine to a dedicated

circuit with a verified ground, using the circuit size given

below. Never replace a circuit breaker with one of higher

amperage without consulting a qualified electrician to

ensure compliance with wiring codes.

This machine must be grounded! The electrical cord supplied with this machine comes with a grounding pin. If

your outlet does not accommodate a ground pin, have it

replaced by a qualified electrician.

If you are unsure about the wiring codes in your area

or you plan to connect your machine to a shared circuit, you may create a fire or circuit overload hazard—

consult a qualified electrician to reduce this risk.

We do not recommend using an extension cord; however,

if you have no alternative, use the following guidelines:

110V Operation

Extension Cords

110V

5-15 PLUG

Figure 7. 5-15 plug and receptacle.

DO NOT work on your electrical system

if you are unsure about electrical

codes and wiring! Seek assistance from

a qualified electrician. Ignoring this

warning can cause electrocution, fire,

or machine damage.

GROUNDED

5-15 RECEPTACLE

Grounding Prong

Neutral Hot

• Use a cord rated for Standard Service (S).

• Do not use a cord longer than 50 feet.

• Ensure that the cord has a ground wire and pin.

• Use the gauge size listed below as a minimum.

Electrical Specifications

Operating Voltage Amp Draw Min. Circuit Size Plug/Receptacle Extension Cord

110V Operation

4A

15A NEMA 5-15 14 Gauge

-10-

-10-

Page 13

ASSEM BLY

Unpacking

Read and understand this

entire instruction manual before performing

any operations with your

machine. Serious personal

injury may occur if safety

and operational information is not understood and

followed.

The SHOP FOX® Model W1704 has been carefully packaged for safe transporting. If you notice

the machine has been damaged, please contact

your authorized SHOP FOX

®

dealer immediately.

ASSEMBLY

Inventory

Layout and inventory the package contents listed below and familiarize yourself with the com-

The Model W1704 is

a heavy machine at

46 lbs. Use assistance

when lifting or moving

the machine.

4

2

6

ponents shown in Figure 8 to ease assembly.

Note: Some parts and hardware may already

be installed on the machine. Check the machine

when you use this inventory list.

Item Qty.

1. Lathe Unit (not shown) ....................... 1

2. Spur Center..................................... 1

3. Live Center ..................................... 1

4. Face Plate ...................................... 1

1

⁄4" Tool Rest .................................. 1

5. 4

6. 7" Tool Rest ..................................... 1

7. Knock-Out Tool ................................ . 1

3

5

7

Figure 8. Loose parts shipped with the lathe.

-11-

Page 14

Machine Placement

Cleaning Machine

• Floor Load: Some workbenches may require

additional reinforcement to support both

the machine and the operator. Make sure

you take these precautions.

• Working Clearances: Consider existing and

anticipated needs, size of material to be

processed through the machine, and space

for auxiliary stands, work tables or other

machinery when establishing a location for

your lathe.

• Lighting: Lighting should be bright enough

to eliminate shadow and prevent eye strain.

• Electrical: Electrical circuits must be

ASSEMBLY

dedicated or large enough to handle

amperage requirements. Outlets must be

located near each machine, so power or

extension cords are clear of high-traffic

areas. Follow local electrical codes for

proper installation of new lighting, outlets,

or circuits.

The bed and other unpainted parts of your lathe

are coated with a waxy grease that protects

them from corrosion during shipment. Clean this

grease off with a solvent cleaner or citrus-based

degreaser. DO NOT use chlorine-based solvents

such as brake parts cleaner or acetone—if you

happen to splash some onto a painted surface,

you will ruin the finish.

NEVER use gasoline or

other petroleum-based

solvents to clean with.

Most have low flash

points, which make them

extremely flammable.

A risk of explosion and

burning exists if these

products are used. Serious

personal injury may occur

if this warning is ignored!

The Model W1704 is a

heavy machine. DO NOT

over-exert yourself while

unpacking or moving your

machine—get assistance.

MAKE your shop “child

safe.” Ensure that your

workplace is inaccessible

to youngsters by closing

and locking all entrances

when you are away. NEVER

allow untrained visitors in

your shop when assembling, adjusting or operating equipment.

ALWAYS work in wellventilated areas far from

possible ignition sources

when using solvents to

clean machinery. Many

solvents are toxic when

inhaled or ingested. Use

care when disposing

of waste rags and

towels to be sure they

DO NOT create fire or

environmental hazards.

-12-

Page 15

Installing Centers

Figure 9.

UNPLUG-POWER CORD

before you do any assembly or adjustment tasks!

Otherwise, serious personal injury to you or others may occur!

Installing spur center into

headstock spindle.

The spur and live centers are taper-fit components that install in the same manner; however,

the spur center always goes into the headstock

spindle and the live center always goes into the

tailstock barrel.

To install the centers, do these steps:

1. UNPLUG THE LATHE!

2. Insert the tapered end of the center into

the spindle and push firmly, as shown in

Figure 9.

3. Check that the center is securely installed

by giving it a quick tug. (A properly installed

center will not pull out by hand.)

Removing Centers

A knock-out tool is included with your lathe to

remove the spur and live centers.

ASSEMBLY

Figure 10. Removing spur center with

knock-out tool.

To remove the centers with the knock-out

tool, do these steps:

1. UNPLUG THE LATHE!

2. Hold a clean rag under the spindle to catch

the center when you remove it.

3. Using the knock-out tool, tap the center

from the outside end of the spindle (as

shown in Figure 10) and catch the center as

it falls out.

-13-

Page 16

Face Plate

The face plate can be installed only if the spur

center has been removed from the headstock

spindle.

To install the face plate, do these steps:

1. UNPLUG THE LATHE!

2. Thread the face plate onto the headstock

spindle.

3. Tighten the face plate by placing a wrench

on the spindle flats and inserting the knockout tool into the spindle shoulder to hold

it in position during tightening. See Figure

ASSEMBLY

11.

Note: Reverse steps 2-3 to remove the face

plate.

Tool Rest

UNPLUG- the power cord

before you do any assembly or adjustment tasks!

Otherwise, serious personal injury to you or others may occur!

Figure 11. Tightening face plate to

headstock spindle.

Before installing a tool rest, decide which

one will be best for your application. Unless

workpiece clearance is an issue, install the

larger tool rest to give yourself more room to

work.

To install the tool rest, do these steps:

1. Insert the tool rest into the tool holder as

shown in Figure 12.

2. Lock the tool rest in place with the tool rest

lock.

Tool Rest

Lock

Figure 12. Tool rest installed on lathe bed.

-14-

Page 17

ADJUSTMENTS

Lock Handles

UNPLUG- the power cord

before you do any assembly or adjustment tasks!

Otherwise, serious personal injury to you or others may occur!

The lock handles on the tool rest holder and the

tailstock can be tightened for a stronger locking action if the factory set locking action is not

tight enough for your needs. However, take care

not to over-tighten any of the parts.

To tighten the lock handles, do these steps:

1. UNPLUG THE LATHE!

1

2. Using a 12mm socket or wrench, tighten

turn one of the lock nuts shown in Figure

13, depending on which component you

wish to tighten.

3. Check the locking mechanism:

• If it is satisfactory, no further adjustments are necessary.

• If it is not satisfactory, repeat steps 2-

3.

⁄4

ADJUSTMENTS

Figure 13. Tool rest holder and tailstock lock

nuts for adjusting lock handles.

Figure 14. Tailstock barrel alignment slot.

Tailstock Barrel

If you find that the tailstock adjustment handle

spins without moving the tailstock barrel, the

tailstock barrel lock may need to be re-aligned

with the catch slot in the tailstock barrel.

To re-align tailstock barrel lock with the catch

slot, do these steps:

1. UNPLUG THE LATHE!

2. Loosen the small setscrew from the side of

the tailstock and loosen the tailstock barrel

lock.

3. Pull the tailstock adjustment handle to slide

the barrel out of the tailstock.

4. Locate the catch slot, shown in Figure 14,

and align it with the barrel lock.

5. Insert the barrel, replace the setscrew, and

barely tighten the barrel lock, then back it

1

⁄4 to 1⁄2 of a turn.

off

-15-

Page 18

OPERATIONS

Test Run

The purpose of a test run is to identify any

unusual noises and vibrations, as well as to

confirm that the machine is performing as

intended.

To test run the Model W1704, do these steps:

1. Turn the variable speed control knob all the

way counter-clockwise or in the LOW direction as far as it will go.

2. Make sure that the spur center has been

removed from the spindle.

3. Pull the paddle switch up to start the lathe.

Once the lathe is running, listen for any

unusual noises. The machine should run

smoothly with little or no vibrations.

• If there are any unusual noises or vibra-

tions, STOP the lathe immediately by

pushing the paddle switch down.

4. Unplug the lathe and investigate the source

of the noise or vibration. DO NOT make any

adjustments to the lathe while it is plugged

in. The lathe should not be run any further

until the problems are corrected.

Projectiles thrown from the machine

could cause serious eye/face injury.

Wear a face shield during assembly

and operation.

Loose hair and clothing could get

caught in machinery and cause serious

personal injury. Keep loose clothing

rolled up and long hair tied up and

away from machinery.

OPERATIONS

-16-

Page 19

Operation Tips

Workpiece

Center Line

Distances

Tool Rest

1

/8"

1

/

4

"

• Mount the workpiece correctly; otherwise,

the operation may be difficult and dangerous. Read the “Spindle Turning” & “Face

Plate Turning” instructions for ideas on how

to set up your lathe correctly.

1

• Position the tool rest approximately

above the center line of the workpiece and

1

approximately

⁄4" away from the workpiece.

See Figure 15 for more details.

⁄8"

Figure 15. Tool rest set 1⁄8" above the

1

centerline and

⁄4" away from workpiece.

Figure 16. Speed dial turned all the way down

to the lowest speed.

• When turning the lathe ON, stand to the

side of the spinning direction until the lathe

reaches full speed and you can verify that

the lathe will not throw the workpiece.

• Always start the lathe and perform all rough

cutting with the speed setting at the lowest

point, as shown in Figure 16.

• Select the right speed for the size of

workpiece you are turning. Use the slower

range on the speed dial for large workpieces

(4" diameter and over); use the middle

range on the speed dial for medium sized

workpieces (2" to 4" diameter); and use

the faster range on the speed dial for small

sized workpieces (under 2" in diameter).

• Keep the turning tool on the tool rest the

ENTIRE time that it is in contact with the

workpiece.

• When turning pieces thicker than 2" x 2", cut

off the corners first (so the workpiece profile

looks similar to the illustrated workpiece in

Figure 15). Figure 17 shows a workpiece

too big for turning with the corners still

on.

OPERATIONS

Figure 17. DO NOT attempt to turn workpieces

thicker than 2" x 2" without first cutting the

corners off!

• When rough cutting face plate work, use

the live center in the tailstock for support,

as can be seen in the setup in Figure 17.

After the rough cutting is complete, move

the tailstock out of the way.

• Learn the correct techniques for each tool

you will use. If you are unsure, read books

or magazines about lathe techniques and

seek training from experienced users.

-17-

Page 20

Selecting Turning

Tools

Lathe tools (Figure 18) come in a variety of

shapes and sizes and usually fall into five major

categories.

• Gouges—Mainly used for rough cutting,

detail cutting, and cove profiles. The rough

gouge is a hollow, double-ground tool with

a round nose, and the detail gouge is a

hollow, double-ground tool with either a

round or pointed nose. Figure 19 shows an

example of a gouge.

• Skew Chisel—A very versatile tool that can

be used for planing, squaring, V-cutting,

beading, and parting off. The skew chisel

is flat, double-ground with one side higher

than the other (usually at an angle of 2040˚). Figure 20 shows an example of a skew

chisel.

• Scrapers—Mainly used where access for

other tools is limited, such as hollowing

operations. This is a flat, double-ground

tool that comes in a variety of profiles

(Round Nose, Spear Point, Square Nose,

etc.) to match many different contours.

Figure 21 shows an example of a round nose

scraper.

Figure 18. Basic set of lathe turning tools.

Figure 19. Gouge.

• Parting Tools—Used for sizing and cutting

off work. This is a flat tool with a sharp

OPERATIONS

pointed nose that may be single- or doubleground. Figure 22 shows an example of a

parting tool.

• Specialty Tools—These are the unique, special function tools to aid in hollowing, bowl

making, cutting profiles, etc.

Figure 20. Skew chisel.

Figure 21. Round nose scraper.

Figure 22. Parting tool.

-18-

Page 21

Figure 23. Typical spindle turning operation.

Spindle Turning

Spindle turning (Figure 23) is the operation performed when a workpiece is mounted between

the headstock and the tailstock.

To set up a spindle turning operation, do

these steps:

1. Mark both ends of your workpiece by draw-

ing diagonal lines from corner to corner.

The intersection point of these lines will

show you the center of your workpiece. See

Figure 24 for details.

2. Using a wood mallet, tap the point of

the spur center into the center of the

workpiece, so that it leaves a center mark,

then remove the spur center.

1

3. Using a

the center mark. (Additionally, if the end of

your workpiece is square, cut

kerfs across the corners to help embed the

spur center.)

⁄4" drill bit, drill a 1⁄4" deep hole at

1

⁄8" deep saw

Figure 24. Workpiece marked diagonally from

corner to corner to determine the center.

Figure 25. Spur center properly embedded into

workpiece.

4. Drive the spur center into the center of the

workpiece with the wood mallet to embed

1

it at least

⁄4", as shown in Figure 25.

5. With the workpiece still attached, insert

the spur center into the headstock spindle.

6. With the live center installed in the tailstock,

slide the tailstock toward the workpiece

until the live center touches the workpiece,

then lock the tailstock in this position.

7. Use the tailstock adjustment knob to push

the live center into the workpiece at least a

1

⁄4".

Projectiles thrown from the machine

could cause serious eye/face injury.

Wear a face shield during assembly

-19-

and operation.

OPERATIONS

Page 22

Face Plate Turning

Face Plate turning (Figure 26) is when a

workpiece is mounted to the face plate, which

is mounted to the headstock spindle.

To mount your workpiece to the face plate, do

these steps:

1. Find the center of your workpiece by draw-

ing diagonal lines from corner to corner

on the side of the workpiece that will be

mounted to the face plate. The intersection

point of these lines will show you the center

of your workpiece.

2. Cut off the corners of the workpiece if it is

thicker than 2" x 2".

3. Center the face plate on the workpiece and

attach it through the face plate holes with

wood screws, as shown in Figure 27.

Figure 26. Typical face plate turning operation.

NOTICE: Only use tap screws or wood

screws with non-tapered heads (Figure 27)

to attach the face plate to the workpiece.

Do NOT use drywall screws or screws with

tapered heads because these can split the

face plate, or the screws may snap off

during operation.

4. Thread the face plate onto the headstock

spindle and tighten securely.

Note: If screws cannot be placed in the

OPERATIONS

workpiece, then a backing block can be

glued to the workpiece then attached to

the face plate with screws.

To mount your workpiece to a backing block,

do these steps:

1. Make the backing block from a piece of

scrap wood that is flat on both sides.

2. Locate and mark the center of both the workpiece and the backing block.

Figure 27. Mounting face plate to a backing

block, which is glued to the workpiece.

1

3. Drill a

4. Glue the center of the backing block to the center of the workpiece (look through the drilled hole to

line up centers), clamp the backing block to the workpiece, and wait for the glue to cure according

to the manufacturer’s recommendation.

⁄4" hole in the center of the backing block.

-20-

Page 23

Figure 28. Typical spindle sanding operation.

Sanding/Finishing

After turning, the workpiece can be sanded

(see example in Figure 28) and finished before

removing it from the lathe.

Wrapping the sandpaper

completely around the

workpiece, will pull your

hands into the moving

workpiece and may cause

injury. Never wrap sandpaper completely around

the workpiece!

Whenever sanding or finishing on the Model

W1704, remove the tool rest holder to increase

personal safety and gain adequate working

room.

Figure 29. Removing tool rest.

To remove the tool rest holder, do these

steps:

1. UNPLUG THE LATHE!

2. Remove the tool rest from the holder, as

shown in Figure 29.

3. Using a 12mm socket or wrench, remove the

lock nut (Figure 30) that is located under

the tool rest holder on the bottom side of

the bed.

4. Pull the tool rest holder off the bed and

replace the lock nut on the threads, so that

it does not get lost.

OPERATIONS

Figure 30. Lock nut that secures the tool

holder to the bed (lathe turned upside-down

for clarity).

-21-

Page 24

MAINTENANCE

Make sure that your

machine is unplugged

during any maintenance

procedures except

where instructed otherwise! If this warning

is ignored, serious personal injury may occur.

General

To ensure optimum performance from your

lathe, make a habit of inspecting it before each

use. Check for the following conditions and

repair or replace when necessary:

• Loose mounting bolts.

Figure 31. Cleaning/lubricating unpainted part

of the bed.

• Worn switch.

• Worn or damaged cords and plugs.

• Any other condition that could hamper the

safe operation of this machine.

Since all bearings are shielded and permanently

lubricated, simply leave them alone until they

need to be replaced. DO NOT lubricate them.

Lubricate the unpainted parts of the bed regularly (Figure 31) to prevent rust and ensure a

smooth sliding action from the tool post holder

and the tailstock. Your goal is to achieve adequate lubrication. However, too much lubrication will attract dirt and sawdust, which may

MAINTENANCE

cause these components to lose their freedom

of movement.

Lubrication

Figure 32. Cleaning spindle tapers.

In addition, clean the headstock and tailstock

barrel tapers (Figure 32) on a regular basis.

-22-

Page 25

WIRING DIAGRAM

PADDLE SWITCH

Bk

Wt

Gn

Wt

Gn

Bk

Bk

Bk

Wt

FUSE

Bk

Wt

Gn

Green

Ground

Wt

Gn

Bk

White

Neutral

Black

Hot

110

VAC

5-15 Plug

CIRCUIT

Wt

Wt

BOARD

Bk

Gn

Wt

Wt

Wt

Wt

Ground

CIRCUIT BREAKER

MOTOR

VARIABLE SPEED

DIAL

PARTS

-23-

Page 26

16

9

7

10

6

5

15

17

18

23

22

55

26

27

28

47

35

8

38

58

32

36

37

53

60

25

34

39

40

41

33

42

43

56

44

50

50A

45

49

48

54

24

52

51

7-1

1

2

3

4

57

14

19

20

21

29

30

31

46

24

11

59

PARTS

PARTS

-24-

Page 27

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 X1704001 BED 35 X1704035 POWER CORD

2 X1704002 RETAINING PLATE 36 X1704036 CIRCUIT BOARD W/BOX

3 XPS05M PHLP HD SCR M5-.8 X 8 37 XPS07M PHLP HD SCR M4-.7 X 8

4 XPSS03M SET SCREW M6-1 X 8 38 XPSB40M CAP SCREW M8-1.25 X 35

5 X1704005 HANDWHEEL 39 XPSB74M CAP SCREW M6-1 X 18

6 X1704006 TAILSTOCK 40 X1704040 MOTOR PLATE

7 X1704007 T-LOCK KNOB BOLT M6-1 X 28 41 X1704041 MOTOR

7-1 X1704007-1 T-LOCK KNOB BOLT M6-1 X 18 42 X1704042 MACHINE NAMEPLATE LABEL

8 XPSB35M CAP SCREW M8-1.25 X 60 43 XPR39M EXT RETAINING RING 8MM

9 X1704009 SLEEVE 44 X1704044 TOOL REST BASE

10 X1704010 ECCENTRIC AXIS 45 X1704045 SPECIAL BOLT M8-1.25 X 32

11 X1704011 TAILSTOCK 46 X1704046 PLATE

14 X1704014 LIVE CENTER ASSEMBLY 47 XPLW04M LOCK WASHER 8MM

15 X1704015 SPUR CENTER 48 X1704048 SLEEVE

16 X1704016 LOCK HANDLE 49 X1704049 ECCENTRIC ROD

17 X1704017 FACE PLATE 50 X1704050 TOOL REST 7" (LARGE)

18 X1704018 HEADSTOCK SPINDLE 50A X1704050A TOOL REST 4-1/2" (SMALL)

19 XP6004 BALL BEARING 6004ZZ 51 X1704051 SPECIAL BOLT M8-1.25 X 32

20 XPR34M EXT RETAINING RING 40MM 52 X1704052 PLATE

21 XPR34M EXT RETAINING RING 40MM 53 X1704053 ELECTRICITY LABEL

22 XP6004 BALL BEARING 6004ZZ 54 X1704016 LOCK HANDLE

23 X1704023 HEADSTOCK 55 X1704055 UNPLUG MACHINE LABEL

24 XPLN04M LOCK NUT M8-1.25 56 X1704056 LATHE WARNING LIST LABEL

25 X1704025 SPEED DIAL LABEL 57 X1704057 READ MANUAL LABEL

26 X1704026 HEADSTOCK SPINDLE NUT 58 XPSW09 SHOP FOX PADDLE SWITCH

27 X1704027 OUTBOARD SPINDLE COVER 59 X1704059 FUSE 8A

28 XPS07M PHLP HD SCR M4-.7 X 8 60 X1704060 VARIABLE SPEED DIAL SWITCH

29 X1704029 DUST MASK WARNING LABEL 61 XPW01M FLAT WASHER 8MM

30 XPSS01M SET SCREW M6-1 X 10 62 XPW04M FLAT WASHER 10MM

31 X1704031 DRIVE PULLEY 63 XPSB100M CAP SCREW M8-1.25 X 15

32 X1704032 BELT K-516 64 XPS74M PHLP HD SCR M4-.7 X 14

33 XPSS01M SET SCREW M6-1 X 10 65 X1704065 CABLE HOLDER

34 X1704034 MOTOR PULLEY

-25-

PARTS

Page 28

TROUBLESHOOTING

SYMPTOM

Motor will not start.

Motor will not start; fuses or

circuit breakers blow.

Motor overheats.

Motor stalls, resulting in blown

fuses or tripped circuit.

POSSIBLE CAUSE

1. Low voltage.

2. Open circuit in motor or loose connections.

3. Lathe switch fuse blown.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose connections.

3. Incorrect fuses or circuit breakers

in power line.

1. Motor overloaded.

2. Air circulation through the motor

restricted.

1. Short circuit in motor or loose connections.

2. Low voltage.

3. Incorrect fuses or circuit breakers

in power line.

4. Motor overloaded.

HOW TO REMEDY

1. Check power line for proper voltage.

2. Inspect all lead connections on motor for loose or open connections.

3. Replace switch fuse located under threaded cap on the backside of the switch box.

1. Inspect cord or plug for damaged insulation and shorted

wires.

2. Inspect all connections on motor for loose or shorted terminals or worn insulation.

3. Install correct fuses or circuit breakers.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

1. Inspect connections on motor for loose or shorted terminals

or worn insulation.

2 Correct the low voltage conditions.

3. Install correct fuses or circuit breakers.

4. Reduce load on motor.

Machine slows or bogs down

when operating.

Loud, repetitious noise coming

from machine

Motor sounds like it is running,

but headstock spindle does not

spin.

Tailstock will not push into

workpiece when handle is

turned.

Tailstock or tool rest holder will not lock down tight

enough.

1. Motor overloaded.

2. Brushes worn.

1. Pulley set screws are missing or

loose.

2. Motor fan is hitting the cover.

3. V-belt is defective.

1. V-belt broken or slipped off pulleys.

1. Tailstock barrel lock not aligned

with catch slot in tailstock barrel.

1. Lock nut needs to be tightened.

1. Reduce load on motor.

2. Replace motor brushes.

1. Inspect pulley set screws. Replace or tighten if necessary.

2. Tighten fan or shim cover.

3. Replace V-belt.

1. Inspect/replace the V-belt.

1. Re-align tailstock barrel lock with catch slot in tailstock barrel, as described on page 15.

1. Tighten the lock nut as described on page 15.

-26-

Page 29

Warranty Registration

Name ___________________________________________________________________________________

Street __________________________________________________________________________________

City _________________________ State ___________________________ Zip ________________________

Phone # ______________________ Email___________________________Invoice # ___________________

Model #_________Serial #______________Dealer Name__________________Purchase Date___________

The following information is given on a voluntary basis. It will be used for marketing purposes to help us

develop better products and services. Of course, all information is strictly confidential.

1. How did you learn about us?

_____ Advertisement _____ Friend ____ Local Store

_____ Mail Order Catalog _____ Website ____ Other:

2. How long have you been a woodworker/metalworker?

_____ 0-2 Years _____ 2-8 Years ____ 8-20 Years _____ 20+ Years

®

3. How many of your machines or tools are Shop Fox

_____ 0-2 _____ 3-5 ____ 6-9 _____ 10+

4. Do you think your machine represents a good value? _____ Yes ____ No

?

CUT ALONG DOTTED LINE

®

5. Would you recommend Shop Fox

products to a friend? _____ Yes ____ No

6. What is your age group?

_____ 20-29 _____ 30-39 ____ 40-49

_____ 50-59 _____ 60-69 ____ 70+

7. What is your annual household income?

_____ $20,000-$29,000 _____ $30,000-$39,000 ____ $40,000-$49,000

_____ $50,000-$59,000 _____ $60,000-$69,000 ____ $70,000+

8. Which of the following magazines do you subscribe to?

____ Cabinet Maker

____ Family Handyman

____ Hand Loader

____ Handy

____ Home Shop Machinist

____ Journal of Light Cont.

____ Live Steam

____ Model Airplane News

____ Modeltec

____ Old House Journal

____ Popular Mechanics

____ Popular Science

____ Popular Woodworking

____ Practical Homeowner

____ Precision Shooter

____ Projects in Metal

____ RC Modeler

____ Rie

____ Shop Notes

____ Shotgun News

____ Today’s Homeowner

____ Wood

____ Wooden Boat

____ Woodshop News

____ Woodsmith

____ Woodwork

____ Woodworker West

____ Woodworker’s Journal

____ Other:

9. Comments: __________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

Page 30

FOLD ALONG DOTTED LINE

FOLD ALONG DOTTED LINE

Place

Stamp

Here

WOODSTOCK INTERNATIONAL INC.

P.O. BOX 2309

BELLINGHAM, WA 98227-2309

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

Page 31

Page 32

Loading...

Loading...