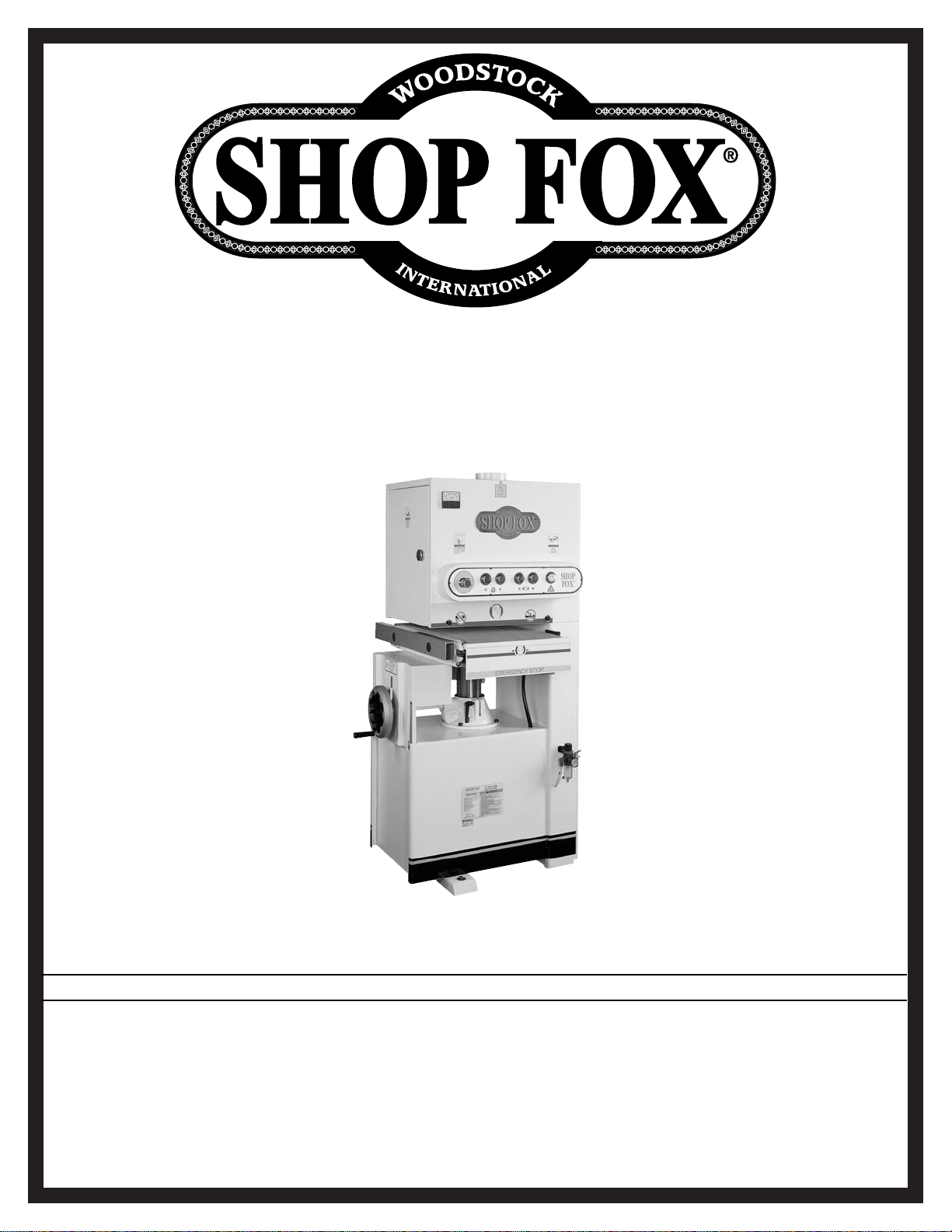

Page 1

INSTRUCTION MANUAL

MODEL W1689

15" Wide Belt Sander

Phone: 1-360-734-3482 • On-Line Technical Support: tech-support@woodstockint.com

COPYRIGHT © August, 2002 BY WOODSTOCK INTERNATIONAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in Taiwan

ONLINE MANUAL DISCLAIMER

THE INFORMATION IN THIS MANUAL REPRESENTS THE CONFIGURATION OF THE MACHINE AS IT IS CURRENTLY BEING SHIPPED. THE MACHINE CONFIGURA-

TION CAN CHANGE AS PRODUCT IMPROVEMENTS ARE INCORPORATED. IF YOU OWN AN EARLIER VERSION OF THE MACHINE, THIS MANUAL MAY NOT

EXACTLY DEPICT YOUR MACHINE . CONTACT CUSTOMER SERVICE IF YOU HAVE ANY QUESTIONS ABOUT DIFFERENCES. PREVIOUS VERSIONS ARE NOT

AVAILABLE ONLINE.

Page 2

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to the State of California to

cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and

other masonry products.

• Arsenic and chromium from chemically

treated lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

Page 3

Table Of Contents

PAGE

1. INTRODUCTION..............................................................................................2

About Your New Sander..............................................................................2

Woodstock Service and Support....................................................................2

Warranty and Returns ................................................................................3

Machine Specifications ..............................................................................3

2. SAFETY ......................................................................................................4

Standard Safety Instructions ....................................................................4-5

Additional Safety Instructions For Sanders ......................................................6

Avoiding Potential Injuries ..........................................................................7

Electrical Requirements ............................................................................8

220V Operation ........................................................................................8

Extension Cords........................................................................................8

Grounding ..............................................................................................8

3. ASSEMBLY INSTRUCTIONS ................................................................................9

Unpacking ..............................................................................................9

Box Contents ..........................................................................................9

Shop Preparation ....................................................................................10

Cleaning Machine ....................................................................................10

Beginning Assembly ................................................................................11

Handwheel Handle ..................................................................................11

Installing Platen ......................................................................................12

Attaching Air Hose ..................................................................................13

Installing Sanding Belts ............................................................................13

Tensioning Belt ......................................................................................14

Pressure Rollers ......................................................................................14

Dust Collection ......................................................................................15

4. ADJUSTMENTS ............................................................................................16

General Information ................................................................................16

Oscillation Timing ..............................................................................16-17

Oscillation Speed ....................................................................................17

Oscillation Return ..............................................................................17-18

Limit Switches ........................................................................................18

Platen Depth ..........................................................................................19

Pressure Rollers..................................................................................19-20

Pressure Roller Tension ............................................................................21

V-Belt Tension ........................................................................................21

Feed Belt Tension ..................................................................................22

Feed Belt Tracking ..................................................................................22

5. OPERATIONS ..............................................................................................23

Starting Sander ......................................................................................23

Selecting Sandpaper ................................................................................23

Table Height ..........................................................................................24

Feed Speed............................................................................................24

Using Load Meter ....................................................................................25

Emergency Brake ....................................................................................25

Operating..........................................................................................25-26

Adjusting Platen......................................................................................26

6. MAINTENANCE ............................................................................................27

General ................................................................................................27

Lubrication ............................................................................................27

Cleaning Belts ........................................................................................28

Servicing Filters ......................................................................................28

Platen Graphite ......................................................................................28

Changing V-Belts ....................................................................................29

Servicing Brake ......................................................................................30

Troubleshooting..................................................................................31-32

Wiring Diagrams..................................................................................33-35

6. CLOSURE ..........................................................................................36

Parts Breakdown and Parts Lists ....................................................37-46

ASSEMBLY OPERATIONS

MAINTENANCE

PARTS

ADJUSTMENTSSAFETYINTRODUCTION

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

Page 4

INTRODUCTION

-2-

INTRODUCTION

About Your New Sander

Your new SHOP FOX®Sander has been specially designed to provide many years of trouble-free service.

Close attention to detail, ruggedly built parts and a rigid quality control program assure safe and reliable operation.

The Model W1689 is a very versatile and easy to use sander. The wide belt sanding action combined with

the pneumatic oscillation produces near finish quality results every time.

Woodstock International, Inc. is committed to customer satisfaction in providing this manual. It is our

intent to make sure all the information necessary for safety, ease of assembly, practical use and durability of this product be included.

If you should have any comments regarding this manual, please feel free to contact us at:

Woodstock Service and Support

We stand behind our machines! In the event that a defect is found, parts are missing or questions arise

about your machine, please contact Woodstock International Service and Support at 1-360-734-3482 or

send e-mail to: tech-support@woodstockint.com

. Our knowledgeable staff will help you troubleshoot

problems, send out parts or arrange warranty returns.

Woodstock International, Inc.

Attn: Technical Department

P.O. Box 2309

Bellingham, WA 98227

Page 5

INTRODUCTION

-3-

INTRODUCTION

Warranty And Returns

Woodstock International, Inc. warrants all SHOP FOX®machinery to be free of defects from workmanship and materials for a period of 2 years from the date of original purchase by the original owner. This

warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents,

lack of maintenance, or to repairs or alterations made or specifically authorized by anyone other than

Woodstock International, Inc.

Woodstock International, Inc. will repair or replace, at its expense and at its option, the SHOP FOX

®

machine or machine part which in normal use has proven to be defective, provided that the original

owner returns the product prepaid to the SHOP FOX

®

factory service center or authorized repair facility

designated by our Bellingham, WA office, with proof of their purchase of the product within 2 years, and

provides Woodstock International, Inc. reasonable opportunity to verify the alleged defect through

inspection. If it is determined there is no defect, or that the defect resulted from causes not within the

scope of Woodstock International Inc.'s warranty, then the original owner must bear the cost of storing

and returning the product.

This is Woodstock International, Inc.'s sole written warranty and any and all warranties that may be

implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited

to the duration of this written warranty. We do not warrant that SHOP FOX

®

machinery complies with

the provisions of any law or acts. In no event shall Woodstock International, Inc.'s liability under this warranty exceed the purchase price paid for the product, and any legal actions brought against Woodstock

International, Inc. shall be tried in the State of Washington, County of Whatcom. We shall in no event

be liable for death, injuries to persons or property or for incidental, contingent, special or consequential damages arising from the use of our products.

Every effort has been made to ensure that all SHOP FOX

®

machinery meets high quality and durability

standards. We reserve the right to change specifications at any time because of our commitment to continuously improve the quality of our products.

Machine Specifications

Sanding Motor Size ..........................................................5 HP, 220V, Single-Phase

Sanding Motor Speed ............................................................................3450 RPM

Conveyor Motor Size........................................................

1

⁄4 HP, 220V, Single-Phase

Total Amps (Both Motors) ..........................................................................27.8A

Maximum Board Width..................................................................................15"

Maximum Board Thickness............................................................................5

1

⁄2"

Minimum Board Length ................................................................................12"

Surface Speed Of Drums ........................................................................2050 FPM

Conveyor Feed Rate ......................................................................13 & 16.4 FPM

Machine Weight ....................................................................................815 lbs

Dust Port ..................................................................................................5"

Page 6

SAFETY

-4-

READ MANUAL BEFORE OPERATING MACHINE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

RESULT IN PERSONAL INJURY.

SAFETY FIRST!

Standard Safety Instructions

1. Thoroughly read the instruction manual before operating your machine. Learn the applications,

limitations and potential hazards of this machine. Keep manual in a safe, convenient place for future

reference. Make sure any other operators have read and understand the manual as well.

2. Keep work area clean and well lighted. Clutter and inadequate lighting invite potential hazards.

3. Ground all tools. If a machine is equipped with a three-prong plug, it must be plugged into a three-

hole grounded electrical outlet or grounded extension cord. If using an adapter to aid in accommodating a two-hole receptacle, ground using a screw to a known ground.

4. Wear eye protection at all times. Use safety glasses with side shields or safety goggles that meet

the national safety standards, while operating this machine.

5. Avoid dangerous environments. Do not operate this machine in wet or open flame environments.

Airborne dust particles could cause an explosion and severe fire hazard.

6. Ensure all guards are securely in place and in working condition.

7. Make sure switch is in the “OFF” position before connecting power to machine.

8. Keep work area clean, free of clutter, grease, etc.

9. Keep children and visitors away. Visitors should be kept at a safe distance away while operating

unit.

10. Childproof workshop with padlocks, master switches or by removing starter keys.

11. Disconnect machine when cleaning, adjusting or servicing.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury, MAY result in property damage.

This symbol is used to alert the user to useful information about proper

operation of the equipment.

NOTICE

Page 7

SAFETY

-5-

12. Do not force the machine. The machine will do a safer and better job if IT does the work.

13. Use the correct tool. Do not force the tool or attachment to do a job for which it was not designed.

14. Wear proper apparel. Do not wear loose clothing, gloves, jewelry, keep long hair tied up, etc.

15. Remove adjusting keys and wrenches. Before turning the machine on, make a habit of checking

that all adjusting keys and wrenches have been removed before turning the machine ON.

16. Use proper extension cord. Examine the extension cord to ensure it is in good condition. Use the

chart below to determine the correct length and gauge of extension cord needed for your particular

needs. The amp rating of the motor can be found on its nameplate. If the motor is dual voltage, be

sure to use the amp rating for the voltage you will be using. If you use an extension cord with an

undersized gauge or one that is too long, excessive heat will be generated within the circuit increasing the chance of a fire or damage to the circuit. Never use an extension cord that does not have a

ground pin and connected ground wire. Immediately replace an extension cord if it shows any signs

of damage.

17. Keep stable footing and balance at all times.

18. Do not leave machine unattended. Wait until it comes to a complete stop before leaving the area.

19. Perform machine maintenance and care. Follow lubrication and accessory attachment instructions

in the manual.

20. Keep machine away from open flame. Operating machines near pilot lights and/or open flames creates a high risk if dust is dispersed in the area. Dust particles and an ignition source may cause an

explosion. Do not operate the machine in high-risk areas, including but not limited to, those mentioned above.

21. If at any time you are experiencing difficulties performing the intended operation, stop using the

machine! Then contact our Service Department or ask a qualified expert how the operation should

be performed.

22. Habits—good and bad—are hard to break. Develop good habits in your shop and safety will become

second-nature to you.

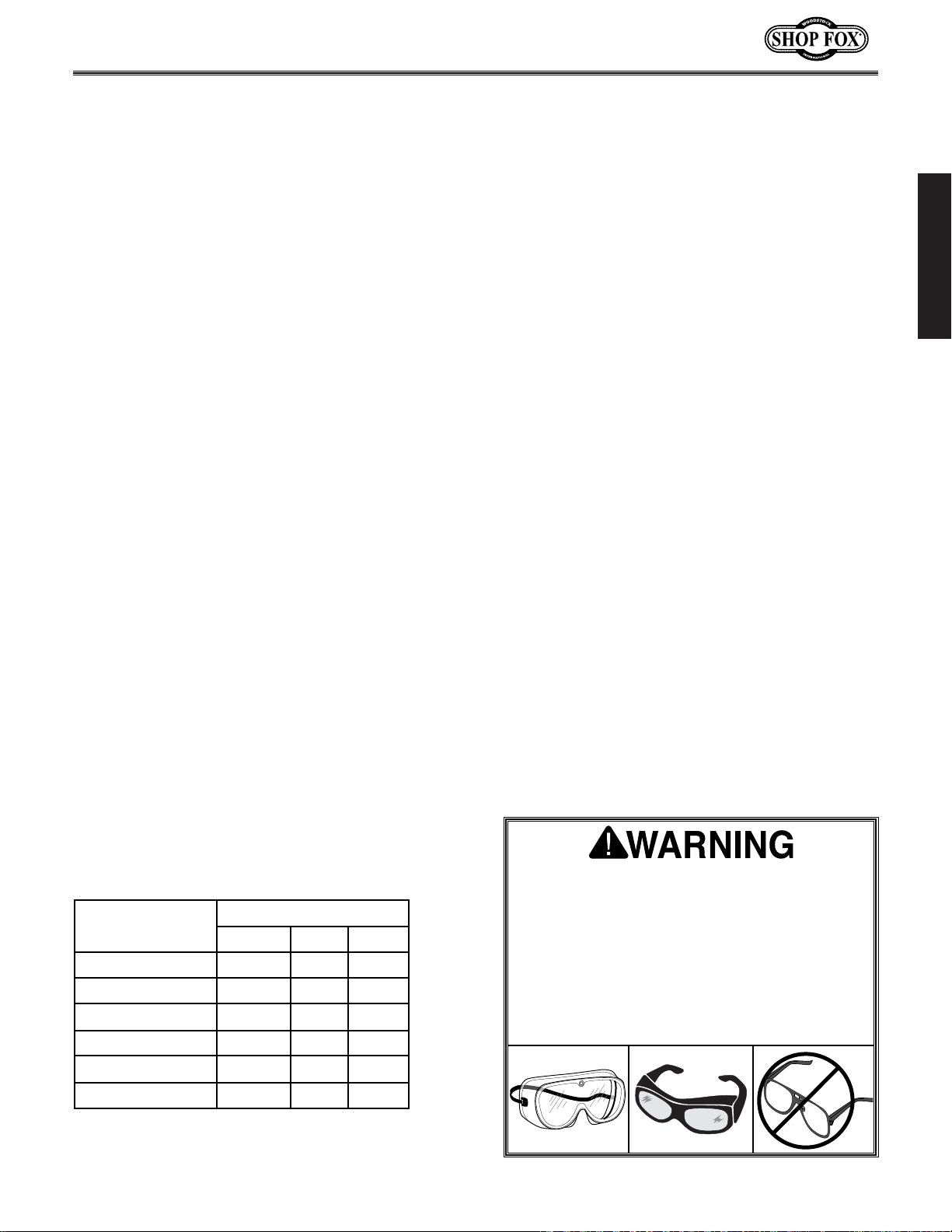

Operating this equipment creates the

potential for flying debris to cause eye

injury. Always wear safety glasses or goggles when operating equipment. Everyday

glasses or reading glasses only have impact

resistant lenses, they are not safety glasses.

Be certain the safety glasses you wear meet

the appropriate standards of the American

National Standards Institute (ANSI).

Length And Gauge

Amp Rating 25ft 50ft 100ft

0-6 #18 #16 #16

7-10 #18 #16 #14

11-12 #16 #16 #14

13-16 #14 #12 #12

17-20 #12 #12 #10

21-30 #10 #10 No

Extension Cord Requirements

Page 8

SAFETY

-6-

Additional Safety Instructions For Sanders

No list of safety guidelines can be complete.

Every shop environment is different. Always

consider safety first, as it applies to your

individual working conditions. Use this and

other machinery with caution and respect.

Failure to follow guidelines could result in

serious personal injury, damage to equipment or poor work results.

1. Always wear a dust mask. Sanding operations create large amounts of fine dust. Some types of dust

may cause allergic reactions or respiratory problems. In addition to wearing a dust mask, always use

a dust collector and overhead air filter for maximum protection.

2. Do not allow your fingers to get pinched between the board and the conveyor belt during feed-

ing. The grip of the conveyor belt may pull the operator’s hand into the machine and cause serious

injury or death. Similarly, do not place hands near the sanding belts during operation.

3. Know the limits of the sander. Do not sand stock thinner than

1

⁄8

" or shorter than 9".

4. Never perform sanding operations with the access doors open.

5. Always inspect stock for staples, nails, dirt or other foreign objects before sanding. These items

may cause damage to your sander or may even be thrown at a high rate of speed from the sander

at the operator.

6. Never allow anyone to stand directly in front or behind the path of the stock as it is being fed

through the sander. The stock may be ejected at a high rate of speed and could cause serious injury

to the operator or bystanders.

7. Treat your sander with respect. Do not force stock into the sander during operation or overload

the sanding drums beyond reasonable limits. Also, only sand natural wood fiber through your sander.

Other materials may damage your machine and open the possibility for operator injury. Keep the

internal components clean and lubricated to ensure that the sander can perform the way it was

intended.

8. Never operate the sander without a working dust collection system. The sander is designed to

properly do its job only when wood dust is being evacuated. The buildup of too much wood dust in

the internal components will cause performance problems and may increase the likelihood of operator injury.

9. Wear the proper clothing during all operation and adjustments. Loose clothing or long hair creates the potential for operator injury because they can easily be caught in the moving parts of the

machine. Roll up loose sleeves, tie back long hair and take any other necessary steps to reduce this

hazard.

Read and understand this

entire instruction manual

before performing any

operations with your

machine. Serious personal

injury may occur if safety

and operational information is not understood and

followed.

Page 9

SAFETY

-7-

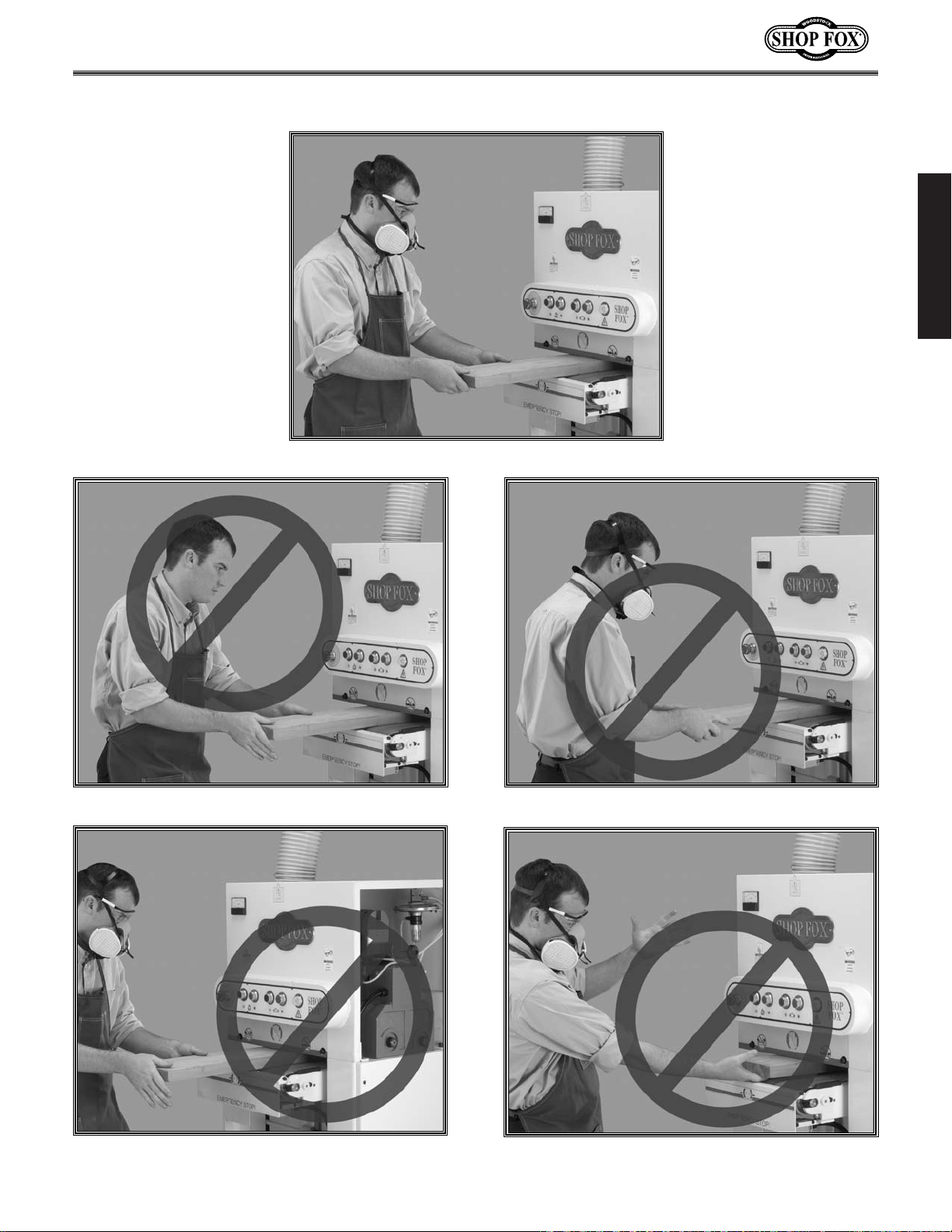

Avoiding Potential Injuries

Figure 1. Correct operation.

Figure 2. DO NOT operate without safety glasses/dust mask!

Figure 3. DO NOT stand behind workpiece!

Figure 4. DO NOT operate with door open!

Figure 5. DO NOT allow hand to get pinched in belt!

Page 10

SAFETY

-8-

Electrical Requirements

220V Operation

We do not recommend using an extension cord

for 220V equipment. Instead, arrange the placement of your machinery and installed wiring to

eliminate the need for extension cords. If you

must use an extension cord, make sure it is

rated Hard Service (grade S) or better. The

extension cord must always contain a ground

wire and plug pin. Always repair or replace

extension cords when they become worn or

damaged.

Extension Cords

Grounding

This machine must be grounded! The electrical

cord supplied with the Model W1679 does not

come with a 220 volt plug. Use a NEMA-style 630 plug and outlet similar to Figure 6. Make sure

your ground source is verified!

The SHOP FOX

®

W1689 has a 5 HP, 220V single-

phase sanding motor and a

1

⁄4

HP, 220V feed

motor. Both of these motors combined draw

approximately 27.8 amps under load.

Use a 30 amp circuit breaker in a circuit that has

wiring rated to handle this amperage draw.

Keep in mind that a circuit being used by other

machines or tools at the same time will add to

the total load being applied. Add up the load

ratings of all machines on the circuit. If this

number exceeds the rating of the circuit breaker or wiring, use a different circuit.

Figure 6. This is a typical NEMA-style 6-30 plug

and outlet.

DO NOT replace the circuit breaker with

one rated at a higher amperage or damage

to the circuit may occur.

Any electrical outlet and circuit that you plug your

machine into must be

grounded. Never remove

the grounding pin from any

plug and always make sure

all wiring to the machine is

grounded before operating.

Serious injury may occur if

this warning is ignored!

6-30R6-30P

Page 11

ASSEMBLY

-9-

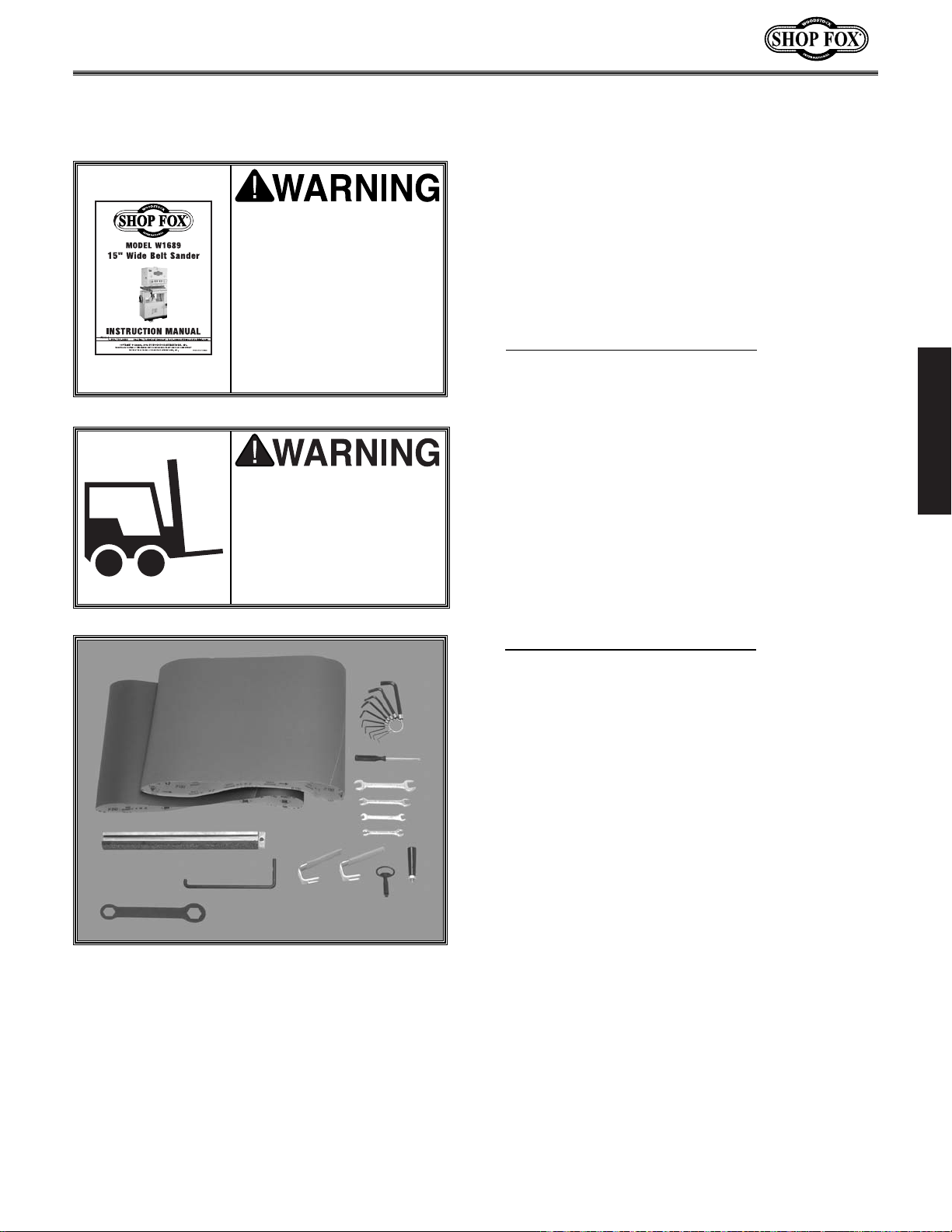

The following is a description of the components

shipped with the SHOP FOX

®

W1689. Lay the

components out in a similar fashion to those in

Figure 7. This will help in identification before

beginning assembly. Should any part be missing,

examine the packaging carefully. If any parts

are missing, find the part number in the back of

this manual and call Woodstock International,

Inc. at 360-734-3482 or e-mail:

tech-support@woodstockint.com

.

Sander ..............................................(1)

Tool Box ............................................(1)

Combination Wrench 8 x 10MM ................(1)

Combination Wrench 11 x 13MM ................(1)

Combination Wrench 12 x 14MM ................(1)

Combination Wrench 17 x 19MM ................(1)

Box Wrench 30 x 37MM ..........................(1)

Phillips Screwdriver ..............................(1)

10-Piece Hex Wrench Set ........................(1)

Door Handles ......................................(2)

Platen ..............................................(1)

Platen Puller ......................................(1)

Handwheel Handle ................................(1)

Sanding Belt #180 ................................(1)

Sanding Belt #240 ................................(1)

Item Qty.

Figure 7. These are the loose parts shipped

with the sander.

Unpacking

Box Contents

The Model W1689 has been carefully packaged

for safe transporting. If you notice the machine

has been damaged, please contact Woodstock

International Service and Support at 1-360-7343482 or send e-mail to:

tech-support@woodstockint.com

.

ASSEMBLY INSTRUCTIONS

Read and understand this

entire instruction manual

before performing any

operations with your

machine. Serious personal

injury may occur if safety

and operational information is not understood and

followed.

The Model W1683 is a

heavy machine at 815

lbs. Use power or

hydraulic equipment to

avoid serious personal

injury or death.

Page 12

ASSEMBLY

-10-

Shop Preparation

• Floor Load: Your sander represents a large

weight load in a small footprint. Most commercial floors are suitable for the sander.

Some residential floors may require additional bracing to support both machine and

operator.

• Working Clearances: Consider existing and

anticipated needs, size of material to be

processed through each machine, and

space for auxiliary stands, work tables or

other machinery when establishing a location for your sander.

• Lighting and Outlets: Lighting should be

bright enough to eliminate shadows and

prevent eye strain. Electrical circuits

should be dedicated or large enough to

handle amperage requirements. Outlets

should be located near each machine so

power or extension cords are clear of hightraffic areas. Observe local electrical codes

for proper installation of new lighting, outlets, or circuits.

Cleaning Machine

The table and other unpainted parts of the

Model W1689 are coated with a waxy grease that

protects them from corrosion during shipment.

For optimum performance from your machine,

make sure you clean all moving parts or sliding

contact surfaces that are coated. Clean this

grease off with a solvent cleaner or citrus-based

degreaser. Do not use chlorine-based solvents—

if you happen to splash some onto a painted surface, you will ruin the finish.

Always make sure that all

entrances to your shop are

locked or that machines

are equipped with safety

lock-out devices to protect

curious children or visitors

from serious injury. Never

allow unsupervised people

in your shop who have not

been fully trained!

Never use flammables

such as gas or other petroleum-based solvents to

clean your machine.

These products have low

flash points and present

the risk of explosion and

severe personal injury!

Never smoke while using

any cleaning solvents.

Smoking may cause explosion or risk of fire when

exposed to these products!

Most solvents used to

clean machinery are

toxic when inhaled or

ingested. When using

these products, work in

a well ventilated area

and keep away from any

potential ignition

sources (pilot lights).

Always dispose of any

waste rags in a sealed

container to make sure

they do not cause fire or

environmental hazards.

Page 13

ASSEMBLY

-11-

Beginning

Although the main components of the SHOP

FOX

®

W1689 are assembled at the factory, some

assembly is required. The following series of

instructions are the recommended sequence

best suited for final assembly.

Tools required that are not included: A high

quality straightedge, a 45˚ angle gauge and an

adjustable wrench.

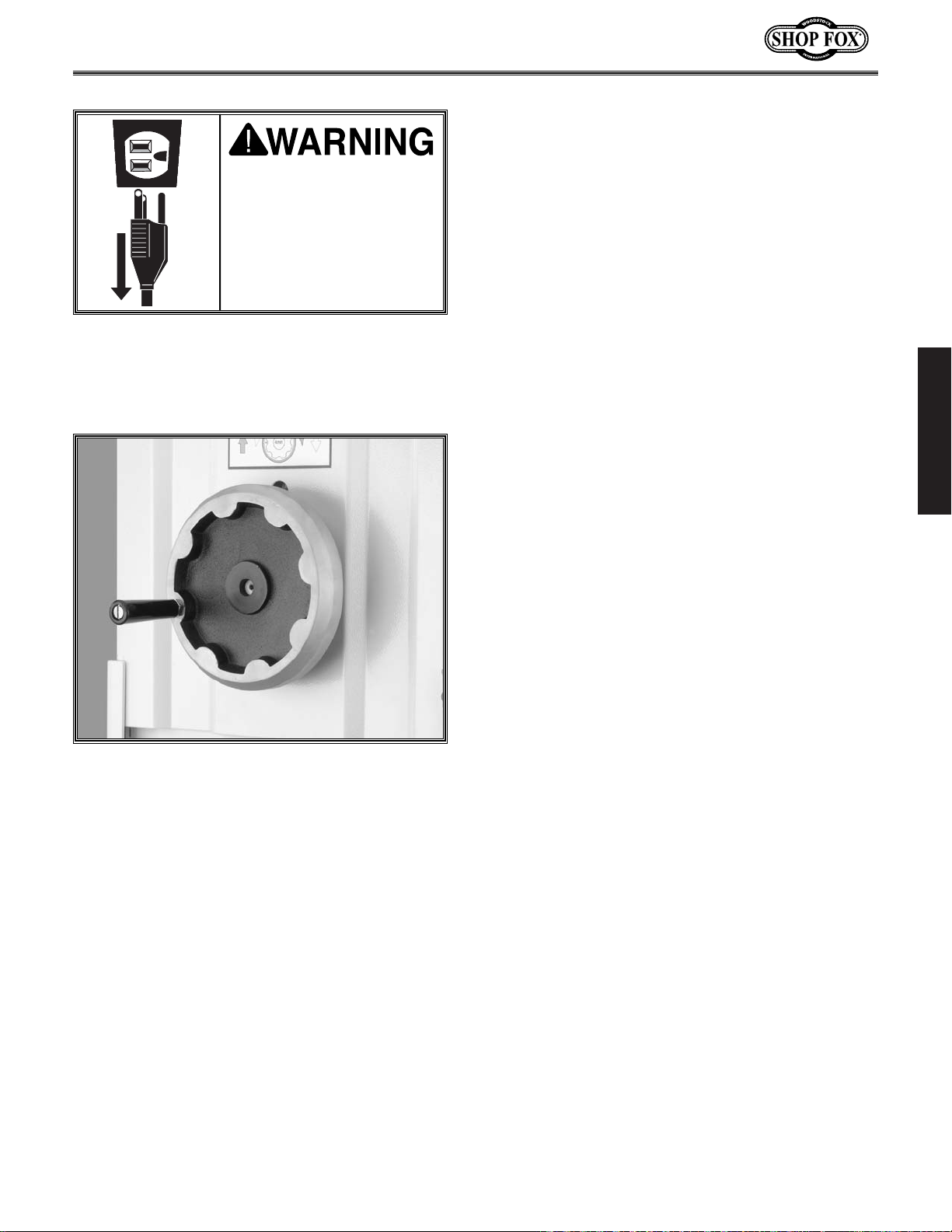

Handwheel Handle

Install the handle on the handwheel as follows:

1. Make sure that the jam nut is threaded com-

pletely onto the handle.

2. Use a flat-head screwdriver to thread the

handle all the way into the handwheel as

shown in Figure 8.

3. Unthread the handle

1

⁄2 a turn to make the

plastic sleeve loose enough rotate around

the handle freely.

4. Tighten the jam nut down to the handwheel.

Figure 8. Handle installed on handwheel.

Make sure that your

machine is unplugged

during all assembly procedures! If this warning

is ignored, serious personal injury may occur.

Page 14

ASSEMBLY

-12-

Figure 9.

Installing platen.

Figure 10. Platen adjustment knob.

Installing Platen

Install the platen into the sander as follows:

1. Facing the front of the sander, open the left

hand access door with the included door

handle.

2. Directly below the adjustment knob is a

slide housing for the platen. Locate the

slide housing and install the platen so that

the graphite pad is on the left-hand side.

Figure 9 shows the correct insertion of the

platen.

When the platen is inserted correctly, it must

be set even with the sanding belt rollers as follows:

1. Lower the conveyor table down as far as it

will go, so that you have enough room to

work under the sanding belt rollers.

2. Place a straightedge across the bottom of

both sanding belt rollers.

3. Using the platen adjustment knob shown in

Figure 10, position the platen so that it

barely touches the straightedge, and thus,

is even with both sanding belt rollers.

The platen at level position is an important reference point for future operations.

Page 15

ASSEMBLY

-13-

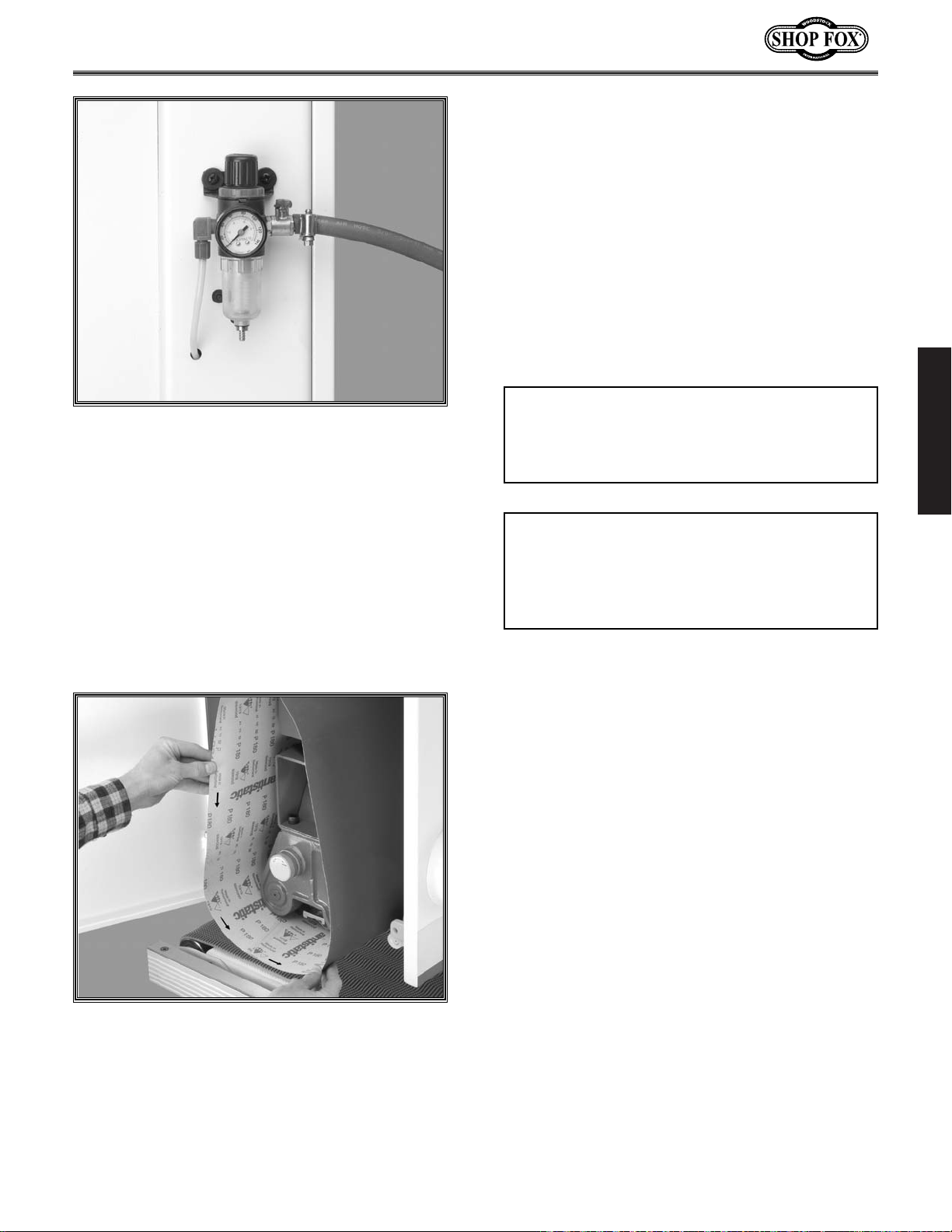

Attaching Air Hose

The regulator on the front of the sander has a

nozzle for attaching the air hose. Connect your

air hose and clamp it in place with a hose clamp

as shown in Figure 11. If you prefer, you can

replace the included air nozzle with a

3

⁄8" male

quick connect air coupling.

When the air hose is installed, regulate the air

pressure to 75 PSI. This is the required operating

pressure for this sander.

Installing

Sanding Belt

The sanding belt must be installed from the left

side of the sander. Before installing, make sure

the protective grease has been cleaned (as

described in “Cleaning Machine” instructions)

from the metal sanding belt rollers.

Pay special attention to the direction of the

arrows on the inside of the sanding belt. These

arrows show the direction that the sanding belt

is designed to rotate during operation. Facing

the inside of the left-hand access door, the

sanding belt will rotate counterclockwise.

Install the sanding belt as shown in Figure 12

and center it on the rollers.

Figure 11. Air hose attached to regulator.

Figure 12. Installing sanding belt over rollers.

The arrows on the inside must point in the

same direction as belt rotation.

DO NOT exceed 75 PSI or damage to the air

system may result!

NOTICE

Keep the air pressure shut off when not in

use to reduce wear and tear on the air system.

NOTICE

Page 16

ASSEMBLY

-14-

Figure 13. Belt tension switch.

Tensioning Belt

The switch shown in Figure 13 controls the

sanding belt tension. When the air pressure is

connected and the switch is flipped up, the belt

will automatically tighten to the correct tension. Flipping the switch down will immediately

release the belt tension. The belt tension will

only engage while the sander has air pressure.

Likewise, the belt tensioner may not work correctly if the air pressure is not set to the

required 75 PSI.

Pressure Rollers

The pressure rollers are factory set, but we

recommend checking them as follows to minimize the potential for personal injury:

1. Make sure that the sander is unplugged

from the power!

2. Make sure that the platen is even with the

sanding belt rollers before continuing.

3. Obtain a board of uniform thickness that is

at least 24" long. Place the board in the center of the conveyor belt and position it

directly under both the front and rear pressure rollers.

4. The air pressure should be connected and

the sanding belt should be installed and tensioned for this next step. Look underneath

the sanding head at the pressure rollers and

sanding belt. Slowly raise the table and confirm that the board makes contact with

both pressure rollers before it touches the

sanding belt.

If the board DOES NOT make contact with both

pressure rollers before touching the sanding

belt, then the pressure rollers must be adjusted.

Refer to the Adjustments section for step-bystep instructions on how this can be done.

The belt must be tightened before starting

the sander!

NOTICE

Page 17

ASSEMBLY

-15-

Dust Collection

The Model W1689 features a 5" dust port that is

located on top of the machine. Before performing any sanding operations, a working dust collector must be attached to the sander as shown

in Figure 14.

The dust collector that is attached to the

Model 1689 must be able to move 800-1200

CFM at the sander dust port. Make sure that

your dust collector and dust collection system

have the ability to move this volume of dust, or

dust buildup will affect the performance of your

sander.

A fine layer of dust may be present on your

stock as it comes out of the sander. This is normal.

Figure 14. Dust collection hose

attached to dust port.

Always wear a dust mask

in addition to using a dust

collector. This machine

produces sawdust that

may cause allergic reactions or respiratory problems.

DO NOT operate this

machine without an adequate dust collection system. This machine creates

substantial amounts of

wood dust while in operation. Failure to use a dust

collection system can

result in short and longterm respiratory illness.

Page 18

ADJUSTMENTS

-16-

ADJUSTMENTS

Make sure that your

machine is unplugged

during any adjustment

procedures unless

instructed to do different! If this warning is

ignored, serious personal injury may occur!

General Information

The adjustments in this section have been factory set and generally do not need to be performed when you first receive your sander; however, we suggest that you become familiar with

these adjustments before operating your

sander. This information will help you understand the machine better and will prepare you

for the types of adjustments that can be made

in the event of any troubleshooting.

Oscillation Timing

When adjusting the oscillation action of the

sander, the first thing you should do is adjust

the balance of the sanding belt side-to-side

movement. When the timing is right, the belt

will take the same amount of time to move in

one direction, as it moved in the other direction. Time the oscillation as follows:

1. With the sanding belt installed and properly

tensioned, open both access doors on the

upper part of the sander, then turn the

sanding belt ON and determine the oscillation timing status.

• If the oscillation timing is correct the sand-

ing belt will move back and forth evenly,

and no further adjustments to the timing

will be needed.

• If the oscillation is incorrect, the belt will

move faster to one side, then slower to the

other—follow step 4 to adjust; or if the belt

comes off the rollers and immediately stops

the sander—follow steps 3-4 to adjust.

3. If the belt moves too far to one side and

stops the sander, then re-adjust the timing

control knob (shown in Figure 15) approxi-

Always wear safety glasses during operations.

Serious injury may occur

if this is warning is ignored!

Always keep loose

clothing and long hair

secured and away from

moving parts.

Figure 15. Oscillation timing knob.

Keep your hands clear of the sanding belt

when making these adjustments!

Page 19

ADJUSTMENTS

-17-

Oscillation Return

The oscillation return is responsible for keeping

the belt in motion during oscillation. Figure 16

shows the valve that controls the oscillation

return. Adjust the oscillation return as follows:

1. Unplug the power but keep the air pressure

going into the machine.

2. Loosen the belt tension and remove the

sanding belt from the sander.

3. Obstruct the airflow between the air eye

fork (shown in Figure 17) with your finger

until the top sanding roller rotates a small

amount then stops.

Oscillation Speed

The valve shown in Figure 16 controls the speed

of the sanding belt oscillation. For normal operations, the oscillation speed should be set so

that it takes approximately 2 seconds to move

each direction of travel or a total of 4 seconds

to move both directions. The oscillation timing

must be balanced before adjusting the speed!

To increase the speed, turn the valve counterclockwise.

To decrease the speed, turn the valve clockwise.

After the speed has been set, tighten the jam

nut under the valve knob so it will not move.

Experiment with different speeds to see how the

results may affect your finished product. Often,

you may find that certain speeds yield better

results for different varieties of stock.

Always keep loose

clothing and long hair

secured and away from

moving parts.

Figure 16. Oscillation speed and oscillation

return control valves.

Figure 17. Air eye fork.

mately 1⁄2

" to the left or right, loosen the

belt tension, recenter the sanding belt on

the rollers and tighten the belt again. Turn

the sanding belt ON and repeat this step

until the belt will not stop the sander when

oscillating.

4. When the belt is oscillating without stopping, loosen the timing knob and slowly

move it until the belt is moving back and

forth in even intervals. Lock the timing knob

to keep the oscillation consistent.

Speed

Return

Page 20

ADJUSTMENTS

-18-

Figure 18. Limit switch adjustment bolt.

4. Keep the airflow blocked and loosen the

jam nut under the valve knob. Turn the

knob clockwise to close the valve.

5. Mover your finger away from the air eye

fork to resume the airflow. Slowly turn the

valve counterclockwise and watch the top

roller for movement.

6. When the top roller starts moving, continue

turning the valve another

1

⁄2 turn. Tighten

the jam nut to keep the new setting in

place. Avoid opening the knob more than

necessary because this will place excessive

pressure on the air system components.

Always wear safety glasses during operations.

Serious injury may occur

if this is warning is ignored!

Limit Switches

Limit switches are placed on both sides of the

belt to act as emergency stops if the belt travels too far to one side during oscillation. Adjust

the limit switches as follows:

1. Release the belt tension, center the sanding

belt on the top roller, then tension the belt

again.

2. Measure the distance from the edge of the

sanding belt to the rubber coated portion of

the limit switch. When correct, the belt and

the switch should be approximately

1

⁄2"

away from each other. If your measurement

is different than this, the limit switch must

be adjusted.

3. The bolt shown in Figure 18 secures the

limit switch to the frame. Loosen this bolt

and slide the limit switch as necessary until

you achieve the proper

1

⁄2" measurement.

4. Tighten the bolt that secures the limit

switch and repeat the adjustment with the

other side if necessary.

5. Plug the sander back in and turn it ON to

ensure that it is working properly. Repeat

these instructions if necessary.

Make sure that your

machine is unplugged

during any adjustment

procedures unless

instructed to do different! If this warning is

ignored, serious personal injury may occur!

Page 21

ADJUSTMENTS

-19-

Figure 19. Platen depth knob.

Figure 20. Boards placed under pressure rollers

as a gauge.

Platen Depth

Occasionally you will need to “reset” the platen

depth and make it even with the sanding belt

rollers. Set the platen depth as follows:

1. Unplug the sander from the power!

2. Lower the conveyor table down as far as it

will go so that you have enough room to

work under the sanding belt rollers.

3. Place a straightedge across the bottom of

both sanding belt rollers.

4. Using the platen adjustment knob shown in

Figure 19, move the platen so that it bare-

ly touches the straightedge, and thus, is

even with both sanding belt rollers.

Pressure Rollers

The pressure rollers can be adjusted in two

ways—the depth and the tension. For proper

depth, the front pressure roller should be

approximately .040" below the level of the sanding rollers and the rear pressure should be

approximate .020" below the level of the sanding rollers. Adjust the pressure roller depth as

follows:

1. Unplug the sander, but keep air pressure

coming in and have the sanding belt

installed and tensioned for the following

steps.

2. Make two adjustment boards that are 24"

long and are of a uniform thickness.

3. Place each board on each side of the conveyor belt so that they are positioned

directly below the front and back pressure

rollers as shown in Figure 20.

Page 22

ADJUSTMENTS

-20-

Figure 21. Pressure roller adjustment bolts.

4. Raise the pressure rollers above the sanding

belt rollers with the adjustment bolts shown

in Figure 21. The pressure roller adjust-

ment bolts can be locked/unlocked with the

recessed setscrews in the head of the bolt.

For the rear pressure rollers, these bolts are

located in the same position on the back

side of the machine.

5. Make sure that the platen is even with the

sanding belt rollers.

6. Raise the table up until the boards barely

touch the sanding belt. This is an important

reference point. Notice the table hand-

wheel position and make a mental note of

its location for the next adjustment.

7. Turn the table handwheel counterclockwise

1

⁄8thof a turn. This will lower the table

approximately

1

⁄

64". Now lower the rear

pressure roller so that both ends barely

touch the boards.

8. Turn the table handwheel counterclockwise

another

1

⁄8thof a turn. Now lower the front

pressure roller so that both ends just touch

the boards.

The pressure rollers should now be properly set.

Keep in mind that roller tension, besides roller

depth, will also affect the feeding operations.

Page 23

ADJUSTMENTS

-21-

Figure 22. Pressure roller adjustment spring.

Figure 23. Motor mount adjustment nuts.

Pressure Roller

Tension

Pressure roller tension is the downward force

that the pressure rollers place on the workpiece

as it passes through the sander. Too little tension will cause the workpiece to pass unevenly

through the sander and may launch the workpiece from the sander. Too much tension may

cause poor and inconsistent sanding results, as

well as premature wear on the conveyor belt.

Adjust the pressure roller tension as follows:

1. Unplug the sander from the power!

2. Verify that the pressure roller depth is set

correctly.

3. Open both access doors on the upper part of

the sander and locate the tension springs

shown in Figure 22.

4. The position of the nut on the adjustment

bolt controls the spring tension. Turn the

nut clockwise to increase the tension and

counterclockwise to decrease the tension.

V-Belt Tension

The V-belts that drive the sanding rollers must

be tensioned properly for best performance.

Tension the V-belts as follows:

1. Unplug the sander from the power!

2. Remove the cover on the right-hand side of

the lower portion of the sander.

3. The two nuts shown in Figure 23 are

responsible for adjusting the V-belt tension.

Turn both nuts clockwise to tighten the Vbelts, or turn both nuts counterclockwise to

loosen the V-belts.

4. The V-belt is properly tightened when it will

move no more than

3

⁄4" in the center with

moderate pressure from your thumb.

Page 24

ADJUSTMENTS

-22-

Feed Belt Tension

The feed belt tension has been set at the factory and should not need to be adjusted when the

machine is new; however, if at any point you

notice that your feed belt is slipping on the

rollers, it should be tensioned. Tension the

feed belt as follows:

1. Unplug the sander from the power source!

2. Position the emergency brake plate up as

far as it will go, so that it is out of the way

of the tension screws (one is shown in

Figure 24). The back feed roller is not

adjustable, and therefore, no adjustment

screws are located at the back of the

sander.

3. Turn the adjustment bolt clockwise to

increase the tension and turn it counterclockwise to decrease the tension. Adjust

each side evenly so that the tracking does

not become misaligned.

4. When the tension is correct, run the belt for

at least three minutes to check the tracking

before resuming sanding operations.

Feed Belt Tracking

If you notice that the feed belt is tracking more

to one side, turn the feed belt OFF immediately

and adjust the tracking. The belt tracking is

adjusted by using the same adjustment screws

that were used during feed belt tensioning.

Tension the feed belt tracking as follows:

1. Use the adjustment screws to position the

feed belt roller evenly on each side.

Measure the roller shaft location in the

mounting brackets with a caliper or fine

ruler to get each side even.

2. Run the feed belt for at least three minutes

to determine if the tracking is correct. If

the belt does not track evenly, make small

adjustments to the side opposite of the belt

travel and repeat this step until it tracks

evenly.

Figure 24. Feed belt tension screw.

Emergency

Brake Plate

Feed Belt

Tension Screw

Page 25

OPERATIONS

-23-

OPERATIONS

Test Run

Once assembly is complete, the machine is

ready for a test run. The purpose of a test run is

to identify any unusual noises and vibrations, as

well as to confirm that the machine is performing as intended. Perform the test run as fol-

lows:

1. Turn both the sanding and feeding belts ON.

2. Once the machine is running, listen for any

unusual noises. A slow, rhythmic air sound

is normal. The machine should run smooth-

ly with little or no vibrations.

3. If there are any unusual noises or vibrations,

shut the machine off immediately.

4. Unplug the machine and investigate the

source of the noise or vibration. DO NOT

make any adjustments to the machine while

it is plugged in. The machine should not be

run any further until the problems are corrected.

Always wear a dust mask

in addition to using a dust

collector. This machine

produces sawdust that

may cause allergic reactions or respiratory problems.

Always wear safety glasses during operations.

Serious injury may occur

if this is warning is ignored!

Always keep loose

clothing and long hair

secured and away from

moving parts.

Selecting Sandpaper

When selecting sandpaper, keep in mind that

the Model W1689 accepts only 16"W x 48"L belts

similar to those shown in Figure 25.

When deciding which grit of sandpaper to use,

consider the type of work, the species of wood

and the stage of finishing. Use these numbers as

a general guide to sandpaper type:

• 60 Grit....................................Coarse

• 80-100 Grit ..............................Medium

• 120-150 Grit ............................Fine

Experiment with each type of sandpaper on

scrap stock that is the same species as your

workpiece.

For best results, do not increase grit numbers

more than 50 on any successive pass.

Figure 25. Sanding belts.

Page 26

OPERATIONS

-24-

Conveyor Table

Height Adjustments

The conveyor table height adjusts by turning the

handwheel shown in Figure 26.

Also shown is the table height scale that measures the movement of the table. This scale is

marked in both inches and millimeters. The

table height scale can be used as a quick guide

to matching workpiece thickness with table

height.

The conveyor table lock knob shown in Figure

27 allows you to lock the table height after

adjustments have been made.

Feed Speed

The feed belt motor offers speeds of 13 and 16

FPM. Figure 28 points out which sprockets are

responsible for which speeds. Change the feed

belt speeds as follows:

1. Unplug the power from the sander!

2. Remove the feed belt motor cover by taking

out the cap screw that secures it.

3. Loosen the four bolts at the motor mount

and slide the motor up. Pull the chain off of

the sprocket that it is currently on.

4. Place the chain on the next sprocket and

slide the motor down to tighten the chain.

Hold the motor down and tighten the motor

mount bolts at the same time.

5. Replace the motor cover before plugging

sander into power!

Figure 26. Table height handwheel and scale.

Figure 27. Handwheel movement diagram.

Figure 28. Feed motor chain and sprockets.

Table

Height

Scale

Table Height Handwheel

Table Height Lock Knob

13 FPM

16 FPM

Page 27

OPERATIONS

-25-

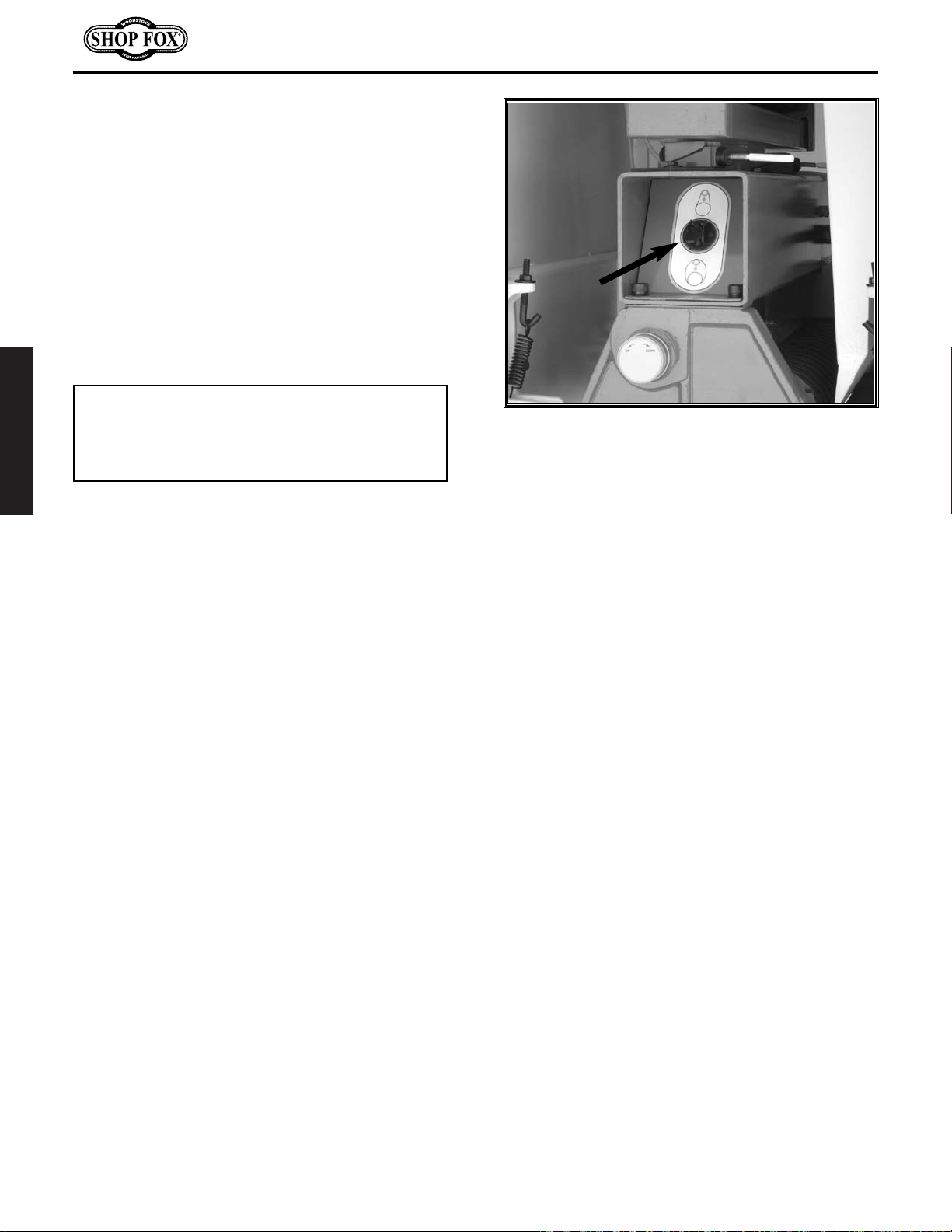

Using Load Meter

The load meter shown in Figure 29 is an impor-

tant gauge for determining how deep of a cut

the sander can take while you are feeding the

workpiece. The load meter displays the current

amperage draw of the sander. As the depth of

cut increases, so does the amperage draw. Use

this meter for consistent sanding depths and to

avoid overloading your sander.

Never exceed 26 amps on the load meter! This

is the maximum amount that the sander can

safely handle.

Operating Sander

The normal depth of cut is no more than 1⁄64".

This depth is the equivalent of turning the table

height handwheel

1

⁄8thof a turn. DO NOT raise

the table more than

1

⁄8thof a turn on one suc-

cessive pass. Attempting to remove too much

material can cause workpiece burning, premature paper wear, paper tearing and undesirable

finished results. Basic sanding operations are

performed as follows:

1. Put on safety glasses and a dust mask, and

start the dust collector.

2. Make the thickness adjustment slightly larger than your workpiece.

Figure 29. Load meter.

Emergency Stop

Figure 30. Emergency stop plate.

The emergency stop shown in Figure 30 is provided to stop the sander quickly. The emer-

gency stop is engaged as follows:

1. Push the bottom of the emergency stop

plate as far as it will go.

2. Hold the emergency stop plate until the

sander has come to a complete stop.

For best results, feed each piece through the

sander two or three times without adjusting

the depth of cut. Turn the workpiece 180˚

and feed it through two or three more times

at this same depth. As always, use your best

judgement. If you no longer hear the sanding belt making contact with the workpiece

on successive cuts, then no further passes are

needed at that depth.

Quick Tip

Page 28

OPERATIONS

-26-

Adjusting Platen

The adjustable platen allows you to achieve different results from your sander, depending on

how it is positioned. To move the platen up or

down, use the knob shown in Figure 32 and

gauge the depth/height by using the scale on

the knob. The three possible platen positions

are as follows:

Platen Up — The platen is moved above the

sanding rollers. The rollers then act like a drum

sander and allow for increased stock removal. In

this position, the ideal belt grit is #100 or coarser. The scratch pattern in this mode will be

short and deep, relative to grit size.

Platen Even — The platen is set even with the

sanding rollers. The rollers act together with the

platen pressure to achieve intermediate or final

finishing. In this position, the ideal belt grit is

between #100 and #180. The scratch pattern in

this position is moderate, relative to grit size.

Platen Down — The platen is moved below the

sanding rollers. With the platen down, the workpiece contact with the sandpaper is only made

at the platen. This position is used for fine finishing, sanding repairs, or sanding lacquer. The

ideal belt grit is #180 or finer. Generally sanding

with the platen down will remove .004" or less.

The scratch pattern in this position will be long

and shallow, relative to grit size.

Figure 32. Platen depth knob.

The platen depth should never be more

than .2mm below the sanding belt rollers or

sanding belt damage/stretching may occur.

This depth can be determined by watching

the scale on the platen knob. (.2mm is the

equivalent of one full turn of the knob.)

NOTICE

3. Feed the workpiece as shown in Figure 31.

4. Adjust the table height while watching the

load meter— remember not to exceed 26

amps!

5. When you achieve a good cut, lock the table

in place and pass the workpiece through the

sander again.

Figure 31. Operator feeding workpiece in

correct position.

Page 29

MAINTENANCE

-27-

MAINTENANCE

Lubrication

Since all bearings are shielded and permanently

lubricated, simply leave them alone until they

need to be replaced. Do not lubricate them.

For other items on this machine, lubricate the

items shown in Figure 33-35. Before applying

lubricant, wipe the area clean.

Your goal is to achieve adequate lubrication.

Too much lubrication will attract dirt and sawdust. These parts of your machine could lose

their freedom of movement as a result.

Regular periodic maintenance on your Model

W1689 will ensure its optimum performance.

Make a habit of inspecting your machine each

time you use it. Check for the following condi-

tions and repair or replace when necessary:

• Loose mounting bolts.

• Worn switch.

• Worn or damaged cords and plugs.

• Damaged drive belt.

• Any other condition that could hamper the

safe operation of this machine.

• Check the entire air system for leaks.

General

Make sure that your

machine is unplugged

during any maintenance

procedures except

where instructed otherwise! If this warning is

ignored, serious personal injury may occur.

Figure 33. Clean and lubricate feed speed chain

with chain lubricant monthly or as needed.

Figure 34. Lubricate table rack with a light

lithium grease monthly or sooner if needed.

Figure 35. Lubricate table column often with

mineral oil.

Page 30

MAINTENANCE

-28-

The filters on the two regulators need to be

emptied and cleaned whenever they get more

than half full. The inside filter shown in Figure

37 will need service more frequently than the

filter on the front of the machine.

Servicing Filters

The graphite pad on the platen will eventually

wear out with use. Replace the graphite sheet

as follows:

1. Remove the platen with the platen puller

tool (shown in Figure 38).

2. Remove the screws and the clamp bar to

separate the graphite pad from the platen.

3. Install the new graphite pad, making sure

that it is wrapped in the same direction as

the old pad, and re-install the clamp bar

and screws.

Platen Graphite

To increase working life of your sanding belts,

we recommend that you routinely clean them

with Pro-Stik

®

Cleaning Pads (shown in Figure

36).

To clean the belts, simply set your table to the

thickness of the cleaning pad and run the pad

through the sander two or three times. DO NOT

take too deep of a cut. The belt should just

barely touch the cleaning pad!

Clean sanding belts whenever they decrease in

performance due to heavy loading.

Cleaning Belts

Figure 36. Pro Stik®cleaning pad.

Figure 38. Platen puller tool.

Figure 37. Check this filter often for service.

Page 31

MAINTENANCE

-29-

Figure 39. Pull casting off of roller ends.

Figure 40. Remove large roller nut.

Figure 41. Remove front sanding roller.

Changing V-Belts

Check the V-belts periodically to check for signs

of glazing, cracking or fraying. If any of these

conditions are present, change both V-belts.

Change the V-belt as follows:

1. Unplug the sander from the power and

shut off the air pressure!

2. Loosen the top nut (turn counterclockwise)

on the motor adjustment bolt. See page 21

for motor adjustment controls. Turn the

bottom nut counterclockwise (or pry motor

up) to loosen and remove the V-belts.

4. In order to take the V-belts off of the roller

pulleys, the rollers must be removed from

the sander. Open both access doors on the

upper part of the machine. At the left-hand

access side, remove the platen knob by

loosening the setscrew near its dial.

5. Remove the two setscrews that secure the

dial plate to the casting and then remove

the two large cap screws that secure the

top of the casting.

6. Pull the casting off of the roller ends as

shown in Figure 39.

7. At the other side of the machine (the righthand side from the front), remove the large

nut shown in Figure 40. The roller may turn

if not held from the other side. This secures

the other end of the front roller shaft to the

sander body.

8. Now, move back to the left-hand side of the

machine and carefully pull out the front

sanding belt roller as shown in Figure 41.

The V-belts can now be easily removed.

9. Install the new V-belts in the reverse order

of removal. To make this process easier,

have a helper hold the V-belts up at the

other side of the sander when you re-install

the roller. When you retighten the large

roller shaft nut, have your helper stand at

the other side of the sander to keep the

roller from turning.

Page 32

MAINTENANCE

-30-

Figure 42. Brake assembly.

Figure 43. Brake caliper removed for access to

brake pads.

Servicing Brake

Any type of foreign material on the brake rotor

creates the potential for improper performance.

Check the brake rotor (shown in Figure 42) reg-

ularly to make sure it is clean. If it needs cleaning, only use automotive brake parts cleaner

and a dry rag. DO NOT use water!

The brake pads (shown in Figure 43) will eventually need to be replaced. Check the brake

pads for replacement as follows:

1. Unplug the sander from the power source

and shut off the air pressure!

2. Remove the motor cover to access the brake

components.

3. The brake pads are made up of a metal

plate and a composite pad. Measure the

thickness of each pad with a fine ruler. If

either of the pads is below

1

⁄

8", then

replace both.

Replace the brake pads as follows:

1. Unplug the sander from the power source

and shut off the air pressure!

2. Remove the caliper from the mounting

bracket. It is held in place by hex nuts and

snap rings on each mounting pin. You may

need to remove the air line to the caliper to

relieve any built up pressure.

3. Remove the cap screws that hold the brake

pads to the caliper. One of these can only

be reached if the caliper is disassembled.

4. Remove the brake rotor and have it professionally surfaced at an automotive or

machine shop. Clean the rotor with automotive brake parts cleaner and handle it with

a dry rag when installing.

5. To finish the job, install the new brake

pads, reassemble and mount the caliper,

and reconnect the air line.

Brake

Rotor

Brake

Caliper

Brake Pads

Page 33

MAINTENANCE

-31-

Troubleshooting

SYMPTOM

Motor will not start.

Motor will not start; fuses or

circuit breakers blow.

Motor overheats.

Motor stalls (resulting in blown

fuses or tripped circuit).

Machine slows when operating.

Loud, repetitious noise coming

from machine

Machine is loud, overheats or

bogs down in the cut.

Edges of wood are rounded.

Uneven thickness from left to

right of board.

Workpiece slips on feed belt.

Straight strip of notches on

workpiece.

Snake shaped marks on workpiece.

POSSIBLE CAUSE

1. Low voltage.

2. Open circuit in motor or loose connections.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose connections.

3. Incorrect fuses or circuit breakers

in power line.

1. Motor overloaded.

2. Air circulation through the motor

restricted.

1. Short circuit in motor or loose connections.

2. Low voltage.

3. Incorrect fuses or circuit breakers

in power line.

4. Motor overloaded.

1. Feed rate too high.

2. Depth of cut too great.

1. Pulley set screws or keys are missing or loose.

2. Motor fan is hitting the cover.

3. V-belt is defective.

1. Excessive depth of cut.

2. Dull sanding belt.

1. Excessive depth of cut.

1. Feed table not parallel to sanding

roller.

2. Feed belt is worn.

1. Pressure rollers set too high.

2. Dirty feed belt.

3. Feed belt is worn.

1. Pressure rollers are dirty or damaged.

1. Sanding belt damaged or dirty.

HOW TO REMEDY

1. Check power line for proper voltage.

2. Inspect all lead connections on motor for loose or open connections.

1. Inspect cord or plug for damaged insulation and shorted

wires.

2. Inspect all connections on motor for loose or shorted terminals or worn insulation.

3. Install correct fuses or circuit breakers.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

1. Inspect connections on motor for loose or shorted terminals

or worn insulation.

2 Correct the low voltage conditions.

3. Install correct fuses or circuit breakers.

4. Reduce load on motor.

1. Feed workpiece slower.

2. Reduce depth of cut.

1. Inspect keys and set screws. Replace or tighten if necessary.

2. Tighten fan or shim cover.

3. Replace V-belt. See Maintenance section.

1. Decrease depth of cut.

2. Replace sanding belt.

1. Reduce depth of cut.

1. Adjust the table.

2. Replace feed belt.

1. Lower pressure rollers.

2. Clean feed belt.

3. Replace feed belt.

1. Clean or repair pressure rollers.

1. Clean or replace sanding belt.

Page 34

MAINTENANCE

-32-

Troubleshooting

SYMPTOM

Lines across width of workpiece.

Glossy spots or streaks on

workpiece.

Sanding belt clogs quickly.

Sanding belt does not tension

correctly; rollers slip under

belt.

Sanding belt runs off to one

side, stopping the sander.

Sanding belt will not start.

Poor, non-aggressive sanding

results.

Conveyor belt not tracking in

center.

Conveyor belt slipping.

Emergency brake stops slow.

Grinding noise when braking.

POSSIBLE CAUSE

1. Sanding belt seam is open or damaged.

1. Worn sanding belt.

2. Rear pressure roller too low.

1. Sanding belt grit too small for particular job.

2. Excessive depth of cut.

3. Wood is too moist.

1. Low air pressure.

2. Air leaks in system.

1. Air eye fork clogged.

2. Oscillation return valve closed.

3. Oscillation timing incorrect.

1. Sanding belt is not tensioned.

2. Limit switches engaged.

3. Emergency stop plate engaged.

1. Platen adjusted incorrectly, above

bottom surface level of lower sanding rollers.

2. Sanding belt loaded with sawdust.

3. Sanding belt worn out.

1. Conveyor rollers moved out of

adjustment.

1. Conveyor rollers have incorrect

tension.

2. Conveyor rollers contaminated with

dirt or dust.

1. Air pressure incorrect.

2. Air leak in system.

3. Brake rotor contaminated with oil.

4. Brake pads worn out.

1. Brakes severely worn out.

HOW TO REMEDY

1. Repair or replace sanding belt.

1. Replace sanding belt.

2. Raise rear pressure roller. (See warning in Pressure Roller

section!)

1. Replace with a coarser grit sanding belt.

2. Reduce depth of cut.

3. Allow wood to dry out.

1. Adjust air pressure to 75 PSI at primary regulator.

2. Inspect all hoses and connections for leaking air; use water

on suspected area to detect bubbles.

1. Clean the intake hole on the air eye fork.

2. Open valve.

3. Adjust oscillation timing.

1. Tension sanding belt.

2. Center sanding belt so it is not touching the limit switches.

3. Make sure emergency stop switch is released.

1. Adjust platen on the same plane as, or lower than, bottom

surface level of lower rollers.

2. Clean sanding belt to unload sawdust.

3. Replace sanding belt with a new one.

1. Re-adjust conveyor rollers.

1. Adjust conveyor rollers to increase tension.

2. Clean conveyor rollers.

1. Adjust air pressure to 75 PSI.

2. Find and fix air leaks.

3. Clean brake rotor with automotive brake parts cleaner.

4. Replace brake pads.

1. Replace brake pads, have rotor turned (possibly replaced).

Page 35

220 Volt Single Phase

MAIN MOTOR

4

1

3

2

BELT

LIMIT

SWITCH

4

1

3

2

EMERGENCY STOP

LIMIT SWITCH

4

1

1

2

3

4

5

6

FEED BELT MOTOR

1

4

5

2

3

6

3

2

12 13 3 3 5 5 U2

V2

W2

U1

V1

W1

Page 36

D

I

C

N

A

I

T

R

O

E

R

W

O

P

X1 X2

E

D

E

F

21

22

B

E

P

L

O

T

T

S

220 Volt Single Phase

E

E

D

F

X2

X1

21

22

B

T

E

R

L

A

T

T

S

N

A

D

S

I

N

G

B

P

E

O

L

T

T

S

14 13

13 14

14 13

21 22

2 3 5 6 8 9 10 11 14 15

X2

X1

21

22

N

A

D

S

I

N

G

B

T

E

R

L

A

T

T

S

E

R

T

13 14

21 22

E

S

T

R

E

S

E

14 13

Page 37

220 Volt Single Phase

-35-

220V POWER

TO REMAIN BLANK

R S T

TO EMERGENCY

THIS TERMINAL

STOP LIMIT

12 13 3 3 5 5 U2

2 3 5 6 8 9 10 11 14 15

TO BELT

LIMIT SWITCHES

TO ELECTRICAL

SWITCH PANEL

TO FEED

MOTOR

W2

V2

TO MAIN MOTOR

U1

V1

W1

2A FUSES

1L13L25

CN 25

2T14T26

L3

T3

23

21

FN1853-39

RESET

26

29

31

A(R.C.)

1L13L25

CN11

2T14T26

13

NC

L3

T3

RESET

1.7

1.9

1.5

1.3

2.1

A(R.C.)

FN1853-39

14

NC

1L13L25

CN11

2T14T26

13

NC

L3

T3

14

NC

Page 38

PARTS

-36-

The following pages contain parts diagrams/lists

and a warranty card for your SHOP FOX

®

Model

W1689.

If you need parts or help in assembling your

machine, or if you need operational information, we encourage you to call our Service

Department. Our trained service technicians will

be glad to help you.

If you have comments dealing specifically with

this manual, please write to us using the address

in the General Information. The specifications,

drawings, and photographs illustrated in this

manual represent the Model W1689 as supplied

when the manual was prepared. However, due

to Woodstock International, Inc.’s policy of continuous improvement, changes may be made at

any time with no obligation on the part of

Woodstock International, Inc. Whenever possible, though, we send manual updates to all owners of a particular tool or machine that have registered their purchase with our warranty card.

Should you receive one, add the new information to this manual and keep it for reference.

We have included some important safety measures that are essential to this machine’s operation. While most safety measures are generally

universal, we remind you that each workshop is

different and safety rules should be considered

as they apply to your specific situation.

We recommend you keep this manual for complete information regarding Woodstock

International, Inc.’s warranty and return policy.

Should a problem arise, we recommend that you

keep your proof of purchase with your manual.

If you need additional technical information

relating to this machine, or if you need general

assistance or replacement parts, please contact

the Service Department at 1-360-734-3482 or email: tech-support@woodstockint.com

.

Additional information sources are necessary to

realize the full potential of this machine. Trade

journals, woodworking magazines, and your

local library are good places to start.

The Model W1689 is specifically designed for

sanding operations. DO NOT MODIFY AND/OR

USE THIS MACHINE FOR ANY OTHER PURPOSE.

MODIFICATIONS OR IMPROPER USE OF THIS

TOOL WILL VOID THE WARRANTY. If you are

confused about any aspect of this machine, DO

NOT use it until all your questions have been

answered.

CLOSURE

Operating this equipment creates the potential for flying debris to cause eye injury.

Always wear safety glasses or goggles when

operating equipment. Everyday glasses or

reading glasses only have impact resistant

lenses, they are not safety glasses. Be certain the safety glasses you wear meet the

appropriate standards of the American

National Standards Institute (ANSI).

As with all power tools, there is danger

associated with the Model W1689. Use the

tool with respect and caution to lessen the

possibility of mechanical damage or operator injury. If normal safety precautions are

overlooked or ignored, injury to the operator or others in the area is likely.

Page 39

PARTS

-37-

1 XPWR1214 COMBO WRENCH 12/14MM

2 X1689002 BOX WRENCH 30/37MM

3 X1689003 PHILLIPS SCREWDRIVER

4 X1689004 TOOL BOX

5 X1689005 ACCESS DOOR HANDLE

6 X1689006 PLATEN TOOL

7 XPWR1719 COMBO WRENCH 17/19MM

8 XPWR1113 COMBO WRENCH 11/13MM

9 XPWR810 COMBO WRENCH 8/10MM

10 X1689010 ALLEN WRENCH SET (10)

REF PART # DESCRIPTION

REF PART # DESCRIPTION

W1689 Parts & Replacement Items

1

2

3

4

5

7

9

8

6

10

Page 40

PARTS

-38-

154

124

160

128

126

157

123

161

127

153

158

155

122

152

150

121

119

149

42

118

120

148

117

143

147

114

116

142

146

144

113

145

115

139

109

108

140

137

125

129

138

156

130

107

102

132

101

103

131

104

136

133

106

105

135

159

134

162

110

141

111

112

Page 41

PARTS

-39-

REF PART # DESCRIPTION REF PART # DESCRIPTION

101 X1689101 QUILL BASE

102 XPLW06M LOCK WASHER 10MM

103 X1689103 WORM GEAR SHAFT

104 XP6203ZZ BEARING 6203-ZZ

105 X1689105 BUSHING

106 XPR18M RETAINING RING S17

107 X1689107 RACK

108 X1689108 CONVEYOR SUPPORT FRAME

109 XPLW04M LOCK WASHER 8MM

110 X1689110 HANDWHEEL

111 XPW03M FLAT WASHER 6MM

112 X1689112 HANDLE M10-1.5 x 20

113 X1689113 SETTING SHAFT

114 XPSS09M SETSCREW M8-1.25 X 20

115 XPSB62M CAP SCREW M10-1.5 X 12

116 XPW06M FLAT WASHER 12MM

117 X1689117 BRAKE PIN

118 XPLW06M LOCK WASHER 10MM

119 X1689119 BRAKE CALIPER

120 XPS14M CAP SCREW M6-1.0 X 12

121 X1689121 BRAKE

122 XPS47M PHLP HD SCR M6-1.0 X 25

123 X1689123 TOP COVER

124 X1689124 PLASTIC CONNECTOR

125 XPB501M HEX BOLT M10-1.5 X 30

126 X1689126 BRAKE ROTOR

127 XPSB75M CAP SCREW M10-1.5 X 18

128 XPSS13M SETSCREW M10-1.5 X 12

129 X1689129 MACHINE BASE

130 XPSB64M CAP SCREW M10-1.5 X 25

131 X1689131 LOCKING HANDLE M10-1.5 x 50

132 XP51102 BEARING 51102

133 XPR34M RETAINING RING R40

134 XPSB64M CAP SCREW M10-1.5 X 25MM

135 X1689135 WORM GEAR

136 X1689136 GEAR SHAFT

137 X1689137 QUILL

138 XPSB74M CAP SCREW M6-1.0 X 18

139 XPSB12M CAP SCREW M8-1.25 X 40

140 XPSB12M CAP SCREW M8-1.25 X 40

141 XPS24M PHLP HD SCR M6-1.0 X 10

142 X1689142 MACHINE BASE COVER

143 X1689143 MOTOR BASE

144 X1689144 LOCK BUSHING

145 XPW04M FLAT WASHER 10MM

146 X1689146 ADJUSTABLE SCREW

147 XPN09M HEX NUT M12-1.75

148 X1689148 EXT RETAINING RING 13MM

149 XPN02M HEX NUT M10-1.5

150 X1689150 BRAKE PAD

151 X1689151 SPRING

152 X1689152 PLATE

153 X1689153 DIAPHRAGM

154 XPS20M PHLP HD SCR M5-.08 X 15

155 X1689155 SPINDLE MOTOR 5HP

156 XPLW06M LOCK WASHER 10MM

157 XPLW06M LOCK WASHER 10MM

158 X1689158 MOTOR PULLEY

159 X1689159 QUILL COVER

160 XPS47M PHLP HD SCR M6-1.0 X 25

161 XPVA78 BELT A78

162 X1689162 MACHINE ID/WARNING LABEL

Page 42

PARTS

-40-

236

REF PART # DESCRIPTION

REF PART # DESCRIPTION

201 X1689201 ROLLER BRACKET L

202 XPLW04M LOCK WASHER 8MM

203 XPSB40M CAP SCREW M8-1.25 X 35