Shimadzu TW Series, TX Series, TXB Series Service Manual

321-78011G

May 2010

Electronic Balances

TW/TX/TXB Series

Service Manual

Precision Balance

- i -

Table of Contents

1. Operations for Adjustment...........................................................................................................................1

1.1. ROM version information.......................................................................................................................................... 1

1.2. Entering the Service Mode ....................................................................................................................................... 1

1.3. Contents of Service Menu ........................................................................................................................................ 2

1.4. Service Mode Functions ........................................................................................................................................... 3

2. Disassembling and Assembling the Balance..........................................................................................5

2.1. TW/TX Series ............................................................................................................................................................... 5

2.1.1. Precautions........................................................................................................................................................... 5

2.1.2. Inspecting the Balance Interior (Removing the Case and Pan Support) ....................................................... 6

2.1.3. Replacing Components....................................................................................................................................... 7

2.2. TXB Series.................................................................................................................................................................. 18

2.2.1. Precautions.........................................................................................................................................................18

2.2.2. Inspecting the Balance Interior (Removing the Case and Pan Support) ..................................................... 19

2.2.3. Replacing Components..................................................................................................................................... 21

3. Checking the Electronic Board.................................................................................................................25

3.1. TW/TX Series ............................................................................................................................................................. 25

3.1.1. Main Board Assy (B2)........................................................................................................................................25

3.1.2. Analog Board Assy (B3).................................................................................................................................... 25

3.1.3. Power Board Assy (B4)..................................................................................................................................... 26

3.2. TXB Series.................................................................................................................................................................. 27

3.2.1. Power Board Assy ............................................................................................................................................. 27

3.2.2. Display Board Assy............................................................................................................................................ 27

3.2.3. Analog Board Assy ............................................................................................................................................ 28

4. Hardware Adjustment.................................................................................................................................29

4.1. TW/TX Series ............................................................................................................................................................. 29

4.1.1. Adjusting the Height of the Detector Assy (U11).............................................................................................29

4.1.2. Adjusting the Tilt Error........................................................................................................................................30

4.1.3. Adjusting the Cornerload Error ......................................................................................................................... 31

4.2. TXB Series.................................................................................................................................................................. 32

4.2.1. Adjusting ZERO balance of load cell ...............................................................................................................33

4.2.2. Adjusting the Corner load Error ........................................................................................................................ 34

5. Software Adjustment...................................................................................................................................35

5.1. EEPROM Initialization.............................................................................................................................................. 35

5.2. Model Selection.........................................................................................................................................................35

5.3. Setting Information Lock ........................................................................................................................................37

5.3.1. Releasing the Setting Information Lock...........................................................................................................37

5.3.2. Setting the Setting Information Lock ................................................................................................................ 37

5.4. Inputting Reference Weight Values for Linearity Adjustment ........................................................................38

5.5. Linearity Adjustment................................................................................................................................................ 39

5.6. Calibration of internal weight ( PCAL ) (Only TW series)................................................................................. 39

- ii -

5.7.

Sensitivity Calibration by External weight .......................................................................................................... 40

5.8. Sensitivity Calibration by internal weight (Only TW series)............................................................................41

5.9. Weight loader check ( Only TW series )...............................................................................................................42

6. EEPROM........................................................................................................................................................43

6.1. PRINT Operations..................................................................................................................................................... 43

6.2. Data Edit (EDIT) Operations ................................................................................................................................... 44

6.3. Backup (BKUP) Operations ...................................................................................................................................44

6.4. Download (RESTR) Operations............................................................................................................................. 44

6.5. All Initialization (INIT) Operations.......................................................................................................................... 45

6.6. EEPROM data editing software............................................................................................................................. 45

7. Updating the Program.................................................................................................................................47

7.1. Programming Tools .................................................................................................................................................47

7.2. Programming............................................................................................................................................................. 47

7.2.1. Downloading the Program to the Tool.............................................................................................................. 47

7.2.2. Preparing the Tool .............................................................................................................................................. 51

7.2.3. Programming...................................................................................................................................................... 52

8. Performance Inspection.............................................................................................................................54

8.1. Reproducibility..........................................................................................................................................................54

8.2. Cornerload Error.......................................................................................................................................................54

8.3. Linearity ...................................................................................................................................................................... 54

8.4. Tilt Error ...................................................................................................................................................................... 54

9. Problems and Solutions.............................................................................................................................56

9.1. General Problem Solutions .................................................................................................................................... 56

9.2. Error Display.............................................................................................................................................................. 57

9.2.1. User Mode Errors............................................................................................................................................... 57

9.2.2. Service Mode Errors..........................................................................................................................................58

9.2.3. Self check when power is turned on ................................................................................................................ 58

10. Troubleshooting.......................................................................................................................................59

10.1. Display Won't Appear..........................................................................................................................................59

10.2. Display Not Showing Correctly......................................................................................................................... 59

10.3. Key Operation Does Not Work.......................................................................................................................... 60

10.4. Poor Reproducibility............................................................................................................................................61

10.5. "ERR H" Is Displayed .......................................................................................................................................... 62

10.6. When Power is Switched On, Display Stops at "CHE 5" or “Software Version” ................................... 63

10.7. When Power is Switched On, Display Stops at "CHE 0".............................................................................64

10.8. Trouble of Weight Loader................................................................................................................................... 65

11. Components List ......................................................................................................................................66

11.1. TW/TWC,TX/TXC series ...................................................................................................................................... 66

- iii -

11.1 .1.

TW/TWC,TX/TXC exploded view .................................................................................................................... 66

11.1 .2. TX/TXC series dedicated jigs ...........................................................................................................................76

11.2. TXB Series ............................................................................................................................................................. 77

11.2 .1. TXB exploded view............................................................................................................................................77

11.2 .2. TXB Series Maintenance Parts ........................................................................................................................ 78

11.2 .3. TXB series dedicated jigs..................................................................................................................................79

11.3. TW/TX/TXB Series Shared Jigs and Tools ..................................................................................................... 79

- 1 -

1. Operations for Adjustment

For the general operations method, see the User's Manual for the TW/TX/TXB Series.

1.1. ROM version information

TX ROM ver. Ver

TX only (except TXC623) Ver 1.XX.XX.XX

TW/TX-L all model Ver 2.XX.XX.XX

TW/TX-N

(*1)

and TW/TX-L all

model

Ver 3.XX.XX.XX

*1: for Japan only

1.2. Entering the Service Mode

Move from user mode to service mode as follows.

(1) In the user mode mass display state, keep pressing (3-5sec.) [BREAK] and [PRINT] keys.

(2) Release the keys.

(3) Press down on the [CAL] and [->O/T<-] keys.

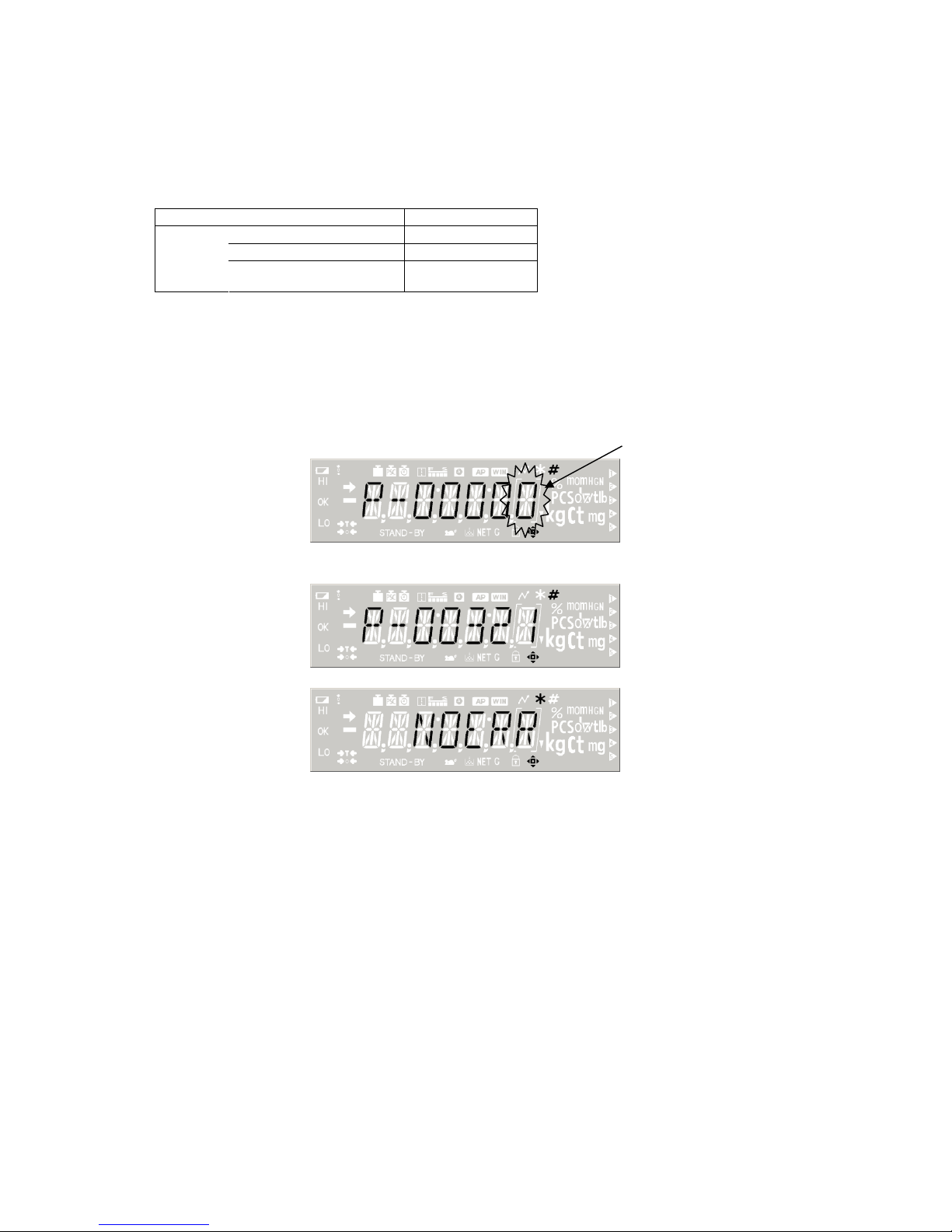

(4) The password input display appears. Flashing

Use the arrow keys to input numbers.

Input 00321 as the maintenance mode password, and press the [MENU/Enter] key.

(5) When the password is approved, the service mode opens.

Alternately, you can enter service mode by inputting the maintenance mode command "@SVC=321" from

the PC.

- 2 -

TYPEDisplay

SHIPDisplay

SoftwareVersion

ADDisplay WAD ※

TAD ※

OAD ※

LAD ※

WG ※

CR ※

SelectType Type list

SetShipment Japan

SI

EXP

ASIA

TA

SirialNO.Input UP5divInput

DOWN5divInput

OEMSetting ON

WeightInput

Min Input

Lock Setting ON ※

NVRAM "PRINT" OUTPUTOFRAMDATA

"EDIT" RAMDATAEDIT

"BK.UP" EEPROM->FLASH

"RESTR" FLASH->EEPROM

"INIT" INITIALIZATIONOFRAMDATA

END

Ok?

Ok?

EditRun

Input

Input

Input

Input

Linear AdjustRun

SettingWeight Input

Ok?

(MaintenanceMode) ※MarkingmeangoingbucktoMeasureMode

AD

ErrorLog

AfterAgeing

Span(ppm/C)

AfterAgeing

ZERODrift(g/C)

BeforeAgeing

Span(ppm/C)

BeforeAgeing

ZERODrift(g/C)

Ok?

OnlyTXBSeries

WeightLoader HOMEPOSITION

LOAD,UNLOAD

OnlyTWSeries

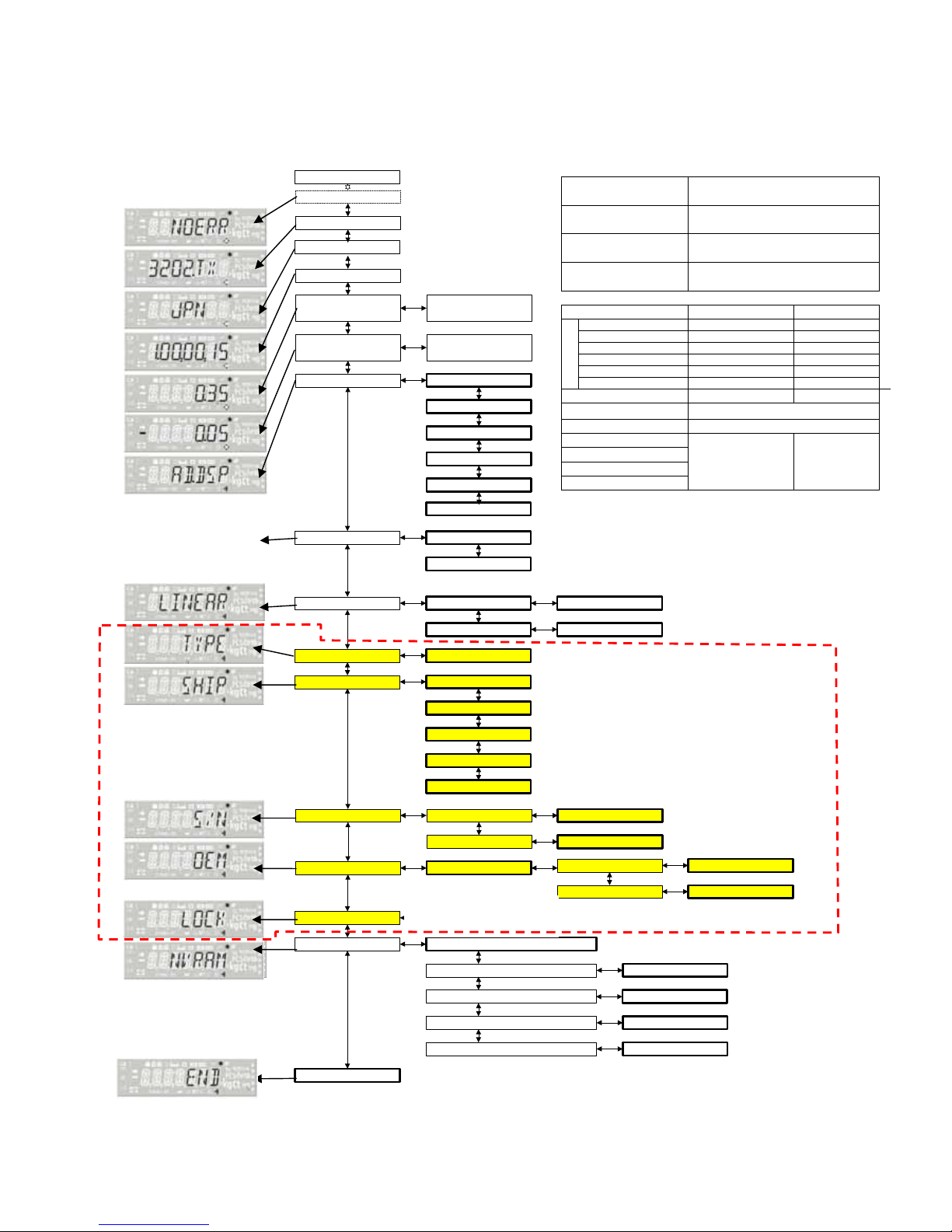

1.3. Contents of Service Menu

The service mode configuration (menu configuration diagram) is shown below.

Display example

[Normal Range (guideline)]

Span after aging

ppm/ °C

0 to ± 3 (TW/TX)

0 to ± 5 (TXB)

Span before aging

ppm/ °C

0 to ± 20 (TW/TX)

0 to ± 80 (TXB)

Zero after aging

g/ °C

0.000 to ± 0.200 (TW/TX/TXB)

Zero before aging

g/ °C

0.000 to ± 0.500 (TW/TX/TXB)

Zero Span

old TXC

1,100,000-2,000,000 2,000,000

common TWC/TXC

200,000-800,000 3,000,000(600ct)

old TX small pan

700,000-1,400,000 2,000,000

common TW/TX small

200,000-1,100,000 2,700,000(420g)

old TX Large pan

500,000-900,000 1,650,000

Wad

(

TW.TX

)

common TW/TX large

200,000-1,100,000 2,700,000(4200g)

WAD (TXB)

60,000 - 80,000 200,000

TAD (TW/TX)(10-30℃)

26,000 – 40,000

TAD (TXB) 15,000 – 29,000

OAD

LAD

WG

CR

±10.000

(g)

Weighing

capacity

(g)

← If no error has occurred,

"NOERR" is displayed.

Press the → key to display

the last five errors recorded

in the log, in order of

occurrence.

Not appear when [LOCK] is ON.

- 3 -

Items in the figure framed in thick lines denote execution items, while those framed in thin lines denote menu

items.

Shaded items are not displayed when the setting information lock is on. Use the arrow keys to move between

items.

Key Explanation

→

Move to an item in a subordinate menu. If the menu item to the left of the arrow has no asterisk mark and is also

shaded, pressing the Enter key on that item opens a subordinate menu item. (In other words, if the higher menu

accepts the Enter key even if it has no enable/disable switch, pressing the Enter key opens the subordinate menu.)

To open the menu from the mass display state, use the MENU key instead of the → key.

←

Return to the item in the higher menu.

↓

Move to items in order.

↑

Move to items in reverse order.

* For the release method of setting information lock, see " 5.3.1 Releasing the Setting Information Lock".

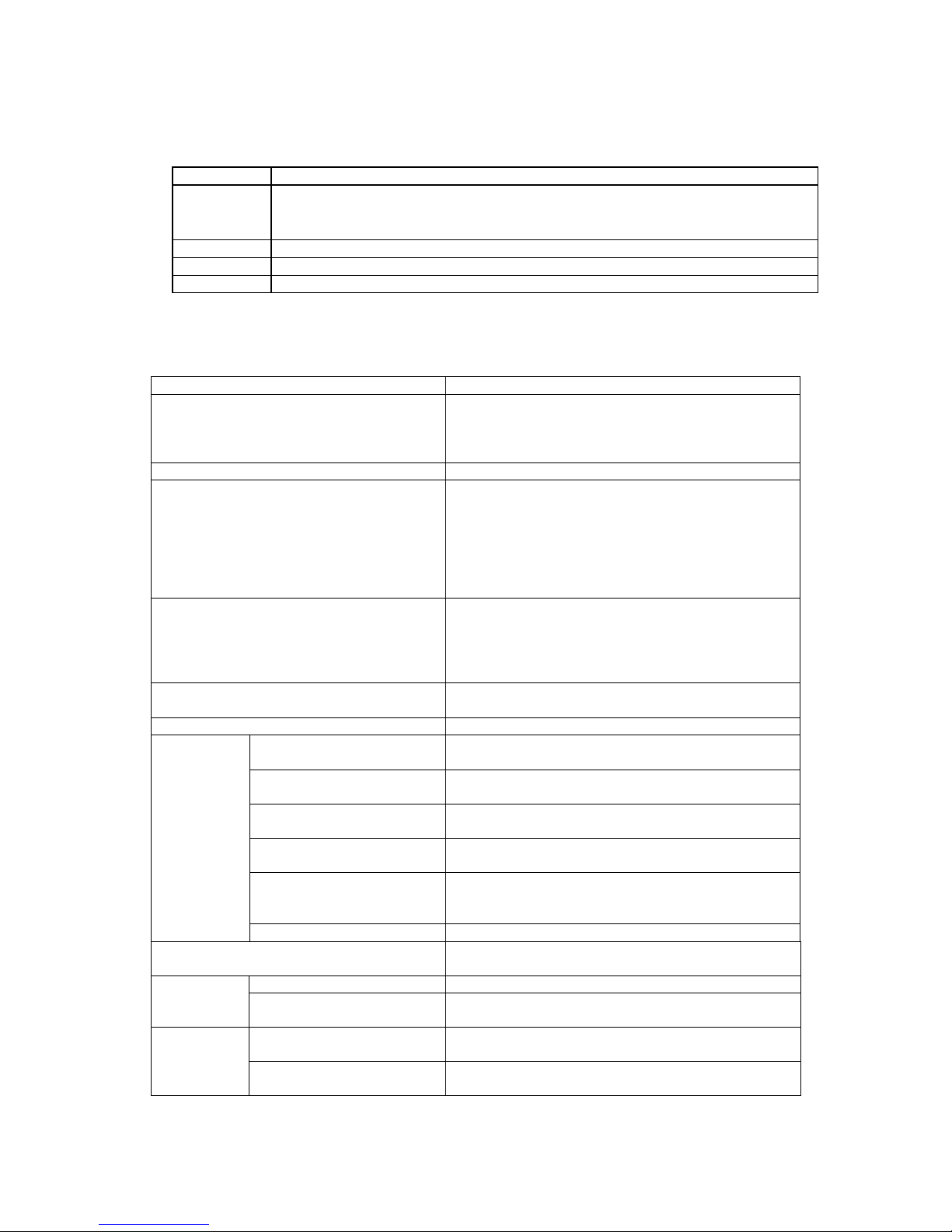

1.4. Service Mode Functions

Service mode functions are shown below.

Function Outline

Error display Displays error codes for errors that have occurred in user

mode.

If no errors have occurred when service mode is opened,

the error display does not appear.

Model name display Displays the model name setting.

Destination display Displays the destination setting.

Ex.: JPN = Japan

SI = Countries and regions that recognize SI units

only

EXP = Overseas (excluding Southeast Asia)

ASIA = Southeast Asia

TA = Type Approval

Software Ver. display Displays the currently mounted software version.

Ex.: 1.00, ##, XX

In principle, 1.00 is the version number for hardware changes

Next, ## is the version number for manuals and other documentation

changes

Finally, XX is the version number for bug fixes and other minor changes

Span temperature coefficient display Displays the span temperature coefficient for before and

after aging.

Zero drift display Displays the amount of zero drift before and after aging.

AD value

display

Mass data (WAD) display Displays mass data as received from AD converter. (Data

subjected to smoothing)

Temperature data (TAD)

display

Digitally displays voltage of temperature sensor mounted

on UniBloc magnet or load cell.

Temperature-corrected mass

data (OAD) display

Displays WAD mass data subjected to temperature

correction. (Data subjected to smoothing)

Linear-corrected mass data

(LAD) display

Displays OAD mass data subjected to linearity correction.

Absolute load (WG) display Displays mass values shown in g units that are subjected

to all correction processing. Displays mass values not

subjected to zero setting or tare weight.

Creep (CR) display (TXB only) Displays WG mass data subjected to creep correction.

Sensitivity calibration Executes sensitivity calibration using the same operation

as user mode.

Return to initial position Internal weight loader system returns to initial position. Weight

Loader check

(Only TW)

Load and Unload Internal weight is loaded or unloaded to UNIT ASSY.

Linearity adjustment Executes the adjustment operation for calculation of the

linearity correction coefficient.

Linearity

adjustment

Weight value input for linearity

adjustment

Inputs the reference weight value used for linearity

adjustment.

- 4 -

Function General

Model selection Selection of the model name automatically sets the basic

information for weighing capacity, minimum display, and

reference mass for adjustment.

Unit for Japan

SI unit

Overseas unit

Unit for Asia

Shipping

settings

Type Approval

Set the units users can use, depending on shipping

destination.

Initial setting = Unit for Japan

Top 5 digits Input the top 5 digits of serial No. Serial No.

input

Bottom 5 digits Input the bottom 5 digits of serial No.

On Sets to OEM model.

Weighing capacity Changes the weighing capacity.

OEM

Minimum display Changes the minimum display.

Setting information lock (error check) Prevents changes to the model, OEM, shipping, and S/N

settings. When the lock is active, all error checks are

enabled.

Data print Outputs data saved in EEPROM to a dedicated printer.

Data edit Edits data saved in EEPROM on balance display unit.

Backup Of the data saved in EEPROM, backs up temperature

correction coefficient, linearity correction coefficient, and

model setting status data to a Flash memory.

Download Writes to EEPROM the data backed up on Flash memory.

NVRAM

All initialize Initializes all data saved in EEPROM.

END Ends service mode.

- 5 -

2. Disassembling and Assembling the Balance

2.1. TW/TX Series

2.1.1. Precautions

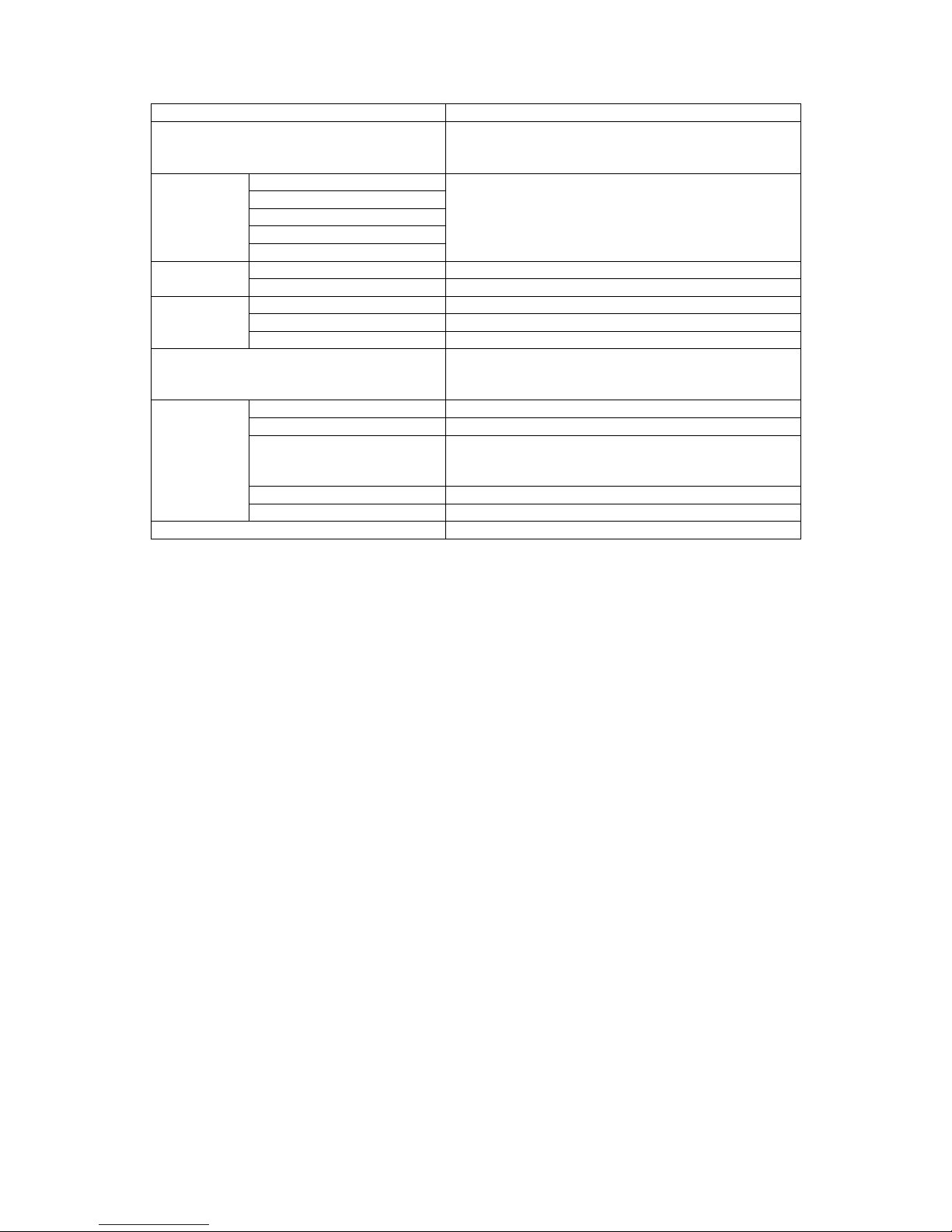

1) Pull the connector straight out when disconnecting. Never pull it out at a bent angle.

* Pulling out at a bent angle could bend the terminal pins, making it difficult to re-insert the

connector.

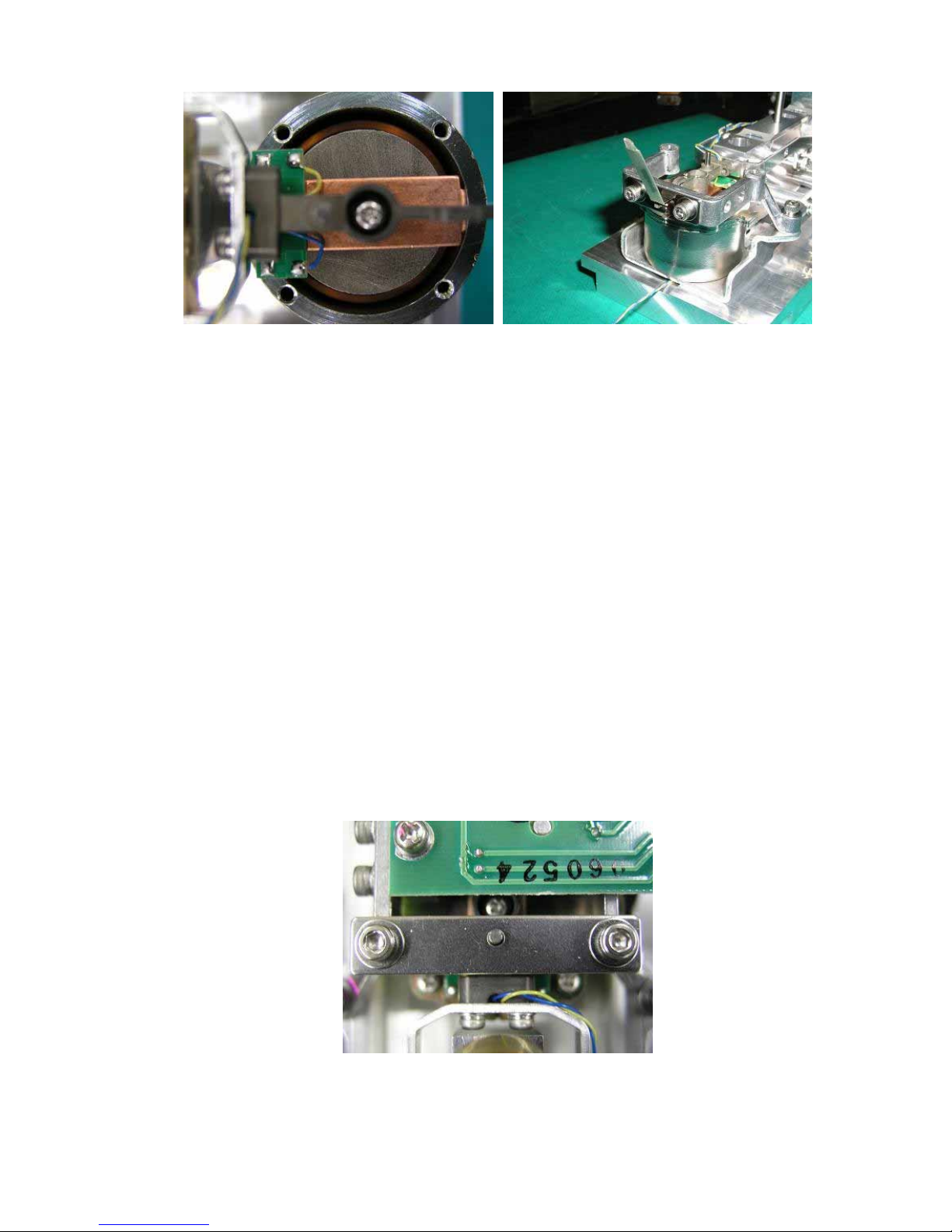

Fig. 1

2) For disassembly and assembly of the unit Assy TX(1), first insert the OPF positioning pin (J1) as far as the

line set in the lever fixing hole on the OPF surface.

* Lift slightly on the lever Assy (U7) to insert the pin. Be careful not to scratch the elastic support.

3) Use a controlled torque driver to tighten the screws to the torques shown in the table below.

Screw Torque [kgf-cm]

M2 1

M2.5 2.5

M3 pan head 9

M3 hexagonal socket head 15

M4 pan head 18

M4 hexagonal socket head 30

- 6 -

2.1.2. Inspecting the Balance Interior (Removing the Case and Pan Support)

[Disassembly]

1) Detach the AC adaptor, then:

[Carat/small pan only] Remove the pan (6), pan support (4), windbreak ring (7) (carat only), and sole plate

(8).

[Large pan only] Remove the pan (6), pan support cap (5), and sole plate (8).

2) [Carat/small pan only] Remove the knob (C10) on the inside of the ceiling glass set (C5), and slide the

ceiling glass set (C5) backward to remove.

3) Remove the P4 M4×12 screw (22) on the back side of the balance top surface, and pull up slightly on the

back side of the case Assy (3), so that it slides toward the front and separates from the base. (Fig. 2)

* In this condition, the main board Assy (B2), analog board Assy (B3), and power board Assy (B4)

can be inspected.

[Assembly]

1) Place the case Assy (3) over the base Assy (2) so that it catches on the front hooks, and tighten using the

P4 M4×12 screw (22) on the back side of the balance top surface.

2) [Carat/small pan only] Slide in the ceiling glass set (C5) from the back of the designated grooves, and

attach the inner knob (C10).

3) [Carat/small pan only] Mount the sole plate (8), windbreak ring (7) (carat only), pan support (4) and pan (6).

[Large pan only] Mount the sole plate (8), cap (5), and pan (6). (Fig. 2)

Fig. 2

4) Use the two front caster Assys (B6) to adjust the level of the balance so that the air bubbles in the level

come to the center of the framed area.

5) [Large pan only] Lower the two rear caster Assys (B6) until they contact the ground.

6) Attach the AC adaptor to the balance, and check the balance operation.

* When placing the case Assy (3) in position, be careful not to pinch the ILS 10S-10S-300 cable or

ILS 11S-11S-440(B9) connected between Main board Assys(B2) and Power Board Assys

(Fig. 3)(Including later procedure after this, photo A shows old TX and B shows TW/TX common.)

- 7 -

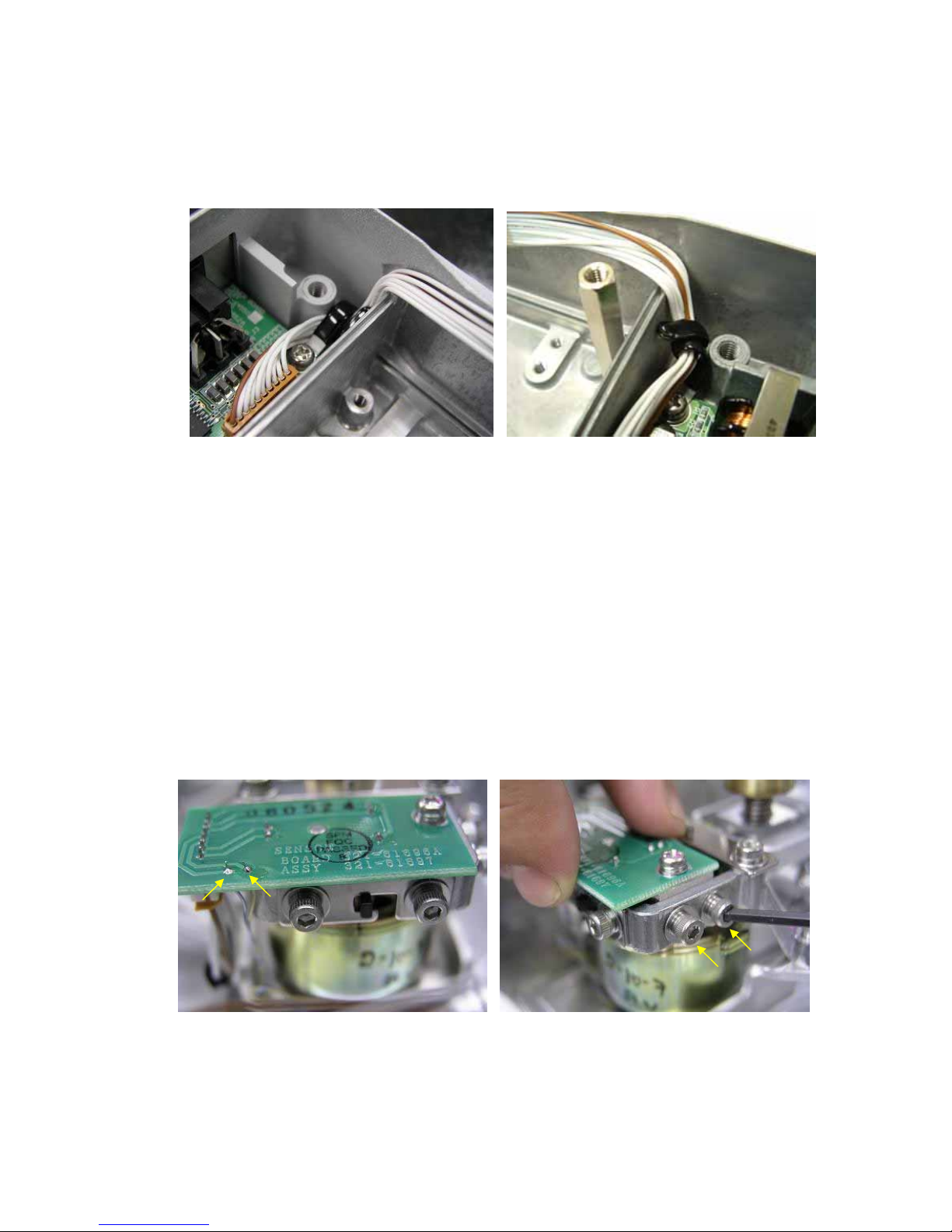

Fig. 3-A Fig. 3-B

2.1.3. Replacing Components

2.1.3.1. Replacing the Front Glass (C8)

1) Detach the AC adaptor, and remove the pan (6), pan support (4), windbreak ring (7) (carat only), and sole

plate (8).

2) Remove the knobs (C10) on the inside of the ceiling glass set (C5) and side glass sets (C6, C7) and slide

the ceiling glass set (C5) and side glass sets (C6, C7) backward to remove.

3) Remove the knobs (C10) in two locations on the front.

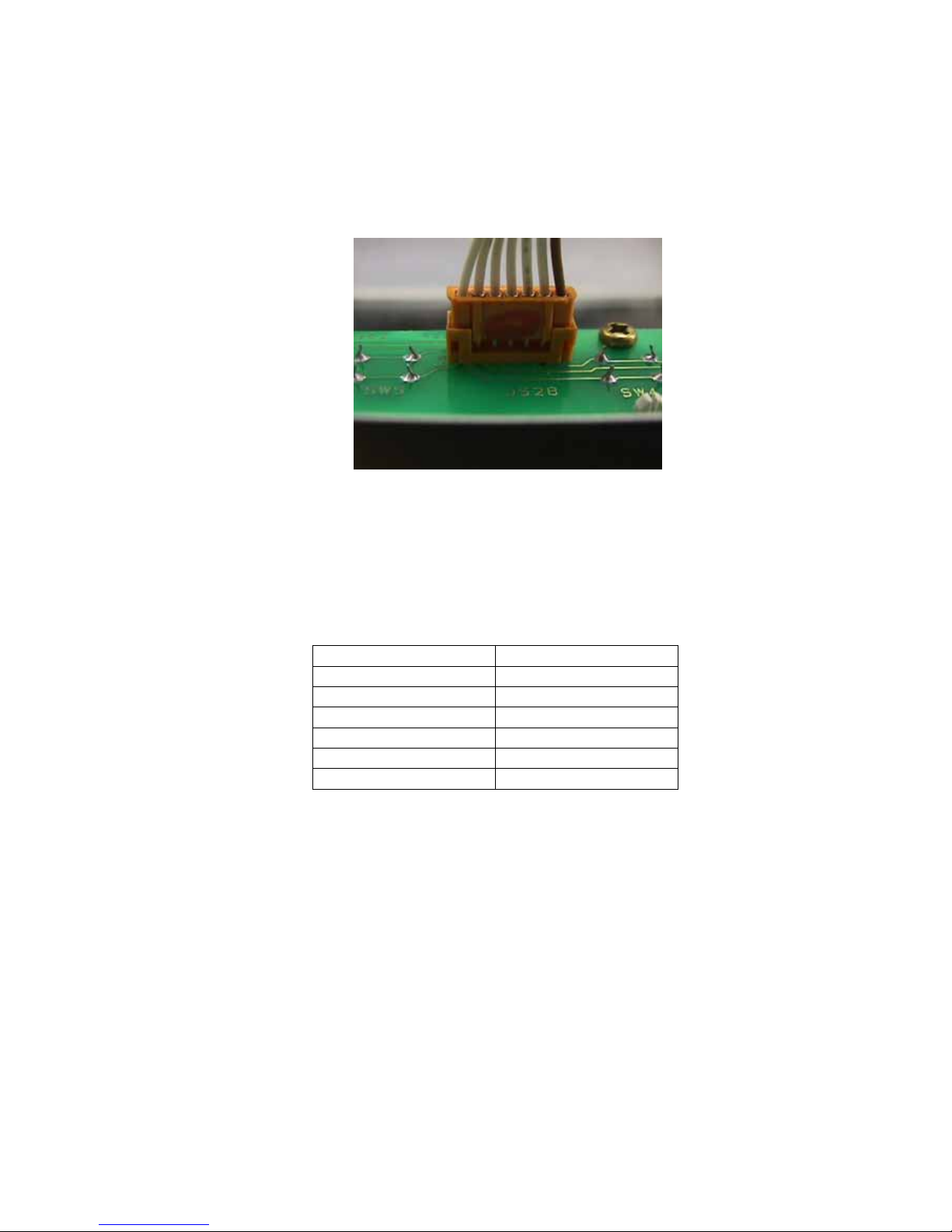

4) Tilt the rear surface of the case roof cover

(C4) and remove it. (Fig. 4)

5) Loosen the P4 M4×12 screw (22) holding the case roof (C3), and remove the case roof (C3).

6) Position the front glass (C8) on the back of the case (C1) front groove, and pull upward to remove the front

glass (C8). (Fig. 5)

7) Follow steps 1) to 6) in reverse to attach the new front glass (C8).

C

Top

A Length: A < B,C > D

D

B

Fig. 4 Fig. 5

- 8 -

2.1.3.2. Replacing the Main Board Assy (B2)

1) Use the procedure in " 2.1.2 Inspecting the Balance Interior (Removing the Case and Pan Support)" to

remove as far as the case Assy (3).

2) Remove the three P4 M4×8 screws (B22) fixing the main board Assy (B2) in place. (Fig.6)

Fig.6-A Fig.6-B

3) Disconnect the J2,J3 and J4 connectors that are connected to the main board Assy (B2).

4) Place the main board Assy (B2) in a location on the right side of the balance that is free of dirt and static

electricity. (Fig. 7)

5) Remove the EEPROM located on the back side the main board Assy (B2) from the socket, taking care to

avoid damaging the EEPROM feet.

6) Mount the EEPROM on the new main board Assy (B2).

7) Follow steps 1) to 3) in reverse to attach the new main board Assy (B2).

Fig.7-A Fig.7-B

- 9 -

2.1.3.3. Replacing the Analog Board Assy (B3)

1) Use the same procedure as steps 1) to 3) in " 2.1.3.2 Replacing the Main Board Assy (B2)" to remove as far

as the main board Assy (B2).

2) [Large pan only] Loosen the two P4 M4×8 screw (22), and remove the large unit cover (9). (Fig.8)

3) [Large pan only] Insert the OPF positioning pin (J1) as far as the line set in the lever fixing hole on the OPF

surface.

4) [Large pan only] Loosen the two P4 M4×14 bolt (23), and remove the large pan support Assy (4). (Fig.9)

Fig.8 Fig.9

5) Disconnect the J1,J2 and J3 connectors that are connected to the analog board Assy (B3) and

loosen and remove the three P4 M4×8 screws (B22) fixing the cover plate,analog (13) . (Fig. 10)

6) Loosen and remove the two P4 M4×8 screws (B22) fixing the analog board Assy (B3) in place. (Fig. 11)

Fig.10 Fig.11

- 10 -

7) Follow steps 1) to 6) in reverse to attach the new analog board Assy (B3).

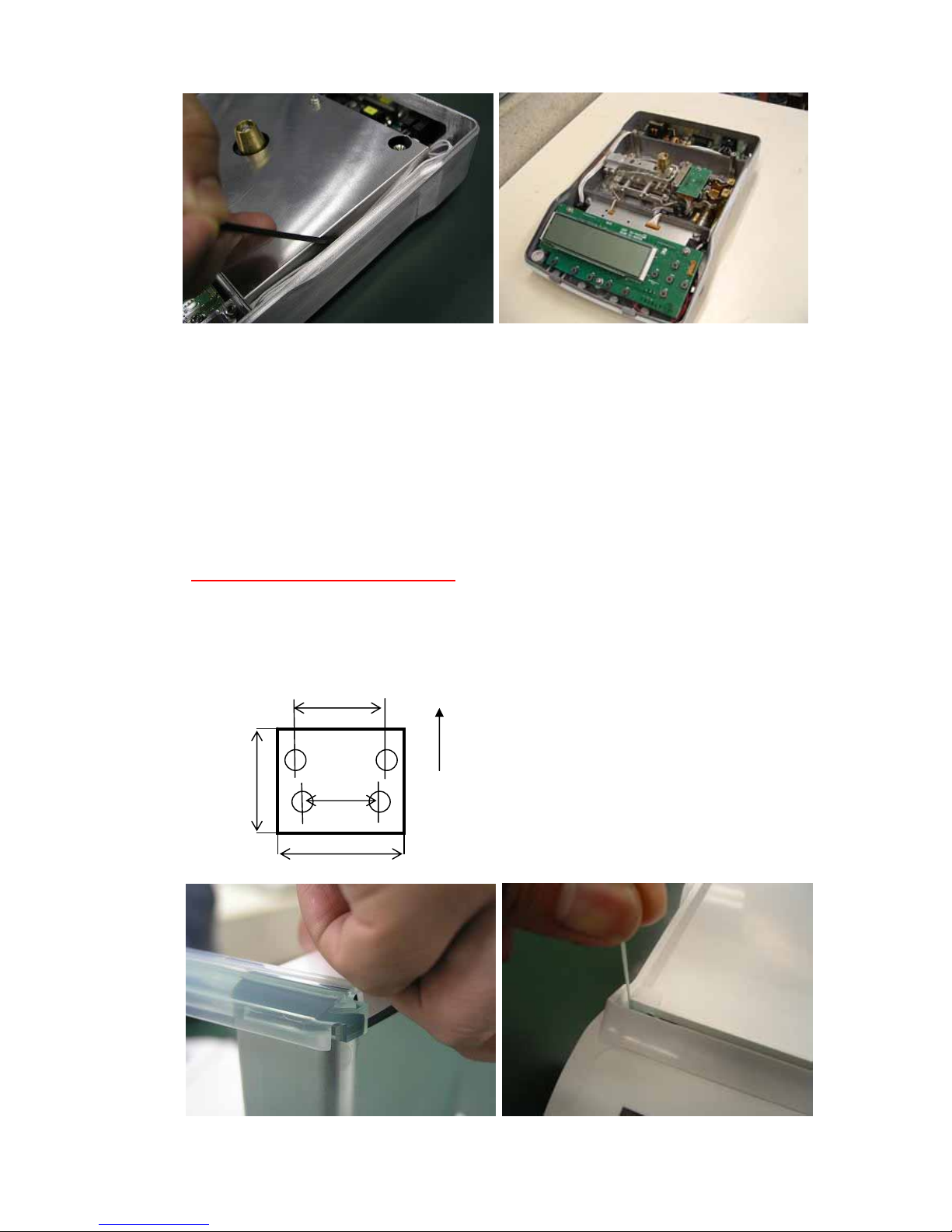

* During assembly, use the CS-5 clip (B26) to securely hold the cables for Main board Assy(B2),the

weight loader Assy(27) (TW only) and Unit assy,TX(1) downward so that the large pan support

Assy (4) and the cables do not contact. (Fig. 12)

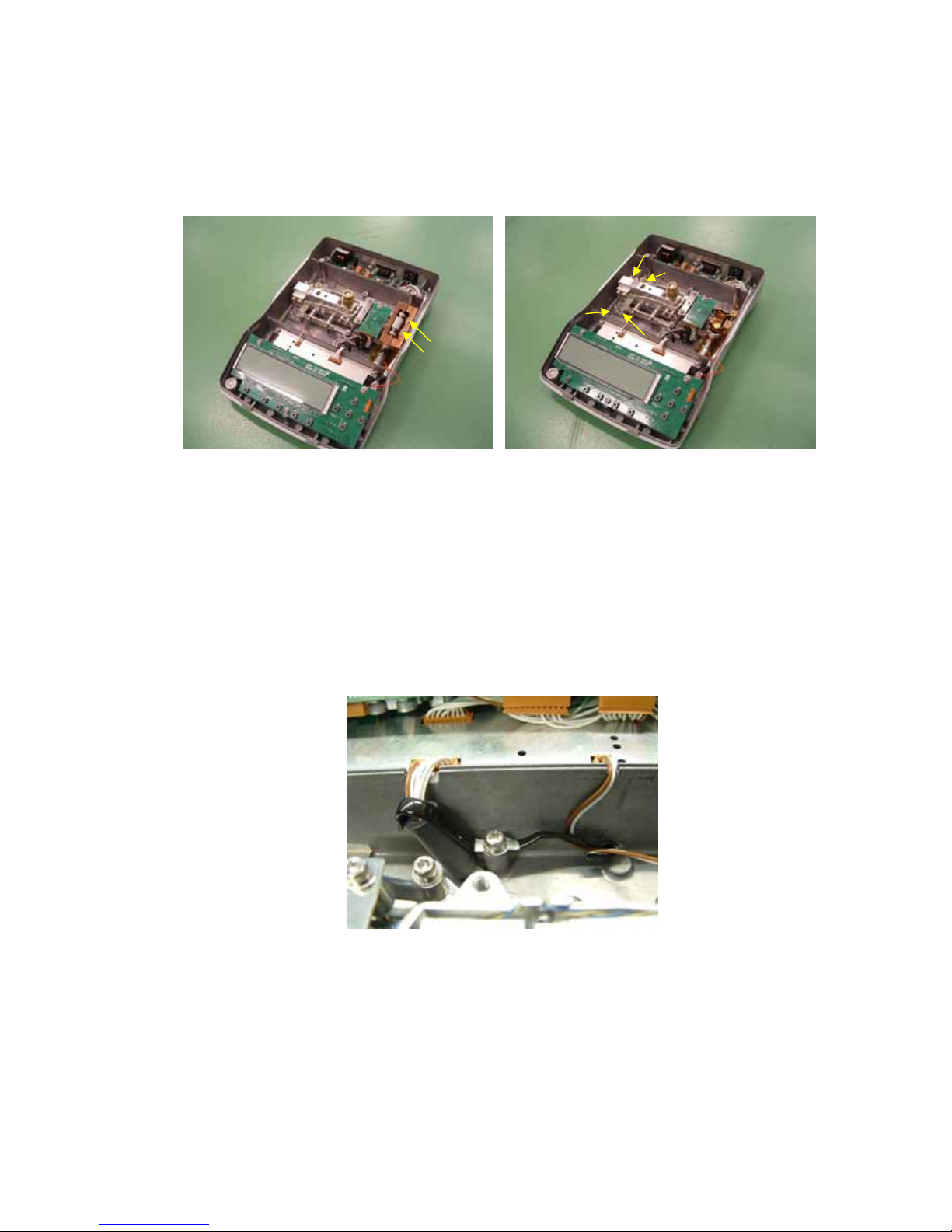

Fig.12-A Fig.12-B1

Fig.12-B2 Fig.12-B3

*Attach pan support Assy (4) using Unit assy locating jig(J2) (Fig.13)

Fig.13

- 11 -

2.1.3.4. Replacing the Power Board Assy (B4)

1) Use the procedure in " 2.1.2 Inspecting the Balance Interior (Removing the Case and Pan Support)" to

remove as far as the case Assy (3).

2) [Large pan only] Loosen the two P4 M4×8 screw (22), and remove the large unit cover (9).

3) [Large pan only] Insert the OPF positioning pin (J1) as far as the line set in the lever fixing hole on the OPF

surface.

4) [Large pan only] Loosen the two P4 M4×14 bolt (23), and remove the large pan support Assy (4).

5) Remove the two screws,D-sub (B25) holding the power board Assy (B4) and I/F panel (B5) in place.

(Fig.14)

6) Loosen the two M3×6 button screws (B23) and remove the I/F panel (B5). (Fig. 15)

Fig.14 Fig.15

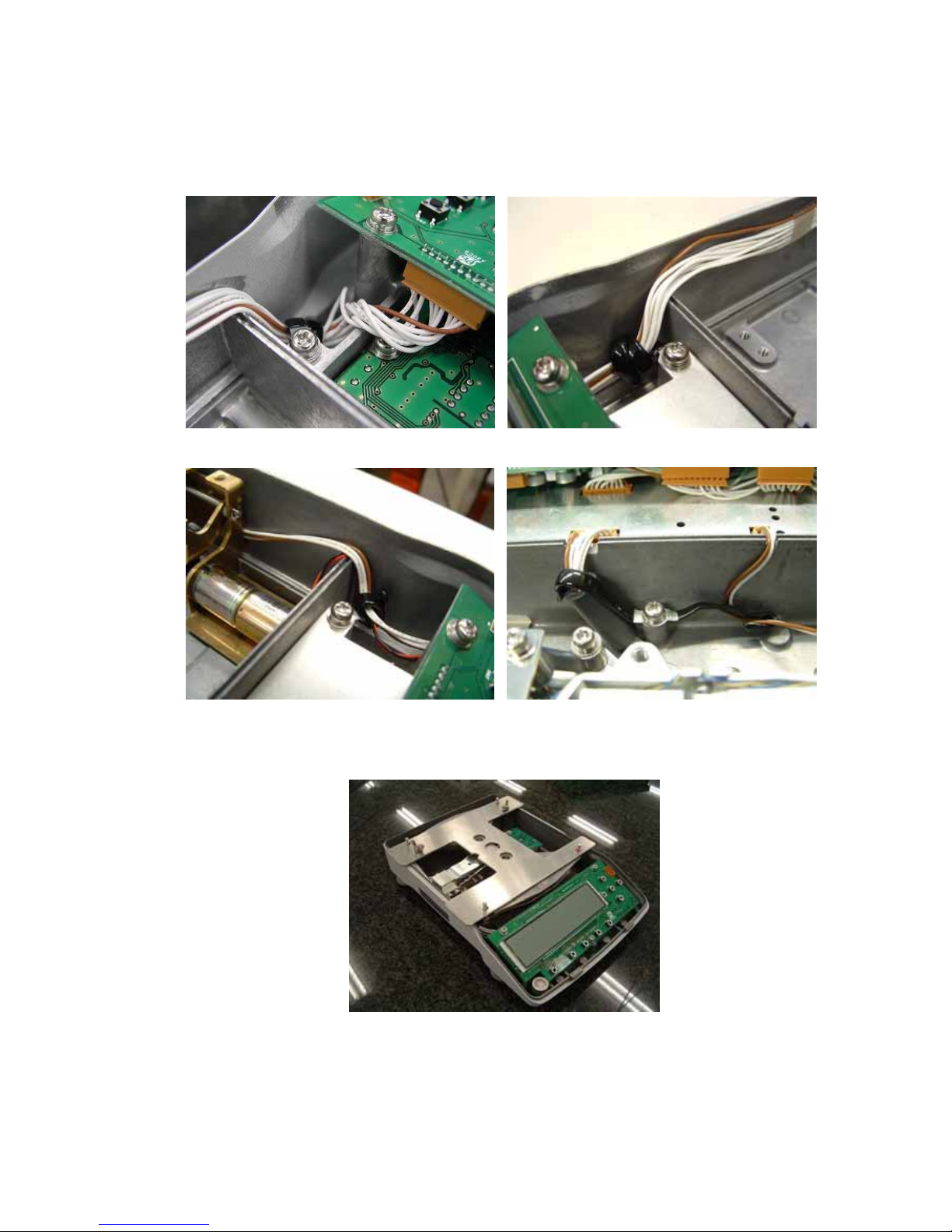

7) [Common design for TW/TX only] Open the cable clamp for ILS 11S-11S-440(B9).

8) Loosen the two P4 M4×8 screws (B22) fixing the power board Assy (B4) in place, and remove together

with the CS-5 clip (B26). (Fig. 16)

* The power board Assy (B4) can be removed by pulling upward at an angle, as shown in Fig. 17.

Fig.16 Fig.17

- 12 -

9) Disconnect the J4 connector that is connected to the power board Assy (B4).

10) Follow steps 1) to 9) in reverse to attach the new power board Assy (B4).

* During assembly, use the cable clamp and the CS-5 clip (B26) to securely hold the cables for

Power board Assy(B4) downward so that the large pan support Assy (4) and the cables do not

contact. (Fig. 16 and 18)

Fig.18-A Fig.18-B

2.1.3.5. Replacing the Detector Assy (U11)

1) Use the procedure in " 2.1.2 Inspecting the Balance Interior (Removing the Case and Pan Support)" to

remove as far as the case Assy (3).

2) Loosen the P4 M4×8 screw (22), and remove the unit cover (9).

3) Insert the OPF positioning pin (J1) as far as the line set in the lever fixing hole on the OPF surface.

4) [Large pan only] Loosen the P4 M4×14 bolt (23), and remove the large pan support Assy (4).

5) Remove the soldering for the temperature sensor cable connected to the detector Assy (U11). (Fig. 19)

* TP1: Yellow wire, TP2: Blue wire

6) Disconnect the J25 connector for the ILS-7S-7S-130 cable (U19) that is connected to the detector Assy

(U11).

* When removing, be careful not to touch the lever Assy (U7) and scratch the elastic support.

7) Loosen and remove the P3 M3×10 socket head bolt (U53) holding the detector Assy (U11) in place. (Fig.

20)

Fig.19 Fig.20

- 13 -

8) Follow steps 4) to 7) in reverse to attach the new detector Assy (U11).

9) Adjust the detector height by following " 4.1.1

Adjusting the Height of the Detector Assy (U11)".

10) Follow steps 1) to 4) in reverse to restore the original status.

* Clamp to securely hold cable,ILS 7S-7S-130(U19) with short loose length so that the

Assy,Detector (U11) do not receive upward or downward force by it. (Fig. 21)

* [TW only] Clamp to securely hold cable,ILS 7S-7S-130(U19) and wires for the temp.sensor

outside of Magnet frame so that the weight lever for Unit assy,TX (1) and the cables do not

contact. (Fig. 22)

Fig.21 Fig.22

2.1.3.6. Replacing the TX Unit Assy (1)

1) Use the procedure in " 2.1.2 Inspecting the Balance Interior (Removing the Case and Pan Support)" to

remove as far as the case Assy (3).

2) [Non-CE only]Loosen the two P4 M4×8 screw (22), and remove the unit cover (9). (Fig.23)

3) Insert the OPF positioning pin (J1) as far as the line set in the lever fixing hole on the OPF surface.

4) [Large pan only] Loosen the two P4 M4×14 bolt (23), and remove the large pan support Assy (4). (Fig.24)

Fig.23 Fig.24

- 14 -

5) [TW only] Loosen the two P4 M3×6 screw (30), and remove the leaf supring,weight loaderr (29) and the

weight(28). (Fig.25)

6) Disconnect the J2 and J3 connectors that are connected to the analog board Assy (B3).

7) Loosen and remove the four P4 M4×14 socket head bolts (23) fixing the TX unit Assy (1) in place. (Fig. 26)

* When lifting up the TX unit Assy (1), do not grab the parallel guide or movable column.

Fig.25 Fig.26

8) Follow steps 4) to 7) in reverse to attach the new TX unit Assy (1).

* During assembly, use the CS-5 clip (B26) to securely hold the cables for Unit Assy,TX(1)

downward so that the large pan support Assy (4) and the cables do not contact. (Fig. 27)

9) Check tilt error and cornerload error by following " 4.1.2 Adjusting the Tilt Error" and " 4.1.3 Adjusting the

Cornerload Error". Adjust them,if they are out of torelance.

10) Follow steps 1) to 3) in reverse to restore the original status.

11) Input EEPROM data of attached with Unit assy.(Refer to 4.1) Address No. 004-05A (Temp. data)

Fig.27

- 15 -

2.1.3.7. Replacing the Weight loader Assy (27)

1) Use the procedure in " 2.1.3.6 Replacing the TX Unit Assy (1)" to remove the TX unit Assy (1).

2) Open the CS-5 clip for the cables of the weight loader assy(27) and disconnect the connector that are

connected to the main board Assy (B2)

3) Loosen and remove the three P4 M3×6 screws (30) fixing the weight loader Assy (27) in place. (Fig. 28)

4) Follow steps 2) to 3) in reverse to attach the new weight loader Assy (B3)

* During assembly, use the CS-5 clip (B26) to securely hold the cable for the weight loader

Assy(27) (TW only) downward so that the large pan support Assy (4) and the cables do not

contact. (Fig. 12)

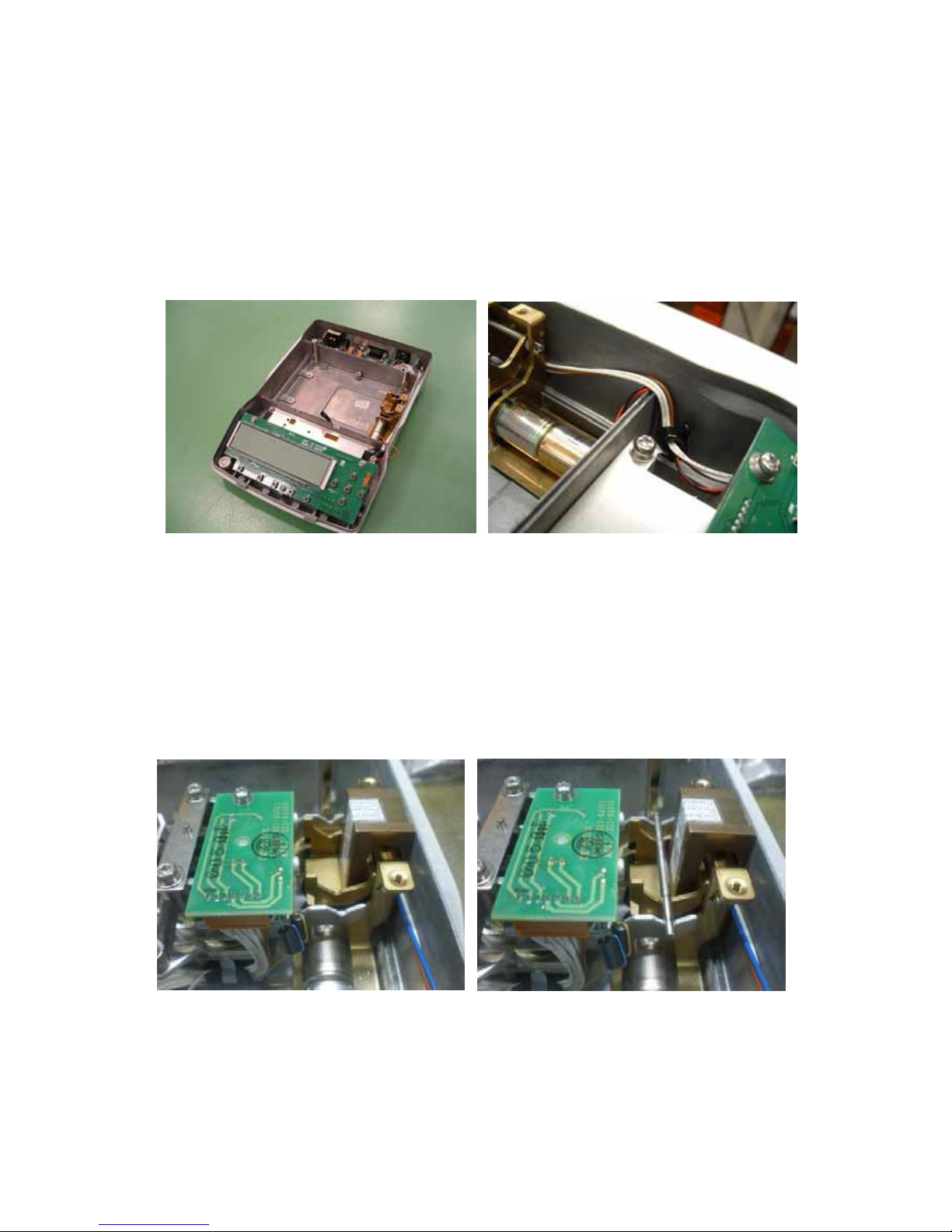

Fig.28 Fig.29

5) Attach the AC adaptor and turn on the power of balance and enter the service mode and

select ”LD.ULD”and stop the arm weight loader on the lower position.

6) Insert Jig bloc,TW weight arm(J9) between the frame and the arm of weight loader Assy(27) to be the arm

on the level. (fig.30)

7) Tighten the four P4 M4×14 socket head bolts (23) temporarily fixing the TX unit Assy (1) in place.

8) Set location pin,weight loader(J8) on the dint of the arm of the weight loader Assy(27) and the weight

lever of the unit Assy,TX(1) and tighten the bolts for TX unit Assy(1) and screws for weight loader Assy(27)

(fig.31)

Fig.30 Fig.31

- 16 -

2.1.3.8. Replacing the Force Coil Assy (L1)

1) Use the procedure in " 2.1.3.6 Replacing the TX Unit Assy (1)" to remove the TX unit Assy (1).

2) Remove the soldering on the lever Assy (U7) side of the two Pt-Ni bands (U17).

* Do not break or damage the PT-Ni bands.

3) Loosen and remove the two P3 M3×14 socket head bolts (U58) fixing the detector frame (U10) in place.

(Fig. 32)

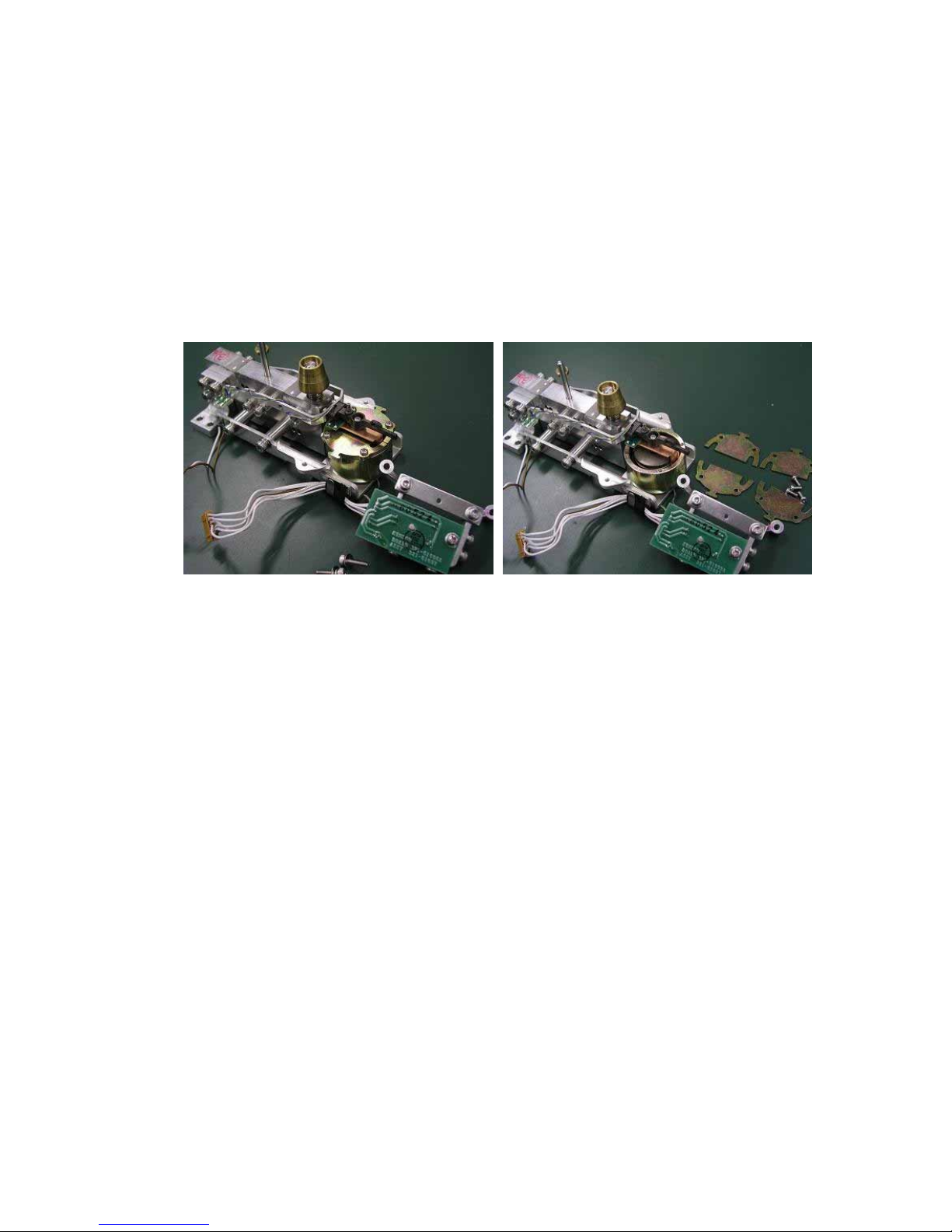

4) Loosen the four M2.5×6 screws (U54) fixing the four magnet lids (U16) in place, and slide the magnet lids

(U16) in the horizontal direction to remove. (Fig. 33)

Fig. 32 Fig. 33

5) Remove the four P3 M3×14 socket head bolts (58) fixing the lever Assy (U7) in place, and remove the lever

Assy (U7) from above.

6) Remove the soldering from the twisted wire (L7) of the force coil Assy (L1) terminal board.

7) Loosen and remove the M2.5×6 screw (L5) and PB SPG M2.6 washer (L6) fixing the force coil Assy (L1) in

place.

8) Use an M2.5×6 screw (L5) to temporarily fix the new force coil Assy (L1) to the lever Assy (U7), and solder

the twisted wire (U7) to the force coil Assy (1). (Fig. 34)

* As viewed from lever Assy (U7) mounting side, Left side: Yellow wire, Right side: Blue wire

9) Insert the lever Assy (U7) from the top of the unit, and use four P3 M3×14 socket head bolts (58) to

temporarily fix it in place.

10) Pass the slit of the lever stopper (U15) attached to the detector frame (U10), and the pinhole of the stopper

plate (U14), through the lever Assy (U7), and use two P3 M3×14 socket head bolts (58) to temporarily fix

the frame detector (U7) in place.

11) Insert the gap setting shim (J3) between the lower edge of the lever shutter on the edge of the lever Assy

(U7) and the lower edge of the slit in the lever stopper (U15), for positioning, and use four P3 M3×14 socket

head bolts (58) to fix in place. (Fig. 35)

12) Remove the temporarily fixed detector frame (U7).

- 17 -

Fig. 34 Fig. 35

13) Looking at the TX unit Assy (1) from the top, tighten the force coil Assy (L1) at the position where the center

of the magnet Assy (U9) aligns with the center of the force coil Assy (L1).

14) Slide in and attach the four magnet lids (U16) from the horizontal direction and use four M2.5×6 screws

(U54) to tighten in place.

15) Again, pass the slit of the lever stopper (U15) attached to the detector frame (U10), and the pinhole of the

stopper plate (U14), through the lever Assy (U7), and use two P3 M3×14 socket head bolts (58) to tighten

the frame detector (U7) in place.

16) Solder the lever Assy (U7) side of the two Pt-Ni bands (U17).

* When soldering, do not twist or break the Pt-Ni bands.

17) Adjust the stopper plate (U14) to a position aligned with the center of the lever Assy (U7) pin, and use an

M3×6 socket head bolt (U57) and M3 washer (U56) to tighten.(Fig. 36)

18) Remove the OPF positioning pin (J1) from the TX unit Assy (1), then gently shake the TX unit Assy (1) to

check that the lever Assy (U7) moves smoothly up and down and that a clear sound is heard when it strikes

the lever stopper (U15). If it does, assembly of the TX unit Assy (1) is complete.

19) Follow steps 4) to 6) of " 2.1.3.6 Replacing the TX Unit Assy (1)" in reverse to attach the new TX unit Assy

(1).

20) Adjust tilt error and cornerload error by following " 4.1.2 Adjusting the Tilt Error" and " 4.1.3 Adjusting the

Cornerload Error".

21) Follow steps 1) to 3) of " 2.1.3.6 Replacing the TX Unit Assy (1)" in reverse to restore the original status.

Fig. 36

- 18 -

2.2. TXB Series

2.2.1. Precautions

1) Pull the connector straight out when disconnecting. Never pull it out at a bent angle.

* Pulling out at a bent angle could bend the terminal pins, making it difficult to re-insert the

connector.

Fig. 1

2) When handling the load cell Assy, be careful not to apply excessive force.

* The cell could be damaged.

3) Use a controlled torque driver to tighten the screws to the torques shown in the table below.

Screw Torque [kgf-cm]

M2 1

M2.5 2.5

M3 pan head 9

M3 hexagonal socket head 15

M4 pan head 18

M4 hexagonal socket head 30

- 19 -

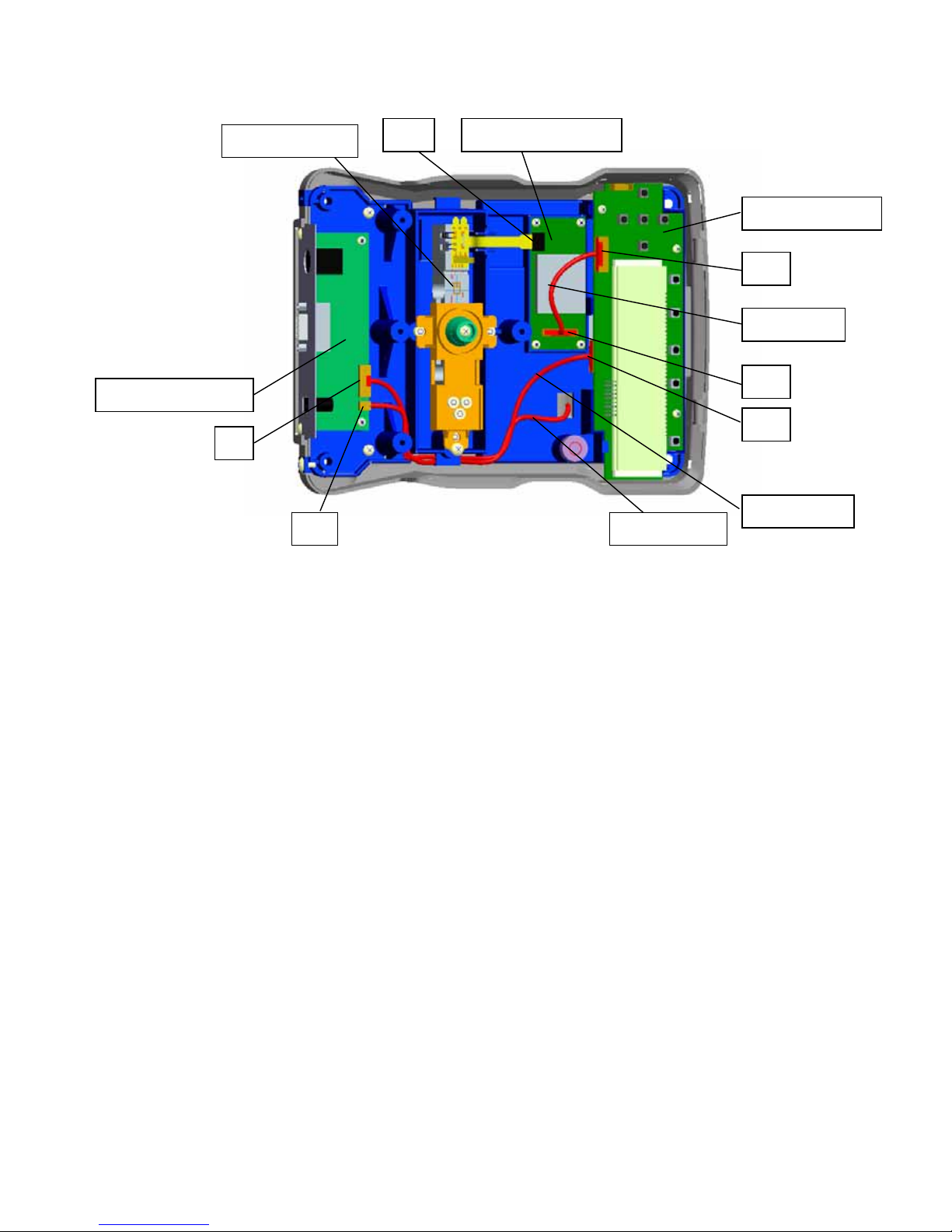

2.2.2. Inspecting the Balance Interior (Removing the Case and Pan Support)

[Disassembly]

1) Detach the AC adaptor, and remove the pan (1), pan support (2), and windbreak ring (3). To remove the

windbreak ring (3), rotate it clockwise as viewed from above.

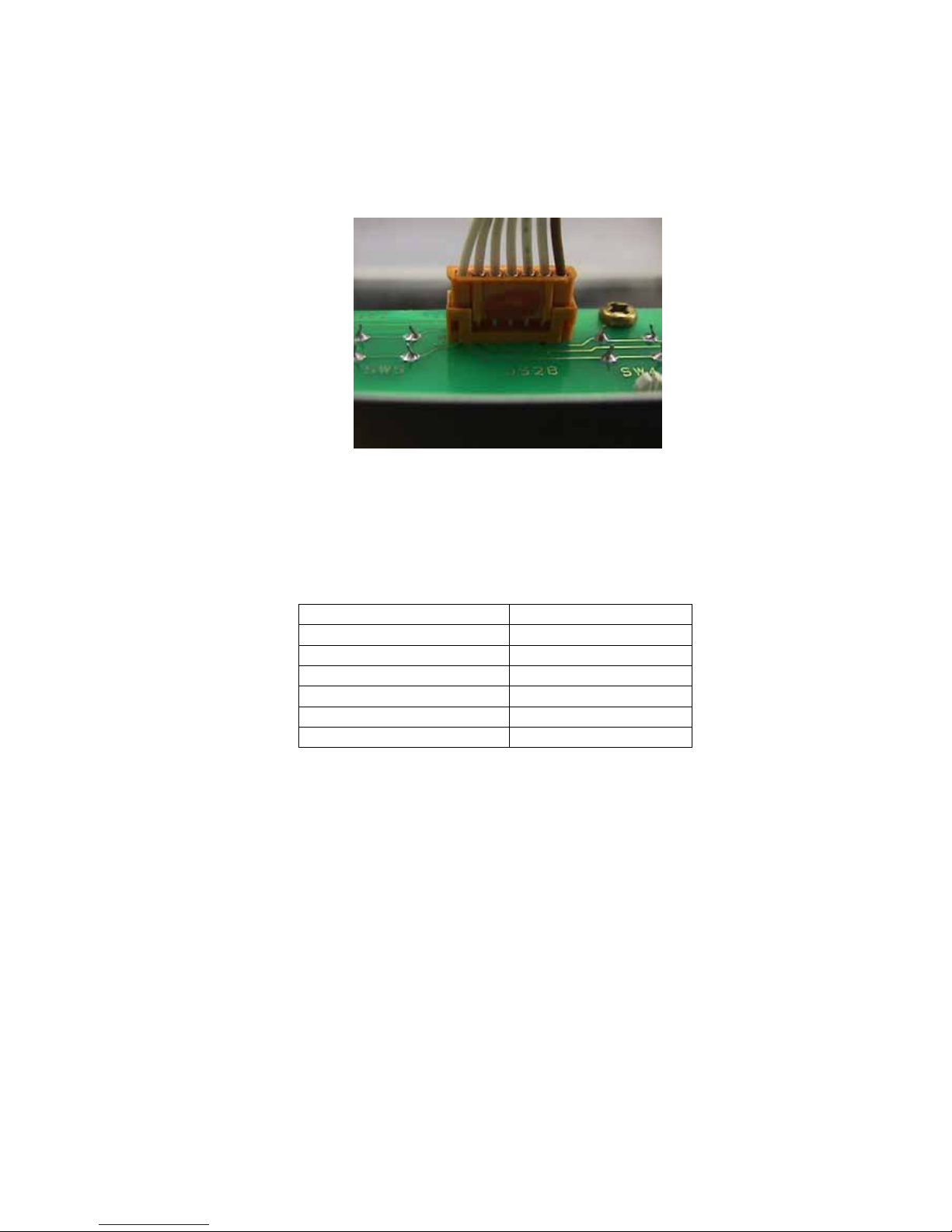

Fig. 1 Large Pan Model Fig. 2 Small Pan Model

2) Remove the two M4×10 pan head screws (21), and remove the metal plate (4) and ring spacer (5). Then,

remove the two M4×8 sems screws (22).

Fig. 3 Large Pan Model Fig. 4 Small Pan Model

(1) Pan

(2) Pan support

(3) Windbreak ring

(4) Metal plate

(5) Ring spacer

(21) M4×10

(22) M4×8

(21)

(22)

Ring spacer positioning

- 20 -

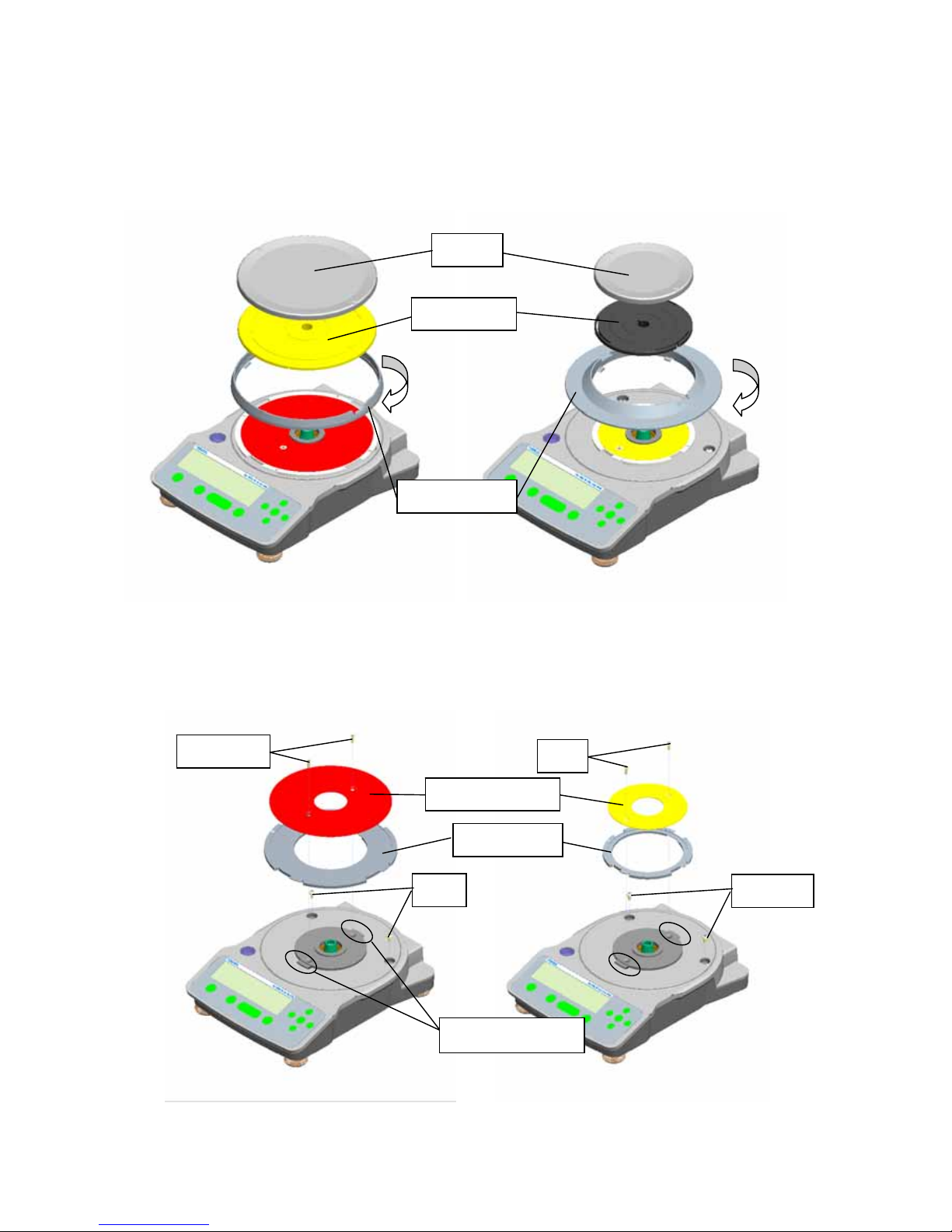

3) Lift up the upper case (6) from the back, and disengage from the hooks at the front of the lower case (7).

Fig. 5 Removing the Upper Case

* In this condition, the main board Assy (B1), analog board Assy (B2), and power board Assy (B3)

can be inspected.

[Assembly]

1) See Fig. 5 to insert the two slits on the front of the upper case (6) into the lower case (7) hooks, and

cover the back of the upper case (6) over the lower case (7).

2) Attach M4×8 sems screws (22) in two locations.

3) Mount the ring spacer (5) to align with the upper case (6) ring spacer positioning projection.

From above, align the metal plate (4) with the pan head screw hole on the ring spacer (5), and attach the

M4×10 pan head screw (21).

4) Attach the windbreak ring (3), pan support (2), and pan (1), in that order.

5) Use the two front level adjustment feet (8) to adjust the level of the balance so that the air bubbles in the

level come to the center of the framed area.

6) [Large pan only] Lower the two rear level adjustment feet (8) until they contact the ground.

7) Attach the AC adaptor to the balance, and check the balance operation.

(6) Upper case

Back: Two hooks

(7) Lower case

@A

@B

@A

@B

- 21 -

2.2.3. Replacing Components

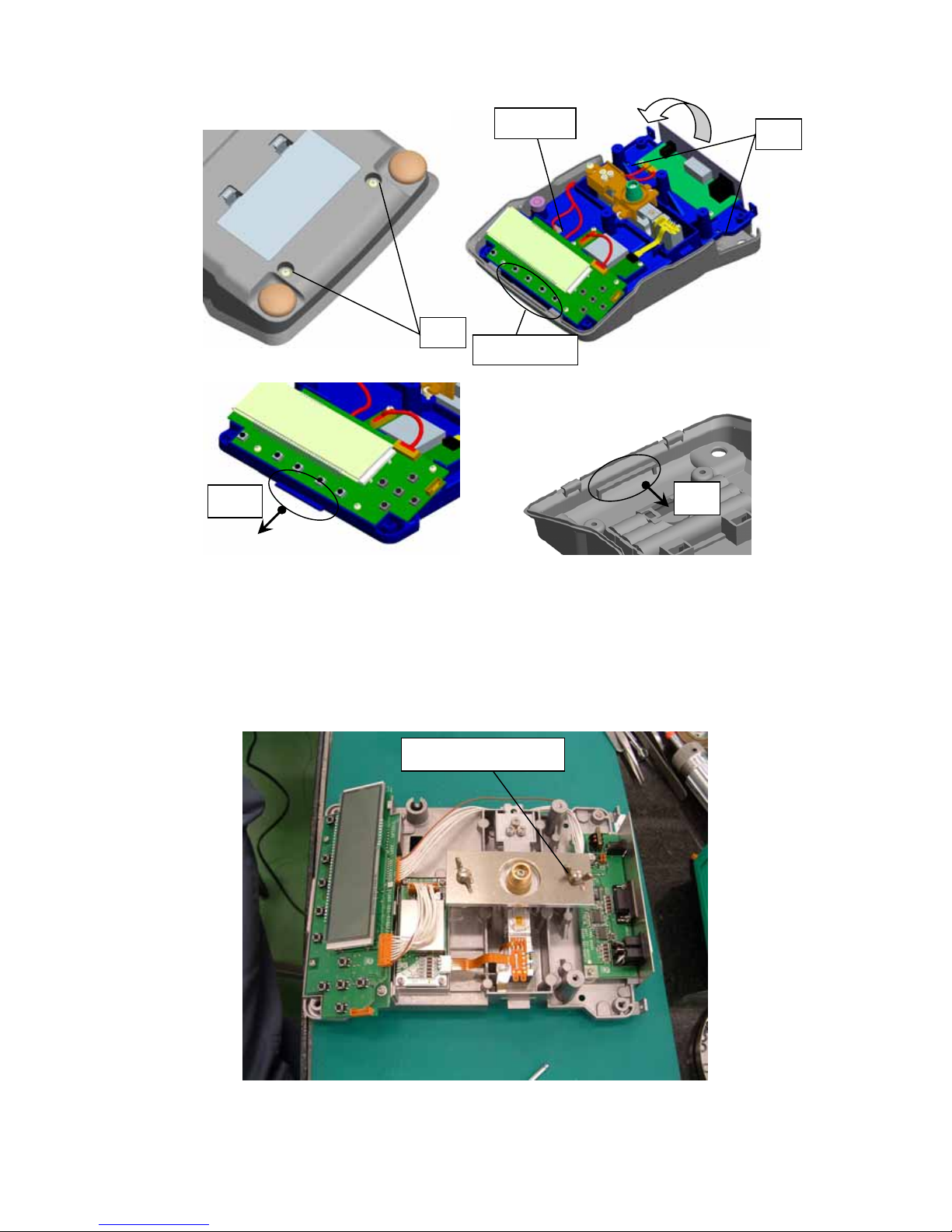

2.2.3.1. Replacing the Main Board Assy (9)

1) Use the procedure in " 2.2.2 Inspecting the Balance Interior (Removing the Case and Pan Support)" to

remove as far as the upper case (6).

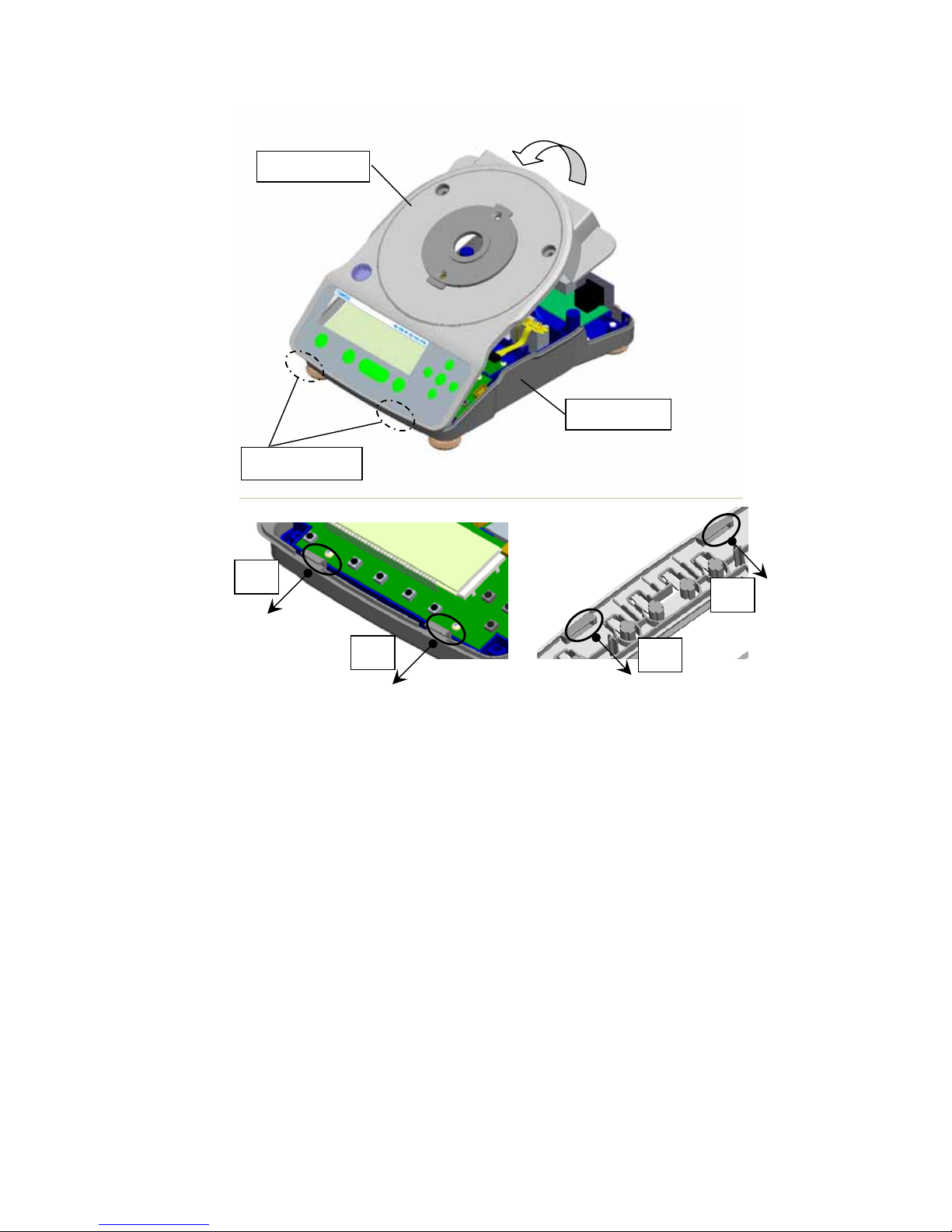

2) Disconnect the connector (C1) for cable 9-9 (13) and the connector (C2) for cable 10-10 (14) that are

connected to the main board Assy (9).

3) Remove the three P4 M4×8 screws (23) fixing the main board Assy (9) in place.

4) Place the main board (9) in a location that is free of dirt and static electricity.

5) Remove the EEPROM located on the back side the main board Assy (9) from the socket, taking care to

avoid damaging the EEPROM feet.

6) Mount the EEPROM on the new main board Assy (9).

7) Follow steps 1) to 3) in reverse to attach the new main board Assy (9).

2.2.3.2. Replacing the Analog Board Assy (10)

1) Use the procedure in " 2.2.2 Inspecting the Balance Interior (Removing the Case and Pan Support)" to

remove as far as the upper case Assy (6).

2) Disconnect the connector (C3) for cable 9-9 (13) that is connected to the analog board Assy (10).

3) Remove the cell Assy (12) flexible board (C4).

* Be careful not to damage the cell Assy.

4) Loosen and remove the four P4 M3×8 screws (23) fixing the analog board Assy (10) in place.

5) Follow steps 1) to 6) in reverse to attach the new analog board Assy (10).

2.2.3.3. Replacing the Power Board Assy (11)

1) Use the procedure in " 2.2.2 Inspecting the Balance Interior (Removing the Case and Pan Support)" to

remove as far as the upper case Assy (6).

2) Disconnect the connector (C5) for cable 10-10 (14), and the connector (C6) for the battery cable (15) that

are connected to the power board Assy (11).

3) Loosen the two M3×6 truss screws (25) fixing the back plate (16) in place.

4) Remove the two M3×8 sems screws (23) fixing the power board Assy (11) in place.

5) Slide the back plate (16) upward, and remove the back plate (16) and power board Assy (11).

(9) Main board ASSY

(10) Analog board ASSY

(11) Power board ASSY

(12) Load cell ASSY

C1

C2

C3

C4

C5

C6

(13) Cable 9-9

(14) Cable 10-10

(15) Battery cable

- 22 -

6) Remove the two CDHWE101S00 screws (24) fixing the power board Assy (11) and back plate (16) in place.

7) Temporarily tighten the two CDHWE101S00 screws (24) fixing the new power board Assy (11) and back

plate (16) in place.

8) Slide the back plate (16) down, and set the back plate (16) so that it is held down by the M3×6 truss screw

(25).

9) Use two M3×8 sems screws (23) to fix the power board Assy (11) in place.

10) Use two M3×6 truss screws (25) to fix the back plate (16) in place.

11) Tighten the two loosely tightened CDHWE101S00 screws (24).

12) Disconnect the connector for cable ILS 10S-10S-270 (B9) that is connected to the power board Assy (B4).

13) Insert the connector (C5) for cable 10-10 (14) and the connector (C6) for the battery cable (15).

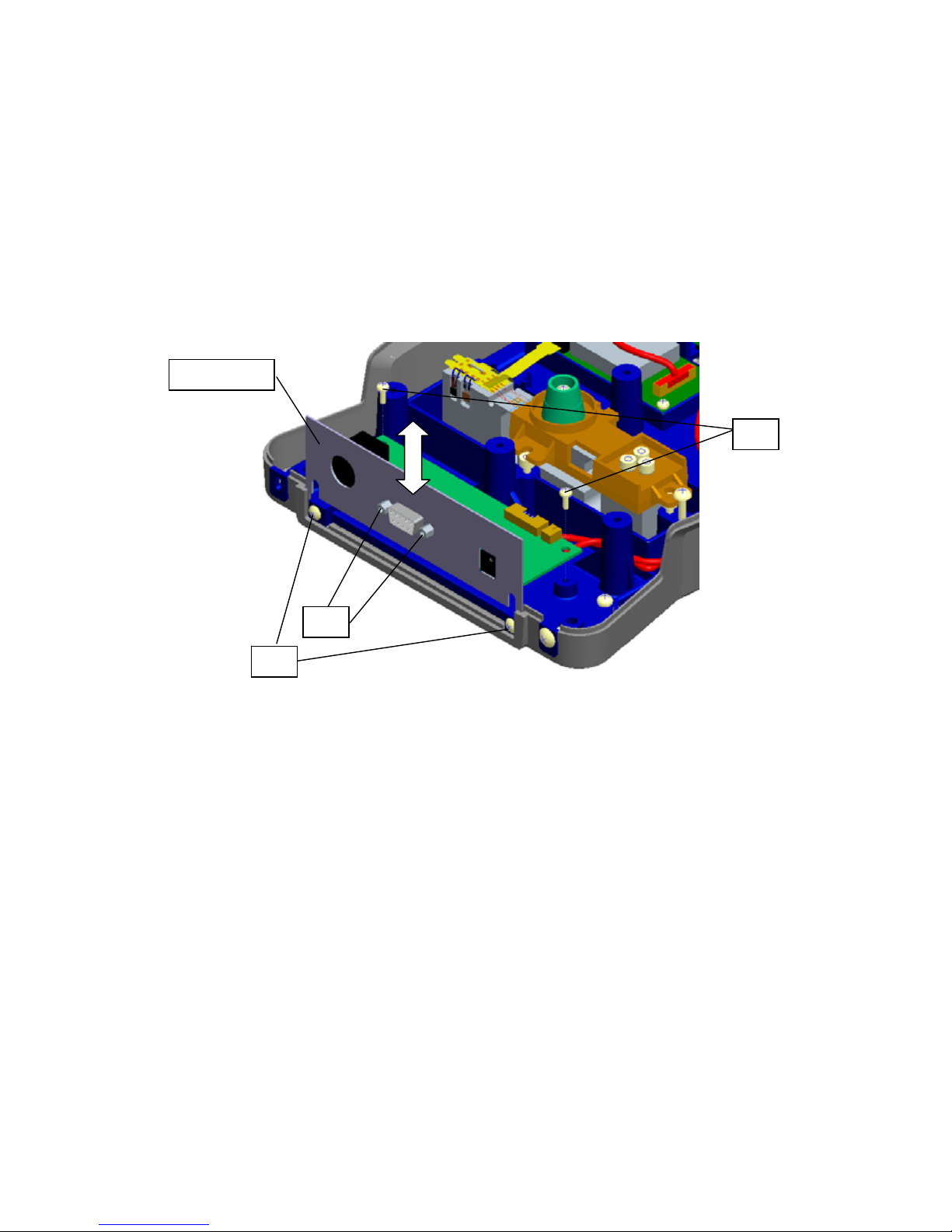

2.2.3.4. Replacing the Load Cell Assy (12)

1) Use the procedure in " 2.2.2 Inspecting the Balance Interior (Removing the Case and Pan Support)" to

remove as far as the upper case Assy (6).

2) Disconnect the connector (C6) for the battery cable (15).

3) Remove the four level adjustment feet (8) on the back of the main body (for the large pan model; the small

pan model has two feet), and the two M4×8 sems screws (22).

* Be careful not to apply force to the load cell Assy.

4) Remove the two M4×8 sems screws (22) fixing the base Assy (17) in place.

5) While removing the connector (C6) from the base Assy (17) hole, lift up the back plate (16) to remove the

base Assy (17).

(16) Back plate

(23)

(24)

(25)

- 23 -

6) Remove the hexagonal socket head bolt on the back of the base Assy (17).

* Be careful not to apply force to the load cell Assy. Also be careful not to drop the load cell Assy.

7) Follow steps 2) to 5) in reverse to attach the new load cell Assy (12).

8) While positioning the load cell Assy with the jig (31), use the hexagonal socket head bolt to attach the load

cell Assy (12).

(22)

(22)

Front hook

s

Cable hole

@C

@C

(31) Cell positioning jig

Loading...

Loading...