Page 1

263-13236E

Magnetically Levitated Turbo Molecular Pump

Model:TMP-3203M (Air cooled type)

Model:TMP-3203MC (Air cooled chemical type)

Model:TMP-3203LM (Wide range type)

Model:TMP-3203LMC (Wide range chemical type)

Model:TMP-3403LMC (Wide range chemical type)

INSTRUCTION MANUAL

Read the instruction manual thoroughly before you use the product.

Keep this instruction manual for future reference.

Semiconductor Equipment Division

Page 2

Introduction

Thank you for choosing the turbo molecular pump made by Shimadzu Corporation.

(hereafter referred to as "turbo molecular pump").

Please read the instruction manual carefully in conjuction with the instruction manual of

"Power Supply Unit" before using turbo molecular pump, and save the instruction manual for

future reference.

Copyrights and Disclaimers

This document is copyrighted by Shimadzu Corporation. Please refrain from reproducing

or copying part or all of this document without permission from Shimadzu.

In an effort to improve the product, this document may be revised in the future without

notice.

Every effort has been made to prepare an accurate and complete manual, but if an error

or omission should be discovered, revisions might not be possible immediately.

Shimadzu does not take responsibility for any effects that may result from the use of this

manual.

Copyright 2003-2006 Shimadzu Corporation.All rights reserved.

©

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

i

Page 3

Precautions for Safe Operation

The instruction manual's nomenclature for warnings and precautions complies with

the following safety warning symbols.

WARNING

CAUTION

NOTICE

Indicates a potentially hazardous situation whitch, if not avoided, could result

in serious injuly or possibly death.

Indicates a potentially hazardous situation whitch, if not avoided, may result in

minor to moderate injuly or equipment damage.

Emphasizes additional information that is provided to ensure the proper use of

this product.

WARNING

Turbo molecular pump repair and/or power supply repair can be very hazardous.

Only trained technicians who are authorized by Shimadzu may do service of

products.

WARNING

Neither overhaul nor modify the pump proper and power supply unit without

admission. Doing so would impair safety of the pump proper.

WARNING

Decisions on system compatibility should be made by the system designer or the person

deciding the specifications after conducting tests as necessary.The responsibility for

guaranteeing the expected performance and safety of the system lies with the person who

decides system compatibility.

ii

263-13236

Page 4

WARNING

・Fix the pump to the device according to 5.1.2.1 and 5.1.2.2. The method to fix the pump is

different depending on the pump model and the size of inlet flange of the pump.

・The device should be fixed to the floor so as not to move. The device should be designed to

endure the torque 1.5 times the rapid shutdown torque to take the safety margin in

preparation for an emergency accident.

・The rotor assembly of the turbo molecular pump rotates at high speed. Large rapid shutdown

torque should be generated when abnormality occurs in the pump by any chance. Incidental

accident will cause the pump to drop out and to make a catastrophe if the pump is fixed by

insufficient method.

WARNING

Do not remove the turbo molecular pump, before safety has been confirmed.

Improper turbo molecular pump use may be hazardous to operator's health in applications not

recommended or approved by Shimadzu. In the event removal of the turbo molecular pump from

an application is required, full protective measures including purging of the turbo molecular pump

with an inert gas and/or apparel are recommended when the turbo molecular pump has been

used in applications that required the use of corrosive, reactive, stimulative, or toxic gases.

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

iii

Page 5

CAUTION

After having operated the turbo molecular pump for evacuation of corrosive gas, keep the

pump internal as vacuumed even after shutdown. Inflow of water content in the air to the pump

internal would cause rapid erosion trouble of the pump internals.

CAUTION

Avoid to install the pump at the following places.

(1) Place where the pump is inevitably exposed to significant vibration and impact.

(2) Unstable place.

(3) Place where the pump is inevitably exposed to magnetic field and radioactive ray.

The pump proper is a precision machine. Be careful not to apply abnormal vibration, shock/

impact to it during transportation.This pump is not connected to grand. Please provide

PE(Protective earth) connection to the chassis of pump in final application.

CAUTION

The following "CAUTIONS" are to prevent operation anomalies.

1.This turbo molecular pump is not approved for use in applications exhausting process gas

containing gallium (Ga, e.g., triethyl gallium, etc.).

2.Protect the pump from any and all types of impact during operation.

3.Do not operate any equipment (i.e. drill motor, welding machine, etc.) that produces electromagnetic pollution, noise, etc., in the immediate proximity of an operating turbo molecular

pumping system (pump, power supply, cables, etc).

4.Do not interrupt the electrical power operating the turbo molecular pump while the turbo

molecular pump is in operation.

5.Do not connect or disconnect the turbo molecular pump control cable during the time the

power supply is "ON".

6.Be sure to use the chemical type pumps to exhaust of gas which contain chlorine, or fluorine.

7.Plasmas may cause the pump rotor to discharge electrically thus damaging the electrical

components.

8.When using the variable speed function to change the pump rotation rate, use a rotation rate

that does not cause resonance with other devices installed at the site.

iv

263-13236

Page 6

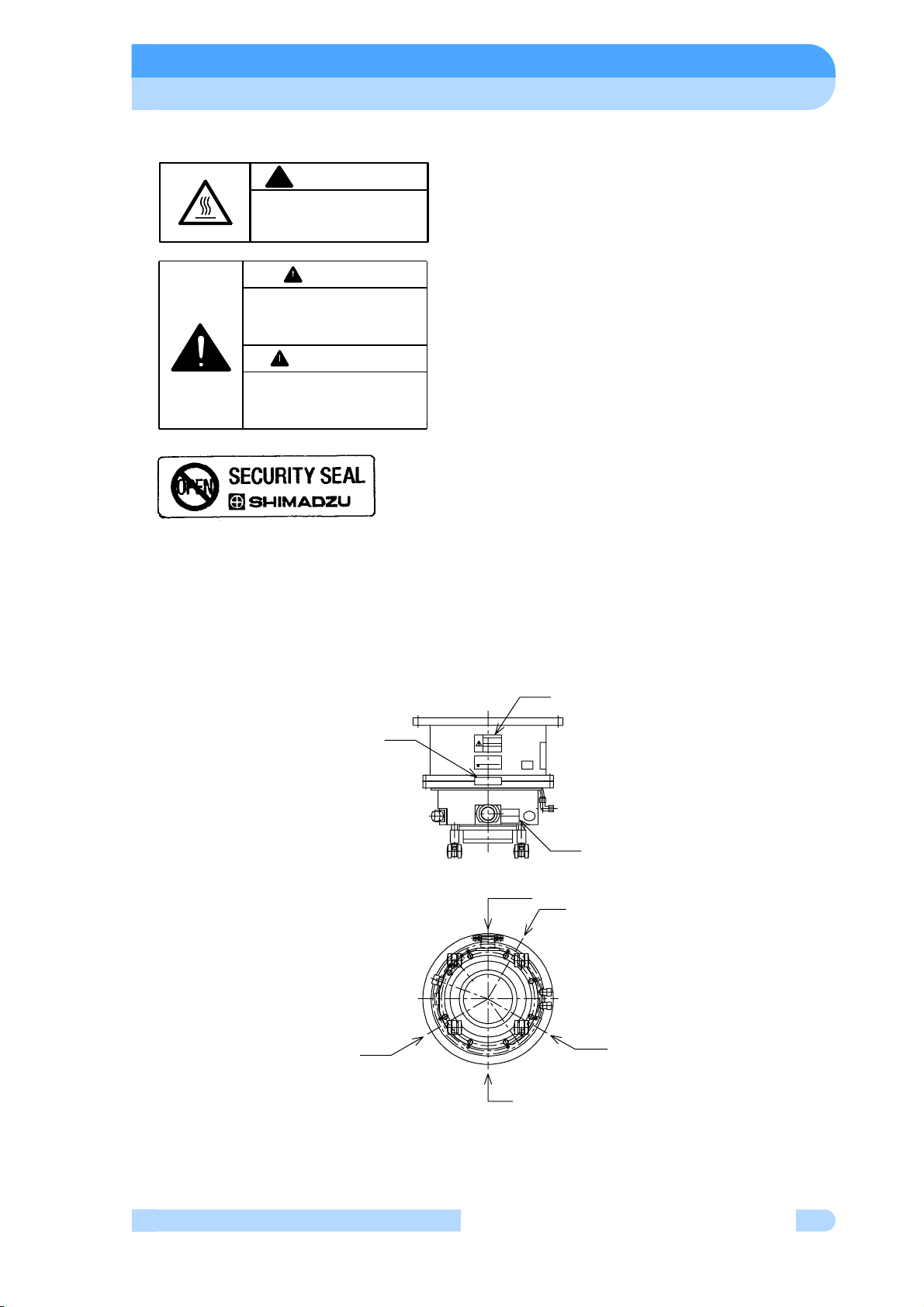

○ Explanation of label

CAUTION

!

HOT SURFACE

Risk of burn. Avoid contact.

やけどのおそれがあります。 触らないで下さい。

高温注意

警 告

ポンプが装置から外れ,人体を傷つける

恐れがあります。取扱説明書に従い確実

にポンプを固定してください。

WARNING

CAN CAUSE INJURY BY DROPED

PUMP, INSTALL PUMP SECURELY

ACCORDING TO INSTRUCTION

MANUAL.

263-16180

(1) HOT SURFACE label

Risk of burn. Keep off from touching surface of the

pump as it is heated.

(2) INSTALL PUMP label

Incidental accident will cause the pump to drop

out and to make a catastrophe if the pump is fixed

by insufficient method.

Fix the pump to the device according to 5.1.2

「Installation of the Pump」.

(3) SECURITY seal

This label certificates that the product was made

or maintenanced by Shimadzu or by Shimadzu

authorized facility .

In case "this label is removed" or "there is a mark

showing once this label has been removed",

Shimadzu warranty shall not be applied to the

product.

○ Location of label

(1)

(3)

(2), (3)

(2)

(2)

(1)

(1)

(1)

Series of TMP-3203 and TMP-3403LMC

Label attachment phase

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

v

Page 7

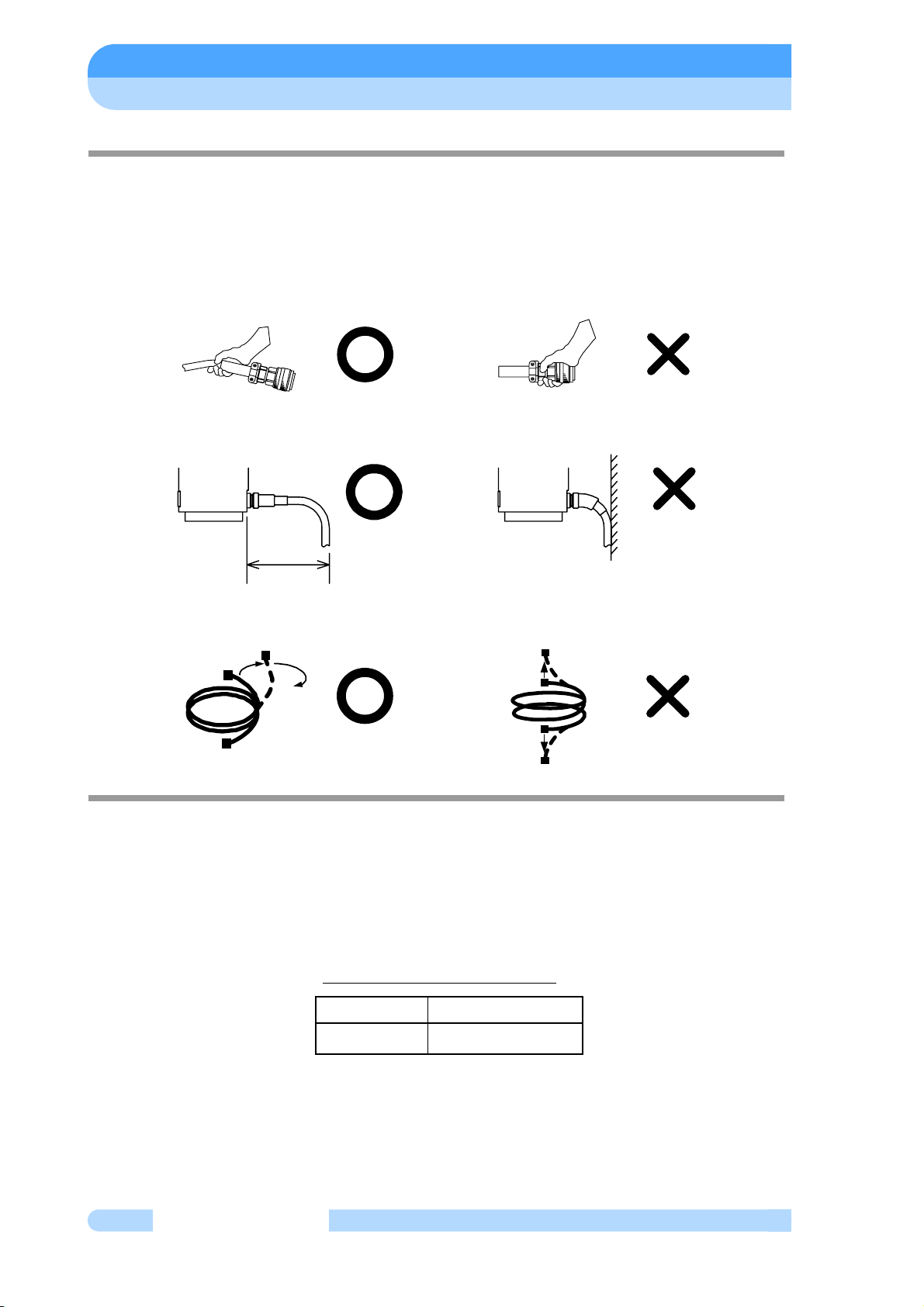

○ Installation Precautions

Do not apply abnormal loads to the turbo molecular pump control cable plug and/or connector.

Abnormal loads may cause cable disconnection.

(1) Do not pull the turbo molecular pump control cable by the connector or plug.

(2) Do not allow any electrical cables to be in tension or to have very tight bending radii.

240mm

(3) Do not twist the turbo molecular pump control cable during connection.

○ Part Replacement

The lifetime of parts are specified as below.

The request for changing parts exceeding the estimated lifetime should be made to Shimadzu

or an approved service company in order for safety and adequate performance of the pump and

power supply unit.

Tabl e 1 Estimated Part Life.

vi

263-13236

Parts List

Cooling fan 5 years

Estimated Part Life

Page 8

○ Air Cooled Turbo Molecular Pump

For the air cooled turbo molecular pumps, it is necessary to clean the cooling fan periodically

because of the cooling fan collecting dust, debris, etc. Shimadzu recommends removal of the

cooling fan for all methods of cleaning (compressed air, etc.) to prevent the particles, cleaning

debris, from accumulating in or on the turbo molecular pump. Please refer to Fig. 1 how to

change fan.

COOLING UNIT

FLOW

CONNECTOR

SCREW

PUMP

Pump model Parts name Parts Number

TMP-3203M

TMP-3203MC

Cooling unit

DV24V

262-76043-01

Fig. 1 How to Change the Cooling Fan Unit

○ Warranty period

12 months on new TMP's from the date of shipment from Shimadzu, or from any of its

worldwide sales offices.

○ Conditional warranty

During the warranty period and under normal operation, if the TMP fails to meet its product

specification due to defects in material and/or workmanship, Shimadzu will, at its discretion,

either repair it or exchange it with a new one for free.

○ Scope of the warranty

The warranty covers only TMPs, controllers and accessories sold by Shimadzu.

○ Warranty of repaired or replacement parts

In-warranty repaired or replacement parts are warranted only for the remaining unexpired

portion of the original warranty period applicable to the parts that have been repaired or replaced.

○ Exemption from the warranty

During the warranty period, Shimadzu will charge for repair or exchange in the following cases:

1) Failure caused by natural disasters or fire.

2) Failure or functional deterioration due to the following:

a) Pumping of special gases and materials

b) Ingestion of foreign objects through the TMP's protective net

c) TMP is operated differently than what is prescribed in the instruction manual

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

vii

Page 9

d) When Shimadzu determines through failure analysis that the cause of failure was due to

abnormal operation or external circumstances. our engineers judge that the cause of the

trouble is an irregular operation

3) Warranty is voided if the "Security Seal" on the product has been removed, hampered with,

or altered.

○ Disposal of Products and Parts

Please contact Shimadzu for proper disposal of its products or parts. There is a possibility to

pollute the environment with the material of the parts, when you dispose this product in an inappropriate way.

○ LIMITATION OF LIABILITY

EXCEPT AS STATED HEREIN, SHIMADZU MAKES NO WARRANTY, EXPRESSED OR

IMPLIED (EITHER IN FACT OR BY OPERATION OF LAW), STATUTORY OR OTHERWISE:

AND, EXCEPT AS STATED HEREIN, SHIMADZU SHALL HAVE NO LIABILITY FOR

SPECIAL OR CONSEQUENTIAL DAMAGES OF ANY KIND OR FROM ANY CAUSE ARISING

OUT OF THE SALE, INSTALLATION, OR USE OF ANY OF ITS PRODUCTS.

viii

263-13236

Page 10

TABLE OF CONTENTS

Introduction

Copyrights and Disclaimers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Precautions for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

○ Explanation of label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

○ Location of label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

○ Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

○ Part Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

○ Air Cooled Turbo Molecular Pump. . . . . . . . . . . . . . . . . . . . . . . . vii

○ Warranty period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Table of contents

○ Conditional warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

○ Scope of the warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

○ Warranty of repaired or replacement parts . . . . . . . . . . . . . . . . . vii

○ Exemption from the warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

○ Disposal of Products and Parts . . . . . . . . . . . . . . . . . . . . . . . . . viii

○ LIMITATION OF LIABILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Section 1 OUTLINE AND DESCRIPTIONS

1.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 Outside drawing of Pump Main Unit . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1.1 Outside drawing of series of TMP-3203 . . . . . . . . . . . . . . . 3

1.2.1.2 Outside drawing of TMP-3403LMC . . . . . . . . . . . . . . . . . . 5

1.2.2 Standard Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 2 IDENTIFICATION AND FUNCTION

2.1 Pump Main Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

ix

Page 11

Table of contents

Section 3 CONSTRUCTION AND PRINCIPLE

3.1 Pump Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Principle of Turbo Molecular Pumping . . . . . . . . . . . . . . . . . . 10

Section 4 SPECIFICATIONS

4.1 Pump Main Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.1 Specification of series of TMP-3203 . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.2 Specification of TMP-3403LMC . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Standards Fulfilled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Section 5 INSTALLATION

5.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.1 Pump Mounting Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.2 Installation of the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1.2.1 Installation of series of TMP-3203 . . . . . . . . . . . . . . . . . . 21

5.1.2.2 Installation of TMP-3403LMC . . . . . . . . . . . . . . . . . . . . . . 23

5.1.3 Example of piping connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1.4 Center of gravity of the pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 Connection of the Pump to the Power Supply Unit . . . . . . . . 26

5.3 Interlock for Vacuum System . . . . . . . . . . . . . . . . . . . . . . . . . 27

Section 6 OPERATION

6.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 Start-up Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2.1 Start-up Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3.1 Start-up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4 Shutting Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.5 Baking Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

x

263-13236

Page 12

Table of contents

Section 7 GAS PURGE

Section 8 TURBO MOLECULAR PUMP RECONDITION

8.1 Turbo Molecular Pump Return Request . . . . . . . . . . . . . . . . 40

8.2 Turbo Molecular Pump Decontamination. . . . . . . . . . . . . . . . 41

8.3 Touch-Down Bearing Replacement . . . . . . . . . . . . . . . . . . . . 41

8.4 Check of the rotor blades. . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Section 9 TROUBLESHOOTING

9.1 Vacuum Pressure Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2 Abnormal Noise and/or Vibration . . . . . . . . . . . . . . . . . . . . . . 44

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

xi

Page 13

Table of contents

This page is intentionally left blank.

xii

263-13236

Page 14

1OUTLINE AND

DESCRIPTIONS

1

1.1 Outline

1.2 Descriptions

1.2.1 Outside drawing of Pump Main Unit

1.2.1.1 Outside drawing of series of TMP-3203

1.2.1.2 Outside drawing of TMP-3403LMC

1.2.2 Standard Accessories

Page 15

SECTION 1 OUTLINE AND DESCRIPTIONS

1

1.1 Outline

The turbo molecular pump is a vacuum pump. The turbo molecular pump is used with a

backing vacuum pump to create a high vacuum in a vacuum chamber.

Typical Applications ; Semiconductor equipments,

Industrial equipments,

R&D applications,

The other ultra high vacuum applications.

The turbo molecular pump (one standard set) consists of the following items.

・Pump 1

・Power Supply Unit 1

・Control Cable 1

・Motor Cable 1

・Standard Accessories 1 Set

This instruction manual explains the operation of the pump unit. For more detailed instructions

regarding the power supply unit, please refer to the Power Supply Unit Instruction Manual.

2

263-13236

Page 16

1.2 Descriptions

1.2 Descriptions

1.2.1 Outside drawing of Pump Main Unit

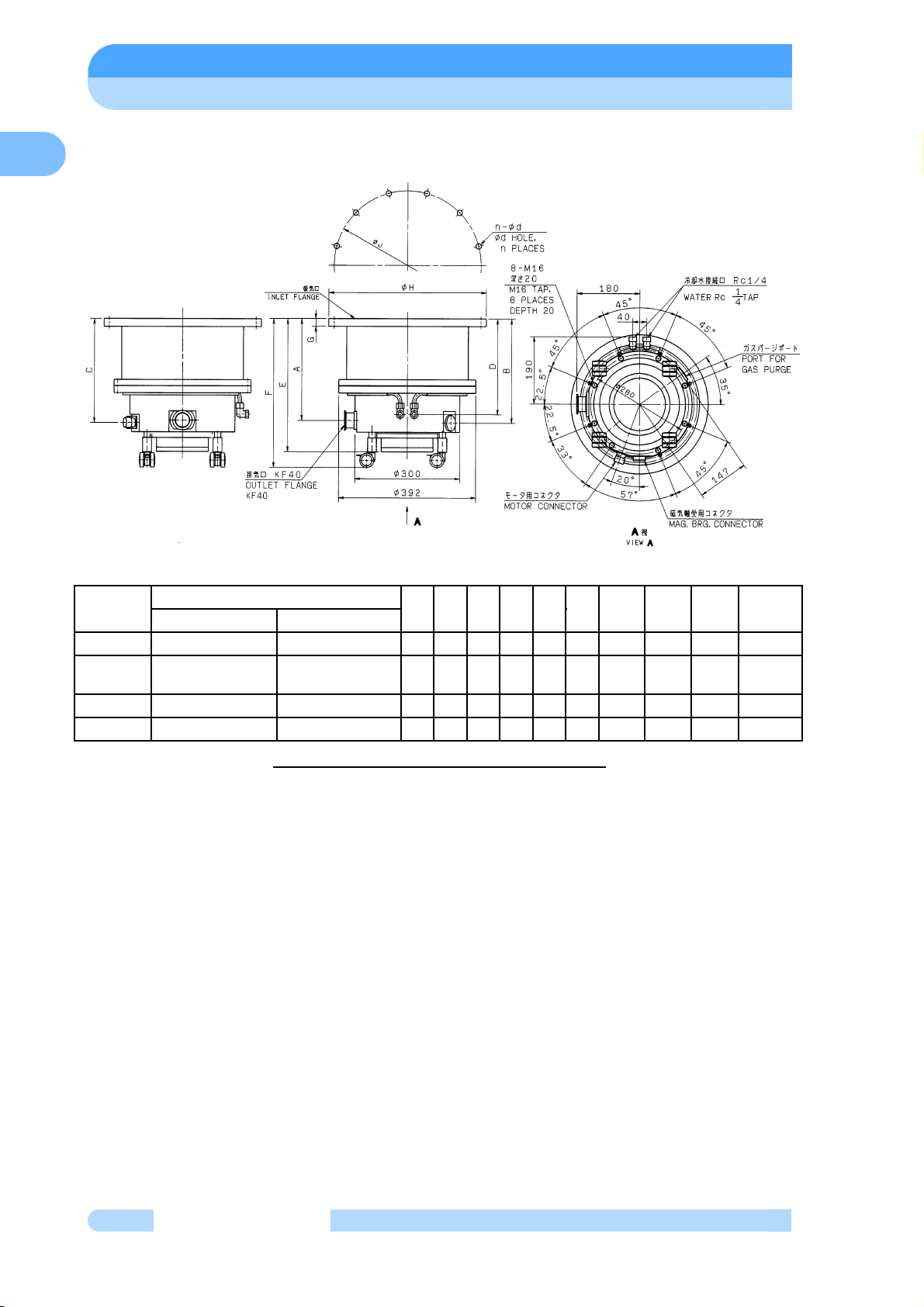

1.2.1.1 Outside drawing of series of TMP-3203

1

INLET

FLANGE

VG350 P/N 262-78430-62 P/N 262-78430-72 287 294 289 375 420 22

ISO320B

Special

VG300 P/N 262-78430-67 P/N 262-78430-77 307 314 309 395 440 18.5

VG250 P/N 262-78430-68 P/N 262-78430-78 331 338 333 419 464 18.5

TMP-3203M TMP-3203MC

P/N 262-78430-63 P/N 262-78430-73 287 294 289 375 420 22.5

Parts number

Fig.1-1

ABCEF G φH φJn-φd

TMP-3203M and TMP-3203MC

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

φ450 φ420 12-φ15

φ425 φ395 12-φ13

φ400 φ370 12-φ13

φ350 φ320 12-φ13

3

Page 17

SECTION 1 OUTLINE AND DESCRIPTIONS

1

INLET

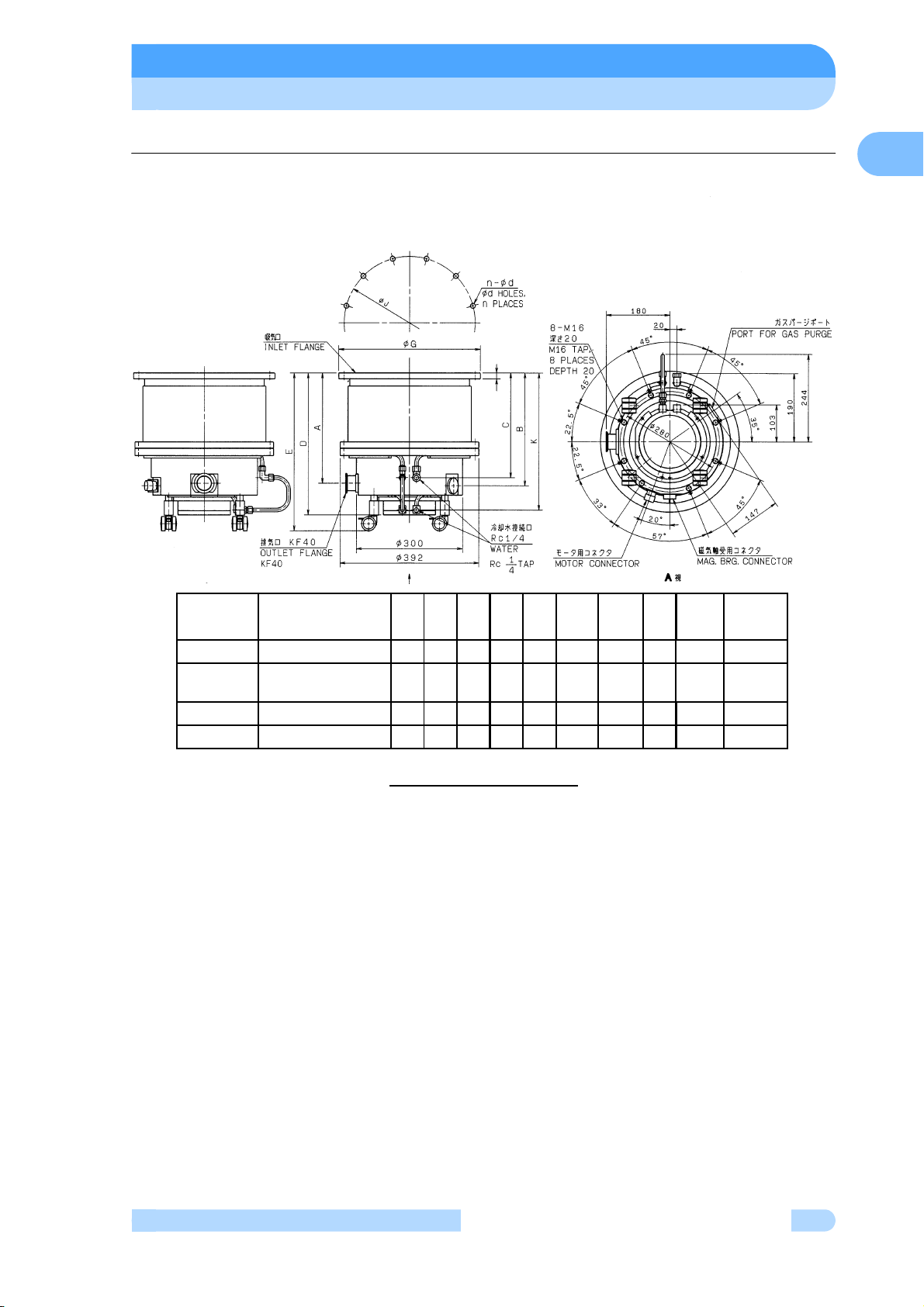

FLANGE

VG350 P/N 262-78430-42 P/N 262-78430-52 287 294 289 270 375 420 22

ISO320B

Special

VG300 P/N 262-78430-47 P/N 262-78430-57 307 314 309 290 375 440 18.5

VG250 P/N 262-78430-48 P/N 262-78430-58 331 338 333 314 419 464 18.5

TMP-3203LM TMP-3203LMC

P/N 262-78430-43 P/N 262-78430-53 287 294 289 270 375 420 22.5

Parts number

ABCDEF G

Fig.1-2 TMP-3203LM and TMP-3203LMC

φH φJ

φ450 φ420 12-φ15

φ425 φ395 12-φ13

φ400 φ370 12-φ13

φ350 φ320 12-φ13

n-φd

4

263-13236

Page 18

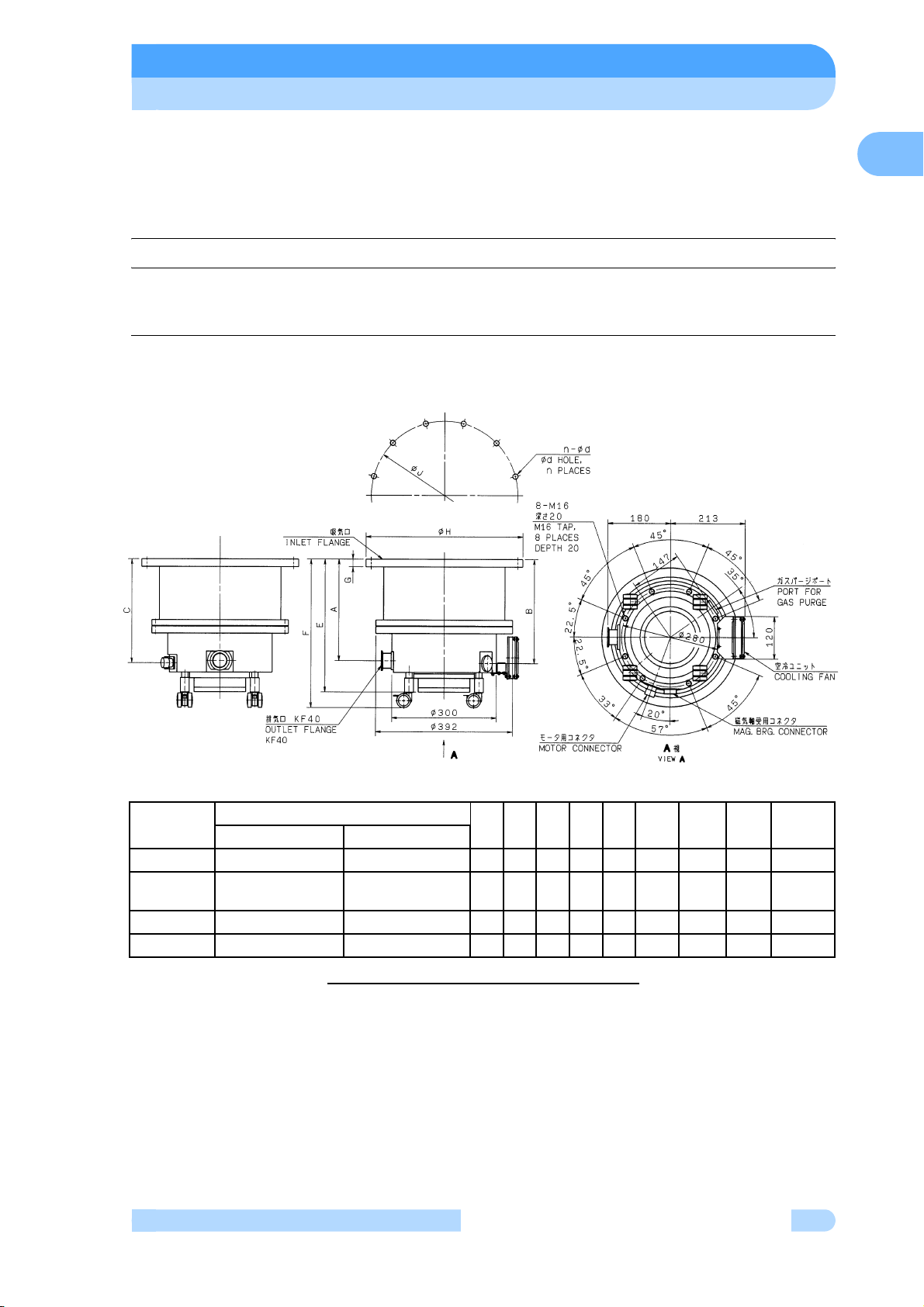

1.2.1.2 Outside drawing of TMP-3403LMC

1.2 Descriptions

1

F

INLET

FLANGE

VG350 P/N 262-78503-52 287 294 270 375 420 22

ISO320B

Special

VG300 P/N 262-78503-57 307 314 290 395 440 18.5

VG250 P/N 262-78503-58 331 338 314 419 464 18.5

Parts number ABCDE F

P/N 262-78503-53 287 294 270 375 420 22.5

Fig.1-3

TMP-3403LMC

φG

φ450

φ425

φ400

φ350

K

φHn-φd

360

φ420 12-φ15

360

φ395 12-φ13

380

φ370 12-φ13

404

φ320 12-φ13

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

5

Page 19

SECTION 1 OUTLINE AND DESCRIPTIONS

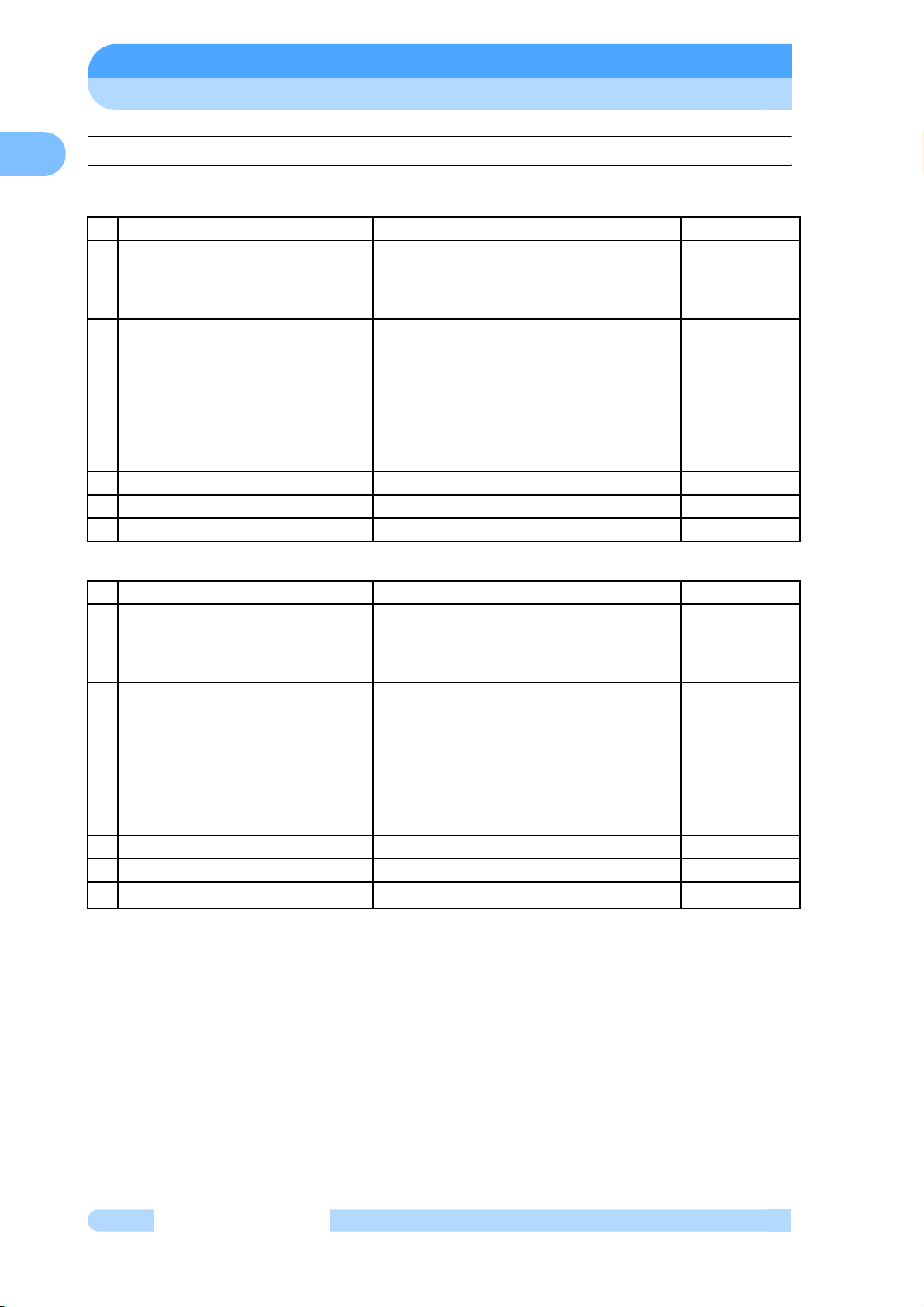

1.2.2 Standard Accessories

1

Series of TMP-3203

Description Q'ty Notes Parts number

O-ring gasket for VG350

Gasket for inlet flange

1

(Note)

Bolt set for inlet flange

2

(Note)

3 Centering with O-ring 1

4Clamp 1

5 Instruction manual 1 English

1

1

O-ring gasket for VG300

O-ring gasket for ISO320B Special

O-ring gasket for VG250

VG350:Hex Head, M12 × 40, 12PC

(A2-70)

VG300:Hex Head, M12 × 35, 12PC

(12.9)

ISO320B Special: Hex Head,

M12 × 40, 12PC (12.9)

VG250:Stud Bolt, M12 × 47, 12PC

(12.9)

KF40

KF40

036-13516

036-13515

036-15554-55

036-13514

─

035-06004-14

035-06004-03

263-13236

TMP-3403LMC

Description Q'ty Notes Parts number

O-ring gasket for VG350

Gasket for inlet flange

1

(Note)

Bolt set for inlet flange

2

(Note)

3 Centering with O-ring 1

4Clamp 1

5 Instruction manual 1 English

(Note) One of followings.

1

1

O-ring gasket for VG300

O-ring gasket for ISO320B Special

O-ring gasket for VG250

VG350:Hex Head, M12 × 40, 12PC

(12.9)

VG300:Hex Head, M12 × 35, 12PC

(12.9)

ISO320B Special: Hex Head,

M12 × 40, 12PC (12.9)

VG250:Stud Bolt, M12 × 47, 12PC

(12.9)

KF40

KF40

036-13516

036-13515

036-15554-55

036-13514

─

035-06004-14

035-06004-03

263-13236

6

263-13236

Page 20

2IDENTIFICATION AND

FUNCTION

2

2.1 Pump Main Unit

Page 21

SECTION 2 IDENTIFICATION AND FUNCTION

2.1 Pump Main Unit

2

1

5

4

3

TMP-3203LM/LMC TMP-3403LMC

1

5

1

5

4

3

26

6

2

8

4

3 2 7

TMP-3203M/MC

Fig.2-1 Pump Main Unit

(1) INLET FLANGE . . . . . . . . . . . . . Inlet flange, joint the turbo molecular pump, VG350,

ISO320B Special, VG30, VG250 are also available.

(2) PORT FOR GAS PURGE . . . . . Gas purge adaptor port

(see Section 7 "GAS PURGE")

(3) OUTLET FLANGE. . . . . . . . . . . Outlet flange, connect a backing vacuum pump or its

related pipe connection, KF40.

(4) MOTOR CONNECTOR. . . . . . . Motor cable receptacle

(5) CONTROL CONNECTOR. . . . . Control cable receptacle

(6) COOLING WATER PIPELINE. . Cooling water pipe connector, Rc1/4

(7) COOLING FAN . . . . . . . . . . . . . Cooling Fan

263-13236

Page 22

3CONSTRUCTION AND

PRINCIPLE

3

3.1 Pump Construction

3.2 Principle of Turbo Molecular Pumping

Page 23

SECTION 3 CONSTRUCTION AND PRINCIPLE

3.1 Pump Construction

Fig. 3-1 is a sectional drawing of the TMP-3203LM and TMP-3203LMC and TMP-3403LMC

3

magnetic bearing type turbo molecular pump. The built-in high frequency motor (1) is accelerated

to the specified revolutions (speed) by the high frequency power supply unit. Rotor blades (4) are

fitted onto the drive shaft (3) and the stator blades (5) are arranged in between the rotor blades.

A positioning spacer (6) is inserted between the stator blades. The configurations and profiles of

the stator blades and rotor blades are designed for high efficiencies in various applications. The

upper stages of the rotor blade and stator blade configurations are ideally designed for high gas

throughput. The compression ratio of the stator blades and rotor blades becomes higher as the

gas molecules converge into the lower stage configurations. The profiles of the stator blades and

rotor blades are matched for the desired function.

A radial magnetic bearing (7) is used at the top and bottom of the drive shaft. The axial

magnetic bearings (8) are used to levitate a disk attached to the drive shaft between the axial

magnetic bearings. Each magnetic bearing is provided with a gap sensor (10) to detect the rotor

position. Fig. 3-2 illustrates the outline of 5 - axes control. The rotor is levitated by the control of

these 5 axes allowing rotational freedom.

A touchdown bearing is used at the top and bottom of the casing for safety protection of the

rotor and pump should the magnetic bearings become damaged. The touchdown bearings are

dry and oil free.

The cooling water pipe (14) is provided to cool the pump. With the air-cooled turbo molecular

pumps TMP-3203M and TMP-3203MC, cooling fans are provided instead of the cooling water

pipe (14).

Fig. 1-1 through Fig. 1-3 show the outside dimensions of the turbo molecular pump.

3.2 Principle of Turbo Molecular Pumping

The principle of turbo molecular pumping assumes gas molecules collide with a surface plane

(the blade of the pump rotor) moving in a radial span of very high speed in a space with an

enlarged mean free gas path (generally a vacuum area of less pressure than 0.1 Pa). Assuming

no heat is exchanged between the gas molecule and the pump rotor blade, the speed of the

pump rotor blade is added to the speed of the gas molecule, converting the gas molecule's nonoriented thermal motion to a motion with direction. Thus the gas molecule has received an

impulse in a desired flow direction.

10

263-13236

Page 24

④

3.2 Principle of Turbo Molecular Pumping

⑬

3

⑪

⑩

③

①

⑭

⑫

⑩

⑤

⑥

⑨

⑦

②

⑨

⑧

Fig.3-1 Pump Sectional Drawing

(1) High frequency motor (6) Spacer (11) Inlet flange

(2) Receptacle (7) Radial magnetic bearing (12) Outlet flange

(3) Drive shaft (8) Axial magnetic bearing (13) Protective net

(4) Rotor blade (9) Touch-down bearing (14) Cooling water pipeline

(5) Stator blade (10) Gap sensor (pipe connection port)

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

11

Page 25

SECTION 3 CONSTRUCTION AND PRINCIPLE

The movement of an object has 6 degrees of freedom. Levitation can be achieved in a turbo

molecular pump by controlling the following 5 degrees of freedom (excluding the rotational

degree (Z axis) of freedom).

Z

3

rotational axis

Parallel movement

Rotation

X

Y

ZZ Z

X Y Y

Radial displacement Axial displacement

Z

X

Z

Y

Movement of rotor and restricted five degrees of freedom

12

263-13236

Z

X

1

X

2

Y

1

Y

2

Fig.3-2 Outline of 5-Axes Control

5-axes control

① X

1

② Y

1

③ X

2

④ Y

2

⑤ Z

Page 26

4SPECIFICATIONS

4

4.1 Pump Main Unit

4.1.1 Specification of series of TMP-3203

4.1.2 Specification of TMP-3403LMC

4.2 Standards Fulfilled

Page 27

SECTION 4 SPECIFICATIONS

4.1 Pump Main Unit

4.1.1 Specification of series of TMP-3203

Turbo molecular pump model TMP-3203M TMP-3203MC TMP-3203LM TMP-3203LMC

Cooling method Cooling fan Water

4

Ultimate pressure (Note 1) 10

Maximum Argon gas through put

(Note 2)

Maximum allowable inlet pressure

(Nitrogen gas)

Maximum allowable outlet

pressure

Pumping speed N

(Note 3) He

Compression ratio N

Rated speed 21000 rpm

Start-up time 13 minutes

Mounting position

Bake-out temperature at an inlet

flange

Vibration level (by Shimadzu's

method)

Inlet flange

Outlet flange KF40

Mass 70 kg

Admissible throughput of purge

gas

Admissible pumping speed of

backing vacuum pump in case of

gas purge

Environmental Temperatures

H

He

H

2

2

2

2

-9

Pa order 10-8 Pa order 10-9 Pa order 10-8 Pa order

250 mL/min 400 mL/min 1200 mL/min 2200 mL/min

0.4 Pa 40 Pa

40 Pa 270 Pa

3200 L/s

3000 L/s

2400 L/s

1 × 109 or more

3 × 10

1 × 10

In any desired direction(Note 4)

120 ℃ or less

0.01 μm or less (0-peak)

VG350(Note 5)

20 to 30 mL/min(Note 2)

1500 L/min or more

Operation : 0 to 40 ℃ / Storage : -25 to 70 ℃

5

4

14

Admissible ambient magnetic field

Water Flow rate

Radial direction

Axial direction

Pressure

Temperature

N/A

3 mT

15 mT

2 to 4 L/min

0.2 to 0.5 MPa

5 to 25 ℃

(Note 1) When using a metal gasket at the inlet flange. When using an o-ring gasket , the

-7

ultimate pressure is 10

Pa order.

(Note 2) mL/min : volume flow rate at 0 ℃ , 1 atm. (Compatible with SCCM.)

(Note 3) Without a protective net. Pumping speed for N

is 2950 L/s with a protective net.

2

(Note 4) The outlet flange of the turbo molecular pump should face horizontally or vertically

when installing the pump horizontally and obliquely.

(Refer to 5.1.1「Pump Mounting Direction」)

(Note 5) VG300, VG250 and ISO320B Special are also available.

263-13236

Page 28

4.1.2 Specification of TMP-3403LMC

Turbo molecular pump model TMP-3403LMC

Cooling method Water

Ultimate pressure 10

Maximum Argon through put

(Note 1)

Maximum allowable inlet pressure

(Nitrogen gas)

Maximum allowable outlet

pressure

Pumping speed N

2

(Note 2) He

H

2

Compression ratio N

He

H

2

2

Rated speed 22020 rpm

Start-up time 15 minutes

Mounting position

In any desired direction(Note 3)

Bake-out temperature at an inlet

flange

Vibration level (by Shimadzu's

method)

0.01 μm or less (0-peak)

Inlet flange

Outlet flange KF40

Mass 70 kg

Admissible throughput of purge

gas

20 to 30 mL/min(Note 1)

Admissible pumping speed of

backing vacuum pump in case of

gas purge

Environmental Temperatures

Operation : 0 to 40 ℃ / Storage : -25 to 70 ℃

-7

Pa order

2200 mL/min

10 Pa

270 Pa

3300 L/s

3100 L/s

2400 L/s

1 × 10

1 × 10

6 × 10

120 ℃ or less

VG350(Note 4)

1500 L/min or more

4.1 Pump Main Unit

4

9

5

4

Admissible ambient magnetic field

Radial direction

Axial direction

Water Flow rate

Pressure

Temperature

3 mT

15 mT

2 to 4 L/min

0.2 to 0.5 MPa

5 to 25 ℃

(Note 1) mL/min : volume flow rate at 0 ℃ , 1 atm. (Compatible with SCCM.)

(Note 2) Without a protective net. Pumping speed for N

is 3000 L/s with a protective net.

2

(Note 3) The outlet flange of the turbo molecular pump should face horizontally or vertically

when installing the pump horizontally and obliquely.

(Refer to 5.1.1「Pump Mounting Direction」)

(Note 4) VG300, VG250 and ISO320B Special are also available.

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

15

Page 29

SECTION 4 SPECIFICATIONS

4.2 Standards Fulfilled

EN61010-1; 2001

4

Safety

EMC

UL61010A-1

SEMI S2

EN1012-2; 1996

EN61326-1; 1997 + A1; 1998 + A2; 2001 class A

EN61000-3-2; 1995 + A14; 2000

SEMI F47

16

263-13236

Page 30

5INSTALLATION

5

5.1 Installation

5.1.1 Pump Mounting Direction

5.1.2 Installation of the Pump

5.1.2.1 Installation of series of TMP-3203

5.1.2.2 Installation of TMP-3403LMC

5.1.3 Example of piping connection

5.1.4 Center of gravity of the pump

5.2 Connection of the Pump to the Power Supply Unit

5.3 Interlock for Vacuum System

Page 31

SECTION 5 INSTALLATION

5.1 Installation

5.1.1 Pump Mounting Direction

This turbo molecular pump can be installed in vertical, the horizontal, inverted, oblique position.

5

The outlet flange of the pump should face horizontally or vertically when installing the pump

horizontally and obliquely.

When an installation direction is non-appropriate, reliability of operation may deteriorate.

(Refer to Fig. 5-1)

Inverted position

Vacuum

chamber

Horizontal position

Outlet

Oblique position

gravity

direction

Horizontal

position

Oblique position

Vertical position

Outlet

upward

18

Vertical position

downward

Fig. 5-1 Mounting Direction of Magnetic Levitated Turbo Molecular Pump

263-13236

gravity

direction

Page 32

5.1 Installation

5.1.2 Installation of the Pump

WARNING

・Fix the pump to the device according to 5.1.2.1 and 5.1.2.2. The method to fix the pump is

different depending on the pump model and the size of inlet flange of the pump.

・The device should be fixed to the floor so as not to move. The device should be designed to

endure the torque 1.5 times the rapid shutdown torque to take the safety margin in

preparation for an emergency accident.

・The rotor assembly of the turbo molecular pump rotates at high speed. Large rapid shutdown

torque should be generated when abnormality occurs in the pump by any chance. Incidental

accident will cause the pump to drop out and to make a catastrophe if the pump is fixed by

insufficient method.

5

CAUTION

Avoid to install the pump at the following places.

(1) Place where the pump is inevitably exposed to significant vibration and impact.

(2) Unstable place.

(3) Place where the pump is inevitably exposed to magnetic field and radioactive ray.The

pump proper is a precision machine. Be careful not to apply abnormal vibration, shock/

impact to it during transportation.

This pump is not connected to grand. Please provide PE(Protective earth) connection to the

chassis of pump in final application.

NOTICE

Before touching the pump internals and the vacuum chamber, put a pair of nylon gloves without

fail. Avoid direct touch with them. Internal contamination of the vacuum chamber or the pump

would cause failure of adequate vacuuming performance.

When using a hydraulic rotary pump with vibration of wide amplitude, as a backing vacuum

pump, undertake proper anti-vibration measure. (As a guideline, control the vibration to 0.1 G /

50 Hz max at the outlet connection port of the turbo molecular pump.)

This pump is a precision pump. To protect the pump from torsion due to external piping load,

use a bellows joint or a flexible tube to either the pump inlet or outlet, without fail.

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

19

Page 33

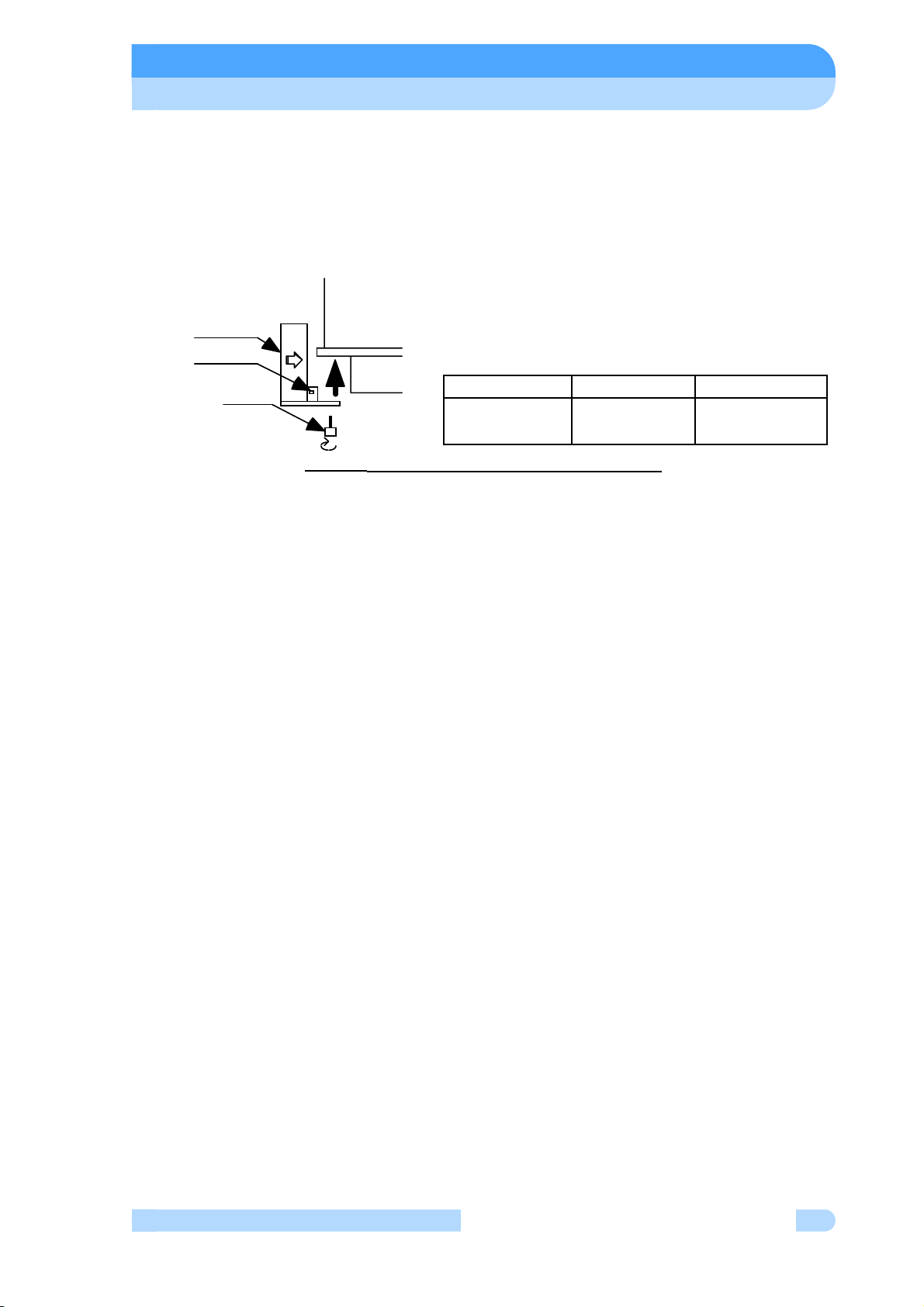

SECTION 5 INSTALLATION

CAUTION

The center of gravity of the pump is indicated in Fig. 5-8. Be sure that the pump does not move

or fall down during installation or storage.

5

CAUTION

The casters provided with the pump are only auxiliary equipment for installation and storage.

Use a trolley etc. for long-distance transportation.

Fix the pump in the manner shown in Fig. 5-2

Vacuum

chamber

PUMP

Fig. 5-2 Lifting Method

Vacuum

chamber

PUMP

20

263-13236

Page 34

5.1 Installation

5.1.2.1 Installation of series of TMP-3203

Please fix the inlet flange of turbo molecular pump to the flange of vacuum chamber , and the

base bottom of the pump to the frame of the device by the bolts of regulated grade, size, number,

and tightening torque for each flange. (Refer to Table 5-1 and Table 5-2)

When you fix the pump, use all of the bolt holes of the inlet flange of the pump.

When you connect piping and the valve, etc. between the vacuum chamber and the turbo

molecular pump

,please fix all the bolt holes to those connection points by the method of fixing

the recommendation shown in Table 5-1and Table 5-2.

VACUUM

CHAMBER

OUTSIDE

DEVICE

DEVICE

FRAME

BASE

BOTTOM

RAPID SHUTDO WN

TORQUE

INLET

FLANGE

Rods whitch have the

sufficient torque

strength.

Fixed both by the inlet flange and the base of TMP

Description Rapid Shutdown Torque

TMP-3203M/MC/LM/LMC

Fig. 5-3 Installation of series of TMP-3203

Table 5-1 The recommended fixing bolt

Fixing method Both by the inlet flange and the base (recommended method)

Inlet flange VG350 VG300

Bolt Size,

Quantity

Inlet flange

Base

Material stainless steel

Grade

Washer

Plain washer and

spring lock washer

VACUUM

CHAMBER

INLET

FLANGE

RAPID SHUTDOWN TORQUE

OUTSIDE

DEVICE

Fixed only by the inlet flange of TMP

59,100 N

・

m

ISO320B

Special

VG250

M12,12PC

M16,8 PC

A2-70(JIS B 1054)

Special washer (Note) and spring lock washer

5

Fixing method Only by the inlet flange

Inlet flange VG350 VG300

Bolt Size,Quantity

M12,12PC

ISO320B

Special

Material stainless steel SCM435 (JIS G 4105) or equivalent

Grade

Washer

A2-70(JIS B 1054)

Plain washer and

spring lock washer

Special washer (Note) and spring lock washer

12.9 (JIS B 1051)

(Note ) The special washers are attached to the inlet flange of TMP when shipping.

Do not remove them at the time of TMP installation.

Refer to Fig. 5-4 for the details of the bolt attaching part.

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

VG250

21

Page 35

SECTION 5 INSTALLATION

Bolt hole

Inlet flange

Spring lock washer

5

Special washer

Fixing bolt

Vacuum chamber

Inlet flange

Special washer

When shipping After installation

Fig. 5-4 Example of the fixing method using the special washer

Table 5 - 2 Tightening torque of the fixing bolt

Size of bolt Tightening torque [N•m]

M12

M16

16

41

~ 26

~ 66

22

263-13236

Page 36

5.1 Installation

5.1.2.2 Installation of TMP-3403LMC

Please fix the inlet flange of turbo molecular pump to the flange of vacuum chamber , and

the base bottom of the pump to the frame of the device by the bolts of regulated grade, size,

number, and tightening torque for each flange. (Refer to Table 5-2 and Table 5-3)

When you fix the pump, use all of the bolt holes of the inlet flange of the pump.

When you connect piping and the valve, etc. between the vacuum chamber and the turbo

molecular pump

,please fix all the bolt holes to those connection points by the method of fixing

the recommendation shown in Table 5-2 and Table 5-3.

VACUUM

CHAMBER

OUTSIDE

DEVICE

DEVICE

FRAME

BASE

BOTTOM

RAPID SHUTDO WN

TORQUE

INLET

FLANGE

Rods whitch have the

sufficient torque

strength.

Fixed both by the inlet flange and the base of TMP

Description Rapid Shutdown Torque

TMP-3403LMC

Fig. 5-5 Installation of TMP-3403LMC

Table 5-3 The recommended fixing bolt

Fixing method Both by the inlet flange and the base (recommended method)

Inlet flange VG350 VG300

Bolt Size,

Quantity

Inlet flange

Base

Material stainless steel

Grade

Washer

Plain washer and

spring lock washer

VACUUM

CHAMBER

INLET

FLANGE

RAPID SHUTDOWN TORQUE

OUTSIDE

DEVICE

Fixed only by the inlet flange of TMP

60,800 N

・

m

ISO320B

Special

VG250

M12,12PC

M16,8 PC

A2-70(JIS B 1054)

Special washer (Note) and spring lock washer

5

Fixing method Only by the inlet flange

Inlet flange VG350 VG300

Bolt Size,Quantity

M12,12PC

ISO320B

Special

Material SCM435 (JIS G 4105) or equivalent

Grade 12.9 (JIS B 1051)

Washer

Plain washer and

spring lock washer

Special washer (Note) and spring lock washer

(Note ) The special washers are attached to the inlet flange of TMP when shipping.

Do not remove them at the time of TMP installation.

Refer to Fig. 5-4 for the details of the bolt attaching part.

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

VG250

23

Page 37

SECTION 5 INSTALLATION

5.1.3 Example of piping connection

Connect a backing vacuum pump or its related pipe connection flange to the outlet flange of

the pump. (See Fig. 5-6)

VACUUM CHAMBER

*

5

MAIN VALVE

*

TURBO MOLECULAR PUMP

FOREVACUUM VALVE

*

FLEXIBLE TUBE

*

BACKING VACUUM

*

PUMP

* marks are not attached to this turbo molecular pump set.

Fig. 5-6 Example of Exhaust Line

When gas purge required, connect the gas purge pipeline to the gas purge port. (For the gas

purge detail, see Section 7 "Gas Purge")

After complete piping connection, check for perfect airtightness by helium leak test.

24

263-13236

Page 38

5.1 Installation

Connection of Cooling Water Line:

Connect cooling water pipes to these pumps. When connecting the cooling water pipes, screw

the pipe joint while also holding the nozzle of the pump with a spanner in order to avoid deforming

the cooling water pipe, as illustrated in Fig. 5-7.

PIPE JOINT

Fig. 5-7 Cooling Water Piping Connection

5.1.4 Center of gravity of the pump

The center of gravity of the pump is shown in Fig. 5-8. Fix securely to avoid moving or falling

down in the event of an earthquake.

155mm

156mm

5

Series of TMP-3203 TMP-3403LMC

Fig. 5-8 Center of gravity of the pump

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

25

Page 39

SECTION 5 INSTALLATION

5.2 Connection of the Pump to the Power Supply Unit

CAUTION

Insert straight the control cable connector after checking its key direction.

Inserting it in oblique direction would cause damage of the connector pins. After the insertion,

5

turn the cable connector clockwise until the rotation lock clicks.

CAUTION

Don't disconnect each cable while the pump is running. Particularly before disconnecting the

control cable, Check complete shutdown of the pump by ROTATION lamp goes out and,

thereafter, turn off the POWER switch.

For information regarding cable connections please refer to the Power Supply Unit Instruction

Manual.

26

263-13236

Page 40

5.3 Interlock for Vacuum System

5.3 Interlock for Vacuum System

(1) When using, as a backing vacuum pump, a vacuum pump with no check mechanism

(backstream flow prevention) such as dry vacuum pump, etc., install a forevacuum valve

between the turbo molecular pump and the backing vacuum pump to prevent rapid inverse

flow of exhausted gas. And close the forevacuum valve before the backing vacuum pump

stops. (See Fig. 5-4)

(2) Even when "ALARM" signal is emitted, don't cut off the power supply while "ROTATION"

signal is being emitted. Even when ALARM lamp lights, don't cut off the power supply while

ROTATION lamp lighting.

(3) If "ALARM" signal is emitted or ALARM lamp lights, shut down the backing vacuum pump

or close the forevacuum valve immediately. Furthermore, when main valve is installed

between the turbo molecular pump and the vacuum chamber, close this valve, too.

Provide a flowmeter on the downstream of cooling water line, otherwise the turbo molecular

pump will shut down and otherwise set up the interlock which the pump can not start against

cut off of water supply.

5

For more information regarding signals, please refer to the Power Supply Unit Instruction

Manual.

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

27

Page 41

SECTION 5 INSTALLATION

5

This page is intentionally left blank

28

263-13236

Page 42

6OPERATION

6

6.1 Outline

6.1.1 Introduction

6.2 Start-up Preparation

6.2.1 Start-up Preparation

6.3 Start-up

6.3.1 Start-up Sequence

6.4 Shutting Down

6.5 Baking Operation

Page 43

SECTION 6 OPERATION

6.1 Outline

CAUTION

Neither disconnect and reconnect each cable while the pump is running.

Particularly for unplugging the control cable from the receptacle, check complete shutdown of

the pump by ROTATION lamp goes out and, thereafter, turn off the POWER switch.

6

CAUTION

Do not turn the power off while the pump is running. The touch-down bearing may need to be

replaced if the power is turned off repeatedly during operation.

If the power is turned off during rotation, power from regenerative braking will keep the rotor

levitated. After slowing down, levitation stops and the rotor is supported by the touchdown

bearing. Therefore, repeated touchdowns will reduce the life of the bearing.

6.1.1 Introduction

Please operate by the Power Supply Unit. For more information regarding an operation, please

refer to the Power Supply Unit Instruction Manual.

30

263-13236

Page 44

6.2 Start-up Preparation

6.2 Start-up Preparation

Please select "LOCAL" or "REMOTE" at the switch of the Power Supply Unit.

For more information regarding operation, please refer to the Power Supply Unit Instruction

Manual.

6.2.1 Start-up Preparation

(1) Feed the cooling water into the cooling line. (for cooling water method)

(2) Turn on the POWER switch of the power supply unit and check if the POWER lamp lights.

And the rotor of the turbo molecular pump is levitated by the magnetic bearing.

(3) Evacuate the turbo molecular pump by using a backing vacuum pump.

(4) Start-up preparation is complete if the pressure in the turbo molecular pump reduces

below 200 Pa.

6

6.3 Start-up

6.3.1 Start-up Sequence

(1) Start-up begins when the 6.2.1 "Start-up Preparation Sequence in LOCAL Mode" is

complete.

(2) For more information regarding an operation, please refer to the Power Supply Unit

Instruction Manual.

REFERENCE

A pressure check using the vacuum gauge attached to the pump inlet shows that the pressure

reduces gradually after rotation starts.

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

31

Page 45

SECTION 6 OPERATION

6.4 Shutting Down

CAUTION

After having operated the turbo molecular pump for evacuation of corrosive gas, keep the

pump internal as vacuumed even after shutdown. Inflow of water content in the air to the pump

internal would cause rapid corrosion trouble of the pump internals. The pump corrosion may

6

result in damaging the vacuum vessel interior and other units, causing pressure fluctuation by

stopping the pump and dispersal of parts.

CAUTION

When reducing internal pressure of the turbo molecular pump up to around the atmospheric

pressure by use of inert gas, etc., adjust the pressure reducing valve so that the internal pressure

of the same pump does not exceed 20 kPa [GAUGE].

For shut-down of the turbo molecular pump, follow the sequence below.

Preparations Prior to Shutting Down Operation:

(1) Check that process gas inflow is in complete stop. When main valve is provided between

the turbo molecular pump and vacuum chamber, close the valve, too.

(2) When purge gas is being fed into the turbo molecular pump, stop the gas feed, too.

(3) When forevacuum valve is provided between the turbo molecular pump and backing

vacuum pump, close the valve, too.

Shutting Down Sequence in LOCAL Mode:

(1) For more information regarding an operation, please refer to the Power Supply Unit

Instruction Manual.

(2) Stop the cooling water flow. (for cooling water method)

When the turbo molecular pump is turned off after pumping a corrosive gas, maintain a vacuum

inside the turbo molecular pump or purge the interior of the pump with an inert gas.

Further, in such a case when a hydraulic rotary vacuum pump is used as backing vacuum

pump and there is possible reverse flow and diffusion of oil from the backing vacuum pump,

return the pump internal pressure to atmospheric pressure using dry nitrogen gas, after complete

shut-down of the pump [ROTATION lamp goes out], to prevent the turbo molecular pump from

being contaminated with oil vapor.

For shutting down the turbo molecular pump in running at high speed with infeed of dry nitrogen

gas to the pump, keep the nitrogen gas flow rate at 1500 mL/min maximum.

32

263-13236

Page 46

6.4 Shutting Down

REFERENCE

ROTATION lamp goes out or "ROTATION" signal turns off when the pump rotational speed is

60rpm or less. Turning off the POWER switch permits the pump rotor to be supported by the

touch-down bearings.

6

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

33

Page 47

SECTION 6 OPERATION

6.5 Baking Operation

CAUTION

During baking operation, cool down the turbo molecular pump in either cooling water or cooling

fan.

6

NOTICE

Baking temperature is not allowed to exceed 120 ℃ .

The baking heater is installed near the inlet flange.

BAKING HEATER

Fig. 6-1 Installation of Baking Heater

Perform baking treatment when the inlet pressure of the turbo molecular pump is 1x10-3 Pa or

less. It is necessary to apply baking to not only the vacuum chamber but also the pump proper

in order to keep an exhausting vessel at super high vacuum. However, the baking temperature

is not allowed to exceed 120

of aluminum alloy.

For baking application to the pump proper, carefully adjust the baking temperature. For the

purpose, special heater is supplied with the pump system considering the temperature

requirements. Use this heater for control of the baking temperature.

℃ because generally the rotor of the turbo molecular pump is made

INLET FLANGE

34

263-13236

Page 48

7GAS PURGE

7

Page 49

SECTION 7 GAS PURGE

The turbo molecular pump incorporates a gas purge port (Fig. 2-1 (2)). Gas purging is not

required for ordinary evacuation. However, a purge gas flow is recommended to protect the

bearings during evacuation of large quantities of corrosive gas during an etching process, for

example. An inert and chemically stable non-condensing gas is most suitable for the purge gas.

Nitrogen is the most popular purge gas. A purge gas flowrate between 20 and 30 mL/min is

appropriate.

Please consult your shimadzu representative, during evacuation of corrosive gas.

The gas-purge adaptor is available without an orifice (recommended) or with an orifice (option).

Refer to Fig. 7-1 to check whether the gas-purge adaptor attached to the purchased pump

incorporates an orifice. Connect the gas-purge adaptor correctly, according to the piping

diagrams below. The diagram shows the KF10 joint, but the method of recognizing the orifice is

the same for all joints.

7

Orifice insertion

position

Without orifice

With orifice

Fig. 7-1 How to Recognize if the Gas-purge Adaptor Incorporates an Orifice

Fig. 7-2 shows an example of a gas-purge piping diagram. Use a filter element size of 5 μm,

or less. Use a stop valve to start and stop the purge gas flow.

Gas supply

± 10 kPa gauge pressure (nitrogen gas)

20

Gas feed start After starting backing vacuum pump; before evacuating process gas

Gas feed stop

After exhausting process gas sufficiently; before stopping backing vacuum

Type of gas Nitrogen gas or argon gas (Purity > 99.99%)

VACUUM CHAMBER

PURGE PORT

TURBO MOLECULAR

PUMP

VALVE

BACKING VACUUM PUMP

FLOWMETER WITH

CONTROL VALVE

REGULATOR

FILTER

GAS

SOURCE

Fig. 7-2 Gas Purge Method (diameter of orifice is φ0.5mm)

36

Joint PART No. Description

KF10 262-77592-19 GP ADAPTOR, 0.5 KF10

UJR 6.35 263-14770 GP ADAPTOR, 0.5 UJR

SWAGELOK

φ6.35

263-14771 GP ADAPTOR, 0.5 SWG

4-VCR 263-14772 GP ADAPTOR, 0.5 VCR

Table. 7-1 Table of Gas-purge Ports (diameter of orifice is φ0.5mm)

263-13236

Page 50

OPTION

A gas purge adaptor with an orifice is available as an option. The gas purge adaptor with an

orifice maintains the purge gas flow between 20 and 30 mL/min if the gas-supply pressure lies

within the range below. Flow control with a flowmeter is not required.

Note: Gas purge adaptors with no orifice

are recommended for applications in which large

amounts of reaction products are generated (e.g., metal etchers). Adaptors with an orifice

willcause clogging.

Gas supply

± 10 kPa gauge pressure (nitrogen gas)

20

Gas feed start After starting backing vacuum pump; before evacuating process gas

Gas feed stop After fully exhausting process gas; before stopping backing vacuum pump

Type of gas Nitrogen gas or argon gas (Purity > 99.99%)

VACUUM CHAMBER

PURGE PORT

TURBO MOLECULAR

PUMP

VALVE

BACKING VACUUM PUMP

FLOWMETER WITH

FLOW ALARM

REGULATOR

FILTER

GAS

SOURCE

Fig. 7-3 Gas Purge Method (diameter of orifice is φ0.05mm)

Joint PART No. Description

KF10 262-77592-03 GP ADAPTOR, 802 KF10

UJR 6.35 262-77592-01 GP ADAPTOR, 802 UJR

SWAGELOK

φ6.35

262-77592-06 GPA, SS-400 STRAIGHT

4-VCR 262-77592-14 GP ADAPTOR, 4-VCR

7

Table. 7-2 Table of Gas-purge Ports (diameter of orifice is φ0.05mm)

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

37

Page 51

SECTION 7 GAS PURGE

7

This page is intentionally left blank.

38

263-13236

Page 52

8TURBO MOLECULAR

PUMP RECONDITION

8

8.1 Turbo Molecular Pump Return Request

8.2 Turbo Molecular Pump Decontamination

8.3 Touch-Down Bearing Replacement

8.4 Check of the rotor blades

Page 53

SECTION 8 TURBO MOLECULAR PUMP RECONDITION

8.1 Turbo Molecular Pump Return Request

WARNING

Improper turbo molecular pump use may be hazardous to operator's health in applications not

recommended or approved by Shimadzu. In the event removal of the turbo molecular pump from

an application is required, full protective measures including purging of the turbo molecular pump

with an inert gas and/or apparel are recommended when the turbo molecular pump has been

used in applications that required the use of corrosive, reactive, stimulative, or toxic gases.

8

Annual overhaul is recommended.

Overhaul, re-manufacturing, refurbishing, or repair of the turbo molecular pump system should

always be performed by Shimadzu or an approved service company. (A copy of this from is

printed at the end of this manuals "Repair of Magnetic Bearing Turbo Molecular Pump")

The following precautions are required before forwarding the turbo molecular pump to

Shimadzu or an approved service company for all service related requests.

(1) The turbo molecular pump must be void of all process gases. Turbo molecular pumps that

were operated in applications using special gases (doping gas, epitaxial gas, film forming

gas, etching gas, etc.), likely have the process by-products, reaction-produced matter, etc.

Remove them from the turbo molecular pump by repeated gas purge to the pump and fill the

pump with an inert gas. The pump interior must be adequately purged with inert gas before

uninstalling from the unit.

(2) The customer is required to submit MSDS (Material Safety Data Sheet) sheets and

information of all gases, materials, etc. that have been associated with the turbo molecular

pump.

Shimadzu will accept and perform service only on turbo molecular pumps that have been

properly prepared as stated in (1) and (2) above. Shimadzu will advice the customer of any failure

precaution/prevention procedures that are appropriate to each individual turbo molecular pump

service request.

40

Remove the pump in the manner shown in Fig. 8-1.

Vacuum

chamber

263-13236

Vacuum

chamber

PUMP

Fig. 8-1 Way to remove the pump

PUMP

Page 54

8.2 Turbo Molecular Pump Decontamination

8.2 Turbo Molecular Pump Decontamination

All expenses incurred with the decontamination of the turbo molecular pump are the

responsibility of the customer.

8.3 Touch-Down Bearing Replacement

The touch-down bearing (Fig. 3-1 (9)) is the only component of Shimadzu's turbo molecular

pump that is subjected to friction and wear, normally occurring only during electrical power

failure. Repeated and/or frequent rotor touch down will cause wear and bigger rotational

resistance and require replacement of touch down bearings.

Shimadzu recommends replacement of the touch-down bearing by Shimadzu or an approved

service company.

8

8.4 Check of the rotor blades

Rotor blades of turbo molecular pump are high-speed rotor made of aluminum alloy. It has the

possibility that material strength deteriorates, specially when corrosive gas is evacuated. Regular

check (Customer is liable for the cost.) by Shimadzu or a Shimadzu approved/authorized service

center is suggested. (Every one year is recommended.) Shimadzu and/or the service center

perform fluorescence penetrant testing of rotor blades in every overhaul task and check and

suggest a rotor replacement to customers if any cracks are found out.

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

41

Page 55

SECTION 8 TURBO MOLECULAR PUMP RECONDITION

8

This page is intentionally left blank.

42

263-13236

Page 56

9TROUBLESHOOTING

9

9.1 Vacuum Pressure Rise

9.2 Abnormal Noise and/or Vibration

Page 57

SECTION 9 TROUBLESHOOTING

9.1 Vacuum Pressure Rise

A rapid rise of vacuum pressure in the turbo molecular pump causes the internal motor of the

turbo molecular pump to start braking and the ALARM lamp lights.

9.2 Abnormal Noise and/or Vibration

Should the turbo molecular pump ever generate abnormal noise and/or vibration, the turbo

molecular pump operation is to be stopped immediately.

But there is possible that a race of touch-down bearing (Fig. 3-1 (9)) may make sounds for

seconds when the pump internal pressure gets back to atmospheric pressure using air (or nonactivity gas). This phenomena is not abnormal and make no damage to the pump, because the

air whirlpool sometimes occurs and then makes the touch-down bearing rotate slightly.

9

44

263-13236

Page 58

Index

B

backing vacuum pump ...................... 8、14、15、24

C

CE MARKING ........................................................ 16

Cooling fan ........................................................vi

cooling water .....................................................8

corrosive gas ......................................................... 41

G

gap sensor ............................................................. 10

gas purge ........................................ 14

、15、36、37

、vii

、25

Index

I

inlet flange ........................................................8、11

O

outlet flange ......................................................8、11

overhaul ................................................................. 40

P

port for gas purge .................................................... 8

R

rapid shutdown torque ........................................... 23

rotor ................................................................10

、11

S

SEMI F47 ............................................................... 16

SEMI S2 ................................................................. 16

T

touch-down bearing ........................................11、41

U

UL .......................................................................... 16

263-13236

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

Index-1

Page 59

Index

This page is intentionally left blank.

Index-2

Magnetically Levitated Turbo Molecular Pump

INSTRUCTION MANUAL

263-13236

Page 60

Excerpt from No. FE8A-0049F

Declaration of Conformity

SHIMADZU CORPORATION SEMICONDUCTOR EQUIPMENT DIVISION

Address :380-1,HORIYAMASHITA,HADANO-CITY,

KANAGAWA, 259-1304, JAPAN

as the Manufacturer

declares in sole responsibility that the following product

Product Name Turbo Molecular Pump

Model name , P/N

Vacuum Pump Power Supply

Model name P / N Model name P / N

TMP-3203LM/LMC/M/MC

TMP-3403LM/LMC/M/MC

Note: –xx (P/N)means 00 to 99 or blank

referred to in this declaration conforms with following directives and standards

Machinery directive 98/37/EC amended by 98/79/EC

EN292-1:1991, EN292-2:1991+A1:1995,

EN1012-2:1996

Low Voltage directive 73/23/EEC amended by 93/68/EEC

EN61010-1:1993+A2:1995

EN61010-1:2001

EMC directive 89/336/EEC amended by 91/263/EEC, 92/31/EEC, 93/68/EEC, 93/97/EEC

EN61326:1997+A1:1998+A2:2001, class A

Note 1) This declaration becomes invalid if technical or operational modifications are

introduced without manufacturer’s consent.

Note 2) This declaration is valid if this product is used alone or in combination with the

accessories of this product or other instruments which fulfill with the

requirement of mentioned directive.

Note3) Importer/Distributor and Authorized Representative in EU is as follows:

KRATOS ANALYTICAL LTD.

Address :

Hadano, JAPAN 3 April 2003

place and date of issue signature

Whartisid, Trafford Wharf Road, Manchester M17 1GP England

262-78430-xx

262-78503-xx

EI-D3203M

EI-D3403M

262-78685-xx

262-78694-xx

Shinzo Inoue

name

Manager of Quality Assurance Dept.

Semiconductor Equipment Division

Shimadzu Corporation

Position

Page 61

FE9M-E0122

TMP Evaluation Form

Please fill out this evaluation form and attach to the product when you send it back to Shimadzu Service Center for repair

service, etc. When you fill out this form, please describe the details as much as possible.

Evaluation items (Please check the item box, and fill out the information at the underline.)

Returned

Request : □ Overhaul □ repair □ others

: □ Pump Type TMP- Product No.

□ Power source Type EI- Product No.

Detail

Alarm name: (If there is status indication lamp, light No is : )

System/Equipment name:

Date of request (date of occurrence): Expected date of treatment completion:

Total operation hours: hrs. Date of operation start: Date of delivery:

Please fill out the following items to make sure of worker's safty.

[Announcement of attraction material and gas]

Repair etc. may not be accepted when attraction material and gas is not removed.

・Type of attraction material:

(Please fill out the etched material in etch system/equipment (GaAs substrate etc.).Please fill out

the material of target in PVD system/equipment (sputter, vacuum evaporation etc.).

・Type of attraction gas

□ Air, nitrogen, etc. (name: ) □ Inert gas such as helium, etc. (name: )

□ Corrosive gas (name: ) □ Reactive/active gas (name: )

□ Virulent gas (name: ) □ Others (name: )

Attraction gas (

□:removed, □:not removed) Influence on man's body.( □ YES, □ NO)

Treatment procedure, handling precaution, etc. for case when attraction gas is not removed.

・Is there a color changes and adhesion at inlet and outlet flange? □ Yes □ No

If there is a color changes and adhesion, we wash the TMP to keep an appropriate performance of

vacuum pump.(additional charges)

Customer(Company)

:Division: Phone #:

Contact Person: (ext.#) Authorized signature:

Use condition of equipment :

Gas purge:□ Used ( ml/min) □ Not used (none)

For the oil type bearing:

Oil type:□ Standard oil □ Fluorine base oil(designated oil) □ Others( )

Oil level:□ near upper limit □ medium point □ near lower limit □ less than lower limit

Others :

Dealer name: Contact Person: Tel

SHIMADZU CORPORATION

Page 62

SHIMADZU CORPORATION. Internatinal Marketing Division

3. Kanda-Nishikicho 1-chome, Chiyoda-ku, Tokyo 101-8448, Japan

Phone:81(3)3219-5641 Fax:81(3)3219-5710

SHIMADZU PRECISION INSTRUMENTS, INC.

Santa Clara Office Vacuum Technology Group

2350 Walsh Avenue, Santa Clara, CA95051, U.S.A.

Phone:1(408)566-0960 Fax:1(408)566-0961

KRATOS ANALYTICAL LTD.

Wharfside, Trafford Wharf Road, Manchester M17 1GP U.K.

Phone:44(161)888-4400 Fax:44(161)888-4402

SHIMADZU (ASIA PACIFIC) PTE LTD.

16 Science Park Drive #01-01 The Pasteur Singapore Science Park, Singapore 118227,

Republic of Singapore

Phone:65-778-6280 Fax:65-779-2935

SHIMADZU INTERNATIONAL TRADING (SHANGHAI) Co., LTD.

24th Floor, Shanghai Xin-Hualian Building No.755 Huaihai Zhong Lu, Shanghai 200020

Phone:86(21)6472-8442 Fax:86(21)6472-8648

Loading...

Loading...