Page 1

228-30179

DIFFERENTIAL REFRACTIVE DETECTOR

RID-1

OA

FOR

SHIMADZU

HIGH

-

PERFORMANCE

LIQUID

CHROMATOGRAPH

USER’S

MANUAL

Read the instruction manual thoroughly before you use the product. Keep

this

instruction

manual

with care

so

that you can use it any time you need it.

SHIMADZU

CORPORATION

CHROMATOGRAPHIC & SPECTROPHOTOMETRIC

INSTRUMENTS DIVISION

KYOTO,

3APAN

Page 2

Copyright 0 Shimadzu Corporation

1995.

.

All rights are reserved, including those to reproduce

this

publication or

parts

thereof in any

form without permission in writing from Shimadzu Corporation.

Information in this publication is subject to change without notice and does not represent

a

commitment on the part of the vendor.

Any errors or omissions which may have occurred in this publication despite the utmost care

taken in its production will be corrected

as

soon

as

possible, but not necessarily immediately

upon detection.

Note that Shimadzu does not have any obligation concerning the effects resulting from the

application of the contents of this manual.

MS, MS

-

DOS, Microsoft and Visual Basic are registerd trademarks, and Windows is

a

trademark of Microsoft Corporation

in

the USA.

IBM is a registerd trademark

of

International Business Machines Corporation in the USA.

TrueType

is

a

registerd trademark of Apple Computer, Inc in the USA.

Page 3

The

RID-1

OA

is the differential refractive index detector for the high-performance liquid

chromatograph.

In

order to operate the unit safely, strictly observe the following points.

1.

Do

not

use

the unit for any purpose other than the above mentioned analysis.

2.

Follow the procedures described in the instruction manual.

3.

Observe the warnings and cautions.

4.

Do

not disassemble

or

modify the unit without approval

from

Shimadzu. Failing to do

so

may lead to a dangerous situation or damage of the unit.

5.

For internal repair of the product, contact your Shimadzu Service Representative.

6.

The pink-color pages and the meshed parts are for our service engineers, and are not

intended for our clients.

Do

not attempt installation of the instruments

as

serious damage

could result.

WARNING IN

THE

INSTRUCTION MANUAL

This instruction stipulates the content of warnings as follows:

-1

Applied in a case that could result in death or serious injury.

-1

Applied in a case that could result in slight injury or physical

damage.

-1

Applied for improvement of operating efficiency or help in

understanding.

I

Page 4

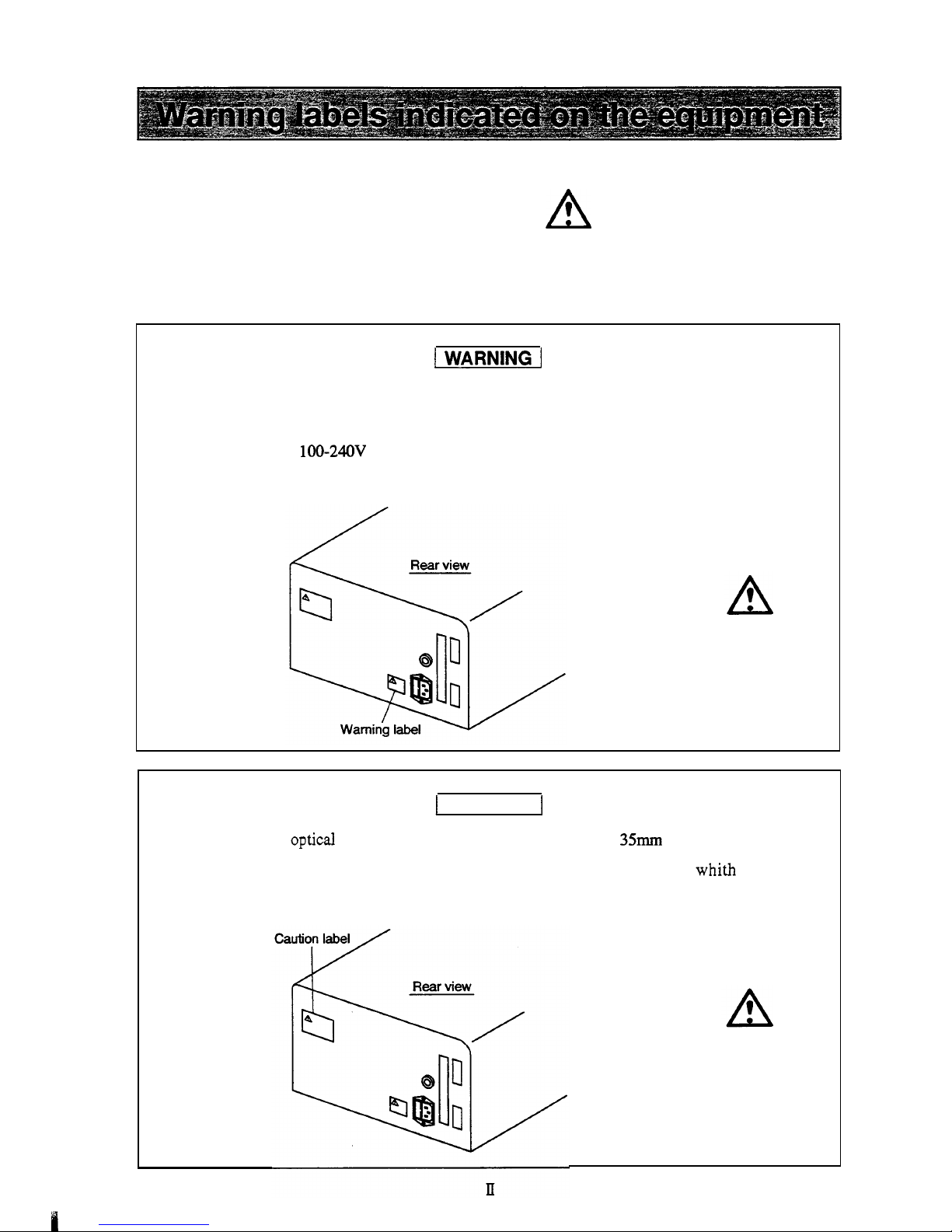

For safety

of

operation, this unit is provided with

the

A

mark

at the portion where special

When operating the

parts

where

this

mark

is

indicated, exercise

special

caution

after

reading

cautions are required.

the

manual.

Replacement

of

fuses

This

unit uses the

following

fuse. Be sure to replace the fuse

of

same

type

and

capacity.

Rated voltage

:

100-24OV

Part

NO.

072-01652-23 250V 5AT

I

CAUTION

I

Do

not bend the optical cable for remote control with the radius

of

35mm

or less.

Bending it with the radius smaller than 35mm may damage the cable,

whith may cause

malfunction

of

the

unit.

Page 5

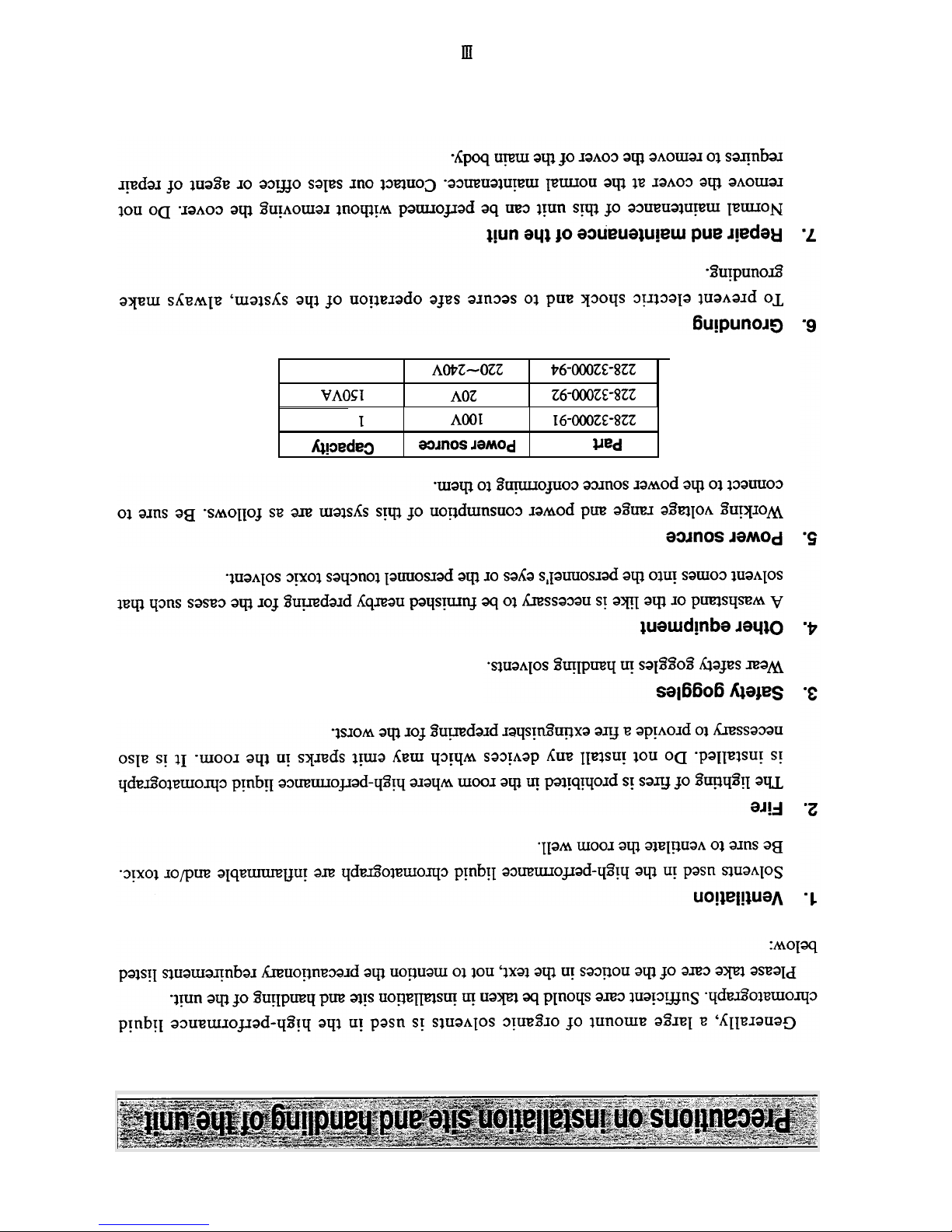

m

VAOS

I

AOX-022

VAOSI

A02

I

96-000ZE-822

26-0002€-822

VAOS

I

hpedea

A001

16-000Zf-822

a3NlOS

JaMOd

'ON

lred

Page 6

8.

Solvent

not

usable

HFIPA

(Hexafluoroisopropyl alcohol) affects the materials used in the flow path and

deteriorate the strength of the material. In the worst case, pipe may explode and high

-

pressure solvent scatters.

As

it is very dangerous, never

use

HFIPA.

9.

Others

The equipment should not be exposed to direct sunlight or strong air currents.

It

is

also

recommended to install in a room where temperature fluctuation

is

small.

N

Page 7

Liquid chromatography using flammable organic solvents as mobile phase requires proper care

against

fire,

explosion, etc. Pakcularly, among various possible accidents, those caused by static

electricity are difficult to anticipate, and tend to occur only with unexpected conditions which

often make countermeasures insufficient.

At a site where preparative liquid chromatography is practiced, a large amount of flammable

substances may be used. Therefore, once an accident happens, it could lead to tremendous

damage.

The mechanism of accident caused by static electrical discharge and preventive measures are

described below. Take due care in safety measures in handling of equipment.

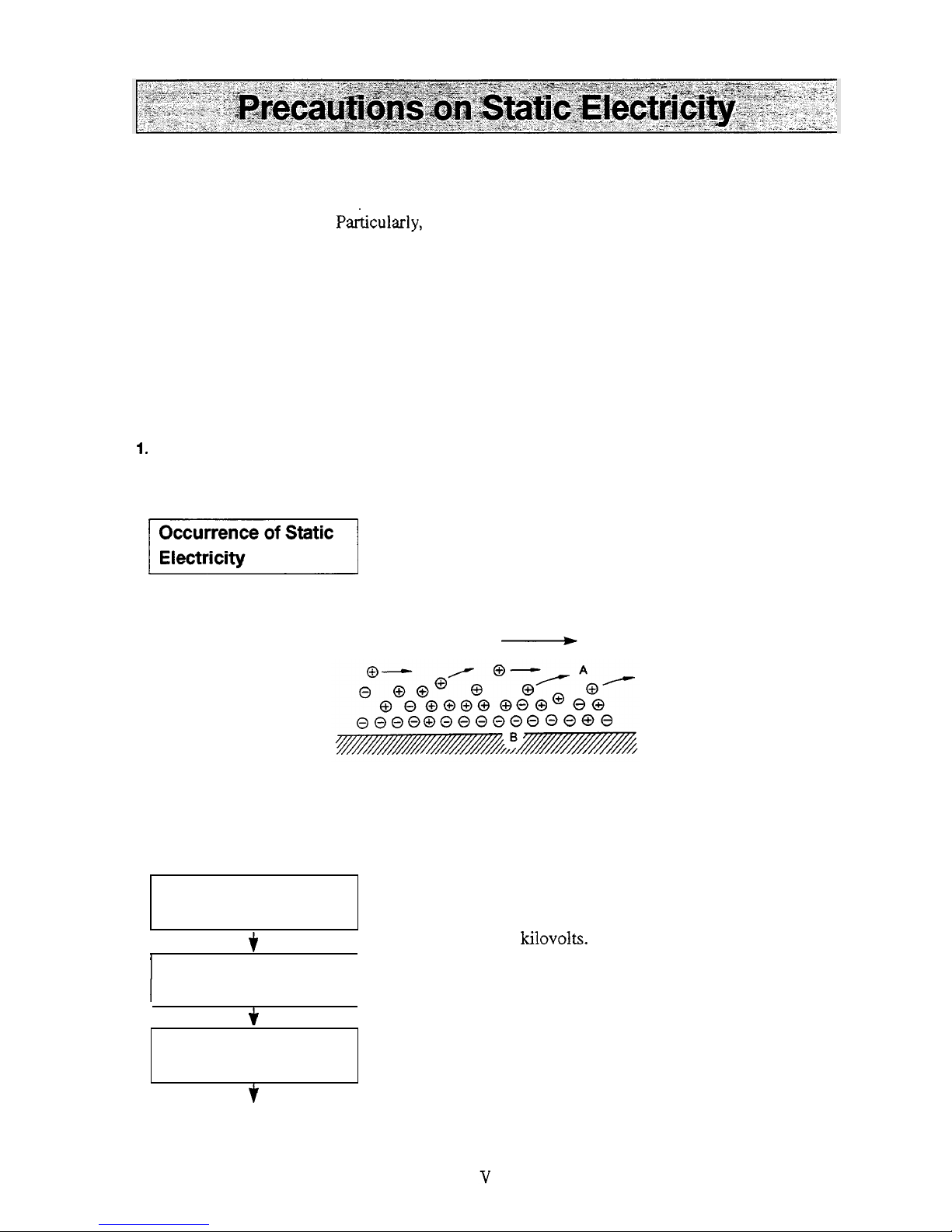

1.

Mechanism

of

Static Electrical Discharge Accident (Example)

Accidents caused by static electricity take place through the following processes.

When liquid is fed at high speed through a small

-

diameter

tube like the pipe of a liquid chromatograph, static electrical

charge occurs by friction between solid and liquid

as

shown in

Fig.

1.

Occurrence

of

Static

Electricity

1

$

-

Flowing liquid

A

Solid

body

A

:

Electric charge

moving with

flowing liquid

B

:

Electric charge

being fixed

to

the

solid surface.

Fig. 1 Occurrence

of

Static Electricity by Friction between Solid and Liquid

Charging and storage

of

static electricity

t

1

Energy release by

1

I

discharge

I

3.

Ignition

of

combustible

substances

f

When the charged liquid is collected in an insulated vessel,

the static charge accumulates gradually, and the voltage can

easily reach

a

few kilovolts.

If

some other conductive object

is

brought near the vessel,

electricity is discharged at a certain distance from the vessel

releasing heat energy.

If flammable gas of sufficient concentration exists nearby,

ignition is caused by this energy.

Page 8

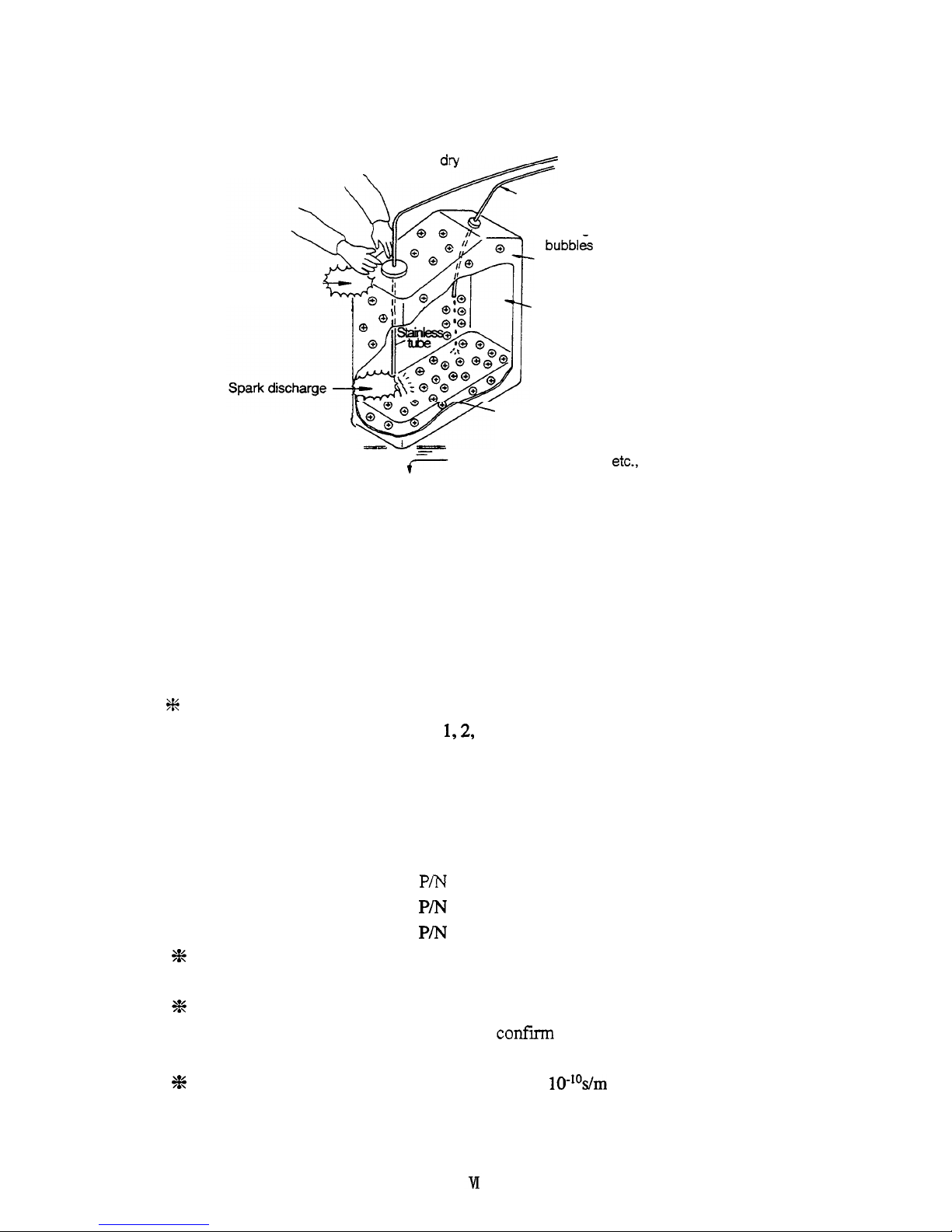

If

air drv

\

Liquid is flowing at high

speed

through a

small

diameter tube.

*Charge is easily accumulated if

bubbles are included in the liquid.

Insulated vessel

(like polyethylene)

Spark discharge

-

””;”oyc

I

Ill

/

Inflammable gas is stored in the

head space

of

the vessel.

(\

n\

Inflammable organic solvent is

charged

to

a great extent.

e

- - -

-

Floor covered

with

rubber, etc.,

provides unwanted insulation.

Fig. 2 Conditions which may cause Accidents

2.

Preventive Measures against Accidents

The principal preventive measure is the prevention of “charging and storage of static

electricity” among those items shown in “Mechanism

of

Static Electrical Discharge

Accident.” The preventive measures are shown below. It is recommended to exercise two

or more measures simultaneously.

3K

Particularly when a large quantity of flammable solvent is held in a large vessel,

be

sure

to observe the preventive measures

1,2,

and

3.

Preventive measure

1.

Use metallic (conductive) waste liquid vessel which is well grounded.

This

releases the

charge of the waste liquid and vessel to ground.

The following items are available.

(1)

Grounding

wire

with clip P/N

228-21353-91

(2)

Metallic

18

liter can

P/N

038-00044

(3)

Metallic 4 liter can

P/N

038-00043-01

3K

+E

Be sure to ground the vessel properly. Disconnecting of grounding wire or poor

grounding defeat the purpose of using

a

metallic vessel.

There are some metallic cans which have no conductivity

due

to

an

oxidized coating

or lacquer on their surface. Be

sure

to

confirm

the grounding

of

vessels by a tester

before application.

When a liquid with almost no conductivity (of

10-lOs/m or less) is discharged into the

vessel, it is necessary to

mix

it with another liquid with some conductivity. (The other

liquid can be placed in the vessel

in

advance.)

%

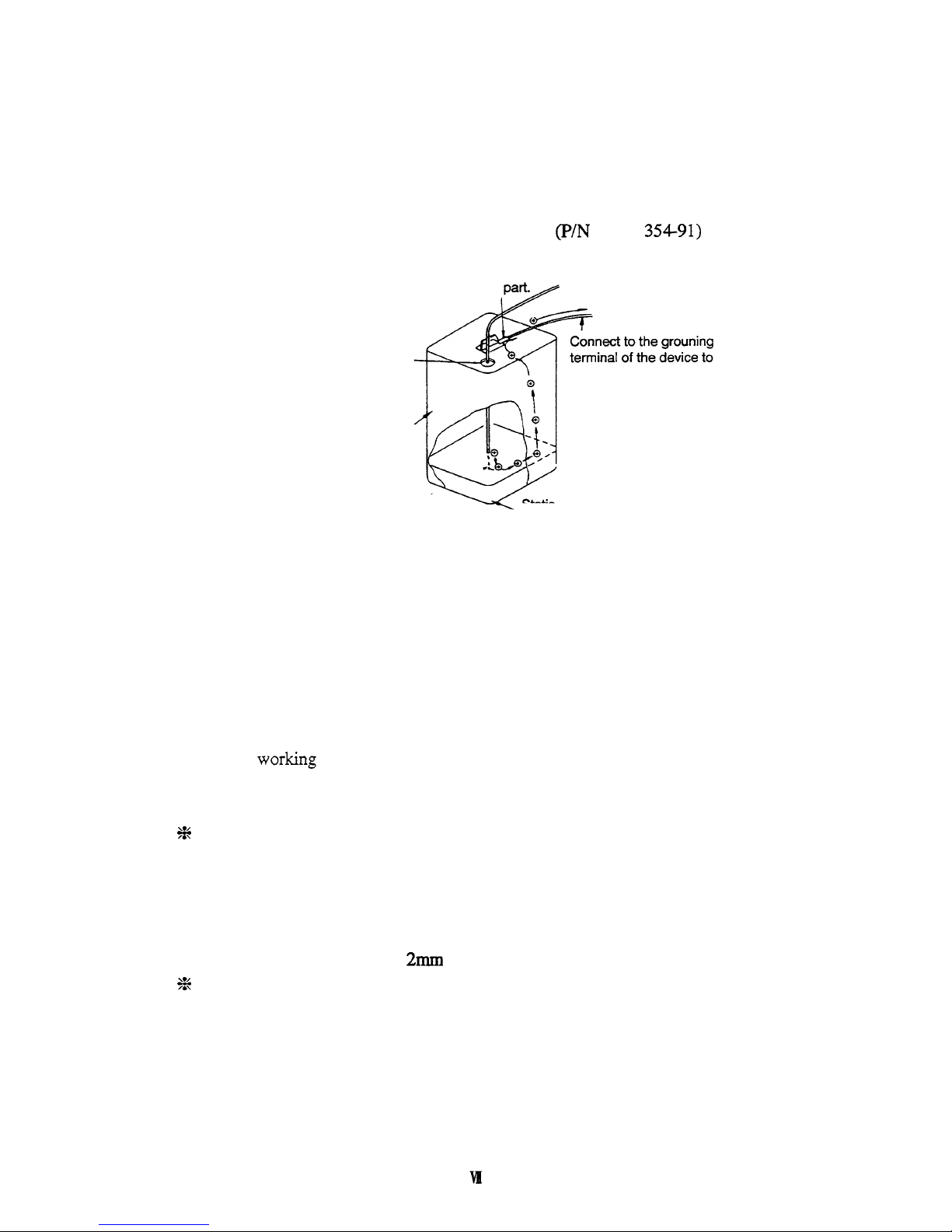

Page 9

Preventive measure

2.

Minimize the clearance

of

both inlet and outlet

of

vessel to prevent flame from entering the

vessel.

(1)

Cap with three holes for

18

liter and 4 liter cans

(P/N

228-21

354-91)

is available.

Connect clip to metallic

Minimize clearance

by

attaching a cap.

ground the metallic vessel.

Metallic

18

litter can

(A

plated can is recommended.)

Static electricity

of

the liquid

is released via vessel.

Fig. 3 Anti-Static Electricity Measures for Vessel

Preventive measure

3.

Do

not approach the vessel with charged objects including the human body.

Charging prevention measures for human body

a)

b) Grounding

of

human body

c) Make

working floor conductive

Prevention of charging of shoes and clothes

Suitable products to be used for those measures a), b), and c) are available on the

market.

When persons who use no charge prevention measures approach dangerous sections,

they have to be grounded beforehand. (For example, they should contact grounded

metal by hand.)

%

Preventive measure

4.

Use pipes with inner diameter of

2mm

or more for waste liquid line for large flow rates.

3%

Inclusion

of

bubbles in the

tube

may increase the amount of charging by ten times.

Check that there is no inclusion

of

air

via

tube

joints.

Page 10

Preventive measure

5.

When it is impossible to use a conductive vessel, use caution in the following points.

a)

Set the vessel

so

that the pipe outlet will be placed below the liquid

level

in the

vessel. Or, dip a grounded metal (ex. pipe connected

to

the main body of device) in

the liquid.

This

method is not effective

for

liquid with small conductivity (10-I0s/m

or

less).

Use

a

vessel

of

the

smallest possible capacity to minimize the damage by

fire

if it

should occur.

Prevent the

room

from

being

dry.

Humidity of

65% or

more has charge prevention

effects.

+E

b)

c)

a

Page 11

1ChapterlI

General

1.1

Outline

..........................................................................................................

1-2

1.2

Features

........................................................................................................

1-3

1.3 Principle

of

Measurement

.............................................................................

1-4

1.4

Row Schematic

............................................................................................

1-6

1

Chapter2 1 Parts List

2.1 Parts and Accessories

...................................................................................

2-2

-1

Component Location and Function

3.1 Front View

....................................................................................................

3-2

3.2 Interior

of

Front Cover. Right Side

..............................................................

3-3

3.3 Rear View

.....................................................................................................

3-4

I

Chapter4 1 Installation

4.1 Basic Installation Requirements

...................................................................

4-2

4.2 Example

of

System Layout

..........................................................................

4-3

4.3

Stacking Modules

.........................................................................................

4-4

4.4 Electrical Connections

..................................................................................

4-5

4.6 Connecting the Recorder and Integrator

.......................................................

4-11

4.7

4.5 Plumbing Connections

..........................................

:

......................................

4-6

Connecting the Drain Tube

for

Solvent Leakage

...........................................

4-13

1-1

Operation

5.1

Precautions

for

Operation

.............................................................................

5-2

5.2 Fundamentals

of

Operation

..........................................................................

5-3

5.3 Plumbing

of

the Flow Selection Block

.........................................................

5-13

5.4

5.5

Creating and Executing

Tie

Programs

.......................................................

5-16

Additional Functions (AUX

-

FUNC)

............................................................

5-21

1

ChaDter

6

I

Initial Performance Test

6.1

System Performance Check

............................................................................

6-2

-1

Control from External Equipment

7.1 Connection with System Controller SCL-1 OA

.............................................

7-2

7.2 Control

form

the SCL-IOA

...........................................................................

7-3

7.3

Connecting External Input and Output Terminals

........................................

7-10

I

Chapter

8 1 Maintenance

8.1

Cleaning the Flow Lines

...............................................................................

8-2

8.2 Span Adjustment

..........................................................................................

8-3

8.3 Replacement

of

Fuse

....................................................................................

8-7

8.4 Periodical Cleaning

......................................................................................

8-8

Page 12

1-1

Performance Verification

9.1 Component Validation

..................................................................................

9-2

9.1

.

1

Test Procedures

of

Stand-alone Unit

......................................................

9-3

9.1.2

Test Procedures Controlled

from

the

SCL

-

1

OA

......................................

9-5

9.2 System Validation

.........................................................................................

9-9

9.2.1 Test Procedure

of

Isocratic LC System

..................................................

9-9

1-1

Troubleshooting

10.1

10.2

Symptoms. Causes and Remedies

................................................................

10-2

List

of

Error

Messages

..................................................................................

10-4

-1

Specifications

...............................................................................

1 1 . 1

RID-1

OA

Specifications 11-2

[-I

Replacement Parts

12.1

Consumables

and

Repair

Parts

.....................................................................

12-2

12.2 Optional

Parts

...............................................................................................

12-4

rChapterl31

Reference

13.1 Solvent Characteristics

.................................................................................

13-2

.

Page 13

Chapter

1

General

1.1

Outline

.....................................................................................................

1-2

1.2

Features

...................................................................................................

1-3

1.3

Principle

of

Measurement

.......................................................................

1-4

1.4

Flow

Schematic

.......................................................................................

1-6

1-1

RID-1OA

-

Page 14

RID-1OA

is

the

differential refractive index detector for the high

performance liquid

chromatogaph developed as a module

of

the

LC

-

1

OA

series.

The

RID-10A

improves analysis productivity and convenience

of

use like a

UV

detector. Its shortened stabilization time, the fact that

it covers various applications from high sensitivity analysis to

sampling analysis preparation

and

more,

RID-1OA

is much

improved in convenience than conventional models.

Only handling instructions for

RID

- 1 OA

and related accessories

are

described

in

this

instruction manual.

For

handling instructions of

other components, please refer to the pertinent instruction manual.

1-2

-

RID-1OA

Page 15

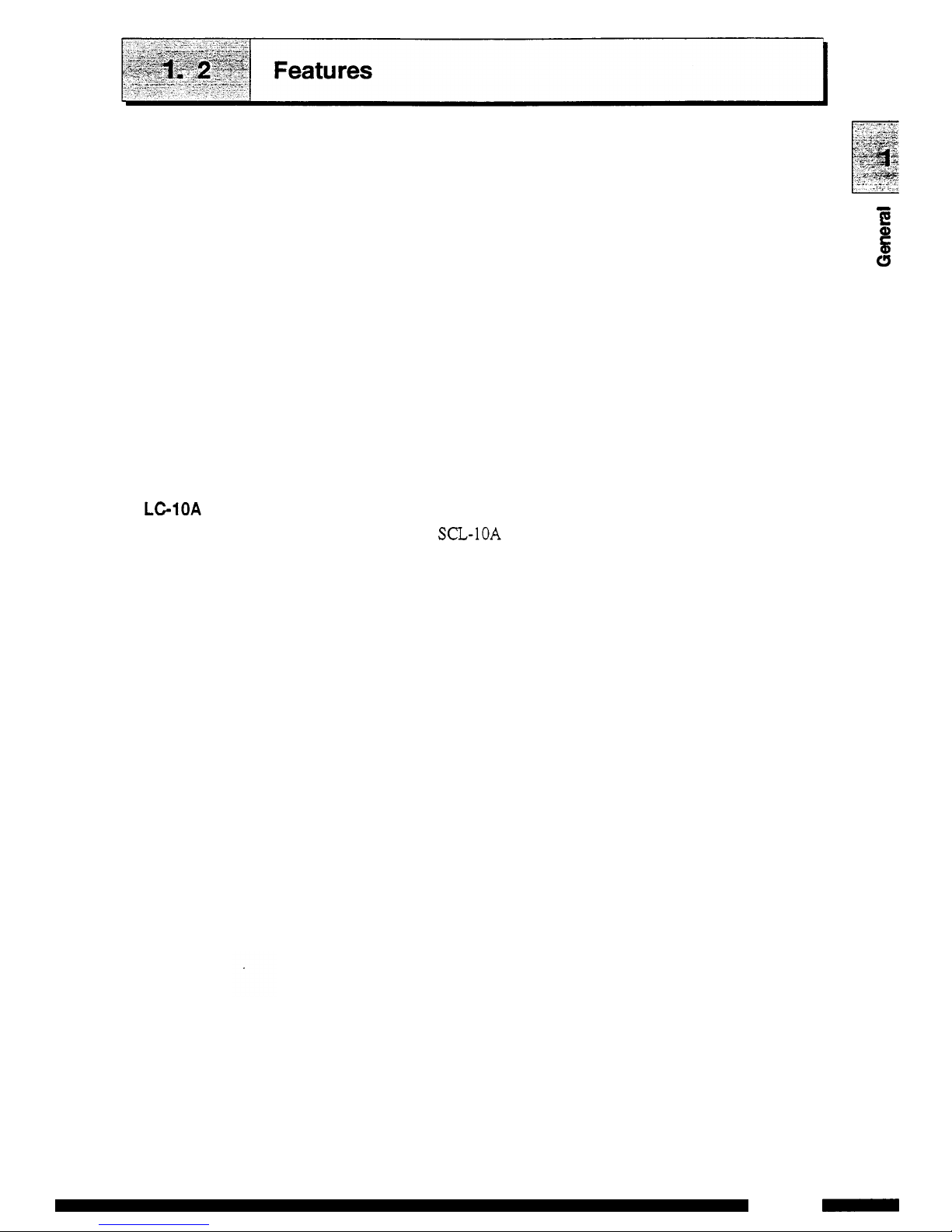

1.

Excellent

stability

Stabilization time after turning on the power has been shortened to

reduce the waiting time for

start

of

analysis. Excellent stability has

been realized by employing the dual temperature control structure

of

the optical system and by improving the thermal design.

-

0

r

t

By adapting the original four-partitioned photodiode,

this

equipment

now covers the wide dynamic range of various applications from

high

sensitive analysis to large scale preparation of high concentration

samples.

2.

Various

applications

3.

Safety measure

4.

Corresponding to the

LC-1OA

series

The standard model is equipped with a leak sensor which enables

automatic performance

of

operations such

as

stopping the pump in

the early stage of organic solvent leakage.

This

equipment is designed for the

LC

-

1

OA

series to have excellent

operability

as

a

component of the total system, including control

from the

SCL-1OA

and

data

processing in the

CLASS

workstation,

etc.

1-3

RID-1OA

-

Page 16

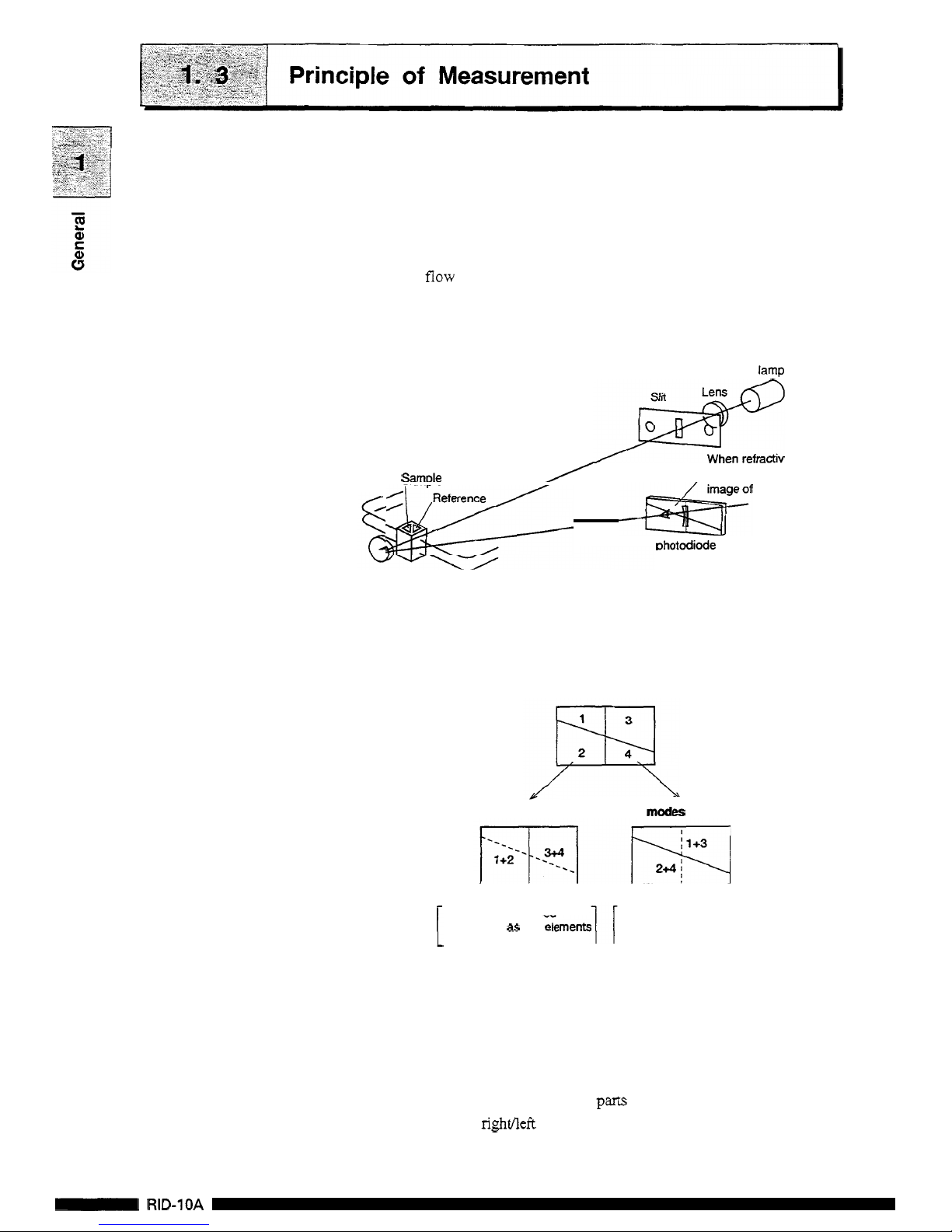

The optical system of this unit is shown in following illustration.

The light radiated from the lamp passes through the lens slit and

through the cell in the form of parallel rays, which is then reflected

by

the

mirror and passed through the cell

to

form an image of the

slit

on

the photodiode.

The

flow

cell consists of the sample side and the reference side.

When

the refractive index

in

the sample side cell varies,

the

image

of the slit moves horizontally.

W

lamp

#

When refractive index

I

When refractive index

,

in the

flow

cell

vanes,

Samole

/

<\-&

~&zf

the

slit

moves.

Dhotodiode

This

unit has a photodiode partitioned in four

as

shown in the figure

below. When selecting a piece of photodiode to use among these

four, the unit is able to provide measurements for both analytical

and preparative work.

In

modes

P

and

L

In

mode

A

1

A

signal is processed

divided into up and down.

regarding

it

as

two

regarding

it

as

two

elements

A

signal is processed

divided into right and left.

Signal processing

in

mode

A

A

signal

is

processed using the right and left portions of the

photodiode

as

individual elements. Data processing is performed as

a two

-

partitioned photodiode divided into right and left.

When the refractive index in the

cell

varies,

the

balance of the incident

light intensity into right and left

parts

of

the photodiode changes. The

change

in

the right/left balance

is

converted into refractive index and

then can

be

recorded.

1-4

-

RID-1OA

Page 17

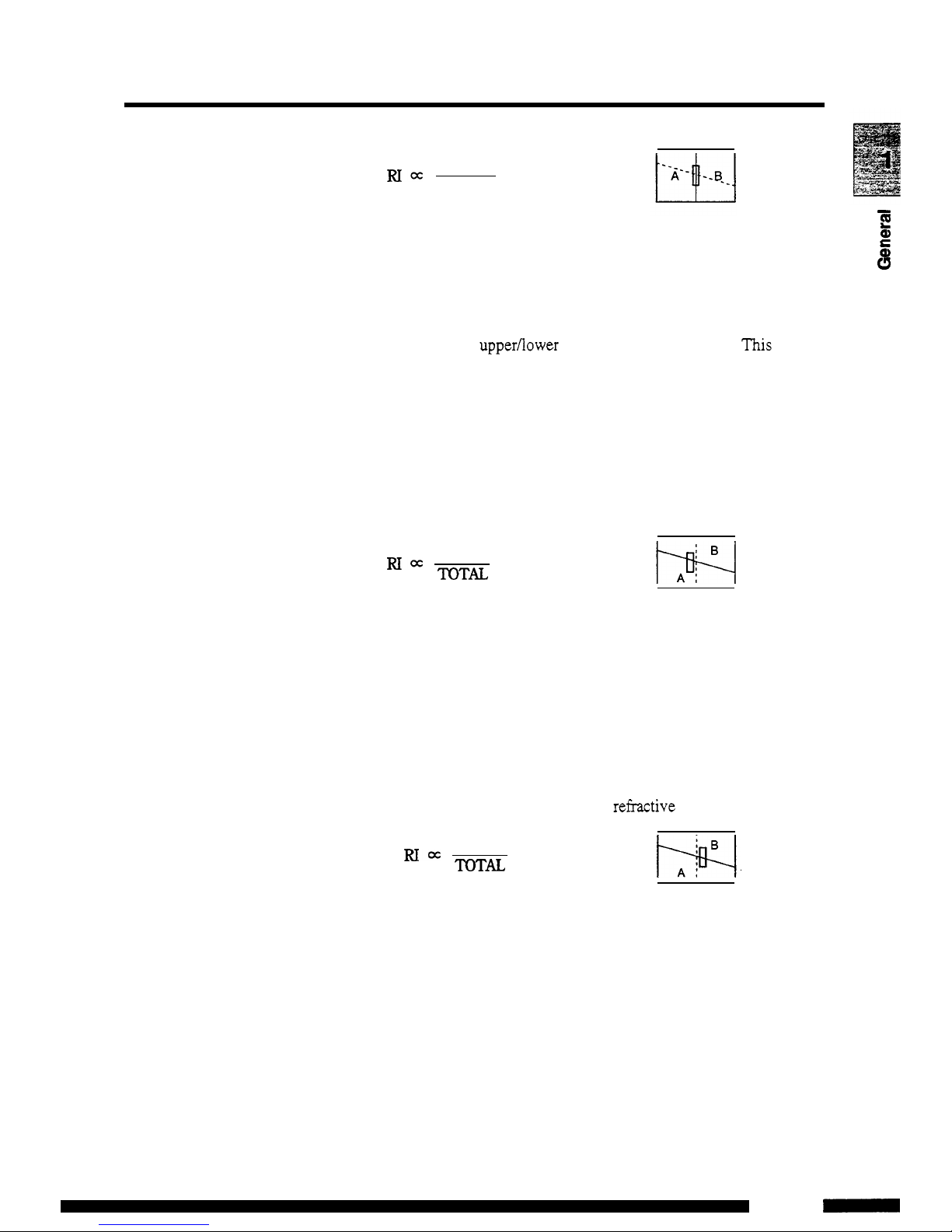

1.3

Principle

of

Measurement

A-B

RIx

TOTAL

Signal processing in mode

P

-

E

a,

Signal processing is performed using the upper and lower parts of

L

Q

the photodiode

as

individual elements. Since the boundary between

the upper and lower parts

is

slanted against a horizontal line, when

an

image of the slit moves horizontally, the balance of the light

intensity

in

the upper/lower parts

of

the diode changes.

This

change

in balance is converted into refractive index. The change

of

the bal

-

ance against the variation

of

the

refractive index is one-twentieth

that

of

mode

A.

In

mode

A,

when the slit image goes beyond the

center line, measurement becomes impossible because the balance

value stops varying, while in mode

P,

measurement is possible

under

these

conditions enabling measurement of a sample with high

concentration.

A-B

TQTU

Signal processing in mode L (An optional

flow

selection

block

is necessary)

Signal processing is performed

as

the same

as

in mode

P,

using

each

of

the upper and lower parts of the diode

as

individual ele

-

ments. However, since the reference side with less flow line resis

-

tance is used

as

the sample cell, the image moves in the reverse

direction

of

that

of

mode

P.

Thus polarity is turned over

before

the

change in balance

is

converted into a refi-active index.

B-A

TOTAL

w.

A

1-5

RID-1OA

-

Page 18

The diagram shows flow lines

in

the RID-10A.

At R flow

OFF

When the R flow switch is

OFT,

the solenoid valve is open at side

A.

The solvent passing through the sample cell flows into the outlet

port, not into the reference cell.

At

R

flow

ON

When the R flow switch

is

ON,

the solenoid valve is open at side

B.

The solvent passing through the sample cell flows into the outlet

port after passing through the reference cell. This

is

used to fill the

sample cell and the reference cell with solvent of equal refractive

index before starting the measurement.

R

flow

ON

Q

!

Outlet

port

Inlet

port

Tubing

volume (At R flow

OFF)

Inlet port to flow cell

63.5

pL

Flow cell volume

9pL

Flow cell to cell outlet port

280.2

pL

S:

Sample

R:

Reference

1-6

-

RID-1OA

Page 19

Chapter

2

Parts List

c

v)

3

2.1

Parts

and

Accessories

..............................................................................

2-2

1

CONTENTS

1

2

-

1

RID-1OA

-

Page 20

1

[Caution]

Part

Name

Signal cable

When connecting the flow line and performing maintenance, be

sure

to use the

parts

described on this page or

“1

2.1,

Consumable

and Repair

Parts

”.

Normal

function

of

the system

is

not

,guaranteed

when

other

parts

are

used.

Parts

No.

Quantity

228-25089-92

1

This equipment consists of the following components. Upon

unpacking,

confirm that all

parts

listed below

are

included

in

your

shipment.

0

RID-IOA

Main Body

Power supply cord

(

120V)

(220-240V)

Optical cable

0

Standard Accessories

071-608 14-

01

1

07 1-608 14-06

070

-

92025-5

1

1

sus

tubing

Teflon tubing

228-22310-00 lm

228-22305-00

50

crn

228- 18495-03 2m

Remote

cable

I

228-28253-91

I

1

Locking plate

Instruction

manual

SC

Coil

ASSY

(220-24OV)

Syringe

Syringe adapter

228-15672-91

Coupling 1.6C

228-16004-03

Male nut PEEK

228- 18565

228

-

1875

1

1

228-301 78

1

228-34050-9

1

1

Drain tubino

kit

I

228-18495-03

I

1

I

2-2

-

RID-1OA

-

Page 21

Chapter

3

Component Location

and Function

3.1

Front

View

...............................................................................................

3-2

3.2

Interior

of

Front Cover,

Right

Side

.........................................................

3-3

3.3

Rear View

................................................................................................

3-4

c

0

(D

0

0

-

c

3-1

RID-1OA

-

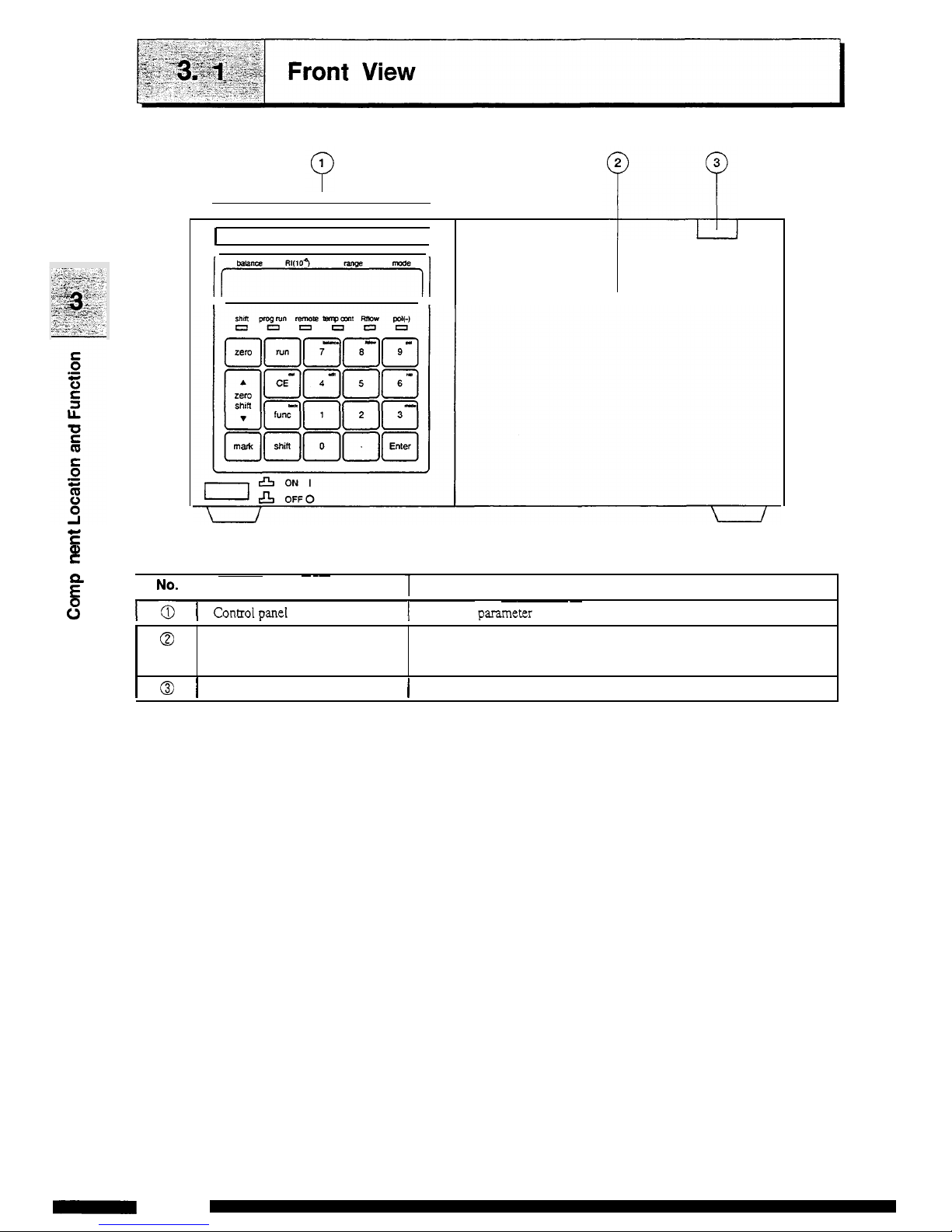

Page 22

w

S

Q,

c

0

E

s

0

I

RID-1OA

I

Front cover

The front cover is opened for mounting

and

dismounting of

flow

cell

and

piping.

~ ~~

I

No-

I

Description

7

Function

~~~

1-0

I

controipanel

I

Performs

parasnetex

setting

and

displays

set

values.

I

@

I

Front cover opening

button

1

Press

this

button

to

open the front cover.

3-2

0

RID-1OA

Page 23

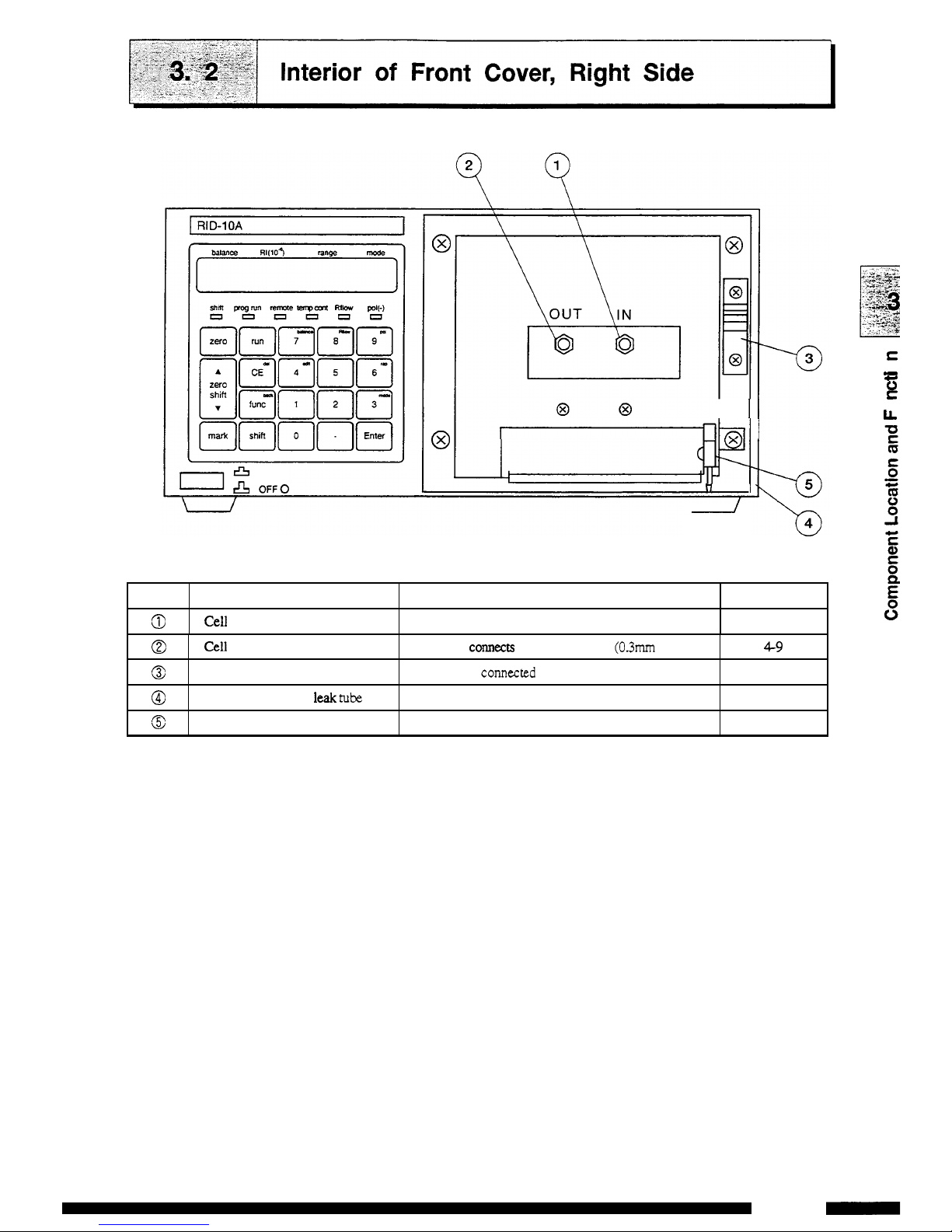

ON

I

I%

OFF0

No.

0

0

0

Description Function

Refer

to

page

Cell inlet

port

Connects the

tube

from

column.

4-8

I II

@I

@

@

@

HI1

I

Cell outlet

port

Tube

holder

Connection

port

for leak

tube

Normally

COM~C~S

back

pressure

tube

(03mm

ID.

x

Im).

4-9

Secures

the connected

tube.

Connects the leak

tube

to

this

port.

4-13

Solvent

leak

sensor

Detects

solvent leaks and

outputs

an

error signal.

10-4

n

I

\

/

S

0

0

E

3

LL

-

c

3-3

RID-1OA

-

Page 24

E

0

0

E

3

LL

.-

c

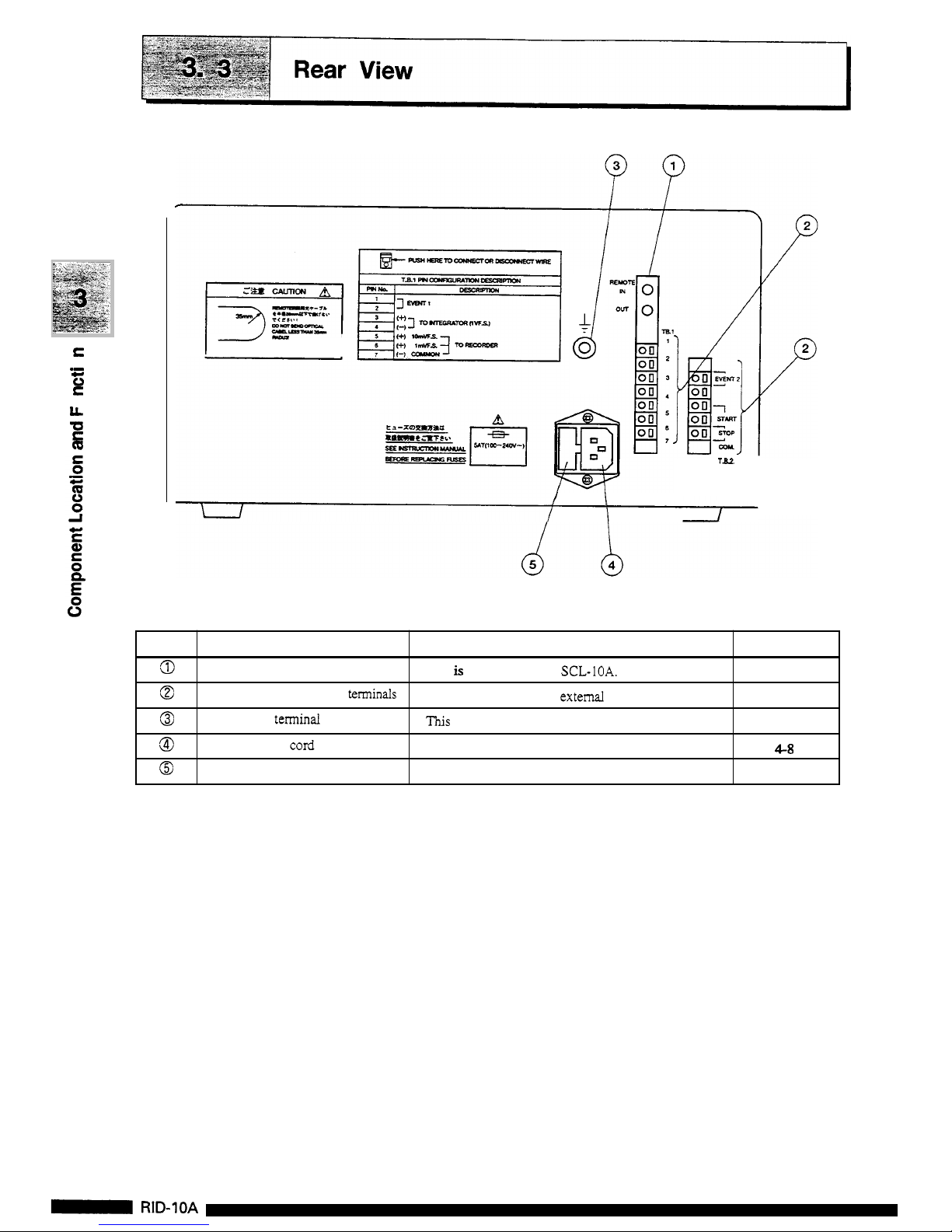

No.

3

6

6

@

c9

‘c,

E

Q

Description

Function

Refer

to

page

This

is

the connector for

SCL-IOA.

7-2

7

-

16

REMOTE

connector

External

input and output

texminals

Grounding terminal

Power supply cord connector

Fuse holder

These terminals connect

external equipment.

This

terminal

is

used

for grounding.

The power supply

cord

is

connected here.

4-8

Two fuses

are

provided

in

this

holder.

8-7

r

I---

I

i

Ta2

I

I

I

\

I

I

3-4

-

RID-1OA

Page 25

Chapter

4

Installation

~~~ ~~~~ ~

(,,NTENTs

1

4.1

Basic Installation Requirements

.............................................................

4-2

4.2

Example

of

System Layout

....................................................................

4-3

4.3

Stacking Modules

...................................................................................

4-4

4.4

Electrical Connections

............................................................................

4-5

4.5

Plumbing Connections

...........................................................................

4-6

4.6

Connecting the Recorder

and

Integrator

................................................

4

-

1 1

4.7

Connecting the

Drain

Tube for Solvent Leakage

...................................

4-13

4-1

RID-1OA

-

Page 26

Basic Installation Requirements

pAGiiiq

To

take full advantage of the RID-1OA’s performance capabilities

and

to

ensure its operational stability over a long service life,

verify that

the

selected installation site satisfies the following

requirements.

1.

Ventilation

2.

Fire

3.

Sink

Ventilate the room where

the

high-perfomance liquid chromatograph

is located since the solvent used is flammable

andor toxic.

Never use

fre in the same room where the high performance liquid

chromatograph is installed. Also, avoid installation in the same

room of other devices which may spark.

Always

keep

a

fire

extinguisher nearby

in

case of accident.

Install a sink nearby for flushing eyes

or

skin which have been in

contact with solvent.

4.

Corrosive gas and dust

Avoid installation in a place exposed to corrosive

gases

or dust.

5.

Electromagnetic noise

Avoid locations subject to intense magnetic or electromagnetic

fields. Use

an

additional noise filter if power line noise interferes.

6.

Space requirements

This system is designed to be used on a table

or

stand, preferably a

solid and flat surface with

a

depth of 60cm

or

more.

See

“4.2,

Example of System Layout” for typical confi,o;urations of systems

and installation space.

7.

Others

Select

an

installation site with

the

following parameters to maintain

full performance of the system.

(1)

Maintain

room temperature within

4--35”C,

without extreme

fluctuations.

(2)

Avoid direct output of a heater or a cooler.

(3)

Avoid exposure to direct sunlight.

(4)

Avoid locations subject to strong vibrations

or

prolonged

weak vibrations.

(5)

Maintain relative humidity within

45-85%.

4-2

-

RID-1OA

Page 27

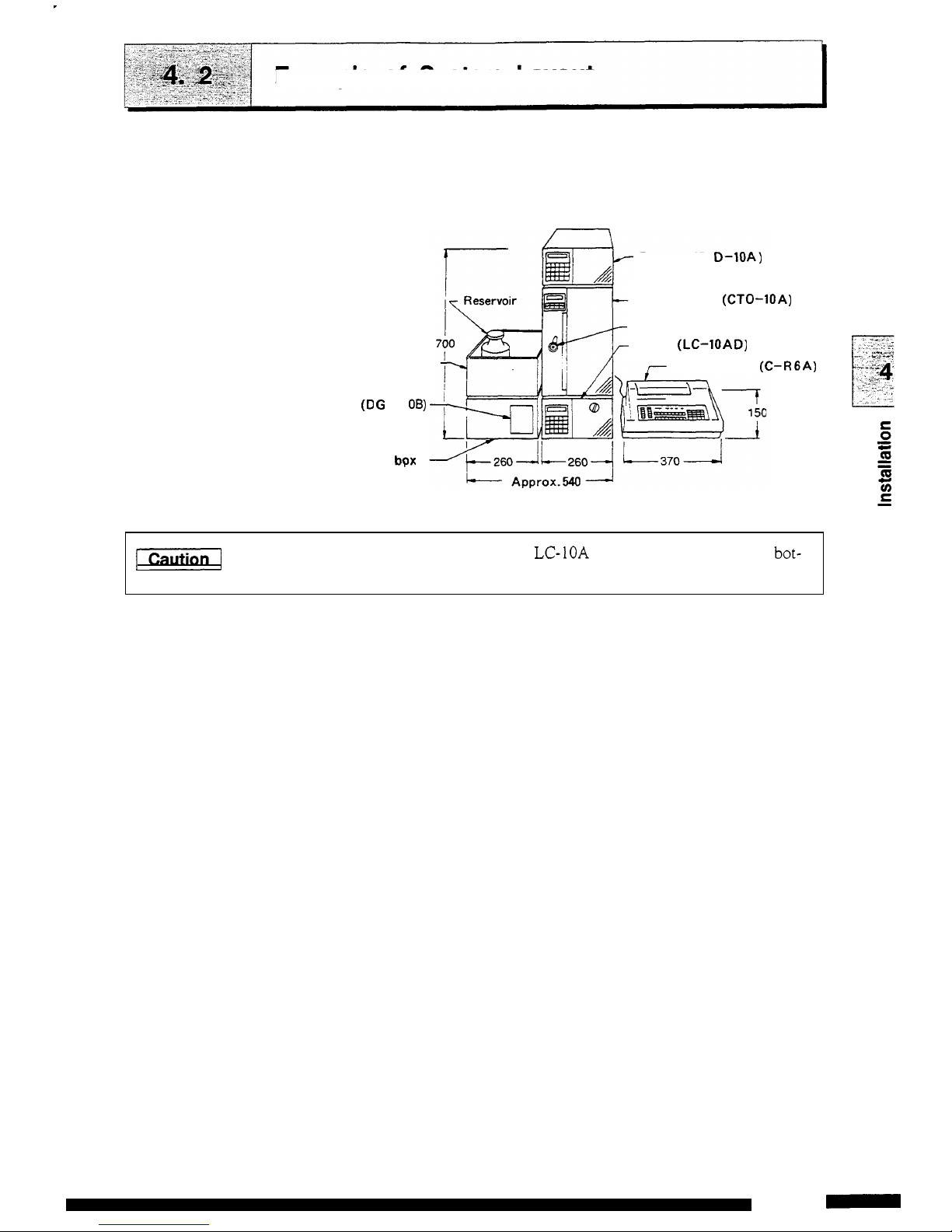

Example

of

System

Layout

Example

of

liquid chromatograph system layout using this equip

-

ment

and

space requirements

are

shown below.

Detector

(RI

0-1QA)

Column oven (CTO-1OA)

Manual injector

(7725)

Pump (LC-IOAD)

Reservoir

box

Chrornatopac (C-RGA)

Degasser

(D

G

U -1

06)

Option

bpx

S

[Caution/

Each component

of

the

LC-1OA

has a little clearance at the bot-

tom. Be careful to keep fingers clear when installing the unit.

4-3

RID-1OA

-

Page 28

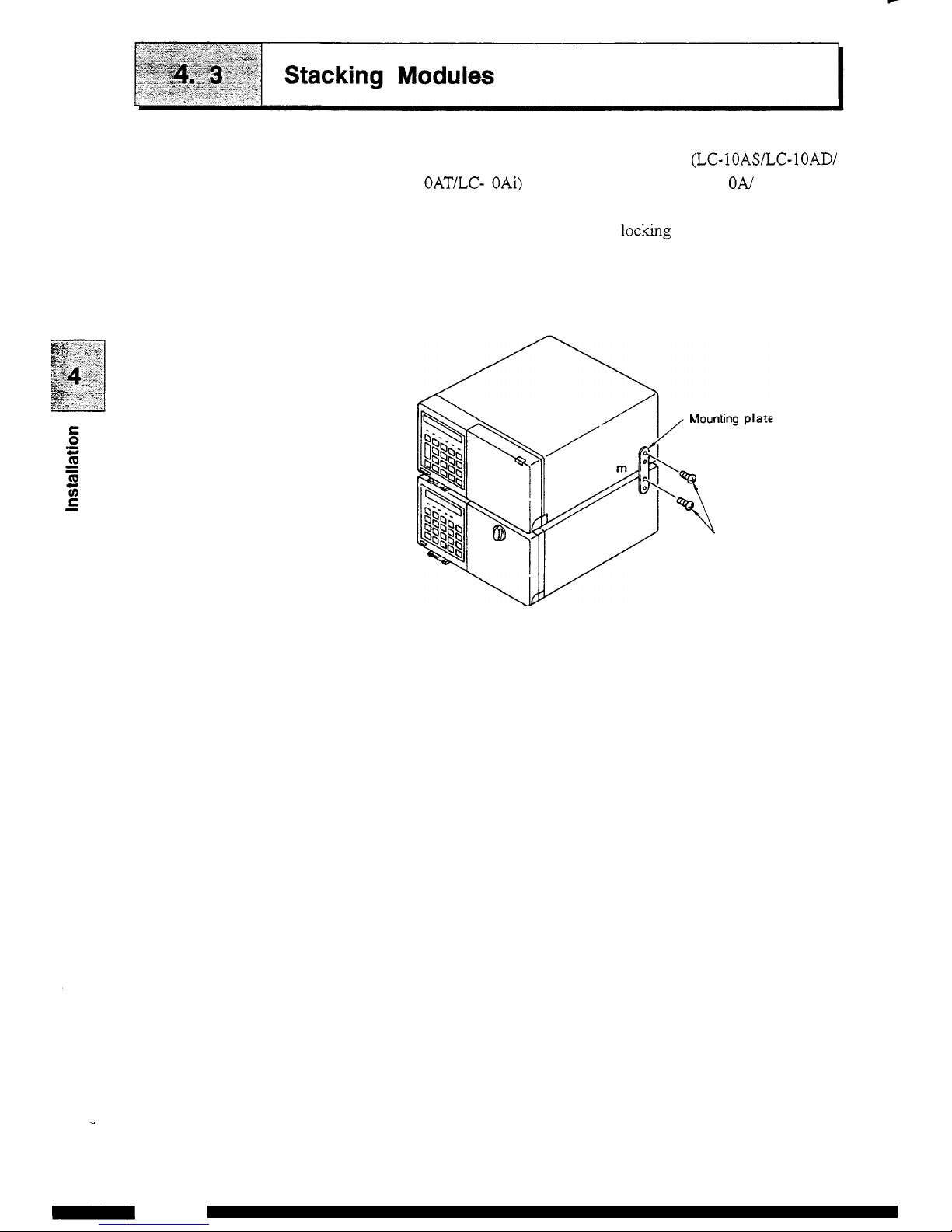

RID-1OA may

be

stacked on the pump (LC-IOASLC-lOAD/

LC- 1 OAT/LC- 1 OAi) or the column oven (CTO

-

1

ON

1 OAC). The

equipment can

be

stacked and locked for safety in case of

an

earthquake, etc. using the supplied locking plate.

(1) Refer to the figure below and remove the screws fastening

the equipment cover.

(2)

Attach the mounting plate using the removed screws.

Tighten the

mounting

plate

using the removed screws.

4-4

-

RID-1OA

Page 29

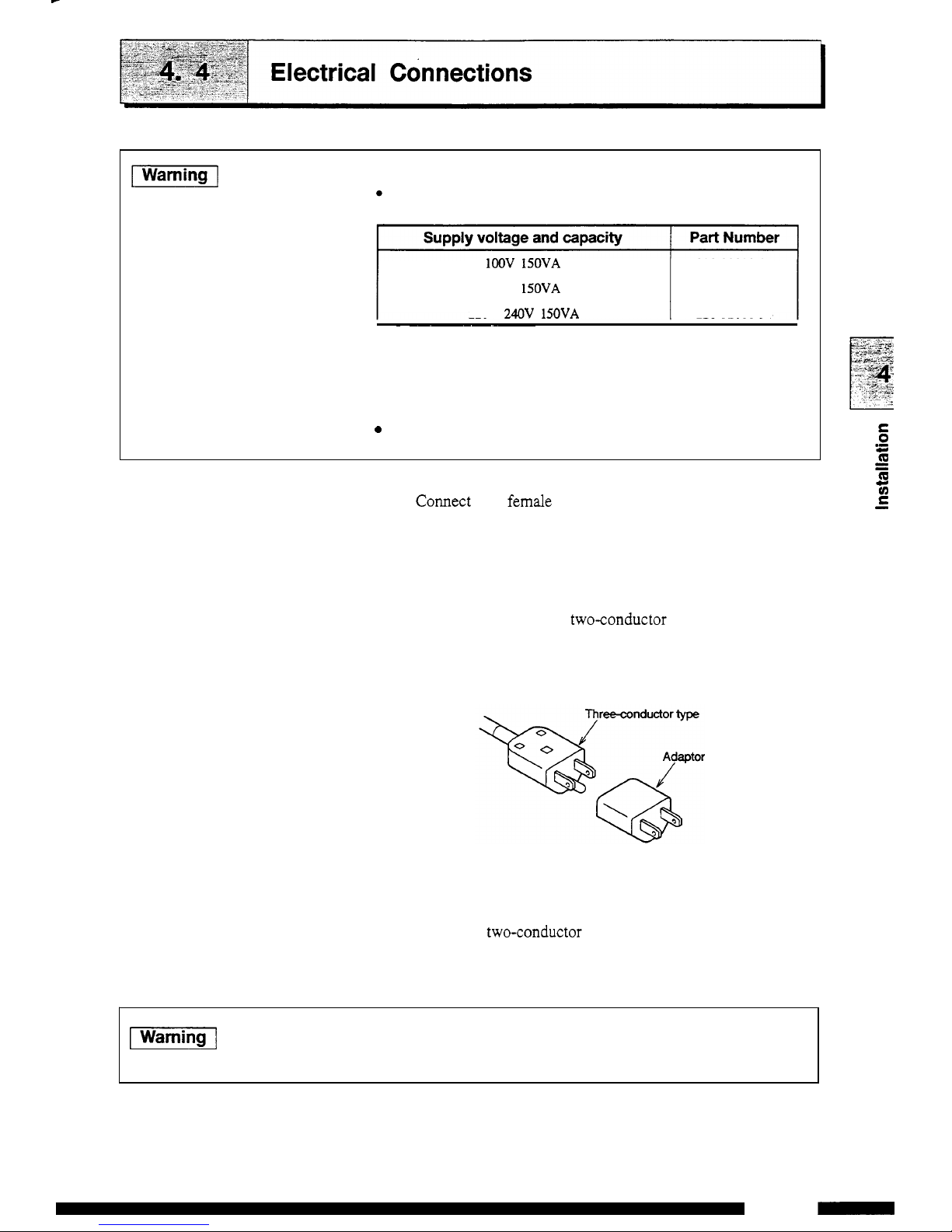

piEG@-[

Check the following points before connecting power supply.

Supply voltage and capacity

lOOV 150VA 228-32000-91

120V

150VA 228-32000-92

220

-

240V 150VA 228-32000-94

~ ~~~~~~~

When the power supply

is

not stable or the capacity insufficient,

satisfactory performance is not possible. Verify the total power

supply for the system before preparing the power supply.

0

Verify that the power switch of the main unit is

turned

OFF.

1.

Connection

to

outlet

(1)

Connect the female connector of the power supply cord

supplied with the unit to the power supply cord connector at

the rear

of

the unit, and plug the male connector into a power

supply outlet.

The supplied power cord is a three

-

conductor (3-prong) type.

When connecting to a

twoconductor (2-prong) type power

supply outlet, use the provided power supply adapter.

(2)

2.

Grounding

(1)

(2)

When the three

-

conductor type power supply outlet

is

used,

the unit is grounded by the power supply cord.

When the

two-conductor type power supply outlet is used,

the unit is not grounded.

In

this

case, ground

from

the

grounding terminal on the

rear

panel of the unit.

piiGi@l

To

prevent electric shock and to secure safe operation of the

system, always ground the unit.

4-5

RID-1OA

-

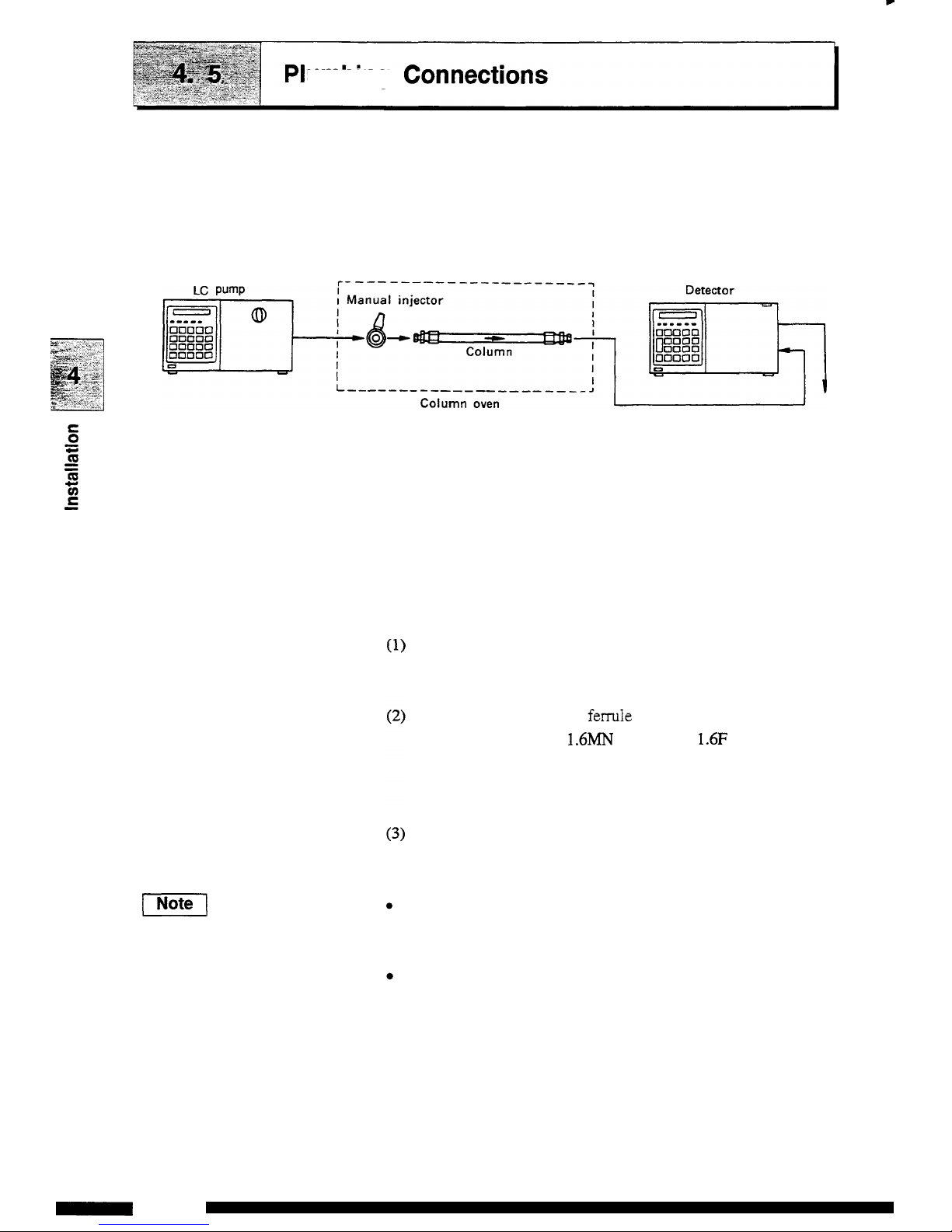

Page 30

F

-

7

umbing

Connections

This section describes proper connection in a typical

flow

line as

shown

in the figure below:

1.

Flow

line in the system

Refer to the column oven instruction manual for installation

of

the

manual injector and column oven. When the column oven is

not

used, an injector holder and a column holder are optionally

available for installation of the manual injector and the column.

2.

Connecting the solvent delivery pump and manual injector

Connection of the solvent delivery pump and the manual injector

are described below.

Cut the

SUS

pipe

(1.6

x

0.3 supplied

as

a liquid pump

accessory) to the necessary length for the pump outlet and

injector port

2.

Install

the male nut and ferrule to both ends of the

SUS

pipe.

Attach the male nut

1.6MN

and ferrule

1.6F

(accessories of

the pump)

to

the pump outlet side, and the male nut and

ferrule (accessories of the manual injector) to the manual

injector.

Connect

an

end of the

SUS

pipe to the pump outlet and the

other end to the injector.

(Notel

Connect the

drain

tube to the manual injector ports 5 and

6.

Adjust the tip of the

drain

tube to meet the needle port of the

injector.

For all connections of the manual injector, use the male nut and

ferrule supplied

as

the manual injector accessory.

4-6

-

RID-1OA

Page 31

4.5

Plumbing

Connections

/

T

Manual

injector

Injector

holder

3.

Connecting injector and column

A typical connection

of

a manual injector and a column is

shown

below:

(1)

Cut the

SUS

pipe

(1.6

x

0.3

supplied to the pump, to the

necessary length for connecting the injector and the column.

(2)

Attach a male nut and a ferrule to the ends

of

this

pipe.

(3)

Connect the ends

of

the

SUS

pipe to the injector and the

column respectively.

Attach the ferrule and the male nut supplied with the injector to

the injector and those supplied to the pump to the column.

Make the pipe length between the injector and the column

as

short

as

possible to prevent sample band broadening.

Cut the pipe on the perpendicular and connect

it

securely to

avoid dead volume.

4-7

RID-1OA

-

Page 32

4.5

Plumbing

Connections

SUS

pipe

PEEK

pipe

Cut perpendicularly

with

a cutter knife.

Cylinder Cut perpendicularly.

&

I

\

d

\

I

Mail nut

1.6MN PEEK

Ferrule

1.6F PEEK

Mail nut

1.6MN

Ferrule

1.6F

Rear

of

manual injector

I

J

To

detector

4.

Connecting detector and column

A

typical connection between the RID-1OA and a column is

described in this section.

(1) Cut

the

supplied

SUS

tubing (50cm long) to the necessary

length for connecting the column outlet and the cell inlet

Po*.

Cut the tube on the perpendicular. When the

tube

is cut on a diagonal,

dead volume is generated which deteriorates separation.

When the flow selection block (option) is used, refer to section

5.3

Piping of

Flow

Selection Block (Option).

Connect the tubing between the column and the detector inlet with

the supplied male PEEK nut

as

shown in the next fi,we. lighten

the male PEEK nut fmly without using tools.

I

Note

I

Insert the tubing into the column joint and the male union securely

until it comes

to

the

end and then tighten the male

PEEK

nut.

Similarly, insert the cell inlet pipe until it comes to the end

and

tighten the male

PEEK

nut

so

that dead volume is minimized.

4-8

-

RID-1OA

Page 33

4.5

Plumbing

Connections

Tubing

(cut

the 50cmlong tube for use)

Manual injector

Main

body

IN

port

Male

nut

PEEK

(Tighten by

hand)

Manual injector

I

by

hand)

5.

Detector outlet side piping

(1)

Prepare a waste liquid bottle.

Connect the

drain

tube to the detector outlet. Select one

from

applied flow rate. Insert the outlet

of

the

drain

tube into the

waste liquid bottle.

the

drain

tubes listed

in

the table below depending on the

C

0

m

-

c

Max.

flow rate

Drain

tube

For extension

Remarks

[Wmin]

Fside diameter (mm) x length

(cm)]

[Inside diameter

(mm)

x

length (cm)]

3

0.3

X

100

1.ox

100

5

0.5

X

100 1.ox 100

20

0.8 X

100 1.6X

100

150

1.6X 100

1.6X

100 At mode L (option)

When using the FFX-1OA fraction collector, connect the inlet tube

of

the FRC-1OA to the detector outlet directly. Note that the

maximum

flow rate varies depending on the preparative head

of

the

FRC.

FRC

-

1OA

inlet pipe

Inside diameter

[m]

x

Length

[cm]

FRC-10A outlet pipe

Inside

diameter

[mm]

x

Length

[cm]

Max.

operating

flow

rate

[mVmin]

Fraction correction head with valve

0.8X

100

1.6X 100

20

(150')

Fraction

correction head with valve

0.3

X

100 1.6X

100

3

Fraction correction head without valve

FRC- 1OA preparative

head

0.3

X

100

*)

An

optional flow selection

block

is necessary.

The solenoid valve and flow cells may

be

damaged by application

of

back

pressure which exceeds the detector resistance pressure.

Do

not use the pipes listed

in

the table which

are

out

of

range.

I

Note

1

To

prevent the detector

from

being damaged by back pressure, it is

useful to connect the relief valve (option) to the detector outlet

when the

unit

is

used with large flow rate, or the piping

is

clogged.

4-9

RID-1OA

-

Page 34

4.5 Plumbing

Connections

Main

body

outlet

port

When piping

for

the detector inlet and outlet is completed, secure

the two piping tubes

in

the tube holder

as

shown

in the

figure

below.

I

1

I

RID-1

OA

I

Fit the tubes

in the tube holder.

/

When the front cover is

dosed.

4-10

-

RID-1OA

Page 35

1.

Connection

with

recorder

Connect the

RECORDER

terminal

of

the

RID-1OA

and the

recorder using the supplied

signal cable.

Recorde-

-t

RID-1OA

[

Tk15th terminal

of

RID-1OA

Recorder

Recorder

Recorder GND

(1

OmV

full

scale recorder)

or

the

6th

terminal

(I

mV

full

scale recorder)

The 7th terminal

of

RID-1OA

Green

~

Green

'

Grounding terminal

When using a stranded wire, twist the end tightly, or tin it with

solder.

Using

a small screwdriver or other tool, depress the rectangular

button adjacent to the appropriate terminal hole. Insert the wire and

release the button to

clamp

the wire

in

position,

as

shown

in the

flapre below.

Wire

-

Press

4-1

1

RID-1OA

-

Page 36

4.6

Connecting the Recorder and Integrator

~~

2.

Connecting

with

Chrornatopac (integrator)

Connect the Chromatopac to the

INTEGRATOR

terminals

(TBl

No. 3 and

No.

4)

in

the external inpuvoutput terminals at the rear

of

the

RID

-

1

OA.

The connection procedure is similar to that in

“1.

Connecting with

recorder.” Connect the cable supplied with the Chromatopac to the

Chromatopac side and connect each terminal

of

the signal cable to

the

terminal block supplied with the Chromatopac.

To

Chromatooac

Terminal

Mock

supplied

with

Chromatopac

supplied

with

Chromat

412

-

RID-1OA

Page 37

Each component

in

the LC-1OA series is designed

so

that solvent

leakage is discharged

from the liquid leak tube connection port

either at

the

right side

or

the lower front side

of

the equipment.

Connect the liquid leak tube if necessary.

1.

Connecting liquid

leak

tube in

LC-1OA

system

Connect the supplied L-type leak tube to the connecting port in

each component.

Connect the straight type joint to the liquid

leak

tube at the bottom

of the equipment

and

insert it into the drain bottle.

L-type leak tuhe

Liqiud leak tube

U

Connecting port

of

\

liquid leak tube Straight

type

joint

Drain

bottle

Use a T-type joint to connect liquid leak tubes for multiple

instruments.

Cut

the

supplied

drain

tube

to an appropriate len,ath.

Attach the

L-type

leak tubes horizontally or downward. Secure

them

to

the side panels

of

the equipment with the supplied lock

catches.

Position

the

waste liquid bottle lower than the bottom

of

the

equipment.

4-13

RID-1OA

-

Page 38

Chapter

5

Operation

5.1

Precautions for Operation

........................................................................

5-2

5.2

Fundamentals of Operation

.....................................................................

5-3

5.3

Plumbing

of

the

Flow

Selection Block

...................................................

5-1

3

5.5

Additional Functions

(AUX-FUNC)

.......................................................

5-21

1

CONTENTS

1

5.4

Creating and Executing Time Programs

.................................................

5

-

1

6

5

-

1

RID-1OA

-

Page 39

I

Caution

I

1.

Be sure to close the front cover during measurement.

The baseline fluctuates when the front cover is opened or

closed during high sensitivity analysis. Noise may be

increased when the front door is kept open.

2.

Precautions to prevent clogging

of

the flow cell.

Dusty

or

clogged flow cells are the most frequent causes

of

trouble in any detector. After analyzing a high concen

tration sample, thoroughly flush it from the flow cell,

using

a

large amount

of

mobile phase.

Buffer solution crystallizes upon drying, and can clog the

flow cell and tubing. Never leave buffer solution in the

unit

as

mobile phase. Always flush the flow lines prior to

shutdown

of

the instrument.

Turn

ON R flow several

times during solvent delivery and replace the reference

flow cell with water.

5-2

-

RID-1OA

Page 40

1.

Turning

power

ON

(1)

Push the power switch

on

the front panel to turn the power

ON

and

OFF.

\

d-

\

"7--

1

Power switch

OFF state

Power switch

ON

state

(2)

When the power is tumed

ON,

the

RID-10A

operates

as

follows:

Turning power

ON

All

of the dots in the display

unit

and all of the indicator

lamps light.

Control program version

No.

is displayed.

balance

wn0-I

ranae

mode

f

Rl

D-1

OA

V%.

%

1

The motor for optical balance adjustment is moved to the

set position and the instrument

seeks

the home position.

-

M(101

rsnge

mode

f'

S

EE

K

I

N

G

H

O

M

E

The position is adjusted

so

that the optical balance is at

the

optimum

position.

balance

RI(10

range

mode

(10

BALANCE

A

(3)

After turning the power

ON,

a memory check is automatically

performed and when no error is

detected

the following display

appears, indicating

that

operation is possible.

This

is the initial

State.

0

4

shift

progrun

remQte

tanpcolll

Rlbw

pol(-)

t=l~nOot=l

The

balance

and

RI

values vary depending

on

the

types

of

instrument.

E

0

-

c

E

Q)

op

5-3

RID-1OA

-

Page 41

5.2

Fundamentals

of

Operation

a

(3

@

0

a

0

2.

Display

unit

RI

(

loa)

Displays refractive index (unit

:

X

lo4

FUU)

Displays full scale of refractive index output to the recorder terminal (unit : XlOkIU)

mode Displays measurement mode.

shift Shift key indicator lamp.

prog run

remote

Time

pro,oram operation indicator lamp. Lights when time program is being executed.

Remote mode indicator lamp. Blinks when

contmlled by

SCL-

1OA.

If

[

NOT

PROTECTED

)

message is displayed and an alarm sounds

after turning the power

ON,

press

a

key. When this message is

displayed, the time program

is

initialized.

When any other error message

is

displayed,

turn

the power

OFF

and contact your Shimadzu Service Representative.

temp cont

The display unit consists of display screen and indicator lamps as

shown below.

Lights when the power is being supplied

to

the temperature controlled heater for optical

system unit.

P PP?

8

@

No.

1

Display

ordescription

I

Function

R flow

Reference flow indicator

lamp. Lights when the liquid is being supplied to the reference

flow line side.

pol

(-1

Polarity indicator lamp.

@I

balance

I

Displays position of the light on photodiode.

3.

Keyboard

The nineteen keys on the front

are

used for operation and

settings and classified into the following

three

types.

(1)

STD-func keys

Press these keys to perform a specified operation immediately

-

(

[Zero

1

key, etc.)

(2)

Shift-func keys

Press

these keys after pressing a

[

shift

1

key to perform

a

specified opeAtion

((7-1

key, etc.).

1-

5-4

-

RID-1OA

Page 42

5.2

Fundamentals

of

Operation

(3)

Edit keys

Use these keys to input parameters and edit a time program

(ten

-

key, etc.).

shift

El

I-1

I.'1

shift

[T]

0

I21

'i

Enter

(1)

STD-func

keys

Auto zero key

(-1

Zero

shift

key

[mark]

Mark key

I.1.)

Run key

(2)

shift-func

keys

(+)key

(shlft)

+

[GGF)

key

(shlftj

+

[R]

key

Press this key to perform zero adjustment. Returns the baseline to

the zero position

set

by

[-)

.

Press

this

key to move the zero position on the recorder. It is

moved upward by pressing

A

side and downward by pressing

V

side.

Press this key to add Mark to the data being recorded in the recorder

by pressing this key. Mark is not valid in the integrator output.

This key is a switch to

start

and stop a time program.

These keys move

to

time program creation mode.

These keys drive the zero glass and adjust its position to'optimal.

These keys switch the solenoid valve to replace the liquid inside

the reference cell with the mobile phase.

@

+=

key

These keys switch the polarity of recorder output.

[pol

(-1

1

LED

is lit for

(-)

polarity.

E

0

.-

c

f

op

5-5

RID-1OA

-

Page 43

5.2 Fundamentals

of

Operation

=+

(mode]

key

(shlftJ+

@

key

(3)

edit

keys

-

19)

Numerical keys

CEnfer)

Enter key

@

Clear key

a3

0"

(shlft+m

Delete key

uu

Function key

m+m

Back key

-

-

4.

Basic

operation

These keys select the measurement mode.

The measurement mode changes

from

A

+ P +

L

3

A.

A

:

Analytical mode

P

:

Preparativemode

L

:

Large-scale preparative mode

For

the operation

of

each mode, refer to section

5.3.2,

Changing the

Measurement Mode.

These keys can be used to set time constant.

Values from

1

to

10

can be set. For the relation between each value

and time constant, refer to section

5.2.9,

Setting the Response.

Input numerical values.

Sets input values.

Returns the display screen to the initial state.

Press

this key to clear an input value when entering a numerical

value. Press this key to clear the display and alarms when an

error

is

displayed. Equipment failure errors cannot be cleared with this key.

Deletes a line in the time program.

Advances to

the

next item in

the

display screen.

AUX.

FUNC

setting screen

is

forwarded.

Returns to the previous item.

AUX.

FUNC

setting screen

is

scrolled backward.

Before starting analysis, flush the detector flow line with mobile

phase. Supply the mobile phase at a flow rate of

1

mUmin, and

then press

(shlftl

and

B.

The solenoid valve is switched and

the

(R)

lamp is lit. Solvent flows

through

the sample and the

reference sides

of

the

detector cell replacing solvent

in

each. Supply

solvent for approximately

20

minutes with Wow ON. Then,

turn

Rflow ON/OFF several times to drive the bubbles out of the cell.

Retum to Mow

OFF

state, and wait

until

the baseline stabilizes.

When the balance value is

more

than

50,

press

and

[F)

to perform optical balance adjustment.

When the baseline

is

stabilized,

start

analysis.

5-6

-

RID-1OA

Page 44

5.2

Fundamentals

of

Operation

I

Note

I

When the liquid inside the flow lines is not sufficiently replaced

with the mobile phase, the baseline takes longer to become stabilized

and the

drift

becomes large.

To

perform effective replacement, turn

R

flow

ON/OFF

several times at an interval of

two

minutes.

Switching flow lines during solvent delivery at large flow rate

in mode

L

may damage the solenoid valve and the flow cell.

Thus, the following message appears when performing

R

flow

in mode

L.

f

CHECK

FLOW

7

Press

[E)

after the flow rate is changed to 1 mumin.

To

avoid trouble caused by bubbles, refer to the following.

When the pump sucks bubbles, degas the solvent with the

ultrasonic cleaner. If dirt on

the suction filter is the cause,

clean the filter with the ultrasonic cleaner or replace it.

Bubbles may not be easily removed when using

an

aqueous

solvent. Flush the flow lines with methanol

or

acetone.

When replacing the aqueous solvent with organic solvent or

vice versa, bubbles may be generated successively. If

bubbles can be observed, flush the flow lines with thoroughly

degassed solvent.

5.

Setting the measurement mode

(Example)

When changing the measurement mode from

A

to

P

Press

[shift)

and

.

The mode is changed to P to perform optical balance

adjustment.

balance

RI

(lo)

range

mode

100

BALANCE

P

0

0

4

P

5-7

RID-1OA

-

Page 45

5.2

Fundamentals

of

Operation

I

Note

I

I

Note

I

When the above operation is repeated, the mode is changed form

LA-+P+LJ

.

Mode L is only applicable when an optional

flow selection block is installed. When

the

block is

not

installed, do

not perform measurement in mode

L.

Refer

to

5.3.1 for the mode setting when using the flow selection

block.

Mode

I

Refractive

index

measurement range

I

Input step

0.01

step

for

0.01

to

1

1

step

for 1 to

500

1 A 1

0.Ol-500X1O4RIU

I

P-L

~1-smx1o"RIu

I

1

step

for

I

to 5000

Select the mode corresponding to the refractive index

of

the

sample

to

be

measured. When the index is

500

x

10"

FUU

or less, use

mode A.

Note that the setting of mode

P

has wider measurement range while

it

has

the larger baseline noise.

The range value will

default to 100 when

the

mode

is

changed

as

described below.

0

When

the

mode

is

switched

to

mode P or L during measurement

with the range

of

0.01

to

1

.OO

in mode

A.

0

When the mode is switched to mode A during measurement

with the range of 501

to

5000

in mode

P

or

L.

6.

Setting measuring range

The procedure to set the recorder range is

as

follows:

Changing the range

from 4 to

16 X lo4

FUUFS

(1)

Press

[f..c)

once in the initial state to access the range

parameter (blinking).

balance

wr10-7

Rnpe

mode

(2)

Input

0,

@and

(E.t.f)

ba)uue

warn

rangs

mode

0

0

16

A

(3)

After a value is input, it

returns

to the initial

state.

5-8

-

RID-1OA

Page 46

5.2 Fundamentals

of

Operation

7.

Changing

the

range

(1)

When a recorder

is

connected

to

the

RECORDER

terminal,

set the range at a value about

1.2

times as much

as

the

expected maximum peak value. Maximum peak will be

about

80%

of the full scale ensuring that peaks remain

on

-

scale.

(2)

When a Chromatopac (integrator)

is

connected

to

the

RECORDER terminal

(lOmV terminal),

peaks

having

refractive index up to about

100

times as much

as

the setting

range can be recorded. Set the measurement range at

a

value

about

1/80

of the expected maximum peak refractive index.

Normally, the recorder range

is

set

at

a value

of

about from

1

to 10 and the plot full scale is adjusted by changing

AmN

on

the

Chromatopac side. The relationship

of

the

setting

range and attenuation of Chromatopac

(ATTEN)

for the plot

full

scale

when connected to the RECORDER terminal

(10mV) is

as

follows:

Plot

full

scale

Plot full

scale

=

Setting range

x

2-/10

[

x

IO?RUFS]

5-9

RID-1OA

-

Page 47

5.2

Fundamentals

of

Operation

AUX RANGE

value

1

2

(Exam

p I e)

When that range

=

1,

ATTEN

=

2

:

Plot full scale

=

1

x

22/10

=

0.4

[

x

lO-kUFS]

(3)

When a Chromatopac is used as a recorder, connect it to the

INTEGRATOR terminal and set the range at

A?TEN on the

Chromatopac side.

It

is

also

necessary to make a rough range

setting on the detector side since the dynamic range

of

the

detector is extremely wide. This setting

is

made by setting a

value in

the

parameter AUX RANGE. Relation between

AUX RANGE value and

INTEGRATOR

terminal output

are

listed in the table below:

INTEGRATOR

terminal output

Remarks

1

x

~O~RIUN

1

x

103

RIUN

Compatible

with

AUX-L

of

RID-6A

~

4

I

~

Compatible

with

AUX-H

of

RD6A

2.5

X

lo4

RIUN

Plot full scale for Chromatopac determined by AUX RANGE value

and

AmN value is

as

follows

:

Plot full scale refractive index

(X

lo4

RIUIFS)

determined

by

AUX RANGE value and AlTEN value.

I

I

AUXRANGE

I

O

I

Oel

I

1

I

10

1

0.25

I

I

1

I

0.21

21

20

I

0.5

I

(Example)

When

AUX

RANGE = 2 and Chromatopac AmN

=

7,

the plot

scale becomes

128~ 1 O%U.

5-10

-

RID-1OA

Page 48

5.2

Fundamentals

of

Operation

8.

Zero adjustment

of

recorder

Before starting analysis, adjust the zero position of the recorder

as

follows:

(1)

Set the measuring range to 0 to short-circuit the recorder

output. SHORT is displayed in the range display. (Refer

to

section

5.2.6,

Setting the Range.)

Adjust the pen position to

0

scale on the chart paper using

the pen position recorder adjusting knob.

(2)

(3)

(4)

Reset the measuring range at a value required for the analysis.

F’ress- ,and the

pen

returns to almost 0 scale on the chart

paper.

(5)

Press

(zeroshiftAV1

to move the baseline to a desired

position and

start

analysis.

(6)

Press the

key to return the baseline to the previous

position.

9.

Setting the

RESPONSE

In

this

equipment, a digital noise filter is used to improve

SIN

ratio.

Response improves when setting the filter response low, but the

noise reduction effect becomes small.

On

the contrary, response is

worsened when setting the response high, but the noise reduction

effect becomes large. Ten digital filter response steps are available

when setting the parameter to

RESPONSE.

RESPONSE

values and

corresponding time constants for analog filters are

as

shown in the

table below:

c

0

-

c

f

00

5-1

1

RID-1OA

-

Page 49

5.2

Fundamentals

of

Operation

value

1

E

0

Q

.

-

+.I

5

op

(

Letters in brackets are response

ofRID6A.

)

at half-height

0.05

sec

0.2

sec

RESPONSE

I

Corresponding time constant of analog

CR

filter

I

Minimum peak width

I

2

3

4

5

6

7

0.1

sec

0.4

sec

0.5

xc

(

F

A

S

T

)

2.2

sec

1.0

sec

4.8

sec

1.5

sec

(STD)

7.2

sec

3.0

sec

(SLOW)

13

sec

6.0

sec

26

sec

9

10

18

I

8.0

sec

I

36

sec

I

10.0

sec

45

sec

2.0

sec

9

sec

1

\\ I //

// I \\

5

[

RESPONSE

@

O

Input a value using numeral keys and press

(Enter).

Press

@

to return to the initial display.

(Note)

As

response is increased,

data

processor response

decreases, peak height decreases, and width at half

-

height

increases. It is recommended that response

be

set at a

value such that, for a given half

-

height width, the peak

height drops no more than

10%.

The relation between

response time,

peak

half-height width, and peak height

reduction is shown in the figure below.

To select a response using the figure, determine the width

at half

-

height of the narrowest peak of interest. Using the

graph,

find the point of intersection between that width

value and the

90%

height value. Set the response which

corresponds to a value

I

the time constant

as

read

from

the graph. Note that response has no effect on peak

area.

Peak

area

does not change even when a low response

value broadens the peak.

100%

-

I

0)

al

r

05

SCC

Y

([I

al

1.0

Scc

a

3.0

fo~

6.0

scc

_-

0

10

10

Peak

width

at half-height

5-12

-

RID-1OA

Page 50

1.

Usage

of

each mode

Refractive index measuring range

(xlobRIU)

Measurement mode

When the RID-1OA is equipped with the flow selection block

(option), measurement mode can be selected for high sensitivity

analysis, preparative and large

-

scale preparative mode. Operation

in

the large scale preparative mode requires the optional block.

Flow

rate range Tubing

(mUmin) connection

Mounting of the flow selection block is performed by a service

engineer. Refer to section

12.3.

Analytical

(A)

Preparative

(P)

Large-scale preparative

(L)

Preparative

-

500

20

Fig.

1

-

5000

20

Fig.

1

-

5000

150

Fig.2

Large-scale

preparative

Mode Setting Application

Analytical A For general analysis. The flow

lines

are

the same

as

that

of

the

RID-10A without

the

flow selection

block. This mode is compatible

with the

FUD-6A.

P

For measuring samples of high

concentration. Samples ten times

S

as

concentrated

as

those for mode

0

-

c

A can

be

measured.

f

L

For measuring samples of high

op

concentration at large flow rate.

Samples

of

the same concentration

as

those of the mode P can be

delivered

at

150

mUmin.

2.

Changing the measurement mode

(1) Selection of mode setting

The

current mode is displayed on the

LED

display. Switch

the

measurement mode by pressing

and

@

.

1

A

:

Analytical mode

L

P

:

Preparative mode

1

L

:

Large-scale preparative mode

Mode setting must be accompanied with corresponding

tubing connection

as

shown in Figs.1 and

2.

5-13

RID-1OA

-

Page 51

5.3

Plumbing

of

the

Flow

Selection

Block

~

Max

flow

rate

(mumin)

50

1.50

E

0

I

c.

f

8

~~~~ ~ ~ ~~ ~~

Drain tubing

For

extension

0.

D.

x

1.

D.

x

Length [rnm]

0.

D.

x

1.

D. x Length [mm]

1.6X0.8X lo00

3.2X 1.6x lo00

3.2 X 1.6 X lo00

3.2 x 1.6

X

lo00

Drain

tube

Use the following types

of

drain

tube for large-scale preparative

Max

flow

rate

(mumin)

50

mode. The longer and/or smaller

I.D.

tubing than the specified

one causes

high

back

pressure beyond the value

in

the specifications

of the detector, which may lead to damage of the detector.

FRClOA

inlet tubing

0.

D.

x

1.

D.

x

Length [mrn]

1.6 X 0.8

x

lo00

(FRC-

1OA

accessory)

FRClOA

outlet tubing

0.

D.

x

1.

D. x Length [rnrn]

3.2

X

1.6

X

lo00

(FRC-

1

OA

accessory)

3.2

X

1.6 X lo00

[Note)

When a fraction collector

FRC-1OA

is

used,

use the following tubing.

I

I

150

I

3.2X 1.6X lo00

I

(FRC- 1

OA

accessory)

When using a fraction collector made by other manufacturer, check

that the back pressure caused by connecting

the

fraction collector

does not exceed the limit that the detector can resist. Pay attention

to pressure change,

as

well

as

back pressure when switching the

preparative valve.

(2)

Changing the tubing connection

Open the front panel and change the piping connection

because large

-

scale preparative mode has different plumbing.

+column

1

Drain

Fig. 1 Tubing connection

in

the

analytical and

preparative

modes.

5-14

-

RID-1OA

Page 52

5.3

Plumbing

of

the

Flow

Selection

Block

f-

Column

Fig.

2

Do

not

tubing

Tubing connection in the largescale preparative mode

set the instrument to mode L with analytical

and

preparative

connection. Similarly, do not set the instrument to mode

A

t

0

or

P

in

large-scale preparative tubing connection.

-

c

0"

5-15

RID-1OA

-

Page 53

t

0

-

c

E

a

OQ

Command

ZERO

MARK

RNGA

1.

Command

list

Commands which can be used for a time progam

are

listed below.

Description Setting range Remarks

Execution of zero adjustment

Marking on output for recorder

Designation

of

output range for recorder (mode A)

Not applicable

Not applicable

0,O.Ol-

500

Unit: x106RIUFS,

RNGP

RESP

Designation

of

output range for recorder (mode

P)

Designation

of

output range for recorder (mode

L)

Designation

of

response

0,

1

-

5000

Recorder is short-circuited when

set to

0.

Refer

to

section

5.2.

Fundamentals

of Operation.

1

-

10

1

EVNT

1

EVEhToutputON/OFF

0,

1,2,

12

Refer

to

section

5.5,

Additional

Functions

.

1

POL

1

~olaritysetting

STOP

I

O’I

Ends a program. Not applicable

Positive polarity

Negative polarity

RNGA

(setting value)

1.40

150

I

LOOP

I

Repeats all preceding steps in

the

pro,.ram.

10-25255

I

Value

0

repeats

a program

256

times.

RNGE

(execution value)

1-00

2.00

[Notel

Setting the RNGA at decimal number

RNGA enables increments

of

0.01

unit steps. However, when set

at

a

range more

than

1.00,

fraction

of

5

and over is counted

as

unit

and

the

rest is omitted.

(Example)

I

Note

I

Execution of RNGA and RNGP

RNGP setting during

a

time promoram is ignored in mode

A.

RNGA setting during a time program is ignored in mode P or

L.

5-16

-

RID-1OA

Page 54

5.4

Creating and Executing Time Programs

2.

Explanation

of

display

screen

The edit mode is used to create a time program.

(1)

Press and

@.

A

screen similar

to

the one below

will