Shibaura N843L, N843, S773L Workshop Manual

SHIBAURA DIESEL ENGINE

MODELS: S773L, N843, N843L

WORKSHOP MANUAL

SUPPORTED BY HUSTLER TURF EQUIPMENT AND EXCEL INDUSTRIES, INC.

FOREWORD

This workshop Manual includes repair and adjustment procedures required for the diesel engine models S7 73L, N843,

and N843L.

When servicing to keep the engine in the best condition, you will find this Manual very useful as a guidebook.

This Workshop Manual was prepared in Jul. 2008. Specifications contained in this Manual are subject to change without

notice for subsequent engineering changes.

109823_2/09 c-2

Table of Contents

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .c-2

Section 1: Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Before beginning service or repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Avoid Fire Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Prepare For Emergencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Engine Starting Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Prevent Battery Explosions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Avoid Acid Burns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Avoid High-pressure Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Understand Correct Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

General Maintenance Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Fuel Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Wear Protective Clothing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Section 2: General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

General Notes Before Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Fundamental Instructions On Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Engine Sectional Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Parts and Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Section 3: Disassembly And Inspection Of Engine. . . . . . . . . . . . . . . . .3-1

Rocker arm assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Cylinder head assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Piston and piston ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Connecting rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Connecting rod bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Disassembly, inspection and reassembly of bearing holder . . . . . . . . . . . . . . . . . .3-9

Crankshaft bearing (bushing) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Flywheel and ring gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Cam shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Timing gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Oil flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Oil filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Water pump assembly and thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Injection pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Nozzle and holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Section 4: Engine Re-assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Relief valve assembly with O-Ring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Crank shaft and bearing holder assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Measure the end play of crankshaft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Oil seal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Rear plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

t-1 109823 2/09

Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Piston and connecting rod assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Suction pipe · Suction filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Oil pan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Oil dipstick · Dipstick guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Front plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Camshaft assembly · Tachometer shaft plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Idle gear · Oil pump assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Timing gear case · Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Crankshaft pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Injection pump assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

‘Oil filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Engine stop solenoid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Cylinder head assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Cap · Push rod · Rocker arm assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Valve clearance adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Oil pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Oil pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Water pump assembly · Bypass hose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Valve cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Glow plug, Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Section 5: Electrical Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Fuel Shutoff Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Engine Glow Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Engine Oil Pressure Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Alternator (40 amp version) (No. 185046320). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Alternator diagnostic procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Trouble Shooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Starter Motor (M001T66081) (No. 185086551). . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Trouble shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Section 6: Trouble-Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Section 7: Servicing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i-1

109823 2/09 t-2

SECTION 1: SAFETY

This safety alert symbol is used to call attention to a

message intended to provide a reasonable degree of

PERSONAL SAFETY for operators and other persons

during the normal operation and servicing of this

equipment.

BEFORE BEGINNING SERVICE OR REPAIR

1. Read and understand all instructions and safety

warnings in this manual and on any decals on the

equipment.

2. Make sure engine and work area are clean.

3. Place engine or machine on stable, level work

area and/or use an approved engine stand.

4. Stop engine and remove ignition key.

5. Allow engine to cool before preforming service.

6. Disconnect negative (-) battery cable before preforming service or repair.

DANGER—denotes immediate hazards which WILL

result in severe personal injury or death.

WARNING—denotes a hazard or unsafe practice which

COULD result in severe personal injury or death.

▲ Provide adequate ventilation when charging

batteries.

▲ Do not smoke near battery.

▲ Never check fuel level with an open flame.

▲ Never use an open flame to look for leaks

anywhere on the equipment.

▲ Never use an open flame as light anywhe re on or

around the equipment.

▲ When preparing engine for storage, remember

that inhibitor is volatile and therefore dangerous.

Seal and tape openings after adding the inhibitor.

Keep container tightly closed when not in use.

▲ Inspect electrical wiring for worn or frayed

insulation. Install new wiring if wires are damaged.

PREPARE FOR EMERGENCIES

Be prepared if a fire starts.

▲

▲ Keep a first aid kit and fire extinguishers available.

▲ Keep emergency numbers for doctor, ambulance

service, hospital, and fire department near the

telephone.

ENGINE STARTING SAFETY

▲ Do not start engine by shorting across starter

terminals.

NOTE:—emphasizes general information worthy of

special attention.

All operators and mechanics should read this manual, and

be instructed about safe operating and maintenance

procedures. If the operators or mechanics cannot read

and understand English, it is the owner’s responsibility to

explain this material to them.

To reduce the potential for injury, comply with these safety

instructions and always pay attention to the safety alert

symbol, which means DANGER or WARNING—“personal

safety instructions.” Failure to comply with the instructions

may result in personal injury or death.

▲

AVOID FIRE HAZARDS

Be prepared if an accident or fire should occur.

▲

Know where the first aid kit and the fire

extinguishers are located and how to use them.

▲ Unauthorized modifications to the engine may

impair the function and/or safety and affect engine

life.

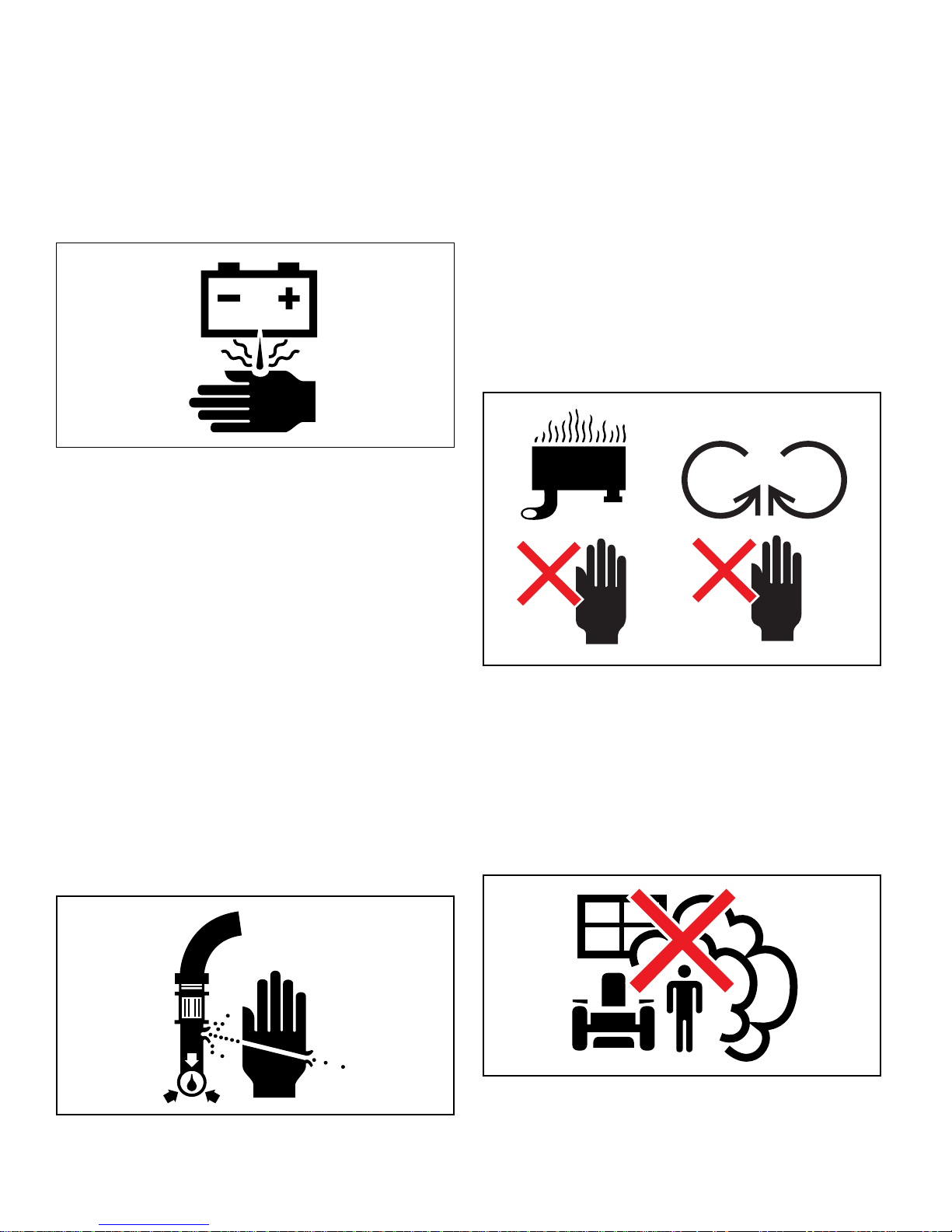

PREVENT BATTERY EXPLOSIONS

109823 2/09 1-1

▲

Battery gas can explode. Keep sparks and flames

away from batteries. Use a flashlight to check

battery electrolyte level.

▲ Never check battery charge by placing a metal

object across the posts. Use a voltmeter or

hydrometer.

▲ Always remove grounded (-) battery cable first

and replace it last.

leak under pressure, use a piec e of cardboard or

wood—never use your hands. Relieve all

pressure in the system before disconnecting or

working on hydraulic lines. To relieve pressure,

lower all attachments and shut off engine.

AVOID ACID BURNS

Sulfuric acid in battery electrolyte is poisonous. It

▲

is strong enough to burn skin, eat holes in clothing

and cause blindness if splashed in eyes.

Avoid the hazard by:

1. Filling batteries in a well-ventilated area.

2. Wearing eye protection and rubber gloves.

3. Avoiding breathing fumes when electrolyte is

added.

4. Avoiding spilling or dripped electrolyte.

If you spill acid on yourself:

1. Flush your skin with water.

2. Apply baking soda or lime to help neutralize the

acid.

3. Flush your eyes with water for 10-15 minutes. Get

medical attention immediately.

If acid is swallowed:

1. Drink large amounts of water or milk.

2. Then drink milk of magnesia, beaten eggs or vegetable oil.

3. Get medical attention immediately.

AVOID HIGH-PRESSURE FLUIDS

▲ Escaping fluid (fuel or hydraulic oil) under

pressure can penetrate skin causing serious

injury . Hydraulic oil may cause infection in a minor

cut or opening in the skin. If exposed to hydraulic

fluid, see a doctor at once.

UNDERSTAND CORRECT SERVICE

Be sure you understand a service procedure

▲

before you work on the machine.

▲ Unauthorized modifications to the machine may

impair the function and/or safety and affect

machine life.

▲ If it is necessary to make checks with the engine

running, always use two people - with the

operator at the controls, able to see the person

doing the checking. Use extra safety precautio ns.

▲ Use caution when running engines to avoid

moving and hot parts.

▲ Use the correct tool for the work. Do not use

makeshift tools or substitute parts.

GENERAL MAINTENANCE PRECAUTIONS

Do not perform work or service while under the

▲

influence of alcohol, medication, or other

substances, or when fatigued.

▲ Never run the engine in an enclos ed area unless

exhaust is vented to the outside. Exhaust gases

contain carbon monoxide which is odorless and

deadly poison.

▲ Before applying pressure to fuel or hydraulic

system, make sure all connections are tight and

all hoses and lines are in good condition. To find a

▲ Never remove radiator cap while the engine is

running. Allow engine to cool and remove cap

slowly to relieve pressure.

▲ Never attempt to make any adjust ment s or rep a irs

to the tractor drive system, mower deck or any

1-2 109823 2/09

attachment while the tractor engine is ru nning or

deck clutch is engaged.

▲ Repairs or maintenance requiring engine power

should be performed by trained personnel only.

▲ Never work under the machine or attachment

unless it is safely supported with stands, blocks or

a hoist.

▲ Always transport machine in a safe manner.

FUEL HANDLING

Fuel is extremely flammable and explosive under

▲

certain conditions Do not smoke while you fill the

fuel tank, service fuel system or handle highly

flammable material.

▲ Do not remove fuel cap or add fuel t o tank when

engine is hot or running. Allow engine to cool for

several minutes.

▲ Do not use open pans of gasoline or diesel fuel

for cleaning parts. Use good commercial,

nonflammable solvents.

▲ Never refuel tractor while engine is running; never

refuel near an open flame or near devices which

can create a spark. Refuel outdoors preferably or

in well ventilated areas.

▲ Immediately clean up any spilled fuel.

▲ dispose of all fluids properly, and in an

environmently correct maner.

WEAR PROTECTIVE CLOTHING

▲

Wear fairly tight fitting clothing and safety

equipment.

▲ Always wear adequate eye protection when

servicing the hydraulic system and battery, or

when grinding mower blades and removing

accumulated debris.

▲ Prolonged exposure to loud noise can cause

impairment or loss of hearing. Always wear

adequate ear protection, such as earplugs, when

operating this equipment as prolonged exposure

to uncomfortable or loud noises can cause

impairment or loss of hearing. Do not wear radios

or music headphones while operating the

machinery. Safe operation requires your full

attention.

109823 2/09 1-3

1-4 109823 2/09

SECTION 2: GENERAL

General Notes Before Service

1. Clean the exterior of the engine, drain oil, fuel and cooling water as necessary before disassembly.

2. Keep the service shop clean, free from dust, and with adequate lighting.

3. Remove oil and grease from disassembled parts, and place them in groups on a clean t abl e.

4. Be safety conscience; check equipment, tools and wear appropriate clothing.

5. Measurements are in the following format:

Type of measurement Units

Length in(mm)

Torque lbf•ft(Nm){kgfm}

Weight oz(g)

Temperature °F(°C)

Pressure

Fundamental Instructions On Service

1. Keep the engine clean, disassemble only those components that need to be disassembled.

The engine is built to close tolerances and clearances.

2. Retain replaced parts for the customer.

3. Always use machine model, serial number, part number and parts name when ordering service parts.

4. Prelube all moving parts during reassembly.

5. Tighten bolts and nuts to specified torque with proper tools, unless otherwise instructed.

PSI(MPa){kgf/cm

2

}

109823 2/09 2-1

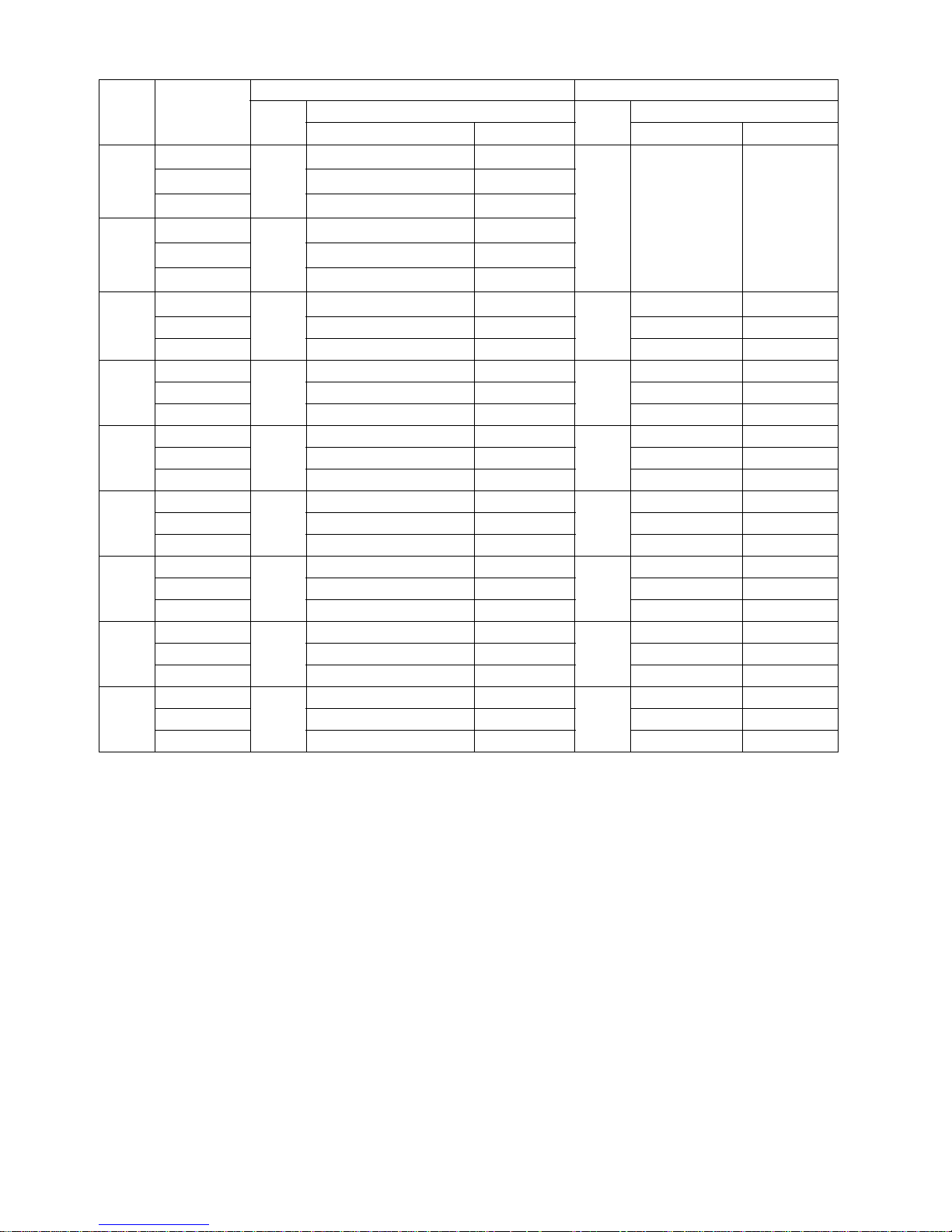

Torque Specifications

Bolt

Size

M5 4T, 4.8 0.8 18.6-35.4 in•lb

M6 4T, 4.8 1.0 43.4-61.1 in•lb

M8 4T, 4.8 1.25 115.1-150.5 in•lb

M10 4T, 4.8 1.5 18.4-24.3 25-33 1.25 20.7-26.6 28-36

M12 4T, 4.8 1.75 27.3-34.7 37-47 1.25 31.7-40.6 43-55

M14 4T, 4.8 2.0 46.5-59.0 63-80 1.5 51.6-64.2 70-87

M16 4T, 4.8 2.0 63.4-81.1 86-110 1.5 67.1-84.1 91-114

M18 4T, 4.8 2.0 83.3-104.0-5.1 113-141 1.5 97.4-119.5 132-162

M20 4T, 4.8 2.5 106.2-132.8 144-180 1.5 126.9-154.9 172-210

Grade No. Coarse Thread Fine Thread

7T, 8T, 8.8 43.4-61.1 in•lb

10T, 11T 59.3-83.2 in•lb

7T, 8T, 8.8 73.5-100.0 in•lb

10T, 11T 106.2-141.6 in•lb

7T, 8T, 8.8 17.0-20.7 23-28 19.2-25.1 26-34

10T, 11T 20.7-26.6 28-36 22.1-29.5 30-40

7T, 8T, 8.8 32.5-41.3 44-56 36.1-46.5 49-63

10T, 11T 39.8-51.6 54-70 42.8-54.6 58-74

7T, 8T, 8.8 48.7-61.2 66-83 55.3-69.3 75-94

10T, 11T 67.9-85.6 92-116 73.0-93.7 99-127

7T, 8T, 8.8 76.7-97.4 104-132 86.3-109.2 117-148

10T, 11T 102.5-129.1 139-175 109.9-135.7 149-184

7T, 8T, 8.8 109.9-136.4 149-185 115.8-141.6 157-192

10T, 11T 151.2-188.1 205-255 163.0-198.4 221-269

7T, 8T, 8.8 144.6-174.1 196-236 170.4-205.8 231-279

10T, 11T 202.8-245.6 275-333 219.8-270.7 298-367

7T, 8T, 8.8 177.0-213.9 240-290 202.8-245.6 275-333

10T, 11T 267.7-325.3 363-441

Pitch

(mm)

Tightening torque Pitch

lbf•ft N•m lbf•ft N•m

f

f

f

f

f

f

f

2.8-4.0 ----- -----

4.9-6.9

6.7-9.4

4.9-6.9

8.3-11.3

12-16

13-17 1.0 11.1-14.8 15-20

(mm)

Tightening torque

2-2 109823 2/09

Engine Sectional Drawing

109823 2/09 2-3

Specifications

Items Specifications

Engine model S773L N843 N843L

Engine type 4-cycle water cooled in-line

overhead valve

No. of cylinders-bore ×

stroke in(mm)

Piston displacement cc 1131 1496 1662

Compression ratio 23.5 to 1 22.5 to 1 22.5 to 1

Combustion chamber type Special swirl chamber Special swirl chamber Special swirl chamber

*Rated output (Gross)

HP(kW)/rpm

Fuel used SAE No.2–D, DIN 51601,

Injection pump Bosch, PFR type Bosch, PFR type Bosch, PFR type

Injection nozzle Throttle type Throttle type Throttle type

Injection governor Centrifugal all–speed con-

*Alternator, voltage. Output 12V–40A 12V–40A 12V–40A

*Starter, Voltage. Output 12V–1.2kW 12V–2.0kW 12V–2.0kW

3-3.031(77) × 3.189(81) 3 - 3.307(84) x 3.54(90) 3 - 3.307(84) x 3.94(100)

25(18.3)/2800 30(22.6)/2800 34(25.1)/2800

BS class A-1

trol

4-cycle water cooled in-line

overhead valve

SAE No.2–D, DIN 51601,

BS class A-1

Centrifugal all–speed con-

trol

4-cycle water cooled in-line

overhead valve

SAE No.2–D, DIN 51601,

BS class A-1

Centrifugal all–speed con-

trol

Lubrication method Pressurized circulation by

trochoid pump

Engine oil used API grade CD API grade CD API grade CD

*Lubrication oil volume

US Qts(L)

Cooling water volume

(Engine only) US Qts(L)

*Engine dry weight lbs(Kg) 207(94) 331(150) 353(160)

Engine

dimensions

Air cleaner Dry type

Notes: 1. The specifications above are subject to change without notice.

*Overall length

in(mm)

*Overall width

in(mm)

*Overall height

in(mm)

5.2(4.9) 6.3(6) 6.3(6)

2.0(1.9) 2.9(2.7) 3.0(2.8)

19.69(500) 21.0(534) 21.0(534)

15.28(388) 18.1(459) 18.1(459)

23.31(592) 25.9(657) 27.1(689)

Pressurized circulation by

trochoid pump

Pressurized circulation by

trochoid pump

2-4 109823 2/09

Engine Removal

Fig. 2-1

1. Water temperature switch

2. Water temperature sensor

3. Radiator hose

4. Alternator

5. Starting motor

Fig. 2-2

1. Air cleaner clogging

sensor

2. Ground wire

3. Glow plug connector

4. Fuel return hose

Fig. 2-3

1. Engine stop solenoid

2. Throttle cable

3. Fuel hose

4. Hydraulic oil pump

5. Engine mounting

hardware

6. Drain cock

3

2

1

4

5

4

3

1

2

3

1

2

4

6

5

Note: Asterisks (*). Items may vary depending on

the type of equipment in which the engine

is Installed.

1. If necessary, remove engine cover or

hood.

2. Remove the muffler and mounting

brackets from the engine.

3. Disconnect the wiring from the air

cleaner clogging sensor if so equipped.

4. Disconnect the wiring from the water

temperature sensor and water temperature switch.

5. Remove the radiator hoses from the

engine.

6. Disconnect the wiring from the alternator.

7. Disconnect the wiring from the starting

8. Remove the ground wire and bolt from

9. Disconnect the fuel return hose from

10. Disconnect the wiring from the engine

11. Disconnect the wiring from the glow

12. Disconnect the wiring from the engine

13. Disconnect the fuel line from the injec-

14. Remove the throttle cable from the

15. Disconnect the drain hose from the

16. Disconnect the oil hoses from the

17. Remove the engine mounting hardware

motor.

the cylinder head.

the fuel return line.

oil pressure switch.

plug connector.

stop solenoid.

tion pump.

engine

drain cock.

hydraulic oil pump.

and hoist the engine from the frame.

109823 2/09 2-5

Parts and Descriptions

5

1

2

4

3

6

7

Index Description

1 Alternator

2 Oil filter

3 Relief valve

4 Oil level gauge•Gauge guide

5 Engine stop solenoid•Seal washer

6 Fuel injection lines

7 Injection pump assembly and shim

Note:

1. Remove the injection fuel lines and engine stop solenoid before removing the injection pump.

2. Raise the injection pump and disconnect the governor link from the

control rack by removing the snap pin.

3. Injection timing is set by the shims between injection pump and block.

Note thickness and number when removing the injection pump.

4. Visually inspect the shim to determine if it is reusable or needs to be

replaced

109823 2/09 2-6

Index Description

9

8

13

10

11

17

16

18

15

12

14

14

15

8 Fuel return line

9 Injection nozzle•Gasket

10 Oil transfer pipe•Eye bolt •Seal washer

11 Connector•Glow plug

12 Oil pressure switch

13 Thermostat housing•Gasket

14 Valve cover•O-ring•Intake manifold•Spacer

15 Rocker arm assembly•O-ring•Cap

NOTE: Remove the caps from intake valves and exhaust valves.

16 Push rod

17 Cylinder head assembly•Head gasket

NOTE: Loosen the cylinder head bolts in several steps and remove the cylinder head

assembly.

18 Tappet

109823 2/09 2-7

Index Description

20

21

20

22

23

24

25

26

27

20 V-belt•Cooling fan•Fan holder•Fan pulley

21 Water pump assembly•Gasket

22 Crankshaft pulley and nut

23 Not available

24 Timing gear case assembly•Gasket

Note: Remove the engine stop solenoid and injection pump assembly first.

25 Idle gear•Oil pump assembly

26 Cam shaft assembly•Plate

Note: Remove the bolts and plate before pulling the camshaft assembly.

27 Front plate•Gasket

109823 2/09 2-8

28

29

30

31

33

32

33

Index Description

28 Oil pan•Gasket•Suction filter•Suction pipe

29 Fly wheel

30 Rear plate or Flywheel cover

31 Oil seal

32 Piston and connecting rod assembly

NOTE:

1. Before extracting piston, remove the carbon deposit from the top of the

cylinder.

2. Keep pistons, connecting rods, caps and bearings grouped by cylinder

number and reassemble to their original locations.

33 Crank shaft and bearing holder assembly

Note: Remove the bolts for bearing holders, and remove the crankshaft and bearing

holder assembly as an assembly.

109823 2/09 2-9

2-10 109823 2/09

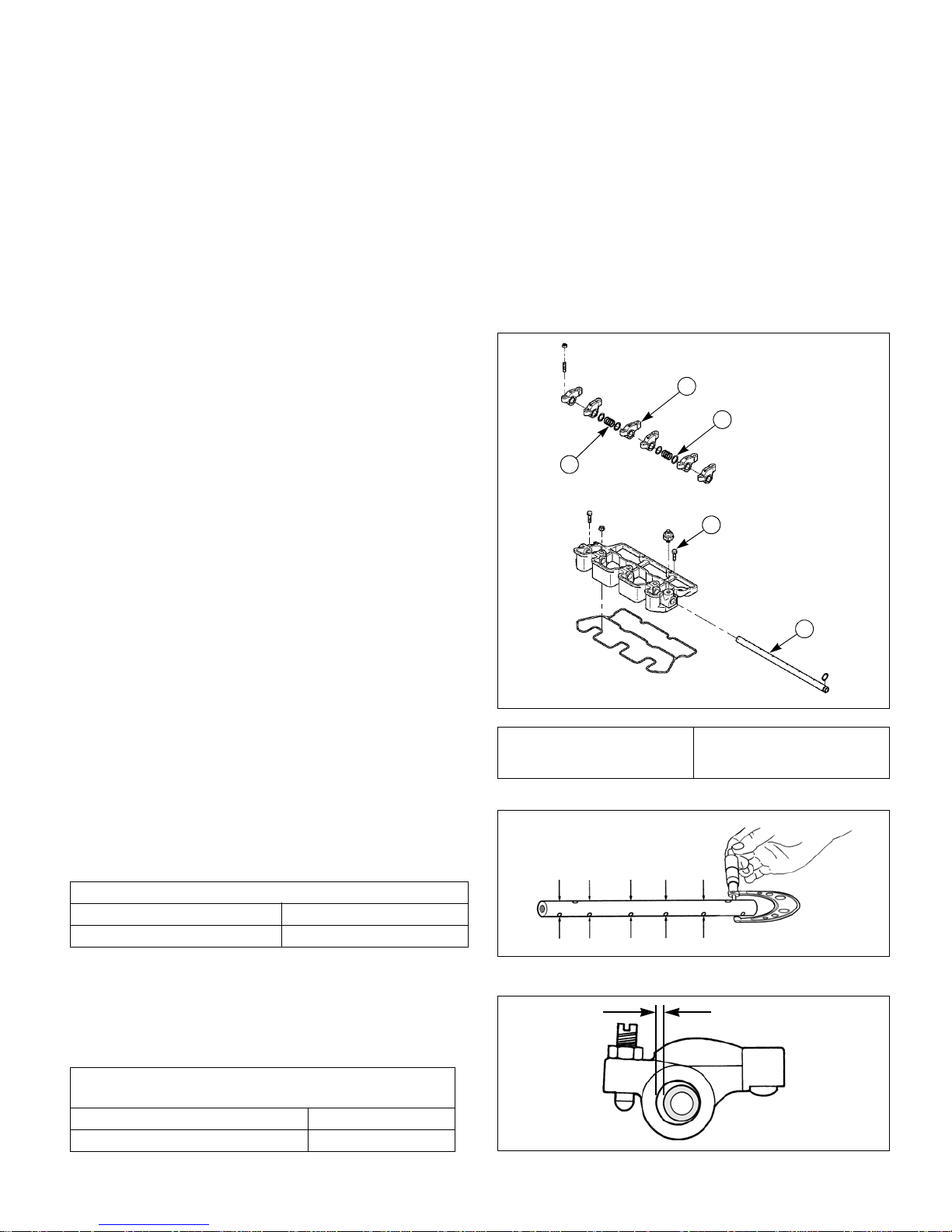

SECTION 3: DISASSEMBLY AND INSPECTION OF ENGINE

Fig. 3-1

1. Screw

2. Rocker arm shaft

3. Rocker arm

4. Spring

5. Shim

3

5

1

2

4

Fig. 3-2

Fig. 3-3

Clearance

Caution: before starting disassembly

1. Check the cylinder block and cylinder head for wear, leakage or damage.

2. Clean oil passages with compressed air and check for clogging.

3. Thoroughly clean parts to remove dust, contaminated oil, carbon, and other foreign material.

4. Remove carbon deposits on the piston, cylinder head, valves, etc. being careful not to damage parts. (Especially for aluminum alloy parts.)

5. Valves, pistons, connecting rods, bearings and other parts, should be marked indicating

cylinder number and reassembled to the original cylinder location.

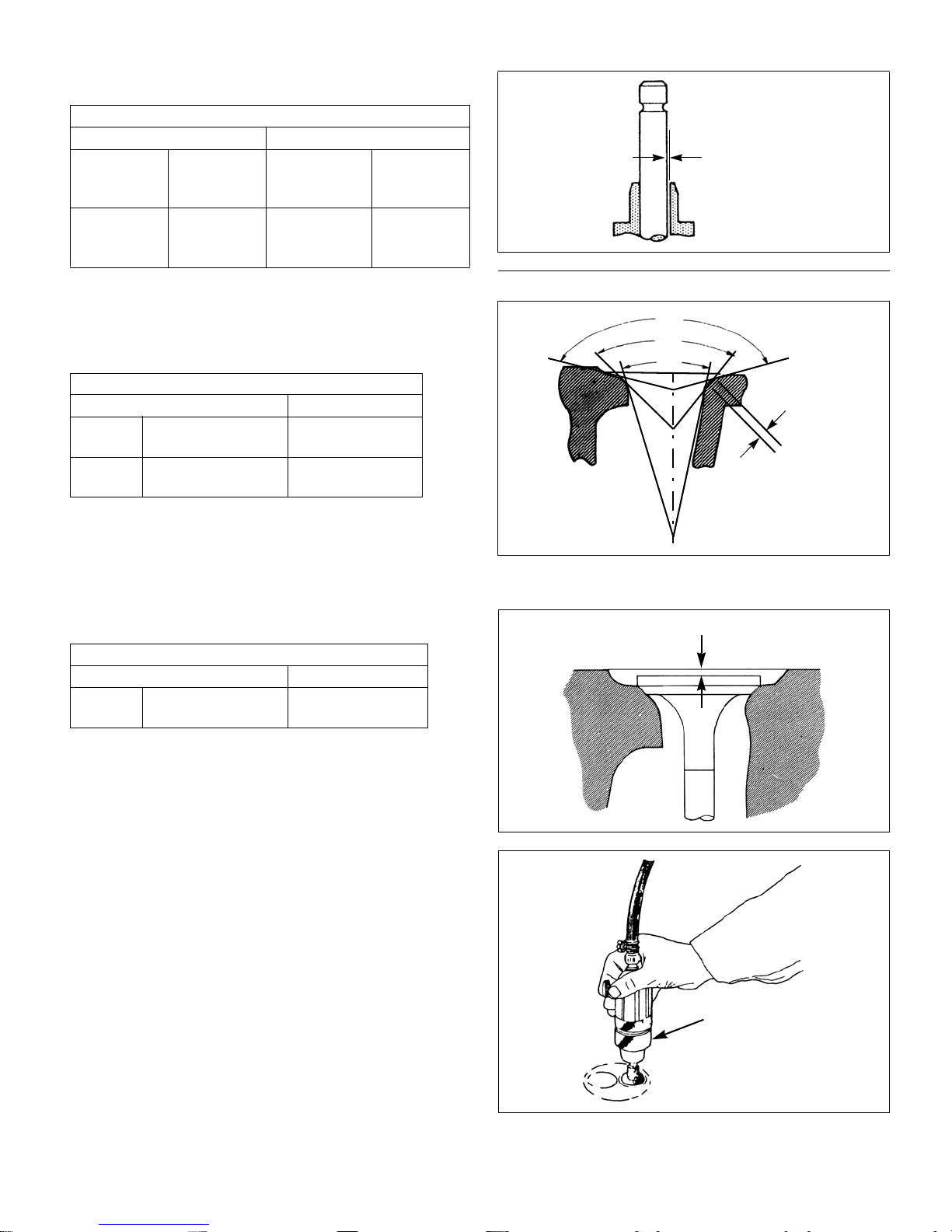

Rocker arm assembly

Disassembly

1. Screw in an M8 bolt at the front en d of the rocker arm

shaft and extract the rocker arm shaft.

2. Take out the spring, shim and rocker arm from the

rocker arm bracket.

Inspection and service

1. Using a micrometer, check outside diameter of the

rocker arm shaft. If the shaft is worn beyond the

service limit, replace the part.

Wear of rocker arm shaft ø in(mm)

Standard assembling value Service limit

0.4587-0.4594(11.65-11.67) Less than 0.4555(11.57)

2. Measure the inside diameter of the rocker arm.

Check the clearance between the rocker arm and

rocker arm shaft. If the clearance is beyond the

service limit, replace the part.

Clearance between rocker arm and rocker arm shaft

Standard assembling value Service limit

0.0013-0.0027(0.032–0.068) More than .008(0.2)

109823 2/09 3-1

in(mm)

3. Check the valve cap-contact surface for uneven

Fig. 3-4

1. Valve guide seal

2. Spring

3. Retainer

4. Valve

5. Valve cotter

1

2

5

3

4

Fig. 3-5

Fig. 3-6

Fig. 3-7

III III

Stem End

Head End

Thickness

wear and streaks. If wear is insignificant, grind flat

with oilstone or grinder, otherwise, re place.

Cylinder head assembly

Disassembly

1. Using a valve spring compressor, compress the

valve spring to remove the valve cotter, retainer,

spring and valve.

2. Remove the valve guide seal.

Inspection and service

1. Check for distortion of cylinder head bottom surface

by using a straight edge. Using Fig. 3-5 as a guide,

and a feeler gage, check for distortion at the six

positions—A through F. If distortion exceeds the

repair value, correct using a surface grinder.

Distortion at cylinder head bottom surface in(mm)

Standard assembling value Repair value

Less than 0.0020(0.05) More than 0.0047(0.12)

2. Valve guide and valve stem

a. Check the head and stem of each valve and

replace if burned, worn, or deformation is

excessive.

b. Measure the out side diameter at positions I, II, and

III on the valve stem with a micrometer and

replace if less than the service limit.

Wear of valve stem ø in(mm)

Intake valve Exhaust valve

Standard

assembling

value

0.274-0.2744

(6.955–6.97)

c. Replace a valve if its head thickness is less than

service limit.

Service limit Standard

assembling

value

Less than

0.2712(6.89)

0.273-0.274

(6.94–6.955)

Service limit

Less than

0.269(6.84)

Valve head thickness in(mm)

Standard assembling value Service limit

0.0305-0.0423(0.775–1.075) Less than 0.0197(0.5)

3-2 109823 2/09

d. Replace the valve if the clearance between the

Fig. 3-8

Clearance

Fig. 3-9

150°

90°

30°

Contact

Width

Fig. 3-10

Fig. 3-11

Recess

Valve

Lapper

stem and guide exceeds the service limit.

Clearance between valve stem and valve guide in(mm)

Intake valve Exhaust valve

Standard

assembling

value

0.0012-

0.0024

(0.03–0.06)

Service limit Standard

assembling

value

More than

0.0079(0.2)

0.0016-

0.0030

(0.04-0.075)

Service limit

More than

0.0100

(0.25)

3. Valve seat

a. Since the valve seat is corrected according to the

valve guide, be sure to check the valve guide for

wear condition first before correcting the seat.

Valve seat contact width in(mm)

Standard assembling value Repair value

In 0.059-0.083

(1.50-2.10)

Exhaust 0.063-0.071

(1.59-1.80)

More than

0.098(2.5)

More than

0.098(2.5)

b. Correct the seat to the standard assembling values

of the contact width and recess using seat cutters

of 15°, 45° and 75°.

c. When the seat recess exceeds the service limit,

replace the cylinder head.

Valve seat recess in(mm)

Standard assembling value Service limit

In,Ex 0.0335-0.0453

(0.85–1.15)

More than

0.0709(1.8)

d. Coat the valve seat surface with compound and

lap the contact surface turning the valve.

e. Check that the valve contact surface is within the

standard value and the contact position is even.

f. When the cylinder head is replaced with a new

head, adjust the seat contact width and seat

recess to the specified values with a seat cutter

before lapping.

109823 2/09 3-3

4. Valve spring

Fig. 3-12

Fig. 3-13

Squareness

Free Length

Replace with long block assembly

AB

Front

1

Ring Sliding Range

a. Check the valve spring visually for damage.

b. Measure the squareness of the spring using a

square on a surface plate and replace if the

service limit is exceeded.

c. Check the free length and spring force with a

spring tester and replace if the service limit is

exceeded.

Standard

Service limit

assembling

value

Squareness in(mm) 0.047(1.2) More than

0.079(2)

Free length in(mm) 1.38(35) Less than

1.3(33.5)

Spring force (when

compressed to

1.20(30.4) in(mm))

17.9 lb

(79.8

f

N){8.1 kgfp}

Less than

15.4 lb

f

N){7 kgf}

(68.6

Reassembly

Reassemble components in the reverse order of

disassembly. When assembling the valve spring, retainer

and cotter, be especially careful not to damage the valve

guide seal. Tighten the glow plu g to the proper to rque—5.6-

10.5 lb

•ft(8-15 Nm) {0.8~1.5 kgf•m}.

f

Cylinder block

Inspection and service

1. Check for cracks, damage and distortion on the top

of the block in the same way as the cylinder head.

2. Measurement of cylinder bore

a. There should be no scratches, rust, corrosion, etc.

on the cylinder bore when checked visually.

b. Measure the cylinder bore at the top, center and

bottom respectively in the crankshaft directio n (A)

and the direction at right angle to it (B). If the

repair value is exceeded, replace engine with long

block.

Distortion on cylinder block top surface in(mm)

Standard assembling value Repair value

Less than 0.0020(0.05) More than 0.0047(0.12)

Cylinder bore dia. ø in(mm)

3.0315-3.0322

More than 3.0394(77.2)

(77-77.019)

3-4 109823 2/09

Piston and piston ring

Fig. 3-14

Fig. 3-15

Snap

Ring

Piston

Pin

1

1

Fig. 3-16

Disassembly

1. Remove the piston ring using a piston ring tool.

2. Remove the snap ring and extract the piston pin.

Inspection

1. Piston

a. Check the piston for cracks, streaking and burnout

on the outside surface and replace if excessive.

b. Measure the longer diameter at 0.39in.(10 mm)

above the lower end of th e piston skirt and bore of

the cylinder in the thrust direction, calculate the

clearance, and replace if the repair value is

exceeded.

Piston skirt bottom longer dia .ø in(mm)

Standard assembling value Service limit

3.0288-3.0298

(76.9325-76.9575)

Clearance between cylinder and piston in(mm)

Standard assembling value Service limit

0.0023-0.0034

(0.0575–0.0865)

Less than

3.0197(76.7)

More than

0.0098(0.25)

c. Measure the piston pin hole diameter and piston

pin outside diameter and replace if the clearance

exceeds the service limit.

Clearance between piston pin hole and piston pin

in(mm)

Standard assembling value Service limit

-0.0000~+0.0003

(-0.000~+0.008)

More than

0.0008(0.02)

109823 2/09 3-5

Loading...

Loading...