Page 1

XL-DK257N

SERVICE MANUAL

No. S2807XLDK257N

MICRO COMPONENT SYSTEM

O

I

D

U

A

IN

MODEL

XL-DK257N Micro Component System consisting of

XL-DK257N (main unit) and CP-DK257N (speaker system).

• In the interests of user-safety (Required by safety regulations in

some countries) the set should be restored to its original condition

and only parts identical to those specified be used.

XL-DK257N

iPod is a registered trademark of Apple Inc.

CONTENTS

PRECAUTIONS FOR USING LEAD-FREE SOLDER

CHAPTER 1. GENERAL DESCRIPTION

[1] Important Service Safety Precaution ................ 1-1

[2] Important Service Notes (for U.S.A only).......... 1-1

[3] Specifications..................................................... 1-2

[4] Name Of Parts ................................................... 1-3

CHAPTER 2. ADJUSTMENTS

[1] CD Section .................................................. 2-1

[2] Test Mode .................................................... 2-2

[3] Standard Specification Of Stereo System

Error Message Display Contents ................. 2-4

CHAPTER 3. MECHANICAL DESCRIPTION

[1] Disassembly ................................................ 3-1

CHAPTER 4. BLOCK DIAGRAM

[1] Block Diagram ............................................. 4-1

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Waveforms Of Servo Circuit ........................ 5-1

[2] IC Voltage .................................................... 5-3

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Notes On Schematic Diagram ..................... 6-1

[2] Types Of Transistor And LED ...................... 6-1

[3] Schematic Diagram ..................................... 6-2

[4] Charts Of Connecting Wires ...................... 6-10

[5] Wiring Side of PWB ................................... 6-12

CHAPTER 7. FLOWCHART

[1] Troubleshooting ........................................... 7-1

CHAPTER 8. OTHER

[1] Function Table Of IC .................................... 8-1

[2] FL Display.................................................... 8-9

PARTS GUIDE

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

!

SHARP CORPORATION

– 1

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

XL-DK257N

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

"MAIN, POWER, AMPLIFIER, HEADPHONE, MICOM REFLASH, DISPLAY, SPEAKER, VOLUME LED LIGHT UP,

iPOD, CD PWB" of this model employs lead-free solder.

The LF symbol indicates lead-free solder, and is attached on the PWB and service manuals. The alphabetical

character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with

conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, were

commend you to use a dedicated soldring bit, if you are not familiar with how to obtain lead-free wire solder or

soldering bit, contact our service station or service branch in your area.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead

solder by 40 C, and as it has poor solder wet ability, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, since the land may be peeled off or the maximum heat-resistance

temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady

soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corrected. Make sure to turn on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit

after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Ref No.

PWB-A

PWB-B

PWB-C

PWB-D 92LPWB7119CDUS

Parts No.

92LPWB7119MANS

92LPWB7119DPLS

92LPWB7119PODS

MAIN (A1), POWER (A2), AMPLIFIER (A3) , HEADPHONE (A4), MICOM REFLASH (A5)

DISPLAY (B1), SPEAKER (B2), VOLUME LED LIGHT UP (B3)

iPOD

CD

Description

– 2

i

Page 3

XL-DK257N

CHAPTER 1.

GENERAL DESCRIPTION

[1] Important Service Safety Precaution

CAUTION : “These servicing instructions are for use by qualified service personnel only. To reduce

the risk of electric shock do not perform any servicing other than that contained in the operating

instructions unless you are qualified to do so”.

WARNING

1. For continued safety, no modification of any circuit should be attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED

PROTECTION AGAINST FIRE

HAZARD, REPLACE ONLY WITH

SAME TYPE F801, F802, 6A, 125V/

F803, F804 2A, 125V/

F805 1.6A, 125V/

F806 5A, 125V FUSES.

ATTENTION: POUR ASSURER

UNE LONGUE PROTECTION CONTRE

UN INCENDIE, REMPLACER SEULEMENT

PAR UN FUSIBLE DE

TYPE F801, F802, 6A, 125V/

F803, F804 2A, 125V/

F805 1.6A, 125V/

F806 5A, 125V FUSES.

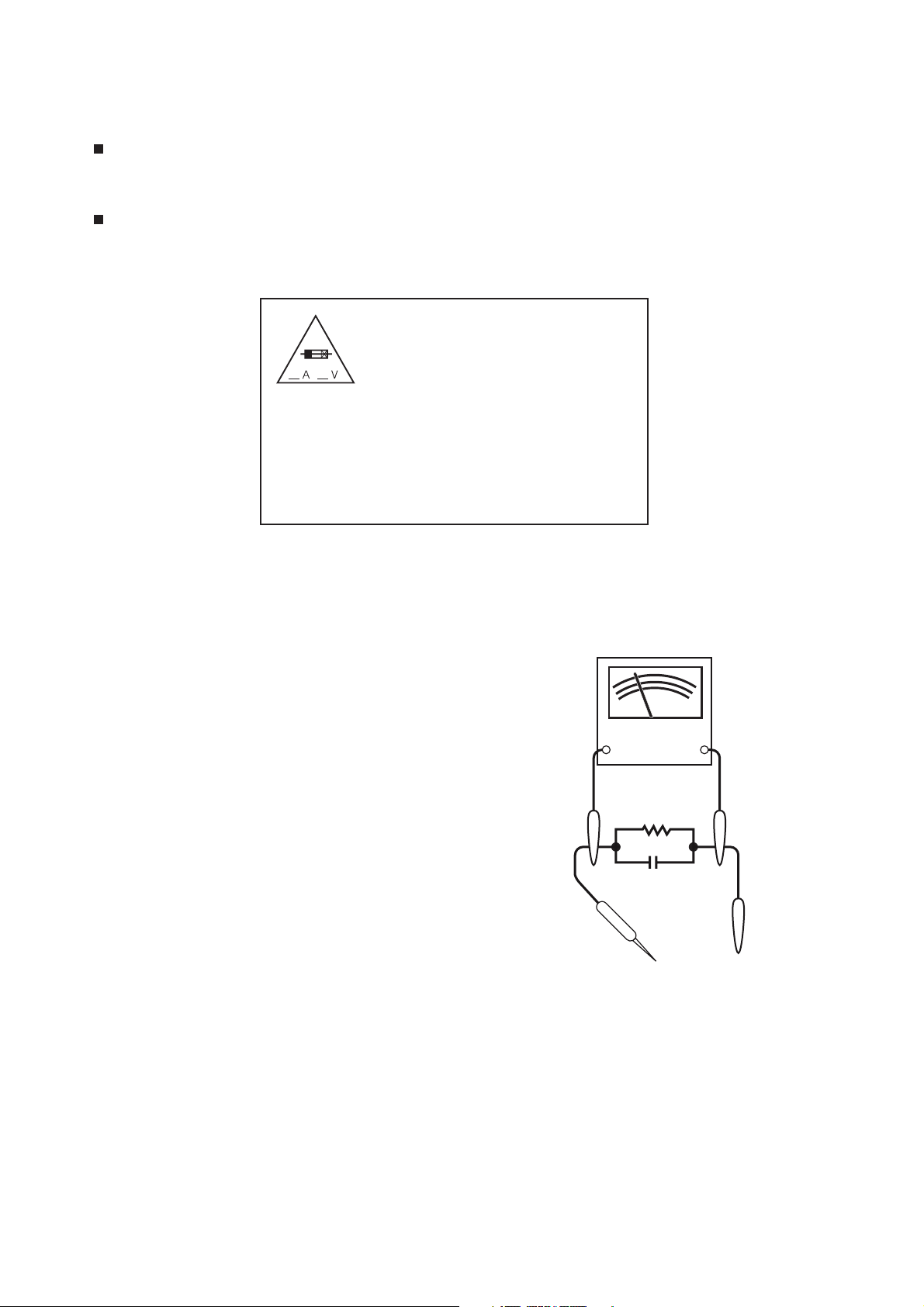

[2] Important Service Notes (for U.S.A only)

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform

the following safety checks.

1. Inspect all lead dress to make certain that leads are not

pinched or that hardware is not lodged between the

chassis and other metal parts in the audio product.

2. Inspect all protective devices such as insulating

materials, cabinet, terminal board, adjustment and

compartment covers or shields, mechanical insulators

etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

Plug the AC line cord directly into a 120 volt AC outlet.

*

* Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series

with all exposed metal cabinet parts and a known

earth ground, such as conduit or electrical ground

connected to earth ground.

Use a VTVM or VOM with 1000 ohm per volt, or

*

higher, sensitivity to measure the AC voltage drop

across the resistor (See diagram).

* Connect the resistor connection to all exposed metal

parts having a return path to the chassis (antenna,

metal cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

VTVM

AC SCALE

1.5k ohms

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

All check must be repeated with the AC line cord plug

connection reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2

milliamp. AC.) Or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the audio product to the owner.

1 – 1

1 – 3

Page 4

XL-DK257N

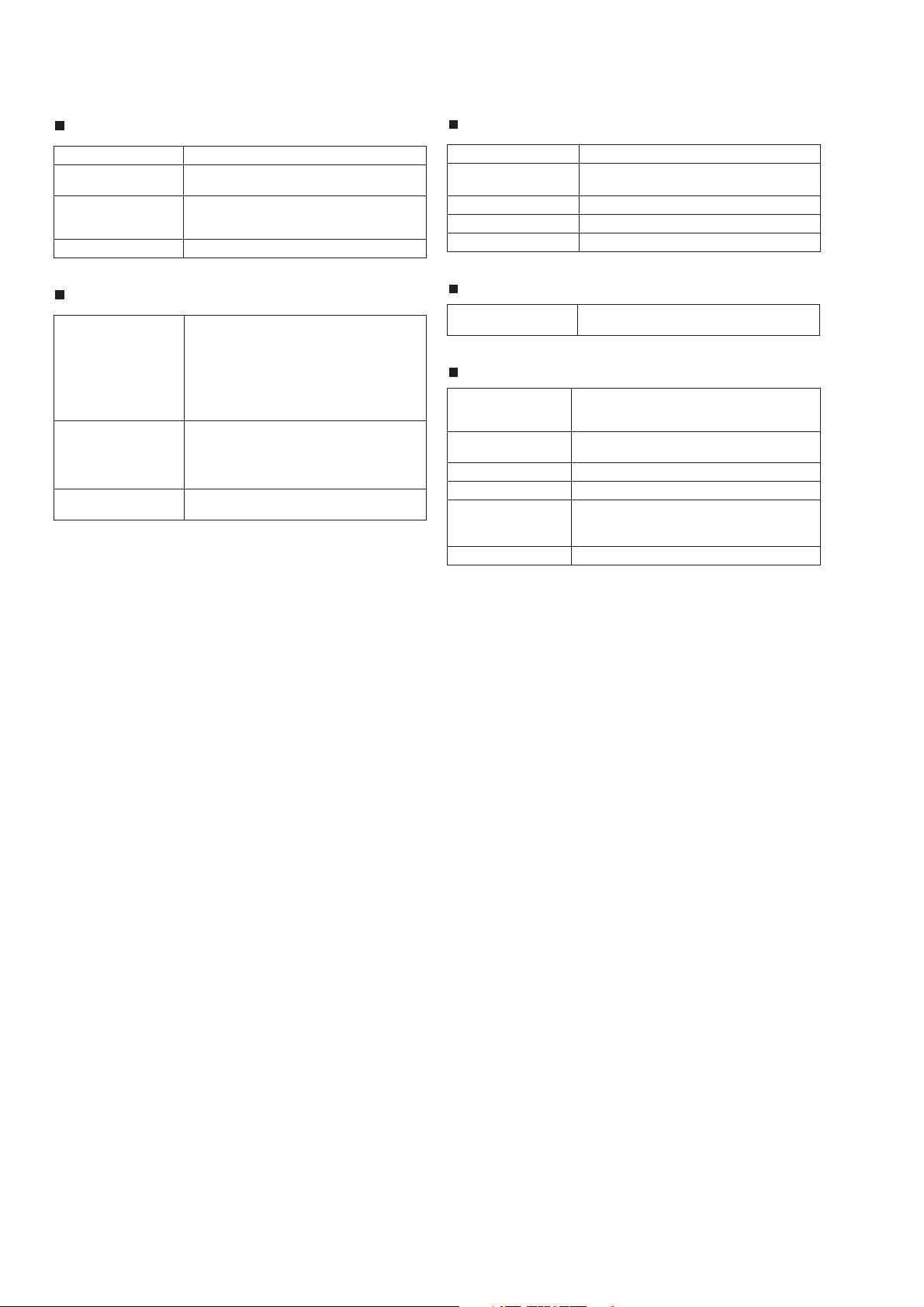

[3] Specifications

General

Power source AC 120 V ~ 60 Hz

Power consumption 56 W

Dimensions Width: 7-1/16" (180 mm)

Weight 9.5 lbs (4.3 kg)

Height: 10-2/8" (260 mm)

Depth: 10-6/8" (273 mm)

Amplifier

Output power

Output terminals Speakers: 4 ohms

Input terminals Audio In (Audio signal):

RMS : Total 160 Watts (80 Watts per

channel into 4 ohms at 1 kHz, 10%

total harmonic distortion.)

FTC : 60 Watts minimum RMS per

channel into 4 ohms from 100 Hz to

20 kHz, 10% total harmonic

distortion.

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

Subwoofer pre-out (audio signal):

150 mV/10 k ohms at 70 Hz

250 mV/47 k ohms

CD player

Type Single disc multi-play compact disc player

Signal readout Non-contact, 3-beam semiconductor laser

D/A converter Multi bit D/A converter

Frequency response 20 - 20,000 Hz

Dynamic range 90 dB (1 kHz)

pickup

Tuner

Frequency range

FM: 87.5 - 108 MHz

AM: 530 - 1,720 kHz

Speaker

Type

Maximum input

power

Rated input power 80 W

Impedance 4 ohms

Dimensions Width: 5-13/16" (148 mm)

Weight 5.40 lbs (2.45 kg)/each

2-way type speaker system

2" (5 cm) tweeter

4-3/4" (12 cm) woofer

160 W

Height: 10-1/4" (260 mm)

Depth: 7-13/16" (198.5 mm)

1 – 4

1 – 2

Page 5

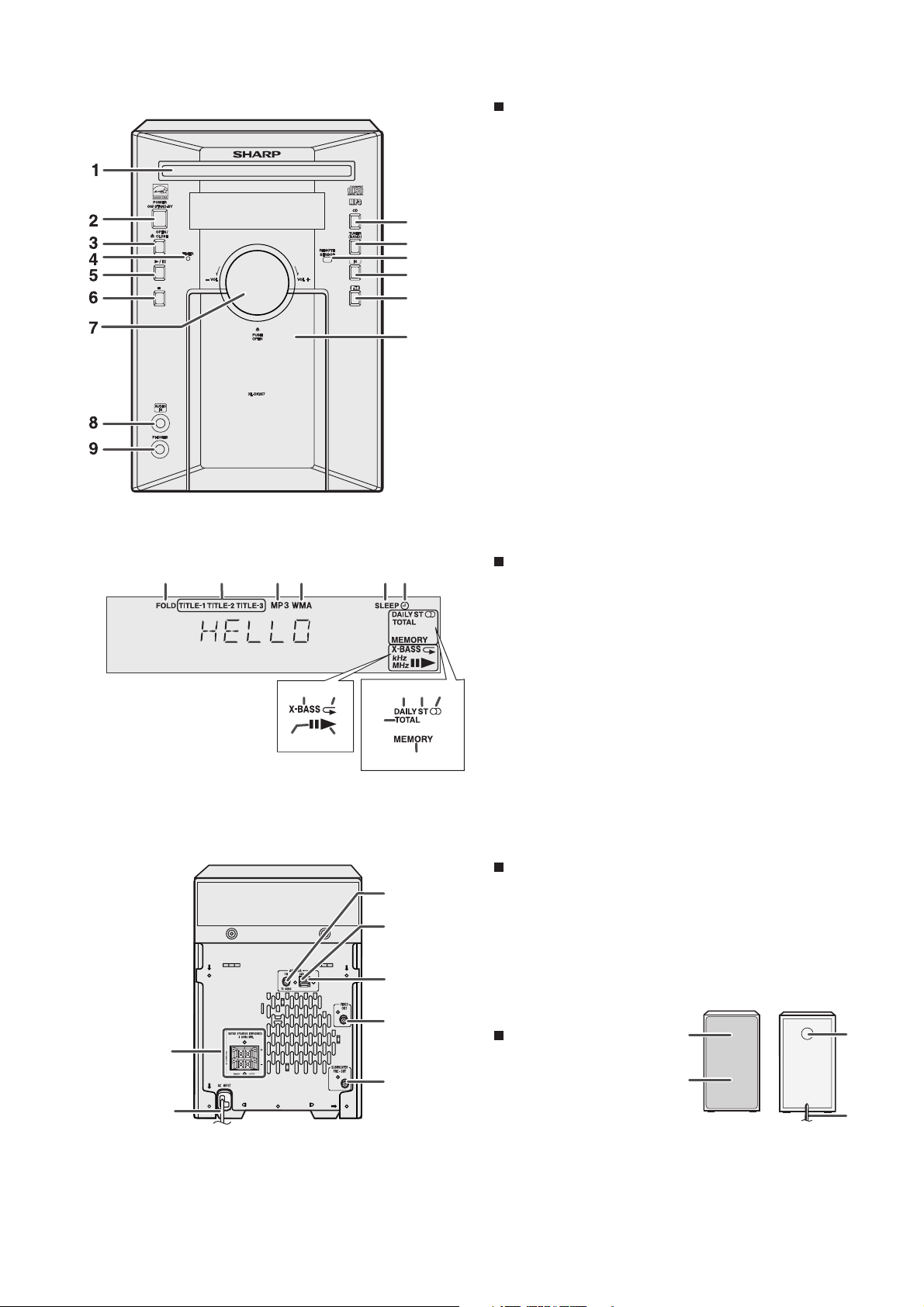

[4] Names Of Parts

4

1

2

3

Docking Station

MICRO COMPONENT SYSTEM

10

11

12

13

14

15

XL-DK257N

Front panel

1. Disc Tray

2. Power On/Stand-by Button

3. Disc Tray Open/Close Button

4. Timer Indicator

5. Disc or iPod Play or Pause button

6. Disc Stop Button

7. Volume Control

8. Audio In Jack

9. Phones Jack

10. CD Button

11. Tuner (Band) Button

12. Remote sensor

13. Audio In Button

14. iPod Button

15. iPod Docking Station

1234 56

12 13

8910

7

14

15

11

3

4

5

Display

1. MP3/WMA Folder Indicator

2. MP3/WMA Title Indicators

3. MP3 Indicator

4. WMA Indicator

5. Sleep Indicator

6. Timer Play Indicator

7. MP3/WMA Total Indicator

8. Daily Timer Indicator

9. FM Stereo Mode Indicator

10. FM Stereo Receiving Indicator

11. Memory Indicator

12. Extra Bass Indicator

13. Disc Repeat Play Indicator

14. Disc Pause Indicator

15. Disc Play Indicator

Rear panel

1. Speaker Terminals

2. AC Power Cord

3. FM 75 Ohms Antenna Jack

4. AM Antenna Ground Terminal

5. AM Loop Antenna Terminal

6. Video Out Jack

7. Subwoofer Pre-output Jack

6

Speaker system

1

7

1. Tweeter

2. Woofer

3. Bass Reflex Duct

4. Speaker Wire

2

1 – 5

1 – 3

Page 6

XL-DK257N

1

2

3

4

5

6

7

8

9

12

10

11

15 16

19

22

1817

13

14

20 21

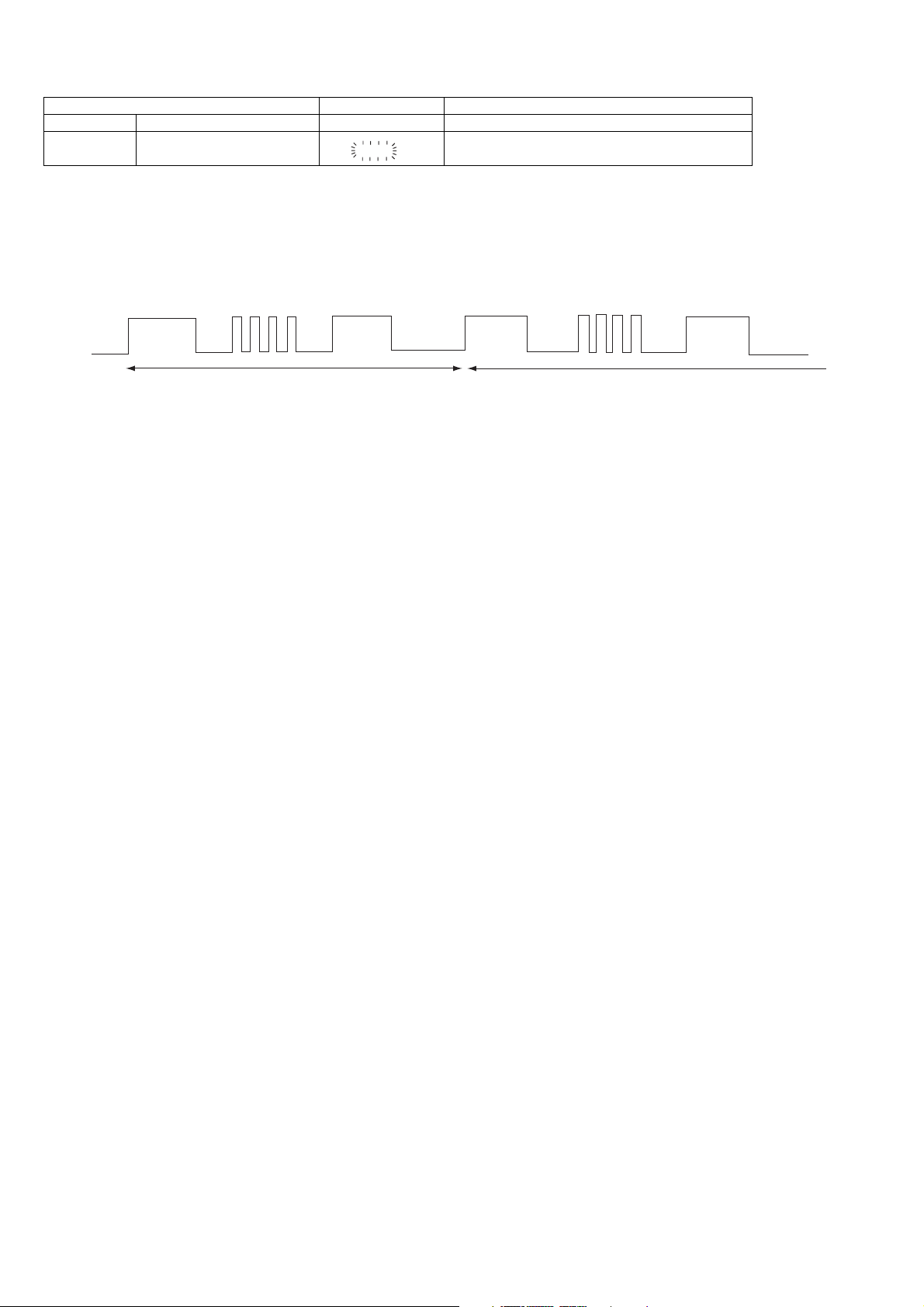

Remote control

1. Remote Control Transmitter

2. Disc Clear/Dimmer, iPod Menu Button

3. Memory, iPod Enter Button

4. Disc Direct Search Buttons

5. Equalizer Mode Select Button

6. Extra Bass/Demo Button

7. Volume Up and Down Buttons

8. Power On/Stand-by Button

9. CD Button

10. Tuner (Band) Button

11. Audio In/iPod Button

12. Disc Stop Button

13. Disc Play or Pause Button

14. iPod Play or Pause Button

15. Tuning Up, Select iPod Menu Items Button

16. CD Track Up or Fast Forward, Tuner Preset Up,

Time Up Button

17. CD Track Down or Fast Reverse, Tuner Preset Down,

Time Down Button

18. Tuning Down, Select iPod Menu Items Button

19. Play Mode Button

20. Display Button

21. Folder Button

22. Clock/Timer Button

1 – 6

1 – 4

Page 7

CHAPTER 2. ADJUSTMENTS

[1] CD Section

1. CD SECTION

• Adjustment

Since this CD system incorporates the following

automatic adjustment functions, readjustment is not

needed when replacing the pickup. Therefore,

different PWBs and pickups can be combined freely.

Each time a disc is changed, these adjustments are

performed automatically. Therefore, playback of

each disc can be performed under optimum

conditions.

Items adjusted automatically

1) Offset adjustment (The offset voltage between the

head amplifier output and the VREF reference

voltage is compensated inside the IC.)

* Focus offset adjustment

* Tracking offset adjustment

2) Tracking balance adjustment

3) Gain adjustment (The gain is compensated inside

the IC so that the loop gain at the gain crossover

frequency will be 0 dB.)

XL-DK257N

* Focus gain adjustment

* Tracking gain adjustment

2 – 1

Page 8

XL-DK257N

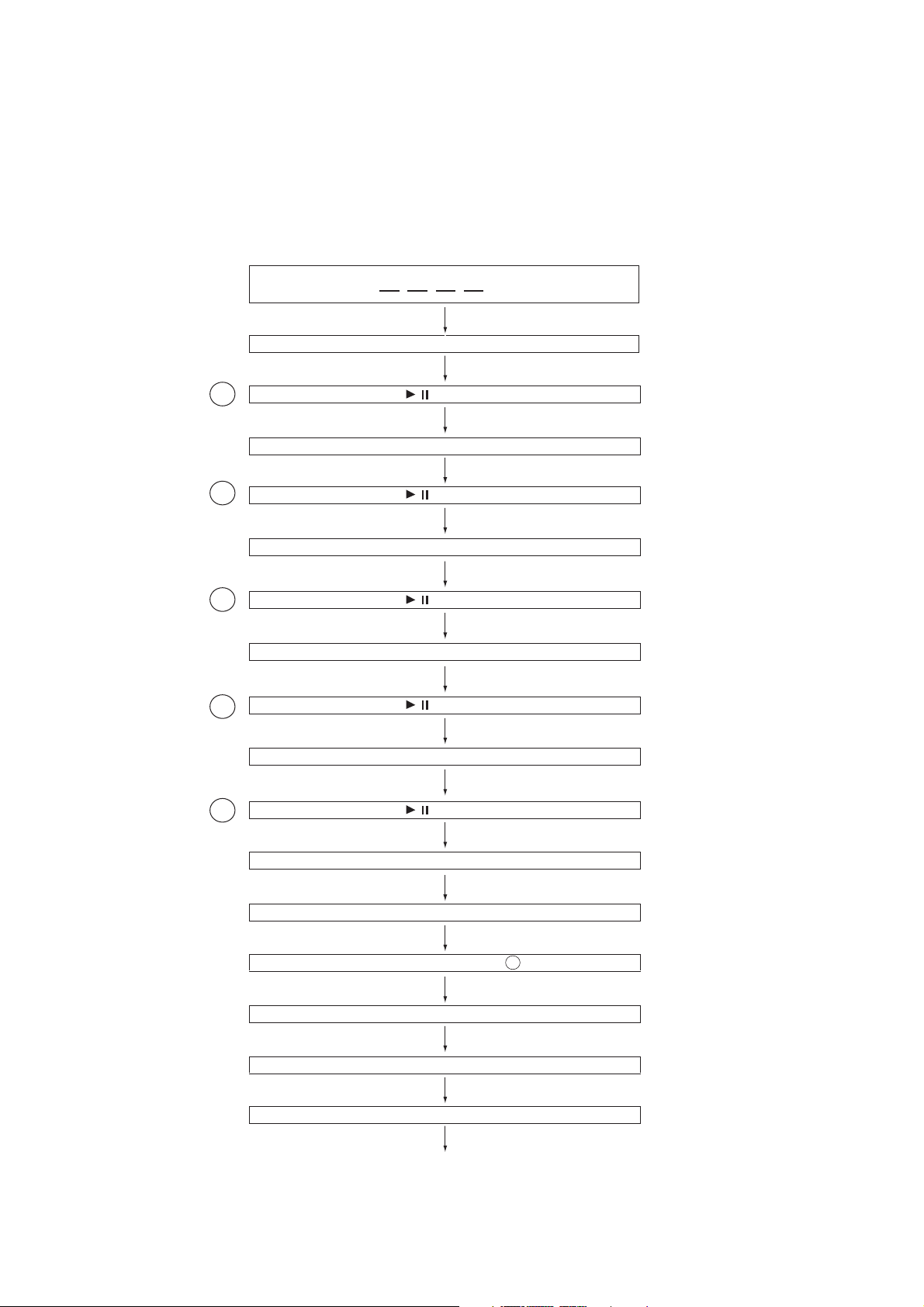

[2] Test Mode

• Setting the test mode

During AC unplug, plug-in AC while pressing down the

POWER button and CD button. Then, press the CD

button to enter the test mode.

Step

Step

Step

Step

C DTEST

OPEN/CLOSE operation is using manual. IL isn’t done

/

1

2

3

4

<< >> key input.

Laser ON.

/

<< >> key input.

Focus ON

/

<< >> key input.

CLV Servo ON

/

<< >> key input.

IL isn’t done

Step

Tracking Servo ON

/

5

Hold down << CD >> key for more than 2 sec.

Start Auto Adjustment at current pick-up location.

<< >> key input.

Reading Sub-code and Display

<<STOP>> key input.

STOP and return to Step

<<STOP>> key input.

1

2 – 2

Page 9

XL-DK257N

STOP and return to Step

Everytime << DISPLAY >> key input

a) Focus Balance = FB : XX

b) Focus Gain = FG : XX

c) Tracking Balance = TB : XX

d) Tracking Gain = TG : XX

e) Focus Offset = FOFF : XX

f) Tracking Offset = TOFF : XX

g) RFRP = RFRP : XX

h) Focus Error

(RW Judgement) = RW : XX - XXXX

i) Focus Error

(Other than RW Judgement) = DA : XX - XXXX

<<STOP>> key input.

STOP and return to Step

Note

Sliding the PICKUP with << >>, << >> button can be set

1

1

in STOP mode or play mode.

During at Step , if press << >> for more than 1 sec, it directly

goes to step .

1

5

/

To cancel: Power OFF

2 – 3

Page 10

XL-DK257N

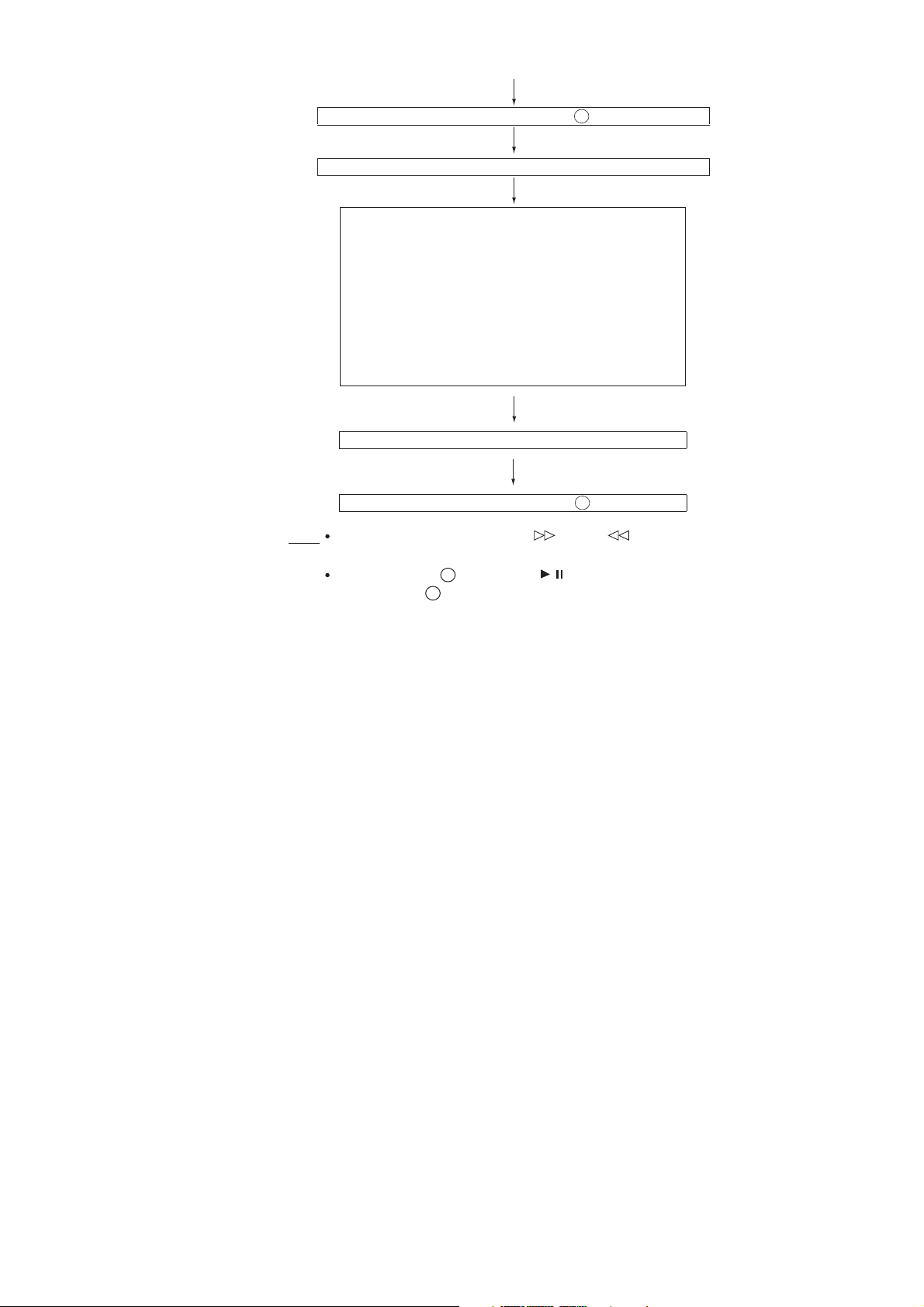

[3] Standard Specification Of Stereo System Error Message Display Contents

Error Contents DISPLAY Notes

CD Focus Not Match/IL Time Over. ‘NO DISC’

TUNER PLL Unlock.

87.50

FM MHz

AMP abnormal detection and +B PROTECTION display

In case AMP abnormal detection or +B PROTECTION had occurred, the unit will automatically enter to stand-by

mode and Timer indicator will flashing as below.

Example: In case of speaker abnormal

PLL Unlock.

ON

TIMER

LED OFF OFF

NO NO. 1.1

NO. 1 : +B PROTECTION

NO. 2 : AMP abnormal

FLASHING FLASHING

OFF

NO. 2

1

FRAME

ON ON ON

OFF OFF OFF OFF

NO. 2

(REPEAT)

BEFORE TRANSPORTING THE UNIT

The following process need to be taken after set tapering/parts replacement.

1. Press the POWER ON/STAND-BY button to enter stand-by mode.

2. While pressing down the POWER button and the CD button, plug-in AC. The Micro Computer version number will

be displayed as "X7U10**".

3. Press the POWER button until "WAIT"--> "FINISHED" appears.

4. Unplug the AC cord and the unit is ready for transporting.

2 – 4

Page 11

XL-DK257N

CHAPTER 3.

MECHANICAL DESCRIPTION

[1] Disassembly

Caution on disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1) Take cassette tape and compact disc out of the unit.

2) Be sure to remove the power supply plug from the

wall outlet before starting to disassemble the unit.

3) Take off nylon bands or wire holders where they

need to be removed when disassembling the unit.

After servicing the unit, be sure to rearrange the

leads where they were before disassembling.

4) Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

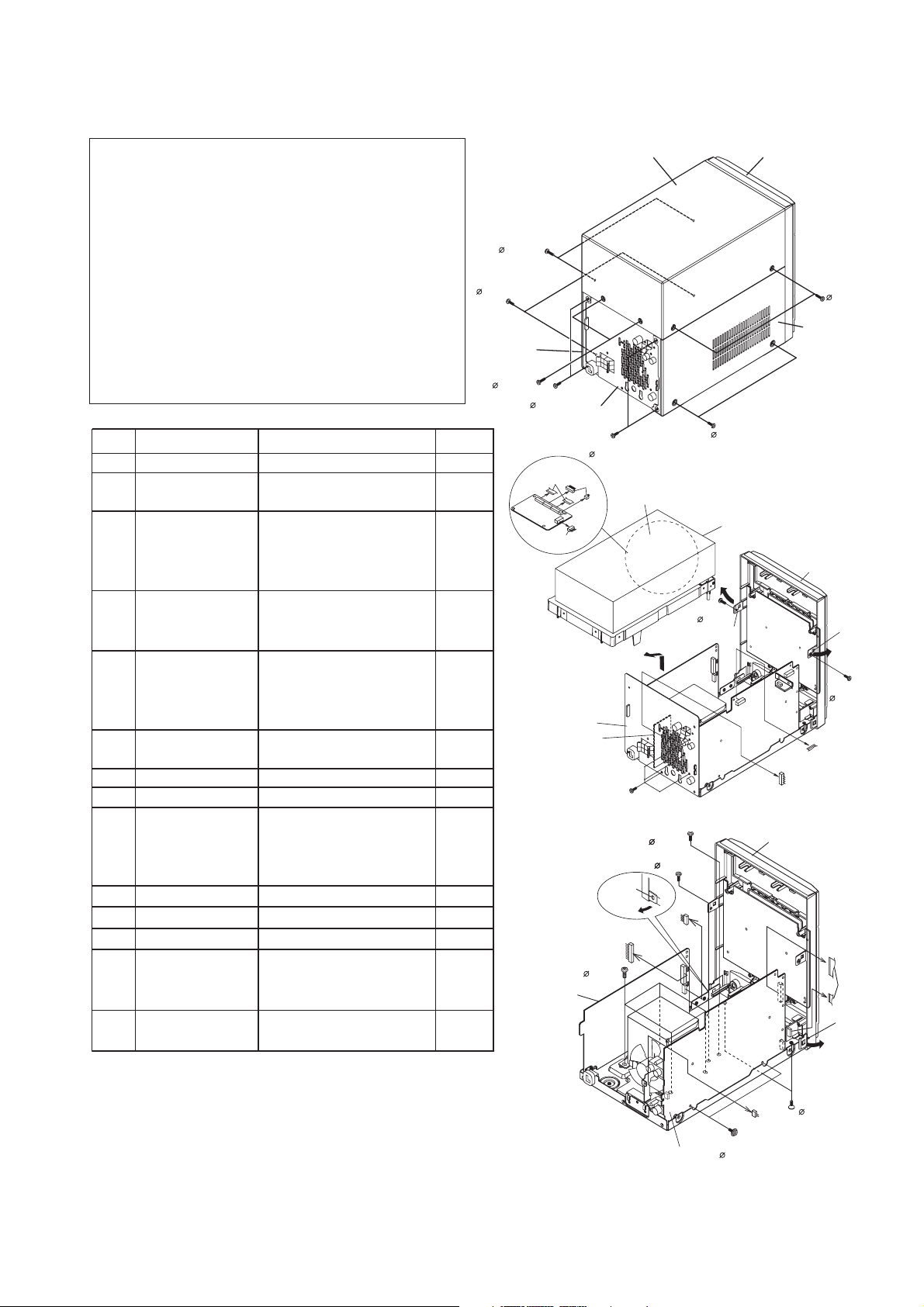

STEP REMOVAL PROCEDURE FIGURE

1 Top Cabinet 1

2 Side Panel

(Left/Right)

3 CD Changer unit 2

4 Rear Panel with 2

Speaker PWB

5 Front Panel 3

6 Main PWB 3

7 Power PWB 3

8 Speaker PWB 4

9 Display PWB 5

10 USB PWB / SUB PWB 5

11 Jack PWB 5

12 Re-Flash PWB 6

13 CD MP3 PWB 7

14 CD Mechanism 7

1. Screw ............................(A1) X 6

1. Screw ............................(B1) X 8

1. Screw ............................(C1) X 2

2. Hook .............................. (C2) X 2

3. Socket ...........................(C3) X 3

4. Flat Cable ...................... (C4) X 2

1. Screw ............................(D1) X 4

2. Socket ...........................(D2) X 1

3. Flat Cable ...................... (D3) X 1

1. Screw ............................(E1) X 3

2. Flat Cable ...................... (E2) X 2

3. Socket ...........................(E3) X 1

4. Hook .............................. (E4) X 2

1. Screw ............................(F1) X 3

2. Socket ........................... (F2) X 2

1. Screw ............................(G1) X 4

1. Screw ............................(H1) X 2

1. Knob ...............................(J1) X 1

2. Nut..................................(J2) X 1

3. Washer...........................(J3) X 1

4. Screw .............................(J4) X 6

1. Screw ............................(K1) X 2

1. Screw ............................ (L1) X 1

1. Screw ........................... (M1) X 1

1. Screw ............................(N1) X 3

2. Flat Cable ...................... (N2) X 2

3. Socket ...........................(N3) X 1

1. Screw ............................(P1) X 4

2. Screw ............................(P2) X 4

1

8

(A1)x2

3x12mm

(B1)x2

3x10mm

Side Panel

(Right)

(A1)x2

3x12mm

(B1)x2

3x10mm

(C4)x2

(C3)x1

Rear Panel

Speaker PWB

Power PWB

Rear Panel

(C3)x2

(G1)x4

4x6mm

(B1)x2

3x10mm

(D1)x4

3x10mm

(E4)x1

PULL

(F2)x1

Top Cabinet

Figure 1

CD MP3 PWB

Figure 2

(E1)x1

3x6mm

(F1)x1

3x6mm

CD Changer Unit

(C1)x1

3x10mm

(E3)x1

(B1)x2

3x10mm

PULL

Hook

(C2)x1

Front Panel

(D2)x1

Front panel

Side Panel

(Left)

Front Panel

(D3)x1

PULL

(A1)x2

3x12mm

Hook

(C2)x1

PULL

(C1)x1

3x10mm

(E2)x2

Hook

(E4)x1

Note:

After removing the connector for the optical pickup from

the connector, wrap the conductive aluminium foil around

the front end of the connector so as to protect the optical

pickup from electrostatic damage.

3 – 1

Main PWB

Figure 3

(F1)x2

3x10mm

(F2)x1

(E1)x2

3x10mm

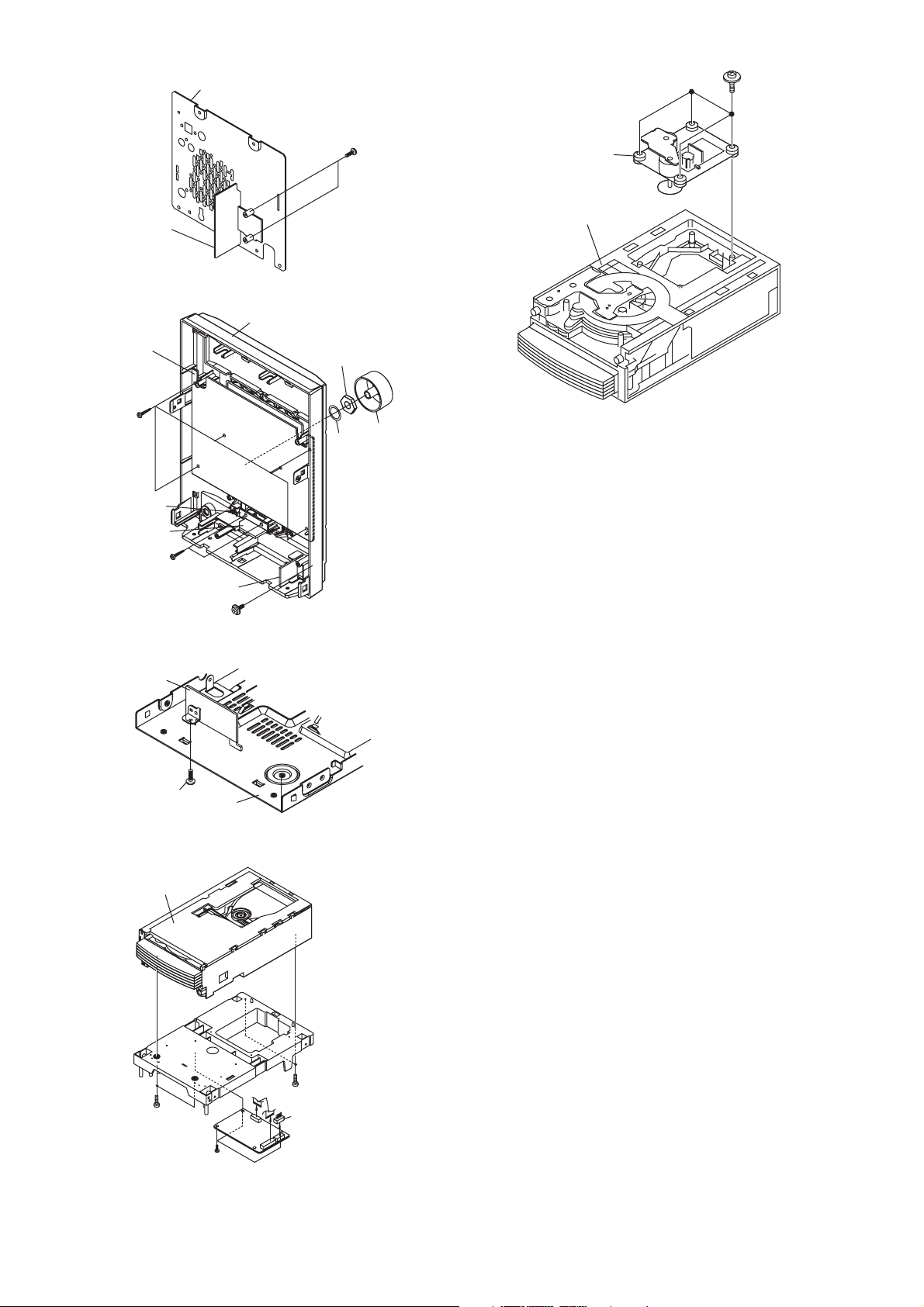

Page 12

XL-DK257N

Speaker PWB

Display PWB

(J4)x6

Ø2.6x10mm

SUB PWB

USB PWB

Rear Panel

Figure 4

Front Panel

(J2)x1

(J3)x1

(H1)x2

Ø3x10mm

(J1)x1

CD Mechanism

CD Changer Unit

Figure 8

(P2)x4

Special

Ø2.6x10mm

Re-Flash PWB

(M1)x1

Ø3x10mm

CD Changer

Unit

(K1)x2

Jack PWB

(L1)x1

Special

Figure 5

Main Chassis

Figure 6

(P1)x2

Ø3x10mm

(N1)x3

Ø3x10mm

Figure 7

(N2)x2

(P1)x2

Ø3x10mm

(N3)x1

3 – 2

Page 13

XL-DK257N

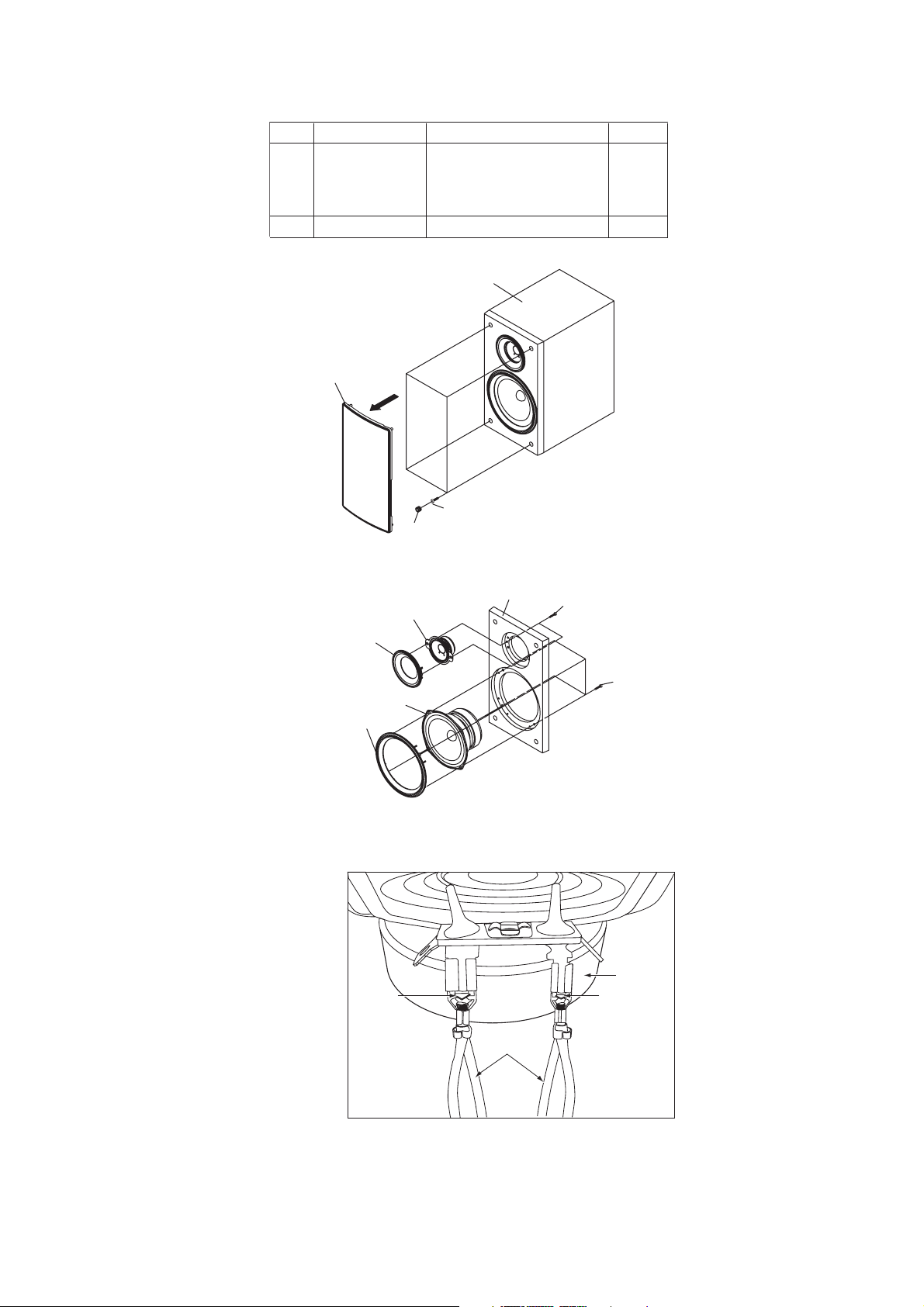

STEP PROCEDURE FIGURE

1 Woofer 1. Net Frame Ass’y............ (A1) X 1

REMOVAL

9, 10

2. Catching Holder............. (A2) X 4

3. Screw ............................ (A3) X 4

4. Screw ............................ (A4) X 4

2 Tweeter 1. Screw ............................ (B1) X 2

Speaker Box

Net Frame Ass’y

(A1) x1

(A3)x4

(A2)x4

Ø4x20mm

10

Figure 9

Tweeter Ring

Woofer

Woofer Ring

LOCKING

TA B

Tweeter

Front Board

Figure 10

SPEAKER

WIRE

(B1)x2

Ø3x14mm

(A4)x4

Ø3.5x14mm

SPEAKER

UNIT

LOCKING TAB

CAUTION TO REMOVE SPEAKER UNIT :

PRESS THESE LOCKING TABS TO RELEASE SPEAKER WIRE

3 – 3

Page 14

XL-DK257N

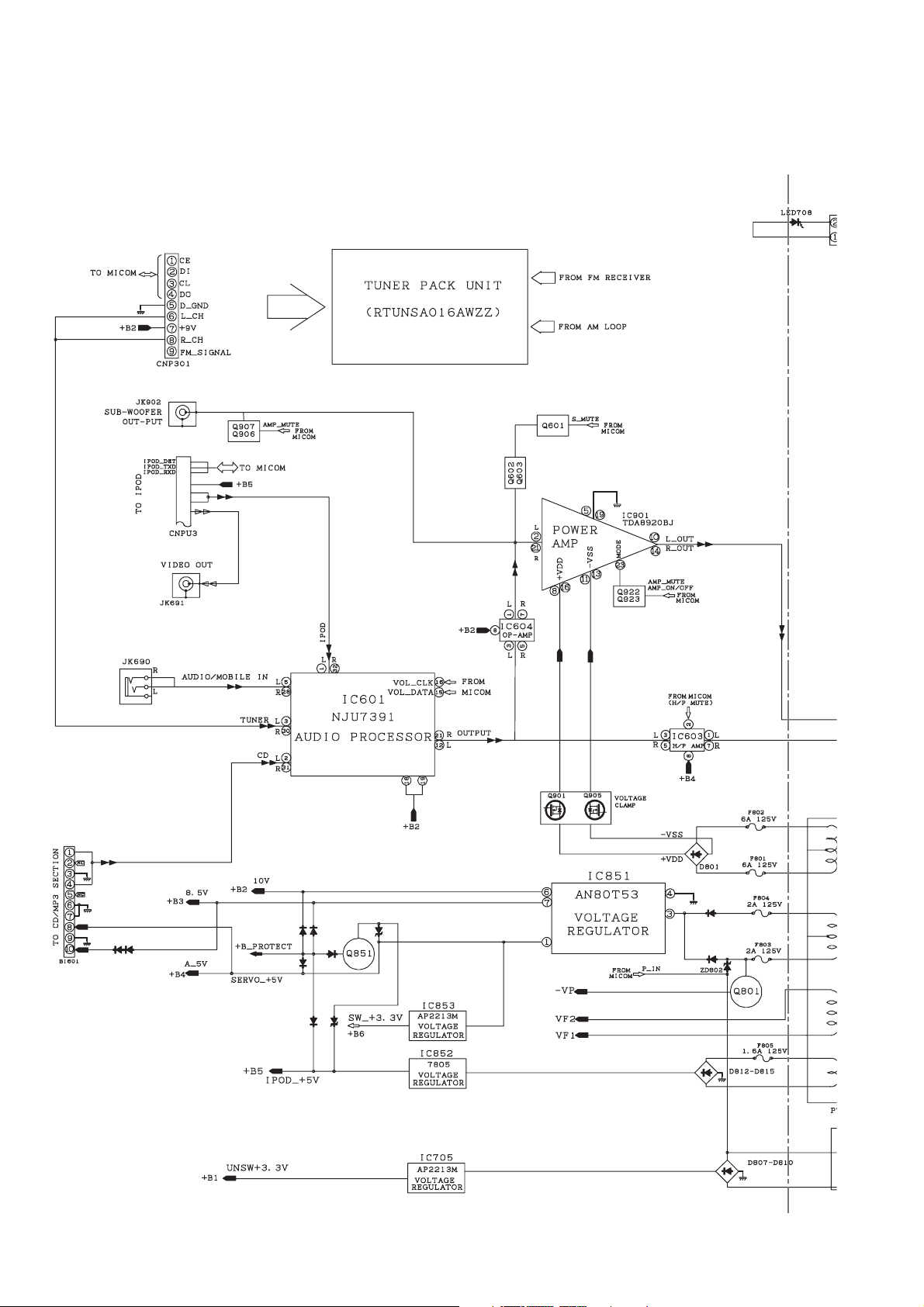

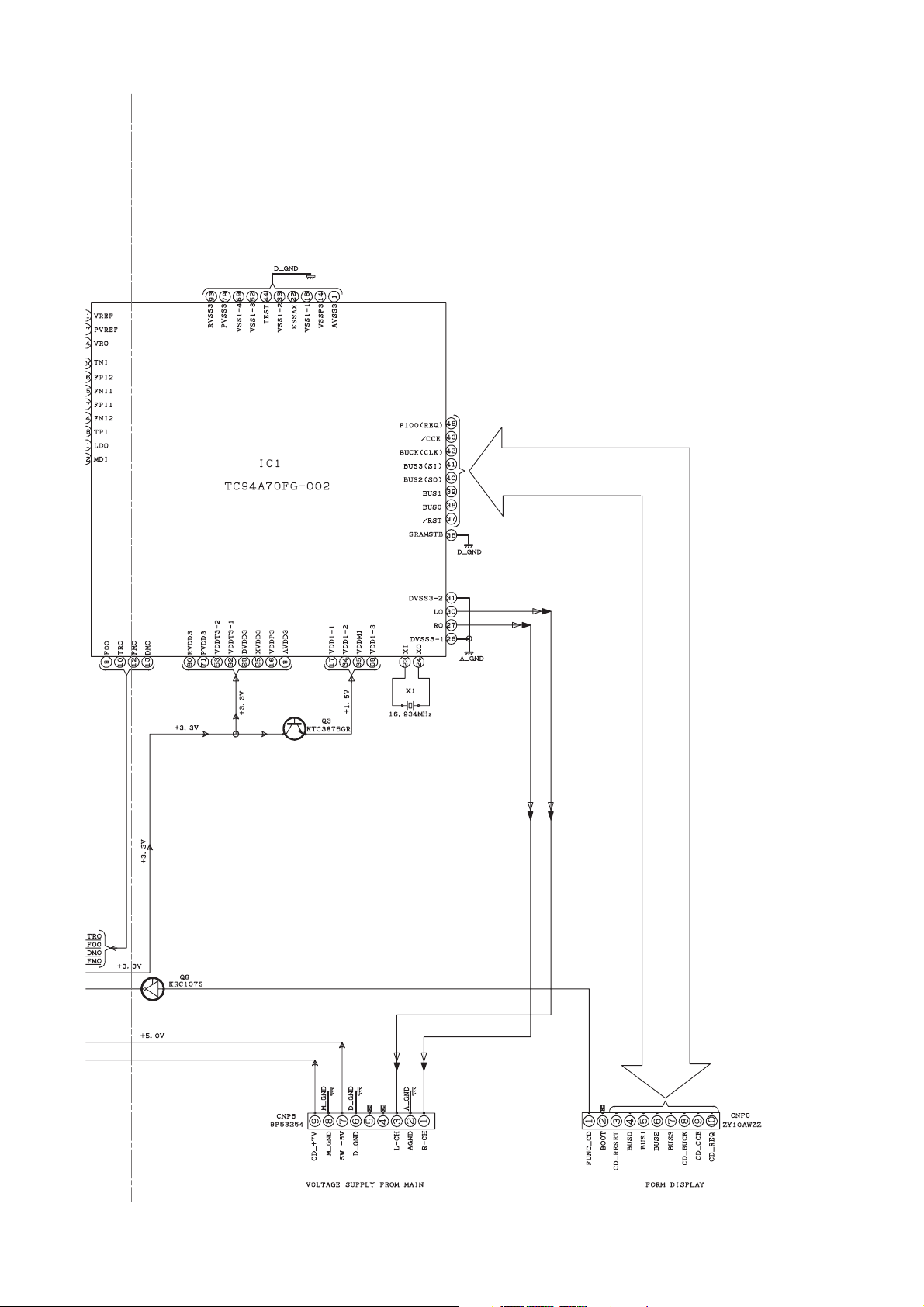

CHAPTER 4. DIAGRAMS

[1] Block Diagram

Figure 1: BLOCK DIAGRAM (1/2)

4 – 1

Page 15

XL-DK257N

120V/60Hz

Figure 2: BLOCK DIAGRAM (2/2)

4 – 2

Page 16

XL-DK257N

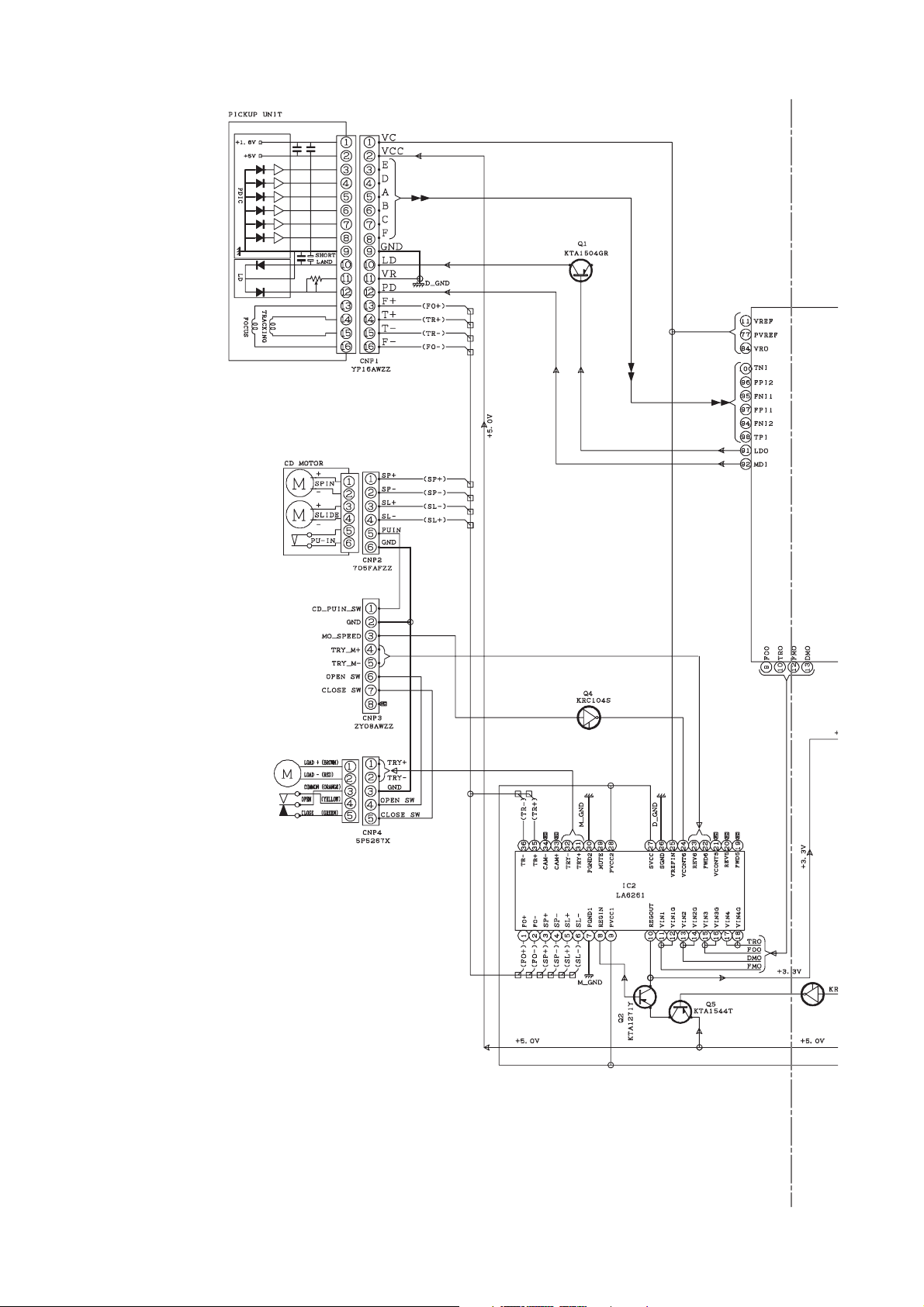

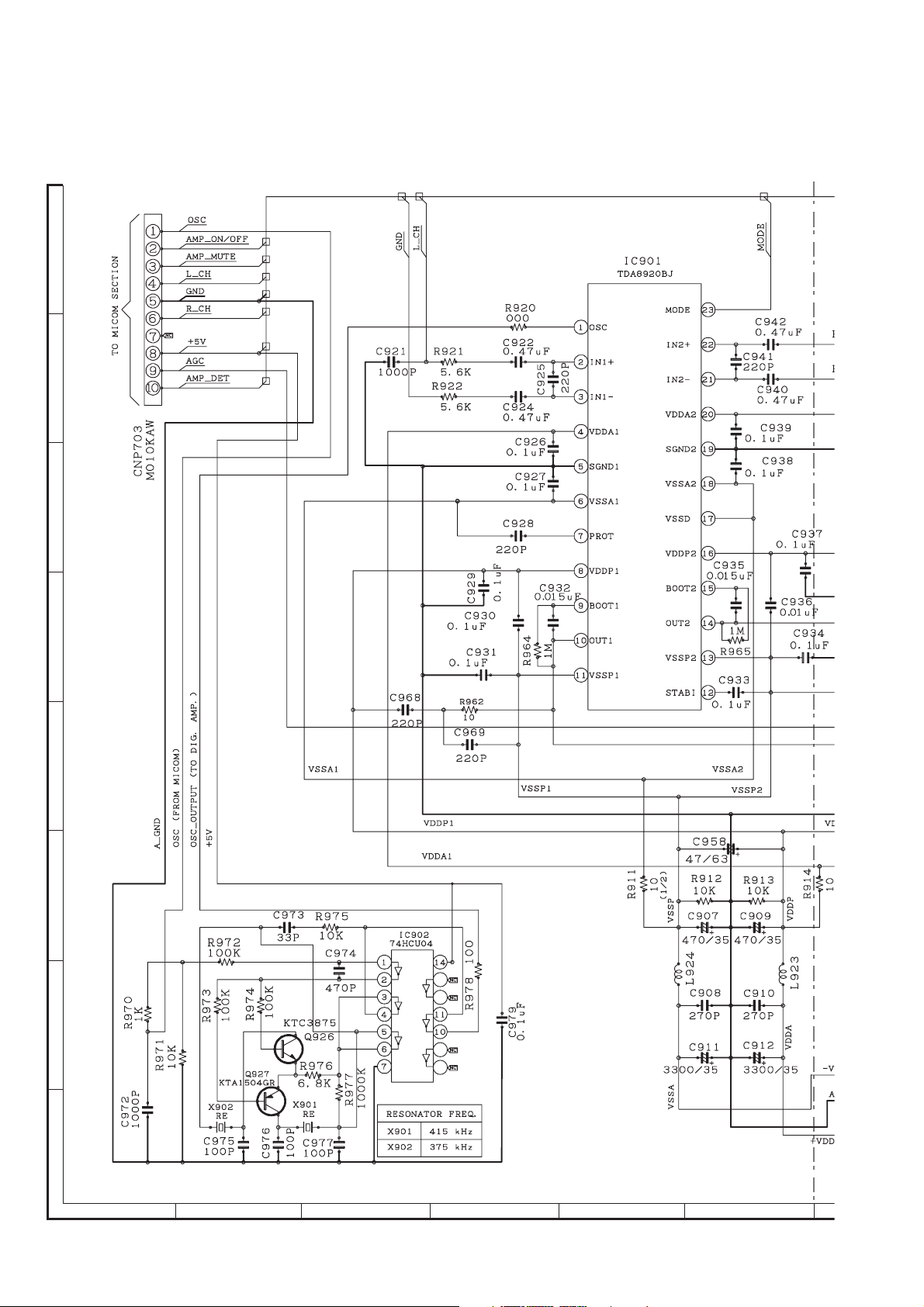

[2] CD Block Diagrams

Figure 4-3: CD BLOCK DIAGRAM (1/2)

4 – 3

Page 17

XL-DK257N

PA016AW

Figure 4-4: CD BLOCK DIAGRAM (2/2)

4 – 4

Page 18

XL-DK257N

FOO

TRO

1

9

10

2

9

13

DMO

FOO

9

13

FOO

DMO

TEI

RFO

FOO

9

6

89

9

FOO

6

TEI

9

FOO

DMO

LPFO

TMAX

13

76

74

67

66

65

BCKI

AIN

LRCKI

89

RFO

7

8

614

5

1

6

1

4

1

619

10115

CHAPTER 5.

CIRCUIT DESCRIPTION

[1] Waveforms Of Servo Circuit

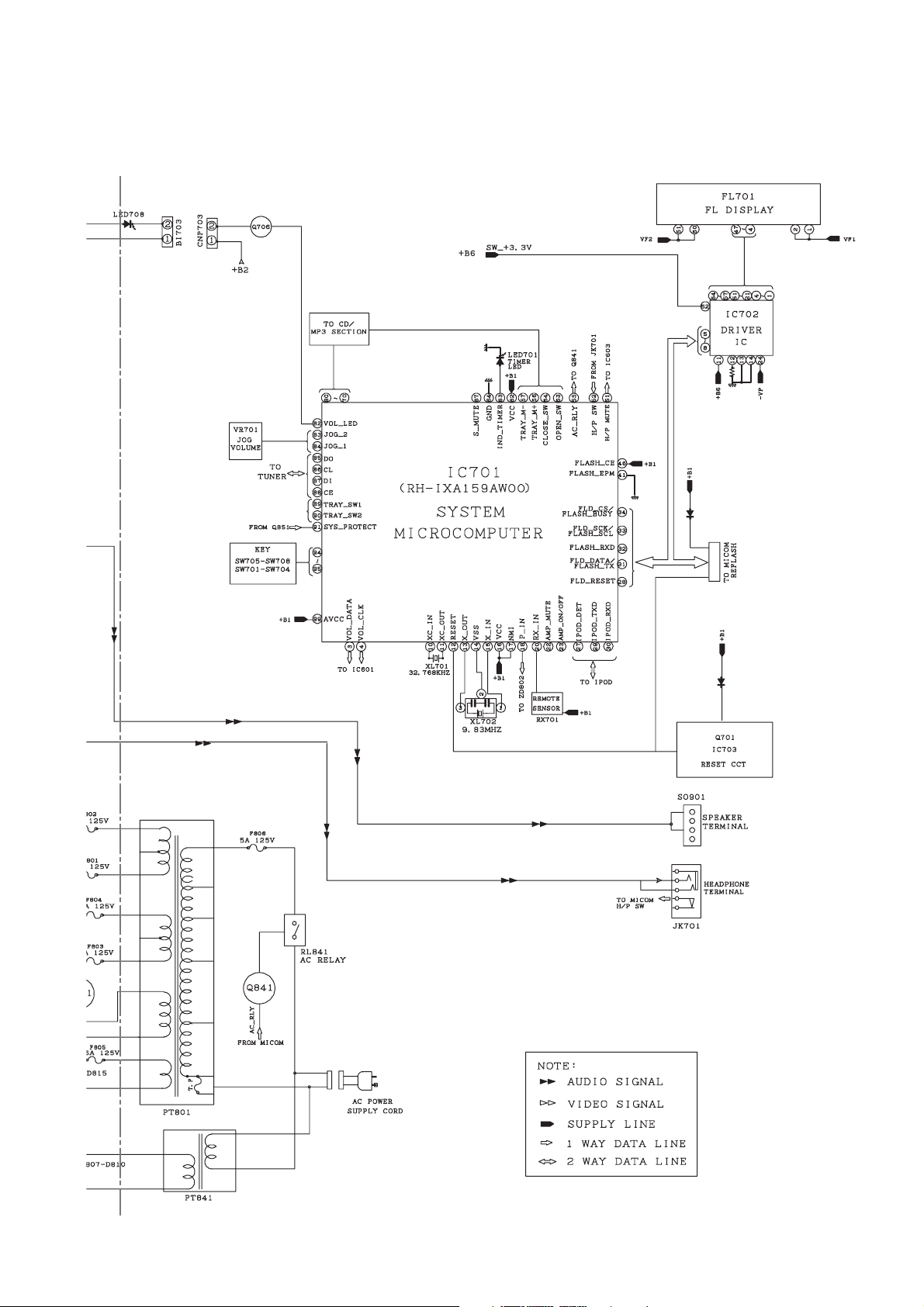

IC1 IC1

IC1 IC1

IC1 IC1

IC1

IC1

IC1

IC1

IC1

IC1

IC1 IC1

IC1

IC1

IC1 IC1

IC1

5 – 1

Page 19

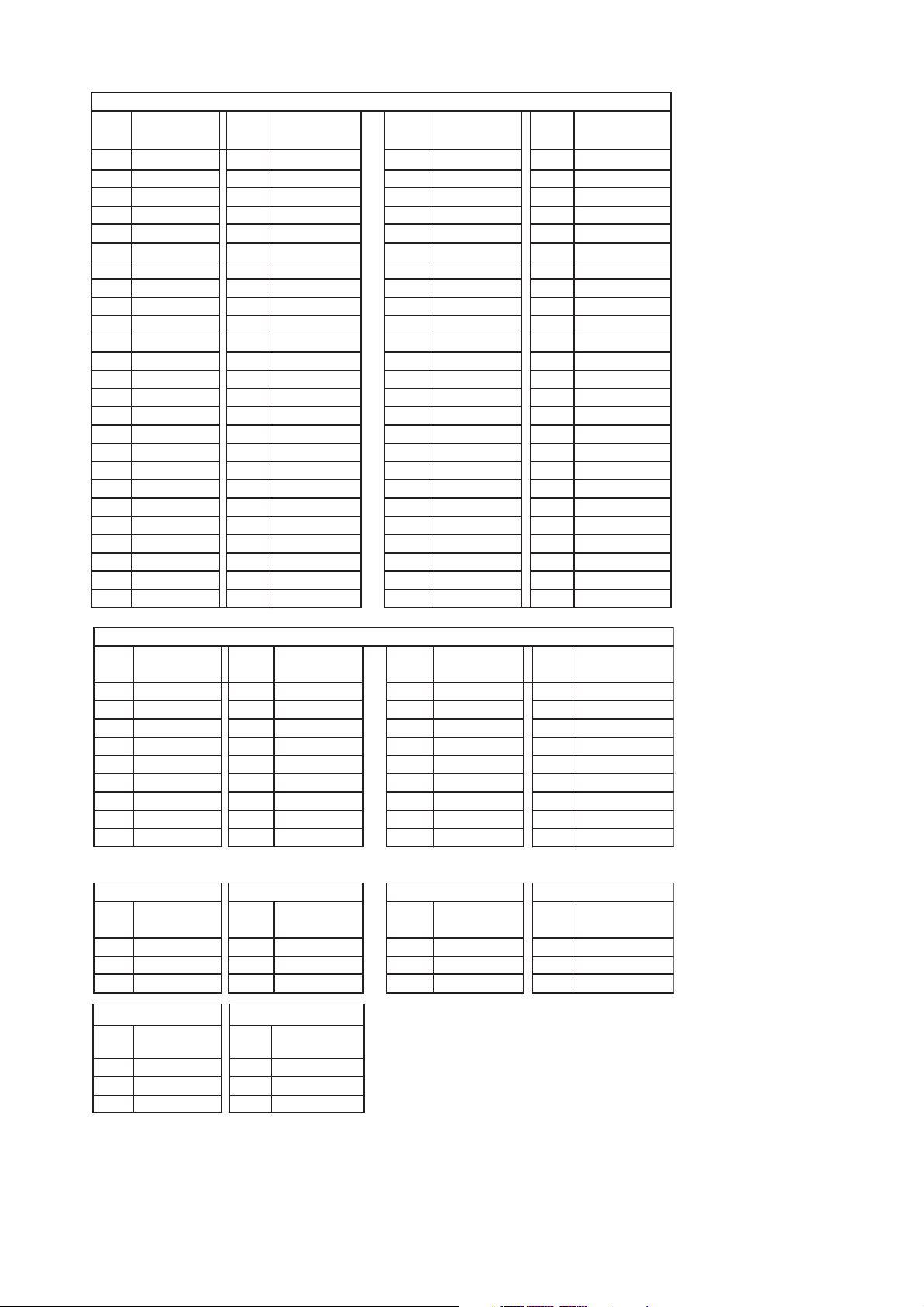

[2] Voltage

IC1

PIN

VOLTAGE

NO

1 0.02 26 0.01 51 1.53 76 3.26

2 1.63 27 1.52 52 0.03 77 1.63

3 0.76 28 3.03 53 3.27 78 0.98

4 0.70

5 0.59 30 1.52 55 0.03 80 1.74

6 0.70

7 1.63 32 3.27 57 1.53 82 1.63

8 3.27 33 0.03 58 3.27 83 1.68

9 1.63 34 4.53 59 0.04 84 1.63

10 1.63 35 1.53 60 3.27 85 1.62

11 1.63 36 0.01 61 0.03 86 1.64

12 1.63 37 3.25 62 0.03 87 1.66

13 1.63 38 2.41 63 0.03 88 1.62

14 0.01 39 2.14 64 0.03 89

15 0.52 40 2.59 65 1.62 90 3.27

16 0.55 41 2.25 66 1.65 91 3.25

17 0.01 42 0.61 67 3.24 92 0.01

18 0.01 43 3.25 68 1.49 93 0.02

19 1.11 44 0.04 69 0.02 94 1.63

20 0.36 45 0.04 70 1.63 95 1.63

21 0.26 46 0.04 71 3.26 96 1.63

22 0.01 47 0.04 72 1.61 97 1.63

23 0.26 73 1.31 98 1.63

24 0.34 49 1.64 74 0.02 99 1.64

25 0.54 50 1.65 75 1.38 100 1.63

PIN

VOLTAGE

NO

29 1.52 54 0.03 79 0.02

31 0.01 56 3.27 81 1.63

48 0.10

PIN

NO

VOLTAGE

PIN

NO

VOLTAGE

XL-DK257N

0.50

IC2

PIN

VOLTAGE

NO

1 3.18 10 3.27 19 3.20 28 7.09

2 3.17 11 1.63 20 3.20 29 0.01

3 3.19 12 1.63 21 0.01 30 1.63

4 3.20 13 1.63 22 0.01 31 2.24

5 3.19 14 1.63 23 0.01 32 3.15

6 3.18 15 1.63 24 0.01 33 3.16

7 0.00 16 1.63 25 0.00 34 2.69

8 4.39 17 1.62 26 7.03 35 3.16

9 7.08 18 1.62 27 7.08 36 3.16

Q1 Q2 Q3 Q4

PIN

VOLTAGE

NO

E 3.26 E 5.05 E 1.48 E 0.01

C 0.89 C 3.26 C 3.26 C 0.02

B 4.37 B 4.37 B 2.17 B 3.11

Q5

PIN

VOLTAGE

NO

E 5.08

C 5.05

B

4.37

PIN

VOLTAGE

NO

PIN

VOLTAGE

NO

Q8

PIN

VOLTAGE

NO

E 0.00

C 0.04

B

2.98

PIN

NO

PIN

NO

VOLTAGE

VOLTAGE

PIN

NO

PIN

NO

VOLTAGE

VOLTAGE

5 – 2

Page 20

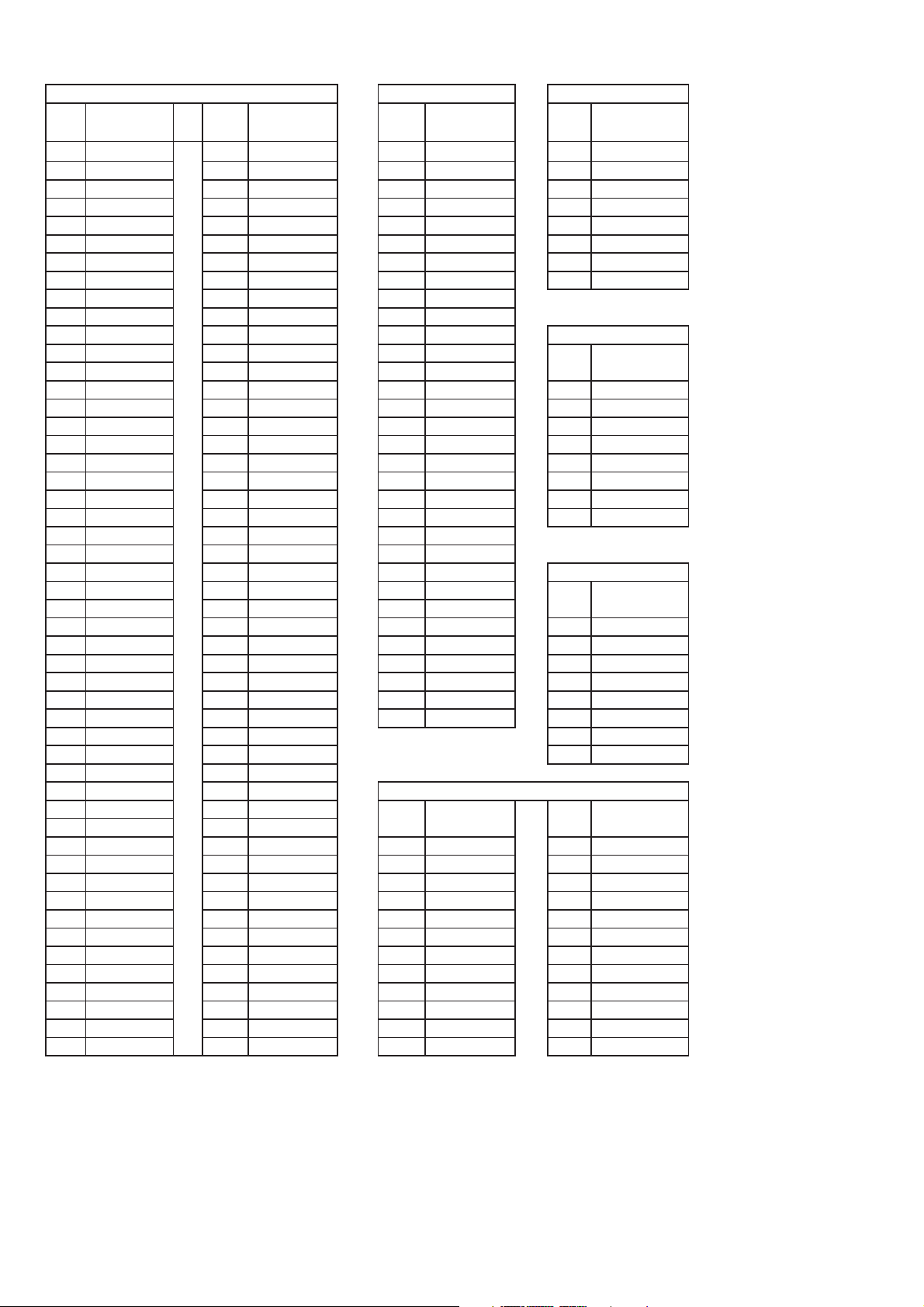

XL-DK257N

IC701 IC601 IC705

VOLTAGE

PIN

NO

1 2.60m 51 3.50m 1 4.10 1 8.43

2 2.60m 52 -0.20m 2 4.10 2 8.49

3 3.13 53 1.88 3 4.10 3 3.77

4 3.13 54 3.28 4 0.40m 4 2.39

5 2.00m 55 3.04 5 4.10 5 0.49

6 3.12 56 2.80m 6 4.12 6 0.49

7 3.13 57 2.30m 7 4.10 7 0.49

8 1.30m 58 2.00m 8 4.12 8 0.49

9 0.50m 59 2.80m 9 4.12

10 0.37 60 2.80m 10 4.11

11 0.65 61 2.80m 11 4.12

12 3.21 62 3.13 12 0.40m

13 1.46 63 1.80m 13 0.40m

14 0.20m 64 0.70m 14 0.40m 1 5.01

15 1.35 65 2.00m 15 3.13 2 5.00

16 3.15 66 2.40m 16 3.13 3 4.88

17 3.15 67 3.04 17 3.13 4 0.70m

18 1.15 68 0.60m 18 9.28 5 4.90

19 1.40m 69 1.10m 19 9.28 6 5.00

20 3.11 70 3.28 20 4.10 7 5.02

21 3.28 71 33.80m 21 4.12 8 10.00

22 1.30m 72 3.13 22 4.12

23 2.30m 73 3.13 23 4.11

24 2.60m 74 2.90m 24 4.12

25 0.90m 75 2.80m 25 4.12

26 1.40m 76 2.10m 26 4.10

27 3.21 77 1.10m 27 4.12 1 2.02

28 3.13 78 3.13 28 4.11 2 216.70m

29 3.21 79 1.50m 29 0.50m 3 2.02

30 3.21 80 3.11 30 4.11 4 -1.80m

31 1.48 81 2.70m 31 4.11 5 2.03

32 4.80m 82 3.11 32 4.11 6 2.04

33 2.13 83 4.90m 7 2.02

34 0.86 84 48.00m 8 5.07

35 4.40m 85 3.28

36 4.50m 86 3.13

37 4.10m 87 2.70m

38 24.20m 88 2.90m

39 23.70m 89 3.10m 1 2.39 13 -26.81

40 4.30m 90 2.00m 2 -0.94 14 -6.32

41 0.90m 91 3.28 3 -0.94 15 -5.91

42 4.30m 92 3.18 4 -0.90 16 -0.81

43 3.80m 93 3.18 5 0.40m 17 -26.60

44 4.20m 94 3.18 6 -26.65 18 -26.60

45 4.20m 95 3.18 7 260.90m 19 0.00

46 3.12 96 1.30m 8 -0.80 20 -0.90

47 3.30m 97 3.18 9 -6.02 21 -0.30m

48 3.70m 98 53.50m 10 -6.53 22 -0.30m

49 3.90m 99 3.13 11 -26.71 23 -0.93

50 3.20m 100 2.90m 12 -14.31

(V)

PIN

NO

VOLTAGE

(V)

VOLTAGE

PIN

NO

PINNOVOLTAGE

(V)

(V)

PIN

NO

PINNOVOLTAGE

PINNOVOLTAGE

IC901

PINNOVOLTAGE

VOLTAGE

IC604

IC603

(V)

(V)

(V)

(V)

5 – 3

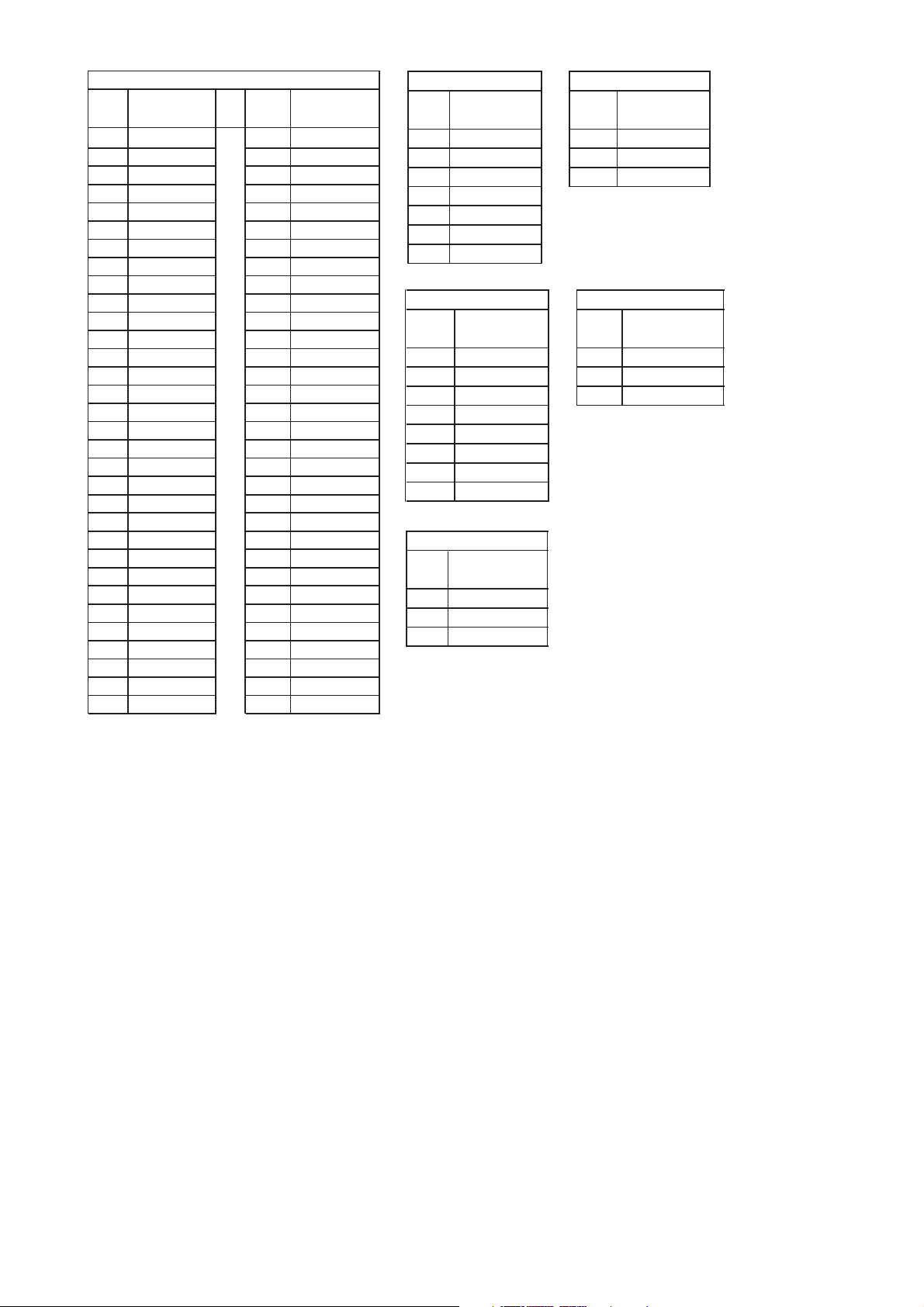

Page 21

XL-DK257N

IC702

VOLTAGE

PIN

NO

1 -26.44 33 -26.42

2 -26.40 34 -28.77

3 -26.40 35 -26.41

4 -26.40 36 -26.40

5 3.24 37 -26.41

6 3.20 38 -24.06

7 3.27 39 -17.00

8 3.24 40 -26.40

9 0.00 41 -24.07

10 0.00 42 -9.89

11 3.29 43 -26.40

12 1.51 44 -9.98

13 1.51 45 -17.00

14 0.00 46 -12.34

15 -24.10 47 -9.94

16 -28.77 48 -26.40

17 -28.78 49 -26.42

18 -28.77 50 -24.06

19 -28.77 51 -14.67

20 -28-75 52 -12.36

21 -28.77 53 -28.76

22 -28.77 54 -28.76

23 -21.70 55 -28.76

24 -28.97 56 -28.75

25 -26.40 57 -26.45

26 -28.77 58 -26.41

27 -28.76 59 -26.41

28 -28.76 60 -26.40

29 21.71 61 -26.40

30 -24.06 62 -26.40

31 -24.07 63 -26.40

32 -24.07 64 -26.40

(V)

PIN

NO

VOLTAGE

(V)

IC851 IC852

PIN

NO

VOLTAGE

(V)

PIN

NO

VOLTAGE

(V)

1 5.10 1 13.24

2 13.00 2 88.4m

3 17.60 3 4.76

m01.01-4

08.615

00.016

64.87

Q905IC853

PIN

NO

VOLTAGE

PIN

NO

VOLTAGE

1 5.07 D 35.10

2 5.07 S 26.53

3 3.28 G 31.77

39.14

m05.01-5

m04.01-6

m02.01-7

8 -10.20m

Q901

PIN

NO

VOLTAGE

D 27.82

S 35.68

G 30.91

5 – 4

Page 22

XL-DK257N

-MEMO-

5 – 5

Page 23

XL-DK257N

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] Notes On Schematic Diagram

•Resistor:

To differentiate the units of resistors, such symbol as

K and M are used: the symbol K means 1000 ohm

and the symbol M means 1000 kohm and the

resistor without any symbol is ohm-type resistor.

Besides, the one with “Fusible” is a fuse type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used:

this symbol P means pico-farad and the unit of the

capacitor without such a symbol is microfarad. As to

electrolytic capacitor, the expression “capacitance/

withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

REF. NO DESCRIPTION POSITION

SW701 POWER ON/STAND-BY ON—OFF

SW702 TRAY OPEN/CLOSE ON—OFF

SW703 PLAY/PAUSE ON—OFF

SW704 STOP ON—OFF

SW705 CD ON—OFF

SW706 iPOD ON—OFF

SW707 TUNER (BAND) ON—OFF

SW708 AUDIO IN ON—OFF

VR701 VOLUME MAX—MIN

• Schematic diagram and Wiring Side of P.W.Board

for this model are subject to change for

improvement without prior notice.

• The indicated voltage in each section is the one

measured by Digital Multimeter between such a

section and the chassis with no signal given.

1. In the tuner section,

indicates AM

indicates FM stereo

2. In the CD section, the CD is stopped.

• Parts marked with “ ” ( ) are

important for maintaining the safety of the set. Be

sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

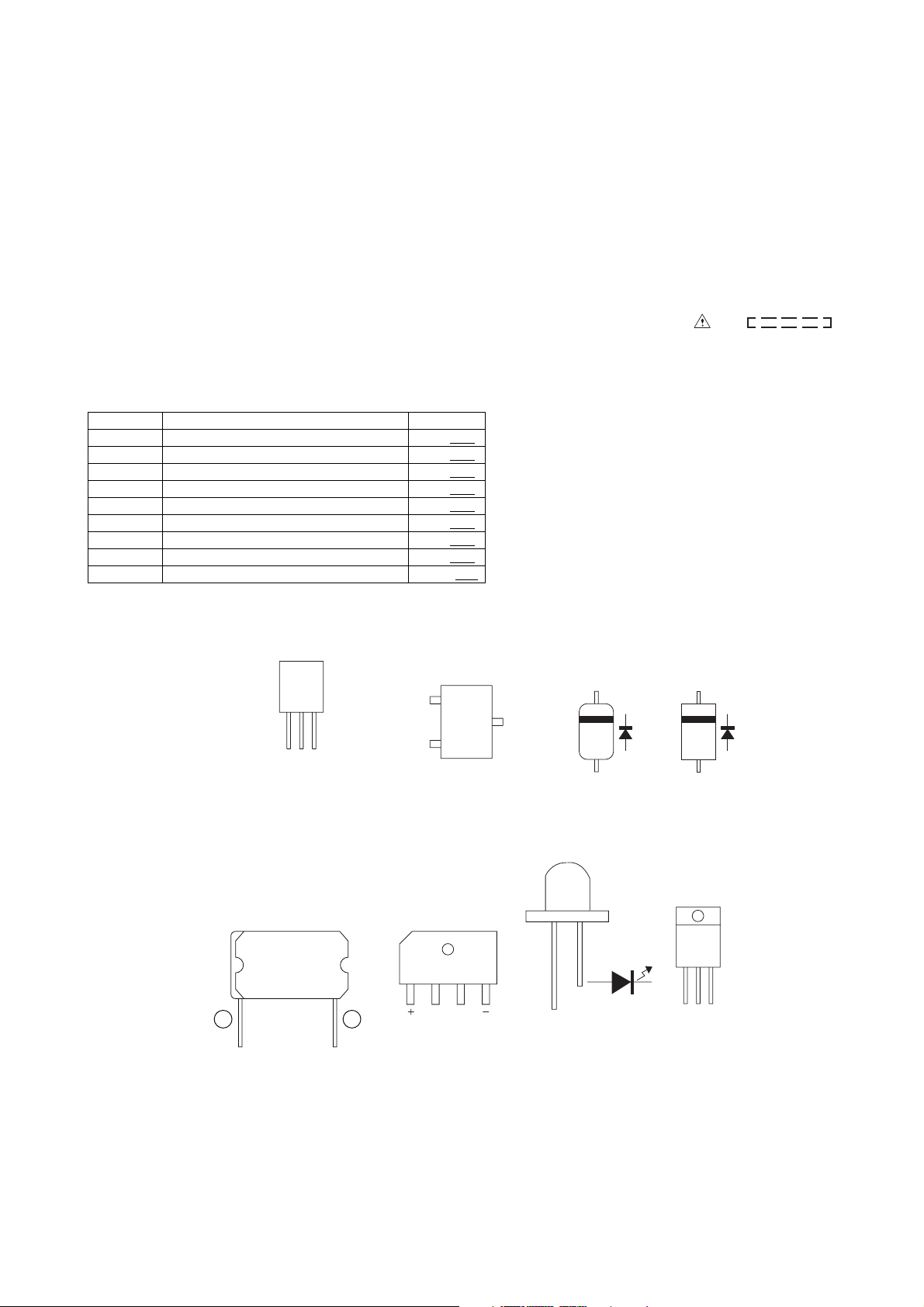

[2] Types Of Transistor And LED

FRONT

VIEW

ECB

(S)(G)(D)

(1)(2)(3)

KTA1271 Y

KTA1274 Y

FRONT

VIEW

123

TDA8920

KTC3199 GR

KTC3203 Y

KTA1266 GR

B

(3)

VIEW

E

(1)

KRA102 S

KRC107

KRC102 S

KRC104 S

KTA1504 GR

KTC3875 GR

KTA1544 T

KRA107 S

FRONT

VIEW

AC AC

10XB60F

TOP

(2)

TOP VIEWTOP VIEW

C

HSS4148

FRONT

VIEW

343VC3F

503BC2E30

1N4004S

DRL204F

MA 111

FRONT

VIEW

123

KIA7805A

NTP18N06LG

6 – 1

Page 24

XL-DK257N

[3] Schematic Diagram

A

ZJ15B

NTP18N06

GD1A4

22/100 22/100

GD1A4

B

C

TO AMPLIFIER SECTION

1K

10K

0.22

ZJ24B

2.2

GD1A4

ZJ27D

ZJ1SB

ZJ5R1B

22K

560

0.22

D

NTP18N06

E

F

47/10

47/10

100/16

G

TO MICOM SECTION

H

1

23456

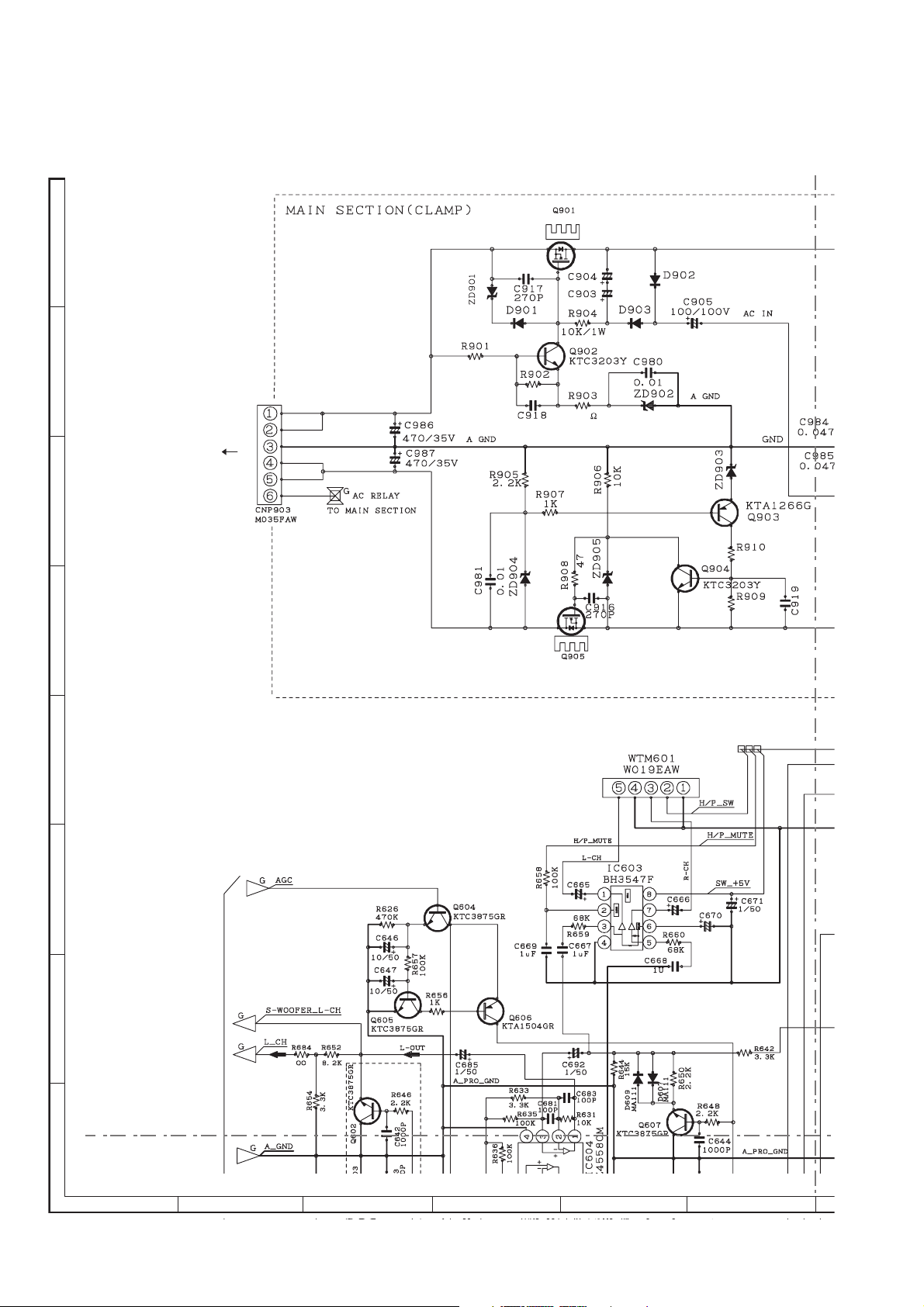

Figure 6-1: MAIN SCHEMATIC DIAGRAM (1/6)

6 – 2

Page 25

FROM POWER SECTION

XL-DK257N

0.22

LUG2

A980AW

2.7K

C632

4700pF

5.6K

5.6K

6.8K

2.7K

7

8 9 10 11 12

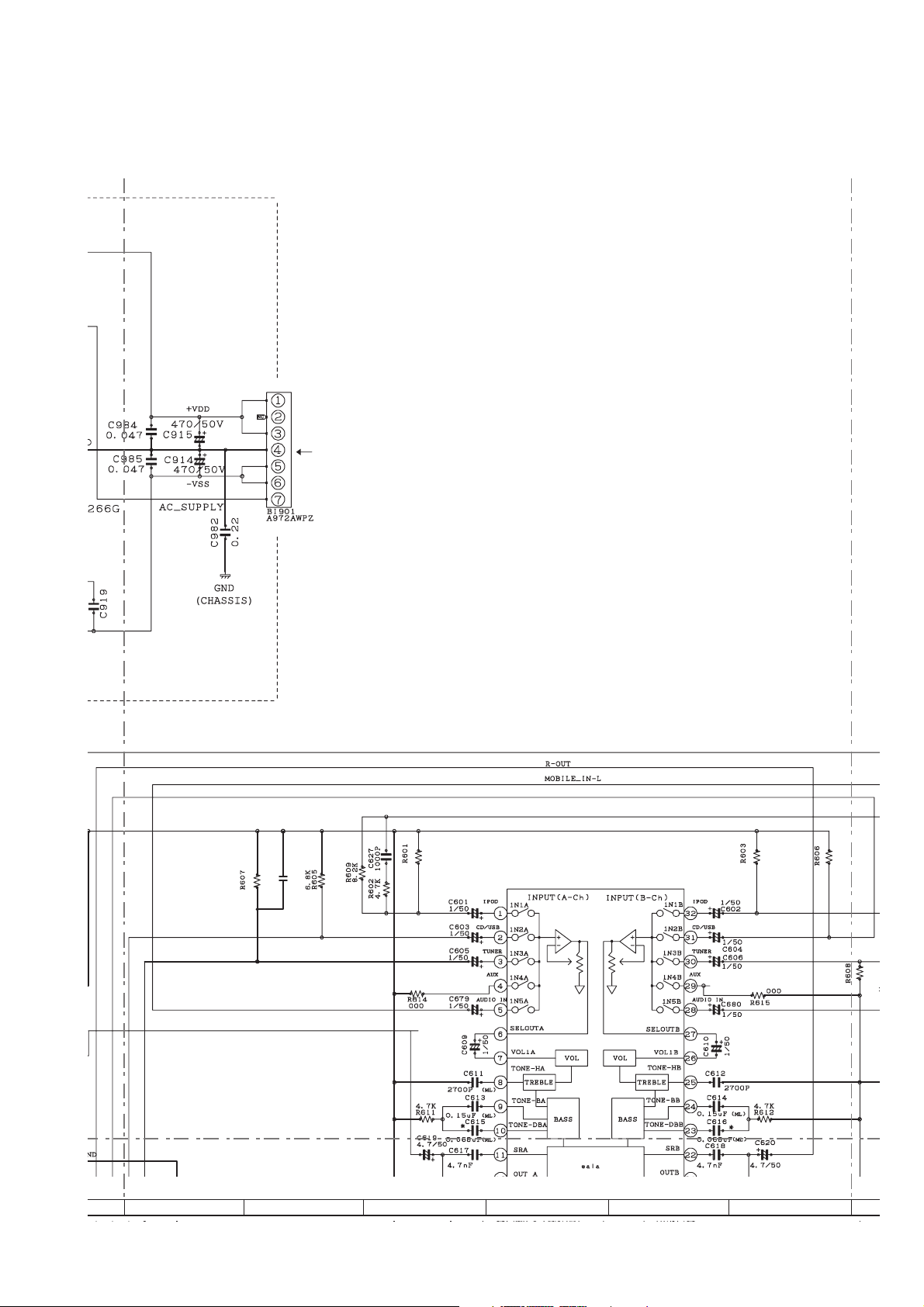

Figure 6-2: MAIN SCHEMATIC DIAGRAM (2/6)

6 – 3

Page 26

XL-DK257N

6.8K

FROM HEADPHONE PWB-A4

2.7K

C633

4700pF

TO CHASSIS

TO MICOM

SECTION

13

14 15 16 17 18

TO IPOD SECTION

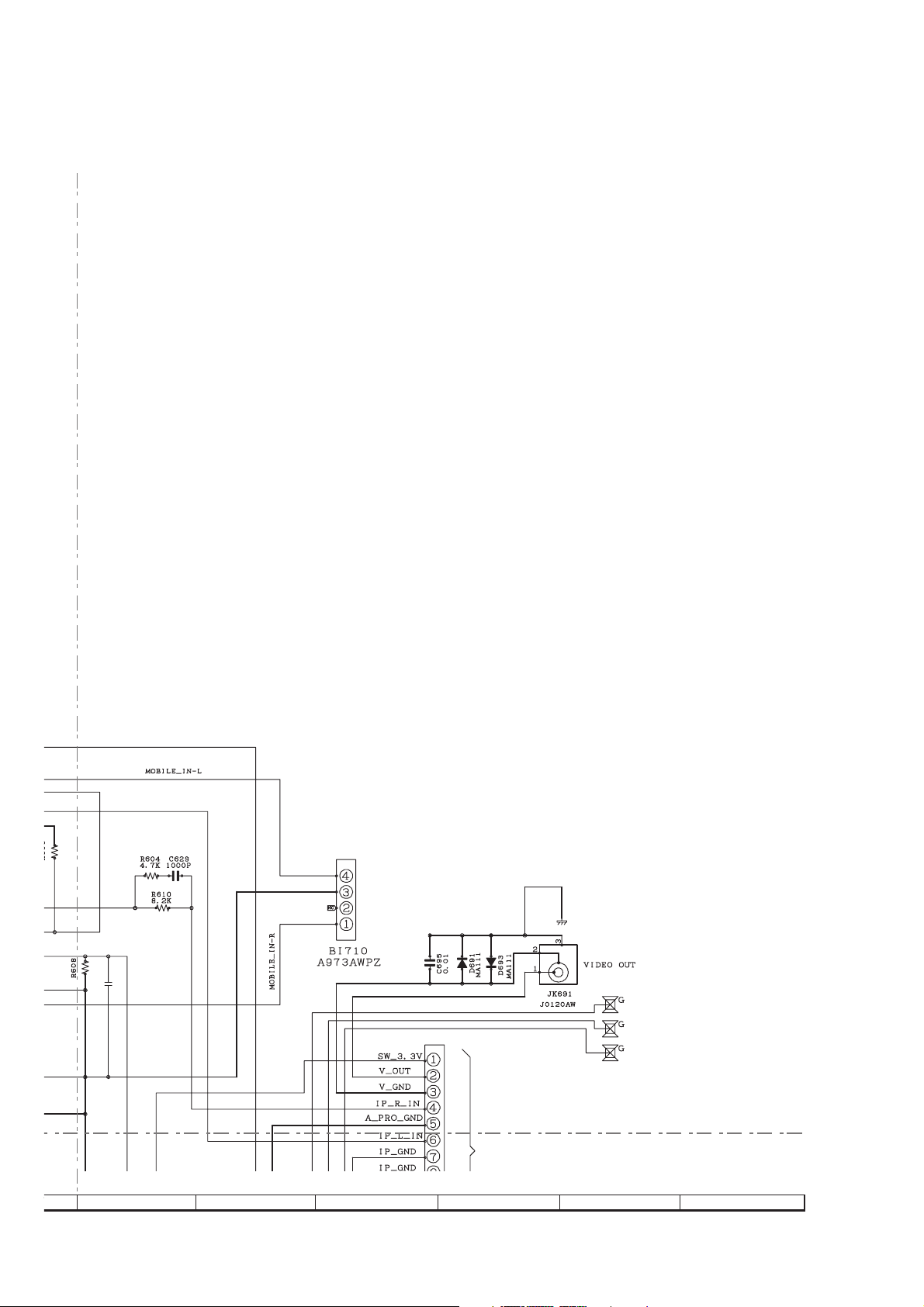

Figure 6-3: MAIN SCHEMATIC DIAGRAM (3/6)

6 – 4

Page 27

XL-DK257N

A

TO MICOM SECTION

B

C

TO CD MP3

IN4004S IN4004S

D

E

F

G

CNP301

ZX11AW

H

1

23456

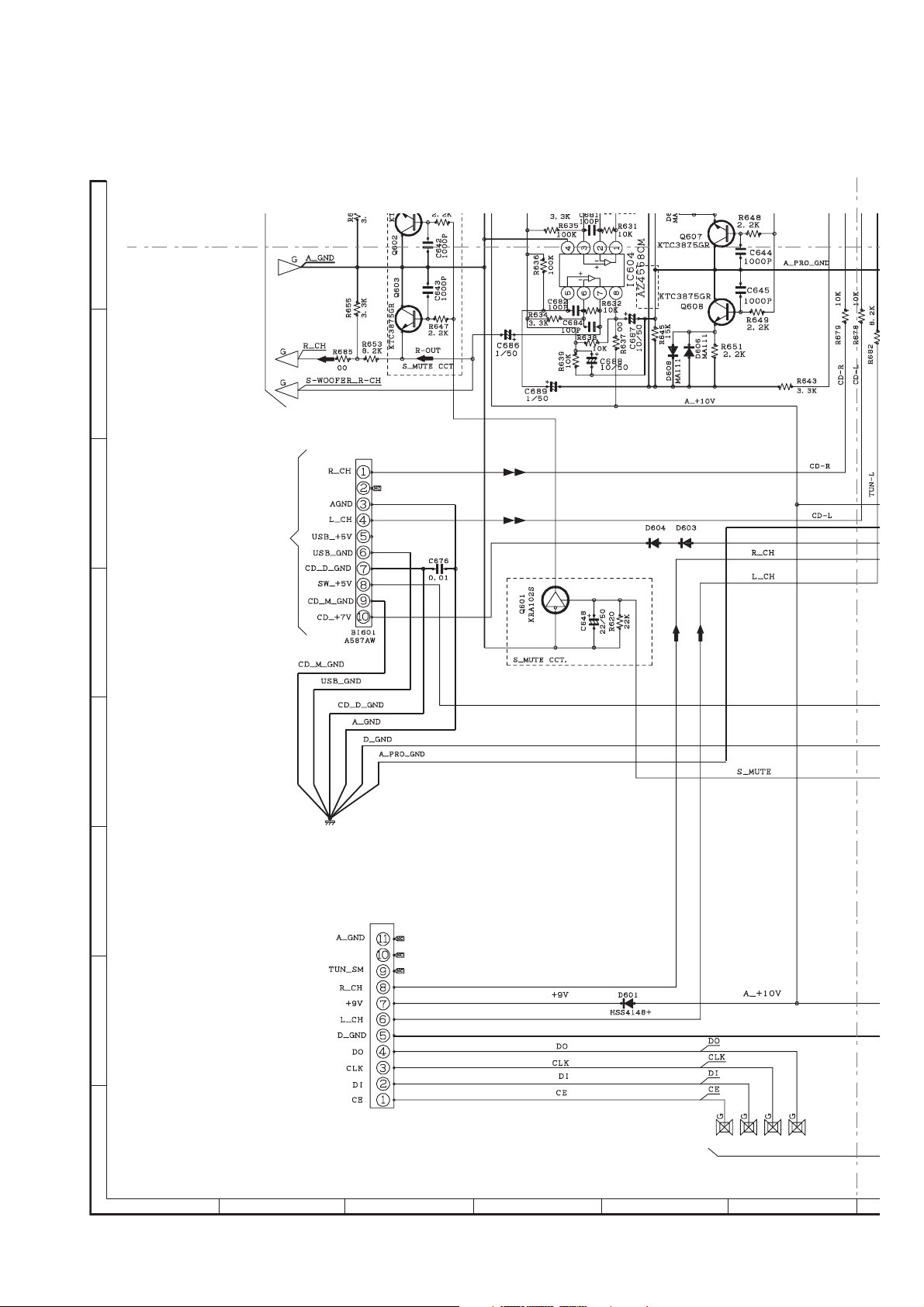

Figure 6-4: MAIN SCHEMATIC DIAGRAM (4/6)

6 – 5

Page 28

XL-DK257N

2.7K

MA111G

MA111G

GND

7

8 9 10 11 12

D905

D906

Figure 6-5: MAIN SCHEMATIC DIAGRAM (5/6)

6 – 6

Page 29

XL-DK257N

2.7K

C633

4700pF

TO MICOM

SECTION

TO IPOD SECTION

JP41

100µH

ZD862

ZJ15B

D851

HSS4148

TO MICOM SECTION

2

13

+13V

FROM POWER SECTION

FROM CLAMP SECTION

14 15 16 17 18

Figure 6-6: MAIN SCHEMATIC DIAGRAM (6/6)

6 – 7

Page 30

XL-DK257N

A

B

AMPLIFIER SECTION

C

D

E

F

13

12

Z2130SCT5T

Z2130SCT5T

G

9

8

H

1

23456

Figure 6-7: AMPLIFIER & SPEAKER SCHEMATIC DIAGRAM (1/2)

6 – 8

Page 31

A523WJ

XL-DK257N

Z2130SCT5T

GND

(CHASSIS)

L921

Z0055

2

3

1

4

L920

Z0055

2

3

1

4

SPEAKER PWB-B2

7

8 9 10 11 12

Figure 6-8: AMPLIFIER & SPEAKER SCHEMATIC DIAGRAM (2/2)

6 – 9

Page 32

XL-DK257N

P

P

A

B

C

TO MAIN SECTION (CLAMP)

D

CHASSIS GND

1.3V

E

TO MAIN SECTION

F

82

G

H

1

23456

Figure 6-9: POWER SCHEMATIC DIAGRAM (1/2)

6 – 10

Page 33

XL-DK257N

PT801

PA105AW

7

PA078AW

8 9 10 11 12

Figure 6-10: POWER SCHEMATIC DIAGRAM (2/2)

6 – 11

Page 34

XL-DK257N

P

0

0

A

B

C

D

VOLUME LED LIGHT-UP PWB-B3

E

F

RP767

680

(1/4)

270

100

100

G

H

1

23456

Figure 6-11: DISPLAY & VOLUME LED LIGHT-UP SCHEMATIC DIAGRAM (1/2)

6 – 12

Page 35

XL-DK257N

270P

1000P

1000P

7

Figure 6-12: DISPLAY & VOLUME LED LIGHT-UP SCHEMATIC DIAGRAM (2/2)

8 9 10 11 12

6 – 13

Page 36

XL-DK257N

A

B

C

D

MICOM SECTION

E

F

CNP701B

WZY18AW

G

H

1

23456

Figure 6-13: MICOM & HEADPHONE SCHEMATIC DIAGRAM (1/6)

6 – 14

Page 37

MICOM REFLASH PWB-A7

SYSTEM MICOM REFLASH PWB

TO EXT JIG

XL-DK257N

FROM DISPLAY SECTION

2.7K

7

8 9 10 11 12

Figure 6-14: MICOM & HEADPHONE SCHEMATIC DIAGRAM (2/6)

G

6 – 15

Page 38

XL-DK257N

HEADPHONE PWB-A4

HEADPHONE

D714

MA111

D715

MA111

5P52147

TO MAIN SECTION

B026AW

TO MAIN SECTION

TO CD MP3 PWB-D

G

13

14 15 16 17 18

O CD MP3 PWB-D

Figure 6-15: MICOM & HEADPHONE SCHEMATIC DIAGRAM (3/6)

6 – 16

Page 39

XL-DK257N

CNP701B

WZY18AW

A

B

C

D

E

F

G

H

1

23456

Figure 6-16: MICOM & HEADPHONE SCHEMATIC DIAGRAM (4/6)

6 – 17

Page 40

XL-DK257N

N

T

2.7K

MA111G

FROM MAIN SECTIO

(AUDIO PRO OUTPU

7

8 9 10 11 12

Figure 6-17: MICOM & HEADPHONE SCHEMATIC DIAGRAM (5/6)

6 – 18

Page 41

XL-DK257N

MA111G

TO CD MP3 PWB-D

N SECTION

O OUTPUT)

TO AMP SECTION

13

14 15 16 17 18

Figure 6-18: MICOM & HEADPHONE SCHEMATIC DIAGRAM (6/6)

6 – 19

Page 42

XL-DK257N

A

B

C

D

E

F

G

H

1

23456

GND

(CHASSIS)

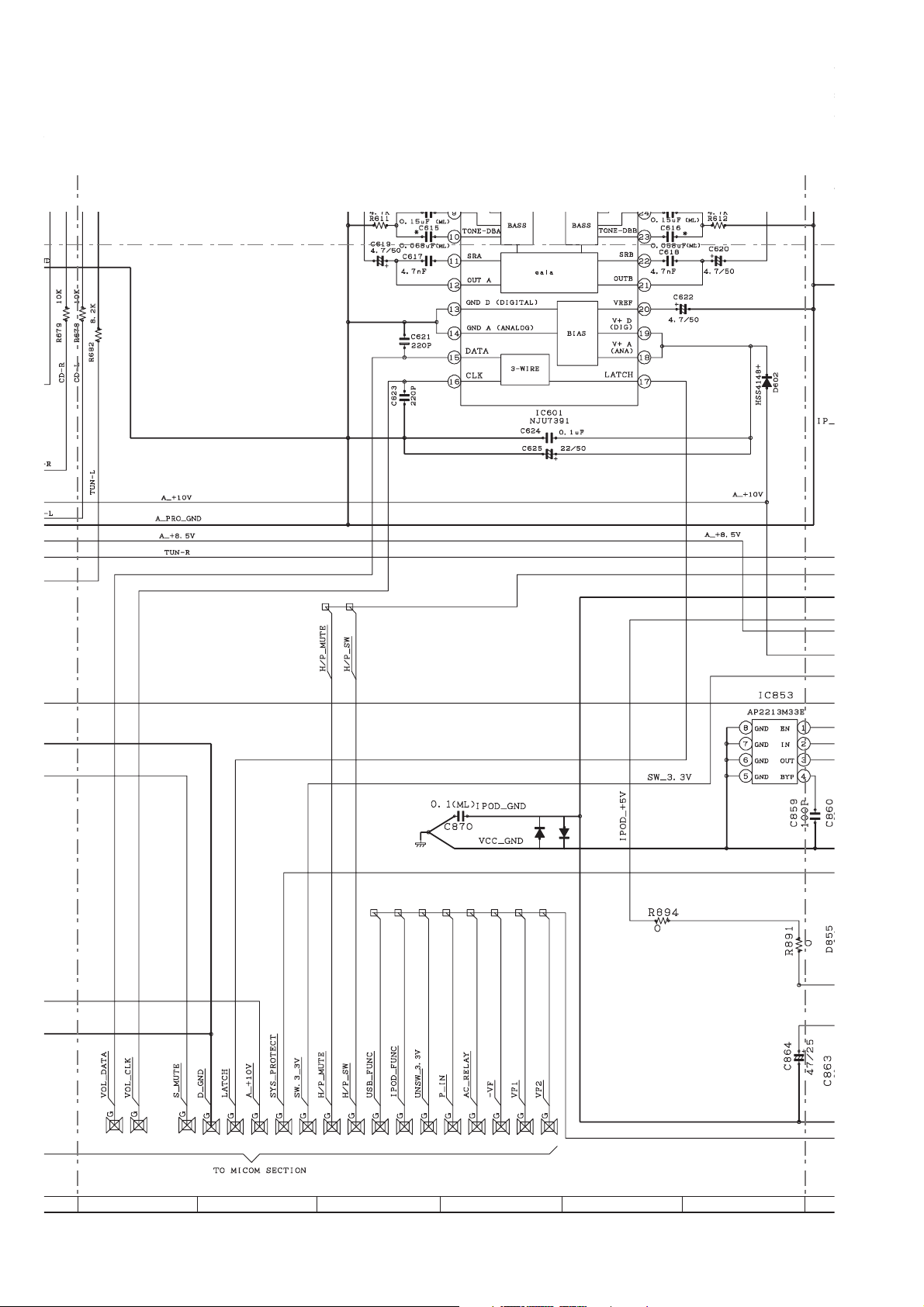

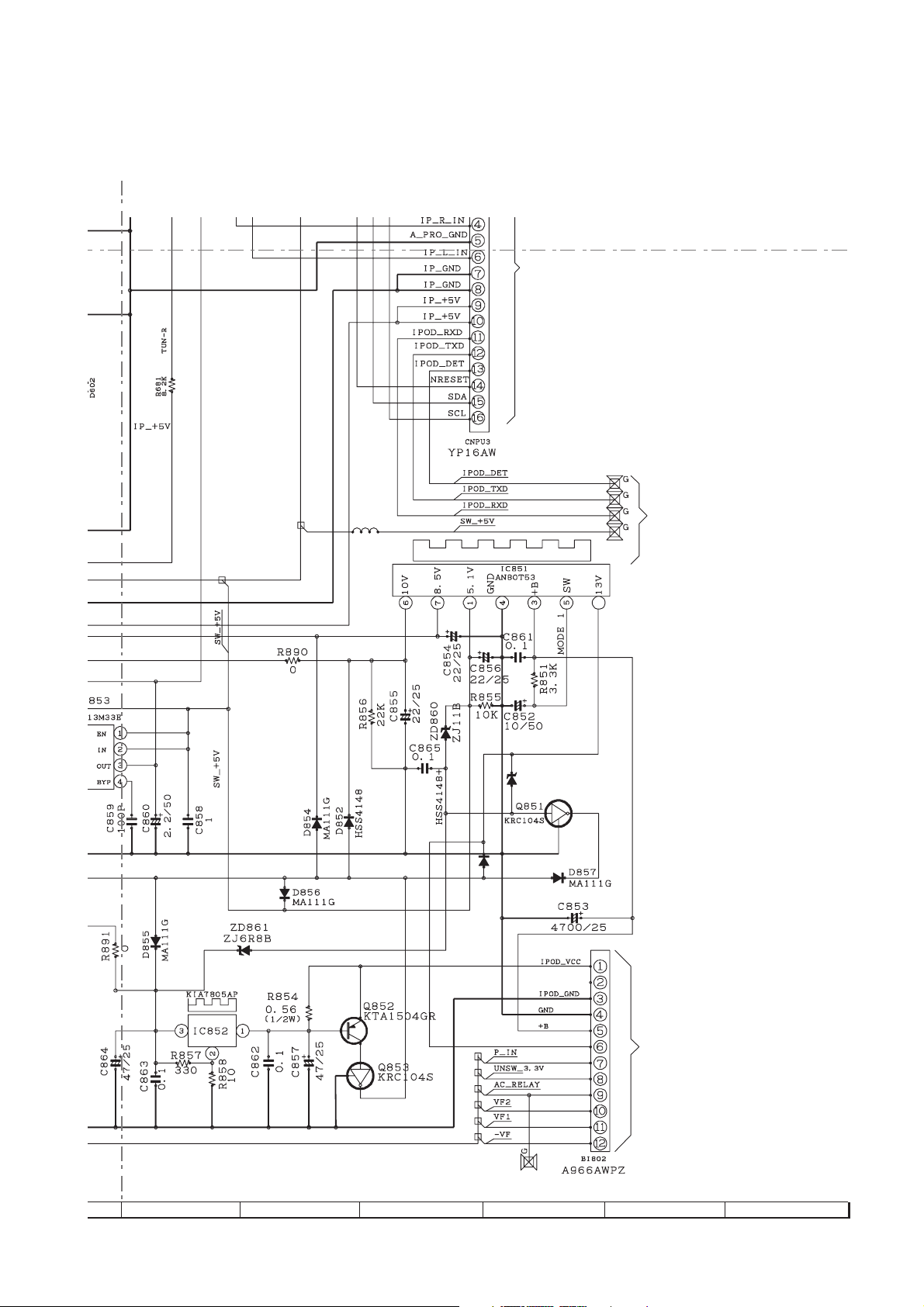

Figure 6-19: iPOD SCHEMATIC DIAGRAM (1/2)

6 – 20

Page 43

XL-DK257N

7

8 9 10 11 12

Figure 6-20: iPOD SCHEMATIC DIAGRAM (2/2)

6 – 21

Page 44

XL-DK257N

A

B

C

D

E

F

G

H

1

23456

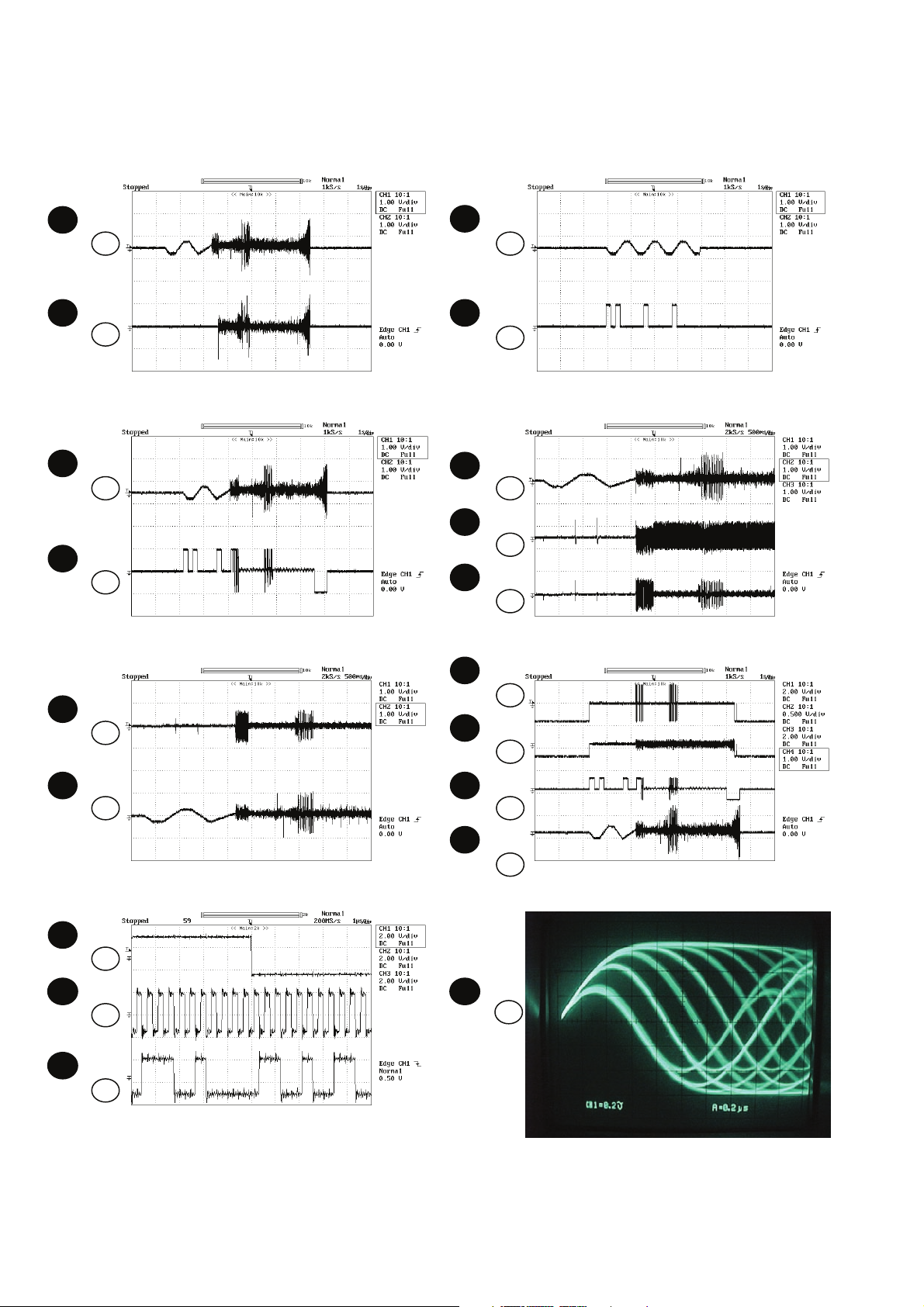

Figure 6-21: CD SERVO SCHEMATIC DIAGRAM (1/2)

6 – 22

Page 45

XL-DK257N

PA016AW

7

8 9 10 11 12

Figure 6-22: CD SERVO SCHEMATIC DIAGRAM (2/2)

6 – 23

Page 46

XL-DK257N

2

108642121416

6

[4] Charts Of Connecting Wires

A

B

FOR

MICOM EXTERNAL

DEVICE

MICOM REFLASH PWB-A5

CNPU2

CNPU1

12345678

12345678

DISPLAY PWB-B1

CNP701A

108642912111413161518

177531

118

CNS703

12

Bi703

12

FFC701

RDGYWHGYWH

GY

RDBLWHBLWHBLWHBLWHBLWH

C

D

SCREW TO

CHASSIS

E

F

CNS801

WH

BK

123456

12345 6

CNP801

CNP801

123456 7 891011

123456 7 891011

LUG 801

POWER PWB-A2

CNP805

AC POWER SUPPLY CORD

AC 120V ~ 60Hz

CNP802

CNS802

TO

CD PWB-D

(CNP5)

CNS601

BR

BK

GY

BK

435678921

GY

BK

GY

BK

GY

GY

WH

GY

WH

GY

RD

GY

12345 67

CNS702

12345 6 7 8

RDWHBKWHBKWHBK

WTM601

Bi901

BKGYBKGYBKGYBK

435678910 2 1

BR

15

FW601

WH

Bi601

WH

BK

WH

BK

WH

BK

WH

RD

LUG 2

SCREW TO

CHASSIS

18

177531

16

15

14

CNP701B

13

12

11

108642

9

Bi702

12345 6 7 89

RDBLWHBLWHBLWHBLWHBLWH

12 345 67 89101112

FFC705

18

8642

7531

CNP705

MAIN PWB-A1

Bi802

CNP903

123456

CNS903

123456

RDBLWHBLWH

BL

FFC702

TO

CD PWB-D

(CNP6)

CNP702

1357

2468910

12345

1

1

CNPU3

G

H

1

23456

Figure 6-23: WIRING CONNECTION (1/2)

6 – 24

Page 47

VOLUME LED LIGHT-UP PWB-B3

12

CNP703

TO

(MOTOR)

CD MECHANISM

TO

CD MOTOR PWB

XL-DK257N

FROM

MAIN PWB-A1

(Bi601)

FROM

MAIN PWB-A1

435678921

CNS601

435678921

CNP6

157531

(CNP702)

108642

97531

1357

2468

GYBKGYBKGYBKGYBKBR

CNP5

FFC705

81 1 10

GR

YL

OR

RD

BR

12345

CNS4

CNP4

12345

CNP3

CD PWB-D

WH

BL

WH

BL

WH

RD

123456

CNS2

CNP2

123456

CNP1

10864291211141316

TO

D PWB-D

(CNP6)

111

1357

9

2468

CNP702

CNPU3

12345678910

16

14

12

108642

CNP301

157531

13

11

9

CNS703

FFC301

PKGYBK

4321

Bi710

JK691

WH

JK902

ANTENNA

FM

GND

AM

116

AUDIO IN

SUBWOOFER

PRE-OUT

TUNER PACK

CNS710

PK

321

BK

WH

FW601

FFC102

HEADPHONE PWB-A4

CNP710

321

CNP708

15

LUG 4

JK703

JK701

AUDIO IN SOCKET

HEADPHONE SOCKET

SCREW TO CHASSIS

iPOD PWB-C

16

CNP102

1

WIRE

SCREW TO CHASSIS

FFC1

1

TO

CD PICK-UP

UNIT

FROM

iPOD EXTERNAL

DEVICE

16

COLOR TABLE

WH

RD

BK

BL

WHITE

RED

BLACK

BLUE

GY GRAY

BR BROWN

PK PINK

OR ORANGE

FFC301

108642

9117531

SPEAKER PWB-B2

12345

Bi902

CNS902

RD

1234

BL

WH

BL

12

3

4

CNP902

SLOT-IN

TO MAIN PWB-A1

(CNS703)

7

AMPLIFIER PWB-A3

12345 67 8 910

CNP703

SO901

R-CH

SPEAKER TERMINAL

L-CH

1234567

Bi903

RD

BLWHBLWHBL

8 9 10 11 12

Figure 6-24: WIRING CONNECTION (2/2)

6 – 25

TO SPEAKER SYSTEM

Page 48

XL-DK257N

[5] Wiring Side Of PWB

MAIN PWB-A1

A

B

2 4 6 8 10 12 1416 18

1357911131517

123

4

6

8

5

7

C

10 9 8 7 6 5 4 3 2 1

12 3 45 6 78 9

D

1357

7654321

246

E

ECB

F

D G S

ECB

D G S

ECB

23456789

1

10 11 12

G

23 45 61

Lead-free solder indication

Lead-free solder is used in the MAIN PWB.

Refer to "Precautions for handling lead-free solder" for instructions

H

and precautions.

1

23456

Figure 6-25: WIRING SIDE OF MAIN PWB (TOP VIEW) (1/2)

6 – 26

Page 49

XL-DK257N

10 12 14 16

2468

1113 15

13579

10

9

11

VIDEO OUT

8

1

2

113355779

2244668810

10 11 12

1234

SUBWOOFER

PRE-OUT

23456789101

7

8 9 10 11 12

Figure 6-26: WIRING SIDE OF MAIN PWB (TOP VIEW) (2/2)

6 – 27

Page 50

XL-DK257N

A

MAIN PWB-A1

B

JP46

C

D

E

F

G

H

1

23456

Figure 6-27: WIRING SIDE OF MAIN PWB (BOTTOM VIEW) (1/2)

6 – 28

Page 51

XL-DK257N

Lead-free solder indication

Lead-free solder is used in the MAIN PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

7

8 9 10 11 12

Figure 6-28: WIRING SIDE OF MAIN PWB (BOTTOM VIEW) (2/2)

6 – 29

Page 52

XL-DK257N

A

POWER PWB-A2

43

5

B

123

C

6

7

8

9

3

TF801

PT841

(SUB)

2

POWER TRANSFORMER

4

RL841

3

2

1

RELAY

1

1

2

D

E

F

G

Lead-free solder indication

Lead-free solder is used in the POWER PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

11 12 138910

POWER TRANSFORMER (MAIN)

PT801

BCE

1011

16 1714 15

123456

123456789

1

23456

Figure 6-29: WIRING SIDE OF POWER PWB (TOP VIEW)

6 – 30

Page 53

-MEMO-

XL-DK257N

6 – 31

Page 54

XL-DK257N

A

AMPLIFIER PWB-A3

B

C

78910

23456

1

D

E

2 4 6 8 10 12 14 1618 20 22

1 3 5 7 9 11131517192123

12345

F

1234567

G

Lead-free solder indication

Lead-free solder is used in the AMPLIFIER PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-30: WIRING SIDE OF AMPLIFIER PWB (TOP VIEW)

6 – 32

Page 55

A

AMPLIFIER PWB-A3

B

C

XL-DK257N

D

E

F

G

Lead-free solder indication

Lead-free solder is used in the AMPLIFIER PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-31: WIRING SIDE OF AMPLIFIER PWB (BOTTOM VIEW)

6 – 33

Page 56

XL-DK257N

A

HEADPHONE PWB-A4

AUDIO IN

B

C

D

321 54

32 1

FOR HEADPHONE ONLY

E

MICOM REFLASH PWB-A5

F

G

Lead-free solder indication

Lead-free solder is used in the HEADPHONE and MICOM REFLASH PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

123456 78

123456 78

1

23456

Figure 6-32: WIRING SIDE OF HEADPHONE AND MICOM REFLASH PWB (TOP VIEW)

6 – 34

Page 57

A

HEADPHONE PWB-A4

B

C

XL-DK257N

D

E

F

G

Lead-free solder indication

Lead-free solder is used in the HEADPHONE PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-33: WIRING SIDE OF HEADPHONE PWB (BOTTOM VIEW)

6 – 35

Page 58

XL-DK257N

2

V

A

DISPLAY PWB-B1

FL701

252627282930313233343536373839404142434445464748495051

B

C

D

2 4 6 8 10 12 14 16 18

1

3 5 7 9 11 13 15 17

E

F

G

H

1

23456

Figure 6-34: WIRING SIDE OF DISPLAY PWB AND VOLUME LED LIGHT-UP (TOP VIEW) (1/2)

6 – 36

Page 59

FL701

XL-DK257N

12345678910111213141516171819202122232425262728

12

VOLUME LED LIGHT-UP PWB-B3

12

Lead-free solder indication

Lead-free solder is used in the DISPLAY PWB and VOLUME LED LIGHT-UP.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

7

Figure 6-35: WIRING SIDE OF DISPLAY PWB AND VOLUME LED LIGHT-UP (TOP VIEW) (2/2)

8 9 10 11 12

6 – 37

Page 60

XL-DK257N

A

DISPLAY PWB-B1

B

C

D

E

F

VOLUME LED LIGHT-UP PWB-B3

G

H

1

Figure 6-36: WIRING SIDE OF DISPLAY PWB AND VOLUME LED LIGHT-UP (BOTTOM VIEW) (1/2)

23456

6 – 38

Page 61

XL-DK257N

Lead-free solder indication

Lead-free solder is used in the DISPLAY PWB and VOLUME LED LIGHT-UP.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

7

Figure 6-37: WIRING SIDE OF DISPLAY PWB AND VOLUME LED LIGHT-UP (BOTTOM VIEW) (2/2)

8 9 10 11 12

6 – 39

Page 62

XL-DK257N

A

SPEAKER PWB-B2

B

C

D

E

1234

F

G

H

1

23456

Figure 6-38: WIRING SIDE OF SPEAKER (TOP VIEW)

Lead-free solder is used in the SPEAKER PWB.

Refer to "Precautions for handling lead-free solder" for

instructions and precautions.

SO901

SPEAKER TERMINAL

Lead-free solder indication

6 – 40

Page 63

A

SPEAKER PWB-B2

B

XL-DK257N

C

D

E

F

G

Lead-free solder indication

H

1

Figure 6-39: WIRING SIDE OF SPEAKER AND VOLUME LED LIGHT-UP PWB (BOTTOM VIEW)

23456

Lead-free solder is used in the SPEAKER PWB.

Refer to "Precautions for handling lead-free solder" for

instructions and precautions.

6 – 41

Page 64

XL-DK257N

A

iPOD PWB-C

B

R136

R139

IC101

R138

R135

R140

D107

CNP102

C114

C113

C111

C100

R137

R122

R123

R128

R129

R132

JP104

R107

R134

R133

R110

R113

R131

C104

Q100

C

D

R115

JP101

JP102

R118

E

C108

C110

C101

L101

D108

C118

F

D109

D105

R121

C112

R120

D104

R119

WIRE

G

Lead-free solder indication

Lead-free solder is used in the iPOD PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-40: WIRING SIDE OF iPOD PWB (TOP VIEW)

6 – 42

Page 65

XL-DK257N

A

B

C

D

iPOD PWB-C

CNP101

E

F

G

H

1

23456

Figure 6-41: WIRING SIDE OF iPOD PWB (BOTTOM VIEW)

6 – 43

Page 66

XL-DK257N

2

A

CD PWB-D

1357

2468

B

123456789

1

C

D

21345

ECB

E

F

213456

4268

10 12 14 16

31579

G

H

1

23456

Figure 6-42: WIRING SIDE OF CD PWB (TOP VIEW) (1/2)

11 13 15

6 – 44

Page 67

XL-DK257N

4268

10

31579

12 14 16

13 15

Lead-free solder indication

Lead-free solder is used in the CD PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

7

8 9 10 11 12

Figure 6-43: WIRING SIDE OF CD PWB (TOP VIEW) (2/2)

6 – 45

Page 68

XL-DK257N

A

CD PWB-D

B

C49

C

C50

C51RA33

D

E

C10

C11

C12

C16

R7

C17

C48

C53

R38

C6

C9

RA14

R1

R2

R3

R5

R4

C7

C18

C20

C55

C8

C14

C13

C21

C19

C23

R37

C71

R55

C52

R34

C54

C24

C25

F

R10

R8

R9

R11

Q1

RA16

G

RA15

R6

C5

Lead-free solder indication

H

Lead-free solder is used in the CD PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-44: WIRING SIDE OF CD PWB (BOTTOM VIEW) (1/2)

6 – 46

Page 69

C71

R55

C72

R56

XL-DK257N

R57

R44

R43

RA44

4

C24

C52

R34

C25

C26

C47

C27

JP4

IC1

C46

CA3

R16

R14

C44

C43

FB2

C45

RA4

C34

R20

C33

R39

C1

R25

JP3

RA5

C3

RA3

C41

FB1

C39

R21

R22

C38

C37

R23

R24

C36

C35

C30

C28

C29

C32

C31

CA4

C56

Q8

C49

C62

C58

C59

R40

Q3

R48

R53

C66

R51

R92

R46

R93

C64

Q4

RA45

Q5

R94

R54

C61

IC2

7

8 9 10 11 12

Figure 6-45: WIRING SIDE OF CD PWB (BOTTOM VIEW) (2/2)

6 – 47

Page 70

XL-DK257N

CHAPTER 7. FLOWCHART

[1] Troubleshooting

1. When the CD does not function

The CD section may not operate when the objective lens of the optical pickup is dirty. Clean the objective lens, and

check the playback operation. When this section does not operate even after the above step is taken, check the

following items.

Remove the cabinet and follow the troubleshooting instructions.

"Track skipping and/or no TOC (Table Of Contents) may be caused by build up of dust other foreign matter on the

laser pickup lens. Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned

below."

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

Parts code

1. CD optical pickup Lens cleaner disc UDSKA0004AFZZ

HOW TO USE

1.

Using the brush in the cleaner cap, apply 1 or 2 drops of the cleaning fluid to the

brush on the CD cleaner disc which has the mark next to it.

2.

Place the CD cleaner disc onto the CD disc tray with the brush side down,then

press the play button.

3.

You will hear music for about 20 seconds and the CD player will automatically stop.

If it still play continuously, press the stop button.

CAUTION

The CD lens cleaner should be effective for 30-50 operations, however if the

brushes become worn out earlier then please replace the cleaner disc.

If the CD cleaner brushes become very wet then wipe off any excess fluid with a soft

cloth.

Do not drink the cleaner fluid or allow it contact with the eyes. In the event of this

happening then drink and / or rinse with clean water and seek medical advice.

The CD cleaner disc must not be used on car CD players or on computer CD-ROM

drives.

All rights reserved. Unauthorized duplicating, broadcasting and renting this product

is prohibited by law.

Cleaning fluid

Cleaner disc

2. When a CD cannot be played

2.1. Pressing the CD operation key is accepted, but playback does not occur.

1) Focus-RF system check

2) Tracking system check

3) Spin system check

4) PLL system check

5) Others

7 – 1

Page 71

(1) Focus-RF system check.

9

1

2

FOO

TRO

9

6

4

5

1

TEI

RFO

FOO

RFO

Although a CD is inserted and the cover is closed, "NO DISC" is displayed.

1. Does the pickup move? No Sled motor (M2A).

Yes

2. Does the focus (lens) move up and down ?

(Waveform drawing Figure 1)

Yes

3. Is the laser lit ? No Check the laser diode driver Q1 peripheral circuit.

Yes

4. Is the turntable rotating ? No Spindle motor (M1A).

When a disc is loaded, start playback operation.

1. Is focus servo activated ?

(Waveform drawing Figure 2)

No Check the focus peripheral circuit.

No Pins 5, 9, 94 and 95 on IC1, Pins 1, 2, 15 and 16 on IC2.

Check the laser diode driver Q1 peripheral circuit.

XL-DK257N

Yes

2. Is the RF waveform normal ?

(Waveform drawing Figure 3)

Press the Tray1 CD Eject Button without inserting a disc, and try

starting the playback operation.

IC1

IC1

Figure 1

No If the level is not normal.

5

IC1

89

Figure 3

IC1

89

IC1

IC1

Figure 2

7 – 2

Page 72

XL-DK257N

9

6

4

1

FOO

TEI

1

6

9

FOO

DMO

(2) Tracking system check.

Check the TE waveform at pin 6 on IC1.

If the waveform shown in Figure 4 appears and soon after NO

DISC appears ?

No

"Initialization" is possible, but play is not possible ?

No

"Initialization" is not possible. Data cannot be read. Check the VCO-PLL (Pins 72, 73, 74,

Yes

Yes

The tracking servo is not activated.

Check the peripheral circuits at pins 6, 7, 10, 98 and 100 on

IC1, pins 17, 18, 35 and 36 on IC2 and FFC1.

A normal jump operation cannot be completed or the

beginning of the track cannot be found.

Check the around pin 10 on IC1.

75, 76 and 78 on IC1) system.

IC1

IC1

Figure 4

(3) Spin system check.

Press the OPEN/CLOSE switch without inserting a disc, and

then try starting the play operation.

1. The turntable rotates a little ?

(Waveform drawing Figure 5)

No

2. The turntable doesn't rotate. Check around pin 13 on IC1, pins 3, 4, 13 and 14 on IC2.

Yes

The spin driver circuit is OK.

IC1

IC1

Figure 5

7 – 3

Page 73

(4) PLL system check.

9

74

7

8

6

1

FOO

DMO

LPFO

TMAX

XL-DK257N

When a disc is loaded, start play operation.

The RF waveform is normal, but the TOC data cannot be read.

IC1

IC1

IC1

Check the TMAX waveform. (Figure 6)

IC1

Check around Pins 72, 73, 74, 75, 76 and 78 on IC1.

Figure 6

(5) Others.

The RF waveform is normal and the time is displayed

normally, but no sound is produced. Or the sound has

dropouts.

Is pin 65, 66 and 67 on IC1. (Figure 7) No There are too many error flags on a damaged disc which makes

error correction impossible.

Yes

If OK, Check the unit.

Check again using a known good disc.

9

IC1

10

IC1

11

IC1

65

67

66

LRCKI

BCKI

AIN

Figure 7

7 – 4

Page 74

XL-DK257N

CHAPTER 8. OTHER

[1] Function Table Of IC

IC2 VHILA6261//-1: Focus/Tracking/Spin/Sled Driver (LA6261)

Pin No. Terminal Name Function

1 FO+ BTL Output pin (+) for focus coil.

2 FO- BTL Output pin (-) for focus coil.

3 SP+ BTL Output pin (+) for spin motor.

4 SP- BTL Output pin (-) for spin motor.

5 SL- BTL Output pin (+) for slide motor.

6 SL+ BTL Output pin (-) for slide motor.

7 PGND1 Power GND for channels 1,2,3 and 4 (BTL).

8 REGIN Regulator pin (External PNP base).

9 PVCC1 Power for channels 1,2,3 and 4 (BTL). (SVCC short-crircuited)

10 REGOUT Regulator pin (External PNP collector).

11 VIN1 Input pin for channel 1

12* VIN1G Input pin for channel 1 (for gain control)

13 VIN2 Input pin for channel 2

14* VIN2G Input pin for channel 2 (for gain control)

15 VIN3 Input pin for channel 3

16* VIN3G Input pin for channel 3 (for gain control)

17 VIN4 Input pin for channel 4

18* VIN4G Input pin for channel 4 (for gain control)

19 FWD5 CH5 Output change pin (FWD). Logic input for bridge.

20 REV5 CH5 Output change pin (REV). Logic input for bridge.

21 VCONT5 Input pin for CH5 output voltage control.

22 FWD6 CH6 Output change pin (FWD). Logic input for bridge.

23 REV6 CH6 Output change pin (REV). Logic input for bridge.

24 VCONT6 Input pin for CH5 output voltage control.

25 VREFIN Reference voltage input pin.

26 SGND Signal system GND.

27 SVCC Signal system power (PVCC1 short - circuited).

28 PVCC2 Power for channel 5 and 6 (H bridge).

29 MUTE Input pin for BTL mute.

30 PGND2 Power GND for channels 5 and 6 (H bridge).

31 TR+ H bridge Output pin (+) for tray motor.

32 TR- H bridge Output pin (-) for tray motor.

33 CAM+ H bridge Output pin (+) for cam motor.

34 CAM- H bridge Output pin (-) for cam motor.

35 TR+ BTL Output pin (+) for tracking coil.

36 TR- BTL Output pin (-) for tracking coil.

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

* Set power system GND to the minimum potential together with SGND.

* Short-circuit three pins of power system SVSS and PVCC1 externally before use.

8 – 1

Page 75

IC2 VHILA6261//-1: Focus/Tracking/Spin/Sled Driver (LA6261)

XL-DK257N

1

CH3

+

2

-

3

+

4

-

5

CH2

6

+

+

7

8

+

9

CH1

VOLTAGE

CONTROL AMP

-

+

+

BTL

+

CH4

36

35

+

-

34

33

32

CH5

Pre DrivePre Drive

31

30

29

28

CH6

10

11

12

13

14

15

16

17

18

1k

1k

1k

1k

11k

11k

11k

11k

22k

+

22k

+

22k

+

22k

+

-

+

DUFFER AMP

For 1/2 VCC

Refcronce

voltage

TSD

Bandgad

Figure 8-1 BLOCK DIAGRAM OF IC

+

DUFFER AMP

For VREF

Mode

Mode

select

select

27

26

25

24

23

22

21

20

19

8 – 2

Page 76

XL-DK257N

IC1 VHITC94A70FG2: CD MP3 DECODER (1/4)

Pin Description

Figure 8-2 BLOCK DIAGRAM OF IC

8 – 3

Page 77

IC1 VHITC94A70FG2: CD MP3 DECODER (2/4)

Pin Description

XL-DK257N

Pin

No.

10 TRo Output 3AI/F Tracking servo equalizer output pin. Output

11 VREF - Reference voltage pin for analog circuits (1.65V). -

12 FMo Output 3AI/F Feed servo equalizer output pin. Output Built-in series resister 3.3kΩ

13 DMo Output 3AI/F Disc servo equalizer output pin. Output

14 VSSP3 - Grounding pin for 3.3V DSP VCO circuits. 15 VCOi Output PD output for VCO (control voltage input for VCO). Output Three-state output

16 VDDP3 - Power supply pin for 3.3V DSP VCO circuit. 17 VDD1 - Power supply pin for 1.5V digital VCO circuit. 18 VSS - Grounding pin for 1.5V digital circuits. 19 FGiN Input 3I/F FG signal input pin for CAV.CLV:L:, CAV FG input. Input Analog Input

20 ioO(/Hso)

21 io1

22 VVSS3 -

23 VXSS3 Input 3AI/F

24 Xo Output 3AI/F Output pin for system clock oscillator circuit. Output X’tal

25 XVDD3 -

26 DVSS3 - Grounding pin for 3.3V digital circuits. 27 Ro Output 3AI/F R channel audio output pin of Audio DAC. Output

28 DVDD3 - Power supply pin for 3.3V Audio DAC circuit. 29 DVR - Reference voltage pin for Audio DAC. 30 Lo Output 3AI/F L channel audio output pin of Audio DAC. Output

31 DVSS3 - Grounding pin for 3.3V Audio DAC circuit. 32 VDDT3 - Power supply pin for 3.3 V digital I/O circuit. - For CD and DSP I/O

33 VSS - Grounding pin for 3.3V digital circuit. - 34 VDD1 - Power supply pin for 1.5V digital circuit. - 35 VDDM1 - Power supply pin for 1.5V 1Mbit SRAM. - 36 SRAMSTB Input 3I/F 1Mbit SRAM stand-by pin. Input Schmitt input

37 /RST Input 3I/F Reset signal input pin. Input Schmitt input

38 BUS0

39 BUS1

40 BUS2(So)

41 BUS3(Si)

42 BUCK(CLK) Input 3I/F

43 /CCE Input 3I/F

44 TEST Input 3I/F

45 IRQ Input 3I/F

46 AoUT3(Po4) Output 3I/F Audio data output pin -3 (DSP general output port -4). Output CMOS PORT

47 AoUT2(Po5) Output 3I/F Audio data output pin -2 (DSP general output port -5). Output CMOS PORT

48 Pio0

Symbol Input / Output Description Default Remarks

1 AVSS3 - Grounding pin for 3.3V CD analog circuits. 2 RFZi Input 3AI/F Input pin for RF ripple zero-cross signal. Input Connect to RFRP 0.033uF

3 RFRP Output 3AI/F RF ripple signal output pin. Output

4 SBAD/RFDC Output 3AI/F

5 FEi Output 3AI/F Focus error signal input pin. Output

6 TEi Output 3AI/F Tracking error signal input pin. Output

7 TEZi Input 3AI/F Tracking error signal zero-cross input pin. Input Connect to TEL by 0.033uF

8 AVDD3 - Power supply pin for 3.3 V CD analog circuits. 9 Foo Output 3AI/F Focus servo equalizer output pin. Output

Input / Output

3I/F

Input / Output

3I/F

Input / Output

3I/F

Input / Output

3I/F

Input / Output

3I/F

Input / Output

3I/F

Input / Output

3I/F

Sub beam addition signal or RFDC (Hologram PUH

RF peak detection signal) signal output pin.

Gerenal input /output ports-0 (CD)

(Playback speed mode flag output Pin.)

Grounding pin for 1.5V digital circuits. Input Schmitt input COMOS PORT

Grounding pin for 3.3V digital system circuits oscillator

circuit.

Input pin for syetem clock oscillator circuit (External

Rfb=1MΩ).

Power supply pin for 3.3 v sy stearm clock oscillator

circuit.

Data input/output pin -0 for microcontroller interface. Input Schmitt input CMOS PORT

Data input/output pin -1 for microcontroller interface. Input Schmitt input CMOS PORT

Data input/output pin -2 for microcontroller interface

(Serial output).

Data input/output pin -3 for microcontroller interface

(Serial output).

Clock input pin for the microcontroller interface.

(Clock input for Serial communication interface)

Chip enable signal input pin for microcontroller

interface.

Setting pin for LSI test mode.

(Connect to GND in normal operation)

DSP interruption pin (Pull down by 100kΩ when not in

use).

DSP general input/output port -0. Input Schmitt input CMOS PORT

Output

Input Schmitt input COMOS PORT

Input X’tal

Input Schmitt input CMOS PORT

Input Schmitt input CMOS PORT

Input Schmitt input

Input Schmitt input

Input Schmitt input

Input Schmitt input

Monitor pin for the signal.

Built-in series resister 3.3kΩ

Connect to VRO and PVREF.

Connect 0.1uF

3-state output (AVDD3,

AVSS3, VREF)

-

-

No capacitor required to DVR

pin when built-in audio DAC is

not in use, however , connect

3.3V to DVDD3 and GND to

DVSS3.

8 – 4

Page 78

XL-DK257N

IC1 VHITC94A70FG2: CD MP3 DECODER (3/4)

Pin Description

Pin

No.

49 Pio1

50 Pio2

51 Pio3

52 VSS - Grounding pin for 3.3V digital circuit. - 53 VDDT3 - Power supply pin for 3.3 V digital I/O circuit. - For CD and DSP I/O

54 SBSK Output 3AI/F Sub code block sync output pin. Output CMOS PORT

55 SBOK Output 3I/F CRCC check result output pin for sub code Q data. Output CMOS PORT

56 IPF Output 3I/F Correction flag output. Output CMOS PORT

57 SFSY Output 3I/F Servo internal register read clock output pin. Output CMOS PORT

58 ZDET Output 3I/F Internal Audio DAC Zero data detection flag output. Output CMOS PORT

59 GPIN Input 3I/F

60 MS Input 3I/F

61 DoUT(Po6) Output 3I/F

62 AoUT1(Po7) Output 3I/F

63 BCKo(Po8) Output 3I/F

64 LRCKo(Po9) Output 3I/F

65 AiN(Pi4) Input 3I/F

66 BCKi(Pi5) Input 3I/F

67 LRCK(Pi6) Input 3I/F

68 VDD1 - Power supply pin for 1.5V digital circuit. 69 VSS - Grounding pin for 1.5V digital circuit. -

70 AWRC Output 3AI/F VCO control pin for active wide-range PLL. Output

71 PVDD3 - Power supply pin for 3.3V CD PLL circuit. -

72 PDo Output 3AI/F EFM and PLCK Phase difference signal output pin. Output

73 TMAXS Output 3AI/F TMAX detection result output pin. Output

74 TMAX Output 3AI/F TMAX detection result output pin. Output

75 LPFN Input 3AI/F PLL circuit LPF amplifier inversion input pin. Input

76 LPFo Output 3AI/F PLL circuit LPF amplifier Output pin. Output

77 PVREF - PLL circuit 1.65 V reference voltage pin. -

78 VCoF Output 3AI/F VCO filter pin Output Connect 0.01uF.

79 PVSS3 - Grounding pin for 3.3V CD PLL circuit. -

80 SLCo Output 3AI/F

81 RFi Input 3AI/F

82 RFRPi Input 3AI/F RF ripple signal input pin. Input -

83 RFEQo Output 3AI/F RF equalizer circuit output pin. Output

84 Vro Output 3AI/F 1.65 V reference voltage output pin. Output

85 RESiN Output 3AI/F

86 VMDiR Reference voltage output pin for LD APC. Connect 0.1uF.

87 TESTR Output 3AI/F

Symbol Input / Output Description Default Remarks

Input / Output

3I/F

Input / Output

3I/F

Input / Output

3I/F

DSP general input/output port -1. Input Schmitt input CMOS PORT

DSP general input/output port -2. Input Schmitt input CMOS PORT

DSP general input/output port -3. Input Schmitt input CMOS PORT

CD General Input port (Pull down by 100KΩ when not

in use).

Microprocessor I/F mode selection pin.

“H”: Parallel I/F, “L”: Serial I/F

Digital Audio output (SPDIF) pin

(DSP general output port -6)

Audio data output pin -1

(DSP general output port -7)

Bit clock output pin for AoUT

(DSP general output port -8)

L/R channel clock output pin

(DSP general output port -9)

Audio data input for Audio DAC

(DSP general input port -4)

Bit clock input pin for AiN

(DSP general input port -5)

L/R channel clock for AiN

(DSP general input port -6)

EFM slice level output pin.

Output impedance =2.5kΩ both of

analog/digital slice mode.

RF signal input pin

Zin is selectable by command.

Pin for connecting a resistor for reference current

generation.

LPF connection pin for RFEQO offset correction

circuit.

Input Schmitt input

Input

Output CMOS PORT

Output CMOS PORT

Output CMOS PORT

Output CMOS PORT

Input Schmitt input

Input Schmitt input

Input Schmitt input

Applicable in CLV/CAV mode.

Connect 0.033 uF.

4-state output ( PVDD3,

Hiz,PVSS3,PVREF)

3-state output

(PVDD3,PVSS3,HiZ)

3-state

output(PVDD3,PVSS3,HiZ)

Connect resister of LPF, refer

to application circuit diagram.

Connect capacitor of LPF, refer

to application circuit diagram.

Connected to VREF and VRO

inside of IC. Connect 0.1uF.

Output

Input Zin: 20kΩ, 10kΩ, 5kΩ

Output Connect 22k//0.01uF.

Output Connect more than 0.015uF.

Connect capacitor according

with servo frequency band.

Connect to RFRPI by 0.1uF, to

RFI by 4700pF.

Connected to VREF and

PVREF inside of IC.

Connect 0.1uF+100uF.

8 – 5

Page 79

IC1 VHITC94A70FG2: CD MP3 DECODER (4/4)

Pin Description

XL-DK257N

Pin

No.

88 AGCi Input 3AI/F RF signal AGC amplifier input pin. Input

89 Rfo Output 3AI/F RF signal generation amplifier output pin. Output

90 RVDD3 - Power supply for 3.3V RF amplifier core circuit.

91 LDo Output 3AI/F Laser diode amplifier output pin.

92 MDi Input 3AI/F Monitor photodiode amplifier input pin. Input Reference Voltage=178mVtyp.

93 RVSS3 - Grounding pin for RF amplifier core circuit.

94 FNi2 Input 3AI/F

95 FNi1 Input 3AI/F

96 FPi2 Input 3AI/F

97 FPi1 Input 3AI/F

98 TPi Input 3AI/F

99 TNPC Output 3AI/F TNI/TPI input common capacitor connection pin. Output Connect to VRO by capacitor.

100 TNi Input 3AI/F

Symbol Input / Output Description Default Remarks

Main beam signal input pin. To be connected to PIN

diode C.

Main beam signal input pin. To be connected to PIN

diode A.

Main beam signal input pin. To be connected to PIN

diode D.

Main beam signal input pin. To be connected to PIN

diode B.

Sub beam signal input pin. To be connected to PIN

diode F.

Sub beam signal input pin. To be connected to PIN

diode E.

Input

Input

Input

Input

Input

Input

* 3A I/F : 3 V analog circuit input/output pin.

1.5 I/F : 1.5 V digital input/output pin.

3 I/F : 3 V digital input/output pin.

Note: The servo output pins (FOO, TRO, FMO, and DMO) become undefined or GND level under the following conditions:

• /RST pin = Low

• Crystal oscillation stopped according to the instructions by the Stop crystal oscillation command.

• Power supply for CD is OFF.

• SRAMSTB pin = High

To prevent the undefined pin states from affecting the servo circuitry or any other mechanical blocks in the system,

appropriate measures should be taken, such as using a driver IC supporting a standby feature to place the system in

standby mode while either of the above conditions is satisfied.

8 – 6

Page 80

XL-DK257N

IC701 RH-IXA159AW00: System Microcomputer (1/5)

NAME

Pin

No.

PORT_TYPE

NO USE

1

P96/ANEX1

NO USE

2

P95/ANEX0

3 VOL_DATA

P94

4 VOL_CLK

P93

5NO USE

P92/TB2IN

6NO USE

P91/TB1IN

7 VOL_LATCH

P90/TB0IN

8BYTE

BYTE

9 CNVSS

CNVSS

10 XCIN

P87/XCIN

11 XCOU T

P86/XCOUT

12 RESET

RESET

13 X_OUT

XOUT

14 GND

VSS

15 X_IN

XIN

16 VCC

VCC1

17 NMI

P85/NMI

18 P-IN

P84/INT2

19 OSC

P83/INT1

20 RX_IN

P82/INT0

21 AMP DET

P81

22 AMP MUTE

P80

23 AMP ON/OFF

P77

24 RDS_VOLT_CONT

P76

25 RDS DATA

P75/TA2IN

INPUT /

OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT Fix "L"

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT Fix "L"

OUTPUT CMOS INPUT / OUTPUT Fix "L"

OUTPUT CMOS INPUT / OUTPUT

INPUT INPUT -

INPUT INPUT -

INPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT 32.768kHz X'tal (SUB-CLOCK)

INPUT INPUT -

OUTPUT CMOS OUTPUT -

- - - CONNECT TO GND(VSS).

INPUT CMOS INPUT -

- - -

INPUT CMOS INPUT -

INPUT CMOS INPUT / OUTPUT OFF

OUTPUT CMOS INPUT / OUTPUT

INPUT CMOS INPUT / OUTPUT

INPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

INPUT CMOS INPUT / OUTPUT

FORM

SOFT

PULLUP

OFF

OFF

OFF

OFF

OFF

FUNCTION OUTLINE

Fix "L"

COMMUNICATION WITH

DATA OUTPUT

COMMUNICATION WITH

CLOCK OUTPUT

COMMUNICATION WITH

LATCH OUTPUT

EXTERNAL BUS. JOINT TO

VSS IF NO USE

USED IN SINGLE MODE.

CONNECT TO VSS

THROUGH PULL DOWN

RESISTOR. EXCLUSIVE USE

FOR VCC DURING FLASH

WRITING

32.768kHz X'tal (SUB-CLOCK)

RESET INPUT. ACTIVE "L"

CONNECT TO WRITER

RESET LINE DURING FLASH

MICOM STANDARD

OSCILLATION OUTPUT

CONNECT TO 9.8MHz

CERAMIC OSCILLATION

MICOM STANDARD

OSCILLATION OUTPUT

CONNECT TO 9.8MHz

CERAMIC OSCILLATION

SUPPLY INPUT TO MICOM

(3.3V)

BACK-UP POWER SUPPLY

CONNECT TO VCC

THROUGH PULL UP RESISTOR. (SET FOR FLASH)

POWER FALURE DETECTION. JUDGE AS POWER

FAILURE IF FAIL TO DETECT

EDGE WITHIN 90 msec.

OSCILLATOR FREQUENCY

ADJUSTMENT. SET FOR

H=415kHz, L=375kHz

REMOCON IN

(SHARP FORMAT)

POWER IC ABNORMAL

DETECT ABNORMAL=L

AMP MUTE CONTROL L:

MUTE OFF, H: MUTE ON

AMP ON/OFF CONTROL L:

OPERATING MODE,

H: STANDBY MODE

RD

S FUNCTION CONTROL H:

FM FUNC ONLY (H MODEL)

RDS DATA in (H MODEL)

8 – 7

Page 81

IC701 RH-IXA159AW00: System Microcomputer (2/5)

XL-DK257N

NAME

Pin

No.

PORT_TYPE

RDS CLK

26

P74/TA2OUT

IPOD_DETECT

27

P73/CTS2/RTS2/TA1IN

FLD RESET

28

P72/CLK2/TA1OUT

IPOD_TXD

29

P71/RXD2/SCL2/TA0IN/TB5IN

IPOD_RXD

30

P70/TXD2/SDA2/TA0OUT

FLD DATA/FLASH_TXD

P67/TXD1/SDA1

31

FLASH_RXD

32

P66/RXD1/SCL1

FLD SCK/FLASH_SCLK

P65/CLK1

33

FLD CS/FLASH_BUSY

P64/CTS1/RTS1/CTS0/CLKS1

34

NO USE

35

P63/TXD0/SDA0

NO USE

36

P62/RXD0/SCL0

NO USE

37

P61/CLK0

CP_SCL

38

P60/CTS0/RTS0

CP_SDA

39

P57/CLKOUT

CP_nRESET

40

P56

FLASH_EPM

41

P55

NO USE

42

P54

NO USE

43

P53

NO USE

44

P52

NO USE

45

P51

FLASH CE

46

P50

NO USE

47

P47

NO USE

48

P46

NO USE

49

P45

NO USE

50

P44

INPUT /

OUTPUT

INPUT CMOS INPUT / OUTPUT OFF RDS CLK (H MODEL)

INPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

INPUT Nch open -

OUTPUT Nch open -

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

INPUT /

OUTPUT

OUTPUT CMOS INPUT / OUTPUT

INPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

INPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

OUTPUT CMOS INPUT / OUTPUT

CMOS INPUT / OUTPUT

FORM

SOFT

PULLUP

OFF

OFF

OFF

OFF

OFF

OFF

FUNCTION OUTLINE

L:IPOD INSERT

H:W/O IPOD

FL DRIVER RESET CONTROL

IPOD COMMUNICATION

DATA IN (OPTION)

IPOD COMMUNICATION

DATA IN (OPTION)

COMMUNICATION WITH FL

DRIVER

( DATA OUT TO FLASH

WRITER.)

INPUT DATA FROM FLASH

WRITER

COMMUNICATION WITH

FL_DRIVE. CLOCK OUTPUT

( INPUT CLOCK FROM

FLASH WRITER. )

COMMUNICATION WITH

FL_DRIVER. Chip Select

( BUSY OUTPUT TO FLASH

WRITER. BUSY: "H")

Fix "L"

Fix "L"

Fix "L"

IPOD CO-PROCESSOR I2C

COMMUNICATION CLOCK

IPOD CO-PROCESSOR I2C

COMMUNICATION DATA

SUMMER TIME SWITCH

OUTPUT

L:NORMAL H:+1HOUR

CONNECT TO VSS

THROUGH PULL DOWN

(SET FLASH WRITING)

Fix "L"

Fix "L"

Fix "L"

Fix "L"

FLASH CHIP ENABLE

Fix "L"

Fix "L"

Fix "L"

Fix "L"

8 – 8

Page 82

XL-DK257N

IC701 RH-IXA159AW00: System Microcomputer (3/5)

Pin

No.

51

52

53