Page 1

SERVICE MANUAL

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Refrigerator-freezer

MODEL

SJ-XF50X-T

No.S0311SJF50XTFT

DESTINATION F

CONTENTS

Refer to "REFRIGERATING-CYCLE REPAIR MANUAL" for handling this refrigerant.

Refrigerant; R600a

[1] PRODUCT SPECIFICATIONS

1. SPECIFICATIONS ………………………… 2

2. ACCESSORIES …………………………… 2

3. AUTOMATIC ICE MAKING ……………… 3

[2] DESIGNATION OF VARIOUS PARTS

1. PART NAMES ……………………………… 4

2. INTERNAL STRUCTURE ………………… 5

3. FLOW OF COOL AIR ……………………… 6

4. TEMPERATURE DISTRIBUTION ………… 7

[3] DIMENSIONS

1.

OUTER DIMENSIONS AND CLEARANCE

…8

2. INNER DIMENSIONS ……………………… 9

[4] ELECTRICAL CIRCUIT DIAGRAMS …………10

1. WIRING DIAGRAM …………………………10

2. ELECTRIC ACCESSORIES LAYOUT …… 11

3.

PRECAUTIONS FOR USING LEAD-FREE SOLDER

……12

[5] ELECTRICAL SYSTEM SPECIFICATIONS …13

1. FUNCTIONAL PART SPECIFICATIONS …13

2. MODE FOR DISPLAY ………………………14

[6]

REFRIGERATION CYCLE SYSTEM SPECIFICATIONS

1. R600A PRECAUTIONS ……………………15

2.

TABLE OF R600A CHARACTERISTICS

…15

3. REFRIGERATION CYCLE DIAGRAM …… 15

[7] TROUBLESHOOTING

1. SELF-DIAGNOSIS MODE …………………18

2.

FORCED STOPPING OF DOOR ALARM BUZZER

…2 2

3.

THERMISTOR CIRCUIT CHECK METHOD

…22

4.

INSPECTION FLOWCHART AND REPAIR ITEMS

…2 3

5.

PLASMACLUSTER OK/NG JUDGMENT

…2 5

[8] DISASSEMBLY/ASSEMBLY

1.

GENERAL DISASSEMBLY SEQUENCE

…2 6

2.

REFRIGERATOR COMPARTMENT DISASSEMBLY

…2 7

3. FREEZER COMPARTMENT/ICE

COMPARTMENT DISASSEMBLY ………29

4.

VEGETABLE COMPARTMENT DISASSEMBLY

…3 1

5. HOW TO REMOVE OP. PWB ASS'Y ……32

6. HOW TO REMOVE TERMINAL BOX ……33

7. HOW TO INSTALL R-SUB PACKING ……33

8.

HOW TO INSTALL DUCT RT ASS'Y COVER

…3 4

9.

ADJUSTMENT OF R-DOOR (DOUBLE DOOR)

…3 5

10

. MAIN PARTS ASSEMBLY …………………36

Parts Guide

Page 2

SJXF50XT

2

[1]

PRODUCT SPECIFICATIONS

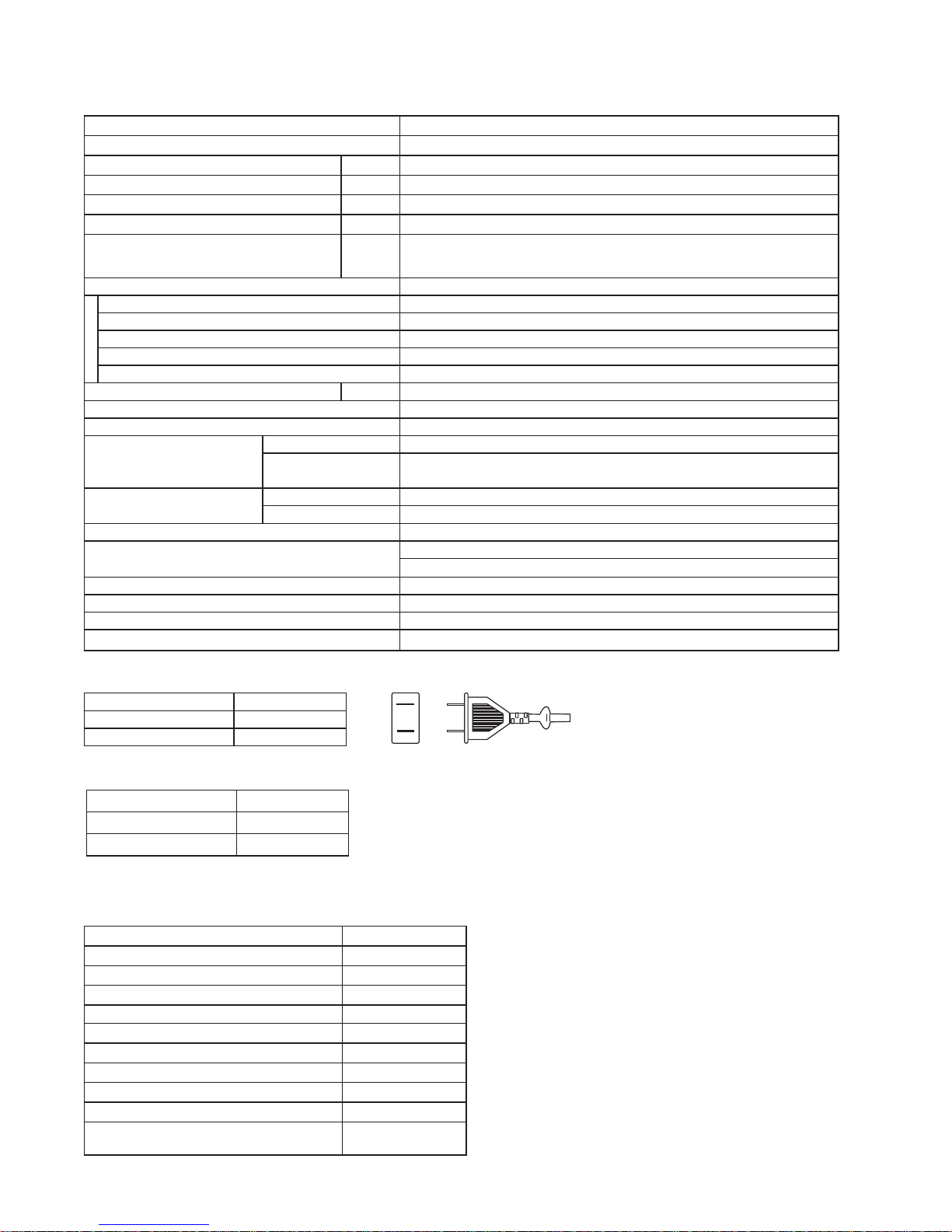

SPECIFICATIONS1.

Item SJ-XF50X-T

Rated voltage/Rated frequency 110V~60Hz

Rated current (W) 118

Rated power input of heating systems (W) 171

Defrosting input (W) 130

Defrosting heater input (W) 130

O u t e r d i m e n s i o n s

Width×Depth×Height

(mm) 685 x 699 x 1820

Rated total storage volume 501L (17.7 cu.ft.)

Refrigerator compartment 268L (9.47 cu.ft.)

Freezer compartment (upper) 28L (0.99 cu.ft.)

Freezer compartment (lower) 96L (3.39 cu.ft.)

Ice compartment 19L (0.67 cu.ft.)

Vegetable compartment 90L (3.18 cu.ft.)

Weight (kg) 89

Refrigerant (Charging quantity) [Flammable] R600a (68g)

Insulation blowing gas [Flammable] Cyclo pentane (HC)

Cabinet

Inner box material ABS plastic

Outer shell material

PET steel

(Hot dipped zinc plated steel sheet with baked polyester resin coating)

Door

Door shell material Steel

Door inner material ABS plastic

Temperature control Automatic(adjustable)

Defrosting system

Heater system

(automatic start, automatic fi nish)

Refrigerator lamp LED (8 pcs)

Adjustable legs 2

Casters 4

Climate class ST

PLUG TYPE

Plug cord 2pin

Plug type A-1

Destination mark F

COLOR

Items -T

Outside color Brown

Inside color White

ACCESSORIES2.

Refrigerator Compartment

R shelf 2

Free set shelf (front/back) 1 each

Chilled case 1

Chilled case tray 1

Case 1

Door pocket (left) 2

Door pocket (right) 2

Egg case 1

Egg tray 1

Bottle pocket (left/right) 1each

Water tank (Tank cap, Lock lever, Slide

cap, Filter case, Water tank, Water fi lter)

1

Page 3

SJXF50XT

3

Freezer compartment (Upper)

Freezer case (Upper) 1

Stainless tray 1

Freezer compartment (Lower)

Freezer case (top) 1

Freezer case (bottom) 1

Ice compartment

Ice storage box 1

Noise-proof sheet 1

Ice scoop 1

Vegetable compartment

Vegetable case 1

Fruit case 1

Pet case 1

Stainless tray 1

Other Accessories and Printed Materials

Foot grille 1

Operation manual 1

Warranty card 1

AUTOMATIC ICE MAKING3.

Water supply method: Storing water in tank/Direct water supply to ice cube maker•

Water tank volume: Approx. 1.0 L•

Ice making capacity (External air temperature: 30ºC, No door opening/closing, Temperature control: “•

中

”, Ice-making mode: “通常”)

Ice cube size Standard Large

Daily Approx. 1.2 kg Approx. 1.5 kg

Once (8 pieces) Approx. 100 g Approx. 230 g

Ice-making time/once•

Ice cube size Standard Large

Ice making

mode

通常

Approx. 2 hours Approx. 3 hours and 30 minutes

明亮

Approx. 6 hours Approx. 8 hours

急速

Approx. 1 hour and 20 minutes Approx. 2 hours

Others: Water filter is attached.•

Ice scoop is provided.

Enables test operation with the cleaning function.

Heat-resistant temperature of water tank: Approx. 60ºC•

Ice storage quantity•

Ice cube size Standard Large

Normal Approx. 4

0

0 to 64 pcs. Approx. 24 to 32 pcs.

Maximum (when leveled) Approx. 88 to 104 pcs. Approx. 40 to 48 pcs.

Page 4

SJXF50XT

4

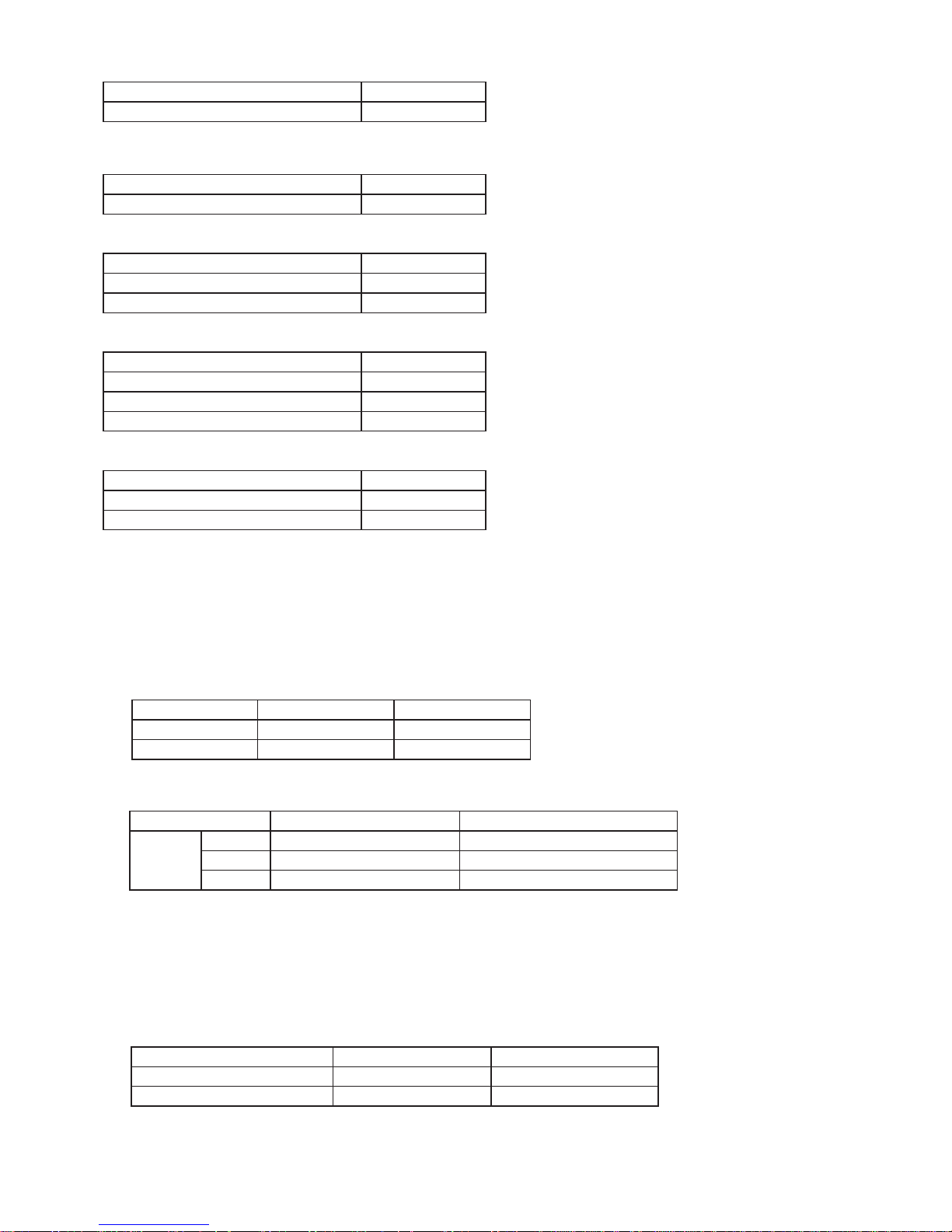

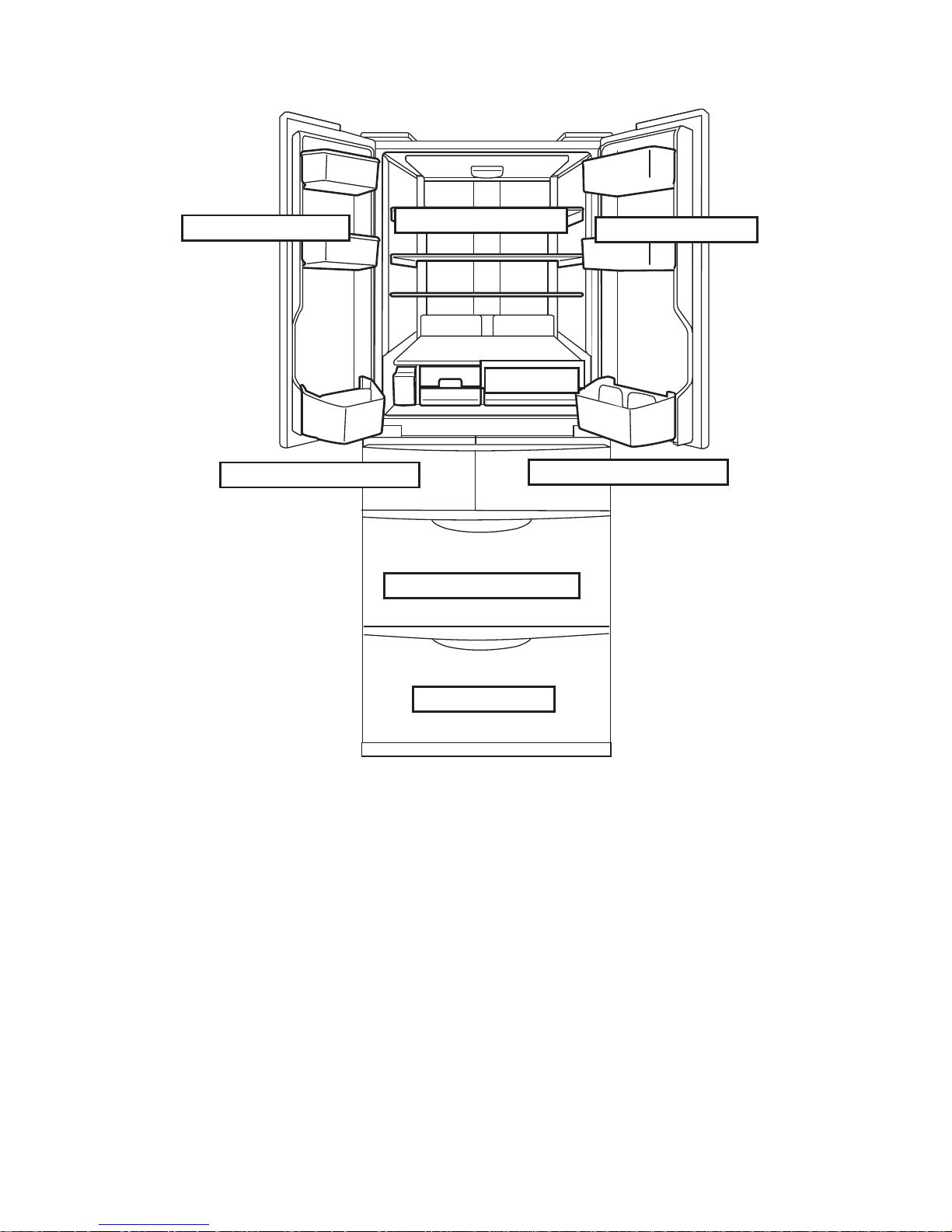

[2] DESIGNATION OF VARIOUS PARTS

PART NAMES1.

Parts names in parentheses "[ ]" are denominations used in the Operation manual.

>@

Ice compartment

Freezer compartment (upper)

Freezer compartment (lower)

Freezer compartment (lower)

Noise-proof sheet

Ice storage box

Ice scoop

F case sus

F case s

F top case

F bottom case

Vegetable case

Fruit case

V case sus

Pet case

Vegetable compartment

Vegetable compartment

Free set shelf

Egg case

Egg tray

Water tank

Cool plate

Case

Chilled case

C case tray

LED

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

Plasmacluster unit

R shelf

Bottle pocket(left)

Bottle pocket(right)

Door pocket(left)

Door pocket(right)

[ ]

[ ]

[ ]

[ ]

Page 5

SJXF50XT

5

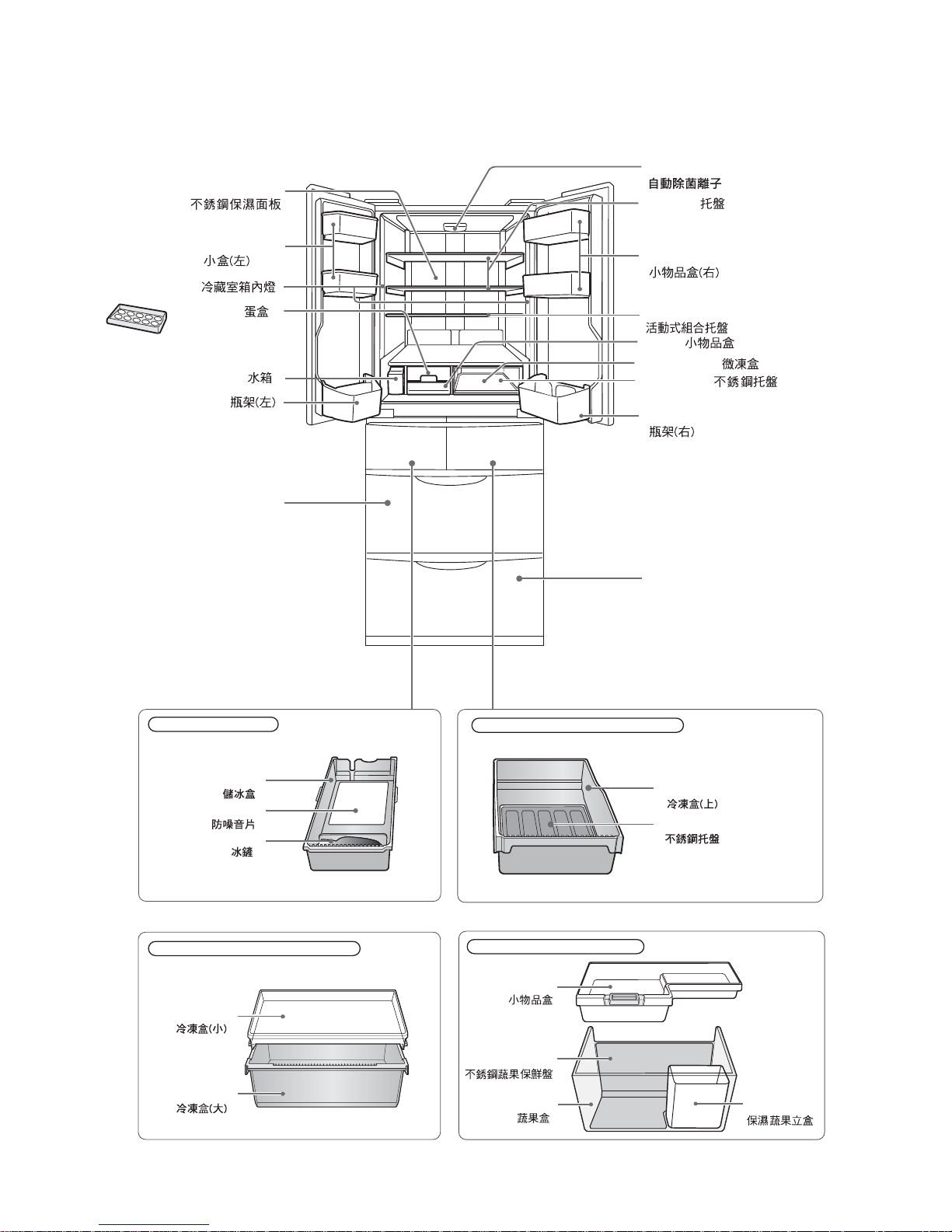

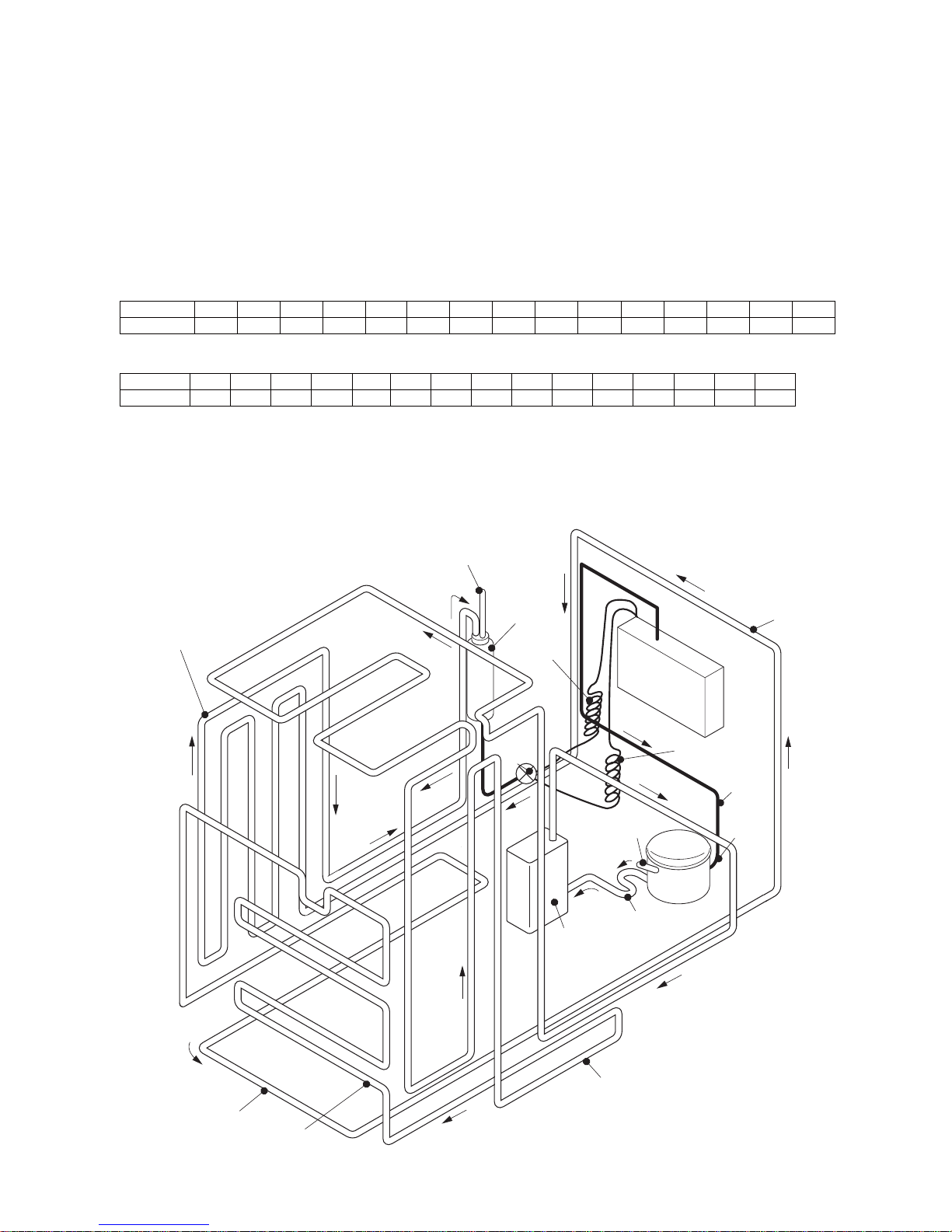

INTERNAL STRUCTURE2.

Catalyzer

Humidity sensor

OP. PWB

Proximity switch

Thermo fuse

Catalyzer

Ice compartment

Freezer compartment (upper)

Vegetable compartment

Refrigerator compartment

R-shower duct ass’y

D-fan motor PCI

Damper ass’y

Thermistor

Ice cube heater

Evaporator

V-thermistor (G-thermistor)

V heater

Damper

Terminal box

(Main PWB, EECON-INV PWB, REACTANCE)

Compressor, protector, valve turret

Fan motor g

Condensor unit

Caster

Evaporating pan

Side view

Adjustable leg ass’y

F proximity switch

Ice maker ass’y

R door switch

LED PWB ass’y

Cool plate

LED PWB ass’y

R-thermistor

Gear pump

Water pipe ass’y

Water pipe heater

Tank heater

F-thermistor

Evaporator

Heater

Front view

Temp.control PWB

Fan motor f

DEF thermistor

Duct heater

Freezer

compartment (lower)

Page 6

SJXF50XT

6

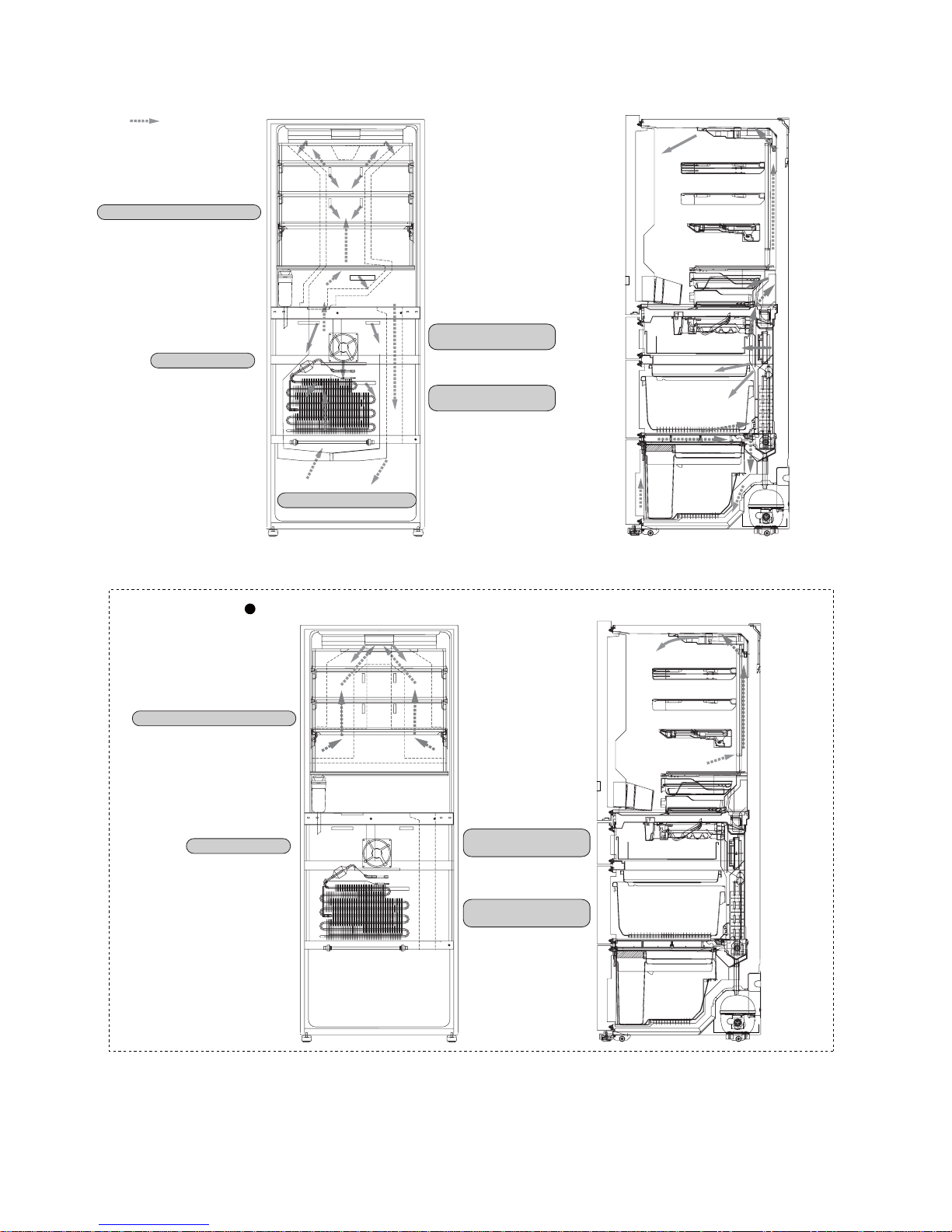

FLOW OF COOL AIR3.

Flow of Cool air

Ice compartment

Refrigerator compartment

Freezer

compartment (lower)

Freezer

compartment (upper)

Vegetable compartment

Side view

Front view

Freezer

compartment (lower)

Freezer

compartment (upper)

Refrigerator compartment

Ice compartment

When Plasmacluster ion is in operation.

Page 7

SJXF50XT

7

TEMPERATURE DISTRIBUTION4.

●

The temperatures above are indications under the condition of no

food inside, doors closed and surrounding temperature is 30 after

stabilized the inside temperature. (Temperature adjustment is "中")

Approx.3 ~ 7°C

Approx.2 ~ 5°C

Approx.3 ~ 7°C

Approx.0 ~ 2°C

Approx.-17 ~ -19°C

Approx.-18 ~ -20°C

Approx.-18 ~ -20°C

Approx.3 ~ 8°C

Page 8

SJXF50XT

8

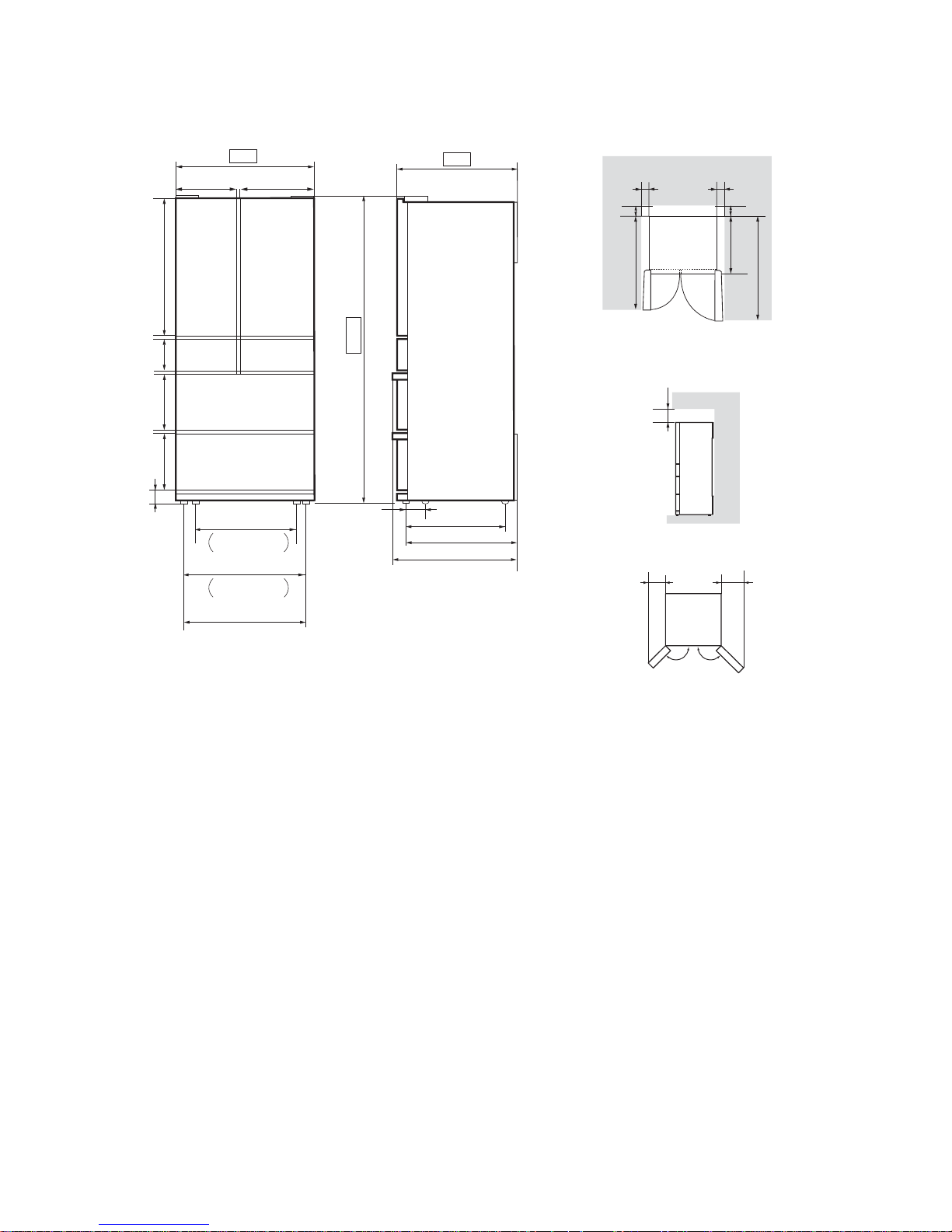

[3] DIMENSIONS

OUTER DIMENSIONS AND CLEARANCE (UNIT:mm)1.

198

281

699

285 396

551

632.5

661.5

608

68

626.5

4

685

1820

853.2180.8

335

365

8

8

15.5

90

50

709

930

1043

705

60 60

Moving wheels

back side

Moving wheels

front side

(Adjustable feet)

More than

More than

More than

135°135°

60

More than

More than

60

Page 9

SJXF50XT

9

INNER DIMENSIONS2.

The dimensions between shelves can be changed by setting the shelves on the other rails.•

311

292

311

562

292

282

118

156

118

67

95

95

96

246

226

355.5

79.5

70

70

398.8

392

383

235

139

44

112

558

543

542

135

269

269

236

268

144

144

75

75

144

75

144

75

138

123

123

183

135

94

163

398.8

89

81

98

68

311

811651

292

123

138

116

145

22

mm

311

106

354

172

206

211

301

213

238

88

253

310

63

218

519

532

393

94.5

109.5

137.5

172

57

Page 10

SJXF50XT

10

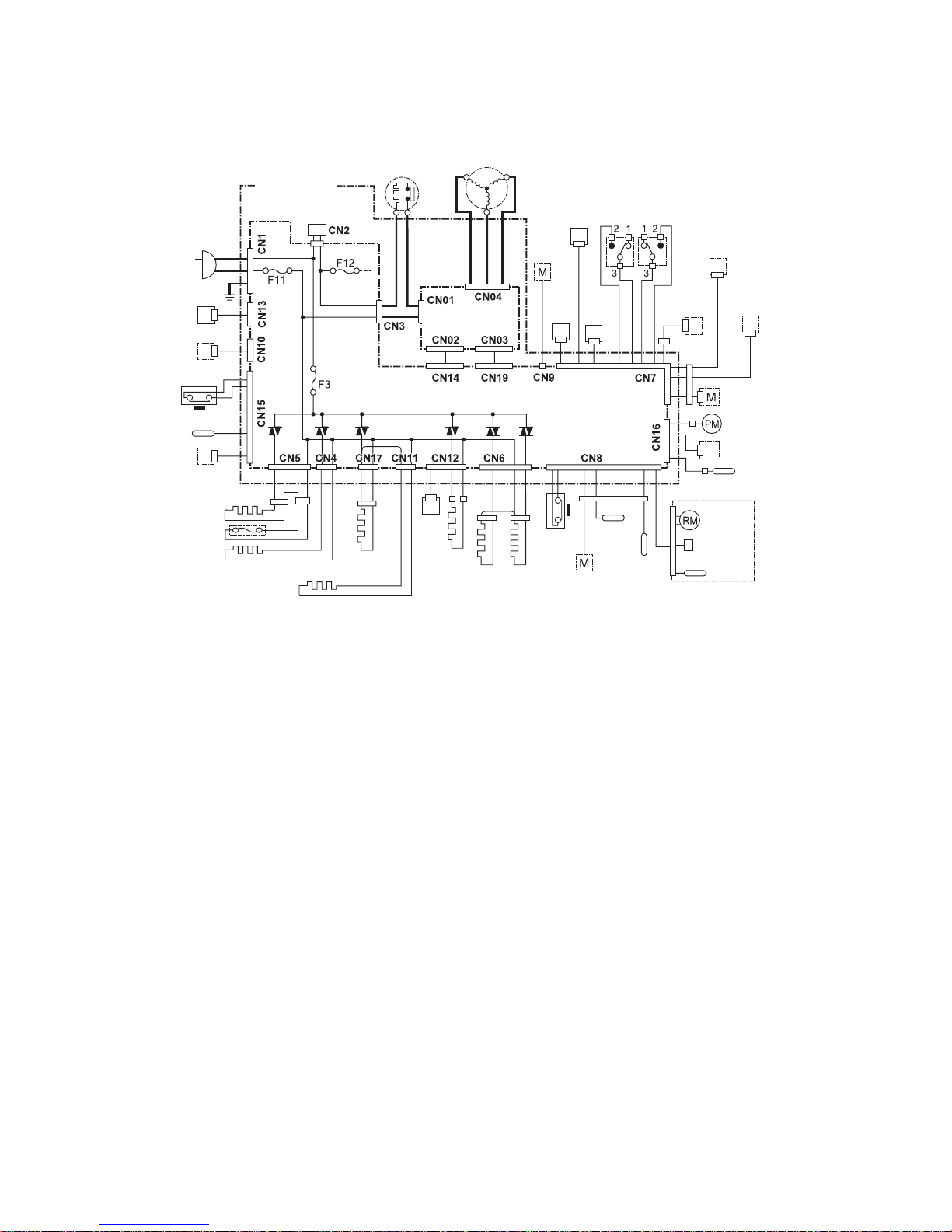

[4] ELECTRICAL CIRCUIT DIAGRAMS

WIRING DIAGRAM1.

Source cord

Reactance

Main PWB

OP

PWB

EECON-INV

PWB

Protector

Compressor

Fan

motor g

Fan

motor f

LED

PWB

(left)

Temp.

control

PWB

Indicator

PWB

Plasmacluster

unit

Motor

D-fan motor PCI

Gear

pump

Damper

R

thermistor

F thermistor

DEF

thermistor

Ice maker unit

Motor

Switch

Thermistor

Proximity

switch

F proximity

switch

Ice cube

heater

R door

heater

V heater

Duct

heater

V thermistor

V damper

Door

switch

(left)

Door

switch

(right)

LED

PWB

(right)

Terminal box

Valve turret

Humidity sensor

Heater

Thermo fuse

Tank heater

Water

pipe

heater

Page 11

SJXF50XT

11

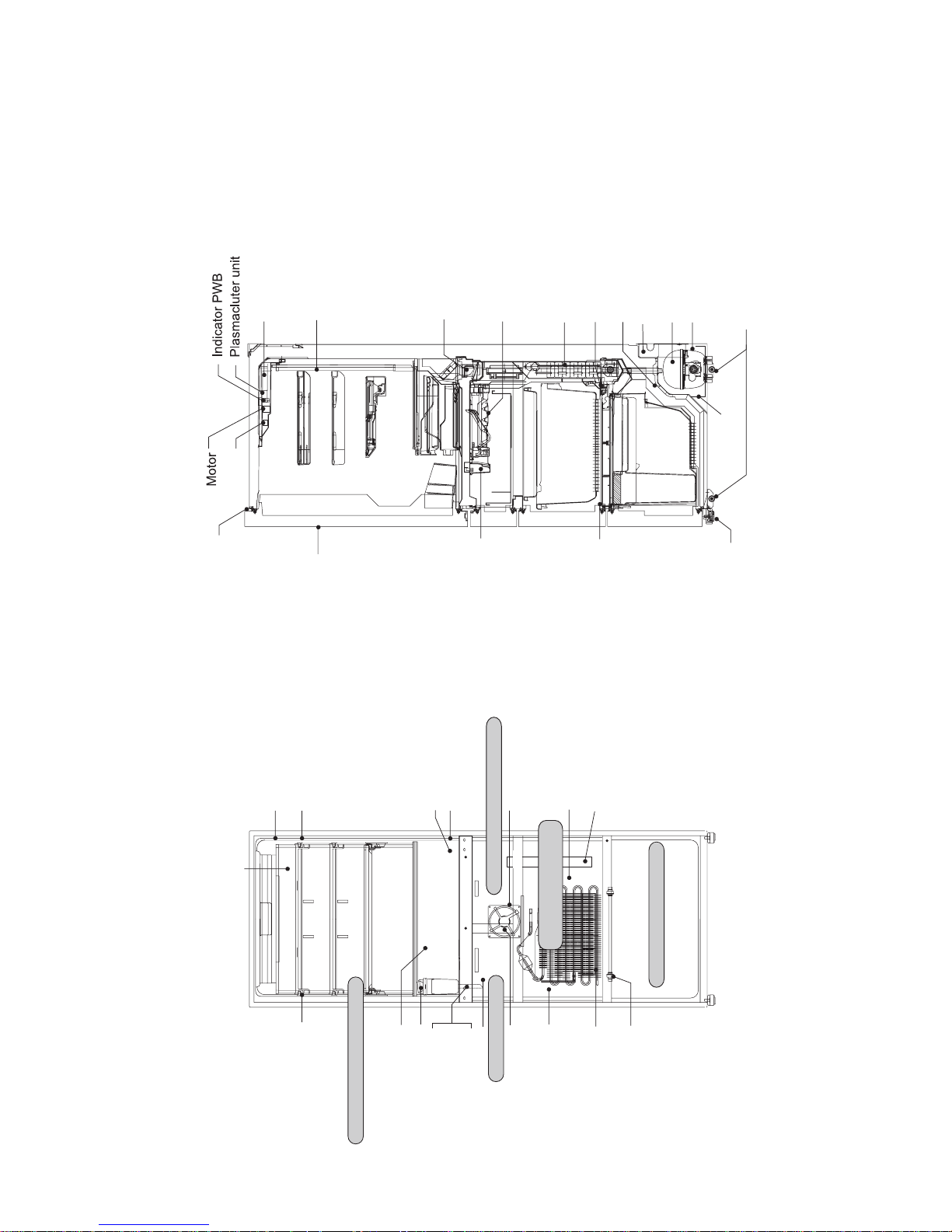

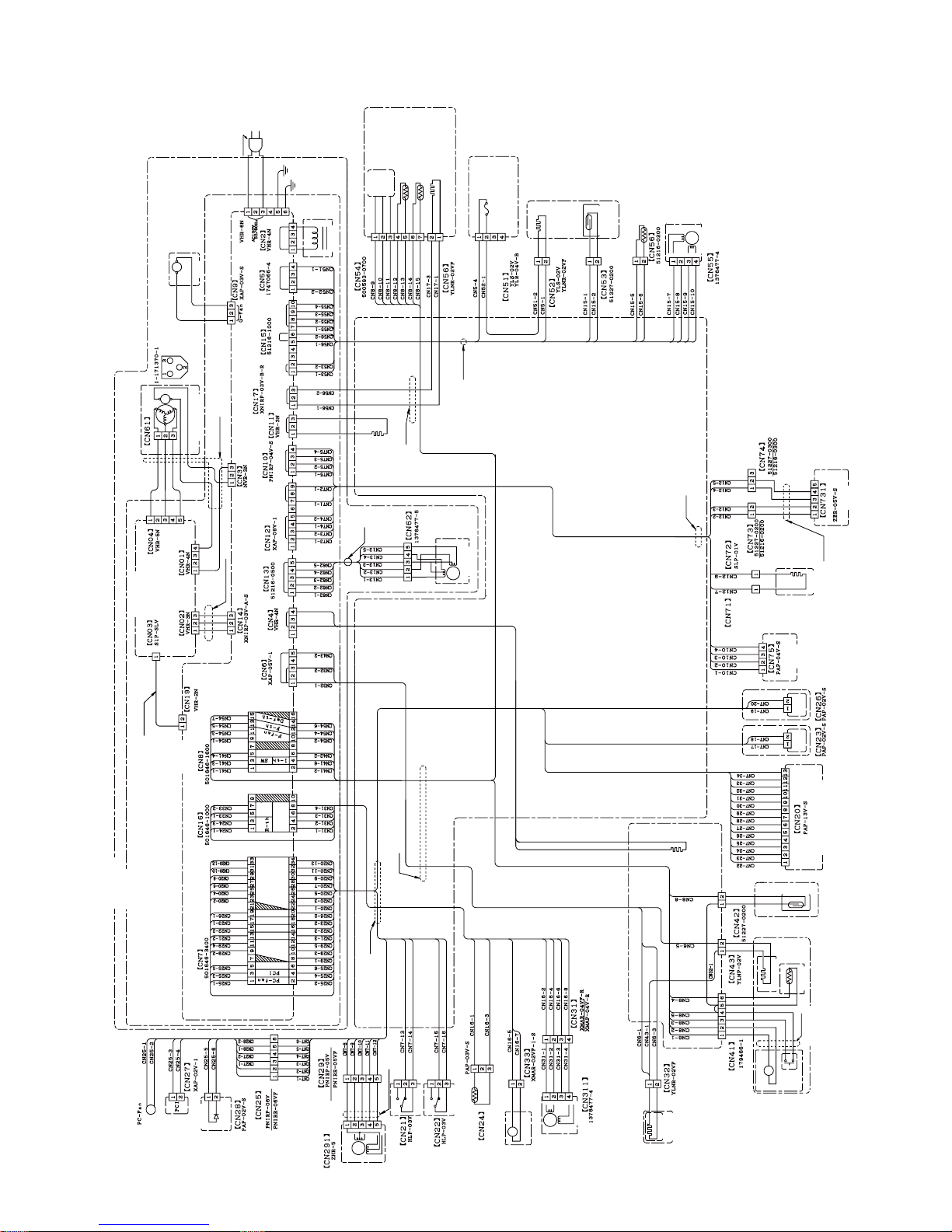

ELECTRIC ACCESSORIES LAYOUT2.

Harness

Harness

Harness

Harness

Harness

Harness

Earth harness

G-fan

Source cord

Black

White

Green

Green

Reactance

Reactance

WhiteWhite

Heater

V thermistor

V damper

YellowBrown

F-proximity

switch

Duct

heater

V-heater

V-heater

Humidity

sensor

R door heater

OP.PWB

Valve turret

Tank heater

Ice cube heater

Water pipe heater

EECON-INV PWB

Green

MAIN PWB

TEMP.CONTROL

PWB

Terminal box

Compressor room

Red

Black

Gray

Yellow

Indicator

PWB

Orange

White

Blue

Motor

Red

Black

Gray

Yellow

Orange

White

Brown

Red

Orange

Yellow

Light green

Blue

Brown

Brown

Black

White

Gray

Red

Red

Orange

Yellow

Light green

Damper harness

Orange

Yellow

Blue

Light green

R door switch

(left)

R door

switch(right)

White

White

Orange

Brown

R thermistor

Red

Red

Yellow

Black

Gear pump

Purple

Purple

Gray

Gray

Blue

Blue

Light green

Light green

R-damper

Brown

White

Orange

Orange

Water pipe

Water pipe

heater

Ice cube tray

Ice cube heater

Brown

Light

green

TEMP. CONTROL PWB

Thermistor

Ice maker unit

Harness

SW

Motor

Red

Brown

Red

Blue

Orange

Light green

Yellow

Yellow

White

White

White

White

White

Light green

Proximity

switch

Black

Black

Red

Orange

Yellow

Light green

Blue

Purple

Gray

White

Black

Brown

Red

Orange

Yellow

Light

green

Blue

Tank heater

LED PWB

(left)

LED PWB

(right)

White

Gray

White

Gray

Humidity

sensor

Brown

Red

Orange

Yellow

R door

heater

White

White

Purple

Blue

OP PWB

Brown Brown

Red

Red

Red

Orange

Orange

Orange

Yellow

Yellow

Yellow

Light

green

V damper

V thermistor

Black

White

Gray

Purple

Blue

Light green

White

Brown

Black

Black

Red

White

White

Gray

Black

Brown

Heater

F proximity

switch

Thermo fuse

Blue

Blue

Orange

Blue

Brown

Yellow

Black

Brown

Fan motor

F thermistor

DEF thermistor

Duct heater

Red

Red

Orange

Yellow

Light green

White

White

White

White

Blue

Blue

Black

Black

Brown

Indicator PWB

LED PWB(right)

LED PWB(left)

R door switch(left)

R door switch(right)

Brown

Brown

Brown

Brown

White

White

White

White

Orange

Orange

Orange

Orange

Orange

Purple

Light green

Light green

Light green

Red

Red

Red

Red

Yellow

Yellow

Yellow

Yellow

Blue

Blue

Blue

Black

Black

Gray

Gray

Gray

Gray

Gear

pump

R

damper

Purple

Light green

Brown

Brown

White

Orange

Orange

Light green

Light green

Red

Yellow

Blue

Red

Red

Black

Yellow

Yellow

Blue

Gray

Proximity switch

Moter

Moter

Inverter DC harness

Yellow

Green

Blue

Black

Blue

Brown

White

Red

Gray

Compressor ass’y

Comp. harness

Compressor

Blue

Protector

Black

Brown

Red

Blue

Gray

Purple

Black

Valve turret

Valve turret

Brown

Orange

Light green

Red

Yellow

Brown

Orange

Light green

White

White

White

White

White

Black

Brown

Brown

Orange

Light green

Light green

Light green

Red

Yellow

Brown

Orange

Brown

Brown

Orange

Red

Red

Yellow

Orange

Red

Yellow

Purple

Page 12

SJXF50XT

12

PRECAUTIONS FOR USING LEAD-FREE SOLDER3.

1) Employing lead-free solder

The PWB of this model employs lead-free solder. This is indicated by the "LF" symbol printed on the PWB and in the

service manual. The suffi x letter indicates the alloy type of the solder.

Example:

Indicates lead-free solder of tin, silver and copper

2) Using lead-free wire solder

When repairing a PWB with the "LF" symbol, only lead-free solder should be used. (Using normal tin/lead alloy

solder may result in cold soldered joints and damage to printed patterns.)

As the melting point of lead-free solder is approximately 40°C higher than tin/lead alloy solder, it is recommend that a

dedicated bit is used, and that the iron temperature is adjusted accordingly.

3) Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is higher and has poorer wettability, (fl ow), to prevent damage

to the land of the PWB, extreme care should be taken not to leave the bit in contact with the PWB for an extended

period of time. Remove the bit as soon as a good fl ow is achieved.The high content of tin in lead free solder will

cause premature corrosion of the bit. To reduce wear on the bit, reduce the temperature or turn off the iron when it is

not required.

Leaving different types of solder on the bit will cause contamination of the different alloys, which will alter their

characteristics, making good soldering more diffi cult. It will be necessary to clean and replace bits more often when

using lead-free solder. To reduce bit wear, care should be taken to clean the bit thoroughly after each use.

Page 13

SJXF50XT

13

[5] ELECTRICAL SYSTEM SPECIFICATIONS

FUNCTIONAL PART SPECIFICATIONS1.

Part Name Specifi cations Function

Fan motor F

Model No.: 4715JL-09W-S37

Rating: DC15V

Power Input: 1.05W (Vs:2.6V)

For cooling

(For freezer compartment)

Fan motor g

Model No.: 4515JL-09W-S10-G01

Rating: DC12V

Power Input: 1.2W

For condensing

(Out side refrigerator)

D-fan motor PCI

Model No.: D09F-12SM20(EX)

Rating: DC12V 0.13A

Power Input: 1.56W

For ion releasing

(For refrigerator compartment)

Damper ass'y (R damper) 415 ± 50Ω (25°C) For refrigerator compartment temperature control

Damper (V damper) 415 ± 50Ω (25°C) For vegetable compartment temperature control

Motor Rating: DC12V 0.13A 300Ω Deodorant/bacteria elimination switching damper

Door switch 5mA 5V DC

For detection of opening or closing of the door

(For refrigerator compartment)

Proximity switch DC15V 100mA 1W

For detection of opening or closing of the door

(For Ice compartment)

F proximity switch DC15V 100mA 1W

For detection of opening or closing of the door

(For freezer compartment (bottom))

Compressor

Model No.: VESD9C+

Rating: 100V 50/60Hz

Resistance value: 9.6Ω (at 25°C)

Protector

MODEL: MSP59AMN-6

Operating temperature: 120°C

For compressor overload prevention

Main PWB For main control

OP.PWB

3.3V 4mA 12mW (Green)

2.3V 10mA 22mW (Red)

3.3V 5mA 16mW (Blue)

For operation panel control (door panel)

LED PWB 15V 72mA x 1.125W For refrigerator compartment illumination

Indicator PWB 3.2V 20mA 38mW For display of Plasmacluster operation

Source cord 125V 7A Source cord (2 Pin + earth)

F thermistor Resistance: 6.4kΩ (at 0°C) For detection of the freezer compartment temperature

R thermistor Resistance: 6.4kΩ (at 0°C) For detection of the refrigerator compartment temperature

DEF thermistor Resistance: 15kΩ (at 0°C) Senses when defrosting is completed

Thermo fuse

Rating: 250 V 10 A

Rated operating temperature: 77°C

For defrosting temperature excessive rise prevention

Thermistor Resistance value: 6.0kΩ (at 0°C) For detection of ice tray temperature

G-thermistor (V-thermistor) Resistance: 1.94Ω (at 0°C) For detection of vegetable compartment temperature

Gear pump Supplies water to the ice cube maker

Heater 110V 130W 93Ω For defrosting

Plasmacluter unit DC12V 20mA For bacteria elimination in compartment

Reactance 9mH±10% Class E wiring

Temp. control PWB For operation panel control (inside)

EECON-INV PWB 100V 50/60Hz For compressor drive

Duct heater 6.0W 1666Ω±7% For prevension of frosting

Humidity sensor 0.5mA DC5V For detection of outside temperature and humidity

Ice cube heater 12W 833Ω For making clear ice cube

Partition heater(R door heater) 3.4W/2910Ω For refrigerator compartment door condensation prevention

Water pipe heater 2.8W/3565Ω For water pipe freezing prevention

Tank heater 1.0W/9638Ω Avoid the water tank from freezing

V heater ass'y 9.0W/1110Ω For vegetable compartment temperature compensation

Valve turret For switching refrigerant

:Unexchengeable parts or Independently unexchangeable parts.

Page 14

SJXF50XT

14

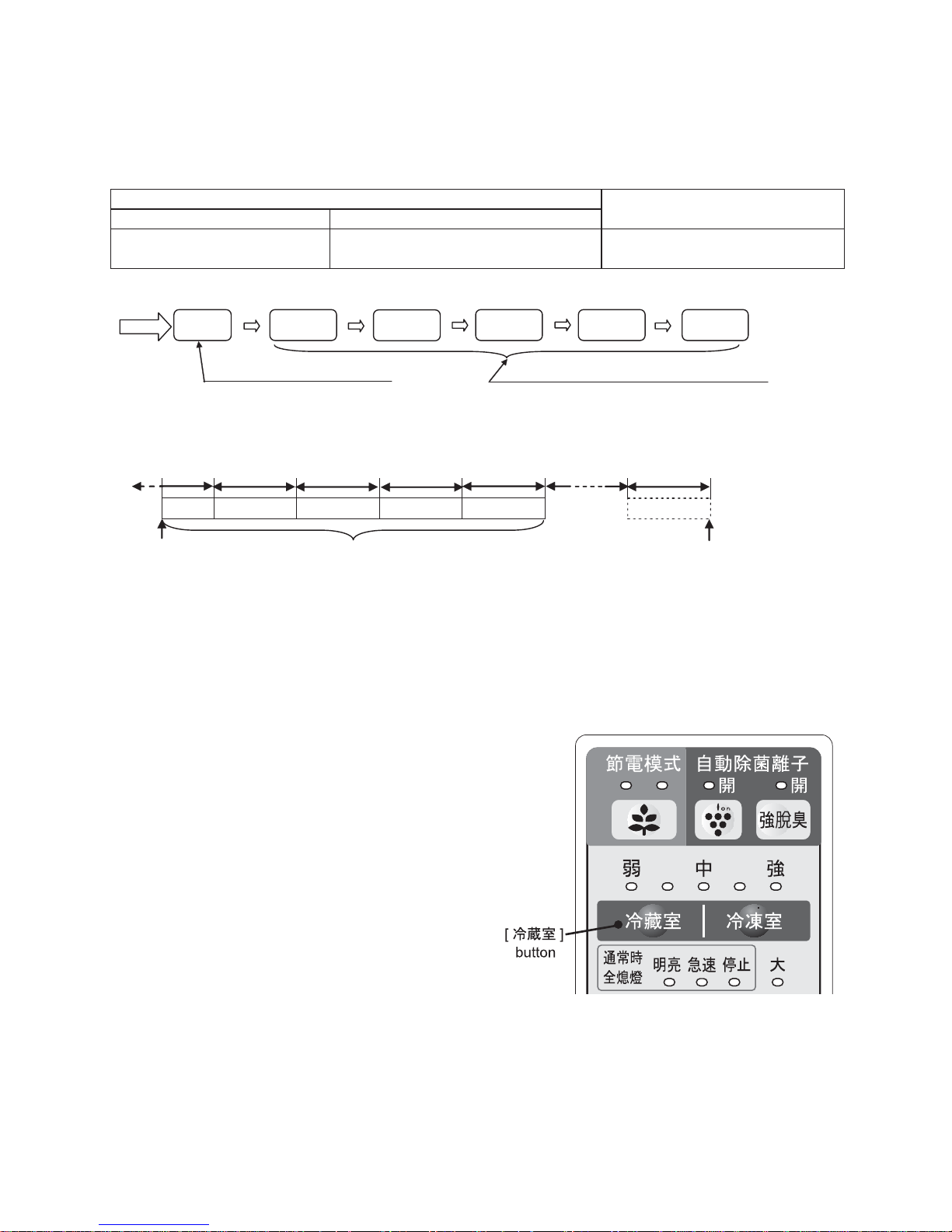

MODE FOR DISPLAY2.

How to set the product in this mode2-1.

Open the doors of the refrigerator compartment and the ice compartment within 2 minutes after turning ON the •

power to the main unit, and press and hold the [

冷凍

] button for 5 seconds or longer.

How to cancel this mode2-2.

With the doors of the refrigerator compartment and the ice compartment opened, press and hold the [•

冷凍

]

button for 5 seconds or longer.

Even if the main power supply is turned OFF, the display mode will be maintained. (not be cancelled)

Operation in the display mode2-3.

Each load (compressor, each fan motor, all heaters, damper, ice release motor, water pump motor) stops.1)

The damper is normally kept opened.2)

Even if the ice compartment or the freezer compartment (lower) door is opened, the door-open buzzer does 3)

not sound.

When the refrigerator compartment door is opened:4)

The refrigerator compartment illumination lamp and indicator LED are lit.•

The cooling/refrigerator compartment PCI fan motor operates.•

The door-open buzzer does not sound.•

Operation panel5)

<Inside of compartment>

The temperature control lamps (five lamps) will blink in sequence one by one.•

If the operation panel button is operated, ordinary operation is executed until the refrigerator compartment door •

is closed.

Note: For indication only. Each mode operation is not executed.

<Outside of compartment>

The operation panel lamps on the door will blink in sequence one by one.•

Page 15

SJXF50XT

15

[6] REFRIGERATION CYCLE SYSTEM SPECIFICATIONS

R600A PRECAUTIONS1.

• Do not use any refrigerant other than R600a.

• Gas leak testers for HFC-134a, CFC-12, HCFC-22, etc., cannot be used.

• A special tool is used for the R600a cycle.

TABLE OF R600A CHARACTERISTICS2.

Refrigerant saturated vapor pressure table R600a

(Unit) Temperature: °C, Pressure: kgf/cm abs

Temperature

Pressure

-20 -15 -10 -5 0 10 15 20 25 30 35 40 45 505

0.74

1.601.340.91 1.11 1.91 2.25 2.64 3.08 3.58 4.13 4.74 5.42 7.006.17

(Unit)Temperature:°C, Pressure: MPa abs

Temperature

Pressure

-20 -15 -10 -5 0 10 15 20 25 30 35 40 45 505

0.073

0.1570.1310.089 0.109 0.187 0.221 0.259 0.302 0.351 0.405 0.465 0.532 0.6860.605

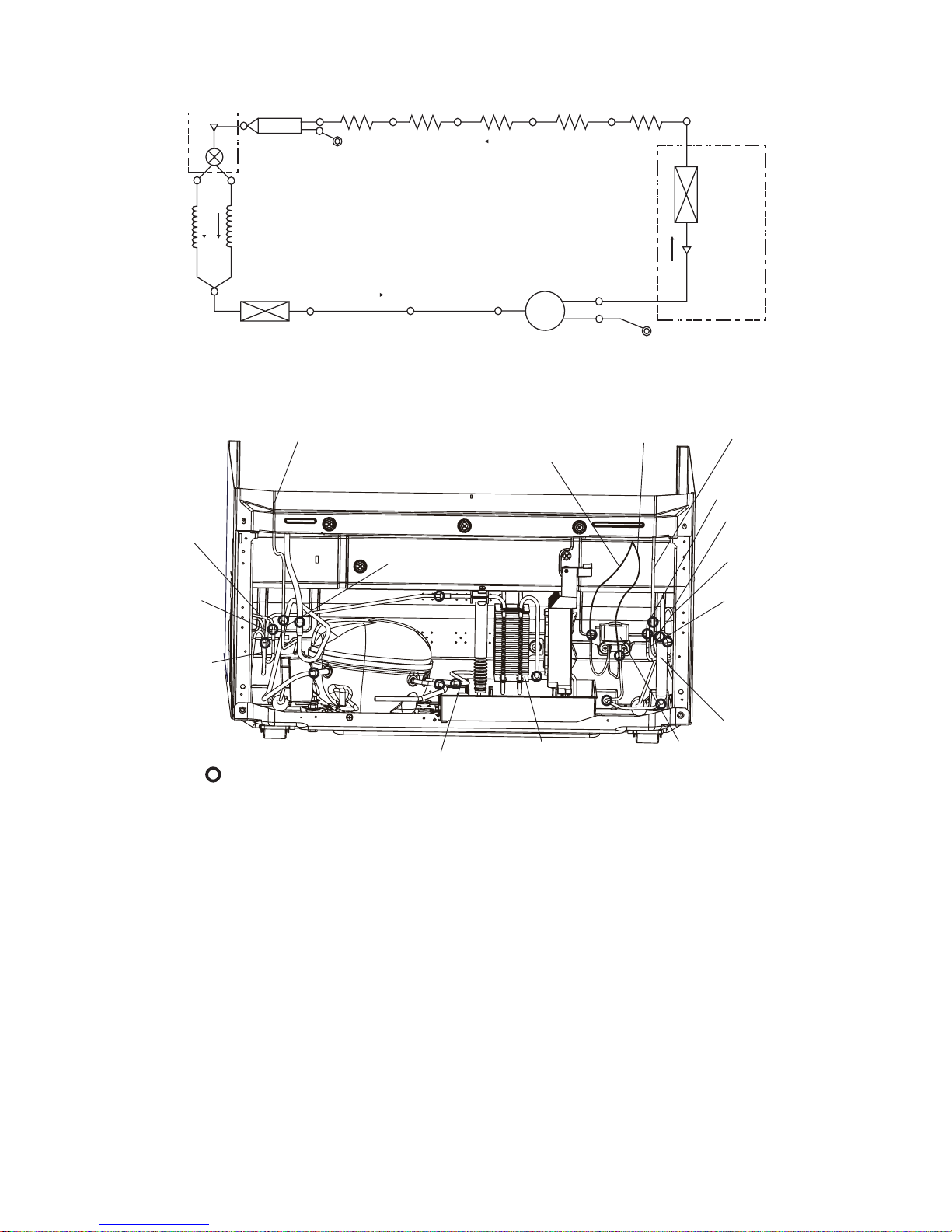

REFRIGERATION CYCLE DIAGRAM3.

Piping Diagram 3-1.

①

②

③

⑤

⑨

⑬

⑭

⑮

⑪

⑧

④

⑯

⑫

⑥

⑩

⑱

⑰

⑦

Charge pipe

←(①~⑱)

Show the order of the refrigerant flow

Back

condenser

Dryer

Capillary

tube A

Evaporator

Capillary

tube B

Suction

connector

Suction

pipe

Charge pipe

Compressor

Discharge pipe

ass’y

Side condenser R

Dew proofing condenser

Bottom condenser

Side condenser L

Extension

barrel

Extra

cond.

unit

ass’y

Page 16

SJXF50XT

16

Schematic diagram3-2.

R-valve ass’y

Charge pipe

(Low presure side)

Side condenser L

Side

condenser R

Dryer

Back condenser

Bottom condenser

Charge pipe

(High presure side)

D.P

condenser

Suction connector

Suction pipe

Compressor

Evaporator

Discharge pipe kit

Extra cond. unit kit

Extra cond.

unit

Capillary tube A

I. D.0.55

Capillary tube B

I. D.0.7

Piping detail drawing3-3.

: Pinch point

Compressor

R-valve ass’y

Side condenser R

Inlet

Dew proofing

condenser Inlet

Side condenser R Outlet

Back condenser ass’y Outlet

Bottom condenser ass’y Outlet

Bottom condenser ass’y Inlet

Capillary tube B

Capillary tube A

Back condenser Inlet

Extra cond.unit

ass’y

Dryer

Dew proofing

condenser Outlet

Side condenser L Outlet

Side condenser L Inlet

Discharge pipe

ass’y

Page 17

SJXF50XT

17

Specifi cations of Refrigerant Valve Operation3-4.

Modes and operating conditions of refrigerant valve (3-way valve)1)

Valve is fully closed:1.

• This mode is used in compressor OFF status.

Only fine capillary is opened:2.

• During normal cooling operation

Only wide capillary is opened:3.

• During cooling operation under large load

Both capillaries are opened4.

• The refrigerator is set in this mode for only one minute after the power supply is turned ON. This mode is used

for vacuuming. During cooling operation, this mode is not used.

• Differentiation between fi ne capillary and wide capillary

- Fine capillary: Capillary tube A

- Wide capillary: Capillary tube B

- The fi ne capillary is identifi ed with a yellow mark.

Fault and status of refrigerant valve2)

• There is no method to give an instruction from the PWB and confi rm the valve position.

Refrigerant valve status Problem

1

Both capillaries are opened, and the valve does not operate.

No problem on cooling operation

No problem

2

Only the fi ne capillary is opened, and the valve does not operate.

Cooling performance deteriorates under large load.

Refrigerant shortage may occur, causing frost around

the evaporator inlet to increase.

3

Only the wide capillary is opened, and the valve does not operate.

No problem on cooling operation

No problem

4

Both capillaries are closed, and the valve does not operate.

Cooling operation is disabled.

Cooling operation is disabled even when the

compressor is ON.

• Fault of the refrigerant valve cannot be displayed in the self-diagnosis mode.

Page 18

SJXF50XT

18

[7] TROUBLESHOOTING

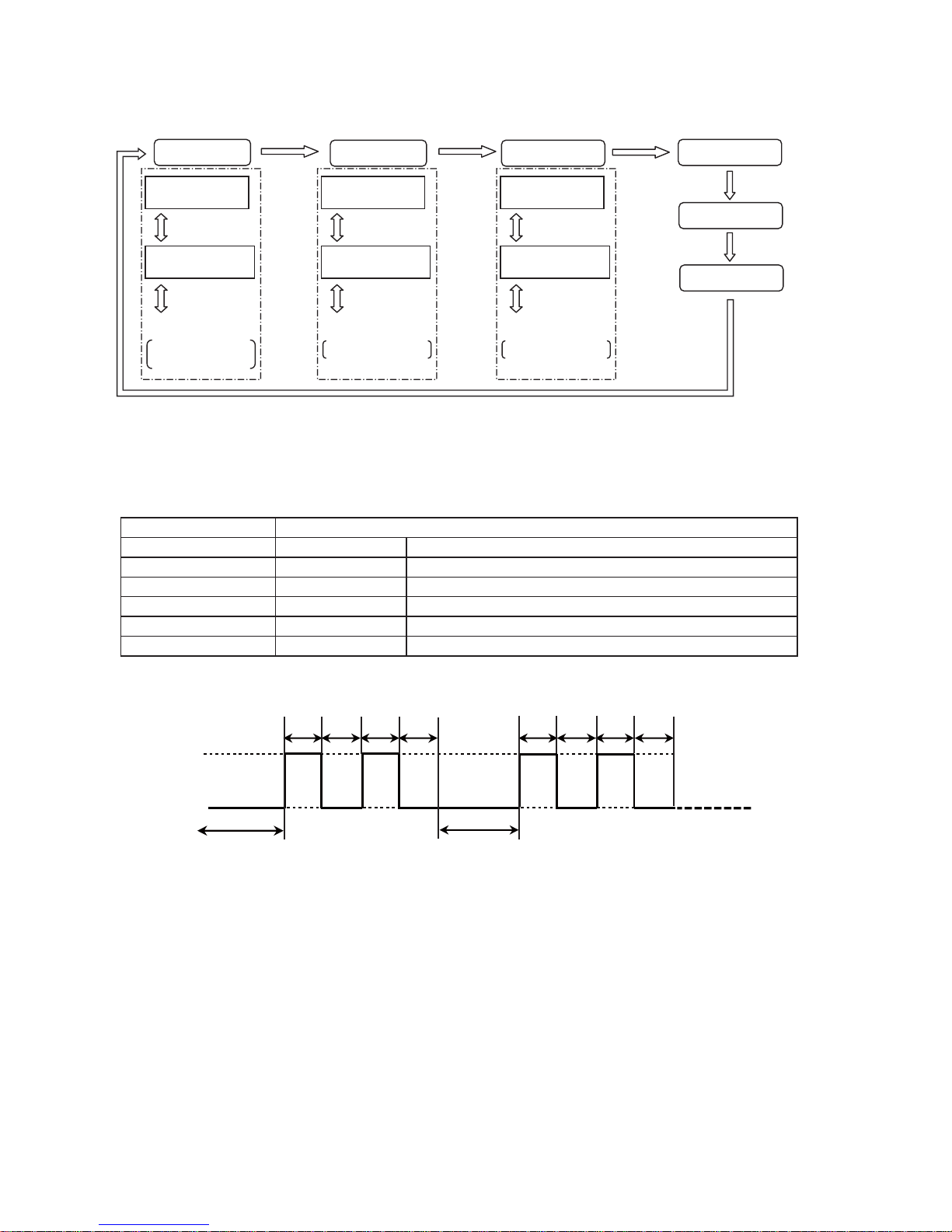

SELF-DIAGNOSIS MODE1.

Outline1-1.

The self-diagnosis mode stores fault data for 5 days in the past (including “today”), and displays them by the date •

in the order of occurrence.

Self-diagnosis data to be displayed

Storage of self-diagnosis result

Current fault Fault history

All faults that have currently occurred

(Displayed in the order of fault number)

Faults that occurred in the past fi ve days

(Displayed by the date in the order of occurrence)

Storage of fault data for the past fi ve days

(Up to 9 items per day)

Self-diagnosis display•

Mode input

“Current”

fault display

“Today” fault

history display

“1-day before”

fault history display

“2-days before”

fault history display

“3-days before”

fault history display

“4-days before”

fault history display

Button

operation

Button

operation

Button

operation

Button

operation

Button

operation

Display priority is given to the upper stages

of self-diagnosis display (Table 1) (All items)

The last fault on that day is displayed first, and the older ones

are displayed in the order of occurrence. (Up to 9 items per day)

(Note 1) Self-diagnosis result data for 5 days (including “today”) are stored. 24 hours from the time when the

refrigerator power supply turned ON is defi ned as “one day”.

24 hours 24 hours 24 hours 24 hours 24 hours 24 hours

Today

Current time

1-day before 2-days before

Stored data

3-days before 4-days before

n-days before

Refrigerator power supply

is turned ON

(Note 2) How to clear stored data

After turning ON the power to the main unit, open the doors of the refrigerator compartment and the ice 1)

compartment within 2 minutes, and press and hold the [

冷凍

] button for 5 seconds or longer.

With the doors of the refrigerator compartment and the ice compartment opened, press and hold the [2)

冷凍

]

button for 5 seconds or longer again.

Self-diagnosis mode1-2.

Mode input method1)

With the refrigerator compartment door opened 1)

(the temperature control lamp unlit), press and hold the

[

冷蔵室

] button for 5 seconds.

(The buzzer sounds, “beep, beep”.)

Open and close the refrigerator compartment door three 2)

times.

(within 10 seconds after keeping the [

冷蔵室

] button

pressed for 5 seconds)

The buzzer sounds “beep”, and the refrigerator enters the 3)

self-diagnosis mode.

* The self-diagnosis mode will be automatically canceled

when the status with no button operation continues for 3 minutes.

* If the refrigerator does not enter the self-diagnosis mode, a fault with the door switch system can be considered.

Page 19

SJXF50XT

19

Operation in the self-diagnosis mode2)

The compressor is forcedly turned ON. (Excepting a period of defrosting operation and compressor ON delay •

time)

The cooling, condenser and R-fan motors are forcedly turned ON.•

(These motors will be forcedly turned ON even while the compressor is OFF. However, when the door is opened,

the motors other than the condenser fan motor are kept OFF.)

The refrigerator compartment/vegetable compartment PCI fan and the PCI are forcedly turned ON. (However, •

when the door is opened, the PCI and fan are kept OFF.)

When the refrigerator compartment door is opened, the R damper is forcedly closed. When the refrigerator •

compartment door is closed, the R damper is forcedly opened. (Opening/closing the refrigerator compartment

door activates the R damper operation.)

During execution of the self-diagnosis mode, and for 20 minutes after cancellation of this mode, self-diagnosis •

data serial output is executed.

During execution of the self-diagnosis mode, and for 20 minutes after cancellation of this mode, the door-open •

buzzer does not sound.

Operation during self-diagnosis mode, and self-diagnosis display3)

Self-diagnosis data is displayed on the temperature control panel. (Refer to self-diagnosis display [Table 1].)1)

Self-diagnosis display can be switched by operating the temperature control panel buttons.2)

Temperature control panel button Operation

[

冷凍室

] Fault data forward scroll

[

冷蔵室

] Fault data reverse scroll

[冷凍] Fault occurrence date forward scroll

To return to the previous

display (Reverse scroll)

To proceed to the next display.

(Forward scroll)

Self-diagnosis (fault) display

To change fault occurrence

date to be displayed.

To indicate occurrence date

of displayed fault.

Page 20

SJXF50XT

20

<Example of button operations and self-diagnosis display>

* During self-diagnosis mode input, the “current” fault is displayed.

・

・

・

・

・

・

・

・

・

[During mode input]

“Current” fault

Display of the fault

at the top of Table 1

Press [冷蔵室].

Press [冷凍室].

Press [冷蔵室].

Press [冷凍室].

Display of the fault at

the second top of Table 1

Display of all faults

that have occurred

Press

[冷凍].

Press

[冷凍].

Press

[冷凍].

“Current” fault history

Press

[冷凍].

Press

[冷凍].

Press

[冷凍].

Display of the

latest fault

Display of the

second latest fault

Press [冷蔵室].

Press [冷凍室].

Press [冷蔵室].

Press [冷凍室].

Press [冷蔵室].

Press [冷凍室].

Press [冷蔵室].

Press [冷凍室].

Display of up to 9 items Display of up to 9 items

“1-day before”

fault history

“2-day before”

fault history

Display of the

last fault

Display of the fault just

before the last

“3-days before”

fault history

“4-days before”

fault history

* During forward/reverse scroll of fault display with [

冷凍室

]/[

冷蔵室

] button, if fault data to be displayed next

does not exist, the buzzer sounds “beep-beep”, and the display will not change.

* To display a fault occurrence date for currently displayed data, press the [

冷凍

] lamp.

Fault occurrence date [

冷凍

] lamp.

Current Unlit OFF

Toda y Li t O N

1-day before Blink once. Repeat "2-sec. OFF"/"0.5 -sec. ON/0.5-sec. OFF".

2-days before Blink twice. Repeat "2-sec. OFF"/"0.5-sec. ON/0.5-sec. OFF" twice.

3-days before Blink three times. Repeat "2-sec. OFF"/"0.5 -sec. ON/0.5-sec. OFF" three times.

4-days before Blink four times. Repeat "2-sec. OFF"/"0.5-sec. ON/0.5-sec. OFF" four times.

Example of lamp indication: “2-days before”

0.5-sec. 0.5-sec. 0.5-sec. 0.5-sec. 0.5-sec. 0.5-sec. 0.5-sec. 0.5-sec.

2-sec. pause 2-sec. pause

Repeat

ON

OFF

Page 21

SJXF50XT

21

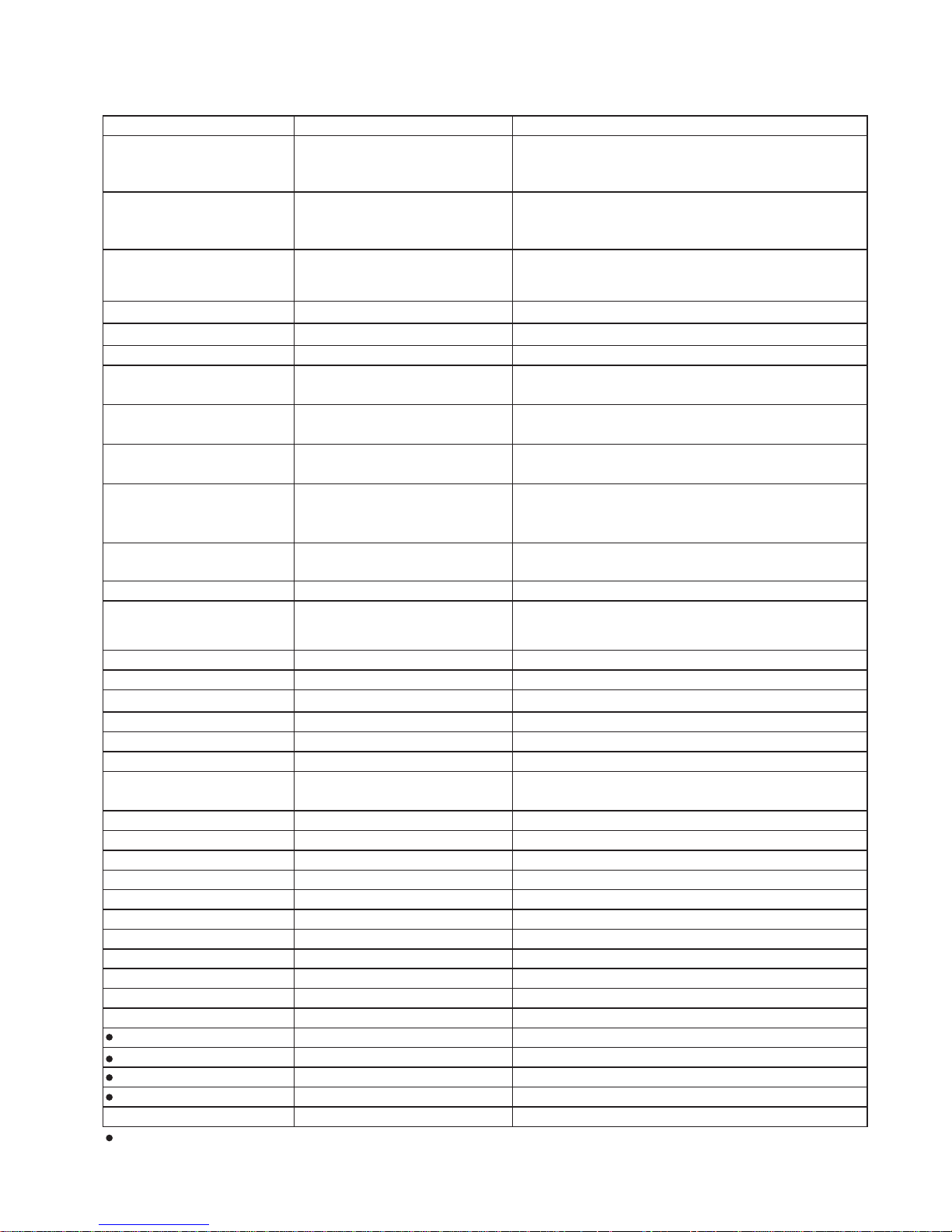

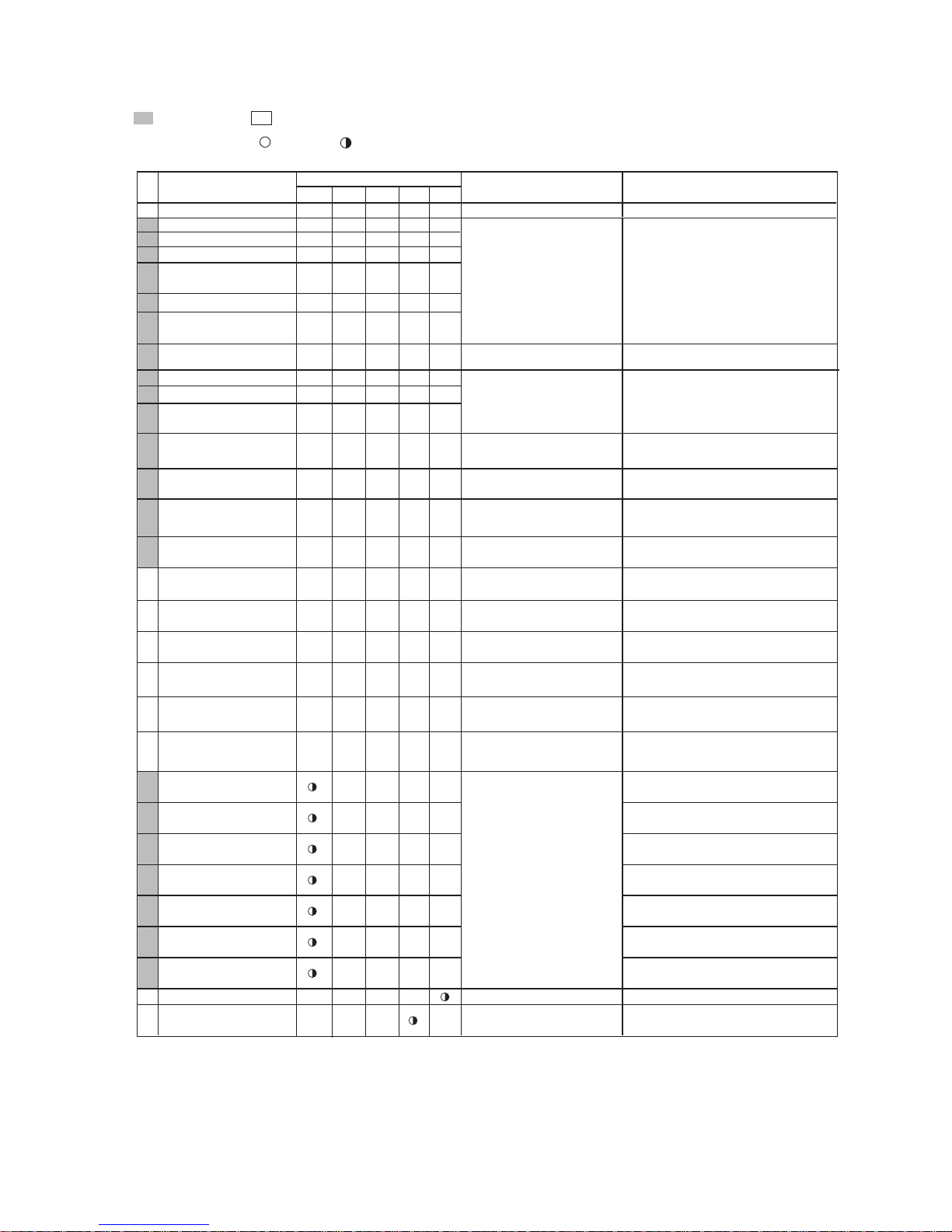

Self-diagnosis display [Table 1] 1-3.

(Problems and problem history related to thermistors, auto ice cube maker, inverter,etc.)

- ○○○○○--

1

○

2

○

3

○○

5

6

○

○○

○

7

○○○

8

○

9

○○

10

○○

12

○○

14

○○○

15

○○○○

16

○

18 ○○

19

○○○

-

20

○○

-

21

○○○

-

22

○○○

-

23

○○○○

-

24

○○

-

25

○

26

○

27

○○

28

○

29

○○

30

○○

31

○○○

32

-

33

-

Status

No.

ExplanationofStatuses

F-thermistor system problem

R-thermistor system problem

V-thermistor system problem

Def-thermistor system problem

External air temperature

thermistor system problem *

There were two defrosted periods (defrosting

heater on time) that lasted for 120 min.

indicates a problem, indicates the status.

Fan motor g system problem

Ice cube maker problems, wiring,

main pwb problems

Without trouble

Thermistor problems, thermistor

wiring short circuit and open

circuit, main pwb problems

Sensorproblems, sensor wiring

short circuit and open circuit,

main pwb problems

A thermistor input value was short circuit

or open circuit.

A thermistor input value was short circuit

or open circuit.

Thermo. fuse or defrosting heater,

open circuit, main pwb problems

Ice cube maker thermistor

system problem

Defrosting problem

Fan motor f system problem

Fan motor problems, fan lock,

wiring, main pwb problems

Description

Ice cube maker

forward operation error

The ice making position detection switch

was produced abnormal signal

at the time

forward operation.

of ice cube maker

Compressor revolution speed

abnormally low

Water tank out of water

The

Water tank

was out of water.

(Detection with thermistor)

Ice storage box full

The Ice storage box was full of ice cubes.

Lamp indication: Lit =

, Blinking = (0.5-sec. ON/0.5-sec. OFF)

Buzzer: Only when a fault is indicated in the current fault display, the buzzer continuously sounds (0.2-sec. ON/1.8-sec. OFF).

Lamp indication (Temperature control LED)

強

弱中

Refrigerator compartment

PCI fan motor fault

Humidity sensor fault

Refrigerator compartment

PCI power supply fault

Power supply clock fault

Ice cube maker

thermistor high temperature

F-thermistor high temperature

R-thermistor high temperature

R-thermistor low temperature

External air temperature

information

Door open information

Inverter wiring error

Inverter overload protection

Inverter startup fault

Inverter overcurrent

Inverter PWB communication

error

Inverter position detection fault

PCI fault, Wiring disconnection

Main PWB fault

Main PWB fault

Compressor fault

Inverter PWB fault

Protector fault, Wiring fault

Main PWB fault

Detection of abnormal current value during

fan motor ON status

Detection of abnormal current value during

plasmacluster ON status

Detection of power supply clock signal

error in main PWB

Thermistor temperature is “-6ºC or higher”

continuously for 6 hours or longer.

F-thermistor temperature is “0ºC or higher”

continuously for 6 hours or longer.

R-thermistor temperature is “+10ºC or higher”

continuously for 6 hours or longer.

R-thermistor temperature is “lower than damper

closing temperature 5ºC” continuously for 2 hours

or longer.

External air temperature is “40ºC or higher”

continuously three times at external air

temperature data update timing.

Door open status has continued for 15 minutes

or longer, or door opening frequency is 200 times

or more/day.

The inverter microprocessor detected

a compressor wiring error.

The inverter microprocessor detected

compressor overload status.

The inverter microprocessor detected abnormal

drop of compressor rotation speed.

The inverter microprocessor detected

a compressor startup fault.

The inverter microprocessor detected overcurrent

in the compressor drive circuit.

Communication error between main

microprocessor and inverter microprocessor

The inverter microprocessor detected

a compressor motor position error.

* The external air temperature thermistor is located on the operation PWB.

Page 22

SJXF50XT

22

FORCED STOPPING OF DOOR ALARM BUZZER2.

* Used when the door switch is faulty.

How to stop

While the door-open buzzer sounds, press the [•

冷蔵室

] and [

冷凍室

] buttons simultaneously and hold them for 3

seconds or longer. (The buzzer sounds three times.)

Forced stopping is cancelled automatically 48 hours later.

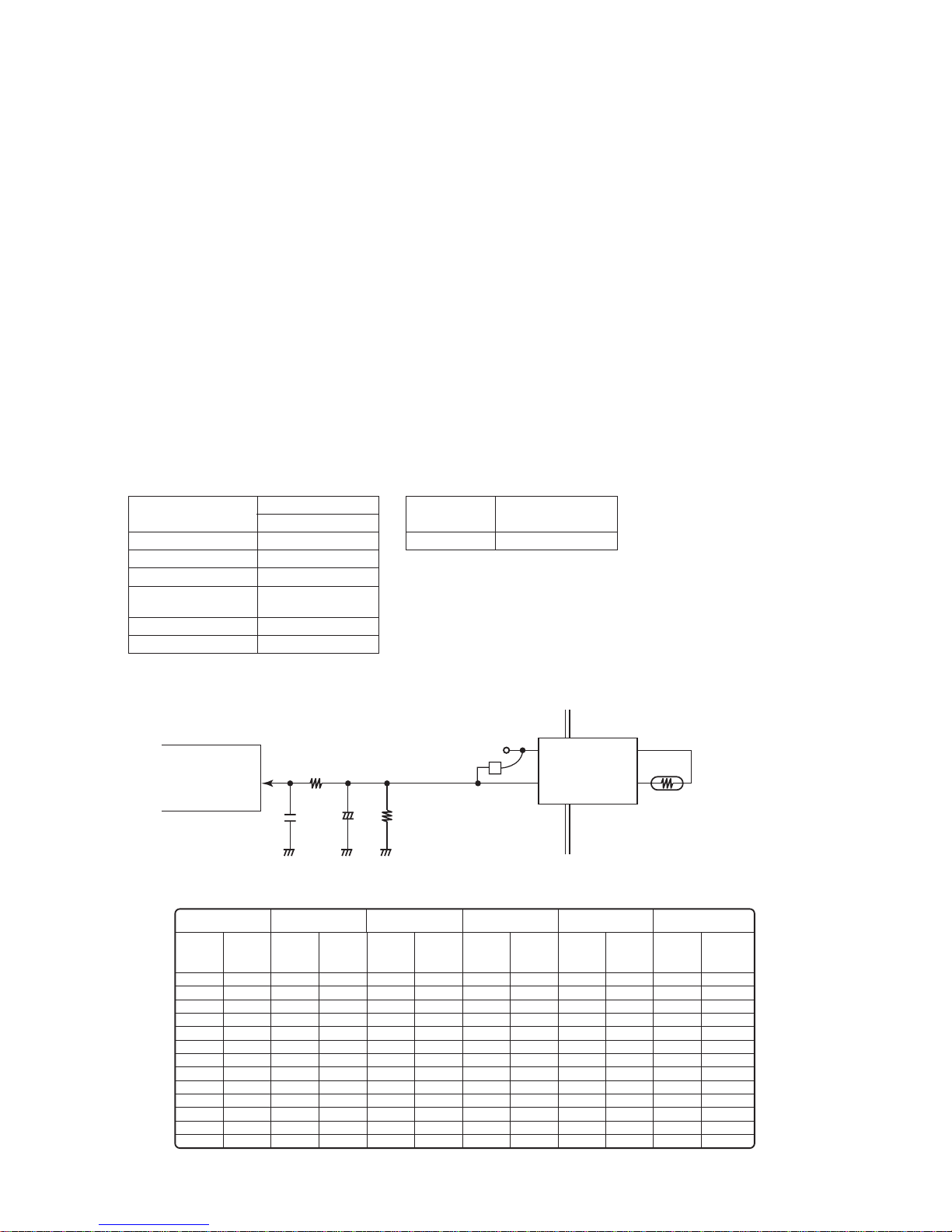

THERMISTOR CIRCUIT CHECK METHOD3.

A thermistor is a semiconductor for which the resistance value changes as the temperature changes.•

This characteristic is used to allow the temperature to be read by a microcomputer.•

(Temperature Resistance value Changed to voltage.)

Check Method1-1.

Disconnect the connectors and measure the thermistor resistances.•

Determination Method1-2.

If the resistance[1] matches, there is a problem with the electronic circuit board.•

If the resistance[1] is different,there is a problem with the harness, connector, or thermistor.•

[ 1 ]

CN8 ⑫

-

⑬

CN8 ⑭

-

⑮

CN16

③-

①

CN10 ④

-

③

CN8 ④

-

⑤

CN10 ②-③

Humidity sensor

Ice cubemaker thermistor

F-thermistor

DEF thermistor

R-thermistor

V-thermistor

External air temperature

thermistor

Resistance Value

*1

(Ω)

pins pins

pins

pins

pins

pins

pins

Voltage Value (V)

*2

CN15 ⑥-⑤

*1. Disconnect connectors and measure the pins on the wiring side(Ω).

Connector

IC1

+

+5V

[1]

Thermistor

Microcomputer

(A/D)

Table of Thermistor Characteristics1-3.

[1]

- 30.0

- 25.0

- 20.0

- 15.0

- 10.0

- 5.0

0.0

5.0

10.0

15.0

20.0

25.0

30.0

35.8

26.1

19.3

14.4

10.9

8.3

6.4

5.0

3.9

3.1

2.5

2.0

1.6

[1]

- 30.0

- 25.0

- 20.0

- 15.0

- 10.0

- 5.0

0.0

5.0

10.0

15.0

20.0

25.0

30.0

35.8

26.1

19.3

14.4

10.9

8.3

6.4

5.0

3.9

3.1

2.5

2.0

1.6

[1]

- 30.0

- 25.0

- 20.0

- 15.0

- 10.0

- 5.0

0.0

5.0

10.0

15.0

20.0

25.0

30.0

83.9

61.2

45.2

33.7

25.5

19.5

15.0

11.7

9.2

7.3

5.8

4.7

3.8

- 30.0

- 25.0

- 20.0

- 15.0

- 10.0

- 5.0

0.0

5.0

10.0

15.0

20.0

25.0

30.0

[1]

F-thermistor

R-thermistor

V-thermistor

DEF thermistor Humidity sensor

Ice cube maker

thermistor

External air

temperature thermistor

Temperature

Resistance

value

Temperature

Resistance

value

Temperature

Resistance

value

Temperature

Resistance

value

Voltage

value

(kΩ)

(°C)

(kΩ)

(°C)

(kΩ)

(°C)

(kΩ)

25.4

19.5

15.1

11.8

9.4

7.5

6.0

4.9

4.0

3.3

2.7

2.2

1.9

[1]

Resistance

value

(kΩ)

(°C) (V)

-

-

-

-

-

-

-

-

0

10

20

30

40

50

60

70

80

90

100

-

-

0.1

0.4

0.7

1.0

1.3

1.5

1.8

2.1

33.1

25.6

20.0

15.8

12.5

10.0

8.1

2.4

2.7

3.0

Temperature

(°C)

- 30.0

- 25.0

- 20.0

- 15.0

- 10.0

- 5.0

0.0

5.0

10.0

15.0

20.0

25.0

30.0

Temperature

(°C)

Page 23

SJXF50XT

23

INSPECTION FLOWCHART AND REPAIR ITEMS4.

During check of the PWB circuits, use thorough caution not to get electric shock.•

To check resistance of electric parts, be sure to disconnect the power supply plug. (Turn OFF the power supply.)•

Problem Self-diagnosis display Check/inspection point Action on error detection

Refrigerator does not

cool at al l

(The compressor

does not wo rk.)

F-ther mistor f ault 1) Con nector i nsert ion che ck (Main P WB, inte rmedia te

connector)

2) Thermi stor res istanc e check (C heck th e value in th e

thermistor characteristic table.)

3) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n.

2) Replace t he ther mistor.

3) Replace t he main PW B.

Invert er wirin g error 1) Inverter PW B – comp ressor w iring c heck (Co nnecto r

inser tion/ wire br eak chec k)

2) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n, or repl ace the wi ring.

2) Replace t he inver ter PWB o r main PWB .

Invert er commu nicati on erro r 1) Inverter P WB – main P WB wiri ng chec k, Protec tor chec k

(Conne ctor ins erti on/w ire brea k check)

2) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n, or repl ace the wi ring/ protect or.

2) Replace t he inver ter PWB o r main PWB .

Invert er overlo ad protec tion 1) Is there any pr oblem ab out the re frige rator hea t radiati on

space?

2) Compre ssor wou nd wire re sistanc e chec k (Refer to pa ge 13)

3) Refrige rant valve o perati on chec k

4) If the above c heck res ults are n ormal:

1) Improve the r efrige rator ins tallat ion con dition .

2) Replace t he comp ressor.

3) Replace t he refr igerant v alve or mai n PWB.

4) Replace t he inver ter PWB or m ain PWB.

Invert er rotati on spee d abnorm al drop

Invert er star tup fault

Inverter overcurrent

Invert er posit ion detec tion fa ult

1) Compres sor wound w ire resi stanc e check (R efer to pag e 13)

2) Refrige rant valve o perati on chec k

3) If the above c heck re sults are n ormal:

1) Replace th e compre ssor.

2) Replace t he refri gerant v alve or main P WB.

3) Replace t he inver ter PWB o r main PWB .

F-ther mistor h igh-t empera ture 1) Connec tor inse rtio n check ( Main PWB , interm ediate

connector)

2) Thermi stor res istanc e check (C heck th e value in th e

thermistor characteristic table.)

3) Compre ssor/f reezin g cycle ch eck

4) If the above c heck res ults are n ormal:

1) Correct t he inst allatio n.

2) Replace t he ther mistor.

3) Replace t he comp ressor /freez ing cycl e.

4) Replace t he inver ter PWB or m ain PWB.

Cooling performance

is in suf fi cient

(The c ompres sor is

working.)

DEF ther mistor f ault

Exter nal air te mperat ure ther mistor f ault

1) Connecto r inser tion c heck (Ma in PWB, i ntermed iate

connector)

2) Thermi stor res istanc e check (C heck th e value in th e

thermistor characteristic table.)

3) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n.

2) Replace t he ther mistor.

3) Replace t he main PW B.

Coolin g fan moto r fault

Conden ser fan mo tor fault

1) Connecto r inser tion c heck (Ma in PWB, i ntermed iate

connector)

2) Fan motor installation/condition/operation check

3) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n.

2) Correc t the inst allati on, or rep lace the f an motor.

3) Replace t he main PW B.

Defros ting faul t 1) Conne ctor inse rtio n check ( Main PW B, inter mediate

connector)

2) Defrost ing heat er resis tance c heck (Che ck the val ue in the

functi onal par t specifi cations.)

3) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n.

2) Replace t he defro sting he ater or tem peratur e fuse.

3) Replace t he main PW B.

Exter nal air te mperat ure infor mation

Door op en infor mation

1) Refriger ator inst allati on/ope rating c onditi on chec k

(Instal lation e nvironm ental te mperat ure, Doo r openin g/clos ing

frequency)

1) Improve the i nstalla tion/o perati ng condi tion.

F-thermistor high temperature

No self- diagnosis faul t

1) F-therm istor co nnecto r inser tion ch eck (Mai n PWB,

intermediate connector)

2) F-ther mistor r esista nce che ck (Chec k the value i n the

thermistor characteristic table.)

3) Coolin g fan motor o perati on chec k (Rotati on spee d is low.)

4) Condens er fan moto r operat ion che ck (Rota tion spe ed is

low.)

5) Compr essor an d freezi ng cycle c heck

6) Door packing inspection and installation/operating conditions

(Instal lation e nvironm ental te mperat ure, door o pening /closi ng

freque ncy, too much s tuffe d food, etc .)

7) If the ab ove check r esults a re norma l:

1) Correct t he inst allatio n.

2) Replace t he ther mistor.

3) Replace t he cool ing fan mot or.

4) Replace t he conde nser fan m otor.

5) Replac e the com presso r/free zing cyc le.

6) Improve th e packin g mounti ng/ins tallat ion/op eratin g

condition.

7) Replac e the inver ter PWB or main PWB .

Freeze r

compar tment is too

much cooled.

F-thermistor fault

1) Connecto r inser tion c heck (Ma in PWB, i ntermed iate

connector)

2) Thermi stor res istanc e check (C heck th e value in th e

thermistor characteristic table.)

3) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n.

2) Replace t he ther mistor.

3) Replace t he main PW B.

Page 24

SJXF50XT

24

Problem Self-diagnosis display Check/inspection point Action on error detection

Refrigerator

compar tment (chilled

case) is not c ooled

well

R-ther mistor f ault 1) Connec tor inse rtion c heck (M ain PWB , interm ediate

connector)

2) Thermi stor res istanc e check (C heck th e value in th e

thermistor characteristic table.)

3) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n.

2) Replace t he ther mistor.

3) Replace t he main PW B.

R-fan mo tor fault 1) Connector ins erti on chec k (Main PW B, inter mediat e

connector)

2) Fan motor installation/condition/operation check

3) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n.

2) Correc t the inst allati on, or rep lace the f an motor.

3) Replace t he main PW B.

R-thermistor high temperature

No self- diagnosis faul t

1) R-dampe r conne ctor inse rtio n check ( Main PW B,

intermediate connector)

2) R-damper installation/condition/operation check

3) R-ther mistor c onnec tor inser tion check (Ma in PWB,

intermediate connector)

4) R-ther mistor re sista nce che ck (Chec k the value i n the

thermistor characteristic table.)

5) R-fan mo tor oper ation ch eck (Rot ation sp eed is low.)

6) Door pac king ins pecti on and installation/operating conditions

(Instal lation e nvironm ental te mperat ure, door o pening /closi ng

freque ncy, too much s tuffe d food, bl ock of co ld air supp ly por t

at the bac k of the chi lled cas e, sucti on por t, etc.)

7) If the ab ove check r esults a re norma l:

1) Correct t he inst allatio n.

2) Correc t the inst allati on, or rep lace the R -damp er.

3) Correc t the inst allati on.

4) Replace t he therm istor.

5) Replac e the R-fa n motor.

6) Improve th e packin g mounti ng/ins tallat ion/op eratin g

condition.

7) Replac e the main P WB.

Refrigerator

compar tment (chilled

case)is to o much

cold.

R-ther mistor f ault 1) Connec tor inse rtion c heck (M ain PWB , interm ediate

connector)

2) Thermi stor res istanc e check (C heck th e value in th e

thermistor characteristic table.)

3) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n.

2) Replace t he ther mistor.

3) Replace t he main PW B.

R-ther mistor l ow tempe rature 1) R-damper c onnec tor inser tion check (Ma in PWB,

intermediate connector)

2) R-damper installation/condition/operation check

3) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n.

2) Correc t the inst allati on, or rep lace the R -damp er.

3) Replace t he main PW B.

Ice mak ing failu re

Ice mak ing spee d is

low

Ice rel ease ope ration e rror 1) Conn ector in sert ion che ck (Main P WB, inte rmedia te

connector)

2) Ice maker ass’y installation/condition/operation check

3) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n.

2) Correc t the inst allati on, or rep lace the i ce maker as s’y.

3) Replace t he main PW B

Ice maker t hermi stor faul t 1) Connecto r inser tion c heck (Ma in PWB, i nterme diate

connector)

2) Thermi stor res istanc e check (C heck th e value in th e

thermistor characteristic table.)

3) If the above c heck re sults are n ormal:

1) Correct t he inst allatio n.

2) Replace t he ther mistor.

3) Replace t he main PW B.

Ice maker t hermi stor hig h tempera ture 1) Con nector i nsert ion che ck (Main P WB, inte rmedi ate

connector)

2) Thermi stor res istanc e check (C heck th e value in th e

thermistor characteristic table.)

3) Door pac king ins pectio n and installation/operating condition

check

4) If the above c heck res ults are n ormal:

1) Correct t he inst allatio n.

2) Replace t he ther mistor.

3) Improve the mounting/installation/operating condition.

4) Replace t he main PW B.

Ice str orage box i s full of ic e cubes 1) Ice sen sor oper ation c heck (Che ck for co ntact w ith the ic e

storage box, etc.)

2) Ice maker a ss y installation/condition/operation check

3) If the above c heck re sults are n ormal:

1) Correct o r replac e the ic e sensor.

2) Correc t the inst allati on, or rep lace the i ce maker as s’y.

3) Replace t he main PW B.

No water in w ater tank 1) Water tank water l evel and ins tallat ion chec k

2) Water pump c onnect or inser tion c heck (Ma in PWB,

intermediate connector)

3) Water pump installation/condition/operation check

4) Water pipe installation/condition check

5) Ice make r therm istor res istanc e chec k (Check th e value in

the ther mistor c harac terist ic table.)

6) If the above c heck re sults are n ormal:

1) Replenish w ater into th e water ta nk. Cor rect the

installation.

2) Correc t the inst allati on.

3) Correc t the inst allati on, or rep lace th e water pump.

4) Correc t the inst allati on.

5) Replac e the ther mistor.

6) Replace t he main PW B.

No self- diagnosis fault 1) Ice maker ass’y and wa ter pump op eratio n check i n ice tray

cleaning operation

2) Water pipe he ater res istanc e check (ap prox. 3.5 k)

3) Water pump/pipe installation/condition/operation check

4) If the above c heck res ults are n ormal:

1) Replace th e ice maker a ss’y or wate r pump.

2) Correc t the co nnecto r install ation, o r replac e the water

pipe heater.

3) Correc t the inst allati on, or rep lace th e water pump /pipe.

4) Replace t he main PW B.

Page 25

SJXF50XT

25

Plasmacluster OK/NG Judgment5.

Judgment procedure1)

Disconnect the power supply, and keep the refrigerator compartment door opened for 5 minutes or longer to raise 1.

the temperature in the refrigerator compartment.

After closing the refrigerator compartment door, connect the power supply, and turn ON the plasmacluster. 2.

(When the plasmacluster is turned ON, the blue LED in the compartment is ON.)

Check the ion at the PCI discharge port with the ion measuring instrument.3.

Refrigerator compartment: Measure PCI while pressing the door switch.

If at least either ion quantity (+ or -) is indicated, the judgment result is acceptable.

This procedure is intended for simplified check of fan motor and plasmacluster operations. Even if the ion •

quantity specified in the catalog cannot be confirmed, it is no problem. *

* Reason why the ion quantity specifi ed in the catalog cannot be confi rmed:

Because the ion quantity specified in the catalog has been measured in stable operating conditions with the •

refrigerator compartment door closed.

If the ion measuring instrument is inserted/removed when the compartment is cooled, condensation occurs with •

the measuring instrument, which disables reliable ion quantity check due to a measuring error.

Measuring position2)

(下)

PCI measuring position

During PCI operation

Refrigerator

compartment

Ice

compartment

Freezer

compartment

(Upper)

Freezer

compartment

(Lower)

Vegetable

compartment

Page 26

SJXF50XT

26

[8] DISASSEMBLY/ASSEMBLY

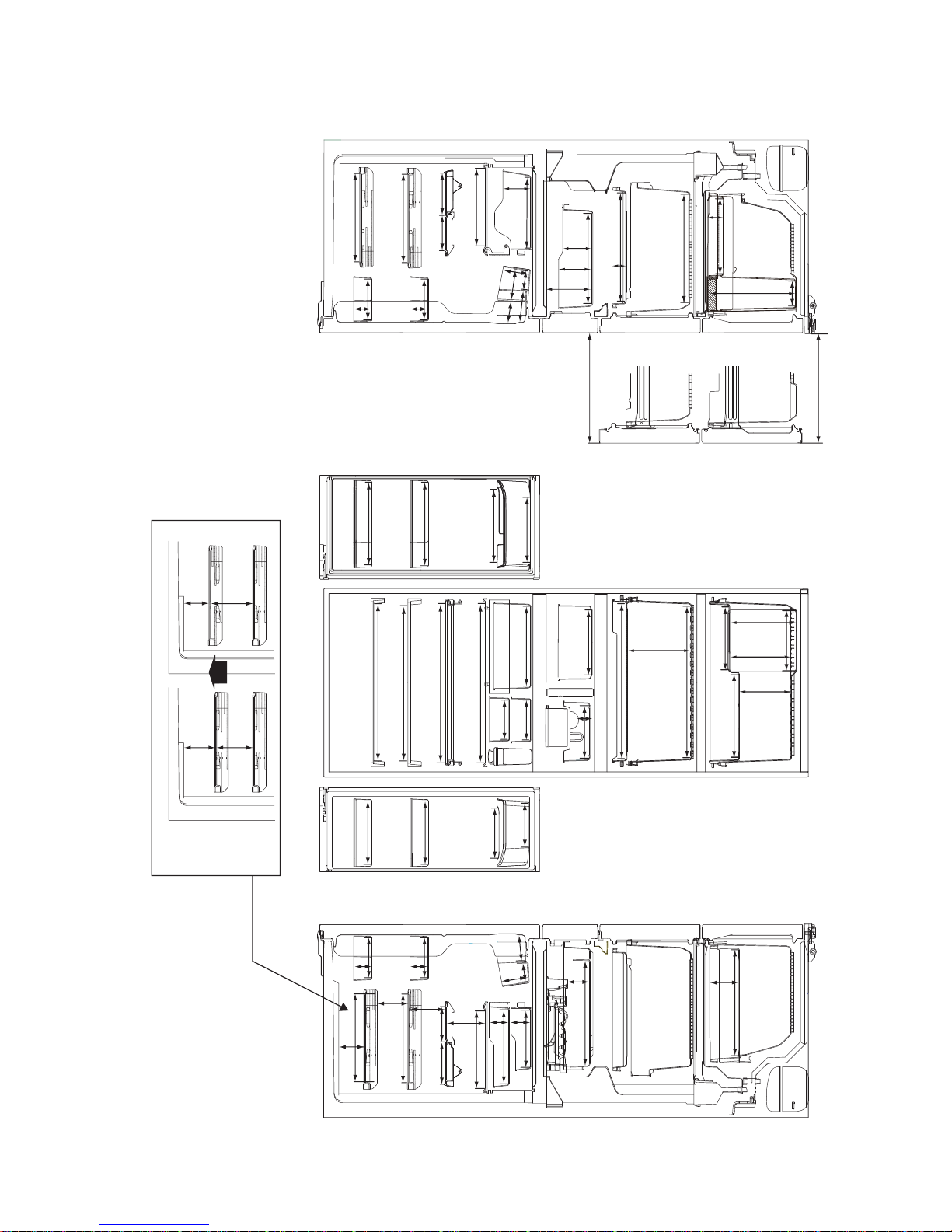

GENERAL DISASSEMBLY SEQUENCE1.

1-2

1-3

1-5

1-6

1-7

2-1-2

2-2

2-3

2-4

2-5

2-3-2

1-4

1-1

1-2

1-3

1-4

1-5

1-6

1-7

(1)

Refrigerator compartment

Accessories (Shelves・Chilled case・Water tank)

Partition support・C-shelf ass’y

Duct RT ass’y

R-shower duct ass’y

PCI box ass’y

R-C box ass’y・

Connector cover R

Pipe cover

2-1-2

2-1

2-2

2-3

2-4

2-5

2-3-2

(2)

Freezer compartment

Accessories

(Ice storage box・

Freezer cases)

SW cover

Ice maker ass’y T-SK

C-part. FI-B

C-part. FI-FK

(When replacing Proximity switch)

E.V cover ass’y

Heater・DEF thermistor holder

(When replacing F proximity switch)

Page 27

SJXF50XT

27

REFRIGERATOR COMPARTMENT DISASSEMBLY2.

Main component Contained parts

RC box ass'y Gear pump, R-thermistor, damper

Pipe cover -

R-shower duct ass'y Catalyzer

D-PCI box ass'y Plasmacluster unit, indicator PWB, D-fan motor PCI, Motor, O catalyzer

Remove the accessories (shelf, chilled case, etc.).1.

Remove the chilled shelf stopper.2.

Raise the back of the shelf slightly from the bottom,

and pull it to the front.

Chilled shelf stopper

C case cover

How to remove C case cover1)

C-shelf ass’y (back side)

C case cover

(C-shelf ass'y with the C case cover attached)

Unhook three claws at the back and pull out the

protrusions in front.

Claws at the back

: Protrusion

C case cover

Installation is the reverse procedure to removal.•

How to remove chilled lock2)

Unhook two claws (if they are tight and stuck, insert

a thin flathead screwdriver (or a steel scale) to

unlatch them) and open the cover.

Remove one screw.

Claws

Chilled lock

Screw

Remove partition support l and partition stay.3.

Pull it while holding it up slightly.

Partition support l

Partition stay

Remove duct RT rivet, and remove duct RT cover.4.

Pull it downward to raise it. (If it is stuck, insert a

fl athead screwdriver to raise it.)

Duct RT cover

Duct RT rivet

Page 28

SJXF50XT

28

Remove the four locations of the inner protrusion.

When the protrusions are unhooked, pull it downward

to remove it.

: Protrusion

Remove R shower duct ass'y.5.

While holding the top by hand, pull the duct to the

front. (Claws are located at 8 places.)

: claw

R shower duct ass’y

Remove the D-PCI box ass'y.6.

Remove three screws.

P

ull the box downward to release the claws at the

front (at 2 places).

(The claws are directly applied to the food liner.

Use caution not to damage the food liner.)

After the claws are released, pull the box

downward, and release the remaining claws.

Disconnect two connectors.

□ : claw

○

: screw

D-PCI box ass’y

Remove the connector cover R (Screw at 1 place, 7.

Claws at 2 places), and disconnect four connectors.

Connector cover R

□ : claw

○

: screw

Remove the RC box ass'y.8.

Remove two screws, and pull the box to the front

while holding the top by hand.

Disconnect the joint pipe connected to the pipe

cover.

RC box ass’y

Joint pipe

Screw

Screw

CAUTION: Precaution for mounting the RC box ass'y

Make sure that the joint pipe is connected. Check for

twisting and lead wire entanglement.

Remove the damper.9.

Remove R-C box insu A/B from R-C box.1)

R-C box

R-C box insu A

R-C box insu B

Damper

Page 29

SJXF50XT

29

Cut A-Sealer R-C box insu A along the joint of R-C 2)

box insu A/B (dotted line).

R-C box insu A

R-C box insu B

Damper

A-sealer

Remove 3) the damper.

Pull out the pipe cover.10.

□ : claw

Pipe cover

FREEZER COMPARTMENT /ICE COMPARTMENT DISASSEMBLY3.

Main component Contained parts

Ice maker ass'y T-SK Ice maker thermistor, Ice maker ass'y, Ice cube heater, I-grill, Ice sensor, Ice cube maker

C-part. FI-FK Proximity switch

EV cover ass'y F-thermistor, DEF thermistor, Fan motor F, Duct heater

Heater DEF thermistor holder ass'y

(In vicinity of evaporator)

Thermo. fuse ass'y, DEF2 thermistor

Remove the accessories (cases and shelves of 1.

freezer compartment and vegetable compartment).

Remove the SW cover. •

(When replacement of F-LED PWB ass’y)

SW cover

Remove the Ice maker ass'y T-SK.2.

Remove the screw and pull it toward you while 1)

pressing the claw on the front.

Remove connector.2)

Flathead screwdriver etc.

Ice meker ass'y T-S

K

Screw

CAUTION: Precautions for handling the ice maker ass'y T-SK

Securely insert the 4 claws. If the claws are not •

inserted completely and they come loose,the ice

maker ass'y T-SK could fall down during ice cube

release or it could sag down and make contact with

the ice storage box.

When connecting the connectors, make sure there •

are no connector insertion problems.

Remove the C-part. FI-B.3.

Remove the screw, and pushing the C-part. from

the left side to release the claw at the front.

Screw

C-part. FI-B

Claw

Page 30

SJXF50XT

30

Remove the C-part. FI-FK. •

(When replacement of F-LED PWB ass’y)

Remove three screws and one claw, and push the

PWB backward.

: screw

C-part. FI-FK

Open the connector cover at the left back 4.

(3 claws, one screw), and disconnect one connector.

Pull out the fl atter one between the two connectors.

□ : claw

Remove the EV cover ass'y.5.

Remove four screws.1)

Remove four claws at the top, and tilt the cover 2)

to the front.

○

: screw

EV cover ass’y

Top of the EV cover

□

: claw

EV cover ass’y

Remove the Heater. (Replacement procedure)6.

CAUTION: The heater is a charged and heating part.

Use caution about the following points:

Place the electric wiring and sleeve of the Heater •

at the specified positions. Make sure that they

will not touch the metal edges of the cooling unit,

heater cover, etc.

Be sure not to damage the piping of the cooling •

unit.

When connecting the connector, check for a •

connector insertion fault.

After replacement of the heater, check continuity •

and insulation.

When handling the heater, hold the rubber cap. Do

not touch the glass pipe with a bare hand. If you

touch the glass pipe, wipe grease off completely.

Pull the top of the evaporator to the front, and 1)

raise it slightly.

Pull out the evaporator obliquely.2)

Twist the straight pipe at the top of the accumulator •

so that the evaporator will not be deformed.

CAUTION

When pulling out the evaporator and bending •

the pipe, use caution so that the pipe will not be

broken or remarkably deformed.

Be careful not to get injury with the fins.•

Evaporator

Page 31

SJXF50XT

31

Remove the aluminum tape that fastens the lead 3)

wire to the drip tray.

Screw

Heater AL

Aluminum tape

Screw

Remove two screws, and remove the heater AL.4)

Open the heater fastening part of the heater AL to 5)

the right and left, and replace the heater.

Fastening part

Heater

Insert the lead wire in the groove of the drip tray, 6)

and apply the aluminum tape to fasten the lead

wire.

Lead wire

Aluminum tape

Groove of drip tray

Re-mount the evaporator in the original condition.7)

CAUTION

Put the bottom of the evaporator on the rib of the •

drip tray, and place the projection of the food liner

at the position shown in the figure.

Set the accumulator piping angle as shown in the •

figure.

Make sure that the pipe is not remarkably •

deformed.

Accumulator

Fastening part

VEGETABLE COMPARTMENT 4.

DISASSEMBLY

Main component Contained parts

-

Damper, G-thermistor

(V-thermistor)

Remove the V door.1.

Remove the Damper cover. 2.

Remove one screw.

Pull the Damper cover while inserting a flathead

screw driver, etc., to have some gap.

Flathead screwdriver etc,

Screw

Damper cover

: claw

Remove the Damper.3.

Close the flap if the flap is closed.

Disconnect one connector and pullout the Damper.

Remove the G-thermistor.4.

G-thermistor

Pull out the

connector

Damper

Close the flap

Page 32

SJXF50XT

32

How to install Damper cover

Drive in the Damper cover after fi tting claws at two places while running through the slit under left.•

Attach one screw.•

Damper cover

: claw

HOW TO REMOVE OP. PWB ASS'Y5.

Remove the PWB cover.1.

Insert a thin flathead screwdriver (or a steel scale) into the slot at the lower side of the PWB cover to unhook

the claws.

: claw

PWB cover

Remove the panel cover.2.

Insert a thin flathead screwdriver (or a steel scale) into the slot at the upper side of the panel cover to unhook

the claws.

: slot

Panel cover

Page 33

SJXF50XT

33

HOW TO REMOVE TERMINAL BOX6.

Remove screws (2 places).•

Terminal box

○

: screw

HOW TO INSTALL R-SUB PACKING7.

Fasten the R-sub packing with the claws of the R-door ass’y (front: 8 places, back: 6 places). •

First, claw either top or bottom of the packing to fasten it, and then claw the remaining points in sequence.

(The fi gure below shows R-door L-ass'y.)

R-sub. packing

: claw

R-door packing

Claw

Page 34

SJXF50XT

34

HOW TO INSTALL DUCT RT ASS'Y COVER8.

Insert two claws (located in the center) of the Duct RT ass'y cover into the holders at the ceiling inside the 1.

refrigerator compartment.

2. After inserting two claws at the right and left side into the holders, tuck the Duct RT rivets into the holders.

①

①

②

②

(outside)

(Inside)

(outside)

* (Inside) will have a gap.

(Inside)

Duct RT rivet

Duct RT ass'y

With a Duct RT rivet inserted,

the claw of the Duct RT ass'y cover is spread apart

and held in place in the holder at the ceiling.

Duct RT rivet

<< Structural view of Duct RT rivet section >>

Duct RT rivet

After inserting the Duct RT rivets, confirm that

the head of the Duct RT rivet and the edge (outside)

of the depression of the cover are at the same height.

【How to remove Duct RT rivet】

There is a space at the back of a Duct RTrivet.

Insert a flathead screwdriver into the space

and pull out the rivet.

Page 35

SJXF50XT

35

ADJUSTMENT OF R-DOOR(DOUBLE DOOR)9.

If the right and left door positions are different:1.

Adjustment with the adjustable legs:

When the right door is lower than the left one, extend the adjusting legs on the right side•

(until the adjusting legs on the opposite side slightly leave the fl oor surface).

When the left door is lower than the right one, extend adjusting legs on the left side.•

If the door does not smoothly open/close2.

If the refrigerator is tilted backward, lay a wide pad on the back of the refrigerator.

Front

Back

Pad (wide)

If the door on the other side is also opened when the door on one side is opened:3.

Measure the clearance between the right and left doors of the refrigerator compartment, as the reference for 1)

adjustment.

Loosen the refrigerator compartment door lower hinge bolt, and slide the refrigerator compartment right door all 2)

the way to the outside.

With the door closed, slide the refrigerator compartment right door all the way to the inside until the closing failure 3)

can be corrected.

Tighten the lower hinge bolt by half to check opening/closing conditions. If there is no problem, tighten the bolt 4)

thoroughly. This completes the adjustment procedure.

If the refrigerator compartment door opening/closing problem persists even after the adjustment of Step 4), adjust 5)

the upper hinge of the refrigerator compartment right/left door. To widen the clearance between the doors, adjust

the upper hinge of the door that is relatively lower. (Use caution so that this adjustment does not cause a closing

failure.)

Check the opening/closing condition to ensure that there is no problem.6)

Refrigerator compartment

left door upper hinge: Adjustable

Refrigerator compartment

right door upper hinge: Adjustable

Refrigerator compartment

left door lower hinge: Not adjustable

Refrigerator compartment

right door lower hinge: Adjustable

<CAUTION>

Do not apply silicone oil to the center packing of the refrigerator compartment right and left doors. Oil fi lm is

generated between the center packing of the right and left doors, causing an opening/closing failure. (When one of

the refrigerator compartment doors is opened, the other door will also open.)

Page 36

SJXF50XT

36

MAIN PARTS ASSEMBLY10.

EV cover ass’y1)

<Components>

Fan louver

EV-insulation B

EV-insulation A

EV.cover sealer N

F-thermistor

EV.cover

Duct heater

A-sealer EV. cover C

A-sealer EV. cover D

A-sealer EV. cover

A-sealer EV. cover E

A-sealer EV. cover B

A-sealer F

Fan motor F

L-band C

EV.cover AL

DEF-thermistor

<Assembling procedure>

Attach the sealer to the fan motor F.1.

Attach the A-sealer F to the fan motor F.•

10~40

Fan motor F

A-sealer F

A-sealer F

Fan motor F

Fan motor F

Start of sealing

No clearance or no overlapping

at the start and end of sealing.

Do not pinch the lead wire

with the seal material.

Sealing specifications

Page 37

SJXF50XT

37

Attach the A-sealer EV. cover B to the harness of duct heater.2.

Duct heater

EV-insulation B

A-sealer EV. cover B

Attachment side

of heater

EV-insulation B

Duct heater

Put it on so that there is no space

between the sealer and the insulation.

A

A

Cross-sectional view A-A

Wrapping the

A-sealer EV. cover B

Attachment of the EV-insulation A and B. 3.

• Fasten these parts with paper tape.

EV-insulation A

EV-insulation B

EV-insulation A

Left side Back sideRight sideFront side

Paper tape

EV-insulation B

Paper tape

EV-insulation A

Paper tape

Apply A-sealer EV. cover B

so that there is

no clearance between

EV-insulation A and B.

Seal the paper tape so that there is no space between EV-insulation A and B.

Page 38

SJXF50XT

38

Mounting the F-thermistor, fan motor F, and EV. insulation ass’y4.

• Fit the EV. insulation ass’y in the EV. cover.

• Wind the EV. cover sealer N on the harness.

• Mount the F-thermistor and fan motor F to the EV. cover.

F-thermistor

EV.cover sealer N

EV.cover

Fan motor F

Noting the mounting direction of

the fan motor F.

(Label is located on this side.)

Wind the sealer

on the harness.

Page 39

SJXF50XT

39

Mounting the fan louver5.

• Mount the DEF-thermistor, and fasten the harness of the fan motor F and the DEF-thermistor with the L-band C.

• Wind the EV. cover sealer N on the lead wire of the DEF-thermistor and the fan motor F.

• Apply the EV. cover AL.

• Mount the fan louvers to the front, and fasten them with two screws.

• Attach the A-sealer EV. covers C, D and E as shown in the fi gure.

• Insert the pins into the connectors.

A-sealer EV. cover D

A-sealer EV. cover C

EV.cover sealer N

Putting around

the harness

A-sealer EV. cover C

A-sealer EV. cover

Fan louver

EV.cover

A-sealer EV. cover

A-sealer EV. cover E

Fan motor F-K

EV.cover

DEF-thermistor

A-sealer EV. cover E

EV. cover AL

EV.cover

F-thermistor

EV-insulation B

Fan louver

EV.cover

A-sealer EV. cover E

A-sealer EV. cover

Fan louver

Paste A-sealer EV. cover across

insulation and molded component.

EV.cover

Fan motor F-K

Fan louver

Screw unnecessary

Screw unnecessary

L-band C

Connector pin insertion specifications

Blue

Blue

White

White

Insert the lead wire

to the connector.

Nos. 1, 2 and 3 connector pins

are already inserted.

Fan motor F connector

DEF-thermistor lead wire

F-thermistor lead wire

Insert the lead wire

to the connector.

Page 40

SJXF50XT

40

R-shower duct ass’y2)

<Components>

A-sealer R-S duct C

Catalyzer

A-sealer R-S duct B

R-shower duct cover T

R-shower duct cover B

R shower duct insu

Cool plate

Center cover L

Center cover R

<Assembling procedure>

Attach the A-sealer R-S duct B and C to the R-shower duct insu.1.

A-sealer R-S duct C

R shower duct insu. sealing specifications

Hook the claw.

Hook the claw.

Lap over

Lap over

Hook the claw.

Hook the claw.

Hook the claw.

R shower duct insu

A-sealer R-S duct B

A-sealer R-S duct B

R-shower duct cover T

R-shower duct cover B

Catalyzer

Insert the catalyzer with the claws spread out.

Page 41

SJXF50XT

41

Attach the R-shower duct cover T and B to the cool plate. (Apply the claw securely.)2.

Fit the Assembly of Step 1 to Assembly of Step 2.3.

A-sealer R-S duct C

Hook the claw.

Hook the claw.

Lap over

Lap over

Hook the claw.

Hook the claw.

Hook the claw.

R shower duct insu

A-sealer R-S duct B (Y)

A-sealer R-S duct B (Y)

R-shower duct cover

T

R-shower duct cover B

Catalyzer

Insert the catalyzer

with the claws spread out.

R-shower duct cover B

Cool plate

Center cover L

Center cover R

Mount center cover. (Apply the claw securely.)4.

Slide the top of Center cover

while warping the Center cover.

Drive in the claw and hook it

on the R-Shower duct insu.

Center cover L

How to install the center cover L/R

Cool plate

R-shower duct cover T

R-shower duct cover B

Insert to the

R-shower duct cover B

Insert the catalyzer.5.

Page 42

SJXF50XT

42

RC box ass’y3)

<Components>

Joint packing

Gear pump

R-C box

Pump cushion

R-thermistor

R-C box insu.B

A-sealer RCBOX A

A-sealer RCBOX B

R-C box insu.A

Damper

Packing holder

Joint pipe

<Assembling procedure>

Insert the joint packing in the gear pump.1.

Insert the packing securely to the innermost position.•

Joint packing

・

・

Gear pump

Mount the assembly of Step 1 to the R-C box.2.

・

Packing holder

Screw

Groove of R-C b

o

Hinge

・

・

Engage the hook.

Page 43

SJXF50XT

43