Page 1

SERVICE MANUAL

S6009SE60APSR

REFRIGERATOR-FREEZER

MODELS

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

SJ-58LSJ-63LSJ-68L-

In the interests of user-safety (Required by safety regulations in some

countries) the set should be restored to its original condition and only

parts identical to those specified should be used.

Refrigerant; HFC-134a

Refer to "HFC-134a COOLING UNIT" Service Manual for handling this refrigerant.

A2G/A2B/A2L/A2A

A2G/A2B/A2L/A2A

A2G/A2B/A2L/A2A

DESTINATION ......................... R,Y

TABLE OF CONTENTS

page

CAUTIONS AND INFORMATIONS.................................................................................................................. 2

SPECIFICATIONS ........................................................................................................................................... 3

DESIGNATION OF VARIOUS PARTS............................................................................................................. 4

LIST OF ELECTRICAL PARTS........................................................................................................................ 5

WIRING DIAGRAM .......................................................................................................................................... 6

FUNCTIONS .................................................................................................................................................... 9

ASSEMBLING PROCEDURES OF MAIN PARTS AND CAUTIONS ............................................................. 12

MODIFICATION PROCEDURE OF THE DOOR OPEN SIDE .......................................................................20

COOLING UNIT ............................................................................................................................................. 23

REPLACEMENT PARTS LIST....................................................................................................................... 25

SHARP CORPORATION

1

Page 2

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

CAUTIONS AND INFORMATIONS

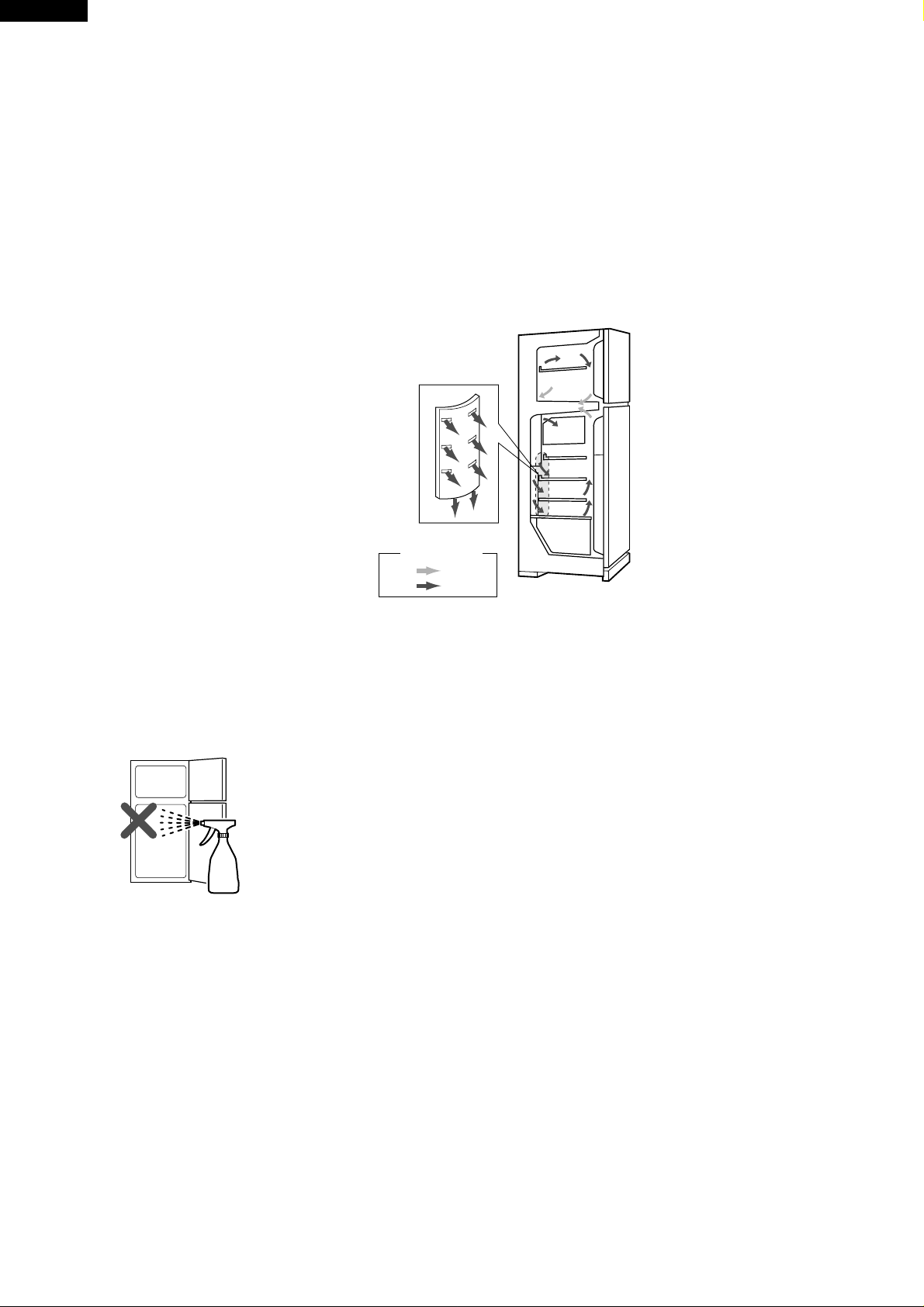

In case of following troubles, the cause is not related with the failure of refrigerator.

Please mention the correct way to the customer for the use of refrigerator when the repairing.

1. Some foods freezed in the refrigerator compartment.

Do not place food directly in front of

cold air outlet.

This may lead to the food freezing.

cold air flow

IN

OUT

2. Some plastic parts were cracked or splitted.

Some household cleaning chemicals may affect the internal

food liner and plastic parts resulting in splitting or cracks

occurring.

When cleaning all plastic parts inside this refrigerator, only

use diluted dishwashing liquid(soapy water). Make sure that

all plastic parts are thoroughly rinsed with water after cleaning.

3. IT IS NORMAL for the refrigerator to produce the following sounds.

Cracking or crunching sound;

Sound produced by expansion and contraction of inner walls and internal parts during cooling.

Squeaking sound;

Sound produced by expansion and contraction of internal parts.

Sound of flowing fluid (gurgling sound, fizzing sound);

Sound of refrigerant flowing in pipes (sound may become louder from time to time).

2

Page 3

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

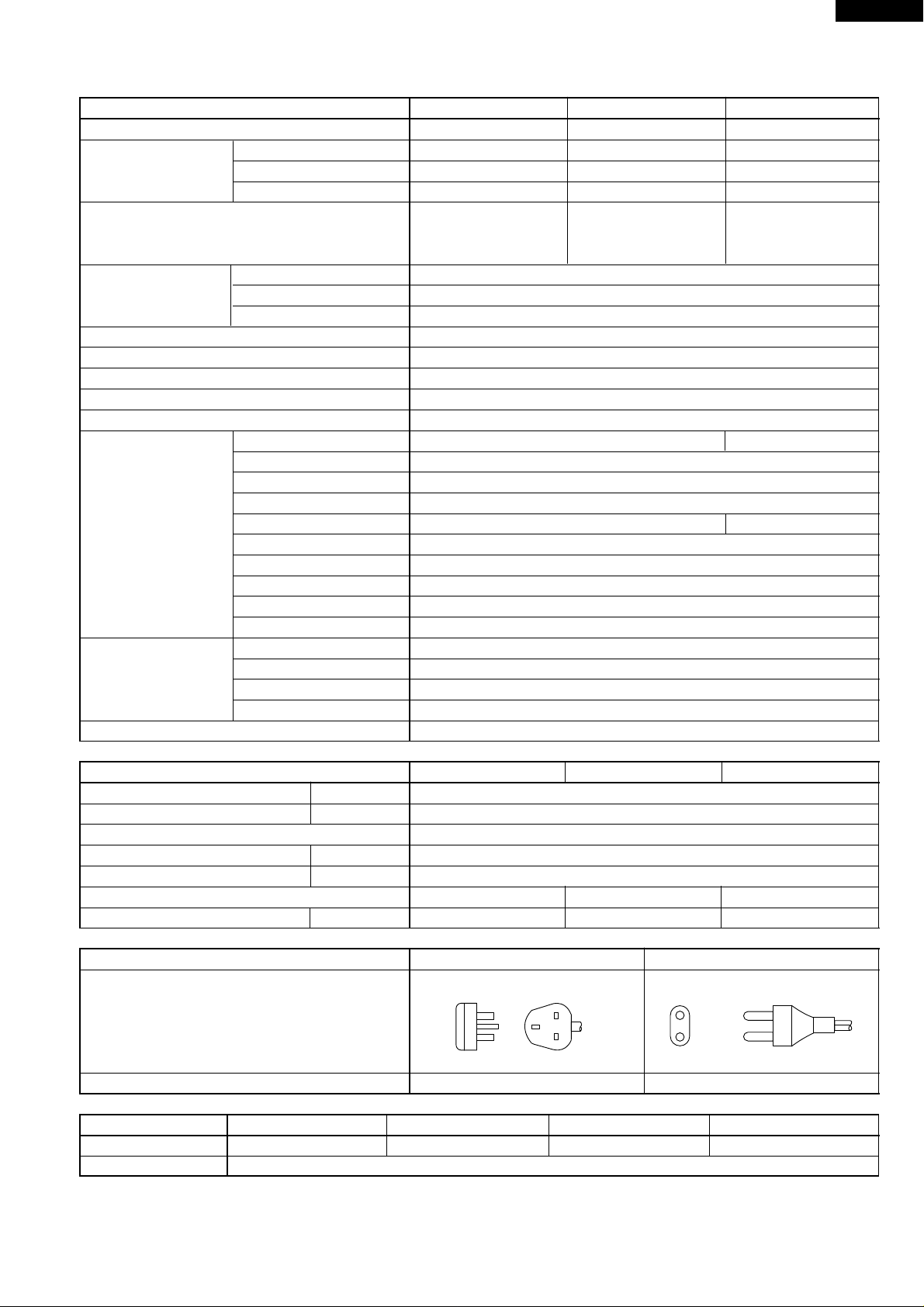

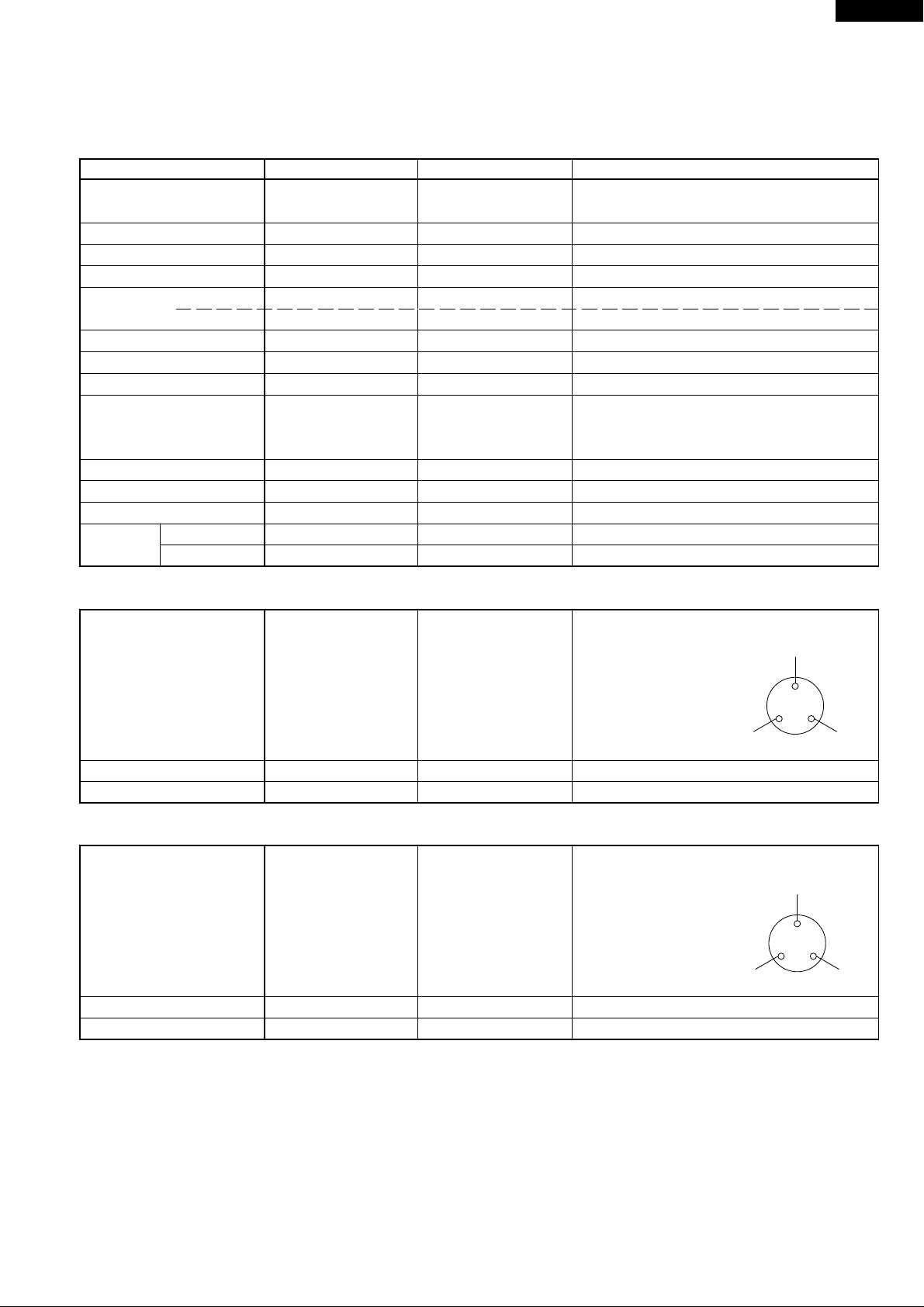

SPECIFICATIONS

Items SJ-58L-A2 SJ-63L-A2 SJ-68L-A2

Type 2-Door 2-Door 2-Door

Outer dimensions Height 1620mm(63.8") 1720mm(67.7") 1820mm(71.7")

(Including spacer) Width 760mm(29.9") 760mm(29.9") 760mm(29.9")

Depth 740mm(29.1") 740mm(29.1") 740mm(29.1")

Rated storage volume 492 liter (17.4 cu.ft) 535 liter (18.9 cu.ft) 577 liter (20.4 cu.ft)

(Rated volume) F: 151 liter (5.3 cu.ft) F: 151 liter (5.3 cu.ft) F: 151 liter (5.3 cu.ft)

R: 341 liter(12.1 cu.ft) R: 384 liter(13.6 cu.ft) R: 426 liter

Defrosting System Heater system

Start Automatic

Finish Automatic

Temperature control Automatic (Adjustable)

No-frost freezer Yes

Interior lamp 2

Caster 4

Evaporating pan 1

Refrigerator R glass shelf ass'y 2 3

Compartment V glass shelf ass'y 1

Vegetable case 1

Fruit case 1

R door pocket 1 2

Egg tray 2

Bottle pocket 2

Utility case pocket 1

Chilled case 1

Tube stand 2

Freezer Freezer shelf ass'y 1

Compartment Ice cube maker Twin ice cube maker

Ice storage box 1

F door pocket 2

Deodorizing system Yes

RATING

Items SJ-58L-A2 SJ-63L-A2 SJ-68L-A2

Rated voltage (V~) 220-240

Rated frequency (Hz) 50

Climate class T

Rated input (W) 170-190

Rated input of heating elements (W) 138-164

Refrigerant (Charging quantity) HFC-134a(120g) HFC-134a(125g) HFC-134a(130g)

Net Weight (kg) 81 83 88

PLUG TYPE

Plug cord 3 pin 2 pin

Plug type BF with PUB label C-2

(15.1 cu.ft)

FUSED

Destination mark R Y

COLOR

Items -A2G -A2B -A2L -A2A

Outside color Gray Blue Green Beige

Inside color White

OPTIONAL ITEM

SJ-L838LD (REFRIGERATOR HINGE KITS). For changing the door to left side opening.

3

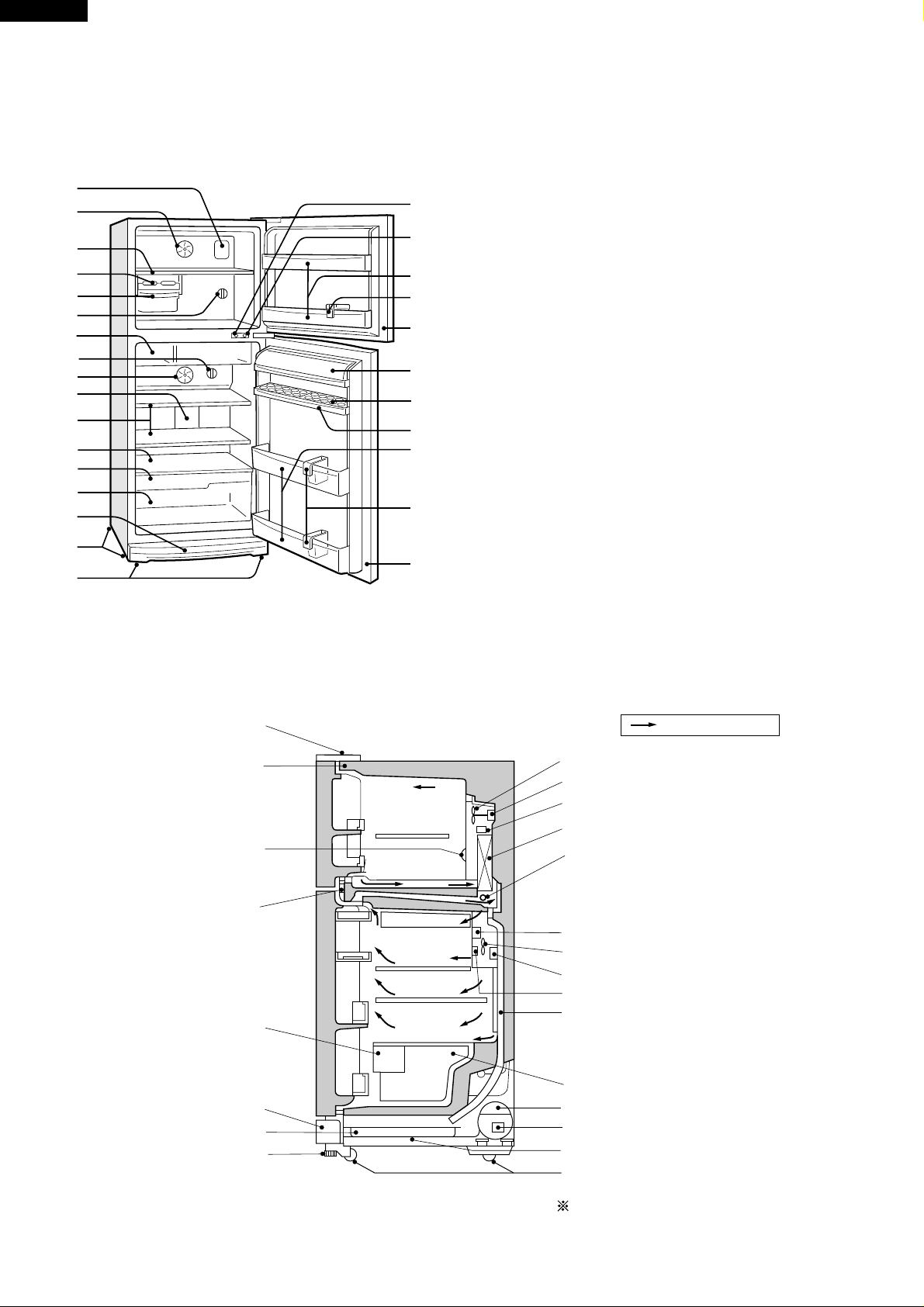

Page 4

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

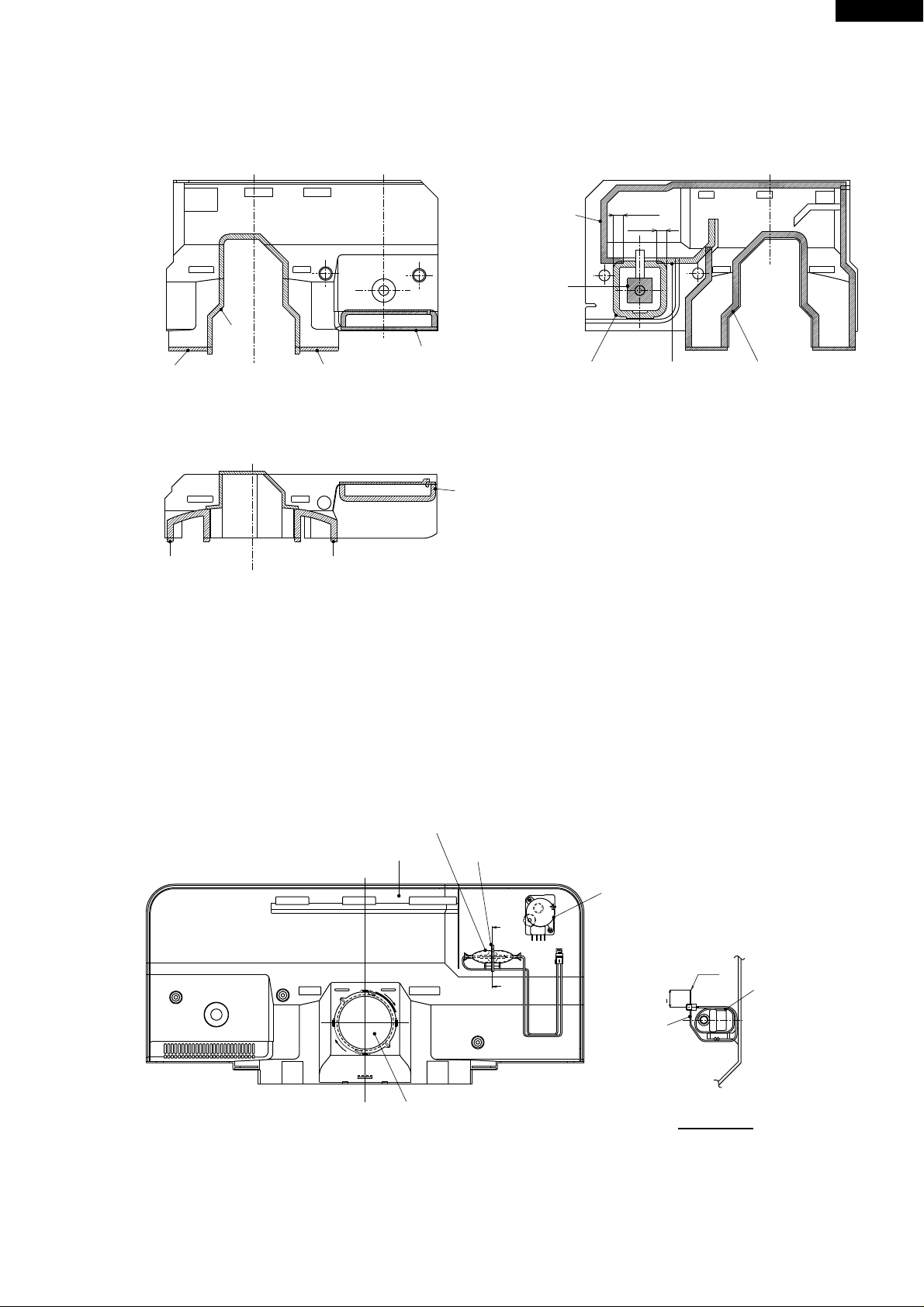

DESIGNATION OF VARIOUS PARTS

Figure D-1. External Description

The names are the denominations used in the

REPLACEMENT PARTS LIST.

1. Freezer light(Lamp)

2. Freezer fan

3. Freezer shelf(F shelf ass'y)

18

4. Ice cube maker

5. Ice cube box(Ice storage box)

19

6. Freezer temp. control knob

7. Chilled case

20

8. Refrigerator temp. control knob

21

9. Refrigerator fan

10. Refrigerator light(Lamp)

22

11. Refrigerator shelf(R glass shelf ass'y)

23

24

(SJ-58L/63L; 2 shelves, SJ-68L; 3 shelves)

12. Shelf(V glass shelf ass'y)

13. Fruit case

14. Vegetable crisper(Vegetable case)

25

15. Evaporating pan & cover

26

16. Caster

17. Adjustable feet(Adjustable leg ass'y)

18. Fan & light switch(for freezer)

19. Fan & light switch(for refrigerator)

27

20. Freezer pocket(F door pocket)

21. Water cup

22. Magnetic door seal(Door packing)

22

23. Utility pocket(Utility case pocket)

24. Egg holder(Egg tray)

25. Free pocket(R door pocket)

(SJ-58L/63L; 1 pocket, SJ-68L; 2 pockets)

26. Bottle pocket

27. Bottle guard(Tube stand)

Upper hinge cover

Hot pipe

Freezer temp. control knob

Hot pipe

Fruit case

Ventilating grille

Evaporating pan

Adjustable leg ass’y

Freezer

compartment

Refrigerator

compartment

Mark: Cold air flow

Freezer fan

Fan motor

Defrost thermostat

Evaporator

Defrost heater

Timer, R-fan themo. ass’y

Refrigerator fan

Damper thermostat

Refrigerator temp. control knob

Drain pipe

Vegetable case

Compressor

Starting relay, Overload relay(Protector)

Sub condenser

Caster

Figure D-2. Constructions

4

This figure shows SJ-63L .

Page 5

Common

Main coil

Aux. coil

LIST OF ELECTRICAL PARTS

ITEMS TYPE NAME RATING SPECIFICATIONS

Thermostat MM1-8123 125V 6A (At normal notch)

250V 3A ON/OFF : -19/-24˚C

Defrost thermostat S101 250V 8A Open/Close : 10/1˚C

Thermo. fuse SF70E 250V 10A Working temp. : 70˚C

F-fan motor 3R00044B 220-240V 50/60Hz Working with ø100 fan

R-fan motor 3R00122A 220-240V 50/60Hz Working with ø80 fan

(R-fan fuse) 123 250V 2A Cut OFF 130˚C

Defrost heater MM6-4198 220-240V 353Ω 150W at 230V

Door switch DSD-5 250V 0.25A 4 terminals push-button type

Damper thermostat MM1-6170 — Open/Close : 3/-2˚C

Defrost timer TMDF904FD2 220-240V Integration type

50/60Hz Cycle time : 10.8/9.0 hours(50/60Hz)

Delay time : 4.3/3.6 min.(50/60Hz)

Lamp socket (F/R) — 250V 1A E-12(Hard plastic body type)

F-lamp — 240V 10W E-12

R-lamp — 240V 15W E-12

R-fan thermo. R-fan thermo.

ass'y

R-fan thermo.heater

S101 250V 8A Open/ Close : 7/15˚C

RSS2 350V, 2W, 10kΩ 1.1W at 230V

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

SJ-58L,63L

Compressor GLY80AA 220-240V/50Hz Cooling capacity : 197kcal/h(50Hz)

Main coil : 10.3Ω

Aux. coil : 14.2Ω

(at 25˚C)

Starting relay UH3003-7 — 14.0 Ω

Overload relay(Protector) 4TM308NFBYY — Open/ Close : 120/61˚C

SJ-68L

Compressor GLY90AA 220-240V/50Hz Cooling capacity : 220kcal/h(50Hz)

Main coil : 8.8Ω

Common

Aux. coil : 14.2Ω

(at 25˚C)

Aux. coil

Starting relay UH3003-7 — 14.0 Ω

Overload relay(Protector) 4TM757NFBYY — Open/ Close : 120/61˚C

Main coil

5

Page 6

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

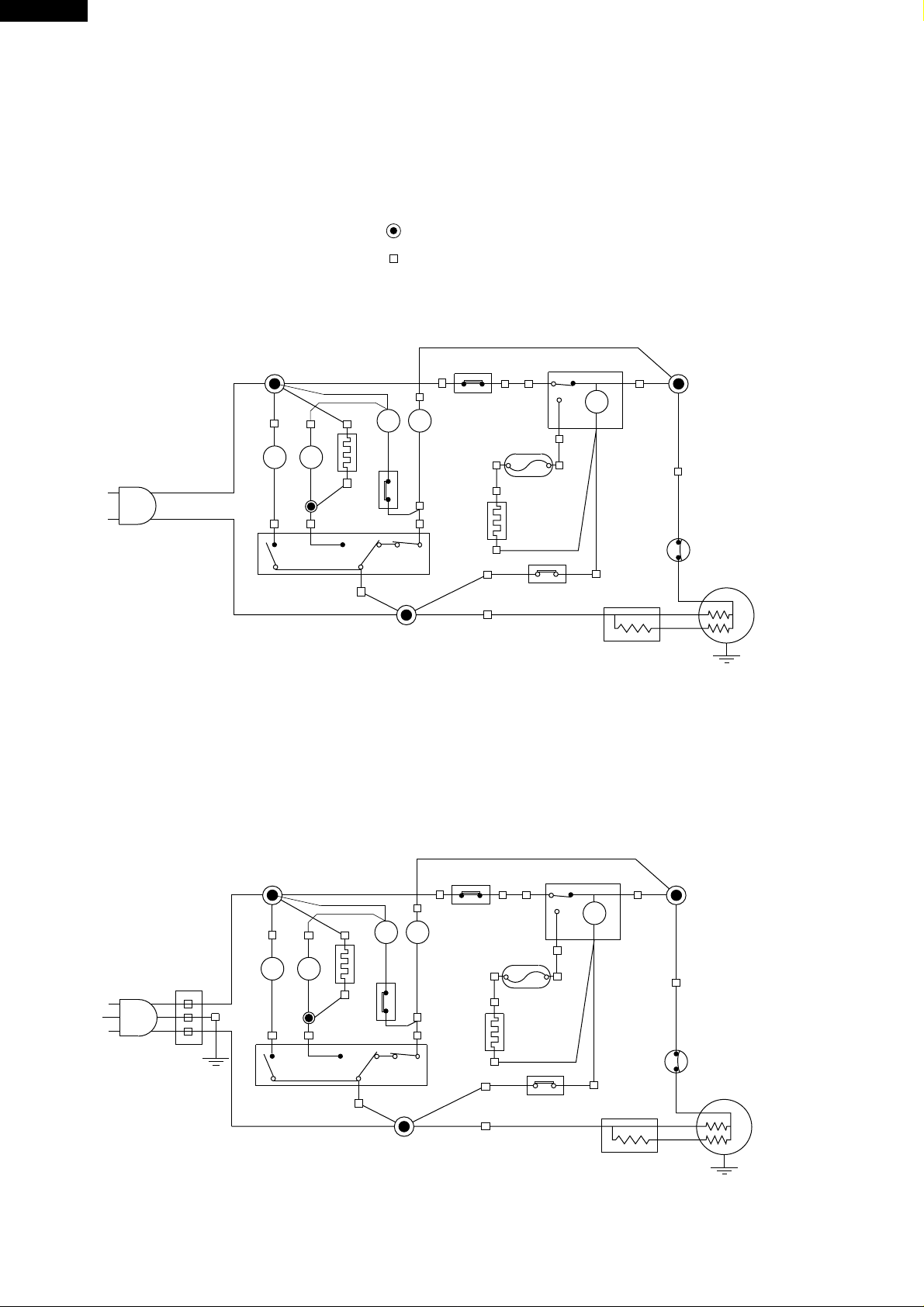

WIRING DIAGRAM

Be sure to replace the electrical parts with specified ones for maintaining the safety and performance of the set.

G

: GRAY

Br

: BROWN

O

: ORANGE

Y

: YELLOW

R

: RED

P

: PINK

B

: BLUE

Bk

: BLACK

S-B

: SKY-BLUE

G-Y

: GREEN-YELLOW

W

: WHITE

F

L

(BR)

R

L

R-FAN THERMO.

HEATER

CONNECTED IN TERMINAL BOX

CONNECTOR

F-THERMOSTAT

(W)

(R)

THERMO.

FUSE

F

R

FMFM

(G)

3

(BK)

TM

12

4

DEFROST

TIMER

(S-B)

2

4

DOOR SWITCH

R-FAN

THERMO.

1

(O)

3

(B)

DEFROST

HEATER

DEFROST

THERMOSTAT

(Y)

Figure W-1. Wiring Diagram (2 pin plug region)

F

FMFM

F-THERMOSTAT

(W)

(R)

THERMO.

FUSE

3

(BK)

(BR)

R

R

F

L

L

R-FAN THERMO.

HEATER

STARTING RELAY

4

TM

DEFROST

TIMER

12

PROTECTOR

COMPRESSOR

C

M

A

(G)

(S-B)

2

4

DOOR SWITCH

R-FAN

THERMO.

1

(O)

3

(B)

DEFROST

HEATER

DEFROST

THERMOSTAT

(Y)

STARTING RELAY

Figure W-2. Wiring Diagram (3 pin plug region)

6

PROTECTOR

COMPRESSOR

C

M

A

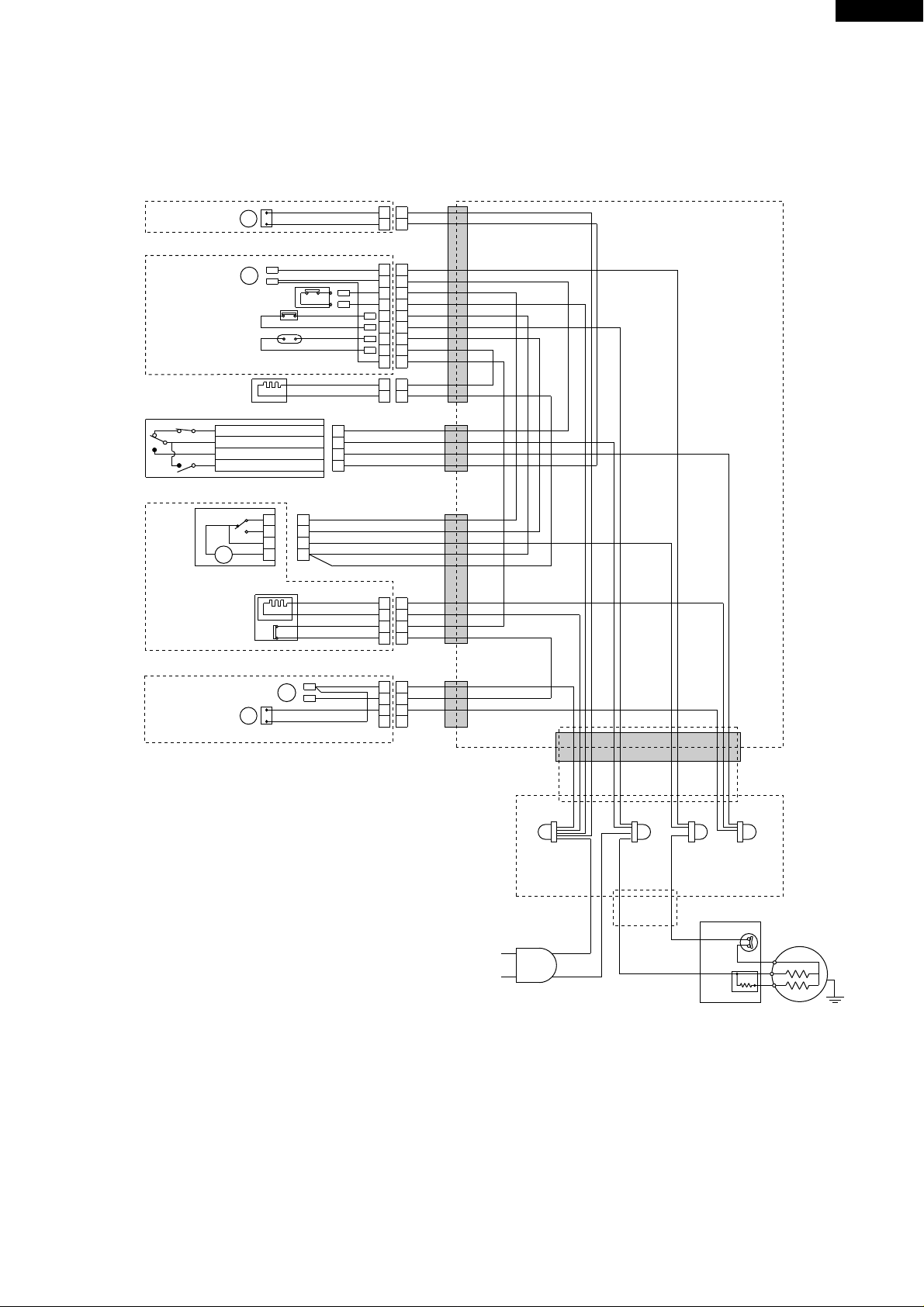

Page 7

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

F LAMP BOX ASS’Y

F-LAMP(10W)

E. V. COVER ASS’Y

F-FAN MOTOR

F-THERMOSTAT

DEF. THERMO. ASS’Y

FUSE ASS’Y

DEF. HEATER ASS’Y

DOOR SWITCH

3 (PUSH CLOSE)

1 (NEUTRAL)

4 (PUSH OPEN)

2 (PUSH OPEN)

R CONTROL COV. ASS’Y

TM

DEFROST TIMER

(R-FAN

THERMO. HEATER)

R FAN THERMO.

LAMP SOCKET

L

LEAD EV-COVER ASS’Y

FM

3

3

2

2

4

4

1

1

CABINET ASS’Y

BR-1

121

W-2

2

GY-1

1

1

OR-1

2

2

R-1

3

3

BR-2

4

4

Y-1

5

5

BL-1

6

6

BK-1

7

7

W-1

8

8

OR-3

99

(W-1)

121

Y-2

2

3

1

4

2

(OR-1)

BL-2

SB-1

(W-2)

(R-1)

(BK-1)

GY-2

(Y-1)

(Y-2)

SB-2

1

1

BR-3

2

2

OR-3

3

3

OR-2

4

4

R LAMP BOX ASS’Y

R-FAN MOTOR

R-LAMP (15W)

G

: GRAY

Br

: BROWN

O

: ORANGE

Y

: YELLOW

R

: RED

P

: PINK

B

: BLUE

Bk

: BLACK

S-B

: SKY-BLUE

G-Y

: GREEN-YELLOW

W

: WHITE

BR-4

1

FM

L

LAMP SOCKET

1

(OR-2)

2

2

SB-3

3

3

4

4

BROWN BLUE

SOURCE CORD

Figure W-3. Electric Accessories Layout (2 pin plug region)

TERMINAL BOX

GRAY

SKY-BLUE

PROTECTOR

STARTING RELAY

TERMINAL COVER

COMPRESSOR

C

M

A

7

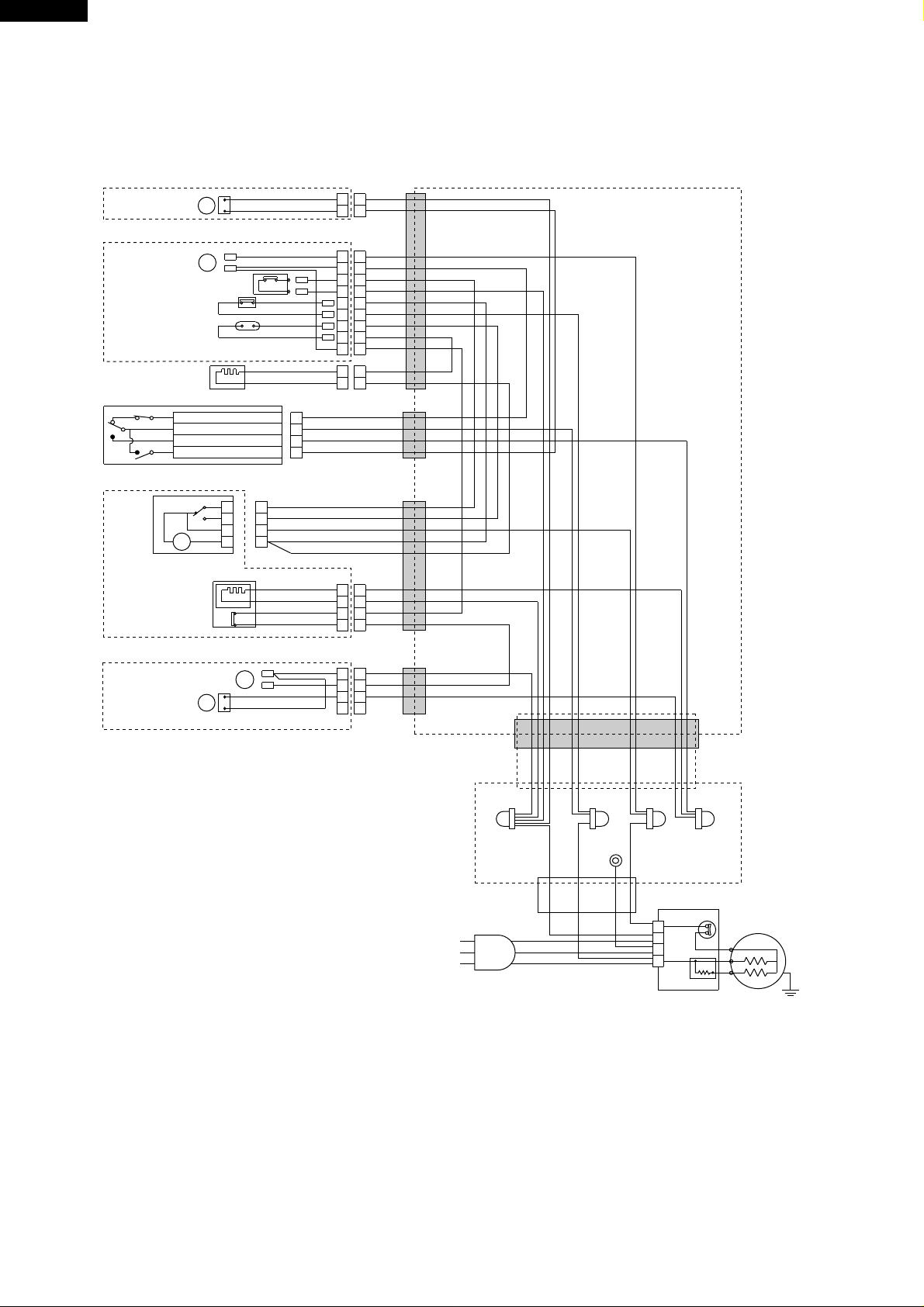

Page 8

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

F LAMP BOX ASS’Y

F-LAMP(10W)

E. V. COVER ASS’Y

F-FAN MOTOR

F-THERMOSTAT

DEF. THERMO. ASS’Y

FUSE ASS’Y

DEF. HEATER ASS’Y

DOOR SWITCH

3 (PUSH CLOSE)

1 (NEUTRAL)

4 (PUSH OPEN)

2 (PUSH OPEN)

R CONTROL COV. ASS’Y

TM

DEFROST TIMER

(R-FAN

THERMO. HEATER)

R FAN THERMO.

LAMP SOCKET

L

LEAD EV-COVER ASS’Y

FM

3

3

2

2

4

4

1

1

CABINET ASS’Y

BR-1

121

W-2

2

GY-1

1

1

OR-1

2

2

R-1

3

3

BR-2

4

4

Y-1

5

5

BL-1

6

6

BK-1

7

7

W-1

8

8

OR-3

99

(W-1)

121

Y-2

2

3

1

4

2

(OR-1)

BL-2

SB-1

(W-2)

(R-1)

(BK-1)

GY-2

(Y-1)

(Y-2)

SB-2

1

1

BR-3

2

2

OR-3

3

3

OR-2

4

4

R LAMP BOX ASS’Y

R-FAN MOTOR

R-LAMP (15W)

G

: GRAY

Br

: BROWN

O

: ORANGE

Y

: YELLOW

R

: RED

P

: PINK

B

: BLUE

Bk

: BLACK

S-B

: SKY-BLUE

G-Y

: GREEN-YELLOW

W

: WHITE

BR-4

1

FM

L

LAMP SOCKET

1

(OR-2)

2

2

SB-3

3

3

4

4

TERMINAL BOX

BROWN BLUE

EARTH

SOURCE CORD

GRAY

SKY-BLUE

PROTECTOR

1

L

E

N

STARTING RELAY

TERMINAL COVER

COMPRESSOR

C

M

A

Figure W-4. Electric Accessories Layout (3 pin plug region)

8

Page 9

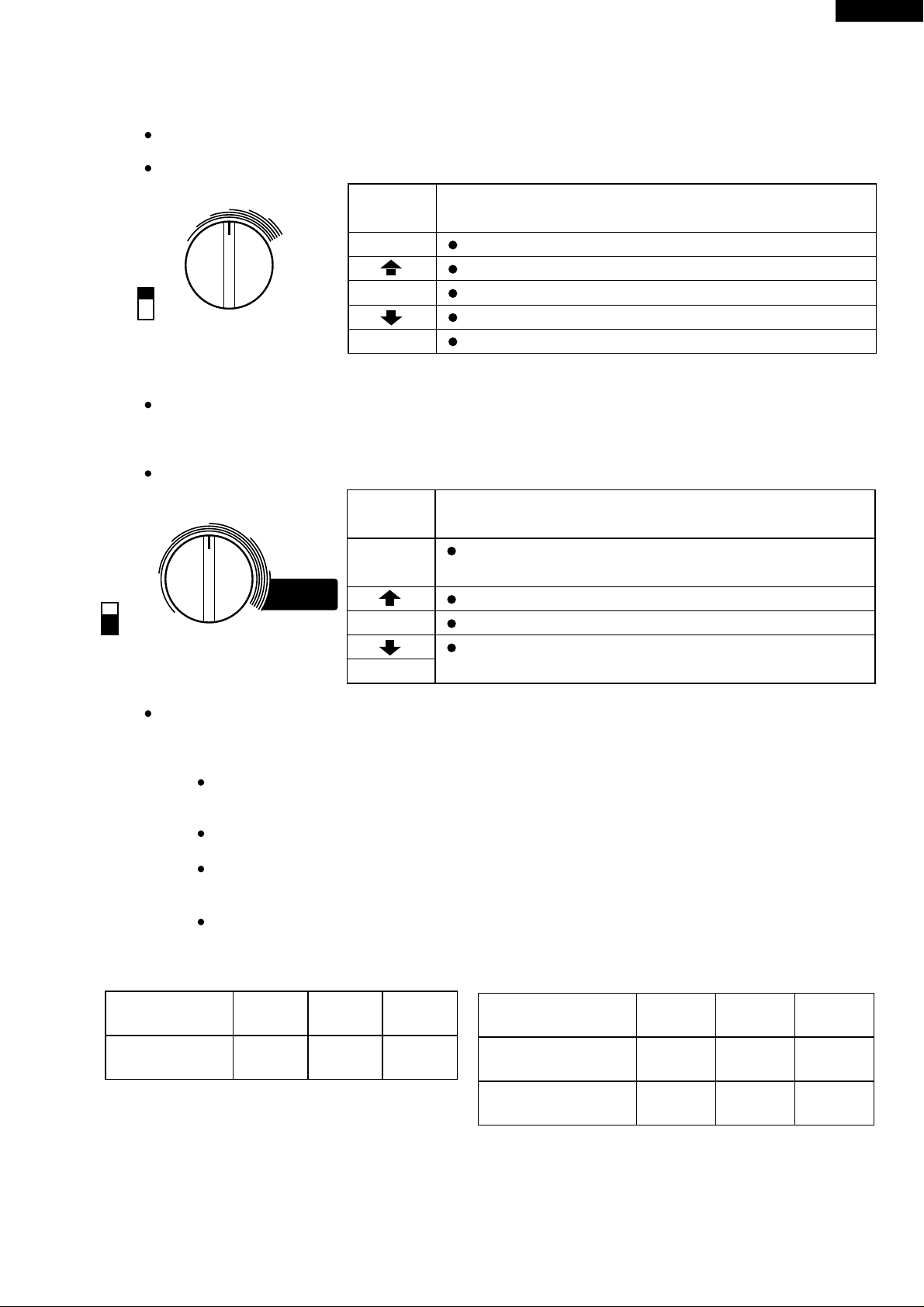

1. ADJUSTABLE TEMPERATURE CONTROL

KNOB

SETTING

MED

CHILLED

ZONE

(Coldest)

MIN

PURPOSE

For keeping freshness of food longer.

For normal operation.

When the refrigerator provides excessive cooling.

When the refrigerator does not provide sufficient cooling.

SETTING OF

REFRIGERATOR TEMP.

CONTROL KNOB

Refrigerator

temperature

Chilled room

temperature

CHILLED

ZONE

(Coldest)

MED MIN

Approx.

0˚c

Approx.

-3˚c

Approx.

3˚c

Approx.

1˚c

Approx.

6˚c

Approx.

4˚c

The values shown above refer to the case where the

freezer temp. control knob is set at "MED".

(1) Temperature control of freezer

Thermostat (senses freezer temperature) operates on ON/OFF switchover to control the compressor and

cool air circulating fan (F-fan motor) , and allows the freezer temperature to keep at a suitable temperature.

However adjust the freezer temp. control knob as follows depending upon the storing condition of foods.

MED

MIN

4

5

3

2

1

6

7

MAX

Coldest

KNOB

SETTING

MAX

(Coldest)

MED

FREEZER TEMP. CONTROL

Figure F-1.

MIN

(2) Temperature control of refrigerator

Damper-thermostat senses temperature of the refrigerator and changes the opening angle of the damper

automatically.

However, as the Damper-thermostat has no function to switch on or off the compressor and F-fan motor,

the freezer temperature control causes temperature in the refrigerator to vary to some extent.

However, adjust the refrigerator temp. control knob as follows depending upon the cooling condition.

FUNCTIONS

PURPOSE

For making ice rapidly or fast freezing.

When restocking with fresh food.

For normal freezing.

For storing frozen food for a short period (up to one month).

When frozen food or ice cream is not stored.

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

MED

4

3

2

5

6

CHILLED

ZONE

1

MIN

7 Coldest

REFRIGERATOR TEMP. CONTROL

Figure F-2.

When the temperature of the refrigerator is higher, R-fan thermo. senses the temperature and the

refrigerator is cooled efficiently by running of R-fan motor.

R-fan thermo. heater energizes when the door is opened intend to promote to running of R-fan motor.

NOTE: The refrigerator temperature is affected also by the freezer temperature. If the freezer temp.

control knob is set at the position "MAX", the temperature tends to be lower than the following

values, and if set at near the position "MIN", temperature tends to be higher.

If the refrigerator is operated for a long time with the freezer temperature control sets the "MAX"

position, foods stored in the refrigerator compartment may also freeze.

When refrigerator temperature control sets to the "CHILLED ZONE", some foods stored may

freeze.

In this case adjust control set back to the "MED" position.

When refrigerator temperature control sets to the "CHILLED ZONE", some foods stored in chilled

case may also become frozen.

(3) Reference value of temperature

SETTING OF

FREEZER TEMP.

CONTROL KNOB

Freezer

temperature

The values shown above refer to the measurement carried out center area and 1/3 of overall height from the bottom

at each of the refrigerator and the freezer after machine has been operated at an ambient temperature of 30˚C with no

food stored and the door closed until the temperature is stabilized.

The values vary depending upon frequency of opening and closing the door, ambient temperature, amount of stored

foods and manner of storing foods.

MAX

(Coldest)

Approx.

-21˚C

MED MIN

Approx.

-18˚C

Approx.

-15˚C

9

Page 10

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

2. DEFROSTING

(1) No defrosting operation is necessary

No defrosting operation is necessary.

As this machine is so designed that a built-in

evaporator cools air and a fan circulates cooled

air, neither the freezer nor the refrigerator is

frosted, though the evaporator is frosted.

(2) Where is melted frost brought

1. Melted frost is brought into the evaporating

pan at the bottom of the set and is evaporated

here by the heat of sub condenser.

2. Be sure that the evaporating pan is inserted

correctly and is level.

The frosted evaporator is defrosted automatically

due to the function of defrosting timer and heater,

requiring no defrosting operation.

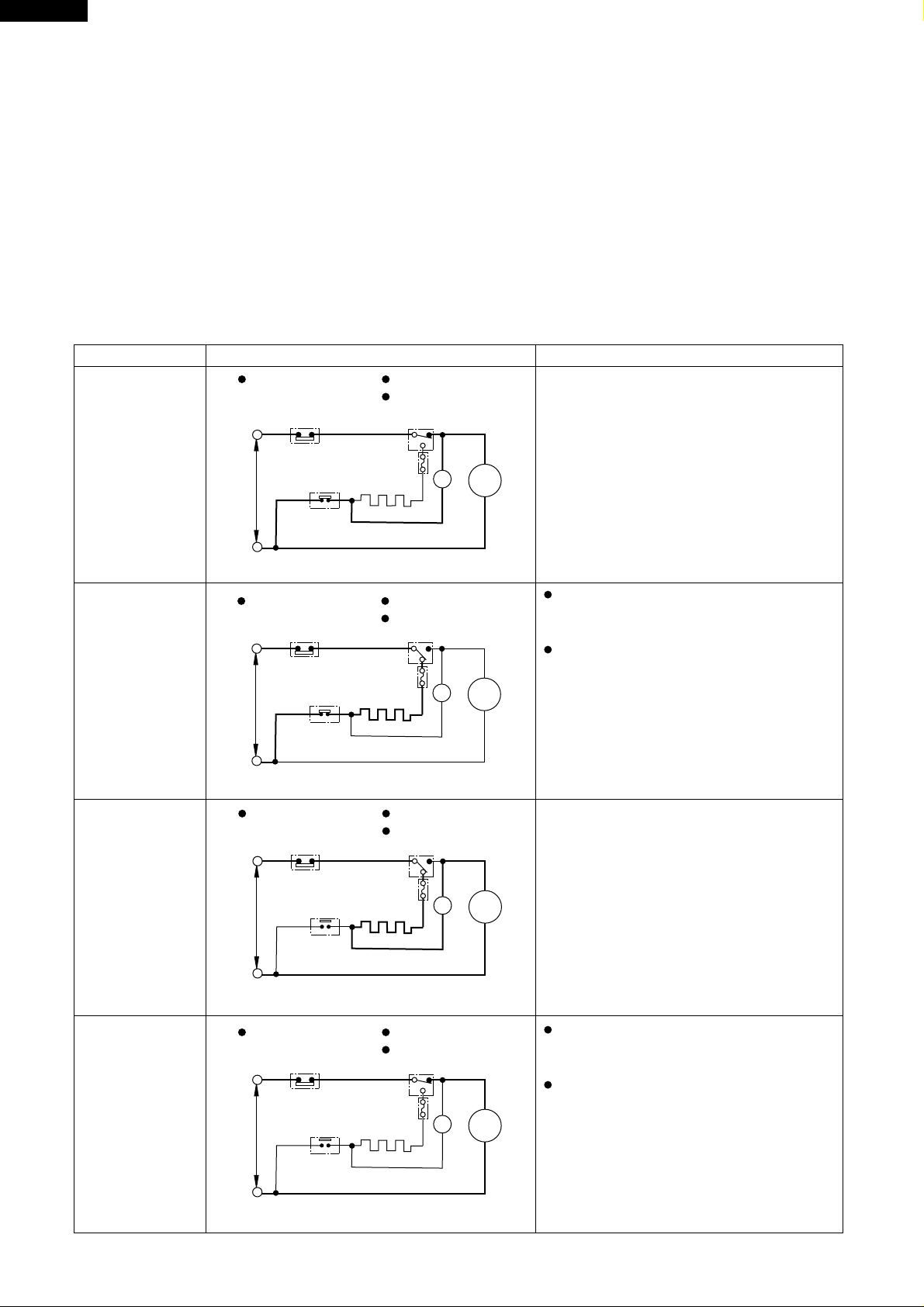

(3) The following circuit diagrams in the table show automatic defrosting function of the refrigerator with

timer and defrost thermostat.

Operation Electric diagram Description

1. Cooling

(Normal)

Defrost thermostat ON Compressor running

Timer motor running

Thermostat

Timer contact

The integration timer integrates running

time of the compressor. When it reaches

cycle time of defrost timer, the timer

contact is changed to start defrosting.

Thermo. fuse

Defrost heater

TM COMP

2. Defrosting

(Time 20 to 30 min.)

3. Drain

(Time approx. 5 min.)

SOURCE

Defrost

thermostat (ON)

Figure F-3.

Defrost thermostat ON Compressor stops

Timer motor stops

Thermostat Timer contact

Thermo. fuse

TM COMP

SOURCE

Defrost heater

Defrost

thermostat (ON)

Figure F-4 .

Defrost thermostat OFF Compressor stops

Timer motor running

Thermostat Timer contact

Thermo. fuse

TM COMP

SOURCE

Defrost heater

Defrost

thermostat (OFF)

Timer motor

Timer motor

Timer motor

Compressor

Compressor

Compressor

The timer contact is changed to start

defrosting, the timer motor stops, and

power is supplied to the defrost heater.

It takes about 20 to 30 min. to defrost.

When little frosted, the defrosting takes

little time. When much frosted, the defrosting takes much time.

When the defrost thermostat becomes

OFF, the timer motor starts running.

During the operation time (delay time

of defrost time)

defrosted water is

drained outside the refrigerator.

4. Restart

(Time approx. 5 min.)

Figure F-5.

Defrost thermostat OFF Compressor running

Timer motor stops

Thermostat Timer contact

Thermo. fuse

TM COMP

SOURCE

Defrost heater

Defrost

thermostat (OFF)

Figure F-6.

10

Timer motor

Compressor

Timer contact is changed to cooling

operation and the compressor starts

running and the timer motor stops.

Defrost thermostat contact becomes ON

when it’s cooled. And the timer motor

starts running. (Figure F-3.)

Page 11

(4) As a reference to determine the causes of trouble, malfunction and phenomena are described below.

Refer to the following when repairing.

1. Disconnection of defrost heater

As off-cycle defrosting is performed, the defrosting time is extremely prolonged. Each time defrosting is

started, the freezer temperature rises and a portion of ice and stored foods are melted.

2. Melted thermo. fuse or opened-circuit due to the defect of defrost thermostat.

When the above mentioned trouble occurs in cooling operation, the timer motor does not run, defrosting

will not take place, and consequently freezing is caused. In the above mentioned condition, when the timer

shaft is turned by hand to defrost, the timer motor runs during the operation time. However, the motor stops

from the time when the contact is changed, and freezing causes.

NOTE:

As the thermo. fuse assembly is intended to prevent dangers, do not use it under shorted condition even

for a short period.

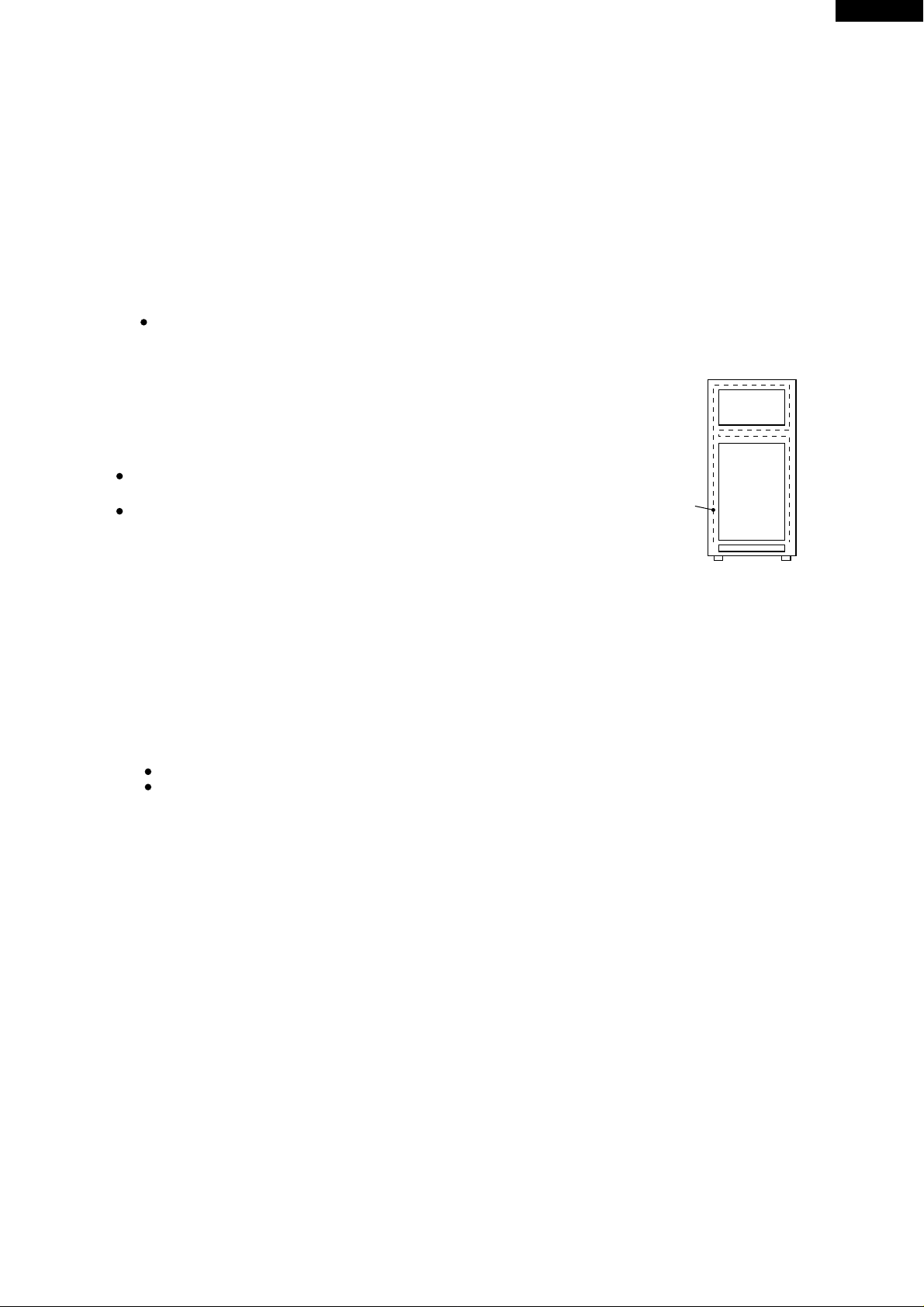

3. DEW PREVENTION

The hot pipe, namely D.P.-condenser, is arranged around the flange part of

cabinet and the C-partition plate, preventing dew from being generated on

the cabinet.

NOTE:

D.P.-condenser pipe may be felt hot if touched by hand while the

compressor is in operation.

If you are asked about this, please explain that the hot pipe serve to

Hot pipe

prevent the dew generation.

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

4. INSPECTION OF INITIAL STARTING

(1) Inspection of cooling unit

1. Set the temperature control knob to "MAX" and check that the compressor starts to operate.

2. Depress the door switch to run the fan and check that cool air is blown out of the cold air outlet of the

freezer and the refrigerator.

3. When the compressor does not work, check that the timer is not set to "defrost" position.

4 It takes about an hour and a half or two hours to put food in the refrigerator after starting operation.

NOTE:

After return the temperature control knob to "MED" position.

When the refrigerator is operated initially after installed, the compressor may vibrate excessively for 1 to 2

min. However, vibration becomes normal if it is continuously operated.

(2) Inspection of defrost device

Operate the refrigerator for 20 to 30 min. and then check the defrost device in the following procedures :

Allow 5 min. to restart the compressor since immediate starting after stopping will cause unsmooth operation.

1. Turn the timer shaft clockwise with a screw driver.

At this time, make certains the timer clinks and the compressor stops.

2. After more than 5 min., turn the shaft further to operate.

Make certain cooling operation is started again.

Figure F-7

11

Page 12

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

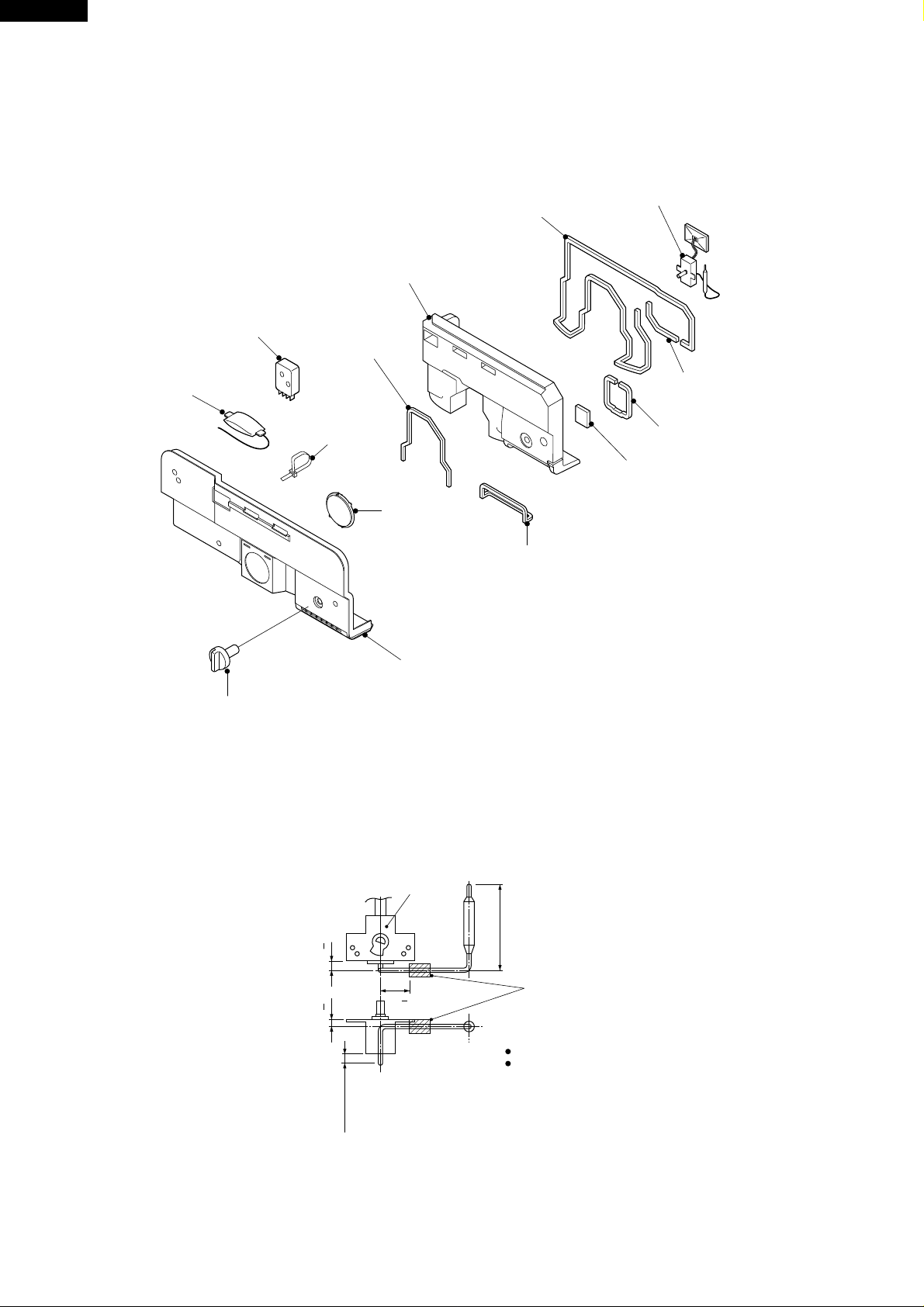

ASSEMBLING PROCEDURES OF MAIN PARTS AND CAUTIONS

CAUTION: DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY REPAIRING.

1. R-CONTROL COV. ASSEMBLY

R fan thermo. ass’y

Defrost timer

R air guider A

RA sealer D

Nylon band

RA sealer A

Damper thermo.

RA sealer C

RA sealer B

Dial sealer

Fan cover

A sealer thermo. cap.

R-temp. control knob

(1) Forming sensor of Damper thermo.

mm

1

++

3

mm

1

5

R-C box cover

Figure A-1

Damper

thermostat

+

25 2 mm

Less than 130 mm

Stick thermo.

cap. sealer

NOTE

Minimum bending radius is R5mm.

There should be no gas leak by reforming of sensor tube.

After forming, fix it to the refrigerator.

Less than 12 mm

Figure A-2

12

Page 13

(2) Sticking of sealers to R air guider A.

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

[Front side]

RA sealer A

[Bottom side]

RA sealer D

RA sealer A

RA sealer ARA sealer A

A sealer

thermo. cap.

A sealer

thermo. cap.

[Back side]

RA sealer A

Dial sealer

OVERLAP 15mm

OVERLAP 15mm

RA sealer CRA sealer B

RA sealer A

Figure A-3

(3) Fixing of Defrost timer, R fan thermo. ass'y cover to R-C box cover.

R fan thermo ass’y

R-C box cover

Nylon band

G

G

Defrost timer

+

10 5mm

Nylon band

Cut

R fan thermo.

ass’y

Fan cover

Figure A-4

SEC. G-G

13

Page 14

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

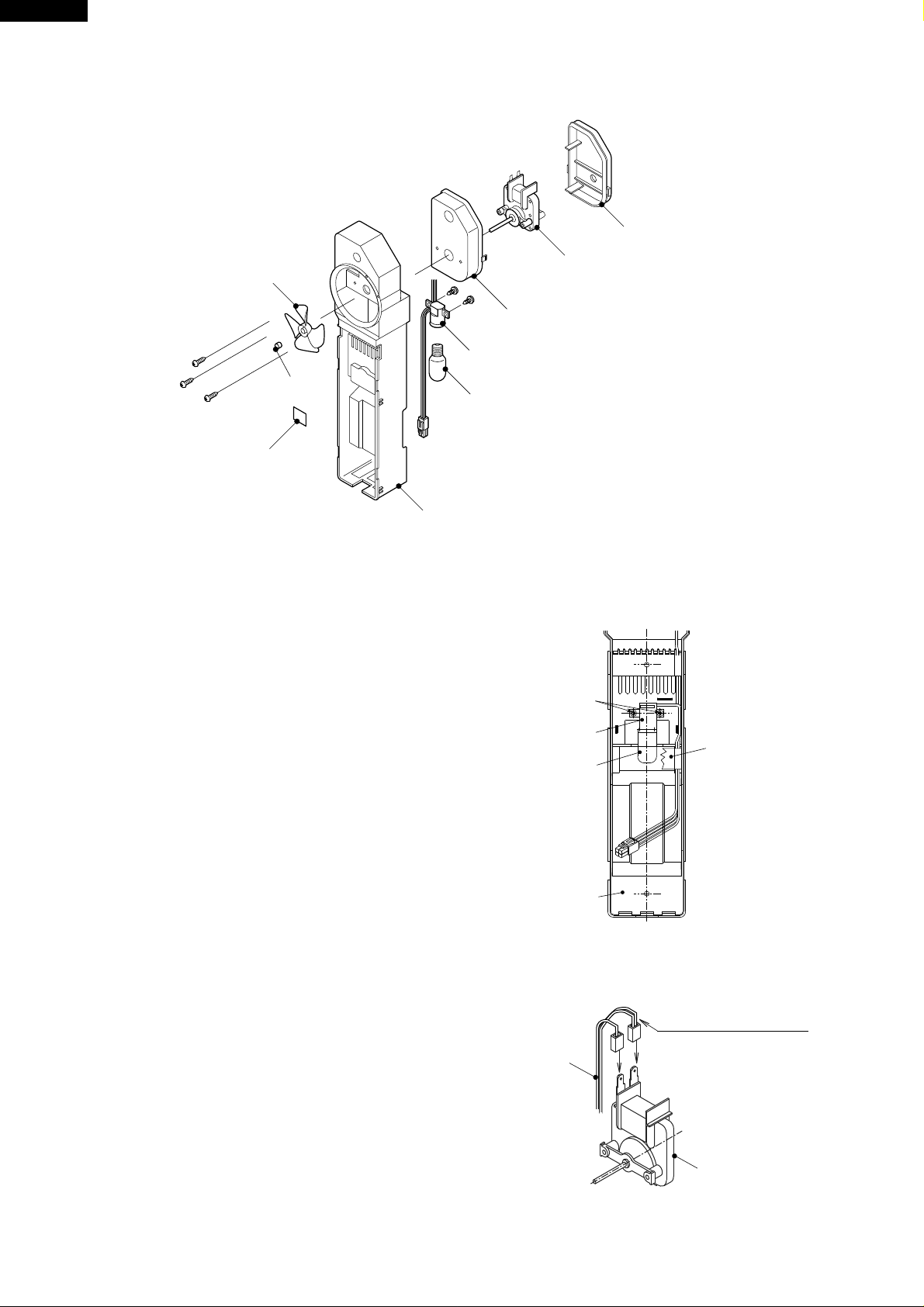

2. R LAMP BOX ASSEMBLY

R fan motor holder B

Propeller fan 80

Fan clamp

Warning label

(1) Fixing of Lamp and Lamp socket.

(1)-1 Screw Lamp 15W into Lamp socket.

(1)-2 Fix Lamp socket on R lamp box by tapping

screws.

R-fan motor

R fan motor holder A

Lamp socket (with lead wires for R-fan motor)

Lamp 15W

R lamp box

Figure A-5

Tapping screw

(1)-3 Insert the terminal of Lamp socket to R-fan motor.

Lamp socket

ALUMINUM TAPE

Lamp 15W

R lamp box

Figure A-6

DOUBLE CLAMPING WIRES

Lamp socket

Fan motor

14

Figure A-7

Page 15

SJ-58L-A2

Fan clamp

Propeller fan 80

F

Shaft

2.3 0.5mm

+

Fan clamp

Slit

Slit of each Fan clamp and Propeller fan

should not be at same position.

Detail of F

SJ-63L-A2

SJ-68L-A2

(2) Fixing of R-fan motor and Fan

(2)-1 Set R-fan motor holder A to R lamp box by

tapping screw.

(2)-2 Set R-fan motor to R fan motor holder A by

machine screw.

(2)-3 Set R fan motor holder B to A.

Propeller fan 80

R fan motor holder B

R fan motor holder A

R-fan motor

Figure A-8

(2)-4 Set Fan clamp to Propeller fan 80 and insert it

to the shaft of R-fan motor.

Figure A-9

(3) Sticking Warning label.

Warning label

Lamp 15W

Figure A-10

15

Page 16

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

3. E.V COVER ASSEMBLY

Defrost thermo. ass’y

E.V cover sealer A

U-sealer

handle

Propeller Fan 100

Fan clamp

Motor

cushion

Fan motor

Fan motor

holder B

E.V cover

F-thermostat

E.V cover

sealer D

(2 pieces)

(1) Sticking of Sealers to E.V cover

L-band C

E.V cover sealer C

Fuse ass’y

Figure A-11

Fan motor

holder A

E.V cover sealer B

Lead E.V-cover

ass’y

E.V cover sealer D (b)

E.V cover sealer B

Overlap 10mm(min)

Sticking start (a)

Sticking start

E.V cover sealer A

Sticking start (b)

E.V cover sealer D (a)

[Front side] [Back side]

E.V cover

Sticking start

Figure A-12

16

Page 17

(2) Fixing of Fan motor and Fan

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

(2)-1 Stick U-sealer handle to Fan motor holder A.

(2)-2 Insert the terminals of Lead EV-cover ass'y to

R-fan motor.

(2)-3 Fix two Motor cushions to R-fan motor, and set it

at Fan motor holder A and B.

Then fix with Tapping screw.

U-sealer handle

Fan motor

holder A

Fan motor holder A

0 1mm

SEC. C-C

Motor cushion

+

7 2mm

+

Figure A-13

Fan motor

holder B

C

C

U-sealer handle

Tapping

screw

(2)-4 Set Fan clamp to Propeller fan 100 and insert

it to the shaft of Fan motor.

D

Fan clamp

Propeller

fan 100

Lead EV-cover ass’y

Figure A-14

Slit

Slit of each Fan clamp

and Propeller fan

should not be at same position.

+

4 0.5mm

Fan motor

RED

BROWN

Fan clamp

17

Shaft

Detail of D

Figure A-15

Page 18

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

(3) Setting of Fan motor ass'y , Defrost thermo. ass'y and Fuse ass'y

more than

3.5mm

[FRONT SIDE]

Lead E.Vcover ass’y

more than

3.5mm

Take out lead wire from

square hole to front, and

seal with E.V cover sealer C.

E.V cover

sealer C

E.V cover

E.V

cover

Fuse

ass’y

Sec. F-F

Tapping screw

Tapping

screw

Aluminum

tape

F

F

Fuse ass’y

ATTENTION

Turn up is lead wire

Aluminum

tape

Not come out of claw

E

E

Set metal side below

Defrost

thermo. ass’y

L-band C

cut

Sec. E-E

L-band C

Defrost

thermo. ass’y

+

10 5mm

(4) Inserting of pins

Figure A-16

Fan motor 1 , 2

WIRE COLOR FOR FAN MOTOR

Defrost thermo. 5

(PINK)

Defrost thermo. 6

(BLUE)

100-110V : WHITE

127V : YELLOW

220-240V : BLUE

F-thermostat 4

(BROWN, inserted)

F-thermostat 3

(RED, inserted)

123

456

789

Fan motor 9

Fuse 8

(WHITE)

Fuse 7

(BLACK)

Note Pins should be inserted surely,

and check by pulling it.

Figure A-17

18

After inserting, fix with vinyl tape.

Vinyl tape

60mm

Figure A-18

Page 19

(5) Setting of F-thermostat

(5)-1 Form capillary tube of F-thermostat.

20mm

R10mm

42mm13mm

20mm

R10mm

Note

230mm

• Bending radius of

capillary tube should be

from R5mm to R10mm.

Figure A-19

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

(5)-2 Insert terminal of Lead EV-cover ass'y.

(5)-3 Set to E.V cover.

RED

(front side)

BROWN

(back side)

Figure A-20

F

19

SEC. F-F

F

Figure A-21

Page 20

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

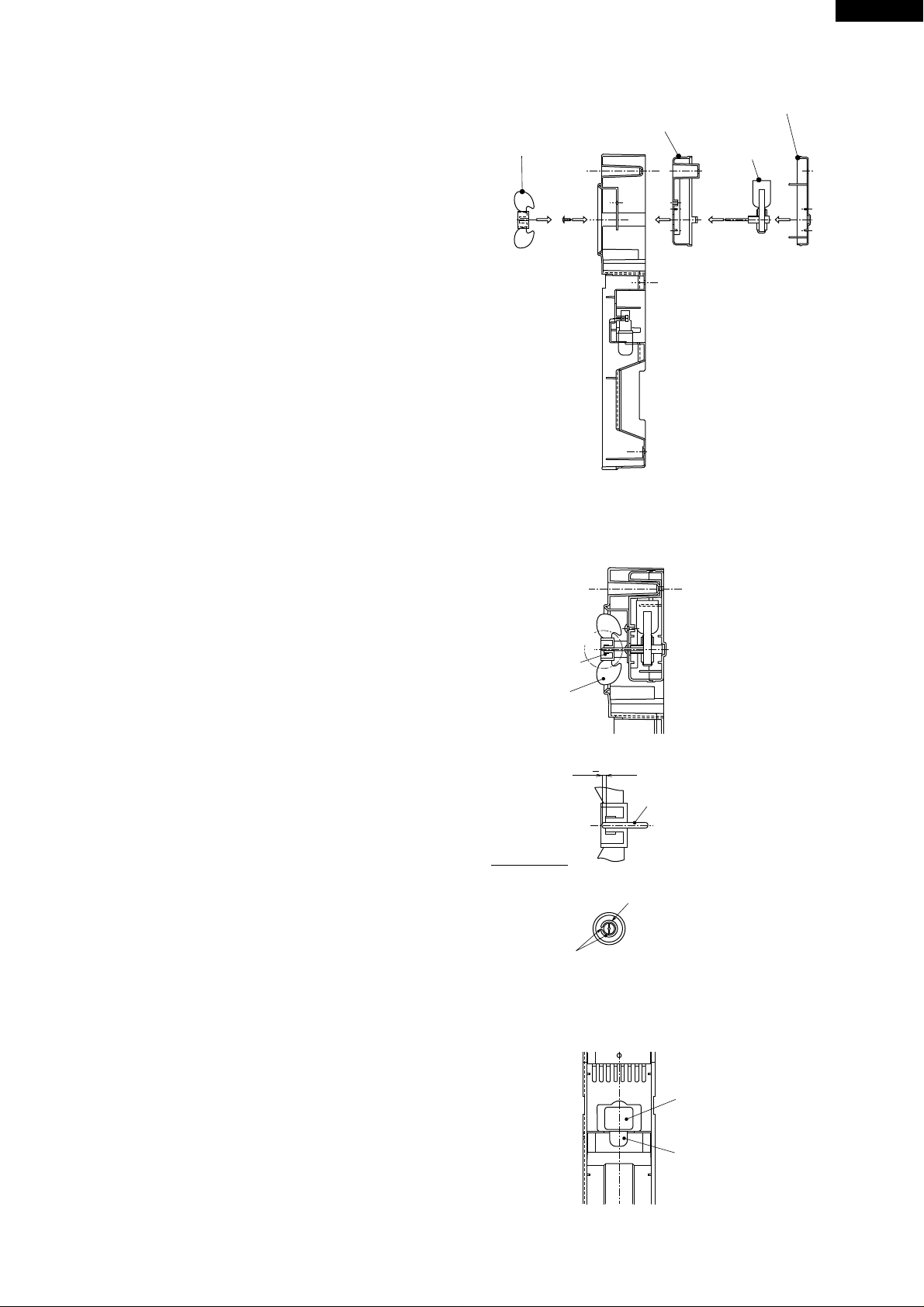

MODIFICATION PROCEDURE OF THE DOOR OPEN SIDE

It is possible to change the door to left side opening.

To modify the door to left side opening, REFRIGERATOR HINGE KITS (for left side opening) SJ-L838LD (optional item )is necessary.

These kits are used to change the refrigerator doors from right to left opening.

if you wish to change the door to left opening for some reason, such as restricted installation

space, ask your authorized service agent for this modification.

by SJ-L838LD OPERATION MANUAL

Parts list

Bottom hinge L

AB

Door hole cover

F

Stopper spring L

(for upper door)

Screw and Cover

G

Stopper spring L

C

(for lower door)

Silicon grease

HJ

Select the same color as the refrigerator exterior.

Door cap cover

D

(for upper door)

Screw cap for handle

(Spare)

Tools required

Phillips and slotted screwdrivers

Drill bit ( 3.8 mm)

Socket wrench or spanner (8 mm) :The socket wrench or spanner is used to detach and attach hinges.

Caution

Always disconnect the power plug from the wall outlet before performing work.

Caution should be taken when handling the doors.

These are heavy and could cause personal injury if mishandled.

Always tighten screws securely. May cause personal injury if door becomes unlatched and falls.

Reattach doors paying careful attention to the door alignment. Failure to fit the door

correctly might cause the cool air to leak out and lower the cooling performance.

Door cap cover

E

(for lower door)

Fitting Instruction

1

Preparation/Removing Doors

1. Remove Evaporating pan cover, Upper hinge cover, and Top cover.

(Carefully remove Upper hinge cover using a screwdriver, making sure that the door is not damaged.)

2. Remove Upper hinge and Spacer, and detach Upper door by lifting off the center hinge.

3. Remove Center hinge and detach Lower door by lifting off the bottom hinge. Remove the 2 Hole caps, replace them on

the screw holes of the removed center hinge, then screw in G (screw and cover) in the center hole.

4. Remove Bottom hinge. Remove the 3 screws on the left side, then install them in the screw holes of Bottom hinge.

1

1

2

1

G

3

G

3

2

3

3

4

4

1

Figure M-1

20

Page 21

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

2

Replacing Handles and Door Parts

1. Remove Screw caps and Screws on each door handle, then remove the handles.

Flatten the surface of the screw holes using the handle of a screwdriver, etc., then mount 3 units of F (Door hole covers)

on each door.

2. Remove the Nylon bearings, Door stopper(Lower door only), Stopper springs on the right side of each door and the cap

on the left side of the Upper door. Furthermore, open the hidden holes on the bottom of the door using a screwdriver,

then remove a screw (Lower door only).

3. Remove Screw caps and Screws on the right side of each door, then remove the Door cap covers and mount D and E

(Door cap covers) on the left side.

4. Replace Nylon bearings to the left side of each door, then mount the Upper door cap on the right side. Furthermore,

mount Door stopper and B and C(Stopper springs) on the left side as well. Screw in a screw in the screw hole on the

lower right of the Lower door.

5. Fix upper portion of Upper handle using one screw on the right side of Lower door, then temporarily fix the handle to the

door using tape.

6. To open screw holes, first make marks on the doorplate surface through the 3 holes of the handle, then temporarily

remove the handle (make sure that the dimensions of the markings are as shown in the diagram).

7. Lightly dent the center of each marking, then open holes using a 3.8 mm drill bit.

Use a drill guide, etc., to prevent the drill bit from entering more than 5 mm.

Make sure to open the hole straight. Opening the hole in an angle will cause the handle to clatter.

The door will be unusable if the hole are too large or too deep or if the screws are tightened too much.

8. Mount the handle using the 4 screws and install Screw caps.

9. Mount Lower handle on the right side of Upper door by repeating steps 5. ~ 8. above.

2

5,6

16mm

27mm

172mm

172mm

7

F

4

2

1

2

3

1

4

D

3

B

2

2

4

3

E

3

1

1

F

2

2

2

4

8

(J)

5mm

5-8

9

4

C

Figure M-2

21

Page 22

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

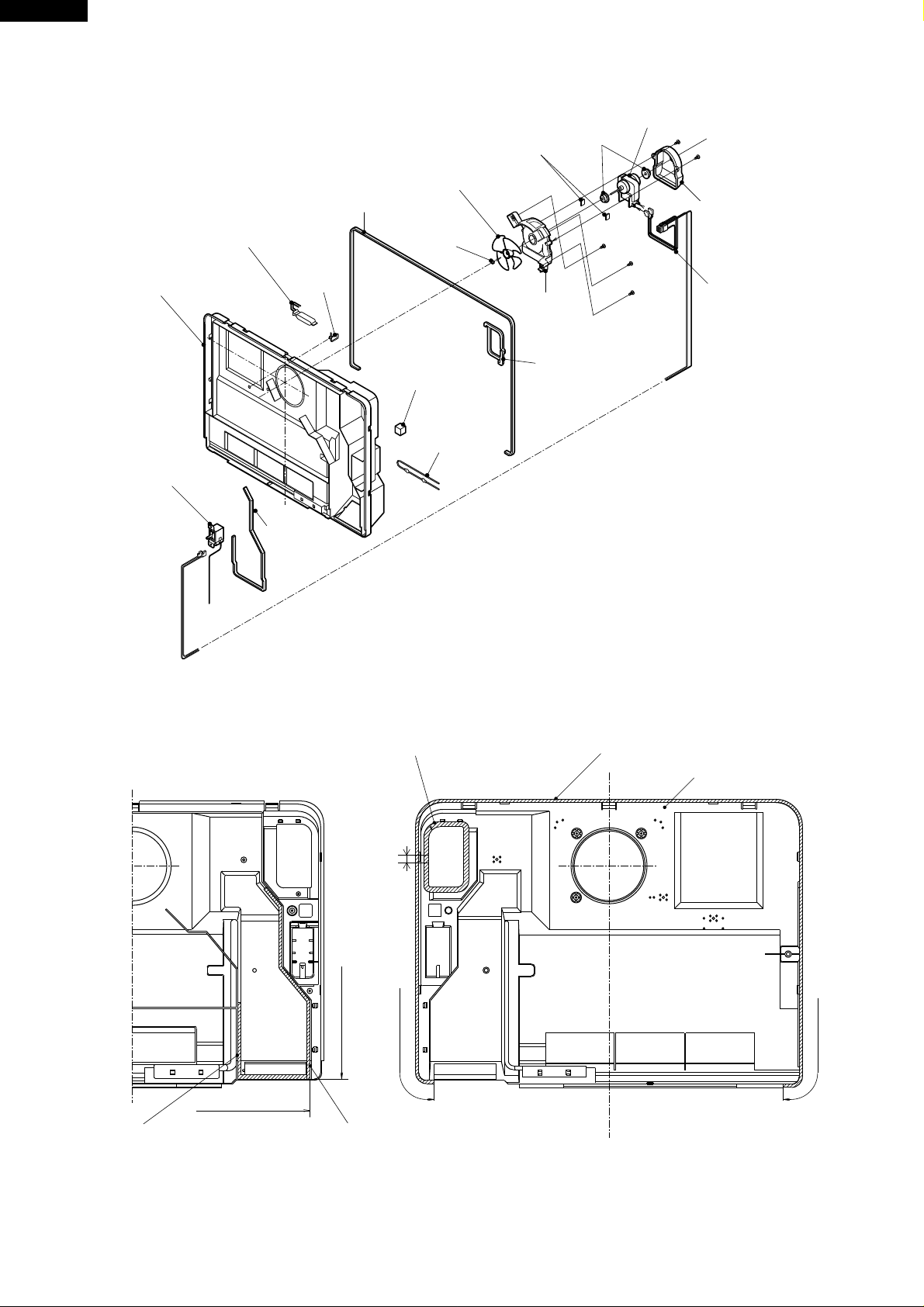

3

Mounting the Door/Finishing

1. Apply Silicon grease H to the shaded portion of part A(Bottom hinge L) and attach it to the left side.

2. Insert Lower door and fit Center hinge vertically inverted. Remove washer if installed. Tighten the screws temporarily.

3. Fit Upper door and attach Upper hinge together with spacer. Tighten the screws temporarily.

4. Adjust the alignment of the door. Ensure that the gap between the cabinet and door is 12 mm. Tighten the upper hinge

screws.

5. Secure Upper door. Open Lower door and tighten the center hinge screws. (No drawing)

6. Check the following. To readjust the door position, loosen Center and Bottom hinges.

Whether the distance to activate the door switch is correct.

Whether each door can be opened/closed smoothly.

Whether each door is properly sealed when closed. (Check by inserting a sheet of paper between the door and

cabinet when closing. The refrigerator is not properly sealed if the paper falls.)

7. Apply Silicon grease H to the shaded portion of the door packing.

8. Replace the cap in Evaporating pan cover on the right side.

9. Reattach Evaporating pan cover, Upper hinge cover and Top cover.

10. Make sure that each door can be opened and closed normally. (If any of the doors cannot open/closes normally, tilt the

refrigerator slightly backward by screwing out the two adjustable feet.) Furthermore, connect the power plug, make sure

that cold air is not leaking from the door packing, and that the cabinet lamp operates properly when the door is

opened/closed.

Retain removed parts in case doors are to be changed back to right opening.

3

4

6

2 1.0mm

2

+

12mm

+

3.5 0.5mm

1

9

9

3

3

2

2

7

A

1

8

9

Figure M-3

22

Page 23

Mark: Refrigerant flow

Mark: Brazing portion

COOLING UNIT

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

Hot pipe L

(Side condenser)

Hot pipe

(DP-condenser)

Hot pipe R

(Side condenser)

Sub. condenser

Compressor

Evaporator

Suction pipe

Back condenser

Figure C-1. Cooling unit

Capillary tube

Dryer

23

Page 24

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

Evaporator

Capillary tube

Suction pipe

Dryer

Charge pipe

Hot pipe

Charge pipe

Compressor

S.P. connector

Sub. condenser Back condenser

Figure C-2. Location

Back condenser to

hot pipe

Compressor butyl

Suction pipe to

Compressor’s suction pipe

Charge pipe L to

Compressor’s process tube

Pinch point

Figure C-3. Location

Suction pipe to

S.P connector

Sub. condenser to

Back condenser

Compressor’s discharge pipe

to Sub. condenser

Pinch Point

Charge pipe L

to Dryer

Hot pipe

to Dryer

Dryer

to Capillary tube

24

Page 25

SERVICE MANUAL

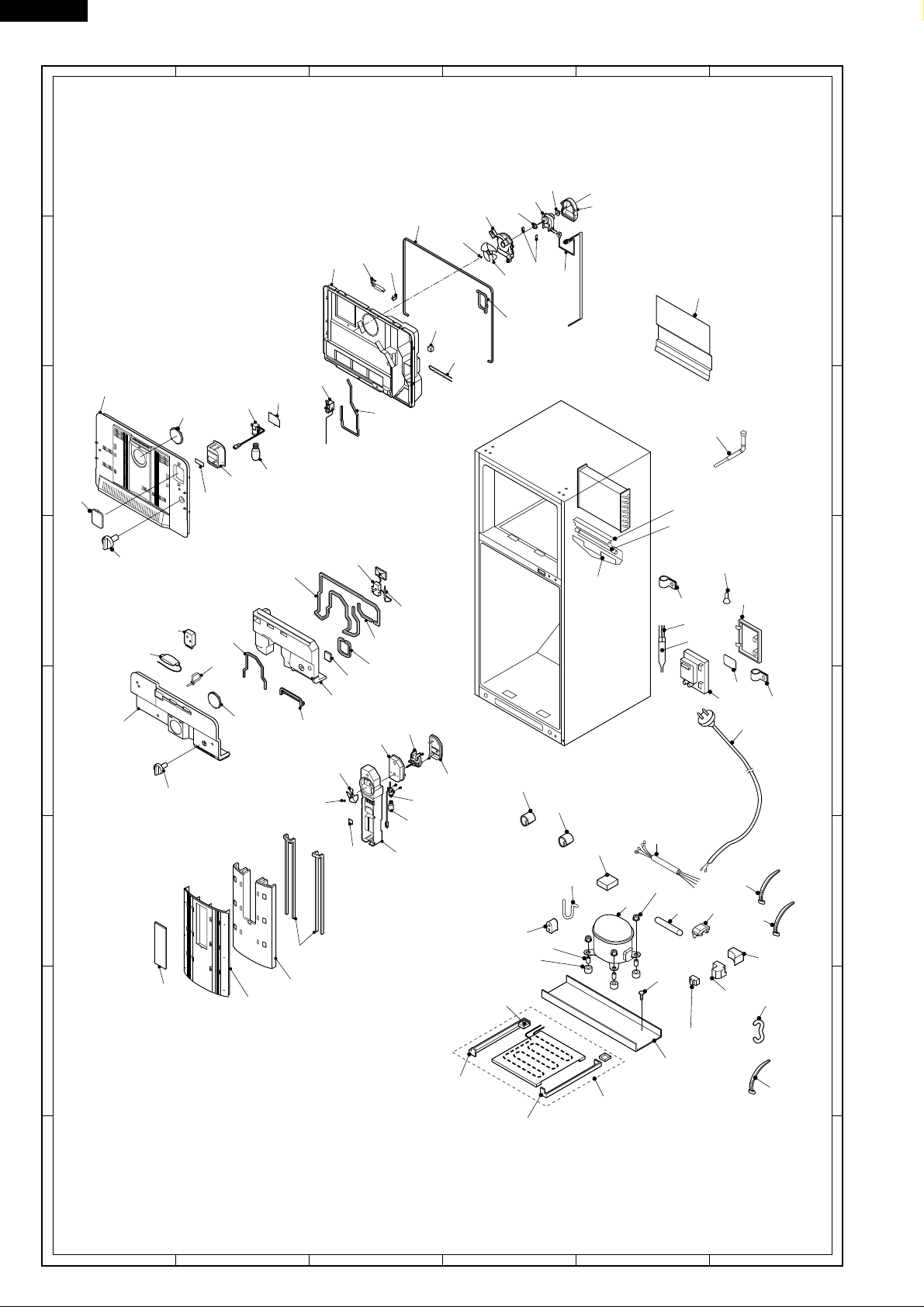

REPLACEMENT PARTS LIST

MODELS

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

SJ-58LSJ-63LSJ-68L-

DESTINATION .................. R

A2G/A2B/A2L/A2A

A2G/A2B/A2L/A2A

A2G/A2B/A2L/A2A

25

Page 26

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

REPLACEMENT PARTS LIST(SJ-58L-A2G/A2B/A2L/A2A)

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-58L SJ-58L SJ-58L SJ-58L

-A2G -A2B -A2L -A2A

ELECTRIC PARTS

1-1 RTHM-A097CBEZ F-thermostat 1111 AX

1-2 RSTT-A144CBE0 Starting relay 1111 AW

1-3 QSWTDA035CBE0 Defrost timer 1111 BB

1-4 PDMP-A046CBEZ Damper thermo 1111 AX

1-5 FTHM-A028CBKZ Defrost thermo.assembly 1111 AN

1-6 RMOTRA040CBE0 Fan motor 1111 AZ

1-7 QSOCAA074CBEZ Lamp socket 1111 AP

1-8 RLMP-A012CBE0 Lamp 1111 AH

1-9 QACC-A096CBE0 Source cord 1111 AX

1-10 QSW-PA090CBZA Door switch 1111 AS

1-11 RHOG-A084CBE0 Protector 1111 AN

1-17 FFS-TA055CBKZ Fuse assembly 1111 AL

1-20 FW-VZA144CBEZ Lead ev-cover assembly 1111 AK

1-21 FHETBA149CBEZ Def.heater assembly 1111 BB

1-22 FCNW-A517CBK0 Relay cord s assembly 1111 AM

1-25 QTAN-A032CBE0 Terminal block 1111 AE

1-27 RMOTRA061CBEZ Fan motor 1111 AW

1-28 RLMP-A029CBEZ Lamp15W 1111 AH

1-29 QSOCAA072CBEZ Lamp socket 1111 AN

1-30 FTHM-A029CBKZ R fan thermo assembly 1111 AQ

MECHANICAL PARTS

2-2 JKNB-A036CBFB F-temp. control knob 1111 AD

2-4 LPLTMA568CBEZ Fl plate AL. 1111 AF

2-7 FLEGPA077CBKZ Leg holder L assembly 1111 AQ

2-7-1 FAJS-A009CBK0 Adjustable leg assembly 2222 AD

2-7-2 LHLD-A533CBPZ Leg holder L 1111 AL

2-8 FLEGPA078CBKZ Leg holder R assembly 1111 AQ

2-8-2 LHLD-A534CBPZ Leg holder R 1111 AP

2-10 PSPAVA083CBEA Upper hinge spacer 1111 AD

2-11 PSPAVA084CBEA Bottom hinge spacer 1111 AC

2-12 PSPAVA075CBEA Center hinge spacer 1111 AD

2-13 DHNG-A363CBMZ Upper hinge assembly 1111 AE

2-14 DHNG-A365CBMZ Bottom hinge R assembly 1111 AE

2-15 DHNG-A364CBMZ Center hinge R assembly 1111 AF

2-16 GCOV-A191CBFZ E.V cover 1111 AS

2-17 LCRA-A010CBE0 Fan clamp 2222 AD

2-19 LHLD-A389CBF0 Motor cushion 2222 AF

2-20 NFANPA020CBFA Propeller fan 100 1111 AE

2-21 PSEL-B845CBEZ E.V cover sealer A 1111 AC

2-22 PSEL-B846CBEZ E.V cover sealer B 1111 AC

2-23 PSEL-A415CBE0 E.V cover sealer C 1111 AC

2-24 PCOVPA164CBFA Terminal cover 1111 AE

2-25 PCOV-A253CBFA F lamp cover 1111 AC

2-26 PCOV-A254CBFA R lamp cover 1111 AF

2-27 GCOVPA119CBRA R-Cbox cover 1111 AS

2-28 HGRL-A184CBRA Fan louver 1111 AU

2-29 GCOV-A162CBFB Upper hinge cover -1-- AD

2-29 GCOV-A162CBFG Upper hinge cover 1--- AD

2-29 GCOV-A162CBFH Upper hinge cover ---1 AD

2-29 GCOV-A162CBFK Upper hinge cover --1- AD

2-30 PCOV-A255CBFA Fan cover 2222 AD

2-31 JKNB-A033CBFB R-temp.control knob 1111 AD

2-36 PCAP-A006CBFS Screw cover -2-- AB

2-36 PCAP-A006CBFU Screw cover --2- AB

2-36 PCAP-A006CBFX Screw cover 2--- AB

2-36 PCAP-A006CBFY Screw cover ---2 AB

2-37 PCAP-A056CBFF Screw cover B 2222 AC

2-38 PGID-A156CBFZ R air guider A 1111 AG

2-41 PSEL-B848CBEZ A-sealer thermo.cap 1111 AC

2-49 LSTPPA108CBFA Chilled stopper 2222 AC

2-50 NFANPA019CBFA Propeller fan 80 1111 AM

2-51 PBOX-A121CBFA F lamp box 1111 AF

2-52 PBOX-A122CBFA R lamp box 1111 AM

2-53 LHLD-A536CBFA R fan motor holder A 1111 AF

2-54 LHLD-A537CBFA R fan motor holder B 1111 AE

2-55 HGRL-A188CBFA Multi louver S 1111 AG

2-56 PFPFPB248CBFZ R-louver insu. S 1111 AE

2-57 PSEL-B861CBEZ A-sealer r-louver 2222 AC

2-59 PCOV-A264CBEZ F lamp box cover 1111 AC

2-63 LHLD-A484CBFA Fan motor holder B 1111 AH

2-64 LHLD-A485CBFA Fan motor holder A 1111 AH

2-65 PSEL-B209CBE0 U-sealer handle 2222 AB

2-66 PSHEMA132CBP0 Heater cover AL 1111 AD

26

Page 27

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-58L SJ-58L SJ-58L SJ-58L

-A2G -A2B -A2L -A2A

2-67 LPLTMA570CBPZ Drain support AL 1 1 1 1 AE

2-69 PSEL-B847CBEZ E.V cover sealer D 2 2 2 2 AC

2-71 PSEL-A552CBE0 Dial sealer 1 1 1 1 AC

2-72 PSEL-B841CBEZ Ra sealer A 2 2 2 2 AC

2-73 PSEL-B842CBEZ Ra sealer B 1 1 1 1 AC

2-74 PSEL-B122CBE0 A-sealer thermo.cap. 1 1 1 1 AB

2-77 LHLD-A391CBE0 Sl-5N clip 1 1 1 1 AD

2-78 LPLTMA399CBP0 Dryer support 1 1 1 1 AD

2-79 LBND-A019CBE0 Nylon band 1 1 1 1 AB

2-80 PBOX-A071CBFA Terminal box 1 1 1 1 AE

2-81 PPIPPA097CBEZ Drain pipe S 1 1 1 1 AE

2-83 PSEL-B849CBEZ Ra sealer C 1 1 1 1 AC

2-84 PSEL-B850CBEZ Ra sealer D 1 1 1 1 AC

2-86 LBND-A026CBE0 Nylon band 1 1 1 1 AD

2-87 LBND-A018CBE0 Fasting band A 1 1 1 1 AP

2-90 HGRL-A179CBFA F shower duct 1 1 1 1 AM

2-91 HGRL-A180CBFA F return cover 2 2 2 2 AC

2-93 PCAP-A068CBFA C sliding cap A 2 2 2 2 AC

2-95 NROL-A027CBEZ V roller 2 2 2 2 AC

2-96 LHLD-A535CBFA Shaft holder 2 2 2 2 AC

2-97 LPIN-A178CB1Z Shaft 2 2 2 2 AC

2-99 GCOV-A192CBFA Top cover 1 - - - AC

2-99 GCOV-A192CBFB Top cover - 1 - - AK

2-99 GCOV-A192CBFC Top cover - - - 1 AD

2-99 GCOV-A192CBFF Top cover - - 1 - AC

2-105 PSEL-B896CBEZ A-sealer FS-A 1 1 1 1 AC

2-106 PSEL-B897CBEZ A-sealer FS-B 2 2 2 2 AC

DOOR PARTS

3-5 FDORFB299CBKZ F-door assembly 1 - - - BK

3-5 FDORFB306CBKZ F-door assembly - 1 - - BM

3-5 FDORFB307CBKZ F-door assembly - - - 1 BK

3-5 FDORFB313CBKZ F-door assembly - - 1 - BL

3-5-1 LSTPPA107CBFA Fd stopper spring R 1 1 1 1 AD

3-5-2 NBRGPA022CBFA Nylon bearing 3S 2 2 2 2 AC

3-5-3 PCOV-A251CBFA Dc cover FR 1 - - - AC

3-5-3 PCOV-A251CBFB Dc cover FR - 1 - - AC

3-5-3 PCOV-A251CBFC Dc cover FR - - - 1 AC

3-5-3 PCOV-A251CBFF Dc cover FR - - 1 - AC

3-6 FPACGA309CBKZ F-door packing 1 1 1 1 AX

3-7 HDECQA384CBFA Handle trim FL 1 1 1 - AD

3-7 HDECQA384CBFB Handle trim FL - - - 1 AG

3-8 JHNDPA117CBFA Door handle FL 1 - - - AK

3-8 JHNDPA117CBFB Door handle FL - 1 - - AM

3-8 JHNDPA117CBFC Door handle FL - - - 1 AN

3-8 JHNDPA117CBFF Door handle FL - - 1 - AP

3-9 PCAP-A067CBFA Screw cover HD 10 - - - AC

3-9 PCAP-A067CBFB Screw cover HD - 10 - - AC

3-9 PCAP-A067CBFC Screw cover HD - - - 10 AD

3-9 PCAP-A067CBFF Screw cover HD - - 10 - AC

3-15 FDORRB181CBKZ R-door assembly 1 - - - BP

3-15 FDORRB183CBKZ R-door assembly - 1 - - BP

3-15 FDORRB184CBKZ R-door assembly - - - 1 BN

3-15 FDORRB189CBKZ R-door assembly - - 1 - BN

3-15-1 LSTP-A058CBM0 R-door stopper R 1 1 1 1 AF

3-15-2 LSTPPA084CBFA Rd-stopper spring R 1 1 1 1 AD

3-15-3 PCOV-A252CBFA Dc cover RR 1 - - - AC

3-15-3 PCOV-A252CBFB Dc cover RR - 1 - - AC

3-15-3 PCOV-A252CBFC Dc cover RR - - - 1 AC

3-15-3 PCOV-A252CBFF Dc cover RR - - 1 - AC

3-17 FPACGA315CBKZ R-door packing 1 1 1 1 AY

3-18 HDECQA385CBFA Handle trim RL 1 1 1 - AG

3-18 HDECQA385CBFB Handle trim RL - - - 1 AG

3-19 JHNDPA118CBFA Door handle RL 1 - - - AK

3-19 JHNDPA118CBFB Door handle RL - 1 - - AM

3-19 JHNDPA118CBFC Door handle RL - - - 1 AN

3-19 JHNDPA118CBFF Door handle RL - - 1 - AP

3-25 FBDGDA280CBYZ Badge assembly 1 1 1 1 AY

OTHER PARTS

4-1 LBND-A023CBE0 L-band C 4 4 4 4 AC

4-3 LX-VZA003CBE0 Special screw 2 2 2 2 AB

4-10 QTAN-A013CBE0 Solderless term. A 4 4 4 4 AH

4-15 LX-BZA018CBE0 Special screw 1 1 1 1 AA

4-17 LX-WZA003CBE0 Washer 4 4 4 4 AA

4-18 LX-BZA076CBEZ Handle screw 10 10 10 10 AC

27

Page 28

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-58L SJ-58L SJ-58L SJ-58L

-A2G -A2B -A2L -A2A

ATTACHMENT PARTS

5-1 UPOK-A166CBRA Bottle pocket 2222 AN

5-3 UPOK-A168CBRA F door pocket 2222 AP

5-4 UPOK-A165CBRA R door pocket 1111 AN

5-5 UTNA-A282CBFB Egg tray 2222 AG

5-6 FSRA-A193CBYZ Ice cube maker 1111 AS

5-9 FSRA-A194CBKZ F shelf assembly 1111 AY

5-13 HGRL-A178CBFA Ventilating grille 1--- AG

5-13 HGRL-A178CBFB Ventilating grille -1-- AM

5-13 HGRL-A178CBFC Ventilating grille ---1 AN

5-13 HGRL-A178CBFF Ventilating grille --1- AN

5-14 USRA-A252CBFA Drain pan 1111 AN

5-15 UYOK-A330CBFA Fruit case 1111 AW

5-16 UYOK-A331CBFA Vegetable case 1111 AZ

5-17 UYOK-A328CBFA Ice storage box 1111 AF

5-18 UYOK-A329CBFA Chilled case 1111 AX

5-19 GDORPA066CBRA Chilled door 1111 AP

5-24 FTNA-A301CBKZ R glass shelf assembly 2222 BC

5-25 FTNA-A302CBKZ V glass shelf assembly 1111 BC

5-26 PCAP-A076CBFA Venti.grille cap 1--- AC

5-26 PCAP-A076CBFB Venti.grille cap -1-- AC

5-26 PCAP-A076CBFC Venti.grille cap ---1 AD

5-26 PCAP-A076CBFF Venti.grille cap --1- AC

5-28 PCAP-A069CBFA V sliding cap L 1111 AC

5-29 PCAP-A070CBFA V sliding cap R 1111 AC

5-31 LRALPA132CBFA Ice tray holder L 1111 AF

5-32 LRALPA133CBFA Ice tray holder R 1111 AF

5-33 LRALPA134CBFA Ice tray holder B 1111 AF

5-34 PCUP-A009CBFA Water cup 1111 AD

5-35 UPOKPA251CBFA Tube stand 2222 AC

5-36 PCOV-A259CBFA Case cover 1111 AH

5-37 UPOK-A167CBRA Utility case pocket 1111 AM

CYCLE PARTS

6-1 PCMPLA196CBE0 Compressor 1111 BX

6-2 PSPAGA028CBE0 Rubber grommet 4444 AD

6-3 FCONSA077CBKZ Sub. condenser assembly 1111 AX

6-3-1 PCOV-A256CBFA Pipe protector L 1111 AF

6-3-2 PCOV-A257CBFA Pipe protector R 1111 AF

6-4 FFRM-A113CBKZ Base frame assembly 1111 AW

6-5 FDRY-A006CBK0 Dryer assembly 1111 AX

6-6 PCLI-A035CBE0 Clip 1111 AC

6-9 PSPAFA020CBE0 Sleeve 4444 AB

6-11 PPIPCA357CBEZ S.p connector 1111 AK

6-15 PGUM-A002CBF0 Absorbent rubber B 1111 AH

6-18 PPIPCA252CBE0 Charge pipe 2222 AD

6-21 PCOVPA165CBE0 Terminal cover 1111 AF

6-27 PSEL-B899CBEZ S-sealer 2222 AC

6-28 PKYU-A143CBEZ S-butyl 1111 AD

6-29 PKYU-A036CBE0 Sp-butyl d-poy 1111 AP

6-30 PKYU-A098CBE0 Compressor butyl 1111 AG

MISCELLANEOUS

90-1 TINS-A491CBRZ Operation manual 1111 AF

90-2 TLAB-A092CBR0 Lamp label 1111 AD

90-3 SPAKCI800YDEZ Packing case 58L 1111 BB

90-5 TLAB-A897CBEZ Case label A2G 4--- AC

90-5 TLAB-A916CBEZ Case label A2B -4-- AC

90-5 TLAB-A927CBEZ Case label A2L --4- AC

90-5 TLAB-A937CBEZ Case label A2A ---4 AB

90-6 CPADBA765YDKZ Bottom pad assembly 1111 AY

90-7 CPADBA764YDKZ Top pad assembly 1111 AR

90-8 TLAB-A876CBRZ Warning label 1111 AC

90-21 TLAB-A939CBRZ Caution label ROF 1111 AD

HOW TO ORDER REPLACEMENT PARTS

To have your order filled promptly and correctly, please furnish the following information.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

28

Page 29

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

REPLACEMENT PARTS LIST(SJ-63L-A2G/A2B/A2L/A2A)

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-63L SJ-63L SJ-63L SJ-63L

-A2G -A2B -A2L -A2A

ELECTRIC PARTS

1-1 RTHM-A097CBEZ F-thermostat 1 1 1 1 AX

1-2 RSTT-A144CBE0 Starting relay 1 1 1 1 AW

1-3 QSWTDA035CBE0 Defrost timer 1 1 1 1 BB

1-4 PDMP-A046CBEZ Damper thermo 1 1 1 1 AX

1-5 FTHM-A028CBKZ Defrost thermo.assembly 1 1 1 1 AN

1-6 RMOTRA040CBE0 Fan motor 1 1 1 1 AZ

1-7 QSOCAA074CBEZ Lamp socket 1 1 1 1 AP

1-8 RLMP-A012CBE0 Lamp 1 1 1 1 AH

1-9 QACC-A096CBE0 Source cord 1 1 1 1 AX

1-10 QSW-PA090CBZA Door switch 1 1 1 1 AS

1-11 RHOG-A084CBE0 Protector 1 1 1 1 AN

1-17 FFS-TA055CBKZ Fuse assembly 1 1 1 1 AL

1-20 FW-VZA144CBEZ Lead ev-cover assembly 1 1 1 1 AK

1-21 FHETBA149CBEZ Def.heater assembly 1 1 1 1 BB

1-22 FCNW-A517CBK0 Relay cord s assembly 1 1 1 1 AM

1-25 QTAN-A032CBE0 Terminal block 1 1 1 1 AE

1-27 RMOTRA061CBEZ Fan motor 1 1 1 1 AW

1-28 RLMP-A029CBEZ Lamp 15W 1 1 1 1 AH

1-29 QSOCAA072CBEZ Lamp socket 1 1 1 1 AN

1-30 FTHM-A029CBKZ R fan thermo assembly 1 1 1 1 AQ

MECHANICAL PARTS

2-2 JKNB-A036CBFB F-temp. control knob 1 1 1 1 AD

2-4 LPLTMA568CBEZ Fl plate AL. 1 1 1 1 AF

2-7 FLEGPA077CBKZ Leg holder L assembly 1 1 1 1 AQ

2-7-1 FAJS-A009CBK0 Adjustable leg assembly 2 2 2 2 AD

2-7-2 LHLD-A533CBPZ Leg holder L 1 1 1 1 AC

2-8 FLEGPA078CBKZ Leg holder R assembly 1 1 1 1 AQ

2-8-2 LHLD-A534CBPZ Leg holder R 1 1 1 1 AP

2-10 PSPAVA083CBEA Upper hinge spacer 1 1 1 1 AD

2-11 PSPAVA084CBEA Bottom hinge spacer 1 1 1 1 AC

2-12 PSPAVA075CBEA Center hinge spacer 1 1 1 1 AD

2-13 DHNG-A363CBMZ Upper hinge assembly 1 1 1 1 AE

2-14 DHNG-A365CBMZ Bottom hinge R assembly 1 1 1 1 AE

2-15 DHNG-A364CBMZ Center hinge R assembly 1 1 1 1 AF

2-16 GCOV-A191CBFZ E.V cover 1 1 1 1 AS

2-17 LCRA-A010CBE0 Fan clamp 2 2 2 2 AD

2-19 LHLD-A389CBF0 Motor cushion 2 2 2 2 AF

2-20 NFANPA020CBFA Propeller fan 100 1 1 1 1 AE

2-21 PSEL-B845CBEZ E.V cover sealer A 1 1 1 1 AC

2-22 PSEL-B846CBEZ E.V cover sealer B 1 1 1 1 AC

2-23 PSEL-A415CBE0 E.V cover sealer C 1 1 1 1 AC

2-24 PCOVPA164CBFA Terminal cover 1 1 1 1 AE

2-25 PCOV-A253CBFA F lamp cover 1 1 1 1 AC

2-26 PCOV-A254CBFA R lamp cover 1 1 1 1 AF

2-27 GCOVPA119CBRA R-cbox cover 1 1 1 1 AS

2-28 HGRL-A184CBRA Fan louver 1 1 1 1 AU

2-29 GCOV-A162CBFB Upper hinge cover - 1 - - AD

2-29 GCOV-A162CBFG Upper hinge cover 1 - - - AD

2-29 GCOV-A162CBFH Upper hinge cover - - - 1 AD

2-29 GCOV-A162CBFK Upper hinge cover - - 1 - AD

2-30 PCOV-A255CBFA Fan cover 2 2 2 2 AD

2-31 JKNB-A033CBFB R-temp.control knob 1 1 1 1 AD

2-36 PCAP-A006CBFS Screw cover - 2 - - AB

2-36 PCAP-A006CBFU Screw cover - - 2 - AB

2-36 PCAP-A006CBFX Screw cover 2 - - - AB

2-36 PCAP-A006CBFY Screw cover - - - 2 AB

2-37 PCAP-A056CBFF Screw cover B 2 2 2 2 AC

2-38 PGID-A156CBFZ R air guider A 1 1 1 1 AG

2-41 PSEL-B848CBEZ A-sealer thermo.cap 1 1 1 1 AC

2-49 LSTPPA108CBFA Chilled stopper 2 2 2 2 AC

2-50 NFANPA019CBFA Propeller fan 80 1 1 1 1 AM

2-51 PBOX-A121CBFA F lamp box 1 1 1 1 AF

2-52 PBOX-A122CBFA R lamp box 1 1 1 1 AM

2-53 LHLD-A536CBFA R fan motor holder A 1 1 1 1 AF

2-54 LHLD-A537CBFA R fan motor holder B 1 1 1 1 AE

2-55 HGRL-A186CBFA Multi louver M 1 1 1 1 AM

2-56 PFPFPB239CBFZ R-louver insu. M 1 1 1 1 AF

2-57 PSEL-B857CBEZ A-sealer R-louver 2 2 2 2 AC

2-59 PCOV-A264CBEZ F lamp box cover 1 1 1 1 AC

2-63 LHLD-A484CBFA Fan motor holder B 1 1 1 1 AH

2-64 LHLD-A485CBFA Fan motor holder A 1 1 1 1 AH

2-65 PSEL-B209CBE0 U-sealer handle 2 2 2 2 AB

2-66 PSHEMA132CBP0 Heater cover AL 1 1 1 1 AD

29

Page 30

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-63L SJ-63L SJ-63L SJ-63L

-A2G -A2B -A2L -A2A

2-67 LPLTMA570CBPZ Drain support AL 1111 AE

2-69 PSEL-B847CBEZ E.V cover sealer D 2222 AC

2-71 PSEL-A552CBE0 Dial sealer 1111 AC

2-72 PSEL-B841CBEZ Ra sealer A 2222 AC

2-73 PSEL-B842CBEZ Ra sealer B 1111 AC

2-74 PSEL-B122CBE0 A-sealer thermo.cap. 1111 AB

2-77 LHLD-A391CBE0 Sl-5N clip 1111 AD

2-78 LPLTMA399CBP0 Dryer support 1111 AD

2-79 LBND-A019CBE0 Nylon band 1111 AB

2-80 PBOX-A071CBFA Terminal box 1111 AE

2-81 PPIPPA097CBEZ Drain pipe S 1111 AE

2-83 PSEL-B849CBEZ RA sealer C 1111 AC

2-84 PSEL-B850CBEZ RA sealer D 1111 AC

2-86 LBND-A026CBE0 Nylon band 1111 AD

2-87 LBND-A018CBE0 Fasting band A 1111 AP

2-90 HGRL-A179CBFA F shower duct 1111 AM

2-91 HGRL-A180CBFA F return cover 2222 AC

2-93 PCAP-A068CBFA C sliding cap A 2222 AC

2-95 NROL-A027CBEZ V roller 2222 AC

2-96 LHLD-A535CBFA Shaft holder 2222 AC

2-97 LPIN-A178CB1Z Shaft 2222 AC

2-99 GCOV-A192CBFA Top cover 1--- AC

2-99 GCOV-A192CBFB Top cover -1-- AK

2-99 GCOV-A192CBFC Top cover ---1 AD

2-99 GCOV-A192CBFF Top cover --1- AC

2-105 PSEL-B896CBEZ A-sealer FS-A 1111 AC

2-106 PSEL-B897CBEZ A-sealer FS-B 2222 AC

DOOR PARTS

3-5 FDORFB299CBKZ F-door assembly 1--- BK

3-5 FDORFB306CBKZ F-door assembly -1-- BM

3-5 FDORFB307CBKZ F-door assembly ---1 BK

3-5 FDORFB313CBKZ F-door assembly --1- BL

3-5-1 LSTPPA107CBFA Fd stopper spring R 1111 AD

3-5-2 NBRGPA022CBFA Nylon bearing 3S 2222 AC

3-5-3 PCOV-A251CBFA Dc cover FR 1--- AC

3-5-3 PCOV-A251CBFB Dc cover FR -1-- AC

3-5-3 PCOV-A251CBFC Dc cover FR ---1 AC

3-5-3 PCOV-A251CBFF Dc cover FR --1- AC

3-6 FPACGA309CBKZ F-door packing 1111 AX

3-7 HDECQA384CBFA Handle trim FL 111- AD

3-7 HDECQA384CBFB Handle trim FL ---1 AG

3-8 JHNDPA117CBFA Door handle FL 1--- AK

3-8 JHNDPA117CBFB Door handle FL -1-- AM

3-8 JHNDPA117CBFC Door handle FL ---1 AN

3-8 JHNDPA117CBFF Door handle FL --1- AP

3-9 PCAP-A067CBFA Screw cover HD 10 - - - AC

3-9 PCAP-A067CBFB Screw cover HD - 10 - - AC

3-9 PCAP-A067CBFC Screw cover HD - - - 10 AD

3-9 PCAP-A067CBFF Screw cover HD - - 10 - AC

3-15 FDORRB173CBKZ R-door assembly 1--- BQ

3-15 FDORRB174CBKZ R-door assembly -1-- BQ

3-15 FDORRB176CBKZ R-door assembly ---1 BP

3-15 FDORRB182CBKZ R-door assembly --1- BR

3-15-1 LSTP-A058CBM0 R-door stopper R 1111 AF

3-15-2 LSTPPA084CBFA Rd-stopper spring R 1111 AD

3-15-3 PCOV-A252CBFA Dc cover RR 1--- AC

3-15-3 PCOV-A252CBFB Dc cover RR -1-- AC

3-15-3 PCOV-A252CBFC Dc cover RR ---1 AC

3-15-3 PCOV-A252CBFF Dc cover RR --1- AC

3-17 FPACGA314CBKZ R-door packing 1111 AY

3-18 HDECQA385CBFA Handle trim RL 111- AG

3-18 HDECQA385CBFB Handle trim RL ---1 AG

3-19 JHNDPA118CBFA Door handle RL 1--- AK

3-19 JHNDPA118CBFB Door handle RL -1-- AM

3-19 JHNDPA118CBFC Door handle RL ---1 AN

3-19 JHNDPA118CBFF Door handle RL --1- AP

3-25 FBDGDA280CBYZ Badge assembly 1111 AY

OTHER PARTS

4-1 LBND-A023CBE0 L-band C 4444 AC

4-3 LX-VZA003CBE0 Special screw 2222 AB

4-10 QTAN-A013CBE0 Solderless term. A 4444 AH

4-15 LX-BZA018CBE0 Special screw 1111 AA

4-17 LX-WZA003CBE0 Washer 4444 AA

4-18 LX-BZA076CBEZ Handle screw 10 10 10 10 AC

30

Page 31

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-63L SJ-63L SJ-63L SJ-63L

-A2G -A2B -A2L -A2A

ATTACHMENT PARTS

5-1 UPOK-A166CBRA Bottle pocket 2 2 2 2 AN

5-3 UPOK-A168CBRA F door pocket 2 2 2 2 AP

5-4 UPOK-A165CBRA R door pocket 1 1 1 1 AN

5-5 UTNA-A282CBFB Egg tray 2 2 2 2 AG

5-6 FSRA-A193CBYZ Ice cube maker 1 1 1 1 AS

5-9 FSRA-A194CBKZ F shelf assembly 1 1 1 1 AY

5-13 HGRL-A178CBFA Ventilating grille 1 - - - AG

5-13 HGRL-A178CBFB Ventilating grille - 1 - - AM

5-13 HGRL-A178CBFC Ventilating grille - - - 1 AN

5-13 HGRL-A178CBFF Ventilating grille - - 1 - AN

5-14 USRA-A252CBFA Drain pan 1 1 1 1 AN

5-15 UYOK-A330CBFA Fruit case 1 1 1 1 AW

5-16 UYOK-A331CBFA Vegetable case 1 1 1 1 AZ

5-17 UYOK-A328CBFA Ice storage box 1 1 1 1 AF

5-18 UYOK-A329CBFA Chilled case 1 1 1 1 AX

5-19 GDORPA066CBRA Chilled door 1 1 1 1 AP

5-24 FTNA-A301CBKZ R glass shelf assembly 2 2 2 2 BC

5-25 FTNA-A302CBKZ V glass shelf assembly 1 1 1 1 BC

5-26 PCAP-A076CBFA Venti.grille cap 1 - - - AC

5-26 PCAP-A076CBFB Venti.grille cap - 1 - - AC

5-26 PCAP-A076CBFC Venti.grille cap - - - 1 AD

5-26 PCAP-A076CBFF Venti.grille cap - - 1 - AC

5-28 PCAP-A069CBFA V sliding cap L 1 1 1 1 AC

5-29 PCAP-A070CBFA V sliding cap R 1 1 1 1 AC

5-31 LRALPA132CBFA Ice tray holder L 1 1 1 1 AF

5-32 LRALPA133CBFA Ice tray holder R 1 1 1 1 AF

5-33 LRALPA134CBFA Ice tray holder B 1 1 1 1 AF

5-34 PCUP-A009CBFA Water cup 1 1 1 1 AD

5-35 UPOKPA251CBFA Tube stand 2 2 2 2 AC

5-36 PCOV-A259CBFA Case cover 1 1 1 1 AH

5-37 UPOK-A167CBRA Utility case pocket 1 1 1 1 AM

CYCLE PARTS

6-1 PCMPLA196CBE0 Compressor 1 1 1 1 BX

6-2 PSPAGA028CBE0 Rubber grommet 4 4 4 4 AD

6-3 FCONSA077CBKZ Sub. condenser assembly 1 1 1 1 AX

6-3-1 PCOV-A256CBFA Pipe protector L 1 1 1 1 AF

6-3-2 PCOV-A257CBFA Pipe protector R 1 1 1 1 AF

6-4 FFRM-A113CBKZ Base frame assembly 1 1 1 1 AW

6-5 FDRY-A006CBK0 Dryer assembly 1 1 1 1 AX

6-6 PCLI-A035CBE0 Clip 1 1 1 1 AC

6-9 PSPAFA020CBE0 Sleeve 4 4 4 4 AB

6-11 PPIPCA357CBEZ S.p connector 1 1 1 1 AK

6-15 PGUM-A002CBF0 Absorbent rubber B 1 1 1 1 AH

6-18 PPIPCA252CBE0 Charge pipe 2 2 2 2 AD

6-21 PCOVPA165CBE0 Terminal cover 1 1 1 1 AF

6-27 PSEL-B899CBEZ S-sealer 2 2 2 2 AC

6-28 PKYU-A143CBEZ S-butyl 1 1 1 1 AD

6-29 PKYU-A036CBE0 Sp-butyl d-poy 1 1 1 1 AP

6-30 PKYU-A098CBE0 Compressor butyl 1 1 1 1 AG

MISCELLANEOUS

90-1 TINS-A491CBRZ Operation manual 1 1 1 1 AF

90-2 TLAB-A092CBR0 Lamp label 1 1 1 1 AD

90-3 SPAKCI777YDEZ Packing case 63L 1 1 1 1 BC

90-5 TLAB-A897CBEZ Case label A2G 4 - - - AC

90-5 TLAB-A916CBEZ Case label A2B - 4 - - AC

90-5 TLAB-A927CBEZ Case label A2L - - 4 - AC

90-5 TLAB-A937CBEZ Case label A2A - - - 4 AB

90-6 CPADBA765YDKZ Bottom pad assembly 1 1 1 1 AY

90-7 CPADBA764YDKZ Top pad assembly 1 1 1 1 AR

90-8 TLAB-A876CBRZ Warning label 1 1 1 1 AC

90-21 TLAB-A939CBRZ Caution label ROF 1 1 1 1 AD

HOW TO ORDER REPLACEMENT PARTS

To have your order filled promptly and correctly, please furnish the following information.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

31

Page 32

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

REPLACEMENT PARTS LIST(SJ-68L-A2G/A2B/A2L/A2A)

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-68L SJ-68L SJ-68L SJ-68L

-A2G -A2B -A2L -A2A

ELECTRIC PARTS

1-1 RTHM-A097CBEZ F-thermostat 1111 AX

1-2 RSTT-A144CBE0 Starting relay 1111 AW

1-3 QSWTDA035CBE0 Defrost timer 1111 BB

1-4 PDMP-A046CBEZ Damper thermo 1111 AX

1-5 FTHM-A028CBKZ Defrost thermo.assembly 1111 AN

1-6 RMOTRA040CBE0 Fan motor 1111 AZ

1-7 QSOCAA074CBEZ Lamp socket 1111 AP

1-8 RLMP-A012CBE0 Lamp 1111 AH

1-9 QACC-A096CBE0 Source cord 1111 AX

1-10 QSW-PA090CBZA Door switch 1111 AS

1-11 RHOG-A105CBE0 Protector 1111 AV

1-17 FFS-TA055CBKZ Fuse assembly 1111 AL

1-20 FW-VZA144CBEZ Lead EV-cover assembly 1111 AK

1-21 FHETBA149CBEZ Def.heater assembly 1111 BB

1-22 FCNW-A517CBK0 Relay cord S assembly 1111 AM

1-25 QTAN-A032CBE0 Terminal block 1111 AE

1-27 RMOTRA061CBEZ Fan motor 1111 AW

1-28 RLMP-A029CBEZ Lamp15W 1111 AH

1-29 QSOCAA072CBEZ Lamp socket 1111 AN

1-30 FTHM-A029CBKZ R fan thermo assembly 1111 AQ

MECHANICAL PARTS

2-2 JKNB-A036CBFB F-temp. control knob 1111 AD

2-4 LPLTMA568CBEZ Fl plate AL. 1111 AF

2-7 FLEGPA077CBKZ Leg holder L assembly 1111 AQ

2-7-1 FAJS-A009CBK0 Adjustable leg assembly 2222 AD

2-7-2 LHLD-A533CBPZ Leg holder L 1111 AL

2-8 FLEGPA078CBKZ Leg holder R assembly 1111 AQ

2-8-2 LHLD-A534CBPZ Leg holder R 1111 AP

2-10 PSPAVA083CBEA Upper hinge spacer 1111 AD

2-11 PSPAVA084CBEA Bottom hinge spacer 1111 AC

2-12 PSPAVA075CBEA Center hinge spacer 1111 AD

2-13 DHNG-A363CBMZ Upper hinge assembly 1111 AE

2-14 DHNG-A365CBMZ Bottom hinge R assembly 1111 AE

2-15 DHNG-A364CBMZ Center hinge R assembly 1111 AF

2-16 GCOV-A191CBFZ E.V cover 1111 AS

2-17 LCRA-A010CBE0 Fan clamp 2222 AD

2-19 LHLD-A389CBF0 Motor cushion 2222 AF

2-20 NFANPA020CBFA Propeller fan 100 1111 AE

2-21 PSEL-B845CBEZ E.V cover sealer A 1111 AC

2-22 PSEL-B846CBEZ E.V cover sealer B 1111 AC

2-23 PSEL-A415CBE0 E.V cover sealer C 1111 AC

2-24 PCOVPA164CBFA Terminal cover 1111 AE

2-25 PCOV-A253CBFA F lamp cover 1111 AC

2-26 PCOV-A254CBFA R lamp cover 1111 AF

2-27 GCOVPA119CBRA R-cbox cover 1111 AS

2-28 HGRL-A184CBRA Fan louver 1111 AU

2-29 GCOV-A162CBFB Upper hinge cover -1-- AD

2-29 GCOV-A162CBFG Upper hinge cover 1--- AD

2-29 GCOV-A162CBFH Upper hinge cover ---1 AD

2-29 GCOV-A162CBFK Upper hinge cover --1- AD

2-30 PCOV-A255CBFA Fan cover 2222 AD

2-31 JKNB-A033CBFB R-temp.control knob 1111 AD

2-36 PCAP-A006CBFS Screw cover -2-- AB

2-36 PCAP-A006CBFU Screw cover --2- AB

2-36 PCAP-A006CBFX Screw cover 2--- AB

2-36 PCAP-A006CBFY Screw cover ---2 AB

2-37 PCAP-A056CBFF Screw cover B 2222 AC

2-38 PGID-A156CBFZ R air guider A 1111 AG

2-41 PSEL-B848CBEZ A-sealer thermo.cap 1111 AC

2-49 LSTPPA108CBFA Chilled stopper 2222 AC

2-50 NFANPA019CBFA Propeller fan 80 1111 AM

2-51 PBOX-A121CBFA F lamp box 1111 AF

2-52 PBOX-A122CBFA R lamp box 1111 AM

2-53 LHLD-A536CBFA R fan motor holder A 1111 AF

2-54 LHLD-A537CBFA R fan motor holder B 1111 AE

2-55 HGRL-A181CBFA Multi louver L 1111 AN

2-56 PFPFPB233CBFZ R-louver insu. L 1111 AG

2-57 PSEL-B843CBEZ A-sealer r-louver 2222 AC

2-59 PCOV-A264CBEZ F lamp box cover 1111 AC

2-63 LHLD-A484CBFA Fan motor holder B 1111 AH

2-64 LHLD-A485CBFA Fan motor holder A 1111 AH

2-65 PSEL-B209CBE0 U-sealer handle 2222 AB

2-66 PSHEMA132CBP0 Heater cover AL 1111 AD

32

Page 33

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-68L SJ-68L SJ-68L SJ-68L

-A2G -A2B -A2L -A2A

2-67 LPLTMA570CBPZ Drain support AL 1 1 1 1 AE

2-69 PSEL-B847CBEZ E.V cover sealer D 2 2 2 2 AC

2-71 PSEL-A552CBE0 Dial sealer 1 1 1 1 AC

2-72 PSEL-B841CBEZ RA sealer A 2 2 2 2 AC

2-73 PSEL-B842CBEZ RA sealer B 1 1 1 1 AC

2-74 PSEL-B122CBE0 A-sealer thermo.cap. 1 1 1 1 AB

2-77 LHLD-A391CBE0 Sl-5N clip 1 1 1 1 AD

2-78 LPLTMA399CBP0 Dryer support 1 1 1 1 AD

2-79 LBND-A019CBE0 Nylon band 1 1 1 1 AB

2-80 PBOX-A071CBFA Terminal box 1 1 1 1 AE

2-81 PPIPPA097CBEZ Drain pipe S 1 1 1 1 AE

2-83 PSEL-B849CBEZ Ra sealer C 1 1 1 1 AC

2-84 PSEL-B850CBEZ Ra sealer D 1 1 1 1 AC

2-86 LBND-A026CBE0 Nylon band 1 1 1 1 AD

2-87 LBND-A018CBE0 Fasting band A 1 1 1 1 AP

2-90 HGRL-A179CBFA F shower duct 1 1 1 1 AM

2-91 HGRL-A180CBFA F return cover 2 2 2 2 AC

2-93 PCAP-A068CBFA C sliding cap A 2 2 2 2 AC

2-95 NROL-A027CBEZ V roller 2 2 2 2 AC

2-96 LHLD-A535CBFA Shaft holder 2 2 2 2 AC

2-97 LPIN-A178CB1Z Shaft 2 2 2 2 AC

2-99 GCOV-A192CBFA Top cover 1 - - - AC

2-99 GCOV-A192CBFB Top cover - 1 - - AK

2-99 GCOV-A192CBFC Top cover - - - 1 AD

2-99 GCOV-A192CBFF Top cover - - 1 - AC

2-105 PSEL-B896CBEZ A-sealer FS-A 1 1 1 1 AC

2-106 PSEL-B897CBEZ A-sealer FS-B 2 2 2 2 AC

DOOR PARTS

3-5 FDORFB299CBKZ F-door assembly 1 - - - BK

3-5 FDORFB306CBKZ F-door assembly - 1 - - BM

3-5 FDORFB307CBKZ F-door assembly - - - 1 BK

3-5 FDORFB313CBKZ F-door assembly - - 1 - BL

3-5-1 LSTPPA107CBFA Fd stopper spring R 1 1 1 1 AD

3-5-2 NBRGPA022CBFA Nylon bearing 3S 2 2 2 2 AC

3-5-3 PCOV-A251CBFA Dc cover FR 1 - - - AC

3-5-3 PCOV-A251CBFB Dc cover FR - 1 - - AC

3-5-3 PCOV-A251CBFC Dc cover FR - - - 1 AC

3-5-3 PCOV-A251CBFF Dc cover FR - - 1 - AC

3-6 FPACGA309CBKZ F-door packing 1 1 1 1 AX

3-7 HDECQA384CBFA Handle trim FL 1 1 1 - AD

3-7 HDECQA384CBFB Handle trim FL - - - 1 AG

3-8 JHNDPA117CBFA Door handle FL 1 - - - AK

3-8 JHNDPA117CBFB Door handle FL - 1 - - AM

3-8 JHNDPA117CBFC Door handle FL - - - 1 AN

3-8 JHNDPA117CBFF Door handle FL - - 1 - AP

3-9 PCAP-A067CBFA Screw cover HD 10 - - - AC

3-9 PCAP-A067CBFB Screw cover HD - 10 - - AC

3-9 PCAP-A067CBFC Screw cover HD - - - 10 AD

3-9 PCAP-A067CBFF Screw cover HD - - 10 - AC

3-15 FDORRB166CBKZ R-door assembly 1 - - - BQ

3-15 FDORRB168CBKZ R-door assembly - 1 - - BR

3-15 FDORRB169CBKZ R-door assembly - - 1 BP

3-15 FDORRB175CBKZ R-door assembly - - 1 - BQ

3-15-1 LSTP-A058CBM0 R-door stopper R 1 1 1 1 AF

3-15-2 LSTPPA084CBFA Rd-stopper spring R 1 1 1 1 AD

3-15-3 PCOV-A252CBFA Dc cover RR 1 - - - AC

3-15-3 PCOV-A252CBFB Dc cover RR - 1 - - AC

3-15-3 PCOV-A252CBFC Dc cover RR - - - 1 AC

3-15-3 PCOV-A252CBFF Dc cover RR - - 1 - AC

3-17 FPACGA310CBKZ R-door packing 1 1 1 1 AY

3-18 HDECQA385CBFA Handle trim RL 1 1 1 - AG

3-18 HDECQA385CBFB Handle trim RL - - - 1 AG

3-19 JHNDPA118CBFA Door handle RL 1 - - - AK

3-19 JHNDPA118CBFB Door handle RL - 1 - - AM

3-19 JHNDPA118CBFC Door handle RL - - - 1 AN

3-19 JHNDPA118CBFF Door handle RL - - 1 - AP

3-25 FBDGDA280CBYZ Badge assembly 1 1 1 1 AN

OTHER PARTS

4-1 LBND-A023CBE0 L-band C 4 4 4 4 AC

4-3 LX-VZA003CBE0 Special screw 2 2 2 2 AB

4-10 QTAN-A013CBE0 Solderless term. A 4 4 4 4 AH

4-15 LX-BZA018CBE0 Special screw 1 1 1 1 AA

4-17 LX-WZA003CBE0 Washer 4 4 4 4 AA

4-18 LX-BZA076CBEZ Handle screw 10 10 10 10 AC

33

Page 34

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-68L SJ-68L SJ-68L SJ-68L

-A2G -A2B -A2L -A2A

ATTACHMENT PARTS

5-1 UPOK-A166CBRA Bottle pocket 2222 AN

5-3 UPOK-A168CBRA F door pocket 2222 AP

5-4 UPOK-A165CBRA R door pocket 2222 AN

5-5 UTNA-A282CBFB Egg tray 2222 AG

5-6 FSRA-A193CBYZ Ice cube maker 1111 AS

5-9 FSRA-A194CBKZ F shelf assembly 1111 AY

5-13 HGRL-A178CBFA Ventilating grille 1--- AG

5-13 HGRL-A178CBFB Ventilating grille -1-- AM

5-13 HGRL-A178CBFC Ventilating grille ---1 AN

5-13 HGRL-A178CBFF Ventilating grille --1- AN

5-14 USRA-A252CBFA Drain pan 1111 AN

5-15 UYOK-A330CBFA Fruit case 1111 AW

5-16 UYOK-A331CBFA Vegetable case 1111 AZ

5-17 UYOK-A328CBFA Ice storage box 1111 AF

5-18 UYOK-A329CBFA Chilled case 1111 AX

5-19 GDORPA066CBRA Chilled door 1111 AP

5-24 FTNA-A301CBKZ R glass shelf assembly 3333 BC

5-25 FTNA-A302CBKZ V glass shelf assembly 1111 BC

5-26 PCAP-A076CBFA Venti.grille cap 1--- AC

5-26 PCAP-A076CBFB Venti.grille cap -1-- AC

5-26 PCAP-A076CBFC Venti.grille cap ---1 AD

5-26 PCAP-A076CBFF Venti.grille cap --1- AC

5-28 PCAP-A069CBFA V sliding cap L 1111 AC

5-29 PCAP-A070CBFA V sliding cap R 1111 AC

5-31 LRALPA132CBFA Ice tray holder L 1111 AF

5-32 LRALPA133CBFA Ice tray holder R 1111 AF

5-33 LRALPA134CBFA Ice tray holder B 1111 AF

5-34 PCUP-A009CBFA Water cup 1111 AD

5-35 UPOKPA251CBFA Tube stand 2222 AC

5-36 PCOV-A259CBFA Case cover 1111 AH

5-37 UPOK-A167CBRA Utility case pocket 1111 AM

CYCLE PARTS

6-1 PCMPLA202CBEZ Compressor 1111 BX

6-2 PSPAGA028CBE0 Rubber grommet 4444 AD

6-3 FCONSA077CBKZ Sub. condenser assembly 1111 AX

6-3-1 PCOV-A256CBFA Pipe protector L 1111 AF

6-3-2 PCOV-A257CBFA Pipe protector R 1111 AF

6-4 FFRM-A113CBKZ Base frame assembly 1111 AW

6-5 FDRY-A006CBK0 Dryer assembly 1111 AX

6-6 PCLI-A035CBE0 Clip 1111 AC

6-9 PSPAFA020CBE0 Sleeve 4444 AB

6-11 PPIPCA357CBEZ S.P connector 1111 AK

6-15 PGUM-A002CBF0 Absorbent rubber B 1111 AH

6-18 PPIPCA252CBE0 Charge pipe 2222 AD

6-21 PCOVPA165CBE0 Terminal cover 1111 AF

6-27 PSEL-B899CBEZ S-sealer 2222 AC

6-28 PKYU-A143CBEZ S-butyl 1111 AD

6-29 PKYU-A036CBE0 Sp-butyl d-poy 1111 AP

6-30 PKYU-A098CBE0 Compressor butyl 1111 AG

MISCELLANEOUS

90-1 TINS-A491CBRZ Operation manual 1111 AF

90-2 TLAB-A092CBR0 Lamp label 1111 AD

90-3 SPAKCI775YDEZ Packing case 68L 1111 BC

90-5 TLAB-A897CBEZ Case label A2G 4--- AC

90-5 TLAB-A916CBEZ Case label A2B -4-- AC

90-5 TLAB-A927CBEZ Case label A2L --4- AC

90-5 TLAB-A937CBEZ Case label A2A ---4 AB

90-6 CPADBA765YDKZ Bottom pad assembly 1111 AY

90-7 CPADBA764YDKZ Top pad assembly 1111 AR

90-8 TLAB-A876CBRZ Warning label 1111 AC

90-21 TLAB-A939CBRZ Caution label ROF 1111 AD

HOW TO ORDER REPLACEMENT PARTS

To have your order filled promptly and correctly, please furnish the following information.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

34

Page 35

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

123456

DOOR PARTS

A

3-9

3-6

A

3-8

B

3-9

3-9

3-9

4-18

4-18

4-18

C

3-7

3-9

3-9

3-9

3-18

4-18

4-18

4-18

4-18

D

E

3-9

3-15

3-19

3-5

4-18

3-25

3-9

3-9

4-18

4-18

3-5-2

3-5-3

3-5-1

3-5-2

3-15-3

5-34

5-36

5-5

B

C

5-3

D

5-37

E

5-4

F

G

H

123456

35

3-15-1

3-15-2

5-35

3-17

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

F

5-1

G

H

Page 36

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

A

123456

CABINET PARTS

A

B

5-31

5-6

5-17

C

D

5-19

2-93

5-32

5-18

5-33

5-9

2-105

2-93

2-90

5-26

2-106

5-14

2-37

2-49

2-36

2-99

2-95

2-96

4-3

2-11

1-10

2-15

2-97

2-13

2-29

2-36

2-12

B

2-10

2-91

C

2-49

2-95

2-96

D

E

5-28

F

G

5-15

5-16

5-24

5-29

5-25

5-13

2-7

2-14

2-7-2

2-7-1

2-8

2-8-2

2-7-1

E

F

G

H

123456

36

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

H

Page 37

123456

CABINET PARTS

A

B

2-16

1-5

4-1

2-21

2-17

2-64

2-19

2-20

1-6

2-65

2-19

1-20

2-63

2-4

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

A

B

2-28

C

2-25

2-2

D

1-3

1-30

2-27

E

2-31

2-30

90-2

2-79

2-51

2-84

1-29

2-30

1-8

2-59

2-72

2-74

2-17

1-1

2-38

2-50

2-71

90-8

1-4

2-83

2-73

2-53

2-69

2-41

1-27

2-52

1-7

1-28

2-23

1-17

2-54

2-22

6-29

6-28

2-67

6-30

1-22

2-66

1-21

2-78

6-18

6-5

2-81

2-80

4-10

2-24

1-9

C

D

2-77

E

F

2-26

G

H

123456

2-55

2-57

2-56

37

6-3-1

6-27

6-15

6-2

6-3-2

6-9

6-11

6-3

6-1

4-17

6-18

4-15

6-4

4-1

1-11

6-21

1-2

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

F

2-86

1-25

6-6

G

2-87

H

Page 38

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

SERVICE MANUAL

REPLACEMENT PARTS LIST

MODELS

SJ-58LSJ-63LSJ-68L-

DESTINATION .................. Y

A2G/A2B/A2L/A2A

A2G/A2B/A2L/A2A

A2G/A2B/A2L/A2A

38

Page 39

SJ-58L-A2

SJ-63L-A2

SJ-68L-A2

REPLACEMENT PARTS LIST(SJ-58L-A2G/A2B/A2L/A2A)

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-58L SJ-58L SJ-58L SJ-58L

-A2G -A2B -A2L -A2A

ELECTRIC PARTS

1-1 RTHM-A097CBEZ F-thermostat 1 1 1 1 AX

1-2 RSTT-A144CBE0 Starting relay 1 1 1 1 AW

1-3 QSWTDA035CBE0 Defrost timer 1 1 1 1 BB

1-4 PDMP-A046CBEZ Damper thermo 1 1 1 1 AX

1-5 FTHM-A028CBKZ Defrost thermo. assembly 1 1 1 1 AN

1-6 RMOTRA040CBE0 Fan motor 1 1 1 1 AZ

1-7 QSOCAA074CBEZ Lamp socket 1 1 1 1 AP

1-8 RLMP-A012CBE0 Lamp 1 1 1 1 AH

1-9 QACC-A101CBE0 Source cord 1 1 1 1 AN

1-10 QSW-PA090CBZA Door switch 1 1 1 1 AS

1-11 RHOG-A084CBE0 Protector 1 1 1 1 AN

1-17 FFS-TA055CBKZ Fuse assembly 1 1 1 1 AL

1-20 FW-VZA144CBEZ Lead ev-cover assembly 1 1 1 1 AK

1-21 FHETBA149CBEZ Def.heater assembly 1 1 1 1 BB

1-22 FCNW-A514CBK0 Relay cord S assembly 1 1 1 1 AN

1-25 QTAN-A032CBE0 Terminal block 1 1 1 1 AE

1-27 RMOTRA061CBEZ Fan motor 1 1 1 1 AW

1-28 RLMP-A029CBEZ Lamp15W 1 1 1 1 AH

1-29 QSOCAA072CBEZ Lamp socket 1 1 1 1 AN

1-30 FTHM-A029CBKZ R fan thermo assembly 1 1 1 1 AQ

MECHANICAL PARTS

2-2 JKNB-A036CBFB F-temp. control knob 1 1 1 1 AD

2-4 LPLTMA568CBEZ Fl plate AL. 1 1 1 1 AF

2-7 FLEGPA077CBKZ Leg holder L assembly 1 1 1 1 AQ

2-7-1 FAJS-A009CBK0 Adjustable leg assembly 2 2 2 2 AD

2-7-2 LHLD-A533CBPZ Leg holder L 1 1 1 1 AL

2-8 FLEGPA078CBKZ Leg holder R assembly 1 1 1 1 AQ

2-8-2 LHLD-A534CBPZ Leg holder R 1 1 1 1 AP

2-10 PSPAVA083CBEA Upper hinge spacer 1 1 1 1 AD

2-11 PSPAVA084CBEA Bottom hinge spacer 1 1 1 1 AC

2-12 PSPAVA075CBEA Center hinge spacer 1 1 1 1 AD