Page 1

SERVICE MANUAL

CODE: 00ZSFA58/SM1E

Reversing Automatic

Document Feeder

MODEL SF-A58

CONTENTS

[ 1 ] PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[ 3 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[ 4 ] STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

[ 5 ] OPERATIONAL DESCRIPTIONS (MECHANISM SECTION) . . . . . . . . . . . 7

[ 6 ] DISASSEMBLY, ASSEMBLY AND ADJUSTMENT . . . . . . . . . . . . . . . . . 18

[ 7 ] CONNECTOR LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

[ 8 ] REPLACEMENT PARTS AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . 25

[ 9 ] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

[10] CIRCUIT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

[11] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

■ PARTS GUIDE

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

[1] PRODUCT OVERVIEW

The SF-A58 is a reversing automatic document feeder (RADF) for the

copier SF-2052. The SF-A56 is capable of automatically copying both

sides of document by inverting the document sheets up-side down,

while feeding them.

Even document sheets of different lengths and the same width may

be set in the document tray, an internal sensor in the ADF senses the

document size when the document is fed. The copier automatically

selects the proper copy paper corresponding to the document size

along with the appropriate magnification ratio.

If the appropriate copy paper, respective to the document size and

the magnification ratio, is not available, the copier stops copying and

indicates the required paper size on the display.

[Display]

• Document feed indicator: Lights when documents are set on

feed tray and indicates that RADF is

ready.

• Remove original indicator: When originals are placed manually,

the LED lights at the same time as

exposure of the last document sheet

is finished. The LED goes out when

the document feed cover is opened.

[3] UNPACKING AND

INSTALLATION

[2] SPECIFICATIONS

• Document setting direction: Face-up

• Document setting position: Center alignment

• Document transfer system: Belt drive

• Document feed sequence: Bottom take-up feeding

(Face-up discharge)

• Document size: A3 ∼ A5 (Portrait), 11" × 17" ∼

8-1/2" × 5-1/2"

• Document changing time: 0.46sec or less

(Excluding the first copy)

• Document weight: Thin paper mode; 35 ∼ 50g/m

Standard mode ; 51 ∼ 128g/m

• Max. No. of documents to be set:

50 sheets (A4, letter)

35 ∼ 80g/m2 (9 ∼ 21lb),

6.5mm thick or less

80 ∼ 128g/m2 (21 ∼ 33lb),

5mm thick or less

• Document stopper: Mechanical stopper (Duplex)

• Dimensions: SF-A56;

592 (W) × 521 (D) × 110 (H)mm

23-5/16" (W) × 20-33/64" (D) ×

4-11/32" (H)

SF-A17;

571 (W) × 521 (D) × 110 (H)mm

22-31/64" (W) × 20-33/64" (D) ×

4-11/32" (H)

• Weight: About 12kg

[Features]

• Document detection on tray (Irregular-sized documents are copied

without size recognition.)

• Recognized paper sizes: Inch series (USA/Canada):

11" × 17", 8-1/2" × 14", 8-1/2" ×

11", 8-1/2" × 11"R, 8-1/2" × 5-1/2"

Inch series (Other areas):

11" × 17", 8-1/2" × 14", 8-1/2" ×

11", 8-1/2" × 11"R, 8-1/2" × 51/2", 8-1/2" × 13"

AB series (Europe, UK):

A3, B4, A4, A4R, A5

AB series (Australia, Other areas):

A3, B4, A4, A4R, A5, 8-1/2" × 13"

Taiwan:

A3, B4, A4, A4R, B5, B5R

• Mixed document: Possible

• Document inversion: Automatic

2

2

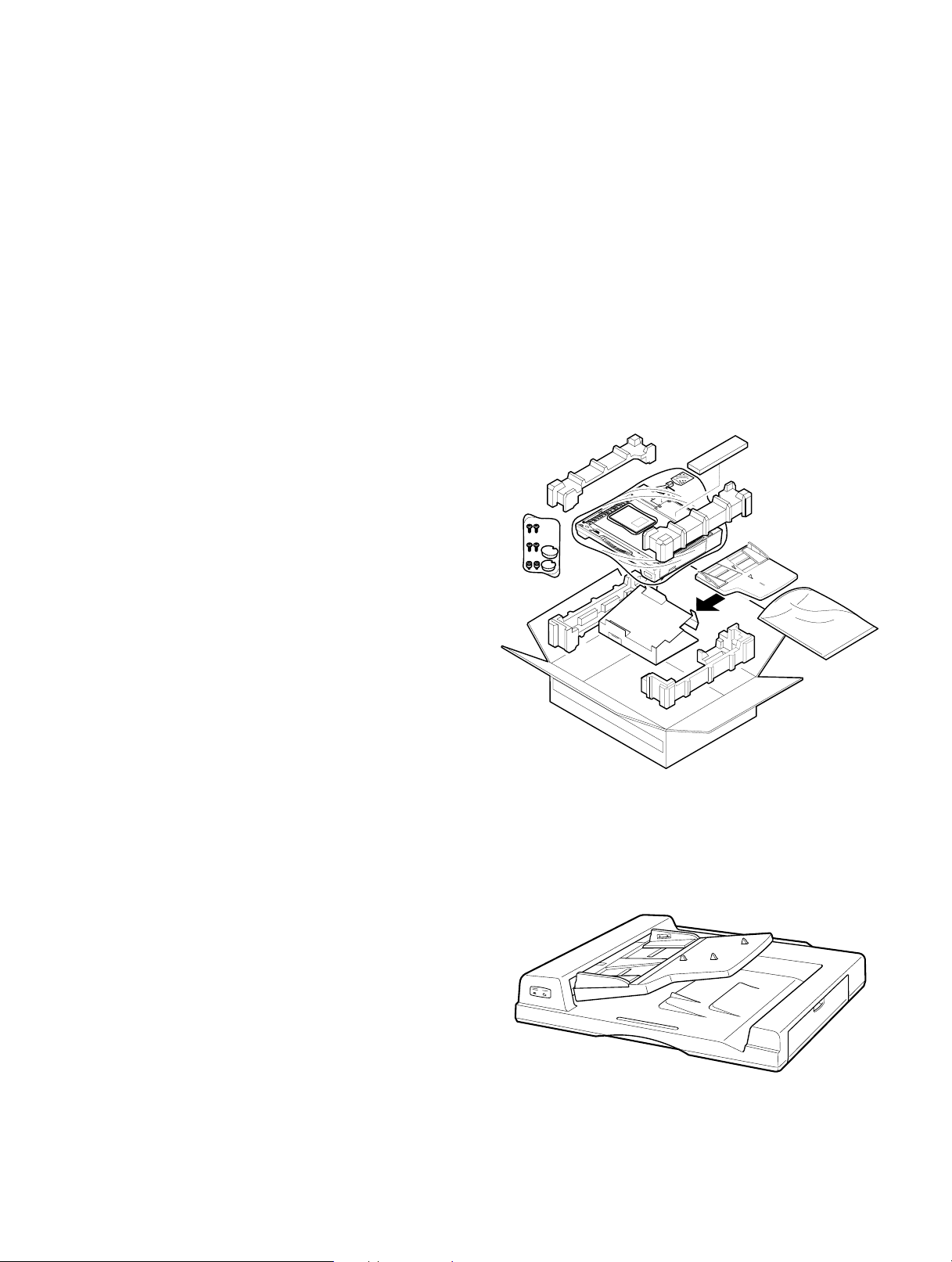

1. Unpackin g

When unpacking, refer to the figure below.

2. Installation

– 1 –

Page 3

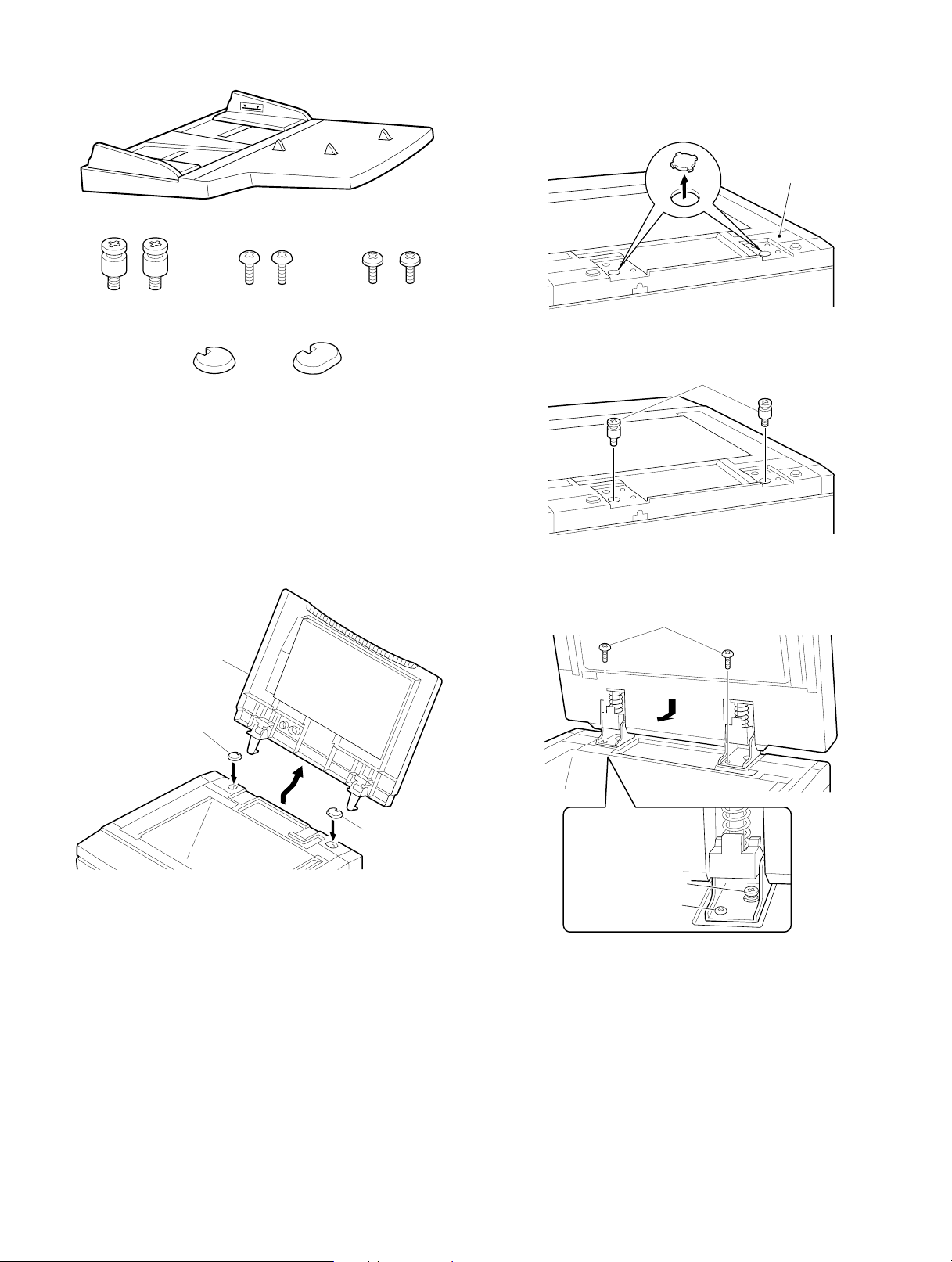

Included parts

2. Mount the ADF onto the copier.

Remove the two cut-outs from the rear part of the upper cover of the

copier.

Cut-outs

Rear part of

upper cover

ADF tray

ADF mounting screws

(2 pcs.)

ADF securing screws

(2 pcs.)

Right cover

(1 pc.)

Tray securing screws

(2 pcs.)

Left cover

(1 pc.)

Unplug the copier and follow the procedure below.

1. Remove the document cover.

Open the document cover and lift it at a slight backward angle to

remove it.

Insert the left and right covers (included parts) into the holes from

which the document cover has been removed.

Document cover

Right cover

Install the two ADF mounting screws.

ADF mounting screws

Fit the ADF mounting screws into the holes in the hinges of the ADF

and secure the ADF with the two ADF securing screws.

ADF securing screws

Left cover

ADF mounting screw

ADF securing screw

– 2 –

Page 4

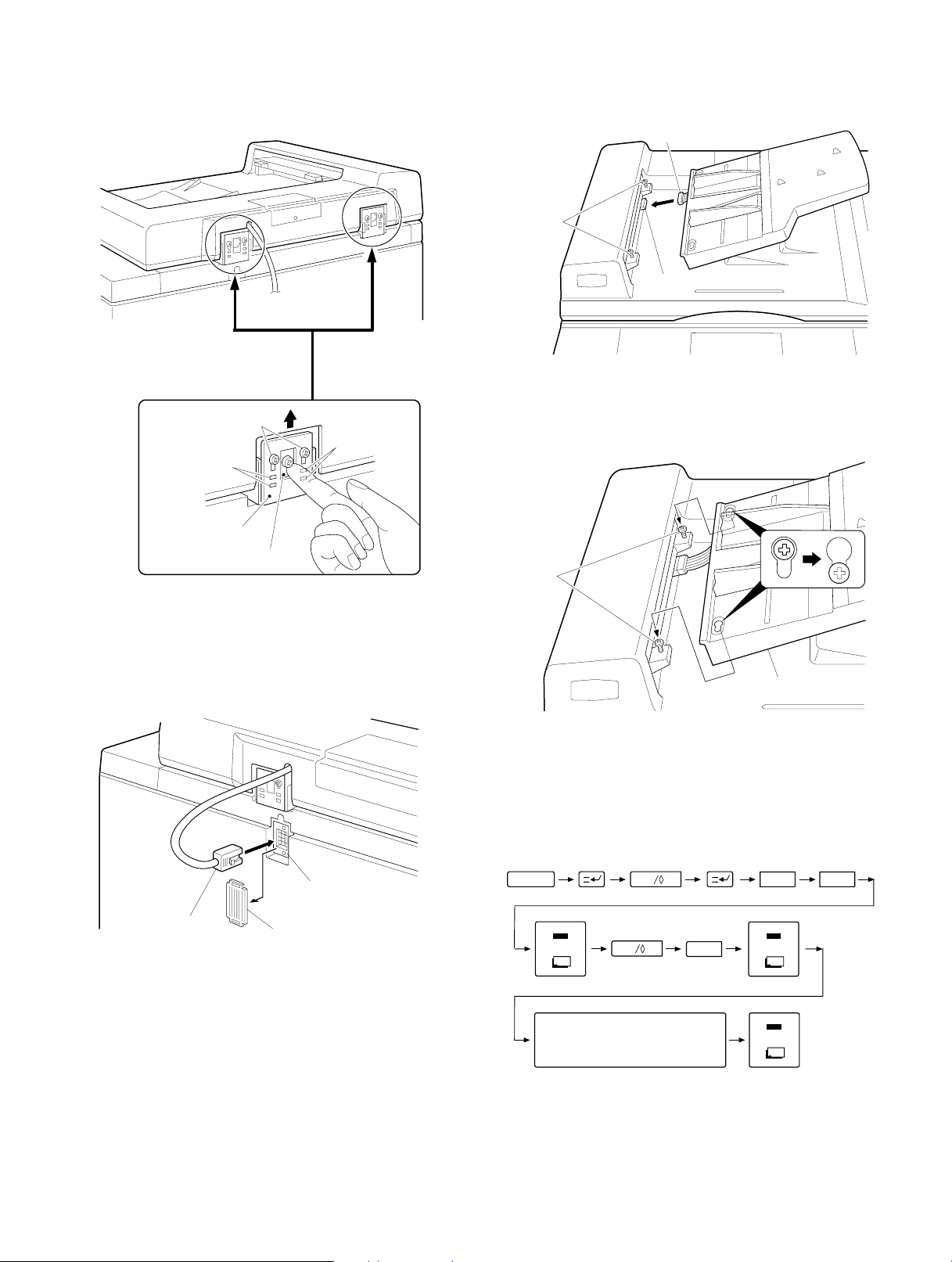

3. Adjust the angle of ADF.

Loosen the two securing screws for the angle adjusting panel attached to the hinge angle and then fasten the loosened screws while

raising the angle adjusting panel completely.

NOTE:

Be sure to check that the protrusion of

the angle adjusting panel is securely

inserted into the long hole of the hinge.

Angle adjusting panel

securing screws

Long hole

Long hole

5. Connect the ADF tray connector.

Thread the M4 x 8 tray securing screws (includedparts) partway into

their holes, then connect the tray connector.

Tray connector

Tray

securing

screws

Connector on the ADF

6. Attach the ADF tray.

Loosen the two ADF tray securing screws, install the tray as shown in

the figure, and fasten the tray securing screws.

Hinge

Angle adjusting panel

NOTE: Be sure to check that the protrusion of the angle adjusting

panel is securely inserted into the long hole of the hinge.

4. Connect the ADF connector.

Remove the connector cover from the copier’s rear cover.

Next, connect the ADF connector to the connector on the copier.

Connector on the copier

ADF connector

Connector cover

Tray

securing

screws

Tray

Plug the copier into a grounded outlet and turn the

power switch on.Then, follow the procedure below.

7. Set the mode.

• Perform the following key operations on the copier to set the

mode.

C0 2

0

1

6

– 3 –

Select an adequate number

from the display of the operation

panel using the 10-key pad.

to set the

mode.

Page 5

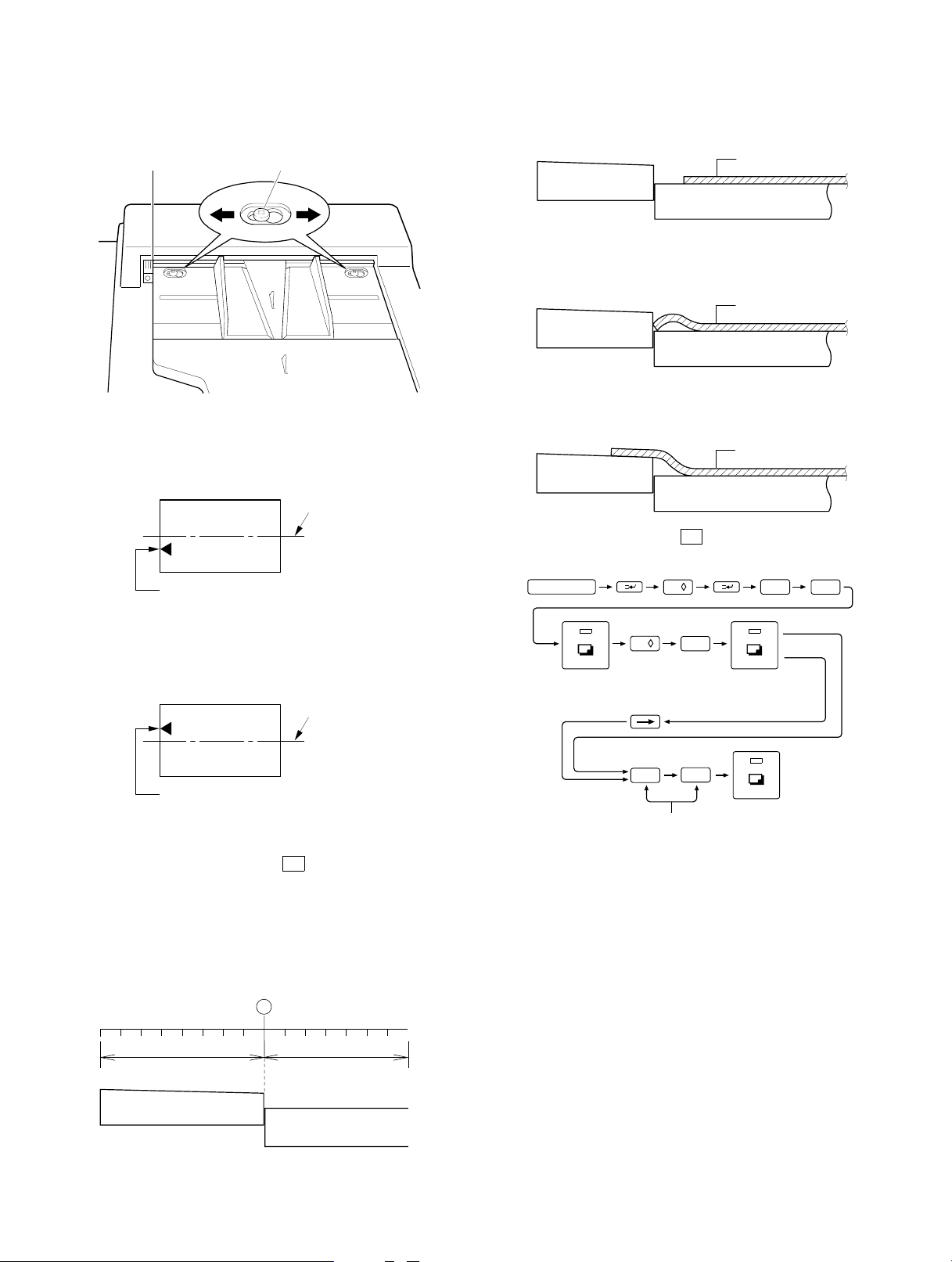

8. Adjust the center of the copy.

Set an original in the ADF tray and make a copy.

When the copy is off center as shown in Fig. 1 or Fig. 2, loosen the

two tray securing screws and adjust the tray by moving it in direction

A or B as shown in the figure.

Mark Tray securing screw

BA

• When off center as shown in fig. 1

Move the tray in direction A and secure it with the two mounting

screws.

Make a copy to check whether it is centered properly.

Fig. 1

Center of copy paper

Setup example

(1) If the leading edge of the original was not fed all the way to the

stopper, enter value which will move the original toward the stopper side.

7, 6, 5, 4...

Original

Stopper

Glass

(2) If the copy image at the leading edge was distorted, enter value

which will move the original toward the glass side.

9, 10, 11...

Original

Stopper

Glass

(3) If the original overrode the stopper, enter value which will move

the original toward the glass side.

9, 10, 11, 12 ...

Original

Stopper

Glass

Center of original image (first copy)

• When off center as shown in fig. 2

Move the tray in direction B and secure it with the two mounting

screws.

Make a copy to check whether it is centered properly.

Fig. 2

Center of original image (first copy)

Center of copy paper

9. Adjust the position of the leading edge of originals

• The position of the leading edge of originals fed from the ADF can

be determined using test command 53 .

• Although the leading edge has been factory set to stop at location

8, it may need to be adjusted depending on the type of originals.

The leading edge position can be adjusted within a range of 8 mm

(8 steps) on the stopper side and 7 mm (7 steps) on the glass side

in 1 mm increments.

Adjustment can be done separately for the one-sided, two-sided,

and thin paper modes.

0

234567

1

8

10 11 12 13 14 15

9

• After selecting test command 53 , enter a selected set value be-

tween 0 and 15 using the copier keys.

C

Set to between 0 and 15 as dictated

by the copier's performance.

The factory setting is "8".

0/

0/

1

(a)

(b)

5 3

(a)

(b)

One-sided mode

Two-sided mode

8mm

Stopper

View from the operator side

7mm

Glass

– 4 –

Page 6

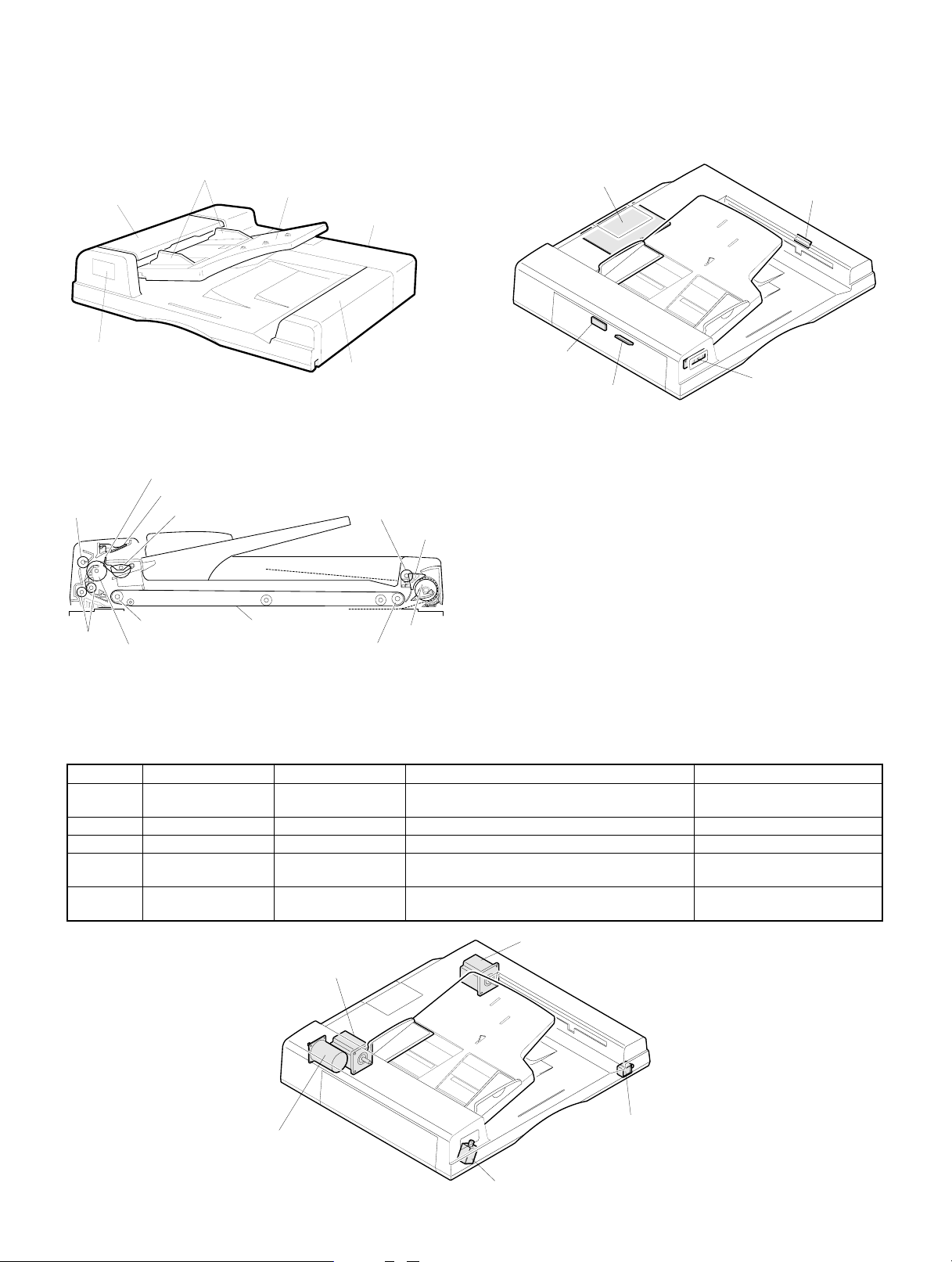

[4] STRUCTURE

A. External fitting

Original guide

Original feed cover

Display lamp

B. Mechanism

Original stopper

Separation

roller

A21 weight plate

Semi-circular roller

Original support

Original transport

cover

Original exit section

cover

Paper exit roller

Flapper

C. PWB distribution

Control PWB

Original reverse

sensor PWB

Original timing

sensor PWB

Reverse sensor

PWB (SF-A56 only)

LED PWB

Resist

roller

Transport belt

drive roller

Paper feed roller

Original transport belt

transport belt

follower roller

Reverse

roller

D. Motors, solenoids, and clutches

■ Motors

Code Name Type Functions and operations Contact/output

DFM Paper feed motor DC motor Drives the pickup roller, the separation roller,

DTM Transport motor Stepping motor Drives the transport belt roller.

DRM Reverse motor Stepping motor Drives the reverse roller and the paper exit roller.

DFSOL Paper feed solenoid DC solenoid Presses the paper feed section weight plate onto

DRSOL Reverse solenoid DC solenoid Drives the reverse flapper to select the paper

DTM

(Transport motor)

and the resist roller.

the original and opens/closes the shutter.

exit path or the reverse feed path.

DRM

(Reverse motor))

When this is ON, the weight

plate and the shutter fall.

When this is ON, the reverse

path is selected.

DFM

(Paper feed motor)

DRSOL

(Reverse solenoid)

DFSOL

(Paper feed solenoid)

– 5 –

Page 7

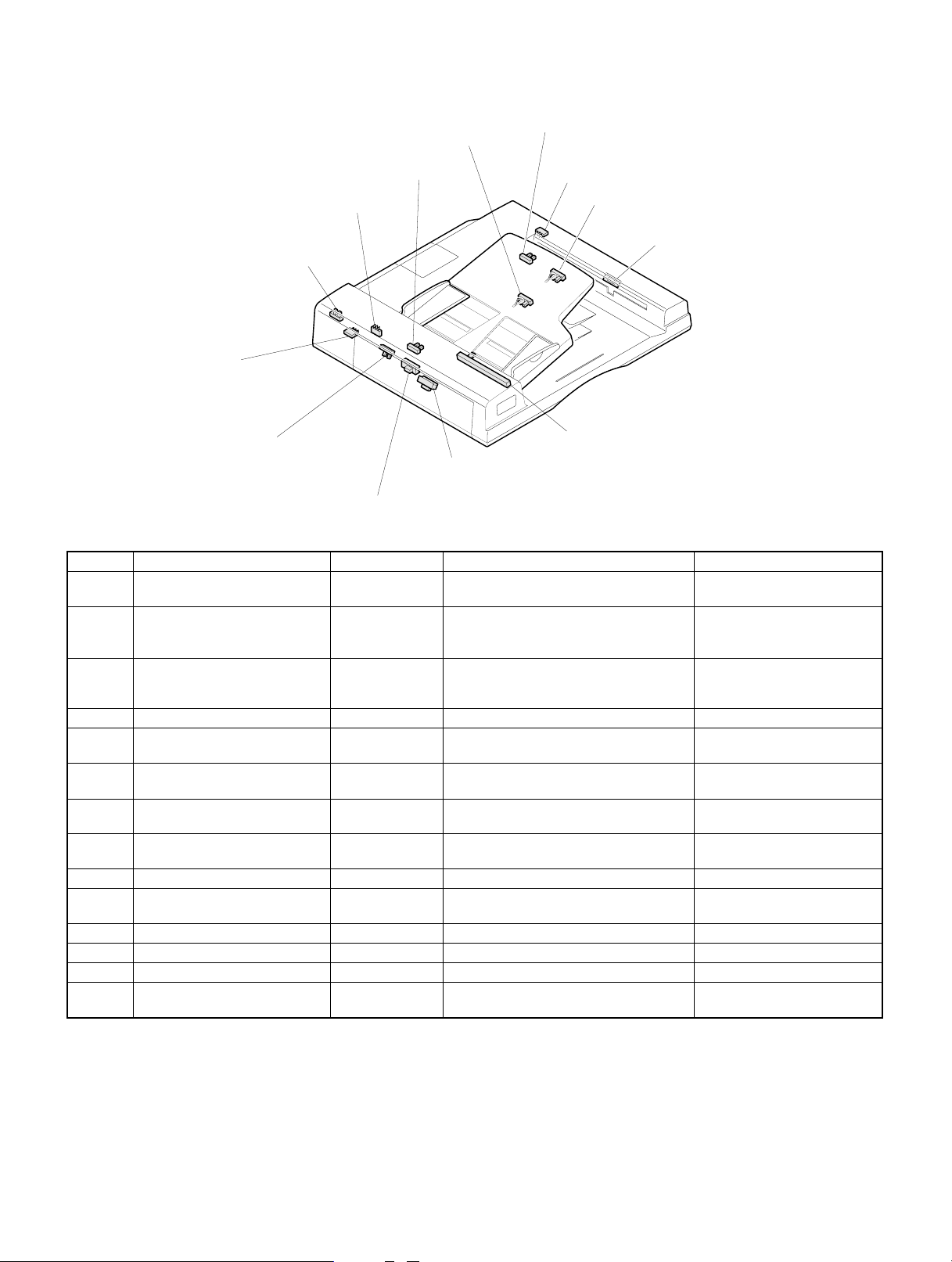

E. Sensor s, swit ch es, det ect or s

DSS

(Original set sensor)

AUOD

(ADF open/close sensor)

DFMRS

(Paper feed motor

rotation sensor)

FGOD

(Paper feed

guide switch)

DWS

(Original width sensor)

DLS1

(Original length sensor 1)

DTD

(Original timing sensor)

DFD

(Original feed sensor)

DLS3

(Original length sensor 3)

TGOD

(Reverse guide switch)

DLS2

(Original length sensor 2)

RDD

(Reverse sensor)

DWVR

(Original width volume)

Code Name Type Functions and operations Contact/output

DFD Original feed sensor Reflection sensor Turns HIGH when the original lead edge

is fed just in front of the resist roller.

DTD Original timing sensor Reflection sensor Turns HIGH when the original lead edge

is transported from the paper feed section

to the vicinity of the transport belt.

RDD Reverse sensor Reflection sensor Turns HIGH when the original lead edge

is transported to the reverse/paper exit

path.

DWVR Original width volume Slide volume Original width detection on the tray

DLS1 Original length sensor 1 Photo interrupter Original length detection on the tray HIGH when the original is

DLS2 Original length sensor 2 Photo interrupter Original length detection on the tray HIGH when the original is

DLS3 Original length sensor 3 Photo interrupter Original length detection on the tray HIGH when the original is

DSS Original set sensor Photo interrupter Original detection on the tray HIGH when the original is

DFMRS Paper feed motor rotation sensor Photo interrupter Paper feed motor rotation detection Pulse output

DWS Original width sensor Photo interrupter Original width detection LOW when the original is

AUOD ADF open/close sensor Microswitch ADF unit open/close detection LOW when closed.

FGOD Paper feed guide switch Microswitch Paper feed cover open/close detection LOW when closed.

TGOD Reverse guide switch Microswitch Reverse cover open/close detection LOW when closed.

DES Paper exit sensor Photo interrupter Turns HIGH when the original lead edge

is transported to the paper exit path

HIGH when the original is

sensed.

HIGH when the original is

sensed.

HIGH when the original is

sensed.

sensed.

sensed.

sensed.

sensed.

sensed.

HIGH when the original is

sensed.

– 6 –

Page 8

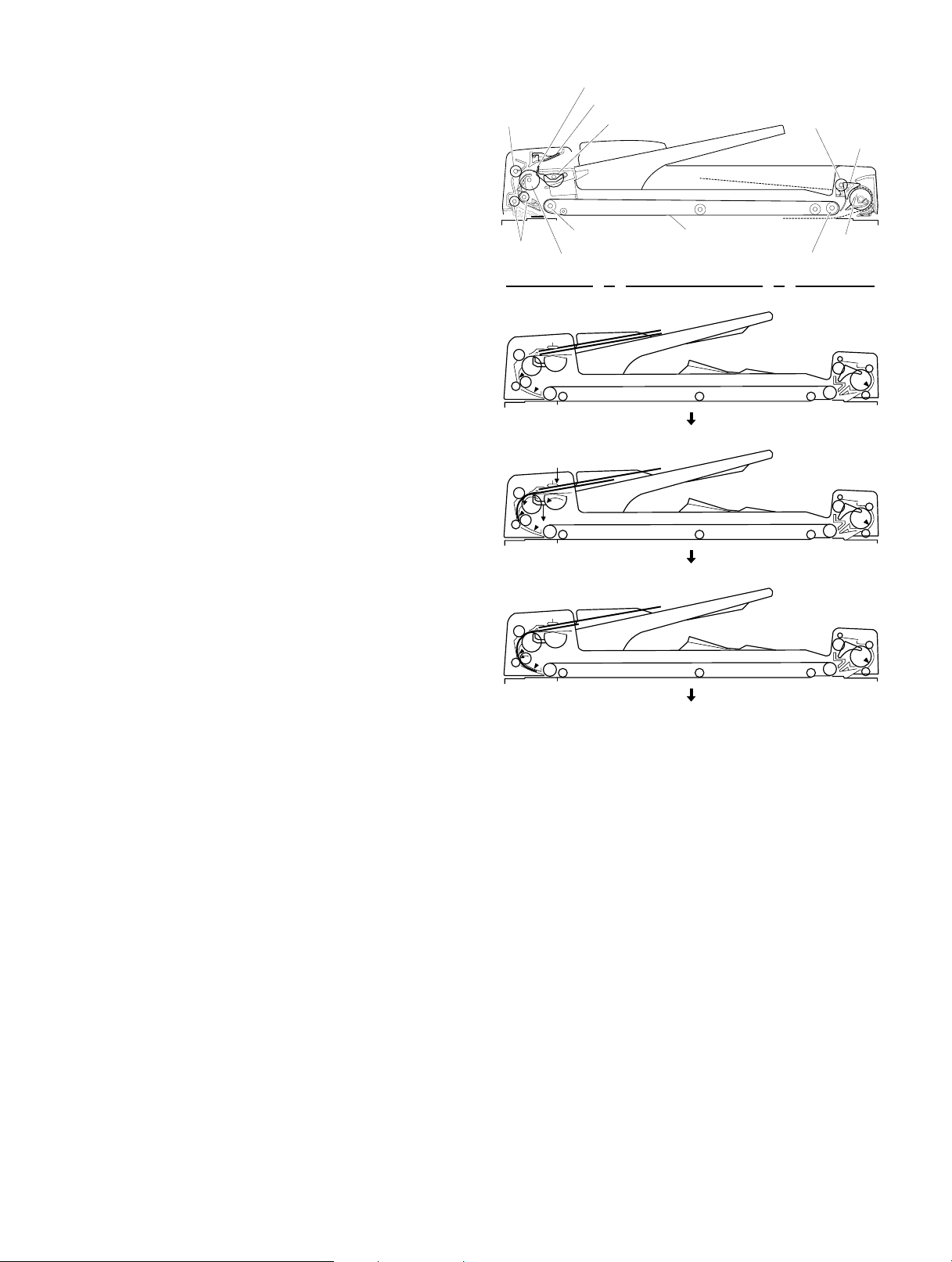

[5] OPERATIONAL DESCRIPTIONS

(MECHANISM SECTION)

A. Operation flowchart

The figures at right show the transport path of an original from the

original setting, through paper feed, copying, to paper exit. For details

of operations, refer to the operation process.

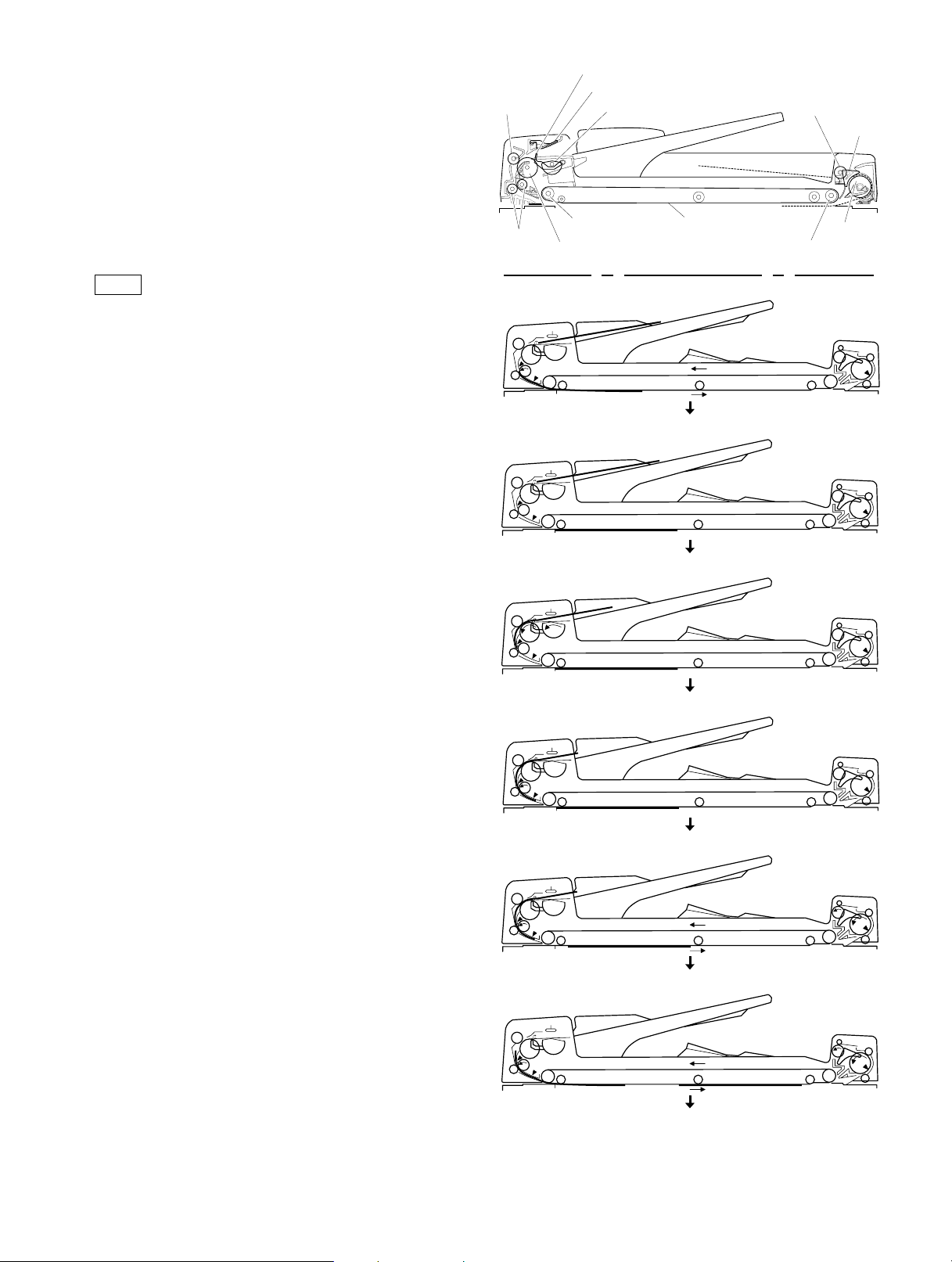

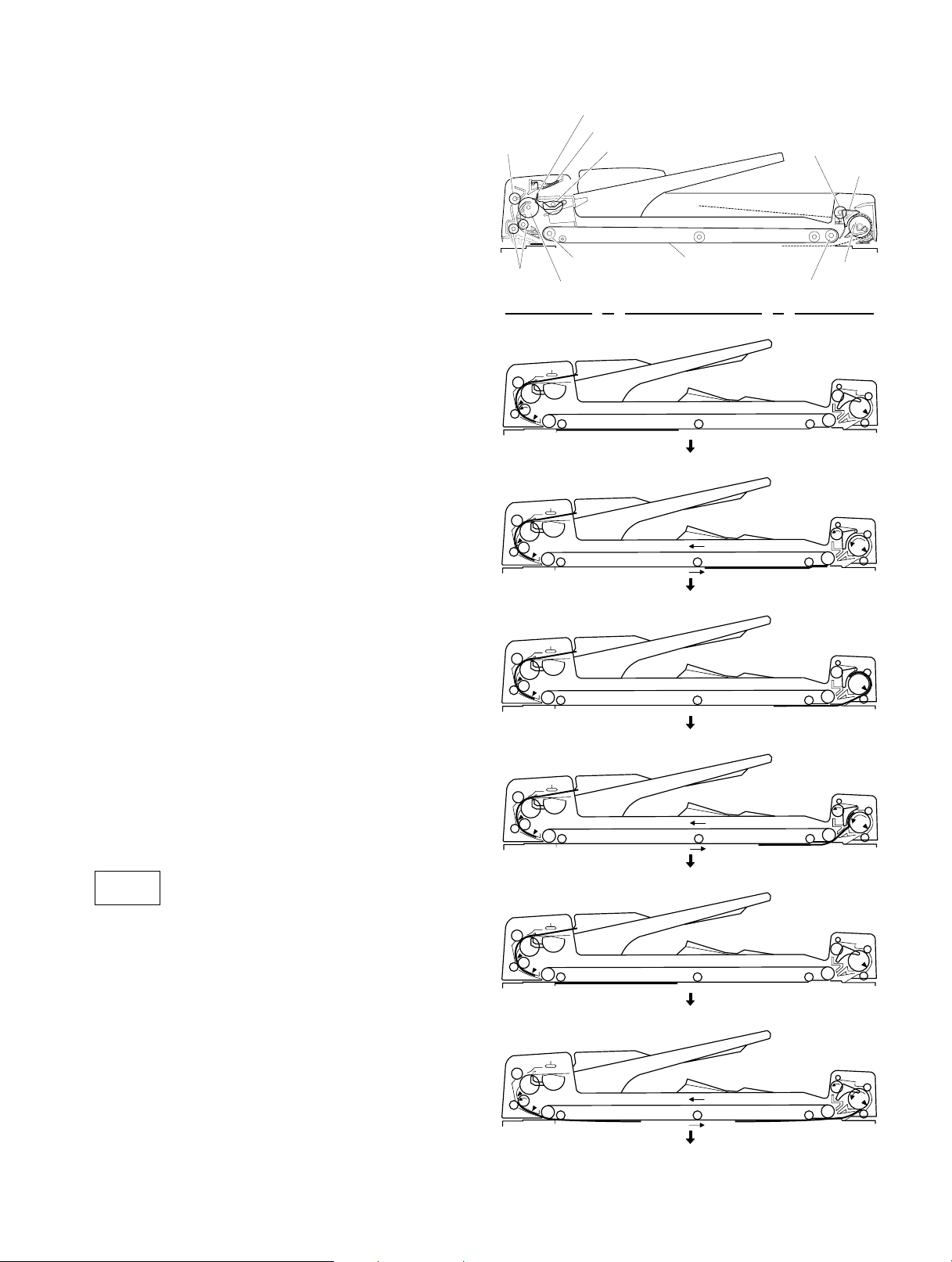

1) ADF mode (single copy mode) copying

START

↓

Step 01: The transport section is closed. (AUOD OFF)

↓

Step 02: An original is set on the original tray. (DSD output HIGH)

↓

Step 03: Original feed display ON

↓

Step 04: Print SW ON

↓

(Preliminary

paper feed):

↓

* A Step 05: Paper feed motor (DFM) forward rotation

↓

Step 06: Reverse motor (DRM) forward rotation (Reverse roller,

↓

Step 07: Transport motor (DTM) forward rotation

↓

For the first original, dummy paper exit is performed.

(Paper feed roller, semi-circular roller rotation)

Since the stopper is up, paper feed is not performed.

paper exit roller rotation)

(Transport belt, rotation)

* B: If there have been some originals on the tray, they

are discharged.

Original stopper

Separation

roller

A21 weight plate

Semi-circular roller

Transport belt

Resist

roller

1) Original set (2 sheets)

2) Preliminary paper feed

3) Preliminary paper feed

drive roller

Paper feed roller

Original transport belt

transport belt

follower roller

Paper exit roller

Flapper

Reverse

roller

* A Step 08: Paper feed motor (DFM) OFF

↓

Step 09: Paper feed motor (DFM) forward rotation

↓

* B Step 10: The reverse sensor (RDD) senses the lead edge of the

↓

Step 11: The original feed sensor (DFD) senses the lead edge of

↓

Step 12: Paper feed motor (DFD) OFF

↓

Step 13: Paper feed motor (DFM) reverse rotation

↓

Step 14: The original width sensor (DWS) senses the original

↓

Step 15: The original timing sensor (DTD) senses the original

↓

Step 16: Paper feed motor (DFM) OFF

↓

Paper feed solenoid (DFSOL) ON

(The weight plate and the stopper move down to press

the original onto the semi-circular roller.)

• Paper feed roller

• Semicircular roller rotation

The original feed is started.

discharged original.

(RDD output HIGH)

the original. (DFD output HIGH)

The original is stopped by the resist roller.

(Resist roller rotation)

The original lead edge is taken up by the resist roller.

width. (Output LOW)

lead edge. (DTD output HIGH)

(The original is stopped with its lead edge taken up by

the resist roller.)

* B Step 17: Reverse sensor (RDD) senses the paper exit rear edge.

↓

Step 18: Transport motor (DTM) OFF

↓

* A Step 19: Original discharge

↓

Step 20: Reverse motor (DRM) OFF

↓

(Paper feed)

↓

Step 21: Transport motor (DTM) forward rotation

↓

Step 22: Paper feed motor (DFM) reverse rotation

↓

* C Step 23: Paper feed solenoid (DFSOL) OFF

↓

Step 24: The original feed sensor (DFD) detects the original rear

↓

(RDD output LOW)

The transport belt is stopped.

(The reverse roller and the paper exit roller are stopped.)

(The transport belt rotates.)

(Resist roller rotation)

The original is sent to the transport section.

(The weight plate and the stopper move up.)

* C: If there is no original on the tray, move up the

stopper and the weight plate.

edge. (DFD output LOW)

– 7 –

Page 9

Step 25: Original width sensor (DWS) output HIGH

↓

Step 26: Original timing sensor (DTD) senses the original rear

↓

Step 27: Transport motor (DTM) OFF

↓

Step 28: Copier mirror base scanning is started.

↓* D

DSS

↓

(Preliminary

paper feed)

↓

Step 29: Paper feed motor (DFM) forward rotation

↓

Step 30: The original feed sensor (DFD) senses the original lead

↓

Step 31: Paper feed motor (DFD) OFF

↓

Step 32: Paper feed motor (DFM) reverse rotation

↓

Step 33: The original width sensor (DWS) senses the original

↓

Step 34: The original timing sensor (DTD) senses the original

↓

Step 35: Paper feed motor (DFM) OFF

↓

Step 36: Copier mirror base scanning is stopped.

↓

(Paper exit)

↓

Step 37: Transport motor (DTM) forward rotation

↓

Step 38: Paper feed motor (DFM) reverse rotation

↓

* C Step 39: Paper feed solenoid (DFSOL) OFF

↓

Step 40: Paper feed sensor (DFD) senses the original rear edge.

↓

Step 42: Original width sensor (DWS) output HIGH

↓

edge. (DFD output LOW)

Paper feed motor (DFM) OFF

(The resist roller is stopped.)

(Transport belt, stops.)

Original stop

LOW (No original on the tray) → After completion of

scanning, go to step 61.

HIGH (There are some originals on the tray.)

↓

(Paper feed roller, semi-circular roller rotation)

The original feed is started.

edge. (DFD output HIGH)

The original is stopped by the resist roller.

(Resist roller rotation)

The original lead edge is taken up by the resist roller.

width.

(Output HIGH)

lead edge. (DTD output HIGH)

(The original is stopped with its lead edge taken up by

the resist roller.)

(Transport belt, rotation)

Reverse motor (DRM) rotation

Reverse roller, paper exit roller rotation

The original discharge is started.

(Resist roller rotation)

The original is sent to the transport section.

(The weight plate and the stopper move up.)

* C When there is no original on the tray, move up the

stopper and the weight plate.)

(DFD output LOW)

Original stopper

Separation

roller

Resist

roller

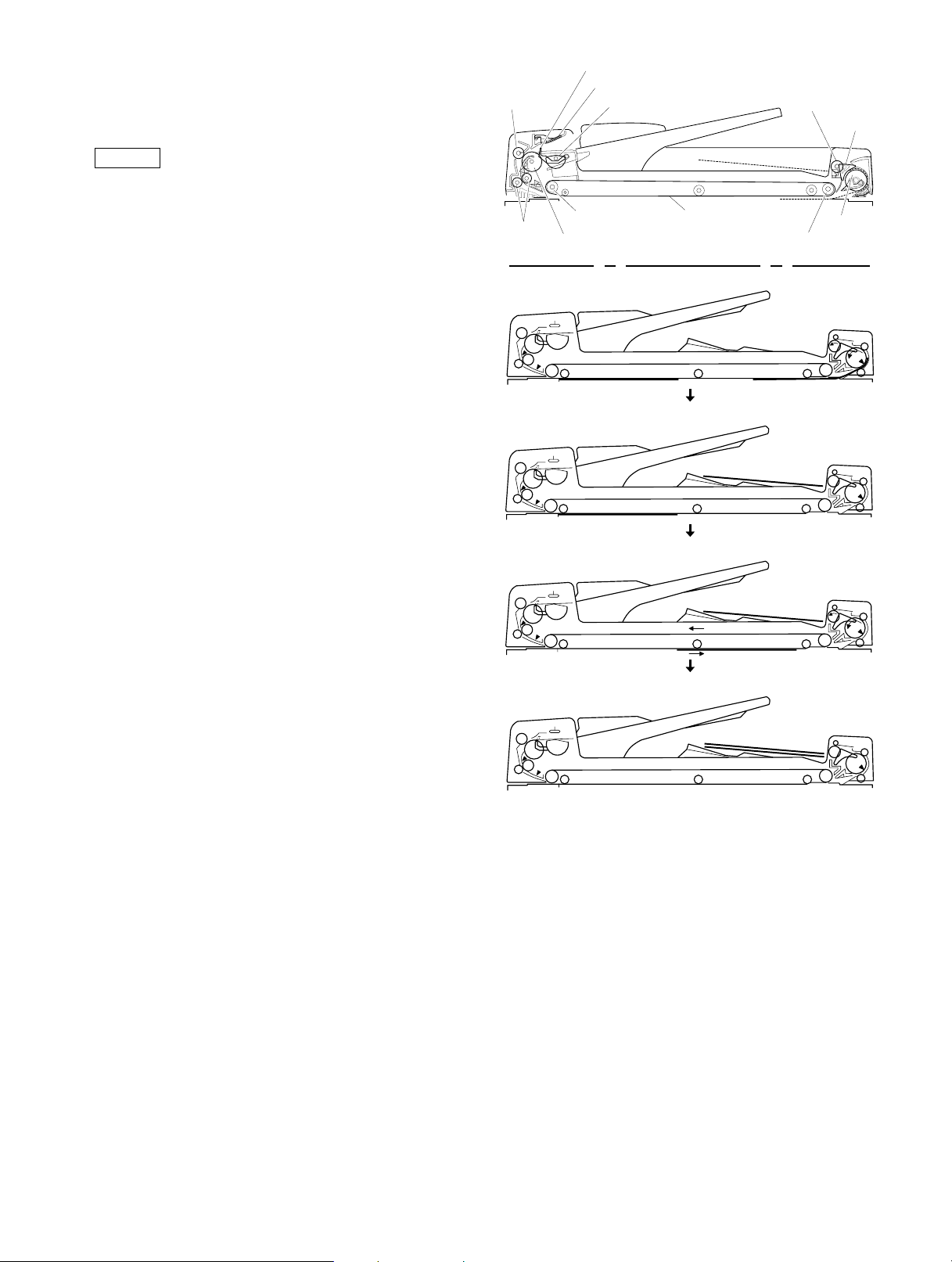

4) Paper feed

5) Original set (The third copy)

6) Preliminary paper feed

7) Preliminary paper feed

8) Paper exit feed

9) Paper exit feed

Step 43: Original timing sensor (DTD) senses the original rear

A21 weight plate

Semi-circular roller

Transport belt

drive roller

Paper feed roller

↓

edge. (DTD output LOW)

Paper feed motor (DFM) OFF

(Resist roller stop)

Paper exit roller

Original transport belt

transport belt

follower roller

Flapper

Reverse

roller

– 8 –

Page 10

Step 44: Transport motor (DTM) OFF

↓

Step 45: Copier mirror base scanning is started.

* E ↓

DSS

↓

(Follows the preliminary

paper feed and the paper

exit procedures.)

↓

Step 46: Paper feed motor (DFM) forward rotation

↓

Step 47: Paper feed sensor (DFD) detects the original lead edge.

↓

Step 48: Paper feed motor (DFM) OFF

↓

Step 49: Paper feed motor reverse rotation

↓

Step 50: Reverse sensor (RDD) senses the discharged original

↓

Step 51: Original width sensor (DWS) senses the original width.

↓

Step 52: Original timing sensor (DTD) senses the original lead

↓

Step 53: Paper feed motor (DFM) OFF

↓

Step 54: (Original exit)

↓

Step 55: Reverse motor (DRM) OFF

↓

Step 56: Copier mirror base scan stop

→

(Paper exit process,

continued)

Step 57: Reverse sensor (RDD) senses the discharged original

↓

Step 58: (Original exit)

↓

Step 59: Reverse motor (DRM) OFF

↓

Step 60: Copier mirror base scan stop

→

(Paper exit)

Step 61: Transport motor (DTM) forward rotation

↓

(Transport belt, paper exit roller stop)

Original stop

LOW (There are no originals on the tray.)

→ Go to step 57 (Follows the paper exit procedure).

HIGH (Some original on the tray)

↓

(Paper feed roller, semicircular roller rotation)

(The original feed is started.)

(DFD output HIGH)

(The original is stopped by the resist roller.)

Resist roller rotation)

(The original lead edge is taken by the resist roller.)

lead edge. (RDD output LOW)

Reverse motor (DRM) rotation down

(Output LOW)

edge. (DTD output HIGH)

(The original lead edge is taken by the resist roller and

stopped.)

To Step 37.

rear edge. (RDD output LOW)

(Reverse roller, paper exit roller stop)

To Step 61: (Paper exit)

(Transport belt rotation)

Reverse motor (DRM) forward rotation

(Reverse roller, paper exit roller rotation)

(The original exit is started.)

Original stopper

Separation

roller

A21 weight plate

Semi-circular roller

Paper exit roller

Flapper

Transport belt

Resist

roller

10) Original set (the second copy)

11) Paper exit complete

12) Paper exit (The second original)

13) Paper exit complete

Step 62: Reverse sensor (RDD) senses the discharged original

Step 63: Reverse sensor (RDD) senses the discharged original

Step 64: (Original exit)

Step 65: Reverse motor (DRM) OFF

END

drive roller

Paper feed roller

↓

↓

↓

↓

lead edge. (RDD output HIGH)

rear edge. (RDD output LOW)

Transport motor (DTM) OFF

(Transport belt stop)

Reverse motor (DRM) rotation down)

(Reverse roller, paper exit roller stop)

Original transport belt

transport belt

follower roller

Reverse

roller

Note: * A: For the first original, the preliminary paper feed opera-

tion is performed.

* B: If there is an original in the original table from the begin-

ning, the original is discharged.

* C: If there is no original on the original tray, the wait plate

and the stopper are raised.

* D: If there is no original on the original tray, the original set

sensor (DSS) output becomes LOW.

– 9 –

Page 11

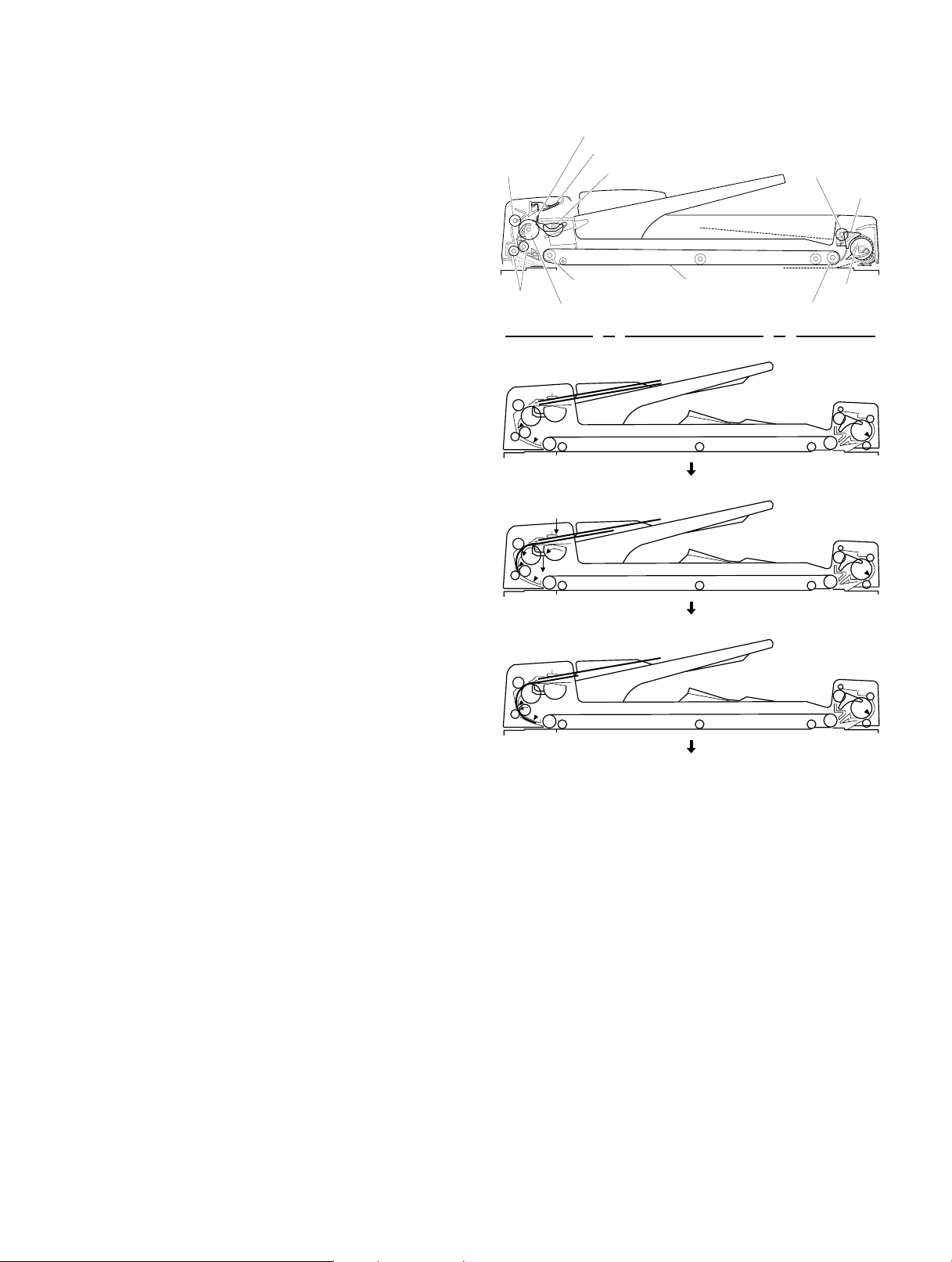

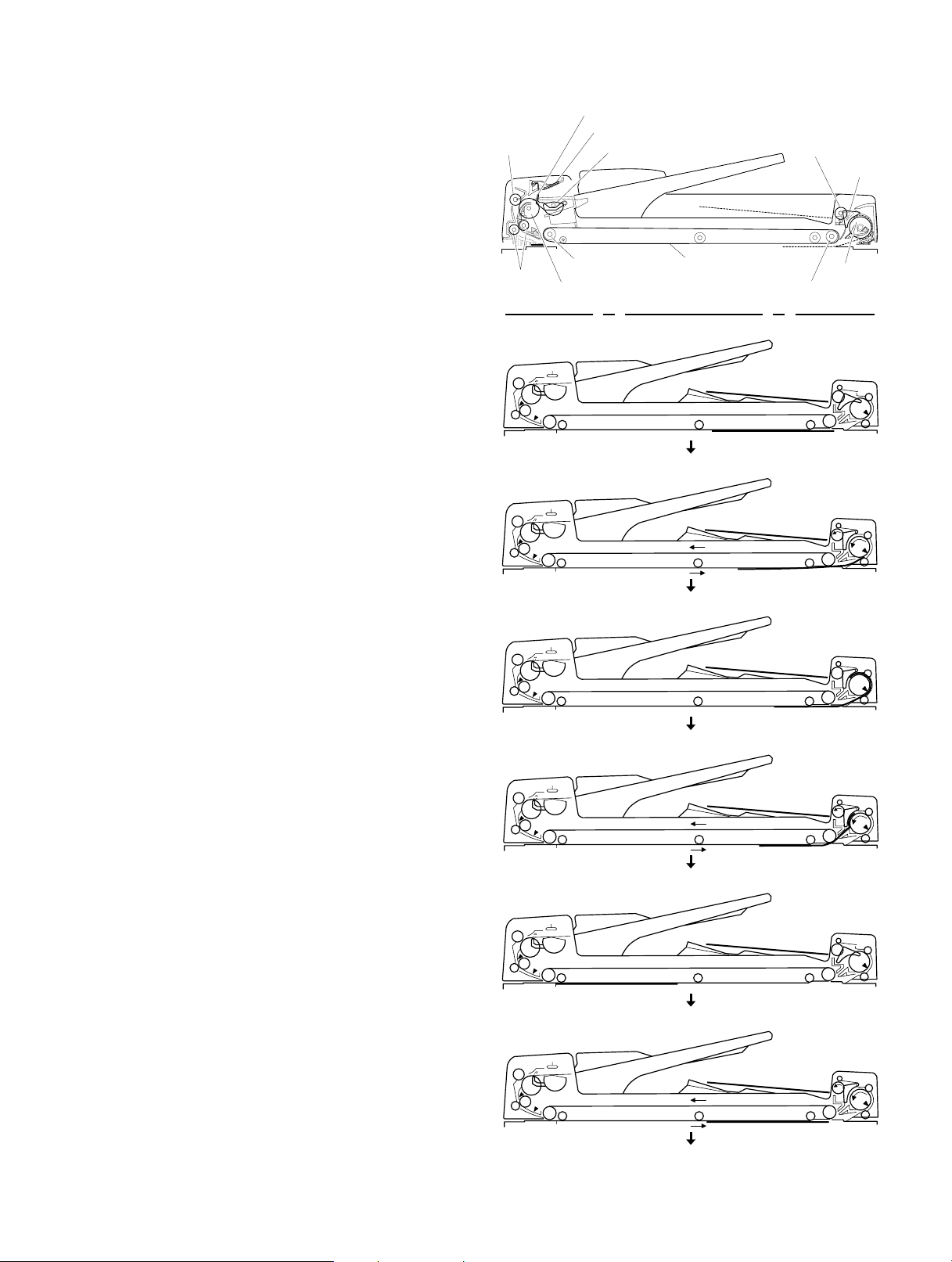

2) RADF mode (duplex copy mode) copying

START

↓

Step 01: The transport section is closed. (AUOD ON)

↓

Step 02: An original is set on the original tray. (DSS output HIGH)

↓

Step 03: Original feed display ON

↓

Step 04: Print SW ON

↓

(Preliminary

paper feed):

↓

* A Step 05: Paper feed motor (DFM) forward rotation

↓

Step 06: Reverse motor (DRM) forward rotation

↓

Step 07: Transport motor (DTM) rotation

↓

* A Step 08: Paper feed motor (DFM) OFF

↓

Step 09: Paper feed motor (DFM) forward rotation

↓

* B Step 10: Reverse sensor (RDD) senses the lead edge of the

↓

Step 11: Original feed sensor (DFD) senses the lead edge of the

↓

Step 12: Paper feed motor (DFM) OFF

↓

Step 13: Paper feed motor (DFM) reverse rotation

↓

Step 14: Original width sensor (DWS) senses the original width.

↓

Step 15: Original timing sensor (DTD) senses the lead edge of

↓

Step 16: Paper feed motor (DFM) OFF

↓

* B Step 17: Reverse sensor (RDD) senses the rear edge of the

↓

Step 18: Transport motor (DTM) OFF

↓

* A: For the first original, dummy paper exit is

performed.

(Paper feed roller, semi-circular roller rotation)

Since the stopper is up, paper feed is not performed.

(Reverse roller, paper exit roller rotation)

(Transport belt rotation)

* B: If there has been an original on the tray, is

discharged.

Paper feed solenoid (DFSOL) ON

(The weight plate and the stopper move down to press

the original onto the semi-circular roller.)

(Paper feed roller, semi-circular roller rotation)

The original feed is started.

discharged original.

(RDD output HIGH)

discharged original. (DFD output HIGH)

The original is stopped by the resist roller.

(Resist roller rotation)

The lead edge of the original is taken up by the resist

roller.)

(Output LOW)

the original. (DTD output HIGH)

(The original is stopped with its lead edge taken up by

the resist roller.)

discharged original. (RDD output LOW)

Reverse motor (DRM) rpm down

(Transport stop)

Original stopper

Separation

roller

Resist

roller

1) Original set ((2 sheets)

2) Preliminary paper feed

3) Preliminary paper feed

* B Step 19: Original discharge

Step 20: Reverse motor (DRM) OFF

(Preliminary

paper feed):

Step 21: Transport motor (DTM) forward rotation

Step 22: Paper feed motor (DFM) reverse rotation

* C Step 23: Paper feed solenoid (DFSOL) OFF

A21 weight plate

Semi-circular roller

Transport belt

drive roller

Paper feed roller

↓

↓

↓

↓

↓

↓

(Reverse roller, paper exit roller stop)

(Paper feed reverse)

Transport motor, reverse motor (DRM) forward rotation

(Reverse roller, paper exit roller rotation)

(Resist roller rotation)

The original is sent to the transport section.

(The weight plate and the stopper move up.)

* C: If there is no original on the original tray, move up

Original transport belt

transport belt

follower roller

the stopper and the weight plate.

Paper exit roller

Flapper

Reverse

roller

– 10 –

Page 12

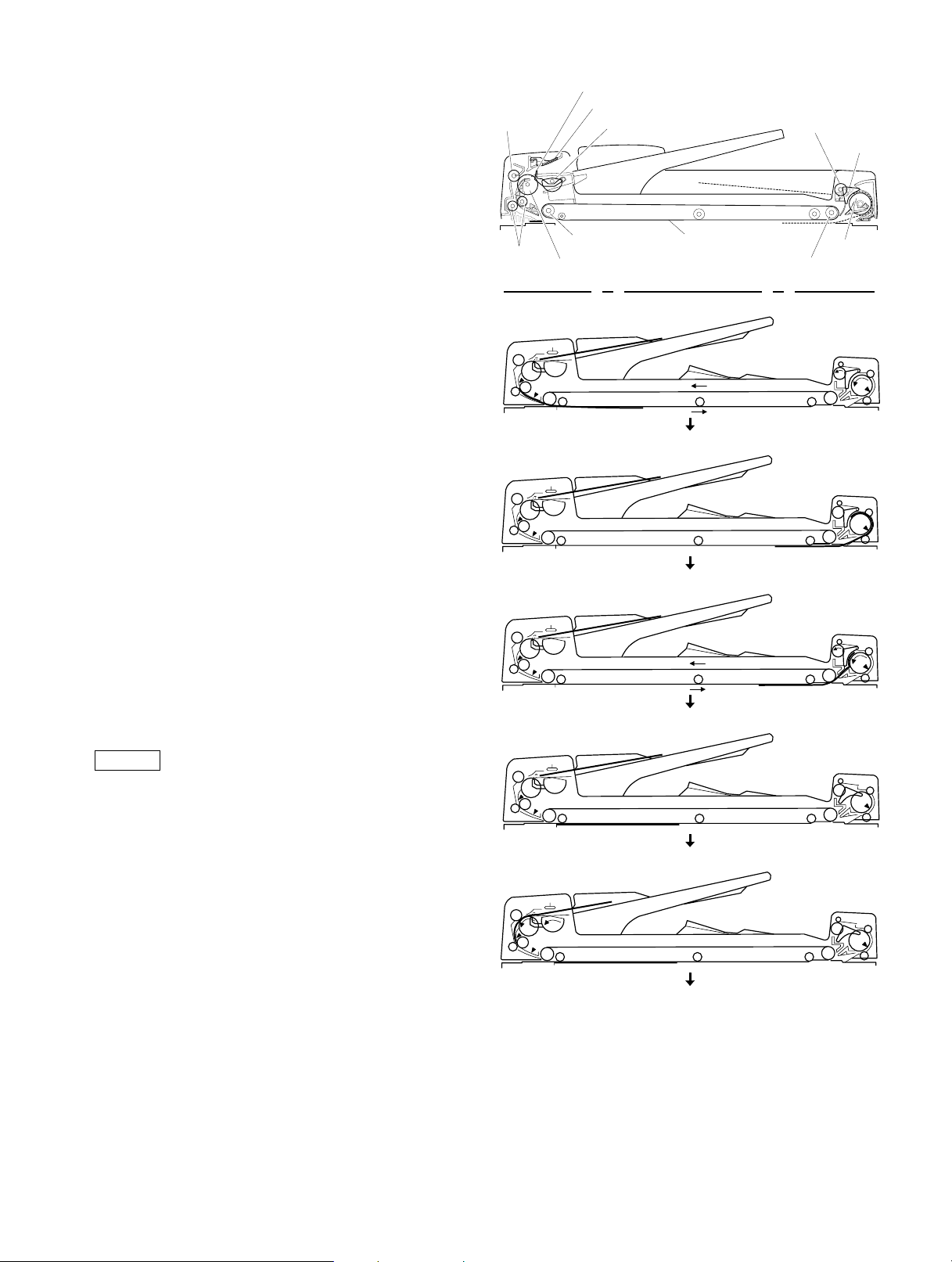

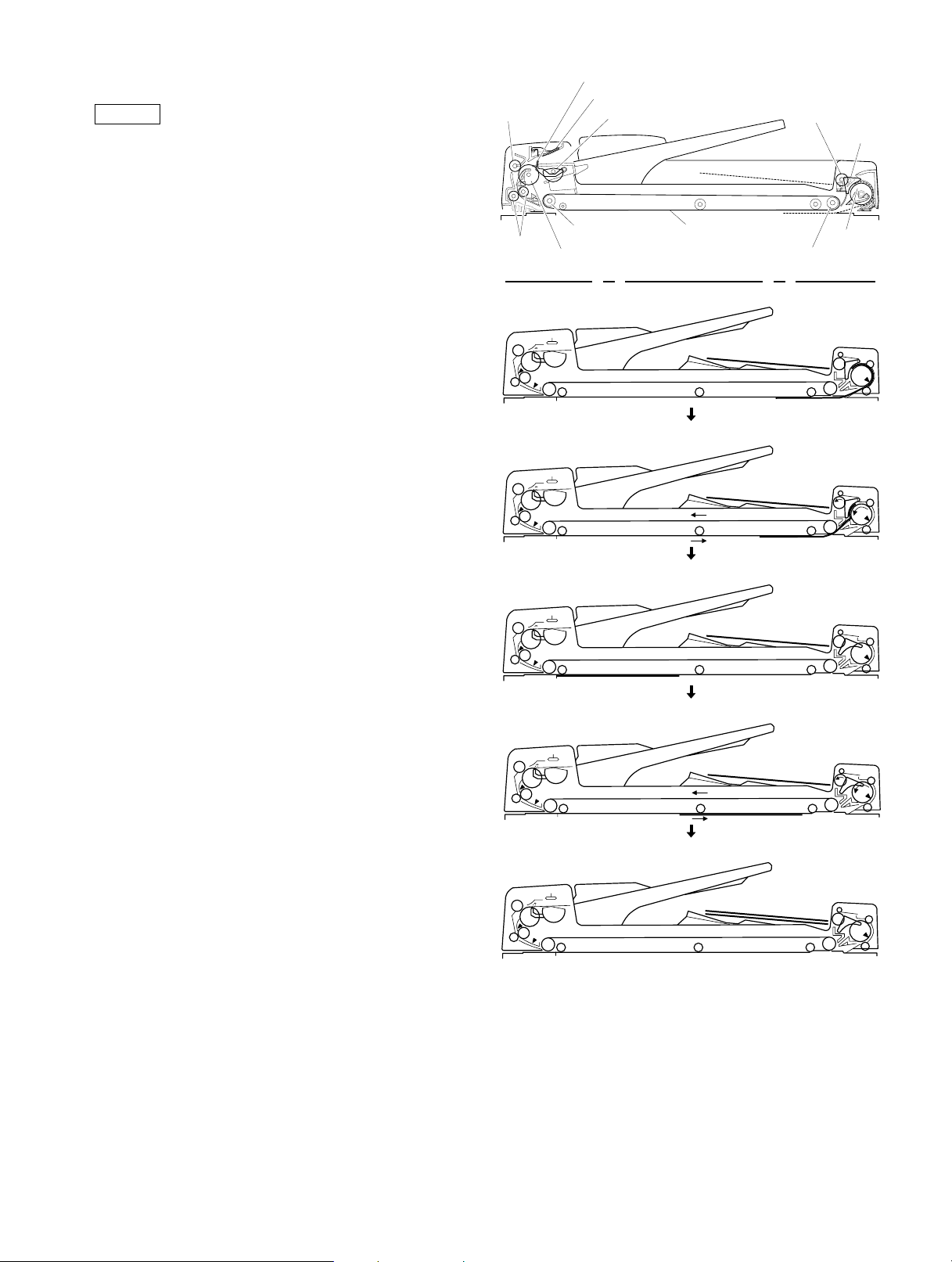

Step 24: Original feed sensor (DFD)

↓

Step 25: Original width sensor (DWS) output HIGH

↓

Step 26: Original timing sensor (DTD) senses the rear edge of the

↓

Step 27: Reverse sensor (RDD) senses the lead edge of the

↓

Step 28: The lead edge of the original is moved counterclockwise

↓

Step 29: Transport motor (DTM) OFF

↓

Step 30: Reverse motor (RDM) OFF

↓

Step 31: Transport motor (DTM) OFF

↓

Step 32: Reverse motor (DRM) forward rotation

↓

Step 33: Reverse sensor (RDD) senses the rear edge of the

↓

Step 34: Reverse motor (DRM) OFF

↓

Step 35: Transport motor (DTM) OFF

↓

Step 36: Original stop

↓

Step 37: Copier mirror base scanning is started.

* D ↓

DSS output

↓

(Preliminary

paper feed)

↓

Step 38: Paper feed motor (DFM) forward rotation

↓

Step 39: Original feed sensor (DFD) senses the lead edge of the

↓

Step 40: Paper feed motor (DFM) OFF

↓

Step 41: Paper feed motor (DFM) forward rotation

↓

Step 42: Original width sensor (DWS) senses the original width.

↓

Step 43: Original timing sensor (DTD) senses the lead edge of

↓

Senses the rear edge of the discharged original. (DFD

output LOW)

original.

(DTD output LOW)

Paper feed motor (DFM) OFF (Resist roller stop)

Reverse solenoid (DRSOL) ON (The flapper moves up.)

original. (RDD output HIGH)

by the flapper.

(Transport belt stop)

(Reverse roller, paper exit roller stop)

(Transport belt rotation)

(Reverse roller, paper exit roller rotation)

The original is transported to the paper feed section.

reverse original.

(RDD output LOW)

(Reverse roller, paper exit roller stop)

(Transport belt stop)

Reverse solenoid (DRSOL) OFF

(The flapper moves down.)

LOW (There is no original on the tray.) → After

completion of mirror base scanning, go to step 46.

(Reverse rotation)

HIGH (There is an original on the tray)

↓

(Paper feed roller, semi-circular roller rotation)

The original feed is started.

original.

(DFD output HIGH)

The original is stopped by the resist roller.

(Resist roller rotation)

The lead edge of the original is taken up by the resist

roller.

(Output LOW)

the original. (DTD output HIGH)

Original stopper

Separation

roller

Resist

roller

4) Paper feed reverse

5) Paper feed reverse (Reverse)

6) Paper feed reverse (Reverse transport)

7) Original set (Back copy of the first original)

8) Preliminary paper feed

A21 weight plate

Semi-circular roller

Transport belt

drive roller

Paper feed roller

Original transport belt

Paper exit roller

transport belt

follower roller

Flapper

Reverse

roller

– 11 –

Page 13

Step 44: Paper feed motor (DFM) OFF

↓

Step 45: Copier mirror base scanning stop

↓

(Reverse

rotation)

↓

Step 46: Reverse solenoid (DRSOL) ON

↓

Step 47: Transport motor (DTM) forward rotation

↓

Step 48: Reverse sensor (RDD) senses the lead edge of the

↓

Step 49: The lead edge of the original is moved counterclockwise

↓

Step 50: Transport motor (DTM) OFF

↓

Step 51: Reverse motor (DRM) OFF

↓

Step 52: Transport motor (DRM) reverse rotation

↓

Step 53: Reverse motor (DRM) reverse rotation

↓

Step 54: Reverse sensor (RDD) senses the rear edge of the

↓

Step 55: Reverse motor (DRM) OFF

↓

Step 56: Transport motor (DTM) OFF

↓

Step 57: Reverse solenoid (DRSOL) OFF

↓

Step 58: Copier mirror base scanning start

↓

Step 59: Copier mirror base scanning stop

* E ↓

First-out

original

↓

(Paper exit

paper feed

reverse)

↓

Step 60: Transport motor (DTM) forward rotation

↓

Step 61: Paper feed motor (DFM) reverse rotation (Resist roller

↓

(The original is stopped with its lead edge taken up by

the resist roller.)

(The flapper moves up.)

(Transport motor rotation)

Reverse motor (DRM) forward rotation

(Rreverse roller, paper exit roller rotation)

original.

(RDD output HIGH)

by the flapper.

(Transport belt stop)

(Reverse roller, paper exit roller stop)

(Transport belt rotation)

(Reverse roller, paper exit roller rotation)

The original is transported to the paper feed section.

reversed original.

(RDD output LOW)

(Reverse roller, paper exit roller stop)

(Transport belt stop)

Original stop

(The flapper moves down)

NONE → After completion of mirror base scanning, go

to step 84.

YES

↓

(Transport belt rotation)

Reverse motor (DRM) forward rotation

Reverse roller, paper exit roller rotation)

The original is discharged.

rotation)

The original is sent to the transport section.

Original stopper

Separation

roller

Resist

roller

9) Preliminary paper feed

10) Reverse

11) Reverse

12) Reverse (Reverse transport)

13) Original set (Front copy of the first original)

14) Paper exit reverse

A21 weight plate

Semi-circular roller

Transport belt

drive roller

Paper feed roller

Original transport belt

Paper exit roller

transport belt

follower roller

Flapper

Reverse

roller

– 12 –

Page 14

* C Step 62: Paper feed solenoid (DFSOL) OFF

↓

Step 63: Original feed sensor (DFD) senses the rear edge of the

↓

Step 64: Original width sensor (DWS) output LOW

↓

Step 65: Original timing sensor (DTD) senses the rear edge of the

↓

Step 66: Reverse sensor (RDD) senses the lead edge of the

↓

Step 67: Reverse sensor (RDD) senses the discharged original

↓

Step 68: Transport motor (DTM) OFF

↓

Step 69: (Original exit)

↓

Step 70: Reverse motor (DRM) OFF

↓

Step 71: Reverse solenoid (DRSOL) ON

↓

Step 72: Transport motor (DTM) forward rotation

↓

Step 73: Reverse sensor (RDD) senses the lead edge of the

↓

Step 74: The lead edge of the original is moved counterclockwise

↓

Step 75: Transport motor (DTM) OFF

↓

Step 76: Reverse motor (DRM) OFF

↓

Step 77: Transport motor (DTM) reverse rotation

↓

Step 78: Reverse motor (DRM) forward rotation

↓

Step 79: Reverse sensor (RDD) senses the rear edge of the

↓

Step 80: Reverse motor (DRM) OFF

↓

Step 81: Transport motor (DTM) off

↓

Step 82: Reverse solenoid (DRSOL) OFF

↓

(The weight plate and the stopper moves up.)

* C: When there is no original on the tray, move up the

stopper and the weight plate.

original.

(DFD output LOW)

original. (DTD output LOW)

discharged original.

(RDD output HIGH)

rear edge. (RDD output LOW)

(Transport belt stop)

(The original is stopped in the transport section.)

(Reverse roller, paper exit roller stop)

(The flapper moves up.)

(Transport belt rotation)

Reverse motor (DRM) forward rotation

(Reverse roller, paper exit roller rotation)

original.

(RDD) output HIGH)

by the flapper.

(Transport belt stop)

(Reverse roller, paper exit roller stop)

(Transport belt rotation)

(Reverse roller, paper exit roller stop)

The original is sent to the paper feed section.

reverse original. (RDD output LOW)

Reverse roller, paper exit roller stop

(Transport belt stop)

Original stop

(The flapper moves down.)

Original stopper

Separation

roller

Resist

roller

15) Paper exit reverse (Paper exit of the first original iscompleted)

16) Paper exit reverse (Reverse)

17) Paper exit reverse (Reverse)

18) Paper exit reverse (Reverse transport)

19) Original set (Back copy of the second original)

20) Reverse

A21 weight plate

Semi-circular roller

Transport belt

drive roller

Paper feed roller

Paper exit roller

Original transport belt

transport belt

follower roller

Flapper

Reverse

roller

– 13 –

Page 15

Step 83: Copier mirror base scanning start

↓* D

DSS output

→

(Paper exit)

↓

Step 84: Transport motor (DTM) forward rotation

↓

Step 85: Reverse sensor (RDD) senses the lead edge of the

↓

Step 86: Reverse sensor (RDD) senses the rear edge of the

↓

Step 87: Original discharge

↓

Step 88: Reverse motor (DRM) OFF

↓

END

LOW (No original on the tray) → After completion of

mirror base scanning, go to step 46 (reverse).

HIGH (There is an original on the tray.)

↓

Go to step 38 (Preliminary paper feed).

(Transport belt rotation)

Reverse motor (DRM) forward rotation

(Reverse roller, paper exit roller rotation)

The original is discharged.

discharged original.

(RDD output HIGH)

discharged original.

(RDD output LOW)

Transport motor (DTM) OFF

(Transport belt stop)

Reverse motor (DRM) rpm down

(Reverse roller, paper exit roller stop)

Note: * A: For the first original, the preliminary paper feed opera-

tion is performed.

* B: When there is an original on the original tray in ad-

vance, it is discharged.

* C: When there is no original on the original tray, move up

the weight plate and the stopper.

* D: When there is no original on the original tray, the

original set sensor (DSS) output becomes LOW.

* E: It depends on whether there is any preliminary fed

original in step 38 ∼ step 44.

Original stopper

Separation

roller

Resist

roller

21) Reverse

22) Reverse (Reverse transport)

23) Original set (Front copy of the second original)

24) Paper exit

A21 weight plate

Semi-circular roller

Transport belt

drive roller

Paper feed roller

Original transport belt

Paper exit roller

transport belt

follower roller

Flapper

Reverse

roller

25) Paper exit complete

– 14 –

Page 16

B. Original size detection

The original size is detected in three ways of different purposes.

1) Original size detection by the original set tray

The original size detection by the original set tray is used in automatic

paper size and automatic magnification selection mode, in order to

recognize the original size when the original is set on the original tray,

allowing the automatic selection of paper size and magnification ratio

of copy.

When originals composed of sheets of different sizes are set, this

detection method recognizes the largest sheet as the original size,

which is determined by the width measured by the original width

volume (DWVR) and the length measured by the original length sensors (DLS1, DLS2, DLS3).

The original size is determined in the timing of original sensing by the

original set sensor (DSS).

DLS3

DLS1

DWVR

DLS2

Sensor state for original size (Size detection on the tray)

Setting of

original tray

and

destination

AB series

Inch series

Original size and

set direction

A5 5 ● ——

B5 6 ● ——

A5R 3 ● ——

A4 7 ● ——

B5R 4 | ——

A4R 5 | ——

8.5" × 13" 5 | ——

B4 6 | ——

A3 7 | ——

8.5" × 5.5" 1 ●●—

8.5" × 5.5"R 0 ●●—

11" × 8.5" 2 ●●—

11" × 8.5R" 1 | ● —

8.5" × 13" 1 ||—

8.5" × 14" 1 ||—

11" × 17" 2 ||—

(Detection level or |: ON ●: OFF )

DWVR DLS1 DLS2 DLS3

Sensor state

Sensor state for original size (Size detection on the tray)

Setting of

original tray

and

destination

Foolscap

conforming

AB series

Foolscap

conforming

inch series

Original size and

set direction

A5 5 ●●—

B5 6 ●●—

A5R 3 ●●—

A4 7 ●●—

B5R 4 | ● —

A4R 5 | ● —

8.5" × 13" 5 ||—

B4 6 ||—

A3 7 ||—

8.5" × 5.5" 1 ●●●

8.5" × 5.5"R 0 ●●●

11" × 8.5" 2 ●●●

11" × 8.5R" 1 | ●●

8.5" × 13" 1 ||●

8.5" × 14" 1 |||

11" × 17" 2 |||

(Detection level or |: ON ●: OFF )

DWVR DLS1 DLS2 DLS3

Sensor state

– 15 –

Page 17

2) Original size detection by the original width sensor

(DWS) in the paper feed section

The original size detection by the original width sensor (DWS) in the

paper feed section is used in automatic paper size and automatic

magnification ration selection mode to determine whether the original

is A4 or A5 (11" x 8.5" or 8.5" x 5.5").

When originals composed of stacked sheets of different sizes are set

in the original tray, the original size cannot be detected by the sensors in the original tray. Therefore, this function is provided to sense

the original size when preliminary paper feed is completed, as far as

originals of A4 or A5 size (11" x 8.5" or 8.5" x 5.5") (portrait) is

concerned. Consequently, if A4- and A5-size (11" x 8.5" or 8.5" x

5.5") originals (portrait) are stacked and set in the original tray, the

original size detection by the paper feed section original width sensor

(DWS) has the priority over the original size detection by the original

set tray.

When A4- and A5-size (11" x 8.5" and 8.5" x 5.5") originals (portrait)

are stacked and set in the original tray, the original length sensors

(DSL1, DSL2, DLS3) are not actuated. Therefore, the original width is

sensed by the paper feed section original width sensor (DWS) to

judge A4 or A5 (11" x 8.5" or 8.5" x 5.5").

Paper feed section original width sensor (DWS)

A4

B5

Paper feed section original width sensor (DWS)

11"x8.5"

8.5"x5.5"

Paper feed section original width sensor (DWS)

Paper feed section original width sensor (DWS) status

Original size

A4 |

B5 ●

|: Output LOW (Detection)

●: Output HIGH

Paper feed section original width sensor (DWS)

Paper feed section original width sensor (DWS) status

Original size

11" × 8.5" |

8.5" × 5.5" ●

– 16 –

|: Output LOW (Detection)

●: Output HIGH

Page 18

3) Original size detection by the paper feed motor

rotation sensor (DFMRS)

This function compensates for the inaccuracy of the original size

recognition in the original tray when originals of different sizes are

stacked in the original tray. That is, results of this function has priority

over the original size detection in the original tray. The pulses of the

slit disc rotation of the feed motor (DFM) are counted in the period

before the rear edge of original is sensed (DFD output LOW) by the

original feed sensor after the feed motor (DFM) has started reverse

rotation, that is, after the resist roller has started rotating and feeding

of original from the fed section to the transport section has been

started, to determine the original length.

To improve detection accuracy, the original width is sensed also by

the paper feed section original width sensor (DWS).

A) Resist roller rotation start (The original is fed from the paper feed

section.)

Original feed sensor (DFS)

A

Resist roller

B) Original feed sensor (DFD) detects the original rear edge.

Original feed sensor (DFD)

B

Resist roller

The paper feed motor rotation sensor (DFMRS) counts the number of

rotations of the paper feed motor (DFM) between A and B to judge

the original length.

– 17 –

Page 19

[6] DISASSEMBLY, ASSEMBLY AND

2. Belt unit dis asse mb ly

ADJUSTMENT

* Descriptions in this chapter excludes simple disassembly and as-

sembly operations. Refer to the parts guide for the disassembly ad

assembly of parts which are not explained here.

* Refer to the description in [7] ACTUAL WIRING DIAGRAM for the

processing of the wiring during assembly.

1. Transport section opening

1 Loosen two screws which are fixing the hinge stopper to allow the

hinge stopper to move.

2 Slide the hinge stopper downward by using the step screw, fit the

dove with the hole and tighten the two fixing screws which were

loosen before.

3 Open the transport section.

1 Open the transport section.

2 Remove two screws as shown in the figure below, and remove the

belt unit as shown with arrow A and arrow B in this sequence.

A

Screw

(Loosen.)

Belt unit

Screw (Loosen.)

Hinge stopper (Move down.)

B

– 18 –

Page 20

3. Paper feed unit disassembly

4. Paper exit un it dis asse mb ly

1 Open the transport section.

2 Remove the tray. (Refer to the installing procedure.)

3 Remove four screw which are fixing the lower cover, and remove

the blower cover.

4 Remove the five fixing screws of the paper feed unit, open the

paper feed cover, and remove the fixing screw.

Paper feed

cover

Paper feed unit

fixing screw

(Loosen.)

Paper feed unit

fixing screws

1 Open the transport section and remove the lower cover.

2 Remove the five fixing screw of the paper exit unit.

3 Remove the paper exit unit harness connector from the control

PWB, and pull out the harness from the edge saddle shown in the

figure below. Then remove the paper exit unit.

Edge saddle

Screw

Screw

Reverse

unit

Paper feed unit

Lower cover

5 Remove the paper feed motor drive belt, and remove the four

harness connectors. Then remove the paper feed unit.

Harness

connector

(Remove.)

Paper feed

unit

Paper feed motor

drive belt (Remove.)

Paper feed

motor

5. Separation roller disassembly

1 Open the paper feed cover.

2 Remove two fixing screws of the separation unit, and remove the

separation unit.

Screw (Remove.)

Separation unit

– 19 –

Page 21

3 Remove two screws from the separation unit, and remove the

separation roller holder unit.

Screw

(Remove.)

Separation roller

holder unit

4 Remove two springs from the separation roller holder, and remove

the bearing and the slide bearing. Remove the separation roller

and the spring clutch.

Spring

(Remove.)

Slide shaft

bearing

Separation roller

Spring clutch

6. Semi-circular roller, paper feed roller

disassembly

1 Open the paper feed cover.

2 Loosen two fixing screws of the tray guide top, and remove two

fixing screws of the side.

3 Remove the harness from the tray guide upper, and remove the

tray guide.

(Be careful not to scratch the harness.)

Side fixing screw

(Remove.)

Tray guide

Side fixing

screw

(Remove.)

Harness

(Remove.)

4 Remove the snaps from the both ends of the pickup shaft and the

separation shaft. (2 kinds of snaps)

5 Remove the pickup shaft bearing and the separation shaft bearing

on the front frame side.

6 Slide the pickup shaft toward the rear frame, and pull out the front

frame side from the chassis.

7 Remove the shaft stopper and the parallel pin from the pickup

shaft and remove the semi-circular shaft.

8 Slide the separation shaft toward the rear frame, and pull out the

front frame side from the chassis.

9 Remove the shaft stopper from the separation shaft, and remove

the paper feed roller.

Top fixing screw

(Remove.)

Bearing

Snap

Shaft bearing

– 20 –

Shaft stop

Pickup shaft

Snap

Rear frame

side

Semi-circular roller

Parallel pin

Shaft stop

Paper feed

roller

Front frame

side

Separation shaft

Page 22

7. Open/close switch attachment

When closing t he t ransport section from the open state, adjust the

DF open SW plate so that the clearance between the glass surface

and the DF spacers L and R (front side) is 10 ∼ 40mm. Then tighten

the fixing screw.

10~40mm

Microswitch

Fixing

screw

DF open SW plate

[Note for assembly]

1 When installing the original transport belt, put the right and left in

parallel, and allow the same clearance between the spacer and

the belt in the front side and in the rear side.

Spacer

Belt unit

Spacer

2 Check that the original transport belt is not on the belt guide.

Spacer

Spacer

8. Original transport belt replacement

1 Remove the belt unit.

2 Remove the two screws shown in the figure below to allow the

belt tension plate to be moved. Remove the transport belt with the

left and the right in parallel.

Original

transport

belt

Screw

(Remove.)

Belt guide

Transport belt

Transport belt

Belt guide

Belt tension plate

– 21 –

Page 23

[7] CONNECTOR LAYOUT

2. Paper feed motor peripheral

1. Control PWB peripheral

IF harness

Control PWB

RU harness

Control PWB

Paper feed motor (DFM)

Paper feed motor

rotation sensor

Original set

sensor (DSS)

TR2 harness

Drive F harness

Paper feed

guide switch

(FGOD)

ASM-earth lead W

SENSOR 2 harness

SENSOR harness

Drive R harness

Drive I/F harness

Control PWB

TR1 harness

SNR harness

SENSOR I/F

harness

Transport motor (DTM)

LED harness

SENSOR I/F

harness

Drive I/F harness

Paper feed motor

(DFM)

Paper feed motor rotation

sensor (DRMRS)

3. Paper feed section (Front side)

SENSOR 2

harness

– 22 –

SOL harness

Paper feed solenoid (DFSOL)

Page 24

4. Paper feed unit

ASM-sensor 2

Original feed

sensor (DFD)

ASM-SOL

ASM-earth lead W

Original width

sensor (DWS)

7. Reverse un it sectio n

(Reversing sensor peripheral)

Reversing guide

switch (TGOD)

ASM-RU

Original timing sensor (DTD)

5. Reverse un it sect io n (Fro nt side)

RU harness

Reverse solenoid (DRSOL)

6. Reverse un it sect io n (Rear side )

Reversing guide

switch (TGOD)

Reversing

motor (DRM)

Reversing sensor (RDD)

8. Paper feed section in the DF cover

ASM-LED

LED PWB

ASM-drive F

ASM-LED

Control PWB

ASM-RU

ASM-drive R

ASM-TR2

ASM-sensor 2

ASM-sensor 1

– 23 –

Page 25

9. ADF open/clo se switch peripheral

ADF open/close switch (AUOD)

3) Inch series (Conforming to other than 13")

AB series (Conforming to 13")

ASM-TRAY

Original length

sensor 1 (DLS1)

ASM-drive IF

10. Tray inside

1) Inch series (Conforming to 13")

Original length

sensor 3 (DLS3)

Original length

sensor 2 (DLS2)

Original length

sensor 1 (DLS1)

ASM-LED

ASM-TRAY2234

Original width volume

sensor (DWVR)

Original width volume

sensor (DWVR)

2) AB series (Conforming to other than 13")

ASM-TRAY

Original length

sensor 2 (DLS2)

Original length

sensor 1 (DLS1)

Original width volume

sensor (DWVR)

– 24 –

Page 26

[8] REPLACEMENT PARTS AND

4. Test mode

MAINTENANCE

1. Replacement parts

Part name Replacement timing

Separation roller 100K copies

Transport belt 100K copies

2. Maintenance parts (Cleaning at every

10K copies)

Clean the parts shown in the table below at maintenance as specified

in the table.

Part name Cleaning method

Original set sensor (DSS) Air blow

Original feed sensor (DFD) Air blow

Original timing sensor (DTD) Air blow

Original width sensor (DWS) Air blow

Paper exit sensor (DES) Air blow

Reverse sensor (RDD) Air blow

Paper feed roller Wipe with alcohol.

Semi-circular roller Wipe with alcohol.

Resist roller Wipe with alcohol.

Paper exit roller Wipe with alcohol.

Reverse roller Wipe with alcohol.

3. DIP switch

The DIP switch on the control PWB shown below allows the individual

operation check of the RADF (ADF).

(1) Control PWB outline

LED

Push switch

DIP seitch (5-pole)

EPROM

(1) Details of the test modes

To enter the test mode, supply the power while pressing the push

switch on the control PWB.

If DIP switch 3 is OFF when supplying the power, the destination is

set to Inch series. If ON, AB series.

If DIP switch 4 is OFF, the normal paper mode, and if ON, the thin

paper mode.

If DIP switch 1 is ON, the transport speed is set to the medium speed.

If DIP switch 5 is ON, the low speed mode. If DIP switch 1 and 5 are

ON, or OFF, the high speed mode.

[Mode setting by the switches when supplying the power]

Switch ON OFF

Push switch

DIP switch 3 AB series destination Inch series destination

DIP switch 4

[Transport speed setting by the switches when supplying the power]

DIP switch 1 DIP switch 5 Transport speed

OFF OFF High speed: 867 [mm/sec]

ON OFF Medium speed: 800 [mm/sec]

OFF ON Low speed: 700 [mm/sec]

ON ON High speed: 867 [mm/sec]

* The above setting is valid only when supplying the power. To

change the mode, be sure to supply the power.

RADF signal unit

operation test mode

Thin paper feed mode Normal paper feed

PPC connection mode

mode

(2) Kinds of test modes

The operation mode is set by the DIP switch state when opening/closing the DF. To change the mode, set the DIP switch and

open/close the DF.

[Kinds]

1 Single paper feed mode

2 Duplex paper feed mode

3 Single aging mode

4 Duplex aging mode

5 Load check mode

2

6 E

PROM initializing + all sensors adjustment mode

7 Each sensor A/D change mode

8 Resist sensor adjustment mode

9 Timing sensor adjustment mode

F Paper exit sensor adjustment mode

(2) DIP switch outline

ON

OFF

SW No.1 2 3 4 5

– 25 –

Page 27

3. Error kinds

The kinds of JAM/error and the LED display examples are shown in

the table below.

JAM/motor lock errors are canceled by opening/closing the DF after

JAM treatment or by supplying the power again.

JAM, error kinds LED display

Not-reached/remaining JAM in

the paper feed section

Not-reached/remaining JAM in

the paper exit section

Paper feed motor lock error REMOVE ORIGINAL LED

Resist/timing sensor

adjustment error (When

supplying power/starting paper

feed)

Paper exit sensor adjustment

error (When supplying

power/starting paper feed)

Sensor adjustment D/A output

upper limit error (Adjustment

mode)

Sensor adjustment D/A output

lower limit error (Adjustment

mode)

REMOVE ORIGINAL LED

blinks at the cycle of 1000msec.

ADF FEED LED blinks at the

cycle of 1000msec.

blinks at the cycle of 2000msec.

REMOVE ORIGINAL LED

blinks at the cycle of 100msec.

ADF FEED LED blinks at the

cycle of 100msec.

ADF FEED LED blinks at the

cycle of 100msec.

REMOVE ORIGINAL LED

blinks at the cycle of 100msec.

3 Single aging mode

ON

OFF

SW No.1 2 3 4 5

When the push switch is pressed, aging is started. The operation

is made when the size of the original on the original paper feed

tray is detected. It is made for each size.

4 Duplex aging mode

ON

OFF

SW No.1 2 3 4 5

When the push switch is pressed, aging is started. The operation

is made when the size of the original on the original paper feed

tray is detected. It is made for each size.

5 Load check mode

ON

4. Each test mode and JAM error

Set the DIP switch on the control PWB and open/close the DF to set

to each mode. The original size and normal paper/thin paper mode

settings are made when supplying the power.

When a JAM or an error occurs, the LED shows the cause. the JAM

or error is canceled by opening/closing the DF after removing the

JAM or by supplying the power again.

1 Single paper feed mode

ON

OFF

SW No.1 2 3 4 5

When an original is set on the paper feed tray, the original feed

LED lights up. When the push switch is pressed, the original on

the paper feed tray is fed. is

2 Duplex paper feed mode

ON

OFF

SW No.1 2 3 4 5

When an original is set on the paper feed tray, the original feed

LED lights up. When the push switch is pressed, the original on

the paper feed tray is fed.

JAM, error kind LED display

Not-reached/remaining JAM

in the paper feed section

Not-reached/remaining JAM

in the paper exit section

Paper feed motor lock error REMOVE ORIGINAL LED blinks

REMOVE ORIGINAL LED blinks

at the cycle of 1000msec.

ADF FEED LED blinks at the cycle

of 1000msec.

at the cycle of 2000msec.

OFF

SW No.1 2 3 4 5

Every time when the push switch is pressed, the operation is

performed in the sequence of 1 ∼ Q.

1 Original feed LED ON/Original remaining LED ON/Paper feed

solenoid ON

↓

2 Reverse solenoid ON, Paper feed solenoid OFF

↓

3 Original feed LED OFF, Original remaining LED OFF, reverse

solenoid OFF

↓

4 Original feed LED ON, Original remaining LED ON, paper feed

solenoid ON, Paper feed motor forward rotation 450mm/s

(preliminary paper feed)

↓

5 Original feed LED OFF, Original remaining LED OFF, paper

feed solenoid OFF, Paper feed motor OFF

↓

6 Original feed LED ON, Original remaining LED OFF, paper

feed motor reverse rotation 450mm/s (2-step first taking)

↓

7 Original feed LED OFF, Original remaining LED OFF, Paper

feed motor OFF

↓

8 Original feed LED ON, Original remaining LED ON, Paper feed

motor reverse rotation 850mm/s (Paper feed operation)

↓

9 Original feed LED OFF, Original remaining LED OFF, Paper

feed motor OFF

↓

F Original feed LED ON, Original remaining LED ON, Transport

motor forward rotation 867mm/s

↓

– 26 –

Page 28

G Original feed LED OFF, Original remaining LED OFF,

Transport motor OFF

↓

H Original feed LED ON, Original remaining LED ON, Transport

motor reverse rotation 867mm/s

↓

I Original feed LED OFF, Original remaining LED OFF,

Transport motor OFF

↓

J Original feed LED ON, Original remaining LED ON, Reverse

motor forward rotation 867mm/s (Reverse operation)

↓

K Original feed LED OFF, Original remaining LED OFF, Reverse

motor OFF

↓

L Original feed LED ON, Original remaining LED ON, Reverse

motor forward rotation 867mm/s

↓

M Reverse motor speed reduction 867 → 297mm/s (Paper exit

speed reduction operation)

↓

N Original feed LED OFF, Original remaining LED OFF, Reverse

motor OFF

↓

O Original feed LED ON, Original remaining LED ON, Reverse

motor forward rotation 867mm/s

↓

P Reverse motor speed reduction 867 → 297mm/s (Paper exit

speed reduction operation)

↓

Q Original feed LED OFF, Original remaining LED OFF, Reverse

motor OFF

↓

Return to 1.

JAM, error kinds LED display

Paper feed motor lock

error

2

6 E

PROM initializing + all sensors adjustment mode

ON

REMOVE ORIGINAL LED blinks

at the cycle of 2000msec.

7 Each sensor A/D change mode

ON

OFF

SW No.1 2 3 4 5

When the push switch is pressed, a measurement is started. At

that time, LED blinks at the cycle of 100msec.

This mode checks the A/D value when the D/A output of the resist

sensor and the timing sensor is changed to 0 ∼ 255 (0[V] ∼ 5[V]).

The measurement program (PDP300.EXE) is required.

When each sensor A/D change mode is started, the D/A value of

the resist sensor and the timing sensor is changed. The A/D value

at that time is sent and at the completion of the operation, the

LCD turns ON.

8 Resist sensor adjustment mode

9 Timing sensor adjustment mode

F Paper exit sensor adjustment mode

When the DIP switch on the control PWB is set to either of the

following and the DF is opened and closed. each sensor adjustment mode is set.

Only the sensors which are set with the DIP switch are adjusted.

To adjust two or more sensors, open and close the DF again after

setting the DIP switch.

Before starting the sensor adjustment, check that there is no JAM

and that the DF is closed.

ON

OFF

SW No.1 2 3 4 5

ON

OFF

SW No.1 2 3 4 5

OFF

SW No.1 2 3 4 5

When the push switch is pressed, E2PROM initializing is performed. At that time, ADF FEED LED blinks at the cycle of

100msec.

When E2PROM initializing is completed, ADF FEED LED turns

ON. In the case of E2PROM initializing error, ADF FEED LED

blinks at the cycle of 2000msec.

Then the adjustments of all the sensors are started. At that time,

REMOVE ORIGINAL LED blinks at the cycle of 100msec.

When the adjustments of all the sensors are completed. REMOVE

ORIGINAL LED turns ON. In the case of a sensor adjustment

error, REMOVE ORIGINAL LED blinks at the cycle of 2000msec.

* Only when E2PROM initializing is completed successfully, the

adjustments of all the sensors are performed.

JAM, error kind LED display

E2PROM initializing error ADF FEED LED blinks at the

cycle of 2000msec.

Sensor adjustment error REMOVE ORIGINAL LED blinks

at the cycle of 2000msec.

– 27 –

ON

OFF

SW No.1 2 3 4 5

When the push switch is pressed, each sensor adjustment is

started. At that time, LED blinks at the cycle of 100msec.

After completion of the sensor adjustment, LED turns ON. In case

of an sensor adjustment error, LED blinks at the cycle of

100msec.

JAM, error kind LED display

Sensor adjustment

upper limit error

Sensor adjustment

lower limit error

REMOVE ORIGINAL LED goes off.

ADF FEED LED blinks at the cycle of

100msec.

REMOVE ORIGINAL LED blinks at the

cycle of 100msec.

ADF FEED LED goes off.

Page 29

[9] TROUBLESHOOTING

A. ADF does not operate. B. Motor error (DFM)

A

B

Is the interface

harness connected

properly ?

YES

Is DC5V

supplied between

CN6-3 and -4 ?

YES

Is DC24V

supplied between

CN6-1 and -2 ?

YES

Is the original set

display lighted ?

YES

Replace the control

PWB.

NO

NO

NO

NO

Connect the harness.

Is the harness

conducting ?

Check the copier PPC or

replace the ADF PEB.

E

Replace the harness.

YES

Is the load

at the motor shaft

normal ?

YES

Does the

motor rotate even

slightly ?

YES

Is the motor

clock sensor output

normal ?

Replace the control

PWB.

NO

NO

NO

Adjust the mechanism load

and the drive system, and

remove foreign materials.

Is a voltage

supplied between

CN5-1 and -2 ?

YES

E

Is a voltage

supplied between

CN5-1 and

CN5-2 ?

NO

NO

Connect the

harness.

YES

Is the

harness

conducting ?

NO

Replace the

harness.

Replace the

motor.

YES

Replace the

control PWB.

– 28 –

Page 30

C. Motor error (DTM, DRM) D. Sensor error (DFD, DTD RDD)

C

Is the motor

harness connected

properly ?

YES

Is the load

at the motor shaft

normal ?

YES

Is the harness

conducting ?

YES

Are the motor

connector pins (*)

conducting

normally ?

YES

NO

Connect the harness

properly.

Adjust the mechanism load

NO

and the drive system, and

remove foreign materials.

NO

Replace the harness.

NO

NO

D

Is the sensor

harness connected

properly ?

YES

Is the mirror

free from paper

dust or dirt ?

YES

Is the automatic

adjustment performed

properly ?

YES

Replace the control

PWB.

NO

Connect the harness

properly.

NO

NO

Clean the mirror.

Is the harness

conducting?

Replace the sensor.

Replace the harness.

NO

YES

Replace the PWB.

(*) DTM: Between CN4-5 and CN4-3, -4

Between CN 4-6 and CN4-1, -2

DRM: Between CN7-3 and CN4-7, -8

Between CN7-4 and CN4-5, -6

Replace the motor.

– 29 –

Page 31

E. Sensor error (DLS1, DLS2, DLS3, DSS,

DWS, DFMRS)

F. Solenoid error (DFSOL, DRSOL)

E

Is the sensor

harness connected

properly ?

YES

Is the harness

conducting ?

YES

Is the control

PWB sensor output

normal ?

YES

Replace the control

PWB.

NO

NO

NO

Connect the harness

properly.

Replace the harness.

Replace the sensor.

F

DRSOL

DRSOL

Is the

solenoid positioned

properly ?

YES

Are the coils

conducting ?

YES

Is the

harness connected

properly ?

YES

Is the harness

conducting ?

YES

NO

NO

Replace the solenoid.

NO

Connect the harness.

NO

Replace the harness.

Adjust.

Replace the control

PWB.

G. Originals cannot be fed.

G

Are the rollers

in the paper feed

section free from

paper dust or

dirt?

YES

Does the

semi-circular roller

rotate ?

YES

NO

Adjust the mechanism load

NO

and the drive system and

remove foreign materials.

B

– 30 –

F

Page 32

H. Originals cannot be reversed. I. Paper jam

H

Is the roller in

the reversing section

free from paper dust

or dirt ?

YES

Does the

reversing roller

rotate ?

YES

Does the

solenoid operate

properly ?

YES

Is the

reversing sensor

output normal ?

YES

Replace the control

PWB.

NO

NO

NO

Adjust the mechanism load

NO

and the drive system and

remove foreign materials.

C

F

D

I

Is the

machine free from

paper jam ?

YES

Is the

original feed sensor

(DFD) normal ?

YES

Is the

original width sensor

(DWS) normal ?

YES

Is the

original reversing

sensor(RDD)

normal ?

YES

Is the

original timing sensor

(DTD) normal ?

NO

Visually check and

remove the paper jam.

NO

NO

NO

NO

D

E

F

D

YES

Replace the control

PWB.

– 31 –

Page 33

[10] ELECTRICAL SECTION

1. Genera l

This circuit controls feeding, stopping, and reversing of the original. It is composed of sensors, switches, the circuit which processes signals from the

copier PPC, the circuit which drives motors, solenoids, and clutches, the CPU, the G/A and its peripheral circuits.

2. Block diagram

DFD

DTD

DFMRS

DWS

DLS1

DLS2

DLS3

TXD

RXD

DTR

DSR

RES

SGND

Communication

I/O circuit

Original feed

sensor input

circuit

Timing sensor

input circuit

DIP switch

push switch

Paper feed motor

rotation sensor

input circuit

Original width

sensor input

circuit

Original length

sensor input

circuit

CPU

(IC11)

Display LED

lighting circuit

Transport

motor drive

circuit

Paper exit

reverse motor

drive circuit

EEPROM

(IC3)

DATA BUS

ADRESS DATA BUS

Reset circuit

Address

latch

(IC2)

A

B

Oscillation

circuit

5.0MHz

ADRESS BUS

ROM

(IC2)

G/A

(IC7)

ADF FEED lamp

REMOTE DOCUMENT lamp

Paper feed

motor drive

circuit

Current

control circuit

Paper feed

solenoid drive

circuit

Reverse

solenoid drive

circuit

A

DFSOL

DRSOL

DFM

DTM

RDD

DSS

DWVR

AUOD

FGOD

TGOD

Reverse

sensor input

circuit

Original set

sensor input

circuit

Original width

volume input

circuit

Cover

open/close

switch input

circuit

Oscillation

circuit

9.83MHz

– 32 –

DC+24V

+5V

SGND

PGND

B

Power input

circuit

Rush current

prevention

circuit

DRM

FD+24V

DC+24V

+5V

Page 34

3. Operations

A. Sensor input circuit

[a] Original timing sensor (DTD)

The original timing sensor is a reflection type sensor, and the LED and the photo transistor are integrated into one. Infrared light emitted from the

LED is reflected by the mirror on the opposite side, and the reflected light enters the photo transistor to increase the photo current in the photo

transistor, detecting "No original."

On the other hand, if there is an original between the LED and the mirror, there is no reflection from the mirror. Therefore the photo current does not

increase and the original is detected.

This circuit is also provided with the automatic adjustment function.

The LED cathode is connected to the voltage-current conversion circuit composed of the operation amp (IC13), Q3, and R94. The current value is

controlled with the D-A output (analog voltage output) from the CPU. That is, the operation is made so that the CPU D-A output value (IC11-67 pin)

is equal to IC13 2 pin input voltage (the voltage drop of LED current by R94).

When, therefore, the D-A output value is changed, the current value is also changed.

On the other hand, the photo current of the photo transistor is converted into a voltage value by load resistor R95, and is inputted to IC9 4 pin and

the CPU 57 pin through the noise filter composed of R10 and C19.

R78, R80, R45, and IC9 form a voltage comparator, which compares the input voltage from the sensor with the threshold voltage (about 2V)

generated by dividing +24V with R78 and R80.

When the sensor input voltage exceeds the threshold voltage, the output of IC9 2pin turns LOW, being inputted to the CPU 72 pin as "No original"

signal.

The CPU 57 pin is an A-D input pin, which converts an analog voltage into a digital value inside the CPU. Since the sensitivity of a sensor generally

varies, it is automatically adjusted with the sensitivity at "No original" as the reference voltage. That is, the sensor voltage at "No original" is A-D

inputted to change the D-A output voltage, varying the LED current (LED light intensity) and controlling by the CPU so that the sensor voltage is the

specified constant level.

The D-A output value at that time is unique to every machine, and is stored in the EEPROM (IC3).

Original timing

sensor DTD

PH110M

TLN119B

173979-3

3

+5V

2

DTD

1

DTDLED

CN20-3

CN20-2

CN20-1

+5v

DTDLED

DTD

+5V

1

3

2SC2712

AN+24V

AGND

R95

3.0K

R10

10K

C19

0.10µ F

AGND

2

1-173981-0

CN3-1

CN3-3

CN3-2

Original timing sensor input circuit

Q3

R78

22K

R80

2.0K

5

4

R86

10K

R45

100K

IC9-1

µ PC339G2

IC13-1

1

µ PC358G2

2

CPU

(IC11)

TP7

3

2

R94

100

C5

1000PF

+5V

R53

4.7K

TP8

TP11

67

72

57

ANO0

P21/INTP0

P71/ANI1

– 33 –

Page 35

[b] Original feed sensor (DFD)

The original feed sensor is a reflection type sensor, and the LED and the photo transistor form a pair. Infrared light emitted from the LED is reflected

by the mirror on the opposite side, and the reflected light enters the photo transistor to increase the photo current in the photo transistor, detecting

"No original."

On the other hand, if there is an original between the LED and the mirror, there is no reflection from the mirror. Therefore the photo current does not

increase and the original is detected.

This circuit is also provided with the automatic adjustment function.

The LED cathode is connected to the voltage-current conversion circuit composed of the operation amp (IC13), Q3, and R94. The current value is

controlled with the D-A output (analog voltage output) from the CPU. That is, the operation is made so that the CPU D-A output value (IC11-68 pin)

is equal to IC13 6 pin input voltage (the voltage drop of LED current by R93).

When, therefore, the D-A output value is changed, the current value is also changed.

On the other hand, the photo current of the photo transistor is converted into a voltage value by emitter resistor R66, and is inputted to IC9 6 pin and

the CPU 56 pin through the noise filter composed of R101and C14.

R79, R81, R46, and IC9 form a voltage comparator, which compares the input voltage from the sensor with the threshold voltage (about 2V)

generated by dividing +24V with R79 and R81.

When the sensor input voltage exceeds the threshold voltage, the output of IC9 1pin turns LOW, being inputted to the CPU 73 pin as "No original"

signal.

The CPU 56 pin is an A-D input pin, which converts an analog voltage into a digital value inside the CPU. Since the sensitivity of a sensor generally

varies, it is automatically adjusted with the sensitivity at "No original" as the reference voltage. That is, the sensor voltage at "No original" is A-D

inputted to change the D-A output voltage, varying the LED current (LED light intensity) and controlling by the CPU so that the sensor voltage is the

specified constant level.

The D-A output value at that time is unique to every machine, and is stored in the EEPROM (IC3).

Original feed

sensor DFD

PH110M

TLN119B

1

2

3

173979-3

+5V

DFD

DFDLED

CN21-1

CN21-2

CN21-3

+5v

DFDLED

DFD

4

6

5

+5V

AGND

R66

9.1K

R11

10K

2SC2712

AN+24V

C14

0.10µ F

1-173981-0

CN3-4

CN3-6

CN3-5

Original feed sensor input circuit

Q4

AGND

R79

22K

R81

2.0K

R87

10K

7

6

R46

100K

IC9-2

µ PC339G2

IC13-2

1

µ PC358G2

1

CPU

TP9

(IC11)

5

6

R93

100

C6

1000PF

+5V

R54

4.7K

TP12

TP10

68

ANO1

73

P22/INTP1

56

P70/ANI0

– 34 –

Page 36

[c] Reverse sensor (RDD)

The reverse sensor is a reflection type sensor, and the LED and the photo transistor are integrated into one. Infrared light emitted from the LED is