Page 1

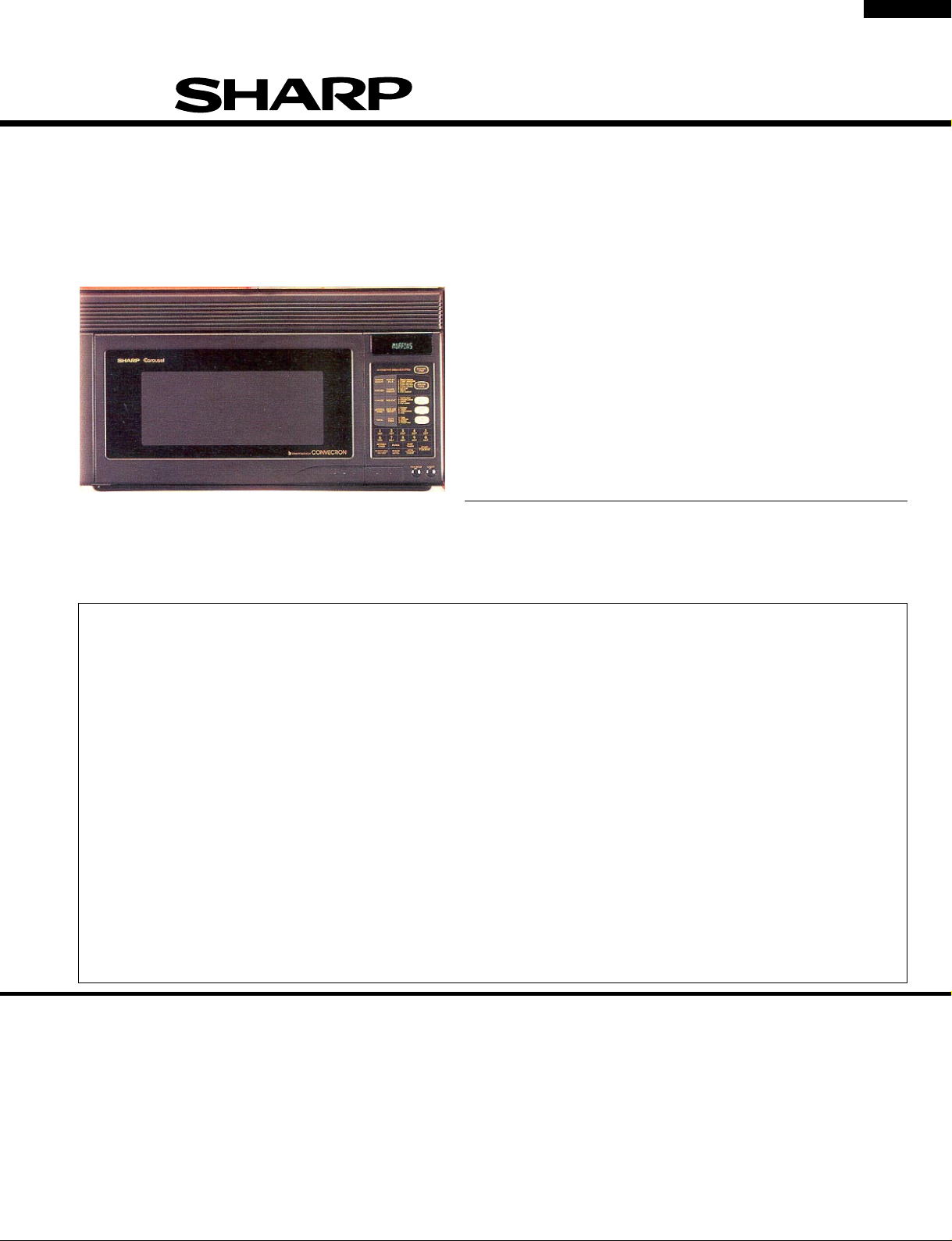

SER VICE MANU AL

S99M138R1855E

O VER THE RANGE

MICROWAVE OVEN

MODEL R-1855A

R-1855A

In the interest of user-safety the oven should be restored to its original

condition and only parts identical to those specified should be used.

This model for the US and Canada markets, Please refer to the appropriate pages for service information.

TABLE OF CONTENTS

Page

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICE TO

AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY.................. INSIDE FRONT COVER

BEFORE SERVICING.......................................................................................................................................... 1

MICROWAVE MEASUREMENT PROCEDURE .................................................................................................. 2

FOREWORD........................................................................................................................................................ 4

PRODUCT SPECIFICATIONS......................................................................................................... .................... 5

GENERAL INFORMATION ................................................................................................................................. 5

OPERATION ........................................................................................................................................................ 7

TROUBLESHOOTING GUIDE............................................................................................................................17

TEST PROCEDURE ...........................................................................................................................................20

TOUCH CONTROL PANEL ................................................................................................................................31

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE................................................................37

PICTORIAL DIAGRAM ....................................................................................................................................... 46

CONTROL PANEL CIRCUIT ..............................................................................................................................47

PRINTED WIRING BOARD ................................................................................................................................48

PARTS LIST........................................................................................................................................................49

PACKING AND ACCESSORIES........................................................................................................ .................55

OR:

This document has been published to be used for after sales service only. The contents are subject to

change without notice.

SHARP ELECTRONICS CORPORA TION

Service Headquarters: Sharp Plaza, Mahwah, New Jersey, 07430-2135

SHARP CORPORATION

SHARP ELECTRONICS OF CANADA LTD.

Head Office: 335 Britannia Road East, Mississauga, Ontario L4Z 1W9

(905) 890-2100

Page 2

R-1855A

PRECA UTIONS T O BE OBSERVED BEFORE AND

DURING SER VICING TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICRO WAVE

ENERGY

(a) Do not operate or allow the oven to be operated with the door open.

(b) Make the following safety checks on all ovens to be serviced before activating the magnetron or

other microwave source, and make repairs as necessary: (1) interlock operation (2) proper door

closing, (3) seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or loosening

of hinges and latches, (5) evidence of dropping or abuse.

(c ) Before turning on microwave power for any service test or inspection within the microwave

generating compartments, check the magnetron, wave guide or transmission line, and cavity for

proper alignment, integrity, and connections.

(d) Any defective or misadjusted components in the interlock, monitor, door seal, and microwave

generation and transmission systems shall be repaired, replaced, or adjusted by procedures

described in this manual before the oven is released to the owner.

(e) A microwave leakage check to verify compliance with the Federal Performance Standard should be

performed on each oven prior to release to the owner.

(RD2110U)

BEFORE SER VICING(USA)

Before servicing an operative unit, perform a microwave emission check as per the Microwave

Measurement Procedure outlined in this service manual.

If microwave emissions level is in excess of the specified limit, contact SHARP ELECTRONICS

CORPORATION immediately @1-800-237-4277.

If the unit operates with the door open, service person should 1) tell the user not to operate the oven

and 2) contact SHARP ELECTRONICS CORPORATION and Food and Drug Administration's Center

for Devices and Radiological Health immediately.

Service personnel should inform SHARP ELECTRONICS CORPORATION of any certified unit found

with emissions in excess of 4mW/cm2. The owner of the unit should be instructed not to use the unit

until the oven has been brought into compliance.

(RD2110U)

BEFORE SER VICING(CANAD A)

Before servicing an operative unit, perform a microwave emission check as per the Microwave

Measurement Procedure outlined in this service manual.

If microwave emissions level is in excess of the specified limit, contact SHARP ELECTRONICS OF

CANADA LTD. immediately.

If the unit operates with the door open, service person should 1) tell the user not to operate the oven

and 2) contact SHARP ELECTRONICS OF CANADA LTD. and NHW, CANADA immediately.

Service personnel should inform SHARP ELECTRONICS OF CANADA LTD. of any certified unit found

with emissions in excess of 4mW/cm2. The owner of the unit should be instructed not to use the unit

until the oven has been brought into compliance.

(RD8100U)

Page 3

WARNING TO SERVICE PERSONNEL

Microwave ovens contain circuitry capable of producing very high voltage and current, contact with

following parts

electrical shock.

(Example)

High Voltage Capacitor, High Voltage Power Trans-

former, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness etc..

Read the Service Manual carefully and follow all

instructions.

may result in a severe, possibly fatal,

R-1855A

Don't Touch !

Danger High Voltage

Before Servicing

1. Disconnect the power supply cord , and then

remove outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

WARNING:RISK OF ELECTRIC SHOCK.

DISCHARGE THE HIGH-VOLTAGE

CAPACITOR BEFORE SERVICING.

The high-voltage capacitor remains charged about 60

seconds after the oven has been switched off. Wait for

60 seconds and then short-circuit the connection of the

high-voltage capacitor (that is the connecting lead of the

high-voltage rectifier) against the chassis with the use of

an insulated screwdriver.

Whenever troubleshooting is performed the power supply

must be disconnected. It may in, some cases, be necessary

to connect the power supply after the outer case has been

removed, in this event,

1. Disconnect the power supply cord, and then remove

outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. Disconnect the leads to the primary of the power

transformer.

5. Ensure that these leads remain isolated from other

components and oven chassis by using insulation tape.

6. After that procedure, reconnect the power supply cord.

When the testing is completed,

1. Disconnect the power supply cord, and then remove

outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. Reconnect the leads to the primary of the power

transformer.

5. Reinstall the outer case (cabinet).

6. Reconnect the power supply cord after the outer case is

installed.

7. Run the oven and check all functions.

After repairing

1. Reconnect all leads removed from components during

testing.

2. Reinstall the outer case (cabinet).

3. Reconnect the power supply cord after the outer case is

installed.

4. Run the oven and check all functions.

Microwave ovens should not be run empty. To test for the

presence of microwave energy within a cavity, place a cup

of cold water on the oven turntable, close the door and set

the power to HIGH and set the microwave timer for two (2)

minutes. When the two minutes has elapsed (timer at zero)

carefully check that the water is now hot. If the water

remains cold carry out Before Servicing procedure and reexamine the connections to the component being tested.

When all service work is completed and the oven is fully

assembled, the microwave power output should be checked

and microwave leakage test should be carried out.

1

Page 4

R-1855A

MICRO WA VE MEASUREMENT PR OCEDURE (USA)

A. Requirements:

1) Microwave leakage limit (Power density limit): The power density of microwave radiation emitted by a microwave oven

should not exceed 1mW/cm2 at any point 5cm or more from the external surface of the oven, measured prior to acquisition

by a purchaser, and thereafter (through the useful life of the oven), 5 mW/cm2 at any point 5cm or more from the external

surface of the oven.

2) Safety interlock switches Primary interlock relay and door sensing switch shall prevent microwave radiation emission

in excess of the requirement as above mentioned, secondary interlock switch shall prevent microwave radiation

emission in excess of 5 mW/cm2 at any point 5cm or more from the external surface of the oven.

B. Preparation for testing:

Before beginning the actual measurement of leakage, proceed as follows:

1) Make sure that the actual instrument is operating normally as specified in its instruction booklet.

Important:

Survey instruments that comply with the requirement for instrumentation as prescribed by the performance standard

for microwave ovens, 21 CFR 1030.10(c)(3)(i), must be used for testing.

2) Place the oven tray in the oven cavity.

3) Place the load of 275±15 ml (9.8 oz) of tap water initially at 20±5OC (68OF) in the center of the oven cavity.

The water container shall be a low form of 600 ml (20 oz) beaker with an inside diameter of approx. 8.5 cm (3-1/2in.)

and made of an electrically nonconductive material such as glass or plastic.

The placing of this standard load in the oven is important not only to protect the oven, but also to insure that any leakage

is measured accurately.

4) Set the cooking control on Full Power Cooking Mode

5) Close the door and select a cook cycle of several minutes. If the water begins to boil before the survey is

completed, replace it with 275 ml of cool water.

C. Leakage test:

Closed-door leakage test (microwave measurement)

1) Grasp the probe of the survey instrument and hold it perpendicular to the gap between the door and the body of the oven.

2) Move the probe slowly, not faster than 1 in./sec. (2.5 cm/sec.) along the gap, watching for the maximum indication on

the meter.

3) Check for leakage at the door screen, sheet metal seams and other accessible positions where the continuity of the

metal has been breached (eg., around the switches, indicator, and vents).

While testing for leakage around the door pull the door away from the front of the oven as far as is permitted by the closed

latch assembly.

4) Measure carefully at the point of highest leakage and make sure that the highest leakage is no greater than 4mW/cm2,

and that the secondary interlock switch does turn the oven OFF before any door movement.

NOTE: After servicing, record data on service invoice and microwave leakage report.

2

Page 5

R-1855A

MICROWAVE MEASUREMENT PROCEDURE (CANADA)

After adjustment of the door switches are completed individually or collectively, switch test and microwave leakage test must

be performed with survey instrument and test result must be confirmed to meet the requirement of the performance standard

for microwave ovens as undermentioned.

A. Requirements:

Every microwave oven shall function in such a manner that when the oven is fully assembled and operating with it's service

controls and user controls adjusted to yield the maximum output, the leakage radiation, at all points at least 5 cm. from the

external surface of the oven, does not exceed:

1) 1.0mW/cm2 with the test load of 275 ± 15 ml of water at an initial temperature 20 ±5oC.

2) 5.0mW/cm

3) 5.0mW/cm

2

when the outer enclosure is removed with a test load of 275 ± 15 ml of water at an initial temperature 20±5oC.

2

without a test load.

B. Preparation for testing:

Before beginning the actual measurement of leakage, proceed as follows:

1) Make sure that the actual instrument is operating normally as specified in its instruction booklet.

Important:

Survey instruments that comply with the requirement for instrumentation as prescribed by CSA and NHW performance standard

for microwave ovens must be used for testing recommended instruments are , NARDA 8100 and NARDA 8200.

2) Place the oven tray in the oven cavity.

3) Place the load of 275±15 ml of tap water initially at 20±5oC in the center of the oven cavity.

The water container shall be a low form of 600 ml beaker with an inside diameter of approx. 8.5 cm (3-1/2 in.) and made

of an electrically nonconductive material such as glass or plastic.

The placing of this standard load in the oven is important not only to protect the oven, but also to insure that any leakage

is measured accurately.

4) Set the cooking control on Full Power Cooking Mode, Close the door and select a cook cycle of several minutes. If the water

begins to boil before the survey is completed, replace it with 275 ml of cool water.

C. Leakage test with enclosure installed :

1) Grasp the probe of the survey instrument and hold it perpendicular to the gap between the door and the body of the oven.

2) Move the probe slowly, not faster than 2.5 cm/sec. along the gap, watching for the maximum indication on the meter.

3) Check for leakage at the door screen, sheet metal seams and other accessible positions where the continuity of the metal

has been breached (eg., around the switches, indicator, and vents).

While testing for leakage around the door pull the door away from the front of the oven as far as is permitted by the closed

latch assembly.

4) Measure carefully at the point of highest leakage and make sure that the highest leakage is no greater than 4mW/cm2, and

that the secondary interlock switch does turn the oven OFF before any door movement.

C. Leakage test without enclosure:

1) Remove the enclosure (cabinet).

2) Grasp the probe of the survey instrument and hold it perpendicular to all mechanical and electric parts of the oven that is

accessible to the user of the oven including, but not limited to, the waveguide, cavity seams, magnetron gap between the

door and the body of the oven.

3) Move the probe slowly, not faster than 2.5 cm/sec. along the gap, watching for the maximum indication on the meter.

4) Measure carefully at the point of highest leakage and make sure that the highest leakage is under 5mW/cm2.

CAUTION: Special attention should be given to avoid electrical shock because HIGH VOLTAGE is generated during this test

No Load test

1) Operate the oven without a load and measure the leakage by the same method as the above test procedure " Leakage

test with enclosure installed"

2) Make sure that the highest leakage should not exceed 5mW/cm2.

NOTE: After servicing, record data on service invoice and microwave leakage report.

3

Page 6

R-1855A

SERVICE MANUAL

OVER THE RANGE

MICROWAVE OVEN

R-1855A

FOREWORD

This Manual has been prepared to provide Sharp Electronics Corp.

Service Personnel with Operation and Service Information for the

SHARP OVER THE RANGE MICROWAVE OVEN, R-1855A.

It is recommended that service personnel carefully study the entire

text of this manual so that they will be qualified to render satisfactory

customer service.

Check the interlock switches and the door seal carefully. Special

attention should be given to avoid electrical shock and microwave

radiation hazard.

WARNING

Never operate the oven until the following points are ensured.

(A) The door is tightly closed.

(B) The door brackets and hinges are not defective.

(C) The door packing is not damaged.

(D) The door is not deformed or warped.

(E) There is no other visible damage with the oven.

PRODUCT DESCRIPTION

GENERAL INFORMATION

OPERATION

TROUBLESHOOTING GUIDE AND

TEST PROCEDURE

TOUCH CONTROL PANEL

COMPONENT REPLACEMENT AND

ADJUSTMENT PROCEDURE

Servicing and repair work must be carried out only by trained service

personnel.

DANGER

Certain initial parts are intentionally not grounded and

present a risk of electrical shock only during servicing.

Service personnel - Do not contact the following parts while

the appliance is energized;

High Voltage Capacitor, Power Transformer, Magnetron,

High Voltage Rectifier Assembly, High Voltage Harness;

If provided, Vent Hood, Fan assembly, Cooling Fan Motor.

All the parts marked “*” on parts list are used at voltages more

than 250V.

Removal of the outer wrap gives access to voltage above 250V.

All the parts marked “∆” on parts list may cause undue microwave

exposure, by themselves, or when they are damaged, loosened

or removed.

USA MODEL

SHARP ELECTRONICS CORPORATION

SHARP PLAZA, MAHWAH,

NEW JERSEY 07430-2135

WIRING DIAGRAMS

PARTS LIST

CANADIAN MODEL

OSAKA, JAPAN

4

Page 7

SPECIFICATION

ITEM DESCRIPTION

Power Requirements 120 Volts / 13.2 Amperes (Microwave), 13.2 Amperes (Convection)

60 Hertz

Single phase, 3 wire grounded

Power Output 850 watts (IEC-705 TEST PROCEDURE)

Operating frequency of 2450MHz

Convection Power Output 1400 watts

Case Dimensions Width 29-15/16"

Height 16-11/32"

Depth 15- 9/32"

Cooking Cavity Dimensions Width 17-1/8"

Height 8-1/16"

1.1 Cubic Feet Depth 13-13/16"

Hood lamp 2 bulbs, 30W x 2, Incandescent light bulbs

Hood fan Horizontal discharge 230 C.F.M. , Vertical discharge 240 C.F.M. ,

Control Complement Touch Control System

Clock ( 1:00 - 12:59 )

Timer (0 - 99 min. 99 seconds)

Microwave Power for Variable Cooking

Repetition Rate;

P-HI ................................................ Full power throughout the cooking time

P-90................................................................... approx. 90% of Full Power

P-80................................................................... approx. 80% of Full Power

P-70................................................................... approx. 70% of Full Power

P-60................................................................... approx. 60% of Full Power

P-50................................................................... approx. 50% of Full Power

P-40.................................................................... approx. 40% of Full Power

P-30.................................................................... approx. 30% of Full Power

P-20................................................................... approx. 20% of Full Power

P-10..................................................................... approx. 10% of Full Powe

P-0....................................................No power throughout the cooking time

R-1855A

CUSTOM HELP pad, SENSOR COOK pad, COMPU BROIL pad, COMPU ROAST pad

COMPU BAKE pad, SENSOR REHEAT pad, MINUTE PLUS pad, POPCORN pad

COMPU DEFROST pad, CONVECTION pad, REHEAT pad, LOW MIX/BAKE pad

HIGH MIX/ROAST pad, BROIL pad, SLOW COOK pad, KITCHEN TIMER pad

Number and temperature selection pads, CLOCK pad, KEEP WARM pad

TURNTABLE ON / OFF pad, POWER LEVEL pad, STOP/CLEAR pad,

START / TOUCH ON pad

Oven Cavity Light Yes 30W x 1 Incandescent light bulb

Safety Standard UL Listed FCC Authorized

DHHS Rules, CFR, Title 21, Chapter 1, Subchapter J

Canadian Standards Association.

Department of National Health and Welfare CANADA, Industry CANADA.

Weight Approx. 71 lbs.

GENERAL INFORMA TION

GROUNDING INSTRUCTIONS

This oven is equipped with a three prong grounding plug. It must be plugged into a wall receptacle that is properly installed

and grounded in accordance with the National Electrical Code and local codes and ordinances.

In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the

electric current.

WARNING: Improper use of the grounding plug can result in a risk of electric shock.

5

Page 8

R-1855A

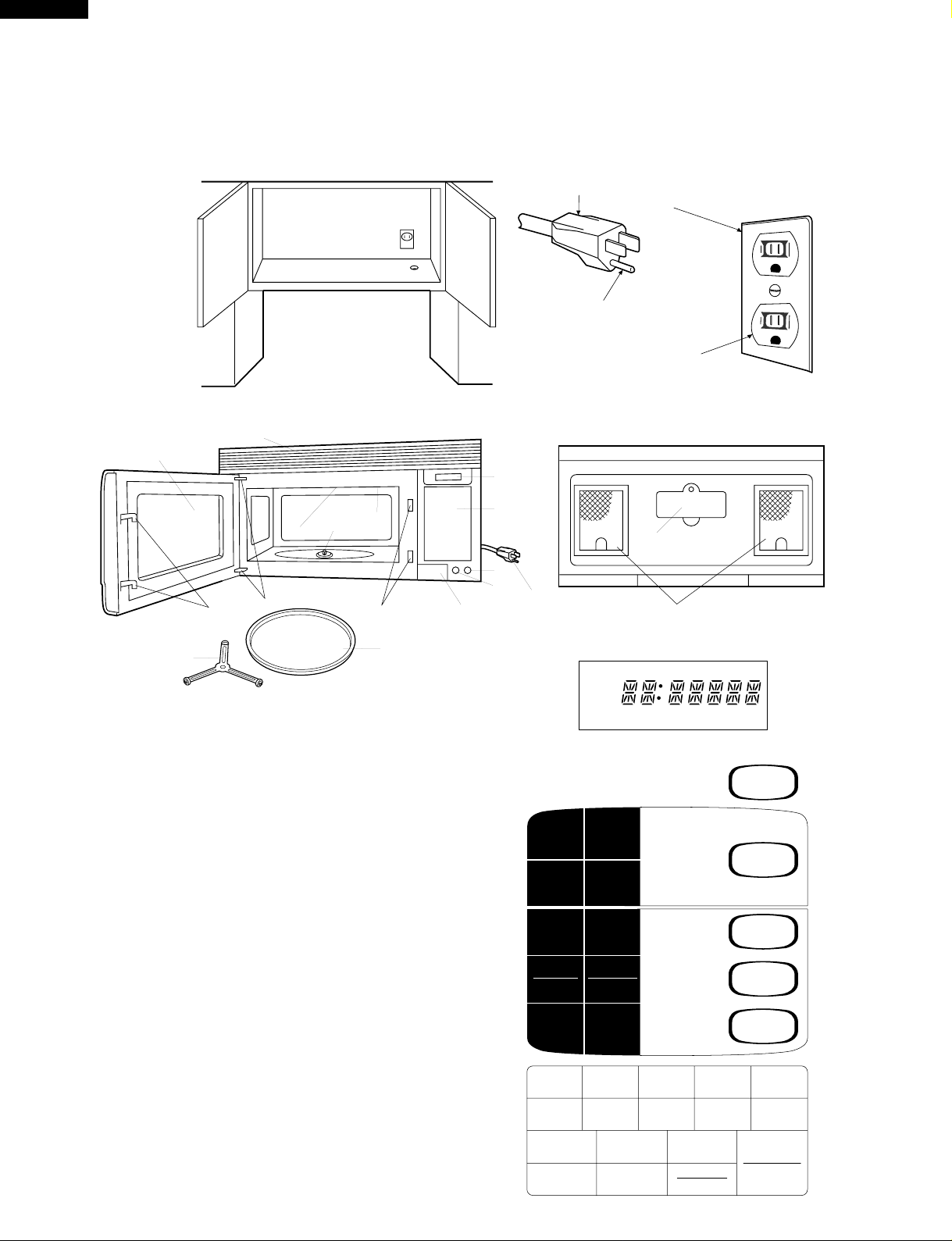

3-Pronged Plug

Grounded

Receptacle Box

Grounding Pin

3-Pronged Receptacle

Electrical Requirements

The oven is equipped with a 3-prong grounding plug. DO NOT UNDER ANY CIRCUMSTANCES CUT OR REMOVE THE

GROUNDING PIN FROM THE PLUG.

The power supply cord and plug must be connected to a separate 120 Volt AC, 60 Hz, 15 Amp. or more branch circuit, using

a grounded receptacle. The receptacle should be located inside the cabinet directly above the Microwave Oven/Hood

system mounting location.

12

1

3

6

2

16

1. Oven door with see-through window.

2. Door hinges.

3. Stirrer cover.

4. Turntable motor shaft.

5. Oven lamp.

It will light when oven is operating or door is open.

6. Door latches.

The oven will not operate unless the door is securely closed.

7. One touch door open button.

Push to open door.

8. FAN-HI/LO button.

Push for High/Low/Off.

9. Light button.

Push for On/Off

10.Auto-Touch control panel.

11.Time display: Digital display, 99 minutes 99 seconds.

12. Ventilation openings.

13.Light Cover.

14.Grease filters.

15.Removable turntable.

The turntable will rotate clockwise or counterclockwise.

Only remove for cleaning.

16.Removable turntable support.

17. Plug

CONTROL PANEL

OVEN DIAGRAM

11

5

4

6

15

10

13

9

8

7

17

14

MIX CONV

DEFROST

SENSOR

TURNTABLE

ON OFF COOK LBS OZ KG HELP

INTERACTIVE COOKING SYSTEM

SENSOR

REHEAT

POPCORN

CONVEC

LOW MIX

BAKE

BROIL

100˚F 150˚F 275˚F 300˚F 325˚F

350˚F 375˚F 400˚F 425˚F 450˚F

KITCHEN

TURNTABLE

ON / OFF

MINUTE

PLUS

COMPU

DEFROST

REHEAT

HIGH MIX

ROAST

SLOW

COOK

12345

67890

TIMER

1 Baked potatoes

2 Frozen vegetables

3 Fresh veg-soft

4 Fresh veg-hard

5 Frozen entrees

6 Hot dogs

7 Bacon

8 Fish, seafood

1 Hamburgers

2 Chicken pieces

3 Steaks

4 Fish steaks

1 Chicken

2 Turkey

3 Turkey breast

4 Pork

1 Cake

2 Brownies

3 Muffins

4 French fries

CLOCK

POWER

LEVEL

KEEP

WARM

STOP

CLEAR

CUSTOM

HELP

SENSOR

COOK

COMPU

BROIL

COMPU

ROAST

COMPU

BAKE

START

TOUCH ON

6

Page 9

OPERATION

DESCRIPTION OF OPERATING SEQUENCE

R-1855A

The following is a description of component functions during

oven operation.

OFF CONDITION

Closing the door activates the door sensing switch and

secondary interlock switch. (In this condition, the monitor

switch contacts are opened.)

When oven is plugged in, 120 volts A.C. is supplied to the

control unit. (Figure O-1).

1. The display will show , , ,

, , , , and

.

To set any program or set the clock, you must first touch

the STOP/CLEAR pad. The display will clear, and " : "

will appear.

COOKING CONDITION

Program desired cooking time touching the NUMBER pads.

When the START pad is touched, the following operations

occur:

1. The contacts of relays are closed and components

connected to the relays are turned on as follows.

(For details, refer to Figure O-2)

RELAY CONNECTED COMPONENTS

RY1 Oven lamp

RY2 Power transformer/ Stirrer motor

RY4 Turntable motor

RY5 Fan motor

2. 120 volts A.C. is supplied to the primary winding of the

power transformer and is converted to about 3.3 volts

A.C. output on the filament winding, and approximately

2000 volts A.C. on the high voltage winding.

3. The filament winding voltage heats the magnetron filament

and the H.V. winding voltage is sent to a voltage doubler

circuit.

4. The microwave energy produced by the magnetron is

channelled through the waveguide into the cavity feedbox, and then into the cavity where the food is placed to

be cooked.

5. Upon completion of the cooking time, the power

transformer, oven lamp, etc. are turned off, and the

generation of microwave energy is stopped. The oven

will revert to the OFF condition.

6. When the door is opened during a cook cycle, monitor

switch, door sensing switch, secondary interlock switch

and third door switch and primary interlock relay are

activated with the following results. The circuits to the

stirrer motor, the cooling fan motor, the turntable motor,

and the high voltage components are de-energized, and

the digital read-out displays the time still remaining in the

cook cycle when the door was opened.

7. The monitor switch is electrically monitoring the operation

of the secondary interlock switch, third door switch and

door sensing switch is mechanically associated with the

door so that it will function in the following sequence.

(1) When the door opens from a closed position, the

primary interlock relay, door sensing switch,

secondary interlock switch and third door switch

open their contacts, and then the monitor switch

contacts close.

(2) When the door is closed from the open position, the

monitor switch contacts first open, and then the

contacts of the secondary interlock switch and third

door switch close.

If the secondary interlock switch, third door switch and door

sensing switch fail with their contacts closed when the door

is opened, the closing of the monitor switch contacts will

form a short circuit through the monitor fuse, third door

switch, secondary interlock switch and primary interlock

relay, causing the monitor fuse to blow.

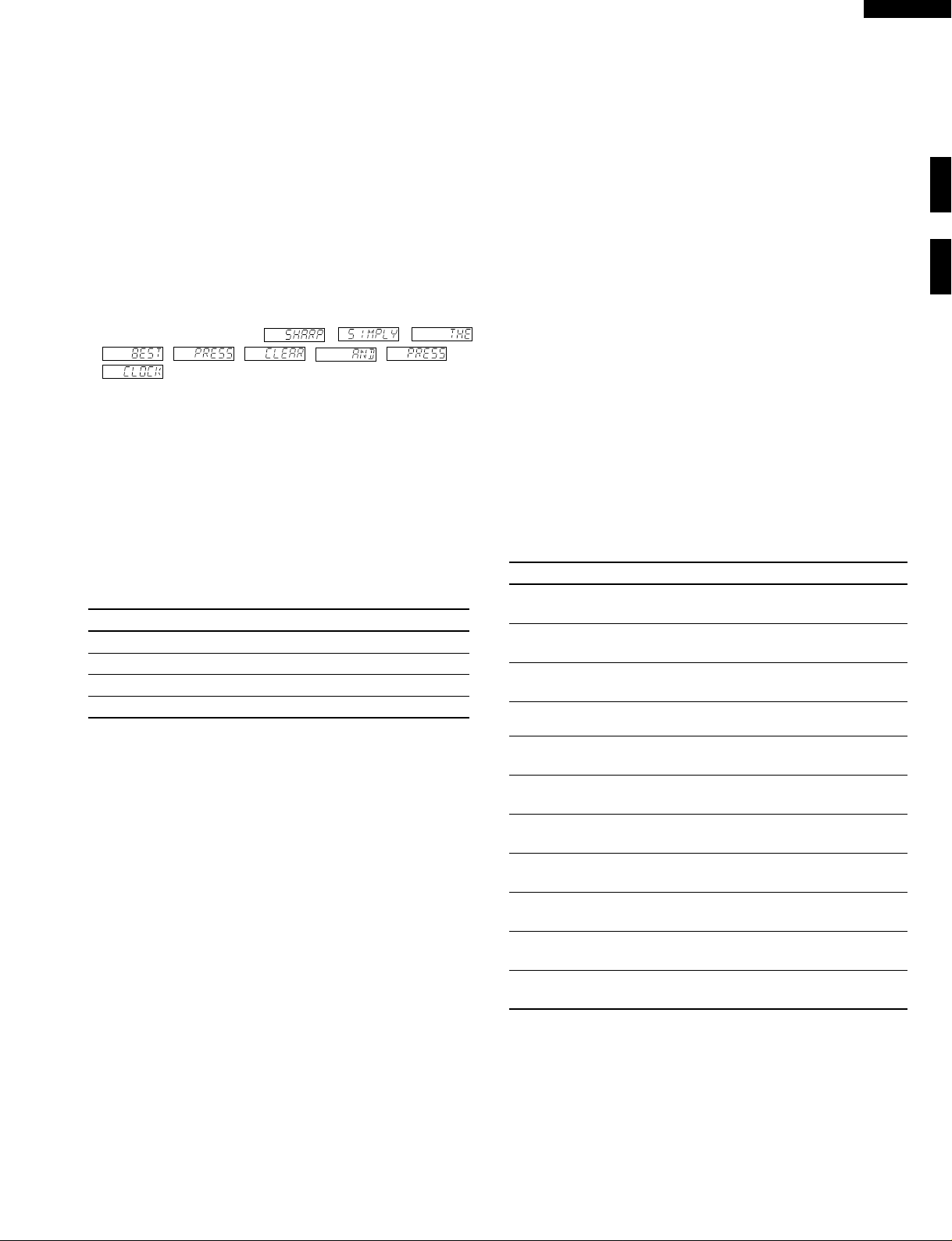

POWER LEVEL P-0 TO P-90 COOKING

When Variable Cooking Power is programmed, the 120

volts A.C. is supplied to the power transformer intermittently through the contacts of relay (RY2) which is operated

by the control unit within an interval second time base.

Microwave power operation is as follows:

VARI-MODE ON TIME OFF TIME

Power 10(P-HI) 32 sec. 0 sec.

(100% power)

Power 9(P-90) 30 sec. 2 sec.

(approx. 90% power)

Power 8(P-80) 26 sec. 6 sec.

(approx. 80% power)

Power 7(P-70) 24 sec. 8 sec.

(approx. 70% power)

Power 6(P-60) 22 sec. 10 sec.

(approx. 60% power)

Power 5(P-50) 18 sec. 14 sec.

(approx. 50% power)

Power 4(P-40) 16 sec. 16 sec.

(approx. 40% power)

Power 3(P-30) 12 sec. 20 sec.

(approx. 30% power)

Power 2(P-20) 8 sec. 24 sec.

(approx. 20% power)

Power 1(P-10) 6 sec. 26 sec.

(approx. 10% power)

Power 0(P-0) 0 sec. 32 sec.

(0% power)

Note: The ON/OFF time ratio does not correspond with the

percentage of microwave power, because approx.

2 seconds are needed for heating of the magnetron

filament.

CONVECTION COOKING CONDITION

PREHEATING CONDITION

Program desired convection temperature by touching the

PREHEAT pad and the temperature pad.

7

Page 10

R-1855A

When the START pad is touched, the following operations

occur:

1. The coil of shut-off relays (RY1, RY4, RY5 and RY7) are

energized, the oven lamp, turntable motor, cooling fan

motor and convection motor are turned on.

2. The coil of relay (RY6) is energized by the control unit.

The damper is moved to the closed position, opening the

damper switch contacts. The opening of the damper

switch contacts sends a signal to the LSI on the control

unit de-energizing the relay (RY6) and opening the

circuit to the damper motor.

3. The coil of heater relay (RY3) is energized by the control

unit and the main supply voltage is applied to the heating

element.

4. When the oven temperature reaches the selected preheat

temperature, the following operations occur:

4-1 The heater relay is de-energized by the control unit

temperature circuit and thermistor, opening the

circuit to the heating element.

4-2. The oven will continue to function for 30 minutes,

turning the heater on and off, as needed to maintain

the selected preheat temperature. The oven will

shutdown completely after 30 minutes

CONVECTION COOKING CONDITION

When the preheat temperature is reached, a beep signal will

sound indicating that the holding temperature has been

reached in the oven cavity. Open the door and place the food

to be cooked in the oven.

Program convection temperature and desired cooking time

by touching the CONVECTION pad, Temperature pad and

NUMBER pad.

When the START pad is touched, the following operations

occur:

1. The numbers on the digital read-out start to count down

to zero.

2. The oven lamp, turntable motor, cooling fan motor and

convection motor are energized.

3. Heater relay (RY3) is energized (if the cavity temperature

is lower than the selected temperature) and the main

supply voltage is applied to the heating element to return

to the selected cooking temperature.

4. Upon completion of the cooking time, the audible signal

will sound, and oven lamp, turntable motor, cooling fan

motor and convection motor are de-energized. At the

end of the convection cycle, if the oven temperature is

above 275OF, the circuit to RY5 will be maintained (by

the thermistor circuit) to continue operation of the

cooling fan motor until the temperature drops below

245OF, at which time the relay will be de-energized,

turning off the fan motor. Relay RY7 will however, open

as soon as the convection cycle has ended, turning off

the convection motor.

5. At the end of the convection cook cycle, shut-off relay

(RY6) is energized turning on the damper motor. The

damper is returned to the open position, closing the

damper switch contacts which send a signal to the

control unit, de-energizing shut-off relay (RY6).

AUTOMATIC MIX COOKING CONDITION

Touch the LOW MIX/BAKE or HIGH MIX/ROAST pad. The

LOW MIX/BAKE pad is preprogrammed for 325OF with 10%

microwave power, while the HIGH MIX/ROAST pad is

preprogrammed for 325OF with 30% microwave power.

Program desired cooking time. When the START pad is

touched, the following operations occur:

1. The numbers on the digital read-out start to count down

to zero.

2. The shut-off relays (RY1, RY4, RY5 and RY7) are

energized, turning on the oven lamp, turntable motor,

cooling fan motor and convection motor.

3. The shut-off relay (RY6) is energized.

The damper plate is closed from the open position.

4. The heater relay (RY3) is energized, applying the main

supply voltage to the heating element.

5. Now, the oven is in the convection cooking condition.

6. When the oven temperature reaches the selected

temperature, the following operations occur:

6-1. The power supply voltage is alternated to the

heating element and power transformer.

6-2. The heating element operates through the heater

relay (RY3) contacts and the power transformer

operates through the primary interlock relay (RY2)

contacts.

6-3. These are operated by the control unit to supply

alternately within a 32 second time base, convection

heat and microwave energy.

The relationship between the convection and microwave

power operations are as follows.

Note: The ON and OFF time ratio does not correspond

with the percentage of microwave power, because

approx. 2 seconds are needed for heating of the

magnetron filament.

26 SEC.6 SEC.

(MICRO.)

(CONVEC.)

(MICRO.)

(CONVEC.)

ON

OFF

LOW MIX

BAKE

12 SEC. 20 SEC.

ON

OFF

ON

OFF

32 SEC.

HIGH MIX

ROAST

MICROWAVE POWER

= APPROX. 10%

CONVECTION

TEMPERATURE

= 325˚F (165˚C)

MICROWAVE POWER

= APPROX. 30%

CONVECTION

TEMPERATURE

325˚F (165˚C)

Note: During alternate Microwave/Convection operation,

the convection heater is energized only if the cavity

temperature drops below the set temperature.

SENSOR COOKING CONDITION

Using the SENSOR COOK, SENSOR REHEAT or POPCORN function, the foods are cooked or defrosted without

figuring time, power level or quantity. When the oven senses

enough steam from the food, it relays the information to its

microprocessor which will calculate the remaining cooking

time and power level needed for best results.

When the food is cooked, water vapor is developed. The

sensor “senses” the vapor and its resistance increases

gradually. When the resistance reaches the value set

according to the menu, supplementary cooking is started.

8

Page 11

R-1855A

The time of supplementary cooking is determined by

experiment with each food category and inputted into the

LSI.

An example of how sensor works:

1. Potatoes at room temperature. Vapor is emitted very

slowly.

MICROWAVE

2. Heat potatoes. Moisture and humidity is emitted rapidly.

You can smell the aroma as it cooks.

AH SENSOR

MICROWAVE

3. Sensor detects moisture and humidity and calculates

cooking time and variable power.

Cooking Sequence.

1. Touch SENSOR COOK, SENSOR REHEAT or

POPCORN pad. When Sensor Cook is touched, to

choose menu the number pad should be touched.

NOTE: The oven should not be operated on SENSOR

COOK, SENSOR REHEAT or POPCORN

immediately after plugging in the unit. Wait five

minutes before cooking on SENSOR COOK,

SENSOR REHEAT or POPCORN.

2. The coil of shut-off relays (RY1, RY4 and RY5) are

energized, the oven lamp, turntable motor and cooling

fan motor are turned on, but the power transformer is not

turned on.

3. After about 32 seconds, the cook relay (RY2) is energized.

The power transformer is turned on, microwave energy

is produced and first stage is started.

The 32 seconds is the cooling time required to remove

any vapor from the oven cavity and sensor.

NOTE: During this first stage, do not open the door or touch

STOP/CLEAR pad.

4. When the sensor detects the vapor emitted from the

food, the display switches over to the remaining cooking

time and the timer counts down to zero.

At this time, the door may be opened to stir food, turn it

or season, etc.

5. When the timer reaches zero, an audible signal sounds.

The shut-off relay and cook relay are de-energized and

the power transformer, oven lamp, etc. are turned off.

6. Opening the door or touching the STOP/CLEAR pad, the

time of day will reappear on the display and the oven will

revert to an OFF condition.

COMPU BROIL, COMPU ROAST, COMPU BAKE

COMPU BROIL, COMPU ROAST and COMPU BAKE will

automatically compute the oven temperature, microwave

power and cooking time for broiling, roasting and baking. Set

the desired program by touching one of the COMPU BROIL,

COMPU ROAST or COMPU BAKE pad, and number pad.

Enter the weight by touching the Number pads. When the

START pad is touched, the following operations occur:

1. The COOK indicator will light and the CONV or MIX

indicator will light.

2. The cooking time will appear on the display and start

counting down to zero. The cooking time is adjusted

automatically according to the weight of the food.

3. The shut-off relays (RY1, RY4, RY5 and RY7) are

energized, turning on the oven lamp, turntable motor,

cooling fan motor and convection motor. The power

supply voltage is applied to the heating element.

4. Now, the oven is in the convection cooking mode or

Automatic Mix Cooking condition.

5. When the oven temperature has reached the

programmed convection temperature, the oven goes

into the programmed cooking mode.

6. At the end of the cooking cycle, the damper is returned

to the open position and the oven will go to the off

condition. The cooling fan will remain on until the oven

has cooled.

COMPU DEFROST COOKING

The COMPU DEFROST key is a special function key to

defrost meats and poultry faster and better. COMPU

DEFROST automatically defrosts roast beef, etc.. When

the COMPU DEFROST is selected and the food weight is

entered by using the COMPU DEFROST pad, the oven will

cook according to the special cooking sequence.

FIRE SENSING FEATURE (MICROWAVE MODE)

This model incorporates a sensing feature which will stop

the oven's operation if there is a fire in the oven cavity during

microwave cooking.

This is accomplished by the LSI repeatedly measuring the

voltage across the temperature measurement circuit (thermistor) during it's 32-seconds time base comparing the

obtained voltage measurements. If the most recent voltage

measured is 100mV greater than the previous voltage

measured, the LSI judges it as a fire in the oven cavity and

switches off the relays to the power transformer and fan

motor. The LSI also stops counting down and closes the

damper plate so that no fresh air will enter the oven cavity.

Please refer to the following section for a more detailed

description.

Operation

The following operation will start 4 minutes after the start

pad is touched. Please refer to the timing diagrams below.

1. The thermistor operates within a 32-seconds time base

and it is energized for three (3) seconds and off for 29

seconds. Two (2) seconds after the thermistor is

energized, the voltage across the temperature

measurement circuit is sampled by the LSI and twenty

one (21) seconds after the thermistor is cut off the LSI

turns on the convection motor for six (6) seconds.

2. The above procedure is repeated. If the difference

between the first voltage measured (in step 1) and the

voltage measured when the procedure is repeated (step

2) is greater than 100mV the LSI makes the judgment

that there is a fire in the oven cavity and will switch off

9

Page 12

R-1855A

the relays to the power transformer and fan motor. The

LSI also stops counting down and closes the damper

door so that no fresh air will enter the oven cavity.

3. Once the fire sensor feature has shut the unit down, the

programmed cooking cycle may be resumed by pressing

the "START" pad or the unit may be reset by pressing the

"CLEAR" pad.

IMPORTANT:

During sensor cooking operation, the fire sensing

operation sequence will not begin until the AH sensor

has detected vapors and initiated a sensor cooking

cycle. This is because the operation of the convection

fan would interfere with the AH sensor's vapor detection.

CONVECTION

MOTOR

THERMISTOR

Sensing

Voltage

0 2 24 30 64 (sec.)

3

ON

OFF

3 sec.

ON

OFF

ON

OFF

Sensing the voltage across the temperature measurement circuit.

6 sec.

32 (sec.)

3. RE-CIRCULATION (INSIDE VENTING)

The air handing is same as VERTICAL VENTING except

that the final air discharge is directed horizontally

through the upper front of the oven into the kitchen. IN

this case, the accessory charcoal filter lit RK-220 must

be provided to filter the air before it leaves the oven.

: AIR FLOW

HOOD FAN MOTOR

HOOD EXHAUST

LOUVER

HOOD

INTAKE

DUCT R

CHARCOAL

FILTER

VENTILATION METHODS HOT AIR EXHAUST

1. VERTICAL VENTING

For this venting method, hot air rising from the

conventional range below is drawn in by the hood fan

motor through the grease filters at the right and left sides

of the base cover, up through the right and left side intake

ducts, then discharged vertically at rear center top of the

oven, into the customer's vent system.

: AIR FLOW

HOOD FAN MOTOR

HOOD

INTAKE

DUCT R

GREASE

FILTER

2. HORIZONTAL VENTING

The air handing is same as VERTICAL VENTING except

that the final air discharge is directed horizontally out

from the top rear of the oven into the customer's vent

system.

: AIR FLOW

HOOD FAN MOTOR

HOOD

INTAKE

DUCT R

TO DUCTTO DUCT

TO DUCT

GREASE

FILTER

10

Page 13

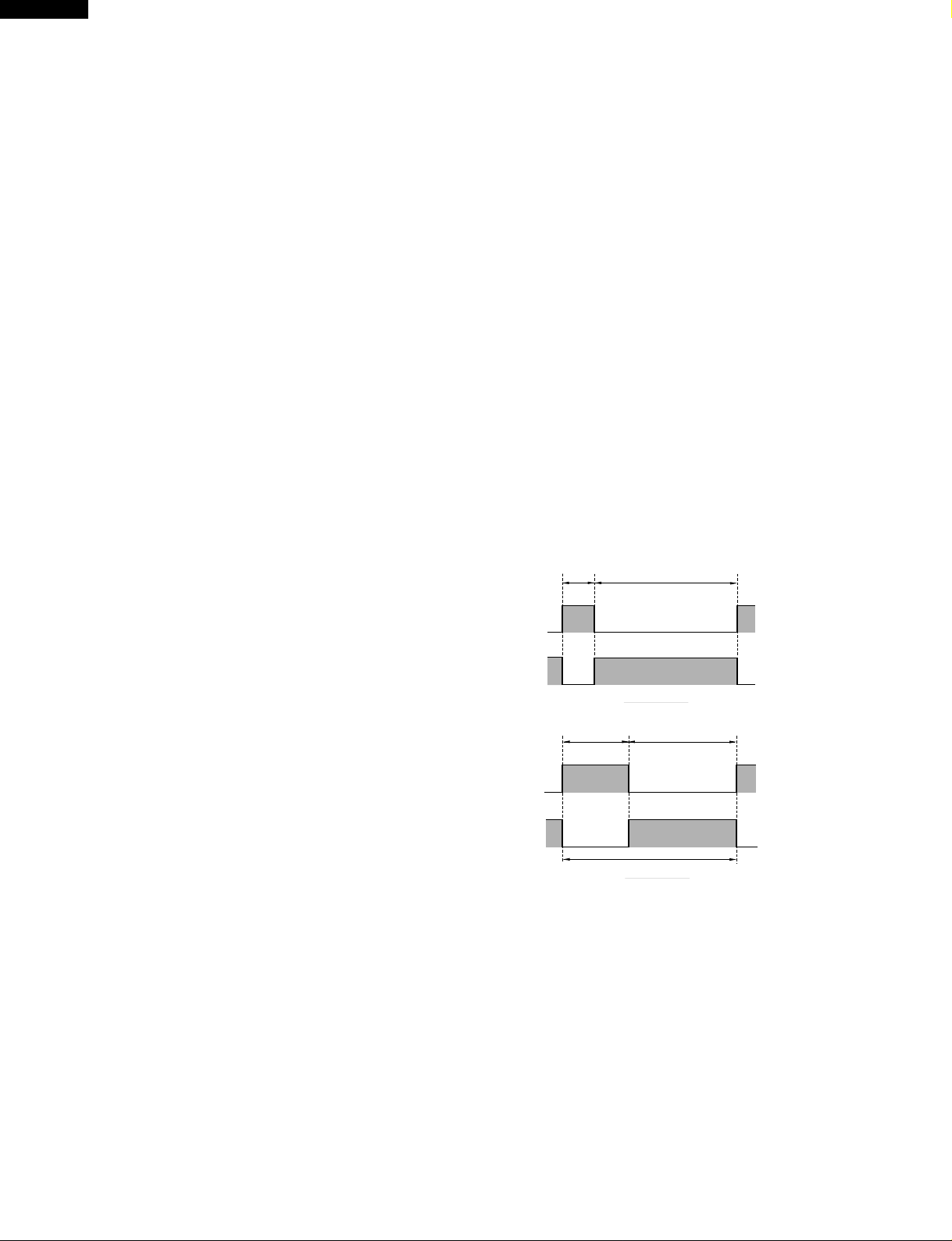

SCHEMATIC

HIGH

VOLTAGE

RECTIFIER

HIGH

VOLTAGE

CAPACITOR

0.9 F

POWER

TRANSFORMER

MAGNETRON

RY8

HL

HL

HOOD

LAMP

HOOD

MOTOR

HOOD

CAPACITOR

GRY BRN

BRN

C1A3A1

GRYBLU

RED

YEL

HOOD FAN

THERMAL

CUT OUTS

BLK

RED

FUSE

20A

RED RED

MAGNETRON

TEMPERATURE

FUSE

C3

BRN

C9

BLK

C5

C7

BLU

PPL

WHT

BLK

RED

YEL

PNK

RY10

RY9

WHT

WHT

RED

BLK

BLK

WHT-WHT

MONITOR

SWITCH

STIRRER

MOTOR

WHT

BRN

BLK

F1 F2 F3

E3 E4E6E5E2E1

RY1RY7RY4RY5RY6

DAMPER

THERMISTOR SWITCH

HEATING

ELEMENT

DOOR

SENSING

SWITCH

BLK

GRN

PNK

RED

N.O.

RY3

PPL

COM

RY3

COM

RY2

N.O.

RY1

DAMPER

MOTOR

FAN

MOTOR

OVEN

LAMP

ORG

OLCMFM

TTM

DM

CONVECTION

MOTOR

SECONDARY

INTERLOCK

SWITCH

TURN

TABLE

MOTOR

ORG

WHT

ORG

BLK

BLK

ORG

ORG

ORG

BLK

BRN WHT

BRN PPL

GRY

B7B1B3B5

A5

ORG

BLU

WHT

PPL

COM

RY1

N.O.

RY2

AH SENSOR

WHT WHT

RY3 RY2

CONTROL UNIT

STM

GRY

THIRD DOOR

SWITCH

120VAC

60Hz

BLK

WHT

GRN

GND

NOISE

FILTER

NOISE

RESISTOR

PNK

PRIMARY INTERLOCK

RELAY

HIGH

VOLTAGE

RECTIFIER

HIGH

VOLTAGE

CAPACITOR

0.9 F

POWER

TRANSFORMER

MAGNETRON

RY8

HL

HL

HOOD

LAMP

HOOD

MOTOR

HOOD

CAPACITOR

GRY BRN

BRN

C1A3A1

GRYBLU

RED

YEL

HOOD FAN

THERMAL

CUT OUTS

BLK

RED

FUSE

20A

RED RED

MAGNETRON

TEMPERATURE

FUSE

C3

BRN

C9

BLK

C5

C7

BLU

PPL

WHT

BLK

RED

YEL

PNK

RY10

RY9

WHT

WHT

RED

BLK

BLK

WHT-WHT

MONITOR

SWITCH

STIRRER

MOTOR

WHT

BRN

BLK

F1 F2 F3

E3 E4E6E5E2E1

RY1RY7RY4RY5RY6

DAMPER

THERMISTOR SWITCH

HEATING

ELEMENT

DOOR

SENSING

SWITCH

BLK

GRN

PNK

RED

N.O.

RY3

PPL

COM

RY3

COM

RY2

N.O.

RY1

DAMPER

MOTOR

FAN

MOTOR

OVEN

LAMP

ORG

OLCMFM

TTM

DM

CONVECTION

MOTOR

SECONDARY

INTERLOCK

SWITCH

TURN

TABLE

MOTOR

ORG

WHT

ORG

BLK

BLK

ORG

ORG

ORG

BLK

BRN WHT

BRN PPL

GRY

B7B1B3B5

A5

ORG

BLU

WHT

PPL

COM

RY1

N.O.

RY2

AH SENSOR

WHT WHT

RY3 RY2

CONTROL UNIT

STM

GRY

THIRD DOOR

SWITCH

120VAC

60Hz

BLK

WHT

GRN

GND

NOISE

FILTER

NOISE

RESISTOR

PNK

PRIMARY INTERLOCK

RELAY

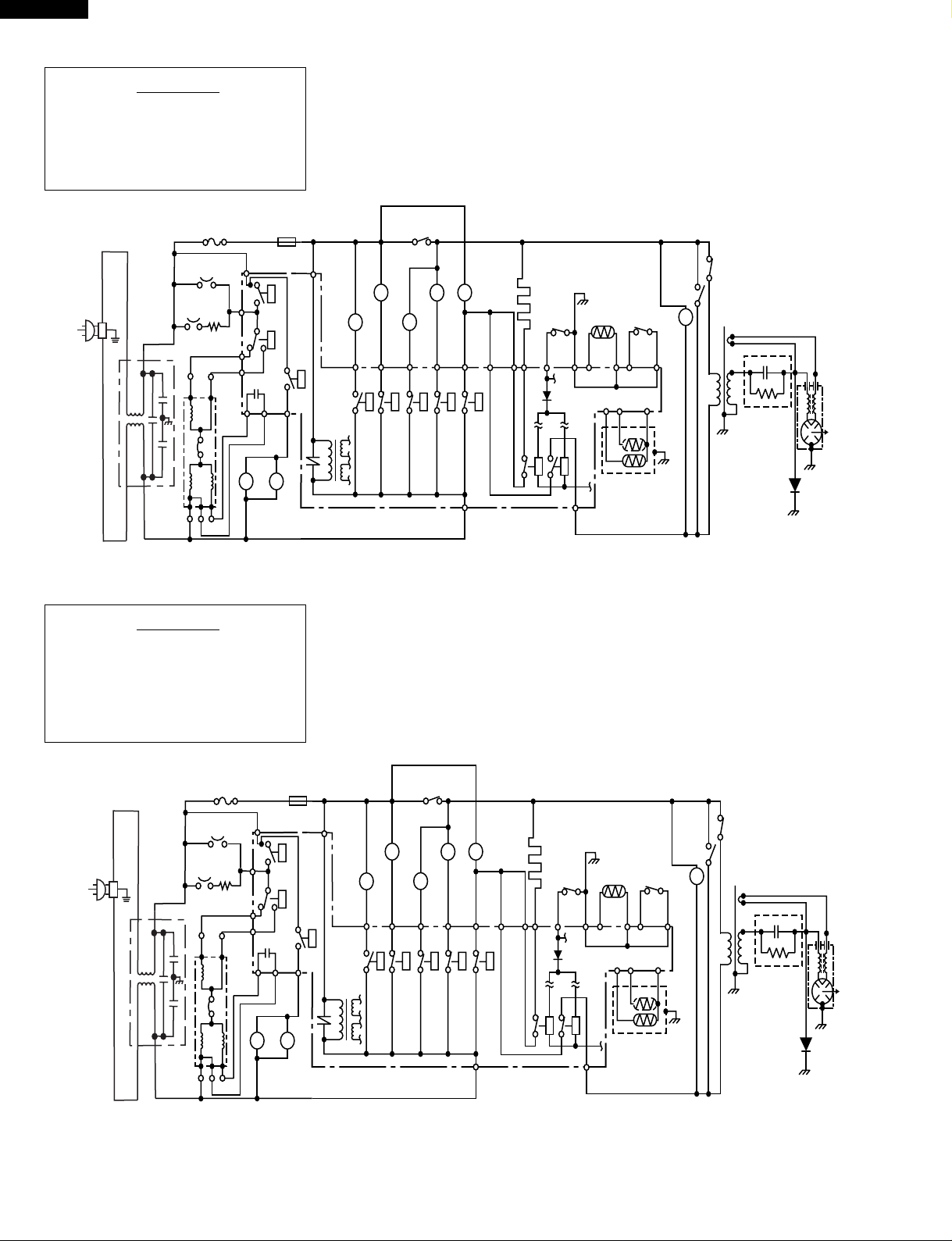

NOTE: CONDITION OF OVEN

1. DOOR CLOSED.

2. CLOCK APPEARS ON DISPLAY.

R-1855A

Note:

When servicing units between serial number 111112 and 112161, use the

schematics in Figure O-1 through O-4.

Ref 2-6(TMAPCB058MRR0)

SCHEMATIC

NOTE: CONDITION OF OVEN

1. DOOR CLOSED.

2. COOKING TIME PROGRAMMED.

3. START PAD TOUCHED.

Figure O-2. Oven Schematic - Microwave Cooking Condition

Ref 2-6(TMAPCB058MRR0)

Figure O-1. Oven Schematic - Off Condition

11

Page 14

R-1855A

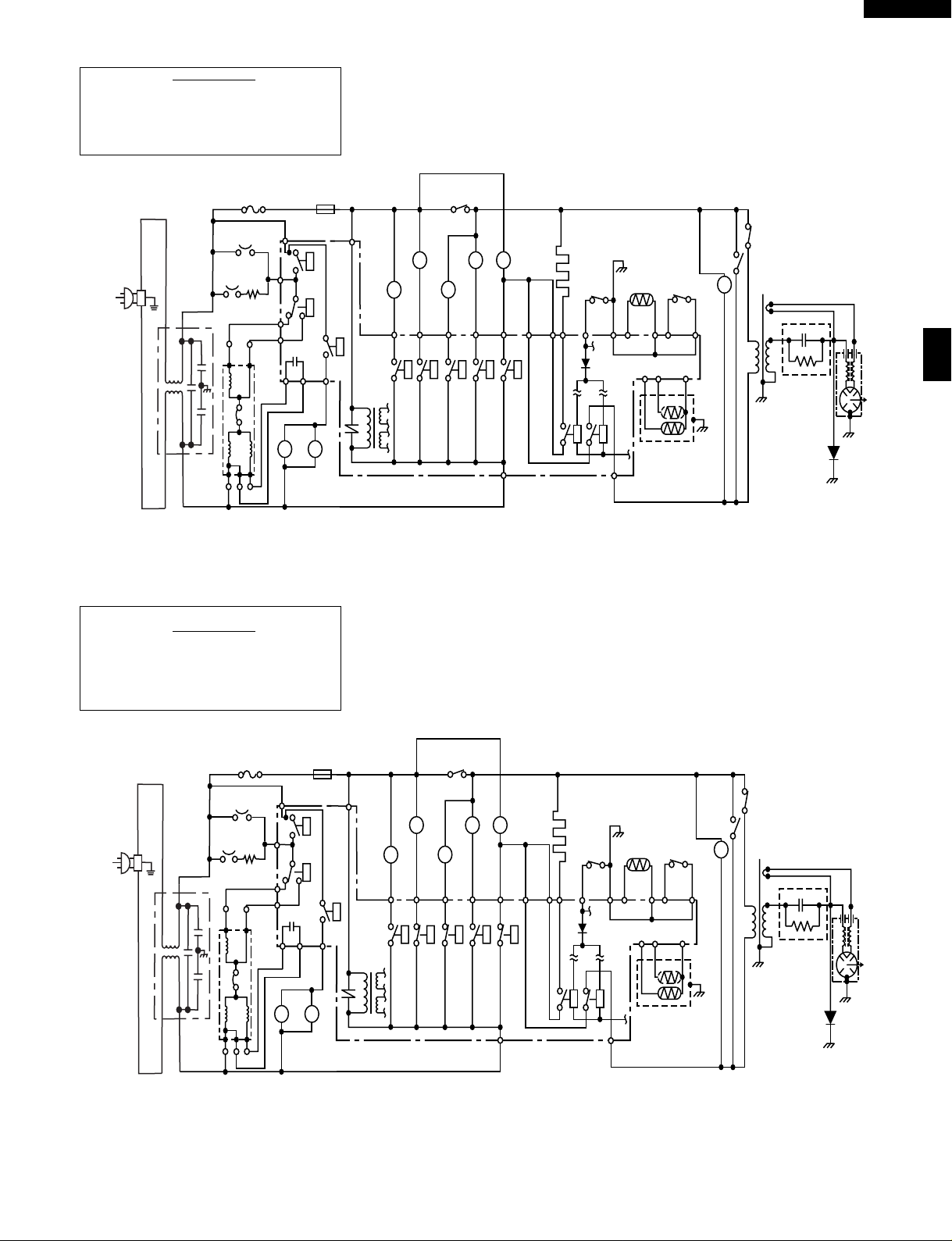

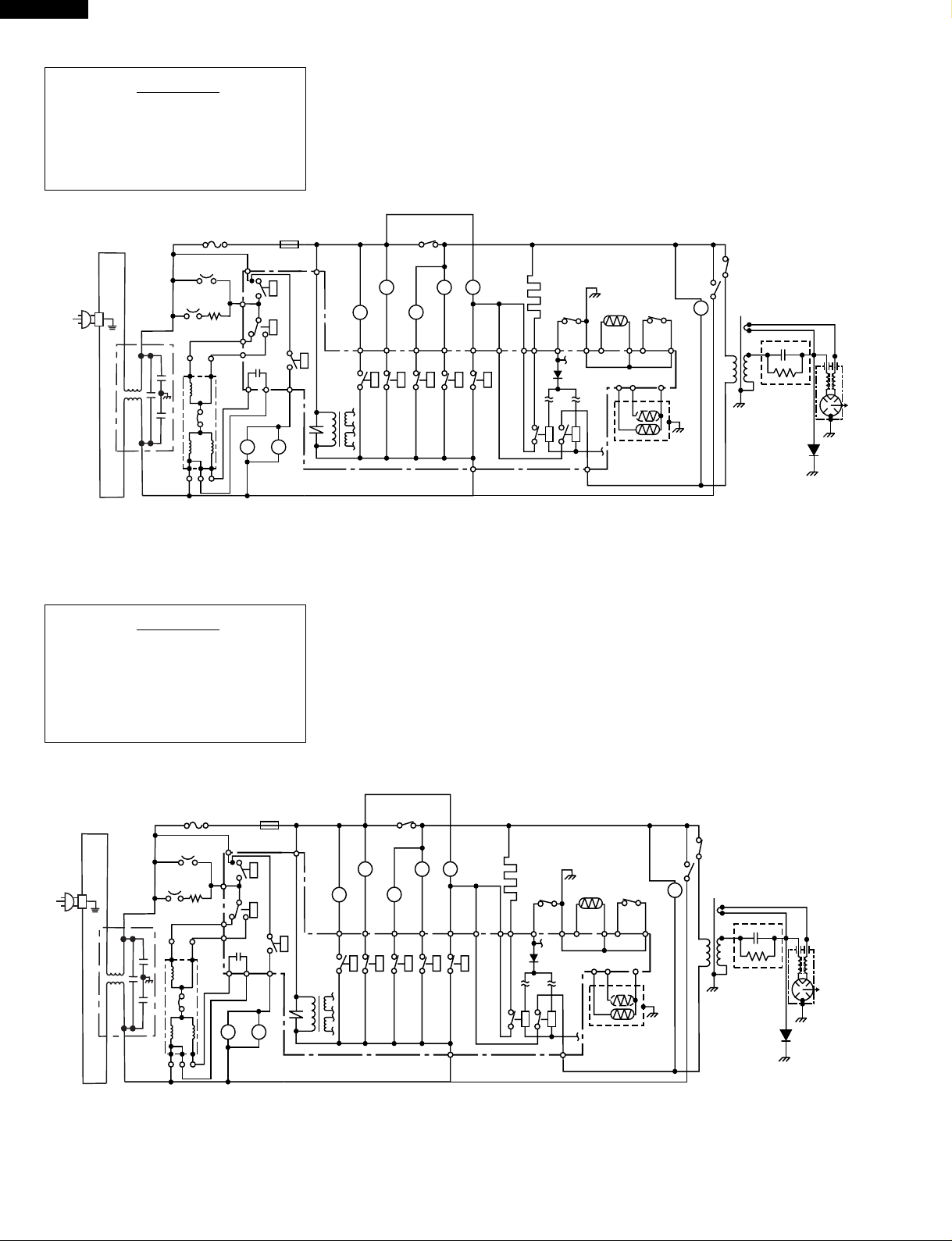

SCHEMATIC

NOTE: CONDITION OF OVEN

1. DOOR CLOSED.

2. CONVECTION PAD TOUCHED.

3. DESIRED TEMP. TOUCHED.

4. START PAD TOUCHED.

120VAC

60Hz

BLK

WHT

GRN

GND

NOISE

FILTER

FUSE

20A

RED RED

BLK

RED

HOOD FAN

THERMAL

CUT OUTS

NOISE

RESISTOR

WHT

BLK

RED

YEL

GRYBLU

BRN

PNK

BLU

PPL

HOOD

MOTOR

C3

C9

C5

C7

HOOD

CAPACITOR

RED

HL

GRY BRN

MAGNETRON

TEMPERATURE

FUSE

BLK

RY9

RY10

YEL

HOOD

BRN

LAMP

HL

PNK

RY8

C1A3A1

A5

ORG

DAMPER

MOTOR

CONTROL UNIT

ORG

DM

BLU

FAN

MOTOR

ORG

TURN

TABLE

MOTOR

PPL

SECONDARY

INTERLOCK

SWITCH

ORG

BLK

CONVECTION

MOTOR

BLK

TTM

WHT

STM

WHT

BLK

WHT-WHT

THIRD DOOR

SWITCH

POWER

TRANSFORMER

RED

HIGH

WHT

VOLTAGE

CAPACITOR

0.9 F

HIGH

VOLTAGE

RECTIFIER

HEATING

ELEMENT

OVEN

LAMP

COM

BRN PPL

RY3

ORG

DOOR

SENSING

SWITCH

RED

N.O.

PPL

RY3

RY3 RY2

THERMISTOR SWITCH

PNK

GRN

PRIMARY INTERLOCK

N.O.

RY2

WHT WHT

BLK

RELAY

DAMPER

BLK

BRN

E3 E4E6E5E2E1

F1 F2 F3

AH SENSOR

BLK

MONITOR

SWITCH

STIRRER

MOTOR

WHT

ORG

BLK

ORG

OLCMFM

WHT

COM

N.O.

BRN WHT

GRY

RY2

RY1

B7B1B3B5

RY1RY7RY4RY5RY6

COM

RY1

GRY

Ref 2-6(TMAPCB058MRR0)

Figure O-3. Oven Schematic - Convection Cooking Condition (CONVEC, PREHEAT, BROIL, SLOW COOK)

SCHEMATIC

NOTE: CONDITION OF OVEN

1. DOOR CLOSED.

2. MIX COOKING PAD TOUCHED.

3. DESIRED TEMP. TOUCHED.

4. COOKING TIME PROGRAMMED.

5. START PAD TOUCHED.

NOTE: RY2 and RY3 will alternately close during cook cycle

MAGNETRON

FUSE

20A

RED RED

BRN

BLK

PNK

RED

HOOD FAN

NOISE

FILTER

THERMAL

CUT OUTS

NOISE

RESISTOR

WHT

BLK

RED

YEL

GRYBLU

HOOD

MOTOR

120VAC

60Hz

BLK

GRN

GND

WHT

Ref 2-6(TMAPCB058MRR0)

Figure O-4. Oven Schematic - Automatic Mix cooking Condition

BLU

PPL

C3

C9

C5

C7

MAGNETRON

TEMPERATURE

FUSE

BLK

HOOD

CAPACITOR

RED

YEL

HOOD

LAMP

HL

GRY BRN

RY9

RY10

HL

BRN

PNK

C1A3A1

RY8

A5

ORG

DAMPER

MOTOR

CONTROL UNIT

DM

ORG

BLU

FAN

MOTOR

ORG

PPL

TURN

TABLE

MOTOR

SECONDARY

INTERLOCK

SWITCH

ORG

BLK

CONVECTION

MOTOR

BLK

TTM

WHT

GRY

B7B1B3B5

12

STM

BLK

WHT

WHT-WHT

THIRD DOOR

SWITCH

POWER

TRANSFORMER

RED

HIGH

WHT

VOLTAGE

CAPACITOR

0.9 F

HIGH

VOLTAGE

RECTIFIER

MAGNETRON

HEATING

ELEMENT

OVEN

LAMP

COM

BRN PPL

RY3

ORG

DOOR

SENSING

SWITCH

RED

N.O.

PPL

RY3

RY3 RY2

THERMISTOR SWITCH

PNK

GRN

PRIMARY INTERLOCK

N.O.

RY2

WHT WHT

BLK

RELAY

DAMPER

BLK

BRN

E3 E4E6E5E2E1

F1 F2 F3

AH SENSOR

BLK

MONITOR

SWITCH

STIRRER

MOTOR

WHT

ORG

BLK

ORG

OLCMFM

WHT

COM

N.O.

BRN WHT

RY2

RY1

RY1RY7RY4RY5RY6

COM

RY1

GRY

Page 15

SCHEMATIC

HIGH

VOLTAGE

RECTIFIER

HIGH

VOLTAGE

CAPACITOR

0.9 F

POWER

TRANSFORMER

MAGNETRON

RY8

HL

HL

HOOD

LAMP

HOOD

MOTOR

HOOD

CAPACITOR

GRY BRN

BRN

C1A3A1

GRYBLU

RED

YEL

HOOD FAN

THERMAL

CUT OUTS

BLK

RED

FUSE

20A

RED RED

MAGNETRON

TEMPERATURE

FUSE

C3

BRN

C9

BLK

C5

C7

BLU

PPL

WHT

BLK

RED

YEL

PNK

RY10

RY9

WHT

WHT

RED

BLK

BLK

WHT-WHT

MONITOR

SWITCH

STIRRER

MOTOR

WHT

BRN

BLK

F1 F2 F3

E3 E4E6E5E2E1

RY1RY7RY4RY5RY6

DAMPER

THERMISTOR SWITCH

HEATING

ELEMENT

DOOR

SENSING

SWITCH

BLK

GRN

PNK

RED

N.O.

RY3

PPL

COM

RY3

COM

RY2

N.O.

RY1

DAMPER

MOTOR

FAN

MOTOR

OVEN

LAMP

ORG

OLCMFM

TTM

DM

CONVECTION

MOTOR

SECONDARY

INTERLOCK

SWITCH

TURN

TABLE

MOTOR

ORG

WHT

ORG

BLK

BLK

ORG

ORG

ORG

BLK

BRN WHT

BRN PPL

GRY

B7B1B3B5

A5

ORG

BLU

WHT

PPL

COM

RY1

N.O.

RY2

AH SENSOR

WHT

WHT

RY3 RY2

CONTROL UNIT

STM

GRY

THIRD DOOR

SWITCH

120VAC

60Hz

BLK

WHT

GRN

GND

NOISE

FILTER

NOISE

RESISTOR

PNK

PRIMARY INTERLOCK

RELAY

NOTE: CONDITION OF OVEN

1. DOOR CLOSED.

2. CLOCK APPEARS ON DISPLAY.

R-1855A

Note:

When servicing units with serial number 112162 and above, use the schematics

in Figure 1-1 through 1-4.

BRN

PNK

HOOD

MOTOR

BLU

PPL

C3

C9

C5

C7

MAGNETRON

TEMPERATURE

FUSE

BLK

HOOD

CAPACITOR

RED

YEL

HOOD

LAMP

HL

GRY BRN

RY9

RY10

120VAC

60Hz

BLK

WHT

GRN

GND

NOISE

FILTER

RED RED

BLK

RED

HOOD FAN

THERMAL

CUT OUTS

NOISE

RESISTOR

WHT

YEL

GRYBLU

FUSE

20A

BLK

RED

Ref 2-6(TMAPCB063MRR0)

SCHEMATIC

NOTE: CONDITION OF OVEN

1. DOOR CLOSED.

2. COOKING TIME PROGRAMMED.

3. START PAD TOUCHED.

SECONDARY

INTERLOCK

SWITCH

ORG

A5

ORG

FAN

ORG

MOTOR

DM

DAMPER

MOTOR

BLU

RY8

C1A3A1

PNK

BRN

HL

CONTROL UNIT

ORG

PPL

TURN

TABLE

MOTOR

TTM

CONVECTION

MOTOR

BLK

WHT

BLK

ORG

BLK

ORG

OVEN

OLCMFM

LAMP

WHT

COM

N.O.

BRN WHT

GRY

RY2

RY1

B7B1B3B5

RY1RY7RY4RY5RY6

COM

RY1

GRY

COM

BRN PPL

RY3

HEATING

ELEMENT

ORG

DOOR

SENSING

SWITCH

RED

N.O.

PPL

RY3

RY3 RY2

Figure 1-1. Oven Schematic - Off Condition

THERMISTOR SWITCH

PNK

GRN

N.O.

RY2

WHT

WHT

BLK

F1 F2 F3

PRIMARY INTERLOCK

RELAY

DAMPER

BLK

BRN

E3 E4E6E5E2E1

AH SENSOR

BLK

MONITOR

SWITCH

STIRRER

MOTOR

WHT

STM

BLK

WHT

WHT-WHT

THIRD DOOR

SWITCH

POWER

TRANSFORMER

RED

HIGH

WHT

VOLTAGE

CAPACITOR

0.9 F

HIGH

VOLTAGE

RECTIFIER

MAGNETRON

Ref 2-6(TMAPCB063MRR0)

Figure 1-2. Oven Schematic - Microwave Cooking Condition

13

Page 16

R-1855A

SCHEMATIC

NOTE: CONDITION OF OVEN

1. DOOR CLOSED.

2. CONVECTION PAD TOUCHED.

3. DESIRED TEMP. TOUCHED.

4. START PAD TOUCHED.

120VAC

60Hz

BLK

WHT

GRN

GND

NOISE

FILTER

RED RED

BLK

RED

HOOD FAN

THERMAL

CUT OUTS

RESISTOR

WHT

YEL

GRYBLU

FUSE

20A

NOISE

BLK

RED

BRN

PNK

HOOD

MOTOR

BLU

PPL

C9

C5

C7

C3

HL

GRY BRN

MAGNETRON

TEMPERATURE

FUSE

BLK

RY9

RY10

HOOD

CAPACITOR

RED

YEL

HOOD

LAMP

A5

ORG

ORG

DM

DAMPER

MOTOR

BLU

RY8

C1A3A1

PNK

BRN

HL

CONTROL UNIT

FAN

MOTOR

ORG

TURN

TABLE

MOTOR

PPL

SECONDARY

INTERLOCK

SWITCH

ORG

BLK

CONVECTION

MOTOR

BLK

TTM

WHT

STM

BLK

WHT

THIRD DOOR

SWITCH

POWER

TRANSFORMER

WHT-WHT

RED

WHT

HIGH

VOLTAGE

CAPACITOR

0.9 F

HIGH

VOLTAGE

RECTIFIER

HEATING

ELEMENT

COM

BRN PPL

RY3

ORG

DOOR

SENSING

SWITCH

RED

N.O.

PPL

RY3

RY3 RY2

PNK

GRN

WHT

WHT

THERMISTOR SWITCH

BLK

PRIMARY INTERLOCK

RELAY

N.O.

RY2

DAMPER

BLK

BRN

E3 E4E6E5E2E1

F1 F2 F3

AH SENSOR

BLK

MONITOR

SWITCH

STIRRER

MOTOR

WHT

ORG

BLK

ORG

OVEN

OLCMFM

LAMP

WHT

COM

N.O.

BRN WHT

GRY

RY2

RY1

B7B1B3B5

RY1RY7RY4RY5RY6

COM

RY1

GRY

Ref 2-6(TMAPCB063MRR0)

Figure 1-3. Oven Schematic - Convection Cooking Condition (CONVEC, PREHEAT, BROIL, SLOW COOK)

SCHEMATIC

NOTE: CONDITION OF OVEN

1. DOOR CLOSED.

2. MIX COOKING PAD TOUCHED.

3. DESIRED TEMP. TOUCHED.

4. COOKING TIME PROGRAMMED.

5. START PAD TOUCHED.

NOTE: RY2 and RY3 will alternately close during cook cycle

MAGNETRON

FUSE

20A

RED RED

BRN

BLK

PNK

RED

HOOD FAN

NOISE

FILTER

THERMAL

CUT OUTS

NOISE

RESISTOR

WHT

BLK

RED

YEL

GRYBLU

HOOD

MOTOR

120VAC

60Hz

BLK

GRN

GND

WHT

Ref 2-6(TMAPCB063MRR0)

BLU

PPL

C3

C9

C5

C7

MAGNETRON

TEMPERATURE

FUSE

BLK

HOOD

CAPACITOR

RED

HOOD

LAMP

HL

GRY BRN

YEL

RY9

RY10

A5

ORG

ORG

DM

DAMPER

MOTOR

BLU

RY8

C1A3A1

PNK

BRN

HL

CONTROL UNIT

FAN

MOTOR

ORG

TURN

TABLE

MOTOR

PPL

SECONDARY

INTERLOCK

SWITCH

ORG

CONVECTION

MOTOR

BLK

TTM

WHT

BLK

ORG

BLK

ORG

OVEN

OLCMFM

LAMP

WHT

COM

N.O.

BRN WHT

GRY

B7B1B3B5

RY2

RY1

RY1RY7RY4RY5RY6

COM

RY1

GRY

COM

BRN PPL

RY3

HEATING

ELEMENT

ORG

RED

N.O.

PPL

RY3

RY3 RY2

DOOR

SENSING

SWITCH

PNK

WHT

THERMISTOR SWITCH

BLK

BLK

F1 F2 F3

PRIMARY INTERLOCK

RELAY

BRN

E3 E4E6E5E2E1

AH SENSOR

GRN

WHT

N.O.

RY2

DAMPER

BLK

MONITOR

SWITCH

STIRRER

MOTOR

WHT

Figure 1-4. Oven Schematic - Automatic Mix cooking Condition

14

STM

BLK

WHT

THIRD DOOR

SWITCH

POWER

TRANSFORMER

WHT-WHT

RED

WHT

HIGH

VOLTAGE

CAPACITOR

0.9 F

HIGH

VOLTAGE

RECTIFIER

MAGNETRON

Page 17

DESCRIPTION AND FUNCTION OF COMPONENTS

R-1855A

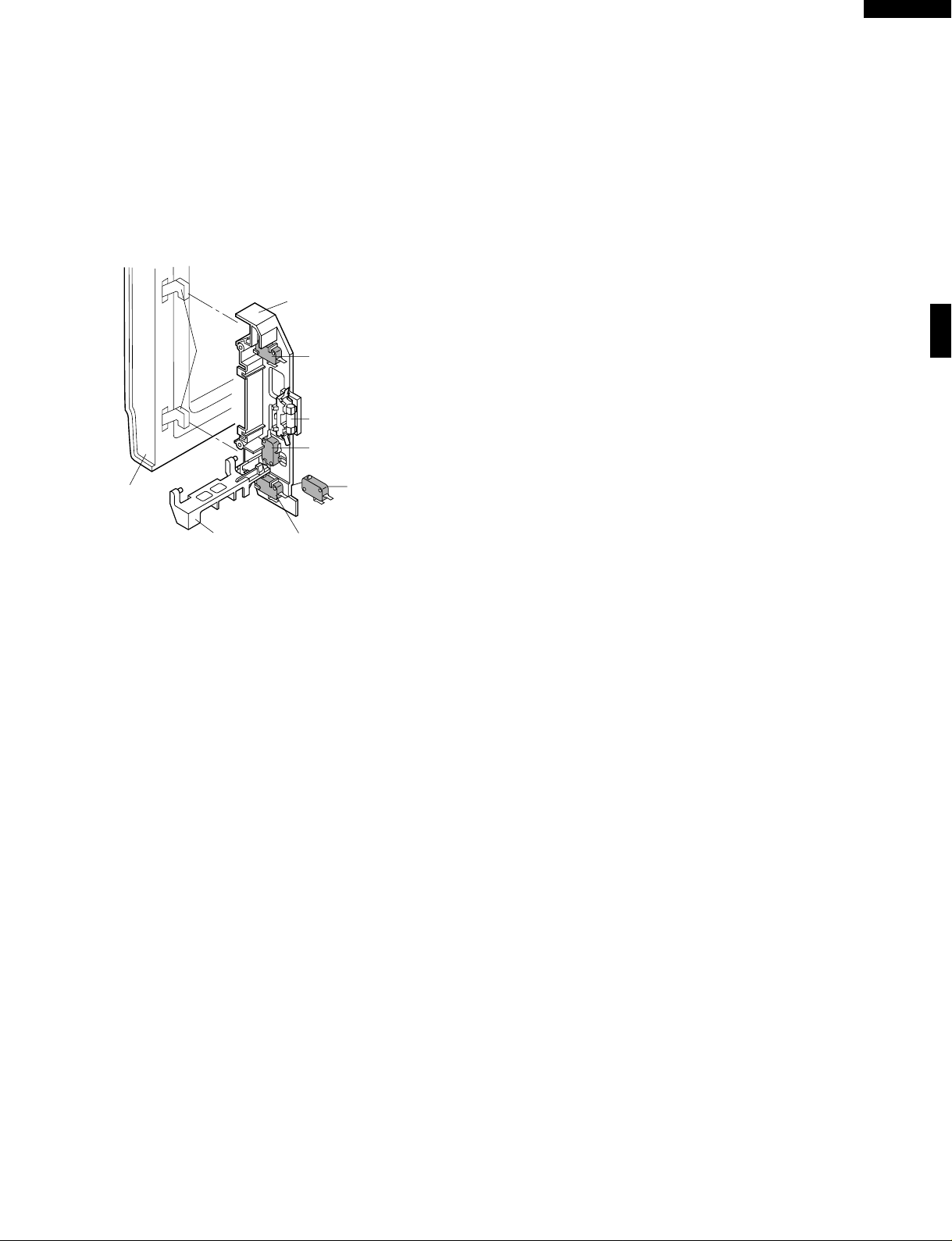

DOOR OPEN MECHANISM

The door is opened by pushing the open button on the control

panel, refer to the Figure D-1.

When the open button is pushed, the open button pushes up

the open lever, and then the open lever pushes up the latch

head. The latch heads are moved upward and released from

latch hook. Now the door will open.

LATCH HOOK

DOOR

LATCH

HEADS

OPEN LEVER

DOOR SENSING

SWITCH

MONITOR FUSE

MONITOR

SWITCH

SECONDARY

INTERLOCK

SWITCH

THIRD

DOOR

SWITCH

Figure D-1. Door Open Mechanism

SECONDARY INTERLOCK SWITCH, THIRD DOOR

SWITCH & DOOR SENSING SWITCH

The secondary interlock switch and third door switch

mounted parrallel to each other horizontally in the upper

positions of the latch hook, the door sensing switch is

mounted horizontally in the upper position of the latch hook.

They are activated by the latch head on the door. When the

door is opened, the switches interrupt the power to all high

voltage components, except the oven lamp . A cook cycle

cannot take place until the door is firmly closed thereby

activating all interlock switches. The interlock system

consists of the door sensing switch and the primary

interlock relay located on the control circuit board.

operate inversely.)

3. If the door is opened, and the primary interlock relay,

secondary interlock switch and third door switch contacts

fail to open, the monitor fuse blows simultaneously with

closing of the monitor switch contacts.

CAUTION: BEFORE REPLACING A BLOWN MONITOR

FUSE, TEST THE PRIMARY INTERLOCK RELAY, THIRD DOOR SWITCH, DOOR SENSING SWITCH, MONITOR SWITCH AND SECONDARY INTERLOCK SWITCH FOR PROPER

OPERATION. (REFER TO CHAPTER "TEST

PROCEDURE").

NOTE: MONITOR FUSE, SECONDARY INTERLOCK

SWITCH AND MONITOR SWITCH ARE

REPLACED AS AN ASSEMBLY.

TEMPERATURE FUSE (MG)

The temperature fuse located near the waveguide is

designed to prevent damage to the magnetron if an over

heated condition develops in the tube due to cooling fan

failure, obstructed air guide, dirty or blocked air intake, etc.

Under normal operation, the temperature fuse remains closed.

However, the temperature fuse will open at 302OF (150OC)

causing the oven to shut down.

THERMAL CUT-OUT (HOOD )

This thermal cut-out located on the base plate right and the

hood intake duct (left), It is designed to automatically turn

on the hood fan motor whenever the hot air rising from the

conventional range below causes the temperature at the

thermal cut-out to rise to 140OF (60OC) or higher, thus

removing this hot air from around microwave oven. When

the temperature around the thermal cut-out drops to 113OF

(45OC) or lower, the thermal cut-out shuts off the food fan

motor.

TURNTABLE MOTOR

The turntable motor rotates the turntable located on the

bottom of the oven cavity, so that the foods on the turntable

cook evenly during cooking. Turntable will turn in either

direction. The turntable motor can be turned off by touching

TURNTABLE ON/OFF pad.

MONITOR SWITCH

The monitor switch is activated (the contacts opened) by the

latch head on the door while the door is closed. The switch

is intended to render the oven inoperative, by means of

blowing the monitor fuse, when the contacts of the secondary interlock switch and third door switch fail to open when

the door is opened.

Functions:

1. When the door is opened, the monitor switch contact close

(to the ON condition) due to their being normally closed.

At this time the primary interlock relay, secondary interlock

switch and third switch are in the OFF condition (contacts

open) due to their being normally open contact switches.

2. As the door goes to a closed position, the monitor switch

contacts are first opened and then the door sensing switch,

secondary interlock switch and third door switch contacts

close. (On opening the door, each of these switches

COOLING FAN MOTOR

The cooling fan motor drives a blade which draws external

cool air. This cool air is directed through the air vanes

surrounding the magnetron and cools the magnetron. This

air is channelled through the oven cavity to remove steam

and vapors given off from the heating foods. It is then

exhausted through the exhausting air vents at the oven

cavity.

HOOD FAN MOTOR

The hood fan motor is a two-speed, single-phase, double

pole induction type, requiring a hood fan capacitor. It is

located outside the upper rear part of the oven cavity, is to

remove, from around the oven, hot air rising from the

conventional electric or gas range over which it is installed.

This air is then expelled either vertically or horizontally

through the customer supplied duct system, or discharged

back into the kitchen.

15

Page 18

R-1855A

STIRRER MOTOR

The stirrer motor drives the stirrer fan to stir the microwave

radiation from the waveguide.

HOOD LAMP

The hood lamps are mounted at the hood lamp angle on the

base cover. When the hood lamp button is pushed, the hood

lamp relay (RY8) contacts close turning both hood lamps on.

HEATING ELEMENT

The heating element is located at the left side of the oven

cavity. It is intended to heat air driven by the convection fan.

The heated air is kept in the oven and force-circulated and

reheated by the heating element.

CONVECTION COOKING SYSTEM

This oven is designed with a hot air heating system where

food is not directly heated by the heating element, but is

heated by forced circulation of the hot air produced by the

heating element.

The air heated by the heating element is circulated through

the convection passage provided on the outer casing of the

oven cavity by means of the convection fan which is driven

by the convection motor. It then enters the inside of the oven

through the vent holes provided on the left side of the oven.

Next, the hot air heats the food on the turntable and leaves

the oven cavity through the vent in the center of the oven

cavity left side wall.

Without leaving the oven, this hot air is reheated by the

heating element, passes through the convection passage

and enters the inside of the oven cavity again, in a continuing

cycle.

In this way, the hot air circulates inside the oven cavity to

raise its temperature and, at the same time, comes into

contact with the food being cooked.

When the temperature inside the oven cavity reaches the

selected temperature, the heating element is de-energized.

When the temperature inside the oven cavity drops below

the selected temperature, the heating element is energized

again. In this way, the inside of the oven cavity is maintained

at approximately the selected temperature.

When the convection time reaches 0, the heating element

is de-energized and the convection fan stops operating and

the oven shuts off.

DAMPER OPEN-CLOSE MECHANISM

Usually, the damper is in the open position except during

convection cooking. Damper position is set automatically

by damper motor, damper switch and motor cam. These

components are operated by a signal that judges if microwave cooking or convection cooking operation is selected

by the control unit.

Microwave Cooking:

Damper is in the open position, because a portion of cooling

air is channeled through the cavity to remove steam and

vapors given off from the heating foods.

It is then exhausted at the top of the oven cavity into a

condensation compartment.

Convection Cooking:

Damper is in the closed position, so that no hot air will be

allowed to leak out the oven cavity.

Damper Operation

1. When power supply cord is plugged in:

1-1. When power supply cord is plugged in, a signal is

sensed in the control unit, and operates shut-off

relay (RY6).

1-2. Contacts of shut-off relay (RY6) close, the damper

motor is energized, opening the damper plate.

1-3. When the damper is moved to the open position by

the damper cam the damper switch is closed (ON

position).

1-4. The signal from damper switch is re-sensed in the

control unit and shut-off relay (RY6) is turned off.

1-5. The 120 volts A.C. to the damper motor is removed

and the motor turns off.

2. When oven is microwave cooking:

Damper is in the open position.

3. When oven is convection cooking:

3-1. Damper motor is energized by touching the

convection, temperature, number and START pads.

3-2. When damper is in the closed position (damper

switch is OFF), its signal is sensed by the control

unit, and shut-off relay (RY6) is de-energized.

3-3. The damper is held in the closed position during the

convection cooking operation.

3-4. At the end of the convection cooking, shut-off relay

(RY6) is energized, and the damper is returned to

the open position.

NOTE: If the damper plate is not in the proper position,

closed during convection or open during microwave,

the control unit will stop oven operation after 1

minute.

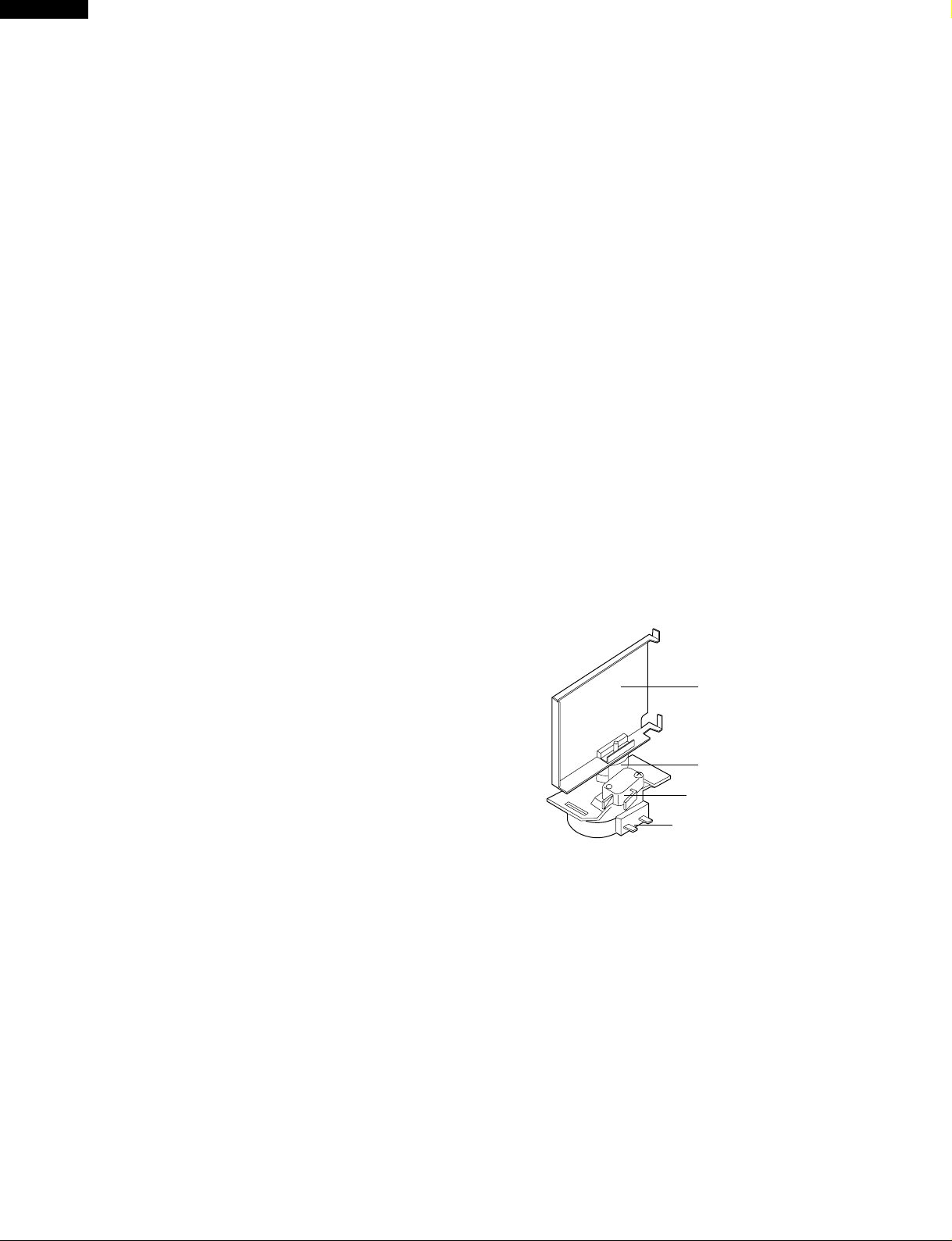

DAMPER PLATE

DAMPER CAM

DAMPER SWITCH

DAMPER MOTOR

Figure D-2. Damper Mechanism

16

Page 19

R-1855A

TROUBLESHOO TING GUIDE

Never touch any part in the circuit with your hand or an uninsulated tool while the power supply is connected.

When troubleshooting the microwave oven, it is helpful to follow the Sequence of Operation in performing the checks. Many

of the possible causes of trouble will require that a specific test be performed. These tests are given a procedure letter

which will be found in the "Test Procedure "section.

IMPORTANT: If the oven becomes inoperative because of a blown monitor fuse, check the secondary interlock switch,

door sensing switch, primary interlock relay(RY2), third door switch and monitor switch, before replacing

the monitor fuse. If the monitor fuse is replaced, the monitor switch and primary switch must also be replaced.

Use part FFS-BA018/KIT as an assembly.

IMPORTANT: Whenever troubleshooting is performed with the power supply cord disconnected. It may in, some cases,

be necessary to connect the power supply cord after the outer case has been removed, in this event,

1. Disconnect the power supply cord, and then remove outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. Disconnect the leads to the primary of the power transformer.

5. Ensure that the leads remain isolated from other components and oven chassis by using insulation tape.

6. After that procedure, reconnect the power supply cord.

When the testing is completed

1. Disconnect the power supply cord, and then remove outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. Reconnect the leads to the primary of the power transformer.

5. Reinstall the outer case (cabinet).

6. Reconnect the power supply cord after the outer case is installed.

7. Run the oven and check all functions.

17

Page 20

R-1855A

TROUBLESHOOTING GUIDE

When troubleshooting the microwave oven, it is helpful to follow the Sequence of Operation in performing the checks. Many

of the possible causes of trouble will require that a specific test be performed. These tests are given a procedure letter which

will be found in the "Test Procedure" section.

CK = Check / RE = Replace

CONDITION

OFF

CONDITION

IDLE

CONDITION

COOKING

CONDITION

(COMMON)

MICROWAVE

COOKING

CONDITION

CONVECTION

COOKING

CONDITION

SENSOR

COOKING

CONDITION

TEST PROCEDURE

POSSIBLE CAUSE

AND

DEFECTIVE PARTS

PROBLEM

Home fuse blows when power cord is plugged into wall receptacle.

Monitor fuse blows when power cord is plugged into wall receptacle.

Display does not illuminate when power cord is first plugged into wall recepta-

cle.

Display does not operate properly when STOP/CLEAR key is touched. (The

time of day should appear on the display with beep sound during normal

condition.)

Oven lamp does not light with door is opened.

Hood fan motor operates when power cord is first plugged into wall receptacle.

Temperature of oven base seems more than 140½F (60½C) because of operation

of the range below. But hood fan motor does not turn on automatically.

(Normally, food fan motor should be operating at low speed.)

Hood lights do not turn on with pushed HOOD LAMP button.

Hood fan motor does not rotate at all with pushed FAN button.

Speed of the hood fan motor does not change when the FAN button is touched

for this function.

Oven lamp does not light in cook cycle. (But it does light when door is opened.)

Fan motor does not operate. (Oven lamp and turntable motor operate.)

Turntable motor does not operate (Oven lamp lights and fan motor operate.)

Cooking cycle runs 1 minute then shuts down.

Oven does not go into cook cycle when START pad is touched

Oven seems to be operating but little or no heat is produced in oven load. (Food

incompletely cooked or not cooked at all at end of cook cycle.)

Oven goes into a cook cycle but extremely uneven heating is produced in oven

load (food).

Variable cooking does not operate properly except Cooking Power 10 (P-HI)

mode.

Function of COMPU DEFROST does not operate properly.

Stirrer motor does not operate. (Other parts operate.)

CONV indicator lights, but oven does not go into cook cycle when START pad

is touched.

CONV indicator lights, but heating element does not heat.

Temperature in the oven cavity is lower or higher than preset.

Convection motor does not operate.

Convection cycle runs 4 minutes and 15 seconds then shuts down.

The oven stops and "ERROR" is displayed or does not end during Sensor

Cooking condition. (Oven does not shuts off after a cup of water is boiling by

Sensor Cooking.)

Oven stops at 32 seconds after starting.

ABCDEFGHIJK L

MAGNETRON

POWER TRANSFORMER

H.V. RECTIFIER

HIGH VOLTAGE CAPACITOR

SEC. INTERLOCK AND DOOR SEN. SWITCH

PRIMARY INTERLOCK SYSTEM

MONITOR SWITCH

DAMPER SWITCH

MONITOR FUSE

TEMPERATURE FUSE (MG)

HOOD THERMAL CUT-OUT

THERMISTOR

18

Page 21

R-1855A

IMPORTANT: If the oven becomes inoperative because of a blown monitor fuse, check the monitor switch, primary

interlock relay, door sensing switch, third door switch and secondary interlock switch before replacing the

monitor fuse. If monitor fuse is replaced, the monitor switch must also be replaced. Use part FFS-BA018/

KIT as an assembly.

M N O P Q R S S S S S S S S S S U V RERE RE RE CKCKRE CK RE RE CK CK W

HOOD FAN MOTOR

DAMPER MOTOR

CONVECTION HEATER

CHECKING TEMPERATURE

CONTROL UNIT

KEY UNIT

RELAY (RY1)

RELAY (RY2)

RELAY (RY3)

RELAY (RY4)

RELAY (RY5)

RELAY (RY6)

RELAY (RY7)

RELAY (RY8)

RELAY (RY9)

RELAY (RY10)

FOIL PATTERN ON PWB.

AH SENSOR

OVEN LAMP OR SOCKET

FAN MOTOR

TURNTABLE MOTOR

STIRRER MOTOR

TURNTABLE OFF CONDITION

CONVECTION MOTOR

HOOD LAMP OR SOCKET

HOOD MOTOR CAPACITOR

SHORTED OR OPENED WIRING

SHORTED IN POWER CORD

NO POWER AT OUTLET

LOW VOLTAGE

NOISE FILTER

19

Page 22

R-1855A

TEST PROCEDURES

PROCEDURE

LETTER

A MAGNETRON ASSEMBLY TEST

1. Disconnect the power supply cord, and then remove outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. To test for an open filament, isolate the magnetron from the high voltage circuit. A continuity check

across the magnetron filament leads should indicate less than 1 ohm.

5. To test for a shorted magnetron, connect the ohmmeter leads between the magnetron filament leads

and chassis ground. This test should indicate an infinite resistance. If there is little or no resistance

the magnetron is grounded and must be replaced.

6. Reconnect all leads removed from components during testing.

7. Reinstall the outer case (cabinet).

8. Reconnect the power supply cord after the outer case is installed.

9. Run the oven and check all functions.

MICROWAVE OUTPUT POWER

The following test procedure should be carried out with the microwave oven in a fully assembled condition

(outer case fitted).

HIGH VOLTAGES ARE PRESENT DURING THE COOK CYCLE, SO EXTREME CAUTION SHOULD

BE OBSERVED.

Power output of the magnetron can be measured by performing a water temperature rise test. This test