Page 1

QT-CD180

SERVICE MANUAL

No. S1102QTCD180/

PORTABLE CD STEREO SYSTEM

MODEL

QT-CD180(BL)

QT-CD180(RD)

QT-CD180(S)

QT-CD180(WH)

• In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified should

be used.

CONTENTS

Page

IMPORTANT SERVICE NOTES (FOR U.S.A. ONLY)....................................................................................................... 2

SPECIFICATIONS ............................................................................................................................................................. 2

NAMES OF PARTS ........................................................................................................................................................... 3

FITTING OF DIAL POINTER ............................................................................................................................................. 3

OPERATION MANUAL ...................................................................................................................................................... 4

DISASSEMBLY.................................................................................................................................................................. 5

REMOVING AND REINSTALLING THE MAIN PARTS..................................................................................................... 6

ADJUSTMENT ................................................................................................................................................................... 8

NOTES ON SCHEMATIC DIAGRAM .............................................................................................................................. 11

TYPES OF TRANSISTOR ............................................................................................................................................... 11

SCHEMATIC DIAGRAM .................................................................................................................................................. 12

WIRING SIDE OF P.W.BOARD....................................................................................................................................... 14

WAVEFORMS OF CD CIRCUIT...................................................................................................................................... 16

TROUBLESHOOTING (CD SECTION) ........................................................................................................................... 17

FUNCTION TABLE OF IC................................................................................................................................................ 21

PARTS GUIDE/EXPLODED VIEW

PACKING OF THE SET (FOR U.S.A. ONLY)

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

QT-CD180

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

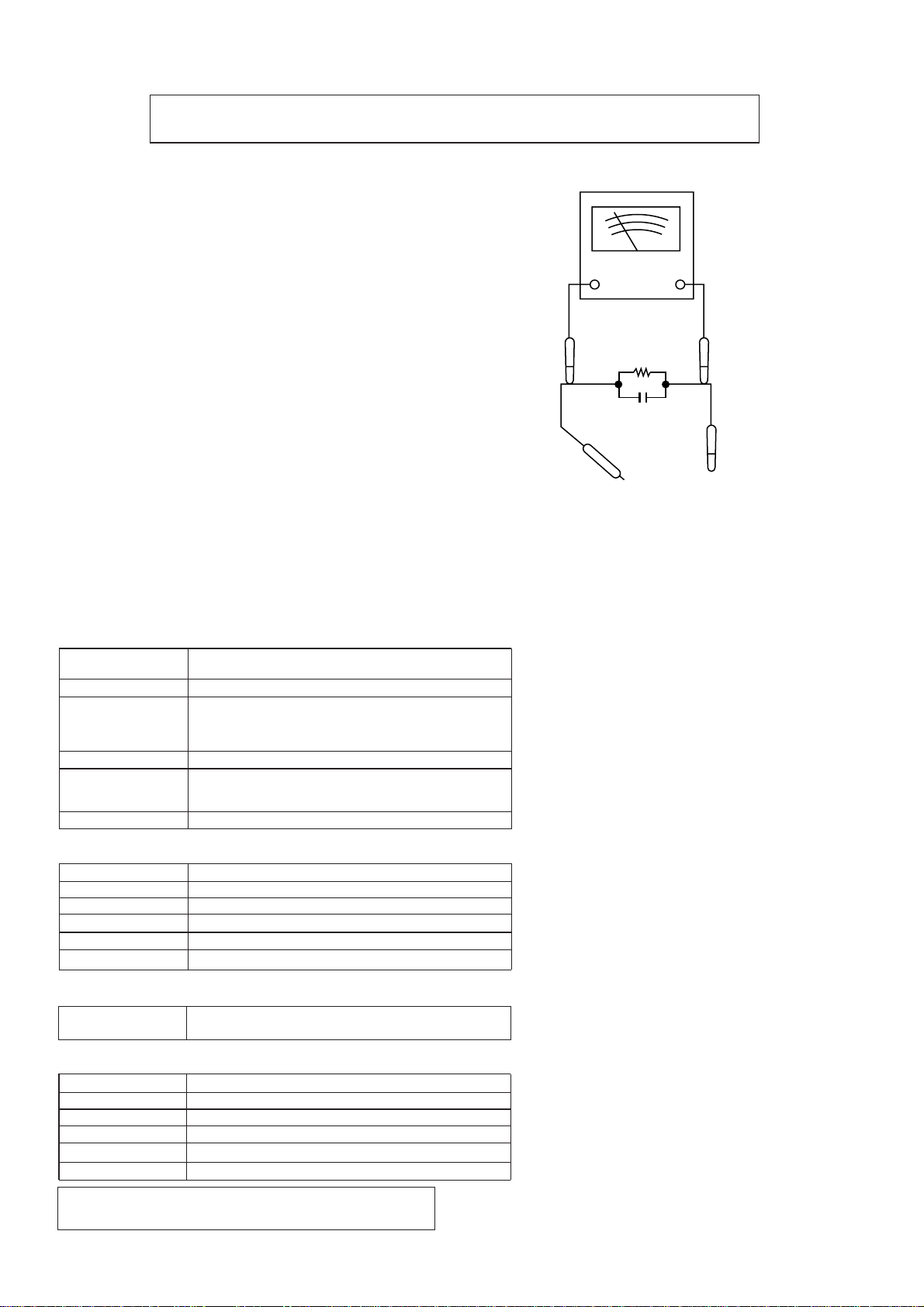

IMPORTANT SERVICE NOTES (FOR U.S.A. ONLY)

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform the

following safety checks.

1. Inspect all lead dress to make certain that leads are not

pinched or that hardware is not lodged between the chassis

and other metal parts in the audio product.

2. Inspect all protective devices such as insulating materials,

cabinet, terminal board, adjustment and compartment

covers or shields, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for leakage

current in the following manner.

* Plug the AC line cord directly into a 120 volt AC outlet.

* Using two clip leads, connect a 1.5k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all exposed

metal cabinet parts and a known earth ground, such as

conduit or electrical ground connected to earth ground.

* Use a VTVM or VOM with 1000 ohm per volt, or higher,

sensitivity to measure the AC voltage drop across the

resistor (See diagram).

* Connect the resistor connection to all exposed metal parts

having a return path to the chassis (antenna, metal cabinet,

screw heads, knobs and control shafts, escutcheon, etc.)

and measure the AC voltage drop across the resistor.

VTVM

AC SCALE

1.5k ohms

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

All check must be repeated with the AC line cord plug connection

reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2 milliamp.

AC.) or more is excessive and indicates a potential shock

hazard which must be corrected before returning the audio

product to the owner.

CONNECT TO

KNOWN EARTH

GROUND

■

General

Power source

Power consumption

Output power

Speakers

Dimensions

Weight

■

Compact disc player

Type

Signal readout

Audio channels

Filter

D/A converter

Wow and flutter

■

Radio

Frequency range

■

Tape recorder

Frequency response

Signal/noise ratio

Wow and fiutter

Motor

Bias system

Erase system

AC 120 V, 60 Hz

DC 9 V [“D” size (UM/SUM-1, R20 or HP-2) battery x 6]

11 W

FTC; 2.0 W min. RMS per channel into 4 ohms from 150

Hz to 20 kHz, with no more than 10 % total harmonic

distortion.

RMS; 2.3 W/CH (DC operation, 10 % T.H.D)

3-1/8" (8 cm) full-range speaker x 2

Width; 14-6/8" (376 mm)

Height; 5-7/8" (150 mm)

Depth; 9" (230 mm)

5.5 lbs. (2.5 kg) without batteries

Compact disc

Non-contact, 3-beam semi-conductor laser pickup

2

8-time oversampling digital filter

1-bit D/A converter

Unmeasurable (less than 0.001% W. peak)

FM; 87.5 - 108 MHz

AM; 530 - 1,720 kHz

50 - 14,000 Hz (Normal tape)

50 dB

0.25 % (WRMS)

DC 9 V electric governor

AC bias

Magnet erase

SPECIFICATIONS

Specifications for this model are subject to change without

prior notice.

– 2 –

Page 3

1234567

QT-CD180

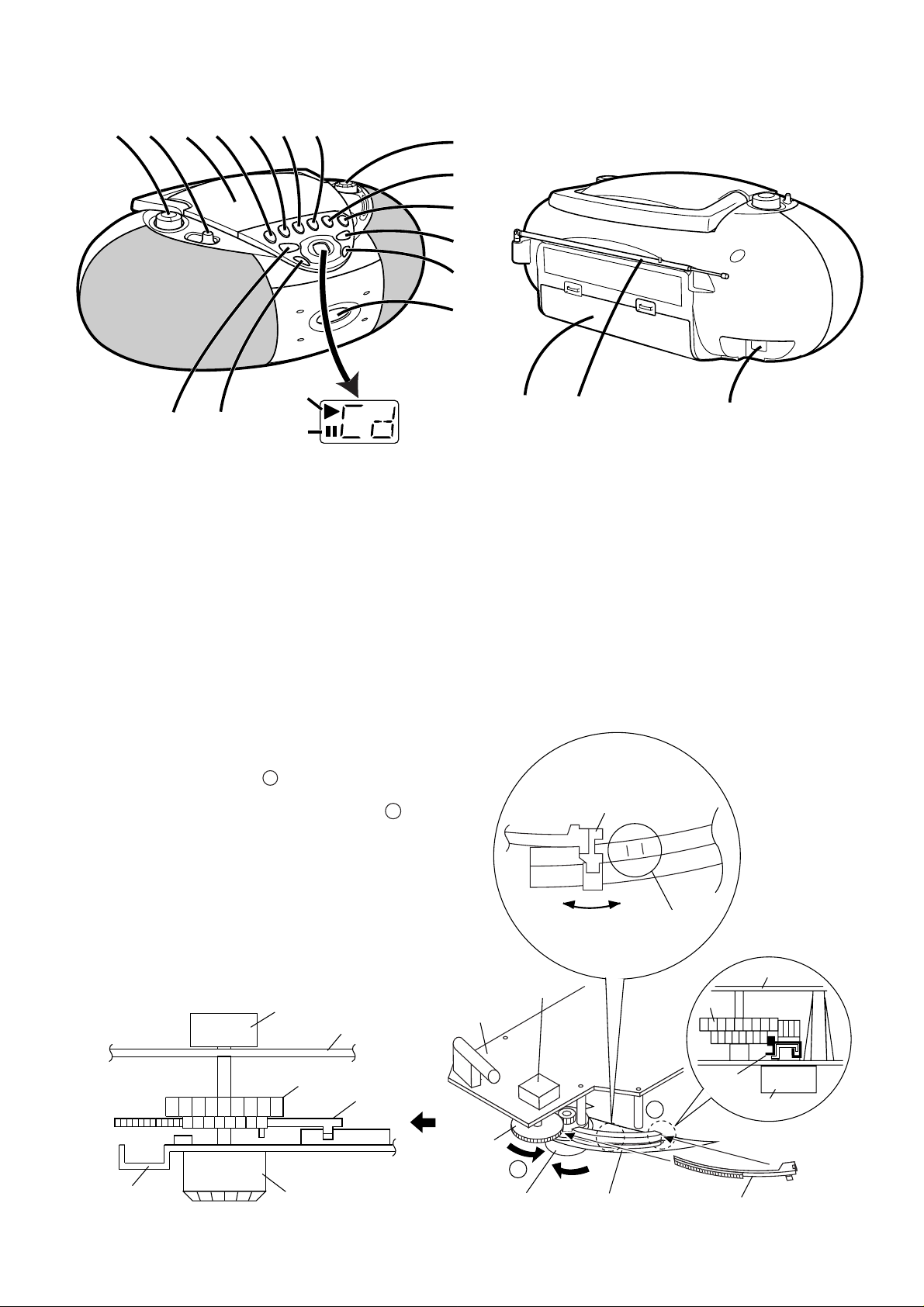

NAMES OF P ARTS

8

9

10

11

12

13

16

14 15

01. Volume Control

02. Function Switch

03. CD Compartment

04. (TAPE) Pause Button

05. (TAPE) Stop/Eject Button

06. (TAPE) Fast Forward Button

07. (TAPE) Rewind Button

08. Tuning Control

09. (TAPE) Play Button

17

10. (TAPE) Record Button

11. (CD) Play/Pause Button

12. (CD) Track Up/Cue Button

13. Cassette Compartment

14. (CD) Stop Button

15. (CD) Track Down/Review

Button

16. (CD) Play Indicator

17. (CD) Pause Indicator

FITTING OF DIAL POINTER

Setting method of the dial pointer

1. Remove the front cabinet. (Refer to Fig.5-2 on page 5,

"Disassembly method".)

2. Remove the dial pointer.

3. Insert the dial pointer from A of the top cabinet so that it

engages with the drum gear.

4. Fully turn the drum in the opposite direction of B and set

it to the FL marks.

5. Reassemble the front cabinet.

18

19

18. Battery Compartment

19. FM Telescopic Rod Antenna

20. AC Power input Socket

Dial Pointer

20

Top Cabinet

Variable

Capacitor

Drum

Tuning Knob

Main PWB

Dial

Pointer

Main PWB

Drum

Tuning Knob

Figure 3-1

– 3 –

Variable

Capacitor

B

FH

FL

A

Top Cabinet

FL Mark

Main PWB

Drum

Dial

Pointer

Tuning Knob

Dial

Pointer

Page 4

QT-CD180

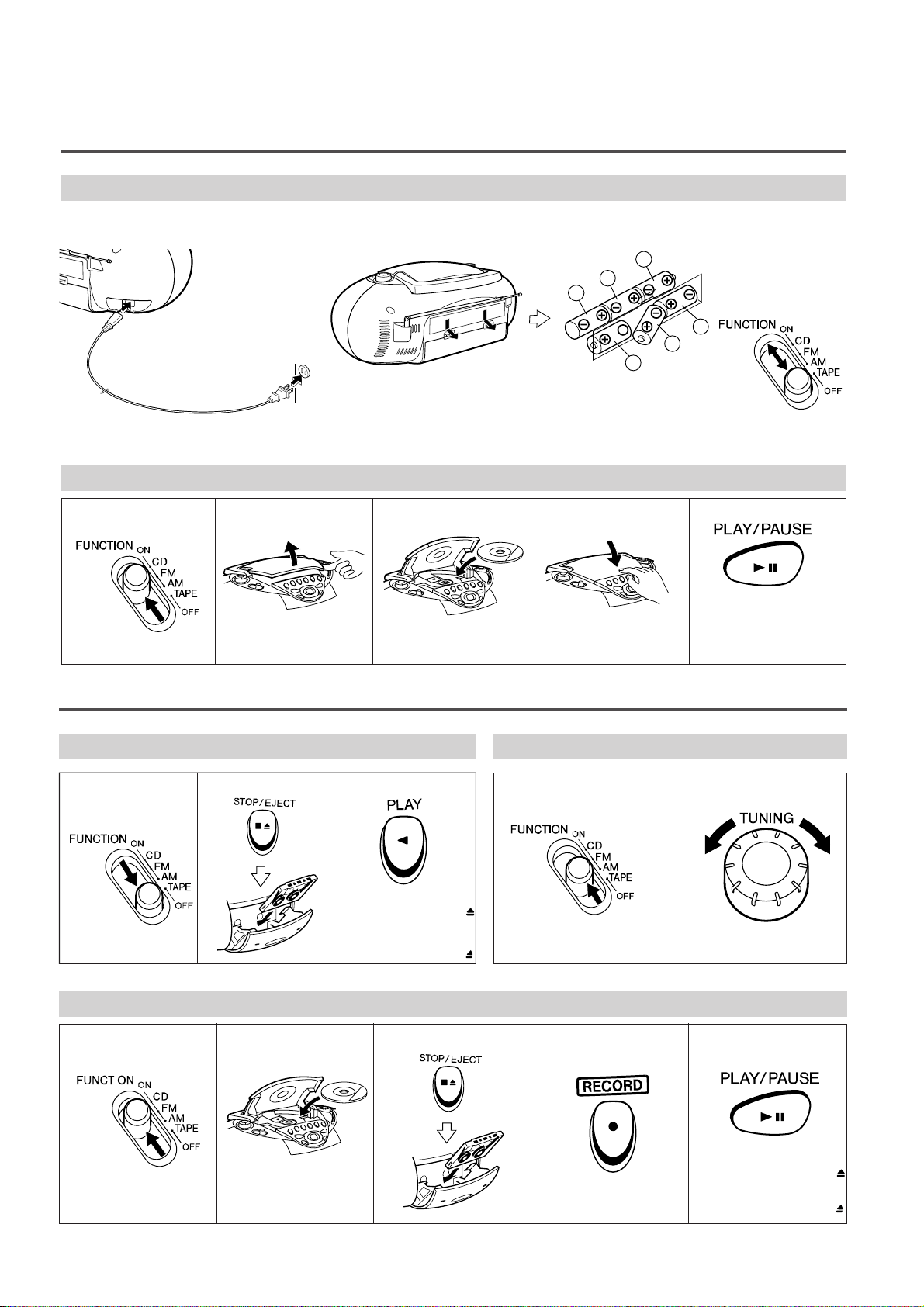

OPERATION MANUAL

Quick Guide /

1

Preparation for use /

■ Operation with AC power

Funccionamiento con corriente alterna

■

T o AC INPUT

A la toma AC INPUT

AC 120 V, 60 Hz

120 V de CA, 60 Hz

To an AC outlet

A un tomacorriente de CA

2

Listening to a CD /

Guía rápida

Preparación para su uso

■ Operation with batteries

Funccionamiento con pilas

■

● 6 “D” size batteries (UM/SUM-1, R20, HP-2 or similar)

● Batteries are not included.

●

6 pilas del tamaño “D” (UM/SUM-1, R20, HP-2 o similares)

●

Las pians no están incluidas.

Audictión de CD

■ Turning the power

ON and OFF

Conexión (ON) y

2

3

1

4

■

desconexión (OFF)

de la alimentación

5

6

123 45

● Label side up.

●

Con el lado de la etiqueta

encarada hacia arriba.

3

Listening to a tape /

Audictión de una cinta

123

To stop playback

Press the STOP/EJECT ■

button.

Para detener la

reproducción

Pulse el botón STOP/EJECT

5

Recording from a CD /

Grabaciones de CD

12

3

■

To stop playback

Press the STOP ■ button.

Para detener la

reproducción

Pulse el botón STOP

4

Listening to the radio /

Audic

tión de la radio

12

.

4

5

■

.

● Load the disc to be

recorded.

Introduzca el disco que

●

va a grabar.

– 4 –

To stop recording

Press the STOP/EJECT ■

button.

Para detener la grabación

Pulse el botón STOP/EJECT

■

.

Page 5

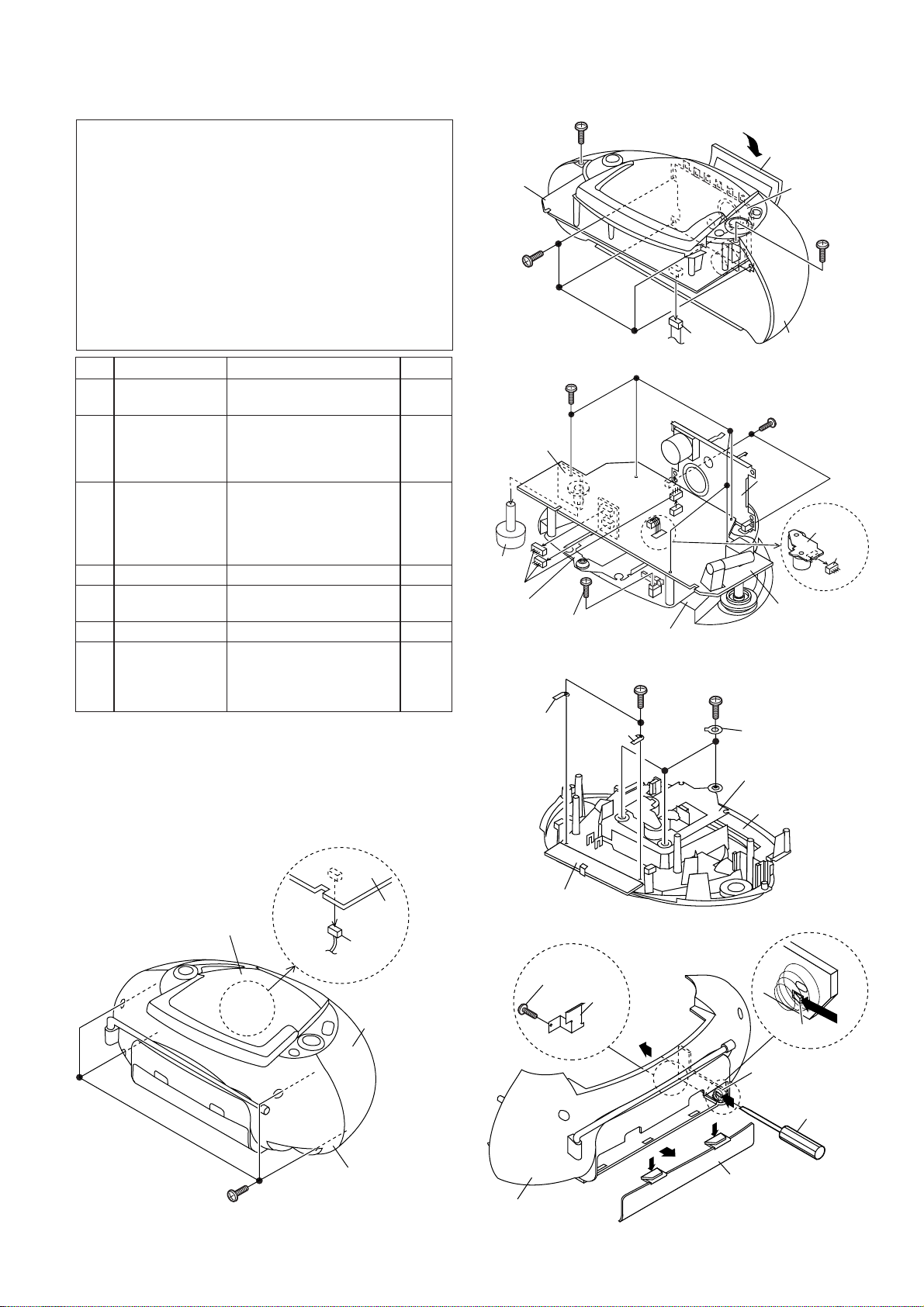

DISASSEMBLY

(C3)x5

ø3x10mm

(D1)x2

ø3x8mm

(C4)x1

ø2.5x10mm

(C5)x1

(C2)x3

(C1)x1

Volume

PWB

Tape

Mechanism

CD Mechanism

CD Motor

PWB

Main PWB

Top Cabinet

Caution on Disassembly

Follow the below-mentioned notes when disassembling the

unit and reassembling it, to keep it safe and ensure excellent

performance:

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need

to be removed when disassembling the unit. After

servicing the unit, be sure to rearrange the leads

where they were before disassembling.

4. Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

STEP REMOVAL PROCEDURE FIGURE

1 Rear Cabinet 1. Screw ................... (A1) x4 5-1

2. Socket .................. (A2) x1

2 Front Cabinet 1. Open the cassette holder 5-2

2. Socket .................. (B1) x1

3. Screw ................... (B2) x4

4. Screw ................... (B3) x2

3 Main PWB 1. Knob..................... (C1) x1 5-3

(With CD Control 2. Socket .................. (C2) x3

PWB) 3. Screw ................... (C3) x5

(Note) 4. Screw ................... (C4) x1

5. Socket .................. (C5) x1

4 Tape Mechanism 1. Screw ................... (D1) x2 5-3

5 CD Control PWB 1. Screw ................... (E1) x2 5-4

(With Main PWB) 2. Bracket................. (E2) x2

6 CD Mechanism 1. Screw ................... (F1) x3 5-4

7 Power PWB 1. Battery Lid............(G1) x1 5-5

2. Screw ................... (G2) x1

3. Bracket ................. (G3) x1

4. Hook..................... (G4) x1

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

Main

PWB

(B2)x4

ø3x10mm

(E2)x1

(B3)x1

ø3x8mm

(E2)x1

(B1)x1

Figure 5-2

Figure 5-3

(E1)x2

ø3x10mm

QT-CD180

Open

Cassette

Holder

Tape

Mechanism

(B3)x1

ø3x8mm

Front Cabinet

(F1)x3

ø2.5x10mm

PWB

Washer x3

CD Mechanism

Top Cabinet

Top Cabinet

(A1)x4

ø3x14mm

Figure 5-1

Main

PWB

(A2)x1

Front Cabinet

Rear Cabinet

CD Control

PWB

Figure 5-4

(G2)x1

ø3x10mm

(G3)x1

(G4)x1

Power PWB

Driver

(G1)x1

Rear Cabinet

Figure 5-5

– 5 –

Page 6

QT-CD180

REMOVING AND REINSTALLING THE MAIN PARTS

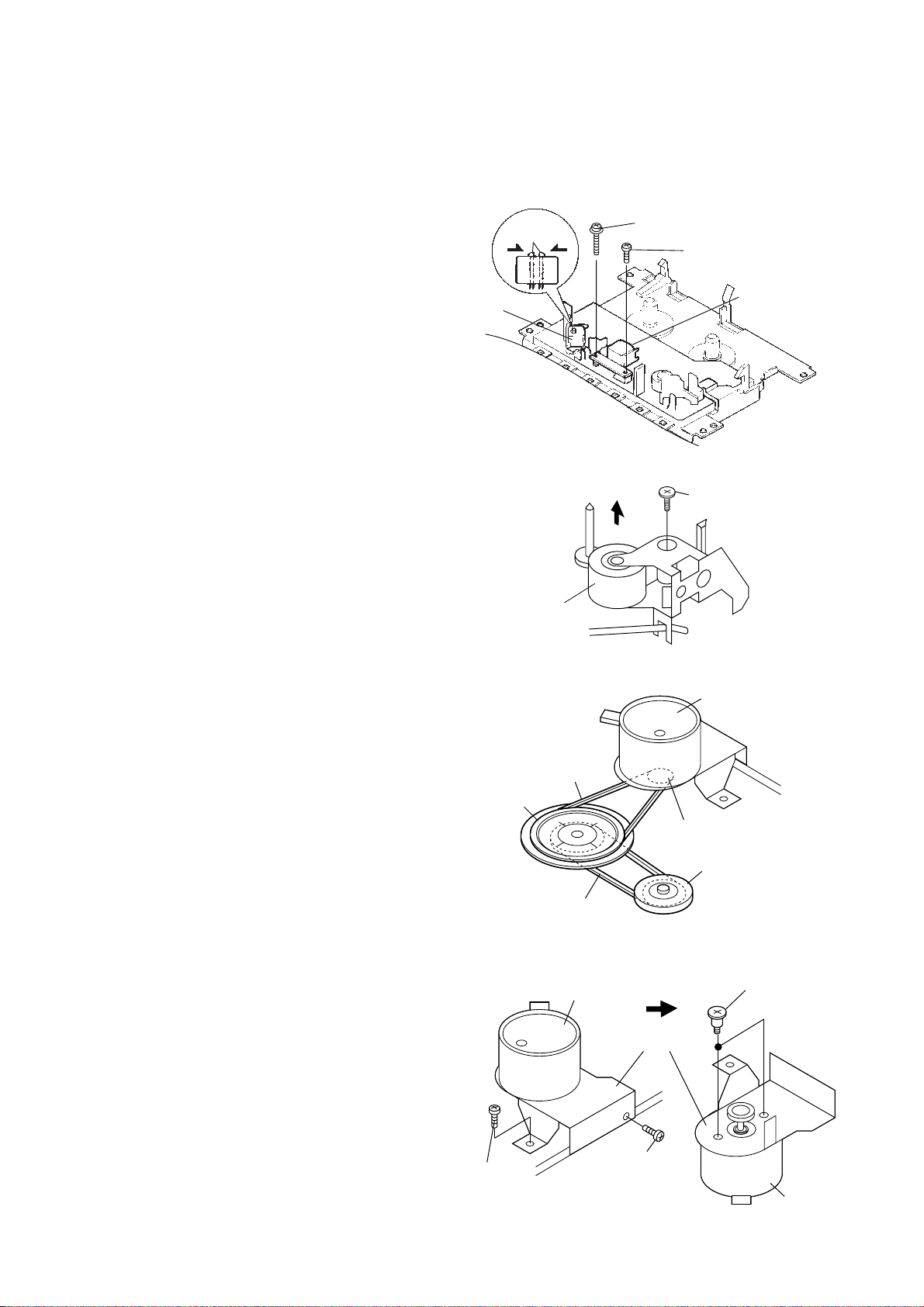

TAPE MECHANISM SECTION

Perform steps 1 to 4 of the disassembly method to remove the

tape mechanism. (See page 5.)

How to remove the record / playback and erase

heads (See Fig. 6-1.)

1. Remove the screws (A1) x 2 pcs., to remove the record/

playback head.

2. Remove the hooks (A2) x 2 pcs., toward the center

position as shown in Fig. 6-1. and then extract the erase

head upward.

Note:

After replacing the heads and performing the azimuth

adjustment, be sure to apply screwlock.

How to remove the pinch roller (See Fig. 6-2.)

1. Remove the screw (B1) x 1 pc., and remove the pinch roller

upwards.

Hook

(A2)x2

Erase Head

Pinch Roller

(A1) x1

ø2x7mm

Figure 6-1

Figure 6-2

(A1) x1

ø2x3mm

(B1) x1

ø1.5x2.5mm

Record/Playback

Head

How to remove the belts (See Fig. 6-3.)

1. Remove the main belt (C1) x 1 pc., from the motor

pulley.

2. Remove the FF/REW belt (C2) x 1 pc., from the REW/FF

roller.

3. Put on the belts in the reverse order of removal.

Note:

When putting on the belt, ascertain that the belt is not twisted,

and clean it.

How to remove the motor

(See Fig. 6-4.)

1. Remove the main belt. (See Fig. 6-3.)

2. Remove the screws (D1) x 2 pcs., to remove the motor

bracket.

3. Remove the screws (D2) x 2 pcs., to remove the motor.

Note:

When mounting the motor, pay attention to the motor bracket

angle.

Main Belt

(C1)x1

Flywheel

FF/REW Belt

(C2)x1

Motor

Motor

Motor Pulley

REW/FF

Roller

Figure 6-3

(D2)x2

Special

Screw

Motor Bracket

– 6 –

(D1) x1

ø2.5x4mm

(D1) x1

ø2.5x4mm

Motor

Figure 6-4

Page 7

QT-CD180

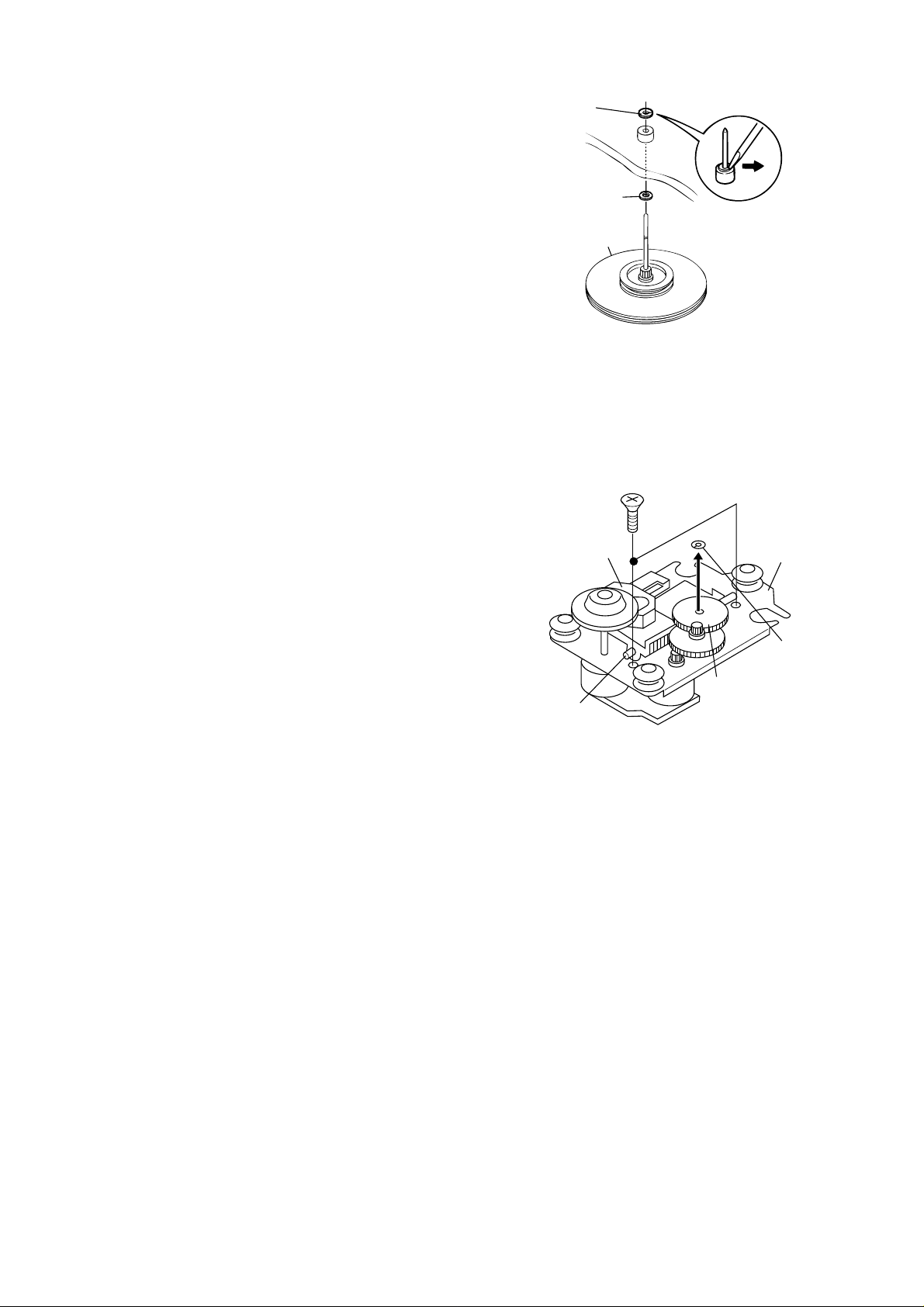

How to remove the flywheel (See Fig. 7-1.)

1. Remove the belt. (See Fig. 6-3.)

2. Remove the stop washer (E1) x 1 pc., with a small

precision screwdriver to extract the flywheel from the

capstan metal.

Note:

When the stop washer is deformed or damaged, replace it

with a new one.

How to reinstall the parts

Install each part in the reverse order of the removal with care.

CD MECHANISM SECTION

Perform steps 1 to 6 of the disassembly method to remove the

CD mechanism. (See page 5.)

How to remove the pickup (See Fig. 7-2.)

1. Remove the screws (A1) x 2 pcs., to remove the shaft

(A2) x1 pc.

2. Remove the stop washer (A3) x1 pc., to remove the gear

(A4) x 1 pc.

3. Remove the pickup.

(E1) x 1

Stop Washer

Washer

Flywheel

(A1) x2

ø2.6 x6mm

Pickup

Figure 7-1

CD

Mechanism

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

Shaft

(A2) x1

Figure 7-2

Gear

(A4) x1

Stop

Washer

(A3) x1

– 7 –

Page 8

QT-CD180

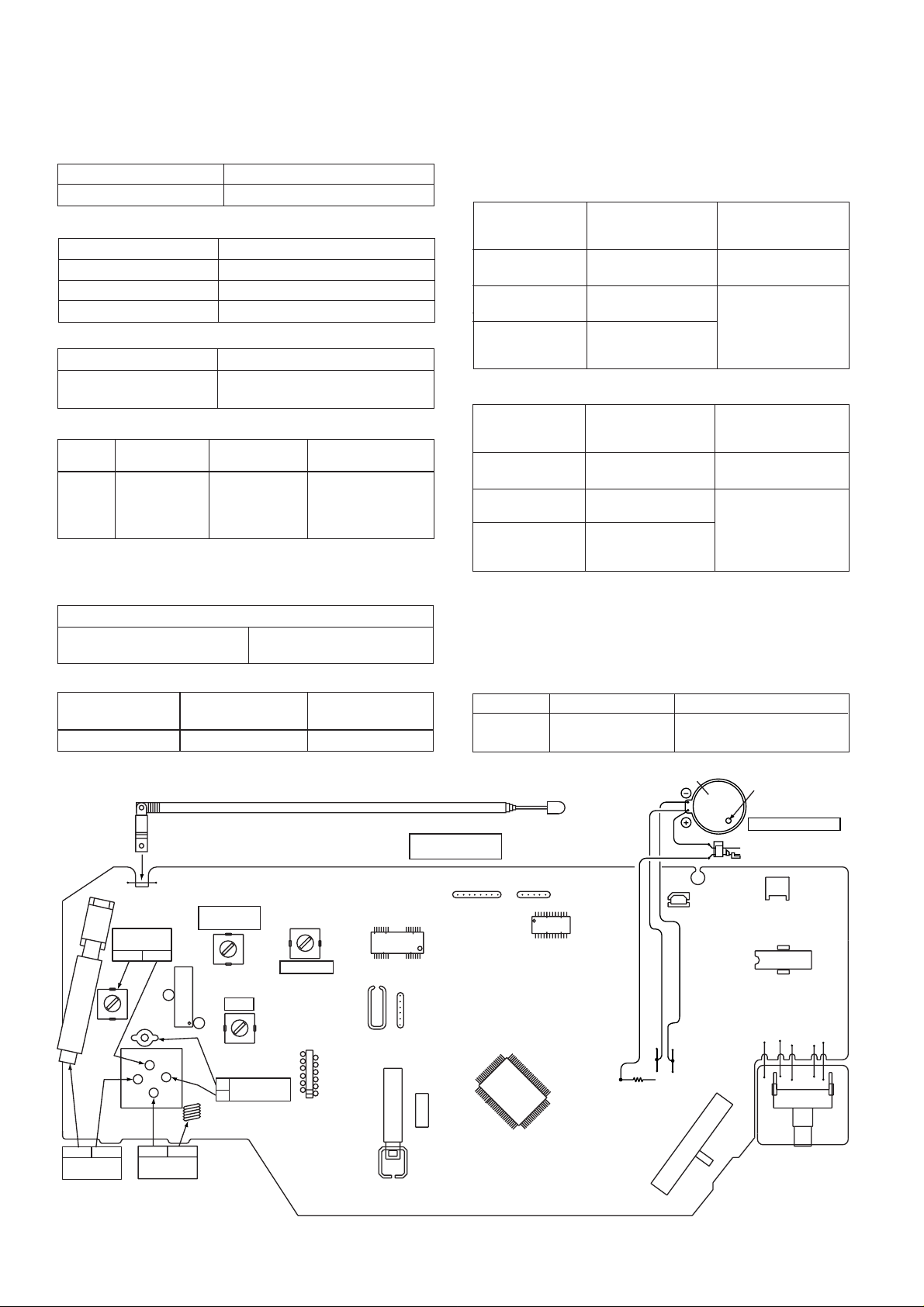

ADJUSTMENT

MECHANISM SECTION

• Driving Force Check

Torque Meter

PLAY: TW-2412 Over 80 g

• Torque Check

Torque Meter

Play: TW-2111 30 to 60 g.cm

Fast Forward: TW-2231 55 to 140 g.cm

Rewind: TW-2231 55 to 140 g.cm

• Head Azimuth

Torque Meter

MTT-114 Output: Speaker Terminal

(CNP201 Load resistance: 4 ohms)

• Tape Speed

Test

Tape

Adjusting

Point

MTT-111 Variable 3,000 ± 90 Hz Output: Speaker

resistor in Terminal

motor. (M601) (CNP201 Load

Specified

Specified Value

Specified Value

Specified Value

Value

Instrument

Connection

resistance: 4 ohms)

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

• FM IF/RF

Test Stage

Specified

Value/Adjusting

Point

FM Detection T2

FM fL: L2

Band Coverage fH: TC2

FM Tracking fL: 88.0 MHz: L1

fH: 108.0 MHz: TC1

• AM IF/RF

Test Stage

AM IF T3 Input: Antenna

AM fL: L4 Input: Antenna

Band Coverage fH: TC4 Output: Speaker

AM Tracking fL: 600 kHz: L3 Terminal (CNP201

Specified

Value/Adjusting

Point

fH: 1,400 kHz: TC3 Load resistance: 4

Instrument

Connection

Input: Pin 1 of IC1

Output: Pin 18 of IC1

Input: Antenna

Output: Speaker

Terminal (CNP201

Load resistance: 4

ohms)

Instrument

Connection

Output: Pin 18 of IC1

ohms)

TAPE SECTION

Position of each switch or control

Volume control Max

Function switch Tape/Power Off

• Bias Oscillation

L301

IC101

2

Instrument

Connection

15

14

11

1

Adjustment Point

Specified Value

L301 80 kHz ± 6 kHz Pin 1 of CNP101

FM ROD ANTENNA

L3

AM BAR

ANTENNA

FM

13

18

24

TC1

DETECTION

12

IC1

1

fL

fH

T2

AM IF

T3

FM BAND

COVERAGE

BIAS OSC.

12

L3

AM BAND

COVERAGE

fL

L4

TC3

L2

TC4

fH

TC2

L1

fL

fH

fL

AM

TRACKING

fH

FM

TRACKING

MAIN PWB

28

IC803

1

BI803

4

3

2

1

SW102

CNP101

• Playback Amplifier Sensitivity Check

Test Tape

Specified Value

MTT-118 1.1 V ± 3 dB Speaker Terminal

TAPE MOTOR

IC802

BI802

1

24

12

IC801

13

BI801

Instrument Connection

(Load resistance: 4 ohms)

M601

TAPE MECHANISM

SW601

TAPE MAIN

2

1

CNP602

SW201

Variable resistor

in motor

23

1

CNP201

IC201

VR201

Figure 8 ADJUSTMENT POINTS

– 8 –

Page 9

QT-CD180

0

CD SECTION

Since this CD system incorporates the following automatic adjustment function, when the pickup is replaced, it is not necessary

to readjust it.

Since this CD unit does not need adjustment, the combination of PWB and laser pickup unit is not restricted.

TEST MODE

Start

Note

While holding down the "Stop" and "Up" button at same time, move the FUNCTION switch to "CD".

1. When the CD LID switch is in the OFF position, (CD LID is open) the unit will be able to enter the test mode.

However, can use the "UP/CUE" and "DOWN/REVIEW" button only.

2. You can only move the pickup.

3. The LCD display should be the same as it is for normal CD operations.

Operation

The use of the "UP/CUE" button will move the pickup to the outermost position.

The use of the "DOWN/REVIEW" button will move the pickup to the innermost position.

LCD MODE

Start

Display

After connecting of the 10 kohm resistor between IC802 27 pin and GND and holding down the "Stop" and "Up"

button at same time, move the FUNCTION switch to "CD".

LASER LIGHTING CONFIRMATION

1. Remove the front cabinet according to the disassembly method.

2. Short the TP of the Figure 9-1 to turn on the CD LID switch (SW810).

3. While holding down the "Stop" and "Up" button at same time, move the FUNCTION switch to "CD".

4. Open the CD LID and press the PLAY button. The laser lights up for a few seconds. (At this time, the pickup lens moves

up and down and adjusts the focus to check if there is a disc or not.)

PREPARATION FOR LASER LIGHT UP

1. Before the laser light up, CD LID switch (SW801) terminals have to be short with the solder.

Resistor of 330ohm is put from 27 pin of IC802, and you must connect it to GND of PWB. (Refer to PWB of Figure9-1.)

MAIN

PWB-A1

OPEN/CLOSE

SW810

CD LID

SWITCH

BR

BR

TP

330 ohm

Resistor

1

PLAY

C847

C846

R862

FW806

REC.

C844

C853

C855

100

R839

R844

GND

CNP101

SW102

H

1

R846

10

A

90

95

5

10

C824

27pin

R861

1234

B

G

X801

80

81

75

85

70

IC802

15

20

25

30

R843

R821

SW102

RECORD/PLAYBACK

C

F

C84

65

60

55

45

40

35

31

C843

C825

D

C106

E

Figure 9-1

51

50

R830

R829

C833

C823

R106

R826

R824

C863

R828

C828

C830

C841

R827

C827

C826

C842

BI803

16

H

GYGYGY

R820

GY

GY

C819

C829

R804

C839

R851

R805

C817

C820

R806

C815

C838

C835

R852

1

7

8

15

20

Q801

R801

5

10

13

24

C816

C804

C801

C802

B

C

C834

28

25

22

21

IC803

20

12

10

5

IC801

1

E

R853

805

1

BI802

R802

BI801

C807

5

8

1

– 9 –

Page 10

QT-CD180

SETTING METHOD FOR LASER LIGHT UP

1. In Power OFF state, set the Function switch to ON, keeping to be pressed the "Stop" and "Up" button at same time.

After CD initialize finish. The CD TEST mode is set, and the LCD indicate to the total tracks of the disc. Release the PLAY button.

The CD TEST mode is set when the LCD indicate to " 1".

Then cut the above circuit.

2. In above TEST mode state, press once the PLAY button.

The laser is light up when LCD indicate to "cd".

SETTING FOR MAXIMUM LASER POWER

1. In above laser light up state, adjust the variable resistor (VR1A) on pickup PWB to maximum laser power.

Maximum laser power : Rotate the variable resistor (VR1A) to clockwise.

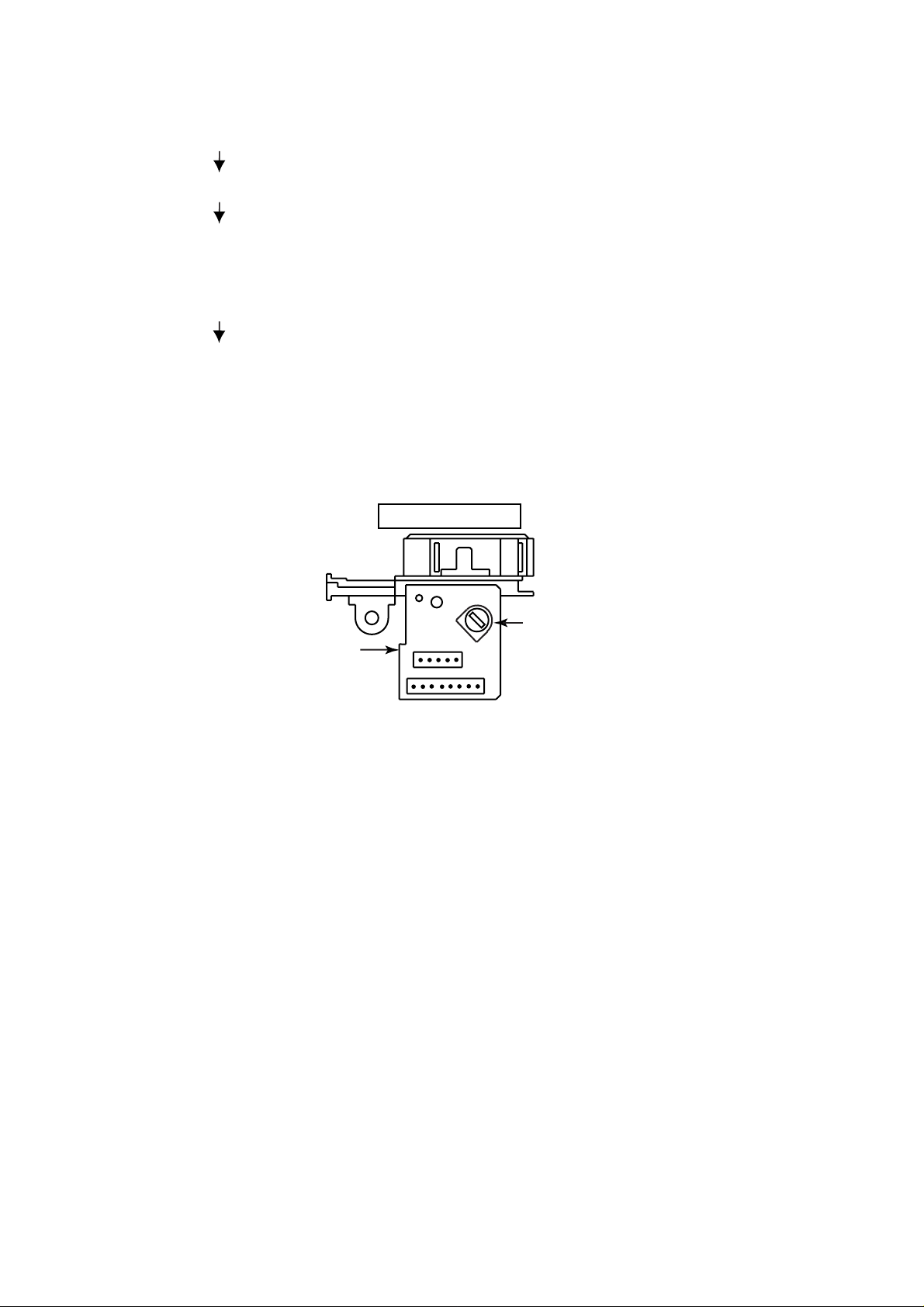

PICKUP UNIT

Pickup PWB

Note :

The TEST mode is cleared by Power OFF.

Variable Resistor

VR1A

Figure 10

– 10 –

Page 11

NOTES ON SCHEMATIC DIAGRAM

QT-CD180

• Resistor:

To differentiate the units of resistors, such symbol as K and

M are used: the symbol K means 1000 ohm and the symbol

M means 1000 kohm and the resistor without any symbol is

ohm-type resistor. Besides, the one with “Fusible” is a fuse

type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means pico-farad and the unit of the capacitor

without such a symbol is microfarad. As to electrolytic

capacitor, the expression “capacitance/withstand voltage”

is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

• The indicated voltage in each section is the one measured by

Digital Multimeter between such a section and the chassis

with no signal given.

REF. NO

SW102 RECODE/PLAYBACK REC—P.B.

SW201 FUNCTION SELECTOR TAPE/OFF—AM/ON—

SW601 TAPE MAIN OFF—ON

SW702 PICKUP IN OFF—ON

SW801 PLAY/PAUSE OFF—ON

SW802 STOP OFF—ON

SW803 TRACK DOWN/REVIEW OFF—ON

SW804 TRACK UP/CUE OFF—ON

SW810 CD LID OFF—ON

DESCRIPTION

POSITION

FM/ON—CD/ON

1. Tuner

( ) : AM mode

: FM mode

2. CD

( ) : Stop state

: Play mode

3. Deck section

Stop mode

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

TYPES OF TRANSISTOR

FRONT

VIEW

ECB

(S)(G)(D)

(1) (2) (3)

KRC107 M

KTA1046 Y

KTA1266 GR

KTA1273 Y

KTC3199 GR

– 11 –

Page 12

QT-CD180

220K

R

1

R

3

R

3

8

6

5

7

8

5

2

R

PICKUP UNIT

LD

A

B

C

D

E

F

G

H

MON

K

E

B

A

F

0.0022

C

0.0022

TR+

FO+

FO–

TR–

M702

SPINDLE

MOTOR

M701

SLED

MOTOR

SW702

PICKUP IN

CD MOTOR PWB-B

PIN

VOLTAGE

NO.

3.8V

115

3.6V

2

2.1V

3

2.1V

4

0V

5

1.7V

6

8.3V

7

0V

8

2.1V

9

2.1V

10

3.8V

11

12

3.8V

13

0V

14

7.7V

PIN

VOLTAGE

NO.

0.82V(0V)

1

0V(0V)

2

0.35V(1.03V)

3

3.81V(3.82V)

4

0V(0.13V)

5

3.92V(3.86V)

6

3.39V(3.18V)

7

3.92V(3.86V)

8

0V(0V)

9

0V(0.14V)

10

0.32V(0.32V)

11

3.14V(3.29V)

12

RECORD/

PLAYBACK HEAD

L-CH

R-CH

ERASE HEAD

1M

1M

M

M

PU-IN

IC803

PIN

NO.

16

17

18

19

20

21

22

23

24

25

26

27

28

AM

TRACKING

AM BAND

COVERAGE

FM

TRACKING

FM BAND

COVERAGE

IC1

PIN

NO.

13

14

15

16

17

18

19

20

21

22

23

24

TAPE

K

E

A

B

F

R+

R–

F+

F–

G

PD

VR

LD

+

–

SP+

SP–

+

SL+

SL–

–

PU-IN

GND

VOLTAGE

0.9V

0.9V

3.8V

3.8V

2.1V

2.1V

8.3V

8.3V

2.1V

2.1V

2.1V

3.8V

3.8V

0V

fH

fL

fH

fL

fH

fL

fH

fL

FM ROD

ANTENNA

VOLTAGE

1.22V(1.22V)

1.22V(1.22V)

3.20V(3.14V)

3.14V(3.92V)

0.7V(0.70V)

1.08V(1.01V)

0.4V(1.02V)

3.92V(3.85V)

3.92V(3.86V)

3.92V(3.86V)

3.92V(3.86V)

3.92V(3.82V)

( ): AM

5

4

3

2

1

1

2

3

4

5

6

7

8

6

5

4

3

2

1

TC3

L3

TC4

L4

TC1

L1

TC2

L2

CNS802

5

4

3

2

1

1

2

3

4

5

6

7

8

CNS801

6

5

4

3

2

1

CNP803

1

2

3

4

( ): CD STOP

1.87V(1.45V)

CNS803

BI802

5

4

3

2

1

1

2

3

4

5

6

7

8

BI801

6

5

4

3

2

1

BI803

K

E

A

B

F

TR+

TR–

FC+

FC–

GND

PD

VR

LD

DM+

DM–

FM+

FM–

SLT+

1N4148

+B

SLT–

FOCUS/TRACKING/

SPIN/SLED DRIVER

MM1469XH

L3

AM BAR

ANTENNA

C21

2P(CH)

18P(CH)

FM BAND

BASS

FILTER

F1

3

2

1

D1

IC1

FM/AM IF MPX.

TA2111N

R104

12K

SW102

R102

RECORD/

150

PLAYBACK

SW102-A

R

P

3

1

2

CNP101

CNS101

1

2

3

4

6

4

5

P

R

SW102-B

8

9

7

P

R

SW102-C

SW102

RECORD/

PLAYBACK

C802

IC803

C2

C1

C20

0.022

SWITCHING

Q801

(4.39V)

KTA1266 GR

0.022

+B

1234

FM RF

24

AMRF IN

0.047

FMRF

1

R103

12K

R101

150

SW102-G

R

20

19

21

C108

820P

16

18

17

R

SW102-F

3.72V(5.0V)

R801

22

2.97V

R802

2.2K

C801

0.01

GND

VO4–

VO4+

VO1–

VO1+

VIN1

TC3

VC3

AM ANT.

FM ANT.

VC1

TC1

22P

(UJ)

L1

23

FMRF

OUT

MIX

OUT

IN

RF GND

AM LOW

CUT

2

4

3

C11

0.47/50

R105

10K

C105

0.0027

R107

P

1K

C107

820P

C111

330P

R108

1K

P

C106

0.0027

R106

10K

VG4

VIN4

VG1

TRB

5

R852

2.2K

C3

VCC

R1 330

C112

330P

C817

100/10

R811

R853

2.2K

BIAS

REG OUT

6

7

R851

2.2K

AM OSC.

FM OSC.

L2

FM

OSC.

RF

AM

AGC

5

C12

T3

AM IF

R109

120

R110

120

22K

VCC

VCC

IC803

GND

MUTE

8

FM

OSC

4.7/50

VCC

1

FNI

2

FPI

3

TPI

4

TNI

5

MDI

6

LDO

7

SEL

8

TEB

9

10

2VRO

11

TEN

TEO

12

C813

47/16

VG3VG2

VIN3VIN2

9

1011 1213 14

TC4

VC4

VC2

TC2

R2

2.7K

VCC

6

R3

220K

AM IF

C109

270P

0V

5

0V

9

0.6V

C110

270P

+B

C815

47/16

IC801

8

9

10

C814

0.047

2

1516171819202122232425262728

OPI+

VO3–

VO3+

GND

VO2+

VO2–

AM OSC.

4P(CH)

AM

OSC

C14

0.022

2

1

CF3

460kHz

C115

0.018(ML)

C113

47/16

3

0.6V

NF1

IN1

BA3311L

IN2

NC

NF2

11

C114

47/16

C116

0.018

(ML)

RFN

GND

RFO

AGCI

RFGC

RFGO

RFIS

RFRP

VRO

FEN

FEO

SBAD

3

OPI–

OPO

DMO

L4

C4

FM

AFC

AM IF IN

C13

220/10

3

R113

IC101

0V

4

C816

0.022

24

23

22

21

20

19

18

17

16

15

14

13

FOO

TRO

FMO

C6

330P

C7

2.2/50

1819202122

17

DET

MPX

IN

7

IC1

TA2111N

CF1

10.7M

FM IF

8.2K

R115

3.9K

FILTER

ALC T

GND

0V0V

7

6

C118

10/16

R114

R116

8.2K

3.9K

IC801

SERVO PRE AMP.

TA2109F

R804

68K

R805

39K

R807

2P(CH)

0.047

C805

C9

0.1/50

FM IF

IN

8

1

R117

3.9K

C117

10/16

4.67V

8

10

2

R806

2.7K

C820

0.1(ML)

C821

100/10

+B

0.022

R5

3.3K

0.1/50

C10

15

LPF2

VCO

GND

9

10 11 12

TUN

T2

FM

DETECTION

R119

C119

0V

C120

3.3K

R120

+B

C806

330/16

1/50

14

LED

C15

3.3K

2.2/50

47/16

D102

1K

C818

56P

C822

13

L-CH

R-CH

FM

DET

ST

LED

10P(CH)

0.01

C121

D101

1N4148

220/10

R125

680K

C122

1N4148

0.047

SW102-H

R

22

C123

13

R

SW102-E

0.01

OUT1

VCC

4.62V

OUT2

C819

0.1(ML)

R803

82K

R4

2.2K

16

LPF1

AM/FM

2

3

1

12

C804

C807

C8

1.89V

R118

3.9K

L802

0.82µH

8.15V

C856

0.001

C16 1/50

C18 0.015(ML)

R8

10K

R121

P

24

23

15

14

R122

(8.3V)

0V(0V)

D2

1N4148

C17 1/50

C19 0.015(ML)

C22

0.1/50

R9

10K

R10

1.8K

SW102

RECORD/

PLAYBACK

IC101

REC/P.B.

EQUALIZER AMP.

BA3311L

P

SW102

RECORD/

PLAYBACK

1.8K

+B

C863

47/16

C841

0.047

C842

0.047

C843

47/16

+B

+B

SWITCHING

Q802

KTA1273 Y

7.48V(7.59V)

R850

1.5K

2

0V(0V)

R7

120

R6

100

6.8K

R126

100

C832

47/16

C834

470P

C835 470P

C836 0.047(ML)

C837 0.047(ML)

C838 0.047(ML)

C839 0.047(ML)

8.21V(8.3V)

( ): CD STOP

4.97V(5.0V)

3

Q803

1

KRC107 M

COR1

CORE

R11

6.8K

C351

0.0022

(ML)

1N4004

R-CH(CD)

C825

47/16

D801

L-CH(CD)

TAPE

AM

FM

CD

TAPE

AM

FM

CD

BIAS OSC.

C826

47P

0.0047

+B

R456

R455

11

10

9

8

14

15

16

17

L301

C352

100/10

R820

R827

15K

C829

C854

0.0068

39K

39K

SW201-B

12

SW201

FANCTION

SELECTOR

13

SW201-C

SW102-D

R

12

11

R351

100

47K

C830

0.01(ML)

C828

0.0027

R828

10K

C833

0.033(ML)

R812

R829

3.3K

R831

3.3K

R833

3.3K

+B

3.3K

R211

L-CH

R-CH

P

10

C354

0.022(ML)

1K

0.01

C84

0.04

SW10

RECO

PLAYB

R352

150

R826

C

X

1

0

• The numbers 1 to 17 are waveform numbers shown in page 16.

1

2

34 5

Figure 12 SCHEMATIC DIAGRAM (1/2)

– 12 –

6

Page 13

QT-CD180

8

4

C825

47/16

C826

47P

47K

R820

R827

15K

C829

0.0047

C854

0.0068

(ML)

(ML)

(ML)

(ML)

01

004

)

+B

R456

39K

R455

39K

APE

11

SW201-B

AM

10

12

FM

9

CD

8

SW201

FANCTION

APE

14

SELECTOR

AM

15

13

FM

16

SW201-C

CD

17

C830

0.01(ML)

C828

0.0027

R828

10K

C833

0.033(ML)

R812

1K

R829

3.3K

R831

3.3K

R833

3.3K

+B

3.3K

R211

L-CH

R-CH

R826

C827

0.015(ML)

R830

10K

R832

3.3K

R834

3.3K

X801

16.93MHz

C845

0.047

220K

C840

0.047

R840

R210

10

R860

100

C857

3.3K

0.01

0.82µH

L801

R215

2.7K

R216

2.7K

C844

100/10

+B

+5V(CD)

R824

12

4.92V

10K

50

TMAX

LPFN

51

LPFO

52

PVREF

53

VCOF

54

AVSS

55

SLCO

56

2.10V

RFI

57

AVDD

58

RFCT

59

RFZI

60

RFRP

61

2.30V(2.1V)

FEI

62

SBAD

63

2.14V

TEI

64

2.14V

TEZI

65

2.18V

FOO

66

2.11V

TRO

67

VREF

68

RFGC

69

TEBC

70

2.10V

FMO

71

2.17V

DMO

72

2VREF

73

SEL

2.47V(0V)

74

VDD2

75

VSS2

76

XVSS

77

2.08V

XI

78

2.57V

XO

79

XVDD

80

81

0V

C853

R836

C852

GND(AUDIO)

GND(POWER)

GND(CD)

C823

0.022

474849

PDO

VSS1

P2VREF

2.10V

4.18V

1.50V

0V

2.10V

4.98V

2.10V

2.10V

2.73V(1.15V)

2.94V(0.989V)

1

2.10V

2.14V

2.10V

14

4.18V

4.97V

82

0V

83

0V

84

17

DVRR

RO

DVSR

84 85 86 87

82 83

C848

0.022

270

C850

0.0022

3.3/50

R837

R838

10K

0.047(ML)

0.047(ML)

NC

46

VDD1

SBOK

0V

4.98V

4.97V(0V)

13

50

2.08V(0V)

51

2.10V(1.34V)

2.01V(4.12V)

52

2.10V

53

5

6

11

15

4

2.48V

2.37V

16

4.72V

2.36V

2.47V0V0V

LO

DVSL

DVRL

DVDD

22/16

C847

22/16

R835

C849

0.0022

C851

10K

VOLUME

PWB-A2

C217

0.0015

R219

2.7K

C215

C216

R220

2.7K

C218

0.0015

NCNCNC

NCNCNC

4142

434445

SPDA

COFS

DOUT

1.66V

2.46V

0.43V(2.36V)

( ): STOP

IC802

7

SERVO/

SPCK

2.49V

/HSO

4.97V

SBSY

0V

SIGNAL

CONTROL

TC9457F0

0V

4.96V

4.95V

0V

REMO-IN

RYNCREC

RESET

NC

NC

88

91 92 93 949596 97 98

89 90

NC

+B

R839

47K

C846

1/50

270

3.3/50

VR201-A

20K(B)

VOLUME

VR201-B

20K(B)

VOLUME

TEST5

0V

98

99

4.96V

MXQ

NC

TEST4

0V

2.33V

2.33V

0V

0.30V

MVSS

MXI

NC

34353637383940

TEST2

TEST3

0V

0V

4.98V

0V

TRAY CLOSE

0V

0V

4.96V

MVDD

C855

C219

10/16

1K

R221

C241

47/16

1K

R222

C220

10/16

0V

0V

NC

3132

33

NC

PUSEL2

TEST0

TEST1

PU IN

4.97V

0V

MUTE

0V

ADIN2

4.98V

ADIN1

4.98V

0V

DISPLAY

PUSEL1

PUSEL0

0V

TRAY OPEN

MVSS1

0V

MVDD1

4.98V

DOOR OUT

DOOR IN

0V

CDSEL1

0V

0V

CDSEL0

2.49V

SEG14

2.49V

SEG13

2.49V

SEG12

2.49V

SEG11

SEG10

2.49V

SEG9

2.49V

2.49V

SEG8

SEG7

2.49V

SEG6

2.49V

SEG5

2.49V

SEG4

2.49V

2.49V

SEG3

SEG2

2.49V

2.33V

COM1

COM2

COM3

99

100

0.022

C221

0.001

C222

0.001

NC

0V

NC

0V

30

29

28

27

26

25

24

23

NC

22

21

NC

20

19

18

17

16

15

14

NC

13

NC

12

NC

NC

11

10

NC

NC

9

8

NC

7

NC

6

NC

5

4

3

2

SEG1

1

NC

2.49V

COM4

2.33V

POWER AMP.

7

8

C235

100/10

9

120

R231

C225

100/10

4

120

R232

C236

100/10

5

6

+B

8.35V

C227

+B

R821

22K

R843

3.3K

C824

0.022

+B

+B

IC201

TA8227P

0V

0V

+

–

0V

4.67V

0.56V

4.33V

0V

9.05V

8.01V

–

0V

+

4.27V

0.56V

1

12

8.02V

+B

C226

0.022

2200/16

MAIN PWB-A1

+B

R844

3.3K

330

R846

+B

C233

470/10

11

C237

100/10

10

C239

0.15(ML)

13

14

C240

C238

0.15(ML)

3

100/10

2

C234

470/10

POWER PWB-A4

R862

22K

R861

3.3K

SW810

CD LID

OPEN/CLOSE

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

FW806

10110

CNP201

CNS201

1

1

2

2

3

3

IC801

VOLTAGE

4.84V

2.04V

2.04V

2.12V(0V)

2.11V(0V)

0.18V(0V)

2.84V(0V)

2.41V(0V)

2.05V

4.08V

2.05V

2.08V

PIN

VOLTAGE

NO.

2.86V(0.99V)

13

14

2.12V

15

2.05V

16

2.05V

17

2.63V(1.15V)

18

2.04V

19

2.07V

20

2.17V

21

2.04V

22

1.47V(0.77V)

23

0V

24

2.05V

( ): CD STOP

CD CONTROL PWB-A3

LCD801

LCD DISPLAY

+B

1

+B

SW801

PLAY/

PAUSE

R847

1K

SW802

STOP

4321

R848

2.2K

SW803

TRACK

DOWN/

REVIEW

5

6

8

7

R849

6.8K

SW804

TRACK UP/

CUE

FM SIGNAL

AM SIGNAL

CD SIGNAL

PLAYBACK SIGNAL

RECORD SIGNAL

+

SP201

L-CH

4 OHM

–

SPEAKERS

–

SP202

R-CH

4 OHM

+

D201

1N4148

SW201

+B

FUNCTION

ZD201

DZ5.1BSB

C203

0.01

SELECTOR

19

R201

2.2K

C202

47/16

SW201-D

20

21

22

23

TAPE

AM

FM

CD

R230

2.7

R

12

R351

100

L301

BIAS OSC.

C352

100/10

SW102-D

11

10

0.022(ML)

SW102

P

RECORD/

PLAYBACK

C354

R352

150

R353

33K

C353

0.0056(ML)

3.32V

RECORDING

BIAS OSCILATOR

Q351

KTC3199 GR

0V

R354

4.7

0.68V

REGULATOR

6

C204

0.022

Q204

KTA1046 Y

5.08V

D202

1N4148

4.39V

R203

REGULATOR

560

9.05V

8.44V

8.44V

Q205

R202

4.7K

D203

1N4148

4.96V

KTC3199 GR

5

TAPE

AM

4

FM

3

CD

2

+B

SW201-A

SW201

FANCTION

SELECTOR

• NOTES ON SCHEMATIC DIAGRAM can be found on page 11.

78 9101112

Figure 13 SCHEMATIC DIAGRAM (2/2)

– 13 –

C652

0.022

CNS602

CNP602

+B+B

1221

DC 9V[ "D" SIZE

(UM/SUM-1,R20 OR HP-2)

BATTERY x 6]

D652

D653

C653

0.022

BATTERY

+

M

–

1N4004

1N4004

SW601

TAPE

MAIN

M601

TAPE

MOTOR

D651

D654

1N4004

1N4004

C651

C654

0.022

0.022

T651

POWER

TRANSFORMER

AC/DC SELECTOR

SO651

AC INLET

SOCKET

AC 120V, 60Hz

AC INPUT

Page 14

QT-CD180

A

B

ERASE HEAD

C

RECORD/PLAYBACK

HEAD(242-4)

D

CD CONTROL

E

PWB-A3

1

F

G

(242-5)

BK

RD

WH

BK

FW806

SW804

TRACK UP/

CUE

8

7

6

5

4

3

2

LCD801

1

R848

R847

SW803

TRACK

DOWN/

REVIEW

VR201-B

C216

VOLUME

PWB-A2

SW201

TAPE

FUNCTION

SELECTOR

AM

FM

CD

ON

SW201

A

D

TAPE

OPEN/CLOSE

GND

BK

CNS101

WH

1

BK

2

RD

3

BK

4

10

SW801

PLAY/

PAUSE

R849

SW810

CD LID

BR

BR

1

PLAY

SW102

C105

R121

MAIN

PWB-A1

SW802

STOP

L3

AM BAR ANTENNA

R838

C850

C847

R105

OFF

L801

FW806

R104

C852

C846

R862

REC.

R103

R839

R844

C121

C218

R220

R219

C217

R836

C844

C853

C855

R113

VR201

VOLUME

C215

C851

C849

R835

100

1

R846

C824

10

CNP101

A

H

R101

C115

R115

R119

D101

R211

R837

C848

90

95

5

10

R861

1234

B

G

R107

C117

R117

R125

L1

VR201-A

R215

B

C845

81

85

IC802

15

C107

C113

C120

R4

R216

C

R210

R456

C857

R860

C832

R840

X801

80

75

70

65

60

45

20

40

25

35

30

31

R843

R821

SW102

RECORD/PLAYBACK

C

D

E

F

R102

C108

R108

C111

R109

C109

IC101

1234567

C123

R6

R7

D2

1

2

F1

C2 C3

TC2

TC1

VC1

VC2

VC4

VC3

TC4

TC3

ZD201

C203

D203

D202

R203

R455

55

C825

C116

C112

9

10

8

D102

C22

3

C840

C843

C106

R114

11

12

C202

R230

51

50

R110

R832

C823

C110

R812

C833

R826

R106

R221

C854

C827

R824

C114

C122

T3

C1

L2

C222 C221

C220

R222

R232

6

5

4

C236

13

3

E

C

B

R820

CF3

R3

C14

5

R1

C6

C241

C836

GY

R118

R122

IC1

Q204

C818

R807

GY

C12

C7

L802

10

15

C819

C829

C839

3

2

1

C226

R804

C817

R851

C15

12

13

D201

D801

R805

CF1

C8

C238

C234

C240

R201

B

R202

C

Q205

E

C204

C837

R834

R833

R831

R830

R829

C863

R828

C828

C830

C841

R827

C826

C842

BI803

16

GYGYGY

WH

R116

C118

R120

C119

R126

11223

C11

1

2024

C4

R2

L4

C821

C820

R806

C815

C838

14

C351

7

8

9

14

IC201

10

11

12

C822

15

20

R801

C835

R852

1

5

7

8

10

Q351

R354

L301

R351

T2

C13

C9

R5

C233

C227

C813

R803

C814

13

24

C816

C804

C801

C802

28

25

22

21

IC803

20

15

B

C

E

C20

C225

C237

Q803

C834

C353

C219

CNP201

CNP602

R850

12

10

5

IC801

1

Q801

ECB

R853

C856

R353

C354

R352

C352

R10

R8

C16

C18

C19

C10

R231

C235

3

2

1

C239

1

2

12

ECB

Q802

R811

BI802

R802

BI801

C807

C805

R11

3

1

5

8

1

COR1

C806

R9

C17

BK

RD

YL

CNS802

BK

1

WH

2

WH

3

WH

4

WH

5

CNS801

WH

8

WH

7

WH

6

WH

5

WH

4

WH

3

WH

2

BK

1

D1

C21

H

BL

BL

1

2

34 5

6

Figure 14 WIRING OF P.W.BOARD (1/2)

– 14 –

Page 15

M601

TAPE MOTOR

(242-6)

BK

RD

TAPE

SW601

TAPE MAIN

(242-7)

BR

YL

PICKUP UNIT

QT-CD180

SO651

YL

YL

C653

C652

AC INLET SOCKET

AC 120V, 60Hz

RD

RD

T651

POWER

TRANSFORMER

CNS602

1

2

BK

RD

RD

+B

GND

D654

D652

D651

D653

C651

RD

RD

RD

C654

CNS201

3 2 1

BL

BK

GY

BL

SP202

R-CH

54321

78654321

BK

SPEAKERS

BK

GY

SP201

L-CH

13

8

15

20

5

10

24

25

IC803

20

12

IC801

1

28

22

21

15

10

5

BATTERYS

DC9 V [ "D" size

(UM/SUM-1,R20 or HP2)

battery x 6 ]

2

3

(232)

100

16

1

5

17

95

85

90

10

15

4

80

81

75

70

IC802

20

25

30

14

65

35

15

1

11

6

7

5

60

55

51

50

45

40

12

13

31

10

9

8

1

7

14

• The numbers 1 to 17 are waveform numbers shown in page 16.

M701

SLED MOTOR

WH

GY

GY

GY

GY

GY

CNS803

1

2

3

4

5

6

CD MOTOR PWB-B

CD MOTOR PWB-B

1

2

3

4

5

6

CNP803

F3895AF

SW702

PICKUP IN

M702

SPINDLE MOTOR

(233)

POWER PWB-A4

COLOR TABLE

BR

RD(R)

OR

GR

GY

WH(W)

BK

PK

BROWN

RED

ORANGE

YELLOW

YL

GREEN

BLUE

BL

VIOLET

VL

GRAY

WHITE

BLACK

PINK

(235)

FM ROD ANTENNA(238)

78 9 101112

Figure 15 WIRING OF P.W.BOARD (2/2)

– 15 –

Page 16

QT-CD180

WAVEFORMS OF CD CIRCUIT

1

IC802 66Pin

2

IC803 20Pin

3

IC803 21Pin

4

IC802 74Pin

5

IC802 62Pin

6

IC802 64Pin

NO DISC FOCUS SEARCH

FOO

FO+

FO-

FOCUS SEARCH TOC IL

SEL

FEI

TEI

STOP PLAY

1

2

3

1

2

3

12

IC802 50Pin

13

IC802 45Pin

14

IC802 72Pin

6

IC802 64Pin

11

IC802 67Pin

15

IC802 71Pin

TMAX

SBOX

DMO

TRO

FMO

STOP PLAY

STOP PLAY

TEI

CUE

1

2

3

1

2

3

5

IC802 62Pin

7

IC802 63Pin

8

IC801 22Pin

5

IC802 62Pin

9

IC801 19Pin

10

IC801 17Pin

FEI

SBAD

RFO

FEI

RFGO

RFRP

STOP PLAY

STOP PLAY

1

2

3

1

2

3

6

IC802 64Pin

11

IC802 67Pin

15

IC802 71Pin

6

IC802 64Pin

11

IC802 67Pin

15

IC802 71Pin

TEI

TRO

FMO

REVIEW

TEI

TRO

FMO

TCD-782 TNO-02 PLAYBACK

1

2

3

1

2

3

6

IC802 64Pin

11

IC802 67Pin

7

IC802 63Pin

TEI

TRO

SBAD

1

2

3

– 16 –

16

IC802 86Pin

17

IC802 82Pin

LO

RO

1

2

Page 17

QT-CD180

TROUBLESHOOTING (CD SECTION)

When the CD does not function

When the CD section does not operate when the objective lens of the optical pickup is dirty, this section may not operate. Clean

the objective lens, and check the playback operation. When this section does not operate even after the above step is taken,check

the following items.

Remove the cabinet and follow the troubleshooting instructions.

"Track skipping and/or no TOC (Table Of Contents) may be caused by build up of dust other foreign matter on the laser pickup

lens. Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below."

Turn off the power, and wipe the lens softly using a cleaning paper moistened with commercially available cleaning solution so

as not to damage it.

Be careful not to touch the lens with bare hands.

Dust gradually accumulates on the objective lens during use, and it may degrade performance.

To avoid this problem, use a cleaning disc designed for CD optical pickup lenses.

HOW TO USE

1. Using the brush in the cleaner cap, apply 1 or 2 drops of the cleaning fluid to the brush on the CD cleaner disc which has

the mark next to it.

2. Place the CD cleaner disc onto the CD disc tray with the brush side down, then press the play button.

3. You will hear music for about 20 seconds and the CD player will automatically stop. If it continues to turn, press the stop button.

CAUTION

The CD lens cleaner should be effective for 30 - 50 operations, however if the brushes become worn out earlier then please

replace the cleaner disc.

If the CD cleaner brushes become very wet then wipe off any excess fluid with a soft cloth.

Do not drink the cleaner fluid or allow it to come in contact with the eyes. In the event of this happening then drink and / or

rinse with clean water and seek medical advice.

The CD cleaner disc must not be used on car CD player or on computer CD ROM drives.

All rights reserved. Unauthorized duplicating, broadcasting and renting product is prohibited by law.

Cleaner Liquid

• The CD function will not work.

The CD operating keys don't work.

Yes

Check the power supply, 16.93 MHz clock, and reset terminal.

Yes

Check the pickup-in switch (SW702) position.

Yes

Check the Focus system.

Cleaning Disc

PARTS CODE:

UDSKA0004AFZZ

Figure 17

– 17 –

Page 18

QT-CD180

• Laser failure.

Is +5V applied to the emitter of Q204 ?

Yes

Is +5V applied to the collector of Q204 ?

Yes

Is +5V applied to the pin 75 (VDD) of IC802 ?

Yes

Is +5V applied to the pin 1 (VCC) of IC801 ?

Yes

Is +0V applied to the pin 74 (SEL) of IC802 ?

Yes

Is approx. 1.8V applied to the collector of Q801.

Yes

Check BI801/CNS801. If it is normal, the optical pickup is

faulty.

No

Check the PWB pattern of Q204.

Check the peripheral parts of IC803 and Q204.

No

Check the PWB pattern between collector of Q204 and pin 75 of

No

IC802.

Check the PWB pattern between collector of Q204 and pin 1 of

No

IC801.

Check the laser come on when pattern cut between pin 8 (SEL) of

No

IC801 and pin 74 (SEL) of IC802.

Check the peripheral parts of IC801 and Q801. If it is normal, the

No

optical pickup is faulty.

• Focus failure.

Does the optical pickup move up and down when the disc is

removed ?

Yes

Is the following waveform output at the pin 62 (FEI) of IC802

when the disc is set ?

Yes

pin 62

(FEI)

pin 86

(FOO)

pin 63

(SBAD)

Is the waveform shown above input at the pin 63 (SBAD) of

IC802 ?

Yes

IC801 is faulty.

No

FAILURE".

Check the periphery of IC801 and BI801/CNS801. Is it normal ?

Check as stated in item "FOCUS SERVO SAWTOOTH WAVE

No

Yes

The optical pickup is faulty.

Check the pattern between pin 13 of IC801 and pin 63 of IC802.

No

Check the periphery of IC801 and BI801/CNS801.

– 18 –

Page 19

• Focus servo sawtooth wave failure.

QT-CD180

Is sawtooh wave output to the pin 66 (FOO) of IC802 ?

Yes

1.5~2.5sec

Is +8.1V applied to the pins 21 and 22 (VCC) of IC803 ?

Yes

Is sawtooth wave obtained between pins 17 and 18 of IC803 ?

Yes

1.5~2.5sec

Is sawtooth wave obtained between pins 3 and 4 of BI801/

CNS801 ? (as shown above)

Yes

BI801/CNS801 connection failure or optical pickup failure.

No

No

No

No

IC802 is faulty.

Check the PWB pattern of IC803.

Check the PWB pattern of IC803.

Check the PWB pattern between BI801/CNS801 and IC803.

• Spindle motor clv servo failure.

Is following wave output to the pin 72 (DMO) of IC802 when

the Function is changed to "PLAY" from "STOP" ?

Yes

DMO

Is above wave obtained between pins 5 and 6 of IC803 ?

Yes

Is above wave obtained between pins 5 and 6 of BI803/

CNS803 ?

Yes

BI803/CNS803 connection failure or optical pickup failure.

No

No

No

Check the procedure in "HF ERROR".

If OK. IC802 is faulty.

Check the PWB pattern between pin 72 (DMO) of IC802 and pins

5 and 6 of IC803. If OK. IC803 is faulty.

Check the PWB pattern between BI803/CNS803 and IC803.

– 19 –

Page 20

QT-CD180

• Track search failure

Does the sled motor run in FF/REW state when the CD

TEST MODE is set ?

Yes

Is the following wave output to the pin 67 (TRO) of IC802

during track search in normal playback ?

Yes

TRO

Is the following wave output to the pins 12 (TEO) of IC801

during track search in normal playback ?

Yes

TEO

TEI

TEZI

Is the above wave output to the pins 64 (TEI) and 65 (TEZI)

of IC802 during track search in normal playback ?

Yes

Is the following wave output to the pin 60 (RFZI) and 61

(RFRP) of IC802 during track search in normal playback ?

RFRF

Yes

REZI

No

No

No

No

No

Check as stated in item "SLED MOTOR OPERATION FAILURE".

IC802 failure.

Check the PWB pattern between pin 67 (TRO) of IC802 and pin

25 of IC803.

Check the PWB pattern between pins 26 and 27 of IC803 and

Optical pickup.

If OK. Optical pickup failure.

Check the PWB pattern between pin 12 (TEO) of IC801 and pins 64

(TEI) and 65 (TEZI) of IC802. If OK. IC801 failure.

Check the PWB pattern between pin 22 (RFO) and 18 (RFIS), 17

(RFRP) of IC801 and pins 60 and 61 of IC802. If OK. IC801 failure.

Normal.

• Sled motor operation failure.

Is following sled feed signal output the pin 71 (FMO) of IC802

when FF/REW key is pressed after the CD TEST MODE is

seted ?

Yes

FF

FMO

Is following sled feed signal input the pins 12 and 13 of IC803

when FF/REW key is pressed after the CD TEST MODE is

seted ?

Yes

FF

SL

Is sled feed signal output the pins 10 and 11 of IC803 ?

Yes

Is sled feed voltage applied between both terminals of sled

motor ?

Yes

Check the CD mechanism (periphery of sled motor).

If the sled motor does not run when DC2.0V is applied to

both terminals of sled motor, the sled motor is faulty.

REW

REW

No

No

No

No

IC802 is faulty.

Check the PWB pattern between pin 71 of IC802 and pins 12 and

13 of IC803.

Check the peripheral parts of IC803. If OK, IC803 is faulty.

Check the BI803/CNS803.

• Sled servo failure.

Is following sled signal output the pin 71 (FMO) of IC802

during playback ?

Yes

FMO

Normal.

No

IC802 is faulty.

– 20 –

Page 21

FUNCTION TABLE OF IC

IC802 VHiTC9457F0-1: Servo/Signal Control (TC9457F0) (1/4)

QT-CD180

Pin No.

1* (OT5)S1 SEG1 Output Segment signal output to the LCD panel.

2 (OT6)S2 SEG2 Output Up to 72 segments in a matrix with COM1 to COM4 can be displayed.

3 (OT7)S3 SEG3 Output All of the S1 to S18 pins can be switched for output ports by a program.

4 (OT8)S4 SEG4 Output Also, the S15 to S18 pins each can be switched for I/O ports individually.

5 (OT9)S5 SEG5 Output When set for I/O ports, these pins become Nch open-drain output.

6* (OT10)S6 SEG6 Output Furthermore, the S11 to S14 and the P8-0 to P8-3 pins can be switched for

7* (OT11)S7 SEG7 Output use as CD signal (CLCK to IPF) input/output pins by a program.

8* (OT12)S8 SEG8 Output • CLCK: Subcodes P thru W data readout clock input/output.

9* (OT13)S9 SEG9 Output Selected between input and output by a command.

10* (OT14)S10 SEG10 Output • DATA: Subcodes P thru W data output.

11*

12*

13*

14*

15 (BCK/S15) CDSEL0 Output • IPF : Correction flag output. When AOUT is C2 correction output, it

16 (AOUT/S16) CDSEL1 Output

17 (MBOV/S17) DOOR IN Output

18 (IPF/S18) DOOR OUT Output

19 MVDD MVDD1 Input Power supply pins.

20 MVSS MVSS1 Input Normally, apply a voltage of 4.5 to 5.5V to VDD.

21* (K0)P1-0 TRAY CLOSE Input 4-bit CMOS I/O ports.

22* (K1)P1-1 TRAY OPEN Input These ports can be set for input or output bit for bit by a program.

23 (K2)P1-2 PUSEL0 Input These pins can be pulled up to VDD or down to GND by program.

24 (K3)P1-3 PUSEL1 Input Therefore, they can be used as key input pins. Also, when they are set for

25

26 (ADin1)P3-1 ADIN1 Input These ports can be set for input or output bit for bit by a program.

27 (ADin2)P3-2 ADIN2 Input The P3-0 to P4-0 pins serve dual purposes as analog inputs for the internal

28* (ADin3)P3-3 MUTE Input 6-bit 4-channel A/D converters.

29 (BUZR/ PU IN Input The internal A/D converters can complete conversion in 6 instruction cycles

Port Name

(CLCK/OT15)

S11 • LRCK: Channel clock (44.1kHz) output.

(DATA/OT16)

S12 Polarity can be inverted by a command.

(SFSY/OT17)

S13 • AOUT: Audio data output.

(LRCK/OT18)

S14 It outputs a high when buffer overflows.

P8-0 outputs a high indicating that correction is impossible.

P8-1

P8-2

P8-3

(DCREF)P3-0

ADin4)P4-0 using a successive approximation method. The required pins can be set for

Terminal Name

SEG11 Output • SFSY: Playback system frame sync signal output.

SEG12 Output It outputs a low for L channel and a high for R channel.

SEG13 Output • BCK : Bit clock (1.4122MHz) output.

SEG14 Output • MBOV: Buffer memory-over signal output.

DISPLAY Input 5-bit CMOS I/O ports.

Input/Output

Function

In a backup state (when the CKSTP instruction executed), the device's

current consumption is reduced to 1µA or less, allowing for the supply

voltage to be lowered to 2.0V.

The device is reset and the program starts from address 0 when a voltage

of 2.7V or more is applied to this pin when it is at 0V (power-on reset).

I/O port, a change of state in this input can be used to clear the clock stop

or wait mode.

A/D analog input bit for bit by a program. P3-0 can be set for reference

voltage input, and the internal power supply (MVDD) can be used for this

reference voltage.

The P4-0 pin serves dual purposes as a buzzer output pin.

The buzzer output can be selected from 8 frequencies, 0.625 to 3kHz.

Each selected frequency can be output in one of four modes: continuous,

single, 10Hz intermittent, and 10Hz intermittent at 1Hz interval.

Whether or not to use and how to control the A/D converter and buzzer all

can be set by a program.

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

– 21 –

Page 22

QT-CD180

IC802 VHiTC9457F0-1: Servo/Signal Control (TC9457F0) (2/4)

Port Name Terminal NamePin No. Input/Output

30 (S12)P4-1 PUSEL2 Input 3-bit CMOS I/O ports.

31* (SO/S11/ NC Input/Output These ports can be set for input or output bit for bit by a program.

SDA)P4-2 These pins serve dual purposes as input or output pins for the serial

32* (SCK/SCL) NC Input/Output interface circuit (SIO).

P4-3 The SIO is a 2-wire/3-wire compatible serial interface. 4 or 8 bits of serial

data, beginning with the MSB or LSB, are serially output from the SO/SDA,

pin at each clock edge on the SCK/SCL pin, and the data on S11 or S12

pin is serially input to the device.

The serial clock (SCK/SCL) allows selection between the internal (450/225/

150/75 kHz) and external sources and a selection of the active edge, rise or

fall. Moreover, since the clock and data can be output via Nch open-drain

outputs, variouts, device controls and communication between controllers

can be greatly facilitated.

When an SIO interrupt is enabled, an interrupt is generated at completion

of SIO execution and the program jumps to address 4.

All inputs to SIO contain a Schmitt trigger circuit.

33 TEST0 TEST0 Input Test mode control input pins.

34 TEST1 TEST1 Input The test mode is selected when these pins are set high and normal

35 TEST2 TEST2 Input operation is selected when they are low.

36 TEST3 TEST3 Input

37 TEST4 TEST4 Input

38 TEST5 TEST5 Input

39* (OT19)/HSO /HSO Output CD control output pins.

40* (OT20)SPCK SPCK Output • /HSO: Playback speed mode output.

41* (OT21)SPDA SPDA Output High = normal speed; Low = double speed.

42* (OT22)COFS COFS Output • SPCK: Processor status signal readout clock output (176.4kHz)

• SPDA: Processor status signal output.

• COFS: Correction system frame clock output (7.35kHz)

These pins can be switched for output ports by a program.

43* DOUT DOUT Input/Output Digital output pin.

44* SBSY SBSY Input/Output Subcode block sync output pin. It outputs a high at the S1 position when

subcode sync is detected.

45* SBOK SBOK Input/Output Subcode Q data CRCC determination result output pin. It outputs a high

when CRCC check is found OK.

46 VDD VDD1 Input/Output CD unit's digital block power supply pins.

47 VSS VSS1 Input/Output Normally, apply 5V to VDD.

When not using a CD (CD off), this power supply can be turned off, with

only the controller power supply kept active, so that the controller alone is

operating. In this case, the CD off bit must be set to 1. When this bit is set

to 1, pins 11 through 18 and pins 39 through 42 all are changed for output

ports if they have been set for CD control signal input/output pins.

48 P2VREF P2VREF Input/Output PLL block-2 VREF pin.

49 PDO PDO Input/Output This pin outputs a phase error between EFM and PLCK signals.

50 TMAX TMAX Input/Output TMAX detection result output pin.

Selected by command bit TMPS.

Longer than preset period: Outputs P2VREF.

Shorter than preset period: Low level (Vss).

Within preset period: High impedance.

51 LPFN LPFN Input/Output Inverted input of low-pass filter amp.

52 LPFO LPFO Input/Output Output of low-pass filter amp.

53 PVREF PVREF Input/Output PLL block VREF pin.

54 VCOF VCOF Input/Output VCO filter pin.

55 AVSS AVSS Input/Output Analog block ground pin.

56 SLCO SLCO Input/Output DAC output pin for data slice level generation.

57 RFI RFI Input/Output RF signal input pin.

58 AVDD AVDD Input/Output Analog block power supply pin.

59 RFCT RFCT Input/Output RFRP signal center level input pin.

60 RFZI RFZI Input/Output RFRP zero-cross input pin.

61 RFRP RFRP Input/Output RF ripple signal input pin.

62 FEI FEI Input/Output Focus error signal input pin.

Function

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

– 22 –

Page 23

IC802 VHiTC9457F0-1: Servo/Signal Control (TC9457F0) (3/4)

QT-CD180

Port Name Terminal NamePin No. Input/Output

63 SBAD SBAD Input/Output Subbeam add signal input pin.

64 TEI TEI Input/Output Tracking error input pin.

This input is read when tracking servo is on.

65 TEZI TEZI Input/Output Tracking error zero-cross input pin.

66 FOO FOO Input/Output Focus equalizer output pin.

67 TRO TRO Input/Output Tracking equalizer output pin.

68 VREF VREF Input/Output Analog reference power supply pin.

69 RFGC RFGC Input/Output RF amplitude adjusting control signal output pin. It outputs 3-level PWM

signals. (PWM carrier = 88.2kHz)

70 TEBC TEBC Input/Output Tracking balance control signal output pin. It outputs 3-level PWM signals.

(PWM carrier = 88.2kHz)

71 FMO FMO Input/Output Focus equalizer output pin. It outputs 3-level PWM signals.

(PWM carrier = 88.2kHz)

72 DMO DMO Input/Output Disc equalizer output pin. It outputs 3-level PWM signals.

(PWM carrier = DSP block 88.2kHz, synchronized to PXO)

73 2VREF 2VREF Input/Output Analog reference power supply pin. (2 x VREF)

74 SEL SEL Input/Output APC circuit on/off signal output pin.

When laser is on, this pin goes to a high-impedance state when UHS = low

and outputs a high when UHS = high

75 VDD VDD2 Input/Output CD unit's digital block power supply pins.

76 VDD VSS2 Input/Output Normally, apply 5V to VDD.

When not using a CD (CD off), this power supply can be turned off, with

only the controller power supply kept active, so that the controller alone is

operating. In this case, the CD off bit must be set to 1. When this bit is set

to 1, pins 11 through 18 and pins 39 through 42 all are changed for output

ports if they have been set for CD control signal input/output pins.

77 XVSS XVSS Input/Output CD's crystal oscillator power supply pins.

Normally, connect these pins to the power supply lines that are used in

common for the VDD and VSS pins.

78 XI XI Input/Output CD's crystal oscillator input/output pins.

79 XO XO Input/Output Normally, connect 16.934MHz here. This clock is used as the system clock

for the CD. After a system reset, it also is used as the system clock on the

controller side.

80 XVDD XVDD Input/Output CD's crystal oscillator input/output pins.

Normally, connect these pins to the power supply lines that are used in

common for the VDD and VSS pins.

81 DVSR DVSR Input/Output R-channel D/A converter unit ground pin.

82 RO RO Input/Output R-channel data forward output pin.

83 DVRR DVRR Input/Output R-channel reference voltage pin.

84 DVDD DVDD Input/Output D/A converter unit power supply pin.

85 DVRL DVRL Input/Output L-channel reference voltage pin.

86 LO LO Input/Output L-channel data forward output pin.

87 DVSL DVSL Input/Output L-channel D/A converter unit ground pin.

88 NC NC Input/Output NC pins. Normally, connect these pins to ground or leave them open.

89* NC/VPP NC Input/Output

90 /RST RESET Input Device's system reset signal input pin.

The device remains reset while RESET is held low and when RESET is

released back high, the CD unit becomes operational and the program

starts from address 0. Normally, a system reset is asserted when a voltage

of 2.7V or more is applied to VDD when it is at 0V (power-on reset).

Therefore, this pin must be pulled high when used for this purpose.

Function

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

– 23 –

Page 24

QT-CD180

IC802 VHiTC9457F0-1: Servo/Signal Control (TC9457F0) (4/4)

Pin No.

91 /HOLD RYNCREC Input This pin is used to input a signal that requests or clears the hold mode.

92 INTR REMO-IN Input External interrupt input pin.

93* MXO MXO Input Crystal oscillator pins for the controller.

94* MXI MXI Input The oscillator clock is used as the timebase for the clock facility or as the

95 MVSS MVSS Input Power supply pins.

96 MVDD MVDD Input Normally, apply a voltage of 4.5 to 5.5V to VDD.

97 OT1 COM1 Output Common signal outputs to the LCD panel.

98 OT2 COM2 Output Up to 72 segments in a matrix with S1 to S18 can be displayed.

99 OT3 COM3 Output Three voltage levels MVDD, VEE (1/2 MVDD), and GND are output for

100 OT4 COM4 Output 83Hz period at 2ms intervals.

Port Name

Terminal Name

Input/Output

Function

Normally, use this pin for CD mode select signal input or battery detection

signal input.

There are two hold modes: clock stop mode (crystal oscillator turned off)

and a wait mode (CPU stopped). These modes are entered by executing

the CKSTP and WAIT instructions, respectively.

The clock stop mode can be requested by a programmed input: low level

detection on HOLD pin or forced execution, and can be cleared by

detecting a high on the HOLD pin or a change of state in its input signal.

When the CKSTP instruction is executed, the clock generator and the CPU

stop operating and the device is placed in a memory backup state. During

this state, the device's current consumption is reduced to 1µA or less.

At the same time, the display output and CMOS output ports are

automatically set low, and the Nch open-drain outputs are turned off.

The wait mode is executed regardles of the input state on the HOLD pin,