Page 1

QT-222W

SERVICE MANUAL

No. SX376QT222W//

RADIO CASSETTE RECORDER

MODEL

MODEL

QT-222W(S)

RADIO CASSETTE RECORDER

QT-222W(BK)

• In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified should

be used.

CONTENTS

Page

SPECIFICATIONS ............................................................................................................................................................. 2

VOLTAGE SELECTION..................................................................................................................................................... 2

AC POWER SUPPLY CORD AND AC PLUG ADAPTOR ................................................................................................. 2

NAMES OF PARTS ........................................................................................................................................................... 3

HOW TO SET THE POINT "0" ON TUNER DIAL MEMORY............................................................................................. 3

DISASSEMBLY.................................................................................................................................................................. 4

REMOVING AND REINSTALLING THE MAIN PARTS..................................................................................................... 5

ADJUSTMENT ................................................................................................................................................................... 6

NOTES ON SCHEMATIC DIAGRAM ................................................................................................................................ 9

TYPES OF TRANSISTOR ................................................................................................................................................. 9

VOLTAGE .......................................................................................................................................................................... 9

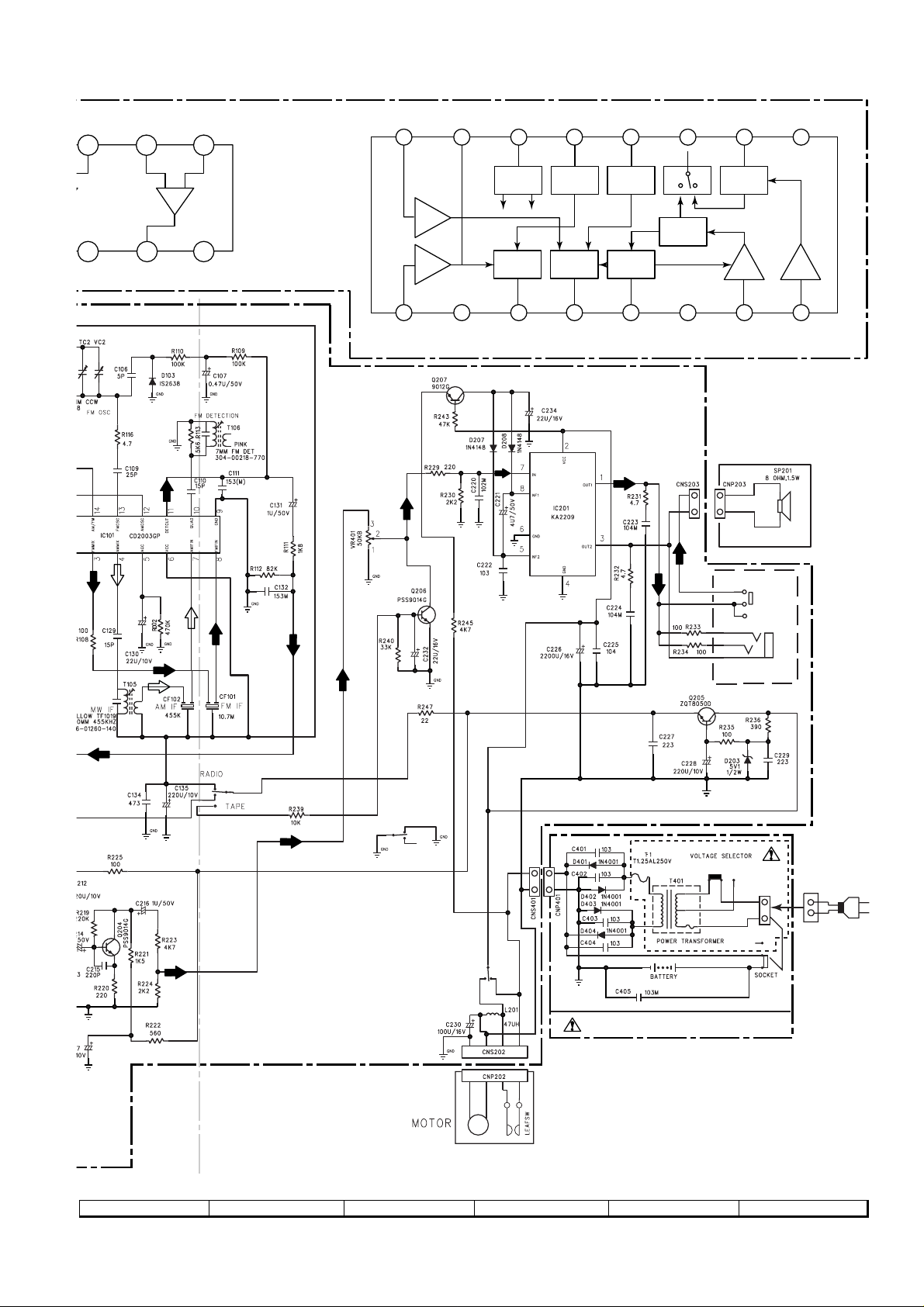

SCHEMATIC DIAGRAM .................................................................................................................................................. 10

WIRING SIDE OF P.W.BOARD....................................................................................................................................... 12

PARTS GUIDE/EXPLODED VIEW

This document has been published to be used

SHARP CORPORATION

– 1 –

for after sales service only.

The contents are subject to change without notice.

Page 2

QT-222W

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

General

Power source

Power consumption

Output power

Speaker

Output terminal

Dimensions

Weight

Radio

Frequency range

SPECIFICATIONS

AC 110-127/220-240 V, 50/60 Hz

DC 6 V [“D” size (UM/SUM-1, R20 or HP-2) battery x 4]

7 W

MPO: 3 W (AC operation, 10 % T.H.D.)

RMS: 1.5 W (DC operation, 10 % T.H.D.)

9.2 cm (3-5/8”) full range speaker x 1

Earphone: 16-50 ohms (recommended: 32 ohms)

Width: 305 mm (12”)

Height: 155 mm (6-1/8”)

Depth: 120 mm (4-3/4”)

1.48 kg (3.3 lbs.) without batteries

FM: 88 - 108 MHz

SW1: 2.3 - 7.3 MHz

SW2: 7.3 - 22 MHz

MW: 526.5 - 1,606.5 kHz

Tape recorder

Frequency response

Signal/noise ratio

Wow and flutter

Motor

Bias system

Erase system

Specifications for this model are subject to change without prior notice.

Before operating the unit on mains, check the preset voltage. If the voltage is different from your local voltage, adjust the voltage

as follows. Slide the selector with a screwdriver to the appropriate voltage number. (AC 110 - 127 V or AC 220 - 240 V)

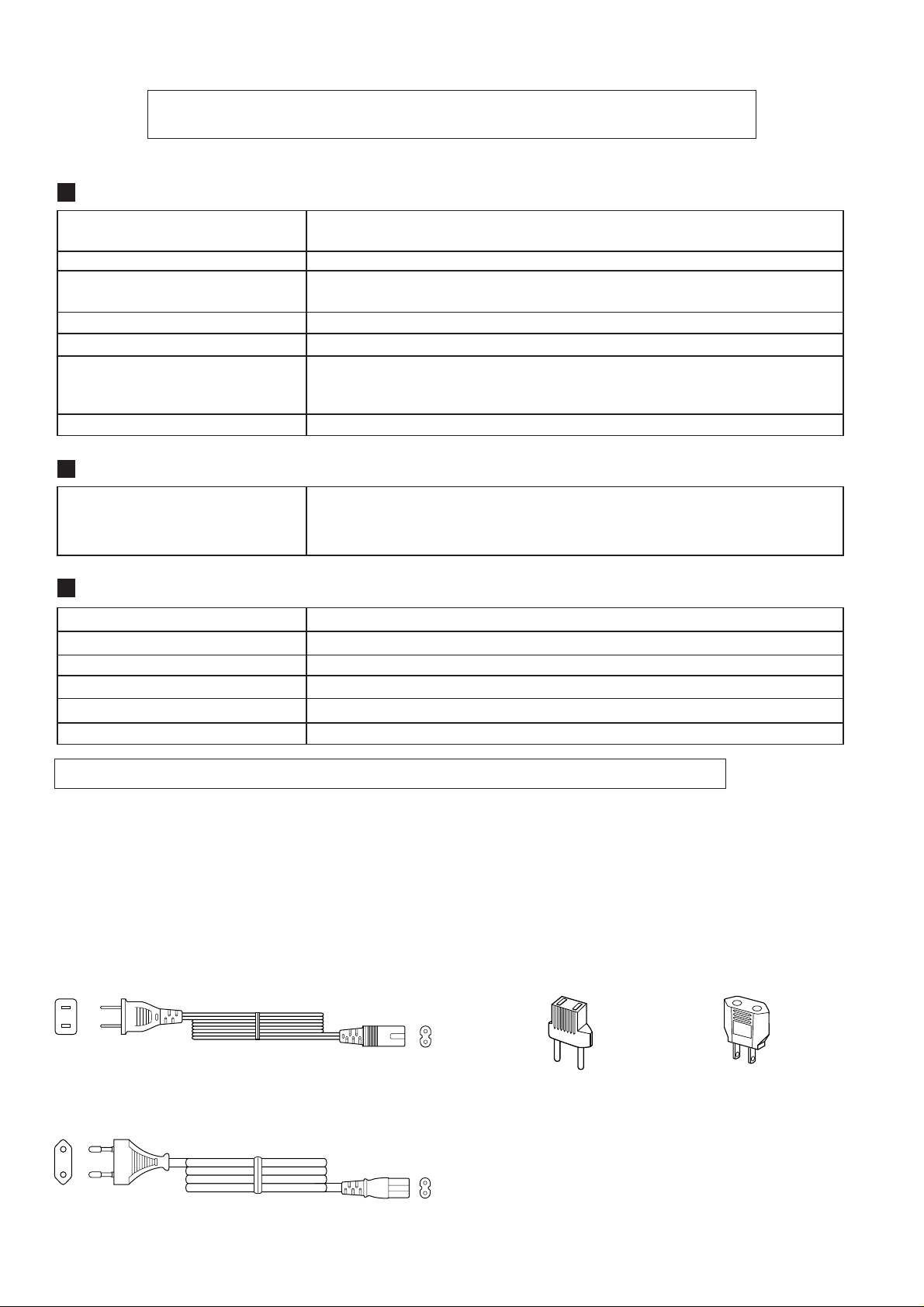

AC POWER SUPPLY CORD AND AC PLUG ADAPTOR

92L24801600292

60 - 12,000 Hz (Normal tape)

40 dB

0.3 % (WRMS)

DC 6 V electric governor

DC bias

Magnet erase

VOLTAGE SELECTION

92L26802125210

92L26802125120

92L24801800222

– 2 –

Page 3

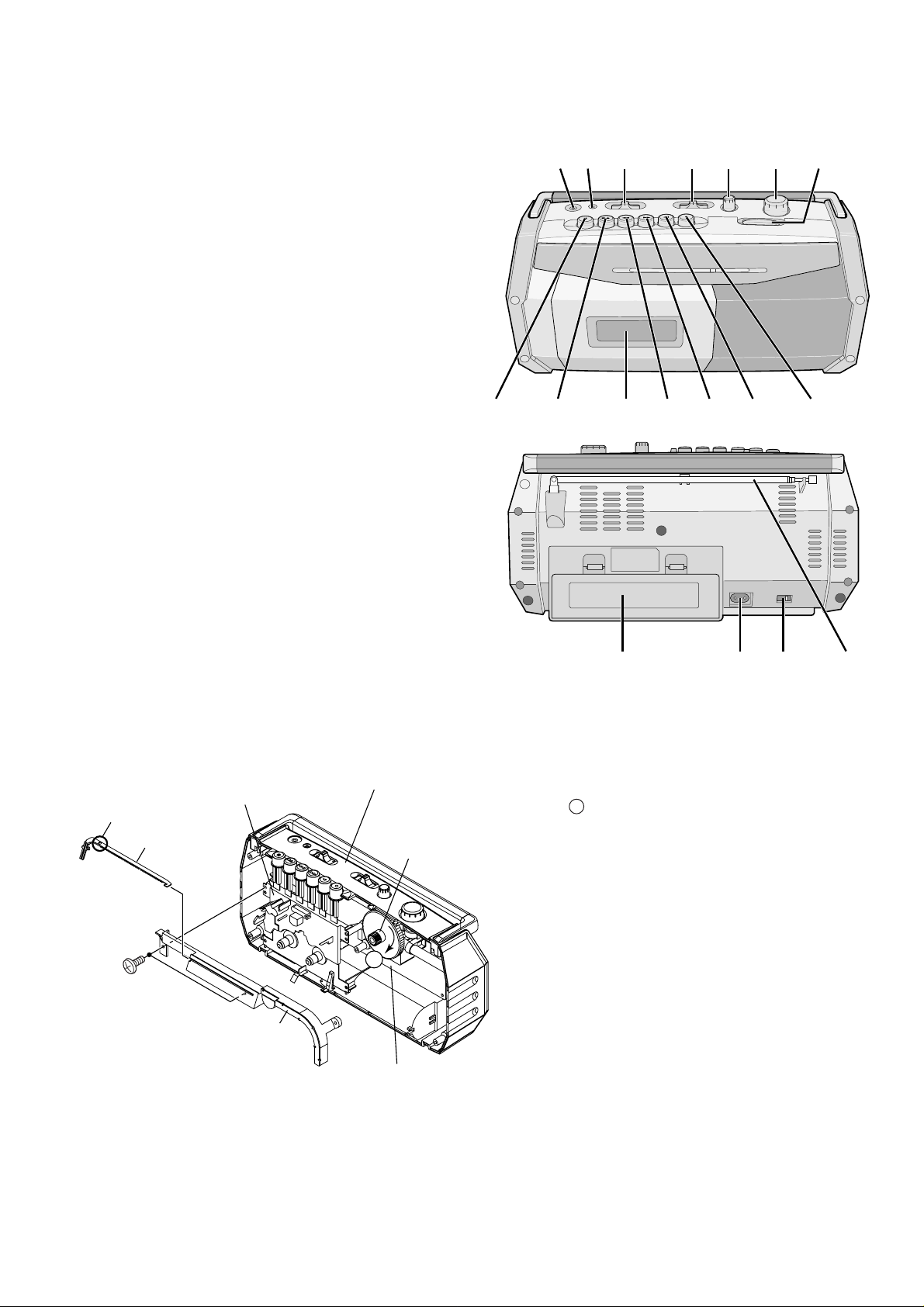

NAMES OF P ARTS

1. Earphone Socket

2. Built-in Microphone

3. Function Switch

4. Band Selector

5. Fine Tuning Control

6. Volume Control

7. Tuning Control

8. Pause Button

9. Stop/Eject Button

10. Cassette Compartment

11. Fast Forward Button

12. Rewind Button

13. Play Button

14. Record Button

15. Battery Compartment

16. AC Input Socket

17. AC Voltage Selector

18. FM/SW Telescopic Rod Aerial

QT-222W

1

23 45 6 7

8 9 10 11 12 13 14

"0" Point

Dial Pointer(219)

Screw(612)

ø3x12mm

15 16 17 18

HOW TO SET THE POINT "0" ON TUNER DIAL MEMORY

1) Firstly, remove the front cabinet.

2) Remove 2 screw from tuning bracket.

3) rotate tuning knob until end of right side (same as arrow

direction A ).

4) Attach the dial pointer slot inside the tuning bracket properly

as shown by arrow.

5) Ensure the dial pointer's step must touch the pointer cover

this point to adjust and set the dial pointer for tuning

adjustment purpose.

6) Fitting the tuning bracket (after assembled with dial pointer)

to the tuning knob.

Tape Mechanism

Tuning Bracket

(214)

Front Cabinet

Tuning Knob

(230)

A

Main PWB

Figure 3

– 3 –

Page 4

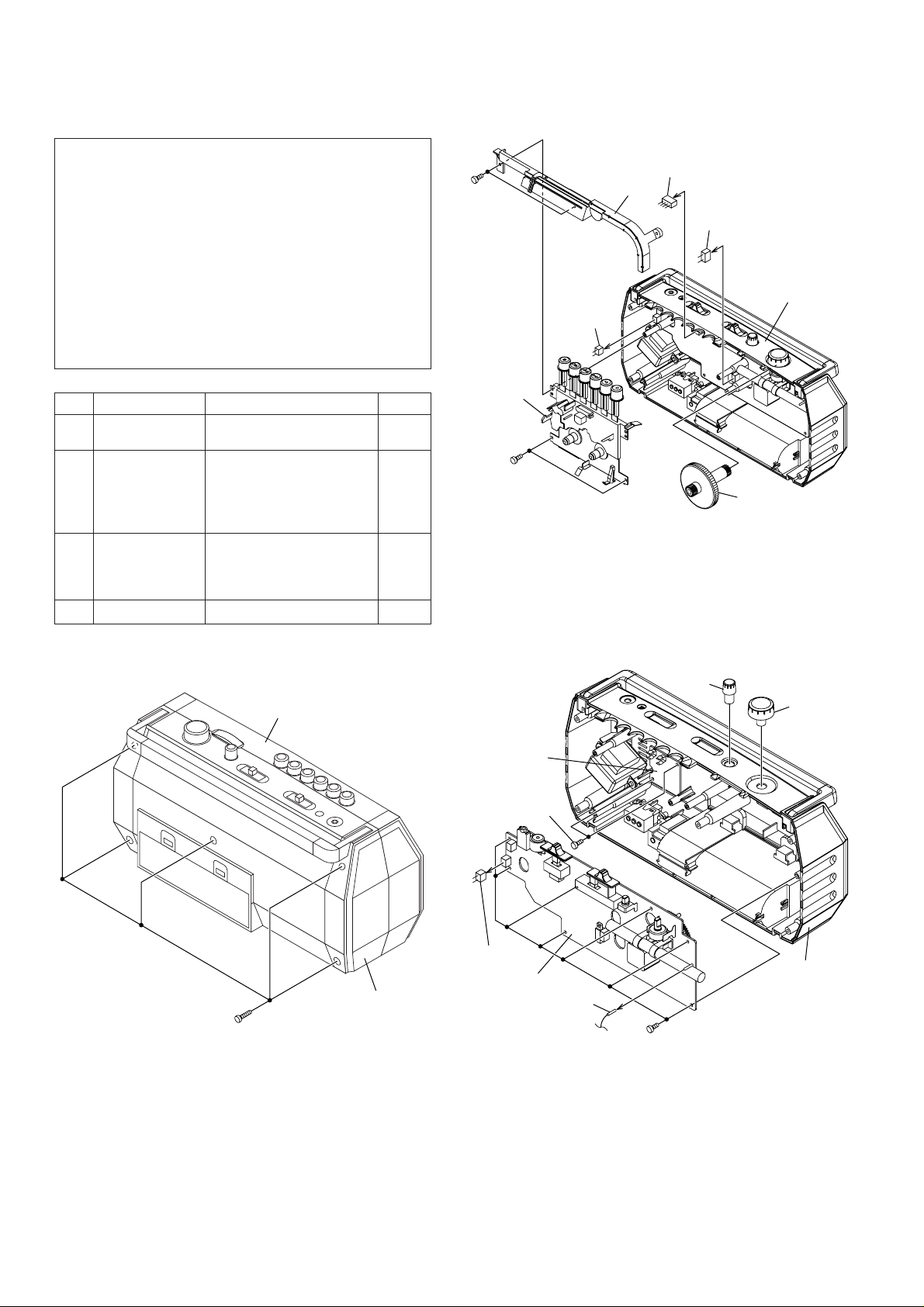

QT-222W

(D1)x2

ø3x10mm

(C4)x1

(C1)x1

(C1)x1

(C3)x1

(C2)x7

ø3x10mm

Power PWB

Main PWB

Front Cabinet

(B2)x1

(B5)x1

(A2)x1

(B5)x1

(B3)x1

(B1)x2

ø3x8mm

(B4)x2

ø3x8mm

Tape

Mechanism

Front Cabinet

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling the

unit and reassembling it, to keep it safe and ensure excellent

performance:

1. Take cassette tape out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need to

be removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were

before disassembling.

4. Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

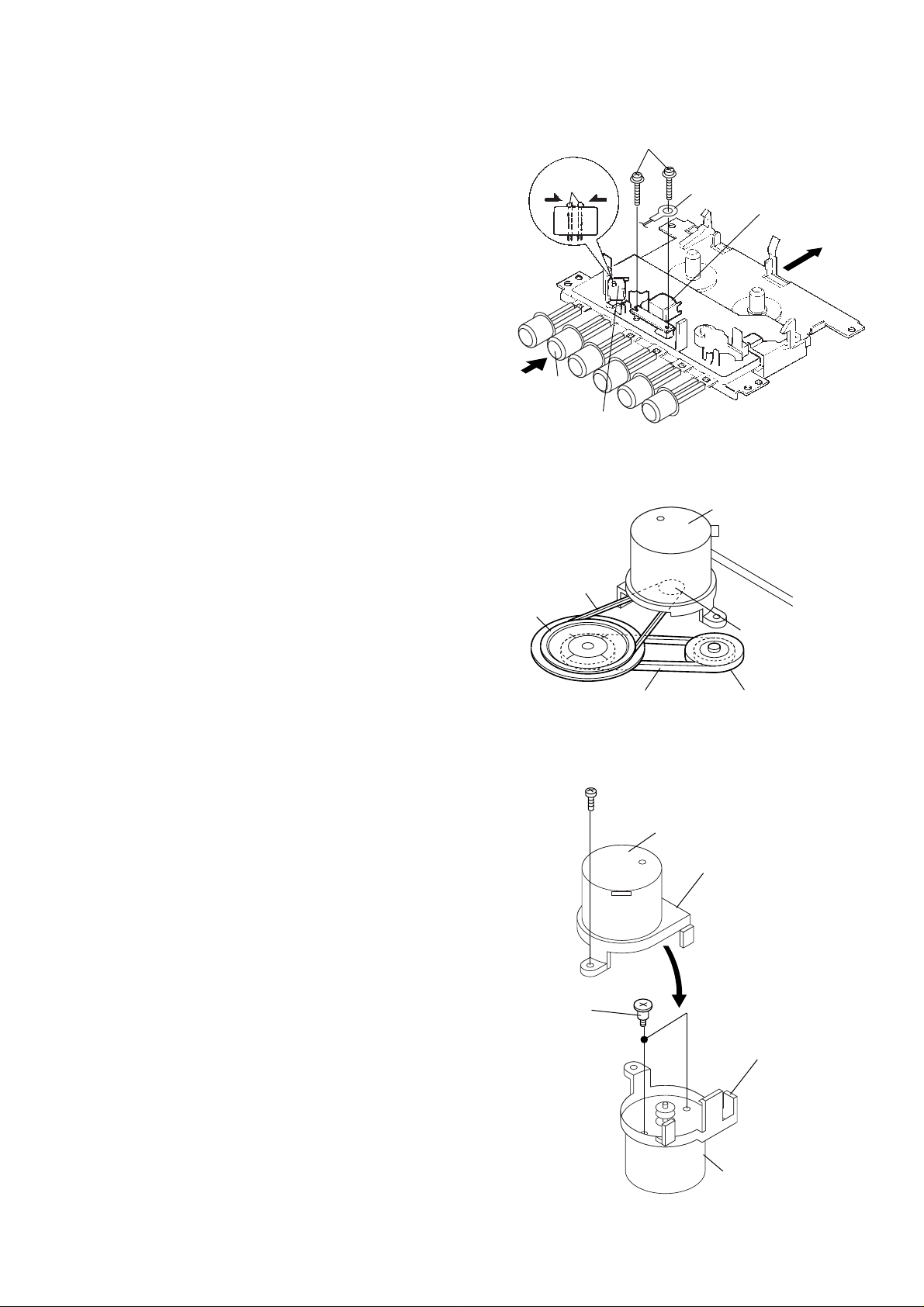

STEP REMOVAL PROCEDURE FIGURE

1 Rear Cabinet 1. Screw ................... (A1) x5 4-1

2. Socket .................. (A2) x1 4-2

2 Tape Mechanism 1. Screw ................... (B1) x2 4-2

2. Tuning Bracket..... (B2) x1

3. Tuning Knob......... (B3) x1

4. Screw ................... (B4) x2

5. Socket .................. (B5) x2

3 Main PWB 1. Knob .....................(C1) x2 4-3

2. Screw ................... (C2) x7

3. Tip ........................ (C3) x1

4. Socket .................. (C4) x1

4 Power PWB 1. Screw ................... (D1) x2 4-3

Figure 4-2

Figure 4-1

Front Cabinet

(A1)x5

ø3x25mm

Rear Cabinet

Figure 4-3

– 4 –

Page 5

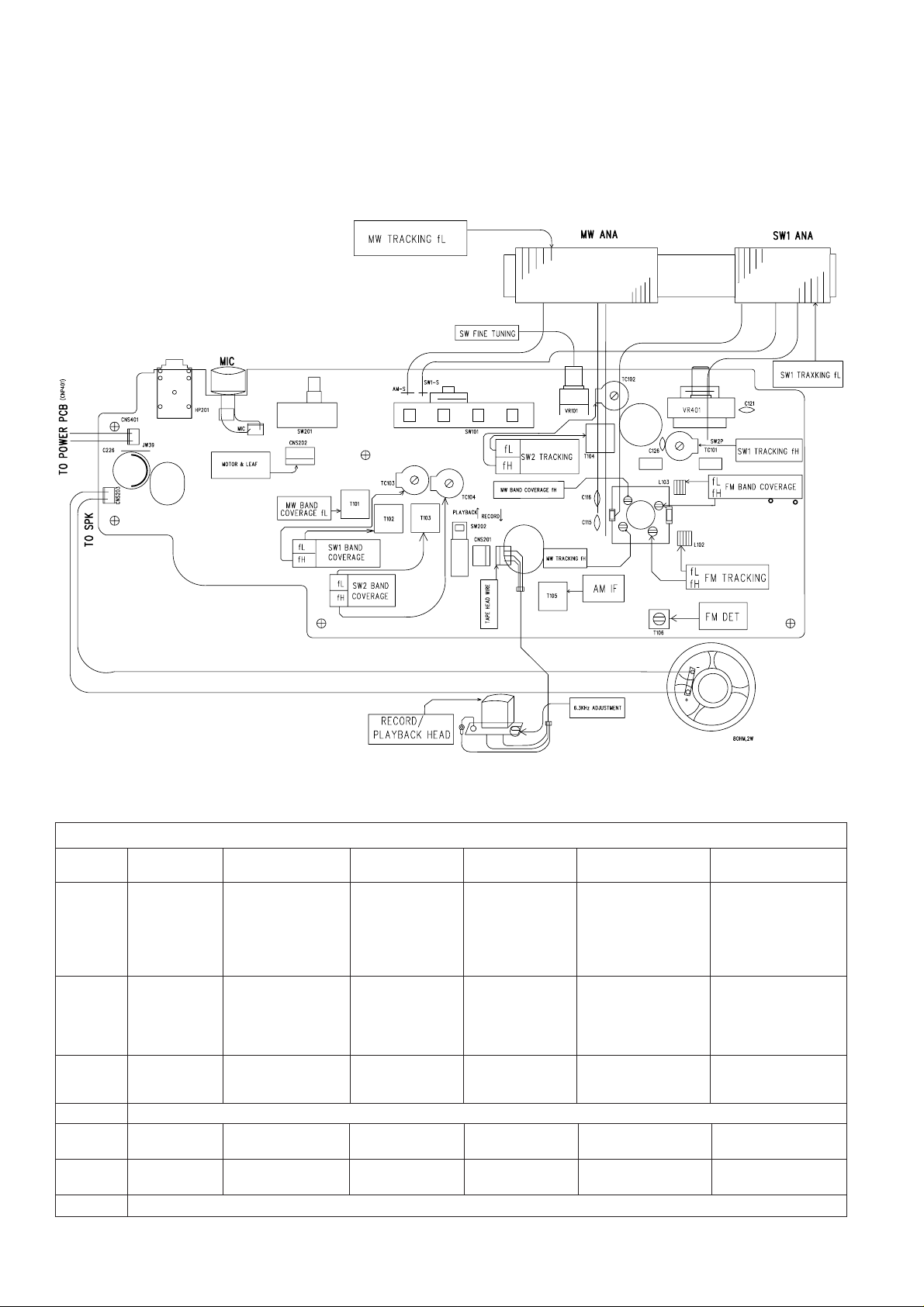

REMOVING AND REINSTALLING THE MAIN PARTS

TAPE MECHANISM SECTION

Perform steps 1 to 2 of the disassembly method to remove the

tape mechanism. (See page 4.)

How to remove the record / playback and erase

heads (See Fig. 5-1.)

1. Remove the screws (A1) x 2 pcs., to remove the record/

playback head.

2. Remove the hooks (A2) x 2 pcs., toward the center position

as shown in Fig. 5-1. and then extract the erase head

upward.

Note:

After replacing the heads and performing the azimuth

adjustment, be sure to apply screwlock.

How to remove the belts (See Fig. 5-2.)

1. Remove the main belt (B1) x 1 pc., from the motor pulley.

2. Remove the FF/REW belt (B2) x 1 pc., from the REW/FF

roller.

3. Put on the belts in the reverse order of removal.

Note:

When putting on the belt, ascertain that the belt is not twisted,

and clean it.

Push

Flywheel

Hook

(A2)x2

PLAY

Button

Erase Head

Main Belt

(B1)x1

QT-222W

(A1)x2

ø2x7mm

Lug Wire

Record/Playback

Head

Figure 5-1

Motor

Motor Pulley

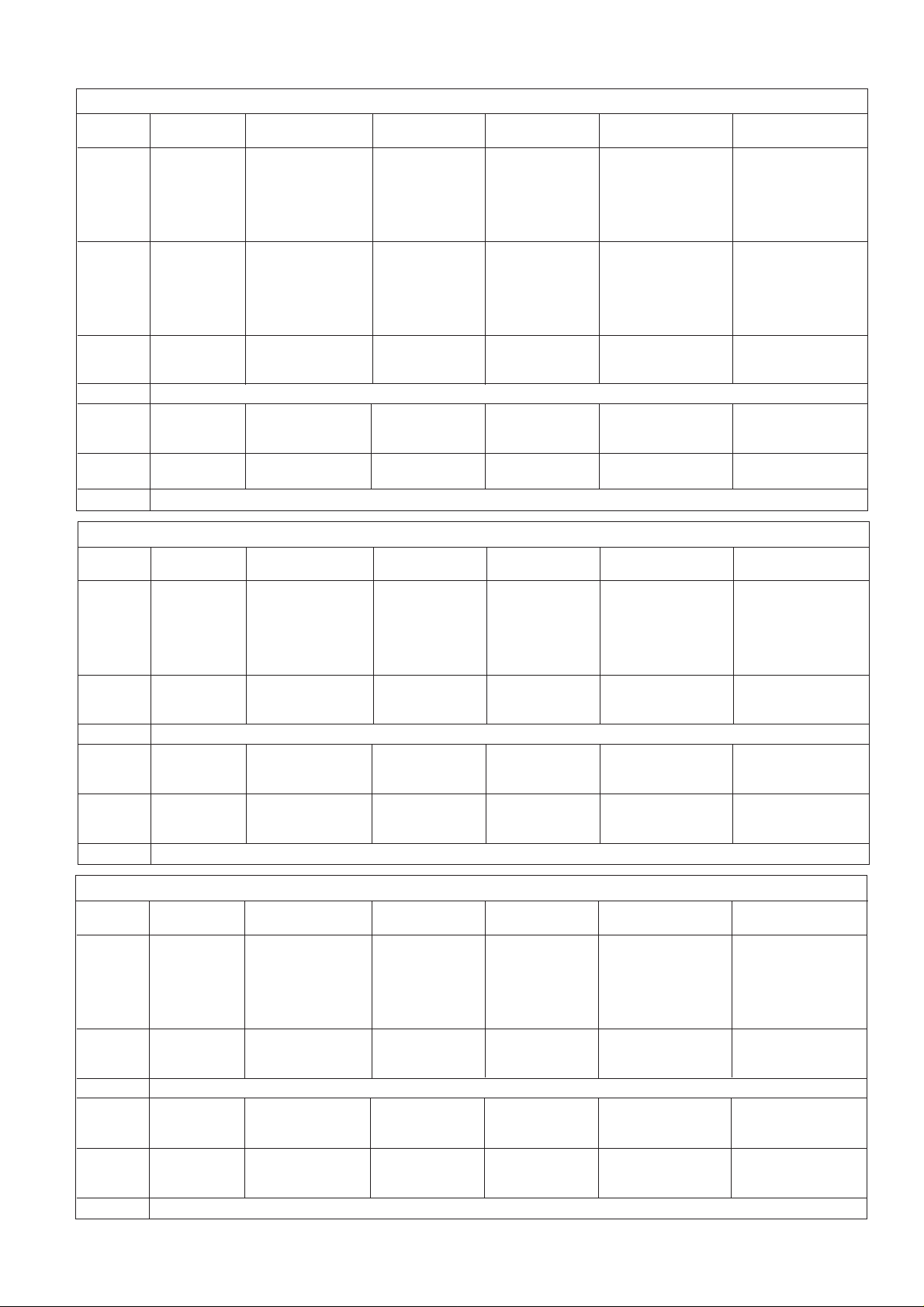

How to remove the motor

(See Fig. 5-3.)

1. Remove the main belt. (See Fig. 5-2.)

2. Remove the screws (C1) x 1 pc., to remove the motor

bracket.

3. Remove the screws (C2) x 2 pcs., to remove the motor.

Note:

When mounting the motor, pay attention to the motor bracket

angle.

FF/REW Belt

(B2)x1

(C1)x1

ø2x4mm

(C2)x2

ø2.6x1.6mm

Special Screw

REW/FF

Roller

Figure 5-2

Motor

Motor Bracket

Motor Bracket

– 5 –

Motor

Figure 5-3

Page 6

QT-222W

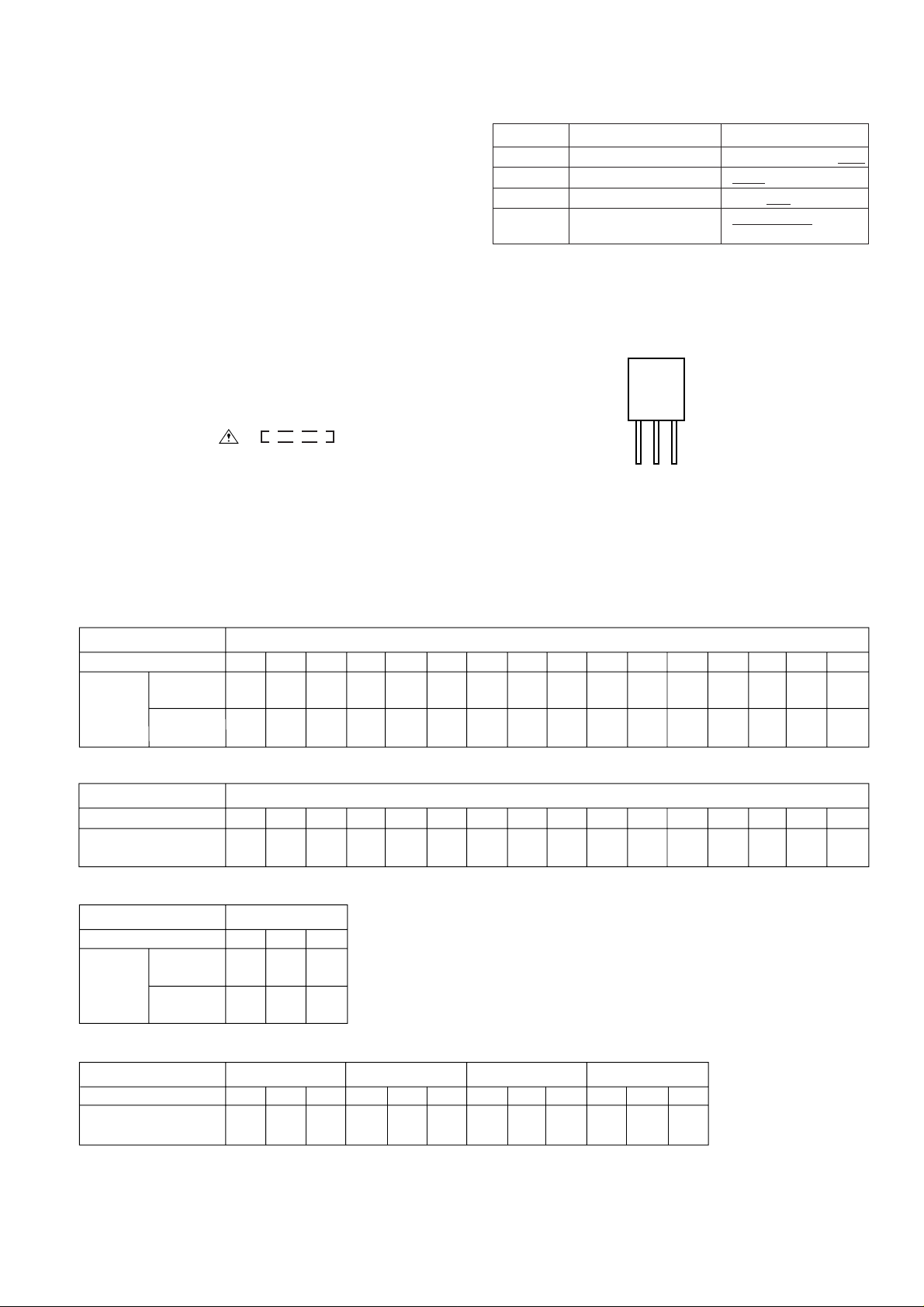

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

ADJUSTMENT

L109

TC2

TC4

TC3

TC1

SPEAKER

Figure 6

FM Section

Step Alignment

Frequency

1 FM IF: (1) FM IF sweep Inject the IF Signal are taken Adjust T106 (1) Band SW in FM.

10.7 MHz generator sweep signal out from point TP3 and repeat to get (2) VOL. & TONE

(T108) (2) Alignment through 300 pF best "S" curve with control in MIN.

FM oscilloscope capacitor to point center at 10.7 MHz position

DETECTION: (3) Power supply TP2 (3) Tune P.V.C. to

(T106) high end

2 FM BAND (1) FM RF sweep Inject the RF Same as step 1 Adjust P.V.C. (TC2) Same as step 1

COVERAGE fH: generator signal directly to get MAX. output

108.2 MHz

3 FM BAND Same as step 2 Same as step 2 Same as step 1 Adjust L103 to get Tune P.V.C. to low

COVERAGE fL: MAX. output end

87.4 MHz

4 Repeat step 2, 3 until no further improvement can be made.

5 FM TRACKING Same as step 2 Same as step 2 Same as step 1 Adjust P.V.C. (TC1) to Tune P.V.C. to

fH: 106 MHz get MAX. output 106 MHz

6 FM TRACKING Same as step 2 Same as step 2 Same as step 1 Adjust L102 to get MAX. Tune P.V.C. to

fL: 90 MHz output 90 MHz

7 Repeat step 5, 6 and then step 2, 3, 5, 6 until no further improvement can be made.

Test Equipment Signal-in Signal-out Adjust Remark

(2) Alignment point TP1

oscilloscope

(3) Power supply

– 6 –

Page 7

QT-222W

MW Section

Step Alignment

Frequency

1 MW IF: 455 kHz (1) AM IF sweep Let the MW ANT Take out the signal Adjust T105 get MAX. (1) Band SW in MW

2 MW (1) MW sweep Same as step 1 Same as step 1 Adjust P.V.C. (TC3) Same as step 1

TRACKING fH: generator with get MAX. output at

1,650 kHz

3 MW BAND Same as step 2 Same as step 1 Same as step 1 Adjust T101 to get Tune P.V.C. to low

COVERAGE fL: MAX. output at 515 kHz end

515 kHz

4 Repeat step 2, 3 until no further improvement can be made.

5 MW BAND Same as step 2 Same as step 1 Same as step 1 Adjust P.V.C. (TC4) Tune P.V.C. to

COVERAGE fH: get MAX. output at 1.400 kHz

1,400 kHz 1,400 kHz

6 MW TRACKING Same as step 2 Same as step 1 Same as step 1 Adjust L109 get MAX. Tune P.V.C. to

fL: 600 kHz output at 600 kHz 600 kHz

7 Repeat step 5, 6 and then step 2, 3, 5,6 until no further improvement can be made.

Test Equipment Signal-in

generator with coil close to the from point TP4 output at 455 kHz position

Signal-out Adjust Remark

loop antenna generator ANT. (2) VOL. control in MIN.

(2) Alignment position

oscilloscope (3) Tune P.V.C. to

(3) Power supply high end

antenna 1,650 kHz

(2) Alignment

oscilloscope

(3) Power supply

SW1 Section

Step

1 SW1 BAND (1) SW1 sweep Let the MW ANT Take out the signal Adjust CT103 get MAX. (1) Band SW in SW1

2 SW1 BAND Same as step 1 Same as step 1 Same as step 1 Adjust T102 get MAX. Tune P.V.C. to low

3 Repeat step 1, 2 until no further improvement can be made.

4 SW1 Same as step 1 Same as step 1 Same as step 1 Adjust CT101 get MAX. Tune P.V.C. to 6 MHz

5 SW1 Same as step 1 Same as step 1 Same as step 1 Adjust L109 get MAX. Tune P.V.C. to

6 Repeat step 4, 5 and then step 1, 2, 4, 5 until no further improvement can be made.

Alignment

Test Equipment

Signal-in Signal-out Adjust Remark

Frequency

COVERAGE fH: generator with coil close to the from point TP4 output at 7.4 MHz position

7.4 MHz

antenna generator ANT. (2) VOL. control in MIN.

(2) Alignment point TP1 position

oscilloscope (3) Tune P.V.C. to

(3) Power supply high end

COVERAGE fL: output at 2.25 MHz end

2.25MHz

TRACKING fH: output at 6 MHz

6 MHz

TRACKING fL: output at 2.6 MHz 2.6 MHz

2.6 MHz

SW2 Section

Step Alignment

Frequency

1 SW2 BAND (1) SW2 sweep Inject the RF Take out the signal Adjust CT104 get MAX. (1) Band SW in SW2

COVERAGE fH: generator signal directly to from point TP4 output at 22.5 MHz position

22.5 MHz (2) Alignment point TP1 (2) VOL. control in MIN.

2 SW2 BAND Same as step 1 Same as step 1 Same as step 1 Adjust T103 get MAX. Tune P.V.C. to low

COVERAGE fL: output at 7.2 MHz end

7.2 MHz

3 Repeat step 1, 2 until no further improvement can be made.

4 SW2 Same as step 1 Same as step 1 Same as step 1 Adjust CT102 get MAX. Tune P.V.C. to

TRACKING fH: output at 19 MHz 19 MHz

19 MHz

5 SW2 Same as step 1 Same as step 1 Same as step 1 Adjust T104 get MAX. Tune P.V.C. to

TRACKING fL: output at 8.5 MHz 8.5 MHz

8.5 MHz

6 Repeat step 4, 5 and then step 1, 2, 4, 5 until no further improvement can be made.

Test Equipment Signal-in Signal-out Adjust Remark

oscilloscope position

(3) Power supply (3) Tune P.V.C. to

high end

– 7 –

Page 8

QT-222W

MECHANISM SECTION

TAPE Section

Step

1 Head Playback test tape Connect VTVM and oscilloscope to Head fixing screw Adjust to get MAX.

2 Bias Frequency Record position Connect frequency counter to TP5 and Adjust 80 kHz ± 1 kHz

3 Beat cancel Record position Same as step 3 SW202 from playback 75 kHz ± 0.5 kHz

Item Condition Connection Adjust

adjustment MTT-113 6.3 kHz speaker output (see Fig 8-2.) audio output

adjustment ground (Bias Oscillation)

to record

Output

1234

1234

CN504

M201

TAPE

MOTOR

T101

TC103

T102

MAIN PWB

TC104

CNP201

T103

1

2

3

4

SW202

RECORD/PLAYBACK

TAPE MAIN

CNS202

Figure 8-1 ADJUSTMENT POINTS

T105

CNS201

1

2

3

RECORD/

PLAYBACK HEAD

ERASE HEAD

TAPE

Erase Head

Head fixing

screw

Figure 8-2

Record/

Playback

Head

Tape Mechanism

– 8 –

Page 9

NOTES ON SCHEMATIC DIAGRAM

QT-222W

• Resistor:

To differentiate the units of resistors, such symbol as K and

M are used: the symbol K means 1000 ohm and the symbol

M means 1000 kohm and the resistor without any symbol is

ohm-type resistor. Besides, the one with “Fusible” is a fuse

type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means pico-farad and the unit of the capacitor

without such a symbol is microfarad. As to electrolytic

capacitor, the expression “capacitance/withstand voltage”

is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

• The indicated voltage in each section is the one measured by

Digital Multimeter between such a section and the chassis

with no signal given.

REF. NO

SW101 BAND SELECTOR FM—MW—SW1—SW2

SW201 FUNCTION TAPE—RADIO

SW202 RECORD/PLAYBACK REC–P.B.

SW401 VOLTAGE SELECTOR AC 220-240 V—

DESCRIPTION POSITION

AC 110-127 V

TYPES OF TRANSISTOR

FRONT

VIEW

ECB

9018G

PSS9014C

ZQT8050D

9012G

VOLTAGE

LOCATION

PIN NO.

WORK

VOLTAGE

(V)

FM

MW -SW1-SW2

123456

0.78 0.00 3.03 0.05 1.44 4.18 4.20 4.10 0.00 3.39 1.25

0.00 0.00 0.70 0.87 0.02 4.30 4.27 4.34 0.00 3.80 1.60 4.36

LOCATION KA2209 (FULL POWER)(IC201)

PIN NO.

WORK VOLTAGE(V)

LOCATION

PIN NO.

WORK

VOLTAGE

(V)

Q202

Q203

123456

3.90 8.00 3.89 0.00 0.60 0.00 0.00 0.59

PSS9014C

EBC

0.02 0.64 1.36

0.00 0.63 1.94

CD 2003GP (IC1)

7

8 9 10 11 12

7

8 9 10 11 12

13 14 15 16

4.23

3.50

4.18

0.91 0.90 4.35 4.23

13 14 15 16

4.20

0.06

LOCATION

PIN NO.

WORK VOLTAGE(V)

Q204:PSS9014

Q207: 9102G

Q205: ZQT8050D

Q101: 9018G

CCBEBECBECBE

0.20 0.90 1.90 7.43 7.13 0.50 4.48 5.13 7.50 0.40 1.10 3.77

– 9 –

Page 10

QT-222W

A

IC201 92L28402209000 (KA2209)

5678

--++

1234

B

FM SIGNAL

SW101

MW/SW1/SW2 SIGNAL

TC3

SW101

C

SW101

SW101

D

SW101

E

SW101

F

SW202

RECORD/

PLAYBACK

G

SW202

RECORD/

PLAYBACK

PLAYBACK SIGNAL

H

RECORD SIGNAL

• NOTES ON SCHEMATIC DIAGRAM can be found on page 9.

1

2

34 5

Figure 10 SCHEMATIC DIAGRAM (1/2)

– 10 –

SW202

RECORD/

PLAYBACK

SW202

RECORD/

PLAYBACK

SW201

FUNCTION

SW201

FUNCTION

+B

6

Page 11

QT-222W

28402209000 (KA2209) IC101 9228402003010 (CD2003GP)

567

-+

234

AM

RF IN

AM

RF

FM

RF

FM

RF IN

12345678

FM

RF OUT

GND1

FM/AM

SW

FM

MIX

AM/

FM SW

FM MIX

FM

OSC

AM

MIX

FM

OSC

AM MIX

AM

OSC

AM

OSC

AGC

AGC VCC

AM

DET

IC BLOCK DIAGRAM

+B

+B

DET

OUT

FM

DET

AM

IF

QUAD

AM

IF IN

FM

IF

910111213141516

GND2

FM

IF IN

+B

HP201

HEADPHONES

+B

+B

SW201

FUNCTION

SW201

FUNCTION

+B

+B

SW201

FUNCTION

+B

+B

+B

SW401

AC 220-240 V AC 110-127 V

AC INPUT

SO401

SOCKET

AC POWER

SUPPLY CORD

AC 110-127 V/

220-240 V,

50/60 Hz

POWER PWB-B

78 9101112

Figure 11 SCHEMATIC DIAGRAM (2/2)

– 11 –

Page 12

QT-222W

A

L109

MAIN PWB-A

SW1 ANA

EBC

C137

SP201

SPEAKER

B

TC2

PVC

VC2

CT4

VC4

VC3

TC1

CT3

VC1

16 15 14 13 12 11 10

2 3 4 5 6 7 8

1

9

C

MW ANA

CNP201

WH

3

BK

2

RD

D

123

1

BR

E

BE

FROM

CNP401

C

E

B

C

CBE

C

BE

4

5

3

6

2

7

1

8

C

B

E

M201

TAPE MOTOR

(245-1)

F

BK

TAPE MAIN

RD

WHWHWH

WH

BK

RD

CNP202

MIC

G

POWER PWB

H

CBE

E

B

C

GND

BK

ERASE

HEAD

(245-3)

RECORD/

PLAYBACK

HEAD (245-2)

RD

WH

BR

1

2

34 5

6

Figure 12 WIRING OF P.W.BOARD (1/2)

– 12 –

Page 13

TO

MAIN PWB

CNS401

QT-222W

POWER-B

F1

T 1.25A L 250 V

WH

BK

RD

WH

AC POWER

SUPPLY CORD

AC 110-127 V/

AC 220-240 V,

50/60 Hz

SW401

VOLTAGE SELECTOR

AC 220 V-240 V AC 110 V-127 V

SO401

AC INPUT

SOCKET

AC 110-127 V/

AC 220-240 V,

50/60 Hz

RD

BK

COLOR TABLE

BROWN

BR

OR

YL

GR

BL

VL

GY

BK

PK

RED

ORANGE

YELLOW

GREEN

BLUE

VIOLET

GRAY

WHITE

BLACK

PINK

RD(R)

WH(W)

(240)

RD

RD

BATTERIES

DC 6 V [“D” size

(UM/SUM-1, R20 or HP-2)

battery x 4]

RD

BL

RD

RD

RD

BL

BK

POWER

TRANSFORMER

T401

WH

WH

BK

(238)

(239)

78 9101112

Figure 13 WIRING OF P.W.BOARD (2/2)

– 13 –

Page 14

QT-222W

–– MEMO ––

– 14 –

Page 15

PARTS GUIDE

RADIO CASSETTE RECORDER

QT-222W

“HOW TO ORDER REPLACEMENT PARTS”

To have your order filled promptly and correctly, please furnish the

following information.

1. MODEL NUMBER 2. REF. No.

3. PART NO. 4. DESCRIPTION

MARK: SPARE PARTS-DELIVERY SECTION

MODEL

QT-222W(S)

RADIO CASSETTE RECORDER

MODEL QT-222W(BK)

For U.S.A. only

Contact your nearest SHARP Parts Distributor to order.

For location of SHARP Parts Distributor,

Please call Toll-Free;

1-800-BE-SHARP

Explanation of capacitors/resistors parts codes

Capacitors

VCC ....................... Ceramic type

VCK........................ Ceramic type

VCT........................ Semiconductor type

VC • • MF ............... Cylindrical type (without lead wire)

VC • • MN............... Cylindrical type (without lead wire)

VC • • TV................ Square type (without lead wire)

VC • • TQ ............... Square type (without lead wire)

VC • • CY ............... Square type (without lead wire)

VC • • CZ ............... Square type (without lead wire)

VC • • • • • • • • • J .. The 13th character represents capacity difference.

("J" ±5%, "K" ±10%, "M" ±20%, "N" ±30%,

"C" ±0.25 pF, "D" ±0.5 pF, "Z" +80-20%.)

If there are no indications for the electrolytic capacitors, error is ±20%.

NOTE:

Parts marked with “ ” are important for maintaining the safety of the set.

Be sure to replace parts with specified ones for maintaining the safety and performance of the set.

Resistors

VRD ....................... Carbon-film type

VRS........................ Carbon-film type

VRN ....................... Metal-film type

VR • • MF ............... Cylindrical type (without lead wire)

VR • • MN............... Cylindrical type (without lead wire)

VR • • TV................ Square type (without lead wire)

VR • • TQ ............... Square type (without lead wire)

VR • • CY ............... Square type (without lead wire)

VR • • CZ ............... Square type (without lead wire)

VR • • • • • • • • • J .. The 13th character represents error.

("J" ±5%, "F" ±1%, "D" ±0.5%.)

If there are no indications for other parts, the resistors are ±5%

carbon-film type.

Loading...

Loading...