Page 1

TopPage

SERVICE MANUAL

CODE: 00ZMX3500NS3E

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM

MX-3500N/4500N

MODEL

CONTENTS

NOTE FOR SERVICINGi

[1] PRODUCT OUTLINE . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . . 2-1

[3] CONSUMABLE PARTS . . . . . . . . . . 3-1

[4] UNPACKING AND INSTALLATION

* For how to unpacking and installation,

refer to the installation manual

(00ZMX3500/I1E).

[5] EXTERNAL VIEW AND INTERNAL

STRUCTURE . . . . . . . . . . . . . . . . . . 5-1

[6] ADJUSTMENTS . . . . . . . . . . . . . . . . 6-1

[7] SIMULATION . . . . . . . . . . . . . . . . . . 7-1

[8] SELF DIAG AND

TROUBLE CODE . . . . . . . . . . . . . . . 8-1

[9] MAINTENANCE . . . . . . . . . . . . . . . . 9-1

[10] ROM VERSION-UP . . . . . . . . . . . . 10-1

[11] ELECTRICAL SECTION. . . . . . . . . 11-1

[12] OTHERS. . . . . . . . . . . . . . . . . . . . . 12-1

MX-3501N/4501N

● DETAILS OF EACH SECTION

[A] EXTERNAL OUTFIT. . . . . . . . . . . . .A-1

[B] OPERATION PANEL . . . . . . . . . . . .B-1

[C] SCANNER SECTION . . . . . . . . . . . C-1

[D] MANUAL PAPER FEED

SECTION . . . . . . . . . . . . . . . . . . . . D-1

[E] TRAY PAPER FEED SECTION . . . .E-1

[F] PAPER TRANSPORT SECTION . . . F-1

[G] DUPLEX SECTION . . . . . . . . . . . . G-1

[H] LSU SECTION . . . . . . . . . . . . . . . . H-1

[i] PHOTOCONDUCTOR SECTION. . . i-1

[J] TONER SUPPLY SECTION . . . . . . . J-1

[K] DEVELOPING SECTION . . . . . . . . .K-1

[L] TRANSFER SECTION . . . . . . . . . . . L-1

[M] PROCESS CONTROL SENSOR,

REGISTRATION SENSOR

SECTION . . . . . . . . . . . . . . . . . . . . M-1

[N] FUSING SECTION . . . . . . . . . . . . . N-1

[O] PAPER EXIT SECTION . . . . . . . . . O-1

[P] DRIVE SECTION . . . . . . . . . . . . . . .P-1

[Q] PWB SECTION. . . . . . . . . . . . . . . . Q-1

[R] FAN AND FILTER SECTION . . . . . R-1

[S] SENSOR, SWITCH SECTION . . . . .S-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

NOTE FOR SERVICING

1. Precautions for servicing. . . . . . . . . . . . . . . . . . . . . . . . . i

2. Warning for servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . i

3. Note for installing site . . . . . . . . . . . . . . . . . . . . . . . . . . . i

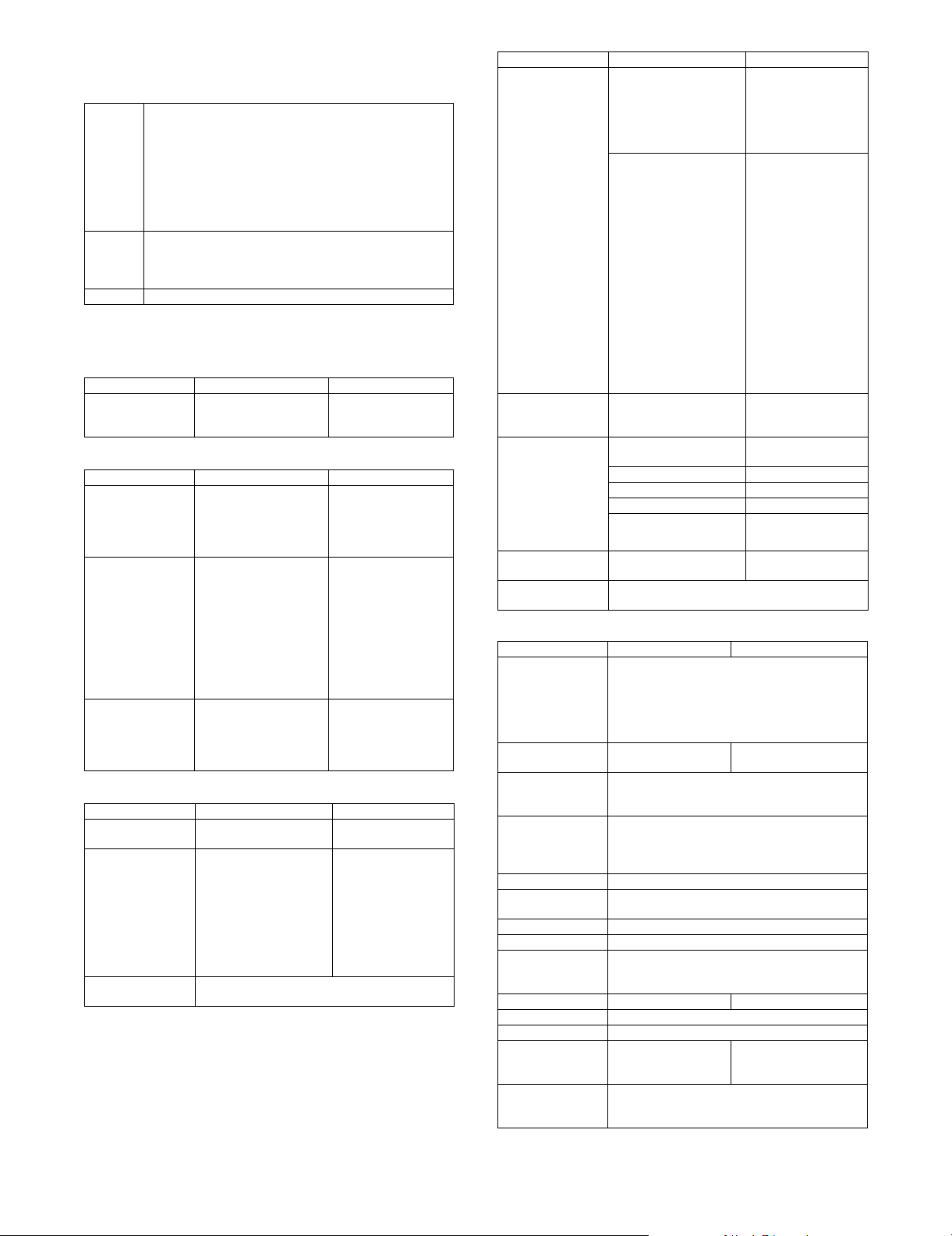

[1] PRODUCT OUTLINE

1. Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

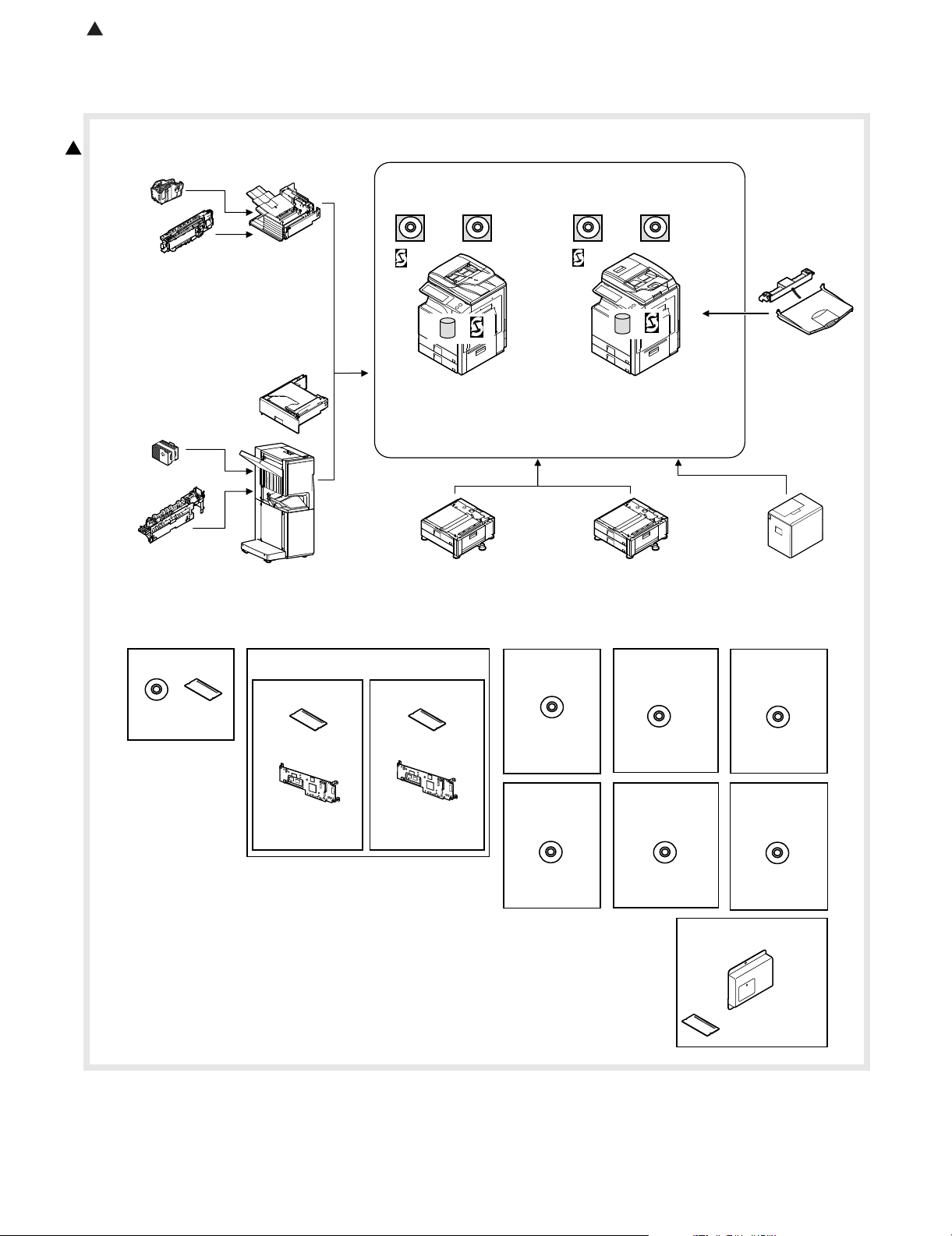

2. Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

[2] SPECIFICATIONS

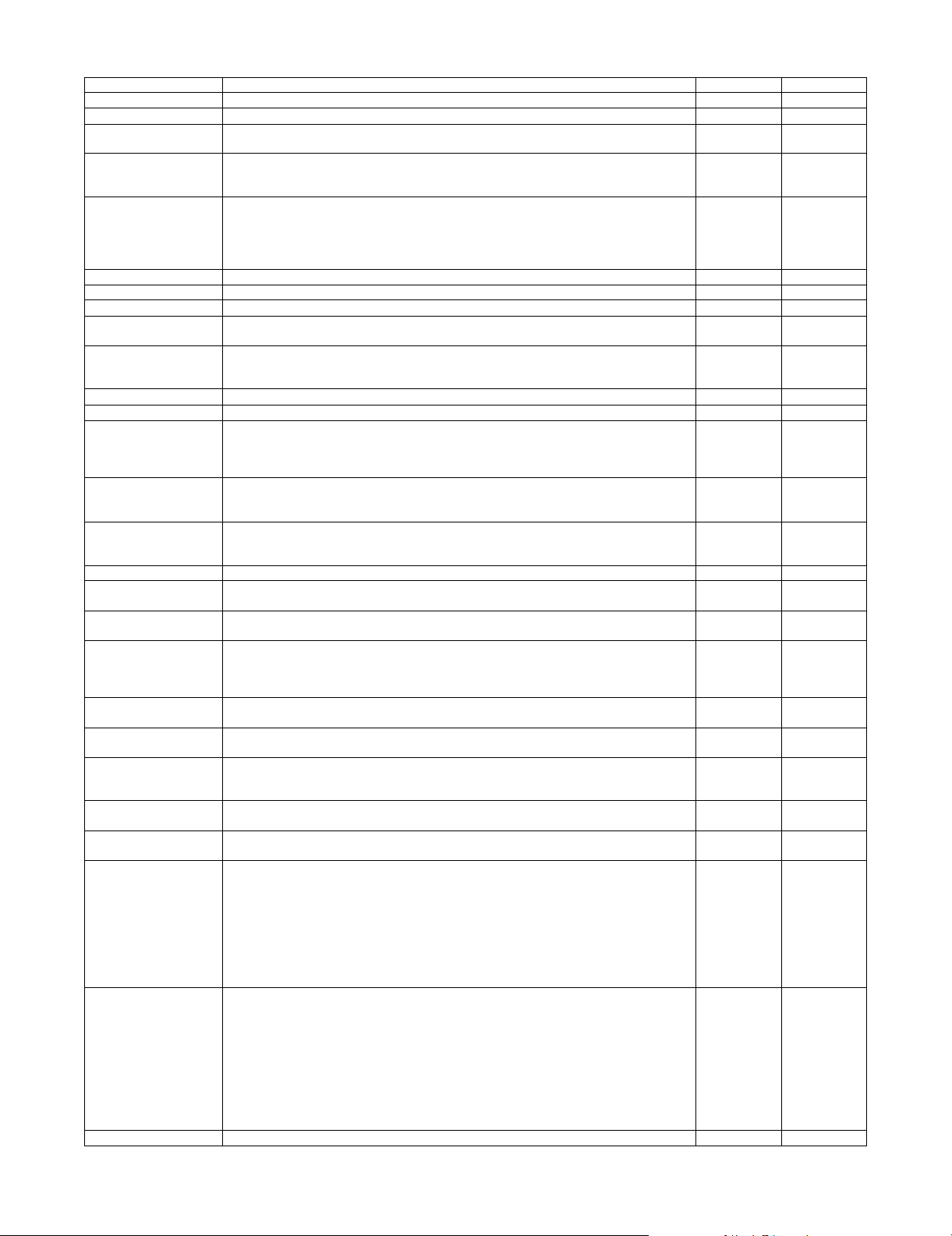

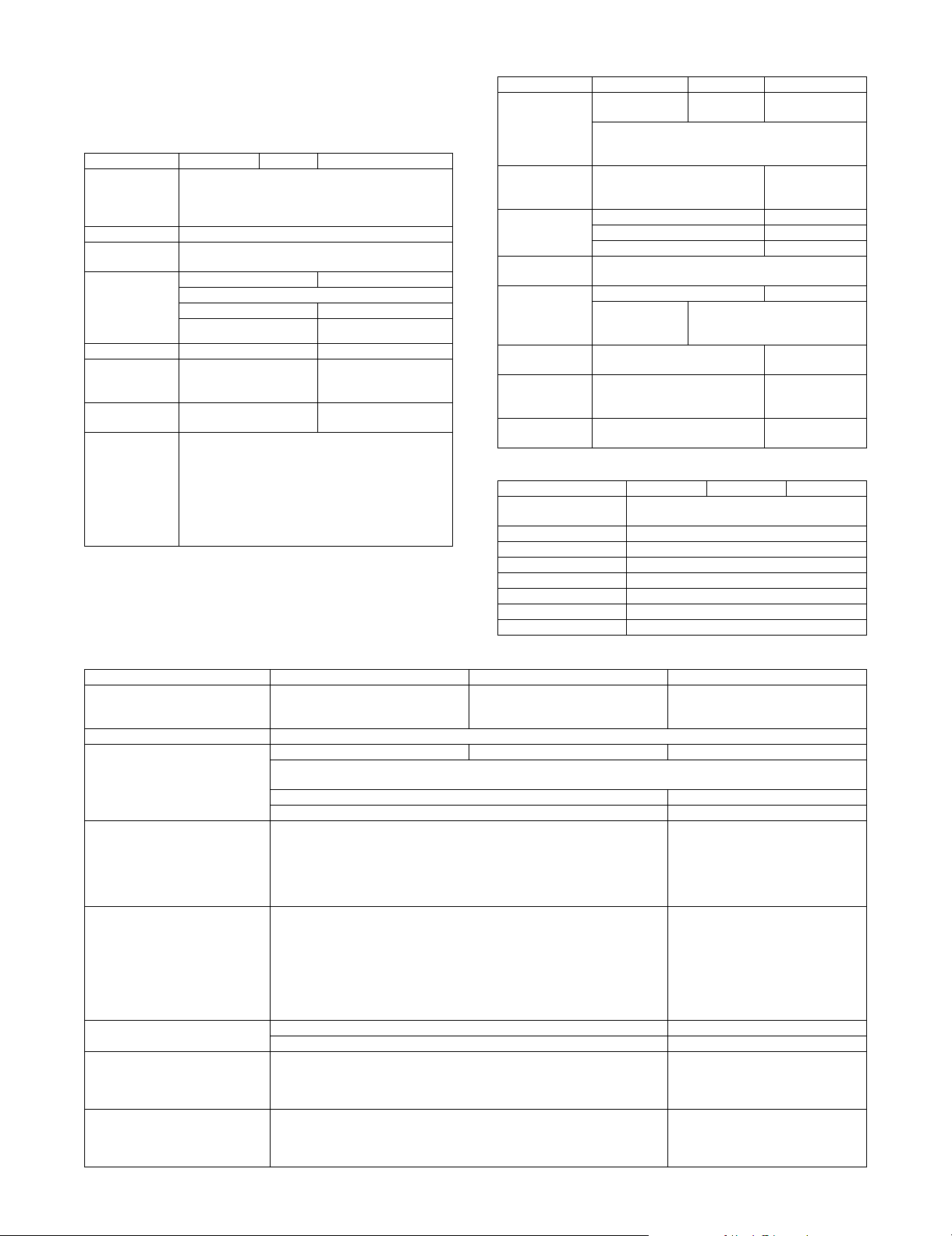

1. Basic specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Functional specifications . . . . . . . . . . . . . . . . . . . . . . .2-5

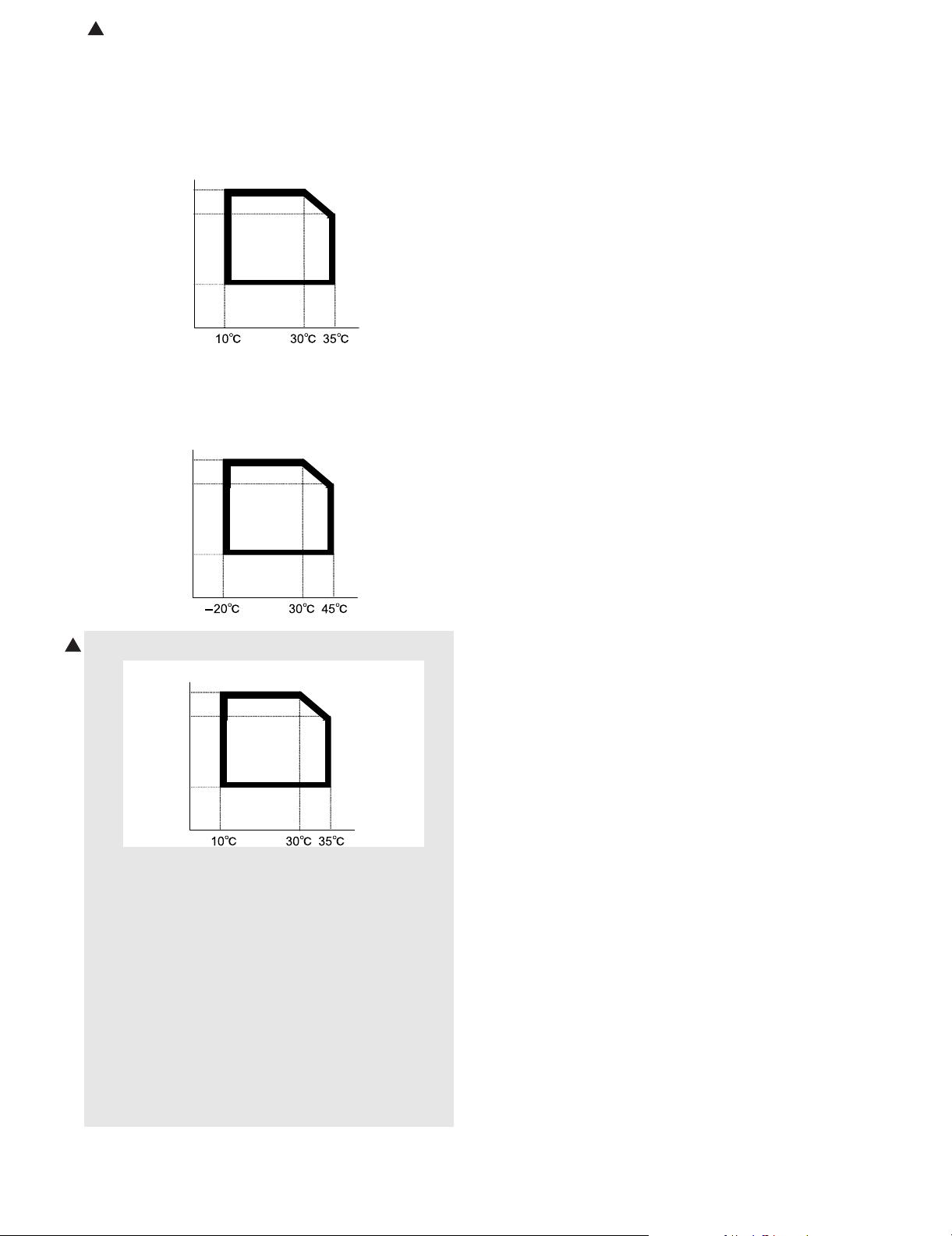

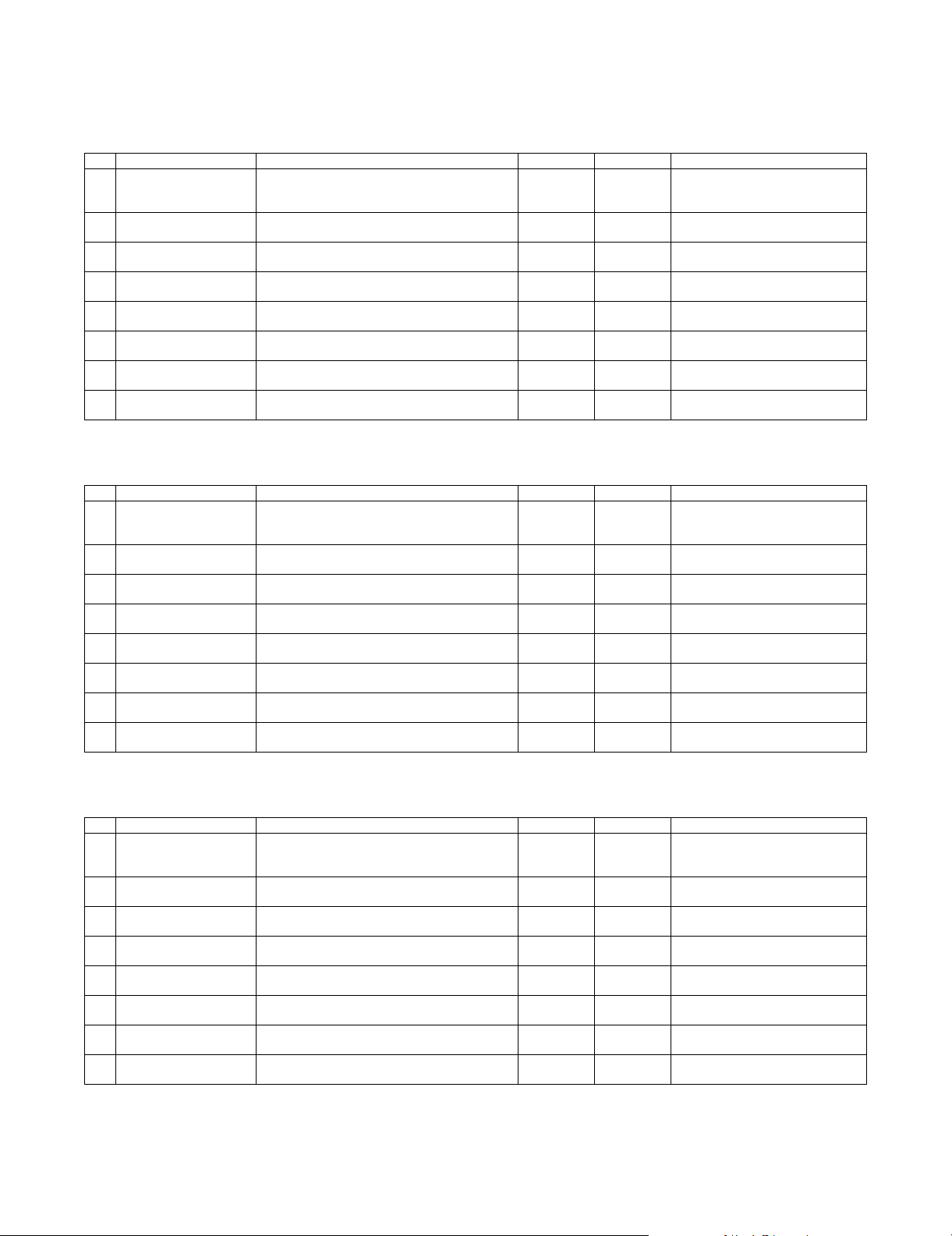

3. Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

[3] CONSUMABLE PARTS

1. Supply system table . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

2. Maintenance parts list . . . . . . . . . . . . . . . . . . . . . . . . .3-2

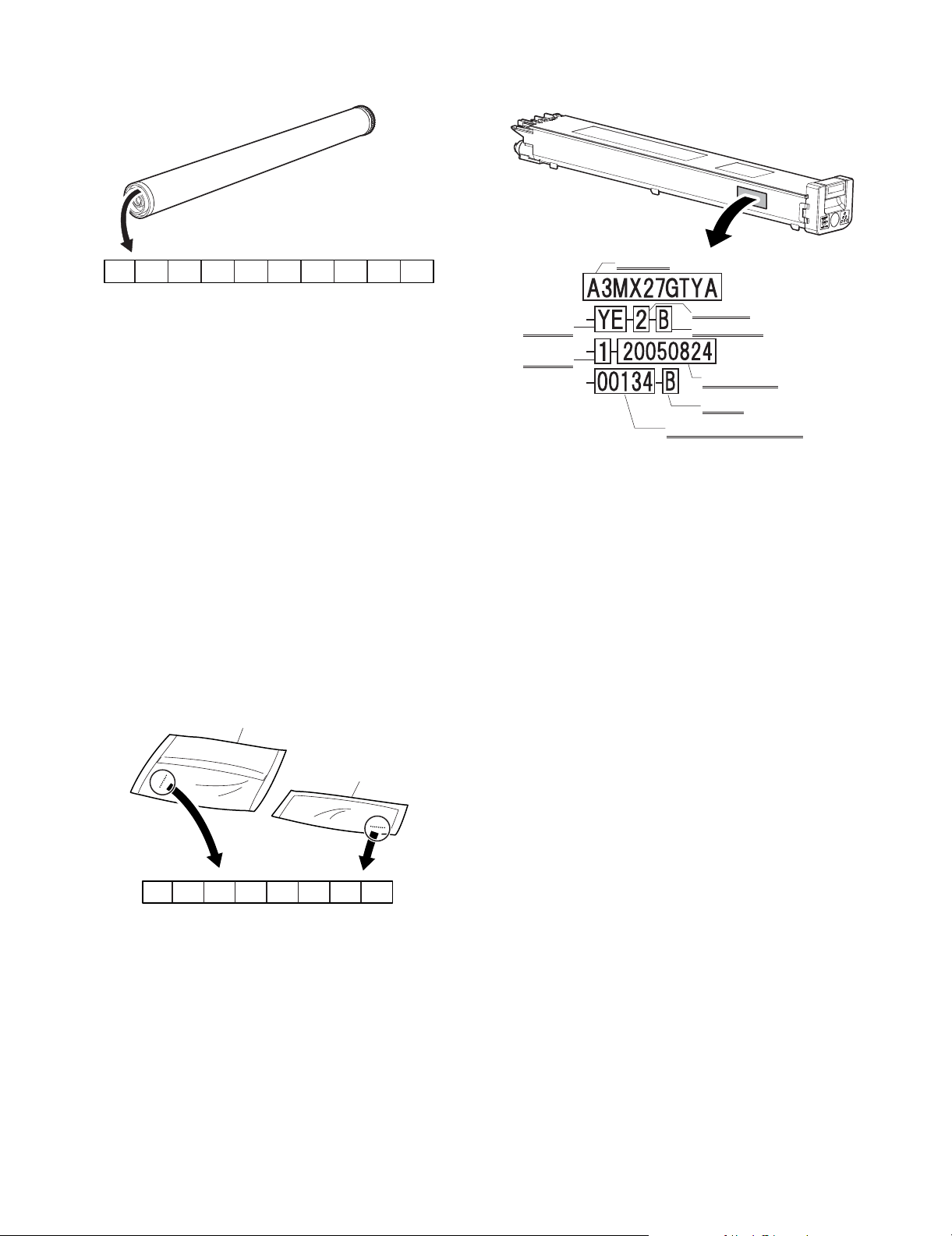

3. Production number identification. . . . . . . . . . . . . . . . . 3-4

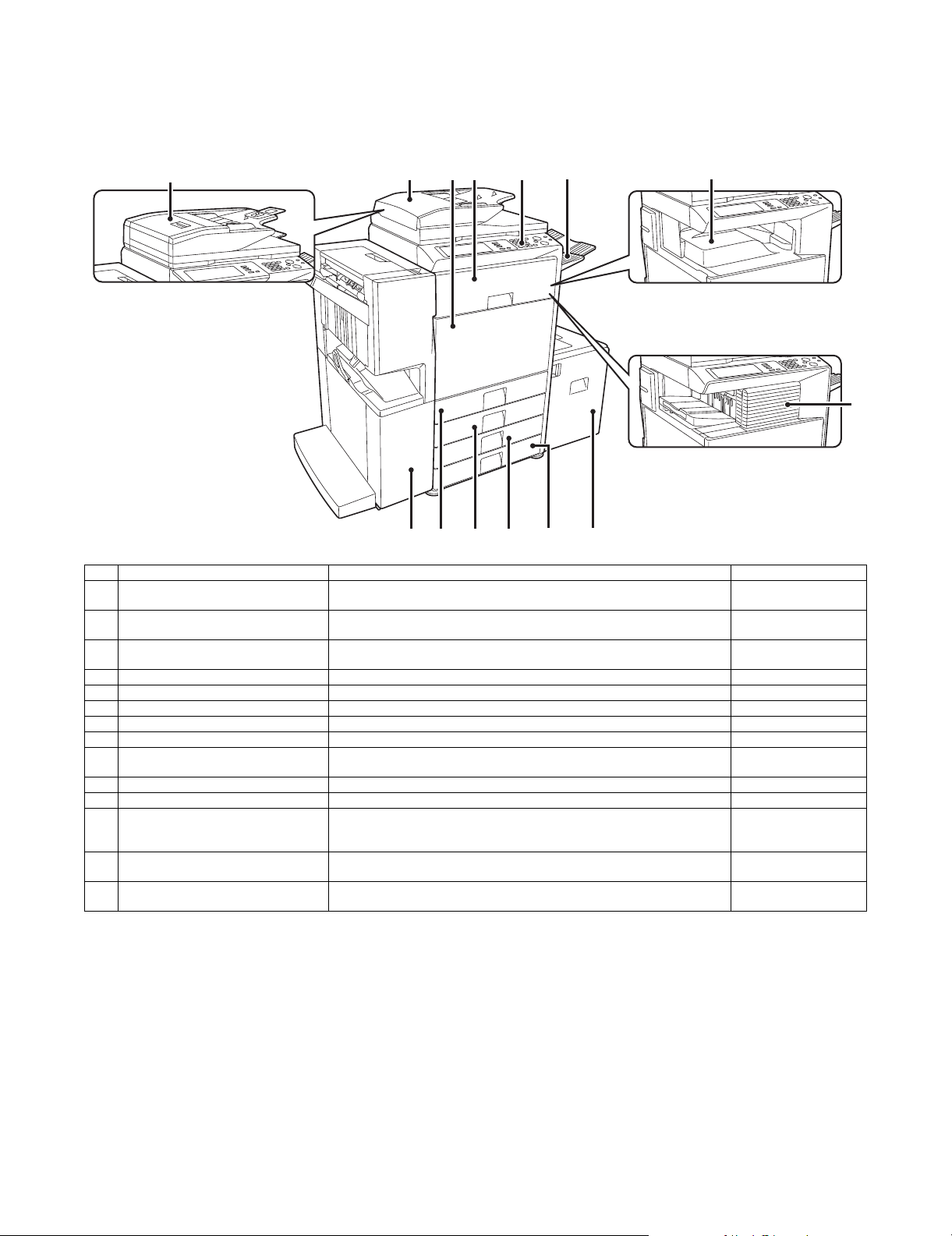

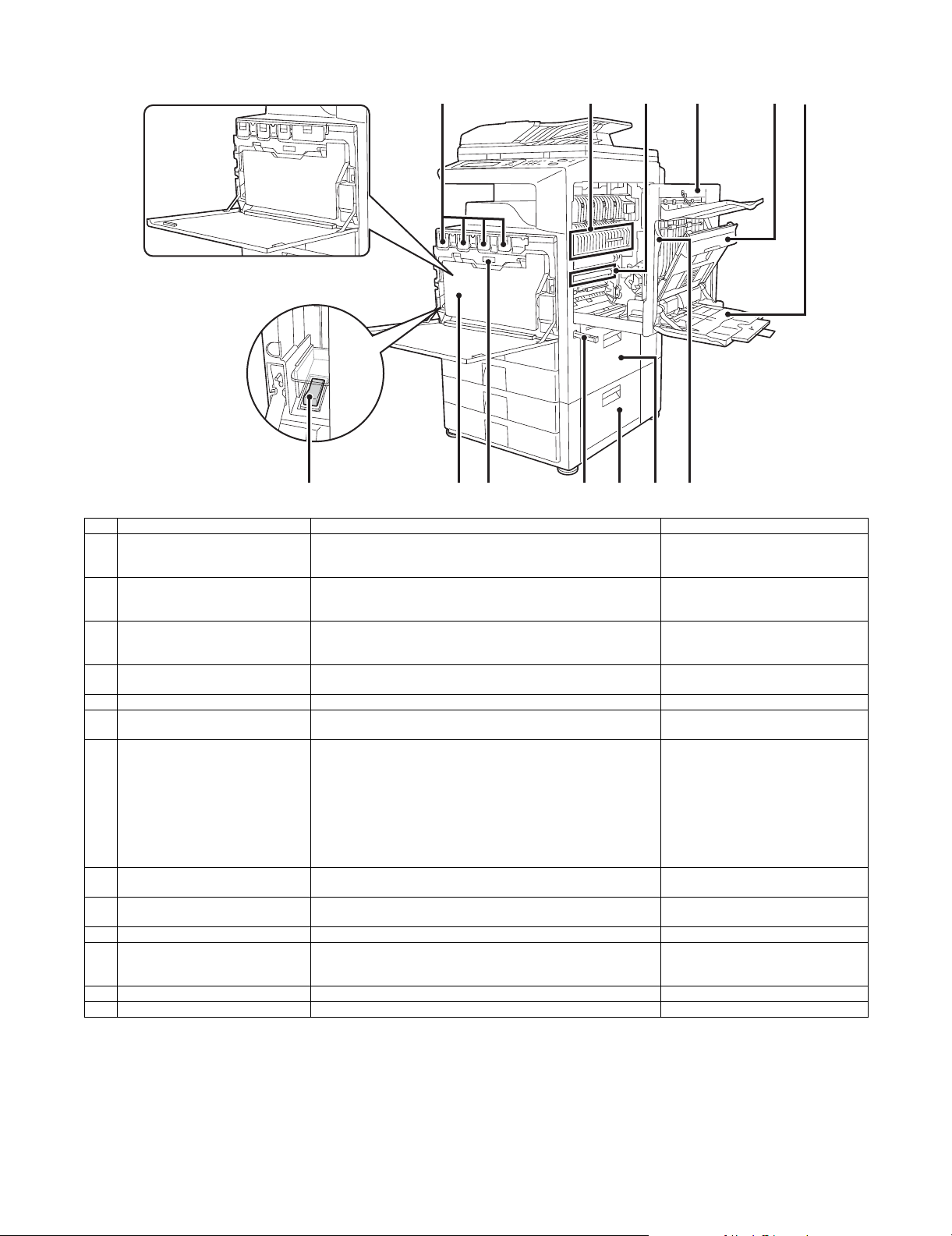

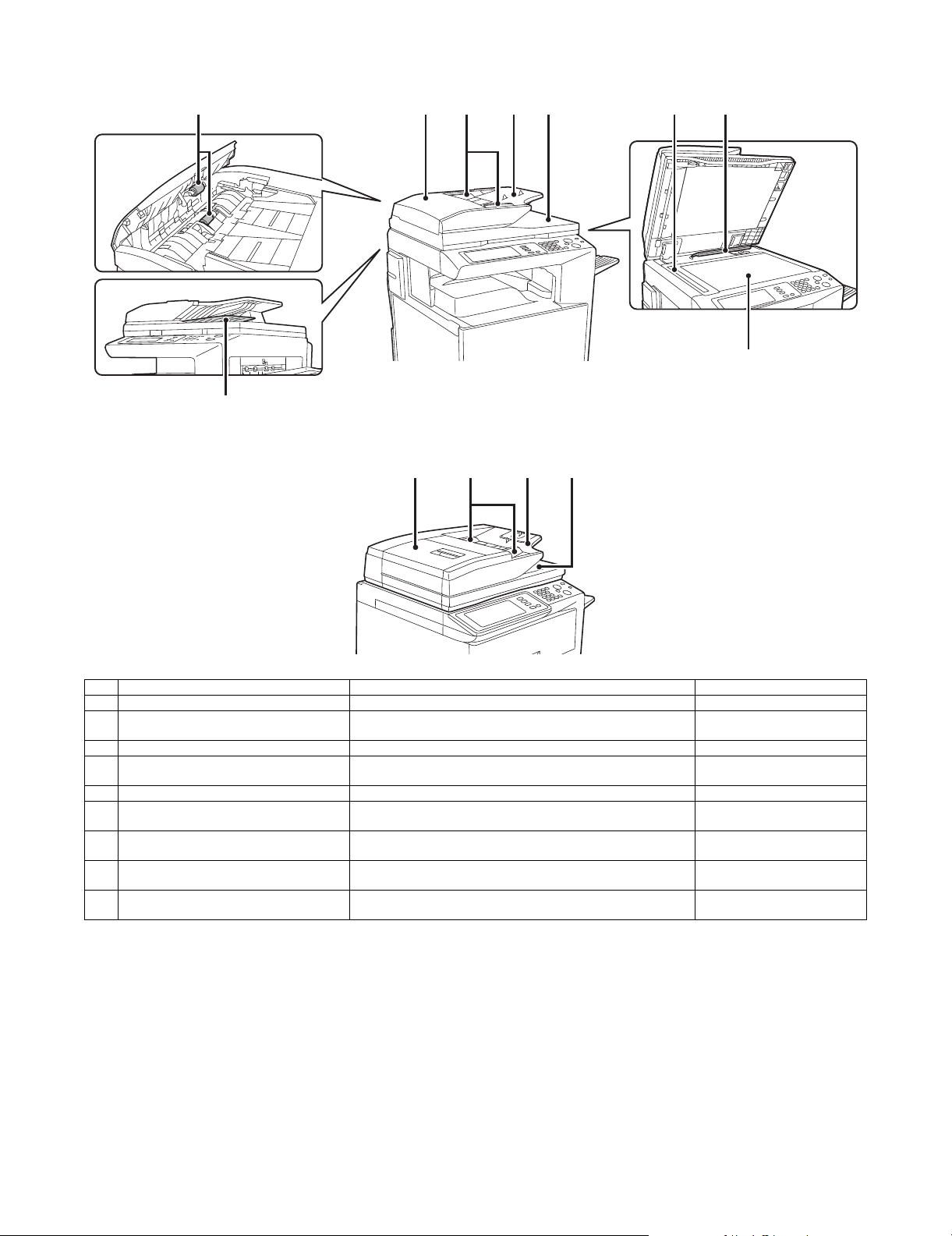

[5] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. Identification of each section and functions . . . . . . . .5-1

[6] ADJUSTMENTS

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

2. Adjustment item list. . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

3. Details of adjustment. . . . . . . . . . . . . . . . . . . . . . . . . .6-2

[7] SIMULATION

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

2. List of simulation codes. . . . . . . . . . . . . . . . . . . . . . . . 7-3

3. Details of simulation . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

[8] SELF DIAG AND TROUBLE CODE

1. Self diag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

2. Trouble code list . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

3. Details of trouble code . . . . . . . . . . . . . . . . . . . . . . . .8-7

[9] MAINTENANCE

1. Maintenance system table . . . . . . . . . . . . . . . . . . . . .9-1

2. Details of maintenance . . . . . . . . . . . . . . . . . . . . . . . .9-4

3. Other related items . . . . . . . . . . . . . . . . . . . . . . . . . .9-15

[10] ROM VERSION-UP

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

2. Version-up procedure . . . . . . . . . . . . . . . . . . . . . . . .10-1

[11] ELECTRICAL SECTION

1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

2. Actual wiring chart. . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

3. Signal list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-30

[12] OTHERS

1. System settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

2. Paper JAM code . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

● DETAILS OF EACH SECTION

[A] EXTERNAL OUTFIT

1. Disassembly and assembly . . . . . . . . . . . . . . . . . . . A-1

[B] OPERATION PANEL

1. Electrical and mechanism relation diagram . . . . . . . B-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . B-2

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . B-2

[C] SCANNER SECTION

1. Electrical and mechanism relation diagram . . . . . . . C-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . C-2

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . C-3

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

[D] MANUAL PAPER FEED SECTION

1. Electrical and mechanism relation diagram . . . . . . . D-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . D-2

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . D-2

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

[E] TRAY PAPER FEED SECTION

1. Electrical and mechanism relation diagram . . . . . . . . E-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . E-3

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . E-4

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-8

[F] PAPER TRANSPORT SECTION

1. Electrical and mechanism relation diagram . . . . . . . . F-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . F-2

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . F-2

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

[G] DUPLEX SECTION

1. Electrical and mechanism relation diagram . . . . . . . . G-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . G-2

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . G-2

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-7

[H] LSU SECTION

1. Electrical and mechanism relation diagram . . . . . . . . H-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . H-2

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . H-3

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-5

[i] PHOTOCONDUCTOR SECTION

1. Electrical and mechanism relation diagram . . . . . . . . . i-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . . i-2

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . . i-3

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i-6

[J] TONER SUPPLY SECTION

1. Electrical and mechanism relation diagram . . . . . . . . J-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . J-2

3. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-3

[K] DEVELOPING SECTION

1. Electrical and mechanism relation diagram . . . . . . . . K-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . K-2

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . K-2

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K-5

[L] TRANSFER SECTION

1. Electrical and mechanism relation diagram . . . . . . . . L-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . L-2

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . L-3

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . L-10

[M] PROCESS CONTROL SENSOR, REGISTRATION

SENSOR SECTION

1. Electrical and mechanism relation diagram . . . . . . . . M-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . M-1

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . .M-2

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .M-3

[N] FUSING SECTION

1. Electrical and mechanism relation diagram . . . . . . . . N-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . N-2

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . N-3

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N-9

[O] PAPER EXIT SECTION

1. Electrical and mechanism relation diagram . . . . . . . . O-1

2. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . O-2

3. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . O-2

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . O-5

[P] DRIVE SECTION

1. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . P-1

2. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

[Q] PWB SECTION

1. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . Q-1

[R] FAN AND FILTER SECTION

1. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . R-1

2. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R-3

[S] SENSOR, SWITCH SECTION

1. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . S-1

Page 3

MX3500N

NOTE FOR SERVICING

This Service Manual uses some symbols to assure safe operation.

This Service Manual uses some symbols to assure safe operation.

Please understand the meanings of photographs before servicing.

WARNING: If this WARNING should be ignored, a serious

danger to life or a serious injury could result.

CAUTION: If this CAUTION should be ignored, an injury or

a damage to properties could result.

1. Precautions for servicing

1) When servicing, disconnect the power plug, the printer cable,

the network cable, and the telephone line from the machine,

except when performing the communication test, etc.

It may cause an injury or an electric shock.

2) There is a high temperature area inside the machine. Use an

extreme care when servicing.

It may cause a burn.

3) There is a high voltage section inside the machine which may

cause an electric shock. Be careful when servicing.

4) Do not disassemble the laser unit. Do not insert a reflective

material such as a screwdriver in the laser beam path.

It may damage eyes by reflection of laser beams.

5) When servicing with the machine operating, be careful not to

squeeze you hands by the chain, the belt, the gear, and other

driving sections.

6) Do not leave the machine with the cabinet disassembled.

Do not allow any person other than a serviceman to touch

inside the machine. It may cause an electric shock, a burn, or

an injury.

7) When servicing, do not breathe toner, developer, and ink

excessively. Do not get them in the eyes.

If toner, developer, or ink enters you eyes, wash it away with

water immediately, and consult a doctor if necessary.

8) The machine has got sharp edges inside. Be careful not to

damage fingers when servicing.

9) Do not throw toner or a toner cartridge in a fire. Otherwise,

toner may pop and burn you.

10) When replacing the lithium battery of the PWB, use a specified

one only.

If a battery of different specification is used, it may be broken,

causing breakdown or malfunction of the machine.

11) When carrying a unit with PWB or electronic parts installed to

it, be sure to put it in an anti-static-electricity bag.

It may cause a breakdown or malfunctions.

• Gas tube

5GTXKEG/CPWCN

• Lightning conductor

• A water pipe or a water faucet, which is not recognized as a

grounding object by the authorities.

• Grounding wire for telephone line

5) Do not damage, break, or work the power cord.

Do not put heavy objects on the power cable. Do not bend it

forcibly or do not pull it extremely.

It may cause a fire or an electric shock.

6) Keep the power cable away from a heat source.

Do not insert the power plug with dust on it into a power outlet.

It may cause a fire or an electric shock.

7) Do not put a receptacle with water in it or a metal piece which

may drop inside the machine.

It may cause a fire or an electric shock.

8) With wet or oily hands, do not touch the power plug, do not

insert the telephone line jack, do not operate the machine, or

do not perform servicing.

It may cause an electric shock.

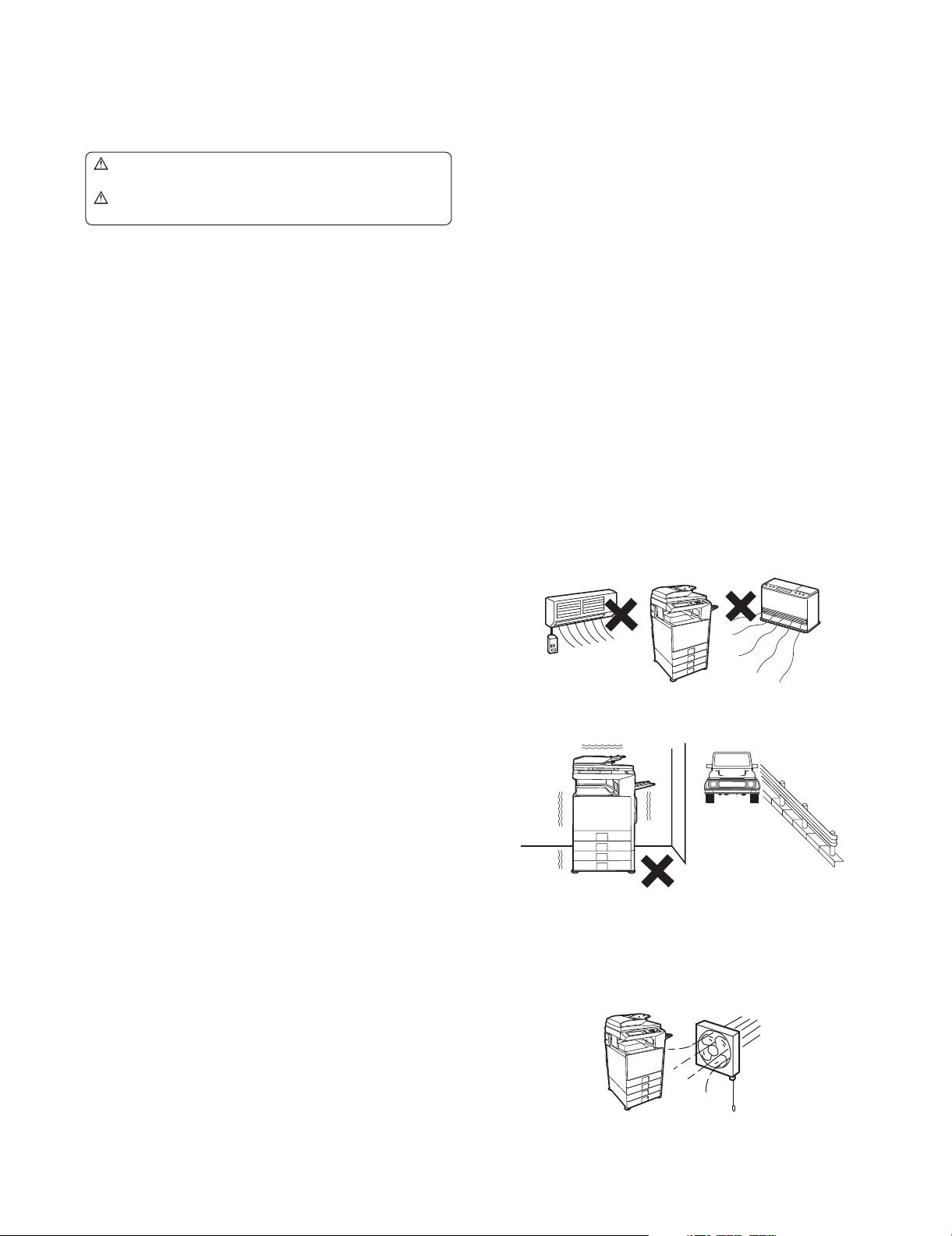

3. Note for installing site

Do not install the machine at the following sites.

1) Place of high temperature, high humidity, low tempera-

ture, low humidity, place under an extreme change in temperature and humidity.

Paper may get damp and form dews inside the machine, causing paper jam or copy dirt.

For operating and storing conditions, refer to the specifications

described later.

2) Place of much vibrations

It may cause a breakdown.

2. Warning for servicing

1) Be sure to connect the power cord only to a power outlet that

meets the specified voltage and current requirements.

Avoid complex wiring, which may lead to a fire or an electric

shock.

It may cause a fire or an electric shock.

2) If there is any abnormality such as a smoke or an abnormal

smell, interrupt the job and disconnect the power plug.

It may cause a fire or an electric shock.

3) Be sure to connect the grounding wire. If an electric leakage

occurs without grounding, a fire or an electric shock may

result.

To protect the machine and the power unit from lightening,

grounding must be made.

4) When connecting the grounding wire, never connect it to the

following points.

It may cause an explosion, a fire or an electric shock.

MX3500N NOTE FOR SERVICING - i

3) Poorly ventilated place

An electro-static type copier will produce ozone inside it.

The quantity of ozone produced is designed to a low level so

as not to affect human bodies. However, continuous use of

such a machine may produce a smell of ozone. Install the

machine in a well ventilated place, and ventilate occasionally.

Page 4

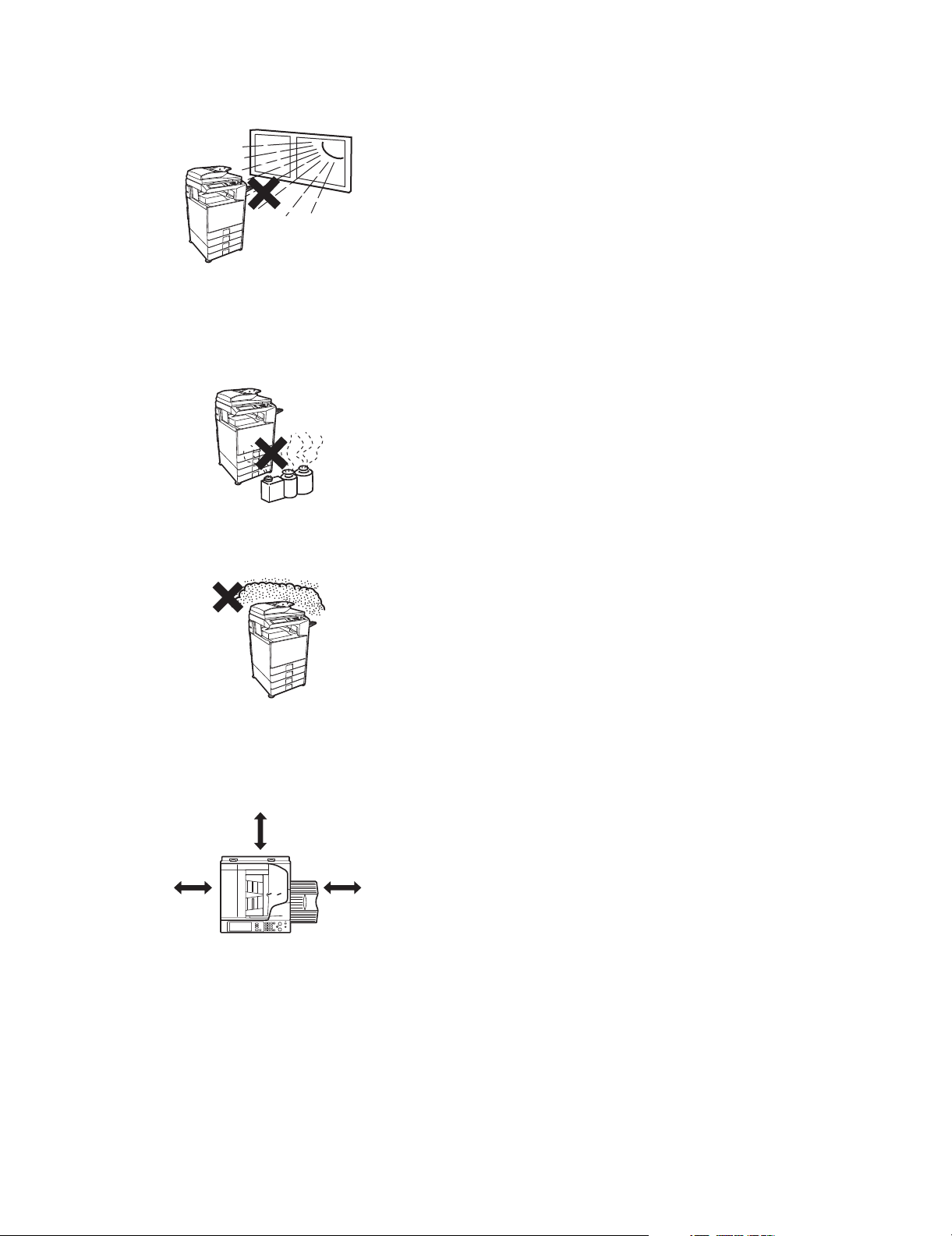

4) Place of direct sunlight.

Plastic parts and ink may be deformed, discolored, or may

undergo qualitative change.

It may cause a breakdown or copy dirt.

5) Place which is full of organic gases such as ammonium

The organic photoconductor (OPC) drum used in the machine

may undergo qualitative change due to organic gases such as

ammonium.

Installation of this machine near a diazo-type copier may result

in dirt copy.

6) Place of much dust

When dusts enter the machine, it may cause a breakdown or

copy dirt.

7) Place near a wall

Some machine require intake and exhaust of air.

If intake and exhaust of air are not properly performed, copy

dirt or a breakdown may be resulted.

30 cm

30 cm

8) Unstable or slant surface

If the machine drops or fall down, it may cause an injury or a

breakdown.

If there are optional paper desk and the copier desk specified,

it is recommendable to use them.

When using the optional desk, be sure to fix the adjuster and

lock the casters.

45 cm

MX3500N NOTE FOR SERVICING - ii

Page 5

MX3500N

[1] PRODUCT OUTLINE

1. Product features

A. Features

(1) Features

1) The employment of newly developed toner reduces the toner

consumption remarkably, realizing high fidelity pictures of

human skin, half tone, and hair. In addition, the employment of

"Auto Color" function, Sharp's unique auto recognition function, reproduces documents of difficult reproduction.

2) The power consumption for FAX standby with the power OFF

is 1W or less, reducing energy expenses of nighttime and load

to the environment.

3) Extension of the lifetime of the OPC drums together with the

frequency of maintenance realizes resource saving.

4) The unique security system inhibits unauthorized use of the

machine, preventing against leak of information.

• The electronic data are encrypted and saved in the hard

disk. When copying or printing or when sending FAX or

scanning, data are automatically erased to protect against

leak of important information (When option installed.).

• The user authentication system by a login name, a pass-

word, and an e-mail address is employed to prevent against

unauthorized use of a third party and to limit the use quantity

and usable functions for each user group. In addition, the

user authentication by the optional IC card read/writer may

be used.

(2) Environmental features

5GTXKEG/CPWCN

• Energy saving design by pre-heat mode/auto power shut-off

mode.

• Conforms to the International EnergyStar program.

• Conforms to the standards of Law on Promoting Green Purchasing.

• Conforms to the Europe RoHS regulations.

(The contents of lead, mercury, hexavalent chromium, cadmium,

PBB [polybrominated biphenyl], PBDE [polybrominated diphenyl

ether] are limited to the regulated level or less.)

5) The open systems architecture (Sharp OSA) is supported

which provides application development environment according to user's needs.

6) Compact area for installation even to a space for a monochrome machine

The machine can be installed to a space for a monochrome

machine, the smallest space in the class of 645mm (W) x

670mm (D), helping backup of color documentations in an

office. The installation of the optional finisher (MX-FNX1)

which is stored in the center paper exit section of the machine

allows stapling and finishing such as punch holes automatically, improving the work efficiency.

MX3500N PRODUCT OUTLINE 1 – 1

Page 6

: May 15 2006

4

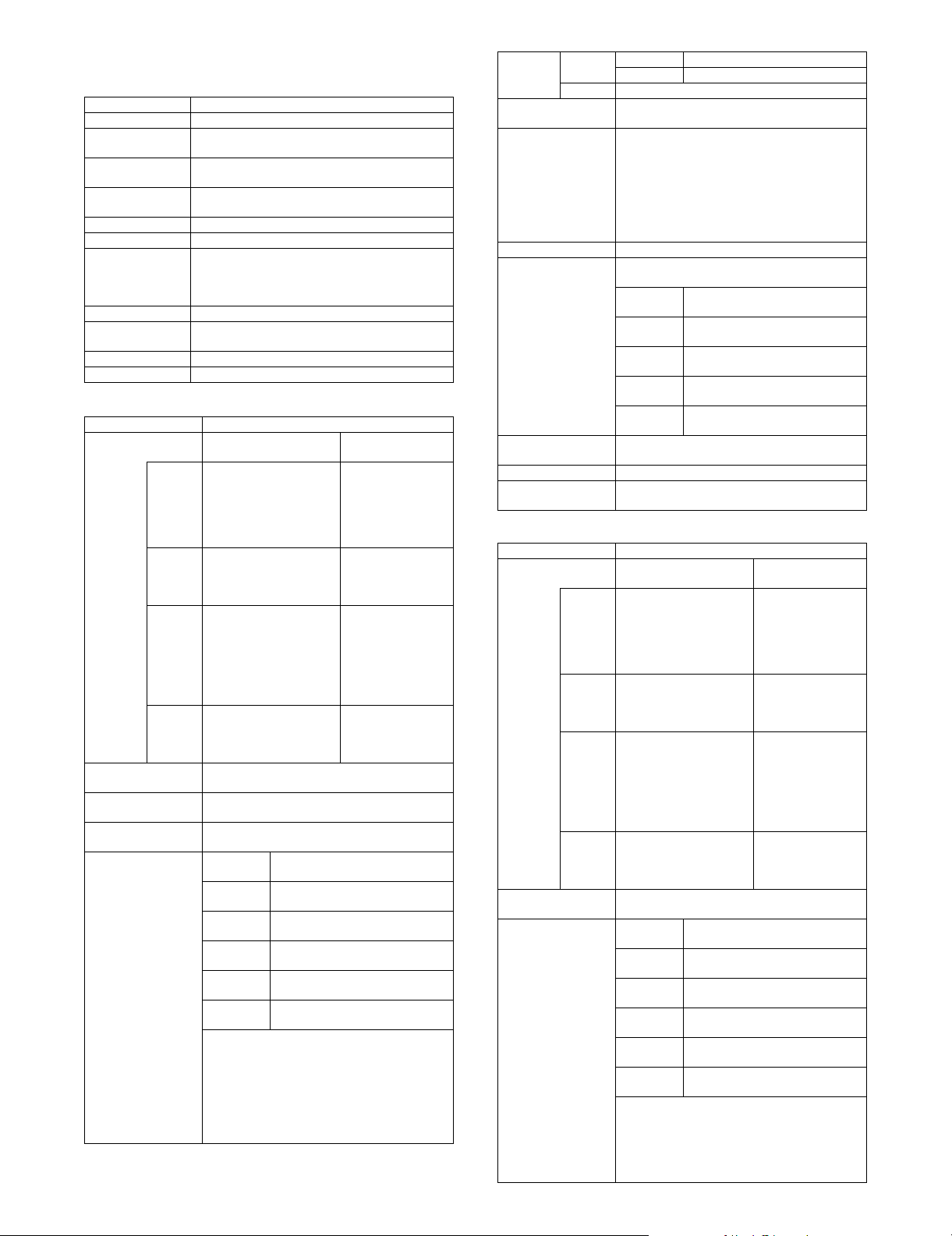

2. Configuration

A. Lineup (Main unit and option)

4

9. Punch module

●

●

●

●

10. Staple cartridge

(Approx. 5000 x 3)

(MX-SCX1)

8. Punch module

●

2-hole (MX-PNX1A)

●

3-hole (MX-PNX1B)

●

4-hole (MX-PNX1C)

●

4-hole (broad space)

(MX-PNX1D)

11. Staple cartridge

(Approx. 5000 x 3)

(AR-SC2)

2-hole (AR-PN1A)

3-hole (AR-PN1B)

4-hole (AR-PN1C)

4-hole (broad space)

(AR-PN1D)

7. Finisher

(MX-FNX1)

5. Paper pass unit

(MX-RBX1)

6. Saddle stitch finisher

(MX-FNX2)

PCL5c/PCL6

driver

RSPF

Network

scanner

(Sharpdesk 1 license)

*&&

Copier/Printer

/Scanner model

(MX-3500N)

(MX-4500N)

1. Stand/1x500 sheet

paper drawer

(MX-DEX3)

PCL5c/PCL6

driver

DSPF

Network

scanner

(Sharpdesk 1 license)

HDD

Copier/Printer

/Scanner model

(MX-3501N)

(MX-4501N)

2. Stand/2x500 sheet

paper drawer

(MX-DEX4)

4. Exit tray unit

(MX-TRX2)

3. Large capacity tray

(MX-LCX1)

12. Barcode font kit

CD

ROM

(AR-PF1)

(Including document control)

13. Commercial

version

Security

ROM

For document

control PWB

(MX-FRX2U)

Data security kit

14.

CC authentication

version

For document

control PWB

(MX-FRX2)

Security

ROM

15. PS3

expansion

kit

CD

(MX-PKX1)

19. Sharpdesk

10 license kit

20. Sharpdesk

50 license kit

CD

(MX-US10/

US50)

16. Internet Fax

expansion kit

CD

(MX-FWX1)

21. Sharpdesk

100 license kit

CD

(MX-USA0)

23. Facsimile expansion kit

17. Sharpdesk

1 license kit

18. Sharpdesk

5 license kit

CD

(MX-USX1/

USX5)

22. Application

integration

module

CD

(MX-AMX1)

(MX-FXX1)

FAX memory (8MB)

(packed together)

MX3500N PRODUCT OUTLINE 1 – 2

Page 7

: May 15 2006

4

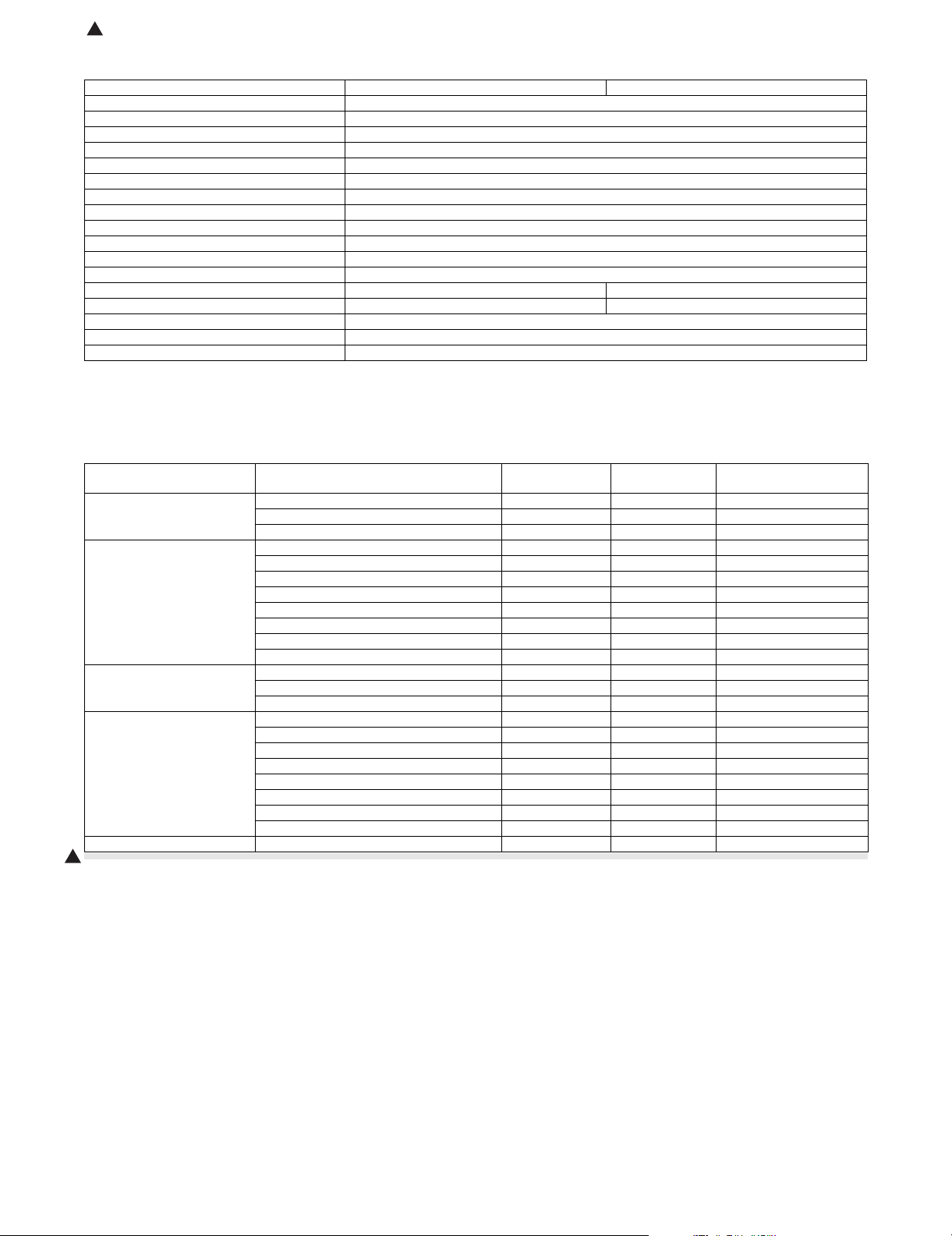

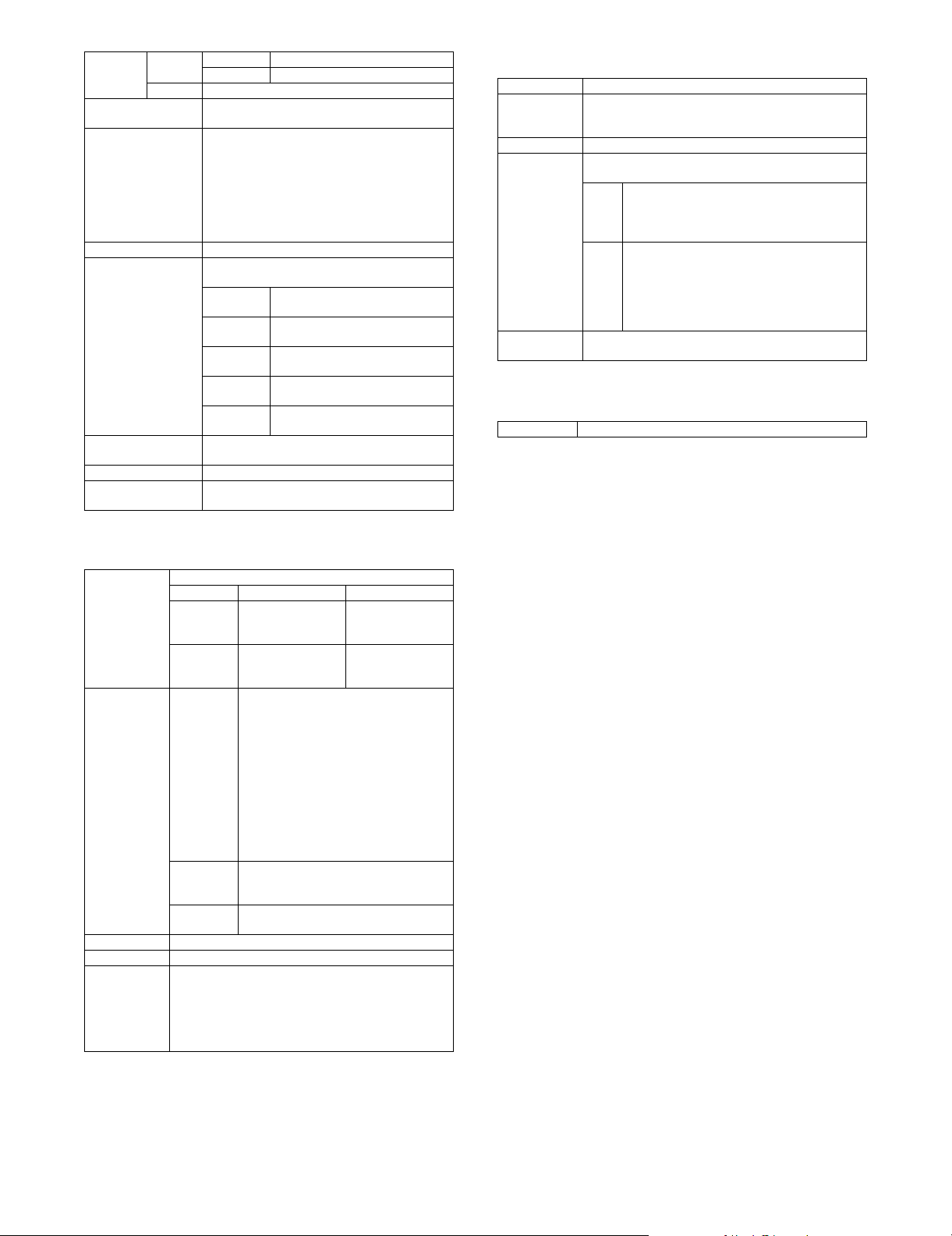

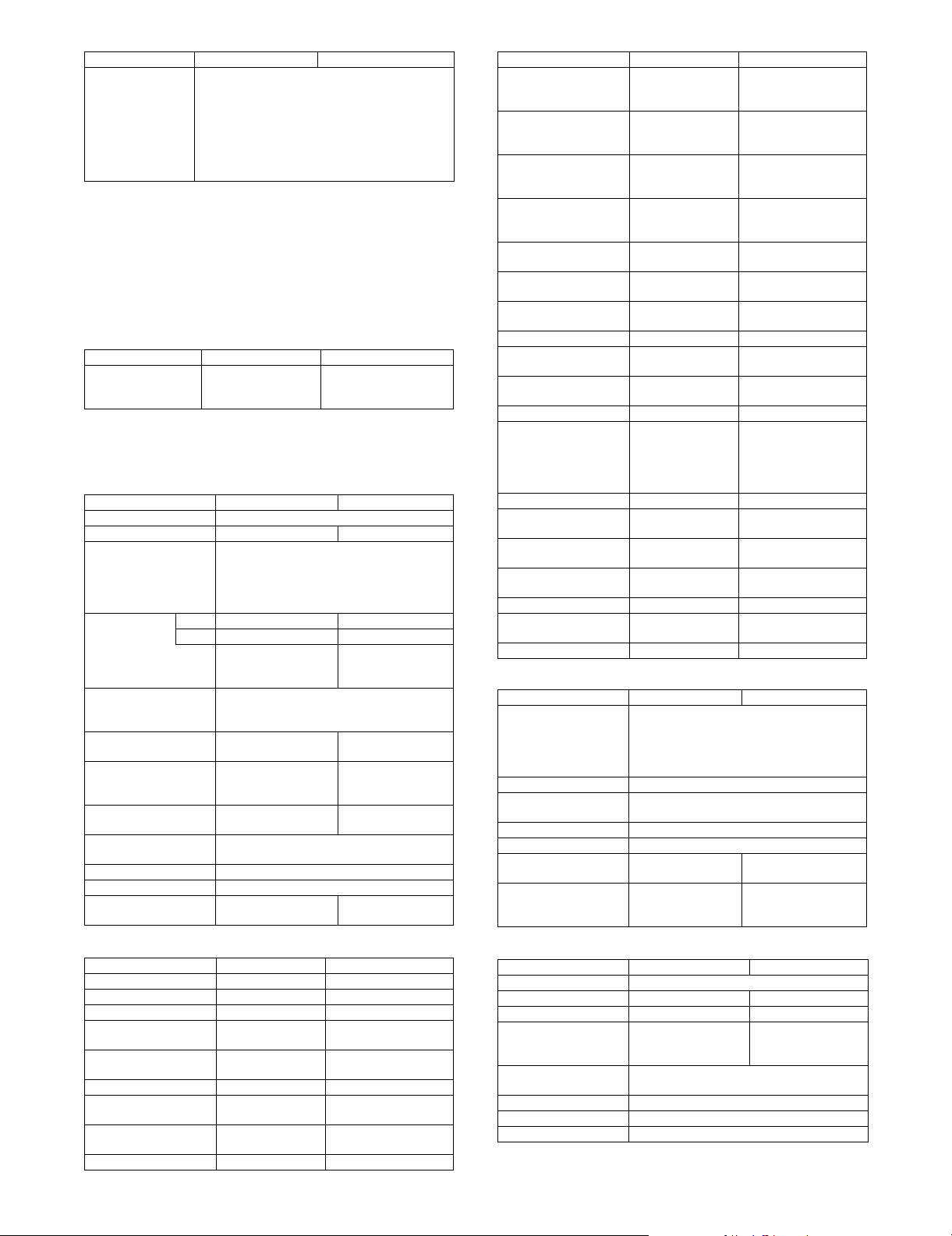

B. Machine configuration

MX-3500N/MX-4500N MX-3501N/MX-4501N

Copier memory (Local memory) (MB) 768

Printer memory (System memory) (MB) 640

Copier STD

GDI printer STD

PCL printer STD

PS printer OP*1

EFI printer OP

Main body LCD MONOCHROME HVGA 8.9"

FAX OP*2

Scanner STD

Filing STD

HDD STD

RSPF STD –

DSPF –STD

Automatic duplex STD

Security OP*1

Internet Fax OP*1

STD: Standard provision, OP: Option

OP*1: Product key target.

OP*2: No support for some areas.

C. Combination of options list

Section Name Model name

Paper feed system 1. Stand/1x500 sheet paper drawer MX-DEX3 OPT

2. Stand/2x500 sheet paper drawer MX-DEX4 OPT

3. Large capacity tray MX-LCX1 OPT (A4)

Paper exit system 4. Exit tray unit MX-TRX2 OPT

5. Paper pass unit MX-RBX1 OPT

6. Saddle stitch finisher MX-FNX2 OPT

7. Finisher MX-FNX1 OPT (Inner finisher)

8. Punch module (For inner finisher) MX-PNX1 A/B/C/D OPT

9. Punch module (For saddle stitch finisher) AR-PN1 A/B/C/D OPT (Common in current models)

10. Staple cartridge (For inner finisher) MX-SCX1 OPT (Approx. 5000 x 3)

11. Staple cartridge (For saddle stitch finisher) AR-SC2 OPT (Approx. 5000 x 3)

Electrical system (ROM) 12. Barcode font kit AR-PF1 OPT (Conventional model)

13. Data security kit MX-FRX2U OPT (Commercial version)

14. Data security kit MX-FRX2 OPT (Authentication version)

Electrical system (Software) 15. PS3 expansion kit MX-PKX1 OPT

16. Internet Fax expansion kit MX-FWX1 OPT (Internet Fax)

17. Sharpdesk 1 license kit MX-USX1 OPT

18. Sharpdesk 5 license kit MX-USX5 OPT

19. Sharpdesk 10 license kit MX-US10 OPT

20. Sharpdesk 50 license kit MX-US50 OPT

21. Sharpdesk 100 license kit MX-USA0 OPT

22. Application integration module MX-AMX1 OPT

Electrical system (FAX) 23. Facsimile expansion kit MX-FXX1 OPT*1

4

MX-3500N/3501N

MX-4500N/4501N

Remarks

STD: Standard provision. OPT: Installable option.

*1: No support for some areas.

MX3500N PRODUCT OUTLINE 1 – 3

Page 8

MX3500N

[2] SPECIFICATIONS

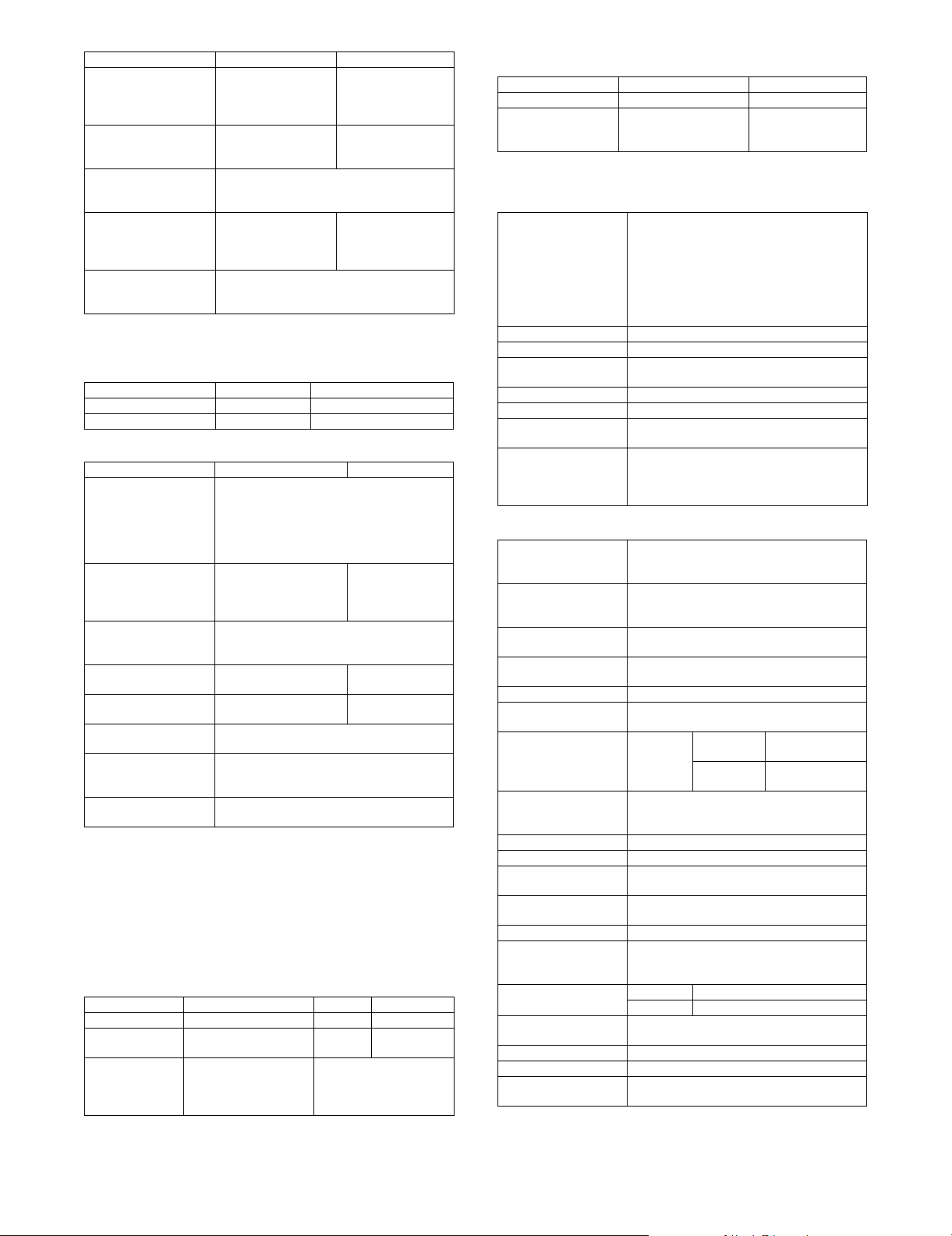

1. Basic specifications

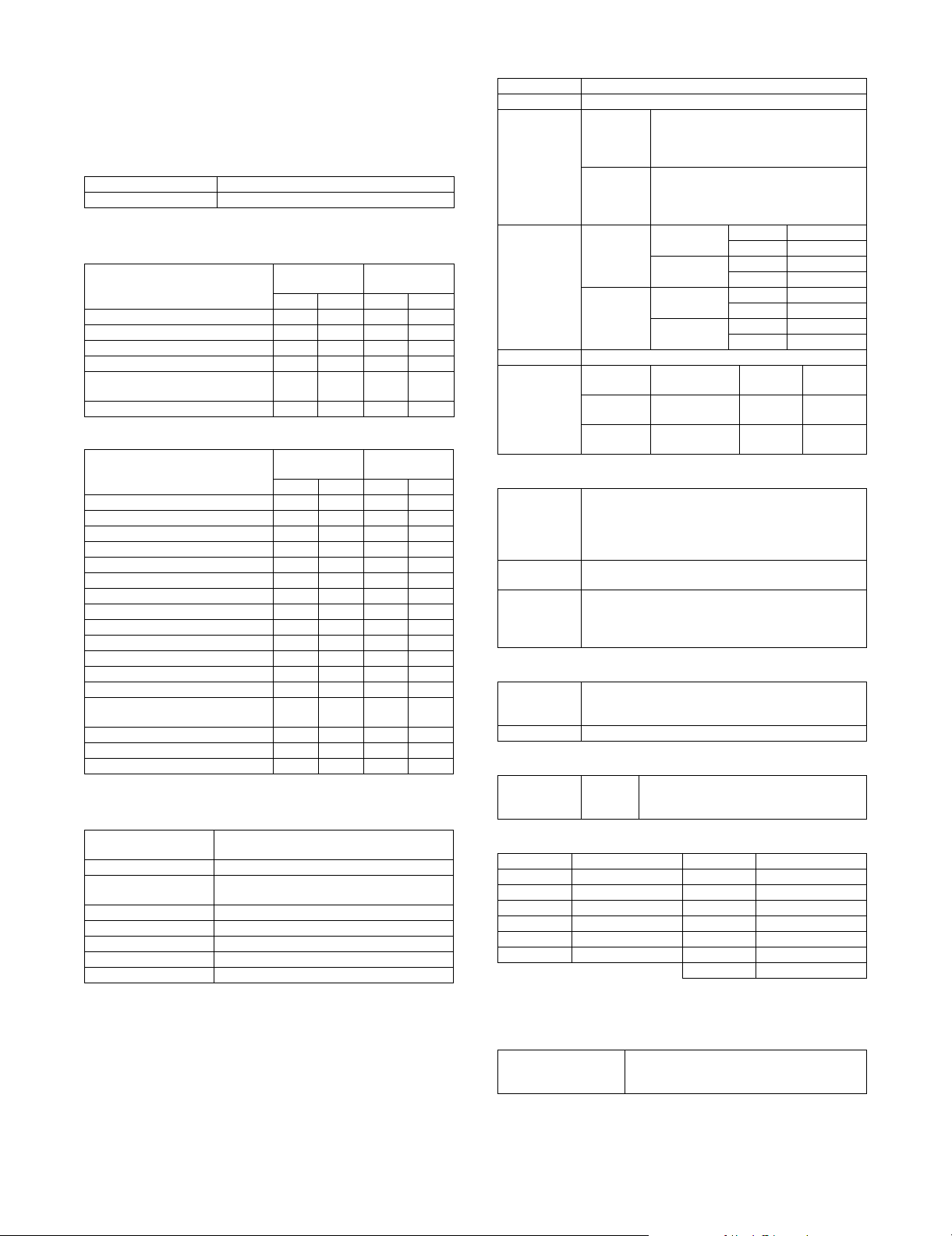

A. Base engine

(1) Type

Type Desk-top

Color support Full color

(2) Engine speed

a. Tray1 – 4 (Main unit), LCC

MX-4500N

Paper size

A3, 11 x 17, 8K 20 17 17 17

B4, 8.5 x 14, 8.5 x 13 22 20 20 20

A5R, 5.5 x 8.5R 32 25 25 25

A4, B5, 8.5 x 11, 16K 45 35 35 35

A4R, B5R, A5R, 8.5 x 11R,

7.25 x 10.5R, 5.5 x 8.5R, 16KR

Extra 19161616

MX-4501N

B/W Color B/W Color

30 25 25 25

b. Manual (Main unit)

MX-4500N

Paper size

A3, 11 x 17, 8K 19 15 16 15

B4, 8.5 x 14, 8.5 x 13 20 16 17 16

A4, 8.5 x 11, 16K 22 18 18 18

B5 41 29 31 29

A4R, 16KR 41 31 31 31

8.5 x 11R 30 20 25 20

B5R, 7.25 x 10.5R 30 21 25 21

A5R, 5.5 x 8.5R 30 22 25 22

12 x 18 32 25 25 25

OHP(A4, 8.5 x 11) 15 14 15 14

OHP(A4R, 8.5 x 11R) 12 10 12 10

Extra 19151615

Envelope 16 15 16 15

Heavy paper (B5, A4, A5R, 8.5 x 11,

8.5 x 5.5R, 16K)

Heavy paper (Postcard HIGH)*1 15 14 15 14

Heavy paper (Postcard LOW)*1 8888

Heavy paper (Other sizes) 8888

MX-4501N

B/W Color B/W Color

15 14 15 14

*1: Switched by the service simulation setting

(3) Engine composition

Photoconductor kind OPC (Drum diameter: Black; I30mm, Color;

Copying method Electronic photo (Laser)

Developing system Dry-type dual-component magnetic brush

Charging system Charged saw-tooth method

Transfer system Intermediate transfer belt

Cleaning system Counter blade

Fusing system Heat roller

Waste toner disposal No toner recycling system

I30mm x 3)

development

MX-3500N

MX-3501N

MX-3500N

MX-3501N

(4) Shifter

5GTXKEG/CPWCN

Typ e Sh ifte r

Paper weight 55 – 209g/m

Paper size Non offset

Productivity

(A4, 8.5x11)

Offset range 30mm

Range of error

(In using the

recommended

paper, A4/8.5

x 11)

mode

(Normal

output)

Offset

mode

Non-offset

(Normal

output)

Offset

mode

Non-offset Not drop from

Offset

mode

2

(17 – 56 lbs)

A3, B4, A4R, B5, B5R, A5R, Postcard, 8K,

16K, 16KR,11 x 17, 8.5 x 14, 8.5 x 13,

8.5 x 11, 8.5 x 11R, 7.25 x 10.5R,

5.5 x 8.5R, Envelope, Extra

A3, B4, A4R, B5, B5R, A5R, Postcard, 8K,

16K, 16KR, 11 x 17, 8.5 x 14, 8.5 x 13,

8.5 x 11, 8.5 x 11R, 7.25 x 10.5R, 5.5 x

8.5R (Not Envelope, Extra)

MX-3500N B/W 35cpm

MX-4500N B/W 45cpm

MX-3500N B/W 35cpm

MX-4500N B/W 45cpm

Horizontal

direction

the tray.

Within 50mm Within

Color 35cpm

Color 35cpm

Color 35cpm

Color 35cpm

Verti cal

direction

--

r10mm

Between

Jobs

Min.10mm

(5) Engine resolution

Resolution Writing:

Smoothing

function

Gradation Writing:

600 x 600dpi

1200 x 600dpi (Monochome printing only.)

* Rotation output not allowed at 1200dpi x 600dpi. PS

expansion kit needed.

None

Monochrome: 2 levels (1bit) * 256 levels equivalent

Color: Each color 2 levels (1bit) / Each color 16 levels

(4bits) * 256 levels equivalent

(6) Warmup

Warmup time 240 sec or less

Pre-heat Yes

* The value may be increased if process-control

processing is being executed.

(7) Jam recovery time

With the door

open

Approx.

60 sec

Condition: After the door is kept open for 60

seconds, standard setting, the polygon

motor halt

(8) Printable area

A3 293 x 413mm 12 x 18 * 279 x 432mm

B4 253 x 357mm 11 x 17 275 x 425mm

A4 206 x 290mm 8.5 x 14 212 x 349mm

B5 178 x 250mm 8.5 x 13 212 x 323mm

A5 144 x 203mm 8.5 x 11 212 x 272mm

7.25 x 10.5 180 x 260mm 5.5 x 8.5 136 x 209mm

Postcard 96 x 141mm 8K 266 x 383mm

16K 191 x 263mm

* The printable area for 12 x 18 must be as large as the A3/11 x 17

page dimension by PCL / PS driver.

(9) Void area

Void area

Image loss

MX3500N SPECIFICATIONS 2 – 1

Top: 4 mm or less

Bottom: 3 mm or less

FR Total: 4 mm or less

Page 9

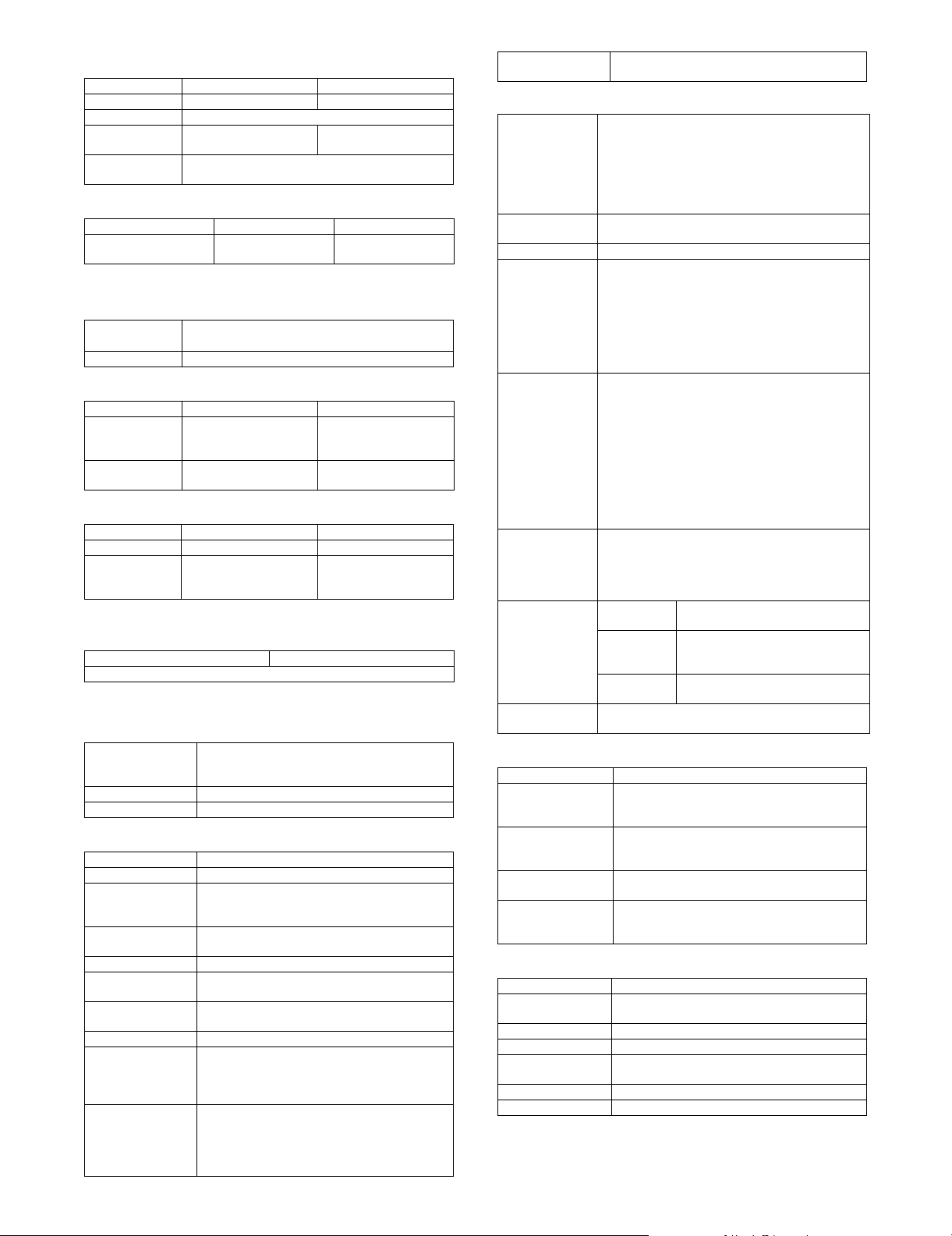

(10) Power source

Voltage / Current 100 – 127V 12A 220 – 240V 8A

Frequency 50/60Hz

Power source

code

Power switch 2 switches (Primary switch: in the front cover;

100V type 200V type

Fixed type (direct) Inlet type

Seconday switch: the operation panel)

(11) Power consumption

Maximum rated power

consumption

*1: Heater is OFF when power source ON.

100V type 200V type

1.44kW 1.84kW

(12) Noise

In action B/W : 63dB or less

Standby B/W : 55dB or less

Color : 63dB or less

(13) Dimensions

Outer dimensions

(W x D x H)

Footprint (W x D) 645 x 670mm

MX-3500N/MX-4500N MX-3501N/MX-4501N

645 x 670 x 950mm

(25 25/64 x 26 3/8 x

37 26/64 inch)

(25 25/64 x 26 3/8 inch)

645 x 670 x 960mm

25 25/64 x 26 3/8 x

37 51/64 inch)

645 x 670mm

(25 25/64 x 26 3/8 inch)

(14) Weight

Main unit Approx. 114kg (251lbs) Approx.123kg (271lbs)

Main unit +

Developer +

Toner cartridge

MX-3500N/MX-4500N MX-3501N/MX-4501N

Approx. 119kg (262lbs) Approx.128kg (282lbs)

(15) Dimensions occupied by Machine (with Multi

Manual/Exit tray extended)

MX-3500N/MX-4500N MX-3501N/MX-4501N

W1075 x D 670mm (W42 21/64 x D26 3/8 inch)

B. Paper feed unit/Transport/Paper exit secton

(1) Machine paper feed tray

Form Standard: Double feeder tray + multi manual

Feeding method Feeding from the upper section with front loading

Heater (Engine part) Service parts

(2) Paper feed tray 1/tray 2

Feeding method Feeding from the upper section with front loading

Heater (Engine part) Service parts

Paper size A3, B4, A4, A4R, B5, B5R, A5R, 8K, 16K, 16KR

Changing of paper

size

Paper type setting Yes

Default paper size

setting

Feedable paper

type/weight

Paper capacity Standard paper: 500 sheets (80g/m

Paper Type Plain paper, pre-printed paper (not including

Paper size detection

* About A5R, 5.5 x

8.5R, 8K, 16K,

16KR, manual

setting.

Maximum: Fourfold feeder tray + multi manual +

large capacity feeder cassette

11 x 17, 8.5 x 14, 8.5 x 13, 8.5 x 11,

8.5 x 11R, 7.25 x 10.5R, 5.5 x 8.5R

Guide adjustment by users

Shipped with max. width of paper guide

Plain paper: 60-105g/m

backing paper), recycled paper, letter head, prepunched paper, colored paper

* Users can set up all of these paper types.

A3, B4, A4, A4R, B5, B5R, A5R, 8.5 x 13

11 x 17, 8.5 x 14, 8.5 x 11, 8.5 x 11R, 7.25 x 10.5R

2

(16-28 lbs)

2

, 21lbs)

Detection of

Remaining Paper

Level detection (4 levels: 100%, 67%, 33%, and

none)

(3) Manual feed tray (Bypass tray)

Paper Size A3, B4, A4, A4R, B5, B5R, A5R, 8K, 16K, 16KR

Changing of

paper size

Paper type setting Yes

Feedable paper

type/weight

Paper capacity Standard paper: 100 sheets

Paper Type Plain paper, pre-printed paper (Excluding back print

Paper size

detection

Detection of

remaining paper

12 x 18, 11 x 17, 8.5 x 14, 8.5 x 13, 8.5 x 11, 8.5 x

11R, 7.25 x 10.5R, 5.5 x 8.5R

Envelope (Monarch / Com-10 / DL / C5 / Rectangle 3 /

Western 2 / Western 4)

Extra Size (Tab paper is limited to A4; tab width

12mm-20mm / 8.5 x 11; tab width 6.1-17mm)

Guide adjustment by users

Thin paper: 55 – 59g/m

Plain paper: 60 – 105g/m

Heavy Paper: 106 – 209g/m

Envelope: 75 – 90g/m

OHP

Label paper

Tab paper

Gloss Paper

Envelope: 20 sheets

OHP: 20 sheets

Heavy paper: 40 sheets

Tab paper: 20 sheets

Gloss paper: 20 sheets *

Other special paper: 1 sheet

* The gloss paper is sucked under a high

temperature environment to cause double feed or

misfeed. In such a case, manually supply paper

sheet by sheet (Select heavy paper).

paper), recycled paper, letter head, pre-punched

paper, colored paper, heavy paper, thin paper, label

paper, OHP, tab paper, envelope.

* Users can set up all of these paper types.

Auto Detect

Auto-AB

Auto Detect

Auto-Inch

For China A3, B4, A4, A4R, B5, B5R, A5R, 11 x

yes or no only

2

(15 – 16 lbs)

2

(16 – 28 lbs)

2

(28 – 56 lbs)

2

(20 – 24 lbs)

A3, B4, A4, A4R, B5, B5R, A5R, 8.5 x

13, Postcard, 8.5 x 11, 11 x 17

12 x 18, 11 x 17, 8.5 x 14, 8.5 x 11,

8.5 x 11R, 5.5 x 8.5R, 7.25 x 10.5R,

A3, B4, A4, B5

17, 8.5 x 14, 8.5 x 11, 8K, 16K

(4) Double-sided

Method Non-Stack

Paper size A3, B4, A4, A4R, B5, B5R, A5R, 8K, 16K, 16KR,

Paper type Plain paper, pre-printed paper (not including

Paper weight

(for duplex operation)

Logo paper support For paper such as letterhead paper with front-

11 x 17, 8.5 x 14, 8.5 x 13, 8.5 x 11, 8.5 x 11R,

8.5 x 5.5R

backing paper), recycled paper, letter head, prepunched paper, colored paper

Plain paper: 60-105g/m

Heavy paper: 106-209g/m

back attributes, the engine control must be cared

for printing side.

2

(16-28 lbs)

2

(28-56 lbs)

(5) Paper exit tray (Center tray)

Exit location/method Face down in the main unit

Exit capacity 500 sheets (A4 or 8.5 x 11 (color recommended

Exit paper size/type All feedable paper except 12x18.

Exit paper detection No

Exit tray full

detection

Shifting function Yes

Rotation sort No

paper))

Yes

MX3500N SPECIFICATIONS 2 – 2

Page 10

(6) Paper exit tray unit (Right tray)

* Option (MX-TRX2)

Form Exit tray unit

Transport standard Center standard

Ejecting location/

method

Tray capacity 100 sheets (A4 or 8.5 x 11 (color recommended

Ejected paper size/

type

Full tray detection Yes

Shifter No

Dimensions W314 x D405 x H52mm

Weight Approx. 0.93kg (2 lbs)

Installation/

maintenance

Optional detection Setting by simulation (Sim. 26-1)

Packaged items Exit tray, full actuator

External ejection from the right face of the main unit

/ face-down ejection

paper))

Any feedable paper except envelope and tab paper.

(W12 23/64 x D15 61/64 x H2 3/64 inch)

With tray extended: W444 x D405 x H52mm (W17

31/64 x D15 61/64 x H2 3/64 inch)

Installation by service personnel.

(7) Reversing single pass feeder

Form RSPF (Reversing single pass feeder)

Scan speed Monochrome

Copy 1-sided: 45 sheets/minute

Fax 1-sided: 48 sheets/minute

Scanner 1-sided: 48 sheets/minute

Internet

Fax

Document setup

direction

Document standard

location

Document transport

method

Document sizes Inch type-1 11 x 17, 8.5 x 14, 8.5 x 11,

(A4/8.5 x 11)

(600 x 300dpi, 1bit)

2-sided: 15 pages/minute

(600 x 300dpi, 1bit)

(200 x 200dpi, 1bit)

2-sided: 15 pages/minute

(200 x 200dpi, 1bit)

(200 x 200dpi, 1bit)

2-sided: 15 pages/minute

(200 x 200dpi, 1bit)

1-sided: 48 sheets/minute

(200 x 200 dpi, 1bit)

2-sided: 15 pages/minute

(200 x 200 dpi, 1bit)

Upward standard (1toN feeding standard)

Center standard (Rear one-side standard for

random feeding)

Sheet-through method

8.5 x 11R, 8.5 x 5.5, A4, A3

Inch type-2 11 x 17, 8.5 x 13, 8.5 x 11,

8.5 x 11R, 8.5 x 5.5, A4, A3

AB type-1 A3, B4, A4, A4R, B5, B5R, A5,

8.5 x 11, 8.5 x 14, 11 x 17

AB type-2 A3, B4, A4, A4R, B5, B5R, A5,

8.5 x 11, 216 x 330, 11 x 17

AB type-3 A3, B4, A4, A4R, A5, 8K, 16K,

16KR, 8.5 x 11, 216 x 330, 11 x 17

Long paper 800mm (Monochrome 2 levels

only)

Mixed feeding (same type / same width) possible

Random feeding (feeding of different types /

different widths)

Only the following combinations of 2 size types

are allowed: A3 and B4; B4 and A4R; A4 and B5;

B5 and A5; and 11-inch and 8.5-inch.

2-sided scanning is disabled during random

feeding.

Color

(A4/8.5 x 11)

1-sided: 35 sheets/

minute (600 x

600dpi, 4bit)

2-sided: 13 pages/

minute (600 x

600dpi, 4bit)

N/A

1-sided: 35 sheets/

minute (200 x

200dpi, 8bit) (when

in full color)

2-sided: 15 pages/

minute (200 x

200dpi, 8bit)

N/A

Document

weights

Document carrying

capacity

Types of document

that may not be

transported

Paper detection Yes

Paper detection size Auto detection (Switching one type of detection

Paper feeding

direction

Document inversion Yes

Simultaneous double-

sided scanning

1-side Thin paper 35 – 49g/m2 (9 – 13 lbs)

Plain paper 50 – 128g/m

2-side 50 – 128 g/m

Maximum: 100 sheets (80g/m

Maximum: 13 mm, 1/2 inch or less

The following documents are NOT allowed:

OHP, second original drawing, tracing paper,

carbon paper, thermal paper, wrinkled / broken /

torn document, document with cuts and pastes,

documents printed by an ink ribbon, and

perforated document except 2-punched / 3punched (Perforated document by punch unit is

allowed.)

unit through system setting)

Inch-1 11 x 17, 8.5 x 14, 8.5 x 11,

Inch-2 11 x 17, 8.5 x 13, 8.5 x 11,

AB-1 A3, B4, A4, A4R, B5, B5R, A5, 8.5

AB-2 A3, B4, A4, A4R, B5, B5R, A5, 8.5

AB-3 A3, B4, A4, A4R, A5, 8K, 16K,

Right hand feeding

Not allowed

2

(13 – 34 lbs)

8.5 x 11R, 5.5 x 8.5, A4, A3

8.5 x 11R, 5.5 x 8.5, A4, A3

x 11, 8.5 x 14, 11 x 17

x 11, 216 x 330, 11 x 17

16KR, 8.5 x 11, 216 x 330, 11 x 17

2

(13 – 34 lbs)

2

, 21lbs), or

(8) Duplex single pass feeder

Form DSPF (Duplex single pass feeder)

Scan speed Monochrome

Copy 1-sided: 45 sheets/minute

Fax 1-sided: 60 sheets/minute

Scanner 1-sided: 60 sheets/minute

Internet

Fax

Document standard

location

Document sizes Inch type-1 11 x 17, 8.5 x 14, 8.5 x 11,

(A4/8.5 x 11)

(600 x 300dpi, 1bit)

2-sided: 45 pages/minute

(600 x 300dpi, 1bit)

(200 x 200dpi, 1bit)

2-sided: 60 pages/minute

(200 x 200dpi, 1bit)

(200 x 200dpi, 1bit)

2-sided: 60 pages/minute

(200 x 200dpi, 1bit)

1-sided: 60 sheets/minute

(200 x 200 dpi, 1bit)

2-sided: 15 pages/minute

(200 x 200 dpi, 1bit)

Center standard (Rear one-side standard for

random feeding)

8.5 x 11R, 8.5 x 5.5, A4, A3

Inch type-2 11 x 17, 8.5 x 13, 8.5 x 11,

8.5 x 11R, 8.5 x 5.5, A4, A3

AB type-1 A3, B4, A4, A4R, B5, B5R, A5,

8.5 x 11, 8.5 x 14, 11 x 17

AB type-2 A3, B4, A4, A4R, B5, B5R, A5,

8.5 x 11, 216 x 330, 11 x 17

AB type-3 8K, A4, A4R, B4, 16K, 16KR,

A5, 8.5 x 11, 216 x 330, 11 x 17

Long paper 800mm (Monochrome 2 levels

only)

Mixed feeding (same type / same width) possible

Random feeding (feeding of different types /

different widths)

Only the following combinations of 2 size types

are allowed: A3 and B4; B4 and A4R; A4 and B5;

B5 and A5; and 11-inch and 8.5-inch.

Color

(A4/8.5 x 11)

1-sided: 35 sheets/

minute (600 x

600dpi, 4bit)

2-sided: 35 pages/

minute (600 x

600dpi, 4bit)

N/A

1-sided: 35 sheets/

minute (200 x

200dpi, 8bit) (when

in full color)

2-sided: 35 pages/

minute (200 x

200dpi, 8bit)

N/A

MX3500N SPECIFICATIONS 2 – 3

Page 11

Document

weights

Document carrying

capacity

Types of document

that may not be

transported

Paper detection Yes

Paper detection size Auto detection (Switching one type of detection

Paper feeding

direction

Document inversion Yes

Simultaneous double-

sided scanning

1-side Thin paper 35 – 49g/m2 (9 – 13 lbs)

Plain paper 50 – 128g/m

2-side 50 – 128 g/m

Maximum: 150 sheets (80g/m

Maximum: 19.5 mm, 3/4 inch or less

The following documents are NOT allowed:

OHP, second original drawing, tracing paper,

carbon paper, thermal paper, wrinkled / broken /

torn document, document with cuts and pastes,

documents printed by an ink ribbon, and

perforated document except 2-punched / 3punched (Perforated document by punch unit is

allowed.)

unit through system setting)

Inch-1 11 x 17, 8.5 x 14, 8.5 x 11,

Inch-2 11 x 17, 8.5 x 13, 8.5 x 11,

AB-1 A3, B4, A4, A4R, B5, B5R, A5, 8.5

AB-2 A3, B4, A4, A4R, B5, B5R, A5, 8.5

AB-3 8K, B4, A4, A4R, 16K, 16KR, A5,

Right hand feeding

Allowed

2

(13 – 34 lbs)

8.5 x 11R, 5.5 x 8.5, A4, A3

8.5 x 11R, 5.5 x 8.5, A4, A3

x 11, 8.5 x 14, 216 x 330, 11 x 17

x 11, 216 x 330, 11 x 17

8.5 x 11, 216 x 330, A3

2

(13 – 34 lbs)

2

, 21lbs), or

C. Scanner section

(1) Resolution/Gradation (or Levels)

(2) Original cover

Scan Range 297 x 432mm

Original Cover

Standard

Location

Detection Yes

Detection Size Auto Detect (One type of detection unit to be switched

Heater

(Scanner part)

Left back as standard

for software destination)

Inch <INCH-1>

11 x 17, 8.5 x 14, 8.5 x 11, 8.5 x 11R, 5.5 x 8.5

<INCH-2>

11 x 17, 8.5 x 13, 8.5 x 11, 8.5 x 11R, 5.5 x 8.5

AB <AB-1>

A3, A4, A4R, A5, B4, B5, B5R

<AB-2>

A3, A4, A4R, A5, B5, B5R, 216 x 330

<AB-3>

8K, A4, A4R, A5, B4, 16K, 16KR

Service parts

D. Fuser section

(1) Type

System Heat roller attachment system

Scan

resolution (dpi)

Original

Cover

RSPF/

DSPF

Transmission

resolution (dpi)

Exposure lamp Xenon

Scan Levels 10bits

Output levels FAX mode: 1bit

Image

process

PC-FAX/

PC-Internet

Fax

Network

TWAIN

Internet Fax mode: 1bit

Scanner mode:

Black & White: 1bit

Gray Scale: 8bit

Full Color: Each color RGB 8bit

Copy mode

Monochrome Color

600 x 600dpi

600 x 300dpi

(Default)

600 x 600dpi

600 x 300dpi

(Default)

(Scanner)

100 x 100dpi / 200 x 200dpi / 300 x 300dpi

/ 400 x 400dpi / 600 x 600dpi

(Internet Fax)

200 x 100dpi (Half tone not allowed) /

200 x 200dpi / 200 x 400dpi /

400 x 400dpi / 600 x 600dpi

(FAX)

Standard (203.2 x 97.8dpi) (Half tone not

allowed) / Fine (203.2 x 195.6 dpi) /

Super fine (203.2 x 391dpi) /

Ultra fine (406.4 x 391 dpi)

200 x 100dpi / 200 x 200dpi / 200 x 400dpi

/ 400 x 400dpi

75dpi / 100dpi / 150dpi / 200dpi / 300dpi /

400dpi / 600dpi or custom: 50-9600dpi

600 x 600dpi

(Default)

600 x 600dpi

(Default)

MX3500N SPECIFICATIONS 2 – 4

Page 12

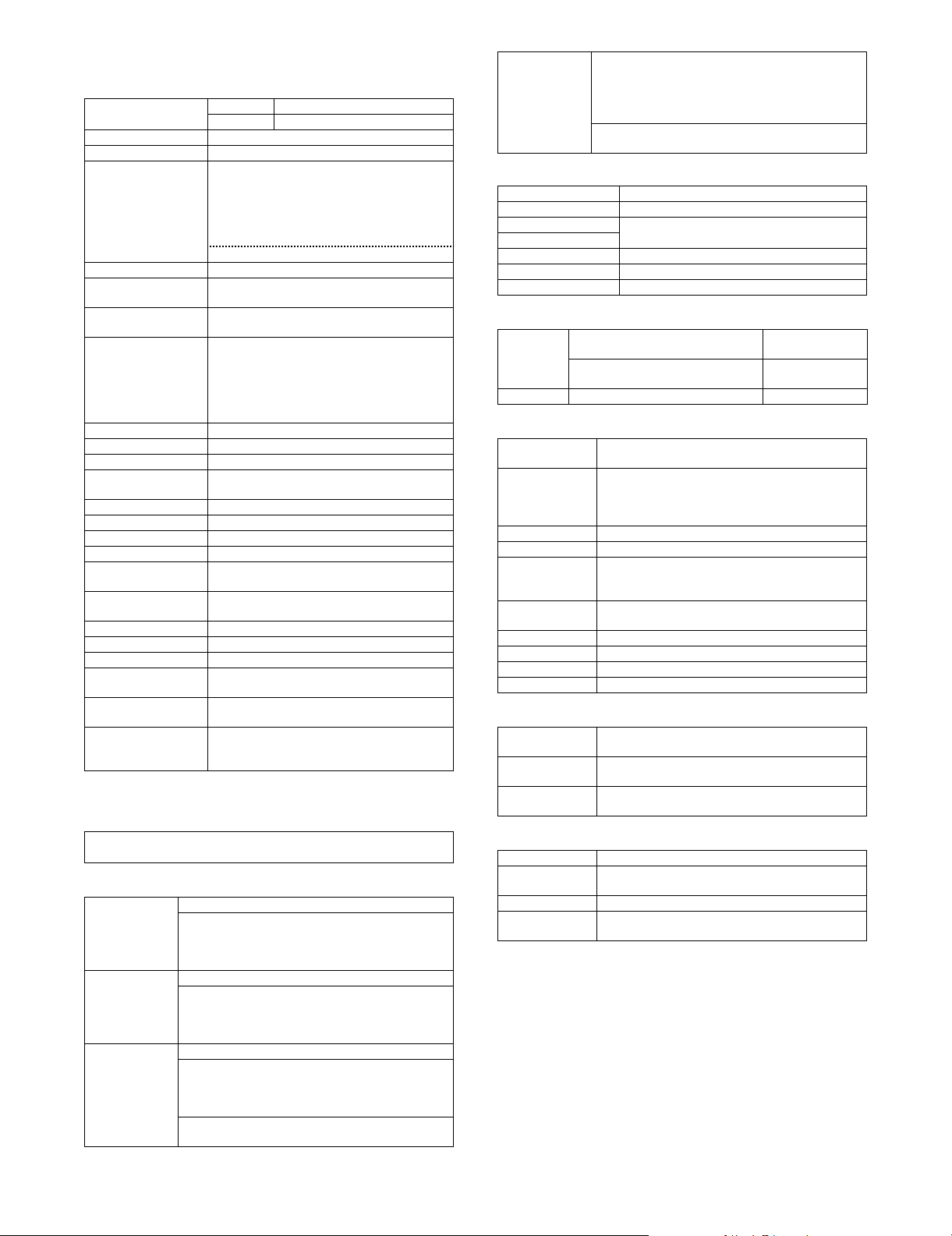

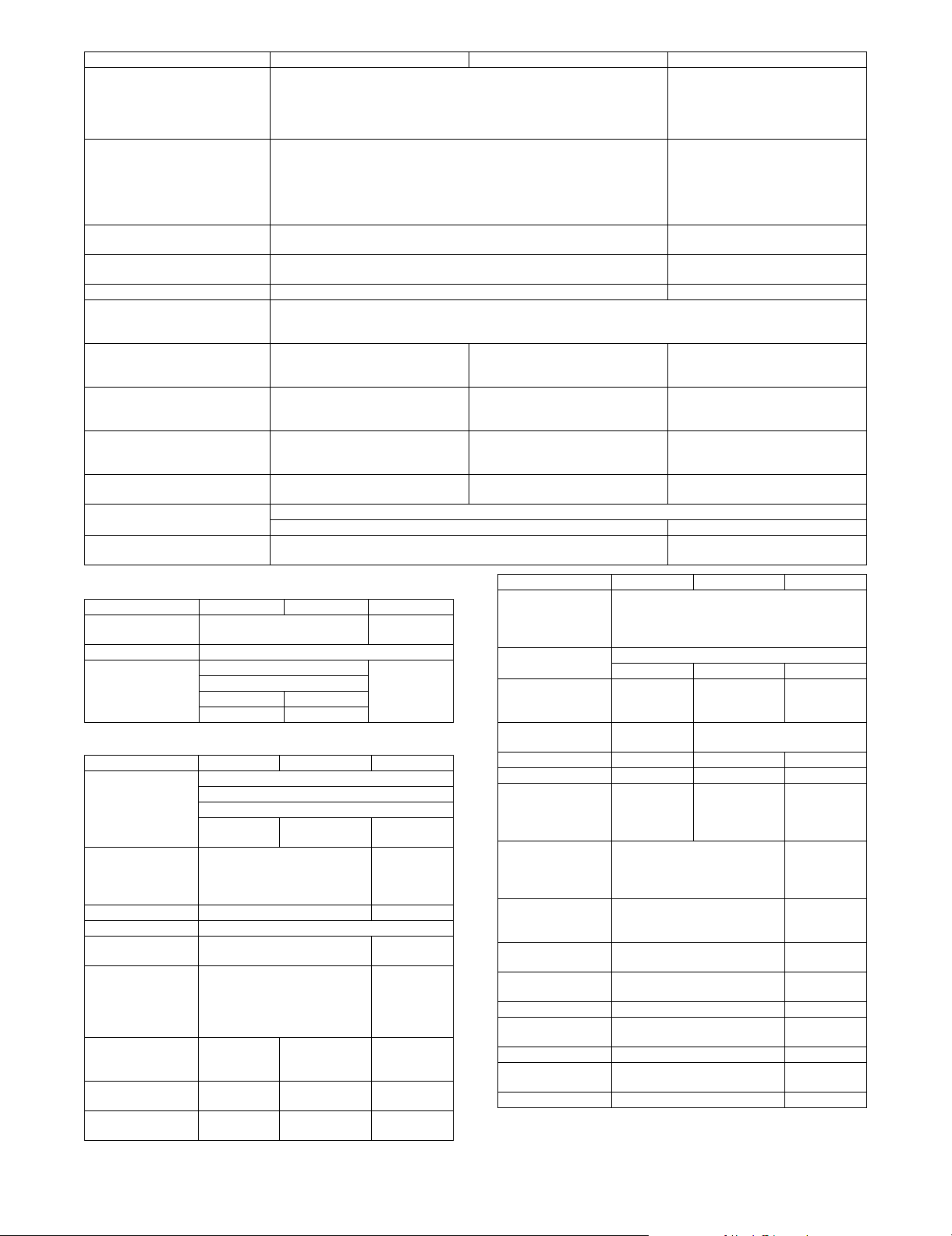

2. Functional specifications

A. Specifications of copy functions

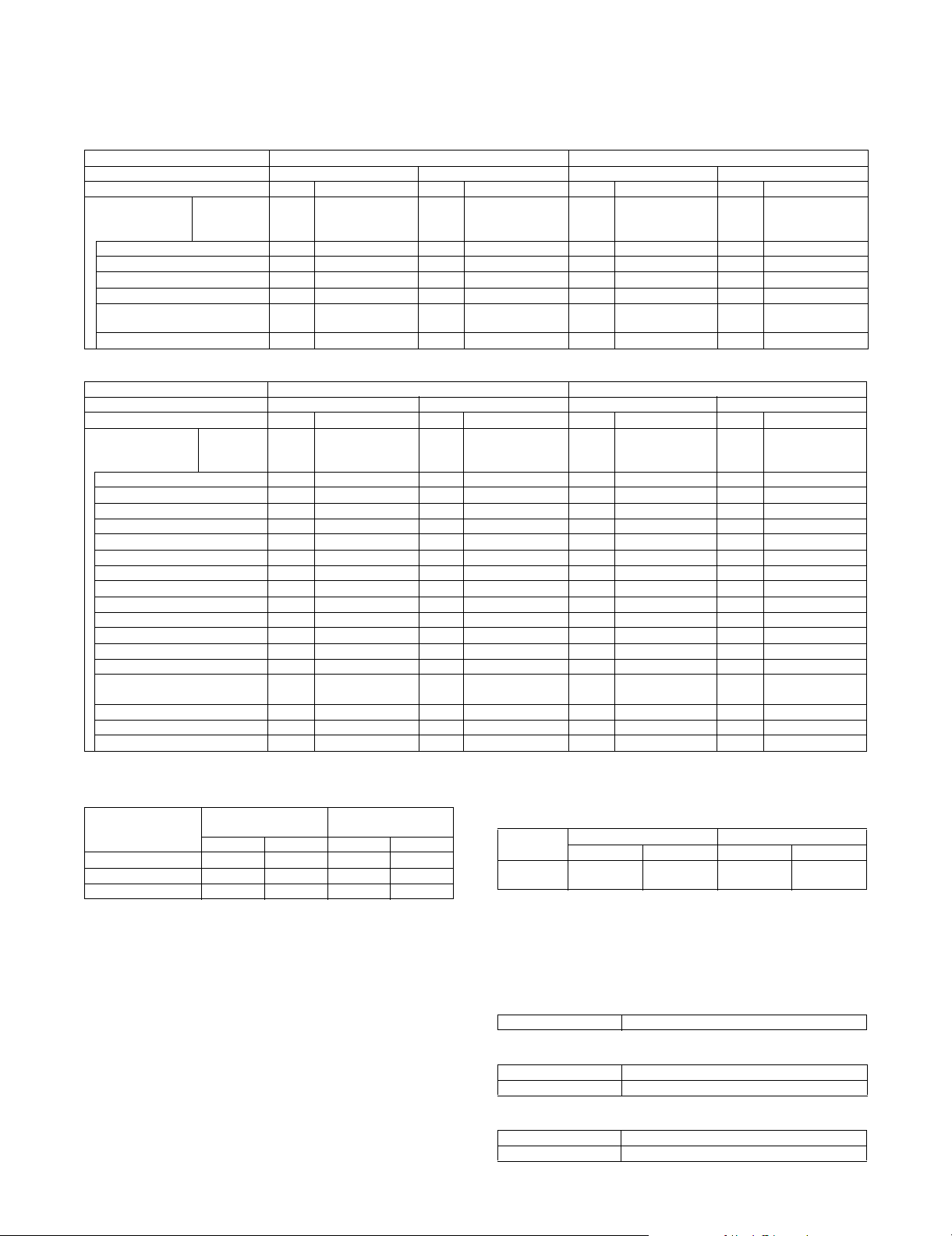

(1) Copy speed (Continuous copy speed)

a. Tray 1 – 4, LCC

Model name MX-4500N/MX-4501N MX-3500N/MX-3501N

Color / B/W Color B/W Color B/W

Print / Copy Print Copy Print Copy Print Copy Pr int Copy

Paper size Magnification Normal Reduction (25%)

A3, 11 x 17, 8K 17 17 20 20 17 17 17 17

B4, 8.5 x 14, 8.5 x 13 20 20 22 22 20 20 20 20

A4, B5, 8.5 x 11, 16K 35 35 45 45 35 35 35 35

A5R, 5.5 x 8.5R 25 25 32 32 25 25 25 25

A4R, B5R, 8.5 x 11R, 16KR,

7.25 x 10.5R

Extra 1616191916161616

25 25 30 30 25 25 25 25

Normal (100%)

Enlargement (400%)

b. Manual feed

Model name MX-4500N/MX-4501N MX-3500N/MX-3501N

Color / B/W Color B/W Color B/W

Print / Copy Print Copy Print Copy Print Copy Print Copy

Paper size Magnification Normal Reduction (25%)

A3W, 12 x 18 15 15 19 19 15 15 16 16

A3, 11 x 17, 8K 16 16 20 20 16 16 17 17

B4, 8.5 x 14, 8.5 x 13 18 18 22 22 18 18 20 20

A4, 8.5 x 11, 16K 29 29 41 41 29 29 31 31

B5 31 31 41 41 31 31 31 31

A5R, 5.5 x 8.5R 25 25 32 32 25 25 25 25

B5R 2222303022222525

8.5 x 11R 21 21 30 30 21 21 25 25

A4R, 7.25 x 10.5R, 16KR 20 20 30 30 20 20 25 25

OHP(A4, 8.5 x 11) 14 14 15 15 14 14 15 15

OHP(A4R, 8.5 x 11R) 10 10 12 12 10 10 12 12

Extra 1515191915151616

Envelope 15 15 16 16 15 15 16 16

Heavy paper (B5, A4, A5R, 8.5 x

11, 8.5 x 5.5R, 16K)

Heavy paper (Postcard HIGH) *1 14 14 15 15 14 14 15 15

Heavy paper (Postcard LOW) *1 8 8 8 8 8 8 8 8

Heavy paper (Other sizes) 8 8 8 8 8 8 8 8

14 14 15 15 14 14 15 15

Normal (100%)

Enlargement (400%)

*1: Switched by the service simulation setting

(2) First copy time

MX-4500N (RSPF),

Platen/RSPF/DSPF

Platen 4.1 sec 6.9 sec 4.7 sec 6.9 sec

RSPF 9.3 sec 14.2 sec 10.1 sec 14.2 sec

DSPF 8.8 sec 15.2 sec 9.5 sec 15.2 sec

MX-4501N (DSPF)

B/W Color B/W Color

[Measuring Conditions]

* Feeding A4/8.5x11paper from the main unit tray 1

* Polygon in rotation

* Auto Color Selection OFF/Auto Color for color OFF

MX-3500N (RSPF),

MX-3501N (DSPF)

Normal Reduction (25%)

Normal (100%)

Enlargement (400%)

Normal Reduction (25%)

Normal (100%)

Enlargement (400%)

(3) Job speed

a. Document changing speed (in copy mode)

S to S 45cpm

* The copy speed in combination of the main unit and the auto

document feed user is defined.

* S to S: A4/8.5 x 11 document, 11 pages and 1 copy (not including

the first copy)

Monochrome: 600 x 300dpi and color: 600 x 600dpi (default)

(4) Continuous copy

Normal Reduction (25%)

Normal Reduction (25%)

(100%)

Normal (100%)

Enlargement (400%)

Normal (100%)

Enlargement (400%)

MX-4500N/MX-4501N MX-3500N/MX-3501N

B/W Color B/W Color

35cpm

(100%)

Normal Reduction (25%)

Normal (100%)

Enlargement (400%)

Normal Reduction (25%)

Normal (100%)

Enlargement (400%)

35cpm

(100%)

35cpm

(100%)

Multi max. number 999 sheets

(5) Resolution

Scan resolution 600 x 600dpi

Writing resolution 600 x 600dpi

(6) Copy document

Document Max. A3 (11 x 17)

Document type Sheet/Book original

MX3500N SPECIFICATIONS 2 – 5

Page 13

(7) Copy magnification ratio

(11) Copy functions

Copy

magnification ratio

Zoom 25 – 400% (25 – 200% for RSPF)

Preset

magnification ratio

XY zoom Yes

Normal: 1:1r0.8%

AB series: 25%, 50%, 70%, 81%, 86%, 100%,

115%, 122%, 141%, 200%, 400%

Inch series: 25%, 50%, 64%, 77%, 100%, 121%,

129% , 200%, 400%

4

(8) Density, copy image quality processing

Exposure mode Automatic (Color: Auto Color, Black-white: Character

Copy document

mode

Color emphasis Effective for Text, Text/Printed photo, Printed photo,

Manual steps 9 steps

Toner save mode Monochrome: Yes

AE)

Text,Text/Printed Photo, Print photo, Text/Photo,

Photo, Map, Pale-color document.

Effective for Text, Text/Printed photo, Printed photo

mode.

Text/Photo, Photo, Map mode.

Color: Yes

Off on printed photo, photo or pale-color document

(9) Color copy mode

Auto Color

Selection copy

Full color mode Enforced full color mode

2-color mode Red-black mode (Change red point in document into

Single color mode Mode to select one color from R/G/B/C/M/Y

Monochrome copy

mode

Copy mode automatically discerning color/

monochrome.

other color)

Mode to select black and another color from R/G/B/

C/M/Y

Enforced monochrome copy mode

(10) Color Adjustment

RGB adjustment Yes

Color balance Yes

Saturation

adjustment

Brightness

adjustment

Contrast

adjustment

Sharpness

adjustment

Background

removal

Auto color

calibration

Registration

adjustment

Yes

Yes

No

Yes

Yes

Allowed by system setting

Allowed by system setting (automatic-manual)

Function Automatic paper

Special

function

selection

Automatic

magnification selection

Paper type select Yes

Auto tray switching Yes

Rotated copy Yes

Electronic sort Yes

Rotated sort No

Job reservation Yes

Program call/

registration.

Preheat function Yes

Auto power shutoff Yes

User authentication 1000

Process control Yes

Document paper size

input

Indeterminate paper

size input

2-sided copy direction

switch

Margin shift Yes

Edge/center erase Yes

Dual page copy Yes

Cover/insertion Yes

Tandem copy Yes

Tab paper insertion Yes (Insertion only. Tab copy not

OHP insertion Yes

Tab c o p y Ye s

Centering Yes

2in1/4in1 Yes

Pamphlet Yes

Card shot Yes

Book copy Yes

Large capacity

document mode

Black-white Inversion Yes (Only black-white copy allowed/

Multi-Page

Enlargement

Mirror image Yes

Photo repeat Yes

Date print Yes (Colored allowed: Bk, C, M, Y)

Character print Yes (Colored allowed: Bk, C, M, Y)

Stamp Yes (Colored allowed: Bk, C, M, Y)

Page printing Yes (Colored allowed: Bk, C, M, Y)

Shading No

Proof copy Yes

Mixed document

feeder

Document Control Yes (with Data Security Kit

Yes (Mixed/random size feeding

supported)

Yes

Type setting allowed

Large rotated copy exceeding A4

supported

Unavailable

Yes (Program name registration to

be examined)

Conditions set up by system setting

Conditions set up by system setting

Yes (Determinate/indeterminate

size)

Yes

Yes

allowed. Staple/Punch not allowed.)

Yes

color copy not allowed upon setup

Not ready)

Yes

Yes (Random + MIX)

equipped)

MX3500N SPECIFICATIONS 2 – 6

Page 14

B. Image send function

(1) Mode

Scanner Scan to e-mail

Internet

Fax

IP-FAX No

(2) Image send function (Push send from the main

a. Support system

Corresponding

server

/protocol

b. Support image

File format Monochrome: TIFF, PDF,

Compression

method

Specified pages per

size (number of

page(s)

specification

allowed)

c. Image processing

Original scanning

color

Auto color selection [When Color start key

Halftone

reproduction

Scan to Desktop

Scan to FTP

Scan to Folder(SMB)

Scan to USB memory

Scan to e-mail with Meta

Scan to Desktop with Meta

Scan to FTP with Meta

Scan to SMB with Meta

Fax to Fax (manual)

Fax to E-mail (inbound routing)

Fax to FTP/Desktop/SMB/E-mail (Document Admin)

Full mode supported (including Simple mode)

unit)

Mode Scanner Internet Fax

Mode Scanner Internet Fax

Mode Scanner Internet Fax

SMTP

FTP(TCP/IP)

SMB

Encrypted PDF

Color: Gray scale, color

TIFF, JPEG, PDF,

Encrypted PDF

[Monochrome]

• Non-compression

• G3 (1-dimensional)

= MH (Modified

Huffman)

•G4

= MMR (Modified MR)

[Color/Gray scale]

• JPEG (High, middle,

low)

Yes ---

Full color, grayscale, B/W B/W

pressed.]

• Auto (When judged as

Color : Full color, When

judged as B/W : B/W (2

value)/Gray scale)

[When B/W start key]

• B/W (2 value)

• Gray scale

Equivalent of 256 steps

POP server

SMTP server

ESMTP server

Monochrome TIFF-FX

(TIFF-F, TIFF-S)

MH, MMR

---

Mode Scanner Internet Fax

Density adjustment Auto + 5 steps

Selection of image

quality

Resolution

(depends on file

format/transmission

method)

Moire reduction

mode

Notes' security

feature

(The image quaity of

"Auto" is the same as that

of "Manual = 3" when

selecting full color/

grayscale.)

Black-white enabled

•Auto

• Manual

Color button enabled

When selecting "Auto":

• Text/printed photo

• Text/photo

•Text

When selecting "Manual":

• Text/printed photo

• Text/Photo

•Text

•Photo

• Printed photo

•Map

--- Half tone (Black-white

100 x 100 dpi 200 x 100dpi

200 x 200 dpi 200 x 200dpi

300 x 300 dpi 200 x 400dpi

400 x 400 dpi 400 x 400dpi

600 x 600 dpi 600 x 600dpi

Yes (Color/grayscale) ---

Yes

d. Specification of Addresses

Mode Scanner Internet Fax

Address

specification

Setting of default

address *1

Number of Onetouch address key

registration

Number of Group (1

key) address

registtation

Program 48

Direct entry of

addresses

Chain dial --Resend Call up nearest 8 addresses. *3

Shortcut for address

selection (quick

key)

CC/BCC sending Yes --Subjet Selective/direct entry from the list

File name Selective/direct entry from the list

Return mail address Selective/direct entry

Transmission

message (message

body)

Specification by one-touch/group/direct address

entry.

Entry from soft keyboard. (Scanner/Internet Fax)

Entry from 10-key. (Fax)

Selection from LDAP server

Input from the externally connected keyboard

Yes ---

Total (number of key): Maximum 999

Number of Group (1 key) address registration :

maximum 500

Number of Group key registration : 5000 (Total

address number included in /999 key)

Input from the soft keyboard and the externally

connected keyboard

Use the 10-key to call up registered numbers of

addresses.

from the list/selection

from LDAP server

Selective/direct entry from the list.

(Number of characters: Maximum of 1800 half-size

characters (900 full size characters))

--(1 default address fixed

as sender name)

Auto + 5 steps

---

only) ON/OFF

(Half tone not allowed)

MX3500N SPECIFICATIONS 2 – 7

Page 15

Mode Scanner Internet Fax

Other functions Mail footer preset (*2), inhibition of address

registration from the main unit, inhibition of address

registration from a Web screen, inhibition of

registration from the network scanner tool,

inhibition of "Resend" in the FAX/image send

mode, inhibition of selection from an address book,

inhibition of direct input, inhibition of send from the

PC internet FAX, and inhibition of send of PC-Fax.

*1: The scanner mode allows setting the default address. To

transmit data, users only have to set the original and press the

start key.

*2: Function to set up a text message that will be added

automatically to the message body upon mail transmission.

Editing upon transmission is not allowed.

*3: Except for FTP, Desktop, SMB, USB memory, Broadcast.

e. Specification of Multiple Addresses

Mode Scanner Internet Fax

Broadcast Yes (500 destinations)

(e-mail/FTP/Desktop

allowed)

Yes (500 destinations)

* Broadcast transmission by scanner, Internet Fax and Fax is

allowed. (B/W (2 value))

f. Transmission function

Memory transmission 94 destinations in all

Rotated transmission --- Yes

Scaled transmission Yes

Recall mode Error --- Yes

Busy --- ---

Long original

transmission

Change of the number

of pages for each file

Job partition through

recognition of white

paper.

Restriction on

transmission size

Large capacity original

mode

Scanning of thin paper Yes

Mixed originals feeder Yes (Random + MIX)

Default date sender

transmission

Scanner Internet Fax

Enlargement/reduction is allowed only from a

fixed size to another. Reduction may be done

on the receiver side with Fax/Internet Fax

sending.

--- Number/time to be

set up through

system setup

Yes

Maximum of 800mm (single side only/blackwhite 2 values only)

Yes ---

No ---

Yes ---

Yes

--- Yes (ON only)

g. Reception function

Scanner Internet Fax

Automatic reduction

setting upon receiving

A3

Automatic reduction

setting upon receiving

letter

Address/Domainspecified reception

allowed

Address/Domainspecified reception not

allowed. (To be rejected)

Received data bypass

output

Reception confirmation

cycle setting

POP3 communications

timeout setting

Index printing --- No

Body text print select

setting

Transfer function upon

disabling of output.

Rooting function --- Yes

Internet Fax/Fax to email (Transfer of Internet

Fax/Fax reception data

to e-mail, inbound

routing)

Exit tray setting --- Yes

Insertion of job

separator sheet

Setting of number of

copies of receive data

Staple function of

received data

Auto wake up print --- Yes

Received data print hold

function

Fax response lamp --- Yes

--- Yes

--- Yes

--- Yes (50 domains)

--- Yes (50 domains)

--- Yes

--- Setting by 0-8 hours/

--- Setting by 30-300/every

--- Yes

--- Yes (1 receiver (of

--- Yes

--- No

--- Yes

--- Yes

--- Yes

h. Report/list function

Scanner Internet Fax

Image sending activity

report

Transaction report Yes

Address/phone number

table

Group table Yes

Program table Yes

Communication original

contents print

List of addresses

allowed or not allowed

for reception

Yes

Time-specified output

Output with memory full

* Maximum of 200 times including both

transmission and reception

Yes

--- Always print/Upon

--- Yes

i. Other Functions

each minute

30 seconds

transfer) registration)

error/no print

Scanner Internet Fax

Automatic reception --- Yes

Manual reception --- Yes

Memory reception --- Yes

Fixed size reduced

reception

Specified size scaled

reception

Rotated reception --- Yes

Setting of received data

print condition

2-sided reception --- Condition setting

2-in-1 reception --- No

--- Yes

--- No

--- No

through system setting

MX3500N SPECIFICATIONS 2 – 8

Time specification Yes

Sender print --- Yes

Page number print --- Yes

Date print --- Yes (Date can be

Page partition

transmission

Page connection No

Edge erase Yes

Center erase Yes

Scanner Internet Fax

expressed

alternatively)

Yes

Page 16

Scanner Internet Fax

2 in 1 No

Background removal Yes

Card scan Yes (Equivalent or enlargement up to the paper

Confirm transmission --- Yes

Forward data

transmission/reception

(Document Admin)

(Allowed for Fax /

Internet Fax

broadcast)

(Only color and gray

scale)

width. The maximum enlargement is not

allowed to exceed 400%)

Yes

Data transmission by PC-Fax/PC-Internet Fax

is allowed, too.

Yes

---

Timeout time Setting

for 1 minute – 240

hours/each minute

* This function means that e-mail address setteing on F code relay

broadcast allowed.

j. Record size

Mode Scanner Internet Fax

Maximum record width --- 293mm / 11-17/32

Record size --- A3 – A5/11 x 17 – 5.5 x 8.5

k. Registration-related settings

Mode Scanner Internet Fax

One-touch/group *1

E-mail

FTP

Desktop

SMB

Internet Fax

Desktop registration Yes

Program Registration of addresses (groups), settings

Return mail address 200 (user registration

Number of sender

registration

Quick key (short cut

registration) *3

Retrieving/scanning of

registered data to other

model

Import/export of address

book

999 destinations

Use of LDAP allowed

Up to 500 registered addresses for each group

dial.

Registered name in 18 full-size character (36

half-size characters)

--Registration by using

Web or NST (network

scanner tool)

(density, image quality) and special functions in

one set is allowed. (48 of them)

--from Web) *2

--- 1 (20 characters)

Yes (001 – 999)

Yes (By address book conversion utility)

Yes (By storage backup)

*1: Since scan/Internet Fax/Fax uses the common address book,

the number of addresses allowed for registration is the sum

total of all modes.

*2: The book for address selection is used when a scan sender is

selected.

*3: Quick key is the function to select an address based on the

registered number of each address within the book for address

selection. Users should be able to select a quick key number.

l. Sound settings

Mode Item Scanner Internet Fax

Reception sound Sound volume setting --- Yes *1

Communication

error sound

Sound setting for

end of original

reading (image

send)

Sound volume setting --- Yes *2

Sound volume setting Yes *1

*1: Large/middle/small. Setup by system setting.

*2: Large/middle/small/no sound. Setup by system setting.

m. Others

Mode Scanner Internet FAX

PC-Internet Fax --- Yes

Trial mode Yes

Scanner: No (Standard)

Meta data: Yes

No

C. PC-Fax functions

(1) PC-Fax/PC-Internet Fax operating environment

OS Windows 98

PC IBM PC/AT compatible machine

CPU Pentium II 300MHz or more

Monitor 640x480 Pixels or more of screen resolution

Memory 64MB or more

HDD Free space of 50MB or more

Interface USB2.0

Communications

protocol

(2) PC-Fax/PC-Internet Fax functions

PC-Fax Send Yes (with Fax equipped)

PC-Internet Fax Send Yes (Necessary options: 256MB expansion

Resolution 200 x 100dpi/200 x 200dpi

Transmission original

sizes

Compression method MH/MMR

Braodcast transmission Yes (Fax, Internet Fax mixture possible.

F code transmission Yes Sub-

Phone book

registration/

transmission function

Use of MFP phone book No

Attach a cover sheet Yes (Not allowed for bradcast transmission)

Create cover sheets

function

Sender print Yes (Editable by PC-Fax driver for only Japan.

Preview function Yes

Transmission

confirmation (Notice to

PC by NJR)

Document filing function Filing Yes

PC-Fax Transmission

log

User authentication Yes

Time r No

R-KEY (Germany/

France only)

Windows Me

Windows NT4.0 Workstation (Service Pack5)

IE4.0 or more

Windows 2000

Windows XP Home Edition

Windows XP Professional

Windows Server 2003

256 or more of colors

10/100BASE-TX

LPR/lp

Port9100(RAW)

IPP

USB2.0

Maximim of 64 digits for Fax number (including

sub-address and passcode)

memory (G model), Internet Fax expansion kit)

Maximum of 64 digits for Internet Fax address

/200 x 400dpi/400 x 400dpi

A3/B4/A4/A5/B5/11 x 17/8.5 x 14/8.5 x 11/5.5 x

8.5/8.5 x 13/8K/16K

Maximum of 500)

address

Passcode Yes Maximum of

Ye s

Ye s

Always printed for abroad.)

Ye s

Quick File Yes

Yes (Re-transmission not allowed)

Ye s

Yes Maximum of

20 digits

20 digits

MX3500N SPECIFICATIONS 2 – 9

Page 17

D. Remote PC Functions (Network TWAIN)

Pull scan (TWAIN) specification

Interfaces LAN Yes

USB No

OS's Windows 98/Me/2000/XP/2003 Server

WHQL validated OS's Windows 2000/XP

Hardware environment System: Must satisfy the operational conditions

2-sided scan Yes

Color modes Mono 2 gradation/Mono Diffusion/Grayscale/Full

Resolutions 75dpi/100dpi/150dpi/200dpi/300dpi/400dpi/

Scanning ranges A3/A4/A4-R/A5/A5-R/B4/B5/B5-R/11 x 17/

Preview function Yes

Zoom preview function Yes

Rotated scan Yes (90-degree/ 180-degree/ 270-degree)

Brightness/contrast

adjustment

Gamma adjustment Yes

Color matching None/For Printer/For CRT/For LCD/ICM

Edge emphasis None/Normal/Sharp/Blur

Black-white inversion Yes

Selection of illuminant

color

Selection of threshold

value

Addition of void area Allowed (4 sides; 2.5mm for each)

Save of setup contents Yes

Save of preview image Yes

Display unit of

scanning range

Notes's security

function

Image acquision

method from the main

unit

for each OS.

HDD: 10MB or more: 100MB or more

recommended.

Monitor: 800 x 600 dots or more; 256 or more of

colors must be available.

Other: Network port

Color

600dpi or custom: 50-9600dpi

8.5 x 11/8.5 x 11-R/7.25 x 10.5/7.25 x 10.5-R/

8.5 x 13/5.5 x 8.5/5.5 x 8.5-R/8.5 x 14/Postcard/

8K/16K/16K-R/Auto/Auto(Mixed size)/Custom

* "Auto" includes the same width (Mix). "Auto

(Mixed size)" means random.

Auto/ manual (-100 – +100)

Yes (Red/Green/Blue/White)

Auto/ manual (1 – 254)

Pixel/mm/inch

Yes

Non-compression

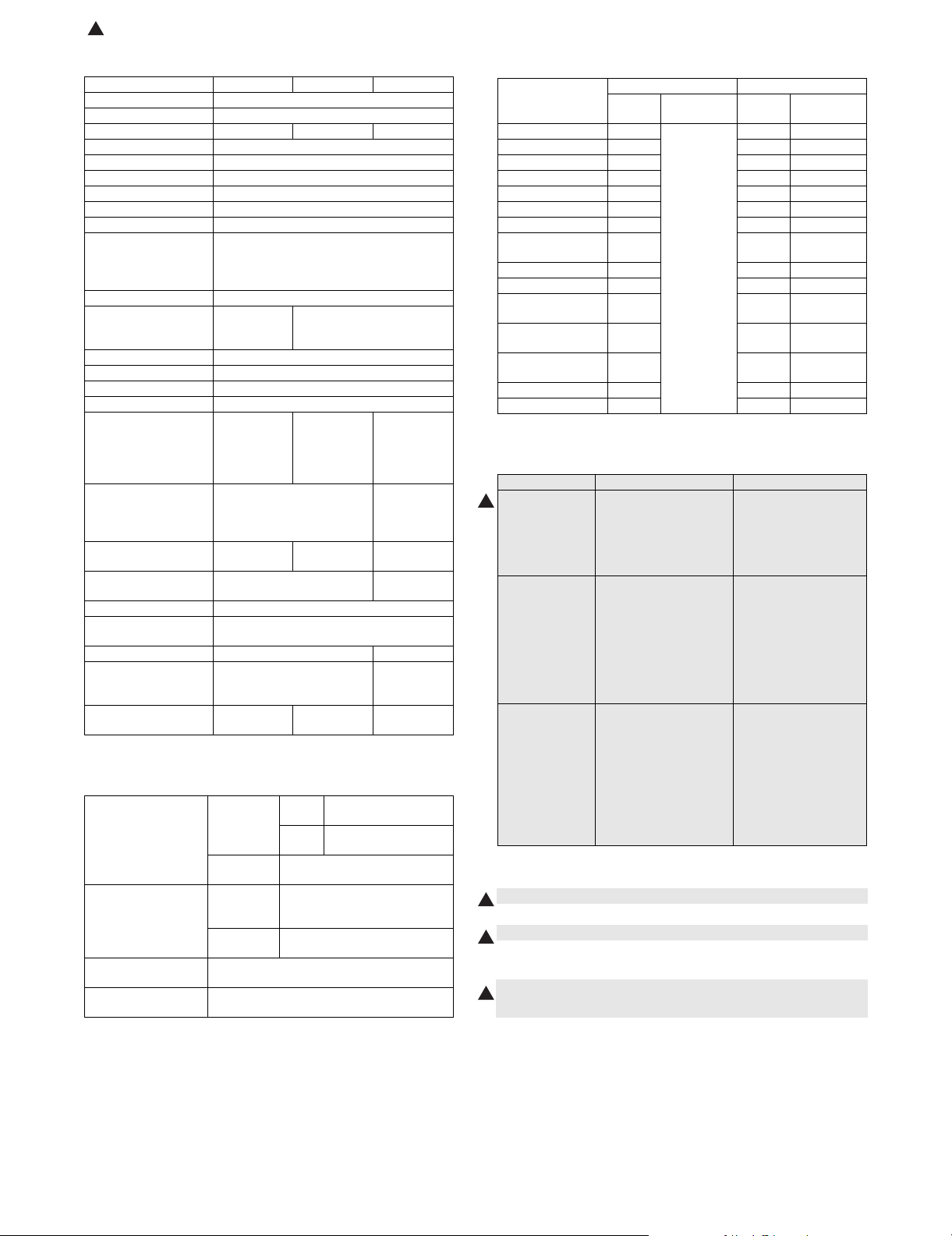

E. Printer function

(1) Platform

• IBM PC/AT compatible machine

• Macintosh

(2) Support OS

Custom PS Windows 98/Me

Windows NT 4.0 SP5 or later

Windows 2000

Windows XP

Custom

PCL5c/6

PPD Windows 98/Me

Windows Server 2003

Windows 98/Me

Windows NT 4.0 SP5 or later

Windows 2000

Windows XP

Windows Server 2003

Windows NT 4.0 SP5 or later

Windows 2000

Windows XP

Windows Server 2003

MacOS 9.0-9.2.2, x 10.1.5, x 10.2.8, x 10.3.3 – 10.3.9,

x 10.4

Adobe PS3 Windows 98 / Me

Windows NT 4.0 SP5 or later

Windows 2000

Windows XP

Windows Server 2003

MacOS 9.0-9.2.2, x 10.1.5, x 10.2.8, x 10.3.3, 10.3.9,

x 10.4

(3) Command system

Command system MX-3500/4500 series

SPLC-c No

PCL5c compatible Standard

PCL6 compatible

BMLinkS No

PS3 compatible Option (PS3 expansion kit: MX-PKX1)

EFI controller Option (EFI printer kit: MX-PEX1)

(4) Installed fonts

For PCL5c/

PCL6

compatible

For PS3 Roman outline fonts = 136 types Option

Roman outline fonts = 80 types

Line printer font (Bitmap) = 1 type

Bar code fonts = 28 types (Can be

provided by the flash ROM kit as well)

Stan da rd

Option

(5) Support print channel

USB USB 1.1: Windows 98/Me/2000/Server 2003/XP only

PSERVER/

RPRINT for

NetWare

environment

LPR UNIX LPR/LPD command-compatible print channel

IPP Print channel in compliance with IPP1.0

PAP :

EtherTalk

(AppleTalk)

FTP Equipped with the function to print data received via

NetBEUI Microsoft NetBEUI compatible print channel

Port9100 9100 TCP port (Raw Port) supported

HTTP Web Submit Print supported

POP3 E-Mail To Print supported

USB 2.0 (High speed): Windows 2000/XP only

Print channel in PSERVER/PRINT mode to be used

in netware environment

Print channel to be used for Machintosh environment

built-in FTP server

(6) Command Compatibility

PCL5c

compatibility

PCL XL

compatibility

PostScript3

compatibility

PCL5c must be compatible with HP Color Laser Jet

4600.

PCL XL must be compatible with HP Color Laser Jet

4600.

Must be compatible with Adobe PS3.

(7) Environmental settings

Setting item Overview

Initial setting Basic settings for printer use such as number of

PCL seting Setting of PCL symbols and fonts

PS setting Whether or not printing is allowed upon PS error is to

copies or printing direction.

be set up.

MX3500N SPECIFICATIONS 2 – 10

Page 18

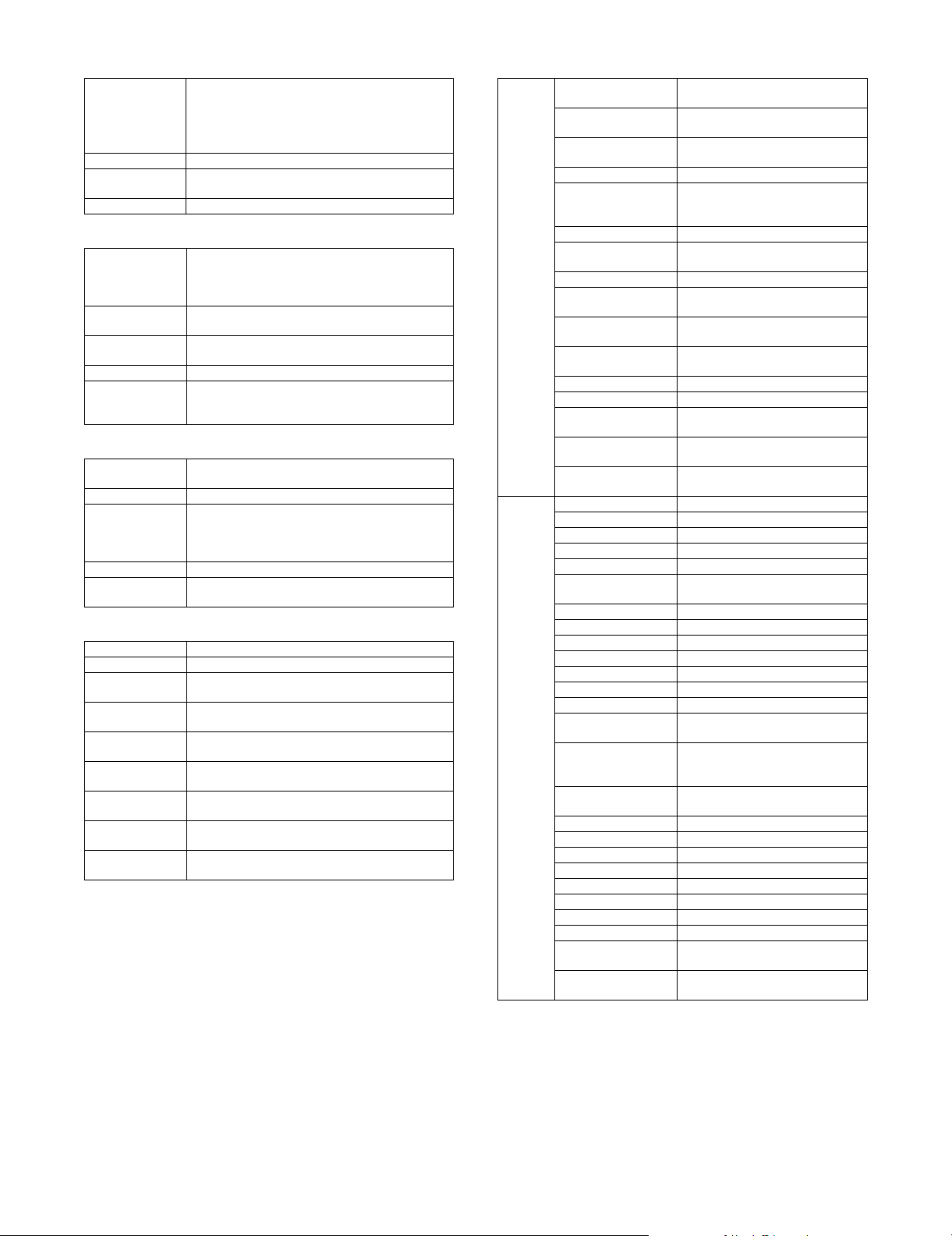

(8) Print functions

Function Content PCL6/5c PS (Option)

Multiple Pamphlet Binds multiple pamphlet outputs into a single booklet. Yes Yes

Bar code font JetCAPS BarDIMM emulation Yes No

Network tandem print Two units connected via network can be used simultaneously for a printout. Yes Yes (Windows

Windows Cluster Print When a Windows server breaks down, a mirror server takes over and executes the suspended

Encryption PDF/PDF/

TIFF/JPEG direct print

E-Mail To Print Direct printing of an attached file upon receipt of the e-mail. Yes Yes

Pull print from front panel Browsing of FTP server from front panel and pull-printing of a specified file (direct printing). Yes Ye s

FTP PUSH print Performs direct print by data transfer from the client PC to the MFP server. Yes Yes

Print by file setup on Web

page [Web Submit Print]

Continuous print function The function executes multiple print jobs continuously as if they are one single job even if the

ROPM The function enables the printout of a multiple number of copies in one RIP processing. Yes Yes

Multi-access RIP processing must be allowed during printing. Printing must also be allowed during scanning. Yes Yes

Paper direction setting for

2-sided printing of

letterhead paper and prepunched paper.

Enable selected paper

type in bypass tray

Setting environmental

control under terminal

server control

Driver delivery function PAU4.0 allows the administrator to deliver a driver to clients. Yes Yes

Form overlay The function downloads a form to the main unit beforehand, sends the contained data only, and

Planet Press Object Lune Corporation's Planet Press (Software to execute the mapping of forms (DL

Improvement of

downloading method of

font form

Management of password

by hidden Web page

Expansion font list In self-print of a font list, ESC command information is needed for BITMAP font. Yes

Bonjour for Macintosh

environment

Document control When printing, the unique pattern for prevention against unauthorized copy

Object judgement (screen

change/color change)

CMYK Simulation Choice of CMYK simulation is as follows.

ICC Profile <Source Profile>

Pantone color For Pantone color support, the profile upload can be made by Web setting. No Yes

print job.

* There may be color differences between machine types

PDF/TIFF/JPEG file can be printed without printer driver.

1) Printing of e-mail attachment file

2) Printing from FTP server

3) Printing from setup file on Web page

4) USB memory

Setting and direct printing of a file on network through Web page. Yes Yes

unit receives an end of job command, in order to support print from the application assuming

printout on continuous pages.

Pages with front-back attribute such letterhead or punch paper are to be printed correctly in

front-back page order for 2-sided printing.

For setting of bypass tray, even if the setup values on the main unit side do not match with those

on the driver side, the printing will be executed in the setting of the driver regardless of the setup

values on the main unit side.

Print setting of each client is memorized under meta frame environment (auto print create

environment). (Setup for each log-in can be skipped.)

inserts the data into the form in the main unit for printout.

beforehand) and variable data in the printer interior)

This expands the function to prevent the deletion and overwriting of the editing functional

enhancement font/form on Web page. A unified UI for the lineup is necessary.

Currently, registration is done by Web page and deleted by PJL. This function is supported by

HDD.

The purpose is to prevent the access even if the hidden Web page address becomes known. Yes Yes

This technology detects and connects peripheral equipment on the network automatically.

The dynamic network connection (computer, peripheral equipment and software) is possible

without user setting.

is embedded in printing.

In the printer color mode output, object of image data (area of photograph/graphic text) is

judged. Print screen (resolution) and profile (color) are changed automatically.

1) Default

2) Custom

Default is defined depending on the destination of service simulation.

1. Japan = Japan Color

2. North America / China / Other abroad inch type = SWOP

3. Europe / Other abroad AB type = Euroscale

Custom profile can upload by Web setting. Notation of driver is Custom.

Example: Use SWOP profile in Japan.

Choice of source profile is as follows.

•sRGB

• AppleRGB

•Custom

Custom profile can upload by Web setting. (The attached ICC profile on devices is available.)

<Output Profile>

There is no user selection for output profile. Sharp provides Custom profile. Upload of profile

supports by service. The tool is set on the Web (service setting). The concrete method of profile

making is to be considered separately.

Yes Yes (Windows

Yes (No for

encrypted

PDF/PDF)

Yes Ye s

Yes Ye s

Yes Ye s

Yes Ye s

Yes

(5c only)

Yes Ye s

Yes

(5c only)

(5c only)

No Yes

Yes (OPT) Yes (OPT)

PCL6: Yes

PCL5: No

No Yes

Yes Ye s

only)

only)

Yes

No

Yes

No

Yes

MX3500N SPECIFICATIONS 2 – 11

Page 19

(9) Windows driver function

PCL5-c/6: Standard

PS: Option (Installation of the PS3 expansion kit (MX-PKX1) are

required.)

a. Frequently used functions

Function PCL5-c/6 PS PPD

Copies (Copy

processing by

MFP/Printer

firmware)

Orientation Portrait/Landscape

Duplex 2-Sided (Book)

Pamphlet

(Pamphlet

processing by

MFP/Printer

firmware)

Binding Edge Top/Left/Right N/A

N-Up Printing 1-Up, 2-Up, 4-Up, 6-Up,

Black N-Up

Border

N-Up Order [2-Up]

2-Up Pamphlet N/A

Multiple 2-Up Pamphlet

Multiple Tiled Pamphlet

8-Up, 9-Up, 16-Up

Yes /N o N /A

d. Exposure

1-999

2-Sided (Tablet)

Tiled Pamphlet

(Windows NT: N/A)

(Windows 9x:

1-Up/2-Up/4-up)

Left to Right

Right to Left

[4, 6, 8, 9, 16-Up]

Right, and Down

Down, and Right

Left, and Down

Down, and Left

b. Paper feed system

Function PCL5-c/6 PS PPD

Paper Size A2 (Fit To Page)

Paper Selection Paper Source

Different Paper Cover Page N/A

Transparency

Inserts

Tab Printing Image Shift N/A

Set Tray Status Set Paper Size

Paper Type

Name (USER

TYPE 1-7)

Input Tray

Options

(PCL6 only)

12 x 18, A3, A4, A5, B4, B5, 11 x 17, 8.5 x 11, 8.5 x 14,

7.25 x 10.5, 8.5 x 13, 5.5 x 8.5, 8K, 16K, DL, C5,

COM10, Monarch, Custom Paper

Paper Type

Last Page N/A

Other Page N/A

Tab Paper

Printing

(PCL6 only)

Set Paper Type

Display Name N/A

Two Trays/Three Trays/Four

Trays

N/A N/A

Auto Selection/

Paper Source /

Paper Type

Blank/Printed

N/A

N/A

N/A

c. Paper exit method

Function PCL5-c/6 PS PPD

Output Tray Center Tray/Right Tray/Offset Tray/Saddle

Staple None/1-Staple/2-Staples

Punch Yes/No

No Offset Yes/No

Large Capacity Tray None/MX-LCX1